Page 1

TC1303A/TC1303B/

TC1303C/TC1304

500 mA Synchronous Buck Regulator,

+ 300 mA LDO with Power-Good Output

Features

• Dual-Output Regulator (500 mA Buck Regulator

and 300 mA Low-Dropout Regulator)

• Power-Good Output with 300ms Delay

• Total Device Quiescent Curre nt = 65 µA, Typ.

• Independent Shutdown for Buck and LDO

Outputs (TC1303)

• Both Outputs Internally Compensated

• Synchronous Buck Regulator:

- Over 90% Typical Efficiency

- 2.0 MHz Fixed-Frequency PWM

(Heavy Loa d)

- Low Output Noise

- Automatic PWM to PFM mode transition

- Adjustable (0.8V to 4.5V) and Standard

Fixed-Output Voltages (0.8V, 1.2V, 1.5V,

1.8V, 2.5V, 3.3V)

• Low-Dropout Regulator:

- Low-Dropout Vol t ag e= 137mV Typ. @

200 mA

- Standard Fixed-Output Voltages

(1.5V, 1.8V, 2.5V, 3.3V)

• Power-Good Function:

- Monitors Buck Output Function (TC1303A)

- Monitors LDO Output Function (TC1303B)

- Monitors Both Buck and LDO Output Func-

tions (TC1303C and TC1304)

- 300 ms Delay Used for Processor Reset

• Sequenced Startup and Shutdown (TC1304)

• Small 10-pin 3X3 DFN or MSOP Package

Options

• Operating Junction Temperature Range:

- -40°C to +125°C

• Undervoltage Lockout (UVLO)

• Output Short Circuit Protection

• Overtemperature Protection

Description

The TC1303/TC1304 combines a 500 mA synchronous buck regulator and 300m A Low-Drop out Regulator (LDO) with a power-good monitor to provide a highly

integrated solution for devices that require multiple

supply voltages. The unique combination of an

integrated buck switching regulator and low-dropout

linear regulator provides the lowest system cost for

dual-output voltage applications that require one lower

processor core voltage and one higher bias voltage.

The 500 mA synchronous buck regul ator swit ches at a

fixed frequency of 2.0 MHz when the load is heavy,

providing a low noise, small-size solution. When the

load on the buck output is reduced to light levels, it

changes operation to a Pulse Frequency Modulation

(PFM) mode to minimize quie scent current draw from

the battery. No intervention is necessary for smooth

transition from one mode to another.

The LDO provides a 300 mA auxiliary output that

requires a single 1 µF ceramic output capacitor,

minimizing board area and cost. The typical dropout

voltage for the LDO output is 137 mV for a 200 mA

load.

For the TC1303/TC1304, the power-good output is

based on the regulation of the buck regulator output, the

LDO output or the combination of both. The TC1304

features start-up and shutdown output sequencing.

The TC1303/TC1304 i s available in either the 10-pin

DFN or MSOP package.

Additional protection features include: UVLO,

overtemperature and overcurrent protection on both

outputs.

For a complete listing of TC1303/TC1304 standard

parts, consult your Microchip representative.

Applications

• Cellular Phones

• Portable Computers

• USB-Powered Devices

• Handheld Medical Instruments

• Organizers and PDAs

© 2005 Microchip Technology Inc. DS21949B-page 1

Page 2

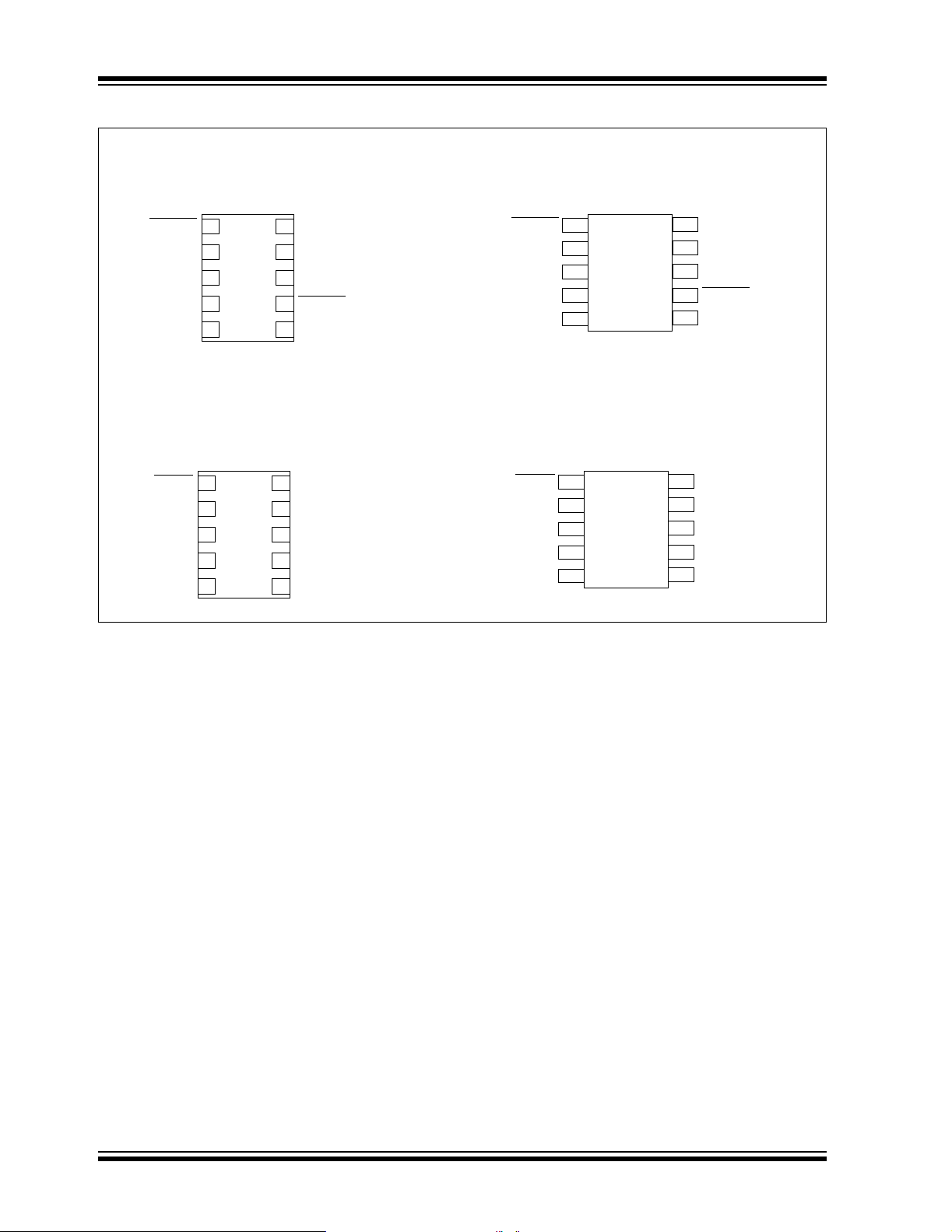

TC1303A/TC1303B/TC1303C/TC1304

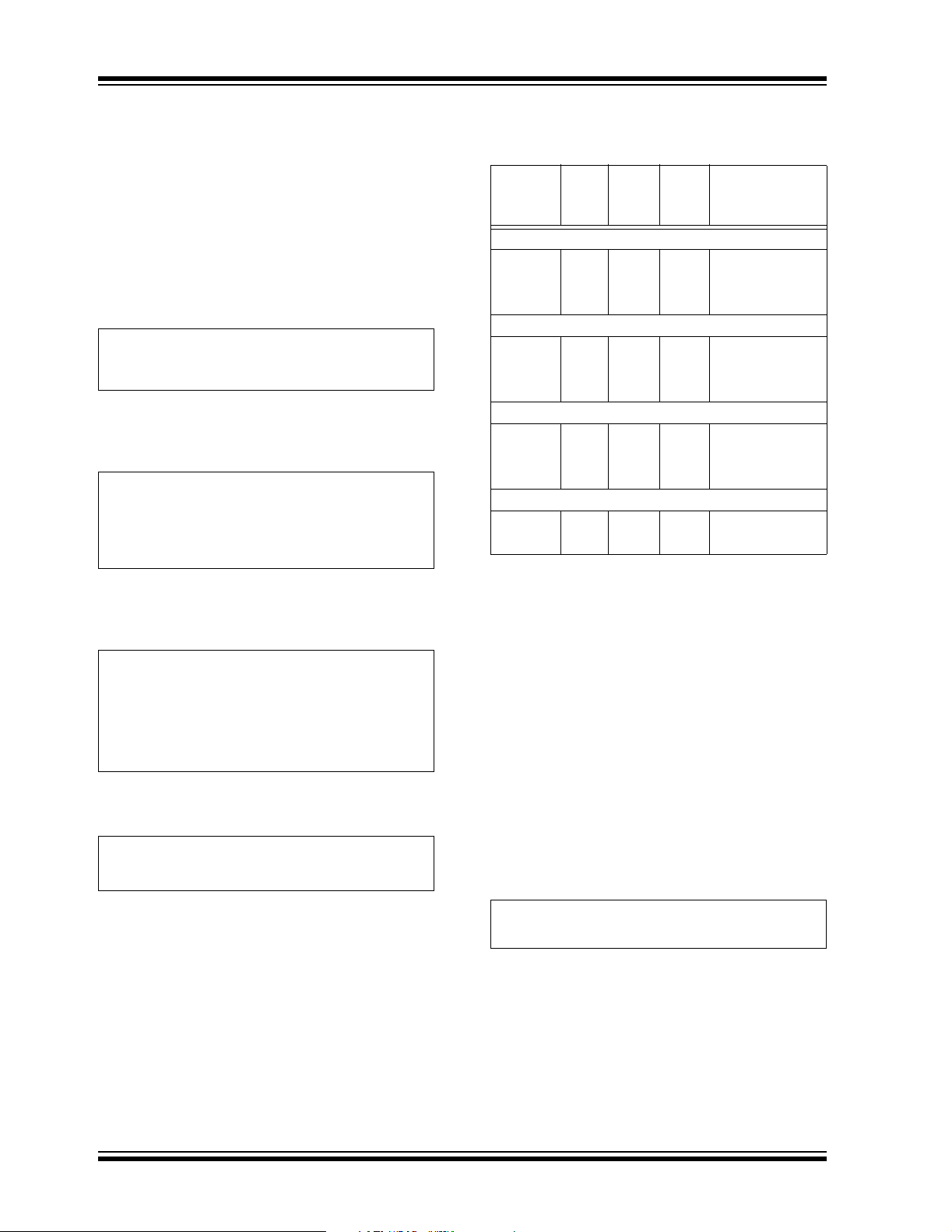

Package Types

TC1303A,B,C

SHDN2

V

IN2

V

OUT2

PG

A

GND

SHDN

V

IN2

V

OUT2

PG

A

GND

10-Lead DFN

1

2

3

4

5

10

9

8

7

6

10-Lead DFN

1

2

3

4

5

10

9

8

7

6

P

GND

L

X

V

IN1

SHDN1

V

FB1/VOUT1

P

GND

L

X

V

IN1

A

GND

V

FB1/VOUT1

TC1304

SHDN2

V

IN2

V

OUT2

PG

A

GND

SHDN

V

IN2

V

OUT2

PG

A

GND

10-Lead MSOP

1

2

3

4

5

10-Lead MSOP

1

2

3

4

5

10

9

8

7

6

10

9

8

7

6

P

GND

L

X

V

IN1

SHDN1

V

FB1/VOUT1

P

GND

L

X

V

IN1

A

GND

V

FB1/VOUT1

DS21949B-page 2 © 2005 Microchip Technology Inc.

