Page 1

CL88030

230 V

AC

Offline LED Driver

Evaluation Board

User’s Guide

2018 Microchip Technology Inc. DS50002772A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in th

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

QUALITY MANAGEMENT S

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, AVR Freaks, BitCloud, chipKIT, chipKIT logo,

CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo,

JukeBlox, KeeLoq, Kleer, LANCheck, LINK MD, maXStylus,

maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip

Designer, QTouch, SAM-BA, SpyNIC, SST, SST Logo,

SuperFlash, tinyAVR, UNI/O, and XMEGA are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMOS,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity,

JitterBlocker, KleerNet, KleerNet logo, memBrain, Mindi, MiWi,

motorBench, MPASM, MPF, MPLAB Certified logo, MPLIB,

MPLINK, MultiTRAK, NetDetach, Omniscient Code Generation,

PICDEM, PICDEM.net, PICkit, PICtail, PowerSmart, PureSilicon,

QMatrix, REAL ICE, Ripple Blocker, SAM-ICE, Serial Quad I/O,

SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2018, Microchip Technology Incorporated, All Rights Reserved.

ISBN: 978-1-5224-3372-9

e

DS50002772A-page 2 2018 Microchip Technology Inc.

Page 3

CL88030

230 V

OFFLINE LED DRIVER

AC

EVALUATION BOARD USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 5

Introduction............................................................................................................ 5

Document Layout .................................................................................................. 5

Conventions Used in this Guide ............................................................................ 6

Recommended Reading........................................................................................ 7

The Microchip Website.......................................................................................... 7

Customer Support ................................................................................................. 7

Document Revision History ................................................................................... 7

Chapter 1. Product Overview

1.1 Introduction ..................................................................................................... 9

1.2 CL88030 Overview ......................................................................................... 9

1.3 CL88030 Key Features .................................................................................. 9

1.4 What is the CL88030 230 V

Evaluation Board (ADM00860)? ............................................................. 11

1.5 What the CL88030 230 V

Evaluation Board Kit Contains ................................................................ 13

Offline LED Driver

AC

Offline LED Driver

AC

Chapter 2. Installation and Operation

2.1 Introduction ................................................................................................... 15

2.2 Getting Started ............................................................................................. 16

2.3 Setup Procedure .......................................................................................... 17

2.4 How Does the CL88030 230 V

Evaluation Board Set Work? .................................................................. 18

2.5 Board Testing ............................................................................................... 19

Appendix A. Schematic and Layouts

A.1 Introduction .................................................................................................. 21

A.2 Board Schematic – ADM00860 .................................................................... 22

A.3 Board Schematic – ADM00861 .................................................................... 23

A.4 ADM00860 – Top Silk .................................................................................. 23

A.5 ADM00860 – Top Copper and Silk .............................................................. 24

A.6 ADM00860 – Top Copper ............................................................................ 24

A.7 ADM00860 – Bottom Copper and Silk ......................................................... 25

A.8 ADM00861 – Top Silk .................................................................................. 25

A.9 AMD00861 – Top Copper and Silk .............................................................. 26

A.10 ADM00861 – Top Copper .......................................................................... 26

A.11 ADM00861 – Bottom Copper and Silk ....................................................... 27

Offline LED Driver

AC

Appendix B. Bill of Materials (BOM)........................................................................... 29

2018 Microchip Technology Inc. DS50002772A-page 3

Page 4

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

Appendix C. Plots and Waveforms

C.1 CL88030 230 V

Evaluation Board Typical Waveforms ..................................................... 31

Offline LED Driver

AC

C.2 CL88030 230 V

Offline LED Driver

AC

Evaluation Board Typical Measurements ............................................... 37

Worldwide Sales and Service .....................................................................................41

DS50002772A-page 4 2018 Microchip Technology Inc.

Page 5

CL88030

230 V

OFFLINE LED DRIVER

AC

EVALUATION BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

CL88030 230 V

include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Website

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the CL88030 230 V

ation Board as a development tool. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information about the CL88030 230

V

AC

• Chapter 2. “Installation and Operation” – Includes instructions on how to get

started with the CL88030 230 V

detailed description of each function.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the CL88030 230 V

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

CL88030 230 V

• Appendix C. “Plots and Waveforms” – Describes the plots and waveforms for

the CL88030 230 V

Offline LED Driver Evaluation Board. Items discussed in this chapter

AC

Offline LED Driver Evaluation Board.

Offline LED Driver Evaluation Board and a

AC

Offline LED Driver Evaluation Board.

AC

Offline LED Driver Evaluation Board.

AC

Offline LED Driver Evaluation Board.

