TC650/TC651

Tiny Integrated Temperature Sensor & Brushless DC Fan

Controller with Over-Temperature Alert

Features

• Integrated TemperatureSensing and Multi-speed

Fan Control

• Built-in Over Temperature Alert (T

• Temperature Proportional Fan Speed Control for

Acoustic Noise Reduction and Longer Fan Life

• PulseWidthModulationOutputDrivefor Cost and

Power Savings

• Solid-State Temperature Sensing

•±1°C (Typical) Accuracy from 25°Cto+70°C

• 2.8V – 5.5V Operating Range

• TC651 includesAuto Fan Shutdown

• Low Operating Current: 50µA(Typical)

OVER

)

Applications

• Thermal Protection For Personal Computers

• Digital Set-Top Boxes

• Notebook Computers

• Data Communications

• Power Supplies

•Projectors

Related Literature

• ApplicationNote: AN771

Device Selection Table

Part Number Package

TC650XXVUA 8-PinSOIC -40°Cto+125°C

TC651XXVUA 8-PinM SOP -40°Cto+125°C

Temperature

Range

Package Type

8-Pin MSOP

8-Pin SOIC

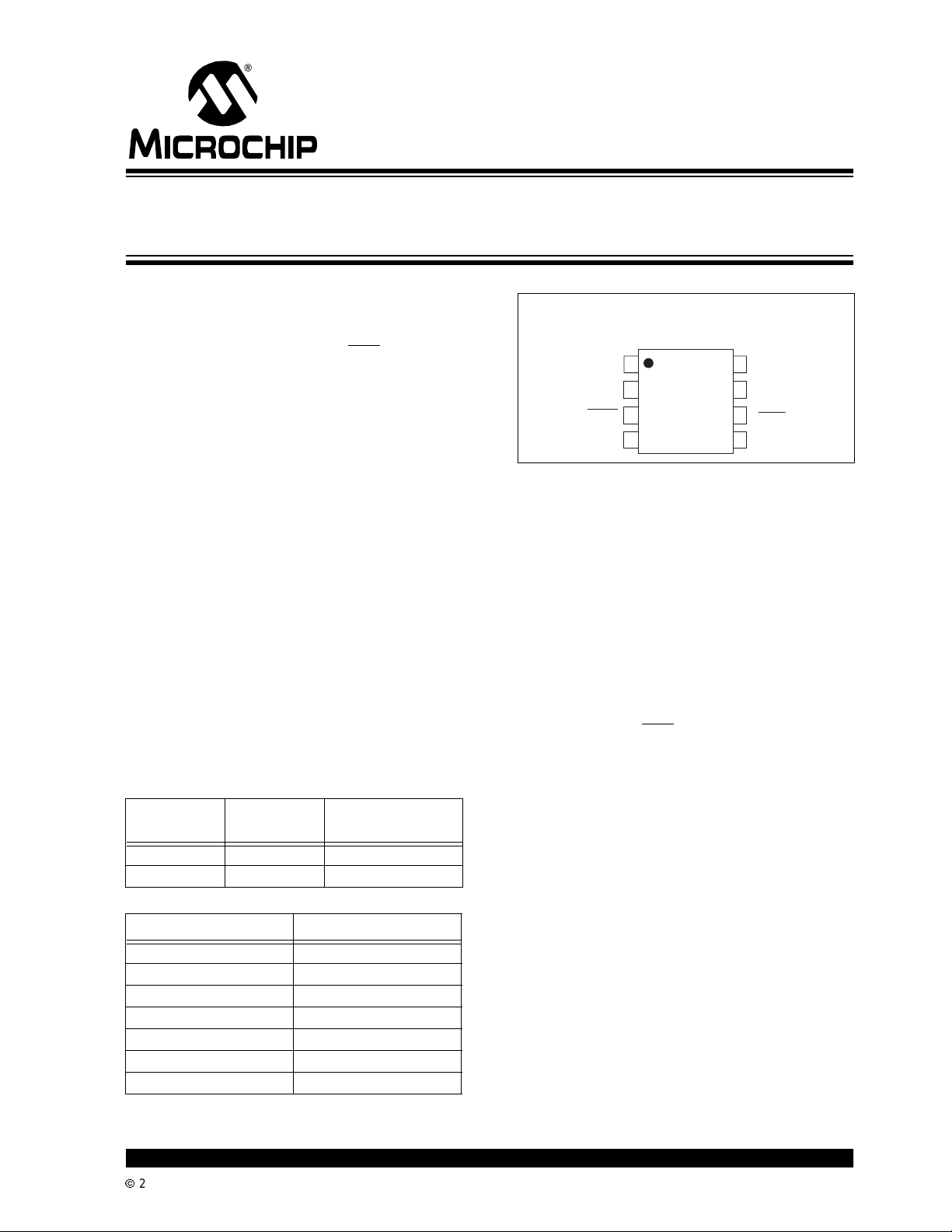

V

DD

NC

SHDN

GND

1

2

3

4

TC650

TC651

8

7

6

5

PWM

GND

T

OVER

NC

General Description

The TC650/TC651 are integrated temperaturesensors

and brushless DC fan speed controllers. The TC650/

TC651 measure their junction temperature and control

thespeedofthefanbasedonthattemperature,making

them especially suited for applications in modern

electronic equipment.

