Page 1

EVB-LAN9252-DIG-IO

EtherCAT® DIG I/O

Evaluation Board

User’s Guide

2014 Microchip Technology Inc. Preliminary DS50002332A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device applications and the like is provided only for your convenience and may be

superseded by updates. It is your responsibility to ensure that your application meets with your specifications. MICROCHIP MAKES NO

REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION, INCLUDING BUT NOT LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE. Microchip disclaims all liability arising from this information and its use. Use of Microchip devices in life support and/or safety applications is entirely at the buyer’s risk, and the buyer agrees to defend, indemnify and hold

harmless Microchip from any and all damages, claims, suits, or expenses resulting from such use. No licenses are conveyed, implicitly or

otherwise, under any Microchip intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC, FlashFlex, flexPWR, JukeBlox, K

MediaLB, MOST, MOST logo, MPLAB, OptoLyzer, PIC, PICSTART, PIC

UNI/O are registered trademarks of Microchip Technology Incorporated in the U.S.A. and other countries.

The Embedded Control Solutions Company and mTouch are registered trademarks of Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, BodyCom, chipKIT, chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net, ECAN, In-Circuit Serial

Programming, ICSP, Inter-Chip Connectivity, KleerNet, KleerNet logo, MiWi, MPASM, MPF, MPLAB Certified logo, MPLIB, MPLINK,

MultiTRAK, NetDetach, Omniscient Code Generation, PICDEM, PICDEM.net, PICkit, PICtail, RightTouch logo, REAL ICE, SQI, Serial

Quad I/O, Total Endurance, TSHARC, USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip Technology Inc. in other countries.

GestIC is a registered trademarks of Microchip Technology Germany II GmbH & Co. KG, a subsidiary of Microchip Technology Inc., in

other countries.

All other trademarks mentioned herein are property of their respective companies.

© 2014, Microchip Technology Incorporated, Printed in the U.S.A., All Rights Reserved.

32

logo, RightTouch, SpyNIC, SST, SST Logo, SuperFlash and

EELOQ, KEELOQ logo, Kleer, LANCheck,

ISBN: 97816312769251

QUALITY MANAGEMENT S

DS50002332A-page 2 Preliminary 2014 Microchip Technology Inc.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

Object of Declaration: EVB-LAN9252-DIG-IO

2014 Microchip Technology Inc. Preliminary DS50002332A-page 3

Page 4

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

NOTES:

DS50002332A-page 4 Preliminary 2014 Microchip Technology Inc.

Page 5

EVB-LAN9252-DIG-IO

ETHERCAT® DIG I/O

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 7

Introduction............................................................................................................ 7

Document Layout .................................................................................................. 7

Conventions Used in this Guide ............................................................................ 8

The Microchip Web Site ........................................................................................ 9

Development Systems Customer Change Notification Service ............................ 9

Customer Support ................................................................................................. 9

Document Revision History ................................................................................. 10

Chapter 1. Overview

1.1 Introduction ................................................................................................... 11

1.2 References ................................................................................................... 12

1.3 Terms and Abbreviations ............................................................................. 12

Chapter 2. Board Details & Configuration

2.1 Power ........................................................................................................... 13

2.1.1 +5V Power ................................................................................................. 13

2.2 Resets .......................................................................................................... 13

2.2.1 Power-on Reset ......................................................................................... 13

2.2.2 Reset Out .................................................................................................. 13

2.2.3 GPIO Reset ............................................................................................... 13

2.3 Clock ............................................................................................................ 14

2.4 Configuration ................................................................................................ 14

2.4.1 Strap Options ............................................................................................ 15

2.4.2 LED Indicators ........................................................................................... 17

2.4.3 EEPROM Switch ....................................................................................... 18

2.4.4 DIG INPUT Mode ...................................................................................... 18

2.4.5 DIG OUTPUT Mode .................................................................................. 18

2.4.6 DIG Bidirectional Mode ............................................................................. 19

2.4.7 Control Signals .......................................................................................... 19

2.5 Mechanicals ................................................................................................. 20

Chapter 3. LAN9252 EEPROM Programming

3.1 Programming the LAN9252 EEPROM ......................................................... 21

Appendix A. EVB-LAN9252-DIG-IO Evaluation Board

A.1 Introduction .................................................................................................. 24

Appendix B. EVB-LAN9252-DIG-IO Evaluation Board Schematics

B.1 Introduction .................................................................................................. 25

Appendix C. Bill of Materials (BOM)

C.1 Introduction .................................................................................................. 33

2014 Microchip Technology Inc. Preliminary DS50002332A-page 5

Page 6

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Worldwide Sales and Service .....................................................................................37

DS50002332A-page 6 Preliminary 2014 Microchip Technology Inc.

Page 7

EVB-LAN9252-DIG-IO

ETHERCAT® DIG I/O

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

EVB-LAN9252-DIG-IO. Items discussed in this chapter include:

Document Layout

•

• Conventions Used in this Guide

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the EVB-LAN9252-DIG-IO as a development tool for the

Microchip LAN9252 EtherCAT® slave controller. The manual layout is as follows:

• Chapter 1. “Overview” – Shows a brief description of the EVB-LAN9252-DIG-IO.

• Chapter 2. “Board Details & Configuration” – Includes details and instructions for using

the EVB-LAN9252-DIG-IO.

• Chapter 3. “LAN9252 EEPROM Programming” – Includes details and instructions for

programming the LAN9252 EEPROM.

• Appendix A. “EVB-LAN9252-DIG-IO Evaluation Board” – This appendix shows the

EVB-LAN9252-DIG-IO.

• Appendix B. “EVB-LAN9252-DIG-IO Evaluation Board Schematics” – This appendix

shows the EVB-LAN9252-DIG-IO schematics.

• Appendix C. “Bill of Materials (BOM)” – This appendix includes the

EVB-LAN9252-DIG-IO Bill of Materials (BOM).

2014 Microchip Technology Inc. Preliminary DS50002332A-page 7

Page 8

EVB-LAN9252-DIG-IO ETHERCAT® DIG I/O USER’S GUIDE

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

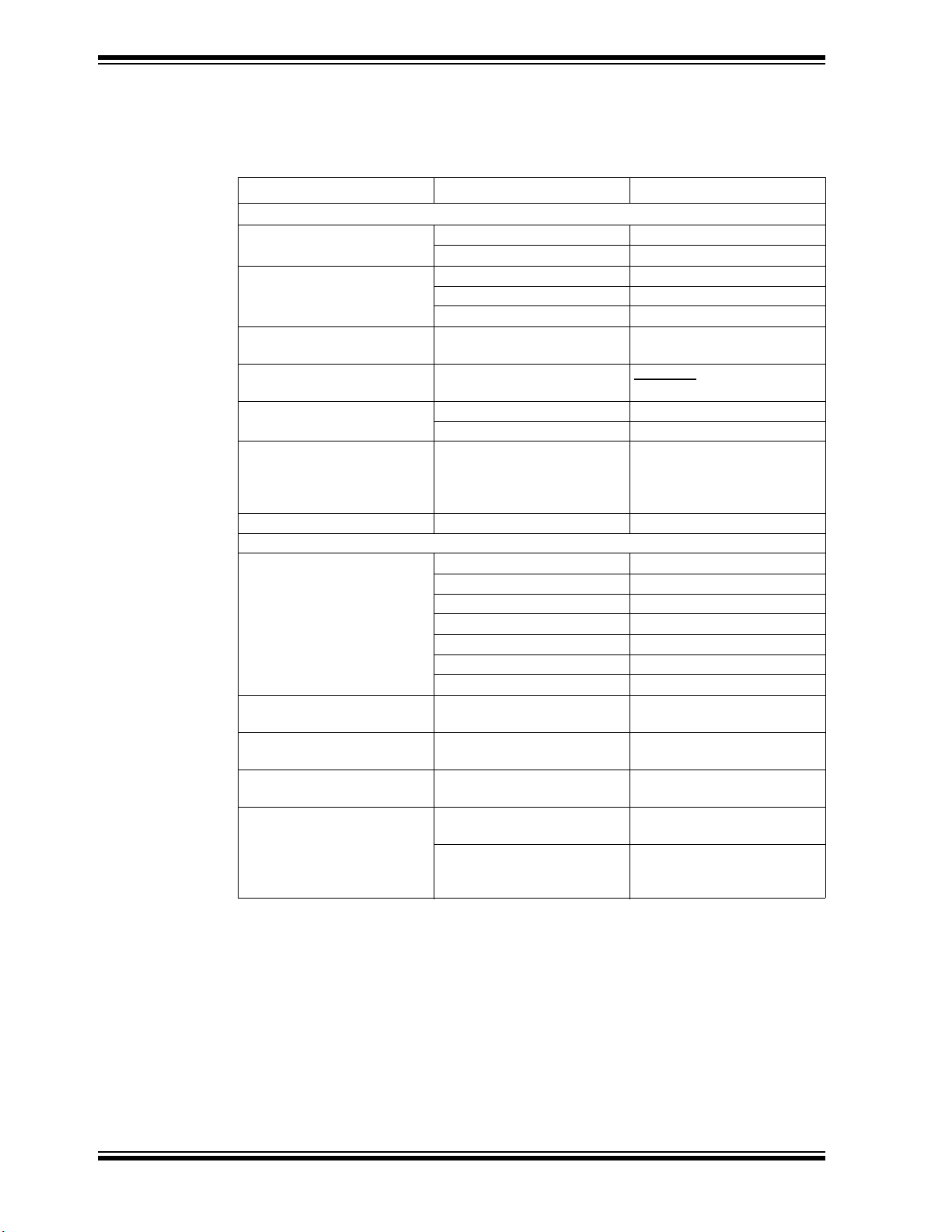

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

®

IDE User’s Guide

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

DS50002332A-page 8 Preliminary 2014 Microchip Technology Inc.

Page 9

Preface

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web site is used

as a means to make files and information easily available to customers. Accessible by using your

favorite Internet browser, the web site contains the following information:

• Product Support – Data sheets and errata, application notes and sample programs,

design resources, user’s guides and hardware support documents, latest software releases

and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical support

requests, online discussion groups, Microchip consultant program member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip press

releases, listing of seminars and events, listings of Microchip sales offices, distributors and

factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip products.

Subscribers will receive e-mail notification whenever there are changes, updates, revisions or

errata related to a specified product family or development tool of interest.

To register, access the Microchip web site at www.microchip.com, click on Customer Change

Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers, assemblers, linkers and

other language tools. These include all MPLAB C compilers; all MPLAB assemblers

(including MPASM assembler); all MPLAB linkers (including MPLINK object linker); and all

MPLAB librarians (including MPLIB object librarian).

• Emulators – The latest information on Microchip in-circuit emulators.This includes the

MPLAB REAL ICE and MPLAB ICE 2000 in-circuit emulators.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit debuggers. This

includes MPLAB ICD 3 in-circuit debuggers and PICkit 3 debug express.

• MPLAB IDE – The latest information on Microchip MPLAB IDE, the Windows Integrated

Development Environment for development systems tools. This list is focused on the

MPLAB IDE, MPLAB IDE Project Manager, MPLAB Editor and MPLAB SIM simulator, as

well as general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include produc-

tion programmers such as MPLAB REAL ICE in-circuit emulator, MPLAB ICD 3 in-circuit

debugger and MPLAB PM3 device programmers. Also included are nonproduction development programmers such as PICSTART Plus and PIC-kit 2 and 3.

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer (FAE) for

support. Local sales offices are also available to help customers. A listing of sales offices and

locations is included in the back of this document.

Technical support is available through the web site at: http://www.microchip.com/support

2014 Microchip Technology Inc. Preliminary DS50002332A-page 9

Page 10

EVB-LAN9252-DIG-IO ETHERCAT® DIG I/O USER’S GUIDE

DOCUMENT REVISION HISTORY

DS50002332A (December 2014)

• Initial Release of this Document.

DS50002332A-page 10 Preliminary 2014 Microchip Technology Inc.

Page 11

1.1 INTRODUCTION

The LAN9252 is a 2-port EtherCAT® slave controller with dual integrated Ethernet

PHYs which each contain a full-duplex 100BASE-TX transceiver and support 100Mbps

(100BASE-TX) operation. 100BASE-FX is supported via an external fiber transceiver.

Each port receives an EtherCAT® frame, performs frame checking and forwards it to

the next port. Time stamps of received frames are generated when they are received.

The Loop-back function of each port forwards the frames to the next logical port if there

is either no link at a port, if the port is not available, or if the loop is closed for that port.

The Loop-back function of port 0 forwards the frames to the EtherCAT® Processing

Unit. The loop settings can be controlled by the EtherCAT® master.

Packets are forwarded in the following order:

Port 0 -> EtherCAT® Processing Unit -> Port 1 -> Port 2.

The EtherCAT® Processing Unit (EPU) receives, analyzes and processes the EtherCAT® data stream. The main purpose of the EtherCAT® Processing unit is to enable

and coordinate access to the internal registers and the memory space of the ESC,

which can be addressed both from the EtherCAT® master and from the local application. Data exchange between master and slave applications is comparable to a

dual-ported memory (process memory), enhanced by special functions for consistency

checking (SyncManager) and data mapping (FMMU). Each FMMU performs bitwise

mapping of logical EtherCAT® system addresses to physical device addresses.

The scope of this document is to describe the EVB-LAN9252-DIG-IO setup, which supports a Digital I/O Interface and corresponding jumper configurations. The LAN9252 is

connected to an RJ45 Ethernet jack with integrated magnetics for 100BASE-TX connectivity. A simplified block diagram of the EVB-LAN9252-DIG-IO is shown in

Figure 1-1.

EVB-LAN9252-DIG-IO

ETHERCAT® DIG I/O

USER’S GUIDE

Chapter 1. Overview

2014 Microchip Technology Inc. Preliminary DS50002332A-page 11

Page 12

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Microchip

LAN9252

EEPROM

EVB-LAN9252-DIG-IO

Straps

Port 0 Port 1

Oscillator

Power

Supply

Module

Control

Signals

5V

07815

07815

Jumper Selection

LEDs LEDs

Switches Switches

Digital I/O Circuit

100BASE-TX

Ethernet

Magnetics &

RJ45

100BASE-TX

Ethernet

Magnetics &

RJ45

Ethernet Ethernet

Fiber-

SFP

Port 0

Fiber-

SFP

Port 1

FIGURE 1-1: EVB-LAN9252-DIG-IO BLOCK DIAGRAM

1.2 REFERENCES

1.3 TERMS AND ABBREVIATIONS

Concepts and material available in the following documents may be helpful when reading this document. Visit www.microchip.com for the latest documentation.

