Page 1

LIN Serial Analyzer

User’s Guide Rev2.0

© 2008 Microchip Technology Inc. DS51675B

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Millennium Copyright A ct. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, microID, MPLAB, PIC,

PICmicro, PICSTART, PRO MATE, rfPIC and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Linear Active Thermistor, Migratable

Memory, MXDEV, MXLAB, SEEVAL, SmartSensor and The

Embedded Control Solutions Company are registered

trademarks of Microchip Technology Incorporated in the

U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Mindi, MiWi,

MPASM, MPLAB Certified logo, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB, Select

Mode, Smart Serial, SmartTel, Total Endurance, UNI/O,

WiperLock and ZENA are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2008, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS51675B-page ii © 2008 Microchip Technology Inc.

Page 3

LIN SERIAL ANALYZER

USER ’S GUIDE REV2.0

Table of Contents

Preface ...........................................................................................................................1

Chapter 1. LIN Serial Analyzer Overview.....................................................................5

1.1 Introduction .....................................................................................................5

1.2 Highlight s ......... ............. .. .. ........................... .. .. ........................... .. .. ................ 5

1.3 LIN Serial A n a lyzer Conten ts ......... .......................... .. ... ............. .. .................. 5

1.4 LIN Serial Analyzer Development Tool ..........................................................5

1.5 LIN Serial A n a ly zer Hardware ................ ... .. ............. .. ... ............. .. .. ............. ... 6

1.6 LIN Serial A n a ly zer Software ............. ........................... .. .. ............. .. ... ........... 8

Chapter 2. Getting Started – Quick Setup....................................................................9

2.1 Highlight s ......... ............. .. .. ........................... .. .. ........................... .. .. ................ 9

2.2 Using the LIN S e ria l Analyzer for the F irs t Time ............... ............................. 9

2.3 Software In st a lla tion ............ ............. .. .. ........................... .. .. ........................... 9

2.4 Running L IN S e rial Analyzer P ro g ram ...... .. .......................... ... ............. .. .. ..... 9

Chapter 3. LIN Serial Analyzer PC Program ..............................................................11

3.1 Highlight s ......... ............. .. .. ........................... .. .. ........................... .. .. .............. 11

3.2 Interface Ov e r view .......................................................... .. .. ......................... 11

3.3 Transaction Window .....................................................................................12

3.4 File Functions ...............................................................................................14

3.5 Setup Functions ...........................................................................................16

3.6 Tools Functions ............................................................................................18

3.7 Start/Stop Logging Button ................................................................. ...........19

3.8 Master Message Group Box .........................................................................19

3.9 Status Bar ..................... .. .. ........................... .. .. ........................... .. .. .............. 22

Appendix A. LIN Serial Analyzer Technical Information ..........................................23

A.1 Highlight s .......... .......................... ... .. .......................... ... .. ............................. 2 3

A.2 LIN Serial Ana lyzer Schem a tic ............ .. ........................................ .. ... ......... 23

Index .............................................................................................................................25

Worldwide Sales and Service ....................................................................................27

© 2008 Microchip Technology Inc. DS51675B-page iii

Page 4

LIN Serial Analyzer User’s Guide Rev2.0

NOTES:

DS51675B-page iv © 2008 Microchip Technology Inc.

Page 5

LIN SERIAL ANALYZER

USER ’S GUIDE REV2.0

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

INTRODUCTION

®

IDE on-line help.

This chapter contains general information that will be useful to know before using the

LIN Serial Analyser. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the LIN Serial Analyser. The manual layout is as

follows:

• Chapter 1. “LIN Serial Analyser Overview” – What the LIN Serial Analyser is,

what makes it a desirable development tool and what features are available.

• Chapter 2. “Getting Started – Quick Setup” – Describes the supplies needed to

set up and begin to use the LIN Serial Analyser.

• Chapter 3. “LIN Serial Analyser PC Program” – Describes the primary

elements of the interface.

• Appendix A. “LIN Serial Analyzer Technical Information” – Provides the

detailed schematic of the LIN Serial Analyser.

