Microchip Technology F1 LV Evaluation Platform for Enhanced PIC Microcontrollers User guide

Page 1

F1 LV Evaluation Platform for

Enhanced PIC® Microcontrollers

User’s Guide

2011 Microchip Technology Inc. DS41614A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, chipKIT,

chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net,

dsPICworks, dsSPEAK, ECAN, ECONOMONITOR,

FanSense, HI-TIDE, In-Circuit Serial Programming, ICSP,

Mindi, MiWi, MPASM, MPLAB Certified logo, MPLIB,

MPLINK, mTouch, Omniscient Code Generation, PICC,

PICC-18, PICDEM, PICDEM.net, PICkit, PICtail, REAL ICE,

rfLAB, Select Mode, Total Endurance, TSHARC,

UniWinDriver, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2011, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-61341-776-8

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS41614A-page 2 2011 Microchip Technology Inc.

Page 3

F1 LV EVALUATION PLATFORM

Table of Contents

Chapter 1. F1 LV Evaluation Platform Overview

1.1 Introduction ............................................................................................. 11

1.2 Platform Contents ................................................................................... 11

1.3 Hardware Features ................................................................................. 11

1.3.1 PIC16LF1947 ........................................................................................ 11

1.3.2 MCP9800 I

1.3.3 PICkit™ 3 Programming/Debug Header ............................................... 12

1.3.4 MCP2200 USB to Serial Converter ....................................................... 12

1.3.5 Two Push Buttons, One Potentiometer, 7 LEDs ................................... 12

1.3.6 One Custom LCD .................................................................................. 12

1.3.7 20-pin Add-on Connector ...................................................................... 12

1.3.8 Current Monitoring Connector ............................................................... 12

1.3.9 Generous Prototyping Area ................................................................... 12

1.3.10 MCP1640 Synchronous Boost Regulator .............................................. 12

1.3.11 MCP1703 LDO Regulator ...................................................................... 12

1.3.12 User Selectable Power Sources ............................................................ 13

2

C™ Temperature Sensor ................................................... 11

USER’S GUIDE

Chapter 2. Getting Started

2.1 Introduction ............................................................................................. 15

2.2 Powering the F1 LV Evaluation Platform ................................................ 16

2.3 Powering with PICkit™ 3 ........................................................................ 16

2.4 Powering from External Power Supply ................................................... 17

2.5 Powering with the ADD-on Expansion Header J3 .................................. 18

2.6 Powering with a AAA Battery .................................................................. 18

2.7 Powering with a USB Cable ................................................................... 19

2.8 Default Firmware .................................................................................... 19

2.8.1 Blinking LEDs ........................................................................................ 19

2.8.2 Measuring the Ambient Temperature .................................................... 19

2.8.3 Add-on Motor Expansion ....................................................................... 20

2.8.4 LCD Display ........................................................................................... 20

2.8.5 User Interface ........................................................................................ 20

Chapter 3. Programming the F1 LV Evaluation Platform

3.1 Introduction ............................................................................................. 21

3.2 Programming/Development Tool Support .............................................. 21

3.3 Hardware Resources .............................................................................. 22

Chapter 4. Demo Code

4.1 Introduction ............................................................................................. 25

4.2 Service Drivers ....................................................................................... 25

4.3 Combined Demo ..................................................................................... 25

4.4 Motor Control GUI Application ................................................................ 25

2011 Microchip Technology Inc. DS41614A-page 3

Page 4

F1 LV Evaluation Platform User’s Guide

4.5 BLDC Demo ........................................................................................... 25

4.6 BDC Demo ............................................................................................. 26

4.7 Unipolar Stepper Demo .......................................................................... 26

4.8 Bipolar Stepper Demo ............................................................................ 26

Chapter 5. Hardware Libraries and Drivers

5.1 Introduction ............................................................................................. 27

5.2 I

5.3 MCP9800 Driver ..................................................................................... 27

5.4 RTCC Driver ........................................................................................... 27

5.5 LCD Driver .............................................................................................. 27

5.6 Using the I

5.7 Using the LCD driver .............................................................................. 30

5.8 Using the RTCC Driver ........................................................................... 33

5.9 Using the MCP9800 Driver ..................................................................... 34

2

C™ Driver ............................................................................................ 27

2

C™ Driver ............................................................................ 28

5.6.1 I2C Data Structures ................................................................................28

5.6.2 I

5.7.1 LCD Data Structures ..............................................................................30

5.7.2 LCD Function Interface ..........................................................................31

5.7.3 LCD Segment Definitions .......................................................................32

5.8.1 RTCC Function Interface .......................................................................33

5.9.1 MCP9800 Function Interface .................................................................34

2

C Function Interface ............................................................................29

Chapter 6. Troubleshooting

6.1 Introduction ............................................................................................. 35

6.2 Common Problems ................................................................................. 35

6.2.1 The board will not power up ...................................................................35

6.2.2 LCD is blank, but everything else works ................................................35

Chapter 7. Schematics

7.1 Introduction ............................................................................................ 37

7.1.1 F1 LV Evaluation Platform Schematic (1 of 4) .......................................38

7.1.2 F1 LV Evaluation Platform Schematic (2 of 4) .......................................39

7.1.3 F1 LV Evaluation Platform Schematic (3 of 4) .......................................40

7.1.4 F1 LV Evaluation Platform Schematic (4 of 4) .......................................41

DS41614A-page 4 2011 Microchip Technology Inc.

Page 5

F1 LV EVALUATION PLATFORM

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

F1 LV Evaluation Platform User’s Guide. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the F1 LV Evaluation Platform User’s Guide as a

development tool to emulate and debug firmware on a target board. The manual layout

is as follows:

• Chapter 1. “F1 LV Evaluation Platform Overview”

• Chapter 2. “Getting Started”

• Chapter 3. “Programming the F1 LV Evaluation Platform”

• Chapter 4. “Demo Code”

• Chapter 5. “Hardware Libraries and Drivers”

• Chapter 6. “Troubleshooting”

• Chapter 7. “Schematics”

2011 Microchip Technology Inc. DS41614A-page 5

Page 6

F1 LV Evaluation Platform User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

®

IDE User’s Guide

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

DS41614A-page 6 2011 Microchip Technology Inc.

Page 7

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use the F1 LV Evaluation Platform. Other useful

documents are listed below. The following Microchip documents are available and recommended as supplemental reference resources.

Readme for F1 LV Evaluation Platform User’s Guide

For the latest information on using F1 LV Evaluation Platform User’s Guide, read the

“Readme for F1 LV Evaluation Platform User’s Guide.txt” file (an ASCII

text file) in the Readmes subdirectory of the MPLAB

Readme file contains update information and known issues that may not be included

in this user’s guide.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB IDE installation directory. The Readme files

contain update information and known issues that may not be included in this user’s

guide.

Preface

®

IDE installation directory. The

2011 Microchip Technology Inc. DS41614A-page 7

Page 8

F1 LV Evaluation Platform User’s Guide

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com/F1LVEval.

This web site is used as a means to make files and information easily available to

customers. Accessible by using your favorite Internet browser, the web site contains

the following information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the HI TECH C

pilers; MPASM™ and MPLAB ASM30 assemblers; MPLINK™ and MPLAB

LINK30 object linkers; and MPLIB™ and MPLAB LIB30 object librarians.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2, ICD3, PICkit™ 3.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 device programmers and PICkit™ 3 development programmers.

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

®

C16, MPLAB C18 and MPLAB C30 C com-

DS41614A-page 8 2011 Microchip Technology Inc.

Page 9

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (November 2011)

• Initial Release of this Document.

