Page 1

MCP2030

Bidirectional Communication

Demo Kit

User’s Guide

© 2006 Microchip Technology Inc. DS51637A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPASM, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

8-bit MCUs, KEELOQ

microperipherals, nonvolatile memory and analog products. In addition,

Microchip’s quality system for the design and manufacture of

development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial EEPROMs,

DS51637A-page ii © 2006 Microchip Technology Inc.

®

Page 3

MCP2030 BIDIRECTIONAL

COMMUNICATION DEMO KIT

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 1

Introduction............................................................................................................ 1

Document Layout .................................................................................................. 1

Conventions Used in this Guide ............................................................................ 2

Recommended Reading........................................................................................ 2

The Microchip Web Site ........................................................................................ 3

Customer Support ................................................................................................. 3

Document Revision History ................................................................................... 4

Chapter 1. Quick Start .................................................................................................. 5

1.1 Introduction ..................................................................................................... 5

Chapter 2. System Overview ........................................................................................ 7

2.1 Overview ........................................................................................................ 7

2.2 Operational Overview ..................................................................................... 8

2.3 Features ....................................................................................................... 10

Chapter 3. Hardware and Firmware Overview .......................................................... 11

3.1 Introduction ................................................................................................... 11

3.2 MCP2030 Base Station Demo Board ........................................................... 11

3.3 MCP2030 Transponder Demo Board ........................................................... 14

Appendix A. Schematic and Layouts ........................................................................ 19

A.1 Introduction .................................................................................................. 19

A.2 Transponder Demo Board - Schematic ...................................................... 20

A.3 Transponder Demo Board - Top Layer and Silk Screen ............................ 21

A.4 Transponder Demo Board - Bottom Layer ................................................. 21

A.5 Base Station Demo Board - Schematic (Page 1) ..................................... 22

A.6 Base Station Demo Board - Schematic (Page 2) ..................................... 23

A.7 Base Station Demo Board - Top Layer and Silk Screen .......................... 24

A.8 Base Station Demo Board - Bottom Layer ............................................... 24

Appendix B. Bill of Materials (BOM) .......................................................................... 25

B.1 Introduction .................................................................................................. 25

Worldwide Sales and Service .................................................................................... 30

© 2006 Microchip Technology Inc. DS51637A-page iii

Page 4

MCP2030 Bidirectional Communication Demo Kit User’s Guide

NOTES:

DS51637A-page iv © 2006 Microchip Technology Inc.

Page 5

MCP2030 BIDIRECTIONAL

COMMUNICATION DEMO KIT

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP2030 Bidirectional Communication Demo Kit. Items discussed in this chapter

include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

DOCUMENT LAYOUT

This document describes the MCP2030 Bidirectional Communication Demo Kit. The

manual layout is as follows:

• Chapter 1. “Quick Start” – Describes the MCP2030 Bidirectional

Communication Demo Kit set-up instructions.

• Chapter 2. “System Overview” – A system overview of the MCP2030

Bidirectional Communication Demo Kit is discussed.

• Chapter 3. “Hardware and Firmware Overview” – Describes the MCP2030

Bidirectional Communication Demo Kit hardware and firmware.

• Appendix A. “Schematic and Layouts” – Shows the schematic and board

layouts for the MCP2030 Bidirectional Communication Demo Kit.

• Appendix B. “Bill of Materials (BOM)” - Lists the parts used to build the demo

boards that make up MCP2030 Bidirectional Communication Demo Kit.

© 2006 Microchip Technology Inc. DS51637A-page 1

Page 6

MCP2030 Bidirectional Communication Demo Kit User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

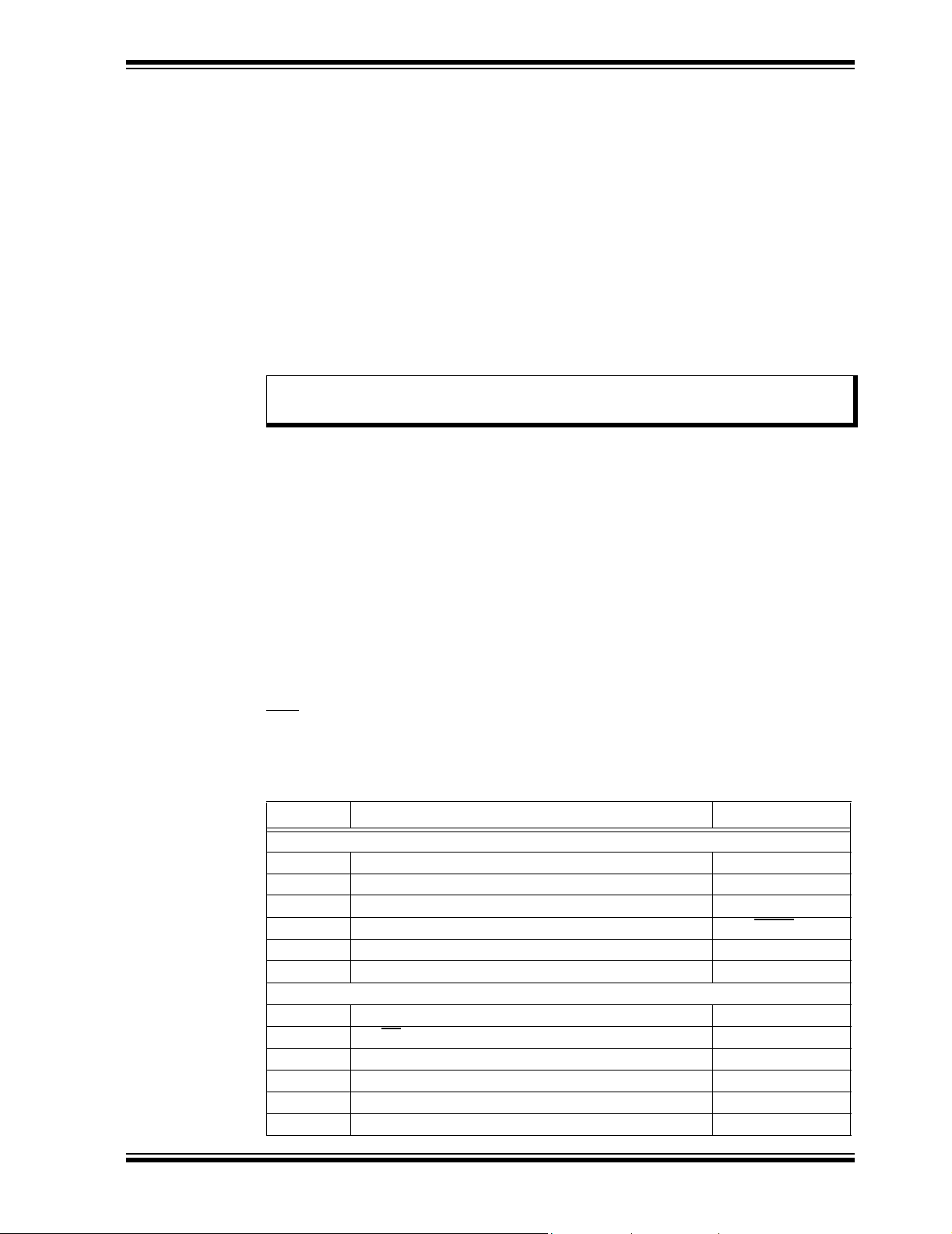

DOCUMENTATION CONVENTIONS

Description Represents Examples

Code (Courier font):

Plain characters Sample code

Filenames and paths

Angle brackets: < > Variables <label>, <exp>

Square brackets [ ] Optional arguments MPASMWIN [main.asm]

Curly brackets and pipe

character: { | }

Lowercase characters in

quotes

Ellipses... Used to imply (but not show) addi-

0xnnn A hexadecimal number where n is a

Italic characters A variable argument; it can be either a

Interface (Arial font):

Underlined, italic text

with right arrow

Bold characters A window or dialog button to click OK, Cancel

Characters in angle

brackets < >

Documents (Arial font):

Italic characters Referenced books MPLAB

Choice of mutually exclusive arguments; An OR selection

Type of data

tional text that is not relevant to the

example

hexadecimal digit

type of data (in lowercase characters)

or a specific example (in uppercase

characters).

A menu selection from the menu bar File > Save

A key on the keyboard <Tab>, <Ctrl-C>

#define START

c:\autoexec.bat

errorlevel {0|1}

“filename”

list

[“list_option...,

“list_option”]

0xFFFF, 0x007A

char isascii (char,

ch);

®

IDE User’s Guide

RECOMMENDED READING

It is recommended that you become familiar with the documents listed below, prior to

using the MCP2030 Bidirectional Communication Demo Kit.

Telecontrolli Data Sheet, “AMHRRQ3-433” , www.telecontrolli.com,

(DS.0015-1.pdf)

Telecontrolli Data Sheet, “AMHRR3-433”, www.telecontrolli.com,

(DS.0016-9.pdf)

Application Note AN710, “Antenna Circuit Design”, (DS00710)

Application note describing LF antenna circuit design for RFID applications.

Application Note AN959, “Using the PIC16F639 MCU for Smart Wireless

Communications” (DS00959)

Application note describing the PIC16F639 as a suitable microcontroller for

bidirectional communications and low-frequency sensing applications.

Application Note AN1024, “PKE System Design Using the PIC16F639” (DS01024)

Application note describing the PIC16F639 for bidirectional communication

applications.

DS51637A-page 2 © 2006 Microchip Technology Inc.

Page 7

MCP2030 Bidirectional Communication Demo Kit User’s Guide

PICkit™ 2 Microcontroller Programmer User’s Guide (DS51553)

Consult this document for instructions on how to use the PICkit 2 Microcontroller

Programmer hardware and software.

