Page 1

MCP42XXEV

Evaluation Board

User’s Guide

2010 Microchip Technology Inc. DS51898A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, HI-TIDE, In-Circuit Serial

Programming, ICSP, Mindi, MiWi, MPASM, MPLAB Certified

logo, MPLIB, MPLINK, mTouch, Octopus, Omniscient Code

Generation, PICC, PICC-18, PICDEM, PICDEM.net, PICkit,

PICtail, REAL ICE, rfLAB, Select Mode, Total Endurance,

TSHARC, UniWinDriver, WiperLock and ZENA are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2010, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-60932-134-5

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS51898A-page 2 2010 Microchip Technology Inc.

Page 3

MCP42XXEV EVALUATION BOARD

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 5

Chapter 1. Product Overview

1.1 Introduction ..................................................................................................... 9

1.2 What is the MCP42XXEV Evaluation Board? ................................................ 9

1.3 What the MCP42XXEV Evaluation Board Kit Includes ................................ 10

Chapter 2. Installation and Operation

2.1 Introduction ................................................................................................... 11

2.2 Features ....................................................................................................... 12

2.3 Getting Started ............................................................................................. 13

2.4 MCP42XXEV Evaluation Board Description ................................................ 13

2.5 Configuring The PICkit™ Serial Analyzer .................................................... 19

2.6 MCP4261 Demo Steps ................................................................................. 28

Appendix A. Schematic and Layouts

A.1 Introduction .................................................................................................. 33

A.2 Schematics and PCB Layout ....................................................................... 33

A.3 Board – Schematic ....................................................................................... 34

A.4 Board – Top Trace, Silk and Pads .............................................................. 35

A.5 Board – Bottom Trace and Pads .................................................................. 36

A.6 Board – Layer 2 Ground Plane ................................................................... 37

A.7 Board – Layer 3 Power Plane ...................................................................... 38

A.8 Board Layout – Top Components ................................................................ 39

A.9 Board – Bottom Silk, Trace and Pads ........................................................ 40

Appendix B. Bill of Materials (BOM)

Worldwide Sales and Service .................................................................................... 42

2010 Microchip Technology Inc. DS51898A-page 3

Page 4

MCP42XXEV Evaluation Board User’s Guide

NOTES:

DS51898A-page 4 2010 Microchip Technology Inc.

Page 5

MCP42XXEV EVALUATION BOARD

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP42XXEV Evaluation Board. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the MCP42XXEV Evaluation Board as a

development tool to emulate and debug firmware on a target board. The manual layout

is as follows:

• Chapter 1. “Product Overview” – Important information about the MCP42XXEV

Evaluation Board.

• Chapter 2. “Installation and Operation” – Includes instructions on how to get

started with this evaluation board.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the MCP42XXEV Evaluation Board.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

MCP42XXEV Evaluation Board.

2010 Microchip Technology Inc. DS51898A-page 5

Page 6

MCP42XXEV Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

®

IDE User’s Guide

“Save project before build”

4‘b0010, 2‘hF1

DS51898A-page 6 2010 Microchip Technology Inc.

Page 7

RECOMMENDED READING

This user’s guide describes how to use the MCP42XXEV Evaluation Board. Other

useful documents are listed below. The following Microchip documents are available

and recommended as supplemental reference resources.

AN1080 Application Note, “Understanding Digital Potentiometer Resistor

Variations” (DS01080)

AN1316 Application Note, “Using Digital Potentiometers for Programmable

Amplifier Gain” (DS01316)

These data sheets provide detailed information regarding the MCP41XX/42XX and

product family:

MCP413X/415X/423X/425X Data Sheet, “7/8-Bit Single/Dual SPI Digital POT with

Volatile Memory” (DS22060)

MCP414X/416X/424X/426X Data Sheet, “7/8-Bit Single/Dual SPI Digital POT with

Non-Volatile Memory” (DS22059)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

In addition, there is a Development Systems Information Line which lists the latest

versions of Microchip's development systems software products. This line also

provides information on how customers can receive currently available upgrade kits.

The Development Systems Information Line numbers are:

1-800-755-2345 – United States and most of Canada

1-480-792-7302 – Other International Locations

2010 Microchip Technology Inc. DS51898A-page 7

Page 8

MCP42XXEV Evaluation Board User’s Guide

DOCUMENT REVISION HISTORY

Revision A (April 2010)

• Initial Release of this Document.

DS51898A-page 8 2010 Microchip Technology Inc.

Page 9

MCP42XXEV EVALUATION BOARD

Chapter 1. Product Overview

1.1 INTRODUCTION

This chapter provides an overview of the MCP42XXEV Evaluation Board and covers

the following topics:

• What is the MCP42XXEV Evaluation Board?

• What the MCP42XXEV Evaluation Board kit includes

1.2 WHAT IS THE MCP42XXEV EVALUATION BOARD?

The MCP42XXEV Evaluation Board allows the system designer to quickly evaluate the

operation of Microchip Technology’s MCP4261 Digital Potentiometer device. This

device is similar to the following devices:

• MCP4231

• MCP4232

• MCP4241

• MCP4242

• MCP4251

• MCP4252

• MCP4261

• MCP4262

• MCP4331

• MCP4332

• MCP4341

• MCP4342

• MCP4351

• MCP4352

• MCP4362

• MCP4131

• MCP4132

• MCP4141

• MCP4142

• MCP4151

• MCP4152

• MCP4161

• MCP4162

The board uses the TSSOP20EV generic PCB and has been populated for the

MCP4261. The 6-pin header (PICkit™ serial) has been jumpered to the MCP4261’s

appropriate pins. This allows the PICkit serial to communicate with the device.

Additional blank PCBs may be ordered by using the order number: TSSOP20EV. Each

TSSOP20EV kit contains 5 PCBs.

