Page 1

44-PIN DEMO BOARD

USER’S GUIDE

© 2007 Microchip Technology Inc. DS41296B

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Millennium Copyright Act. If suc h a c t s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, microID, MPLAB, PIC,

PICmicro, PICSTART, PRO MATE, PowerSmart, rfPIC, an d

SmartShunt are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

AmpLab, FilterLab, Linear Active Thermistor, Migratable

Memory, MX DEV, MXLAB, PS logo, SEEVAL, SmartSensor

and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Mindi, MiWi,

MPASM, MPLAB Certified logo, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartT el, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology I ncorporat ed in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporated, Pr inted in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

MCUs and dsPIC® DSCs, KEELOQ

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial

DS41296B-page ii © 2007 Microchip Technology Inc.

®

Page 3

44-PIN DEMO BOARD

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 1

Introduction............................................................................................................1

Document Layout .................................................................................................. 1

Conventions Used in this Guide............................................................................ 2

Warranty Reg is tration............................................................................................ 3

Recommended Reading............................... .. ................................................. .. .. ..3

The Microchip Web Site....................... ...................... ...................... .....................4

Development Systems Customer Change Notification Servi ce............................4

Customer Support...................................... ................................... .................. ......5

Document Revision History................................................................................... 5

Chapter 1. 44-Pin Demo Board Overview

1.1 Introduction .....................................................................................................7

1.2 Highlight s ......... ............. .. .. ........................... .. .. ........................... .. .. ................ 7

1.3 Devices Supported by the 44-Pin Demo Board .............................................. 7

1.4 44-Pin De m o Boa r d O v e rview ... .. ........................... .. ...................................... 8

1.5 Running th e D e fa u l t De mo n stration ....... ........................... .. ........................... 8

Chapter 2. Mid-Range PIC® Microcontroller Architectural Overview

2.1 Introduction......................................................................................................9

2.2 Memory Organization......................................................................................9

2.3 Instruct io n Formats................................................................. ... .. .................. 10

2.4 Assembl er Bas ic s............................................................... .. .. ....................... 11

Chapter 3. 44-Pin Demo Board Lessons

3.1 Introduction....................................................................................................13

3.2 44-Pin De m o Boa rd Lessons ............ ............. .. ........................................ .. ...13

3.2.1 Lesson 1: Hello World (Light a LED) .........................................................14

3.2.2 Blink (Delay Loop) .....................................................................................15

3.2.3 Lesson 3: Rotate (Move the LED) .............................................................17

3.2.4 Lesson 4: Analog-to-Digital ....................................................................... 19

3.2.5 Lesson 5: Variable Speed Rotate .............................................................. 22

3.2.6 Lesson 6: Switch Debouncing ................................................................... 23

3.2.7 Lesson 7: Reversible Variable Speed Rotate ............................................ 24

3.2.8 Lesson 8: Function Calls ...........................................................................26

3.2.9 Lesson 9: Timer0 ....................................................................................... 26

3.2.10 Lesson 10: Interrupts ...............................................................................28

3.2.11 Lesson 11: Indirect Data Addressing ......................................................30

3.2.12 Lesson 12: Look-up Table (ROM Array) ..................................................32

© 2007 Microchip Technology Inc. DS41296B-page iii

Page 4

44-Pin Demo Board User’s Guide

Appendix A. Hardware Schematics

A.1 Introduction...................................................................................................35

Worldwide Sales and Service......................................................................................38

DS41296B-page iv © 2007 Microchip Technology Inc.

Page 5

44-PIN DEMO BOARD

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

44-Pin Demo Board. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the 44-Pin Demo Board as a development tool to

emulate and debug firmware on a target board. The manual layout is as follows:

• Chapter 1. “44-Pin Demo Board Ove rvi ew” – This chapter provides an

overview of the 44-Pin Demo Board for Microchip’s 44-pin Thin Quad Flatpack

(TQFP) PIC

• Chapter 2. “Mid-Ra nge PIC

chapter provides an overview of the mid-range PIC

• Chapter 3. “44-Pin Demo Board Lessons” – This chapter provides lessons that

introduce mid-range PIC

Demo board features.

• Appendix A. “Hardware Schematics” – Illustrates the 44-Pin Demo Board

hardware schematic diagram, PCB layout and Bill of Materials.

®

Microcontroller Units (MCU).

®

Microcontroller Ar chitectural Overview” – This

®

MCU assembly instructions and cover basic 44-Pin

®

microcontroller architecture.

© 2007 Microchip Technology Inc. DS41296B-page 1

Page 6

44-Pin Demo Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

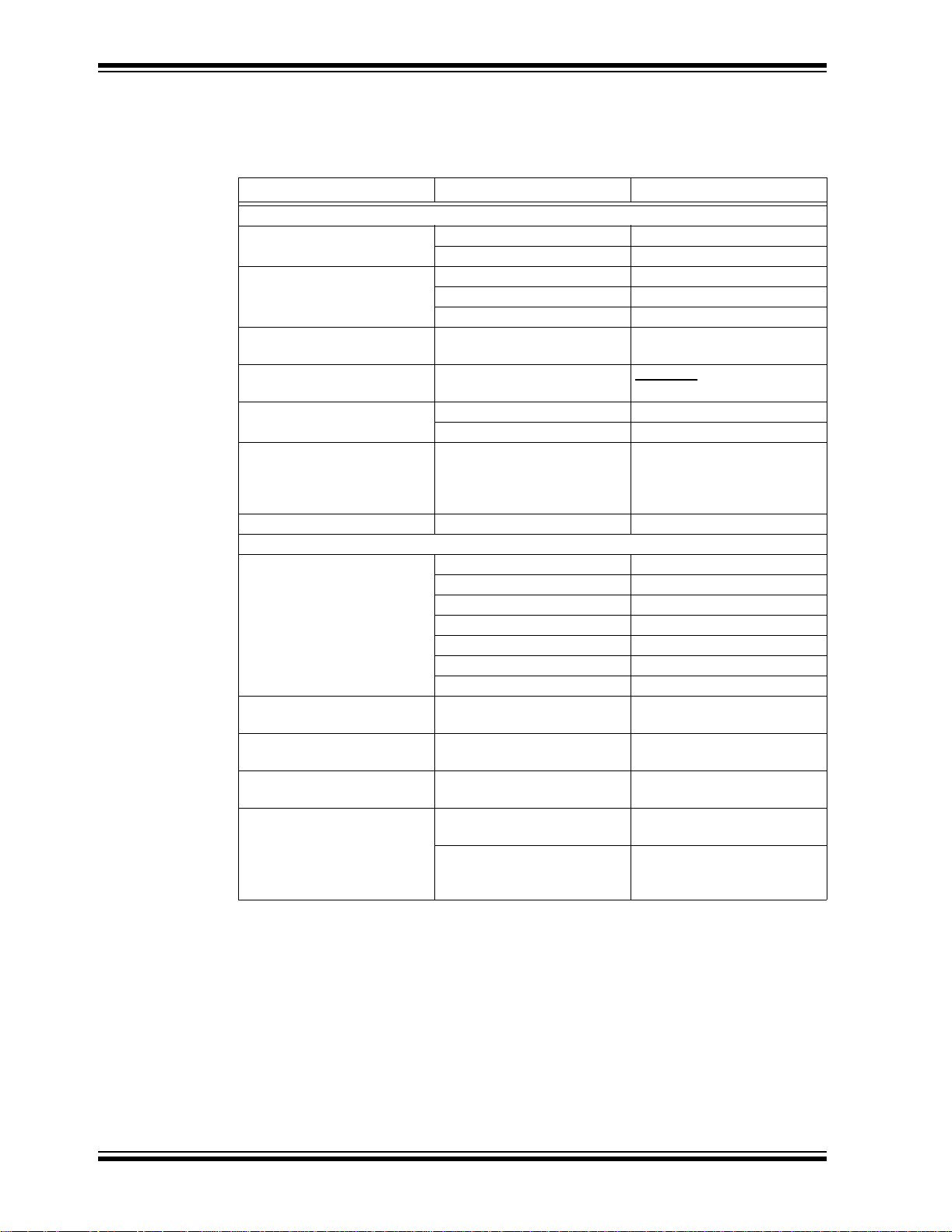

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books “MPLAB

Emphasized text ...is the only comp ile r...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brac kets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sam ple source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

®

IDE User’s Guide”

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

DS41296B-page 2 © 2007 Microchip Technology Inc.

Page 7

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use the 44-Pin Demo Board. Other useful documents are listed below. The following Microchip documents are available and

recommended as supplemental reference resources.

PIC16F88X Data Sheet (DS41291)

Consult this document for information regarding the PIC16F88X 28/40/44-Pin

Flash-Based, 8-Bit CMOS Microcontrollers with nanoWatt Technology device

specification.