AC

Offline LED Driver Evalu-

AC

2018 Microchip Technology Inc. DS50002772A-page 5

Page 6

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

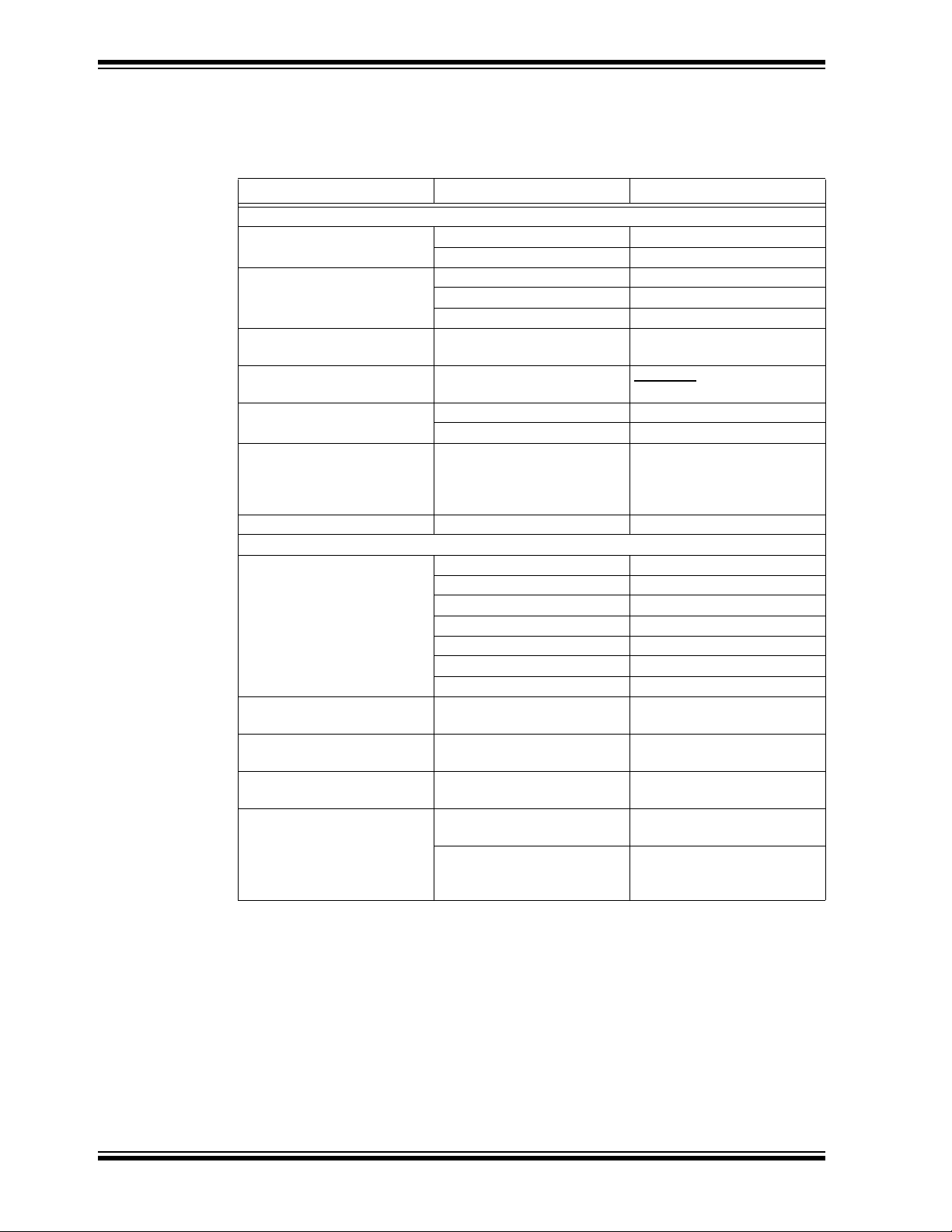

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB® IDE User’s Guide

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

DS50002772A-page 6 2018 Microchip Technology Inc.

Page 7

RECOMMENDED READING

Preface

This user's guide describes how to use the CL88030 230 V

Evaluation Board. Another useful document is listed below. The following Microchip

document is available and recommended as supplemental reference resource:

• CL88030 Data Sheet - Sequential Linear LED Driver with Four or Six Taps

(DS20006049)

THE MICROCHIP WEBSITE

Microchip provides on-line support via our website at www.microchip.com. This

website is used as a means to make files and information easily available to customers.

Accessible by using your favorite internet browser, the website contains the following

information:

• Product Support – Data sheets, errata, application notes, sample programs,

design resources, user’s guides, hardware support documents, latest software

releases, and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

CUSTOMER SUPPORT

Offline LED Driver

AC

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or Field Application Engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the website at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (August 2018)

• Initial release of this document.

2018 Microchip Technology Inc. DS50002772A-page 7

Page 8

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

NOTES:

DS50002772A-page 8 2018 Microchip Technology Inc.

Page 9

Chapter 1. Product Overview

1.1 INTRODUCTION

CL88030

230 V

OFFLINE LED DRIVER

AC

EVALUATION BOARD USER’S GUIDE

This chapter provides an overview of the CL88030 230 V

ation Board and covers the following topics:

• CL88030 Overview

• CL88030 Key Features

• What is the CL88030 230 V

• What the CL88030 230 V

1.2 CL88030 OVERVIEW

The CL88030 driver Integrated Circuit (IC) is a sequential linear LED driver, 4-tap

version, targeted to provide a flexible solution to drive LEDs from AC line voltages up

to 277 V

A sequential linear LED driver is an LED driver, operating from an AC voltage source

and comprised of multiple linear current regulators driving various tap points along a

long string of LEDs connected to the rectified AC. High efficiency is achieved by

shutting off upstream regulators when downstream regulators achieve regulation.

The CL88030 is in a DFN-10 package. The power dissipation for this device is much

lower than the CL8800 or CL88020 one, due to the external FETs. The bottom tab is

not necessary for thermal reasons, but it is necessary to provide 11 electrical

connections for the CL88030.

and at high-output powers.

AC

1.3 CL88030 KEY FEATURES

Offline LED Driver Evalu-

AC

Offline LED Driver Evaluation Board (ADM00860)?

AC

Offline LED Driver Evaluation Board Kit Contains

AC

• Scalable:

- AC line voltage limited only by external FETs

- Output power limited only by external FETs

• No Inductors:

- Reduces BOM cost and circuit complexity

• Efficient Operation:

- Typical electrical efficiencies of 80% to 90% across the AC input voltage

range

• No High Frequencies:

- Inherently low-conducted EMI, no need for input filters

• Inherently Dimmer Compatible:

- Works with most leading-edge and trailing-edge phase-cut dimmers

- Requires no special circuitry to detect and to handle dimmers

- May require an RC network across the AC line to provide adequate TRIAC

latching current

• Two Versions - 4-tap (CL88030) and 6-tap (CL88031):

- Higher taps increase efficiency and lower Total Harmonic Distortion (THD)

- Fewer taps reduce costs

2018 Microchip Technology Inc. DS50002772A-page 9

Page 10

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

• Reduced Output Ripple (optional):

- An external capacitor with four diodes provides lower output ripple

- Strobing occurs at low line

- Provides continuous power to the driver

• Active Line Regulation:

- Active circuitry provides better regulated output power over variations in AC

line voltage

- –12%/+0% line regulation typical

- Prevents driver from overheating at high AC line voltages

- Prevents excessive currents at low line

- Required for reasonable line regulation and efficient operation, given only four

or six taps

- If unused, the ALR pin is left open in the application

• Overtemperature Protection (OTP), Optional:

- An inexpensive external NTC thermistor provides remote temperature

sensing. The thermistor may be near the LEDs to provide nearly direct

monitoring of LED temperature.

- OTP is linear (no on/off cycling)

- A widely available, 470 k NTC provides an 85°C maximum temperature

- Temperature adjustable via selection of NTC thermistor resistance

- If unused, the OTP pin is tied to BIAS

• Two Current-setting Resistors:

- Different hold-up and direct AC currents lower the THD and output ripple

- Tap current ratios internally set

- Reduces component count

- Fewer pins

- Simplifies application design

- Single-point current control for reduced EMI

DS50002772A-page 10 2018 Microchip Technology Inc.

Page 11

Product Overview

GND

GND

GND

GND

1 2

CRPL2

15uF

1 2

CRPL1

15uF

GND

1

2

3

MMBD1503A

D3

1

2

3

MMBD1503A

D2

387V

600V

1A

GND

7.5R

Rset1

3.24R

Rset2

28k

Ralr2

221k

Rotpu

200k

Rbias

4.7uF

Cbias

4.7uF

Calr

TP1

TP2

TP9 TP10

TP6 TP7TP5 TP8

TP3

TP4

TP14

TP13

TP12

TP11

1

2

J1

MOV1

4 1

23

~

~

+

-

D1

10R

Rtp1

10R

Rtp2

0R

Rotpl

1M

Ralr1

-t

470k

Rntc

GND

)

