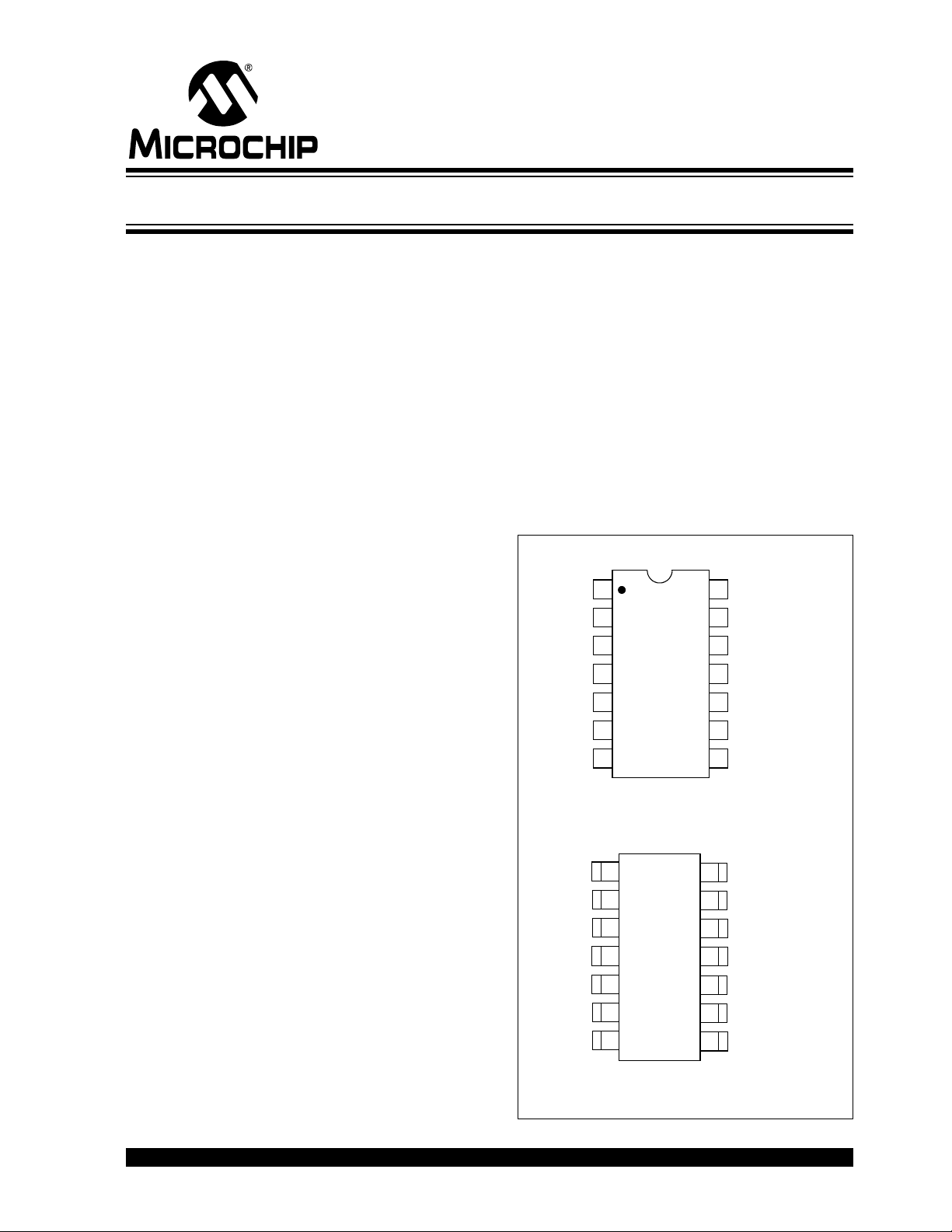

TC9400/9401/9402

1

2

3

4

5

6

7

14

13

12

11

10

9

8

V

DD

NC

AMPLIFIER OUT

THRESHOLD

DETECTOR

FREQ/2 OUT

OUTPUT COMMON

PULSE FREQ OUT

I

BIAS

ZERO ADJ

I

IN

V

SS

V

REF

OUT

GND

V

REF

1

2

3

4

5

6

7

14

13

12

11

10

9

8

TC9400

TC9401

TC9402

14-Pin Plastic DIP/CERDIP

14-Pin SOIC

TC9400

TC9401

TC9402

NC = No Internal Connection

V

DD

NC

AMPLIFIER OUT

THRESHOLD

DETECTOR

FREQ/2 OUT

OUTPUT COMMON

PULSE FREQ OUT

I

BIAS

ZERO ADJ

I

IN

V

SS

V

REF

OUT

GND

V

REF

Voltage-to-Frequency / Frequency-to-Voltage Converters

Features:

VOLTAGE-TO-FREQUENCY

• Choice of Linearity:

- TC9401: 0.01%

- TC9400: 0.05%

- TC9402: 0.25%

• DC to 100 kHz (F/V) or 1 Hz to 100 kHz (V/F)

• Low Power Dissipation: 27 mW (Typ.)

• Single/Dual Supply Operation:

- +8V to +15V or ±4V to ±7.5V

• Gain Temperature Stability: ±25 ppm/°C (Typ.)

• Programmable Scale Factor

FREQUENCY-TO-VOLTAGE

• Operation: DC to 100 kHz

• Choice of Linearity:

- TC9401: 0.02%

- TC9400: 0.05%

- TC9402: 0.25%

• Programmable Scale Factor

Applications:

• Microprocessor Data Acquisition

• 13-bit Analog-to-Digital Converters (ADC)

• Analog Data Transmission and Recording

• Phase Locked Loops

• Frequency Meters/Tachometer

• Motor Control

• FM Demodulation

General Description:

The TC9400/9401/9402 are low-cost Voltage-to-Frequency (V/F) converters, utilizing low-power CMOS

technology. The converters accept a variable analog

input signal and generate an output pulse train, whose

frequency is linearly proportional to the input voltage.

The devices can also be used as highly accurate

Frequency-to-Voltage (F/V) converters, accepting

virtually any input frequency waveform and providing a

linearly proportional voltage output.

A complete V/F or F/V system only requires the

addition of two capacitors, three resistors, and reference voltage.

