Page 1

MCP2221

I2C Demonstration Board

User’s Guide

2016 Microchip Technology Inc. DS50002480A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEEL

®

OQ

code hopping

QUALITY MANAGEMENT S

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate,

dsPIC, FlashFlex, flexPWR, Heldo, JukeBlox, KeeLoq,

KeeLoq logo, Kleer, LANCheck, LINK MD, MediaLB, MOST,

MOST logo, MPLAB, OptoLyzer, PIC, PICSTART, PIC32 logo,

RightTouch, SpyNIC, SST, SST Logo, SuperFlash and UNI/O

are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

ClockWorks, The Embedded Control Solutions Company,

ETHERSYNCH, Hyper Speed Control, HyperLight Load,

IntelliMOS, mTouch, Precision Edge, and QUIET-WIRE are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, Any Capacitor, AnyIn, AnyOut,

BodyCom, chipKIT, chipKIT logo, CodeGuard, dsPICDEM,

dsPICDEM.net, Dynamic Average Matching, DAM, ECAN,

EtherGREEN, In-Circuit Serial Programming, ICSP, Inter-Chip

Connectivity, JitterBlocker, KleerNet, KleerNet logo, MiWi,

motorBench, MPASM, MPF, MPLAB Certified logo, MPLIB,

MPLINK, MultiTRAK, NetDetach, Omniscient Code

Generation, PICDEM, PICDEM.net, PICkit, PICtail,

PureSilicon, RightTouch logo, REAL ICE, Ripple Blocker,

Serial Quad I/O, SQI, SuperSwitcher, SuperSwitcher II, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

GestIC is a registered trademarks of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2016, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

ISBN: 978-1-5224-0492-7

DS50002480A-page 2 2016 Microchip Technology Inc.

Page 3

Object of Declaration: MCP2221 I2C Demonstration Board User’s Guide

2016 Microchip Technology Inc. DS50002480A-page 3

Page 4

MCP2221 I2C Demonstration Board User’s Guide

NOTES:

DS50002480A-page 4 2016 Microchip Technology Inc.

Page 5

MCP2221 I2C DEMONSTRATION

BOARD USER’S GUIDE

Table of Contents

Preface ...........................................................................................................................7

Introduction............................................................................................................ 7

Document Layout .................................................................................................. 7

Conventions Used in this Guide ............................................................................ 8

Recommended Reading........................................................................................ 9

The Microchip Web Site ........................................................................................ 9

Customer Support ................................................................................................. 9

Document Revision History ................................................................................... 9

Chapter 1. Product Overview

1.1 Introduction ................................................................................................... 11

1.2 MCP2221 I

1.3 What the MCP2221 I

2

C Demonstration Board Description ......................................... 11

2

C Demonstration Board Kit Includes ......................... 13

Chapter 2. Installation and Operation

2.1 Minimum System Requirements .................................................................. 15

2.2 Board Setup ................................................................................................. 15

2.3 Jumpers and Connectors Description .......................................................... 16

2.4 Test Points Description ................................................................................ 18

Chapter 3. Testing Board Features

3.1 About the MPC2221 I2C Demo Board Application ....................................... 19

3.2 General Information Panel Description ........................................................ 20

3.3 Feature Tabs ................................................................................................ 21

Chapter 4. Creating Custom I2C Software Applications

4.1 USB to I2C .................................................................................................... 39

4.2 PIC16F1509 as I

2

4.3 I

C Slave Addresses .................................................................................... 41

2

C Master .......................................................................... 40

Chapter 5. Troubleshooting

5.1 Board Not Detected by PC ........................................................................... 43

5.2 USB Driver Installation Issues ...................................................................... 43

5.3 PC Application Reports “MCP2221 Not Connected” .................................... 43

5.4 PC Application Reports I

5.5 Issues Programming the PIC

2

C Errors ............................................................... 44

®

Microcontroller ............................................. 44

2016 Microchip Technology Inc. DS50002480A-page 5

Page 6

MCP2221 I2C Demonstration Board User’s Guide

Appendix A. Schematics and Layouts

A.1 Introduction .................................................................................................. 45

A.2 Board – Interface Schematic ........................................................................ 46

A.3 Board – Slaves Schematic ........................................................................... 47

A.4 Board – Top Silk .......................................................................................... 48

A.5 Board – Top Copper and Silk ....................................................................... 48

A.6 Board – Top Copper .................................................................................... 49

A.7 Board – Bottom Copper ............................................................................... 49

A.8 Board – Bottom Copper and Silk ................................................................. 50

A.9 Board – Bottom Silk ..................................................................................... 50

Appendix B. Bill of Materials (BOM)...........................................................................51

Worldwide Sales and Service .....................................................................................54

DS50002480A-page 6 2016 Microchip Technology Inc.

Page 7

MCP2221 I2C DEMONSTRATION

BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP2221 I

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the MCP2221 I2C Demonstration Board as an

evaluation tool to debug a target motor system. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information on the board.

• Chapter 2. “Installation and Operation” – Covers the initial setup of this board

and the Graphical User Interface (GUI).

• Chapter 3. “Testing Board Features” – Describes how to use the board’s

capabilities.

• Chapter 4. “Creating Custom I

information for the custom usage of the board.

• Chapter 5. “Troubleshooting”– Provides procedures for troubleshooting the

most common problems encountered when installing and operating the board.

• Appendix A. “Schematics and Layouts” – Shows the schematic and layout

diagrams for the board.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the board.

2

C Demonstration Board. Items discussed in this chapter include:

2

C Software Applications”– Provides

2016 Microchip Technology Inc. DS50002480A-page 7

Page 8

MCP2221 I2C Demonstration Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS50002480A-page 8 2016 Microchip Technology Inc.

Page 9

RECOMMENDED READING

This user’s guide describes how to use the MCP2221 I2C Demonstration Board. Other

useful documents are listed below. The following Microchip documents are available

and recommended as a supplemental reference resource.

• MCP2221 Data Sheet – “USB 2.0 to I

(DS20005292)

• PAC1710/20 Data Sheet – “Single and Dual Hig h-Side Curr ent-Sense Monitor

with Power Calculation” (DS20005386)

• MCP3221 Data Sheet – “Low-Power 12-Bit A/D Converter With I

(DS21732)

• MCP9808 Data Sheet – “±0.5°C Maximum Accuracy Digital Temperature Sensor”

(DS25095)

• PIC16(L)F1508/9 Data Sheet – “20-Pin Flash, 8-Bit Microcontrollers with XLP

Technology” (DS40001609)

• MCP4706/4716/4726 Data Sheet – “8-/10-/12-Bit Voltage Output

Digital-to-Analog Converter with EEPROM and I

• MCP23008/MCP23S08 Data Sheet – “8-Bit I/O Expander with Serial Interface”

(DS21919)

Preface

2

C™/UART/Protocol Converter with GPIO”

2

C™ Interface”

2

C™ Interface” (DS22272)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web site

is used as a means to make files and information easily available to customers. Accessible

by using your favorite Internet browser, the web site contains the following information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (April 2016)

• Initial release of this document.

2016 Microchip Technology Inc. DS50002480A-page 9

Page 10

MCP2221 I2C Demonstration Board User’s Guide

NOTES:

DS50002480A-page 10 2016 Microchip Technology Inc.

Page 11

MCP2221 I2C DEMONSTRATION

BOARD USER’S GUIDE

Chapter 1. Product Overview

1.1 INTRODUCTION

This chapter provides an overview of the MCP2221 I2C Demonstration Board and

covers the following topics:

• MCP2221 I

• What the MCP2221 I

1.2 MCP2221 I2C DEMONSTRATION BOARD DESCRIPTION

2

C Demonstration Board Description

2

C Demonstration Board Kit Includes

The MCP2221 I2C Demonstration Board allows the user to communicate through a PC

application to I

converter (bridge). Additionally, it can create a USB to RS-232 (UART) bridge using the

same MCP2221 board.

