Page 1

MGC3130

Hillstar Development Kit

User’s Guide

2013 Microchip Technology Inc. DS40001721A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

FlashFlex, K

PICSTART, PIC

and UNI/O are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MTP, SEEVAL and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

Analog-for-the-Digital Age, Application Maestro, BodyCom,

chipKIT, chipKIT logo, CodeGuard, dsPICDEM,

dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, HI-TIDE, In-Circuit Serial

Programming, ICSP, Mindi, MiWi, MPASM, MPF, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, Omniscient Code

Generation, PICC, PICC-18, PICDEM, PICDEM.net, PICkit,

PICtail, REAL ICE, rfLAB, Select Mode, SQI, Serial Quad I/O,

Total Endurance, TSHARC, UniWinDriver, WiperLock, ZENA

and Z-Scale are trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

GestIC and ULPP are registered trademarks of Microchip

Technology Germany II GmbH & Co. KG, a subsidiary of

Microchip Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2013, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 9781620775134

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

32

logo, rfPIC, SST, SST Logo, SuperFlash

QUALITY MANAGEMENT S

DS40001721A-page 2 2013 Microchip Technology Inc.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

Object of Declaration: MGC3130 Hillstar Development Kit User’s Guide

2013 Microchip Technology Inc. DS40001721A-page 3

Page 4

MGC3130 Hillstar Development Kit User’s Guide

NOTES:

DS40001721A-page 4 2013 Microchip Technology Inc.

Page 5

MGC3130 HILLSTAR DEVELOPMENT KIT

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 7

Introduction............................................................................................................ 7

Document Layout .................................................................................................. 7

Conventions Used in this Guide ............................................................................ 8

Warranty Registration............................................................................................ 9

Recommended Reading........................................................................................ 9

The Microchip Web Site ...................................................................................... 10

Development Systems Customer Change Notification Service .......................... 10

Customer Support ............................................................................................... 11

Revision History .................................................................................................. 11

Chapter 1. Overview

1.1 Introduction ................................................................................................... 13

1.2 Hillstar Concept and Deliverables ................................................................ 13

1.3 Hillstar Development Kit Package Content .................................................. 14

1.4 Hillstar Development Kit Reference Electrodes ........................................... 15

1.5 MGC3130 Software Package – Aurea GUI and GestIC Library ................... 17

1.6 MGC3130 Software Development Kit (SDK) ................................................ 17

Chapter 2. Getting Started

2.1 Prerequisites ................................................................................................ 19

2.2 Step 1: Build-up Development Kit ................................................................ 19

2.3 Step 2: Connecting Hillstar Development Kit with Your PC ......................... 20

2.4 Step 3: Install Windows CDC Driver ............................................................. 20

2.5 Step 4: Start Aurea ....................................................................................... 20

Chapter 3. Hillstar Boards – Hardware Description

3.1 Overview ...................................................................................................... 23

3.1.1 I2C™ to USB Bridge .................................................................................. 23

3.1.2 MGC3130 Unit ........................................................................................... 23

3.1.3 95x60 mm Reference Electrode PCB ........................................................ 23

3.2 MGC3130 Unit ............................................................................................. 24

3.3 Hillstar 95x60 mm Reference Electrode ...................................................... 25

2

3.4 I

C to USB Bridge ....................................................................................... 27

Chapter 4. Design In: Hillstar In Target Application

4.1 Introduction ................................................................................................... 29

4.2 Integration Examples .................................................................................... 29

Chapter 5. Troubleshooting

2013 Microchip Technology Inc. DS40001721A-page 5

Page 6

MGC3130 Hillstar Development Kit User’s Guide

Appendix A. Schematics

A.1 Introduction .................................................................................................. 35

A.2 Bill of Materials ............................................................................................. 35

A.3 Board – Schematics and Layout .................................................................. 37

Appendix B. Sensitivity Profile and Capacitances

B.1 Introduction .................................................................................................. 41

B.2 Sensitivity Profiles ........................................................................................ 41

B.3 Electrode Capacities .................................................................................... 42

Appendix C. Parameterization Support

C.1 How to Build a Hand Brick ........................................................................... 43

C.2 Usage of the Hand Brick as Artificial Hand .................................................. 45

Appendix D. Driver Installation Manual

D.1 Open Device Manager ................................................................................. 47

D.2 Select Device ............................................................................................... 47

D.3 Locate Driver ............................................................................................... 48

D.4 Verify Communication .................................................................................. 48

Appendix E. Glossary

Worldwide Sales and Service .....................................................................................50

DS40001721A-page 6 2013 Microchip Technology Inc.

Page 7

MGC3130 HILLSTAR DEVELOPMENT

KIT USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

INTRODUCTION

®

IDE online help.

This chapter contains general information that will be useful to know before using the

Hillstar Development Kit. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Revision History

DOCUMENT LAYOUT

This document describes the installation and use of the MGC3130 Hillstar

Development Kit. The document is organized as follows:

• Chapter 1. “Overview”

• Chapter 2. “Getting Started”

• Chapter 3. “Hillstar Boards – Hardware Description”

• Chapter 4. “Design In: Hillstar In Target Application”

• Chapter 5. “Troubleshooting”

• Appendix A. “Schematics”

• Appendix B. “Sensitivity Profile and Capacitances”

• Appendix C. “Parameterization Support”

• Appendix D. “Driver Installation Manual”

• Appendix E. “Glossary”

2013 Microchip Technology Inc. DS40001721A-page 7

Page 8

MGC3130 Hillstar Development Kit User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS40001721A-page 8 2013 Microchip Technology Inc.

Page 9

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user's guide describes how to use the Hillstar Development Kit. Other useful

documents are listed below. The following Microchip documents are available and

recommended as supplemental reference resources.

•“MGC3130 GestIC

(DS40001716). This document describes the MGC3130 system characteristic

parameters and the design process. It enables the user to generate a good

electrode design and to parameterize the full GestIC system.

• “MGC3130 GestIC

This document is the interface description of the MGC3130’s GestIC Library. It

outlines the function of the Library’s message interface, and contains the

complete message reference to control and operate the MGC3130 system.

• “MGC3130 Single-Zone 3D Gesture Controller Data Sheet” (DS40001667).

Consult this document for information regarding the MGC3130 3D Tracking and

Gesture Controller.

• “MGC3130 Aurea Graphical User Interface User’s Guide” (DS40001681). This

document describes how to use the MGC3130 Aurea Graphical User Interface.

Preface

®

Design Guide: Electrodes and System Design

®

Library Interface Description User’s Guide” (DS40001718).

2013 Microchip Technology Inc. DS40001721A-page 9

Page 10

MGC3130 Hillstar Development Kit User’s Guide

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers, assemblers, linkers

and other language tools. These include all MPLAB

assemblers (including MPASM™ assembler); all MPLAB linkers (including

MPLINK™ object linker); and all MPLAB librarians (including MPLIB™ object

librarian).

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB REAL ICE™ and MPLAB ICE 2000 in-circuit emulators.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debuggers. This includes MPLAB ICD 3 in-circuit debuggers and PICkit™ 3

debug express.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB IDE Project Manager, MPLAB Editor and

MPLAB SIM simulator, as well as general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

production programmers such as MPLAB REAL ICE in-circuit emulator, MPLAB

ICD 3 in-circuit debugger and MPLAB PM3 device programmers. Also included

are nonproduction development programmers such as PICSTART

PICkit 2 and 3.

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

®

C compilers; all MPLAB

®

Plus and

DS40001721A-page 10 2013 Microchip Technology Inc.

Page 11

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support.

REVISION HISTORY

Revision A (October, 2013)

This is the initial release of this document.

Preface

2013 Microchip Technology Inc. DS40001721A-page 11

Page 12

MGC3130 Hillstar Development Kit User’s Guide

NOTES:

DS40001721A-page 12 2013 Microchip Technology Inc.

Page 13

MGC3130 HILLSTAR DEVELOPMENT

Chapter 1. Overview

1.1 INTRODUCTION

The MGC3130 is the first product based on Microchip’s GestIC® technology. It is

developed as a mixed-signal controller. The MGC3130 has one transmit and five very

sensitive receive channels that are capable to detect changes of a transmitted electrical

field (E-field) corresponding to capacitive changes in the femtofarad (1 fF = 10

range.

In order to transmit and receive an electrical field, electrodes have to be connected to

the transmitting and receiving channels of the MGC3130 controller. The spatial

arrangement of the electrodes allows the chip to determine the center of gravity of the

electric field distortion, and thus position tracking and gesture recognition of a user’s

hand in the detection space.

1.2 HILLSTAR CONCEPT AND DELIVERABLES

The Hillstar Development Kit is designed to support an easy integration of Microchip’s

MGC3130 3D Tracking and Gesture Controller into customer’s applications. It provides

MGC3130 system setup, related hardware and software references.

With the MGC3130 Software Package, including Aurea Graphical User Interface and

GestIC Library, the MGC3130 Software Development Kit (SDK) and PIC18 Host

Reference code, design-in is easy in five steps:

1. Feature Definition

2. Electrode Design

3. MGC3130 Parameterization

4. Host Application Programming

5. Verification

Hillstar hardware builds a complete MGC3130 reference system consisting of three

individual PCBs:

• MGC3130 Unit

2

•I

C™ to USB Bridge

• Reference Electrode with a 95x60 mm sensitive area

It can be plugged to a PC via USB cable and used for evaluation of MGC3130 chip and

GestIC technology. During the customer’s design-in process the individual boards can

be combined according to the customers need.

Three examples are given below:

• Combine MGC3130 Unit and I

electrodes

•Use I

• Combine MGC3130 Unit and Electrodes to develop gesture-driven applications

2

C to USB Bridge to parameterize and debug the MGC3130 application

circuitry in the customer’s design

for PC based or embedded software environments

2

C to USB Bridge to evaluate customized

KIT USER’S GUIDE

-15

F)

2013 Microchip Technology Inc. DS40001721A-page 13

Page 14

MGC3130 Hillstar Development Kit User’s Guide

The Hillstar Development Kit provides an artificial test hand, further called hand brick,

helping to stimulate the human hand operating the GestIC application. The hand brick

has to be used during the design-in process to parametrize and evaluate customer’s

applications. The hand brick’s surface is conductive and connected to GND via cable

in order to reproduce the grounding conditions of the human body.

