查询TC7129CJL713供应商

4-1/2 Digit Analog-to-Digital Converters with

TC7129

On-Chip LCD Drivers

Features:

• Count Resolution: ±19,999

• Resolution on 200mV Scale: 10 μV

• True Differential Input and Reference

• Low Power Consumption: 500 μA at 9V

• Direct LCD Driver for 4-1/2 D ig it s , Dec im al Po ints,

Low Battery Indicator, and Continuity Indicator

• Overrange and Underrange Outputs

• Range Select Input: 10:1

• High Common Mode Rejection Ratio: 110 dB

• External Phase Compensation Not Required

Applications:

• Full-Featured Multimeters

• Digital Measu rem en t Dev ic es

Device Selection Table

Package

Code

TC7129CPL Normal 40-Pin PDIP 0°C to +70°C

TC7129CKW Formed 44-Pin PQFP 0°C to +70°C

TC7129CLW – 44-Pin PLCC 0°C to +70°C

Pin

Layout

Package

Temperature

Range

General Description:

The TC7129 is a 4-1/2 di git Analog-to-Dig ital Con verter

(ADC) that directly drives a multiplexed Liquid Crystal

Display (LCD). Fabricated in high-performance, lowpower CMOS, the TC7129 ADC is designed specifically for high-resolution, battery-powered digital multimeter applications. The traditional dual-slope method

of A/D conversion has been enhanced with a successive integration technique to produce readings accurate to better than 0.005% of full-scale and resolution

down to 10 μV per count.

The TC7129 includes f eatures impor tant to multimeter

applications. It detects and ind icat es l ow bat ter y con dition. A continuity outp ut drives an annunciator on the

display and can be used with an external driver to sound

an audible alarm. Overrange and underrange o utputs,

along with a range-ch ange input, provi de the ability to

create auto-ranging instruments. For snapshot readings, the TC7129 includes a latch-and-hold input to

freeze the present reading. This combination of features

makes the TC7129 the ideal choice for full-featured

multimeter and digital measurement applications.

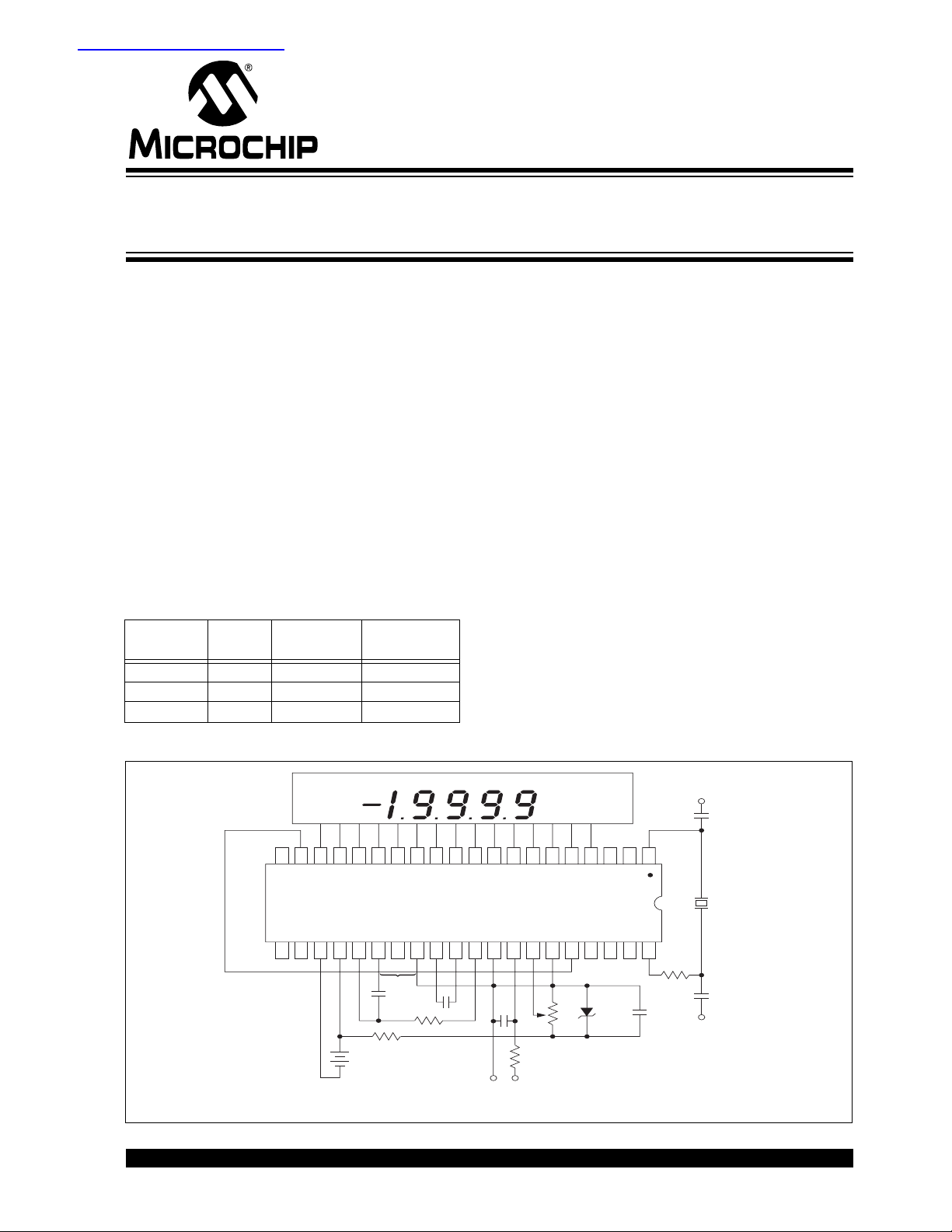

Typical Application

Low Battery

20

+

9V

*

N

ote

:

RC network between pins 26 and 28 is not required.