Preface

2011 Microchip Technology Inc. DS41614A-page 9

Page 10

F1 LV Evaluation Platform User’s Guide

NOTES:

DS41614A-page 10 2011 Microchip Technology Inc.

Page 11

Chapter 1. F1 LV Evaluation Platform Overview

1.1 INTRODUCTION

Thank you for choosing the F1 LV Evaluation Platform. This kit allows you to begin

development using the PIC16LF1947 microcontroller (MCU).

The PIC16LF1947 is the first in a family of enhanced mid-range microcontrollers.

These architectural enhancements allow for more memory and faster computation than

that of legacy PIC16 microcontrollers.

The PIC16F1 and PIC12F1 family of microcontrollers are a series of 8-bit

microcontrollers derived from the popular PIC16 series of 8-bit PIC

The F1 LV derivatives feature an enhanced CPU, support for extended amounts of

memory, improved peripherals, and XLP low power. The F1 LV Evaluation Platform

allows you to evaluate these features for your application in a simple, low-cost platform.

This chapter introduces the F1 LV Evaluation Platform:

• Platform Contents

• Hardware Features

F1 LV EVALUATION PLATFORM

USER’S GUIDE

®

microcontrollers.

1.2 PLATFORM CONTENTS

The F1 LV Evaluation Platform contains the following items:

1. F1 LV Evaluation Platform Demo Board – www.microchip.com/

1.3 HARDWARE FEATURES

The F1 LV Evaluation Platform has the following hardware features:

1.3.1 PIC16LF1947

The PIC16LF1947 is a 64-pin full-featured device, including:

1. Enhanced PIC16 instruction set

2. 16K words of Flash memory

3. 1K of RAM

4. 256 bytes of EEPROM

5. 2 CCPs and 3 enhanced CCPs

6. MSSP (I

7. Enhanced USART

8. 8- and 16-bit timers

9. 32 MHz internal oscillator

10. Low-power 32 kHz crystal oscillator

11. LCD controller

12. LF Operating Range: 1.8-3.6V

2

C™, SPI)

F1LVEval

1.3.2 MCP9800 I2C™ Temperature Sensor

The MCP9800 is a low-power, I2C temperature sensor with selectable 9 to 12 bits of

output resolution.

2011 Microchip Technology Inc. DS41614A-page 11

Page 12

F1 LV Evaluation Platform User’s Guide

1.3.3 PICkit™ 3 Programming/Debug Header

The PICkit 3 is a low-cost development tool that allows programming and debugging of

the PIC16LF1947 MCU using the PICkit ICSP™ header.

1.3.4 MCP2200 USB to Serial Converter

The MCP2200, with the associated driver, makes the F1 LV Evaluation platform appear

as a serial port when connected to a PC. The demo code includes utilities to control the

various add-on boards through this serial interface.

1.3.5 Two Push Buttons, One Potentiometer, 7 LEDs

Simple applications need the basic user interface elements. Two push buttons, one

potentiometer and 4 green LEDs are available for any application. The remaining three

LEDs are used as indicators, a red LED is used to indicate the board is powered, the

remaining two LEDs are green and indicate RX/TX communication through the USB

Serial Converter.

1.3.6 One Custom LCD

The LCD glass supplied on this board is a Microchip custom display with icons for a

battery indicator, 4 large numerical digits, 2 small numerical digits, adjustable decimal

point, colon for time keeping, 4 function mode (Fx) indicators, 8 segment bar, a

three-segment battery power indicator and 1 custom Microchip symbol. The

PIC16LF1947 makes controlling the LCD very simple.

1.3.7 20-pin Add-on Connector

This connector expands the F1 LV Evaluation Board with optional add-on boards.

Currently, there are 4 motor control add-ons planned or in production. The

PIC16LF1947 has complete control of 3 phases, so other 1, 2, or 3-phase motor

topologies are supported.

1.3.8 Current Monitoring Connector

To demonstrate the Extreme Low Power (XLP) features of the PIC16LF1947, a

precision ammeter can be connected to the current monitoring connector. This allows

your application to be easily optimized for the lowest possible current.

1.3.9 Generous Prototyping Area

Our circuits are not your circuits. A prototyping area has been provided to extend the

functionality of this demo board to demonstrate the utility of the PIC16LF1947 in your

application.

1.3.10 MCP1640 Synchronous Boost Regulator

The MCP1640 is a compact, high-efficiency, fixed frequency, synchronous step-up

DC-DC converter. Through the use of this component, the F1 LV Evaluation board has

the option of boosting an AAA 1.8V battery to 3.3V, which is then used to power the

board and supporting circuitry.

1.3.11 MCP1703 LDO Regulator

The MCP1703 is a low-dropout voltage regulator with a 250 mA maximum output.

Through the use of this component, the user has the option of powering the F1 LV

Evaluation board through the USB Serial Converter connector. The USB supplies 5V,

and the MCP1703 reduces this to the operating voltage of 3.3V.

DS41614A-page 12 2011 Microchip Technology Inc.

Page 13

F1 LV Evaluation Platform Overview

1.3.12 User Selectable Power Sources

The F1 LV Evaluation board operates at 3.3V and comes with a flexable range of

powering options.

• J5 – (EXT SUPP) The user can power the board from a external power supply

connected to the +/- headers.

• J6 – (EXP PWR) The user can power the board from any Add-on board through

the expansion connector.

• J7 – (AAA BATT) The user can power the board by inserting a single AAA battery

into B1 battery clamp.

• J8 – (USB PWR) The user can power the board by connecting a USB cable to J2

USB SERIAL CONV header.

2011 Microchip Technology Inc. DS41614A-page 13

Page 14

F1 LV Evaluation Platform User’s Guide

NOTES:

DS41614A-page 14 2011 Microchip Technology Inc.

Page 15

2.1 INTRODUCTION

This chapter gives instructions to get your F1 LV Evaluation Platform powered up and

running the default demonstration. The following sections include:

• Powering the F1 LV Evaluation Platform

• Default Firmware

• Programming the F1 LV Evaluation Platform with the PICkit™ 3

• Measuring the current consumption

FIGURE 2-1: F1 LV EVALUATION PLATFORM

F1 LV EVALUATION PLATFORM

USER’S GUIDE

Chapter 2. Getting Started

2011 Microchip Technology Inc. DS41614A-page 15

Page 16

F1 LV Evaluation Platform User’s Guide

2.2 POWERING THE F1 LV EVALUATION PLATFORM

The PIC16LF1947 supplied with your F1 LV Evaluation Platform requires a supply

voltage of 1.8V-3.6V. Voltages above 3.6V will degrade or damage the device. There

are five ways to supply the necessary power.

1. Use PICkit 3

Select Power Supply Source via cross jumper configuration

2. External Power Source, J5

3. Use the Add-on Expansion Header, J6

4. Use an AAA Battery, J7, or

5. Use USB Cable, J8.

2.3 POWERING WITH PICkit™ 3

To power with the PICkit 3, perform the following steps:

1. Make sure a jumper or an ammeter is connected across J4.

2. Configure the PICkit 3 to supply a voltage between 1.8 and 3.6V. For proper LCD

contrast, the supply should be 3.3V.

3. Attach the PICkit 3 to the PICkit ICSP™ connector at the end of the board.

4. Activate the PICkit 3 power output.

Note: When powering from the PICkit 3, all power supply jumpers (J5 - J8) should

be removed.

FIGURE 2-2: POWERING FROM PICkit™ 3

DS41614A-page 16 2011 Microchip Technology Inc.