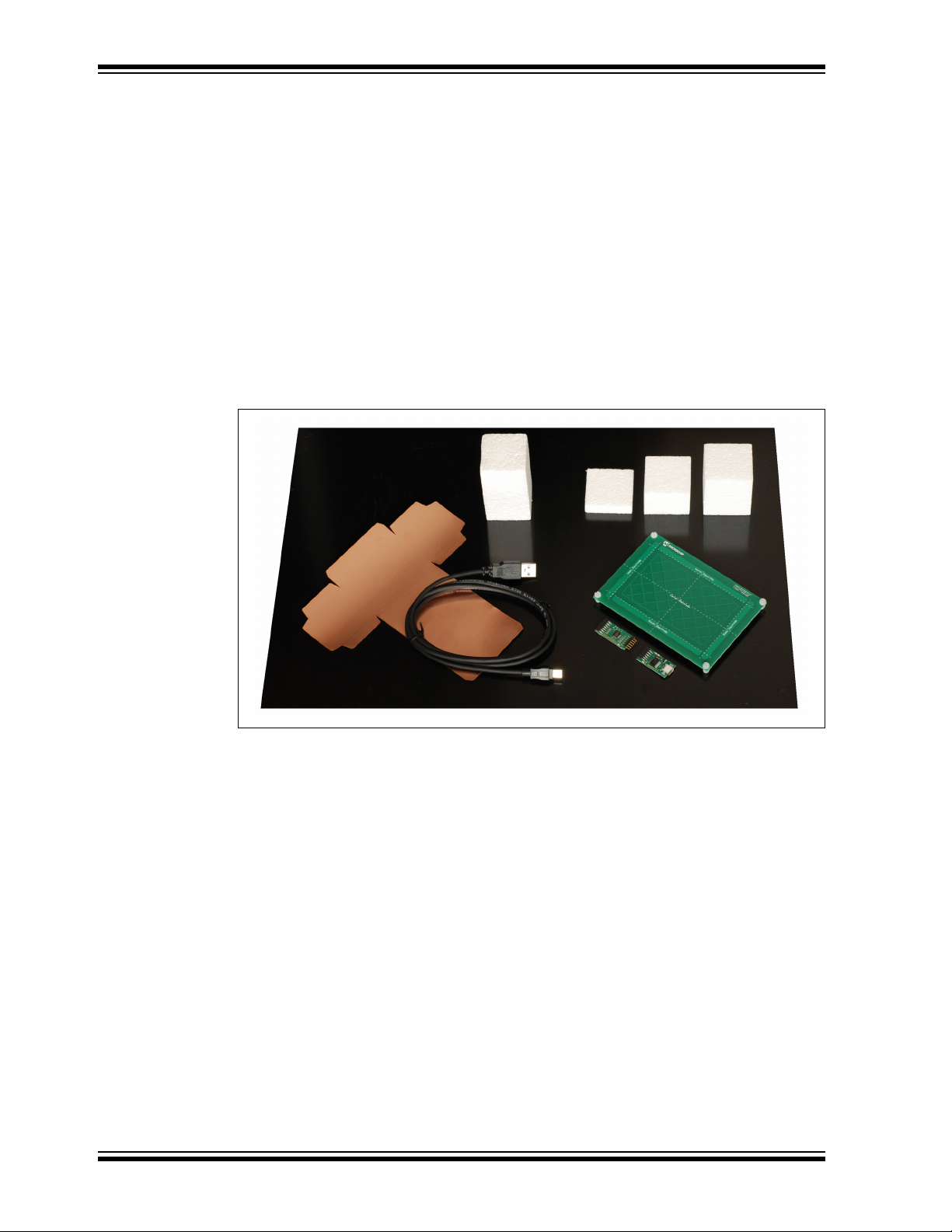

1.3 HILLSTAR DEVELOPMENT KIT PACKAGE CONTENT

The Hillstar Development Kit package content is listed below:

• MGC3130 Module

2C

•I

to USB Bridge Module

• 4-layer reference electrode (95x60 mm sensitive area)

• ‘Hand brick’ set (self-assembly, four foam blocks, one copper foil)

• USB Cable for PC connection

FIGURE 1-1: HILLSTAR DEVELOPMENT KIT

The ‘hand brick’ set is used during the design-in process for sensor calibration and

performance evaluation purposes. For usage and assembly information, refer to

Appendix C. “Parameterization Support”.

DS40001721A-page 14 2013 Microchip Technology Inc.

Page 15

1.4 HILLSTAR DEVELOPMENT KIT REFERENCE ELECTRODES

140x90

100x50

95x60

80x80

50x30

30x30

The Hillstar development kit includes a collection of layout references (Gerber files) for

electrode designs and ready-to-use sensor modules with MGC3130 backside

assembly.

The following electrode designs are included:

• 140x90 mm sensitive area – outline 168 x 119 mm

• 95x60 mm sensitive area – outline of 120 x 85 mm

• 80x80 mm sensitive area – outline 104 x 104 mm

• 100x50 mm sensitive area – outline 128 x 72 mm

• 50x30 mm sensitive area – outline 63 x 47 mm

• 30x30 mm sensitive area – outline 49 x 49 mm

Sensor Modules

• 95x60 mm sensitive area – outline of 120 x 85 mm

• 30x30 mm sensitive area – outline 49 x 52 mm

Overview

FIGURE 1-2:

HILLSTAR DEVELOPMENT KIT REFERENCE

ELECTRODES

Dimensions of the designs are given in Table 1-1 and Figure 1-3 below.

2013 Microchip Technology Inc. DS40001721A-page 15

Page 16

MGC3130 Hillstar Development Kit User’s Guide

TABLE 1-1: ELECTRODE DIMENSIONS

Sensitive Area 140x90 mm 95x60 mm

Versi on 1.0 1.0 1.0 1.0 1.0 1.0

Layer 22 2222

Aspect Ratio approx. 3:2 approx. 3:2 1:1 approx. 2:1 5:3 1:1

A 168 mm 120 mm 104 mm 128 mm 63 mm 49 mm

B 119 mm 85 mm 104 mm 72 mm 47 mm 49 mm

C 138 mm 95,7 mm 79.8 mm 103,6 mm 50 mm 31.8 mm

D 88,7 mm 60,5 mm 79.8 mm 99,6 mm 46 mm 27,3 mm

E 131,7 mm 91,7 mm 75,8 mm 99,6 mm 46 mm 27,3 mm

F 5 mm 5 mm 5 mm 5 mm 2,5 mm 3,5 mm

G 128 mm 85,7 mm 69,8 mm 93,6 mm 44 mm 25,8 mm

H 78,7 mm 50, 5 mm 69, 8 mm 36, 8 mm 24 mm 25,8 mm

Center Electrode

cross-hatching

Tx Electrode

cross-hatching

-under center

electrode

-outside center

electrode

Note 1: These dimensions are also valid for 95x60 mm sensor module.

2: These dimensions are also valid for 30x30 mm sensor module except the B dimension which is equal to

52 and Tx electrode which is solid instead of cross-hatched.

3% 3% 5% 5% 5% 5%

50 %

20 %

50%

20%

(1)

80x80 mm 100x50 mm 50x30 mm 30x30 mm

50%

20%

50 %

20 %

50 %

20 %

50 %

20 %

(2)

DS40001721A-page 16 2013 Microchip Technology Inc.

Page 17

FIGURE 1-3: ELECTRODE DIMENSIONS

D

C

B

A

E

F

G

H

F

Tx

Rx

Overview

The Gerber data of all electrode reference designs are included in the MGC3130

Hillstar Hardware Reference package and can be downloaded from Microchip’s web

site www.microchip.com/GestICGettingStarted.

1.5 MGC3130 SOFTWARE PACKAGE – AUREA GUI AND GestIC LIBRARY

The MGC3130 Software Package contains all relevant system software and

documentation. Hillstar Development Kit is supported by MGC3130 Software Package

0.4 and following versions.

The package contains:

• Aurea PC software

• GestIC Library binary file

• GestIC Parameterization files

• Windows CDC driver

• Documentation

The latest MGC3130 software package can be downloaded from Microchip’s web site

www.microchip.com/GestICGettingStarted.

1.6 MGC3130 SOFTWARE DEVELOPMENT KIT (SDK)

The MGC3130 Software Development Kit (SDK) supports the integration of MGC3130

into a software environment. Thus, it includes a C reference code for GestIC API, a

precompiled library for Windows operating systems and a demo application using the

GestIC API interface.

Hillstar Development Kit is supported by MGC3130 SDK 0.4 and the following versions.

The latest SDK can be downloaded from Microchip’s web site

www.microchip.com/GestICGettingStarted.

2013 Microchip Technology Inc. DS40001721A-page 17

Page 18

MGC3130 Hillstar Development Kit User’s Guide

NOTES:

DS40001721A-page 18 2013 Microchip Technology Inc.

Page 19

Hillstar Development Kit can be used as a stand-alone GestIC system and evaluated

in conjunction with the Aurea PC software. This section describes how to get started.

2.1 PREREQUISITES

The following prerequisites have to be fulfilled:

• PC with Windows

and minimum screen resolution of 1024x768

• Hillstar Development Kit (MGC3130 Unit, I

electrode)

• MGC3130 Software Package 0.4 and following versions

The MGC3130 Software Package is available as a .zip file. Unzip the file, run

setup.exe and install the package to your PC. The folder structure is as shown in

Figure 2-1.