Package Type

© 2007 Microchip Technology Inc. DS21483D-page 1

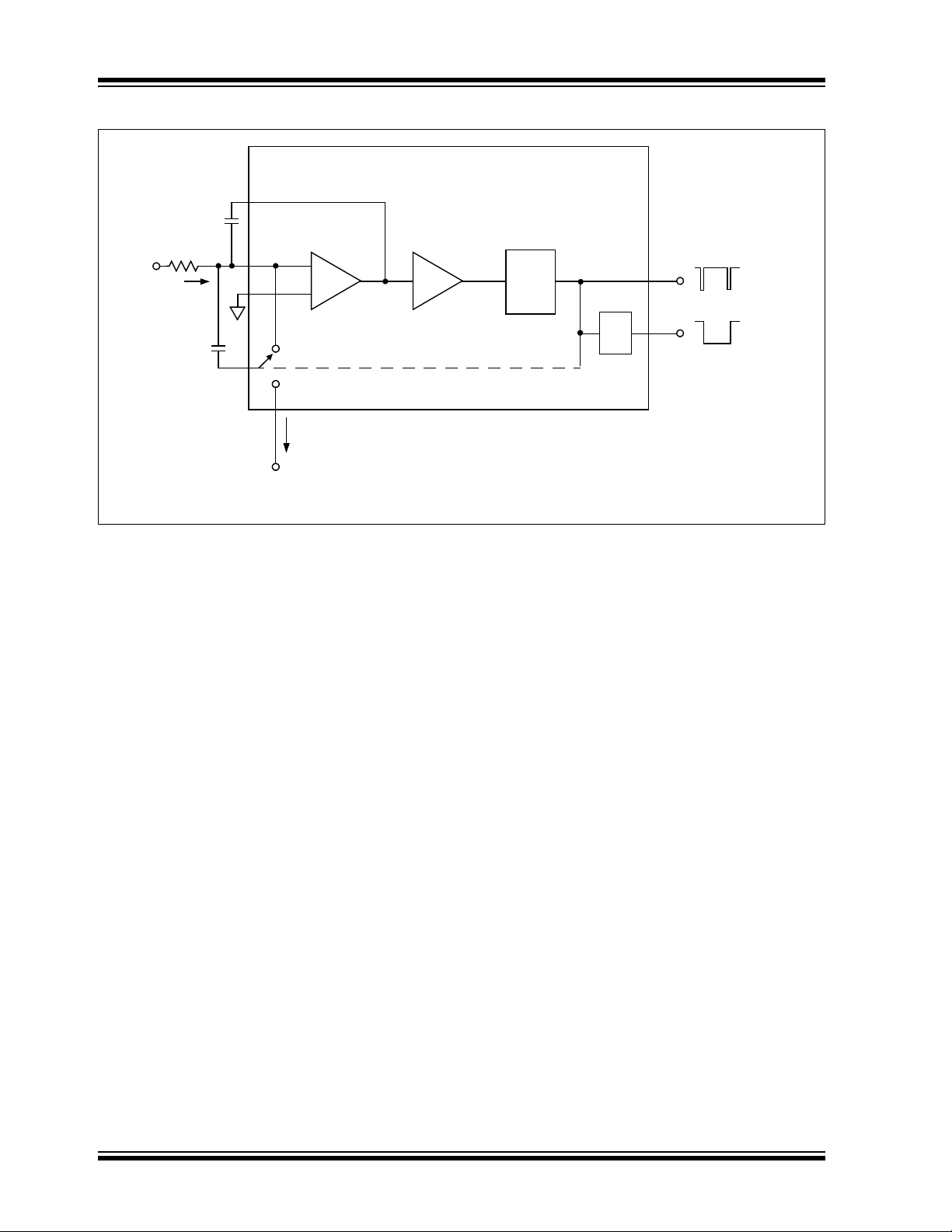

TC9400/9401/9402

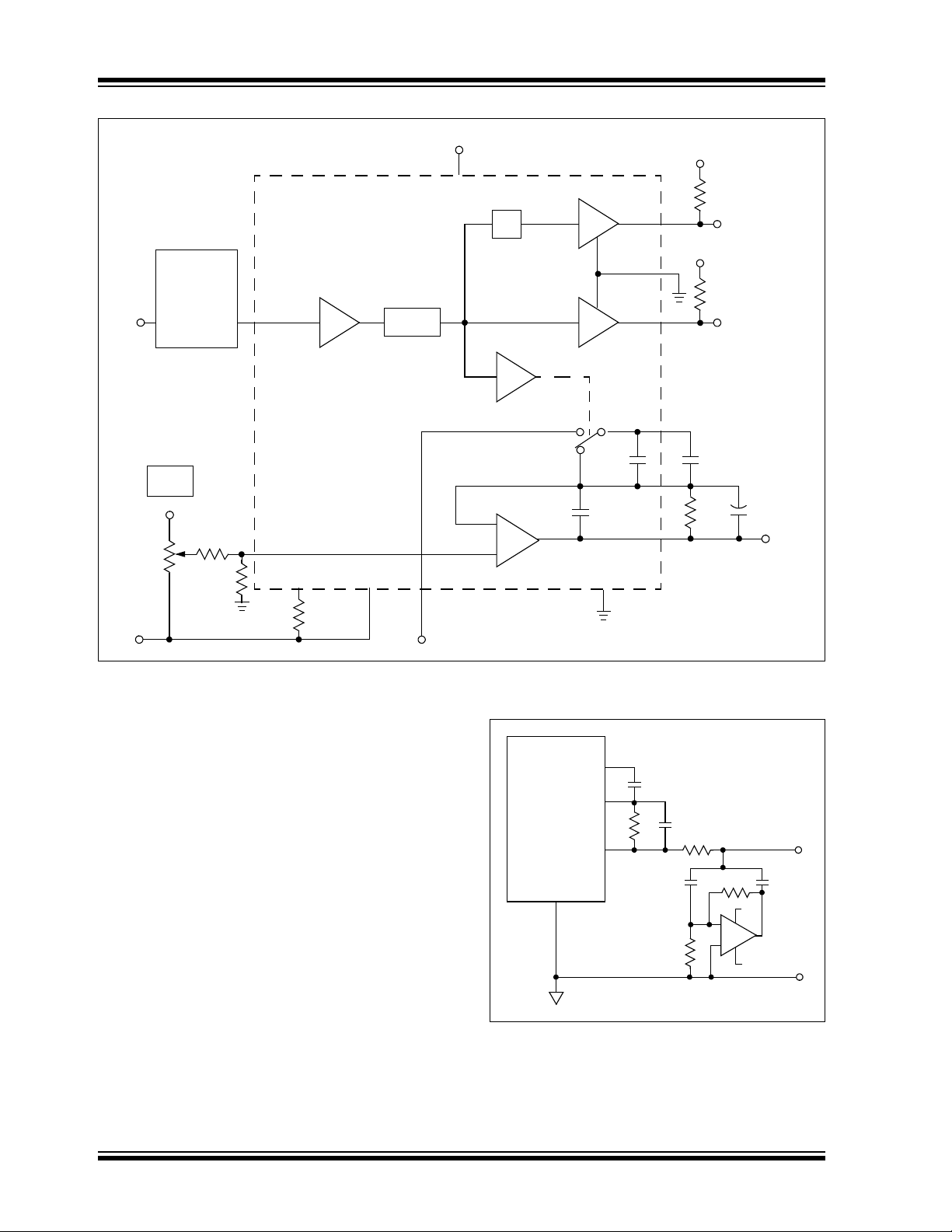

I

IN

I

REF

TC9400

R

IN

Integrator

Op Amp

Integrator

Capacitor

Threshold

Detector

One

Shot

Pulse Output

Pulse/2 Output

÷2

Input

Voltage

Reference

Capacitor

Reference

Voltage

Functional Block Diagram

DS21483D-page 2 © 2007 Microchip Technology Inc.

TC9400/9401/9402

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings †

VDD – VSS ......................................................................+18V

..................................................................................10 mA

I

IN

– V

V

OUTMAX

– VSS .....................................................................-1.5V

V

REF

Storage Temperature Range .........................-65°C to +150°C

Operating Temperature Range:

C Device ...................................................... 0°C to +70°C

E Device.................................................... -40°C to +85°C

Package Dissipation (T

8-Pin CerDIP........................................................800 mW

8-Pin Plastic DIP ..................................................730 mW

8-Pin SOIC...........................................................470 mW

Common.................................................23V

OUT

≤ 70°C):

A

† Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device. These

are stress ratings only and functional operation of the device

at these or any other conditions above those indicated in the

operation sections of the specifications is not implied.

Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability.

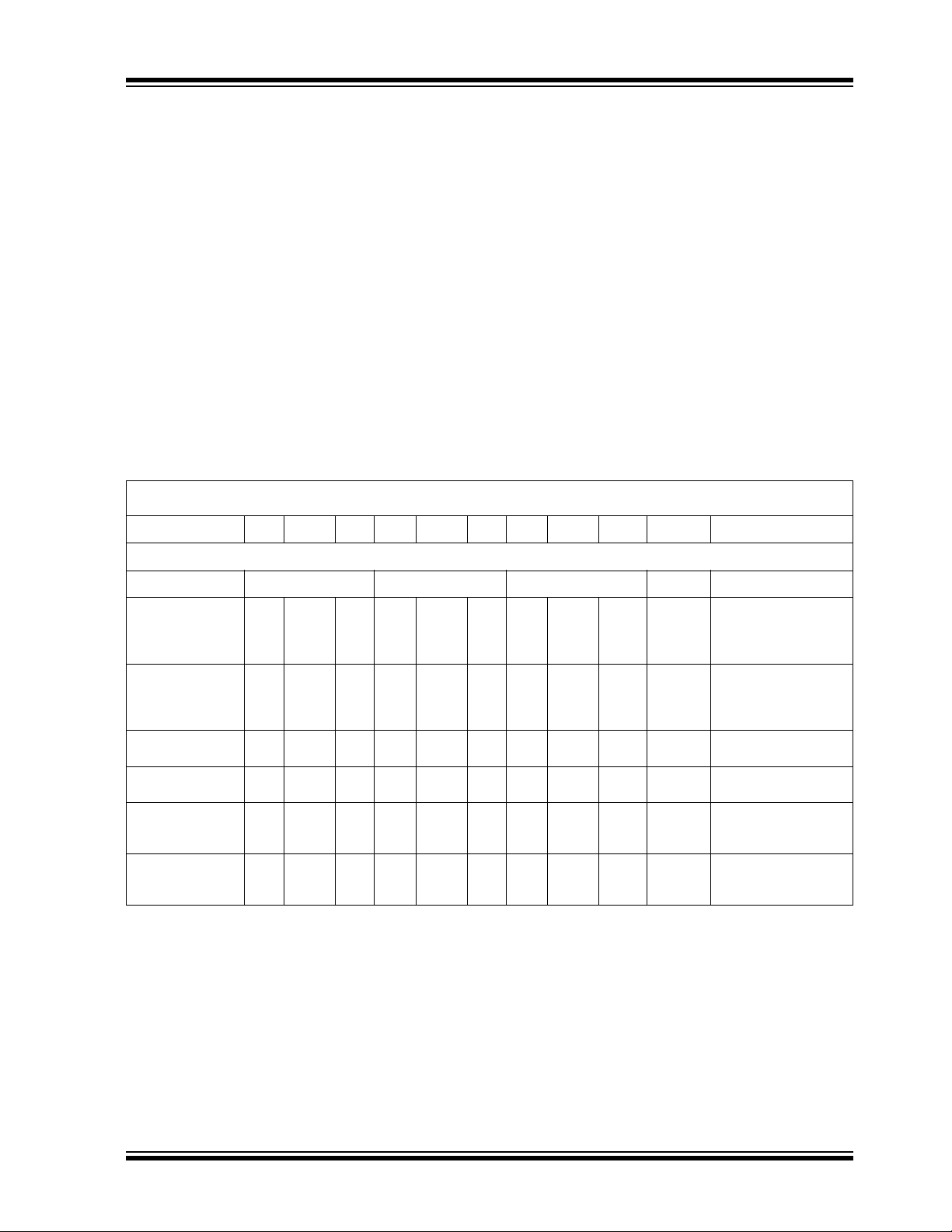

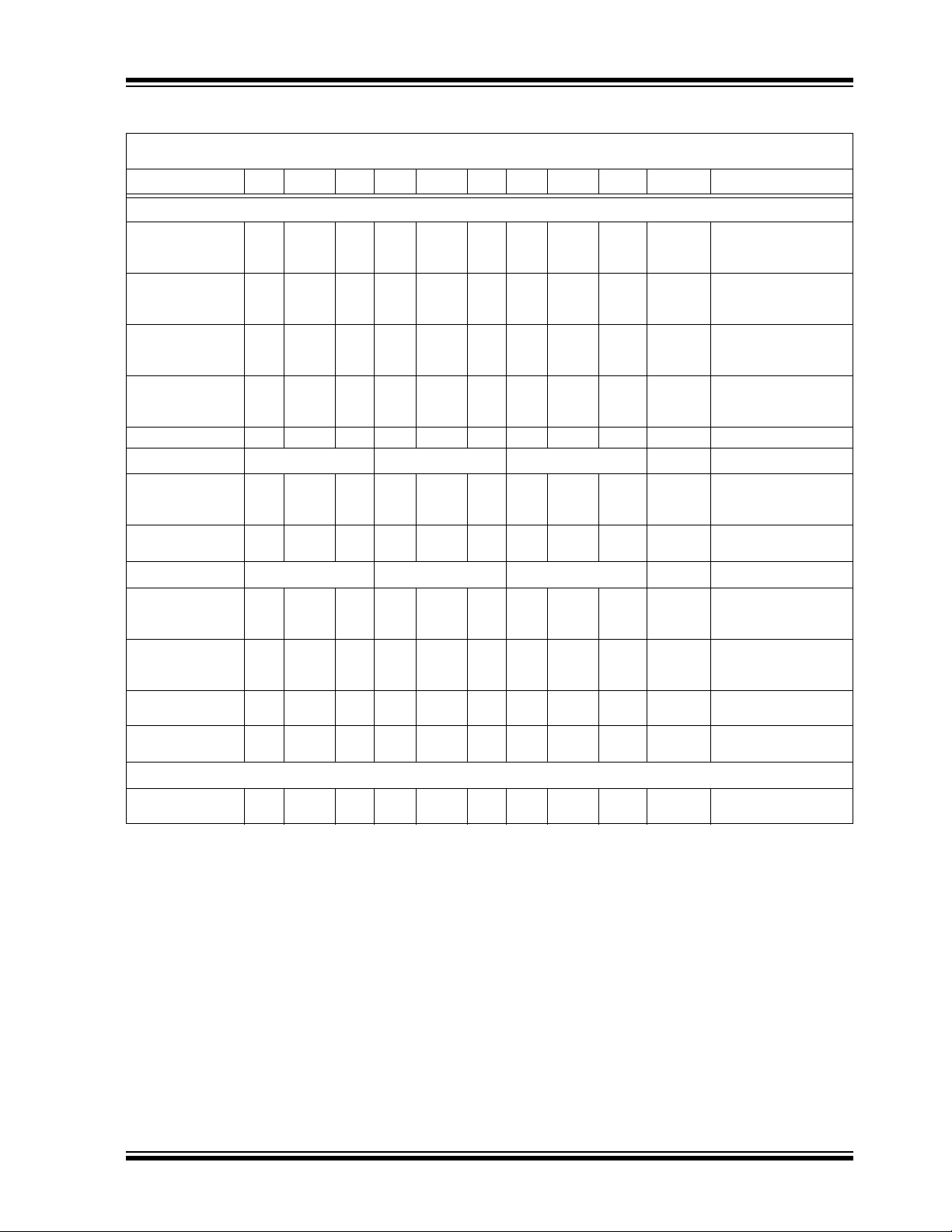

TC940X ELECTRICAL SPECIFICATIONS

Electrical Characteristics: unless otherwise specified, VDD = +5V, VSS = -5V, V

10 kHz. T

= +25°C, unless temperature range is specified (-40°C to +85°C for E device, 0°C to +70°C for C device).

