Voltage Supervisor SOT-23-5/6

Evaluation Board

User’s Guide

© 2006 Microchip Technology Inc. DS51527B

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor, Mindi,

MiWi, MPASM, MPLIB, MPLINK, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, REAL ICE, rfLAB, rfPICDEM, Select

Mode, Smart Serial, SmartTel, Total Endurance, UNI/O,

WiperLock and ZENA are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its

PICmicro

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping devices, Serial

DS51527B-page ii © 2006 Microchip Technology Inc.

VOLTAGE SUPERVISOR SOT-23-5/6

EVALUATION BOARD USER’S GUIDE

Table of Contents

Preface ............................................................................................................................ 1

Chapter 1. Product Overview ........................................................................................ 5

1.1 Introduction ..................................................................................................... 5

1.2 What is the Voltage Supervisor SOT-23-5/6 Evaluation Board? .................... 5

1.3 What the Voltage Supervisor SOT-23-5/6 Evaluation Board Kit Includes ...... 5

Chapter 2. Installation and Operation .......................................................................... 7

2.1 Introduction ..................................................................................................... 7

2.2 Features ......................................................................................................... 7

2.3 Getting Started ............................................................................................... 8

2.4 Voltage Supervisor SOT-23-5/6 Evaluation Board Description .................... 16

2.5 Voltage Supervisor/Voltage Detector Circuits .............................................. 19

2.6 Digital Potentiometer Circuit ......................................................................... 23

Appendix A. Schematics and Layouts ....................................................................... 25

A.1 Introduction .................................................................................................. 25

A.2 Schematics and PCB Layout ....................................................................... 25

A.3 Schematic .................................................................................................. 26

A.4 Board Layout – Top Layer, Bottom Layer and Silk Screen .......................... 27

A.5 Board Layout – Top Layer and Silk Screen ................................................. 28

A.6 Board Layout – Bottom Layer ...................................................................... 29

A.7 Board Layout – Ground Plane ..................................................................... 30

A.8 Board Layout – Power Layer ....................................................................... 31

A.9 Board Layout – Top Components and Silk Screen ...................................... 32

Appendix B. Bill Of Materials (BOM) .......................................................................... 33

Appendix C. Microchip SOT-23-5/6 Device Compatibility ........................................ 35

C.1 Introduction .................................................................................................. 35

C.2 PCB Compatibility ........................................................................................ 35

C.3 Ideas on Evaluating An LDO ....................................................................... 39

Worldwide Sales and Service ..................................................................................... 40

© 2006 Microchip Technology Inc. DS51527B-page iii

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

NOTES:

DS51527B-page iv © 2006 Microchip Technology Inc.

VOLTAGE SUPERVISOR SOT-23-5/6

EVALUATION BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

Voltage Supervisor SOT-23-5/6 Evaluation Board. Items discussed in this chapter

include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the Voltage Supervisor SOT-23-5/6 Evaluation

Board. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information about the Voltage

Supervisor SOT-23-5/6 Evaluation Board.

• Chapter 2. “Installation and Operation”– Includes instructions on how to get

started with the Voltage Supervisor SOT-23-5/6 Evaluation Board.

• Appendix A. “Schematics and Layouts” – Shows the schematic and layout

diagrams for the Voltage Supervisor SOT-23-5/6 Evaluation Board.

• Appendix B. “Bill Of Materials (BOM)” – Lists the parts used to build the

Voltage Supervisor SOT-23-5/6 Evaluation Board.

• Appendix C. “Microchip SOT-23-5/6 Device Compatibility” – Explains how this

board may be used with other Microchip analog devices in the SOT-23-5 or

SOT-23-6 packages.

© 2006 Microchip Technology Inc. DS51527B-page 1

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB® IDE User’s Guide

Emphasized text ...is the only compiler...

RECOMMENDED READING

Table 1-1 shows the device and associated data sheet literature number. These

documents can be downloaded from the Microchip web site at: www.microchip.com.

