Page 1

F1 LV Evaluation Platform

Motor Control Add-Ons

User’s Guide

2012 Microchip Technology Inc. DS41629A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, chipKIT,

chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net,

dsPICworks, dsSPEAK, ECAN, ECONOMONITOR,

FanSense, HI-TIDE, In-Circuit Serial Programming, ICSP,

Mindi, MiWi, MPASM, MPLAB Certified logo, MPLIB,

MPLINK, mTouch, Omniscient Code Generation, PICC,

PICC-18, PICDEM, PICDEM.net, PICkit, PICtail, REAL ICE,

rfLAB, Select Mode, Total Endurance, TSHARC,

UniWinDriver, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2012, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

QUALITY MANAGEMENT S

DS41629A-page 2 2012 Microchip Technology Inc.

ISBN: 9781620761236

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

F1 LV EVALUATION PLATFORM

MOTOR CONTROL ADD-ONS

Table of Contents

Chapter 1. F1 LV Evaluation Platform Overview

1.1 Introduction ............................................................................................. 13

1.2 Hardware Overview ................................................................................ 13

1.2.1 Evaluation Platforms .............................................................................. 13

1.2.2 Add-on Boards ....................................................................................... 13

1.2.3 USB Interface ........................................................................................ 14

1.2.4 Add-on Board Power ............................................................................. 14

1.2.5 Add-on Board Memory .......................................................................... 14

1.3 PC Software Overview ........................................................................... 14

1.4 Using the F1LVDemo Control Software ................................................. 17

1.4.1 Software Updates .................................................................................. 17

1.4.2 Serial Link .............................................................................................. 17

1.4.3 Connecting the F1 LV Evaluation Platform to the Add-on Board .......... 17

1.4.4 Connecting the F1 LV Evaluation Platform to the PC ............................ 17

1.4.5 Open Versus Closed Loop .................................................................... 18

1.4.6 Changing Motor Parameters ................................................................. 18

1.4.7 Saving and Restoring Motor Parameters .............................................. 18

1.4.8 Hints for Optimum Performance ............................................................ 19

1.4.9 Header File Versus GUI Motor Parameters ........................................... 19

Chapter 2. The BLDC Add-on Board

2.1 Overview ................................................................................................. 21

2.1.1 Features ................................................................................................ 21

2.1.2 What’s Included ..................................................................................... 21

2.1.3 Reference Documents ........................................................................... 22

2.2 Board Setup ............................................................................................ 22

2.3 Hardware ................................................................................................ 22

2.3.1 General Architecture .............................................................................. 22

2.3.2 Attaching the Motor ............................................................................... 23

2.3.3 Power-Up ............................................................................................... 23

2.3.4 Power Stage .......................................................................................... 23

2.3.5 Protection .............................................................................................. 24

2.3.6 Speed Control ........................................................................................ 24

2.4 Demo Software ....................................................................................... 24

2.4.1 Introduction ............................................................................................ 24

2.4.2 The Motor Control GUI Application ........................................................ 24

2.4.3 BLDC Parameter Optimization .............................................................. 25

Chapter 3. The Brushed DC Add-on Board

3.1 Getting Started ....................................................................................... 29

3.1.1 Overview ................................................................................................ 29

3.1.2 Features ................................................................................................ 29

3.1.3 What’s Included ..................................................................................... 29

2012 Microchip Technology Inc. DS41629A-page 3

Page 4

F1 LV Evaluation Platform Motor Control Add-Ons

3.1.4 Reference Documents ...........................................................................30

3.2 Board Setup ............................................................................................ 30

3.3 Hardware ................................................................................................ 30

3.3.1 General Architecture ..............................................................................30

3.3.2 Attaching the Motor ................................................................................31

3.3.3 Power-Up ...............................................................................................31

3.3.4 Power Stage ..........................................................................................31

3.3.5 Protection ...............................................................................................32

3.3.6 UNI/O

3.3.7 Speed Control ........................................................................................32

3.4 Demo Software ....................................................................................... 32

3.4.1 Introduction ............................................................................................32

3.4.2 The Motor Control GUI Application ........................................................32

Chapter 4. The Bipolar Stepper Add-on Board

4.1 Getting Started ....................................................................................... 33

4.1.1 Overview ................................................................................................33

4.2 Features ................................................................................................. 33

4.2.1 What’s Included .....................................................................................33

4.2.2 Reference Documents ...........................................................................33

4.3 Getting Started ....................................................................................... 34

4.4 Hardware ................................................................................................ 34

4.4.1 General Architecture ..............................................................................34

4.4.2 Attaching the Motor ................................................................................35

4.4.3 Power-Up ...............................................................................................35

4.4.4 Power Stage ..........................................................................................35

4.4.5 Protection ...............................................................................................36

4.4.6 UNI/O

4.4.7 Speed Control ........................................................................................36

4.4.8 Current Control ......................................................................................36

4.5 Demo Software ....................................................................................... 37

4.5.1 Introduction ............................................................................................37

4.5.2 The Motor Control GUI Application ........................................................37

4.6 Optimizing Stepper Motor Parameters ................................................... 38

4.6.1 Stepper Motor Closed-Loop Drive Overview .........................................38

4.6.2 Optimizing DUTY_SCALE and SPEED_SCALING_CONST .................39

®

Memory Chip .............................................................................32

®

Memory Chip .............................................................................36

Chapter 5. The Unipolar Stepper Add-on Board

5.1 Getting Started ....................................................................................... 41

5.1.1 Overview ................................................................................................41

5.1.2 Features .................................................................................................41

5.1.3 What’s Included .....................................................................................41

5.1.4 Reference Documents ...........................................................................42

5.2 Getting Started ....................................................................................... 42

5.3 Hardware ................................................................................................ 42

5.3.1 General Architecture ..............................................................................42

5.3.2 Attaching the Motor ................................................................................43

5.3.3 Power-Up ...............................................................................................43

5.3.4 Power Stage ..........................................................................................43

5.3.5 Protection ...............................................................................................44

DS41629A-page 4 2012 Microchip Technology Inc.