Page 3

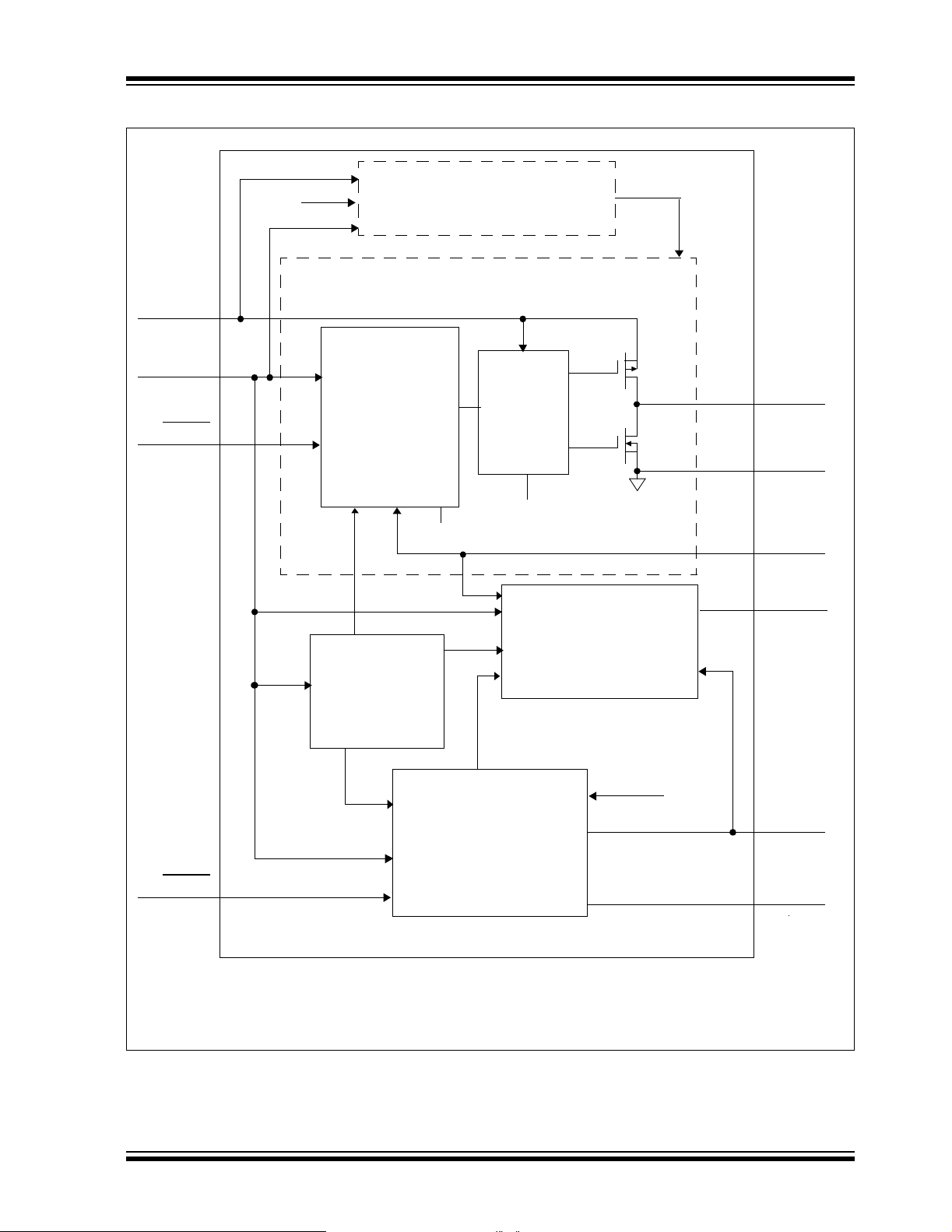

TC1303A/TC1303B/TC1303C/TC1304

Functional Block Diagram – TC1303

V

IN1

V

IN2

SHDN1

V

REF

Undervoltage Lockout

(UVLO)

UVLO

Synchronous Buck Regulator

PDRV

L

X

Control

A

GND

Driver

NDRV

P

GND

Sense Switcher for A,C

TC1303A

(1),B(2),C(1)

P

GND

options

P

GND

V

OUT1/VFB1

PG

PG Generator with Delay

V

REF

SHDN2

Note 1: PG open-drain for A,C options

2: PG push-pull output for B option

Sense LDO for B,C

LDO

UVLO

V

A

OUT2

GND

© 2005 Microchip Technology Inc. DS21949B-page 3

Page 4

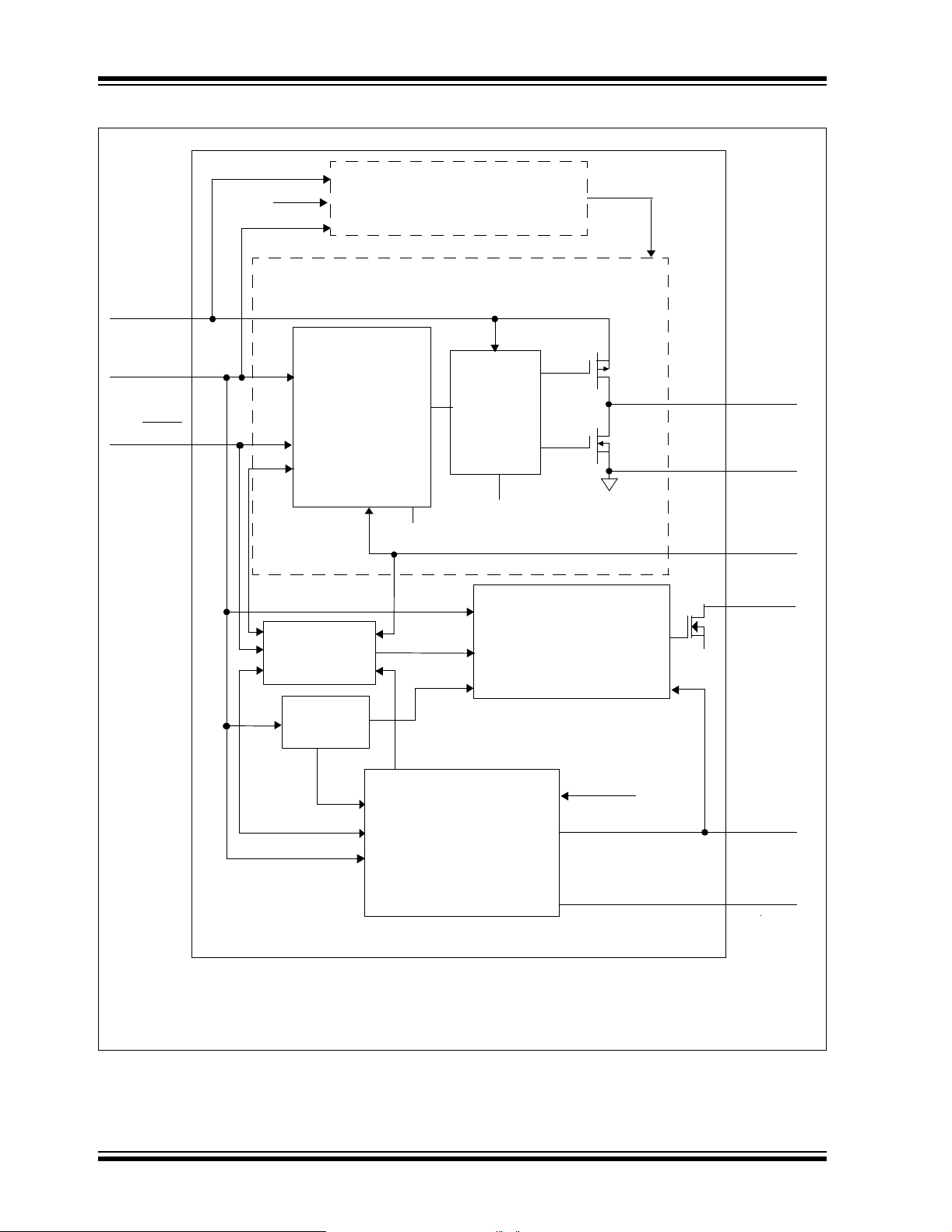

TC1303A/TC1303B/TC1303C/TC1304

Functional Block Diagram – TC1304

V

IN1

V

IN2

SHDN

V

REF

Control

Output Voltage

Sequencer ckt.

Undervoltage Lockout

(UVLO)

Synchronous Buck Regulator

Driver

P

GND

A

GND

TC1304

PG Generator with Delay

PDRV

NDRV

(Note)

UVLO

P

GND

A

GND

L

X

P

GND

V

OUT1/VFB1

PG

V

REF

Note: PG open-drain for TC1304

LDO

UVLO

V

A

OUT2

GND

DS21949B-page 4 © 2005 Microchip Technology Inc.

Page 5

TC1303A/TC1303B/TC1303C/TC1304

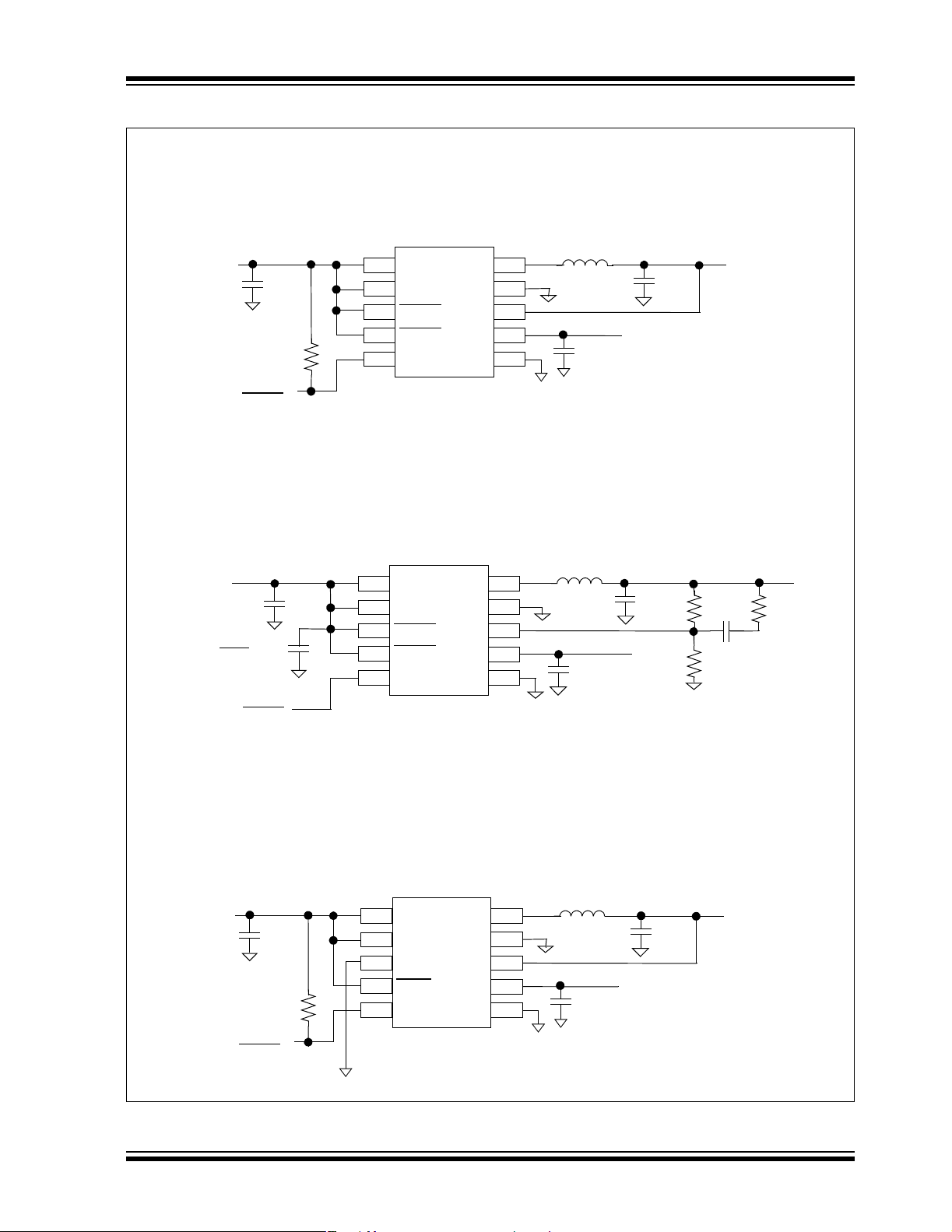

Typical Application Circuits

V

IN

2.7V to 4.2V

4.7 µF

R

PULLUP

Processor

RESET

TC1303A

Fixed-Output Application

10-Lead MS OP

8

2

7

1

V

IN1

V

IN2

SHDN1

PG

P

V

V

A

L

GND

OUT1

OUT2

GND

9

X

10

6

3SHDN2

54

TC1303B

Adjustable-Output Application

10-Lead DFN

4.7 µH

4.7 µF

1µF

V

OUT2

2.5V @ 300 mA

V

OUT1

1.5V @ 500 mA

4.5V to 5.5V

*Optional

Capacitor

V

IN2

2.7V to 4.2V

Input

Voltage

V

IN

1.0 µF

Processor

RESET

4.7 µF

R

PULLUP

Processor

RESET

4.7 µF

8

2

7

1

V

IN1

V

IN2

SHDN1

SHDN2

PG

V

V

P

GND

OUT1

OUT2

A

GND

9

L

X

10

6

3

54

(Note)

Note: Connect DFN package exposed pad to A

TC1304

Fixed-Output Application

10-Lead MSOP

V

8

IN1

V

2

IN2

A

7

GND

1

PG

P

V

V

A

GND

OUT1

OUT2

GND

L

9

X

10

6

3SHDN

54

4.7 µH

4.7 µF

1µF

4.7 µH

1µF

V

OUT2

3.3V @

300 mA

GND

4.7 µF

V

OUT2

2.5V @ 300 mA

200 kΩ 4.99 kΩ

33 pF

121 kΩ

.

