Page 1

MCP8063

12V 3-Phase BLDC

Sensorless Fan Controller

Demonstration Board

User’s Guide

2014 Microchip Technology Inc. DS50002248A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

FlashFlex, K

PICSTART, PIC

and UNI/O are registered trademarks of Microchip T echnology

Incorporated in the U.S.A. and other countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MTP, SEEVAL and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

Analog-for-the-Digital Age, Application Maestro, BodyCom,

chipKIT, chipKIT logo, CodeGuard, dsPICDEM,

dsPICDEM.net, dsPICw orks, dsSPEAK, ECAN,

ECONOMON ITO R , FanSense, HI-T IDE, In-Circuit S e ri a l

Programming, ICSP, Mindi, MiWi, MPASM, MPF, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, Omniscient Code

Generation, PICC, PICC-18, PICDEM, PICDEM.net, PICkit,

PICtail, REAL ICE, rfLAB, Select Mode, SQI, Serial Quad I/O,

Total Endurance, TSHARC, UniWinDriver, WiperLock, ZENA

and Z-Scale are trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

GestIC and ULPP are registered trademarks of Microchip

Technology Germany II GmbH & Co. KG, a subsidiary of

Microchip Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2014, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-63276-036-4

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

32

logo, rfPIC, SST, SST Logo, SuperFlash

QUALITY MANAGEMENT S

DS50002248A-page 2 2014 Microchip Technology Inc.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

Object of Declaration: MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board User’s Guide

2014 Microchip Technology Inc. DS50002248A-page 3

Page 4

MCP8063 12V 3-Phase BLDC Sensorless Fan Controll er Demonstration Board User’s Guide

NOTES:

DS50002248A-page 4 2014 Microchip Technology Inc.

Page 5

MCP8063 12V 3-PHASE BLDC

SENSORLESS FAN CONTROLLER

DEMONSTRATION BOARD

USER ’S GUIDE

Table of Contents

Preface ...........................................................................................................................7

Introduction............................................................................................................7

Document Layout .................................................................................................. 7

Conventions Used in this Guide............................................................................ 8

Recommended Reading.............................................................. .. ........................9

The Microchip Web Site........................................................................................ 9

Customer Support....................... ....................................................... ...................9

Document Revision History................................................................................... 9

Chapter 1. Product Overview

1.1 Introduction ...................................................................................................11

1.2 MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration

Board Hardwa re De s cription . ................................................................. 12

1.3 What the MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board Kit Includes ..........................................................12

Chapter 2. Installation and Operation

2.1 Getting Sta rted ............................................................................................. 13

2.2 MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration

Board Software Description ............ ............. ... .. ...................................... 15

Appendix A. Schematics and Layouts

A.1 Introduction ..................................................................................................21

A.2 Board – Schematic ... .................................................................... ................ 22

A.3 Board – Top Sil k ............ ................ .............................................................. 23

A.4 Board – Top Copper and Silk .......................................................................24

A.5 Board – Top Copper ....................................................................................25

A.6 Board – Bottom Copper ...............................................................................26

A.7 Board – Bottom Copper and Silk .................................................................27

A.8 Board – Bott o m Si lk ......................................................................... ............ 28

Appendix B. Bill of Materials

Worldwide Sales and Service ....................................................................................32

2014 Microchip Technology Inc. DS50002248A-page 5

Page 6

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

NOTES:

DS50002248A-page 6 2014 Microchip Technology Inc.

Page 7

MCP8063 12V 3-PHASE BLDC

SENSORLESS FAN CONTROLLER

DEMONSTRATION BOARD

USER ’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board. Items

discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the MCP8063 12V 3-Phase BLDC Sensorless

Fan Controller Demonstration Board as an evaluation tool to debug on a target motor

system. The manual layout is as follows:

• Chapter 1. “Produ ct Over view” – Important information about the MCP8063

12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board.

• Chapter 2. “Installation and Operation” – Includes instructions on how to get

started with the MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board.

• Appendix A. “Schematics and Layouts” – Shows the schematic and layout

diagrams for the MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board.

• Appendix B. “Bill of Materials” – Lists the parts used to build the MCP8063 12V

3-Phase BLDC Sensorless Fan Controller Demonstration Board.

