Page 1

dsPICDEM™ 2

Development Board

User’s Guide

© 2005 Microchip Technology Inc. DS51558A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of Microchip’s products as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor,

MPASM, MPLIB, MPLINK, MPSIM, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, rfLAB, rfPICDEM, Select Mode,

Smart Serial, SmartTel, Total Endurance and WiperLock are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2005, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEEL

®

OQ

code hopping

DS51558A-page ii © 2005 Microchip Technology Inc.

Page 3

dsPICDEM™ 2

DEVELOPMENT BOARD

USER’S GUIDE

Tabl e of Conten ts

Preface ........................................................................................................................... 1

Chapter 1. Introduction

1.1 Introduction ..................................................................................................... 7

1.2 Highlights ........................................................................................................ 7

1.3 dsPICDEM™ 2 Development Board .............................................................. 7

1.4 dsPICDEM™ 2 Development Board Resources ............................................ 8

1.5 Sample Application Projects ......................................................................... 12

1.6 Host System Environment ............................................................................ 12

Chapter 2. Getting Started

2.1 Introduction ................................................................................................... 13

2.2 Highlights ...................................................................................................... 13

2.3 Getting Started ............................................................................................. 13

2.4 Out-of-the-Box Demo ................................................................................... 14

2.5 Device Programming Process ...................................................................... 17

2.6 In-Circuit Debugging Process ....................................................................... 19

2.7 Summary ...................................................................................................... 20

Chapter 3. Using the dsPIC30F2010

3.1 Introduction ................................................................................................... 21

3.2 Highlights ...................................................................................................... 21

3.3 Board Setup for the dsPIC30F2010 Sample Application ............................. 21

3.4 Device Programming .................................................................................... 23

3.5 Observing the Sample Application ............................................................... 24

3.6 In-Circuit Debugging ..................................................................................... 25

3.7 Summary ...................................................................................................... 26

Chapter 4. Using the dsPIC30F2011

4.1 Introduction ................................................................................................... 27

4.2 Highlights ...................................................................................................... 27

4.3 Board Setup for the dsPIC30F2011 Sample Application ............................. 27

4.4 Device Programming .................................................................................... 29

4.5 Observing the Sample Application ............................................................... 30

4.6 In-Circuit debugging ..................................................................................... 31

4.7 Summary ...................................................................................................... 32

Chapter 5. Using the dsPIC30F2012

5.1 Introduction ................................................................................................... 33

5.2 Highlights ...................................................................................................... 33

5.3 Board Setup for the dsPIC30F2012 Sample Application ............................. 33

5.4 Device Programming .................................................................................... 35

© 2005 Microchip Technology Inc. DS51558A-page i

Page 4

dsPICDEM 2 Development Board User’s Guide

5.5 Observing the Sample Application ............................................................... 36

5.6 In-Circuit Debugging ..................................................................................... 37

5.7 Summary ...................................................................................................... 38

Chapter 6. Using the dsPIC30F3010

6.1 Introduction ................................................................................................... 39

6.2 Highlights ...................................................................................................... 39

6.3 Board Setup for the dsPIC30F3010 Sample Application ............................. 39

6.4 Device Programming .................................................................................... 41

6.5 Observing the Sample Application ............................................................... 42

6.6 In-Circuit Debugging ..................................................................................... 43

6.7 Summary ...................................................................................................... 44

Chapter 7. Using the dsPIC30F3011

7.1 Introduction ................................................................................................... 45

7.2 Highlights ...................................................................................................... 45

7.3 Board Setup for the dsPIC30F3011 Sample Application ............................. 45

7.4 Device Programming .................................................................................... 47

7.5 Observing the Sample Application ............................................................... 48

7.6 In-Circuit Debugging ..................................................................................... 49

7.7 Summary ...................................................................................................... 50

Chapter 8. Using the dsPIC30F3012

8.1 Introduction ................................................................................................... 51

8.2 Highlights ...................................................................................................... 51

8.3 Board Setup for the dsPIC30F3012 Sample Application ............................. 51

8.4 Device Programming .................................................................................... 53

8.5 Observing the Sample Application ............................................................... 54

8.6 In-Circuit Debugging ..................................................................................... 55

8.7 Summary ...................................................................................................... 56

Chapter 9. Using the dsPIC30F3013

9.1 Introduction ................................................................................................... 57

9.2 Highlights ...................................................................................................... 57

9.3 Board Setup for the dsPIC30F3013 Sample Application ............................. 57

9.4 Device Programming .................................................................................... 59

9.5 Observing the Sample Application ............................................................... 60

9.6 In-Circuit Debugging ..................................................................................... 61

9.7 Summary ...................................................................................................... 62

Chapter 10. Using the dsPIC30F3014

10.1 Introduction ................................................................................................. 63

10.2 Highlights .................................................................................................... 63

10.3 Board Setup for the dsPIC30F3014 Sample Application ........................... 63

10.4 Device Programming .................................................................................. 65

10.5 Observing the Sample Application ............................................................. 66

10.6 In-Circuit Debugging ................................................................................... 67

10.7 Summary .................................................................................................... 68

DS51558A-page ii © 2005 Microchip Technology Inc.

Page 5

Chapter 11. Using the dsPIC30F4011

11.1 Introduction ................................................................................................. 69

11.2 Highlights .................................................................................................... 69

11.3 Board Setup for the dsPIC30F4011 Sample Application ........................... 69

11.4 Device Programming .................................................................................. 71

11.5 Observing the Sample Application ............................................................. 72

11.6 In-Circuit Debugging ................................................................................... 73

11.7 Summary .................................................................................................... 74

Chapter 12. Using the dsPIC30F4012

12.1 Introduction ................................................................................................. 75

12.2 Highlights .................................................................................................... 75

12.3 Board Setup for the dsPIC30F4012 Sample Application ........................... 75

12.4 Device Programming .................................................................................. 77

12.5 Observing the Sample Application ............................................................. 78

12.6 In-Circuit Debugging ................................................................................... 79

12.7 Summary .................................................................................................... 80

Chapter 13. Using the dsPIC30F4013

13.1 Introduction ................................................................................................. 81

13.2 Highlights .................................................................................................... 81

13.3 Board Setup for the dsPIC30F4013 Sample Application ........................... 81

13.4 Device Programming .................................................................................. 83

13.5 Observing the Sample Application ............................................................. 84

13.6 In-Circuit Debugging ................................................................................... 85

13.7 Summary .................................................................................................... 86

Chapter 14. Hardware

14.1 Hardware Overview .................................................................................... 87

Appendix A. Hardware Drawings and Schematics

A.1 Introduction .................................................................................................. 95

Appendix B. Writing to LCD

B.1 Overview .................................................................................................... 103

B.2 LCD Hardware Setup ................................................................................. 103

B.3 LCD Software Specification ....................................................................... 103

B.4 LCD Firmware Programming: .................................................................... 104

Appendix C. Board Errata

C.1 H7 and H6 Labelling Error ......................................................................... 105

Index ........................................................................................................................... 107

Worldwide Sales and Service .................................................................................. 114

© 2005 Microchip Technology Inc. DS51558A-page iii

Page 6

dsPICDEM 2 Development Board User’s Guide

DS51558A-page iv © 2005 Microchip Technology Inc.

Page 7

dsPICDEM™ 2

DEVELOPMENT BOARD

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available, including errata

documents applicable to this product. Also, refer to the errata information in Appendix C.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

dsPICDEM 2 Development Board. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use dsPICDEM 2 Development Board as a development tool to emulate and debug firmware on a target board. The manual layout is as

follows:

• Chapter 1. Introduction – This chapter introduces the dsPICDEM 2

Development Board, provides a brief description of the hardware components on

the board and introduces the demonstration software provided with each of the

supported dsPIC30F devices.

• Chapter 2. Getting Started – This chapter describes the out-of-the-box operation

of the dsPICDEM 2 Development Board. It also provides a detailed descripton of

how to perform programming and in-circuit debugging operations.

• Chapter 3. Using the dsPIC30F2010 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F2010 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F2010 using the sample application.

© 2005 Microchip Technology Inc. DS51558A-page 1

Page 8

dsPICDEM 2 Development Board User’s Guide

• Chapter 4. Using the dsPIC30F2011 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F2011 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F2011using the sample application.

• Chapter 5. Using the dsPIC30F2012 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F2012 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F2012 using the sample application.

• Chapter 6. Using the dsPIC30F3010 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F3010 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F3010 using the sample application.

• Chapter 7. Using the dsPIC30F3011 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F3011 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F3011 using the sample application.

• Chapter 8. Using the dsPIC30F3012 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F3012 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F3012 using the sample application.

• Chapter 9. Using the dsPIC30F3013 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F3013 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F3013 using the sample application.

• Chapter 10. Using the dsPIC30F3014 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F3014 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F3014 using the sample application.

• Chapter 11. Using the dsPIC30F4011 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F4011 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F4011 using the sample application.

• Chapter 12. Using the dsPIC30F4012 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F4012 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F4012 using the sample application.

• Chapter 13. Using the dsPIC30F4013 – This chapter describes how to configure

the dsPICDEM 2 Development Board for use with the dsPIC30F4013 Digital

Signal Controller. It provides suggested procedures for device programming and

in-circuit debugging of the dsPIC30F4013 using the sample application.

• Chapter 14. Hardware – This chapter provides detailed information related to the

hardware components used on the dsPICDEM 2 Development Board.

• Appendix A. Hardware Drawings and Schematics – This appendix illustrates

the dsPICDEM 2 Development Board layout and includes complete schematic

diagrams.

• Appendix B. Writing to LCD – This appendix provides detailed instructions for

writing to the 2 x 16 character LCD.

• Appendix C. Board Errata – This appendix describes errata associated with

certain revisions of the dsPICDEM 2 Development Board.

• Index – This section provides cross-reference listing of terms, features and

sections of this document.

• Worldwide Sales and Service – A listing of Microchip sales and service locations

and telephone numbers worldwide.

DS51558A-page 2 © 2005 Microchip Technology Inc.

Page 9

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books

Initial caps A window the Output window

Quotes A field name in a window or

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

‘b

nnnn

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier font:

Plain Courier Sample source code #define START

Italic Courier A variable argument file.o, where file can be

0xnnnn A hexadecimal number where

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

Preface

MPLAB® IDE User’s Guide

Emphasized text ...is the

A dialog the Settings dialog

A menu selection select Enable Programmer

“Save project before build”

dialog

A menu path

A tab Click the Power tab

A binary number where n is a

digit

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

n is a hexadecimal digit

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

File>Save

‘b00100, ‘b10

any valid filename

0xFFFF, 0x007A

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

only

compiler...

© 2005 Microchip Technology Inc. DS51558A-page 3

Page 10

dsPICDEM 2 Development Board User’s Guide

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user's guide describes how to use dsPICDEM 2 Development Board. Other useful

documents are listed below. The following Microchip documents are available and recommended as supplemental reference resources.

dsPIC30F Family Reference Manual (DS70046)

Consult this document for detailed information on the dsPIC30F device operation. The

manual explains the operation of the dsPIC30F MCU family architecture and peripheral

modules but does not cover the specifics of each device. Refer to the appropriate

device data sheet, mentioned below, for device-specific information.

dsPIC30F Data Sheet, Motor Control and Power Conversion Family (DS70082)

Consult this document for information regarding the dsPIC30F Motor Control and

Power Conversion devices. Reference information found in this data sheet includes:

• Device memory map

• Device pinout and packaging details

• Device electrical specifications

• List of peripherals included on the device

dsPIC30F Data Sheet, General Purpose and Sensor Families (DS70083)

Consult this document for information regarding the dsPIC30F General Purpose and

Sensor devices. Reference information found in this data sheet includes:

• Device memory map

• Device pinout and packaging details

• Device electrical specifications

• List of peripherals included on the device

dsPIC30F Programmer’s Reference Manual (DS70030)

This manual is a software developer’s reference for the dsPIC30F 16-bit MCU family

of devices. This manual describes the instruction set in detail and also provides general

information to assist the user in developing software for the dsPIC30F MCU family.

dsPIC30F Family Overview, dsPIC

16-bit Digital Signal Controller (DS70043)

This document provides an overview of the features and functionality of the dsPIC DSC

product family. It helps determine how the dsPIC 16-bit Digital Signal Controller Family

fits a specific product application. For detailed information about any of the functionality,

refer to the

MPLAB

This document details Microchip Technology’s language tools for dsPIC DSC devices

based on GNU technology. The language tools discussed are:

• MPLAB ASM30 Assembler

• MPLAB LINK30 Linker

• MPLAB LIB30 Archiver/Librarian

• Other Utilities

dsPIC30F Family Reference Manual

®

ASM30, MPLAB LINK30 and Utilities User’s Guide (DS51317)

®

High Performance

(DS70046).

DS51558A-page 4 © 2005 Microchip Technology Inc.