PIC12F635/PIC16F636/639 Data Sheet (DS41232)

Data sheet for the PIC12F635/PIC16F636/639 8/14-pin Flash-based, 8-bit CMOS

microcontrollers with nanoWatt technology.

PIC18F2585/2680/4585/4680 Data Sheet (DS39625)

Data sheet for the PIC18F2585/2680/4585/4680 28/40/44-pin enhanced Flash

microcontrollers with ECAN

MCP2030 Data Sheet, “Three-Channel Analog Front-End Device“ (DS21981)

Data sheet for the MCP2030 device.

TC4421/TC4422 Data Sheet, “High-Speed MOSFET Drivers” (DS21420)

Data sheet for the TC4421/TC4422 9A High-Speed MOSFET Driver. Gives an

overview of the device including electrical characteristics.

MCP3421 Data Sheet, “18-Bit Delta-Sigma Analog-to-Digital Converter with I

Interface and On-Board Referece” (DS22003)

Data sheet for the MCP3421 18-Bit Delta-Sigma Analog-to-Digital Converter.

™

technology, 10-bit A/D and nanoWatt technology.

2

C

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product Selector Guide, latest Microchip press

releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor, representative or field application engineer

for support. Local sales offices are also available to help customers. A listing of sales

offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

© 2006 Microchip Technology Inc. DS51637A-page 3

Page 8

MCP2030 Bidirectional Communication Demo Kit User’s Guide

DOCUMENT REVISION HISTORY

Revision A (December 2006)

• Initial Release of this Document.

DS51637A-page 4 © 2006 Microchip Technology Inc.

Page 9

1.1 INTRODUCTION

This section provides the user a quick step-by-step instruction guide on how to set-up

the MCP2030 Bidirectional Communication Demo Kit.

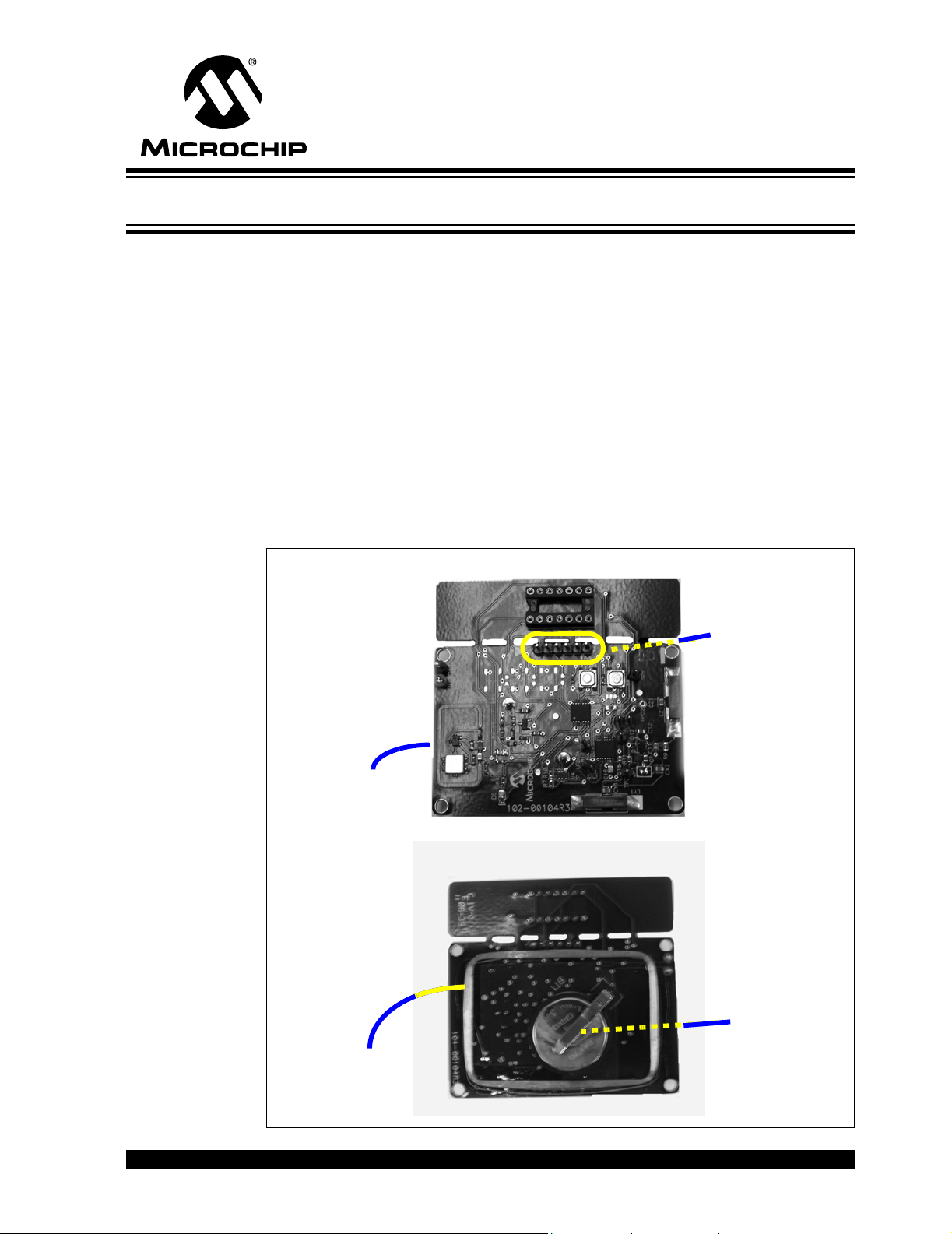

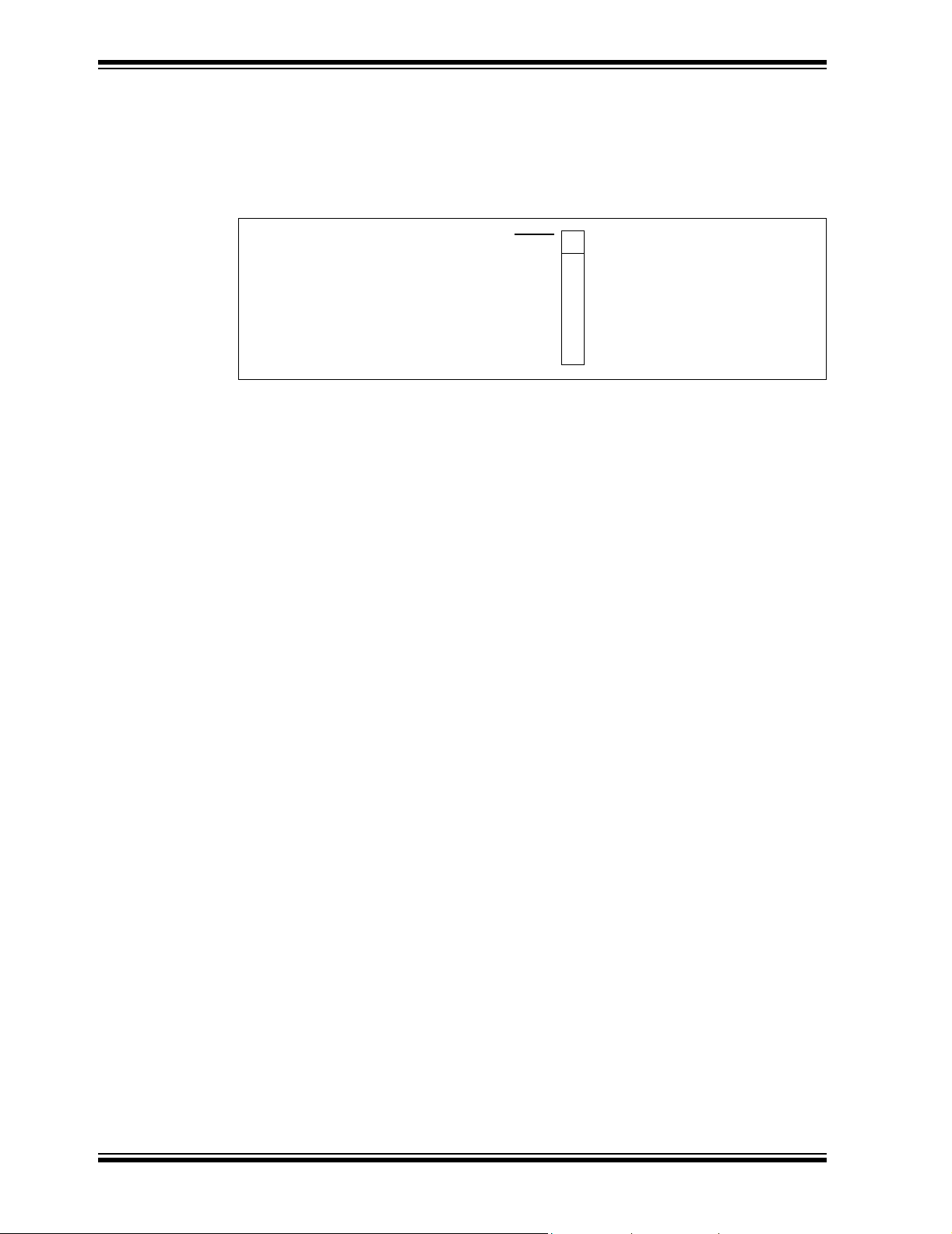

1.1.1 Transponder Unit

Connect power to the Transponder unit by inserting a 3V NiHM (CR2032) battery to the

battery holder in the bottom side of the Transponder. When the Transponder is

powered on, it is waiting for a 125 kHz low frequency (LF) command from the Base

Station unit. On the PCB, there are three LF antenna coils: One large air-core coil on

the bottom side and two ferrite-core coils on the top side. These three coils detect

125 kHz low frequency (LF) signals from x, y, and z directions. The Transponder also

has a SAW (Surface Acoustic Wave) based UHF transmitter. A rectangular loop trace

on the PCB is the UHF antenna. The Transponder has two LED diodes. A green LED

(D6) will blink when the Transponder receives a valid LF command, and a red LED (D7)

will blink when it transmitting an UHF response.