V

OUT1

1.2V @ 500 mA

V

OUT1

2.1V @

500 mA

© 2005 Microchip Technology Inc. DS21949B-page 5

Page 6

TC1303A/TC1303B/TC1303C/TC1304

1.0 ELECTRICAL CHARACTERISTICS

† Notice: Stresses above those listed under “Maximum

Ratings” may cause permanent damage to the device. This is

a stress rating only and functional operation of the device at

those or any other conditions above those indicated in the

Absolute Maximum Ratings †

operational listings of this specification is not implied.

Exposure to maximum rating conditions fo r ext ended pe riods

V

- A

IN

All Other I/O .......................... .... (A

L

to P

X

P

GND

Output Short Circuit Current .................................Continuous

......................................................................6.0V

GND

........................ ...................... -0.3V to (V

GND

to A

...................................................-0.3V to +0.3V

GND

- 0.3V) to (V

GND

+ 0.3V)

IN

+ 0.3V)

IN

may affect device reliability.

Power Dissipation (Note 7) ..........................Internally Limited

Storage temperature.................................... .-65°C to +150°C

Ambient Temp. with Power Applied.................-40°C to +85°C

Operating Junction Tempe rature...................- 40°C to +125°C

ESD protection on all pins (HBM) ....................................... 3kV

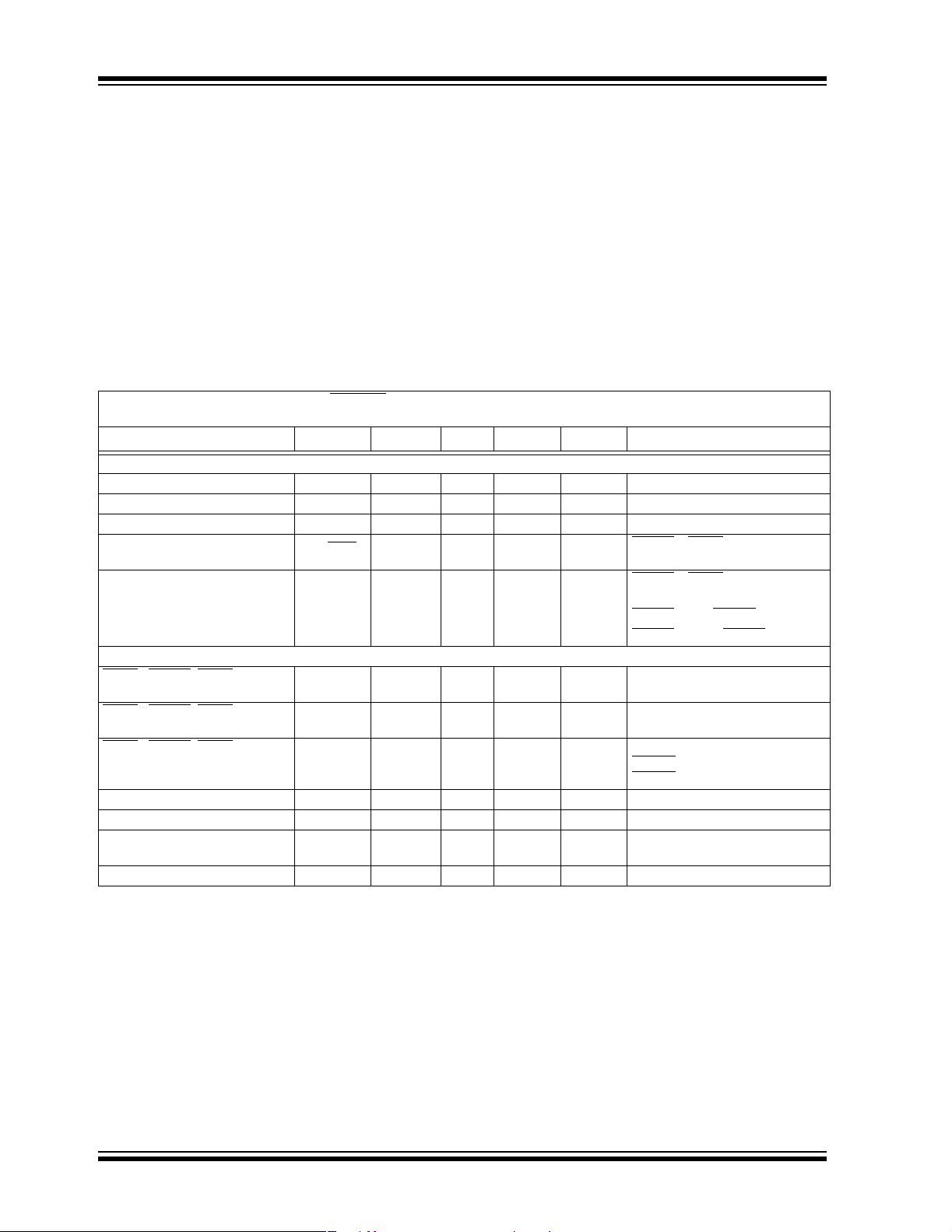

DC CHARACTERISTICS

Electrical Characteristics: V

= 100 ma, I

I

OUT1

OUT2

IN1=VIN2

= 0.1 mA TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C.

Parameters Sym Min Typ Max Units Conditions

Input/Output Characteristics

Input Voltage V

Maximum Output Current I

Maximum Output Current I

Shutdown Current

Combined V

IN1

and V

TC1303A,B Operating I

TC1303C, TC1304 Operating I

Synchronous Buck I

LDO I

Q

Current

IN2

Q

Q

Shutdown/UVLO/Thermal Shutdown Characteristics

SHDN

1,SHDN2, SHDN (TC1304)

Logic Input Voltage Low

SHDN

1,SHDN2, SHDN (TC1304)

Logic Input Voltage High

1,SHDN2, SHDN (TC1304)

SHDN

Input Leakage Current

Thermal Shutdown T

Thermal Shutdown Hysteresis T

Undervoltage Lockout

(V

OUT1

and V

OUT2

)

Undervoltage Lockout Hysteresis UVLO

Note 1: The Minimum V

2: V

3: TCV

is the regulator output voltage setting.

RX

OUT2

has to meet two conditions: VIN ≥ 2.7V and VIN ≥ VRX + V

IN

= ((V

OUT2max

4: Regulation is measured at a constant junction temperature using low duty-cycle pulse testing. Load regulation is tested

over a load range from 0.1 mA to the maximum specified output current.

5: Dropout voltage is defined as the input-to-output voltage differential at which the output voltage drops 2% below its

nominal value measured at a 1V differential.

6: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable junction

temperature and the thermal resistance from junction to air. (i.e. T

dissipation causes the device to initiate thermal shutdown.

7: The integrated MOSFET switches have an integral diode from the L

these diodes are forward-biased, the package power dissipation limits must be adhered to. Thermal protection is not

able to limit the junction temperature for these cases.

8: V

IN1

and V

are supplied by the same input source.

IN2

= SHDN1,2 =3.6V, C

IN

OUT1_MAX

OUT2_MAX

I

IN_SHDN

I

Q

Q

I

Q

OUT1=CIN

2.7 — 5.5 V Note 1, Note 2, Note 8

500 —— mANote 1

300 —— mANote 1

— 0.05 1 µA SHDN1 = SHDN2=GND

— 65.0

70.1

= 4 .7 µF, C

110

110

OUT2

— 38 — µA SHDN1 = VIN, SHDN2 = GND

— 46 — µA SHDN1 = GND, SHDN2 = V

V

IL

V

IH

I

IN

SHD

SHD-HYS

——15 %V

45 ——%VINV

-1.0 ±0.01 1.0 µA V

— 165 — °C Note 6, Note 7

—10— °C

UVLO 2.4 2.55 2.7 VV

– V

-

HYS

OUT2min

— 200 — mV

) * 106)/(V

OUT2

* DT).

, TJ, θJA). Exceeding the maximum allowable power

A

pin to VIN, and from LX to P

X

=1µF, L =4.7µH, V

OUT1

µA SHDN1 = SHDN2=V

I

=0mA, I

OUT1

V

IN

IN1=VIN2

IN1=VIN2

IN1=VIN2

SHDNX

SHDN

IN1

DROPOUT, VRX

Y =V

Falling

= VR1 or VR2.

OUT2

= 2.7V to 5.5V

= 2.7V to 5.5V

= 2.7V to 5.5V

=GND

IN

. In cases where

GND

(ADJ) = 1.8V,

IN2

=0mA

IN2

DS21949B-page 6 © 2005 Microchip Technology Inc.

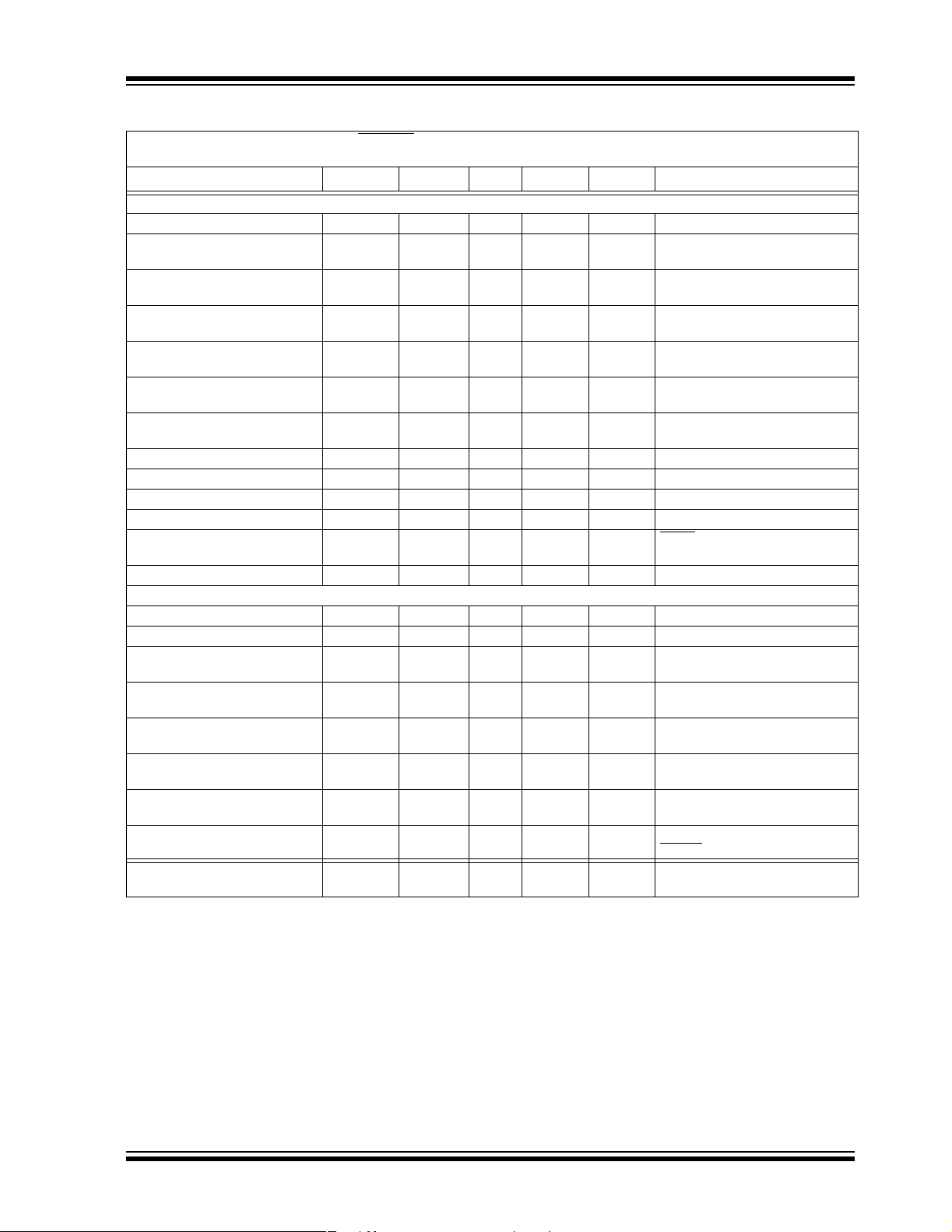

Page 7

TC1303A/TC1303B/TC1303C/TC1304

DC CHARACTERISTICS (CONTINUED)

Electrical Characteristics: V

= 100 ma, I

I

OUT1

OUT2

IN1=VIN2

= 0.1 mA TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C.

