Page 1

dsPICDEM™ 1.1 Plus

Development Board

User’s Guide

© 2006 Microchip Technology Inc. DS70099D

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Millennium Copyright Act. If suc h a c t s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPASM, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartT el, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology I ncorporat ed in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Pr inted in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its

®

8-bit MCUs, KEELOQ

PIC

microperipherals, nonvolatile memory and analog products. In addition,

Microchip’s quality system for the design and manufacture of

development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial EEPROMs,

DS70099D-page ii © 2006 Microchip Technology Inc.

Page 3

dsPICDEM™ 1.1 PLUS

DEVELOPMENT BOARD

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 1

Chapter 1. Introduction

1.1 Introduction .....................................................................................................9

1.2 Highlight s ......... ............. .. .. ........................... .. .. ........................... .. .. ................ 9

1.3 dsPICDEM™ 1.1 Plus DEVELOPMENT BOARD Kit ....................................9

1.4 dsPICDEM™ 1.1 Plus Development Board Features ..................................10

1.5 Supported Plug-In Modules ..........................................................................11

1.6 Running the dsPICDEM™ 1.1 Plus Demonstration Program ......................12

Chapter 2. Using dsPIC30F Devices

2.1 Introduction ...................................................................................................13

2.2 Highlight s ......... ............. .. .. ........................... .. .. ........................... .. .. .............. 13

2.3 Tutori al Ove rview .................. .. .. ........................... .. .. .................................... 13

2.4 Creating the Pro j e c t .......................................................................... ... .. ....... 14

2.5 Building the Code .........................................................................................19

2.6 Programming the Chip ................................................................................. 21

2.7 Debugging the Code ....................................................................................25

Chapter 3. dsPIC30F Demonstration Program Operation

3.1 Introduction ...................................................................................................29

3.2 Highlight s ......... ............. .. .. ........................... .. .. ........................... .. .. .............. 29

3.3 Demonstra tion Program Op e ra tion .... .. ........................................................ 2 9

3.4 Data and Control Flow ..................................................................................36

3.5 dsPIC30F Demonstration Performance Metrics ...........................................39

3.6 Board Self-Test Code Module Summary ...................... ...................... .. ........42

Chapter 4. Using dsPIC33F and PIC24H/24F Devices

4.1 Introduction ...................................................................................................43

4.2 Highlight s ......... ............. .. .. ........................... .. .. ........................... .. .. .............. 43

4.3 Tutorial Ov e r view ..... .. .......................... .. ........................... .. .. .............. .. ....... 43

4.4 Creating the Pro j e c t .......................................................................... ... .. ....... 44

4.5 Building the Code .........................................................................................49

4.6 Programming the Chip ................................................................................. 51

4.7 Debugging the Code ....................................................................................55

4.8 Additional Code Examples ................................................................... .. ......59

Chapter 5. dsPICDEM™ 1.1 Developmen t Ha rdwa re

5.1 dsPICDEM™ 1.1 Plus Development Board Hardware Overview .................61

© 2006 Microchip Technology Inc. DS70099D-page iii

Page 4

dsPICDEM™ 1.1 Plus Development Board User’s Guide

Appendix A. Hardware Drawings and Schematics

A.1 Introduction ..................................................................................................67

A.2 Highlight s ................ .......................... ... .. .......................... ... .. ....................... 67

Appendix B. LCD Controller Specification

B.1 Overview .......... ........................................ .. .. ........................... .. .. ................. 75

B.2 LCD Controller Interface .............................................................................. 75

B.3 Commands ................................................................................................... 76

B.4 General Commands .....................................................................................78

B.5 Character commands ................................................................................... 79

B.6 Pixel comm a n ds ............................................................................... .. .. ........ 81

B.7 Column com mands ................ ..................................................... ... .. ............ 8 2

B.8 Example s ................ ........................................ .. ........................................ .. . 83

Index .............................................................................................................................85

Worldwide Sales and Service .....................................................................................88

DS70099D-page iv © 2006 Microchip Technology Inc.

Page 5

dsPICDEM™ 1.1 PLUS

DEVELOPMENT BOARD

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

dsPICDEM™ 1.1 Plus Development Board. Items discussed in this chapter include:

• About This Guide

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

ABOUT THIS GUIDE

This document describes how to use the dsPICDEM™ 1.1 Plus Development Board as

a development tool to emulate and debug firmware on a target board. The manual

layout is as follows:

• Chapter 1: Introduction – This chapter introduces the dsPICDEM™ 1.1 Plus

Development Board and provides a brief description of the hardware.

• Chapter 2: Using dsPIC30F Devices – This chapter goes through a basic

step-by-step process for getting your dsPICDEM™ 1.1 Plus Development Board

up and running with the MPLAB

devices.

• Chapter 3: Demonstration Program Operation – This chapter presents a

detailed description of the operational functionality of the sample code, which is

preprogrammed into the dsPIC30F device.

®

In-Circuit Debugger 2 (ICD 2) using dsPIC30F

© 2006 Microchip Technology Inc. DS70099D-page 1

Page 6

dsPICDEM™ 1.1 Plus Development Board User’s Guide

• Chapter 4. Using dsPIC33F/PIC24H Devices – This chapter goes through a

basic step-by-step process for getting your dsPICDEM™ 1.1 Plus Development

Board up and running with the MPLAB

• Chapter 5: dsPICDEM™ 1.1 Plus Development Board Hardware – This chapter presents the features of the dsPICDEM™ 1.1 Plus Development Board in

more detail.

• Appendix A: Hardware Drawings and Schematics – This Appendix illustrates

the dsPICDEM™ 1.1 Plus Development Board layout and hardware schematic

diagrams.

• Appendix B: LCD Controller Specification – This section pr esent s the 1 22 x 32

Graphics LCD Controller Interface Specifications.

• Index – This section provides cross-reference listing of terms, features and

sections of this document.

• Worldwide Sales and Service – A listing of Microchip sales and service locations

and telephone numbers worldwide.

®

ICD 2 using dsPIC30F devices.

DS70099D-page 2 © 2006 Microchip Technology Inc.

Page 7

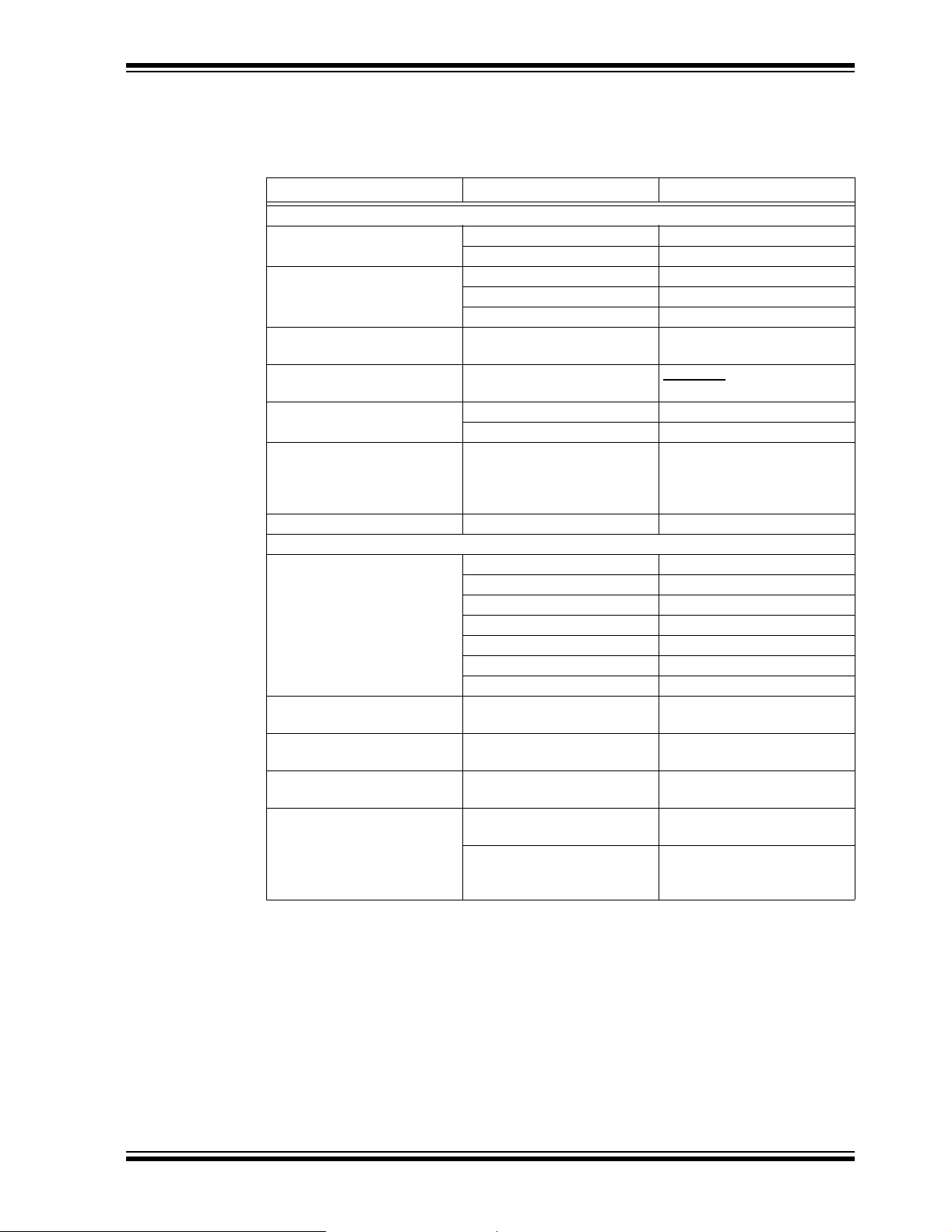

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Initial caps A window the Output window

Quotes A field name in a window or

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sam ple source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

Preface

®

IDE User’s Guide

Emphasized text ...is the only comp ile r...

A dialog the Settings dialog

A menu selection select Enable Programmer

“Save project before build”

dialog

A menu path File>Save

A tab Click the Power tab

4‘b0010, 2‘hF1

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

any valid filename

[options]

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

© 2006 Microchip Technology Inc. DS 70099D-page 3

Page 8

dsPICDEM™ 1.1 Plus Development Board User’s Guide

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use the dsPICDEM™ 1.1 Plus Development Board.

Other useful documents are listed below:

dsPIC30F Family Reference Manual (DS70 046)

Consult this document for detailed information on the dsPIC30F device operation. The

manual explains the operation of the dsPIC30F MCU family architecture and peripheral

modules but does not cover the specifics of each device. Refer to the appropriate

device data sheet, mentioned below, for device-specific information.

dsPIC30F/33F Programmer’s Reference Manual (DS70157)

This manual is a software developer’s reference for the dsPIC30F/33F 16-bit MCU

device families. This manual describes the instruction set in detail and also provides

general information to assist the user in developing software for the dsPIC30F MCU

family.

dsPIC30F Family Overview (DS70043)

This document provides an overview of the features and functionality of the dsPIC

DSC product family. It helps determine how the dsPIC 16-bit Digital Signal Controller

Family fits a specific product application. For detailed information about any of the

functionality, refer to the “dsPIC30F Family Reference Manual” (DS70 046 ).

PIC24H Family Data Sheet (DS70175)

This data sheet summarizes the features of the PIC24H family of devices. It provides

essential information needed to develop software for these devices.

dsPIC33F Family Data Sheet (DS70165)

This data sheet summarizes the features of the dsPIC33F family of devices. It provides

essential information needed to develop software for these devices.

MPLAB

This document details Microchip Technology’s language tools for dsPIC DSC devices

based on GNU technology. The language tools discussed are:

• MPLAB ASM30 Assembler

• MPLAB LINK30 Linker

• MPLAB LIB30 Archiver/Librarian

• Other Utilities

MPLAB

The purpose of this document is to help you use Microchip’s MPLAB C30 C compiler

for dsPIC

guage tool, based on source code from the Free Software Foundation (FSF). For more

information about the FSF, see www.fsf.org.

Other GNU language tools available from Microchip are:

• MPLAB ASM30 Assembler

• MPLAB LINK30 Linker

• MPLAB LIB30 Librarian/Archiver

®

ASM30, MPLAB® LINK30 and Utilities User’s Guide (DS51317)

®

C30 C Compiler User’s Guide (DS51284)

®

DSC devices to develop your application. MPLAB C30 is a GNU-based lan-

®

DS70099D-page 4 © 2006 Microchip Technology Inc.

Page 9

Preface

MPLAB IDE Simulator, Editor User’s Guide (DS51025)

Consult this document for more information pertaining to the installation and features

of the MPLAB Integrated Development Environment (IDE) Software.

To obtain any of these documents, contact the nearest Microchip sales location

(see back page) or visit the Microchip web site at: www.microchip.com.

© 2006 Microchip Technology Inc. DS 70099D-page 5

Page 10

dsPICDEM™ 1.1 Plus Development Board User’s Guide

THE MICROCH IP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listin g

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB C18 and MPLAB C30 C compilers; MPASM™

and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 object linkers;

and MPLIB™ and MPLAB LIB30 object librarians.

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB ICE 2000 and MPLAB ICE 4000.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 and PRO MATE

Plus and PICkit

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

®

™

1 development programmers.

II device programmers and the PICSTART®

DS70099D-page 6 © 2006 Microchip Technology Inc.

Page 11

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision D (October 2006)

This revision reflects an upgrade to the dsPICDEM™ 1.1 Plus Development Board to

allow it to accommodate dsPIC30F, dsPIC33F, PIC24H and PIC24F devices.

