Microchip TC1072-1.8VCH713, TC1072-2.5VCH713, TC1072-2.6VCH713, TC1072-2.7VCH713, TC1072-2.85VCH713 Schematic [ru]

...

TC1072/TC1073

R

6

1

4

2

3

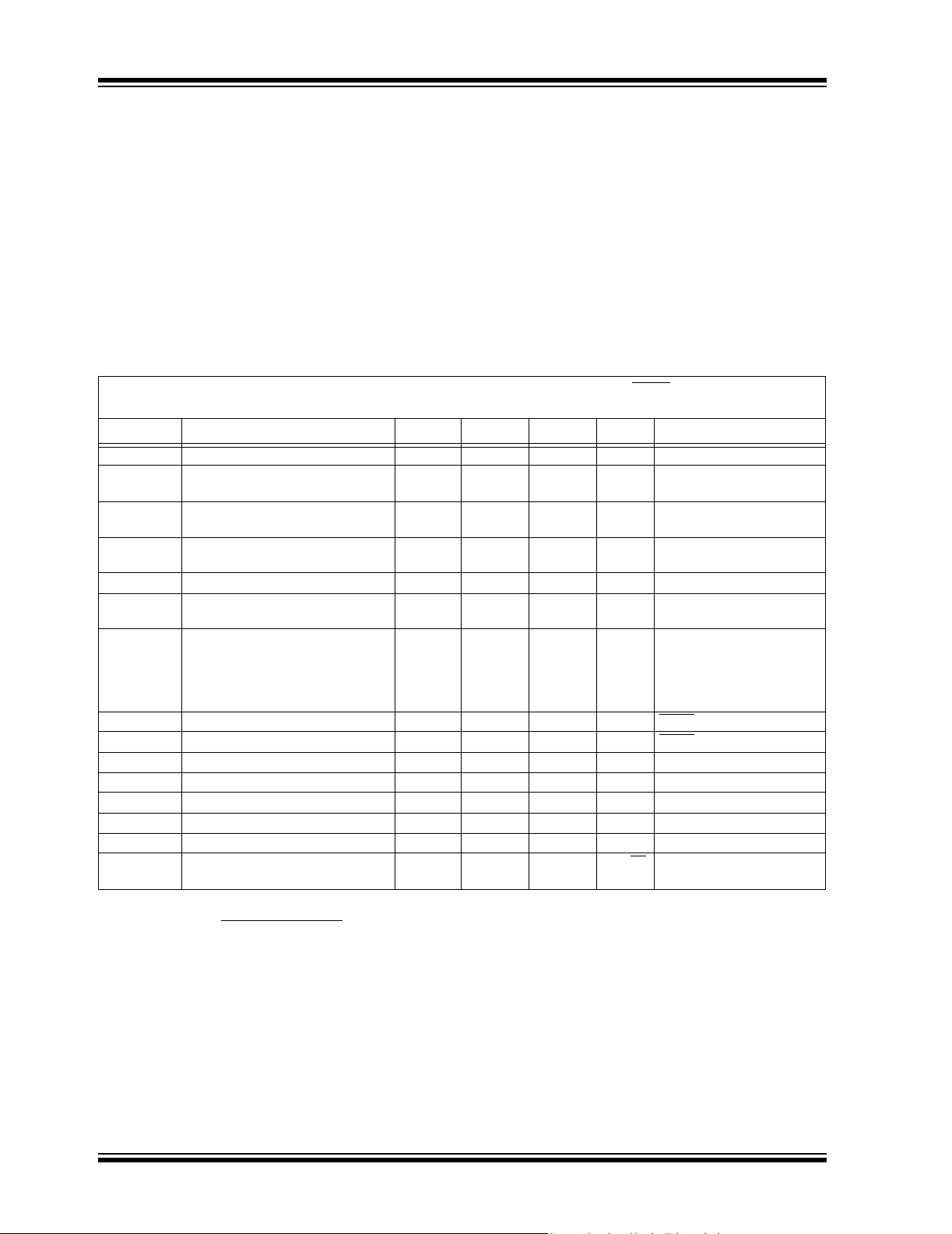

6-Pin SOT-23

V

OUT

ERROR

SHDNGNDV

IN

5

Bypass

50mA and 100mA CMOS LDOs with Shutdown, ERROR Output and V

Features:

• 50 µA Ground Current for Longer Battery Life

• Very Low Dropout Voltage

• Choice of 50 mA (TC1072) and 100 mA (TC1073)

Output

• High Output Voltage Accuracy

• Standard or Custom Output Voltages

• Power-Saving Shutdown Mode

• ERROR

Output Can Be Used as a Low Battery

Detector or Processor Reset Generator

• Bypass Input for Ultra Quiet Operation

• Overcurrent and Overtemperature Protection

• Space-Saving 6-Pin SOT-23 Package

• Pin Compatible Upgrades for Bipolar Regulators

• Standard Output Voltage Options:

- 1.8V, 2.5V, 2.6V, 2.7V, 2.8V, 2.85V, 3.0V,

3.3V, 3.6V, 4.0V, 5.0V

• Other output voltages are available. Please

contact Microchip Technology Inc. for details.

Applications:

• Battery Operated Systems

• Portable Computers

• Medical Instruments

• Instrumentation

• Cellular/GSM/PHS Phones

• Linear Post-Regulators for SMPS

• Pagers

General Description

The TC1072 and TC1073 are high accuracy (typically

±0.5%) CMOS upgrades for older (bipolar) low dropout

regulators. Designed specifically for battery-operated

systems, the devices’ CMOS construction eliminates

wasted ground current, significantly extending battery

life. Total supply current is typically 50 µA at full load

(20 to 60 times lower than in bipolar regulators).

The devices’ key features include ultra low noise

operation (plus optional Bypass input); very low

dropout voltage (typically 85 mV, TC1072 and 180 mV,

TC1073 at full load) and fast response to step changes

in load. An error output (ERROR

) is asserted when the

devices are out-of-regulation (due to a low input

voltage or excessive output current). ERROR

used as a low battery warning or as a processor

signal (with the addition of an external RC

RESET

network). Supply current is reduced to 0.5 µA (max)

and both V

and ERROR

OUT

are disabled when the

shutdown input is low. The devices incorporate both

overtemperature and overcurrent protection.

The TC1072 and TC1073 are stable with an output

capacitor of only 1 µF and have a maximum output

current of 50 mA, and 100 mA, respectively. For higher

output current versions, please see the TC1185,

TC1186, TC1187 (I

TC1108 and TC1173 (I

= 150 mA) and TC1107,

OUT

= 300 mA) data sheets.