FIGURE 2-1: FOLDER STRUCTURE

MGC3130 HILLSTAR DEVELOPMENT KIT

USER’S GUIDE

Chapter 2. Getting Started

®

XP, Windows 7 or Windows 8 operating system and USB port

2

C to USB Bridge, 95x60 mm frame

2.2 STEP 1: BUILD-UP DEVELOPMENT KIT

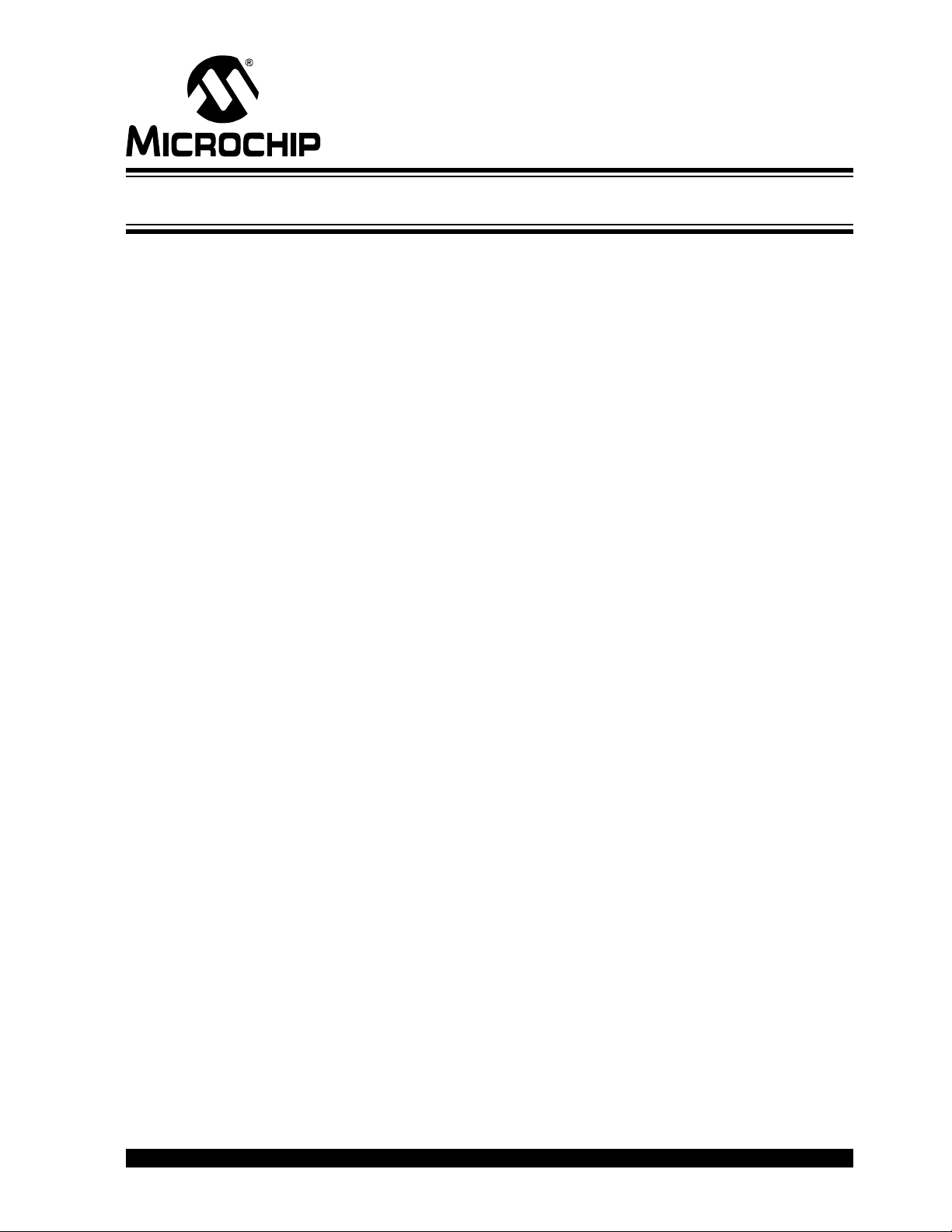

Connect Electrodes, MGC3130 Unit and I2C to USB Bridge as shown in Figure 2-2.

Note: Make sure the MGC3130 Unit and the I2C USB Bridge are already con-

nected before plugging in the USB connection.

2013 Microchip Technology Inc. DS40001721A-page 19

Page 20

MGC3130 Hillstar Development Kit User’s Guide

I2C™ to USB Bridge

FIGURE 2-2: HILLSTAR DEVELOPMENT KIT ASSEMBLING

2.3 STEP 2: CONNECTING HILLSTAR DEVELOPMENT KIT WITH YOUR PC

Use the supplied USB cable to connect the Hillstar Development Kit to your PC. The

Power LEDs on both, I

Furthermore, LED 1 on the I

1 is flashing slow (~1 Hz), the Windows CDC driver is already installed on your PC.

Please skip the next step and go to Section 2.5 “Step 4: Start Aurea”.

2

C to USB Bridge and MGC3130 Unit will illuminate.

2

C to USB Bridge will flash very fast (~10 Hz). In case LED

2.4 STEP 3: INSTALL WINDOWS CDC DRIVER

The Windows CDC driver can be found in the MGC3130 Software Package in folder

04_Driver.

When the Hillstar Development Kit is connected to your PC for the first time, Windows

requests the appropriate device driver and guides you through the installation process.

Alternatively, you can install the driver manually, (e.g., using the device manager). An

example for Windows 7 is given in Appendix D. “Driver Installation Manual”.

2.5 STEP 4: START AUREA

Aurea Graphical User Interface, shown in Figure 2-3, is included in the MGC3130

Software Package in the folder 02_Aurea.

Open Aurea.exe. Aurea detects the connected device automatically and is ready for

use.

DS40001721A-page 20 2013 Microchip Technology Inc.

Page 21

FIGURE 2-3: AUREA GRAPHICAL USER INTERFACE

Evaluate Colibri Suite Discover Signals Setup MGC3130

1. Positions Tracking

2. Gesture Recognition

3. Demo applications

1. View signals

2. Write log file

3. Advanced features

1. AFE parameterisation

2. Colibri Suite parameterization

3. Update GestIC Library

4. Measure Electrode capacitances

Getting Started

2013 Microchip Technology Inc. DS40001721A-page 21

Page 22

MGC3130 Hillstar Development Kit User’s Guide

NOTES:

DS40001721A-page 22 2013 Microchip Technology Inc.

Page 23

MGC3130 HILLSTAR DEVELOPMENT

1

3

9

68

2

4

5

7

10

11

13

12

I2C™ to USB Bridge

MGC3130 Unit Reference Electrode PCB

Chapter 3. Hillstar Boards – Hardware Description

3.1 OVERVIEW

The Hillstar key components are listed below and highlighted in Figure 3-1.

FIGURE 3-1: HILLSTAR DEVELOPMENT KIT OVERVIEW

KIT USER’S GUIDE

3.1.1 I2C™ to USB Bridge

1. PIC18F14K50 USB microcontroller

2. USB mini-B connector

3. MCP1801T LDO voltage regulator (converts 5V USB to 3.3 V board supply)

4. Status LEDs (power, communication status)

5. Data interface: 6-pin socket for data communication and power supply

3.1.2 MGC3130 Unit

6. MGC3130 3D Tracking and Gesture Controller

7. Data interface: 6-pin header for data communication and power supply

8. Status LED (power)

9. Interface select

10. Electrode interface: 7-pin socket

3.1.3 95x60 mm Reference Electrode PCB

11. Receive electrodes

12. Acrylic cover glass (120 x 85 x 2 mm)

13. Electrode interface: 7-pin header (mounted on backside)

2013 Microchip Technology Inc. DS40001721A-page 23

Page 24

MGC3130 Hillstar Development Kit User’s Guide

The Gerber data of all Hillstar Development Kit components are included in the

MGC3130 Hillstar Hardware Reference package and can be downloaded from

Microchip’s web site www.microchio.com/GestICGettingStarting.

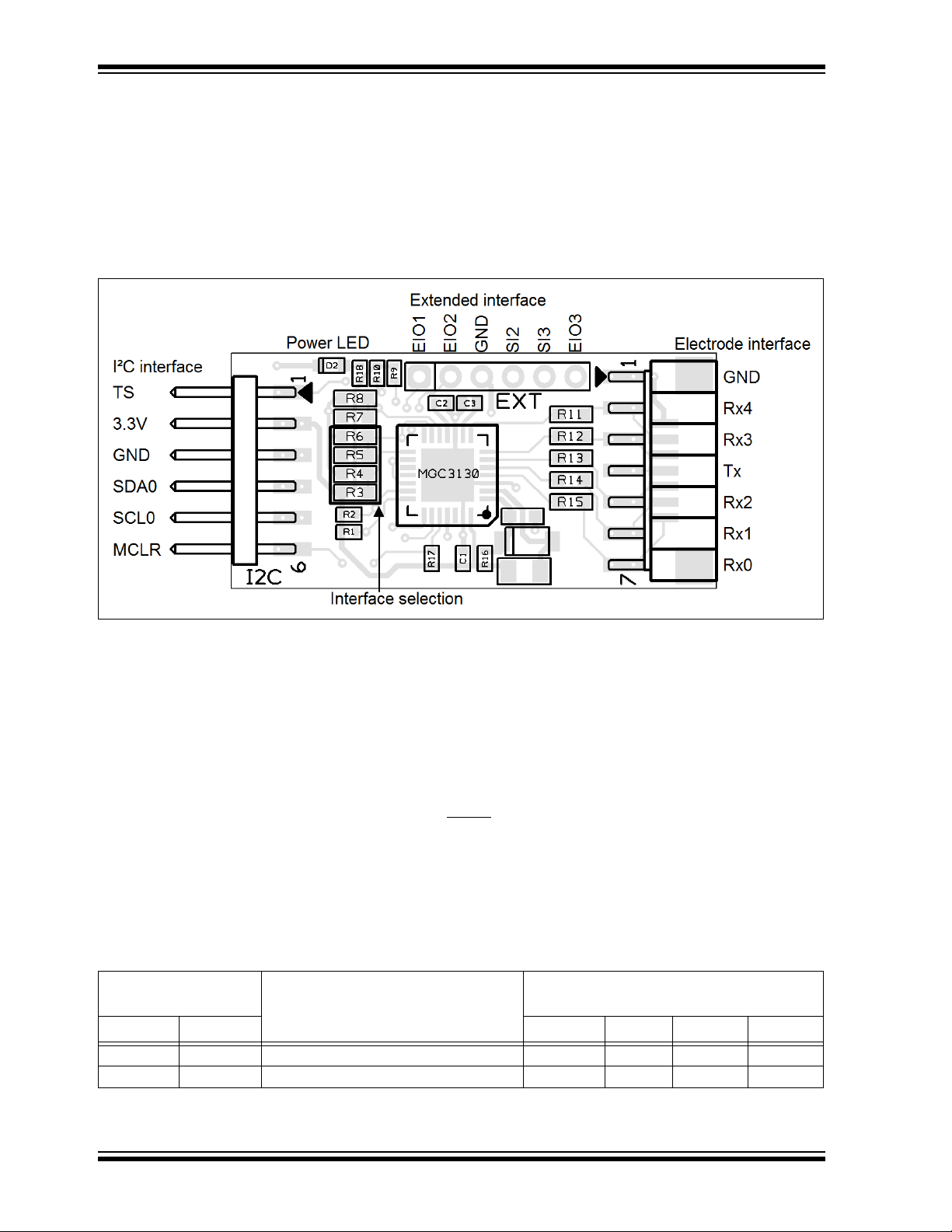

3.2 MGC3130 UNIT

The key element of the MGC3130 Unit is Microchip’s MGC3130 3D Tracking and

Gesture Controller. The layout print of the unit is shown in Figure 3-2.