© 2008 Microchip Technology Inc. DS51675B-page 1

Page 6

LIN Serial Analyzer User’s Guide Rev2.0

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

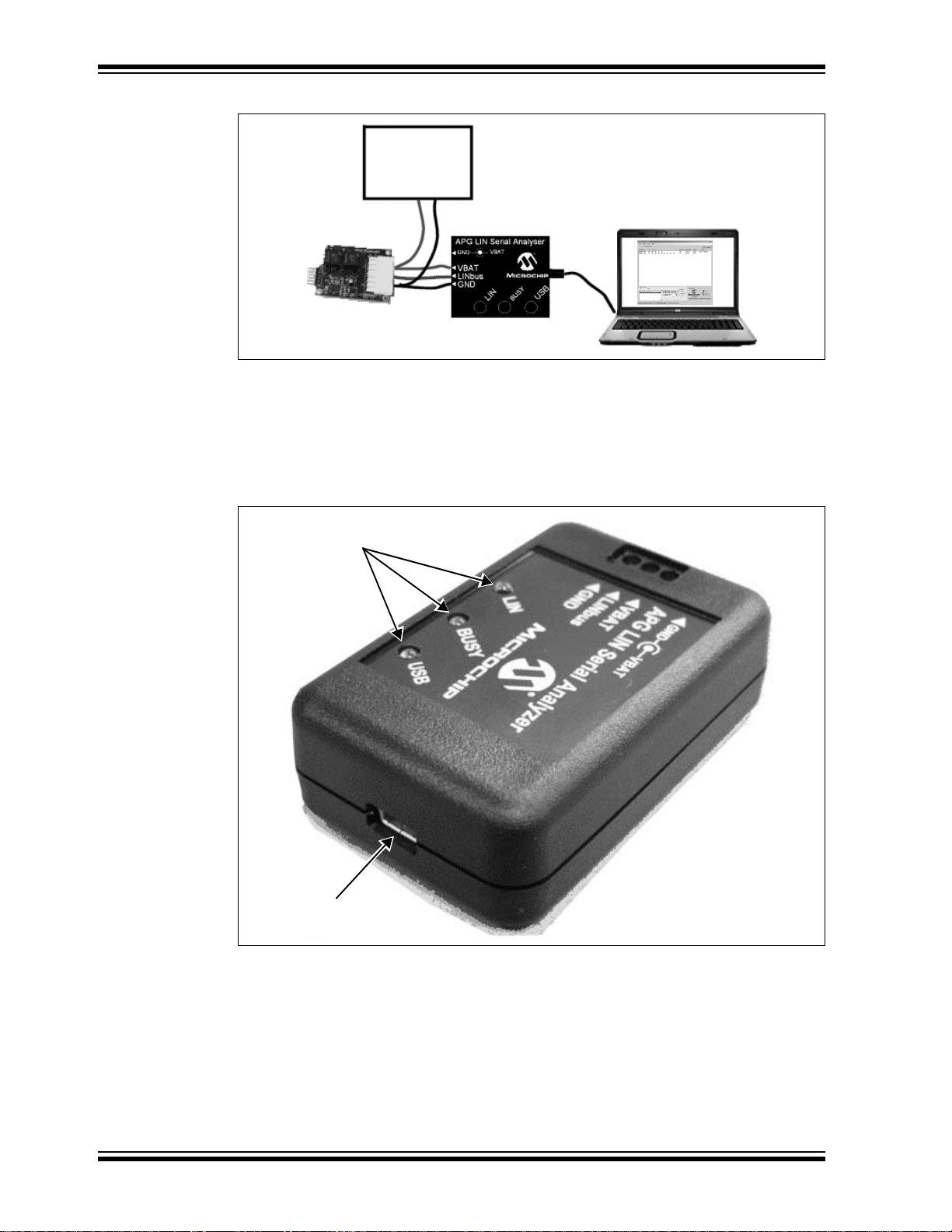

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only comp ile r...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sam ple source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

File names autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

®

IDE User’s Guide

“Save project before build”

4‘b0010, 2‘hF1

any valid file name

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

DS51675B-page 2 © 2008 Microchip Technology Inc.

Page 7

RECOMMENDED READING

This user’s guide describes how to use LIN Serial Analyser. Other useful documents

are listed below. The following Microchip documents are available and recommended

as supplemental reference resources.

It is recommended that you become familiar with the documents listed below before

using the LIN Serial Analyser.

PICkit™ Serial Analyzer User’s Guide (DS51647)

LIN Specification Package 2.1

© LIN Consortium, 2006. http://www.lin-subbus.org.

LIN Network for Vehicle Applications – Surface Vehicle Recommended Practice

(J2602/1)

© SAE 2006. http://www.sae.org.

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com.

DOCUMENT REVISION HISTORY

Revision A (June 2007)

• Initial release of this document.

Revision B (June 2008)

• Release describes new features of Revision 2.0 software.

© 2008 Microchip Technology Inc. DS51675B-page 3

Page 8

LIN Serial Analyzer User’s Guide Rev2.0

NOTES:

DS51675B-page 4 © 2008 Microchip Technology Inc.

Page 9

Chapter 1. LIN Serial Analyser Overview

1.1 INTRODUCTION

The LIN Serial Analyser development system enables a Personal Computer (PC) to

communicate with a LIN (Local Interface Network) bus. The PC program uses a graphical user interface to enter and display message frames occurring on the target bus.

The LIN Serial Analyser connects to the system network using a three-position terminal

block.

Chapter 2. “Getting Started” will guide you through installing the PC program, the

Windows

1.2 HIGHLIGHTS

This chapter discusses:

• LIN Serial Analyser Contents

• LIN Serial Analyser Development Tool

• LIN Serial Analyser Hardware

• LIN Serial Analyser Softwar e

LIN SERIAL ANALYZER

USER ’S GUIDE REV2.0

®

operating system drivers and setting up the hardware.

1.3 LIN SERIAL ANALYSER CONTENTS

The LIN Serial Analyser kit contains the following items:

• LIN Serial Analyser

• Mini-B USB Cable

• LIN Serial Analyser CD-ROM

1.4 LIN SERIAL ANALYSER DEVELOPMENT TOOL

The LIN Serial Analyser consists of several components, that together, make a network

debug and analysis tool. The user interface program runs on Microsoft

operating system compatible computers with a USB port.

The LIN Serial Analyser connects to the PC using a mini-B USB cable. The LIN Serial

Analyser interfaces to the target network using a three-position, screw-type terminal