• LAN9252 Data Sheet

• AN 8.13 Suggested Magnetics

• EVB-LAN9252-DIG-IO Schematics

IDE - Integrated Development Environment

ESC - EtherCAT® Slave Controller

EVB - Engineering Validation Board

HAL - Hardware Abstraction Layer

HBI - Host Bus Interface

SPI - Serial Protocol Interface

SSC - Slave Stack Code

DS50002332A-page 12 Preliminary 2014 Microchip Technology Inc.

Page 13

Chapter 2. Board Details & Configuration

2.1 POWER

EVB-LAN9252-DIG-IO

ETHERCAT® DIG I/O

USER’S GUIDE

This section includes sub-sections on the following EVB-LAN9252-DIG-IO details:

•Power

• Resets

• Clock

• Configuration

• Mechanicals

2.1.1 +5V Power

Power is supplied to the LAN9252 by a +3.3V on-board regulator, which is powered by

a +5V external wall adapter (Manufacturer: TRIAD MAGNETICS and P/N:

WSU050-3000). The LAN9252 includes an internal +1.2V regulator which supplies

power to the internal core logic. Assertion of the D1 Green LED indicates successful

generation of +3.3V output. The SW1 switch must be in the ON position for the +5V to

power the +3.3V regulator.

2.2 RESETS

2.2.1 Power-on Reset

A power-on reset occurs whenever power is initially applied to the LAN9252 or if the

power is removed and reapplied to the LAN9252. This event resets all circuitry within

the LAN9252. After initial power-on, the LAN9252 can be reset by pressing the reset

switch SW2. The reset LED D2 will assert (red) if when the LAN9252 is in reset condition. For stability, a delay of approximately 180ms is added from the +3.3V output to

reset release.

2.2.2 Reset Out

The LAN9252 reset pin can be configured as an output to reset the SoC. The RST# pin

becomes an open-drain output and is asserted for the minimum required time of 80ms.

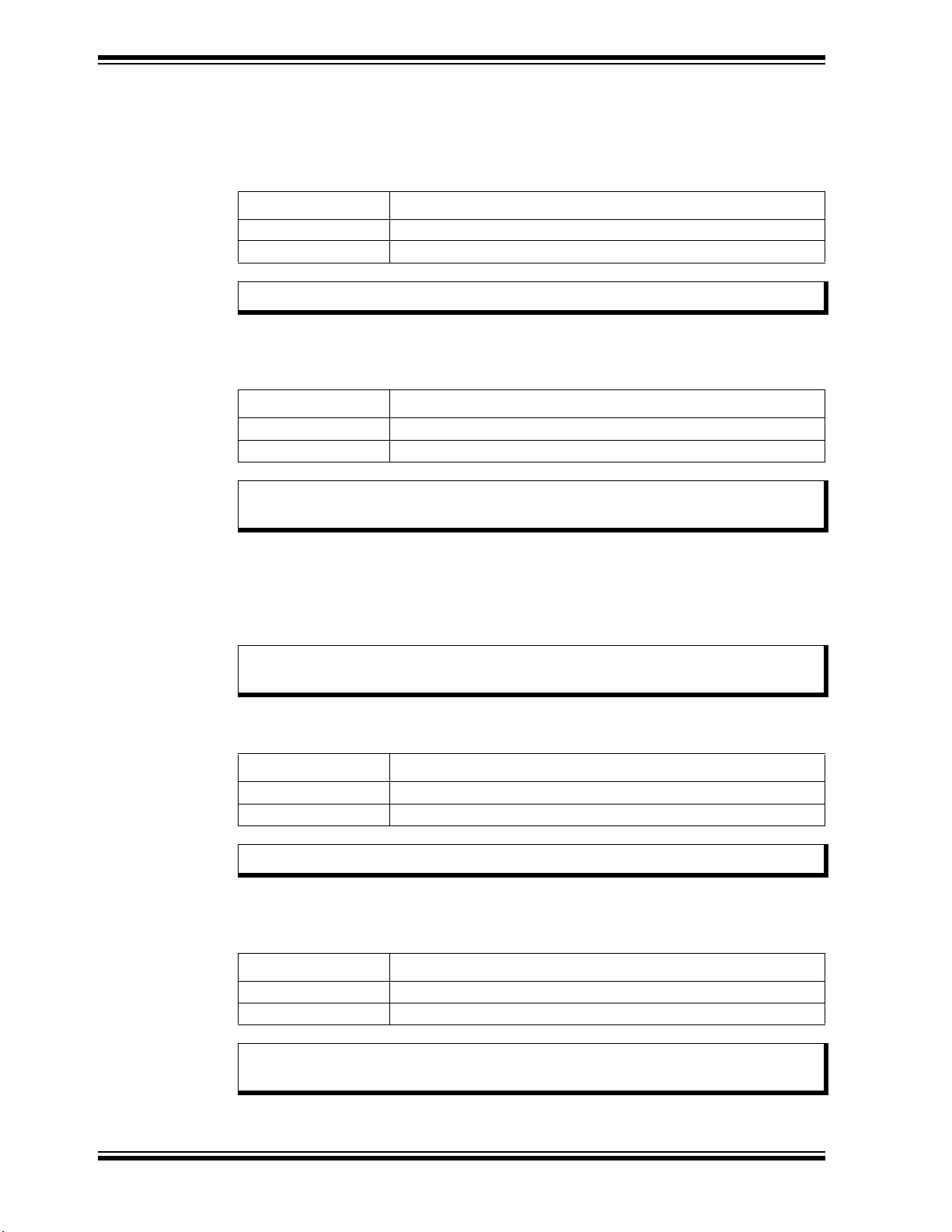

2.2.3 GPIO Reset

The EVB-LAN9252-DIG-IO provides the option to reset the LAN9252 through a PIC

GPIO pin [95(RG14)]. The SW10 switch is used for this selection, as shown in

Ta bl e 2 -1 .

TABLE 2-1: RESET CONFIGURATION SWITCH

Switch Short Pins Knob Position Function

SW10 1-3 1-2 System Reset (SYS_RST) (Default)

SW10 1-2 1-3 GPIO Reset (GPIO_RST)

2014 Microchip Technology Inc. Preliminary DS50002332A-page 13

Page 14

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Input Switches

Digital Output

LEDs

Digital I/O

Control Signals

PowerReset

RJ45

(with Magnetics)

Port 1Port 0

EEPROMStraps

Microchip

LAN9252

2.3 CLOCK

The EVB-LAN9252-DIG-IO utilizes an external 25Mhz 25ppm crystal from Cardinal

Components Inc. (P/N: CSM1Z-A5B2C5-40-25.0D18-F).

2.4 CONFIGURATION

The following sub-sections describe the various board features and configuration settings. A top view of the EVB-LAN9252-DIG-IO is shown in Figure 2-1.

FIGURE 2-1: EVB-LAN9252-DIG-IO TOP VIEW WITH CALLOUTS

DS50002332A-page 14 Preliminary 2014 Microchip Technology Inc.

Page 15

Board Details & Configuration

2.4.1 Strap Options

2.4.1.1 CHIP MODE SELECTION

Table 2-2 details the LAN9252 chip mode configuration straps.

TABLE 2-2: CHIP MODE CONFIGURATION STRAP

Header Description Pins Settings

J4,J5,J7,J8 Chip mode configuration strap

inputs. This strap determines

the number of active ports and

port types.

Note: For proper operation, chip mode must be in 2-port mode, where Port 0 =

PHY A and Port 1 = PHY B. This requires J4, J5, J7, and J8 to be

pulled-down (2-3) shorted. All other configurations are not supported by this

EVB.

2.4.1.2 EEPROM SIZE CONFIGURATION

The EEPROM size configuration strap (J6 & J9) determines the supported EEPROM

size range. A low selects 1Kbits (128 x 8) through 16Kbits (2K x 8)_24C16. A high

selects 32Kbits (4K x 8) through 512Kbits (64K x 8) or 4Mbits (512K x 8)_24C512.

1-2

Short 1-2 for high (pull-up)

2-3

Short 2-3 for low (pull-down) (default)

TABLE 2-3: EEPROM SIZE CONFIGURATION STRAP

Header Description Pins Settings

J6, J9 EEPROM size configuration

strap inputs. This strap determines the supported

EEPROM size range.

1-2

Short 1-2 for high (pull-up) (default)

2-3

Short 2-3 for low (pull-down)

2.4.1.3 COPPER AND FIBER STRAPS

The LAN9252 supports 100BASE-TX (Copper) and 100BASE-FX (Fiber) modes. In

100BASE-FX operation, the quality of the receive signal is provided by the external

transceiver as either an open-drain, CMOS level, Loss of Signal (SFP) or a LVPECL

Signal Detect (SFF).

This EVB supports 100BASE-TX (Copper) and SFP 100BASE-FX (Fiber) modes. By

default Copper Mode is active. Fiber Mode is supported as an assembly option. To

select the Copper or Fiber Mode, the respective strap and signal routing resister

assembly options must to be configured.

Note: Vendor part number for SFP: Finisar/FTLF1217P2,

for SFF: Avago Technologies US Inc/AFCT-5971LZ

2014 Microchip Technology Inc. Preliminary DS50002332A-page 15

Page 16

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

2.4.1.3.1 Copper Mode

The EVB-LAN9252-DIG-IO is set to Copper Mode by default. Table 2-4 details the

required strap resistor settings for Copper Mode operation.

TABLE 2-4: COPPER MODE STRAP RESISTORS

Resistors Description

R79 (10K) Configures Port 0 & 1 to Copper Mode

R76, R80 (10K) Configures Port 0 and Port 1 to Copper Mode, respectively

Note: R75, R77, and R78 must not be populated (DNP).

Additionally, the signal routing resistors detailed in Table 2-5 must be assembled for

Copper Mode operation.

TABLE 2-5: COPPER MODE SIGNAL ROUTING RESISTORS

Resistors Description

R17, R19, R21, R23 Port 0 Copper Mode enabled

R31, R33, R35, R37 Port 1 Copper mode enabled

Note: R16, R18, R20, R22, R30, R32, R34, and R36 (0402 package) must not be

populated (DNP).

2.4.1.3.2 Fiber Mode

The EVB-LAN9252-DIG-IO supports SFP type 100BASE-FX. To enabled Fiber Mode,

the respective strap and signal routing registers must be configured.

Note: Copper Mode related resistors must be DNP while Fiber Mode is active

(See Section 2.4.1.3.1 “Copper Mode”).

Table 2-6 details the required strap resistor settings for Fiber Mode operation.

TABLE 2-6: FIBER MODE STRAP RESISTORS

Resistors Description

R77 (10K) Configures Port 0 & 1 to FX-LOS Mode

R75, R78 (10K) Configures Port 0 and Port 1 to Fiber Mode, respectively

Note: R76, R79, and R80 must not be populated (DNP).

Additionally, the signal routing resistors detailed in Table 2-7 must be assembled for

Fiber Mode operation.

TABLE 2-7: FIBER MODE SIGNAL ROUTING RESISTORS

Resistors Description

R16, R18, R20, R22 Port 0 Fiber Mode enabled

R30, R32, R34, R36 Port 1 Fiber mode enabled

Note: R17, R19, R21, R23, R31, R33, R35, and R37 (0402 package) must not be

populated (DNP).

DS50002332A-page 16 Preliminary 2014 Microchip Technology Inc.

Page 17

Board Details & Configuration

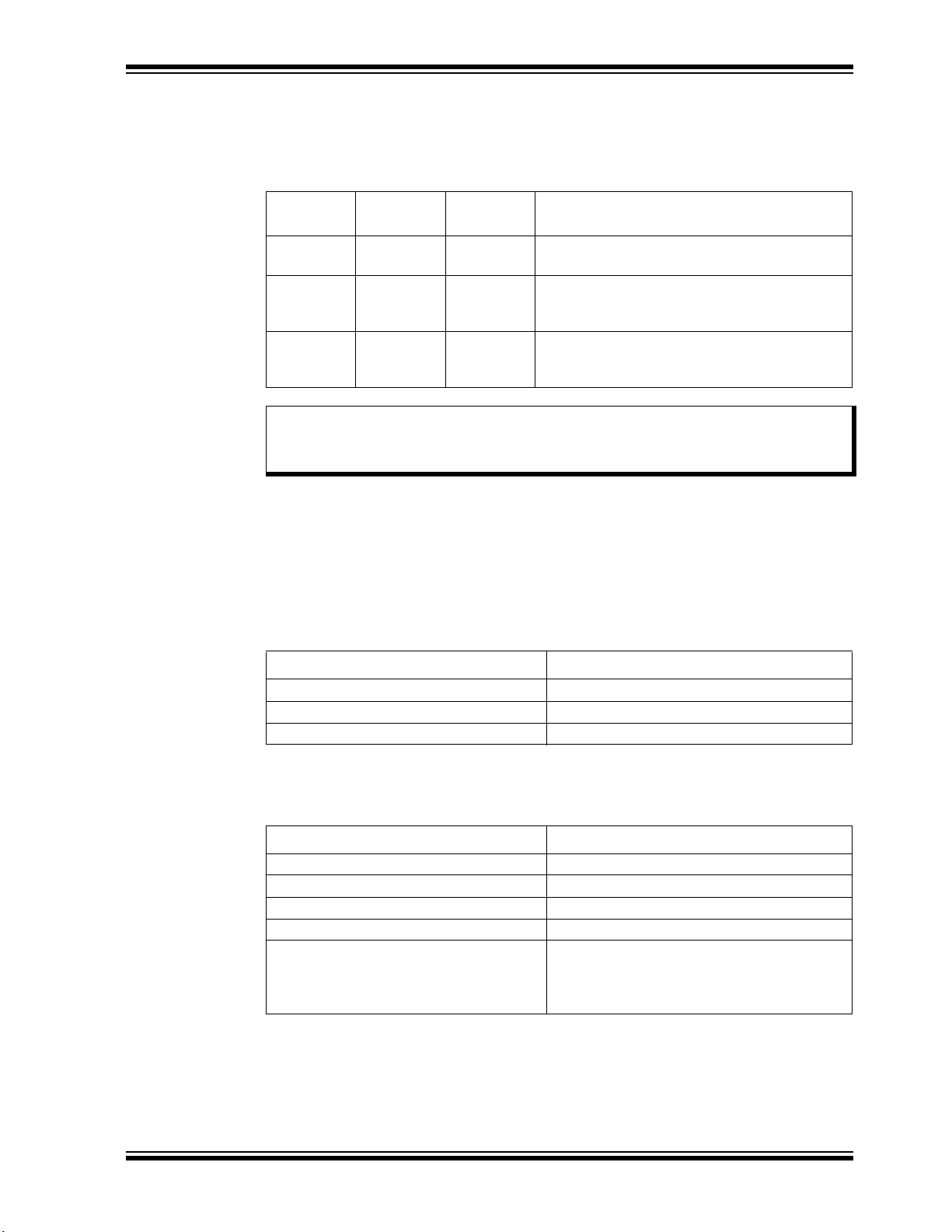

2.4.1.3.3 FX-LOS Fiber Mode Strap

FX-LOS strap details are shown in Table 2-8. These strap settings determine if the

ports are to operate in FX-LOS Fiber Mode or FX-SD/Copper Mode.