OUT

Package Type

Bypass

REF

can be

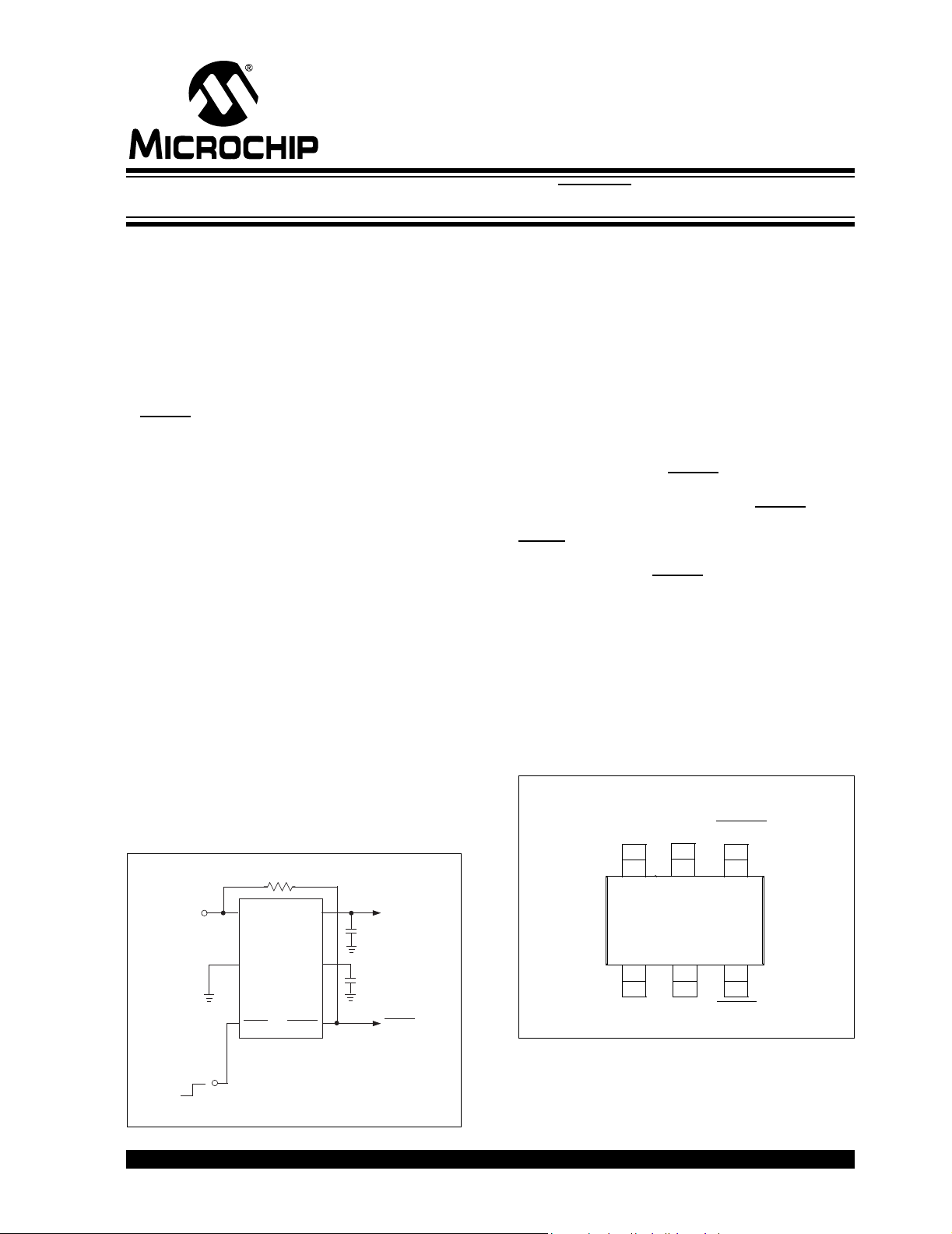

Typical Application Circuit

R

P

V

1

IN

V

IN

TC1072

TC1073

2

GND

3

Shutdown Control

(from Power Control Logic)

© 2007 Microchip Technology Inc. DS21354D-page 1

SHDN

V

OUT

Bypass

ERROR

6

5

4

+

1 µF

C

BYPASS

470 pF

V

OUT

ERRO

TC1072/TC1073

TC V

OUT

= (V

OUTMAX

– V

OUTMIN

) x 10

6

V

OUT

x ΔT

1.0 ELECTRICAL CHARACTERISTICS

† Note: Stresses above those listed under "Absolute

Maximum Ratings" may cause permanent damage to

the device. These are stress ratings only and functional

operation of the device at these or any other conditions

Absolute Maximum Ratings†

Input Voltage .........................................................6.5V

Output Voltage...........................(-0.3V) to (V

+ 0.3V)

IN

above those indicated in the operation sections of the

specifications is not implied. Exposure to Absolute

Maximum Rating conditions for extended periods may

affect device reliability.

Power Dissipation................Internally Limited (Note 6)

Maximum Voltage on Any Pin ........ VIN +0.3V to -0.3V

Operating Temperature Range...... -40°C < T

< 125°C

J

Storage Temperature..........................-65°C to +150°C

TC1072/TC1073 ELECTRICAL SPECIFICATIONS

Electrical Characteristics: Unless otherwise noted, VIN=V

Boldface type specifications apply for junction temperatures of -40°C to +125°C.

Symbol Parameter Min Typ Max Units Test Conditions

V

IN

I

OUTMAX

V

OUT

TCV

OUT

ΔV

OUT

ΔV

OUT/VOUT

V

IN-VOUT

I

IN

I

INSD

Input Operating Voltage 2.7 — 6.0 V Note 9

Maximum Output Current 50

Output Voltage VR –

V

Temperature Coefficient —

OUT

/ΔVINLine Regulation — 0.05 0.35 %(VR + 1V) ≤ VIN ≤ 6V

Load Regulation — 0.5 2.0 %IL = 0.1 mA to I

Dropout Voltage —

Supply Current — 50 80 µA SHDN

Shutdown Supply Current — 0.05 0.5 µA SHDN

PSRR Power Supply Rejection Ratio — 64 — dB F

I

OUTSC

ΔV

T

SD

ΔT

OUT

SD

Output Short Circuit Current — 300 450 mA V

/ΔPDThermal Regulation — 0.04 — V/W Notes 5, 6

Thermal Shutdown Die Temperature — 160 — °C

Thermal Shutdown Hysteresis — 10 — °C

eN Output Noise — 260 — nV/√Hz

Note 1: VR is the regulator output voltage setting. For example: VR= 2.5V, 2.7V, 2.85V, 3.0V, 3.3V, 3.6V, 4.0V, 5.0V.

2:

+ 1V, IL= 0.1 mA, CL=3.3μF, SHDN

OUT

100

—

—

—

—

VR ±0.5% VR + 2.5% V Note 1

2.5%

—

40

2

20

—

—

—

65

85

180

—

—

—

—

120

250

>VIH, TA=+25°C.

mAmATC1072

TC1073

ppm/°C Note 2

(Note 3)

mV I

=0.1mA

L

I

=20mA

L

IL=50mA

IL= 100 mA (Note 4),

TC1073

RE

OUT

IL=I

470 pF from Bypass to GND

=VIH, IL= 0 (Note 8)

=0V

≤ 1kHz

=0V

OUTMAX

OUTMAX

3: Regulation is measured at a constant junction temperature using low duty cycle pulse testing. Load regulation is tested over a load range

from 0.1 mA to the maximum specified output current. Changes in output voltage due to heating effects are covered by the thermal

regulation specification.

4: Dropout voltage is defined as the input to output differential at which the output voltage drops 2% below its nominal value.

5: Thermal Regulation is defined as the change in output voltage at a time T after a change in power dissipation is applied, excluding load or

line regulation effects. Specifications are for a current pulse equal to I

6: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable junction temperature and the

thermal resistance from junction-to-air (i.e., T

thermal shutdown. Please see Section 5.0 “Thermal Considerations” for more details.

7: Hysteresis voltage is referenced by V

8: Apply for Junction Temperatures of -40°C to +85°C.

9: The minimum VIN has to justify the conditions = VIN≥ VR+V

, TJ, θJA). Exceeding the maximum allowable power dissipation causes the device to initiate

A

.

R

DROPOUT

at VIN=6V for T=10 ms.

LMAX

and VIN≥ 2.7V for IL= 0.1 mA to I

OUTMAX

.

DS21354D-page 2 © 2007 Microchip Technology Inc.

TC1072/TC1073

TC V

OUT

= (V

OUTMAX

– V

OUTMIN

) x 10

6

V

OUT

x ΔT

TC1072/TC1073 ELECTRICAL SPECIFICATIONS (CONTINUED)

Electrical Characteristics: Unless otherwise noted, VIN=V

Boldface type specifications apply for junction temperatures of -40°C to +125°C.