Page 11

MPLAB® C30 C Compiler User’s Guide (DS51284)

The purpose of this document is to help you use Microchip’s MPLAB C30 C compiler

for dsPIC DSC devices to develop your application. MPLAB C30 is a GNU-based language tool, based on source code from the Free Software Foundation (FSF). For more

information about the FSF, see www.fsf.org.

Other GNU language tools available from Microchip are:

• MPLAB ASM30 Assembler

• MPLAB LINK30 Linker

• MPLAB LIB30 Librarian/Archiver

MPLAB

Consult this document for more information pertaining to the installation and features

of the MPLAB Integrated Development Environment (IDE) Software.

To obtain any of these documents, contact the nearest Microchip sales location

(see back page) or visit the Microchip web site at: www.microchip.com.

®

IDE Simulator, Editor User’s Guide (DS51025)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB C18 and MPLAB C30 C compilers; MPASM™

and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 object linkers;

and MPLIB™ and MPLAB LIB30 object librarians.

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB ICE 2000 and MPLAB ICE 4000.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2.

© 2005 Microchip Technology Inc. DS51558A-page 5

Page 12

dsPICDEM 2 Development Board User’s Guide

• MPLAB® IDE – The latest information on Microchip MPLAB IDE, the Windows®

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 and PRO MATE

Plus and PICkit

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

In addition, there is a Development Systems Information Line which lists the latest

versions of Microchip's development systems software products. This line also

provides information on how customers can receive currently available upgrade kits.

The Development Systems Information Line numbers are:

1-800-755-2345 – United States and most of Canada

1-480-792-7302 – Other International Locations

Customers may also exchange ideas with each other and with Microchip personnel by

logging on to http:\\forum.microchip.com.

®

1 development programmers.

®

II device programmers and the PICSTART®

DOCUMENT REVISION HISTORY

Revision A (June 2005)

• Initial Release of this Document.

DS51558A-page 6 © 2005 Microchip Technology Inc.

Page 13

1.1 INTRODUCTION

The dsPICDEM™ 2 Development Board is a development and evaluation tool that

helps you create embedded applications using dsPIC30F Digital Signal Controllers

(DSC) in 18-pin PDIP, 28-pin SPDIP and 40-pin PDIP packages. The dsPICDEM™ 2

Development Board provides both a hardware and software baseline capability to help

jump start your application.

Sockets are provided for 28 and 40-pin devices in the dsPIC30F Motor Control family

and 18, 28 and 40-pin devices in the dsPIC30F General Purpose and Sensor family.

For each device supported by the board, the product CD includes a sample application

program designed specifically for that device. Thus, regardless of the dsPIC30F device

you choose for your application, you also have sample code appropriate to that device.

1.2 HIGHLIGHTS

This chapter discusses:

• dsPICDEM™ 2 Development Board

• dsPICDEM™ 2 Development Board Resources

• Sample Application Projects

• Host System Environment

dsPICDEM™ 2

DEVELOPMENT BOARD

USER’S GUIDE

Chapter 1. Introduction

1.3 dsPICDEM™ 2 DEVELOPMENT BOARD

The dsPICDEM™ 2 Development Board (Figure 1-1) includes a dsPIC30F4011 Digital

Signal Processor in the 40-pin motor control socket, a power supply regulator, crystal

oscillators for each set of sockets, an ICD header for the MPLAB ICD 2 In-Circuit

Debugger and both UART and CAN ports for external communication. In addition, the

board is populated with prototyping hardware, including LED indicators, push-button

switches, a potentiometer, a temperature sensor and an LCD screen. All pins on all the

device sockets are accessible on prototyping areas. Also included is the dsPICDEM™

2 Development Kit CD, which contains software and this User’s Guide.

Key hardware features include:

• Multiple sockets for 18, 28 and 40-pin PDIP and SPDIP devices

• dsPIC30F4011 40-pin PDIP sample device installed on the board

• 5V regulator provides V

indicates when the power is on.

• Connector for MPLAB

Emulator

• RS-232 interface

• Controller Area Network (CAN) interface

• Temperature sensor and analog potentiometer to simulate A/D inputs

• Pushbutton switches and LED indicators to simulate digital input and output

• 2x16 ASCII Character LCD with SPI™ interface

• 2x20 prototyping header area for user hardware expansion (header not provided)

DD and AVDD from a 9V DC power supply. An LED

®

ICD 2 In-Circuit Debugger or MPLAB ICE 4000 In-Circuit

© 2005 Microchip Technology Inc. DS51558A-page 7

Page 14

dsPICDEM 2 Development Board User’s Guide

FIGURE 1-1: dsPICDEM™ 2 DEVELOPMENT BOARD

1.4 dsPICDEM™ 2 DEVELOPMENT BOARD RESOURCES

The dsPICDEM™ 2 Development Board accommodates the devices listed in

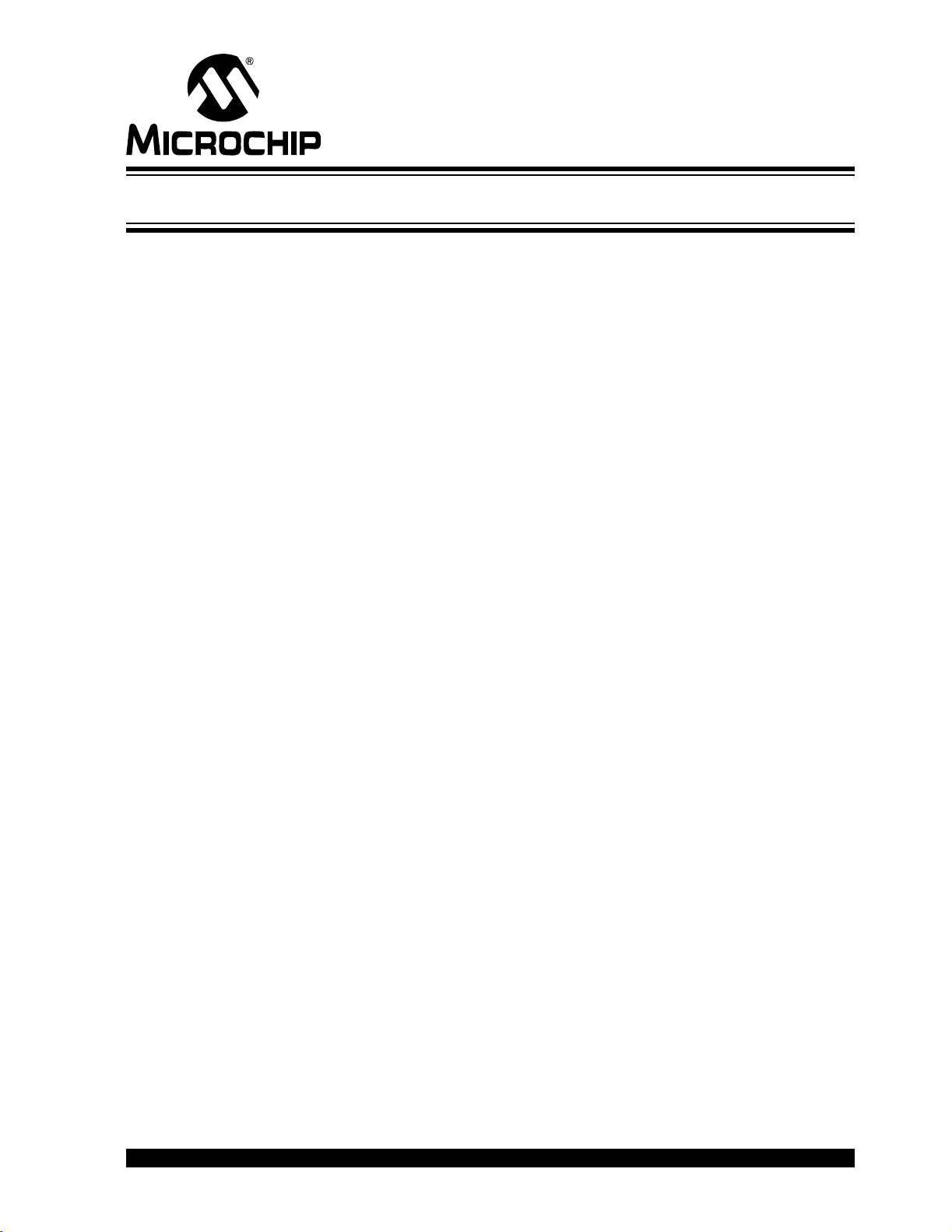

Ta bl e 1 - 1.

TABLE 1-1: DEVICES SUPPORTED BY dsPICDEM™ 2

dsPIC30F Device Pins Socket Resources

Motor Control Family

2010 28 U2B1 Six 10-bit A/D (500 ksps) channels,

UART, SPI, I2C™ and 20 I/O pins*

3010 28 U2B1 Six 10-bit A/D (500 ksps) channels,

UART, SPI, I

3011 40 U2A1 Nine 10-bit A/D (500 ksps) channels, two

UARTs, SPI, I

4011 40 U2A1 Nine 10-bit A/D (500 ksps) channels, two

UARTs, SPI, I

4012 28 U2B1 Six 10-bit A/D (500 ksps) channels,

UART, SPI, I

General Purpose and Sensor Family

2011 18 U1C1 Eight 12-bit A/D (100 ksps) channels,

UART, SPI, I

3012 18 U1C1 Eight 12-bit A/D (100 ksps) channels,

UART, SPI, I

2012 28 U1B1 Ten 12-bit A/D (100 ksps) channels,

UART, SPI, I

3013 28 U1B1 Ten 12-bit A/D (100 ksps) channels, two

UARTs, SPI, I

3014 40 U1A1 13 12-bit A/D (100 ksps) channels, two

UARTs, SPI, I

4013 40 U1A1 13 12-bit A/D (100 ksps) channels, two

UARTs, SPI, I

* Includes pins shared by the peripheral functions

2

C and 20 I/O pins*

2

C and 30 I/O pins*

2

C, CAN and 30 I/O pins*

2

C, CAN and 20 I/O pins*

2

C and 12 I/O pins*

2

C and 12 I/O pins*

2

C and 20 I/O pins*

2

C and 20 I/O pins*

2

C and 30 I/O pins*

2

C, CAN and 30 I/O pins*

DS51558A-page 8 © 2005 Microchip Technology Inc.

Page 15

Introduction

The dsPICDEM™ 2 must be configured for the device you have chosen for your application. Switches and headers are provided to connect hardware components on the

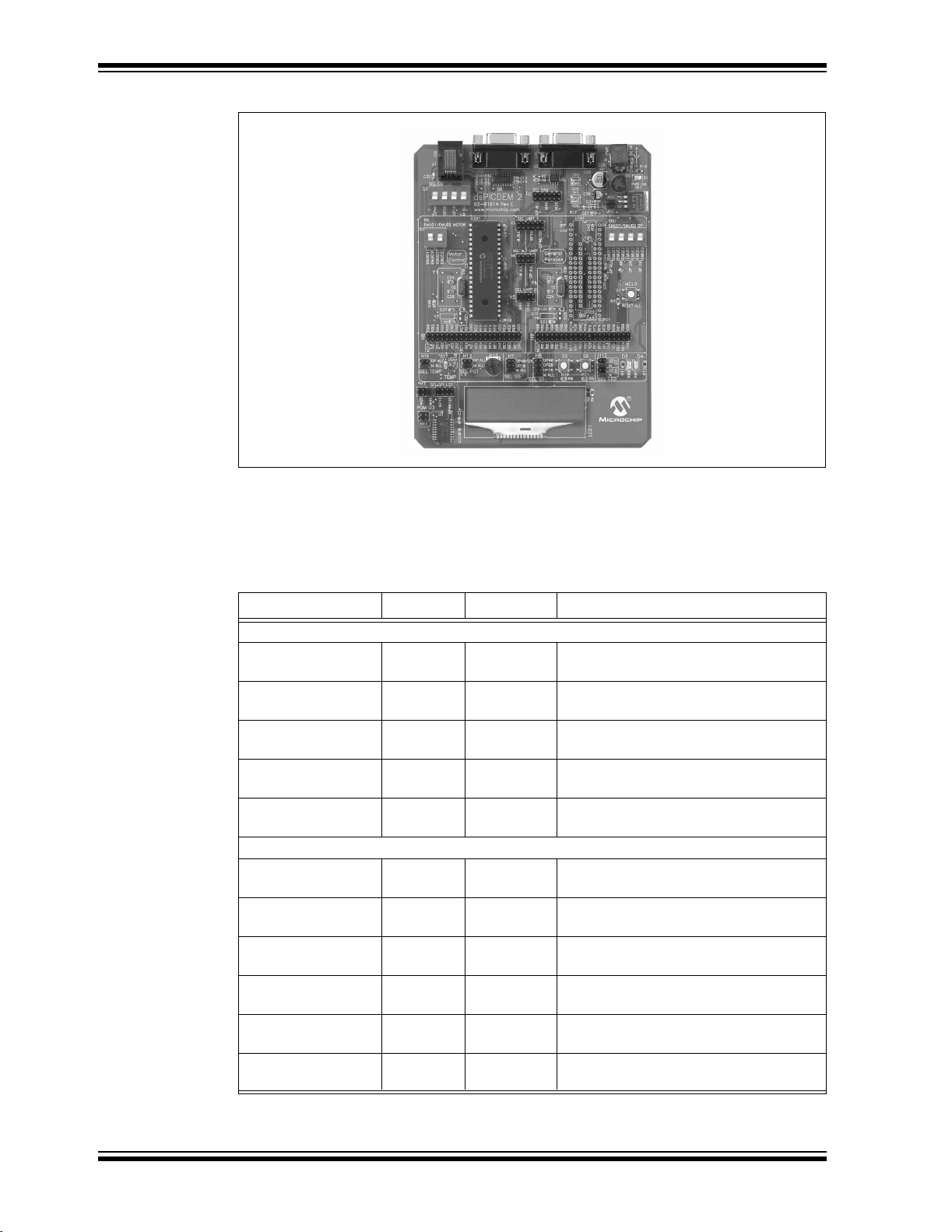

board with corresponding pins on the dsPIC30F device. Figure 1-2 shows the location

of hardware components and configuration headers that need to be set up depending

on the dsPIC30F device.