Page 5

5.3.6 UNI/O® Memory Chip ............................................................................ 44

5.3.7 Speed Control ........................................................................................ 44

5.3.8 Current Control ...................................................................................... 44

5.4 Demo Software ....................................................................................... 45

5.4.1 Introduction ............................................................................................ 45

5.4.2 The Motor Control GUI Application ........................................................ 45

5.5 Optimizing Stepper Motor Parameters ................................................... 46

5.5.1 Stepper Motor Closed-Loop Drive Overview ......................................... 46

5.5.2 Optimizing DUTY_SCALE and SPEED_SCALING_CONST ................ 47

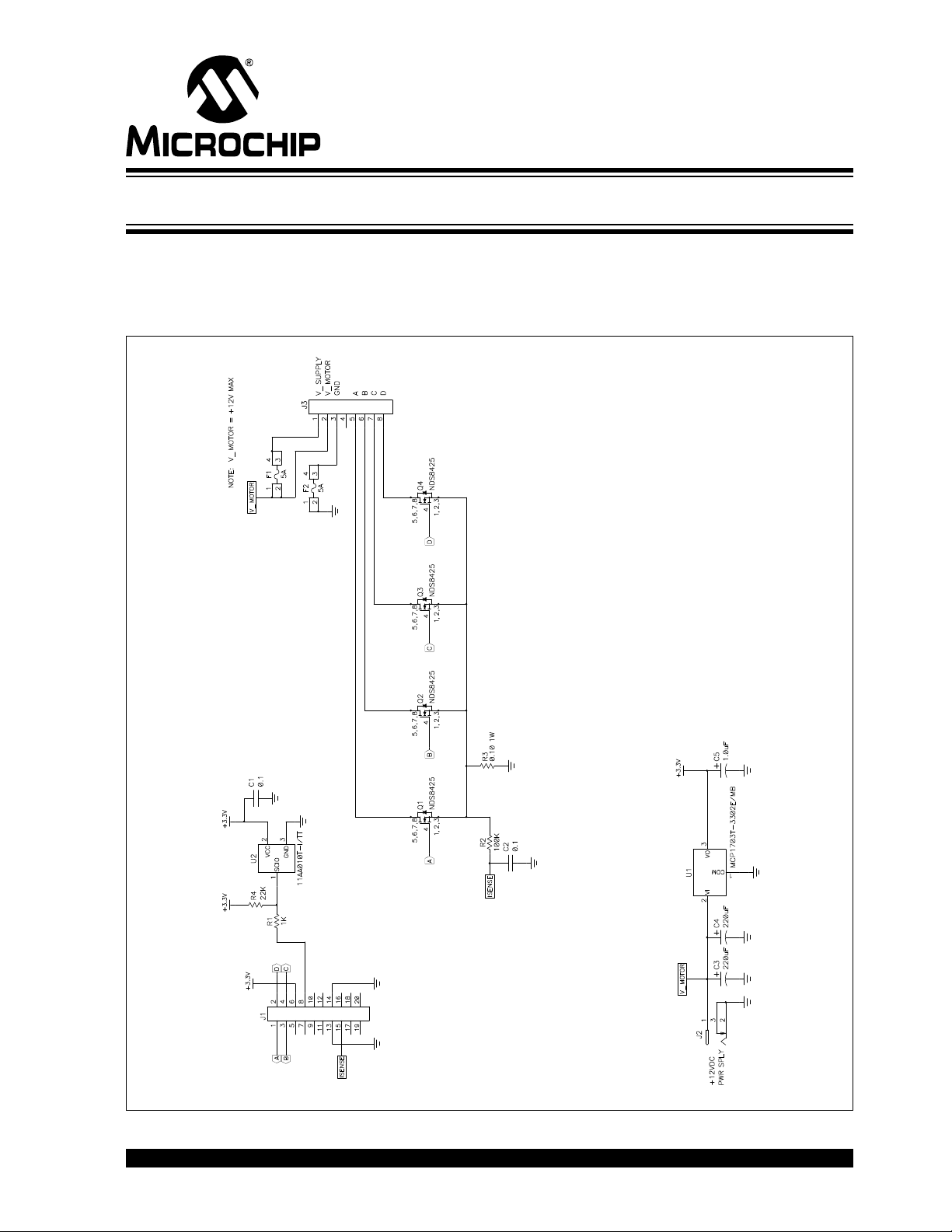

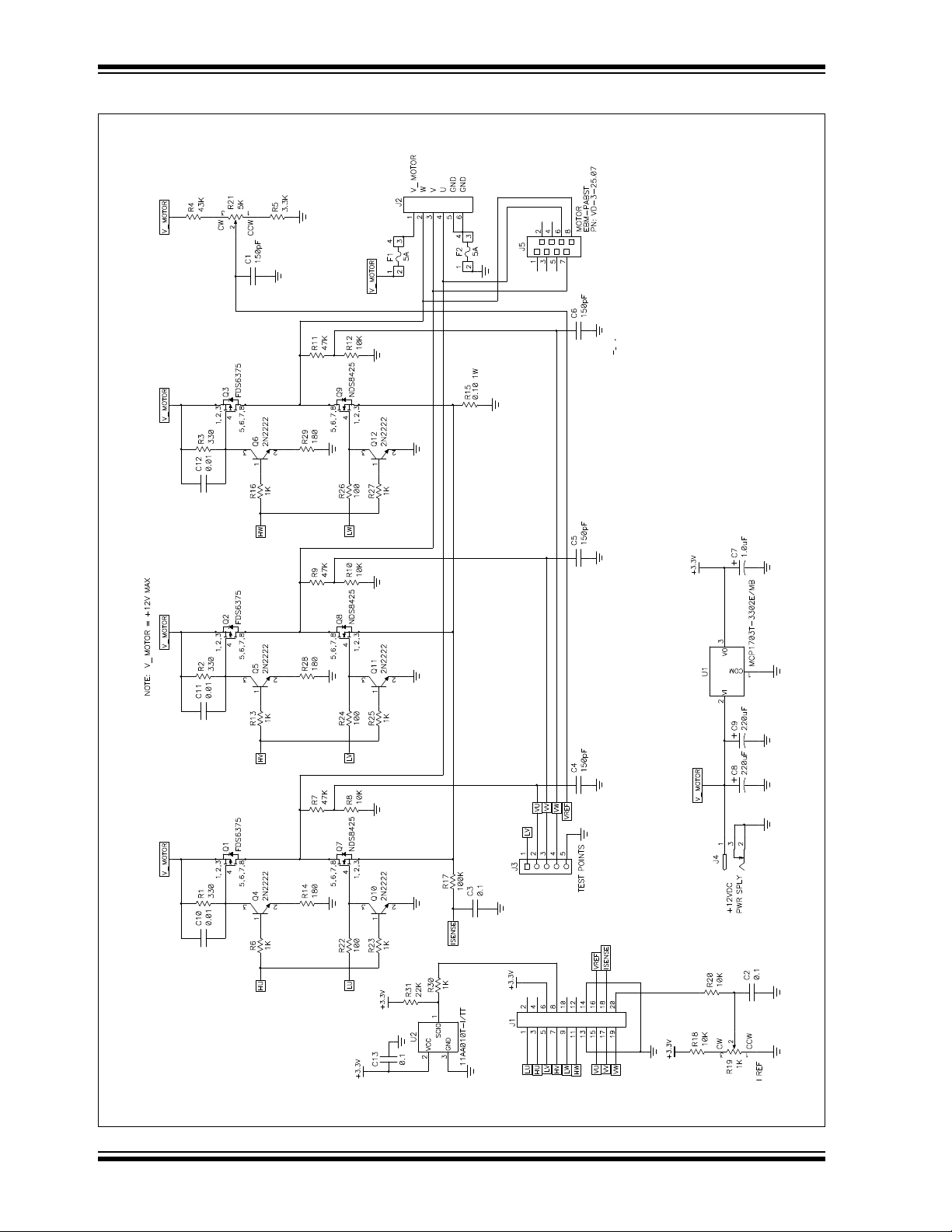

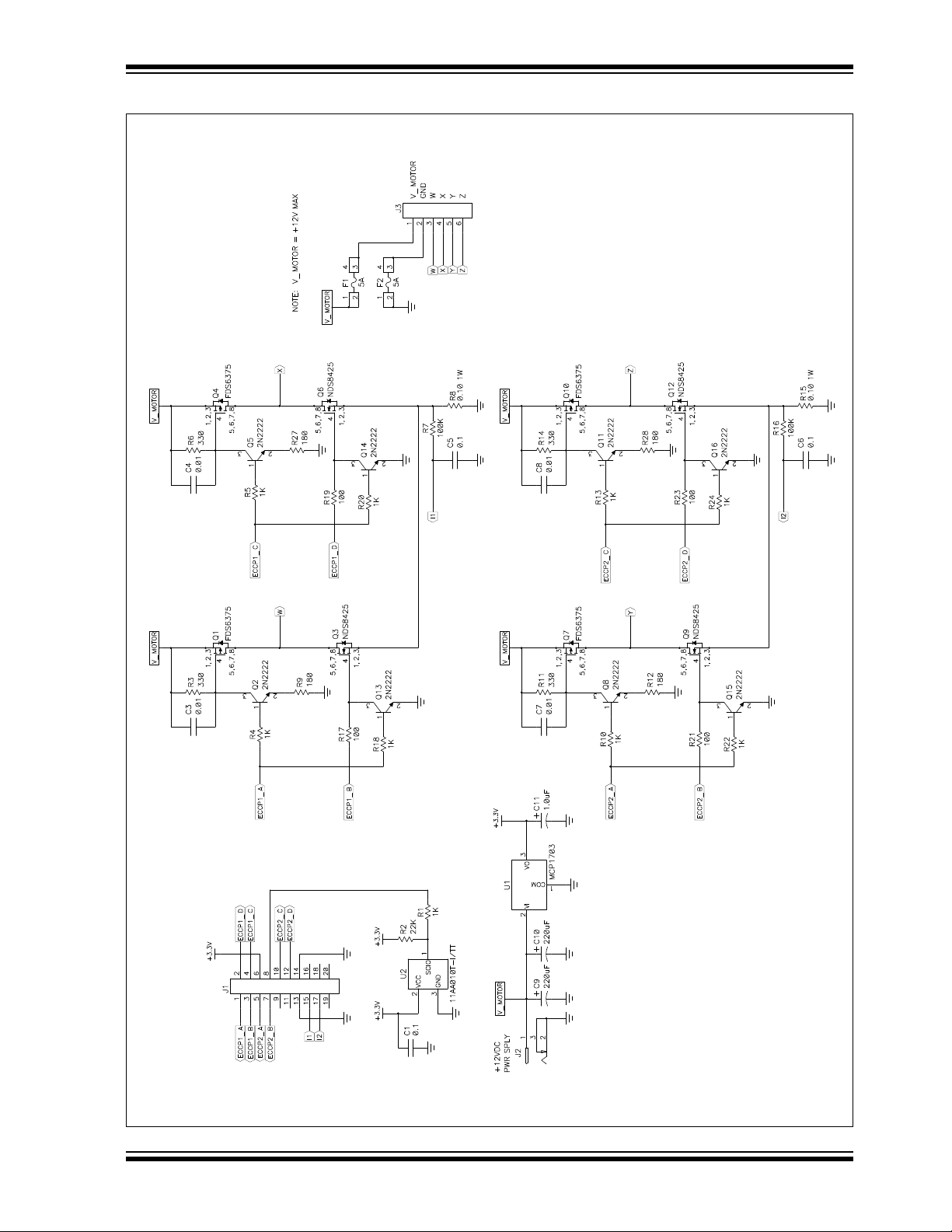

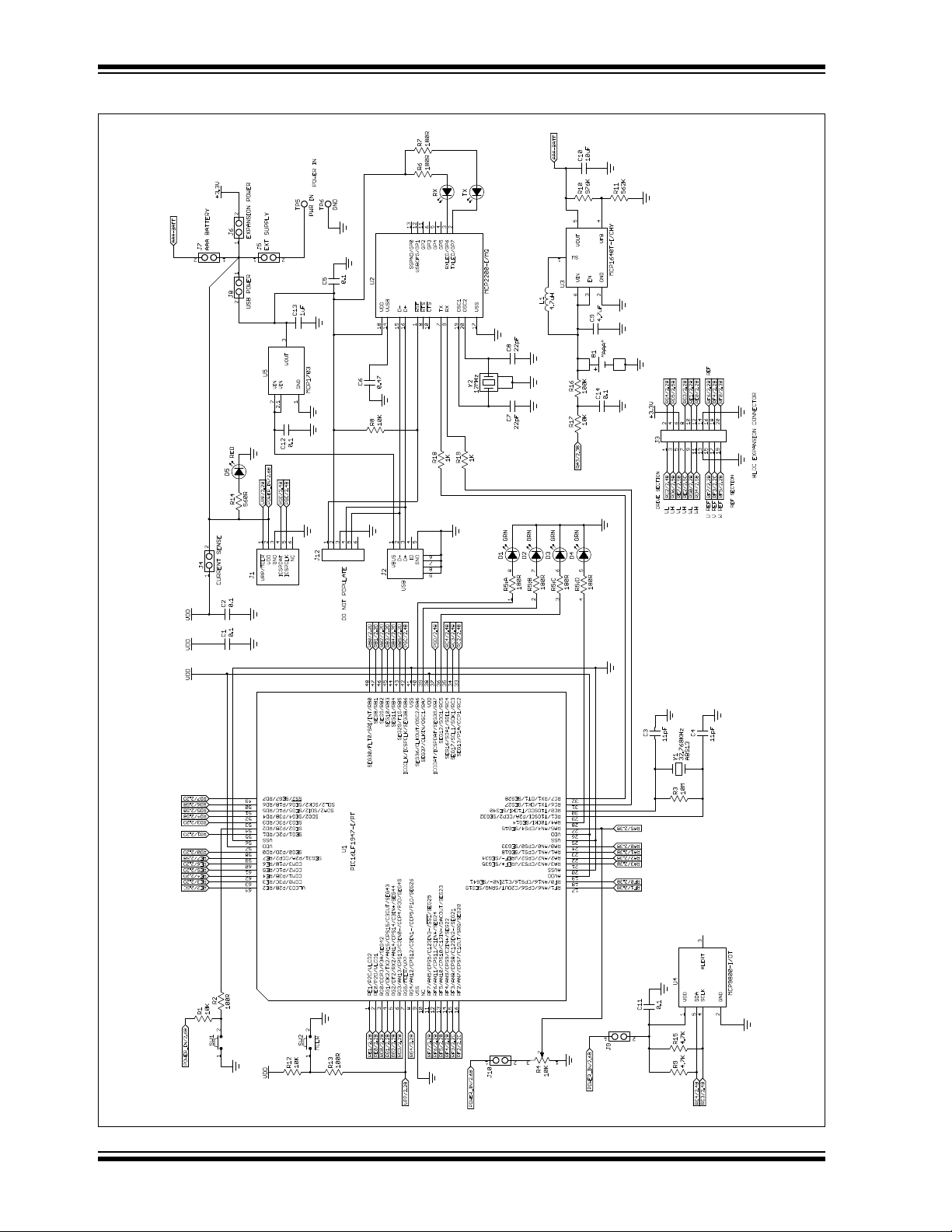

Appendix A. Board Layout and Schematics

A.1 Introduction ............................................................................................. 49

Appendix B. Conversion Factors

B.1 Conversion Factor Derivations ............................................................... 55

B.2 Start-up: Speed ...................................................................................... 55

B.3 Slow Step ............................................................................................... 55

B.4 Stepper Run and Stop Percentages ....................................................... 56

B.5 Degrees Per Step ................................................................................... 56

B.6 Stepper: Min and Max Duty Percent ....................................................... 56

B.7 Constants Derived From Stepper Parameters ....................................... 56

B.7.1 DUTY_SCALE Constant ........................................................................ 56

B.7.2 SPEED_SCALING_CONST Constant ................................................... 57

B.8 uStep Table ............................................................................................ 57

2012 Microchip Technology Inc. DS41629A-page 5

Page 6

F1 LV Evaluation Platform Motor Control Add-Ons

NOTES:

DS41629A-page 6 2012 Microchip Technology Inc.

Page 7

F1 LV EVALUATION PLATFORM

MOTOR CONTROL ADD-ONS

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

INTRODUCTION

®

IDE online help.

This chapter contains general information that will be useful to know before using the

F1 LV Evaluation Platform Motor Control Add-ons User’s Guide. Items discussed in this

chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the F1 LV Evaluation Platform Motor Control

Add-ons User’s Guide as a development tool to emulate and debug firmware on a

target board. The manual layout is as follows:

• Chapter 1. “F1 LV Evaluation Platform Overview”

• Chapter 2. “The BLDC Add-on Board”

• Chapter 3. “The Brushed DC Add-on Board”

• Chapter 4. “The Bipolar Stepper Add-on Board”

• Chapter 5. “The Unipolar Stepper Add-on Board”

• Appendix A. “Board Layout and Schematics”

• Appendix B. “Conversion Factors”

