Page 1

DM160232

Serial Memory Single-Wire

Evaluation Kit User’s Guide

2018 Microchip Technology Inc. DS20005939A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

QUALITY MANAGEMENT S

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, A VR Freaks, BeaconTh ings, BitCloud, chip KIT , chipK IT

logo, CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR,

Heldo, JukeBlox, K

MD, maXStylus, maXTouch, MediaLB, megaAVR, MOST, MOST

logo, MPLAB, OptoLyzer, PIC, picoPower, PICSTART, PIC32

logo, Prochip Designer, QTouch, RightTouch, SAM-BA, SpyNIC,

SST, SST Logo, SuperFlash, tinyAVR, UNI/O, and XMEGA are

registered trademarks of Microchip T echnology Incorporated in

the U.S.A. and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMO S,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppress i on, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, CodeGuard,

CryptoAuthentication, CryptoCompanion, CryptoController,

dsPICDEM, dsPICDEM.net, Dynamic Average Matching, DAM,

ECAN, EtherGREEN, In-Circuit Serial Programmi ng, ICSP, InterChip Connectivity, JitterBlocker, KleerNet, KleerNet logo, Mindi,

MiWi, motorBench, MP A SM, MPF, MPLAB Certified logo, MPL IB,

MPLINK, MultiTRAK, NetDetach, Omniscient Code Genera tio n,

PICDEM, PICDEM.net, PICkit, PICtail, PureSilicon, QMatrix,

RightTouch logo, REAL IC E, Ripple Blocker, SAM-ICE, Serial

Quad I/O, SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II,

Total Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of Mic rochip

Technology Incorporated in t he U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

Silicon Stora ge Technology is a regis tered trademar k of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG , a subsidiary of Microchip T echnolog y

Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2018, Microchip Technol ogy Incorp orated, All Right s Res erved.

ISBN: 978-1-5224-2671-4

EELOQ, KEELOQ logo, Kleer, LANCheck, LINK

DS20005939A-page 2 2018 Microchip Technology Inc.

Page 3

DM160232 SERIAL MEMORY

SINGLE-WIRE EVALUATION KIT

USER’S GUIDE

Table of Contents

Preface ...........................................................................................................................5

Chapter 1. Product Overview

1.1 Introduction .....................................................................................................9

1.2 AT21CS Seri e s D e v ic e Ov e r view ................ .. .. .............. .. .. .......................... ... 9

1.3 DM160232 Evaluation Kit Overview ...............................................................9

1.4 Evaluation K it C o n te n ts .. .. ............................................................................ 10

1.5 Supported Devices .......................................................................................10

1.6 Operational Requirements ...........................................................................10

Chapter 2. Installation and Operation

2.1 Introduction ...................................................................................................11

2.2 Installing th e USB B a se B o a rd Driver .... ... ................................................... 11

2.3 Installing the Graphical User Interface (GUI) ............................................... 12

2.4 Evaluation K it S e tu p P ro c e dure ....... .. .......................................................... 15

Chapter 3. Graphical User Interface (GUI)

3.1 Introduction ...................................................................................................17

3.2 Main Title Ba r ........ .......................................... ............................................. 18

3.3 Query Devic e ......... ............................. .......................................................... 18

3.4 System Sta tu s ....... ..................................................................... .................. 18

3.4.1 Kit Part Number .........................................................................................18

3.4.2 Firmware Revision .....................................................................................19

3.4.3 Socket Board Temp ...................................................................................19

3.4.4 Device in Socket ........................................................................................ 19

3.4.5 Kit Protocol ................................................................................................19

3.4.6 Socket Board SN # ....................................................................................19

3.5 Device Conditions ........................................................................................19

3.5.1 Supply Voltage Slider ................................................................................19

3.5.2 Frequency (Kbps) Slider ............................................................................20

3.6 Device Sta t u s ........ ... .......................... .. .. ...................................................... 20

3.6.1 Serial Number ...........................................................................................20

3.6.2 Slave Address ...........................................................................................20

3.6.3 MFG ID Register .......................................................................................20

3.6.4 Security Register User Space ...................................................................20

3.6.5 Zone X Lock State .....................................................................................21

3.7 Set Device Pro tection .............. .. ..................................................... .. ... ......... 21

3.8 Device Sp e ci fi ca t io n . ..................................................... .. .. ........................... 21

3.9 Transaction Log ............................................................................................22

3.9.1 Clear Log ...................................................................................................22

3.9.2 Export Log .................................................................................................22

3.9.3 Legend ......................................................................................................22

2018 Microchip Technology Inc. DS20005939A-page 3

Page 4

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

3.10 GUI Memory Array ................................................... ... .. .............................2 3

3.11 Array A ct io n s ... .. .................................................................................. ....... 24

3.11.1 HEX ........................... ....... ...... ...... ...........................................................24

3.11.2 ASCII ................................ ...... .................................................................24

3.11.3 LOAD ...... ...... ....... .................................................................................... 24

3.11.4 SAVE ............ ....... ...... ....... ...................................... ....... ...... ....... ...... ....... 25

3.11.5 PROGRAM .......... ............................................. ....................................... 2 5

3.11.6 REFRESH ................................................. ....... ...... ....... ...... ....... ...... ....... 26

3.12 Secur ity R e gi s te r ........................................................................................ 26

3.13 Array B u tton s .............................................................................................. 27

3.13.1 Read ............. ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ...... ....... 27

3.13.2 Write .......................... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... .............28

3.13.3 Go To Address ........................................................................................29

3.13.4 Other Actions ............................................. .............................................. 30

3.13.5 Support ......... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ...... ....... 30

Chapter 4. USB Base Board Firmware Upgrade

4.1 Introduction ...................................................................................................31

4.2 Installing the Graphical User Interface (GUI) ............................................... 36

4.3 USB Base Board DFU Mode ................................. .. .....................................36

4.4 FLIP Software Utility ..................................................................................... 38

Chapter 5. Troubleshooting Guide

Appendix A. Schematics

A.1 Introduction ..................................................................................................44

A.2 SWI Socket Board (02-10681) .....................................................................45

A.3 USB Base Board (02-10682) ............................................. .. .. ......................46

Appendix B. Bill of Materials (BOM)

Worldwide Sales and Service ....................................................................................50

2018 Microchip Technology Inc. DS20005939A-page 4

Page 5

DM160232 SERIAL MEMORY

SINGLE-WIRE EVALUATION KIT

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptio ns may differ from those in thi s document. Please ref er to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” numb er. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

DM160232 Serial Memory Single-Wire Evaluation Kit. Items discussed in this chapter

include:

• Document Layout

• Conventions Used in This Guide

• Recommended Reading

• The Microchip Website

• Customer Support

• Revision History

DOCUMENT LAYOUT

This document describes how to use the DM160232 Serial Memory Single-Wire

Evaluation Kit as a tool to demonstrate the best in class features, functionality, and

low-power operation of the AT21CS Series single-wire Serial EEPROM devices.

The document is organized as follow s:

• Chapter 1. “Product Overview”

• Chapter 2. “Installation and Operation”

• Chapter 3. “Graphic al User In terf ace (GUI)”

• Chapter 4. “USB Base Board Firmware Upgrade”

• Chapter 5. “Troubleshooting Guide”

• Appendix A. “Schematics”

• Appendix B. “Bill of Materials (BOM)”

2018 Microchip Technology Inc. DS20005939A-page 5

Page 6

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Gu ide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic chara c ters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, Italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mut ually exclus ive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

2018 Microchip Technology Inc. DS20005939A-page 6

Page 7

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

RECOMMENDED READING

This user’s guide describes how to use the DM160232 Serial Memory Single-Wire

Evaluation Kit. The following documents are available and recommended as

supplemental reference resources.

• Serial Memory Single-Wire Quick Start Guide – “Serial Memory Single-Wire

Evaluation Kit Quick Start Guide” (DS20005780) – This quick start guide

provides a brief overview on the DM160232 Evaluation Kit’s functionalities,

features and capabilities.

• A T21CS01/A T21CS1 1 Dat a Sheet – “Single-Wire, I/O Powered 1-Kbit (128 x 8)

Serial EEPROM with a Unique, Factory-Programmed 64-Bit Serial Number”

(DS200005857) – This document provides all the necessary information on the

AT21CS01/AT21CS11 Serial EEPROM single-wire devices including features,

general description, device operation, specifications and ordering information.

• AN8976 – “AT21CS Series Reset and Discovery” – This document provides

informati o n on th e AT21CS Series Reset f unc tion and the AT21CS Serie s D isc overy function. Additionally, a comparison between the Single-Wire Interface (SWI)

Discovery event and the Maxim/Dallas One-Wire Discovery event is discussed to

facilitate the understanding of which device type is on the bus.

THE MICROCHIP WEBSITE

Microchip provides online support via our website at www.microchip.com. This website

is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the website contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip website at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest info rmatio n on Microc hip C comp ilers, as semblers , linker s

and other language tools. These include all MPLAB C compilers; all MPLAB

assemblers (including MPASM™ assembler); all MPLAB linkers (including

MPLINK™ object linker); and all MPLAB librarians (including MPLIB™ object

librarian).