FIGURE 1-2: dsPICDEM™ 2 HARDWARE COMPONENTS

UART Connection (J2)

CAN Connection (J3)

MPLAB® Programmer

/Debugger Connection (J1)

Selector S2 (for programming

and debugging)

Selector S3 (for debugging

motor control devices)

Oscillator for motor control

device (Y2)

Concentric sockets for

motor control devices

(U2A1 & U2B1 under

dsPIC30F4011)

External connection prototyping

headers (H8 and H9)

Temperature Header (H10)

Temperature Sensor (U5)

LCD SPI Header (H1)

LCD Controller Programming

Header (H11)

SPI™ controller for LCD

CAN Header (H2)

Power Supply

Power Supply jumpers

(JP1 and JP2)

UART1 Header (H3)

Selector (S4) for debugging

general purpose devices

Alternate UART1 Header (H4)

Concentric sockets for

General Purpose devices

(U1A1, U1B1, U1C1)

Reset switch (S1)

Oscillator for General

Purpose device (Y5)

UART2 Header (H5)

Output LEDs (D3 and D4)

LED Header (H12)

Switches (S5 and S6)

Switches Header (H6 and H7)

Analog Pot (R15)

Pot Header (H13)

LCD (LCD1)

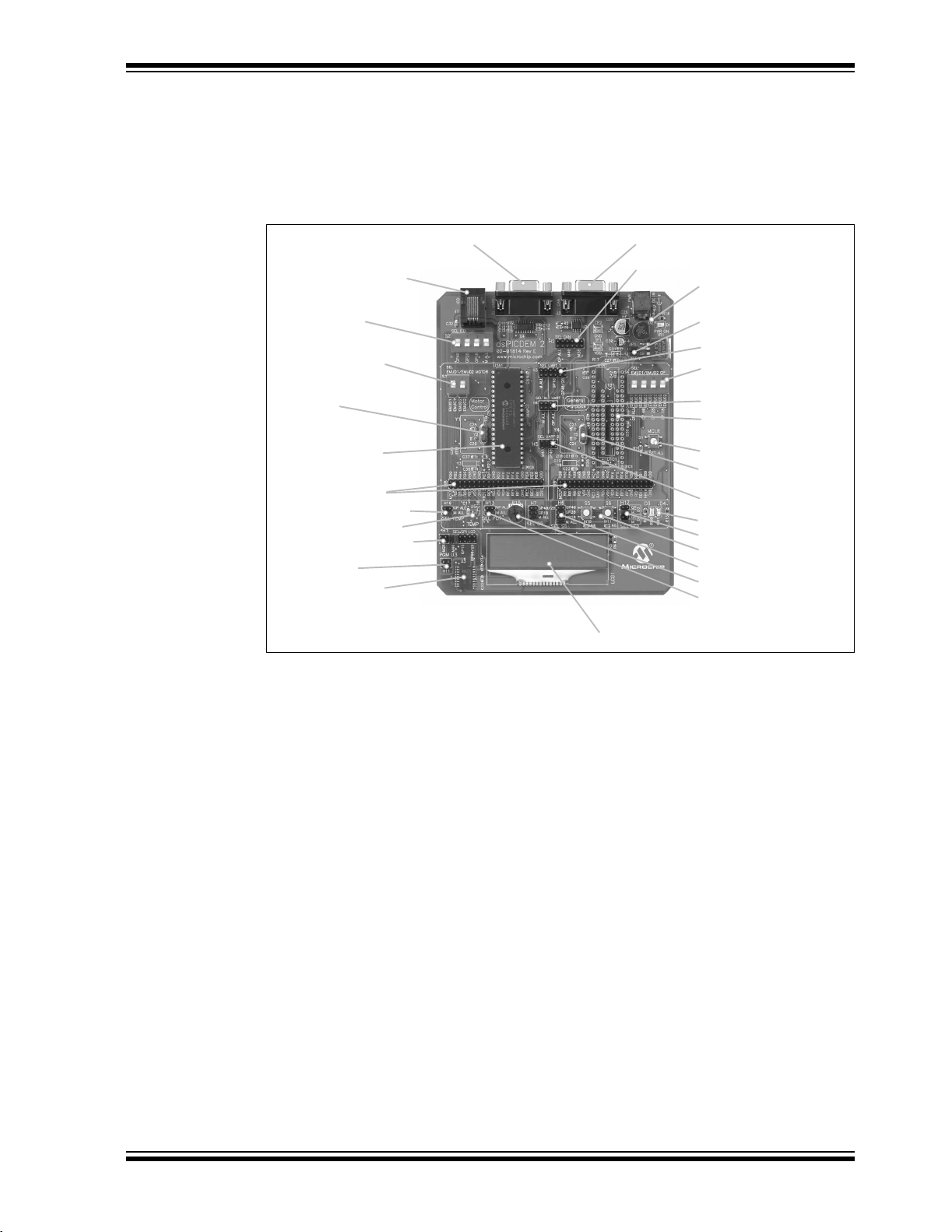

1.4.1 dsPIC30F Device Sockets

For convenience, the board provides separate sockets for Motor Control family devices

and general purpose/sensor family devices. As shown in Figure 1-3, the left side of the

board includes concentric sockets (U2B1 and U2A1) for 28 and 40-pin devices, respectively, in the Motor Control family. The right side includes concentric sockets (U1C1,

U1B1 and U1A1) for 18, 28 and 40-pin devices, respectively, in the General Purpose

and Sensor family.

© 2005 Microchip Technology Inc. DS51558A-page 9

Page 16

dsPICDEM 2 Development Board User’s Guide

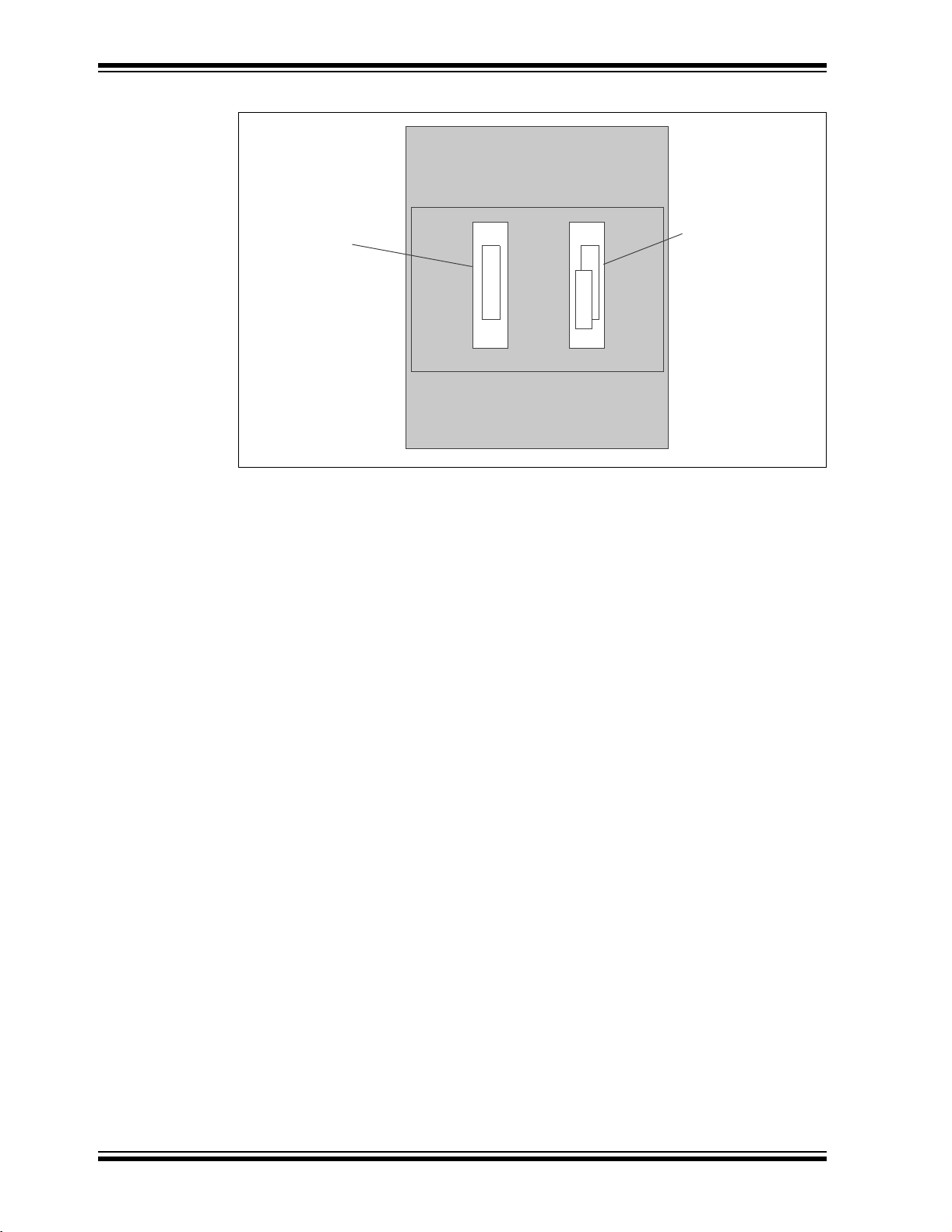

FIGURE 1-3: dsPICDEM™ 2 DEVELOPMENT BOARD LAYOUT

Sockets for Motor

Control Family

Devices:

dsPIC30F2010

dsPIC30F3010

dsPIC30F3011

dsPIC30F4011

dsPIC30F4012

U2A1

U2B1

U1A1

U1B1

U1C1

Sockets for General

Purpose and Sensor

Family Devices:

dsPIC30F2011

dsPIC30F3012

dsPIC30F2012

dsPIC30F3013

dsPIC30F3014

dsPIC30F4013

1.4.2 MPLAB ICD 2 Header

An RJ11 connector (J1) allows the MPLAB ICD 2 Debugger/Programmer to be used

with the dsPIC30F device you have plugged into the board. Switches S2, S3 and S4

physically connect this interface to the device sockets. Switch S2 connects the MPLAB

ICD 2 interface to the default programming and debugging pins on the dsPIC30F

devices (PGC/EMUC and PGD/EMUD). This switch should be turned on during

programming.

Switches S3 and S4 connect the MPLAB ICD 2 interface to alternative debugging pins

on the dsPIC30F devices (EMUC1/EMUD1 and EMUC2/EMUD2). These switches

should be turned off during device programming and turned on during debugging, if

needed.

1.4.3 UART Connection

A DB9 connector (J2) facilitates external RS-232RS-232 communication. Headers H3,

H4 and H5 connect this interface to the UART peripheral in the dsPIC DSC device.

Header H3 selects UART1. Header H4 selects alternate pins for UART1 in all

dsPIC30F devices supported by this board. Header H5 selects UART2 in dsPIC30F

devices that provide two UARTs (dsPIC30F3011, 3013, 3014, 4011 and 4013).

1.4.4 CAN Connection

A second DB9 connector (J3) is used for CAN communication. Header H2 selects the

dsPIC DSC device for the CAN interface. The CAN interface is supported by

dsPIC30F4011, 4012 and 4013 devices.

1.4.5 Power Supply

The dsPICDEM™ 2 power supply IS powered from an AC/DC wall adapter that

furnishes 9 VDC to the PWR jack (J4). The power supply is split at the regulator to

provide a separate, de-coupled analog supply voltage useful in designs taking

advantage of the dsPIC30F A/D converters. The power supply includes an on-board

+5V regulator for supplying V

Jumpers (JP1 and JP2) let you disconnect the power supply from the board if you want

to supply external DC power via terminals TP1 and TP2.

