Page 1

mTouch™ AR1100

Analog Resistive USB and RS-232

Touch Screen Controller Board

User’s Guide

2011 Microchip Technology Inc. DS41604A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, chipKIT,

chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net,

dsPICworks, dsSPEAK, ECAN, ECONOMONITOR,

FanSense, HI-TIDE, In-Circuit Serial Programming, ICSP,

Mindi, MiWi, MPASM, MPLAB Certified logo, MPLIB,

MPLINK, mTouch, Omniscient Code Generation, PICC,

PICC-18, PICDEM, PICDEM.net, PICkit, PICtail, REAL ICE,

rfLAB, Select Mode, Total Endurance, TSHARC,

UniWinDriver, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2011, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-61341-491-0

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS41604A-page 2 2011 Microchip Technology Inc.

Page 3

mTouch™ AR1100 User’s Guide

Table of Contents

Preface ...........................................................................................................................5

Introduction............................................................................................................5

Document Layout .................................................................................................. 6

Recommended Reading.............................................................. .. ........................6

The Microchip Web Site........................................................................................ 6

Customer Support.................... .................................... .................. .......................7

Document Revision History................................................................................... 7

Chapter 1. Product Overview

1.1 Introduction .....................................................................................................9

1.2 Product Description ........................................................................................9

Chapter 2. Connections

2.1 Mounting .......................................................................................................13

2.2 Power ............. .. ............................. .............................................................. 13

2.3 Communic a ti o n ............ ............... ................................................................. 14

2.4 Sensor ........ ............................................................................................... ... 1 6

Chapter 3. Operation

3.1 Configur ation .............. ............................................................................... .. . 19

3.2 Communic a ti o n ............ ............... ................................................................. 19

3.3 Data Forma t ............. ....................................................... ............................. 1 9

3.4 LED Indica t o r ......... ........................................ .. .. ........................................... 2 1

Chapter 4. Software Device Drivers

Chapter 5. Accessories

5.1 Communic a ti o n Ca b le s ................................................................................ 25

5.2 Touch Scre e n C a bl e s ..................................................................... .............. 25

Chapter 6. Support

Chapter 7. Touch Screen Sel ection

Index .............................................................................................................................31

Worldwide Sales and Service ....................................................................................32

2011 Microchip Technology Inc. DS41604A-page 3

Page 4

mTouch™ AR1100 User’s Guide

NOTES:

DS41604A-page 4 2011 Microchip Technology Inc.

Page 5

mTouch™ AR1100 User’s Guide

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

INTRODUCTION

This chapter conta ins the gener al infor mati on that will b e use ful to kno w befor e usin g

the mTouc h™ AR1100 Ana log Resistive USB and RS-232 Tou ch Screen Controller

Board. Items discussed in this chapter include:

• Document Layout

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

®

IDE on-line help.

2011 Microchip Technology Inc. DS41604A-page 5

Page 6

mTouch™ AR1100 User’s Guide

DOCUMENT LAYOUT

This document describes how to use the mT ouch™ AR1 100 Analog Resistive USB and

RS-232 Touch Screen Controller Board. The manual layout is as follows:

• Chapter 1. “Product Overview”

• Chapter 2. “Connect ion s”

• Chapter 3. “Operation”

• Chapter 4. “Software Device Drivers”

• Chapter 5. “Access ories ”

• Chapter 6. “Support”

• Chapter 7. “Touch Screen Selection”

RECOMMENDED READING

This user’s gui de descr ibes how to use the m Touch™ AR110 0 Analo g Resisti ve USB

and RS-232 Touch Screen Controller Board. Other useful documents are listed below.

The following Microc hi p d ocu men ts are av ai la ble an d r ec omm end ed as su ppl em ental

reference resources.

Readme for mTouch™ AR1100 Analog Resistive USB and RS-232 Touch Screen

Controller Board

For the latest information on using mTouch™ AR1100 Analog Resistive USB and

RS-232 T ouch Screen Controller Board, read the “Readme.txt” file in the main i nst al lation directory. The Readme file contains updated information and known issues that

may not be included in this user’s guide.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readme subdirectory of the MPLAB IDE installation directory. The Readme files

contain update information and known issues that may not be included in this user’s

guide.