A

Parameter Min Typ Max Min Typ Max Min Typ Max Units Test Conditions

Voltage-to-Frequency

GND

= 0V, V

REF

= -5V, R

= 100 kΩ, Full Scale =

BIAS

Accuracy TC9400 TC9401 TC9402

Linearity 10 kHz — 0.01 0.05 — 0.004 0.01 — 0.05 0.25 %

Linearity 100 kHz — 0.1 0.25 — 0.04 0.08 — 0.25 0.5 %

Gain Temperature

Drift (Note 1)

Gain Variance — ±10 — — ±10 — — ±10 — % of

Zero Offset

(Note 2)

Zero Temperature

Drift (Note 1)

Note 1: Full temperature range; not tested.

2: I

= 0.

IN

3: Full temperature range, I

4: I

OUT

5: Threshold Detect = 5V, Amp Out = 0V, full temperature range.

6: 10 Hz to 100 kHz; not tested.

7: 5 µs minimum positive pulse width and 0.5 µs minimum negative pulse width.

8: t

= tF = 20 ns.

R

9: R

≥ 2kΩ, tested @ 10 kΩ.

L

10: Full temperature range, V

— ±25 ±40 — ±25 ±40 — ±50 ± 100 ppm/°C

— ±10 ±50 — ±10 ±50 — ±20 ±100 mV Correction at Zero

— ±25 ±50 — ±25 ±50 — ±50 ±100 µV/°C Variation in Zero Offset

= 10 mA.

= 10 µA.

OUT

= -0.1V.

IN

Full Scale

Full Scale

Full Scale

Nominal

Output Deviation from

Straight Line Between

Normalized Zero and

Full Scale Input

Output Deviation from

Straight Line Between

Normalized Zero Reading and Full Scale Input

Variation in Gain A due

to Temperature Change

Variation from Ideal

Accuracy

Adjust for Zero Output

when Input is Zero

Due to Temperature

Change

© 2007 Microchip Technology Inc. DS21483D-page 3

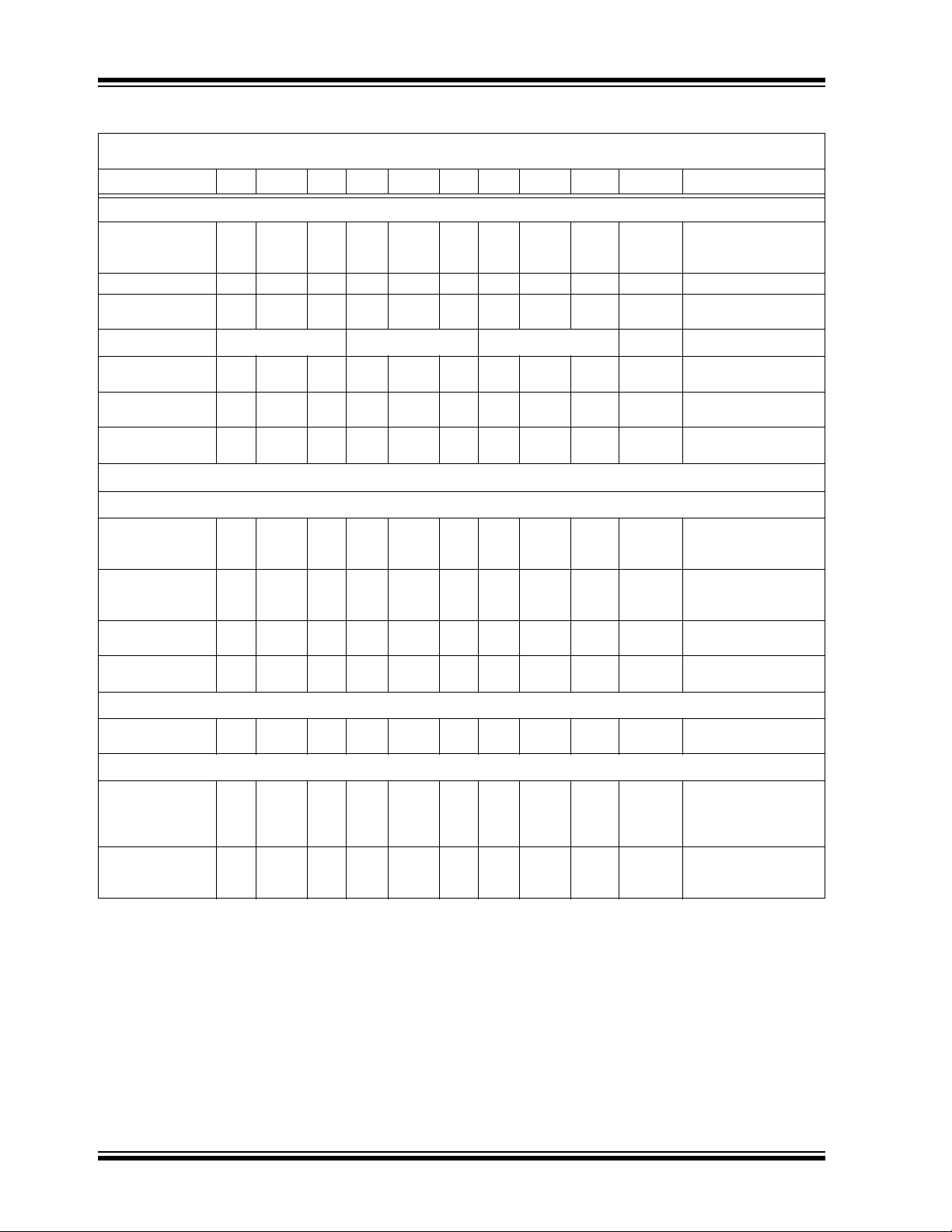

TC9400/9401/9402

TC940X ELECTRICAL SPECIFICATIONS (CONTINUED)

Electrical Characteristics: unless otherwise specified, VDD = +5V, VSS = -5V, V

10 kHz. T

= +25°C, unless temperature range is specified (-40°C to +85°C for E device, 0°C to +70°C for C device).

A

Parameter Min Typ Max Min Typ Max Min Typ Max Units Test Conditions

Analog Input

I

Full Scale — 10 — — 10 — — 10 — µA Full Scale Analog Input

IN

I

Over Range — — 50 — — 50 — — 50 µA Over Range Current

IN

Response Time — 2 — — 2 — — 2 — Cycle Settling Time to 0.1%

Digital Section TC9400 TC9401 TC9402

@ IOL = 10mA — 0.2 0.4 — 0.2 0.4 — 0.2 0.4 V Logic “0” Output

V

SAT

V

– V

OUTMAX

Common (Note 4)

OUT

Pulse Frequency

— — 18 — — 18 — — 18 V Voltage Range Between

—3——3——3 — µs

Output Width

Frequency-to-Voltage

Supply Current

I

Quiescent

DD

(Note 5)

I

Quiescent

SS

(Note 5)

V

Supply 4 — 7.5 4 — 7.5 4 — 7.5 V Operating Range of

DD

Supply -4 — -7.5 -4 — -7.5 -4 — -7.5 V Operating Range of

V

SS

Reference Voltage

V

– V

REF

SS

Accuracy

Non-Linearity

(Note 10)

Input Frequency

Range

(Notes 7 and 8)

Note 1: Full temperature range; not tested.

2: I

= 0.

IN

3: Full temperature range, I

4: I

OUT

5: Threshold Detect = 5V, Amp Out = 0V, full temperature range.

6: 10 Hz to 100 kHz; not tested.

7: 5 µs minimum positive pulse width and 0.5 µs minimum negative pulse width.

8: t

= tF = 20 ns.

R

9: R

≥ 2kΩ, tested @ 10 kΩ.

L

10: Full temperature range, V

— 1.5 6 — 1.5 6 — 3 10 mA Current Required from

— -1.5 -6 — -1.5 -6 — -3 -10 mA Current Required from

-2.5 — — -2.5 — — -2.5 — — V Range of Voltage

— 0.02 0.05 — 0.01 0.02 — 0.05 0.25 %

10 — 100k 10 — 100k 10 — 100k Hz Frequency Range for

= 10 mA.

= 10 µA.

OUT

= -0.1V.

IN

GND

= 0V, V

= -5V, R

REF

Full Scale

= 100 kΩ, Full Scale =

BIAS

Current to achieve

Specified Accuracy

Full Scale

Voltage (Note 3)

Output and Common

Positive Supply during

Operation

Negative Supply during

Operation

Positive Supply

Negative Supply

Reference Input

Deviation from ideal

Transfer Function as a

Percentage Full Scale

Voltage

Specified Non-Linearity

DS21483D-page 4 © 2007 Microchip Technology Inc.

TC9400/9401/9402

TC940X ELECTRICAL SPECIFICATIONS (CONTINUED)

Electrical Characteristics: unless otherwise specified, VDD = +5V, VSS = -5V, V

10 kHz. T

= +25°C, unless temperature range is specified (-40°C to +85°C for E device, 0°C to +70°C for C device).

A

Parameter Min Typ Max Min Typ Max Min Typ Max Units Test Conditions

Frequency Input

Positive Excursion 0.4 — V

0.4 — V

DD

0.4 — V

DD

Negative Excursion -0.4 -2 -0.4 — -2 -0.4 — -2 V Voltage Required to

Minimum Positive

—5——5——5 — μs Time between

Pulse Width

(Note 8)

Minimum Negative

— 0.5 — — 0.5 — — 0.5 — μs Time Between

Pulse Width

(Note 8)

Input Impedance — 10 — — 10 — — 10 MΩ

Analog Outputs TC9400 TC9401 TC9402

Output Voltage

(Note 9)

—V

DD

– 1 — — V

– 1 — — V

DD

Output Loading 2 — — 2 — — 2 — — kΩ Resistive Loading at

Supply Current TC9400 TC9401 TC9402

I

Quiescent

DD

(Note 10)

I

Quiescent

SS

(Note 10)

V

Supply 4 — 7.5 4 — 7.5 4 — 7.5 V Operating Range of

DD

Supply -4 — -7.5 -4 — -7.5 -4 — -7.5 V Operating Range of

V

SS

— 1.5 6 — 1.5 6 — 3 10 mA Current Required from

— -1.5 -6 -1.5 -6 — -3 -10 mA Current Required from

Reference Voltage

V

REF

– V

SS

-2.5 — — -2.5 — — -2.5 — — V Range of Voltage

Note 1: Full temperature range; not tested.

2: I

= 0.

IN

3: Full temperature range, I

4: I

= 10 µA.

OUT

OUT

= 10 mA.

5: Threshold Detect = 5V, Amp Out = 0V, full temperature range.

6: 10 Hz to 100 kHz; not tested.

7: 5 µs minimum positive pulse width and 0.5 µs minimum negative pulse width.

8: t

= tF = 20 ns.

R

9: R

≥ 2kΩ, tested @ 10 kΩ.

L

10: Full temperature range, V

= -0.1V.