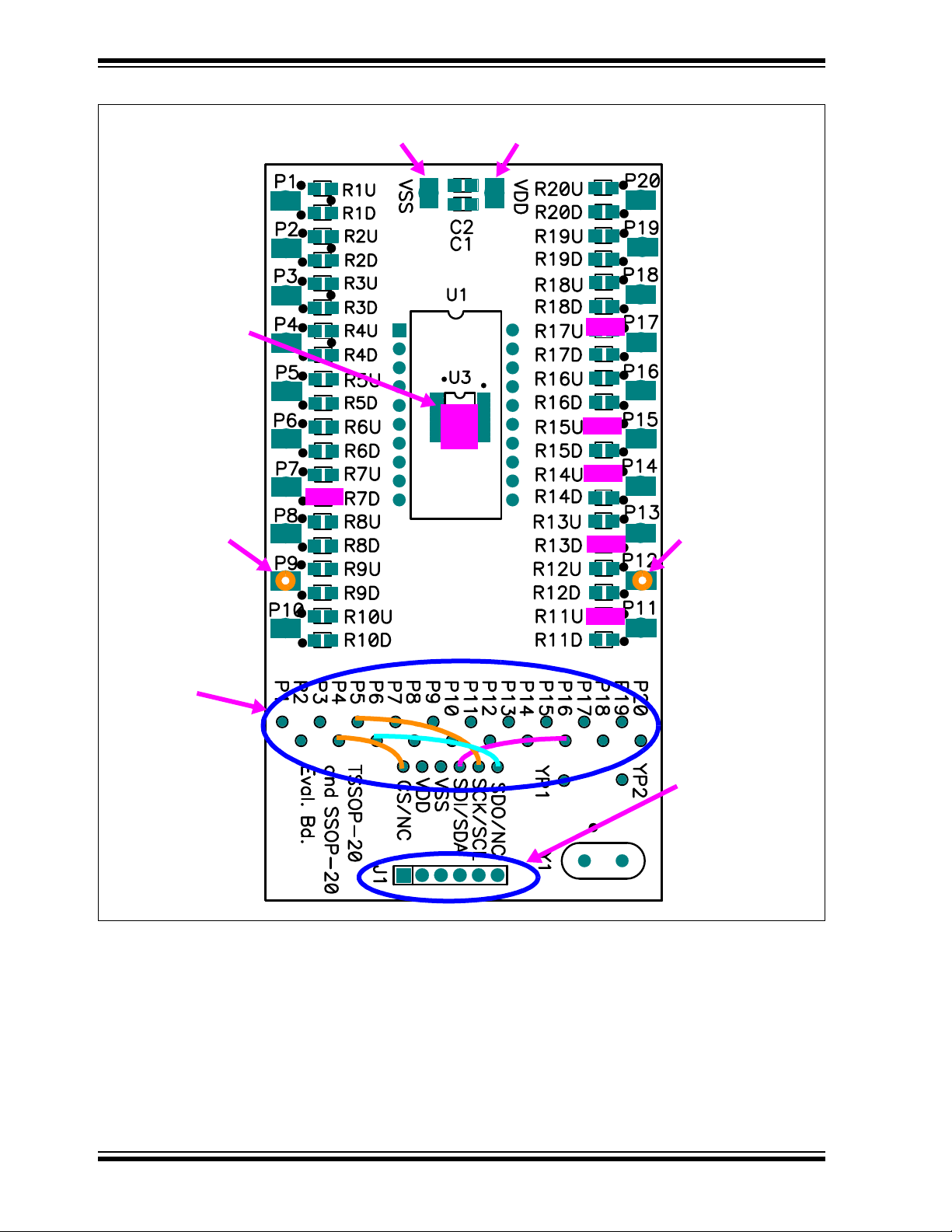

Figure 1-1 shows the top view of the populated TSSOP20EV PCB which creates the

MCP42XXEV Evaluation Board.

USER’S GUIDE

2010 Microchip Technology Inc. DS51898A-page 9

Page 10

MCP42XXEV Evaluation Board User’s Guide

0

0

0

0

10 k

10 k

4261

Four Blue Wire

PICkit™ Serial

1x6 Male Header,

MCP4261-103E/ST

installed in U3

Connected to

Ground Plane

Connected to

Power Plane

Through hole Test

Point (Orange)

Through hole Test

Point (Orange)

Wiper 0

Wiper 1

(TSSOP-14 package

with 90 right angle

Jumpers to connect

interface (SPI) to

device pins

bottom aligned to

TSSOP-20 footprint)

FIGURE 1-1: MCP42XXEV Evaluation Board Using the TSSOP20EV Evaluation Board

(MCP4361 installed in U3 – Package Bottom Aligned).

1.3 WHAT THE MCP42XXEV EVALUATION BOARD KIT INCLUDES

DS51898A-page 10 2010 Microchip Technology Inc.

This MCP42XXEV Evaluation Board kit includes:

• MCP42XXEV Evaluation Board

• One TSSOP-20 and SSOP-20 Evaluation Board blank PCB, 102-00272.

Extra blank PCBs can be ordered (order #: TSSOP20EV)

• Important Information Sheet

Page 11

Chapter 2. Installation and Operation

2.1 INTRODUCTION

The MCP42XXEV Evaluation Board allows the system designer to quickly evaluate the

operation of the MCP4261 10 k (-103) digital potentiometer device using the PICkit

Serial Analyzer. The PICkit Serial Analyzer is available separately (order number:

DV164122).

This board is a minimum configuration for the device. As well as the device, other

desired passive components (resistors and capacitors) and connection posts may be

installed.

The board can also be very easily jumpered into a customer’s existing circuit. This

gives an indication of the MCP4261 device performance, but is affected by the jumper

lead length and the EM noise that the jumpers pick up.

The device’s Resistor Network 0 has been configured in a Potentiometer mode with the

A terminal connected to V

with a 0 resistor. Resistor Network 1 can be evaluated for rheostat operation.

The MCP42XXEV Evaluation Board uses the generic TSSOP20EV Evaluation Board

PCB. The kit includes a second PCB which is blank for the user to populate as desired.

Additional PCBs may be ordered (order number: TSSOP20EV). The TSSOP20EV kit

includes 5 blank PCBs.

Other boards can easily be built up using the TSSOP20EV PCB to allow evaluation of

other resistance options (5 k, 50 k, or 100 k) or any of the other digital

potentiometer devices in the following packages:

• TSSOP-20 package

- MCP4331, MCP4341, MCP4351, or MCP4361

• TSSOP-14 package

- MCP4332, MCP4342, MCP4352, MCP4362, MCP4231, MCP4241,

MCP4251, MCP4261, MCP4631, MCP4641, MCP4651, MCP4661,

MCP42010, MCP42050, or MCP42100

The board also has a 6-pin interface (PICkit serial, ICSP™, etc.) whose signals can

easily be jumpered to any of the device’s pins.