THE MICROCHI P WEB SITE

Microchip provides o nline support through our web site at www.micr ochip.com.This

web site is used as a means to make files and information easily available to

customers. Acces sible by using your favo rite Internet browse r, the web site contains

the following information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listin g

• Business of Microchip – Product selector and ordering guides, latest Microchi p

press releases, list ing of seminars and events, listings of Microchip sal es offices,

distributors and factory representatives

DS41604A-page 6 2011 Microchip Technology Inc.

Page 7

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (August 2011)

Initial release of this document.

Preface

2011 Microchip Technology Inc. DS41604 A-page 7

Page 8

mTouch™ AR1100 User’s Guide

NOTES:

DS41604A-page 8 2011 Microchip Technology Inc.

Page 9

Chapter 1. Product Overview

1.1 INTRODUCTION

The Microchip mTouchTM AR1100 Analog Resistive USB and RS-232 Touch Screen

Controller Board represents a feature-rich, fully-integrated universal touch screen

controller solution. The AR1100 Touch Screen Controller Board automatically selects

between USB and RS-232 communication protocols, as well as supports 4, 5 or 8-wire

analog resistive touch screens from any of a variety of touch screen manufacturers.

The AR1100 Touch Screen Controller Board dynamically adapts to the various touch

screen electrical characteristics such as sensitivity, contact resistance, and

capacitance to provide optimal performance with minimal design time.

Building on the AR1000 series, the new AR1100 T ouch Screen Controller Board offers

customers an easy to integrate solution for low-cost, high-performing resistive touch

with the advantages of USB plug and play, support for USB mouse or digitizer,

advanced touch response and accuracy, field-flash updatability, and free drivers for

most operating systems to enable low-risk designs for a wide variety of touch sensing

requirements.

The AR1100 Touch Screen Controller Board supports large displays like industrial controls, self-service kiosks, and POS terminals, as well as smaller tablet displays, handheld consumer devices, and medical devices.

Resistive touch provides the advantages of easy integration, low total system cost and

acceptance of finger, glove or stylus input, and USB communication is the industry

standard for attaching peripherals to a computer. The AR1100 Touch Screen Controller

Board is an easy-to-integrate touch screen controller that meets all of these needs in a

single-chip solution or production ready-board product. The device comes with free

drivers for most major operating systems, making it easy for designers to quickly create

low-risk touch interface solutions.

mTouch™ AR1100 User’s Guide

1.2 PRODUCT DESCRIPTION

The mTouch™ AR1100 Touch Screen Controller Board auto-detects communication

(RS-232 or USB) and uses a jumper to select between 5-wire and 4/8-wire analog

resistive touch screens. The AR1100 Touch Screen Controller Board is ready to go out

of the box with little or no configuration.

1.2.1 Part Number

AR1100BRD

1.2.2 AR1100 Core Feat ures:

•RoHS Compliant

• Automatically detects communication type

- RS-232 (9600 BAUD) and USB (2.0 Compliant)

- Full-speed USB device HID compliant at 12 Mb/sec.

- Low-power Suspend mode for USB < 500 uA

- Low-power Sleep mode for RS-232 <10 uA

2011 Microchip Technology Inc. DS41604A-page 9

Page 10

mTouch™ AR1100 User’s Guide

• USB plug and play

- USB mouse (HID-MOUSE) or

- Single-touch Win7 digitizer (HID-DIGITIZER)

• Jumper-selectable sensor support

-5 wire

- 4/8 wire

• Dynamic rise-time and sampling capability

• Resolution:

- 10-bit measurement (1024x1024)

- 12-bit reporting (4096x4096) of processed touch coordinates

- Report rate: 150 rps (typical)

- Touch screen resistance – 2k ohm sheet resistance lead to lead.