• Changed board name to dsPICDEM™ 1.1 Plus Development Board.

• Modified power supply circuits to accommodate both 3.3 V and 5V devices.

• Added tutorial and code examples for using the dsPICDEM™ 1.1 Plus Development Board with dsPIC33F and PIC24H/F devices (see Chapter 4. “Using

dsPIC33F and PIC24H/24F Devices”).

Preface

Revision C (September 2005)

• Last Release of this Document.

• Previous releases contained Advance Information that was updated in

Revision C.

© 2006 Microchip Technology Inc. DS 70099D-page 7

Page 12

dsPICDEM™ 1.1 Plus Development Board User’s Guide

NOTES:

DS70099D-page 8 © 2006 Microchip Technology Inc.

Page 13

dsPICDEM™ 1.1 PLUS

1

DEVELOPMENT BOARD

Chapter 1. Introduction

1.1 INTRODUCTION

The dsPICDEM™ 1.1 Plus Development Board Kit serves as a development and evaluation tool for dsPIC30F/33F High Performance Digital Signal Controllers and

PIC24H/24F PIC

1.2 HIGHLIGHTS

This chapter discusses:

• dsPICDEM™ 1.1 Plus Development Board Kit

• dsPICDEM™ 1.1 Plus Development Board Features

• Supported Plug-In Modules

• Running the

1.3 dsPICDEM™ 1.1 PLUS DEVELOPMENT BOA RD KIT

®

microcontrollers.

dsPICDEM™ 1.1 Demonstration Program

USER’S GUIDE

The dsPICDEM™ 1.1 Plus Development Board Kit contains the following items:

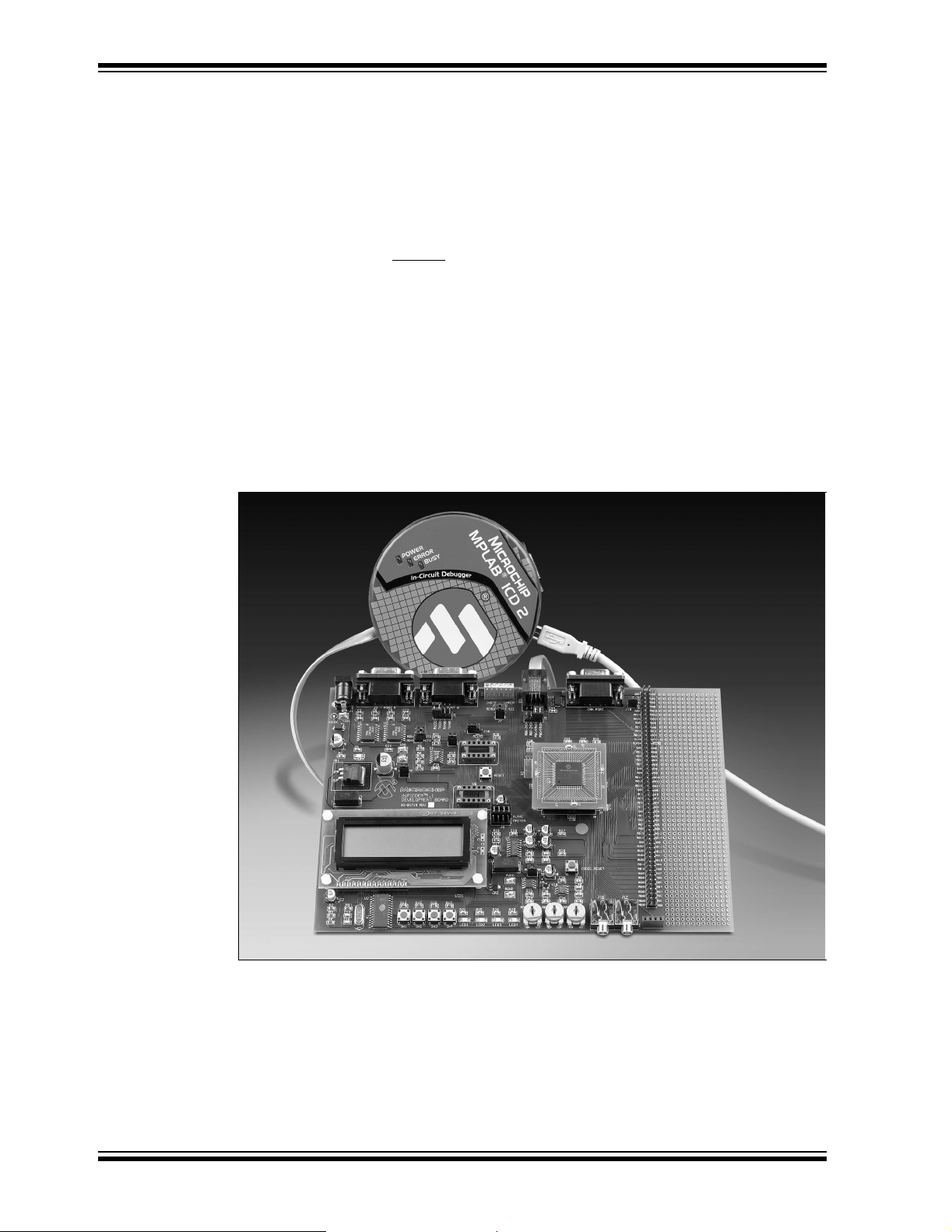

• The dsPICDEM™ 1.1 Plus Printed Circuit Board (Figure 1-1)

• Preprogrammed dsPIC30F6014A Plug-in Module (Figure 1-2)

• 9V DC Power Supply

• RS-232 Interface Cable

• dsPICDEM™ 1.1 Plus Development Board Kit CD containing demonstration

programs

FIGURE 1-1: dsPICDEM™ 1.1 PLUS DEVELOPMENT BOARD

5

2

7

10

26

9

8 7

8

6

27

25

13

4

3

3

11

10

5

14

1

12

4

18

1

16

© 2006 Microchip Technology Inc. DS70099D-page 9

Page 14

dsPICDEM™ 1.1 Plus Development Board User’s Guide

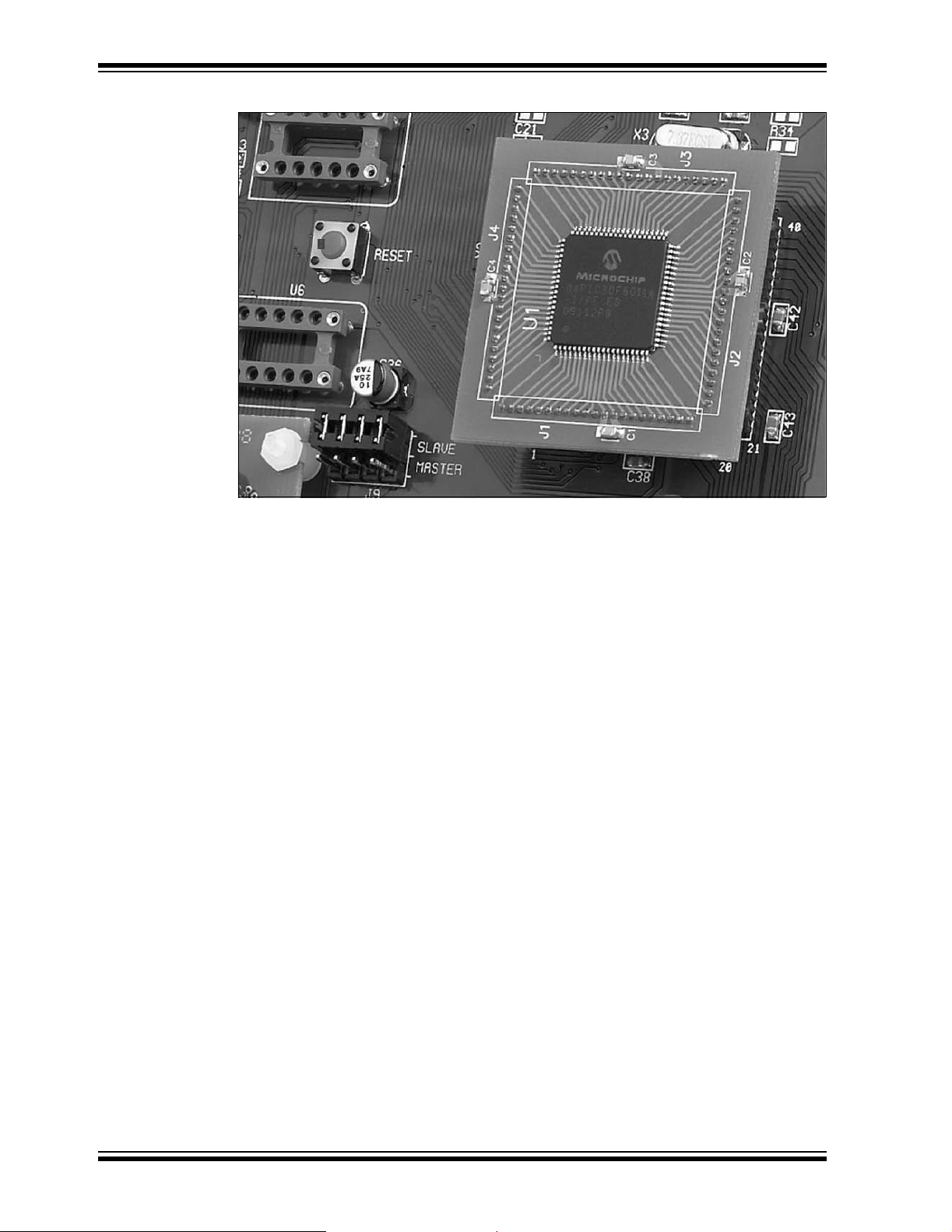

FIGURE 1-2: dsPIC30F6014A PLUG-IN MODULE

1.4 dsPICDEM™ 1.1 PLUS DEVEL OPMENT BOARD FEATURES

The dsPICDEM™ 1.1 Plus Development Board supports the following features:

Development Board Power

• Separate on-board +5V and +3.3V regulators for VDD and AVDD with direct input

from 9V, AC/DC wall adapter

• 9V DC power source input jack for development board

• LED power-on indicator

MPLAB ICD 2 and MPLAB ICE 4000 Connections

• MPLAB ICD 2 programming connector

• Jumper J8 for selection of processor interfaced to the MPLAB ICD 2

Debugger/Programmer

• Emulation header for connection to MPLAB ICE 4000 Emulator

• Pad location for 80-pin TQFP dsPIC DSC device

Serial Communication Channels

• Two RS-232 communication channels

• 6-pin terminal block and configuration jumper for RS-485 and RS-422

communication on UART1 from the dsPIC DSC device

• Single CAN communication channel

DS70099D-page 10 © 2006 Microchip Technology Inc.

Page 15

Introduction

Voice Band Codec

• Si3000 Voice band Codec chip (U7)

• Jumper J9 for selection of Si3000 Codec mode (Master/Slave)

• Socket U6, optional clock oscillator for Si3000 Voice band Codec

• 4-pin header for the Codec Line In and Line Out

• One 3.5 mm phono jack for the Codec left and right speaker outputs

• One 3.5 mm phono jack for the Codec MIC input

• Codec reset push button switch

Analog

• Three 5 kΩ Potentiometers (RP1-RP3)

• Microchip TC1047A Thermal Sensor (U9)

• MCP41010 Digital Potentiometer (U8)

• MCP602 Operational Amplifiers configured as low-pass filters for temperature

sensor and digital potentiometer (U10)

Device Clocking

• 7.3728 MHz crystal (X3) for dsPIC DSC device

• Socket U5, clock oscillator for dsPIC DSC device (alternate clock source, X3

removed)

• Pad for 32.768 kHz crystal (X2) and load caps

Miscellaneous

• Reset push button switch and jumper (J10) for resetting the PIC18F242 LCD

controller or the dsPIC DSC device

• Four red LEDs (LED1-LED4)

• Four push button switches (SW1-SW4) for external input stimulus

• 122 x 32 dot addressable LCD

• PIC18F242 LCD controller

• 2 x 50 prototyping header for user hardware expansion (header not installed)

• Prototype area for user hardware

1.5 SUPPORTED PLUG-IN MODULES

The dsPICDEM™ 1.1 Plus Development Board supports these Plug-In Modules:

• dsPIC30F6014A 80L Plug-In Module (MA300014)

• dsPIC33FJ256GP710 100-to-80L Plug-In Module (MA330012)

© 2006 Microchip Technology Inc. DS70099D-page 11

Page 16

dsPICDEM™ 1.1 Plus Development Board User’s Guide

1.6 RUNNING THE dsPICDEM™ 1.1 PLUS DEMONSTRATION PROGRAM

The dsPICDEM™ 1.1 Plus Development Board is supplied with a pre-loaded demonstration program that exercises principal CPU functions and peripheral options that

interact with typical user application programs.

When you apply power to the dsPICDEM™ 1.1 Plus Development Board, the LCD

menu displays these demonstration functions:

• Data Acquisition Display

• Digital Signal Processing (DSP) Operations

• Dual Tone Multi-Frequency (DTMF) Generation

Switches SW2-SW4 select one of these three choices. Each choice offers a submenu,

which provides for additional options using switches SW1-SW4.

Refer to Chapter 3. “dsPIC30F Demonstration Program Operation” for full details

on the demonstration code operation .

DS70099D-page 12 © 2006 Microchip Technology Inc.

