dsPIC30F6010

Data Sheet

High Performance

Digital Signal Controllers

2004 Microchip Technology Inc. Advance Information DS70119B

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical

components in life support systems is not authorized except

with express written approval by Microchip. No licenses are

conveyed, implicitly or otherwise, under any intellectual

property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart and rfPIC are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

AmpLab, FilterLab, microID, MXDEV, MXLAB, PICMASTER,

SEEVAL, SmartShunt and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Application Maestro, dsPICDEM, dsPICDEM.net,

dsPICworks, ECAN, ECONOMONITOR, FanSense,

FlexROM, fuzzyLAB, In-Circuit Serial Programming, ICSP,

ICEPIC, Migratable Memory, MPASM, MPLIB, MPLINK,

MPSIM, PICkit, PICDEM, PICDEM.net, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, rfLAB, Select Mode,

SmartSensor, SmartTel and Total Endurance are trademarks

of Microchip Technology Incorporated in the U.S.A. and other

countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2004, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in October

2003. The Company’s quality system processes and procedures are for

its PICmicro

EEPROMs, microperipherals, non-volatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping devices, Serial

DS70119B-page ii Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

dsPIC30F6010 Enhanced Flash

16-bit Digital Signal Controller

High Performance Modified RISC CPU:

• Modified Harvard architecture

• C compiler optimized instruction set architecture

with flexible addressing modes

• 84 base instructions

• 24-bit wide instructions, 16-bit wide data path

• 144 Kbytes on-chip Flash program space

(Instruction words)

• 8 Kbytes of on-chip data RAM

• 4 Kbytes of non-volatile data EEPROM

• Up to 30 MIPs operation:

- DC to 40 MHz external clock input

- 4 MHz-10 MHz oscillator input with

PLL active (4x, 8x, 16x)

• 44 interrupt sources

- 5 external interrupt sources

- 8 user selectable priority levels for each

interrupt source

- 4 processor trap sources

• 16 x 16-bit working register array

DSP Engine Features:

• Dual data fetch

• Accumulator write back for DSP operations

• Modulo and Bit-Reversed Addressing modes

• Two, 40-bit wide accumulators with optional

saturation logic

• 17-bit x 17-bit single cycle hardware fractional/

integer multiplier

• All DSP instructions single cycle

• ± 16-bit single cycle shift

Peripheral Features:

• High current sink/source I/O pins: 25 mA/25 mA

•Timer module with programmable prescaler:

- Five 16-bit timers/counters; optionally pair

16-bit timers into 32-bit timer modules

• 16-bit Capture input functions

• 16-bit Compare/PWM output functions

TM

•3-wire SPI

2

CTM module supports Multi-Master/Slave mode

•I

and 7-bit/10-bit addressing

• 2 UART modules with FIFO Buffers

• 2 CAN modules, 2.0B compliant

modules (supports 4 Frame modes)

Motor Control PWM Module Features:

• 8 PWM output channels

- Complementary or Independent Output

modes

- Edge and Center Aligned modes

• 4 duty cycle generators

• Dedicated time base

• Programmable output polarity

• Dead-time control for Complementary mode

• Manual output control

• Trigger for A/D conversions

Quadrature Encoder Interface Module

Features:

• Phase A, Phase B and Index Pulse input

• 16-bit up/down position counter

• Count direction status

• Position Measurement (x2 and x4) mode

• Programmable digital noise filters on inputs

• Alternate 16-bit Timer/Counter mode

• Interrupt on position counter rollover/underflow

2004 Microchip Technology Inc. Advance Information DS70119B-page 1

dsPIC30F6010

Analog Features:

• 10-bit Analog-to-Digital Converter (A/D) with

4 S/H Inputs:

- 500 Ksps conversion rate

- 16 input channels

- Conversion available during Sleep and Idle

• Programmable Low Voltage Detection (PLVD)

• Programmable Brown-out Detection and Reset

generation

Special Microcontroller Features:

• Self-reprogrammable under software control

• Power-on Reset (POR), Power-up Timer (PWRT)

and Oscillator Start-up Timer (OST)

• Flexible Watchdog Timer (WDT) with on-chip low

power RC oscillator for reliable operation

• Fail-Safe clock monitor operation detects clock

failure and switches to on-chip low power RC

oscillator

• Programmable code protection

• In-Circuit Serial Programming™ (ICSP™)

• Selectable Power Management modes

- Sleep, Idle and Alternate Clock modes

• Enhanced Flash program memory:

- 10,000 erase/write cycle (min.) for

industrial temperature range, 100K (typical)

• Data EEPROM memory:

- 100,000 erase/write cycle (min.) for

industrial temperature range, 1M (typical)

CMOS Technology:

• Low power, high speed Flash technology

• Wide operating voltage range (2.5V to 5.5V)

• Industrial and Extended temperature ranges

• Low power consumption

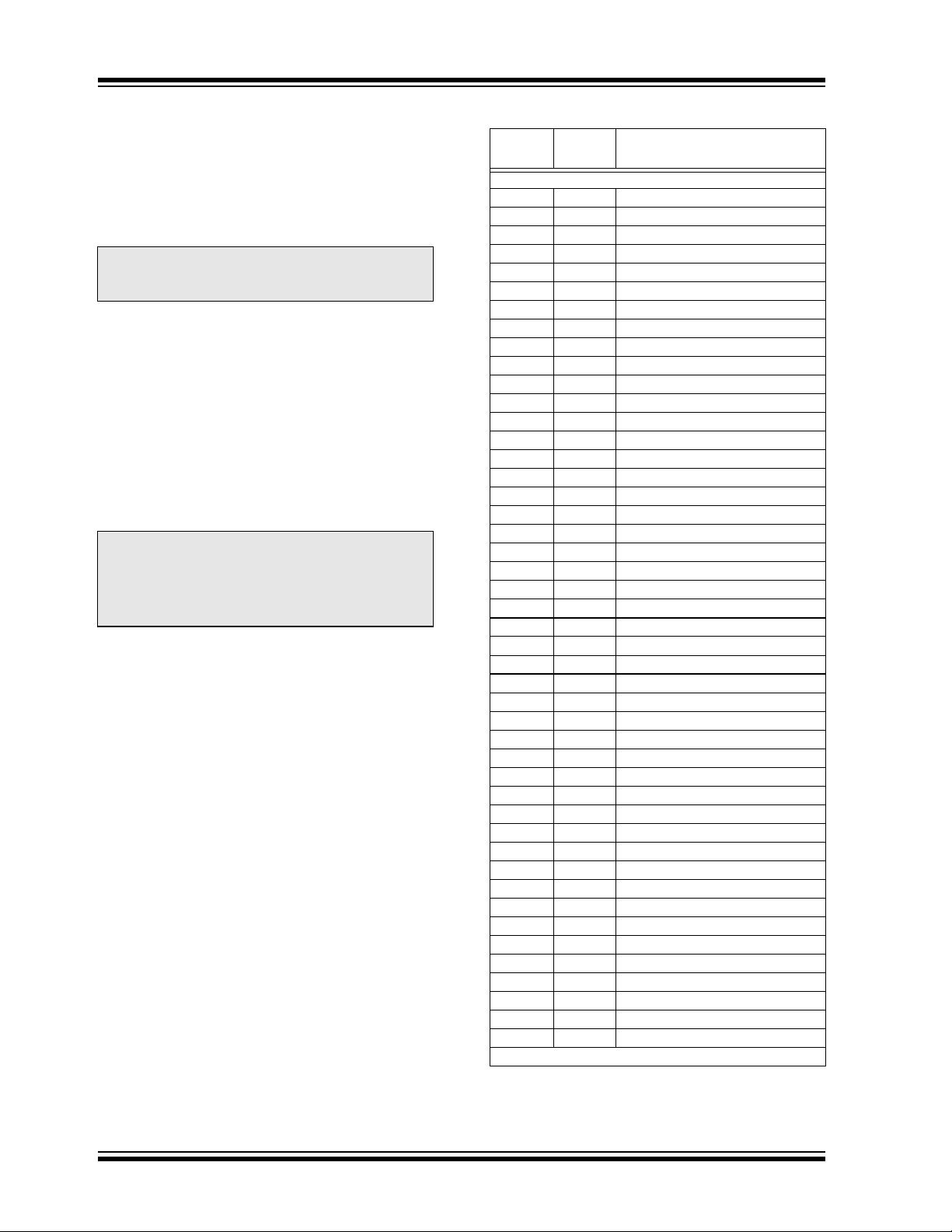

dsPIC30F Motor Control and Power Conversion Family*

Device Pins

Program

Mem. Bytes/

Instructions

SRAM

Bytes

EEPROM

Bytes

Timer

16-bit

Input

Cap

Output

Comp/Std

PWM

Moto

Control

PWM

A/D 10-bit

500 Ksps

Quad

Enc

TM

UART

SPI

TM

2

C

CAN

I

dsPIC30F2010 28 12K/4K 512 1024 3 4 2 6 ch 6 ch Ye s 1 1 1 -

dsPIC30F3010 28 24K/8K 1024 1024 5 4 2 6 ch 6 ch Ye s 1 1 1 -

dsPIC30F4012 28 48K/16K 2048 1024 5 4 2 6 ch 6 ch Ye s 1 1 1 1

dsPIC30F3011 40/44 24K/8K 1024 1024 5 4 4 6 ch 9 ch Ye s 2 1 1 -

dsPIC30F4011 40/44 48K/16K 2048 1024 5 4 4 6 ch 9 ch Ye s 2 1 1 1

dsPIC30F5015 64 66K/22K 2048 1024 5 4 4 8 ch 16 ch Ye s 1 2 1 1

dsPIC30F6010 80 144K/48K 8192 4096 5 8 8 8 ch 16 ch Yes 2 2 1 2

* This table provides a summary of the dsPIC30F6010 peripheral features. Other available devices in the dsPIC30F

Motor Control and Power Conversion Family are shown for feature comparison.

