Page 1

MCP19114 - Flyback

Stand-Alone

Evaluation Board

User’s Guide

2014 Microchip Technology Inc. DS50002255A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

FlashFlex, K

PICSTART, PIC

and UNI/O are registered trademarks of Microchip T echnology

Incorporated in the U.S.A. and other countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MTP, SEEVAL and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

Analog-for-the-Digital Age, Application Maestro, BodyCom,

chipKIT, chipKIT logo, CodeGuard, dsPICDEM,

dsPICDEM.net, dsPICw orks, dsSPEAK, ECAN,

ECONOMON ITO R , FanSense, HI-T IDE, In-Circuit S e ri a l

Programming, ICSP, Mindi, MiWi, MPASM, MPF, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, Omniscient Code

Generation, PICC, PICC-18, PICDEM, PICDEM.net, PICkit,

PICtail, REAL ICE, rfLAB, Select Mode, SQI, Serial Quad I/O,

Total Endurance, TSHARC, UniWinDriver, WiperLock, ZENA

and Z-Scale are trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

GestIC and ULPP are registered trademarks of Microchip

Technology Germany II GmbH & Co. KG, a subsidiary of

Microchip Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2014, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-63276-035-7

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

32

logo, rfPIC, SST, SST Logo, SuperFlash

QUALITY MANAGEMENT S

DS50002255A-page 2 2014 Microchip Technology Inc.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

Object of Declaration: MCP19114 - Flyback Stand-Alone Evaluation Board

User’s Guide

2014 Microchip Technology Inc. DS50002255A-page 3

Page 4

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

NOTES:

DS50002255A-page 4 2014 Microchip Technology Inc.

Page 5

MCP19114 - FLYBACK STAND-ALONE

EVALUATION BOARD USER’S GUIDE

Table of Contents

Preface ...........................................................................................................................7

Introduction............................................................................................................7

Document Layout .................................................................................................. 7

Conventions Used in this Guide............................................................................ 8

Recommended Reading.............................................................. .. ........................9

The Microchip Web Site........................................................................................ 9

Customer Support....................... ....................................................... ...................9

Document Revision History................................................................................... 9

Chapter 1. Product Overview

1.1 Introduction ...................................................................................................11

1.2 MCP19114 Short Overview ..........................................................................11

1.3 What is the MCP19114 Flyback Stand-Alone Evaluation Board? ................12

1.4 MCP19114 Flyback Stand-Alone Evaluation Board Kit Contents ................12

Chapter 2. Installation and Operation

2.1 Introduction ...................................................................................................13

2.2 Getting Sta rted ............................................................................................. 13

Chapter 3. Graphical User Interface (GUI)

3.1 Introduction ...................................................................................................19

3.2 Configur in g Parameters ............ ................................................................... 20

Appendix A. Schematic and Layouts

A.1 Introduction ..................................................................................................25

A.2 Board – Schematic ... .................................................................... ................ 26

A.3 Board – Top Sil k ........ .. .. .............................................................................. 27

A.4 Board – Top Copper and Silk .......................................................................28

A.5 Board – Top Copper ....................................................................................29

A.6 Board – Inner Plane 1 – GROUND ..............................................................30

A.7 Board – Inner Plane 2 – POWER ................................................................31

A.8 Board – Bottom Copper ...............................................................................32

A.9 Board – Top Copper and Silk .......................................................................33

A.10 Board – Bo tt om Silk ............ .. .. ........................... .. .. ............. ... .. .................. 34

Appendix B. Bill of Materials (BOM)

Worldwide Sales and Service ....................................................................................38

2014 Microchip Technology Inc. DS50002255A-page 5

Page 6

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

NOTES:

DS50002255A-page 6 2014 Microchip Technology Inc.

Page 7

MCP19114 - FLYBACK

STAND-ALONE EVALUATION

BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP19114 - Flyback Stand-Alone Evaluation Board. Items discussed in this chapter

include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to install the MCP19114 - Flyback Stand-Alone

Evaluation Board. It also describes how to operate the Evaluation Board. The manual

layout is as follows:

• Chapter 1. “Product Overview” – Important information about the MCP19114 Flyback Stand-Alone Evaluation Board.

• Chapter 2. “Installation and Operation” – Includes instructions on how to get

started with the MCP19114 - Flyback Stand-Alone Evaluation Board.

• Chapter 3. “Graphic al User In terf ace (GUI) ” – Includes instructions on the

MCP19114-Flyback Standalone GUI.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the MCP19114 - Flyback Stand-Alone Evaluation Board.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

MCP19114 - Flyback Stand-Alone Evaluation Board.

2014 Microchip Technology Inc. DS50002255A-page 7

Page 8

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic chara c ters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brac kets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mut ually exclus ive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS50002255A-page 8 2014 Microchip Technology Inc.

Page 9

RECOMMENDED READING

This user's guide describes how to use MCP19114 - Flyback Stand-Alone Evaluation

Board. Other useful documents are listed below. The following Microchip documents

are available and recommended as supplemental reference resources.

• MCP19114/5 Data Sheet – “Digitally Enhanced Power Analog Synchronous

Low-Side PWM Controller” (DS20005281)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (March 2014)

• Initial Release of this Document.

2014 Microchip Technology Inc. DS50002255A-page 9

Page 10

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

NOTES:

DS50002255A-page 10 2014 Microchip Technology Inc.

Page 11

Chapter 1. Product Overview

1.1 INTRODUCTION

This chapter provides an overview of the MCP19114 - Flyback Stand-Alone Evaluation

Board and covers the following topics:

• MCP19114 Short Overview

• What is the MCP19114 - Flyback Stand-Alone Evaluation Board?

• MCP19114 - Flyback Stand-Alone Evaluation Board Kit Contents

1.2 MCP19114 SHORT OVERVIEW

The MCP19114 is a highly integrated, mixed-signal, analog pulse width-modulation

(PWM) current mode controller with an integrated microcontroller core and offers synchronous or asynchronous operation. Since the MCP19114 device uses traditional

analog control circuitry to regulate the output current or voltage, the integration of the

®

PIC

Microcontroller mid-range core is used to provide complete customization of the

device’s operating parameters, protection levels, programmable offset, deadtimes,

slope compensation and fault handling procedures.

The MCP19114 has two internal LD Os. A 5V LDO (V

the digital circuitry and can supply limited external power at the V

(AV

) provides power to the internal analog circuitry and supplies the reference volt-

DD

age to the ADC. This device features synchronous low-side integrated drivers and

4k word non-volatile memory, all in a space-saving 24-pin 4mm x 4mm QFN package.

Finally, to support traditional MOSFET s, pin 18 (V

the two low-side synchronous gate drivers. The evaluation board is populated with the

Microchip TC1240A voltage doubler. Resistor population provides the option of

powering V

populated) or 5V (R22 populated, R19, R21 not populated) gate-drive capability.

User firmware, including device configuration, is loaded using Microchip’s MPLAB X

- Integrated Development Environment (IDE). A graphical user’s interface (GUI) is

used to communicate with and edit operating parameters of the MCP19114. The GUI

communicates via I

The GUI offers the user the ability to adjust the programmable features available in the

MCP19114. The GUI cannot stop the user from uploading incorrect settings to the

device. Incorrect settings may have unintended consequences, including, but not limited to, unstable operation, damaging the load, and even damaging of the MCP19114

device. It is the user's responsibility to understand the system effects of the parameters

they enter.

with 10V via the TC1240A voltage doubler (R19, R21 populated, R22 not

DR

2

C™ using the PICkit™ Serial Analyzer.

MCP19114 - FLYBACK

STAND-ALONE EVALUATION

BOARD USER’S GUIDE

) provides internal power to all

DD

) is used to provide input power to

DR

pin. A 4V LDO

DD

®

2014 Microchip Technology Inc. DS50002255A-page 11

Page 12

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

V

IN

V

DR

I

SP

P

GND

V

S

I

P

V

IN

PDRV

BIN

DIMI

DESAT_N

MCLR

CCD

MCP19114

I

COMP

I/O

Temp SNS

EN

2

SDRV

A

GND

V

DD

I

FB

4x424LDQFN

V

DD

I/O

I/O

I/O

2

V

DD

5V

DESAT_P

I

SN

V

DD

V

DD

I/O

2

FIGURE 1-1: Typical MCP19114 Flyback Application – Two String LED Driver.