2

1

3

Q1

2

1

3

Q2

2

1

3

Q3

2

1

3

Q4

GT1

1

GT2

2

GT3

3

GT4

4

NC

5

NC

6

CS

7

OTP

8

BIAS

9

ALR

10

GND

11

CL88030

IC1

(24.8V, 10..200mA

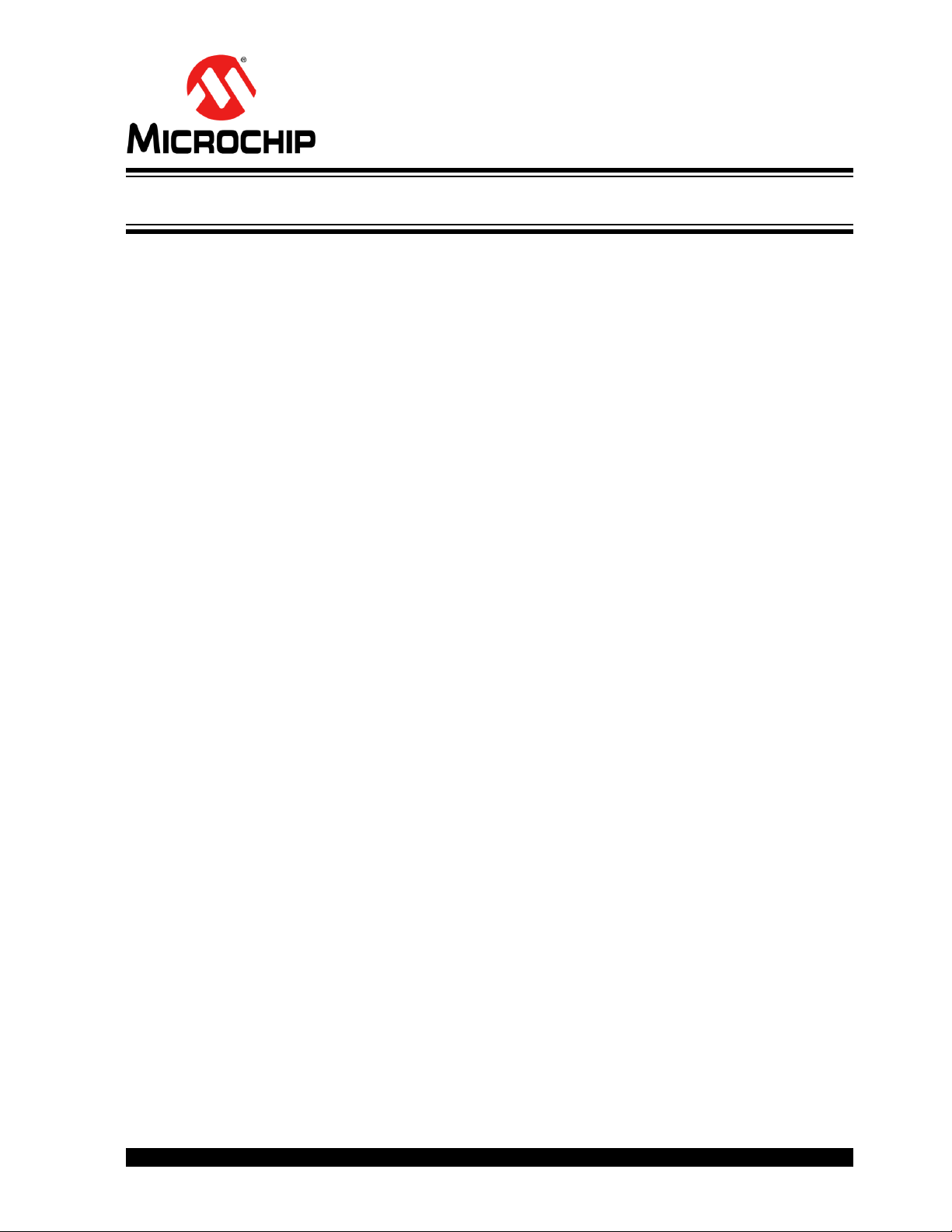

FIGURE 1-1: Typical CL88030 230 V

1.4 WHAT IS THE CL88030 230 V

Offline LED Driver Evaluation Board Circuit.

AC

OFFLINE LED DRIVER EVALUATION

AC

BOARD (ADM00860)?

The CL88030 230 V

designated LED Load Board (ADM00861) represent a complete solution for a LED

lighting application, powered directly from the 230 V

Technology's CL88030 sequential linear LED driver. The application achieves efficient

operation without magnetics or conventional switching techniques and is a flexible

solution that allows users to design and test their own LED Load. The available LED

Load is made with 12 LEDs. Since no high frequencies are present, it exhibits inherently low conducted and radiated EMI without the need of input filters or shielding.

Because the current through the LEDs follows the AC input voltage, Power Factor

Correction (PFC) circuitry is not needed. With the addition of an RC network, the

CL88030 is compatible with both leading-edge and trailing-edge dimmers.

