Page 1

TC7109/A

12-Bit µA-Compatible Analog-to-Digital Converters

Features

• Zero Integrator Cycle forFast Recovery from

Input Overloads

• Eliminates Cross-Talk in Multiplexed Systems

• 12-Bit Plus Sign Integrating A/D Converter with

Over Range Indication

• Sign Magnitude Coding Format

• True DifferentialSignal Input and Differential

Reference Input

• Low Noise: 15µV

• Input Current: 1pA Typ.

• No Zero Adjustment needed

• TTL Compatible, Byte Organized Tri-State

Outputs

• UART Handshake Mode for simple Serial Data

Transmissions

P-P

Typ.

Device Selection Table

PartNumber

(TC7109X)*

TC7109CKW 44-Pin PQFP 0°C to +70°C

TC7109CLW 44-Pin PLCC 0°Cto +70°C

TC7109CPL 40-PinPDIP 0°C to +70°C

TC7109IJL 40-PinCERDIP -25°Cto +85°C

*The “A” version has a higher I

Package

OUT

Temperature

Range

on the digital lines.

General Description

The TC7109A is a 12-bit plus sign, CMOS low power

analog-to-digital converter (ADC). Only eight passive

components and a crystal are required to form a

complete dual slope integrating ADC.

TheimprovedV

featuresmakeitan attractiveper-channelalternativeto

analog multiplexing for many data acquisition applications. These features include typical input bias current

of 1pA, drift of less than 1µV/°C, input noise t ypically

15µV

erence allow measurement of bridge typetransducers,

such as load cells, strain gauges, and temperature

transducers.

The TC7109A provides a versatile digital interface. In

the Direct mode, chip select and HIGH

enable control parallel bus interface.In the Handshake

mode, the TC7109Awill operate with industry standard

UART sin controlling serial data transmission – ideal for

remote data logging. Controland monitoring of conversion timing is provided by the RUN/HOLD

STATUS output.

For applications requiring more resolution, see the

TC500, 15-bit plus sign ADC datasheet.The TC7109A

has improved over range recovery performance and

higher output drive capability than the original TC7109.

All new (or existing) designs should specify the

TC7109A wherever possible.