TABLE 2-8: FX-LOS MODE STRAP SETTINGS

R77 (10K) R79 (10K)

Populate DNP 3.3 A level above 2V selects FX-LOS for Port 0 and

Populate Populate 1.5 A level of 1.5V selects FX-LOS for Port 0 and

DNP Populate 0 (Default) A level of 0V selects FX-SD / copper twisted pair

Note: The above strap details describe the LAN9252 function. This EVB does not

support SFF Fiber Mode. Therefore, FX-SD related straps are not applicable.

Reference

Volta g e ( V )

Function

Port 1

FX-SD / copper twisted pair for Port 1, further

determined by FXSDB

for Ports 0 and 1, further determined by FXSDA

and FXSDB

2.4.2 LED Indicators

The D3 and D4 LEDs are used to indicate the Link/Activity status on the corresponding

EVB ports, as detailed in Table 2-9. The Link/Act LED should be ON at each port when

the cable is present. If the Link/Act LED is not ON, it indicates there is an issue with the

connection or cable.

TABLE 2-9: D3 AND D4 LINK/ACTIVITY LED STATUS INDICATORS

State Description

Off Link is down

Flashing Green Link is up with activity

Steady Green Link is up with no activity

Additionally, the D5 LED is used as a RUN indicator (green) to shows the AL status of

the EtherCAT® State Machine (ESM), as detailed in Table 2-10.

TABLE 2-10: D5 RUN LED STATUS INDICATOR

State Description

Off The device is in the INITIALIZATION state

Blinking (on 200ms, off 200ms) The device is in the PRE-OPERATIONAL state

Single Flash (on 200ms, off 1000ms) The device is in the SAFE-OPERATIONAL state

On The device is in the OPERATIONAL state

Flickering (on 50ms, off 50ms) The device is booting and has not yet entered

the INITIALIZATION state, or the device is in the

BOOTSTRAP state and firmware download is in

progress. (Optional. Off when not implemented.)

2014 Microchip Technology Inc. Preliminary DS50002332A-page 17

Page 18

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

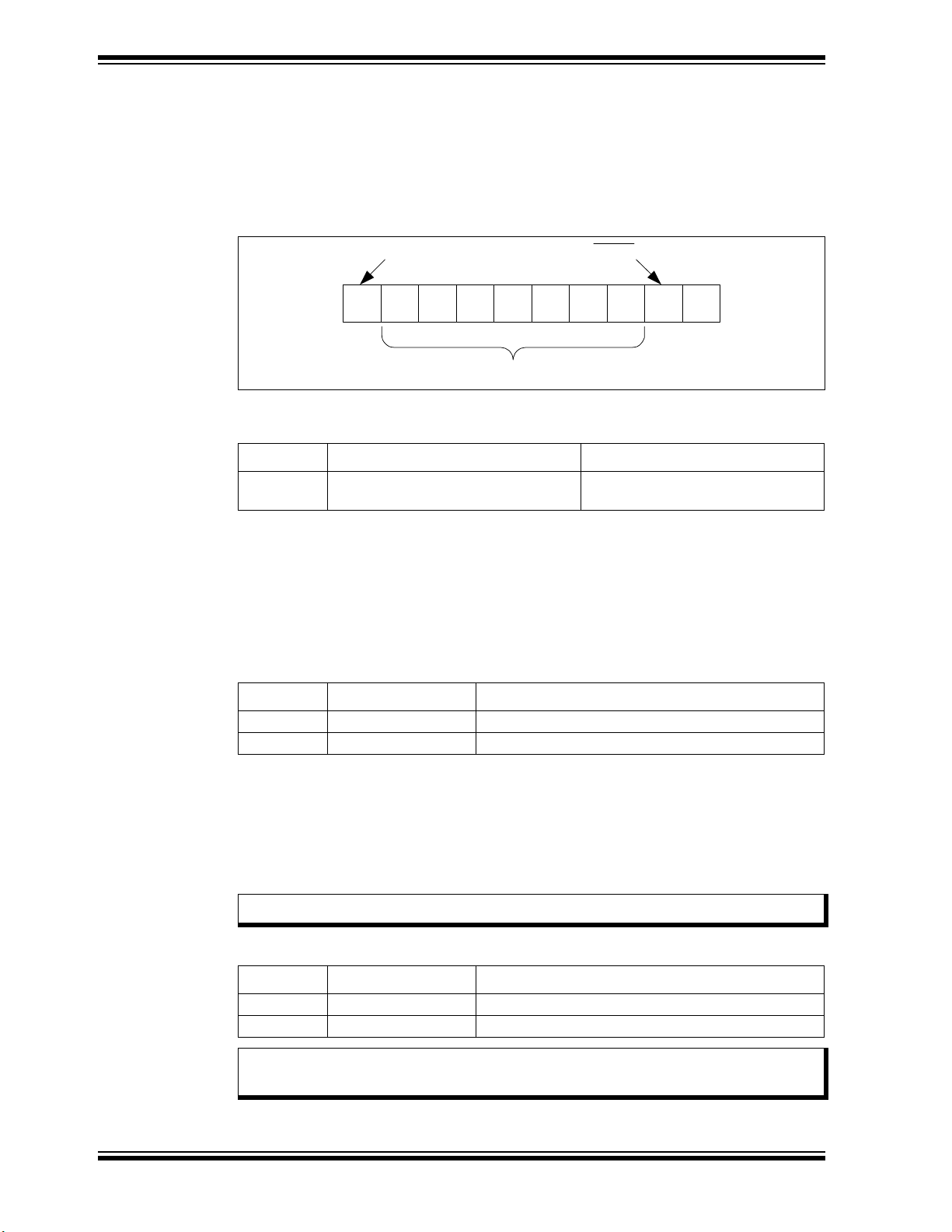

R/W AA1 A00 A20 11

Start Read/Write

Slave Address

2.4.3 EEPROM Switch

The EVB-LAN9252-DIG-IO utilizes 0x50 (7-bit) I2C slave addressing. The SW3 switch

can be used to select the A0, A1, and A2 address bits, as shown in Figure 2-2 and

Table 2-11. The eighth bit of the slave address determines if the master device wants

to read or write to the EEPROM (24C512).

FIGURE 2-2: SLAVE ADDRESS ALLOCATION

TABLE 2-11: EEPROM SWITCH

Switch Description Settings

SW3 I2C EEPROM address selection switch

(A0, A1, A2). See Figure 2-2.

ON for logic 0 (default)

OFF for logic 1

2.4.4 DIG INPUT Mode

The DIG INPUT Mode can be selected through the headers J10 and J11:

• Logic 1 : (Default) SW4 & SW5 Off position. DIG I/P 0 to 15 tied to pull-up (R98 to

R113)

• Logic 0 : The respective knob of 2-way, 8-position dip switch (SW4 & SW5) need

to be moved to ON side. Signals can be selected individually.

TABLE 2-12: DIGITAL I/O INPUT MODE SELECTION

Header Description Short Pins

J10 Digital Input 0 to 7 1&2, 4&5, 7&8, 10&11, 13&14, 16&17, 19&20, 22&23

J11 Digital Input 8 to 15 1&2, 4&5, 7&8, 10&11, 13&14, 16&17, 19&20, 22&23

2.4.5 DIG OUTPUT Mode

The DIG OUTPUT Mode can be selected through the headers J10 and J11. The

updated Digital I/O values can be seen on the LEDs (D6 to D21):

• Logic 1 : LED illuminated

• Logic 0 : LED not illuminated.

Note: LED (D6 to D21) anode connected to ASIC.

TABLE 2-13: DIGITAL I/O OUTPUT MODE SELECTION (DEFAULT MODE)

Header Description Short Pins

J10 Digital I/O 0 to 7 2&3, 5&6, 8&9, 11&12, 14&15, 17&18, 20&21, 23&24

J11 Digital I/O 8 to 15 2&3, 5&6, 8&9, 11&12, 14&15, 17&18, 20&21, 23&24

Note: The control signal OE_EXT should be connected high by shorting J12 pins

DS50002332A-page 18 Preliminary 2014 Microchip Technology Inc.

15 and 16.

Page 19

Board Details & Configuration

2.4.6 DIG Bidirectional Mode

The DIG Bidirectional Mode can be selected by shorting the respective test point pins

with the headers J10 and J11, as detailed in Table 2-14. The input and output signal

states in this mode are the same as detailed in Section 2.4.4 “DIG INPUT Mode” and

Section 2.4.5 “DIG OUTPUT Mode”.

TABLE 2-14: DIGITAL I/O BIDIRECTIONAL MODE DESCRIPTION

Description Short Pins

Digital I/O 0 to 7 TP5 & J10.1, TP6 & J10.4, TP7 & J10.7, TP8 & J10.10 TP9 & J10.13,

TP10 & J10.16, TP11 & J10.19, TP12 & J10.22, TP13&J10.3,

TP14&J10.6, TP15&J10.9, TP16& J10.12, TP17&J10.15,

TP18&J10.18, TP19& J10.21, TP20&J10.24

Digital I/O 8 to 15 TP21 & J11.1, TP22 & J11.4, TP23 & J11.7, TP24 & J11.10, TP25 &

J11.13, TP26 & J11.16, TP27 & J11.19, TP28 & J11.22, TP29&J11.3,

TP30&J11.6, TP31&J11.9, TP32& J11.12, TP33&J11.15,

TP34&J11.18,TP35& J11.21, TP36&J11.24

2.4.7 Control Signals

All control signals can be probed and controlled via the J12 header, as shown in

Table 2-15.

TABLE 2-15: J12 HEADER CONTROL SIGNAL MAPPING

J12 Pin Number J12 Signal J12 Pin Number J12 Signal

13V323V3

3WD_STATE4 GND

5EOF6GND

7SOF8GND

9LATCH010 GND

11 LATCH1 12 GND

13 WD_TRIG 14 GND

15 OE_EXIT 16 3V3

17 OUTVALID 18 GND

19 LATCH_IN 20 GND

Note: J12 pins 15 & 16 must be shorted in output mode.

2.4.7.1 WD_STATE

This pin is the SyncManager Watchdog State output. A “0” indicates the watchdog has

expired. The state of this signal can be seen in the LED D22.

Note: This signal is not driven (high impedance) until the EEPROM is loaded.

2.4.7.2 LATCH_IN

This pin is the external data latch signal. The input data is sampled each time a rising

edge of LATCH_IN is recognized. By default, this signals is pulled high through

R131and can be made low using switch SW6.

2014 Microchip Technology Inc. Preliminary DS50002332A-page 19

Page 20

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

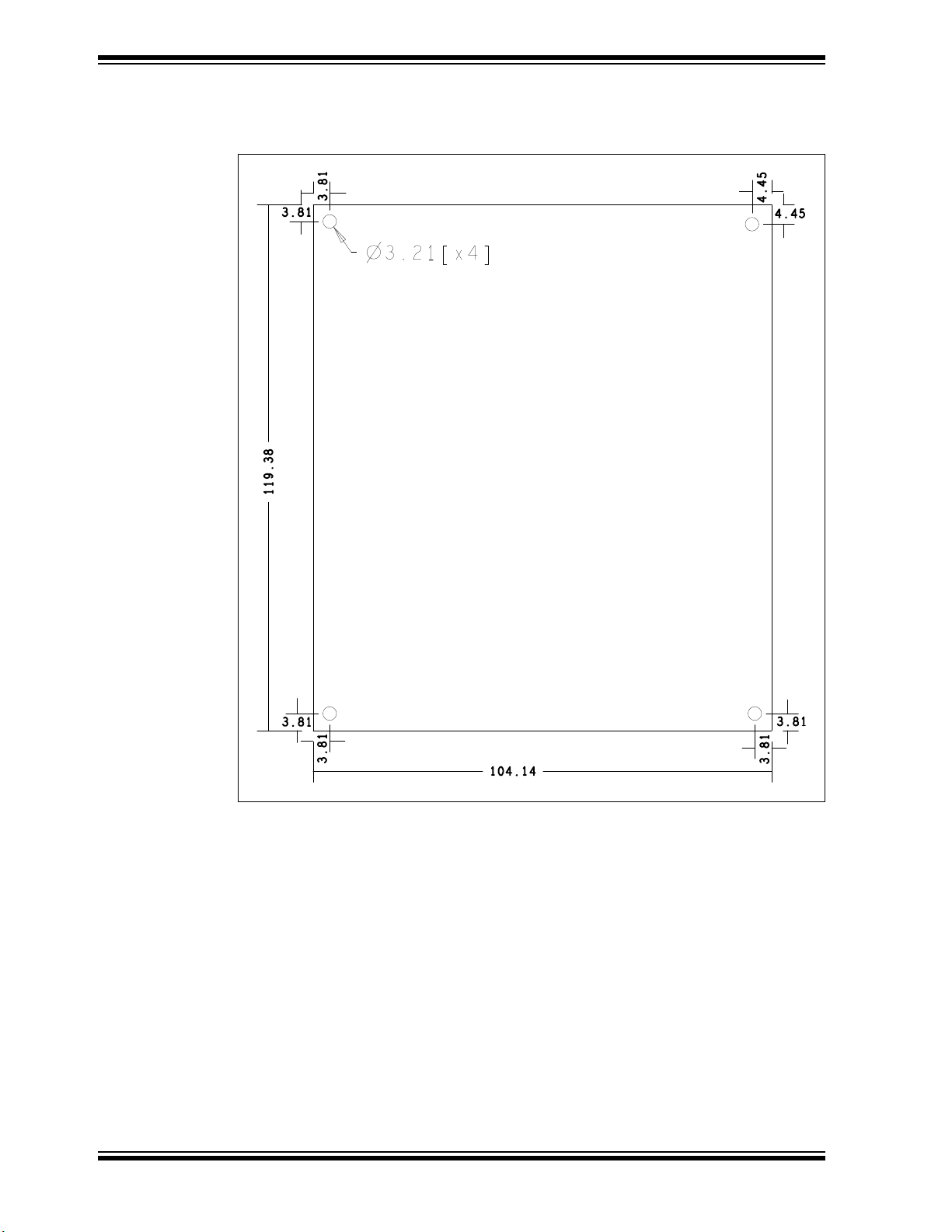

2.5 MECHANICALS

FIGURE 2-3: EVB-LAN9252-DIG-IO MECHANICAL DIMENSIONS

DS50002332A-page 20 Preliminary 2014 Microchip Technology Inc.