Temperature data is converted from the on-chip

thermal sensing element and translated into a

fractionalfan speed from 40% to 100%. A temperature

selection guide i n the data sheet is used to choose the

low and high temperature limits to control the fan. The

TC650/TC651 also include a single trip point over

temperature alert (T

additionaltemperature sensors. In addition, the TC651

features an auto fan shutdown function for additional

power savings.

The TC650/TC651are easy to use, requireno software

overhead and are therefore the ideal choice for

implementing thermal management in a variety of

systems.

) that eliminates the need for

OVER

XTemperature

A25

B30

C35

D40

E45

F50

G55

The "X" denotes a suffix for temperature threshold settings.

Contact factory for other temperature ranges.

2002 Microchip TechnologyInc. DS21450B-page 1

TC650/TC651

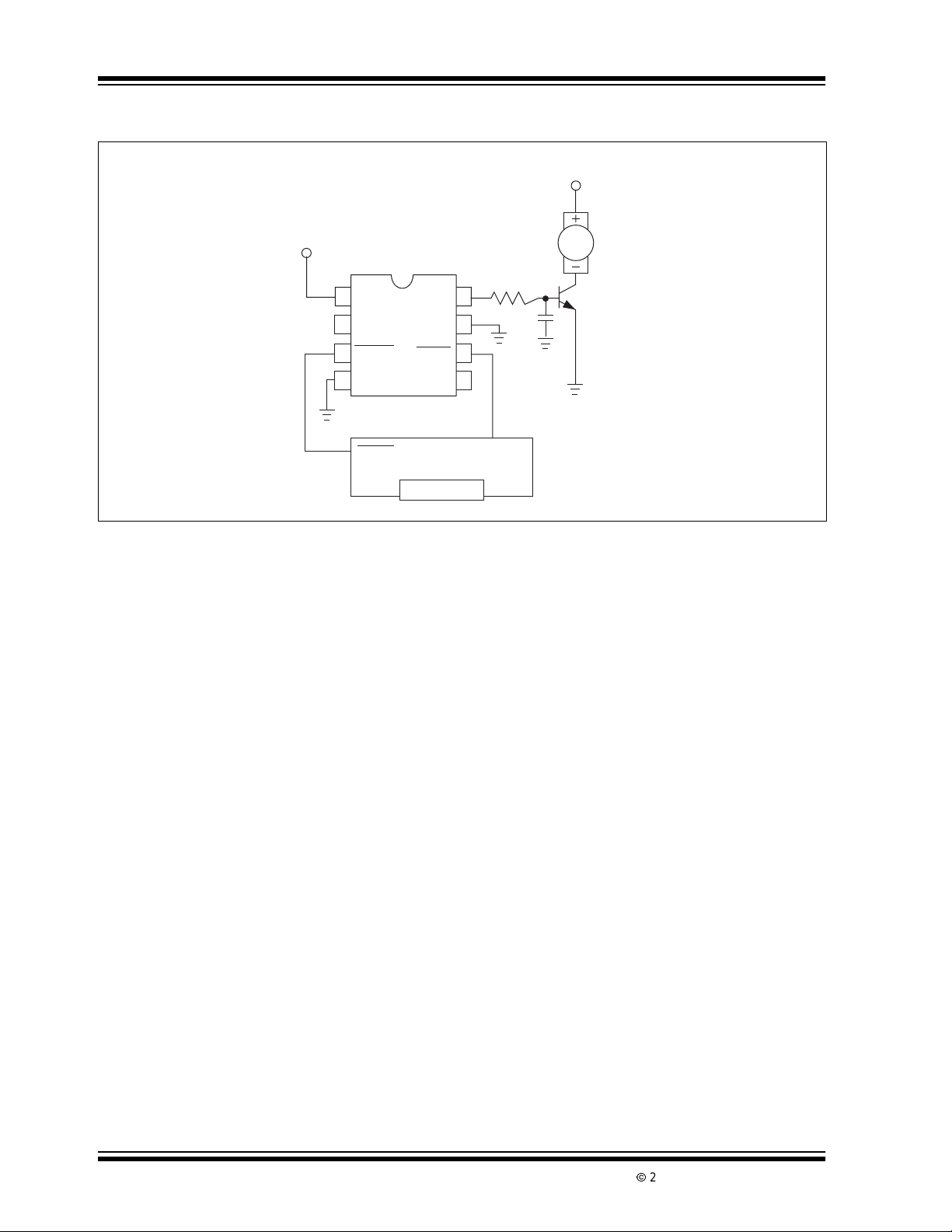

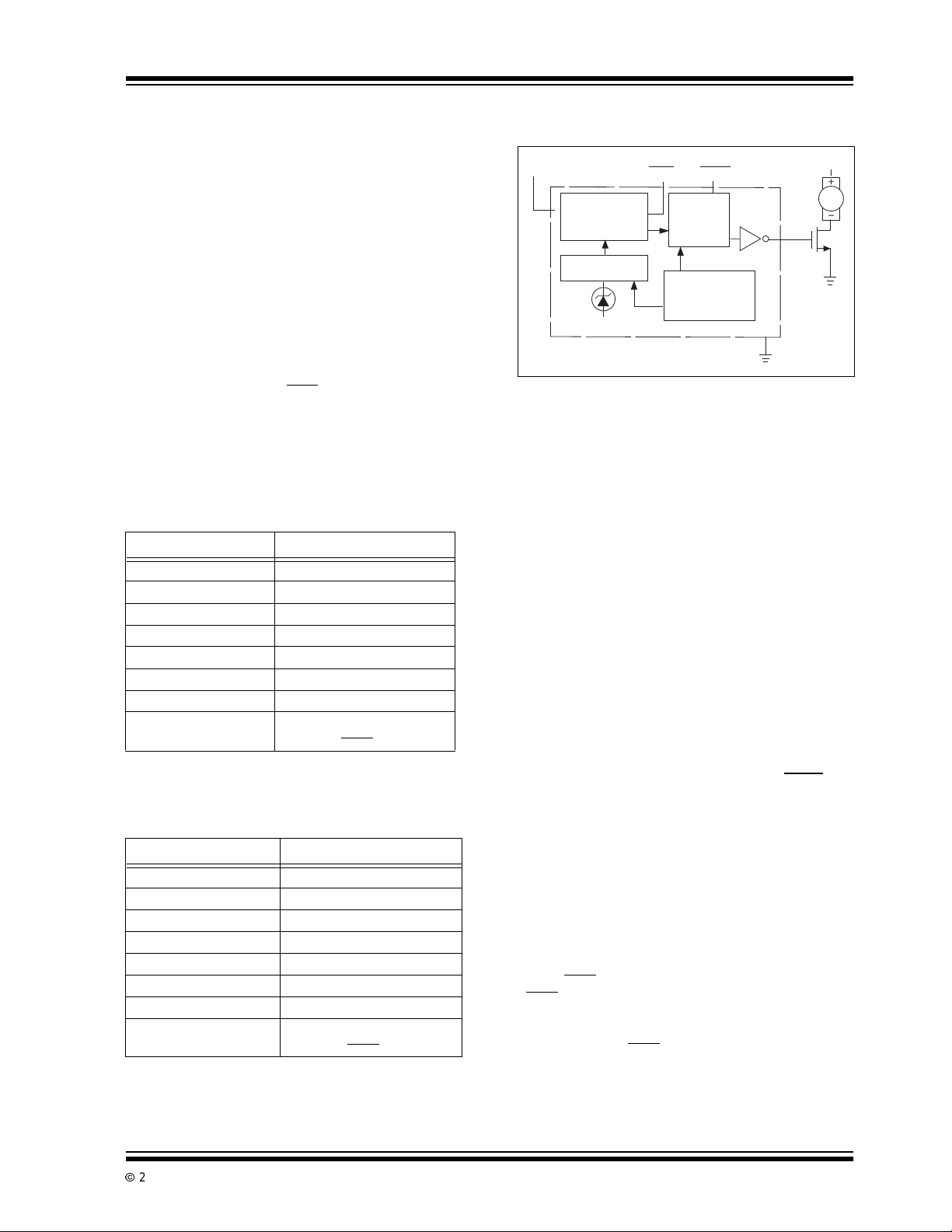

Typical Application Diagram

+5V V

DD

TC650

TC651

+12V

DC Fan

500mA

1

2

3

4

GND

V

DD

NC

SHDN

GND

SHDN Control

PWM

GND

T

OVER

µController

8

7

6

NC

5

Over-Temp.

