Page 1

Digital Power Starter Kit

User’s Guide

2012 Microchip Technology Inc. DS52078A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology I ncorporat ed in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, chipKIT,

chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net,

dsPICworks, dsSPEAK, ECAN, ECONOMONITOR,

FanSense, HI-TIDE, In-Circuit Serial Programming, ICSP,

Mindi, MiWi, MPASM, MPLAB Certified logo, MPLIB,

MPLINK, mTouch, Omniscient Code Generation, PICC,

PICC-18, PICDEM, PICDEM.net, PICkit, PICtail, REAL ICE,

rfLAB, Select Mode, Total Endurance, TSHARC,

UniWinDriver, WiperLock and ZENA are trademarks of

Microchip Technology I ncorporat ed in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2012, Microchip Technology Incorporat ed, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

QUALITY MANAGEMENT S

DS52078A-page 2 2012 Microchip Technology Inc.

ISBN: 978-1-62076-353-7

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

2012 Microchip Technology Inc. DS52078A-page 3

Page 4

Digital Power Starter Kit User’s Guide

NOTES:

DS52078A-page 4 2012 Microchip Technology Inc.

Page 5

DIGIT AL POWER STARTER KIT

USER’S GUIDE

Safety Notice

The following safety notices and operating instructions should be adhered to avoid a

safety hazard. If in any doubt, consult your supplier.

DANGER – The Digital Power Starter Kit contains two resistive loads that are intended

to dissipate power in the form of heat. Depending on the output power level, it is possible for the resistive load to become hot to the touch or to any surface in direct contact

with the board.

WARNING – The Digital Power St arter Kit should only be installed, operated, serviced

or modified by qualified personnel. Any service or modification performed by the user

is done at the user’s own risk and voids all warranties.

CAUTION – Particular care should be taken during code development as unexpected

voltage regulation behavior is possible. Ensure that the power supply connected to the

Digital Power Starter Kit is properly protected against overcurrent event caused by

code development.

General Notices:

• The Digital Power Starter Kit is intended for evaluation and development purposes

and should only be operated in a normal laboratory environment as defined by

IEC 61010-1:2001.

• Clean with a dry cloth only.

• Operate flat on a bench away from any surface items that might become in contact with the board. Do not move during operation and avoid direct contact with

the bottom layer of the board.

• The Digital Power Starter Kit should not be connected or operated if there is any

apparent damage to the unit.

2012 Microchip Technology Inc. DS52078A-page 5

Page 6

Digital Power Starter Kit User’s Guide

NOTES:

DS52078A-page 6 2012 Microchip Technology Inc.

Page 7

DIGIT AL POWER STARTER KIT

USER’S GUIDE

Table of Contents

Safety Notice .................................................................................................................5

Preface ...........................................................................................................................9

Chapter 1. Introduction

1.1 Overview ............. ......................................................................................... 15

1.2 Kit Contents .............. .................................................................................... 15

1.3 Starter Kit Functionality and Features ..........................................................16

1.4 Electrica l Spe c ifications ........... ....................................................... .............. 18

Chapter 2. Hardware

2.1 Top Assembly .... .. ................................................................................ .. .. ..... 19

2.2 Signal Configuration .....................................................................................21

2.3 Application Components ..............................................................................22

2.4 Board Connectors ........................................................................................23

2.5 Indicators and Human Interfaces .................................................................23

2.6 Test Point s ............ ... ..................................................... .. .. ........................... 24

2.7 Power Rating of Converter Stages ............................... ................................25

2.8 Programmer/Debugger .................................................................................26

Chapter 3. Demonstration Program Operation

3.1 Program De mo n s tration .............. ................................................................. 27

3.2 Code Demo n s tr a tio n ............. .......................... .. ... ........................................ 29

3.3 Other Code Examples ......................... .. .. ............................. .. ......................29

Appendix A. Board Layout and Schematics..............................................................31

Worldwide Sales and Service ....................................................................................38

2012 Microchip Technology Inc. DS52078A-page 7

Page 8

Digital Power Starter Kit User’s Guide

NOTES:

DS52078A-page 8 2012 Microchip Technology Inc.

Page 9

DIGIT AL POWER STARTER KIT

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs and/

or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

INTRODUCTION

®

IDE on-line help.

This preface contains general information that will be useful to know before using the

Digital Power Starter Kit. Topics discussed in this preface include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This user’s guide provides an overview of the Digital Power Starter Kit. The document

is organized as follows:

• Chapter 1. “Introduction” – This chapter introduces the Digital Power Starter Kit

and provides a brief overview of its features.

• Chapter 2. “Hardwa re ” – This chapter describes the board layout and the main

components of the Digital Power Starter Kit.

• Chapter 3. “Demonstration Program Operation” – This chapter describes the

demonstration software that is preloaded on the device that accompanies the

Digital Power Starter Kit.

• Appendix A. “Board Layout and Schematics” – This appendix provides

diagrams of the hardware layout, as well as schematic diagrams for the Digital

Power Starter Kit.