IN

GND

= 0V, V

DD

REF

= -5V, R

= 100 kΩ, Full Scale =

BIAS

V Voltage Required to

Turn Threshold

Detector On

Turn Threshold

Detector Off

Threshold Crossings

Threshold Crossings

– 1 — V Voltage Range of Op

DD

Amp Output for

Specified Non-Linearity

Output of Op Amp

Positive Supply During

Operation

Negative Supply During

Operation

Positive Supply

Negative Supply

Reference Input

© 2007 Microchip Technology Inc. DS21483D-page 5

TC9400/9401/9402

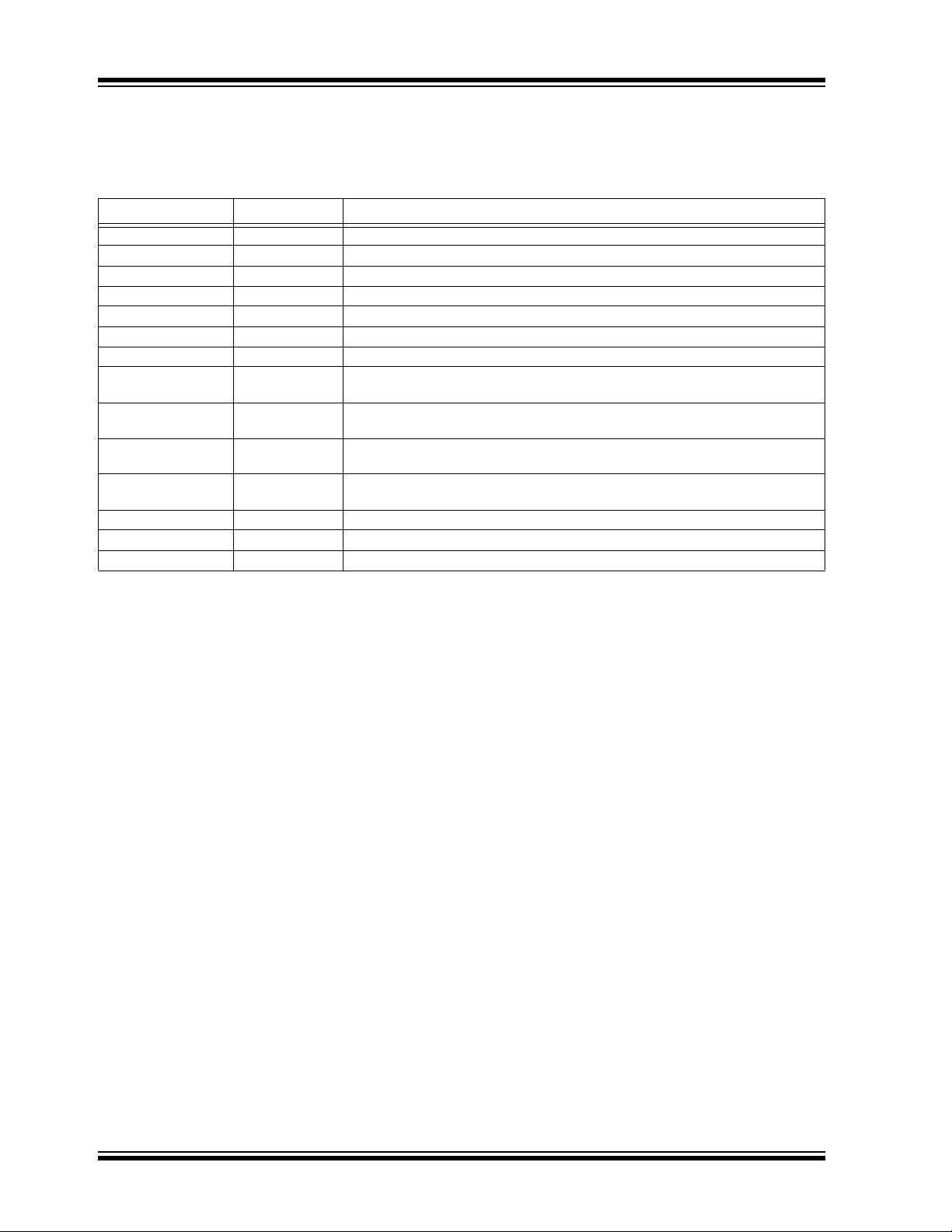

2.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 2-1.

TABLE 2-1: PIN FUNCTION TABLE

Pin No. Symbol Description

1I

2 ZERO ADJ Low frequency adjustment input.

3I

4V

5V

6 GND Analog ground.

7V

8 PULSE FREQ

9OUTPUT

10 FREQ/2 OUT This open drain output is a square wave at one-half the frequency of the pulse output

11 THRESHOLD

12 AMPLIFIER OUT Output of the integrator amplifier.

13 NC No internal connection.

14 V

BIAS

IN

SS

OUT Reference capacitor connection.

REF

REF

OUT

COMMON

DETECTOR

DD

This pin sets bias current in the TC9400. Connect to VSS through a 100 kΩ resistor.

Input current connection for the V/F converter.

Negative power supply voltage connection, typically -5V.

Voltage reference input, typically -5V.

Frequency output. This open drain output will pulse LOW each time the Freq.

Threshold Detector limit is reached. The pulse rate is proportional to input voltage.

Source connection for the open drain output FETs.

(Pin 8). Output transitions of this pin occur on the rising edge of Pin 8.

Input to the Threshold Detector. This pin is the frequency input during F/V operation.

Positive power supply connection, typically +5V.

2.1 Bias Current (I

BIAS

)

An external resistor, connected to VSS, sets the bias

point for the TC9400. Specifications for the TC9400 are

based on R

= 100 kΩ ±10%, unless otherwise

BIAS

noted.

Increasing the maximum frequency of the TC9400

beyond 100 kHz is limited by the pulse width of the

pulse output (typically 3 µs). Reducing R

BIAS

will

decrease the pulse width and increase the maximum

operating frequency, but linearity errors will also

increase. R

can be reduced to 20 kΩ, which will

BIAS

typically produce a maximum full scale frequency of

500 kHz.

2.2 Zero Adjust

This pin is the non-inverting input of the operational

amplifier. The low frequency set point is determined by

adjusting the voltage at this pin.

2.3 Input Current (IIN)

The inverting input of the operational amplifier and the

summing junction when connected in the V/F mode. An

input current of 10 μA is specified, but an over range

current up to 50 μA can be used without detrimental

effect to the circuit operation. I

junction of an operational amplifier. Voltage sources

cannot be attached directly, but must be buffered by

external resistors.

connects the summing

IN

2.4 Voltage Capacitor (V

The charging current for C

is supplied through this

REF

REF

Out)

pin. When the op amp output reaches the threshold

level, this pin is internally connected to the reference

x C

voltage and a charge, equal to V

REF

, is removed

REF

from the integrator capacitor. After about 3μsec, this pin

is internally connected to the summing junction of the

op amp to discharge C

. Break-before-make switch-

REF

ing ensures that the reference voltage is not directly

applied to the summing junction.

2.5 Voltage Reference (V

REF

)

A reference voltage from either a precision source, or

the V

supply is applied to this pin. Accuracy of the

SS

TC9400 is dependent on the voltage regulation and

temperature characteristics of the reference circuitry.

Since the TC9400 is a charge balancing V/F converter,

the reference current will be equal to the input current.

For this reason, the DC impedance of the reference

voltage source must be kept low enough to prevent

linearity errors. For linearity of 0.01%, a reference

impedance of 200Ω or less is recommended. A 0.1 µF

bypass capacitor should be connected from V

REF

ground.

to

DS21483D-page 6 © 2007 Microchip Technology Inc.

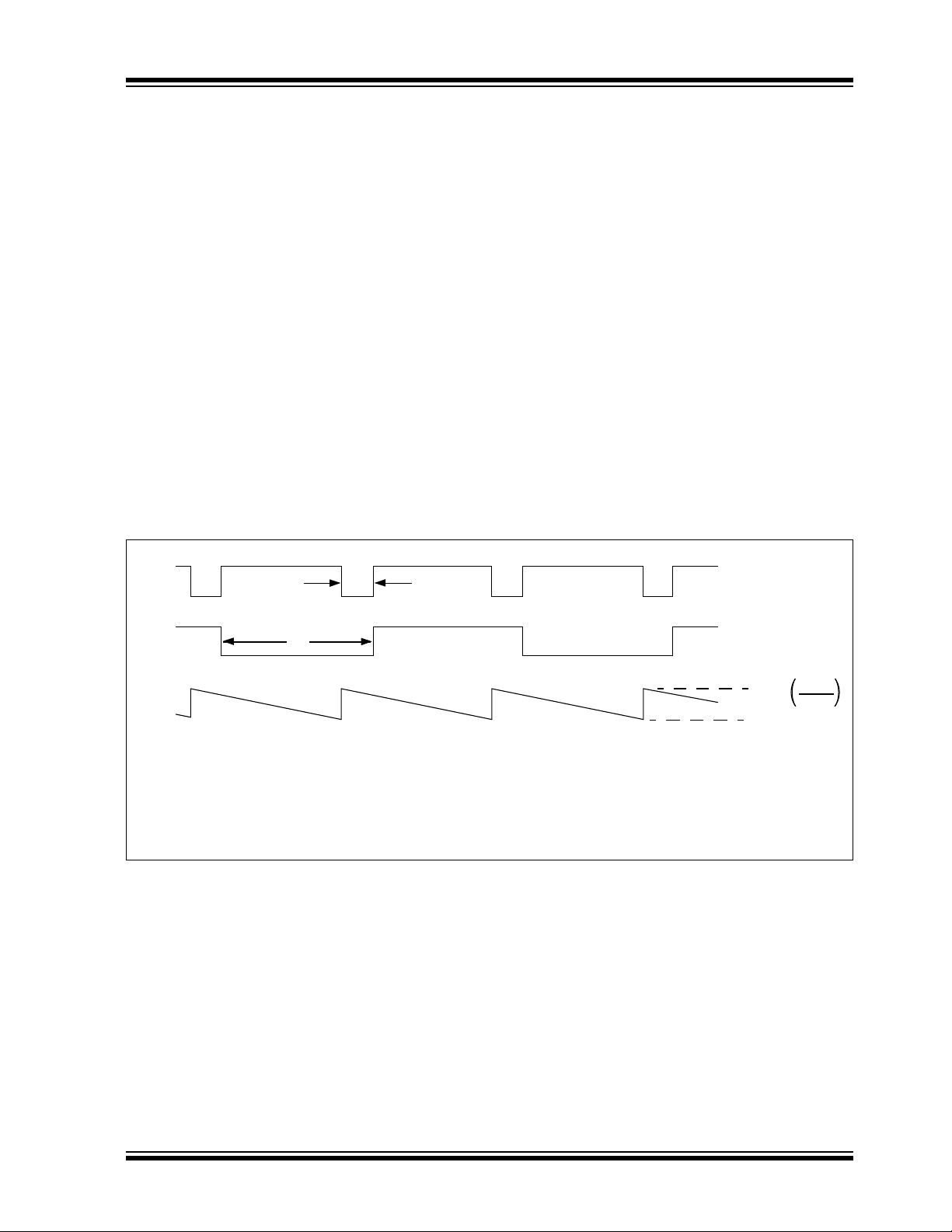

TC9400/9401/9402

3ms

Typ.

1/f

F

OUT

F

OUT

/2

Amp Out

V

REF

0V

C

REF

C

INT

Note 1: To adjust F

MIN

, set VIN = 10 mV and adjust the 50 kΩ offset for 10 Hz output.

2: To adjust F

MAX

, set VIN = 10V and adjust RIN or V

REF

for 10 kHz output.