- Calibration data stored on local EEPROM

- User EEPROM available – 96 bytes

- Flash/Data EEPROM retention: >40 years

- Industry-leading touch response and accuracy

- ESD protection – both communication and touch screen connections

• Static Protection: 24 kVA

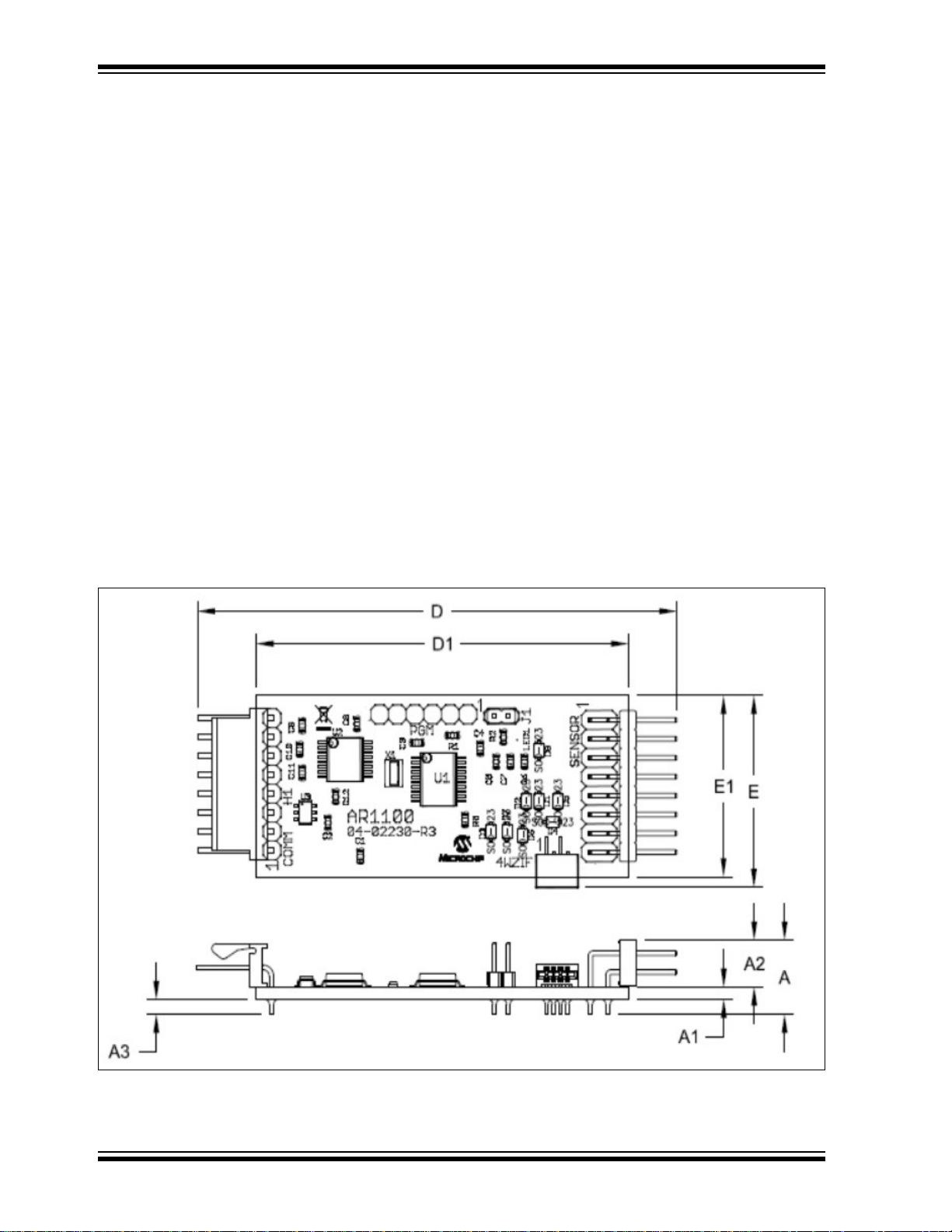

1.2.3 Mechanical

1.2.3.1 DIMENSIONS

FIGURE 1-1: PCB – MECHANICAL DRAWING

DS41604A-page 10 2011 Microchip Technology Inc.

Page 11

Product Overview

TABLE 1-1: PCB – MECHANICAL DIMENSIONS

Units: Millimeters Inches

Dimension Limits: MIN. NOM. MAX. MIN. NOM. MAX.