Parameters Sym Min Typ Max Units Conditions

Synchronous Buck Regulator (V

Adjustable Output Voltage Range V

Adjustable Reference Feedback

Voltage (V

FB1

)

Feedback Input Bias Current

)

(I

FB1

Output Voltage Tolerance Fixed

(V

)

OUT1

Line Regulation (V

Load Regulation (V

Dropout Voltage V

)V

OUT1

)V

OUT1

OUT1

Internal Oscillator Frequency F

Sta rt Up T ime T

R

P-Channel R

DSon

N-Channel R

R

DSon

Pin Leakage Current I

L

X

Positive Current Limit Threshold +I

LDO Output (V

Output Voltage Tolerance (V

OUT2

)

OUT2

Temperature Coefficient TCV

Line Regulation ΔV

Load Regulation, V

Load Regulation, V

Dropout Voltage V

≥ 2.5V ΔV

OUT2

< 2.5V ΔV

OUT2

> 2.5V VIN – V

OUT2

Power Supply Rejection Ratio PSRR — 62 — dB f ≤ 100 Hz, I

Output Noise eN — 1.8 — µV/(Hz)

Output Short Circuit Current

(Average)

Note 1: The Minimum V

2: V

3: TCV

is the regulator output voltage setting.

RX

OUT2

has to meet two conditions: VIN ≥ 2.7V and VIN ≥ VRX + V

IN

= ((V

OUT2max

4: Regulation is measured at a constant junction temperature using low duty-cycle pulse testing. Load regulation is tested

over a load range from 0.1 mA to the maximum specified output current.

5: Dropout voltage is defined as the input-to-output voltage differential at which the output voltage drops 2% below its

nominal value measured at a 1V differential.

6: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable junction

temperature and the thermal resistance from junction to air. (i.e. T

dissipation causes the device to initiate thermal shutdown.

7: The integrated MOSFET switches have an integral diode from the L

these diodes are forward-biased, the package power dissipation limits must be adhered to. Thermal protection is not

able to limit the junction temperature for these cases.

8: V

IN1

and V

are supplied by the same input source.

IN2

= SHDN1,2 =3.6V, C

)

OUT1

OUT1

V

FB1

I

VFB1

V

OUT1

LINE-REG

LOAD-REG

VIN – V

OUT1

OSC

SS

DSon-P

DSon-N

LX

LX(MAX)

)V

OUT2

OUT

/

OUT2

ΔV

IN

/

OUT2

I

OUT2

/

OUT2

I

OUT2

OUT2

I

OUTsc2

– V

OUT2min

OUT1=CIN

= 4 .7 µF, C

=1µF, L =4.7µH, V

OUT2

OUT1

0.8 — 4.5 V

0.78 0.8 0.82 V

— -1.5 — nA

-2.5 ±0.3 +2.5 % Note 2

—0.2— %/VV

—0.2— %V

=VR+1V to 5.5V,

IN

= 100 mA

I

LOAD

+1.5V, I

IN=VR

500 mA (Note 1)

— 280 — mV I

= 500 mA, V

OUT1

(Note 5)

1.6 2.0 2.4 MHz

—0.5— msT

= 10% to 90%

R

— 450 650 mΩ IP=100 mA

— 450 650 mΩ IN=100 mA

-1.0 ±0.01 1.0 μA SHDN = 0V, VIN = 5.5V, LX = 0V,

L

= 5.5V

X

— 700 — mA

-2.5 ±0.3 +2.5 % Note 2

— 25 — ppm/°C Note 3

-0.2 ±0.02 +0.2 %/V (VR+1V) ≤ VIN ≤ 5.5V

-0.75 -0.08 +0.75 %I

-0.9 -0.18 +0.9 %I

— 137

205

300

500

mV I

— 240 — mA R

DROPOUT, VRX

) * 106)/(V

OUT2

* DT).

, TJ, θJA). Exceeding the maximum allowable power

A

pin to VIN, and from LX to P

X

½

= 0.1 mA to 300 mA (Note 4)

OUT2

= 0.1 mA to 300 mA (Note 4)

OUT2

= 200 mA (Note 5)

OUT2

I

= 300 mA

OUT2

= I

OUT2

=GND

≤ 1Ω

OUT1

=50mA,

= 0 µF

C

IN

f ≤ 1 kHz, I

SHDN1

LOAD2

= VR1 or VR2.

. In cases where

GND

(ADJ) = 1.8V,

= 100 mA to

LOAD

=3.3V

OUT1

= 50 mA,

OUT2

© 2005 Microchip Technology Inc. DS21949B-page 7

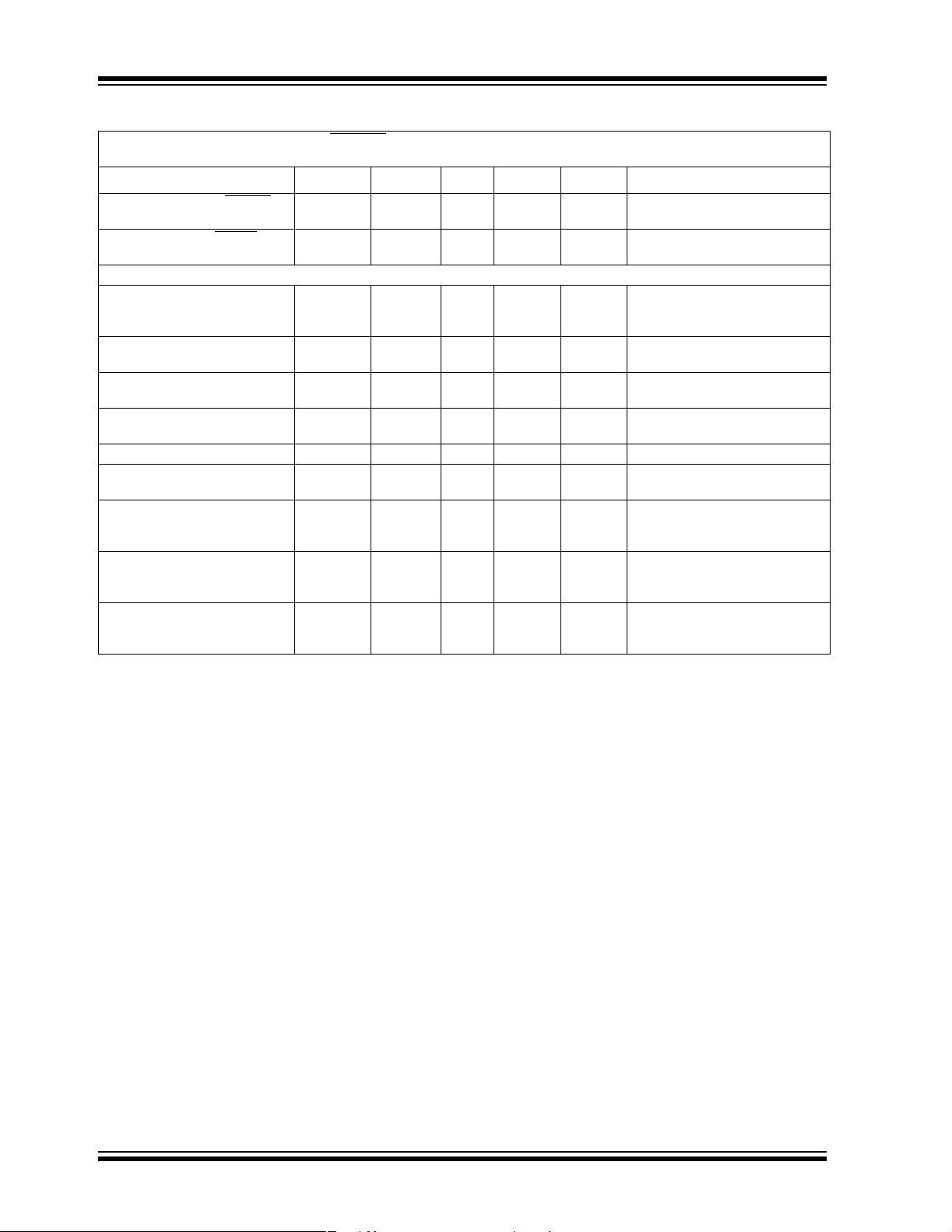

Page 8

TC1303A/TC1303B/TC1303C/TC1304

DC CHARACTERISTICS (CONTINUED)

Electrical Characteristics: V

= 100 ma, I

I

OUT1

OUT2

IN1=VIN2

= 0.1 mA TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C.

Parameters Sym Min Typ Max Units Conditions

Wake-Up Time (From SHDN2

mode), (V

Settling Time (From SHDN2

mode), (V

OUT2

OUT2

)

)

Power-Good (PG)

Voltage Range PG V

PG Threshold High

(V

OUT1

or V

OUT2

)

PG Threshold Low

(V

OUT1

or V

OUT2

)

PG Threshold Hysteresis

(V

OUT1

and V

OUT2

)

PG Threshold Tempco ΔVTH/ΔT — 30 — ppm/° C

PG Delay t

PG Active Time-out Period t

PG Output Voltage Low PG_V

PG Output Voltage High

(TC1303B only)

Note 1: The Minimum V

2: V

3: TCV

is the regulator output voltage setting.

RX

OUT2

has to meet two conditions: VIN ≥ 2.7V and VIN ≥ VRX + V

IN

= ((V

OUT2max

4: Regulation is measured at a constant junction temperature using low duty-cycle pulse testing. Load regulation is tested

over a load range from 0.1 mA to the maximum specified output current.

5: Dropout voltage is defined as the input-to-output voltage differential at which the output voltage drops 2% below its

nominal value measured at a 1V differential.

6: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable junction

temperature and the thermal resistance from junction to air. (i.e. T

dissipation causes the device to initiate thermal shutdown.

7: The integrated MOSFET switches have an integral diode from the L

these diodes are forward-biased, the package power dissipation limits must be adhered to. Thermal protection is not

able to limit the junction temperature for these cases.

8: V

IN1

and V

are supplied by the same input source.

IN2

= SHDN1,2 =3.6V, C

t

WK

t

S

PG

V

TH_H

V

TH_L

V

TH_HYS

RPD

RPU

OL

OH

) * 106)/(V

0.9* V

– V

PG_V

OUT2min

OUT1=CIN

= 4 .7 µF, C

— 31 100 µs I

— 100 — µs I

1.0

1.2

—5.5

5.5

—9496 % of

89 92 — % of

—2—% of

— 165 — µs V

=1µF, L =4.7µH, V

OUT2

OUT1

OUT1

VTA = 0°C to +70°C

= -40°C to +85°C

T

A

V

≤ 2.7 I

IN

On Rising V

V

OUTX

V

OUTX=VOUT1

On Falling V

V

V

OUTX

OUTX

V

OUTX=VOUT1

V

OUTX=VOUT1

OUT1

to (V

140 262 560 ms V

——0.2 VV

OUT2

—— VV

DROPOUT, VRX

* DT).

OUT2

, TJ, θJA). Exceeding the maximum allowable power

A

pin to VIN, and from LX to P

X

OUT1

to V

I

SINK

OUT1

IPG= 1.2 mA V

I

= 100 µA, 1.0V < V

PG

OUT1

V

OUT2

V

OUT2

OUT1

= I

= 50 mA

OUT2

= I

= 50 mA

OUT2

= 100 µA

SINK

OUT1

or V

OUT1

or V

or V

or V

- 100 mV)

TH

or V

TH +

OUT2

OUT2=VTH

100 mV,

=(V

= 1.2 mA

or V

OUT2=VTH

IN2

or V

OUT2=VTH

≥ 1.8V, IPG= - 500 µA

< 1.8V,IPG= - 300 µA

= VR1 or VR2.

. In cases where

GND

(ADJ) = 1.8V,

or V

OUT2

OUT2

or V

OUT2

OUT2

OUT2

+ 100 mV)

TH

- 100 mV

-100mV

>2.7V

< 2.7V

IN2

+ 100 mV

,

DS21949B-page 8 © 2005 Microchip Technology Inc.

Page 9

TC1303A/TC1303B/TC1303C/TC1304

TEMPERATURE SPECIFICATIONS

Electrical Specifications: Unless otherwise indicated, all limits are specified for: VIN = +2.7V to +5.5V

Parameters Sym Min Typ Max Units Conditions

Temperature Ranges

Operating Junction Temperature

Range

Storage Temperature Range T

Maximum Junction Temperature T

Thermal Package Resistances

Thermal Resistance, 10L-DFN θ

Thermal Resistance, 10L-MSOP θ

T

J

A

J

JA

JA

-40 — +125 °C Steady state

-65 — +150 °C

— — +150 °C Transient

— 41 — °C/W Typical 4-layer Board with

Internal Ground Plane and 2 Vias

in Thermal Pad

— 113 — °C/W Typical 4-layer Board with

Internal Ground Plane

© 2005 Microchip Technology Inc. DS21949B-page 9

Page 10

TC1303A/TC1303B/TC1303C/TC1304

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and t ables provided fol lowi ng this note are a st a t istic al summary based on a l im ite d n um ber of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated, V

(ADJ) = 1.8V, TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C. TA= +25°C. Adjustable- or fixed-

V

OUT1

output voltage options can be used to generate the Typical Performance Characteristics.

