Page 1

Atmel BTLC1000-MR110CA

User Manual

Description

The BTLC1000-MR110CA is an ultra-low power Bluetooth® SMART (BLE 4.1) module with

Integrated Transceiver, Modem, MAC, PA, TR Switch, and Power Management Unit (PMU). It can

be used as a Bluetooth Low Energy link controller or data pump with external host MCU.

The qualified Bluetooth® Smart protocol stack is stored in dedicated ROM, the firmware includes

L2CAP service layer protocols, Security Manager, Attribute protocol (ATT), Generic Attribute Profile

(GATT) and the Generic Access Profile (GAP). Additionally, application profiles such as Proximity,

Thermometer, Heart Rate, Blood Pressure and many others are supported and included in the

protocol stack.

The module contains all circuitry required including a ceramic high gain antenna, 26MHz crystal

and PMU circuitry. The customer simply needs to place the module on his board and provide

power.

Table of Contents

Description .......................................................................................................................... 1

1 Electrical Specifications ............................................................................................... 2

1.1 Absolute Maximum Ratings ...................................................................................................................... 2

1.2 Recommended Operating Conditions ....................................................................................................... 2

1.3 Restrictions for Power States ................................................................................................................... 3

1.4 Power-Up Sequence ................................................................................................................................. 3

2 Application Information ................................................................................................ 4

3 Placement and Routing Guidelines ............................................................................. 4

3.1 Power and Ground.................................................................................................................................... 4

4 FCC Information ............................................................................................................ 5

5 Interferers ...................................................................................................................... 5

List of Figures

Figure 1: Power-Up Sequence............................................................................................................................................ 3