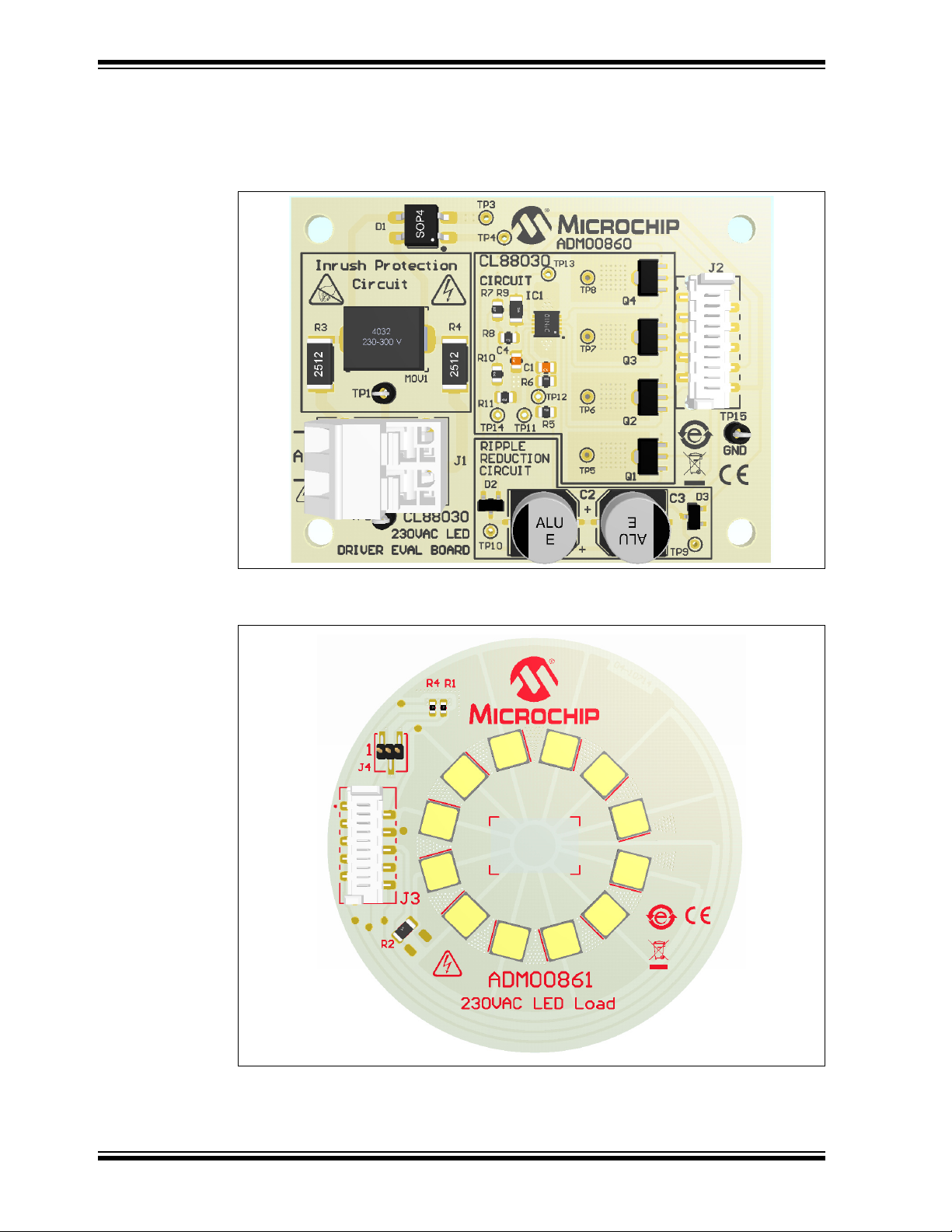

Note: The LED Load (ADM00861) is provided on a double-layer 60 mm diameter

FR4 (0.6 mm thick) PCB, ready to be mounted on a pin-fin heat sink. The

kit includes a black anodized pin-fin heat sink and a double-sided adhesive

thermal tape necessary to mount the LED Load on it. The LED Load is also

developed to be used with another LED Driver board from the CL88 series

(ADM00866, CL8800 LED Driver Board), so it is equipped with a selectable

(by means of a jumper) NTC or PTC thermistor, making Overtemperature

Protection (OTP) possible. For the current application, the selection activates the NTC thermistor by mounting the jumper between positions 2 and

3 of the J4 header.

Offline LED Driver Evaluation Board (ADM00860) and a

AC

line and based on Microchip

AC

2018 Microchip Technology Inc. DS50002772A-page 11

Page 12

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

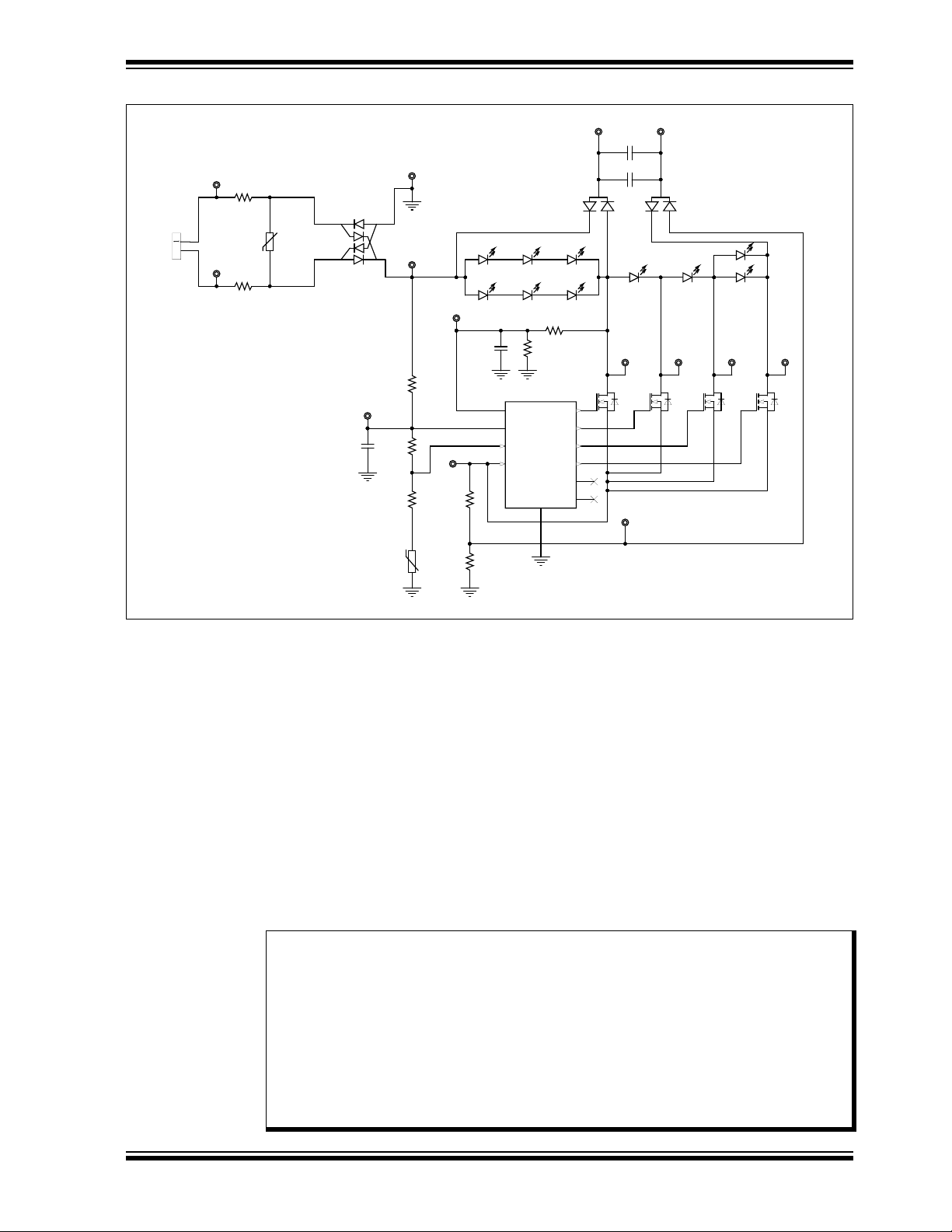

The LED Driver PCB (ADM00860) is made on a 1.6 mm standard double-layer FR4.

The kit includes a 10-wire flat cable to connect the LED Driver Board to the LED Load.

All circuitry and hardware are provided, along with transient protection and OTP. Plug

into a 230 V

outlet (50 Hz or 60 Hz) to get started.

AC

FIGURE 1-2: CL88030 230 V

(ADM00860) – Top View.

Offline LED Driver Evaluation Board

AC

FIGURE 1-3: CL88030 LED Load Board (ADM00861) – Top View.

DS50002772A-page 12 2018 Microchip Technology Inc.

Page 13

Product Overview

1.5 WHAT THE CL88030 230 V

KIT CONTAINS

The CL88030 230 V

• CL88030 230 V

• 10-wire interconnection flat cable

• 4 nylon stand-offs with corresponding screws

• Important Information Sheet

Note: The CL88030 LED Load Board (ADM00861) is available for purchase from

www.microchipdirect.com. The CL88030 LED Load Board kit includes:

• CL88030 LED Load Board (ADM00861)

• LED Load pin-fin heat sink

• Thermal double-sided adhesive tape

• Important Information Sheet

AC

OFFLINE LED DRIVER EVALUATION BOARD

AC

Offline LED Driver Evaluation Board kit includes:

AC

Offline LED Driver Evaluation Board (ADM00860)

2018 Microchip Technology Inc. DS50002772A-page 13

Page 14

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

NOTES:

DS50002772A-page 14 2018 Microchip Technology Inc.