DS70119B-page 2 Advance Information 2004 Microchip Technology Inc.

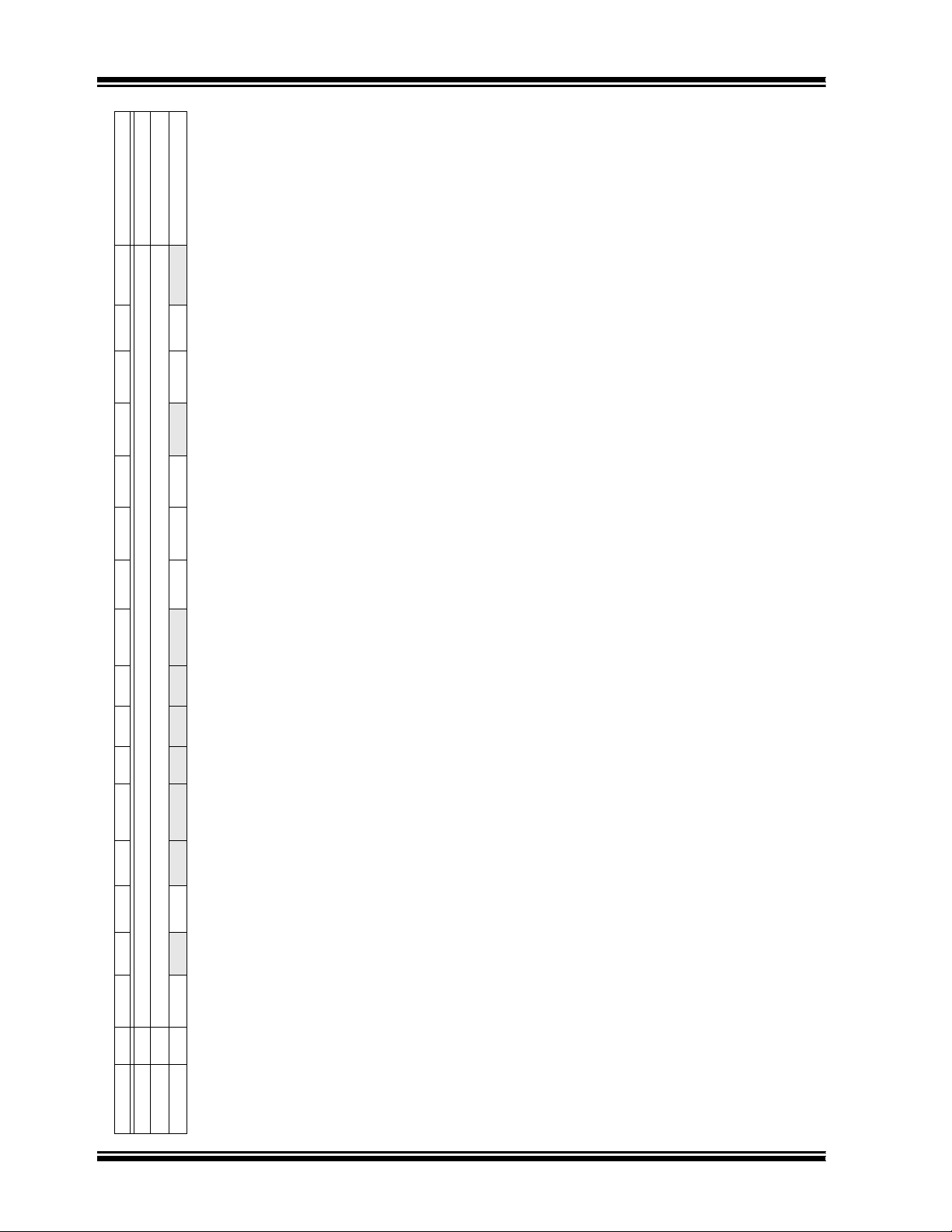

Pin Diagram

80-Pin TQFP

PWM2L/RE2

PWM1H/RE1

PWM2H/RE3

PWM3L/RE4

PWM1L/RE0

C2RX/RG0

C2TX/RG1

C1TX/RF1

C1RX/RF0

DD

OC8/CN16/UPDN/RD7

OC6/CN14/RD5

VSS

OC7/CN15/RD6

V

dsPIC30F6010

IC5/RD12

OC4/RD3

OC5/CN13/RD4

IC6/CN19/RD13

OC3/RD2

EMUD2/OC2/RD1

PWM3H/RE5

PWM4L/RE6

PWM4H/RE7

T2CK/RC1

T4CK/RC3

SCK2/CN8/RG6

SDI2/CN9/RG7

SDO2/CN10/RG8

MCLR

SS2/CN11/RG9

V

VDD

FLTA/INT1/RE8

FLTB/INT2/RE9

AN5/QEB/CN7/RB5

AN4/QEA/CN6/RB4

AN3/INDX/CN5/RB3

/LVDIN/CN4/RB2

AN2/SS1

PGC/EMUC/AN1/CN3/RB1

PGD/EMUD/AN0/CN2/RB0

80

79

1

2

3

4

5

6

7

8

9

10

SS

11

12

13

14

15

16

17

18

19

20

21

22

2324252627282930313233

AN7/RB7

VREF-/RA9

VREF+/RA10

AN6/OCFA/RB6

DD

AV

75

767877

AVSS

727473

7170696867666564636261

dsPIC30F6010

VSS

AN8/RB8

AN9/RB9

AN11/RB11

AN10/RB10

DD

V

34

AN12/RB12

AN13/RB13

37

36

35

AN14/RB14

IC7/CN20/RD14

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

IC8/CN21/RD15

U2TX/CN18/RF5

U2RX/CN17/RF4

EMUC1/SOSCO/T1CK/CN0/RC14

EMUD1/SOSCI/CN1/RC13

EMUC2/OC1/RD0

IC4/RD11

IC3/RD10

IC2/RD9

IC1/RD8

INT4/RA15

INT3/RA14

SS

V

OSC2/CLKO/RC15

OSC1/CLKI

DD

V

SCL/RG2

SDA/RG3

EMUC3/SCK1/INT0/RF6

SDI1/RF7

EMUD3/SDO1/RF8

U1RX/RF2

U1TX/RF3

AN15/OCFB/CN12/RB15

Note: Pinout subject to change.

2004 Microchip Technology Inc. Advance Information DS70119B-page 3

dsPIC30F6010

Table of Contents

1.0 Device Overview ...................................................................................................................................................................... 5

2.0 CPU Architecture Overview.................................................................................................................................................... 11

3.0 Memory Organization ............................................................................................................................................................. 19

4.0 Address Generator Units........................................................................................................................................................ 31

5.0 Interrupts ................................................................................................................................................................................ 37

6.0 Flash Program Memory.......................................................................................................................................................... 43

7.0 Data EEPROM Memory ......................................................................................................................................................... 49

8.0 I/O Ports ................................................................................................................................................................................. 53

9.0 Timer1 Module ....................................................................................................................................................................... 57

10.0 Timer2/3 Module .................................................................................................................................................................... 61

11.0 Timer4/5 Module .................................................................................................................................................................... 67

12.0 Input Capture Module............................................................................................................................................................. 71

13.0 Output Compare Module ........................................................................................................................................................ 75

14.0 Quadrature Encoder Interface (QEI) Module ......................................................................................................................... 79

15.0 Motor Control PWM Module ................................................................................................................................................... 85

16.0 SPI™ Module ......................................................................................................................................................................... 95

17.0 I2C Module ............................................................................................................................................................................. 99

18.0 Universal Asynchronous Receiver Transmitter (UART) Module .......................................................................................... 107

19.0 CAN Module ......................................................................................................................................................................... 115

20.0 10-bit High Speed Analog-to-Digital Converter (A/D) Module .............................................................................................. 127

21.0 System Integration ............................................................................................................................................................... 135

22.0 Instruction Set Summary ...................................................................................................................................................... 149

23.0 Development Support........................................................................................................................................................... 157

24.0 Electrical Characteristics ...................................................................................................................................................... 163

25.0 Packaging Information.......................................................................................................................................................... 207

On-Line Support................................................................................................................................................................................. 217

Systems Information and Upgrade Hot Line ...................................................................................................................................... 217

Reader Response .............................................................................................................................................................................. 218

Product Identification System............................................................................................................................................................. 219

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@mail.microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150.

We welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

• The Microchip Corporate Literature Center; U.S. FAX: (480) 792-7277

When contacting a sales office or the literature center, please specify which device, revision of silicon and data sheet (include

literature number) you are using.

Customer Notification System

Register on our web site at www.microchip.com/cn to receive the most current information on all of our products.

DS70119B-page 4 Advance Information 2004 Microchip Technology Inc.

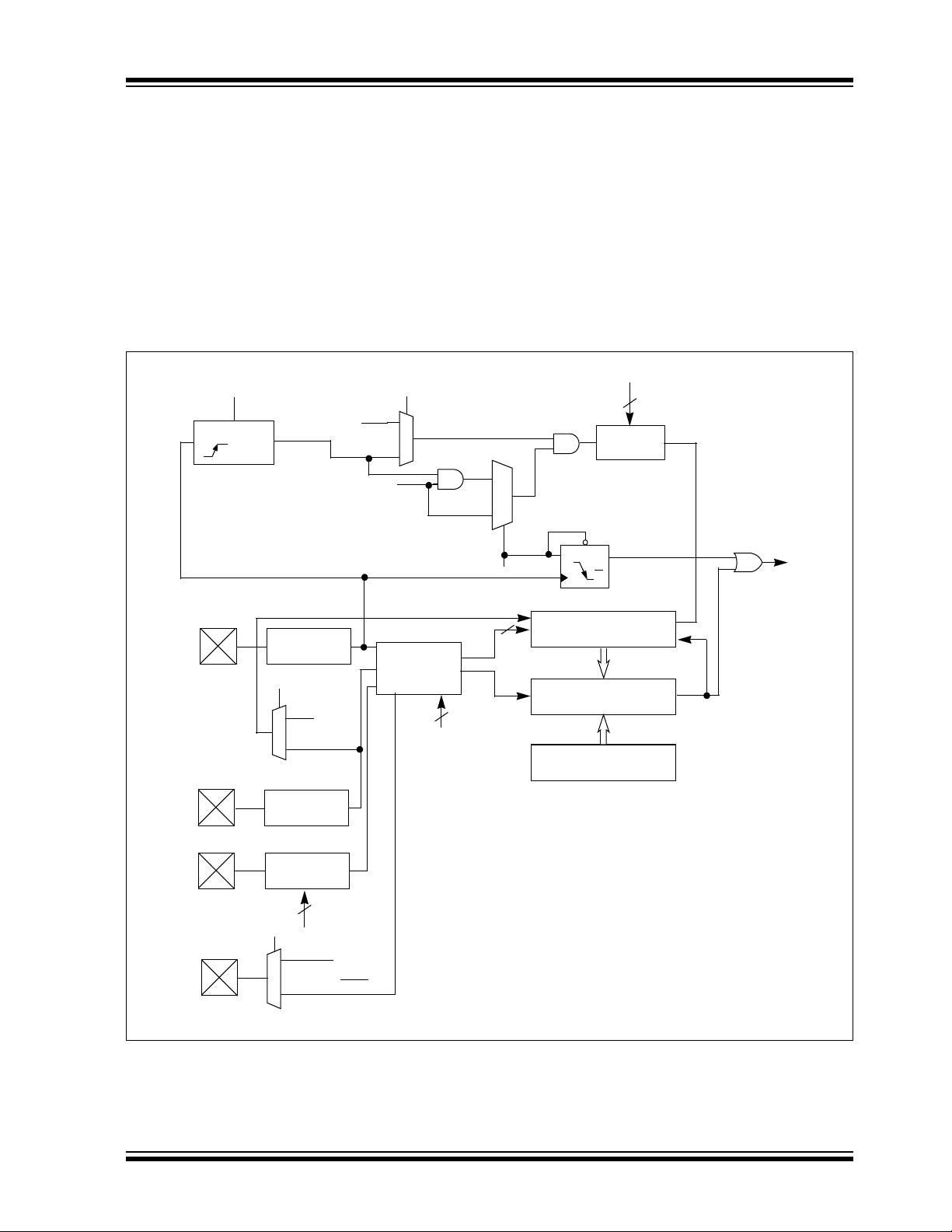

1.0 DEVICE OVERVIEW

This document contains device specific information for

the dsPIC30F6010 device. The dsPIC30F devices

contain extensive Digital Signal Processor (DSP) functionality within a high performance 16-bit microcontroller

(MCU) architecture. Figure 1-1 shows a device block

diagram for the dsPIC30F6010 device.

dsPIC30F6010

2004 Microchip Technology Inc. Advance Information DS70119B-page 5

dsPIC30F6010

FIGURE 1-1: dsPIC30F6010 BLOCK DIAGRAM

Interrupt

Controller

24

Address Latch

Program Memory

(144 Kbytes)

Data EEPROM

(4 Kbytes)

Data Latch

Control Signals

to Various Blocks

OSC1/CLKI

Generation

CAN1,

CAN2

SPI1,

SPI2

24

24

16

Instruction

Decode &

Control

Timing

MCLR

VDD, VSS

AVDD, AVSS

PSV & Table

Data Access

Control Block

Stack

Control

16

24

Start-up Timer

10-bit ADC

Timers

Y Data Bus

8

16

PCH PCL

PCU

Program Counter

Logic

Power-up

Oscillator

POR/BOR

Watchdog

Low Voltage

ROM Latch

IR

Timer

Reset

Timer

Detect

Input

Capture

Module

Loop

Control

Logic

Decode

QEI

16

Y Data

(4 Kbytes)

Address

Y AGU

DSP

Engine

16

Output

Compare

Module

Motor Control

PWM

X Data Bus

16

16

Data LatchData Latch

16

X RAGU

X WAGU

16

16 x 16

16

ALU<16>

16

X Data

(4 Kbytes)

Address

Latch

Divide

Unit

UART1,

UART2

RAM

Latch

16

Effective Address

W Reg Array

16

16

RAM

I2C

16

PORTA

16

PORTB

16

PORTC

PORTD

PORTE

VREF-/RA9

VREF+/RA10

INT3/RA14

INT4/RA15

AN0/CN2/RB0

AN1/CN3/RB1

AN2/SS1/LVDIN/CN4/RB2

AN3/INDX/CN5/RB3

AN4/QEA/CN6/RB4

AN5/QEB/CN7/RB5

PGC/EMUC/AN6/OCFA/RB6

PGD/EMUD/AN7/RB7

AN8/RB8

AN9/RB9

AN10/RB10

AN11/RB11

AN12/RB12

AN13/RB13

AN14/RB14

AN15/OCFB/CN12/RB15

T2CK/RC1

T4CK/RC3

EMUD1/SOSCI/CN1/RC13

EMUC1/SOSCO/T1CK/CN0/RC14

OSC2/CLKO/RC15

EMUC2/OC1/RD0

EMUD2/OC2/RD1

OC3/RD2

OC4/RD3

OC5/CN13/RD4

OC6/CN14/RD5

OC7/CN15/RD6

OC8/CN16/UPDN/RD7

IC1/RD8

IC2/RD9

IC3/RD10

IC4/RD11

IC5/RD12

IC6/CN19/RD13

IC7/CN20/RD14

IC8/CN21/RD15

PWM1L/RE0

PWM1H/RE1

PWM2L/RE2

PWM2H/RE3

PWM3L/RE4

PWM3H/RE5

PWM4L/RE6

PWM4H/RE7

FLTA/INT1/RE8

FLTB/INT2/RE9

C2RX/RG0

C2TX/RG1

SCL/RG2

SDA/RG3

SCK2/CN8/RG6

SDI2/CN9/RG7

SDO2/CN10/RG8

SS2

/CN11/RG9

PORTG PORTF

C1RX/RF0

C1TX/RF1

U1RX/RF2

U1TX/RF3

U2RX/CN17/RF4

U2TX/CN18/RF5

EMUC3/SCK1/INT0/RF6

SDI1/RF7

EMUD3/SDO1/RF8

DS70119B-page 6 Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

Table 1-1 provides a brief description of the device I/O

pinout and the functions that are multiplexed to a port

pin. Multiple functions may exist on one port pin. When

multiplexing occurs, the peripheral module’s functional

requirements may force an override of the data

direction of the port pin.

TABLE 1-1: dsPIC30F6010 I/O PIN DESCRIPTIONS

Pin Name

AN0-AN15 I Analog Analog input channels.

DD P P Positive supply for analog module.

AV

SS P P Ground reference for analog module.

AV

CLKI

CLKO

CN0-CN23 I ST Input change notification inputs.

COFS

CSCK

CSDI

CSDO

C1RX

C1TX

C2RX

C2TX

EMUD

EMUC

EMUD1

EMUC1

EMUD2

EMUC2

EMUD3

EMUC3

IC1-IC8 I ST Capture inputs 1 through 8.

INDX

QEA

QEB

UPDN

INT0

INT1

INT2

INT3

INT4

LVDIN I Analog Low Voltage Detect Reference Voltage input pin.

Legend: CMOS = CMOS compatible input or output Analog = Analog input

Pin

Type

I

O

I/O

I/O

I

O

I

O

I

O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I

I

I

O

I

I

I

I

I

ST = Schmitt Trigger input with CMOS levels O = Output

I = Input P = Power

Buffer

Type

AN0 and AN1 are also used for device programming data and clock inputs,

respectively.