2012 Microchip Technology Inc. DS52078A-page 9

Page 10

Digital Power Starter Kit User’s Guide

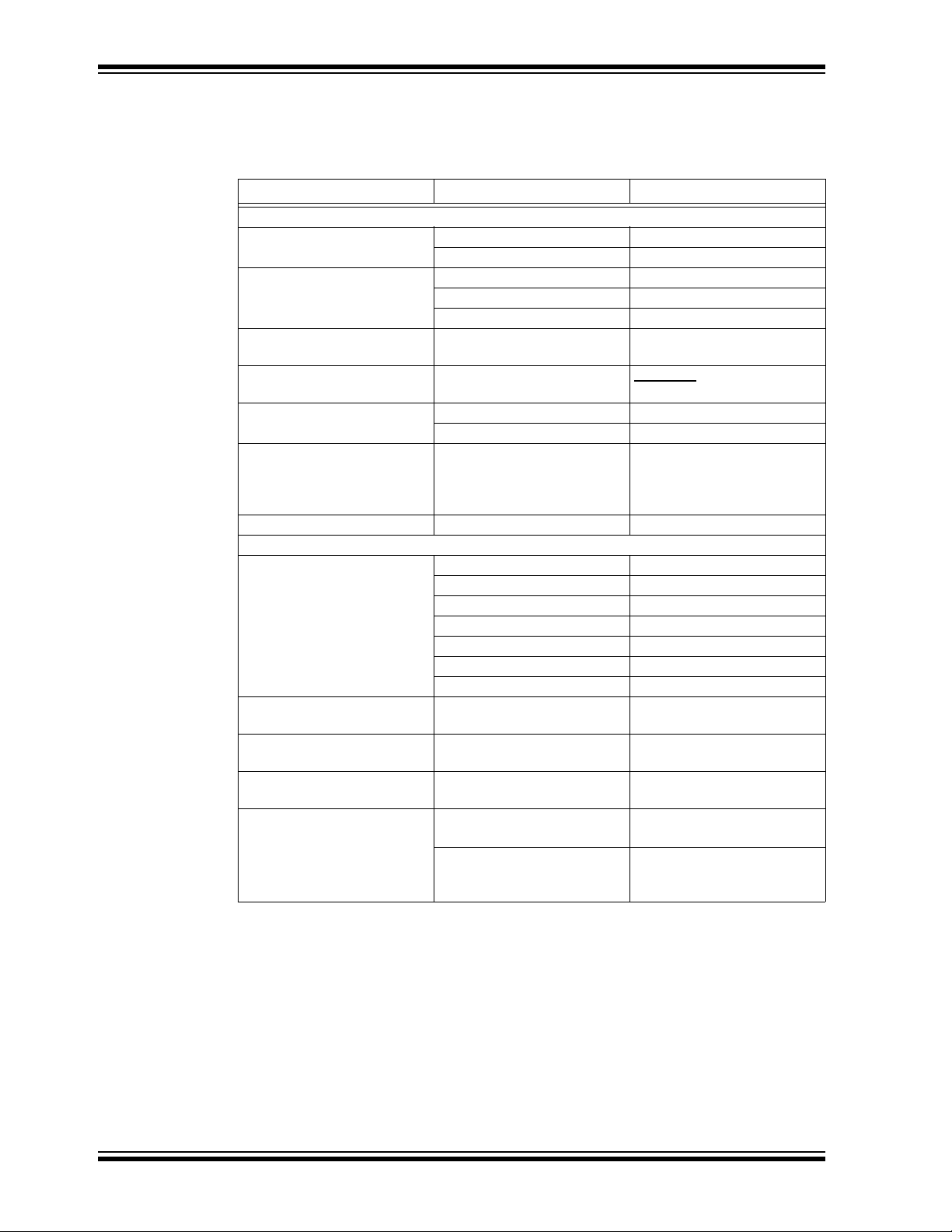

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic chara c ters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brac kets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [] Optional arguments mcc18 [options] file

Curly braces and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mut ually exclus ive

arguments; an OR selection

Represents code supplied by

user

®

IDE User’s Guide

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

DS52078A-page 10 2012 Microchip Technology Inc.

Page 11

RECOMMENDED READING

This user’s guide describes how to use the Digital Power Starter Kit. The device-specific

data sheets contain current information on programming the specific microcontroller or

digital signal controller devices. The following Microchip documents are available and

recommended as supplemental reference resources:

MPLAB® C Compiler for PIC24 MCUs and dsPIC® DSCs User’s Guide

(DS51284)

This comprehensive guide describes the usage, operation and features of Microchip’s

MPLAB C compiler (formerly MPLAB C30) for use with 16-bit devices.

MPLAB® IDE User’s Guide (DS51519)

This user’s guide describes how to set up the MPLAB IDE software and use it to create

projects and program devices.

MPLAB X IDE User’s Guide (DS52027)

This document describes how to set up the MPLAB X IDE software and use it to create

projects and program devices.

Readme Files

Preface

For the latest information on using the Digital Power Starter Kit Board, read the

Readme.txt text file in the Readme subdirectory of the MPLAB IDE installation directory

from the Digital Power Start er Kit co de ex am pl e. T he Read me fil e co ntains update

information and kn own issu es t ha t may no t be inclu de d in th is u ser’s g uide.

dsPIC33FJ06GS001/101A/102A/202A and dsPIC33FJ09GS302 Dat a Sheet

(DS75018)

Refer to this document for detailed information on this family of dsPIC33F SMPS Digital

Signal Controllers (D SCs). Reference information found in this data sheet includes:

• Device memory maps

• Device pinout and packaging details

• Device electrical speci fic ati on s

• List of peripherals included on the devices

dsPIC33F/PIC24H Family Reference Manual Sections

Family Reference Manual (FRM) sections are available, which explain the operation of

the dsPIC

specifics of each device family are discussed in the individual family’s device

data sheet.

®

DSC and PIC24H MCU family architecture and peripheral modules. The

dsPIC33F Flash Programming Specification for Devices with Volatile

Configuration Bits (DS70659)

Refer to this document for information on instruction sets and firmware development.

Microchip SMPS Resources

• AN1114 “Switch Mode Power Suppl y (SMPS) Topologies (Part I)” (DS01114)

• AN1207 “Switch Mode Power Supply (SMPS) Topologies (Part II)” (D S01 207 )

• TB062 “Frequently Asked Questions (FAQs) About dsPIC

(DS93062)

To obtain any of these documents, visit the Microchip web site at www.microchip.com.

2012 Microchip Technology Inc. DS52078A-page 11

®

DSC SMPS Devices”

Page 12

Digital Power Starter Kit User’s Guide

THE MICROCHI P WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listin g

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB

assemblers; MPLINK™ and MPLAB 16-bit object linkers; and MPLIB™ and

MPLAB 16-bit object librarians.

• Emulators – The latest information on the Microchip MPLAB REAL ICE™

in-circuit emulator.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 3.

• MPLAB IDE – The latest information on Microchip MPLAB IDE, the Windows

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 device programmer and the PICkit™ 3 development

programmers.