FIGURE 3-2: MGC3130 UNIT

The unit provides a 2 mm 7-pin board-to-board connector (socket) to connect the

electrode. The interface includes the following signals: GND, Rx4, Rx3, Tx, Rx2, Rx1,

and Rx0. Alternatively, the board-to-board connector can be replaced by a 1 mm

Flexible Printed Circuitry (FPC) connector which is prepared as a design option. The

five Rx channels of the MGC3130 (Rx0…Rx4) are connected to the receive electrodes

via 10 k resistors in order to suppress irradiated high-frequency signals (R11, R12,

R13, R14, and R15). The MGC3130 signal generator is connected via the Tx signal to

the transmit electrode.

The data connection to the Hillstar I

2

C to USB Bridge is realized by a 6-pin 2 mm

board-to-board connector (header). The interface includes the following signals: EIO0,

3.3V, GND, SDA0, SCL0, and MCLR

. Alternatively, it is possible to use a 1 mm FPC

connector which can be assembled to the bottom side.

The MGC3130 unit acts as an I

2

C slave device. Table 3-1 shows the configuration of

the MGC3130 interface selection pins (IS1, IS2) which can be pulled to V

via resistors (R3, R4, R5, and R6) to select the I

2

C slave address. The I2C device

address 0x42 is set as default.

TABLE 3-1: MGC3130 UNIT I2C™ INTERFACE SELECTION

MGC3130 Interface

Selection Pins

IS2 IS1 R3 R4 R5 R6

00I2C™0 Slave Address = 0x42 (default) n.p. 10 k n.p. 10 k

2

10I

C™0 Slave Address = 0x43 10 k n.p. n.p. 10 k

Mode (Address)

Assembly Option

For Schematics, Layout and Bill of Material of the MGC3130 Unit please refer to

Appendix A.

DD or to GND

DS40001721A-page 24 2013 Microchip Technology Inc.

Page 25

Hillstar Boards – Hardware Description

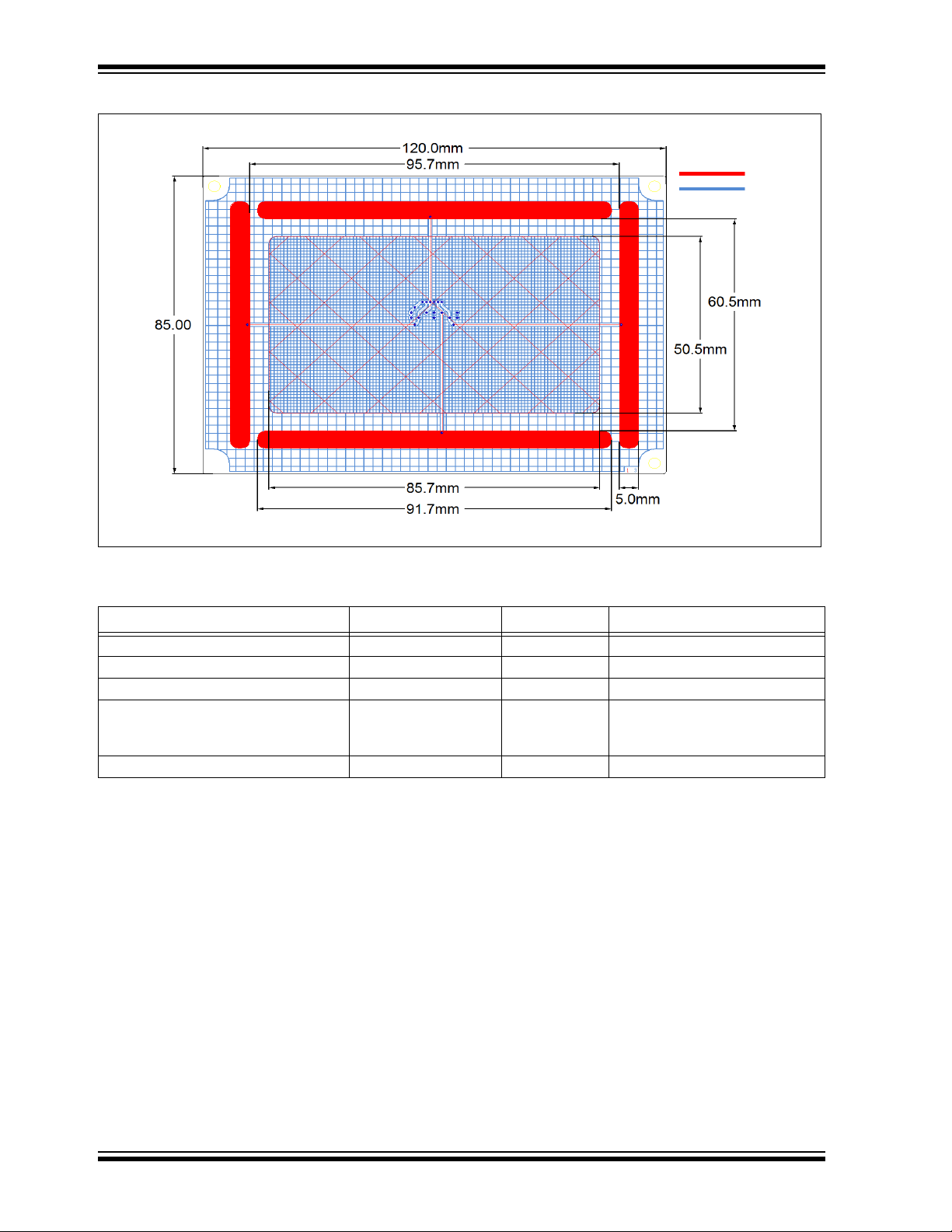

3.3 HILLSTAR 95x60 mm REFERENCE ELECTRODE

The 95x60 mm Reference Electrode provided with the Hillstar Development Kit

consists of one Tx and a set of five Rx electrodes (north, east, south, west, center),

which are placed in two different layers. An additional ground layer is placed

underneath the Tx electrode and shields the electrode’s back from external influences.

FIGURE 3-3: HILLSTAR PCB ELECTRODE

The PCB is connected to the MGC3130 Unit by the 2 mm 7-pin board-to-board

connector. The interface includes the following signals: GND, Rx4, Rx3, Tx, Rx2, Rx1,

and Rx0.

The dimension of the board is 120 x 85 mm; the sensitive area is 95 x 60 mm.

The five Rx electrodes include four frame electrodes and one center electrode, as

shown in Figure 3-3. The frame electrodes are named according to their cardinal

directions: north, east, south and west. The dimensions of the four Rx frame electrodes

define the maximum sensing area. The center electrode is structured (cross-hatched)

to get a similar input signal level as the four frame electrodes.

The Tx electrode spans over the complete area underneath the Rx electrodes. It is

cross-hatched to reduce the capacitance between Rx and Tx (C

below the center electrode covers 50% of the copper plane, the area around only 20%.

The Rx feeding lines are embedded into the Tx electrode in the third layer (refer to

Figure 3-4 and Figure 3-5). This supports shielding of the feeding lines.

Dimensions are given in Table 3-2.

2013 Microchip Technology Inc. DS40001721A-page 25

). The Tx area

RxTx

Page 26

MGC3130 Hillstar Development Kit User’s Guide

FIGURE 3-4: ELECTRODE LAYOUT

TABLE 3-2: HILLSTAR ELECTRODE DIMENSIONS

Length Width Design

Horizontal Electrodes (Rx) 91.7 mm 5 mm solid

Vertical Electrodes (Rx) 70.5 mm 5 mm solid

Center Electrode (Rx) 85.7 mm 50.5 mm 3% cross-hatched

Tx Electrode (refer to Figure 3-4)

Part I (under center electrode)

Part II (outside Part I)

Ground Area 120 mm 85 mm solid

120 mm

85.7 mm

120 mm

85 mm

50.5 mm

85 mm

50% cross-hatched

20% cross-hatched

The electrode PCB is based on a 4-layer PCB design using FR4 material. Three

functional layers are used:

• Layer 1 (Top): Rx electrodes

• Layer 3: Tx electrode and Rx feeding lines

• Layer 4 (Bottom): Ground

Layer 2 is not used.

DS40001721A-page 26 2013 Microchip Technology Inc.

Page 27

Hillstar Boards – Hardware Description

Tx: 35 µm

Tx

Rx : 18 µm

GND: 18 µm

Not Used: 35 µm

0.25 mm

0.15 mm

935 µm

540 µm

1.546 mm

Top layer

Bottom

layer

2ndlayer

3

rd

layer

Rx feeding line

™

FIGURE 3-5: PCB LAYER STACK

In a target system design the GND layer is not required. It is added for the Hillstar sensing electrode as a shielding layer and shall simulate the presence of static components

which are placed in a target device underneath the sensing electrodes.

Note: Please refer to the “MGC3130 GestIC® Design Guide” for the electrodes

equivalent circuitry, capacitances (C

values.