2

C slave devices by using the MCP2221 device as a USB to I2C master

1.2.1 Board Features Controlled through PC Application

Here are the main features of the demonstration board when used with its dedicated

PC application:

• Users can perform measurements for resistors (above 10Ω) or capacitors (above

40 nF), using the MCP2221 device’s Analog-to-Digital Converter (ADC) and

General Purpose Input/Output (GPIO) pins

• Real-time monitoring and logging of the current, and power consumptions of a

USB device using the PAC1710 current, voltage and power sensor

• Real-time monitoring and logging of the ambient temperature using the MCP9808

temperature sensor

• Real-time monitoring and logging of the voltage level recorded by the MCP3221

device’s 12-bit ADC

• Configuration and control of up to 8 GPIOs, available from the MCP23008 I/O

expander, as well as continuously monitoring the state of the pins (when used as

digital inputs)

• PIC16F1509 configuration to issue multiple warnings through an RGB LED when

any of the featured readings are outside of user settable conditions (such as

“measured USB current is above 50 mA”)

• Storing the above mentioned configuration, as well as other random data, in a

24LC128 128-Kbit Electrically Erasable Programmable Read-Only Memory

(EEPROM)

• Output voltage level control of the MCP4726 Digital-to-Analog Converter (DAC)

• Creating a USB to RS-232 bridge, based on the MCP2221 device and a Texas

Instrument’s MAX3232 transceiver; alternately creating a USB to UART bridge to

the PIC16F1509 microcontroller

2016 Microchip Technology Inc. DS50002480A-page 11

Page 12

MCP2221 I2C Demonstration Board User’s Guide

1.2.2 Other Hardware Features

The board also provides features that are independent of the software application:

• 5V or 3.3V user-selectable V

demonstration board and all on-board devices.

2

•I

C female socket (similar to the PICkit™ Serial Analyzer) for connectivity to external slaves, as well as test points for the I

disconnect the on-board, 4.7 k

• In-Circuit Serial Programming™ (ICSP™) male connector to debug or program

the PIC16F1509 using a PICkit 3 programmer or another compatible tool.

• The option to connect the PIC16F1509 device’s Universal Asynchronous

Receiver/Transmitter (UART) to the board’s RS-232 connector (through the

MAX3232 transceiver).

• A small prototyping area which includes extensions of the board’s power (V

and ground (GND) lines.

• Test points to measure the current, voltage or power of non-USB devices (as well

as receive configurable interrupts) using the PAC1710 current-sensing chip.

• Option to connect the interrupt pin of the MCP23008 I/O expander to an external

interrupt pin of the PIC16F1509 for custom applications.

1.2.3 I2C Devices Available on the Board

, up to 500 mA operating capability for the

DD

2

C lines, and the option to

pull-up resistors for the I2C data and clock lines.

DD

)

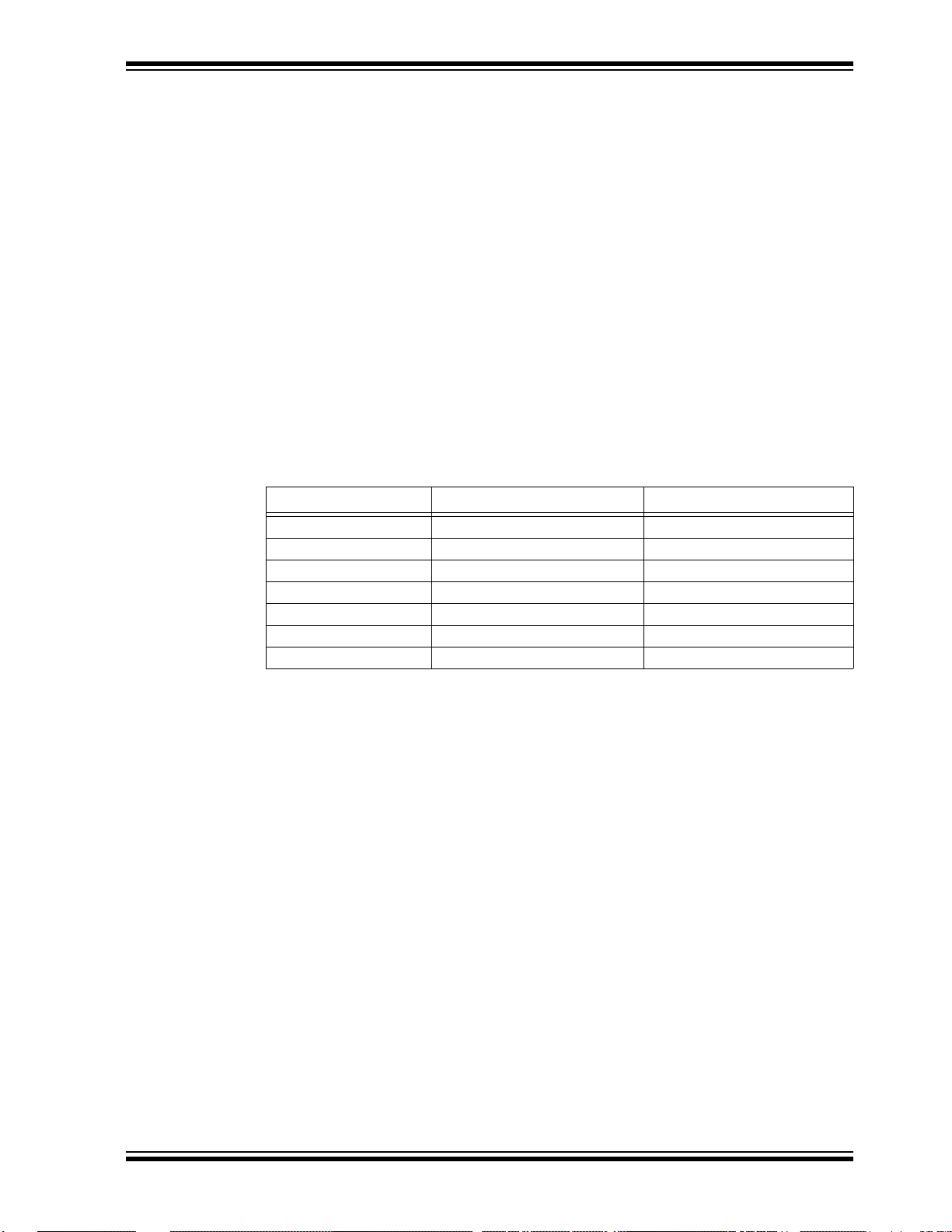

Ta bl e 1 -1 identifies the I2C devices (master and slaves) available on the MCP2221 I2C

Demonstration Board.

TABLE 1-1: I

Device

Name

MCP2221 Master USB to I

PAC1710 Slave Single High-Side Current Sense Monitor with Power Calculation

24LC128 Slave 128-Kbit EEPROM

MCP9808 Slave Temperature Sensor

MCP3221 Slave 1-Channel, 12-Bit Analog-to-Digital Converter (ADC)

MCP4726 Slave 12-Bit Digital-to-Analog Converter (DAC)

MCP23008 Slave 8-Bit I/O Expander

PIC16F1509 Slave 8-Bit Microcontroller (preprogrammed to perform as I

2

C DEVICES AVAILABLE ON THE MCP2221 BOARD

I2C

Master/Slave

2

C/UART/SMBus Protocol Converter with GPIO

(Master Mode)

Description

2

C slave)

DS50002480A-page 12 2016 Microchip Technology Inc.

Page 13

Figure 1-1 illustrates the components on the top view.

MCP2221

PIC16F1509

PAC 1710

24LC128

MCP9808

MCP3221

MCP4726

MCP23008

FIGURE 1-1: MCP2221 TOP VIEW – I

2

C DEVICES ON THE BOARD

1.3 WHAT THE MCP2221 I2C DEMONSTRATION BOARD KIT INCLUDES

The MCP2221 I2C Demonstration Board Kit (ADM00678) includes:

2

• MCP2221 I

• Preprogrammed PIC16F1509 Microcontroller

• Two Mini-USB Cables

• Important Information Sheet

C Demonstration Board

2016 Microchip Technology Inc. DS50002480A-page 13

Page 14

MCP2221 I2C Demonstration Board User’s Guide

NOTES:

DS50002480A-page 14 2016 Microchip Technology Inc.

Page 15

MCP2221 I2C DEMONSTRATION

Chapter 2. Installation and Operation

2.1 MINIMUM SYSTEM REQUIREMENTS

BOARD USER’S GUIDE

The MCP2221 I2C Demonstration Board is designed to be used in a Microsoft®

Windows

(client profile). Users can utilize the Microsoft.NET Framework 4 web installer package

to download and install the Microsoft.NET Framework 4 components.

For USB connectivity, the minimal physical requirement for the PC is a standard

USB 2.0 port. The board connects to the PC via the mini-USB connector (J4). In case

the board connects to the PC through a USB hub, use a self-powered hub.

2.2 BOARD SETUP

Before the MCP2221 I2C Demonstration Board can be used, a few steps must be

performed to install the PC software and configure the board’s hardware.

