Page 1

MCP3903

ADC Evaluation Board

for 16-Bit MCUs

User’s Guide

© 2011 Microchip Technology Inc. DS51994A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, chipKIT,

chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net,

dsPICworks, dsSPEAK, ECAN, ECONOMONITOR,

FanSense, HI-TIDE, In-Circuit Serial Programming, ICSP,

Mindi, MiWi, MPASM, MPLAB Certified logo, MPLIB,

MPLINK, mTouch, Omniscient Code Generation, PICC,

PICC-18, PICDEM, PICDEM.net, PICkit, PICtail, REAL ICE,

rfLAB, Select Mode, Total Endurance, TSHARC,

UniWinDriver, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2011, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-61341-426-2

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS51994A-page 2 © 2011 Microchip Technology Inc.

Page 3

MCP3903 ADC EVALUATION BOARD

FOR 16-BIT MCUs USER’S GUIDE

Table of Contents

Preface ...........................................................................................................................1

Introduction............................................................................................................1

Document Layout .................................................................................................. 1

Conventions Used in this Guide............................................................................ 2

Recommended Reading.............................................................. .. ........................3

The Microchip Web Site........................................................................................ 3

Customer Support.................... .................................... .................. .......................3

Document Revision History................................................................................... 3

Chapter 1. Hardware Description

1.1 Overview ............. ........................................................................................... 5

1.2 PIM Module / MCP3903 Connection and Peripheral Usage Overview ..........7

1.3 Analog Input Structure ......................................... ...........................................9

1.4 USB to Serial Converter ................................................................................. 9

Chapter 2. Code Example

2.1 dsPIC3 3 Examp le D e sc ription . .. .................................................................. . 11

Appendix A. Schematics and Layouts

A.1 Introduction ..................................................................................................15

A.2 Schematic - Analog .. .. .. .......................... ... .. ................................................. 16

A.3 Schematic - LCD and UART .......................................................................17

A.4 Schematic - USB and Memory .....................................................................18

A.5 Schematic - Microcontro lle r (MCU) .. .. ........................... .. .. ........................... 19

A.6 Schematic - PIM Module ..............................................................................20

A.7 Schematic - Power ... .. .................................................................................. 2 1

A.8 Board - Top Trace and Top Silk .............................. .......................... ...........22

A.9 Board - Bottom Trace and Bottom Silk ........................................................22

A.10 Board - Lay e r # 2 VD D ......... .......................... .. ... ........................................ 23

A.11 Board - Lay e r # 3 GN D ........ ....................................................................... 23

A.12 Board - Top SILK and PADS ........................................... .. .. ......................24

A.13 Board - Bot to m S IL K a n d PA D S ................................................................ 24

Appendix B. Bill of Materials (BOM)

Worldwide Sales and Service ....................................................................................28

© 2011 Microchip Technology Inc. DS51994A-page 3

Page 4

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

DS51994A-page 4 © 2011 Microchip Technology Inc.

Page 5

MCP3903 ADC EVALUATION BOARD

FOR 16-BIT MCUs USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP3903 ADC Evaluation Board for 16-Bit MCUs. Items discussed in this chapter

include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the MCP3903 ADC Evaluation Board for 16-Bit

MCUs as a development tool to emulate and debug firmware on a target board. The

manual layout is as follows:

• Chapter 1. “Hardwa re Desc ript ion ”– Provides important information about the

hardware.

• Chapter 2. “Code example ”– Describes the firmware.

• Appendix A. “Schematics and Layouts”– Shows the schematic and board

layouts.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

MCP3903 ADC Evaluation Board for 16-Bit MCUs.

© 2011 Microchip Technology Inc. DS51994A-page 1

Page 6

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

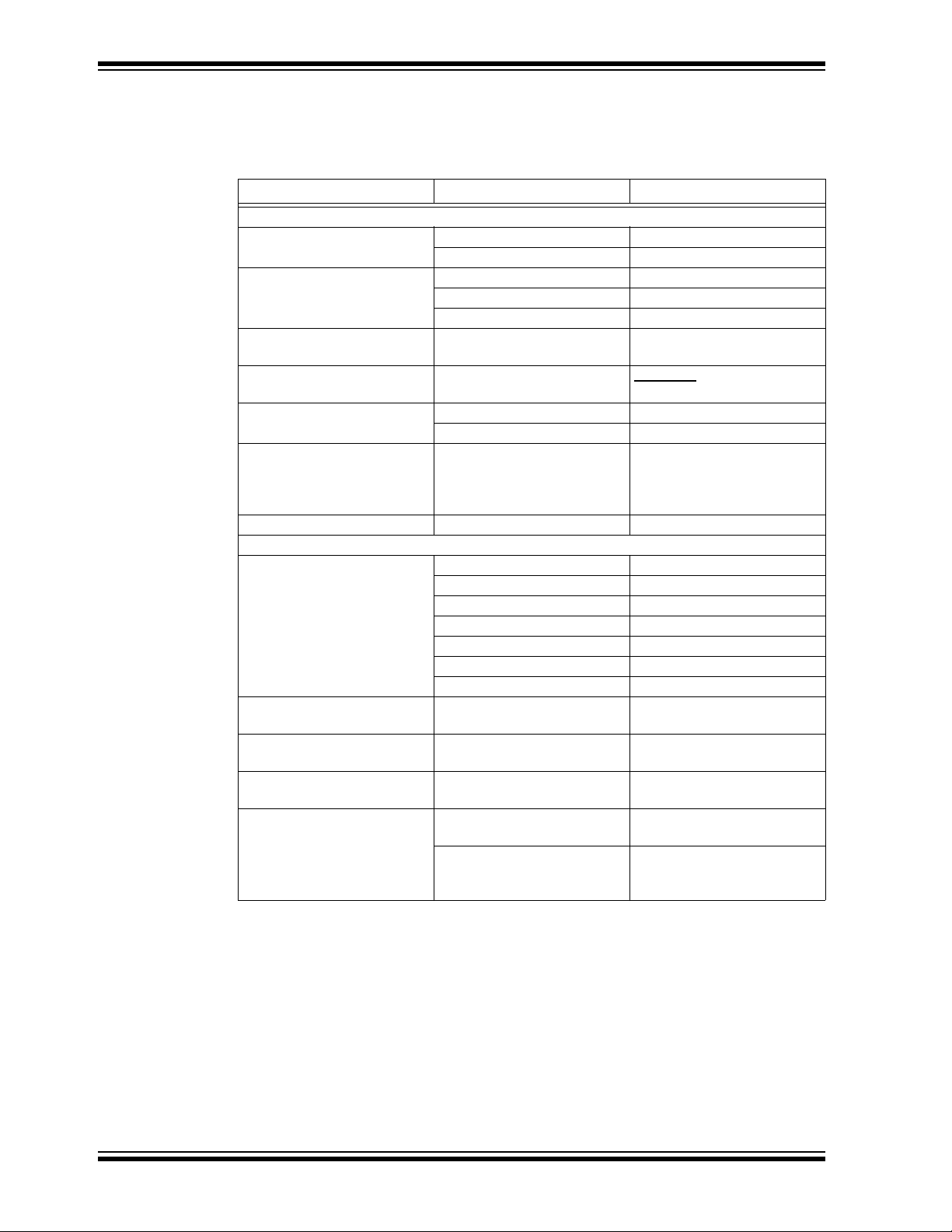

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic chara c ters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brac kets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mut ually exclus ive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS51994A-page 2 © 2011 Microchip Technology Inc.

Page 7

RECOMMENDED READING

This User's Guide describes how to use MCP3903 ADC Evaluation Board for 16-Bit

MCUs. Other useful documents are listed below. The following Microchip document is

available and recommended as a supplemental reference resource:

• MCP3903 Data Sheet - “Six Channel Delta Sigma A/D Converter”

(DS25048B)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com.

DOCUMENT REVISION HISTORY

Revision A (July 2011)

• Initial Release of this Document.

© 2011 Microchip Technology Inc. DS51994A-page 3

Page 8

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

NOTES:

DS51994A-page 4 © 2011 Microchip Technology Inc.