RxTx

, C

RxG

, Tx

) and their typical

RxG

3.4 I2C TO USB BRIDGE

Connecting the MGC3130 Unit to a PC requires an I2C to USB Bridge. The Hillstar

Bridge works as a Composite Device Class (CDC). It controls the USB transfer towards

the host PC and handles the I

provides 3.3V power supply and the MCLR

The bridge function is handled by Microchip’s PIC18F14K50 USB microcontroller.

The board is equipped with a mini USB connector (Type A) and a 2 mm 6-pin female

board-to-board connector for the I

includes the following signals: EIO0, 3.3V, GND, SDA0, SCL0, and MCLR

to Figure 3-6.

FIGURE 3-6: I

2

C™ TO USB BRIDGE

2

C communication with the MGC3130 Unit. Moreover, it

signal to the MGC3130 Unit.

2

C interface. The interface to the MGC3130 Unit

. Please refer

2013 Microchip Technology Inc. DS40001721A-page 27

Page 28

MGC3130 Hillstar Development Kit User’s Guide

PIC18F14K50

RB4

RB6

RC0

RC6

RA0

RA1

SDA

SCL

TS

3.3V

1.8kΩ

10kΩ

1.8kΩ

MCLR

10kΩ

MGC3130

SI0

SI1

EIO0

MCLR

I2CTMto USB BridgeMGC3130 Unit

USB D+

USB D-

USB

I2CTMMasterI2CTMSlave

PC

The I2C to USB Bridge is powered via the USB port. Microchip’s Low Dropout (LDO)

Voltage Regulator MCP1801 is used to transform the 5V USB power to 3.3V required

for the PIC18F14K50. By default, 3.3V are also routed to the MGC3130 Unit via the I

interface. The 3.3V power supply towards the MGC3130 Unit can be cut by removing

the 0 resistor R7.

The LEDs indicate the following:

• POWER – signals that the I

• LED1 – blinks fast (~10 Hz) to indicate that there is no USB connection

established

• LED1 – blinks slow (~1 Hz) to indicate that the USB connection is established

• LED 2 – is on when there is data on the I

• LED 2 – is off when there is no data on the I

The communication between Bridge and MGC3130 Unit is accomplished via a 2-wire

2

I

C compatible serial port. Please refer to Figure 3-7.

In addition, the Hillstar Development Kit integrates an open-drain transfer status line

(TS) and the MGC3130 MCLR

TS is connected to the RC0 pin of the PIC18F14K50 and MCLR

For a detailed description of the I

Gesture Controller Data Sheet” (DS40001667).

The default I

2

C address of the bridge is set to 0x42 but can also be switched to 0x43

by changing the firmware running on the PIC18F14K50.

2

C to USB Bridge is powered (3.3V)

2

C bus

2

C bus

signal, according to the MGC3130 reference circuitry.

to RC6.

2

C interface refer to the “MGC3130 Single-Zone 3D

2

C

FIGURE 3-7: I

Note: To update the PIC18F14K50 firmware, please refer to ‘MGC3130

PIC18F14K50 Host Reference Code’, available on

www.microchip.com/GestICGettingStarted.’

2

C™ AND USB DATA INTERFACE

2

For Schematics, Layout and Bill of Material of the I

C to USB Bridge please refer to

Appendix A.

DS40001721A-page 28 2013 Microchip Technology Inc.

Page 29

Chapter 4. Design In: Hillstar In Target Application

4.1 INTRODUCTION

The Hillstar Development Kit is designed to support an easy integration of Microchip’s

MGC3130 3D Tracking and Gesture Controller into customer’s applications.

The three Hillstar PCBs can be plugged to a PC via USB cable and used for

evaluation of MGC3130 chip and GestIC technology.

During the customer’s design-in process the individual boards can be combined

according to the customers need.

Three examples are given below:

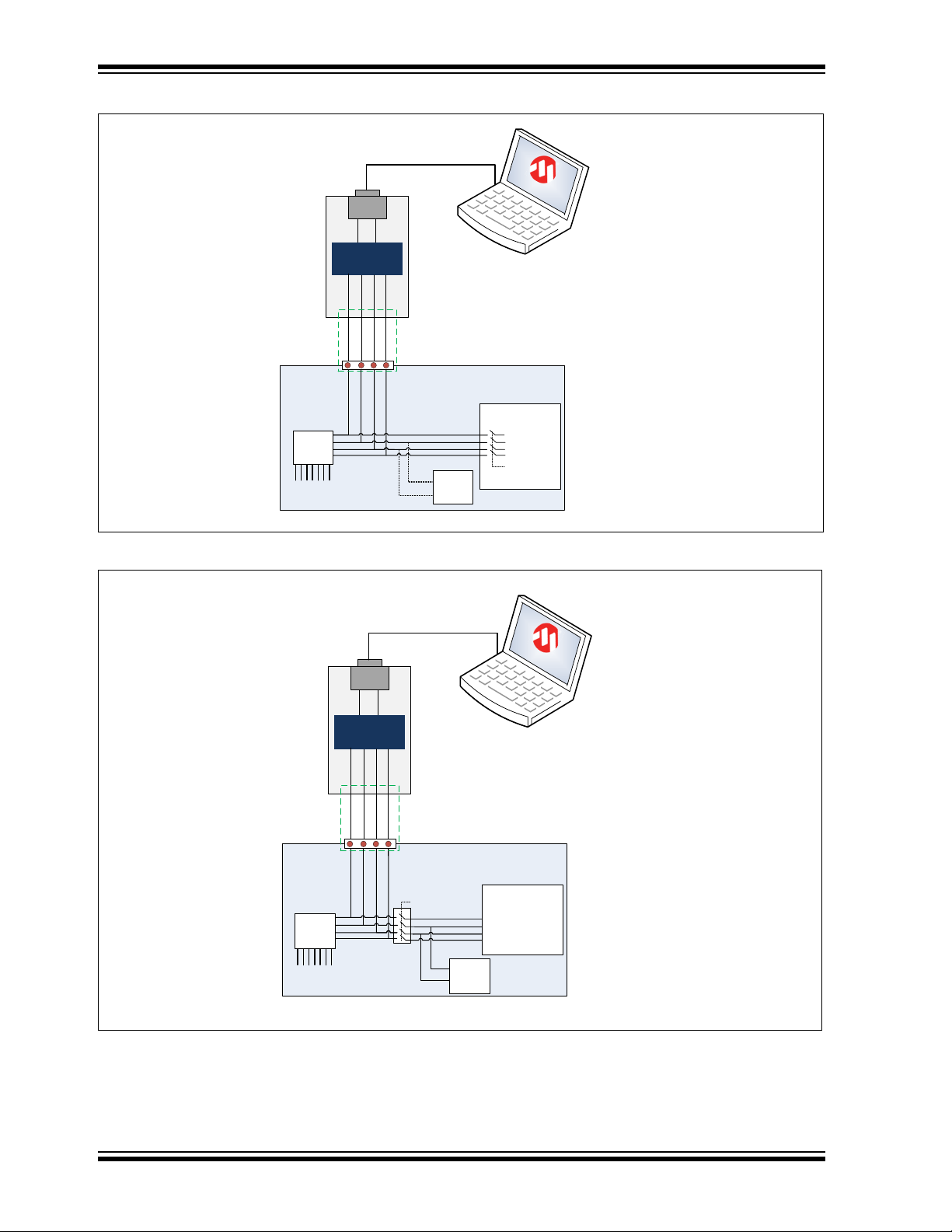

• Combine MGC3130 Unit and I

electrodes

•Use I

circuitry in the customer’s design (in-circuit)

• Combine MGC3130 Unit and Electrodes to develop gesture-driven applications

for PC-based or embedded software environments

For in-circuit parameterization and debugging it is mandatory to control the MGC3130

via Aurea Control Software. For that purpose, the customer’s application should

provide an appropriate hardware or software interface.

MGC3130 HILLSTAR DEVELOPMENT

KIT USER’S GUIDE

2

C to USB Bridge to evaluate customized

2

C to USB Bridge to parameterize and debug the MGC3130 application

4.2 INTEGRATION EXAMPLES

The following figures show typical hardware circuits for MGC3130 integration into a

customer’s application.

Figure 4-1 and Figure 4-2 show the control via I

to USB Bridge acts as an I

• Switched off (I

• Switched to Slave or Listen mode or

• Disconnected (through an external switch, refer to Figure 4-2)

