Page 1

USB7216

6-Port USB 3.2 Gen 2 Type-C® Controller Hub

Highlights

• 6-Port USB Smart Hub with:

- Native USB Gen 2 Type-C® support on

downstream port 1

- Three Standard USB 3.2 Gen 2 downstream ports

- Two Standard USB 2.0 downstream ports

- Internal Hub Feature Controller enables:

-USB to I2C/SPI/I2S/GPIO bridge endpoint support

-USB to internal hub register write and read

• USB Link Power Management (LPM) support

• Programming of firmware image to external SPI

memory device from USB host

• USB-IF Battery Charger revision 1.2 support on

downstream ports (DCP, CDP, SDP)

• Enhanced OEM configuration options available

through either OTP or external SPI memory

• Available in 100-pin (12mm x 12mm) VQFN

RoHS compliant package

• Commercial and industrial grade temperature

support

Target Applications

• Standalone USB Hubs

• Laptop Docks

• PC Motherboards

• PC Monitor Docks

• Multi-function USB 3.2 Gen 2 Peripherals

Key Benefits

• USB 3.2 Gen 2 compliant 10 Gbps, 5 Gbps,

480 Mbps, 12 Mbps, and 1.5Mbps operation

- 5V tolerant USB 2.0 pins

- 1.21V tolerant USB 3.2 Gen 2 pins

- Integrated termination and pull-up/down resistors

• Native USB Type-C Support

- Type-C CC Pin with integrated Rp and Rd resistors

- Integrated multiplexer on USB Type-C enabled

ports. USB 3.2 Gen 2 PHYs are disabled until a

valid Type-C attach is detected, saving idle power.

- Control for external VCONN supply

• Supports battery charging of most popular battery

powered devices on all ports

- USB-IF Battery Charging rev. 1.2 support

(DCP, CDP, SDP)

®

- Apple

- Chinese YD/T 1591-2006/2009 charger emulation

- European Union universal mobile charger support

- Supports additional portable devices

portable product charger emulation

• On-chip Microcontroller

- manages I/Os, VBUS, and other signals

• 96kB RAM, 256kB ROM

• 8kB One-Time-Programmable (OTP) ROM

- Includes on-chip charge pump

• Configuration programming via OTP Memory, SPI

external memory, or SMBus

• FlexConnect

- The roles of the upstream and all downstream

ports are reversible on command

• Multi-Host Endpoint Reflector

- Integrated host-controller endpoint reflector via

CDC/NCM device class for automotive applications

• USB Bridging

- USB to I2C, SPI, I2S, and GPIO

• PortSwap

- Configurable USB 2.0 differential pair signal swap

• PHYBoost

- Programmable USB transceiver drive strength for

recovering signal integrity

• VariSense

- Programmable USB receive sensitivity

• USB Power Delivery Billboard Device Support

- Internal port can enumerate as a Power Delivery

Billboard device to communicate Power Delivery

Alternate Mode negotiation failure cases to host

• Compatible with Microsoft Windows 10, 8, 7, XP,

Apple OS X 10.4+, and Linux hub drivers

• Optimized for low-power operation and low thermal dissipation

• 100-pin VQFN package (12mm x 12mm)

* USB Type-C® and USB-C® are registered trademarks of USB

Implementers Forum.

2018 - 2020 Microchip Technology Inc. DS00003143B-page 1

Page 2

USB7216

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of

your Microchip products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications

Department via E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data

sheet to (480) 792-4150. We welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner

of any page. The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may

exist for current devices. As device/documentation issues become known to us, we will publish an errata sheet. The

errata will specify the revision of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

DS00003143B-page 2 2018 - 2020 Microchip Technology Inc.

Page 3

USB7216

1.0 PREFACE

1.1 General Terms

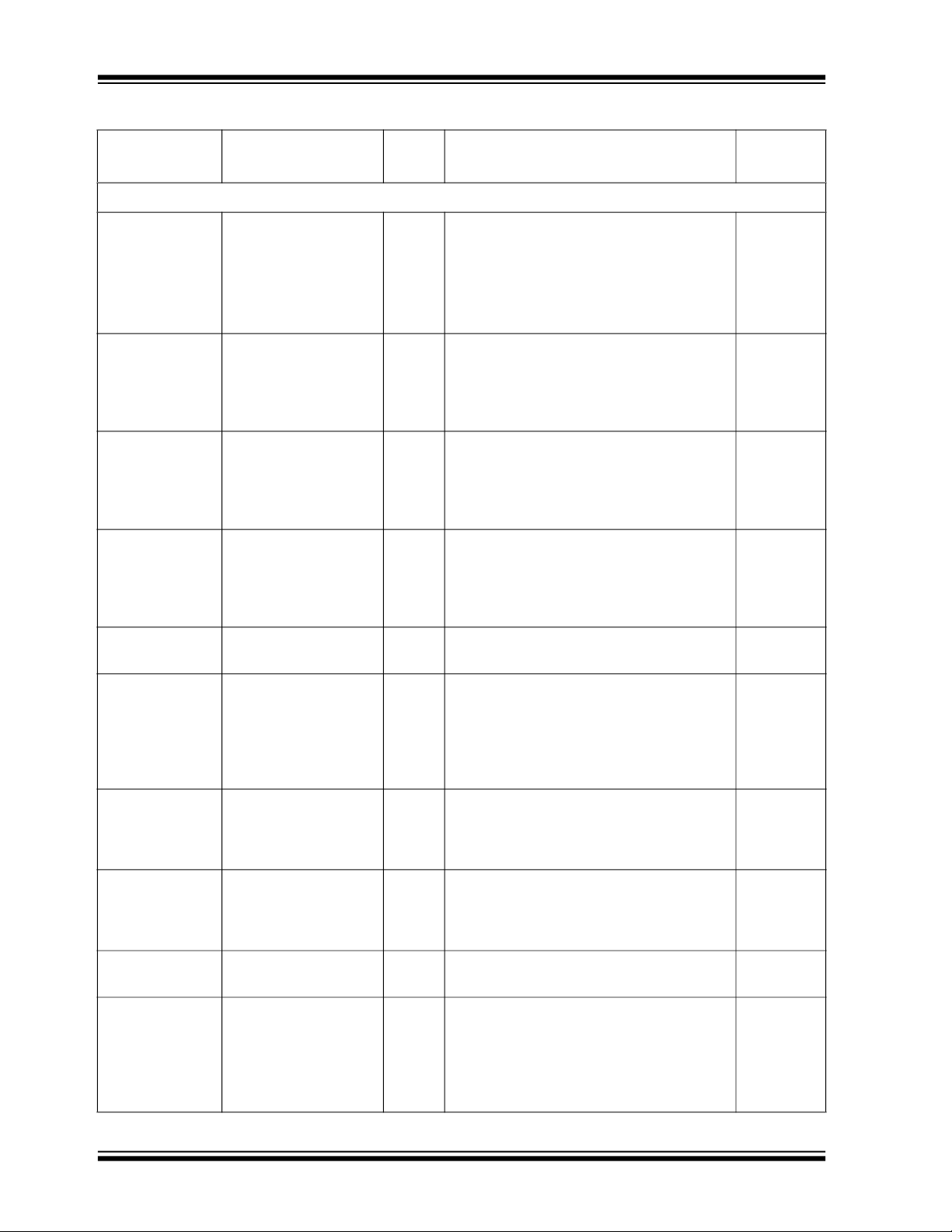

TABLE 1-1: GENERAL TERMS

Term Description

ADC Analog-to-Digital Converter

Byte 8 bits

CDC Communication Device Class

CSR Control and Status Registers

DFP Downstream Facing Port

DWORD 32 bits

EOP End of Packet

EP Endpoint

FIFO First In First Out buffer

FS Full-Speed

FSM Finite State Machine

GPIO General Purpose I/O

HS Hi-Speed

HSOS High Speed Over Sampling

Hub Feature Controller The Hub Feature Controller, sometimes called a Hub Controller for short is the internal

processor used to enable the unique features of the USB Controller Hub. This is not to

be confused with the USB Hub Controller that is used to communicate the hub status

back to the Host during a USB session.

2

C Inter-Integrated Circuit

I

LS Low-Speed

lsb Least Significant Bit

LSB Least Significant Byte

msb Most Significant Bit

MSB Most Significant Byte

N/A Not Applicable

NC No Connect

OTP One Time Programmable

PCB Printed Circuit Board

PCS Physical Coding Sublayer

PHY Physical Layer

PLL Phase Lock Loop

RESERVED Refers to a reserved bit field or address. Unless otherwise noted, reserved bits must

always be zero for write operations. Unless otherwise noted, values are not guaranteed when reading reserved bits. Unless otherwise noted, do not read or write to

reserved addresses.

SDK Software Development Kit

SMBus System Management Bus

UFP Upstream Facing Port

UUID Universally Unique IDentifier

WORD 16 bits

2018 - 2020 Microchip Technology Inc. DS00003143B-page 3

Page 4

USB7216

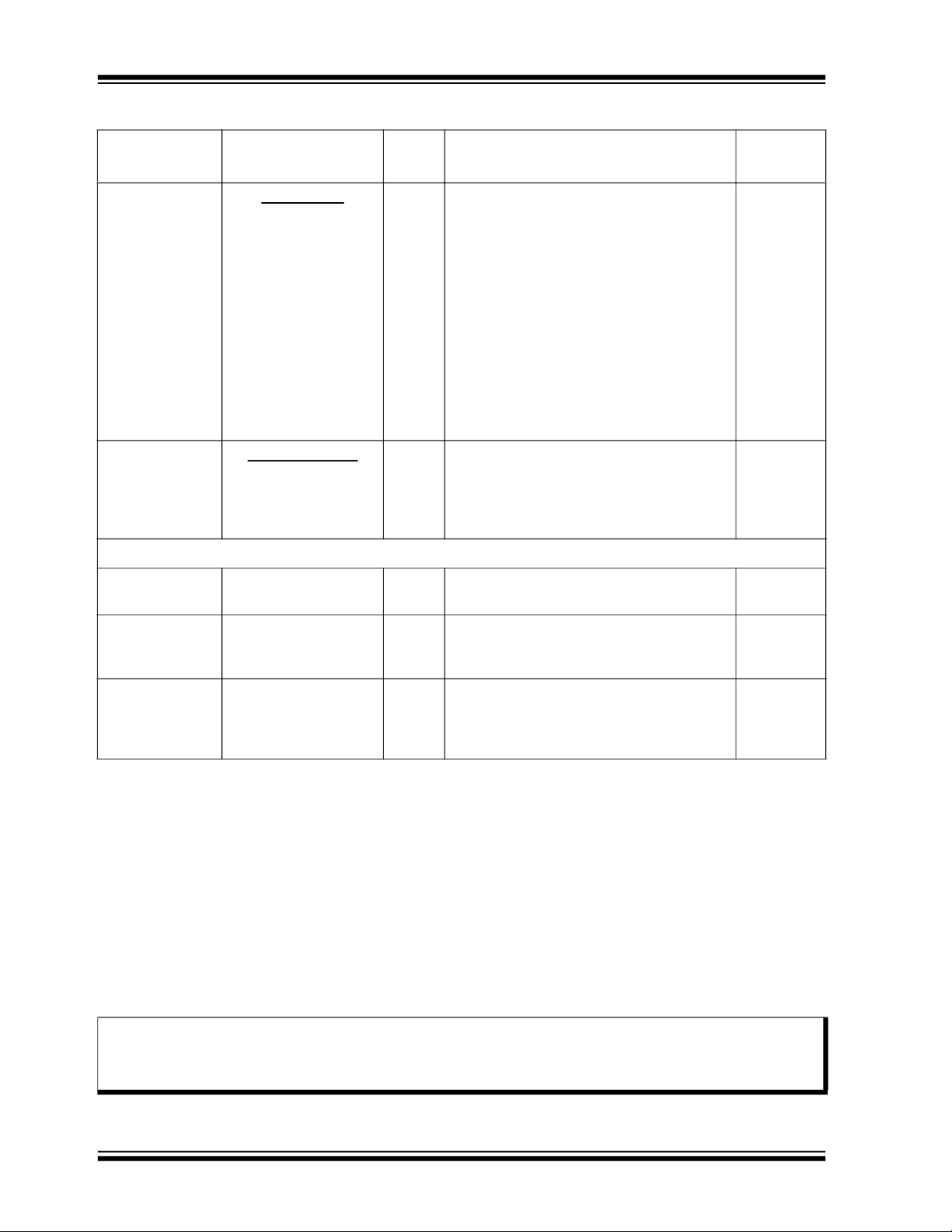

1.2 Buffer Types

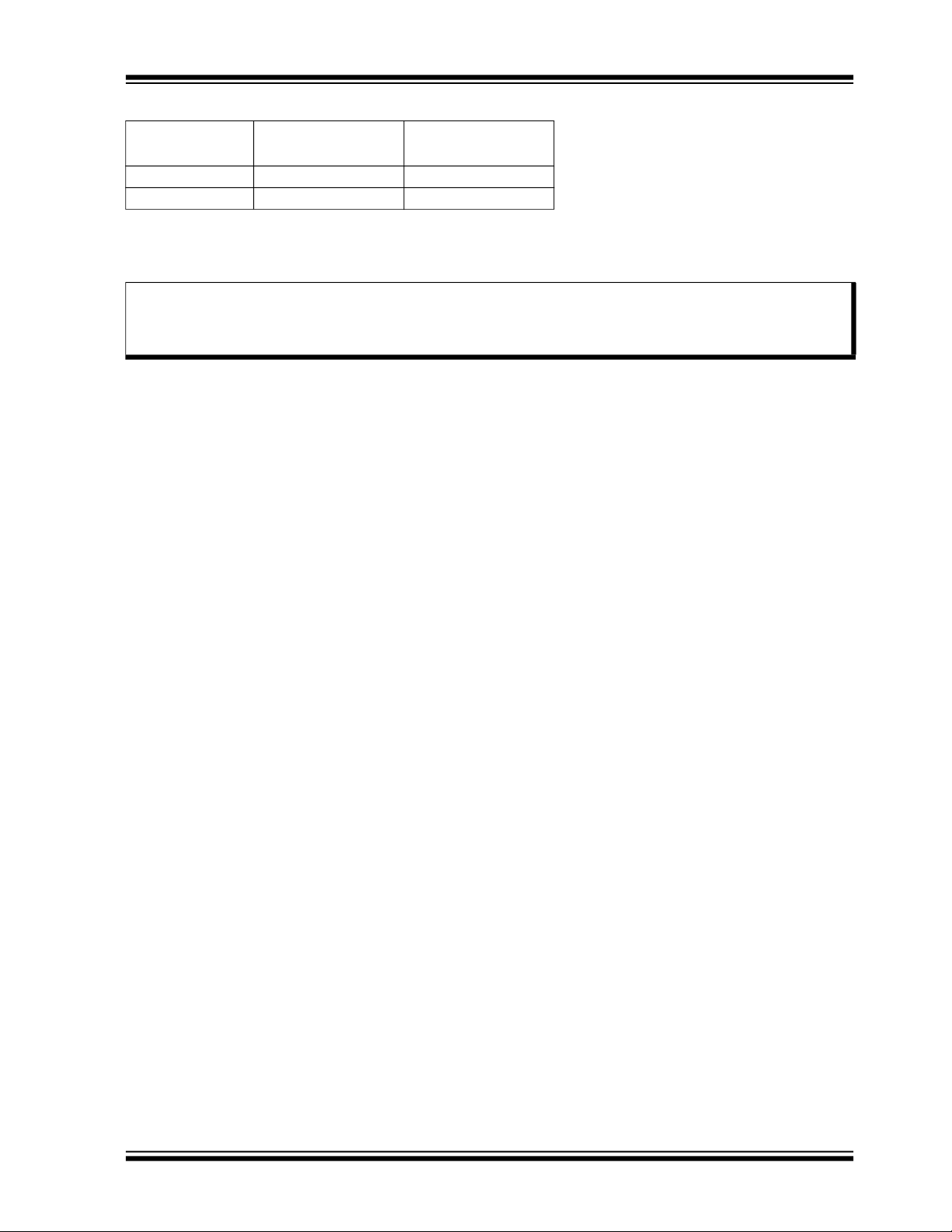

TABLE 1-2: BUFFER TYPES

Buffer Type Description

I Input.

IS Input with Schmitt trigger.