Page 9

1.1 OVERVIEW

The MCP3903 ADC Evaluation Board for 16-Bit MCUs system lets users evaluate the

performance of the MCP3903 six-channel ADC. It also provides a development

platform for 16-bit PIC

compatible with the Explorer-16 and other high pincount PIC demo boards. The system

comes with programmed PIC24FJ128GA010 PIM modules that communicate with the

LabView GUI for data exchange and ADC setup.

1.1.1 Feature Highlights

• Six-channel ADC MCP3903 output display using serial communication to the

• Simultaneous 4 ksps at 91 dB Signal-to-Noise and Distortion Ratio (SINAD)

• System and ADC performance analysis through graphical PC tools showing Time

• Robust hardware design with analog grounding and analog/digital separation,

• Pigtail Plus connectors for Explorer-16 daughter board compatibility.

MCP3903 ADC EVALUATION BOARD

FOR 16-BIT MCUs USER’S GUIDE

Chapter 1. Hardware Description

®

MCU-based applications, using existing 100-pin PIM systems,

PC Software Interface and LCD

performance. The ADC can run up to 64 ksps.

domain scope plot, Frequency Domain (FFT), and statistical numerical analysis.

allowing low noise evaluation of the MCP3903 devices. Separate power supplies

and power planes - 4 layer board.

© 2011 Microchip Technology Inc. DS51994A-page 5

Page 10

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

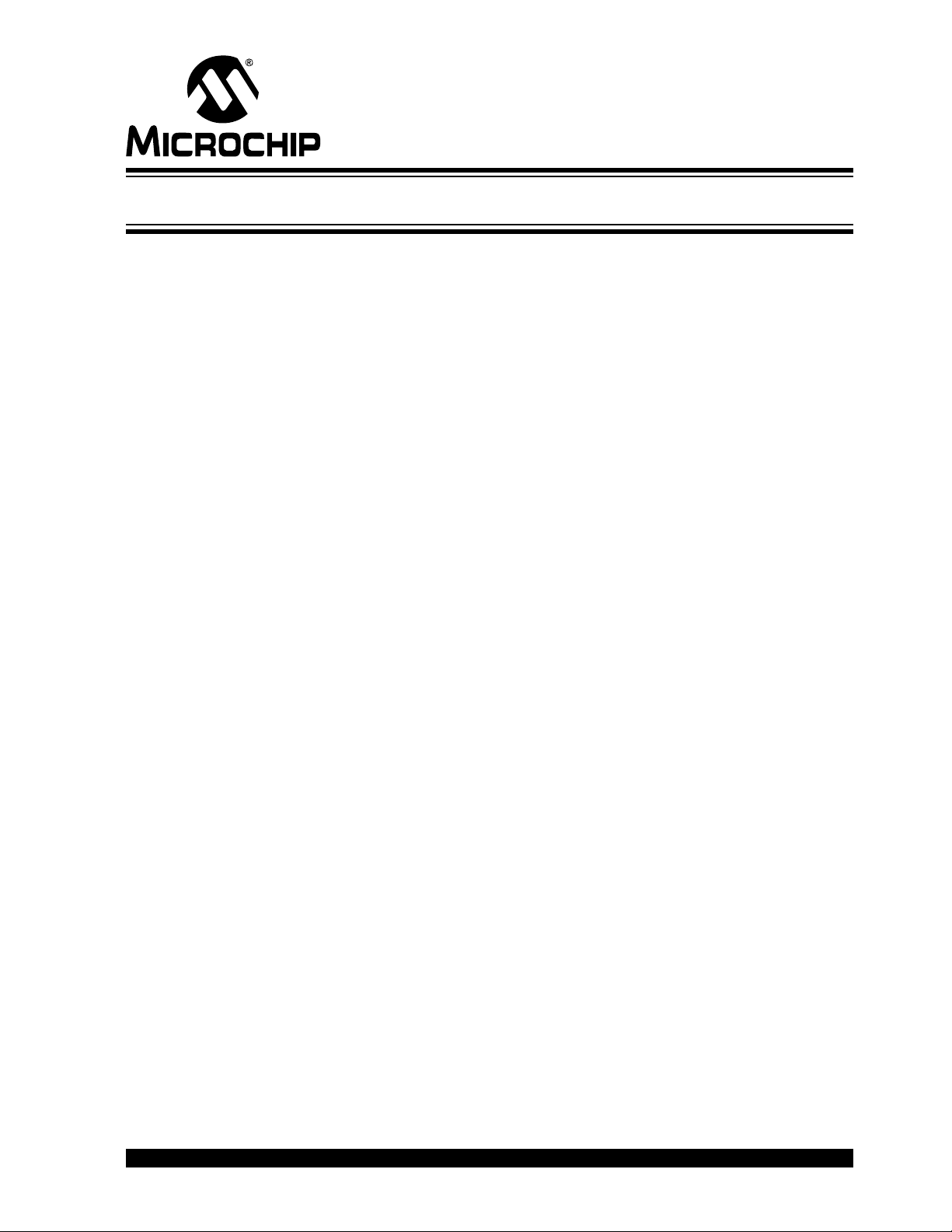

FIGURE 1-1: MCP3903 ADC Evaluation Board for 16-Bit MCUs.

DS51994A-page 6 © 2011 Microchip Technology Inc.

Page 11

Hardware Description

1.2 PIM MODULE / MCP3903 CONNECTION AND PERIPHERAL USAGE OVERVIEW

The MCP3903 ADC Evaluation Board for 16-Bit MCUs contains a 100-pin PIM socket,

compatible with Microchip’s PIM modules. The system comes with a PIM module: the

PIC24FJ128GA010.

For a complete description of the firmware programmed with these two modules, see

Chapter 1. “Hardwa re Desc ript ion ”.

RA9/10

RB8/9/10

RF2/U1RX

RF3/U1TX

OC1/RD0

IC4/RD11

IC3/RD10

INT3/RA4

SCK1/RF6

SDI1/RF7

SDO1/RF8

PIM Module

RA5

RA4

RESET

DR

CS

SCK

SDO

SDI

D6 D7

CONTROL SWITCHES (X3)

UART SERIAL TO PC COMMUNICATION

DGND DVdd

(Green)

MCP3903

SPI Serial

Interface

OSC2

Clock Generation/

Phase Correction

Six Channels

Sigma-Delta

ADC

OSC1

AVDDAGND

INT

Vref

CH0+

CH0-

CH1+

CH1-

CH2+

CH2-

CH3+

CH3-

CH4+

CH4-

CH5+

CH5-

FIGURE 1-2: Digital Connection Overview PIM/MCP3903 Connections.

Ports A, B, and D are used for signals such as push buttons, output LEDs, CS

MCLR

(for MCP3903 data mode setting). Output Capture 1 is used for MCP3903’s

and

clock generation. Serial communication is achieved through the MSSP module 1.

The MCP3903 device is an ADC with a second order modulator and a third order sync

filter . This Delt a-Sigma A/D co nverter has an adj ustable ov ersampling rat io. The CLKIN

pin of the MCP3903 is the ADC’s clock (MCLK) input. The MCP3903 ADC Evaluation

Board for 16-Bit MCUs offers two different options for the MCP3903 master clock

(MCLK).

© 2011 Microchip Technology Inc. DS51994A-page 7

Page 12

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

1.2.1 Using the Crystal X2

The MCP3903 ADC Evaluation Board for 16-Bit MCUs is populated with a 3.58 MHz

crystal, being used as a clock source, by placing jumpers in the following position on

the MCP3903 Digital I/O header block:

CLKOUT

CLKIN

CLKIN

XTAL

XTAL

PIM OC1

FIGURE 1-3: ADC Clock Selection Jumpers - External Crystal.

1.2.2 Driving the Clock with the PIM Module

The PIC® MCU can be used to generate the CLKIN (MCLK) signal for the MCP3903,

setting the ADC sample rate through the use of the output compare module OC1. To

use this, make the following jumper change to the MCP3903 Digital I/O header block:

CLKOUT

CLKIN

CLKIN

FIGURE 1-4: ADC Clock Selection Jumpers - Clock from MCU.

