Page 1

MCP401X/2X

Digital Potentiometer

Evaluation Board

User’s Guide

© 2005 Microchip Technology Inc. DS51546B

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of Microchip’s products as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor,

MPASM, MPLIB, MPLINK, MPSIM, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, rfLAB, rfPICDEM, Select Mode,

Smart Serial, SmartTel, Total Endurance and WiperLock are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2005, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEEL

®

OQ

code hopping

DS51546B-page ii © 2005 Microchip Technology Inc.

Page 3

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

Tabl e of Conten ts

Preface ........................................................................................................................... 1

Chapter 1. Product Overview

1.1 Introduction ..................................................................................................... 5

1.2 What is the MCP402X Digital Potentiometer Evaluation Board? ................... 5

1.3 What the MCP402X Digital Potentiometer Evaluation Board Kit Includes ..... 6

Chapter 2. Installation and Operation

2.1 Introduction ..................................................................................................... 7

2.2 PCB Description ............................................................................................. 7

2.3 Test and Operating Instructions ................................................................... 10

2.4 Firmware Description ................................................................................... 17

Appendix A. Schematic and Layouts

A.1 Introduction .................................................................................................. 19

A.2 Schematic .................................................................................................. 20

A.3 MCP402X Board Layout – Top Layer + Silk-screen ................................. 21

A.4 MCP402X Board Layout – Bottom Layer ................................................. 21

A.5 MCP402X Board Layout – Top Silkscreen ............................................... 22

A.6 MCP402X Board Layout – Bottom Layer + Silk-screen ........................... 22

Appendix B. Bill Of Materials (BOM)

Appendix C. Using the BFMP Programmer to Power the Board

C.1 Powering the Board Using the BFMP Programmer ..................................... 25

Appendix D. Potential Programming Issue of the MCP402XEV

D.1 Introduction .................................................................................................. 27

Appendix E. 00066_MCP402XEV.ASM Source Code

E.1 Introduction .................................................................................................. 29

Worldwide Sales and Service .................................................................................... 42

© 2005 Microchip Technology Inc. DS51546B-page iii

Page 4

MCP401X/2X Evaluation Board User’s Guide

NOTES:

DS51546B-page iv © 2005 Microchip Technology Inc.

Page 5

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP402X Digital Potentiometer Evaluation Board. Items discussed in this chapter

include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the MCP402X Digital Potentiometer Evaluation

Board. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information about the MCP402X

Digital Potentiometer Evaluation Board.

• Chapter 2. “Installation and Operation” – Includes instructions on how to get

started with this evaluation board.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the MCP402X Digital Potentiometer Evaluation Board.

• Appendix B. “Bill Of Materials (BOM)” – Lists the parts used to build the

MCP402X Digital Potentiometer Evaluation Board.

• Appendix C. “Using the BFMP Programmer to Power the Board” – Shows

how to interface the BFMP board with the MCP402X Digital Potentiometer Evaluation Board.

• Appendix D. “Potential Programming Issue of the MCP402XEV” – Discusses

possible programming issues with Rev 1 and Rev 2 of the MCP402X Digital

Potentiometer Evaluation Board.

• Appendix E. “00066_MCP402XEV.ASM Source Code” – Provides information

about the application firmware, as well as the location of the source code.

© 2005 Microchip Technology Inc. DS51546B-page 1

Page 6

MCP401X/2X Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books

Emphasized text ...is the

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

‘b

nnnn

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

0xnnnn A hexadecimal number where

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path

A tab Click the Power tab

A binary number where n is a

digit

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

n is a hexadecimal digit

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

MPLAB® IDE User’s Guide

“Save project before build”

File>Save

‘b00100, ‘b10

any valid filename

0xFFFF, 0x007A

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

only

compiler...

RECOMMENDED READING

This user's guide describes how to use the MCP402X Digital Potentiometer Evaluation

Board. The following Microchip documents are available and recommended as

supplemental reference resources.

MCP4011/2/3/4,

(DS21978).

MCP4021/2/3/4,

Data Sheet (DS21945).

PIC10F200/202/204/206,

DS51546B-page 2 © 2005 Microchip Technology Inc.

“Low-Cost, 64-Step Volatile Digital POT in SOT-23”

Data Sheet

“Low-Cost NV Digital POT in SOT-23 with WiperLock™ Technology”

“6-Pin, 8-Bit Flash Microcontrollers”

Data Sheet (DS41239)

Page 7

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

Preface

DOCUMENT REVISION HISTORY

Revision B (December 2005)

• Updated to include MCP401X devices

• Enhancement of Operation Description

• Added Appendix C. “Using the BFMP Programmer to Power the Board” -

Programming the MCP402X Digital Potentiometer Evaluation Board

• Added Appendix D. “Potential Programming Issue of the MCP402XEV”- A

description of potential programming issues (and their solutions) with the

MCP402X Digital Potentiometer Evaluation Board

Revision A (April 2005)

• Initial Release of this Document

© 2005 Microchip Technology Inc. DS51546B-page 3

Page 8

MCP401X/2X Evaluation Board User’s Guide

NOTES:

DS51546B-page 4 © 2005 Microchip Technology Inc.

Page 9

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

Chapter 1. Product Overview

1.1 INTRODUCTION

This chapter provides an overview of the MCP402X Digital Potentiometer Evaluation

Board and covers the following topics:

• What is the MCP402X Digital Potentiometer Evaluation Board?

• What the MCP402X Digital Potentiometer Evaluation Board includes

1.2 WHAT IS THE MCP402X DIGITAL POTENTIOMETER EVALUATION BOARD?

The MCP402X Digital Potentiometer Evaluation Board (MCP402XEV) allows the

system designer to quickly evaluate the operation of Microchip Technology’s

MCP401X/2X Digital Potentiometer products.

The MCP402X Digital Potentiometer Evaluation Board PCB was designed to support:

• 8-pin, 150 mil SOIC MCP4021-XXX/SN devices

• SOT-23-6 MCP4022-XXX/OT devices

• SOT-23-6 MCP4023-XXX/OT devices

• SOT-23-5 MCP4024-XXX/OT devices

• 8-pin, 150 mil SOIC MCP4011-XXX/SN devices

• SOT-23-6 MCP4012-XXX/OT devices

• SOT-23-6 MCP4013-XXX/OT devices

• SOT-23-5 MCP4014-XXX/OT devices

In addition to supporting the MCP401X/2X, the MCP402XEV also utilizes the SOT-23-6

PIC10F20X microcontroller.

The PIC10F20X is supplied with example firmware that debounces the INCR and

DECR push buttons and generates the simple U/D

MCP401X/2X to increment and decrement the potentiometer’s wiper. It also generates

the simple U/D

potentiometer’s wiper.

protocol required by the MCP402X to lock and unlock the

protocol required by the

© 2005 Microchip Technology Inc. DS51546B-page 5

Page 10

MCP401X/2X Evaluation Board User’s Guide

1.3 WHAT THE MCP402X DIGITAL POTENTIOMETER EVALUATION BOARD KIT

INCLUDES

This MCP402X Digital Potentiometer Evaluation Board Kit includes:

• One populated Printed Circuit Board (PCB)

- MCP4021-103/OT

- PIC10F206-I/OT with 00066_MCP402XEV.HEX programmed into memory

- Two push button switches: one for Increment commands (INCR), one for

Decrement commands (DECR)

- Decoupling capacitors

- 5 resistors to isolate the switches and create a voltage divider with the

MCP4021-103/OT

• One blank PCB to allow rapid prototyping of a specific digital potentiometer

configuration

• 2 samples each of the MCP4021-202/OT, MCP4021-502/OT, MCP4021-103/OT

and MCP4021-503/OT

• 1 PIC10F20X-I/OT sample

• MCP401X/2X Digital Potentiometer Evaluation Board User’s Guide

(electronic version on CD) (DS51546)

DS51546B-page 6 © 2005 Microchip Technology Inc.

Page 11

Chapter 2. Installation and Operation

2.1 INTRODUCTION

The MCP402X Digital Potentiometer Evaluation Board provides a tested,

out-of-the-box example of a MCP401X/2X application. The circuit description is

described in Section 2.2 “PCB Description”, while the test and operating instructions

are described in Section 2.3 “Test and Operating Instructions”. A supplied blank

PCB allows rapid prototyping of the designer’s specific MCP401X/2X device, along

with other desired passive components (resistor and capacitors) and connection posts.