MCP2030 BIDIRECTIONAL

COMMUNICATION DEMO KIT

USER’S GUIDE

Chapter 1. Quick Start

Top Sid e

UHF

Antenna

125 kHz

Air Core

Antenna Coil

PICkit™ 2

Debug Express

Bottom Side

3V Lithium

Battery

© 2006 Microchip Technology Inc. DS51637A-page 5

Page 10

MCP2030 Bidirectional Communication Demo Kit User’s Guide

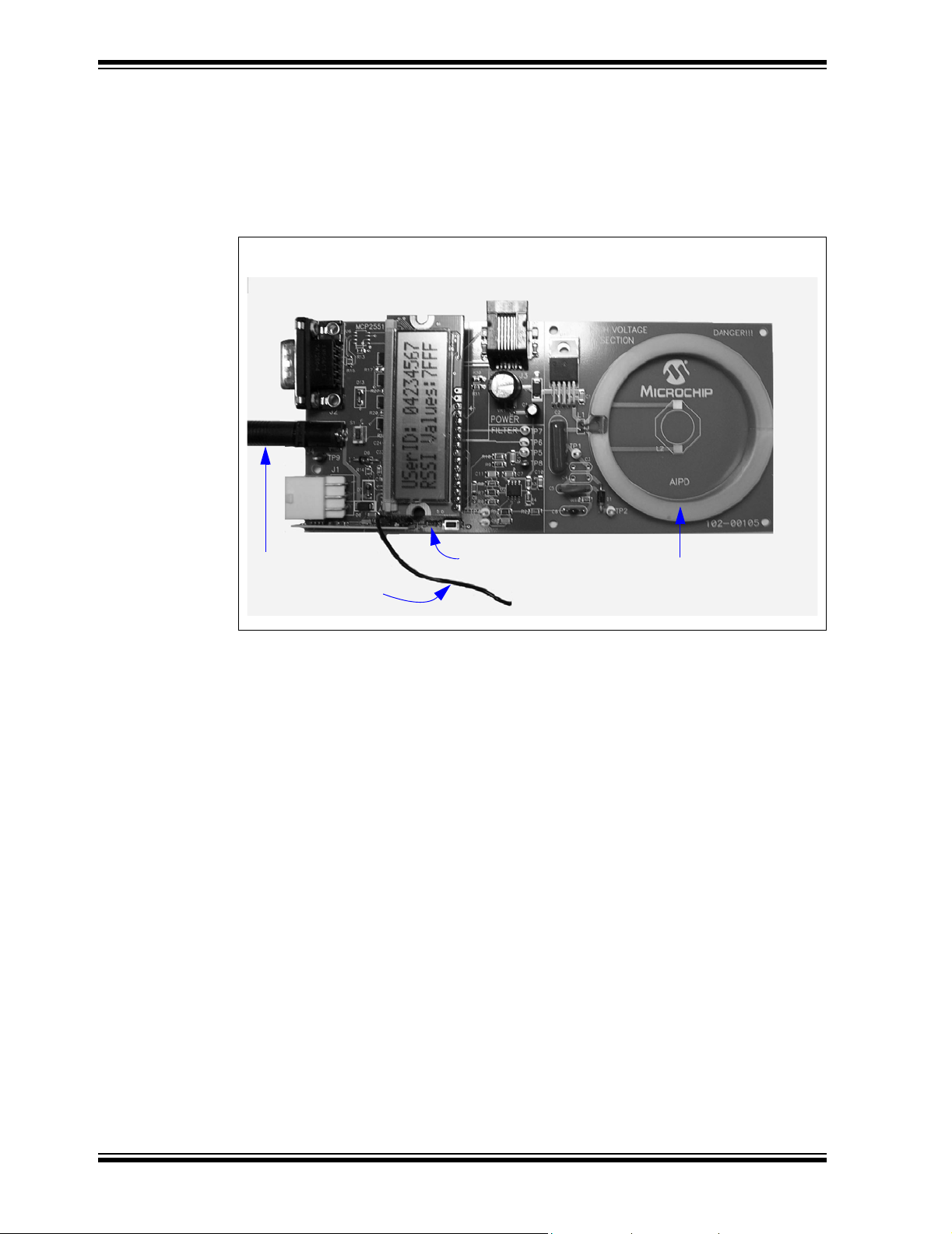

1.1.2 Base Station Unit:

Supply power to the Base Station unit with a 9V - 18V power supply. As soon as the

power is supplied, the LED D2 will light on, and the unit starts transmitting an LF

command.The unit also waits for the responses from the Transponder at any time,

except during the transmission of the LF command. When the unit receives a valid

response from the Transponder, the LED D3 will blink and the received Transponder

ID and RSSI (Received Signal Strength Indicator) value will be displayed on the LCD.

MPLAB® ICD 2

Programming Jack

9V

Power

Supply

UHF

Antenna

UHF Receiver

Module

125 kHz LF

Antenna

1.1.3 When both the Base Station and Transponder units are

powered-on:

When the two units are powered-on, they will communicate by themselves. The Base

Station sends a 125 kHz LF command and the Transponder responds to the command.

When the Transponder is placed within about 2 meters to the Base Station unit, the two

units may have a successful communication with each other and the Base Station unit

will display the received Transponder ID and RSSI value on the LCD. This is called a

bidirectional communication. User can test the RSSI by moving the Transponder within

the Base Station’s LF field. The RSSI value will increase as the Transponder comes

closer to the Base Station antenna and decrease as moves away from it. The two units

are communicating with each other as long as the boards are powered. You can also

test one directional communication from the Transponder to the Base Station unit by

pressing button switch (SW3 or SW4) on the Transponder. The range of the one

directional communication is about 20 meters.

This MCP2030 Bidirectional Communication Demo Kit shows you how to create a

smart hands-free bidirectional communication system using the stand-alone MCP2030

and microcontroller. All MCU firmware used for both the Transponder and Base Station

units are included in the CD ROM provided with the MCP2030 Bidirectional Communication Demo Kit. The user can easily modify the firmware for their own applications.

DS51637A-page 6 © 2006 Microchip Technology Inc.