O12 Output buffer with 12 mA sink and 12 mA source.

OD12 Open-drain output with 12 mA sink

PU 50 μA (typical) internal pull-up. Unless otherwise noted in the pin description, internal pull-

PD 50 μA (typical) internal pull-down. Unless otherwise noted in the pin description, internal

ICLK Crystal oscillator input pin

OCLK Crystal oscillator output pin

I/O-U Analog input/output defined in USB specification.

I-R RBIAS.

A Analog.

AIO Analog bidirectional.

P Power pin.

ups are always enabled.

Internal pull-up resistors prevent unconnected inputs from floating. Do not rely on internal

resistors to drive signals external to the device. When connected to a load that must be

pulled high, an external resistor must be added.

pull-downs are always enabled.

Internal pull-down resistors prevent unconnected inputs from floating. Do not rely on

internal resistors to drive signals external to the device. When connected to a load that

must be pulled low, an external resistor must be added.

DS00003143B-page 4 2018 - 2020 Microchip Technology Inc.

Page 5

USB7216

1.3 Pin Reset States

The pin reset state definitions are detailed in Table 1-3. Refer to Section 3.1, Pin Assignments for details on individual

pin reset states.

TABLE 1-3: PIN RESET STATE LEGEND

Symbol Description

AI Analog input

AIO Analog input/output

AO Analog output

PD Hardware enables pull-down

PU Hardware enables pull-up

Y Hardware enables function

Z Hardware disables output driver (high impedance)

PU Hardware enables internal pull-up

PD Hardware enables internal pull-down

1.4 Reference Documents

1. Universal Serial Bus Revision 3.2 Specification, http://www.usb.org

2. Battery Charging Specification, Revision 1.2, Dec. 07, 2010, http://www.usb.org

2

3. I

C-Bus Specification, Version 1.1, http://www.nxp.com/documents/user_manual/UM10204.pdf

2

4. I

S-Bus Specification, http://www.sparkfun.com/datasheets/BreakoutBoards/I2SBUS.pdf

5. System Management Bus Specification, Version 1.0, http://smbus.org/specs

Note: Additional USB7216 resources can be found on the Microchip USB7216 product page at www.micro-

chip.com/USB7216.

2018 - 2020 Microchip Technology Inc. DS00003143B-page 5

Page 6

USB7216

2.0 INTRODUCTION

2.1 General Description

The Microchip USB7216 hub is a low-power, OEM configurable, USB 3.2 Gen 2 hub controller with 6 downstream ports

and advanced features for embedded USB applications. The USB7216 is fully compliant with the Universal Serial Bus

Revision 3.2 Specification and USB 2.0 Link Power Management Addendum. The USB7216 supports 10 Gbps SuperSpeed+ (SS+), 5 Gbps SuperSpeed (SS), 480 Mbps Hi-Speed (HS), 12 Mbps Full-Speed (FS), and 1.5 Mbps LowSpeed (LS) USB downstream devices on four standard USB 3.2 Gen 2 downstream ports and only legacy speeds (HS/

FS/LS) on two standard USB 2.0 downstream ports.

The USB7216 is a standard USB 3.2 Gen 2 hub that supports native basic Type-C with integrated CC logic on downstream port 1. The downstream Type-C port includes an internal USB 3.2 Gen 2 multiplexer; no external multiplexer is

required for Type-C support.

The USB7216 supports the legacy USB speeds (HS/FS/LS) through a dedicated USB 2.0 hub controller that is the culmination of seven generations of Microchip hub feature controller design and experience with proven reliability, interoperability, and device compatibility. The SuperSpeed hub controller operates in parallel with the USB 2.0 controller,

decoupling the 10/5 Gbps SS+/SS data transfers from bottlenecks due to the slower USB 2.0 traffic.

The USB7216 enables OEMs to configure their system using “Configuration Straps.” These straps simplify the configuration process assigning default values to USB 3.2 Gen 2 ports and GPIOs. OEMs can disable ports, enable battery

charging and define GPIO functions as default assignments on power up removing the need for OTP or external SPI

ROM.

The USB7216 supports downstream battery charging. The USB7216 integrated battery charger detection circuitry supports the USB-IF Battery Charging (BC1.2) detection method and most Apple devices. The USB7216 provides the battery charging handshake and supports the following USB-IF BC1.2 charging profiles:

• DCP: Dedicated Charging Port (Power brick with no data)

• CDP: Charging Downstream Port (1.5A with data)

• SDP: Standard Downstream Port (0.5A[USB 2.0]/0.9A[USB 3.2] with data)

Additionally, the USB7216 includes many powerful and unique features such as:

The Hub Feature Controller, an internal USB device dedicated for use as a USB to I

external circuits or devices to be monitored, controlled, or configured via the USB interface.

Multi-Host Endpoint Reflector, which provides unique USB functionality whereby USB data can be “mirrored” between

two USB hosts (Multi-Host) in order to perform a single USB transaction.This capability is fully covered by Microchip

intellectual property (U.S. Pat. Nos. 7,523,243 and 7,627,708) and is instrumental in enabling Apple CarPlay

the Apple iPhone

FlexConnect, which provides flexible connectivity options. One of the USB7216’s downstream ports can be reconfigured to become the upstream port, allowing master capable devices to control other devices on the hub.

PortSwap, which adds per-port programmability to USB differential-pair pin locations. PortSwap allows direct alignment

of USB signals (D+/D-) to connectors to avoid uneven trace length or crossing of the USB differential signals on the

PCB.

PHYBoost, which provides programmable levels of Hi-Speed USB signal drive strength

in the downstream port transceivers. PHYBoost attempts to restore USB signal integrity

in a compromised system environment. The graphic on the right shows an example of

Hi-Speed USB eye diagrams before and after PHYBoost signal integrity restoration. in

a compromised system environment.

VariSense, which controls the Hi-Speed USB receiver sensitivity enabling programmable levels of USB signal receive

sensitivity. This capability allows operation in a sub-optimal system environment, such as when a captive USB cable is

used.

Port Split, which allows for the USB 3.2 Gen 2 and USB 2.0 portions of downstream ports 2, 3, and 4 in Configuration

1 and downstream port 4 (only) in Configuration 2 to operate independently and enumerate two separate devices in

parallel in special applications.

USB Power Delivery Billboard Device, which allows an internal device to enumerate as a Billboard class device when

a Power Delivery Alternate Mode negotiation has failed. The Billboard device will enumerate temporarily to the host PC

when a failure occurs, as indicated by a digital signal from an external Power Delivery controller.

®

becomes a USB Host.

2

C/SPI/GPIO interface that allows

™

, where

DS00003143B-page 6 2018 - 2020 Microchip Technology Inc.

Page 7

USB7216

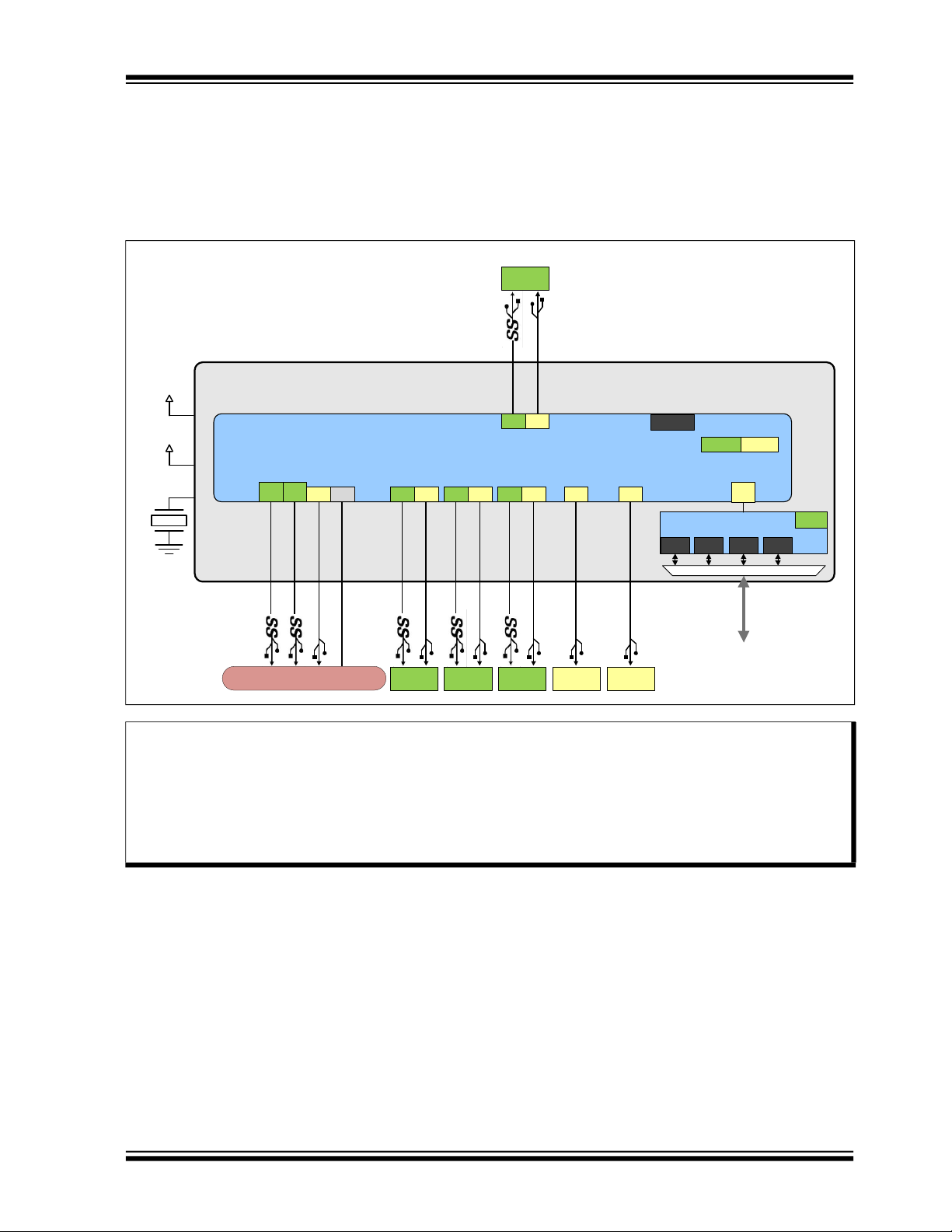

Hub Con troller Lo gic

I2C/SPI

25 Mhz

USB3 USB2

P5

‘A’

USB7216

+3.3 V

VCORE

PHY2PHY1

PHY2

‘B’

PHY1

‘A’

P1

‘C’

CC

P2

‘A’

PHY3 PHY3

P3

‘A’

PHY4 PHY4

P4

‘A’

PHY5 PHY5

P6

‘A’

PHY6

Hub Feature Controller

GPIO SMB

OTP

SPI I2S

Mux

HFC

PHY

PHY0PHY0

P0

‘B’

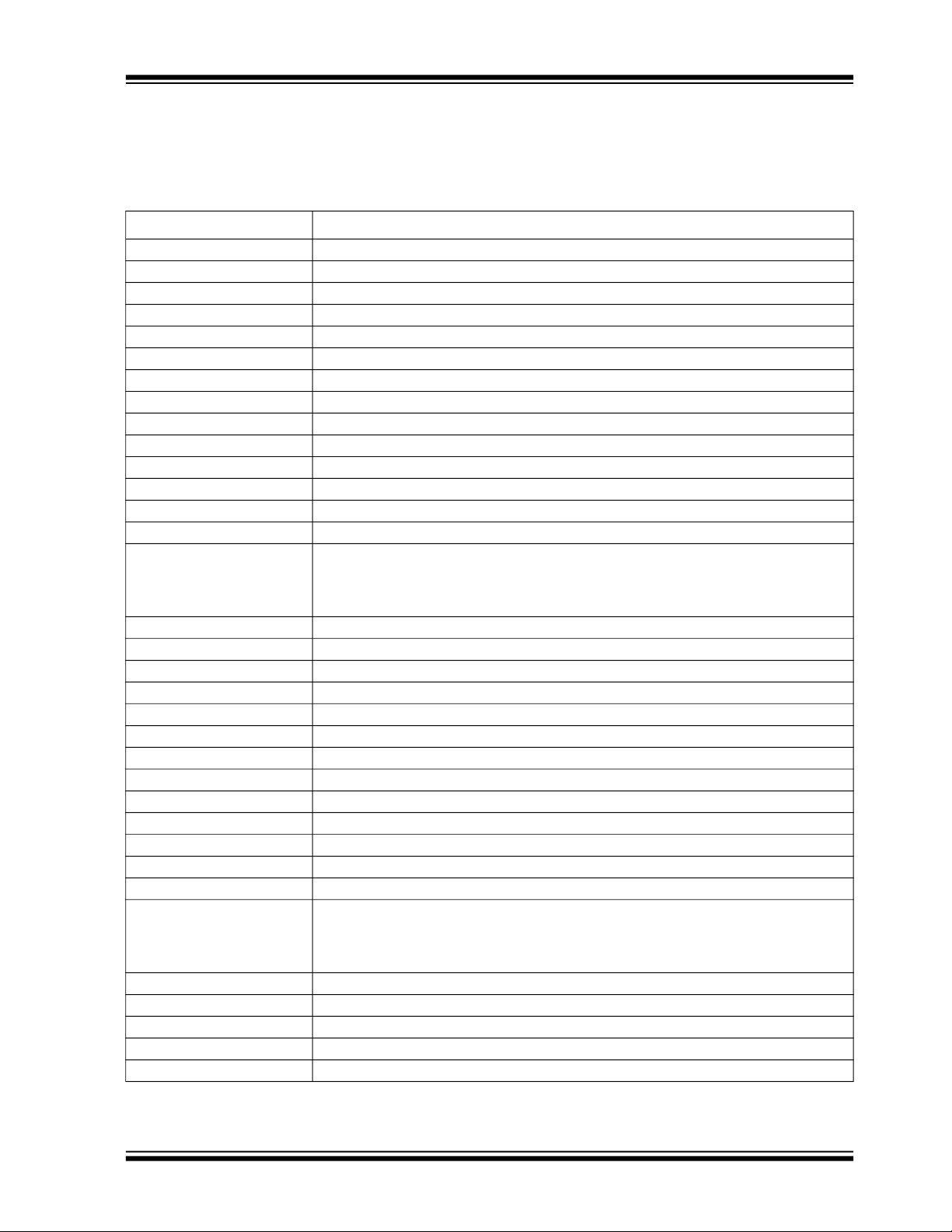

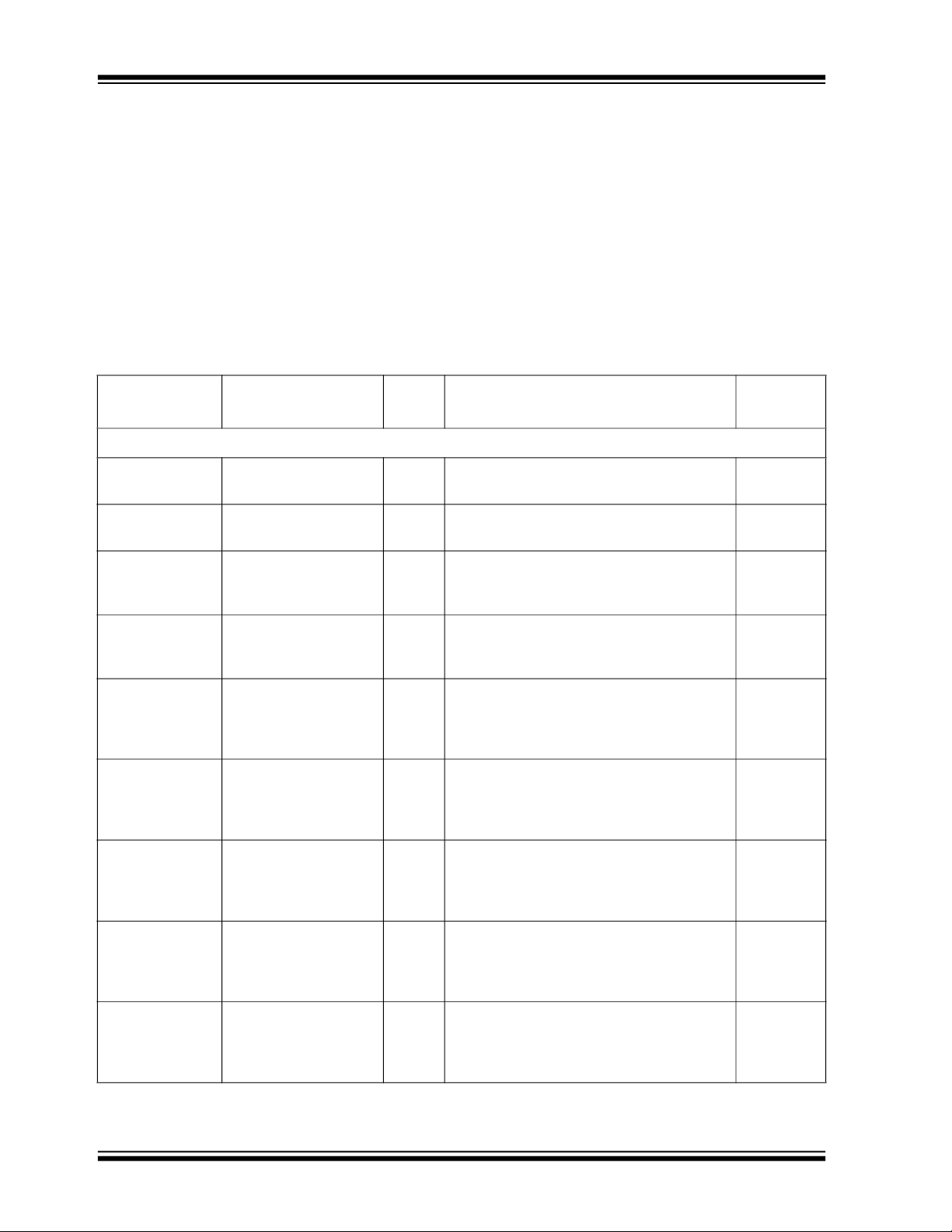

The USB7216 can be configured for operation through internal default settings. Custom OEM configurations are supported through external SPI ROM or OTP ROM. All port control signal pins are under firmware control in order to allow

for maximum operational flexibility and are available as GPIOs for customer specific use.