®

C compiler; MPASM™ and MPLAB 16-bit

®

DS52078A-page 12 2012 Microchip Technology Inc.

Page 13

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (June 2012)

This is the initial released version of the document.

Preface

2012 Microchip Technology Inc. DS52078A-page 13

Page 14

Digital Power Starter Kit User’s Guide

NOTES:

DS52078A-page 14 2012 Microchip Technology Inc.

Page 15

This chapter introduces the Digital Power Starter Kit and provides an overview of its

features. The topics covered include:

• Kit Contents

• Starter Kit Functionality and Features

• Electrical Specifications

1.1 OVERVIEW

Modern power supplies are becoming smaller, more efficient, more flexible and less

expensive. These desirable enhancements have come about as Digital Signal Controllers (DSCs) are incorporated into Switch Mode Power Supply (SMPS) designs. The

board provided in the kit is intended to introduce and demonstrate the capabilities and

features of Microchip SMPS families of devices. The Digital Power Starter Kit features

an on-board programmer/debugger, which eliminates the need for any additional

programmer or hardware interface.

The software for the demonstration application that is preprogrammed into the onboard dsPIC33F Digital Signal Controller (DSC) is available for download from the

Microchip web site at: http://www.microchip.com.

DIGIT AL POWER STARTER KIT

USER’S GUIDE

Chapter 1. Introduction

Note: Refer to the Readme file provided with the Digital Power Starter Kit demon-

1.2 KIT CONTENTS

The Digital Power Starter Kit contains the following:

• Digital Power Starter Kit Board

• 9V Power Supply

•USB Cable

Note: If you are missing any part of the kit, contact a Microchip sales office for

stration software for instructions on how to run the demonstration application.

Refer to the Information Sheet that is provided with the starter kit package for

additional resources and instructions on how to use the starter kit for

programming and debugging appli ca tio n software .

assistance. A list of worldwide Microchip offices for sales and service is

provided at the end of this document.

2012 Microchip Technology Inc. DS52078A-page 15

Page 16

Digital Power Starter Kit User’s Guide

VDD

VIN

5k

5k

Resistive

Load

VFB Buck

VIN

PWM1L

PWM1H

PWM2H

Current Sense

Buck

VFB Buck

SW1

Resistive

Load

VFB Boost

PWM2L

VIN

PWM4H

AN0

AN1

AN2

AN3

AN4

AN6

Current Sense

Boost

Vin_FB

RB8

AN5

Temperature

Sensor

AN7

On-Board

Debugger

Voltage/Current/

Temperature/Fault

LCD

USB

PC

dsPIC33FJ09GS302

VFB Boost

1.3 STARTER KIT FUNCTIONALITY AND FEATURES

The Digital Power Starter Kit is a power supply board that consists of one independent

DC/DC synchronous Buck converter and one independent DC/DC Boost converter.

Figure 1-1 illustrates a high-level block diagram of the Starter Kit.

The Digital Power Starter Kit provides closed-loop Proportional-Integral-Derivative

(PID) control in the software to maintain the desired output voltage level. The dsPIC

DSC device provides the necessary memory and peripherals for A/D conversion, PWM

generation, analog comparison and general purpose I/O, preventing the need to

perform these functions in external circuitry.

SMPS dsPIC DSC devices are specifically designed to provide low-cost and efficient

control for a wide range of power supply topologies. The specialized peripherals facilitate

closed-loop feedback control of switch mode power supplies, providing communication

for remote monit o rin g an d supe r vis ory co nt ro l.

The dsPIC33F SMPS family of devices provide the following features:

• Integrated program and data memory on a single chip

• Ultra-fast interrupt response time with interrupt priority logic

• Up to 2 Msps, on-chip ADC with Successive Approximation Register (SAR), an d

three Sample-and-Hold (S&H) circuits.

• Three independent, high-resolution PWM generators, specially designed to support

different power topologies

• Two high-speed analog comparators for control loop implementation and system

protection

• On-chip system communications (I

• On-chip fast RC oscillator for lower system cost

• High-current sink/source for PWM pins (16 mA/16 mA)

• CPU performance (40 MIPS)

• Extensive power-saving features

2

C™/SPI/UART)

®

FIGURE 1-1: DIGITAL POWER STARTER KIT SYSTEM DIAGRAM

DS52078A-page 16 2012 Microchip Technology Inc.

Page 17

Introduction

1.3.1 Power Stages

• One synchronous Buck converter power stage

• One Boost converter pow er stage

• Voltage/current measurement and display for digital controlled Buck converter

• Voltage/current measurement and display for digital controlled Boost converter

• MOSFET controlled 5W resistive load on Buck Converter Output (BUCK_Out)

• MOSFET controlled 5W resistive load on Boost Converter Output (BOOST_Out)

1.3.2 Additional Features

• 5 kOhm Potentiometers (P1 and P2), used to adjust the duty cycle of the

load resistors

• On-board temperature sensor, located near the resistive load; this enables the user

to program a temperature protection limit

• Input voltage sense, used to detect under/overvoltage conditions

• Connector for PICkit Serial Analyzer (J3)

• LED power-on indicator (D1)

• LED output voltage indicators (D5 and D12)

• LCD used to display voltage, current, temperature and Fault conditions

1.3.3 Start er Kit Power

• +9V power connector (J2) supplies power to the Digital Power Starter Kit

• USB connection jack (J5) supplies power/connection to the on-board debugger

• Buck and Boost converters are both operated in Voltage mode (default), but can

also be reprogrammed to operate in Average Current or Peak Current Control mode

2012 Microchip Technology Inc. DS52078A-page 17

Page 18

Digital Power Starter Kit User’s Guide

1.4 ELECTRICAL SPECIFICATIONS

TABLE 1-1: DC INPUT RATING (J2)

Parameter Minimum Typical Maximum Unit

Voltage 7.0 9 11 V

Current 1 — — A

TABLE 1-2: BUCK CONVERTER ELECTRICAL SPECIFICATIONS

Parameter Minimum Typical Maximum Unit

Output Voltage (default programmed) — 3.3 — V

Output Voltage (programmable range) 1.2 — 4.5 V

Output Voltage Ripple — 50 — mV (pk-pk)

Output Current — — 1.5 A

Load Regulation:

V

OUT = 3.3V, IOUT = 0.02-1.5A, VIN = 9V

Switching Frequency — 350 — kHz

Output Power — — 5 W

TABLE 1-3: BOOST CONVERTER ELECTRICAL SPECIFICATIONS

Parameter Minimum Typical Maximum Unit

—50—mV/A

Output Voltage (default programmed) — 15 — V

Output Voltage (programmable range) 11 — 18 V

Output Voltage Ripple — 100 — mV (pk-pk)

Output Current — — 0.4 A

Load Regulation:

V

OUT = 15V, IOUT = 0.02-0.3A, VIN = 9V

Switching Frequency — 350 — kHz

Output Power — — 5 W

—50—mV/A

DS52078A-page 18 2012 Microchip Technology Inc.