© 2006 Microchip Technology Inc. DS21459D-page 1

0.1 µF

10 kΩ

27262524232221

*

13141516171819

28

150 kΩ

1011

12

TC7129

29

+

1 µF

–

9

323130

0.1

µF

V

Continuity

8

33

100 kΩ

+

IN

V+

5 pF

1234567

120 kHz

3534

36

20

kΩ

39

40

3837

330 kΩ

10 pF

0.1 µF

V+

TC7129

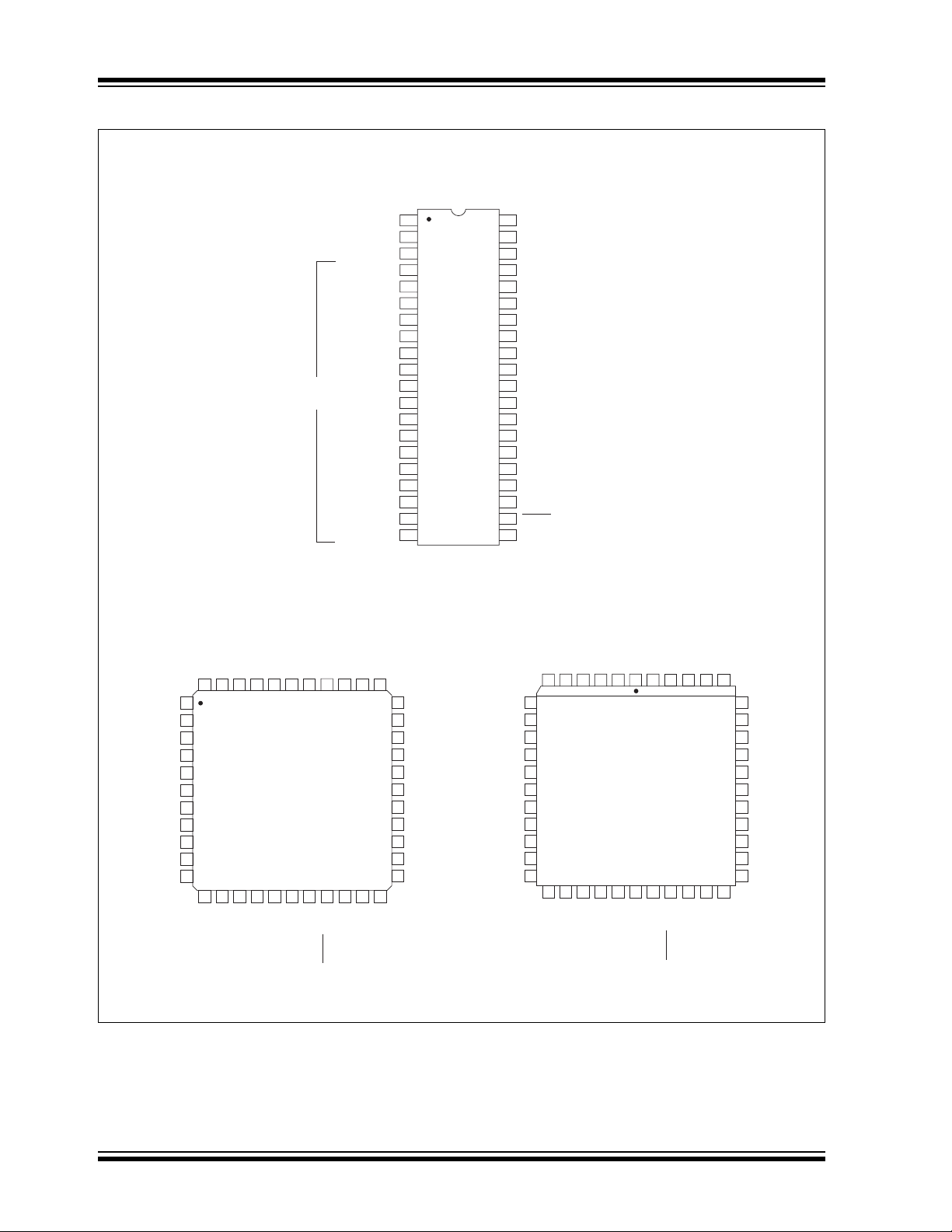

Package Types

ANNUNICATOR

B2, C2, LO BATT

Display

Output

Lines

B

, C1, CONT

1

A

F1, E1, DP

A

F2, E2, DP

B3, C

A

F3, E3, DP

B4, C

A4, G4, D

F4, E4, DP

, G1, D

1

, G2, D

2

MINUS

3

,

, G3, D

3

4

DP4/OR

OSC1

OSC3

BC

,

BP

BP

BP

V

DISP

40-Pin PDIP

1

2

3

4

5

1

6

1

7

8

2

9

2

10

11

3

12

3

13

5

14

4

15

4

16

3

17

2

18

1

19

20

TC7129CPL

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

OSC2

DP

1

DP

2

RANGE

DGND

REF LO

REF HI

IN HI

IN LO

BUFF

-

C

REF

+

C

REF

COMMON

CONTINUITY

INT OUT

INT IN

V+

V-

LATCH/HOLD

DP3/UR

, E1, DP

F

1

B2, C2, BATT

, G2, D

A

2

F2, E2, DP

B3, C

MINUS

3

,

A

, G3, D

3

F3, E3, DP

B4, C

A4, G4, D

F4, E4, DP

44-Pin QFP 44-Pin PLCC

1

, D

, CONT

1

1

, G

, C

1

1

ANNUNCIATOR

OSC3

A

44 43 42 41 39 3840

1

1

B

OSC1NCOSC2

2

3

2

4

2

5

NC

6

7

3

8

3

BC

9

4

5

,

10

4

11

4

12 13 14 15 17 18

BP3BP

1

2

BP

TC7129CKW

16

/OR

4

DISP

V

DP

NC

/UR

3

DP

1DP2

DP

RANGE

37 36 35 34

19 20 21 22

V-

V+

DGND

33

32

31

30

29

28

27

26

25

24

23

INT IN

REF LO

REF HI

IN HI

IN LO

BUFF

NC

C

-

REF

C

+

REF

COMMON

CONTINUITY

INT OUT

F1, E1, DP

B2, C2, BATT

, G2, D

A

2

F2, E2, DP

B3, C

3

,

A

, G3, D

3

F3, E3, DP

B4, C

A4, G4, D

F4, E4, DP

MINUS

NC

BC

4

,

LATCH/HOLD

1

, D

, CONT

1

1

, G

, C

1

1

A

B

6543 1442

7

1

8

9

2

10

2

11

12

13

3

3

5

4

4

18 19 20 21 23 24

3BP2

BP

ANNUNCIATOR

OSC3

OSC1NCOSC2

TC7129CLW

22

1

/OR

BP

DISP

4

V

DP

NC

/UR

3

DP

DP1DP2RANGE

43 42 41 40

25 26 27 28

V-

V+

LATCH/HOLD

DGND

39

38

37

36

35

34

33

3214

3115

3016

2917

INT IN

REF LO

REF HI

IN HI

IN LO

BUFF

NC

-

C

REF

C

+

REF

COMMON

CONTINUITY

INT OUT

DS21459D-page 2 © 2006 Microchip Technology Inc.

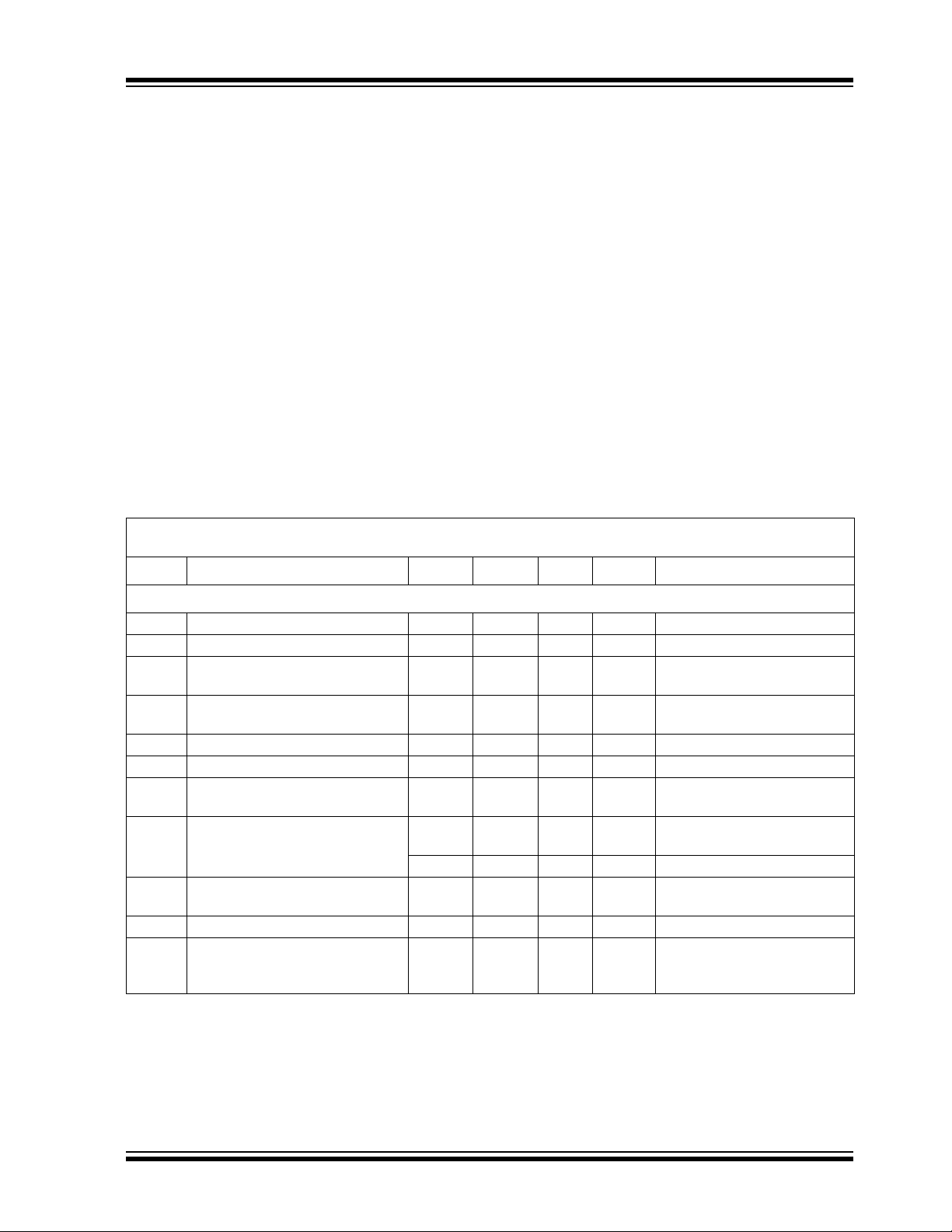

TC7129

1.0 ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings*

Supply Voltage (V+ to V-).......................................15V

*Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device. These

are stress ratings only and functional operation of the device

at these or any other conditions above those indicated in the

operation sections of the specifications is not implied.

Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability.

Reference Voltage (REF HI or REF LO)........ V+ to V–

Input Voltage (IN HI or IN LO) (Note 1).......... V+ to V–

.......................................... V+ to (DGND – 0.3V)

V

DISP

Digital Input (Pins 1, 2, 19, 20,

21, 22, 27, 37, 39, 40).......................... DGND to V+

Analog Input (Pins 25, 29, 30) ....................... V+ to V–

Package Power Dissipation (T

≤ 70°C)