The signal frequency from OC1 can be changed by the user from the PC software by

changing the value in the Sampling Speed Control box from the Edit menu. A low

number will generate a high frequency signal. The value of the sampling rate, which is

directly proportional to the clock frequency from OC1, is indicated in the sampling

speed indicator box in the PC software (see Figure 2-3) for the dsPIC33 example. In

the PIC24F example, the sampling speed is constant at 4.8 ksps, regardless of the

OSR value.

XTAL

XTAL

PIM OC1

DS51994A-page 8 © 2011 Microchip Technology Inc.

Page 13

1.3 ANALOG INPUT STRUCTURE

Two differential input paths allow external signal sources to be easily connected to the

MCP3903 input. Edge connectors JP1 and JP2 are 3-pin connectors that act both as

crew-type and clip-on post connectors.

Note: To use an edge connector as a post connector, pull up the blue plastic top

to access the posts.

JP1 and JP2 can be used to force either channel from a differential to a single-ended

configuration. R3 and R4 (on CH0), and R1 and R2 (on CH2) act as locations for

burden resistor connectors for any current transformer inputs.

1.4 USB TO SERIAL CONVERTER

The MCP3903 ADC Evaluation Board for 16-Bit MCUs also contains a USB connection

for connecting the evaluation board to a PC. On the board, there is an MCP2200 USB

to UART converter that creates a virtual COM port on the PC. The MCP3903 ADC

Evaluation Board for 16-Bit MCUs also features a RS232 connector just in case it is

required. The RS232 Line driver is connected to the same UART pins of the MCU. For

this reason, a 3-pin jumper (J5) is present on the evaluation board to select which serial

communication will be used: USB or RS232. The following figure summarizes the

connections between the ADC, MCU, USB to serial converter and RS232 line driver.

Hardware Description

PIM

Module

RF6/SCK1

RF7/SDI1

RF8/SDO1

USB con

RS232

USB

MCP2200

TX

RX

RS232 Driver

RF3/U1TX

RF2/U1RX

RX

TX

FIGURE 1-5: Serial Communication Block Diagram.

MCP3903

ADC

SCK

SDO

SDI

© 2011 Microchip Technology Inc. DS51994A-page 9

Page 14

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

NOTES:

DS51994A-page 10 © 2011 Microchip Technology Inc.

Page 15

MCP3903 ADC EVALUATION BOARD

FOR 16-BIT MCUs USER’S GUIDE

Chapter 2. Code Example

2.1 DSPIC33 EXAMPLE DESCRIPTION

If the user needs to evaluate the ADC on a system that uses dsPIC33 microcontrollers,

then a PIM connector with a dsPIC33FJ256GA710A can be used on the evaluation

board.

Using this example, the user can modify all MCP3903 internal registers from the PC

software “MCP390x Data VIEW”. The UART communication speed is at 115.2 kbps.

2.1.1 SPI Communication

To transfer data from the ADC to the MCU, the SPI communication is controlled by

DMA1. DMA1 channel is set up to use nul data write to read the MCP3903 register

correctly. The DMA1 reads 7 bytes, but the first byte is not used. Before a new DMA

read takes place, the CS pin must be controlled in the software and the MCU must wait

for a new external interrupt 3 that indicates a new acquisition.

After the DMA1 transfer is finished, the DMA buffer content is moved into the Vch0 and

Vch1 buffers. The loop is repeated until Vch0 and Vch1 are filled.

Timer 8 and Timer 9 are configured to work as a 32-bit timer. This timer starts when the

acquisition is started and stopped when data buffers are full. The value indicated by this

timer will be used to evaluate the sampling speed of the ADC on the PC interface.

After the buffers are filled with the samples, the internal registers of MCP3903 are read

also using DMA1, now configured to read 16 bytes. The state of the MCP3903 internal

registers will be stored into the MCU, since later they will be sent to the PC GUI.

To set the MCP3903 configuration registers, MCU must write on the SPI bus. For this

purpose, the DMA0 channel is used and is set to do a thirteen bytes transfer from MCU

to MCP3903.

2.1.2 UART Communication

To send the acquired samples from the MCU to the PC, the UART peripheral is used.

On the board, the user can use the RS232 DB9 connector to connect to a serial port

on PC side, or it can use the USB port that creates a virtual serial port on the PC, thanks

to the MCP2200 USB to TTL converter that is connected to the MCU.

The RX pins of the MAX2323 and the MCP2200 are tightened together with the TX pin

of the UART2 from the MCU. The user needs to select from jumperJ5 if the MCU

receives data from MCP2200 or MAX2323. In firmware, the MCU is using DMA2 to do

the transfer from MCU to the PC. To receive data from the PC through UART, the RX

interrupt is used.

© 2011 Microchip Technology Inc. DS51994A-page 11

Page 16

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

Start

Initialization

Init ia lis a tion

G e t s a m ple s in to b u ffer [51 2 ]

Read Internal Registers

Wa it for P C G UI

command

Com mand

rec eiv ed

YES

C h e ck v alid ity

Command valid

YES

Write internal registers

Send samples from Buffer [512]

Send internal registers

Send FFT

(not computed here )

Update channels selection

NO

FIGURE 2-1: dsPIC33 Example Flow Chart.

2.1.3 PC Software

NO

The PC receives the data and displays it on the MCP390x Data View. The program can

display and process only two channels at the same time. To select the desired

channels, the SW4 (RD13) must be pressed.

DS51994A-page 12 © 2011 Microchip Technology Inc.

Page 17

Code Example

FIGURE 2-2: MCP3903 Data View Software - Main Screen.

Connectivity is done through the serial port. First, the user must identify the com port

number from My computer > Manage > Device Manager. After this, in “VISA resource

names”, users must find and select the correct com port number. Only after this, can

the START button be pressed to begin the data acquisition.

FIGURE 2-3: MCP3903 Data View Software - Registers and Settings Screen.

From the Edit menu, the user can open the Registers and Settings window to control

the internal registers of the MCP3903, the sampling speed of the ADC or if any

averaging should be done on the acquired samples.

From the buffer length, the user can select the amount of data that will be processed.

The maximum length is 512. From the Sampling Speed Control, the user can change

the sampling speed of the ADC. By writing a lower value, the sampling speed is

increased, and for higher values it is decreased. The accurate value of the sampling

speed is indicated in the Sampling speed indicator.

If the user wants to investigate the effect of averaging on the performance indicator, the

desired value can be written in the “Averages” control. It must be noted that the

processed buffer will decrease by a factor equal to the value of the average.

The Write Register and Read Register tabs are used to set the internal registers of

the MCP3903. With the Write Register tab they are written and with the Read

Register tab, the user can check the settings of the registers.

© 2011 Microchip Technology Inc. DS51994A-page 13

Page 18

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

The Waveform Graphs will show the signal in Time domain, while the Signal Spectrum

graphs shows the signal in Frequency domain. From the Graphs menu, under the

Signal Spectrum option, the user can find the Switch Y-axis scale option. From here,

it is possible to change the Y axis of the Signal Spectrum in linear scale or in logarithmic

scale. The spectrum signal information is obtained by performing a Fast Fourier

transformation over the Time domain signal. This Fourier transformation can be done

after the signal has been windowed. For this, the user must select the type of window

from the Window control on the lower area of the main window.

The Histogram Graph can be used to investigate the distribution of the codes. This is

especially helpful to check if a DC signal distribution is Gaussian. From the Graphs

menu, under the Histogram option, the user can Change the n umber of bits , with the

default being 40.

The indicators from the lower area of the program indicate other performance

parameters of the ADC. The main one is SINAD and related to it is Effective Number

of Bits (ENOB), used to indicate the AC signal performance. The ENOB value is

computed according to the formula below:

EQUATION 2-1:

ENOB

For DC signals, the Noise RMS signal in µV is displayed. For AC signals, the indicator

will show the RMS value of the signal.

