Page 1

HV583

128-Channel High-Voltage Driver IC

Evaluation Board

User’s Guide

2015 Microchip Technology Inc. DS50002447A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

FlashFlex, flexPWR, JukeBlox, K

LANCheck, MediaLB, MOST, MOST logo, MPLAB,

OptoLyzer , PIC, PICSTART, PIC

SST, SST Logo, SuperFlash and UNI/O are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

The Embedded Control Solutions Company and mTouch are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, BodyCom, chipKIT, chipKIT logo,

CodeGuard, dsPICDEM, dsPICDEM.net, ECAN, In-Circuit

Serial Programming, ICSP , I nter-Chip Connectivity, KleerNet,

KleerNet logo, MiWi, motorBench, MPASM, MPF, MPLAB

Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach,

Omniscient Code Generation, PICDEM, PICDEM.net, PICkit,

PICtail, RightTouch logo, REAL ICE, SQI, Serial Quad I/O,

Total Enduranc e, TSHARC , USBC heck, VariSense,

ViewSpan, WiperLock, Wireless DNA, and ZENA are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2015, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

ISBN: 978-1-5224-0112-4

EELOQ, KEELOQ logo, Kleer,

32

logo, RightT ouch, S pyNIC,

QUALITY MANAGEMENT S

DS50002447A-page 2 2015 Microchip Technology Inc.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

Object of Declaration: HV583 128-Channel High-Voltage Driver IC Evaluation Board

2015 Microchip Technology Inc. DS50002447A-page 3

Page 4

NOTES:

DS50002447A-page 4 2015 Microchip Technology Inc.

Page 5

HV583

128-CHANNEL HIGH-VOLTAGE DRIVER IC

EVALUATION BOARD USER’S GUIDE

Table of Contents

Preface ...........................................................................................................................7

Introduction............................................................................................................7

Document Layout .................................................................................................. 7

Conventions Used in this Guide............................................................................ 8

Warranty Reg is tr at io n...... .. ............... .......................................... ........................... 8

Recommended Reading.............................................................. .. ........................9

The Microchip Web Site........................................................................................ 9

Development Systems Customer Change Notification Servi ce.................. ..........9

Customer Support....................... ....................................................... .................10

Document Revision History................................................................................. 10

Chapter 1. Product Overview

1.1 Introduction ...................................................................................................11

1.2 HV583 Dev ic e Ove rview .......................................... .. ... ............................... 11

1.3 HV583 Eva lu a ti on Bo a rd O v er view ................................... .. .. ....................... 11

1.4 HV583 Eval u ation Board Kit Con te n ts ............ ................ ............................. 13

Chapter 2. Installation and Operation

2.1 Getting Sta rted ............................................................................................. 15

2.2 Setup Procedure ..........................................................................................15

2.3 Using the Evaluation Board with a Generic Logic Signal

Pattern Generator ................................................................................... 17

2.4 Using the Evaluation Board with the PIC32 Starter Kit (DM320001) ........... 19

Appendix A. Schematic and Layouts

A.1 Introduction ..................................................................................................25

A.2 Evaluatio n B o ar d – S c he matic .... ........................... .. .. .............. .. .. ............. .. . 26

A.3 Evaluatio n B o ar d – T o p S il k .............................................. .. ......................... 27

A.4 Evaluation Board – Top Copper and Silk .....................................................27

A.5 Evaluation Board – Top Copper ...................................................................28

A.6 Evaluation Board – Ground Plane ...............................................................28

A.7 Evaluatio n B o ar d – Mid L ay e r 1 ............. ........................... .. .. ....................... 29

A.8 Evaluatio n B o ar d – Mid L ay e r 2 ............. ........................... .. .. ....................... 29

A.9 Evaluation Board – Power Plane .................................................................30

A.10 Evaluation Board – Bottom Copper ...........................................................30

A.11 Evaluation Board – Bottom Copper and Silk ..............................................31

A.12 Evaluatio n B oa r d – Bo tto m Silk ..... .......................................... .................. 31

Appendix B. Bill of Materials (BOM)...........................................................................33

Appendix C. HV583 Typical Waveforms

C.1 Introduction ..................................................................................................35

Worldwide Sales and Service ....................................................................................40

2015 Microchip Technology Inc. DS50002447A-page 5

Page 6

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

NOTES:

DS50002447A-page 6 2015 Microchip Technology Inc.