2012 Microchip Technology Inc. DS41629A-page 7

Page 8

F1 LV Evaluation Platform Motor Control Add-Ons

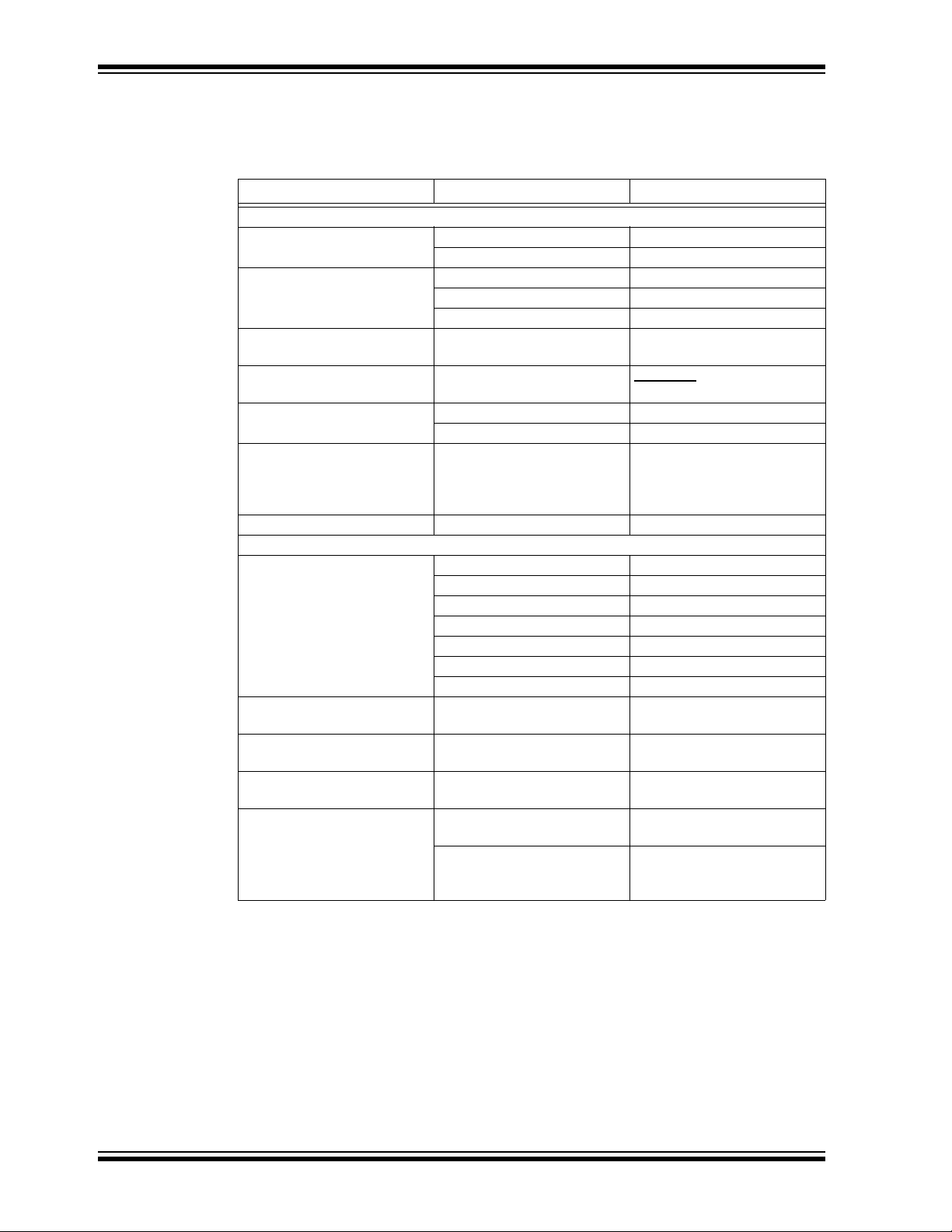

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS41629A-page 8 2012 Microchip Technology Inc.

Page 9

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use the F1 LV Evaluation Platform Motor Control

Add-ons User’s Guide. Other useful documents are listed below. The following Microchip documents are available and recommended as supplemental reference

resources.

Readme for F1 LV Evaluation Platform Motor Control Add-ons User’s Guide

For the latest information on using F1 LV Evaluation Platform Motor Control Add-ons

User’s Guide, read the “Readme for F1 LV Evaluation Platform Motor Con-

trol Add-ons User’s Guide.txt” file (an ASCII text file) in the Readmes subdirectory of the MPLAB IDE installation directory. The Readme file contains update

information and known issues that may not be included in this user’s guide.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB IDE installation directory. The Readme files

contain update information and known issues that may not be included in this user’s

guide.

Preface

2012 Microchip Technology Inc. DS41629A-page 9

Page 10

F1 LV Evaluation Platform Motor Control Add-Ons

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the HI-TECH C

pilers; MPASM™ and MPLAB ASM30 assemblers; MPLINK™ and MPLAB

LINK30 object linkers; and MPLIB™ and MPLAB LIB30 object librarians.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2, MPLAB ICD 3, PICkit™ 3.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 device programmers and PICkit™ 3 development programmers.

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

®

C16, MPLAB C18 and MPLAB C30 C com-

DS41629A-page 10 2012 Microchip Technology Inc.

Page 11

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (March 2012)

• Initial Release of this Document.

Preface

2012 Microchip Technology Inc. DS41629A-page 11

Page 12

F1 LV Evaluation Platform Motor Control Add-Ons

NOTES:

DS41629A-page 12 2012 Microchip Technology Inc.

Page 13

Chapter 1. F1 LV Evaluation Platform Overview

1.1 INTRODUCTION

This user’s guide offers a quick start-up and eventual troubleshooting for the motor

control add-ons used together with the F1 LV Evaluation Platform. For more details

regarding the supported applications, control algorithms, hardware and software support, please visit the reference sections inside this user’s guide.

1.2 HARDWARE OVERVIEW

1.2.1 Evaluation Platforms

The F1 Evaluation and F1 LV Evaluation Boards are stand-alone evaluation platforms

for investigating the capabilities of the PIC16(L)F1XXX family of devices. F1 is an

abbreviation for all PIC

number. All F1 devices are enhanced mid-range devices. Only enhanced mid-range

devices have the F1 notation.

There are two development boards for evaluating the F1 devices:

• F1 Evaluation Platform with 44-pin PIC16LF1937 microcontroller

• F1 LV Evaluation Platform with 64-pin PIC16LF1947 microcontroller

This document refers primarily to the F1 LV Evaluation Platform.

The F1 LV Evaluation Platform is the second generation evaluation platform for the

enhanced mid-range devices with more I/O pins and expanded capability. For more

information about the F1 LV Evaluation Platform refer to DS41614, “F1 LV Evaluation

Platform for Enhanced PIC

F1 LV EVALUATION PLATFORM

MOTOR CONTROL ADD-ONS

®

microcontroller devices with the notation “F1” in the device

®

Microcontrollers User’s Guide”.

1.2.2 Add-on Boards

Four motor control add-on boards are available for use in conjunction with the F1 LV

Evaluation Platform. This document describes those boards and the companion control

software for evaluating and optimizing motor control. The four motor control boards

include:

TABLE 1-1:

Motor Type ID Shown on Platform LCD Part Number F1 LV Eval F1 Eval

Brushless DC bldc DM164130-2 Yes Yes

Brushed DC bdc DM164130-6 Yes No

Bipolar Stepper bstp DM164130-7 Yes No

Unipolar Stepper ustp DM164130-8 Yes No

The software and hardware interface of the F1 Evaluation Board supports only the

BLDC Add-on Board. The software supplied and preloaded on the F1 LV Evaluation

Platform supports all four of the add-on boards.

2012 Microchip Technology Inc. DS41629A-page 13

Page 14

F1 LV Evaluation Platform Motor Control Add-ons

1.2.3 USB Interface

The F1 LV Evaluation Platform includes a USB to serial interface. This provides the

capability to control the motors in real time without entering Debug mode. PC control

software communicates with the F1 LV Evaluation Platform software to create an integrated motor control evaluation system. The PC software and interface driver are available for free download from the Microchip web site at www.microchip.com/F1Eval

1.2.4 Add-on Board Power

When using an add-on board, the F1 LV Evaluation Platform power should be supplied

from the add-on board. The J6 jumper option makes this connection. There is no

jumper option to supply power to the add-on board from the F1 LV Evaluation Platform,

because most of the platform power options do not have sufficient capacity. When

power is applied to the F1 LV Evaluation Platform through the add-on board, then the

®

UNI/O

ures itself to operate the motor identified in the memory. This automatic configuration

also applies to the PC control software.

1.2.5 Add-on Board Memory

Every add-on board, with one exception, includes a UNI/O memory device that contains:

• board ID

• board revision

• parameters associated with the motor supplied with the add-on board

When the F1 LV Evaluation Platform senses that an add-on board is attached, the initial

display shows the motor type and add-on board revision. Motor speed can be controlled with either the potentiometer on the F1 LV Evaluation Platform or with the PC

interface speed control. Additional motor capabilities are available through the PC control interface. These are described in more detail in the sections specific to each motor.

The first generation BLDC boards do not have a UNI/O memory. When the F1 LV

Evaluation Platform does not detect a UNI/O memory, it then checks voltages on other

selected J3 connections to determine if a BLDC circuit is present. When a BLDC board

without UNI/O memory is detected, the motor parameters are then retrieved from the

F1 LV Evaluation Platform EEPROM memory. The factory defaults for these parameters match those needed for the motor originally supplied with the BLDC board. If the

parameters are modified for another motor, then the File->RAM->EEPROM

save those parameters to the F1 LV Evaluation Platform EEPROM memory in lieu of

the UNI/O memory.

The advantage that the UNI/O equipped boards have is that several different add-on

boards can each support and remember the settings for a different motor. Various

BLDC motors can be accommodated when working with the first generation BLCD

Add-on Board, by saving and recalling the motor parameters to and from the PC disc

storage with the File->Save…

memory is detected and read. The F1 LV Evaluation Platform software config-

and File->Open… options.

.

option will

1.3 PC SOFTWARE OVERVIEW

The F1LVDemo software is a Graphical User Interface (GUI) providing control of the

motor speed and direction. The GUI also provides access to key parameters of the

motor operation. The control parameters vary by motor type. Each parameter and

method of optimization are described in detail in the motor sections of this document.

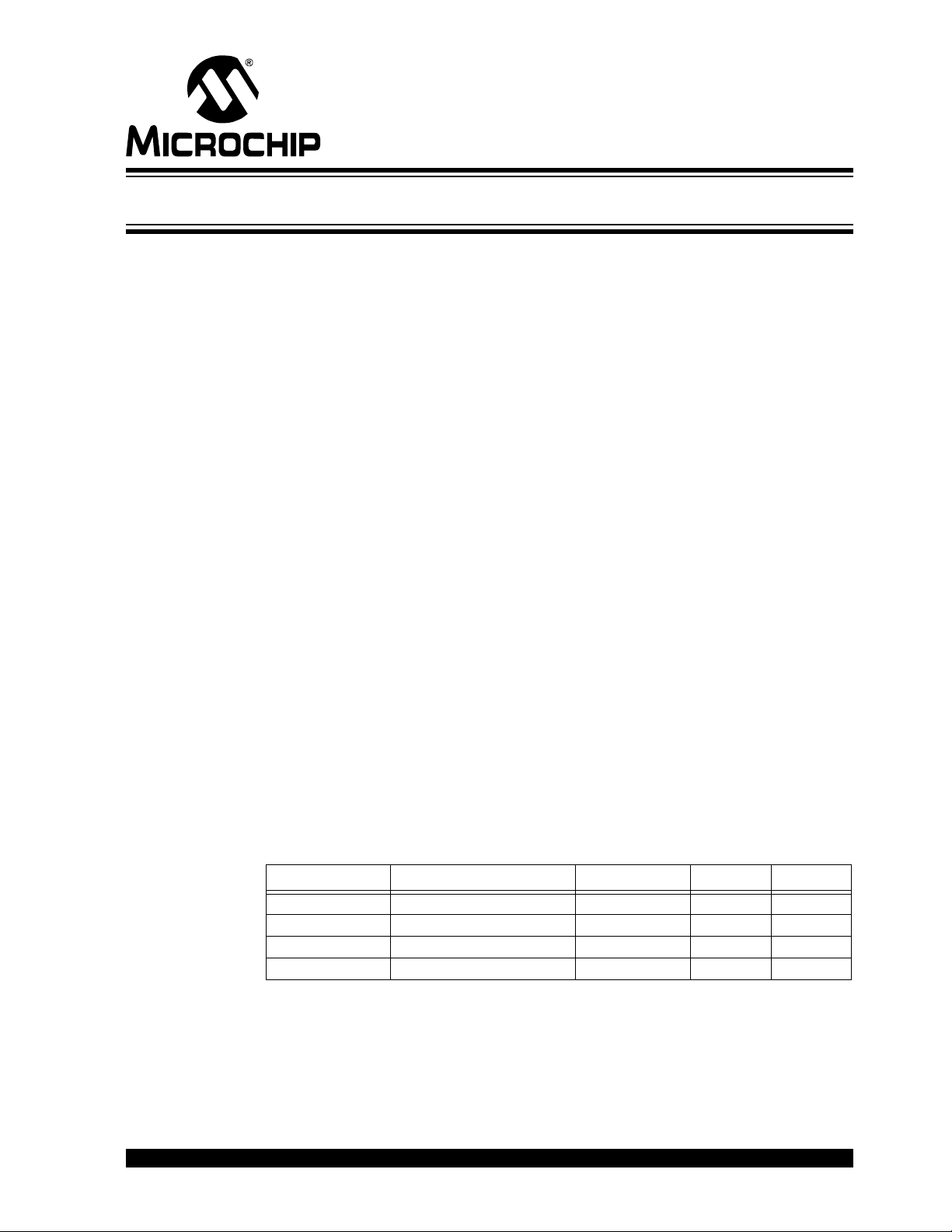

Figure 1-1 and Figure 1-2 show the front panel of the PC control GUI. Features of the

control GUI are identified and described below.