SINAD 1.76–

----------------------------------- -=

6.02

DS51994A-page 14 © 2011 Microchip Technology Inc.

Page 19

Appendix A. Schematics and Layouts

A.1 INTRODUCTION

This appendix contains the following schematics of the MCP3903 ADC Evaluation

Board for 16-Bit MCUs.

• Schemati c - Analog

• Schemati c - LCD and UART

• Schemati c - USB and Memor y

• Schemati c - Mic roc ont roll er (MCU)

• Schemati c - PIM Modul e

• Schemati c - Pow er

• Board - Top Trace and Top Silk

• Board - Bottom Trace and Bottom Silk

• Board - Layer #2 V

• Board - Layer #3 GND

• Board - Top Silk and Pads

• Board - Bottom Silk and Pads

MCP3903 ADC EVALUATION BOARD

FOR 16-BIT MCUs USER’S GUIDE

DD

© 2011 Microchip Technology Inc. DS51994A-page 15

Page 20

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

A.2 SCHEMATIC - ANALOG

DateRevision Notes

3/31/10

F

Initial Release Build

1

REV

ADC/MPU/MEMORY

1

2

3

4

4

6

B.Popescu

of

1

F

A.Hapenciuc

Sheet

Eng:3Drawn by:

1

ADC_MPU_MEMORY.SCHDOC

M

MCP3903 Eval Board for 16-bit MCU

18PF

C37

1MR40

X2

3.579545MHZ

GNDA GNDA

C38

18PF

P1515P1313P1111P99P77P55P33P1

RF3/U1TX

GNDA

HDR2X8-O/E

10k

R57

JP6

3903_DR +3.3V

246

JP5

HDR3X2

100 R43

135

ADC CLOCK SELECT

2

1

3903_CLKIN

+3.3V

3903_RESET

3903_SDO

3903_SCK

3903_SDI

10

R59

100R69

100

100R54

GNDA

100R63

100 R68

100NF

C44

R55

25

23

26

27

24

28

SDI

SCK

SDO

DVDD

RESET

3903_CS

CS

3903_DR

100R56

16

20

21

22

17

15

18

19

DRA

DRB

DRC

OSC1

OSC2

AGND

DGND

REFIN-

P8

GNDA

P22P44P66P8

1

3903_SDO

3903_RESET

3903_SDI

8

3903_SCK

P1010P1212P1414P16

3903_CS

3903_DR

RF2/U1RX

16

Title

U9

+5V

10

R60

100NF

C45

GNDA

CH0+

AVDD1CH0-3CH1-

2

CH1+

5

4

CH3-

CH2+6CH2-7CH3+9CH4+

8

CH4-

11

10

CH5-12CH5+

MCP3903_SO28

REFIN+

14

13

GNDA

C46

100NF

3/18/10

C

Filename:

Date:

Size

68NF

68NF

C58

GNDA

DNP

R94

GNDA

GNDAGNDA

R99

DNP

C56

68NF

R100

ABC DE

1K

R98

1K

+

GNDA

246

JP9

HDR3X2

135

C

G

GNDA

DNP

R103

NET00083

NET00093

GNDA

3

2

P0C

P0B

GND

CH0+

1K

R97

-

JP10

G

GNDA

DNP

R102

NET00088

3

1

P1C

P0A

CH1-

CH0-

1

68NF

68NF

C57

68NF

C54

GNDA

GNDA

DNP

R93

R96

C55

68NF

1K

R95

-

+

GNDA

246

HDR3X2

135

GNDA

GNDA

DNP

DNP

R104

R101

GNDA

2

1

P1B

P1A

GND

CH1+

DNP

R62

GNDA

GNDA

GNDAGNDA

GNDA

R87

DNP

DNP

GNDA

C52

68NF

1K

R88

+

GNDA

246

JP7

HDR3X2

135

GNDA

DNP

R91

GNDA

2

3

P2B

P2C

GND

CH2+

1K

1K

R85

R86

-

GNDA

DNP

R90

1

P2A

CH2-

+

246

JP8

HDR3X2

135

GNDA

DNP

R89

3

P3C

CH3-

68NF

C53

DNP

R52

R84

DNP

C51

68NF

1K

R83

-

GNDA

GNDA

DNP

R92

GNDA

1

2

P3B

P3A

GND

CH3+

C7

GNDA

GNDA

DNP

R9

GNDA

GNDA

GNDAGNDA

R10

GNDA

DNP

GNDA

C8

68NF

1K

R7

+

GNDA

246

JP2

HDR3X2

135

GNDA

DNP

R3

GNDA

3

2

P4B

P4C

GND

CH4+

-

GNDA

R4

1K

R5

DNP

1

P4A3P5C

CH4-

1K

R11

+

GNDA

246

JP1

HDR3X2

135

GNDA

R1

GNDA

GND

CH5-

2

C9

GNDA

DNP

R8

GNDA

GNDAGNDA

R6

DNP

C10

68NF

1K

R12

-

GNDA

DNPR2DNP

1

P5A2P5B

CH5+

ABC DE

4

DS51994A-page 16 © 2011 Microchip Technology Inc.

Page 21

A.3 SCHEMATIC - LCD AND UART

Schematics and Layouts

D

C

Date

3/31/10

Description

Initial Design

1

Rev

4

2

B.Popescu

A.Hapenciuc

Eng:

Drawn by:

of

Sheet

6

5

Rev

5

3/18/10

Size

M

B

Date:

MCP3903 Eval Board for 16-bit MCU

Title

C D

NET00073

NET00074

NET00071

3

DB9RF

GNDA

TX

RX

1K

1K

R32

R33

U6RX

RF3/U1TX

GNDA

GNDA

U6

2

100NF

C30

+3.3V

20

19

FORCEOFF

SN75C3223PW

EN1C1+

2

RC13

C35

NET00063

100NF

100NF

C36

+3.3V

18

VCC

NET00065

100NF

GNDA

GND

17

T1OUT

NET00064

C33

RX

GNDA

14

15

13

16

R1IN

R1OUT

FORCEON

C2+5V+3C1-4C2-6V-7R2IN

8

NET00068

NET00066

100NF

NET00067

TX

T1IN

T2OUT

C34

12

9

J3

RD15/U1RTS

RC14

11

T2IN

INVALID

R2OUT

10

RD14/U1CTS

162738495

NET00075

GNDA

1

RE2/PMPD2

RE1/PMPD1

RE0/PMPD0

RE3/PMPD3

6

DB15DB04DB37DB59DB6

RE5/PMPD5

RE4/PMPD4

10

DB48DB2

RE7/PMPD7

RE6/PMPD6

11

DB7

RE0/PMPD0

7

RE2/PMPD2

RE1/PMPD1

RE3/PMPD3

RE4/PMPD4

DB411DB29DB512DB310DB18DB0

RE6/PMPD6

RE5/PMPD5

14

13

DB6

RE7/PMPD7

DB7

LCD_EXPLORER 16.SCHDOC

Filename:

B

LCD/EXPLORER 16

LCD1

LCD_2X16_BOTH

E

3

RD5/PMPRD

RD4/PMPWR

A B

1

2

VCC13RS1R/W2VEE14GND

VEE

RB15/PMPA0

NET00052

R18

NONE

+5V

GND1

15

12

GNDA

100NF

C12

R17

NONE

GNDA

+3.3V

LCD2

LCD_TM162JCAWG1

GND

VCC2RS4E6R/W5VC

1

3

+3.3V

GNDA

RD5/PMPRD

RD4/PMPWR

RB15/PMPA0

+3.3V

10K

R15

3

GNDA

R16

1.3K

VEE

A

4

© 2011 Microchip Technology Inc. DS51994A-page 17

Page 22

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

A.4 SCHEMATIC - USB AND MEMORY

4

4

6

B.Popescu

of

3

F

A.Hapenciuc

Sheet

Eng:3Drawn by:

3

GNDA

GNDA

GNDA

GNDA

GNDA GNDA

RB7/AN7/PGD

RB6/AN6/PGC

MCP3903 Eval Board for 16-bit MCU

Title

Size

M

C

dsPIC33.SCHDOC

3/18/10

Filename:

Date:

DateRevision Notes

3/31/10

1

2

3

F

1K

R37

GNDA

1K

R36

REV

Initial Schematic Design

1

dsPIC33

+3.3V

D7

RH6

RED

GM1JR35200AE

RA10/PMPA6

RA9/PMPA7

+3.3V

NONER29

47UF

C23

+

GNDA

GNDA

0.0R26

C24

100NF

VDDCORE

ENVREG

+3.3V

NONE

R25

0.0

R22

GNDA

GNDA

100

R38

D6

RH7

SML-512MW

GREEN

GNDA

100

R39

RD1

76

RD2

RD2

77

RD3/PMPBE

RD12

RD4/PMPWR

RD5/PMPRD

RD6

RD7

ENVREG

RF0

RF1

RG1

RG0

RA6

RA7

RE0/PMPD0

RE1/PMPD1

RG14

RG12

RG13

RE2/PMPD2

RE3/PMPD3

RE4/PMPD4

SS1/RD3

78

IC5/RD12

79

CN19/RD13

80

PMPWR/OC5/RD4

81

PMPRD/CN14/RD5

82

SDA2/CN15/RD6

83

SCL2/CN16/RD7

84

VCAP/VDDCORE

85

VREG

86

RF0

87

RF1

88

RG1

89

RG0

90

RA6

91

RA7

92

PMPD0/RE0

93

PMPD1/RE1

94

RG14

95

RG12

96

RG13

97

PMPD2/RE2

98

PMPD3/RE3

99

PMPD4/RE4

100

U7

18PF

C32

GNDA

X3

7.3728MHZ

GNDA

C31

18PF

3903_CLKIN

RD9

RC13

RC14

GNDA

72

73

74

70

71

69

75

VSS

RC13

RC14

IC2/RD9

OC1/RD0

IC3/RD10

IC4/RD11

RG15

T3CK/RC27T5CK/RC4

VDD

PMPD5/RE53PMPD6/RE6

PMPD7/RE75PMPA3/SDO2/CN10/RG8

6

1

2

4

+3.3V

RC2

RG15

RE6/PMPD6

RE7/PMPD7

RE5/PMPD5

RD8

1MR34

RA15/INT4

RD8

67

68

INT4/RA15

IC1/RTCC/RD8

T4CK/RC38T2CK/RC1

9

RC4

RC3

66

10

3903_DR

GNDA

64

65

VSS

INT3/RA14

PMPA4/SDI2/CN9/RG7

PMPA5/SCK2/CN8/RG6

11

12

USB_SCK

USB_SDO

RG3/SDA1

RG2/SCL1

OSC1

OSC2

+3.3V

R35

NONE

3903_RESET

3903_CS

RA2/SCL2

RA3/SDA2

+3.3V

63

56

62

61

58

59

60

57

RA2

RA3

VDD

TDI/RA4

TDO/RA5

SCL1/RG2

SDA1/RG3

OSC1/CLKI/RC12

OSC2/CLK0/RC15

dsPIC33FJ256GP710-I/PF

INT1/RE8

VSS15VDD16MCLR

RA0/TMS17INT2/RE9

C1IN+/AN5/CN7/RB5

PMPA2/SS2/CN11/RG914C1IN-/AN4/CN6/RB4

18

13

19

20

+3.3V

GNDA

USB_SS

PIC24_MCLR

RA0/TMS

RE8/INT1

RE9/INT2

RB5/AN5

USB_SDI

2.2K

2.2K

3903_SCK

3903_SDO

53

55

54

SDI1/RF7

SCK1/INT0/RF6

C2IN+/AN3/CN5/RB3

23

22

21

RB4/AN4

RB3/AN3

R28

R27

3903_SDI

SDO1/RF8

C2IN-/AN2/SS1/RB2

RB2/SS1/AN2

+3.3V

+3.3V

RF3/U1TX

RF2/U1RX

51

52

U1TX/RF3

U1RX/RF2

PGD1/AN0/RB0

PGC1/AN1/CN3/RB1

25

24

RB0/AN0

RB1/AN1

100NF

C15

+3.3V

100NF

C14

+3.3V

100NF

C16

+3.3V

100NF

C20

+3.3V

100NF

C27

+3.3V

100NF

C28

+3.3V

U2TX/RF5

50

U2RX/RF4

49

CN21/RD15

48

CN20/RD14

47

VDD

46

VSS

45

PMPA0/AN15/CN12/RB15

44

PMPA1/AN14/RB14

43

AN13/RB13

42

AN12/RB12

41

U2CTS/RF12

40

U2RTS/RF13

39

TCK/RA1

38

VDD

37

VSS

36

TDO/AN11/RB11

35

CVREF/AN10/RB10

34

C2OUT/AN9/RB9

33

C1OUT/AN8/RB8

32

AVSS

31

AVDD

30

PMPA6/RA10

29

PMPA7/RA9

28

PGD/OCFA/RB7

27

PGC2/RB6

26

100NF

C18

+3.3V

GNDA

100NF

C17

+3.3V

GNDA

100NF

C19

+3.3V

GNDA

100NF

C22

+3.3V

GNDA

100NF

C25

+3.3V

GNDA

100NF

C26

+3.3V

GNDA

RF5/PMPA8/U2TX RD1

RF4/PMPA9/U2RX

RD15/U1RTS

RD14/U1CTS

+3.3V RD13

RB15/PMPA0

GNDA

RB14/PMPA1

RB13/PMPA10

RB12/PMPA11 VDDCORE

RF12/U2CTS

RF13/U2RTS

RA1/TCK

+3.3V

RB11/PMPA12

GNDA

RB10/PMPA13

RB9/AN9

RB8/AN8

+3.3V

GNDA

RA10/PMPA6

RA9/PMPA7

PIC24_MCLR

10K

R21

+3.3V

+3.3V

GNDA

56312

4

P6

HDR6X1

PIC24 ICD

ABC DE

4

ABC DE

1

PIC24_MCLR

1KR31

+3.3V

100NF

C29

4.7K

R30

SW1

B3S-1002P

GNDA

RD7

1KR24

+3.3V

100NF

C21

4.7K

R23

GNDA

SW2

B3S-1002P

GNDA

RD6

1KR20

+3.3V

100NF

C13

4.7K

R19

GNDA

SW3

B3S-1002P

GNDA

RD13

1KR14

+3.3V

100NF

C11

4.7K

R13

GNDA

GNDA

SW4

B3S-1002P

GNDA

2

DS51994A-page 18 © 2011 Microchip Technology Inc.

Page 23

Schematics and Layouts

A.5 SCHEMATIC - MICROCONTROLLER (MCU)

4

4

6

B.Popescu

of

2

F

A.Hapenciuc

Sheet

Eng:3Drawn by:

DateRevision Notes

3/31/10

10/26/10

1

2

3

F

2

MCP2200 _ USB.SCHDOC

M

3/18/10

MCP3903 Eval Board for 16-bit MCU

C

Filename:

Date:

Size

Title

REV

Initial Schematic Design

MCP2200 communication

2

1

J2E

J2B

J2A

J2D

J2C

5

2

4

1

3

USB

DATAVIEW PORT

D-

D+

GNDA

USB_+5V

U6RX

RF2/U1RX

RF3/U1TX

HDR1X3

J5

U5-RX

ABC DE

1

MCP2200

C41

0.1uF

GNDA

D-

D+

RX

CTS

RTS

GP2

VSS

VUSB

GP0/SSPND

GP1/USBCFG

U5

VDD

470

R47

GNDA

C39

0.1uF

RESONATOR-CSTCE

MCP2200_SSOP20

GP4

GP3

GP7/TxLED

GP6/RxLED

OSC1

OSC2

TX

GP5

X1

12MHz

RST

470

R41

470

R44

GNDA

21

USB_+5V

D1

RED

4 3

GREEN

ABC DE

2

4

© 2011 Microchip Technology Inc. DS51994A-page 19

Page 24

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

A.6 SCHEMATIC - PIM MODULE

2

DateRevision Notes

1

3/31/10

F

3

4

4

6

B.Popescu

of

4

F

A.Hapenciuc

Sheet

Eng:3Drawn by:

4

PIM MODULE.SCHDOC

M

3/18/10

MCP3903 Eval Board for 16-bit MCU

C

Filename:

Date:

Size

Title

REV

Initial Schematic Design

1

RF3/U1TX

RF2/U1RX

4

26101216

P9

3

159

3903_SCK

RB2/SS1/AN2

RF3/U1TX

RF2/U1RX

4

26101216

J4

3

159

3903_SCK

RB2/SS1/AN2

RG2/SCL1

8

7

3903_SDO

RG2/SCL1

8

7

3903_SDO

RG3/SDA1

3903_SDI

RG3/SDA1

3903_SDI

GNDA

GNDA

GNDA

GNDA

RB4/AN4

RB1/AN1

14

13

11

15

RB3/AN3

RB0/AN0

RB4/AN4

RB1/AN1

14

13

11

15

RB3/AN3

RB0/AN0

+5V

+9V

+3.3V

RD15/U1RTS

RE8/INT1

18

2026303436

17

1925293335

+5V

+9V

+3.3V

RE9/INT2

GNDA

RD14/U1CTS

GNDA GNDA

+5V

+9V

+3.3V

RD15/U1RTS

RE8/INT1

18

2026303436

17

1925293335

+5V

+9V

+3.3V

RE9/INT2

GNDA

RD14/U1CTS

GNDA

GNDA

RF4/PMPA9/U2RX

RF5/PMPA8/U2TX

RA3/SDA2

RA2/SCL2

RF1

RF0

42

38

282224

404450

MEC1-160-02-L-D MATE

41

37

272123

394349

RG1

RG0

RG9/PMPA2/SS2

RG7/PMPA4/SDI2

RG6/PMPA5/SCK2

RG8/PMPA3/SDO2

GNDA

RF4/PMPA9/U2RX

RF5/PMPA8/U2TX

RA3/SDA2

RA2/SCL2

RF1

RF0

42

38

282224

404450

MEC1-160-02-L-D

41

37

272123

394349

RG1

RG0

GNDA GNDA

RG9/PMPA2/SS2

RG7/PMPA4/SDI2

RG6/PMPA5/SCK2

RG8/PMPA3/SDO2

RB9/AN9

RB8/AN8

RB9/AN9

RB8/AN8

RA10/PMPA6

GNDA

RA9/PMPA7

GNDA

RA10/PMPA6

GNDA

RA9/PMPA7

3903_DR

RA15/INT4

3903_DR

RA15/INT4

RF13/U2RTS

524648

54

514547

53

RF12/U2CTS

RF13/U2RTS

524648

54

514547

53

RF12/U2CTS

+5V

+3.3V

56

586068

55

575967

+5V

+3.3V

+5V

+3.3V

56

586068

55

575967

+5V

+3.3V

+9V

RG1

RG0

66

62

65

61

+9V

+9V

RG1

RG0

66

62

65

61

+9V

RG13

RG15

RG13

RG15

RG14

RG12

RG14

RG12

RA1/TCK

RA0/TMS

RA1/TCK

RA0/TMS

3903_RESET

RA7

74

73

RA6

3903_CS

3903_RESET

RA7

74

73

RA6

3903_CS

RB13/PMPA10

RB11/PMPA12

PIC24_MCLR

RB7/AN7/PGD

80

767072

8478828892

79

756971

7781838791

RB5/AN5

RB6/AN6/PGC

RB12/PMPA11

RB10/PMPA13

RB13/PMPA10

RB11/PMPA12

PIC24_MCLR

RB7/AN7/PGD

80

767072

8478828892

79

756971

7781838791

RB5/AN5

RB6/AN6/PGC

RB12/PMPA11

RB10/PMPA13

RB15/PMPA0

RC2

86

85

RB14/PMPA1

RB15/PMPA0

RC2

86

85

RB14/PMPA1

RD3/PMPBE

RD5/PMPRD

RD9

RD7

RD1

RC14

RC4

104

1009496

90

98

102

999395

89

97

103

101

RD8

RD6

RD2

RC3

RC13

3903_CLKIN

RD4/PMPWR

RD3/PMPBE

RD5/PMPRD

RD9

RD7

RD1

RC14

RC4

104

1009496

90

98

102

999395

89

97

103

101

RD8

RD6

RD2

RC3

RC13

3903_CLKIN

RD4/PMPWR

GNDA

+3.3V

RE7/PMPD7

RE5/PMPD5

RE3/PMPD3

RE1/PMPD1

RD13

118

120

106

108

117

119

113 114

109 110

115 116

107

105

111 112

RD12

+3.3V

GNDA

RE6/PMPD6

RE4/PMPD4

RE2/PMPD2

RE0/PMPD0

GNDA

+3.3V

RE7/PMPD7

RE5/PMPD5

RE3/PMPD3

RE1/PMPD1

RD13

118

120

106

108

117

119

113 114

109 110

115 116

107

105

111 112

RD12

+3.3V

GNDA

RE6/PMPD6

RE4/PMPD4

RE2/PMPD2

RE0/PMPD0

PIM MODLUE

ABC DE

RD3/PMPBE

RD12

RD4/PMPWR

RD5/PMPRD

RD6

RD7

ENVREG

RF0

RF1

RG1

RG0

RA6

RA7

RE0/PMPD0

RE1/PMPD1

RG14

RG12

RG13

RE3/PMPD3

RE4/PMPD4

3903_CLKIN

RD9

RC14

RC13

GNDA

72

70

71

69

73

74

75

VSS

RC13

RC14

IC2/RD9

OC1/RD0

IC3/RD10

IC4/RD11

RD1

76

RD2

77

SS1/RD3

78

IC5/RD12

79

CN19/RD13

80

PMPWR/OC5/RD4

81

PMPRD/CN14/RD5

82

SDA2/CN15/RD6

83

SCL2/CN16/RD7

84

VCAP/VDDCORE

85

VREG

86

RF0

87

RF1

88

RG1

89

RG0

90

RA6

91

RA7

92

PMPD0/RE0

93

PMPD1/RE1

94

RG14

95

RG12