Page 17

2.4 POWERING FROM EXTERNAL POWER SUPPLY

To power from an external power supply, perform the following steps:

1. Make sure a jumper or an ammeter is connected across J4.

2. Connect V

3. Verify the supply voltage to be between 1.8 and 3.6V. For proper LCD contrast,

the supply should be 3.3V.

4. Populate EXT PWR jumper, J5.

5. Turn on the power supply.

FIGURE 2-3: POWERING WITH EXTERNAL POWER SUPPLY

REF+ to EXT SUPP (+), connect VREF- to EXT SUPP(-).

Getting Started

2011 Microchip Technology Inc. DS41614A-page 17

Page 18

F1 LV Evaluation Platform User’s Guide

2.5 POWERING WITH THE ADD-ON EXPANSION HEADER J3

The add-on expansion hardware will supply the F1 LV Evaluation board with 3.3V DC

through use of a linear regulator. This allows the 5-12V motor power supply to power

the PIC16LF1947. J3, pin 6, is the source for the 3.3V power. To use this power

perform the following steps.

1. Make sure a jumper or an ammeter is connected across J4.

2. Verify that any attached PICkit 3 is not supplying power.

3. Populate the EXP PWR jumper, J6.

4. Attach the add-on expansion board.

5. Connect power to the add-on expansion board.

FIGURE 2-4: EXPANSION SLOT POWER

2.6 POWERING WITH A AAA BATTERY

To power with a single AAA battery, the MCP1640 Boost Regulator is used to take the

supplied 1.8V and convert it to 3.3V.

1. Make sure the jumper or an ammeter is connected across J4.

2. Insert AAA battery into B1 battery clip.

3. Populate AAA BATT jumper, J7.

FIGURE 2-5: POWERING FROM BATTERY

DS41614A-page 18 2011 Microchip Technology Inc.

Page 19

2.7 POWERING WITH A USB CABLE

To power with the USB cable, perform the following steps:

1. Make sure a jumper or an ammeter is connected across J4.

2. The USB cable will supply 5V DC to the F1 LV Evaluation board. The MCP1703

converts the 5V to 3.3V supply voltage for the PIC16LF1947.

3. Populate the USB PWR jumper, J8.

FIGURE 2-6: USB POWER

Getting Started

2.8 DEFAULT FIRMWARE

The default firmware supplied with your F1 LV Evaluation Board Demo performs the

following functions:

1. Blink LEDs

2. Measure the ambient temperature

3. Run an attached add-on board motor (the firmware will auto-detect the add-on

motor type, or indicate if no add-on board is attached.)

4. Display time/temperature/pot position/motor RPM on the LCD

5. User interface with a button and pot

For the latest firmware go to www.microchip.com/F1

2.8.1 Blinking LEDs

LED RA4 is used to indicate timing of the demonstration main loop. The LED toggles

at each cycle through the demonstration program main loop. LEDs RA6, RA7 and RC5

are add-on board dependent, their function will change depending on the add-on board

attached.

2.8.2 Measuring the Ambient Temperature

The MCP9800 is polled when in Temperature Measurement mode. The measured

temperature is filtered, scaled to either Centigrade or Fahrenheit and displayed on the

LCD.

LVEval

2011 Microchip Technology Inc. DS41614A-page 19

Page 20

F1 LV Evaluation Platform User’s Guide

2.8.3 Add-on Motor Expansion

A main task of the demo code is to allow the user to connect any of the expansion

add-on motor boards and have the PIC16LF1947 determine the motor type and adjust

the drive accordingly. The code provided with the F1 LV Evaluation board works with

the following add-on boards:

- BLDC (DM164130-2)

- BDC (DM164130-6)

- Unipolar Stepper (DM164130-7)

- Bipolar Stepper (DM164130-8)

2.8.4 LCD Display

The time, temperature, pot position and motor speed are displayed on the LCD. The

LCD is a display with multipurpose icons. The display uses 4 commons and 28

segment drives. The Timer1 oscillator is used to clock the display peripheral and allow

the LCD to display data even in Sleep. Normally, the Timer1 counter would be used to

drive the display, but this timer is required for the BLDC software. This requires

configuring the LCD peripheral for a Type B waveform for this demo. The Type B

waveform requires coordinating LCD updates when the peripheral is ready. The BLDC

Interrupt requirements preclude using the built-in LCD interrupt for update

coordination, therefore, the LCD interrupt is polled as part of the main loop. Type A

waveforms can update the display without the extra coordination complexity. The

different waveform types are described in section 21.9 of the PIC16LF1947 data sheet

(DS41414). Because the LCD is clocked from the 32.768 kHz crystal, the LCDIF

operates at a multiple of the crystal frequency, providing a very accurate time base for

the real-time clock.

2.8.5 User Interface

Due to the extreme simplicity of this board, only a single button and a single pot are

available for user input. A MCLR button is also present for the demonstration, this will

function as a master clear switch. These two elements allow the user to cycle through

the display elements, change the motor speed and change the time.

Pressing and releasing the button cycles through the following display modes:

1. Add-on Motor Indicator

2. Setable AM/PM Clock

3. 24-hr clock with seconds

4. Temperature (C)

5. Temperature (F)

6. POT ADC Value

7. Motor RPM (BLDC and stepper motors only)

By holding down the RD2 button during the Setable Clock mode, the minutes will begin

to increment. The minutes will increment from 0-9; when the minutes increment past 9,

the minutes will begin to increase by factors of 10. When incrementing reaches an hour,

the hours will begin to increment and the minutes will stay at 00. The AM/PM indicator

will automatically change accordingly. To set the clock, first set the hours and release

the button. Then, set the tens of minutes and release the button. Finally, set the

seconds. To synchronize the seconds, increment the minutes one final time at the

instant the time reference advances to the next minute.

Turning the pot will change the motor speed.

When an expansion board is present, the F1 LV Evaluation code will automatically

detect the add-on type and modify the motor drive accordingly.

DS41614A-page 20 2011 Microchip Technology Inc.

Page 21

F1 LV EVALUATION PLATFORM

USER’S GUIDE

Chapter 3. Programming the F1 LV Evaluation Platform

3.1 INTRODUCTION

The F1 LV Evaluation Platform makes extensive use of the on-board peripherals of the

PIC16LF1947. This chapter provides guidance concerning the tools used for

programming the F1 LV Evaluation Board and a map of the board function to I/O pin

and pin function.

3.2 PROGRAMMING/DEVELOPMENT TOOL SUPPORT

The following development tools support the F1 LV Evaluation Platform:

1. PICkit™ 3

2. ICD 3

3. REAL ICE™ in-circuit emulator (with adapter AC164110)

The PICkit™ or ICD 3 tools can also power the F1 LV Evaluation Platform, therefore,

no additional hardware is required to get started. The ICSP pins of the PIC16LF1947

are dedicated to the PICkit ICSP connector, eliminating interactions between the

Evaluation Platform and the programmer/debugger.

If you are developing with the REAL ICE emulator ICD, you will need the AC164110

adaptor, or the high-speed trace adaptor. These adaptors provide the inline 6-pin

connector required by the PICkit ICSP programming capability interface. You will also

need a power supply, please see Chapter 2. “Getting Started” for more on powering

the F1 LV Evaluation Platform.