DS41629A-page 14 2012 Microchip Technology Inc.

Page 15

FIGURE 1-1:

1

11

121718

2 3 4 5 6 7 8

9

16

10

1315 14

1. Motor Parameters pull-down menu. Save

and recall to and from disc.

2. Speed control (relative 0 to 255):

• Commutation rate in open loop

• Drive level in closed loop

3. Zero cross advance/retard (BLDC only).

4. Motor drive voltage control (open loop). In

BLDC closed loop this control reverts to a

balance control.

5. BLDC open-loop single-step button.

6. Open/closed-loop control selection (BLDC

and stepper motors only).

7. Panic STOP button – Forces drive and com-

mutation to zero.

8. Motor direction selection.

9. Number of motor poles (BLDC only).

10. Serial port selection.

11. Serial link Open/Close button.

12. Motor type indicator.

13. Motor RPM – click label to update.

14. Initial drive level for start-up.

15. Initial speed setting for start-up.

16. PC Software version.

17. F1 LV Evaluation Platform software version.

18. Run time and static motor parameters tabs.

F1 LV Evaluation Platform Overview

2012 Microchip Technology Inc. DS41629A-page 15

Page 16

F1 LV Evaluation Platform Motor Control Add-ons

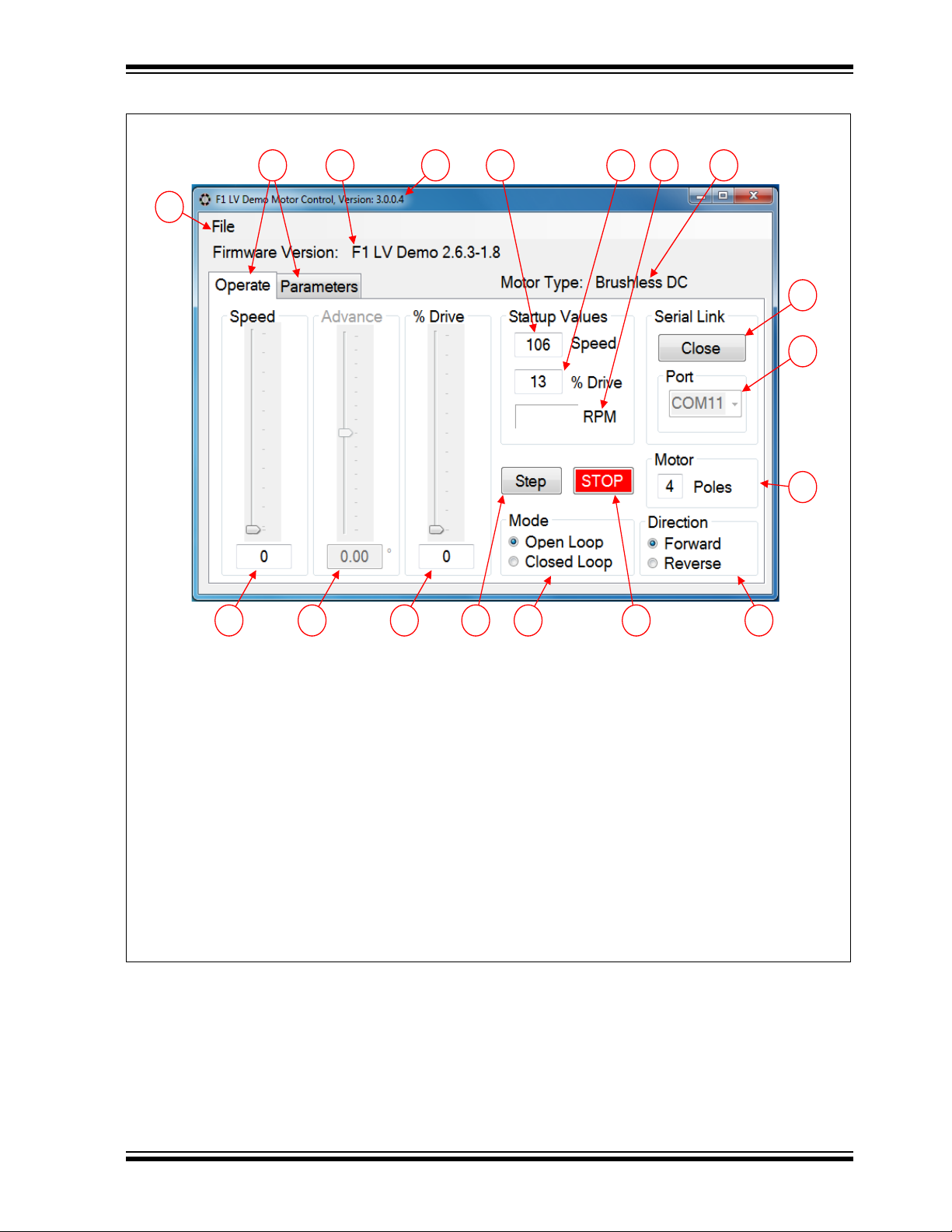

19

20

21

33 32

22 23 25 26 2724

28

29

31 30

19. BLDC flyback voltage blanking time.

20. BLDC dwell time at each start-up step.

21. BLDC milliseconds to remain in Open-Loop

mode at start-up before closing the loop.

22. BLDC minimum commutation time below

which a stall is detected.

23. BLDC error feedback multiplication factor.

Each shift divides error by 2.

24. Stepper motor steps in each drive phase

when microstepping is selected.

25. Button to invoke new microstep sinusoid

drive look-up table.

26. Peak drive level in microstep look-up table.

27. Stepper motor commutation mode selection.

28. Stepper motor maximum RPM commutation

rate when speed control is set at maximum.

29. Degrees per step physical attribute of the

attached motor.

30. Maximum drive voltage duty cycle applied

when speed control is at the maximum

RPM. This prevents excessive overdrive of

the motor.

31. Stepper motor drive voltage duty cycle

applied when speed control is at the lowest

run speed above stop.

32. Percent of speed control setting, relative to

maximum, below which the motor drive is

removed and the motor is stopped.

33. Percent of speed control setting, relative to

maximum, above which the motor starts

from a stopped state.

FIGURE 1-2:

DS41629A-page 16 2012 Microchip Technology Inc.

Page 17

F1 LV Evaluation Platform Overview

1.4 USING THE F1LVDEMO CONTROL SOFTWARE

1.4.1 Software Updates

The software supplied and preloaded into the F1 LV Evaluation Platform supports all

four of the add-on motor control boards. The preloaded software is the latest version

available at time of manufacture. Source code including any updates is available for

free download from the Microchip web site: www.microchip.com/F1Eval

All motors can be controlled with the PC-based F1LVDemo control GUI. The

F1LVDemo control software is available for free download from the Microchip web site:

www.microchip.com/F1Eval

1.4.2 Serial Link

The F1LVDemo control GUI operates through a USB to serial interface that appears as

a standard RS-232 serial port to the PC operating system. The USB interface on the

F1 LV Evaluation Platform is an MCP2200 USB to Serial interface device. Ensure that

the drivers for this interface are loaded in the PC before making the connection. Interface drivers can be downloaded for free from the MCP2200 product page of the Microchip web site.

1.4.3 Connecting the F1 LV Evaluation Platform to the Add-on Board

.

.

Perform the following steps in the order shown to establish the link between the

F1LVDemo control software and the F1 LV Evaluation Platform.

1. Connect the desired add-on board to the F1 LV Evaluation Platform J3.

2. Connect the supplied motor to the add-on board.

3. Ensure the following jumpers are in place on the F1 LV Evaluation Platform:

• J10 – Pot Enable

• J9 – Temperature Sense Enable

• J4 – I Sense break

• J6 – Expansion Board Power

4. Turn the RF2 potentiometer fully counter clockwise.

5. Each add-on board is equipped with a linear 3.3 Volt regulator that supplies

power to the F1 LV Evaluation Platform.

Apply 9-12 V

2.5 mm power jack or directly to the appropriate pins of the add-on board motor con-

nector. The power jack connector is designed to accept 9 V

former. The center pin is the positive terminal. When power is applied the F1 LV

Evaluation Platform LCD will display the motor type and add-on board revision.

At this point the motor can be operated stand-alone with the potentiometer on the F1

LV Evaluation Platform. Additional motor controls are accessible only with the control

GUI.

DC power to the add-on board. Power can be applied through the black

DC, 0.75 amp wall trans-

1.4.4 Connecting the F1 LV Evaluation Platform to the PC

6. Connect a USB cable from the PC to the F1 LV Evaluation Platform J2.

7. Execute the F1LVDemo program.

8. Select the communication port associated with the F1 LV Evaluation Platform.

This will most likely be the highest numbered communication port in the selection

box.

9. The communication port list is built during the F1LVDemo program initialization.

If you connect to the board after the program is started, the communication port

will not appear in the selection list.

2012 Microchip Technology Inc. DS41629A-page 17

Page 18

F1 LV Evaluation Platform Motor Control Add-ons

10. Click the Open button. After the link to the F1 LV Evaluation Platform is estab-

lished, the F1 LV Evaluation Platform software version will be displayed, as well

as the detected motor type.

When the link is established, all user accessible motor parameters stored in the add-on

board will be retrieved and shown in the corresponding controls of the GUI. Controls

not applicable to the detected motor will be disabled and grayed out.

1.4.5 Open Versus Closed Loop

The open-loop and closed-loop selections apply only to brushless DC and stepper

motors. In open-loop operation, the motor voltage and speed controls are independent.

In closed-loop operation the speed control functions as the control for both the speed

and voltage.

Brushless DC is truly a closed-loop operation where the applied voltage is set with the

speed control and the motor speed responds automatically to keep the back EMF

voltage equal to the applied voltage.

Stepper motor closed-loop operation is technically not closed loop. Both the motor

voltage and speed outputs simultaneously follow the single-speed control input as

independent open-loop functions of the minimum and maximum speed and drive

parameters.

1.4.6 Changing Motor Parameters

To change a motor parameter, type the new value into the corresponding text box. The

initial key press clears the previous value and changes the value to red. Red indicates

that the value has not been sent to the Platform RAM. When the enter key is pressed

the value is immediately sent to the Evaluation Platform RAM and the display returns

to the default black. The entry can be terminated without updating the Platform RAM

by pressing the Escape key. Changed parameters reside in volatile RAM only. Any

Platform Reset will restore the RAM values to those in the Platform EEPROM memory.

Unexpected Platform Resets will cause inconsistencies between the parameters

displayed in the GUI and those in the Platform RAM. Select the pull-down menu

File->RAM->Display

Platform RAM.

option to resynchronize the displayed values with those in the

1.4.7 Saving and Restoring Motor Parameters

Sometimes it is useful to try many different motor setups when optimizing performance.

Setups can be saved to disc storage with the pull-down menu File->Save…

Previously stored setups can be recovered with the pull-down menu File->Open…

option. Parameters retrieved from disc update both the display and the Platform RAM.

When the optimum setup is determined those parameters can be saved to the Platform

nonvolatile memory with the pull-down menu File->RAM->EEPROM

Parameters saved to EEPROM will be restored to RAM on every Platform Reset. The

values in the Platform EEPROM can be restored to RAM without a Reset with the

pull-down menu File->EEPROM->RAM

The EEPROM can also be restored to the factory defaults with the pull-down menu

File->Defaults->EEPROM

the source code and programming the Platform program memory after recompiling the

source code.

option. The factory defaults can be altered only by changing

option.

option.

option.

DS41629A-page 18 2012 Microchip Technology Inc.

Page 19

F1 LV Evaluation Platform Overview

1.4.7.1 CATASTROPHIC RECOVERY

In the unlikely event the UNI/O memory becomes erased or damaged, the memory can

be completely restored with the File->Restore->(add-on type)

should only be used if the add-on board fails the automatic detection process. Take

care to select the add-on type corresponding to the attached board. Failure to do so will

cause unexpected operation possibly resulting in permanent damage to the add-on

board hardware.

1.4.8 Hints for Optimum Performance

The BLDC and stepper motors are interrupt driven. The motor commutation interrupts

take precedence over all other operations. All services other than the motor commutation are polled. When the motor is operating at very rapid commutation rates, the time

for other services can become severely limited. For most situations, the serial link service is able to keep up with the activity from the PC. However, when a rapid series of

commands is coupled with rapid commutations, the serial link can appear to stall. To

avoid this situation, use the slider controls for only small and slow changes. Enter numbers directly into the slider text box when a large change to the slider control is desired.