™

PICkit

Consult this document for instructions on how to use the PICkit 2 Microcontroller

Programmer software and hardware.

MPLAB

Consult this document for more information pertaining to the features and functions of

the MPLAB In-Circuit Debugger (ICD) software.

MPLAB

Consult this document for more information pertaining to the installation and features

of the MPLAB Integrated Development Environment (IDE) Software.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB IDE installation directory. The Readme files

contain update information and known issues that may not be included in this user’s

guide.

2 Microcontroller Programmer User’s Guide (DS51553)

®

ICD User’s Guide (DS51184)

®

IDE User’s Guide (DS51519)

Preface

© 2007 Microchip Technology Inc. DS41296B-page 3

Page 8

44-Pin Demo Board User’s Guide

THE MICROCH IP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listin g

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB C18 and MPLAB C30 C compilers; MPASM™

and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 object linkers;

and MPLIB™ and MPLAB LIB30 object librarians.

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB ICE 2000 and MPLAB ICE 4000.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 and PRO MATE

Plus and PICkit™ 2 development programmers.

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

®

II device programmers and the PICSTART®

DS41296B-page 4 © 2007 Microchip Technology Inc.

Page 9

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (August 2006)

• Initial release of this document.

Revision B (December 2006)

• Updated Chapter 1. “PICkit™ 2 Overview”.

• Added Chapter 2. “ Mid- Rang e PIC

• Added Chapter 3. “44- Pin Demo Board Lesson s”.

• Changed PICmicro

• Changed PICkit® to PICkit™.

• Removed Development Systems Information Line from Customer Support

bulleted list.

• Updated schematic in Appendix.

®

to PIC

®.

Preface

®

Microcontroller Archi te ctur al Overv iew ” .

© 2007 Microchip Technology Inc. DS41296B-page 5

Page 10

44-Pin Demo Board User’s Guide

NOTES:

DS41296B-page 6 © 2007 Microchip Technology Inc.

Page 11

Chapter 1. 44-Pin Demo Board Overview

1.1 INTRODUCTION

44-PIN DEMO BOARD

USER’S GUIDE

The 44-Pin Demo Board is a small and simple demonstration PCB for Microchip’s

44-pin Thin Quad Flatpack (TQFP) PIC

with a PIC16F887 MCU, eight LEDs, push button and potentiometer. The demo board

has several test points to access the I/O pins of the MCU and a surface mount

prototyping area. The MCU can be programmed with the PICkit™ 2 Microcontroller

Programmer or the MPLAB

®

ICD 2 using the RJ-11 to 6-pin inline adapter (AC1641 10).

®

Microcontroller Units (MCU). It is populated

1.2 HIGHLIGHTS

This chapter discusses:

• Devices supported by the 44-Pin Demo Board

• The 44-Pin Demo Board Overview

• Running the Default Demonstration

1.3 DEVICES SUPPORTED BY THE 44-PIN DEMO BOARD

The 44-Pin Demo Board can be used with virtually any 44-pin Thin Quad Flatpack

(TQFP) PIC MCU. The assembled 44-Pin Demo Board is populated with a

PIC16F887-I/PT microcontroller.

Additional 44-Pin Demo Boards can be ordered from Microchip Technology and distributors. Part number, DM164120-2, comes with one assembled and two blank 44-Pin

Demo Boards. The blank demo board can be used for evaluating or prototyping circuits

using any of the 44-pin devices listed below.

44-pin TQFP Flash Devices:

• PIC16F74 • PIC16F747 • PIC16F77

• PIC16F777 • PIC16F871 • PIC16F874A

• PIC16F877A • PIC16F887 • PIC16F914

• PIC16F917 • PIC18F4220 • PIC18F4221

• PIC18F4320 • PIC18F4321 • PIC18F4331

• PIC18F4410 • PIC18F4420 • PIC18F4423

• PIC18F4431 • PIC18F4450 • PIC18F4455

• PIC18F4480 • PIC18F44J10 • PIC18F4510

• PIC18F4515 • PIC18F4520 • PIC18F4523

• PIC18F4525 • PIC18F4550 • PIC18F4580

• PIC18F4585 • PIC18F45J10 • PIC18F4610

• PIC18F4620 • PIC18F4680 • PIC18F4682

• PIC18F4685

© 2007 Microchip Technology Inc. DS41296B-page 7

Page 12

44-Pin Demo Board User’s Guide

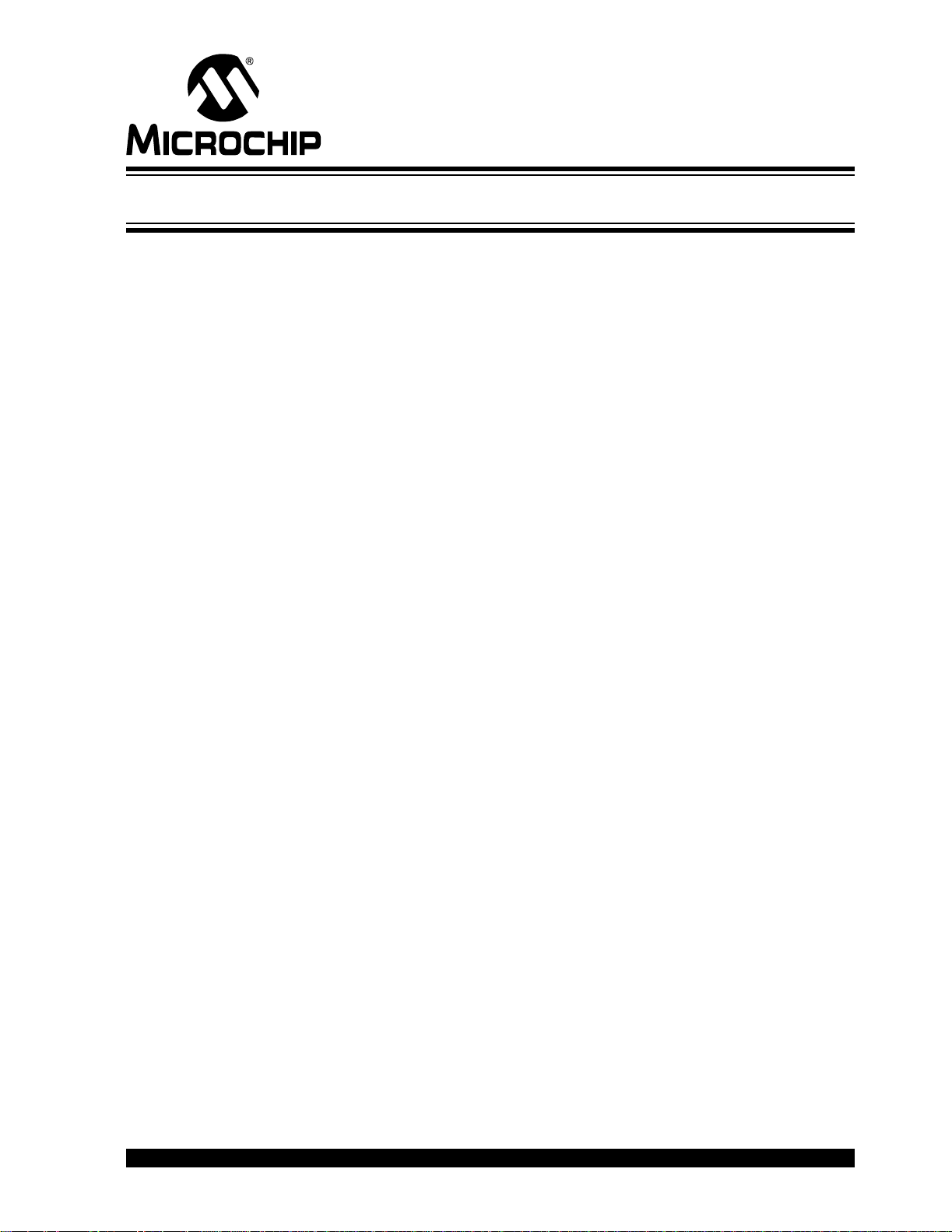

1.4 44-PIN DEMO BOARD OVERVIEW

The 44-Pin Demo Board is populated with a PIC16F887 MCU (U1), eight LEDs

(DS1-DS8), push button (SW1) and potentiometer (RP1). The board layout is shown in

Figure 1-1. The demo board has several test points to access the I/O pins of the MCU

and a surface mount prototyping area. The MCU can be programmed with the PICkit™

2 Microcontroller Programmer from header P1.

FIGURE 1-1: 44-PIN DEMO BOARD

PICkit™ 2 Programming Header

Potentiometer RP1

Push Button SW1

LEDs DS1-DS8

Surface Mount

Prototyping

Area

1.5 RUNNING THE DEFAULT DEMONSTRATION

The assembled 44-Pin Demo Board comes preprogrammed with a demonstration

program. To use this program, power the demo board (3.0-5.5 V

Microcontroller Programmer , or a bench power supply connected to header P2. To use

the PICkit™ 2 Microcontroller Programmer , connect it to a PC USB port using the USB

cable. St art the PICkit™ 2 Microcontroller Progr ammer PC app lication and click on the

target power box to apply power to the demo board. The demo program will blink the

eight red lights in succession. Press the push button switch, labeled SW1, and the

sequence of the lights will reverse. Rotate the potentiometer, RP1, and the light

sequence will blink at a different rate.