DS51558A-page 10 © 2005 Microchip Technology Inc.

DD and AVDD. An LED indicates when the power is on.

Page 17

Introduction

1.4.6 Reset Switch

This pushbutton switch (S1) is tied to the MCLR pin on the dsPIC30F device. It is used

to reset the device regardless of the socket used.

1.4.7 Device Clocking

Device clocking can be provided by on-chip RC oscillators, on-board crystal oscillators

or external sources. Crystal (Y1) provides a 7.3728 MHz oscillator for the motor control

device. Crystal (Y2) provides a 7.3728 MHz oscillator for the general purpose and

sensor devices.

1.4.8 Analog and Digital Inputs

The dsPICDEM™ 2 provides the following sensors that can be used to provide input

signals to your application program:

• Temperature sensor (U5)

• Potentiometer (R15)

• Pushbutton switches (S5 and S6)

1.4.8.1 TEMPERATURE SENSOR

The temperature sensor is a TC1047A that provides an analog signal to analog

channel AN3 in either the general purpose or motor control device via header H10.

1.4.8.2 ANALOG POTENTIOMETER

A 5-kOhm potentiometer provides an analog signal to analog channel AN2 in either the

general purpose or motor control device via header H13. The voltage source to the

potentiometer is provided by VR1, through a low-pass filter. VR1 is the main voltage

regulator for all components on the development board.

1.4.8.3 PUSHBUTTON SWITCHES

Two pushbutton switches, S5 and S6, are connected to external interrupt pins INT0 and

INT1, respectively, on the dsPIC30F device via headers H6 and H7, respectively.

1.4.9 Digital Outputs

The dsPICDEM™ 2 provides the following output devices that can be used to display

output information from your application program:

• LED Indicators (D3 and D4)

• LCD Display (LCD1/LCD2)

1.4.9.1 LED INDICATORS

LEDs D3 and D4 are connected to port pins RB0 and RB1, respectively on the installed

dsPIC DSC device via header H12. The LED anodes are tied to VDD through a 1.2K

resistor.

1.4.9.2 LCD DISPLAY

A 2 x 16 character dot matrix LCD display is provided on the development board. The

installed dsPIC30F device writes characters to the LCD via the clock (SCK1) and data

(SDO1) pins on the device’s SPI1 module.

1.4.10 External Connections

Prototyping areas H8 and H9 provide external connections from the motor control and

general purpose devices, respectively. These connections allow you to use hardware

and test equipment not provided on the dsPICDEM™ 2 board.

© 2005 Microchip Technology Inc. DS51558A-page 11

Page 18

dsPICDEM 2 Development Board User’s Guide

1.5 SAMPLE APPLICATION PROJECTS

The dsPICDEM™ 2 Development Kit CD contains sample projects for each of the

dsPIC DSC devices supported by the dsPICDEM™ 2 Development Board. These sample programs are intended to jump start your application development by showing you

how to implement and configure dsPIC30F peripherals such as A/D converters, external interrupts, timers, SPI, and UART interfaces and I/O ports. Complete C source code

is provided that shows how to how to write interrupt service routines and how to use

device control register structures for configuring peripherals and I/O ports. These sample C files are bundled into MPLAB IDE projects that let you begin work out of the box.

The sample application projects and source code were created with:

• MPLAB IDE v7.11

• MPLAB C30 v1.32

The sample application projects for each dsPIC30F device are located in the folder:

path/dsPICDEM 2 Development Kit/Example Software/

1.6 HOST SYSTEM ENVIRONMENT

A host system is used to support the MPLAB IDE and ICD 2 development tools (as well

as HyperTerminal® communication). Minimum requirements are:

• PC-compatible system with an Intel Pentium class or higher processor, or

equivalent

• A minimum of 16 MB RAM

• A minimum of 40 MB available hard drive space

• CD ROM drive

• Microsoft Windows

®

98, Windows NT®4.0, Windows 2000 or Windows XP

DS51558A-page 12 © 2005 Microchip Technology Inc.

Page 19

2.1 INTRODUCTION

The dsPICDEM™ 2 Development Board provides both a hardware and software baseline capability to help jump start your application. The board is pre-configured for and

populated with a dsPIC30F4011 Digital Signal Controller (DSC). The dsPIC30F4011 is

preprogrammed with a sample application program ready to run out of the box.

This chapter describes how to run the application and evaluate the program to take

advantage of the sample software.

2.2 HIGHLIGHTS

Items discussed in this chapter include:

• Getting Started

• Out-of-the-Box Demo

• Device Programming Process

• In-Circuit Debugging Process

• Summary

dsPICDEM™ 2

DEVELOPMENT BOARD

USER’S GUIDE

Chapter 2. Getting Started

2.3 GETTING STARTED

The dsPICDEM 2 sample application program demonstrates key functionality of the

dsPIC30F devices. This sample application program processes analog data from a

temperature sensor and potentiometer provided on the board. It also processes

interrupts generated from pushbutton switches on the board. Based on the input data,

the program creates output in the form of LED indicators, which blink in response to the

pushbutton switches, and an LCD screen, which displays the temperature and

potentiometer values. The program also uses the dsPIC30F’s UART module to mirror

LCD information (via RS-232 connection) to a remote terminal.

The sample application is written in C language and tailored specifically for each

dsPIC30F device supported by the dsPICDEM™ 2 Development Board. Figure 2-1

outlines helpful processes to get you started using the dsPICDEM 2 board.

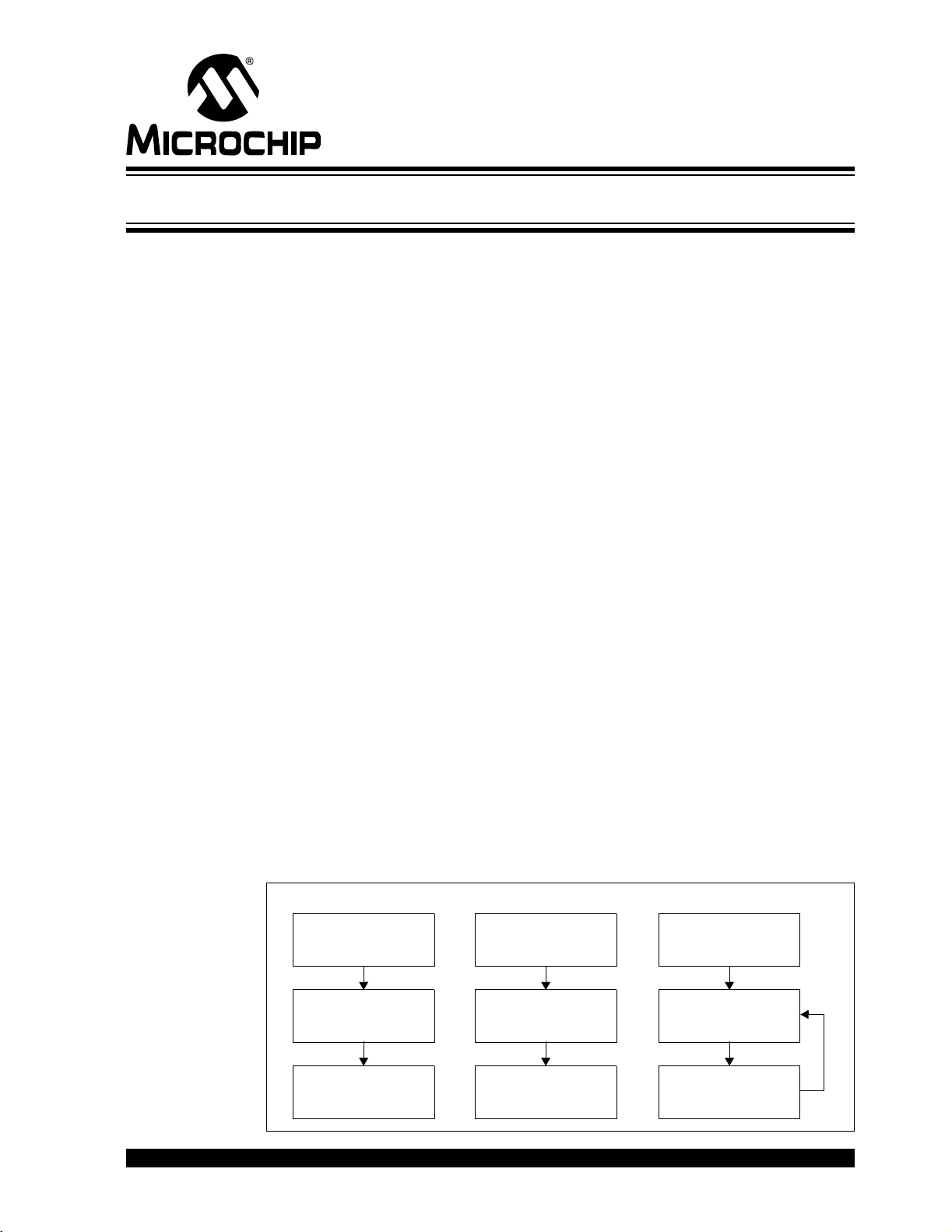

FIGURE 2-1: GETTING STARTED PROCESSES

Out-of-the-Box Demo Device Programming In-Circuit Debugging

Connect your PC to the

dsPICDEM™ 2 board

(see Figure 2-2)

Launch HyperTerminal

(see Connect PC and Start

HyperTerminal Session)

Open the MPLAB® IDE

workspace for selected

dsPIC30F device (see

Setting up MPLAB IDE)

®

Build project and program

the dsPIC30F device

(see Build the Project)

Select MPLAB ICD 2 as

Debugger, build project and

program device

Set breakpoint and

examine application

program code

Apply power to board and

run application

(see Observe Sample

Application)

© 2005 Microchip Technology Inc. DS51558A-page 13

Release device from reset

& observe application (see

Run the Application)

Evaluate program for

applicability to your need

Page 20

dsPICDEM 2 Development Board User’s Guide

Out-of-the-box, you can power up the dsPICDEM™ 2 Development Board and run the

sample application on the dsPIC30F4011 device. The objective of this process is to

acquaint you with the board and demonstrate how the dsPIC30F device interacts with

the hardware components used for the demo (see Section 2.4 “Out-of-the-Box

Demo”).

Eventually, as you develop your own application, you will need to program and debug

the dsPIC30F device. The second phase of the getting-started process is programming

the device for stand-alone operation. For this process, you attach the MPLAB ICD 2

In-Circuit Debugger to the dsPICDEM 2 board, designate it as a programmer in MPLAB

IDE, build your program in MPLAB IDE and then program the device with MPLAB ICD

2. The procedures for this process are outline in Section 2.5 “Device Programming

Process”, using the dsPIC30F4011 device as an example.

To examine program operation on a step-by-step basis, you need to set up MPLAB ICD

2 as a debugger. For this process you attach the MPLAB ICD 2 In-Circuit Debugger to

the dsPICDEM 2 board, designate it as a debugger in MPLAB IDE, build your program

in MPLAB IDE and then program the device for debug mode with MPLAB ICD 2. The

procedures for this process are outline in Section 2.6 “In-Circuit Debugging

Process”, using the dsPIC30F4011 device as an example.

2.4 OUT-OF-THE-BOX DEMO

As the first phase of your getting-started process, you only need to connect your PC to

the dsPICDEM™ 2 Development Board, apply power to the board and observe the

sample application on the board and on HyperTerminal

®

.

2.4.1 dsPICDEM 2 Configuration

Out-of-the-box, the dsPICDEM™ 2 Development Board is configured to operate with

the dsPIC304011 device. When you use a different type of supported device you need

to reconfigure the board for that device. In general, you follow this process to reconfigure the dsPICDEM™ 2 Development Board. For the out-of-the-box configuration, you

simply can verify these settings:

1. Select a supported dsPIC30F device and plug it into the appropriate socket (not

necessary out of the box).

2. Note the hardware configuration for the dsPIC30F4011device:

This functionality: Is set up by this hardware component:

Program/Debug device Switch S2 switched OFF

Alternate Debugging Switch S3 or S4 – all switches OFF

Temperature (A/D) H10 set to M ALL

Potentiometer (A/D) H13 set to M ALL

CAN H2 open

UART1 H3 open

Alternate UART1 H4 set to M ALL

UART2 H5 open

LCD (SPI) H1 set to M 40

SPI™ Controller ProgrammingH11 open

Switch S5 (INT0) H6 set to M ALL

Switch S6 (INT1) H7 set to M ALL

External connections H8 or H9 open

LEDs D3 and D4 (I/O) H12 set to M

Power Supply Jumpers JP1 and JP2

Note: Chapters 3-13 provide specific set-up instructions for each type of

dsPIC30F device supported by the dsPICDEM™ 2 Development Board.

DS51558A-page 14 © 2005 Microchip Technology Inc.