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB REAL ICE™ and MPLAB ICE 2000 in-circuit emulators.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debuggers. This includes MPLAB ICD 3 in-circuit debuggers and PICkit™ 3

debug express.

2018 Microchip Technology Inc. DS20005939A-page 7

Page 8

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Gu ide

• MPLAB IDE – The latest information on Microchip MPLAB IDE, the Windows®

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB IDE Project Manager, MPLAB Editor and

MPLAB SIM simulator, as well as general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

production programmers such as MPLAB REAL ICE in-circuit emulator, MPLAB

ICD 3 in-circuit debugger and MPLAB PM3 device programmers. Also included

are nonproduction development programmers such as PICSTART

PICkit 2 and 3.

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the website at:

http://www.microchip.com/support.

®

Plus and

REVISION HISTORY

Revision A (02/2018)

• Initial release of this document.

2018 Microchip Technology Inc. DS20005939A-page 8

Page 9

DM160232 SERIAL MEMORY

SINGLE-WIRE EVALUATION KIT

Chapter 1. Product Overview

1.1 INTRODUCTION

Microchip Technology’s DM160232 Serial Memory Single-Wire Evaluation Kit allows

the user to read, write and verify the AT21CS Series Serial EEPROM devices using the

single-wire bus protocol.

This chapter introduces the DM160232 Serial Memory Single-Wire Evaluation Kit and

provides an overview of its features. Topics covered include:

• AT21CS Series Device Overview

• DM160232 Evaluation Kit Overview

• DM160232 Evaluation Kit Contents

• Supported Devices

1.2 AT21CS SERIES DEVICE OVERVIEW

The AT21CS Series is a family of Serial Electrically Erasable and Programmable

Read-Only Memory (EEPROM) that utilizes the Single-Wire Interface (SWI) protocol.

The family software addressing scheme allows up to eight devices to share a common

single-wire bus. The device is optimized for use in many industrial and commercial

applications where low-power and low-voltage operation are essential. Some

applications examples include analog sensor calibration data storage, ink and toner

printer cartridge identification, and management of after-market consumables. The

family is available in space-saving package options and operates with an external

pull-up voltage on the SI/O line.

USER’S GUIDE

1.3 DM160232 EVALUATION KIT OVERVIEW

The Serial Memory Single-Wire Evaluation Kit (DM160232) is an easy-to-use

interactive user tool to demonstrate the best in class features, functionality and

low-power operation of the AT21CS Series Serial EEPROM devices. The evaluation

kit is for engineers, developers and decision makers to allow for fast system

prototyping using the Single-Wire Interface (SWI) protocol. The Serial Memory

Single-Wire Evaluation Kit includes a Graphical User Interface (GUI) which allows the

user to configure, demonstrate and personalize the single-wire Serial EEPROM

device.

2018 Microchip Technology Inc. DS20005939A-page 9

Page 10

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

1.4 EVALUATION KIT CONTENTS

The Serial Memory Single-Wire Evaluation Kit includes the following:

• SWI Socket Board (02-10681) (Figure 1-1)

• USB Base Board (02-10682) (Figure 1-2)

• Five AT21CS01-STUM10-T devices, with one installed in the SWI Socket Board’s

SOT23 socket

• Important Information Sheet

FIGURE 1-1: SWI SOCKET BOARD (02-10681)

FIGURE 1-2: USB BASE BOARD (02-10682)

1.5 SUPPORTED DEVICES

The following table indicates the supported devices for the DM160232 Serial Memory

Single-Wire Evaluation Kit.

T ABLE 1-1: SUPPORTED DEVICES

Device Protocol

AT21CS01-STUM##-T Single-Wire 3-lead SOT23 1.7V-3.6V 15.4 or 125 kbps

Note: ## indicates one of eight slave address combinations. Please see the

corresponding device data sheet for more information about these slave

address combinations.

1.6 OPERATIONAL REQUIREMENTS

For the Serial Memory Single-Wire Evaluation Kit to function properly, the following

hardware and software requirements must be met:

• PC compatible system

• An available USB port on PC

• At least 1.8 MB of free disk space

•Windows

Note 1: Testing has been performed on a 64-bit Windows® 7 operating system.

®

7 or higher operating systems

Package

Type

(1)

Voltage

Range

Communication

Speed

2018 Microchip Technology Inc. DS20005939A-page 10

Page 11

DM160232 SERIAL MEMORY

“I Agree” checkbox

Install

button

SINGLE-WIRE EVALUATION KIT

Chapter 2. Installation and Operation

2.1 INTRODUCTION

Setup for the Serial Memory Single-Wire Evaluation Kit is straightforward. To start, both

the USB Base Board driver and the SWI Graphical User Interface (GUI) will need to be

downloaded and installed on the user’s PC. Once both are installed, the user should

perform a simple hardware setup sequence. Once completed, simply plug in the USB

Base Board to an available USB port on the user’s PC and launch the SWI GUI.

WARNING

Read the DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

(this document) fully before proceeding to evaluation kit setup.

2.2 INSTALLING THE USB BASE BOARD DRIVER

The following steps are needed to successfully install the USB Base Board driver:

1. Go to http://www.microchip.com/DM160232 to download the USB Base Board

driver.

2. Navigate to Documentation and Software and select the USB Base Board Driv er .

3. Download and open the setup file indicated below.

driver-atmel-bundle-7.0.888.exe

4. If the Open File – Security Warning pops up, press the Run button.

5. Once prompted, read the license terms and conditions. When ready, click the

checkbox and press the Install button (Figure 2-1).

USER’S GUIDE

Note: If prompted, allow the program to make changes to your PC.

FIGURE 2-1: LICENSE TE RMS AND CONDITIONS

2018 Microchip Technology Inc. DS20005939A-page 11

Page 12

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Close button

6. Let the program setup the driver. A progress or status bar is included to show the

overall progress of the installation. Once completed, press the Close button to

complete the USB Base Board driver installation (Figure 2-2).

FIGURE 2-2: USB DRIVER INSTALLATION COMPLETE

2.3 INSTALLING THE GRAPHICAL USER INTERFACE (GUI)

The following steps are needed to successfully install the GUI software:

Note: If an earlier version of the DM160232 SWI Evaluation Kit GUI was previ-

ously installed, it is recommended to uninstall the previous version before

installing the new version. This will ensure robust GUI operation.

1. Go to http://www.microchip.com/DM160232 to download the GUI software.

2. Navigate to Documentation and Software and select the DM1 602 32 S W I

Evaluation Kit GUI software.

3. Download and open the setup file

x.x.x indicates the GUI version.

4. If the Open File – Security Warning pops up, press the Run button.

Note: If prompted, allow the program to make changes to your PC.

5. Select the Installation Destination Location from the Graphical User Interface

(GUI). Press the Next button when ready (Figure 2-3). The default Destination

Location is:

C:\Program Files (x86)\Microchip\Serial Memory Evaluation

Kits\Single-Wire

Note: When referring to location of files on the user’s PC, this document is

assuming that the default installation was used when the GUI was installed.

If the default installation is not used, it is the user’s responsibility to

determine the reference file location.

.

: DM160232_x.x.x_setup.exe, where

2018 Microchip Technology Inc. DS20005939A-page 12

Page 13

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Next button

Next button

FIGURE 2-3: GUI INSTALLATION LOCATION

6. The next step is to select the Start Menu folder. By default, the setup will create

a Start Menu folder named Microchip if one is not already present on the user’s

PC. Press the Next button when ready to continue (Figure 2-4).

FIGURE 2-4: GUI START MENU FOLDER

2018 Microchip Technology Inc. DS20005939A-page 13

Page 14

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Install

button

Finish

button

7. Once the Destination location and the Start Menu folder have been selected, the

setup will prompt the user if they are ready to install the software. Press the

Install button when ready (Figure 2-5).

FIGURE 2-5: GUI READY TO INSTALL

8. Let the program setup the SWI GUI. A progress or status bar is included to show

the overal l prog ress of the i nst allat ion. On ce com pleted , pre ss the Finish button

to complete the SWI GUI installation (Figure 2-6).

FIGURE 2-6: GUI INSTALLATION COMPLETE

2018 Microchip Technology Inc. DS20005939A-page 14

Page 15

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Device properly

seated in SOT23

socket

2.4 EVALUATION KIT SETUP PROCEDURE

In order to start using the evaluation kit, simply plug the SWI Socket Board into the

USB Base Board using the H1 and J1 headers. See Figure 2-7 for illustration.

FIGURE 2-7: DM160232 USB BASE BOARD AND SWI SOCKET BOARD

Once both the boards are connected, verify that there is a device correctly installed in

the SOT23 socket on the SWI Socket Board. If there is not a device installed, the user

must install a device from the supported device list into the SOT23 socket. To ensure

robust GUI and hardware operation, it is recommended that when installing a

supported device, the USB Base Board be disconnected from the user’s PC.