2014 Microchip Technology Inc. DS50002248A-page 7

Page 8

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic chara c ters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brac kets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mut ually exclus ive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS50002248A-page 8 2014 Microchip Technology Inc.

Page 9

RECOMMENDED READING

This user' s guid e descr ib es ho w to us e the MCP80 63 1 2V 3-P has e BLD C Sens or less

Fan Controller Demonstration Board. Another useful document is listed below. The

following Microchip document is available and recommended as a supplemental

reference resource.

• MCP8063 Data Sheet – “3-Phase Brushless DC Sinusoidal Sensorless Motor

Driver” (DS20005257)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (March 2014)

• Initial Release of this Document.

2014 Microchip Technology Inc. DS50002248A-page 9

Page 10

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

NOTES:

DS50002248A-page 10 2014 Microchip Technology Inc.

Page 11

Chapter 1. Product Overview

18V V

IN

USB Connection

Daugther board plug ge d

18V V

IN

on its socket

+

-

Mini USB

USB

PWRON

LED

LED

LED

connector

Daugther board

fan connector

ADM00532 with daugther board

WVU

1.1 INTRODUCTION

The MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board

allows the control and monitoring of Microchip 12V fan driver devices, such as the

MCP8063 or MTD6501, using a PC software connected to the MCP8063 12V 3-Phase

BLDC Sensorless Fan Controller Demonstration Board via a USB connection.

The MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board

software provides several features, such as fan driver power supply control and

monitoring, pulse-width modulation (PWM) control, and speed and current

consumption monitoring. It also allows automatic application testing.

MCP8063 12V 3-PHASE BLDC

SENSORLESS FAN CONTROLLER

DEMONSTRATION BOARD

USER ’S GUIDE

FIGURE 1-1: System Overview.