Overall Length D 67.51 69.02 70.56 2.658 2.718 2.778

Overall Width E 24.28 25.81 27.33 0.956 1.016 1.076

PCB Length D1 52.07 53.59 55.12 2.050 2.110 2.17

PCB Width E1 2.29 24.38 25.91 0.090 0.960 1.02

Overall Height A — — 11.63 — — 0.458

PCB Thickness A1 1.42 15.75 1.73 0.056 0.620 0.068

Component H eight A2 — 6.35 7.87 — 0.250 0.310

Through Hole Lead Trim Length A3 — — 2.03 — — 0.080

Note 1: Passive components omitted from some views for clarity.

2: Dimensions and tolerances per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Refe rence Dimension, usually without tolerance, for infor mation purposes

only.

WARNING

Although Microchip Technology Inc. has taken steps to protect your touch screen controller

from transient voltage, it is important to make all grounding, communication and touch screen

connections to the controller and touch screen. This must be done before powering on your

computer, video monitor or touch screen controller. Failure to follow this procedure may result

in damage to your controller and/or communication port. If you believe that your application

will require additional static protection, it is up to you to determine the appropriate static

protection needed to protect your electronics from transient voltage.

Failure to take the necessary precautions may result in damage to your controller.

Microchip does not warranty the Microchip controller boa rd a gain st t ransie nt stati c di scharge damage

.

2011 Microchip Technology Inc. DS41604A-page 11

Page 12

mTouch™ AR1100 User’s Guide

1.2.4 Electrical

T ABLE 1-2: PCB – ELECTRICAL SPECIFICATIONS

Conditions Min. Typical Max. Units

Supply Voltage 3.3 5.0 V

Supply Current RS-232 (idle) 16 mA

RS-232 (touch) 18

USB (idle) 17

USB (touch) 25

Suspend Current RS232 10 µA

USB 330

Operating temperature Chip -40 125 °C

Board -25 85 °C

Resolution V

Response Time Nor mal 8 ms

Detect Voltage Threshold 1.65 V

Touch Screen Resistance 2000

Touch Capacitance 0 0.5 µF

Note 1: Additional literature is available from Microchip Technology Inc. – definitions,

specifications, and other general touch screen information.

CC: +5V, VDD: Gnd 1024 x 1024 Pixels

Waking 10

DS41604A-page 12 2011 Microchip Technology Inc.

Page 13

mTouch™ AR1100 User’s Guide

Chapter 2. Connections

FIGURE 2-1: CONNECTIONS – OVERVIEW

2.1 MOUNTING

Two static ground mounting holes (0.122" diameter) are provided. T ake special care to

insulate the controller from system and from EMI and RFI generating components of

the display. Use conductive 4-40 stand-offs or ground-lead wires terminated to the

grounded system enclosure or PC board to insure proper static protection and

grounding. STANDOFFS MUST NOT TOUCH ANY PORTION OF THE CIRCUIT.

Position the controller in a location that minimizes bending or creasing of the touch

screen overlay connection tail. Wear to the tail, printed traces, or tail header will

negatively impact touch screen performance.

2.2 POWER

Power to the AR1100 Touch Screen Controller Board is provided by the H1

communication connector as seen in Figure 2-2. In USB Communication mode, power

can be derived from the USB bus. In RS-232 mode – regulated power (3.3V – 5.0V) is

provided from an external source. Check connections before applying power to the

controller as reversing polarity WILL damage the board.

FIGURE 2-2: POWER

2011 Microchip Technology Inc. DS41604A-page 13

Page 14

mTouch™ AR1100 User’s Guide

WARNING

SUPPLYING POWER FROM TWO DIFFERENT POWER SOURCES WILL

PERMANENTLY DESTROY YOUR CONTROLLER, YOUR COMPUTER, OR YOUR

MONITOR.

If the Microchip AR1100 Touch Screen Controller Board is installed into a monitor application where the end user will decide to use USB communication or RS-232 communication, the board must be powered internally. Because the board cannot be supplied

with power from USB and internal 5V, it is recommended that the power (pin 1) contact

be removed from the USB socket to insure that multiple power source connections are

not permitted.