DS41296B-page 8 © 2007 Microchip Technology Inc.

DC) using a PICkit™ 2

Page 13

44-PIN DEMO BOARD

USER’S GUIDE

Chapter 2. Mid-Range PIC® Microcontroller Architectural Overview

2.1 INTRODUCTION

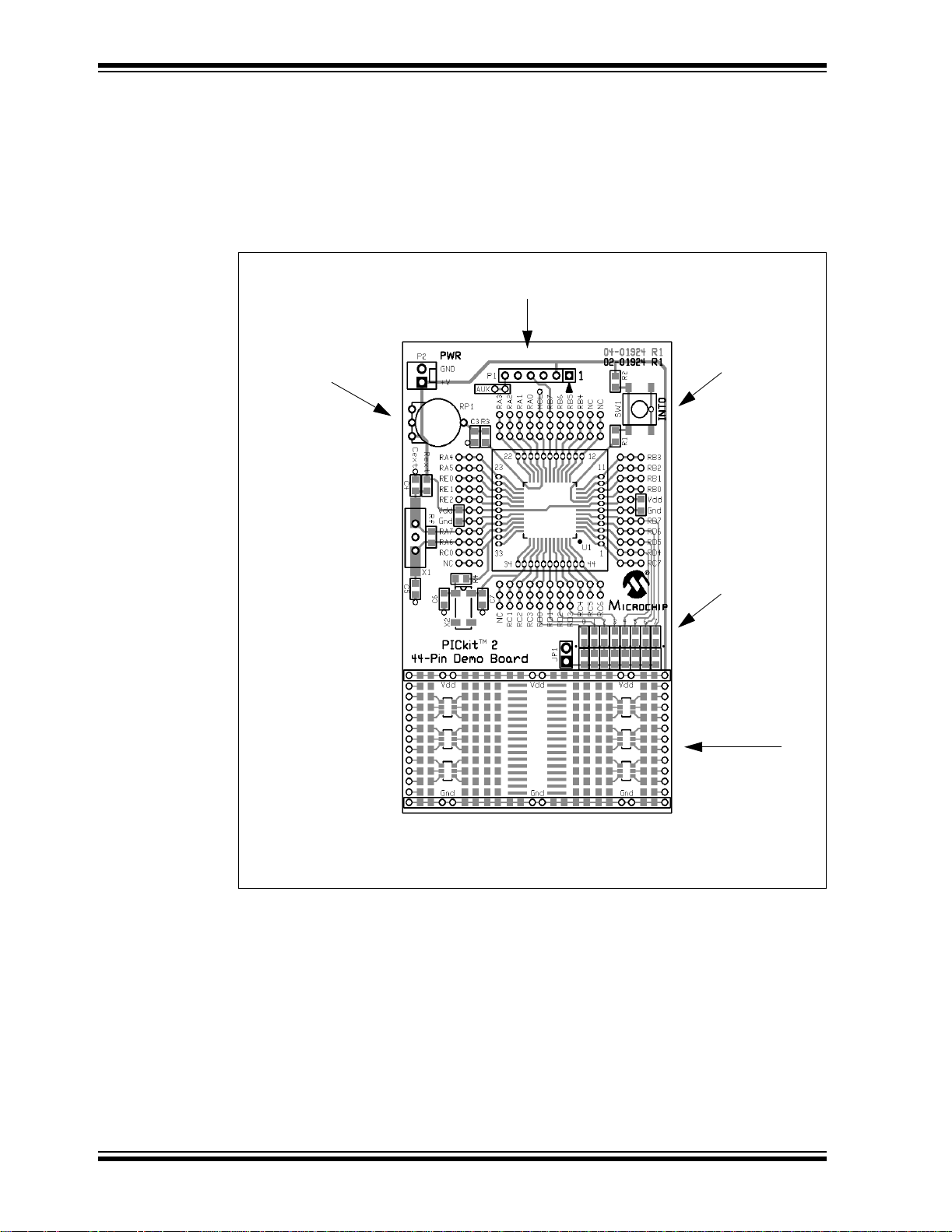

This chapter provides a simple overview of the mid-range PIC® microcontroller

architecture.

FIGURE 2-1: SIMPLIFIED MID-RANGE PIC

DIAGRAM

INT

13

Program Counter

8-Level Stack (13-bit)

Direct Addr

Program

OSC1/CLKI

OSC2/CLKO

Flash

4k x 14

Program

Memory

14

Bus

Instruction Reg

8

Instruction

Decode and

Control

Timing

Generation

®

MICROCONTROLLER BLOCK

Data Bus

RAM

256 bytes

File

Registers

9

Addr MUX

7

3

8

W Reg

8

FSR Reg

STATUS Reg

MUX

ALU

8

RAM Addr

Indirect

Addr

Internal

Oscillator

Block

2.2 MEMORY ORGANIZATION

PIC® microcontrollers are designed with separate program and data memory areas.

This allows faster execution as the address and data busses are separate and do not

have to do double duty.

© 2007 Microchip Technology Inc. DS41296B-page 9

Page 14

44-Pin Demo Board User’s Guide

Data Memory is held in file regi ster s. Ins truc tions referr ing to fil e regi sters us e 7 bit s,

so only 128 file registers can be addressed. Multiple file registers are arranged into

“banks”. Two bits in the STATUS register, RP0 and RP1, allow accessing different

banks. These two bits effectively become the top two bits of the file register address.

The additional banks may or may not be implemented, depending on the device.

Mid-range devices reserve the first 32 addresses of each bank for Special Function

Registers (SFRs). SFRs are how the program interacts with the peripherals and some

core features. The controls and data registers are memory mapped into the SFR space.

Addresses above 0x20 to the end of each bank are General Purpose Registers

(GPRs), where program variables may be stored.

Some frequently used registers may be accessed from any bank. For example, the

STATUS register is always available no matter which bank is selected via the RP bits.

The last 16 bytes (0x70-0x7F) of the GPRs may also be accessed from any bank.

Program Memory is accesse d via a 13 -bit Progr am Counte r (PC). The lower 8 bi ts are

accessible via SFR (PCL), and the upper 5 are at a PCLATH. See the PIC16F88X Data

Sheet’s (DS41291) section on PCL and PCLATH for more details on the PC. PCLATH

becomes important when program memory size exceeds 1k instructions, and also for

the table look-up in Lesson 12.

Mid-range PIC

erwise noted, the lessons in this manual use the Internal Oscillator running at 4 MHz.

®

MCUs may be clocked by a number of different devices. Unless oth-

2.3 INSTRUCTION FORMATS

Most instructions follow one of three formats: Byte oriented instructions, Bit oriented

instructions and Literal instructions.

Byte instructions contain a 7-bit data address, a destination bit, and a 6-bit op code.

The data address plus the RP0 and RP1 bits create a 9-bit data memory address for

one operand. The other operand is the Working register (called W or WREG). After the

instruction executes, the destination bit (d) specifies whether the result will be stored in

the WREG (‘w’) or back in the original file register (‘f’). For example:

ADDWF data,f

adds the contents of WREG and file register data, with the result going back into data.

Bit instructions operate on a specific bit within a file register. They contain 7 bits of data

address, a 3 -b it num ber and t he re mai nin g 4 bi t s are op co de. Thes e ins tr uct ions may

set or clear a specific bit within a file register. They may also be used to test a specific

bit within a file register. For example:

BSF STATUS,RP0

set the RP0 bit in the STATUS register.

Literal instructions contain the data operand within the instruction. The WREG

becomes the other operand. Calls and GOTO’s use 11 bits as a literal address.

MOVLW 'A'

Moves the ASCII value of ‘A’ (0x41) into the WREG.

DS41296B-page 10 © 2007 Microchip Technology Inc.

Page 15

Mid-Range PIC® Microcontroller Architectural Overview

2.4 ASSEMBLER BASICS

Numbers in the Assembler

Unless otherwise specified, the assembler assumes any numeric constants in the

program are hexadecimal (base 16). Binary (base 2), Octal (base 8), Decimal (base

10), and ASCII coding are also supported.