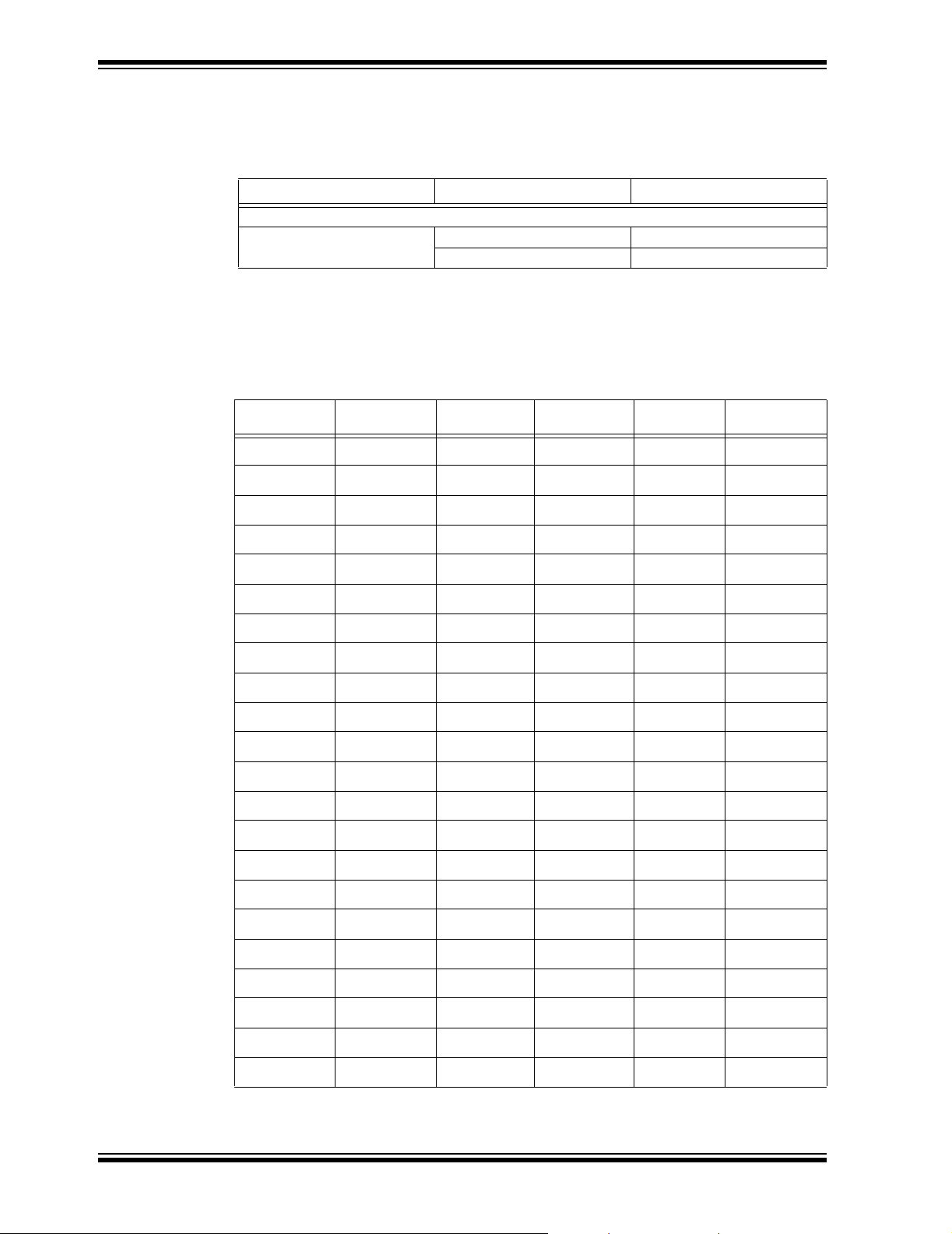

TABLE 1-1: DEVICES AND DATA SHEET LITERATURE NUMBERS

Device Literature # Device Literature # Device Literature #

MCP601 21314 MCP6541 21690 TC52 21430

MCP601R 21314 MCP6541R 21690 TC53 21432

MCP606 11177 MCP6546 21714 TC54 21434

MCP6001 21733 MCP6546R 21714 TC105 21349

MCP6001R 21733 MCP3221 21732 TC77 20092

MCP6001U 21733 MCP9800 21909 MCP603 21314

MCP6231 21881 MCP9802 21909 TC1035 21343

MCP6231R 21881 MCP4012 21978 MCP4022 21916

MCP6231U 21881 MCP4013 21978 MCP4023 21916

MCP6241 21882 MCP4014 21978 MCP4024 21916

MCP6241R 21882 TC1014 21335 MCP73826 21705

MCP6241U 21882 TC1015 21335 PIC10F200 41239

MCP1316 21985 TC1017 21813 PIC10F202 41239

MCP1317 21985 TC1054 21350 PIC10F204 41239

MCP1318 21985 TC1055 21350 PIC10F206 41239

MCP1319 21985 TC1070 21353 TC1185 21350

MCP1320 21985 TC1071 21353

MCP1321 21985 TC1034 21343 TC1187 21368

TC1186 21353

MCP1322 21985 TC1037 21344 TC1223 21368

TC2014 21662 TC1038 21344 TC1224 21368

TC2015 21662 TC1039 21344 TC2055 21663

TC2185 21662 TC2054 21663 TC2186 21663

DS51527B-page 2 © 2006 Microchip Technology Inc.

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor, representative or field application engineer

for support. Local sales offices are also available to help customers. A listing of sales

offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

Preface

DOCUMENT REVISION HISTORY

Revision B (May 2006)

• Updated Bill of Materials (BOM) to show RoHS-compliant part numbers.

Revision A (January 2005)

• Initial Release of this Document.

© 2006 Microchip Technology Inc. DS51527B-page 3

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

NOTES:

DS51527B-page 4 © 2006 Microchip Technology Inc.

VOLTAGE SUPERVISOR SOT-23-5/6

EVALUATION BOARD USER’S GUIDE

Chapter 1. Product Overview

1.1 INTRODUCTION

This chapter provides an overview of the Voltage Supervisor SOT-23-5/6 Evaluation

Board and covers the following topics:

• What is the Voltage Supervisor SOT-23-5/6 Evaluation Board?

• What the Voltage Supervisor SOT-23-5/6 Evaluation Board Kit includes

1.2 WHAT IS THE VOLTAGE SUPERVISOR SOT-23-5/6 EVALUATION BOARD?

The Voltage Supervisor SOT-23-5/6 Evaluation Board allows the system designer to

quickly evaluate the operation of Microchip Technology’s voltage supervisors and

voltage detectors in the SOT-23-5 (5-pin SOT-23) or SOT-23-6 (6-pin SOT-23)

packages.

The Voltage Supervisor SOT-23-5/6 Evaluation Board Printed Circuit Board (PCB)

supports the four different SOT-23-6 pinouts (which also supports compatible

SOT-23-5 footprints) and one SOT-23-5 footprint.

The Voltage Supervisor SOT-23-5/6 Evaluation Board has been made generic so that

other devices in the SOT-23-5 and SOT-23-6 packages may be supported with this

board. Microchip device families supported include:

• Voltage Supervisors/Voltage Detectors

• Nonvolatile Digital Potentiometers (Digi-Pots)

• Operational Amplifiers (Op Amps)

• Comparators

• Low Drop-out Regulators (LDOs)

• Thermal sensors

• Analog-to-Digital Converters (ADCs)

• PFM/PWM Step-Down DC/DC Controllers

• Battery Charger Controllers

•PICmicro

®

Microcontrollers

1.3 WHAT THE VOLTAGE SUPERVISOR SOT-23-5/6 EVALUATION BOARD KIT

INCLUDES

This Voltage Supervisor SOT-23-5/6 Evaluation Board Kit includes:

• Five Voltage Supervisor SOT-23-5/6 Evaluation Board PCBs

• Three voltage supervisor device samples that can be installed on the Voltage

Supervisor SOT-23-5/6 Evaluation Board PCBs

• Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

(Electronic version on CD)

© 2006 Microchip Technology Inc. DS51527B-page 5

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

NOTES:

DS51527B-page 6 © 2006 Microchip Technology Inc.

Chapter 2. Installation and Operation

2.1 INTRODUCTION

The blank Printed Circuit Board (PCB) allows the desired voltage supervisor/voltage

detector device to be installed along with other desired passive components (resistors

and capacitors) and connection posts.

The PCB supports four different SOT-23-6 and one SOT-23-5 pinouts. Two of these

pinouts are used by the voltage supervisor/voltage detector product family, while the

other pinouts are used by other Microchip analog and PICmicro

products (see Appendix C. “Microchip SOT-23-5/6 Device Compatibility”). The

PIC10F2XX devices uses the last pinout. This board is generic so that other devices

may be supported. However, the silk-screen markings are designed for ease-of-use

with the voltage supervisor devices.

2.2 FEATURES

The Voltage Supervisor SOT-23-5/6 Evaluation Board has the following features:

• Connection terminals may be either through-hole or surface-mount

• Four SOT-23-6 pinouts supported

- Also supports V

• One SOT-23-5 pinout supported

• Footprints for optional passive components for:

- Power supply filtering

- Device bypass capacitor

- Output filtering

- Output pull-up resistor

- Output pull-down resistor

- Output loading resistor

- Output series resistor

• Footprints for two optional switches for:

- Voltage supervisor manual resets

- PIC10F2XX general purpose inputs

• Silk screen area to write specifics of implemented circuit (on back of PCB), such

as TC52 2.7V, 10 kΩ (to indicate that the device is the TC52 with the 2.7V trip

point and an external 10 kΩ pull-up resistor on the output)

VOLTAGE SUPERVISOR SOT-23-5/6

EVALUATION BOARD USER’S GUIDE

®

microcontroller

DD/VSS

footprint-compatible SOT-23-5 devices

© 2006 Microchip Technology Inc. DS51527B-page 7

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

2.3 GETTING STARTED

The Voltage Supervisor SOT-23-5/6 Evaluation Board is a blank PCB that allows the

user to configure the circuit to their exact requirements. The passive components use