Page 7

HV583

128-CHANNEL HIGH-VOLTAGE DRIVER IC

EVALUATION BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DS50000000A”, where “50000000” is the document number and “A” is the revision level of

the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

HV583 128-Channel High-Voltage Driver IC Evaluation Board. Items discussed in this

chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the HV583 128-Channel High-Voltage Driver IC

Evaluation Board as a development tool. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information about the HV583

128-Channel High-Voltage Driver IC Evaluation Board.

• Chapter 2. “Installation and Operation” – This chapter includes a detailed

description of each function of the HV583 128-Channel High-Voltage Driver IC

Evaluation Board and instructions on how to use it.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the HV583 128-Channel High-Voltage Driver IC Evaluation Board.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the HV583

128-Channel High-Voltage Driver IC Evaluation Board.

• Appendix C. “HV583 Typical Waveforms” – Describes the various plots and

waveforms for the HV583 128-Channel High-Voltage Driver IC Evaluation Board.

2015 Microchip Technology Inc. DS50002447A-page 7

Page 8

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic chara c ters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Te xt in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mut ually exclus ive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly. Sending in the Warranty Registration Card entitles users to receive new product updates.

Interim software releases are available at the Microchip web site.

DS50002447A-page 8 2015 Microchip Technology Inc.

Page 9

RECOMMENDED READING

This user’s guide describes how to use the HV583 128-Channel High-Voltage Driver

IC Evaluation Board. Other useful documents are listed below. The following Microchip

documents are available and recommended as supplemental reference resources.

• HV583 Data Sheet – “128-Channel Serial to Parallel Converter with Push-Pull

Outputs” (DS20005461).

Additional documentation (including schematic and code samples) is available under

the PIC32 Starter Kit (DM320001) section on the web site.

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This

web site is used as a means to make files and information easily available to

customers. Accessible by using your favorite Internet browser, the web site contains

the following information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s custom er not ifi cati on service h elp s kee p cust omer s current on M icrochi p

products. Subscribers will rece ive e-mail notification whenever there are chang es, updates,

revisions or errata rela ted to a spec ified prod uct famil y or developme nt tool of interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest info rmatio n on Microc hip C comp ilers, as semblers , linker s

and other language tools. These include all MPLAB

assemblers (including MPASM™ assembler); all MPLAB linkers (including

MPLINK™ object linker); and all MPLAB librarians (including MPLIB™

object librarian).

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB REAL ICE™ and MPLAB ICE 2000 in-circuit emulators.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debuggers. This includes MPLAB ICD 3 in-circuit debuggers and PICkit™ 3

debug express.

• MPLAB IDE – The latest information on Microchip MPLAB IDE, the Windows

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB IDE Project Manager, MPLAB Editor and

MPLAB SIM simulator, as well as general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

production programmers such as MPLAB REAL ICE in-circuit emulator, MPLAB

ICD 3 in-circuit debugger and MPLAB PM3 device programmers. Also included

are nonproduction development programmers, such as PICkit 2 and 3.

®

C compilers; all MPLAB

®

2015 Microchip Technology Inc. DS50002447 A-page 9

Page 10

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support

DOCUMENT REVISION HISTORY

Revision A (December 2015)

• Initial release of this documen t.

DS50002447A-page 10 2015 Microchip Technology Inc.

Page 11

Chapter 1. Product Overview

1.1 INTRODUCTION

This chapter covers the following topics:

• HV583 Device Overview

• HV583 Evaluation Board Overview

• HV583 Evaluation Board Kit Contents

1.2 HV583 DEVICE OVERVIEW

The HV583 is a unipolar 128-channel, low-voltage serial to high-voltage parallel

converter with push-pull outputs, dedicated to printer driver and plasma display

applications. The device has been designed for applications that require high channel

count and high output voltage swing (0-80V) with current sinking and sourcing

capabilities of 30 mA.

The device consists of four parallel 32-bit Shift registers, a 128-bit latch and

128 high-voltage outputs. The 32-bit Shift registers can operate up to a 40 MHz speed

rate, allowing for fast data update. The parallel arrangement of the registers permits

four times the speed of a single register, providing a fast update rate for the 128 output

channels. Data flow can be shifted from a clockwise to a counterclockwise direction via

the DIR pin. All high-voltage outputs can be forced to a low-level, high-level or

high-impedance state (high Z) through the OL

HV583

128-CHANNEL HIGH-VOLTAGE DRIVER IC

EVALUATION BOARD USER’S GUIDE

, OH and OE pins, respectively.