1.3 WHAT IS THE MCP19114 - FLYBACK STAND-ALONE EVALUATION BOARD?

The MCP19114 - Flyback Stand-Alone Evaluation Board is intended to demonstrate

how the MCP19114 device operates in a synchronous flyback topology. It is configured

to regulate load current and is also well-suited to drive LED loads. Nearly all operational

and control system parameters are programmable by utilizing the integrated PIC

Microcontroller core.

The MCP19114 comes preprogrammed with firmware designed to operate with the

GUI interface. MPLABX IDE software can be used to download user defined firmware,

and thus tailoring it to their specific application.The evaluation board contains headers

for In-Circuit Serial Programming

Several test points have been designed into the printed circuit board for easy access

and development purposes. The MCP19114 - Flyback Stand-Alone Evaluation Board

is also intended to demonstrate an optimized Printed Circuit Board (PCB) layout that

minimizes parasitics while increasing efficiency and power density. Proper PCB layout

is critical to achieve optimum MCP19114 operation as well as power train efficiency and

noise minimization. MPLABX IDE, MCP19114 - Flyback Stand-Alone GUI and

MCP19114 - Flyback Stand-Alone Firmware are available for download from

Microchip’s web site. See Chapter 3. “Graphical User Interface (GUI)” for details.

1.4 MCP19114 - FLYBACK STAND-ALONE EVALUATION BOARD KIT CONTENTS

DS50002255A-page 12 2014 Microchip Technology Inc.

The MCP19114 - Flyback Stand-Alone Evaluation Board includes the following items:

• MCP19114 - Flyback Stand-Alone Evaluation Board (ADM00578)

• Important Information Sheet

™

(ICSP) as well as I2C communication.

Page 13

Chapter 2. Installation and Operation

2.1 INTRODUCTION

2.1.1 MCP19114 - Flyback Stand-Alone Eval uation Board Features

The MCP19114 is a digitally-enhanced, power analog, synchronous low-side

pulse-width modulation (PWM) controller. The graphical user interface was developed

to assist users in easily configuring the MCP19114 and evaluating it in their target

application.

The MCP19114 - Flyback St and-Alone Evaluation Board is designed to operate from a

single supply (nominal 8V to 14V, 24V maximum). The primary side MOSFET has a

maximum V

exceeded when determining input and output conditions for their application. The

coupled inductor has a 2:1 ratio. The secondary MOSFET has a 200V maximum V

rating.

The default configuration provides the gate drive supply (V

ceramic and bulk capacitors are supplied on the input to reduce the root mean square

(RMS) ripple current and lessen input voltage deviation caused by load transients.

Ceramic capacitors are also provided on the output to reduce voltage ripple and provide energy to the output while the primary side is being re-energized.

The MCP19114 - Flyback Stand-Alone Evaluation Board is fully assembled, programmed and tested to evaluate and demonstrate the MCP19114 operating performance. Users will need to download and install the MCP19114 - Flyback Stand-Alone

GUI from the Microchip website and become familiar with its operation before powering

the MCP19114 - Flyback Stand-Alone Evaluation Board.

MCP19114 - FLYBACK

STAND-ALONE EVALUATION

BOARD USER’S GUIDE

rating of 100V. Users should be cautious that this 100V rating is not

DS

) with 10V. Adequate

DR

DS

2.2 GETTING STARTED

2.2.1 Configuration Requirements

To power up and run the MCP19114 - Flyback Stand-Alone Evaluation Board, the

following is required:

• MCP19114 - Flyback Stand-Alone GUI

• MCP19114 - Flyback Stand-Alone Evaluation Board

• PICkit Serial Analyzer

Note: The factory-loaded firmware REQUIRES the use of the provided GUI to

function. Without the GUI, the evaluation board will not operate.

2.2.2 Installing the MCP19114 - Flyback Stand-Alone GUI

Follow the steps to download and install the MCP19114 - Flyback Stand-Alone GUI:

1. Download the MCP19114 - Flyback St and-Alone GUI software package from the

Microchip web site.

2. Extract the content of the archive files on the computer.

3. Double-click the setup.exe file to start software installation. Press the Install

button in the Application Install window (Figure 2-1). Once the installation

completes, the GUI window will open (see Figure 3-1 in Chapter 2. “Installation

and Operation”).

2014 Microchip Technology Inc. DS50002255A-page 13

Page 14

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

V

OUT

GND

GND

V

IN

FIGURE 2-1: MCP19114 - Flyback Stand-Alone GUI Installation Window.

2.2.3 Power Input and Output Connection

The MCP19114 comes programmed with generic firmware compatible with the

standalone GUI. It is up to the user to modify or create new firmware dedicated to their

stand-alone application if different functionality is required.

Note: If the default firmware is modified, the GUI may no longer be compatible

with the MCP19114 - Flyback Stand-Alone Evaluation Board.

2.2.3.1 APPLYING POWER

Use the V

the Positive terminal (Red) connected to V

and GND Test Points as shown below. Nominal VIN is +8V to +14V with

IN

and the Negative terminal (Black)

IN

connected to GND.

FIGURE 2-2: Applying Power to the Board.

CAUTION

The Primary side MOSFET is Rated to 100V. The transformer turns ratio is 1:2. Do Not

DS50002255A-page 14 2014 Microchip Technology Inc.

exceed the 100V MOSFET Rating.

Primary MOSFET (OFF) VDS = 0.5 x V

OUT+VIN

.

Page 15

Installation and Operation

2.2.4 Preprogrammed MCP19114 - Flyback Stand-Alone Evaluation

Board

The MCP19114 - Flyback Stand-Alone Evaluation Board comes with preprogrammed

firmware installed to operate with the GUI. T o reprogram the device, the following tools

are required:

• MPLAB X IDE (version 1.5 or l ater)

• MPLAB

• MCP19114 - Flyback Stand-Alone Firmware

• MCP19114 - Flyback Stand-Alone Evaluation Board

• PICkit™ 3 In-Circuit Debugger/Programmer

Follow the steps to install all necessary software and start reprogramming the

MCP19114 device:

1. If MPLAB X is already installed, go to Step 2. If not, download MPLAB X from:

2. If an XC8 compatible C-compiler, or an equivalent, is already installed in

3. Download the MCP19114 - Flyback Stand-Alone Firmware (*.zip) from

4. Unzip the MCP19114 - Flyback Stand-Alone Firmware archive. Place the

®

XC8 C Compiler (v1.3 or later)

www.microchip.com/mplabx, and follow the MPLAB X installation instr uct io ns.

MPLAB X, go to Step 3. If not, you can download a free version of Microchip's

XC8 from: www.microchip.com/mplabxc. The XC8 user guide, installation

instructions, and download links are available on this page.

www.microchip.com/mcp19114 under "Documentation & Software/Software".

MCP19114 project folder in the desired folder location.

Note: When installed, MPLAB X IDE automatically creates a project folder. In

Windows

drive\Users\user_name\MPLABXProjects.

5. Power up the MCP19114 - Flyback Stand-Alone Evaluation Board.

6. Connect the PICkit 3 In-Circuit Debugger to the MCP19114 - Flyback

Stand-Alone Evaluation Board via the 6-pin connector J3, as seen in Figure 2-3

(for more information about PICkit 3 In-Circuit Debugger refer to the “PICkit™ 3

In-Circuit Debugger/Programmer User’s Guide For MPLAB® X IDE” - DS521 16).

®

, this folder can typically be found under

2014 Microchip Technology Inc. DS50002255A-page 15

Page 16

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

FIGURE 2-3: PICkit 3 In-Circuit Debugger/Programmer Connected to the

MCP19114 - Flyback Stand-Alone Evaluation Board.

7. Open MPLAB X IDE to load MCP19114 - Flyback Stand-Alone Firmware. From

the File menu select Open Project (Figure 2-4).

FIGURE 2-4: Opening Project in MPLAB X IDE.

DS50002255A-page 16 2014 Microchip Technology Inc.

Page 17

Installation and Operation

Make and Program Device

Main Project Button

Programming/Verify Complete Result

8. Browse for the location of the extracted firmware. Select the

MCP19114_Stand_Alone from the list, then check the Open as Main Project

option. Press the Open Project button to complete loading the file.

FIGURE 2-5: Loading Firmware into MPLAB X IDE.