+ 1V, IL= 0.1 mA, CL=3.3μF, SHDN

OUT

>VIH, TA= +25°C.

Symbol Parameter Min Typ Max Units Test Conditions

SHDN Input

V

IH

V

IL

ERROR

V

INMIN

V

OL

V

TH

V

HYS

t

DELAY

Note 1: VR is the regulator output voltage setting. For example: VR= 2.5V, 2.7V, 2.85V, 3.0V, 3.3V, 3.6V, 4.0V, 5.0V.

SHDN

Input High Threshold 45 — — %VINVIN= 2.5V to 6.5V

Input Low Threshold — — 15 %VINVIN= 2.5V to 6.5V

SHDN

Open Drain Output

Minimum VIN Operating Voltage 1.0 — — V

Output Logic Low Voltage — — 400 mV 1 mA Flows to ERROR

ERROR Threshold Voltage — 0.95 x V

— V See Figure 4-2

R

ERROR Positive Hysteresis — 50 — mV Note 7

V

to ERROR

OUT

2:

3: Regulation is measured at a constant junction temperature using low duty cycle pulse testing. Load regulation is tested over a load range

from 0.1 mA to the maximum specified output current. Changes in output voltage due to heating effects are covered by the thermal

regulation specification.

4: Dropout voltage is defined as the input to output differential at which the output voltage drops 2% below its nominal value.

5: Thermal Regulation is defined as the change in output voltage at a time T after a change in power dissipation is applied, excluding load or

line regulation effects. Specifications are for a current pulse equal to I

6: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable junction temperature and the

thermal resistance from junction-to-air (i.e., T

thermal shutdown. Please see Section 5.0 “Thermal Considerations” for more details.

7: Hysteresis voltage is referenced by V

8: Apply for Junction Temperatures of -40°C to +85°C.

9: The minimum VIN has to justify the conditions = VIN≥ VR+V

Delay — 2.5 — ms Vout falling from VR to

VR-10%

at VIN=6V for T=10 ms.

LMAX

, TJ, θJA). Exceeding the maximum allowable power dissipation causes the device to initiate

A

.

R

and VIN≥ 2.7V for IL= 0.1 mA to I

DROPOUT

OUTMAX

.