2.3 COMMUNICATION

The AR1100 Touch Screen Controller Board will automatically detect and configure

itself for the active communication protocol – RS-232 or USB HID. The controller will

default to RS-232 communication until USB activity is detected. Once the active

communication mode is determined, the inactive mode is decommissioned to minimize

power consumption. The active communication will remain in effect until power is

removed from the controller.

2.3.1 RS-232

Microchip cable harness p/n: C72-080S1F-09XDXF is a standard 6' long, round

shielded cable terminated by a DB-9 female connector and an 8-position single-row

socket. This cable has a ground termination wire running the length of the cable which

may be utilized to ground the controller board through the DB-9 connector. In any case,

for best performance, a jacketed, shielded cable is recommended.

FIGURE 2-3: RS-232 CONNECTIONS

DS41604A-page 14 2011 Microchip Technology Inc.

Page 15

2.3.2 USB

Microchip cable harness p/n: C72-080S1F-04XAXM-D is a 6' long, jacketed shielded

cable terminated by a Type “A” USB plug and an 8-position, single-row socket. DO NOT

SUPPLY POWER FROM BOTH RS-232 AND USB.

FIGURE 2-4: USB

Connections

WARNING

SUPPLYING POWER FROM TWO DIFFERENT POWER SOURCES COULD

PERMANENTLY DAMAGE YOUR CONTROLLER, YOUR COMPUTER, AND/OR

YOUR MONITOR.

If the Microchip AR1100 Touch Screen Controller Board is installed into a monitor application where the end user will decide to use USB communication or RS-232 communication, the board must be powered internally. Because the board cannot be supplied

with power from USB and internal 5V, it is recommended that the power (pin 1) contact

be removed from the USB socket to insure that multiple power source connections are

not permitted.

2011 Microchip Technology Inc. DS41604A-page 15

Page 16

mTouch™ AR1100 User’s Guide

2.4 SENSOR

The AR1100 Touch Screen Controller Board supports 4, 5 and 8-wire sensors. A 2x8

pin header (“SENSOR”) seen in the mechanical diagram is the connection point for all

3 sensor types. Additionally, a 4-conductor flat flex connector can be used with 4-wire

sensors. An illustration of sensor wiring/construction is given below for reference (see

Figure 2-5).

FIGURE 2-5: SENSOR CONNECTIONS

2.4.1 Connector: “4WZIF” – 4-Conductor FFC (flat flex)

JST part number: JST-04FM-1.st (LF)(SN) (4-position low insertion force flat flex

connector)

TABLE 2-1: 4WZIF PIN ASSIGNMENTS

PIN# FUNCTION

1Y2X3Y+

4X+

DS41604A-page 16 2011 Microchip Technology Inc.

Page 17

2.4.2 Connector: ‘SENSOR’ – 2x8 Header

Sullins part number: PTC08DBAN. 2 x 8, 0.100" spacing, .024" sq.post, .230" mating

length.

TABLE 2-2: SENSOR PIN ASSIGNMENTS

Function Pin# Function

Y+ 1 2 YX+ 3 4 SY5WSX- 5 6 SY+

X- 7 8 Y+

Y- 9 10 XX- 11 12 5WSXY+ 13 14 SX+

X+ 15 16 X+

FIGURE 2-6: SENSOR CONNECTIONS

Connections

2011 Microchip Technology Inc. DS41604A-page 17

Page 18

mTouch™ AR1100 User’s Guide

NOTES:

DS41604A-page 18 2011 Microchip Technology Inc.

Page 19

3.1 CONFIGURATION

The AR1100 Touch Screen Controller Board is operational out of the box.

Communication protocol is detected automatically (as described below) and the

Mechanical mode jumper selects between 5-wire (jumper on) and 4/8-wire (jumper off).

If a USB cable is connected, the AR1100 T ouch Screen Controller Board will default to

Mouse mode (HID-MOUSE). Additional configuration is possible (but generally, not

necessary) using commands described in the AR1100 IC data sheet. The Microchip AR

Configuration Utility Software can be used with the AR1100 Touch Screen Controller

Board to modify (fine tune) operational parameters, change the ‘default’ USB device or

actually update the control firmware. Any change made to the factory defaults is saved

to internal, nonvolatile memory.