The USB7216 is available in commercial (0°C to +70°C) and industrial (-40°C to +85°C) temperature range. An internal

block diagram of the USB7216 in an upstream Type-B application is shown in Figure 2-1.

FIGURE 2-1: USB7216 INTERNAL BLOCK DIAGRAM - UPSTREAM TYPE-B APPLICATION

Note: All port numbering in this document is LOGICAL port numbering with the device in the default configuration.

2018 - 2020 Microchip Technology Inc. DS00003143B-page 7

LOGICAL port numbering is the numbering as communicated to the USB host. It is the end result after any

port number remapping or port disabling. The PHYSICAL port number is the port number with respect to

the physical PHY on the chip. PHYSICAL port numbering is fixed and the settings are not impacted by

LOGICAL port renumbering/remapping. Certain port settings are made with respect to LOGICAL port numbering, and other port settings are made with respect to PHYSICAL port numbering. Refer to the “Configuration of USB7202/USB7206/USB725x” application note for details on the LOGICAL vs. PHYSICAL

mapping and additional configuration details.

Page 8

USB7216

Thermal slug connects to VSS

1009998979695949392

9089888786

85

91

16

15

14

13

12

11

10

9

8

6

5

4

3

2

1

7

41

40

39

37

36

35

34

33

32

31

30

29

28

27

26

75

74

73

72

71

70

68

67

66

65

69

64

63

62

61

60

38

25

24

23

22

21

20

19

18

17

50

49

48

46

45

44

43

42

47

59

58

57

56

55

54

53

52

51

84

83

8180797877

76

82

Microchip

USB7216

(Top View 100-VQFN)