Page 19

This chapter describes the hardware components of the Digital Power Starter Kit.

1

2

4

5

3

6

7

8

Topics covered include:

• Top Assembly

• Signal Configuration

• Application Components

• Board Connectors

• Indicators and Human Interfaces

• Test Points

• Power Rating of Converter Stages

• Programmer/Debugger

2.1 TOP ASSEMBLY

The top and bottom assembly of the board is shown in Figure 2-1 and Figure 2-2.

Table 2-1 and Table 2-2 provide a description of the components.

DIGIT AL POWER STARTER KIT

USER’S GUIDE

Chapter 2. Hardware

FIGURE 2-1: DIGITAL POWER STARTER KIT (TOP VIEW)

2012 Microchip Technology Inc. DS52078A-page 19

Page 20

Digital Power Starter Kit User’s Guide

1

2

3

4

5

6

TABLE 2-1: DIGITAL POWER STARTER KIT COMPONENTS (TOP)

Number Description

1 dsPIC33FJ09GS302 Digital Signal Controller (DSC) (U3)

2 9V Power Connector (J2)

3 2x16 Character LCD

4 Boost Converter Stage

5 Buck Converter Stage

6 Push Button (SW1)

7 Potentiometers (P1 and P2)

8 Voltage Regulator (3.3V)

FIGURE 2-2: DIGITAL POWER STARTER KIT (BOTTOM VIEW)

TABLE 2-2: DIGITAL POWER STARTER KIT COMPONENTS (BOTTOM)

Number Description

1 Voltage Regulator (5V)

2 On-Board Programmer/Debugger

3 Programmer/Debugger USB Connector (J5)

4 Buck Converter Resistive Load

5 Boost Converter Resistive Load

6 On-Board Temperature Sensor

DS52078A-page 20 2012 Microchip Technology Inc.

Page 21

2.2 SIGNAL CONFIGURATION

Table 2-3 provides a full list of the dsPIC33FJ09GS302 DSC connections and a brief

functional description of the pins used in the Digital Power Starter Kit.

TABLE 2-3: dsPIC33FJ09GS302 CONFIGURATION DETAILS

Digital Power Starter Kit

Signal Label

Pin

#

dsPIC33FJ09GS302

Device Pin Name

Hardware

Description/Function

ICSP_MCLR_VPP_Target 1 MCLR

CS_BUCK 2 AN0/CMP1A/RA0 Analog – Buck Current Sense

VFB_BUCK 3 AN1/CMP1B/RA1 Analog – Buck Vo ltage Feedback

CS_BOOST 4 AN2/CMP1C/CMP2A/RA2 Analog – Boost Current Sense

VFB_BOOST 5 AN3/CMP1D/CMP2B/RP0/CN0/RB0 Analog – Boost Voltage Feedback

VIN_FB 6 AN4/ISRC4/CMP2C/RP9/CN9/RB9 Analog – Input Voltage Feedback

EXT POT2 7 AN5/ISRC3/CMP2D/RP10/CN10/RB10 Analog – 5k Potentiometer

—8VSS Ground

EXT POT1 9 OSC1/CLKI/AN6/ISRC2/RP1/CN1/RB1 Analog – 5k Potentiometer

Temp_Sensor 10 OSC2/CLKO/AN7/ISRC1//RP2/CN2/RB2 Analog – Temperature Sensor

PGD2 11 PGED2/DACOUT/INT0/RP3/CN3/RB3 Data I/O pin for programming/

PGC2 12 PGEC2/EXTREF/RP4/CN4/RB4 Clock Input pin for programming/

—13V

SW 14 PGED3/RP8/CN8/RB8 SW1 Push Button

LCD_Reset 15

LCD_RSelect 16 TDO/RP5/CN5/RB5 LCD Register Select Signal

SCL/TX 17 PGED1/TDI/SCL1/RP6/CN6/RB6 LCD Serial Clock

SDA/RX 18

—19VSS Ground

—20VCAP CPU Logic Filter Capacitor Connection

PWM4H 21 TMS/RP11/CN11/RB11 Boost MOSFET PWM Signal

LCD_CSB 22

Load BUCK 23 PWM2H/RP13/CN13/RB13 Buck-Resistive Load Driver PWM Signal

Load BOOST 24 PWM2L/RP14/CN14/RB14 Boost-Resistive Load Driver PWM

PWM1H 25 PWM1H/RA4 Buck High Side MOSFET PWM Signal

PWM1L 26 PWM1L/RA3 Buck Low Side MOSFET PWM Signal

—27AV

—28AV

DD Positive Supply for peripheral logic and

PGEC3/RP15/CN15/RB15 LCD Active-Low Reset Signal

PGEC1/SDA1/RP7/CN7/RB7 LCD_Data

TCK/RP12/CN12/RB12 LCD Active-Low Chip Select Signal

SS Ground Referen ce for analog modul es

DD Positive Supply for a nalog modules ; this

Master Clear (Reset) Input

debugging Communication Channel 2

debugging Communication Channel 2

I/O pins

Signal

pin must be c onnected at all times

2012 Microchip Technology Inc. DS52078A-page 21

Page 22

Digital Power Starter Kit User’s Guide

2.3 APPLICATION COMPONENTS

Table 2-4 describes the application components that are available on the Digital Power

Starter Kit (see Figure 2-1 and Figure 2-2 for component locations).