, and auto-zero. True differential input and ref-

P-P

source current and other TC7109A

OH

/LOW byte

input and

2002 Microchip TechnologyInc. DS21456B-page 1

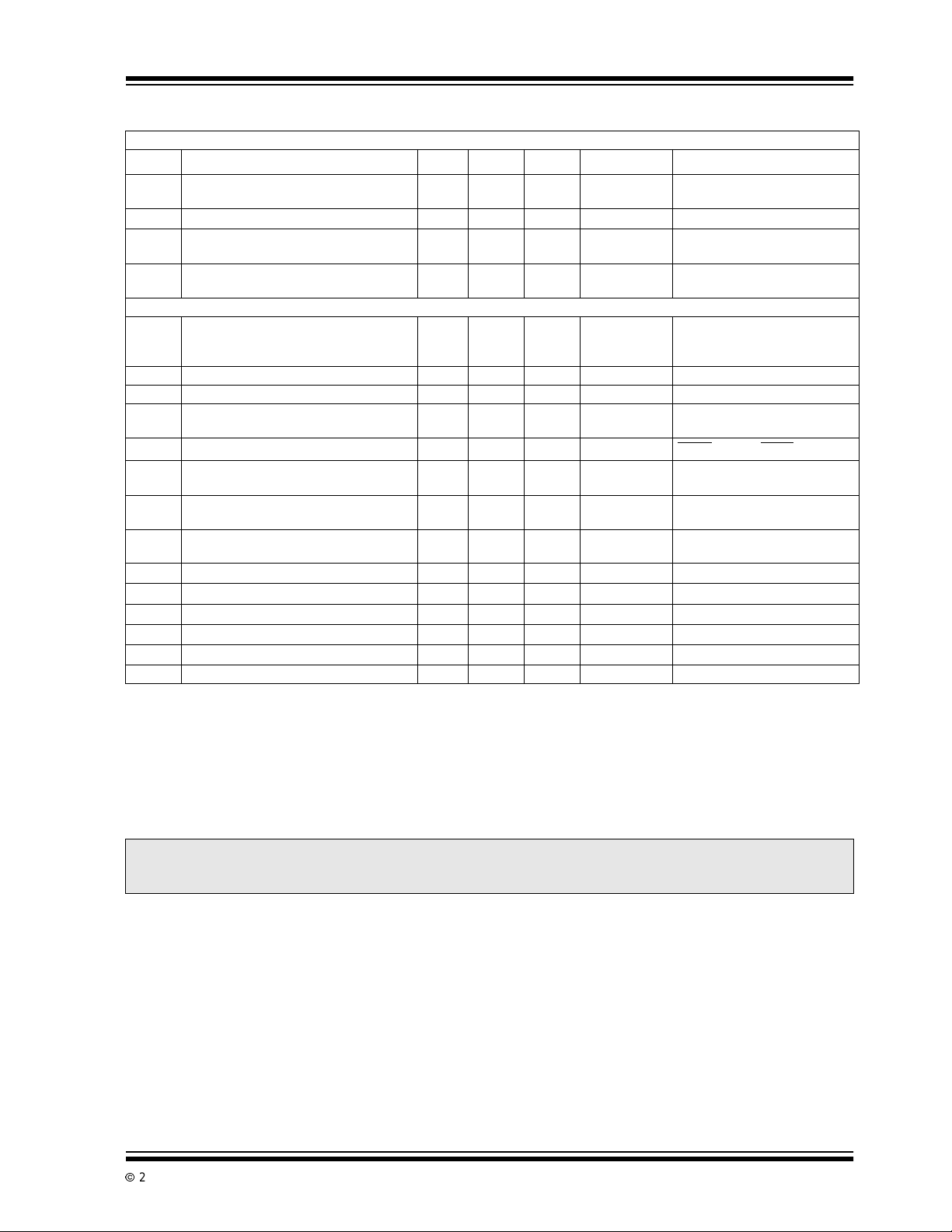

Page 2

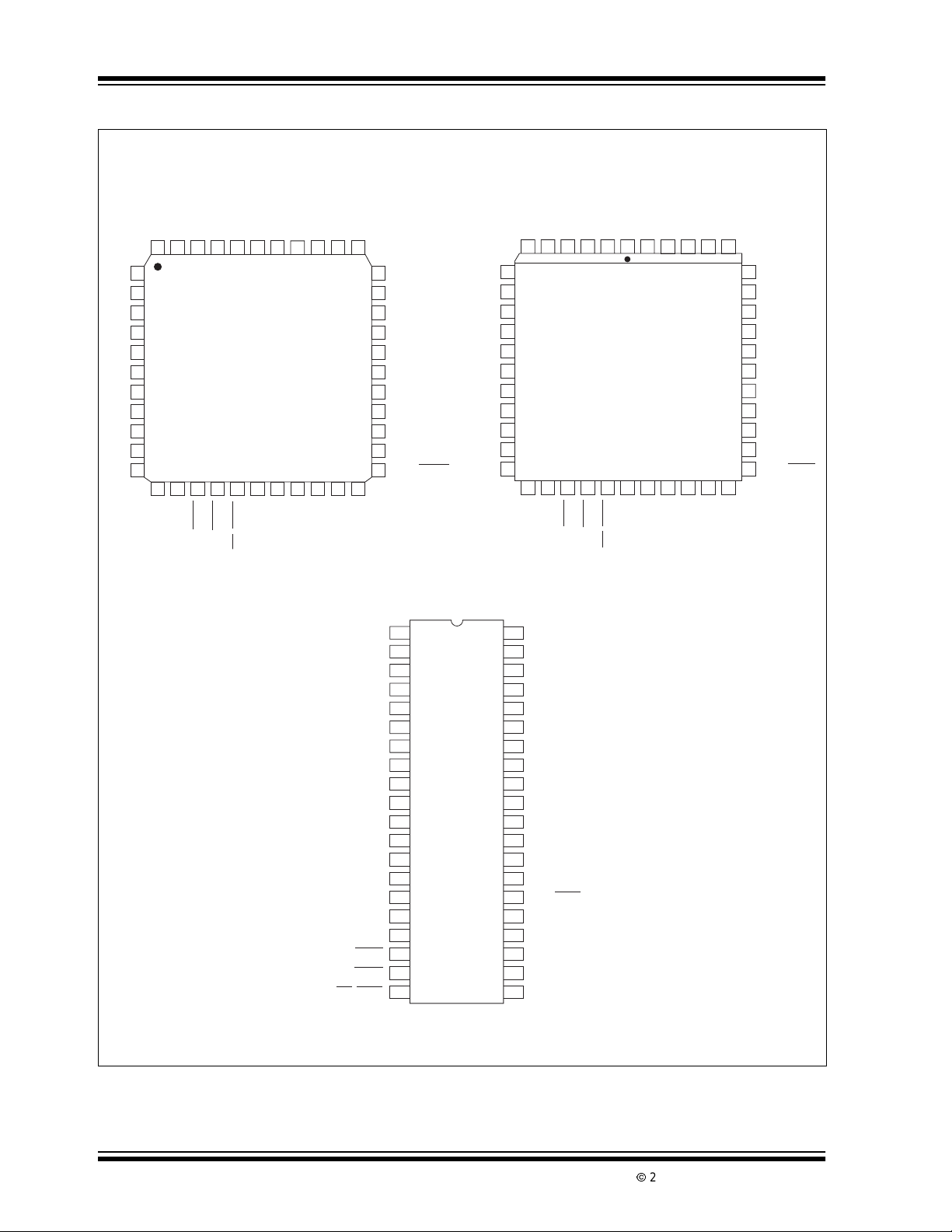

TC7109/A

Package Type

12

OR

B

44 43 42 41 39 3840

B

1

11

B

2

10

B

3

9

B

4

8

B

5

7

6

NC

B

7

6

B

5

B

4

B

3

B

2

12 13 14 15 17 18

1

B

TEST

44-Pin PQFP

STATUS

POL

GND

NC

TC7109ACKW

TC7109CKW

16

LBEN

NC

HBEN

CE/LOAD

REF CAP-

REF IN-

V+

37 36 35 34

19 20 21 22

MODE

OSC IN

OSC OUT

REF IN+

REF CAP+

33

32

31

30

29

28

27

268

259

2410

2311

BUFF

OSC SEL

OSC OUT

B

B

NC

11

10

B

9

B

8

B

7

B

6

B

5

B

4

B

3

B

2

IN HI

IN LO

COMMON

INT

AZ

NC

BUFF

REF OUT

V-

SEND

RUN/HOLD

40-Pin PDIP/CERDIP

44-Pin PLCC

12

B

6543 1442

7

8

9

10

11

12

13

18 19 20 21 23 24

1

B

OR

TEST

POL

LBEN

STATUS

TC7109ACLW

TC7109CLW

HBEN

GND

22

CE/LOAD

V+

NC

43 42 41 40

25 26 27 28

NC

MODE

REF CAP-

REF IN-

OSC IN

OSC OUT

REF IN+

REF CAP+

39

38

37

36

35

34

33

3214

3115

3016

2917

BUFF

OSC SEL

OSC OUT

IN HI

IN LO

COMMON

INT

AZ

NC

BUFF

REF OUT

V-

SEND

RUN/HOLD

GND

1

STATUS

CE/LOAD

POL

OR

B

B

B

B

B

B

B

B

B

B

B

B

TEST

LBEN

HBEN

2

3

4

5

12

6

11

10

7

TC7109A

8

9

9

8

10

7

6

11

12

5

13

4

14

3

15

2

16

1

17

18

19

20

NC = No internal connection

TC7109

40

V+

39

REF IN-

38

REF CAP-

37

REF CAP+

36

REF IN+

35

IN HI

IN LO

34

33

COMMON

32

INT

31

AZ

30

BUFF

REF OUT

29

28

V-

27

SEND

26

RUN/HOLD

25

BUFF OSC OUT

24

OSC SEL

23

OSC OUT

22

OSC IN

21

MODE

DS21456B-page 2

2002 Microchip TechnologyInc.

Page 3

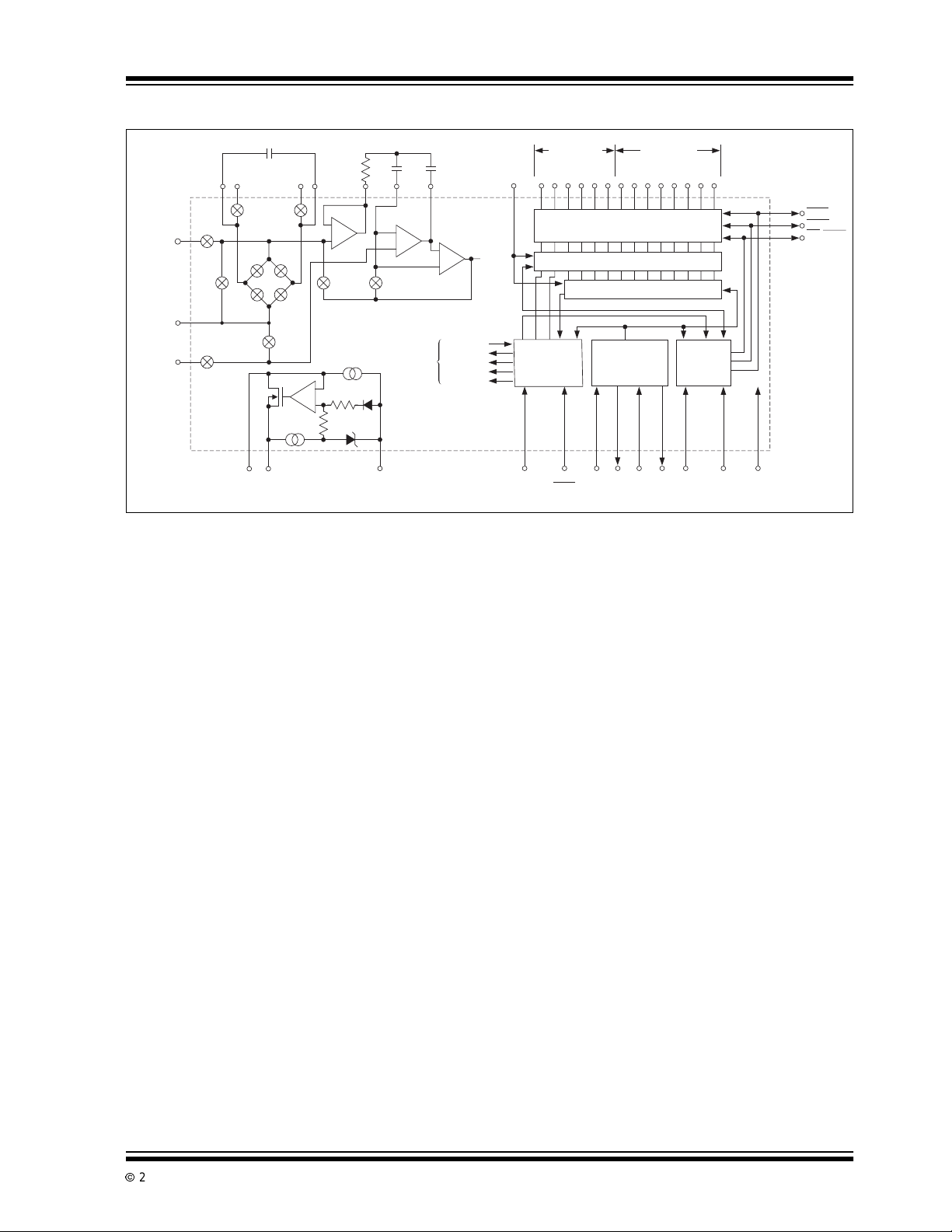

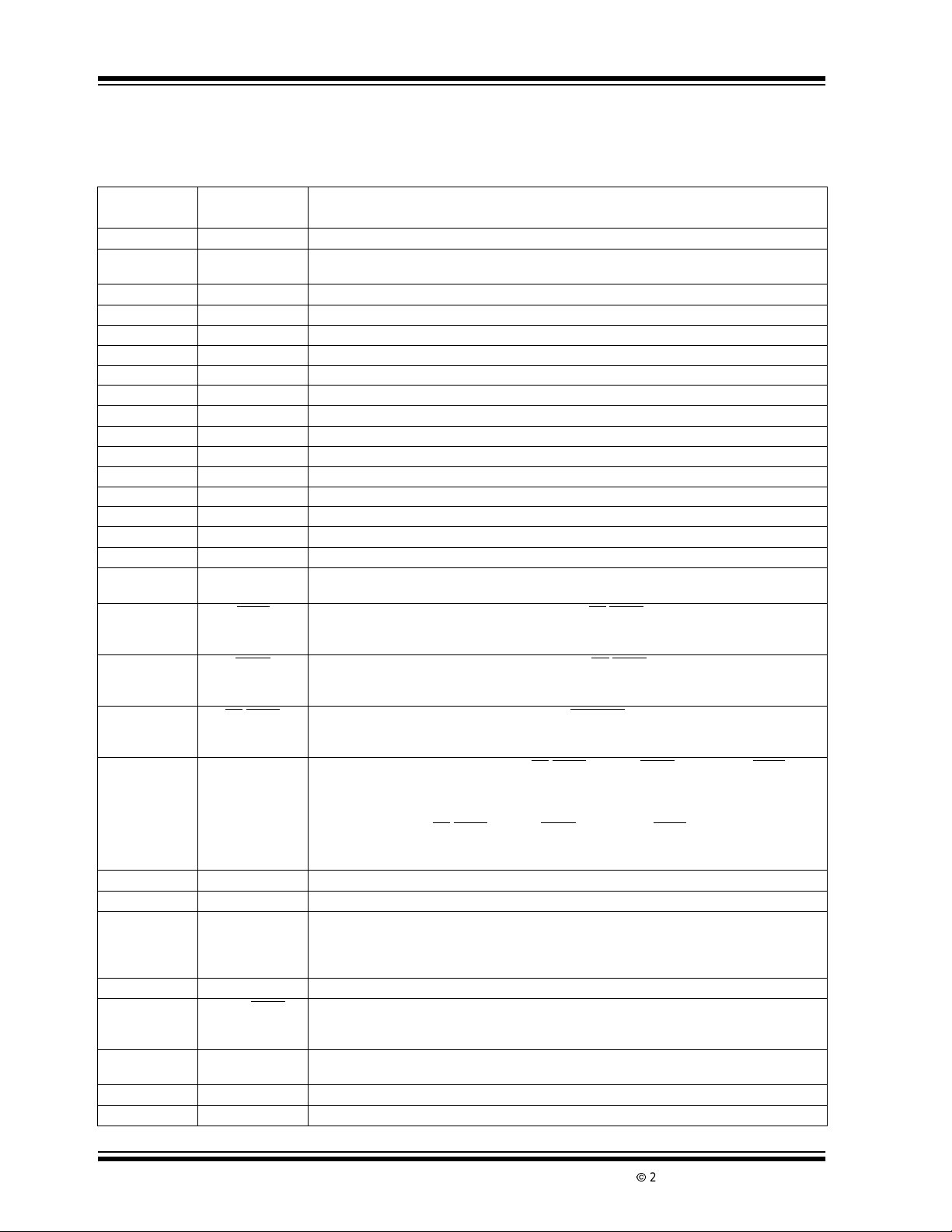

Typical Application

C

REF

REF

REF

IN+

CAP+

37 36

AZZIAZ

INT

35

Input

High

Common

Input Low

AZ

33

INT

34

DE (±)

DE

(–)DE(+)

DE

(+)

AZ

ZI

DE

(–)

TC7109/A

POL

TEST

Conversion

Control Logic

High Order

Byte Inputs

10

OR

B9B8B7B6B5B4B3B2B

B12B11B

16 Three-State Outputs

14 Latches

12-Bit Counter

Oscillator and

Clock Circuitry

Latch

Clock

Low Order

Byte Inputs

15 16

Handshake

Logic

1

18

LBEN

19

HBEN

20

CE/LOAD

TC7109A

REF

IN-

ZI

R

INT

REF

CAP-

3839

Buffer

–

+

ZI

10µA

–

+

6.2V

BUFF

C

AZ

3130

Integrator

–

+

AZ

To Analog

Section

AZ

32

C

INT

INT

Comparator

Comp Out

INT

DE (±)

17 3 4 5 6 7 8 9 10 11 12 13 14

Comp

Out

AZ

ZI

29

28 40

REF

V-

OUT

226222324

OSC

RUN/

V+

Status

HOLD

OSC

IN

OUT

OSC

SEL

25

BUFF

OSC

OUT

21

Mode

27

Send

1

GND

2002 Microchip TechnologyInc. DS21456B-page 3

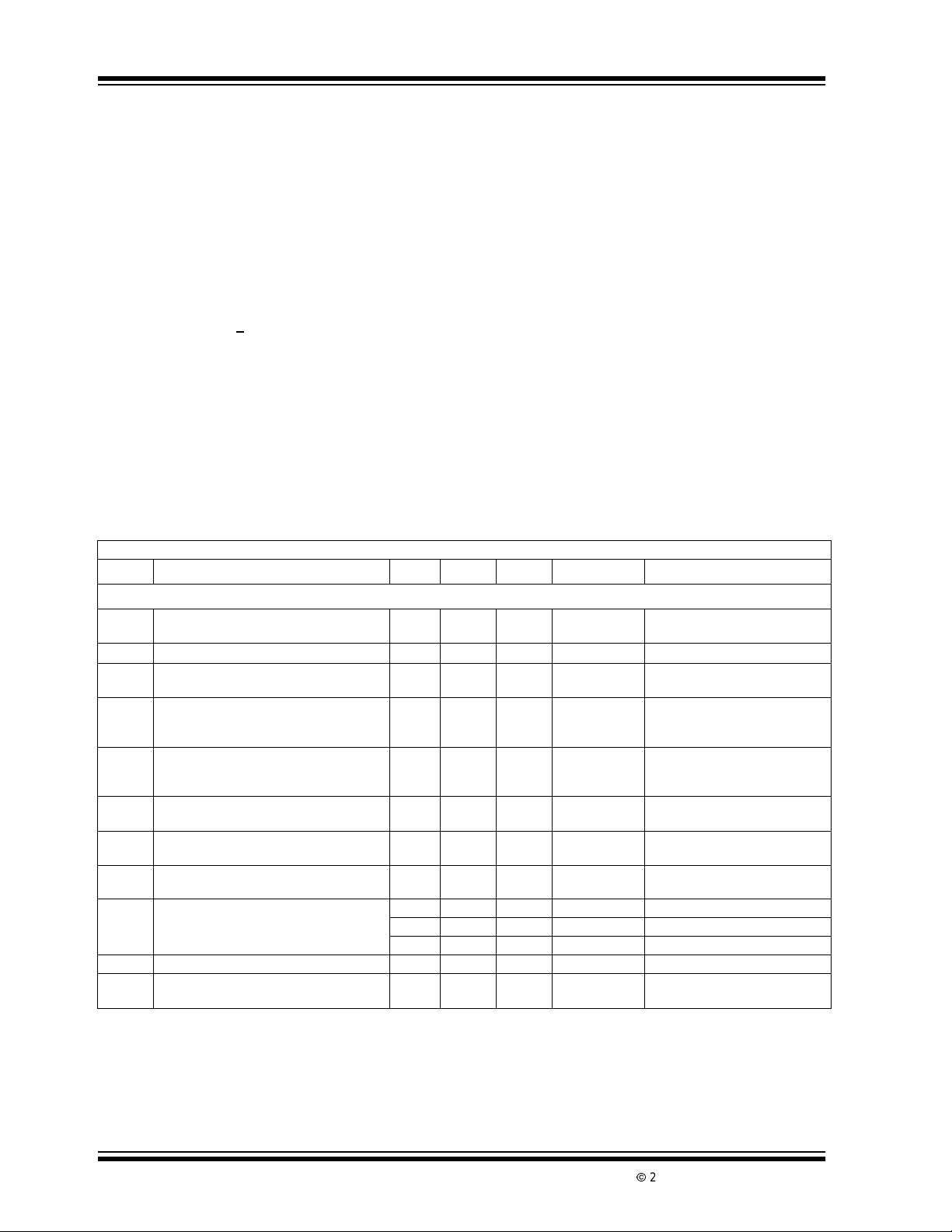

Page 4

TC7109/A

1.0 ELECTRICAL

CHARACTERISTICS

Absolute Maximum Ratings*

Positive Supply Voltage (GND to V+)..................+6.2V

*Stresses above those listed under "Absolute Maximum

Ratings" may cause permanent damage to the device. These

are stress ratings only and functional operation of the device

at these or any other conditions above those indicated in the

operation sections of the specifications is not implied.