3.2 COMMUNICATION

The AR1100 Touch Screen Controller Board supports both RS-232 and USB. The controller will automatically detect and select between the two at power-up. The USB support is further defined to be one of three devices – HID-GENERIC, HID-MOUSE or

HID-DIGITIZER – the controller can be configured to power-up as any of the three

devices but the factory default is HID-MOUSE.

mTouch™ AR1100 User’s Guide

Chapter 3. Operation

3.3 DATA FORMAT

The touch report data format for each communication protocol is defined below. The

HID-MOUSE and HID-DIGITIZER are compatible with intrinsic drivers of Windows

and Windows 7, respectively. The HID-GENERIC and RS-232 protocols require

custom handling.

3.3.1 Mode: HID-GENERIC, RS-232

TABLE 3-1: TOUCH REPORT FORMAT – GENERIC

BYTE

1 1 RRR RRR P

2 0 X6 X5 X4 X3 X2 X1 X0

300X11X10X9X8X7X6

4 0 Y6 Y5 Y4 Y3 Y2 Y1 Y0

500Y11Y10Y9Y8Y7Y6

Note 1: P Pen state 1: Pen down; 0: Pen up

R (Reserved)

X X ordinate of touch location (12 bits)

Y Y ordinate of touch location (12 bits)

BIT

7654321 0

®

XP

2011 Microchip Technology Inc. DS41604A-page 19

Page 20

mTouch™ AR1100 User’s Guide

3.3.2 Mode: HID-MOUSE

The USB ‘report’ format is given below:

TABLE 3-2: TOUCH REPORT FORMAT – MOUSE

BYTE

76543210

1 0 0 0 0 0 B3 B2 B1

2X7X6X5X4X3X2X1X0

30 000 X11X10X9X8

4Y7Y6Y5Y4Y3Y2Y1Y0

50 000 Y11Y10Y9Y8

Note 1: B1 Button 1 depressed (configurable, reacts to touch event/state (see

the description below)

B2 Button 2 depressed (always 0)

B3 Button 3 depressed (always 0)

X X ordinate of touch location (12 bits)

Y Y ordinate of touch location (12 bits)

As seen in T able 3-2 above, the AR1100 Touch Screen Controller Board provides flexibility to the ‘Button 1’ field in the HID-MOUSE touch report. The value of ‘Button 1’ and

the touch reports issued in reaction to touch events is dictated by the operational

parameter, TouchMode, (described in the AR1100 Resistive USB and RS-232 Touch

Screen Controller data sheet, DS41606). In the summary below, touch report field “P”

(pen) corresponds to ‘Button 1’.

BIT

3.3.2.1 SUMMARY OF PARAMETER: TouchMode

In reaction to each touch state/event, the AR1100 issues 0,1,2 or 3 touch reports with

pen state “P” (a 1-bit field) set as described below.

TouchMode[7:5] = PD[2:0] Response to event PD (PEN/TOUCH DOWN)

b000 No touch report issued in response to the event

b001 Touch report w/ P=0

b010 Touch report w/ P=1

b011 Touch report w/ P=1, then Touch report w/ P=0

b100 Touch report w/ P=0, then Touch report w/ P=1, then Touch report w/ P=0

b101 Touch report w/ P=0, then Touch report w/ P=1

TouchMode[4:3] = PM[1:0] Response to event PM (PEN/TOUCH MOVEMENT)

b000 No touch report issued in response to the event

b001 Touch report w/ P=0

b010 Touch report w/ P=1

DS41604A-page 20 2011 Microchip Technology Inc.