TABLE 2-4: APPLICATION COMPONENTS

Component Label Item Description

Top Assembly Components (see Figure 2-1)

dsPIC33FJ09GS302 DSC U3 1 Provides the processing power for the demonstration applica-

tions and application development on the starter kit. The MCU

features 9 Kbytes of Flash program memory and 1 Kbyte of

RAM. The demonstration application uses the MCU device’s

on-chip FRC oscillator with PLL as a clock source.

9V Power Connector J2 2 A 9V power supply powers the dsPIC33FJ09GS302 DSC and

supplies the power to both of the DC/DC converters on the

starter kit. To operate the starter kit, connect the power supply

provided with the starter kit to J2.

2x16 Character LCD LCD1 3 User-programmable 2x16 character LCD.

Boost Converter Stage N/A 4 5W step-up converter (Boost).

Buck Converter Stage N/A 5 5W step-down converter (Buck).

Potentiometer P1 & P2 7 T wo Potentiometers (POTs). Each POT is connected to an analog

input pin of the DSC, providing an analog reference voltage from

3.3V to ground (0V).

Voltage Regulator U2 8 Voltage regulator (3.3V) provides power to the

dsPIC33FJ09GS302 DSC, LCD, push button, potentiometers

and temperature sensor.

Bottom Assembly Components (see

Voltage Regulator U1 1 Voltage regulator (5V) provides power to the 3.3V regulator and

to the Buck stage gate driver (U9).

On-Board Programmer/

Debugger

Programmer/Debugger

USB Connector

Buck Resistive Load N/A 4 MOSFET controlled 2.2 Ohm resistive load (5W max).

Boost Resistive Load N/A 5 MOSFET controlled 48.3 Ohm resistive load (5W max).

On-Board Temperature

Sensor

N/A 2 Controls the programming/debugging operations of the target

dsPIC33FJ09GS302 DSC.

J5 3 Provides power to the programmer/debugger and bidirectional

communication between the host PC and starter kit.

U7 6 The temperature sensor is strategically placed near the load

resistors. It is intended to provide the board temperature to the

DSC and to disable bo th of th e res is tiv e lo ad s if th e tem pe r atu re

exceeds the set limit.

Figure 2-2)

DS52078A-page 22 2012 Microchip Technology Inc.

Page 23

2.4 BOARD CONNECTORS

Table 2-5 describes the hardware connections available on the Digital Power Starter Kit

(see Figure 2-1 and Figure 2-2 for component locations).

TABLE 2-5: HARDWARE CONNECTIONS

Label Hardware Element Description

J1 Connector for PICkit™ Serial Analyzer (not populated).

J2 9V power supply (not populated).

J3 ICSP™ programmer interface connector for programming the

dsPIC33FJ09GS302 DSC.

J4 ICSP programmer interface connector for programming the

PIC24FJ256GB106 MCU USB-to-UART bridge (not populated).

J5 Mini-USB connector provides bidirectional communication between the host

PC and the on-board programmer/debugger.

2.5 INDICATORS AND HUMAN INTERFACES

Table 2-6 describes the user interfaces available on the starter kit.

TABLE 2-6: INDICATORS AND HUMAN INTERFACES

Label Hardware Element Description

SW1 Push button switch, which is connected to the RB8 port pin. When momentarily

pressed, the LCD measurement and board status information is changed.

D1 Power-on status LED, which indicates that the Digita l Power Starter Kit is

powered by the 9V supply.

D14 USB bus indic ator , which in dicates that the de vice is connected to the USB bu s

and the programmer/debugger is powered.

P1 and P2 Two variable resis tors (pote ntiometers). Each pote ntiometer is connected to an

analog input pin, providing an analog reference voltage from 3.3V to ground

(0V).

D12 Buck converter power-on status LED, which indicates when the Buck DC/DC

converter is enabled.

D5 Boost c onv erte r po w er-on status LED, which indicates when the Boost D C/D C

converter is enabled. Because of the Boost conf iguration, this LED wil l be

illuminated when +9V is present at the J2 connector.

LCD1 User-programmable 2x16 character LCD display.

Hardware

2012 Microchip Technology Inc. DS52078A-page 23

Page 24

Digital Power Starter Kit User’s Guide

TP22 TP12TP11

TP13 TP12

TP11

TP17

TP10

TP9

TP14

TP15

TP6

TP1

+9VGND

GND

GND

BOOST_OUT

GND

BUCK_OUT

2.6 TEST POINTS

Table 2-7 describes the test points that are available on the Digital Power Starter Kit.

See Figure 2-3 for test point locations.

TABLE 2-7: TEST POINTS

Test Point Description

+9V 9V Power Supply test point

BUCK_OUT Output Voltage for the Buck Stage test point

BOOST_OUT Output Voltage fo r the Boost Stage test point

TP1 3.3V Supply Voltage test point

TP5 Boost Stage Switch Node test point

TP6 Boost Stage BODE test point

TP9 Buck Stage BODE test point

TP10 Buck Stage Current Sense test point

TP11 Buck Stage High-Side MOSFET Gate Signal test point

TP12 Buck Stage Low-Side MOSFET Gate Signal test point

TP13 Boost Stage MOSFET Gate Signal test point

TP14 Buck Stage Output Voltage Feedback test point

TP15 Boost Stage Output Voltage Feedback test point

TP16 Resistive Load MOSFET Gate Signal (Boost) test point

TP17 Resistive Load MOSFET Gate Signal (Buck) test point

TP22 Buck Stage Switch Node test point

FIGURE 2-3: DIGITAL POWER STAR TER KIT TEST POINT LOCATIONS

DS52078A-page 24 2012 Microchip Technology Inc.

Page 25

2.7 POWER RATING OF CONVERTER STAGES

The Digital Power Starter Kit is designed to be a self-contained power supply board with

variable 5W loads connected to each DC/DC converter.