© 2007 Microchip Technology Inc. DS21354D-page 3

TC1072/TC1073

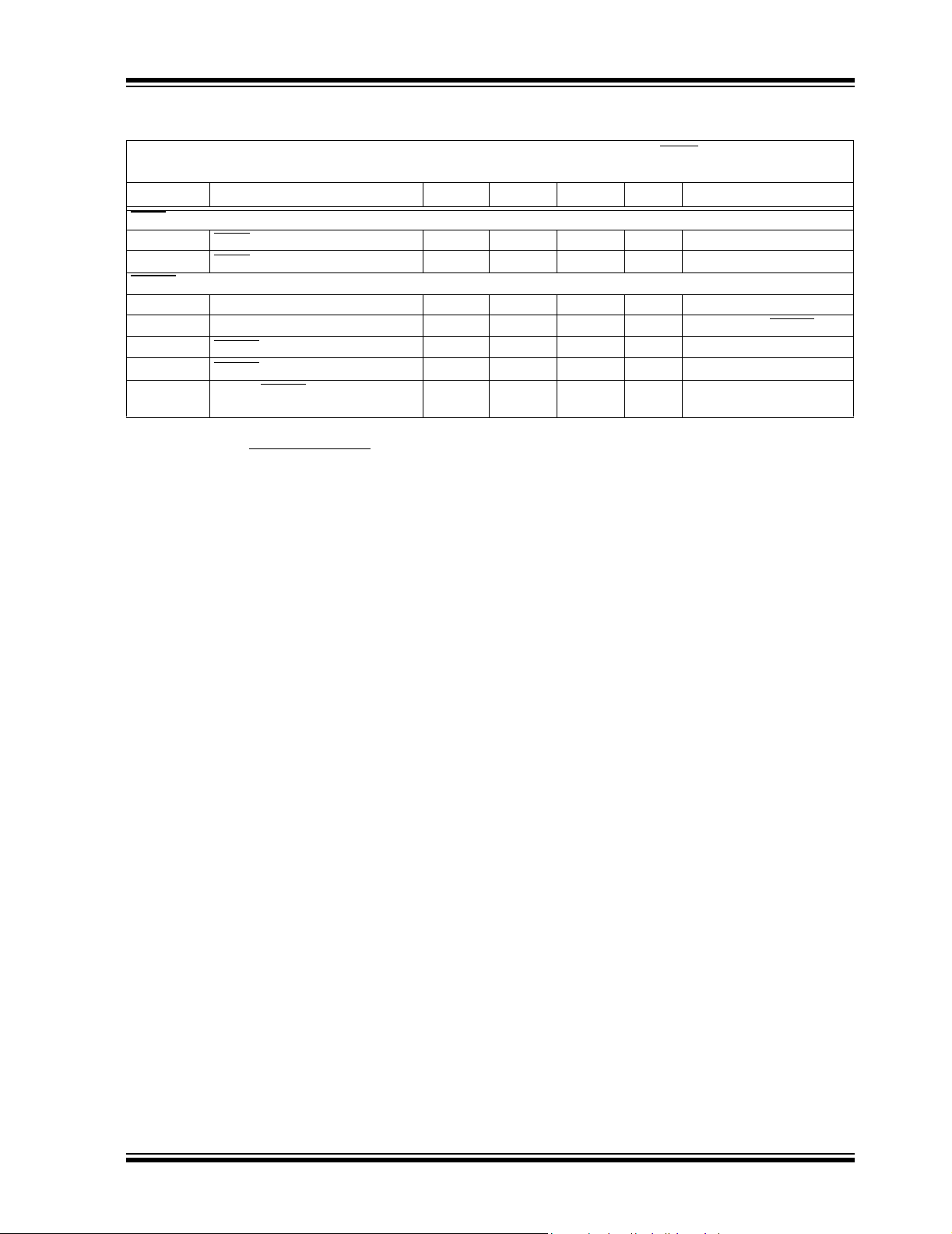

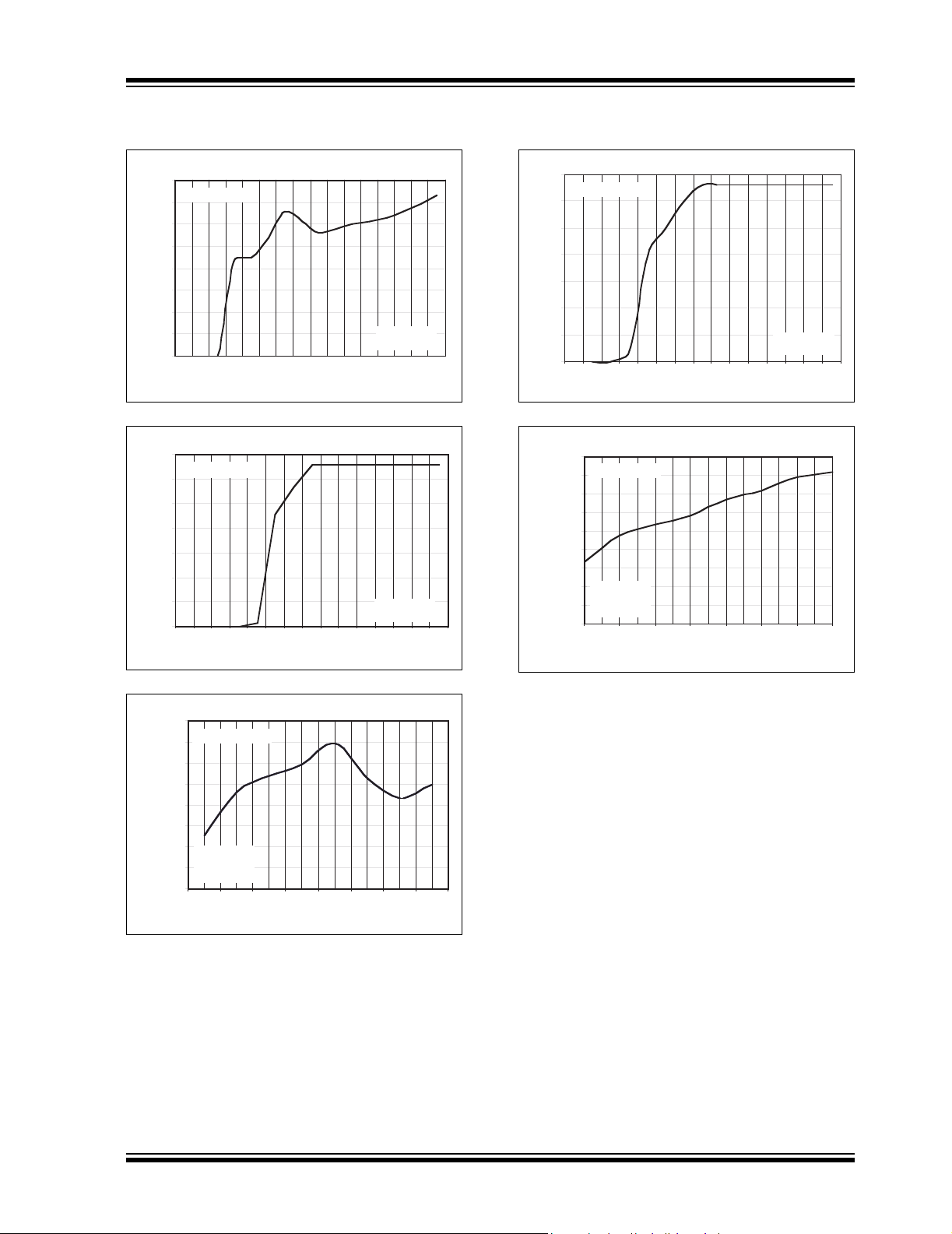

2.0 TYPICAL CHARACTERISTICS CURVES

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise specified, all parts are measured at temperature = +25°C.

0.020

0.018

0.016

0.014

0.012

0.010

0.008

0.006

0.004

DROPOUT VOLTAGE (V)

0.002

0.000

0.200

0.180

0.160

0.140

0.120

0.100

0.080

0.060

0.040

DROPOUT VOLTAGE (V)

0.020

0.000

Dropout Voltage vs. Temperature (V

I

= 10mA

LOAD

C

= 1µF

IN

C

= 1µF

OUT

-40 -20 0 20 50 70 125

Dropout Voltage vs. Temperature (V

I

= 100mA

LOAD

C

= 1µF

IN

C

= 1µF

OUT

-40 -20 0 20 50 70 125

TEMPERATURE (°C)

TEMPERATURE (°C)

OUT

OUT

= 3.3V)

= 3.3V)

Dropout Voltage vs. Temperature (V

0.100

I

0.090

0.080

0.070

0.060

0.050

0.040

0.030

0.020

DROPOUT VOLTAGE (V)

0.010

0.000

0.300

0.250

0.200

0.150

0.100

0.050

DROPOUT VOLTAGE (V)

0.000

= 50mA

LOAD

C

= 1µF

IN

C

= 1µF

OUT

-40 -20 0 20 50 70 125

Dropout Voltage vs. Temperature (V

I

= 150mA

LOAD

C

= 1µF

IN

C

= 1µF

OUT

-40 -20 0 20 50 70 125

TEMPERATURE (°C)

TEMPERATURE (°C)

OUT

OUT

= 3.3V)

= 3.3V)

(V

90

80

70

A)

µ

60

50

40

30

GND CURRENT (

20

10

0

Ground Current vs. VIN (V

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5

V

(V)

IN

OUT

= 3.3V)

I

LOAD

C

C

= 10mA

= 1µF

IN

OUT

= 1µF

90

80

70

A)

µ

60

50

40

30

GND CURRENT (

20

10

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5

Ground Current vs. V

V

(V)

IN

= 3.3V)

IN

OUT

I

= 100mA

LOAD

C

= 1µF

IN

C

= 1µF

OUT

DS21354D-page 4 © 2007 Microchip Technology Inc.