Page 21

Getting Started

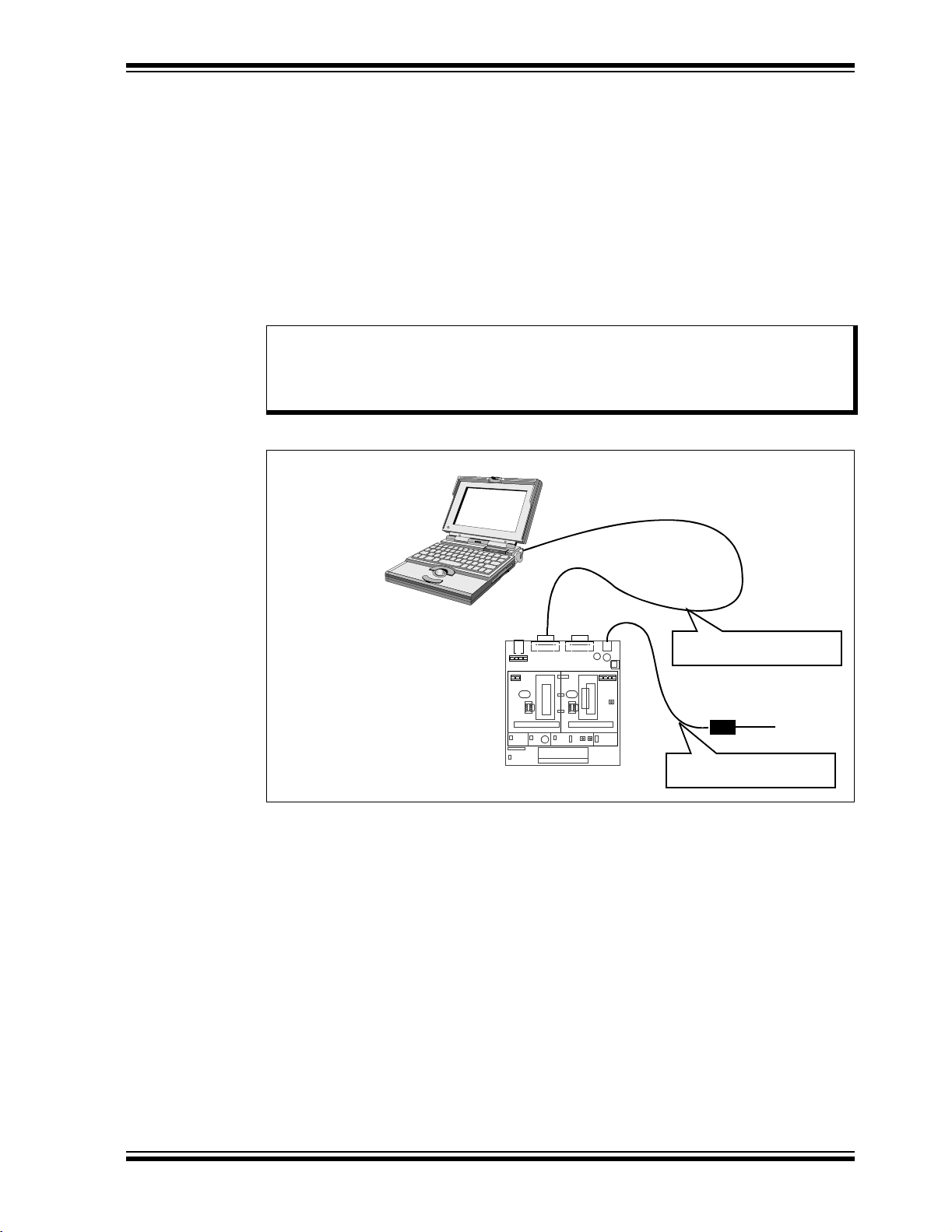

2.4.2 Connect PC and Start HyperTerminal Session

Follow the information in Figure 2-2 to set up your PC to operate with the dsPICDEM™

2 Development Board.

1. Use an RS-232 cable to connect the serial port on your PC to the UART connector (J2) on the board.

2. On your PC, start a HyperTerminal session and set it up with these port settings:

9600 baud

8 data bits

No parity

1 stop bit

No flow control

Note: For convenience, each of the sample program folders contains a utility that

automatically launches HyperTerminal set up to run with the demo program. Double clicking the file (Hyperterminal_RS232_dsPICDEM2.ht)

starts the session.

FIGURE 2-2: SETUP DIAGRAM

PC running HyperTerminal

®

dsPICDEM™ 2 Development Board

running sample application

J1 J2

UART

J2

1234

GP 40

GP 28

GP 18

M ALL

12

Motor

Control

H8 H9

CAN

J3

U2A1 U1A1

U2B1

General

Purpose

J4

Connect RS-232 cable to

PC

1234

U1B1

U1C1

9 VDC Power Cable

115 VAC

Apply power to the board

© 2005 Microchip Technology Inc. DS51558A-page 15

Page 22

dsPICDEM 2 Development Board User’s Guide

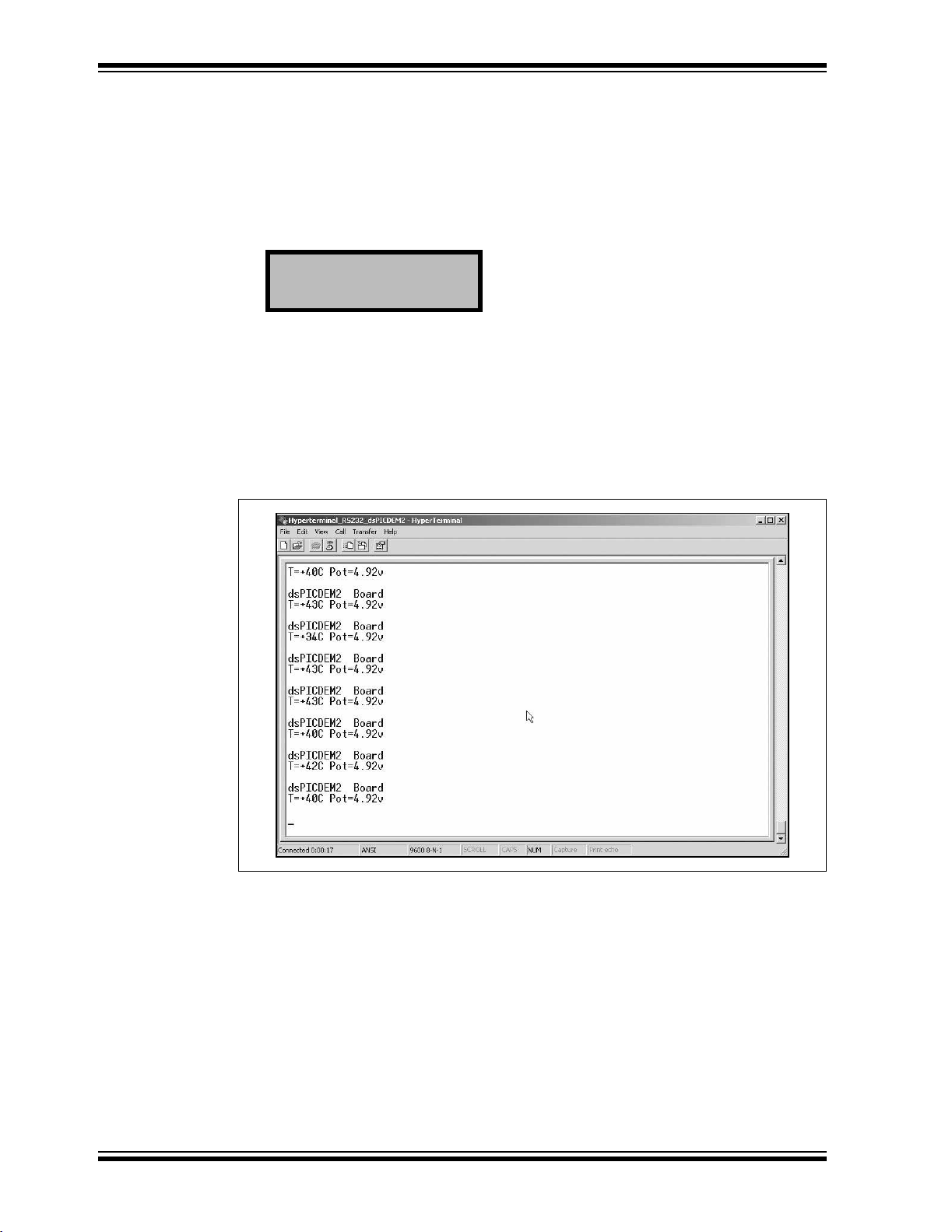

2.4.3 Observe Sample Application

To run and observe the sample application follow these steps:

1. Plug the 9 VDC cable into the DC IN connector (J4). The PWR ON indicator

should illuminate.

2. Press the RESET ALL pushbutton (S1). The LCD displays the current tempera-

ture and voltage values, which represent the A/D conversions from the temperature sensor and potentiometer, respectively.

dsPICDEM™ 2 Board

T=+18C Pot=3.42v

The LED indicators (D3 and D4) should initially be off and then start to blink.

3. Touch the temperature sensor for a moment and observe the temperature reading. It should increase as your finger warms the sensor.

4. Adjust the potentiometer clockwise and observe the voltage reading increase.

Then readjust it counterclockwise and observe the voltage reading decrease.

5. Observe the HyperTerminal screen and note that the information is updated to

match the LCD (see Figure 2-3).

FIGURE 2-3: TYPICAL HyperTerminal

6. Press pushbutton S5 (INT0) once and note that the rate at which D3 and D4 blink

changes. As you press S5 again, observe that the blink rate cycles from

extremely fast (both LEDs appear to be on) to fast (blinking rapidly) to moderate

(blinking slowly) to slow (appear to be switching on and off).

7. Press pushbutton S6 (INT1) once and note that D3 and D4 blink alternately. As

you press S6 again, note the LEDs cycle between blinking together and blinking

alternately.

®

SESSION

DS51558A-page 16 © 2005 Microchip Technology Inc.

Page 23

2.5 DEVICE PROGRAMMING PROCESS

The second phase of the getting-started process introduces the MPLAB Integrated

Development Environment (IDE) and MPLAB ICD 2 In-Circuit Debugger. The

emphasis in this phase is to program the sample application into a dsPIC30F4011

device. After observing the demonstration, this process gets you ready to examine

what you observed.

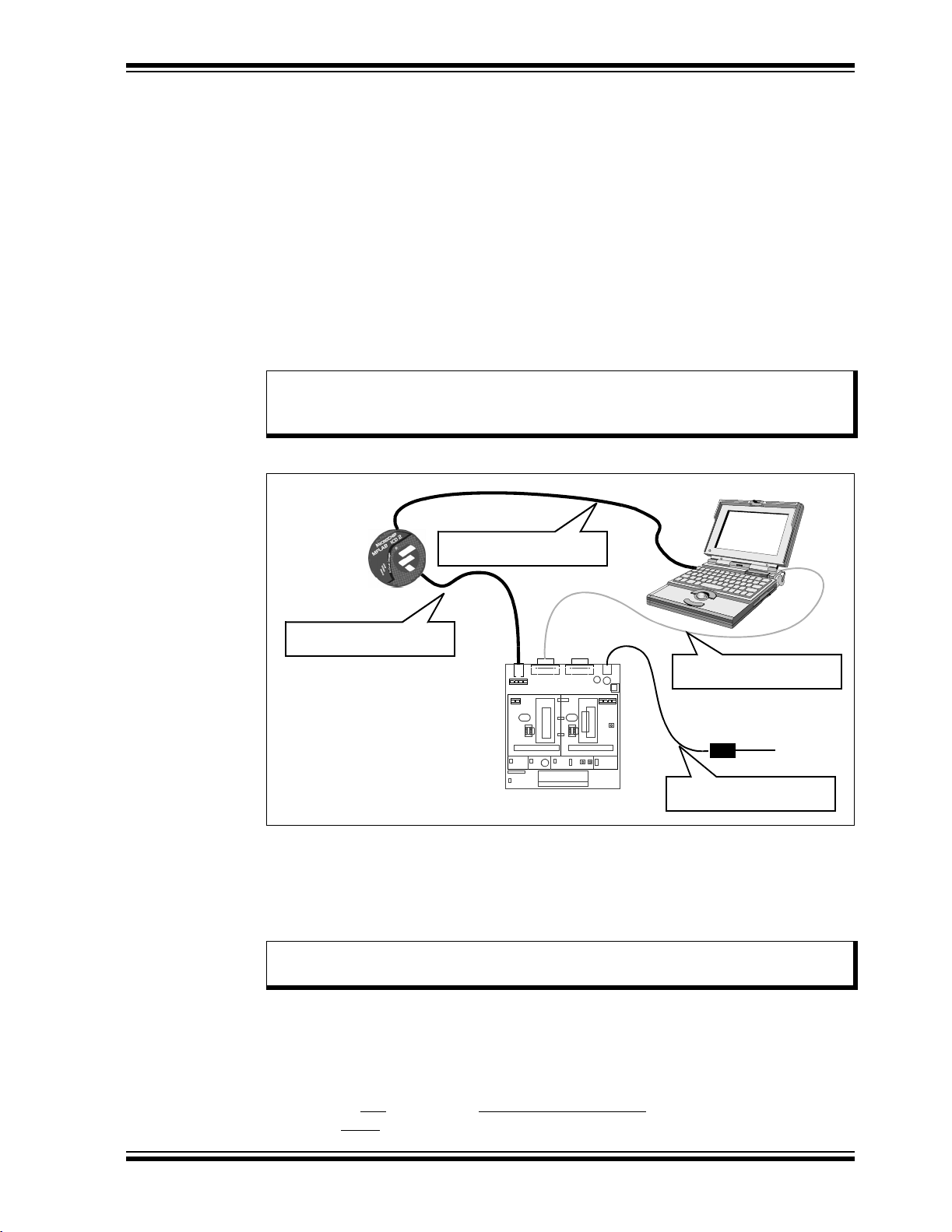

2.5.1 Connect MPLAB ICD 2

Follow the information in Figure 2-2 to set up the MPLAB ICD 2 for use as a

programmer.