A

Plastic DIP .....................................................1.23W

PLCC .............................................................1.23W

Plastic QFP....................................................1.00W

Operating Temperature Range ...............0°C to +70°C

Storage Temperature Range..............-65°C to +150°C

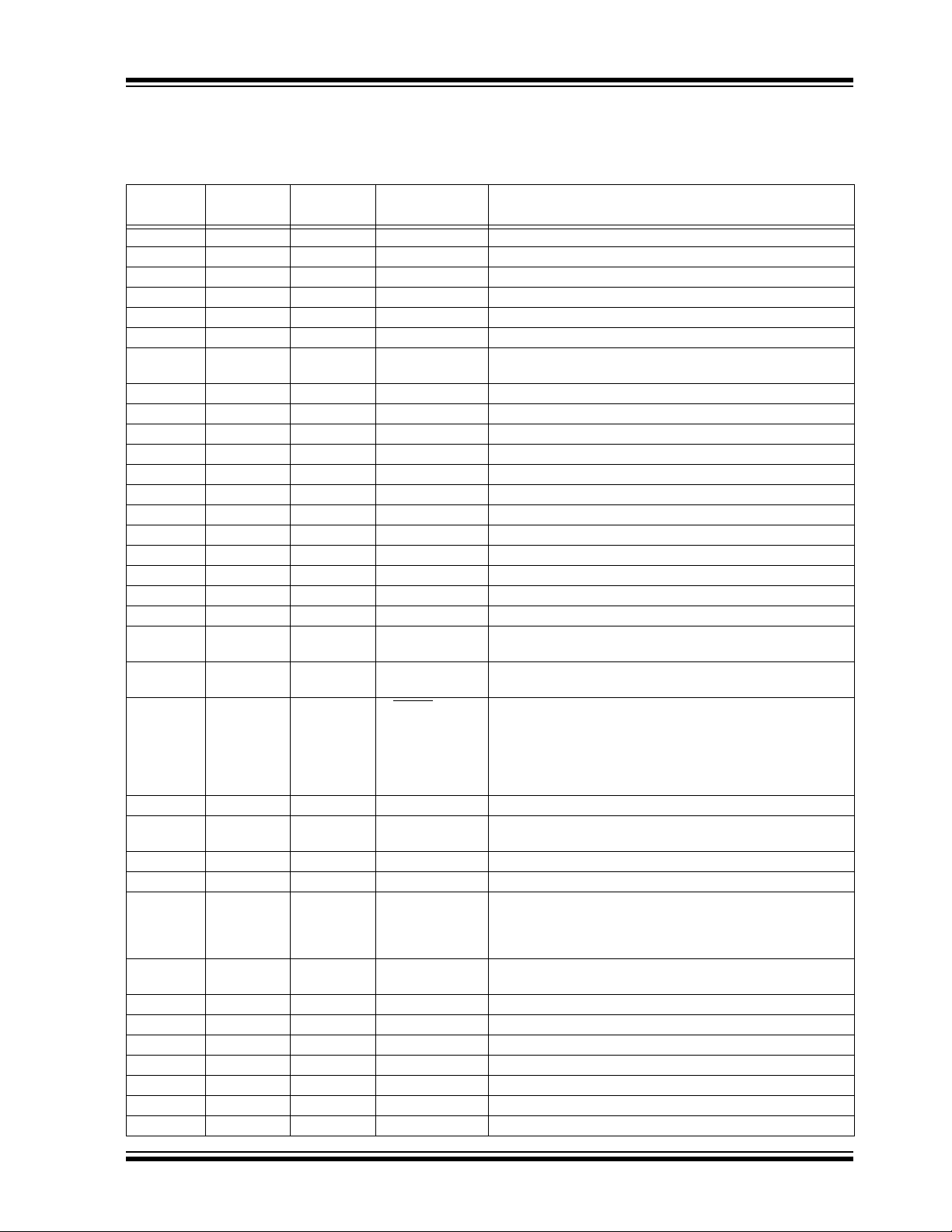

TC7129 ELECTRICAL SPECIFICATIONS

Electrica l Characteristics: V+ to V– = 9V, V

Pin numbers refer to 40-pin DIP.

Symbol Parameter Min Typ Max Unit Test Conditions

= 1V, TA = +25°C, f

REF

= 120 kHz, unless otherwise indicated.

CLK

Input

Zero Input Reading –0000 0000 +0000 Counts V

Zero Reading Drift — ±0.5 — μV/°C V

Ratiometric Reading 9996 — 10000 Counts VIN = V

= 0V, 200 mV scale

IN

= 0V, 0°C < TA < +70°C

IN

= 1000 mV,

REF

Range = 2V

Range Change Accuracy 0.9999 1.0000 1.0001 Ratio V

= 1V on High Range,

IN

= 0.1V on Low Range

V

IN

RE Rollover Error — 1 2 Counts VIN– = VIN+ = 199 mV

NL Linearity Error — 1 — Counts 200mV Scale

CMRR Common Mode Rejection Ratio — 110 — dB V

= 1V, VIN = 0V,

CM

200 mV scale

CMVR Common Mode Voltage Range — (V-) +

—VV

IN

= 0V

1.5

— (V+) – 1 — V 200mV scale

e

N

Noise (Peak-to-Peak Value not

Exceeded 95% of Time)

I

IN

Input Leakage Current — 1 1 0 pA VIN = 0V, pins 32, 33

Scale Factor Temperature

Coefficient

— 14—μV

P-PVIN

— 2 7 ppm/°C V

= 0V

200 mV scale

= 199 mV,

IN

0°C < T

External V

< +70°C

A

REF

= 0 ppm/°C

Note 1: Input voltages may exceed supply voltages, provided input current is limited to ±400 μA. Currents above

this value may result in invalid display readings, but will not destroy the device if limited to ±1 mA.

Dissipation ratings assume device is mounted with all leads soldered to printed circuit board.

© 2006 Microchip Technology Inc. DS21459D- page 3

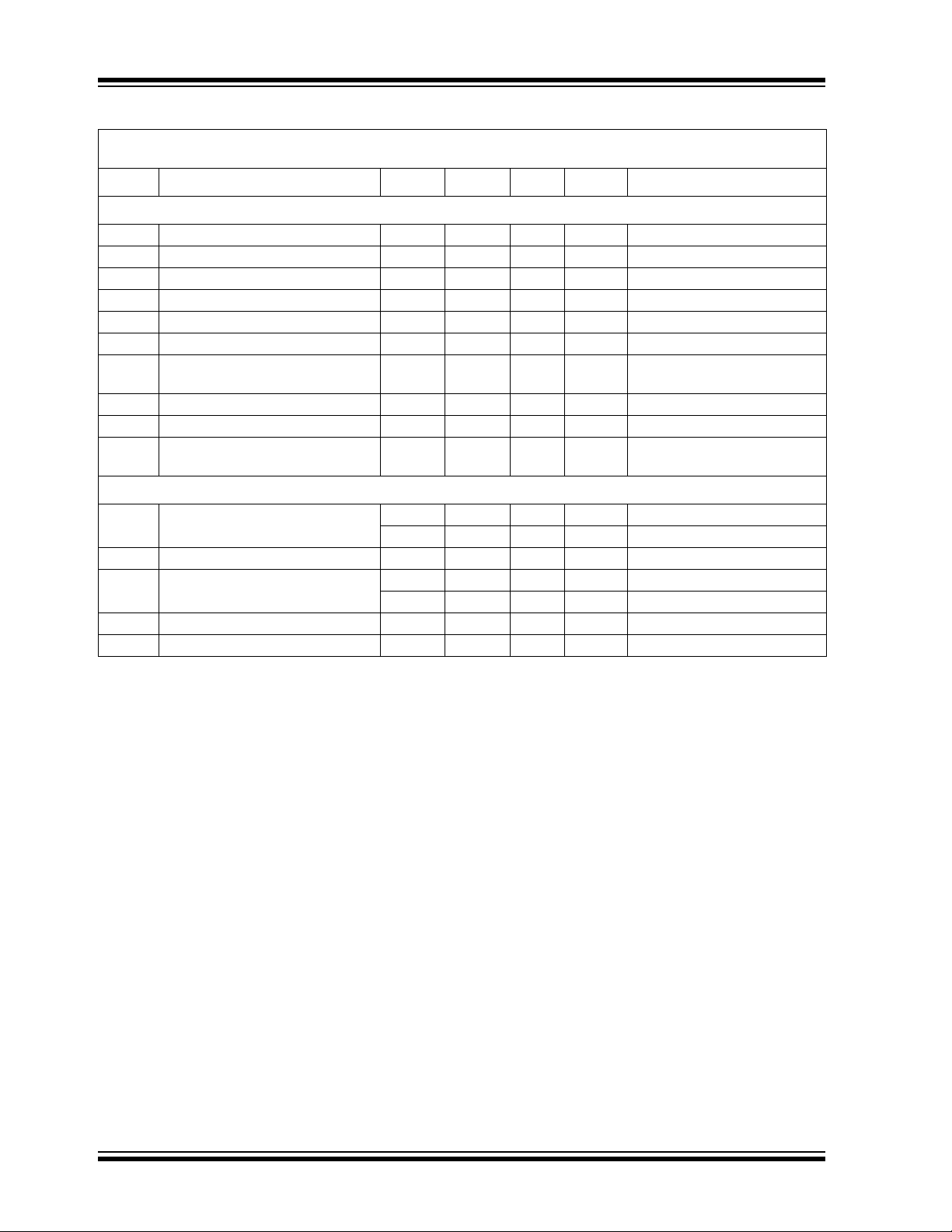

TC7129

TC7129 ELECTRICAL SPECIFICATIONS (CONTINUED)

Electrica l Characteristics: V+ to V– = 9V, V

Pin numbers refer to 40-pin DIP.

Symbol Parameter Min Typ Max Unit Test Conditions

Power

V

COM

Common Voltage 2.8 3.2 3.5 V V+ to pin 28

Common Sink Current — 0.6 — mA ΔCommon = +0.1V

Common Source Current — 10 — μA ΔCommon = -0.1V

DGND Digital Ground Voltage 4.5 5.3 5.8 V V+ to pin 36, V+ to V– = 9V

Sink Current — 1.2 — mA ΔDGND = +0.5V

Supply Voltage Range 6 9 12 V V+ to V–

I

S

Supply Current Excluding

Common Current

f

CLK

Clock Frequency — 120 360 kHz

Resistance — 50 — kΩ V

V

DISP

Low Battery Flag Activation

Voltage

Digital

Continuity Comparator Threshold

Voltages

Pull-down C urrent — 2 10 μA Pins 37, 38, 39

“Weak Output” Current

Sink/Source

Pin 22 Source Current — 40 — μA

Pin 22 Sink Current — 3 — μA

Note 1: Input voltages may exceed supply voltages, provided input current is limited to ±400 μA. Currents above

this value may result in invalid display readings, but will not destroy the device if limited to ±1 mA.