2.7.1 BUCK CONVERTER

The Buck converter stage is rated for a maximum power output of 5W to the dedicated

on-board resistive load. The output voltage and output current should remain within its

Safe Operating Area (SOA) to avoid damage to the board, as shown in the graph in

Figure 2-4. The output voltage of the Buck converter (BUCK_Out) can be programmed

to be from a 1.2V to 4.5V output, with a default programmed voltage of 3.3V . The hardware gain [5k/(3.3k + 5k)] of the voltage feedback from the BUCK_Out is provided by

the resistor divider network, R97 and R105. Additionally, a 20 Ohm resistor, R90, for

bode plot measurements is also in series with the feedback network. The hardware

gain of the current feedback is provided by the current transformer (T1) with turns ratio

(1:60) and burden resistor, R69.

FIGURE 2-4: BUCK CONVERTER SOA CURVE

Hardware

2012 Microchip Technology Inc. DS52078A-page 25

Page 26

Digital Power Starter Kit User’s Guide

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

11 12 13 14 15 16 17 18 19

Output Voltage, V

Output Current, A

2.7.2 Boost Converter

The Boost converter stage is rated for a maximum output power of 5W to the dedicated

on-board resistive load. The output voltage and output current should remain within the

Boost converter Safe Operating Area (SOA) to avoid damage to the board, as shown

in the graph in Figure 2-5. The output voltage of the Boost converter (BOOST_Out) can

be programmed to be from an 11V to 18V output, with a default programmed voltage

of 15V. The hardware gain [20k/(20k + 3.3k)] of the voltage feedback from the

BOOST_Out is provided by the resistor divider network of R41 and R51. Additionally,

a 20 Ohm resistor, R30, for bode plot measurements is also in series with the feedback

network. The hardware gain of the current feedback is provided by the current sense

resistor, R61.

FIGURE 2-5: BOOST CONVERTER SOA CURVE

2.8 PROGRAMMER/DEBUGGER

The Digital Power Starter Kit includes an on-board programmer/debugger circuit that

provides connectivity over USB. This circuit is hard-wired to the dsPIC DSC device to

provide ICSP™ debugging/programming capability.

2.8.1 Programmer/Debugger Components

Table 2-8 describes the programmer/debugger components that are available on the

Digital Power Starter Kit (see Figure2-2 for component locations).

TABLE 2-8: PROGRAMMER/DEBUGGER COMPONENTS

Compone nt Label Item # Description

On-Board Programmer/

Debugger

Programmer/Debugger

USB Connector

DS52078A-page 26 2012 Microchip Technology Inc.

N/A 2 Controls the programming/debugging operations of the target

dsPIC33FJ09GS302 DSC.

J5 3 Provides power to the programmer/debugger, and bidirectional

communication between the host PC and the Digital Power

Starter Kit.

Page 27

Chapter 3. Demonstration Program Operation

The dsPIC33FJ09GS302 Digital Power Starter Kit is preprogrammed with a

demonstration application that illustrates simultaneous Proportional-Integral-Derivative

(PID) control of the output voltage for the two DC/DC converter circuits on board the

Digital Power Starter Kit. This code can be downloaded from the Microchip web site

(www.microchip.com).

This section covers the following topics:

• Program Demonstration

• Code Demonstration

• Other Code Examples

3.1 PROGRAM DEMONSTRATION

The demonstration program provides simultaneous closed-loop control of the output

voltage for both DC/DC converter stages of the Digital Power Starter Kit.

One PID loop controls the Buck converter output voltage (BUCK_Out) at 3.3V. The

other PID loop controls the Boost converter output voltage (BOOST_Out) at 15V.

The PID control scheme consists of the following parameters:

• Proportional Error Gain (P-Gain) – This parameter produces a correction factor

that is proportional to the magnitude of the output voltage error.

• Integral Error Gain (I-Gain) – This parameter uses the cumulative voltage error to

generate a correction factor that eliminates any residual error due to limitations in

offset voltages and measurement resolution.

• Derivative Error Gain (D-Gain) – This parameter produces a correction factor that

is proportional to the rate of change of the output error voltage, which helps the

system respond quickly to changes in system conditions.

The demonstration program requires no manual preparation except to connect 9V

power to the J2 connector.

DIGIT AL POWER STARTER KIT

USER’S GUIDE

2012 Microchip Technology Inc. DS52078A-page 27

Page 28

Digital Power Starter Kit User’s Guide

Start

ADC Interrupt

End

Yes

No

No

Yes

Soft Start

Routine

Disable

Outputs

Does Fault

Condition Exist?

Is Soft

Start Active?

Initialization Routines:

• Peripherals – ADC, PWM, Timers, GPIO,

LCD, etc.

• Variables – PID Gain Terms, Data Buffers

• Interrupts – ADC, Timers

• Set Soft Start Flag

Idle Loop Functions:

• Check VIN

• Check Soft Start Flag

• Check/Reset Fault Timers and Flag

• Measure Temperature and Potentiometer’s Position

• Update LCD Display Information

• Perform Non-Critical Functions (i.e., user application

tasks)

ADC Interrupt Routines:

• Measure VOUT

• Calculate PID Gain Parameters

• Update PWM Duty Cycle

Fault Check Routine

Soft Start Routine

FIGURE 3-1: SMPS DEMONSTRATION PROGRAM FLOW CHART

DS52078A-page 28 2012 Microchip Technology Inc.

Page 29

3.2 CODE DEMONSTRATION

3.2.1 System Initialization

When power is applied to the board, the program starts by executing the following

system initialization routines:

• Peripherals – The required periph erals (PWM, ADC, T i mers and GPIO) are

configured and en abled

• V ariables – Program variables are defined. RAM locations and register usage are

defined and documented

• Constants – Program constants are defined, including reference set points for

both Buck output voltage and Boost output voltage, input voltage, current limits,

Fault conditions, PWM periods and Timer periods

• Interrupts – The ADC and Timer interrupts are set up and enabled

3.2.2 Fault Check

The program checks for input under/overvoltage, output overvoltage and board temperature limit. If a Fault occurs, the PWM outputs are disabled until the Fault condition

is cleared. If no Fault is detected, the program proceeds.