Exposure to Absolute Maximum Rating conditions for

extended periods may affectdevice reliability.

Negative Supply Voltage ( GND to V-).....................-9V

Analog Input Voltage (Low to High)

(Note 1)

....V+ to V-

Reference Input Voltage:

(Low to High) (Note 1) ............................. V+ to V-

Digital Input Voltage:

(Pins 2-27) (Note 2) ...........................GND – 0.3V

Power Dissipation, T

< 70°C (Note 3)

A

CerDIP ........................................................2.29W

Plastic DIP ..................................................1.23W

PLCC ..........................................................1.23W

PQFP ..........................................................1.00W

Operating Temperature Range

Plastic Package (C) .........................0°C to +70°C

Ceramic Package (I) .....................-25°C to +85°C

StorageTemperature Range..............-65°C to +150°C

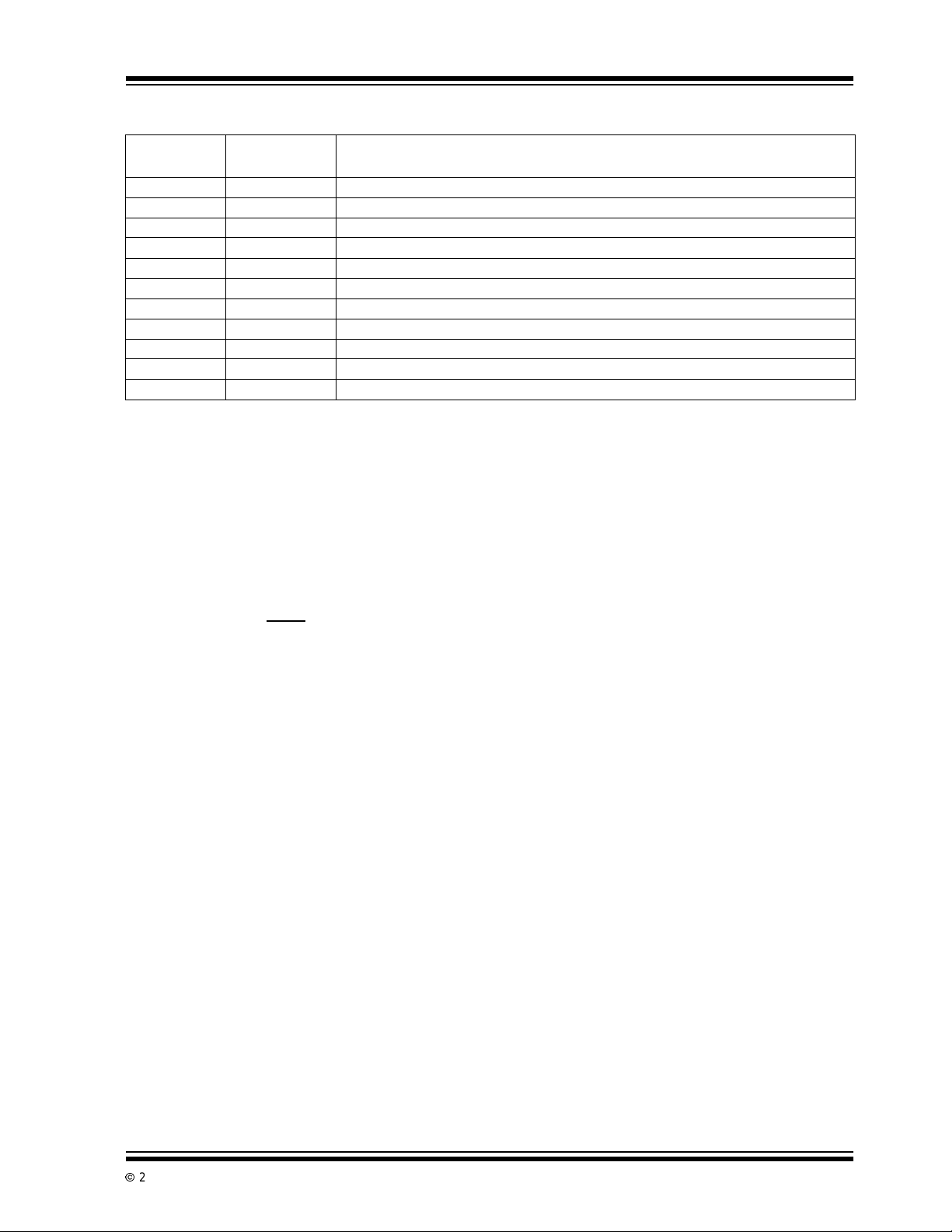

TC7109/TC7109A ELECTRICA L SPECIFICATIONS

Electrical Characteristics: All parameters with V+ = +5V, V-= -5V, GND = 0V, TA= +25°C, unless otherwise indicated.

Symbol Parameter Min Typ Max Unit Test Conditions

Analog

Overload Recovery Time (TC7109A) — 0 1 Measurement

Cycle

Zero InputReading -0000

Ratio Metric Reading 3777

NL Non-Linearity (Max Deviation

from Best Straight Line Fit)

Rollover Error (Differencein Readingfor

Equal Positive and Inputs near

(Full Scale)

CMRR Input Common Mode

Rejection Ratio

V

CMR

e

N

I

IN

TC

TC

Note 1: Input voltages may exceed supply voltages if input current is limited to ±100µA.

CommonMode Voltage Range V-+1.5 — V+ -1.5 V Input High, InputLow and

Noise (P-P Value Not

Exceeded 95% of Time)

Leakage Current at Input — 1 10 pA VIN, All Packages: +25°C

Zero Reading Drift — 0.2 1 µV/°C VIN=0V

ZS

Scale Factor Temperature Coefficient — 1 5 µV/°C VIN= 408.9mV = >7770

FS

2: Connecting any digital inputs or outputsto voltages greater than V+ or less than GND may cause destructive device

latchup. Therefore, it is recommended that inputsfrom sources other than the same power supply shouldnotbe applied

to the TC7109A beforeitspowersupply is established. In multiple supply systems, the supply to the device should be

activated first.

3: Thislimit refers to that of thepackage and will not occur during normal operation.

±00008+00008Octal Reading VIN= 0V; Full Scale = 409.6mV

8

3777

8

4000

-1 ±0.2 +1 Count Full Scale = 409.6mV to 2.048V

-1 ±0.02 +1 Count Full Scale = 409.6mV to

—50 — µV/V V

—15 — µVVIN= 0V,Full Scale = 409.6mV

— 20 100 pA C Device:0°C≤ T

— 100 250 pA I Device: -25°C ≤ T

40008Octal Reading VIN=V

8

8

REF

V

=204.8mV

REF

Over Full Operating

T emperature Range

2.048VOver Full Operating

T emperature Range

±1V, VIN=0V

CM

Full Scale = 409.6mV

Common Pins

≤ +70°C

A

A

Reading,ExtRef = 0ppm/°C

≤ +85°C

8

DS21456B-page 4

2002 Microchip TechnologyInc.

Page 5

TC7109/A

TC7109/TC7109A ELECTRICAL SPECIFICATIONS (CONTINUED)

Electrical Characteristics: All parameters with V+ = +5V, V-= -5V, GND = 0V, TA= +25°C, unless otherwise indicated.

Symbol Parameter Min Typ Max Unit Test Conditions

+

I

I

S

V

REF

TC

Digital

V

OH

V

OL

V

IH

V

IL

t

W

Note 1: Input voltages may exceed supply voltages if input current is limited to ±100µA.

Supply Current (V+ to GND) — 700 1500 µAVIN= 0V, Crystal Oscillator

3.58MHzTestCircuit

Supply Current (V+ to V-) — 700 1500 µA Pins 2-21, 25, 26, 27, 29 Open

Reference Out Voltage -2.4 -2.8 -3.2 V Referenced to V+, 25kΩ

Between V+ and Ref Out

Ref Out Temperature Coefficient — 80 — ppm/°C 25kΩ Between V+ and Ref Out

REF

OutputHighVoltage

I

=700µA

OUT

3.5 4.3 — V TC7109: I

OutputLowVoltage — 0.2 0.4 µAI

0°C ≤ T

Pins 3 -16, 18, 19,20

TC7109A: I

OUT

≤ +70°C

A

OUT

OUT

=1.6mA

=100µA

=700µA

OutputLeakage Current — ±0.01 ±1 µA P ins 3 -16 High Impedance

Control I /O Pull-up Current — 5 — µF Pins 18, 19, 20 V

Mode Input at GND

Control I/O Loading — — 50 pF HBEN

,Pin19;LBEN,Pin18

InputHighVoltage 2.5 — — V Pins 18 -21, 26, 27

Referenced to GND

Input Low Voltage — — 1 V Pins 18-21, 26, 27

Referenced to GND

Input Pull-up Current —

—

Input Pull-down Current — 1 — µAPins21,V

Oscillator OutputCurrent, High — 1 — mA V

Oscillator OutputCurrent, Low — 1.5 — mA V

Buffered Oscillator Output Current High — 2 — mA V

Buffered Oscillator Output Current Low — 5 — mA V

25

5

—

—

µA

µA

Pins 26, 27; V

Pins 17, 24; V

OUT

–2.5V

OUT

–2.5V

OUT

–2.5V

OUT

–2.5V

OUT

OUT

OUT

=GND=+3V

Mode Input Pulse Width 60 — — nsec

2: Connecting any digital inputs or outputsto voltages greater than V+ or less than GND may cause destructive device

latchup. Therefore, it is recommended that inputsfrom sources other than the same power supply shouldnotbe applied

to the TC7109A beforeitspowersupply is established. In multiple supply systems, the supply to the device should be

activated first.

3: Thislimit refers to that of thepackage and will not occur during normal operation.

=V+–3V

OUT

=V+–3V

=V+– 3V

HANDLING PRECAUTIONS: Thesedevices are CMOS andmust be handledcorrectlyto prevent damage. Package

and store only in conductive foam, antistatic tubes, or other conductingmaterial. Use proper antistatic handling procedures. Do not connectin circuits under "power-on" conditions, as high transients may cause permanent damage.

2002 Microchip TechnologyInc. DS21456B-page 5

Page 6

TC7109/A

2.0 PIN DESCRIPTIONS

ThedescriptionsofthepinsarelistedinTable2-1.

TABLE 2-1: PIN FUNCTION TABLE

Pin Number

(40-Pin PDIP)

1 GND Digital ground, 0V, ground return for all digital logic.

2 STATUS Output HIGH during integrate and de-integrate until datais latched. Output LOW when

3 POL Polarity - High for positive input.

4 OR Over Range - High if over ranged (Three-State Data bit).

5B

6B

7B

8B

9B

10 B

11 B

12 B

13 B

14 B

15 B

16 B

17 TEST Input High - Normal operation. Input LOW - Forces all bit outputs HIGH.

18 LBEN

19 HBEN

20 CE

21 MODE Input LOW - DirectOutputmodewhereCE

Symbol Description

analogsection is in auto-zero or zero integrator configuration.

12

11

10

9

8

7

6

5

4

3

2

1

Bit 12 (Most Significant bit) (Three-State Data bit).

Bit 11 (Three-State Data bit).

Bit10(Three-StateDatabit).

Bit 9 (Three-State Data bit).

Bit 8 (Three-State Data bit).

Bit 7 (Three-State Data bit).

Bit 6 (Three-State Data bit).

Bit 5 (Three-State Data bit).

Bit 4 (Three-State Data bit).

Bit 3 (Three-State Data bit).