Alert

C

SLOW

GND

DS21450B-page 2

2002 Microchip TechnologyInc.

TC650/TC651

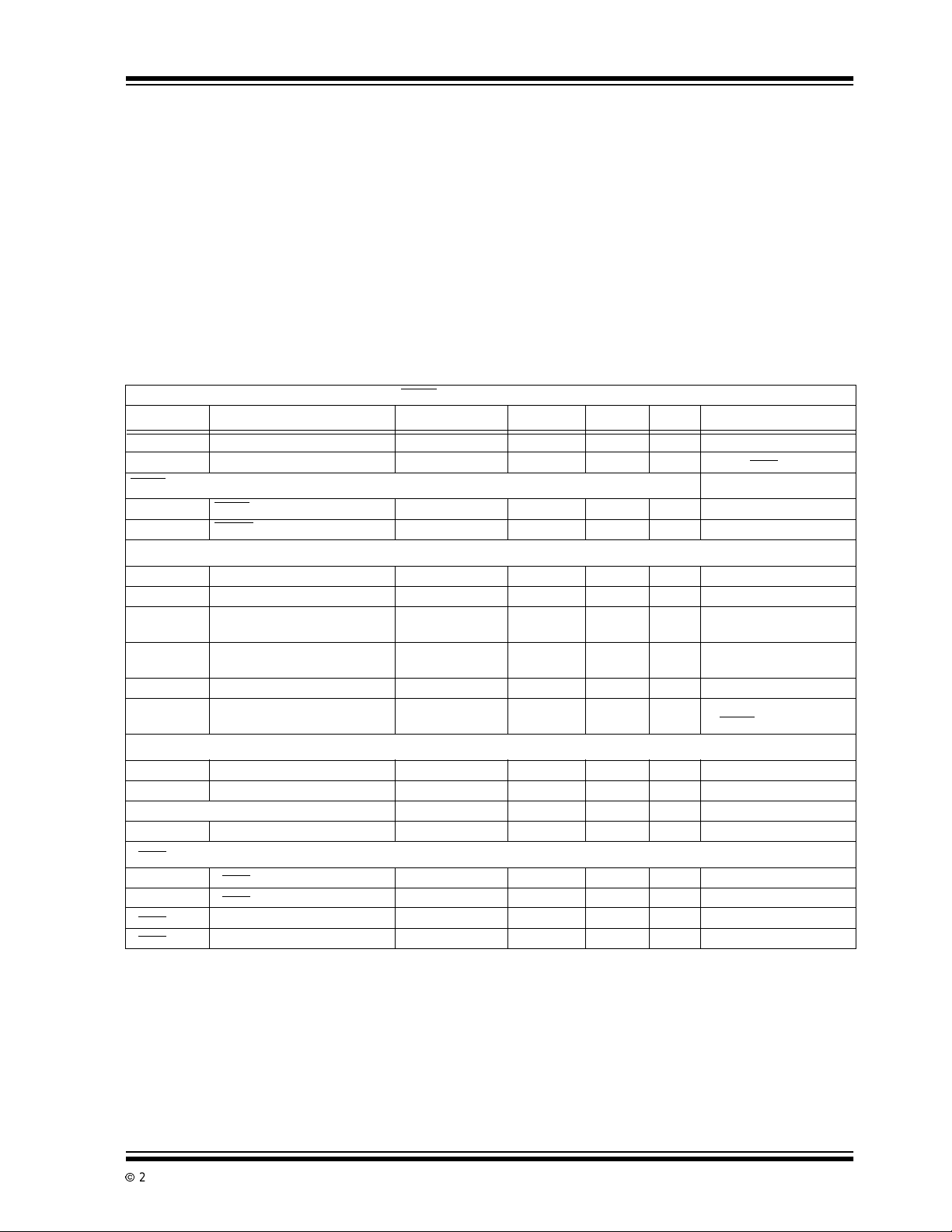

1.0 ELECTRICAL

CHARACTERISTICS

*Stresses above those listed under "Absolute Maximum Ratings"maycause permanentdamage to thedevice.These are

stress ratings only and functional operation of the device at

these or any other conditions above those indicated in the

Absolute Maximum Ratings*

Input Voltage (VDDto GND)...................................+6V

operation sections of the specifications is not implied. E xposure to Absolute Maximum R ating conditions for extended

periodsmay affectdevice reliability.

Output Voltage (OUT to GND) .................................6V

Voltage On Any Pin.......(GND – 0.3V) to (V

Package Thermal Resistance (θ

) ..............250°C/W

JA

DD

+0.3V)

Operating Temperature Range ..........-40°Cto+125°C

Storage Temperature .........................-65°Cto+150°C

TC650/TC651 EL ECTRI CAL SPECIFICATIONS

Electrical Characteristics: VDD= 2.8V to 5.5V, SHDN =VDD,TA=-40°Cto125°C unlessotherwise specified.

Symbol Parameter Min Typ. Max Units Test Conditions

V

DD

I

DD

SHDN

V

IH

V

IL

PWM Output

V

OL

V

OH

t

R

t

F

f

OUT

t

STARTUP

Temperature Accuracy

T

H ACC

(T

H –TL) ACC

T

HYST

T

OVER

V

HIGH

V

LOW

T

OVER ACC

T

OVER HYST

Note 1: Transition from 90% to 100% Duty Cycle.