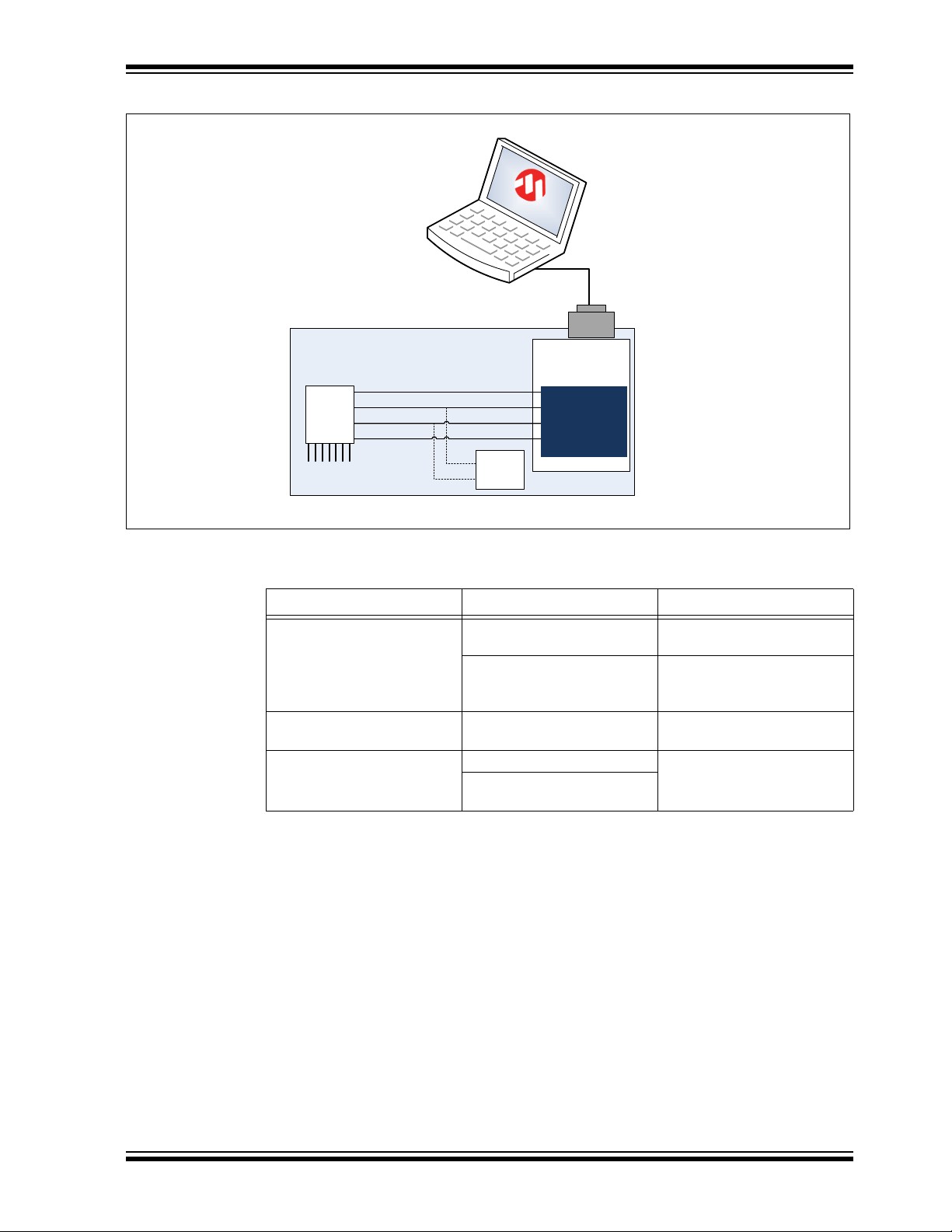

As an alternative, it is also possible to establish an USB connection between the application processor and a PC without using an I

4-3.

2

C lines configured as high Z, refer to Figure 4-1)

2

2

C master, the application processor I2C should be:

C and an external PC. The Hillstar I2C

2

C to USB Bridge. Please refer to Figure

2013 Microchip Technology Inc. DS40001721A-page 29

Page 30

MGC3130 Hillstar Development Kit User’s Guide

Customer application

Bridge

TS

USB to I²C

(HID)

I²C SCL

I²CtoUSB

Bridge

Application

Processor

USB

Reset

For debugging and

parametetrization

purposes

USB cable

To electrodes

I²C SDA

TS

I²C SDA

I²C SCL

Reset

MGC

3130

High Z for

bridge

access

I2C

client

AUREA

Customer application

Bridge

TS

USB to I²C

(HID)

I²C SCL

I²CtoUSB

Bridge

Application

Processor

USB

Reset

For debugging and

parametetrization

purposes

USB cable

To electrodes

I²C SDA

TS

I²C SDA

I²C SCL

Reset

MGC

3130

I2C

client

AUREA

open for

bridge

access

FIGURE 4-1: MGC3130 PARAMETERIZATION CIRCUIT WITH INTERNAL SWITCH

FIGURE 4-2: MGC3130 PARAMETERIZATION CIRCUIT WITH EXTERNAL SWITCH

DS40001721A-page 30 2013 Microchip Technology Inc.

Page 31

Design In: Hillstar In Target Application

Customer application

Application

Processor

For debugging and

parametetrization

purposes

USB cable

To electrodes

TS

I²C SDA

I²C SCL

Reset

MGC

3130

I2C

client

AUREA

USB to I²C

(CDC/HID)

FIGURE 4-3: MGC3130 PARAMETERIZATION CIRCUIT FOR USB BASED APPLICATIONS

TABLE 4-1: MGC3130 PARAMETERIZATION CIRCUITS COMPARISON

Parameterization Circuit Advantages Drawbacks

With Internal Switch Easy Approach Processor pins need to be

switchable to high Z

Low hardware efforts No other clients can be

controlled during Aurea

access

With External Switch Communication to other I2C™

Additional hardware switch

clients not interrupted

USB Based Applications No hardware efforts Additional software efforts

Works if other I

2

C™ clients

connected to the bus

2013 Microchip Technology Inc. DS40001721A-page 31

Page 32

MGC3130 Hillstar Development Kit User’s Guide

NOTES:

DS40001721A-page 32 2013 Microchip Technology Inc.

Page 33

MGC3130 HILLSTAR DEVELOPMENT

KIT USER’S GUIDE

Chapter 5. Troubleshooting

Troubleshooting Information

Power LED does not illuminate

In case the power LED does not illuminate it is likely that the board is not powered.

Possible Solutions:

• Check the board is connected to your PC’s USB port.

• Change the USB cable or use a different USB port on your PC.

• Check if the PC is switched on.

LED 1 blinks fast

When LED 1 blinks fast (~10 Hz) the USB connection is not established towards the PC.

Possible Solutions:

• Make sure the Windows CDC driver is installed (refer to Appendix D. “Driver Installation Man-

ual”).

• Makes sure the MGC3130 Unit and the I

in the USB connection (refer to Section 2.2 “Step 1: Build-up Development Kit”).

• Reconnect the board by unplugging and plugging in again the USB connection.

Signal streaming stops

Signal stream in Aurea GUI stops when there is no approach towards the sensing area. This behavior is

intended. When using the Aurea GUI, the Wake-up on Approach feature is automatically enabled.

Possible Solutions:

Disable the Wake-up on Approach feature in the Real-Time Control bar of Aurea by unchecking the

Approach Detection/Power Saving check box for continuous signal streaming.

No Position data displayed, Electrode signals are zero

Signal matching parameters have been mismatched and accidentally stored into the Flash.

Possible Solutions:

• Perform “Autoparameterization” in the AFE Parameterization of Aurea Setup tab. Make sure there is

no hand approach towards the electrodes during autoparamterization process.

• Restore the default Signal Matching parameters by re-flashing the original MGC3130 GestIC

Library file.

LED 1 and 2 on I

When LED 1 and LED 2 on the I

is in Bootloader Update mode and therefore not operating code. The PIC18F14K50 will start in Bootloader

Update mode in case the MGC3130 Unit is not connected to the I

Possible Solutions:

• Please disconnect the I2C™ to USB Bridge from USB. Connect the MGC3130 Unit and the I2C™ to

USB Bridge first and then plug in the USB connection.

2

C™ to USB Bridge are off

2

C™ to USB Bridge are off but the power LED is on, the PIC18F14K50

2

C™ to USB Bridge are already connected before plugging

®

2

C™ to USB Bridge.

2013 Microchip Technology Inc. DS40001721A-page 33

Page 34

MGC3130 Hillstar Development Kit User’s Guide

NOTES:

DS40001721A-page 34 2013 Microchip Technology Inc.

Page 35

Appendix A. Schematics

A.1 INTRODUCTION

This appendix contains the MGC3130 Hillstar Development Kit schematic and Bill of

Materials.

A.2 BILL OF MATERIALS

TABLE A-1: I2C™ TO USB BRIDGE BILL OF MATERIALS

Qty. Description Name

1 Connector, Mini USB 5-pin Type B, SMD BU1

1 Connector, 2 mm socket 6-pin, SMD BU2

1 Capacitor, 100 nF, 10%, X7R, SMD 0402 C1

3 Capacitor, 1 µF, 10%, X5R, 10 V, SMD 0402 C2, C3, C5

1 Capacitor, 10 µF, 20%, X5R, 6.3 V, SMD 0603 C4

3 LED, 571 nm, green clear, 0603 SMD D1, D2, D3

1 IC, MCP1801T LDO, Voltage Regulator, 3.3V, 150 mA, 5-Pin SOT-23 IC1

1 IC, PIC18F14K50 USB Flash Microcontroller, 20-Pin SSOP IC2

3 Resistor, 1 kΩ, 1%, 1/16W, SMD 0402 R3, R4, R6

1 Resistor, 150 kΩ, 1%, 1/16W, SMD 0402 R5

1 Resistor, 0 kΩ, 1%, 1/16W, SMD 0603 R7

1 Crystal, 12 MHz, 33 pF, SMD XTAL1

MGC3130 HILLSTAR DEVELOPMENT

KIT USER’S GUIDE

TABLE A-2: HILLSTAR – I2C™ TO USB BRIDGE MOUNTING OPTION

Qty. Description Name

1 Connector, 1 mm FPC 6-pin, SMD ST1

2013 Microchip Technology Inc. DS40001721A-page 35

Page 36

MGC3130 Hillstar Development Kit User’s Guide

TABLE A-3: HILLSTAR – MGC3130 UNIT BILL OF MATERIALS

Qty. Description Name

1 Connector, 2 mm socket 7-pin, SMD BU1

1 Connector, 2 mm header 6-pin, SMD ST1

1 Capacitor, 100 nF, 10%, X7R, SMD 0402 C1

2 Capacitor, 4,7 µF, 20%, X5R, 6.3V, SMD 0402 C2, C3

1 LED, 571 nm green clear, 0603 SMD D2

1 IC, MGC3130, 28-Pin QFN IC1

2 Resistor, 1,8 kΩ, 1%, 1/16W, SMD 0402 R1, R2

8 Resistor, 10 kΩ, 1%, 1/16W, SMD 0603 R4, R6, R7,

R11, R12, R13,

R14, R15

1 Resistor, 0 kΩ, 1%, 1/16W, SMD 0402 R16

1 Resistor, 10 kΩ, 1%, 1/16W, SMD 0402 R17

1 Resistor, 1 kΩ, 1%, 1/16W, SMD 0402 R18

TABLE A-4: HILLSTAR – MGC3130 UNIT MOUNTING OPTION

Qty. Description Name

1 Connector, 1 mm FPC 6-pin, SMD ST3

A-5: HILLSTAR – ELECTRODE BILL OF MATERIALS

Qty. Description Name

1 Connector, 2 mm header 7-pin, SMD ST1

DS40001721A-page 36 2013 Microchip Technology Inc.