If a stalled control condition occurs, try to regain control by clicking on the red STOP

button. If that does not restore control, the last resort is to press the F1 LV Evaluation

Platform MCLR button.

option. This option

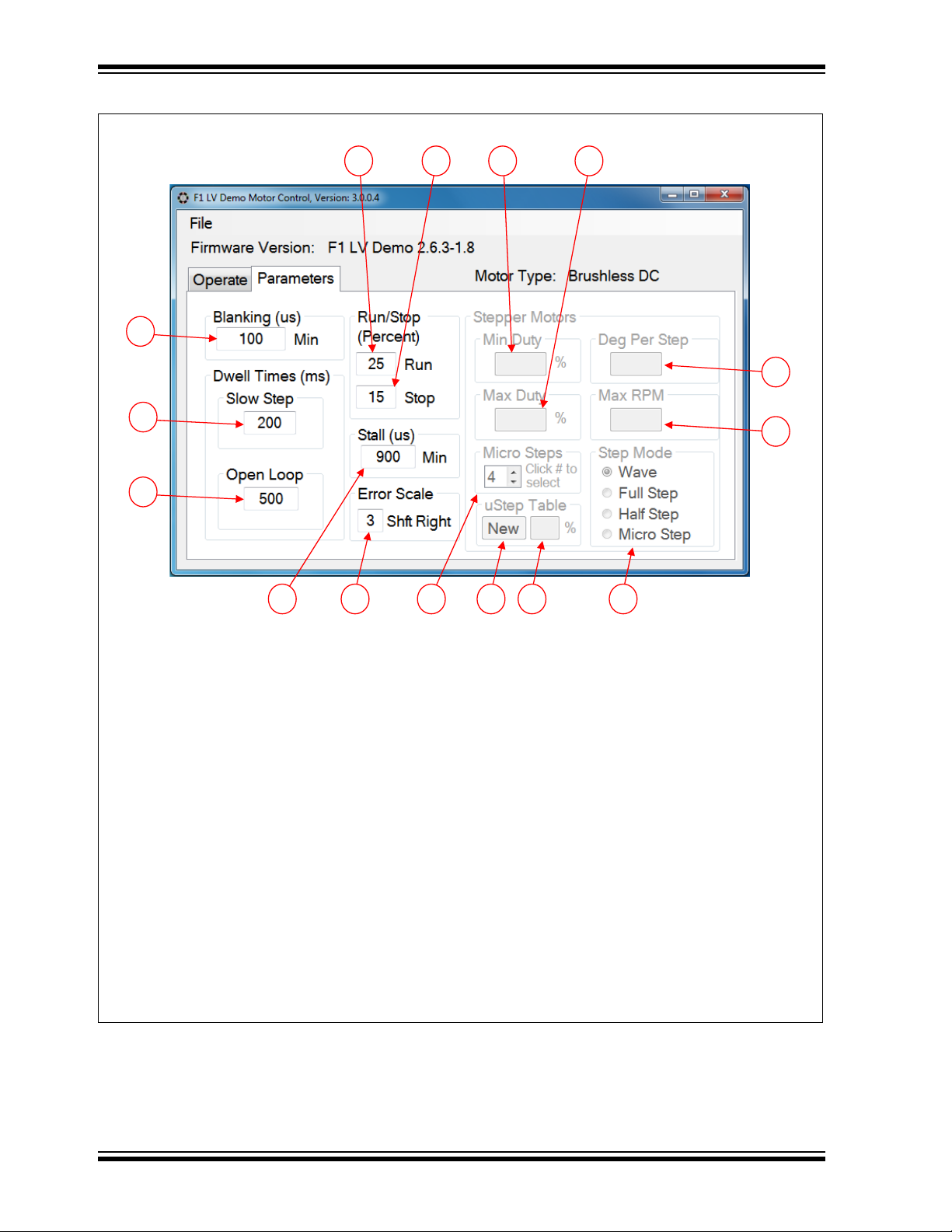

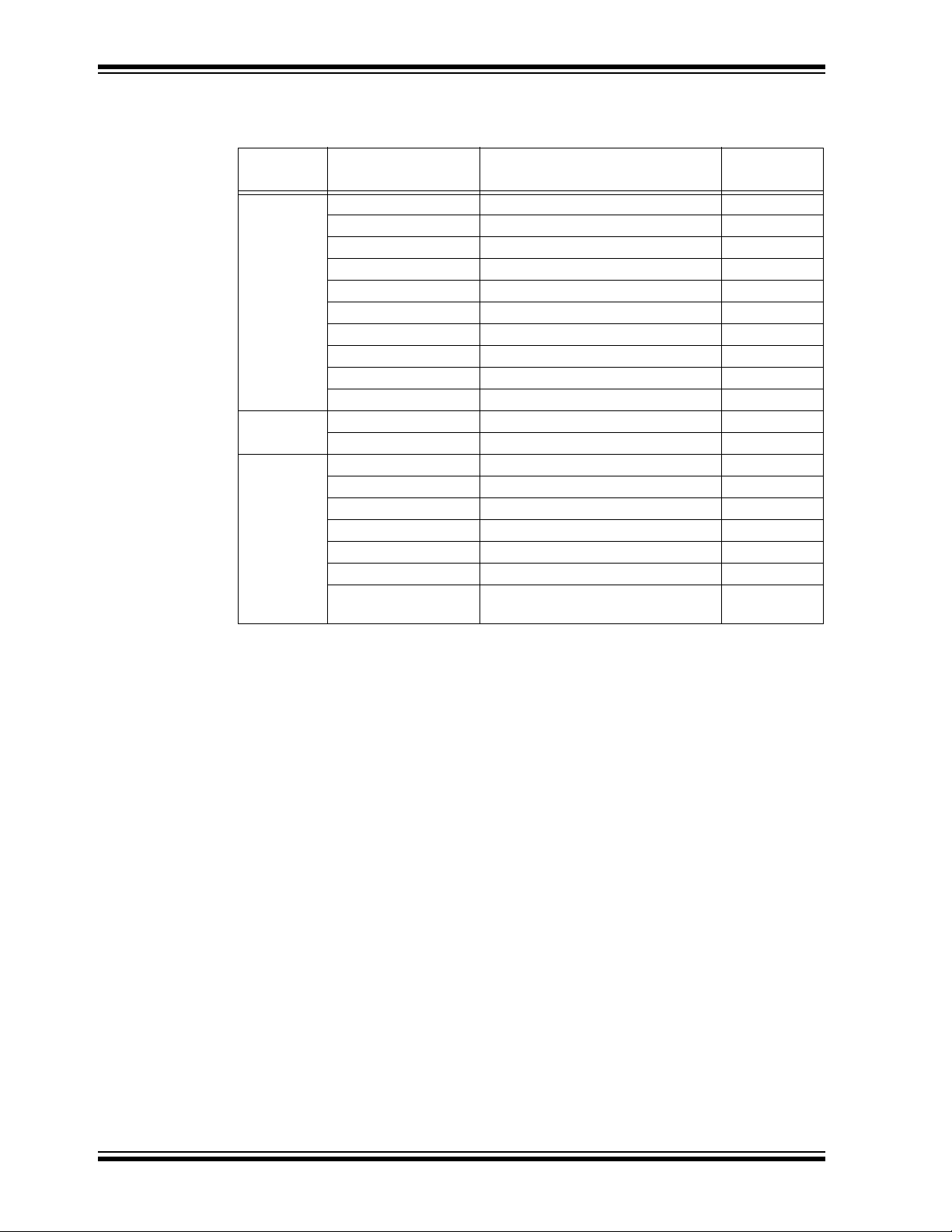

1.4.9 Header File Versus GUI Motor Parameters

The default motor parameters are defined in the F1 LV Evaluation Platform source code

motor header files. The following table correlates the GUI parameters with the equivalent header file parameters. The conversion factor is the value by which the header file

parameter is multiplied to derive the GUI parameter. In all cases, whether in the table

or text, parameters expressed as all caps may be found exactly as shown in the header

files.

See Appendix B. “Conversion Factors” for more information on the parameters and

the associated conversion factors.

2012 Microchip Technology Inc. DS41629A-page 19

Page 20

F1 LV Evaluation Platform Motor Control Add-ons

TABLE 1-2:

Motor Type GUI Parameter Header File Parameter

BLDC

(EBM)

BDC

(PAN14)

Unipolar

(42HS03)

and

Bipolar

(39HS)

STEPPER

Start-up: Percent Drive MED_START_DRIVE_PCT 1

Start-up: Speed (RPM) START_RPM 1

Poles NUM_POLES 1

Blanking BLANKING_COUNT_us 1

Slow Step TIMEBASE_SLOW_STEP 10

Open Loop OPEN_LOOP_ms 1

Stall STALL_COUNT_us 1

Run Percent LOW_RESTORE_REQUEST_PCT 1

Stop Percent LOW_OFF_REQUEST_PCT 1

Error Scale ERROR_SCALE 1

Run Percent LOW_RESTORE_REQUEST_PCT 1

Stop Percent LOW_OFF_REQUEST_PCT 1

Run Percent REQUEST_ON 0.392

Stop Percent REQUEST_OFF 0.392

Min. Duty Percent MIN_DUTY 0.392

Max. Duty Percent MAX_DUTY 0.392

Degrees per Step MOTOR_STEP_ANGLE 0.1

Max RPM MAX_RPM 1

uStep Table Bipolar_CCP_Val[]

Unipolar_CCP_Val[]

Conversion

Factor

Varies

DS41629A-page 20 2012 Microchip Technology Inc.

Page 21

Chapter 2. The BLDC Add-on Board

2.1 OVERVIEW

The BLDC add-on (DM164130-2) allows you to drive virtually most sensorless

three-phase brushless DC motors used in consumer electronics, ranging from small

HVAC applications to complex media reading/writing drives. The add-on is shipped

together with the ebm-papst BLDC motor, to which it connects through a ribbon cable

to a special connector on the board (J5). Alternatively, any other 5-12V BLDC motor

can be used by hooking it up through the J2 connector.

2.1.1 Features

The key features of this board include the following:

Connectors:

• Male 20-pin connector (J1) to match the F1 LV Evaluation Platform

• Generic 6-pin BLDC motor connector (J2)

• 6-pin ebm-papst motor interface (J5)

• 5-12V power supply input connector (J4)

Typical BLDC drive:

• Three P-type and 3 N-type MOSFETs forming three half bridges for the three

• Six bipolar transistors to command the MOSFETs

• Sensing resistor for current measurement (R15)

Control:

• R21 for adjusting the zero crossing voltage

• R19 for adjusting the over-current Fault detect (software for this function is not

F1 LV EVALUATION PLATFORM

MOTOR CONTROL ADD-ONS

motor phases

implemented).

Note: The function labels on these two controls are reversed on the R2 revision

of these boards.

Protection:

• Power fuses (F1, F2)

Power supply:

• 3.3V voltage regulator (U1)

2.1.2 What’s Included

The BLDC add-on part number (DM164130-2) contains:

• BLDC Add-on Board designed for the F1 Evaluation Platform

• ebm-papst motor (P/N: VD-3-25.07)

• 28 AWG ribbon cable to match the ebm-papst motor

2012 Microchip Technology Inc. DS41629A-page 21

Page 22

F1 LV Evaluation Platform Motor Control Add-ons

2.1.3 Reference Documents

This section points you to technical application support.

AN857, ”Brushless DC Motor Control Made Easy”

AN885, ”Brushless DC (BLDC) Motor Fundamentals”

AN899, ”Brushless DC Motor Control Using PIC18FXX31 MCUs”

AN970, ”Using the PIC18F2431 for Sensorless BLDC Motor Control”

AN1305, ”Sensorless 3-Phase Brushless Motor Control with the PIC16FXXX”

You can obtain these reference documents from your nearest Microchip sales office

(listed in the last page of this document) or by downloading them from the Microchip

web site.

2.2 BOARD SETUP

WARNING

The BLDC Motor Control Add-on Board is intended to drive three-phase brushless DC

motors. Before connecting the motor, make sure the power rating of the motor is equal

to or less than the power rating of the board, as shown in Appendix B. “Conversion

Factors”. Also, make sure the configuration parameters inside the software or the GUI

are correct for the motor you are using. Failure to comply with this warning could lead

to malfunction of the board and the motor, and could result in physical harm.