3.2.3 Soft Start

Demonstration Program Operation

The Soft Start routine ramps up the output voltage in a close-loop fashion to bring the

system within the operating range of the PID control loop. This routine ensures that the

output does not overshoot the desired voltage; it also limits the current at start-up.

3.2.4 ADC Interrupt

The ADC interrupt is the heart of the demo program. This routine takes up approximately 75% of the execution time. It performs all the PID calculations and applies any

needed corrections to the output.

Note: The ADC interrupt can occur any time during program execution. The ADC

interrupt takes priority over any other tasks that the program is performing.

3.2.5 System Idle Loop

All auxiliary functions are performed in the system Idle routine. This is the time available

to the CPU while the demo program is waiting for an ADC interrupt. Non-critical

functions can be performed in this loop. During this time the LCD is refreshed, the

potentiometers position, input voltage, Fault timers and Soft Start flag are checked.

3.3 OTHER CODE EXAMPLES

There are several other SMPS code examples available on the Microchip web site.

Refer to the Readme files located in each code example folder for details on what

each code example demonstrates. Check the Microchip web site

(www.microchip.com/SMPS) for the latest updates to the code examples and for

additional code examples.

2012 Microchip Technology Inc. DS52078A-page 29

Page 30

Digital Power Starter Kit User’s Guide

NOTES:

DS52078A-page 30 2012 Microchip Technology Inc.

Page 31

DIGIT AL POWER STARTER KIT

Appendix A. Board Layout and Schematics

FIGURE A-1: DIGITAL POWER STARTER KIT LAYOUT (TOP)

USER’S GUIDE

2012 Microchip Technology Inc. DS52078A-page 31

Page 32

Digital Power Starter Kit User’s Guide

FIGURE A-2: DIGITAL POWER STARTER KIT LAYOUT (BOTTOM)

DS52078A-page 32 2012 Microchip Technology Inc.

Page 33

Board Layout and Schematics

231

J2

GND

10K

R1

GND

+9V

VIN_FB

+3.3V

GND

R3 DNP

R5 DNP

I2CAUX2

R6

DNP

R7

DNP

+3.3V

BAT54S LT1G

3

1

2

D2

DNP

BAT54 S

LT1

G

3

1

2

D3

DN

P

+3.3V

GND

SDA/RX

SCL/TX

R24

DNP

EXT_POT 1

Temp_Sens

Vin_FB

EXT_POT2

CS_BO OST

GND

VFB_BOOST

PGD2

PGC2

+3.3V

SW

LCD_RSElect

SCL/TX

GND

VFB_BUCK

CS_BUC K

AGND

AVDD

PWM1L

PWM1H

Load_BOOST

Load_BUCK

LCD_CSB

GND

SDA/RX

NHD-C0 216CZ -F S W -F BW -3V 3

RST1RS2CSB3SCL4SI5VSS6VDD7VOUT8C1+9C1+10LED+ALED-

K

LCD1

0RR11

0RR13

0RR14

0RR15

0RR18

0RR21

LCD_Reset

LCD_Reset

LCD_RSelect

LCD_CSB

SCL/TX

SDA/RX

GND

+3.3V

GND

GND

GND

2 4

1

3

SW1

10K

R8

0R

R9

GND

+3.3V

SW

P1

5K

P2

5K

+3.3V

+3.3V

GND

GND

EXT_POT1

EXT_POT2

PWM4H

R25

DNP

I2CAUX1

I2CAUX

1

I2CAUX

2

C2

GND

GND

GND

Green

D1

GND

330R

R2

+3.3V

0R

R17

GND

+3.3V

10K

R12

ICSP_MCL R_VPP_TAR GET

12345

6

J3

DNP

ICSP_MCL

R_VPP_TA RG ET

+3.3V

PGC2

PGD2

GND

+3.3V

R22 DN

P

R19 DN P

0RR16

0RR20

GND

1

GND

2

3

TAB(GND)

4

U2

VIN1GND

2

VOUT

3

TAB(GND)

4

U1

MCP1703T-5002

GND

+5V

GND

10 PF

C57

60.4R

0.25W

R2 3

MCLR1AN0/CMP1A/RA02AN1/CMP1B1/RA13AN2/CMP1C/CMP2A/RA24AN3/CMP1D /CMP2B/RP0(1)/CN0/RB05AN4 /I SR C4 /C MP 2C /R P9( 1) /CN 9/R B96AN5/I SRC3/CM P2D/RP10(1) /CN10/RB107OSC1/CL KI /AN6/ISRC2/ RP1(1) /CN1/RB19OSC2/CL KO/A N7/ISRC1/ RP2(1)/CN 2/RB210PGED2/DA COUT /INT0/RP 3(1)/CN3/RB311PGEC2/EX T REF /R P4(1)/CN4/RB 412VDD