Supply Voltage 2.8 — 5.5 V

Supply Current — 50 90 µAPWM,T

Input

SHDN Input High Threshold 65 — — %V

SHDN Input Low Threshold — — 15 %V

PWM Output Low Voltage — — 0.3 V I

PWM Output HighVoltage VDD-0.5 — — V I

DD

DD

SINK

SOURCE

PWM Rise Time — 10 — µsec IOH=5mA,1nFfrom

PWM to GND

PWM Fall Time — 10 — µsec IOL=1mA,1nFfrom

PWM to GND

PWM Frequency 10 15 — H z

Start-upTime — 32/f

High Temperature Accuracy TH–3 T

OUT

H

—secVDDRises from GND,

or S HDN

TH+3 °C Note1

Temp. Range Accuracy -1.0 — +1.0 °C(TH-TL) ≤ 20°C

-2.5 — +2.5 °C(T

H-TL

Auto-shutdown Hysteresis — (TH-TL)/5 — °CTC651Only

Output

T

Output High Voltage VDD-0.5 — — V I

OVER

T

Output Low Voltage — — 0.4 V I

OVER

SOURCE

SINK

Absolute Accuracy — TH+10 — °C At Trip Point

Trip Point Hysteresis — 5 — °C

OVER

=1mA

=5mA

Released

) ≥ 20°C

=1.2mA

=2.5mA

are open

2002 Microchip TechnologyInc. DS21450B-page 3

TC650/TC651

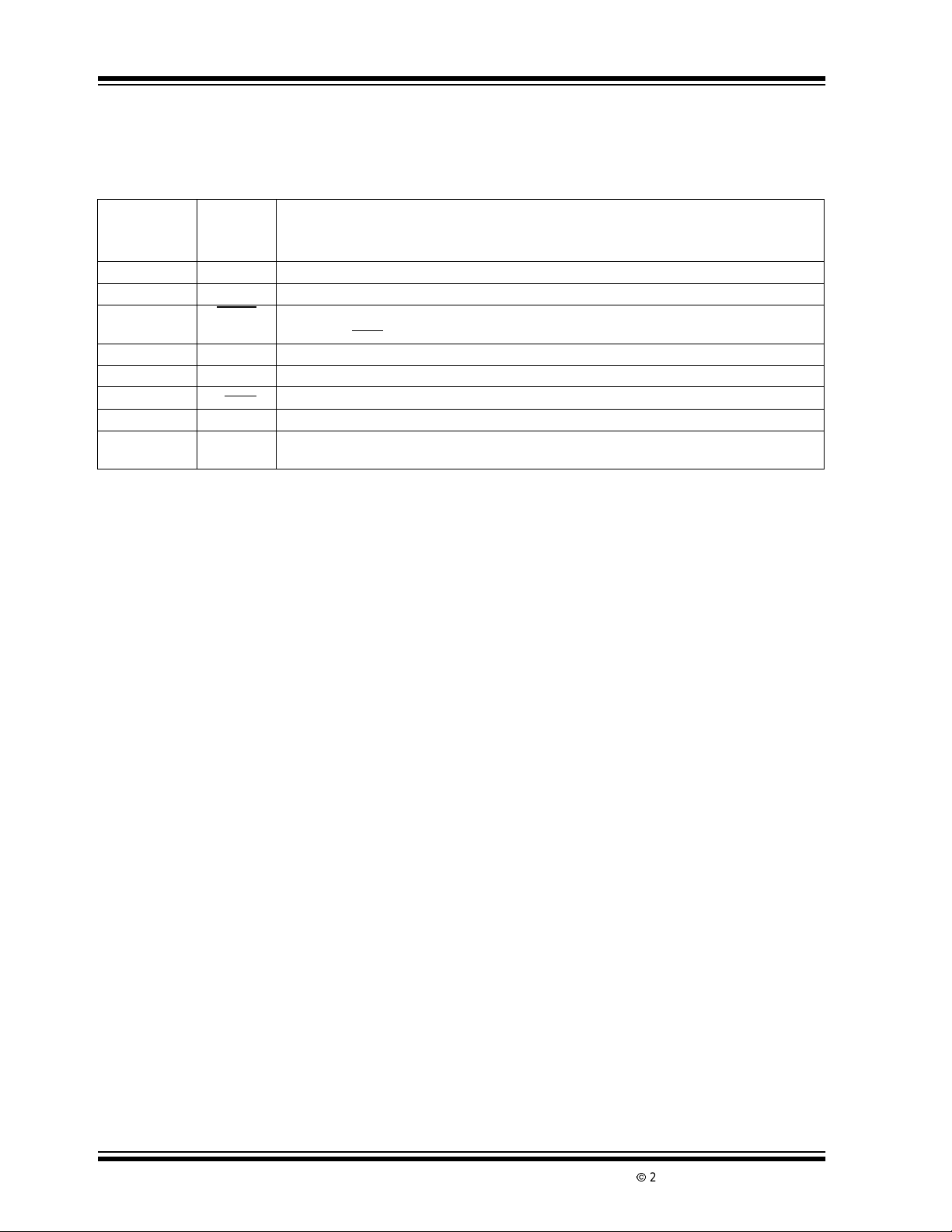

2.0 PIN DESCRIPTIONS

ThedescriptionsofthepinsarelistedinTable2-1.