2011 Microchip Technology Inc. DS41614A-page 21

Page 22

F1 LV Evaluation Platform User’s Guide

3.3 HARDWARE RESOURCES

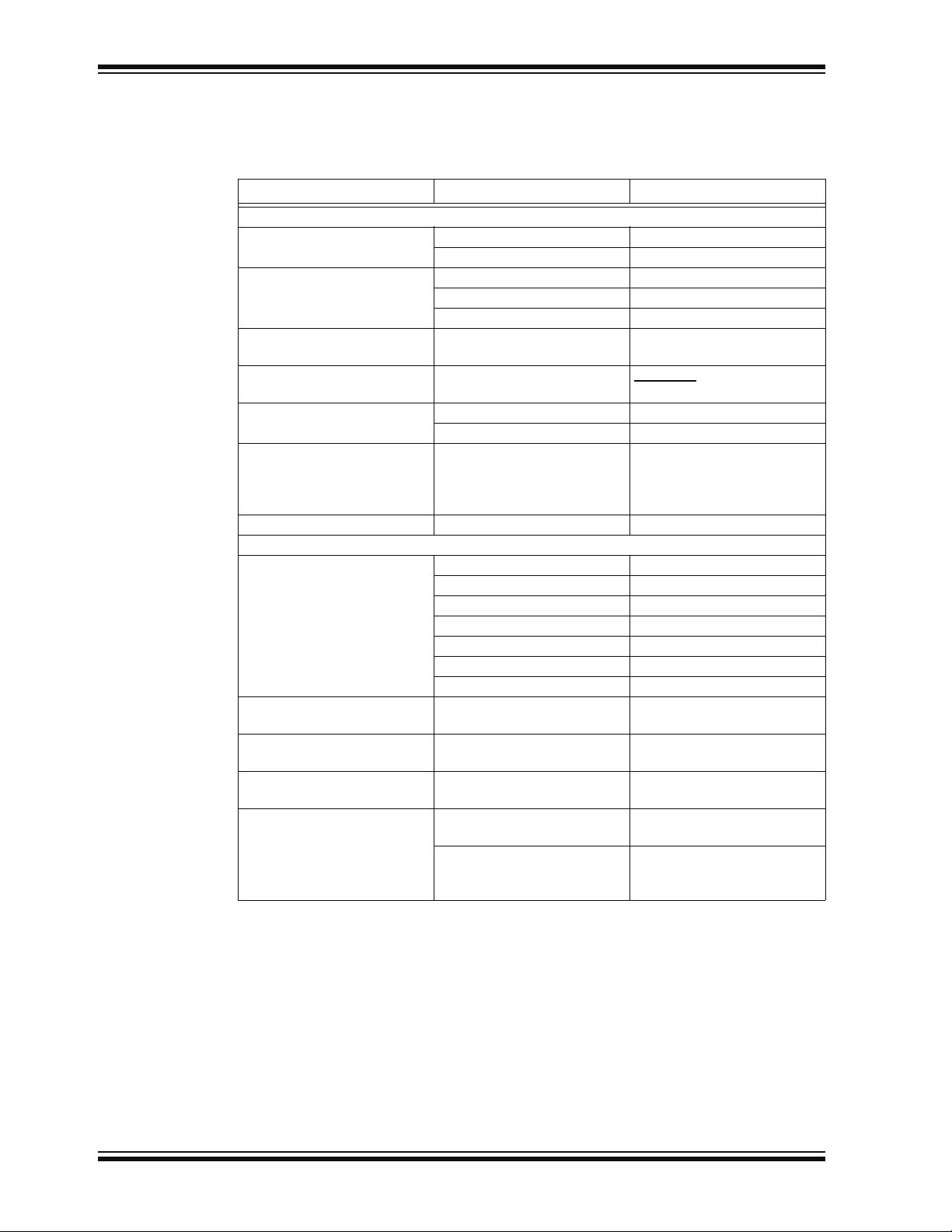

TABLE 3-1: HARDWARE RESOURCES

Pin Number PORT ID I/0 Use Name Description

1 RE1 0 RE1 J3 – Pin 10

2 RE0 0 RE0 J3 – Pin 12

3 RG0 0 P3A Low Side Drive C; J3 – Pin 9

4 RG1 I LCD SEG43 S1/S2/S3/S4

5 RG2 I LCD SEG44 T1/T2/T3/T4

6 RG3 0 R3 J3 – Pin 8

7 RG5 I MCLR/V

8 RG4 0 RG4 J3 – Pin 2

9V

10 NC NC Pin tied to VDD

11 RF7 I AN5 C12IN3- BEMF A; J3 – Pin 15

12 RF6 I AN1 C1IN+ BEMF Reference; J3 – Pin 16

13 RF5 I AN10 C12IN1- BEMF C; J3 – Pin 19

14 RF4 I AN9 C2IN+ Current Sense Reference; J3 – Pin 18

15 RF3 I AN8 C12IN2- BEMF B; J3 – Pin 17

16 RF2 0 RF2 C1OUT

17 RF1 I LCD SEG19 S5/S6/S7/S8

18 RF0 I AN16 C12IN0- Current Sense; J3 – Pin 20

19 A

20 A

21 RA3 I AN3 RA3 Battery Voltage

22 RA2 I LCD SEG34 6A/6D/6E/6F

23 RA1 I LCD SEG18 5B/5C/5G/P5

24 RA0 I LCD SEG33 5A/5D/5E/5F

25 V

26 V

27 RA5 I AN4 RA5 Speed Control Input (New Layout)

28 RA4 0 RA4 LED [D4]

29 RC1 I RC1 T1OSCI

30 RC0 0 RC0 T1OSCO

31 RC6 0 TX1 Serial Transmit

32 RC7 I RX1 Serial Receive

33 RC2 0 P1A Low Side Drive B; J3 – Pin 1

34 RC3 I SCK1 I

35 RC4 I SDA1 I

36 RC5 0 RC5 Phase C LED, LED [D3]

37 RB7 0 RGD ICSP™ Data (TestPoint 1)

38 V

39 RA7 0 RA7 Phase B LED; LED [D2]

40 RA6 0 RA6 Phase A LED; LED [D1]

41 V

42 RB6 0 PGC ICSP Clock (TestPoint 1)

43 RB5 I LCD SEG29 F2/6B/6C/6G

PP MCLR

SS Supply Return

VDD Power Supply

VSS Supply Return

SS Supply Return

DD Power Supply

2

C™ Clock

2

C Data

DD Power Supply

SS Supply Return

DS41614A-page 22 2011 Microchip Technology Inc.

Page 23

Programming the F1 LV Evaluation Platform

TABLE 3-1: HARDWARE RESOURCES (CONTINUED)

44 RB4 I LCD SEG11 F1/F3/F4/P6

45 RB3 I LCD SEG10 4B/4C/4G/P4

46 RB2 I LCD SEG9 4A/4D/4E/4F

47 RB1 I LCD SEG8 3B/3C/3G/P3

48 RB0 I LCD SEG30 3A/3D/3E/3F

49 RD7 I LCD SEG7 2B/2C/2G/P2

50 RD6 0 P1B High Side Drive A; J3 – Pin 3

51 RD5 0 RD5 J3 – Pin 4

52 RD4 0 P3B High Side Drive C; J3 – Pin 11

53 RD3 I LCD SEG3 2A/2D/2E/2F

54 RD2 I RD2 Push Button

55 RD1 I LCD SEG1 1B/1C/1G/1P

56 V

57 V

58 RD0 I LCD SEG0 1A/1D/1E/1F

59 RE7 0 P2A Low Side Drive B; J3 – Pin 5

60 RE6 I LCD COM3 COM4

61 RE5 I LCD COM2 COM3

62 RE4 I LCD COM1 COM2

63 RE3 I LCD COM0 COM1

64 RE2 0 P2B High Side Drive B; J3 – Pin 7

SS Supply Return

DD Power Supply

2011 Microchip Technology Inc. DS41614A-page 23

Page 24

F1 LV Evaluation Platform User’s Guide

NOTES:

DS41614A-page 24 2011 Microchip Technology Inc.