2.2.1 Software Installation

Follow these steps to install the required software:

1. Download the support material (PC application) that can be found on the board’s

page at www.microchip.com.

2. Unzip the archive and install the .exe file. The setup process should also

perform the USB driver installation, if needed. If there are driver-related issues,

refer to Section 5.2 “USB Driver Installation Issues”.

2.2.2 Hardware Setup

Follow these steps to set up the hardware:

1. Check if the board is properly powered from USB by setting jumper J19 to either

5V or 3.3V; by default, it is set to 5V.

2. Connect the MCP2221 I

port (J4).

®

XP (SP3 or later) environment, based on the Microsoft.NET Framework 4

2

C Demonstration Board to a PC through the mini-USB

2016 Microchip Technology Inc. DS50002480A-page 15

Page 16

DS50002480A-page 16 2016 Microchip Technology Inc.

Legend:

1 = Enable potentiometer R13 for MCP3221 ADC 6 = Enable LEDs, LD2-LD9, for MCP23008 GPIO expander

2 = Enable board’s I

2

C pull-up resistors, R10 and R11 7 = Enable SDA (data) line of PIC16F1509 for I2C connectivity

3 = Connect UART RX of PIC16F1509 to UART TX of MCP2221 8 = Enable SCL (clock) line of PIC16F1509 for I

2

C connectivity

4 = Connect UART RX of MCP2221 to UART TX of PIC16F1509 9 = Enable RGB LED (connect to PIC16F1509)

5 = Set board voltage (V

DD

) to 5V

1

2

3

4

5

6

7

8

9

MCP2221 I

2.3 JUMPERS AND CONNECTORS DESCRIPTION

Refer to Figure 2-1 to view the default settings for the jumpers and connectors.

FIGURE 2-1: DEFAULT JUMPERS AND CONNECTORS CONFIGURATIONS

2

C Demonstration Board User’s Guid e

Page 17

Installation and Operation

Ta bl e 2 -1 describes the functions of all the board’s jumpers and connectors.

TABLE 2-1: MCP2221 BOARD JUMPERS CONFIGURATION

Jumper

Designator

J1 PDIP socket for PIC16F1509 microcontroller.

J2 Female connector to the MCP4726 Digital-to-Analog Converter; one pin is the DAC output and the

other connects to the ground.

J3 Male connector to the MCP4726 Digital-to-Analog Converter; one pin is the DAC output and the other

connects to the ground.

J4 Mini-B type USB female connector for power and connectivity for MCP2221 from the PC.

J5 RS-232 female connector.

2

J6 Jumper connecting the I

connected by default.

J7 Female connector to the MCP3221 Analog-to-Digital Converter; one pin is the ADC custom input and

the other connects to the ground; for custom input, disconnect jumper J18.

J8 Male connector to the MCP3221 Analog-to-Digital Converter; one pin is the ADC custom input and the

other connects to the ground; for custom input, disconnect jumper J18.

J9 Jumper connecting the I

connected by default.

J10 Female connector for the MCP9808 temperature sensor. One pin connects to the sensor’s ALERT

and the other to the ground.

J11 Male connector for the MCP9808 temperature sensor. One pin connects to the sensor’s ALERT pin and

the other to the ground.

J12 Jumper for configuring the UART/RS-232 traffic directions:

• MCP2221 to PIC16F1509: Short-circuit (RX MCU) with (TX USB), then (TX MCU) with (RX USB).

This is the default setting.

• MCP2221 to RS232

• PIC16F1509 to RS232:

J13 Female connector for measuring resistances and capacitances. The ‘–’ (minus) sign indicates the

ground pin in case of measuring polarized capacitors.

J14 Jumper enabling the RGB LED LD1 that connects to the PIC16F1509. The jumper is connected by

default.

J15 Jumper allowing the possibility to connect the interrupt pin of the MCP23008 I/O expander to pin RA2 of

the PIC16F1509. The jumper is not connected by default (not populated).

J16 Female connector to the eight I/O pins of the MCP23008 I/O expander. When using the connector,

consider disabling the LEDs connected to the I/O pins by removing jumper J20.

J17 Male connector to the eight I/O pins of the MCP23008 I/O expander. When using the connector,

consider disabling the LEDs connected to the I/O pins by removing jumper J20.

J18 Jumper connecting the potentiometer R13 to the ADC input pin of the MCP3221 DAC. Disconnect

jumper to allow custom voltage measurements via connectors J7/J8. The jumper is connected by

default.

J19 Jumper for selecting the voltage level (V

3.3V or middle and right hand side pins for 5V. The default setting is for 5V.

J20 Jumper enabling LEDs LD2-LD9 that are connected to the I/O pins of the MCP23008 I/O expander;

consider removing it if using connectors J16 and J17. The jumper is connected by default.

J21 Mini-B type USB female connector used for measuring current, voltage and power with the PAC1710.

This side goes towards the USB voltage source, such as a PC.

J22 A type USB female connector used for measuring current/voltage/power with the PAC1710. Connect

the USB device (load) through this jumper.

J23 In-Circuit Serial Programming™ (ICSP™) connector for the PIC16F1509, compatible with the

PICkit™ 3 debugger/programmer; the white triangle indicates the first pin (MCLR

C SDA (data) pin of the PIC16F1509 to the board’s SDA line. This jumper is

2

C SCL (clock) pin of the PIC16F1509 to the board’s SCL line. This jumper is

: Short-circuit (RX RS-232) with (RX USB), then (TX RS-232) with (TX USB).

Short-circuit (RX RS-232) with (RX MCU), then (TX RS-232) with (TX MCU).

Function Description

) of the board: connect left hand side and middle pins for

DD

/VPP).

pin

2016 Microchip Technology Inc. DS50002480A-page 17

Page 18

MCP2221 I2C Demonstration Board User’s Guide

TABLE 2-1: MCP2221 BOARD JUMPERS CONFIGURATION (CONTINUED)

Jumper

Designator

Function Description

J24 Jumper enabling the 4.7 pull-up resistors for the I2C data (SDA) and clock (SCL) lines on the board.

Consider removing it if the demonstration board connects to an external I

2

has I

C pull-up resistors. The jumper is connected by default.

J25 I2C female connector; similar to the PICkit™ Serial Analyzer connector; however, this one only has the

power and I

not connected.

2

C lines (VDD, GND, SDA, SCL). The white triangle indicates the first pin. Pins 1 and 6 are

2

C slave circuit which already

2.4 TEST POINTS DESCRIPTION

Ta bl e 2 -2 describes the board’s test points.

TABLE 2-2: MCP2221 BOARD TEST POINTS CONFIGURATION

T est Point

Designator

TP1 Test point for measuring resistance or capacitance. If required, connect the positive pin of the polarized

capacitor to this test point.

TP2 Test point (connected to ground) for measuring resistance or capacitance. If required, connect the

negative pin of the polarized capacitor to this test point.

TP3 Test point for the ALERT

application.

TP4 Test point for the load side (target USB device) of the PAC1710 measuring circuit.

TP5 Test point for the source side (USB Host/PC) of the PAC1710 measuring circuit.

TP6 Test point for the I2C SDA line of the board.

TP7 Test point for the I2C SCL line of the board.

TP8 Test point connected to ground.

pin of the PAC1710. This test point is not used by the demonstration board’s

Description

DS50002480A-page 18 2016 Microchip Technology Inc.

Page 19

MCP2221 I2C DEMONSTRATION

Setup Area

General Information Panel

Feature Tabs

BOARD USER’S GUIDE

Chapter 3. Testing Board Features

This section describes the working principles and limitations that should be taken into

account when using the board with the dedicated PC application, as well as the actual

steps to use all of the demonstration kit’s features.

It is assumed that the user has already successfully run the installation process

described in Section 2.2 “Board Setup”.

3.1 ABOUT THE MPC2221 I2C DEMO BOARD APPLICATION

The PC application for the device is named the MCP2221 I2C Demo Board Application.

The three main sections that can be observed in Figure 3-1 are the Feature tabs,

General Information panel and Setup area.

FIGURE 3-1: THE MCP2221 I

2

C DEMO BOARD APPLICATION – INITIAL VIEW

2016 Microchip Technology Inc. DS50002480A-page 19

Page 20

MCP2221 I2C Demonstration Board User’s Guide

For more information on the General Information panel, see Section 3.2 “General

Information Panel Description”.

The Feature tabs determine the content of the Setup area. For more information, see

Section 3.3 “Feature Tabs”.