2014 Microchip Technology Inc. DS50002248A-page 11

Page 12

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

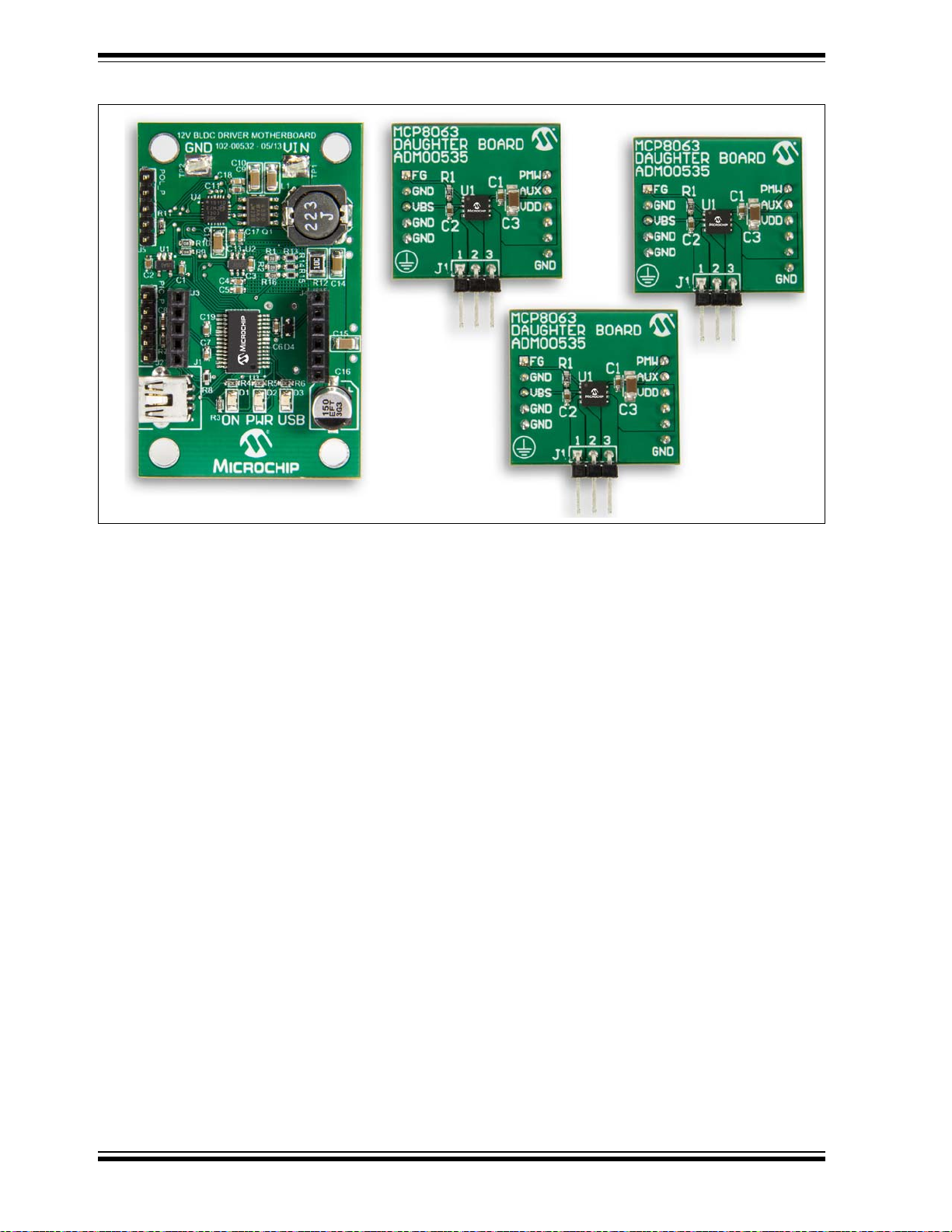

FIGURE 1-2: MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board Overview.

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board Hardware description

The MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board

contains several components, such as:

• -PIC24FJ64GB002 microcontroller for USB connection, PWM generation, FG

frequency measurement, V

component communication

• -MCP1824 LDO regulator to provide 3.3V to the microcontroller

• -MCP19110 buck regulator to provide power supply to the fan driver

• -MCP3421 Delta-Sigma ADC for sensing the fan driver current consumption

More details on the schematic are available in Appendix A. “Schematics and

Layouts”.

measurement, activation of other signals and

DD

1.2 WHAT THE MCP8063 12V 3-PHASE BLDC SENSORLESS FAN CONTROLLER DEMONSTRATION BOARD KIT INCLUDES

The MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board

includes:

• MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board

(ADM00532)

• 3 x MCP8063 daughter boards (ADM00535)

• A mini-USB cable

• Important Information Sheet

DS50002248A-page 12 2014 Microchip Technology Inc.

Page 13

Chapter 2. Installation and Operation

18V V

IN

+

-

Mini-USB

USB

PWR

ON

LED

LED LED

connector

Daughter board

fan connector

ADM00532 with Daughter Board

Daughter board plugged on

its socket

1

6

3

4

5

Daughter board socket

18V V

IN

+

-

Mini-USB

USB

PWR

ON

LED

LED

LED

connector

ADM00532 w/o Daughter Board

Legend:

1 = Power input connector (16V to 20V) 4 = ON, PWR (fan driver powered) and USB status

LED indicators

2 = Daughter board socket 5 = Mini-USB connector

3 = Daughter board fan connector 6 = Plugged daughter board

1

4

2

5

Daughter board socket

18V V

IN

+

-

Mini-USB

USB

PWR

ON

LED

LED

LED

connector

ADM00532 w/o Daughter Board

1

4

2

5

2.1 GETTING STARTED

The following sections describe how to use the MCP8063 12V 3-Phase BLDC

Sensorless Fan Controller Demonstration Board.

2.1.1 Software Installation

Download the MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board software installer from the board web page. The GUI can also be

downloaded from this web page.

Note: This application requires Microsoft .NET Framework 3.5 or later.

2.1.2 Board Installation

Figure 2-1 identifies the required points for using the MCP8063 12V 3-Phase BLDC

Sensorless Fan Controller Demonstration Board.

MCP8063 12V 3-PHASE BLDC

SENSORLESS FAN CONTROLLER

DEMONSTRATION BOARD

USER ’S GUIDE

FIGURE 2-1: Top View - Hardware Component s.

2014 Microchip Technology Inc. DS50002248A-page 13

Page 14

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

To use the MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration

Board, follow these steps:

1. Plug in a daughter board on its socket (see Figure 2-1).

2. To plug in a 3-phase BLDC sensorless fan, use the daughter board fan

connector. Note that the connection can be done in normal or reverse mode. If

the fan rotates in reverse mode, the connector can be flipped to rotate in normal

mode.