Before beginning the start-up procedure, complete a visual check of the board and the

motor for connectivity and mechanical damage. If damage is found, DO NOT power-up

the board. Otherwise, you may further damage the equipment. Contact Microchip’s

local office or distributor immediately.

A step-by-step connecting procedure is available in Section 1.4.3 “Connecting the

F1 LV Evaluation Platform to the Add-on Board”. If using the ebm-papst motor,

attach the ribbon cable from the motor at step 2. Also, make sure that POR R4 on the

evaluation platform is turned fully CCW.

If using a different motor, connected through J2, please keep in mind to attach each

motor phase firmly to the connector. The red connector supplied with the board is

designed to accept 22 AWG wire. Bad contacts can damage the add-on and will wear

out the motor in time. There is no rule for attaching a specific motor lead to a phase line

on the add-on. Keep in mind the correspondences on the software side when testing

or measuring directly on that motor phase.

Adjust R21 90 degrees CCW from the mid-point CCW when operating the ebm-papst

motor. R21 should be set to its mid-point for other motors.

2.3 HARDWARE

2.3.1 General Architecture

The BLDC add-on uses a typical three half-bridges control configuration suitable for

three-phase BLDC motors, using six MOSFETS commanded through six bipolar

transistors. Sensorless control is done in the software without any other external

components.

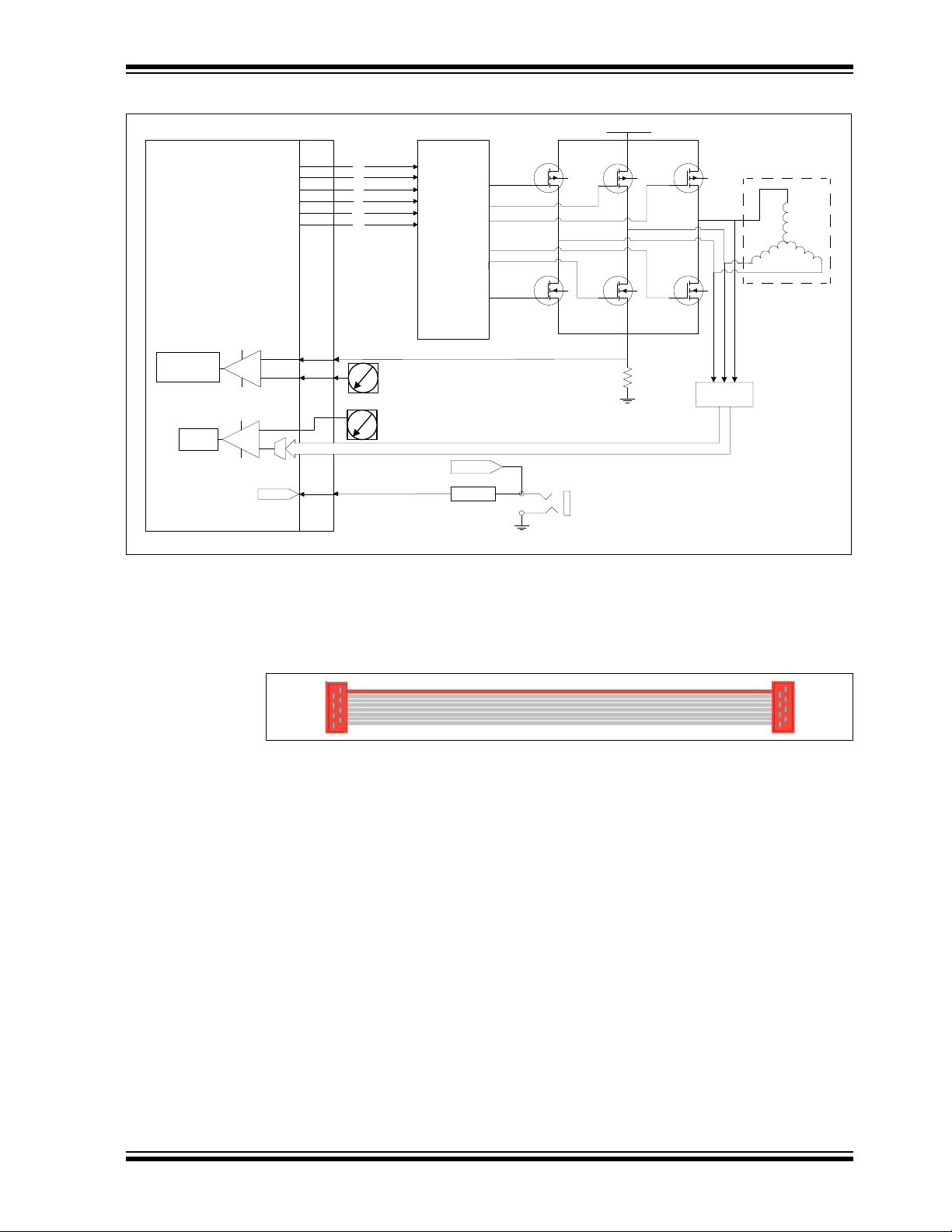

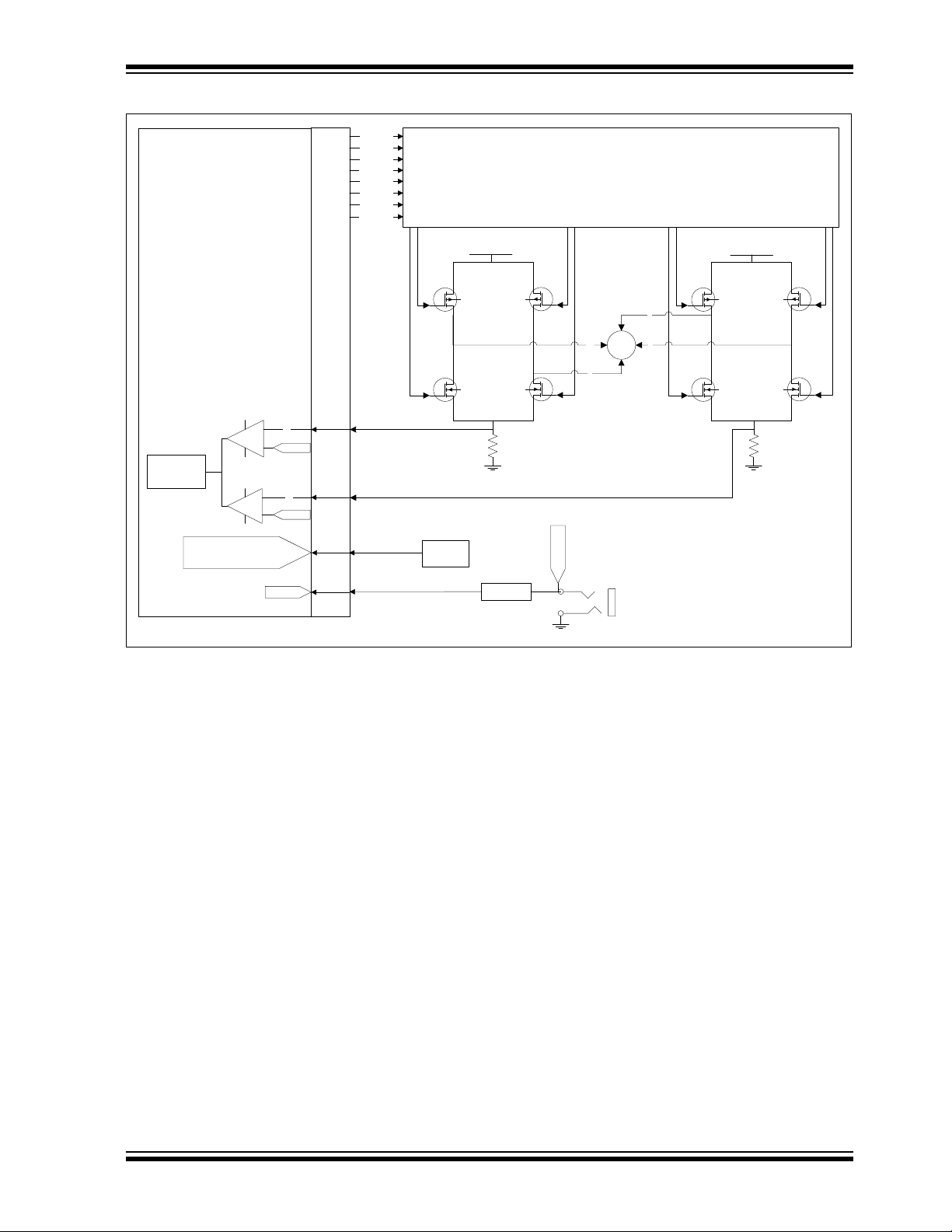

Figure 2-1 provides a simplified block diagram of the development board hardware,

coupled to the F1 LV Evaluation Platform:

DS41629A-page 22 2012 Microchip Technology Inc.

Page 23

The BLDC Add-on Board

PIC16LF1947

J1

Bipolar

Transistor

Inverter

Q1

Q7

V_MOTOR

R15

J3

V_MOTOR

VinVout

U1

3.3V

_

+

Current meas.

autoshutdown

Q8

Q9

U

VW

R19

R21

_

+

Scaling

Zero

Cross

Q2

Q3

HU

LU

HV

LV

HW

LW

VU, VV, VW

Motor

+

_

FIGURE 2-1: THE BLDC MOTOR CONTROL ADD-ON ARCHITECTURE

2.3.2 Attaching the Motor

The BLDC add-on kit includes the three-phase 24V ebm-papst motor. This motor can

be attached through a dedicated 28AWG 8-wire ribbon cable using connector J5.

FIGURE 2-2: THE EBM-PAPST MOTOR CONNECTOR

However, you can use your own three-phase BLDC motor by attaching its leads to the

J2 connector. The red connector supplied with the board is designed to accept 22 AWG

wire.

2.3.3 Power-Up

Voltage is supplied through the 2.5 mm jack connector J4, with a maximum rating of

+12 V

DC. The F1 LV Evaluation Platform should be configured to use expansion board

power by inserting the power jumper on J6. See the “F1 LV Evaluation Platform for

Enhanced PIC

®

Microcontrollers User’s Guide” (DS41614A) for more details.

2.3.4 Power Stage

The BLDC add-on incorporates the classic three half-bridges drive made from P and

N-type MOSFETs (for more details, please refer to the BLDC board schematic in

Appendix A. “Board Layout and Schematics”). The maximum current rating is 8A

on each MOSFET. Please keep this in mind when designing your application or

modifying the add-on hardware.

The stage contains six PWM (HU, LU, HV, LV, HW, LW) inputs and three back EMF

sense outputs (VU, VV, VW). The BLDC motor attaches to the three driver outputs (U,

2012 Microchip Technology Inc. DS41629A-page 23

V, W) .

Page 24

F1 LV Evaluation Platform Motor Control Add-ons

Motor current is measured by using the R15 shunt resistor, placed in-between the

Power Stage lowside and ground, and connected to the PIC16F1947 through the J1

connector. (Current sensing is not implemented in the F1 LV Evaluation software.)

2.3.5 Protection

Two 5A fuses (F1 and F2) are used to protect your add-on in case of an overcurrent

situation in the output drivers. In case one or both of them get burnt, remove power

immediately from the board and inspect the add-on for further damage. Do not replace

the burnt fuses with other values than the ones provided with the board.

2.3.6 Speed Control

Speed control can be performed through either the Motor Control GUI or the 10K POT

R4 located on the F1 LV Evaluation Platform.

2.4 DEMO SOFTWARE

2.4.1 Introduction

The F1 LV Evaluation demonstration program uses a single combined demo. The

combined demo source code is organized into sectional code for ease of

accommodating several motor types. This chapter provides an overview to the

functions provided by the BLDC demo.

The BLDC demo code is designed to operate a sensorless BLDC control. The software

can be easily tuned to the needs of your application or motor by changing the

parameters on-the-fly, by modifying the motor parameters in the F1LVDemo GUI.

2.4.2 The Motor Control GUI Application

Using the Motor Control Application GUI, you can change the following parameters:

• Motor poles number

• Speed [arbitrary range 0 to 255]

• The timing balance between zero-cross and commutation periods [degrees]

• Phase advance [degrees]

• Start-up speed [arbitrary range 0 to 255]

• Drive voltage [% of full scale]

• The minimum blanking period [us]

• Dwell timings: closed-loop slow stepping [ms] and open loop [ms]

• Run/stop hysteresis drive voltage [% of full scale]

• Minimum motor stalling period [us]

• Error scaling factor [divisor power of 2].