Dissipation ratings assume device is mounted with all leads soldered to printed circuit board.

= 1V, TA = +25°C, f

REF

= 120 kHz, unless otherwise indicated.

CLK

— 0.8 1.3 mA V+ to V– = 9V

to V+

DISP

6.3 7.2 7.7 V V+ to V–

100 200 — mV V

— 200 400 mV V

pin 27 = High

OUT

pin 27 = Low

OUT

— 3/3—μA Pins 20, 21 sink/sourc e

— 3/9—μA Pin 27 sink/source

DS21459D-page 4 © 2006 Microchip Technology Inc.

TC7129

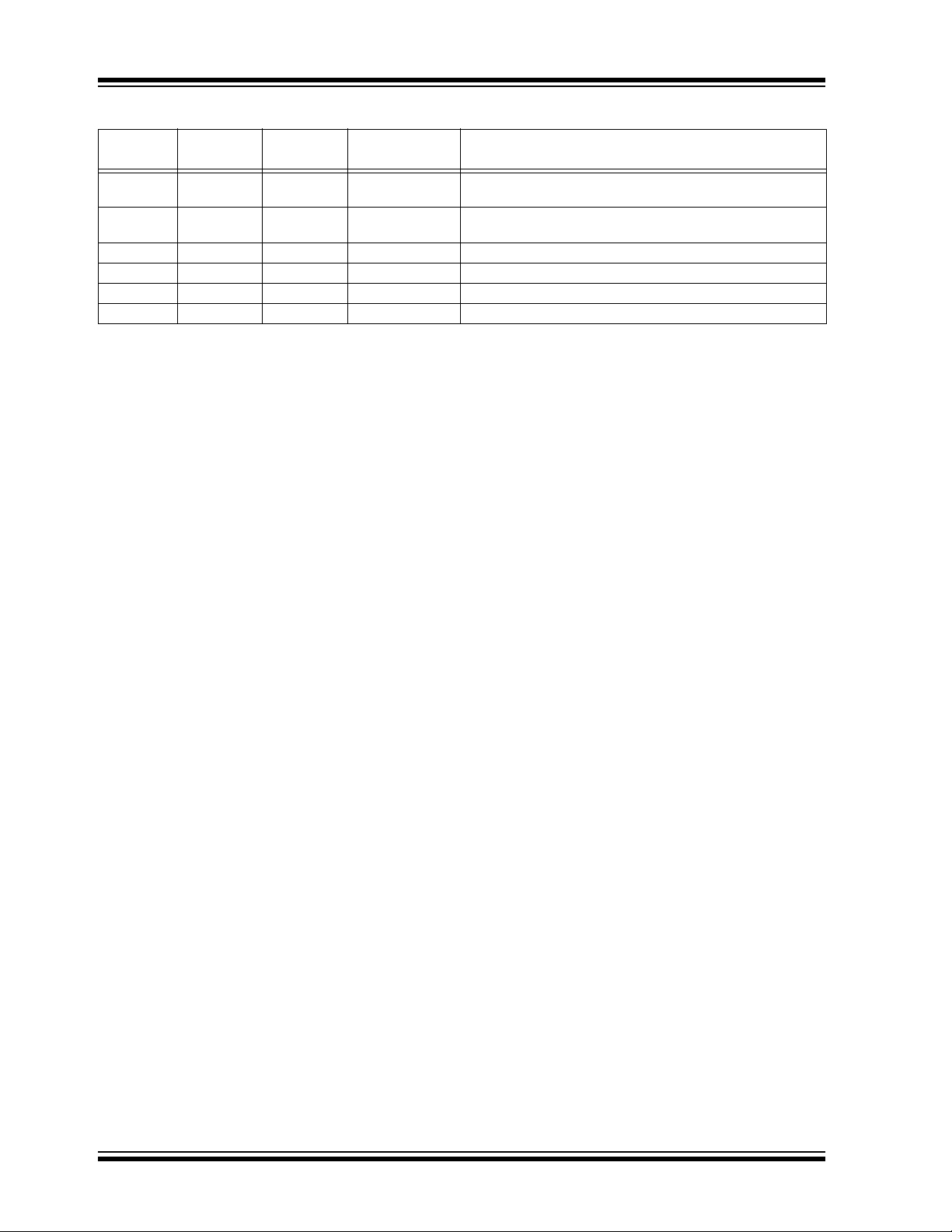

2.0 PIN DESCRIPTIONS

Descriptions of the pins are listed in Table 2-1.

TABLE 2-1: PIN FUNCTION TABLE

Pin No.

40-Pin PDIP

1 40 2 OSC1 Input to first clock inverter.

2 41 3 OSC3 Output of second clock inverter.

3 42 4 ANNUNCIATOR Backplane square wave output for driving annunciators.

443 5B

544 6A

617F

728B

839A

9410F

10 5 11 B

11 7 13 A

12 8 14 F

13 9 15 B

14 10 16 A

15 11 17 F

16 12 18 BP

17 13 19 BP

18 14 20 BP

19 15 21 V

20 16 22 DP

21 18 24 DP

22 19 25 LATCH

23 20 26 V– Negative power supply terminal.

24 21 27 V+ Positive power supply terminal and positive rail for display

25 22 28 INT IN Input to integrator amplifier.

26 23 29 INT OUT Output of integrator amplifier.

27 24 30 CONTINUITY Input: When low, continuity flag on the display is off. When high,

28 25 31 COMMON Sets common mode voltage of 3.2V below V+ for DE, 10X, etc.

29 26 32 C

30 27 33 C

31 29 35 BUFFER Output of buffer amplifier.

32 30 36 IN LO Negative input voltage terminal.

33 31 37 IN HI Positive input voltage terminal.

34 32 38 REF HI Positive reference voltage.

35 33 39 REF LO Negative reference voltage

Pin No.

44-Pin PQFP

Pin No.

44-Pin PLCC

Symbol Function

, C1, CONT Output to display segments.

1

, G1, D

1

, E1, DP

1

, C2,

2

Output to display segments.

1

Output to display segments.

1

Output to display segments.

LO BATT

, G2, D

2

, E2, DP

2

, C3, MINUS Output to display segments.

3

, G3, D

3

, E3, DP

3

, C4, BC

4

, D4, G

4

, E4, DP

4

3

2

1

DISP

/OR Input: When high, turns on most significant decimal point.

4

/UR Input: Second-most significant decimal point on when high.

3

Output to display segments.

2

Output to display segments.

2

Output to display segments.

3

Output to display segments.

3

Output to display segments.

5

Output to display segments.

4

Output to display segments.

4

Backplane #3 output to display.

Backplane #2 output to display.

Backplane #1 output to display.

Negative rail for display drivers.

Output: Pulled high when result count exceeds ±19,999.

Output: Pulled high when result count is less than ±1000.

/HOLD Input: When floating, ADC operates in Free Run mode. When

pulled high, the last displayed reading is held. When pulled low,

the result counter contents are shown incrementing during the

de-integrate phase of cycle.

Output: Negative going edge occurs when the data latches are

updated. Can be used for converter status signal.

drivers.

continuity flag is on.

Output: High when voltage between inputs i s less than +200 mV .

Low when voltage between inputs is more than +200 mV.

Can be used as pre-regulator for external reference.

+ Positive side of external reference capacitor.

REF

– Negative side of external reference capacitor.

REF

© 2006 Microchip Technology Inc. DS21459D- page 5

TC7129

TABLE 2-1: PIN FUNCTION TABLE (CONTINUED)

Pin No.

40-Pin PDIP

36 34 40 DGND Internal ground reference for digital section. See Section 4.2.1

37 35 41 RANGE 3 μA pull-down for 200 mV scale. Pulled high externally for 2V

38 36 42 DP

39 37 43 DP

40 38 44 OSC2 Output of first clock inverter. Input of second clock inverter.

— 6,17, 28, 39 12, 23, 34, 1 NC No connection.

Pin No.

44-Pin PQFP

Pin No.

44-Pin PLCC

Symbol Function

“±5V Power Supply”.

scale.

2

1

Internal 3 μA pull-down. When high, decimal point 2 will be on.

Internal 3 μA pull-down. When high, decimal point 1 will be on.

DS21459D-page 6 © 2006 Microchip Technology Inc.