Page 37

A.3 BOARD – SCHEMATICS AND LAYOUT

™

FIGURE A-1: HILLSTAR GestIC® UNIT SCHEMATIC

Schematics

2013 Microchip Technology Inc. DS40001721A-page 37

Page 38

MGC3130 Hillstar Development Kit User’s Guide

Top View

Bottom View

™

FIGURE A-2: ASSEMBLY OF MGC3130 UNIT

FIGURE A-3: HILLSTAR I

2

C™ TO USB BRIDGE SCHEMATIC

DS40001721A-page 38 2013 Microchip Technology Inc.

Page 39

FIGURE A-4: ASSEMBLY OF HILLSTAR I2C™ TO USB BRIDGE

Top View

Bottom View

™

Schematics

2013 Microchip Technology Inc. DS40001721A-page 39

Page 40

MGC3130 Hillstar Development Kit User’s Guide

NOTES:

DS40001721A-page 40 2013 Microchip Technology Inc.

Page 41

MGC3130 HILLSTAR DEVELOPMENT

25

36

48

63

88

120

158

204

256

293

319

317

296

285

312

320

299

257

211

164

130

98

76

58

43

34

0

50

100

150

200

250

300

350

400

450

500

signal deviation / digits

distance to West

West -> East

SD North

SD East

SD South

SD West

SD Center

SD: Signal Deviation

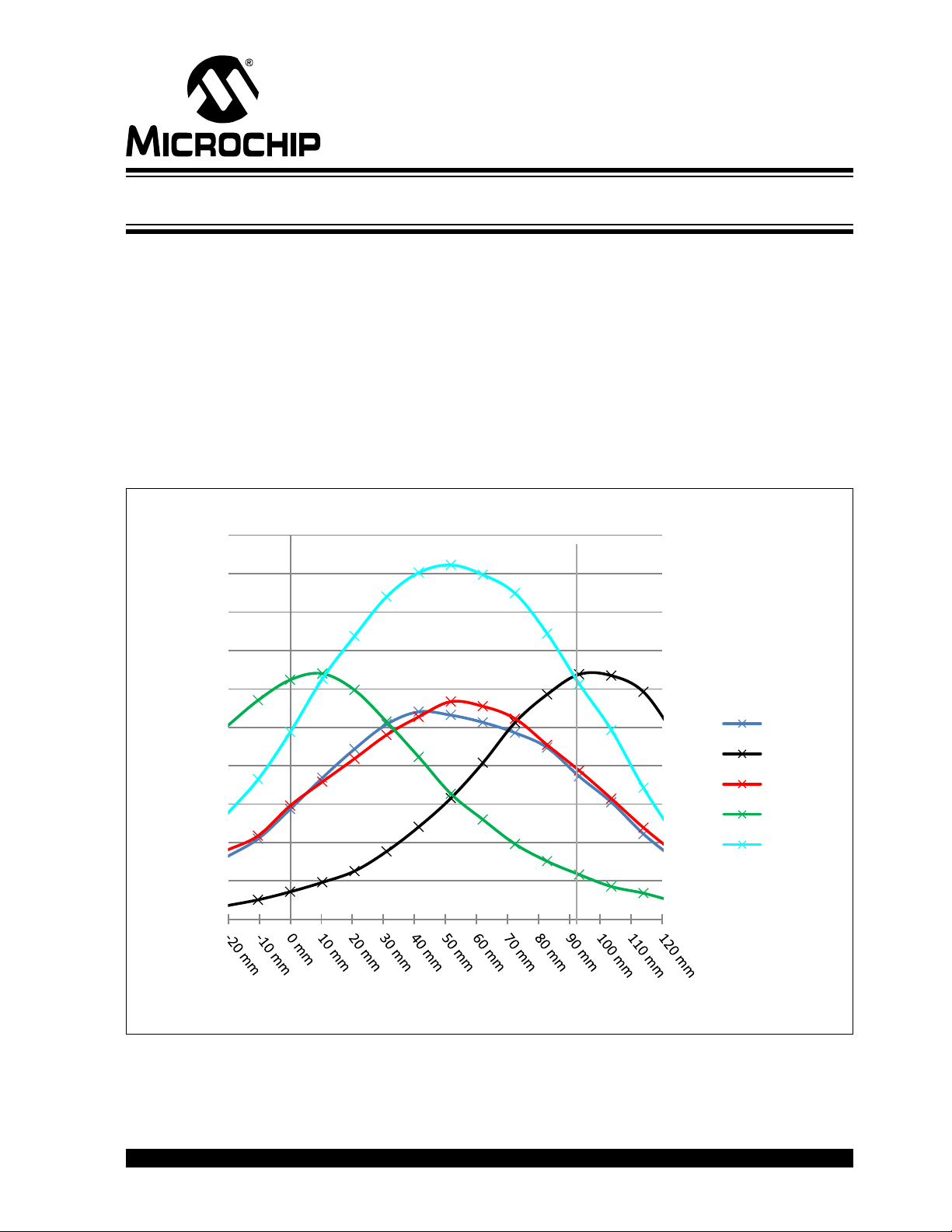

Appendix B. Sensitivity Profile and Capacitances

B.1 INTRODUCTION

This appendix contains the sensitivity profile and the electrode capacitances of the

Hillstar Development Kit hardware.

The measurement procedure of both, the sensitivity profile and the electrode

capacitances are outlined in “MGC3130 GestIC

B.2 SENSITIVITY PROFILES

The sensitivity profiles were conducted using a 40x40x70 mm hand brick and a 30 mm

spacer brick.

FIGURE B-1: SENSITIVITY PROFILE FROM WEST TO EAST

KIT USER’S GUIDE

®

Design Guide”.

2013 Microchip Technology Inc. DS40001721A-page 41

Page 42

MGC3130 Hillstar Development Kit User’s Guide

320

339

354

355

353

329

292

266

227

193

150

131

103

84

64

78

90

110

135

171

207

255

283

319

350

375

382

382

363

334

0

50

100

150

200

250

300

350

400

450

500

signal deviation / digits

distance to North

North -> South

SD North

SD East

SD South

SD West

SD Center

SD: Signal Deviation

FIGURE B-2: SENSITIVITY PROFILE FROM NORTH TO SOUTH

B.3 ELECTRODE CAPACITIES

The capacitances between the Rx electrodes and GND (C

pF input capacitance of the MGC3130 Rx input buffer (C

TABLE B-3: HILLSTAR ELECTRODE CAPACITIES

Channel CRxG CRxTx

North 9 pF 20 pF

East 9 pF 18 pF

South 9 pF 20 pF

West 8 pF 18 pF

Center 7 pF 65 pF

C

TxG

= 590 pF

) does not include the 5

RxG

).

Buf

DS40001721A-page 42 2013 Microchip Technology Inc.

Page 43

MGC3130 HILLSTAR DEVELOPMENT

Appendix C. Parameterization Support

C.1 HOW TO BUILD A HAND BRICK

For parameterization and performance evaluation of the customer’s electrode design,

the Hillstar Development Kit contains a set of hand and spacer bricks. The hand brick

is a conductive block of 40x40x70 mm and represents a human hand. It must be

connected to ground via cable in order to simulate the grounding conditions of the

human body.

The Hillstar package contains an assembly set to build the hand brick consisting of a

Styrofoam block (40x40x70 mm) and an adhesive copper foil.

The following section explains how to assemble the hand brick.

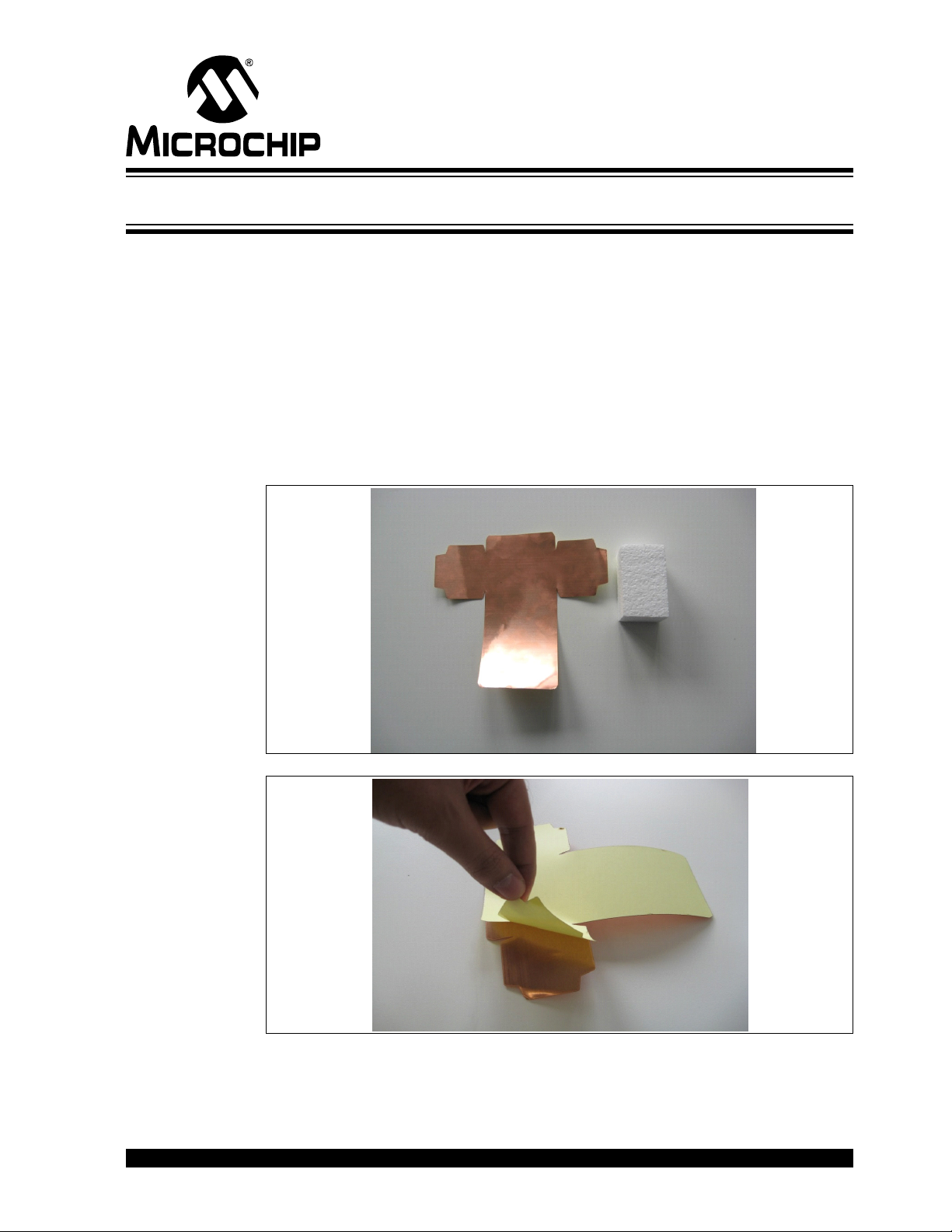

1. Take the copper layer and the Styrofoam block with the dimensions of

(40x40x70 mm).