2.2 PCB DESCRIPTION

The MCP402X Digital Potentiometer Evaluation Board has the following features:

• 150 mil, 8-pin SOIC pinout (U1) supports the MCP4021 and MCP4011 devices

• SOT-23-6 pinout (U2) supports the MCP4022/23/24 and MCP4012/13/14 devices

• SOT-23-6 pinout (U3) supports the PIC10F20X devices

• Connection terminals can be left unpopulated for easy connection using small

alligator clip leads (clamped across the edge of the board) or populated with either

through-hole or surface-mount terminals

• Footprints for optional passive components for:

- Power supply filtering

- Device bypass capacitor

- Terminal “A” pull-up resistor

- Terminal “B” pull-down resistor

• Footprints for two switches:

- INCR button operation can be detected by the PIC10F20X to generate

Increment commands (move wiper toward terminal A)

- DECR button operation can be detected by the PIC10F20X to generate

Decrement commands (move wiper toward terminal B)

• Button sequence instructions are printed on the back of the PCB

Appendix A.2 “Schematic” illustrates the schematic for the MCP402XEV.

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

Note: The PIC10F20X firmware (00066_MCP402XEV.HEX) must be

programmed into the microcontroller before the MCP402XEV is functional.

© 2005 Microchip Technology Inc. DS51546B-page 7

Page 12

MCP401X/2X Evaluation Board User’s Guide

2.2.1 Evaluating the MCP4021 and MCP4011

The MCP4021/11-XXXI/SN is an 8-pin digital potentiometer device with terminals A, B

and W available on the device pins. Footprint U1 supports the 150 mil SOIC package.

Resistors R2 and R3 are 2.5 k

MCP4021-103I/SN digital potentiometer. This creates a “windowed” voltage divider

with a transfer function illustrated in Equation 2-1.

EQUATION 2-1: WINDOWED POTENTIOMETER – VOLTAGE DIVIDER

CALCULATION

V

wiper

Note 1: DO NOT populate U2 if using U1.

2: The MCP4011 has high-voltage tolerant pins and, therefore, accepts

high-voltage Increment and Decrement commands. Since this device is

nonvolatile, the WiperLock™ Technology feature is not present.

Ω on the populated PCB, along with the 10 kΩ

V

DDRwb

------------------------------------------R2 R3 R

++

R3+()⋅

5.0V d 10k

---------------------------------------------------------------------

==

nom

⋅

()63⁄2.5k+()

⋅

2.5k 2.5k 10k++

Where:

d = the wiper setting (0 to 63)

2.2.2 Evaluating the MCP4022 and MCP4012

The MCP4022/12-XXXI/OT is a 6-pin, stand-alone digital rheostat with terminals A and

W available on the device pins. Footprint U2 supports the SOT-23-6 package. An

“INCR” command moves the wiper toward terminal A, thus causing the resistance

across the rheostat to decrease. A “DECR” command moves the wiper toward terminal

B, thus causing the resistance across the rheostat to increase.

Note 1: DO NOT populate U1 if using U2.

2: The included MCP4021 digital potentiometer samples could be used to

evaluate the MCP4022 simply by not populating R3 and letting terminal

B float.

3: The MCP4012 has high-voltage tolerant pins and, therefore, accepts

high-voltage Increment and Decrement commands. Since this device is

nonvolatile, the WiperLock™ Technology feature is not present.

DS51546B-page 8 © 2005 Microchip Technology Inc.

Page 13

Installation and Operation

2.2.3 Evaluating the MCP4023 and MCP4013

The MCP4023/13-XXXI/OT is a 6-pin, grounded digital potentiometer with terminals A

and W available on the device pins. Footprint U2 supports the SOT-23-6 package.

Populating R2 will create a voltage divider with a transfer function illustrated in

Equation 2-2.

EQUATION 2-2: GROUNDED POTENTIOMETER – VOLTAGE DIVIDER

CALCULATION

V

wiper

VDDRwb⋅

-------------------------R2 R

+

5.0V d 10k

-----------------------------------------------

==

nom

Where:

d = the wiper setting (0 to 63)

Note 1: DO NOT populate U1 if using U2.

2: The included MCP4021 digital potentiometer samples could be used to

evaluate the MCP4023 simply by shorting terminal B to GND.

3: The MCP4013 has high-voltage tolerant pins and, therefore, accepts

high-voltage Increment and Decrement commands. Since this device is

nonvolatile, the WiperLock™ Technology feature is not present.

⋅63⁄

()

⋅

2.5k 10k+

2.2.4 Evaluating the MCP4024 and MCP4014

The MCP4024/14-xxxI/OT is a 5-pin, grounded digital rheostat with the W terminals

available on the device pins. Footprint U2 supports the SOT-23-5 package. An “INCR”

command moves the wiper toward terminal A, thus causing the resistance across the

rheostat to increase. A “DECR” command moves the wiper toward terminal B, thus

causing the resistance across the rheostat to decrease.

Note 1: DO NOT populate U1 if using U2.

2: The included MCP4021 digital potentiometer samples could be used to

evaluate the MCP4024 simply by not populating R

float and by shorting terminal B to GND.

3: The MCP4014 has high-voltage tolerant pins and, therefore, accepts

high-voltage Increment and Decrement commands. Since this device is

nonvolatile, the WiperLock™ Technology feature is not present.

, letting terminal A

2

© 2005 Microchip Technology Inc. DS51546B-page 9

Page 14

MCP401X/2X Evaluation Board User’s Guide

2.3 TEST AND OPERATING INSTRUCTIONS

The populated PCB is configured to create a voltage divider from VDD to VSS using a

2.5 kΩ pull-up resistor (R2), the MCP4021-103I/SN (10 kΩ) and a 2.5 kΩ pull-down

resistor (R3). To quickly evaluate the digital potentiometer’s performance, the following

test equipment is required:

• 2.7V to 5.5V power supply

• Voltmeter or Digital Multimeter (DMM)

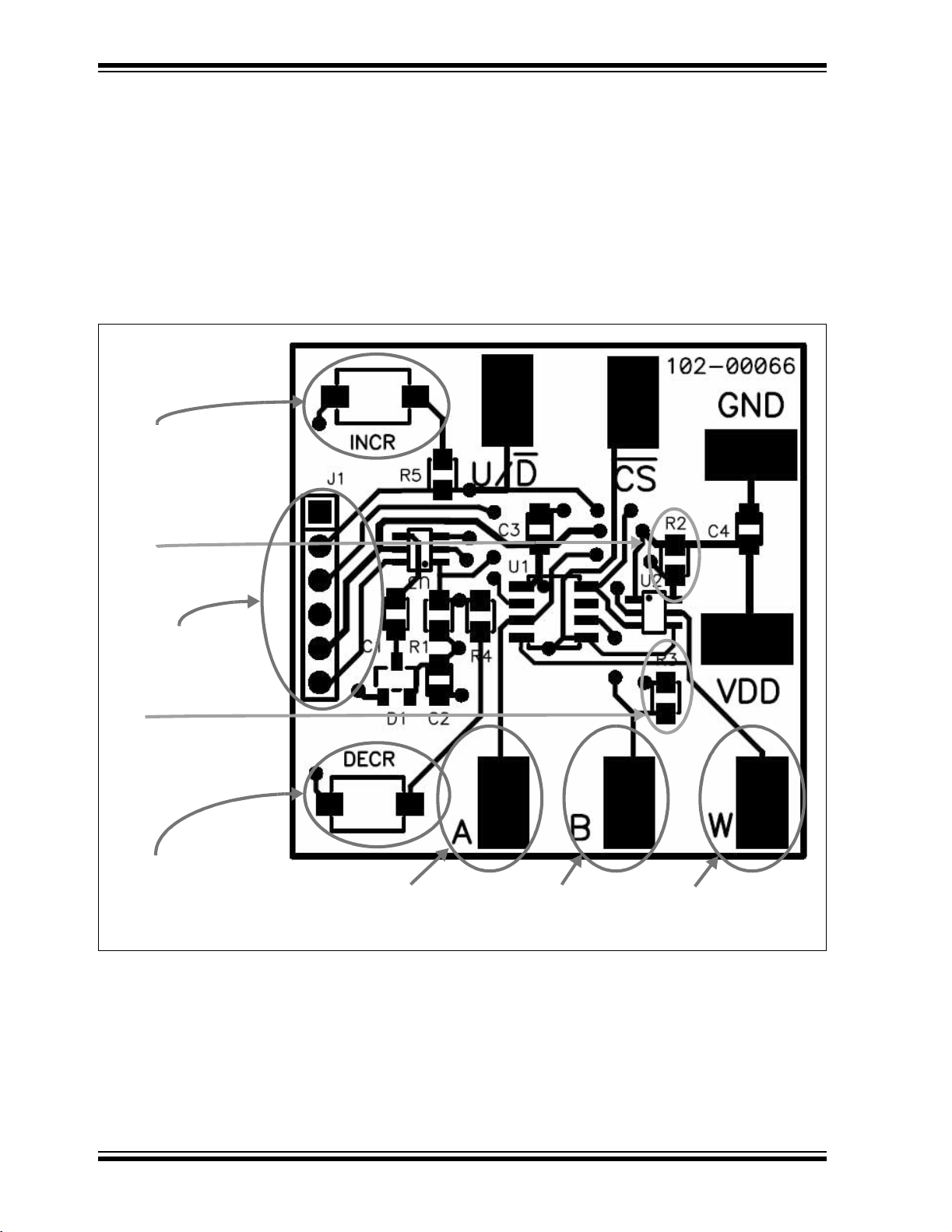

Figure 2-1 shows the Digital Potentiometer Evaluation Board PCB, components and

the connection points that will be used in the step-by-step demonstration.