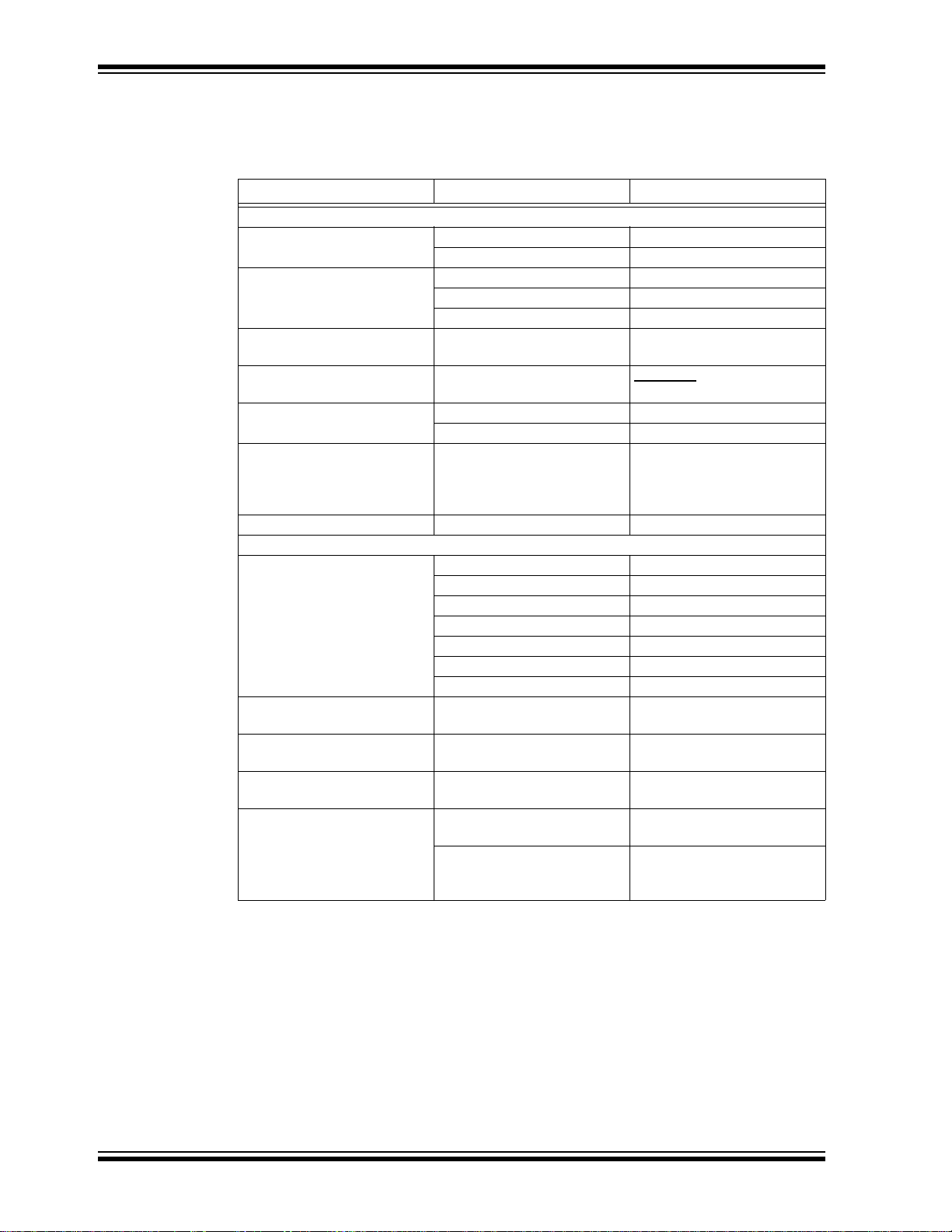

block. Figure 1-1 illustrates the LIN Serial Analyser tool connected to a network.

®

Windows®

© 2008 Microchip Technology Inc. DS51675B-page 5

Page 10

LIN Serial Analyzer User’s Guide Rev2.0

FIGURE 1-1: LIN SERIAL ANALYSER DEVELOPMENT TOOL

Optional

Power

Supply

Board Under Test

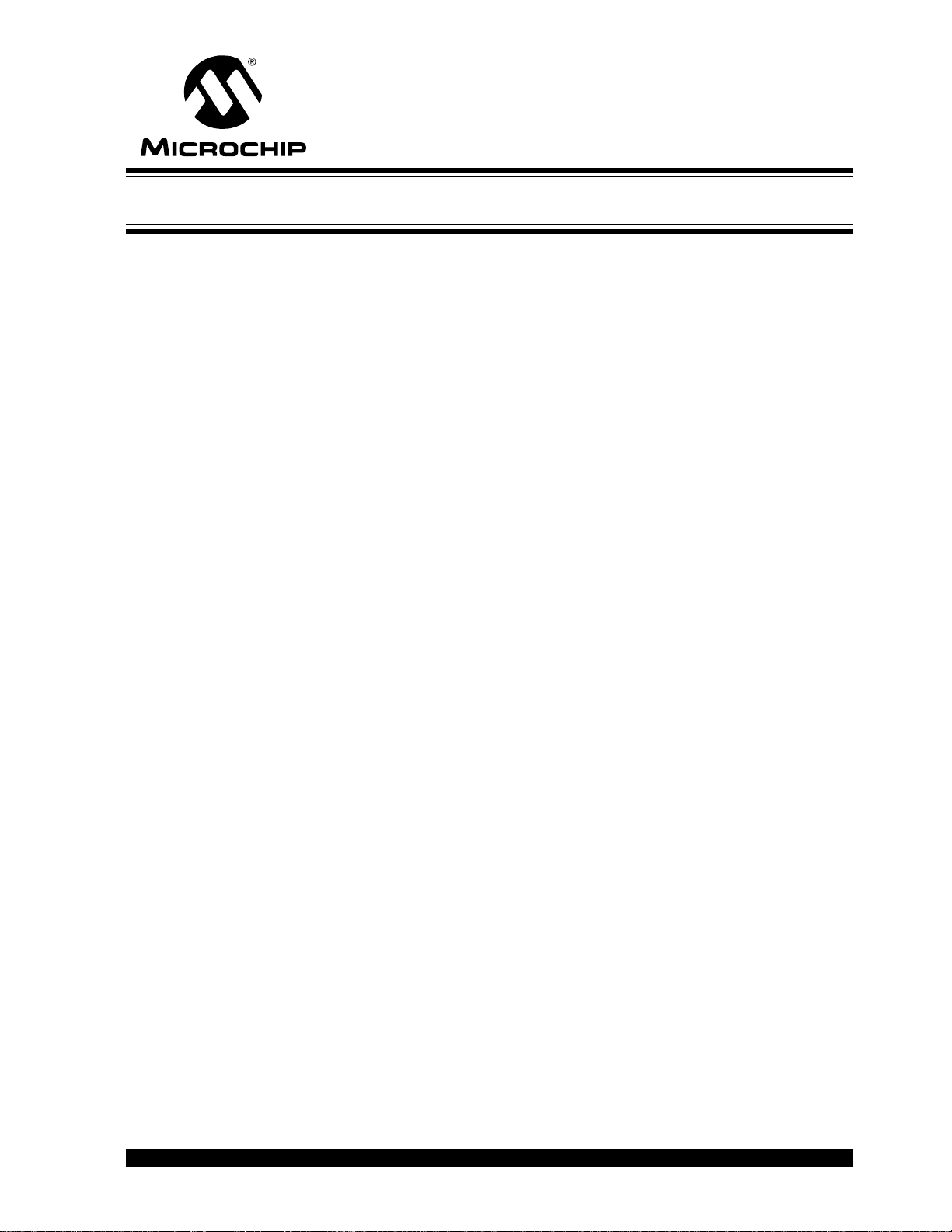

1.5 LIN SERIAL ANALYSER HARDWARE

The LIN Serial Analyser connects to a Microsoft® Windows® operating system

compatible computer using a USB port. It interfaces to the target network using a

three-position, screw-type terminal block.

FIGURE 1-2: LIN SERIAL ANALYSER

Status LEDs

LIN Tool

PC

USB Port

1.5.1 Status LEDs

The Status LEDs indicate the status of the LIN Serial Analyser. An illuminated LED

means:

• USB (green) – Power has been applied to the LIN Serial Analyser by the USB

port.

• Busy (yellow) – The LIN Serial Analyser is communicating with the LIN network.

• LIN (blue) – The LIN Serial Analyser is connected to the target bus.

DS51675B-page 6 © 2008 Microchip Technology Inc.

Page 11

LIN Serial Analyser Overview

1.5.2 USB Port Connection

The USB port connection is a USB mini-B connector. Connect the LIN Serial Analyser

to the PC using the cable supplied with the device.

FIGURE 1-3: LIN SERIAL ANALYSER NETWORK AND POWER

Terminal

Block

Screws

Auxiliary

Power

1.5.3 Network Communication Connector

The communication connector connects to the target device using a three-position,

screw clamp terminal block. The pin assignments, labeled on the top of the device, are:

• VBAT – Positive battery connection for voltage supplied by the vehicle

• LIN – Bidirectional data I/O

• GND – Common chassis, power and serial ground

1.5.4 Power Jack

The device us es a stan dard, 6.5 x 2.5 DC pow er plug. Th e center pi n is posit ive. Powe r

can be supplied either through the power plug or the network connector as the two are

internally connected.