9. Once the project is opened, click Make and Program Device Main Project

button on the tool bar to program the device. Wait until the program process is

complete.

FIGURE 2-6:

2014 Microchip Technology Inc. DS50002255A-page 17

Selecting and Executing the Make and Program Device Main Project in MPLAB X IDE.

Page 18

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

NOTES:

DS50002255A-page 18 2014 Microchip Technology Inc.

Page 19

Chapter 3. Graphical User Interface (GUI)

3.1 INTRODUCTION

The MCP19114 - Flyback Stand-Alone GUI requires a Windows® XP/7/8 operating

system, a USB port and a minimum screen resolution of 1024 x 768. To run the

software, follow the steps described in this section.

1. Apply an input voltage in the normal operating range (8V to 14V) at the V

Ground test points.

2. Connect the PICkit Serial Analyzer to the PC via USB port and then connect the

analyzer to the Control Board via the 6-pin serial connector J5 (Figure 3-1).

MCP19114 - FLYBACK

STAND-ALONE EVALUATION

BOARD USER’S GUIDE

and

IN

FIGURE 3-1: PICkit Serial Analyzer Connection to the Board.

3. To start the GUI, select Start > All Programs > Microchip Technology

Inc. > MCP19114 Flyback Standalone GUI. The interface detects the

MCP19114 device automatically and is ready for use (see Figure 3-2).

2014 Microchip Technology Inc. DS50002255A-page 19

Page 20

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

System

Parameters

Operating

Status Box

Control

Buttons

Register

Adjust Online

FIGURE 3-2: MCP19114 - Flyback Stand-Alone GUI - Initial Screen.

3.2 CONFIGURING PARAMETERS

As depicted in Figure 3-2, the MCP19114 - Flyback St and-Alone GUI is divided into four

parts:

• System Parameters

• Register Online Adjust

• Control Buttons

• Operating Status Box

3.2.1 System Parameters

3.2.1.1 DRIVERS ENABLE/DISABLE

The Drivers Enable/Disable section defaults to OFF when starting the MCP19114 Flyback Stand-Alone GUI. When this is set to ON, all other adjustable parameters

become active for adjustment. When OFF is selected, the GUI will turn off the drivers

and make all of the parameters unavailable for change so they cannot be altered.

3.2.1.2 PARAMETERS

This section controls the Switching Frequency, Maximum Duty Cycle, Output Current

and Current Sense Resistor parameters. The switching frequency is user

programmable in Fixed Frequency mode over the range of 60 kHz to 1 MHz. Switching

Frequency can be adjusted in 10 kHz intervals. The maximum duty cycle is

programmable from 0 to 100%.

DS50002255A-page 20 2014 Microchip Technology Inc.

Page 21

Graphical User Interface (GUI)

CAUTION

Increasing switching frequency results in increased switching losses in the MOSFETs.

It is the user's responsibility to ensure MOSFETs are operated within their safe

operating range.

Users can adjust the Output Current over a range of 0 to 500 mA. The Current Sense

Resistor (R6) value on the MCP19114 - Flyback Stand-Alone Evaluation Board is

200 m. Both of these values are used to calculate the set point value written to the

VREFCON register. DO NOT raise the resistor value in the GUI without changing the

resistor on the evaluation board to match. Failure to do so could result in damage to

the evaluation board.

Note: Attempting to write a value larger than 0xFF to VREFCON is prohibited by

the GUI.

3.2.1.3 OPERATING MODE

This section controls whether the Flyback converter is operated in Fixed-Frequency,

Quasi-Resonant, Synchronous or Asynchronous Modes. When running in Fixed

Frequency mode, the switching frequency parameters are adjustable. The third button

is for Synchronous Operation. When the EN ON button is selected on the GUI, the

Synchronous Operation box is automatically selected by default, putting the evaluation

board in Synchronous mode. If the Synchronous Operation box is unchecked, the

evaluation board is set to Asynchronous operation which disables the secondary driver

(SDRV).

FIGURE 3-3: Operating Mode Options.

3.2.1.4 PROTECTION

The Protection control allows the user to set levels for the three adjustable protection

features. Input Voltage Under Voltage Lockout (VIUVLO), Input Voltage Overvoltage

Lockout (VINOVLO) and Output Voltage Overvoltage (OV) can all be configured in this

section of the GUI.

FIGURE 3-4: Protection Options.

2014 Microchip Technology Inc. DS50002255A-page 21

Page 22

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

The VINUVLO and VINOVLO Protection parameters are configurable per their

specified ranges. The specified range for VINUVLO is 4V to 20V . The default VINUVLO

setting in the GUI is 8V. The specified VINOVLO range is 9V to 24V. The default

VINOVLO setting in the GUI is 18V . The Output OV has a configurable range between

0V and 60V. The default OV setting in the GUI is 40V.

The LED (D2) on the evaluation board is used to indicate various fault conditions. The

firmware will flash this LED to indicate each of the following fault conditions:

• VIN UVLO FAULT: Short Flash Routine

• VIN OVLO FAULT: Long Flash Routine

• OUTPUT OV FAULT: Short/Long Flash Routine

WARNING

Use caution when changing from these default settings to ensure that damage will not

occur. The VINUVLO, VINOVLO and Output OV controls adjust the VINUVLO, VINOVLO

and OVREFCON registers, respectively.

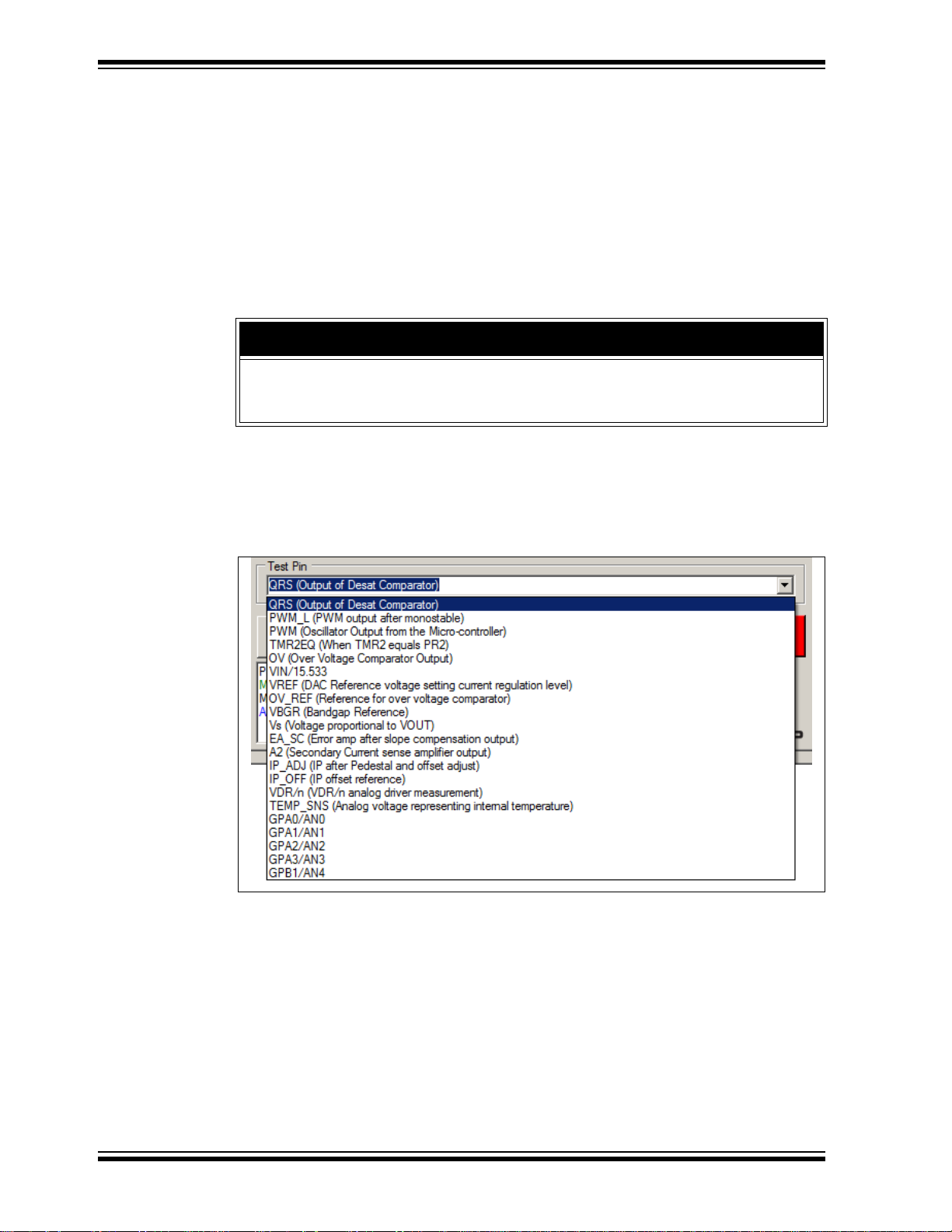

3.2.1.5 TES T PIN

This section of the GUI has a drop-down menu that allows users to select and connect

test signals to GPIO GP A0. These signals are accessible at the test point labeled TEST .