3. Start the MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board software.

4. Plug the mini-USB cable from the USB port of a computer to the MCP8063 12V

3-Phase BLDC Sensorless Fan Controller Demonstration Board connector. The

ON LED should light up.

5. If required, let the computer identify the MCP8063 12V 3-Phase BLDC

Sensorless Fan Controller Demonstration Board. The USB LED should light up

once if the USB connection is ready.

6. Restart the computer, if required.

7. Connect the power supply to the V

power supply should be able to deliver up to 1.0A. The GUI should report the V

value of the board.

test point. VIN value is 18V ±10%. The

IN

IN

Note: The order of these steps is provided as an example and can be changed.

DS50002248A-page 14 2014 Microchip Technology Inc.

Page 15

Installation and Operation

Legend:

1 = Power Control group box 5 = Instant current and speed measurement

2 = Speed Settings group box 6 = PWM duty cycle signal control

3 = Chart group box 7 = Fan driver power supply lev el co ntro l

4 = Current and speed chart display 8 = Buttons for access to other tabs

4

5

6

7

8

3

2

1

2.2 MCP8063 12V 3-PHASE BLDC SENSORLESS FAN CONTROLLER DEMONSTRATION BOARD SOFTWARE DESCRIPTION

The MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board

software window contains three tabs. The first tab is for controlling and monitoring the

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board, the

second tab is the Measurement Settings tab and the third tab is the Measurement

Results tab.

2.2.1 Control Tab

Figure 2-2 shows the options and functions available to control and monitor the board.

Note: All functions presented in Figure 2-2 are enabled only when the MCP8063

12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board is

connected to the PC via a USB connection.

FIGURE 2-2: GUI – Control Tab.

2014 Microchip Technology Inc. DS50002248A-page 15

Page 16

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

2.2.1.1 POWER CONTROL

The Power Control group box contains the Turn On/Off VDD button which allows the

power supply of the fan driver to be enabled/disabled.

Before enabling the fan driver power, verify the input voltage level indicated for the

board. It should be between 16V to 20V. Running outside this range may work, but

stability cannot be guaranteed. The power supply part on the board is not able to

generate a voltage level above the input voltage level.

The current is monitored and the fan driver power supply will shut down if the current

goes above 2.5A.

2.2.1.2 SPEED SETTINGS

This group box allows monitoring the FG pin frequency from the fan driver in hertz. This

frequency is converted to mechanical speed (Revolutions Per Minute - RPM) by

considering the plugged fan is a 4P/6S fan (two pairs of poles). If the plugged motor

contains a different number of poles, the value can be adapted in order to display the

correct mechanical RPM.

2.2.1.3 CHART

This part allows controlling the chart described in Section 2.2.1.4 “Display Chart”.

The chart adds 10 values per second. The three buttons have the following functions:

• Start/Stop – Allows the value acquisition to start or stop

• Clear – Removes all the values added to the chart

• Auto Scale – Allows the default scaling to be restored. In Default Scaling mode,

the chart will automatically adjust the scaling to ensure the complete view of all

the added values. In addition, when selecting a part of the chart with the mouse, it

is possibl e to zoom in the selection. The mouse wheel zoom in/out is also

enabled.

2.2.1.4 DISPLAY CHART

Once enabled, the chart will display the speed curve in RPM and the measured current

curve in mA over time. The chart adds 10 values per second.

2.2.1.5 CURRENT AND SPEED INDICATOR

This part clearly shows the instant current consumption and the instant speed.

2.2.1.6 PWM PIN

The PWM Pin box provides a slide bar to set the PWM duty cycle on the fan driver PWM

pin. The gauge below indicates the PWM duty cycle currently applied by the MCP8063

12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board.

2.2.1.7 FAN DRIVER POWER SUPPLY LEVEL CONTROL

The fan driver Power Supply Pin box also provides a slide bar to set the desired voltage

value for the fan driver. The gauge below indicates the instant fan driver power supply

value measured by the MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board.

DS50002248A-page 16 2014 Microchip Technology Inc.

Page 17

Installation and Operation

Legend:

1 = Measurement Settings group box

2 = Startup measurement

3 = PWM Change Measurement group box

4 = Speed Curve and Stability Measurement group box

5 = Measurement Control group box

1

2

3

4

5

2.2.2 Measurement Settings Tab

The Measurement Settings tab is used to check if the fan is correctly adapted to the

fan driver by testing the fan behavior in different tests, several times, under different

conditions.