TABLE 2-1: PIN FUNCTION TABLE

Pin No.

(8-Pin MSOP)

(8-Pin SOIC)

1V

2 NC No Internal Connect.

3 SHDN

4 GND Ground. Ground return for all TC650/TC651 functions.

5 NC No Connect.

6T

7 GND Ground.

8 PWM PWM Fan Drive Output. Pulse width modulated rail-to-rail logic output. Nominal

Symbol Description

DD

OVER

Power Supply Input. May be independent of fan power supply.

Fan Shutdown, Active-Low Input. During Shutdown mode the chip still monitors temperature and T

Over-Temperature Alert, Active-Low Output.

Frequency is 15Hz.

is low if temperature rises above factory set point.

OVER

DS21450B-page 4

2002 Microchip TechnologyInc.

TC650/TC651

3.0 DETAILED DESCRIPTION

The TC650/TC651 acquire and convert their junction

temperature (T

sensor with a typical accuracy of ±1°C. The temperature

data is digitally stored in an internal register. The

register is compared with pre-defined threshold values.

The six threshold values are equally distributed over a

pre-defined range of t emperatures (see Table 3-1 and

Table 3-2). The TC650/TC651 control the speed of a

DC brushless fan using a fractional speed control

scheme.The output stage requiresonly a 2N2222-type

small-signal BJT for fans up to 300mA. For larger

current fans (up to 1 Amp) a logic-level N-channel

MOSFET may be used. In addition to controlling the

speed of the fan, the TC650/TC651 include an on-chip

over-temperature alarm (T

when the temperatureof the chip exceeds T

(typical).Thisfeature eliminatest he need for a separate

temperature sensor for over-temperature monitoring.

TABLE 3-1: TEMPERATURE RANGE

Temperature (T = T

T

L

T

1

T

2

T

3

T

4

<=T<T

T

H

T

) information from an on-chip solid-state

J

) thatgives a low signal

OVER

DEFINITION FOR T C650

(MINIMUM-SPEED MODE)

) PWM Duty Cycle

J

T<T

L

<=T<T

<=T<T

<=T<T

<=T<T

<=T<T

OV

1

2

3

4

H

OV

< = T 100% wi th OverTempAlert

(T

40%

50%

60%

70%

80%

90%

100%

OVER

=L)

by 10°C,

H

FIGURE 3-1: FUNCTIONAL BLOCK

DIAGRAM

V

DD

Temperature

Set Point and

Trim Range

A/D Converter

Temperature Sensor

T

OVER

SHDN

Duty Cycle

Logic

Control

Oscillator

V+

PWM

3.1 PWM Output

The PWM pin is designed to drive a low cost transistor

or MOSFET as thelow side power switching element in

the system. This output has an asymmetric

complementary drive and is optimized for driving NPN

transistors or N-channel MOSFETs. Since the system

relies on PWM rather than linear power control, t he

dissipation in the power switch is kept to a minimum.

Generally, very small devices (TO-92 or SOT

packages) will suffice. The frequency of the PWM is

about 15Hz. The PWM is also the time base for the

Start-up Timer (see paragraphs below). The PWM duty

cycle has a range of 40% to 100% for the TC650 and

50% to 100% for the TC651.

3.2 Start-Up Timer

To ensure reliable fan start-up,the Start-upTimerturns

PWM high for about 2 seconds whenever the fan is

started from the off state. This occurs at power-up and

when coming out of Shutdown mode.

TABLE 3-2: TEMPERATURE RANGE

DEFINITION FOR T C651

(AUTO-SHUTDOWN MODE)

Temperature (T = T

T<T

L

<=T<T

T

L

<=T<T

T

1

<=T<T

T

2

<=T<T

T

3

<=T<T

T

4

<=T<T

T

H

< = T 100% withOver-TempAlert

T

OV

Note:The temperature regions defined by the six temperature thresholds are pre-defined in the TC650/TC651 by means of trimming. Once

aT

andTHare programmed, the T1–T4thresholds are automatically

L

equally spaced between T

2002 Microchip TechnologyInc. DS21450B-page 5

) PWM Duty Cycle

J

1

2

3

4

H

OV

(T

OVER

and TH.