RESET_N

DP1_VBUS_MON

PF31

DP1_CC1

USB3DN_RXDM1A

USB3DN_RXDP1A

VCORE

USB3DN_TXDM1A

USB3DN_TXDP1A

USB2DN_DM1/PRT_DIS_M1

PF30

USB3DN_RXDM1B

USB2DN_DP1/PRT_DIS_P1

USB3DN_RXDP1B

VCORE

USB3DN_TXDM1B

USB3DN_TXDP1B

USB2DN_DM5/PRT_DIS_M5

USB2DN_DP5/PRT_DIS_P5

DP1_CC2

CFG_STRAP1

CFG_STRAP2

CFG_STRAP3

TESTEN

VCORE

USB2DN_DP2/PRT_DIS_P2

USB3DN_TXDP3

USB2DN_DM3/PRT_DIS_M3

VCORE

USB3DN_TXDM3

USB2DN_DM2/PRT_DIS_M2

USB2DN_DP3/PRT_DIS_P3

USB3DN_RXDM2

VCORE

USB3DN_TXDM2

USB3DN_TXDP2

VDD33

USB3DN_RXDP2

PF9

USB3DN_RXDP3

USB2DN_DM6/PRT_DIS_M6

USB3DN_RXDM3

PF3

VDD33

PF5

PF4

PF6

PF8

PF7

USB2DN_DP6/PRT_DIS_P6

PF17

SPI_D3/PF25

SPI_D0/CFG_BC_E N/PF22

SPI_CLK/PF21

VDD33

SPI_D1/PF23

PF19

PF26

TEST3

SPI_CE_N/CFG_NON_REM/PF20

TEST1

PF10

PF13

VDD33

TEST2

SPI_D2/PF24

PF18

PF15

PF16

VDD33

VCORE

PF12

PF29

PF11

PF14

PF27

PF28

VCORE

VCORE

USB3DN_TXDM4

USB3DN_TXDP4

USB2DN_DM4/PRT_DIS_M4

USB2DN_DP4/PRT_DIS_P4

VBU S_MO N_UP

VDD33

USB3UP_TXDM

USB3UP_TXDP

USB2UP_DM

USB2UP_DP

VDD33

USB3DN_RXDM4

USB3DN_RXDP4

RBIAS

VDD33

XTALI/CLK_IN

XTALO

ATEST

USB3UP_R XDM

USB3UP_R XDP

VCORE

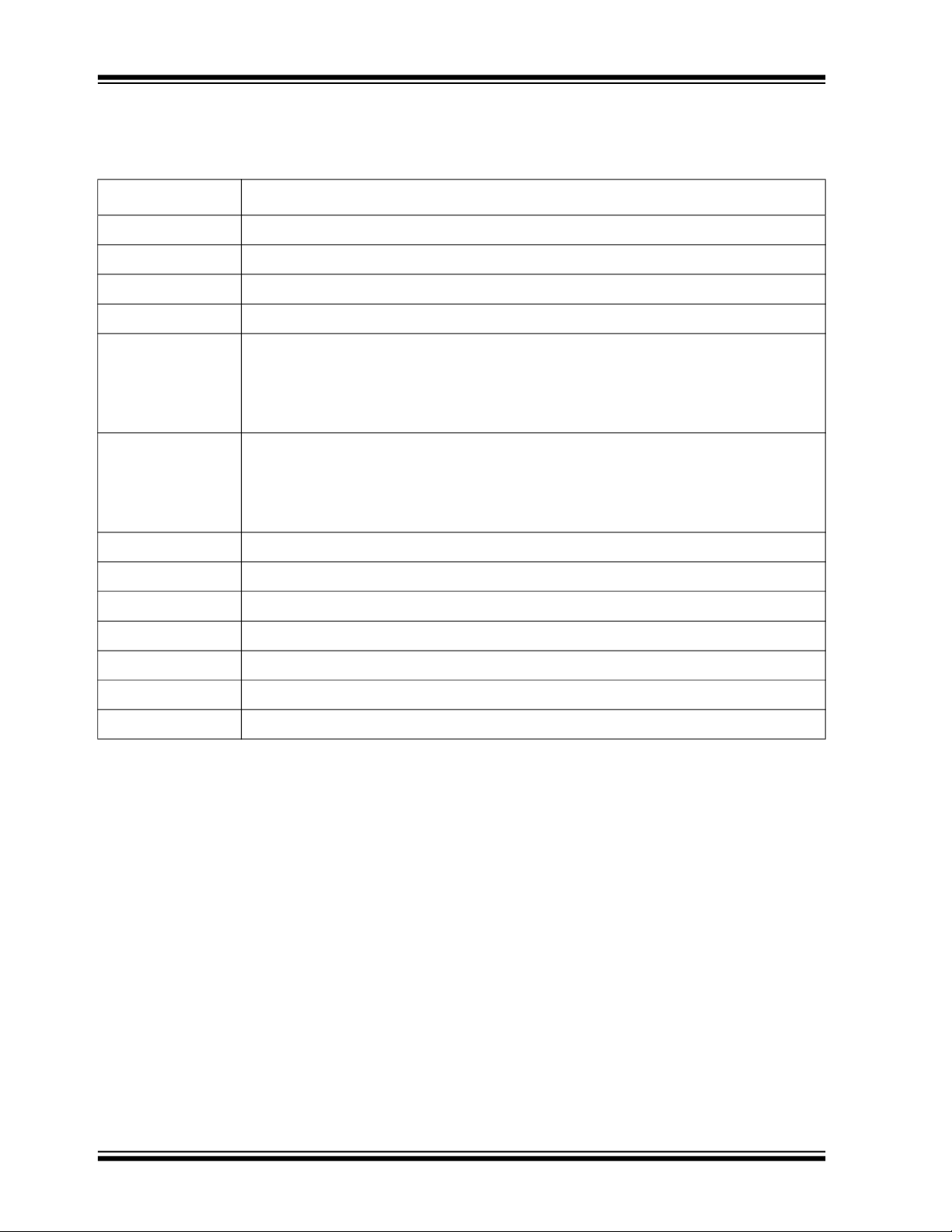

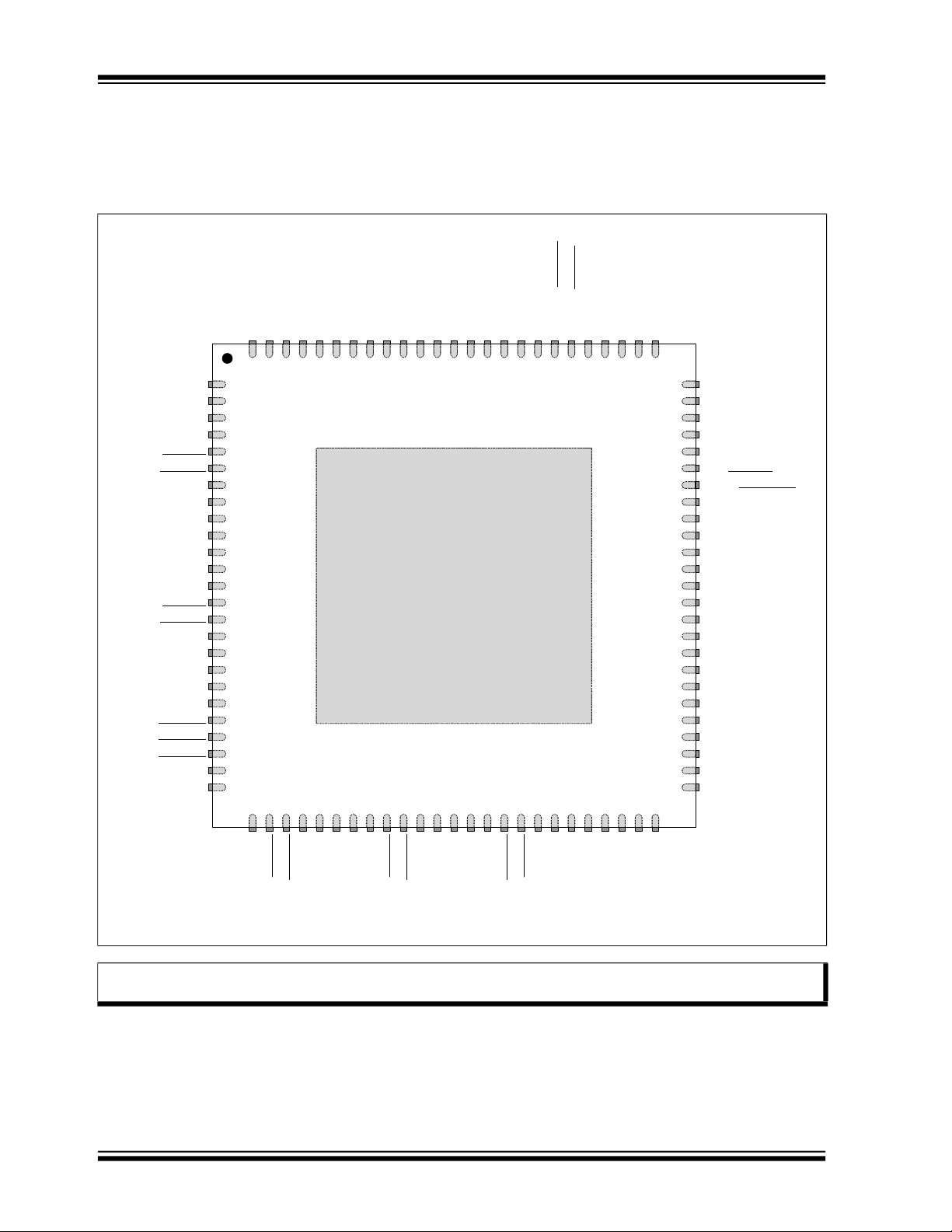

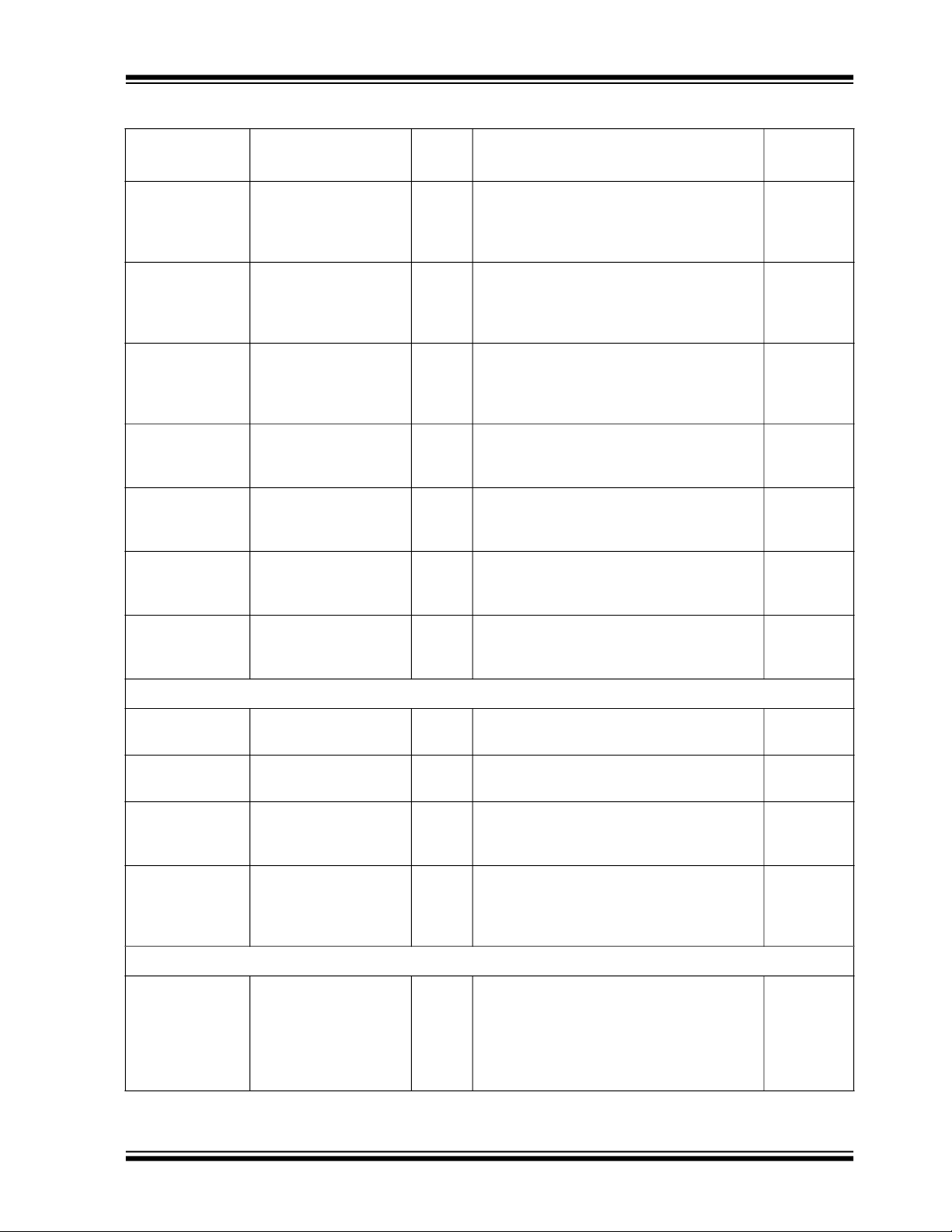

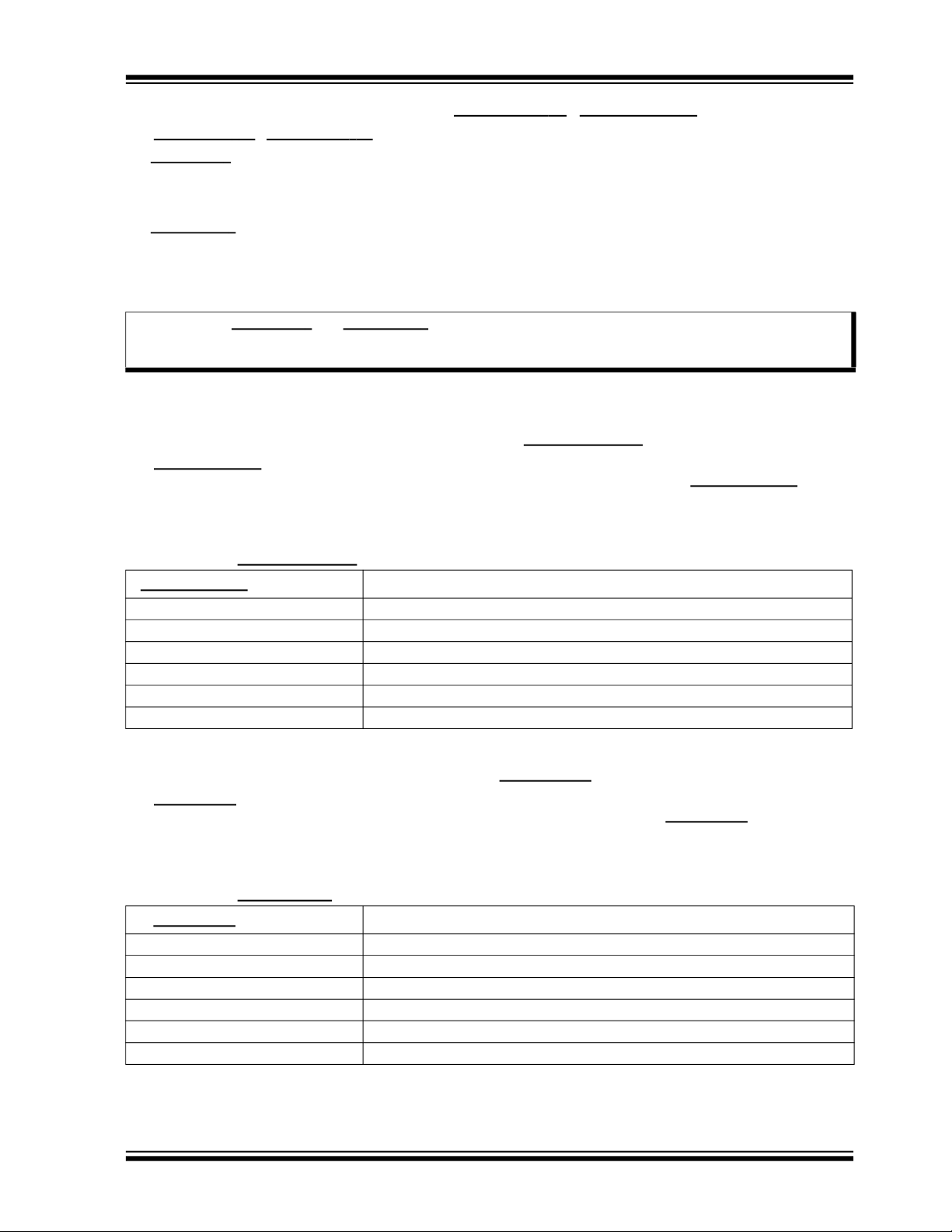

3.0 PIN DESCRIPTIONS

3.1 Pin Assignments

FIGURE 3-1: USB7216 100-VQFN PIN ASSIGNMENTS

Note: Configuration straps are identified by an underlined symbol name. Signals that function as configuration

straps must be augmented with an external resistor when connected to a load.

DS00003143B-page 8 2018 - 2020 Microchip Technology Inc.

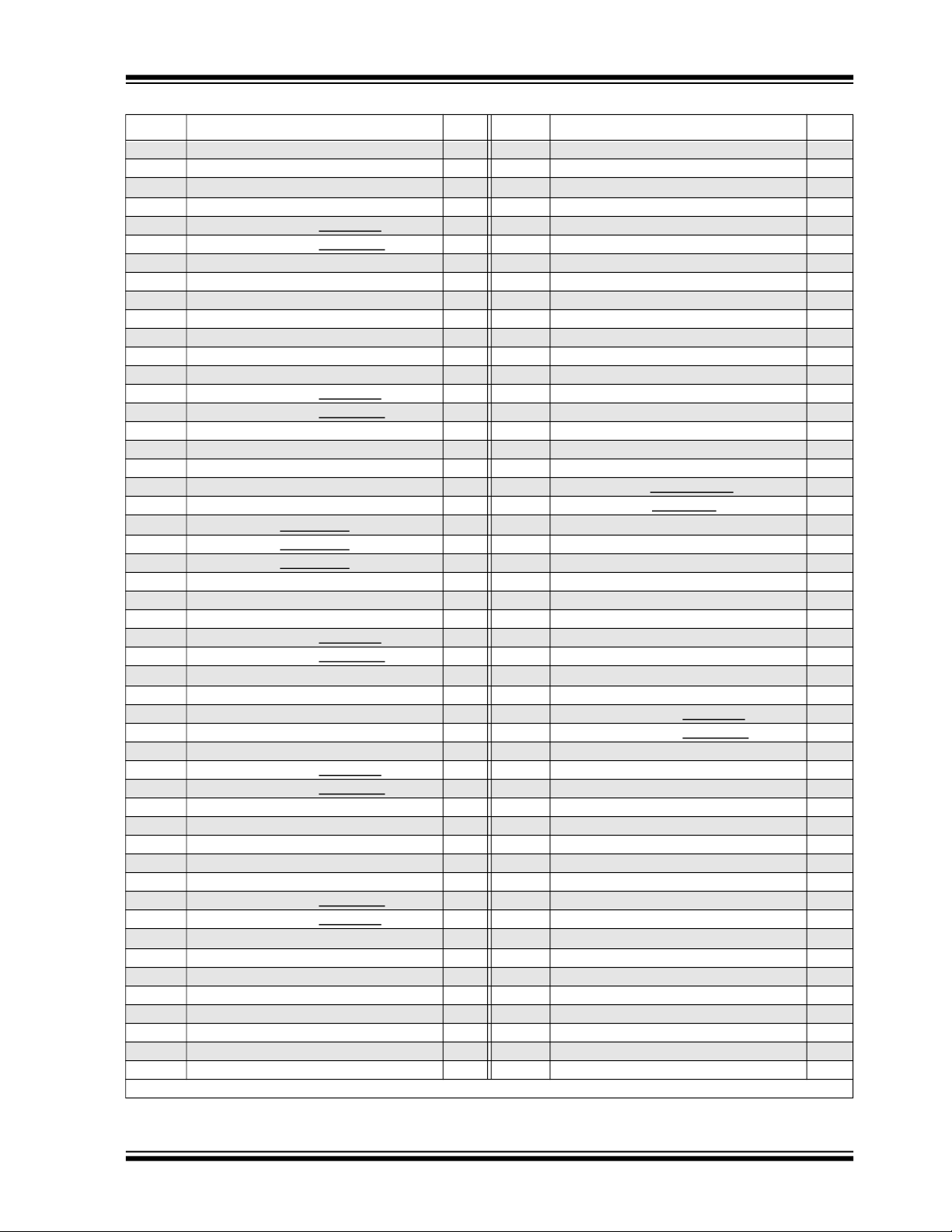

Page 9

USB7216

Pin Num Pin Name Reset Pin Num Pin Name Reset

1 RESET_N Z 51 PF10 PD

2 PF30 Z 52 PF11 PD

3 PF31 Z 53 VDD33 Z

4 DP1_VBUS_MON AI 54 PF12 PD

5 USB2DN_DP1/PRT_DIS_P1 AIO PD 55 VCORE Z

6 USB2DN_DM1/PRT_DIS_M1 AIO PD 56 PF13 PD

7 USB3DN_TXDP1A AO PD 57 PF14 PD

8 USB3DN_TXDM1A AO PD 58 PF15 PD

9 VCORE Z 59 PF16 PD

10 USB3DN_RXDP1A AI PD 60 PF17 PD

11 USB3DN_RXDM1A AI PD 61 PF18 Z

12 DP1_CC1 AI 62 VDD33 Z

13 DP1_CC2 AI 63 TEST1 Z

14 USB2DN_DP5/PRT_DIS_P5 AIO PD 64 TEST2 Z

15 USB2DN_DM5/PRT_DIS_M5 AIO PD 65 TEST3 Z

16 USB3DN_TXDP1B AO PD 66 PF19 Z

17 USB3DN_TXDM1B AO PD 67 VDD33 Z

18 VCORE Z 68 SPI_CLK/PF21 Z

19 USB3DN_RXDP1B AI PD 69 SPI_CE_N/CFG_NON_REM/PF20 PU

20 USB3DN_RXDM1B AI PD 70 SPI_D0/CFG_BC_EN/PF22 Z

21 CFG_STRAP1 Z 71 SPI_D1/PF23 Z

22 CFG_STRAP2 Z 72 SPI_D2/PF24 Z

23 CFG_STRAP3 Z 73 SPI_D3/PF25 Z

24 TESTEN Z 74 PF29 Z

25 VCORE Z 75 PF26 Z

26 VDD33 Z 76 PF27 Z

27 USB2DN_DP2/PRT_DIS_P2 AIO PD 77 PF28 Z

28 USB2DN_DM2/PRT_DIS_M2 AIO PD 78 VCORE Z

29 USB3DN_TXDP2 AO PD 79 VDD33 Z

30 USB3DN_TXDM2 AO PD 80 VBUS_MON_UP AI

31 VCORE Z 81 USB2DN_DP4/PRT_DIS_P4 AIO PD

32 USB3DN_RXDP2 AI PD 82 USB2DN_DM4/PRT_DIS_M4 AIO PD

33 USB3DN_RXDM2 AI PD 83 USB3DN_TXDP4 AO PD

34 USB2DN_DP3/PRT_DIS_P3 AIO PD 84 USB3DN_TXDM4 AO PD

35 USB2DN_DM3/PRT_DIS_M3 AIO PD 85 VCORE Z

36 USB3DN_TXDP3 AO PD 86 USB3DN_RXDP4 AI PD

37 USB3DN_TXDM3 AO PD 87 USB3DN_RXDM4 AI PD

38 VCORE Z 88 VDD33 Z

39 USB3DN_RXDP3 AI PD 89 USB2UP_DP AIO Z

40 USB3DN_RXDM3 AI PD 90 USB2UP_DM AIO Z

41 USB2DN_DM6/PRT_DIS_M6 AIO PD 91 USB3UP_TXDP AO PD

42 USB2DN_DP6/PRT_DIS_P6 AIO PD 92 USB3UP_TXDM AO PD

43 VDD33 Z 93 VCORE Z

44 PF3 Z 94 USB3UP_RXDP AI PD

45 PF4 Z 95 USB3UP_RXDM AI PD

46 PF5 Z 96 ATEST AO

47 PF6 Z 97 XTALO AO

48 PF7 Z 98 XTALI/CLK_IN AI

49 PF8 Z 99 VDD33 Z

50 PF9 Z 100 RBIAS AI

Exposed Pad (VSS) must be connected to ground.

2018 - 2020 Microchip Technology Inc. DS00003143B-page 9

Page 10

USB7216

3.2 Pin Descriptions

This section contains descriptions of the various USB7216 pins. The “_N” symbol in the signal name indicates that the

active, or asserted, state occurs when the signal is at a low voltage level. For example, RESET_N indicates that the

reset signal is active low. When “_N” is not present after the signal name, the signal is asserted when at the high voltage

level.

The terms assertion and negation are used exclusively. This is done to avoid confusion when working with a mixture of

“active low” and “active high” signal. The term assert, or assertion, indicates that a signal is active, independent of

whether that level is represented by a high or low voltage. The term negate, or negation, indicates that a signal is inactive.

The “If Unused” column provides information on how to terminate pins if they are unused in a customer design.

Buffer type definitions are detailed in Section 1.2, Buffer Types.

TABLE 3-1: PIN DESCRIPTIONS

Name Symbol

Upstream USB

3.2 Gen 2 TX D+

Upstream USB

3.2 Gen 2 TX D-

Upstream USB

3.2 Gen 2 RX D+

Upstream USB

3.2 Gen 2 RX D-

Downstream

Port 1 USB 3.2

Gen 2 TX D+

Orientation A

Downstream

Port 1 USB 3.2

Gen 2 TX D- Ori-

entation A

USB3DN_TXDP1A I/O-U Downstream USB Type-C

USB3DN_TXDM1A I/O-U Downstream USB Type-C “Orientation A”

Buffer

Type

USB 3.2 Gen 2 Interfaces

USB3UP_TXDP I/O-U Upstream USB 3.2 Gen 2 Transmit Data

Plus.

USB3UP_TXDM I/O-U Upstream USB 3.2 Gen 2 Transmit Data

Minus.

USB3UP_RXDP I/O-U Upstream USB 3.2 Gen 2 Receive Data

Plus.

USB3UP_RXDM I/O-U Upstream USB 3.2 Gen 2 Receive Data

Minus.

SuperSpeed+ Transmit Data Plus, port 1.

SuperSpeed+ Transmit Data Minus, port 1.

Description If Unused

®

“Orientation A”

Float

Float

Weak pulldown to

GND

Weak pulldown to

GND

Float

Float

Downstream

Port 1 USB 3.2

Gen 2 RX D+

Orientation A

Downstream

Port 1 USB 3.2

Gen 2 RX DOrientation A

Downstream

Port 1 USB 3.2

Gen 2 TX D+

Orientation B

DS00003143B-page 10 2018 - 2020 Microchip Technology Inc.

USB3DN_RXDP1A I/O-U Downstream USB Type-C “Orientation A”

SuperSpeed+ Receive Data Plus, port 1.

USB3DN_RXDM1A I/O-U Downstream USB Type-C “Orientation A”

SuperSpeed+ Receive Data Minus, port 1.

USB3DN_TXDP1B I/O-U Downstream USB Type-C “Orientation B”

SuperSpeed+ Transmit Data Plus, port 1.

Weak pulldown to

GND

Weak pulldown to

GND

Float

Page 11

TABLE 3-1: PIN DESCRIPTIONS (CONTINUED)

USB7216

Name Symbol

Downstream

Port 1 USB 3.2

Gen 2 TX D-

Orientation B

Downstream

Port 1 USB 3.2

Gen 2 RX D+

Orientation B

Downstream

Port 1 USB 3.2

Gen 2 RX D-

Orientation B

Downstream

Ports 2-4 USB

3.2 Gen 2 TX D+

Downstream

Ports 2-4 USB

3.2 Gen 2 TX D-

Downstream

Ports 2-4 USB

3.2 Gen 2 RX D+

USB3DN_TXDM1B I/O-U Downstream USB Type-C “Orientation B”

USB3DN_RXDP1B I/O-U Downstream USB Type-C “Orientation B”

USB3DN_RXDM1B I/O-U Downstream USB Type-C “Orientation B”

USB3DN_TXDP[2:4] I/O-U Downstream SuperSpeed+ Transmit Data

USB3DN_TXDM[2:4] I/O-U Downstream SuperSpeed+ Transmit Data

USB3DN_RXDP[2:4] I/O-U Downstream SuperSpeed+ Receive Data

Buffer

Type

Description If Unused

SuperSpeed+ Transmit Data Minus, port 1.