1.6 LIN SERIAL ANALYSER SOFTWARE

1.6.1 User Interface Program

The LIN Serial Analyser PC program displays all of the board’s bus activity via the

software’s Transaction window, displayed on the connected PC. This is useful for

“sniffing” the bus and tracking message frames.

Chapter 3. “LIN Serial Analyser PC Program” explains the installation and operation

of the program.

Network

Connection

1.6.2 Firmware

The LIN Serial Analyser firmware is explained in Chapter 9. “PICkit™ Serial Analyzer

Firmware” of the “PICkit™ Serial Analyzer User’s Guide” (DS51647).

© 2008 Microchip Technology Inc. DS51675B-page 7

Page 12

LIN Serial Analyzer User’s Guide Rev2.0

1.6.3 Dynamically Linked Library (DLL)

The LIN Serial Analyser DLL is explained in Chapter 10. “PICkit™ Serial Analyzer

DLL” of the “PICki t™ Serial An alyzer User’s Guide” (DS51647).

DS51675B-page 8 © 2008 Microchip Technology Inc.

Page 13

LIN SERIAL ANALYZER

USER ’S GUIDE REV2.0

Chapter 2. Getting Started – Quick Setup

2.1 HIGHLIGHTS

This chapter discusses:

• Using the LIN Serial Analyzer for the First Time

• Software Installation

• Running LIN Serial Analyser Program

2.2 USING THE LIN SERIAL ANALYZER FOR THE FIRST TIME

The LIN Serial Analyser is shipped preprogrammed and ready for use. The user needs

to supply:

• A wiring harness with appropriate connections to its system network

• A power supply (nominal 13.8V)

Before making any connections, the software must be installed on the host system. The

user must have administrator level rights to install some of the required programs. For

more information, see Section 2.3 “Software Installation”.

Power is supplied either through the round, power plug or the terminal block. The

positive and negative terminals and power plug are common. Supplied power must be

in the range of 8.0V to 30.0V with a nominal value of 12.0-14.4V. Less than 5.0 mA of

current is required to power the LIN transceiver section of the unit.

Internal jumper, E1, configures the unit as either a master or slave node. A 1.0 kΩ bus

pull-up resistor is enabled when E1 is connected across A and B. With the jumper

removed, an internal 30 kΩ resistor is retained.

The unit is configured as a master node as shipped.

2.3 SOFTWARE INSTALLATION

All necessary files are contained on the Compact Disc (CD) supplied with the device.

2.3.1 Installing the LIN Serial Analys er Program

1. Run setup.exe from the CD.

2. Select Install when prompted and follow any instructions.

Note: The LIN Serial Analyser program requires the Microsoft

version 2.0.

The PC host program is uninstalled with the control panel’s add/remove utility.

®

.NET Framework

2.4 RUNNING LIN SERIAL ANALYSER PROGRAM

Before starting the LIN Serial Analyser software:

• The analyzer must be connected to the PC by a USB cable

• The analyzer must be powered up

The analyzer’s green USB and blue LIN lights will be on when these conditions are

met.

© 2008 Microchip Technology Inc. DS51675B-page 9

Page 14

LIN Serial Analyzer User’s Guide Rev2.0

There is a hard-wired, loopback bus path, so connection to a network is not needed for

testing the installation.

To start the software:

1. On the Windows operating system taskbar, click Start.

2. Click All Programs>Microchip Technology Inc.>

3. Click Setup>COM port

4. From the pull-down menu, select the USB port to be used.

Note: Only available, plugged in USB ports are displayed by the pull-down menu.

If the correct serial port is not displayed, verify that the USB hardware is

correctly installe d.

5. In the menu’s text box, type the appropriate baud rate value.

6. Click OK.

7. Verify operation by selecting one of the preset messages from the Master

Message area.

Bus activity is indicated by the analyzer’s yellow BUSY light flickering.

A message will be displayed in the Bus Transaction window with:

•A time-stamp

• The correct ID parity bits

• The calculated checksum

• Any detected error conditions

.

LIN Serial Analyser.

DS51675B-page 10 © 2008 Microchip Technology Inc.

Page 15

Chapter 3. LIN Serial Analyser PC Program

3.1 HIGHLIGHTS

This chapter discusses:

• Interface Overview

• Transaction Window

• File Functions

• Setup Functions

• Tools Functions

• Start/Stop Logging Button

• Master Message Group Box

•Status Bar

3.2 INTERFACE OVERVIEW

When the LIN Serial Analyser’s software program starts, the window, shown in Figure ,

appears. The commands are accessed through the pull-down menus at the top of the

interface.LIN Serial Analyzer User Interface

LIN SERIAL ANALYZER

USER ’S GUIDE REV2.0

Pull-Down

Menus

Start/Stop

Logging

Button

Transaction

Window

Master

Message

Group Box

Status B ar

© 2008 Microchip Technology Inc. DS51675B-page 11

Page 16

LIN Serial Analyzer User’s Guide Rev2.0

3.3 T RANSACTION WINDOW

This window, shown in Figure 3-1, constantly monitors and display bus traffic when in

the “Display All” mode. Any message frames seen on the bus are shown, regardless of

the source.

The data is displayed as it is seen on the bus without modification.

This section describes the window’s fields.

FIGURE 3-1: MESSAGE FRAMES DISPLAY

3.3.1 TimeStamp

This field of the Transaction window displays the time, in seconds, since the last frame

was received. The value is reset to zero when the window is cleared.

The value can also be cleared by clicking on the “TimeStamp” column label.

3.3.2 ID (Identifier)

This field displays the ID byte, including the upper two parity bits.

3.3.3 Data

From zero to eight data bytes are displayed in this field. The data is in the hexadecimal

format (without the leading characters, ‘0x’), with the bytes separated by spaces.

3.3.4 Checksum

The last field of a frame is the checksum. The checksum contains the inverted, eight-bit

sum with carry, over all data bytes or all data bytes and the protected identifier.

3.3.5 ChkSumType

This field indicates whether a “classic” or “enhanced” equation was used for the checksum calculation. For messages sent via the Master Message group box, the type of

calculation is configured in the checksum portion of the Master Message group box

(see Section 3.8.3 “Checksum Group”).

• Classic – Checksum calculation over the data bytes only. Used for the master

request frame, slave response frame and communications with LIN 1.x slaves.

An eight-bit sum with carry is equivalent to the sum of all values and subtracts

255 every time the sum is greater than or equal to 256.

• Enhanced – Checksum calculation over the data bytes and the protected identifier

byte. Used for communication with LIN 2.x slaves.