Note: Due to the small size of the 3-lead SOT23 package, it is recommended to

use tweezers in order to properly install the supported device into the SWI

Socket Board socket.

Figure 2-8 illustrates a supported device which is properly seated in the SOT23 socket.

Once the device is seated properly, close the socket lid to finish installing the supported

device.

FIGURE 2-8: SUPPORTED DEVICE IN SOT23 SOCKET

Once a supported device is installed in the SOT23 socket, the user can then plug in the

USB Base Board into one of their computer’s USB ports. Once the USB Base Board

enumerates on the user’s PC, open the GUI by selecting either the desktop icon (SWI

GUI) or navigating to the Start Menu folder that was created when the DM160232 SWI

Evaluation Kit GUI software was installed.

2018 Microchip Technology Inc. DS20005939A-page 15

Page 16

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

NOTES:

2018 Microchip Technology Inc. DS20005939A-page 16

Page 17

Chapter 3. Graphical User Interface (GUI)

3.1 INTRODUCTION

The Serial Memory Single-Wire Evaluation Kit includes a Graphical User Interface

(GUI) which is used as an interface between the user’s PC and the evaluation kit

hardware. The GUI allows the user to easily interact with the single-wire Serial

EEPROM using built-in read and write features. The GUI also highlights the

value-added features of the installed supported device. In the subsequent sections, the

GUI features and functions are explained in detail to help the user to interact with the

installed single- wire Seri al EE PROM .

The GUI version and USB Base Board firmware version must match in order to use the

GUI. If the GUI and USB Base Board versions do not match and the USB Base Board

has an earlier version programmed, perform a USB Base Board device firmware

upgrade using the GUI version. Refer to the Chapter 4. “USB Base Board Firmware

Upgrade” for details on the firmware upgrade process. If the GUI version is earlier than

the USB Base Board, download the latest version of the GUI (refer to

Section 2.3 “Installing the Graphical User Interface (GUI)” for additional

information).

DM160232 SERIAL MEMORY

SINGLE-WIRE EVALUATION KIT

USER’S GUIDE

FIGURE 3-1: GRAPHICAL USER INTERFACE

2018 Microchip Technology Inc. DS20005939A-page 17

Page 18

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Query Device

button

3.2 MAIN TITLE BAR

The title bar displays the GUI version and the USB Base Board connection status.

Figure 3-2, shown below, illustrates a GUI version of 1.6.8.

FIGURE 3-2: TITLE BAR

3.3 QUERY DEVICE

The GUI will perform an auto-query when the GUI is launched or when the USB Base

Board is initially connected to the PC. Afterwards, the user can initiate a device query

at any time with the QUERY DEVICE button (Figure 3-3). The Device Query feature

utilizes the Single-Wire Interface (SWI) Reset and Discovery Response feature in order

to determine whether the supported device was installed properly. Querying the device

will populate or re-populate the GUI with the content read from the installed device.

FIGURE 3-3: QUERY DEVICE

FIGURE 3-4: DEVICE QUERY PROGRESS BAR

3.4 SYSTEM STATUS

The System Status pane is populated with information related to the evaluation kit

hardware. These include the “Kit Part Number”, “Firmware Revision”, the installed

supported device or “Device In Socket”, the “Kit Protocol”, and the “Socket Board Sn #”

(serial number).

FIGURE 3-5: SYSTEM STATUS PANE

3.4.1 Kit Part Number

This displays the evaluation kit part number.

2018 Microchip Technology Inc. DS20005939A-page 18

Page 19

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

3.4.2 Firmware Revision

This is the version of the firmware programmed in the USB Base Board.

3.4.3 Socket Board Temp

This is not utilized in the DM160232 Serial Memory Single-Wire Evaluation Kit.

3.4.4 Device in Socket

The GUI identifies the installed supported device by reading the Manufacturer ID

register of the installed device.

3.4.5 Kit Protocol

Identifies the communication protocol used by the evaluation kit’s socket board.

3.4.6 Socket Board SN #

The SWI Socket Board serial number is retrieved from the A T24CS02 serialized Serial

EEPROM located on the SWI Socket Board. Every SWI Socket Board will have its own

unique serial number.

3.5 DEVICE CONDITIONS

The Device Conditions pa ne (Figure 3-6) allows the u ser to set the supply voltage to

the SWI Socket Boa rd and the comm unic ation spe ed or frequenc y of the Si ngle-Wi re

Interface (SWI) protocol.

FIGURE 3-6: DEVICE CONDITIONS PANE

3.5.1 Supply Voltage Slider

The voltage slider provides the ability to change the supply voltage to the SWI Socket

Board along with the installed device V

to pull up the SI/O line. The user can change the V

or dragging the indicator to the desired V

are determined by the installed device specification. Because the supply voltage is

common between every device on the SWI Socket Board, a test point is included to

measure V

PUP to the installed device and VCC supply to the AT24CS02. Whenever the

GUI is initially started, the voltage slider will default to 3.3V to ensure the installed

supported device has sufficient V

PUP voltage. The VPUP refers to the voltage used

PUP by either clicking along the slider

PUP. The upper and lower limits of the VPUP

PUP to communicate.

2018 Microchip Technology Inc. DS20005939A-page 19

Page 20

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

3.5.2 Frequency (Kbps) Slider

The frequency slider provides the ability to change the I/O or communication speed

between the host controller (USB Base Board) and the installed device. The user can

change the I/O speed by either clicking along the slider or dragging the indicator to the

desired I/O speed. The upper and lower frequency limits of the frequency slider are

determined by the installed device specification. Whenever the GUI is initially started,

the frequency slider will default to High-Speed mode to ensure the installed supported

device is able to communicate with the host controller.

Note: The Device Query feature communicates with the Serial EEPROM using

High-Speed mode. Therefore, whenever the Device Query feature is used,

it will revert the installed device back to High-Speed mode regardless of the

current frequency slider setting.

3.6 DEVICE STATUS

The Device Status pane shows various Serial EEPROM device features including the

serial number, the device slave address, the Manufacturer (MFG) ID register, the lock

state of the Security register, and the lock state of the memory zones (Zone 0 -Zone 3)

(Figure 3-7).

FIGURE 3-7: DEVICE STATUS PANE

3.6.1 Serial Number

Displays the serial number read from the Security register of the installed supported

device. The serial number is displayed in hexadecimal.

3.6.2 Slave Address

Displays the preprogrammed device slave address of the installed device. The slave

address is populated with A2 bit first, A1 bit second, and A0 bit last. The slave address

is displayed in binary.

3.6.3 MFG ID Register

Reports the content of the installed device’s Manufacturer ID register. The data is

displayed in hexadecimal.

3.6.4 Security Register User Space

Displays the lock state of the Security register. If the register is not locked, UNLOCKED

is displayed. If the register is locked, LOCKED is displayed.

2018 Microchip Technology Inc. DS20005939A-page 20

Page 21

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

3.6.5 Zone X Lock State

Displays the lock state for the respective memory zones (Zone 0 through Zone 3). If the

zone is not locked, UNLOCKED is displayed. If the zone is locked, LOCKED is

displayed.

3.7 SET DEVICE PROTECTION

The Set Device Protection pane (Figure 3-8) allows the user to independently lock the

four memory zones and the Security register based on the user’s preference. The user

locks a zone or the Security register by pressing the button to the right of that memory

region. The button also indicates the current lock status of that zone or the Security

register and the button shading is based on the current lock status.

pressed, a warning message is displayed to make sure the user intends to lock that

zone or the Security register.

Note: Once the Security register or a memory zone is locked, it cannot be

unlocked and is permanently set to ROM (Read-Only-Memory).

FIGURE 3-8: SET DEVICE PROTECTION PANE

Once a button is

3.8 DEVICE SPECIFICATION

The Device Specification pane (Figure 3-9) displays key device parameters, which can

be found in the installed device’s data sheet. These parameters include “Voltage

Range”, “Frequency Range”, “Endurance Rating”, and “Data Retention”.

FIGURE 3-9: DEVICE SPECIFICATION PANE

2018 Microchip Technology Inc. DS20005939A-page 21

Page 22

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Clear Log button

Export Log button

Show Legend

checkbox

3.9 T RANSACTION LOG

The Transaction Log records all single-wire communication with the installed device as

well as highlights the communication protocol according to the legend. The Transaction

Log reports the data on the single-wire bus in hexadecimal. The Transaction Log can

be used in conjunction with an oscilloscope connected to the SI/O and GND test points

to help the user decode the captured protocol.

Note: The Transaction Log does not capture the Reset and Discovery Response

sent to the installed device. The Reset and Discovery Response can be

observed by performing a device query while monitoring an oscilloscope

connected to the SI/O and GND test points.

FIGURE 3-10: TRANSACTION LOG

3.9.1 Clear Log

The CLEAR LOG button clears the Transaction Log. The Clear Log function is helpful

when the user wants to look at a specific type or group of single-wire protocol.

3.9.2 Export Log

The EXPORT LOG button exports the Transaction Log in HTML format. The exported

Transaction Log can be used as a reference without having to resend protocol to the

installed device.