Figure 2-3 sho ws the Measurement Settings tab. See the sections below for further

details.

FIGURE 2-3: GUI - Measurement Settings T ab.

2014 Microchip Technology Inc. DS50002248A-page 17

Page 18

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

2.2.2.1 MEASUREMENT SETTINGS

The Measurement Sett ing s Group box is used to specify the measurement corners

required. Once the automatic measurement starts (see 2.2.2.5 “Measurement

Control”), all specified corners will be tested for all selected tests. The list below details

the available corner settings:

• PWM Corners Measurement – Requires the PWM Max (%), PWM Step (%) and

PWM Min (%) v alues setting. The software will start with the maximum value

entered, and will decrease the PWM by the step value until it reaches the

minimum entered PWM value.

• Power Supply level corners are similar to the PWM corners. A power supply

level corner includes all PWM corners. This means that all PWM corners are

measured for one power supply voltage level.

• Startup check duration from Power-On [s] – If the speed of the fan is measured

as 0 RPM after this delay, the startup is considered a fail. The recommended

value for this field is 5s.

• Waiting time between each iteration [s] – Specifies how ma ny seconds are

allocated to stop the fan between two tests. This value will depend on the fan lag.

• Number of iterations per corner – Number of iterations for one corner.

2.2.2.2 STARTUP TEST SETTINGS

When the Enable startup test box is checked, the startup measurements are enabled,

measuring ev er y corne r for thi s test . If Enable startup test is not enabled, the startup

test is skipped. The other tests will be executed if they are enabled.

2.2.2.3 PWM CHANGE

The PWM Change measurement starts up with a PWM value of 100%. After the

specified startup delay (entered in the Startup check duration from Power-On [s]

field), the PWM changes depending on the PWM corner specified. The software will

then verify if the fan is still running. This last check will occur after a delay value is

specified in the Braking Delay [s] field.

In order to save time, it is possible to not stop and restart the fan, if the last PWM

change has been done successfully by checking the Do not restart if PWM change

success check box.

2.2.2.4 SPEED CURVE AND STABILITY

This measurement requires a specified number of samples in a specified condition to

check speed stability . If the Do speed curve for the whole PWM range (100% to 5%,

each 1%) and/or the Do speed curve for the whole PSM range (14V to 2V, each

0.1V) check boxes are not checked, the corners previously set are measured. For this

test, the iterations numbering will always be 1. When one of these check boxes is

checked, the software will override the specified settings.

This test will report the current average, the maximum and minimum measured speed,

the stability in % and the sigma variation.

2.2.2.5 MEASUREMENT CONTROL

This group box contains a check box and a button that allows the user to control the

test work flow:

• Stop Measuring – Starts and stops the required measuring

• Autosave at the end of the measurements – If checked, a measurement result

file will be automatically done when all the tests has been done. See

2.2.3.1 “Measurement Results” for the file location.

DS50002248A-page 18 2014 Microchip Technology Inc.

Page 19

Installation and Operation

Legend:

1 = Measurement Results group box

2 = Measurement Results table

1

2

2.2.3 Measurement Results tab

The Measurement Results tab is used to check the results of the test and manage

where the data will be stored.

Figure 2-4 sho ws the Measurement Results sub-tab:

FIGURE 2-4: GUI - Measurement Results Tab.

2014 Microchip Technology Inc. DS50002248A-page 19

Page 20

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

2.2.3.1 MEASUREMENT RESULTS

This group box contains three buttons that allow the user to control the result data

storage:

• Select location for result file – Opens a window allowing the user to specify

where the result file will be stored. Please verify that the selected location has

write access. In addition, Microsoft

order for the MCP8063 12V 3-Phase BLDC Sensorless Fan Controller

Demonstration Board Software to create a Microsoft Excel file. If Microsoft Excel

is not installed, it is possible to copy the data from the result table and paste it in

an appropriate software.

• Save current results – Stores the current measurement displayed in the result

table in a Microsoft Excel file.

• Clear All Results – Clears the current results from the result table.

2.2.3.2 RESULT TABLE

The results ar e st o re d in t hi s t a bl e. Al l th e t ests have the first si x co lu mns in co m mon ,

while the other columns are significant only for a specific test.