Also, the motor can be run in open/closed loop and forward/reverse.

Clicking on the ‘RPM’ text in the Operate tab will display the motor speed in the text

box next to it.

DS41629A-page 24 2012 Microchip Technology Inc.

Page 25

The BLDC Add-on Board

2.4.3 BLDC Parameter Optimization

Brushless motors depend on the software to commutate the motor. The software must

determine the rotor position relative to the stator so as to commutate the driver circuitry

at specific rotor positions. The rotor position is determined in sensorless motors by

voltages induced into the stator by rotor motion. The induced voltage is referred to as

back EMF or BEMF. When the rotor is stationary, there is no BEMF from which to

determine the rotor position. Starting the motor requires commutating the motor blindly,

without the benefit of feedback, to start the rotor in motion fast enough to sense the

BEMF, and close the loop on rotor position for commutation.

The motor speed, in response to the applied voltage, varies by motor design. We need

to match the initial drive voltage and open-loop commutation rate to the motor to

accomplish two objectives:

1. prevent excessive current in the motor

2. start rotation fast enough to sense the BEMF

When the motor is running, the BEMF on the driven pair of stator windings matches the

applied voltage. The BEMF on the undriven winding starts at one power rail at the

beginning of the commutation period and ends at the other power rail at the end of the

commutation period. However, this is only true when the motor is running at the design

speed. At any other speed, the BEMF is effectively undetectable. Unfortunately, the

motor will not start if we apply a voltage, and then commutate at the rate for which the

motor is designed. To start the motor, we need to commutate slower than the design

rate and then ramp up to the design speed.

The task of motor optimization is to find a combination of applied voltage and

commutation rate for which the motor will start to rotate. From there, the control

algorithm will ramp-up the commutation rate to where the BEMF can be sensed. The

Motor Control GUI enables us to independently set the applied motor voltage and

commutation rate to find a combination that works. Use the following steps to

experiment with your motor optimization:

1. Set POT R21 to middle range for your motor or 90 degrees CCW from the middle

range for the ebm-papst motor supplied with the BLDC Add-on Board.

2. Select Open-Loop mode.

3. Set the speed control to a nominal rate, such as 100.

4. Slowly increase the % Drive control until the motor starts to turn.

5. Slowly increase the speed control until it is just faster than the motor can go.

6. Slowly reduce the speed control until the motor starts to rotate again.

7. Note the % Drive setting, then enter 0 into the % drive control text box.

8. Re-enter the % drive setting noted in step 6, and observe that the motor starts

spinning.

9. Repeat steps 7 and 8 to verify the motor always starts reliably. If it does not, then

reduce the speed control slightly and repeat steps 6, 7 and 8.

10. When you are satisfied with the start response obtained by steps 6, 7 and 8, then

enter the final speed control value into the Speed Start-up value text box. The

equivalent RPM will be displayed.

Note: The displayed RPM value is only accurate if the motor has the number of

poles indicated. The number of poles only matters if you want the RPM

value to represent the mechanical operation. If you are not sure how many

poles your motor has, then you can determine this by leaving the % Drive

where it is, setting the speed to zero, and count the number of Step button

clicks it takes to make one full motor revolution. Divide this number by

three, that is the number of poles.

2012 Microchip Technology Inc. DS41629A-page 25

Page 26

F1 LV Evaluation Platform Motor Control Add-ons

11. Enter the % Drive number into the % Drive start-up value.

12. Click the Parameters tab and verify or enter the following nominal values:

a) Blanking: 100 us

b) Slow Step: 200 ms.

c) Open Loop: 500 ms.

d) Run: % Drive entered in step 13.

e) Stop: 2 less than Run

f) Stall: 900 us

g) Error Scale: 3

13. Click the Operate tab and select Closed-Loop mode.

14. Hold your breath, cross your fingers, and slowly increase the speed control to the

point where the motor starts. With any luck, your motor will start and immediately

lock onto the BEMF feedback to become fully operational in Closed-Loop mode.

When that happens, you can increase the speed control to the desired rate. Click

on the RPM label to perform one reading of the motor RPM.

Now that you are able to operate the motor in closed loop, at least at slow speed, you

need to complete the optimization of the other motor parameters. The following

procedures describe each parameter and its adjustment.

2.4.3.1 BLANKING

The blanking interval is required so the BEMF sense does not falsely trigger on the

flyback voltage caused by commutation. You can observe this pulse on any motor lead

while the motor is running. The flyback pulse voltage occurs immediately following the

unmodulated drive period. The width of the flyback pulse varies depending on the

inductance of the motor windings and the motor load current. Measure this pulse under

worst-case motor operation and set the blanking time to at least the measured time

plus some margin. The blanking time must be less than 50% of the minimum

commutation period, and ideally much less than that. You may notice during

measurement that some modulation pulses immediately following the flyback pulse

extend beyond the mid-level of the drive voltage. Treat those pulses as part of the time

that must be blanked.

2.4.3.2 SLOW-STEP DWELL TIME

During start-up, the motor windings are energized for a short period to pre-position the

rotor. Slow step is the length of time that the windings are energized. Large high inertia

motors take longer to reach the position, and therefore need extra time. Experiment

and use the shortest time that works.

2.4.3.3 OPEN-LOOP DWELL TIME

The open-loop time is the amount of time that the motor operates in Open-Loop mode

before the ramp-up to BEMF detection starts. The open-loop voltage and commutation

rate is the same that you entered in the start-up parameters. Small low inertia motors

start well going straight from slow step pre-position into the ramp-up to BEMF

detection. For those motors you can enter an open-loop time of zero. Larger motors

need time to stabilize at the open-loop rate before ramping up. Experiment to find the

value that works best for your motor.

2.4.3.4 RUN/STOP PERCENTAGE

The run value should match the start-up drive value to ensure a smooth transition from

open loop to ramp-up. Once BEMF lock is obtained, most motors are able to maintain

lock below the start-up drive value. Experiment to find the stop value that ensures

reliable motor operation at slow speed.

DS41629A-page 26 2012 Microchip Technology Inc.

Page 27

The BLDC Add-on Board

2.4.3.5 STALL

A motor that stalls may appear to the control algorithm as if it is still running at high

speed. Blanking, modulation, and intrinsic motor characteristics all play a part in a false

BEMF indication. When this happens, the commutation rate will ramp up to a rate much

higher than the motor is able to operate. This feature is used to detect a stall condition.

Determine an appropriate stall detection time by measuring the commutation period of

the motor at maximum speed. Enter this period minus some margin as the stall period.

If the commutation period is ever shorter than the stall period, then the motor will be

immediately stopped.

2.4.3.6 ERROR SCALE

The control algorithm compares the actual time from commutation to where the BEMF

crosses the mid-drive level. This is referred to as the zero cross event. The zero cross

event is expected half way through the commutation period. The error between the

expected and actual measured time is scaled down by the error scale factor and added

back into the commutation time, thereby forming the closed-loop operation. The error

scale value determines the loop gain. Less gain will result in a slower, but more stable

response. Conversely, higher gain will result in a faster response, but less stable

operation. The error is scaled by performing right shifts on the error value. More shifts

means less of the error is getting back into the loop, resulting in less loop gain. The

commutation time is a 16-bit integer with a 17

will use all 16 bits. BEMF error for slow motors can be large so a correspondingly large

error scale can be tolerated. However, as the motor speed increases the commutation

time decreases and not all 16 bits are significant. At very high speeds the magnitude

of the error is small relative to the full 16-bit number and large error scales cannot be

tolerated, because the full error value may be shifted to a value of zero. For most

motors, an error scale value of three works well. Again, experiment to see what works

best for your particular motor.

th

sign bit. Very slow commutation rates

2.4.3.7 ADVANCE AND BALANCE CONTROLS

The advance and balance controls should be maintained at zero for normal motor

operation. These controls are only used to observe the effects of manipulating the zero

crossing event. The advance control advances or retards the zero crossing event. The

balance control extends or shortens the commutation time after the zero crossing

event. It is interesting to observe on an oscilloscope how the motor reacts to these

disturbances.

2.4.3.8 ZERO-CROSSING ADJUSTMENT

A potentiometer, R21, is included on the BLDC Add-on Board for adjusting the zero

crossing reference voltage. Most motors require a reference voltage of half the applied

motor voltage. However, the winding pattern of some motors results in a nonlinear

BEMF response. Such a motor is the ebm-papst motor supplied with the add-on board.

This motor has an S-shaped BEMF response and operates best when the zero

crossing reference is lower than half the applied motor voltage. If you have difficulty

starting the motor, even after going through all the optimization steps, then check the

position of R21 and try moving the position slightly more and less than the 90 degree

CCW starting position. Once you get the motor operating in closed loop, fine tune the

zero crossing reference with R21. This is accomplished by observing the waveform of

one of the motor terminals. Adjust R21 so that the rising and falling slopes of the

waveform are equal in appearance.

2012 Microchip Technology Inc. DS41629A-page 27

Page 28

F1 LV Evaluation Platform Motor Control Add-ons

NOTES:

DS41629A-page 28 2012 Microchip Technology Inc.

Page 29

Chapter 3. The Brushed DC Add-on Board

3.1 GETTING STARTED

3.1.1 Overview

The BDC add-on (DM164130-6) allows you to drive virtually most brushed DC motors

used in consumer electronics. The add-on is shipped together with the NMB brushed

DC motor (PAN14EE12AA1) mounted on the board. The motor voltage is supplied

through jumper J5. Alternatively, any other 5-12V BDC motor can be used by hooking

it up through the J4 connector and removing the shorting block from J5.

3.1.2 Features

The key features of this board include the following:

Connectors:

• Male 20-pin connector (J1) to match the F1 LV Evaluation Platform

• Generic 4-pin BLDC motor connector (J4) for 22 AWG wire

• 5-12V power supply input connector (J3)

Typical BDC drive:

• Two N-type and two P-type MOSFETs arranged as an H-bridge

• Four NPN bipolar transistors to command the MOSFETs

• Sensing resistor for current measurement (R15)

Control:

REF POT, for general over-current adjustment (over-current detection is not

•V

implemented in the demo software).

Protection:

• 5A power fuses (F1, F2)

Power Supply:

• 3.3V voltage regulator (U1)

Parameter storage:

• 128 x 8 UNI/O

F1 LV EVALUATION PLATFORM

MOTOR CONTROL ADD-ONS

®

Serial EEPROM (U2)

3.1.3 What’s Included

The BDC add-on with part number DM164130-6 contains:

• BDC Add-on Board designed for the F1 Evaluation Platform

• NMB motor (P/N: PAN14EE12AA1)

2012 Microchip Technology Inc. DS41629A-page 29

Page 30

F1 LV Evaluation Platform Motor Control Add-Ons

3.1.4 Reference Documents

This section points you to application technical support.

AN696, PIC18CXXX/PIC16CXXX DC Servomotor

AN718, Brush-DC Servomotor Implementation Using PIC17C756A

AN893, Low-Cost Bidirectional Brushed DC Motor Control Using the PIC16F684

AN905, Brushed DC Motor Fundamentals

You can obtain these reference documents from your nearest Microchip sales office

(listed in the last page of this document) or by downloading them from the Microchip

web site.

3.2 BOARD SETUP

WARNING

Before connecting the motor, make sure the power rating of the motor is equal to or

less than the power rating of the board, as shown in Appendix B. “Conversion Factors”. Also, make sure the configuration parameters inside the software or the GUI are

correct for the motor you are using. Failure to comply with this warning could lead to

malfunction of the board and the motor, and could result in physical harm.

Before beginning the start-up procedure, complete a visual check of the board and the

motor for connectivity and mechanical damage. If damage is found, DO NOT power-up

the board. Otherwise, you may further damage the equipment. Contact Microchip’s

local office or distributor immediately.

A step-by-step connecting procedure is available in Section 1.4.3 “Connecting the

F1 LV Evaluation Platform to the Add-on Board”. Please make sure that POT R4

on the Evaluation Platform is turned fully CCW.

To connect either the NMB motor (with Jumper J5) or a brushed DC motor of your

choice (through terminals V and U of add-on connector J4), keep in mind to attach each

motor phase firmly to the connector. Bad contacts can damage the add-on and will

wear out the motor in time. There is no rule for attaching a specific motor lead to a

phase line on the add-on. Keep in mind the correspondences on the software side

when testing or measuring directly on that motor phase.