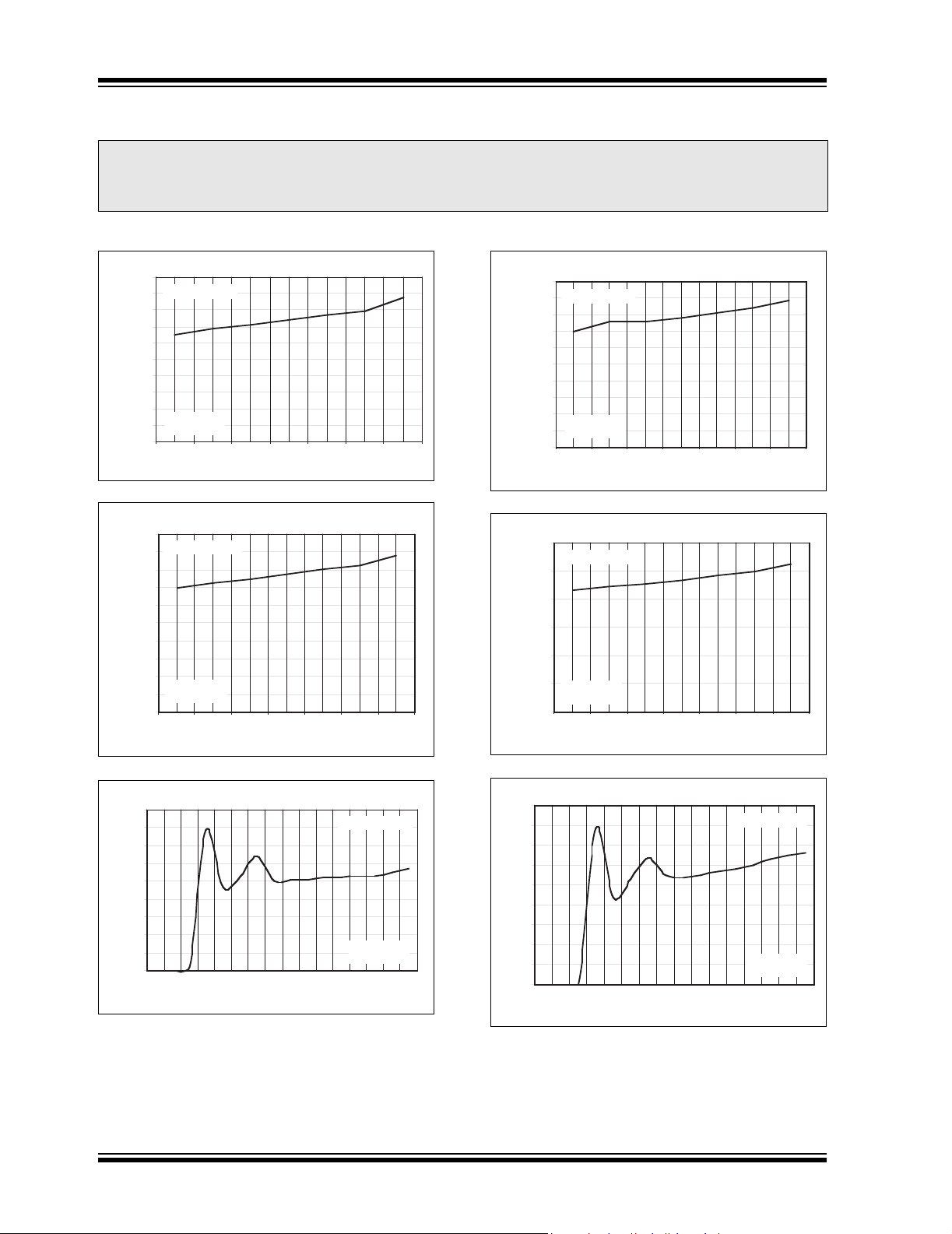

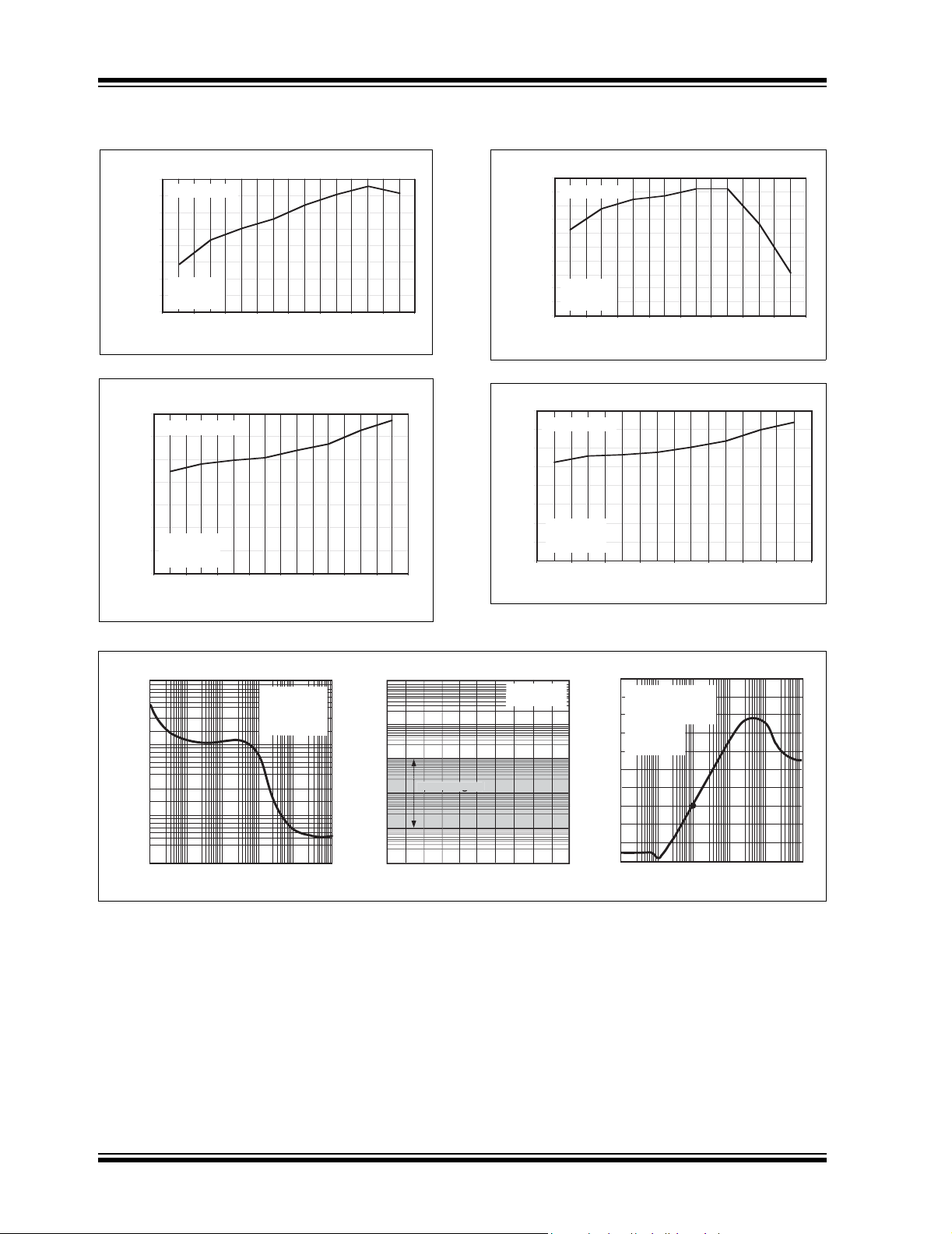

TC1072/TC1073

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

I

LOAD

= 100mA

C

IN

= 1µF

C

OUT

= 1µF

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7

VIN (V)

V

OUT

(V)

V

OUT

vs.

V

IN

(V

OUT

= 3.3V)

3.274

3.276

3.278

3.280

3.282

3.284

3.286

3.288

3.290

-40 -20 -10 0 20 40 85 125

I

LOAD

= 150mA

C

IN

= 1µF

C

OUT

= 1µF

VIN = 4.3V

TEMPERATURE (°C)

V

OUT

(V)

Output Voltage vs. Temperature (V

OUT

= 3.3V)

Note: Unless otherwise specified, all parts are measured at temperature = +25°C.

80

70

Ground Current vs. VIN (V

I

= 150mA

LOAD

60

50

40

30

20

GND CURRENT (µA)

10

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5

VIN (V)

OUT

= 3.3V)

C

C

= 1µF

IN

OUT

= 1µF

3.5

I

= 0

LOAD

3

2.5

2

(V)

OUT

1.5

V

1

0.5

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7

V

vs.

V

(V

OUT

= 3.3V)

IN

OUT

C

= 1µF

IN

= 1µF

C

OUT

V

(V)

IN

3.320

3.315

Output Voltage vs. Temperature (V

I

= 10mA

LOAD

3.310

3.305

3.300

(V)

3.295

OUT

V

3.290

3.285

C

= 1µF

IN

C

= 1µF

3.280

OUT

VIN = 4.3V

3.275

-40 -20 -10 0 20 40 85 1 25

TEMPERATURE (°C)

OUT

= 3.3V)

© 2007 Microchip Technology Inc. DS21354D-page 5

TC1072/TC1073

0

10

20

30

40

50

60

70

-40 -20 -10 0 20 40 85 125

GND CURRENT (

µ

A)

I

LOAD

= 10mA

V

IN

= 6V

C

IN

= 1µF

C

OUT

= 1µF

TEMPERATURE (°C)

Temperature

vs. Quiescent Current

(V

OUT

= 5V)

Stable Region

S

n

K

Note: Unless otherwise specified, all parts are measured at temperature = +25°C.

(V

OUT

= 5V)

(V)

OUT

V

4.994

4.992

4.990

4.988

4.986

4.984

4.982

4.980

4.978

4.976

4.974

Output Voltage vs. Temperature

I

= 150mA

LOAD

V

= 6V

IN

C

= 1µF

IN

C

= 1µF

OUT

-40 -20 -10 0 2 0 40 85 125

(V)

OUT

V

5.025

5.020

5.015

5.010

5.005

5.000

4.995

4.990

4.985

Output Voltage vs. Temperature

I

= 10mA

LOAD

V

= 6V

IN

C

= 1µF

IN

C

= 1µF

OUT

-40 -20 -10 0 20 40 85 125

TEMPERATURE (°C)

TEMPERATURE (°C)

(V

= 5V)

OUT

NOISE (µV/√Hz)

10.0

Output Noise vs. Frequency

1.0

0.1

0.0

0.01K

0.1K

FREQUENCY (Hz)

R

LOAD

= 1µF

C

OUT

CIN = 1µF

C

= 0

BYP

1K 10K 100K

= 50Ω

1000K

Stability Region vs. Load Current

1000

100

(Ω)

10

ESR

OUT

C

1

table Regio

0.1

0.01

10

203040

0

LOAD CURRENT (mA)

Temperature vs. Quiescent Current (V

80

I

LOAD

70

60

50

40

30

20

V

IN

GND CURRENT (µA)

C

IN

10

C

OUT

0

-40 -20 -10 0 20 40 85 125

C

= 1µF

OUT

to 10µF

50 60 70 80 90 100

= 150mA

= 6V

= 1

µ

= 1µF

F

TEMPERATURE (°C)

-30

I

-35

V

V

-40

V

-45

C

C

-50

-55

-60

PSRR (dB)

-65

-70

-75

-80

0.01K

OUT

Power Supply Rejection Ratio

10mA

OUT =

= 4V

IN

DC

= 100mV

IN

OUT

IN

OUT

AC

= 0

0.1K

=

=

3V

1µF

p-p

1K 10K

FREQUENCY (Hz)

= 5V)

100K

1000

DS21354D-page 6 © 2007 Microchip Technology Inc.