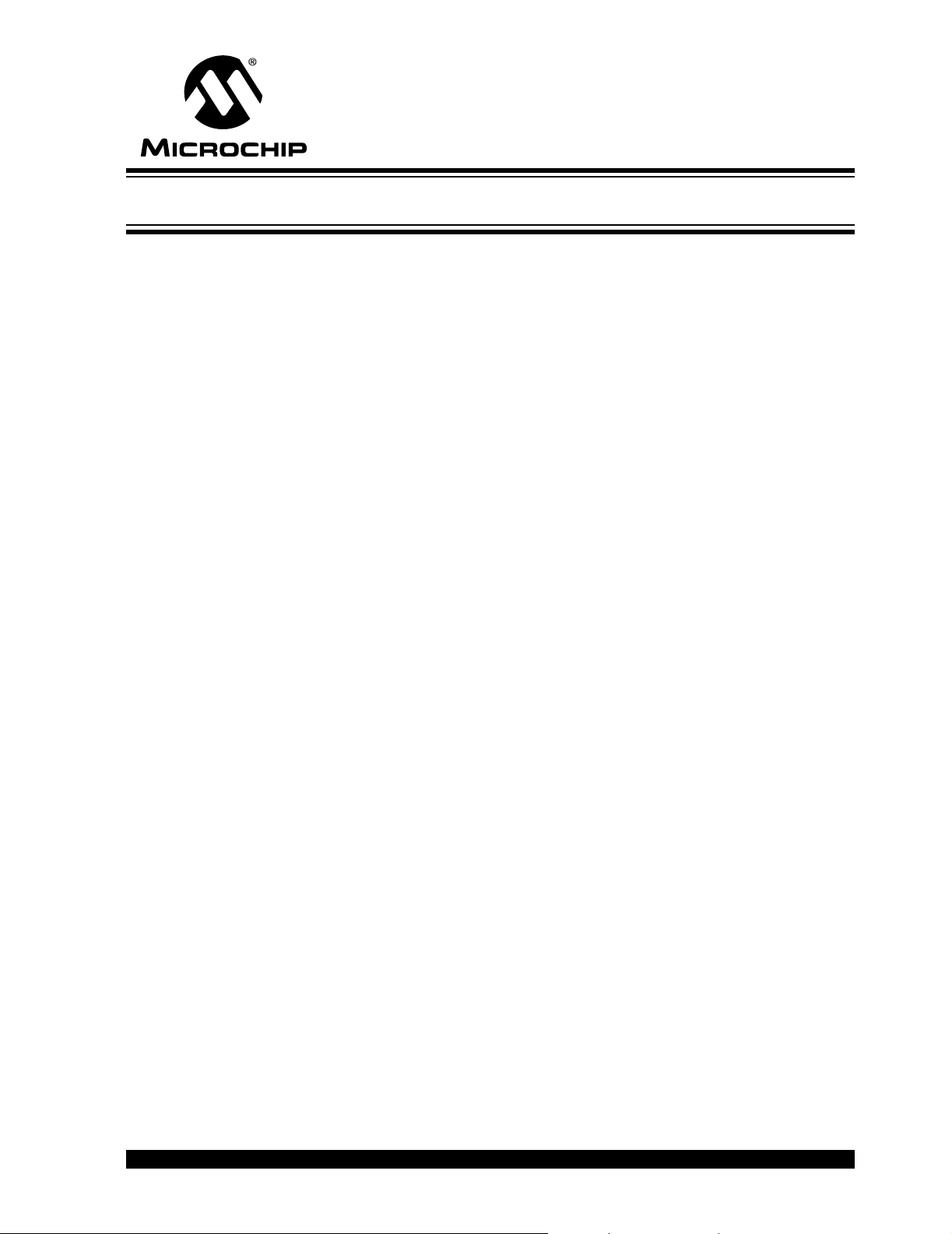

the surface-mount 805 package layout. Figure 2-1 shows the board circuit.

This evaluation board supports the following Microchip device families:

• Voltage Supervisors/Voltage Detectors

• Nonvolatile Digital Potentiometers (Digi-Pots)

• Operational Amplifiers (Op Amps)

• Comparators

• Low Drop-Out Regulators (LDOs)

• Thermal Sensors

• Aanalog-to-Digital Converters (ADCs)

• PFM/PWM Step-Down DC/DC Controllers

• Battery Charger Controllers

•PICmicro

Table 2-1 shows these product families, the devices that are supported and which

SOT-23-5/6 layout option to use. Devices that are in a 5-pin SOT-23 package can be

installed into the SOT-23-6 footprint.

Table 2-2 shows which circuit option needs to be used for a given voltage

supervisor/voltage detector. There are currently no voltage supervisors/voltage

detectors that use the option B, C or E pinout. For other Microchip analog devices,

please refer to Appendix C. “Microchip SOT-23-5/6 Device Compatibility”.

®

Microcontrollers

DS51527B-page 8 © 2006 Microchip Technology Inc.

Installation and Operation

V

DD

V

SS

A B C D E

2 6 2 3 2

BFMP Header (Top)

1

2

3

4

5

6

No Connect

TP3A (ICSPCLK)

TP1A (ICSPDT)

TP2A (V

TP5A (V

TP6A (V

SS

DD

PP

C5F

A B C D E

6 2 1 2 5

TP1A

R2A

TP 1

C5B

C1

1

2

3

C2

U1

Option A

R3A

C5A

6

5

TP4A

R2D

4

R3D

C5D

1

2

3

U2

Option B

6

5

4

TP5A

R2E

R3E

C5E

R1A

R1D

R1E

(V

OUT

V

)

IN+

A B C D E

1 1 6 1 1

S2

TP 4

(WDI

V

IN–

A B C D E

4 4 4 4 4

TP 5

(WDI

V

IN–

)

)

A B C D E

5 5 5 5 6

1

C3

)

)

2

3

U3

Option C

6

5

4

C6

)

1

5

TP2A

2

TP1A

C4

Option D

3

U4

4

TP3A

TP3A

Footprint Option

(A, B, C, D or E)

Pin Number of that

R2C

R3C

C5C

A B C D E

3 3 3 — 3

R1C

S1

TP 3

(MR

V

IN+

)

For:

Footprint Version

(1, 2, 3, 4, 5 or 6)

Footprint Option/Pin Number

Combination (Pad A3)

FIGURE 2-1: Voltage Supervisor SOT-23-5/6 Evaluation Board Circuit.