Page 21

Operation

TouchMode[2:0] = PU[2:0] Response to event PU (PEN/TOUCH UP)

b000 No touch report issued in response to the event

b001 Touch report w/ P=0

b010 Touch report w/ P=1

b011 Touch report w/ P=1, then Touch report w/ P=0

b100 Touch report w/ P=0, then Touch report w/ P=1, then Touch report w/ P=0

b101 Touch report w/ P=0, then Touch report w/ P=1

3.3.3 Mode: HID-DIGITIZER

The USB ‘report’ format is given below:

TABLE 3-3: TOUCH REPORT FORMAT – DIGITIZER

BYTE

76543210

1000000PT

200000000

3X7X6X5X4X3X2X1X0

40000X11X10X9X8

5Y7Y6Y5Y4Y3Y2Y1Y0

60000Y11Y10Y9Y8

Note 1: T1 Tip switch

P Proximity (in range) – always 1

X X ordinate of touch location (12 bits)

Y Y ordinate of touch location (12 bits)

BIT

For flexibility, the value and behavior of the ‘tip switch’ data entity (“T”) reflects the pen

up/down state (similar to the ‘Button 1’ description in HID-MOUSE mode.

3.4 LED INDICATOR

The Microchip AR1100 T ouch Screen Controller Board is equipped with a LED indicator

to display controller status as follows:

TABLE 3-4: LED INDICATOR

LED blinks slowly (once per second) Controller is powered, awake

LED blinks rapidly (5 ti me s per second) Controller detects a touch.

LED is off Controller has no power or is

Behavior Status

and no touch is detected.

asleep (suspended).

2011 Microchip Technology Inc. DS41604A-page 21

Page 22

mTouch™ AR1100 User’s Guide

NOTES:

DS41604A-page 22 2011 Microchip Technology Inc.

Page 23

mTouch™ AR1100 User’s Guide

Chapter 4. Software Device Drivers

Microchip Technology has device driver software available for all AR1100 touch screen

controller chip and board solutions.

The software drivers may be downloaded at no additional charge at: www.micro-

chip.com/mtouch

The Microchip device driver software enables you to configure the touch screen

operation to meet your needs. The following is a list of features available with

Microchip’s software:

1. Touch screen calibration/linearization/alignment (4, 9, 25-point)

2. Adjustable calibration inset

3. Touch modes:

-Normal mouse emulation

-Touch-Up mode

-Touch-Down mode

4. Other special features are also included. Please see the complete driver

manuals available at the www.microchip.com web site for further details.

Note: Microchip device drivers vary between operating systems and operating

system varieties and versions.

2011 Microchip Technology Inc. DS41604A-page 23

Page 24

mTouch™ AR1100 User’s Guide

NOTES:

DS41604A-page 24 2011 Microchip Technology Inc.

Page 25

Chapter 5. Accessories

5.1 COMMUNICATION CABLES

TABLE 5-1: COMMUNICATION CABLES

Part Number Description

C72-080S1F-09XDXF 6' RS-232 cable. Female DB9 to 8-position SIP socket

C72-080S1F-04XAXM-D 6' USB cable. Male type A USB to 8-postion SIP socket

5.2 TOUCH SCREEN CABLES

TABLE 5-2: TOUCH SCREEN CABLES

Part Number Description

C18-040S1F-040G1M

mTouch™ AR1100 User’s Guide

Direct connect to H1 header

Direct connect to H1 header

4-Wire – 18", 4-position, 0.100" SIP header to SIP socket.

Direct connect to SENSOR header

C18-050S1F-050G1M

C18-080S1F-080G1M

C12-040S1F-041Z1F 4-Wire – 12", 4-position, 0.100" socket to 1 mm flat flex

10022-100

10023-100 6" 5-wire touch screen ‘crossover’ cable, 5-position SIP

10024-100 6" 8-wire touch screen ‘crossover’ cable, 8-position SIP

5-Wire – 18", 5-position, 0.100" SIP header to SIP socket

Direct connect to SENSOR header

8-Wire – 18", 8-position, 0.100" SIP header to SIP socket

Direct connect to SENSOR header

conector.

Direct connect to flat flex connector

6" 4-wire touch screen ‘crossover’ cable, 4-position SIP

socket to SIP header

Direct connect to SENSOR header

socket to SIP header

Direct connect to SENSOR header

socket to SIP header

Direct connect to SENSOR header

2011 Microchip Technology Inc. DS41604A-page 25

Page 26

mTouch™ AR1100 User’s Guide

NOTES:

DS41604A-page 26 2011 Microchip Technology Inc.