1.3 HV583 EVALUATION BOARD OVERVIEW

The HV583 128-Channel High-Voltage Driver IC Evaluation Board facilitates the quick

implementation for display and printer driver applications with its flexible input/output

connection interface.

The evaluation board is designed to be operated together with the Microchip

T echnology PIC32 Starter Kit (DM320001) or with a generic signal pattern generator via

the dedicated J5 pin header connector (see Figure 1-1).

There are 32 test point pads corresponding to the first 32-bit register (D1A/D1B) that

control the high-voltage outputs: HV

with the test point pads to facilitate the analysis of the high-voltage output channels.

Refer to Figure 1-1 and to the HV583 Data Sheet.

All output channels are available via a 160-position, high-density array female

connector, where only 128 positions are used (refer to the Evaluation Board –

Schematic in Appendix A. “Schematic and Layouts” for more details).

OUT

0, 4, 8...124. Ground pads are provided along

2015 Microchip Technology Inc. DS50002447A-page 11

Page 12

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

POWER CONNECT

128-it

>atch

VDD

VPP

HV

OUT

0

HV

OUT

127

D

0

D

1

D

2

D

3

D

4

D

5

D

6

D

7

Q

0

Q

1

Q

2

Q

3

Q

4

Q

5

Q

6

Q

7

D

124

D

125

D

126

D

127

Q

124

Q

125

Q

126

Q

127

PGND

DGND

D1B

D1A

D2B

D2A

D3B

D3A

D4B

D4A

CLK

RST

LE

OH

OL

OE

DIR

32-it

^hift

Zegister

32-it

^hift

Zegister

32-it

^hift

Zegister

32-it

^hift

Zegister

1

2

3

4

5

6

Legend:

1

=

FX10A-120S/12-SV(71) connector (J2) for PIC32 Starter Kit (DM320001), not inclu ded

2

=

Header connector for (generic) signal pattern generator (J5), not installed

3

=

HV583 169-Ball TFBGA package

4=Power connection pin header

5

=

32 HV

OUT

n test points and ground pads

6

=

160-posit ion, high-density array female connector

The HV583 contains four parallel 32-bit Shift registers. Each 32-bit Shift register features two po rts that ca n be set as ei ther i nput s or out put s by co ntrol ling t he DIR pin, a s

shown in the following list:

• setting the DIR pin high enables the DnA pins as inputs and the DnB pins as

outputs (counterclockwise input data)

• setting the DIR pin low configures DnB pins as inputs and DnA pins as outputs

(clockwise input data)

Shunt (zero Ohm) resistors are placed right after the pin header connectors (D1B to

D4B) to facilitate the adjustment of the Input registers in any desired manner.

Note: The HV583 128-Channel High-Voltage Driver IC Evaluation Board comes

equipped with shunt resistors only on the DnB pins. Shunt resistors are not

installed on the DnA pins.

1.3.1 HV583 Evaluation Board Block Diagram

Figure 1-1 presents the HV583 128-Channel High-Voltage Driver IC Evaluation Board

block diagram with the main sections labeled and explained.

FIGURE 1-1: HV583 128-Channel High-Voltage Driver IC Evaluation Boa rd Bloc k Diagr am.

DS50002447A-page 12 2015 Microchip Technology Inc.

Page 13

1.4 HV583 EV ALUATION BOARD KIT CONTE NTS

The HV583 128-Channel High-Voltage Driver IC Evaluation Board Kit includes:

• HV583 128-Channel High-Voltage Driver IC Evaluation Board (ADM00677)

• Important Information Sheet

Product Overview

FIGURE 1-2: HV583 128-Channel High-Voltage Driver IC Evaluation Boar d – Top View.

2015 Microchip Technology Inc. DS50002447A-page 13

Page 14

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

NOTES:

DS50002447A-page 14 2015 Microchip Technology Inc.

Page 15

Chapter 2. Installation and Operation

2.1 GETTING STARTED

The HV583 128-Channel High-Voltage Driver IC Evaluation Board is fully assembled

and tested.

2.1.1 Tools Required for Operation

• A low DC power supply for VDD (and VDD_PIC) that can produce 5V

• A high DC power supply for V

• A logic signal driver: PIC32 Starter Kit (DM320001) or a generic signal pattern

generator

• An oscilloscope and/or a multimeter to observe waveforms and measure electrical

parameters.