Page 17

Chapter 2. Using dsPIC30F Devices

2.1 INTRODUCTION

This chapter is a self-paced tutorial to get you started using the dsPICDEM™ 1.1 Plus

Development Board with dsPIC30F devices. The tutorial demonstrates the main features of MPLAB IDE Integrated Development Environment and the MPLAB ICD 2

In-Circuit Debugger as they are used with the dsPICDEM™ 1.1 Plus Development

Board. Upon completing this tutorial, you should be able to:

• Create a project using the Project Wizard.

• Assemble and link the code and set the Configuration bits.

• Set up MPLAB IDE to use the MPLAB ICD 2 In-Circuit Debugger.

• Program the chip with the MPLAB ICD 2.

• View the code execution in program memory and source code.

• View registers in a Watch window.

• Set a breakpoint and make the code halt at a chosen location.

• Use the function keys to Reset, Run, Halt and Single Step the code.

dsPICDEM™ 1.1 PLUS

DEVELOPMENT BOARD

USER’S GUIDE

2.2 HIGHLIGHTS

Items discussed in this chapter include:

• Tutorial Overview

• Creating the Project

• Building the Code

• Programming the Chip

• Debugging the Code

2.3 TUTORIAL OVERVIEW

The tutorial program in Tut6014a.s (included with the CD-ROM) is written in

assembly code. This program displays text on the LCD and flashes an LED. The

source file is used with a linker script file (p30f6014a.gld) and an include file

(p30f6014a.inc) to form a comple te proje ct. The tutoria l is a si mple pr oject th at uses

a single source code file. More complex projects might use multiple assembler and

compiler source files as well as library files and precompiled object files. For simplicity ,

this tutorial uses only one source file.

There are four steps to this tutorial:

1. Create a project in MPLAB IDE.

2. Assemble and link the code.

3. Program the chip with the MPLAB ICD 2.

4. Debug the code with the MPLAB ICD 2.

© 2006 Microchip Technology Inc. DS70099D-page 13

Page 18

dsPICDEM™ 1.1 Plus Development Board User’s Guide

2.4 CREATING THE PROJECT

The first step is to create a project and a workspace in MPLAB IDE. Usually, you will

have one project in one workspace.

Note: These instructions presume the use of MPLAB 7.20 or newer.

A project contains the files needed to build an application (source code, linker script

files, etc.) along with their associations to various build tools and build options.

A workspace contains one or more projects and information on the selected device,

debug tool and/or programmer, open windows and their location and other IDE

configuration settings.

MPLAB IDE contains a Project Wizard to help create new projects. Before starting,

create a folder for the project files for this tutorial (C:\Tutorial is assumed in the

instructions that follow). From the dsPICDEM 1_1 Plus Development Board

code\Tutorial Code folder on the dsPICDEM™ 1.1 Plus Development Kit CD,

copy the Tut6014a.s file into the C:\Tutorial fold er.

Note: All files copied from the CD are read only. If the file needs to be edited, the

attributes will need to be changed.

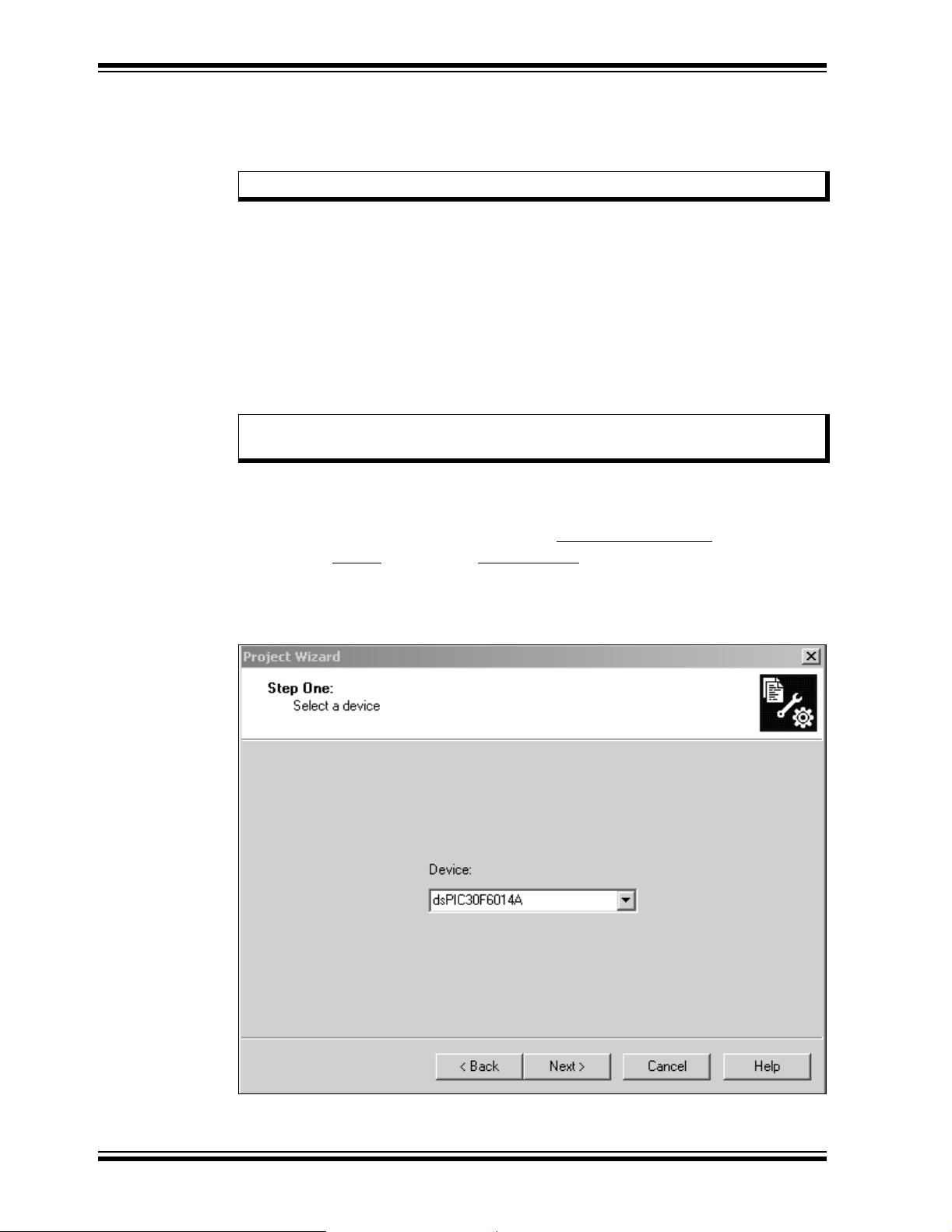

2.4.1 Select a Device

1. Start MPLAB IDE.

2. Close any workspace that might be open (File>Close Workspace

3. From the Project

4. From the Welcome screen, click Next> to display the Project Wizard Step One

dialog (see Figure 2-1).

FIGURE 2-1: PROJECT WIZARD, STEP 1, SELECT A DEVICE

menu, select Project Wizard.

).

DS70099D-page 14 © 2006 Microchip Technology Inc.

Page 19

Using dsPIC30F Devices

5. From the Device: pull-down list, select dsPIC30F6014A and click Next>. The

Project Wizard Step Two dialog displays (see Figure 2-2).

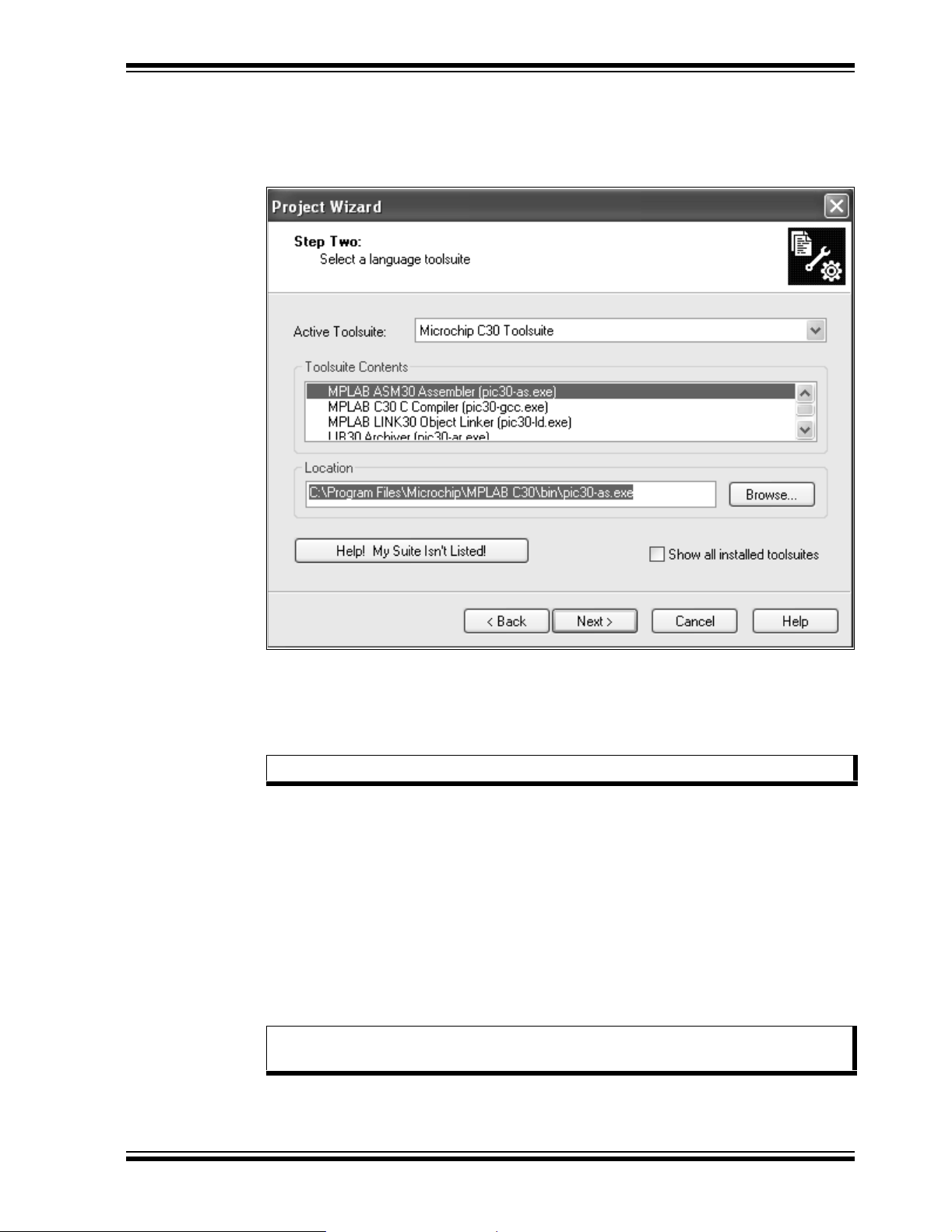

FIGURE 2-2: PROJECT WIZARD, STEP 2, SELECT LANGUAGE

TOOLSUITE

2.4.2 Select Language Toolsuite

1. From the Active Toolsuite: pull-down menu, select Microchip C30 Toolsuite.

This toolsuite includes the assembler and linker that will be used (the C Compiler

is not used).

Note: Steps 2-4 are optional.

2. In the Toolsuite Contents block, select MPLAB ASM30 Assembler

(pic30-as.exe).

3. In the Location block, click Browse... and navigate to:

C:\Program Files\Microchip\MPLAB ASM30 Suite

\bin\pic30-as.exe

4. With MPLAB LINK 30 Object Linker (pic30-Id.exe) selected in Toolsuite

Contents, click Browse... and navigate to:

C:\Program Files\Microchip\MPLAB ASM30 Suite

\bin\pic30-id.exe

5. Click Next> to continue. The Project Wizard Step Three dialog displays

(see Figure 2-3).

Note: The tool locations for your environment may be different from those shown

in this tutorial.