Additional information on using the TSSOP20EV Evaluation Board PCB or for

modifying the MCP42XXEV Evaluation Board is available in the TSSOP20EV User’s

Guide (DS51875). Appendix A. “Schematic and Layouts” has information on the

PCB schematic and layout while Figure 2-2 shows components that are installed on the

PCB.

MCP42XXEV EVALUATION BOARD

USER’S GUIDE

through a 0 resistor and the B terminal connected to VSS

DD

2010 Microchip Technology Inc. DS51898A-page 11

Page 12

MCP42XXEV Evaluation Board User’s Guide

2.2 FEATURES

The MCP42XXEV Evaluation Board has the following features:

• MCP4261-103E/ST is installed (bottom aligned in U3)

•0 resistors connect MCP4261 V

ground plane (see Figure 2-2)

•0 resistors connect MCP4261’s Resistor Network 0 A terminal signal to power

plane, resistor network is in a voltage divider configuration (see Figure 2-2)

•0 resistors connect MCP4261’s Resistor Network 0 B terminal signal to ground

plane, resistor network is in a voltage divider configuration (see Figure 2-2)

• Through-hole connection terminal (orange) for all wiper pins

• Connection terminal points for all device pins (either through-hole or

surface-mount)

• Footprints for optional passive components (SMT 805 footprint) for:

- Power supply filtering (C

and C2 footprints)

1

- Device bypass capacitor (RxD footprint for device pin connected to V

• Silk-screen area to write specifics of implemented circuit (on back of PCB), such

as MCP4261 10 k

• PICkit Serial Analyzer Header

The included TSSOP20EV board has the following features:

• Connection terminals may be either through-hole or surface-mount

• Three package type footprints supported:

-TSSOP-20

-TSSOP-14

-TSSOP-8

-SSOP-20

- DIP-20 (600 mil body)

• Footprints for optional passive components (SMT 805 footprint) for:

- Power supply filtering (C

and C2 footprints)

1

- Device bypass capacitor (RxD footprint for device pin connected to V

- Output filtering (RxD footprint)

- Output pull-up resistor (RxU footprint)

- Output pull-down resistor (RxD footprint)

- Output loading resistor (RxD footprint)

• Silk-screen area to write specifics of implemented circuit (on back of PCB), such

as MCP4261 10 k

• PICkit Serial Analyzer/PICkit 2 programming (ICSP™) Header

and VSS signals to the appropriate power or

DD

DD

DD

)

)

DS51898A-page 12 2010 Microchip Technology Inc.

Page 13

Installation and Operation

2.3 GETTING STARTED

The MCP42XXEV Evaluation Board allows quick evaluation of the MCP4261-103E/ST

device. The understanding of the device characteristics (such as the resistor network)

is applicable to any of the devices in the MCP42XX family. The MCP4261-103 device

has a typically R

• Using the PICkit Serial Analyzer for interface communication

• Jumpering the MCP42XXEV Evaluation Board into your application circuit to

control the MCP4261-103 device

This user guide will discuss the steps needed to evaluate the MCP4261-103E/ST

device using the PICkit Serial Analyzer (order number: DV164122).

Section 2.5 “Configuring The PICkit™ Serial Analyzer” shows the steps to configure the PICkit Serial Analyzer as well as create User Script files which are used to

communicate with the MCP4261, based on the device’s SPI communication protocol

format.

2.4 MCP42XXEV EVALUATION BOARD DESCRIPTION

The MCP42XXEV Evaluation Board uses the flexible TSSOP20EV Evaluation Board

PCB. This simple evaluation board allows the system designer to quickly evaluate the

operation of the MCP4261-103 device (R

lyzer or by jumpering the board into their application system. The PICkit Serial Analyzer

is available separately (order number: DV164122).

resistance of 10 k. Evaluation can be done by:

AB

AB(TYP)

= 10 k) using the PICkit Serial Ana-

2.4.1 The Hardware

Figure 2-2 shows the component layout of the MCP42XXEV Evaluation Board. This is

a small four-layer board (3.9" x 2.1" (99.06 mm x 53.34 mm)). There are twenty-two

connection points/pads that can use either through-hole or surface-mount connector

posts.

The pad labeled V

is connected to the PCB ground plane. All the passive components that are connected

to V

or VSS are connected to either the power plane or ground plane.

DD

The twenty remaining PCB pads correspond to the device pins (i.e., pad 1 connects to

pin 1).

Each pad has two passive components associated with them: a pull-up resistor and a

pull-down resistor. The pull-up resistor is always RXU and the pull-down resistor is

RXD. The “X” is a numeric value that corresponds to a particular pad (1 to 8). As an

example, Pad 5’s pull-up resistor is R5U. Capacitor C1 and C2 are the power supply

filtering capacitors. For whichever pin is the device’s V

can be used for the device’s bypass capacitor. Table 2-2 describes the components.

A 6-pin header interface is available to support the PICkit serial or the PIC

In-Circuit Serial Programming™ (ICSP™) interface.

The MCP4261 is bottom aligned in the U3 footprint so that the interface signals are on

the same U3 package pins as the MCP4361 device. This is done to show the footprint

compatibility between the MCP42X1 and MCP43X1 devices.

is connected to the PCB power plane, while the pad labeled VSS

DD

, the RxD component footprint

DD

®

MCU

2010 Microchip Technology Inc. DS51898A-page 13

Page 14

MCP42XXEV Evaluation Board User’s Guide

19

20

12

11

1

2

DIP-20 (1)

J1

NC

V

DD

VSS

SDA

SCL

NC

TSSOP-20 (1)

1

2

9

20

19

12

10

11

9

10

Requires blue

PICkit™ Serial/ICSP™

Interface

wire jumpering

to connect the

PICkit™ Interface

to the selected

device

P20

P19

P12

P11

P1

P2

P9

P10

P1

R

1U

R

1D

P2

R

2U

R

2D

P19

R

19U

R

19D

P20

R

20U

R

20D

NC

V

DD

VSS

SDI

SCK

SDO

C1

C2

V

DD

V

SS

1

2

9

20

19

12

10

11

SSOP-20

P1

P2

P9

P10

P19

P20

P11

P12

VIA2

VIA1

XTAL

PIC® MCU Circuitry (bottom of PCB)

C3

C4

Note: The MCP42X1 (TSSOP-14) device will use the TSSOP-20 footprint and be bottom

aligned to illustrate MCP42X1 and MCP43X1 footprint compatibility.