Hexadecimal

Decima

Octal

Binary

ASCII

Org

(Origin)

l .12 or D'12'

12 or 0x12 or H'12'

O'12'

B'00010010'

A'c' or 'c'

Org tells the Assembler an address at which to start generating code. Normally

we start coding at the Reset vector address ‘0000’, but it could be anywhere.

Baseline devi ces have a Rese t vector at the last loc ation in pr ogram memo ry , s o

it’s good practice to have a GOTO instruction pointing to the beginning of the

program.

End

End tells the assembler to stop assembling. There must be one at the end of the

program. It does not necessarily have to be at the end of the file, but nothing after

the end statement will be assembled.

Defining Data Memory Locations

There are three ways to name a location (see Example 2-1). All are equivalent in

that the location name label will be substituted with the value assigned to it during

assembly.

EXAMPLE 2-1: DEFINING DATA MEMORY

#define Length 0x20 ;c-like syntax

Length equ 0x20 ;equate 0x20 with the symbol

cblock 0x20 ;start a block of variables

Length ;this will be at address 0x20

Width ;this will be at address 0x21

Area:2 ;this is 2 bytes long, starting at

;address 0x22

Girth ;this will be at address 0x24

endc

Note that if used as a literal, the label names will take on the value assigned. If used as

an address operand in an instruction, the label names point to the contents of the file

register with the address of the label’s value.

Unless there is a reason to name a specific location address, the cblock/endc

method is preferred. The advantage is that as variables come and go through the

development process, the cblock keeps the block to a minimum. Using one of the

other methods, you may have to go back and find an unused location.

© 2007 Microchip Technology Inc. DS41296B-page 11

Page 16

44-Pin Demo Board User’s Guide

NOTES:

DS41296B-page 12 © 2007 Microchip Technology Inc.

Page 17

Chapter 3. 44-Pin Demo Board Lessons

3.1 INTRODUCTION

The following lessons cover basic 44-Pin Demo Board features. Refer to applicable

documents as needed. Any updates to the applicable documents are available on

Microchip’s web site.

The code and hex files may be installed from the PICkit™ 2 CD-ROM under path

Install /Lessons.

3.2 44-PIN DEMO BOARD LESSONS

• Lesson 1: Hello World (Light a LED)

• Lesson 2: Blink (Delay Loop)

• Lesson 3: Rotate (Move the LED)

• Lesson 4: Analog-to-Digital

• Lesson 5: Variable Speed Rotate

• Lesson 6: Switch Debounce

• Lesson 7: Reversible Variable Speed Rotate

• Lesson 8: Function Calls

• Lesson 9: Timer0

• Lesson 10: Interrupts

• Lesson 11: Indirect Data Addressing

• Lesson 12: Look-up Table (ROM Array)

44-PIN DEMO BOARD

USER’S GUIDE

© 2007 Microchip Technology Inc. DS41296B-page 13

Page 18

44-Pin Demo Board User’s Guide

3.2.1 Lesson 1: Hello World (Light a LED)

The first lesson shows how to turn on a LED. This is the PIC

of “Hello World” and discusses the I/O pin structures.

New Instructions

BSF Bit set

BCF Bit clear

The LEDs are connected to I/O pins RD0 through RD7. When one of these I/O pins

drives high, the LED turns on. The I/O pins can be configured for input or output. On

start-up, the default is input. The TRIS Special Function Register bits use the convention of ‘0’ for output and ‘1’ for input. We want digital output so these must be

configured.

EXAMPLE 3-1: PICKIT 2, LESSON 1: “HELLO WORLD”

; PICkit 2 Lesson 1 - "Hello World"

;

#include <p16F887.inc>

__CONFIG _CONFIG1, _LVP_OFF & _FCMEN_OFF & _IESO_OFF &

_BOR_OFF & _CPD_OFF & _CP_OFF & _MCLRE_OFF &

_PWRTE_ON & _WDT_OFF & _INTRC_OSC_NOCLKOUT

__CONFIG _CONFIG2, _WRT_OFF & _BOR21V

®

microcontroller version

org 0

Start:

BSF STATUS,RP0 ; select Register Bank 1

BCF TRISD,0 ; make IO Pin RD0 an output

BCF STATUS,RP0 ; back to Register Bank 0

BSF PORTD,0 ; turn on LED RD0 (DS0)

GOTO $ ; wait here

END

Now lets look at the program that makes this happen.

; Starts a comment. Any text on the line following the semicolon

is ignored.

#include Brings in an include file defining all the Special Function Regis-

ters available on the PIC16F887. Also, it defines valid memory

areas. These definitions match the names used in the device

data sheet.

__Config Defines the Configuration Word. The labels are defined in the

p16F887.inc file. The labels may be logically ANDed

together to form the word.

Org 0 Tells the assembler where to start generating code. Code may

be generated for any area of the part. Mid-range PIC

®

controller devices start at address ‘0’, also called the Reset

vector.

BCF TRISC,0 Tells the processor to clear a bit in a file register. TRISD is the

tri-state register for pin 0 of PORTD. A ‘1’ in the register makes

the pin an input; a ‘0’ makes it an output. We want to make it an

output, so the bit must be cleared.

BSF PORTD,0 Tells the processor to set pin 0 of PORTD. This will force the I/O

pin to a high condition turning on the LED.

GOTO $ Tells the processor to go to the current instruction.

micro-

DS41296B-page 14 © 2007 Microchip Technology Inc.

Page 19

44-Pin Demo Board Lessons

For more information, refer to the I/O Ports section of the PIC16F882/883/884/886/887

Data Sheet (DS41291).

3.2.2 Blink (Del ay Loop)

The first lesson showed how to turn on a LED, this lesson shows how to make it blink.

While this might seem a trivial change from Lesson 1, it gives a context to explore

several more instructions.

New Instructions

CLRF Clear file register

INCF Increment file register

DECF Decrement file register

INCFSZ Increment file register, Skip next instruction if zero

DECFSZ Decrement file register, Skip next instruction if zero

GOTO Jump to a new location in the program

EXAMPLE 3-2: PICKIT 2, LESSON 2: BLINK

Loop

BSF PORTD,0 ;turn on LED D0

BCF PORTD,0 ;turn off LED D0

GOTO Loop ;do it again

While adding a BCF instruction and making it loop will make it blink. It will blink so fast

you won’t see it, it will only look dim. That loop requires 4 instruction times to execute.

The first instruction turns it on. The second one turns it off. The GOTO takes two instruc-

tion times, which means it will be on for 25% of the time.

As configur ed , t he P I C

®

microcontroller executes 1 million instructions per second. At

this rate, the blinking needs to be slowed down so that the blinking can be seen, which

can be done by using a delay loop.

Note: Counting cycles – Relating clock speed to instruction speed. The processor

requires 4 clocks to execute an instruction. Since the internal oscillator as

used in these lessons runs at 4 MHz, the instruction rate is 1 MHz.

© 2007 Microchip Technology Inc. DS41296B-page 15

Page 20

44-Pin Demo Board User’s Guide

Increment or Decrement a File Register

The INCFSZ and DECFSZ instructions add or subtract one from the contents of

the file register and skips the next instruction when the result is zero. One use is

in the delay loop as shown in Example 3-3.

CLRF Clears the counter location.

DECFSZ Decrements the location, and if the result is zero, the next instruction is

skipped.

EXAMPLE 3-3: DELAY LOOP

Short Loop

CLRF Delay

Loop

DECFSZ Delay,f

GOTO Loop

Long Loop

CLRF Delay1

CLRF Delay2

Loop

DECFSZ Delay1,f

GOTO Loop

DECFSZ Delay2,f

GOTO Loop

The GOTO Loop (in Example 3-3) backs up and does it again. This loop takes 3

instruction times; one for the decrement and two for the GOTO (see note) and the

counter will force it to go around 256 times, which takes it a total of 768 instruction times

(768 μs) to execute.

Even that is still too fast for the eye to see. It can be slowed down even more by adding

a second loop around this one.

The inner loop still takes 768 μs plus 3 for the outer loop, but now it’s executed another

256 times, (768 + 3) * 256 = 197376 μs = 0.197s.

Note: GOTO instructions take two instructions due to the pipelined design of the

processor. The processor fetches the next instruction while executing the

current instruction. When a program branch occurs, t he fetched instruction

is not executed.

Open Blink.asm and build the lesson. Next, import the hex file into the PICkit 2 and

program the device. Note the LED now flashes at about a 2.5 Hz rate.

DS41296B-page 16 © 2007 Microchip Technology Inc.

Page 21

44-Pin Demo Board Lessons

3.2.3 Lesson 3: Rotate (Move the LED)

Building on Lessons 1 and 2, which showed how to light up a LED and then make it

blink with a delay loop, this lesson adds rotation. It will light up DS8 and then shift it to

DS7, then DS6 and on down to DS1, and then back to DS8.