3.9.3 Legend

The Transaction Log legend highlights the different data bytes in the single-wire

protocol that is being sent/received; the device address byte is shown in red, the word

address byte is shown in blue, data input by te(s) is shown in green, and data output

byte(s) or the response is shown in black. The Show Legend function can either show

or hide the Transaction Log legend.

2018 Microchip Technology Inc. DS20005939A-page 22

Page 23

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

3.10 GUI MEMORY ARRAY

The GUI memory array is initially populated with the data read from the installed Serial

EEPROM. The data of the GUI memory array is organized in 8-byte rows, left to right,

and in ascending order. The GUI memory array will always be displayed in 8-byte row

lengths regardless of the installed device’s page size. The GUI memory array data

can be modified by the user by using various GUI features which are outlined in the

subsequent sections .

The GUI memory array features memory cell shading that is used to highlight the

different state of that me mory c ell or ce lls. Green shading indicates that the cell or cells

have not been locked and the user can write to that word address or range of word

addresses. Red shading indicates that cell or cells have been locked and now functions

as Read-Only-Memory (ROM). Yellow shading indicates that the memory array cell or

cells have been changed in the internal GUI buffer and have not been written to the

Serial EEPROM (see Section 3.11.5 “PROGRAM” for additional information).

FIGURE 3-11: MEMORY ARRAY

When the user hovers the mouse cursor over the GUI memory array, a pop-up appears

to show the data in HEX, data in ASCII, Address, Zone: #, and Zone Protection state

of that particular memory cell. This is illustrated in Figure 3-12.

FIGURE 3-12: ARRAY HOVER

The user can change the content of a cell by double-clicking a word address or memory

cell in the GUI memory array or GUI Security register (see Figure 3-13). In order to

change the content of a cell, the user should update the value, followed by pressing the

Update Cell button. Once the cell is updated, the cell shading will become yellow. This

indicates to the user that they must then program the device using the Program Feature

(see Section 3.11.5 “PROGRAM” for additional information).

2018 Microchip Technology Inc. DS20005939A-page 23

Page 24

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Update Cell

button

Hex button

ASCII button

Load button

Save button

Program button

Refresh button

FIGURE 3-13: ARRAY UPDATE CELL

3.11 ARRAY ACTIONS

Array actions allow the user to manipulate the GUI memory array in terms of how the

data is displayed (HEX or ASCII) and also allow the user to save the GUI memory array

or load a previous array.

FIGURE 3-14: ARRAY ACTIONS

2018 Microchip Technology Inc. DS20005939A-page 24

3.11.1 HEX

The HEX button displays the GUI memory array in hexadeci ma l (HE X) form at.

3.11.2 ASCII

The ASCII button displays the GUI memory array in American Standard Code for

Information Interchange (ASC II) forma t.

3.11.3 LOAD

The LOAD button gives the user the option to load a previous saved GUI memory array

either HEX (.hex) or TEXT (.txt) file. The file, once loaded, will be used to populate the

internal GUI buffer. Once the file is loaded in the GUI array buffer, the user must

program the installed device using the PROGRAM button (see

Section 3.11.5 “PROGRAM” for additional information).

Note: The loaded file must follow a specific format. In order to determine the

correct file format, it is recommended to save a GUI memory array as a

reference (see Section 3.11.4 “SAVE” for additional information) and refer

to that file when formatting the data.

Page 25

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

File type selection

buttons

FIGURE 3-15: LOAD

3.11.4 SAVE

The SAVE button gives the user the ability to save the current state of the GUI memory

array. The GUI memory array can be saved as either a HEX (.hex) file or TEXT (.txt)

file based on the user preference. Once a file type is selected, a file explorer will pop

up prompting the user to specify the file directory and name of the file.

Note: When using the Save feature, the software will create the data for the saved

file based on the internal GUI buffer and not on the actual data from the

Serial EEPROM.

FIGURE 3-16: SAVE

3.11.5 PROGRAM

The Program feature can be used to write to the Serial EEPROM memory array,

Security register, lock Zone 0 to Zone 3, and lock the Security register. When the

PROGRAM button is pressed, the current internal GUI buffer will be written to the Serial

EEPROM memory. The Program feature must be used when a cell is updated

(yellow shaded), or when a file (.hex or .txt) is loaded. If the Program feature is not

used, the data in the internal GUI buffer will not be written to the Serial EEPROM.

The Program feature can also be used to lock the four memory zones and/or the

Security register. Each zone and the Security register can be locked independently of

each other by placing a check mark in the corresponding box.

When the Program feature is used to program the Serial EEPROM memory array or

Security register, that entire memory region will be written with the current data in the

internal GUI buffer rather than only the changed values. If a specific data byte or bytes

are to be programmed, it is recommended to use the Write feature

(see Section 3.13.2 “Write” for additional information).

Note: By default, the memory array is selected. Therefore, if the user only wants

to write the Security register or lock a zone or register, the user must

unselect the memory array and select the particular operation to be

performed.

2018 Microchip Technology Inc. DS20005939A-page 25

Page 26

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Write checkboxes

Lock checkboxes

Refresh status bar

FIGURE 3-17: PROGRAM

3.11.6 REFRESH

The REFRESH button reads the Serial EEPROM memory array and Security register

of the installed device and then populates the GUI memory array and Security register

with that data. If there is data in the internal GUI buffer (yellow-shaded cell) when the

Refresh feature is used, that data will be replaced with the data read from the Serial

EEPROM. After the completion of any write operation to the Serial EERPOM, the GUI

will automatically update the GUI memory array and Security register using the Refresh

feature.

Note: If a new device is installed while leaving the USB Base Board connected to

the user’s PC, it is recommended to use the Device Query feature instead

of the Refresh feature to ensure robust GUI operation.

FIGURE 3-18: REFRESH

3.12 SECURITY REGISTER

The Security register consists of a factory-programmed unique serial number in the

lower 8 bytes (address 0x00h to 0x07h), an 8-byte page that is reserved for future use

with data of 0xFFh (address 0x08 to 0x0F), and a writable portion in the upper 16 bytes

(address 0x10h to 0x1Fh) of the Security regis ter. Th e red-shaded ce ll s indi cate they

are locked and cannot be modified by the user; green-shaded cells indica te that the cel l

or cells are unlocked and can be modified by the user; yellow shading indicates that the

memory array cell or cells have been changed in the internal GUI buffer and have not

been written to the Serial EEPROM.

2018 Microchip Technology Inc. DS20005939A-page 26

Page 27

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

The entire Security register can be locked by either using the Program feature (see

Section 3.11.5 “PROGRAM”) or using the Set Device Protection pane (see

Section 3.7 “Set Device Protection”).

Note: Once the Security register has been locked, it cannot be unlocked and is

permanently set to ROM (Read-Only-Memory).

FIGURE 3-19: SECURITY REGISTER

3.13 ARRAY BUTTONS

The array buttons, which are located below the GUI Security register, allow the user to

perform read and write operations to the Serial EEPROM, use the Go To Address

feature to highlight a specific word address in the GUI memory array, and also provides

various support functions.