1. With an RJ11 cable, connect the MPLAB ICD 2 to the ICD header (J1) on the

board.

2. Use a USB cable to connect the MPLAB ICD 2 to your PC.

Note: Make sure that the USB driver for the MPLAB ICD 2 has been installed on

your PC (see the

regarding the installation of MPLAB ICD 2).

MPLAB® ICD 2 User’s Guide

Getting Started

, DS51331, for more details

FIGURE 2-4: MPLAB

®

ICD 2 CONNECTION DIAGRAM

PC running MPLAB

®

IDE

MPLAB ICD 2

Connect USB cable to PC

Connect RJ-11 cable to ICD

dsPICDEM™ 2 Development Board

running dsPIC30F4011 sample

J1 J2

UART

J2

1234

GP 40

GP 28

GP 18

M ALL

12

Motor

Control

H8 H9

U2A1 U1A1

U2B1

J4

CAN

J3

1234

U1B1

General

Purpose

U1C1

Connect RS-232 cable to

PC

9 VDC Power Cable

115 VAC

application

Apply power to the board

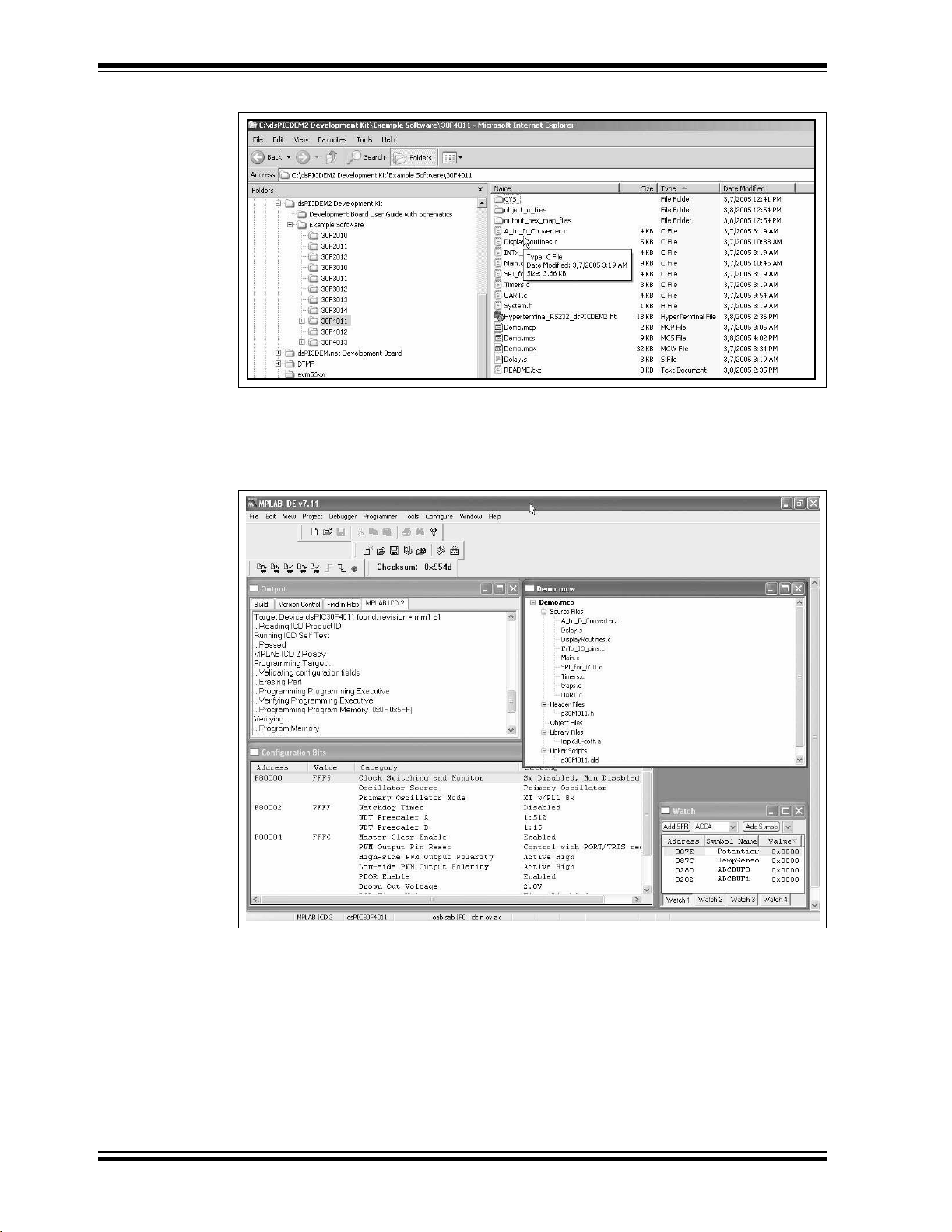

2.5.2 Setting up MPLAB IDE

The sample application program files on the dsPICDEM 2 CD contain a workspace and

project information needed by MPLAB IDE, MPLAB ICD 2 and MPLAB C30.

The first step is to open the sample application project in MPLAB IDE.

Note: These instructions presume the use of MPLAB IDE version 7.11 or newer

and MPLAB C30 version 1.32 or newer.

A project contains the files needed to build an application (source code, linker script

files, etc.) along with their associations to various build tools and build options. A workspace contains information on the selected device, debug tool and/or programmer,

open windows and their location, and other MPLAB IDE configuration settings.

1. Start MPLAB IDE.

2. From the

where

© 2005 Microchip Technology Inc. DS51558A-page 17

File

menu select

[path]

is the location of the sample application files.

Open Workspace>[path],

as shown in Figure 2-5,

Page 24

dsPICDEM 2 Development Board User’s Guide

FIGURE 2-5: OPEN WORKSPACE DIALOG

3. Select 30F4011/Demo.mcw. A project and workspace is created in MPLAB IDE.

As shown in Figure 2-6, Demo.mcw is the workspace file and Demo.mcp is the

project file.

FIGURE 2-6: PROJECT WORKSPACE IN MPLAB

®

IDE

DS51558A-page 18 © 2005 Microchip Technology Inc.

Page 25

2.5.3 Build the Project

Getting Started

1. Select

2. Observe the progress of the build in the Output window.

3. When BUILD SUCCEEDED displays you are ready to program the device.

4. Program the dsPIC30F4011device (

Project>Build All

.

2.5.4 Run the Application

1. From the

exectution

2. On the board, turn off the M ALL switch in S2.

3. As the code begins executing, note that the operation is identical to what you

observed out-of-the-box (see Section 2.4.3 “Observe Sample Application”)

Programmer

.

menu, select

2.6 IN-CIRCUIT DEBUGGING PROCESS

MPLAB IDE lets you run, halt and step the program. It lets you set breakpoints to

examine the code at specific locations or on occurrence of specific events. It also lets

you examine the contents of the RAM and registers. The MPLAB ICD 2 allows you to

run the application on the dsPICDEM 2 while monitoring it in MPLAB IDE on your PC.

The examination process requires that three changes be made to the sample

application setup.

• The dsPIC30F4011 device must be reprogrammed to recognize the MPLAB ICD

2 as a debugger rather than as a programmer.

• MPLAB IDE must be reconfigured to specify the pins on the dsPIC30F device to

be used for debugging.

• The dsPICDEM 2 board must be physically reconfigured to ensure that it connects

the MPLAB ICD 2 debugger to the pins on the dsPIC30F device that were

specified in MPLAB IDE.

Programmer>Program

Release from Reset to

)

enable code

Note: The primary programming and debugging functions (PGC/EMUC,

PGD/EMUD) on the dsPIC30F device are multiplexed with other peripheral

modules on the device used by the sample application. Thus it is necessary

to use an alternate pair of debugging pins (EMUC1/EMUD1,

EMUC2/EMUD2 or EMUC3/EMUD3) to examine the baseline code

provided in the sample application.

2.6.1 Select MPLAB ICD 2 as Debugger

To change MPLAB ICD 2 from a programmer to a debugger for a dsPIC30F4011

device:

1. From the

MPLAB ICD 2 as the debug tool in MPLAB IDE.

2. From the

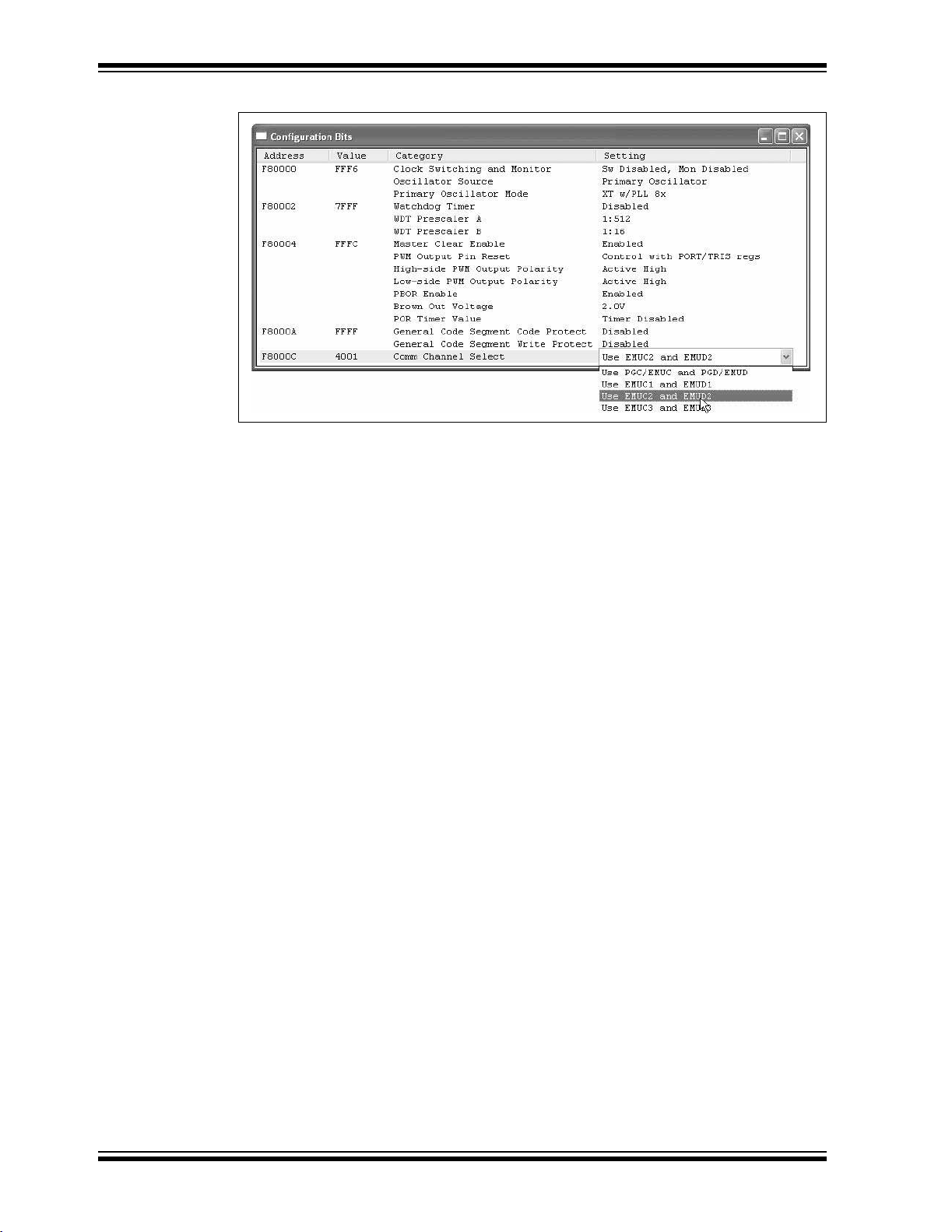

window displays the current configuration settings for the device, as shown in

Figure 2-7.