© 2006 Microchip Technology Inc. DS70099D-page 15

Page 20

dsPICDEM™ 1.1 Plus Development Board User’s Guide

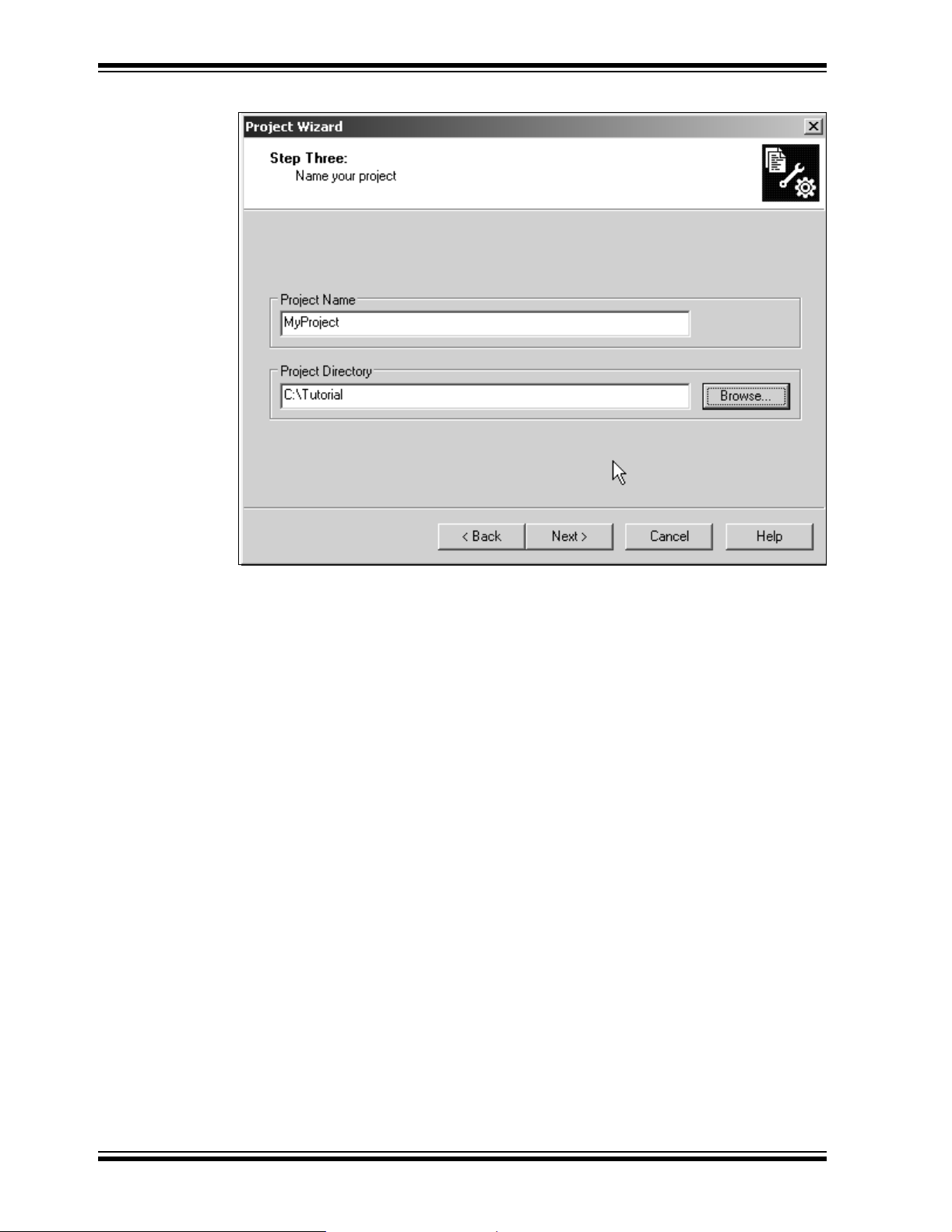

FIGURE 2-3: PROJECT WIZARD, STEP 3, NAME YOUR PROJECT

2.4.3 Name Your Project

1. In the Project Name text box, type MyProject.

2. Click Browse... and navigate to C:\Tutorial to place your project in the

Tutorial folder.

3. Click Next> to continue. The Project Wizard Step Four dialog displays

(see Figure 2-4).

DS70099D-page 16 © 2006 Microchip Technology Inc.

Page 21

Using dsPIC30F Devices

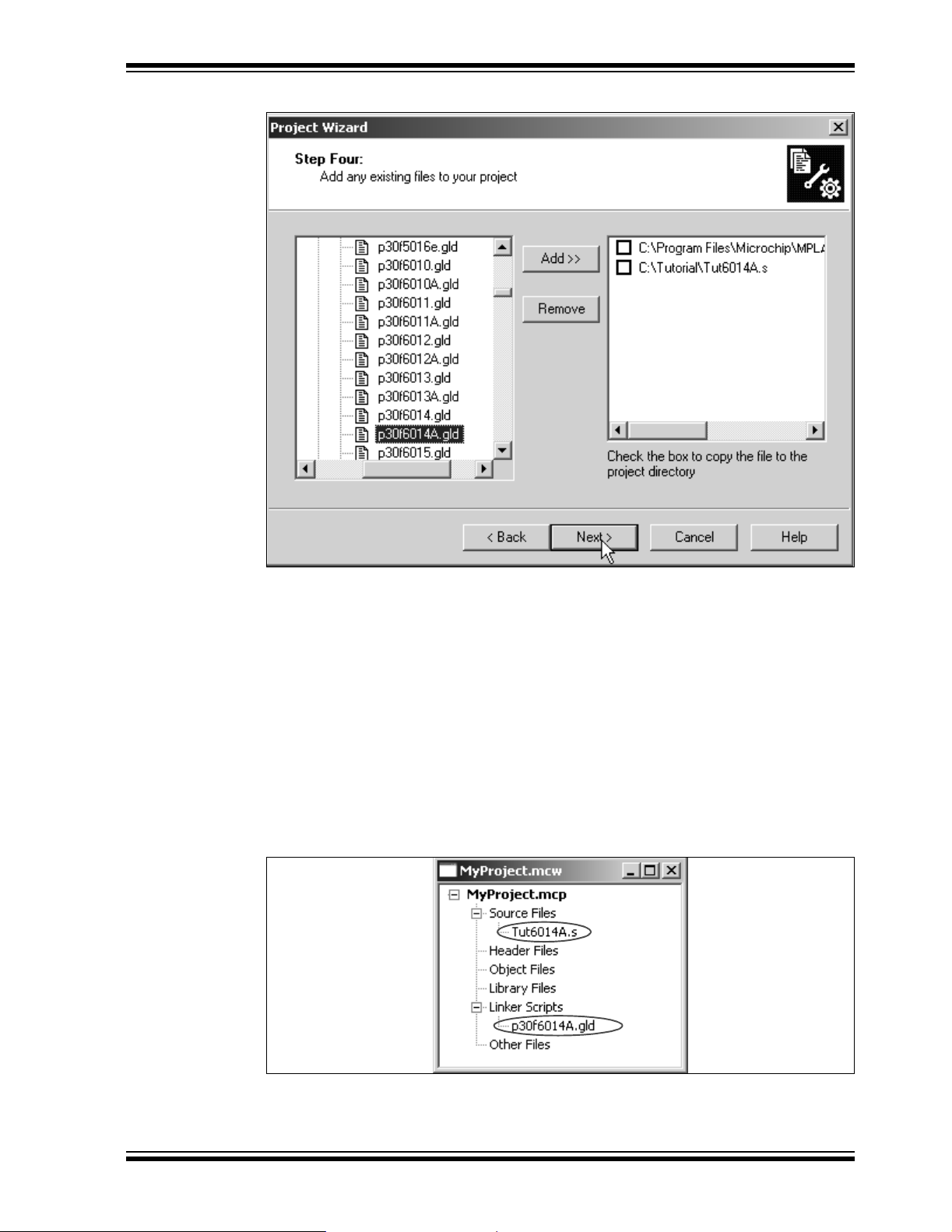

FIGURE 2-4: PROJECT WIZARD, STEP 4, ADD FILES TO PROJECT

2.4.4 Add Files to Project

1. Locate the C:\Tutorial folder and select the Tut6014A.s file.

2. Click Add>> to include the file in the project.

3. Expand the C:\Program Files\Microchip\MPLAB ASM30 Suite\Sup-

port\gld folder and select the p30f6014A.gld file.

4. Click Add>> to include the file in the project. The project now has two files.

5. Click Next> to continue.

6. When the summary screen displays, click Finish.

After the project wizard completes, the MPLAB IDE project window shows the

Tut6014A.s file in the Source Files folder and the p30f6014A.gld file in the Linker

Scripts folder (see Figure 2-5).

FIGURE 2-5: MPLAB

®

IDE PROJECT WINDOW

© 2006 Microchip Technology Inc. DS70099D-page 17

Page 22

dsPICDEM™ 1.1 Plus Development Board User’s Guide

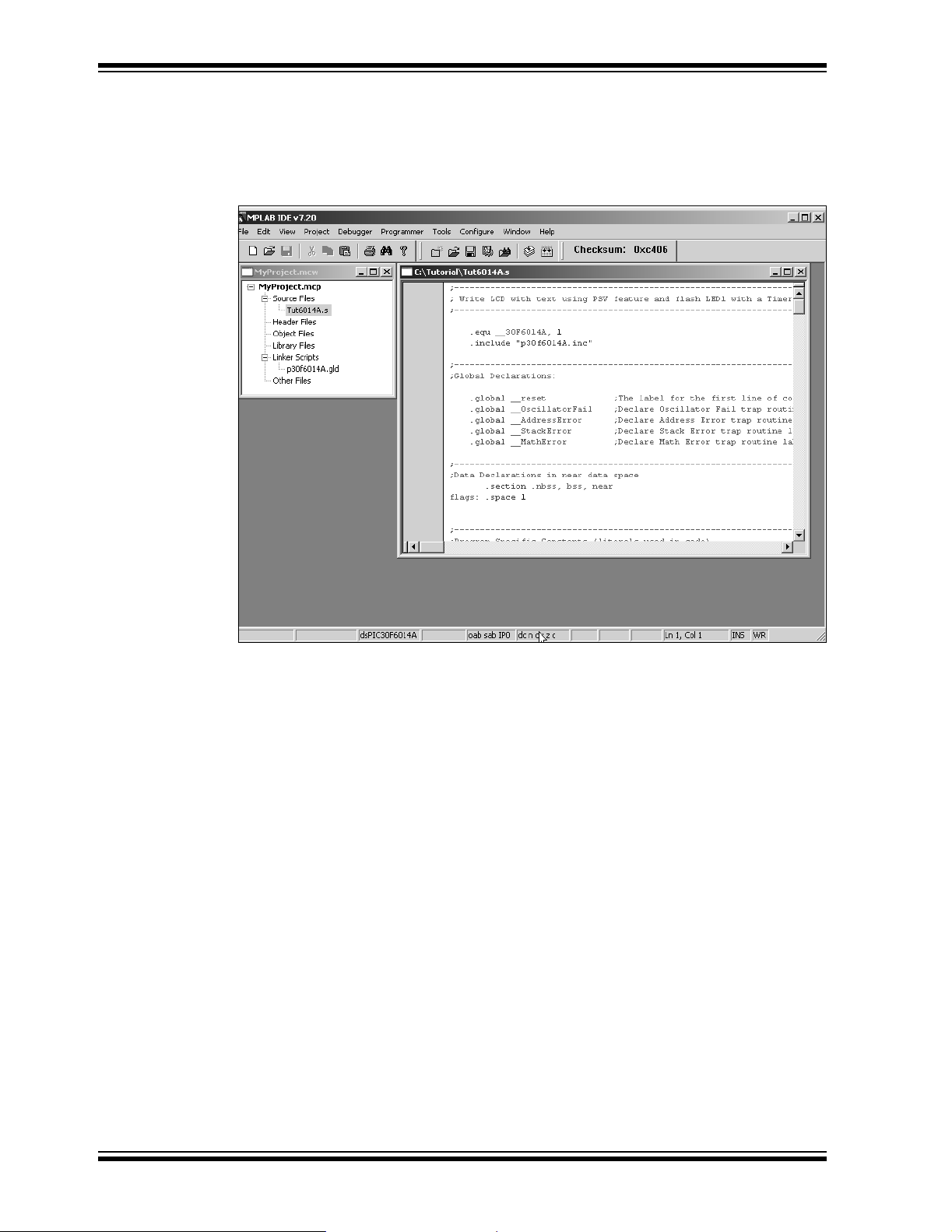

A project and workspace has now been created in MPLAB IDE. MyProject.mcw is

the workspace file and MyProject.mcp is the project file. Double click the

Tut6014A.s file in the project window to open the file. MPLAB IDE should now look

similar to Fi gu r e 2-6.

FIGURE 2-6: MPLAB

®

IDE WORKSPACE WINDOWS

DS70099D-page 18 © 2006 Microchip Technology Inc.

Page 23

2.5 BUILDING THE CODE

In this project, building the code consists of assembling the Tut6014A.s file to create

an object file, Tut6014A.o, and then linking the object file to create the

Tut6014A.hex and Tut6014A.cof output files. The .hex file contains the data necessary to program the device and the .cof file contains additional information that lets

you debug at the source code level.

Before building, there are settings required to tell MPLAB IDE where to find the include

files and to reserve space for the extra debug code when the MPLAB ICD 2 is used.

The following line is near the top of the Tut6014A.s file:

.include "p30f6014A.inc"

This line causes a standard include file to be used. Microchip provides these files with

all the Special Function Register (SFR) labels already defined for convenience.

To build the code, select Build Option s>Project

Options dialog displays, as shown in Figure 2-7.

FIGURE 2-7: BUILD OPTIONS

Using dsPIC30F Devices

from the Project> menu. The Build

Browse to the location of the

assembler Include folder.

© 2006 Microchip Technology Inc. DS70099D-page 19

Page 24

dsPICDEM™ 1.1 Plus Development Board User’s Guide

2.5.1 Identify Assembler Include Path

1. Select the General tab.

2. At the Assembler Include Path, $(AINDIR) box, click Browse... and navigate

to:

C:\Program Files\Microchip\MPLAB ASM30 Suite\Support\Inc

This path tells MPLAB IDE where to find the Include files.