2.2 SETUP PROCEDURE

HV583

128-CHANNEL HIGH-VOLTAGE DRIVER IC

EVALUATION BOARD USER’S GUIDE

with a voltage range up to +80V

PP

To prepare the HV583 128-Channel High-Voltage Driver IC Evaluation Board for

operation, the following steps must be followed:

WARNING

Read the HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s

Guide (this document) fully before proceeding to board setup.

1. Connect the power supplies by following the steps indicated by this power-up

sequence:

a) Connect GND

b) Apply V

c) Connect VDD_PIC (if PIC32 Starter Kit is mounted and used)

d) Set logic input signals to a known state

e) Apply V

Note 1: If the PIC32 Starter Kit is used and connected to the USB debug cable,

Note: To power down the board, follow the reverse order of the power-up

DD

PP

there is no need to power the VDD_PIC pin.

sequence.

(1)

2015 Microchip Technology Inc. DS50002447A-page 15

Page 16

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

Board Power-up

Sequence:

1. GND

2. V

DD

3. VDD_PIC

4. Logic signals

to known state

5. V

PP

FIGURE 2-1: Board Power-up Sequence.

2. Apply the voltage settings by following the steps indicated in Table 2-1.

TABLE 2-1: VOLTAGE SETTINGS

Step Terminal Name Description

1 GND Ground

2V

3 VDD_PIC 5.0V, power supply for PIC32 Starter Kit

4VPP+15V to +80V, high-voltage power supply for all HV

Note 1: If the PIC32 Starter Kit is used and not connected to the USB debug cable.

DD

5.0V, logic power supply for HV583

After following the power-up sequence and applying the voltage settings correctly, the

evaluation board is ready to operate.

The HV583 128-Channel High-Voltage Driver IC Evaluation Board can be driven by a

generic signal pattern generator or by the suggested PIC32 Starter Kit (DM320001).

Section 2.3 “Using the Evaluation Board with a Generic Logic Signal Pattern

Generator” and Section 2.4 “Using the Evaluation Board with the PIC32 Starter

Kit (DM320001)” elaborate on the operation and evaluation process in detail.

(1)

OUT

n

DS50002447A-page 16 2015 Microchip Technology Inc.

Page 17

Installation and Operation

J5 Pin

Header Connector

2.3 USING THE EVALUATION BOARD WITH A GENERIC LOGIC SIGNAL PATTERN GENERATOR

2.3.1 Introduction

The HV583 128-Channel High-Voltage Driver IC Evaluation Board can be operated by

a generic logic signal pattern generator, or by any signal driver, via the J5 pin header

connector (pin header not installed).

FIGURE 2-2: J5 Pin Header Connector.

The user must ensure the minimum DC and AC electrical parameters are achieved by

the signal pattern generator. For more information, refer to the HV583 data sheet

(DS20005461).

2.3.2 Operating the Evaluation Board

When operating the evaluation board with a generic logic signal pattern generator, the

VDD_PIC pin should not be powered on. The VDD_PIC pin is an optional power pin

used only for the PIC32 Starter Kit (DM320001).

In case a read operation is required for the signal driver, it is recommended to operate

the pattern generator at the same voltage potential as the evaluation board (V

for instance, the signal pattern generator is operating at a lower voltage (e.g., 3.3V)

than that of the evaluation board (5.0V), this will cause the ESD protection diodes of

the signal generator to forward bias and possibly damage the board.

If a read-back operation is required by the generic signal pattern generato r (or

by any signal driver), the operational voltage level of the logic signals must be

equal to the voltage potential of the evaluation board (V

WARNING

DD

). If,

DD

).

2015 Microchip Technology Inc. DS50002447A-page 17

Page 18

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

CLK

D1B

LE

t

SU1

= 5 ns (MIN)

OE

DIR

D2B, D3B, D4B

RST

th1= 5 ns (MIN)

HV

OUT

124, HV

OUT

116

HV

OUT

108

Rest of channels OFF

32123456 3031

Data Transmission

V

OH

V

OL

t

pHZ

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

t

pLH

t

r

Time: 0

OH,OL

Figure 2-3 presents the logic diagram of a sample data transmission for testing and

understanding the functionality of the HV583.

FIGURE 2-3: Sample Data Transmission Timing Diagram.

DS50002447A-page 18 2015 Microchip Technology Inc.