FIGURE 3-20: ARRAY BUTTONS

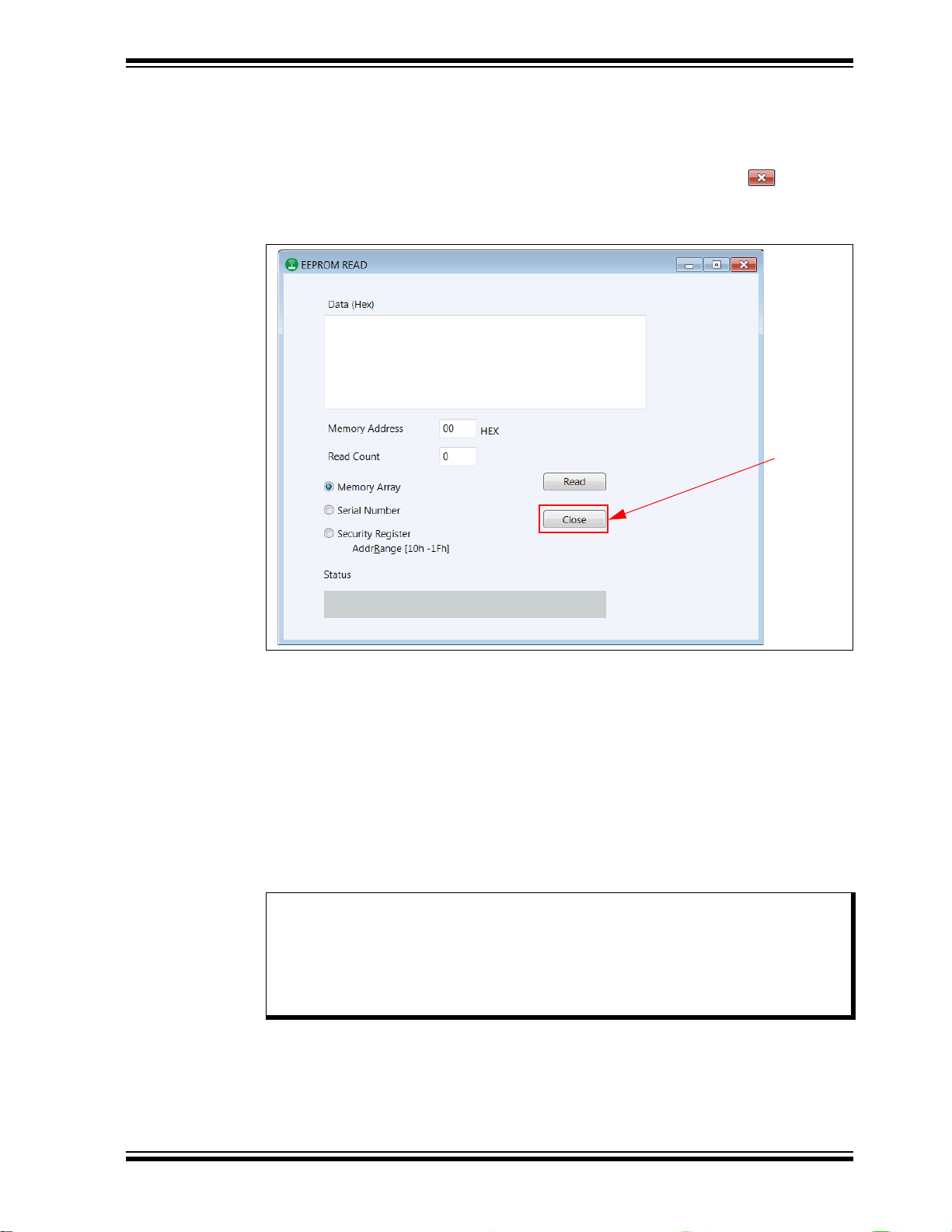

3.13.1 Read

The Read feature allows the user to read the entire Serial EEPROM memory array, a

specific word address or a range of word addresses, the serial number, and/or the

Security register of the Serial EEPROM. When the READ button is pressed, a pop-up

window appears allowing the user to enter details related of the read operation to be

performed.

Note: The Read feature will not update the GUI memory array or GUI Security

register. To update the GUI, use the Refresh feature (see the

Section 3.11.6 “REFRESH”for additional information).

The user can input a starting word address using the Memory Address field that the

read operation will start at (in hexadecimal), the Read Count or the amount of bytes to

be read, and the user can select what read operation is to be performed (Memory

Array, Serial N umber, or Security Register). Once all the input data has been filled,

press the READ button to start the read operation. A status message is included at the

bottom of the window to notify the user that the read operation is complete by displaying

“Successful”.

Note: If the user performs a read operation to the Security register or reads the

serial number, the GUI will automatically populate the starting memory

address for the user stating at the first byte of either the writable portion

(upper 16 bytes) of the Security register or the serial number depending on

which is selected. The user can change the starting address, but the GUI

will limit the word address to the Security register boundaries.

2018 Microchip Technology Inc. DS20005939A-page 27

Page 28

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Close

button

Once the read operation is complete, the data will be displayed in hexadecimal in the

Data (Hex) field. The user can perform as many read operations as preferred from this

window. For each new read operation, the Data field will be re-written using the data

read from the current read operation being performed. Once all read operations are

completed, the user can close the window by pressing the red button ( ) in the top

right hand corner of the pop-up window or pressing the Close button.

FIGURE 3-21: READ OPERATION

3.13.2 Write

The Write feature allows the user to write the entire Serial EEPROM memory array, a

specific word address or a range of word addresses, and the writable portion of the

Security register. When the WRITE button is pressed, a pop-up window appears

allowing the user to enter details related to the write operation to be performed.

The user inputs the data that is to be written in the Data field (in hexadecimal). The user

then selects the starting word address using the Memory Address (hex) field that the

write operation will start at (in hexadecimal). The Count, or the number of bytes to be

written, is filled automatically based on the amount of data bytes in the “Data” field. The

user can also select whether the write operation will occur in the Serial EEPROM

memory array or the Security register.

Note: If the user performs a write operation to the Security register, the GUI will

automatically populate the memory address for the user stating at the first

byte of the writable portion (upper 16 bytes) of the Security register. The

user can change the starting word address of the write operation, but the

GUI limits the word address to the writable portion (upper 16 bytes) of the

Security register.

The GUI limits write operations to the physical device boundary (address of 0x7Fh for

the memory array and address of 0x1Fh for the Security register).The write operation

will be aborted if the address boundary of that particular memory region is exceeded.

2018 Microchip Technology Inc. DS20005939A-page 28

Page 29

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Close button

Once all the input data has been input, press the WRITE button to start the write

operation. A status message is included at the bottom of the window to notify the user

that the write operation is complete by displaying “Successful”.

Note: Due to the construction of the Serial EEPROM devices, the write operation

is limited to the page size or boundary of the installed device. If the “Data”

field exceeds the page boundary of the installed device, the GUI will

automatically parse the data into the correct page size and perform multiple

write operations until the entire data field has been written to the Serial

EEPROM.

Once the entire write operation is complete, the user can close the window by pressing

the red button ( ) in the top right-hand corner of the pop-up window or pressing the

Close button. Once either is pressed, a progress bar for the Refresh feature is

displayed and the entire GUI memory array and Security register are read and the GUI

is updated accordingly.

FIGURE 3-22: WRITE OPERATION

3.13.3 Go To Address

The Go To Address feature allows the user to jump to a specific word address in the

GUI memory array. Once the Go To Address button is pressed, the memory address

that was input will be highlighted in a black box in the GUI memory array.

Note: The Go T o Address feature does not work for the GUI Security register and

only works for addresses within the GUI memory array.

FIGURE 3-23: GO TO ADDRESS

2018 Microchip Technology Inc. DS20005939A-page 29

Page 30

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

3.13.4 Other Actions

The OTHER ACTIONS button is reserved for future use (RFU) if future GUI

enhancements are made.

3.13.5 Support

The SUPPORT button provides a hyperlink to various support pages. The support

feature allows the user to select between three support classes.

• “Contact Support” which directs the user to the Microchip support portal

• “Order more Samples” which directs the use to microchipDIRECT

• “Find other Devices” which directs the user to Microchip Serial EEPROM memory

page

FIGURE 3-24: SUPPOR T

2018 Microchip Technology Inc. DS20005939A-page 30

Page 31

Chapter 4. USB Base Board Firmware Upgrade

Install

button

4.1 INTRODUCTION

The Microchip Technology Serial Memory Evaluation Kits have a built-in ability to

upgrade the USB Base Board using a sequence of steps along with using the Atmel

FLexible In-system Programming (FLIP) software.

The following steps are needed to successfully install the FLIP Software Utility:

1. Go to http://www.microchip.com/DM160232 to download the FLIP Software

Utility

2. Navigate to Documentation and Software and select the FLIP Software Utility.

DM160232 SERIAL MEMORY

SINGLE-WIRE EVALUATION KIT

USER’S GUIDE

3. Download and open the setup file

JRE - Flip Installer - x.x.x.xxx.exe (x.x.x.xxx indicates the version)

4. Once the setup file is opened, if Java Runtime is already installed or a newer

version is already installed, the setup will automatically start and you may skip to

Step 8. If no Java Runtime or an older version is present on the user’s PC, when

prompted, press the Install button to start the Java Runtime installation.

Note: If prompted, allow the program to make changes to your PC.

FIGURE 4-1: JAVA RUNTIME ENVIRONMENT SETUP

.

2018 Microchip Technology Inc. DS20005939A-page 31

Page 32

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Close

button

Setup

button

Accept button

5. Let the program setup the Java Runtime. A progress or status bar is included to

show the overall progress of the installation. Once completed, press the Close

button.

FIGURE 4-2: JAVA RUNTIME INSTALLATION

6. When prompted, select “Typical setup” and press the Accept button to accept

the License Agreement.

Note: For this example, the Typical setup was used. If the user selects a Custom

setup, it is the user’s responsibility to ensure the FLIP Software Utility is

installed correctly.

FIGURE 4-3: JAVA RUNTIME TYPICAL SETUP

2018 Microchip Technology Inc. DS20005939A-page 32

Page 33

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Finish

button

Next

button

7. Let the program setup the Java Runtime. A progress or status bar is included to

show the overall progress of the installation. Once completed, press the Finish

button to complete the Java Runtime installation.

FIGURE 4-4: JAVA RUNTIME COMPLETION

8. Once the Java Runtime is installed, the FLIP Setup Wizard is automatically

started. Once ready, click the Next button to continue.

FIGURE 4-5: FLIP SETUP WIZARD

2018 Microchip Technology Inc. DS20005939A-page 33

Page 34

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

“I accept”

checkbox

Next button

Next

button

9. Read the License Agreement. When finished, accept the terms in the License

Agreement by checking the box and press the Next button to continue.

FIGURE 4-6: FLIP LICENSE AGREEMENT

10. The next step is to select the installation location. The default installation location

is set to C:\Program Files (x86)\Atmel\Flip x.x.x (x.x.x indicates

the version). It is recommended that the default installation location is used.