The checksum is calculated both ways when a message frame is received. A match is

displayed either as “Classic” or “Enhanced”. If neither result matches the incoming

data, “ERROR” is displayed.

3.3.6 Baud

This field shows the actual, calculated bit rate observed during the Auto-Baud Detect

period of the current frame.

DS51675B-page 12 © 2008 Microchip Technology Inc.

Page 17

LIN Serial Analyser PC Program

3.3.7 Errors

This field displays any of the error types described in this section. If multiple errors are

detected, only one is displayed .

3.3.7.1 PARITY The parity is calculated on the frame identifier bits as shown in Equation 3-1.

EQUATION 3-1: PARITY CALCULATIONS

P0 = ID0 ℘? ID1 ℘? ID2 ℘?

P1 = - (ID1 ℘? ID3 ℘? ID4 ℘? I

† P0 is bit 6 and P1 is bit 7 of the ID byte.

3.3.7.2 TX BIT A slave or master node that is transmitting a bit on the bus also monitors the bus. A TX

bit error is when the bit or byte value that is received is different from the bit or byte

value that is transmitted.

Note: This function is not currently implemented.

3.3.7.3 CHECKSUM A checksum error is when the inverted modulo-256 sum over all received data bytes

and the protected identifier (when using enhanced checksum) and the received

checksum byte field does not result in $FF.

3.3.7.4 FRAMING A byte field framing error is when the ninth bit after a valid Start bit is dominant. This

check does not apply to the Break character.

Note: This function is not currently implemented.

†

3.3.7.5 NO ANSWER This value displays when a new Break/Sync/ID header was detected, but no data was

received within the bus time-out period.

3.3.7.6 BREAK This displays when data characters were received before a valid Sync Break header

was detected.

Note: This function is not currently implemented.

3.3.7.7 BUS TIME-OUT This value indicates that the time interval allocated for an eight-byte message expired.

This time is set to approximately 140% of a single bit time.

The time-out may also be configured to a fixed value not dependent on baud rate.

3.3.7.8 SWBREAK This value displays when a valid Sync Break is not detected by the UART . A Break was

“assumed” because the first byte received was 0x00, but without a framing error.

Note: This function is not currently implemented.

© 2008 Microchip Technology Inc. DS51675B-page 13

Page 18

LIN Serial Analyzer User’s Guide Rev2.0

3.4 FILE FUNCTIONS

3.4.1 Open

The “Open” dialog box loads configuration and master message frames from a

user-selected file into the “Master Frames” field, so that they can be sent (see

Section 3.8.1 “Master Frames Field”).

By default, the dialog box, shown in Figure 3-2, displays the file that was last used in

the previous session.

T o display the dialog box, go to the pull-down menus at the top of the user interface and

select File>Open

FIGURE 3-2: FILE OPEN WINDOW

.

3.4.2 Save

The “Save” dialog box saves configuration and master message frames, displayed

in the “Master Frames” field, to a previously selected *.ini file (see

Section 3.8.1 “Master Frames Field”.) By default, the dialog box populates the

file name that was last used in the previous session.

T o display the dialog box, go to the pull-down menus at the top of the user interface and

select File>Save

DS51675B-page 14 © 2008 Microchip Technology Inc.

.

Page 19

LIN Serial Analyser PC Program

3.4.3 Save As

The “Save As” dialog box saves or appends configuration and master message

frames, displayed in the “Master Frames” field, to a preselected file (see

Section 3.8.1 “Master Frames Field”). The default file name is the last used file from

the previous session.

To display the dialog box, shown in Figure 3-3, go to the pull-down menus at the top of

the user interface and select File>Save As

FIGURE 3-3: FILE “Save As” WINDOW

.

3.4.4 Print, Print Setup, Print Preview

These three functions relate to printing the contents of the Transaction window.

Print Setup

will appear.

The printing function clears the contents of the Transaction window, but does not reset

the time-stamp.

All of these functions are accessible through the File

configures the printing attributes and Print Preview displays how the print

pull-down menu.

3.4.5 Exit

Selecting File>Exit terminates the LIN Serial Analyser software program.

© 2008 Microchip Technology Inc. DS51675B-page 15

Page 20

LIN Serial Analyzer User’s Guide Rev2.0

3.5 SETUP FUNCTIONS

The Tools pull-down menu has the following commands.

3.5.1 Setup COM port

The “Setup COM port” function selects the USB communication port to use.

Note: The “COM port” drop-down list box displays only available, plugged-in USB

ports. If the correct serial port is not displayed in the menu, verify that the

USB hardware is correctly installed.

The menu also sets the baud rate to apply to master transactions.

The “Timeout in mS” text box displays the current time-out value for a message frame

and may be modified by the user. To enable the time-out value to vary with the baud

rate, enter a value of 0.

FIGURE 3-4: “Setup COM port” WINDOW

To display the dialog box, select Setup>COM port

.

DS51675B-page 16 © 2008 Microchip Technology Inc.

Page 21

LIN Serial Analyser PC Program

3.5.2 Log File

The Log File setup function specifies the new or existing file that will store bus

transactions.

If an existing file that already contains data is selected, any new messages will be

appended to the end of the file.

FIGURE 3-5: LOG FILE SETUP WINDOW

To display the dialog box, select Setup>Log File

.

© 2008 Microchip Technology Inc. DS51675B-page 17

Page 22

LIN Serial Analyzer User’s Guide Rev2.0

3.5.3 Slave Response

The Slave Response setup function specifies message frames that are published to the

bus whenever the correct ID is recognized.

FIGURE 3-6: SLAVE RESPONSE SETUP WINDOW

To display the dialog box, select Setup>Slav e Response

.

3.5.4 Slave Response Frames Field

The “Slave Response Frames” field is composed of 0 to n rows of one or more messages that are sent over the bus in response to a valid ID byte. These messages can

be entered manually, loaded from a previously saved session, or both.

When the response is sent, it is displayed in the Transaction window if it is open and

active.

Messages in the “Slave Response Frames” field can also be saved for reuse (see

Section 3.4.2 “Save” and Section 3.4.3 “Save As”).

3.5.4.1 RESPONSE SYNTAX

Messages must consist of the ID byte without parity bits and the data bytes, all

separated by spaces. All inputs are in hexadecimal radix.

The checksum is not included; it is calculated at send time unless the “forced” Checksum option is selected.

Comments or notes may be attached to each frame by prefacing it with a

semi-colon (;). Any text after the semi-colon will be disregarded and not transmitted. All

notes will be saved in the selected .ini file and reloaded when reopened.

DS51675B-page 18 © 2008 Microchip Technology Inc.