ST/CMOS—External clock source input. Always associated with OSC1 pin function.

Oscillator crystal output. Connects to crystal or resonator in Crystal

Oscillator mode. Optionally functions as CLKO in RC and EC modes. Always

associated with OSC2 pin function.

Can be software programmed for internal weak pull-ups on all inputs.

ST

ST

ST

—

ST

—

ST

—

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

CMOS

ST

ST

ST

ST

ST

Data Converter Interface frame synchronization pin.

Data Converter Interface serial clock input/output pin.

Data Converter Interface serial data input pin.

Data Converter Interface serial data output pin.

CAN1 bus receive pin.

CAN1 bus transmit pin.

CAN2 bus receive pin.

CAN2 bus transmit pin.

ICD Primary Communication Channel data input/output pin.

ICD Primary Communication Channel clock input/output pin.

ICD Secondary Communication Channel data input/output pin.

ICD Secondary Communication Channel clock input/output pin.

ICD Tertiary Communication Channel data input/output pin.

ICD Tertiary Communication Channel clock input/output pin.

ICD Quaternary Communication Channel data input/output pin.

ICD Quaternary Communication Channel clock input/output pin.

Quadrature Encoder Index Pulse input.

Quadrature Encoder Phase A input in QEI mode.

Auxiliary Timer External Clock/Gate input in Timer mode.

Quadrature Encoder Phase A input in QEI mode.

Auxiliary Timer External Clock/Gate input in Timer mode.

Position Up/Down Counter Direction State.

External interrupt 0.

External interrupt 1.

External interrupt 2.

External interrupt 3.

External interrupt 4.

Description

2004 Microchip Technology Inc. Advance Information DS70119B-page 7

dsPIC30F6010

TABLE 1-1: dsPIC30F6010 I/O PIN DESCRIPTIONS (CONTINUED)

Pin Name

FLTA

FLTB

PWM1L

PWM1H

PWM2L

PWM2H

PWM3L

PWM3H

PWM4L

PWM4H

MCLR

OCFA

OCFB

OC1-OC8

OSC1

OSC2

PGD

PGC

RA9-RA10

RA14-RA15

RB0-RB15 I/O ST PORTB is a bi-directional I/O port.

RC1

RC3

RC13-RC15

RD0-RD15 I/O ST PORTD is a bi-directional I/O port.

RE0-RE9 I/O ST PORTE is a bi-directional I/O port.

RF0-RF8 I/O ST PORTF is a bi-directional I/O port.

RG0-RG3

RG6-RG9

SCK1

SDI1

SDO1

SS1

SCK2

SDI2

SDO2

SS2

SCL

SDA

SOSCO

SOSCI

Legend: CMOS = CMOS compatible input or output Analog = Analog input

Pin

Typ e

I

I

O

O

O

O

O

O

O

O

I/P ST Master Clear (Reset) input or programming voltage input. This pin is an active

I

I

O

I

I/O

I/O

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I

O

I

I/O

I

O

I

I/O

I/O

O

I

ST = Schmitt Trigger input with CMOS levels O = Output

I = Input P = Power

Buffer

Typ e

ST

ST

—

—

—

—

—

—

—

—

ST

ST

—

ST/CMOS—Oscillator crystal input. ST buffer when configured in RC mode; CMOS

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

ST

—

ST

ST

ST

—

ST

ST

ST

—

ST/CMOS

PWM Fault A input.

PWM Fault B input.

PWM 1 Low output.

PWM 1 High output.

PWM 2 Low output.

PWM 2 High output.

PWM 3 Low output.

PWM 3 High output.

PWM 4 Low output.

PWM 4 High output.

low Reset to the device.

Compare Fault A input (for Compare channels 1, 2, 3 and 4).

Compare Fault B input (for Compare channels 5, 6, 7 and 8).

Compare outputs 1 through 8.

otherwise.

Oscillator crystal output. Connects to crystal or resonator in Crystal Oscillator

mode. Optionally functions as CLKO in RC and EC modes.

In-Circuit Serial Programming data input/output pin.

In-Circuit Serial Programming clock input pin.

PORTA is a bi-directional I/O port.

PORTC is a bi-directional I/O port.

PORTG is a bi-directional I/O port.

Synchronous serial clock input/output for SPI1.

SPI1 Data In.

SPI1 Data Out.

SPI1 Slave Synchronization.

Synchronous serial clock input/output for SPI2.

SPI2 Data In.

SPI2 Data Out.

SPI2 Slave Synchronization.

Synchronous serial clock input/output for I

Synchronous serial data input/output for I

32 kHz low power oscillator crystal output.

32 kHz low power oscillator crystal input. ST buffer when configured in RC

mode; CMOS otherwise.

Description

2

C.

2

C.

DS70119B-page 8 Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

TABLE 1-1: dsPIC30F6010 I/O PIN DESCRIPTIONS (CONTINUED)

Pin Name

T1CK

T2CK

T3CK

T4CK

T5CK

U1RX

U1TX

U1ARX

U1ATX

U2RX

U2TX

DD P — Positive supply for logic and I/O pins.

V

SS P — Ground reference for logic and I/O pins.

V

REF+ I Analog Analog Voltage Reference (High) input.

V

REF- I Analog Analog Voltage Reference (Low) input.

V

Legend: CMOS = CMOS compatible input or output Analog = Analog input

Pin

Type

I

I

I

I

I

I

O

I

O

I

O

ST = Schmitt Trigger input with CMOS levels O = Output

I = Input P = Power

Buffer

Type

ST

ST

ST

ST

ST

ST

—

ST

—

ST

—

Description

Timer1 external clock input.

Timer2 external clock input.

Timer3 external clock input.

Timer4 external clock input.

Timer5 external clock input.

UART1 Receive.

UART1 Transmit.

UART1 Alternate Receive.

UART1 Alternate Transmit.

UART2 Receive.

UART2 Transmit.

2004 Microchip Technology Inc. Advance Information DS70119B-page 9

dsPIC30F6010

NOTES:

DS70119B-page 10 Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

2.0 CPU ARCHITECTURE OVERVIEW

This document provides a summary of the

dsPIC30F6010 CPU and peripheral function. For a

complete description of this functionality, please refer

to the dsPIC30F Family Reference Manual (DS70046).

2.1 Core Overview

The core has a 24-bit instruction word. The Program

Counter (PC) is 23 bits wide with the Least Significant

(LS) bit always clear (see Section 3.1), and the Most

Significant (MS) bit is ignored during normal program

execution, except for certain specialized instructions.

Thus, the PC can address up to 4M instruction words

of user program space. An instruction pre-fetch mechanism is used to help maintain throughput. Program

loop constructs, free from loop count management

overhead, are supported using the DO and REPEAT

instructions, both of which are interruptible at any point.

The working register array consists of 16x16-bit registers, each of which can act as data, address or offset

registers. One working register (W15) operates as a

software stack pointer for interrupts and calls.

The data space is 64 Kbytes (32K words) and is split

into two blocks, referred to as X and Y data memory.

Each block has its own independent Address Generation Unit (AGU). Most instructions operate solely

through the X memory AGU, which provides the

appearance of a single unified data space. The

Multiply-Accumulate (MAC) class of dual source DSP

instructions operate through both the X and Y AGUs,

splitting the data address space into two parts (see

Section 3.2). The X and Y data space boundary is

device specific and cannot be altered by the user. Each

data word consists of 2 bytes, and most instructions

can address data either as words or bytes.

There are two methods of accessing data stored in

program memory:

• The upper 32 Kbytes of data space memory can

be mapped into the lower half (user space) of program space at any 16K program word boundary,

defined by the 8-bit Program Space Visibility Page

(PSVPAG) register. This lets any instruction

access program space as if it were data space,

with a limitation that the access requires an additional cycle. Moreover, only the lower 16 bits of

each instruction word can be accessed using this

method.

• Linear indirect access of 32K word pages within

program space is also possible using any working

register, via table read and write instructions.

Table read and write instructions can be used to

access all 24 bits of an instruction word.

Overhead-free circular buffers (modulo addressing) are

supported in both X and Y address spaces. This is primarily intended to remove the loop overhead for DSP

algorithms.

The X AGU also supports bit-reversed addressing on

destination effective addresses, to greatly simplify input

or output data reordering for radix-2 FFT algorithms.

Refer to Section 4.0 for details on modulo and

bit-reversed addressing.

The core supports Inherent (no operand), Relative, Literal, Memory Direct, Register Direct, Register Indirect,

Register Offset and Literal Offset Addressing modes.

Instructions are associated with predefined Addressing

modes, depending upon their functional requirements.

For most instructions, the core is capable of executing

a data (or program data) memory read, a working register (data) read, a data memory write and a program

(instruction) memory read per instruction cycle. As a

result, 3-operand instructions are supported, allowing

C = A+B operations to be executed in a single cycle.

A DSP engine has been included to significantly

enhance the core arithmetic capability and throughput.

It features a high speed 17-bit by 17-bit multiplier, a

40-bit ALU, two 40-bit saturating accumulators and a

40-bit bi-directional barrel shifter. Data in the accumulator or any working register can be shifted up to 16 bits

right or 16 bits left in a single cycle. The DSP instructions operate seamlessly with all other instructions and

have been designed for optimal real-time performance.