L

“OFF”

50%

60%

70%

80%

90%

100%

=L)

3.3 Over-Temperature Alert (T

This pin goes low whenthe THset point is exceeded by

o

10

C (typical). This indicates that the fan is at

OVER

maximum drive and the potential exists for system

overheating; either heat dissipation in the system has

gone beyond the cooling system's design limits, or

some FAULT exists such as fan bearing failure or an

airflow obstruction. This output may be treated as a

“System Overheat” warning and used to t rigger system

shutdown, or bring other fans to f ull speed in the

system. The f an will continue to run at 100% speed

while T

T

OVER

is at or near the T

falls through the T

maintains the T

is asserted. Built-in hysteresis prevents

OVER

from “chattering” when measured temperature

+ 10°C trip point. As t emperature

H

+ 10°C trip point, hysteresis

H

output low until measured

OVER

temperature is 5°C above the trip point setting.

)

TC650/TC651

3.4 Shutdown (SHDN)

The fan can be unconditionallyshutdown by pullinglow

the SHDN

pin. During shutdown, the PWM output is

low. This is i deal for notebook computers and other

portable applications when you need to change

batteries and must not have the f an running at that

time. Thermal monitoring and T

operation during shutdown. I

shutdown current is

DD

OVER

are still in

around 50µA.

3.5 Auto-Shutdown Mode

The TC651 features auto-shutdown; when the

temperature is below the factory set point at minimum

speed (T

), PWM is low and the fan is automatically

L

shut off (Auto-shutdownmode). This feature is ideal for

notebookcomputersandotherportableequipmentthat

need t o conserve as much battery power as possible

and thus run a fan when it is only absolutely needed.

The TC651 will continue to be active so as to m onitor

temperatureforTover. The TC651 exitsAuto-shutdown

modewhen the temperature rises above the factory set

point (T

).

1

3.6 Temperature Selection G uide

(Minimum Fan Speed/Full Speed)

TLand THcanbeselectedin5°Cincrements.THmust

be chosen at least 10

o

C higher than TL.TLcan range

anywhere from 25°C to 35°C.

As an example, suppose you wanted the fan to run at

40% speed at 25°C or less and go to full speed at

45°C. Youwouldorderthepartnumber TC650AEVUA.

As another example, suppose you wanted the fan to

turn on at 30°C and go to full speed at 45°C. You

would order the part number TC651BEVUA.

The five temperature regions defined by the six

thresholds are defined in the TC650/TC651 by means

of factory trimming. Once a T

T

thresholds are automatically equally spaced

4

between T

Temp.

Range

and TH.

L

T

L

and THare set, the T1–

L

T

H

Part #

10°C 25 35 AC

30 40 BD

35 45 C E

15°C 25 40 AD

30 45 BE

35 50 CF

20°C 25 45 AE

30 50 BF

35 55 CG

30°C 25 55 AG

Note:The Bo ld Type temperature settings are available for

ordering. Contact factory for other temperature selections.

DS21450B-page 6

2002 Microchip TechnologyInc.

4.0 TYPICAL APPLICATIONS

4.1 Reducing Switching Noise

For fans consuming more than 300mA, a slowdown

capacitor (C

switching PWM induced noise (see Figure 4-1). The

value of t his capacitor should be 4.7µFto47µF,

depending on the fan current consumption.

See Application Note AN771 “Suppressing Acoustic

Noise in PWM Fan Speed Control Systems” for more

information.

FIGURE 4-1: REDUCING SWITCHING

+5V V

DD

) is recommended for reducing

SLOW

NOISE

+12V

TC650

TC651

DC Fan

500mA

TC650/TC651

1

2

3

4

GND

V

NC

SHDN

GND

SHDN Control

DD

PWM

GND

T

OVER

NC

µController

8

C

SLOW

7

6

5

Over-Temp.

Alert

GND

2002 Microchip TechnologyInc. DS21450B-page 7

TC650/TC651

5.0 TYPICAL CHARACTERISTICS

The graphs and tables provided following this note ar e a statistical summary based on a limited number of samples

and are provided for informational purposes only. The performance characteristics listed herein are not t ested or

guaranteed. In some graphs or tables, the data presented may be outside the specified operating range ( e.g., outside specified power supply range) and therefore outside the warranted range

(µA)

DD

I

450

400

(mV)

OL

V

150

100

500

350

300

250

200

50

0.0

IDD vs. Temperature

90

80

70

V

60

50

40

30

20

10

0

-50

PWM, I

VDD = 2.8V

0

123 4 567

=

DD

-25

0

TEMPERATURE (˚C)

SINK

5.6

V

= 2.7

DD

50

25

75 100 125 150

vs. VOL, TA = 25˚C

= 5.5V

V

DD

8

910

(mA)

I

SINK

Temperature Accuracy vs. V

3.0

2.5

2.0

1.5

1.0

V

= 5.6

Temp Accuracy (˚C)

0.5

0.0

PWM, I

1.0

0.9

0.8

0.7

0.6

OH (V)