Once the installation location has been selected, press the Next button.

FIGURE 4-7: FLIP INSTALLATION LOCATION

2018 Microchip Technology Inc. DS20005939A-page 34

Page 35

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Install

button

Finish

button

1 1. The next step is to choose a Start Menu folder. By default, the Start Menu folder

is set to Flip x.x.x, where x.x.x indicates the FLIP version. It is recommended that

the default Start Menu folder is used. Once ready, press the Install button to

continue.

FIGURE 4-8: FLIP START MENU FOLDER

12. Let the program setup the FLIP Software Utility. A progress or status bar is

included to show the overall progress of the installation. Click the Next button

during the installation progress, if prompted. Once completed, press the Finish

button to complete the FLIP Software Utility installation.

FIGURE 4-9: FLIP SOFTWARE UTILITY COMPLETE

2018 Microchip Technology Inc. DS20005939A-page 35

Page 36

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

4.2 INSTALLING THE GRAPHICAL USER INTERFACE (GUI)

Once the FLIP Software Utility has been successfully installed on the user’s PC, the

next step is to download and install the latest version of the DM160232 SWI Graphical

User Interface (GUI) software.

The following steps are necessary to successfully install the GUI software:

1. Go to http://www.microchip.com/DM160232 to download the GUI software.

2. Navigate to “Documentation and Software” and select the “DM160232 SWI GUI

software”.

3. Download and open the setup file.

DM160232_x.x.x_setup.exe (x.x.x indicate the GUI version)

4. Install the GUI using the procedure outlined in Section 2.3 “Installing the

Graphical User Interface (GUI)”.

Note: If an earlier version of the SWI GUI was previously installed, it is recom-

mended to uninstall the previous version before installing the new version.

This will ensure robust GUI operation.

4.3 USB BASE BOARD DFU MODE

Once the latest version of the GUI has been installed on the user’s PC, the next step

is to plug in the USB Base Board into a USB port without the SWI Socket Board

connected. The PC will recognize the USB Base Board as “AVR MEGA Virtual Com

Port” in the PC’s Devices and Printers window from the Control Panel if there is

firmware already loaded in the USB Base Board (Figure 4-10). Note that the COM port

numeration may change based on the user’s PC.

FIGURE 4-10: AVR MEGA VIRTUAL COM PORT

2018 Microchip Technology Inc. DS20005939A-page 36

Page 37

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

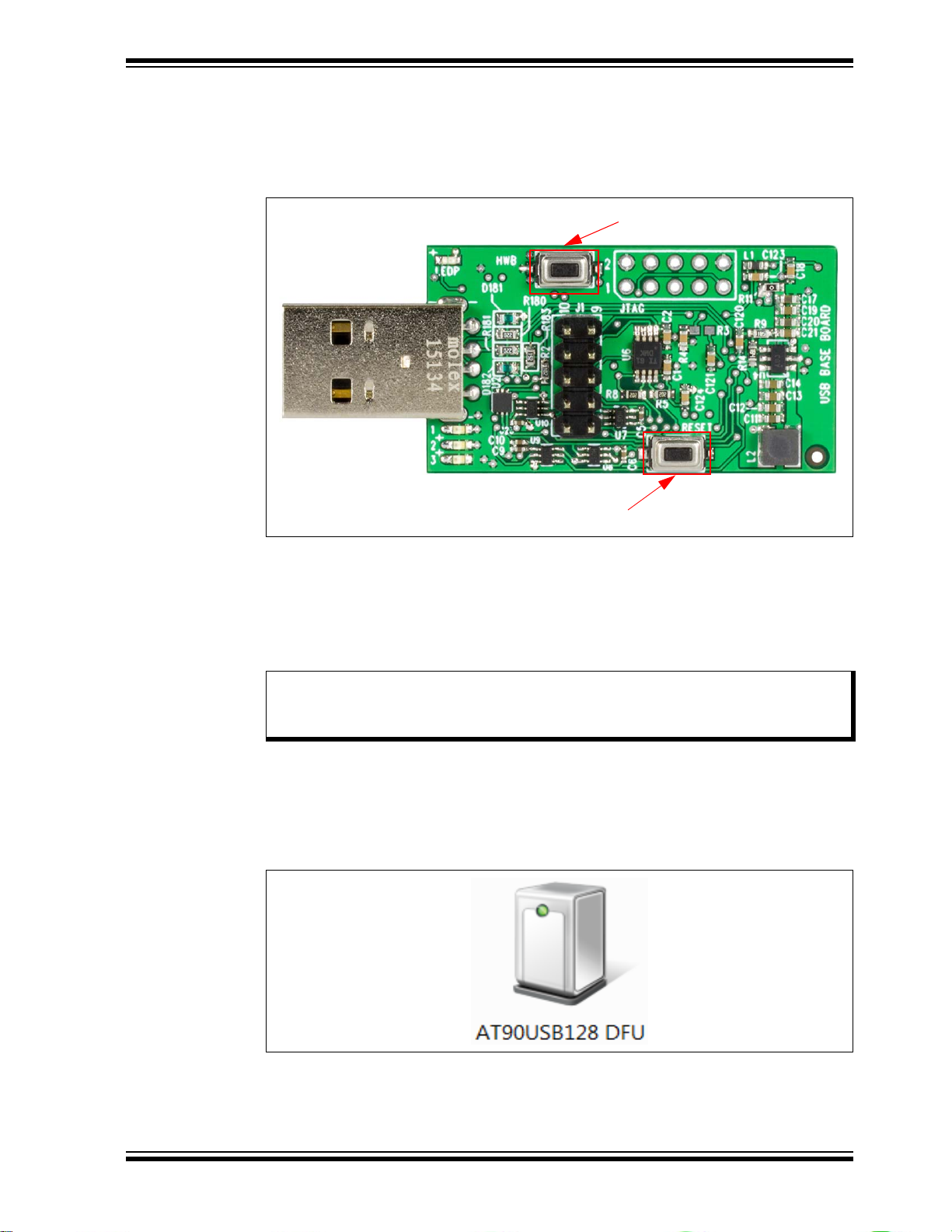

HWB button

RESET button

Once the USB Base Board is plugged in and recognized by the PC, the user should

enable DFU mode on the USB Base Board. DFU mode is enabled by a specific

sequence of HWB and RESET buttons. Refer to Figure 4-11 for locations of the HWB

and RESET buttons.

FIGURE 4-11: USB BASE BOARD BUTTONS

Once the HWB and RESET buttons have been located, use the specific press and hold

sequence shown below to enable DFU mode on the USB Base Board.

• Press and hold the HWB button

• Press and release the RESET button

• Release the HWB button

Note: Once DFU mode is enabled on the USB Base Board, the rest of the

firmware upgrade process must be completed in order to ensure robust

USB Base Board operation.

Once the USB Base Board has DFU mode enabled, allow the PC to relearn the USB

Base Board as “AT90USB128 DFU” (Figure 4-12). If the PC does not automatically

recognize the USB Base Board as stated above and shown below, it is recommended

to unplug the USB Base Board from the PC and restart the procedure.

FIGURE 4-12: AT90USB128 DFU COM PORT

2018 Microchip Technology Inc. DS20005939A-page 37

Page 38

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

4.4 FLIP SOFTWARE UTILITY

Once the USB Base Board has DFU mode enabled and the COM port is relearned by

the PC, perform the following sequence using the FLIP Software Utility to upgrade the

USB Base Board firmware.

1. Open the FLIP Software Utility (Figure 4-13) by either selecting the desktop icon

(if created) or selecting “Flip x.x.x” (x.x.x indicates the version) from the Start

Menu folder.

FIGURE 4-13: FLIP SOFTWARE UTILITY

2. After opening the FLIP Software Utility, navigate to the Device Selection icon as

shown below. Select the “AT90USB1287” as the device and press the OK button.

2018 Microchip Technology Inc. DS20005939A-page 38

Page 39

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Device

Selection icon

AT90USB1287

FIGURE 4-14: DEVICE SELECTION

2018 Microchip Technology Inc. DS20005939A-page 39

Page 40

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Communication

Medium icon

USB

File

Load HEX Files

3. Once the target device has been selected, click on the Communication Medium

icon as shown below and select “USB”. Once “USB” is selected, an additional

dialog box is displayed. Press the Open button to continue.

FIGURE 4-15: COMMUNICATION MEDIUM SELECTION

4. Once the communication between the PC and the AT90USB1287 (USB Base

Board microcontroller) has been established, navigate to File and select “Load

HEX Files” as shown in Figure 4-16.

FIGURE 4-16: LOAD FILE

2018 Microchip Technology Inc. DS20005939A-page 40

Page 41

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Run button

Verify PASS

message

5. Proceed to load the SWI firmware. Navigate to the firmware found at:

C:\Program Files (x86)\Microchip\Serial Memory Evaluation

Kits\Single-Wire\Firmware

Note: If the default installation was not used when the DM160232 SWI GUI was

installed, it is the user’s responsibility to determine the SWI firmware file

location.