3.2 GENERAL INFORMATION PANEL DESCRIP T ION

3.2.1 The Device Status Label

The Device status label displays whether the board is connected to the PC. One of the

following messages is generated by the system:

• MCP2221 Connected

• MCP2221 not Connected

3.2.2 The Using Custom VID/PID... Button

When clicking the Using Custom VID/PID... button, the Select VID & PID window is

displayed. The window contains information on the VID/PID combination to find the

drivers that are to be used for the USB device.

FIGURE 3-2: THE SELECT VID & PID WINDOW

By default, the values are 0x4D8 for the VID and 0xDD for the PID. New values can be

inserted in the “Look for VID (Hexadecimal Form)” and the “Look for PID (Hexadecimal

Form)” fields. After inserting the new values, click the Update Settings button. Users

can return to the default values by clicking the Use Default Values button.

3.2.3 The I2C Communication Status Box

By default, the “I2C Communication Status” text box is blank. It is populated when

actions are performed in the Feature tabs. The information is system-generated and

read-only.

Message examples include: “EEPROM write successful”, “Pins states updated”,

“Settings saved” and others. If errors are displayed, see Section 5.4 “PC Application

Reports I

2C Errors”

.

3.2.4 The Clear I2C Status Box Button

Click the Clear I2C Status Box button to clear the I2C Communication Status box.

Note that clearing the text in the box does not cancel or revert any previously performed

action.

DS50002480A-page 20 2016 Microchip Technology Inc.

Page 21

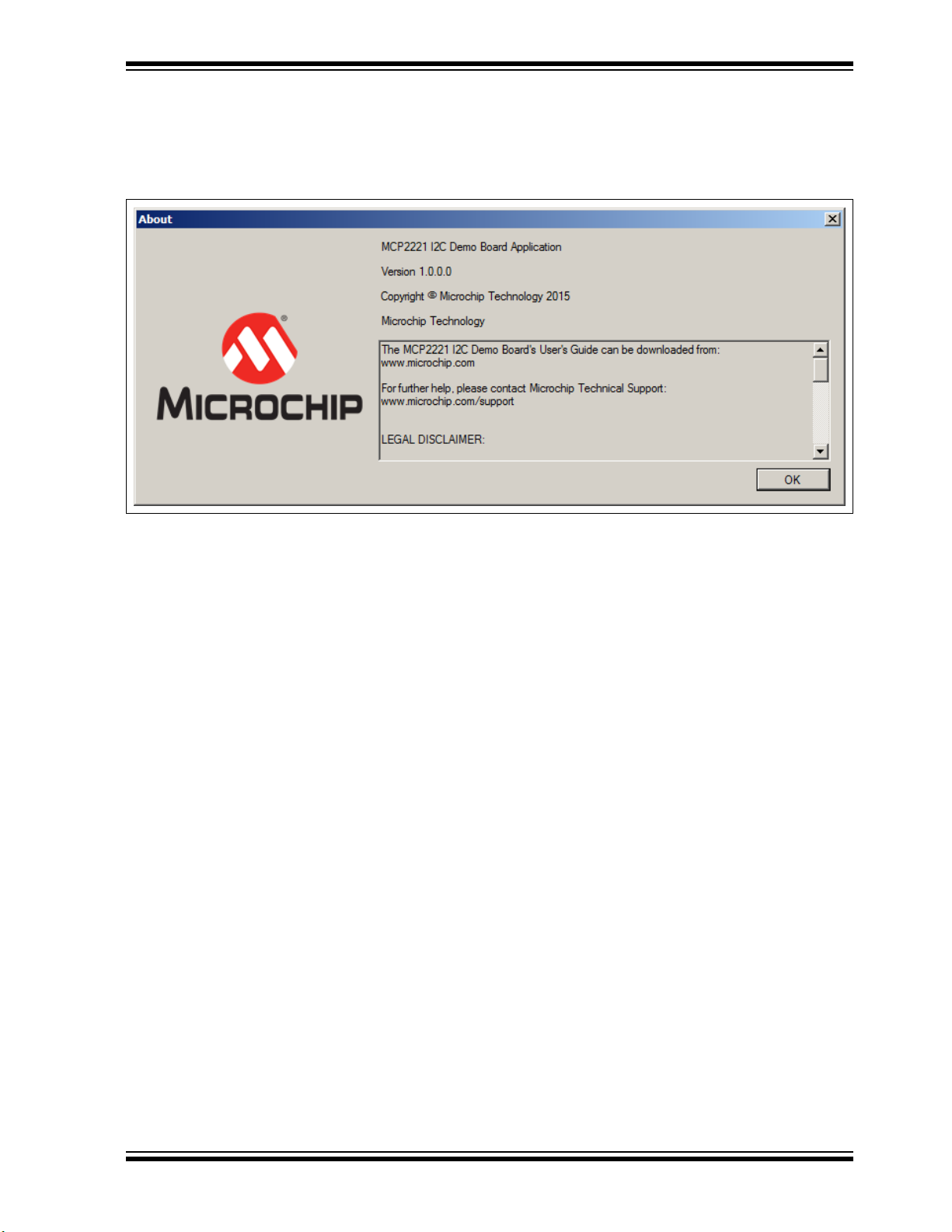

3.2.5 The About Button

Click the About button to open a window that contains information on the application’s

version and legal disclaimers. Click the OK button to close the window.

FIGURE 3-3: THE ABOUT WINDOW

Testing Board Features

3.3 FEATURE TABS

The left panel of the application contains nine tabs that allow the user to explore all the

board’s features:

• Measure R, C

• Measure USB Power

• Measure Temperature

• Read/Write EEPROM

• Read ADC

• Configure DAC

• GPIO Expander

• RGB LED Notifications

• UART Communication

Each tab displays a dedicated setting area when selected.

3.3.1 Measure R, C Tab

Capacitance is determined by measuring the capacitor’s charging time. In case of large

capacitors, the charging time is software limited to 10 seconds, after which, a

mathematical formula is applied to determine the approximate capacitance. The

charging current is provided by a digital output pin of the MCP2221 board and limited

by a 470 kΩ resistor. The Measure R, C tab also generates a charging graph for the

capacitor, as well as an indicator of its voltage.

Resistance is determined by placing the unknown resistor in series with another known

one, thus creating a voltage divider where relative voltage values are sufficient to

calculate the resistance.

Prior to performing measurements, the pins must be correctly placed in the connector

marked with J13 or use the test points, TP1 and TP2.

2016 Microchip Technology Inc. DS50002480A-page 21

Page 22

MCP2221 I2C Demonstration Board User’s Guide

3.3.1.1 TAB OPERATION

To measure a resistor or capacitor, select the Measure R, C tab.

• Click the Measure Resistance button to measure the resistance. The system

displays the approximate resistance and a capacitor charging graph.

• Click the Measure Capacitance button to measure capacitance. The system

displays the approximate capacitance and a capacitor charging graph.

Note: In case of a polarized capacitor, make sure the pins are correctly placed –

the ‘+’ (plus) and ‘–’ (minus) signs on the board must be next to connectors,

J13 and TP2.

Figure 3-4 shows an example of measuring resistance.

FIGURE 3-4: MEASURING RESISTANCE

3.3.1.2 CONSIDERATIONS AND WARNINGS

• The minimum supported values are around 10Ω for resistors and 40 nF for capacitors.

• To maintain a certain level of accuracy, the maximum recommended values to

measure are ~1 MΩ for resistors and 470

µ

F for capacitors.

• The measurement accuracy may be, in some cases, of about ±10%, therefore the

MCP2221 I

2

C Demonstration Board Kit is not recommended for precision

measurements.

• For both capacitor and resistance measurements, voltages are generated by

digital output pins and measured using the analog input pins of the MCP2221 I

2

C

Demonstration Board.

DS50002480A-page 22 2016 Microchip Technology Inc.

Page 23

Testing Board Features

3.3.2 Measure USB Power Tab

The Measure USB Power tab allows users to perform current, voltage or power

measurements of a USB device.

Prior to measuring the current/power of the USB device, make sure that:

• The load to be measured (for example a USB mouse) is connected to the

MCP2221 board’s USB socket marked with J22

• The power source (such as the PC) is connected to the mini-USB socket marked

with J21

3.3.2.1 TAB OPERATION

Users can determine what measurements the system should perform by selecting at

least one of the following check boxes: “Chart Voltage”, “Chart Current” or “Chart

Power”.

The “Show Numbers” check box determines whether numerical values for voltage,

current and power will also be indicated in real time inside its corresponding text box.

If the check box is selected, current and power will be indicated in real time.