The Test Pin can be configured to output several analog or digital parameters. See

Figure 3-5 for the list of signals.

FIGURE 3-5: Test Pin Options.

3.2.1.6 SWITCHES ENABLE/DISABLE

There are two general purpose MOSFET low-side series switches located on

MCP19114 - Flyback Stand-Alone Evaluation Board (LSW1 and LSW2). The control

boxes in the Switches Enable/Disable section of the GUI allow the user to turn these

switches ON (checked) and OFF (unchecked).

DS50002255A-page 22 2014 Microchip Technology Inc.

Page 23

Graphical User Interface (GUI)

Leading

Edge

Blanking

Primary Driver

Deadtime

Input Current

Offset

Slope

Compensation

Secondary

Driver Deadtime

Special

Function

Registers

Update Section

3.2.1.7 ADVANCED REGISTER UPDATE

This section of GUI gives the user more options to configure and operate the

MCP19114 - Flyback Stand-Alone Evaluation Board. The adjustable parameters

include Leading Edge Blanking (LEB), Primary Driver (PDRV) Deadtime, Secondary

Driver (SDRV) Deadtime, Input Current Offset and Slope Compensation. In addition,

this section allows users to update up to four Special Function Registers (SFR) at the

same time. For more information on Special Function Registers, refer to the

MCP19114/5 Data Sheet – “Digitally Enhanced Power Analog Synchronous Low-Side

PWM Controller” (DS20005281).

FIGURE 3-6: Advanced Register Update Options.

3.2.2 Register Online Adjust

The Register Onlin e Adj ust secti on of t he GUI al low s the user to hav e dire ct co ntro l of

register values at any time when operating the MCP19114. The device data sheet contains information on register address locations and content. Reads and writes are done

in hexadecimal format. Users must select the proper bank, which is especially important when executing a write. It is good practice to always execute an address read

before a write, to check for expected results. This may help prevent an unintended write

to an improper address or bank. Please note that the Update button will not update this

section.

FIGURE 3-7: Register Online Adjust Options.

2014 Microchip Technology Inc. DS50002255A-page 23

Page 24

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

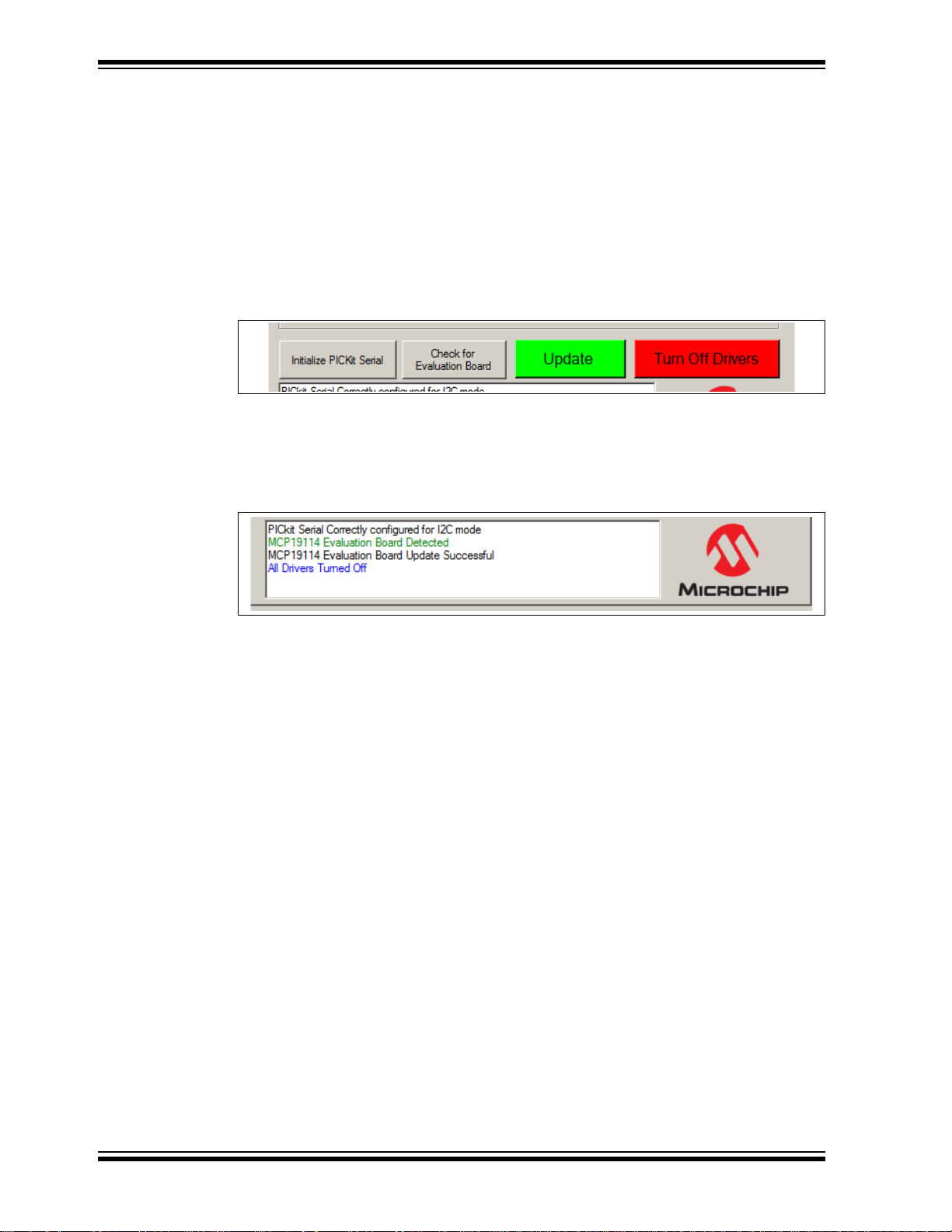

3.2.3 Control Buttons

The two buttons on the left are user selectable self-test options. The Initialize PICkit

Serial button checks communication between your computer and PICkit Serial

Analyzer. The Check for Evaluation Board can be selected by the user to manually

ask software to detect the evaluation board.

The Update button will apply the configuration settings made in Operating Mode,

Parameters, Protection, Switches Enable/Disable, Advanced Register Update and will

turn on the output drivers. It will not update the Register Online Adjust section.

The Turn Off Drivers button is a Master Stop that shuts off the output drivers. Pressing

this button will disable both Primary and Secondary drivers.

FIGURE 3-8: Control Buttons.

3.2.4 Operating Status Box

This box provides messages to the user and operating status. Examples of status messages are shown in Figure 3-9.

FIGURE 3-9: Operating Status Box.

DS50002255A-page 24 2014 Microchip Technology Inc.

Page 25

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the following schematics and layouts for the MCP19114 Flyback Stand-Alone Evaluation Board:

• Board – Schematic

• Board – Top Layer

• Board – Top Copper

• Board – Mid Layer 1

• Board – Mid Layer 2

• Board – Bottom Copper

• Board – Bottom Layer

MCP19114 - FLYBACK

STAND-ALONE EVALUATION

BOARD USER’S GUIDE

2014 Microchip Technology Inc. DS50002255A-page 25

Page 26

DS50002255A-page 26 2014 Microchip Technology Inc.