Page 25

4.1 INTRODUCTION

The F1 LV Evaluation Platform demo is located at www.microchip.com/F1LVEval. The

F1 LV Evaluation demonstration program uses a single Combined Demo. The Combined Demo source code is organized into sectional code for ease of portability:

This chapter provides an overview to the functions provided by these demos.

4.2 SERVICE DRIVERS

Multiple services drivers are utilized during this demo for operation. For user ease,

these drivers have been separated for easy portability.

- The I

- Using the LCD and RTCC drivers, the LCD is used for display of the clock,

- The UNI/O

2

C driver is used by the MCP9800 driver to read the current temperature

from the on-board MCP9800 I

temperature, motor status and motor type.

is being attached, and which firmware should be used.

F1 LV EVALUATION PLATFORM

USER’S GUIDE

Chapter 4. Demo Code

2

C temperature sensor.

®

driver is used to read from each add-on board which motor type

4.3 COMBINED DEMO

The combined demo combines all the software from all the previous demos to show the

power of the PIC16LF1947. In this demo, the user can attach any of the (4) add-on

motor boards for use. The F1 LV Evaluation Board will auto-detect the type of motor

add-on used and automatically configure accordingly for use. All drivers are reused

from the previous demos. The RTCC is driven from the LCD peripheral.

The combined demo is preprogrammed in the F1 LV Evaluation Platform.

4.4 MOTOR CONTROL GUI APPLICATION

The F1 LV Evaluation Platform is developed to connect through the MCP2200 to the

user’s computer emulating a serial port. The GUI is capable of detecting which F1 LV

add-on board is being used. Through the application, the user is capable of exploring

the many options made with these motor types.

The GUI is capable of detecting and displaying which firmware version is being used

through the F1 LV Evaluation Platform, and also which add-on board is connected. The

features of the GUI in use with the F1 LV Evaluation Platform with its add-on boards is

discussed in the Add-on User’s Guide.

4.5 BLDC DEMO

The BLDC demo controls a sensorless, brushless DC motor connected to the PIC16F1

BLDC Expansion board (DM164130-2). Motors of the same type, but other than the

motor supplied, can also be driven by making appropriate modifications to the motor

control parameters.

Refer to application note AN1305, “Sensorless 3-Phase Brushless Motor Control with

the PIC16FXXX”, for detailed information regarding BLDC motor control.

2011 Microchip Technology Inc. DS41614A-page 25

Page 26

F1 LV Evaluation Platform User’s Guide

4.6 BDC DEMO

The BDC demo controls a brushed DC motor connected to the PIC16F1 BDC

Expansion board (DM164130-6). Motors of the same type, but other than the motor

supplied, can also be driven by making appropriate modifications to the motor control

parameters.

4.7 UNIPOLAR STEPPER DEMO

The Unipolar Stepper Demo controls a Unipolar stepper motor connected to the

PIC16F1 Unipolar Expansion board (DM164130-8). Motors of the same type, but

other than the motor supplied, can also be driven by making appropriate modifications

to the motor control parameters.

4.8 BIPOLAR STEPPER DEMO

The Bipolar Stepper Demo controls a Unipolar stepper motor connected to the

PIC16F1 Bipolar Expansion board (DM164130-7). Motors of the same type, but other

than the motor supplied, can also be driven by making appropriate modifications to

the motor control parameters.

DS41614A-page 26 2011 Microchip Technology Inc.

Page 27

Chapter 5. Hardware Libraries and Drivers

5.1 INTRODUCTION

The demo code uses a common set of libraries to provide I2C, real-time clock,

MCP9800 and LCD services. These libraries may be useful for other applications so

they are documented here. These drivers are located at

5.2 I2C™ DRIVER

The I2C driver allows I2C requests to be queued and then handled either by interrupts

or by polling. The driver is configured during compilation to support polling or interrupts.

2

The I

C and LCD demos configure the driver for interrupt mode. The Combined Demo

polls the I

5.3 MCP9800 DRIVER

The MCP9800 driver uses the I2C driver to get the current temperature. The

mcp9800_get_temp function is fully blocking, so once a request is queued, the driver

polls the I

interrupts, the mcp9800_get_temp function repeatedly calls the I2C_handler

function to process all the I

mcp9800_get_temp function simply inserts an I2C_TRANSACTION_T into the I

transaction queue and waits for the transaction to complete.

F1 LV EVALUATION PLATFORM

USER’S GUIDE

www.microchip.com/F1LVEval

2

C handler within the MCP9800 driver.

2

C subsystem until the data is complete. If the I2C driver is operating without

2

C events. If the I2C driver is operating with interrupts, the

2

.

C

5.4 RTCC DRIVER

A software RTCC is managed by the supplied RTCC driver. This driver implements the

time() function required by the C compiler. Time is internally kept as seconds since

January 1, 1970. Standard C functions can be used to convert the time to the current

date. This driver has two modes. In the first mode, it expects to be called once per

second by the Timer1 interrupt. In the second mode, it expects to be called on every

LCD mode B frame. This allows the RTCC to keep accurate time even if Timer1 is

being used by some other function, such as the BLDC motor driver.

5.5 LCD DRIVER

The LCD driver contains the initialization code required for the LCD peripheral and the

mapping code required to control the LCD supplied with this demo board. It is a good

starting point for the LCD driver your unique application will require.

2011 Microchip Technology Inc. DS41614A-page 27

Page 28

F1 LV Evaluation Platform User’s Guide

5.6 USING THE I2C™ DRIVER

The supplied software includes an I2C Master mode driver with the following features:

1. Interrupt driven or polled

2. Queued requests

3. Minimum memory requirements

4. Uses Restart to maximize bus bandwidth

5. Multiple atomic I

6. Completion flag for each queued block of I

5.6.1 I2C Data Structures

Two data structures are defined to simplify interactions with the I2C driver.

5.6.1.1 I2C_RESULTS

The I2C_RESULTS is an enumerated type with the following enumerations:

TABLE 5-1: I2C_RESULTS_T

I2C_REQUEST_PENDING Request is in the queue or in process but it is not

I2C_REQUEST_COMPLETE The request is finished successfully.

I2C_REQUEST_STUCK_START The request was aborted. The Start condition did

I2C_REQUEST_ADDRESS_NO_ACK The request was aborted. No ACK occurred on

I2C_REQUEST_DATA_NO_ACK The request was aborted. Not all of the data

I2C_REQUEST_LOST_STATE The I

The data completion flag for an I

I2C_REQUEST_PENDING until the request is complete. If the request completed

without errors, the value will be I2C_REQUEST_COMPLETE. If there were errors, the

value will reflect one of the other 4 error conditions.

2

C transactions allowed at each queue entry

2

C request is of type I2C_RESULTS. This flag will be

2

C commands.

done.

not clear correctly.

the address, so the target device must not exist

or is not functioning.

could be sent because the device did not ACK a

byte.

2

C state machine had a RAM corruption

and the default case caught the failure. This will

infinite loop so you should never see it.

5.6.1.2 I2C_TRANSACTION_REQUEST_BLOCK

The I2C_TRANSACTION_REQUEST_BLOCK is a structure representing one

transaction on the I

2

C bus. A transaction contains the following elements:

1. A 7- or 10-bit address. Address type is determined automatically by the driver.

R/W mode is implicit in the address and specified by bit 0.