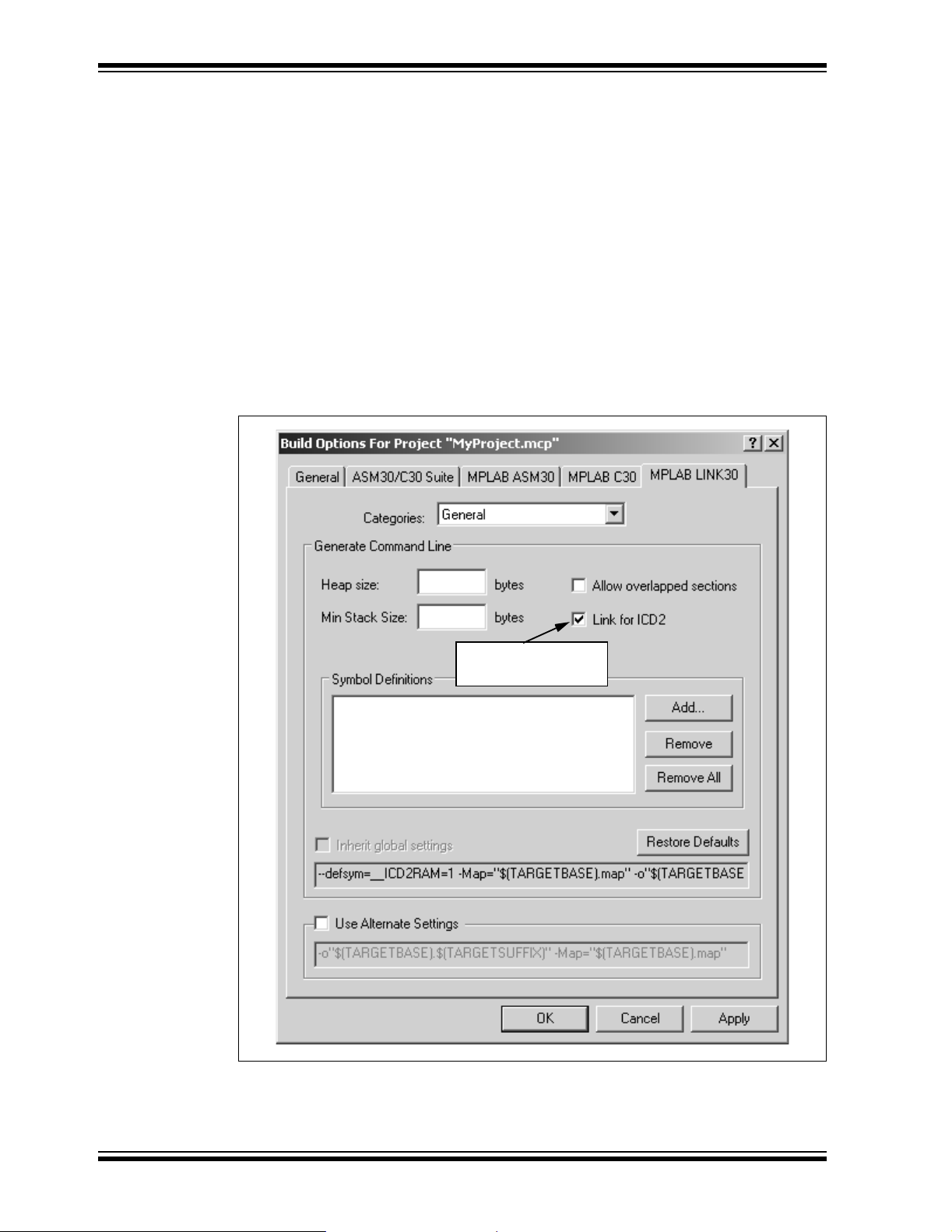

2.5.2 Link for ICD 2

1. Select the MPLAB LINK30 tab to view the linker settings (see Figure 2-8).

2. Check Link for ICD 2.

3. Click Apply, then click OK. The text box closes while the linker reserves space

for the debug code used by the MPLAB ICD 2.

4. Click OK again to save these changes. The project is now ready to build.

FIGURE 2-8: MPLAB

®

LINK30 BUILD OPTIONS

Check Link for ICD2

DS70099D-page 20 © 2006 Microchip Technology Inc.

Page 25

Using dsPIC30F Devices

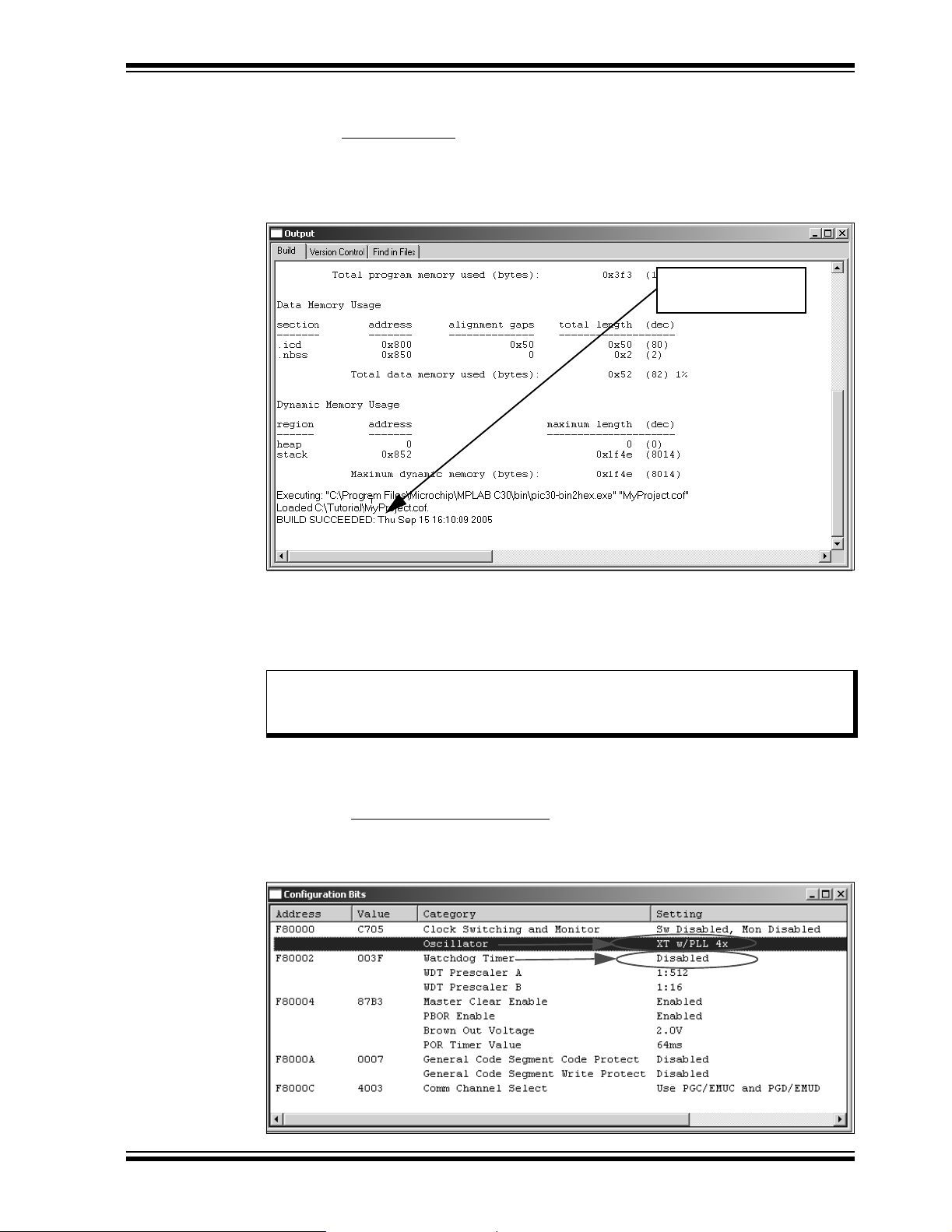

2.5.3 Build the Project

1. Select P r oj ect >B ui ld All.

2. Observe the progress of the build in the Output window (Figure 2-9).

3. When BUILD SUCCEEDED displays you are ready to program the device.

FIGURE 2-9: BUILD OUTPUT WINDOW

2.6 PROGRAMMING THE CHIP

The MPLAB ICD 2 In-Circuit Debugger can be used to program and debug the

dsPIC30F6014A device in-circuit on the dsPICDEM™ 1.1 Plus Development Board.

Note: Before proceeding, make sure that the USB driver for the MPLAB ICD 2 has

been installed on your PC (see the “MPLAB

DS51331) for more details regarding the installation of MPLAB ICD 2.

Status shows

BUILD SUCCEEDED

®

ICD 2 User’s Guide”,

Use the following procedures to program the dsPIC30F6014A device.

2.6.1 Set Up the Device Configuration

1. Use the Configure>Configuration Bits menu to display the configuration settings.

2. Set up the Configuration bits as shown in Figure 2-10.

FIGURE 2-10: CONFIGURATION SETTINGS

© 2006 Microchip Technology Inc. DS70099D-page 21

Page 26

dsPICDEM™ 1.1 Plus Development Board User’s Guide

The highlighted configuration settings may need to change to the these values:

Primary Oscillator Mode: XT w/PLL 4x

Watchdog Timer: Disabled

2.6.2 Connect the MPLAB ICD 2 In-Circuit Debugger

1. Before set ting up the hardware, check that the following jumpers are in place:

AVDD_JMP: On

J8: 33F PGD3/30F, 33F PGD3/30F

J10: MCLR1

VDD_JMP: On

J21 On (5V)

J22 On (5V)

2. Connect the MPLAB ICD 2 to the PC with the USB cable (see Figure 2-11).

3. Connect the MPLAB ICD 2 to the dsPICDEM™ 1.1 Plus Development Board

with the short RJ-11 (telephone) cable.

4. Apply power to the board.

FIGURE 2-11: dsPICDEM™ 1.1 PLUS DEVELOPMENT BOARD

CONNECTED TO MPLAB

®

ICD 2 IN-CIRCUIT DEBUGGER

DS70099D-page 22 © 2006 Microchip Technology Inc.

Page 27

Using dsPIC30F Devices

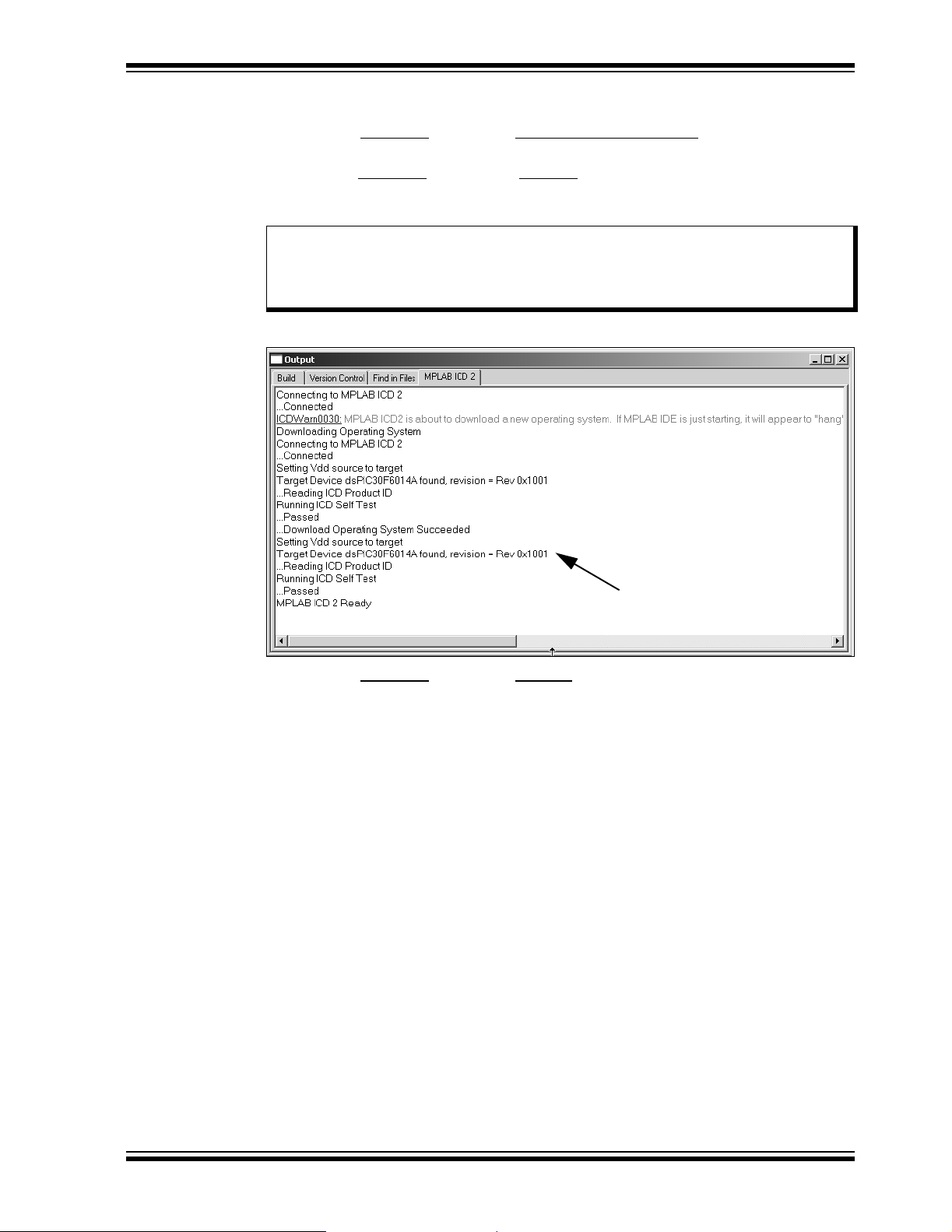

2.6.3 Enable MPLAB ICD 2 Connection

1. From the Debugger menu, click Select Tool>MPLAB ICD 2 to designate the

MPLAB ICD 2 as the debug tool in MPLAB IDE.

2. From the Debugger

The MPLAB ICD 2 should report that it found the dsPIC30F6014A device, as

shown in Figure 2-12.

Note: MPLAB IDE may need to download new firmware if this is the first time the

MPLAB ICD 2 is being used with a dsPIC30F device. Allow it to do so. If

any errors are shown, double click the error message to get more

information.

menu, select Connect to connect the debugger to the device.