SuperSpeed+ Receive Data Plus, port 1.

SuperSpeed+ Receive Data Minus, port 1.

Plus, ports 2 through 4.

Minus, ports 2 through 4.

Plus, ports 2 through 4.

Float

Weak pulldown to

GND

Weak pulldown to

GND

Float

Float

Weak pulldown to

GND

Downstream

Ports 2-4 USB

3.2 Gen 2 RX D-

Upstream USB

2.0 D+

Upstream USB

2.0 D-

Downstream

Ports 1-6 USB

2.0 D+

Downstream

Ports 1-6 USB

2.0 D-

SPI Clock SPI_CLK I/O-U SPI clock. If the SPI interface is enabled,

USB3DN_RXDM[2:4] I/O-U Downstream SuperSpeed+ Receive Data

Minus, ports 2 through 4.

USB 2.0 Interfaces

USB2UP_DP I/O-U Upstream USB 2.0 Data Plus (D+). Mandatory

USB2UP_DM I/O-U Upstream USB 2.0 Data Minus (D-). Mandatory

USB2DN_DP[1:6] I/O-U Downstream USB 2.0 Ports 1-6 Data Plus

(D+).

USB2DN_DM[1:6] I/O-U Downstream USB 2.0 Ports 1-6 Data Minus

(D-)

SPI Interface

this pin must be driven low during reset.

Weak pulldown to

GND

Note 3-9

Note 3-9

Connect

directly to

3.3V

Connect

directly to

3.3V

Weak pulldown to

GND

2018 - 2020 Microchip Technology Inc. DS00003143B-page 11

Page 12

USB7216

VBUS_P1

43K

49.9K

DP1_VBUS_MON

TABLE 3-1: PIN DESCRIPTIONS (CONTINUED)

Name Symbol

SPI Data 3-0 SPI_D[3:0] I/O-U SPI Data 3-0. If the SPI interface is enabled,

SPI Chip

Enable

SPI_CE_N I/O12 Active low SPI chip enable input. If the SPI

Buffer

Type

Description If Unused

these signals function as Data 3 through 0.

Note 3-1 SPI_D0 operates as the

CF G _ BC _E N

external SPI memory is not

used. It must be terminated

wit h t h e sel e c t ed st r a p

resistor to 3.3V or GND.

SP I _ D[ 1 : 3 ] sh o u l d b e

connected to GND through

a weak pull-down.

interface is enabled, this pin must be driven

high in powerdown states.

Note 3-2 Operates as the

CFG_NO N _REM

external SPI memory is not

used. It must be terminated

wit h t h e sel e c t ed st r a p

resistor to 3.3V or GND.

s t r a p i f

str ap if

Note 3-1

Note 3-2

Downstream

Port 1 Type-C

Voltage Monitor

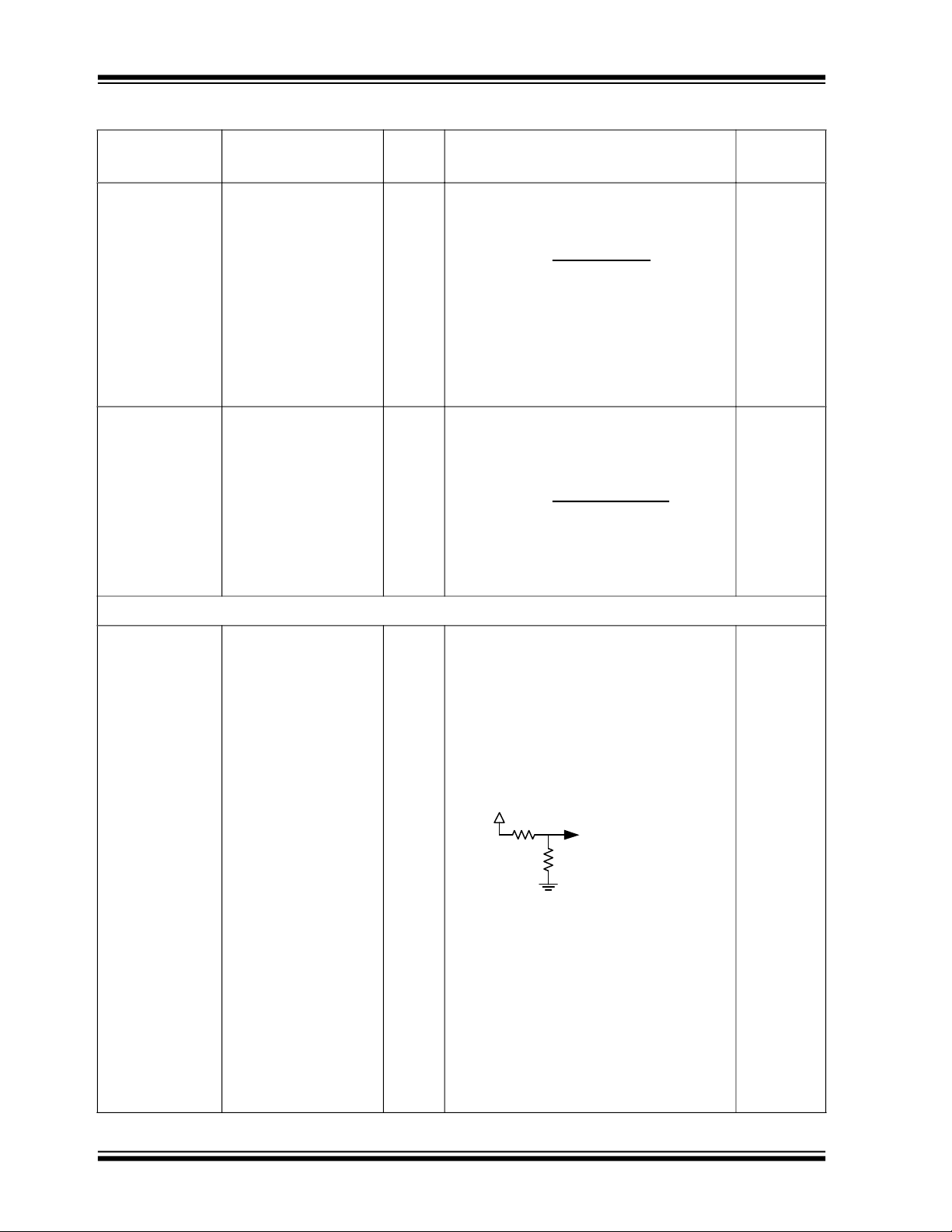

USB Type-C Connector Control

DP1_VBUS_MON AIO Used to detect Type-C VBUS vSafe5V and

vSafe0V states on Port 1. A nominal voltage

of 2.7V (2.4V min -3.0V max) is required to

detect the presence of vSafe5V.

Externally, VBUS can be as high as 5.25 V,

which can be damaging to this pin. The

amplitude of VBUS must be reduced by a

voltage divider. The recommended voltage

divider is shown below. 1% tolerance resistors are recommended.

For proper Type-C port operation, it is critical that this pin actually be connected to

VBUS of the port through the recommended

resistor divider. This pin should not be tied

permanently to a fixed voltage power rail.

Note 3-3 If unused: Weak pull-down

to GND. This pin may be

le ft unu s e d if Port 1 is

disabled or reconfigured to

ope rate in legacy Type-A

m o d e t h r o ug h h u b

configuration.

Note 3-3

DS00003143B-page 12 2018 - 2020 Microchip Technology Inc.

Page 13

TABLE 3-1: PIN DESCRIPTIONS (CONTINUED)

VBUS_UP

43K

49.9K

VBUS_MON_UP

USB7216

Name Symbol

Downstream

Port 1 Type-C

CC1

Downstream

Port 1 Type-C

CC2

Buffer

Type

DP1_CC1 I/O12 Used for Type-C attach and orientation

detection on Port 1. Includes configurable

Rp/Ra selection. Connect this pin directly to

the CC1 pin of the respective Type-C connector.

Note 3-4 If unused: Weak pull-down

DP1_CC2 I/O12 Used for Type-C attach and orientation

detection on Port 1. Includes configurable

Rp/Ra selection. Connect this pin directly to

the CC2 pin of the respective Type-C connector.

Note 3-5 If unused: Weak pull-down

Description If Unused

to GND. This pin may only

be left unused if Port 1 is

disabled or reconfigured to

ope rate in legacy Type-A

m o d e t h r o ug h h u b

configuration.

to GND. This pin may only

be left unused if Port 1 is

disabled or reconfigured to

ope rate in legacy Type-A

m o d e t h r o ug h h u b

configuration.

Note 3-4

Note 3-5

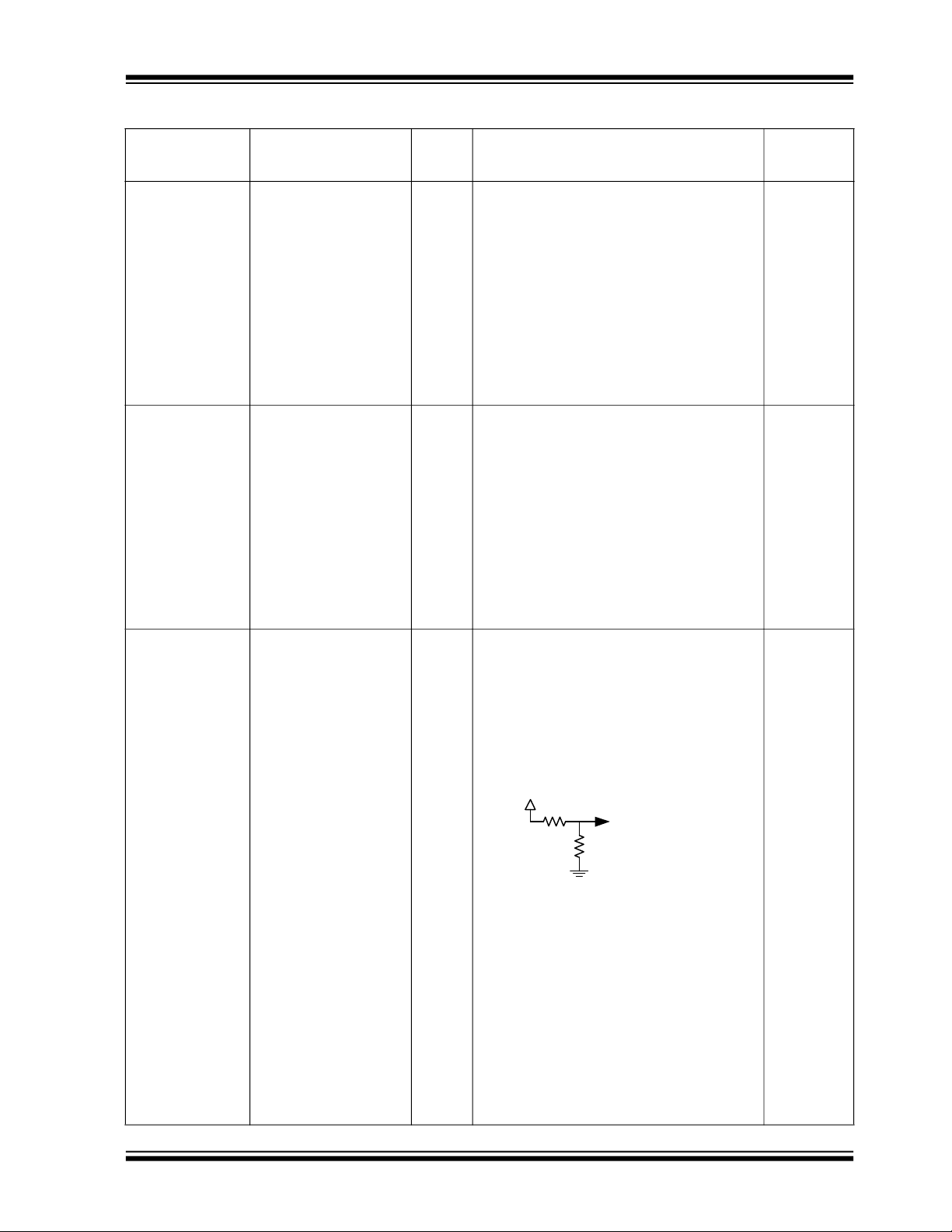

Upstream

Voltage Monitor

VBUS_MON_UP I/O12 Used to detect VBUS on the upstream port.

Externally, VBUS can be as high as 5.25 V,

which can be damaging to this pin. A nominal voltage of 2.7V (2.4V min -3.0V max) is

required to detect the presence of vSafe5V.

The amplitude of VBUS must be reduced by

a voltage divider. The recommended voltage

divider is shown below. 1% tolerance resistors are recommended.

Note: For embedded host applications,

this pin should be controlled by

an I/O on the host processor to a

2.68V logic level.

Mandatory

Note 3-9

2018 - 2020 Microchip Technology Inc. DS00003143B-page 13

Page 14

USB7216

TABLE 3-1: PIN DESCRIPTIONS (CONTINUED)

Name Symbol

Programmable

Function Pins

Test 1 TEST1 A Test 1 pin.

Test 2 TEST2 A Test 2 pin.

Test 3 TEST3 A Test 3 pin.

PF[31:3] I/O12 Programmable function pins.

Buffer

Type

Miscellaneous

Description If Unused

Note 3-6 If unused: depends on the

co n fi g ure d pin functi on.

Ref e r to S e c t io n 3. 3 .4 ,

PF [ 3 1 : 3 ] C o n f i g ur a ti on

(CFG_STRAP[2:1])

This signal is used for test purposes and

must always be pulled-up to 3.3V via a 10

k

resistor.

This signal is used for test purposes and

must always be pulled-up to 3.3V via a 10

k

resistor.

This signal is used for test purposes and

must always be pulled-up to 3.3V via a 10

k

resistor.

Note 3-6

Pull to 3.3V

through a

10 k

resistor

Pull to 3.3V

through a

10 k

resistor

Pull to 3.3V

through a

10 k

resistor

Reset Input RESET_N IS This active low signal is used by the system

to reset the device.

Bias Resistor RBIAS I-R A 12.0 k

ground to this pin to set the transceiver’s

internal bias settings. Place the resistor as

close the device as possible with a dedicated, low impedance connection to the

ground plane.

Test TESTEN I/O12 Test pin.

This signal is used for test purposes and

must always be connected to ground.

Analog Test ATEST A Analog test pin.

This signal is used for test purposes and

must always be left unconnected.

External 25 MHz

Crystal Input

External 25 MHz

Reference Clock

Input

XTALI ICLK External 25 MHz crystal input Mandatory

CLK_IN ICLK External reference clock input.

The device may alternatively be driven by a

single-ended clock oscillator. When this

method is used, XTALO should be left

unconnected.

1.0% resistor is attached from

Mandatory

Note 3-9

Mandatory

Note 3-9

Connect to

GND

Float

Note 3-9

Mandatory

Note 3-9

DS00003143B-page 14 2018 - 2020 Microchip Technology Inc.

Page 15

TABLE 3-1: PIN DESCRIPTIONS (CONTINUED)

USB7216

Name Symbol

External 25 MHz

Crystal Output

Port 6-1 D+

Disable

Configuration

Strap

Buffer

Type

XTALO OCLK External 25 MHz crystal output Float

Configuration Straps

PRT_DIS_P[

6:1] I Port 6-1 D+ Disable Configuration Strap.

These configuration straps are used in conjunction with the corresponding

PRT_DIS_M[

related port (6-1). See Note 3-10.

Both USB data pins for the corresponding

port must be tied to 3.3V to disable the

associated downstream port.

Description If Unused

6:1] straps to disable the

(only if single-ended

clock is

connected

to

CLK_IN)

N/A

Port 6-1 D-

Disable

Configuration

Strap

Non-Removable

Ports

Configuration

Strap

PRT_DIS_M[

CFG_NON_REM

6:1] I Port 6-1 D- Disable Configuration Strap.

These configuration straps are used in conjunction with the corresponding

PRT_DIS_P[

related port (6-1). See Note 3-10.

Both USB data pins for the corresponding

port must be tied to 3.3V to disable the

associated downstream port.

I Non-Removable Ports Configuration Strap.

This configuration strap controls the number

of reported non-removable ports. See

Note 3-10 .

Note 3-7 Mandatory if external SPI

6:1] straps to disable the

me mor y is not us e d for

f i r m w a r e e x e c u t i o n . I f

ext e r na l S P I memory is

us e d f o r fi r m w a r e

ex e c u t i o n, t he n

configuration strap resistor

should be omitted.