3. Change the “Comm Channel Select” parameter to Use EMUC2 and EMUD2.

4. On the dsPICDEM 2 board, change the setting on switch S3 to turn on EMUC2

and EMUD2.

5. Program the dsPIC30F device (

6. On the dsPICDEM 2 board, turn off M ALL on switch S2.

7. Reset the program and run it. From the

Reset

Debugger

Configure

. Then select

menu, click

menu, select

Select Tool>MPLAB ICD 2

Debugger>Program

Debugger>Run

Configuration Bits...

Debugger

.

menu, select

to designate the

The Configuration Bits

menu).

Reset>Processor

© 2005 Microchip Technology Inc. DS51558A-page 19

Page 26

dsPICDEM 2 Development Board User’s Guide

FIGURE 2-7: CONFIGURATION BITS WINDOW

2.6.2 Debugging the Code

The MPLAB ICD 2 In-Circuit Debugger can be used to run, halt and step the code. A

breakpoint can be set to halt the program after the code has executed the instruction

at the breakpoint. The contents of the RAM and registers can be viewed whenever the

processor has been halted.

The MPLAB ICD 2 In-Circuit Debugger uses the following function keys to access the

main debugging functions:

<F5> Halt

<F6> Reset

<F7> Single Step

<F9> Run

In addition, there are more functions available by right clicking on a line of source code.

These functions include the ability to set simple and advanced breakpoints.

2.7 SUMMARY

This chapter has provided a suggested process for using the dsPICDEM™ 2

Development Board to jump start your own application. If you have reviewed this

process, you should be able to:

• Configure the dsPICDEM™ 2 Development Board for the dsPIC30F device you

select for your application.

• Set up MPLAB IDE to use the MPLAB ICD 2 In-Circuit Debugger.

• Locate the sample application for your dsPIC30F device.

• Program the chip with the MPLAB ICD 2.

• View the code execution in program memory and source code.

• Reset, Run, Halt and Single-Step the code.

DS51558A-page 20 © 2005 Microchip Technology Inc.

Page 27

Chapter 3. Using the dsPIC30F2010

3.1 INTRODUCTION

This chapter assumes you have chosen the dsPIC30F2010 for your application. The

dsPICDEM 2 Development Board supports a dsPIC30F2010 device in a 28-pin SPDIP

package, as shown in Figure 3-1. This device provides six 10-bit A/D (500 ksps)

channels, a UART, an SPI module, an I

application program provides a software baseline for building your own embedded

solution.

FIGURE 3-1: 28-PIN SPDIP dsPIC30F2010

dsPICDEM™ 2

DEVELOPMENT BOARD

USER’S GUIDE

2

C™ module and 20 I/O pins. A sample

U2B1

EMUD3/AN0/VREF+/CN2/RB0

EMUC3/AN1/V

EMUD1/SOSCI/T2CK/U1ATX/CN1//RC13

EMUC1/SOSCO/T1CK/U1ARX/CN0/RC14

AN2/SS1/CN4/RB2

AN3/INDX/CN5/RB3

AN4/QEA/IC7/CN6/RB4

AN5/QEB/IC8/CN7/RB5

OSC2/CLKO/RC15

EMUD2/OC2/IC2/INT2/RD1

MCLR

REF-/CN3/RB1

OSC1/CLKI V

VDD

1

28

AV

DD

2

3

4

5

6

7

SS

8

9

10

11

12

13

14

AVSS

27

PWM1L/RE0

26

PWM1H/RE1

25

PWM2L/RE2

24

PWM2H/RE3

23

PWM3L/RE4

22

PWM3H/RE5V

21

DD

20

V

SS

19

dsPIC30F2010

PGC/EMUC/U1RX/SDI1/SDA/RF2

18

PGD/EMUD/U1TX/SDO1/SCL/RF3

17

FLTA/INT0/SCK1/OCFA/RE8

16

15

EMUC2/OC1/IC1/INT1/RD0

3.2 HIGHLIGHTS

This chapter discusses:

• Board Setup for the dsPIC30F2010 Sample Application

• Device Programming

• Observing the Sample Application

• In-Circuit Debugging

• Summary

3.3 BOARD SETUP FOR THE dsPIC30F2010 SAMPLE APPLICATION

The dsPICDEM 2 Development Board supports dsPIC30F devices that have multiple

peripheral devices multiplexed on some pins. Therefore, the jumper set up of various

headers depends on which of the dsPIC30F peripherals are used by the application.

This section demonstrates how the board is set up for the dsPIC30F2010 device to

support the dsPIC30F2010 example software in the dsPICDEM 2 Development Kit CD.

Follow these steps to configure the hardware on the dsPICDEM 2 Development Board

for the sample application.

1. Disconnect the power source.

2. Remove any dsPIC30Fxxxx device currently plugged into the dsPICDEM 2

Development Board.

© 2005 Microchip Technology Inc. DS51558A-page 21

Page 28

dsPICDEM 2 Development Board User’s Guide

3. Plug the dsPIC30F2010 into socket U2B1.

4. Configure the hardware components as shown in Table 3-1.

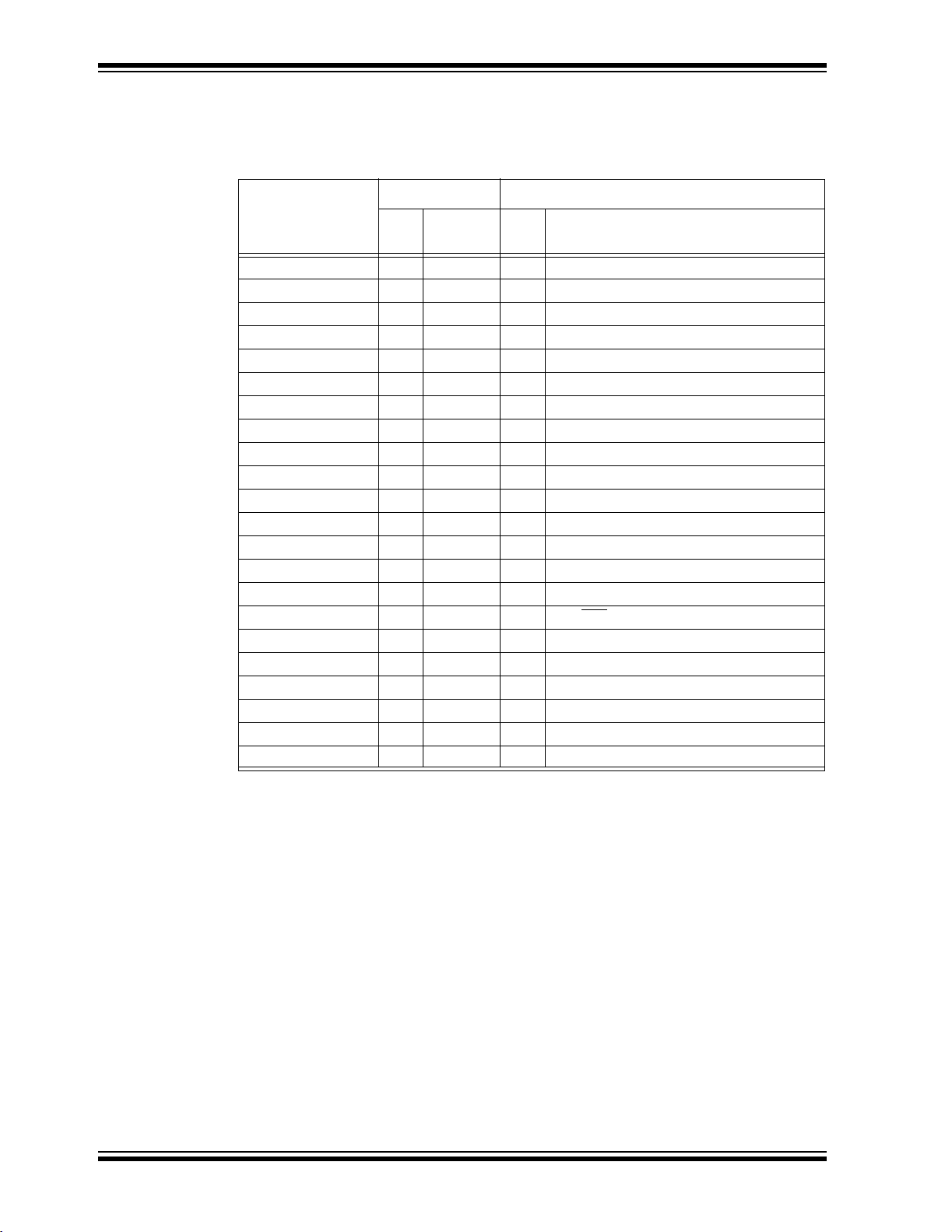

TABLE 3-1: dsPIC30F2010 CONFIGURATION SETTINGS

Header Socket U2B1

Component

Jumper JP1 JP1 Jumper — 5 VDC jumper installed

Jumper JP2 JP2 Jumper — 5 VDC jumper installed

Selector Switch S2 M ALL ON 17,18 PGC and PGD

Selector Switch S3 OFF — Not used in this configuration

Selector Switch S4 OFF — Not used in this configuration

PGM U3 H11 Open — —

CAN Tx H2 Open — —

CAN Rx H2 Open — —

UART1 Tx* H3 Open — —

UART1 Rx* H3 Open — —

Alternate UART1 Tx*H4 M ALL 11 EMUD1/SOSCI/T2CK/U1ATX/CN1/RC13

Alternate UART1 Rx*

UART2 Tx* H5 Open — —

UART2 Rx* H5 Open — —

Temperature Sensor H10 M ALL 5 AN3/INDX/CN5/RB3

Potentiometer H13 M ALL 4 AN2/SS1

Switch S5 H6 M ALL 16 FLTA/INT0/SCK1/OCFA/RE8

Switch S6 H7 M ALL 15 EMUC2/OC1/IC1/INT1/RD0

LED D3 H12 M D3 2 EMUD3/AN0/V

LED D4 H12 M D4 3 EMUC3/AN1/V

LCD - SPI™ Clock

LCD - SPI Data

* On this device, multiplexing of various peripherals on the pins does not allow the

*

simultaneous use of:

– Switch S5 and LCD

– Primary UART1 pins and LCD.

Since only one DB-9 connector is provided for RS-232 communication, you can

select either UART1 (primary or alternate pins) or UART2, but not both.

No.

H4 M ALL 12 EMUC1/SOSCO/T1CK/U1ARX/CN0/RC14

*

H1 M28 16 FLTA/INT0/SCK1/OCFA/RE8

H1 M28 17 PGD/EMUD/U1TX/SDO1/SCL/RF3

Jumper

Setting

Pin Device Functions (see Figure 3-1)

/CN4/RB2

REF+/CN2/RB0

REF-/CN3/RB1

5. Connect the RS-232 cable from the PC to the UART connector (J2).

6. Reapply power to the DC IN connector (J4). The PWR ON LED should illuminate.

7. Load the sample application program for the dsPIC30F2010 (see

Section 3.4 “Device Programming”).

DS51558A-page 22 © 2005 Microchip Technology Inc.

Page 29

3.4 DEVICE PROGRAMMING

Load the sample application program for the dsPIC30F2010 using this process:

1. Plug the RJ11cable from the MPLAB ICD 2 into the ICD header (J1). Make sure

the USB cable from the MPLAB ICD 2 is connected to your PC.

2. Start MPLAB IDE.

3. Open the dsPIC30F2010 sample project (

path/dsPICDEM 2 Development Kit/Example Software/30F2010/Demo.mcw

Note: For detailed information and procedures on using the MPLAB IDE and ICD

2 refer to Chapter 2 “Getting Started”.