TC7129

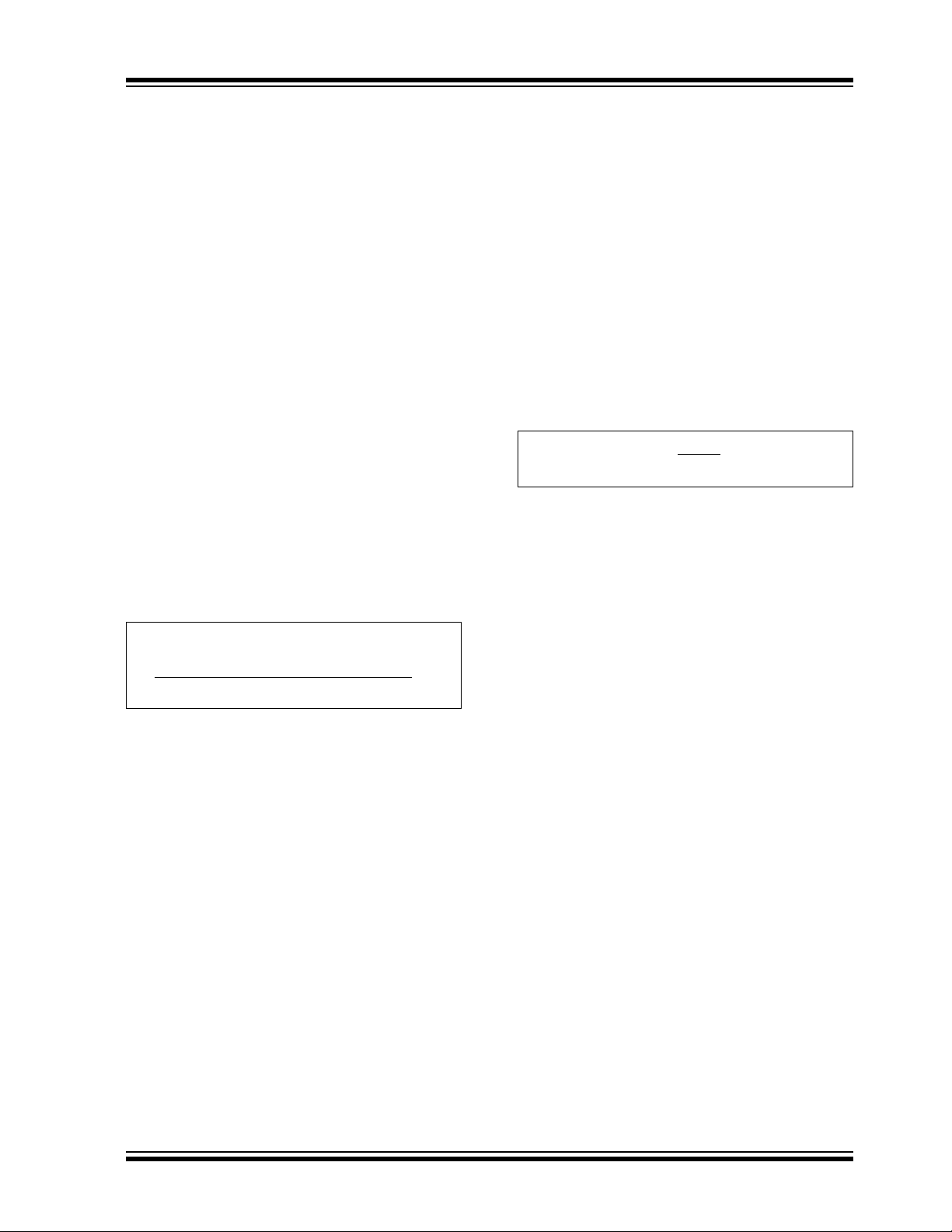

3.0 DETAILED DESCRIPTION

(All pin designations refer to 40-pin PDIP.)

The TC7129 is designed to be the heart of a high-

resolution analog measurement instrument. The only

additional components required are a few passive

elements: a voltage reference, a LCD and a power

source. Most component values are not critical;

substitutes can be chosen based on the information

given below.

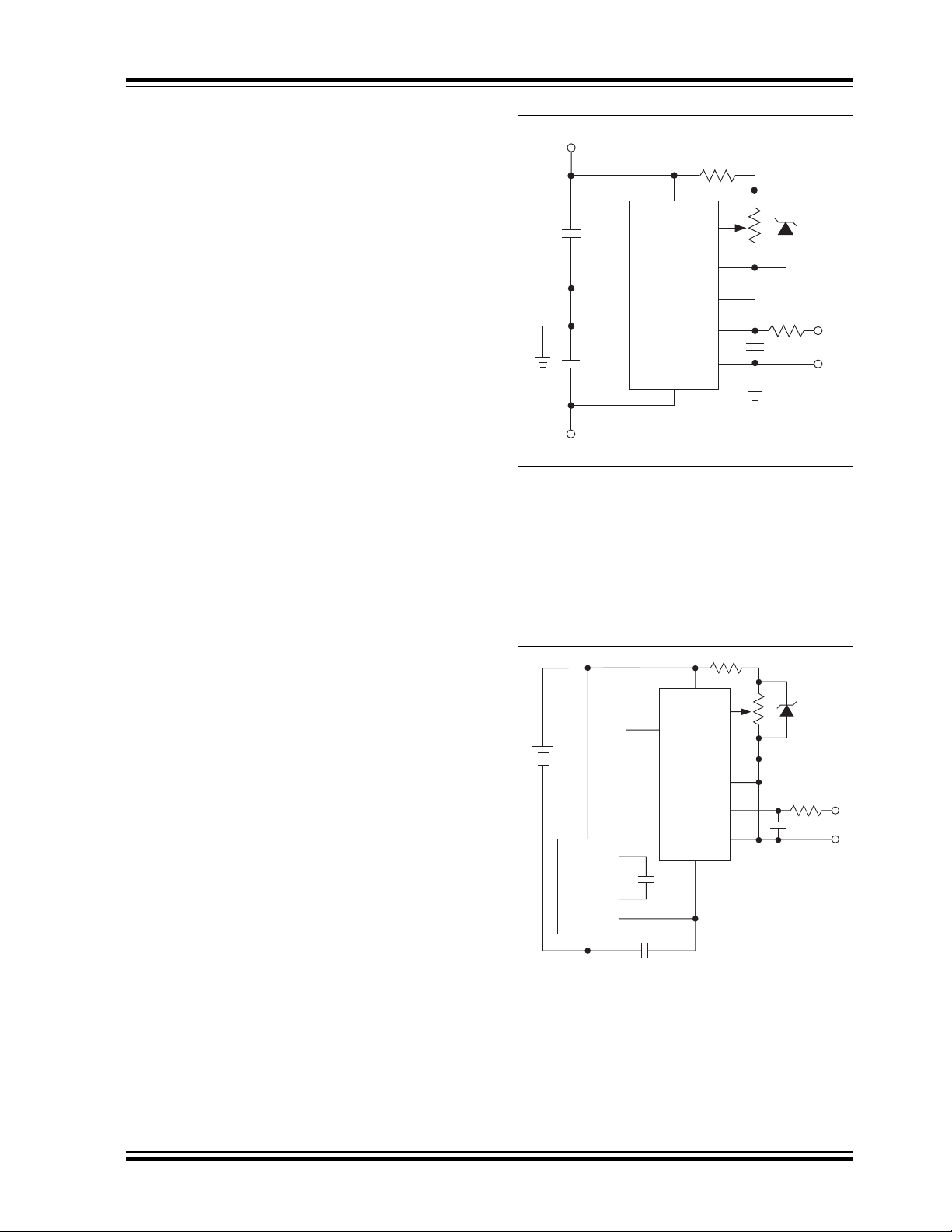

The basic circuit for a digital multimeter application is

shown in Figure 3-1. See Section 4.0 “Typical Appli-

cations”, for variations. Typical values for each

component are shown. The sections below give

component selection criteria.

3.1 Oscillator (X

The primary criterion for selecting the crystal oscillator

is to choose a frequency tha t achieves maxim um rejection of line frequency noise. To do this, the integration

phase should last an integral number of line cycles.

The integration phase of the TC7129 is 10,000 clock

cycles on the 200 mV range and 1000 clock cycles on

the 2V range. One cl ock c yc le is eq ua l to tw o os cil la t or

cycles. For 60 Hz rejection, the oscillator frequency

should be chosen so that the period of one line cycle

equals the integration time for the 2V range.

, CO1, CO2, RO)

OSC

The resistor and cap acitor values are not crit ica l; those

shown work for most applications. In some situations,

the capacitor values may have to be adjusted to

compensate for parasitic capacitance in the circuit. The

capacitors can be low-cost ceramic devices.

Some applications can use a simple RC network

instead of a crystal oscillator. The RC oscillator has

more potential for jitter, especially in the least

significant digit. See Section 4.5 “RC Oscillator”.

3.2 Integrating Resistor (R

The integrating resistor sets the charging current for

the integrating capacitor. Choo se a v alu e that provides

a current between 5μA and 20 μA at 2V, the maxim um

full-scale input. The typical value chosen gives a

charging current of 13.3 μA:

INT

)

EQUATION 3-1:

I

CHARGE

Too high a value for R

noise pickup and increases errors due to leakage

current. Too low a value degrades the linearity of the

integration, leading to inaccurate readings.

2V

=

INT

13.3 µA

150 kΩ

increases the sensitivity to

EQUATION 3-1:

1/60 second = 16.7 msec =

1000 clock cycles *2 OSC cycles/clock cycle

OSC Frequency

This equation gi ves an osc illa tor f requenc y of 120kHz.

A similar calculation gives an optimum frequency of

100 kHz for 50 H z rejection.

© 2006 Microchip Technology Inc. DS21459D- page 7

TC7129

Low Battery Continuity

V+

20

DP

4

/OR

DP

3

/UR

V

DISP

LATCH/

HOLD

V–

V+

+

INT IN

9V

13141516171819

Display Drive Outputs

CONTINUITY

COMMON

INT OUT

27262524232221

28

C

INT

0.1 µF

150 kΩ

10 kΩ

R

BIAS

12

TC7129

C

C

REF

REF

+

–

29

C

+

REF

1 µF

R

INT

9

1011

BUFF

IN LO

323130

– +

0.1

µF

C

V

IN HI

33

IF

IN

8

REF HI

R

IF

100 kΩ

REF LO

DGND

3534

36

R

REF

20

kΩ

ANNUNC

RANGE

DP

2

3837

D

REF

OSC3

DP

1

39

1234567

OSC1

OSC2

40

C

RF

0.1 µF

5 pF

120

kHz

330 kΩ

R

O

10 pF

V+

C

O1

Crystal

C

O2

Figure 3-1: Standard Circuit.