1

2

3

U5

Option E

6

5

4

TP5A

TP6A

TP4A

A B C D E

3 3 3 — 3

Version A use: MCP13XX

Version B use: MCP1035

Version C use: MCP4022

Version D use: TC52

Version E use: PIC10F200

© 2006 Microchip Technology Inc. DS51527B-page 9

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

TABLE 2-1: SUPPORTED SOT-23-5 AND SOT-23-6 DEVICES

Family Device Option # of Pins

Voltage Supervisors/Detectors TC52 D 5

TC53C D 5

TC53N D 5

TC54 D 5

MCP13XX A 5

Digital Potentiometers (Digi-Pots) – Volatile MCP4012 C 6

MCP4013 C 6

MCP4014 C 5

Digital Potentiometers (Digi-Pots) –

Nonvolatile

Operational Amplifiers (Op Amps) MCP601 A 5

Comparators MCP6541 A 5

Thermal Sensors MCP9800 C 5

Analog-to-Digital Converter (ADC) MCP3221 C 5

MCP4022 C 6

MCP4023 C 6

MCP4024 C 5

MCP601R B 5

MCP603 A 6

MCP606 A 5

MCP6001 A 5

MCP6001R B 5

MCP6001U A 5

MCP6231 A 5

MCP6231R B 5

MCP6231U A 5

MCP6241 A 5

MCP6241R B 5

MCP6241U A 5

TC1034 B 5

TC1035 B 6

MCP6541R B 5

MCP6546 A 5

MCP6546R B 5

TC1037 A 5

TC1038 A 6

TC1039 A 6

MCP9802 C 5

TC77 A 5

DS51527B-page 10 © 2006 Microchip Technology Inc.

Installation and Operation

TABLE 2-1: SUPPORTED SOT-23-5 AND SOT-23-6 DEVICES (CONTINUED)

Family Device Option # of Pins

PICmicro® Microcontrollers PIC10F200 E 6

PIC10F202 E 6

PIC10F204 E 6

PIC10F206 E 6

Low Drop-Out Regulators (LDOs) TC1014 C 5

TC1015 C 5

TC1017 C 5

TC1054 C 5

TC1055 C 5

TC1070 C 5

TC1071 C 5

TC1185 C 5

TC1186 C 5

TC1187 C 5

TC1223 C 5

TC1224 C 5

TC2014 C 5

TC2015 C 5

TC2054 C 5

TC2055 C 5

TC2185 C 5

TC2186 C 5

PFM/PWM Step-Down DC/DC Controller TC105 D 5

Battery Charger Controller MCP73826 E 6

© 2006 Microchip Technology Inc. DS51527B-page 11

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

TABLE 2-2: VOLTAGE SUPERVISOR / VOLTAGE DETECTOR DEVICES AND EVALUATION

BOARD CIRCUIT/FOOTPRINT OPTION

Device

Supported

on

MCP1316 Option A RST

Output Signal

(Active State)

(L) Push-Pull

Output Type

MCP1317 Option A RST (H) Push-Pull

MCP1318 Option A RST (H) and RST (L) Push-Pull

MCP1319 Option A RST (H) and RST

MCP1320 Option A RST

(L) Open-Drain R = TBD

MCP1321 Option A RST (H) and RST

MCP1322 Option A RST (H) and RST

TC52 Option D V

TC53C Option D V

TC53N Option D V

TC54VC Option D V

TC54VN Option D V

(L),

OUT1

V

(L)

OUT2

(L) Push-Pull

OUT

(L) Open-Drain R2A = 47 kΩ

OUT

(L) Push-Pull

OUT

(L) Open-Drain R2A = 47 kΩ

OUT

(L) Push-Pull

(L) Push-Pull and Open-Drain R = TBD

(L) Push-Pull and Open-Drain R = TBD

Open-Drain C4 = 0.1 µF, R2A = 47 kΩ

Comment/Recommended

Component Values

R2E = 47 kΩ, C1 = 1 µF

DS51527B-page 12 © 2006 Microchip Technology Inc.

Installation and Operation

2.3.1 The Hardware

Figure 2-2 shows the layout of the Voltage Supervisor SOT-23-5/6 Evaluation Board.

This is a small four-layer board (1.5" x 2" (38.1 mm x 50.8 mm)). There are six

connection points/pads that can use either through-hole or surface-mount connector

posts.

Additionally, a test point is available between the device pin and the PCB pad that may

be useful if the in-line resistor (R1A, R1C, R1D or R1E) is installed.

The different SOT-23 layout options are outlined in Section 2.4.3 “SOT-23-6 and

SOT-23-5 Footprints”, with Opt A, Opt B, Opt C, Opt D and Opt E indicating the layout

option of that SOT-23-5/6 footprint.

There are six pads on the PCB. One is labeled VDD, one is labeled VSS, with all pads

having a label that indicates the footprint option used (shown as “A B C D E”) and a

label underneath that indicates the pin number of that footprint. This footprint option/pin

number combination will be used to indicate the remaining pads. If the device is placed

in the option A footprint, the remaining pads would be A1, A3, A4 and A6, where the

VDD pad is also A6 and the VSS pad is A2. Figure 2-2 has text added on each pad to

show what the “pad name” would be (A1, A2, A3, A4, A5 and A6). If the device required

the option C footprint, what is currently A1 for option A would then be referred to as pad

C6 for option C.

Each of these four pads has four passive components associated with them. A pull-up

resistor, a pull-down resistor, an in-line resistor and a filtering/load capacitor. The

pull-up resistor is always R2x, the pull-down resistor is R3x, the in-line resistor is R1x

and the filtering/load capacitor is C5x. The “x” is an alpha character that corresponds

to a particular pad. So pad A1’s pull-up resistor is R2A.

The green area of Figure 2-2 shows the silk screen on the bottom layer of the PCB.

This is where the details of the implemented circuit can be written.

Resistor R2x is a pull-up resistor that may need to be installed for devices with an

open-drain output. Though resistor R3x is not currently required, it was placed for

possible future requirements. Resistor R1x is not required, but may be useful if this

board is to be interfaced into existing circuits. If resistor R1x is to be installed, remember to cut the trace that “shorts out” R3. Capacitors C1, C2, C3, C4, C6, C5A, C5C,

C5D, C5E and C5F are bypass capacitors that may be required to be installed, depending on the device selected and the system requirements (such as the noise present on

the power supply). Table 2-3 describes the components.

© 2006 Microchip Technology Inc. DS51527B-page 13

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

A6

A3

A1

A5

A2

FIGURE 2-2: Voltage Supervisor SOT-23-5/6 Evaluation Board Layout with added “Pad Names”.

A4

TABLE 2-3: OPTIONAL PASSIVE COMPONENTS

Device Comment

C1, C2, C3, C4, C5, C5F, C6 Power supply bypass capacitor

C5A, C5C, C5D, C5E Output filter capacitor

R1, R3A, R3C, R3D, R3E Pull-up resistor

R2, R2A, R2C, R2D, R2E Pull-down resistor

R1A, R1C, R1D, R1E In-line resistance of device output

S1, S2 Switches

DS51527B-page 14 © 2006 Microchip Technology Inc.

Installation and Operation

2.4 VOLTAGE SUPERVISOR SOT-23-5/6 EVALUATION BOARD DESCRIPTION

The Voltage Supervisor SOT-23-5/6 Evaluation Board PCB is designed to be flexible in

the type of device evaluation that can be implemented.

The following sections describe each element of this evaluation board in further detail.

2.4.1 Power and Ground

The Voltage Supervisor SOT-23-5/6 Evaluation Board can have connection posts

installed for the power (V

through-hole or surface-mount connectors.

For device evaluation, the use of an external variable power supply or waveform

generator is required. The type of equipment used will determine the evaluation that

may be performed.