Bit 2 (Three-State Data bit).

Bit 1 (Least Significant bit) (Three-State Data bit).

Note: This input is used for test purposes only.

Low Byte Enable - with MODE (Pin 21) LOW, and CE/LOAD (Pin 20) LOW, taking this pin

LOW activates low order byte outputs,B

low byte flag outputused in Handshakemode. (SeeFigure 3-7, Figure 3-8, and Figure 3-9.)

. With MODE (Pin 21) HIGH, this pin serves as

1–B8

High Byte Enable - with MODE (Pin 2 1) LOW, and CE/LOAD (Pin 20) LOW, taking this pin

LOW activates high order byte outputs, B

pin serves as high byte flag output used in Handshakemode.See Figures3-7,3-8,and3-9.

, POL, OR. With MODE (Pin 21) HIGH, this

9–B12

/LOAD Chip Enable/Load - with MO DE (Pin 21) LOW, CE/LOAD servesas a master output enable.

When HIGH,B

strobeis used in handshakemode. (See Figure 3-7, Figure 3-8, and Figure 3-9.)

, POL, OR outputs are disabled. When MODE (Pin 21) is HIGH, a load

1–B12

/LOAD(Pin 20), HBEN (Pin 19), and LBEN (Pin

18) act as inputs directlycontrolling byte outputs. InputP ulsed H IGH - Causes immediate

entryintoHandshake mode and output of data as in Figure3-9.

Input HIGH- enablesCE

/LOAD (Pin 20), HBEN (Pin 19), and LBEN (Pin 18) as outputs,

Handshake mode will be entered and data output as in Figure 3-7 and Figure 3-9

at conversions completion.

22 OSC IN Oscillator Input.

23 OSC OUT Oscillator Output.

24 OSC SEL Oscillator Select - Input HIGH configures OSC IN, OSC OUT ,BUFF OSC OUT as RC

oscillator - clock will be same phase and duty cycle as BUFF OSC OUT. Input LOW

configures OSC IN, OSC OUT for crystal oscillator - clock frequency will be 1/58 of frequency

at BUFF OSC OUT.

25 BUFFOSC OUT BufferedOscillator Output.

26 RUN/HOLD

Input HIGH - Conversionscontinuously performed every 8192clockpulses.

InputLOW-Conversionin progress completed; converterwill stop in auto-zero seven counts

beforeintegrate.

27 SEND Input- Used in Handshake mode to indicateability of an external device to accept data.

Connect to V+ if not used.

28 V- Analog Negative Supply - Nominally -5V with respect to GND (Pin 1).

29 REF OUT Reference Voltage Output - Nominally 2.8V down from V+ (Pin 40).

DS21456B-page 6

2002 Microchip TechnologyInc.

Page 7

TABLE 2-1: PIN FUNCTION TABLE (CONTINUED)

Pin Number

(40-Pin PDIP)

30 BUFF Buffer Amplifier Output.

31 AZ Auto-Zero Node - Inside foil of C

32 INT Integrator Output - Outside foil of C

33 COMMON Analog Common - System is auto-zeroedto COMMON.

34 IN LO Differential Input Low Side.

35 IN HI Differential Input High Side.

36 REF IN+ Differential Reference Input Positive.

37 REF CAP+ Reference Capacitor Positive.

38 REF CAP- Reference Capacitor Negative.

39 REF IN- Differential Reference Input Negative.

40 V+ Positive Supply Voltage - Nominally +5V with respectto GND (Pin 1).

Note: All Digital levels are positive true.

Symbol Description

.

AZ

.

INT

TC7109/A

3.0 DETAILED DESCRIPTION

(All Pin Designations Refer to 40-Pin DIP.)

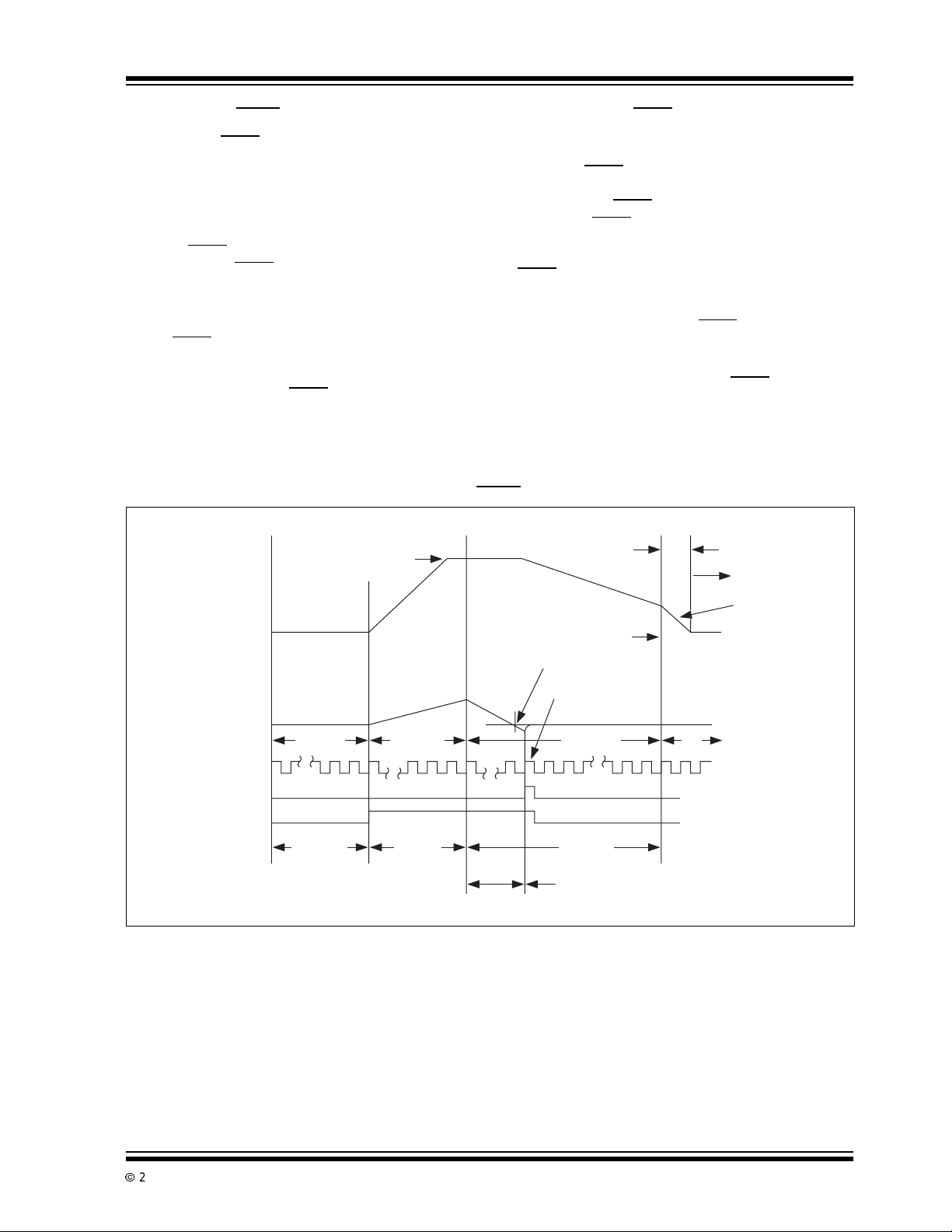

3.1 Analog Section

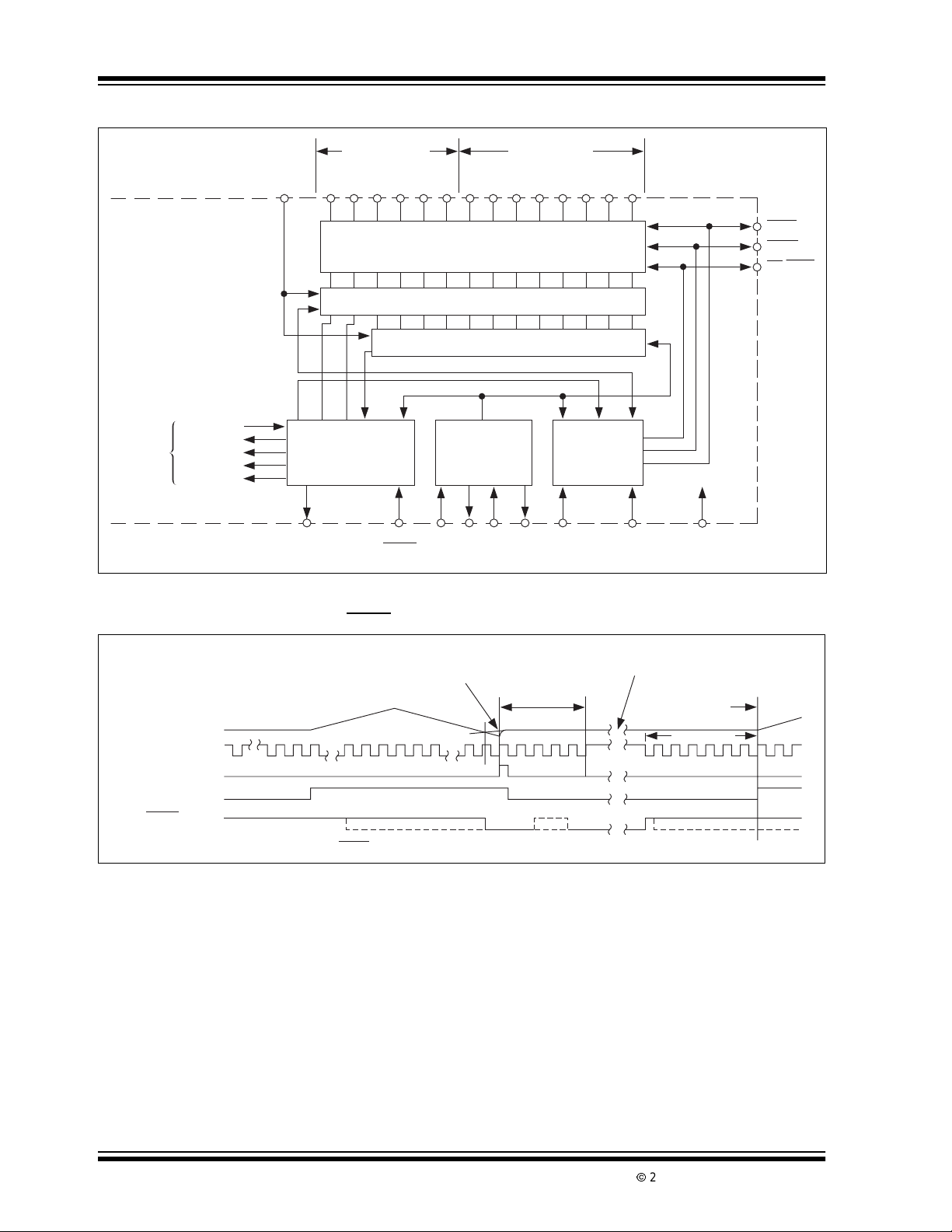

The Typical Application diagram on page 3 shows a

block diagram of the analog section of the TC7109A.

The circuit will perform conversions at a rate determined by the clock frequency (8192 clock periods per

cycle), when the RUN/HOLD

nected to V+. Each measurement cycle is divided into

four phases, as shown in Figure 3- 1. They are:

(1) Auto-Zero (AZ), (2) Signal Integrate (INT), (3) Reference De-integrate (DE), and (4) Zero Integrator (ZI).

3.1.1 AUTO-ZERO PHASE

The buffer and the integrator inputs are disconnected

from input high and input low and connected to analog

common.The reference capacitorischargedto the reference voltage. A feedback loop is closed around the

system to charge the auto-zero capacitor, C

pensate for offset voltage in the buffer amplifier, i ntegrator, and comparator. Since the comparator is

included in the l oop, the AZ accuracy is limited only by

the noise of the system. The offset referred to the input

is less than 10µV.

input is left open or con-

,tocom-

AZ

3.1.2 SIGNAL INTEGRATE PHASE

The bufferandintegrator inputsareremovedfrom common and connected to input high and input low. The

auto-zero loop is opened. The auto-zero capacitor is

placed in series in the loop to provide an equal and

opposite compensating offset voltage. The differential

voltage between input high and input low is integrated

for a fixedtime of 2048 clock periods. At the end of this

phase, the polarity of the integrated signal is determined. If the input signal has no return to the converter's power supply, input low can be tied to analog

common to establish the correct Common mode

voltage.