Increment (INCR)

Switch

Resistor R2

(A to VDD)

Baseline Flash MCU

Programmer (BFMP)

Interface

Resistor R3

(B to GND)

Decrement (DECR)

Switch

FIGURE 2-1: Digital Potentiometer Evaluation Board Overview.

Digital

Potentiometer

Node A Pad

Digital

Potentiometer

Node B Pad

Digital

Potentiometer

Wiper W Pad

DS51546B-page 10 © 2005 Microchip Technology Inc.

Page 15

Installation and Operation

2.3.1 Test Setup

1. Connect the power supply “+” to VDD and the “–” to GND.

2. Connect the voltmeter to the W terminal and GND.

The voltmeter should reflect the wiper setting with respect to Equation 2-3.

EQUATION 2-3: POPULATED PCB – VOLTAGE DIVIDER CALCULATION

V

DDRwb

V

wiper

------------------------------------------R2 R 3 R

++

Where:

d = the wiper setting (0 to 63)

Using R2 and R3 = 2.5 kΩ:

• If a 2 kΩ MCP4021 is utilized, the output range will be approximately 1.79V to

3.21V.

• If a 5 kΩ MCP4021 is utilized, the output range will be approximately 1.25V to

3.75V.

• If a 10 kΩ MCP4021 is utilized, the output range will be approximately 0.83V to

4.17V.

• If a 50 kΩ MCP4021 is utilized, the output range will be approximately 0.23V to

4.77V.

R3+()⋅

5.0V d 10k

---------------------------------------------------------------------

==

AB

⋅

()63⁄2.5k+()

⋅

2.5k 2.5k 10k++

© 2005 Microchip Technology Inc. DS51546B-page 11

Page 16

MCP401X/2X Evaluation Board User’s Guide

2.3.2 MCP402X Digital Potentiometer Evaluation Board Firmware

Operation

The 00066_MCP402XEV.HEX firmware programmed into the PIC10F20X provides a

very simple interface to operate the MCP402X digital potentiometer. There are ten

basic commands supported for the user to exercise the MCP402X digital

potentiometer.

Table 2-1 shows the firmware commands of the Digital Potentiometer Evaluation

Board.

DS51546B-page 12 © 2005 Microchip Technology Inc.

Page 17

MCP401X/2X Evaluation Board User’s Guide

#4

(Release)

#3

(Release)

(5)

#2

(Depress)

(5)

#1

(Depress)

INCR/DECR

MCP401x will

Wiper is “locked”

Works when

“unlocked”

INCR DECR

(for < 2 sec)

DECR INCR

(for < 2 sec)

INCR DECR

(for > 2 sec)

voltage for the CS pin.

IHH MIN

After

Command

Wiper is

“locked”

CS

and U/D pins?

High Voltage on

) greater than 5.0V to allow the simple charge pump to generate the V

DD

Value in EEPROM

Saves Wiper

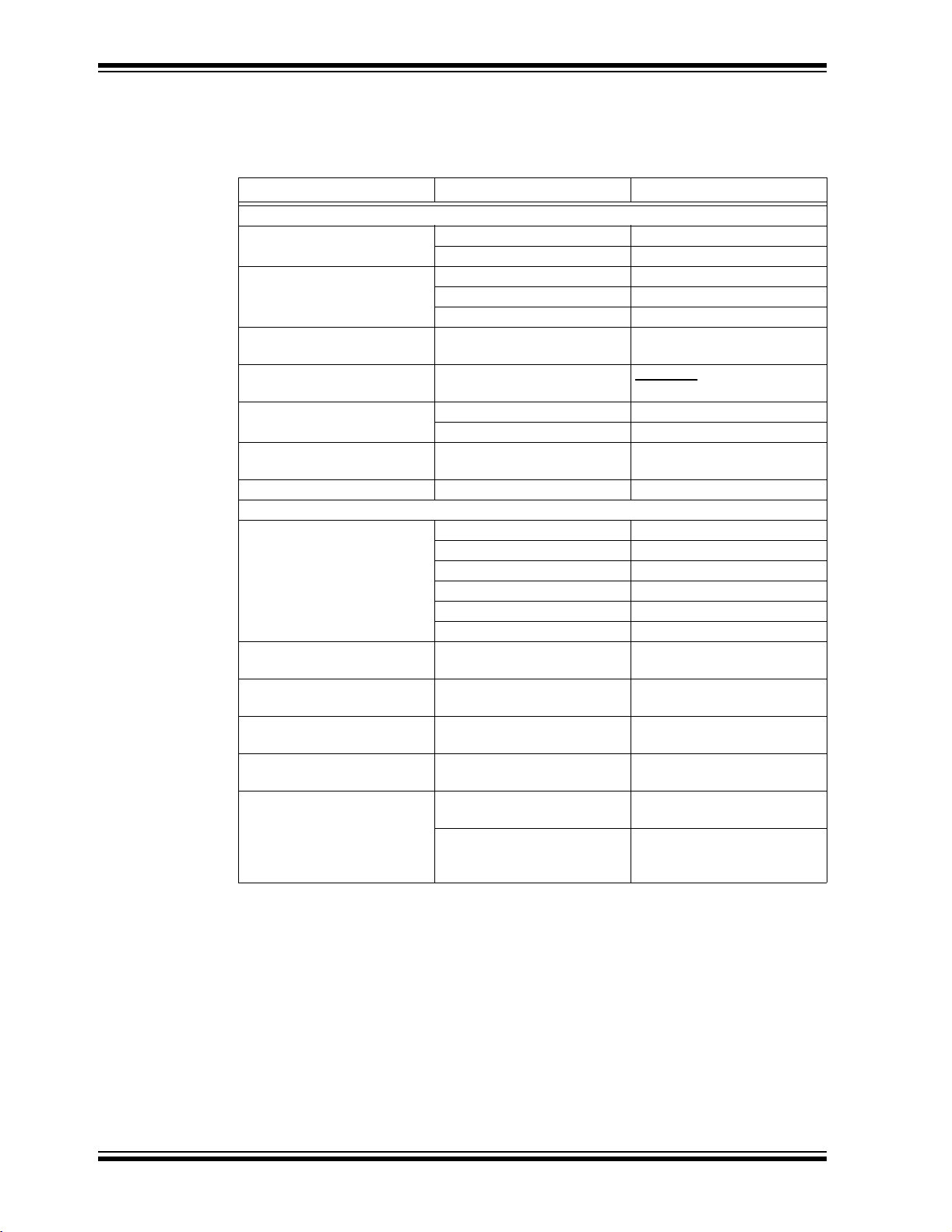

Yes No — — No Yes INCR (for > 2 sec) — — —

Yes No — — No Yes INCR (for < 2 sec)— ——

Yes Ye s — Yes Yes Ye s INCR (for < 2 sec) DECREMENT

Command Button Sequence

# of

Steps

(1)

Yes Yes Yes — Yes Yes INCR (for < 2 sec) DECREMENT

(1)

(1)

1

1

(6)

(6)

(2)

(2)

(6)

Yes Yes — Yes Yes Yes INCR (for < 2 sec) DECREMENT

Yes No — — No Yes DECR (for < 2 sec) — — —

(3)

64

(3)

(6)

Increment/Decrement -

(Low Voltage/High Voltage)

#

1 INCR - (Low Voltage) 1

3 INCR - (High Voltage)

2 INCR - (High Voltage)

4 INCR - (Low Voltage) 64

5 INCR - (High Voltage)

6 DECR - (Low Voltage) 1

TABLE 2-1: DIGITAL POTENTIOMETER EVALUATION BOARD FIRMWARE INCREMENT/DECREMENT COMMANDS

Yes No — — No Ye s DEC R (for > 2 sec)— — —

Yes Ye s Yes — Yes Ye s DECR (for < 2 sec) INCR (for < 2 sec) INCR DECR

(4)

1

9 DECR - (Low Voltage) 64

8 DECR - (High Voltage)

Yes Ye s — Yes Yes Ye s DECR (for < 2 sec) INCR (for > 2 sec) DECR INCR

(4)

64

(6)

10 DECR - (High Voltage)

Note 1: Move wiper W towards node A (Increment wiper 1 step).

Yes Yes — Yes Yes Yes DECR (for < 2 sec) INCR (for < 2 sec) DECR INCR

(3)

1

(6)

7 DECR - (High Voltage)

2: Move wiper W to node A (Increment wiper 64 steps). Forces the wiper setting to “full-scale” (wiper W = node A).

requires the INCR button to be depressed. Then, before 2 seconds elapses, the DECR button must be depressed. Next, before 2 seconds elapses, the INCR

button must be released. The DECR button can then be released.