2.4.2 Pads A1, A3, A4 and A5 (for Footprint Option A)

The Voltage Supervisor SOT-23-5/6 Evaluation Board can have a connection post

installed for the pads A1, A3, A4 and A5 signals. Depending on the device installed,

this could be an input, output or bidirectional I/O signal. The layout allows either a

through-hole connector or a surface mount connector.

For device evaluation, the use of an oscilloscope or Digital Voltmeter (DVM) is required.

The type of equipment used will determine the evaluation that may be performed.

) and ground (VSS) planes. The layout allows either

DD

© 2006 Microchip Technology Inc. DS51527B-page 15

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

2.4.3 SOT-23-6 and SOT-23-5 Footprints

There are four SOT-23-6 and one SOT-23-5 pinout options that the Voltage Supervisor

SOT-23-5/6 Evaluation Board PCB supports. Figure 2-3 shows these four pinouts.

Figure 2-4 shows the single SOT-23-5 pinout option. Some devices may use different

nomenclature for the pin names, such as GND instead of V

RESET (or RESET

) or RST instead of V

OUT

.

Other Microchip analog devices may be used with this PCB if the power and ground

pins match one of these four options. Appendix C. “Microchip SOT-23-5/6 Device

Compatibility” discusses other Microchip analog devices that may be used with this

PCB.

, VIN instead of VDD and

SS

Option A

1

V

2

SS

3

V

DD

6

5

4

V

Option B Option C Option E

V

SS

V

DD

V

SS

DD

1

2

3

6

5

4

FIGURE 2-3: SOT-23-6 (and SOT-23-5) Pinout Options.

Option D

1

V

2

DD

V

3

SS

5

4

FIGURE 2-4: SOT-23-5 Pinout Option.

2.4.4 Passive Components (R1x, R2x, R3x, C5x, R1, R2, C1, C2, C3,

C4 and C6)

The footprints for these components are present to allow maximum flexibility in the use

of this PCB to evaluate a wide range of SOT-23-3 devices. The purpose of these components may vary depending on the device under evaluation and how it is to be used

in the desired circuit. Please refer to the device data sheet for the recommended

components that should be used when evaluating that device.

1

2

3

6

5

4

1

V

2

SS

3

6

V

5

DD

4

2.4.5 Switches (S1 and S2)

The footprints for these components are present to allow maximum flexibility in the use

of this PCB to evaluate a wide range of SOT-23-5 and SOT-23-6 devices. The purpose

of these components may vary depending on the device under evaluation and how it is

to be used in the desired circuit. Please refer to the device data sheet for the

recommended components that should be used when evaluating that device.

2.4.6 BFMP Interface (Header J1)

The Baseline Flash Microcontroller Programmer (BFMP) interface allows a

PIC10F2XX device that is populated in the SOT-23-6 version E footprint to be

programmed with programmers that support this interface, such as the BFMP

programmer (part number PG164101).

DS51527B-page 16 © 2006 Microchip Technology Inc.

Installation and Operation

2.5 VOLTAGE SUPERVISOR/VOLTAGE DETECTOR CIRCUITS

Currently, the voltage detectors/voltage supervisors use either footprint option A or

footprint option D.

2.5.1 Option D Circuit

Using the TC53C or TC54VC, no passive components would be required and the

device V

Using the TC53N or TC54VN, an external pull-up resistor is required. This resistor

would be installed in the R2A location and the device V

D1 pad.

The TC52 is a dual-channel voltage detector. This means that the device has a V

and a V

Locations R2A and R2E should be installed with 47 kΩ resistors.

Detect voltage 2 (V

typically used to indicate a low-power situation, with V

system. Typically, a 0.1 µF capacitor would be on the V

location).

Power supply filtering may be required, so a 0.1 µF capacitor is suggested in the C4

location.

could be monitored on the D1 pad.

OUT

could be monitored on the

OUT

output. Both outputs are open-drain and require a pull-up resistor.

OUT2

) is lower than detect voltage 1 (V

OUT2

OUT1

being used to reset the

OUT2

pin (installed in the C5E

OUT2

). Therefore, V

OUT1

OUT1

is

V

SS

A B C D E

2 6 2 3 2

TP3A

R2C

C5C

Footprint Version

(A, B, C, D or E)

Pin Number of that

Footprint Version

(1, 2, 3, 4, 5 or 6)

R3C

Option D

1

2

C4

3

S1

R1C

A B C D E

5 5 5 5 6

TP1A

C5A

5

TC5X

4

U4

C5E

TP 3

(MR

V

)

IN+

A B C D E

3 3 3 — 3

Footprint Option/Pin Number

Combination (Pad D5)

C5D

C5F

TP5A

TP4A

R2A

R3A

R2E

R3E

R2D

R3D

R1A

R1D

R1E

V

DD

A B C D E

6 2 1 2 5

TP 1

(V

OUT

V

)

IN+

A B C D E

1 1 6 1 1

TP 5

(WDI

V

IN–

A B C D E

5 5 5 5 6

S2

(WDI

V

IN–

A B C D E

4 4 4 4 4

)

TP 4

)

FIGURE 2-5: Voltage Supervisor Circuit using Option D Footprint.

© 2006 Microchip Technology Inc. DS51527B-page 17

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

2.5.2 Option A Circuit

The MCP13XX devices are only in the SOT-23-5 (5-pin) package, therefore option A

footprint pin 5 is not connected to the device. Once the device is released, please refer

to the data sheet to determine your desired circuit.

V

DD

C5F

A B C D E

6 2 1 2 5

V

SS

A B C D E

2 6 2 3 2

TP3A

R2C

C5C

Footprint Version

(A, B, C, D or E)

Pin Number of that

Footprint Version

(1, 2, 3, 4, 5 or 6)

R3C

C1

R1C

A B C D E

3 3 3 — 3

C5A

Option A

1

2

3

S1

Footprint Option/Pin Number

Combination (Pad A3)

6

5

MCP13XX

4

U1

TP 3

(MR

VIN+)

A B C D E

3 3 3 — 3

MCP13XX devices

do not use this pin.

TP1A

C5E

C5D

TP5A

TP4A

R2A

R3A

R2E

R3E

R2D

R3D

R1A

R1D

R1E

TP 1

(V

OUT

VIN+)

A B C D E

1 1 6 1 1

TP 5

(WDI

V

IN

A B C D E

5 5 5 5 6

S2

(WDI

VIN–)

A B C D E

4 4 4 4 4

–)

TP 4

FIGURE 2-6: Voltage Supervisor Circuit using Option A Footprint.

DS51527B-page 18 © 2006 Microchip Technology Inc.

V

SS

Installation and Operation

2.5.3 A Circuit with the PIC10F200 and a Voltage Supervisor

(MCP13XX)

The PIC10F200 can be used to show the operation of the Watchdog Timer feature

(WDI) or the Manual Reset (MR

devices.

Figure 2-7 shows the schematic to interface the appropriate MCP13XX device to the

PIC10F200 to exercise the Watch Dog Timer (WDI) and Manual Reset (MR

functionality of the device.

After the release of the MCP13XX devices, please check the Microchip web site for an

application note or technical brief that will demonstrate one of the MCP13XX devices

using the Voltage Supervisor SOT-23-5/6 Evaluation Board.