FIGURE 2-1: TSSOP20EV Evaluation Board Circuit.

DS51898A-page 14 2010 Microchip Technology Inc.

Page 15

0

0

0

0

10 k

10 k

4261

Four Blue Wire Jumpers to connect

PICkit™ Serial interface (SPI) to device pins

1x6 Male Header, with 90 right angle

MCP4261-103E/ST

Installed in U3 (TSSOP-14 package bottom aligned to TSSOP-20 footprint)

Connected to

Ground Plane

Connected to

Power Plane

Through hole Test

Point (Orange)

Through hole Test

Point (Orange)

Wiper 0

Wiper 1

Installation and Operation

FIGURE 2-2: MCP42XXEV Evaluation Board Component Placement Using the TSSOP20EV

Evaluation Board (Top).

2010 Microchip Technology Inc. DS51898A-page 15

Page 16

MCP42XXEV Evaluation Board User’s Guide

TABLE 2-1: INSTALLED PASSIVE COMPONENTS

Component Description Comment

R11U, R17U 0 SMT 805 Pull-up resistor

R14U, R15U 10 k SMT 805 Pull-up resistor

R7D, R13D 0 SMT 805 Pull-down resistor

U3 MCP4261-103E/ST R

P9, P12 Test Point – through-hole connector

(orange)

J1 1x6 Male Header, 100 mil spacing 90°

angle.

— Blue Wire:

(2)

(1)

= 10 k

AB(TYP)

Device bottom aligned in U3 footprint

PICkit™ Serial/ICSP™ Header

See Figure 2-2

J1 CS/NC via to P4 via

J1 SDI/SDA via to P16 via

J1 SCK/SCL via to P5 via

J1 SDO/NC via to P6 via

Note 1: Whichever pin is the device’s VDD pin, that corresponding RXD footprint can be used for the device’s

bypass capacitor. So if Pin 8 is the device’s V

2: All passive components use the surface mount 805 footprint.

pin, then install the bypass capacitor in the R8D footprint.

DD

DS51898A-page 16 2010 Microchip Technology Inc.

Page 17

Installation and Operation

TABLE 2-2: OPTIONAL PASSIVE COMPONENTS – NOT INSTALLED

(2)

Component Comment

C1, C2 Power supply bypass capacitors

(3)

C3, C4 PIC® MCU Crystal capacitors

R1U, R2U, R3U, R4U, R5U, R6U, R7U, R8U,

Pull-up resistor

R9U, R12U, R13U, R16U, R18U, R19U, R20U

R1D, R2D, R3D, R4D, R5D, R6D, R8D, R9D,

Pull-down resistor

(1)

R10D, R11D, R12D, R14D, R15D, R16D, R17D,

R18D, R19D, R20D

U1, U2 Alternate package footprints

VDD, GND Power and Ground plane connection

points

®

Y1 Can connect to either PIC

MCUs main

oscillator or to the Timer oscillator circuit.

P1, P2, P3, P4, P5, P6, P8, P10, P11, P13, P14,

Test Point connectors

P15, P16, P17, P18, P19, P20

Note 1: Whichever pin is the device’s V

used for the device’s bypass capacitor. So if Pin 8 is the device’s V

pin, that corresponding RXD footprint can be

DD

pin, then

DD

install the bypass capacitor in the R8D footprint.

2: All passive components use the surface mount 805 footprint.

3: If the board is powered via the V

and GND connection points, the use of bypass

DD

capacitors on C1 and C2 may improve performance. The benefit is reduced if the

board is powered via the PICkit™ serial interface.

2010 Microchip Technology Inc. DS51898A-page 17

Page 18

MCP42XXEV Evaluation Board User’s Guide

A

D

3

A

D

2

A

D

1

A

D

0

C1C0D9D

8

Register Memory

Command Byte

Data

Address

Bits

Command

Bits

A

D

3

A

D

2

A

D

1

A

D

0

C1C0D9D8D7D6D5D4D3D2D1D

0

Register Memory

16-bit Command

Data

Address

Bits

Command

Bits

0 0 = Write Data

0 1 = INCR

1 0 = DECR

1 1 = Read Data

C C

1 0

Command

Bits

8-bit Command

Command Byte

Data Byte

(Increment or Decrement)

(Read Data or Write Data)

2.4.2 The MCP4261 Device

To make variations to the commands sent to the MCP4261 device (from the commands

shown in the demo section), one must know the device memory map (see Table 2-3)

and the command formats (see Figure 2-3). For additional device operational

information, refer to the MCP4261 device data sheet (DS22059).

TABLE 2-3: MEMORY MAP AND THE SUPPORTED COMMANDS

).

Memory

Typ e

Allowed Commands

Increment, Decrement

Increment, Decrement

RAM Read, Write Increment, Decrement

pin to the VIH level and then back to the active

Address Function

00h Volatile Wiper 0 RAM Read, Write,

01h Volatile Wiper 1 RAM Read, Write,

02h Nonvolatile Wiper 0 EEPROM Read, Write

03h Nonvolatile Wiper 1 EEPROM Read, Write

04h Volatile

TCON0 Register

05h STATUS Register RAM Read Write, Increment,

06h-0Fh Data EEPROM EEPROM Read, Write

Note 1: When an EEPROM write is active, these are invalid commands and will generate

an error condition. The user should use a read of the STATUS register to determine

when the write cycle has completed. To exit the error condition, the user must take

pin to the VIH level and then back to the active state (VIL or V

the CS

2: This command on this address will generate an error condition. To exit the error

condition, the user must take the CS

state (V

IL

or V

IHH

Disallowed

Commands

—

—

(1)

Increment, Decrement

(1)

Increment, Decrement

Decrement

(1)

Increment, Decrement

).

IHH

(2)

FIGURE 2-3: MCP42XX SPI Command Formats.

DS51898A-page 18 2010 Microchip Technology Inc.