3.3 Integrating Capacitor (C

The charge stored in the integrating capacitor during

the integrate phase is directly proportional to the input

voltage. The primary selection criterion for C

choose a value that gives the highest voltage swing

while remaining within the high-linearity portion of the

integrator output ran ge. An integrat or swing of 2V i s the

recommended value. The capacitor value can be

calculated using the following equation:

INT

)

is to

INT

EQUATION 3-1:

x I

t

INT

V

SWING

INT

Where t

C

=

INT

is the integration time.

INT

Using the values derived above (assuming 60 Hz

operation), the equation becomes:

EQUATION 3-2:

C

16.7 msec x 13.3 μA

= = 0.1 μA

INT

2V

The capacitor should have low dielectric absorption to

ensure good integration linearity. Polypropylene and

Teflon® capacitors are usually suitable. A good

measurement of the dielectric absorption is to connect

the reference capacitor across the inputs by

connecting:

Pin-to-Pin:

20 → 33 (C

30 → 32 (C

+ to IN HI)

REF

– to IN LO)

REF

A reading between 10,000 and 9998 is acceptable;

anything lower indicates unacceptably high dielectric

absorption.

3.4 Reference Capacitor (C

REF

)

The reference capacitor stores the reference voltage

during several phases of the measurement cycle. Low

leakage is the primary selection criterion for this component. The value must be high enough to offset the

effect of stray cap acit anc e at the c ap acito r terminals . A

value of at least 1 μF is recommended.

DS21459D-page 8 © 2006 Microchip Technology Inc.

3.5 Voltage Reference

(D

, R

REF

REF

, R

The reference potentiometer (R

BIAS

, CRF)

) provides an

REF

adjustment for adjusting the reference voltage; any

value above 20 kΩ is adequate. The bias resistor

) limits the current through D

(R

BIAS

150 μA. The reference filter capacitor (C

RC filter with R

to help eliminate noise.

BIAS

to less than

REF

) forms an

RF

3.6 Input Filter (RIF, CIF)

For added stability, an RC input noise filter is usually

included in the circuit. The input filter resistor value

should not exceed 100 kΩ. A typical RC time constant

value is 16.7 msec to help reject line frequency noise.

The input filter capacitor should have low leakage for a

high-impedance input.

+5V

0.1 µF

0.1 µF

0.1 µF

36

DGND

TC7129

24

V+

REF HI

REF LO

COMMON

IN HI

IN LO

V–

23

TC7129

34

35

28

33

V

32

IN

+

–

3.7 Battery

The typical circuit uses a 9V battery as a power so urce.

However , a ny v alue b etwee n 6V a nd 12V can b e use d.

For operation from batteries with voltages lower than

6V and for operation from power supplies, see

Section 4.2 “Powering the TC7129”.

4.0 TYPICAL APPLICATIONS

4.1 TC7129 as a Replacement Part

The TC7129 is a direct pin-f or-pi n rep lac ement part for

the ICL7129. Note , howev er, that the ICL7129 require s

a capacitor an d resistor between pins 26 and 28 for

phase compensation. Since the TC7129 uses internal

phase compensat ion, these p art s are not requir ed and,

in fact, must be removed from the circuit for stable

operation.

4.2 Powering the TC7129

While the most common power source for the TC7129

is a 9V battery, there are other possibilities. Some of

the more common ones are explained below.

4.2.1 ±5V Power Supply

Measurements are made with respect to power supply

ground. DGND (pin 36) is set intern ally to about 5V less

than V+ (pin 24); it is not i ntende d to be a pow er su pply

input and must not be tied directly to power supply

ground. It can be used as a refe rence for externa l logic,

as explaine d i n Section 4.3 “Connecting to External

Logic”, (see Figure 4-1).

-5V

Figure 4-1: Powering the TC7129 From

a ±5V Pow er Supply.

4.2.2 Low Voltage Battery Source

A battery with voltage between 3.8V and 6V can be

used to power the TC7129 when used with a voltage

doubler circuit, as shown in Figure 4-2. The voltage

doubler uses the TC7660 DC-to-DC voltage converter

and two external capacitors.

24

+

3.8V

to

6V

8

TC7660

3

2

4

5

36

+

10 µF

+

V+

REF HI

DGND

REF LO

COMMON

TC7129

V–

10 µF

IN HI

IN LO

23

34

35

28

33

32

+

V

IN

–

Figure 4-2: Powering the TC7129 From

a Low-Voltage Battery.

© 2006 Microchip Technology Inc. DS21459D- page 9

TC7129

–

4.2.3 +5V Power Supply

Measurements are made with respect to power supply

ground. COMMON (pin 28) is connected to REF LO

(pin 35). A voltage doubler is needed, since the supply

voltage is less than the 6V minimum needed by the

TC7129. DGND (pin 36) must be isolated from power

supply ground (see Figure 4-3).

+5V

24

V+

0.1 µF

34

TC7129

35

36

8

V+

TC7660

GND

3

0.1 µF

2

4

5

10 µF

DGND

+

10 µF

+

28

33

32

V–

23

+

V

IN

+

V

24

External

Logic

I

LOGIC

36

TC7129

DGND

23

V-

Figure 4-4: Extern al Logi c Refere nc ed

Directly to DGND.

V+

24

External

Logic

TC7129

Figure 4-3: Powering the TC7129 From

a +5V Power Supply.

4.3 Connecting to External Logic

External logic can be directly referenced to DGND

(pin 36), provided that the supply current of the externa l

logic does not exceed the sink current of DGND

(Figure 4-4). A safe value for DGND sink current is

1.2 mA. If the sink current is expected to exceed this

value, a buffer is recommended (see Figure4-5).

–

36

+

DGND

I

LOGIC

23

V–

Figure 4-5: Extern al Logi c Refere nc ed

to DGND with Buffer.

4.4 Temperature Compensation

For most applications , V

directly to DGND (pin 36). For applications with a wide

temperature range, some LCDs require that the drive

levels vary with temperature to maintain good viewing

angle and display contrast. Figure 4-6 shows two

circuits that c an be adjus ted to give t emperat ure com pensation of about 10mV/°C between V+ (pin 24) and

. The diode between DGND and V

V

DISP

have a low turn-on voltage because V

exceed 0.3V below DGND.

(pin 19) can be conne cted

DISP

DISP

DISP

should

cannot

DS21459D-page 10 © 2006 Microchip Technology Inc.

TC7129

V

V+

1N4148

39 kΩ

200 kΩ

24

TC7129

5 kΩ

75 kΩ

–

+

19

V

DISP

36

DGND

23

V–

Figure 4-6: Temperature Compensating Circuits.

4.5 RC Oscillator

For applications in which 3-1/2 digit (100μV) resolution

is sufficient, an RC oscillator is adequate. A recommended value for the capacitor is 51 pF. Other values

can be used as long as the y a re s ufficiently larger than

the circuit parasitic capacitance. The resistor value is

calculated as:

EQUATION 4-1:

0.45

R =

Freq * C

For 120 kHz frequency and C = 51 pF, the calculated

value of R is 75kΩ. The RC oscillator and the crystal

oscillator circuits are shown in Figu re 4-7.

TC7129

1 40 2

Ω

270 k

5 pF

+

120 kHz

10 pF

V+

V+

20 kΩ

39 kΩ

2N2222

19

36

18 kΩ

24

TC7129

V

DISP

DGND

23

V–

4.6 Measuring Techniques

Two important techniques are used in the TC7129:

successive integration and digital auto-zeroing.

Successive integratio n is a refinement to the trad itional

dual-slope conversion technique.

4.7 Dual-Slope Conversion

A dual-slope conversion has two basic phases: integrate and de-integra te. During the integrate phase, th e

input signal is integrated for a fixed period of time; the

integrated volt age level is thus proporti onal to the inp ut

voltage. During the de-integrate phase, the integrated

voltage is ram pe d d ow n at a fixed slope, and a counter

counts the clock cycles until the integrator voltage

crosses zero . T he co un t is a me as u rem en t o f t he ti me

to ramp the integrated v oltag e to zero and i s, therefor e,

proportional to the input voltage being measured. This

count can then be sc aled an d disp layed as a mea surement of the input vol tage. F igure 4-8 shows the phases

of the dual-slope conversion.

Integrate

De-integrate

Zero

Crossing

TC7129

1 40 2

Ω

75 k

51 pF

Figure 4-7: Oscillator Circuits.

Time

Figure 4-8: Dual-Slope Conversion.

The dual-slope method has a fundamental limitation.

The count can onl y stop on a c lock cycle, s o t hat me asurement accuracy is limited to the clock frequency. In

addition, a delay in the zero-crossing comparator can

add to the inaccuracy. Figure 4-9 shows these errors in

an actual measurement.

© 2006 Microchip Technology Inc. DS21459D- page 11

TC7129

r

Integrate

Time

De-integrate

Clock Pulses

Figure 4-9: Accuracy Errors in Dual-Slope Conversion.

Zero Integrate

and Latch

INT

1

Integrate

DE

1

De-integrate

REST X10

Overshoot due to zero-crossing between

clock pulses

Integrator Residue Voltage

Overshoot caused by comparato

delay of 1 clock pulse

DE

2

REST X10

DE

3

Zero Integrate

TC7129

Note: Shaded area greatly expanded in time and amplitude.