A B C D E

2 6 2 3 2

C1

Option A

1

2

3

U1

MCP13XX

) inputs that are available on some of the MCP13XX

C5F

TP1A

R2A

C5A

6

5

4

MCP13XX devices

do not use this pin.

R3A

R1A

TP4A

)

V

DD

A B C D E

6 2 1 2 5

TP 1

(V

OUT

VIN+)

A B C D E

1 1 6 1 1

TP 4

C6

BFMP Header (Top)

1

2

3

4

5

6

No Connect

TP3A (ICSPCLK)

TP1A (ICSPDT)

V

SS

V

DD

TP5A (VPP)

Footprint Option

(A, B, C, D or E)

Pin Number of that

Footprint Version

(1, 2, 3, 4, 5 or 6)

TP3A

C5C

A B C D E

3 3 3 — 3

GP1

GP0

1

2

PIC10F200

3

U5

Option E

R2C

R3C

Footprint Option/Pin Number

Combination (Pad A3)

GP3/MCLR

6

5

GP2

4

R1C

FIGURE 2-7: MCP13XX and a PIC10F200 Circuit.

S1

C5E

TP5A

R2E

R3E

TP 3

(MR

VIN+)

R1E

A B C D E

3 3 3 — 3

(WDI

VIN–)

A B C D E

4 4 4 4 4

TP 5

(WDI

VIN–)

A B C D E

5 5 5 5 6

© 2006 Microchip Technology Inc. DS51527B-page 19

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

2.5.4 Evaluating a Voltage Supervisor or Voltage Detector Device

When evaluating a voltage supervisor/voltage detector device, a minimum set of test

equipment should be available. Table 2-4 shows the recommended test equipment.

TABLE 2-4: TEST EQUIPMENT

Hardware Connect to: Comment

Variable Power

Supply

Arbitrary

Waveform

Generator

Digital Multi-Meter

(D.M.M.)

Oscilloscope V

Test Light (LED) V

Note 1: The pad connection to connect to the V

device and the footprint option used.

A typical system that would be used to evaluate the voltage supervisor or voltage

detector device is shown in Figure 2-8. This also shows an example of input and output

waveforms for a voltage supervisor or voltage detector device.

VDD, VSS This allows the voltage to the SOT23 Evaluation Board

to be varied so the device output can be monitored.

VDD, VSS This is like a variable power supply, but allows program-

mability into the input signal that the device will be

subjected to. This also allows a particular waveform to

be repeated (such as a 60 Hz sine wave that varies from

1V to 5V).

(1)

V

OUT

Used to indicate the output state (low or high) of the

voltage supervisor/voltage detector.

(1)

OUT

Allows the device conditions and response to be

evaluated due to the ability to capture this information.

This is useful for faster signals and cases where small

spikes need to be detected.

(1)

OUT

Used to visually indicate the output state (low or high) of

the voltage supervisor/voltage detector. Ensure that the

current requirements of this LED can be supplied by the

device’s output pin.

or RST pin will be dependent on the

OUT

SOT-23-5/6 Evaluation Board PCB

Variable

Power

Supply

or

Arbitrary

Waveform

Generator

Arbitrary Waveform

Generator

Output

Test

Point or

V

OUT

Voltage

Supervisor

or

Voltage

Detector

Device VDD out of valid operating range.

Output voltage may be indeterminate.

FIGURE 2-8: Evaluation System.

C5

R2

R3

R1

Test Point

PCB

Pad

Oscilloscope

DS51527B-page 20 © 2006 Microchip Technology Inc.

2.6 DIGITAL POTENTIOMETER CIRCUIT

The Voltage Supervisor SOT-23-5/6 Evaluation Board can be utilized to demonstrate

and test Microchip’s SOT-23-5 and SOT-23-6 nonvolatile digital potentiometers. This is

accomplished by populating the PCB with the desired MCP401X or MCP402X device,

a PIC10F2XX microcontroller, two momentary switches and a few resistors.

Note: Microchip Technology Inc. offers a built-up evaluation board for the

MCP402X Digital Potentiometer (MCP402XEV). Additional information

regarding this evaluation board may be found on the CD-ROM directory:

CD-ROM:\00066 - MCP402X Digital Potentiometer Evaluation Board. Within this directory, you will find the user’s guide for this

evaluation board, the PIC10F200 program (firmware) and assembled HEX

file (00066_MCP402XEV.hex).

The code supplied for this evaluation board may be easily modified to demonstrate

operation of the Voltage Supervisor SOT-23-5/6 Evaluation Board.

Section 2.3 and Section 2.4 of the MCP401X/2X Digital Potentiometer Evaluation

Board User’s Guide (DS51546) discuss the MCP402XEV firmware. This firmware can

easily be modified to demonstrate using the Voltage Supervisor SOT-23-5/6 Evaluation

Board.

Figure 2-9 illustrates an example circuit. This circuit uses the MCP4023 and

PIC10F200 devices with all the components installed. The PCB silk-screen indicates

the VDD and VSS pads. The remaining PCB pads will be referred to by their footprint

option/pin number combination. These combinations are C3, C4, C5 and C6.

The PIC10F2XX will need to be programmed to make the system work. The

PIC10F2XX device can be programmed via the Baseline Flash Microcontroller

Programmer (BFMP) header (J1). The program (firmware) configures the GP1 and

GP2 pins to be outputs (driving high) and the GP0 and GP3 pins to be inputs. The GP1

and GP2 pins are individually polled to determine if either switch S1/D (down) and S2/U

(up) are depressed.

If the nonvolatile MCP402X device is used, the digital potentiometer setting can be

stored in nonvolatile memory, power can be cycled and the digital potentiometer will be

at the last saved setting for the volatile versions of the device. The wiper will go to its

default setting when power is cycled.

Installation and Operation

Note: The PIC10F2XX program (firmware) must take care in the timing require-

ments of the GP1 and GP2 pins, due to the multiplexing of the PIC10F2XX

GP1 pin with the MCP4023 U/D

the PIC10F2XX GP2 pin with the MCP4023 CS pin and switch S2.

© 2006 Microchip Technology Inc. DS51527B-page 21

pin and Switch S1, and the multiplexing of

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

A B C D E

V

DD

1 1 1 1 1

C6

1

2

PIC10F200

3

U5

Option E

C5F

Option C

1

2

MCP4023

B

V

DD

V

SS

W

A

6

5

6

5

4

C3

R2A

0Ω

V

SS

A B C D E

2 2 2 2 2

A B C D E

A

6 6 6 6 6

A B C D E

W

5 5 5 5 5

3

U/D CS

U3

4

TP4A

Cut Trace

S2

A B C D E

R1D

Cut Trace

4 4 4 4 4

2.2 kΩ

Cut Trace

TP3A

S1

A B C D E

3 3 3 3 3

BFMP Header (Top)

1

2

3

4

5

6

No Connect

TP3A (ICSPCLK)

TP1A (ICSPDT)

V

SS

V

DD

TP5A (VPP)

Footprint Option

(A, B, C, D or E)

Pin Number of that

Footprint Version

R1C

2.2 kΩ

A B C D E

3 3 3 — 3

Cut Trace

Footprint Option/Pin Number

Combination (Pad C3)

(1, 2, 3, 4, 5 or 6)

FIGURE 2-9: Circuit Utilizing the MCP4023 Digital Pot and the PIC10F200 Microcontroller.