Atmel-42376B-BTLC1000-MR210P-SmartConnect-Datasheet_02102015

Page 2

1 Electrical Specifications

1.1 Absolute Maximum Ratings

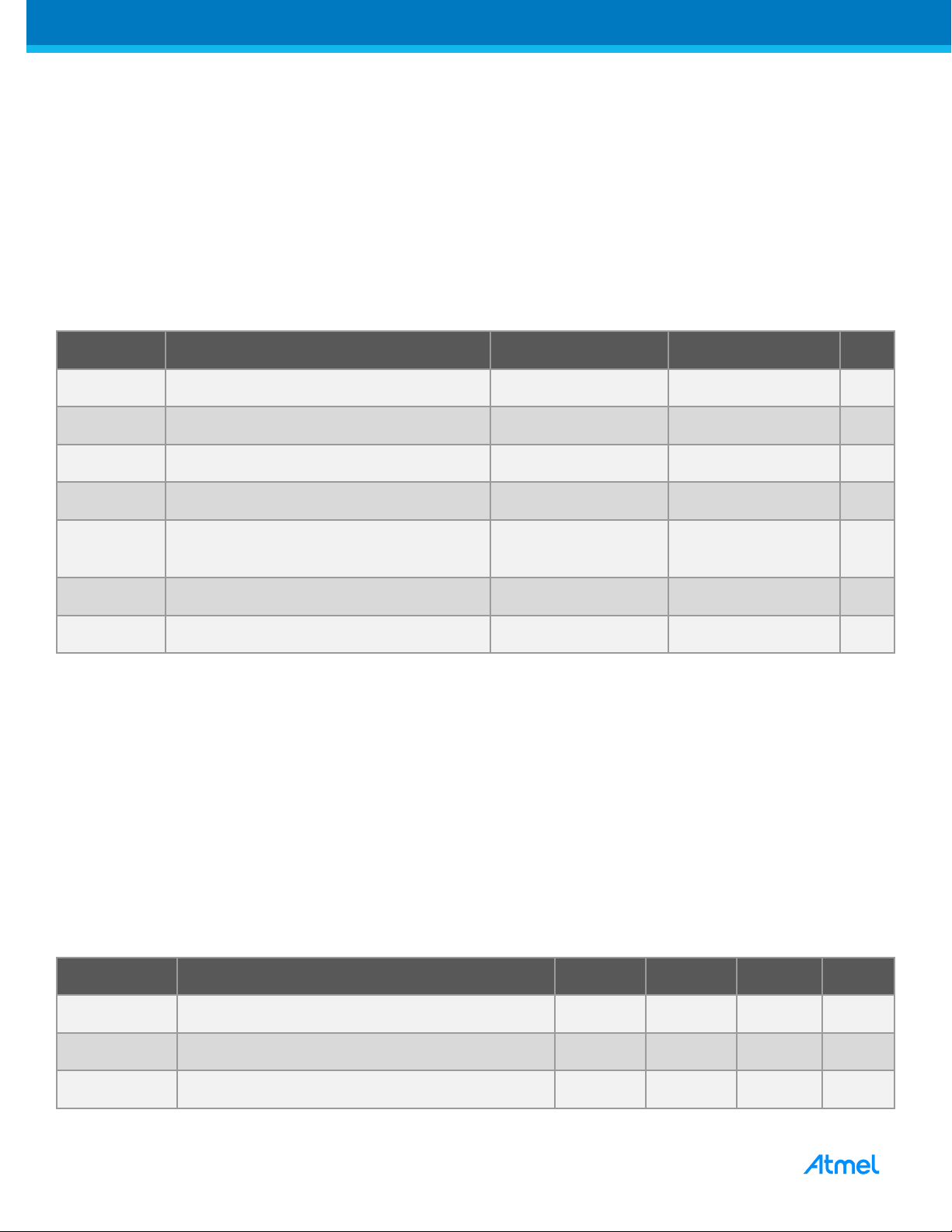

Table 1: BTLC1000-MR110CA Absolute Maximum Ratings

Symbol Characteristic Min Max Unit

VDDIO I/O Supply Voltage -0.3 4.6 V

VBATT Battery Supply Voltage -0.3 5.0 V

(1)

V

Digital Input Voltage -0.3 VDDIO V

IN

(2)

V

Analog Input Voltage -0.3 1.5 V

AIN

V

ESDHBM

(3)

ESD Human Body Model

-1000, -2000

(see notes below)

TA Storage Temperature -65 150

Junction Temperature 125

+1000, +2000

(see notes below)

o

oC

Notes:

1. VIN corresponds to all the digital pins

2. V

corresponds to the following analog pins: VDDRF_RX, VDDAMS, RFIO, XO_N, XO_P, VDD_SXDIG,

AIN

VDD_VCO

3. For V

, each pin is classified as Class 1, or Class 2, or both:

ESDHBM

o The Class 1 pins include all the pins (both analog and digital)

o The Class 2 pins include all digital pins only

o V

is +/-1kV for Class1 pins. V

ESDHBM

is +/-2kV for Class2 pins.

ESDHBM

1.2 Recommended Operating Conditions

Table 2: BTLC1000-MR110CA Recommended Operating Conditions

Symbol Characteristic Min Typ Max Units

V

C

VDDIO I/O Supply Voltage Low Range 1.62 1.80 4.3 V

VBATT Battery Supply Voltage

Operating Temperature -40 85

2 2

BTLC1000-MR110CA [DATA SHEET]

Atmel-42376B-BTLC1000 Hardware Design Guide_02102015

1.8

(note 1)

3.6 4.3 V

o

C

Page 3

3

Notes:

1. VBATT supply must be greater than or equal to VDDIO

1.3 Restrictions for Power States

When VDDIO is off (either disconnected or at ground potential), a voltage must not be applied to the device pins.

This is because each pin contains an ESD diode from the pin to the VDDIO supply. This diode will turn on when

a voltage higher than one diode-drop is supplied to the pin. This in turn will try to power up the part through the

VDDIO supply.

If a voltage must be applied to the signal pads while the chip is in a low power state, the VDDIO supply must be

on.