2. An 8-bit baud rate. This is the value placed in SPADD. Predefined constants are

included that compute the SPADD value given an FOSC value. Set FOSC with

a #define before #including the I2C.h file.

3. A buffer_length. This is the number of bytes available for reading or writing

at the supplied data buffer.

4. A Buffer Pointer. Your application will allocate a block of memory for an I

2

C

transaction. Pass a pointer to this block via the Buffer Pointer. The block must

remain valid until the transaction is complete (i.e., if you allocate the block as a

non-static array within a function, you must not leave the function until the I

2

C

transaction is complete or the array may be reused by a different function).

DS41614A-page 28 2011 Microchip Technology Inc.

Page 29

Hardware Libraries and Drivers

initialize()

{

i2c_init;

}

Send_data()

{

I2C_TRANSACTION_REQUEST_BLOCK trb_list[5];

I2C_RESULTS flag;

… populate the trb’s …

i2c_insert(5,trb_list, &flag);

}

Send_one_byte()

{

I2C_TRANSACTION_REQUEST_BLOCK trb_list;

unsigned char data;

I2C_RESULTS flag;

data_block = .. my data byte ..

i2c_build_write_trb(&trb_list,ADDRESS, 1, &data, i2c_200K);

i2c_insert(1,&trb,&flag);

}

5.6.2 I2C Function Interface

5.6.2.1 i2c_init

The function i2c_init configures the I

transaction in the transaction queue.

FIGURE 5-1:

5.6.2.2 i2c_insert

The function i2c_insert places one complete set of Transaction Request Block

(TRBs). TRBs can be bundled into an array of multiple TRBs and inserted as one large

request. The driver will ensure that all the TRBs in the list will be processed sequentially

2

with I

C restarts separating them.

FIGURE 5-2:

2

C driver and makes it ready to receive

5.6.2.3 i2c_build_write_trb / i2c_build_read_trb

The i2c_build_write_trb and i2c_build_read_trb functions are helpers to

assemble the I2C_TRANSACTION_REQUEST_BLOCKS from passed parameters.

FIGURE 5-3:

5.6.2.4 i2c_write_block / i2c_read_block

The i2c_write_block and i2c_read_block functions are helpers that assemble

a TRB, insert it into the queue and wait for the transaction to complete.

2011 Microchip Technology Inc. DS41614A-page 29

Page 30

F1 LV Evaluation Platform User’s Guide

Send_one_byte()

{

unsigned char data;

i2c_write_block(ADDRESS, 1, &data, i2c_200K);

}

Interrupt_service_routine()

{

i2c_handler();

}

typedef union

{

UINT16 val;

struct

{

unsigned digit0 : 4;

unsigned digit1 : 4;

unsigned digit2 : 4;

unsigned digit3 : 4;

};

} BCD_TYPE;

FIGURE 5-4:

5.6.2.5 i2c_handler

2

The i2c_handler function must be called for each I

function can be placed into the Interrupt Service Routine for your application or, you

can simply poll it often. If the i2c_write_block or i2c_read_block functions are

used when the driver is configured for polling, then this function will repeatedly be

called until the transaction completes.

FIGURE 5-5:

5.7 USING THE LCD DRIVER

C state to be handled. This

The supplied LCD driver configures the LCD module for the I/O pins used by the F1 LV

Evaluation Platform. Icon definitions are provided to simplify the software. A BCD to

7-segment display mapping function is also provided to further simplify control of the

LCD glass. For more information concerning the LCD peripheral, please consult the

LCD chapter in the PIC16LF1947 data sheet (DS41414).

5.7.1 LCD Data Structures

5.7.1.1 BCD_TYPE

To simplify BCD to the 7-segment display mapping, a BCD segment data type has been

provided. This data type is simply four 4-bit fields representing digits 0, 1, 2 and 3.

FIGURE 5-6:

DS41614A-page 30 2011 Microchip Technology Inc.

Simply place the number you want displayed in each digit position and call

lcd_display_digits.

Page 31

Hardware Libraries and Drivers

System_initialize()

{

lcd_init();

}

void display_int(int t)

{

BCD_TYPE bcd;

bcd.digit0 = t %10;

t /= 10;

bcd.digit1 = t % 10;

t /= 10;

bcd.digit2 = t % 10;

t /= 10;

bcd.digit3 = t%10;

lcd_display_digits(bcd);

}

void update_blinking()

{

if(time(0) % 2) // if an odd number of seconds

{

lcd_display_on();

}

else

{

lcd_display_off();

}

}

5.7.2 LCD Function Interface

5.7.2.1 lcd_init

This function configures the LCD peripheral for this board and this glass. Type B

waveforms are used to allow the LCD peripheral to be used for the real-time clock

function. The Timer1 oscillator is configured as the LCD clock source.

FIGURE 5-7:

5.7.2.2 lcd_display_digits

This function accepts a BCD_TYPE variable and maps each digit to the correct

segments. Mapping the segments is done in two stages. First, the digit is converted to

the correct 7-segment mapping. Then, the 7-segment mapping is converted to the

actual glass segments with a long series of “if-else” statements. This function will need

extensive work in the “if-else” statements for applications driving different glass.

FIGURE 5-8:

5.7.2.3 lcd_display_on/lcd_display_off

These two functions simply turn the LCD peripheral off. The Timer1 oscillator is left

running. One use for these functions is to implement display blinking.

FIGURE 5-9:

2011 Microchip Technology Inc. DS41614A-page 31

Page 32

F1 LV Evaluation Platform User’s Guide

void display_volts(int v)

{

display_int(v);

DP3 = 0;

DP2 = 0;

S1 = 0;

S2 = 0;

AMPS = 0;

VOLT = 1;

KILO = 0;

OHMS = 0;

if (v < 0)

MINUS = 1;

else

MINUS = 0;

}

5.7.3 LCD Segment Definitions

FIGURE 5-10: LCD DISPLAY

TABLE 5-2:

PIN

12345678910111213141516

COM1

1A 1B 2A 2B 3A 3B 4A 4B F1 F2 6D PS 5D S8 S1 T1

COM2

1F 1G 2F 2G 3F 3G 4F 4G F3 6C 6E 5C 5E S7 S2 T3

COM3

1E 1C 2E 2C 3E 3C 4E 4C F4 6G 6F 5G SF S6 S3 T2

COM4

1D P1 2D P2 3D P3 4D P4 P6 6B 6A 5B 5A S5 S4 T4

There are many segments present on the F1 LV Evaluation Platform LCD. To access

these segments, simply set the supplied #defines to ‘1’ or ‘0’.

17 18 19 20

COM1

COM2

COM3

COM4

DS41614A-page 32 2011 Microchip Technology Inc.

FIGURE 5-11:

Page 33

5.8 USING THE RTCC DRIVER

System_initialization()

{

rtcc_init();

}

System_interrupt_service_routine()

{

If(TMR1IF & TMR1IE)

{

TMR1IF = 0;

rtcc_handler();

}

}

The RTC driver simply keeps track of seconds. The power-up initial value is ‘0’,

however, a function (rtcc_set) is provided to change that value. To keep the seconds

up-to-date, the function, rtcc_handler, must be called more frequently than the

defined value of CLOCKS_PER_SECOND. There are two options for the RTCC driver.

The first option is to use the Timer1 counter to provide a 1 Hz interrupt

(CLOCKS_PER_SECOND = 1). The second option is to use the LCD write-allowed

interrupt flag to provide a 128 Hz event (CLOCKS_PER_SECOND = 128). The two

choices are selected by defining use_lcdif or undefining use_lcdif.

5.8.1 RTCC Function Interface

5.8.1.1 rtcc_init

Initialize the RTCC function including Timer1, if required.