®

Excel® 2003 or later has to be installed in

DS50002248A-page 20 2014 Microchip Technology Inc.

Page 21

Appendix A. Schematics and Layouts

A.1 INTRODUCTION

This appendix contains the following schematics and layouts for the MCP8063 12V

3-Phase BLDC Sensorless Fan Controller Demonstration Board:

• Board – Schematic

• Board – Top Silk

• Board – Top Copper and Silk

• Board – Top Copper

• Board – Bottom Copper

• Board – Bottom Copper and Silk

• Board – Bottom Silk

MCP8063 12V 3-PHASE BLDC

SENSORLESS FAN CONTROLLER

DEMONSTRATION BOARD

USER ’S GUIDE

2014 Microchip Technology Inc. DS50002248A-page 21

Page 22

DS50002248A-page 22 2014 Microchip Technology Inc.

PIC_LED_3

VBIAS_IC

FG_IC

PIC_LED_2

3.3V

SDA

SCL

SDA

USB_D_N

USB_D_P

MCLRZ

PIC_LED_2

PGEC

3.3V

PIC_LED_3

PGEC

PIC_LED_1

VDD_IC

PWM_IC

USB_D_N

USB_D_P

GND

H1

DN

DP

3.3V

PIC24F PART

1

2

3

4

5

J2

PGED

3.3V

PGED

PIC_LED_1

IC SOCKET PART

D2

SCL

DIR_IC

H1

nc

V_USB

470R

R8

100nF

C6

10K

R5

100K

R3

100nF

C4

100nF

C8

1uF

C1

D3

D1

1

2

3

4

5

6

7

J1

USB CONNECTION PART

100nF

C7

10K

R7

10K

R6

10K

R4

VIN+

1

VSS

2

SCL

3

SDA

4

VDD

5

VIN-

6

U2

MCP3421A1T-E/CH

IC VOLTAGE AND CURRENT MONITORING PART

MCLRZ

SCL

NET00014

NET00017NET00019

V_BUS

5V_USB

*MCLR/VPP/RA5

1

*U1CTS/SCL1/CN22/RB8

17

*U1RTS/SDA1/CN21/RB9

18

SOSCI/*U2RTS/CN1/RB4

11

SOSCO/T1CK/*U2CTS/CN0/RA4

12

AN0/VREF+/CN2/RA0

2

AN1/VREF-/CN3/RA1

3

AN4/C1INB/C2IND/U1RX/U1BCLK/CN6/RB2

6

AN5/C1INA/C2INC/CN7/RB3

7

AN10/CVREF/RTCC/OCFA/C1OUT/INT1/CN12/RB14

25

AN11/SDO1/CTPLS/CN13/RB13

24

AN12/HLVDIN/CTED2/CN14/RB12/VUSB

23

VDD_2

13

VDD

28

U1TX/INT0/CN23/RB7

16

REFO/SS1/T2CK/T3CK/CN11/RB15

26

IC1/CN9/RA7

19

OC1/C2OUT/INT2/CTED1/CN8/RA6

20

OSCI/CLKI/CN30/RA2

9

OSCO/CLKO/CN29/RA3

10

PGC1/AN3/C1INC/C2INA/U2RX/U2BCLK/CN5/RB1

5

PGC2/SCK1/CN15/RB11/DN

22

PGC3/SCL1/CN24/RB6/VBUS

15

PGD1/AN2/C1IND/C2INB/U2TX/CN4/RB0

4

PGD2/SDI1/PMD2/CN16/RB10/DP

21

PGD3/SDA1/CN27/RB5

14

VSS_2

8

VSS

27

U3

PIC24FJ64GB002-1/SS

3.3V

3.3V

3.3V

PWM_IC

RESERVE1_PIC

3.3V

3.3V

1K

R9

1K

R10

SCL SDA

PWM_PIC

VIN

1

GND

2

*SHDN

3

PWRGD

4

VOUT

5

U1

MCP1824T-3302E/OT

5V_USB

12

D4

DIODE_SCHOTTKY_SMC

VDD_IC

VDD_IC

GND

GND

GND

GND

GND

GND

GND

GND

GND

VBIAS

GND

FG

RPROG

GND

J3

VDD

PWM

GND

DIR

VDD