FIGURE 2-12: ENABLING MPLAB

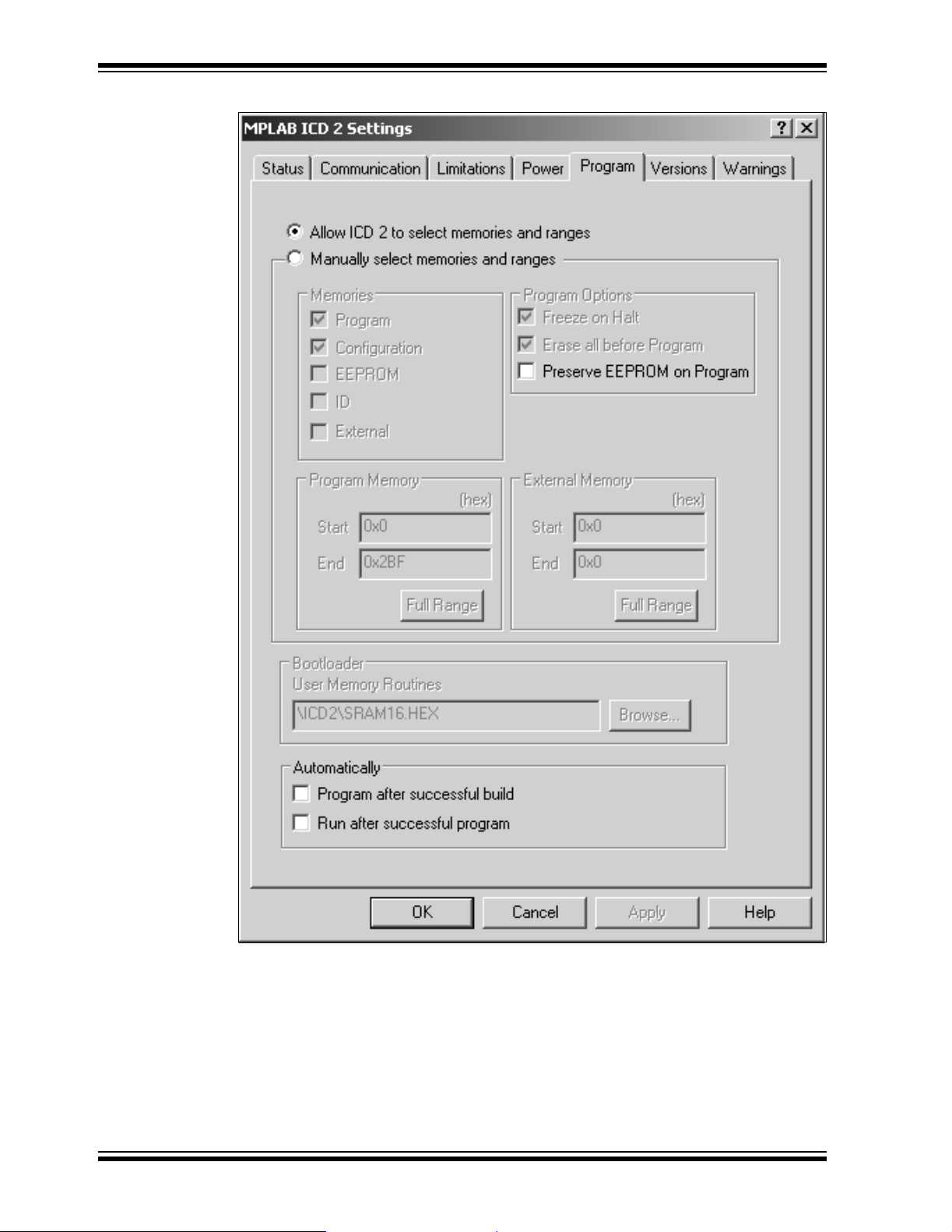

3. From the Debugger

menu, click Settings to display the MPLAB ICD Debugger

®

ICD 2

Status shows that target

device has been found

.

settings.

4. Select the Program tab.

5. Check Allow ICD 2 to select memories and ranges, as shown in Figure 2-13.

This setting will speed up operations by programming only a small part of the

total program memory.

© 2006 Microchip Technology Inc. DS70099D-page 23

Page 28

dsPICDEM™ 1.1 Plus Development Board User’s Guide

FIGURE 2-13: SETTING PROGRAM MEMORY SIZE

DS70099D-page 24 © 2006 Microchip Technology Inc.

Page 29

Using dsPIC30F Devices

2.6.4 Program the dsPIC30F6014A Device

1. From the Debugger menu, select Program. The Output window (Figure 2-14)

displays the program steps as they occur.

2. Observe the process in the Output window. When “MPLAB ICD 2 Ready”

displays, the device is programmed and ready to run.

FIGURE 2-14: PROGRAMMING THE dsPIC30F6014A DEVICE

3. Use the Debugger>Reset

code. LED1 should start blinking and the LCD display should show the text in

Figure 2-15.

FIGURE 2-15: TUTORIAL LCD DISPLAY

2.7 DEBUGGING THE CODE

The MPLAB ICD 2 In-Circuit Debugger can be used to run, halt and step the code. A

breakpoint can be set to halt the program after the code has executed the instruction

at the breakpoint. The contents of the RAM and registers can be viewed whenever the

processor has been halted.

The MPLAB ICD 2 In-Circuit Debugger uses the following function keys to access the

main debugging functions:

<F5> Halt

<F6> Reset

<F7> Single Step

<F9> Run

In addition, there are more functions available by right clicking on a line of source code.

The most important of these are “Set Breakpoint” and “Run to Cursor”.

menu to reset the code, then Debugger>Run to run the

DSPIC30F 16-BIT

DIGITAL SiGNAL

CONTROLLER

© 2006 Microchip Technology Inc. DS70099D-page 25

Page 30

dsPICDEM™ 1.1 Plus Development Board User’s Guide

2.7.1 Display the Code

1. From the View menu, select Program Memory.

2. On the Program Memory window, select the Symbolic tab, as shown in

Figure 2-16.

FIGURE 2-16: PROGRAM MEMORY WINDOW

3. Press <F5> to halt the processor and press <F6> to reset. The program memory

now shows a green arrow pointing to the line of code at address 0, the reset

location.

The instruction at this location is goto __reset. This code is added by the

linker to make the program branch to the start of the code in the Tut6014A.s

file. The code uses the __reset label at the start of the executable code and

declares the label as global to have visibility outside the source file

(see Example 2-1).

EXAMPLE 2-1: CODE START-UP

.global __reset

.text

__reset: mov #__SP_init, W15

mov #__SPLIM_init, W0

mov W0, SPLIM

The linker also provides values for the __SP_init and __SPLIM_init

constants to initialize the stack pointer (W15), since the linker determines what

RAM is available for the stack.

DS70099D-page 26 © 2006 Microchip Technology Inc.

Page 31

Using dsPIC30F Devices

2.7.2 Step the Program

1. Press <F7> to single step the code. The green arrow now points to the code at

__reset in the Tut6014A.s source code as shown in Figure 2-17.

2. Right click the line of code mov w0,LATD and choose Run to Cursor

arrow then points to the line mov w0,TRISD, because it has executed the prior

lines of code up to and including mov #0xFFF0,w0.

FIGURE 2-17: SOURCE CODE WINDOW

. The green

3. From the View

4. From the Add SFR pull-down list, display TRISD.

5. Click Add SFR to add the TRISD register to the Watch window.

6. Next, select PORTD from the pull-down list and click Add SFR.

7. Press <F7> a few times and watch the values of TRISD and PORTD SFRs

change.

FIGURE 2-18: WATCH WINDOW DISPLAY

Note: The value displayed for PORTD may be different on your system

depending on what load is on PORTD.

menu, select Watch to open a Watch window (Figure 2-18).

© 2006 Microchip Technology Inc. DS70099D-page 27

Page 32

dsPICDEM™ 1.1 Plus Development Board User’s Guide

2.7.3 Set Breakpoint

1. To set a breakpoint, right click a code line and select Set Breakpoint from the

pop-up menu.

Note: An alternate method is to simply double click the line. This feature may

need to be enabled using the Edit>Properties

As an example, find the following line of code and set a breakpoint on this line.

WrtNextChr: btss flags, #0

A red stop sign should appear in the gutter (gray bar on the left) of the source

code window.

2. Press <F9> to run the code. The program halts on the instruction following the

breakpoint as shown in Figure 2-19.

Note: The instruction on which the code halts could be elsewhere in the code if

the breakpoint was set on or immediately after a branch instruction. Refer

to Section 12, “Important Notes”, in the Readme file for the MPLAB

ICD 2.txt file located in the E:\MPLAB IDE\READMES directory for

additional operational information.

FIGURE 2-19: SETTING BREAKPOINT

menu.

In this example, every time <F9> is pressed to run the code it sends one character to

the display and stops at the breakpoint. After the first four spaces, the characters will

start to appear on the LCD display.

DS70099D-page 28 © 2006 Microchip Technology Inc.

Page 33

dsPICDEM™ 1.1 PLUS

DEVELOPMENT BOARD

USER’S GUIDE

Chapter 3. dsPIC30F Demonstration Program Operation

3.1 INTRODUCTION

A dsPIC30F DSC device shipped with the dsPICDEM™ 1.1 Plus Development Board

includes a pre-programmed demonstration program. This demonstration program

exercises several of the dsPIC30F peripherals, such as the 12-bit Analog-to-Digital

Converter (ADC) and Codec interface and several of the unique CPU features. This

chapter discusses these examples and explains the functionality they demonstrate. For

detailed information on the dsPICDEM™ 1.1 Plus Development Board hardware, refer

to Chapter 5. “dsPICDEM™ 1.1 Development Hardware”.

3.2 HIGHLIGHTS

Items discussed in this chapter are:

• Demonstration Program Operat ion

• Data and Control Flow

• dsPIC30F Demonstration Performance Metrics

• Board Self-Test Code Module Summary

3.3 DEMONSTRATION PROGRAM OPERATION

The dsPIC30F device included with your dsPICDEM™ 1.1 Plus Development Board is

programmed to automatically initiate the demonstration code when power is applied to

the board. This code is divided into two separate modules:

• Demonstration code module

• Board self-test code module

This chapter is mostly devoted to describing the demonstration program. The end of

the chapter includes a brief summary of the board self-test code module, which has

been included on the CD as a library archive only. See 3.6 “Board Self-Test Code

Module Summary”.

3.3.1 Demonstration Code Module Summary

When power is applied to the dsPICDEM™ 1.1 Plus Development Board, the LCD

displays the Demo Main Menu, as shown in Figure 3-1.

FIGURE 3-1: POWER-UP DISPLAY

dsPIC30F 16-BIT

DIGITAL SIGNAL

CONTROLLER

DEMO MAIN MENU – S1

From this menu, pressing switch SW1 displays the menu options for the demonstration

program, as shown in Figure 3-2.

© 2006 Microchip Technology Inc. DS70099D-page 29

Page 34

dsPICDEM™ 1.1 Plus Development Board User’s Guide

FIGURE 3-2: DEMO MENU OPTIONS

MENU OPTIONS

DATA ACQ DISPLAY –S2

DSP OPERATIONS –S3

DTMF GENERATION –S4

From this menu you can choose one of three demonstration modes:

• Data Acquisition Display mode

• Digital Signal Processing (DSP) Operations mode

• Dual Tone Multi-Frequency (DTMF) Generation mode

3.3.1.1 DATA ACQUISITION DISPLAY MODE The Data Acquisition Display mode demonstrates the capability of the dsPIC30F

device to convert inputs from five different analog signal sources at varying sampling

rates.

Data Acquisition mode is initiated by pressing switch SW2. Figure 3-3 shows the

resulting display on the LCD.

FIGURE 3-3: DATA ACQUISITION DISPLAY

F = 1000HZ TEMP = +23DGC

RP1 = 1.67V RP2 = 2.95V

RP3 = 2.62V

MAIN – s1

This display shows the values of the following analog signal sources:

• Potentiometers RP1-RP3

The three potentiometers available on the dsPICDEM™ 1.1 Plus Development

Board, RP1, RP2 and RP3, are connected to analog input pins AN6, AN4 and

AN5, respectively, on the dsPIC30F device.

• Temperature Sensor U9:

T emperature sensor, TC1047A, is connected to the analog input pin, AN8, on the

dsPIC30F device.

• Frequency:

A fundamental sine-wave signal is generated by stepping the MCP41010 digital

potentiometer (U8) output at an 8 kHz rate. The analyzed frequency is displayed

on the LCD.

The 12-bit ADC on the dsPIC30F device is used to convert these analog input sources.

T o estimate the frequency of the generated sine-wave signal, the program converts and

buffers 256 samples of the signal on pin AN3 and then performs a Fast-Fourier

Transform (FFT) on the buffer. The ADC is interrupt driven to sample and convert at a

16 kHz rate for this operation. AN3 is converted on every alternate conversion, thus

delivering an effective sampling rate of 8 kHz for the signal presented at AN3.

The program scans input pins AN4, AN5, AN6 and AN8 to sample and convert the

values of the temperature sensor and potentiometer signals and delivers one sample

of each of these signals to the LCD display.

DS70099D-page 30 © 2006 Microchip Technology Inc.

Page 35

dsPIC30F Demonstration Program Operation

Y ou can also display the data acquisition values on the communications HyperT erminal

on your PC. Use a DB-9 cable to connect “J2 – PORT A” on the development board to

the RS-232 serial port on the PC, as shown in Figure 3-4.