Figure 4-10: Integration Waveform.

Integrator

Residual Voltage

DS21459D-page 12 © 2006 Microchip Technology Inc.

TC7129

4.8 Successive Integration

The successive integration tech nique picks up where

dual-slope conversion ends. The overshoot voltage

shown in Figure 4-9 (called the “integrator residue

voltage”) is me asured to obtain a correction to the initial

count. Figure 4-10 shows the cycles in a successive

integration measurement.

The waveform shown is for a ne gative input s ignal. The

sequence of ev ents during the measure ment cycle is

shown in Table 4-1.

TABLE 4-1: MEASUREMENT CYCLE

SEQUENCE

Phase Description

INT

Input signal is integrated for fixed time (1000 clock

1

cycles on 2V scale, 10,000 on 200 mV).

Integrator voltage is ramped to zero. Counter

DE

1

counts up until zero-crossing to produce reading

accurate to 3-1/2 digits. Residue represents an

overshoot of the actual input voltage.

REST Rest; circuit settles.

X10 Residue voltage is amplified 10 times and

inverted.

Integrator voltage is ramped to zero. Counter

DE

2

counts down until zero-crossing to correct reading

to 4-1/2 digits. Residue represents an undershoot

of the actual input voltage.

REST Rest; circuit settles.

X10 Residue voltage is amplified 10 times and

inverted.

Integrator voltage is ramped to zero. Counter

DE

3

counts up until zero-crossing to correct reading to

5-1/2 digits. Residue is discarded.

4.9 Digital Auto-Zeroing

To eliminate the effect of amplifier offset errors, the

TC7129 uses a digital auto -zeroing techniqu e. After the

input voltage is measured as described above, the

measurement is repeated with the inputs shorted

internally. The reading with inputs shorted is a

measurement of the internal errors and is subtracted

from the previous reading to obtain a corrected

measurement. Digit al auto -zeroing el iminates the need

for an external auto-zeroing capacitor used in other

ADCs.

4.10 Inside the TC7129

Figure 4-11 shows a simplified block diagram of the

TC7129.

© 2006 Microchip Technology Inc. DS21459D- page 13

TC7129

Low Battery Continuity

OSC1

OSC2

OSC3

RANGE

L/H

CONT

V–

DGND

V+

TC7129

Segment Drives

Latch, Decode Display Multiplexer

Up/Down Results Counter

Sequence Counter/Decoder

Control Logic

Analog Section

Backplane

Drives

Annunciator

Drive

V

DISP

DP

1

DP

2

UR/DP

OR/DP

REF HI

REF LO

INT OUT

INT IN

3

4

COMMON INHIIN

LO

Figure 4-11: TC7129 Functional Block Diagram.

IN HI

Common

IN LO

Continuity

INT

INT

1

INT

1

,

–

V

200 mV

REF HI

2

+

C

REF

REF LO

DE

DE

DE- DE+

DE+

DE–

INT

–

+

Continuity

Comparator

500 k

–

+

ZI, X10

REST

Ω

Buffer

R

INT

Figure 4-12: Integrator Block Diagram.

BUFF

C

INT

Integrator

–

+

100 pF

TC7129

X10

10

Comparator 1

pF

+

–

To Display Driver

To Digital

Section

Comparator 2

DS21459D-page 14 © 2006 Microchip Technology Inc.

4.11 Integrator Section

The integrator section includes the integrator, comparator, input buffer amplifier and analog switches (see

Table 4-2) used to change the circuit configuration

during the separate measurement phases described

earlier. (See Figure 4-12).

TABLE 4-2: SWITCH LEGENDS

Label Description

Label Meaning.

DE Open during all de-integrate phases.

DE– Closed during all de-integrate phases when

input voltage is negative.

DE+ Closed during all de-integrate phases when

INT

INT

INT Open during both integrate phases.

REST Closed during the rest phase.

X10 Closed during the X10 phase.

X10 Open during the X10 phase.

The buffer amp li fier has a common mode inp ut vol t age

range from 1.5V above V– to 1V be low V+. The integrator amplifier can swing to within 0.3V of the rails.

However, for best linearity, the swing is usually limited

to within 1V. Both amplifiers can supply up to 80 μA of

output cur re nt , b u t sh ou l d be l im it e d to 20 μA for good

linearity.

input voltage is positive.

Closed during the first integrate phase

1

(measurement of the input voltage).

Closed during the second integrate phase

2

(measurement of the amplifier offset).

ZI Closed during the zero integrate phase.

TC7129

–

IN HI

COM

IN LO

CONT

200 mV

V

–

+

500 k

Ω

Figure 4-13: Continuity Indicator Circuit.

TC7129

DP4/OR, Pin 20

/UR, Pin 21

DP

LATCH/HOLD Pin 22

CONTINUITY, Pin 27

3

Figure 4-14: Input/Output Pin Schematic.

500 kΩ

+

Buffer

TC7129

To Display Driver

(Not Latched)

4.12 Continuity Indicator

A comparator with a 200 mV threshold is connected

between IN HI (pin 33) and IN LO (pin 32). Whenever

the voltage between inputs is less than 200 mV, the

CONTINUITY output (pin 27) will be pulled high,

activating the continuity annunciator on the display.

The continuity pin c an also be us ed as an input to drive

the continuity annunciator directly from an external

source (see Figure 4-13).

A schematic of the input/o utput nature of thi s pin is also

shown in Figure 4-14.

4.13 Common and Digital Ground

The common and digital ground (DGND) outputs are

generated from internal Zener diodes. The voltage

between V+ and DGND is the internal supply voltage

for the digital section of the TC7129. Common can

source approximately 12μA; DGND has essentially no

source capability (se e Figure4-15).

© 2006 Microchip Technology Inc. DS21459D- page 15

TC7129

24

V+

–

+

12 µA

N

Logic

Section

3.2V

COM

28

5V

36

P

DGND

TC7129

N

23

V–

Figure 4-15: Digital Ground (DGND) and

Common Outputs.

4.14 Low Battery

The low battery annun ciato r turns o n whe n supp ly vo ltage between V– and V+ drop s below 6.8V. The internal

zener diode has a threshold of 6.3V. When the supply

voltage drop s below 6.8V, the transistor tied to V– turn s

off pulling the “Low Battery” point high.

4.15 Sequence and Results Counter

A sequence counter and associated control logic provide signals that operate the analog switches in the

integrator section . The comparat or output from the integrator gates the res ults coun ter. The resul ts count er is

a six-sectio n up/down decade co unter that holds the

intermediate results from each successive integration.

4.16 Overrange and Underrange

Outputs

When the results counter holds a value greater than

±19,999, the DP

When the results counter value is less than ±1000, the

DP3/UR output (Pin 21) is driven high. Both s ignal s are

valid on the falling edge of LATCH

not change until the end of the next conversion cycle.

The signals are upd ated a t the end o f each conv ersion,

unless the L

21 can also be used as inputs for external control of

decimal point s 3 a nd 4. Fig ure 4-14 shows a schematic

of the input/output nature of these pins.

/OR output (Pin 20) is driven high.

4

/HOLD (L/H) and do

/H input (Pin 22) is held high. Pins 20 and

4.17 LATCH/Hold

The L/H output goes low during the last 100 cycles of

each conversion. This pulse latches the conversion

data into the display driv er secti on of the TC7129. Thi s

pin can also be used as an inp ut. When dr iven high, th e

display will not be updated; the previous reading is

displayed. When driven low, the display reading is not

latched; the sequence counter reading will be

displayed. Since the counter is counting much faster

than the backplanes are being updated, the reading

shown in this mode is somewhat erratic.

4.18 Display Driver

The TC7129 drives a triplexed LCD with three backplanes. The LCD can include decimal points, polarity

sign and annunciators for continuity and low battery.

Figure 4-16 shows the assignment of the display

segments to the backplanes and segment drive lines.

The backplane drive frequency is obtained by dividing

the oscillator freq uency by 1200. Thi s result s in a b ackplane drive frequency of 100 Hz for 60 Hz operation

(120 kHz crystal) and 83.3 Hz for 50 Hz operation

(100 kHz crystal).

Backplane waveforms are shown in Figure 4-17.

These appear on outputs BP

and 18). They remain the same, regardless of the

segments being driven.

Other display output lines (pins 4 through 15) have

waveforms that vary depending on the displayed

values. Figure 4-18 shows a set of waveforms for the

A, G, D outputs (pins 5, 8, 11 and 14) for several

combinations of “ON” segments.

The ANNUNCIATOR DRIVE output (pin 3) is a square

wave, running at the backplane frequency (100 Hz or

83.3 H z) with a peak-to-peak voltage equal to DGND

voltage. Connec ting an an nunci ator to pin 3 turn s it on;

connecting it to its backplane turns it off.

, BP2, BP3 (pins 16, 17

1

DS21459D-page 16 © 2006 Microchip Technology Inc.

TC7129

Low Battery

Continuity

BP

BP

1

2

Backplane

Connections

BP

3

Low Battery Continuity

F

E

DP

4

4

4

,

,

G

D

A

4

4

4

,

,

C

BC

B

4

4

4

,

,

E

DP

F

3

3

3

,

,

G

D

A

3

3

3

,

,

B

C

MINUS

3

3

,

,

B

1

,

A

1

,

F

1

,

B

2

,

A

2

,

F

2

,

C

Continuity

1

,

G

D

1

,

E

DP

1

,

C

Low Battery

2

,

G

D

2

,

E

DP

2

,

1

1

2

2

Figure 4-16: Display Segment Assignments.