Page 21

Chapter 3. LAN9252 EEPROM Programming

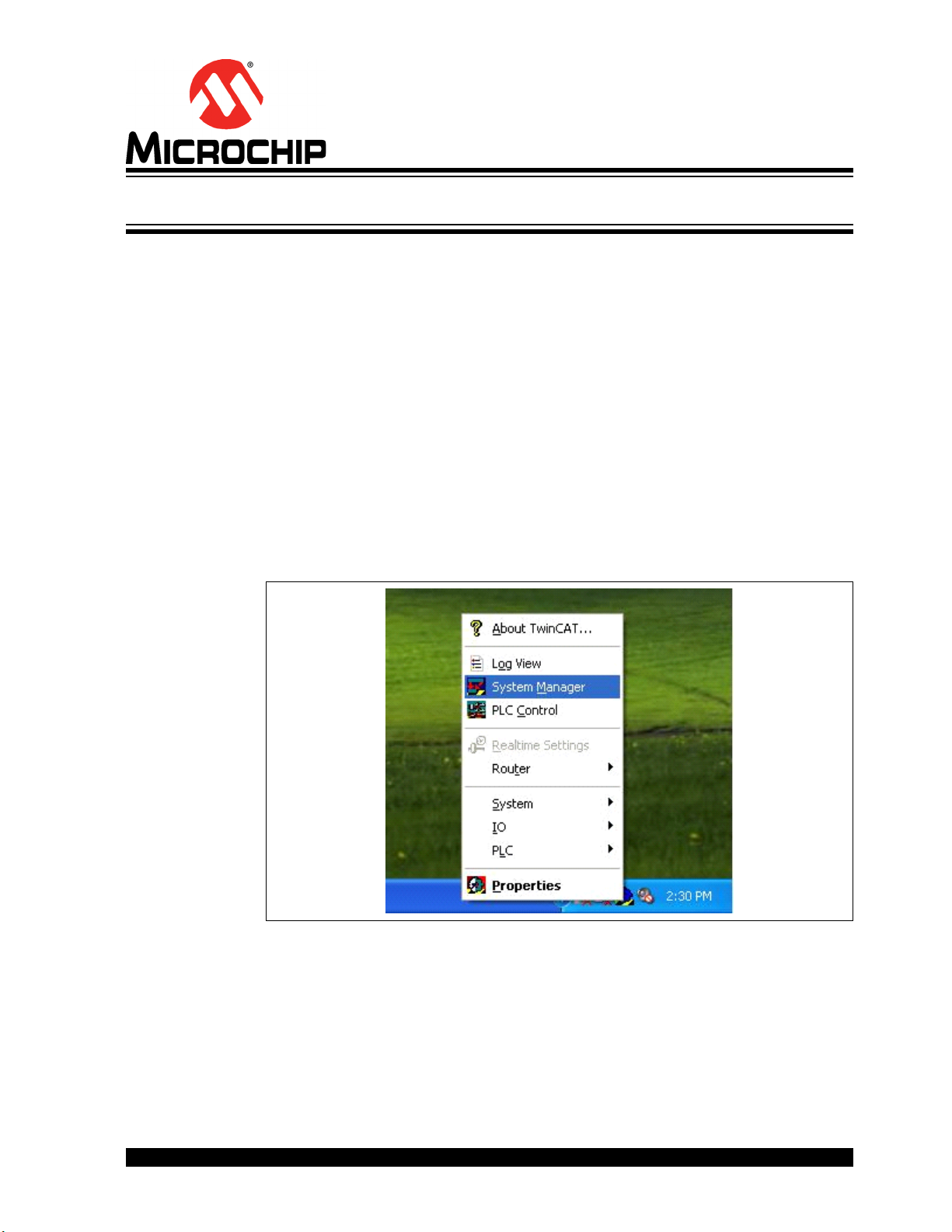

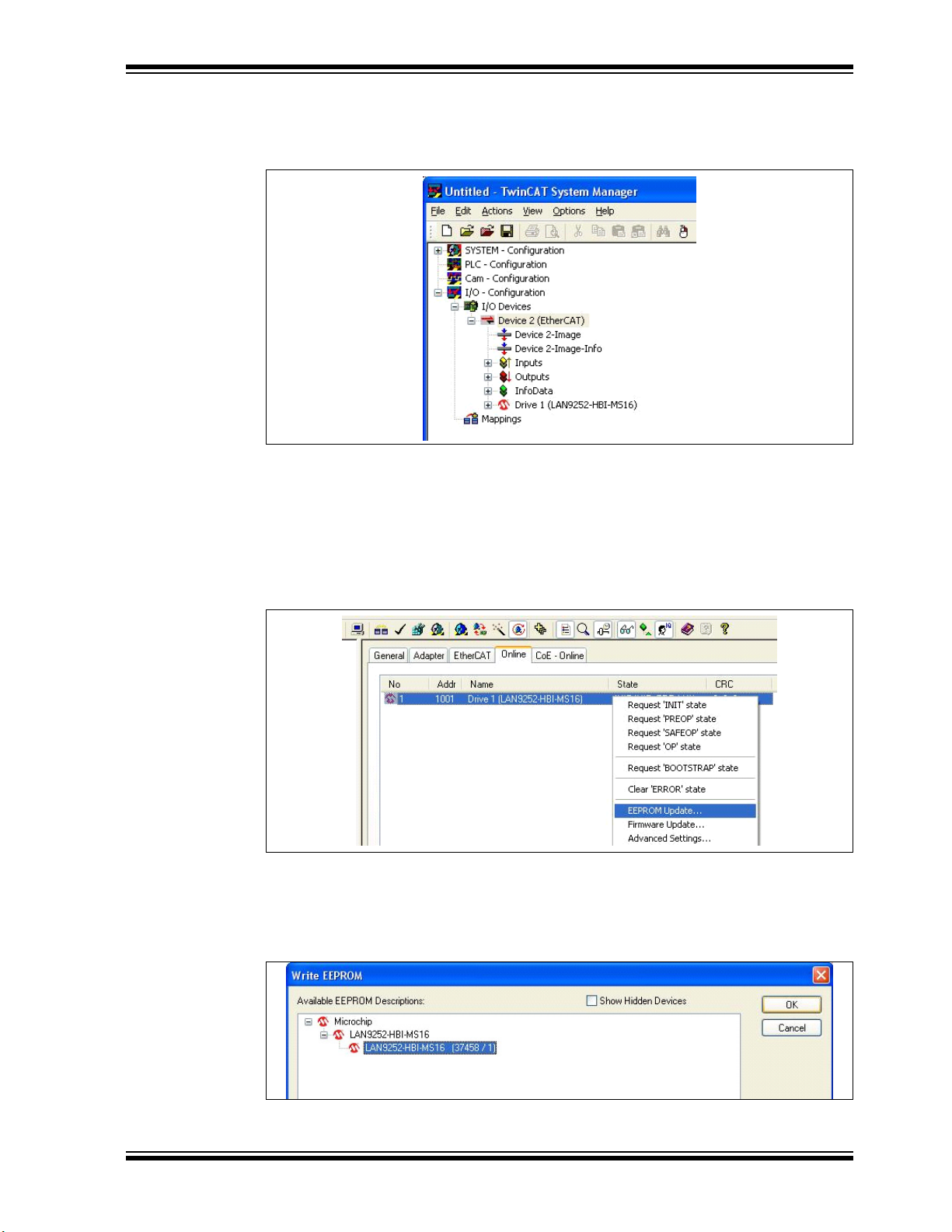

3.1 PROGRAMMING THE LAN9252 EEPROM

The LAN9252 configures itself to the desired mode (SPI, 6 HBI modes) by reading the

strap settings located in EEPROM. The LAN9252 EEPROM is programmed and validated via the TwinCAT master tool. The programming procedure is as follows:

Note 1: This example utilizes the TwinCAT tool. Procedures may differ when using

other EtherCAT® master tools.

2: Ensure the system network properties are configured properly for the Eth-

erCAT® frames, Ethernet cable linking your system, and EtherCAT® slave

board.

1. Load the corresponding ESI file in the directory path “C:\TwinCAT\Io\EtherCAT”.

For this demo, the ESI file for the 16-Bit Multiplexed Single-Phase Mode is used.

2. If TwinCAT installed successfully, a TwinCAT icon will be shown in the bottom-right corner of the desktop. After clicking the icon, a pop-up list will display.

Select “System Manager”, as shown in Figure 3-1.

EVB-LAN9252-DIG-IO

ETHERCAT® DIG I/O

USER’S GUIDE

FIGURE 3-1: TWINCAT SYSTEM MANAGER

2014 Microchip Technology Inc. Preliminary DS50002332A-page 21

Page 22

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

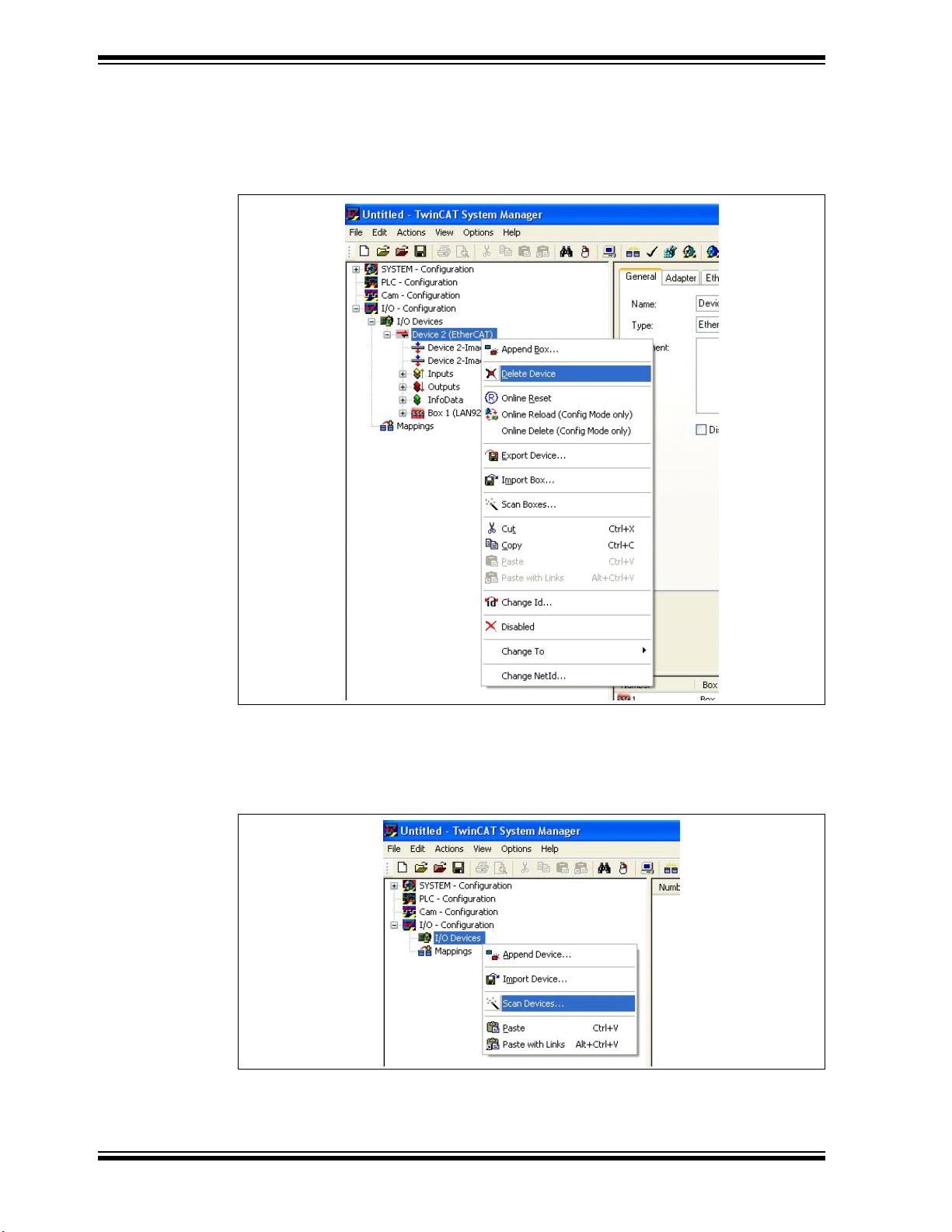

3. If any devices are present, delete them accordingly by clicking the device and

selecting “Delete Device”, as shown in Figure 3-2.