13

VSS

8

PGED3/RP 8(1)/CN8/R B8

14

PGEC3/R P15/CN15/

RB1

5

15

TDO

/RP5(1

)/CN5/RB 5

16

PGED1/TDI/SCL1/RP6(1)/CN 6

/

RB6

17

PGEC1/S DA1/RP7(1)/C N7/RB7

18

VSS

19

VCAP

20

TMS/RP 11(1)/CN11/R B11

21

TCK/RP

12(1)/CN12/RB

12

22

PWM2H/R P13(1)/CN13/ RB13

23

PWM2L/RP 14(1)/CN14/RB14

24

PWM1H/RA4

25

PWM1L/RA 3

26

AVSS

27

AVDD

28

U3

TP1

TP 19

+9V

FID2 FID3 FID4

1

VDD2GND

3

456

J1

DNP

BAT54 SLT1G

3

1

2

D15

+3.3V

GND

BAT54S L T1

G

3

1

2

D16

+3.3V

GND

L3

R4

2.21K

TP4

10 PF

VIN VOUT

MCP1703-3302E/DB

C3

0.1 PF

C4

10 PF

C1

0.01 PF

C5

0.01 PF

C6

0.1 PF

PICkit™ 2

C11

0.1 PF

dsPIC33FJ09GS302

C8

0.1 PF

C7

0.1 PF

C4

10 PF

C10

1 PF

C9

1

PF

C12

1 PF

C13

0.1 PF

FIGURE A-3: DIGITAL POWER STARTER KIT SCHEMATIC

2012 Microchip Technology Inc. DS52078A-page 33

Page 34

Digital Power Starter Kit User’s Guide

+9V

GND GND

4

1

2

3

5

Q2

+9V

IN A2GND3IN B

4

OUT B

5

VDD

6

OUT A

7

NC

8

NC

1

U4

3.30K

R58

GND

5.1

R52

1/8W

GND

10K

R57

20R

R30

3.30K

R51

10K

R35

Green

D5

GND

20.0K

R41

D4

GND

1K

R59

1K

R63

1K

R60

1K

R64

GND

AVDD

GND

CS_BO OST

PWM4H

NTM S5838N LR2G

4

1

2

3

5

6

7

8

Q1

10K

R40

IN A2GND3IN B

4

OUT B

5

VDD

6

OUT A

7

NC

8

NC

1

U6

+9V

Load_BOOST

Load_BUCK

3.30K

R66

3.30K

R67

GND

Place close to dsPIC® DSC

VFB_BOOST

1

VSS

2

VDD

5

IN-4IN+

3

U5

AGND

C20

DNP

AGND

GND

AGND

60.4R

0.25W

R26

60.4R

0.25W

R27

60.4R

0.25W

R28

60.4R

0.25W

R29

60.4R

0.25W

R31

60.4R

0.25W

R32

60.4R

0.25W

R33

60.4R

0.25W

R34

60.4R

0.25W

R36

60.4R

0.25W

R37

60.4R

0.25W

R38

60.4R

0.25W

R39

60.4R

0.25W

R43

60.4R

0.25W

R44

60.4R

0.25W

R45

60.4R

0.25W

R46

60.4R

0.25W

R47

60.4R

0.25W

R48

60.4R

0.25W

R49

60.4R

0.25W

R50

18 pF

C24

10K

R54

10K

R65

C21

DNP

AVDD

OUT B

0.5R

0.5W

R61

R53

DNP

11R

R42

3.30K

R143

GND

18 pF

C25

TP5

TP6

BOOST_Out

TP2

TP15

TP13

TP16

0R

R56

0R

R62

470 pF

C19

TC4427ACOA

C22

4.7 PF

C23

0.1 PF

MCP6021T-E/OT

TC4427ACOA

C26

0.1 PF

C17

220 PF

C18

1 PF

MCP87050

L1

150 PH

C15

0.1 PF

C16

22 PF

FIGURE A-4: DIGITAL POWER STARTER KIT SCHEMATIC (BOOST CONVERTER)

DS52078A-page 34 2012 Microchip Technology Inc.

Page 35

Board Layout and Schematics

+9V

GND

4

1

2

3

5

6

Q3

+5V

3.30K

R106

3.30K

R107

GND

PWM1H

PWM1L

GND

D9

DNP

R79

5.1R 1/8W

10K

R74

R96

5.1R 1/8W

GND

R91

DNP

C39

DNP

GND

3.30K

R97

20R

R90

Green

D12

GND

NTMS 5838NLR2G

4

1

2

3

5

6

7

8

Q4

10K

R98

4.99K

R105

GND

VFB_BUCK

GND

GND

+3.3 V

Temp_S ens

10K

R104

PHASE

1

PWM_HI2PWM_LO

3

GND

4

LOWDR

5

VCC

6

BOOT

7

HIGHDR

8

U9

C28

DNP

1K

R68

R70

DNP

6

4 7

8

T1

TRANS _CST2 _06 0L

GND

CS_BUC K

18pF

C40

GND

2

VOUT

3

VDD

4

U7

GND

OUT B

2.74R

0.25W

R75

2.74R

0.25W

R76

2.74R

0.25W

R77

2.74R

0.25W

R78

2.74R

0.25W

R80

2.74R

0.25W

R81

2.74R

0.25W

R82

2.74R

0.25W

R83

2.74R

0.25W

R85

2.74R

0.25W

R86

2.74R

0.25W

R87

2.74R

0.25W

R88

2.74R

0.25W

R92

2.74R

0.25W

R93

2.74R

0.25W

R94

2.74R

0.25W

R95

2.74R

0.25W

R99

2.74R

0.25W

R100

2.74R

0.25W

R101

2.74R

0.25W

R102

11R

R71

TP22

TP9

TP10

BUCK_Out

TP3

TP14

R142

DNP

GND

TP11

TP12

TP17

4

1

2

3

5

6

Q5

BAT5 4S LT1G

3

1

2

D7

2.21K

R103

120R

R69

120R

R72

C34

0.1 PF

C33

4.7 PF

C31

220 PF

MCP87050

C29

0.1 PF

MCP9700

C30

0.1 PF

C32

0.1 PF

MCP14700-E/SN

MCP87050

L2

22 PH

C35

6.3V

150 PF

C37

6.3V

150 PF

C38

22 PF

C36

1 PF

FIGURE A-5: DIGITAL POWER STARTER KIT SCHEMATIC (BUCK CONVERTER)

2012 Microchip Technology Inc. DS52078A-page 35

Page 36

Digital Power Starter Kit User’s Guide

NOTES:

DS52078A-page 36 2012 Microchip Technology Inc.

Page 37

NOTES:

2012 Microchip Technology Inc. DS52078A-page 37

Page 38

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Techn ical Su pport:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-67 33

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7 000

Fax: 86-10-8528-2104

China - Chengdu

Te l: 86-28-8665-55 11

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9 588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-2819- 3187

Fax: 86-571-2819-3189

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2 460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502- 7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5 533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2 829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203- 2660

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5 300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7 252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Osaka

Tel: 81-66-152-7160

Fax: 81-66-152-9310

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-330-9305

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244- 39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53 -63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627- 144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708- 08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

11/29/11

DS52078A-page 38 2012 Microchip Technology Inc.

Loading...

Loading...