Page 11

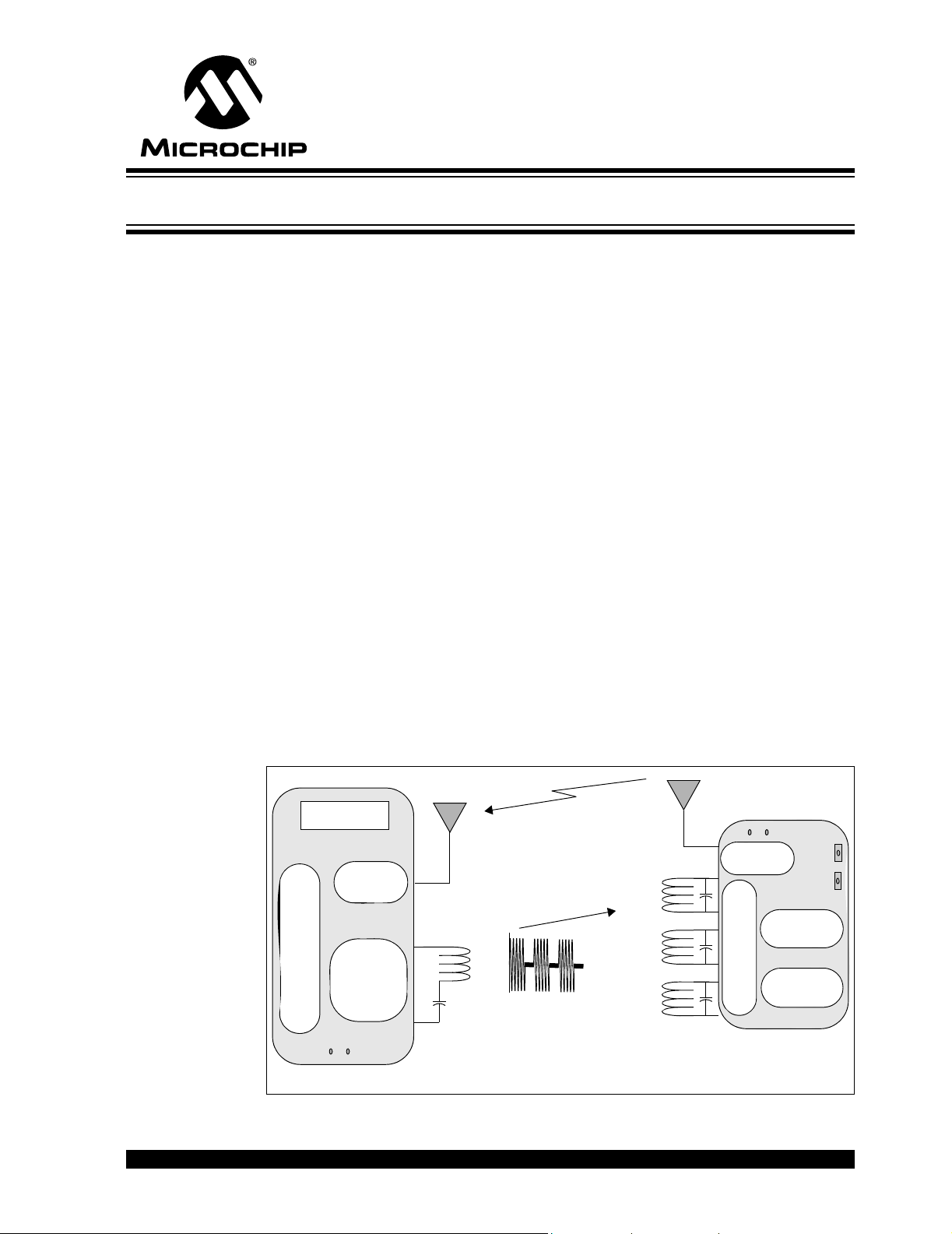

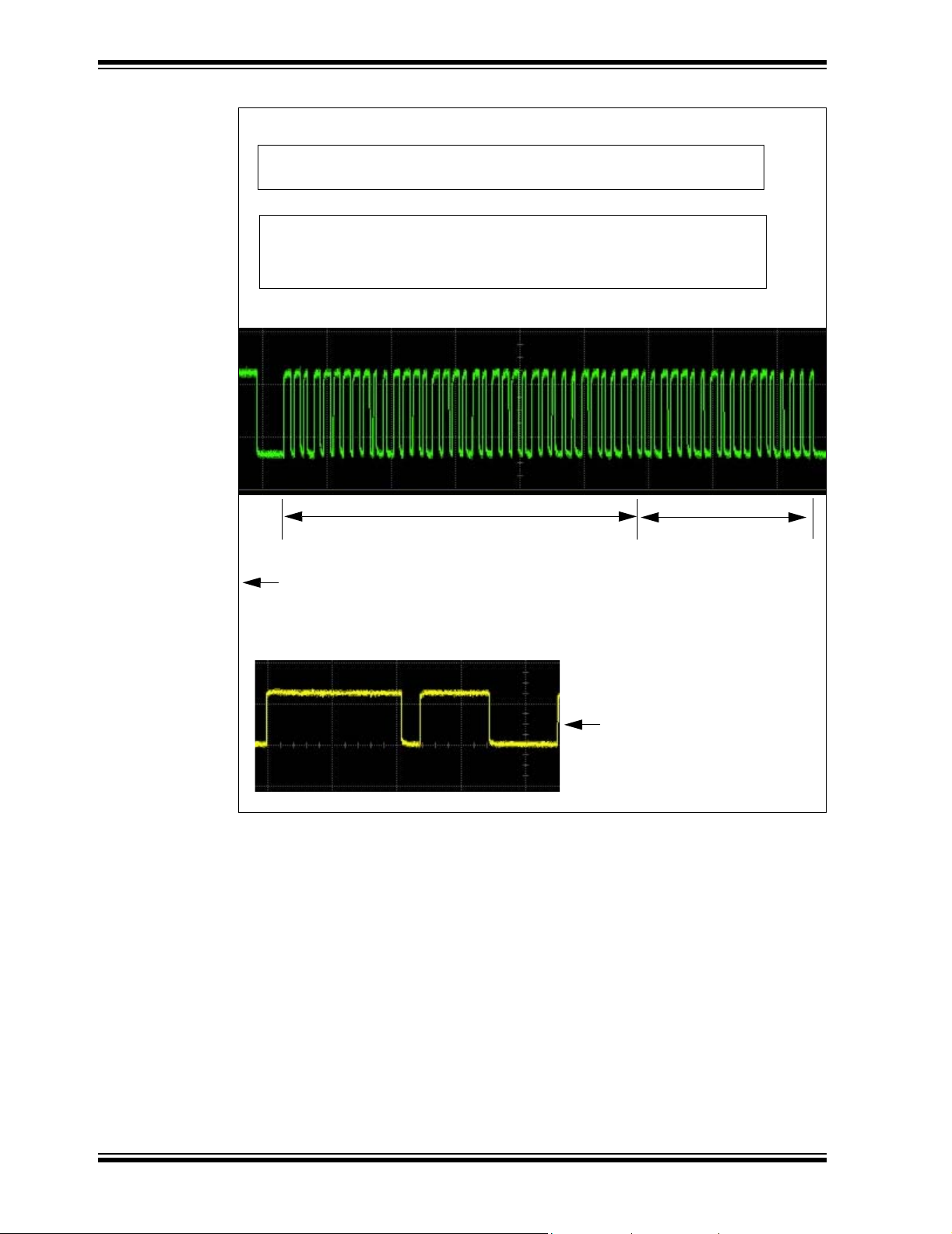

2.1 OVERVIEW

This section describes how to use the MCP2030 Bidirectional Communication Demo

Kit.

The MCP2030 Bidirectional Communication Demo Kit consists of two Transponders

and a Base Station unit. The Transponder consists of an MCP2030 (stand-alone

three-axis analog front-end device), a PIC16F636, and an MCP3421(18-bit

delta-sigma analog-to-digital converter). Unlike the existing PKE Reference Design

System (P/N: APGRD001) from Microchip Technology Inc., this Transponder uses

stand-alone devices for the bidirectional passive keyless entry (PKE) operation. This

system also demonstrates the received signal strength indicator (RSSI) function using

the MCP3421 delta-sigma ADC. When the Transponder receives a Base Station command, it transmits its ID and sampled RSSI value. By monitoring or mapping the RSSI

values, the user can estimate location or motion of the transponder with respect to the

Base Station unit. For example, for the automotive passive keyless entry (PKE) applications, the Base Station mounted inside the vehicle can determine whether the transponder is located inside or outside of the vehicle, or in the front or back seat in the

vehicle.

The Base Station unit consists of a PIC18F4680, a low frequency (LF) power amplifier,

an LF receiver section, a 434 MHz UHF receiver module, an LCD display, and

CAN/LIN transceiver sections. The components in the LF receiver section and the

CAN/LIN transceiver sections are populated on the PCB for future use, but their

functions are not utilized for this demo version. Any user who needs these features can

contact Microchip Technology Inc. for further information.

The MCP2030 Bidirectional Communication Demo Kit has been designed for easy

modification by customers. The firmware of both the Transponder and Base Station

units can be easily modified using the MPLAB

MCP2030 BIDIRECTIONAL

COMMUNICATION DEMO KIT

Chapter 2. System Overview

®

in-circuit serial programmers.

USER’S GUIDE

Response

LCD

434 MHz AM

Receiver

(PIC18F4680)

Microcontroller

Base Station Transponder

LF

Transmitter/

Receiver

LED

125 kHz

LC Series

Resonant Circuit

LF Command

(125 kHz)

(UHF)

Ant. X

Ant. Y

Ant. Z

125 kHz

LC Parallel

Resonant Circuit

434 MHz

Transmitter

(PIC16F636)

(MCP2030)

Analog Front-End

LED

Button

SW

MCU

ADC

(MCP3421)

FIGURE 2-1: MCP2030 Bidirectional Communication System Block Diagram.

© 2006 Microchip Technology Inc. DS51637A-page 7

Page 12

MCP2030 Bidirectional Communication Demo Kit User’s Guide

2.2 OPERATIONAL OVERVIEW

When the MCP2030 Base Station unit is powered on using a 9 V power supply and the

MCP2030 transponder demo board is powered-on using a 3V lithium battery, the

system works as follows:

(a) The Base Station unit transmits an LF command. Requesting the Transponder’s ID

and RSSI data.

(b) When the Transponder receives the LF command, it transmits its 32-bit ID and RSSI

data via the UHF (434 MHz) link.

(c) When the Base Station unit receives the response from the Transponder, it displays

the Transponder ID and RSSI value on the LCD.

(d) The system repeats steps (a) through (c) as long as the power is supplied.

(e) If the button switch SW3 or SW4 on the Transponder is pressed, the Transponder

transmits the button data (SW3: Unlock door, SW4: Lock door). The Base Station unit

displays the button message on the LCD.

Figure 2-2 shows the communication sequence between the Base Station and the

Transponder units. Figure 2-3 shows the Base Station’s LF command and the

demodulated data by the MCP2030.

10 bit LF Command

from Base Station

Change back

Demodulated data output

from MCP2030

MCP3421

converts

RSSI to digital

values

Transponder Data Stream:

Header + 32 ID bits + 16 RSSI bits + 6 Parity bits + Stop bit

= Header + 54 Data bits + 1 Stop bit

MCP2030 configuration

register for

demodulated output

Continuous LF for

RSSI Sample

MCU Sends

a Soft Reset

Command to

MCP2030

ADC conversion

Completed here

FIGURE 2-2: Base Station Command and Transponder Response.

at pin 9

of U1

at pin 3

of U3

at pin 8

of U3

at pin 5

of U3

DS51637A-page 8 © 2006 Microchip Technology Inc.

Page 13

System Overview

10 bit LF Command

from Base Station

Demodulated data output

from MCP2030

AGC Stabilization time

(4 ms)

Gap for 500 μ s

MCP3421

converts

RSSI to digital

values

Transponder Data Stream:

Header + 32 ID bits + 16 RSSI bits + 6 Parity bits + Stop bit

= Header + 54 Data bits + 1 Stop bit

LF Command from Base Station

Change back

MCP2030

Wake-Up Filter

Demodulated Data:

1100-0011-Parity-Stop = C3 (hex)

when the Base Station transmits

LSB first.

Configuration

Register

Continuous LF for

RSSI Sample

MCU Sends

a Soft Reset

Command to

MCP2030

ADC conversion

Completed here

Reading

ADC Conversion Data for RSSI

SPI Command

for RSSI Output

I2C Command

for ADC

FIGURE 2-3: Received Base Station Command and Demodulated Data.