FIGURE 3-2: TWINCAT DELETE DEVICE

4. Scan for EtherCAT® slave devices by clicking “I/O devices” and selecting “Scan

Devices”, as shown in Figure 3-3.

FIGURE 3-3: TWINCAT SCAN DEVICES

DS50002332A-page 22 Preliminary 2014 Microchip Technology Inc.

Page 23

LAN9252 EEPROM Programming

5. After scanning is complete, the right panel of the TwinCAT window will appear as

shown in Figure 3-4.

FIGURE 3-4: TWINCAT DEVICE LIST

6. After a successful scan, click the “Device 2 (EtherCAT)” drop down bar on the left

panel of the TwinCAT tool (as highlighted in Figure 3-4). Then click the “Online”

tab on the right-side panel of the TwinCAT tool, as shown in Figure 3-5. Right

click the LAN9252 listing and select “EEPROM Update” from the contextual

menu.

FIGURE 3-5: TWINCAT EEPROM UPDATE

7. Upon selecting “EEPROM Update”, the Write EEPROM window will open. Click

the “OK” button to initiate EEPROM programming.

FIGURE 3-6: TWINCAT WRITE EEPROM

2014 Microchip Technology Inc. Preliminary DS50002332A-page 23

Page 24

EVB-LAN9252-DIG-IO

ETHERCAT® DIG I/O

USER’S GUIDE

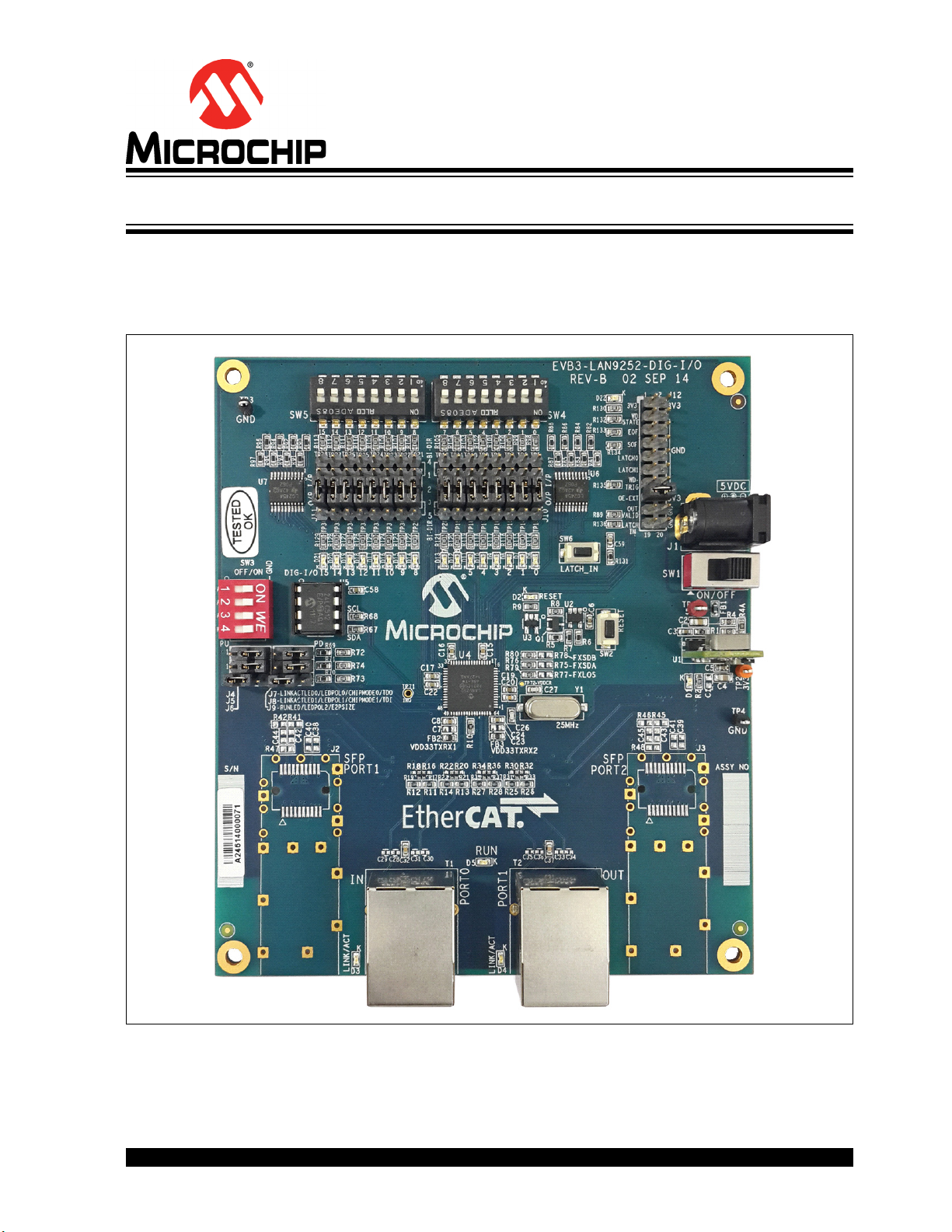

Appendix A. EVB-LAN9252-DIG-IO Evaluation Board

A.1 INTRODUCTION

This appendix shows the EVB-LAN9252-DIG-IO Evaluation Board.

FIGURE A-1: EVB-LAN9252-DIG-IO EVALUATION BOARD

2014 Microchip Technology Inc. Preliminary DS50002332A-page 24

Page 25

EVB-LAN9252-DIG-IO

ETHERCAT® DIG I/O

USER’S GUIDE

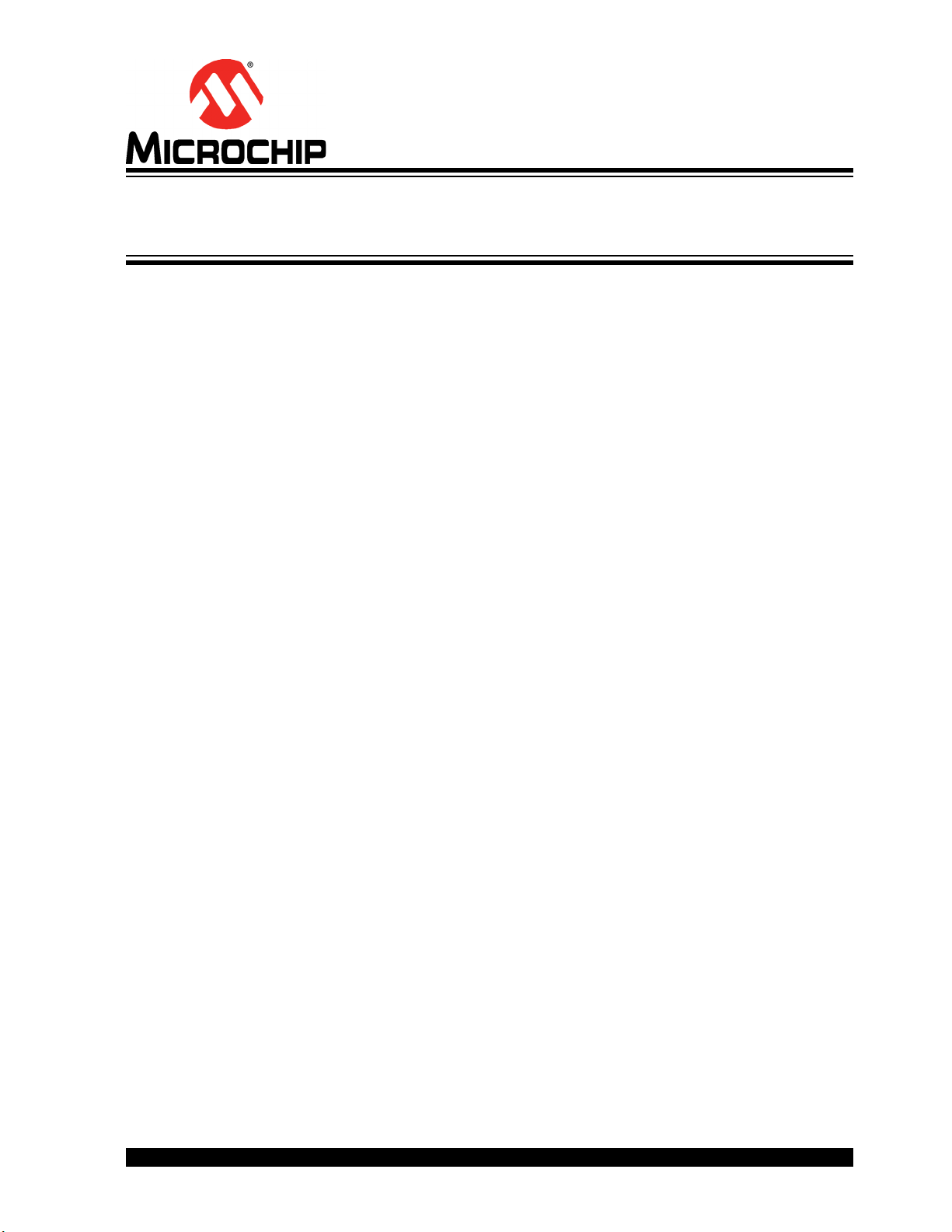

Appendix B. EVB-LAN9252-DIG-IO Evaluation Board

Schematics

B.1 INTRODUCTION

This appendix shows the EVB-LAN9252-DIG-IO Evaluation Board Schematics.

2014 Microchip Technology Inc. Preliminary DS50002332A-page 25

Page 26

DS50002332A-page 26 Preliminary 2014 Microchip Technology Inc.

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

Reset Generator

POWER SUPPLY

(Rb)

(Ra)

OKR-T/3-W12-C

3 V REGULATOR, 3A

( 3V3 fixed when Rb=470E)

"3V3 Present"

Note:

1.POR -> Reset to ASIC & SOC (Default)

2.RESET O/P from ASIC -> Reset to EX-PH Y (PORT2) & SOC :Only Ethercat sku

3.RESET from SOC (GPIO/RST-O/P) -> Reset to ASIC

4.RESET from Push Botton -> Reset to ASIC & SOC

"Reset"

RESET Options

5V_SW

EN12_1

VOUT_3V3

5V_EXT

3V3

3V3

5V

3V3

3V3

3V3

3V3

RST#

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

39

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

Power Supply & RST

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

39

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

Power Supply & RST

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

39

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

Power Supply & RST

EVB3-9252-DIG-I/O-RevB

U2

TPS3125

SOT23_5

Threshold = 2.64V

Delay = 180ms

RESET#

1

GND

2

RESET

3

MR#

4

VDD

5

TP2

ORANGE

D2

RED

1

A2C

Q1

NDS355AN_NMOS

1

G

3

S

2

D

C5

0.1uF

R5

4.75K

1%

U1

3_Amp

GND

3

VIN

2

ENABLE1TRIM

5

VOUT

4

J1

1

2

3

D1

GRN

1

A

2

C

R1 0E

R2

1K

C6

0.1uF

TP3

BLACK

FB1

2A/0.05DCR

R4A

33E

1%

C2

10uF

25V

C1

4.7uF

DNP

R3

3.30K

1%

TP1

RED

R6

10.0K

1/10W

1%

12

C4

10uF

SW2

sw_pb_2P

R7

100

1/10W

1%

1 2

R8 1K

TP4

BLACK

C3

0.1uF

R9 2.2K

U3

74LVC1G14

2 4

53

1

SW1

P/N:1101M2S3CQE2

Switch, SPDT, Slide

2

3

1

R4

470E

1%

FIGURE B-1: EVB-LAN9252-DIG-IO SCHEMATIC POWER SUPPLY & RESET

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Page 27

2014 Microchip Technology Inc. Preliminary DS50002332A-page 27

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

Note:

OSCVSS need to connect to Chip gnd.

Power Supply Filtering

Low ESR

IRQ

REG_EN

RBIAS

VDD12TX1

VDD12TX2

VDD12TX2

VDD12TX1

OSCO

OSCI

3V3

VDD33TXRX1

VDD33TXRX2

VDDCR

VDD33TXRX1

VDD33TXRX2

3V3

3V3

3V3 3V3

3V3

VDDCR

FXSDA/FXLOSA

ATEST/FXLOSEN

RXPA

RXNA

TXNA

TXPA

TXNB

TXPB

RXNB

RXPB

FXSDB/FXLOSB

GPIO0

GPIO1

GPIO2

I2C2_SCL

I2C2_SDA

RST#

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

49

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

LAN9252 (Part1)

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

49

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

LAN9252 (Part1)

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

49

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

LAN9252 (Part1)

EVB3-9252-DIG-I/O-RevB

C15

0.1uF

C26 18pF

C12

1.0uF DNP

FB3

2A/0.05DCR

C25

0.1uF

C13

0.1uF

C10

0.1uF

C210.1uF

C180.1uF

C23

1.0uF

DNP

C11

0.1uF

C27 18pF

FB4

2A/0.05DCR

BLM18EG221SN1D

POWER

INT PORT0INT PORT1

OSC

I2C

OTHER

SIGNALS

GPIO

(Only for

Lan9252)

U4A

LAN9252

FXSDENA/FXSDA/FXLOSA

9

FXSDENB/FXSDB/FXLOSB

10

VDD33TXRX1

51

TXNA

52

TXPA

53

RXNA

54

RXPA

55

VDD12TX1

56

RBIAS

57

VDD33BIAS

58

VDD12TX2

59

RXPB

60

RXNB

61

TXPB

62

TXNB

63

VDD33TXRX2

64

OSCI

1

OSCO

2

OSCVDD12

3

OSCVSS

4

REG_EN

7

ATEST/FXLOSEN

8

RST#

11

IRQ

44

TESTMODE

41

I2CSCL/EESCL/TCK

43

I2CSDA/EESDA/TMS

42

LINKACTLED0/TDO/LEDPOL0/CHIP_MODE0

48

LINKACTLED1/TDI/LEDPOL1/CHIP_MODE1

46

RUNLED/LEDPOL2/E2PSIZE

45

VDD33

5

VDDIO114VDDIO220VDDIO332VDDIO437VDDIO5

47

VDDCR16VDDCR224VDDCR3

38

GND

65

C220.1uF

C9

1.0uF

DNP

C14

0.1uF

C24

0.1uF

TP71

WHITE

DNP

C16

0.1uF

C20470pF

FB2

2A/0.05DCR

R10 12.1K

1%

Y1

25.000MHz

25ppm

1 2

C7

1.0uF

DNP

FB5

2A/0.05DCR

BLM18EG221SN1D

C17

0.1uF

TP72

SMT

C19

1uF

C8

0.1uF

FIGURE B-2: EVB-LAN9252-DIG-IO SCHEMATIC LAN9252 PT1

EVB-LAN9252-DIG-IO Evaluation Board Schematics

Page 28

DS50002332A-page 28 Preliminary 2014 Microchip Technology Inc.