New Instructions

MOVLW Loads WREG with a literal value

MOVWF Moves the contents of WREG to a file register

MOVF Moves the contents of a file register, either to WREG or back into

the file register (see note)

RRF Rotate file register right

RLF Rotate file register left

Note: Moving a file register to itself looks like a NOP at first. However, it has a

useful side effect in that the Z flag is set to reflect the value. In other words,

MOVF fileregister,f is a convenient way to test whether or not the

value is zero without affecting the contents of the WREG.

Rotate Program Flow

• First, initialize the I/O port and the Display,

• Copy the Display variable to the I/O Port, then

• Delay for a little while

• Rotate the display

FIGURE 3-1: ROTATE PROGRAM FLOW

Initialize I/ O Por t

Put Up Display

Delay

Rotate Display

Did it overflow?

No

Reset Display

Yes

© 2007 Microchip Technology Inc. DS41296B-page 17

Page 22

44-Pin Demo Board User’s Guide

Rotate

The rotate instructions (RRF or RLF) shift all the bits in the file register right or left by

one position, through the Carry bit. The Carry bit is shifted into the byte and receives

the bit shifted out of the byte. The Carry bit should be cleared before rotation so

unwanted bits are not introduced into the display byte. The Carry bit also indicates

when the display byte is empty. When it is, reinsert the ‘1’ at bit 3.

PIC microcontrollers have two rotate instructions: Rotate Left (RLF) and Rotate Right

(RRF). These instructions rotate the contents of a file register and Carry bit one place.

The Carry bit is found in the STATUS Special Function Register.

FIGURE 3-2: ROTATE LEFT

Carry

File Register

EXAMPLE 3-4: ROTATE EXAMPLE

Start:

BSF STATUS,RP0 ; select Register Bank 1

CLRF TRISD ; make IO PortD all output

BCF STATUS,RP0 ; back to Register Bank 0

MOVLW 0x80

MOVWF Display

MainLoop:

MOVF Display,w ; Copy the display to the LEDs

MOVWF PORTD

OndelayLoop:

DECFSZ Delay1,f ; Delay .197 s

GOTO OndelayLoop

DECFSZ Delay2,f

GOTO OndelayLoop

BCF STATUS,C ; ensure the carry bit is clear

RRF Display,f ; rotate display right

BTFSC STATUS,C ; Did the bit rotate into the carry?

BSF Display,7 ; yes, put it into bit 7.

GOTO MainLoop

DS41296B-page 18 © 2007 Microchip Technology Inc.

Page 23

44-Pin Demo Board Lessons

3.2.4 Lesson 4: Analog-to-Digital

This lesson shows how to configure the ADC, run a conversion, read the analog voltage

controlled by the potentiometer (RP1) on the board, and display the high order 8 bits

on the display.

The PIC16F887 has an on-board Analog-to-Digital Converter (ADC) with 10 bits of resolution on any of 14 channels. The converter can be referenced to the device’s V

an external voltage reference. The 44-pin Demo Board references it to V

DD as provided

by the PICk it 2 Mic ro cont rol ler Pr og ram mer. The answer from t he A DC is r epr esen te d

by a ratio of the voltage to the reference.

ADC = V/V

REF * 1023

Converting the answer from the ADC back to voltage requires solving for V.

V = ADC/1023 * V

REF

Two of the three factors on the right side of the equation are constants and may be calculated in advance. This eliminates the need to actually divide, but still requires fixed

or floating point multiply to solve the equation on the fly.

However, sometimes, such as when reading a sensor, calculating the voltage is only

the first step. There may be additional math to calculate the meaningful data from the

sensor. For example, when reading a thermistor, calculating the voltage is only the first

step on the way to getting the temperature.

There are other means to convert ADC values, including a straight table look-up or a

piece-wise linear interpolation. Each of these represents different speed/memory

trade-offs.

The schematic (Appendix A. “Hardware Schematics”) shows the wiper on the potentiometer is connected to pin RA0 on the PIC16F887.

Here’s the checklist for this lesson:

• Configure PORTA as an analog input, TRISA<0> = 1, ANSEL<0> = 1

• Select justification and V

REF source in ADCON1.

• Select clock scaling and channel in ADCON0.

DD or

© 2007 Microchip Technology Inc. DS41296B-page 19

Page 24

44-Pin Demo Board User’s Guide

3.2.4.1 ADCON1

The ADCON1 register sets the justification of the 10-bit result in the 16-bit result read

through registers ADRESL and ADRESH. Setting the result to Left Justified means the

8 Most Significant bits and read from ADRESH and the 2 Least Significant bits are read

from bits 7 and 6 of ADRESL. ADCON1 also sets the voltage reference sources V

VREF-. VREF- is the voltage at which the result will be zero. VREF+ is the voltage at

and

which the result will be maximum (1023). We select the PIC16F887 V

voltages respectively .

REF+

SS and VDD

REGISTER 3-1: ADCON1: A/D CONTROL REGISTER 1

R/W-0 U-0 R/W-0 R/W-0 U-0 U-0 U-0 U-0

ADFM

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

- n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 ADFM: A/D Conversion Result Format Selection bit

bit 6 Unimplemented: Read as ‘0’

bit 5 VCFG1: Voltage Reference bit

bit 4 VCFG0: Voltage Reference bit

bit 3-0 Unimplemented: Read as ‘0’

—VCFG1VCFG0— — — —

1 = Right jus tified

0 = Left justified

1 = VREF- pin

0 = Vss

1 = V

REF+ pin

0 = VDD

3.2.4.2 ADCON0

ADCON0 controls the ADC operation. Bit 0 turns on the ADC module and bit 1 starts a

conversion. Bits <7:6> select the ratio between the processor clock and conversion

speed and bits <5:2> select which channel the ADC will operate on. The ratio between

the processor clock and conversion speed is important because the ADC needs at

least 1.6 μs per bit. Accuracy degrades if the clock speed is too high. As the processor

clock speed increases, an increasingly large divider is necessary to keep the conversion bit speed above 1.6 μs. Four MHz gives the fastest conversion rate above the minimum at 8:1 ratio. This results in a conversion speed of 2 μs per bit. Refer to the “T

AD

vs. Device Operating Frequencies” Table in the Analog-to-Digital section of the

PIC16F882/883/884/886/887 Data Sheet (DS41291) for recommended configurations.

For purposes of this lesson, the ADC must be turned on and pointed to channel AN0

on pin RA0.

The ADC needs about 5 μs, after changing channels, to allow the ADC sampling capacitor to settle. Finally , we can start the conversion by setting the GO bit in ADCON0. The

bit also serves as the DONE

flag. That is, the ADC will clear the same bit when the con-

version is complete. The answer is then available in ADRESH:ADRESL. This lesson

takes the high order 8 bits of the result and copies them to the display LEDs attached

to PORTD.

DS41296B-page 20 © 2007 Microchip Technology Inc.

Page 25

44-Pin Demo Board Lessons

See the Analog-to-Digital section in the PIC16F882/883/884/886/887 Data Sheet

(DS41291) for more details on the ADC module.

REGISTER 3-2: ADCON0: A/D CONTROL REGISTER 0

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

ADCS1 ADCS0 CHS3 CHS2 C HS1 CHS0 GO/DONE ADON

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘ 0’

- n = Value at POR ‘ 1’ = Bi t is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-6 ADCS<1:0>: A/D Conversion Clock Select bits

00 = F

OSC/2

OSC/8

01 = F

10 = F

OSC/32

RC (clock derived from a dedicated internal oscillat or = 500 kHz max)

11 = F

bit 5-2 CHS<3:0>: Analog Channel Select bits

0000 =AN0

0001 =AN1

0010 =AN2

0011 =AN3

0100 =AN4

0101 =AN5

0110 =AN6

0111 =AN7

1000 =AN8

1001 =AN9

1010 =AN10

1011 =AN11

1100 =AN12

1101 =AN13

1110 =CV

1111 = Fixed Ref (0.6 volt fixed reference)

bit 1 GO/DONE: A/D Conversion Status bit

1 = A/D conversion cycle in pro gr ess. Setting this bit starts an A/D conver si on cycle.

This bit is automatically cleared by hardware when the A/D conversion has

0 = A/D conversion comple ted/ not in progress

bit 0 ADON: ADC Enable bit

1 = ADC is enabled

0 = ADC is disabled and cons um es no operating current

REF

completed.

© 2007 Microchip Technology Inc. DS41296B-page 21

Page 26

44-Pin Demo Board User’s Guide

3.2.5 Lesson 5: Variable Speed Rotate

Lesson 5 combines Lessons 3 and 4 by using the Analog-to-Digital Converter (ADC)

to control the speed of rotation.

New Instructions

BTFSS Bit test, skip if set

BTFSC Bit test, skip if clear

A conversion is run on every pass through the main loop. The result controls the length

of the outer loop (see Example 3-5).