3: Move wiper W towards node B (Decrement wiper 1 step).

4: Move wiper W to node B (Decrement wiper 64 steps). Forces the wiper setting to “zero scale” (wiper W = node B).

5: If there is more than one sequence, the button sequence #1 must continue to be held down while progressing to sequence #2. Example: Command # 2.

6: High-voltage commands require a system voltage (V

DS51546B-page 13 © 2005 Microchip Technology Inc.

Page 18

MCP401X/2X Evaluation Board User’s Guide

2.3.3 Running the Ratiometric Voltage Demo

Table 2-2 provides step-by-step instructions to perform a demonstration of the

MCP402X Digital Potentiometer Evaluation Board. Measuring Ratiometric Voltage

TABLE 2-2: MEASURING RATIOMETRIC VOLTAGE

Step Action Result

1 Power up the populated Digital Potentiometer

Evaluation Board.

Voltage calculations use a system voltage of 5V.

Board can be powered via a valid voltage (such as 5V)

on the VDD and GND PCB Pads, or by connecting a

BFMP programmer that is connected to an active PC’s

USB port (powered via the USB connection).

2 Set DMM to measure the required voltage range

(0V to 5.5V).

Connect the DMM ground connection to the

evaluation board GND terminal and the DMM V/Ω

connection to terminal W of the evaluation board.

3 Turn on DMM. On DMM:

4 On the Digital Potentiometer Evaluation Board:

Implement Command #5 (see Table 2-1).

5 On the Digital Potentiometer Evaluation Board:

Implement Command #4 (see Table 2-1).

6 On the Digital Potentiometer Evaluation Board:

Implement Command #6 (see Table 2-1).

7 On the Digital Potentiometer Evaluation Board:

Implement Command #6 (see Table 2-1) 15 more

times.

8 On the Digital Potentiometer Evaluation Board:

Turn off/disconnect power supply.

9 On the Digital Potentiometer Evaluation Board:

Reapply power to Digital Potentiometer Evaluation

Board.

10 On the Digital Potentiometer Evaluation Board:

Implement Command #3 (see Table 2-1).

—

—

DMM will display the voltage determined by the

current non-volatile setting of the wiper.

On the Digital Potentiometer Evaluation Board:

WiperLock™ Technology is disabled and the wiper is

incremented from power-on position.

On DMM:

Voltage increments approximately 0.05V.

On the Digital Potentiometer Evaluation Board:

Wiper is forced to the full-scale position

(Wiper W = node A).

On DMM:

Voltage equals approximately 4.17V.

On the Digital Potentiometer Evaluation Board:

Wiper is decremented one position from the full-scale

position.

On DMM:

Voltage equals approximately 4.12V.

On the Digital Potentiometer Evaluation Board:

Wiper is decremented to the 25% position from

node A (full-scale) to node B (zero-scale).

On DMM:

Voltage equals approximately 3.33V.

On DMM:

Voltage equals approximately 0V.

On DMM:

Voltage equals approximately 3.33V. This shows that

the MCP4021 retained the last selected wiper setting.

On the Digital Potentiometer Evaluation Board:

Wiper is incremented one position and the wiper is

locked (WiperLock Technology is enabled).

On DMM:

Voltage equals approximately 3.38V.

DS51546B-page 14 © 2005 Microchip Technology Inc.

Page 19

Installation and Operation

TABLE 2-2: MEASURING RATIOMETRIC VOLTAGE (CONTINUED)

Step Action Result

11 On the Digital Potentiometer Evaluation Board:

Implement Command #1 (see Table 2-1).

12 On the Digital Potentiometer Evaluation Board:

Turn off/disconnect power supply.

13 On the Digital Potentiometer Evaluation Board:

Re-apply power to Digital Potentiometer Evaluation

Board.

On the Digital Potentiometer Evaluation Board:

Wiper is NOT moved due to the wiper being locked

(WiperLock™ Technology is enabled).

On DMM:

Voltage equals approximately 3.38V.

On DMM:

Voltage equals approximately 0V.

On DMM:

Voltage equals approximately 3.38V. This shows that

the MCP4021 retained the last saved wiper setting.

© 2005 Microchip Technology Inc. DS51546B-page 15

Page 20

MCP401X/2X Evaluation Board User’s Guide

2.3.4 Wiper Voltages

Table 2-3 shows the relation between the wiper position and the voltage on the wiper

when 5.0 volts is applied to the MCP402X Digital Potentiometer Evaluation Board

where the resistors R2 and R3 are 2500Ω and the MCP4011 resistor value (R

10 kΩ. Equation 2-4 shows the formula for these calculations.

EQUATION 2-4: CALCULATING THE VOLTAGE ON THE MCP402X DIGITAL

POTENTIOMETER EVALUATION BOARD

R3 Wiper Position RAB()63ڥ()+()

Voltage at Wiper System V

Where:

-----------------------------------------------------------------------------------------

•=

DD

R3 R

AB

R2++

AB

) is

R

DD

R2

R3

AB

=

=

=

=

5.0V

2.5 kΩ

2.5 kΩ

10 kΩ

System V

The typical step resistance for the 10 kΩ MCP4021 is approximately 158.73Ω. With a

5V supply and a 15 kΩ total resistance (2.5 kΩ + 2.5 kΩ + 10 kΩ), the delta voltage per

step is approximately 0.053V.

TABLE 2-3: WIPER POSITION AND CORRESPONDING VOLTAGE

Wiper Wiper Wiper Wiper

Position

(1)

00

01 0.866 17 1.733 33 2.579 49 3.426

02 0.939 18 1.786 34 2.632 50 3.479

03 0.992 19 1.839 35 2.685 51 3.532

04 1.045 20 1.892 36 2.738 52 3.585

05 1.098 21 1.944 37 2.791 53 3.638

06 1.151 22 1.997 38 2.844 54 3.690

07 1.204 23 2.050 39 2.897 55 3.743

08 1.257 24 2.103 40 2.950 56 3.796

09 1.310 25 2.156 41 3.003 57 3.849

10 1.362 26 2.209 42 3.056 58 3.902

11 1.415 27 2.262 43 3.108 59 3.955

12 1.468 28 2.315 44 3.161 60 4.008

13 1.521 29 2.368 45 3.214 61 4.061

14 1.574 30 2.421 46 3.267 62 4.114

15 1.627 31 2.474 47 3.320 63

Note 1: This is zero-scale, wiper is connected to terminal B.

Volta ge

(V)

0.833 16 1.680 32 2.526 48 3.373

2: This is full-scale, wiper is connected to terminal A.

Position

Voltage

(V)

Position

Voltage

(V)

Position

(2)

4.167

Voltage

(V)

DS51546B-page 16 © 2005 Microchip Technology Inc.

Page 21

2.4 FIRMWARE DESCRIPTION

The 000066_MCP402XEV.ASM source code was written using assembly language for

the PIC10F206 microcontroller. Refer to Appendix E. “00066_MCP402XEV.ASM

Source Code”. The firmware initializes its I/O so that it can poll the INCR and DECR

buttons every millisecond. If the button has been depressed for 40 out of 50 ms, it is

considered to be debounced and asserted. The button state is used to determine if a

new “Action State” is desired. This simple state machine then decodes the desired

action. Once the desired command has been determined, a subroutine that performs

the desired command is executed. The low-voltage commands are driven directly from

the PIC10F206 I/O, but the high-voltage commands require some additional hardware

to generate the required 8V signal.

When a high-voltage command is required, the PIC10F206’s unique OSCOUT feature

is utilized. The OSCOUT function allows the instruction clock to be driven on

GP2/OSCOUT under software control. A simple charge pump consisting of 2 – 0.01 µF

capacitors and a BAV99 dual diode is constructed as seen in Appendix

A.2 “Schematic”. When the OSCOUT is enabled, a 1 MHz clock drives the charge

pump that produces an 8.4V signal on the MCP401X/2X’s CS

V

= 5.0V). Utilizing such a charge pump requires special attention to the timing of the

DD

CS

& U/D signals.

Refer to the comments in the 00066_MCP402XEV.ASM source code for more details

on the firmware’s operation. Refer to Appendix E. “00066_MCP402XEV.ASM Source

Code”.

Installation and Operation

pin (assuming

© 2005 Microchip Technology Inc. DS51546B-page 17

Page 22

MCP401X/2X Evaluation Board User’s Guide

NOTES:

DS51546B-page 18 © 2005 Microchip Technology Inc.

Page 23

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the following schematics and layout diagrams for the MCP402X

Digital Potentiometer Evaluation Board.

• Schematic – Shows the schematic of the MCP402X Digital Potentiometer Evaluation Board. The populated PCB was built using this schematic.