FIGURE 5-12:

Hardware Libraries and Drivers

5.8.1.2 rtcc_handler

The rtcc_handler function must be called frequently to keep the internal seconds

counter accurate.

FIGURE 5-13:

5.8.1.3 rtcc_set

After system initialization, the seconds counter is cleared to ‘0’. The standard C

libraries equate 0 seconds to Midnight, Jan 1, 1970. That time has expired a long time

ago, so a new time in seconds can be configured with rtcc_set().

2011 Microchip Technology Inc. DS41614A-page 33

Page 34

F1 LV Evaluation Platform User’s Guide

#include <time.h>

Time_set() // set the time & date to 1 second after midnight, July 4, 2009

{

struct tm time_str;

time_t unix_time;

time_str.tm_year = 2009; // the year

time_str.tm_mon = 7; // the month

time_str.tm_mday = 4; // the day of the month

time_str.tm_hour = 0; // the hour (0-23)

time_str.tm_min = 0; // the minutes

time_str.tm_sec = 1; // the seconds

time_str.tm_isdst = -1; // daylight savings time modifier

unix_time = mktime(&time_str);

rtcc_set(unix_time);

}

System_init()

{

i2c_init();

mcp9800_init();

}

Thermostat()

{

int temperature;

temperature = mcp9800_get_temp();

if(temperature > 260)

{

turn_on_air_conditioner();

}

}

FIGURE 5-14:

5.8.1.4 time

The standard C libraries require the application to supply the time function. This

function returns the current time_t value or loads a supplied time_t value. The

interrupts are saved and restored to make this function safe for use with interrupt driven

code.

5.9 USING THE MCP9800 DRIVER

The MCP9800 is an I2C temperature sensor. The MCP9800 driver provides a simple

interface to the features in the sensor.

5.9.1 MCP9800 Function Interface

5.9.1.1 mcp9800_init

This function configures the MCP9800 for 12-bit temperature, Continuous Conversion

mode. In this mode, the temperature is always ready to be read from the I

FIGURE 5-15:

5.9.1.2 mcp9800_get_temp

This function reads the current temperature and scales the result to degrees C * 10.

DS41614A-page 34 2011 Microchip Technology Inc.

(24.3C is returned 243)

FIGURE 5-16:

2

C interface.

Page 35

Chapter 6. Troubleshooting

6.1 INTRODUCTION

There may come a time when you need to determine why your F1 LV Evaluation

Platform is not performing correctly. This chapter lists a few of the problems that can

prevent proper operation.

6.2 COMMON PROBLEMS

6.2.1 The board will not power up

Make sure the power supply jumper is populating the proper pins. Confirm the ISENSE,

J4, jumper is populated or an ammeter is connected. Then, go back and review

Chapter 2. “Getting Started” of this manual.

6.2.2 LCD is blank, but everything else works

The demo code in supplied with the F1 LV Evaluation Platform uses the Timer1

oscillator to drive the LCD. If the Timer1 oscillator is not oscillating, the LCD will remain

blank. Here are some steps to assure that the Timer1 oscillator is working properly.

1. Clean and dry the board especially around the components at the top right corner

of the PIC16LF1947.

2. Make sure no foreign material is shorting the crystal leads.

3. If you are using the RC0 and RC1 pins for some other function, you should

modify lcd_init to reconfigure the LCD peripheral for a different clock

source.

The Timer1 oscillator of the PIC16LF1947 is a very low-power design that can be easily

disrupted by stray leakage. In an actual application, Microchip recommends that the

crystal circuit be conformal coated to prevent leakage. Please review Application Note

AN1288, “Design Practices for Low-Power External Oscillators” for more information.

F1 LV EVALUATION PLATFORM

USER’S GUIDE

2011 Microchip Technology Inc. DS41614A-page 35

Page 36

F1 LV Evaluation Platform User’s Guide

NOTES:

DS41614A-page 36 2011 Microchip Technology Inc.

Page 37

7.1 INTRODUCTION

To help understand the features of the F1 LV Evaluation Platform, the schematics are

included here.