3: To increase F

OUTMAX

to 100 kHz, change C

REF

to 2 pF and C

INT

to 75 pF.

4: For high performance applications, use high stability components for R

IN

, C

REF

. V

REF

(metal film

resistors and glass capacitors). Also, separate output ground (Pin 9) from input ground (Pin 6).

2.6 Pulse Freq Out

This output is an open-drain N-channel FET, which

provides a pulse waveform whose frequency is proportional to the input voltage. This output requires a pullup resistor and interfaces directly with MOS, CMOS,

and TTL logic (see Figure 2-1).

2.7 Output Common

The sources of both the FREQ/2 OUT and the PULSE

FREQ OUT are connected to this pin. An output level

swing from the drain voltage to ground, or to the V

SS

supply, may be obtained by connecting this pin to the

appropriate point.

2.8 Freq/2 Out

This output is an open-drain N-channel FET, which

provides a square-wave one-half the frequency of the

pulse frequency output. The FREQ/2 OUT output will

change state on the rising edge of PULSE FREQ OUT.

This output requires a pull-up resistor and interfaces

directly with MOS, CMOS, and TTL logic.

2.9 Threshold Detector Input

In the V/F mode, this input is connected to the AMPLIFIER OUT output (Pin 12) and triggers a 3 µs pulse

when the input voltage passes through its threshold. In

the F/V mode, the input frequency is applied to this

input.

The nominal threshold of the detector is half way

between the power supplies, or (V

+ VSS)/2 ±400

DD

mV. The TC9400’s charge balancing V/F technique is

not dependent on a precision comparator threshold,

because the threshold only sets the lower limit of the op

amp output. The op amp’s peak-to-peak output swing,

which determines the frequency, is only influenced by

external capacitors and by V

REF

.

2.10 Amplifier Out

This pin is the output stage of the operational amplifier.

During V/F operation, a negative going ramp signal is

available at this pin. In the F/V mode, a voltage

proportional to the frequency input is generated.

FIGURE 2-1: Output Waveforms.

© 2007 Microchip Technology Inc. DS21483D-page 7

TC9400/9401/9402

–

+

+5V

+

5V

14

V

DD

+

5V

R

L

10 kΩ

R

L

10 kΩ

8

10

9

F

OUT

F

OUT

/2

11

3ms

Delay

Self-

Star t

12

5

20 kΩ

60 pF

Op Amp

C

INT

820 pF

C

REF

180 pF

12 pF

R

IN

1MΩ

V

IN

+5V

-5V

50 kΩ

510 kΩ

10 kΩ

3

1

Offset

Adjust

I

IN

Zero Adjust

0V –10V

I

BIAS

V

SS

4

-5V

2

Output

Common

V

REF

OUT

R

BIAS

100 kΩ

AMP OUT

TC9400

TC9401

TC9402

GND

6

Threshold

Detector

Threshold

Detect

Reference Voltage

(Typically -5V)

÷2

V

REF

7

-3V

INPUT

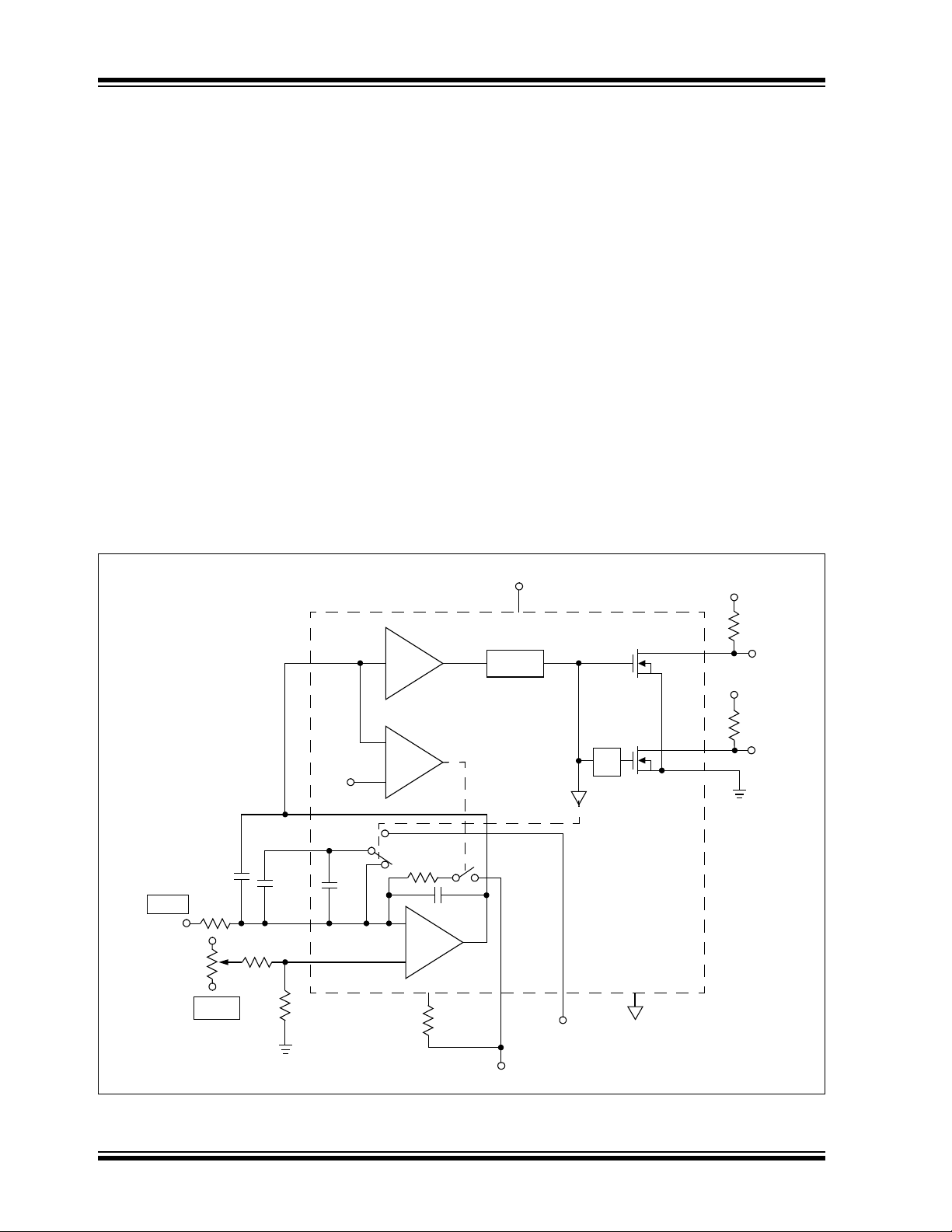

3.0 DETAILED DESCRIPTION

3.1 Voltage-to-Frequency (V/F) Circuit

Description

The TC9400 V/F converter operates on the principal of

charge balancing. The operation of the TC9400 is

easily understood by referring to Figure 3-1. The input

voltage (V

resistor. This current is then converted to a charge on

the integrating capacitor and shows up as a linearly

decreasing voltage at the output of the op amp. The

lower limit of the output swing is set by the threshold

detector, which causes the reference voltage to be

applied to the reference capacitor for a time period long

enough to charge the capacitor to the reference voltage. This action reduces the charge on the integrating

capacitor by a fixed amount (q = C

the op amp output to step up a finite amount.

At the end of the charging period, C

This dissipates the charge stored on the reference

capacitor, so that when the output again crosses zero,

the system is ready to recycle. In this manner, the continued discharging of the integrating capacitor by the

input is balanced out by fixed charges from the refer-

) is converted to a current (IIN) by the input

IN

x V

REF

REF

), causing

REF

is shorted out.

ence voltage. As the input voltage is increased, the

number of reference pulses required to maintain

balance increases, which causes the output frequency

to also increase. Since each charge increment is fixed,

the increase in frequency with voltage is linear. In

addition, the accuracy of the output pulse width does

not directly affect the linearity of the V/F. The pulse

must simply be long enough for full charge transfer to

take place.

The TC9400 contains a “self-start” circuit to ensure the

V/F converter always operates properly when power is

first applied. In the event that, during power-on, the op

amp output is below the threshold and C

is already

REF

charged, a positive voltage step will not occur. The op

amp output will continue to decrease until it crosses the

-3.0V threshold of the “self-start” comparator. When

this happens, an internal resistor is connected to the op

amp input, which forces the output to go positive until

the TC9400 is in its normal Operating mode.

The TC9400 utilizes low-power CMOS processing for

low input bias and offset currents, with very low power

dissipation. The open drain N-channel output FETs

provide high voltage and high current sink capability.

FIGURE 3-1: 10 Hz to 10 kHz V/F Converter.

DS21483D-page 8 © 2007 Microchip Technology Inc.

3.2 Voltage-to-Time Measurements

The TC9400 output can be measured in the time

domain as well as the frequency domain. Some microcomputers, for example, have extensive timing capability, but limited counter capability. Also, the response

time of a time domain measurement is only the period

between two output pulses, while the frequency

measurement must accumulate pulses during the

entire counter time-base period.

Time measurements can be made from either the

TC9400’s PULSE FREQ OUT output, or from the

FREQ/2 OUT output. The FREQ/2 OUT output

changes state on the rising edge of PULSE FREQ

OUT, so FREQ/2 OUT is a symmetrical square wave at

one-half the pulse output frequency. Timing measurements can, therefore, be made between successive

PULSE FREQ OUT pulses, or while FREQ/2 OUT is

high (or low).

TC9400/9401/9402

© 2007 Microchip Technology Inc. DS21483D-page 9

TC9400/9401/9402

Frequency Out

V

IN

R

IN

--------

1

V

REF

()C

REF

()

------------------------------------

•

=

VIN

FULL SCALE

10 μA

RIN ≅

10V

10

μ

A

RIN ≅ = 1 M

Ω

4.0 VOLTAGE-TO-FREQUENCY

(V/F) CONVERTER DESIGN

INFORMATION

4.1 Input/Output Relationships

The output frequency (F

input voltage (V

) by the transfer equation:

IN

EQUATION 4-1:

4.2 External Component Selection

4.2.1 R

The value of this component is chosen to give a full

scale input current of approximately 10 µA:

EQUATION 4-2:

EQUATION 4-3:

IN

) is related to the analog

OUT

4.2.3 C

REF

The exact value is not critical and may be used to trim

the full scale frequency (see Section 6.1 “Input/Out-

put Relationships”, Input/Output Relationships).

Glass film or air trimmer capacitors are recommended

because of their stability and low leakage. Locate as

close as possible to Pins 5 and 3 (see Figure 4-1).

500

400

300

(pF) +12pF

200

REF

C

100

0

10 kHz

100 kHz

-2 -3 -4 -5 -6 -7

-1

V

REF

FIGURE 4-1: Recommended C

V

.

REF

4.2.4 V

DD

, V

SS

(V)

V

DD

V

SS

R

IN

V

IN

T

A

= +5V

= -5V

= 1MW

= +10V

= +25°C

REF

vs.

Power supplies of ±5V are recommended. For high

accuracy requirements, 0.05% line and load regulation

and 0.1 µF disc decoupling capacitors, located near the

pins, are recommended.