Mandatory

Note 3-9

Note 3-7

2018 - 2020 Microchip Technology Inc. DS00003143B-page 15

Page 16

USB7216

TABLE 3-1: PIN DESCRIPTIONS (CONTINUED)

Name Symbol

Battery Charging

Configuration

Strap

Device Mode

Configuration

Straps 3-1

+3.3V I/O Power

Supply Input

CFG_STRAP[3:1]

Buffer

Type

CFG_BC_EN

VDD33 P +3.3 V power and internal regulator input. Mandatory

I/O12 Battery Charging Configuration Strap.

This configuration strap controls the number

of BC 1.2 enabled downstream ports. See

Note 3-10.

Note 3-8 Mandatory if external SPI

I Device Mode Configuration Straps 3-1.

These configuration straps are used to

select the device’s mode of operation. See

Note 3-10.

Power/Ground

Description If Unused

Mandatory

Note 3-9

me mor y is not us e d for

f i r m w a r e e x e c u t i o n . I f

ex t e r na l S P I memory is

us e d f o r fi r m w a r e

ex e c u t i o n, t he n

configuration strap resistor

should be omitted.

Mandatory

Note 3-9

Note 3-9

Digital Core

Power Supply

Input

Ground VSS P Common ground.

Note 3-9 Configuration strap values are latched on Power-On Reset (POR) and the rising edge of RESET_N

(external chip reset). Configuration straps are identified by an underlined symbol name. Signals that

function as configuration straps must be augmented with an external resistor when connected to a

load. For additional information, refer to Section 3.3, Configuration Straps and Programmable

Functions.

Note 3-10 Pin use is mandatory. Cannot be left unused.

VCORE P Digital core power supply input. Mandatory

Note 3-9

Mandatory

Note 3-9

This exposed pad must be connected to the

ground plane with a via array.

3.3 Configuration Straps and Programmable Functions

Configuration straps are multi-function pins that are used during Power-On Reset (POR) or external chip reset

(RESET_N) to determine the default configuration of a particular feature. The state of the signal is latched following

deassertion of the reset. Configuration straps are identified by an underlined symbol name. This section details the various device configuration straps and associated programmable pin functions.

Note: The system designer must guarantee that configuration straps meet the timing requirements specified in

Section 9.6.2, Power-On and Configuration Strap Timing and Section 9.6.3, Reset and Configuration Strap

Timing. If configuration straps are not at the correct voltage level prior to being latched, the device may

capture incorrect strap values.

DS00003143B-page 16 2018 - 2020 Microchip Technology Inc.

Page 17

USB7216

3.3.1 PORT DISABLE CONFIGURATION (PRT_DIS_P[6:1] / PRT_DIS_M[6:1])

The PRT_DIS_P[6:1] / PRT_DIS_M[6:1] configuration straps are used in conjunction to disable the related port (6-1)

For PRT_DIS_P

0 = Port x D+ Enabled

1 = Port x D+ Disabled

For PRT_DIS_M

0 = Port x D- Enabled

1 = Port x D- Disabled

x (where x is the corresponding port 6-1):

x (where x is the corresponding port 6-1):

Note: Both PRT_DIS_P

the associated downstream port. Disabling the USB 2.0 port will also disable the corresponding USB 3.0

port.

x and PRT_DIS_Mx (where x is the corresponding port) must be tied to 3.3 V to disable

3.3.2 NON-REMOVABLE PORT CONFIGURATION (CFG_NON_REM)

The CFG_NON_REM configuration strap is used to configure the non-removable port settings of the device to one of

six settings. These modes are selected by the configuration of an external resistor on the CFG_NON_REM

resistor options are a 200 kΩ pull-down, 200 kΩ pull-up, 10 kΩ pull-down, 10 kΩ pull-up, 10 Ω pull-down, and 10 Ω pullup, as shown in Table 3-2.

pin. The

TABLE 3-2: CFG_NON_REM RESISTOR ENCODING

CFG_NON_REM Resistor Value Setting

200 kΩ Pull-Down All ports removable

200 kΩ Pull-Up Port 1 non-removable

10 kΩ Pull-Down Ports 1, 2 non-removable

10 kΩ Pull-Up Ports 1, 2, 3 non-removable

10 Ω Pull-Down Ports 1, 2, 3, 4 non-removable

10 Ω Pull-Up Ports 1, 2, 3, 4, 5, 6 non-removable

3.3.3 BATTERY CHARGING CONFIGURATION (CFG_BC_EN)

The CFG_BC_EN configuration strap is used to configure the battery charging port settings of the device to one of six

settings. These modes are selected by the configuration of an external resistor on the CFG_BC_EN

options are a 200 kΩ pull-down, 200 kΩ pull-up, 10 kΩ pull-down, 10 kΩ pull-up, 10 Ω pull-down, and 10 Ω pull-up, as

shown in Table 3-3.

pin. The resistor

TABLE 3-3: CFG_BC_EN RESISTOR ENCODING

CFG_BC_EN Resistor Value Setting

200 kΩ Pull-Down Battery charging not enable on any port

200 kΩ Pull-Up BC1.2 DCP and CDP battery charging enabled on Port 1

10 kΩ Pull-Down BC1.2 DCP and CDP battery charging enabled on Ports 1, 2

10 kΩ Pull-Up BC1.2 DCP and CDP battery charging enabled on Ports 1, 2, 3

10 Ω Pull-Down BC1.2 DCP and CDP battery charging enabled on Ports 1, 2, 3, 4

10 Ω Pull-Up BC1.2 DCP and CDP battery charging enabled on Ports 1, 2, 3, 4, 5, 6

2018 - 2020 Microchip Technology Inc. DS00003143B-page 17

Page 18

USB7216

3.3.4 PF[31:3] CONFIGURATION (CFG_STRAP[2:1])

The USB7216 provides 29 programmable function pins (PF[31:3]). These pins can be configured to 2 predefined configuration via the CFG_STRAP[2:1]

CFG_STRAP[2:1]

pins, as detailed in Table 3-4. Resistor values and combinations not detailed in Table 3-4 are reserved

and should not be used.

pins. These configurations are selected via external resistors on the

Note: CFG_STRAP3

is not used and must be pulled-down to ground via a 200 k resistor.

TABLE 3-4: CFG_STRAP[2:1] RESISTOR ENCODING

Mode

CFG_STRAP2

Resistor Value

Configuration 1 200 kΩ Pull-Down 200 kΩ Pull-Down

Configuration 2 200 kΩ Pull-Down 200 kΩ Pull-Up

A summary of the configuration pin assignments for each of the 2 configurations is provided in Table 3-5. For details on

behavior of each programmable function, refer to Table 3-6.

CFG_STRAP1

Resistor Value

TABLE 3-5: PF[31:3] FUNCTION ASSIGNMENT

Pin

Configuration 1

(SMBus/I

2

C)

PF3 DP1_VCONN2 DP1_VCONN2

PF4 DP1_VCONN1 DP1_VCONN1

PF5 DP1_DISCHARGE DP1_DISCHARGE

PF6 GPIO70 GPIO70

PF7 GPIO71 MIC_DET

PF8 GPIO72 GPIO72

PF9 GPIO73 GPIO73

PF10 PRT_CTL2_U3 I2S_SDI

PF11 PRT_CTL3_U3 I2S_MCLK

PF12 PRT_CTL4_U3 PRT_CTL4_U3

PF13 PRT_CTL4 PRT_CTL4

PF14 PRT_CTL3 PRT_CTL3

PF15 PRT_CTL2 PRT_CTL2

PF16 PRT_CTL5 PRT_CTL5

PF17 PRT_CTL1 PRT_CTL1

PF18 ALERT0 ALERT0

PF19 - I2S_SDO

PF20 SPI_CE_N SPI_CE_N

PF21 SPI_CLK SPI_CLK

PF22 SPI_D0 SPI_D0

PF23 SPI_D1 SPI_D1

PF24 SPI_D2 SPI_D2

PF25 SPI_D3 SPI_D3

PF26 SLV_I2C_CLK I2S_SCK

PF27 SLV_I2C_DATA PRT_CTL6

PF28 PRT_CTL6 I2S_LRCK

(

) (

PF29

Note 3-1

Configuration 2

(I2S)

)

Note 3-1

DS00003143B-page 18 2018 - 2020 Microchip Technology Inc.

Page 19

USB7216

TABLE 3-5: PF[31:3] FUNCTION ASSIGNMENT (CONTINUED)

Pin

PF30 MSTR_I2C_CLK MSTR_I2C_CLK

PF31 MSTR_I2C_DATA MSTR_I2C_DATA

Note 3-1 The default function is not used in the USB7216.

Note: The default PFx pin functions can be overridden with additional configuration by modification of the pin mux

registers. These changes can be made during the SMBus configuration stage, by programming to OTP

memory, or during runtime (after hub has attached and enumerated) by register writes via the SMBus slave

interface or USB commands to the internal Hub Feature Controller Device.

Configuration 1

(SMBus/I

2

C)

Configuration 2

(I2S)

2018 - 2020 Microchip Technology Inc. DS00003143B-page 19

Page 20

USB7216

TABLE 3-6: PROGRAMMABLE FUNCTIONS DESCRIPTIONS

Function

Buffer

Type

Master SMBus/I

MSTR_I2C_CLK I/O12 Bridging Master SMBus/I

1). External 1k-10k pull-up resistors to 3.3V are required if the I

Master Interface is to be used.

MSTR_I2C_DATA I/O12 Bridging Master SMBus/I

1). External 1k-10k pull-up resistors to 3.3V are required if the I

Master Interface is to be used.

Slave SMBus/I

SLV_I2C_CLK I/O12 Slave SMBus/I

2

C controller clock (SMBus/I2C controller 2). External 1k-10k pull-up resistors to 3.3V are required if the I

Interface is to be used.

SLV_I2C_DATA I/O12 Slave SMBus/I

2

C controller data (SMBus/I2C controller 2). External

1k-10k pull-up resistors to 3.3V are required if the I

face is to be used.

2

I

S Interface

I2S_SDI I I

I2S_SDO O12 I

I2S_SCK O12 I

I2S_LRCK O12 I

I2S_MCLK O12 I

MIC_DET I I

2

S Serial Data In Weak pull-

2

S Serial Data Out Weak pull-

2

S Continuous Serial Clock Weak pull-

2

S Word Select / Left-Right Clock Weak pull-

2

S Master Clock Weak pull-

2

S Microphone Plug Detect

0 = No microphone plugged into the audio jack

1 = Microphone plugged into the audio jack

Description If Unused

2

C Interface

2

C controller clock (SMBus/I2C controller

2

C

Weak pulldown to

GND

2

C controller data (SMBus/I2C controller

2

C

Weak pulldown to

GND

2

C Interface

2

C Slave

Weak pulldown to

GND

2

C Slave Inter-

Weak pulldown to

GND

down to

GND

down to

GND

down to

GND

down to

GND

down to

GND

Weak pulldown to

GND

DS00003143B-page 20 2018 - 2020 Microchip Technology Inc.

Page 21

TABLE 3-6: PROGRAMMABLE FUNCTIONS DESCRIPTIONS (CONTINUED)

USB7216

Function

ALERT0 I Alert 0

DP1_VCONN1 I/O12 Port 1 VCONN1 enable. Active high signal.

DP1_VCONN2 I/O12 Port 1 VCONN2 enable. Active high signal.

Buffer

Type

Description If Unused

Miscellaneous

Interrupt input for connection to the local companion (UPD360/

UPD350) power delivery controller’s IRQ# signal.

0 = VCONN is turned off.

1 = VCONN is turned on. If DP1_VCONN1 is asserted and >3.0V is

not sensed on the CC1 line, a VCONN fault condition is detected.

Note 3-1 This pin can be left unused only if Port 1 is

disabled or reconfigured to operate as a legacy

Type-A port via OTP/SMBus/SPI configuration.

0 = VCONN is turned off.

1 = VCONN is turned on. If DP1_VCONN2 is asserted and >3.0V is

not sensed on the CC2 line, a VCONN fault condition is detected.

Note 3-2 This pin can be left unused only if Port 1 is

disabled or reconfigured to operate as a legacy

Type-A port via OTP/SMBus/SPI configuration.

Weak pulldown to

GND

(Note 3-1)

Weak pulldown to

GND

(Note 3-2)

DP1_DISCHARGE I/O12 Port 1 DISCHARGE enable. Active high signal.

0 = VBUS discharging is not active.

1 = VBUS is being discharged to GND. This pin only asserts for a

short duration when VBUS is being discharged from 5V (vSafe5V)

to 0V (vSafe0V).

Note 3-3 This pin can be left unused only if Port 1 is

disabled or reconfigured to operate as a legacy

Type-A port via OTP/SMBus/SPI configuration.

PRT_CTL6 I/O12

(PU)

Port 6 power enable / overcurrent sense

When the downstream port is enabled, this pin is set as an input

with an internal pull-up resistor applied. The internal pull-up

enables power to the downstream port while the pin monitors for an

active low overcurrent signal assertion from an external current

monitor on USB port 6.

This pin will change to an output and be driven low when the port is

disabled by configuration or by the host control.

Note: This signal controls both the USB 2.0 and USB 3.2 por-

tions of the port.

Note 3-4 This pin can be left unused only if Port 6 is

disabled via strap/OTP/SMBus/SPI configuration.

Weak pulldown to

GND

(Note 3-3)

Float

(Note 3-4)

2018 - 2020 Microchip Technology Inc. DS00003143B-page 21

Page 22

USB7216

TABLE 3-6: PROGRAMMABLE FUNCTIONS DESCRIPTIONS (CONTINUED)

Function

PRT_CTL5 I/O12

PRT_CTL4 I/O12

Buffer

Type

(PU)

(PU)

Description If Unused

Port 5 power enable / overcurrent sense

When the downstream port is enabled, this pin is set as an input

with an internal pull-up resistor applied. The internal pull-up

enables power to the downstream port while the pin monitors for an

active low overcurrent signal assertion from an external current

monitor on USB port 5.

This pin will change to an output and be driven low when the port is

disabled by configuration or by the host control.

Note: This signal controls both the USB 2.0 and USB 3.2 por-

tions of the port.

Note 3-5 This pin can be left unused only if Port 5 is

disabled via strap/OTP/SMBus/SPI configuration.

Port 4 power enable / overcurrent sense

When the downstream port is enabled, this pin is set as an input

with an internal pull-up resistor applied. The internal pull-up

enables power to the downstream port while the pin monitors for an

active low overcurrent signal assertion from an external current

monitor on USB port 4.

This pin will change to an output and be driven low when the port is

disabled by configuration or by the host control.

Note: When PortSplit is disabled, this signal controls both the

USB 2.0 and USB 3.2 portions of the port. When

PortSplit is enabled, this signal controls the USB 2.0

portion of the port only.

Note 3-6 This pin can be left unused only if Port 4 is

disabled via strap/OTP/SMBus/SPI configuration.

Float

(Note 3-5)

Float

(Note 3-6)

PRT_CTL3 I/O12

(PU)

DS00003143B-page 22 2018 - 2020 Microchip Technology Inc.

Port 3 power enable / overcurrent sense

When the downstream port is enabled, this pin is set as an input

with an internal pull-up resistor applied. The internal pull-up

enables power to the downstream port while the pin monitors for an

active low overcurrent signal assertion from an external current

monitor on USB port 3.

This pin will change to an output and be driven low when the port is

disabled by configuration or by the host control.

Note: When PortSplit is disabled, this signal controls both the

USB 2.0 and USB 3.2 portions of the port. When

PortSplit is enabled, this signal controls the USB 2.0

portion of the port only.

Note 3-7 This pin can be left unused only if Port 3 is

disabled via strap/OTP/SMBus/SPI configuration.

Float

(Note 3-7)

Page 23

TABLE 3-6: PROGRAMMABLE FUNCTIONS DESCRIPTIONS (CONTINUED)

USB7216

Function

PRT_CTL2 I/O12

PRT_CTL1 I/O12

Buffer

Type

(PU)

(PU)

Description If Unused

Port 2 power enable / overcurrent sense

When the downstream port is enabled, this pin is set as an input

with an internal pull-up resistor applied. The internal pull-up

enables power to the downstream port while the pin monitors for an

active low overcurrent signal assertion from an external current

monitor on USB port 2.