Generated data can be saved using the “Log into .CSV File …” check box. When the

check box is selected, the Open window opens to allow users to select the .csv file or

create a new document, where the measured data can be logged. Figure 3-5 depicts

this action.

FIGURE 3-5: SELECTING A .csv FILE

It is advisable to use comma separated values for the.csv file type to be Microsoft

®

Excel

compatible.The .csv file is generated by the application, with four columns,

and each set of readings is placed on a row. The columns are: Data entry index,

Voltage (in Volts), Current (in Amps), Power (in Watts). Logging can be turned off by

clearing the check box.

®

2016 Microchip Technology Inc. DS50002480A-page 23

Page 24

MCP2221 I2C Demonstration Board User’s Guide

Click the Start Measurement button for the system to start performing measurements.

Pressing the Stop Measurement button interrupts the measurements.The Reset

Measurement button clears all the previously generated data and prepares the system

for new measurements.

The Measure All One Time button is for the application to retrieve, in real time, just

one set of numeric values (for voltage, current and power) and to write them in the corresponding text box below it. This can be used as an alternate solution to

Start Measurement in order to save system resources.

Figure 3-6 shows an example for measuring the current, voltage and power of a USB

Flash drive when connected to the PC via the measuring circuit.

FIGURE 3-6: MEASURING CURRENT, VOLTAGE AND POWER OF A USB DEVICE

DS50002480A-page 24 2016 Microchip Technology Inc.

Page 25

Testing Board Features

3.3.2.2 WARNINGS AND CONSIDERATIONS

• When measuring the current/power consumption, it is recommended to connect

the loads (devices) that do not draw a current above ~2.5A.

• A shunt resistor of 0.025Ω is used, which sets the PAC1710 chip’s full-scale cur-

rent value to 3.2A. However, current limitations are also imposed by the MCP2221

board’s design.

• In case of continuous measurement, samples are taken once every 100 milliseconds,

so higher frequency variations may not be noticed by the application.

• The software provides the option not to display specific variations (such as populating the voltage graph, for example) to reduce the amount of tasks that the PC

must perform. This is especially useful when the PC is running low on system

resources (like processor usage or memory filling).

• Even when switching to a different tab (such as measuring resistors), if the

monitoring is enabled, then it will not be automatically halted unless the board is

physically disconnected from the PC. Therefore, it is recommended to stop

performing the measurements when they are no longer required.

3.3.2.3 NOTIFICATIONS FUNCTIONALITY

The MCP2221 board also provides three access points (TP3, TP4 and TP5), described

in Section 2.3 “Jumpers and Connectors Description”.

The PAC1710 chip can be configured to signal notifications via the ALERT

connected to the TP3 test point of the MCP2221 I

For custom measurements, it’s highly recommended to read the data sheet for the

PAC1710 chip, as well as view the schematic and layouts of the board, available in

Appendix A. “Schematics and Layouts” of this document.

2

C Demonstration Board.

pin that’s

3.3.3 Measure Temperature Tab

The temperature sensor is built into the MCP9808 chip. The sensor’s accuracy

depends on the temperature value intervals, as seen in the following table:

Temperature Value Intervals Accuracy

-40°C to +125°C ±0.25° (typical)

-20°C to +100°C ±0.5°C (maximum)

-40°C to +125°C ±1°C (maximum)

In the case of continuous monitoring, samples are taken once every 100 milliseconds,

so higher frequency variations may not be noticed by the software.

The software provides the option not to display specific variations (for example, populating the temperature graph) to reduce the amount of tasks that the PC must perform.

This is especially useful when the PC is running low on system resources (such as

processor usage or memory filling).

Even when switching to a different application tab, if the monitoring is enabled, then it

will not be automatically halted unless the board is physically disconnected from the

PC. Therefore, it is recommended to stop performing the measurements when they are

no longer required.

2016 Microchip Technology Inc. DS50002480A-page 25

Page 26

MCP2221 I2C Demonstration Board User’s Guide

3.3.3.1 TAB OPERATION

The Measure Temperature tab allows users to perform temperature measurements.

The “Show in Chart” check box determines if a graph is displayed during the real-time

measurements. Users can choose the measuring unit (Fahrenheit or Celsius) inside

the “Unit” radio button group.

The functionalities of the “Show Numbers” and the “Log into .CSV File...” check boxes

are similar to the ones described in Sec tion 3.3.2 “Measure USB Power Tab”.

However, the .csv file contains two columns and each set of readings is placed on a

row. The columns are: Data entry index and Temperature.

The functionalities of the Start Measurement, Stop Measurement and Reset

Measurement buttons are similar to the ones described in Section 3.3.2 “Measure

USB Power Tab”.

Click the Measure Temperature Once button for the application to retrieve, in real

time, just one set of numeric values (for temperature) and to write them in the

corresponding text box below it. This can be used as an alternate solution to Measure

Temperature, in order to save system resources.

For example, the application can be set so that temperatures exceeding 26°C will result

in an orange LED blinking on the board. Custom LED notifications are described in

Section 3.3.8 “RGB LED Notifications Tab”.

Figure 3-7 shows an example for measuring the temperature in °C.

FIGURE 3-7: TEMPERATURE MEASUREMENT

DS50002480A-page 26 2016 Microchip Technology Inc.

Page 27

Testing Board Features

3.3.3.2 NOTIFICATIONS FUNCTIONALITY

The MCP9808 temperature sensor can be configured to output an alert signal when the

temperature changes beyond the specified boundary limits. The signal can be read on

the MCP2221 board through the pin extensions marked with J10 and J11. More

information is available in Section 2.3 “Jumpers and Connectors Description”.

3.3.4 Read/Write EEPROM Tab

The 24LC128 EEPROM is organized into 256 pages of memory (numbered from 0 to

255), each containing 64 bytes of data. The MCP2221 I

plays the memory content per page, organized in a matrix of 16 rows and 4 columns.

Data and addresses are displayed in hexadecimal form.

The last page of the EEPROM, page 255, is also used to store the LED notifications

configuration that is described in S ection 3.3.8 “RGB LED Notifications Tab”.

By default, all the memory bytes are set as 0xFF.

Writing to a data cell will cause the EEPROM to rewrite the cell’s entire page.

3.3.4.1 TAB OPERATION

Follow these steps to write to a specific cell or page of the EEPROM:

1. Select the Read/Write EEPROM tab.

2. From the “Select Page” drop-down, choose the EEPROM memory page you

want to read or write.

3. The address of the cell can be determined by adding the column and row indexes

in the matrix table below. Edit a cell by double-clicking on it and entering the 8-bit

value in hexadecimal form (example: for 0x1C, write 1C). Users must enter a

valid number in hexadecimal form, between 0x00 and 0xFF.

4. To update the EEPROM content, click the Write Page button. Figure 3-8 shows

an example of writing the 0x1A value to address 0x1D0

Number 7).

2

C Demo Board Application dis-

(Memory Page

2016 Microchip Technology Inc. DS50002480A-page 27

Page 28

MCP2221 I2C Demonstration Board User’s Guide

FIGURE 3-8: WRITING INTO THE EEPROM

To read an EEPROM page:

1. Select the desired page number from the “Select Page” drop-down.

2. Click the Read Page button.

The Erase All EEPROM Data button resets the entire content of the EEPROM to 0xFF.

The Reset Entire T able to 0xFF button only affects the displayed matrix, not the actual

EEPROM memory.

DS50002480A-page 28 2016 Microchip Technology Inc.

Page 29

Testing Board Features

3.3.5 Read ADC Tab

The MCP3221 Analog-to-Digital Converter uses both a fixed 2.5V voltage reference

and the power supply from an MCP1525 voltage reference chip, which allows the

conversion to be independent of the demo board’s power line: 3.3V/5V.

Therefore, the analog voltage to be measured must be between 0 and 2.5V. The board

can be used to measure the voltage from:

• Potentiometer R13, from the 2.5V supply that’s also powering the MCP3221 if

jumper J18 is connected (the default setting);

or

• An external source (via J7 and J8) if jumper J18 is disconnected.

In case of continuous monitoring, samples are taken once per 100 milliseconds, so

higher frequency variations may not be noticed by the PC application.

The software provides the option not to display specific variations (such as populating

the ADC graph) to reduce the amount of tasks that the PC must perform. This is

especially useful when the PC is running low on system resources (such as processor

usage or memory filling). Even when switching to a different application tab, if the

monitoring is enabled, then it will not be automatically halted unless the board is

physically disconnected from the PC. Therefore, it is recommended to stop performing

the measurements when they are no longer required. Prior to performing measurements, make sure to select the analog voltage source by connecting or removing

jumper J18. See Tab le 2 -1 for more information.