DS51527B-page 22 © 2006 Microchip Technology Inc.

VOLTAGE SUPERVISOR SOT-23-5/6

EVALUATION BOARD USER’S GUIDE

Appendix A. Schematics and Layouts

A.1 INTRODUCTION

This appendix contains the schematics and layouts for the Voltage Supervisor

SOT-23-5/6 Evaluation Board. Diagrams included in this appendix:

• Board Schematic - Digital Circuitry

• Board - Top Layer

A.2 SCHEMATICS AND PCB LAYOUT

Figure A.3 shows the schematic of the Voltage Supervisor SOT-23-5/6 Evaluation

Board.

Figure A.4 shows the layout for the top layer of the Voltage Supervisor SOT-23-5/6

Evaluation Board. The layer order is shown in Figure A-1.

FIGURE A-1: LAYER ORDER

Top Layer

Ground Layer

Power Layer

Bottom Layer

© 2006 Microchip Technology Inc. DS51527B-page 25

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

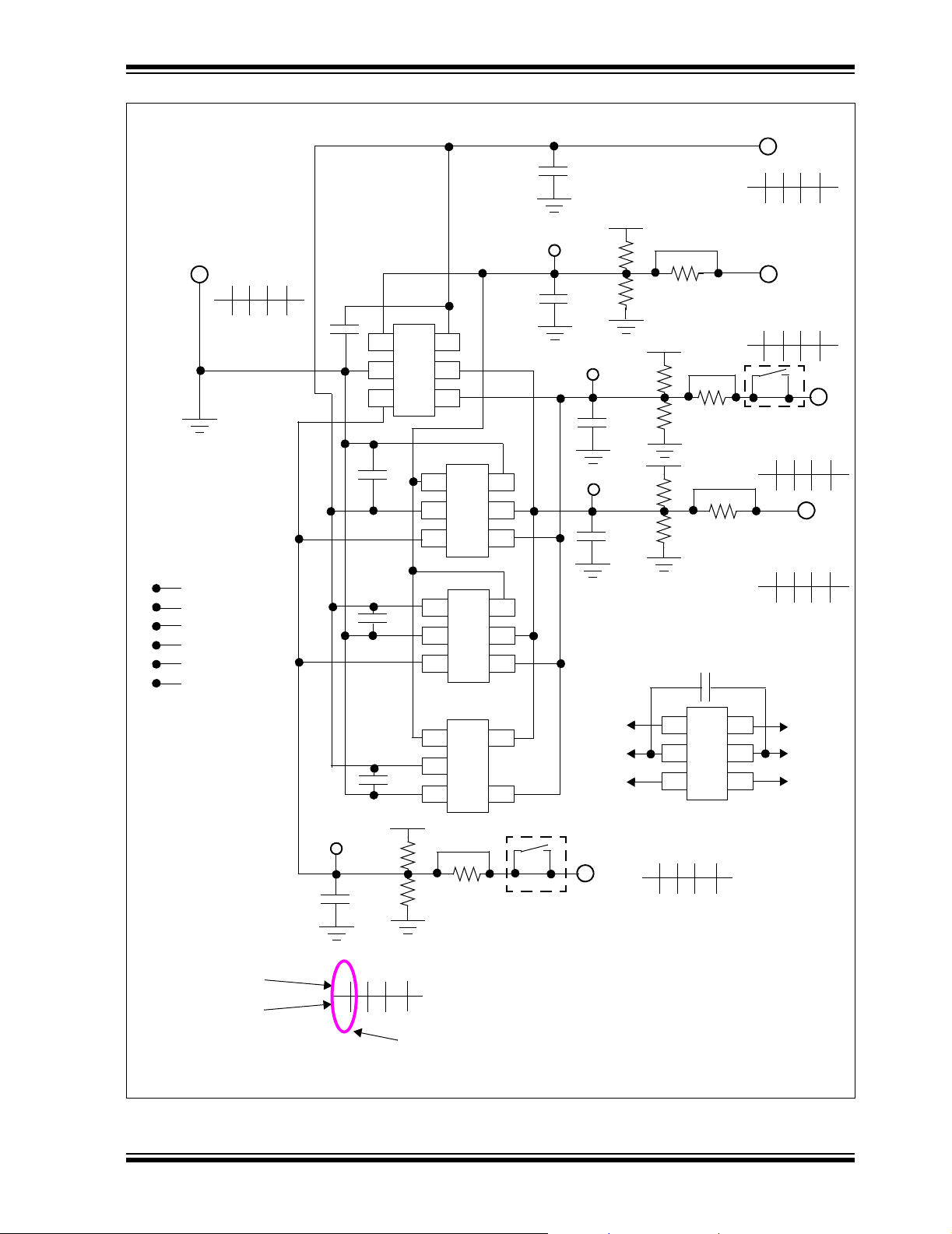

A.3 SCHEMATIC

MM

DS51527B-page 26 © 2006 Microchip Technology Inc.

Schematics and Layouts

A.4 BOARD LAYOUT – TOP LAYER, BOTTOM LAYER AND SILK SCREEN

© 2006 Microchip Technology Inc. DS51527B-page 27

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

A.5 BOARD LAYOUT – TOP LAYER AND SILK-SCREEN

DS51527B-page 28 © 2006 Microchip Technology Inc.

A.6 BOARD LAYOUT – BOTTOM LAYER

Schematics and Layouts

© 2006 Microchip Technology Inc. DS51527B-page 29

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

A.7 BOARD LAYOUT – GROUND PLANE

DS51527B-page 30 © 2006 Microchip Technology Inc.

A.8 BOARD LAYOUT – POWER LAYER

Schematics and Layouts

© 2006 Microchip Technology Inc. DS51527B-page 31

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

A.9 BOARD LAYOUT – TOP COMPONENTS AND SILK SCREEN

DS51527B-page 32 © 2006 Microchip Technology Inc.

VOLTAGE SUPERVISOR SOT-23-5/6

EVALUATION BOARD USER’S GUIDE

Appendix B. Bill Of Materials (BOM)

TABLE B-1: BILL OF MATERIALS

Qty

1 PCB 103-00050 Voltage Supervisor SOT-23-5/6 Evaluation

0 U1, U2, U3, U5 SOT-23-6 Device

0 U4 SOT-23-5 Device

0 C1, C2, C3, C4, C6 Device Power Supply Bypass Capacitor

0 C5F Power Supply Bypass Capacitor

0 C5A, C5C, C5D,

0 R2A, R2C, R2D,

0 R3A, R3C, R3D,

0 R1A, R1C, R1D,

0 R1 BFMP Header pin 1 pull up resistor

0 R2 BFMP Header pin 1 pull down resistor

0 J1 BFMP Header (6-pin, 100 mil spacing) — —

0 TP1A, TP3A, TP4A,

0S1, S2

0 S1, S2 Surface-mount Switch Panasonic EVQ-PJ504K

0V

0V

Note 1: This reference is a description of the silk screen name “A B C D E” that matches the footprint version

Reference Description Manufacturer Part Number

Board PCB

(Only one of U1 - U5 installed per board)

(Only one of U1 - U5 installed per board)

Microchip

Technology Inc.