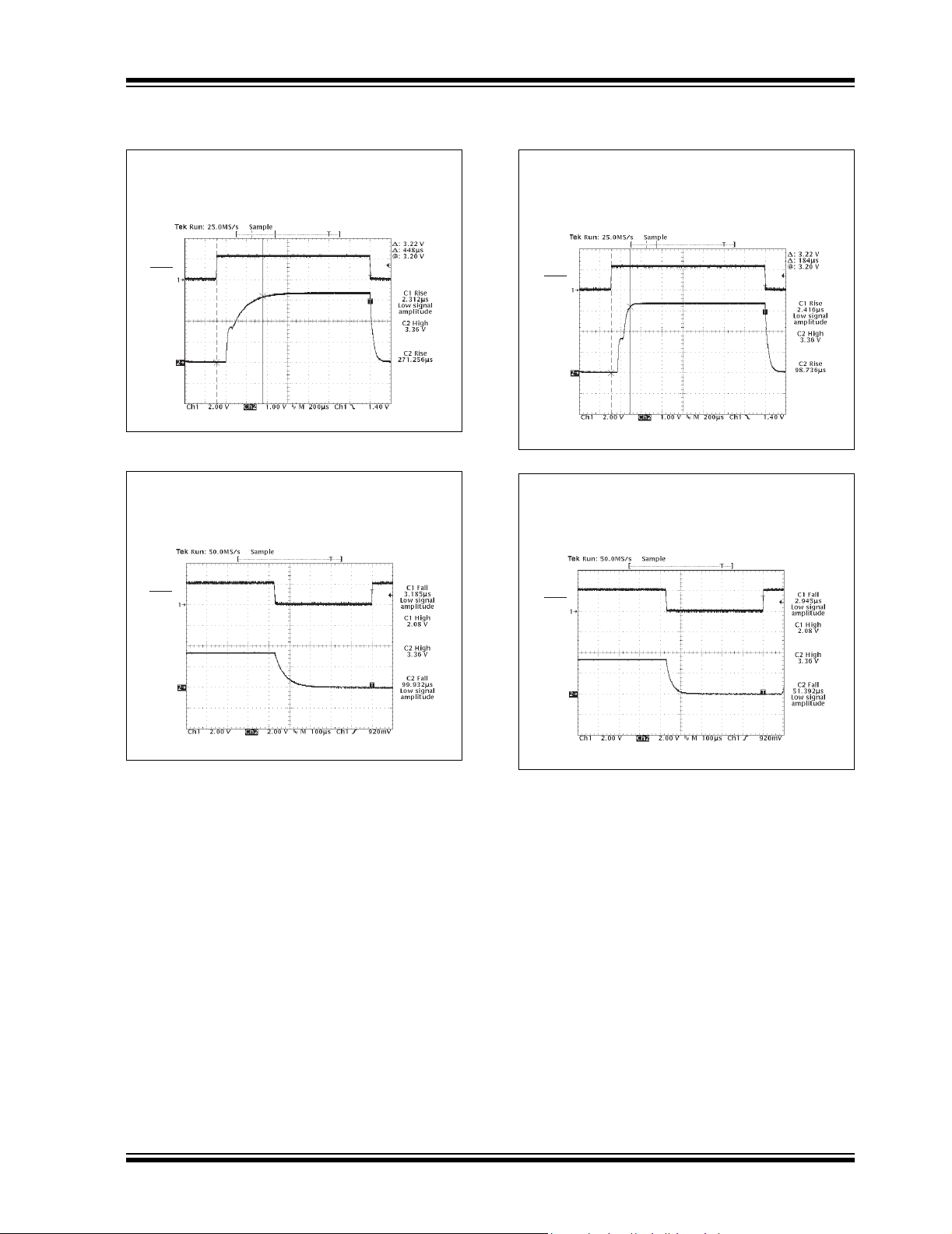

TC1072/TC1073

V

OUT

Measure Rise Time of 3.3V LDO with Bypass Capacitor

Conditions: CIN = 1µF, C

OUT

= 1µF, C

BYP

= 470pF, I

LOAD

= 100mA

VIN = 4.3V, Temp = 25°C, Rise Time = 448µS

V

SHDN

Measure Fall Time of 3.3V LDO with Bypass Capacitor

Conditions: CIN = 1µF, C

OUT

= 1µF, C

BYP

= 470pF, I

LOAD

= 50mA

VIN = 4.3V, Temp = 25°C, Fall Time = 100µS

V

OUT

V

SHDN

Note: Unless otherwise specified, all parts are measured at temperature = +25°C.

Measure Rise Time of 3.3V LDO without Bypass Capacitor

Conditions: CIN = 1µF, C

VIN = 4.3V, Temp = 25°C, Rise Time = 184µS

V

SHDN

V

OUT

Measure Fall Time of 3.3V LDO without Bypass Capacitor

Conditions: CIN = 1µF, C

VIN = 4.3V, Temp = 25°C, Fall Time = 52µS

OUT

OUT

= 1µF, C

= 1µF, C

BYP

BYP

= 0pF, I

= 0pF, I

LOAD

LOAD

= 100mA

= 100mA

V

SHDN

V

OUT

© 2007 Microchip Technology Inc. DS21354D-page 7

TC1072/TC1073

Measure Rise Time of 5.0V LDO with Bypass Capacitor

Conditions: CIN = 1µF, C

OUT

= 1µF, C

BYP

= 470pF, I

LOAD

= 100mA

VIN = 6V, Temp = 25°C, Rise Time = 390µS

V

OUT

V

SHDN

Note: Unless otherwise specified, all parts are measured at temperature = +25°C.

Measure Rise Time of 5.0V LDO without Bypass Capacitor

Conditions: CIN = 1µF, C

V

SHDN

V

OUT

V

= 6V, Temp = 25°C, Rise Time = 192µS

IN

OUT

= 1µF, C

BYP

= 0pF, I

LOAD

= 100mA

Measure Fall Time of 5.0V LDO with Bypass Capacitor

Conditions: CIN = 1µF, C

V

SHDN

V

OUT

= 6V, Temp = 25°C, Fall Time = 167µS

V

IN

OUT

= 1µF, C

BYP

= 470pF, I

LOAD

= 50mA

Measure Fall Time of 5.0V LDO without Bypass Capacitor

Conditions: CIN = 1µF, C

V

SHDN

V

OUT

= 6V, Temp = 25°C, Fall Time = 88µS

V

IN

OUT

= 1µF, C

BYP

= 0pF, I

LOAD

= 100mA

DS21354D-page 8 © 2007 Microchip Technology Inc.