Using the dsPIC30F2010

File>Open Workspace)

.

from

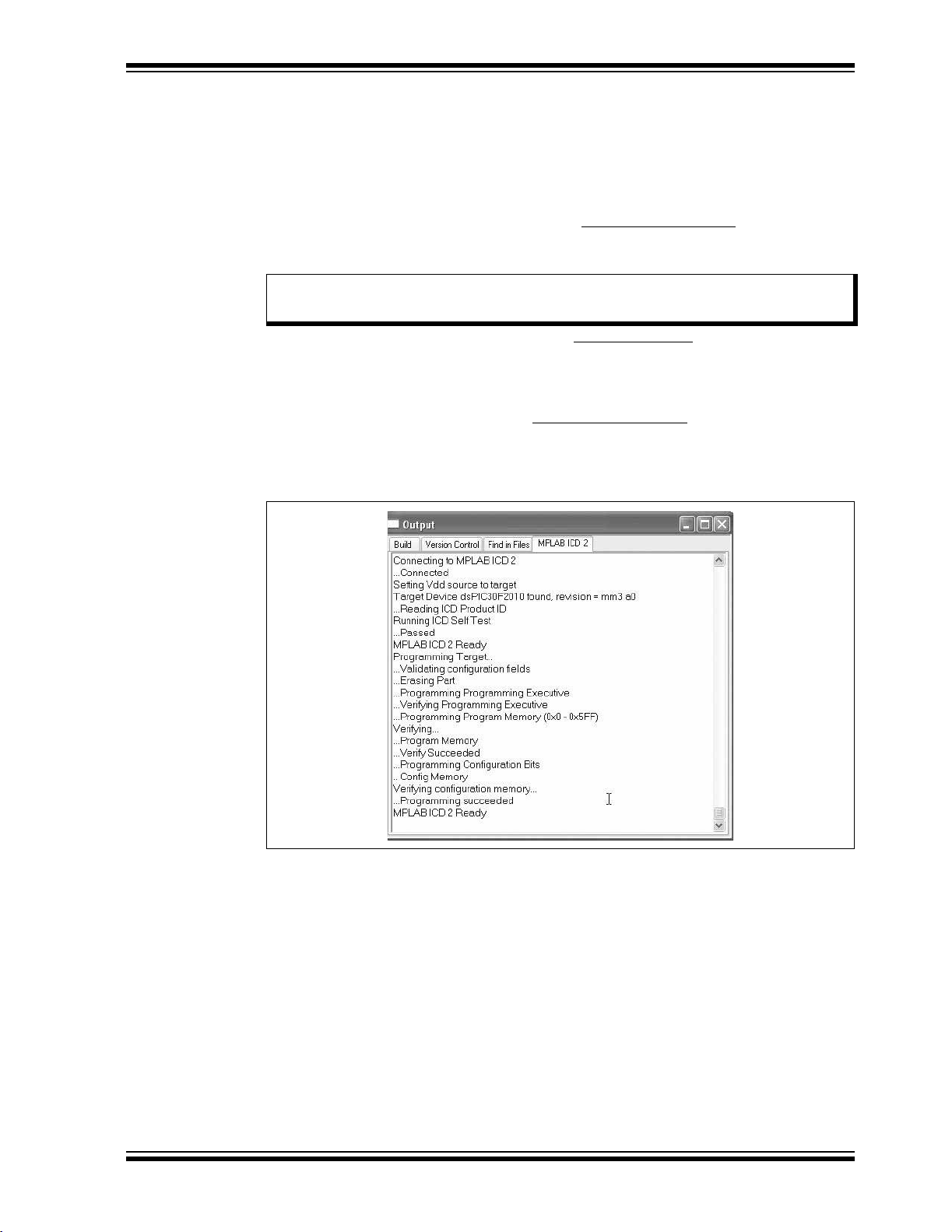

4. Build the sample project in MPLAB IDE (

5. On the dsPICDEM™ 2 board set all positions on switches S3 and S4 to OFF.

Then set switch S2 to M ALL. The MPLAB ICD 2 is now connected to the PGC

and PGD pins on the dsPIC30F2010.

6. Download the sample application (

(Figure 3-2) displays the status as the download occurs and indicates when the

programming has succeeded.

FIGURE 3-2: PROGRAMMING THE dsPIC30F2010 DEVICE

Project>Build All)

Programmer>Program

.

). The Output window

7. Disconnect the MPLAB ICD 2 cable from the ICD header. The program is now

ready to run (see Section 3.5 “Observing the Sample Application”).

© 2005 Microchip Technology Inc. DS51558A-page 23

Page 30

dsPICDEM 2 Development Board User’s Guide

3.5 OBSERVING THE SAMPLE APPLICATION

1. Press RESET ALL. The program begins to run.

2. Set up a HyperTerminal session on the PC to run with these parameters:

Port Setting Value

Bits per second 9600

Data bits 8

Parity None

Stop bits 1

Flow control None

As a shortcut, you can launch the Hyperterminal_RS232_dsPICDEM2.ht

file in the dsPICDEM 2 Development Kit/Example Software/30F2010

folder.

3. See information on LCD. Note that the HyperTerminal displays the same

information.

4. Adjust temperature and note LCD and HyperTerminal readings.

5. Adjust potentiometer and note LCD and HyperTerminal readings.

6. Observe the rate at which LEDs D3 and D4 blink.

7. Press S6 (INT1) and note the affect on D3 and D4.

DS51558A-page 24 © 2005 Microchip Technology Inc.

Page 31

3.6 IN-CIRCUIT DEBUGGING

The sample application program is intended to illustrate how the processor and

peripheral modules handle the functionality provided on the dsPICDEM 2 Development

Board. The MPLAB ICD 2 In-Circuit Debugger was used to program the sample

application into the dsPIC30F device. You can also use the MPLAB ICD 2 In-Circuit

Debugger to examine this baseline code to determine specific applicability to your

application.

The examination process requires that three changes be made to the sample

application setup.

• The dsPIC30F2010 device must be reprogrammed to recognize the MPLAB ICD

2 as a debugger rather than as a programmer.

• MPLAB IDE must be reconfigured to specify the pins on the dsPIC30F2010

device to be used for debugging.

• The dsPICDEM 2 board must be physically reconfigured to ensure that it connects

the MPLAB ICD 2 debugger to the pins on the dsPIC30F2010 device that were

specified in MPLAB IDE.

The primary programming and debugging functions (PGC/EMUC, PGD/EMUD) on the

dsPIC30F device are multiplexed with other peripheral modules on the device used by

the sample application. Thus it is necessary to use an alternate pair of debugging pins

(EMUC1/EMUD1, EMUC2/EMUD2 or EMUC3/EMUD3) to examine the baseline code

provided in the sample application.

Using the dsPIC30F2010

3.6.1 Setting Up MPLAB ICD 2 for Debugging

To change MPLAB ICD 2 from a programmer to a debugger:

1. From the

MPLAB ICD 2 as the debug tool in MPLAB IDE.

2. From the

window displays the current configuration settings for the device, as shown in

Figure 3-3.

3. Change the “Comm Channel Select” parameter to Use EMUC2 and EMUD2.

4. On the dsPICDEM 2 board, change the setting on switch S3 to turn on EMUC2

and EMUD2.

5. Remove any jumpers on headers H6 and H7.

6. Reprogram the dsPIC30F device (

7. On the dsPICDEM 2 board, turn off M ALL on switch S2.

8. Reset the program and run it. From the

Reset

Debugger

Configure

. Then select

menu, click

menu, select

Select Tool>MPLAB ICD 2

Debugger>Run

Configuration Bits...

Debugger>Program

Debugger

.

menu, select

to designate the

The Configuration Bits

menu).

Reset>Processor

© 2005 Microchip Technology Inc. DS51558A-page 25

Page 32

dsPICDEM 2 Development Board User’s Guide

FIGURE 3-3: CONFIGURATION BITS WINDOW

3.6.2 Examining the Code

After the application has been reprogrammed to use the MPLAB ICD 2 as a debugger,

you can use MPLAB IDE to run, halt and step the program. You can set breakpoints to

halt the program and examine the actual code at any point. You can also examine the

contents of the RAM and registers whenever the processor is halted.

Refer to Section 2.3 “Getting Started” for an overview of the sample application.

Flowcharts illustrate each of these processes:

• Startup and initialization

• Main loop processing

• A/D conversion processing

• External interrupt processing

The dsPICDEM 2 Development Kit/Example Software/30F2010 folder

contains fully annotated code files that you can examine, compare and copy.

3.7 SUMMARY

This chapter has provided specific instructions for using the dsPICDEM 2 Development

Board with a dsPIC30F2010 device. If you have reviewed this process, you should be

able to:

• Configure the dsPICDEM 2 Development Board for the dsPIC30F2010 device.

• Set up MPLAB IDE to use the MPLAB ICD 2 In-Circuit Debugger.

• Locate the sample application for the dsPIC30F2010 device.

• Program the chip with the MPLAB ICD 2.

• Examine the sample application and identify applicable code for your embedded

solution.

DS51558A-page 26 © 2005 Microchip Technology Inc.

Page 33

Chapter 4. Using the dsPIC30F201 1

4.1 INTRODUCTION

This chapter assumes you have chosen the dsPIC30F2011 for your application. The

dsPICDEM 2 Development Board supports a dsPIC30F2011 device in an 18-pin PDIP

package, as shown in Figure 4-1. This device provides eight 12-bit A/D (100 ksps)

channels, a UART, an SPI module, an I

tion program provides a software baseline for building your own embedded solution.

FIGURE 4-1: 18-PIN PDIP dsPIC30F2011

dsPICDEM™ 2

DEVELOPMENT BOARD

USER’S GUIDE

2

C module and 12 I/O pins. A sample applica-

EMUD3\AN0/V

EMUD3\AN1/VREF-/CN3/RB1

AN2/SS1

U1A1

EMUD1/SOSCI/T2CK/U1ATX/CN1/RC13

EMUC1/SOSCO/T1CK/U1ARX/CN0/RC14

REF+/CN2/RB0

/LVDIN/CN4/RB2

AN3/CN5/RB3

OSC2/CLKO/RC15

MCLR

OSC1/CLKI

1

2

3

4

5

6

7

8

9

18

DD

AV

17

AV

SS

16

AN6/SCK1/INT0/OCFA/RB6

15

EMUD2/AN7/OC2/IC2/INT2/RB7

14

DD

V

V

SS

13

PGC/EMUC/AN5/U1RX/SDI1/SDA/CN7/RB5

12

11

PGD/EMUD/AN4/U1TX/SDO1/SCL/CN6/RB4

EMUC2/OC1/IC1/INT1/RD0

10

dsPIC30F2011

4.2 HIGHLIGHTS

This chapter discusses:

• Board Setup for the dsPIC30F2011 Sample Application

• Device Programming

• Observing the Sample Application

• In-Circuit debugging

• Summary

4.3 BOARD SETUP FOR THE dsPIC30F2011 SAMPLE APPLICATION

The dsPICDEM 2 Development Board supports dsPIC30F devices that have multiple

peripheral devices multiplexed on some pins. Therefore, the jumper set up of various

headers depends on which of the dsPIC30F peripherals are used by the application.

This section demonstrates how the board is set up for the dsPIC30F2011 device to

support the dsPIC30F2011 example software in the dsPICDEM 2 Development Kit CD.

Follow these steps to configure the hardware on the dsPICDEM 2 Development Board

for the sample application.

1. Disconnect the power source.

2. Remove any dsPIC30Fxxxx device currently plugged into the dsPICDEM 2

Development Board.

3. Plug the dsPIC30F2011 into socket U1C1.

© 2005 Microchip Technology Inc. DS51558A-page 27

Page 34

dsPICDEM 2 Development Board User’s Guide

4. Configure the hardware components as shown in Table 4-1.

TABLE 4-1: dsPIC30F2011 CONFIGURATION SETTINGS

Header Socket U1A1

Component

Jumper JP1 JP1 Jumper — 5 VDC jumper installed

Jumper JP2 JP2 Jumper — 5 VDC jumper installed

Selector Switch S2 GP 18 ON 11,12 PGC and PGD

Selector Switch S3 OFF — Not used in this configuration

Selector Switch S4 OFF — Not used in this configuration

PGM U3 H11 Open — No jumper connections

CAN Tx H2 Open — —

CAN Rx H2 Open — —

UART1 Tx* H3 Open — —

UART1 Rx* H3 Open — —

Alternate UART1 Tx

Alternate UART1 Rx *H4 GP ALL 9 EMUC1/SOSCO/T1CK/U1ARX/CN0/RC14

UART2 Tx* H5 Open — —

UART2 Rx* H5 Open — —

Temperature Sensor H10 GP ALL 5 AN3/CN5/RB3

Potentiometer H13 GP ALL 4 AN2/SS1

Switch S5 H6 Open — —

Switch S6 H7 GP 18 10 EMUC2/OC1/IC1/INT1/RD0

LED D3 H12 GP D3 2 AN0/V

LED D4 H12 GP D4 3 AN1/V

LCD - SPI™ Clock* H1 GP 18 16 AN6/SCK1/INT0/OCFA/RB6

LCD - SPI Data* H1 GP18 11

* On this device, multiplexing of various peripherals on the pins does not allow the

simultaneous use of:

– Switch S5 and LCD

– Primary UART1 pins and LCD.

Since only one DB-9 connector is provided for RS-232 communication, you can

select either UART1 (primary or alternate pins) or UART2, but not both.

No.

* H4 GP ALL 8 EMUD1/SOSC1/T2CK/U1ATX/CN1/RC13

Jumper

Setting

Pin Device Functions (see Figure 4-1)

/LVDIN/CN4/RB2

REF+/CN2/RB0

REF-/CN3/RB1

PGD/EMUD/AN4/U1TX/SDO1/SCL/CN6/RB4

5. Connect the RS-232 cable from the PC to the UART connector (J2).

6. Reapply power to the DC IN connector (J4). The PWR ON LED should illuminate.

7. Load the sample application program for the dsPIC30F2011 (see

Section 4.4 “Device Programming”).