Page 19

Installation and Operation

FX10A-120S/12-SV(71)

J2 Connector

2.4 USING THE EVALUATION BOARD WITH THE PIC32 STARTER KIT (DM320001)

2.4.1 Introduction

The HV583 128-Channel High-Voltage Driver IC Evaluation Board can be operated by

the Microchip PIC32 Starter Kit (DM320001) via the FX10A-120S/12-SV(71)

connector, J2 (see Figure 2-4).

Note: Several PIC32 Starter Kits might be compatible with the HV583 Evaluation

Board, but only the DM320001 is supported with code.

2.4.2 Software Requirements

In order to operate the PIC32 Starter Kit, the MPLAB® X IDE software and MPLAB®

XC32 compiler must be installed in the user’s system. Software and compilers are

available for download on the Microchip web site at: www.microchip.com.

For detailed information regarding the installation and usage of MPLAB

refer to the “MPLAB

®

X IDE User’s Guide” (DS50002027).

2.4.3 Connecting the PIC32 Starter Kit to the HV583 Evaluation Board

Mount the PIC32 Starter Kit (DM320001) onto the J2 connector before powering up the

board. Follow the power-up sequence and apply the voltage settings indicated in

Section 2.2 “Setup Procedure”.

X IDE software,

FIGURE 2-4: FX10A-120S/12-SV(71 ) Conn ector, J2.

2015 Microchip Technology Inc. DS50002447A-page 19

Page 20

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

TRASMIT DATA

TO

H

VOUT

n

MAKE ALL H

VOUT

n

LOW

START

INITIALIZE PORTS

NO

YES

SW1?

YES

NO

SW2?

SW3?

YES

NO

YES

MAKE ALL H

VOUT

n

HIGH

NO

ANY BUTTON

PRESS

2.4.4 PIC32 Starter Kit Software Code

The source code for driving the HV583 128-Channel High-Voltage Driver IC Evaluation

Board, PIC32_HV583.x, is available for download on the Microchip web site. The

objective of the code is to provide a starting platform for utilizing the HV583 evaluation

board.

The code flowchart is presented in Figure 2-5.

FIGURE 2-5: Program Code Flowchart.

DS50002447A-page 20 2015 Microchip Technology Inc.

Page 21

Installation and Operation

Table 2-2 provides a summary of the software code operation.

TABLE 2-2: SOFTWARE CODE OPERATION

Switch Description

SW1 LED 1 turns on, data is sent to Input registers, D1B, D2B, D3B and D4B

SW2 LED 2 turns on, makes all (HV

SW3 LED 3 turns on, makes all (HV

Note 1: Push button switches are located on the PIC32 Starter Kit; see Figure 2-6 and

Section 2.4.6 “Modifying the Control Signals and Data in the Code”.

n) High-Voltage channels low (GND)

OUT

n) High-Voltage channels high (VPP)

OUT

(1)

FIGURE 2-6: HV583 128-Channel High-Voltage Driver IC Evaluation Board with PIC32 Starter Kit (DM320001) Connected on J2 – Top View.

2.4.5 Programming the PIC32 Starter Kit

This section assumes that the MPLAB X IDE software and the MPLAB XC32 compiler

are installed on the user’s system, and the PIC32 Starter Kit is connected to the PC via

the USB debug cable.

To load the PIC32_HV583.x code, follow these steps:

1. Open the MPLAB X IDE and then the PIC32_HV583.x program code.

2. Select the Clean and Build Project icon ( ). Ignore warning messages.

3. Select the Make and Program Device icon ( ).

2015 Microchip Technology Inc. DS50002447A-page 21

Page 22

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

FIGURE 2-7: MPLAB® X IDE Workspace.

2.4.6 Modifying the Control Signals and Data i n the Code

To modify the control signals and the data to be sent to the HV583, open the

HV583_defines.h file located under the Header Files folder.

To change the control signals, LE, OE, DIR, RST, OH

file labeled, INPUT CONTROL SIGNALS (see Figure 2-8), and modify accordingly.

Data transmission is controlled by pressing the push button switches on the PIC32

Starter Kit (see Figure 2-6). The user can select one of three available cases:

• HV583_CASE_1_ENABLE and HV583_CASE_1_DISABLE control the data

transmission; selectable by pr es si ng SW 1.

• HV583_CASE_2_ENABLE makes all HV

n channels low; selectable by

OUT

pressing SW2.

• HV583_CASE_3_ENABLE makes all HV

n channels high; selectable by

OUT

pressing SW3.

and OL, locate the section in the

FIGURE 2-8: Input Control Signals: LE, OE, DIR, RST, OH

and OL.