80

I

= I

= 0 mA SHDN1 = V

OUT1

OUT2

76

72

VIN = 5.5V

68

64

Switcher and LDO (µA)

Q

I

VIN = 3.6V

60

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ambient Temperature (°C)

FIGURE 2-1: IQ Switcher and LDO Current vs. Ambient Temperature (TC1303A,B).

78

SHDN1 = V

IN2

SHDN2 = V

76

74

72

70

68

Switcher and LDO (µA)

Q

I

66

-40 -25 -10 5 20 35 50 65 80 95 110 125

IN2

Ambient Temperature (°C)

IN1

VIN = 5.5V

VIN = 4.2V

VIN = 3.6V

= V

= SHDN1,2 = 3.6V, C

IN2

SHDN2 = V

VIN = 4.2V

OUT1=CIN

IN2

IN2

= 4.7 µF , C

55

I

= 0 mA

OUT2

50

45

40

LDO (µA)

Q

I

35

=1µF, L =4.7µH,

OUT2

VIN = 3.6V

VIN = 5.5V

VIN = 4.2V

SHDN1 = A

SHDN2 = V

30

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ambient Temperature (°C)

FIGURE 2-4: I

LDO Current vs. Ambient

Q

Temperature.

100

95

90

I

= 100 mA

85

80

75

70

Efficiency (%)

65

OUT1

60

V

55

OUT1

I

I

OUT1

OUT1

= 250 mA

= 500 mA

50

2.7 3.05 3.4 3.75 4.1 4.45 4.8 5.15 5.5

Input Voltage (V)

SHDN1 = V

SHDN2 = A

IN2

GND

GND

IN2

FIGURE 2-2: I

Switcher and LDO

Q

Current vs. Ambient Temperature

FIGURE 2-5: V

Input Voltage (V

OUT1

Output Efficiency vs.

OUT1

= 1.2V).

(TC1303C, TC1304).

SHDN1 = V

55

I

= 0 mA

OUT1

VIN = 5.5V

SHDN2 = A

IN2

GND

50

45

40

VIN = 4.2V

Switcher (µA)

Q

I

35

VIN = 3.6V

30

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ambient Temperature (°C)

FIGURE 2-3: I

Switcher Current vs.

Q

Ambient Temperature.

DS21949B-page 10 © 2005 Microchip Technology Inc.

100

95

90

85

Efficiency(%)

80

OUT1

V

75

V

IN1

= 4.2V

70

0.005 0.104 0.203 0.302 0.401 0.5

FIGURE 2-6: V

I

OUT1

(V

OUT1

= 1.2V).

SHDN1 = V

SHDN2 = A

V

IN1

V

= 3.0V

IN1

(A)

I

OUT1

Output Efficiency vs.

OUT1

= 3.6V

IN2

GND

Page 11

TC1303A/TC1303B/TC1303C/TC1304

Note: Unless otherwise indicated, V

V

(ADJ) = 1.8V, TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C. TA= +25°C. Adjustable- or fixed-

OUT1

IN1

= V

= SHDN1,2 = 3.6V, C

IN2

OUT1=CIN

= 4.7 µF , C

=1µF, L =4.7µH,

OUT2

output voltage options can be used to generate the Typical Performance Characteristics.

V

100

95

I

= 100 mA

OUT1

90

I

OUT1

= 250 mA

85

80

75

Efficiency(%)

70

OUT1

V

65

60

2.7 3.05 3.4 3.75 4.1 4.45 4.8 5.15 5.5

FIGURE 2-7: V

Input Voltage (V

100

95

90

85

Efficiency(%)

OUT1

80

V

75

0.005 0.104 0.203 0.302 0.401 0.5

OUT1

VIN = 3.0V

SHDN1 = V

SHDN2 = A

I

= 500 mA

OUT1

Input Voltage (V)

Output Efficiency vs.

OUT1

= 1.8V).

SHDN1 = V

SHDN2 = A

VIN = 3.6V

I

(A)

OUT1

IN2

GND

VIN = 4.2V

IN2

GND

100

Efficiency (%)

OUT1

V

FIGURE 2-10: V

I

(V

OUT1

1.206

1.202

(V)

OUT1

1.198

V

1.194

= 3.6V

IN1

95

90

85

80

75

V

= 4.2V

IN1

V

= 5.5V

IN1

SHDN1 = V

SHDN2 = A

70

65

60

0.005 0.104 0.203 0.302 0.401 0.5

I

(A)

OUT1

Output Efficiency vs.

OUT1

V

IN1

= 3.6V

SHDN1 = V

SHDN2 = A

OUT1

1.21

= 3.3V).

1.19

0.005 0.104 0.203 0.302 0.401 0.5

I

(A)

OUT1

IN2

GND

IN2

GND

FIGURE 2-8: V

I

OUT1

(V

OUT1

= 1.8V).

100

I

= 100 mA

96

92

88

Efficiency (%)

OUT1

84

V

OUT1

I

OUT1

= 250 mA

80

3.60 3.92 4.23 4.55 4.87 5.18 5.50

FIGURE 2-9: V

Input Voltage (V

OUT1

Output Efficiency vs.

OUT1

SHDN1 = V

SHDN2 = A

I

= 500 mA

OUT1

Input Voltage (V)

Output Efficiency vs.

OUT1

= 3.3V).

IN2

GND

FIGURE 2-11: V

(V

OUT1

(V)

OUT1

V

= 1.2V).

1.82

1.815

1.81

1.805

1.8

1.795

1.79

0.005 0.104 0.203 0.302 0.401 0.5

FIGURE 2-12: V

(V

OUT1

= 1.8V).

OUT1

V

= 3.6V

IN1

OUT1

I

OUT1

vs. I

(A)

vs. I

OUT1

SHDN1 = V

SHDN2 = A

OUT1

IN2

GND

© 2005 Microchip Technology Inc. DS21949B-page 11

Page 12

TC1303A/TC1303B/TC1303C/TC1304

= V

Note: Unless otherwise indicated, V

V

(ADJ) = 1.8V, TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C. TA= +25°C. Adjustable- or fixed-

OUT1

IN1

= SHDN1,2 = 3.6V, C

IN2

OUT1=CIN

output voltage options can be used to generate the Typical Performance Characteristics.

= 4.7 µF , C

=1µF, L =4.7µH,

OUT2

3.4

3.36

3.32

(V)

OUT1

3.28

V

3.24

3.2

0.005 0.104 0.203 0.302 0.401 0.5

FIGURE 2-13: V

(V

= 3.3V).

OUT1

2.20

2.15

2.10

2.05

2.00

Frequency (MHz)

OUT1

1.95

V

1.90

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

V

= 4.2V

IN1

I

(A)

OUT1

vs. I

OUT1

OUT1

Input Voltage (V)

SHDN1 = V

SHDN2 = A

SHDN1 = V

SHDN2 = A

IN2

GND

IN2

GND

0.820

0.815

0.810

V

IN1

= 3.6V

0.805

FB Voltage (V)

0.800

OUT1

V

0.795

0.790

-40

-25

5

2035506580

-10

Ambient Temperature (°C)

FIGURE 2-16: V

Adjustable Feedback

OUT1

Voltage vs. Ambient Temperature.

0.6

)

"

0.55

TA = 25 °C

0.5

0.45

0.4

Switch Resistance (

0.35

OUT1

V

0.3

3.3 3.5 3.7 3.9 4.1 4.3 4.5 4.7 4.9 5.1 5.3 5.5

Input Voltage (V)

SHDN1 = V

SHDN2 = A

SHDN1 = V

SHDN2 = A

95

IN2

GND

N-Channel

P-Channel

IN2

GND

110

125

FIGURE 2-14: V

OUT1

vs. Input Voltage.

2.00

1.98

1.96

1.94

Frequency (MHz)

1.92

OUT1

V

1.90

-40

-25

-10

5

203550

Ambient Temperature (°C)

FIGURE 2-15: V

OUT1

vs. Ambient Temperature.

Switching Frequency

SHDN1 = V

SHDN2 = A

65

IN2

GND

80

95

110

125

Switching Frequency

FIGURE 2-17: V

OUT1

vs. Input Voltage.

0.65

)

"

0.55

0.45

Switch Resistance (

0.35

OUT1

V

0.6

0.5

0.4

0.3

V

= 3.6V

IN1

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ambient Temperature (°C)

FIGURE 2-18: V

OUT1

vs. Ambient Temperature.

Switch Resist ance

SHDN1 = V

SHDN2 = A

P-Channel

IN2

GND

N-Channel

Switch Resist ance

DS21949B-page 12 © 2005 Microchip Technology Inc.

Page 13

TC1303A/TC1303B/TC1303C/TC1304

= 3.3V

= - 40°C

= + 25°C

= + 85°C

= - 40°C

= + 25°C

= + 85°C

= - 40°C

= + 25°C

= + 85°C

Note: Unless otherwise indicated, V

V

(ADJ) = 1.8V, TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C. TA= +25°C. Adjustable- or fixed-

OUT1

IN1

= V

= SHDN1,2 = 3.6V, C

IN2

OUT1=CIN

= 4.7 µF , C

=1µF, L =4.7µH,

OUT2

output voltage options can be used to generate the Typical Performance Characteristics.

I

= 150 mA

0.4

SHDN1 = V

IN2

0.35

SHDN2 = A

GND

0.3

0.25

0.2

Dropout Voltage (V)

0.15

OUT1

V

0.1

-40

-25

-10

5

Ambient Temperature (°C)

FIGURE 2-19: V

Ambient Temperature.

I

OUT1

20

355065

Dropout Voltage vs.

OUT1

80

V

OUT1

= 500 mA

95

110

125

1.492

1.49

1.488

1.486

Output Voltage(V)

1.484

OUT2

V

1.482

FIGURE 2-22: V

Input Voltage (V

1.802

1.800

1.798

1.796

Output Voltage (V)

1.794

OUT2

V

1.792

OUT2

T

A

T

A

T

A

2.73.053.43.754.14.454.85.155.5

Input Voltage (V)

Output Voltage vs.

OUT2

= 1.5V).

OUT2

I

= 150 mA SHDN1 = A

OUT2

T

A

T

A

T

A

SHDN1 = A

SHDN2 = V

SHDN2 = V

2.7 3.05 3.4 3.75 4.1 4.45 4.8 5.15 5.5

Input Voltage (V)

GND

IN2

GND

IN2

FIGURE 2-20: V

OUT1

and V

OUT2

Load Switching Waveforms vs. Time.

FIGURE 2-21: V

OUT1

and V

OUT2

Load Switching Waveforms vs. Time.

Heavy

Light

FIGURE 2-23: V

Input Voltage (V

2.508

2.506

2.504

2.502

2.500

Output Voltage (V)

2.498

OUT2

V

2.496

OUT2

I

= 150 mA

OUT2

3.3 3.5 3.7 3.9 4.1 4.3 4.5 4.7 4.9 5.1 5.3 5.5

FIGURE 2-24: V

Input Voltage (V

OUT2

Output Voltage vs.

OUT2

= 1.8V).

T

A

T

A

T

A

Input Voltage (V)

Output Voltage vs.

OUT2

= 2.5V).

SHDN1 = A

SHDN2 = V

GND

IN2

© 2005 Microchip Technology Inc. DS21949B-page 13

Page 14

TC1303A/TC1303B/TC1303C/TC1304

= - 40°C

= + 25°C

= + 85°C

= 3.3V

= 2.5V

= 1.5V

= 3.3V

= 2.6V

= 1.5V

= V

Note: Unless otherwise indicated, V

V

(ADJ) = 1.8V, TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C. TA= +25°C. Adjustable- or fixed-

OUT1

IN1

= SHDN1,2 = 3.6V, C

IN2

OUT1=CIN

output voltage options can be used to generate the Typical Performance Characteristics.

= 4.7 µF , C

=1µF, L =4.7µH,

OUT2

3.298

I

= 150 mA

OUT2

3.297

3.296

3.295

3.294

Output Voltage (V)

3.293

OUT2

V

3.292

3.60 3.92 4.23 4.55 4.87 5.18 5.50

FIGURE 2-25: V

Input Voltage (V

0.30

0.25

0.20

0.15

Dropout Voltage (V)

0.10

OUT2

V

0.05

-40

OUT2

I

OUT2

I

OUT2

-25

-10

Ambient Temperature (°C)

T

A

T

A

T

A

Input Voltage (V)

Output Voltage vs.

OUT2

= 3.3V).