96

RG13

97

PMPD2/RE2

98

PMPD3/RE3

99

PMPD4/RE4

100

MOD1

PIM 100-PIN

RG15

T3CK/RC27T5CK/RC4

VDD

PMPD5/RE53PMPD6/RE6

PMPD7/RE75PMPA3/SDO2/CN10/RG8

6

1

2

4

+3.3V

RC2

RG15

RE7/PMPD7

RE6/PMPD6

RE5/PMPD5

RA15/INT4

RD8

68

67

INT4/RA15

IC1/RTCC/RD8

T4CK/RC38T2CK/RC1

9

RC4

RC3

3903_DR

GNDA

66

65

VSS

INT3/RA14

PMPA4/SDI2/CN9/RG7

PMPA5/SCK2/CN8/RG6

11

10

USB_SCK

USB_SDO

3903_RESET

3903_CS

RG2/SCL1

RA2/SCL2

RA3/SDA2

OSC1

OSC2

+3.3V

62

61

60

64

58

57

59

63

RA2

RA3

VDD

TDI/RA4

TDO/RA5

SCL1/RG2

OSC1/CLKI/RC12

OSC2/CLK0/RC15

INT1/RE8

VSS15VDD16MCLR

RA0/TMS17INT2/RE9

PMPA2/SS2/CN11/RG914C1IN-/AN4/CN6/RB4

18

13

19

12

+3.3V

GNDA

RA0/TMS

RE9/INT2

RE8/INT1

PIC24_MCLR

USB_SS

USB_SDI

3903_SCK

3903_SDO

RG3/SDA1

54

56

55

SDI1/RF7

SDA1/RG3

SCK1/INT0/RF6

C2IN+/AN3/CN5/RB3

C1IN+/AN5/CN7/RB5

22

20

21

RB4/AN4

RB3/AN3

RB5/AN5

3903_SDI

RF3/U1TX

RF2/U1RX

53

52

51

U1TX/RF3

U1RX/RF2

SDO1/RF8

PGD1/AN0/RB0

C2IN-/AN2/SS1/RB2

PGC1/AN1/CN3/RB1

25

23

24

RB0/AN0

RB1/AN1

RB2/SS1/AN2

U2TX/RF5

50

U2RX/RF4

49

CN21/RD15

48

CN20/RD14

47

VDD

46

VSS

45

PMPA0/AN15/CN12/RB15

44

PMPA1/AN14/RB14

43

AN13/RB13

42

AN12/RB12

41

U2CTS/RF12

40

U2RTS/RF13

39

TCK/RA1

38

VDD

37

VSS

36

TDO/AN11/RB11

35

CVREF/AN10/RB10

34

C2OUT/AN9/RB9

33

C1OUT/AN8/RB8

32

AVSS

31

AVDD

30

PMPA6/RA10

29

PMPA7/RA9

28

PGD/OCFA/RB7

27

PGC2/RB6

26

RF5/PMPA8/U2TX RD1

RF4/PMPA9/U2RX RD2

RD15/U1RTS

RD14/U1CTS

+3.3V RD13

RB15/PMPA0

RB14/PMPA1

RB13/PMPA10

RB12/PMPA11 VDDCORE

RF12/U2CTS

RF13/U2RTS

RA1/TCK

+3.3V

RB11/PMPA12

GNDA

RB10/PMPA13

RB9/AN9

RB8/AN8

+3.3V

GNDA GNDA

RA10/PMPA6

RA9/PMPA7 RE2/PMPD2

RB7/AN7/PGD

RB6/AN6/PGC

ABC DE

1

2

4

DS51994A-page 20 © 2011 Microchip Technology Inc.

Page 25

A.7 SCHEMATIC - POWER

Schematics and Layouts

D

C

Date

3/31/10

Description

Initial Design

1

Rev

3

GNDA

GNDA

EXT +5V

+9V IN

135

JP3

HDR3X2

246

GNDA GNDA

GNDA

2

GNDAGNDA

TP1

GND

PJ-202-30

+3.3V

100

R58

+3.3V

100NF

C5

2

OUT

GND

1

U3

LM1117-3.3

IN

3

4.7UF

C6

D5

L1

BLUE

GM1B55250AC

+5V

10UH

GNDA

POWER

10UF

C1

4.7UF

C2

USB

1

4

4

B.Popescu

A.Hapenciuc

Eng:

Drawn by:

of

Sheet

6

6

Rev

6

3/18/10

Size

M

B

Date:

MCP3903 Eval Board for 16-bit MCU

Title

C D

POWER

USB_+5V

GNDA

C3

100NF

2

OUT

GND

1

U1

LM1117-5.0

+9V

POWER

+9V IN

GNDA

IN

3

10UF

C4

GNDA

D3

A K

MBR0520LT1

GNDA

321

J1

RAPC722

GNDA

EXT_+5V

2

1

P11B

P11A

POWER

EXT +5V

A B

1

2

3

4

POWER.SCHDOC

Filename:

B

A

© 2011 Microchip Technology Inc. DS51994A-page 21

Page 26

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

A.8 BOARD - TOP TRACE AND TOP SILK

A.9 BOARD - BOTTOM TRACE AND BOTTOM SILK

DS51994A-page 22 © 2011 Microchip Technology Inc.

Page 27

A.10 BOARD - LAYER #2 VDD

Schematics and Layouts

A.11 BOARD - LAYER #3 GND

© 2011 Microchip Technology Inc. DS51994A-page 23

Page 28

MCP3903 ADC Evaluation Board for 16-Bit MCUs User’s Guide

A.12 BOARD - TOP SILK AND PADS

A.13 BOARD - BOTTOM SILK AND PADS

DS51994A-page 24 © 2011 Microchip Technology Inc.

Page 29

MCP3903 ADC EVALUATION BOARD

FOR 16-BIT MCUs USER’S GUIDE

Appendix B. Bill of Materials (BOM)

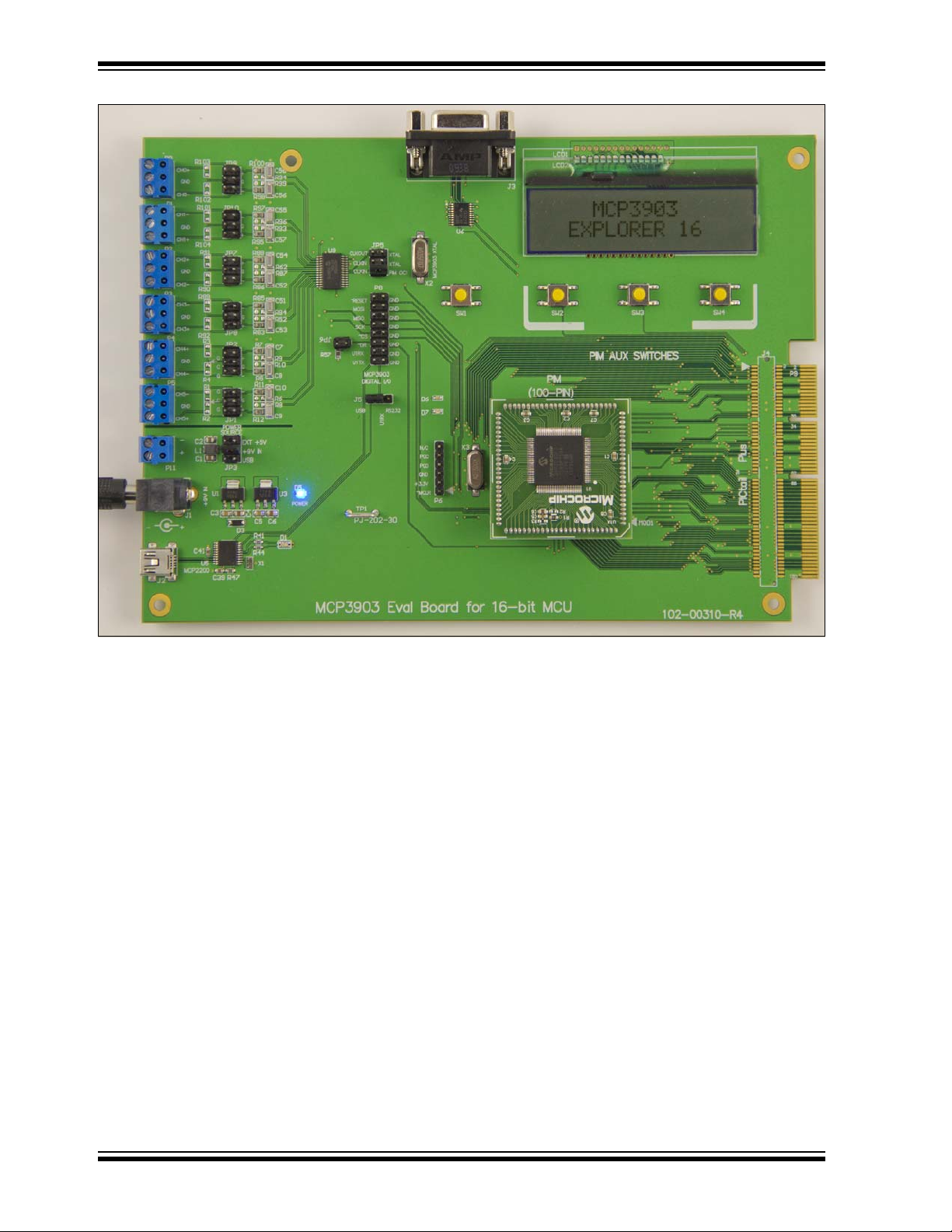

TABLE B-1: BILL OF MATERIALS (BOM)