FIGURE 3-4: dsPICDEM™ 1.1 PLUS DEVELOPMENT BOARD TO PC

CONNECTION

Development Board

J2

DB-9 Cable

After connecting the table, configure HyperTerminal for the port settings shown in

Figure 3-5. HyperTerminal will show a composite display of the data acquisition values

at an update rate of 1.14 seconds.

FIGURE 3-5: HYPERTERMINAL CONFIGURATION SETTINGS

PC

RS-232

Port

To return to the Menu Options display after running the Data Acquisition demo, press

switch SW1.

© 2006 Microchip Technology Inc. DS70099D-page 31

Page 36

dsPICDEM™ 1.1 Plus Development Board User’s Guide

3.3.1.2 DSP OPERATIONS MODE

From the Menu Options display, pressing switch SW3 launches the DSP Operations

demo, which displays the digital signal values shown in Figure 3-6. This display

provides information on the various signal processing operations that are performed on

the signal at analog input pin, AN3.

FIGURE 3-6: DSP OPERATIONS DISPLAY

F = 1000 BIN = 032

256 PT TFFT =018175CY

I I R TFILT =028649CY

MAIN – s1 CHNGFILT – S2

The DSP operations display shows several parameters for a sampled sine-wave

signal. A fundamental sine-wave signal is generated by stepping the MCP41010 digital

potentiometer (U8) output at an 8 kHz rate. The output of the digital potentiometer is

applied to a Low-Pass (LP) filter with a cutoff frequency of approximately 4 kHz. This

LP filter removes the high-frequency components and yields a sine wave adequate for

this demonstration. Five frequencies are developed and selected by varying

potentiometer RP1, as shown in Table 3-1.

TABLE 3-1: FREQUENCIES VS. POTENTIOMETER SETTING

Potentiometer Setting Resulting Frequency

0 ≤ RP1 ≤ 1V 100 Hz

1 ≤ RP1 ≤ 2V 500 Hz

2 ≤ RP1 ≤ 3V 1000 Hz

3 ≤ RP1 ≤ 4V 1500 Hz

4 ≤ RP1 ≤ 5V 2000 Hz

The filtered output of the MCP41010 is routed to pin AN3/RB3, which is an input to the

12-bit ADC. The ADC collects 256 samples from the MCP41010 at an 8 kHz sample

rate. These samples are optionally subjected to a digital filtering algorithm. The

following three digital filtering options are provided and selected by switch SW2:

•None

• Infinite Impulse Response (IIR)

• Finite Impulse Response (FIR)

Subsequently, their spectral components are estimated. The frequency estimate of the

signal on pin AN3/RB3 is displayed on the first row of the DSP Operations display.

DS70099D-page 32 © 2006 Microchip Technology Inc.

Page 37

dsPIC30F Demonstration Program Operation

Figure 3-7 depicts the flow of data from the time the analog input is converted by the

dsPIC30F device to the time the frequency is estimated.

FIGURE 3-7: DSP OPERATIONS FLOW DIAGRAM

T

FILT

Generated

Sine Wave

Low-Pass

Filter

x1(t) x2(t) x[n]

To display

on LCD

ADC

12-bit,

8 kHz sampling

Magnitude

computation and

peak-frequency

detection

Bandpass

IIR/FIR filter

y[n]

256-point FFT

X

2

FFT

T

FFT

Figure 3-8 shows the frequency response of the IIR filter implementation. The IIR filter

is only employed for demonstrating filter operation.

FIGURE 3-8: FREQUENCY RESPONSE: IIR FILTER

© 2006 Microchip Technology Inc. DS70099D-page 33

Page 38

dsPICDEM™ 1.1 Plus Development Board User’s Guide

Figure 3-9 shows the frequency response of the FIR filter implemented on the

dsPIC30F. The FIR filter is only employed for demonstrating filter operation.

FIGURE 3-9: FREQUENCY RESPONSE: FIR FILTER

The signal frequency determined by analyzing the 256-point FFT and associated bin is

displayed on the LCD. Cycle counts for the digital filters and FFT are displayed on the

LCD.

To quit this demonstration and return to the main menu, press switch SW1.

3.3.1.3 DTMF GENERATION MODE

From the Me nu O pti ons disp lay, pressing sw it ch SW4 lau nche s th e DT MF Ge nera tio n

demo and takes you to the DTMF operation menu (Figure 3-10).

FIGURE 3-10: DTMF TONE GENERATION MENU

DTMF TONE 0123456789

NEXT –s2

SELECT –s3

PLAY SEQ –s4 MAIN –s1

When this display is active, switches SW2-SW4 control tone generation, as shown in

Table 3-2.

TABLE 3-2: DTMF TONE GENERATION CONTROLS

Switch Function

SW2 Moves blinking cursor to the next DTMF Tone digit

SW3 Plays the DTMF tone associated with the digit selected by s2

SW4 Plays a predetermined sequence of ten DTMF tones

DS70099D-page 34 © 2006 Microchip Technology Inc.

Page 39

dsPIC30F Demonstration Program Operation

Each DTMF tone consists of two sinusoids: a high-frequency component and a lowfrequency component. In the DTMF tones implemented for this demonstration, the

high-frequency component is at a level 8 dB lower than the low-frequency component.

You can listen to the generated tones by using either a headset or a passive speaker

connected to the “SPKR OUT” jack (J17).

Note: For a passive speaker, use a Radio Shack Model # 40-1434 Fold-up Stereo

Speaker System or an equivalent device.

If you connected your PC for the Data Acquisition Display demo (see Section 3.3.1.1),

you can use the <0>-<9> keys on the PC keyboard to select a DTMF tone.

To quit this demonstration and return to Menu Options, press switch SW1.

3.3.2 Demonstrated Features and Peripherals

The following two sections summarize the key dsPIC30F MCU, DSP and peripheral

features implemented in this general purpose demonstration program.

3.3.2.1 dsPIC30F MCU/DSP FEATURES The demonstration program uses several unique dsPIC30F MCU/DSP features for

various processing functions, including:

• DSP Engine for FFT, FIR and IIR computations

- 40-bit accumulators with Saturation, Overflow and Rounding modes

- Multiply-and-Accumulate (MAC) class of DSP instructions

• Bit-Reversed Addressing for 256-point FFT input data in preparation for the FFT

“butterfly” computations

• Modulo Addressing for accessing arrays in a circular fashion for FIR filtering

- Two modulo buffers have been implemented, one each in X and Y data

spaces.

• Hardware Loop instructions

- DO and REPEAT instructions provide minimal overhead when executing a

block of instructions repetitively.

• Program Space Visibility (PSV)

- Large tables for FIR filter coefficients, sine tables etc., are stored in and

accessed from program memory.

3.3.2.2 dsPIC30F DEMO PERIPHERALS The demonstration program also implements several dsPIC30F peripherals for various

tasks. These peripherals include:

• Timer1 – Configured as a 16-bit timer

• Timer2 – Configured as 16-bit timer with a 256:1 prescaler

• Timer3 – Configured as 16-bit timer with a 256:1 prescaler

• Timer4 and Timer5 – Configured as a 32-bit timer

• UART2 TX/RX – Used to transmit demo data to the PC and receive commands

from the PC keyboard

• SPI 2 – Used to communicate to the 122 x 32 Addressable-Pixel LCD via the

PIC18F242 LCD controller and MCP41010 digital potentiometer

• 12-bit ADC – Used to convert multiple analog signals, including temperature and

sine-wave signals generated by the MCP41010 digital potentiometer through a

low-pass filter

© 2006 Microchip Technology Inc. DS70099D-page 35

Page 40

dsPICDEM™ 1.1 Plus Development Board User’s Guide

• Data Converter Interface – Interfaced to an external Si3000 voice band Codec for

transmission of DTMF PCM signals

• INTx pins – Used for detecting switch SW1-SW4 inputs

• Hierarchical/Prioritized Interrupt Control with nesting enabled

3.4 DATA AND CONTROL FLOW

3.4.1 Power-up Sequence

The power-up peripheral initialization sequence is shown in Table 3-3.

TABLE 3-3: POWER-UP PERIPHERAL INITIALIZATION SEQUENCE

Seq Module or Function Initialization Process

1 Timer1 Configured to count to 125 µS, but not enabled.

2 Timer2 Configured to count to 1 second using a 256:1 prescaler

setting.

3 Timer3 Configured to count up to 1.14 seconds using the 256:1

prescaler setting.

4 Timer4 and Timer5 Configured to operate in the 32-bit Timer mode, but not

enabled until needed.

5 Interrupt Service

Routine (ISR)

6 UART2 Both the transmitter and receiver are configured for

7 SPI 2 Initially configured to operate in an interrupt-driven mode at

8 Data Converter

Interface (DCI)

9 Si3000 Configured for Slave mode. The Si3000 line and speaker

10 DCI Re-initialized to o per ate w ith all fou r bu f fe r s in inte rrup t-dri ven

1 1 External interrupt

pins INT1-INT4

12 12-bit ADC Configured to operate at 16000 Hz sampling rate and gener-

13 Interrupts Peripheral interrupts are configured. Nested interrupts are

Processing is enabled for Timer2 and Timer3.

interrupt-driven operation at 57600 baud.

F

CY/8 Hz (where FCY = 7.3728 MHz). The module communi-

cates at F

LCD controller. When it is used to step the MCP41010, it

operates in the 16-bit mode at FCY/32 Hz.

Configured for Master mode. Initially configured to use two of

four buffers. T ransm its/rec eives in time slot 1 at the frame rate

of 7200 Hz for configuring the Si3000 external voice band

Codec.

ports are enabled. Signal attenuation is set to 0 dB. The ADC

input from the Si3000 is atten uated by 34.5 dB and is not used

in this demo.

mode for transmitting D TMF PCM wo rds to the Si3000 Codec.

Configured to interrupt on the falling edge and used for

switches SW1-SW4, respectively.

ate an interrupt every 16 sample-convert sequences. The

ADC samples channel AN3 (sine wave), AN4 (RP2), AN5

(RP3), AN6 (RP1) and AN8 (temperature sensor U9).

enabled.

CY/8 Hz in 8-bit mo de while displ aying resul ts on the

DS70099D-page 36 © 2006 Microchip Technology Inc.

Page 41

dsPIC30F Demonstration Program Operation

3.4.2 Main Loop Code Execution

The step-by-step Main Loop execution sequence is shown in Table 3-4.

TABLE 3-4: MAIN LOOP CODE EXECUTION SEQUENCE

Seq Program Task

1 12-bit ADC collects 256 samples from the digit al potentiomete r output on AN3 into

a RAM buffer. It also collects one sam ple ea ch f r om AN 4 (RP2), AN5 (RP3), AN6

(RP1) and AN8 (Temperature Sensor U9). All A/D conversions are performed in

an interrupt-driven configuration.

2 Buffered data set is filtered using an IIR filter to remove line noise. The filter can

be changed to an FIR filter or no filter from the DSP menu options. The filtering

operation is benchmarked using the Timer4/5 pair.

3 A complex in-place 256-point FFT is performed on the filtered data set, resulting

in complex frequency data (x + jy). This operation is benchmarked using the

Timer4/5 pair.

4 Squared magnitude is computed for each frequency bin in an in-place fashion

5 The magnitude data is run through a routine that returns the frequency bin and

6 The magnitude of the largest element is compared against a threshold and

7 If a Timer3 count has expired, a software flag is set to inform the CPU that the

8 Any user choices entered via the switches SW1-SW4 are checked and the new

9 The changes are communicated to the PIC18F242 LCD controller via the SPI 2

10 In the special case of the DTMF menu, the main routi ne may al so kick off the DCI

2

+ y2).

(x

magnitude of the largest element.

captured if it is greater than the threshold so that low-level noise does not show

up as a frequency estimate. (Provides a simplified peak-detection algorithm.)

results recorded ma y no w be dis played. This ensures that the CPU refreshes the

display buffers.

user selections are applied. May involve a change of display screen or some

parameter displayed on the LCD.

module.

module operation when the user requests DTMF tone generation.

© 2006 Microchip Technology Inc. DS70099D-page 37

Page 42

dsPICDEM™ 1.1 Plus Development Board User’s Guide

3.4.3 Interrupts Used in the Demo

3.4.3.1 EXTERNAL INTERRUPTS TO MAIN ROUTINE

External interrupts INT1-INT4 are controlled by switches SW1-SW4.

These switches provide selection capabilities for the demo program. The most recent

switch presses are recorded in a variable within the interrupt routines. In the main

routine, the variable is analyzed to determine what action is requested by the recent

switch event.

3.4.3.2 DCI INTERRUPTS AND DTMF

The DCI module interrupts the CPU when all four TXBUF registers have been

transmitted. The DCI is used to send out DTMF tones to the Codec. The tonal

components are stored as sinusoid tables in program memory and accessed using

Program Space Visibility (PSV).

The DCI ISR keeps track of the number of samples sent. The DTMF tones are

transmitted by adhering to International Telecommunication Union (ITU-T)

specifications. For example, the ON time for tones is greater than 40 mS and the OFF

time is less than 23 mS. The actual values are 100 mS of ON time and 15 mS of OFF

time. When playing a pre-recorded sequence of tones, a PAUSE time is added

between successive tones. This time is equal to the ON time of the tone. Also, the high

and low frequency of the DTMF tone are separated by 8 dB. The high frequencies are

reduced in magnitude relative to the low frequencies by 8 dB.