10u

C4

10u

C5

1210

1210

1u

C3

1206

PGND PGND PGND

3.3u

C8

4.7u

C7

1206 1206

PGND PGND

DNP

C9

DNP

C10

1206

1206

PGND

PGND PGND

50m

R4

0612

0

R3

0603

DNP

C13

0603

SGND

2.2u

C6

2.2u

C11

SDRV

D1A

D1B

3.92k

R1

3.92k

R2

VDD

VDD

DSAT_N

DSAT_P

200m

R6

PGND

0612

0603

0603

0

R5

0603

DNP

C14

0603

ISN

ISP

100k

R7

4k

R9

SGND

1n

C18

0603

SGND

0603

0603

DNP

C1

DNP

C2

1206

1206

PGND PGND

DSAT_N

SDRV

DSAT_P

ISP

ISN

GPA0/AN0/ALT_ICSPDAT/TEST_OUT

1

GPA1/AN1/CLKPIN/ALT_ICSPCLK

2

GPA2/AN2/T0CKI/ALT_ICSPCLK

3

GPA3/AN3

4

GPA7/SCLK/ICSPCLK

5

GPA6/CCD/ICSPDAT

6

GPA5/MCLR/TEST_EN

7

GPB0/SDA

8

DESAT_N

9

DESAT_P/ISOUT

10

ISP

11

ISN

12

IP

13

14

15

SDRV

16

PDRV

17

VDR

18

VDD

19

VIN

20

VS

21

IFB

22

ICOMP

23

GPB1/AN4/VREF2

24

G

G

_I

CSPCLK

G

_I

CSPCLK

G

G

G

AT

G

G

A

D

/I

SO

I

SP

SN

I

SDRV

V

V

V

N

VS

I

COMPG

AGND PGND25EP

U1

MCP19114_QFN24

1.02 k

R11

10n

C19

220 p

C17

PGNDSGND SGND

SHDN

4

C+

6

VOUT

5

C-

3

GND

2

VIN

1

U2

SGND

1u

C12

DNP

R8

SW1

SW2

VS

VS

ICSPCLK

ICSPDAT