Note that the value is an approximation and the exact

relationship is defined by the transfer equation. In

practice, the value of R

typically would be trimmed to

IN

obtain full scale frequency at VIN full scale (see

Section 4.3 “Adjustment Procedure”, Adjustment

Procedure). Metal film resistors with 1% tolerance or

better are recommended for high accuracy applications

because of their thermal stability and low noise

generation.

4.2.2 C

The exact value is not critical but is related to C

INT

REF

by

the relationship:

≤

C

3C

REF

INT

≤ 10C

REF

Improved stability and linearity are obtained when

≤ 4C

C

INT

. Low leakage types are recommended,

REF

although mica and ceramic devices can be used in

applications where their temperature limits are not

exceeded. Locate as close as possible to Pins 12

and 13.

4.3 Adjustment Procedure

Figure 3-1 shows a circuit for trimming the zero

location. Full scale may be trimmed by adjusting R

V

REF

, or C

. Recommended procedure for a 10 kHz

REF

IN

full scale frequency is as follows:

1. Set V

to 10 mV and trim the zero adjust circuit

IN

to obtain a 10 Hz output frequency.

2. Set V

to 10V and trim either RIN, V

IN

REF

, or C

REF

to obtain a 10 kHz output frequency.

If adjustments are performed in this order, there should

be no interaction and they should not have to be

repeated.

4.4 Improved Single Supply V/F

Converter Operation

A TC9400, which operates from a single 12 to 15V

variable power source, is shown in Figure 4-2. This

circuit uses two Zener diodes to set stable biasing

levels for the TC9400. The Zener diodes also provide

the reference voltage, so the output impedance and

temperature coefficient of the Zeners will directly affect

power supply rejection and temperature performance.

Full scale adjustment is accomplished by trimming the

input current.

,

DS21483D-page 10 © 2007 Microchip Technology Inc.

TC9400/9401/9402

R1

910 kΩ

R4

1µF

D2

5.1 VZ

R2

910 kΩ

R5

91 kΩ

Rp

Offset

20 kΩ

100 kΩ

D1

5.1 VZ

0.1 µF

100 kΩ

C

REF

C

INT

1.2 kΩ

+12 to +15V

10 10 kΩ

Output

Frequency

Digital

Ground

Analog Ground

Input

Voltage

(0 to 10V)

R3

Gain

TC9400

11

12

5

3

2

6

7

1

4

14

9

10

8

Threshold

Detect

Amp Out

C

REF

I

IN

Zero Adjust

GND

V

REF

I

BIAS

Output

Common

F

OUT

/2

F

OUT

V

DD

V

SS

100 kΩ

kΩ

Component Selection

F/S Freq. C

REF

C

INT

1 kHz 2200 pF 4700 pF

10 kHz 180 pF 470 pF

100 kHz 27 pF 75 pF

Trimming the reference voltage is not recommended

for high accuracy applications unless an op amp is

used as a buffer, because the TC9400 requires a lowimpedance reference (see Section 2.5 “Voltage Ref-

erence (VREF)”, V

pin description, for more infor-

REF

mation).

The circuit of Figure 4-2 will directly interface with

CMOS logic operating at 12V to 15V. TTL or 5V CMOS

logic can be accommodated by connecting the output

pull-up resistors to the +5V supply. An optoisolator can

also be used if an isolated output is required; also, see

Figure 4-3.

FIGURE 4-2: Voltage-to-Frequency.

© 2007 Microchip Technology Inc. DS21483D-page 11

TC9400/9401/9402

V+ = 8V to 15V (Fixed)

14

8

10 kΩ

10 kΩ

F

OUT

F

OUT

/2

10

149

100 kΩ

0V–10V

I

IN

180

pF

820

pF

3

5

12

11

7

0.01

µF

2

kΩ

8.2

kΩ

6

2

V2

R2

0.9Ω

R1

0.2

R

1

R

IN

1MΩ

I

IN

V

REF

TC9400

Offset

Adjust

Gain

Adjust

5V

0.01

µF

V

IN

V+ R

1

R

2

10V 1 MΩ 10 kΩ

12V 1.4 MΩ 14 kΩ

15V 2 MΩ 20 kΩ

F

OUTIIN

1

V

2V7

–()C

REF

()

----------------------------------------- -

=

I

IN

VINV2–()

R

IN

------------------------- -

V+ V

2

–()

0.9R

1

0.2R

1

+()

-------------------------------------- -+=

FIGURE 4-3: Fixed Voltage – Single Supply Operation.

DS21483D-page 12 © 2007 Microchip Technology Inc.

5.0 FREQUENCY-TO-VOLTAGE (F/V) CIRCUIT DESCRIPTION

When used as an F/V converter, the TC9400 generates

an output voltage linearly proportional to the input

frequency waveform.

Each zero crossing at the threshold detector’s input

causes a precise amount of charge (q = C

to be dispensed into the op amp’s summing junction.

This charge, in turn, flows through the feedback

resistor, generating voltage pulses at the output of the

op amp. A capacitor (C

pulses into a DC voltage, which is linearly proportional

to the input frequency.

) across R

INT

INT

x V

REF

averages these

REF

TC9400/9401/9402

)

© 2007 Microchip Technology Inc. DS21483D-page 13

TC9400/9401/9402

V

OUT

= [V

REF CREF RINT

] F

IN

+5V

14

64

+5V

-5V

V

DD

1.0

11

33 kΩ

IN914

V

SS

DET

TC9400

(a) ±5V Supply

(b) Single Supply

0.01 µF

Frequency

Input

0V

GND

+8V to +15V

14

10 kΩ

4

+5V

V

DD

1.0

11

33 kΩ

IN914

V

SS

DET

TC9400

0.01 µF

Frequency

Input

0V

0.1 µF

10 kΩ

MΩ

MΩ

6.0 F/V CONVERTER DESIGN INFORMATION

6.1 Input/Output Relationships

The output voltage is related to the input frequency

(FIN) by the transfer equation:

EQUATION 6-1:

The response time to a change in FIN is equal to (R

C

). The amount of ripple on V

INT

proportional to C

can be increased to lower the ripple. Values of

C

INT

and the input frequency.

INT

is inversely

OUT

1 µF to 100 µF are perfectly acceptable for low frequencies.

When the TC9400 is used in the Single Supply mode,

is defined as the voltage difference between Pin 7

V

REF

and Pin 2.

INT

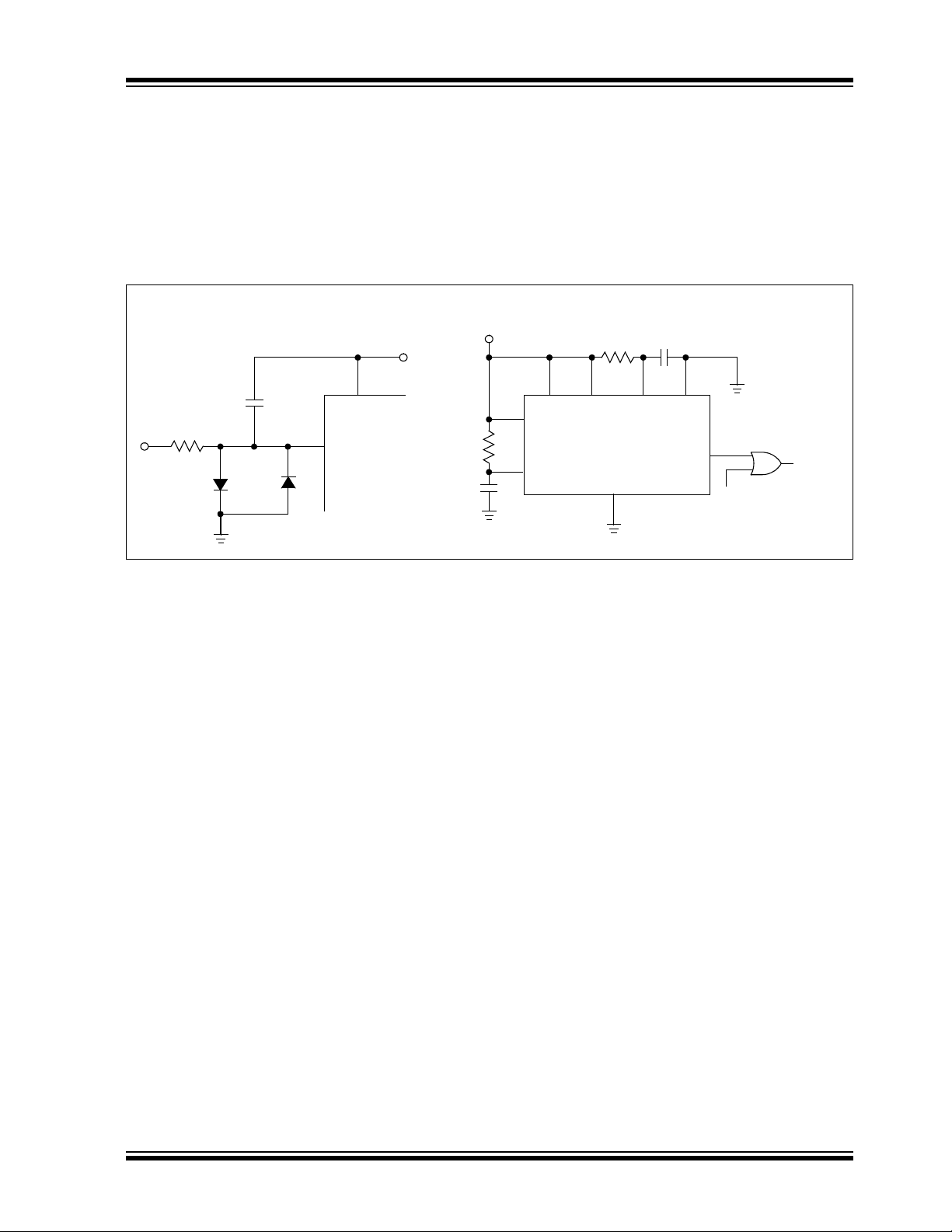

6.2 Input Voltage Levels

The input frequency is applied to the Threshold

Detector input (Pin 11). As discussed in the V/F circuit

section of this data sheet, the threshold of Pin 11 is

approximately (V

voltage range extends from V

the threshold. If the voltage on Pin 11 goes more than

2.5 volts below the threshold, the V/F mode start-up

comparator will turn on and corrupt the output voltage.

The Threshold Detector input has about 200 mV of

hysteresis.

In ±5V applications, the input voltage levels for the

TC9400 are ±400 mV, minimum. If the frequency

source being measured is unipolar, such as TTL or

CMOS operating from a +5V source, then an AC

coupled level shifter should be used. One such circuit

is shown in Figure 6-1(a).

The level shifter circuit in Figure 6-1(b) can be used in

single supply F/V applications. The resistor divider

ensures that the input threshold will track the supply

voltages. The diode clamp prevents the input from

going far enough in the negative direction to turn on the

start-up comparator. The diode’s forward voltage

decreases by 2.1 mV/°C, so for high ambient

temperature operation, two diodes in series are

recommended.

+ VSS)/2 ±400 mV. Pin 11’s input

DD

to about 2.5V below

DD

FIGURE 6-1: Frequency Input Level Shifter.

DS21483D-page 14 © 2007 Microchip Technology Inc.