EXAMPLE 3-5: VARIABLE SPEED ROTATE EXAMPLE

...

BSF ADCON0,GO_DONE ; start conversion

BTFSS ADCON0,GO_DONE ; this bit will change to zero when

; the conversion is complete

GOTO $-1

MOVF ADRESH,w ; Copy the display to the LEDs

ADDLW 1

MOVWF Delay2

A2DDelayLoop:

DECFSZ Delay1,f ; Delay Loop shortened by the ADResult

; as controlled by the potentiometer.

GOTO A2DDelayLoop

DECFSZ Delay2,f

GOTO A2DDelayLoop

FIGURE 3-3: VARIABLE SPEED ROTATE PROGRAM FLOW

Initialize I/O Port

Initialize ADC

Put Up Display

Get ADC Result

Delay Using ADC

Rotate Display

Did it overflow?

No

Yes

Reset Display

DS41296B-page 22 © 2007 Microchip Technology Inc.

Page 27

44-Pin Demo Board Lessons

3.2.6 Lesson 6: Switch Debouncing

Mechanical switches play an important and extensive role in practically every computer, microprocessor and microcontroller application. Mechanical switches are inexpensive, simple and reliable. However, switches can be very noisy electrically. The

apparent noise is caused by the closing and opening action that seldom results in a

clean electrical transition. The connection makes and breaks several, perhaps even

hundreds, of times before the final switch state settles.

The problem is known as switch bounce. Some of the intermittent activity is due to the

switch contacts actually bouncing off each other. Imagine slapping two billiard balls

together. The hard non-resilient material doesn’t absorb the kinetic energy of motion.

Instead, the energy dissipates over time and friction in the bouncing action against the

forces push the billiard balls together. Hard metal switch contacts react in much the

same way. Also, switch contacts are not perfectly smooth. As the contacts move

against each other, the imperfections and impurities on the surfaces cause the electrical connection to be interrupted. The result is switch bounce.

The consequences of uncorrected switch bounce can range from being just annoying

to catastrophic. For example, imagine advancing the TV channel, but instead of getting

the next channel, the selection skips one or two. This is a situation a designer should

strive to avoid.

Switch bounce has been a problem even before the earliest computers. The classic

solution involved filtering, such as through a resistor-capacitor circuit, or through re-settable shift registers (see Figure 3-4 and Figure 3-5). These methods are still effective

but they involve additional cost in material, installation and board real estate. Debouncing in software eliminates these additional costs.

FIGURE 3-4: FILTERING DEBOUNCE SOLUTION

+V

R2

R1

C

SW

Filtered

Switch

Output

1

FIGURE 3-5: SHIFT REGISTER DEBOUNCE SOLUTION

+V

R1

Filtered

Switch

Output

SW

D

CLK

Qn

CLR

Debounce

Clock

© 2007 Microchip Technology Inc. DS41296B-page 23

Page 28

44-Pin Demo Board User’s Guide

One of the simplest ways to switch debounce is to sample the switch until the signal is

stable or continue to sample the signal until no more bounces are detected. How long

to continue sampling requires some investigation. However, 5 mS is usually plenty

long, while still reacting fast enough that the user won’t notice it.

Lesson 6 shows how to sample the line at a 1 mS rate waiting for a number of sequential state changes, which is a simple matter of counting to 5, then resetting the counter

every time it’s still in the original unchanged state.

The Switch on the 44-Pin Demo Board doesn’t bounce much, but it is good practice to

debounce all switches in the system.

FIGURE 3-6: SIMPLE SWITCH DEBOUNCE PROGRAM FLOW

Yes

Increment Counter

Is Counter = 5 ?

Yes

Change State

Reset Counter

Switch has

changed states?

No

Delay 1 mS

No

Reset Counter

3.2.7 Lesson 7: Reversible Variable Speed Rotate

Lesson 7 combines Lessons 5 and 6 using the button to reverse the direction of rotation

when the button is pressed and adjusting the potentiometer to control the speed of

rotation.

The program needs to keep track of rotation direction and new code needs to be added

to rotate in the other direction.

Lesson 5 rotates right and checks for a ‘1’ in the Carr y bi t to d et ermi ne w hen t o re st art

the sequence. In Lesson 7, we’ll also need to rotate left and check for a ‘1’ in bit 7 of

the display. When the ‘1’ shows up in bit 7 of the display, insert it into the bit 0 position.

DS41296B-page 24 © 2007 Microchip Technology Inc.

Page 29

44-Pin Demo Board Lessons

EXAMPLE 3-6: REVERSIBLE VARIABLE SPEED ROTATE EXAMPLE

Original Version:

Rotate:

RRF Display,f

BTFSC STATUS,C ; Did the bit rotate into the carry?

BSF Display,7 ; yes, put it into bit 7.

Bidirectional Version:

Rotate:

BCF STATUS,C ; ensure the carry bit is clear

BTFSS Direction,0

GOTO RotateLeft

RotateRight:

RRF Display,f

BTFSC STATUS,C ; Did the bit rotate into the carry?

BSF Display,7 ; yes, put it into bit 7.

GOTO MainLoop

RotateLeft:

RLF Display,f

BTFSC STATUS,C ; did it rotate out of the display

BSF Display,0 ; yes, put it into bit 0

GOTO MainLoop

© 2007 Microchip Technology Inc. DS41296B-page 25

Page 30

44-Pin Demo Board User’s Guide

3.2.8 Lesson 8: Function Calls

Lesson 8 shows the reversible LEDs but with the Delay Loop rewritten as a function.

New Instructions

CALL Invokes functions or subroutines

RETURN Terminates functions or subroutines

RETLW Terminates functions or subroutines

Functions or Subroutines are invoked with the CALL instruction and terminated with

a RETURN or RETLW instruction. RETURN jumps back to the original program at the

location following the CALL. RETLW also returns to the calling program, but loads the

WREG with a constant.

®

The mid-range PIC

addresses.

If a ninth CALL is made, it will overwrite the first one and then the program will not be

able to RETURN all the way back.

Passing Arguments

Arguments to the subroutine may be passed in a number of ways. WREG is a convenient place to pass one byte and the FSR may be used to pass another byte, if not otherwise used. If more data must be passed, a buffer must be allocated.

When the Delay function is pulled out to a subroutine, the ADC result is moved into

WREG, then the CALL transfers control to the Delay subroutine. The RETURN trans-

fers control to the MOVLW following the CALL.

microcontroller devi ce ’s CALL stack can hold up to 8 return

EXAMPLE 3-7: FUNCTION CALL EXAMPLE

MOVF ADRESH,w ; Move conversion value (delay) to w

ADDLW 1 ; add 1 otherwise entering with 0 takes

; longer than entering with 1.

CALL Delay ; Call delay function

; returns here when done

...

GOTO XXX

; Delay Function. Enter with number of 771uS delays in Wreg

Delay:

MOVWF Delay2

DelayLoop:

DECFSZ Delay1,f

GOTO DelayLoop

DECFSZ Delay2,f

GOTO DelayLoop

RETURN ; goes back to instruction after call

3.2.9 Lesson 9: Timer0

Timer0 is a counter implemented in the processor. It may be used to count processor

clock cycles or external events. Lesson 9 configures it to count instruction cycles and

set a flag when it rolls over. This frees up the processor to do meaningful work rather

than just counting cycles for a delay.

Timer0 is an 8-bit counter with an optional prescaler, which is configured to divide by

256 before reaching the Timer0 counter.

DS41296B-page 26 © 2007 Microchip Technology Inc.

Page 31

44-Pin Demo Board Lessons

FIGURE 3-7: TIMER0 SIMPLIFIED

Clock/4 or

T0CKI pin

Prescaler may be configured

to divide by 2, 4, 8, 16, 32, 64,

128 or 256.

TMR0 is a Special Function Register (SFR) and may be read or modified by the program. The prescaler is not a SFR and thus cannot be read or modified by the program.

However, writing to TMR0 clears the prescaler.

The timer may be fed either by the same clock that drives the processor or by an external event. Driven by the processor clock, it increments once for every instruction cycle.

This is a convenient method of marking time and is better than delay loops, as it allows

the processor to work on the problem rather than waste cycles in delay loops.

The prescaler is configured through the OPTION_REG, see Figure 3-8.

FIGURE 3-8: PRESCALER CONFIGURATION THROUGH OPTION_REG

X X T0CS T0SE PSA PS2 PS1 PS0

bit 7 bit 0

Prescaler T0IFTMR0

Flag set when

TMR0 overflows.

Must be cleared

in software.

Legend:

X: Don’t cares – not Timer0 related.

T0CS: Timer0 Clock Source 0 for Instruction Clock.

T0SE: Timer0 Source Edge – Don’t care when connected to instruction clock.