TEST_EN

SDA

VDD

5

5

2

2

1

1

3

3

4

4

6

6

J3

HDR1X6-SMT

SGND

10k

R10

ICSPDAT

ICSPCLK

VDD

VDD

TEST_EN

VOUT

SW1 SW2

LSW1 LSW2

PGND PGND

4.7u

C16

4.7u

C15

SGND

PGND

10k

R12

10k

R13

475

R18

AK

D2

SGND

10k

R14

VDD

1u

C20

PGND

0

R16

0

R17

0.1u

C21

PGND

25341

Q1

GPA2

TEST_OUT

TEST_OUT

TEST

VS

VS

SDRV

SDRV

DSAT_P

DSAT_P

DSAT_N

DSAT_N

SW1

SW1

PDRV

SW2

SW2

VREF2

IFB

ICOMP

ISN

ISP

0

R15

25341

Q2

25341

Q3

25341

Q4

JUMPER JUMPER

SGND

SDA

ICSPCLK5

5

2

2

1

1

3

3

4

4

6

6

J5

HDR1X6-SMT

TC1240A

100V

50V

50V

0603

50V

0603

0603

0603

0603

16V

0603

16V

0603

0603

25V

0603

25V

0603

0603

0603

0603 0603 0603

0603

50V

50V

1206

50V

50V

1206

0603

0603

0603

5

4

310

11

7

8

2

0

R21

0603

1 2

NT1

SGND

PGND

10

0603

21

3

R19

R22

10

0603

VDD

VIN

PGND

VOUT

LSW1 LSW2

IP

10k

R23

PGND1

D3

TP1

VIN

VDR

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

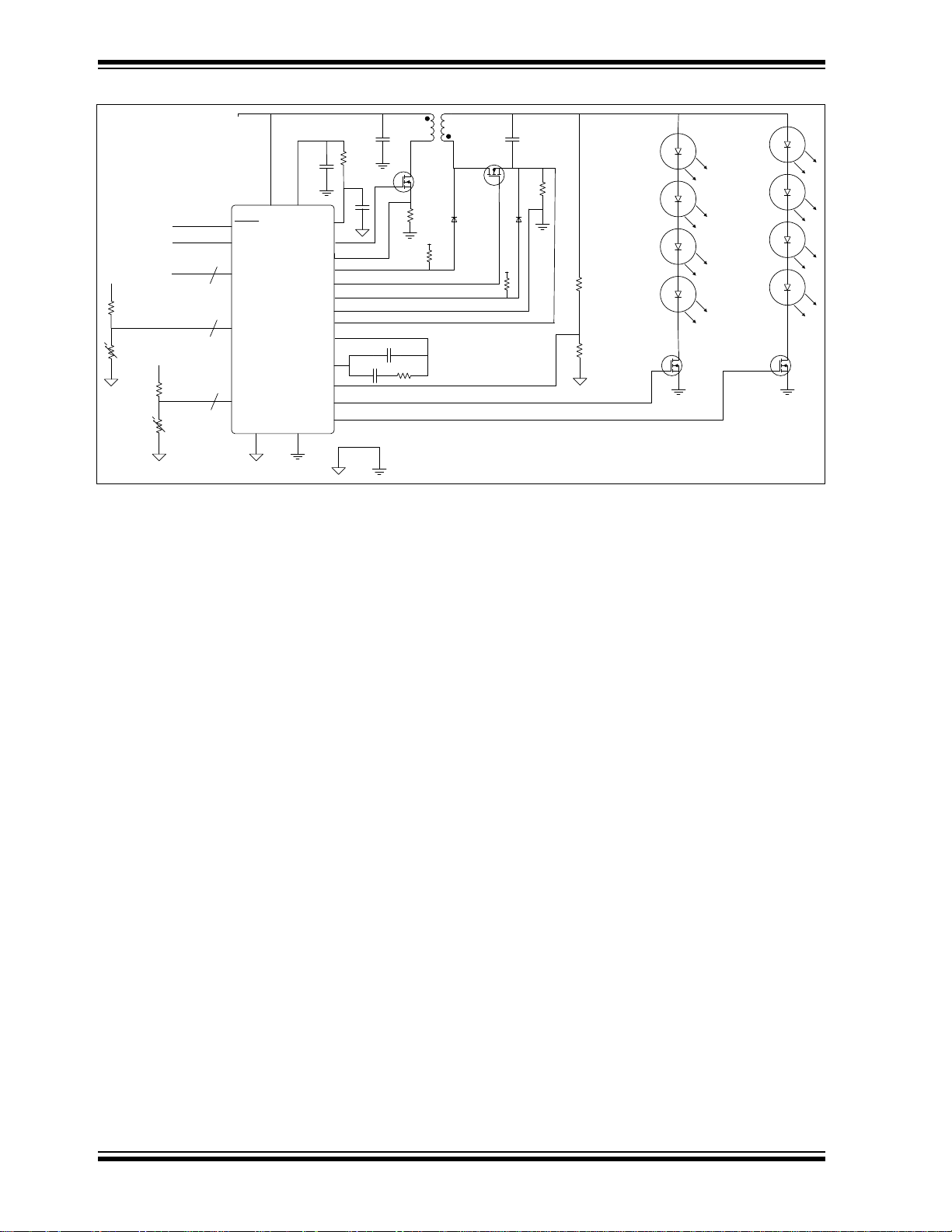

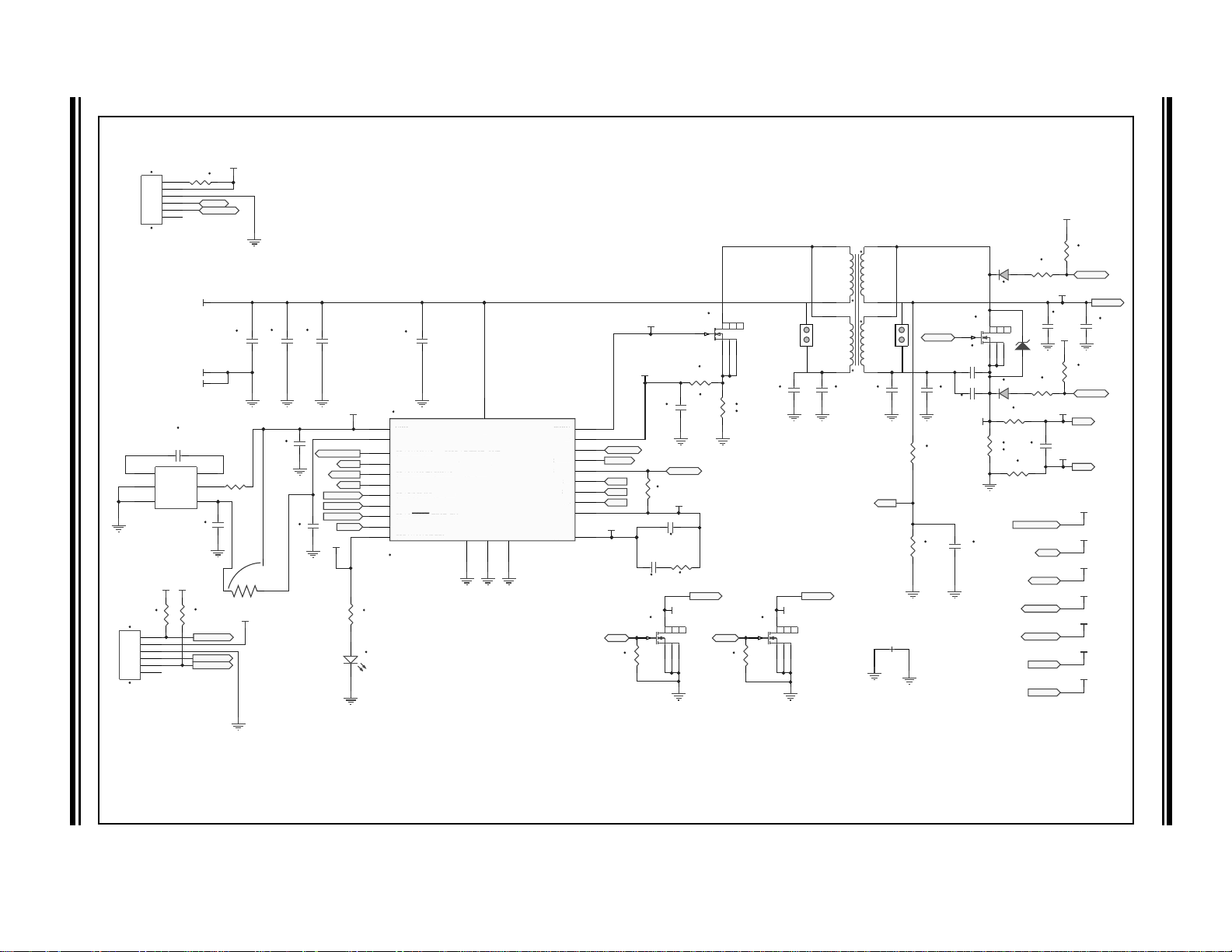

A.2 BOARD – SCHEMATIC

I

DD

DR

PA0/AN0/ALT_ICSPDAT/TEST_OUT