• Board Layout – Top Layer + Silk-screen

• Board Layout – Top Silk-Screen

• Board Layout – Bottom Layer + Silk-screen

• Board Layout – Bottom Layer

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

© 2005 Microchip Technology Inc. DS51546B-page 19

Page 24

MCP401X/2X Evaluation Board User’s Guide

A.2 SCHEMATIC

M

DS51546B-page 20 © 2005 Microchip Technology Inc.

Page 25

Schematic and Layouts

A.3 MCP402X BOARD LAYOUT – TOP LAYER + SILK-SCREEN

A.4 MCP402X BOARD LAYOUT – BOTTOM LAYER

© 2005 Microchip Technology Inc. DS51546B-page 21

Page 26

MCP401X/2X Evaluation Board User’s Guide

A.5 MCP402X BOARD LAYOUT – TOP SILK-SCREEN

A.6 MCP402X BOARD LAYOUT – BOTTOM LAYER + SILK-SCREEN

DS51546B-page 22 © 2005 Microchip Technology Inc.

Page 27

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

Appendix B. Bill Of Materials (BOM)

TABLE B-1: BILL OF MATERIALS

Qty Reference Description Manufacturer Part Number

2 C1,C2,C3 Cap 0.01 µF 50V CERAMIC

X7R 0805

1 C4 Cap .1 µF 25V CERAMIC

X7R 0805

1 D1 Dual Diode, SOT-23-3,

May substitute with

Fairchild

2 INCR, DECR Switch LT Touch 6X3.5

100 GF SMD

1 J1 Conn Header 6pos .100 VERT TIN

(Optional)

1R1 Res 7.5kΩ 1/10W 1%

0805 SMD

2 R2,R3 Res 2.5 kΩ 1/10W 1%

0805 SMD

2 R4,R5 Res 2.5 kΩ 1/10W 1%

0805 SMD

1 U1 MCP4021-103/SN 10 kΩ

Digital Potentiometer

1 U3 PIC10F206, 6-Pin,

8-Bit Flash Microcontrollers

1 U2 MCP4022/23/24 5/6 Pin Digital

Potentiometer (Optional)

7 A,B,W,VDD,GND,

U/D

,CS

Test Point PC Compact SMT

(Optional)

®

BAV99

®

Kemet

Panasonic

ECG

ON Semiconductor

Panasonic Corporation –

ECG

Molex

Electronics Corp

Panasonic Corporation –

ECG

Panasonic Corporation –

ECG

Panasonic Corporation –

ECG

Microchip Technology Inc. MCP4021-103/SN

Microchip Technology Inc. PIC10F206-I/OT

Microchip Technology Inc. MCP4024-502/OT

Keystone

®

Corporation –

®

®

/Waldom®

®

Electronics 5016

C0805C103K5RACTU

ECJ-2VB1E104K

BAV99LT1

EVQ-PJS04K

22-28-4061

ERJ-6ENF5111V

ERJ-6ENF5111V

ERJ-6ENF5111V

© 2005 Microchip Technology Inc. DS51546B-page 23

Page 28

MCP401X/2X Evaluation Board User’s Guide

NOTES:

DS51546B-page 24 © 2005 Microchip Technology Inc.

Page 29

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

Appendix C. Using the BFMP Programmer to Power the Board

C.1 POWERING THE BOARD USING THE BFMP PROGRAMMER

The BFMP programmer (PG164101) uses a 6-pin interface for programming. The

PICkit™ 2 Flash Starter Kit (PG164120 or DV164120) uses the same interface.

The MCP402X Digital Potentiometer Evaluation Board (MCP402XEV) plugs into the

BFMP (or PICkit™ 2 Flash Starter Kit) in the orientation shown in Figure C-1.

USB Cable to PC

BFMP Board

(Top-side)

Pin #1 Pin #1

FIGURE C-1: BFMP Hardware and MCP402X Digital Potentiometer Evaluation

Board.

BFMP Header connector

MCP402XEV

Board

(Bottom-side)

© 2005 Microchip Technology Inc. DS51546B-page 25

Page 30

MCP401X/2X Evaluation Board User’s Guide

These programmers use the PICkit™ 1 Baseline Flash Programmer software. This GUI

should be configured as shown in Figure C-2. Selecting Device Power causes the

BFMP to power the attached board all the time (not just during programming). This

allows the MCP402X Digital Potentiometer Evaluation Board to be easily demonstrated

without needing to carry a power supply (although a DMM is still required).

Select PIC10F206

FIGURE C-2: PICkit™ 1 Baseline Flash Programmer - Configuration #2.

Note: When programming the MCP402X Digital Potentiometer Evaluation Board,

under

“Board Controls”

the PIC10F206 is only powered during the programming cycle.

DS51546B-page 26 © 2005 Microchip Technology Inc.

Ensure Device Power IS checked and

2.5 kHz Osc is NOT checked.

, DO NOT check Device Power. This ensures that

Page 31

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

Appendix D. Potential Programming Issue of the MCP402XEV

D.1 INTRODUCTION

When programming the MCP402XEV with a Microchip programmer (such as the BPMF

or MPLAB

ICSPDAT pin. This issue relates to PCBs marked 104-00066 and 104-00066R2.

Due to the current path to ground that is present with the D1 and R1 components

through capacitor C2, the programming voltage on the ICSPDAT signal may not meet

the voltage requirements of the PIC10F206 GP1 pin.

To address this when programming the board, lift up one of the terminals of capacitor

C2 (see Figure D-1). This will stop the ICSPDAT signal voltage from being loaded down

while capacitor C2 is charging. The schematic is shown in Figure D-2.

After programming, capacitor C2 must be reconnected to the circuit. This is because

this circuit generates the high voltage for the high voltage commands.

®

ICD 2), the PIC10F206 may not program correctly due to the load on the

This capacitor connection needs

to be opened for programming.

After programming has been

completed, this capacitor needs

to be reconnected in the circuit.

lift this end

FIGURE D-1: MCP402XEV R2 PCB Layout – ECN #1.

© 2005 Microchip Technology Inc. DS51546B-page 27

Page 32

MCP401X/2X Evaluation Board User’s Guide

M

This is the node that needs to

be open when programming.

FIGURE D-2: MCP402XEV R2 Schematic PCB R2, ECN #1.

JP1

C2

DS51546B-page 28 © 2005 Microchip Technology Inc.

Page 33

MCP401X/2X EVALUATION

BOARD USER’S GUIDE

Appendix E. 00066_MCP402XEV.ASM Source Code

E.1 INTRODUCTION

This appendix documents the example PIC10F20X source code used on the populated

PCB. The source code is described in detail by the comments within the.ASM file. The

00066_MCP402XEV.ASM, PIC10F206.INC and MCP402XEV.HEX files can be found

on the Microchip web site (www.microchip.com) and on the included CD.

Software License Agreement

The software supplied herewith by Microchip Technology Incorporated (the “Company”) is intended and supplied to you, the

Company’s customer, for use solely and exclusively with products manufactured by the Company.

The software is owned by the Company and/or its supplier, and is protected under applicable copyright laws. All rights are reserved.

Any use in violation of the foregoing restrictions may subject the user to criminal sanctions under applicable laws, as well as to civil

liability for the breach of the terms and conditions of this license.

THIS SOFTWARE IS PROVIDED IN AN “AS IS” CONDITION. NO WARRANTIES, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE APPLY TO THIS SOFTWARE. THE COMPANY SHALL NOT, IN ANY CIRCUMSTANCES, BE LIABLE FOR

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, FOR ANY REASON WHATSOEVER.

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE

TITLE “MCP402XEV Firmware”

;********************************************************************************************

; Author: Jim Simons

; Tools: MPLAB(r) 7.10 using MPLINK(tm)

; Editor: ComicSans 8pt w/8 character Tabs

; Files: 00066_MCP402XEV.asm

; p10f206.inc

;

; Description: Exercise the MCP402x devices using the MCP402x EV board.

; Simply use the INCR & DECR buttons to execute the INCR & DECR serial commands.