To change the data to be sent to the Input registers of the HV583, scroll to the bottom

of the file, locate the section, DATA TO SEND TO REGISTERS, and change the values

as desired (see Figure 2-9).

The HV583 consists of four 32-bit Shift registers.

The first 32-bit register uses D1A/D1B as input/output pins. The second register uses

D2A/D2B, the third register uses D3A/D3B and the fourth register uses D4A/D4B.

In the code, DATA_1, corresponds to the first bit of data to be sent to all of the four

registers. The Least Significant Bit (LSB) corresponds first to D1A/D1B, second to

D2A/D2B, third to D3A/D3B, and fourth to D4A/D4B.

DS50002447A-page 22 2015 Microchip Technology Inc.

Page 23

Installation and Operation

FIGURE 2-9: Data to Send to the HV583 Input Registers.

The code flow is specified in the main.c file (see Figure 2-7) located under the Source

Files folder.

NOTICE

By default, the code provided sends data into the DnB Input registers of the HV583.

WARNING

The PIC32 Starter Kit (DM320001) cannot be used to read data back from the

HV583 Evaluation Board because of the difference in the logic voltage level:

3.3V (PIC32) vs. 5.0V (V

in the PIC32 board to forward bias and possibly damage the board.

2015 Microchip Technology Inc. DS50002447A-page 23

). If used, this will cause the ESD protection diodes

DD

Page 24

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

NOTES:

DS50002447A-page 24 2015 Microchip Technology Inc.

Page 25

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the following layouts and schematic for the HV583

128-Channel High-Voltage Driver IC Evaluation Board (ADM00677):

• Evaluation Board – Schematic

• Evaluation Board – Top Silk

• Evaluation Board – Top Copper and Silk

• Evaluation Board – Top Copper

• Evaluation Board – Ground Plane

• Evaluation Board – Mid Layer 1

• Evaluation Board – Mid Layer 2

• Evaluation Board – Power Plane

• Evaluation Board – Bottom Copper

• Evaluation Board – Bottom Copper and Silk

• Evaluation Board – Bottom Silk

HV583

128-CHANNEL HIGH-VOLTAGE DRIVER IC

EVALUATION BOARD USER’S GUIDE

2015 Microchip Technology Inc. DS50002447A-page 25

Page 26

DS50002447A-page 26 2015 Microchip Technology Inc.

HV583

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

A.2 EVALUATION BOARD – SCHEMATIC

Page 27

A.3 EVALUATION BOARD – TOP SILK

Schematic and Layouts

A.4 EVALUATION BOARD – TOP COPPER AND SILK

2015 Microchip Technology Inc. DS50002447A-page 27

Page 28

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

A.5 EVALUATION BOARD – TOP COPPER

A.6 EVALUATION BOARD – GROUND PLANE

DS50002447A-page 28 2015 Microchip Technology Inc.

Page 29

A.7 EVALUATION BOARD – MID LAYER 1

Schematic and Layouts

A.8 EVALUATION BOARD – MID LAYER 2

2015 Microchip Technology Inc. DS50002447A-page 29

Page 30

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

A.9 EVALUATION BOARD – POWER PLANE

A.10 EVALUATION BOARD – BOTTOM COPPE R

DS50002447A-page 30 2015 Microchip Technology Inc.

Page 31

Schematic and Layouts

A.11 EVALUATION BOARD – BOTTOM COPPER AND SILK

A.12 EVALUATION BOARD – BOTTOM SILK

2015 Microchip Technology Inc. DS50002447A-page 31

Page 32

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

NOTES:

DS50002447A-page 32 2015 Microchip Technology Inc.

Page 33

HV583

128-CHANNEL HIGH-VOLTAGE DRIVER IC

EVALUATION BOARD USER’S GUIDE

Appendix B. Bill of Materials (BOM)