PSA: Prescaler Assignment 0 assigns to Timer0.

PS: Prescaler rate select ‘111’ – full prescaler, divide by 256.

Lesson 9 configures Timer0 with the prescaler for a maximum delay on Timer0. The

prescaler will divide the processor clock by 256 and Timer0 will divide that by 256

again. Thus, the Timer0 Flag will be set every 65536 μs (0.0000001 second * 256 *

256), or about 15 times a second. The main program sits in a loop waiting for the

rollover and when it does, it increments the display and then loops back.

© 2007 Microchip Technology Inc. DS41296B-page 27

Page 32

44-Pin Demo Board User’s Guide

EXAMPLE 3-8: TIMER0 EXAMPLE

org 0

BSF STATUS,RP0 ; Bank 1

MOVLW b'00000111' ; configure Timer0. Sourced from the

; Processor clock

MOVWF OPTION_REG ; Maximum Prescaler

CLRF TRISD ; Make PortD all output

CLRF Display

BCF STATUS,RP0 ; Bank 0

ForeverLoop:

BTFSS INTCON,T0IF ; wait here until Timer0 rolls over

GOTO ForeverLoop

BCF INTCON,T0IF ; flag must be cleared in software

INCF Display,f ; increment display variable

MOVF Display,w ; send to the LEDs

MOVWF PORTD

GOTO ForeverLoop

3.2.10 Lesson 10: Interrupts

New Instructions

RETFIE Return from Interrupt

SWAPF Swap nibbles in file regis ter

Interrupt Sources

Most of the peripherals can generate an interrupt, and some of the I/O pins may be

configured to generate an interrupt when they change state.

When a peripheral needs service or an event occurs, it sets its interrupt flag. Each

interrupt flag is ANDed with its enable bit and then these are ORed together to form a

Master Interrupt. This master interrupt is ANDed with the Global Interrupt Enable (GIE).

See the Interrupt Logic Figure in the PIC16F882/883/884/886/887 Data Sheet

(DS41291) for a complete drawing of the interrupt logic. The enable bits allow the PIC

microcontroller to limit the interrupt sources to certain peripherals.

FIGURE 3-9: INTERRUPT LOGIC SIMPLIFIED

Interrupt Flag

Interrupt Enable

Master Interrupt

Global Interrupt Enable

Other Interrupt Sources

DS41296B-page 28 © 2007 Microchip Technology Inc.

Page 33

44-Pin Demo Board Lessons

When the master interrupt line is asserted, the PIC microcontroller finishes the current

instruction, stores the next address on the CALL stack then jumps to the Interrupt Service Routine (ISR). It also clears the GIE bit, preventing another interrupt from occurring while servicing the current one.

Save Current Context

The first thing the ISR must do is to save the current context of the processor so it can

be restored before returning to the main program. Certain SFRs that may be changed

in the ISR should be saved, such as the WREG and STA TUS registers at the very least.

Make sure to save the WREG first, as moving other SFRs into it will destroy the value

needing to be saved. The last 16 bytes of each PIC16F887 file register page are

unbanked and are good places to save the context, as they may be accessed from any

register page without regard to the RP0 and RP1 bits in the STATUS register. The

location of unbanked registers may vary from part to part. Check the register map to

find the unbanked region for a specific part.

Identify Triggering Event

Next, the ISR has to figure out what triggered the interrupt. It has to check the interrupt

flags to determine what caused the interrupt. When it finds the source, it can then

service the peripheral.

Restore Context

Once the peripheral is serviced, it needs to restore the context and resume the main

program. The “context” is the state of the SFRs when the interrupt occurred. Restoring

the context is a little harder than it might seem at first. The obvious method doesn’t work

because the MOVF W_Temp,w may affect the Z flag, which was restored in the previous instruction. Instead, a pair of SWAPF instructions can restore WREG without affect-

ing the flags in the STATUS register. SWAPF exchanges the high and low nibbles. The

first SWAPF switches the nibbles in the file register and the second one switches them

back and puts the result in WREG.

EXAMPLE 3-9: CONTEXT RESTORE

;incorrect context restore

MOVF STATUS_Temp,w

MOVWF STATUS

MOVF W_Temp ;this may change the Z bit

;in the Status register

;good context restore

MOVF STATUS_Temp,w

MOVWF STATUS

SWAPF W_Temp,f ;swap in place

SWAPF W_Temp,w ;swap with Wreg destination

Finally, RETFIE transfers control back to the original program and sets the GIE bit,

re-enabling interrupts.

© 2007 Microchip Technology Inc. DS41296B-page 29

Page 34

44-Pin Demo Board User’s Guide

FIGURE 3-10: SWAPF INSTRUCTION

Before

After

1 0 1 0 0 0 1 1

1 0 1 00 0 1 1

3.2.11 Lesson 11: Indirect Data Addressing

The FSR (File Select Register) allows a file register address to be specified. A subsequent read or write to the INDF (Indirect File register) refers to the file register

addressed by the FSR.

This may be used to implement a moving average filter. The moving average keeps a

list of the last n values and averages them together. The Filter needs two parts: A

circular queue and a function to calculate the average.

FIGURE 3-11: MOVING AVERAGES

Conceptual View

Time

n 105 102 101 104 99 103 105 107 103

n + 1 106 105 102 101 104 99 103 105 103

n + 2 110 106 105 102 101 104 99 103 104

Average

The rest move down one

Newest value inserted here

Implementation View

Time

n 107 105 101 104 99 101 102 105 103

Pointer to oldest value

n + 1 106 105 102 101 99 101 102 105 103

Older value overwritten, pointer advanced

n + 2 106 110 103 99 99 101 102 105 104

Pointer advanced

Calculating averages in a mid-range PIC microcontroller is best accomplished by using

the FSR to keep track of where the next value will be inserted. This ensures the oldest

value is always overwritten with the newest and doesn’t waste time moving values

within the memory.

Average

DS41296B-page 30 © 2007 Microchip Technology Inc.

Page 35

44-Pin Demo Board Lessons

EXAMPLE 3-10: FILE SELECT REGISTER EXAMPLE

;insert new value into a queue, enter with new value in

;Wreg

MOVF temp ;save the latest value

MOVF QueuePointer,w

MOVWF FSR ;load FSR with the queue pointer

MOVF temp,w

MOVWF INDF ;Write the new value to the queue

INCF QueuePointer, f ;Advance the pointer

Lesson 11 adds a Moving Average Filter to the Analog-to-Digital code in Lesson 4.

Turning the potentiometer changes the value read by the Ana lo g-to- Dig ital conv erte r.

The averag ed value is then sent to the LED di splay . The av eraging f ilter only runs every

0.2 seconds to slow down the display changes and make it visible. The display appears

to count from the old potentiometer position to the new position.

The filter averages the last 8 readings. Choosing a power of two for the number of samples allows division by simple rotates instead of having to use a true division routine.

Additionally, rather than summing the array every time, it’s faster to keep a running

sum, then subtract out the oldest value in the queue and adding in the new value.

© 2007 Microchip Technology Inc. DS41296B-page 31

Page 36

44-Pin Demo Board User’s Guide

3.2.12 Lesson 12: Look-up Table (ROM Array)

Lesson 8 introduced function calls. Lesson 12 shows how function calls and calculated

modification of the Program Counter may be used to implement a look-up table (see

Example 3-11).

It is sometimes useful to implement a table to convert from one value to another.

Expressed in a high-level language it might look like this:

y = function(x);

That is for every value of x, it returns the corresponding y value.

Look-up tables are a fast way to convert an input to meaningful data because the trans-

fer function is pre-calculated and “looked up” rather than calculated on the fly.

PIC microcontrollers implement these by directly modifying the Program Counter (PC).

An example might be a function that converts hexadecimal numbers to the ASCII

equivalent. Each digit’s individual nibble can be pulled out of the number and used as

the index to the look-up table. The index advances the PC to the appropriate RETLW

instruction to load WREG with the corresponding constant and returns to the calling

program.

EXAMPLE 3-11: LOOK-UP TABLE

;Enter with index in Wreg

LookupTable

ADDWF PCL,f ;jump to

RETLW '0' ;index 0

RETLW '1' ;index 1

...

RETLW 'F' ;index 15

If the table falls across a 256 byte program memory boundary, or if somehow the

look-up table is called with an out of bounds index value, it will jump to a location out of

the table.

Good programming practices dictate a few additional instructions. First, since the table

has only sixteen entries, make sure a number no larger than 16 is passed in. The simplest way to do this is to logically AND the contents of WREG before modifying PCL:

ANDLW 0x0F. More complex error recovery schemes may be appropriate, depending

on the application.