Page 19

Installation and Operation

2.5 CONFIGURING THE PICkit™ SERIAL ANALYZER

2.5.1 Modifying the CommScripts.txt file

Example 2-1 shows the User Scripts for the MCP43XX devices (from MCP43XXEV

Evaluation Board). These script files are compatible with the MCP42XX devices, with

the exception of commands to Wiper 2, Wiper 3, or TCON1 registers (commands

shaded in red).

These User Scripts need to be added to the PICkit serial’s CommScripts.txt file.

The default install location of this file is:

C:\Program Files\Microchip\PICkit Serial Analyzer

Once these are saved in the CommScripts.txt file and the Master SPI mode is

selected as the communication mode, these User Scripts will be available to select

from.

NOTICE

Note 1: It is recommended that you make a backup of your CommScript.txt

file before making any edits with a text editor.

2: It has been observed that coping the text from this PDF and pasting into

the PICkit serial’s CommScript.txt file will cause errors due to the

blank spacing used in the PDF file. Please copy from the MCP43XX

CommScript.txt file available from the Microchip web site

(MCP43XXEV Evaluation Board product page).

EXAMPLE 2-1: MCP43XX SCRIPT FILE (COMMSCRIPTS.TXT)

WriteWiper0 SPI SPICSON SPIDATOUT 0x02 0x00 0x3F SPICSOFF

ReadWiper0 SPI SPICSON SPIDATIO 0x02 0x0C 0xA5 SPICSOFF

WriteWiper1 SPI SPICSON SPIDATOUT 0x02 0x10 0x3F SPICSOFF

ReadWiper1 SPI SPICSON SPIDATIO 0x02 0x1C 0xA5 SPICSOFF

WriteWiper2 SPI SPICSON SPIDATOUT 0x02 0x60 0x3F SPICSOFF

ReadWiper2 SPI SPICSON SPIDATIO 0x02 0x6C 0xA5 SPICSOFF

WriteWiper3 SPI SPICSON SPIDATOUT 0x02 0x70 0x3F SPICSOFF

ReadWiper3 SPI SPICSON SPIDATIO 0x02 0x7C 0xA5 SPICSOFF

WriteWiper0NV SPI SPICSON SPIDATOUT 0x02 0x20 0x3F SPICSOFF

ReadWiper0NV SPI SPICSON SPIDATIO 0x02 0x2C 0xA5 SPICSOFF

WriteTCON0 SPI SPICSON SPIDATOUT 0x02 0x40 0xFF SPICSOFF

ReadTCON0 SPI SPICSON SPIDATIO 0x02 0x4C 0xA5 SPICSOFF

WriteTCON1 SPI SPICSON SPIDATOUT 0x02 0xA0 0xFF SPICSOFF

ReadTCON1 SPI SPICSON SPIDATIO 0x02 0xAC 0xA5 SPICSOFF

ReadSTATUS SPI SPICSON SPIDATIO 0x02 0x5C 0xA5 SPICSOFF

INCRWiper0 SPI SPICSON SPIDATIO 0x01 0x04 SPICSOFF

DECRWiper0 SPI SPICSON SPIDATIO 0x01 0x08 SPICSOFF

2010 Microchip Technology Inc. DS51898A-page 19

Page 20

MCP42XXEV Evaluation Board User’s Guide

2.5.2 Working With the PICkit™ Serial Analyzer

Figure 2-4 shows the PICkit Serial window after the program has started. The

Transaction window indicates if the PICkit serial GUI located the PICkit Serial Analyzer

hardware. When starting the PICkit Serial Analyzer for the first time, some setup

questions may be asked. If you have any questions, please refer to the PICkit Serial

Analyzer documentation, available at www.Microchip.com/PICkitSerial

.

FIGURE 2-4: PICkit™ Serial Main Window at Start-up.

DS51898A-page 20 2010 Microchip Technology Inc.

Page 21

Installation and Operation

We need to select the PICkit Serial Analyzer GUI to be in SPI Master mode. Figure 2-5

shows how to select the proper mode. Select PICkit Serial Analyzer -> Select

Communications Mode -> SPI Master menu item (make sure the SPI Master item is

checked).

FIGURE 2-5: PICkit™ Serial Selecting Communications Mode.

2010 Microchip Technology Inc. DS51898A-page 21

Page 22

MCP42XXEV Evaluation Board User’s Guide

Now we need to configure the mode that we selected. Figure 2-6 shows how to

configure the Communications mode. Select PICkit Serial Analyzer -> Configure

Communications Mode menu item. This will open a new window:

FIGURE 2-6: PICkit™ Serial Main Window at Start-up.

DS51898A-page 22 2010 Microchip Technology Inc.

Page 23

Installation and Operation

Figure 2-7 shows the Configure Communications Mode window. Ensure that your

window options and settings are the same as this window, and then select the Save

Changes button. The Configure Communications Mode window may now be closed.

FIGURE 2-7: PICkit™ Serial Configure Communications Mode Window.

2010 Microchip Technology Inc. DS51898A-page 23

Page 24

MCP42XXEV Evaluation Board User’s Guide

Now we are going to open the Script Builder window, select the Communications ->

Script -> Script Builder menu item (see Figure 2-8).

FIGURE 2-8: PICkit™ Serial – Script Builder Menu Selection.

DS51898A-page 24 2010 Microchip Technology Inc.