Page 23

LIN Serial Analyser PC Program

3.5.4.2 DEVELOPING AND STORING RESPONSE CONTENT To manually add a slave response message content to the “Slave Response Frames”

field:

1. Click the Add button. A second window displays for creation of the new message.

2. Type the message in the text box.

3. Click OK.

To load a pre-existing message to the “Slave Response Frames” field:

WARNING

Importing a file into the “Slave Response Fram es” fi eld ov er writes any content that previously had been in that field.

1. From the pull-down menus, select File>Open

2. In the dialog box’s list box, select the desired *.ini file.

3. Click Open.

To delete some slave message content:

1. In the “Slave Response Frames” field, select the content to be deleted by doing

one of the following:

•To select adjacent rows of cont ent – Click on the first row, scroll down to the

last row and hold down <Shift> while clicking.

•To select non-adjacent rows of content – Hold down <Ctrl> while clicking each

row.

2. Click Delete.

To edit some slave message content:

1. In the “Master Frames” field, select the content line to be edited

1. Click Edit. A second window displays to edit hte message.

2. Make and corrections or additions to the message in the text box.

3. Click OK

To store a slave response message(s) into the buffer:

1. In the “Slave Responser Frames” field, select the content to be stored by doing

one of the following:

•To select adjacent rows of cont ent – Click on the first row, scroll down to the

last row and hold down <Shift> while clicking.

•To select non-adjacent rows of content – Hold down <Ctrl> while clicking each

row.

2. Click Save.

The highlighted message content is stored, working top-to-bottom through the

“Slave Response Frames” field.

The internal buffer status is updated to reflect the amount a bytes used and

remaining. If the amount of buffer space is exceeded, the Save operation is

aborted and a error message displayed. Reduce the number or size of the messages to be written to the buffer and retry the Save.

. The “Open” dialog box appears.

© 2008 Microchip Technology Inc. DS51675B-page 19

Page 24

LIN Serial Analyzer User’s Guide Rev2.0

To save a slave reponse message to a file:

1. See Section 3.4.2 “Save” and Section 3.4.3 “Save As”.

3.5.4.3 SLAVE RESPON S E FR AMES FIELD ELEMENTS This section describes the “Slave Response Frames ” field’s two elements.

3.5.4.3.1 ID

The “ID” element displays the identifier byte that is compared to identifier bytes

received from the bus. The ID is entered without the upper two parity bits. Parity is calculated and appended when the message frame is stored in the inernal buffer memory.

The acceptable range of values is 00 to 3F hex (0 to 63 decimal).

3.5.4.3.2 DATA

The “Data” portion of the “Slave Response Frames” field displays zero to eight-byte val-

ues, separated by spaces. This are the actual bytes sent over the bus in response to a

recognized ID.

3.5.5 Slave Response Message Controls

3.5.5.1 SAVE BUTTON Clicking this button stores the selected message content highlighted in the “Slave

Response Frames” field (see the “Save” procedure in Section 3.5.4.2 “Developing

and Storing Response Content”).

3.5.5.2 ADD BUTTON Click the Add button to add a new message to the “Slave Response” field

3.5.5.3 EDIT BUTTON Allows the selected message in the “Slave Response Frames” field to be edited.

3.5.5.4 DELETE BUTTON Clicking the Delete button deletes the content that is highlighted in the “Master Frames”

field. (see the “Delete” procedure in Section 3.5.4.2 “Developing and Storing

Response Content”).

3.5.5.5 CLEAR ALL BUTTON Clicking this button clears the both the contents of the “Slave Response Frames” win-

dow and the internal buffer memory. The buffer status is updated to show no used bytes

and bytes remaining.

3.5.6 Checksum Group

The checksum value is computed at send time. Selecting one of the

option buttons in the “Checksum” group, shown at right, determines

the type of checksum that will be calculated for all transmitted

master message frames, highlighted in the “Master Frames” field.

• classic – The checksum includes all data bytes.

• enhanced – The checksum includes identifier byte and all data

bytes.

• forced – (Enabled only in Debug mode.) The last byte in the message string is

sent in place of the calculated checksum. This is useful in checking master error

handling.

DS51675B-page 20 © 2008 Microchip Technology Inc.

Page 25

LIN Serial Analyser PC Program

The checksum returned by the slave will be displayed in the “Checksum” field of the

Transaction window (see Section 3.3.5 “ChkSumType”.)

© 2008 Microchip Technology Inc. DS51675B-page 21

Page 26

LIN Serial Analyzer User’s Guide Rev2.0

3.6 TOOLS FUNCTIONS

This sections lists the commands on the Tools pull-down menu.

3.6.1 Debug Mode

Selecting Tools>Debug Mode enables the user to debug bus or slave operational

issues.

One function forces a user-supplied checksum to be appended to a master message

to check a slave for proper error handling. In this mode, the generation of identifier

parity bits is inhibited and the identifier byte is transmitted without modification.

3.6.2 Suppress Bus Time-out Error

The current implementation of the master task cannot refer to a LIN descriptor file, so

there is no way to determine the length of any received message. To calculate an

appropriate time-out value, multiply the length of an eight-byte frame times 140% of the

bit rate.

This value can be overridden by entering a fixed time-out value in the COM Setup

window, described in Section 3.5.1 “Setup COM port”.

3.6.3 Clear Monitor Window

This function clears the Transaction window and resets the time-stamp.

3.6.4 Filters

This opens a window to display all messages received through the Transaction window

but are sorted by ID number. The window is ‘live’ and shows current bus traffic. New

message frames received will overwrite previous data. This is useful in monitoring constanly changes data.

3.6.5 Transmit

This option selects the Transmit Only mode. No received messages are displayed in

the Transaction window.

3.6.6 Listen (Filter)

This option selects the Listen Only mode. Only non-duplicated messages are displayed

in the Transaction window.

When “snooping” bus message frames, this prevents the Transaction window from

becoming cluttered with repeated frames.

3.6.7 Display All (Snoop) Default

This function selects the Display All mode. All messages seen on the bus are

displayed.

This mode is best used with the data logging feature to capture all bus traffic for later

analysis.

DS51675B-page 22 © 2008 Microchip Technology Inc.

Page 27

LIN Serial Analyser PC Program

e

3.7 START/STOP LOGGING BUTTON

This button – located in the top, right corner of the interface – starts, pauses, or stops

the capturing of messages to the log file.

Before starting the logging process, select and open a log file (see Section 3.5.2 “Log

File”).

To pause the logging process, click the button a second time.

3.8 MASTER MESSAGE GROUP BOX

This functions in the group box to act as a master node on the LIN bus, sending the

previously constructed frames to the slaves on the bus.