Page 15

Chapter 2. Installation and Operation

2.1 INTRODUCTION

CL88030

230 VAC OFFLINE LED DRIVER

EVALUATION BOARD USER’S GUIDE

The CL88030 230 V

string of inexpensive, low-current LEDs directly from the AC mains. A basic driver circuit consists of the CL88030, six resistors, four FETs and a bridge rectifier. Two to four

additional components are optional for various levels of transient protection, also with

a low-price NTC to assure remote OTP. No capacitors, EMI filters or power factor

correction circuits are needed.

The operation principle is identical to the CL88020 one, the difference being the output

FETs that are outside the IC and so, the power capability of the application is higher

and the input/output capability is also higher. A string of series/parallel LEDs is tapped

at four locations. Four linear current regulators sink current at each tap through a single

control point and are sequentially turned on and off. High efficiency is achieved by shutting off upstream regulators when downstream regulators achieve regulation. This

makes controlling overall input current easier than trying to control multiple current

paths, thereby tracking the input sine wave voltage. Voltage across each regulator is

minimized when conducting, providing high efficiency. It implements a self-commutation technique using only the tap currents. This technique inherently provides smooth

transitions from one regulator to the next, without relying on tap voltages or the rectified

AC to coordinate the transitions. The current waveform can be tailored to optimize for

input voltage range, active line/load regulation, output power/current, efficiency, power

factor, THD, dimmer compatibility and LED utilization. With the addition of a Resistor-Capacitor (RC) network, the driver is compatible with a wider range of phase-cut

dimmers. The data sheet includes a description of the driver’s operation mode, with

design guidelines and examples. Additional topics include optimization/tradeoffs in performance (output power, efficiency, LED utilization, driver dissipation, output ripple,

component selection, input current THD, PF and line regulation). Transient protection,

OTP and ripple reduction circuit are also covered. Explanations are provided for tap

sequencing, active line regulation and OTP.

Offline LED Driver evaluation board is designed to drive a long

AC

2.1.1 Board Features

The CL88030 230 V

following features:

• Input Voltage: 230 V

• Typical Output Capability: up to 130 mA

• Efficiency: over 83%

• Maximum Output Power: 14W (it depends on the cooling provided)

The CL88030 LED Load board (ADM00861) has the following features:

• 12 Osram Duris

• A 10-wire Flat Cable Input Connector

• One NTC for OTP

2018 Microchip Technology Inc. DS50002772A-page 15

Offline LED Driver evaluation board (ADM00860) has the

AC

+/-15%, 50/60 Hz

rms

®

S8 family LEDs (GW P9LR31.EM) Grouped in Four Taps

Page 16

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

2.2 GETTING STARTED

The CL88030 230 V

and demonstrate the CL88030 LED Driver.

Offline LED Driver evaluation board is fully tested to evaluate

AC

WARNING

The ADM00860 source board and ADM00861 LED Load board do NOT provide electrical

isolation between the AC line and the lamp circuitry. Dangerous voltages are present

when connected to the AC line. Exercise caution!

Consider the following recommendations before starting the setup process:

• Place the CL88030 LED Driver evaluation board and the LED Load assembly on

a non-conductive surface when connected to the AC line.

• Do not come into contact with any of the two demonstration unit boards while they

are connected to the AC line.

• Disconnect the demonstration units from the AC line before performing any work

on any of them.

• Do not connect instruments having earth-referenced inputs, such as most

oscilloscopes (use isolation transformers).

• It is suggested that utility power for testing is provided from an AC source with a

floating output, and that differential voltage probes are used.

Failure to adhere to these guidelines may result in damage to the demo unit, the test

instruments, and/or can put in danger the person conducting the tests.

2.2.1 Prerequisites

Since the power of the application is about 15 watts, for a continuous operation of the

LED Load (more than 30s), attach the provided heat sink using the double-sided adhesive thermal tape by following these steps:

1. Before you start, make sure that the surface of the heat sink and of the PCB are

dry and clean (use cotton made smooth material to clean if needed).

2. Detach the protection foil on the thermal tape from one side.

3. Attach the open portion of the thermal tape to the base of the heat sink.

4. Detach the second protection foil from the thermal tape.

5. Attach the PCB (ADM00861) to the heat sink.

6. Slowly press the top of the PCB to be sure that the thermal contact will be made

all over the board.

DS50002772A-page 16 2018 Microchip Technology Inc.

Page 17

2.3 SETUP PROCEDURE

Installation and Operation

Powering the CL88030 230 V

Offline LED Driver evaluation board is easy. The only

AC

connections to be made are from the LED Driver board to the LED Load assembled on

a pin-fin heat sink, using the provided 10-wire flat cable, and from the LED Driver Board

to the AC line via the power cord.

Follow these steps:

1. Read the getting started recommendations and precautions.

2. Set the jumper J4 on the LED Load board between positions 2 and 3 to activate

the NTC for the OTP (this is specific when using the LED Load with ADM00860).

3. Connect the CL88030 LED Driver evaluation board and the CL88030 LED Load

board by means of the provided 10-wire flat cable, between J2 and J3 connectors. It is recommended to exercise caution, as the connectors on the flat cable

are protected from incorrect connection.

4. Connect the power cord on J1 on the LED Driver board. The input connector J1

is placed on the left side of the LED Driver board, which is marked with the

inscription: AC.

5. Use a colored plexiglass above the LED Load board for eyes protection against

extreme light.

6. Plug the power cord into a 230 V

outlet and apply 230 VAC±15%, 50 Hz. While

AC

it is possible for the values to be below this range, it is recommended not to

exceed 277 V

. In this case, the transient protection feature is automatically

AC

activated. Line frequency is not critical (50 Hz or 60 Hz).

A variable AC power supply is needed for testing and evaluation in the laboratory. The

power supply requires an output capability of at least 20W and a voltage range from

0V

to 300 VAC. This can also be obtained from an auto-transformer supplied from

AC

the mains or an electronic AC/AC power supply (for example, the Chroma ATE Inc.

61500 series).

Note: Auto-transformers do not provide isolation from the utility mains.

Figure 2-1 illustrates the connection between ADM00860 and ADM00861.

FIGURE 2-1: Connection Diagram.

2018 Microchip Technology Inc. DS50002772A-page 17

Page 18

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

2.4 HOW DOES THE CL88030 230 V

BOARD SET WORK?

The CL88030 230 V

the current through the four LED taps while maintaining a high-input power factor (PF)

and low THD. The ADM00860 includes a CL88030 IC, which is a sequential linear LED

driver controlling four taps. Tap sequencing assures the regulators are turned on and

off at the proper times. Tap sequencing also controls the smooth transition from one

regulator to the next, without generating EMI-causing glitches in input current. Two concepts are involved:

• The first is a single-point control. All tap currents pass through a single control

point. This makes controlling overall input current easier than trying to control multiple current paths.