Input Coil Voltage

at pin 9 of U1

at pin 3 of U3

at pin 8 of U3

for RSSI data

© 2006 Microchip Technology Inc. DS51637A-page 9

Page 14

MCP2030 Bidirectional Communication Demo Kit User’s Guide

2.3 FEATURES

2.3.1 MCP2030 Base Station Unit

Features of the Base station Unit are as follows:

• Send an LF command continuously requesting the Transponder ID and RSSI data

• Display the received Transponder responses

• MPLAB

Note: LF talkback, CAN and LIN feature support: Components are populated, but

2.3.2 MCP2030 Transponder Unit

Features of the Transponder are as follows:

• Detect the LF command

• Sample the RSSI values

• Transmit 32 bit Transponder ID and 16 bit RSSI data

• Two push button switches (SW3 and SW4) for Unlock and Lock door commands

• Two LED outputs:

- Green LED that blinks when the Transponder receives a valid LF command.

- Red LED that blinks when the Transponder is transmitting RF data or

®

ICD 2 In Circuit Serial Programming™ (ICSP™)

not used for this demo version.

receiving invalid LF command.

DS51637A-page 10 © 2006 Microchip Technology Inc.

Page 15

MCP2030 BIDIRECTIONAL

COMMUNICATION DEMO KIT

Chapter 3. Hardware and Firmware Overview

3.1 INTRODUCTION

The following section provides an overview of the hardware and MCU firmware

algorithm used in the MCP2030 Bidirectional Communication Demo Kit.

3.2 MCP2030 BASE STATION DEMO BOARD

3.2.1 Technical Specifications

Normal Operating Voltage: 9 - 18V, Current Rating > 500 mA

LF Frequency

(LF Command Frequency)

UHF AM Receiving Frequency: 433.92 MHz

Liquid Crystal Display (LCD): 2x16 characters

Communication Protocols: See

USER’S GUIDE

125 kHz

Figure 2-2, Figure 3-1, Figure 3-2

3.2.2 Microcontroller (PIC18F4680)

The PIC18F4680 is used in this unit. The MCU provides an 125 kHz PWM for LF

command and decodes incoming Transponder responses. If the response is valid, it

displays the received data on the LCD and also blinks the LED D3. The PIC18F4680

has both a CAN controller and a LIN compatible EUSART features. The CAN and LIN

transceiver components are populated on the Base Station Demo Board, but their functions are not implemented for this demo version.

3.2.3 433.92 MHz UHF Receiver Module

The Base Station Demo Board uses a 433.92 MHz AM super-regenerative compact

hybrid receiver module. The AM UHF receiver receives the responses from the

Transponder. The receiver has very high frequency stability over a wide operating

temperature and tolerance of mechanical vibrations or manual handling. The AM

receiver module has about -90 dBm of input sensitivity. The user can use their own

receiver module of any frequency of interest as long as the frequency and

modulation/demodulation method matches with those of the transmitter on the

Transponder.

3.2.4 LCD

A standard 16 pin 2x16 monochromes LCD is used to display the response from the

Transponder.

© 2006 Microchip Technology Inc. DS51637A-page 11

Page 16

MCP2030 Bidirectional Communication Demo Kit User’s Guide

3.2.5 125 kHz Low Frequency Command Initiator

The 125 kHz PWM from the PIC18F4680 is power boosted by the MOS FET driver

(TC4422). The PWM square pulse becomes a sine wave as the current passes through

the LC series resonant circuit formed by L1 and C2, C3, and C4 on the Base Station

Demo Board. The current that is passing through the L1 generates a magnetic field.

When this magnetic field transmitted from the Base Station Demo Board is passing

through the Transponder Demo Board’s antenna coil, it produces a voltage. This

voltage is detected by the MCP2030 LF front-end device and the information carried on

the voltage is processed by the PIC16F636 microcontroller on the transponder.

See Recommended Reading for more details of the near-field magnetic coupling

principles.

3.2.6 Power

Power can be supplied through J1 power jack. The voltage should be in the range of

9 - 18 VDC with a current rating greater than 500 mA.

3.2.7 MCU FIRMWARE ALGORITHM

The bidirectional communication method between the Base Station Demo Board and

Transponder Demo Board is shown in Figure 2-2. The Base Station Demo Board sends

an LF command, receives the responses from the Transponder Demo Board, and displays the received responses on the LCD. The Base Station Demo Board repeats the

transmitting and receiving functions as long as its power supply is connected.

Figure 3-1 shows the LF command data format and waveform. The receiving data for-

mat is shown in Figure 3-5. The MCU firmware for the communication algorithm is

included on the MCP2030 Bidirectional Communication Demo Kit CD ROM.

AGC Stabilization Time

4ms

High Duration

AGC Stabilization Time

Gap

500 ms

Gap

Wake-Up Filter

2ms

High Duration

Wake-Up Filter

Low Duration

Transmitting Data: LSB First

2ms

Command Type

+ Continuous LF

3C+Parity + Stop bit

+LF turns-on for 50 ms

Receiving Data: LSB First

Command Type (3C)

= 1100 0011P

= LSB first of 3C (hex)

Continuous LF Field

This allows the Transponder

to sample the RSSI data

Waiting for Response

32 bit ID+RSSI+Parity Bits

(Parity bit per byte)

Stop bit

FIGURE 3-1: Base Station Demo Board LF Command Data Format.

DS51637A-page 12 © 2006 Microchip Technology Inc.

Page 17

MCP2030 Bidirectional Communication Demo Kit User’s Guide

The LF command Base Station Demo Board consists of a 125 kHz carrier modulated

as follows:

1: 4 ms ON for AFE’s AGC stabilization.

2: 500 µs OFF.

3: 2 ms ON followed by a 2 ms OFF (AFE’s output enable filter). This pattern is

dependant on the configuration setting of the receiving AFE.

4: 10 bit of command type (3C), parity, and Stop bit. The bits are transmitted Least

Significant bits (LSb) first. The data is encoded with PWM method. (see

Figure 3-2).

5: 50 ms ON for RSSI sample.

6: Waiting for a valid response from the Transponder.

500 µs

250 µs

500 µs

Bit Period

FIGURE 3-2: PWM Data Encoding Format.

250 µs

LOGIC ‘0’

LOGIC ‘1’

© 2006 Microchip Technology Inc. DS51637A-page 13

Page 18

MCP2030 Bidirectional Communication Demo Kit User’s Guide

3.3 MCP2030 TRANSPONDER DEMO BOARD

3.3.1 Technical Specifications

LF Input Frequency: 125 kHz

LF Input Modulation Format: Amplitude Modulation

Encoding Method: Pulse Width Modulation (PWM)

Operating Voltage: 2 - 3.6V. See Note 1

LF Input Sensitivity: ~3 mVPP. See Note 2

LF Detection Range: Up to 3 meters

Transmitting Frequency: 433.92 MHz

UHF Range: Up to ~ 20 meters

Bidirectional Communication Range Up to 3 meters

Note 1: The minimum requirement for V

the V

stable.

2: Contact Microchip Technology Inc. for the device option with higher

than 3 mVpp sensitivity.

less than 2.7V, the ADC result of the RSSI value may not be

DD

3.3.2 Microcontroller (PIC16F636)

of the MCP3421ADC is 2.7V. For

DD

The Transponder Demo Board uses a PIC16F636 microcontroller. This MCU is the

same device that is used inside the PIC16F639 which is a dual die package device

(PIC16F639 = PIC16F636 die + MCP2030 die in a single 20-pin package). The MCU

interfaces with the MCP2030 stand-alone analog front-end device for LF

communications and the MCP3421 delta-sigma analog-to-digital converter for RSSI

data conversion. When the MCU is first powered-up, it writes the MCP2030

configuration registers and also writes the configuration register of the MCP3421 ADC

(for 16 bit and one-shot mode).The MCP3421 stays in a low power standby mode after

one conversion. The MCU also stays in a low power sleep mode while the MCP2030

is looking for a valid LF command.

The MCU is waken up by the demodulated output from the MCP2030 or by a button

switch event (SW3 and SW4). The MCU decodes the demodulated output data from

the MCP2030. If the data is a valid command, it blinks the green LED (D6) and reads

the RSSI value by controlling the MCP3421 ADC. Once the RSSI value is acquired, the

MCU feeds the transponder ID and the RSSI data into the 433.92 MHz UHF

transmitter. The transmitted data from the UHF transmitter is detected by the RF

receiver in the Base Station Demo Board and the data is displayed on the LCD.

When a button switch is pressed, the MCU feeds a corresponding data into the UHF

transmitter. The red LED (D7) blinks each time the transponder transmits the UHF

response. The red LED also blinks when the transponder receives invalid data.

3.3.3 Three-Input LF (125 kHz) Front-End (MCP2030)

The MCP2030 detects the Base Station Demo Board’s LF command using three LF

antenna coils that are mounted on the Transponder Demo Board PCB. The Configuration registers of the MCP2030 are configured by the MCU when the Transponder Demo

Board is powered up the first time, and are re-configured during operation. The MCU

controls the MCP2030 for two different outputs: (a) Demodulated data and (b)

Received Signal Strength Indicator output (RSSI). When it is detecting input signals,

the device is configured for the demodulated data output. Once the MCU finds a valid

LF command, then the MCU re-configures the MCP2030 for the RSSI output. In this

case, the MCP2030 outputs the RSSI current that is proportional to the LF input signal

DS51637A-page 14 © 2006 Microchip Technology Inc.

Page 19

MCP2030 Bidirectional Communication Demo Kit User’s Guide

strength. This current output is fed into a resistor and the voltage across the resistor is

fed into the MCP3421 ADC input pin. The converted16-bit ADC output is then fed into

the MCU.