This window will cause a bus conflict if another master appears on the network. Any

conflict will be shown in an active Transaction window as a bus error.

The group box, shown in Figure 3-7, consists of the:

• “Master Frames” field

• “Checksum” group

• Message controls

FIGURE 3-7: MASTER MESSAGE GROUP BOX

“Master Fram

Field

“Checksu

Group

Message

Controls

3.8.1 Master Frames Field

The “Master Frames” field is composed of 0 to n rows of one or more messages that

can be sent over the bus for test purposes. These messages can be entered manually,

loaded from a previously saved session, or both.

When the message is sent, it and any response is displayed in the Transaction window

if it is open and active.

Messages in the “Master Frames” field can also be saved for reuse (see

Section 3.4.2 “Save” and Section 3.4.3 “Save As”).

3.8.1.1 MESSAGE SYNTAX Messages must consist of the ID byte without parity bits and the data bytes, all

separated by spaces. All inputs are in hexadecimal radix.

The checksum is not included; it is calculated at send time.

Comments or notes may be attached to each frame by prefacing it with a

semi-colon (;). Any text after the semi-colon will be disregarded and not transmitted. All

notes will be saved in the selected .ini file and reloaded when reopened.

© 2008 Microchip Technology Inc. DS51675B-page 23

Page 28

LIN Serial Analyzer User’s Guide Rev2.0

3.8.1.2 DEVELOPING AND STORING MESSAGE CONTENT

To manually add message content to the “Master Frames” field:

1. Click the Add button. A second window displays for creation of the new mes-

sage.

2. Type the message in the text box.

3. Click OK.

To load a pre-existing message to the “Master Frames” field:

WARNING

Importing a file into the “Master Frames” field overwrites any content that previously

had been in that field.

1. From the pull-down menus, select File>Open

2. In the dialog box’s list box, select the desired *.ini file.

3. Click Open.

To delete some message content:

1. In the “Master Frames” field, select the content to be deleted by doing one of the

following:

•To select adjacent rows of cont ent – Click on the first row, scroll down to the

last row and hold down <Shift> while clicking.

•To select non-adjacent rows of content – Hold down <Ctrl> while clicking each

row.

2. Click Delete.

To edit some message content:

1. In the “Master Frames” field, select the content line to be edited

1. Click Edit. A second window displays to edit hte message.

2. Make and corrections or additions to the message in the text box.

3. Click OK

To send a message:

1. In the “Master Frames” field, select the content to be sent by doing one of the

following:

•To select adjacent rows of cont ent – Click on the first row, scroll down to the

last row and hold down <Shift> while clicking.

•To select non-adjacent rows of content – Hold down <Ctrl> while clicking each

row.

2. Click Send.

The highlighted message content is sent, working top-to-bottom through the

“Master Frames” field.

The message is sent once. (For information on continuall y se ndi ng the

highlighted message content, see Section 3.8.3 “Checksum Group”.)

. The “Open” dialog box appears.

DS51675B-page 24 © 2008 Microchip Technology Inc.

Page 29

LIN Serial Analyser PC Program

To store a message:

1. See Section 3.4.2 “Save” and Section 3.4.3 “Save As”.

3.8.1.3 MASTER FRAMES FIELD ELEMENTS This section describes the “Master Frames” field’s two elements.

3.8.1.3.1 ID

The “ID” element displays the identifier byte to be sent without the upper two parity bits.

Parity is calculated and appended at send time unless the application is in the Debug

mode (see Section 3.6.1 “Debug Mode”).

The acceptable range of values is 00 to 3F hex (0 to 63 decimal).

3.8.1.3.2 DATA

The “Data” portion of the “Master Frames” field displays zero to eight-byte values,

separated by spaces.

3.8.2 Message Controls

3.8.2.1 SEND BUTTON Clicking this button transmits the message content that is highlighted in the “Master

Frames” field (see the “Send” procedure in Section 3.8.1.2 “Developing and Storing

Message Content”).

When the Send button is clicked, the message is sent once (see

Section 3.8.3 “Checksum Group”).

If the Transaction window is open and active, the message and any response will be

displayed.

3.8.2.2 CONTINUOUS BUTTON Clicking the Continuous button sends the selected message entry or entries continu-

ously, at an interval defined in the time control text box, described next. A second click

of the button stops the continuous transmissions.

Any number of messages may be selected for continuous broadcast. They will be

transmitted in the order they appear in the “Master Frames” field.

3.8.2.3 TIME CONTROL Used in conj unction with the Continuous button, this text box sets the interval, in

milliseconds, between message frames being sent in the Continuous mode.

Note: Due to service latency time in the Windows operating system environment,

the minimum time interval may be as high as 200 ms, regardless of desired

time set in the control box. Intervals less than 200 ms will be serviced as

fast as possible, but may not be less than the operating system minimum.

3.8.2.4 ADD BUTTON Click the Add button to add a new message to the “Master Frames” field

3.8.2.5 EDIT BUTTON Allows the selected message in the “Master Frames” field to be edited.

© 2008 Microchip Technology Inc. DS51675B-page 25

Page 30

LIN Serial Analyzer User’s Guide Rev2.0

3.8.2.6 DELETE BUTTON

Clicking the Delete button deletes the content that is highlighted in the “Master Frames”

field. (see the “Delete” procedure in Section 3.8.1.2 “Developing and Storing Message

Content”).

3.8.3 Checksum Group

The checksum value is computed at send time. Selecting one of the

option buttons in the “Checksum” group, shown at right, determines

the type of checksum that will be calculated for all transmitted

master message frames, highlighted in the “Master Frames” field.

• classic – The checksum includes all data bytes.

• enhanced – The checksum includes identifier byte and all data

bytes.

• forced – (Enabled only in Debug mode.) The last byte in the message string is

sent in place of the calculated checksum. This is useful in checking slave error

handling.

If a slave response is requested (a ID value with no data bytes), the checksum is not

computed and the field is left blank.

The checksum returned by the slave will be displayed in the “Checksum” field of the

Transaction window (see Section 3.3.5 “ChkSumType”.)

3.9 STATUS BAR

The status bar at the bottom of the Interface window displays:

• Currently selected baud rate of master messages

• Dynamic LIN network status

DS51675B-page 26 © 2008 Microchip Technology Inc.

Page 31

LIN SERIAL ANALYZER

USER ’S GUIDE REV2.0

Appendix A. LIN Serial Analyzer Technical Information

A.1 HIGHLIGHTS

This chapter discusses:

• LIN Serial Analyzer Schemati c

A.2 LIN SERIAL ANALYZER SCHEMATIC

The LIN Serial Analyzer management hardware diagram is shown in Figure A-1.