Page 25

Installation and Operation

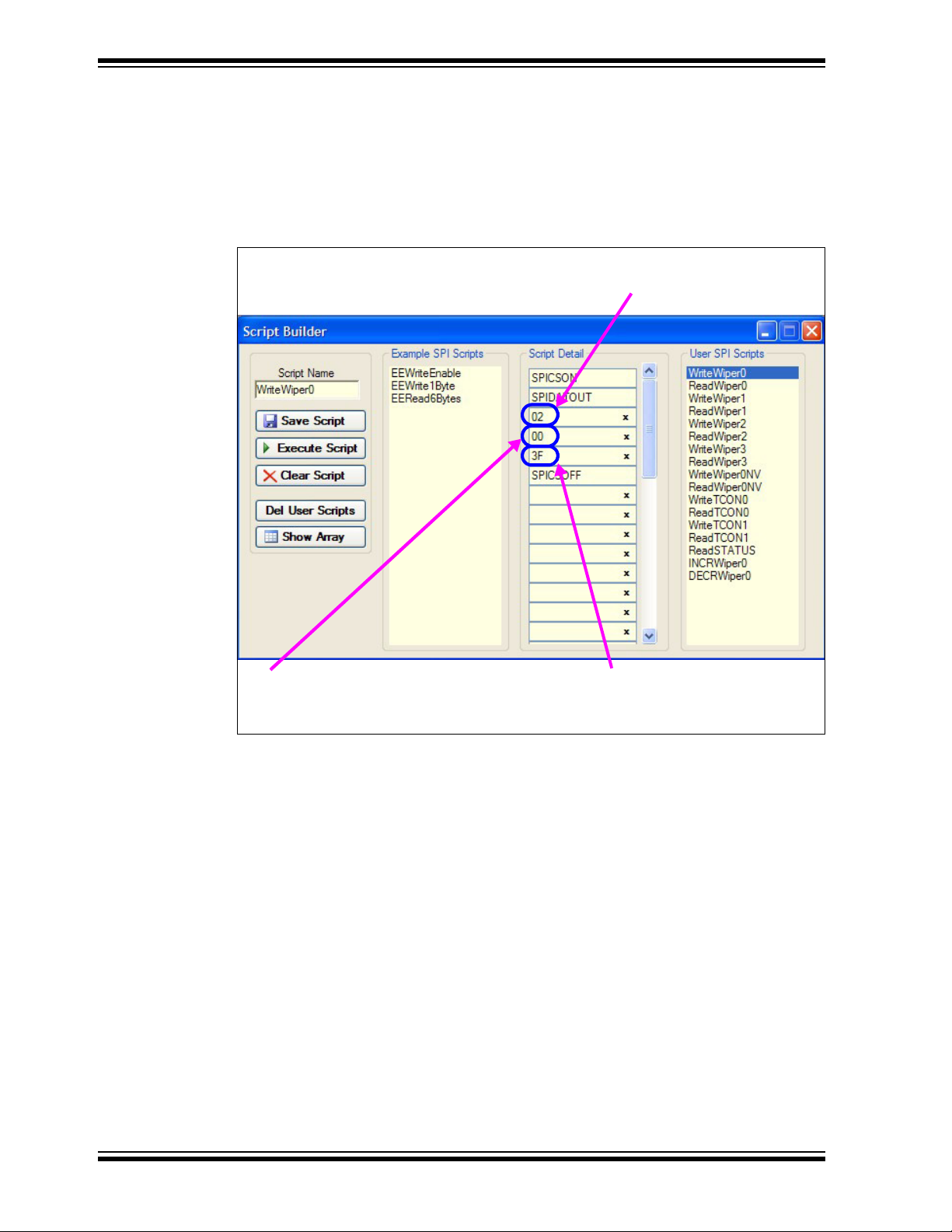

The Script Builder window is shown in Figure 2-9. In this window we see the User SPI

Scripts including the ones that were added to the CommScripts.txt file.

FIGURE 2-9: PICkit™ Serial Main Window at Start-up.

2010 Microchip Technology Inc. DS51898A-page 25

Page 26

MCP42XXEV Evaluation Board User’s Guide

Number of Bytes that will

be written

Data Byte #1 Data Byte #2

(Device Register Address + (Write Data “D7:D0”

Command + Data bit “D8”

Double clicking on the WriteWiper0 User SPI Script will load the script details.

Figure 2-10 shows what the values mean in the Script Details. These values are hex

numbers.

The first value (02h), is the number of bytes that will be written. The second byte is a

data byte and contains the device register address, the Device command, and the two

Most Significant bits (MSb) of the write data. The third byte is the 2nd data byte and

contains the remaining 8 bits of the write data.

FIGURE 2-10: Example Write Script.

DS51898A-page 26 2010 Microchip Technology Inc.

Page 27

Installation and Operation

Number of Bytes that will

be written

Data Byte #2

(Write Data “D7:D0”

Data Byte #1

(Device Register Address +

Command + Data bit “D8”

Double clicking on the ReadWiper0 User SPI Script will load the script details.

Figure 2-11 shows what the values mean in the Script Details. These values are hex

numbers.

The first value (02h), is the number of bytes that will be written. The second byte is a

data byte and contains the device register address, the Device command, and the two

Most Significant bits (MSb) of the read data. The third byte is the 2nd data byte and

contains the remaining 8 bits of the read data.

During Read commands, the value of the two LSbs of Data Byte #1 and all of the bits

of Data Byte #2 are not important. The bytes are required for the SPI clock generation.

2010 Microchip Technology Inc. DS51898A-page 27

FIGURE 2-11: Example Read Script.

Page 28

MCP42XXEV Evaluation Board User’s Guide

2.6 MCP4261 DEMO STEPS

This demo assumes that you know how to configure the PICkit Serial Analyzer for

Master SPI operation. See Section 2.5 “Configuring The PICkit™ Serial Analyzer”

or the “PICkit Serial Analyzer User’s Guide” (DS51647) for additional information.

1. Plug the PICkit serial device into the PC’s USB port.

2. Plug the MCP42XXEV board into the PICkit serial.

3. Add the User Scripts (see Example 2-1) to the CommScripts.TXT file.

4. Start the PICkit serial GUI.

5. Ensure the GUI is in Master SPI Communication mode (see Figure 2-5).

6. Ensure that the Master SPI configuration is appropriately configured (see

Figure 2-7).

7. Measure the Wiper 0 voltage on the MCP42XXEV board (see Figure 2-2) using

an oscilloscope or digital multimeter. Measure voltage from the ground plane

(GND) to the wiper (P12). The voltage on the wiper should be ~ V

8. Open the Script Builder window (see Figure 2-8).

9. Double click on the “WriteWiper0” script in the Example SPI Scripts column. This

loads the Script Detail column (see Figure 2-10).

10. Click on the Execute Script button. This executes the script shown in the Script

Detail column, which will update the wiper value to 3Fh. The wiper voltage will

now be ~V

updated to indicate the execution of the script.

11. Select the “ReadWiper0” script in the User SPI Scripts column. It should look like

Figure 2-11.