VDD

J4

V_BUS

VBIAS_IC

-ISEN+ISEN

GND

10uF

C19

FG_IC

DIR_IC

+VSEN

10uF

C5

5V_USB

10uF

C2

5V_USB

3.3V

100nF

C3

12

10uF

C10

VIN

1 2

22uH - 33uH

L1

12

10uF

C9

12

10uF

C14

GND

GND

GND

VDR

PGEC_POL

GPB2/AN5GPA0/AN0/AN_TEST

GPA1/AN1/CLKPIN

GPA2/AN2/T0CKI/INT

PGED_POL

GPA3/AN3

MCLRZ_POL

12

10uF

C12

VIN

GND

12

10uF

C15

GND

5.0V

1 2

0.1

R12

GND

+ISEN

-ISEN

-ISEN

+ISENSCL

SDA

RESERVE1_PIC

1

TP2

1

TP1

GND

VIN

PGEC_POL

1

2

3

4

5

J5

PGED_POL

10K

R11

MCLRZ_POL

GND

5.0V

S1

0

G1

1

S2

2

G2

3

D2

4

D2

5

D1

6

D1

7

Q1

Dual N

VDD_ADJ

VDD_IC

100nF

C13

GPA0/AN0/ANALOG_TEST

1

GPA1/AN1/CLKPIN

2

GPA2/AN2/T0CKI/INT

3

GPA3/AN3

4

GPA7/SCL/ICSPCK

5

GPA6/ICSPDAT

6

GPA5/MCLR

7

GPA4

8

GPB0/SDA

9

GND

10

VIN

11

PGND

12

LDRV

13

VDR

14

PHASE

15

HDRV

16

BOOT

17

VDD

18

-ISEN

19

+ISEN

20

+VSEN

21

-VSEN

22

GPB1/AN4/EAPIN

23

GPB2/AN5

24

EP

25

G

L

OG_TEST

G

KPIN

/I

NT

G

/I

CSPCK

G

AT

G

GPA4G

A

GND

V

PGNDLDRV

V

PHASE

HDRVBOOT

VDD

-ISEN

N

+VS

-VSENGPB1/AN4/EAPIN

GPB2/AN5

T

U4

GPB1/AN4

1uF

C17

1uF

C18

200nF

C11

4.0K

R13

1K

R1

1K

R2

4.0K

R14

1K

R16

4.0K

R15

+VSEN

150uF

C16

LDO 3.3V

POWER PART (POL)

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

A.2 BOARD – SCHEMATIC

PA0/AN0/ANA

PA1/AN1/CL

GPA2/AN2/T0CKI

PA3/AN3

GPA7/SCL

PA6/ICSPD

PA5/MCLR

EN

+SE

PB0/SD

IN

DR

Page 23

A.3 BOARD – TOP S ILK

Schematics and Layouts

2014 Microchip Technology Inc. DS50002248A-page 23

Page 24

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

A.4 BOARD – TOP COPPER AND SILK

DS50002248A-page 24 2014 Microchip Technology Inc.

Page 25

A.5 BOARD – TOP COP PER

Schematics and Layouts

2014 Microchip Technology Inc. DS50002248A-page 25

Page 26

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

A.6 BOARD – BOTTOM COPPER

DS50002248A-page 26 2014 Microchip Technology Inc.

Page 27

A.7 BOARD – BOTTOM COPPER AND SILK

Schematics and Layouts

2014 Microchip Technology Inc. DS50002248A-page 27

Page 28

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

A.8 BOARD – BOTTOM SILK

DS50002248A-page 28 2014 Microchip Technology Inc.

Page 29

MCP8063 12V 3-PHASE BLDC

SENSORLESS FAN CONTROLLER

DEMONSTRATION BOARD

USER ’S GUIDE

Appendix B. Bill of Mater ials

TABLE B-1: BILL OF MATERIALS (BOM)