= 300 mA

= 200 mA

5

203550

SHDN1 = A

SHDN2 = V

SHDN1 = A

SHDN2 = V

658095

GND

IN2

0.005

0.000

-0.005

-0.010

-0.015

SHDN1 = A

V

OUT2

SHDN2 = V

V

OUT2

GND

IN2

I

= 100 µA

OUT2

-0.020

-0.025

Line Regulation (%/V)

-0.030

OUT2

V

-0.035

-40 -25 -10 5 20 35 50 65 80 95 110 125

V

OUT2

Ambient Temperature (°C)

FIGURE 2-28: V

Line Regulation vs.

OUT2

Ambient Temperature.

0.1

V

= 3.6V SHDN1 = A

0.0

IN2

V

OUT2

SHDN2 = V

GND

IN2

-0.1

-0.2

Load Regulation (%)

-0.3

OUT2

V

-0.4

-40

-25

110

125

-10

V

OUT2

5

20

35

50

65

Ambient Temperature (° C)

GND

IN2

V

OUT2

80

95

110

125

FIGURE 2-26: V

OUT2

Ambient Temperature (V

0.3

0.2

0.1

Dropout Voltage (V)

OUT2

V

0.0

I

OUT2

I

OUT2

= 300 mA

= 200 mA

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ambient Temperature (°C)

FIGURE 2-27: V

OUT2

Ambient Temperature (V

Dropout Voltage vs.

= 2.5V).

OUT2

SHDN1 = A

SHDN2 = V

Dropout Voltage vs.

= 3.3V).

OUT2

GND

IN2

FIGURE 2-29: V

Load Regulation vs.

OUT2

Ambient Temperature.

350

325

300

275

250

225

PG Active Delay Time (ms)

200

-40 -25 -10 5 20 35 50 65 80 95 110 125

VIN = 3.6V

SHDN1 = V

SHDN2 = V

Ambient temperature (°C)

IN2

IN2

FIGURE 2-30: PG Active Delay Time-out vs. Ambient Temperature.

DS21949B-page 14 © 2005 Microchip Technology Inc.

Page 15

TC1303A/TC1303B/TC1303C/TC1304

Note: Unless otherwise indicated, V

V

(ADJ) = 1.8V, TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C. TA= +25°C. Adjustable- or fixed-

OUT1

IN1

= V

= SHDN1,2 = 3.6V, C

IN2

OUT1=CIN

= 4.7 µF , C

=1µF, L =4.7µH,

OUT2

output voltage options can be used to generate the Typical Performance Characteristics.

96

)

VIN = 3.6V

OUT2

95

94

PG Threshold Hi

SHDN1 = V

SHDN2 = V

IN2

IN2

93

92

PG Threshold Low

91

PG Threshold (% of V

90

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ambient Temperature (°C)

FIGURE 2-31: PG Threshold Voltage vs. Ambient Temperature.

(V)

OL

PG V

0.02

0.018

0.016

0.014

0.012

0.01

VIN = 3.6V

IOL = 1.2 mA

-25

-10

5

-40

Ambient Temperature (°C)

203550

SHDN1 = V

SHDN2 = V

658095

IN2

IN2

110

FIGURE 2-34: V

Rejection vs. Frequency.

125

0

SHDN1 = GND

-10

-20

-30

-40

PSRR (dB)

-50

OUT2

-60

V

V

I

C

OUT2

OUT2

= 0 µF

IN

= 1.5V

= 30 mA

C

OUT2

C

= 1.0 µF

= 4.7 µF

OUT2

-70

-80

0.01 0.1 1 10 100 1000

Frequency (kHz)

Power Supply Ripple

OUT2

10

SHDN1 = A

SHDN2 = V

Hz)

1

Noise (μV/

0.1

VIN = 3.6V

OUT2

V

I

OUT2

OUT2

= 2.5V

= 50 mA

V

0.01

0.01 0.1 1 10 100 1000 10000

Frequency (kHz)

GND

IN2

FIGURE 2-32: PG Output Voltage Level

FIGURE 2-35: V

Noise vs. Frequency.

OUT2

Low vs. Ambient Temperature.

V

= 2.8V

3.0

2.5

2.0

(V)

OH

1.5

PG V

1.0

VIN = 3.6V

0.5

= 500 µA

I

OH

0.0

-40 -25 -10 5 20 35 50 65 80 95 110 125

FIGURE 2-33: PG Output Voltage Level High vs. Ambient Temperature.

OUT2

V

= 2.5V

OUT2

V

= 1.5V

OUT2

Ambient Temperature (°C)

SHDN1 = V

SHDN2 = V

IN2

IN2

FIGURE 2-36: V

Load Step Response

OUT1

vs. Time.

© 2005 Microchip Technology Inc. DS21949B-page 15

Page 16

TC1303A/TC1303B/TC1303C/TC1304

= V

Note: Unless otherwise indicated, V

V

(ADJ) = 1.8V, TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C. TA= +25°C. Adjustable- or fixed-

OUT1

output voltage options can be used to generate the Typical Performance Characteristics.

IN1

= SHDN1,2 = 3.6V, C

IN2

OUT1=CIN

= 4.7 µF , C

=1µF, L =4.7µH,

OUT2

FIGURE 2-37: V

vs. Time.

FIGURE 2-38: V

Response vs. Time.

Load Step Response

OUT2

and V

OUT1

OUT2

Line Step

FIGURE 2-40: V

OUT1

and V

OUT2

Shutdown

Waveforms.

FIGURE 2-41: Power-Good Output Timing.

FIGURE 2-39: V

OUT1

and V

OUT2

Start-up

Waveforms.

DS21949B-page 16 © 2005 Microchip Technology Inc.

FIGURE 2-42: Start-up Waveforms (TC1304).

Page 17

TC1303A/TC1303B/TC1303C/TC1304

Note: Unless otherwise indicated, V

V

(ADJ) = 1.8V, TA= +25°C. Boldface specifications apply over the TA range of -40°C to +85°C. TA= +25°C. Adjustable- or fixed-

OUT1

output voltage options can be used to generate the Typical Performance Characteristics.

IN1

= V

= SHDN1,2 = 3.6V, C

IN2

OUT1=CIN

= 4.7 µF , C

=1µF, L =4.7µH,

OUT2

FIGURE 2-43: Shutdown Waveforms (TC1304).

© 2005 Microchip Technology Inc. DS21949B-page 17

Page 18

TC1303A/TC1303B/TC1303C/TC1304

3.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

Pin No.

TC1303

Name

1 SHDN2

1 — SHDN

TC1304

Name

Function

— Active Low Shutdown Input for LDO Output Pin

Active Low Shutdown Input both Buck Regulator Output and LDO Output.

Initiates sequencing up and down

2V

3V

IN2

OUT2

V

V

IN2

OUT2

Analog Input Supply Voltage Pin

LDO Output Voltage Pin

4 PG PG Power-Good Output Pin

5A

6V

GND

FB/VOUT1VFB/VOUT1

A

GND

Analog Ground Pin

Buck Feedback Voltage (Adjustable Version) / Buck Output Voltage

(Fixed Version) Pin

7 SHDN1 — Active Low Shutdown Input for Buck Regulator Output Pin

7—A

8V

9L

10 P

IN1

X

GND

EP Exposed

Pad

GND

V

IN1

L

P

GND

Exposed

Pad

3.1 TC1303 LDO Shutdown Input Pin

(SHDN2

SHDN2 is a logic-level input us ed to turn the LDO Regulator on and off. A logic-high (> 45% of V

enable the regulator output. A logic-low (< 15% of V

will ensure that the output is turned off.

)

3.2 TC1304 Shutdown Input Pin

(SHDN

SHDN is a logic-level inp ut used to initia te the sequencing of the LDO output, then the buck regulator output.

A logic-high (> 45% of V

outputs. A logic-low (< 15% of V

outputs are turned off.

)

), will enable the regulator

IN

IN

3.3 LDO Input Voltage Pin (V

V

is a LDO power input su pply pin. C onnect vari able

IN2

input voltage source to V

. Connect V

IN2

together with board traces as short as possible. V

provides the input voltage for the LDO. An additional

capacitor can be added to lower the LDO regulator

input ripple voltage.

3.4 LDO Output Voltage Pin (V

V

is a regulated LDO output voltage pin. Connect

OUT2

a 1 µF or larger capacitor to V

OUT2

and A

Analog Ground Pin

Buck Regulator Input Voltage Pin

Buck Inductor Output Pin

X

Power Ground Pin

For the DFN p ackage, the c enter expos ed p ad i s a t hermal p ath to remove

heat from the device. Elect rically thi s pad is at ground po tential and sh ould

be connected to A

GND

3.5 Power-Good Output Pin (PG)

PG is an output level indicating that V

within 94% of regulation. The PG output is configured

), will

IN

)

IN

as a push-pull for the TC1303B and open-drain output

for the TC1303A, TC1303C and TC1304.

3.6 Analog Ground Pin (A

A

is the analog ground connection. Tie A

GND

analog portion of the ground plane (A

physical layout information in Section 5.0 “Application

Circuits/Issues” for grounding recommendations.

3.7 Buck Regulator Output Sense Pin

) will ensure that the

)

IN2

and V

IN1

IN2

IN2

For V

the center of the output voltage divider to the V

For fixed-output voltage options, connect the output of

the buck regulator to this pin (V

3.8 Buck Regulator Shutdown Input

(V

FB/VOUT1

adjustable-output voltage options, connect

OUT1

Pin (SHDN1

SHDN1 is a logic-level input used to turn the buck

OUT2

for proper

GND

)

regulator on and off. A logic-high (> 45% of V

enable the regulator output. A logic-low (< 15% of V

will ensure that the output is turned off.

operation.

(LDO) is

OUT2

)

GND

to the

GND

). See the

GND

)

pin.

FB

).

OUT1

)

), will

IN

)

IN

DS21949B-page 18 © 2005 Microchip Technology Inc.

Page 19

TC1303A/TC1303B/TC1303C/TC1304

3.9 Buck Regulator Input Voltage Pin

(V

)

IN1

V

is the buck regulator power input supply pin.

IN1

Connect a variable input voltage source to V

Connect V

short as possible.

IN1

and V

together with board traces as

IN2

IN1

3.10 Buck Inductor Output Pin (LX)

Connect LX directly to the buck inductor. This pin

carries large signal-level current; all connections

should be made as short as possible.

3.1 1 Power Ground Pin (P

Connect all large-signal level ground returns to P

These large-signal, level ground traces should have a

.

small loop area and length to prevent coupling of

switching noise to sensitive traces. Please see the

physical layout information supplied in Section 5.0

“Application Circuits/Issues” for grounding

recommendation s.

GND

)

.

GND

3.12 Exposed Pad (EP)

For the DFN package, connect the EP to A

vias into the A

GND

plane.

GND

, with

© 2005 Microchip Technology Inc. DS21949B-page 19

Page 20

TC1303A/TC1303B/TC1303C/TC1304

4.0 DETAILED DESCRIPTION

4.1 Device Overview

The TC1303/TC1304 combines a 500 mA synchronous buck regulator with a 300mA LDO and a powergood output. This uniq ue combination provi des a small,

low-cost solution for applications that require two or

more voltage ra ils. The buck re gulator c an deliv er highoutput current over a wide range of input-to-output

voltage ratios while maintaining high efficiency. This is

typically used for the lower-voltage, high-current

processor core. The LDO is a minimal parts-count

solution (single-output capacitor), providing a regulated

voltage for an auxiliary rail. The typical LDO dropout

voltage (137 mV @ 200 mA) allows the use of very low

input-to-output LDO differential voltages, minimizing

the power loss internal to the LDO pass transistor. A

power-good output i s prov ided, indicati ng tha t th e buck

regulator output, the LDO output or both outputs are in

regulation. Additional features include independent

shutdown inputs (TC1303), UVLO, output voltage

sequencing (TC1304), overcurrent and

overtemperature shutdown.

4.2 Synchronous Buck Regulator

The synchro nous buc k regulat or is capab le of su pplying a 500 mA continuous output current over a wide

range of input and output voltages. The output voltage

range is from 0.8V (min) to 4.5V (max). The regulator

operates in three d ifferen t modes, a utomatic ally se lecting the most efficient mode of operation. During heavy

load conditions, the TC1303/TC1304 buck converter

operates at a high, fixed frequency (2.0 MHz) using

current mode control. This mi nim iz es outp ut ripp le and

noise (less than 8 mV peak-to-peak ripple) while mai ntaining high efficiency (typically > 90%). For st a ndby or

light load applications, the buck regulator will automatically switch to a power-saving Pulse Frequency

Modulation (PFM) mod e. T his m in im ize s the quiescent

current draw on the battery, while keeping the buck

output voltage in regulation. The typical buck PFM

mode current is 38 µA. The buck regulator is capable of

operating at 100% duty cycle, minimizing the voltage

drop from input-to-output for wide input, batterypowered applications. For fixed -outpu t volta ge applic ations, the feedba ck d ivide r and c ontrol loop compe nsation components are integrated, eliminating the need

for external components. The buck regulator output is

protected ag ainst overcurrent, sh ort circuit and overtemperature. While shut down, the synchronous buck

N-channel and P-channel switches are off, so the L

pin is in a high-impedance state (this allows for

connecting a source on th e output of the b uck regulator

as long as its voltage does not exceed the input

voltage).