TC1072/TC1073

I

LOAD

V

OUT

Load Regulation of 3.3V LDO

Conditions: CIN = 1µF, C

OUT

= 2.2µF, C

BYP

= 470pF,

VIN = V

OUT

+ 0.25V, Temp = 25°C

I

LOAD

= 50mA switched in at 10kHz, V

OUT

is AC coupled

Load Regulation of 3.3V LDO

Conditions: CIN = 1µF, C

OUT

= 2.2µF, C

BYP

= 470pF,

V

IN

= V

OUT

+ 0.25V, Temp = 25°C

I

LOAD

= 150mA switched in at 10kHz, V

OUT

is AC coupled

I

LOAD

V

OUT

Note: Unless otherwise specified, all parts are measured at temperature = +25°C.

Load Regulation of 3.3V LDO

Conditions: CIN = 1µF, C

VIN = V

I

= 100mA switched in at 10kHz, V

LOAD

I

LOAD

V

OUT

Conditions: VIN = 4V, + 1V Squarewave @ 2.5kHz

= 2.2µF, C

OUT

+ 0.25V, Temp = 25°C

OUT

is AC coupled

OUT

Line Regulation of 3.3V LDO

BYP

= 470pF,

V

IN

V

OUT

CIN = 0µF, C

I

LOAD

= 1µF, C

OUT

= 100mA, VIN & V

= 470pF,

BYP

are AC coupled

OUT

© 2007 Microchip Technology Inc. DS21354D-page 9

TC1072/TC1073

Note: Unless otherwise specified, all parts are measured at temperature = +25°C.

Line Regulation of 5.0V LDO

Conditions: VIN = 6V, + 1V Squarewave @ 2.5kHz

V

IN

V

OUT

CIN = 0µF, C

I

LOAD

= 1µF, C

OUT

= 100mA, VIN & V

= 470pF,

BYP

are AC coupled

OUT

Thermal Shutdown Response of 5.0V LDO

Conditions: VIN = 6V, CIN = 0µF, C

V

OUT

I

was increased until temperature of die reached about 160°C, at

LOAD

which time integrated thermal protection circuitry shuts the regulator

off when die temperature exceeds approximately 160°C. The regulator

remains off until die temperature drops to approximately 150°C.

OUT

= 1µF

DS21354D-page 10 © 2007 Microchip Technology Inc.

3.0 PIN DESCRIPTIONS

TC1072/TC1073

The descriptions of the pins are listed in

Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

Pin No.

(6-Pin SOT-23)

1V

2 GND Ground terminal.

3 SHDN

4ERROROut-of-Regulation Flag. (Open drain output).

5 Bypass Reference bypass input.

6V

Symbol Description

IN

OUT

Unregulated supply input.

Shutdown control input.

Regulated voltage output.

3.1 Input Voltage Supply (VIN)

Connect unregulated input supply to the VIN pin. If

there is a large distance between the input supply and

the LDO regulator, some input capacitance is

necessary for proper operation. A 1 µF capacitor

connected from V

most applications.

to ground is recommended for

IN

3.2 Ground (GND)

Connect the unregulated input supply ground return to

GND. Also connect the negative side of the 1 µF typical

input decoupling capacitor close to GND and the

negative side of the output capacitor C

OUT

to GND.

3.4 Out-Of-Regulation Flag (ERROR

ERROR goes low when V

approximately – 5%.

is out-of-tolerance by

OUT

)

3.5 Reference Bypass Input (Bypass)

Connecting a 470 pF to this input further reduces

output noise.

3.6 Regulated Voltage Output (V

Connect the output load to V

connect the positive side of the LDO output capacitor

as close as possible to the V

of the LDO. Also

OUT

pin.

OUT

OUT

)

3.3 Shutdown Control Input (SHDN

The regulator is fully enabled when a logic-high is

applied to SHDN

a logic-low is applied to SHDN

output voltage falls to zero, ERROR

and supply current is reduced to 0.5 µA (maximum).

. The regulator enters shutdown when

. During shutdown,

is open-circuited

)

© 2007 Microchip Technology Inc. DS21354D-page 11

TC1072/TC1073

V

TH

V

OUT

ERROR

V

IH

V

OL

HYSTERESIS (VH)

t

DELAY

4.0 DETAILED DESCRIPTION

The TC1072 and TC1073 are precision fixed output

voltage regulators. (If an adjustable version is desired,

please see the TC1070/TC1071/TC1187 data sheet.)

Unlike bipolar regulators, the TC1072 and TC1073’s

supply current does not increase with load current. In

addition, V

over the entire 0 mA to I

important consideration in RTC and CMOS RAM

battery back-up applications).

Figure 4-1 shows a typical application circuit. The

regulator is enabled any time the shutdown input

) is at or above VIH, and shutdown (disabled)

(SHDN

when SHDN

controlled by a CMOS logic gate, or I/O port of a

microcontroller. If the SHDN

should be connected directly to the input supply. While

in shutdown, supply current decreases to 0.05 µA

(typical), V

circuited.

Shutdown Control

(to CMOS Logic or Tie

to VIN if unused)

remains stable and within regulation

OUT

OUTMAX

load current range, (an

is at or below VIL. SHDN may be

input is not required, it

+

1 µF

C1

C3, 470 pF

R1

1M

0.2 µF

C2

is open-

V

OUT

BATTLOW

or RESET

falls to zero volts, and ERROR

OUT

+

Battery

V

IN

+

1 µF

GND

SHDN

C2 Required Only

if ERROR is used as a

Processor RESET Signal

TC1072

TC1073

(See Text)

V

OUT

Bypass

ERROR

V+

FIGURE 4-2: Error

Output Operation.

4.2 Output Capacitor

A 1 µF (minimum) capacitor from V

recommended. The output capacitor should have an

effective series resistance greater than 0.1Ω and less

than 5.0Ω, and a resonant frequency above 1 MHz. A

1 µF capacitor should be connected from V

there is more than 10 inches of wire between the

regulator and the AC filter capacitor, or if a battery is

used as the power source. Aluminum electrolytic or

tantalum capacitor types can be used. (Since many

aluminum electrolytic capacitors freeze at

approximately -30°C, solid tantalums are

recommended for applications operating below -25°C.)

When operating from sources other than batteries,

supply-noise rejection and transient response can be

improved by increasing the value of the input and

output capacitors and employing passive filtering

techniques.

to ground is

OUT

IN

to GND if

4.3 Bypass Input

FIGURE 4-1: Typical Application Circuit.

A 470 pF capacitor connected from the Bypass input to

ground reduces noise present on the internal

4.1 ERROR

Open-Drain Output

reference, which in turn significantly reduces output

noise. If output noise is not a concern, this input may be

ERROR

regulation by more than –5% (typical). This condition

may be caused by low input voltage, output current

limiting, or thermal limiting. The ERROR

value (e.g. ERROR

is driven low whenever V

=VOL at 4.75V (typical) for a 5.0V

falls out of

OUT

output voltage

left unconnected. Larger capacitor values may be

used, but results in a longer time period to rated output

voltage when power is initially applied.

regulator and 2.85V (typical) for a 3.0V regulator).

ERROR

output operation is shown in Figure 4-2.

Note that ERROR is active tDELAY (typically, 2.5 µs)

after V

above VTH by V

As shown in

battery low flag, or as a processor RESET

falls to VTH, and inactive when V

OUT

HYS

.

Figure 4-1, ERROR can be used as a

rises

OUT

signal (with

the addition of timing capacitor C2). R1 x C2 should be

chosen to maintain ERROR

RESET

input for at least 200 ms to allow time for the

below VIH of the processor

system to stabilize. Pull-up resistor R1 can be tied to

V

, VIN or any other voltage less than (VIN + 0.3V).

OUT

DS21354D-page 12 © 2007 Microchip Technology Inc.

TC1072/TC1073

Where:

PD

≈

(V

INMAX

– V

OUTMIN)ILOADMAX

P

D

V

INMAX

V

OUTMIN

I

LOADMAX

= Worst-case actual power dissipation

= Minimum regulator output voltage

= Maximum output (load) current

= Maximum voltage on V

IN

P

DMAX

= (T

JMAX

– T

AMAX

)

θ

JA

where all terms are previously defined.