Page 27

mTouch™ AR1100 User’s Guide

Chapter 6. Support

Webticket Support System: http://support.microchip.com

In the event that you need to contact Microchip via telephone or via our support e-mail,

please take a minute to identify these items prior to contacting Microchip technical

support staff.

• Information about Microchip reseller, if not purchased directly from Microchip

• Touch Screen type and Manufacturer

• Communication type

• Microchip driver and revisio n

• Operating system and service pack releases

• A brief summary of the problem that you are having

2011 Microchip Technology Inc. DS41604A-page 27

Page 28

mTouch™ AR1100 User’s Guide

NOTES:

DS41604A-page 28 2011 Microchip Technology Inc.

Page 29

mTouch™ AR1100 User’s Guide

Chapter 7. Touch Screen Selection

The 4 and 8-wire touch screens are typically produced with higher resistance

transparent conductive film (ITO Indium Tin Oxide) than 5-wire touch screens. Most

often, touch screen resistance falls within 100-400 Ohm per square. Because 4 and

8-wire touch screens typically have a higher resistance than 5-wire sensors, you will

find most battery-powered applications using this technology. You will also find that 4

and 8-wire touch screens are more linear than 5-wire ones.

The 5-wire touch screens are typically more mechanically durable (top sheet does not

need to be linear) and are less affected by environmental variation. 5-wire touch

screens come in a wide variety of sheet resistance. In some cases, because of the

5-wire construction, the resistance may be lower than the 50 Ohm specification. While

these touch screens require more power to drive them, this does not imply poor quality.

Once resistance drops below an optimum level, so does the resolution. In contrast, as

resistance increases, depending upon the construction, contact resistance begins to

negatively affect the touch screen’s performance. The negative effect of a high or low

resistance touch screen can be managed by properly implementing the correct circuit.

It should be understood that extremes in either direction will negatively influence the

performance of any efficient circuit design. In order to maximize efficiency and

performance, a higher resistance, linear, environmentally stable touch screen is

recommended.

Your product design requirements will help you identify the touch screen technology

and construction that will best suit your application. Please contact Microchip

Technology Inc. for more unbiased touch screen material science information and a list

of recommended Microchip controller designs to fit your application.

2011 Microchip Technology Inc. DS41604A-page 29

Page 30

mTouch™ AR1100 User’s Guide

NOTES:

DS41604A-page 30 2011 Microchip Technology Inc.

Page 31

mTouch™ AR1100 User’s Guide

Index

A

Accessories..............................................................25

AR1100 Core Features.............................................. 9

AR1100BRD .............................................................. 9

C

Communication...................................................14, 19

Communication Cables............................................25

Configuration............................................................19

Connections............................................................. 13

Customer Support...................................................6

, 7

D

Data Format............................................................. 19

Document Layout....................................................... 6

Documentation Layout............................................... 6

Documentation Revision History................................6

E

Electrical .................................................................. 12

I

Internet Address.........................................................6

Introduction.............................................................5

, 9

L

LED Indicator...........................................................19

M

Mechanical............................................................... 10

Microchip Internet Web Site.......................................6

Mode

HID-DIGITIZER.................................................21

HID-GENERIC, RS-232....................................19

HID-MOUSE..................................................... 20

Mounting.................................................................. 13

O

Operation.................................................................19

P

Power.......................................................................13

Preface.......................................................................5

Product Description....................................................9

Product Overview.......................................................9

R

Reading, Recommended............. ...... ..... ...................6

Recommended Reading............................................6

S

Sensor......................................................................16

Software Device Drivers...........................................23

Support .................................................................... 27

T

The Microchip Web Site .............................................6

Touch Screen Cables...............................................25

Touch Screen Selection...........................................29

W

WWW Address...........................................................6

2011 Microchip Technology Inc. DS41604A-page 31

Page 32

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Te chn ica l Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-2819-3187

Fax: 86-571-2819-3189

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-330-9305

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

08/02/11

DS41604A-page 32 2011 Microchip Technology Inc.

Loading...

Loading...