Similarly, to prevent the pin-to-ground diode from turning on, do not apply a voltage that is more than 0.3V below

ground to any pin.

1.4 Power-Up Sequence

The power-up/down sequence for BTLC1000 is shown in Figure 1. The timing parameters are provided in Table

3.

Figure 1: Power-Up Sequence

Table 3: Power-Up Sequence Timing

Atmel-42376B-BTLC1000 Hardware Design Guide_02102015

BTLC1000-MR110CA [DATA SHEET]

Page 4

Parameter Min Max Units Description Notes

t

BIO

t

0 ms VDDIO rise to CHIP_EN rise

IOCE

0 ms VBATT rise to VDDIO rise

VBATT and VDDIO can rise simultaneously or

can be tied together.

CHIP_EN must not rise before VDDIO. CHIP_EN

must be driven high or low, not left floating.

2 Application Information

The BTLC1000-MR110 module is fully self-contained. To use the module, just provide VBAT and VDDIO

supplies. See Table 2 for the recommended voltages.

3 Placement and Routing Guidelines

It is critical to follow the recommendations listed below to achieve the best RF performance:

• The board should have a solid ground plane. The center ground pad of the device must be solidly connected to

the ground plane by using a 3 x 3 grid of vias. Each ground pin of the module should have a ground via placed

either in the pad or right next to the pad going down to the ground plane.

• When the module is placed on the motherboard, a provision for the antenna must be made. There should be

nothing under the portion of the module which contains the antenna. This means the antenna should not be

placed directly on top of the motherboard PCB. This can be accomplished by, for example, placing the module

at the edge of the board such that the module edge with the antenna extends beyond the main board edge by

6.5mm. Alternatively, a cut out in the motherboard can be provided under the antenna. The cutout should be at

least 22mm x 6.5mm. Ground vias spaced 2.5mm apart should be placed all around the perimeter of the

cutout. No large components should be placed near the antenna.

• Keep away from antenna, as far as possible, large metal objects to avoid electromagnetic field blocking.

• Do not enclose the antenna within a metal shield.

• Keep any components which may radiate noise or signals within the 2.4GHz – 2.5GHz frequency band far

away from the antenna or better yet, shield those components. Any noise radiated from the main board in this

frequency band will degrade the sensitivity of the module.

3.1 Power and Ground

Dedicate one layer as a ground plane. Make sure that this ground plane does not get broken up by routes.

Power can route on all layers except the ground layer. Power supply routes should be heavy copper fill planes

to insure the lowest possible inductance. The power pins of the module should have a via directly to the power

plane as close to the pin as possible. Decoupling capacitors should have a via right next to the capacitor pin and

this via should go directly down to the power plane – that is to say, the capacitor should not route to the power

plane through a long trace. The ground side of the decoupling capacitor should have a via right next to the pad

which goes directly down to the ground plane. Each decoupling capacitor should have its own via directly to the

ground plane and directly to the power plane right next to the pad. The decoupling capacitors should be placed

as close to the pin that it is filtering as possible.

4 4

BTLC1000-MR110CA [DATA SHEET]

Atmel-42376B-BTLC1000 Hardware Design Guide_02102015

Page 5

5

4 FCC Information

Each module has a label with an FCC ID, however the product User Manual must contain the following statement: “This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation”.

The module must be installed into the end product to provide a separation distance of at least 5 mm from all

persons and must not be co-located or operating in conjunction with any other antenna or transmitter.

If the module’s label is not visible when installed, then an additional permanent label referring to the enclosed

module: “Contains Transmitter Module FCC ID: 2ADHKBTLC1000” must be installed on the product in a visible

location.

This equipment has been tested and found to comply with the limits for a class B digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency energy and if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the module/product.

- Increase the separation between the equipment and module/product.

- Consult the dealer or an experienced radio/TV technician for help.

Changes and modifications made to the equipment without the approval of manufacturer could void the user's

authority to operate this equipment.