The function of the MCP2030 is controlled by its configuration register settings. Highly

intelligent signal detection and response (bidirectional communications) is possible by

utilizing the MCP2030 configuration register settings. The user can easily change or

modify the included firmware for different settings of the MCP2030 configuration

registers for their own applications.

3.3.4 UHF Transmitter (433.92 MHz)

A 433.92 MHz UHF transmitter is used to transmit the Transponder Demo Board data

to the Base Station Demo Board. The UHF transmitter is based on a surface acoustic

wave (SAW) resonator. The transmitter is turned on during the high duration of the data

and off during the low duration of the bit data.

Note: The design and layout of this transmitter is not sufficient to ensure

compliance with EC or FCC regulations.

3.3.5 Analog-to-Digital Converter (MCP3421)

The Transponder Demo Board uses an MCP3421 ADC to convert the analog RSSI

output of the MCP2030 to digital data. The MCP3421 is a delta-sigma analog-to-digital

converter with 12, 14, 16, and 18 bit mode options. In this demo board, the converter

is configured for the 16 bit and one-shot mode. When the transponder is powered-up,

the MCU sends an I

conversion. After one conversion, the device stays in a low power standby mode.

During this mode, the device draws only about 1 µA. When the MCP2030 analog

front-end device receives a valid Base Station command, then the MCU sends an I

read command to the MCP3421 ADC for the analog-to-digital data conversion. At this

moment, the Base Station Demo Board transmits a continuous LF signal for about

50 ms allowing the MCP2030 to collect the RSSI values. The RSSI voltage across the

RSSI load resistor is fed into the MCP3421 input pin. After the MCU sends the I

command, it is waiting for the MCP3421 to complete the conversion by checking the

RDY

bit of the MCP3421 output. In typical operation, it takes about 50 ms to complete

a 16 bit conversion. See Figure 2-2 and Figure 2-3 for more information on the ADC

operation.

2

C write command to the MCP3421 for one-shot mode and 16 bit

2

C read

2

C

TABLE 3-1: PIC16F636 I/O CONNECTIONS

PORT Pin Function Notes

Port A

RA0 Switch 4 ICSP™ Data

RA1 ICSP Clock

RA2 Switch 3

RA3 ICSP MCLR

RA4 LFDATA Input from MCP2030, SPI SDIO for MCP2030

RA5 SPI SCLK Output for MCP2030

Port C

RC0 RF Active LED

RC1 SPI CS

RC2 I2C SDA for MCP3421

RC3 I

RC4 Valid LFDATA Input Indicator LED

RC5 RF Data Out

© 2006 Microchip Technology Inc. DS51637A-page 15

output for MCP2030

2

C SCL for MCP3421

Page 20

MCP2030 Bidirectional Communication Demo Kit User’s Guide

3.3.6 Programming of the Transponder

The Transponder Demo Board has a Programming Connector (J1) for In-Circuit Serial

Programming™ (ICSP™). See Figure 3-3 for the J1 Programming Connector. The

transmitter can therefore be re-programmed using the PICkit

removing the microcontroller from the board.

®

2 (or PICkit® 1) without

MCLR

ICSPDAT

ICSPCLK

no connection

1

V

2

CC

V

3

SS

4

5

6

FIGURE 3-3: J1 Programming Connector.

3.3.7 Power

The Transponder Demo Board is powered by a standard Lithium 3V coin cell battery.

3.3.8 Microcontroller Firmware Algorithm

When the Transponder Demo Board is powered on, the PIC16F636 (MCU) programs

the configuration registers of the MCP2030 and also the configuration register of the

MCP3421 (ADC). After these set-up procedures, the MCU enters a low-power sleep

mode while the MCP2030 is looking for a valid LF command. The MCU is waken-up by

the demodulated output from the MCP2030 or button switch event. If the MCU receives

a valid demodulated data from the MCP2030, then it transmits its 32 bit transponder ID

followed by the 16 bit received signal strength indicator (RSSI) data. If the MCU is

waken-up by a switch event (SW3 and SW4), it transmits the corresponding switch

event data. The data is always attached to the header (See Figure 3-5). The Transponder ID is set to “04234567” and programmed in the EEPROM. The RSSI data is proportional to the LF signal strength. Therefore, the RSSI data increases as the

Transponder Demo Board comes closer to the Base Station Demo Board. The Transponder Demo Board transmits each byte LSB first and also transmits a parity bit at

end of each byte. See Figure 3-5 for more details of the Transponder Demo Board data

stream. Figure 3-4 shows the firmware flow chart.

The MCU firmware is included in the MCP2030 Bidirectional Communication Demo Kit

CD ROM.

DS51637A-page 16 © 2006 Microchip Technology Inc.

Page 21

MCP2030 Bidirectional Communication Demo Kit User’s Guide

Power-up

MCU Programs the MCP2030

Configuration Registers

No

Button Pressed?

Yes

MCU wakes up

Encode the SW event data

SW3: Unlock Door

SW4: Lock Door

pin High?

ALERT

Yes

MCU Configure the MCP3421 ADC

for One-Shot and 16 bit Mode

while the MCP2030 detects input signals

MCU in Sleep Mode

No

Input Signal in?

Yes

Input Signal

Disappeared for

> 16 ms?

No

Meet wake-up

filter?

Yes

MCU wakes up

Send I2C Read Command

to the MCP3421 for RSSI

No

Yes

No

Soft Reset

Send Response via

RF Link

FIGURE 3-4: Communication Flow-Chart of the Transponder Demo Board.

© 2006 Microchip Technology Inc. DS51637A-page 17

Page 22

MCP2030 Bidirectional Communication Demo Kit User’s Guide

Ex: For the transponder ID = 04234567 and acquired RSSI value = C6CF

Transponder ID = 04-23-45-67 = 00000100-00100011-01000101-01100111

Acquired RSSI Data = C6-CF = 11000110-11001111

Ex: Transmitting data with LSB first:

0010000P-11000100P-10100010P-11100110P-01100011P-1110011P

Where P = Odd Parity bit of the byte

Transponder ID (32 bits + 4 Parity bits)

Header:

4 ms high duration + 500 µs low duration + 2 ms high duration + 2 ms low duration

Header Waveform

RSSI Data + Parity

(16 bits + 2 Parity bits)

FIGURE 3-5: EXAMPLE: Transponder Response for ID and RSSI

DS51637A-page 18 © 2006 Microchip Technology Inc.

Page 23

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the schematics and PCB layouts for the MCP2030 Bidirectional

Communication Demo Kit. This Appendix includes:

• Transponder Demo Board - Schematic (102-00104)

• Transponder Demo Board - Top Layer (with silk screen)

• Transponder Demo Board - Bottom Layer

• Base Station Demo Board - Schematic (Page 1) (102-00105)

• Base Station Demo Board - Schematic (Page 2) (102-00105)

• Base Station Demo Board - Top Layer (with silk screen)

• Base Station Demo Board - Bottom Layer

MCP2030 BIDIRECTIONAL

COMMUNICATION DEMO KIT

USER’S GUIDE

© 2006 Microchip Technology Inc. DS51637A-page 19

Page 24

MCP2030 Bidirectional Communication Demo Kit User’s Guide

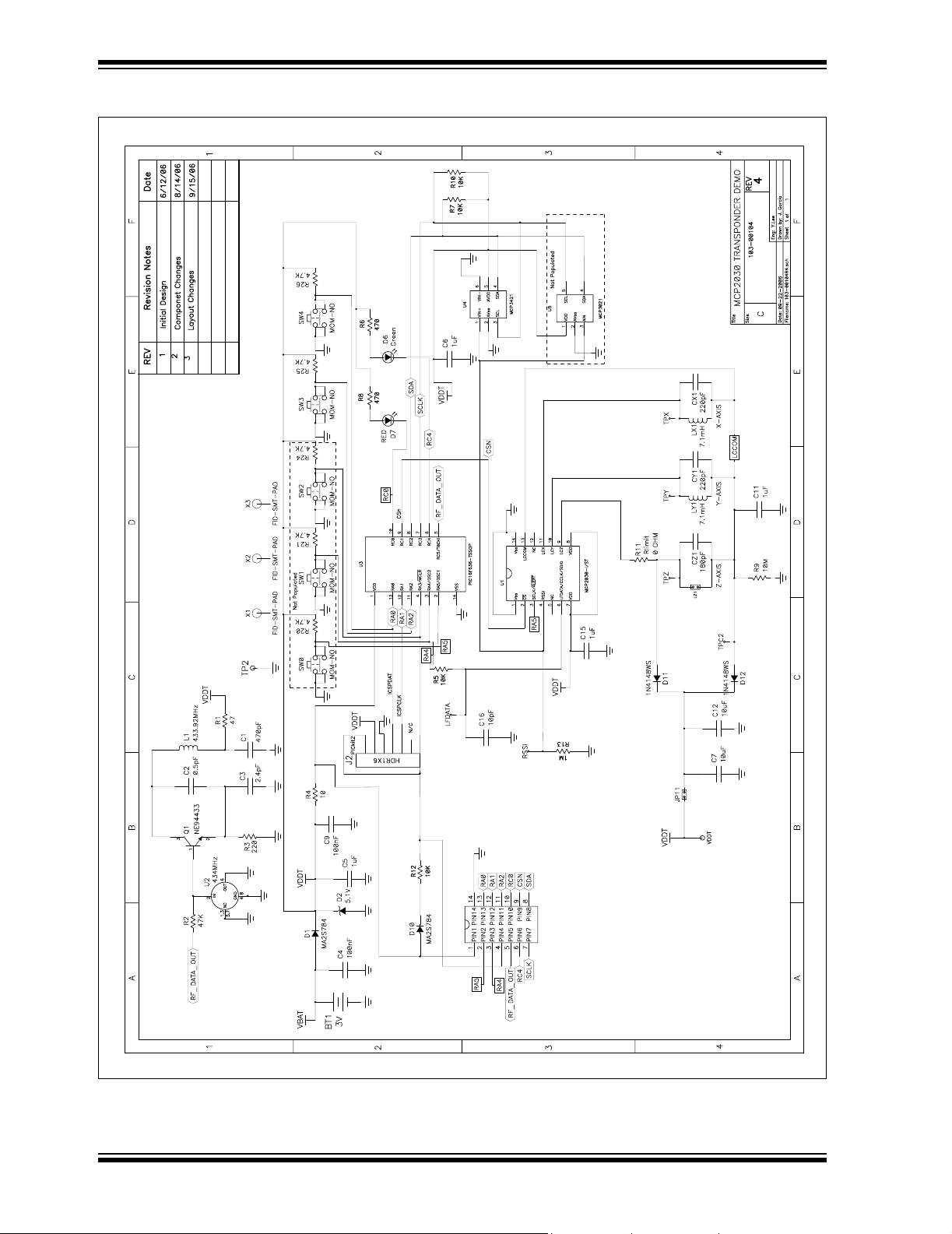

A.2 TRANSPONDER DEMO BOARD - SCHEMATIC

M

DS51637A-page 20 © 2006 Microchip Technology Inc.