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

Note:

Capacitors C28 through C31 are optional for EMI purposes

and are not populated on the LAN9252 evaluation board.

These capacitor s are required for op eration in an EMI

constrained environment.

Note:

Capacitors C33 through C36 are optional for EMI purposes

and are not populated on the LAN9252 evaluation board.

These capacitor s are required for op eration in an EMI

constrained environment.

PORT0

PORT1

COP-RXPA

COP-TXNA

COP-RXNA

COP-TXPA

COP-RXPB

COP-TXNB

COP-RXNB

COP-TXPB

VDD33TXRX2

VDD33TXRX1

FX_SFP-RXPA

FX_SFP-RXNA

TXPA

TXNA FX_SFP-TXNA

FX_SFP-TXPA

RXPA

RXNA

FX_SFP-RXPB

FX_SFP-RXNB

TXPB

TXNB FX_SFP- TXNB

FX_SFP-TXPB

RXPB

RXNB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

59

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

Copper Mode Interface

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

59

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

Copper Mode Interface

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

59

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

Copper Mode Interface

EVB3-9252-DIG-I/O-RevB

R17 0E

R35 0

R22 0E

DNP

R33 0

XMIT

RCV

75

75 75

1000 pF

2 kV

RJ45

1

4 & 5

2

3

7 & 8

6

75

GRN

YEL

T1

Pulse J0011D01BNL

RD+

3

RXCT

5

RD-

6

TD+

1

TXCT

4

TD-

2

CHS GND

8

GND13GND114MTG15MTG1

16

NC

7

C

10

A

9

C1

11

A1

12

XMIT

RCV

75

75 75

1000 pF

2 kV

RJ45

1

4 & 5

2

3

7 & 8

6

75

GRN

YEL

T2

Pulse J0011D01BNL

RD+

3

RXCT

5

RD-

6

TD+

1

TXCT

4

TD-

2

CHS GND

8

GND13GND114MTG15MTG1

16

NC

7

C

10

A

9

C1

11

A1

12

C29

10pF

50V

5%

DNP

R23 0E

C36

10pF

50V

5%

DNP

C31

10pF

50V

5%

DNP

R30 0E

DNP

R27

49.9

1/10W

1%

R38 0E

RES1210

R20 0E

DNP

R31 0E

R13

49.9

1/10W

1%

R25

49.9

1/10W

1%

R24 0E

RES1210

C33

10pF

50V

5%

DNP

R21 0E

R11

49.9

1/10W

1%

R36 0E

DNP

R28

49.9

1/10W

1%

C28

10pF

50V

5%

DNP

C35

10pF

50V

5%

DNP

R14

49.9

1/10W

1%

R29

0E

C32

0.022uF

50V

10%

R37 0E

C37

0.022uF

50V

10%

R15

0E

R18 0E

DNP

R16 0E

DNP

C30

10pF

50V

5%

DNP

R26

49.9

1/10W

1%

R12

49.9

1/10W

1%

R34 0E

DNP

C34

10pF

50V

5%

DNP

R19 0

R32 0E

DNP

FIGURE B-3: EVB-LAN9252-DIG-IO SCHEMATIC COPPER MODE INTERFACE

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Page 29

2014 Microchip Technology Inc. Preliminary DS50002332A-page 29

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

Fiber Port 0 :SFP Interface

Fiber Port 1 :SFP Interface

Note:Place

capacitors,

and resistors

close to FOT

Note:Place

resistors

close to

ASIC

Note:Place

capacitors,

and resistors

close to FOT

Note:Place

resistors

close to

ASIC

SFP_VCCT

SFP_VCCR

SFP_TD-

SFP_TD+

SFP_RD-

SFP_RD+

SFP_VCCT2

SFP_VCCR2

SFP_TD2-

SFP_TD2+

SFP_RD2-

SFP_RD2+

SFP_VCCT

SFP_VCCT2

3V3

3V3

3V3

3V3

FXSDA/FXLOSA FXSDB/FXLOSB

FX_SFP-TXPA

FX_SFP-RXNA

FX_SFP-RXPA

FX_SFP-TXNA

FX_SFP-RXNB

FX_SFP-RXPB

FX_SFP-TXPB

FX_SFP-TXNB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

69

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

SFP Interface

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

69

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

SFP Interface

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

69

Tuesday, October 21, 2014

LAN9252-DIG-IO-EVB

SFP Interface

EVB3-9252-DIG-I/O-RevB

+

C50

10uF

16V

DNP

C47

0.1uF

R49

130

C42 0.1uF

+

C48

10uF

16V

R56

4.7K

C39 0.1uF

C38 0.1uF

R50

130

L3 1uH

C44 0.1uF

C41 0.1uF

R57

4.7K

C49

0.1uF

+

C56

10uF

16V

R58

4.7K

C43 0.1uF

C40 0.1uF

R48

100

L1 1uH

R45

49.9

R59

4.7K

R41

49.9

C45 0.1uF

R46

49.9

C57

0.1uF

R42

49.9

R53

4.7K

L4 1uH

R54

4.7K

+

C52

10uF

16V

R44

82

R55

4.7K

R47

100

+

C54

10uF

16V

J3

FTLF1217P2

VeeT1TXFault2TX Disable3MOD-DEF(2)4MOD-DEF (1)5MOD-DEF (0)6Rate Select7LOS8VeeR9VeeR1

10

VeeR311VeeR2

14

RD-

12

RD+

13

VccR

15

VccT

16

VeeT2

17

TD+

18

TD-

19

VeeT1

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

C51

0.1uF

R43

82

L2 1uH

R60

4.7K

J2

FTLF1217P2

VeeT1TXFault2TX Disable3MOD-DEF(2)4MOD-DEF (1)5MOD-DEF (0)6Rate Select7LOS8VeeR9VeeR1

10

VeeR311VeeR2

14

RD-

12

RD+

13

VccR

15

VccT

16

VeeT2

17

TD+

18

TD-

19

VeeT1

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

R51

130

C53

0.1uF

C55

0.1uF

R40

82

+

C46

10uF

16V

DNP

R52

130

R39

82

FIGURE B-4: EVB-LAN9252-DIG-IO SCHEMATIC SFP INTERFACE

EVB-LAN9252-DIG-IO Evaluation Board Schematics

Page 30

DS50002332A-page 30 Preliminary 2014 Microchip Technology Inc.

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

GPIO [0:2] & LED_POL_Strap

LINK/ACT for PORT0

6LJQDOV)XQFWLRQV

*3,2 /,1.$&7/('7'2/('32/&+,3B02'(

*3,2 /,1.$&7/('7',/('32/&+,3B02'(

*3,2 581/('/('32/(36,=(

Note:

--To use GPIOs as LED

* Short 2-3 of both jumpers (ex. for GPIO0 short 2-3 of J4 & J7)

7KH/('LVVHWDVDFWLYHORZ

&+,3B02'(

7KH/('LVVHWDVDFWLYHKLJK

&+,3B02'(

6LJQDO1DPH

&RQQHFWRU

--

/RJLF

(36,=(

--

--

--

--

--

7KH/('LVVHWDVDFWLYHORZ

7KH/('LVVHWDVDFWLYHKLJK

7KH/('LVVHWDVDFWLYHORZ

((35206L]H .ELWV.[WKURXJK.ELWV.[RU0ELWV.[/$1RQO\

7KH/('LVVHWDVDFWLYHKLJK

((35206L]H .ELWV[WKURXJK.ELWV.[

Strap Details

I2C EEPROM

TH IC.

Different sizes can be mounted

I2C EEPROM Lower size

Below 16K(2K X 8) (24FC04)

I2C EEPROM Higher size

Above 16K(2K X 8) (24FC512 )

FX_Los_Strap_1 & 2

FX_Mode_Strap_1 & 2

5 5

5HI9ROWDJH )XQFWLRQ

3RXSXODWH

'13

9

$ERYH9VHOHFWV);/26IRUSRUWVDQG

3RXSXODWH 3RXSXODWH 9

/HYHORI9VHOHFWV);/26IRUSRUWDQG

);6'FRSSHUWZLVWHGSDLUIRUSRUW

IXUWKHUGHWHUPLQHGE\);6'%

3RXSXODWH

'HIDXOW

'13

'HIDXOW

'HIDXOW

/HYHORI96HOHFWV);6'FRSSHUWZLVWHGSDLU

IRUSRUWV$DQG%

IXUWKHUGHWHUPLQHGE\);6'$DQG);6'%

LINK/ACT for PORT1

RUNLED

/('3RODULW\6WUDS

&+,3B02'(>@

3RUW'HVFULSWLRQ

>'HIDXOW@

325702'(

5(6(59('

3257

'2:1675($002'(

3RUW 3+<$

3RUW 3+<%

5(6(59('

3RUW 3+<$

3RUW 3+<%

3RUW 0,,

3RUW 0,,

3RUW 3+<%

3RUW 3+<$

3257

83675($002'(

02'(

&+,3B02'(>@6WUDS'HWDLOV

3257

&RSSHU

'HIDXOW

)LEHU

3RXSXODWH

'13

3257

5 5

55

3257

02'(

)LEHU

5 5

5 5

&RSSHU

'HIDXOW

>'HIDXOW@

LED1_CATHODE

GPIO1

GPIO1

LED1_ANODE

LED2_ANODE

LED0_CATHODE

LED2_CATHODE

GPIO0

GPIO0 GPIO2

GPIO2

LED0_ANODE

LED0_ANODE

LED0_CATHODE

LED1_ANODE

LED1_CATHODE

LED2_ANODE

LED2_CATHODE

I2C2_2

I2C2_3

I2C2_7

I2C2_1

3V3

3V3

3V3

3V3

3V3

3V3

3V3 3V3 3V3

GPIO0

GPIO1

GPIO2

I2C2_SDA

I2C2_SCL

ATEST/FXLOSEN

FXSDA/FXLOSA

FXSDB/FXLOSB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

79

Monday, December 08, 2014

LAN9252-DIG-IO-EVB

STRAP,GPIO,I2C & FXLOS

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

79

Monday, December 08, 2014

LAN9252-DIG-IO-EVB

STRAP,GPIO,I2C & FXLOS

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

79

Monday, December 08, 2014

LAN9252-DIG-IO-EVB

STRAP,GPIO,I2C & FXLOS

EVB3-9252-DIG-I/O-RevB

R634.7K

J7

123

D4

GRN

1

A2C

R78 10K

DNP

R71

10.0K

12

R74

1K

R76 10K

R77

10K

DNP

J5

123

C58

0.1uF

R672K

J8

123

R654.7K

R73

1K

R75 10K

DNP

D3

GRN

1

A2C

SW3

SW DIP-4/SM

1

2

3

4

8

7

6

5

J4

123

U5

24FC512

GND

4

VCC

8

SDA

5

SCL

6

A0

1

A1

2

A2

3

WP

7

R80 10K

R72

1K

R70

10.0K

12

R644.7K

J6

123

R69

10.0K

12

R664.7K

J9

123

R79

10K

D5

GRN

1

A2C

R682K

FIGURE B-5: EVB-LAN9252-DIG-IO SCHEMATIC STRAP, GPIO, I2C & FXLOS

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Page 31

2014 Microchip Technology Inc. Preliminary DS50002332A-page 31

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

DIG-IO

Note: Placement Instruction

Place the TPs in 100 mil distan ce from the respective IN_DIGIOx or OUT_D IGIOx PINS of J10 & J11