© 2008 Microchip Technology Inc. DS51675B-page 27

Page 32

LIN Serial Analyzer User’s Guide Rev2.0

FIGURE A-1: LIN SERIAL ANALYZER SCHEMATIC

P2

BUS

V

D-2D+3nc4GND

1

5

USB Mini-B

R14.7KLED1 Blue LED

R2470

LED2 Yellow LED

DD

V

R7

R5

C4

C3

3

R4470

CC

V

LED3 Green LED

R6 0

100K

100K

.01 MF

1.0 MF

V

DD

C10

CC

V

0.1 MF

D5

C9

470 nF

RX

TX

CSWAKE

FAULT/TXE

1N4004

BUSY

20

18

19

RB0/INT0/AN12

RB1/INT1/AN10

25

22

24

23

21

RB6KBI2/PGC

RB3/AN9/VPO

RB7/KBI3/PGD

RB5/KBI1/PGM

RB4/AN11/KBI0

RB2/AN8/INT2/VMO

CC

V

V

DD

17

4

2

8

TX

1

RX

U2

/RE3

PP

11

13

10

9

12

14

USB

V

RC4/D-/VM

RC5/D+/VP

15

RC6/TX/CK

RC7/RX/DT

8

RC2/CCP1

RC1/T1OSI/UOE

RC0/T1OSO/T13CKI

-

+

REF

REF

GND

GND

16

5

CC

V

R104.7K

PIC18F2450-QFN

RA3/AN3/V

RA4/T0CLI/RCV

RA5/AN4/LVDIN

3

4

2

USB_ATTACH

R9 100K

D3

1N4148WX-TP

BB

V

D2 1N4004

BAT

GND

LBUS

V

123

J1

C2

C1

D1

U1

.01 MF

10 MF

7

CS/WAKE

V

BAT

FAULT/TXE

LIN

6

R3 1K

E1

C5

D4

1 2

P6SMB43AT3G

GND

MCP2021-500

5

220 pF

MMBZ27VCLT1G

231

LIN_ATTACH

P1

26

J2

MCLR/V

OSC1/CLKIN

6

C6 22 pF

CC

V

12345

TM

PICkit 2

OSC2/CLKOUT/RA6

7

20 MHz

Y1

C8 22 pF

0.1 MF

C7

6

RA0/AN0

RA1/AN1

1

27

28

R810K

RA2/AN2/V

DS51675B-page 28 © 2008 Microchip Technology Inc.

Page 33

Index

LIN SERIAL ANALYZER

USER ’S GUIDE REV2.0

B

Buttons

Start/Stop Logging............................................19

C

Clear Monitor Window Function...............................18

Customer Support......................................................3

D

Data Field Element .................................................. 21

Debug Mode Function..............................................18

Display All (Snoop) Default Function.......................18

Documentation

Additional Reading........................... ...... ..... ...... ..3

Conventions........................................................2

Layout................................................................. 1

E

Exit Function.......................... ...... ...... ..... ...... ........... 15

F

File Menu

Exit....................................................................15

Open................................................................. 14

Print .................................................................. 15

Save..................................................................14

Save As ............................................................ 15

H

Hardware

Connecting to PC.............................................. ..6

Contents of Kit................................. ...... ............. 5

LIN Serial Analyzer Schematic.........................24

Network Connector............................................. 7

Overview ............................................................. 5

Power Jack.........................................................7

Status LEDs........................................................6

USB Connection.................................................7

I

ID Field Element ......................................................20

Installing Software......................................................9

Internet Address.........................................................3

L

LIN Serial Analyzer User Interface........................... 11

Listen (Filter) Function............................ .................18

Log File Function.....................................................17

M

Master Frames Field

Data ..................................................................21

Deleting Message Content..................... ...........20

Developing and Storing

Message Content...............................20

ID ......................................................................20

Loading Pre-Existing Message Content............20

Manually Creating a Message ..........................20

Saving Message Content..................................20

Sending Messages...........................................20

Master Message Group Box....................................19

Checksum Group..............................................22

Master Frames Field.........................................19

Master Frames Field Elements.........................20

Message Controls.............................................21

Message Controls

Continuous Button............................................21

Delete Button....................................................21

Send Button......................................................21

Time Control .....................................................21

Messages

Creating Manually.............................................20

Deleting Message Content..................... ...........20

Developing and Storing.......................... ...........20

Loading Pre-Existing Content...........................20

Saving Message Content..................................20

Sending.............................................................20

Microchip Internet Web Site.......................................3

O

Open Function..........................................................14

P

Print Function...........................................................15

Print Preview Function.............................................15

Print Setup Function.................................................15

S

Save As Function............................................... ......15

Save Function................... ..... ...... ...... ..... .................14

Setup COM port Function........................................16

Setup Menu..............................................................16

Log File.............................................................17

Setup COM port................................................16

© 2008 Microchip Technology Inc. DS51675B-page 25

Page 34

LIN Serial Analyzer User’s Guide Rev2.0

Software

Dynamically Linked Library (DLL).......................8

File Menu..........................................................14

Firmware.............................................................8

Installation...........................................................9

Interface Window..............................................11

Master Message Group Box .............................19

Overview.............................................................8

Prelaunch Tasks.................................................9

Setup Menu.......................................................16

Starting the Software ........................................10

Status Bar.........................................................22

Tools Menu.......................................................18

Transaction Window.........................................12

Start/Stop Logging Button........................................19

Suppress ‘Bus Timeout’ Error Function..... ..... ...... ....18

T

Tools Menu ..............................................................18

Clear Monitor Window.......................................18

Debug Mode .....................................................18

Display All Default.............................................18

Listen (Filter).....................................................18

Suppress ‘Bus Timeout’ Error...........................18

Transmit............................................................18

Transaction Window.................................................12

Baud..................................................................12

Checksum.........................................................12

ChkSumType ....................................................12

Data...................................................................12

Errors ................................................................13

Break..........................................................13

Bus Time-out..............................................13

Checksum..................................................13

Framing......................................................13

No Answer .................................................13

Parity..........................................................13

SWBreak....................................................13

TX Bit.............................. ...... ...... ..... ...... ....13

ID (Identifier) .....................................................12

TimeStamp........................................................ 12

Transmit Function.....................................................18

W

WWW Address...........................................................3

DS51675B-page 26 © 2008 Microchip Technology Inc.

Page 35

NOTES:

Index

© 2008 Microchip Technology Inc. DS51675B-page 27

Page 36

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

06/25/07

DS51675B-page 32 © 2008 Microchip Technology Inc.

Loading...

Loading...