The MAC class of instructions can concurrently fetch

two data operands from memory, while multiplying two

W registers. To enable this concurrent fetching of data

operands, the data space has been split for these

instructions and linear for all others. This has been

achieved in a transparent and flexible manner, by dedicating certain working registers to each address space

for the MAC class of instructions.

The core does not support a multi-stage instruction

pipeline. However, a single stage instruction pre-fetch

mechanism is used, which accesses and partially

decodes instructions a cycle ahead of execution, in

order to maximize available execution time. Most

instructions execute in a single cycle, with certain

exceptions.

The core features a vectored exception processing

structure for traps and interrupts, with 62 independent

vectors. The exceptions consist of up to 8 traps (of

which 4 are reserved) and 54 interrupts. Each interrupt

is prioritized based on a user assigned priority between

1 and 7 (1 being the lowest priority and 7 being the

highest) in conjunction with a predetermined ‘natural

order’. Traps have fixed priorities, ranging from 8 to 15.

2004 Microchip Technology Inc. Advance Information DS70119B-page 11

dsPIC30F6010

2.2 Programmer’s Model

The programmer’s model is shown in Figure 2-1 and

consists of 16x16-bit working registers (W0 through

W15), 2x40-bit accumulators (AccA and AccB),

STATUS register (SR), Data Table Page register

(TBLPAG), Program Space Visibility Page register

(PSVPAG), DO and REPEAT registers (DOSTART,

DOEND, DCOUNT and RCOUNT), and Program

Counter (PC). The working registers can act as data,

address or offset registers. All registers are memory

mapped. W0 acts as the W register for file register

addressing.

Some of these registers have a shadow register associated with each of them, as shown in Figure 2-1. The

shadow register is used as a temporary holding register

and can transfer its contents to or from its host register

upon the occurrence of an event. None of the shadow

registers are accessible directly. The following rules

apply for transfer of registers into and out of shadows.

• PUSH.S and POP.S

W0, W1, W2, W3, SR (DC, N, OV, Z and C bits

only) are transferred.

• DO instruction

DOSTART, DOEND, DCOUNT shadows are

pushed on loop start, and popped on loop end.

When a byte operation is performed on a working register, only the Least Significant Byte of the target register is affected. However, a benefit of memory mapped

working registers is that both the Least and Most

Significant Bytes can be manipulated through byte

wide data memory space accesses.

2.2.1 SOFTWARE STACK POINTER/

FRAME POINTER

The dsPIC® devices contain a software stack. W15 is

the dedicated software stack pointer (SP), and will be

automatically modified by exception processing and

subroutine calls and returns. However, W15 can be referenced by any instruction in the same manner as all

other W registers. This simplifies the reading, writing

and manipulation of the stack pointer (e.g., creating

stack frames).

Note: In order to protect against misaligned

stack accesses, W15<0> is always clear.

W15 is initialized to 0x0800 during a Reset. The user

may reprogram the SP during initialization to any

location within data space.

W14 has been dedicated as a stack frame pointer as

defined by the LNK and ULNK instructions. However,

W14 can be referenced by any instruction in the same

manner as all other W registers.

2.2.2 STATUS REGISTER

The dsPIC core has a 16-bit Status Register (SR), the

LS Byte of which is referred to as the SR Low Byte

(SRL) and the MS Byte as the SR High Byte (SRH).

See Figure 2-1 for SR layout.

SRL contains all the MCU ALU operation status flags

(including the Z bit), as well as the CPU Interrupt Priority Level status bits, IPL<2:0>, and the REPEAT active

status bit, RA. During exception processing, SRL is

concatenated with the MS Byte of the PC to form a

complete word value which is then stacked.

The upper byte of the SR register contains the DSP

Adder/Subtractor status bits, the DO Loop Active bit

(DA) and the Digit Carry (DC) status bit.

2.2.3 PROGRAM COUNTER

The Program Counter is 23 bits wide. Bit 0 is always

clear. Therefore, the PC can address up to 4M

instruction words.

DS70119B-page 12 Advance Information 2004 Microchip Technology Inc.

FIGURE 2-1: dsPIC30F6010 PROGRAMMER’S MODEL

W0/WREG

W1

W2

W3

W4

DSP Operand

Registers

DSP Address

Registers

W13/DSP Write Back

W5

W6

W7

W8

W9

W10

W11

W12/DSP Offset

W14/Frame Pointer

W15/Stack Pointer

dsPIC30F6010

D0D15

PUSH.S Shadow

DO Shadow

Legend

Working Registers

DSP

Accumulators

PC22

7

22

22

TABPAG

TBLPAG

7

PSVPAG

PSVPAG

AD39 AD0AD31

AccA

AccB

0

Data Table Page Address

0

DOSTART

SPLIM

PC0

Program Space Visibility Page Address

15

RCOUNT

15

DCOUNT

DOEND

Stack Pointer Limit Register

AD15

Program Counter

0

0

REPEAT Loop Counter

0

DO Loop Counter

0

DO Loop Start Address

DO Loop End Address

15

CORCON

OA OB SA SB

2004 Microchip Technology Inc. Advance Information DS70119B-page 13

OAB SAB

SRH

DA DC

IPL2 IPL1

RA

IPL0 OV

SRL

0

Core Configuration Register

N

C

Z

Status Register

dsPIC30F6010

2.3 Divide Support

The dsPIC devices feature a 16/16-bit signed fractional

divide operation, as well as 32/16-bit and 16/16-bit

signed and unsigned integer divide operations, in the

form of single instruction iterative divides. The following

instructions and data sizes are supported:

1. DIVF – 16/16 signed fractional divide

2. DIV.sd – 32/16 signed divide

3. DIV.ud – 32/16 unsigned divide

4. DIV.sw – 16/16 signed divide

5. DIV.uw – 16/16 unsigned divide

The divide instructions must be executed within a

REPEAT loop. Any other form of execution (e.g. a series

of discrete divide instructions) will not function correctly

because the instruction flow depends on RCOUNT. The

divide instruction does not automatically set up the

RCOUNT value, and it must, therefore, be explicitly and

correctly specified in the REPEAT instruction, as shown

in Table 2-1 (REPEAT will execute the target instruction

{operand value+1} times). The REPEAT loop count must

be set up for 18 iterations of the DIV/DIVF instruction.

Thus, a complete divide operation requires 19 cycles.

Note: The Divide flow is interruptible. However,

the user needs to save the context as

appropriate.

TABLE 2-1: DIVIDE INSTRUCTIONS

Instruction Function

DIVF Signed fractional divide: Wm/Wn → W0; Rem → W1

DIV.sd Signed divide: (Wm+1:Wm)/Wn → W0; Rem → W1

DIV.sw (or DIV.s) Signed divide: Wm/Wn → W0; Rem → W1

DIV.ud Unsigned divide: (Wm+1:Wm)/Wn → W0; Rem → W1

DIV.uw (or DIV.u) Unsigned divide: Wm/Wn → W0; Rem → W1

2.4 DSP Engine

The DSP engine consists of a high speed 17-bit x

17-bit multiplier, a barrel shifter, and a 40-bit adder/

Subtractor (with two target accumulators, round and

saturation logic).

The dsPIC30F devices have a single instruction flow

which can execute either DSP or MCU instructions.

Many of the hardware resources are shared between

the DSP and MCU instructions. For example, the

instruction set has both DSP and MCU Multiply

instructions which use the same hardware multiplier.

The DSP engine also has the capability to perform inherent accumulator-to-accumulator operations, which

require no additional data. These instructions are ADD,

SUB and NEG.

The DSP engine has various options selected through

various bits in the CPU Core Configuration Register

(CORCON), as listed below:

1. Fractional or integer DSP multiply (IF).

2. Signed or unsigned DSP multiply (US).

3. Conventional or convergent rounding (RND).

4. Automatic saturation on/off for AccA (SATA).

5. Automatic saturation on/off for AccB (SATB).

6. Automatic saturation on/off for writes to data

memory (SATDW).

7. Accumulator Saturation mode selection

(ACCSAT).

Note: For CORCON layout, see Table 4-2.

A block diagram of the DSP engine is shown in

Figure 2-2.

TABLE 2-2: DSP INSTRUCTION

SUMMARY

Instruction Algebraic Operation

CLR A = 0

ED A = (x – y)

EDAC A = A + (x – y)

MAC A = A + (x * y)

MOVSAC No change in A

MPY A = x * y

MPY.N A = – x * y

MSC A = A – x * y

2

2

DS70119B-page 14 Advance Information 2004 Microchip Technology Inc.