Placement should be such a way that, jumpers should be able to

added between the t est points and J10 or J11 connectors

DIGIO0

DIGIO1

DIGIO2

DIGIO3

DIGIO5

DIGIO6

DIGIO7

OUT_BUF_DIGIO0

OUT_BUF_DIGIO1

OUT_BUF_DIGIO2

OUT_BUF_DIGIO3

OUT_BUF_DIGIO4

OUT_BUF_DIGIO5

OUT_BUF_DIGIO6

OUT_BUF_DIGIO7

OUT_BUF_DIGIO14

OUT_BUF_DIGIO15

DIGIO4

DIGIO8

DIGIO9

DIGIO10

DIGIO11

DIGIO13

DIGIO14

DIGIO15

OUTVALID

OUT_BUF_DIGIO8

OUT_BUF_DIGIO9

OUT_BUF_DIGIO10

OUT_BUF_DIGIO11

OUT_BUF_DIGIO12

OUT_BUF_DIGIO13

OUTVALID

DIGIO12

3V3

3V3

3V3

LATCH1

LATCH0

DIGIO0

DIGIO1

DIGIO2

DIGIO3

DIGIO4

DIGIO5

DIGIO6

DIGIO7

DIGIO8

DIGIO9

DIGIO10

DIGIO11

DIGIO13

DIGIO14

DIGIO15

OE_EXT

LATCH_IN

OUTVALID

WD_TRIG

SOF

EOF

WD_STATE

DIGIO12

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

89

Wednesday, October 22, 2014

LAN9252-DIG-IO-EVB

LAN9252-Part2

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

89

Wednesday, October 22, 2014

LAN9252-DIG-IO-EVB

LAN9252-Part2

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

89

Wednesday, October 22, 2014

LAN9252-DIG-IO-EVB

LAN9252-Part2

EVB3-9252-DIG-I/O-RevB

TP14

TP5

TP29

TP30

TP35

TP19

4.7K R83

U6

74LC245A/SO

A0

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

OE

19

DIR

1

B0

18

B1

17

B2

16

B3

15

B4

14

B5

13

B6

12

B7

11

VCC

20

GND

10

TP31

TP6

TP32

TP7

TP12

TP9

4.7K R87

4.7K R84

TP23

TP36

4.7K R81

TP22

4.7K R96

4.7K R91

TP21

TP26

TP15

4.7K R88

4.7K R94

TP17

4.7K R82

4.7K R86

TP16

TP8

4.7K R97

TP11

R89

10K

TP20

TP13

4.7K R92

4.7K R93

4.7K R95

TP24

U4B

LAN9252

SYNC/LATCH1

18

SYNC/LATCH0

34

A4/DIGIO12/GPI12/GPO12/MII_RXD0

27

A3/DIGIO11/GPI11/GPO11/MII_RXDV

26

A2/ALEHI/DIGIO10/GPI10/GPO10/LINKACTLED2/MII_LINKPOL/LEDPOL6

29

A1/ALELO/OE_EXT/MII_CLK25

25

A0/D15/AD15/DIGIO9/GPI9/GPO9/MII_RXER

33

D14/AD14/DIGIO8/GPI8/GPO8/MII_TXD3/TX_SHIFT1

15

D13/AD13/DIGIO7/GPI7/GPO7/MII_TXD2/TX_SHIFT0

16

D12/AD12/DIGIO6/GPI6/GPO6/MI I_TXD1

21

D11/AD11/DIGIO5/GPI5/GPO5/MI I_TXD0

22

D10/AD10/DIGIO4/GPI4/GPO4/MII_TXEN

23

D9/AD9/LATCH_IN/SCK

19

D8/AD8/DIGIO2/GPI2/GPO2/MII_MDIO

40

D7/AD7/DIGIO1/GPI1/GPO1/MII_MDC

39

D6/AD6/DIGIO0/GPI0/GPO0/MII_RXCLK

36

D5/AD5/OUTVALID/SCS#

50

D3/AD3/WD_TRIG/SIO3

35

D2/AD2/SOF/SIO2

12

D1/AD1/EOF/SO/SIO1

13

D0/AD0/WD_STATE/SI/SIO0

17

RD/RD_WR/DIGIO15/GPI15/GPO15/MII_RXD3

31

WR/ENB/DIGIO14/GPI14/GPO14/MII_RXD2

30

CS/DIGIO13/GPI13/GPO13/MII_RXD1

28

D4/AD4/DIGIO3/GPI3/GPO3/MII_LINK

49

TP18

TP28

TP33

U7

74LC245A/SO

A0

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

8

A7

9

OE

19

DIR

1

B0

18

B1

17

B2

16

B3

15

B4

14

B5

13

B6

12

B7

11

VCC

20

GND

10

TP10

TP27

4.7K R85

TP25

TP34

4.7K R90

FIGURE B-6: EVB-LAN9252-DIG-IO SCHEMATIC LAN9252 PT2

EVB-LAN9252-DIG-IO Evaluation Board Schematics

Page 32

DS50002332A-page 32 Preliminary 2014 Microchip Technology Inc.

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

'HIDXOW

6:6:DUHLQ2))SRVLWLRQ3XOOXSDFWLYH

)RU3XOO'RZQPRYH6:6:WR21SRVLWLRQ

Digital INPUTS

Digital OUTPUTS

LED for WD_STATE

I/P

O/P

1-2 side short of J11 = Input Mode

2-3 side short of J11 = Output Mode

1-2 side short of J10 = Input Mode

2-3 side short of J10 = Output Mode

41 2 3 5

DIG-IO JUMPER OPTIONS

Short 1-2 = Input Mode

Short 2-3 = Output Mode

Short 1-4 & 3-5 = Bidirectional Mode

J10 & J11

TP5 to 12 TP13 to 20

TP21 to 28 TP29 to 36

41 2

12

23

35

IN_DIGIO0

IN_DIGIO1

IN_DIGIO2

IN_DIGIO6

IN_DIGIO3

IN_DIGIO4

IN_DIGIO5

IN_DIGIO7

IN_DIGIO8

IN_DIGIO9

IN_DIGIO10

IN_DIGIO14

IN_DIGIO11

IN_DIGIO12

IN_DIGIO13

IN_DIGIO15

OUT_DIGIO0

OUT_DIGIO1

OUT_DIGIO2

OUT_DIGIO3

OUT_DIGIO4

OUT_DIGIO5

OUT_DIGIO6

OUT_DIGIO7

OUT_DIGIO8

OUT_DIGIO9

OUT_DIGIO10

OUT_DIGIO11

OUT_DIGIO12

OUT_DIGIO13

OUT_DIGIO14

OUT_DIGIO15

IN_DIGIO0

DIGIO0

IN_DIGIO1

DIGIO1

IN_DIGIO2

DIGIO2

IN_DIGIO3

DIGIO3

IN_DIGIO4

DIGIO4

IN_DIGIO5

DIGIO5

IN_DIGIO6

DIGIO6

IN_DIGIO7

DIGIO7

IN_DIGIO8

DIGIO8

IN_DIGIO9

DIGIO9

IN_DIGIO10

DIGIO10

IN_DIGIO11

DIGIO11

IN_DIGIO12

DIGIO12

IN_DIGIO13

DIGIO13

IN_DIGIO14

DIGIO14

IN_DIGIO15

DIGIO15

OUT_DIGIO0

OUT_DIGIO1

OUT_DIGIO2

OUT_DIGIO3

OUT_DIGIO4

OUT_DIGIO5

OUT_DIGIO6

OUT_DIGIO7

OUT_DIGIO8

OUT_DIGIO9

OUT_DIGIO10

OUT_DIGIO11

OUT_DIGIO12

OUT_DIGIO13

OUT_DIGIO14

OUT_DIGIO15

WD_STATE

LATCH_IN

3V3

3V3

3V3

3V3

DIGIO0

DIGIO1

DIGIO2

DIGIO3

DIGIO4

DIGIO5

DIGIO6

DIGIO7

DIGIO8

DIGIO9

DIGIO10

DIGIO11

DIGIO12

DIGIO13

DIGIO14

DIGIO15

OUTVALID

WD_STATE

EOF

SOF

LATCH0

LATCH1

WD_TRIG

OE_EXT

LATCH_IN

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

99

Wednesday, October 22, 2014

LAN9252-DIG-IO-EVB

DIG-I/O

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

99

Wednesday, October 22, 2014

LAN9252-DIG-IO-EVB

DIG-I/O

EVB3-9252-DIG-I/O-RevB

Size:

Part Number:

Rev

Date:

Sheet

of

Chennai

India

Project

Name:

Page:

Name:

Board

LAN9252-DIG-IO-EVB

B

B

99

Wednesday, October 22, 2014

LAN9252-DIG-IO-EVB

DIG-I/O

EVB3-9252-DIG-I/O-RevB

R13410K

R13210K

R1231K

J10

HDR_3x8

1 3

4

2

5

6

789

11

13 15

10 12

14

161718

192021

22 24

23

SW5

SW DIP-8

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

R10210K

R1211K

R10710K

R1181K

R9910K

SW6

sw_pb_2P

R10410K

R10510K

R1161K

R1151K

R1291K

R11210K

R10310K

R11010K

R1261K

R1241K

R10610K

R1221K

R13610K

D22

GRN

1

A2C

R10110K

R131

100K

C59

0.1uF

R11110K

R1201K

D21

GRN

1

A2C

D15

GRN

1

A2C

D20

GRN

1

A2C

D14

GRN

1

A2C

D19

GRN

1

A2C

D13

GRN

1

A2C

D18

GRN

1

A2C

D12

GRN

1

A2C

D17

GRN

1

A2C

D16

GRN

1

A2C

R1191K

R13510K

R1171K

R130 1K

D11

GRN

1

A2C

R9810K

D10

GRN

1

A2C

D9

GRN

1

A2C

D8

GRN

1

A2C

J12

1

3 4

2

5 6

7 8

9

11

13

15

10

12

14

16

17 18

19 20

D7

GRN

1

A2C

D6

GRN

1

A2C

R1281K

R1141K

R10810K

R1271K

R10010K

R13310K

SW4

SW DIP-8

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

R1251K

J11

HDR_3x8

1 3

4

2

5

6

789

11

13 15

10 12

14

161718

192021

22 24

23

R11310K

R10910K

FIGURE B-7: EVB-LAN9252-DIG-IO SCHEMATIC DIGITAL I/O

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Page 33

EVB-LAN9252-DIG-IO

ETHERCAT® DIG I/O

USER’S GUIDE

Appendix C. Bill of Materials (BOM)

C.1 INTRODUCTION

This appendix includes the EVB-LAN9252-DIG-IO Evaluation Board Bill of Materials (BOM).

2014 Microchip Technology Inc. Preliminary DS50002332A-page 33

Page 34

DS50002332A-page 34 Preliminary 2014 Microchip Technology Inc.

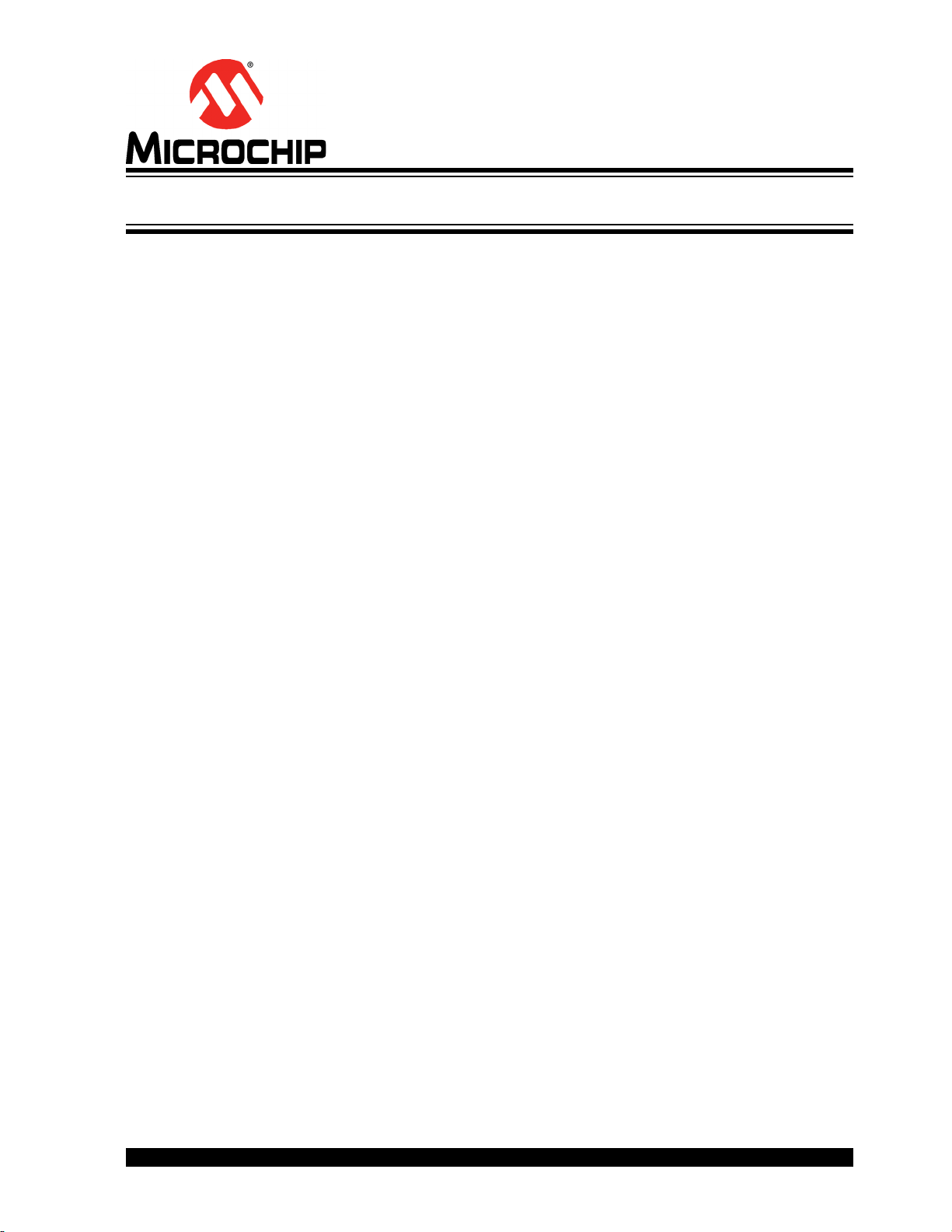

Item Quantity Reference Part PCB Footprint DNP Vender Vender Part NO

12

218

31

41

52

62

721

81

95

10 1

11 6

12 2

13 1

14 1

15 3

16 22

17 1

18 1

19 1

20 1

21 4

22 1

23 1

24 1

25 8

26 8

C2,C4

C3,C5,C6,C8,C10,C11,C13,C14,C15,C16,C17,C18,C21,

C22,C24,C25,C58,C59

C19

C20

C26,C27

C32,C37

D1,D3,D4,D5,D6,D7,D8,D9,D10,D11,D12,D13,D14,D1

5,D16,D17,D18,D19,D20,D21,D22

D2

FB1,FB2,FB3,FB4,FB5

J1

J4,J5,J6,J7,J8,J9

J10,J11

J12

Q1

R1,R15,R29

R2,R8,R72,R73,R74,R114,R115,R116,R117,R118,R119

,R120,R121,R122,R123,R124,R125,R126,

R127,R128,R129,R130

R3

R4

R4A

R5

R6,R69,R70,R71

R7

R9

R10

R11,R12,R13,R14,R25,R26,R27,R28

R17,R19,R21,R23,R31,R33,R35,R37

10uF CAP0805 No Murata GRM21BR61E106KA73L

0.1uF CAP0603 No Murata GRM188R71E104KA01D

1uF CAP0603 No Murata GRM188R61C105KA93D

470pF CAP0603 No Kemet C0603C471K3RACTU

18pF CAP0603 No Murata GRM1885C1H180JA01D

0.022uF CAP0603 No Kemet C0603C223K5RACTU

GRN LED0603 No Wurth electronics 150 060 GS7 500 0

RED LED0603 No Wurth electronics 150 060 RS7 500 0

2A/0.05DCR RES0603 No Murata BLM18EG221SN1D

SKT_PWR_2R0mm_4A_THRU_RA th_conn_pwrjack_dc-210_rt No Cui Stack PJ-002AH

HDR_1x3 TH_CONN_1X3P No FCI 68000-103HLF

HDR_3x8 TH_CONN_3x8P No FCI 68000-108HLF

2x10 TH_CONN_2x10P No FCI 67997-220HLF

NDS355AN_NMOS sot23-NDS No Fairchild NDS355AN

0E RES0603 No Panasonic ERJ-3GEY0R00V

1K RES0603 No Panasonic ERJ-3GEYJ102V

3.30K RES0603 No Yageo America 9C06031A3301FKHFT

470E RES0603 No BOURNS CR0603-FX-4700ELF

33E RES0603 No BOURNS CR0603-FX-33R0ELF

4.75K RES0603 No Panasonic ERJ-3EKF4751V

10.0K RES0603 No Panasonic ERJ-3EKF1002V

100 RES0603 No Panasonic ERJ-3EKF1000V

2.2K RES0603 No Panasonic ERJ-3GEYJ222V

12.1K RES0603 No Rohm MCR01MZPF1202

49.9 RES0603 No Yageo America 9C06031A49R9FKHFT

0E RES0402 No Panasonic ERJ-2GE0R00X

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Page 35

DS50002332A-page 35 Preliminary 2014 Microchip Technology Inc.