Page 25

MCP2030 Bidirectional Communication Demo Kit User’s Guide

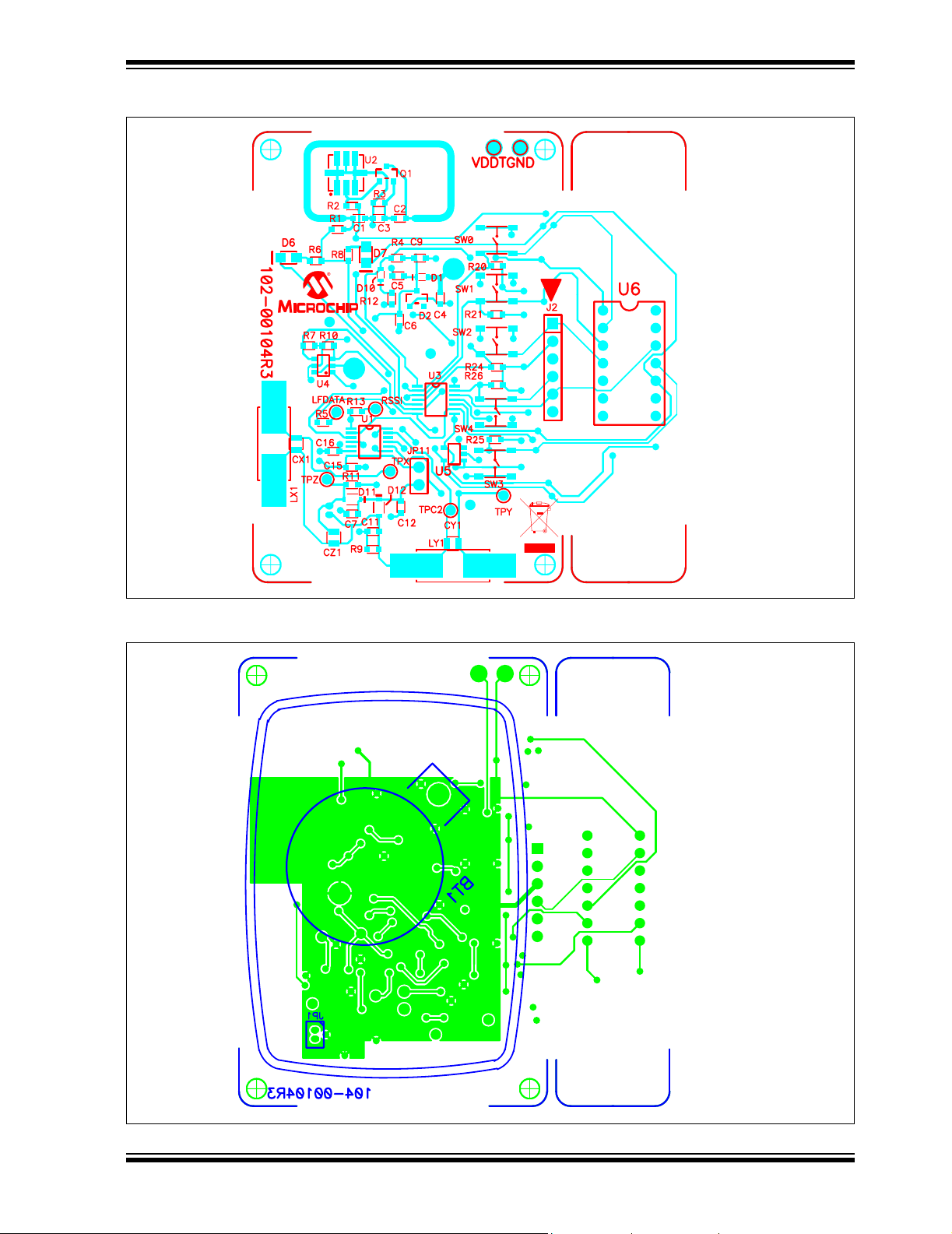

A.3 TRANSPONDER DEMO BOARD - TOP LAYER AND SILK SCREEN

A.4 TRANSPONDER DEMO BOARD - BOTTOM LAYER

© 2006 Microchip Technology Inc. DS51637A-page 21

Page 26

MCP2030 Bidirectional Communication Demo Kit User’s Guide

A.5 BASE STATION DEMO BOARD - SCHEMATIC (PAGE 1)

M

DS51637A-page 22 © 2006 Microchip Technology Inc.

Page 27

MCP2030 Bidirectional Communication Demo Kit User’s Guide

A.6 BASE STATION DEMO BOARD - SCHEMATIC (PAGE 2)

M

© 2006 Microchip Technology Inc. DS51637A-page 23

Page 28

MCP2030 Bidirectional Communication Demo Kit User’s Guide

A.7 BASE STATION DEMO BOARD - TOP LAYER AND SILK SCREEN

A.8 BASE STATION DEMO BOARD - BOTTOM LAYER

DS51637A-page 24 © 2006 Microchip Technology Inc.

Page 29

MCP2030 BIDIRECTIONAL

COMMUNICATION DEMO KIT

USER’S GUIDE

Appendix B. Bill of Materials (BOM)

B.1 INTRODUCTION

This appendix contains the bill of materials of the MCP2030 Bidirectional

Communication Demo Kit. This Appendix includes:

• Transponder Demo Board - Bill of Materials

• Base Station Demo Board - Bill of Materials

TABLE B-1: TRANSPONDER DEMO BOARD - BILL OF MATERIALS

Reference

Qty

Designator

1 BT1 HOLDER BATTERY COIN 20MM 1-CELL Keystone Electronics

1 C1 CAP CERAMIC 470PF 50V NP0 0603 Panasonic® - ECG ECJ-1VC1H471J

1 C2 CAP 0.5PF 50V CERAMIC 0603 SMD Panasonic - ECG ECJ-1VC1H0R5C

1 C3 CAP CERAMIC 2.4PF 50V C0G 0603 Rohm MCH185A2R4CK

2 C4, C9 CAP .10UF 16V CERAMIC X7R 0603 Kemet

4 C5, C6,

C11, C15

2 C7, C12 CAP CERAMIC 10UF 6.3V X5R 0603 Panasonic - ECG ECJ-1VB0J106M

1 C16 CAP CERM 10PF 10% 100V NP0 0603 AVX Corporation 06031A100KAT2A

1 Coin

Battery

2 CY1, CX1 CAP CERAMIC 220PF 50V 0603 SMD Panasonic - ECG ECJ-1VC1H221J

1 CZ1 CAP CERAMIC 180PF 50V 0603 SMD Panasonic - ECG ECJ-1VC1H181J

2 D1, D10 DIODE SCHOTTKY 30V 100MA SS-MINI Panasonic - SSG MA2S78400L

1 D2 DIODE ZENER 5.1V 0.35W SOT-23 Fairchild Semiconductor

1 D6 LED GREEN CLEAR 0805 SMD LITE-ON INC LTST-C170GKT

1 D7 LED RED CLEAR 0805 SMD LITE-ON INC LTST-C170CKT

2 D11, D12 DIODE SWITCH 75V 200MW SOD323 Diodes Inc 1N4148WS-7-F

1 J2 LOW PROFILE,SOLDERTAIL

1 JP11 HEADER,.1" ST MALE,1RW, 2PIN,

1 JP11 Shunt SHUNT,SHORTING BLOCKS,BLK,OPEN JAMECO VALUEPRO 7600-B-R

2 LY1, LX1 INDUCTOR, RFID TRANSPONDER Coilcraft 4308RV-715X_LB

1 LZ1 Precision wound Air Coils

1 Q1 TRANSISTOR NPN OSC FT=2GHZ

1 R1 RES 47.5 OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF47R5V

1 R2 RES 47.5K OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF4752V

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components

CAP 1UF 16V CERAMIC F 0603 Panasonic - ECG ECJ-1VF1C105Z

BATTERY LITHIUM COIN

3 VOLT 20MM

HEADER,.1" ST MALE, 1RW, 6PIN,

(10) .025" PST,.23GOLDTAIL

Part will be Provided

SOT23

Description Manufacturer Part Number

®

103

®

Electronics Corp C0603C104K4RACTU

Energizer Battery

Company

——

——

——

NEC NE94433-T1B-A

CR2012

®

BZX84C5V1

© 2006 Microchip Technology Inc. DS51637A-page 25

Page 30

MCP2030 Bidirectional Communication Demo Kit User’s Guide

TABLE B-1: TRANSPONDER DEMO BOARD - BILL OF MATERIALS (CONTINUED)