- V

0.5

DD

V

0.4

0.3

0.2

0.1

0.0

DD

V

= 2.7

DD

T

T

1

L

SOURCE

0

246 81012141618 20

T

vs. (VDD - VOH), TA = 25˚C

VDD = 2.8V

I

SOURCE

T

T

2

THRESHOLD

(mA)

T

3

4

VDD = 5.5V

TH

T

H

T

OVER

1.0

0.9

0.8

0.7

0.6

OH (V)

0.5

- V

DD

0.4

V

0.3

0.2

0.1

0.0

, I

0

DS21450B-page 8

SOURCE

VDD = 2.8V

123 4 567

vs. (V

I

SOURCE

V

DD

= 5.5V

DD

(mA)

- VOH), TA = 25˚C

8

910

2002 Microchip TechnologyInc.

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

Package marking data not available at this time.

6.2 Taping Form

Component Taping Orientation for 8-Pin MSOP Devices

PIN 1

TC650/TC651

User Direction of Feed

W

P

Standard Reel Component Orientation

for TR Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

8-Pin MSOP 12 mm 8 mm 2500 13 in

Component Taping Orientation for 8-Pin SOIC (Narrow) Devices

User Direction of Feed

PIN 1

W

P

Standard Reel Component Orientation

for TR Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

8-Pin SOIC (N) 12 mm 8 mm 2500 13 in

2002 Microchip TechnologyInc. DS21450B-page 9

TC650/TC651

.

8

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

8

C

6.3 Package Dimensions

8-Pin MSOP

PIN 1

.026 (0.65) TYP.

.016 (0.40)

.010 (0.25)

-Pin SOI

.122 (3.10)

.114 (2.90)

.006 (0.15)

.002 (0.05)

.122 (3.10)

.114 (2.90)

.157 (3.99

.150 (3.81

.197 (5.00)

.189 (4.80)

.043 (1.10)

MAX.

.244 (6.20

.228 (5.79

6° MAX.

.008 (0.20)

.005 (0.13)

.028 (0.70)

.016 (0.40)

Dimensions: inches (mm)

DS21450B-page 10

.050 (1.27) TYP

.197 (5.00

.189 (4.80

.020 (0.51

.013 (0.33

.010 (0.25

.004 (0.10

.069 (1.75

.053 (1.35

.050 (1.27

.016 (0.40

.010 (0.25

.007 (0.18

Dimensions: inches (mm)

2002 Microchip TechnologyInc.

TC650/TC651

SALES AND SUPPORT

Data Sheets

Products supportedby a preliminaryDataSheetmayhavean erratasheet describingminoroperationaldifferences and recommendedworkarounds.To determine if an erratasheetexists for a particular device,please contactone of the following:

1. Your local Microchip sales office

2. TheMicrochip Corporate Literature Center U.S. FAX:(480)792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Pleasespecify which device, revision of silicon and Data Sheet (includeLiterature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn)to receive the most currentinformationon our products.

2002 Microchip TechnologyInc. DS21450B-page 11

TC650/TC651

NOTES:

DS21450B-page 12

2002 Microchip TechnologyInc.

TC650/TC651

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringementof

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, FilterLab,

K

EELOQ,microID,MPLAB,PIC,PICmicro,PICMASTER,

PICSTART, PRO MA TE, SEEVAL and The Embedded Control

SolutionsCompany areregiste red trademarksof MicrochipTechnologyIncorp or ated in the U.S.A. and other countries .

dsPIC, ECONOMONITOR, FanSense, FlexROM, fuz z yLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, microPort,

Migratable Memory, MPASM, MPLIB, MPLINK, MPSIM,

MXDEV, PICC, PICDEM, PICDE M.net, rfPIC, Select Mode

and TotalEndurancearetrademarksofMicrochipTechnology

Incorporated in the U.S.A.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip TechnologyIncorporated in t he U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

®

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systemsisISO 9001certified.

2002 Microchip TechnologyInc. DS21450B-page 13

8-bit MCUs, KEELOQ®code hopping

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-6766200 Fax: 86-28-6766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1315, 13/F , Shenzhen Kerry Centre,

Renminnan Lu

Shenzhen 518001, China

Tel: 86-755-2350361 Fax: 86-755-2366086

Hong Kong

Microchip Technology Hongkong Ltd.

Unit 901-6, To wer2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T ., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Microchip Technology Taiwan

11F-3, No. 207

Tung HuaNorth Road

Taipei, 105, T aiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Denmark

Microchip Technology Nordic ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Microchip Technology GmbH

Gustav-Heinemann Ring 125

D-81739 Munich, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

United Kingdom

Arizona Microchip Technology Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, EnglandRG41 5TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

03/01/02

DS21450B-page 14

*DS21450B*

2002 Microchip Technology Inc.

Loading...

Loading...