• The second concept is called self-commutation. Using only the tap currents

themselves, this technique inherently provides smooth transitions from one regulator to the next without relying on tap voltages or the rectified AC to coordinate

the transitions. This avoids having to monitor high voltages and is more precise.

These two concepts work together to properly sequence the current regulators and to

provide glitch-free operation and thus avoiding conducted EMI.

The CL88030 230 V

necessary to perform, as well as OTP, Active Line Regulation (ALR) and Ripple

Reduction Circuit (RRC).

The OTP operates linearly, gradually reducing the output power as temperature

increases. To accomplish this it uses an inexpensive, external NTC thermistor to

remotely sense LED temperature. The thermistor is located on the LED Load board, in

close proximity to the LEDs, providing near-direct LED temperature monitoring. The

OTP temperature is adjustable via selection of the NTC resistance.

The ALR circuit maintains fairly constant output power over variations in AC line

voltage. It is not a closed loop system that directly monitors and corrects output power.

Instead, it monitors the average voltage applied to the LED string and uses it to adjust

the reference voltage provided to the tap current regulators.

The RRC providing low output ripple is achieved using a capacitor and four diodes. The

capacitor may consist of one or more paralleled ceramic capacitors or electrolytic. The

CL88030 with RRC operates in four phases: recharge, hold-up, direct, and under certain conditions, idle. All active current paths include Segment 1 (TAP1), assuring uninterrupted light output on it during all phases of operation, excluding the idle. This

reduces overall ripple, which means about 0.15 flicker index.

For more information, see the CL88020 data sheet.

Offline LED Driver evaluation board set is designed to control

AC

Offline LED Driver evaluation board contains all the circuitry

AC

OFFLINE LED DRIVER EVALUATION

AC

DS50002772A-page 18 2018 Microchip Technology Inc.

Page 19

2.5 BOARD TESTING

To start testing the evaluation board, follow these steps:

1. Connect the input AC source and the output LED Load, as shown in Figure 2-1.

2. Use an eye protection filter to check that all the four taps light up on the LED Load

Board.

3. Power the board at 230 V

4. Verify each tap current through the LEDs. It should be within a range of 65 mA

and 134 mA. It can be measured by separating each wire from the

inter-connection 10-wire flat cable between the CL88030 LED Driver board and

the CL88030 LED Load board.

5. If a variable AC source is available, set the input voltage to any value between

180 V

application delivers between 10W and 14W electric output power.

6. Power-down the AC source.

Installation and Operation

, 50 Hz-60 Hz.

AC

and 245 VAC. The LED Load delivers nearly constant lumen power. The

AC

2018 Microchip Technology Inc. DS50002772A-page 19

Page 20

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

NOTES:

DS50002772A-page 20 2018 Microchip Technology Inc.

Page 21

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

CL88030

230 V

OFFLINE LED DRIVER

AC

EVALUATION BOARD USER’S GUIDE

This appendix contains the following schematics and layouts for the CL88030 230 V

Offline LED Driver Evaluation Board (ADM00860) and for the CL88030 230 VAC LED

Load Board (ADM00861):

• Board Schematic – ADM00860

• Board Schematic – ADM00861

• ADM00860:

- ADM00860 – Top Silk

- ADM00860 – Top Copper and Silk

- ADM00860 – Top Copper

- ADM00860 – Bottom Copper and Silk

• ADM00861:

- ADM00861 – Top Silk

- AMD00861 – Top Copper and Silk

- ADM00861 – Top Copper

- ADM00861 – Bottom Copper and Silk

AC

2018 Microchip Technology Inc. DS50002772A-page 21

Page 22

DS50002772A-page 22 2018 Microchip Technology Inc.

GND

GND

GND

GND

GND

CMB02070X1809GB200

CRM2512-JW-100ELF

CU4032K275G2 275VAC

600V

1A

GND

GND

TP9

TP10

TP6 TP7TP5 TP8

TP3

TP4

TP14

TP13

TP12

TP11

1

2

TERMINAL 1x2

J1

OSTHD020080

387V

4032

10%

MOV1

4 1

23

~

~

+

-

MB6S

D1

1M 0805 1%

R5

TP2

0R

1206

1%

R9

1

2

3

MMBD1503A

D3

1

2

3

MMBD1503A

D2

10R

2512

5%

R4

10R

2512

5%

R3

TP1

221k

0805

1%

R8

7.5R

0805

1%

R10

3.24R

0805

1%

R11

28k

0805

1%

R6

4.7uF

25V

0805

C1

4.7uF

25V

0805

C4

TP15

112345678910

J2

15uF

160V

AL-E

C2

15uF

160V

AL-E

C3

200k

0805

1%

R7

GT1

1

GT2

2

GT3

3

GT4

4

NC

5

NC

6

CS

7

OTP

8

BIAS

9

ALR

10

GND

11

CL88030

IC1

2

1

3

VN2460N8-G

Q1

2

1

3

VN2460N8-G

Q2

2

1

3

VN2460N8-G

Q3

2

1

3

VN2460N8-G

Q4

A.2 BOARD SCHEMATIC – ADM00860

1

CL88030 230 V

AC

Offline LED Driver Evaluation Board User’s Guide

Page 23

A.3 BOARD SCHEMATIC – ADM00861

LED1-12 Osram Duris S8 GW P9LR31.EM

WHITE

LD1

WHITE

LD2

WHITE

LD3

WHITE

LD4

WHITE

LD5

WHITE

LD6

WHITE

LD7

WHITE

LD8

WHITE

LD9

WHITE

LD10

WHITE

LD12

WHITE

LD11

1

2345678910

J3

0R

1206

1%

R2

0R

1206

1%

DNP

R3

NCP18WM474J03RB

Molex 0908140810

470k

-t

R1

3.3R

+t

R4

1

2

3

J4

TP5TP6 TP7TP16

TP15

TP8 TP3

PRG18BC3R3MM1RB

Schematic and Layouts

1

A.4 ADM00860 – TOP SILK

2018 Microchip Technology Inc. DS50002772A-page 23

Page 24

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

A.5 ADM00860 – TOP COPPER AND SILK

A.6 ADM00860 – TOP COPPER

DS50002772A-page 24 2018 Microchip Technology Inc.

Page 25

A.7 ADM00860 – BOTTOM COPPER AND SILK

Schematic and Layouts

A.8 ADM00861 – TOP SILK

2018 Microchip Technology Inc. DS50002772A-page 25

Page 26

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

A.9 AMD00861 – TOP COPPER AND SILK

A.10 ADM00861 – TOP COPPER

DS50002772A-page 26 2018 Microchip Technology Inc.

Page 27

A.11 ADM00861 – BOTTOM COPPER AND SILK

Schematic and Layouts

2018 Microchip Technology Inc. DS50002772A-page 27

Page 28

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

NOTES:

DS50002772A-page 28 2018 Microchip Technology Inc.