P

DMAX

= (T

JMAX

– T

AMAX

)

θ

JA

= (125 – 55)

220

= 318 mW

5.0 THERMAL CONSIDERATIONS

5.1 Thermal Shutdown

Integrated thermal protection circuitry shuts the

regulator off when die temperature exceeds 160°C.

The regulator remains off until the die temperature

drops to approximately 150°C.

5.2 Power Dissipation

The amount of power the regulator dissipates is

primarily a function of input and output voltage, and

output current. The following equation is used to

calculate worst-case actual power dissipation:

EQUATION 5-1:

The maximum allowable power dissipation

Equation 5-2) is a function of the maximum ambient

(

temperature (T

perature (T

JMAX

tion-to-air (θ

of approximately 220°C/Watt.

), the maximum allowable die tem-

AMAX

) and the thermal resistance from junc-

). The 6-Pin SOT-23 package has a θ

JA

JA

Equation 5-1 can be used in conjunction with

Equation 5-2 to ensure regulator thermal operation is

within limits. For example:

Given:

= 3.0V ±5%

V

INMAX

V

OUTMIN

I

LOADMAX

T

JMAX

T

AMAX

= 2.7V – 2.5%

= 40 mA

= 125°C

= 55°C

Find: 1. Actual power dissipation

2. Maximum allowable dissipation

Actual power dissipation:

P

≈

(V

D

= [(3.0 x 1.05) – (2.7 x 0.975)] x 40 x 10

INMAX

– V

OUTMIN)ILOADMAX

–3

= 20.7 mW

Maximum allowable power dissipation:

In this example, the TC1072 dissipates a maximum of

20.7 mW; below the allowable limit of 318 mW. In a

similar manner,

Equation 5-1 and Equation 5-2 can be

used to calculate maximum current and/or input

voltage limits.

EQUATION 5-2:

© 2007 Microchip Technology Inc. DS21354D-page 13

5.3 Layout Considerations

The primary path of heat conduction out of the package

is via the package leads. Therefore, layouts having a

ground plane, wide traces at the pads, and wide power

supply bus lines combine to lower θ

increase the maximum allowable power dissipation

limit.

and therefore

JA

TC1072/TC1073

1

& = part number code + threshold voltage

2

(two-digit code)

3

represents year and quarter code

4

represents production lot ID code

W, Width of

Carrier Tape

User Direction of Feed

P,Pitch

Standard Reel Component

Orientation

Reverse Reel Component

Orientation

PIN 1

Device

Marking

PIN 1

Carrier Tape, Number of Components per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

6-Pin SOT-23 8 mm 4 mm 3000 7 in

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

6.2 Taping Form

(V)

1.8 EY FY

2.5 E1 F1

2.6 ET FT

2.7 E2 F2

2.8 EZ FZ

2.85 E8 F8

3.0 E3 F3

3.3 E4 F4

3.6 E9 F9

4.0 E0 F0

5.0 E6 F6

TC1072

Code

TC1073

Code

DS21354D-page 14 © 2007 Microchip Technology Inc.

TC1072/TC1073

6-Lead Plastic Small Outline Transistor (CH) [SOT-23]

Notes:

1. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.127 mm per side.

2. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 6

Pitch e 0.95 BSC

Outside Lead Pitch e1 1.90 BSC

Overall Height A 0.90 – 1.45

Molded Package Thickness A2 0.89 – 1.30

Standoff A1 0.00 – 0.15

Overall Width E 2.20 – 3.20

Molded Package Width E1 1.30 – 1.80

Overall Length D 2.70 – 3.10

Foot Length L 0.10 – 0.60

Footprint L1 0.35 – 0.80

Foot Angle φ 0° – 30°

Lead Thickness c 0.08 – 0.26

Lead Width b 0.20 – 0.51

b

E

4

N

E1

PIN 1 ID BY

LASER MARK

D

1

2

3

e

e1

A

A1

A2

c

L

L1

φ

Microchip Technology Drawing C04-028B

© 2007 Microchip Technology Inc. DS21354D-page 15

TC1072/TC1073

NOTES:

DS21354D-page 16 © 2007 Microchip Technology Inc.

APPENDIX A: REVISION HISTORY

Revision D (February 2007)

• Page 1: Ground current changed to 50 µA.

• Package type changed from SOT-23A to SOT-23.

• Added voltage options.

•T

• Section 3.0 “Pin Descriptions”: Added pin

• Section 4.1 “ERROR Open-Drain Output”:

• Changed Figure 4-2.

• Updated Packaging Information.

Revision C (January 2006)

• Undocumented changes.

Revision B (May 2002)

• Undocumented changes.

added to Table 1-1.

DELAY

descriptions.

Defined t

DELAY

.

TC1072/TC1073

Revision A (March 2002)

• Original Release of this Document.

© 2007 Microchip Technology Inc. DS21354D-page 17

TC1072/TC1073

NOTES:

DS21354D-page 18 © 2007 Microchip Technology Inc.

TC1072/TC1073

PART NO. — X XXXXX

Threshold PackageTemperature

Range

Device

Device TC1072: CMOS LDO with Shutdown, ERROR Output & V

REF

Bypass

TC1073: CMOS LDO with Shutdown, ERROR

Output & V

REF

Bypass

Threshold voltage

(typical)

1.8 = 1.8V

2.5 = 2.5V

2.6 = 2.6V

2.7 = 2.7V

2.8 = 2.8V

2.85 = 2.85V

3.0 = 3.0V

3.3 = 3.3V

3.6 = 3.6V

4.0 = 4.0V

5.0 = 5.0V

Temperature Range V = -40° C to +125° C

Package CH713 = Plastic small outline transistor (CH) SOT-23,

6 lead, (tape and reel).

Examples:

a) TC1072-1.8VCH713: 1.8V

b) TC1072-2.5VCH713 2.5V

c) TC1072-2.6VCH713 2.6V

d) TC1072-2.7VCH713 2.7V

e) TC1072-2.8VCH713 2.8V

f) TC1072-2.85VCH713 2.85V

g) TC1072-3.0VCH713 3.0V

h) TC1072-3.3VCH713 3.3V

i) TC1072-3.6VCH713 3.6V

j) TC1072-4.0VCH713 4.0V

k) TC1072-5.0VCH713 5.0V

a) TC1073-1.8VCH713: 1.8V

b) TC1073-2.5VCH713 2.5V

c) TC1073-2.6VCH713 2.6V

d) TC1073-2.7VCH713 2.7V

e) TC1073-2.8VCH713 2.8V

f) TC1073-2.85VCH713 2.85V

g) TC1073-3.0VCH713 3.0V

h) TC1073-3.3VCH713 3.3V

i) TC1073-3.6VCH713 3.6V

j) TC1073-4.0VCH713 4.0V

k) TC1073-5.0VCH713 5.0V

X.X

Vol tag e

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

© 2007 Microchip Technology Inc. DS21354D-page 19

TC1072/TC1073

NOTES:

DS21354D-page 20 © 2007 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, KEELOQ, KEELOQ logo, microID, MPLAB, PIC,

PICmicro, PICSTART, PRO MATE, PowerSmart, rfPIC, and

SmartShunt are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

AmpLab, FilterLab, Linear Active Thermistor, Migratable

Memory, MXDEV, MXLAB, PS logo, SEEVAL, SmartSensor

and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Mindi, MiWi,

MPASM, MPLAB Certified logo, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

MCUs and dsPIC® DSCs, KEELOQ

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial

© 2007 Microchip Technology Inc. DS21354D-page 21

®

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

12/08/06

DS21354D-page 22 © 2007 Microchip Technology Inc.

Loading...

Loading...