Qty Reference Description Manufacturer Part Number

3 C1, C17 – C18 Cap. ceramic 1 µF 6.3V 10% X5R

0603

3 C2, C5, C19 Cap. ceramic 10 µF 6.3V 20% X5R

0603

6C3–C4,

C6 – C8, C13

1 C1 1 Cap. ceramic 0.22µF 16V 10% X7R

5C9–C10,

C12,

C14 – C15

1 C16 Cap. alum. 150 µF 25V 20% SMD Panasonic® - ECG EEE-FTE151XAP

3 D1 – D3 LED chip-led 633 NM red 0805 SMD OSRAM

1 D4 Schottky diode 30V 0.2A SOD323 NXP Semiconductor 1PS76SB10,115

1 J1 Conn. USB recept. 5 POS rt. angle Molex

2 J2, J5 Conn. header 5 POS 0.050" T/H

1 J3 Conn. recept. 5 POS 0.100 vert.

1 J4 Conn. recept. 6 POS 0.100 vert.

1 L1 Inductor power 22 µH 30% shield

PCB Printed Circuit Board – MCP8063

1 Q1 MOSFET N-Channel dual 30V

5R1–R2,

R9 – R10, R16

1 R3 Res. 100 k 1/10W 1% 0603 TE Connectivity, Ltd. 1622827-1

5 R4 – R7, R1 1 Res. 10.0 k 1/10W 1% 0603 TE Connectivity, Ltd. 1622829-1

3 R13 – R15 Res. 4.02 k 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF4021V

1 R8 Res. 470 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF4700V

1 R12 Res. 0.1 1/3W 1% 1210 SMD Panasonic - ECG ERJ-L14KF10CU

2 TP1 – TP2 PC test point mini SMD Keystone Electronics

Cap. ceramic 0.1 µF 25V 20% X7R

0603

0603

Cap. ceramic 10 µF 10V Y5V 1206 TDK Corporation C3216Y5V1A106Z/1.15

gold

gold

gold

SMD

12V 3-Phase BLDC Senso rles s Fa n

Controller Demonstration Board

8-SOIC

Res. 1.00 k 1/10W 1% 0603 TE Connectivity, Ltd. 1622866-1

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The

released BOM used in manufacturing uses all RoHS-compliant components.

TDK Corporation C1608X5R0J105K

TDK Corporation C1608X5R0J106M080AB

TDK Corporation C1608X7R1E104M080AA

TDK Corporation C1608X7R1C224K080AC

LS R976-NR-1

Opto Semiconductors

GmbH.

®

Samtec, Inc. TMS-105-02-G-S

TE Connectivity, Ltd. 5-534237-3

TE Connectivity, Ltd. 534237-4

Bourns®, Inc. SRU1048-220Y

— 104-00532

Vishay Siliconix SI4330DY-T1-E3

Corp.

548190519

5019

2014 Microchip Technology Inc. DS50002248A-page 29

Page 30

MCP8063 12V 3-Phase BLDC Sensorless Fan Controller Demonstration Board User’s Guide

TABLE B-1: BILL OF MATERIALS (BOM) (CONTINUED)

Qty Reference Description Manufacturer Part Number

1 U1 IC reg. LDO 3.3V 0.3A 5-lead

SOT-23

1 U2 IC ADC 18 bit 3.75 SPS 1 ch. 6-lead

SOT-23

1 U3 IC MCU 16 bit 64 KB Flash 28-lead

SSOP

1 U4 IC reg. controller Buck PWM 24-lead

QFN

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The

released BOM used in manufacturing uses all RoHS-compliant components.

Microchip Technology

Inc.

Microchip Technology

Inc.

Microchip Technology

Inc.

Microchip Technology

Inc.

MCP1824T-3302E/OT

MCP3421A1T-E/CH

PIC24FJ64GB002-1/SS

MCP19110-E/MJ-ND

DS50002248A-page 30 2014 Microchip Technology Inc.

Page 31

NOTES:

Bill of Materials

2014 Microchip Technology Inc. DS50002248A-page 31

Page 32

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

New Yor k , NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Canada - Toronto

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-8792-8115

Fax: 86-571-8792-8116

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8864-2200

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-3019-1500

Japan - Osaka

Tel: 81-6-6152-7160

Fax: 81-6-6152-9310

Japan - Tokyo

Tel: 81-3-6880- 3770

Fax: 81-3-6880-3771

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Taiwan - Taipei

Tel: 886-2-2508-8600

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Dusseldorf

Tel: 49-2129-3766400

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Pforzheim

Tel: 49-7231-424750

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Venice

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Poland - Wars a w

Tel: 48-22-3325737

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

03/21/14

DS50002248A-page 32 2014 Microchip Technology Inc.

Loading...

Loading...