In addition, there are some nuances to be aware of should the table cross a 256 word

boundary. The Program Counter is 13 bits wide, but only the lower 8 bits are represented in PCL (see Figure 3-12). The remaining 5 bits are stored in PCLATH. However,

an overflow of the lower 8 bits is not automatically carried over into PCLATH. Instead,

be sure to check for and handle that case in the code. See the PCL and PCLATH

section in the PIC16F882/883/884/886/887 Data Sheet (DS41291) for more details of

how PCLATH is used.

DS41296B-page 32 © 2007 Microchip Technology Inc.

Page 37

44-Pin Demo Board Lessons

FIGURE 3-12: PC LOADING AS DESTINATION OF INSTRUCTION

PCH PCL

12 8 7 0

PC

PCLATH<4:0>

5

PCLATH

8

Instruction with

PCL as

Destination

ALU Result

This lesson uses the look-up table to implement a binary to Gray code converter. Gray

code is a binary code in which only a single bit changes from one sequence to the next.

They are frequently used in encoder applications to avoid wild jumps between states.

Binary encoders are typically implemented as an opaque disk with slots sensed by light

sensors. Due to different threshold levels on different bits, bits may change at slightly

differently times yielding momentary invalid results. Gray code prevents this because

only one bit changes from one sequence to the next. The current code is correct until

it transitions to the next.

The algorithm to convert between binary and Gray code is fairly complex. For a small

number of bits, the table look-up is smaller and faster.

This lesson takes the Analog-to-Digital value upper nibble and converts it to Gray code

displayed on the first four LEDs. The code changes one bit at a time as the potentiom-

eter rotates across its range (seeExample 3-12).

Gray Code Converter

Decimal

Binary

0 0000

1 0001

2 0011

3 0010

4 0110

5 0111

6 0101

7 0100

8 1100

9 1101

10 1111

11 1110

12 1010

13 1011

14 1001

15 1000

© 2007 Microchip Technology Inc. DS41296B-page 33

Page 38

44-Pin Demo Board User’s Guide

EXAMPLE 3-12: CONVERT BINARY TO GRAY CODE

BinaryToGrayCode

ANDLW 0x0F ;mask off invalid entries

MOVWF temp

MOVLW high TableStart ;get high order part of the

;beginning of the table

MOVWF PCLATH

MOVLW low TableStart ;load starting address of table

ADDWF temp,w ;add offset

BTFSC STATUS,C ;did it overflow?

INCF PCLATH,f ;yes: increment PCLATH

MOVWF PCL ;modify PCL

TableStart

RETLW b'0000' ;0

RETLW b'0001' ;1

RETLW b'0011' ;2

RETLW b'0010' ;3

RETLW b'0110' ;4

RETLW b'0111' ;5

RETLW b'0101' ;6

RETLW b'0100' ;7

RETLW b'1100' ;8

RETLW b'1101' ;9

RETLW b'1111' ;10

RETLW b'1110' ;11

RETLW b'1010' ;12

RETLW b'1011' ;13

RETLW b'1001' ;14

RETLW b'1000' ;15

DS41296B-page 34 © 2007 Microchip Technology Inc.

Page 39

Appendix A. Hardware Schematics

A.1 INTRODUCTION

This appendix contains the 44-Pin Demo Board schematic, PCB layout and Bill of

Materials.

FIGURE A-1: 44-PIN DEMO BOARD SCHEMATIC DIAGRAM

44-PIN DEMO BOARD USER’S

GUIDE

®

PIC

© 2007 Microchip Technology Inc. DS41296B-page 35

Page 40

44-Pin Demo Board User’s Guide

FIGURE A-2: 44-PIN DEMO BOARD SILKSCREEN

FIGURE A-3: 44-PIN DEMO BOARD TOP COPPER

DS41296B-page 36 © 2007 Microchip Technology Inc.

Page 41

Hardware Schematics

FIGURE A-4: 44-PIN DEMO BOARD BOTTOM COPPER

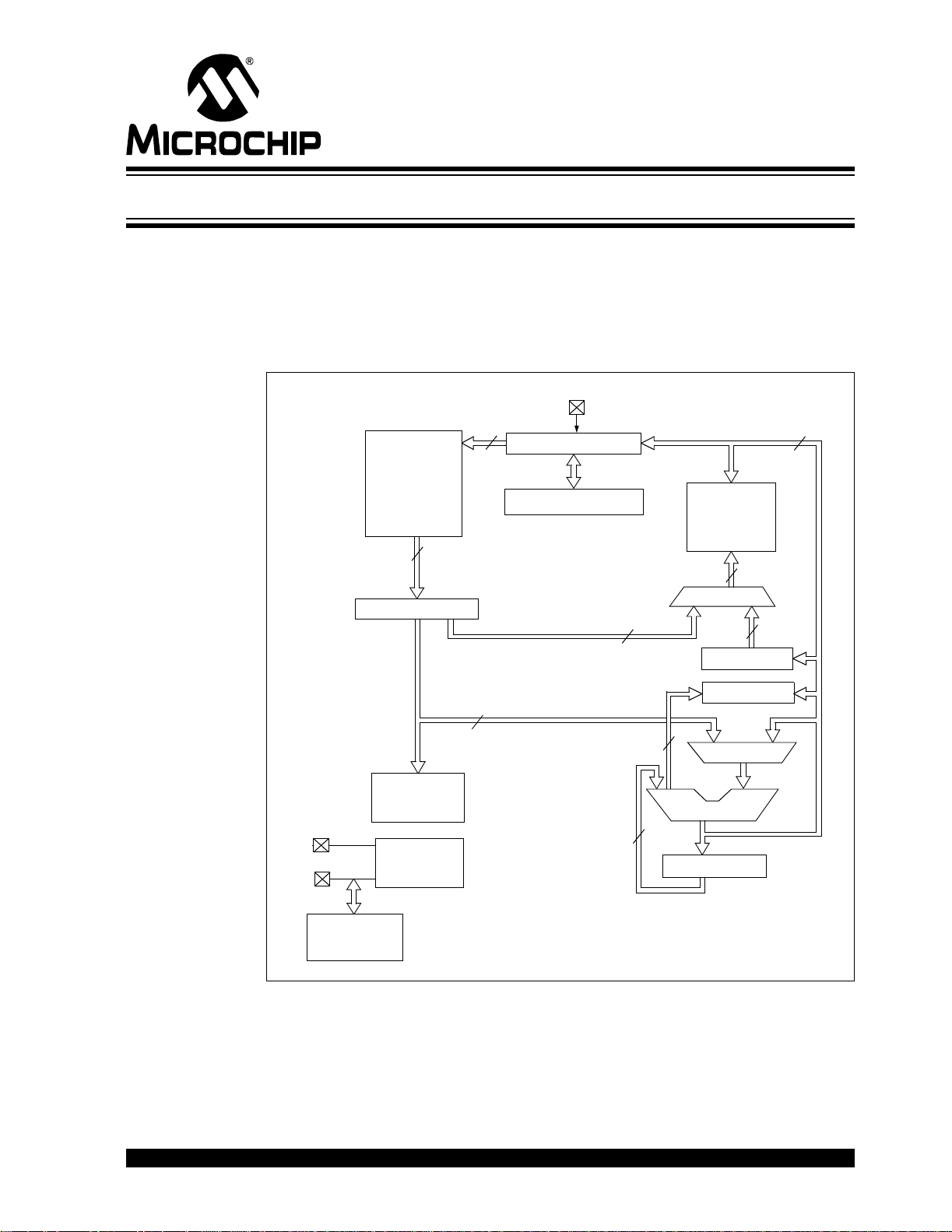

TABLE A-1: 44-PIN DEMO BOARD BILL OF MATERIALS

Bill of Materials

Designation Qty Description

C1, C2, C3 3 Capacitor, Ceramic, 0805 SMT, 0.1 μF, 16V, 5%, X7R

R5-R12 8 Resistor, 0805 SMT, 750Ω, 5%, 1/8W

R1, R3 2 Resistor, 0805 SMT, 1 kΩ, 5%, 1/8W

R2 1 Resistor, 0805 SMT, 10 kΩ, 5%, 1/8W

RP1 1 Potentiometer 10 kΩ, thumbwheel

DS1-DS8 8 LED, 0805 SMT, Red Clear

SW1 1 Switch, push button, momentary

U1 – Microcontroller 1 44-pin PIC

P1 1 Connector, header, right-angle, 6-pin, 0.100” spacing, 0.025”

square

JP1 1 Connector, header, 2-pin, 0.100” spacing, 0.025” square

Rubber feet 4 Bumpon square, 0.40 x 0.10, black

®

MCU

© 2007 Microchip Technology Inc. DS41296B-page 37

Page 42

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Techn ical Su pport:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-67 33

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2 100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5 511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5 533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2 829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5 300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7 250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53 -63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708- 08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

12/08/06

DS41296B-page 38 © 2007 Microchip Technology Inc.

Loading...

Loading...