3.1.3 DE-INTEGRATE P HA SE

Input high i s connected across the previously charged

reference capacitor and input low is internally connected to analog common. Circuitry within the chip

ensuresthecapacitor will be connectedwiththecorrect

polarity to cause the integrator output to return to the

zero crossing (established by auto-zero), with a fixed

slope. The time, represented by the number of clock

periods counted for the output to return to zero, is

proportionalto the input signal.

2002 Microchip TechnologyInc. DS21456B-page 7

Page 8

TC7109/A

3.1.4 Z ERO INTEGRATOR PHASE

The ZI phase only occurs when an input over range

condition exists. The function of the ZI phase is to eliminateresidualchargeon the integratorcapacitorafteran

overrangemeasurement.Unless removed,the residual

chargewillbe transferredto the auto-zerocapacitorand

cause an errorin the succeeding conversion.

The ZI phase virtually eliminates hysteresis, or "crosstalk" in multiplexed systems. An over range input on

one channel will not cause an erroron the next channel

measured. This feature is especially useful in thermocouple measurements, where unused (or broken t hermocouple) inputs are pulled to the positive supply rail.

During ZI, the referencecapacitorischargedto the reference voltage. The signal inputs are disconnected

fromthebufferandintegrator.Thecomparatoroutputis

connected to the buffer input, causing the integrator

output to be driven rapidly to 0V (Figure 3-1). The ZI

phase only occurs following an overrange and lasts for

a maximum of 1024 clock periods.

3.1.5 DIFFERENTIAL INPUT

The TC7109A has been optimized for operation with

analog common near digital ground. With +5V and -5V

power supplies, a full ±4V full scale integrator swing

maximizes the analog section's performance.

A typical CMRR of 86dB is achieved for input differential voltages anywhere within the typical Comm on

mode range of 1V below the positive supply, to 1.5V

above the negative supply. However, for optimum performance, the IN HI and IN LO inputs should not come

within 2V of either supply rail. Since the integrator also

swings with the Common mode voltage, care must be

exercised to ensure the integrator output does not saturate. A worst case condition is near a full scale negative differential input voltage with a large positive

Common mode voltage. The negative input signal

drives the integrator positive when most of its swing

has been used up by the positive Common mode voltage. In such cases, the integrator swing can be

reduced to less than the recommended ±4V full scale

value, with some loss of accuracy. The integrator output can swing to within 0.3V of either supply without

loss of linearity.

3.1.6 DIFFERENTIAL REFERENCE

The reference voltage can be generated anywhere

within the power supply voltage of the converter. Rollover voltage is the main source of Common mode

error, caused by the referencecapacitorlosingor gaining charge, due to stray capacity on its nodes. With a

large Common mode voltage, the reference capacitor

can gain charge (increasevoltage) when called upon to

de-integrate a positive signal and lose charge

(decrease voltage) when called upon to de-integrate a

negative input signal. This difference in reference for

(+) or (–) i nput voltages will causea rollovererror. This

error can be held to less than 0.5 count, worst case, by

using a large r eference capacitor in comparison to the

stray capacitance. To minimize rollover error from

these sources, keep the reference Common mode

voltage near or at analog common.

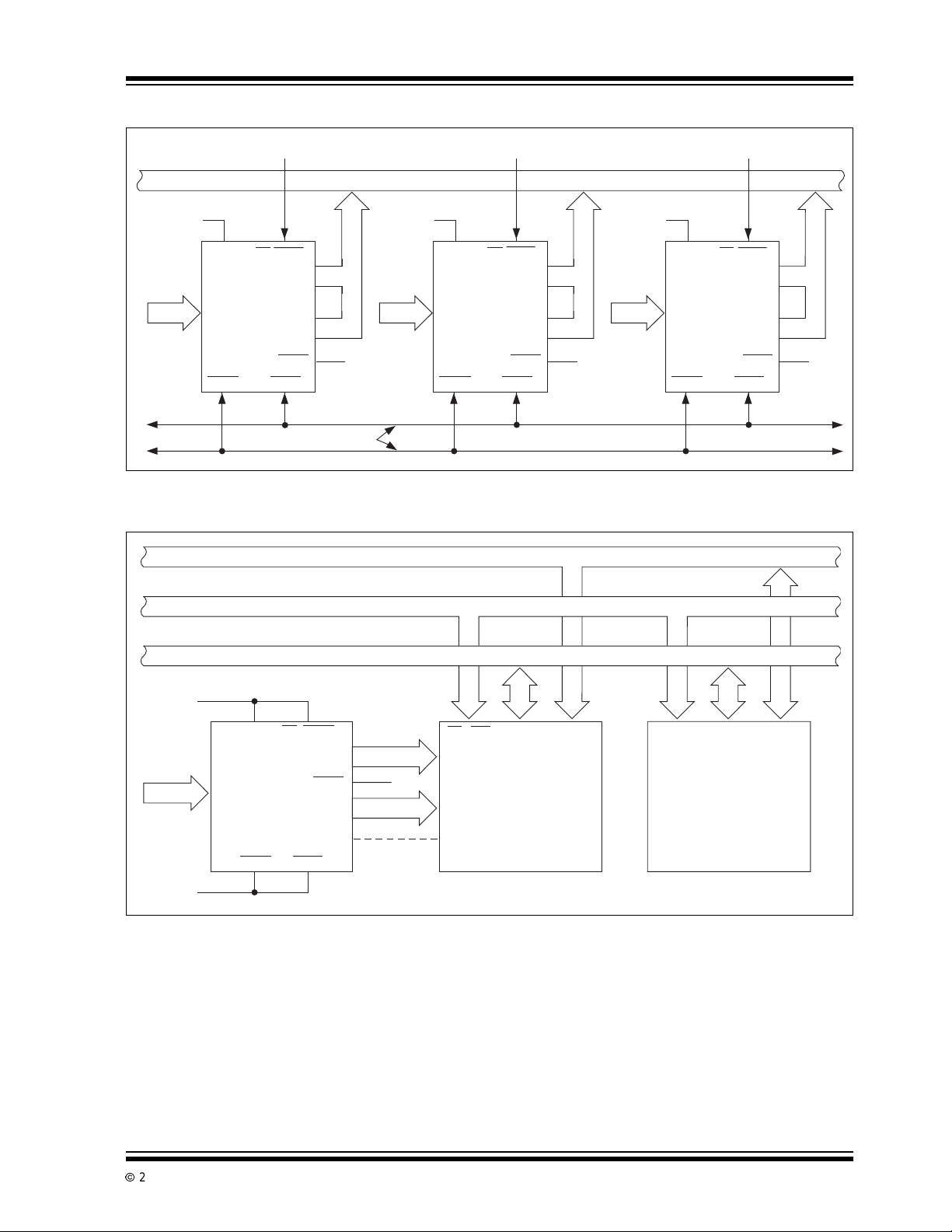

3.2 Digital Section

The di gital section is shown in Figure 3-2 and includes

the clock oscillator and scaling circuit, a 12-bit binary

counter with output latches and TTL compatible threestate output drivers, UART handshake logic, polarity,

over range, and control logic. Logic levels are referred

to as LOW or HIGH.

Inputs driven from TTL gates should have 3kΩ to 5kΩ

pull-up resistors added for maximum noise immunity.

For minimum power consumption, all inputs should

swing from GND (LOW) to V+ (HIGH).

3.2.1 STATUS OUTPUT

During a conversion cycle, the STATUS output goes

high at the beginning of signal integrate and goes low

one-half clock period after new data from the conversion has been stored in the output latches (see

Figure 3-1). The signal may be used as a "data valid"

flag to drive interrupts, or for monitoring the status of

theconverter.(Datawillnotchange while statusislow.)

3.2.2 MODE INPUT

The Output mode of the converter is controlled by the

MODE input. The converter is in its "Direct" Output

mode, when the MODE input i s LOW or left open. The

output data is directly accessible under the control of

the chip and byte enable inputs (this input is provided

with a pull-down resistor to ensure a LOW level when

the pin is left open). When the MODE input is pulsed

high, the converter enters the UART Handshake mode

and outputs the data in 2 bytes, then returnsto "Direct"

mode. When the MODE input is kept HIGH, the converter will output data in the Handshake mode at the

end of every conversion cycle. With MODE = 0 (direct

bus transfer), the send input should be tied toV+. (See

"Handshake Mode".)

DS21456B-page 8

2002 Microchip TechnologyInc.

Page 9

TC7109/A

t

3.2.3 RUN/HO LD INPUT

With the RUN/HOLD input high, or open, the circuit

operates normally as a dual slope ADC, as shown in

Figure 3-1. Conversion cycles operate continuously

with the output latches updated after zero crossing in

the De-integrate mode. An internal pull-up resistor is

provided to ensure a HIGH level with an open i nput.

The RUN/HOLD

sion time. If RUN/HOLD

crossing in the De-integrate mode, the circuit will jump

to auto-zero and eliminate that portion of time normally

spent in de-integrate.

If RUN/HOLD

complete with minimum time in de-integrate. It will stay

in auto-zero for the minimum time and waitin auto-zero

for a HIGH at the RUN/HOLD

Figure 3-3, the STATUS output will go HIGH, 7 clock

input may be used to shorten conver-

goes LOW any timeafter zero

stays or goes LOW, t he conversion will

input. As shown in

periods after RUN/HOLD

converter will begin the integrate phase of the next

conversion.

The RUN/HOLD

interface. The converter may be held at IDLE in autozero with RUN/HOLD

when RUN/HOLD

valid when the STATUS output goes LOW (or is transferred to the UART; see "Handshake Mode"). RUN/

HOLD

may now go LOW, terminating de-integrate and

ensuring a minimum auto-zero time before stopping to

wait for the next conversion. Conversion time can be

minimized by ensuring RUN/HOLD

de-integrate, after zero crossing, and goes HIGH after

the hold point is reached.

The required activity on the RUN/HOLD

provided by connecting it to the buffered oscillator output.In this mode, the inputvaluemeasureddetermines

the conversion time.

FIGURE 3-1: CONVERSION TIMING (RUN/HOLD PIN HIGH

Integrator

Saturates

Integrator Output

for Over Range Input

Integrator Output

for Normal Input

Internal Clock

AZ

Phase I

INT

Phase II

No Zero Crossing

Zero Crossing

Occurs

Zero Crossing

Detected

Phase III

DE

is changed to HIGH, and t he

input allows controlled conversion

LOW.Theconversionisstarted

goes HIGH, and the new data is

goes LOW during

input can be

ZI

AZ

Zero Integrator

Phase forces

Integrator Outpu

to 0V

AZ

Internal Latch

Status Output

2002 Microchip TechnologyInc. DS21456B-page 9

2048

Counts

Min.

Number of Counts to Zero Crossing

Fixed

2048

Counts

Proportional to V

4096

Counts

Max

After Zero Crossing, Analog section will

IN

be in Auto-Zero Configuration

Page 10

TC7109/A

FIGURE 3-2: DIGITAL SECTION

To

Analog

Section

COMP OUT

AZ

INT

DE (±)

TEST17POL3OR

ZI

High Order

Byte Outputs

B

B

B

B

12

11

10

4

5

6

7

Conversion

Control Logic

2262223242521

STATUS RUN/

HOLD

B

9

8

8

9

14 Three-State Outputs

14 Latches

12-Bit Counter

Oscillator and

Clock Circuitry

OSCINOSC

OUT

10

OSC

SEL

B

7

Latch

Clock

Low Order

Byte Outputs

B

B

6

5

11

12

BUFF

OSC

OUT

B

4

13

Handshake

MODE

14

B

3

15

Logic

B

2

B

1

16

27

SEND

1

GND

18

19

20

LBEN

HBEN

CE/LOAD

FIGURE 3-3: TC7109A RUN/HOLD

Determinated at

Zero Crossing

Integrator Output

Internal Clock

Internal Latch

Status Output

RUN/HOLD Input

RUN/HOLD input is ignored until end of auto-zero phase.*Note:

OPERATION

Detection

Auto-Zero Phase I

Min 1790 Counts

Max 2041 Counts

*

Static in

Hold State

INT

Phase II

7 Counts

DS21456B-page 10

2002 Microchip TechnologyInc.

Page 11

TC7109/A

3.2.4 DIRECT MODE

The data outputs (bits 1 through8, low order bytes;bits

9 through 12, polarity and over range high order bytes)

are accessible under control of the byte and chip

enable terminals as inputs, with the MODE pin at a

LOW level. These three inputs are all active LOW.