Qty Reference Description Manufacturer Part Number

2 C1,C4 CAP CER 10UF 16V Y5V 0805 TDK Corp. C2012Y5V1C106Z

25 C11<>C22

C24<>C30

C33,C34,C35

C36,C39,C41

2 C2,C6 CAP CER 4.7UF 25V Y5V 0805 TDK Corp. C2012Y5V1E475Z

1 C23 CAPACITOR TANT 47UF 6.3V 20% SMD Kemet

5 C3,C5,C44

C45,C46

4 C31,C32

C37,C38

12 C7,C8,C9, C10

C51<>C58

1 D1 LED 2X1.2MM RD/GN WTR CLR SMD Kingbright Corp. APHBM2012SURKCGKC

1 D3 DIODE SCHOTTKY 20V 0.5A SOD123 ON Semi. MBR0520LT1G

1 D5 LED BLUE 470NM CLEAR LENS (0603

1 D6 LED 570NM GRN WHT/DIFF 0603 SMD Rohm Semi. SML-512MWT86

1 D7 LED RED 470NM CLEAR LENS (0603

4 Ea. Conner of

PCB

4 Ea. Conner of

PCB

1 J1 CONN POWERJACK MINI .08" R/A T/H Switchcraft

1 J2 Mini USB Type B Surface Mount Samtec MUSB-05-S-B-SM-A

1 J3 C ONN D-S UB RCP T R/A 9POS 15GO LD Tyco Electroni cs 1734354-2

1 J4 "DO NOT INSTALL"

1 J5 3 x 1 Header 2.54mm - 8 JP1,JP2,JP3

JP5,JP7,JP8

JP9,JP10

1 JP6 2 x 1 Header 2.54mm - 9 Jumper Shunts CONN JUMPER SHORTING TIN Sullins Connector

Note 1: The component s l isted in t his Bi ll of Mate rials are re presen tat ive o f the PCB a ssembl y. The released BOM

used in manufacturing uses all RoHS-compliant components.

CAP CER .10UF 25V X7R 10% 0603 TDK Corp. C1608X7R1E104K

®

CAP CER .10UF 25V X7R 10% 0805 TDK Corp. C2012X7R1E104K

CAP CER 18PF 50V C0G 5% 0603 TDK Corp. C1608C0G1H180J

CAP CER 68000PF 25V C0G 5% 1206 TDK Corp. C3216C0G1E683J

Para Light Corp. L-C191LBCT-U1

Blue)

Para Light Corp. L-C192KRCT-U1

Red)

STANDOFF HEX .500/4-40THR NYLON Keystone 1902C

SCREW MACH PHIL 4-40X3/8 NYLON Building Fasteners NY PMS 440 0038 PH

®

Samtec MEC1-160-02-L-D-A

120-pin MINI EDGE CARD SOCKET

3 X 2 Header 2.54mm on center 6

mm/2.5mm

Samtec TSW-103-07-G-D

Solutions

T491A476M006AT

RAPC722X

STC02SYAN

© 2011 Microchip Technology Inc. DS51994A-page 25

Page 30

Bill of Materials (BOM)

TABLE B-1: BILL OF MATERIALS (BOM) (CONTINUED)

Qty Reference Description Manufacturer Part Number

1 L1 Shielded 10uH Power Inductor 0805 Coilcraf t 0805PS-103KLC

1 LCD1 "DO NOT INSTALL" - 1 LCD2 16X2 FTN Reflective No. BLWT COG 3V Tianma TM162JCAWG1

4 MOD1 25 X 1 Header 1.27mm on center Samtec MTMS-125-01-G-S-230

6 P0,P1,P2,P3

P4,P5

1 P0,P1,P2,P3

P4,P5,P11

1 P11 CONN TERM BLK PLUG 6A 3.5MM 2POS Keystone 8722

1 P6 6 x 1 Header 2.54mm - 1 P8 8 X 2 CONN HEADER 8POS .100" DUAL

1 P9 "DO NOT INSTALL” - 1 PCB RoHS Compliant Bare PCB, MCP3901

24 R1,R2,R3,R4

R6,R8,R9

R10,R16,

R52,R62

R84,R87

R89<>R94

R96,R99

R101<>R104

4 R13,R19

R23,R30

8 R14,R20, R24,

R31 R32,R33

R36, R37

3 R21,R57 RES 10.0K OHM 1/10W 1% 0603 SMD Rohm Semi. MCR03EZPFX1002

5 R17,R18,R25

R29,R35

2 R15,R22,R26 RES 0.0 OHM 1/10W 5% 0603 SMD Rohm Semi. MCR03EZPJ000

2 R27,R28 RES 2.20K OHM 1/10W 1% 0603 SMD Rohm Semi. MCR03EZPFX2201

2 R34,R40 RES 1.00M OHM 1/10W 1% 0603 SMD Rohm Semi. MCR03EZPFX1004

10 R38,R39,R43,R

54,R55,R56,R5

8 R63,R68,R69

3 R41,R44,R47 RES 470 OHM 1/10W 5% 0603 SMD Panasonic ERJ-3GEYJ471V

7 R44,R70,R71,

R72,R74,R75

R76

Note 1: The component s l isted in t his Bi ll of Mate rials are re presen tat ive o f the PCB a ssembl y. The released BOM

used in manufacturing uses all RoHS-compliant components.

CONN TERM BLK PLUG 6A 3.5MM 3POS Keystone 8723

TERM BLK PIN HEADER 24Pin Pos One

24 Pin Header for 1 Board (20 pins

needed)

TIN

Eval. Board for 16-bit MCU

(0805) "DO NOT INSTALL" - -

RES 4.70K OHM 1/10W 1% 0603 SMD Rohm Semi. MCR03EZPFX4701

RES 1.00K OHM 1/10W 1% 0603 SMD Rohm Semi. MCR03EZPFX1001

(0603) "DO NOT INSTALL" - -

RES 100 OHM 1/10W 1% 0603 SMD Rohm Semi. MCR03EZPFX1000

RES 100K OHM 1/10W 1% 0603 SMD Rohm Semi. MCR03EZPFX1003

Keystone 8724

Samtec TSW-104-17-T-D

- 104-00221

© 2011 Microchip Technology Inc. DS51994A-page 26

Page 31

Bill of Materials (BOM)

TABLE B-1: BILL OF MATERIALS (BOM) (CONTINUED)

Qty Reference Description Manufacturer Part Number

12 R5,R7,R11

R12,R83,R85

R86,R88,R95

R97,R98 R100

2 R59,R60 RES 10.0 OHM 1/8W 1% 0805 SMD Rohm Semi. MCR10EZHF10R0

4 SW1,SW2

SW3,SW4

1 TP1 Wire Test Point 0.3" Length Components Corp. PJ-202-30

1 U1 IC REG LDO 800MA 5.0V SOT-223 National Semi. LM1117MP-5.0/NOPB

1 U3 IC REG LDO 800MA 3.3V SOT-223 National Semi. LM1117MP-3.3/NOPB

1 U6 IC DRVR/RCVR MLTCH RS232 20TSSOP Texas Instruments SN75C3223PWR

1 U7 "DO NOT INSTALL" - 1 U9 IC ENERGY METER 28SSOP Microchip MCP3903

1 X2 CRYSTAL 3.579545MHZ 18PFFUND

Note 1: The component s l isted in t his Bi ll of Mate rials are re presen tat ive o f the PCB a ssembl y. The released BOM

used in manufacturing uses all RoHS-compliant components.

RES 1.0K OHM .1% 1/4W 0805 SMD Susumu Co., LTD. RGH2012-2E-P-102-B

SWITCH TACT 6MM 230GF H=4.3MM Omron Electronic

Components ECB Division

Abracon Corp. ABLS-3.579545MHZ-B2-T

SMD

B3S-1002P

© 2011 Microchip Technology Inc. DS51994A-page 27

Page 32

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-2819-3180

Fax: 86-571-2819-3189

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-6578-300

Fax: 886-3-6578-370

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Fax: 886-7-330-9305

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

05/02/11

DS51994A-page 28 © 2011 Microchip Technology Inc.

Loading...

Loading...