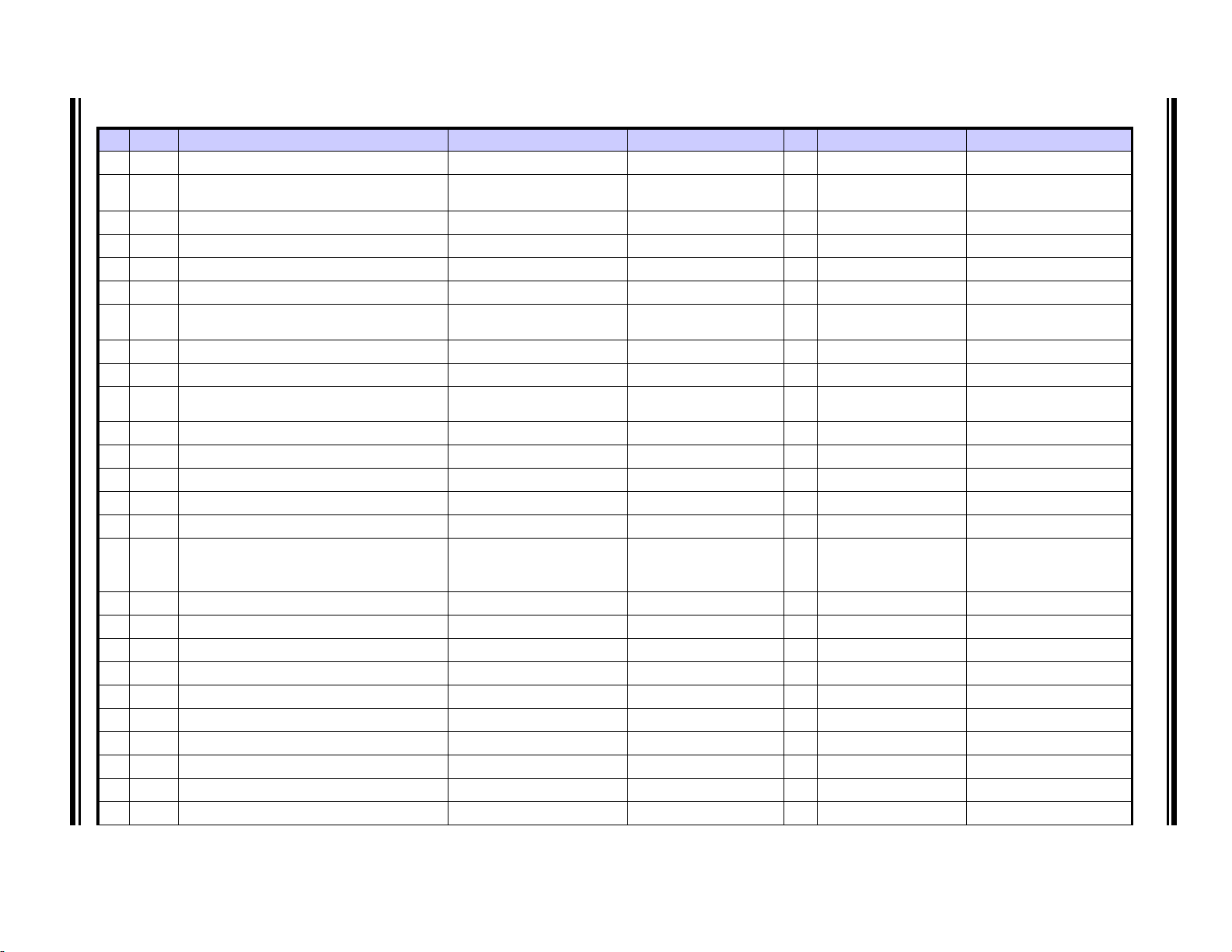

27 2

28 2

29 25

30 1

31 20

32 1

33 2

34 1

35 2

36 1

37 1

38 2

39 32

40 2

41 1

42 1

43 1

44 1

45 1

46 2

47 1

R24,R38

R67,R68

R76,R79,R80,R89,R98,R99,R100,R101,R102,R103,R10

4,R105,R106,R107,R108,R109,R110,R111,R112,R113,

R132,R133,R134,R135,R136

R131

R81,R82,R83,R84,R85,R86,R87,R88,R90,R91,

R92,R93,R94,R95,R96,R97,R63,R64,R65,R66

SW1

SW2,SW6

SW3

SW4,SW5

TP1

TP2

TP3,TP4

TP5,TP6,TP7,TP8,TP9,TP10,TP11,TP12,TP13,TP14,TP1

5,TP16,TP17,TP18,TP19,TP20,TP21,TP22,

TP23,TP24,TP25,TP26,TP27,TP28,TP29,TP30,

T1,T2

U1

U2

U3

U4

U5

U6,U7

Y1

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

0E RES1210 No Vishay CRCW12100000Z0EA

2K RES0603 No Panasonic ERJ-3GEYJ202V

10K RES0603 No Panasonic ERJ-3GEYJ103V

100K RES0603 No Panasonic ERJ-3EKF1003V

4.7K RES0603 No Panasonic ERJ-3EKF4701V

SW-SPDT-SLIDE sw_ck_1101m2s3cqe2 No C&K 1101M2S3CQE2

sw_pb_2P sw_pb_2P No Panasonic EVQ-PJU04K

SW DIP-4/SM TH_SW_DIP4 No Wurth electronics 418117270904

SW DIP-8 SW_DIP_SMT_8P-ade08s04 No TE 1-1825058-9/ade08s04

RED TH_TP_60D40 No Keystone 5000

ORANGE TH_TP_60D40 No Keystone 5003

BLACK TH_TP_60D40 No Keystone 5001

WHITE TH_TP No FCI 68000-101HLF

Pulse - J0011D01BNL th_conn_pulse_rj45_j0026 No Pulse Electronics J0011D01BNL

3_Amp TH_DC-DC_VERT_5PIN_P67 No Murata OKR-T/3-W12-C

TPS3125 SOT23_5 No TI TPS3125L30DBVR

74LVC1G14 SOT23_5 No TI SN74L VCIG14DBVR

LAN9252 IC_QFN64 No Microchip LAN9252

24FC512 IC_DIP8_300 No Microchip 24FC512-I/P

74LC245A/SO IC_SO20-MO-153 No TI SN74LVC245APWR

25.000MHz XTAL_HCM49 No Cardinal Components Inc. CSM1Z-A5B2C5-40-25.0D18-F

Page 36

DS50002332A-page 36 Preliminary 2014 Microchip Technology Inc.

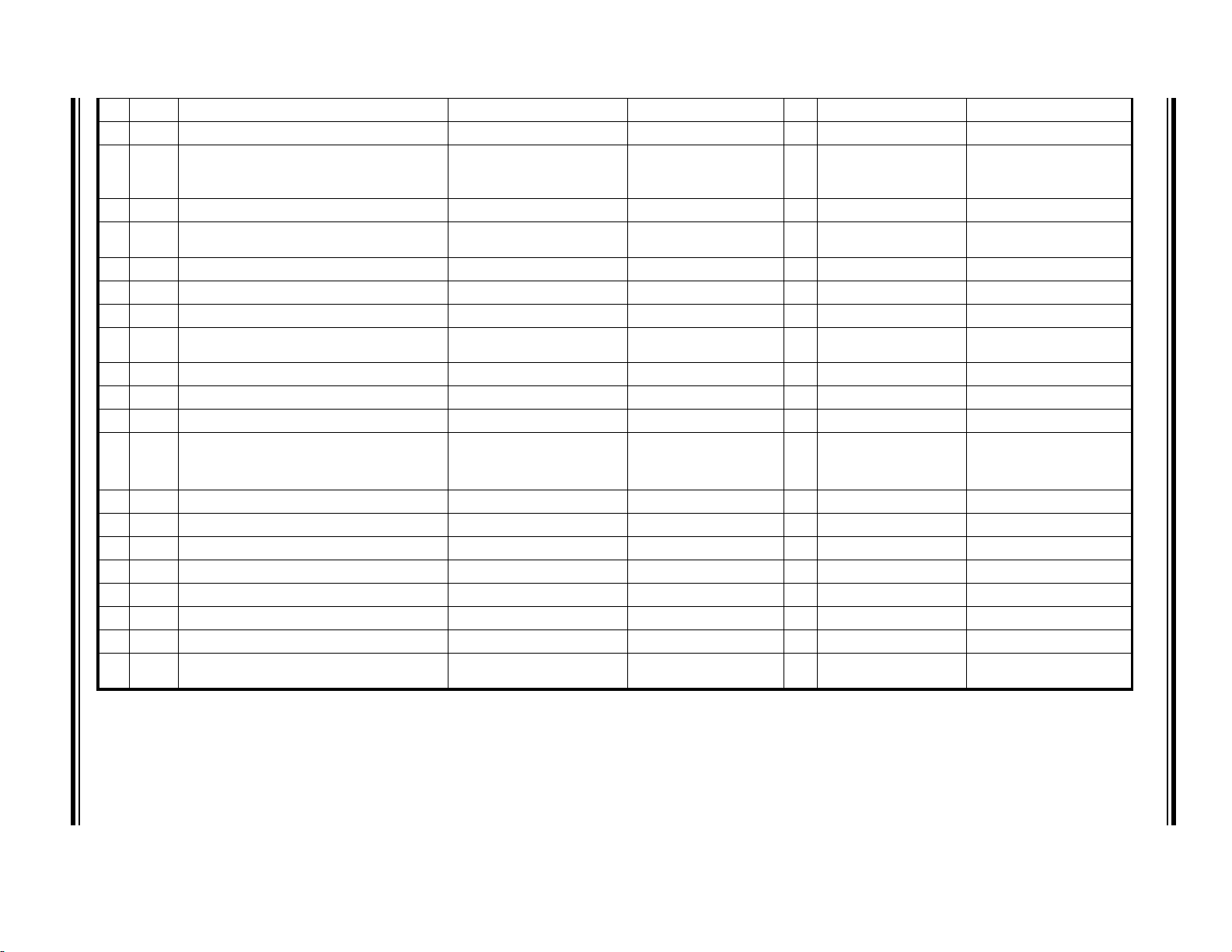

Do NOT Populate components:

Item Quantity Reference Part PCB Footprint DNP Vender Vender Part NO

1 1 C1 4.7uF CAP0603 DNP Murata GRM188R60J475KE19D

2 4 C7,C9,C12,C23 1.0uF CAP0603 DNP Murata GRM188R61C105KA93D

3 8 C28,C29,C30,C31,C33,C34,C35,C36 10pF CAP0402 DNP Murata GRM1885C1H100JA01D

414

5 6 C46,C48,C50,C52,C54,C56 10uF CAP_B_3528 DNP Kemet B45190E3106K209

6 2 J2,J3 FTLF1217P2 CONN_FX_SFP_FTLF1217P2 DNP Finisar 775-1011-ND

7 4 L1,L2,L3,L4 1uH L0805 DNP

8 8 R16,R18,R20,R22,R30,R32,R34,R36 0 RES0402 DNP

9 4 R39,R40,R43,R44 82 RES0603 DNP Panasonic ERJ-3EKF1300V

10 4 R41,R42,R45,R46 49.9 RES0603 DNP Yageo America 9C06031A49R9FKHFT

11 2 R47,R48 100 RES0603 DNP Panasonic ERJ-3EKF1000V

12 4 R49,R50,R51,R52 130 RES0603 DNP Panasonic ERJ-3EKF1300V

13 8 R53,R54,R55,R56,R57,R58,R59,R60 4.7K RES0603 DNP Panasonic ERJ-3EKF4701V

14 3 R75,R77,R78 10K RES0603 DNP Panasonic ERJ-3GEYJ103V

15 1 TP71 WHITE TH_TP_60D40 DNP Keystone 5002

16 1 TP72 SMT tp-smd40 DNP NA NA

C38,C39,C40,C41,C42,C43,C44,C45,C47,C49,

C51,C53,C55,C57

0.1uF CAP0603 DNP Murata GRM188R71E104KA01D

EVB-LAN9252-DIG-IO EtherCAT® DIG I/O User’s Guide

Page 37

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Canada - Toronto

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2943-5100

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-8792-8115

Fax: 86-571-8792-8116

China - Hong Kong SAR

Tel: 852-2943-5100

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8864-2200

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-3019-1500

Japan - Osaka

Tel: 81-6-6152-7160

Fax: 81-6-6152-9310

Japan - Tokyo

Tel: 81-3-6880- 3770

Fax: 81-3-6880-3771

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Taiwan - Taipei

Tel: 886-2-2508-8600

Fax: 886-2-2508-0102