F1 LV EVALUATION PLATFORM

USER’S GUIDE

Chapter 7. Schematics

2011 Microchip Technology Inc. DS41614A-page 37

Page 38

F1 LV Evaluation Platform User’s Guide

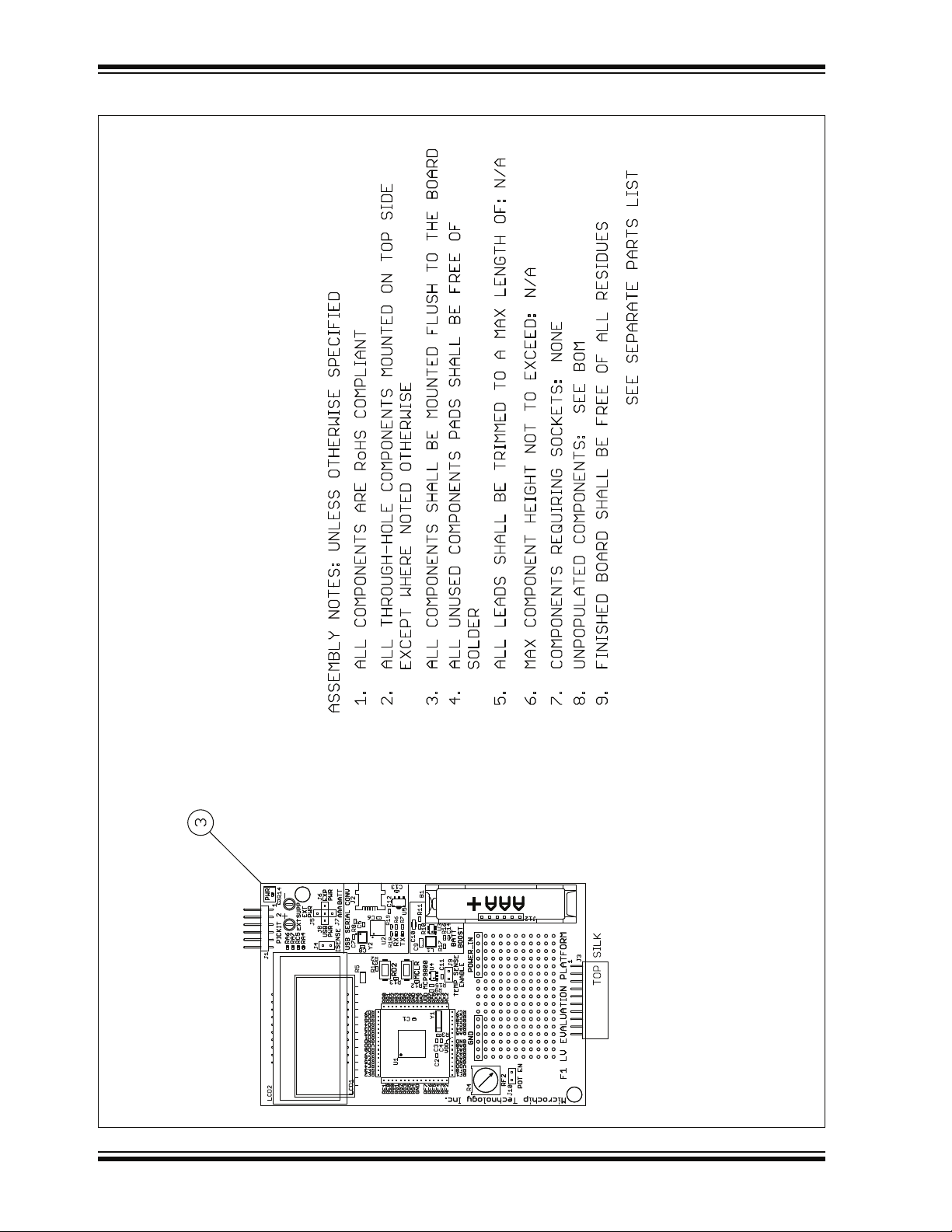

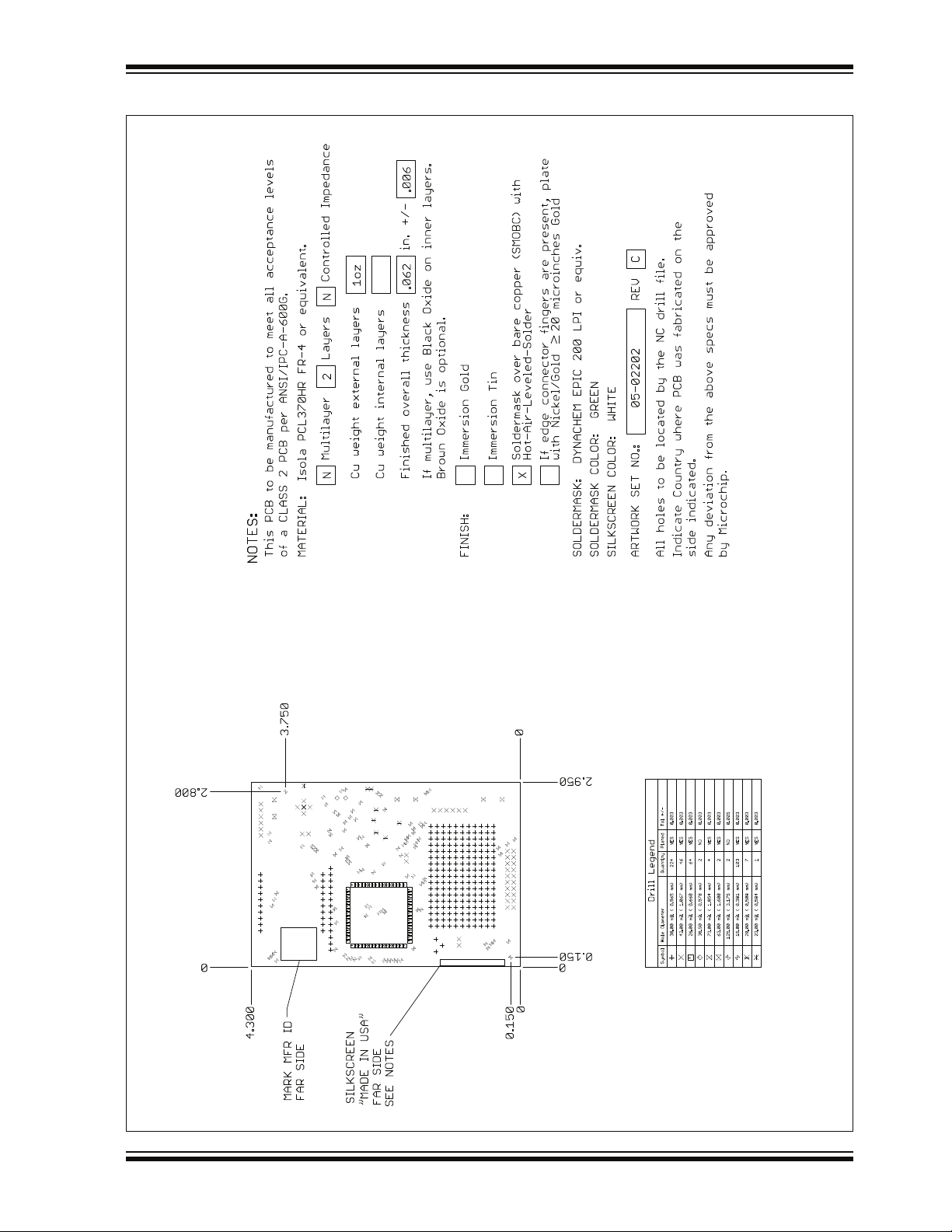

7.1.1 F1 LV Evaluation Platform Schematic (1 of 4)

DS41614A-page 38 2011 Microchip Technology Inc.

Page 39

7.1.2 F1 LV Evaluation Platform Schematic (2 of 4)

Schematics

2011 Microchip Technology Inc. DS41614A-page 39

Page 40

F1 LV Evaluation Platform User’s Guide

7.1.3 F1 LV Evaluation Platform Schematic (3 of 4)

DS41614A-page 40 2011 Microchip Technology Inc.

Page 41

7.1.4 F1 LV Evaluation Platform Schematic (4 of 4)

Schematics

2011 Microchip Technology Inc. DS41614A-page 41

Page 42

F1 LV Evaluation Platform User’s Guide

NOTES:

DS41614A-page 42 2011 Microchip Technology Inc.

Page 43

F1 LV EVALUATION PLATFORM

USER’S GUIDE

Index

A

AC164110 ................................................................ 21

Ammeter .................................................................. 19

B

BLDC Demo............................................................. 25

C

Centigrade ............................................................... 19

Combined Demo ...................................................... 25

Common Problems .................................................. 35

Customer Notification Service.................................... 8

Customer Support...................................................... 9

D

Documentation

Conventions........................................................ 6

Layout ................................................................. 5

E

Enhanced Mid-Range Microcontrollers.................... 11

F

F1 LV Evaluation Platform ....................................... 11

F1 LV Evaluation Platform Schematic...................... 38

H

Hardware Features .................................................. 11

16-bit timers ...................................................... 11

32 MHz internal oscillator ................................. 11

CCPs ................................................................ 11

EEPROM .......................................................... 11

Enhanced USART ............................................ 11

LCD controller................................................... 11

RAM.................................................................. 11

Hardware Libraries and Drivers ............................... 27

I

ICSP pins ................................................................. 21

Internet Address......................................................... 8

L

LCD Display ............................................................. 20

LCD Function Interface............................................ 31

lcd_display_digits.............................................. 31

lcd_display_on / lcd_display_off ....................... 31

lcd_init............................................................... 31

M

MCP9800 ................................................................. 11

Temperature sensor ......................................... 11

Microchip Internet Web Site ....................................... 8

P

PIC® microcontrollers .............................................. 11

PIC16 series............................................................. 11

PIC16F1 Evaluation Kit............................................ 11

PIC16F1 family......................................................... 11

PIC16LF1937........................................................... 11

PICkit ICSP™ programming capability interface...... 21

PICkit Serial ............................................................. 19

PICkit™ 2 ................................................................. 21

PICkit™ 3 ................................................................. 21

Platform Contents .................................................... 11

F1 LV Evaluation Platform Demo Board ........... 11

Powering with PICkit 3 ............................................. 16

JP2.................................................................... 16

PICkit ICSP connector ...................................... 16

Voltage.............................................................. 16

Programming and debugging ................................... 12

R

Reading, Recommended ........................................... 7

Readme...................................................................... 7

REAL ICE™ In-circuit Emulator ............................... 21

S

Supply Voltage......................................................... 16

U

User Interface........................................................... 20

W

Warranty Registration ................................................ 7

WWW Address........................................................... 8

X

XLP Low Power........................................................ 11

2011 Microchip Technology Inc. DS41614A-page 43

Page 44

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-2819-3187

Fax: 86-571-2819-3189

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-330-9305

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

08/02/11

DS41614A-page 44 2011 Microchip Technology Inc.

Loading...

Loading...