FIGURE 2-2: DSP ENGINE BLOCK DIAGRAM

40

Carry/Borrow Out

Carry/Borrow In

40-bit Accumulator A

40-bit Accumulator B

Saturate

Adder

Negate

dsPIC30F6010

S

a

40

Round

Logic

16

t

u

r

a

t

e

Y Data Bus

40

Sign-Extend

33

17-bit

Multiplier/Scaler

40

40

Barrel

Shifter

32

32

40

16

X Data Bus

16

Zero Backfill

16

To/From W Array

2004 Microchip Technology Inc. Advance Information DS70119B-page 15

16

dsPIC30F6010

2.4.1 MULTIPLIER

The 17x17-bit multiplier is capable of signed or

unsigned operation and can multiplex its output using a

scaler to support either 1.31 fractional (Q31) or 32-bit

integer results. Unsigned operands are zero-extended

into the 17th bit of the multiplier input value. Signed

operands are sign-extended into the 17th bit of the multiplier input value. The output of the 17x17-bit multiplier/

scaler is a 33-bit value, which is sign-extended to 40

bits. Integer data is inherently represented as a signed

two’s complement value, where the MSB is defined as

a sign bit. Generally speaking, the range of an N-bit

two’s complement integer is -2

16-bit integer, the data range is -32768 (0x8000) to

32767 (0x7FFF), including 0. For a 32-bit integer, the

data range is -2,147,483,648 (0x8000 0000) to

2,147,483,645 (0x7FFF FFFF).

When the multiplier is configured for fractional multiplication, the data is represented as a two’s complement

fraction, where the MSB is defined as a sign bit and the

radix point is implied to lie just after the sign bit

(QX format). The range of an N-bit two’s complement

fraction with this implied radix point is -1.0 to (1-2

For a 16-bit fraction, the Q15 data range is -1.0

(0x8000) to 0.999969482 (0x7FFF), including 0 and

has a precision of 3.01518x10

16x16 multiply operation generates a 1.31 product,

which has a precision of 4.65661x10

The same multiplier is used to support the MCU multiply instructions, which include integer 16-bit signed,

unsigned and mixed sign multiplies.

The MUL instruction may be directed to use byte or

word sized operands. Byte operands will direct a 16-bit

result, and word operands will direct a 32-bit result to

the specified register(s) in the W array.

N-1

-5

N-1

to 2

. In fractional mode, a

-10

.

– 1. For a

1-N

2.4.2 DATA ACCUMULATORS AND

ADDER/SUBTRACTOR

The data accumulator consists of a 40-bit adder/

subtractor with automatic sign extension logic. It can

select one of two accumulators (A or B) as its preaccumulation source and post-accumulation destination. For the ADD and LAC instructions, the data to be

accumulated or loaded can be optionally scaled via the

barrel shifter, prior to accumulation.

2.4.2.1 Adder/Subtractor, Overflow and

Saturation

The adder/subtractor is a 40-bit adder with an optional

zero input into one side and either true or complement

data into the other input. In the case of addition, the

carry/borrow

true data (not complemented), whereas in the case of

subtraction, the carry/borrow

other input is complemented. The adder/subtractor

generates overflow status bits SA/SB and OA/OB,

which are latched and reflected in the status register.

• Overflow from bit 39: this is a catastrophic

overflow in which the sign of the accumulator is

destroyed.

• Overflow into guard bits 32 through 39: this is a

recoverable overflow. This bit is set whenever all

the guard bits are not identical to each other.

The adder has an additional saturation block which

controls accumulator data saturation, if selected. It

uses the result of the adder, the overflow status bits

described above, and the SATA/B (CORCON<7:6>)

).

and ACCSAT (CORCON<4>) mode control bits to

determine when and to what value to saturate.

Six status register bits have been provided to support

saturation and overflow; they are:

1. OA:

AccA overflowed into guard bits

2. OB:

AccB overflowed into guard bits

3. SA:

AccA saturated (bit 31 overflow and saturation)

or

AccA overflowed into guard bits and saturated

(bit 39 overflow and saturation)

4. SB:

AccB saturated (bit 31 overflow and saturation)

or

AccB overflowed into guard bits and saturated

(bit 39 overflow and saturation)

5. OAB:

Logical OR of OA and OB

6. SAB:

Logical OR of SA and SB

The OA and OB bits are modified each time data

passes through the adder/Subtractor. When set, they

indicate that the most recent operation has overflowed

into the accumulator guard bits (bits 32 through 39).

The OA and OB bits can also optionally generate an

arithmetic warning trap when set and the corresponding overflow trap flag enable bit (OVATEN, OVBTEN) in

the INTCON1 register (refer to Section 5.0) is set. This

allows the user to take immediate action, for example,

to correct system gain.

input is active high and the other input is

input is active low and the

DS70119B-page 16 Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

The SA and SB bits are modified each time data passes

through the adder/subtractor, but can only be cleared by

the user. When set, they indicate that the accumulator

has overflowed its maximum range (bit 31 for 32-bit saturation, or bit 39 for 40-bit saturation) and will be saturated (if saturation is enabled). When saturation is not

enabled, SA and SB default to bit 39 overflow and thus

indicate that a catastrophic overflow has occurred. If the

COVTE bit in the INTCON1 register is set, SA and SB

bits will generate an arithmetic warning trap when saturation is disabled.

The overflow and saturation status bits can optionally

be viewed in the Status Register (SR) as the logical OR

of OA and OB (in bit OAB) and the logical OR of SA and

SB (in bit SAB). This allows programmers to check one

bit in the Status Register to determine if either accumulator has overflowed, or one bit to determine if either

accumulator has saturated. This would be useful for

complex number arithmetic which typically uses both

the accumulators.

The device supports three Saturation and Overflow

modes.

1. Bit 39 Overflow and Saturation:

When bit 39 overflow and saturation occurs, the

saturation logic loads the maximally positive 9.31

(0x7FFFFFFFFF) or maximally negative 9.31

value (0x8000000000) into the target accumulator. The SA or SB bit is set and remains set until

cleared by the user. This is referred to as ‘super

saturation’ and provides protection against erroneous data or unexpected algorithm problems

(e.g., gain calculations).

2. Bit 31 Overflow and Saturation:

When bit 31 overflow and saturation occurs, the

saturation logic then loads the maximally positive 1.31 value (0x007FFFFFFF) or maximally

negative 1.31 value (0x0080000000) into the

target accumulator. The SA or SB bit is set and

remains set until cleared by the user. When this

Saturation mode is in effect, the guard bits are not

used (so the OA, OB or OAB bits are never set).

3. Bit 39 Catastrophic Overflow

The bit 39 overflow status bit from the adder is

used to set the SA or SB bit, which remain set

until cleared by the user. No saturation operation

is performed and the accumulator is allowed to

overflow (destroying its sign). If the COVTE bit in

the INTCON1 register is set, a catastrophic

overflow can initiate a trap exception.

2.4.2.2 Accumulator ‘Write Back’

The MAC class of instructions (with the exception of

MPY, MPY.N, ED and EDAC) can optionally write a

rounded version of the high word (bits 31 through 16)

of the accumulator that is not targeted by the instruction

into data space memory. The write is performed across

the X bus into combined X and Y address space. The

following addressing modes are supported:

1. W13, Register Direct:

The rounded contents of the non-target accumulator are written into W13 as a 1.15 fraction.

2. [W13]+=2, Register Indirect with Post-Increment:

The rounded contents of the non-target accumulator are written into the address pointed to by

W13 as a 1.15 fraction. W13 is then

incremented by 2 (for a word write).

2.4.2.3 Round Logic

The round logic is a combinational block, which performs a conventional (biased) or convergent (unbiased)

round function during an accumulator write (store). The

Round mode is determined by the state of the RND bit

in the CORCON register. It generates a 16-bit, 1.15 data

value which is passed to the data space write saturation

logic. If rounding is not indicated by the instruction, a

truncated 1.15 data value is stored and the LS Word is

simply discarded.

Conventional rounding takes bit 15 of the accumulator,

zero-extends it and adds it to the ACCxH word (bits 16

through 31 of the accumulator). If the ACCxL word (bits

0 through 15 of the accumulator) is between 0x8000

and 0xFFFF (0x8000 included), ACCxH is incremented. If ACCxL is between 0x0000 and 0x7FFF,

ACCxH is left unchanged. A consequence of this algorithm is that over a succession of random rounding

operations, the value will tend to be biased slightly

positive.

Convergent (or unbiased) rounding operates in the

same manner as conventional rounding, except when

ACCxL equals 0x8000. If this is the case, the LS bit (bit

16 of the accumulator) of ACCxH is examined. If it is ‘1’,

ACCxH is incremented. If it is ‘0’, ACCxH is not modified. Assuming that bit 16 is effectively random in

nature, this scheme will remove any rounding bias that

may accumulate.

The SAC and SAC.R instructions store either a truncated (SAC) or rounded (SAC.R) version of the contents

of the target accumulator to data memory, via the X bus

(subject to data saturation, see Section 2.4.2.4). Note

that for the MAC class of instructions, the accumulator

write back operation will function in the same manner,

addressing combined MCU (X and Y) data space

though the X bus. For this class of instructions, the data

is always subject to rounding.

2004 Microchip Technology Inc. Advance Information DS70119B-page 17

dsPIC30F6010

2.4.2.4 Data Space Write Saturation

In addition to adder/subtractor saturation, writes to data

space may also be saturated, but without affecting the

contents of the source accumulator. The data space

write saturation logic block accepts a 16-bit, 1.15 fractional value from the round logic block as its input,

together with overflow status from the original source

(accumulator) and the 16-bit round adder. These are

combined and used to select the appropriate 1.15 fractional value as output to write to data space memory.