6. Once the HEX file has been loaded into the FLIP Software Utility , press the Run

button to program the new firmware to the AT90USB1287 as shown below. A

progress or status bar is included to show the overall progress of the hex image

program.

FIGURE 4-17: RUN FLIP SOFTWARE

7. If the “Verified Pass” is reported in the FLIP Software Utility (see Figure 4-18),

close the FLIP Software Utility and remove the USB Base Board from the PC.

The USB Base Board Firmware Upgrade procedure is complete.

Note: If the USB Base Board was updated successfully, the PC will recognize the

USB Base Board as “AVR MEGA Virtual Com Port” (see Figure 4-10).

If the “Verified Pass” is not shown, or any other error is displayed, it is

recommended to unplug the USB Base Board from the PC and restart the entire

firmware upgrade procedure.

FIGURE 4-18: FLIP SOFTWARE COMPLETE

2018 Microchip Technology Inc. DS20005939A-page 41

Page 42

DM160232 SERIAL MEMORY

SINGLE-WIRE EVALUATION KIT

USER’S GUIDE

Chapter 5. Troubleshooting Guide

ISSUE: USB BASE BOARD IS NOT RECOGNIZED BY THE USER’S PC

SOLUTION:

ISSUE: GUI STATES THE USER MUST PERFORM A FIRMWARE UPDATE

SOLUTION: Perform the USB Base Board Firmware Upgrade using the procedure outlined in

The USB Base Board driver is not installed or not installed properly. Download and

install the USB Base Board driver using the procedure outlined in

Section 2.2 “Installing the USB Base Board Driver”.

The USB Base Board firmware was not programmed properly or has become

corrupted. Perform the USB Base Board Firmware Upgrade using the procedure

outlined in Chapter 4. “USB Base Board Firmware Upgrade”.

TO THE USB BASE BOARD

Chapter 4. “USB Base Board Firmware Upgrade”.

ISSUE: GUI STATES THERE IS NO DEVICE INSTALLED IN THE SWI

SOCKET BOARD

SOLUTION: Close the GUI and remove the USB Base Board from the PC. Verify that the SWI

Socket Board and the USB Base Board are connected properly. Also verify that the

device is installed correctly in the SOT23 socket on the SWI Socket Board. Refer to

Section 2.4 “Evaluation Kit Setup Procedure” for additional information. Make sure

the socket lid is shut without any binding. Plug the SWI Socket Board into the USB

Base Board and restart the GUI. If the problem persists, contact your local Sales

representative for additional support or create a support ticket at

www.microchip.com/support.

2018 Microchip Technology Inc. DS20005939A-page 42

Page 43

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

NOTES:

2018 Microchip Technology Inc. DS20005939A-page 43

Page 44

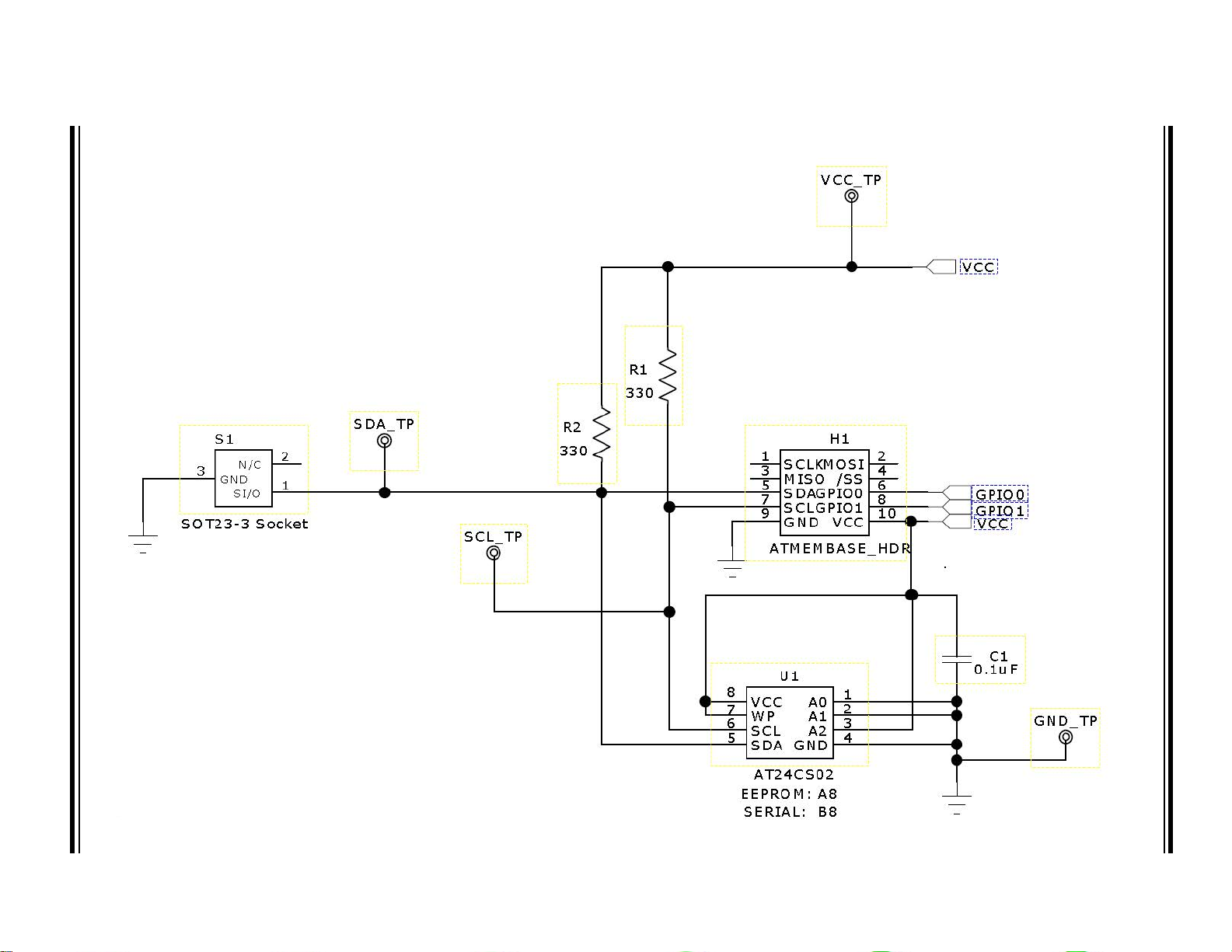

A.1 INTRODUCTION

This appendix contains the following schematics for the DM160232 Serial Memory

Single-Wire Evaluation Kit:

• SWI Socket Board (02-10681)

• USB Base Board (02-10682)

Note: Electronic versions of the SWI Socket Board and USB Base Board sche-

DM160232 SERIAL MEMORY

SINGLE-WIRE EVALUATION KIT

USER’S GUIDE

Appendix A. Schematics

matics can be downloaded from http://www.microchip.com/DM160232

under “Documentation and Software”.

2018 Microchip Technology Inc. DS20005939A-page 44

Page 45

2018 Microchip Technology Inc. DS20005939A-page 45

A.2 SWI SOCKET BOARD (02- 10681)

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Page 46

2018 Microchip Technology Inc. DS20005939A-page 46

PROCESSOR

USB

RESET MEB

BOOTLOADER

JTAG

CONNECTOR PORT

Oscillator

+5V

3.3V POWER CIRCUIT

VCCB: CONTROLLER SIDE

DAC & U NITY G AIN AMP LIFIER

Reroute u5 power connection

VCCA: DUT SIDE

VCCA <= VCCB

16 ADC

Note: V CC also serve s as Vref

LEVE L SHIFTE R

VCCA [0.8V to 5.5V]

VCCB [2.2 V to 5.5V]