BP

1

BP

2

BP

3

Figure 4-17: Backplane Waveforms.

b Segment

Line

All Off

a Segment

On

d, g Off

a, g On

d Off

All On

Figure 4-18: Typical Display Output

Waveforms.

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

DD

H

L

DISP

DD

H

L

DISP

DD

H

L

DISP

DD

H

L

DISP

© 2006 Microchip Technology Inc. DS21459D- page 17

TC7129

5.0 PACKAGING INFORMATION

5.1 Package Marking Information

Package mar k ing data not available a this time.

5.2 Taping Forms

Pin 1

User Direction of Feed

P, Pitch

Pin 1

W, Width

of Carrier

Tape

S tandard Reel Component Orientation

Component Taping Orientation for 44-Pin PQFP Devices

User Direction of Feed

Reverse Reel Component Orientation

Pin 1

W

P

Standard Reel Component Orientation

for 713 Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

44-Pin PQFP 24 mm 16 mm 500 13 in

Note: Drawing does not represent total number of pins.

DS21459D-page 18 © 2006 Microchip Technology Inc.

40-Lead Plastic Dual In-line (P) – 600 mil Body (PDIP)

E1

D

TC7129

2

n

E

β

eB

Number of Pins

Pitch

Molded Package Thickness

Lead Thickness

Overall Row Spacing §

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010” (0.254mm) per side.

JEDEC Equivalent: MO-011

Drawing No. C04-016

1

A

c

A1

n

p

A2

c

eB

α

β

B1

B

MILLIMETERSINCHES*Units

0.38.015A1Base to Seating Plane

α

A2

L

p

MAXNOMMINMAXNOMMINDimension Limits

4040

2.54.100

4.834.454.06.190.175.160ATop to Seating Plane

4.063.813.56.160.150.140

15.8815.2415.11.625.600.595EShoulder to Shoulder Width

14.2213.8413.46.560.545.530E1Molded Package Width

52.4552.2651.942.0652.0582.045DOverall Length

3.433.303.05.135.130.120LTip to Seating Plane

0.380.290.20.015.012.008

1.781.270.76.070.050.030B1Upper Lead Width

0.560.460.36.022.018.014BLower Lead Width

17.2716.5115.75.680.650.620

1510515105

1510515105

© 2006 Microchip Technology Inc. DS21459D- page 19

TC7129

44-Lead Plastic Leaded Chip Carrier (LW) – Square (PLCC)

E

E1

#leads=n1

D

D1

2

n

1

CH2 x 45° CH1 x 45°

A3

α

A2

c

Number of Pins

Pitch

Molded Package Thickness

Side 1 Chamfer Height

Footprint Length

Lead Thickness

Lower Lead Width

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010” (0.254mm) per side.

JEDEC Equivalent: MO-047

Drawing No. C04-048

E2

β

n

p

A2

A3

CH2Corner Chamfer (others)

D2

c

α

β

.145 .153 .160 3.68 3.87 4.06

A

35°

B1

B

p

D2

MILLIMETERSINCHES*Units

.028 .035 0.71 0.89

0.51.020A1Standoff §

A1

4444

1.27.050

1111n1Pins per Side

MAXNOMMINMAXNOMMINDimension Limits

4.574.394.19.180.173.165AOverall Height

0.860.740.61.034.029.024

1.271.141.02.050.045.040CH1Corner Chamfer 1

0.250.130.00.010.005.000

17.6517.5317.40.695.690.685EOverall Width

17.6517.5317.40.695.690.685DOverall Length

16.6616.5916.51.656.653.650E1Molded Package Width

16.6616.5916.51.656.653.650D1Molded Package Length

16.0015.7514.99.630.620.590E2Footprint Width

16.0015.7514.99.630.620.590

0.330.270.20.013.011.008

0.810.740.66.032.029.026B1Upper Lead Width

0.530.510.33.021.020.013B

10501050

10501050

DS21459D-page 20 © 2006 Microchip Technology Inc.

TC7129

44-Lead Plastic Quad Flatpack (KW) 10x10x2.0 mm Body, 1.95/ 0.25 mm Lea d Form (PQFP)

E

E1

p

D

D1

2

1

B

n

c

Units INCHES MILLIMETERS

Dimension Limits MIN NOM MAX MIN NOM MAX

Number of Pins

Pitch

Overall Height A - - .096 - - 2.45

Molded Package Thickness A2 .077 .079 .083 1.95 2.00 2.10

§

Standoff

Foot Length L .029 .035 .041 0.73 0.88 1.03

Foot Angle

Overall Width E .547 BSC 13.90 BSC

Overall Length D .547 BSC 13.90 BSC

Molded Package Width E1 .394 BSC 10.00 BSC

Molded Package Length D1 .394 BSC 10.00 BSC

Lead Thickness

Lead Width B .012 - .018 0.30 - 0.45

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

§

Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010" (0.254mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

REF: Reference Dimension, usually without tolerance, for information purposes only.

See ASME Y14.5M

JEDEC Equivalent: MO-112 AA-1

Drawing No. C04-119

A1 .010 - - 0.25 - -

n

p

φ

c

α

β

CHAMFER VARIES

φ

.004 - .009 0.11 - 0.23

A2

L

A1

44 44

.031 BSC 0.80 BSC

0° 3.5° 7° 0° 3.5° 7°

5° - 16° 5° - 16°

5° - 16° 5° - 16°

F

β

1.95 REF..077 REF.FFootprint

Revised 07-21-05

α

A

*

© 2006 Microchip Technology Inc. DS21459D- page 21

TC7129

NOTES:

DS21459D-page 22 © 2006 Microchip Technology Inc.

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. XX

Device

Device: TC7129: 4-1/2 Digit Analog-to-Digital Converter

X

Temp.

Pkg

XX

Taping

Direction

Examples:

a) TC7129CPL: 40-Pin PDIP

b) TC7129CKW713: 44-Pin PQFP

c) TC7129CLW: 44-Pin PLCC

TC7129

Tape and Reel

Temperature: C = 0°C to +70°C

Package: PL = 40-Pin PDIP

Taping Direction: 713 = Standard Taping

I = -25°C to +85°C

KW = 40-Pin PQFP

LW = 44-Pin PLCC

JL = 40-Pin CDIP

© 2006 Microchip Technology Inc. DS21459D-page 23

TC7129

NOTES:

DS21459D-page 24 © 2006 Microchip Technology Inc.

TC7129

THE MICROCHIP WEB SITE

Microchip provides onlin e support v ia our W WW site at

www.m ic roc hi p.c om . Thi s web si te i s us ed as a m ean s

to make files and information easily available to

customers. Accessible by using your favorite Internet

browser, the web site contains the following

information:

• Product Support – Data sheets and errata,

application notes and sample programs, design

resources, user’s guides and hardware support

documents, lat est softwa re releases and archived

software

• General Technical Support – Frequently Asked

Questions (FAQ), technical support requests,

online discussion groups, Microchip consultan t

program member listing

• Business of Microchip – Product selector and

ordering guides, latest Microchip press releases,

listing of s eminars and events, listings of

Microchip sales offices, distributors and factory

representatives

CUSTOMER CHANGE NOTIFICATION

SERVICE

CUSTOMER SUPPORT

Users of Microchip products can receive assistance

through several channels:

• Distributor or Representative

• Local Sal es Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor,

representative or field application engineer (FAE) for

support. Local sales offices are also available to help

customers. A listing of sales offices and locations is

included in the back of this document.

T echnic al support is avail able throug h the web si te

at: http://support.microchip.com

Microchip’s customer notification service helps keep

customers current on Microchip products. Subscribers

will receive e-mail notification whenever there are

changes, updates, revisions or errata related to a

specified produ ct family or develo pment tool of inte rest.

To register, access the Microchip web site at

www.microchip.com, click on Customer Change

Notification and follow the registration instructions.

© 2006 Microchip Technology Inc. DS21459D-page 25

TC7129

READER RESPONSE

It is our intentio n to pro vi de you with the best documentation possible to ens ure suc c es sfu l u se of y ou r M ic roc hip product. If you wish to provid e your c omment s on org anizatio n, clarity, subject matter, and ways i n which o ur docum entatio n

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this document.

To:

RE: Reader Response

From:

Application (optional):

Would you like a reply? Y N

Device: Literature Number:

Questions:

1. What are the best featu res of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this document easy to follow? If not, why?

Technical Publications Manager

Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________

Total Pages Sent ________

FAX: (______) _________ - _________

DS21459DTC7129

4. What additions to the document do you think would enhance the structure and subject?

5. What deletions from the document could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

DS21459D-page 26 © 2006 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are com mitted to continuously improving the code protect ion f eatures of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Mill ennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP , ICEPIC, Linear Active Thermistor, Mindi,

MiWi, MPASM, MPLIB, MPLINK, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, REAL ICE, rfLAB, rfPICDEM, Select

Mode, Smart Serial, SmartTel, Total Endurance, UNI/O,

WiperLock and ZENA are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its

PICmicro

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping devices, Serial

© 2006 Microchip Technology Inc. DS21459D-page 27

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-5160-8631

Fax: 91-11-5160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

02/16/06

DS21459D-page 28 © 2006 Microchip Technology Inc.

Loading...

Loading...