3.3.5.1 TAB OPERATION

Select the Read ADC tab to perform ADC measurements.

The “Show in Chart” check box determines whether a chart is generated by the system

to illustrate the measured values.

The functionalities of the “Show numbers” and the “Log into .CSV File...” check boxes

are similar to the ones described in Sec tion 3.3.2 “Measure USB Power Tab”.

However, the .csv file contains two columns and each set of readings is placed on a

row. The columns are: Data entry index, Voltage (in Volts).

The functionalities of the Start Measurement, Stop Measurement and Reset

Measurement buttons are similar to the ones described in Section 3.3.2 “Measure

USB Power Tab”.

The Measure ADC Voltage Once button is for the application to retrieve, in real time,

just one set of numeric values (for voltage) and to write them inside the text box below

it. This can be used as an alternate solution to Start Measurement in order to save

system resources.

Custom LED notifications (for example: voltage readings above 2.31V results in a green

LED blinking on the board) are described in Section 3.3.8 “RGB LED Notifications Tab”.

2016 Microchip Technology Inc. DS50002480A-page 29

Page 30

MCP2221 I2C Demonstration Board User’s Guide

Figure 3-9 shows an example for measuring the voltage:

FIGURE 3-9: VOLTAGE MEASUREMENT

DS50002480A-page 30 2016 Microchip Technology Inc.

Page 31

Testing Board Features

3.3.6 Configure DAC Tab

The MCP4726 DAC (Digital-to-Analog Converter) uses an MCP1525 as a 2.5V voltage

reference, thus allowing it to generate a fixed voltage no matter if the board’s power

(V

) is set to 3.3V or 5V.

DD

The MCP4726 also has the option to set a 2x reference gain, which means that only if

the MCP2221 I

analog voltage output can be as high as 5V. This option can be enabled from the PC

application.

3.3.6.1 TAB OPERATION

Follow these steps to set the voltage value for the DAC:

1. Select the Configure DAC tab.

2. From the Select Reference Voltage radio button group, choose the preferred

voltage. The default value is 2.5V. Note that users should only select 5V if the

V

DD

3. To set the output voltage, use one of the following formats:

- Inside the text box corresponding to the “Write Value in Volts” text box, type

in the numeric value;

or

- Select the “Set Voltage in Real Time” check box, then adjust the slider. The

resulting values will be shown in the text box corresponding to “Write Value

in Volts (Example: 2.35)” label. Use a period (.) and not a comma (,) to write

the value.

4. Regardless of the method used to set the output voltage, the voltages are only

submitted to the board after the user clicks the Set Voltage button. The value is

also displayed below the “Current Voltage” label, inside the corresponding

read-only text box.

5. To read the output voltage value back from the chip’s register, click the Read

V oltage Dat a button. The value is displayed in the read-only text box, below the

“Current Voltage” label.

2

C Demonstration Board works at 5V (jumper J19 is set to 5V), then the

value is 5V.

2016 Microchip Technology Inc. DS50002480A-page 31

Page 32

MCP2221 I2C Demonstration Board User’s Guide

Figure 3-10 shows how to configure the DAC to output 1.45V.

FIGURE 3-10: CONFIGURING THE DIGITAL-TO-ANALOG CONVERTER

3.3.7 Digital I/O Pins Tab

The MCP23008 pin expander provides access to eight configurable digital input/output

pins. Short-circuiting jumper J20 connects LEDs, LD2, LD3,…,LD9, to the eight pins.

The eight general purpose pins are also accessible via connectors J16 and J17. For

example, if a pin is configured as an output and intended to be connected to an external

circuit or component via J16 or J17, it may help to remove jumper J20 in order to

preserve the pin’s current driving strength.

In case a pin is used as a digital input, a logical high input signal should match the

demonstration board’s power level (3.3V or 5V, determined via jumper J19). For more

information on voltage tolerances, see the “MCP23008/MCP 23S 08 Data Sheet”

(DS21919).

Even when switching to a different application tab (such as for measuring resistors), if

the pin state monitoring (auto-read) is enabled, then it will not be automatically halted

unless the board is physically disconnected from the PC. Therefore, it is recommended

to stop performing the readings when they are no longer required.

Custom LED notifications for pin GP0 (for example: the pin having a logical high state

results in a yellow LED blinking on the board) are described in Section 3.3.8 “RGB

LED Notifications Tab”.

DS50002480A-page 32 2016 Microchip Technology Inc.

Page 33

Testing Board Features

3.3.7.1 TAB OPERATION

To control the digital I/O pins, follow these steps:

1. Select the GPIO Expander tab.

2. Configure the pin directions (input or output) under the “Set GPIO Direction”

section. The configuration only becomes active after the user clicks the Submit

Pin Directions button.

3. For the pins that are set as outputs, the “Configure Pin State (if Output)” section

allows the user to change their state in one of the following ways:

- All at once, if the “Instant Command” check box is cleared and when

clicking the Submit Pin States button;

or

- Individually (real-time state toggling), the “Instant Command” check box is

selected.

In case a pin is configured as an input, these pin state control commands are ignored.

Reading the states for all eight general purpose pins can be done by either:

• Automatically (continuously, every 100 milliseconds), in case the “Auto Read

Every 100ms” check box is selected;

or

• Manually, by clicking on the Read Pin States button.

Figure 3-11 shows an example of using the GPIO Expander tab.

FIGURE 3-11: INTERFACING THE GPIO EXPANDER

2016 Microchip Technology Inc. DS50002480A-page 33

Page 34

MCP2221 I2C Demonstration Board User’s Guide

3.3.7.2 UNIMPLEMENTED FEATURES

The MCP23008 also has a separate interrupt output pin which can be used to signal to

2

the I

C master, a logical state change of one of its input pins.

By default, the interrupt pin is not connected to the MCP3221. It can be connected to

the RA2 pin of the PIC16F1509 by short-circuiting jumper J15, in case of a custom

application, where, for example, the PIC16F1509 is programmed to perform as an I

master.

3.3.8 RGB LED Notifications Tab

LED notifications can be configured to indicate certain events related to the readings

described in the previous sections.

The LED can indicate events every 500 milliseconds (including 100 milliseconds of

specific color) allocated per I

• PAC1710 USB voltage, current or power consumption

• MCP9808 temperature sensor

• MCP3221 analog voltage value

• MCP23008 GP0 pin state change

In the remaining 100 milliseconds from one time period, the LED will be powered off.

In case a device does not have notifications enabled for its corresponding time interval,

the LED will also be powered off.

As a general observation, higher frequency events may not be noticed in time to be

signaled by the LED.

Notifications are done using the RGB LED LD1, that is fully controlled by three

Pulse-Width Modulation (PWM) pins of the PIC16F1509, which receives commands

2

(as I

C slave) from the MCP2221 DLL through the MCP2221 board. The LED color and

brightness are configured from the PC application. It is recommended to avoid light

color tones, because they can translate into very intense LED brightness.

Prior to attempting to configure the LED notifications, make sure that:

• The PIC16F1509 microcontroller is present in socket J1 and that it can

communicate via I

2

C (jumpers J6 and J9 must be connected)

• Jumper 14 is connected to enable the RGB LED LD1

2

C device:

2

C

DS50002480A-page 34 2016 Microchip Technology Inc.

Page 35

Testing Board Features

3.3.8.1 TAB OPERATION

Follow these steps to enable a notification:

1. Open the RGB LED Notifications tab.

2. The Preview Color… button brings up the Color window, allowing users to

choose colors.

FIGURE 3-12: COLOR WINDOW

3. After selecting the desired colors, click the OK button and the system changes

the LED color accordingly.

4. To enable a specific notification, select the color you want in the “Blink” radio

button group corresponding to the notification. You can either:

- Select the default color (blue, red, green or white) available for each of the

four notifications;

or

- Set any color by selecting the “custom color...” radio button. In the Color

window (Figure 3-12), choose one of the basic colors or define a new color

and click OK.

5. Set the notification conditions, including the numeric value for comparison, if

applicable.

6. Click the corresponding “Enable” check box.

7. Optional. Users can also click the Save Preferences into EERPROM button to

save the current created configuration inside the 24LC128 EEPROM that’s on

the MCP2221 board (data is stored inside its last memory page, 255). Also, the

Load Preferences from EEPROM button can be used to restore configurations

from the EEPROM.