5 Interferers

One of the biggest problems with RF receivers is poor performance due to interferers on the board radiating

noise into the antenna or coupling into the RF traces going to input LNA. Care must be taken to make sure that

there is no noisy circuitry placed anywhere near the antenna or the RF traces. All noise generating circuits should

also be shielded so they do not radiate noise that is picked up by the antenna. Also, make sure that no traces

route underneath the RF portion of the BTLC1000. Also, make sure that no traces route underneath any of the

RF traces from the antenna to the BTLC1000 input. This applies to all layers. Even if there is a ground plane on

a layer between the RF route and another signal, the ground return current will flow on the ground plane and

Revision History

Atmel Corporation 1600 Technology Drive, San Jose, CA 95110 USA T: (+1)(408) 441.0311 F: (+1)(408) 436.4200 │ www.atmel.com

© 2014 Atmel Corporation.

Atmel Confidential: For Release Only Under Non-Disclosure Agreement (NDA)

Atmel®, Atmel logo and combinations thereof, Enabling Unlimited Possibilities®, and others are registered trademarks or trademarks of Atmel Corporation in U.S. and

other countries. ARM®, ARM Connected® logo, and others are the registered trademarks or trademarks of ARM Ltd. Other terms and product names may be trademarks

of others.

DISCL AIMER: The informat ion in thi s documen t is provi ded in con nection with Atmel products . No lice nse, expre ss or impl ied, by es toppel or otherwise, to any i ntellect ual proper ty right

is grant ed by this docume nt or in connecti on with the sale of Atmel pro ducts. EXCEPT AS SET FORTH IN THE ATMEL TERMS AND CONDITIONS OF SALES L OCATED ON THE ATMEL

WEBSI TE, ATMEL A SSUMES NO LIABILITY WHATSOEV ER AND DISC LAIMS ANY E XPRESS, I MPLIED OR ST ATUTORY WARRANTY RELAT ING TO ITS PRODUCTS I NCLUDING,

BUT NOT LIMITED TO , THE IMPLI ED WARRANT Y OF MERCH ANTABILIT Y, FITNES S FOR A PARTI CULAR PUR POSE, OR NO N-INFRING EMENT. IN NO EVENT SH ALL ATMEL B E

LIABL E FOR ANY DIRECT, INDIRECT, CONSEQ UENTIAL, PUNITIV E, SPECIA L OR INCIDENTAL D AMAGES ( INCLUDING, WITHOUT LIMITATION, DA MAGES FOR LOSS AND

PROFIT S, BUSINE SS INTERRU PTION, OR LOSS OF INFO RMATION) ARISING OUT OF THE USE OR INABILITY TO U SE THIS DOC UMENT, EVE N IF ATMEL HAS BEEN ADVI SED

OF THE POSSI BILITY OF SUCH DAMAG ES. Atmel makes no rep resentati ons or warr anties wi th respect to the accuracy or completeness of the contents of thi s document and reserves

the rig ht to make changes to specifi cations and produ cts descrip tions at any ti me without no tice. Atmel does not make any commitment to update the information conta ined herei n. Unless

speci fically provided otherwise , Atmel p roducts a re not su itable f or, and s hall not be used in, automoti ve appli cations. Atmel products ar e not intended, authorized , or warranted for use

as co mponents in appli cations intended to suppo rt or sus tain li fe.

SAFET Y-CRITICAL, MILITARY, AND AUTOMOTIVE APPLICATI ONS DISCL AIMER: At mel produ cts are not designe d for and wi ll not be used in con nection with any ap plications where

Atmel-42376B-BTLC1000 Hardware Design Guide_02102015

BTLC1000-MR110CA [DATA SHEET]

Page 6

6 6

BTLC1000-MR110CA [DATA SHEET]

Atmel-42376B-BTLC1000 Hardware Design Guide_02102015

Loading...

Loading...