VCCA <= VCCB

MCP16251

1

2

C123

0.1uF

1

2

C121

0.1uF

1

2

C120

0.1uF

1

PE6

2

PE7

3

UVCC

4

D-

5

D+

6

UGND

7

UCAP

8

VBUS

9

PE3

10

PB0

11

PB1

12

PB2

13

PB3

14

PB4

15

PB5

16

PB6

17

PB718PE419PE520RESET_21VCC22GND23XTAL224XTAL125PD026PD127PD228PD329PD430PD531PD632PD7

33

PE0

34

PE1

35

PC0

36

PC1

37

PC2

38

PC3

39

PC4

40

PC5

41

PC6

42

PC7

43

PE2

44

PA7

45

PA6

46

PA5

47

PA4

48

PA3

49

PA250PA151PA0

52

VCC

53

GND

54

PF755PF656PF557PF458PF359PF260PF161PF0

62

AREF

63

GND

64

AVCC

65

IC2

AT90USB1287-64QFN

2

1

C124

0.1uF

1

SCLK

3

MISO

5

SDA

7

SCL

9

GND

2

MOSI

4

/SS

6

GPIO0

8

GPIO1

10

VCC

J1

ATMEMBASE_HDR

1

3

5

7

2

4

6

8

910

JTAG

10POS .100 MALE HDR

C117

0.1uF

1

2

C126

20pF

1

2

C125

20pF

1A12

B1

RESET

PUSH_BTN

R151

47K

1

2

C151

0.1uF

C184

0.1uF

R184

47K

1A12

B1

HWB

PUSH_BTN

D182

TVS DIODE

1

2

3

4

USB

USB

R180

22

D181

TVS DIODE

R183

1.5K

R181

22

LEDP

1

2

R144

4.7K

1

1

2

R103

825

2

1

2

R104

825

1

2

3

4

Y121

16MHz Xtal

3

1

2

R105

825

1

2

R6

180

1

2

R7

180

12

L1

10uH

1

2

R3

DNI

1

2

R4

0.1uF

1

VCC

2

VIN

3

GND4CS

5

SDO

6

SCK

7

CPAD

U2

LTC2450

1

VDD

2

CS

3

SCK

4

SDI5LDAC

6

VREF

7

VSS

8

VOUT

U3

MCP4921T-E/MS

1

2

C15

0.1uF

1

2

C16

0.1uF

1

2

C18

0.1uF

C101

1.0uF

C102

1.0uF

C103

10uF

1

VIN

2

GND

3EN4

BYPASS

5

OUT

U1

576-1281-1-ND

1

OUTA

2

V-

3

+INA4-INA

5

V+

U5

1

VCCA

2

SCLA

3

SDAA

4

GND

5

EN

6

SDAB

7

SCLB

8

VCCB

U6

TCA9617A_8-SSOP

1

2

C2

0.1uF

1

2

C3

0.1uF

1

2

C4

0.1uF

1

2

R2

1K

1

2

R8

2K

1

2

R5

2K

1

2

R12

DNI

1

2

R13

0

1

VCCA

2

A

3

GND4EN

5

Y

6

VCCY

U7

1

VCCA

2

A

3

GND4EN

5

Y

6

VCCY

U8

1

VCCA

2

A

3

GND4EN

5

Y

6

VCCY

U9

C5

1.0uF

C6

1.0uF

C7

1.0uF

C8

1.0uF

C9

1.0uF

C10

1.0uF

1

2

C1

0.1uF

R1

1.5

3

EN

2

GND

1

SW

4

FB

5

VOUT

6

VBAT

U4

12

L2

4.7uH

1

2

R9

499K

1

2

R14

143K

C11

4.7uF

C12

4.7uF

C13

4.7uF

C14

4.7uF

C17

4.7uF

C19

4.7uF

C20

4.7uF

C21

4.7uF

R11

0

1

VCCA

2

A

3

GND4EN

5

Y

6

VCCY

U10

C22

1.0uF

C23

1.0uF

1

2

R10

0

1

FD1

FIDUCIAL_PAD

1

FD2

FIDUCIAL_PAD

1

FD3

FIDUCIAL_PAD

1

FD4

FIDUCIAL_PAD

DP_USB

DM_USB

PE4

SDA

SCL

VCC

RESET_MEB

VCC

VCC

MISO

MOSI

SCLK

SS

VCC

GPIO1

GPIO0

SS_DUT

SCL_DUT

SDA_DUT

MISO_DUT

VCC

VCC

VCC

RESET_MEB

DP_USB

DM_USB

PE4

HWB

HWB

5V5

SCLK_DUT

DUT_VCC

XTAL1

XTAL2

GPIO0

MOSI_DUT

XTAL1

XTAL2

TCK

TDO

TMS

TDI

TCK

TMS

TDO

TDI

VCC

GND

GND

VCC

SCLK

MISO

ADCCS

GPIO1

ADCCS

VCC

MOSI

SCLK

CS_DAC

/LDAC

VUSB

CS_DAC

DUT_VCC

VCC

/LDAC

GPIO1

DUT_VCC

SCL

SDA

DUT_VCC

VCC

3V3

5V5

3V3

VCC

DUT_VCC

SCLK_DUT

MISO_DUT

MOSI_DUT

SCLK

MISO

MOSI

VCC

SCL_DUT

SDA_DUT

VUSB

VCC

SS_DUT

SS

A.3 USB BASE BOARD (02-10682 )

DM160232 Serial Memory Single-Wire Evaluation Kit User’s Guide

Page 47

DM160232 SERIAL MEMORY

SINGLE-WIRE EVALUATION KIT

USER’S GUIDE

Appendix B. Bill of Materials (BOM)

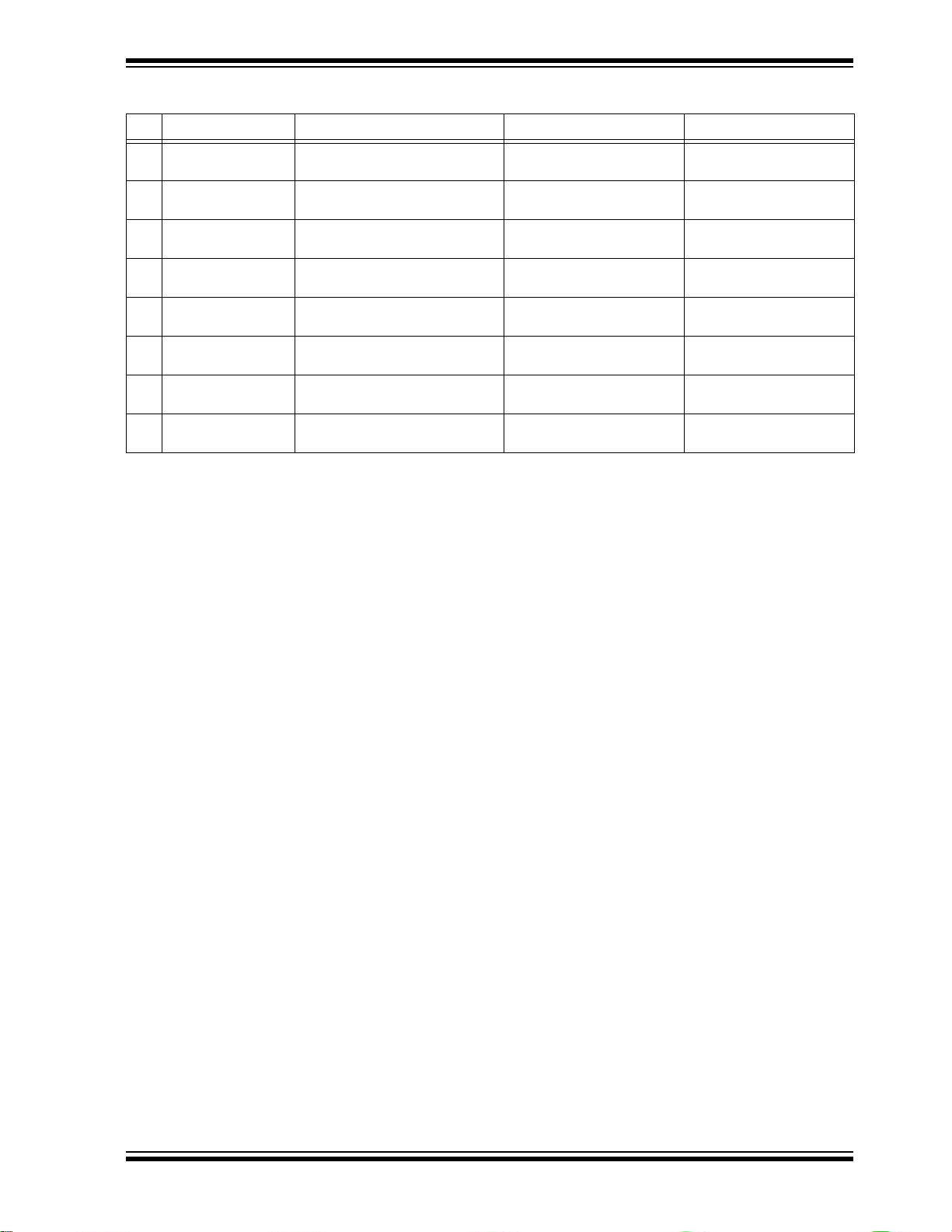

TABLE B-1: SWI SOCKET BOARD (02-10681)

Qty Reference Description Manufacturer Part Number

1 C1 Ceramic Capacitor, 0.1 µF, 50V, 20%

X5V SMD 0603

1 H1 Receptacle Connector, 100",

10 positions Dual Gold

1 PCB Printed Circuit Board – DM160232 SWI

Socket Board

2 R1, R2 Resistor-SMD, 330 Ohms, 5%, 1/10W,

0603

1 S1 3-lead SOT23 Socket Sensata Technologies

4 T1, T2, T3, T4 PC Test Point, Compact SMT Keystone Electronics

1 U1 Atmel 2 Kb Serialized 2-wire device

SOIC-8

1 SOCKET Installed Atmel 1 Kb Serialized SWI

device SOT23

4 N/A Loose Atmel 1 Kb Serialized SWI device

SOT23

Note 1: The components listed in this Bill of Mate rials are repre senta tive of the PC B assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

(1)

Yageo Corporation CC0603ZRY5V9BB104

Samtec Inc. SSW-105-01-F-D