This pin will change to an output and be driven low when the port is

disabled by configuration or by the host control.

Note: When PortSplit is disabled, this signal controls both the

USB 2.0 and USB 3.2 portions of the port. When

PortSplit is enabled, this signal controls the USB 2.0

portion of the port only.

Note 3-8 This pin can be left unused only if Port 2 is

disabled via strap/OTP/SMBus/SPI configuration.

Port 1 power enable / overcurrent sense

When the downstream port is enabled, this pin is set as an input

with an internal pull-up resistor applied. The internal pull-up

enables power to the downstream port while the pin monitors for an

active low overcurrent signal assertion from an external current

monitor on USB port 1.

Float

(Note 3-4)

Float

(Note 3-4)

This pin will change to an output and be driven low when the port is

disabled by configuration or by the host control.

Note: This signal controls both the USB 2.0 and USB 3.2 por-

tions of the port.

Note 3-9 This pin can be left unused only if Port 1 is

disabled via strap/OTP/SMBus/SPI configuration.

PRT_CTL4_U3 O12 Port 4 USB 3.2 PortSplit power enable

This signal is an active high control signal used to enable to the

USB 3.2 portion of the downstream port 4 when PortSplit is

enabled. When PortSplit is disabled, this pin is not used.

Note: This signal should only be used to control an embedded

USB 3.2 device.

PRT_CTL3_U3 O12 Port 3 USB 3.2 PortSplit power enable

This signal is an active high control signal used to enable to the

USB 3.2 portion of the downstream port 3 when PortSplit is

enabled. When PortSplit is disabled, this pin is not used.

Note: This signal should only be used to control an embedded

USB 3.2 device.

Float

Float

2018 - 2020 Microchip Technology Inc. DS00003143B-page 23

Page 24

USB7216

TABLE 3-6: PROGRAMMABLE FUNCTIONS DESCRIPTIONS (CONTINUED)

Function

PRT_CTL2_U3 O12 Port 2 USB 3.2 PortSplit power enable

GPIOx I/O12 General Purpose Input/Output

Buffer

Type

Description If Unused

This signal is an active high control signal used to enable to the

USB 3.2 portion of the downstream port 3 when PortSplit is

enabled. When PortSplit is disabled, this pin is not used.

Note: This signal should only be used to control an embedded

USB 3.2 device.

(x = 70-73)

Float

Weak pulldown to

GND

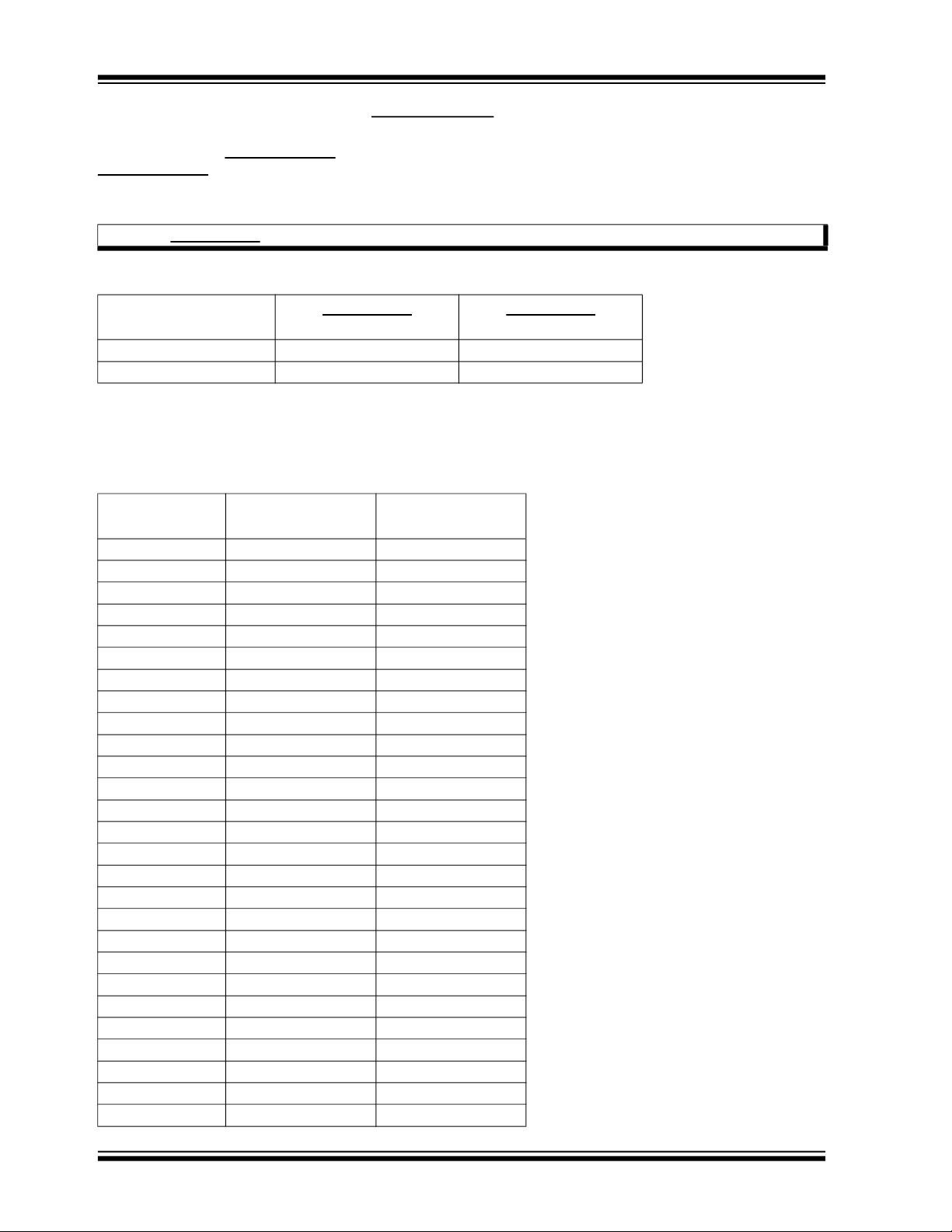

3.4 Physical and Logical Port Mapping

The USB72xx family of devices are based upon a common architecture, but all have different modifications and/or pin

bond outs to achieve the various device configurations. The base chip is composed of a total of 6 USB3 PHYs and 7

USB2 PHYs. These PHYs are physically arranged on the chip in a certain way, which is referred to as the PHYSICAL

port mapping.

The actual port numbering is remapped by default in different ways on each device in the family. This changes the way

that the ports are numbered from the USB host’s perspective. This is referred to as LOGICAL mapping.

The various configuration options available for these devices may, at times, be with respect to PHYSICAL mapping or

LOGICAL mapping. Each individual configuration option which has a PHYSICAL or LOGICAL dependency is declared

as such within the register description.

The PHYSICAL vs. LOGICAL mapping is described for all port related pins in Table 3-7. A system design in schematics

and layout is generally performed using the pinout in Section 3.1, Pin Assignments, which is assigned by the default

LOGICAL mapping. Hence, it may be necessary to cross reference the PHYSICAL vs. LOGICAL look up tables when

determining the hub configuration.

Note: The MPLAB Connect tool makes configuration simple; the settings can be selected by the user with respect

to the LOGICAL port numbering. The tool handles the necessary linking to the PHYSICAL port settings.

Refer to Section 6.0, Device Configuration for additional information.

DS00003143B-page 24 2018 - 2020 Microchip Technology Inc.

Page 25

USB7216

TABLE 3-7: USB7216 PHYSICAL VS. LOGICAL PORT MAPPING

Device

Pin

10 USB3DN_RXDP1A X X

11 USB3DN_RXDM1A X X

14 USB2DN_DP5 X X

15 USB2DN_DM5 X X

16 USB3DN_TXDP1B X X

17 USB3DN_TXDM1B X X

19 USB3DN_RXDP1B X X

20 USB3DN_RXDM1B X X

27 USB2DN_DP2 X X

28 USB2DN_DM2 X X

29 USB3DN_TXDP2 X X

30 USB3DN_TXDM2 X X

32 USB3DN_RXDP2 X X

33 USB3DN_RXDM2 X X

34 USB2DN_DP3 X X

35 USB2DN_DM3 X X

36 USB3DN_TXDP3 X X

37 USB3DN_TXDM3 X X

39 USB3DN_RXDP3 X X

40 USB3DN_RXDM3 X X

41 USB2DN_DM6 X X

42 USB2DN_DP6 X X

81 USB2DN_DP4 X X

82 USB2DN_DM4 X X

83 USB3DN_TXDP4 X X

84 USB3DN_TXDM4 X X

86 USB3DN_RXDP4 X X

87 USB3DN_RXDM4 X X

89 USB2UP_DP X X

90 USB2UP_DM X X

91 USB3UP_TXDP X X

92 USB3UP_TXDM X X

94 USB3UP_RXDP X X

95 USB3UP_RXDM X X

Pin Name (as in datasheet)

5 USB2DN_DP1 X X

6 USB2DN_DM1 X X

7 USB3DN_TXDP1A X X

8 USB3DN_TXDM1A X X

LOGICAL PORT NUMBER PHYSICAL PORT NUMBER

0 1 2 3 4 5 6 0 1 2 3 4 5 6

2018 - 2020 Microchip Technology Inc. DS00003143B-page 25

Page 26

USB7216

+3.3V

Supply

USB721 6

3.3V Internal Logic

VDD33

(x8)

VSS

(exposed pad)

Digital Core

Internal Logic

VCORE

(x9)

VCORE

Supply

+3.3V

0. 1uF

0. 001uF

x8

+3.3V

4. 7uF

VCORE

0. 1uF

0. 001uF

x9

VCOR E

4. 7uF

USB7216

SPI_CE_N

SPI_CLK

SPI_D0

SPI_D1

Quad-SPI Flash

CE#

CLK

SIO0

SIO1

SPI_D2

SPI_D3

SIO2/WPn

SIO3/HOLDn

+3.3V

10K

4.0 DEVICE CONNECTIONS

4.1 Power Connections

Figure 4-1 illustrates the device power connections.

FIGURE 4-1: POWER CONNECTIONS

4.2 SPI Flash Connections

Figure 4-2 illustrates the Quad-SPI flash connections.

FIGURE 4-2: QUAD-SPI FLASH CONNECTIONS

DS00003143B-page 26 2018 - 2020 Microchip Technology Inc.

Page 27

4.3 SMBus/I2C Connections

+3.3V

USB721 6

x_I2 C_C LK

x_I2C_DAT

SMBus/I2C

Clock

Data

4.7K

+3.3V

4.7K

USB721 6

I2S_LRCK

I2S_SDO

I2S_SD

I2S_MCLK

CODEC

I2S_SCK

+3. 3V

10K

10K

I2S

MSTR_I2C_CLK

MSTR_I2C_DAT

I2C

Audio Jack

MIC_DET

Figure 4-3 illustrates the SMBus/I2C connections.

FIGURE 4-3: SMBUS/I2C CONNECTIONS

4.4 I2S Connections

Figure 4-4 illustrates the I2S connections.

USB7216

FIGURE 4-4: I

2

S CONNECTIONS

2018 - 2020 Microchip Technology Inc. DS00003143B-page 27

Page 28

USB7216

Combine OTP

Config Data

In SPI Mode

& Ext. SPI ROM

present?

YES

NO

Run From

External SPI ROM

(SPI_INIT)

SMBus Slave Pull-ups?

RESET_N deasserted

Modify Config

Based on Config

Straps

(CFG_ROM)

Load Config from

Internal ROM

YES

NO

(SMBUS_CHECK)

Perform SMBus/I2C

Initializati on

SOC Done?

YES

NO

(CFG_SMBUS)

(CFG_OTP)

Hub Connect

(USB_ATTACH)

Normal Operation

(NORMAL_MODE)

(CFG_STRAP)

Configuration 1?

YES

NO

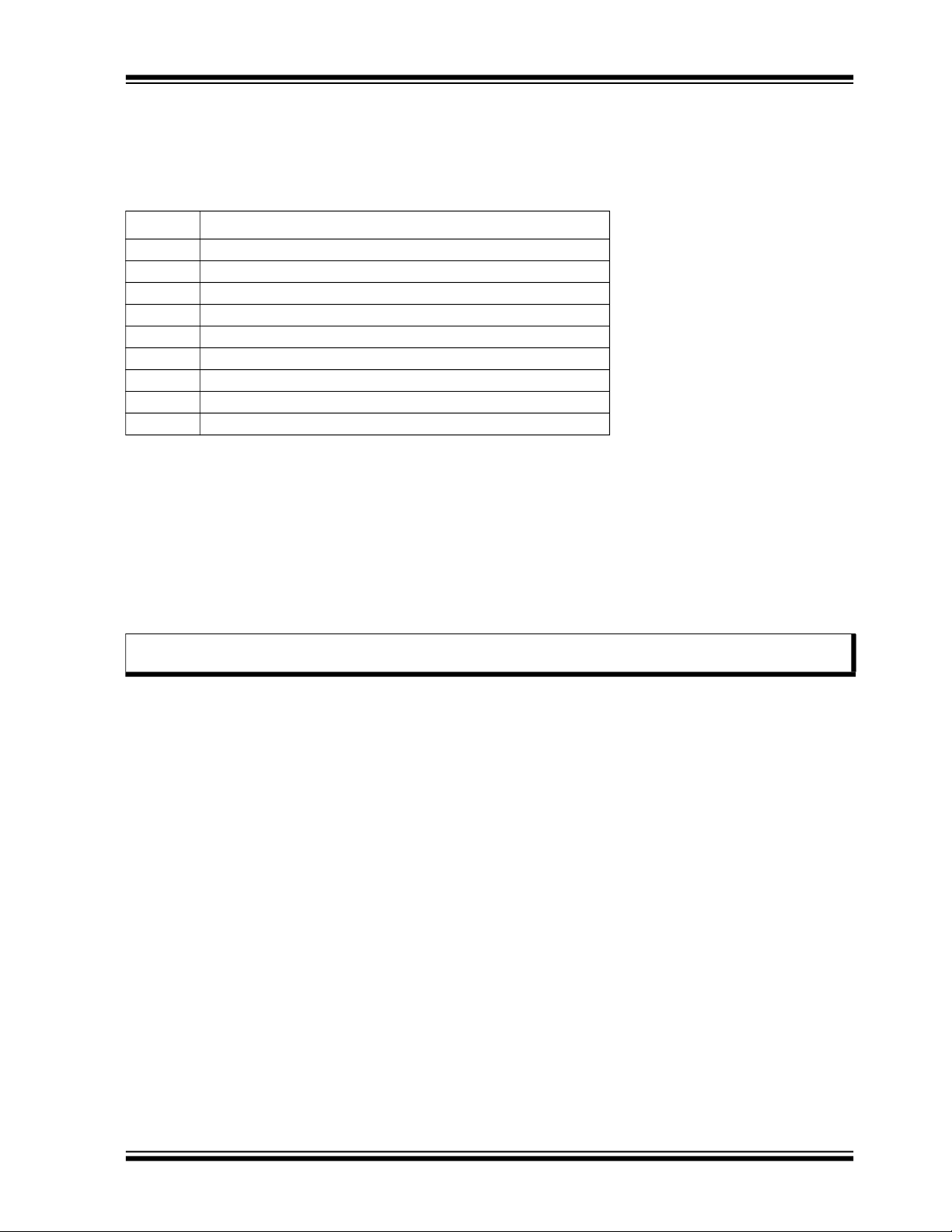

5.0 MODES OF OPERATION

The device provides two main modes of operation: Standby Mode and Hub Mode. These modes are controlled via the

RESET_N pin, as shown in Table 5-1.

TABLE 5-1: MODES OF OPERATION

RESET_N Input Summary

0 Standby Mode: This is the lowest power mode of the device. No functions are active

other than monitoring the RESET_N input. All port interfaces are high impedance and

the PLL is halted. Refer to Section 8.11, Resets for additional information on RESET_N.

1 Hub (Normal) Mode: The device operates as a configurable USB hub. This mode has

various sub-modes of operation, as detailed in Figure 5-1. Power consumption is based

on the number of active ports, their speed, and amount of data received.

The flowchart in Figure 5-1 details the modes of operation and details how the device traverses through the Hub Mode

stages (shown in bold). The remaining sub-sections provide more detail on each stage of operation.