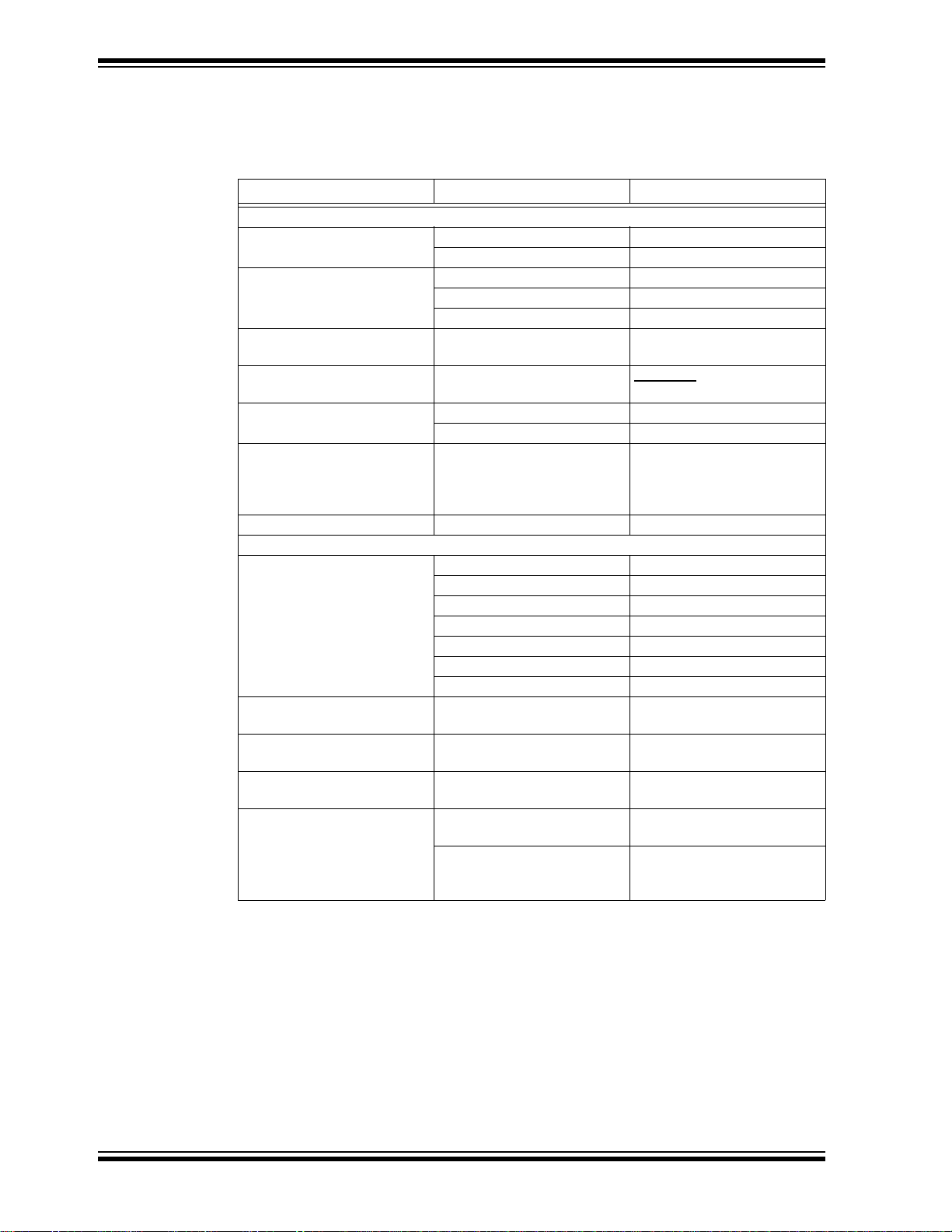

TABLE B-1: BILL OF MATERIALS (BOM)

Qty. Designator Description Manufacturer Part Number

1 C1 Ceramic Capacitor, 1 µF, 100V AVX Corporation 12061C105KAT2A

1 C2 Ceramic Capacitor, 0.1 µF, 25V AVX Corporation 06033C104JAT2A

1 J1 160 Position High-Density Array

Connector, Female

1 J2 Board-to-Board High-S peed Connector ,

120 Positions, w/Post, SMD

1 J3 Connector Header, 4 Positions,

100", SGL, Gold

4 GND Connector PC Pin, Circular,

0.030 Diameter, Gold

6 N/A Rubber Bumper Square, 0.5"L x 0.5"W,

Black

1 PCB HV583 128-Channel High-Voltage

Driver IC Evaluation Board – Printed

Circuit Board

4 R1, R3, R5,

R7

4 R2, R4, R6, R8Resistor, SMD, 0.0Ohm, Jump er,

1 U1 HV583, Unipolar 128-Channel

Note: The component s listed in this Bill of Materia ls are repre senta tive of the PCB assemb ly. The released BOM

used in manufacturing uses all RoHS-compliant components.