Internal pull-up resistors are provided for an inactive

HIGH level when left open. When chip enable is LOW,

a byte enable input LOW will allow the outputs of the

byte to become active. A variety of parallel data

accessing techniques may be used, as shown in t he

"Interfacing" section. (See Figure 3-4 and Table 3-1.)

The access of data should be synchronized with the

conversion cycle by m onitoring the STATUS output.

This prevents accessing data while it is being updated

and eliminates the acquisition of erroneous data.

FIGURE 3-4: TC7109A DIRECT MODE

OUTPUT TIMING

t

CE/LOAD

As Input

HBEN

As Input

LBEN

As Input

High Byte

Data

Low Byte

Data

t

BEA

t

DAB

= High Impedance

Data

Valid

t

DAB

t

DAC

CEA

Data

Valid

Data

Valid

t

DHC

TABLE 3-1: TC7109A DIRECT MODE

TIMING REQUIREMENTS

Symbol Description Min Typ Max Units

Byte EnableWidth 200 500 — nsec

t

BEA

t

DAB

t

DHB

t

CEA

t

DAC

t

DHC

Data Access Time

from Byte Enable

DataHoldTimefrom

ByteEnable

Chip Enable Width 300 500 nsec

Data Access Time

from Chip Enable

DataHoldTimefrom

Chip Enable

— 150 300 nsec

— 150 300 nsec

— 200 400 nsec

— 200 400 nsec

3.2.5 HANDS HAK E MODE

An alternative means of interfacing the TC7109A to

digital systems is provided when the Handshake OutputmodeoftheTC7109Abecomesactiveincontrolling

the flow of data, insteadof passivelyrespondingtochip

and byte enable inputs. This mode allows a directinterface between the TC7109A and industry standard

UARTs with no external logic required. The TC7109A

provides all the control and flag signals necessary to

sequence the two bytes of data into the UART and initiate their transmission in serial form when triggered

into the Handshake mode. The cost of designing

remote data acquisition stationsis reduced using serial

data transmission to minimize the number of lines to

the central controlling processor.

The MODE input controls the Handshake mode. When

the MODE input is heldHIGH, the TC7109A enters the

Handshakemodeafternewdatahas beenstoredinthe

output latches at the end of every conversion performed (see Figure 3-7 and Figure 3-8). Entry into the

Handshake mode may be triggered on demand by the

MODE input. At any time during the conversion cycle,

the LOW-to-HIGH transition of a short pulse at t he

MODE input will cause immediate entry into the Handshake mode. If this pulse occurs while new data is

being stored, the entry into H andshake mode is

delayed until the data is stable. The MODE input is

ignored i n the Handshake mode, and until the converter completes the output cycle and clears theHandshake mode, data updating will be inhibited (see

Figure 3-9).

When the MODE input is HIGH, or when the converter

enters the Handshake m ode, the chip and byte enable

inputs become TTL compatible outputs, which provide

the output cycle control signals (see Figure 3-7,

Figure 3-8 and Figure 3-9). The SEND input is used by

the converter as an indication of the ability of the

receivingdevice(suchas aUART)toacceptdatainthe

Handshake mode. The sequence of the output cycle

with SEND held HIGH is shown in Figure 3-7. The

Handshake mode (internal MODE HIGH) is entered

after the data latch pulse (the CE

HBEN

terminals are active as outputs, since MODE

remainsHIGH).

The HIGH level at the SEND input is sensed on the

same HIGH-to-LOW internal clock edge. On the next

LOW-to-HIGH internal clock edge, the high order byte

(bits 9 t hrough 12, POL, and OR) outputs are enabled

and the CE

LOWlevel.The CE

/LOAD and the HBEN outputs assume a

/LOAD output remains LOW for one

full internal clock period only; the data outputs remain

activefor 1-1/2internalclockperiods;andthehighbyte

enable remains LOW for 2 clock periods.

/LOAD, LBEN and

2002 Microchip TechnologyInc. DS21456B-page 11

Page 12

TC7109/A

The CE/LOAD output LOW level, or LOW-to-HIGH

edge, may be usedas a synchronizing signal to ensure

valid data, and the byte enable as an output may be

used asa byte identificationflag.WithSENDremaining

HIGH, the converter completes the output cycle using

CE

/LOAD and LBEN, while the low order byte outputs

(bits 1 through 8) are activated. When both bytes are

sent, the Handshake mode is t erminated. The t ypical

UART interfacing timing is shown in Figure 3-8.

The SEND input is used to delay portions of the

sequence, or handshake, to ensure correct data transfer. This timing diagram shows an industry standard

HD6403 or CDP1854 CMOS UART to interface to

serial data channels. The SEND input to the TC7109A

is driven by the TBRE (Transmitter Buffer Register

Empty) output of the UART, and the CE

the TC7109A drives the TBRL (Transmitter Buffer Register Load) input to the UART. The eight transmitter

buffer register inputs accept the parallel data outputs.

With the UART transmitter buffer register empty, the

SEND input will be HIGH when the Handshake mode is

entered, after new data is stored. The high order byte

outputs become active and the CE

inputs will go LOW a fter SEND is sensed. When CE/

LOAD

goes HIGH at the end of one clock period, the

high order byte data is clocked intothe UART transmitterbufferregister.TheUARTTBREoutputwillgoLOW,

which halts the output cycle with the HBEN output

LOW,and the high orderbyte outputs active. When the

UART has transferred the data to the transmitter register and cleared the transmitter buffer register, the

TBRE returns HIGH. The high order byte outputs are

disabled on t he next TC7109A internal clock HIGH-toLOW edge, and one-half internal clock later, t he HBEN

outputreturns HIGH. The CE/LOADand LBEN outputs

go LOW at the same t ime asthe low orderbyte outputs

become active. When the CE

the end of one clock period, the low order data is

clocked into the UART transmitter buffer register, and

TBRE again goes LOW. The next TC7109A internal

clock HIGH-to-LOW edge will sense when TBRE

returns to a HIGH, disabling the data inputs. One-half

internal clock later, the Handshake mode is cleared,

and the CE

HIGH and stay active, if MODE still remains HIGH.

Handshake output sequences may be performed on

demand by triggering the converter into Handshake

mode with a LOW-to-HIGHedge on the MODEinput.A

handshake output sequence triggered is shown in

Figure 3-9. The SEND input is LOW when the converter enters Handshake mode. The whole output

sequence is controlled by the SEND input, and the

sequence for the first (high order) byte is similar to t he

sequence for the second byte.

Figure 3-9 also shows t hat the output sequence can

take longer than a conversion cycle. New data will not

be latched when the Handshake mode is still in

progress and is, therefore, lost.

/LOAD, HBEN and LBEN terminals return

/LOAD returns HIGH at

/LOAD input of

/LOAD and HBEN

3.3 Oscillator

The oscillatormay be over driven, or may be operated

as an RC or crystal oscillator. The OSCILLATOR

SELECT input optimizes the internal configuration of

the oscillator for RC or crystal operation. The OSCILLATOR SELECT input i s provided with a pull-up resistor. When the OSCILLATOR SELECT input is HIGH or

left open, the oscillator is configured for RC operation.

The internal clock will be the same frequency and

phase as the signal at the BUFFERED OSCILLATOR

OUTPUT. Connect the resistor and capacitor as in

Figure 3-5. The circuitwilloscillateatafrequency given

by f = 0.45/RC. A 100kΩ resistor is recommended for

useful ranges of frequency. The capacitor value should

be chosen such that2048 clock periods are closeto an

integral multiple of the 60Hz period for optimum 60Hz

line rejection.

FIGURE 3-5: TC7109A RC

OSCILLATOR

OSC

23

OSC

OUT

R

= 0.45/RC

24

22

OSC

OSC

SEL

IN

V+ or Open

With OSCILLATOR SELECT input LOW, two on-chip

capacitors and a feedback device are added to the

oscillator. In this configuration, the oscillator will operate with most crystals in the 1MHz to 5MHz range, with

no external components (Figure 3-6). The OSCILLATORSELECT input LOW insertsa fixed 458 divider circuit between the BUFFERED OSCILLATOR OUTPUT

and the internal clock. A 3.58MHz TV crystal gives a

division ratio, providing an integration time given by:

F

EQUATION 3-1:

t = (2048 clock periods) = 33.18msec

58

3.58MHz

25

Buffered

OSC OUT

C

DS21456B-page 12

2002 Microchip TechnologyInc.

Page 13

TC7109/A

g

FIGURE 3-6: CRY S TAL OSCILLATOR

The error is less than 1% from two 60Hz periods, or

33.33msec, which will give better t han 40dB, 60Hz

V+

Clock

rejection. The converter will operate reliably at conversion rates up to 30 per second, corresponding to a

clock frequency of 245.8kHz.

÷

58

When the oscillator is to be over driven, the OSCILLATOROUTPUT should be left open, and the over driving

24

OSC

SEL

22

OSC

IN

23

OSC

OUT

25

Buffered

OSC OUT

signal should be applied at the OSCILLATOR INPUT.

The internal clock will be of the same duty cycle, fre-

quency and phase as the input signal. When the

OSCILLATOR SELECT is at GND, the clock will be

GND

Crystal

1/58 of the input frequency.

FIGURE 3-7: TC7109A HANDSHAKE WITH SEND INPUT HE LD POSITIVE

Integrator Output

Internal Clock

Internal Latch

Status Output

Mode Input

Internal Mode

Send Input

CE/LOAD

HBEN

High Byte Data

LBEN

Low Byte Data

UART

Norm

Zero Crossing Occurs

Zero Crossing Detected

Send Sensed Send Sensed

Data Valid

Mode High Activates

CE/LOAD, HBEN, LBEN

Data Invalid

Terminates

UART Mode

Mode Low, not

in Handshake Mode

Disables Outputs

CE/LOAD,

HBEN,

LBEN

Three-State

= Don't Care

2002 Microchip TechnologyInc. DS21456B-page 13

=

Hi

h Impendance

Three-State

=

will Pull-up

Page 14

TC7109/A

g

e

FIGURE 3-8: TC7109A HANDSHAKE - TYPICAL UART INTERFA CE TIMING

Zero Crossing Occurs

Integrator Output

Internal Clock

Internal Latch

Status Output

Mode Input

Internal Mode

Send Input (UART TBRE)

CE/LOAD Output (UART TBRL)

HBEN

UART

Norm

Zero Crossing Detected

Send

Sensed

Sensed

Send

Send

Sensed

Terminates

UART Mode

High Byte Data

LBEN

Low Byte Data

= Don't Care

Data Valid

=

Three-State High Impedance

Data Valid

FIGURE 3-9: TC7109A HANDSHAKE TRIGGERED BY MODE INPUT

Zero Crossing Occurs

Positive Transiton causes

Entry into UART Mode

Internal Clock

Internal Latch

Status Output

Mode Input

Internal Mode

Send Input

CE/LOAD as Output

UART

Norm

Send

Sensed

Status Output unchanged

in UART Mode

Send

Sensed

DE Phase III

Zero Crossing Detected

Latch Pulse inhibited in UART Mod

Terminates

Send

Sensed

UART Mode

HBEN

High Byte Data

LBEN

Low Byte Data

DS21456B-page 14

= Don't Care

Data Valid

Data Valid

Three-State

=

h Impedance

Hi

Three-State

=

with Pull-up

2002 Microchip TechnologyInc.

Page 15

TC7109/A

3.4 Test Input

The counterand itsoutputsmaybetestedeasily.When

the TEST input is connectedto GND, the internal clock

is disabled and the counter outputs are all forced into

the HIGH state. When the input returns to the 1/2

(V+ – GND) voltageor to V+ and one clock is input, the

counter outputs wi ll all be clocked to the LOW state.