FIGURE 5-1: HUB MODE FLOWCHART

DS00003143B-page 28 2018 - 2020 Microchip Technology Inc.

Page 29

USB7216

5.1 Boot Sequence

5.1.1 STANDBY MODE

If the RESET_N pin is asserted, the hub will be in Standby Mode. This mode provides a very low power state for maximum power efficiency when no signaling is required. This is the lowest power state. In Standby Mode all downstream

ports are disabled, the USB data pins are held in a high-impedance state, all transactions immediately terminate (no

states saved), all internal registers return to their default state, the PLL is halted, and core logic is powered down in order

to minimize power consumption. Because core logic is powered off, no configuration settings are retained in this mode

and must be re-initialized after RESET_N is negated high.

5.1.2 SPI INITIALIZATION STAGE (SPI_INIT)

The first stage, the initialization stage, occurs on the deassertion of RESET_N. In this stage, the internal logic is reset,

the PLL locks if a valid clock is supplied, and the configuration registers are initialized to their default state. The internal

firmware then checks for an external SPI ROM. The firmware looks for an external SPI flash device that contains a valid

signature of “2DFU” (device firmware upgrade) beginning at address 0x3FFFA. If a valid signature is found, then the

external SPI ROM is enabled and the code execution begins at address 0x0000 in the external SPI device. If a valid

signature is not found, then execution continues from internal ROM (CFG_ROM stage).

The required SPI ROM must be a minimum of 1 Mbit, and 60 MHz or faster. Both 1, 2, and 4-bit SPI operation is supported. For optimum throughput, a 2-bit SPI ROM is recommended. Both mode 0 and mode 3 SPI ROMs are also supported.

If the system is not strapped for SPI Mode, code execution will continue from internal ROM (CFG_ROM stage).

5.1.3 CONFIGURATION FROM INTERNAL ROM STAGE (CFG_ROM)

In this stage, the internal firmware loads the default values from the internal ROM. Most of the hub configuration registers, USB descriptors, electrical settings, etc. will be initialized in this state.

5.1.4 CONFIGURATION STRAP READ STAGE (CFG_STRAP)

In this stage, the firmware reads the following configuration straps to override the default values:

• CFG_STRAP[3:1]

• PRT_DIS_P[

• PRT_DIS_M[

• CFG_NON_REM

• CFG_BC_EN

If the CFG_STRAP[3:1]

it will move to the CFG_OTP stage. Refer to Section 3.3, Configuration Straps and Programmable Functions for information on usage of the various device configuration straps.

6:1]

6:1]

pins are set to Configuration 1, the device will move to the SMBUS_CHECK stage, otherwise

5.1.5 SMBUS CHECK STAGE (SMBUS_CHECK)

Based on the PF[31:3] configuration selected (refer to Section 3.3.4, PF[31:3] Configuration (CFG_STRAP[2:1])), the

firmware will check for the presence of external pull up resistors on the SMBus slave programmable function pins. If 10K

pull-ups are detected on both pins, the device will be configured as an SMBus slave, and the next state will be CFG_SMBUS. If a pull-up is not detected in either of the pins, the next state is CFG_OTP.

5.1.6 SMBUS CONFIGURATION STAGE (CFG_SMBUS)

In this stage, the external SMBus master can modify any of the default configuration settings specified in the integrated

ROM, such as USB device descriptors, port electrical settings, and control features such as downstream battery

charging.

There is no time limit on this mode. In this stage the firmware will wait indefinitely for the SMBus/I

external SMBus master writes to register 0xFF to end the configuration in legacy mode. In non-legacy mode, the SMBus

command USB_ATTACH (opcode 0xAA55) or USB_ATTACH_WITH_SMBUS (opcode 0xAA56) will finish the configuration.

2

C configuration. The

2018 - 2020 Microchip Technology Inc. DS00003143B-page 29

Page 30

USB7216

5.1.7 OTP CONFIGURATION STAGE (CFG_OTP)

Once the SOC has indicated that it is done with configuration, all configuration data is combined in this stage. The

default data, the SOC configuration data, and the OTP data are all combined in the firmware and the device is programmed.

Note: If the same register is modified in both CFG_SMBUS and CFG_OTP stages, the value from CFG_OTP will

overwrite any value written during CFG_SMBUS.

5.1.8 HUB CONNECT STAGE (USB_ATTACH)

Once the hub registers are updated through default values, SMBus master, and OTP, the device firmware will enable

attaching the USB host by setting the USB_ATTACH bit in the HUB_CMD_STAT register (for USB 2.0) and the

USB3_HUB_ENABLE bit (for USB 3.2). The device will remain in the Hub Connect stage indefinitely.

5.1.9 NORMAL MODE (NORMAL_MODE)

Lastly, the hub enters Normal Mode of operation. In this stage full USB operation is supported under control of the USB

Host on the upstream port. The device will remain in the normal mode until the operating mode is changed by the system.

If RESET_N is asserted low, then Standby Mode is entered. The device may then be placed into any of the designated

hub stages. Asserting a soft disconnect on the upstream port will cause the hub to return to the Hub Connect stage until

the soft disconnect is negated.

DS00003143B-page 30 2018 - 2020 Microchip Technology Inc.

Page 31

USB7216

6.0 DEVICE CONFIGURATION

The device supports a large number of features (some mutually exclusive), and must be configured in order to correctly

function when attached to a USB host controller. Microchip provides a comprehensive software programming tool,

MPLAB Connect Configurator (formerly ProTouch2), for OTP configuration of various USB7216 functions and registers.

All configuration is to be performed via the MPLAB Connect Configurator programming tool. For additional information

on this tool, refer to the MPLAB Connect Configurator programming tool product page at http://www.microchip.com/

design-centers/usb/mplab-connect-configurator.

Additional information on configuring the USB7216 is also provided in the “Configuration of the USB7202/USB725x”

application note, which contains details on the hub operational mode, SOC configuration stage, OTP configuration, USB

configuration, and configuration register definitions. This application note, along with additional USB7216 resources,

can be found on the Microchip USB7216 product page at www.microchip.com/USB7216.

Note: The USB7216 requires external firmware to operate. Functions such as Power Delivery will not operate

without external firmware. Refer to the “Configuration of the USB7202/USB725x” application note for addi-

tional information.

Note: Device configuration straps and programmable pins are detailed in Section 3.3, Configuration Straps and

Programmable Functions.

Refer to Section 7.0, Device Interfaces for detailed information on each device interface.

2018 - 2020 Microchip Technology Inc. DS00003143B-page 31

Page 32

USB7216

7.0 DEVICE INTERFACES

The USB7216 provides multiple interfaces for configuration, external memory access, etc.. This section details the various device interfaces:

• SPI/SQI Master Interface

• SMBus/I2C Master/Slave Interfaces

• I2S Interface

Note: For details on how to enable each interface, refer to Section 3.3, Configuration Straps and Programmable

Functions.

For information on device connections, refer to Section 4.0, Device Connections. For information on device

configuration, refer to Section 6.0, Device Configuration.

Microchip provides a comprehensive software programming tool, MPLAB Connect Configurator (formerly

ProTouch2), for configuring the USB7216 functions, registers and OTP memory. All configuration is to be

performed via the MPLAB Connect Configurator programming tool. For additional information on this tool,

refer to th MPLAB Connect Configurator programming tool product page at http://www.microchip.com/

design-centers/usb/mplab-connect-configurator.

7.1 SPI/SQI Master Interface

The SPI/SQI controller has two basic modes of operation: execution of an external hub firmware image, or the USB to

SPI bridge. On power up, the firmware looks for an external SPI flash device that contains a valid signature of 2DFU

(device firmware upgrade) beginning at address 0x3FFFA. If a valid signature is found, then the external ROM mode is

enabled and the code execution begins at address 0x0000 in the external SPI device. If a valid signature is not found,

then execution continues from internal ROM and the SPI interface can be used as a USB to SPI bridge.

The entire firmware image is then executed in place entirely from the SPI interface. The SPI interface will remain continuously active while the hub is in the runtime state. The hub configuration options are also loaded entirely out of the

SPI memory device. Both the internal ROM firmware image and internal OTP memory are completely ignored while executing the firmware and configuration from the external SPI memory.

The second mode of operation is the USB to SPI bridge operation. Additional details on this feature can be found in

Section 8.9, USB to SPI Bridging.

Table 7-1 details how the associated pins are mapped in SPI vs. SQI mode

TABLE 7-1: SPI/SQI PIN USAGE

SPI Mode SQI Mode Description

SPI_CE_N SQI_CE_N SPI/SQI Chip Enable (Active Low)

SPI_CLK SQI_CLK SPI/SQI Clock

SPI_D0 SQI_D0 SPI Data Out; SQI Data I/O 0

SPI_D1 SQI_D1 SPI Data In; SQI Data I/O 1

- SQI_D2 SQI Data I/O 2

- SQI_D3 SQI Data I/O 3

Note: For SPI/SQI master timing information, refer to Section 9.6.10, SPI/SQI Master Timing.

DS00003143B-page 32 2018 - 2020 Microchip Technology Inc.

Page 33

USB7216

7.2 SMBus/I2C Master/Slave Interfaces

The device provides three independent SMBus/I2C controllers (Slave, Master, and Power Delivery Master) which can

be used to access internal device run time registers or program the internal OTP memory. The device contains two 128

byte buffers to enable simultaneous master/slave operation and to minimize firmware overhead in processed I

ets. The I

The SMBus/I

2

C interfaces support 100KHz Standard-mode (Sm) and 400KHz Fast Mode (Fm) operation.

2

C interfaces are assigned to programmable pins (PFx) and therefore the device must be programmed into

specific configurations to enable specific interfaces. Refer to Section 3.3.4, PF[31:3] Configuration (CFG_STRAP[2:1])

for additional information.

2

C pack-

Note: For SMBus/I

2

C timing information, refer to Section 9.6.7, SMBus Timing and Section 9.6.8, I2C Timing.

7.3 I2S Interface

The device provides an integrated I2S interface to facilitate the connection of digital audio devices. The I2S interface

conforms to the voltage, power, and timing characteristics/specifications as set forth in the I

consists of the following signals:

• I2S_SDI: Serial Data Input

• I2S_SDO: Serial Data Output

• I2S_SCK: Serial Clock

• I2S_LRCK: Left/Right Clock (SS/FSYNC)

• I2S_MCLK: Master Clock

• MIC_DET: Microphone Plug Detect

Each audio connection is half-duplex, so I2S_SDO exists only on the transmit side and I2S_SDI exists only on the

receive side of the interface. Some codecs refer to the Serial Clock (I2S_SCK) as Baud/Bit Clock (BCLK). Also, the Left/

Right Clock is commonly referred to as LRC or LRCK. The I

2

S and other audio protocols refer to LRC as Word Select

(WS).

The following codec is supported by default:

• Analog Devices ADAU1961 (24-bit 96KHz)

2

S interface is assigned to programmable pins (PFx) and therefore the device must be programmed into specific

The I

configurations to enable the interface. Refer to Section 3.3.4, PF[31:3] Configuration (CFG_STRAP[2:1]) for additional

information.

2

S-Bus Specification, and

Note: For I

2

S timing information, refer to Section 9.6.9, I2S Timing. For detailed information on utilizing the I2S

interface, including support for other codecs, refer to the application note “USB7202/USB725x I

2

S Opera-

tion”, which can be found on the Microchip USB7216 product page at www.microchip.com/USB7216.

7.3.1 MODES OF OPERATION

The USB audio class operates in three ways: Asynchronous, Synchronous and Adaptive. There are also multiple operating modes, such as hi-res, streaming, etc.. Typically for USB devices, inputs such as microphones are Asynchronous,

and output devices such as speakers are Adaptive. The hardware is set up to handle all three modes of operation. It is

recommended that the following configuration be used: Asynchronous IN; Adaptive OUT; 48Khz streaming mode; Two

channels: 16 bits per channel.

7.3.1.1 Asynchronous IN 48KHz Streaming

In this mode, the codec sampling clock is set to 48Khz based on the local oscillator. This clock is never changed. The

data from the codec is fed into the input FIFO. Since the sampling clock is asynchronous to the host clock, the amount

of data captured in every USB frame will vary. This issue is left for the host to handle. The input FIFO has two markers,

a low water mark (THRESHOLD_LOW_VAL), and a high water mark (THRESHOLD_HIGH_VAL). There are three registers to determine how much data to send back in each frame. If the amount of data in the FIFO exceeds the high water

mark, then HI_PKT_SIZE worth of data is sent. If the data is between the high and low water mark, the normal MID_PKT_SIZE amount of data is sent. If the data is below the low water mark, LO_PKT_SIZE worth of data is sent.

2018 - 2020 Microchip Technology Inc. DS00003143B-page 33

Page 34

USB7216

7.3.1.2 Adaptive OUT 48KHz Streaming

In this mode, the codec sampling clock is initially set to 48Khz based on the local oscillator. The host data is fed into the

OUT FIFO. The host will send the same amount of data on every frame, i.e. 48KHz of data based on the host clock. The

codec sampling clock is asynchronous to the host clock. This will cause the amount of data in the OUT FIFO to vary. If

the amount of data in the FIFO exceeds the high water mark, then the sampling clock is increased. If the data is between

the high and low water mark, the sampling clock does not change. If the data is below the low water mark, the sampling

clock is decreased.

7.3.1.3 Synchronous Operation

For synchronous operation, the internal clock must be synchronized with the host SOF. The Frame SOF is nominally

1mS. Since there is significant jitter in the SOFs, there is circuitry provided to measure the SOFs over a long period of

time to get a more accurate reading. The calculated host frequency is used to calculate the codec sampling clock.

DS00003143B-page 34 2018 - 2020 Microchip Technology Inc.

Page 35

USB7216

SOC

VBUS[n]

INT

SCL

SDA

Microchip

Hub

DC Power

8.0 FUNCTIONAL DESCRIPTIONS

This section details various USB7216 functions, including:

• Downstream Battery Charging

• Port Power Control

• CC Pin Orientation and Detection

• PortSplit

• FlexConnect

• Multi-Host Endpoint Reflector

• USB to GPIO Bridging

• USB to I2C Bridging

• USB to SPI Bridging

• Link Power Management (LPM)

• Resets

8.1 Downstream Battery Charging

The device can be configured by an OEM to have any of the downstream ports support battery charging. The hub’s role

in battery charging is to provide acknowledgment to a device’s query as to whether the hub system supports USB battery

charging. The hub silicon does not provide any current or power FETs or any additional circuitry to actually charge the

device. Those components must be provided externally by the OEM.

FIGURE 8-1: BATTERY CHARGING EXTERNAL POWER SUPPLY

If the OEM provides an external supply capable of supplying current per the battery charging specification, the hub can

be configured to indicate the presence of such a supply from the device. This indication, via the PRT_CTLx pins, is on

a per port basis. For example, the OEM can configure two ports to support battery charging through high current power

FETs and leave the other two ports as standard USB ports.

The port control signals are assigned to programmable pins (PFx) and therefore the device must be programmed into

specific configurations to enable the signals. Refer to Section 3.3.4, PF[31:3] Configuration (CFG_STRAP[2:1]) for addi-

tional information.

For detailed information on utilizing the battery charging feature, refer to the application note “USB Battery Charging

with Microchip USB7202 and USB725x Hubs”, which can be found on the Microchip USB7216 product page www.microchip.com/USB7216.

2018 - 2020 Microchip Technology Inc. DS00003143B-page 35

Page 36

USB7216

USB Power

Switch

50k

PRTPWR

EN

OCS

OCS

Pull‐UpEnable

5V

USB

Device

FILTER

PRT_CTLx

8.2 Port Power Control

Port power and over-current sense share the same pin (PRT_CTLx) for each port. These functions can be controlled

directly from the USB hub, or via the processor.

Note: The PRT_CTLx function is assigned to programmable function pins (PFx) via configuration straps. Refer

to Section 3.3.4, PF[31:3] Configuration (CFG_STRAP[2:1]) for additional information.

Note: The port power control for the USB 2.0 and USB 3.2 portions of a specific port can also be individually con-

trolled via the PortSplit function. Refer to Section 8.4, PortSplit for additional information.

8.2.1 PORT POWER CONTROL USING USB POWER SWITCH

When operating in combined mode, the device will have one port power control and over-current sense pin for each

downstream port. When disabling port power, the driver will actively drive a '0'. To avoid unnecessary power dissipation,