4.2.1 FIXED-FREQUENCY PWM MODE

While operating in Pulse Width Modulation (PWM)

mode, the TC1303/TC1304 buck regulator switches at

a fixed, 2.0 MHz frequency. The PWM mode is suited

for higher load current operation, maintaining low output noise and high conv ersion ef ficie ncy. PFM-to-PWM

mode transition is initiated for any of the following

conditions:

• Continuous inductor current is sensed

• Inductor peak current excee ds 100mA

• The buck regulator output voltage has dropped

out of regulation (step load has occurred)

The typical PFM-to-PWM threshold is 80 mA.

4.2.2 PFM MODE

PFM mode is entered w hen the out put load on th e buck

regulator is very light. Once detected, the converter

enters the PFM mode automatically and begins to skip

pulses to minimize unnecessary quiescent current

draw by reducing the number of switching cycles per

second. The typical quiescent current for the switching

regulator is less than 35 µA. The transition from PWM

to PFM mode occurs when discontinuous inductor

current is sensed or the peak inductor current is less

than 60 mA (typ.). The typical PWM to PFM mode

threshold is 30 mA. For low input-to-output differential

voltages, the PWM-to-PF M mode th reshol d can be low

due to the lack of ripple current. I t is reco mmended that

be one volt greater than V

V

IN1

transitions.

for PWM-to-PFM

OUT1

4.3 Low Drop Out Regulator (LDO)

The LDO output is a 300 mA low-dropout linear regulator that provides a regulated output voltage with a

single 1 µF external capacitor. The output voltage is

available in fixed options only, ranging from 1.5V to

3.3V. The LDO is stable using ceramic output capaci-

tors that inherently provide lower output noise and

reduce the size and cost of the regulator solution. The

quiescent current consumed by the LDO output is

typically less than 40 µA, with a typical dropout voltage

of 137 mV at 200 mA. While operating in Dropout

mode, the LDO quiescent current will increase, minimizing the necessa ry voltage dif ferential nee ded for the

LDO output to maintain regulation. The LDO output is

protected against overcurrent and overtemperature

conditions.

X

DS21949B-page 20 © 2005 Microchip Technology Inc.

Page 21

TC1303A/TC1303B/TC1303C/TC1304

4.4 Power-Good

A Power-Good (PG) output signal is generated based

off of the buck regulator output voltage (V

LDO output voltage (V

) or the combination of both

OUT2

outputs. A fixed delay time of approximately 262 ms is

generated once the monitored output voltage is above

the power-good thresh old (ty pic al ly 94% of V

the monitored output voltage falls out of reg ul atio n, th e

falling PG threshold is typically 92% of the output

voltage. The PG outpu t sign al is pull ed up to th e outp ut

voltage, indicating that power is good and pulled low,

indicating that the output is out of regulation. The typical quiescent current draw for power-good circuitry is

less than 10 µA.

If the monitored output voltage falls below the powergood threshold, the power-good ou tput will transition to

the Low state. The power-g ood circui try has a 16 5 µs

delay when detecting a falling output voltage. This

helps to in crease the noise imm unity of th e power-good

output, avoiding fals e triggerin g of the PG signal d uring

line and load transients.

V

TH_H

V

OUT1

or V

OUT2

t

RPU

V

OH

t

RPD

OUT1

OUTX

), the

). As

4.5 Power Good Output Options

There are three monitoring options for the TC1303

family.

For the TC1303A, only the buck regulator output

voltage (V

depends only on V

For the TC1303B, only the LDO ou tput volt age (V

is monitored. The PG output signal depends only on

.

V

OUT2

For the TC1303C and TC1304, both the buck regu lator

output voltage and LDO output voltage are monitored.

If either one of the output s fa ll out of regulati on, the PG

will be low . On ly if b oth V

PG voltage threshold limits will the PG output be high.

For the TC1303A,C and TC1304, the PG output pin is

open drain and can be pu ll ed up to any level within th e

given absolute maximum ratings (A

+ 0.3V).

TABLE 4-1: PG AVAILABLE OPTIONS

Part

Number

TC1303A Yes No Open-Drain

TC1303B No Yes Push-Pull

TC1303C Yes Yes Open-Drain

TC1304 Yes Yes Open-Drain

) is monitored. The PG output signal

OUT1

PG Output

(V

OUT1

Buck

OUT1

.

)

OUT1

and V

PG

Output

LDO

(V

OUT2

are within the

OUT2

- 0.3V) to (V

GND

PG Output

)

Type

(V

OUT2

OUT2

)

)

IN

PG

FIGURE 4-1: Power-Good Timing.

V

OL

© 2005 Microchip Technology Inc. DS21949B-page 21

Page 22

TC1303A/TC1303B/TC1303C/TC1304

4.6 TC1304 Sequencing

The TC1304 devic e fe atu r es an integrated sequen cin g

option. A sequencing circ uit using only the SHDN

(Pin1), will turn on the LDO output (V

SHDN

* 160 µ s delay on trailing edge

OUT2

FIGURE 4-2: TC1304 Sequencing Circuit.

TC1304

Power Up Timing From SHDN

V

IN1/VIN2

input,

) and delay

V

OUT2

Enable

V

OUT1

Enable

the turn on of the Buck Regulator output (V

the LDO output is in regulation. During power-down,

the sequencing circuit will turn off the Buck Regulator

output prior to turning off LDO output.

160 µs Delay*

To PG

Delay CKT.

160 µs Delay*

92% of V

92% of V

+

–

OUT2

+

–

OUT1

4.7 Soft Start

Both outputs of the TC1303/TC1304 are controlled

during start-up. Less than 1% of V

shoot is observed du ring s tart-up f rom V

the UVLO voltage or either S

HDN1 or SHDN2 being

enabled.

OUT1

or V

rising above

IN

OUT1

OUT2

) until

over-

SHDN

500 µs

V

OUT1

+ t

t

WK

S

V

OUT2

300ms

Power Good

FIGURE 4-3: TC1304 Power-up Timing

from SHDN

.

4.8 Overtemperature Protection

The TC1303/TC1304 has an integrated overtemperature protection circuit that monitors the device junction

temperature and shuts the device off if the junction temperature exceeds the typical 165°C threshold. If the

overtemperature threshold is reached, the soft start is

reset so that, once the junction temperature cools to

approximately 155°C, the device will automatically

restart.

DS21949B-page 22 © 2005 Microchip Technology Inc.

Page 23

TC1303A/TC1303B/TC1303C/TC1304

5.0 APPLICATION CIRCUITS/ISSUES

5.1 Typical Applications

The TC1303/TC1304 50 0 mA buck regulator + 300 mA

LDO with power-good operates over a wide input voltage range (2. 7 V t o 5. 5 V) a nd i s i d ea l f or s i ng le - c el l LiIon battery-powered applications, USB-powered applications, three-cell NiMH or NiC d applications an d 3V to

5V regulated input appl icatio ns. The 10-pin MSOP and

3X3 DFN packages provide a small footprint with

minimal external components.

5.2 Fixed Output Application

A typical V

shown in “Typical Application Circuits”. A 4.7 µF

ceramic input capacitor, 4.7 µF V

V

IN1

capacitor, 1.0 µF ceramic V

inductor make up the entire external component solution for this dual-output application. No external dividers or compensation components are necessary. For

this application, the in put volta ge range is 2.7V to 4.2V,

= 1.5V at 500 mA, while V

V

OUT1

300 mA.

5.3 Adjustable Output Application

A typical V

shown in “Typical Application Circuits”. For this

application, the buck reg ulator ou tput vol tage is adjus table by using two external resistors as a voltage

divider. For adjustable-output voltages, it is recommended that the top resistor divider value be 200 k

The bottom resistor divider can be calculated using the

following formula:

EQUATION 5-1:

fixed-output voltage application is

OUT1

capacitor and 4.7 µH

OUT2

adjustable output application is also

OUT1

V

⎛⎞

R

BOTRTOP

--------------------------------

×=

⎝⎠

V

OUT1VFB

OUT1

OUT2

FB

–

ceramic

=2.5V at

Ω.

An additional V

capacitor can be added to reduce

IN2

high-frequency noise on the LDO input voltage pin

(V

). This additional cap aci tor (1 µF on page 5) is not

IN2

necessary for typical applications.

5.4 Input and Output Capacitor Selection

As with all buck-derived dc-dc s witching re gulators , the

input current is pulled from the source in pulses. This

places a burden on the TC1303/TC1304 input filter

capacitor. In most applications, a minimum of 4.7 µF is

recommended on V

pin). In applications that have high source impedance,

or have long leads, (10 inches) connecting to the input

source, additional capacitance should be used. The

capacitor type can b e ele ctrolytic (aluminum, t a ntalum,

POSCAP, OSCON) or ceramic. For most portable electronic applications, ceramic capacitors are preferred

due to their small size and low cost.

For applications tha t requir e very low noise on the LDO

output, an additional capacitor (typically 1 µF) can be

added to the V

IN2

Low ESR electrolytic or ceramic can be used for the

buck regulator output capacitor. Again, ceramic is

recommended because of its physical attributes and

cost. For most applications , a 4.7 µF is recommended.

Refer to Table 5-1 for recommended values. Larger

capacitors (up to 22 µF) can be used. There are some

advantages in load step performance when using

larger value capacitors. Ceramic materials X7R and

X5R have low temperature coefficients and are well

within th e acceptable ESR range required.

T ABLE 5-1: TC1303A, TC1303B, TC1303C,

C(V

min 4.7 µF none 4.7 µF 1 µF

max none none 22 µF 10 µF

(buck regulator input voltage

IN1

pin (LDO input voltage pin).

TC1304 RECOMMENDED

CAPACITOR VALUES

)C(V

IN1

)C

IN2

OUT1

C

OUT2

Example:

R

V

R

R

=200kΩ

TOP

=2.1V

OUT1

=0.8V

V

FB

=200kΩ x (0.8V/(2.1V – 0.8V))

BOT

=123kΩ (Standard Value = 121 kΩ)

BOT

For adjustable-output applications, an additional R-C

compensation is necessary for the buck regulator

control loop stability. Recommended values are:

R

COMP

C

COMP

© 2005 Microchip Technology Inc. DS21949B-page 23

=4.99kΩ

=33pF

Page 24

TC1303A/TC1303B/TC1303C/TC1304

5.5 Inductor Selection

For most applications, a 4.7 µH inductor is recommended to minimize noise. There are many different

magnetic core materi als an d p a ck age options to select

from. That decision is based on size, cost and acceptable radiated energy levels. Toroid and shielded ferrite

pot cores will have low radiated energy, but tend to be

larger and highe r is cost. W ith a typi cal 2.0 MHz switching frequency, the inductor ripple current can be

calculated based on the following formulas.

EQUATION 5-2:

V

OUT

DutyCycle

Duty cycle represents the percentage of switch-on

time.

EQUATION 5-3:

T

DutyCycle

ON

Where:

= Switching Frequency.

F

SW

=

-------------

V

IN

×=

1

----------

F

SW

T ABLE 5-2: TC1303A, TC1303B, TC1303C,

TC1304 RECOMMENDED

INDUCTOR VALUES

Part

Number

Coiltronics

Value

(µH)

®

DCR

Ω

(MAX)

MAX

I

DC

(A)

SD10 2.2 0.091 1.35 5.2, 5.2, 1.0 max.

SD10 3.3 0.108 1.24 5.2, 5.2, 1.0 max.

SD10 4.7 0.154 1.04 5.2, 5.2, 1.0 max.

Coiltronics

SD12 2.2 0.075 1.80 5.2, 5.2, 1.2 max.

SD12 3.3 0.104 1.42 5.2, 5.2, 1.2 max.

SD12 4.7 0.118 1.29 5.2, 5.2, 1.2 max.

Sumida Corporation

®

CMD411 2.2 0.116 0.950 4.4, 5.8, 1.2 max.

CMD411 3.3 0.174 0.770 4.4, 5.8, 1.2 max.

CMD411 4.7 0.216 0.750 4.4, 5.8, 1.2 max.

Coilcraft

®

1008PS 4.7 0.35 1.0 3.8, 3.8, 2.74 max.