Note: Changing a numeric value used for the comparison will clear the “Enable”

check box.

2016 Microchip Technology Inc. DS50002480A-page 35

Page 36

MCP2221 I2C Demonstration Board User’s Guide

Figure 3-13 shows how the LED is configured to blink (blue color) in case the measured

USB current exceeds 85 mA.

FIGURE 3-13: CONFIGURING LED NOTIFICATIONS

DS50002480A-page 36 2016 Microchip Technology Inc.

Page 37

Testing Board Features

3.3.9 UART Communication Tab

There are several combinations of connectivity, which are determined through

jumper J12:

• (Default Setting): MCP2221 (from PC) to PIC16F1509. Every time the

®

PIC

microcontroller receives a character from the MCP2221, it increments its

value and sends it back.

• MCP2221 (from PC) to RS-232 connector.

• PIC16F1509 to RS-232. Unless the PIC microcontroller is reprogrammed, it will

behave the same as in Case 1 described above.

For the first two cases, data loss (sent or received) may be noticed inside the PC

application’s text box due to the nature of the .NET Framework that is used by the

application. A work around is to use a third-party PC application for COM port bridging.

3.3.9.1 TAB OPERATION

To receive information on the COM ports present in the system, follow these steps:

1. Open the UART Communication tab.

2. Click the Get COM Ports Info button for the system to display information (in the

text box below it) about the COM ports present in the system; this can be used

to determine the COM port number of the MCP2221 USB to I

from the demonstration board.

3. Select the COM port number from the drop-down box. The system will populate

the “Baud:”, “Data Bits:” and “Stop Bits:” fields. For example, the settings in the

case of communication between MCP2221 and PIC16F1509 (determined

through jumper J12) are: Baud: 9600, Data Bits: 8, Stop Bits: 1.

4. Open the COM port by clicking the Open Port button.

5. Received data is automatically added inside the read-only text box on the

right-hand side as red colored text.

To send data, follow these steps:

1. Open the UART Communication tab.

2. Enter the information you want to communicate in the text boxes corresponding

to the Text 1, Text Line 2 and Text Line 3 buttons, under the “Send data:”

section.

3. “Sent data:” can be seen inside the read-only text box on the right-hand side

(combined with the received data) if the “Show Sent Data” check box is selected.

4. The buttons, Text Line 2 and Text Line 3, place the sent/received data on a new

line inside the text box.

5. To clear the text box, click the Clear Serial Data Box button.

2

C/UART converter

2016 Microchip Technology Inc. DS50002480A-page 37

Page 38

MCP2221 I2C Demonstration Board User’s Guide

Figure 3-14 shows an example of sending the text ‘12’ to the PIC microcontroller and

receiving ‘23’ back.

FIGURE 3-14: UART COMMUNICATION WITH THE PIC16F1509

DS50002480A-page 38 2016 Microchip Technology Inc.

Page 39

MCP2221 I2C DEMONSTRATION

BOARD USER’S GUIDE

Chapter 4. Creating Custom I2C Software Applications

This chapter provides a few suggestions on how to get started in developing custom

applications that involve I

Board.

Section 4.1 “USB to I

Interface (GUI) lies on a USB Host (such as a PC or Android device).

Section 4.2 “PIC16F1509 as I

board (or a pin-compatible PIC

while also using (or not) the MCP2221.

Section 4.3 “I

found on the demonstration board.

4.1 USB TO I2C

This section discusses two aspects of a USB to I2C custom application:

• Interfacing the MCP2221 I

• Connecting external I

4.1.1 Using a Different Operating System or Application

The MCP2221 can be accessed via USB from several types of operating systems:

Windows

are available on the MCP2221 official web site.

Also available for download are several applications that can be used for I

and for GPIO pin configuration, such as the MCP2221 I

Windows or the MCP2221 Terminal Android Application for Android.

In order to create a custom application (GUI), the user can call the MCP2221 associated functions (for its configuration or actual data transfer) through the DLL files that

can be downloaded from the same location.

For Android, the source code for the application and the available libraries can be used

as a basis for developing a new application.

See the “Recommended Reading” section for more information on the I

devices.

2

C communication, using the MCP2221 I2C Demonstration

2

C”: The MCP2221 is the I

2

C Master”: The PIC16F1509 which is available on the

®

microcontroller) is presumed to be the I2C master,

2

C Slave Addresses”: Lists the I

2

C Demonstration Board from a different PC

application, or even, an operating system.

2

C slaves to the MCP2221 I2C Demonstration Board.

®

, Linux®, Mac® or Android. The required USB drivers and related information

2

C master and the Graphical User

2

C slave addresses of the devices

2

2

C/SMBus Terminal for

C transfer

2

C slave

4.1.2 Connecting External I2C Slaves to the Board

The MCP2221 I2C Demonstration Board also provides the possibility to connect

external I

from the PICkit™ Serial Analyzer in terms of I

indicates the first pin of the socket.

2016 Microchip Technology Inc. DS50002480A-page 39

2

C slave devices using the female connector J25. This is same as the one

2

C connectivity. The white colored triangle

Page 40

MCP2221 I2C Demonstration Board User’s Guide

These are the pin designations:

- Pin 1: Not connected

-Pin 2: V

user-selectable (3.3V or 5V via jumper J19)

- Pin 3: GND (ground connection)

- Pin 4: SDA (I

-Pin 5: SCL (I

- Pin 6: Not connected

Additional test points are available in the case, for example, of connecting a logical

analyzer to the demo board’s I

- TP6: Test point connected to the I

- TP7: Test point connected to the I

- TP8: Test point connected to ground

(power) must be provided by the I2C demonstration board and it is

DD

2

C data line)

2

C clock line)

2

C bus:

2

C data line

2

C clock line

Note: If the externally connected I

connected to the I

board can be disconnected by removing jumper J24.

4.2 PIC16F1509 AS I2C MASTER

There may be the case where it is desirable to have the PIC16F1509 microcontroller

as the I

information related to the hardware connectivity (power supply and I

communication), as well as programming the PIC16F1509.

4.2.1 Hardware Connectivity

For powering the board, there are two possibilities:

1. From the PC, via the mini-USB connector J4 (USB Host) or a from a USB charger

2. By connecting an external power supply (between 3.3V and 5V) to the board’s

2

C master with no required USB communication. This section contains

adapter that provides a constant 5V (DC) and at a recommended minimum of

200 mA. In this case, the board’s voltage level can be set to either 3.3V or 5V,

depending on how jumper J19 is connected.

V

power line, ideally through:

DD

• The V

pin that is available on the ICSP™ (In-Circuit Serial Programming™)

DD

connector marked with J23;

or

• The V

pin that is available on the female connector J25.

DD

2

2

C data and clock lines, the ones available on the demo

C slave already has its own pull-up resistors

2

C

Note: In case a power supply is connected directly to the V

line, jumper J19

DD

should be completely disconnected to avoid unwanted current flow. This

flow could affect the board’s MCP1825 voltage regulator or the USB

connector marked with J4.

To enable I

• The PIC16F1509 connects to the I

• The I

2

C communication, make sure that:

2

2

C data and clock lines’ pull-up resistors are connected; if no pull-up

C bus by short-circuiting jumpers J6 and J9.

resistors are externally connected to the board, then jumper J24 must be

connected.

DS50000000A-page 40 2016 Microchip Technology Inc.

Page 41

Creating Custom I2C Software Applications

4.2.2 Programming the PIC16F1509

The PIC16F1509 can be programmed via the ICSP (In-Circuit Serial Programming)

connector marked with J23, with tools such as the PICkit™ 3 or compatible

debuggers/programmers. In case there are programming issues, consult

Chapter 5. “Troubleshooting” in this document.

The source code for the PIC microcontroller can be written using MPLAB

the XC8 C compiler that are available for download at http://www.microchip.com.

Part of the code, including for the I

MPLAB Code Configurator plug-in.

4.3 I2C SLAVE ADDRESSES

This section lists the addresses of the I2C slave devices that are available on the

demonstration board. The values displayed in Ta ble 4 -1 are in the 8-bit form and can

be used directly as parameters during application development when calling the

MCP2221.DLL functions.

The 8-bit equivalent (write address) of a 7-bit I

left-shift-once (or multiplication by 2) of the 7-bit address.