If the SATDW bit in the CORCON register is set, data

(after rounding or truncation) is tested for overflow and

adjusted accordingly. For input data greater than

0x007FFF, data written to memory is forced to the maximum positive 1.15 value, 0x7FFF. For input data less

than 0xFF8000, data written to memory is forced to the

maximum negative 1.15 value, 0x8000. The MS bit of

the source (bit 39) is used to determine the sign of the

operand being tested.

If the SATDW bit in the CORCON register is not set, the

input data is always passed through unmodified under

all conditions.

2.4.3 BARREL SHIFTER

The barrel shifter is capable of performing up to 16-bit

arithmetic or logic right shifts, or up to 16-bit left shifts

in a single cycle. The source can be either of the two

DSP accumulators or the X bus (to support multi-bit

shifts of register or memory data).

The shifter requires a signed binary value to determine

both the magnitude (number of bits) and direction of the

shift operation. A positive value will shift the operand

right. A negative value will shift the operand left. A

value of 0 will not modify the operand.

The barrel shifter is 40 bits wide, thereby obtaining a

40-bit result for DSP shift operations and a 16-bit result

for MCU shift operations. Data from the X bus is presented to the barrel shifter between bit positions 16 to

31 for right shifts, and bit positions 0 to 15 for left shifts.

DS70119B-page 18 Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

3.0 MEMORY ORGANIZATION

3.1 Program Address Space

The program address space is 4M instruction words. It

is addressable by the 23-bit PC, table instruction

Effective Address (EA), or data space EA, when

program space is mapped into data space, as defined

by Table 3-1. Note that the program space address is

incremented by two between successive program

words, in order to provide compatibility with data space

addressing.

User program space access is restricted to the lower

4M instruction word address range (0x000000 to

0x7FFFFE), for all accesses other than TBLRD/TBLWT,

which use TBLPAG<7> to determine user or configuration space access. In Table 3-1, Read/Write instructions, bit 23 allows access to the Device ID, the User ID

and the configuration bits. Otherwise, bit 23 is always

clear.

FIGURE 3-1:

Space

User Memory

PROGRAM SPACE

MEMORY MAP FOR

dsPIC30F6010

Reset - GOTO Instruction

Reset - Target Address

Interrupt Vector Table

Reserved

Alternate Vector Table

User Flash

Program Memory

(48K instructions)

Reserved

(Read 0’s)

Data EEPROM

(4 Kbytes)

000000

000002

000004

Vector Tables

00007E

000080

000084

0000FE

000100

017FFE

018000

7FEFFE

7FF000

7FFFFE

800000

Space

Configuration Memory

UNITID (32 instr.)

Device Configuration

Reserved

Reserved

Registers

Reserved

DEVID (2)

8005BE

8005C0

8005FE

800600

F7FFFE

F80000

F8000E

F80010

FEFFFE

FF0000

FFFFFE

2004 Microchip Technology Inc. Advance Information DS70119B-page 19

dsPIC30F6010

TABLE 3-1: PROGRAM SPACE ADDRESS CONSTRUCTION

Access Type

Access

Space

<23> <22:16> <15> <14:1> <0>

Instruction Access User 0 PC<22:1> 0

TBLRD/TBLWT User

TBLPAG<7:0> Data EA <15:0>

(TBLPAG<7> = 0)

TBLRD/TBLWT Configuration

TBLPAG<7:0> Data EA <15:0>

(TBLPAG<7> = 1)

Program Space Visibility User 0 PSVPAG<7:0> Data EA <14:0>

FIGURE 3-2: DATA ACCESS FROM PROGRAM SPACE ADDRESS GENERATION

23 bits

Using

Program

Counter

0

Program Space Address

0Program Counter

Select

Using

Program

Space

Visibility

Using

Table

Instruction

Note: Program Space Visibility cannot be used to access bits <23:16> of a word in program memory.

0

1/0

User/

Configuration

Spac e

Select

PSVPAG Reg

8 bits

TBLPAG Reg

8 bits

1

24-bit EA

EA

15 bits

EA

16 bits

Byte

Select

DS70119B-page 20 Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

3.1.1 DATA ACCESS FROM PROGRAM

MEMORY USING TABLE

INSTRUCTIONS

This architecture fetches 24-bit wide program memory.

Consequently, instructions are always aligned. However, as the architecture is modified Harvard, data can

also be present in program space.

There are two methods by which program space can

be accessed; via special table instructions, or through

the remapping of a 16K word program space page into

the upper half of data space (see Section 3.1.2). The

TBLRDL and TBLWTL instructions offer a direct method

of reading or writing the LS Word of any address within

program space, without going through data space. The

TBLRDH and TBLWTH instructions are the only method

whereby the upper 8 bits of a program space word can

be accessed as data.

The PC is incremented by two for each successive

24-bit program word. This allows program memory

addresses to directly map to data space addresses.

Program memory can thus be regarded as two 16-bit

word wide address spaces, residing side by side, each

with the same address range. TBLRDL and TBLWTL

access the space which contains the LS Data Word,

and TBLRDH and TBLWTH access the space which

contains the MS Data Byte.

Figure 3-2 shows how the EA is created for table operations and data space accesses (PSV = 1). Here,

P<23:0> refers to a program space word, whereas

D<15:0> refers to a data space word.

A set of Table Instructions are provided to move byte or

word sized data to and from program space.

1. TBLRDL: Table Read Low

Word: Read the LS Word of the program

address;

P<15:0> maps to D<15:0>.

Byte: Read one of the LS Bytes of the program

address;

P<7:0> maps to the destination byte when byte

select = 0;

P<15:8> maps to the destination byte when byte

select = 1.

2. TBLWTL: Table Write Low (refer to Section 6.0

for details on Flash Programming).

3. TBLRDH: Table Read High

Word: Read the MS Word of the program

address;

P<23:16> maps to D<7:0>; D<15:8> always

be = 0.

Byte: Read one of the MS Bytes of the program

address;

P<23:16> maps to the destination byte when

byte select = 0;

The destination byte will always be = 0 when

byte select = 1.

4. TBLWTH: Table Write High (refer to Section 6.0

for details on Flash Programming).

FIGURE 3-3: PROGRAM DATA TABLE ACCESS (LS WORD)

PC Address

0x000000

0x000002

0x000004

0x000006

Program Memory

‘Phantom’ Byte

(Read as ‘0’).

00000000

00000000

00000000

00000000

23

TBLRDL.W

16

TBLRDL.B (Wn<0> = 1)

8

TBLRDL.B (Wn<0> = 0)

0

2004 Microchip Technology Inc. Advance Information DS70119B-page 21

dsPIC30F6010

FIGURE 3-4: PROGRAM DATA TABLE ACCESS (MS BYTE)

TBLRDH.W

PC Address

0x000000

0x000002

0x000004

0x000006

Program Memory

‘Phantom’ Byte

(Read as ‘0’)

00000000

00000000

00000000

00000000

23

TBLRDH.B (Wn<0> = 1)

3.1.2 DATA ACCESS FROM PROGRAM

MEMORY USING PROGRAM

SPACE VISIBILITY

The upper 32 Kbytes of data space may optionally be

mapped into any 16K word program space page. This

provides transparent access of stored constant data

from X data space, without the need to use special

instructions (i.e., TBLRDL/H, TBLWTL/H instructions).

Program space access through the data space occurs

if the MS bit of the data space EA is set and program

space visibility is enabled, by setting the PSV bit in the

Core Control register (CORCON). The functions of

CORCON are discussed in Section 2.4, DSP Engine.

Data accesses to this area add an additional cycle to

the instruction being executed, since two program

memory fetches are required.

Note that the upper half of addressable data space is

always part of the X data space. Therefore, when a

DSP operation uses program space mapping to access

this memory region, Y data space should typically contain state (variable) data for DSP operations, whereas

X data space should typically contain coefficient

(constant) data.

Although each data space address, 0x8000 and higher,

maps directly into a corresponding program memory

address (see Figure 3-5), only the lower 16-bits of the

24-bit program word are used to contain the data. The

upper 8 bits should be programmed to force an illegal

instruction to maintain machine robustness. Refer

to the dsPIC30F Programmer’s Reference Manual

(DS70030) for details on instruction encoding.

16

TBLRDH.B (Wn<0> = 0)

Note that by incrementing the PC by 2 for each program memory word, the LS 15 bits of data space

addresses directly map to the LS 15 bits in the corresponding program space addresses. The remaining

bits are provided by the Program Space Visibility Page

register, PSVPAG<7:0>, as shown in Figure 3-5.

Note: PSV access is temporarily disabled during

Table Reads/Writes.

For instructions that use PSV which are executed

outside a REPEAT loop:

• The following instructions will require one instruction cycle in addition to the specified execution

time:

- MAC class of instructions with data operand

pre-fetch

- MOV instructions

- MOV.D instructions

• All other instructions will require two instruction

cycles in addition to the specified execution time

of the instruction.

For instructions that use PSV which are executed

inside a REPEAT loop:

• The following instances will require two instruction

cycles in addition to the specified execution time

of the instruction:

- Execution in the first iteration

- Execution in the last iteration

- Execution prior to exiting the loop due to an

interrupt

- Execution upon re-entering the loop after an

interrupt is serviced

• Any other iteration of the REPEAT loop will allow

the instruction, accessing data using PSV, to

execute in a single cycle.