TC9400/9401/9402

Offset

Adjust

10 kΩ

.01 µF

6.2V

IN914

33 kΩ

100 kΩ

500 kΩ

0.1 µF

100 kΩ

V+ = 10V to 15V

1

47 pF

V

OUT

Frequency

Input

TC9400

6

10 kΩ

2

11

1.0

4

14

12

3

5

GND

V

REF

OUT

I

IN

Zero

Adjust

V

REF

I

BIAS

Amp Out

V

DD

V

SS

GND

6

7

1.0 kΩ

V+

1.0 kΩ

0.01 µF

.001 µF

DET

Note: The output is referenced to Pin 6, which is at 6.2V (Vz). For frequency meter applications,

a 1 mA meter with a series scaling resistor can be placed across Pins 6 and 12.

MΩ

MΩ

0.5 ms

Min

5.0 ms

Min

Delay = 3 ms

Input

F

OUT

F

OUT

/2

FIGURE 6-2: F/V Single Supply F/V Converter.

and F

/2 are not used in the F/V mode. How-

OUT

6.3 Input Buffer

F

OUT

ever, these outputs may be useful for some applications, such as a buffer to feed additional circuitry. Then,

will follow the input frequency waveform, except

F

OUT

that F

will go high 3 µs after FIN goes high; F

OUT

will be square wave with a frequency of one-half F

/2

OUT

OUT

.

FIGURE 6-3: F/V Digital Outputs.

If these outputs are not used, Pins 8, 9 and 10 should be

connected to ground (see Figure 6-3 and Figure 6-4).

© 2007 Microchip Technology Inc. DS21483D-page 15

TC9400/9401/9402

TC9400A

TC9401A

TC9402A

+5V

14

V

DD

V+

V+

F

OUT

/2

F

OUT

Output

Common

10

9

8

5

3

12

12 pF

C

REF

56 pF

C

INT

1000 pF

R

INT

1MΩ

60 pF

Amp

Out

V

OUT

V

SS

I

BIAS

14

10 kΩ

2.2 kΩ

100 kΩ

2kΩ

-5V

+5V

Zero Adjust

2

7

(Typically -5V)

V

REF

F

IN

11

Threshold

Detector

3ms

Delay

*

*

*

*Optional If

Buffer is Needed

Offset

Adjust

V

REF

OUT

I

IN

42

–

+

Op

Amp

+

V

REF

See

Figure 7-1:

Frequency

Input Level

Shifter

6

GND

Threshold

Detect

1

47 pF

V

OUT

TC9400

12

3

5

V

REF

OUT

I

IN

GND

AMP OUT

6

.001 µF

+

–

1

3

2

.01 µF

1MΩ

0.1 µF

+5

7

6

4

-5

TL071

200Ω

MΩ

MΩ

FIGURE 6-4: DC – 10 kHz Converter.

6.4 Output Filtering

The output of the TC9400 has a sawtooth ripple superimposed on a DC level. The ripple will be rejected if the

TC9400 output is converted to a digital value by an

integrating Analog-to-Digital Converter, such as the

TC7107. The ripple can also be reduced by increasing

the value of the integrating capacitor, although this will

reduce the response time of the F/V converter.

The sawtooth ripple on the output of an F/V can be

eliminated without affecting the F/V’s response time by

using the circuit in Figure 6-1. The circuit is a

capacitance multiplier, where the output coupling

capacitor is multiplied by the AC gain of the op amp. A

moderately fast op amp, such as the TL071, should be

used.

DS21483D-page 16 © 2007 Microchip Technology Inc.

FIGURE 6-5: Ripple Filter.

TC9400/9401/9402

V

DD

14

11

1000 pF

Threshold

Detector

1kΩ

F

IN

V

DD

100 kΩ

1µF

3

4

8

6

F

IN

12516

V

CC

B R C

Q

V

SS

A

CLRA

CD4538

TC9400

(a) (b)

To TC9400

7.0 F/V POWER-ON RESET

In F/V mode, the TC9400 output voltage will occasionally be at its maximum value when power is first

applied. This condition remains until the first pulse is

applied to F

applications, this is not a problem because proper

operation begins as soon as the frequency input is

applied.

. In most frequency measurement

IN

In some cases, however, the TC9400 output must be

zero at power-on without a frequency input. In such

cases, a capacitor connected from Pin 11 to V

usually be sufficient to pulse the TC9400 and provide a

Power-on Reset (see Figure 7-1 (a) and (b)). Where

predictable power-on operation is critical, a more

complicated circuit, such as Figure 7-1 (b), may be

required.

DD

will

FIGURE 7-1: Power-On Operation/Reset.

© 2007 Microchip Technology Inc. DS21483D-page 17

TC9400/9401/9402

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

3

e

XXXXXXXXXXXXXX

YYWWNNN

14-Lead CERDIP

XXXXXXXXXXXXXX

0731256

Example: (Front View)

TC9400EJD

14-Lead PDIP

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

YYWWNNN

Example: (Front View)

14-Lead SOIC (.150”)

XXXXXXXXXXX

XXXXXXXXXXX

YYWWNNN

Example: (Front View)

Y2026

Example: (Back View)

Y2026

Example: (Back View)

TC9400

CPD ^^

0731256

TC9400

EOD

^^

0731256

Example: (Back View)

Y2026

8.0 PACKAGE INFORMATION

8.1 Package Marking Information

3

e

3

e

DS21483D-page 18 © 2007 Microchip Technology Inc.

3

e

TC9400/9401/9402

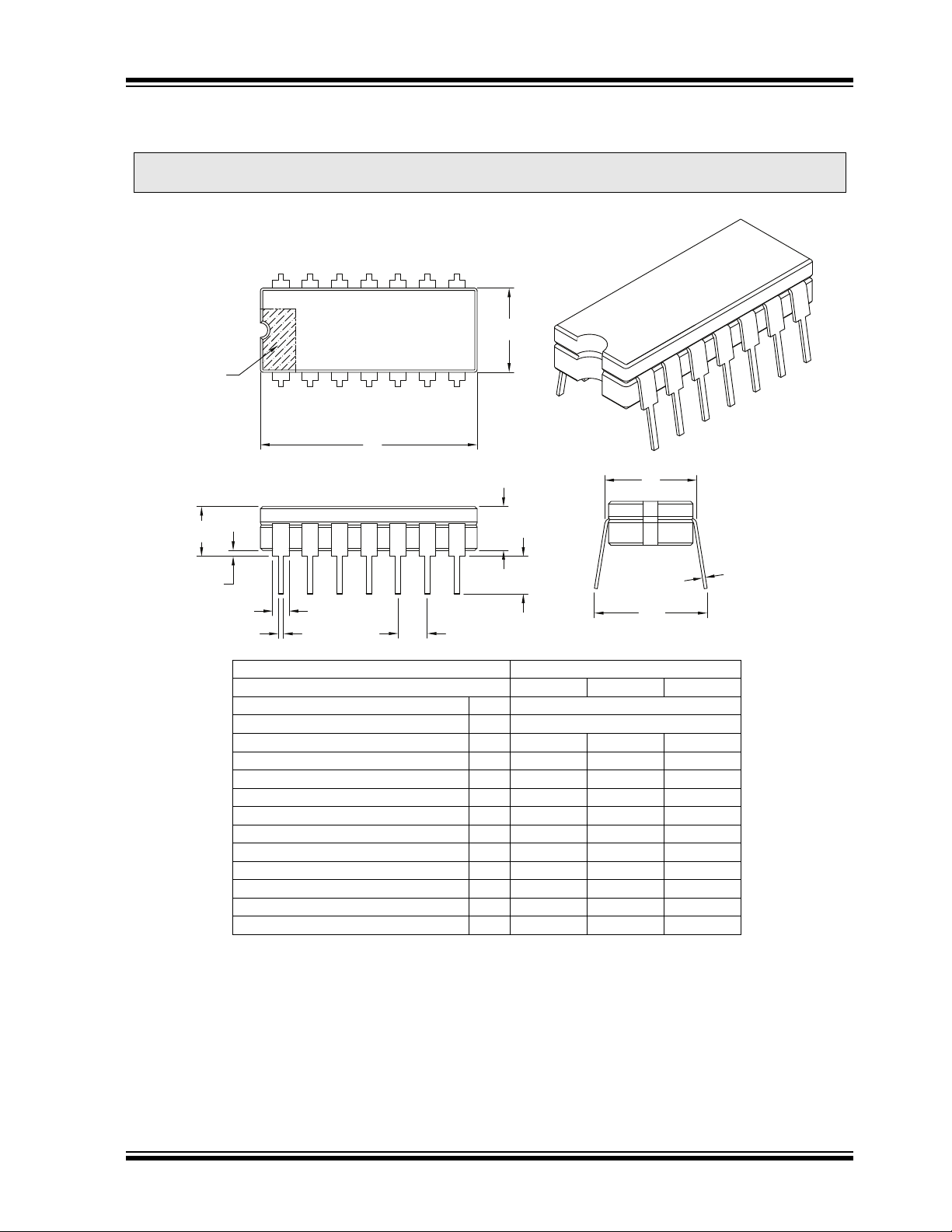

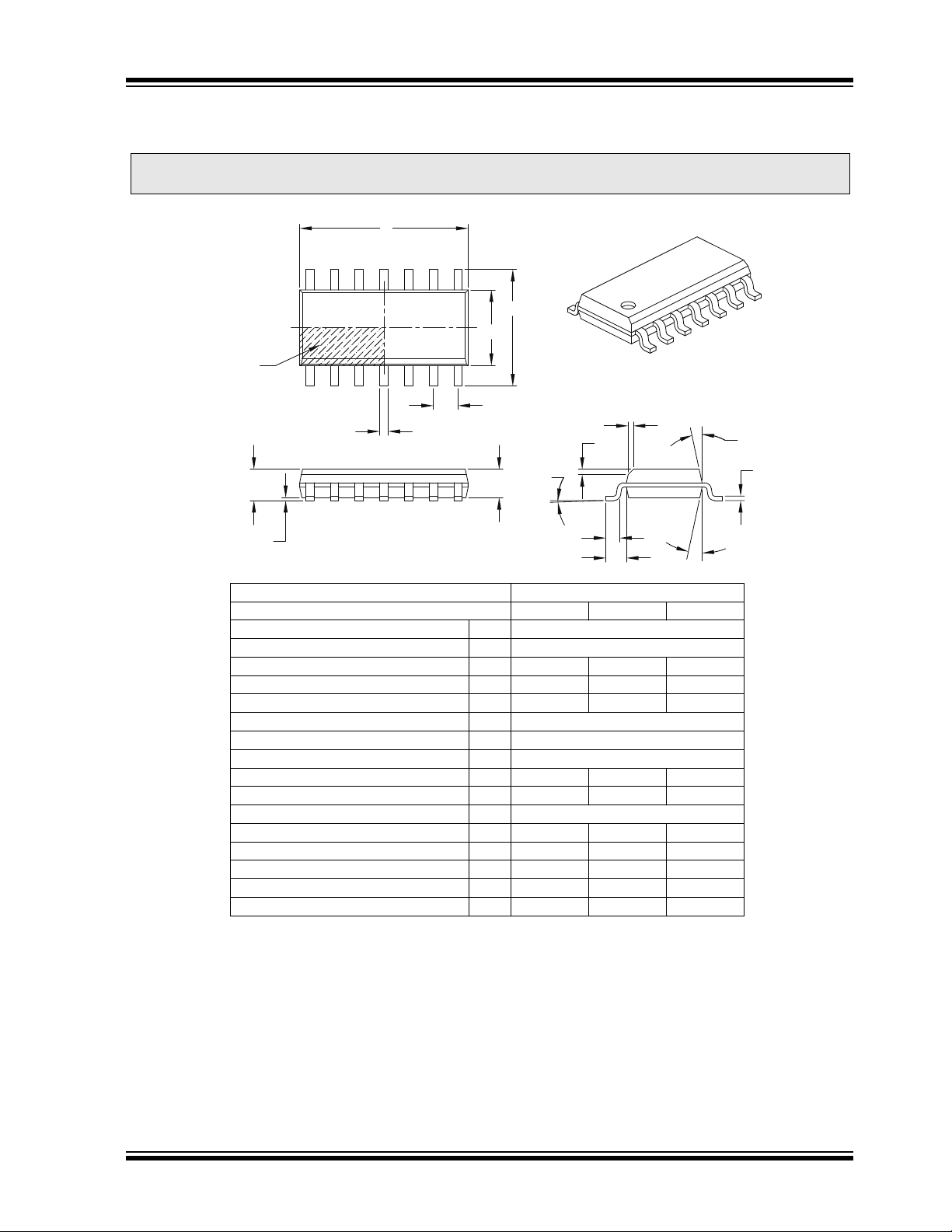

14-Lead Ceramic Dual In-Line (JD) – .300" Body [CERDIP]