3.4.3.3 UART RECEIVE INTERRUPTS

Single DTMF tones may also be played by entering numeric characters (0-9) on the PC

keyboard during the HyperTerminal session. The UART receives this keyboard

character, and a receiver interrupt communicates this data to the DCI to start a tone

generation process.

3.4.3.4 UART TRANSMIT INTERRUPTS

Every 1.14 seconds, data is transmitted via the UART to the HyperTerminal session

window. Four bytes are loaded at a time in the Transmitter Buffer registers. The term

“data” refers to the following:

• Analog data such as RP1, RP2 and RP3

• Temperature sensor data

• FFT frequency and bin number of the sampled input sine-wave signal

• Cycle count information for the FFT, FIR or IIR algorithms

• Chosen Filter Type – IIR, FIR or None

3.4.3.5 SPI INTERRUPTS, DIGITAL POT AND THE LCD CONTROLLER

The SPI 2 module is used to perform two functions:

• When the demo code is waiting for the ADC to collect 256 samples of data on pin

AN3, the SPI 2 module is used by the Timer1 ISR to transmit sine-wave samples

to the MCP41010 every 125 microseconds at a data rate of 230 kHz.

• When code execution reaches the DSP stage (i.e., filtering, FFT etc.) the SPI 2

module is used to send data to the PIC18F242 LCD controller on the expansion

board at a data rate of 921.6 KHz (F

display. All 80 characters are refreshed by the SPI 2 module.

CY/8). The LCD has a 4 row x 20-character

DS70099D-page 38 © 2006 Microchip Technology Inc.

Page 43

dsPIC30F Demonstration Program Operation

3.4.3.6 TIMER1 Timer1 is a 16-b it t imer that us es th e instr ucti on cycl e as it s ti me base . It is co nfi gure d

to time out and generate an interrupt every 125 microseconds. The Timer1 Interrupt

Service Routine (ISR) loads the SPI 2 buffer with a value from a sine table. The SPI 2

module is then used to transmit the sine sample to digital potentiometer MCP41010.

The MCP41010 output is connected to pin AN3/RB3 of the dsPIC30F device.

3.4.3.7 TIMER2 LEDs 1-4 count upward in binary form from 0 through 15. The count rate is controlled

by the 16-bit Timer2 module, which expires every second as it is operated in a 256:1

prescale mode, with the instruction cycle being the count interval.

3.4.3.8 TIMER3 The Timer3 count is configured to expire every 1.14 seconds. In the Timer3 ISR, a

software flag is used to determine whether data needs to be updated to the PC via the

UART2 module. Thus data is not transmitted to the PC all the time so that the data on

the HyperTerminal window is legible. Data sent to the LCD, however, is refreshed

continuously since it does not have a “scrolling” effect.

3.5 dsPIC30F DEMONSTRATION PERFORMANCE METRICS

The dsPIC30F performance metrics are primarily based upon acquisition and

processing of the 256 discrete samples. The discrete samples are acquired by the ADC

sampling of a sine-wave signal applied to analog channel input AN3.

The sine-wave signal is generated as a result of stepping the MCP41010 digital

potentiometer at an 8 kHz rate with its output applied to a low-pass filter with a cutoff

frequency of approximately 4 kHz.

This acquisition and processing sequence repeats in a continuous loop.

Upon user command via the LCD menu system (or optionally from PC keys <0>-<9>),

DTMF tones are generated. During this time additional CPU MIPS are required.

This demonstration was developed for the development board that is supplied with a

7.3728 MHz crystal. The dsPIC30F is programmed for the XTx4PLL mode of

operation, effectively yielding 7.3728 MIPS. Additional MIPS are not required for this

demo but could have been obtained by using the XTx8PLL and XTx16PLL modes of

operation yielding 14.7456 and 29.4912 MIPS.

Note: The demo code as supplied has specific timing parameters derived from

the 7.3728 MHz crystal with the XTx4PLL mode. Changing the device time

base will require modification of several time-specific parameters.

© 2006 Microchip Technology Inc. DS70099D-page 39

Page 44

dsPICDEM™ 1.1 Plus Development Board User’s Guide

Following is a summary of the processing time for each of the main demo functions.

The data is based upon a 256 sample size.

• Acquisition of 256 discrete sine-wave data points sampled at 8 kHz

- Total acquisition time = 32 mS (256/8000)

• FIR filtering – 72,734 instruction cycles for block processing 256 samples in a

273-tap band-pass filter

- 9.87 mS @ 7.3728 MIPS

• IIR filtering – 28,649 instruction cycles for block processing 256 samples in a

9-section bi-quad bandpass filter

- 3.89 mS @ 7.3728 MIPS

• 256-point complex FFT – 18,176 instruction cycles

- 2.47 mS @ 7.3728 MIPS

Note: Filtering and FFT operations may be interrupted by the DCI, Timer2 or

UART2 modules. The time metrics presented above account for the

interrupt handler processing time from these interrupts.

• The interrupt-driven UART2 transmitter is triggered every 1.14 seconds by Timer3

to send out approximately 145 characters.

- At 57600 baud, transmission of 145 characters requires approximately 25 mS

• SPI 2 transmits 160 characters (80 control and 80 data) @ F

F

CY = 7.3728 MHz) to the PIC18F242 LCD controller for LCD screen updates.

CY/8 Hz (where

3.5.1 Performance Metric Summary with FIR Filter

The overall CPU performance metric is calculated on how many complete processing

cycles can be performed over a 1 second interval. In one second, the dsPIC30F

spends the following amounts of time in each of the three major functions:

• FFT Computation:

- 22.55 x 256-point complex FFT s = 55.69 mS

• FIR Filter Computation:

- 22.55 x 273-tap FIR filters = 223 mS

Coefficients stored in program memory

• CPU Idle:

- Waiting for ADC data = 721 mS

The 22.55 multiplier used in the above computations is based upon how many times in

one second 256 samples can be acquired and then processed by the FIR and FFT

algorithms.

For example:

• 32 mS for acquisition of 256 samples

• 9.87 mS for FIR filtering

• 2.47 mS for 256-point FFT

Adding these three major timing metrics results in 44.34 mS. Therefore, this

44.34 mS cycle is repeated 22.55 times in a 1 second interval.

Total MIPS required = 2.1 MIPS out of available 7.3728 MIPS.

FIR filter specifications are listed in Table 3-5.

DS70099D-page 40 © 2006 Microchip Technology Inc.

Page 45

dsPIC30F Demonstration Program Operation

TABLE 3-5: FIR FILTER SPECIFICATIONS

Specification Value

FIR filter type BandPass

Kaiser Window – 273 coefficients

Passband ripple 0.001 dB

Stopband ripple 100 dB

Passband cutoff frequencies 300 Hz and 3800 Hz

Stopband cutoff frequencies 100 Hz and 3990 Hz

Sampling frequency 8000 Hz

The filter coefficients and code were generated by the Digital Filter Design Tool.

3.5.2 Performance Metric Summary with IIR Filter

The following overall CPU performance metric is calculated on how many complete

processing cycles can be performed over a 1 second interval.

• FFT Computation:

- 26 x 256-point complex FFTs = 64.2 mS

• IIR Filter Computation:

- 26 x 9 second order elliptic section IIR filters = 101 mS

Coefficients stored in program memory

• CPU Idle:

- Waiting for ADC data = 834 mS

The 26 multiplier used in the above computations is based upon how many times in one

second 256 samples can be acquired and then processed by the IIR and FFT

algorithms.

For example:

• 32 mS for acquisition of 256 samples

• 3.89 mS for IIR filtering

• 2.47 mS for 256-point FFT

Adding these three major timing metrics results in 38.3 mS. Therefore, this

38.3 mS cycle is repeated approximately 26 times in a 1 second interval.

Total MIPS required = 1.22 MIPS out of available 7.3728 MIPS.

IIR filter specifications are listed in Table 3-6.

TABLE 3-6: IIR FILTER SPECIFICATIONS

Specification Value

IIR filter type Bandpass, Elliptic, 9 Second Order Sections

Passband ripple 0.001 dB

Stopband ripple 100 dB

Passband cutoff frequencies 200 Hz and 3850 Hz

Stopband cutoff frequencies 100 Hz and 3990 Hz

Sampling frequency 8000 Hz

The filter coefficients and code were generated by the Digital Filter Design Tool.

© 2006 Microchip Technology Inc. DS70099D-page 41

Page 46

dsPICDEM™ 1.1 Plus Development Board User’s Guide

3.6 BOARD SELF-TEST CODE MODULE SUMMARY

The Board Self-Test Code module can be used to check that peripheral elements used

by the main demonstration program are operating correctly.

To run this code module:

1. Apply power to the dsPICDEM™ 1.1 Plus Development Board,

2. Press and hold down switch SW1 while pressing and releasing the Reset switch.

3. Release SW1.

At this point, the dsPIC DSC device enters into a basic test code execution loop while

displaying the test code results on the LCD. The following data is displayed on the LCD:

• RP1-RP3 – As the potentiometers are rotated through their range, the displayed

value will vary from 0 to 0FFF.

• When SW1-SW4 are depressed, LED1-LED4 should light, respectively.

• At 25°C/77°F, the temperature sensor will yield a count of approximately

26x-27x. Touching U9 (TC1047A temperature sensor) should increase this count.

• A running counter is being sent to the Codec and read back when pins 2 and 3 of

J12 are connected together. There is an attenuation factor and a large phase shift

so the value will not be the same but the counter should be incrementing. (Jumper

J9 must be configured for the Slave setting.)

• A running counter is sent to the MCP41010 digital potentiometer. The D POT

value should be counting on the LCD.

When pin J2-3 is connected to J5-2 and pin J2-2 is connected to J5-3, “OK” will appear

on the lower right corner of the screen at power-up.

DS70099D-page 42 © 2006 Microchip Technology Inc.

Page 47

dsPICDEM™ 1.1 PLUS

DEVELOPMENT BOARD

USER’S GUIDE

Chapter 4. Using dsPIC33F and PIC24H/24F Devices

4.1 INTRODUCTION

This chapter is a self-paced tutorial to help you get started using the dsPICDEM™ 1.1

Plus Development Board with dsPIC33F and PIC24H/24F devices. The tutorial demonstrates the main features of MPLAB IDE Integrated Development Environment and

the MPLAB ICD 2 In-Circui t Debugge r as they are us ed with the dsPICDEM™ 1.1 Plus

Development Board. Upon completing this tutorial, you should be able to:

• Create a project using the Project Wizard.

• Assemble and link the code and set the Configuration bits.

• Set up MPLAB IDE to use the MPLAB ICD 2 In-Circuit Debugger.

• Program the chip with the MPLAB ICD 2.

• View the code execution in program memory and source code.

• View registers in a Watch window.

• Set a breakpoint and make the code halt at a chosen location.

• Use the function keys to Reset, Run, Halt and Single Step the code.

4.2 HIGHLIGHTS

Items discussed in this chapter include:

• Tutorial Overview

• Creating the Project

• Building the Code

• Programming the Chip

• Debugging the Code

• Additional Code Examples

4.3 TUTORIAL OVERVIEW

The tutorial program in Tutorial.c displays text on the LCD and flashes an LED. The

source file is used with a linker script file (p33FJ256GP710.gld) to form a complete

project. The tutorial is a simple project that uses a single source code file. More

complex projects might use multiple assembler and compiler source files as well as

library files and precompiled object files. For simplicity, this tutorial uses only one

source file.

There are four steps to this tutorial:

1. Create a project in MPLAB IDE.

2. Compile and link the code.

3. Program the chip with the MPLAB ICD 2.

4. Debug the code with the MPLAB ICD 2.

© 2006 Microchip Technology Inc. DS70099D-page 43

Page 48

dsPICDEM™ 1.1 Plus Development Board User’s Guide

4.4 CREATING THE PROJECT

The first step is to create a project and a workspace in MPLAB IDE. Usually, you will

have one project in one workspace.

Note: These instructions presume the use of MPLAB 7.31 or newer.

A project contains the files needed to build an application (source code, linker script

files, etc.) along with their associations to various build tools and build options.

A workspace contains one or more projects and information on the selected device,

debug tool and/or programmer, open windows and their location, and other IDE

configuration settings.

MPLAB IDE contains a Project Wizard to help create new projects. Before starting,

create a folder for the project files for this tutorial (C:\Tutorial is assumed in the

instructions that follow). From the dsPICDEM 1_1 Plus Development Board

code\Tutorial Code for dsPIC33FJ256GP710 folder on the dsPICDEM™ 1.1

Plus Development Kit CD, copy the Tutorial.c file into the C:\Tutorial folder.

Note: All files copied from the CD are read only. If the file needs to be edited, the

attributes will need to be changed.

4.4.1 Select a Device

1. Start MPLAB IDE.

2. Close any workspace that might be open (File>Close Workspace

3. From the Project

4. From the Welcome screen, click Next> to display the Project Wizard Step One

dialog (see Figure 4-1).

FIGURE 4-1: PROJECT WIZARD, STEP 1, SELECT A DEVICE

menu, select Project Wizard.

).

DS70099D-page 44 © 2006 Microchip Technology Inc.

Page 49

Using dsPIC33F and PIC24H/24F Devices

5. From the Device: pull-d own li st, selec t dsPIC33FJ256GP710 and click Next>.

The Project Wizard Step Two dialog displays (see Figure 4-2).

FIGURE 4-2: PROJECT WIZARD, STEP 2, SELECT LANGUAGE

TOOLSUITE

4.4.2 Select Language Toolsuite

1. From the Active Toolsuite: pull-down menu, select Microchip C30 Toolsuite.