Page 29

CL88030

230 V

OFFLINE LED DRIVER

AC

EVALUATION BOARD USER’S GUIDE

Appendix B. Bill of Materials (BOM)

TABLE B-1: BILL OF MATERIALS (BOM) FOR ADM00860

Qty. Reference Description Manufacturer Part Number

2 C1, C4 Capacitor Ceramic, 4.7 µF, 25V, 10%,

X7R, SMD 0805

2 C2, C3 Capacitor Aluminium, 15 µF, 160V, 20%,

SMD E

1 D1 Diode, Bridge Rectifier, MB6S, 1V, 0.5A,

600V, SMD, SOIC-4

2 D2, D3 Diode Array, MMBD1503A, 1.1V, 200 mA,

200V, SMD, SOT-23-3

1 IC1 Microchip Analog LED Driver

CL88030-E/MF, DFN-10

1 J1 Terminal Block, 5.08 mm, 1x2, Female,

16-22AWG,12A, TH, R/A

1 J2 Connector Header-1.27 Male, 1x10, Tin,

SMD Vertical

1 MOV1 Varistor, 430V, 1.2 kA, SMD 4032 EPCOS TDK B72660M0271K093

1 PCB CL88030 230 V

uation Board – Printed Circuit Board

4 Q1, Q2, Q3, Q4Transistor FET, N-Channel, 600V, 200 mA,

1.6W, SOT-89

2 R3, R4 Resistor, TKF, 10R, 5%, 1W, SMD 2512 Panasonic

1 R5 Resistor, TKF, 1M, 1%, 1/8W, SMD 0805 Panasonic – ECG ERJ-6ENF1004V

1 R6 Resistor, TKF, 28k, 1%, 1/8W, SMD 0805 Vishay

1 R7 Resistor, TKF, 200k, 1%, 1/8W, SMD 0805 Multicomp Inc. MCPWR05FTEW2003

1 R8 Resistor, TKF, 221k, 1%, 1/8W, SMD 0805 Vishay/Dale CRCW0805221KFKEA

1 R9 Resistor, TKF, 0R, 1%, 1/4W, SMD 1206 TT Electronics Plc. WCR1206-R005JI

1 R10 Resistor, TKF, 7.5R, 1%, 1/8W, SMD 0805 Vishay/Dale CRCW08057R50FKEA

1 R11 Resistor, TKF, 3.24R, 1%, 1/8W, SMD

0805

3TP1, TP2,

TP15

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Miscellaneous, Test Points, Multi-Purpose,

Miniature, Black

Offline LED Driver Eval-

AC

TDK Corporation C2012X7R1E475K125AB

Nichicon Corporation ULT2C150MNL1GS

Fairchild

Semiconductor

Fairchild

Semiconductor

Microchip Technology

Inc.

On-Shore Technology,

Inc.

Digi-Key

Microchip Technology

Inc.

Microchip Technology

Inc.

®

Vishay/Dale CRCW08053R24FKEA

Keystone Electronics

Corp.

®

®

Electronics WM19277-ND

®

– ECG ERJ-1TYJ100U

/Dale CRCW080528K0FKEA

MB6S

MMBD1503A

CL88030-E/MF

OSTHD020080

04-10710-R1

VN2460N8-G

5001

2018 Microchip Technology Inc. DS50002772A-page 29

Page 30

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

TABLE B-2: BILL OF MATERIALS (BOM) FOR ADM00860 - MECHANICAL PARTS

Qty

Reference Description Manufacturer Part Number

.

1 CBL1 Mechanical HW Cable, Picoflex™, IDT to

IDT, 10-COND, 250 mm

4HS1, HS2,

HS3, HS4

1 LABEL1 Label Assembly, W/REV Level (Small

4 SCR1, SCR2,

SCR3, SCR4

4 STANDOFF1,

STANDOFF2,

STANDOFF3,

STANDOFF4

1 TAPE1 Mechanical HW, Tape, Thermal Sheet,

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Mechanical HW Heat Sink,

L8.5 mm x W6.35 mm x H4.8 mm, Black

Modules), PER MTS-0002

Mechanical HW Screw, #6-32 x 1/4”,

PanHead, PHIL, Nylon

Mechanical HW Stand-Off, #6-32 x 3/8", F,

HEX, Nylon

L254W254, custom 9 x 7 mm

®

Molex

Assmann Electronics Inc. V5618A

B&F Fasteners Supply NY PMS 632 0025 PH

Keystone Electronics

Corp.

Bergquist Company

GmbH

0923151025

1903B

BP100-0.008-00-1010

TABLE B-3: BILL OF MATERIALS (BOM) FOR ADM00861

Qty. Reference Description Manufacturer Part Number

1 HS2 Mechanical HW Heat Sink, D60 mm x H30 mm,

9.1W, Black

1 J3 Connector Header, 1.27 mm, Male, 1x10, Tin,

SMD, Vertical

1 J4 Connector Header, Male, 1x3, 1.27 mm, AU,

SMD

1 LABEL1 Label, AIPD Board Assembly

12 LD1, LD2,

LD3, LD4,

LD5, LD6,

LD7, LD8,

LD9, LD10,

LD11, LD12

1 PCB1 CL88030 LED Load Board

1 R1 Resistor NTC Thermistor, 470k, 5%, 100 mW,

1 R2 Resistor, TKF, 0R, 1%, 1/4W, SMD, 1206 TT Electronics Plc. WCR1206-R005JI

0R3 DO NOT POPULATE TT Electronics Plc. WCR1206-R005JI

1 R4 Resistor, Fuse Resettable, 180 mA, 16V, PTC,

1 SH4 Mechanical HW Jumper, 1.27 mm, 1x2, Gold Sullins Connector

1 TAPE 1 Mechanical HW, Tape, Thermal Sheet,

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Diode LED, White, 24.8V, 150 mA, 500 lm,

2700K, SMD, L5W5H0.7

– Printed Circuit

Board

0603

SMD, 0603

L254W254, custom D60 mm

MechaTronix

Kaohsiung Co., Ltd.

Digi-Key Electronics WM19277-ND

Harwin Plc. M50-3630342

OSRAM Opto

Semiconductors

GmbH

Microchip

Technology Inc.

Murata Electronics

North America, Inc.

Murata Electronics

North America, Inc.

Solutions

Bergquist Company

GmbH

LPF60A30-5-B

GW

P9LR31.EM-PPPR-XX5

8-1-150-R18

04-10714-R1

NCP18WM474J03RB

PRG18BC3R3MM1RB

NPB02SVAN-RC

BP100-0.008-00-1010

DS50002772A-page 30 2018 Microchip Technology Inc.

Page 31

230 V

I max. = 90.5 mA Output Current 30.0 mA/div

at

230 VAC RMS Line

2.0 ms/div

Output Current at 255 V

AC

RMS Line

30.0 mA/div

I max. = 70 mA

2.0 ms/div

OFFLINE LED DRIVER

AC

EVALUATION BOARD USER’S GUIDE

Appendix C. Plots and Waveforms

CL88030

C.1 CL88030 230 V

WAVEFORMS

C.1.1 Total Output Current at 230 VAC and 255 VAC Input

FIGURE C-1: Total Output Current at 230 VAC Line Input Voltage.