12. Click on the Execute Script button. This executes the script shown in the Script

Detail column. The Transaction window (see Figure 2-13) will be updated to

indicate the execution of the script. The data read is shown in the last line.

13. Double click on the “WriteWiper0” script in the Example SPI Scripts column. This

loads the Script Detail column and modifies the Wiper 0 data to 1FFh (see

Figure 2-12).

14. Click on the Execute Script button. This executes the script shown in the Script

Detail column, which will update the wiper value to 1FFh. The wiper voltage will

now be ~V

to indicate the execution of the script.

15. Select the “ReadWiper0” script in the User SPI Scripts column. It should look like

Figure 2-11.

16. Click on the Execute Script button. This executes the script shown in the Script

Detail column. The Transaction window (see Figure 2-13) will be updated to

indicate the execution of the script. The data read is shown in the last line.

17. In the Transaction window, click the Clear button.

18. On the PICkit Serial Analyzer command bar, click the Reset button.

19. Select the “WriteWiper0” script in the User SPI Scripts column and then click on

the Execute Script button.

20. Select the “ReadWiper0” script in the User SPI Scripts column and then click on

the Execute Script button.

/4 (~1.25V). The Transaction window (see Figure 2-13) will be

DD

(~5V). The Transaction window (see Figure 2-13) will be updated

DD

/2 (~2.5V).

DD

DS51898A-page 28 2010 Microchip Technology Inc.

Page 29

Installation and Operation

Write Command to Wiper 0 Register (D8 = 1)

Wiper 0 Data (D7:D0 = ‘FFh’)

21. Select the “DECRWiper0” script in the User SPI Scripts column and then click on

the Execute Script button three times.

22. Select the “ReadWiper0” script in the User SPI Scripts column and then click on

the Execute Script button. The Transaction window shows the scripts that were

executed and the current value of the Wiper 0 (see Figure 2-14).

23. In the Transaction window, click the Clear button.

24. On the PICkit Serial Analyzer command bar, click the Reset button.

25. Select the “WriteWiper0” script in the User SPI Scripts column and then click on

the Execute Script button.

26. Select the “ReadWiper0” script in the User SPI Scripts column and then click on

the Execute Script button.

27. Select the “INCRWiper0” script in the User SPI Scripts column and then click on

the Execute Script button three times.

28. Select the “ReadWiper0” script in the User SPI Scripts column and then click on

the Execute Script button. The Transaction window shows the scripts that were

executed and the current value of the Wiper 0 (see Figure 2-15)

29. You can repeat the sequence of writing values to the wiper register or writing then

reading the values back.

NOTICE

If at any time during script execution, an error message is generated in the Transaction

window, it is good practice to reset the PICkit™ Serial Analyzer (PKSA). The PKSA can

be reset using the “Reset” toolbar icon. Verify that subsequent script operations do not

generate errors.

FIGURE 2-12: MCP42XX Write Wiper 0 Script File – Updating Wiper Value.

2010 Microchip Technology Inc. DS51898A-page 29

Page 30

MCP42XXEV Evaluation Board User’s Guide

9-bit data value (03Fh)

9-bit data value (03Fh)

written to

read from

9-bit data value (1FFh)

written to

9-bit data value (1FFh)

read from

Wiper 0 register

Wiper 0 register

Wiper 0 register

Wiper 0 register

Data value (03Ch) read from Wiper 0 register after 3 Decrement Commands

Data value (03Fh) read

from Wiper 0 register

FIGURE 2-13: MCP4261 Transaction Window – Wiper 0 Writes and Reads.

FIGURE 2-14: MCP4261 Transaction Window – Wiper 0 Decrements.

DS51898A-page 30 2010 Microchip Technology Inc.

Page 31

Installation and Operation

Data value (042h) read from Wiper 0 register after 3 Increment Commands

Data value (03Fh) read

from Wiper 0 register

FIGURE 2-15: MCP4261 Transaction Window – Wiper 0 Increments.

2010 Microchip Technology Inc. DS51898A-page 31

Page 32

MCP42XXEV Evaluation Board User’s Guide

2.6.1 The TSSOP20EV PCB and Supported Digital Potentiometers

Table 2-4 shows the current digital potentiometers that are supported by the

TSSOP20EV PCB.

TABLE 2-4: TSSOP20EV PCB SUPPORTED DIGITAL POTENTIOMETERS

Device TSSOP-20 TSSOP-14 Comment

MCP4231 — Yes Dual Pot, SPI Interface

MCP4241 — Yes Dual Pot, SPI Interface

MCP4251 — Yes Dual Pot, SPI Interface

MCP4261 — Yes Dual Pot, SPI Interface

MCP4331 Yes — Quad Pot, SPI Interface

MCP4341 Yes — Quad Pot, SPI Interface

MCP4351 Yes — Quad Pot, SPI Interface

MCP4361 Yes — Quad Pot, SPI Interface

MCP4631 — Yes Dual Pot, I

MCP4641 — Yes Dual Pot, I

MCP4651 — Yes Dual Pot, I2C™ Interface

MCP4661 — Yes Dual Pot, I2C™ Interface

MCP42010 — Yes Dual Pot, SPI Interface

MCP42050 — Yes Dual Pot, SPI Interface

MCP42100 — Yes Dual Pot, SPI Interface

2

C™ Interface

2

C™ Interface

DS51898A-page 32 2010 Microchip Technology Inc.

Page 33

MCP42XXEV EVALUATION BOARD

Top Layer

Ground Layer

Power Layer

Bottom Layer

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the schematics and layouts for the MCP42XXEV Evaluation

Board. Diagrams included in this appendix:

• Board – Schematic

• Board – Top Trace, Silk and Pads

• Board – Bottom Trace and Pads

• Board – Layer 2 Ground Plane

• Board – Layer 3 Power Plane

• Board Layout – Top Components

• Board – Bottom Silk, Trace and Pads

A.2 SCHEMATICS AND PCB LAYOUT

Board – Schematic shows the schematic of the MCP42XXEV Evaluation Board. The

layer order is shown in Figure A-1.

USER’S GUIDE

FIGURE A-1: Layer Order.

2010 Microchip Technology Inc. DS51898A-page 33

Page 34

MCP42XXEV Evaluation Board User’s Guide

M

A.3 BOARD – SCHEMATIC

DS51898A-page 34 2010 Microchip Technology Inc.