;

; Serial Commands Action State

; _______________ ______ _____

; LV Increment w/EE Depress UP, Release UP LVwEE = 1 3

; LV Decrement w/EE Depress DOWN, Release DOWN LVwEE = 1 4

; LV Increment w/o EE Depress UP, Release UP LVwEE = x 3

; LV Decrement w/o EE Depress DOWN, Release DOWN LVwEE = x 4

; LV 64 Increments Depress UP, Hold for 2s, Release UP 1

; LV 64 Decrements Depress DOWN, Hold for 2s, Release DOWN 2

; HV Incr w/o WL Depress UP, Depress DOWN, Release UP, Release DOWN 11

; HV Decr w/o WL Depress DOWN, Depress UP, Release DOWN, Release UP 12

; HV 64 Incr w/o WL Depress UP, Depress DOWN, Hold for 2s, Release UP, Release DOWN 5

; HV 64 Decr w/o WL Depress DOWN, Depress UP, Hold for 2s, Release DOWN, Release UP 6

; HV Incr w/WL Depress UP, Depress DOWN, Release DOWN, Release UP 13

; HV Decr w/WL Depress DOWN, Depress UP, Release UP, Release DOWN 14

;

© 2005 Microchip Technology Inc. DS51546B-page 29

Page 34

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

;**********************************************************************************************

; Connections/Schematic

;**********************************************************************************************

;

; MCP pin MCP4021 MCP4022 MCP4023 MCP4024

; _______ _______ _______ _______ _______

; 1 Vdd Vdd Vdd Vdd

; 2 Vss Vss Vss Vss

; 3 A U/D U/D U/D

; 4 W CS CS CS

; 5 CS W W W

; 6 B A A ; 7 - - - ; 8 U/D - - ;

; MCP402x PIC10F206 Ext Components

; _______ _________ ______________

; Vdd Vdd 0.1uF - Vss

; Vss Vss ; A - 2.5k - Vdd

; W - ; B - 2.5k - Vss

; CS GP0/ICSPDAT (int pu) 2.5k - DECR - Vss, 7.5k - CS & BAV99

; U/D GP1/ICSPCLK (int pu) 2.5k - INCR - Vss

; - GP2/OSCOUT 0.01uF - BAV99 - 0.01uF - Vss

; - GP3/Vpp (int pu) optional SW or Jumper put on BFMP header pins 4 & 6

;

;**********************************************************************************************

; Assemble Time Variables

SaveWiper equ 1 ; comment this line prevent LV commands from Saving the Wiper

;

;**********************************************************************************************

; Configure the PIC

;**********************************************************************************************

list p=10F206 ; list directive to define processor

#include <p10F206.inc> ; processor specific variable definitions

__CONFIG _MCLRE_OFF & _CP_OFF & _WDT_ON

ERRORLEVEL -302

© 2005 Microchip Technology Inc. DS51546B-page 30

Page 35

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

;**********************************************************************************************

; General Pupose Register Definitions

;**********************************************************************************************

GPRS UDATA

State res 1 ; variable to track the “state” value

; this code functions as a state machine

; bits 3:0 stores the state 0-15 indicator

; bits 7:6 stores the debounced button states

OldState res 1 ; allows program to see if State changed

Exit res 1 ; variable to count the number ms to test for a button press

DebounceUP res 1 ; variable to count the number of ms UP was pressed

DebounceDOWN res 1 ; variable to count the number of ms DOWN was pressed

DLYCNT1 res 1 ; variable for the delay subroutines

DLYCNT2 res 1 ; variable for the delay subroutines

#define UD GPIO,1 ; GP1 tied to UD & has “INCR” switch connected via 2.2k resistor

#define CS GPIO,0 ; GP0 tied to CS & has “DECR” switch connected via 2.2k resistor

#define UP GPIO,1 ; Momentary switch UP

#define DOWN GPIO,0 ; Momentary switch DOWN

#define CP GPIO,2 ; OSCOUT pin for Charge Pump

#define PowerDown GPIO,3 ; Vpp for programming & PowerDown input to put uC to SLEEP

#define HV_CS OSCCAL,FOSC4 ; Drives CS to HVDD (drive CS high first)

#define UP_State State,7 ; Debounced UP State - using bits 5:4 are critical

#define DOWN_State State,6 ; Debounced DOWN State - using bits 5:4 are critical

;***********************************************************************************************

; Reset Code

;***********************************************************************************************

RESET CODE ; processor reset vector + 1

;ResetVector ; Device resets to 0x1FF to get the factory calibration

goto Start ; Lower half of memory reserved for subroutines

;***********************************************************************************************

; Main Code

;***********************************************************************************************

MAIN CODE

Start

Init_Oscillator

; Internal RC calibration value is placed at location 0xFF by Microchip

; as a movlw k, where the k is a literal value.

movwf OSCCAL ; update register with factory cal value

; bcf OSCCAL,FOSC4 ; make sure the FOSC4 is disabled to shut charge pump off

StateMachineReset

movlw b’11110011’ ; Disable the Comparator & make inputs digital

movwf CMCON0

; bcf CMCON0, CMPON ; needs to be on to get GP2 as a General Purpose Output

movlw b’10011010’ ; disable Wake-Up on Pin Change,

; enable weak pullups for button inputs

; T0CS must be 0 for GP2 TRIS to be active

; set up for 72ms WDT

option

Init

clrf State

clrf OldState

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

© 2005 Microchip Technology Inc. DS51546B-page 31

Page 36

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

ButtonCheck ; Debounce Buttons

btfss PowerDown ; If pulled low, put uC to SLEEP

goto LowPowerMode

bsf UP_State

bsf DOWN_State ; initialize Button_State to indicate no button pressed

movlw .50 ; debounce the buttosns for 50mS to see if pressed

movwf Exit

movlw .40 ; if pushed for 40 of 50 tests, then valid UP

movwf DebounceUP

movwf DebounceDOWN

DebounceLoop

call GPIO_TestUP ; make GP1/INCR/UD an input (w/pu enabled)

movlw .99

call VAR5TcyDELAY ; 5 + (99*5) = 500us

btfss UP

decfsz DebounceUP,f

goto CheckDOWN

bcf UP_State ; UP Button Pressed

CheckDOWN

call GPIO_TestDOWN ; make GP0/DECR/CS an input (w/pu enabled)

movlw .99

call VAR5TcyDELAY ; 5 + (99*5) = 500us

btfss DOWN

decfsz DebounceDOWN,f

goto DebounceLoopTest

bcf DOWN_State ; DOWN Button Pressed

DebounceLoopTest

decfsz Exit,f

goto DebounceLoop

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

movf State,w

call DetermineState ; subroutine to determine the next state

movwf State

xorwf OldState,w

btfss STATUS,Z

call PerformState ;State changed, now do something

movlw .5

call VAR1000TcyDELAY ; Make sure EE Write Cycle has finished

movf State,w

movwf OldState

goto ButtonCheck ; Loop for button presses

;***********************************************************************************************

; State Machine Code

;***********************************************************************************************

State0 goto StateMachineReset ; State 0, no action, shouldn’t get here

State1 ; UP button pressed

movlw .200 ; 200x10mS = 2s

movwf Exit

© 2005 Microchip Technology Inc. DS51546B-page 32

Page 37

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

Loop1_2sec

call GPIO_TestDOWN ; make GP0/DECR/CS an input (w/pu enabled)

movlw .5 ; 5ms delay

call VAR1000TcyDELAY

btfss DOWN ; if DOWN gets pressed, exit

retlw .1

call GPIO_TestUP ; make GP1/INCR/UD an input (w/pu enabled)

movlw .5 ; 5ms delay

call VAR1000TcyDELAY

btfsc UP ; if UP gets released, exit

retlw .1

decfsz Exit,f

goto Loop1_2sec

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

movlw .64

call LV_Increment

; movlw .4

; call VAR1000TcyDELAY ; add a 4mS delay for E/W cycle

call GPIO_TestUP ; make GP1/INCR/UD an input (w/pu enabled)

LV_IncrExit

clrwdt

btfss UP ; if UP gets released, exit

goto LV_IncrExit

clrf State

retlw .1

State2 ; DOWN button pressed

movlw .200 ; 200x10mS = 2s

movwf Exit

Loop2_2sec

call GPIO_TestUP ; make GP1/INCR/UD an input (w/pu enabled)

movlw .5 ; 5ms delay

call VAR1000TcyDELAY

btfss UP ; if UP gets pressed, exit

retlw .2

call GPIO_TestDOWN ; make GP0/DECR/CS an input (w/pu enabled)

movlw .5 ; 5ms delay

call VAR1000TcyDELAY

btfsc DOWN ; if DOWN gets released, exit

retlw .2

decfsz Exit,f

goto Loop2_2sec

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

undesired U/D commands

movlw .64

call LV_Decrement

; movlw .4

; call VAR1000TcyDELAY ; add a 4mS delay for E/W cycle

call GPIO_TestDOWN ; make GP0/DECR/CS an input (w/pu enabled)