Reference

Qty

Designator

1 R3 RES 221 OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF2210V

1 R4 RES 10.0 OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF10R0V

4 R5, R7,

RES 10.0K OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF1002V

R10, R12

2 R6, R8 RES 475 OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF4750V

1 R9 RES 10.0M OHM 1/10W 1% 0603 SMD Yageo

1 R11 RES ZERO OHM 1/10W 5% 0603 SMD Panasonic - ECG ERJ-3GEY0R00V

1 R13 RES 1.00M OHM 1/10W 1% 0603 SMD Yageo Corporation RC0603FR-071ML

3 R20, R21,

DO NOT POPULATE — —

R24

2 R25, R26 RES 4.75K OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF4751V

3SW0, SW1,

SW2

LIGHT TOUCH SWITCH SMD 260GF

5MM - DO NOT POPULATE

2 SW3, SW4 LIGHT TOUCH SWITCH SMD 260GF

5MM

1 U1 Three-Channel Analog Front-End Device Microchip Technology Inc. MCP2030-I/ST

1 U2 RESONATOR SAW 433.92MHZ 1 PORT ECS Inc ECS-SDR1-4339-TR

1 U3 PIC16F636-TSSOP Microchip Technology Inc. PIC16F636-ST

1 U4 18-Bit Analog-to-Digital Converter with I2C

Interface and On-Board Reference

1 U5 DO NOT POPULATE — —

1 U6 SOCKET,IC,14PIN,MACHINE TOOLED

LOW PROFILE,SOLDERTAIL

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components

Description Manufacturer Part Number

®

Corporation RC0603FR-0710ML

——

Panasonic - ECG EVQ-PLMA15

Microchip Technology Inc. PIC18F4680-I/P

JAMECO VALUEPRO 6100-14-R

TABLE B-2: BASE STATION DEMO BOARD - BILL OF MATERIALS

Reference

Qty

Designator

1ANTENNA

LEAD

5 C1, C7, C10,

WIRE 24AWG STRAND BLACK 6.8

INCHES LONG

CAP .1UF 50V CERM CHIP 1206 X7R Panasonic

C16, C24

1 C2 CAP .01UF 400V POLYPROPYLENE Panasonic - ECG ECQ-P4103JU

1 C5 CAP 2200PF 500V CERAMIC DISC

Y5P

1 C6 CAP CER 1UF 10V X5R RAD TDK

1 C8 CAP CERAMIC 100PF 50V NP0 1206 Yageo Corporation

1 C9 CAP CERAMIC 10000PF 50V NP0

1206

1 C11 CAP CERAMIC 470PF 50V NP0 1206 Kemet

1 C12 CAP 270PF 50V CERAMIC X7R 1206 Yageo Corporation CC1206KRX7R9BB271

1 C13 CAP 100UF 50V ELECT FC RADIAL Panasonic - ECG EEU-FC1H101

1 C14 CAP 47UF 10V ELECT FC RADIAL Panasonic - ECG EEU-FC1A470

1 C15 CAP 10UF 10V TANTALUM TE SMD Kemet

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Description Manufacturer Part Number

Alpha Wire Company 3050 BK005

®

- ECG ECJ-3VB1H104K

Panasonic - ECG D222K33Y5PL63L0R

®

Corporation FK28X5R1A105K

®

CC1206JRNPO9BN101

Panasonic - ECG ECJ-3FC1H103J

®

Electronics Corp C1206C471J5GACTU

®

Electronics Corp T491A106K010AT

DS51637A-page 26 © 2006 Microchip Technology Inc.

Page 31

MCP2030 Bidirectional Communication Demo Kit User’s Guide

TABLE B-2: BASE STATION DEMO BOARD - BILL OF MATERIALS (CONTINUED)

Reference

Qty

Designator

2 C17, C18, CAP 1UF 16V CERAMIC 0805 X5R Panasonic - ECG ECJ-2FB1C105K

2 C22, C23 CAP CERAMIC 20PF 50V NP0 1206 Yageo Corporation CC1206JRNPO9BN200

1 D1 DIODE ULTRA FST SW 600V 1A

DO-41

2 D2, D3 LED 2X3MM 565NM GRN WTR CLR

SMD

4 D4, D9, D10,

D11

2 D5, D8 DIODE SCHOTTKY 100V 1.5A D-64 International Rectifier 10MQ100NPBF

1 D6 DIODE ZENER 27V 1W 5% DO-41 Diodes Inc 1N4750A-T

2 D7, D13 DIODE SWITCH 75V 500MW MIN-

1 J1 CONN HEADER 6PS R/A DL .163

1 J2 CONN D-SUB PLUG R/A 9POS PCB AUTyco Electronics/Amp 5747250-4

1 J3 CONN MOD JACK 6-6 R/A PCB 50AU Tyco Electronics/Amp 5520470-3

1 J4 CONN POWER JACK 2.5MM PCB

1 L1 IND 160UH 500V AIR MC Davis Microchip-160mH

1 LCD1 LCD MODULE 16X2 CHARACTER Lumex

1 LCD

Connector

1 LCD

HEADER

1 R1 RES 392K OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF3923V

1 R2 RES 11.0K OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF1102V

1 R3 RES 10 OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF10R0V

1 R4 RES 49.9 OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF49R9V

1 R5 RES 162K OHM 1/4W 1% 1206 SMD Yageo Corporation 9C12063A1623FKHFT

1 R6 RES 3.92K OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF3921V

1 R7 RES 16.5K OHM 1/4W 1% 1206 SMD Yageo Corporation 9C12063A1652FKHFT

1 R8 RES 64.9 OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF64R9V

1 R9 RES 4.87K OHM 1/4W 1% 1206 SMD Yageo Corporation 9C12063A4871FKHFT

1 R10 RES 5.11K OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF5111V

1 R12 RES 1.00K OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF1001V

1 R13 RES 4.75K OHM 1/8W 1% 0805 SMD Yageo Corporation 9C08052A4751FKHFT

1 R14 RES 1.00K OHM 1/8W 1% 0805 SMD Panasonic - ECG ERJ-6ENF1001V

1 R15 RES 121 OHM 1/8W 1% 0805 SMD Panasonic - ECG ERJ-6ENF1210V

1 R16 RES 274 OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF2740V

2 R18, R19 RES 15.0K OHM 1/8W 1% 0805 SMD Panasonic - ECG ERJ-6ENF1502V

1 R20 RES 24.9K OHM 1/8W 1% 0805 SMD Panasonic - ECG ERJ-6ENF2492V

1 R26 RES 30K OHM 1/8W 5% 0805 SMD Panasonic - ECG ERJ-6GEYJ303V

1 R27 RES 10.0K OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF1002V

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

1N5819 RECT SCHOTTKY 1A 40V

DO-214AA

IMELF

GOLD

CIRC

CONN SOCKET 16 PIN STRIP SAMTEC SSW-116-02-G-S

CONN HEADER 17POS .100 VERT TIN ValuePro 7000-1X17SG

Description Manufacturer Part Number

Diodes Inc UF1005-T

Lumex Opto/Components

Inc

Micro Commercial Co. SK14-TP

Diodes Inc LL4148-13

®

Tyco

Electronics/Amp 1-770969-1

CUI Inc PJ-102B

®

Opto/Components

Inc

SML-LX23GC-TR

LCM-S01602DTR/M

© 2006 Microchip Technology Inc. DS51637A-page 27

Page 32

MCP2030 Bidirectional Communication Demo Kit User’s Guide

TABLE B-2: BASE STATION DEMO BOARD - BILL OF MATERIALS (CONTINUED)

Reference

Qty

Designator

2 R28,R29 RES 4.75K OHM 1/4W 1% 1206 SMD Panasonic - ECG ERJ-8ENF4751V

2 S1, S2 SWITCH LT TOUCH 6X3.5 100GF SMD Panasonic - ECG EVQ-PJS04K

7 TP1 - TP7 TEST POINT PC MULTI PURPOSE

WHT

2 TP8 & TP9 TEST POINT PC MULTI PURPOSE

BLK

1 U1 9A High Speed MOSFET Driver Microchip Technology Inc. TC4422CAT

1 U2 Rail-to-Rail Input/Output, 10 MHz Op

Amp

1 U3 28/40-Pin High-Performance, Enhanced

Flash

1 U3 Socket IC Socket 40 PIN .600 GOLD Mill-Max Manufacturing

1 U4 Receiver AM Hybrid 433 MHz Module http://www.okwelectron-

1 U5 LIN Transceiver with Voltage Regulator Microchip Technology Inc. MCP201-I/SN

1 U6 Microcontroller with CAN High-Speed

CAN Transceiver

1 VR1 IC 5.0 100MA LDO VREG SOT23 National Semiconductor

1 Y1 CRYSTAL 20.000MHZ 20PF HC-49/US ECS Inc ECS-200-20-4X

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Description Manufacturer Part Number

Keystone Electronics

Keystone Electronics 5011

Microchip Technology Inc. MCP6022-I/SN

Microchip Technology Inc. PIC18F4680-I/P

Corp.

ics.com/index.html

Microchip Technology Inc MCP2551-I/SN

®

5012

110-43-640-41-001000

AMHRR3-433

®

LM3480IM3-5.0

DS51637A-page 28 © 2006 Microchip Technology Inc.

Page 33

MCP2030 Bidirectional Communication Demo Kit User’s Guide

NOTES:

© 2006 Microchip Technology Inc. DS51637A-page 29

Page 34

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

12/08/06

DS51637A-page 30 © 2006 Microchip Technology Inc.

Loading...

Loading...