Page 35

A.4 BOARD – TOP TRACE, SILK AND PADS

Schematic and Layouts

2010 Microchip Technology Inc. DS51898A-page 35

Page 36

MCP42XXEV Evaluation Board User’s Guide

A.5 BOARD – BOTTOM TRACE AND PADS

DS51898A-page 36 2010 Microchip Technology Inc.

Page 37

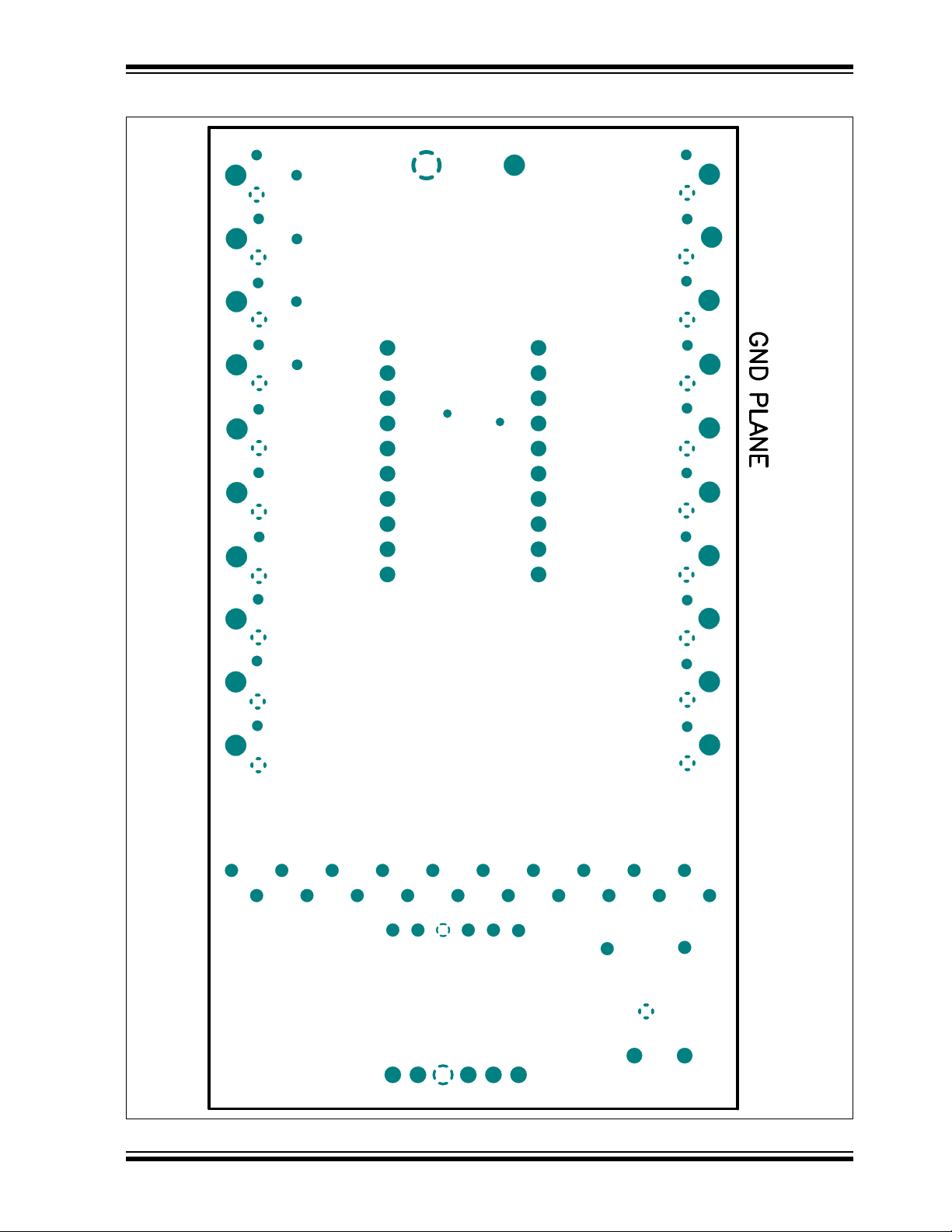

A.6 BOARD – LAYER 2 GROUND PLANE

Schematic and Layouts

2010 Microchip Technology Inc. DS51898A-page 37

Page 38

MCP42XXEV Evaluation Board User’s Guide

A.7 BOARD – LAYER 3 POWER PLANE

DS51898A-page 38 2010 Microchip Technology Inc.

Page 39

A.8 BOARD LAYOUT – TOP COMPONENTS

Schematic and Layouts

2010 Microchip Technology Inc. DS51898A-page 39

Page 40

MCP42XXEV Evaluation Board User’s Guide

A.9 BOARD – BOTTOM SILK, TRACE AND PADS

DS51898A-page 40 2010 Microchip Technology Inc.

Page 41

MCP42XXEV EVALUATION BOARD

USER’S GUIDE

Appendix B. Bill of Materials (BOM)

TABLE B-1: BILL OF MATERIALS

Qty Reference Description Manufacturer Part Number

1 J1 CONN HEADER 6POS .100 R/A TIN Molex/Waldom

Electronics Corp

2 P9, P12 TEST POINT PC MULTI PURPOSE

THROUGH HOLE (Orange)

1PCB Note 1 Microchip Technology

2 R14U, R15U RES 10K OHM 1/8W 5% 0805 SMD Panasonic – ECG ERJ-6GEYJ103V

4 R7D, R11U

R13D, R17U

1 U3 MCP4261 10 K OHM Digital Potentiometer

Note 1: This assembly uses RoHS Compliant TSSOP-20 to DIP-20 Evaluation Board.

2: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS compliant components.

RES 0.0 OHM 1/8W 5% 0805 SMD Panasonic – ECG ERJ-6GEY0R00V

device Device bottom aligned in U3 footprint

(See Assembly Drawing)

Keystone Electronics 5013

Inc.

Microchip Technology

Inc.

22-05-2061

104-00295

MCP4261-103E/ST

2010 Microchip Technology Inc. DS51898A-page 41

Page 42

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-6578-300

Fax: 886-3-6578-370

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

01/05/10

DS51898A-page 42 2010 Microchip Technology Inc.

Loading...

Loading...