The counteroutputlatches are enabledwhen the TEST

input is taken to a level halfway between V+ and GND,

allowingthe counter contents to be examined any time.

3.5 Component Value Selection

The integrator output swing for full scale should be as

large as possible. For example, with ±5V supplies and

COMMON connected to GND, the nominal integrator

output swing at full scale is ±4V. Since the integrator

output can go to 0.3V from either supply without significantly effecting linearity, a 4V integrator output swing

allows 0. 7V for variations in output swing, due to component value and oscillator tolerances. With ±5V supplies and a Comm on mode voltage range of ±1V

required, the component values should be selected to

provide ±3V integrator output swing. Noise and rollover errors will be slightly worse than in the ±4V case.

For large Common mode voltage ranges, the integrator

output swing must be reduced further. This will

increase both noise and rollover errors. To improve

performance,±6V supplies may be used.

3.5.1 INTEG RATING C APACITOR

The integrating capacitor, C

give the maximum integrator output voltage swing that

will not saturate the integrator to within 0.3V fromeither

supply. A ±3.5V to ±4V i ntegrator output swing is nominal for the TC7109A, with ±5V supplies and analog

common connected to GND. For 7-1/2 conversions per

second (61.72kHz internal clock frequency), nominal

values C

tively. These values should be changed if different

clock frequencies are used to maintain the integrator

output voltage s wing. The value of C

and CAZare 0.15µF and 0.33µF, respec-

INT

EQUATION 3-2:

C

INT

The integrating capacitor must have low dielectric

absorption to prevent rollover errors. Polypropylene

capacitors give undetectable errors, at reasonable

cost, up to +85°C.

(2048 Clock Period) (20µA)

=

Integrator Output Voltage Swings

3.5.2 INTEG RATING RESISTOR

The integrator and buffer amplifiers have a class A output stage with 100µA of quiescent current. They supply

20µA of drive current with negligible non-linearity. The

integratingresistor should be large enough to remain in

, should be selected to

INT

is given by:

INT

this very linear region over the input voltage range, but

small enough that undue leakage requirements are not

placedon the PC board.For 2.048Vfullscale,a 100kΩ

resistor is recommended and for 409.6mV full scale, a

20k resistor is recommended. R

other values of f ull scale by:

maybe selected for

INT

EQUATION 3-3:

R

INT

Full Scale Voltage

=

20µA

3.5.3 AUT O-ZERO CA PACITOR

As the auto-zero capacitor is made large, the system

noise is reduced. Since the TC7109A incorporates a

zero integrator cycle, the size of the auto-zero capacitordoesnotaffectoverload recovery.Theoptimalvalue

of the auto-zero capacitor is between 2 and 4 times

C

. A typical value for CAZis 0.33µF.

INT

The inner foil of C

the outer foil tothe RC summing junction.Theinnerfoil

of C

tion and the outer foil to Pin 32, for best rejection of

stray pickups.

should be connected to the RC summing junc-

INT

shouldbe connectedto Pin 31 and

AZ

3.5.4 REF ERENCE CAPACITOR

A1µF capacitor is recommended for most circuits.

However,wherea largeCommon mode voltage exists,

a larger value is required to prevent rollover error (e.g.,

the reference low is not analog common), and a

409.6mV scale is used. The rollover error will be held

to 0.5 count with a 10µF capacitor.

3.5.5 REFERENCE VOLTAGE

Togeneratefullscaleoutputof 4096counts,theanalog

input required is V

use a reference of 204.8mV. In many applications,

where the ADC is connected to a transducer, a scale

factorwillexistbet ween the input voltageandthedigital

reading. For instance, in a measuring system, the

designer might like to have a full scale reading when

the voltage for the transducer is 700mV. Instead of

dividing the input down to 409.6mV, the designer

should use the input voltage directly and select

V

= 350mV. Suitable values for integrating resistor

REF

and capacitor would be 34kΩ and 0.15µF. This makes

the system slightly quieter and also avoids a divider

networkon the input. Another advantage of this system

occurs when temperature and weight measurements,

with an offset or tare, are desired for non-zero input.

The offsetmaybeintroduced by connectingthevoltage

output of the transducer between common and analog

high,and the offset voltage between common and analog low, observing polarities carefully. In processor

based systems using the TC7109A, it may be more

desirable to use software and perform this type of scaling or tare subtraction digitally.

IN

=2V

. For 409.6mV full scale,

REF

2002 Microchip TechnologyInc. DS21456B-page 15

Page 16

TC7109/A

3.5.6 REF ERENCE SOURCES

A major factor in the absolute accuracy of the ADC is

the stability of the reference voltage. The 12-bit resolution of the TC7109A is one part in 4096, or 244 ppm.

Thus, for the on-board reference temperature coefficient of 70ppm/°C, a temperature differenceof 3°C will

introduce a one-bit absolute error. Where the ambient

temperature is not controlled, or where high accuracy

absolute measurements are being made, it is recommended that an external high quality reference be

used.

A reference output (Pin 29) is provided, which may be

used with a resistive divider to generate a suitable reference voltage (20mA may be sunk without significant

variationinoutputvoltage). A pull-up bias deviceis provided,whichsourcesabout10µA.The outputvoltageis

nominally2.8VbelowV+.Whenusingtheon-boardr eference, REF OUT (Pin 29) should be connected to

REF IN- (pin 39), and REF IN+ should be connected to

the wiper of a precision potentiometer between REF

OUT and V+. The test circuit shows the circuit for a

204.8mV reference, generated by a 2kΩ precision

potentiometer in series with a 24kΩ fixed resistor.

4.0 INTERFACING

4.1 Direct Mode

Combinations of chip enable and byte enable control

signals, which may be used when interfacing the

TC7109A to parallel data lines, are shown in Figure 4-1.

TheCE

/LOAD input may be tied low, allowing either byte

to be controlled by its own enable (see Figure 4-1(A)).

Figure 4-1(B) shows the HBEN

inputs, and CE

/LOAD as a masterenable, which could

be the READ st robe available from most microproces-

and LBEN as flag

sors. Figure 4-1(C) shows a configuration where the

two byte enables are connected together. The CE

LOAD

is a chip enable, and the HBEN and LBEN may

be used as a second chip enable, or connected to

ground. The 14 data outputs will be enabled at the

same time. In the direct MODE, SEND should be tied

to V+.

Figure 4-2 shows interfacing several TC7109A's to a

bus, ganging the HBEN

converters together, and using the CE

and LBEN signals to several

/LOAD input to

select the desired converter.

Figure 4-3 through Figure 4-5give practical circuits uti-

lizing the parallel three-state output capabilities of the

TC7109A. Figure 4-3 shows parallel interface to the

8748/49 systems via an 8255 PPI, where the TC7109A

data outputs ar e active at all times. This interface can

be used i n a read-after-update sequence, as shown in

Figure 4-4. The data is accessed by the high-to-low

transition of the STATUS driving an interrupt to the

microcontroller.

The RUN/HOLD

input is also used to initiate conver-

sions under software control.

Direct interfacing to most microcontroller busses i s

easily accomplished through the three-state output of

the TC7109A.

Figure 4-8 is a typical connection diagram. To ensure

requirements for setup and hold times, minimum pulse

widths, and the drive limitations on long busses are

met, it is necessary to carefully consider the system

timing in this type of interface. This type of interface is

used when the memory peripheral address density is

low, providing simple address decoding. Interrupt handling can be simplified by using an interface to reduce

the componentcount.

/

FIGURE 4-1: DIRECT MODE CHIP AND BY T E ENABLE COMBINATION

GND

A. B. C.

MODE CE/LOAD

B9 - B

POL, OR

12

6

GND

MODE CE/LOAD

TC7109A

B

- B

8

1

Analog In

RUN/HOLD

Control

DS21456B-page 16

8

LBENHBEN

Convert

Analog In

GND or

Chip Select 2

Chip Select 1

B1 - B

POL, OR

TC7109A

RUN/HOLD

LBENHBEN

12

14

Convert

GND

MODE CE/LOAD

Analog In

Chip Select

B9 - B

12

POL, OR

6

TC7109A

B

- B

8

1

8

RUN/HOLD

LBENHBEN

Byte Flags

2002 Microchip TechnologyInc.

Convert

Page 17

FIGURE 4-2: THREE-STATING SEVERAL TC7109AS TO A SMALL BUS

TC7109/A

GND

Analog In

Converter Select

MODE CE/LOAD

B9 - B

POL, OR

TC7109A

- B

B

1

RUN/HOLD

LBENHBEN

Byte Select Flags

GND

12

6

8

8

Analog In

+5V

Converter Select Converter Select

GND

MODE CE/LOAD

B

-

9

POL, OR

TC7109A

- B

B

1

RUN/HOLD

LBENHBEN

B

12

6

8

8

Analog In

+5V

MODE CE/LOAD

TC7109A

B9 - B

POL, OR

- B

B

1

RUN/HOLD

LBENHBEN

12

6

8

8

+5V

FIGURE 4-3: FULL TIME PARALLEL INTERFACE TO µPD8748H/494 MICROCONTROLLERS

Address Bus

GND

Analog In

GND

MODE

TC7109A

CE/LOAD

B9 - B

12

POL, OR

RUN/HOLD

B1 - B

STATUS

LBENHBEN

8

6

+5V

8

See Text

RD WR D7 - D0

PA5 - PA0

µPD8255A

(Mode 0)

PB7 - PB0

PC5

Control Bus

Data Bus

A0 - A1

CS

µPD8748H/49H

2002 Microchip TechnologyInc. DS21456B-page 17

Page 18

TC7109/A

FIGURE 4-4: FULL TIME PARALLEL INTERFACE TO µPD8748H/494 MICROCONTROLLERS

Address Bus

Control Bus

Data Bus

GND

Analog In

GND

MODE

TC7109A

CE/LOAD

B9 - B

POL, OR

RUN/HOLD

B1 - B

STATUS

LBENHBEN

12

8

6

8

STB

1µF

+5V

(See Text)

A

10kΩ

RD WR D7 - D0

PA5 - PA0

PC6

PB7 - PB0

PC4

µPD8255A

A0 - A1

CS

INTR

PC6 INTR

µPD8748H/49H

A

FIGURE 4-5: TC7109A HANDSHAKE INTERFACE TO µPD 8748H/ 494 MICROCONTROLLERS

Address Bus

Control Bus

Data Bus

Analog In

DS21456B-page 18

TC7109A

B9 - B

12

POL, OR

B

- B

1

CE/LOAD

SEND

RUN/HOLD

MODE

A

A

RD WR D7 - D0

PA7 - PA0

PC4

PC5

PC6

PC

PC7

µPD8255A

(Mode 1)

6

8

8

STB

IBF

A0 - A1

CS

PC3

µPD8748H/49H

INTR

2002 Microchip TechnologyInc.

Page 19

TC7109/A

y

4.2 Handshake Mode

The Handshake mode provides an interface to a wide

variety of external devices. The byte enables may be

used as byte identification flags, or as load enables,

and external latches may be clocked by the risingedge

of CE

/LOAD. A handshake interface to Intel®microprocessors using an 8255 PPI is shown in Figure 4-5. The

handshake operation with the 8255 is controlled by

inverting its Input Buffer Full ( IBF) flag to drive the

SEND input to the TC7109A, and using the CE

to drive the 8255strobe. The internal control register of

the PPI should be set in MODE 1 f or the port used. If

the 8255 IBF flag is LOW and the TC7109A is in Handshake mode,the next word will bestrobedintotheport.

The strobe will cause IBF t o go HIGH (SEND goes

LOW), which wi ll keep the enabledbyte outputs active.

The PPI will generate an interrupt which, when executed, will resultin the data being r ead. The IBF will be

reset LOW when the byte is read, causing the

TC7109A to sequence into the next byte. The MODE

inputtotheTC7109A is connectedtothe controllineon

the PPI.