8

0

DS70119B-page 22 Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

FIGURE 3-5: DATA SPACE WINDOW INTO PROGRAM SPACE OPERATION

Program Space

Data Space

0x0000

EA<15> =

Data

Space

EA

BSET CORCON,#2 ; PSV bit set

MOV #0x21, W0 ; Set PSVPAG register

MOV W0, PSVPAG

MOV 0x8200, W0 ; Access program memory location

Note: PSVPAG is an 8-bit register, containing bits <22:15> of the program space address

16

EA<15> = 1

Upper half of Data

Space is mapped

into Program Space

(i.e., it defines the page in program space to which the upper half of data space is being mapped).

15

0

15

; using a data space access

0x8000

15

0xFFFF

PSVPAG

Address

Concatenation

(1)

0x21

8

23 15 0

23

Data Read

0x108000

0x108200

0x10FFFF

3.2 Data Address Space

The core has two data spaces. The data spaces can be

considered either separate (for some DSP instructions), or as one unified linear address range (for MCU

instructions). The data spaces are accessed using two

Address Generation Units (AGUs) and separate data

paths.

3.2.1 DATA SPACE MEMORY MAP

The data space memory is split into two blocks, X and

Y data space. A key element of this architecture is that

Y space is a subset of X space, and is fully contained

within X space. In order to provide an apparent linear

addressing space, X and Y spaces have contiguous

addresses.

2004 Microchip Technology Inc. Advance Information DS70119B-page 23

When executing any instruction other than one of the

MAC class of instructions, the X block consists of the 64

Kbyte data address space (including all Y addresses).

When executing one of the MAC class of instructions,

the X block consists of the 64 Kbyte data address

space excluding the Y address block (for data reads

only). In other words, all other instructions regard the

entire data memory as one composite address space.

The MAC class instructions extract the Y address space

from data space and address it using EAs sourced from

W10 and W11. The remaining X data space is

addressed using W8 and W9. Both address spaces are

concurrently accessed only with the MAC class

instructions.

A data space memory map is shown in Figure 3-6.

Figure 3-7 shows a graphical summary of how X and Y

data spaces are accessed for MCU and DSP

instructions.

dsPIC30F6010

FIGURE 3-6: dsPIC30F6010 DATA SPACE MEMORY MAP

2 Kbyte

SFR Space

8 Kbyte

SRAM Space

MS Byte

Address

0x0001

0x07FF

0x0801

0x17FF

0x1801

0x27FF 0x27FE

0x8001

16 bits

LSBMSB

SFR Space

X Data RAM (X)

Y Data RAM (Y)

0x0000

0x07FE

0x0800

0x17FE

0x1800

0x1FFE0x1FFF

0x28000x2801

0x8000

LS Byte

Address

8 Kbyte

Near

Data

Space

Optionally

Mapped

into Program

Memory

0xFFFF

X Data

Unimplemented (X)

0xFFFE

DS70119B-page 24 Advance Information 2004 Microchip Technology Inc.

dsPIC30F6010

FIGURE 3-7: DATA SPACE FOR MCU AND DSP (MAC CLASS) INSTRUCTIONS EXAMPLE

SFR SPACE

UNUSED

(Y SPACE)

X SPACE

Non-MAC Class Ops (Read/Write) MAC Class Ops Read Only

MAC Class Ops (Write)

Indirect EA using any W Indirect EA using W8, W9 Indirect EA using W10, W11

Y SPACE

UNUSED

SFR SPACE

UNUSED

X SPACE

X SPACE

2004 Microchip Technology Inc. Advance Information DS70119B-page 25

dsPIC30F6010

3.2.2 DATA SPACES

The X data space is used by all instructions and supports all addressing modes. There are separate read

and write data buses. The X read data bus is the return

data path for all instructions that view data space as

combined X and Y address space. It is also the X

address space data path for the dual operand read

instructions (MAC class). The X write data bus is the

only write path to data space for all instructions.

The X data space also supports Modulo Addressing for

all instructions, subject to Addressing mode restrictions. Bit-Reversed Addressing is only supported for

writes to X data space.

The Y data space is used in concert with the X data

space by the MAC class of instructions (CLR, ED,

EDAC, MAC, MOVSAC, MPY, MPY.N and MSC) to provide two concurrent data read paths. No writes occur

across the Y bus. This class of instructions dedicates

two W register pointers, W10 and W11, to always

address Y data space, independent of X data space,

whereas W8 and W9 always address X data space.

Note that during accumulator write back, the data

address space is considered a combination of X and Y

data spaces, so the write occurs across the X bus.

Consequently, the write can be to any address in the

entire data space.

The Y data space can only be used for the data prefetch operation associated with the MAC class of

instructions. It also supports Modulo Addressing for

automated circular buffers. Of course, all other instructions can access the Y data address space through the

X data path, as part of the composite linear space.

The boundary between the X and Y data spaces is

defined as shown in Figure 3-6 and is not user programmable. Should an EA point to data outside its own

assigned address space, or to a location outside physical memory, an all-zero word/byte will be returned. For

example, although Y address space is visible by all

non-MAC instructions using any Addressing mode, an

attempt by a MAC instruction to fetch data from that

space, using W8 or W9 (X space pointers), will return

0x0000.

3.2.3 DATA SPACE WIDTH

The core data width is 16-bits. All internal registers are

organized as 16-bit wide words. Data space memory is

organized in byte addressable, 16-bit wide blocks.

3.2.4 DATA ALIGNMENT

To help maintain backward compatibility with

PICmicro

usage efficiency, the dsPIC30F instruction set supports

both word and byte operations. Data is aligned in data

memory and registers as words, but all data space EAs

resolve to bytes. Data byte reads will read the complete

word, which contains the byte, using the LS bit of any

EA to determine which byte to select. The selected byte

is placed onto the LS Byte of the X data path (no byte

accesses are possible from the Y data path as the MAC

class of instruction can only fetch words). That is, data

memory and registers are organized as two parallel

byte wide entities with shared (word) address decode,

but separate write lines. Data byte writes only write to

the corresponding side of the array or register which

matches the byte address.

As a consequence of this byte accessibility, all effective

address calculations (including those generated by the

DSP operations, which are restricted to word sized

data) are internally scaled to step through word aligned

memory. For example, the core would recognize that

Post-Modified Register Indirect Addressing mode,

[Ws++], will result in a value of Ws+1 for byte

operations and Ws+2 for word operations.

All word accesses must be aligned to an even address.

Mis-aligned word data fetches are not supported, so

care must be taken when mixing byte and word operations, or translating from 8-bit MCU code. Should a misaligned read or write be attempted, an Address Error

trap will be generated. If the error occurred on a read,

the instruction underway is completed, whereas if it

occurred on a write, the instruction will be executed but

the write will not occur. In either case, a trap will then

be executed, allowing the system and/or user to examine the machine state prior to execution of the address

fault.

®

devices and improve data space memory

TABLE 3-2: EFFECT OF INVALID

MEMORY ACCESSES

Attempted Operation Data Returned

EA = an unimplemented address 0x0000

W8 or W9 used to access Y data

space in a MAC instruction

W10 or W11 used to access X

data space in a MAC instruction

All effective addresses are 16 bits wide and point to

bytes within the data space. Therefore, the data space

address range is 64 Kbytes or 32K words.

DS70119B-page 26 Advance Information 2004 Microchip Technology Inc.

0x0000

0x0000

FIGURE 3-8: DATA ALIGNMENT

15 8 7 0

0001

0003

0005

Byte 1 Byte 0

Byte 3 Byte 2

Byte 5 Byte 4

LS ByteMS Byte

0000

0002

0004

dsPIC30F6010

All byte loads into any W register are loaded into the

LS Byte. The MSB is not modified.

A sign-extend (SE) instruction is provided to allow

users to translate 8-bit signed data to 16-bit signed

values. Alternatively, for 16-bit unsigned data, users

can clear the MSB of any W register by executing a

zero-extend (ZE) instruction on the appropriate

address.

Although most instructions are capable of operating on

word or byte data sizes, it should be noted that some

instructions, including the DSP instructions, operate

only on words.

3.2.5 NEAR DATA SPACE

An 8 Kbyte ‘near’ data space is reserved in X address

memory space between 0x0000 and 0x1FFF, which is

directly addressable via a 13-bit absolute address field

within all memory direct instructions. The remaining X

address space and all of the Y address space is

addressable indirectly. Additionally, the whole of X data

space is addressable using MOV instructions, which

support memory direct addressing with a 16-bit

address field.

3.2.6 SOFTWARE STACK

The dsPIC device contains a software stack. W15 is

used as the Stack Pointer.

The stack pointer always points to the first available

free word and grows from lower addresses towards

higher addresses. It pre-decrements for stack pops and

post-increments for stack pushes, as shown in

Figure 3-9. Note that for a PC push during any CALL

instruction, the MSB of the PC is zero-extended before

the push, ensuring that the MSB is always clear.

Note: A PC push during exception processing

will concatenate the SRL register to the

MSB of the PC prior to the push.