3.3 HARDWARE

3.3.1 General Architecture

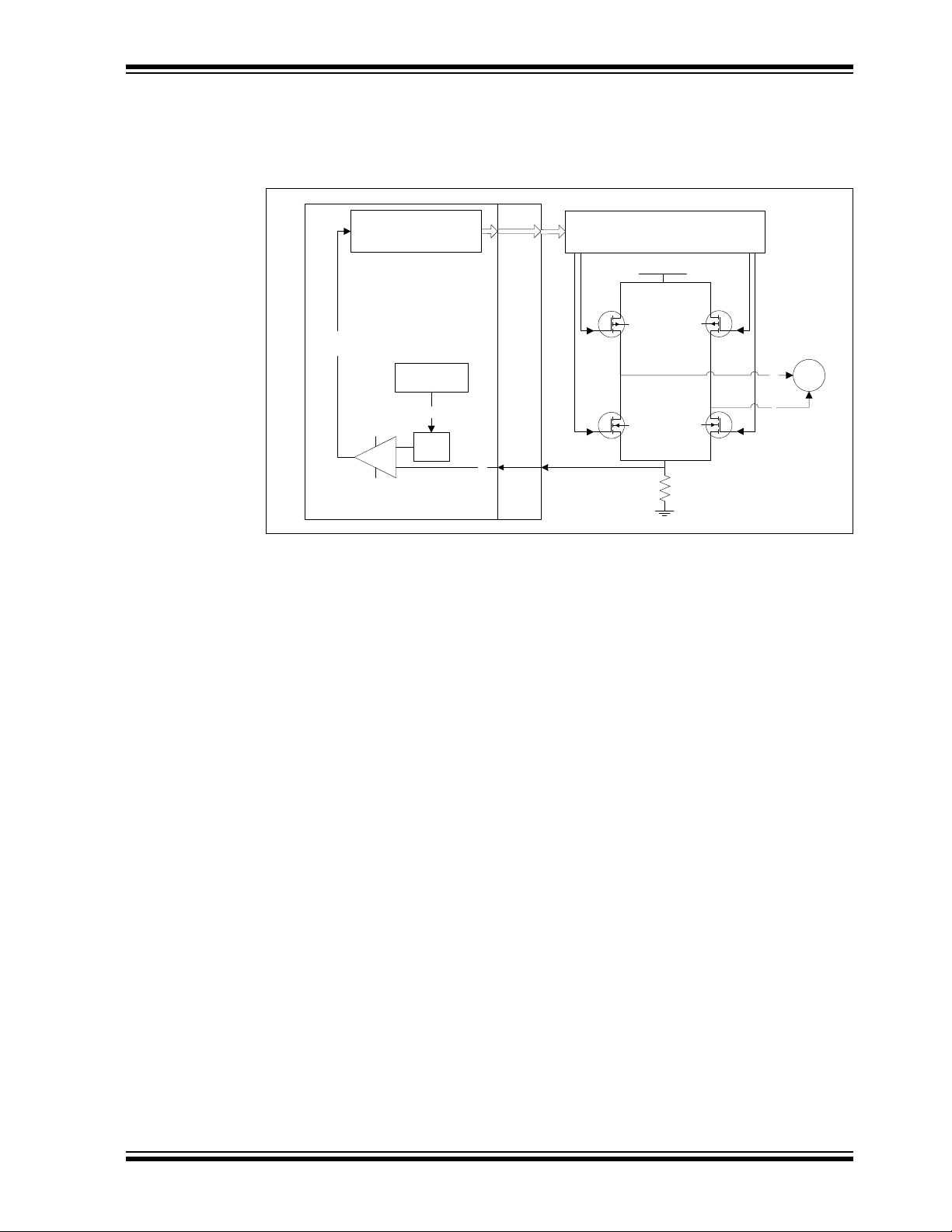

The BDC add-on uses a typical H-bridge control configuration suitable for two-phase

BDC motors, using four MOSFETS commanded through four bipolar transistors. The

demo software varies the motor speed by pulse-width modulating the H-bridge drive.

Figure 3-1 provides a simplified block diagram of the development board hardware,

coupled to the F1 LV Evaluation Platform:

DS41629A-page 30 2012 Microchip Technology Inc.

Page 31

The Brushed DC Add-on Board

PIC16LF1947

J1

Bipolar Transistor Command Bridge

A

B

C

D

Q1

Q5

U

Q2

Q6

V

V_MOTOR

ISENSE

Current

measurement

+

-

R15

J3

V_MOTOR

VinVout

U1

3.3V

R13

VREF

1K

EEPROM

Detect add-on type

read/write parameters

IRef

FIGURE 3-1: THE BDC MOTOR CONTROL ADD-ON ARCHITECTURE

3.3.2 Attaching the Motor

The BDC add-on kit includes a 12V NMB PAN14EE12AA1 motor. This motor is

mounted on the board. The voltage is supplied to the motor through jumper J5. To use

an alternate motor, remove the shorting block from J5 and attach the two motor leads

to lines V and U. The V_MOT and GND connections are for a lab supply and are to be

used in lieu of the 2.5 mm power connector.

3.3.3 Power-Up

Voltage is supplied through the 2.5 mm jack connector J3, with a maximum rating of

+12VDC. The F1 LV Evaluation Platform must be configured to use expansion board

power by inserting the power jumper on J6. See “F1 LV Evaluation Platform for

Enhanced PIC

3.3.4 Power Stage

The BDC add-on incorporates the classic full H-bridge drive made from two N-type and

two P-type MOSFETs. The maximum current rating is 8A on each MOSFET. Please

keep this in mind when designing your application or modifying the add-on hardware.

®

Microcontrollers User’s Guide” (DS41614) for more details.

2012 Microchip Technology Inc. DS41629A-page 31

Page 32

F1 LV Evaluation Platform Motor Control Add-Ons

The stage contains four PWM (A, B, C, D) inputs and two driver outputs (VU and VV)

to be attached to each terminal of the BDC motor (U, V).

The current on the H-bridge is measured on the R15 shunt resistor, placed in-between

the Power Stage lowside and ground, and connected to the PIC16F1947 through the

J1 connector.

3.3.5 Protection

Two 5A fuses (F1 and F2) are used to protect your add-on in case of an overcurrent

situation in the output drivers. In case one or both of them get burnt, remove power

immediately from the board and inspect the add-on for further damage. Do not replace

the burnt fuses with other values than the ones provided with the board.

3.3.6 UNI/O® Memory Chip

The UNI/O® memory chip stores the board ID and the application parameters. It is

accessed by the Motor Control GUI at start-up in order to recognize which of the four

boards is attached to the F1 LV Evaluation Platform, thus loading the appropriate

parameters for the add-on used.

3.3.7 Speed Control

Speed control can be performed through either the Motor Control GUI, or the 10K POT

R4 found on the F1 LV Evaluation Board.

3.4 DEMO SOFTWARE

3.4.1 Introduction

The F1 LV Evaluation demonstration program uses a single combined demo. The

combined demo source code is organized into sectional code for ease of

accommodating several motor types. This chapter provides an overview to the

functions provided by the BDC demo.

The BDC demo code is designed to operate a brushed DC motor. All that is needed to

operate a brushed DC motor is a supply voltage, because brushed DC motors self

commutate. The only adjustable parameters for brushed DC motors are the start and

stop thresholds. Voltage is applied to the motor when the speed control is greater than

the Run percent, and is removed when the speed control is less than the Stop percent.

3.4.2 The Motor Control GUI Application

Using the Motor Control Application GUI, you can change the following parameters:

• Speed [arbitrary range 0 to 255]

• Run/Stop hysteresis drive voltage [% of full scale]

The demo is designed to operate a brushed DC motor in an Open-Loop mode only.

Also, the motor can be run either forward or reverse.

Voltage control is the most simple control method for DC motors. It is based on a

directly proportional relationship between the applied voltage and speed. Using the

Speed slider in the Motor Control GUI or the POT on the F1 Evaluation Platform to

adjust speed, you actually adjust the amount of voltage applied to the motor.

The Run/Stop hysteresis is configurable through the Run/Stop input boxes in the

Parameters tab of the GUI. The Run percentage is the percentage of full-scale control

input above which the motor will run. The Stop percentage is the percentage of

full-scale control input below which the motor will stop. Separate thresholds allows for

hysteresis in the run control.

DS41629A-page 32 2012 Microchip Technology Inc.

Page 33

Chapter 4. The Bipolar Stepper Add-on Board

4.1 GETTING STARTED

4.1.1 Overview

The bipolar stepper add-on (DM164130-7) allows you to drive common two-phase

bipolar stepper motors used in consumer electronics, ranging from CNCs, printers,

optical disc drives and small load positioning systems. The add-on is shipped together

with the Leadshine 39HS02 bipolar stepper motor pre-wired to plug directly into add-on

connector J3. Alternatively, any other 5-12V bipolar stepper motor can be used by

hooking it up through the J3 connector.

4.2 FEATURES

The key features of this board include the following:

Connectors:

• Male 20-pin connector (J1) to match the F1 LV Evaluation Platform

• Generic 6-pin bipolar stepper motor connector (J3)

• 5-12V power supply input connector (J2)

Typical Bipolar Stepper drive:

• Four P-type and four N-type MOSFETS comprising two full H-bridges each of

which drives one motor phase

• One sensing resistor for current measurement (R3).

Protection:

• 2x5A power fuses (F1, F2)

Power Supply:

• 3.3V voltage regulator (U1)

Parameter storage:

• 1k x 8 UNI/O

F1 LV EVALUATION PLATFORM

MOTOR CONTROL ADD-ONS

®

Serial EEPROM (U2)

4.2.1 What’s Included

The bipolar stepper add-on with part number DM164130-7 contains:

• Bipolar Stepper Add-on Board designed for the F1 Evaluation Platform

• Leadshine motor (P/N: 39HS02)

4.2.2 Reference Documents

This section points you to application technical support.

AN907, ”Stepping Motors Fundamentals”

AN906, ”Stepper Motor Control Using the PIC16F684”

AN822, ”Stepper Motor Microstepping with PIC18C452”

®

AN1307, ”Stepper Motor Control with dsPIC

2012 Microchip Technology Inc. DS41629A-page 33

DSCs”

Page 34

F1 LV Evaluation Platform Motor Control Add-Ons

You can obtain these reference documents from your nearest Microchip sales office

(listed in the last page of this document) or by downloading them from the Microchip

web site.

4.3 GETTING STARTED

WARNING

The Bipolar Motor Control Add-on Board is intended to drive two-phase bipolar stepper

motors. Before connecting the motor, make sure the power rating of the motor is equal

to or less than the power rating of the board, as shown in Appendix B. “Conversion

Factors”. Also, make sure the configuration parameters inside the software or the GUI

are correct for the motor you are using. Failure to comply with this warning could lead

to malfunction of the board and the motor, and could result in physical harm.

Before beginning the start-up procedure, complete a visual check of the board and the

motor for connectivity and mechanical damage. If damage is found, DO NOT power-up

the board. Otherwise, you may further damage the equipment. Contact Microchip’s

local office or distributor immediately.

A step-by-step connecting procedure is available in Section 1.4.3 “Connecting the

F1 LV Evaluation Platform to the Add-on Board”. Please make sure that POT R4

on the F1 Evaluation Platform is turned fully CCW.

If using a different motor, connected through J3, please keep in mind to attach each

motor terminal firmly to the connector. Bad contacts can damage the add-on and will

wear out the motor in time. There is no rule for attaching a specific motor lead to a

phase line on the add-on. Keep in mind the correspondences on the software side

when testing or measuring directly on that motor phase.

On the F1 LV Evaluation Platform, use push button RD2 to step through the application

menu on the LCD display. To have more control over the motor using a real-time communication tool, please refer to the next section.

4.4 HARDWARE

4.4.1 General Architecture

The bipolar stepper add-on uses a simple bipolar stepper drive formed by four independent N-type MOSFETs suitable for two-phase bipolar stepper motors. Open-loop control, closed-loop control, full step, half step, microstepping commutation can be done in

the software.

Figure 4-1 provides a simplified block diagram of the development board hardware,

coupled to the F1 LV Evaluation Platform:

DS41629A-page 34 2012 Microchip Technology Inc.

Page 35

The Bipolar Stepper Add-on Board

PIC16LF1947

J1

Bipolar Transistor Command Bridge