PA1/AN1/CLKPIN/ALT

PA2/AN2/T0CKI/ALT

PA3/AN3

PA7/SCLK/ICSPCLK

PA6/CCD/ICSPD

PA5/MCLR/TEST_EN

PB0/SD

PB1/AN4/VREF2

PDR

P

DESAT_N

ESAT_P

UT

FB

Page 27

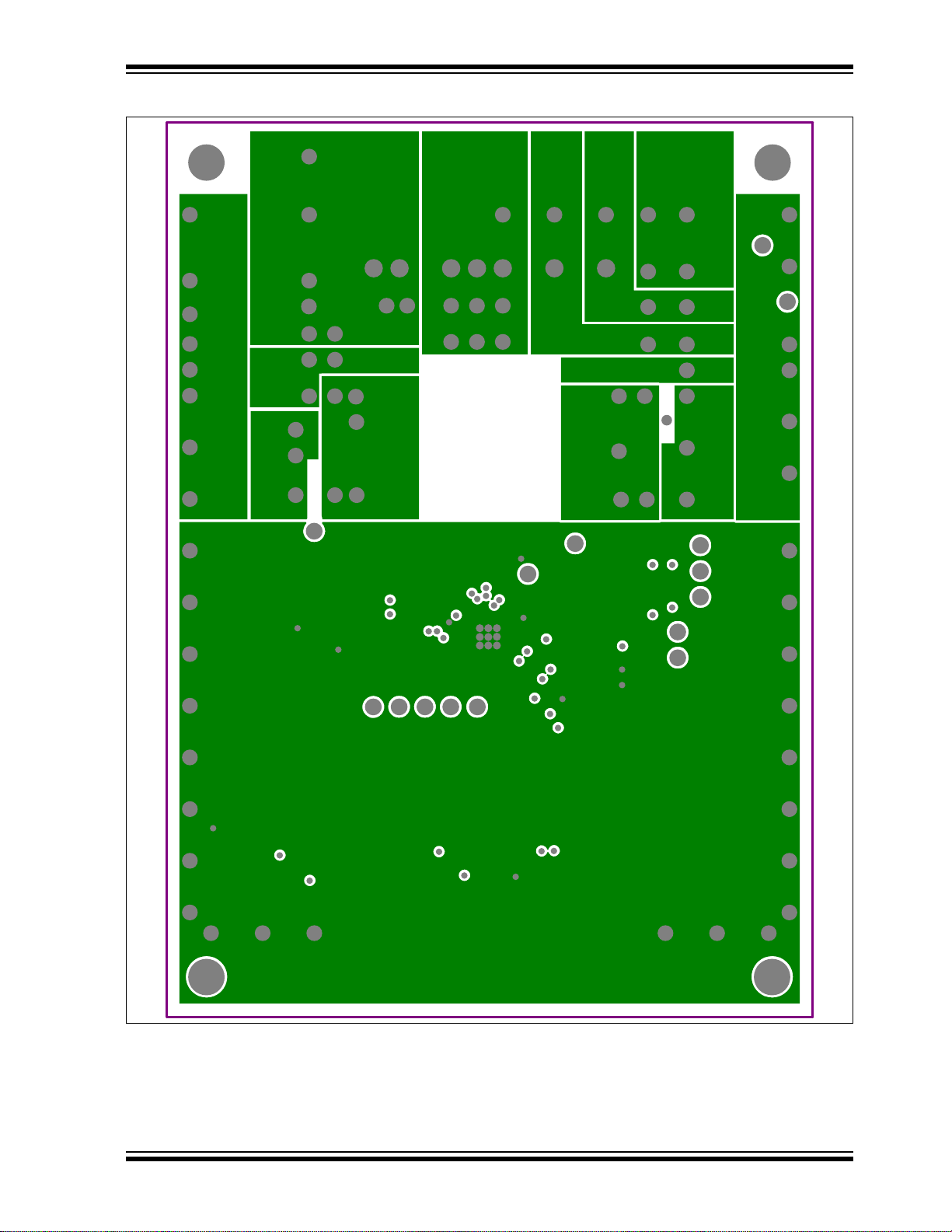

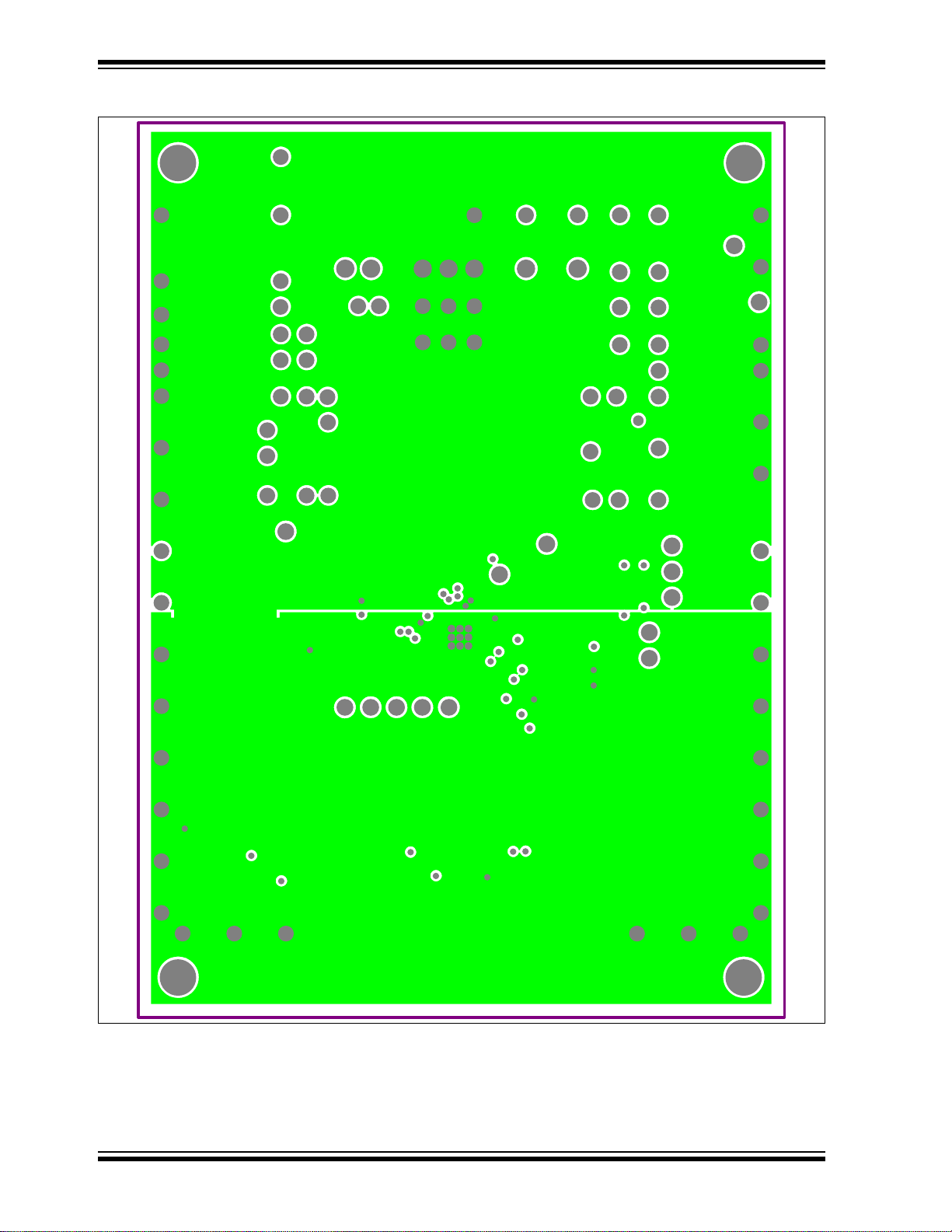

A.3 BOARD – TOP LAYER

Schematic and Layouts

2014 Microchip Technology Inc. DS50002255A-page 27

Page 28

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

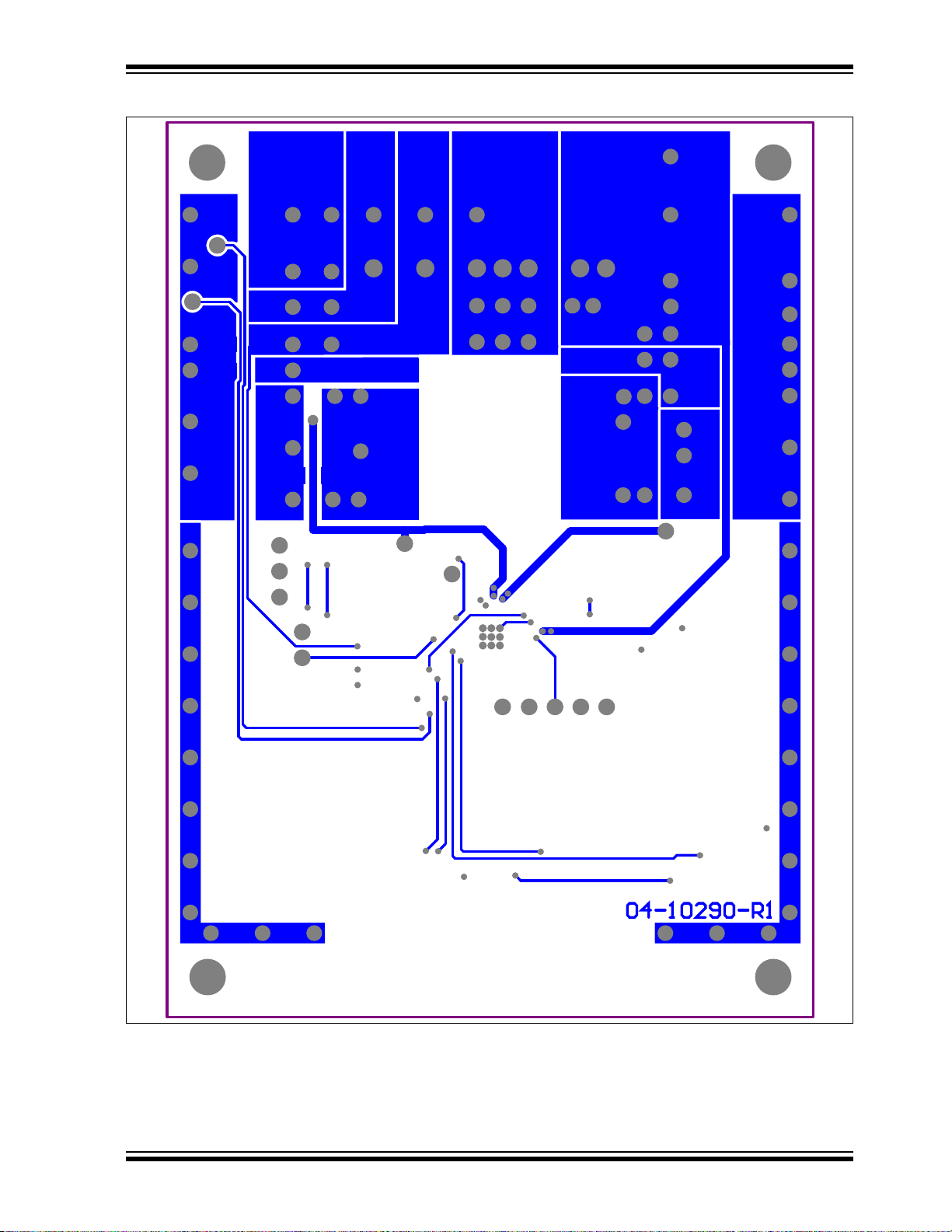

A.4 BOARD – TOP COPPER

DS50002255A-page 28 2014 Microchip Technology Inc.

Page 29

A.5 BOARD – MID LAYER 1

Schematic and Layouts

2014 Microchip Technology Inc. DS50002255A-page 29

Page 30

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

A.6 BOARD – MID LAYER 2

DS50002255A-page 30 2014 Microchip Technology Inc.

Page 31

A.7 BOARD – BOTTOM COPPER

Schematic and Layouts

2014 Microchip Technology Inc. DS50002255A-page 31

Page 32

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

A.8 BOARD – BOTTOM LAYER

DS50002255A-page 32 2014 Microchip Technology Inc.

Page 33

MCP19114 - FLYBACK

STAND-ALONE EVALUATION

BOARD USER’S GUIDE

Appendix B. Bill of Materials (BOM)