LV_DecrExit

clrwdt

btfss DOWN ; if DOWN gets released, exit

goto LV_DecrExit

clrf State

retlw .2

State3 ; LV Increment

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

movlw .1

call LV_Increment

clrf State

retlw .3

© 2005 Microchip Technology Inc. DS51546B-page 33

Page 38

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

State4 ; LV Decrement

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

movlw .1

call LV_Decrement

clrf State

retlw .4

State5 ; Both buttons pressed

movlw .200 ; 200x10mS = 2s

movwf Exit

Loop5_2sec

call GPIO_TestUP ; make GP1/INCR/UD an input (w/pu enabled)

movlw .5 ; 5ms delay

call VAR1000TcyDELAY

btfsc UP ; if UP gets released, exit

retlw .5

call GPIO_TestDOWN ; make GP0/DECR/CS an input (w/pu enabled)

movlw .5 ; 5ms delay

call VAR1000TcyDELAY

btfsc DOWN ; if DOWN gets released, exit

retlw .5

decfsz Exit,f

goto Loop5_2sec

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

movlw .64

call HV_Increment_WL_Disable

; movlw .4

; call VAR1000TcyDELAY ; add a 4mS delay for E/W cycle

HV_IncrExit clrwdt

call GPIO_TestDOWN ; make GP0/DECR/CS an input (w/pu enabled)

movlw .10

call VAR1000TcyDELAY ; add a 10mS delay for settling time

btfss DOWN ; if DOWN gets released, exit

goto HV_IncrExit

call GPIO_TestUP ; make GP1/INCR/UD an input (w/pu enabled)

movlw .10

call VAR1000TcyDELAY ; add a 10mS delay for settling time

btfss UP ; if UP gets released, exit

goto HV_IncrExit

clrf State

retlw .5

State6

movlw .200 ; 200x10mS = 2s

movwf Exit

Loop6_2sec

call GPIO_TestUP ; make GP1/INCR/UD an input (w/pu enabled)

movlw .5 ; 5ms delay

call VAR1000TcyDELAY

btfsc UP ; if UP gets released, exit

retlw .6

call GPIO_TestDOWN ; make GP0/DECR/CS an input (w/pu enabled)

movlw .5 ; 5ms delay

call VAR1000TcyDELAY

btfsc DOWN ; if DOWN gets released, exit

retlw .6

decfsz Exit,f

goto Loop6_2sec

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

movlw .64

call HV_Decrement_WL_Disable

; movlw .4

; call VAR1000TcyDELAY ; add a 4mS delay for E/W cycle

© 2005 Microchip Technology Inc. DS51546B-page 34

Page 39

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

HV_DecrExit clrwdt

call GPIO_TestUP ; make GP1/INCR/UD an input (w/pu enabled)

movlw .10

call VAR1000TcyDELAY ; add a 10mS delay for settling time

btfss UP ; if UP gets released, exit

goto HV_DecrExit

call GPIO_TestDOWN ; make GP0/DECR/CS an input (w/pu enabled)

movlw .10

call VAR1000TcyDELAY ; add a 10mS delay for settling time

btfss DOWN ; if DOWN gets released, exit

goto HV_DecrExit

clrf State

retlw .6

State7

State8

State9

State10

State11 ; HV Increment w/o WL

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

movlw .1

call HV_Increment_WL_Disable

clrf State

retlw .11

State12 ; HV Increment w/o WL

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

movlw .1

call HV_Decrement_WL_Disable

clrf State

retlw .12

State13 ; HV Decrement w/WL

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

call HV_Increment_WL_Enable

clrf State

retlw .13

State14 ; HV Decrement w/WL

call InitGPIO ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

call HV_Decrement_WL_Enable

clrf State

retlw .14

State15

goto StateMachineReset

;***********************************************************************************************

; Low Power Mode

;***********************************************************************************************

LowPowerMode

movlw b’11111000’ ; make all I/O pins an output

tris GPIO

movlw b’11111111’

movwf GPIO ; output high

movlw b’10011111’ ; disable Wake-Up on Pin Change,

; enable weak pullups for button inputs

; T0CS must be 0 for GP2 TRIS to be active

; set up for 2.3ms WDT

option

sleep ; put into lowest power setting

goto Start ; shouldn’t get here

SUBS CODE

© 2005 Microchip Technology Inc. DS51546B-page 35

Page 40

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

;***********************************************************************************************

; State Machine Subroutines

;***********************************************************************************************

DetermineState

swapf State,f

rrf State,f

rrf State,w

andlw b’00111111’ ; mask invalid states

addwf PCL,f

S0_00 retlw .0 ; both buttons pressed at same time, shouldn’t be here

S0_01 retlw .1 ; UP button pressed, change state

S0_10 retlw .2 ; DOWN button pressed, change state

S0_11 retlw .0 ; no change

S1_00 retlw .5 ; both buttons pressed, change state

S1_01 retlw .1 ; no change

S1_10 retlw .0 ; shouldn’t be here, reset state

S1_11 retlw .3 ; UP button released, change state

S2_00 retlw .6 ; both buttons pressed, change state

S2_01 retlw .0 ; shouldn’t be here, reset state

S2_10 retlw .2 ; no change

S2_11 retlw .4 ; DOWN button released, change state

S3_00 retlw .0 ; shouldn’t be here, reset state

S3_01 retlw .0 ; shouldn’t be here, reset state

S3_10 retlw .0 ; shouldn’t be here, reset state

S3_11 retlw .0 ; shouldn’t be here, reset state

S4_00 retlw .0 ; shouldn’t be here, reset state

S4_01 retlw .0 ; shouldn’t be here, reset state

S4_10 retlw .0 ; shouldn’t be here, reset state

S4_11 retlw .0 ; shouldn’t be here, reset state

S5_00 retlw .5 ; no change

S5_01 retlw .7 ; DOWN button released, change state

S5_10 retlw .9 ; UP button released, change state

S5_11 retlw .0 ; shouldn’t be here, reset state

S6_00 retlw .6 ; no change

S6_01 retlw .10 ; DOWN button released

S6_10 retlw .8 ; UP button released

S6_11 retlw .0 ; shouldn’t be here, reset state

S7_00 retlw .5 ; both buttons pressed again, change state

S7_01 retlw .7 ; no change

S7_10 retlw .0 ; shouldn’t be here, reset state

S7_11 retlw .13 ; UP button released, change state

S8_00 retlw .6 ; both buttons pressed again, change state

S8_01 retlw .0 ; shouldn’t be here, reset state

S8_10 retlw .8 ; no change

S8_11 retlw .14 ; DOWN button released, change state

S9_00 retlw .5 ; both buttons pressed again, change state

S9_01 retlw .0 ; shouldn’t be here, reset state

S9_10 retlw .9 ; no change

S9_11 retlw .11 ; DOWN button released, change state

S10_00 retlw .6 ; both buttons pressed again, change state

S10_01 retlw .10 ; no change

S10_10 retlw .0 ; shouldn’t be here, reset state

S10_11 retlw .12 ; DOWN button released, change state

S11_00 retlw .0 ; shouldn’t be here, reset state

S11_01 retlw .0 ; shouldn’t be here, reset state

S11_10 retlw .0 ; shouldn’t be here, reset state

S11_11 retlw .0 ; shouldn’t be here, reset state

S12_00 retlw .0 ; shouldn’t be here, reset state

S12_01 retlw .0 ; shouldn’t be here, reset state

S12_10 retlw .0 ; shouldn’t be here, reset state

S12_11 retlw .0 ; shouldn’t be here, reset state

S13_00 retlw .0 ; shouldn’t be here, reset state

S13_01 retlw .0 ; shouldn’t be here, reset state

© 2005 Microchip Technology Inc. DS51546B-page 36

Page 41

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

S13_10 retlw .0 ; shouldn’t be here, reset state

S13_11 retlw .0 ; shouldn’t be here, reset state

S14_00 retlw .0 ; shouldn’t be here, reset state

S14_01 retlw .0 ; shouldn’t be here, reset state

S14_10 retlw .0 ; shouldn’t be here, reset state

S14_11 retlw .0 ; shouldn’t be here, reset state

S15_00 retlw .0 ; shouldn’t be here, reset state

S15_01 retlw .0 ; shouldn’t be here, reset state

S15_10 retlw .0 ; shouldn’t be here, reset state

S15_11 retlw .0 ; shouldn’t be here, reset state

PerformState

movf State,w

andlw b’00001111’ ; mask all states >15

addwf PCL,f ; jump to desired State

retlw .0 ; State 0, no action

goto State1 ; (2s for repeating LV increment)

goto State2 ; (2s for repeating LV decrement)

goto State3

goto State4

goto State5 ; (2s for repeating HV increment)

goto State6 ; (2s for repeating HV decrement)

retlw .7 ; State 7, no action

retlw .8 ; State 8, no action

retlw .9 ; State 9, no action

retlw .10 ; State 10, no action

goto State11

goto State12

goto State13

goto State14

goto StateMachineReset ; State 15... shouldn’t be here

;***********************************************************************************************

InitGPIO

movlw b’00001011’ ; initialize UP and DOWN switches to be high & CP to be low.

movwf GPIO

movlw b’11111100’ ; make GP0/DECR/CS & GP1/INCR/UD outputs, block undesired U/D commands

tris GPIO

retlw b’11000000’

GPIO_TestUP

movlw b’00001011’ ; initialize UP and DOWN switches to be high & CP to be low.

movwf GPIO

movlw b’11111100’ ; make both GP0/DECR/CS & GP1/INCR/UD outputs, prevent undesired U/D

commands

tris GPIO

movlw b’11111110’ ; make GP1/INCR/UD an input (w/pu enabled)

tris GPIO

retlw b’10000000’