1812PS 4.7 0.11 1.15 5.9, 5.0, 3.81 max

Size

WxLxH (mm)

The inductor ac ripple current can be calculated using

the following relationship:

EQUATION 5-4:

ΔI

L

VLL

--------

×=

Δt

Where:

= voltage ac ross the indu ctor (VIN – V

V

L

OUT

)

Δt = on-time of P-channel MOSFET

Solving for ΔIL= yields:

EQUATION 5-5:

V

L

------

ΔI

L

When considering inductor ratings, the maximum DC

current rating of t he inductor should b e at leas t equal to

the maximum bu ck reg u lat or lo ad cu rr ent ( I

one half of the peak-to-peak inductor ripple current

(1/2 * ΔI

buck converter I

). The inductor DC resistance can add to the

L

2

R losses. A rating of less than 200 mΩ

is recommended . Overall e ffi ciency will be im proved b y

using lower DC resistance inductors.

Δt×=

L

), plus

OUT1

5.6 Thermal Calculations

5.6.1 BUCK REGULATOR OUTPUT

(V

The TC1303/TC1304 is availab le in two di fferen t 10-pin

packages (MSOP and 3X3 DFN). By calculating the

power dissipation and applying the package thermal

resistance, (θ

The maximum continuous junction temperature rating

for the TC1303/TC1304 is +125°C.

To quickly estimate the internal power dissipation for

the switching buck regulator, an empirical calculation

using measured efficiency can be used. Given the

measured efficiency (Section 2.0 “Typical Perfor-

mance Curves”), the internal power dissipation is

estimated below:

EQUATION 5-6:

V

×

OUT1IOUT1

⎛⎞

-------------------------------------

⎝⎠

Efficiency

The first term is equal to the input power (definition of

efficiency, P

equal to the delivered power. The difference is internal

power dissipation. This is an estimate assuming that

most of the power lost is internal to the TC1303B.

There is some percentage of power lost in the buck

inductor, with very little loss in the input and output

capacitors.

)

OUT1

), the junction tempe rature is estim ated.

JA

V

OUT/PIN =

×()– P

OUT1IOUT1

Efficiency). The second term is

=

Dissipation

DS21949B-page 24 © 2005 Microchip Technology Inc.

Page 25

TC1303A/TC1303B/TC1303C/TC1304

As an example, for a 3.6V input, 1.8V ou tput with a load

of 400 mA, the efficiency taken from Figure 2-8 is

approximat ely 84%. The intern al power dissipatio n is

approximately 137 mW.

5.6.2 LDO OUTPUT (V

OUT2

)

The internal power dissipation within the

TC1303/TC1304 LDO is a function of input voltage,

output voltage an d output cu rrent. Equa tion5-7 can be

used to calculate the internal power dissipation for the

LDO.

EQUATION 5-7:

P

LDO

Where:

The maximum power dissipation capability for a

package can be calculated given the junction-toambient thermal resistance and the maximum ambient

temperature for the applica tion. The foll owing equ ation

can be used to determine the package’s maximum

internal power dissipation.

P

LDO

V

IN(MAX)

V

OUT(MIN)

V

IN MAX )()VOUT2 MIN()

–()I

×=

= LDO Pass device internal

power dissipation

= Maximum input voltage

= LDO mi nimum output voltage

OUT2 M AX )()

5.6.3 LDO POWER DISSIPATION

EXAMPLE

Input Voltage

VIN =5V±10%

LDO Output Voltage and Current

= 3.3V

V

OUT

I

=300mA

OUT

Internal Power Dissipation

P

LDO(MAX)

P

P

=(V

= (5.5V – 0.975 x 3.3V ) x 300 mA

LDO

= 684.8 mW

LDO

IN(MAX)

– V

OUT2(MIN)

) x I

OUT2(MAX)

5.7 PCB Layout Information

Some basic design guidelines should be used when

physically placing the TC1303/TC1304 on a Printed

Circuit Board (PCB). The TC1303/TC1304 has two

ground pins , identified as A

P

(power ground). By separating grounds, it is

GND

possible to minimize the switching frequency noise on

the LDO output. Th e firs t priori ty, while placing external

components on the board, is the input capacitor (C

Wiring should be short and wide; the input current for

the TC1303/TC1304 can be as high as 800 mA. The

next priority would be the buck regulator output

capacitor (C

) and inductor (L1). All three of these

OUT1

(analog ground) and

GND

IN1

components are placed near their respective pins to

minimize trace length. The C

IN1

and C

returns are connected closely together at the P

plane. The LDO optional input capacitor (C

LDO output c apaci tor C

are returned to the A

OUT2

OUT1

capacitor

GND

) and

IN2

GND

plane. The analog ground plane and power ground

+V

OUT1

P

GND

+V

IN1

Plane

). All

1

GND

plane are connected at one point (shown near L

other signals (SHDN1

, SHDN2, feedback in the

adjustable-output case) should be referenced to A

and have the A

- Via

* C

Optional

IN2

A

GND

C

IN2

+V

IN2

+V

OUT2

C

O

A

GND

plane underneath them.

GND

A

to P

GND

1

2

3

4

T

U

2

5

GND

L

1

TC1303B

A

GND

10

9

8

7

6

Plane

C

C

OUT1

N

I

P

1

GND

FIGURE 5-1: Component Placement, Fixed 10-Pin MSOP.

There will be some difference in la yout for the 10-p in

DFN package due to the thermal pad. A typical fixedoutput DFN layout is shown below. For the DFN layout,

IN1

to V

the V

the board around the TC1303/TC1304 thermal pad.

- Via

* C

A

GND

+V

IN2

+V

OUT2

A

GND

).

FIGURE 5-2: Component Placement, Fixed 10-Pin DFN.

connection is routed on the bottom of

IN2

A

to P

GND

GND

Optional

IN2

C

OUT1

PGND

C

IN2

C

O

U

1

2

3

4

T

2

5

A

GND

10

9

8

7

6

TC1303B

Plane

C

N

1

I

P

L

1

GND

+V

P

GND

+V

Plane

OUT1

IN1

© 2005 Microchip Technology Inc. DS21949B-page 25

Page 26

TC1303A/TC1303B/TC1303C/TC1304

5.8 Design Example

V

V

=2.0V @ 500mA

OUT1

=3.3V @ 300mA

OUT2

VIN=5V±10%

L = 4.7µH

Calculate PWM mode inductor ripple current

Nominal Duty

Cycle = 2.0V/5.0V = 40%

P-channel

Switch-on time = 0.40 x 1/(2 MHz) = 200 ns

V

L

=(VIN-V

OUT1

)=3V

ΔIL=(VL/L) x TON=128mA

Peak inductor current:

I

L(PK)

=I

+1/2ΔIL= 564 mA

OUT1

Switcher power loss:

Use efficiency estimate for 1.8V from Figure 2-8

Efficiency = 84%, P

DISS1

= 190 mW

Resistor Divider:

R

= 200 kΩ

TOP

R

= 133 kΩ

BOT

LDO Output:

P

P

P

=(V

DISS2

DISS2

DISS2

V

OUT2(MIN)

= (5.5V – (0.975) x 3.3V) x 30 0 mA

= 684.8 mW

IN(MAX)

–

)xI

OUT2(MAX)

Total

Dissipation = 190 mW + 685 mW = 874 mW

Junction Temp Rise and Maximum Ambient

Operating Temperature Calculations

10-Pin MSOP (4-Layer Board with internal Planes)

=113°C/Watt

Rθ

JA

Junction Temp.

Rise = 874 mW x 113° C/Watt = 98.8°C

Max. Ambient

Temperature = 125°C - 98.8°C

Max. Ambient

Temperature = 26.3°C

10-Pin DFN

= 41° C/Watt (4-Layer Board with

Rθ

JA

internal planes and 2 vias)

Junction Temp.

Rise = 874 mW x 41° C/Watt = 35.8°C

Max. Ambient

Temperature = 125°C - 35.8°C

Max. Ambient

Temperature = 89.2°C

This is above the +85°C max. ambient temperature.

DS21949B-page 26 © 2005 Microchip Technology Inc.

Page 27

TC1303A/TC1303B/TC1303C/TC1304

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

10-Lead MSOP* Example:

Example:

10-Lead DFN

— 1 = TC1303B

XXXXXX

YWWNNN

11H0/E

520256

— 2 = TC1303A

— 3 = TC1303C

— 4 = TC1304

— 1 = 1.375V V

— H = 2.6V V

OUT2

OUT1

XXXX

YYWW

NNN

11H0

0520

— 0 = Default

* The MSOP package for this device has not

Third letter represents V

configuration:

OUT2

been qualified at the time of this publication.

Contact your Microchip sales office for

availability.

Code V

OUT2

A 3.3V J 2.4V S 1.5V

Code V

OUT1

Code V

B3.2VK2.3VT —

Second letter represents V

Code V

OUT1

Code V

A3.3VJ2.4VS1.5V

B3.2VK2.3VT1.4V

C3.1VL2.2VU1.3V

D 3.0V M 2.1V V 1.2V

E 2.9V N 2.0V W 1.1V

F 2.8V O 1.9V X 1.0V

G2.7VP1.8VY0.9V

H 2.6V Q 1.7V Z Adj

I 2.5V R 1.6V 1 1.375V

configuration:

OUT1

OUT1

Code V

OUT1

C3.1VL2.2VU —

D3.0VM2.1VV —

E2.9VN2.0VW —

F2.8VO1.9VX —

G2.7VP1.8VY —

H2.6VQ1.7VZ —

I2.5VR1.6V

Fourth letter represents +50 mV Increments:

Code Code

0 Default 2 +50 mV to V2

1 +50 mV to V1 3 +50 mV to V1

and V2

256

OUT2

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

3

e

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designator ( )

3

e

can be found on the outer packaging for this package.

Note: In the even t the full M icrochip p art numb er cann ot be marked o n one lin e, it wil l

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

© 2005 Microchip Technology Inc. DS21949B-page 27

Page 28

TC1303A/TC1303B/TC1303C/TC1304

10-Lead Plastic Dual Flat No Lead Package (MF) 3x3x0.9 mm Body (DFN) – Saw Singulated

p

E

b

n

L

PIN 1

ID INDEX

AREA

(NOTE 2)

TOP VIEW

A3

Number of Pins

Pitch

Overall Height

Standoff

Lead Thickness

Overall Length

Exposed Pad Length

Overall Width

Exposed Pad Width

Lead Width

Lead Length

*Controlling Parameter

Notes:

Package may have one or more exposed tie bars at ends.1.

Pin 1 visual index feature may vary, but must be located within the hatched area.2.

3.

Exposed pad dimensions vary with paddle size.

4. JEDEC equivalent: Not registered

Drawing No. C04-063

Dimension Limits

3)

(Note

3)

(Note

Units

n

e

A

A1

A3

E

E2

D

D2

b

L

A1

D

EXPOSED

METAL

PAD

21

E2

BOTTOM VIEW

A

EXPOSED

TIE BAR

(NOTE 1)

MIN

INCHES

NOM

10

.020 BSC

.031

.000 .001

.008 REF.

.112 .118 .124 2.85 3.00 3.15

.055

.047

.008

.012

-- --

-- -.010

.016

.039

.002

.096

.069

.015

MILLIMETERS*

MINMAX NOM

10

0.50 BSC

0.80

0.00

0.20 REF.

1.39

1.20

0.18

0.30.020

Revised 05/24/04

0.90.035

0.02

3.00.112 .118 2.85.124 3.15

0.25

0.40

D2

MAX

1.00

0.05

2.45

1.75

0.30

0.50

DS21949B-page 28 © 2005 Microchip Technology Inc.

Page 29

TC1303A/TC1303B/TC1303C/TC1304

10-Lead Plastic Micro Small Outline Package (UN) (MSOP*)

E

E1

p

B

n

c

(F)

β

Number of Pins

Dimension Limits

Pitch

Overall Height

Molded Package Thickness

Standoff

Overall Width

Molded Package Width

Overall Length

Foot Length

Foot Angle

Lead Thickness

Lead Width

Mold Draft Angle Top

Mold Draft Angle Bottom

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not

exceed .010" (0.254mm) per side.

JEDEC Equivalent: MO-187

Drawing No. C04-021

Units

MIN

n

p

A

A2

A1

E

E1

D

L

φ

c

B

α

β

D

2

1

φ

L

L1

INCHES

NOM

10

.020 TYP

-.030

.000

.016 .024

0° - 8°

.003

.006

5° -

5° -

.033

.193 BSC

.118 BSC

.118 BSC

.037 REFFFootprint

.009

A

A1

-

-

.043

.037

.006

.031

.009

.012

15°

15°

A2

MILLIMETERS*

MINMAX

0.75

0.00

0.40

0.08

0.15

NOM

10

0.50 TYP.

--

5° 15°

5° 15°

0.85

-

4.90 BSC

3.00 BSC

3.00 BSC

0.60

0.95 REF

-

-

0.23

-

-

α

MAX

1.10

0.95

0.15

0.80

8°0°

0.23

0.30

* The MSOP package for the TC1303B has not been qualified at the time of this publication.