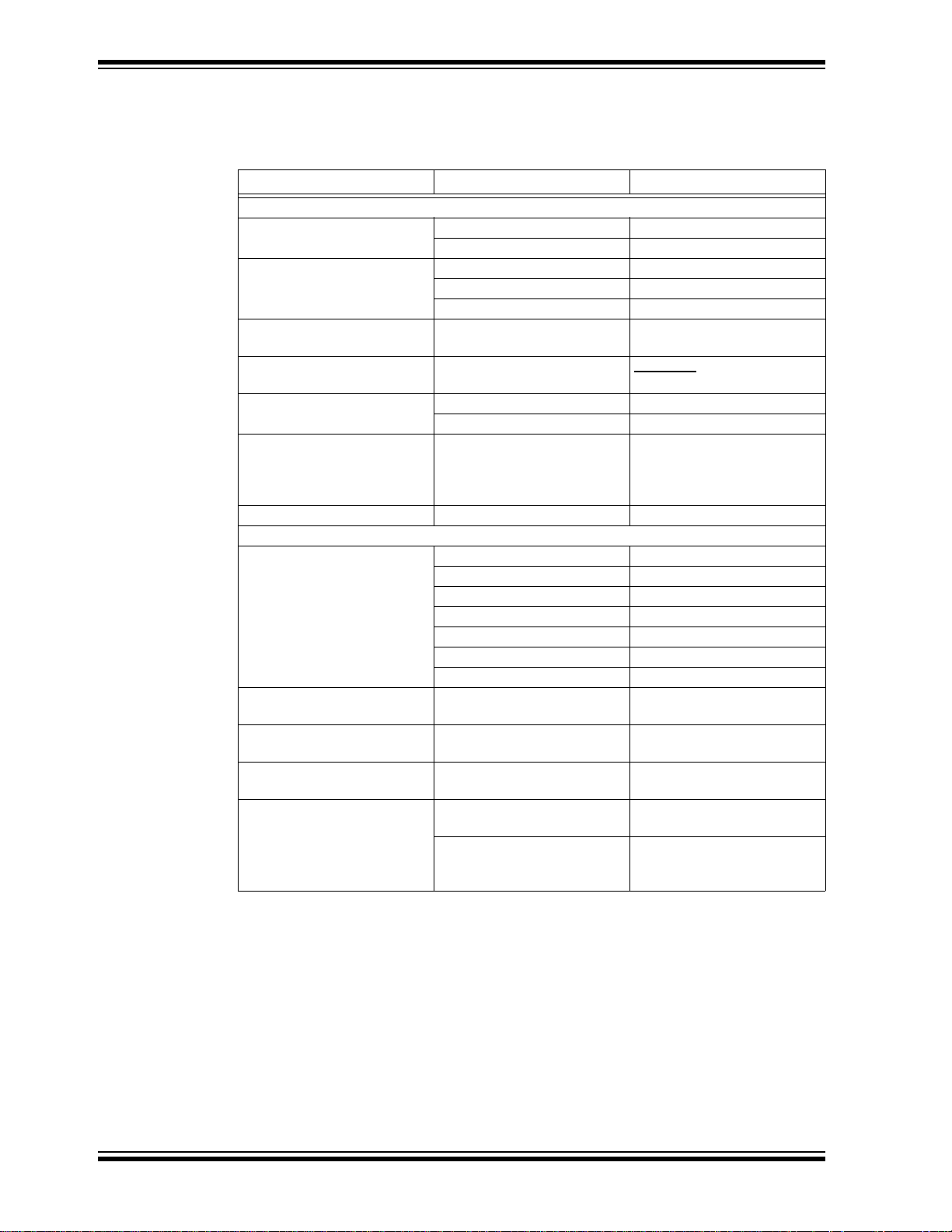

TABLE 2-1: BILL OF MATERIALS (BOM)

Qty. Reference Description Manufacturer Part Number

4 4-40 screw Machine screw 4-40 1/4 B&F

44-40

standoff 1/4

4 C1, C2,

C9, C10

1 C3 Cap. ceramic 1 µF, 100V , X7R, Auto 1206 TDK Corporation CGA5L2X7R2A105M/SOFT

2 C4, C5 Cap. ceramic 10 µF, 50V, X7R, Auto 1210 Taiyo Yuden Co., Ltd. UMK325AB7106MM-T

2 C6, C11 Cap. ceramic 2.2µF, 50V, X7R, Auto 1206 TDK Corporation CGA5L3X7R1H225K

1C7 Cap. ceramic 4.7 µF, 50V, X7R, Auto 1206 TDK Corporation C3216X7R1H475K160AC

1C8 Cap. ceramic 3.3 µF, 50V, X7R, Auto 1206 TDK Corporation C3216X7R1H335K160AC

2 C12, C20 Cap. ceramic 1 µF , 25V , X7R, Auto 0603 TDK Corporation CGA3E1X7R1E105K

2 C13, C14 DO NOT POPULATE ——

2 C15, C16 Cap . ceramic 4.7 µF, 16V , X5R, Auto 0603 TDK Corporation C1608X5R1C475K

1 C17 Cap. ceramic 220pF, 50V, COG 0603 Murata Electronics

1 C18 Cap. ceramic 1 nF, 50V, COG 0603 Murata Electronics

1 C19 Cap. ceramic 10 nF 50V 10% X7R 0603 TDK Corporation C1608X7R1H103K080AA

1C21 Cap. ceramic 0.1 µF, 50V, X7R, Auto 0603 TDK Corporation CGA3E2X7R1H104K

1 D1A, D1B Diode SW DBL 200V 225 mA SOT143B NXP Semiconductor BAV23, 215"

1 D2 LED, super red, clear 0603 Lite-On

1 D3 TVS diode 90 VWM 146 VC SMA U ni-Dir Littelfuse

2 J3,J5 Header, 6 Pos., 2.54 mm, SMT, vert., gold Samtec, Inc. TSM-106-01-L-SV

1 PCB Printed Circuit Board - MCP19114 -

3 Q1, Q3, Q4 N-Channel MOSFET, 100V Vishay

1 Q2 MOSFET N-Ch. 200V 15.2A

2 R1, R2 Res. 3.92 k 1/10th Watt, 1% 0603

6 R3, R5, R15,

R16, R17,

R21

1 R4 Res. 50 m 1 Watt, 1% 0612 SMD Susumu Co., LTD. PRL1632-R050-F-T1

1 R6 Res. 200 m 1 Watt, 1% 0612 SMD Rohm Semiconductor LTR18EZPFLR200

1 R7 Res. 100 k 1/10th Watt, 1% 0603 SMD Panasonic - ECG ERJ-3EKF1003V

1R8 DO NOT POPULATE ——

1 R9 Res. 4.02 k 1/10th Watt, 1% 0603 SMD Panasonic - ECG ERJ-3EKF4021V

Hex standoff 4-40 aluminum1/4 Keystone Electronics 2201

DO NOT POPULATE ——

Flyback Stand-Alone Evaluation Board

8TSDSON

SMD

Res. 0.0 1/10W 0603 SMD Panasonic - ECG ERJ-3GE Y0R00V

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The

released BOM used in manufacturing uses all RoHS-compliant components.

™ Fasteners Supply PMSSS 440 0025 PH

®

GCM1885C1H221JA16D

®

GCM1885C1H102JA16D

®

Technology

Corporation

®

— 04-10290

Intertechnology, Inc.

Infineon

Technologies AG

®

Panasonic

- ECG ERJ-3EKF3921V

LTST-C190KRKT

SMAJ90A

SIS890DN-T1-GE3

BSZ900N20NS3 G

2014 Microchip Technology Inc. DS50002255A-page 33

Page 34

MCP19114 - Flyback Stand-Alone Evaluation Board User’s Guide

TABLE 2-1: BILL OF MATERIALS (BOM) (CONTINUED)

Qty. Reference Description Manufacturer Part Number

4 R10, R12,

R13, R14

1R11 Res. 1.02k 1/10th Watt, 1% 0603 SMD Panasonic - ECG ERJ-3EKF1021V

1 R18 Res. 475 1/10th Watt, 1% 0603 SMD Panasonic - ECG ERJ-3EKF4750V

1 R19 Res. 10.0 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF10R0V

1R22 DO NOT POPULATE ——

1 R23 Res. 10 k1/10th Watt, 1% 0603 SM D Panasonic - ECG E RJ-3 EKF10 02 V

1 T1 Uni-Cuk Transformer 1:2 Wurth

1 U1 Digitally Enhanced PWM Power

1 U2 Charge Pump, Doubler Microchip

6 VIN, PGND,

PGND1,

VOUT,

LSW1, LSW2

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The

released BOM used in manufacturing uses all RoHS-compliant components.

Res. 10 k 1/10th Watt, 1% 06 03 SMD Panasonic - ECG ERJ-3EKF1002 V

®

Group 750341878

Microchip

Analog Controller

Test point PC compact SMT Keystone

Technology Inc.

Technology Inc.

Electronics Corp.

MCP19114-E/MJ

TC1240A-E/CH

5016

DS50002255A-page 34 2014 Microchip Technology Inc.

Page 35

NOTES:

Bill of Materials (BOM)

2014 Microchip Technology Inc. DS50002255A-page 35

Page 36

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

New Yor k , NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Canada - Toronto

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-8792-8115

Fax: 86-571-8792-8116

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8864-2200

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-3019-1500

Japan - Osaka

Tel: 81-6-6152-7160

Fax: 81-6-6152-9310

Japan - Tokyo

Tel: 81-3-6880- 3770

Fax: 81-3-6880-3771

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Taiwan - Taipei

Tel: 886-2-2508-8600

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Dusseldorf

Tel: 49-2129-3766400

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Pforzheim

Tel: 49-7231-424750

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Venice

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Poland - Wars a w

Tel: 48-22-3325737

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

03/21/14

DS50002255A-page 36 2014 Microchip Technology Inc.

Loading...

Loading...