B

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

N

NOTE 1

1

2

D

A

A1

b1

b

Number of Pins N 14

Pitch e .100 BSC

Top to Seating Plane A – – .200

Standoff § A1 .015 – –

Ceramic Package Height A2 .140 – .175

Shoulder to Shoulder Width E .290 – .325

Ceramic Package Width E1 .230 .288 .300

Overall Length D .740 .760 .780

Tip to Seating Plane L .125 – .200

Lead Thickness c .008 – .015

Upper Lead Width b1 .045 – .065

Lower Lead Width b .015 – .023

Overall Row Spacing E2 .320 – .410

Notes:

1. Pin 1 visual index feature may vary, but must be located within the hatched area.

2. § Significant Characteristic.

3. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

e

Dimension Limits MIN NOM MAX

E1

A2

L

Units INCHES

Microchip Technology Drawing C04-002

E

c

E2

© 2007 Microchip Technology Inc. DS21483D-page 19

TC9400/9401/9402

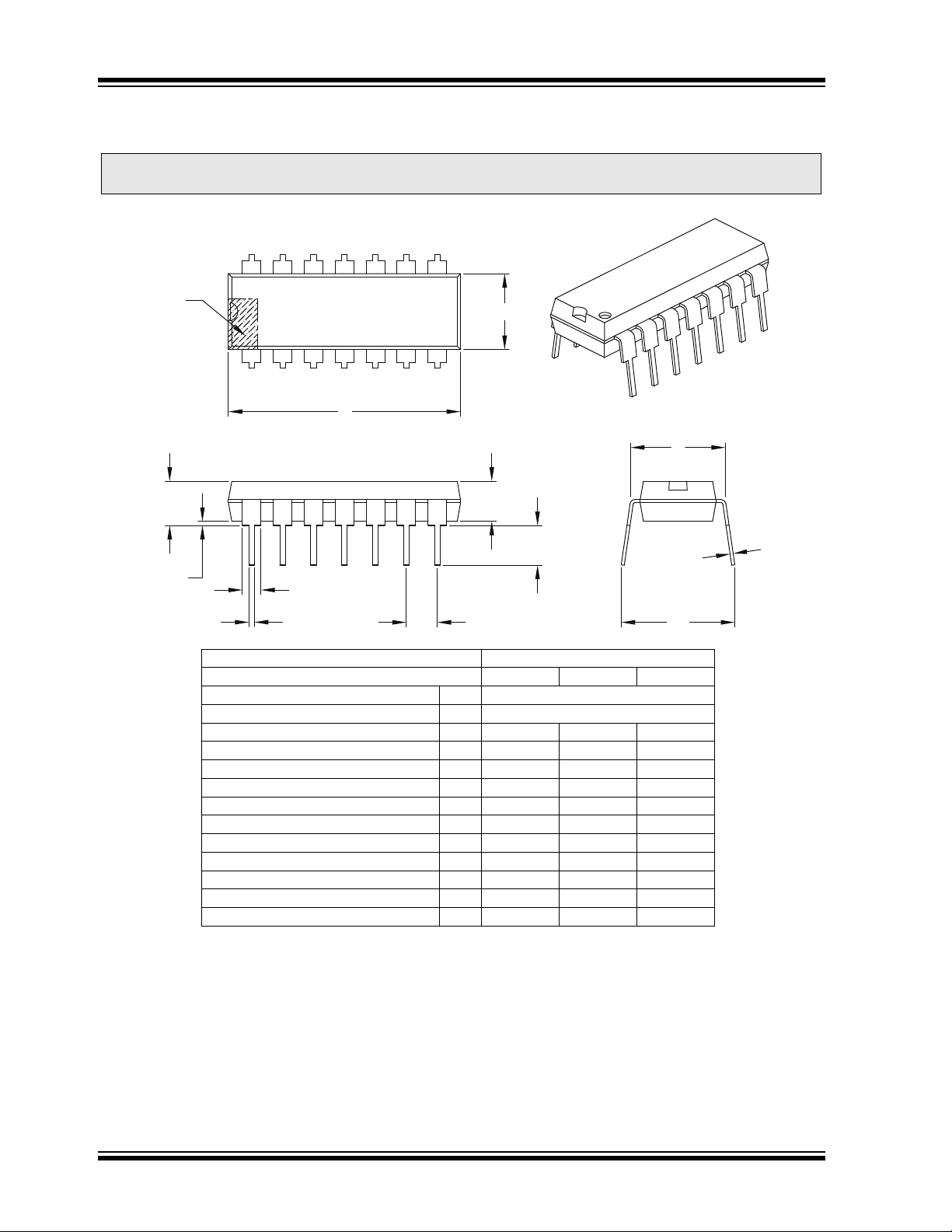

14-Lead Plastic Dual In-Line (PD) – 300 mil Body [PDIP]

Notes:

1. Pin 1 visual index feature may vary, but must be located with the hatched area.

2. § Significant Characteristic.

3. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010" per side.

4. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

Units INCHES

Dimension Limits MIN NOM MAX

Number of Pins N 14

Pitch e .100 BSC

Top to Seating Plane A – – .210

Molded Package Thickness A2 .115 .130 .195

Base to Seating Plane A1 .015 – –

Shoulder to Shoulder Width E .290 .310 .325

Molded Package Width E1 .240 .250 .280

Overall Length D .735 .750 .775

Tip to Seating Plane L .115 .130 .150

Lead Thickness c .008 .010 .015

Upper Lead Width b1 .045 .060 .070

Lower Lead Width b .014 .018 .022

Overall Row Spacing § eB – – .430

N

E1

D

NOTE 1

12

3

E

c

eB

A2

L

A

A1

b1

b e

Microchip Technology Drawing C04-005B

DS21483D-page 20 © 2007 Microchip Technology Inc.

TC9400/9401/9402

14-Lead Plastic Small Outline (OD) – Narrow, 3.90 mm Body [SOIC]

Notes:

1. Pin 1 visual index feature may vary, but must be located within the hatched area.

2. § Significant Characteristic.

3. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15 mm per side.

4. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 14

Pitch e 1.27 BSC

Overall Height A – – 1.75

Molded Package Thickness A2 1.25 – –

Standoff § A1 0.10 – 0.25

Overall Width E 6.00 BSC

Molded Package Width E1 3.90 BSC

Overall Length D 8.65 BSC

Chamfer (optional) h 0.25 – 0.50

Foot Length L 0.40 – 1.27

Footprint L1 1.04 REF

Foot Angle φ 0° – 8°

Lead Thickness c 0.17 – 0. 25

Lead Width b 0.31 – 0. 51

Mold Draft Angle Top α 5° – 15°

Mold Draft Angle Bottom β 5° – 15°

NOTE 1

N

D

E

E1

1

2 3

b

e

A

A1

A2

L

L1

c

h

h

α

β

φ

Microchip Technology Drawing C04-065B

© 2007 Microchip Technology Inc. DS21483D-page 21

TC9400/9401/9402

NOTES:

DS21483D-page 22 © 2007 Microchip Technology Inc.

APPENDIX A: REVISION HISTORY

Revision D (September 2007)

The following is the list of modifications:

1. Corrected Figure 6-1.

2. Added History section.

3. Updated package marking information and

package outline drawings

4. Added Product identification System section.

Revision C (May 2006)

Revision B (May 2002)

Revision A (April 2002)

• Original Release of this Document.

TC9400/9401/9402

© 2007 Microchip Technology Inc. DS21483D-page 23

TC9400/9401/9402

NOTES:

DS21483D-page 24 © 2007 Microchip Technology Inc.

TC9400/9401/9402

PART NO. X /XX

PackageTemperature

Range

Device

Device TC9400: Voltage-to-Frequency Converter

TC9401: Voltage-to-Frequency Converter

TC9402: Voltage-to-Frequency Converter

Temperature Range E = -40°C to +85°C (Extended)

C=0°C to +70°C (Commercial)

Package JD = Ceramic Dual-Inline (.300” Body), 14-lead

PD = Plastic Dual-Inline (300 mil Body), 14-lead

OD = Plastic Small Outline (3.90 MM Body), 14-lead

OD713 = Plastic Small Outline (3.90 MM Body), 14-lead

Tape and Reel.

Examples:

a) TC9400COD: 0°C to +70°C,

14LD SOIC package.

b) TC9400COD713:0°C to +70°C,

14LD SOIC package,

Tape and Reel

c) TC9400CPD: 0°C to +70°C,

14LD PDIP package.

d) TC9400EJD: -40°C to +85°C,

14LD PDIP package.

a) TC9401CPD: 0°C to +70°C,

14LD PDIP package.

b) TC9401EJD: -40°C to +85°C,

14LD CERDIP package.

a) TC9402CPD: 0°C to +70°C,

14LD PDIP package.

b) TC9402EJD: -40°C to +85°C,

14LD CERDIP package.

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

© 2007 Microchip Technology Inc. DS21483D-page 25

TC9400/9401/9402

NOTES:

DS21483D-page 26 © 2007 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, microID, MPLAB, PIC,

PICmicro, PICSTART, PRO MATE, rfPIC and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Linear Active Thermistor, Migratable

Memory, MXDEV, MXLAB, SEEVAL, SmartSensor and The

Embedded Control Solutions Company are registered

trademarks of Microchip Technology Incorporated in the

U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Mindi, MiWi,

MPASM, MPLAB Certified logo, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB, Select

Mode, Smart Serial, SmartTel, Total Endurance, UNI/O,

WiperLock and ZENA are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

© 2007 Microchip Technology Inc. DS21483D-page 27

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

06/25/07

DS21483D-page 28 © 2007 Microchip Technology Inc.

Loading...

Loading...