GPIO_TestDOWN

movlw b’00001011’ ; initialize UP and DOWN switches to be high & CP to be low.

movwf GPIO

movlw b’11111100’ ; make both GP0/DECR/CS & GP1/INCR/UD outputs, prevent undesired U/D

commands

tris GPIO

movlw b’11111101’ ; make GP0/DECR/CS an input (w/pu enabled)

tris GPIO

retlw b’01000000’

© 2005 Microchip Technology Inc. DS51546B-page 37

Page 42

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

;***********************************************************************************************

; Button Isolation Subroutines

;***********************************************************************************************

; Low Voltage Increment & Decrement Subroutines

;***********************************************************************************************

LV_Increment

movwf Exit ; load the loop counter

bsf UD

goto $+1 ; creates a 3us total delay

bcf CS

movlw .100 ; 5*100 = 500us delay to pull down CS

movwf DLYCNT1

DLOOP_LVI

clrwdt ;or NOP

nop

decfsz DLYCNT1,f

goto DLOOP_LVI

LV_IncrLoop

bcf UD

goto $+1

bsf UD

goto $+1 ; creates a 3us total delay

decfsz Exit,f ; Have we incremented the wiper enough?

goto LV_IncrLoop

IFDEF SaveWiper

bcf UD

goto $+1 ; creates a 3us total delay

ENDIF

bsf CS

retlw 0x00 ; Follow w/long delay to ramp CS & EEPROM Write Cycle

LV_Decrement

movwf Exit ; load the loop counter

bcf UD

goto $+1 ; creates a 3us total delay

bcf CS

movlw .100 ; 5*100 = 500us delay to pull down CS

movwf DLYCNT1

DLOOP_LVD

clrwdt ;or NOP

nop

decfsz DLYCNT1,f

goto DLOOP_LVD

IFDEF SaveWiper

goto LV_DecrLoop+4 ; skip first Decrement since final edge is rising

ENDIF

LV_DecrLoop

bsf UD

goto $+1 ; creates a 3us total delay

bcf UD

goto $+1 ; creates a 3us total delay

decfsz Exit,f ; Have we decremented the wiper enough?

goto LV_DecrLoop

IFDEF SaveWiper

bsf UD

goto $+1 ; creates a 3us total delay

ENDIF

bsf CS ; Follow w/long delay to ramp CS & EEPROM Write Cycle

retlw 0x01

© 2005 Microchip Technology Inc. DS51546B-page 38

Page 43

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

;***********************************************************************************************

; High Voltage Increment & Decrement Subroutines

;***********************************************************************************************

HV_Increment_WL_Disable

movwf Exit ; load the loop counter

bsf UD

goto $+1 ; creates a 3us total delay

bsf HV_CS ; starts 1Mhz Charge Pump

movlw .100 ; 5*100 = 500us delay for Charge Pump ramp time

movwf DLYCNT1

DLOOP_HVI

clrwdt ;or NOP

nop

decfsz DLYCNT1,f

goto DLOOP_HVI

HV_IncrLoop

bcf UD

goto $+1 ; creates a 3us total delay

bsf UD

goto $+1 ; creates a 3us total delay

decfsz Exit,f ; Have we incremented the wiper enough?

goto HV_IncrLoop

bcf HV_CS ; shut off 1Mhz Charge Pump

bcf CS ; helps pull the signal down from HV

goto $+1

bsf CS

retlw 0x02 ; Follow w/long delay to discharge pump & EEPROM Write Cycle

HV_Decrement_WL_Disable

movwf Exit ; load the loop counter

bcf UD

goto $+1 ; creates a 3us total delay

bsf HV_CS ; starts 1Mhz Charge Pump

movlw .100 ; 5*100 = 500us delay for Charge Pump ramp time

movwf DLYCNT1

DLOOP_HVD

clrwdt ;or NOP

nop

decfsz DLYCNT1,f

goto DLOOP_HVD

HV_DecrLoop

bsf UD

goto $+1 ; creates a 3us total delay

bcf UD

goto $+1 ; creates a 3us total delay

decfsz Exit,f ; Have we decremented the wiper enough?

goto HV_DecrLoop

bcf HV_CS ; shut off 1Mhz Charge Pump

bcf CS ; helps pull the signal down from HV

goto $+1

bsf CS

retlw 0x03 ; Follow w/long delay to discharge pump & EEPROM Write Cycle

HV_Increment_WL_Enable

bsf UD

goto $+1 ; creates a 3us total delay

bsf HV_CS ; starts 1Mhz Charge Pump

movlw .100 ; 5*100 = 500us delay for Charge Pump ramp time

movwf DLYCNT1

© 2005 Microchip Technology Inc. DS51546B-page 39

Page 44

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

DLOOP_HVIWL

clrwdt ;or NOP

nop

decfsz DLYCNT1,f

goto DLOOP_HVIWL

bcf UD

goto $+1 ; creates a 3us total delay

bsf UD

goto $+1 ; creates a 3us total delay

bcf UD

goto $+1 ; creates a 3us total delay

bcf HV_CS ; shut off 1Mhz Charge Pump

bcf CS ; helps pull the signal down from HV

goto $+1

bsf CS

retlw 0x04 ; Follow w/long delay to discharge pump & EEPROM Write Cycle

HV_Decrement_WL_Enable

bcf UD

bsf CS

goto $+1 ; creates a 3us total delay

bsf HV_CS ; starts 1Mhz Charge Pump

movlw .100 ; 5*100 = 500us delay for Charge Pump ramp time

movwf DLYCNT1

DLOOP_HVDWL

clrwdt ;or NOP

nop

decfsz DLYCNT1,f

goto DLOOP_HVDWL

bsf UD

goto $+1 ; creates a 3us total delay

bcf HV_CS ; shut off 1Mhz Charge Pump

bcf CS ; helps pull the signal down from HV

goto $+1

bsf CS

retlw 0x05 ; Follow w/long delay to discharge pump & EEPROM Write Cycle

;***********************************************************************************************

; VARIABLE DELAY SUBROUTINES

;***********************************************************************************************

; DLYCNT1 = F9h = 249d DLYCNT2 = W

; DELAY = T((4 DLYCNT1 + 4) DLYCNT2 + 4)

;

; ex. To create a 300ms delay when using a 4Mhz osc, 300-250 = 50

; movlw .50 ;load .50 into WREG

; call VAR1000TcyDELAY ;call VAR1000TcyDELAY = 50ms delay w/4MHz Osc

; call VAR1000TcyDELAY ;call VAR1000TcyDELAY = 250ms delay w/4MHz Osc

; ;total = 300ms delay

;************

; The value in W at the time of the CALL = x. Delay = 1000Tcy*x

VAR1000TcyDELAY

movwf DLYCNT2 ; LOADS CONTROLLING DLY # INTO PRIMARY COUNTER

DLOOP2

movlw .249 ; MAXIMIZES THE SECONDARY DLY COUNTER

movwf DLYCNT1

DLOOP1

clrwdt ;or NOP

decfsz DLYCNT1,f ; DECREMENT AND TEST SECONDARY LOOP FOR ZERO

goto DLOOP1 ; CONTINUE SECONDARY LOOP

decfsz DLYCNT2,f ; DECREMENT AND TEST PRIMARY DLY COUNTER

goto DLOOP2 ; CONTINUE PRIMARY LOOP

retlw .250 ; preload W for the next CALL VAR1000TcyDELAY

© 2005 Microchip Technology Inc. DS51546B-page 40

Page 45

00066_MCP402XEV.ASM Source Code

TABLE E-1: 00066_MCP402XEV.ASM SOURCE CODE (CONTINUED)

;************

; VARIABLE 5 Tcy DELAY UP TO 256*5Tcy+5Tcy

; DLYCNT1 = W

; DELAY = T(1 + 5 DLYCNT1 - 1) + CALL + RETLW

;

; ex. To create a 250us delay, (250/5)-1 = 49

; movlw .49 ;load .49 into WREG

; call VAR5TcyDELAY ;call VAR5TcyDELAY

;************

; The value in W at the time of the CALL = x. Delay = 5*Tcy + 5Tcy

VAR5TcyDELAY

movwf DLYCNT1 ; LOADS CONTROLLING DLY # INTO PRIMARY COUNTER

DLOOP3 clrwdt ;or NOP

nop

decfsz DLYCNT1,f ; DECREMENT AND TEST ZERO

goto DLOOP3 ; CONTINUE LOOP

retlw .250 ; preload W for the next CALL VAR5TcyDELAY

;***********************************************************************************************

end

© 2005 Microchip Technology Inc. DS51546B-page 41

Page 46

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-2229-0061

Fax: 91-80-2229-0062

India - New Delhi

Tel: 91-11-5160-8631

Fax: 91-11-5160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

10/31/05

DS51546B-page 42 © 2005 Microchip Technology Inc.

Loading...

Loading...