DO NOT POPULATE ——

1/10W

Low-voltage Serial to

High-Voltage Parallel Converter with

Push-Pull Outputs

Molex®, LLC 0465574145

Hirose Electric Co. Ltd. FX10A-120S/12-SV(71)

Samtec Inc. TSW-104-07-G-S

Mill-Max Manufacturing

Corp.

3M SJ-5518 (BLACK)

— 04-10436

Stackpole Electronics,

Inc.

Microchip Technology

Inc.

3132-0-00-15-00-00-08-0

RMCF0603ZT0R00

HV583GA-G

2015 Microchip Technology Inc. DS50002447A-page 33

Page 34

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

NOTES:

DS50002447A-page 34 2015 Microchip Technology Inc.

Page 35

Appendix C. HV583 Typical Waveforms

5V/Div

5V/Div

5V/Div

5V/Div

Time = 800 ns/Div

C.1 INTRODUCTION

Waveforms presented in this section correspond to two consecutive data

transmissions: Transmission 1 and Transmission 2. No load is connected to the output

channels.

C.1.1 Transmission 1

HV583

128-CHANNEL HIGH-VOLTAGE DRIVER IC

EVALUATION BOARD USER’S GUIDE

Turns on HV

124, 116, 108 and 0. Turns off the rest of the HV

OUT

channels.

OUT

The control signals not shown in the waveforms have the states listed in Table C-1:

TABLE C-1: TRANSMISSION 1: CONTROL SIGNAL STATES

Signal State

DIR Low

RST Low

OH

OL

D2B Low

D3B Low

D4B Low

High

High

FIGURE C-1: Transmission 1.

2015 Microchip Technology Inc. DS50002447A-page 35

Page 36

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

5V/Div

5V/Div

5V/Div

40V/Div

Time = 800 ns/Div

20V/Div

5V/Div

Time = 100 ns/Div

FIGURE C-2: Transmission 1: HV

124 Displayed Instead of OE.

OUT

FIGURE C-3: Transmission 1: Zoom Version, LE and HV

OUT

124.

DS50002447A-page 36 2015 Microchip Technology Inc.

Page 37

C.1.2 Transmission 2

5V/Div

5V/Div

5V/Div

5V/Div

Time = 800 ns/Div

HV583 Typical Waveforms

Turns on HV

channels. This transmission illustrates the turn-off transition for HV

a high level (V

116, 108 and 0. Turns off HV

OUT

) due to Transmission 1.

PP

124 and the rest of the HV

OUT

OUT

OUT

124, which i s at

The control signals not shown in the waveforms have the states listed in Table C-2:

TABLE C-2: TRANSMISSION 2: CONTROL SIGNAL STATES

Signal State

DIR Low

RST Low

OH

OL

D2B Low

D3B Low

D4B Low

High

High

FIGURE C-4: Transmission 2.

2015 Microchip Technology Inc. DS50002447A-page 37

Page 38

HV583 128-Channel High-Voltage Driver IC Evaluation Board User’s Guide

5V/Div

5V/Div

5V/Div

40V/Div

Time = 800 ns/Div

20V/Div

5V/Div

Time = 100 ns/Div

FIGURE C-5: Transmission 2: HV

124 Displayed Instead of OE.

OUT

FIGURE C-6: Transmission 2: Zoom Version, LE and HV

OUT

124.

DS50002447A-page 38 2015 Microchip Technology Inc.

Page 39

NOTES:

HV583 Typical Waveforms

2015 Microchip Technology Inc. DS50002447A-page 39

Page 40

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Te chn ica l Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

New Yor k , NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Canada - Toronto

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2943-5100

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Dongguan

Tel: 86-769-8702-9880

China - Hangzhou

Tel: 86-571-8792-8115

Fax: 86-571-8792-8116

China - Hong Kong SAR

Tel: 852-2943-5100

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8864-2200

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

ASIA/PACIFIC

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-3019-1500

Japan - Osaka

Tel: 81-6-6152-7160

Fax: 81-6-6152-9310

Japan - Tokyo

Tel: 81-3-6880- 3770

Fax: 81-3-6880-3771

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-213-7828

Taiwan - Taipei

Tel: 886-2-2508-8600

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Dusseldorf

Tel: 49-2129-3766400

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Venice

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Poland - Wars a w

Tel: 48-22-3325737

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

07/14/15

DS50002447A-page 40 2015 Microchip Technology Inc.

Loading...

Loading...