KIT USER’S GUIDE

2. Revert the copper layer and remove the glue foil.

2013 Microchip Technology Inc. DS40001721A-page 43

Page 44

MGC3130 Hillstar Development Kit User’s Guide

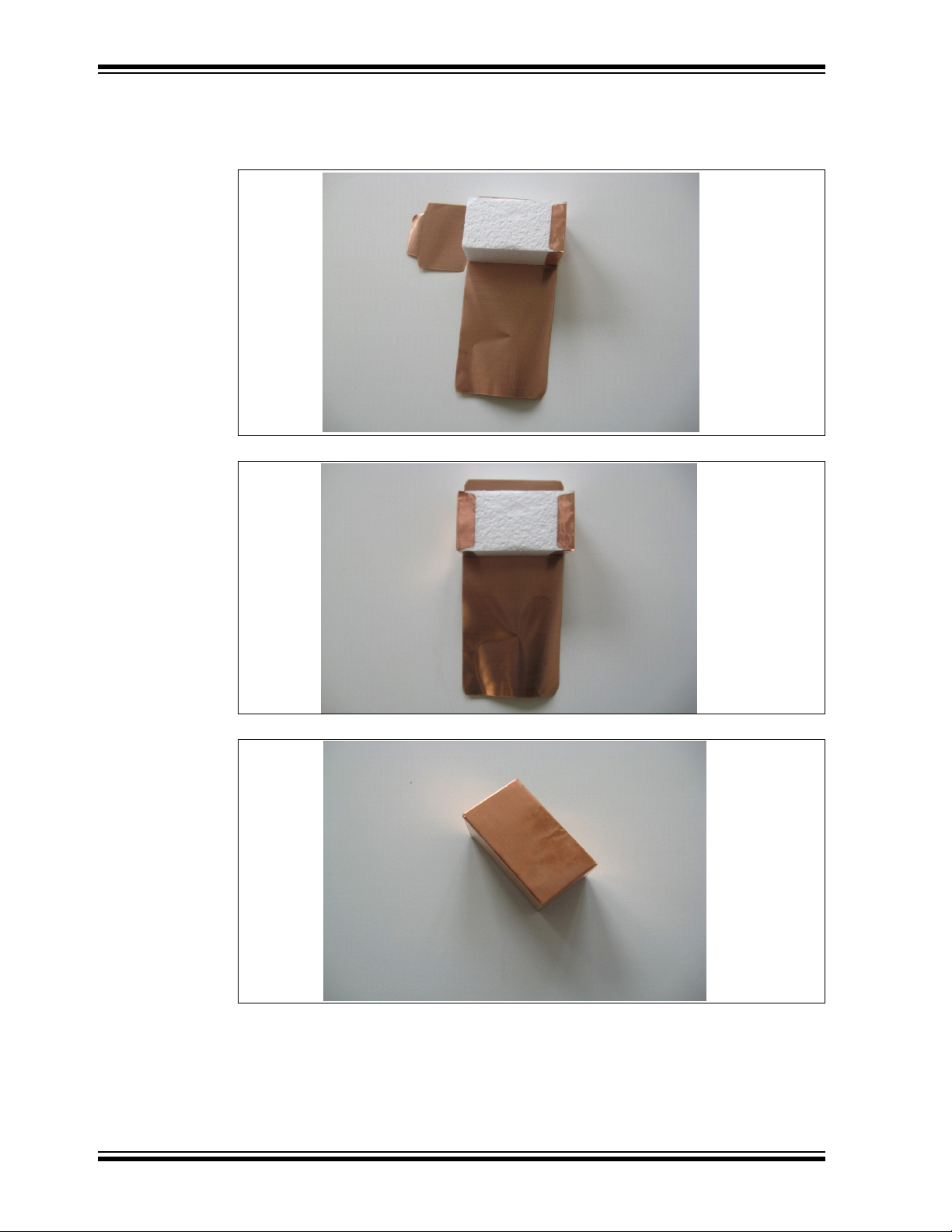

3. Place the Styrofoam block on the copper layer exactly on the middle. Be

careful to be accurate! Fold the copper. Follow along the inside lines, and

fold the copper inward. Start with right, left sides and then with middle part.

Align the folds.

4. Finish up your box. Tape all of the sides together, and you’re done.

DS40001721A-page 44 2013 Microchip Technology Inc.

Page 45

Parameterization Support

Thin wire for grounding (e.g.

0,15mm diameter, 50cm length)

5. Solder a thin wire (approx. 50 cm) on the top of the brick which will be con-

nected later to ground.

6. Finished.

C.2 USAGE OF THE HAND BRICK AS ARTIFICIAL HAND

For parameterization and performance evaluation purposes of the customer’s

electrode design, the kit contains a set of hand and spacer bricks. This artificial hand

brick simulates Human Hand effect and is made of a Styrofoam block covered with light

copper and has a fixed size. Spacer bricks (Styrofoam block without copper layer) are

used to position the hand brick in different heights to the electrode. Because of a εr≈1of

Styrofoam, the spacer brick does not influence the measurement results.

For quick parameterization, the ground wire connected to the hand brick should be

maintained using your hand which emulates the ground connection. The wire should

be hold at 50 cm minimum and the line should also be straight to avoid any influence

to the system sensitivity as shown in Figure C-1.

For parameterization process, please refer to “MGC3130 GestIC

the appropriate wizards in Aurea PC software.

®

Design Guide” and

2013 Microchip Technology Inc. DS40001721A-page 45

Page 46

MGC3130 Hillstar Development Kit User’s Guide

FIGURE C-1: USAGE OF ARTIFICIAL HAND

DS40001721A-page 46 2013 Microchip Technology Inc.

Page 47

MGC3130 HILLSTAR DEVELOPMENT

Appendix D. Driver Installation Manual

Go through the following steps to manually install the Windows CDC Driver on your PC.

D.1 OPEN DEVICE MANAGER

While the Hillstar Development Board is connected to your PC press Start, right-click

on Computers and select Manage. This will bring up the Computer Management

window shown in Figure D-1. On the left sidebar select Device Manager.

FIGURE D-1: COMPUTER MANAGEMENT

KIT USER’S GUIDE

D.2 SELECT DEVICE

1. Right Click on GestIC Bridge and select Update Driver Software.

2. Select Search Method

3. The window shown in Figure D-2 will open. Choose Browse my Computer for

driver software.

2013 Microchip Technology Inc. DS40001721A-page 47

Page 48

MGC3130 Hillstar Development Kit User’s Guide

FIGURE D-2: Update Driver Software

D.3 LOCATE DRIVER

1. Click Browse and navigate to the driver files on your local drive (refer to

Figure D-3).

2. Press Next and the driver will be installed.

FIGURE D-3: Browse for Driver Software

D.4 VERIFY COMMUNICATION

The driver is properly installed and the communication between the PC and the Hillstar

Development Board is successfully established when LED 1 and LED 2 blink

alternatively.

DS40001721A-page 48 2013 Microchip Technology Inc.

Page 49

MGC3130 HILLSTAR DEVELOPMENT

KIT USER’S GUIDE

Appendix E. Glossary

TABLE E-1: GestIC® GLOSSARY

Term Definition

AFE Analog front end

Application Host PC or embedded controller which controls the MGC3130

Aurea MGC3130 PC control software with graphical user interface

®

Colibri Suite Embedded DSP suite within the GestIC

Deep Sleep MGC3130 Power-Saving mode

E-field Electrical field

Frame Electrodes Rectangular set of four electrodes for E-field sensing

®

GestIC

GestIC

Gesture Recognition Microchip’s stochastic HMM classifier to automatically detect and

Gesture Set A set of provided hand movement patterns

Hand Brick Copper coated test block (40x40x70 mm)

HMM Hidden Markov Model

MGC3130 Single-Zone 3D Gesture Sensing Controller

Position Tracking GestIC

Sabrewing MGC3130 evaluation board

Self Wake-up MGC3130 Power-Saving mode

Sensing Area Area enclosed by the four frame electrodes

Sensing Space Space above sensing area

Signal Deviation Term for the delta of the sensor signal on approach of the hand

Spacer Brick Spacer between the sensor layer and hand brick

SPU Signal Processing Unit

Approach Detection GestIC

Technology Microchip’s patented technology providing 3D free-space gesture

recognition utilizing the principles of electrical near-field sensing

®

Library Includes the implementation of MGC3130 features and is delivered

as a binary file preprogrammed on the MGC3130

classify hand movement patterns

®

technology feature

versus non-approach

(Styrofoam block 40x40xh mm) with h= 1 / 2 / 3 / 5 / 8 / 12 cm

®

technology feature: Power-Saving mode of the MGC3130

with approach detection

Library

2013 Microchip Technology Inc. DS40001721A-page 49

Page 50

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-2819-3187

Fax: 86-571-2819-3189

China - Hong Kong SAR

Tel: 852-2943-5100

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8864-2200

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-3019-1500

Japan - Osaka

Tel: 81-6-6152-7160

Fax: 81-6-6152-9310

Japan - Tokyo

Tel: 81-3-6880- 3770

Fax: 81-3-6880-3771

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-213-7828

Fax: 886-7-330-9305

Taiwan - Taipei

Tel: 886-2-2508-8600

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

08/20/13

DS40001721A-page 50 2013 Microchip Technology Inc.

Loading...

Loading...