OFFLINE LED DRIVER EVALUATION BOARD TYPICAL

AC

2018 Microchip Technology Inc. DS50002772A-page 31

FIGURE C-2: Total Output Current at 255 VAC Line Input Voltage.

Page 32

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

TAP 1 Curr e nt

30.0 mA/div

Line Voltage

230 V

AC

RMS

100.0V/div

I max. = 58.7 mA

4.0 ms/div

I max. = 74.8 mA

30.0 mA/div

Line Voltage

230 V

AC

RMS

100.0V/div

TAP2 Current

4.0 ms/div

C.1.2 TAPs 1, 2, 3, 4 Currents at 230 V

AC

FIGURE C-3: TAP1 Current at 230 VAC Line Input Voltage.

FIGURE C-4: TAP2 Current at 230 V

DS50002772A-page 32 2018 Microchip Technology Inc.

Line Input Voltage.

AC

Page 33

Plots and Waveforms

I max. = 84.7 mA

30.0 mA/div

Line Voltage

230 VAC RMS

TAP3 Current

4.0 ms/div

I max. = 89.5 mA

30.0 mA/div

Line Voltage 230 V

AC

RMS

TAP 4 Curr e nt

4.0 ms/div

FIGURE C-5: TAP3 Current at 230 VAC Line Input Voltage.

FIGURE C-6: TAP4 Current at 230 V

2018 Microchip Technology Inc. DS50002772A-page 33

Line Input Voltage.

AC

Page 34

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

Start at 230 VAC RMS

Line Input

I max. = 159 mA

30.0 mA/div

I Output = 68.0 mA RMS

200 ms/div

Stop

Line Input 230 VAC RMS

100.0V/div

Input Line Current

30.0 mA/div

66.0 mA RMS

4.0 ms/div

FIGURE C-7: Output Current on Startup at 230 VAC Line Input Voltage.

DS50002772A-page 34 2018 Microchip Technology Inc.

FIGURE C-8: Input Current and Line Input Voltage Waveforms.

Page 35

Plots and Waveforms

Input Line Current

30.0 mA/div

at 230 V

AC

Input Line

I max. = 92 mA

TAP4

TAP3

TAP2

TAP1

2.0 ms/div

Input Line Current at 230 V

AC

RMS Line Input

TAP1

TAP 2

TAP 3

TAP4

400.0 us/div

30.0 mA/div

FIGURE C-9: Input Current Waveform – TAPs Commutation.

2018 Microchip Technology Inc. DS50002772A-page 35

FIGURE C-10: Input Current Waveform – TAPs 1-4 Commutation Detail.

Page 36

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

Output Current with RRC

25.0 mA/div

I max. = 87.0 mA

Discharging the RRC CapacitorCharging the RRC Capacitor

4.0 ms/div

C.1.3 Output Current with Ripple Reduction Circuit (RRC) at 230 VAC

Input

FIGURE C-11: Output Current with RRC at 230 VAC Line Input Voltage.

DS50002772A-page 36 2018 Microchip Technology Inc.

Page 37

Plots and Waveforms

7

8

9

10

11

12

13

14

15

16

175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260

Input Power (W)

Input Voltage (V

RMS

)

0.7

0.75

0.8

0.85

0.9

0.95

1

175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260

PF

Input Voltage (V

RMS

)

C.2 CL88030 230 V

OFFLINE LED DRIVER EVALUATION BOARD TYPICAL

AC

MEASUREMENTS

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

FIGURE C-12: Input Power vs. Input Voltage (V

FIGURE C-13: Power Factor vs. Input Voltage (V

RMS

RMS

).

).

2018 Microchip Technology Inc. DS50002772A-page 37

Page 38

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3

175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260

V

ALR

(V)

Input Voltage (V

RMS

)

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260

Output Power (LED Load) (W)

Line Voltage (V

RMS

)

FIGURE C-14: V

DS50002772A-page 38 2018 Microchip Technology Inc.

FIGURE C-15: Output Power (Electric) vs. Input Line Voltage (V

Pin vs. Input Line Voltage (V

ALR

RMS

).

).

RMS

Page 39

Plots and Waveforms

50

60

70

80

90

100

175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260

EFF (%)

Input Voltage (V

RMS

)

1400

1450

1500

1550

1600

1650

1700

1750

1800

1850

1900

1950

2000

175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260

265

Light Output (Lm)

Line Voltage (V

RMS

)

FIGURE C-16: Electric Efficiency vs. Input Line Voltage (V

2018 Microchip Technology Inc. DS50002772A-page 39

FIGURE C-17: Light Output vs. Input Voltage (V

RMS

).

RMS

).

Page 40

CL88030 230 VAC Offline LED Driver Evaluation Board User’s Guide

118

120

122

124

126

128

130

132

175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260

265

LUMENS/W

Line Voltage (V

RMS

)

FIGURE C-18: Luminous Efficacy (Lumens/W) vs. Input Voltage (V

RMS

).

DS50002772A-page 40 2018 Microchip Technology Inc.

Page 41

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

China - Beijing

Tel: 86-10-8569-7000

China - Chengdu

Tel: 86-28-8665-5511

China - Chongqing

Tel: 86-23-8980-9588

China - Dongguan

Tel: 86-769-8702-9880

China - Guangzhou

Tel: 86-20-8755-8029

China - Hangzhou

Tel: 86-571-8792-8115

China - Hong Kong SAR

Tel: 852-2943-5100

China - Nanjing

Tel: 86-25-8473-2460

China - Qingdao

Tel: 86-532-8502-7355

China - Shanghai

Tel: 86-21-3326-8000

China - Shenyang

Tel: 86-24-2334-2829

China - Shenzhen

Tel: 86-755-8864-2200

China - Suzhou

Tel: 86-186-6233-1526

China - Wuhan

Tel: 86-27-5980-5300

China - Xian

Tel: 86-29-8833-7252

China - Xiamen

Tel: 86-592-2388138

China - Zhuhai

Tel: 86-756-3210040

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

India - New Delhi

Tel: 91-11-4160-8631

India - Pune

Tel: 91-20-4121-0141

Japan - Osaka

Tel: 81-6-6152-7160

Japan - Tokyo

Tel: 81-3-6880- 3770

Korea - Daegu

Tel: 82-53-744-4301

Korea - Seoul

Tel: 82-2-554-7200

Malaysia - Kuala Lumpur

Tel: 60-3-7651-7906

Malaysia - Penang

Tel: 60-4-227-8870

Philippines - Manila

Tel: 63-2-634-9065

Singapore

Tel: 65-6334-8870

Taiwan - Hsin Chu

Tel: 886-3-577-8366

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Taiwan - Taipei

Tel: 886-2-2508-8600

Thailand - Bangkok

Tel: 66-2-694-1351

Vietnam - Ho Chi Minh

Tel: 84-28-5448-2100

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

Finland - Espoo

Tel: 358-9-4520-820

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-67-3636

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Israel - Ra’anana

Tel: 972-9-744-7705

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-7289-7561

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

DS50002772A-page 41 2018 Microchip Technology Inc.

10/25/17

Loading...

Loading...