®

X IDE and

2

C master, can be generated automatically using the

2

C address is the result of a

TABLE 4-1: LIST OF I

Device I2C Write 8-Bit Address I2C Read 8-Bit Address

24LC128 0xA0 0xA1

MCP23008 0x40 0x41

MCP3221 0x9A 0x9B

MCP4726 0xC0 0xC1

MCP9808 0x32 0x33

PAC1710 0x5C 0x5D

PIC16F1509 0x10 0x11

2

C SLAVE ADDRESSES

2016 Microchip Technology Inc. DS50000000A-page 41

Page 42

MCP2221 I2C Demonstration Board User’s Guide

NOTES:

DS50000000A-page 42 2016 Microchip Technology Inc.

Page 43

MCP2221 I2C DEMONSTRATION

BOARD USER’S GUIDE

Chapter 5. Troubleshooting

This chapter handles a number of possible scenarios that may occur when the

MCP2221 I

2

C Demonstration Board does not function as expected.

5.1 BOARD NOT DETECTED BY PC

In case the PC does not signal, either visually or acoustically, that the MCP2221 board

has been connected, perform the following actions:

• Check the board’s power selection jumper. Make sure jumper J19 is connected

and that its default position is for 5V operation.

• Connect the PC to the correct on-board mini-USB socket. The board communi-

cates with the PC and it is also powered using the mini-USB connector marked

with J4, not J21.

• Verify that enough power is provided to the board. If the board connects through a

USB hub, then the hub should be self-powered.

5.2 USB DRIVER INSTALLATION ISSUES

When connecting the MCP2221 board to a PC running a Windows® operating system,

the USB driver should install automatically. In case the process is not successful, the

driver can be downloaded from http://www.microchip.com/mcp2221, extracted to a

folder on the local drive and then installed manually, as described below.

1. From the Start menu, select Control Panel>Device Manager

to the PC and see what device is added to the list under Ports.

2. Right-click on the device and click the Update Driver Software… button.

3. Manually select the folder where the driver has been extracted.

4. Click OK.

After the driver installs, a system restart may be required.

. Connect the board

5.3 PC APPLICATION REPORTS “MCP2221 NOT CONNECTED”

When a USB device (such as the MCP2221) connects to the USB Host (such as the

PC), the host will ask for the device’s Product and Vendor IDs (VID & PID).

The default values for the MCP2221 are 0x4D8 and 0xDD. In case any of these values

has been changed by the user, and the USB.inf driver file has been customized

accordingly and has been installed properly, then the PC application will report the

“MCP2221 not connected” error message. In such a case, the application can be

configured to look for a device with custom values by clicking the Using Custom

VID/PID… button.

Note: The MCP2221 I

inside the MCP2221 board. This can be done using the MCP2221 Utility

which can be downloaded from http://www.microchip.com. However, extra

knowledge in terms of legal and technical implications is required.

2016 Microchip Technology Inc. DS50002480A-page 43

2

C Demo Board Application does not rewrite the VID & PID

Page 44

MCP2221 I2C Demonstration Board User’s Guide

5.4 PC APPLICATION REPORTS I2C ERRORS

If the text box corresponding to the I2C Communication Status label indicates an error

followed by a number, then the physical and logical setup of the I

checked. Perform the following verifications:

• Check the pull-up resistors. External I

2

C circuits connected to the MCP2221 I2C

Demonstration Board may have their own pull-up resistors for the I

clock lines, in which case, jumper J24 should be removed depending on the

resulting resistances; otherwise, J24 must be connected.

• Check for slave address conflicts. In case there are external I

to the board, make sure there are no overlapping addresses. The list of addresses

of the devices available on the board is detailed in Section 4.3 “I

Addresses of this document.

• Check the I

2

C error codes. The codes are available inside the “MCP2221

Breakout Module User’s Guide” (DS50002282, package version 06/17/2015)

available at www.microchip.com.

5.5 ISSUES PROGRAMMING THE PIC® MICROCONTROLLER

In case the PICkit™ 3 (or another Microchip debugger/programmer compatible to the

PIC microcontroller) is configured to provide power to the target device, but reports that

PIC16F1509 cannot be programmed, the cause may be that the PICkit 3 cannot

provide enough power to the PIC device.

In such a case, it is recommended to power the MCP2221 board externally through:

• The mini-USB connector marked as J19 (as opposed to powering from the

PICkit 3) from the PC;

or

• A USB charger that provides a constant 5V (DC) at a recommended minimum of

200 mA if the microcontroller supports this voltage level.

2

C bus should be

2

C data and

2

C slaves connected

2

C Slave

DS50002480A-page 44 2016 Microchip Technology Inc.

Page 45

Appendix A. Schematics and Layouts

A.1 INTRODUCTION

MCP2221 I2C DEMONSTRATION

BOARD USER’S GUIDE

This appendix contains the schematics and layouts for the following devices which are

included in the MCP2221 I

• Board – Interface Schematic

• Board – Slaves Schematic

• Board – Top Silk

• Board – Top Copper and Silk

• Board – Top Copper

• Board – Bottom Copper

• Board – Bottom Copper and Silk

• Board – Bottom Silk

2

C Demonstration Board Kit (ADM00678):

2016 Microchip Technology Inc. DS50002480A-page 45

Page 46

DS50002480A-page 46 2016 Microchip Technology Inc.

VDD

1

GP0

2

GP1

3

RST

4

UART RX

5

UART TX

6

GP2

7

GP3

8

SDA

9

SCL

10

VUSB

11

D-

12

D+

13

VSS

14

VDD

GP0GP1RS

UA

U

GP2GP3

SDA

SCL

VUS

D-

D

VSS

U3

MCP2221

ID

4

VBUS

1

GND

5

D-

2

D+

3

0

USB Mini-B

J4

GND

D_N

D_ND_P

D_P

VDD

5V

VUSB

SCL

SDA

GP3

GP0

GP1

RESET

RX_MCP

TX_MCP

GP2

GND

VIN

1

GND

2

VOUT

3

U2

MCP18255V

4.7uF

10V

0603

C15

GNDGND

0.1uF

16V

0603

C16

GND

123

HDR-2.54 Male 1x3

J19

4.7uF

10V

0603

C17

GND

VDD

5V

10k

0603

5%

R2

VDD

SCL SDA

10k

0603

1%

R3

10k

0603

1%

R5

GND

TP LOOP Black

TP1

12

HDR-2.54 Female 1x2

J13

GND

TP LOOP Black

TP2

10k

0603

1%

R4

0.1uF

16V

0603

C14

0.47uF

6.3V

0603

C2

VDD

GND GND

USB connector for MCP2221 Power module I2C Pull-Up R esistors

470k

0603

1%

R6

4.7k

0603

5%

R10

4.7k

0603

5%

R11

12

HDR-2.54 Male 1x2

J24

GND

VDD

1

2

3

4

5

6

HDR-2.54 Female 1x6

J25

SDA

SCL

TP LOOP Black

TP7

TP LOOP Black

TP6

SCL

SDA

TP LOOP Black

TP8

GND

MCP2221 and R/C measurement circuit I2C bus pinouts

1

2

3

4

5

6

7

8

9

DE-9 Female

J5

112

34

56

78

HDR-2.54 Male 2x4

J12

TX_MAX

RX_MAX

RX_MAX TX_MAX

TX_PIC/RB7

TX_MCP

GND

0.1uF

16V

0603

C6

GND

VDD

0.1uF

16V

0603

C4

0.1uF

16V

0603

C5

GND

0.1uF

16V

0603

C1

0.1uF

16V

0603

C3

MAX3232 UART adapter and RS-232 connector

RX_MCP

RX_PIC/RB5

UART connectivity selection jumpers

4

5

6

7

8

9

10

16

15

14

13

12

11

17

1

2

3

19

18

20

J1

VDD

RA5

RA4

MCLR/RA3

RC5

RC4

RC3

RC6

RC7

TX_PIC/RB7

VSS

RA0/ICSPDAT

RA1/ICSPCLK

RA2

RC0

RC1

RC2

RB4

RX_PIC/RB5

RB6

GND

10k

0603

5%

R1

2

1

43

GREEN

RED

BLUE

5

6

CLX6A-FKB-CK1P1G1BB7R3R3

LD1

LED_RGB

GND

12

HDR-2.54 Male 1x2

J14

12

HDR-2.54 Male 1x2

J9

12

HDR-2.54 Male 1x2

J6

SCL

SDA

IO_INT

PIC16F1509 microcontroller

1

2

3

4

5

6

HDR-2.54 Male 1x6

J23

MCLR/RA3

VDD VDD

VSS

RA0/ICSPDAT

RA1/ICSPCLK

RA2

1.5k

0603

5%

R7

3.3k

0603

5%

R8

2.7k

0603

5%

R9

12