The data from every conversion will be sequenced in

two bytes in the system, if this output is left HIGH, or

tied HIGH separately. (The data access must take less

time than a conversion.) The output sequence can be

obtained on demand if this output is made to go from

LOW to HIGH and the interrupt may be used to reset

the MODE bit.

/LOAD

Conversionsmay be obtained on command undersoftware control by driving the RUN/HOLD

input to the

TC7109A by a bit of the 8255. Another peripheral

devicemaybeserviced by the unusedportofthe8255.

The Handshake mode is particularly useful for directly

interfacingtoindustrystandardUARTs (such as Intersil

HD-6402), providing a means of serially transmitting

converted data with minimum component count.

A typical UART connection is shown in Figure 4-6. In

this circuit, any word received by the UART causes the

UART DR (Data Ready) output to go HIGH. TheMODE

input to the TC7109A goes HIGH, triggering the

TC7109A into Handshake mode. The high order byte is

output to the UART and when the UART has transferred the data to the Transmitter register, TBRE

(SEND) goes HIGH again, LBEN

will go HIGH, driving

the UART DRR (Data Ready Reset), which will signal

the end of the transfer of data from theTC7109A to the

UART.

An extension of the typical connection to several

TC7109A's with one UART is shown in Figure 4-7. I n

thiscircuit,thewordreceivedbytheUART(availableat

the RBR outputs when DR is HIGH) is used to select

which converter will handshake with the UART. Up to

eight TC7109A's may interface with one UART, with no

external components. Up to 256 converters may be

accessed on one serial line with additional

components.

FIGURE 4-6: TC7109 TYPICAL UART INTERFACE

CD4060B

15

+5V

GND

+5V

5–12

GND

Serial

Input

Serial

Output

1

3

4

13

14

15

16

20

25

Q3

RESET

V

GND

RRD

RBR1–8

HD-640R

CMOS UART

PE

FE

OE

SFD

RR1

TRO

*Note:

*TBR1–8

For lowest power consumption, TBR1-TBR8 inputs should have 100kΩ pull-up resistors to +5V.

Send an

word to UART to transmit latest result.

TRC

RRC

EPE

CLS1

CLS2

SBS

CRL

TRE

DRR

DR

TBRL

TBRE

MR

PI

40

17

39

38

37

36

35

GND

34

+5V

26–33

24

18

19

23

22

21

GND

+5V

CLK

1011

1

GND

6

8

8

GND

25

BUFF OSC OUT

2

STATUS

19

HBEN

3–8

B

9

POL, OR

9–16

B

1

17

TEST

18

LBEN

21

MODE

20

CE/LOAD

27

SEND

TC7109A

- B12,

- B

8

V+

REF IN-

REF CAP-

REF CAP+

REF IN+

IN HI

IN LO

COM

INT

AZ

BUFF

REF OUT

V-

RUN/HOLD

OSC SEL

OSC OUT

OSC IN

40

+5V

39

38

37

36

35

34

33

32

C

AZ

31

0.33µF

30

29

R

28

-5V

26

+5V or Open

24

GND

23

22

1µF

0.01µF

C

0.15µF

INT

100kΩ

3.58MHz

Crystal

1MΩ

INT

20kΩ

–

External

Reference

+

+

Input

–

Analog GND

0.2V

REF

1V

REF

2002 Microchip TechnologyInc. DS21456B-page 19

Page 20

TC7109/A

FIGURE 4-7: HANDSHAKE INTERFACE FOR M ULT IPLEXED CONVERTERS

Analog In

FIGURE 4-8:

CE/

LOAD

TC7109A

RUN/HOLD

SENDMODE

B9 - B

POL, OR

- B

B

1

LBENHBEN

TBRL DRR

12

6

8

8

6402 CMOS UART

TBRE RBR1 - RBR8 SFD TBR1 - TBR8

23

8-Bit Data Bus

Analog In

TC7109A

+5V

CE/

LOAD

B9 - B

POL, OR

RUN/HOLD

GND

SENDMODE

B

LBENHBEN

- B

1

12

8

Serial Output

Serial Input

6

Analog In

8

+5V

CE/

LOAD

TC7109A

RUN/HOLD

SENDMODE

B9 - B

POL, OR

- B

B

1

LBENHBEN

12

6

8

8

+5V

+5V

GND

+5V

+5V

+5V

+5V

GND

23

1

T0

4

RESET

5

SS

6

INT

µPD8748H/49H

P20 - P27

CMOS

Microcomputer

10

11

25

26

39

40

20

7

9

EA

WR

PSEN

ALE

PROG

V

DD

T1

V

CC

GND

P14 - P17

DB0 - DB7

XTAL2XTAL1

2

21-24,

35-38

8

+5V

GND

40

17

1

V+

GND

TEST

REF IN-

REF CAP-

REF CAP+

REF IN+

Other I/O

31-34

TC7109A

5

6

8

26

2

18

19

3-8

9-16

20

RUN/HOLD

STATUS

LBEN

HBEN

B9 - B12,

BUFF OSC OUT

POL, OR

B

- B

1

8

CE/LOAD

REF OUT

OSC SEL

OSC OUT

OSC IN

P13

P12

P11

P10

RD

30

29

28

27

12-19

8

8

IN HI

HI LO

COM

INT

AZ

BUFF

V-

SEND

MODE

39

38

37

36

35

34

33

32

31

30

29

28

27

25

24

23

22

21

C

AZ

0.33µF

-5V

GND

1µF

1MΩ

0.01µF

C

INT

0.15µF

R

INT

20k

10 kΩΩ

3.58MHz

Crystal

–

External

Reference

+

+

Input

–

Analog

GND

0.2 V

REF

1 V

REF

DS21456B-page 20

2002 Microchip TechnologyInc.

Page 21

TC7109/A

y

5.0 INTEGRATING CONVERTER

FEATURES

The output ofintegrating ADCs represents the integral,

or average, of an input voltage over a fixed period of

time. Compared with t echniques in which the input is

sampled and held, t he integrating converter averages

the effects of noise. A second important characteristic

is that time is used to quantize the answer, resulting in

extremely small non-linearity errors and no missing

output codes. The integrating converter also has very

good rejection of frequencies whose periods are an

integral multiple of the measurement period. This feature can be used to advantage in reducing line

frequency noise (Figure 5-1).

FIGURE 5-1: NORMAL MODE

REJECTION OF DUAL

SLOPE CONVERTER AS

A FUNCTION OF

FREQUENCY

30

t = Measurement

Period

20

10

Normal Mode Rejection Plan

0

0.1/t 1/t 10/t

Input Frequenc

2002 Microchip TechnologyInc. DS21456B-page 21

Page 22

TC7109/A

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

Package marking data not available at this time.

6.2 Taping Form

Component Taping Orientation for 44-Pin PQFP Devices

User Direction of Feed

PIN 1

W

P

Standard Reel Component Orientation

for TR Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

44-Pin PQFP 24 mm 16 mm 500 13 in

Note: Drawing does not represent total number of pins.

Component Taping Orientation for 44-Pin PLCC Devices

User Direction of Feed

PIN 1

W

DS21456B-page 22

P

Standard Reel Component Orientation

for TR Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

44-Pin PLCC 32 mm 24 mm 500 13 in

Note: Drawing does not represent total number of pins.

2002 Microchip TechnologyInc.

Page 23

6.3 Package Dimensions

TC7109/A

40-Pin PDIP (Wide)

.200 (5.08)

.140 (3.56)

.150 (3.81)

.115 (2.92)

.110 (2.79)

.090 (2.29)

2.065 (52.45)

2.027 (51.49)

.070 (1.78)

.045 (1.14)

.022 (0.56)

.015 (0.38)

PIN 1

.555 (14.10)

.530 (13.46)

.040 (1.02)

.020 (0.51)

.015 (0.38)

.008 (0.20)

.610 (15.49)

.590 (14.99)

3° MIN.

.700 (17.78)

.610 (15.50)

Dimension: inches (mm)

40-Pin CERDIP (Wide)

.098 (2.49) MAX.

2.070 (52.58)

2.030 (51.56)

.210 (5.33)

.170 (4.32)

.200 (5.08)

.125 (3.18)

.110 (2.79)

.090 (2.29)

.065 (1.65)

.045 (1.14)

.020 (0.51)

.016 (0.41)

PIN 1

.540 (13.72)

.510 (12.95)

.030 (0.76) MIN.

.060 (1.52)

.020 (0.51)

.150 (3.81)

MIN.

.015 (0.38)

.008 (0.20)

.620 (15.75)

.590 (15.00)

3° MIN.

.700 (17.78)

.620 (15.75)

Dimension: inches (mm)

2002 Microchip TechnologyInc. DS21456B-page 23

Page 24

TC7109/A

(

6.3 Package Dimensions (Continued)

44-Pin PQFP

.018 (0.45)

.012 (0.30)

.031 (0.80) TYP.

44-Pin PLCC

.695 (17.65)

.685 (17.40)

.656 (16.66)

.650 (16.51)

PIN 1

.398 (10.10)

.390 (9.90)

.557 (14.15)

.537 (13.65)

PIN 1

.398 (10.10)

.390 (9.90)

.557 (14.15)

.537 (13.65)

.050 (1.27) TYP.

.009 (0.23)

.005 (0.13)

.096

7° MAX.

.041 (1.03)

.026 (0.65)

.010 (0.25) TYP.

.083 (2.10)

.075 (1.90)

2.45) MAX.

Dimension: inches (mm)

.021 (0.53)

.013 (0.33)

.630 (16.00)

.591 (15.00)

.032 (0.81)

.026 (0.66)

DS21456B-page 24

.656 (16.66)

.650 (16.51)

.695 (17.65)

.685 (17.40)

.180 (4.57)

.165 (4.19)

.020 (0.51) MIN.

.120 (3.05)

.090 (2.29)

Dimension: inches (mm)

2002 Microchip TechnologyInc.

Page 25

NOTES:

TC7109/A

2002 Microchip TechnologyInc. DS21456B-page 25

Page 26

TC7109/A

SALES AND SUPPORT

Data Sheets

Products supportedby a preliminary Data Sheet may have an errata sheet describing minor operational differences and recommendedworkarounds.To determine if an errata sheet exists for a particulardevice, please contactoneof the following:

1. Your local Microchip sales office

2. The Microchip CorporateLiterature Center U.S. FAX: (480)792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Pleasespecify which device, revision of silicon and Data Sheet (includeLiterature#) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

DS21456B-page 26

2002 Microchip TechnologyInc.

Page 27

TC7109/A

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, FilterLab,

K

EELOQ,microID,MPLAB,PIC,PICmicro,PICMASTER,

PICSTART, PRO MATE, SEEVAL and The Embedded Control

SolutionsCompany areregiste red trademarksof MicrochipTechnologyIncorp or ated in the U.S.A. and other countries .

dsPIC, ECONOMONITOR, FanSense, FlexR OM , fuzz yLA B,

In-Circuit Serial Programming, ICSP, ICEPIC, microPort,

Migratable Memory, MPASM, MPLIB, MPLINK, MPSIM,

MXDEV, PICC, PICDEM, PICDEM .n et , rfPIC, Select Mode

and TotalEndurancearetrademarksofMicrochipTechnology

Incorporated in the U.S.A.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip TechnologyIncorporated in t he U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View,California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

®

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systemsisISO 9001certified.

2002 Microchip TechnologyInc. DS21456B-page 27

8-bit MCUs, KEELOQ®code hopping

Page 28

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-6766200 Fax: 86-28-6766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1315, 13/F , Shenzhen Kerry Centre,

Renminnan Lu

Shenzhen 518001, China

Tel: 86-755-2350361 Fax: 86-755-2366086

Hong Kong

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Microchip Technology Taiwan

11F-3, No. 207

Tung HuaNorth Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Denmark

Microchip Technology Nordic ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Microchip Technology GmbH

Gustav-Heinemann Ring 125

D-81739 Munich, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

United Kingdom

Arizona Microchip Technology Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, EnglandRG41 5TU

Tel: 44 118 921 5869 Fax: 44-118921-5820

03/01/02

DS21456B-page 28

*DS21456B*

2002 Microchip Technology Inc.

Loading...

Loading...