Microchip

Technology Inc.

Microchip

Technology Inc.

103-00050

User-specified

User-specified

— User-specified

Surface-mount (805 package)

(Optional - Application-dependent)

— User-specified

Surface-mount (805 package)

(Optional - Application-dependent)

C5E

Output Filer Capacitor

Surface-mount (805 package)

— User-specified

(Optional - Application-dependent)

R2E

Output Pull-up resistor

Surface-mount (805 package)

— User-specified

(Optional - Application-dependent)

R3E

Output Pull-down resistor

Surface-mount (805 package)

— User-specified

(Optional - Application-dependent)

R1E

Output inline resistor

Surface-mount (805 package)

— User-specified

(Optional - Application-dependent)

(2)

——

(2)

——

5012

EVQ-ATA048

5012

5016

TP5A, H1TP

(3)

, VSS, A1

DD

(1)

(1)

, A4

A3

, VSS, A1

DD

(1)

(1)

, A4

A3

(1)

, A5

(1)

, A5

Through-hole Test Point connector Keystone

Through-hole Switch

V

,

(1)

,

(1)

, VSS and the other PCB Pads (A1

DD

(1)

, A5

A4

V

, VSS and the other PCB Pads (A1

DD

(1)

, A5

A4

(1)

) through-hole connector

(1)

) surface-mount connector

(3)

(1)

(1)

, A3

, A3

(1)

(1)

,

,

Electronics

Panasonic

Keystone

Electronics

Keystone

Electronics

®

®

®

®

option to the package pin number (“1 2 3 4 5 6”).

For example, A1 means footprint version option A, package pin number 1.

2: The current BFMP programming specifications has pin 1 (J1-1) unconnected. These footprints are to

support possible future functionality enhancements.

3: Revision 1 of the PCB has through-holes that are too small to support this switch. For Revision 1 boards,

please use surface-mount switches.

© 2006 Microchip Technology Inc. DS51527B-page 33

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

NOTES:

DS51527B-page 34 © 2006 Microchip Technology Inc.

VOLTAGE SUPERVISOR SOT-23-5/6

EVALUATION BOARD USER’S GUIDE

Appendix C. Microchip SOT-23-5/6 Device Compatibility

C.1 INTRODUCTION

This appendix documents other Microchip analog devices that can be evaluated using

the Voltage Supervisor SOT-23-5/6 Evaluation Board. New devices may be introduced

after the publication of this document that may be supported. Compare the pinout of

the device to the PCB schematic/layout to determine compatibility of any SOT-23-5

(5-pin SOT-23) or SOT-23-6 (6-pin SOT-23) packaged device.

C.2 PCB COMPATIBILITY

There are four SOT-23-6 (6-pin SOT-23) pinouts that the Voltage Supervisor

SOT-23-5/6 Evaluation Board PCB supports. Figure C-1 shows these four pinouts.

There is an additional SOT-23-5 (5-pin SOT-23) pinout that the Voltage Supervisor

SOT-23-5/6 Evaluation Board PCB supports. Figure C-2 shows this pinout. Other

Microchip analog devices may be used with this PCB if the power and ground pins

match these available options. Though these devices may use different nomenclature

for the pin names, as long as the power and ground signals match one of the four

options, this PCB should be able to be used to evaluate that device.

Table C-1 shows the Microchip analog device part number, the analog family the device

belongs to, which footprint option to use and the recommended components to use for

the circuit. Please refer to the device data sheet for complete information on the

application circuit.

Option A

1

V

2

SS

3

V

6

DD

5

4

Option B Option C Option E

V

1

V

2

DD

3

6

5

4

SS

V

DD

V

SS

FIGURE C-1: SOT-23-6 (and SOT-23-5) Pinout Options.

Option D

1

V

2

DD

V

3

SS

5

4

FIGURE C-2: SOT-23-5 Pinout Option.

1

2

3

6

5

4

1

V

2

SS

3

6

V

5

DD

4

© 2006 Microchip Technology Inc. DS51527B-page 35

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

TABLE C-1: MICROCHIP ANALOG AND PIC®MICRO DEVICES AND SOT-23-5/6 EVALUATION

BOARD CIRCUIT/FOOTPRINT OPTION SELECTION

Device Family Device

Digital Potentiometers

(Digi-Pots) – Volatile

Digital Potentiometers

(Digi-Pots) – Nonvolatile

Operational Amplifiers

(Op Amps)

MCP4012 C 6 See Device Data Sheet (DS21978) for

MCP4013 C 6 See Device Data Sheet (DS21978) for

MCP4014 C 5 See Device Data Sheet (DS21978) for

MCP4022 C 6 See Device Data Sheet (DS21916) for

MCP4023 C 6 See Device Data Sheet (DS21916) for

MCP4024 C 5 See Device Data Sheet (DS21916) for

MCP601 A 5 See Device Data Sheet (DS21314) for

MCP601R B 5 See Device Data Sheet (DS21314) for

MCP603 A 6 See Device Data Sheet (DS21314) for

MCP606 A 5 See Device Data Sheet (DS11177) for

MCP6001 A 5 See Device Data Sheet (DS21733) for

MCP6001R B 5 See Device Data Sheet (DS21733) for

MCP6001U A 5 See Device Data Sheet (DS21733) for

MCP6231 A 5 See Device Data Sheet (DS21881) for

MCP6231R B 5 See Device Data Sheet (DS21881) for

MCP6231U A 5 See Device Data Sheet (DS21881) for

MCP6241 A 5 See Device Data Sheet (DS21882) for

MCP6241R B 5 See Device Data Sheet (DS21882) for

MCP6241U A 5 See Device Data Sheet (DS21882) for

TC1034 B 5 See Device Data Sheet (DS21343) for

TC1035 B 6 See Device Data Sheet (DS21343) for

Option

Supported

On

# of

Pins

Comment

Recommended Component Values:

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

DS51527B-page 36 © 2006 Microchip Technology Inc.

Microchip SOT-23-5/6 Device Compatibility

TABLE C-1: MICROCHIP ANALOG AND PIC®MICRO DEVICES AND SOT-23-5/6 EVALUATION

BOARD CIRCUIT/FOOTPRINT OPTION SELECTION (CONTINUED)

Option

Device Family Device

Comparators MCP6541 A 5 See Device Data Sheet (DS21696) for

MCP6541R B 5 See Device Data Sheet (DS21696) for

MCP6546 A 5 See Device Data Sheet (DS21714) for

MCP6546R B 5 See Device Data Sheet (DS21714) for

TC1037 A 5 See Device Data Sheet (DS21344) for

TC1038 A 6 See Device Data Sheet (DS21344) for

TC1039 A 6 See Device Data Sheet (DS21344) for

Thermal Sensors MCP9800 C 5 C3 = 0.1 µF

MCP9802 C 5 C3 = 0.1 µF

TC77 A 5 C1 = 0.1 µF

A/D Converter (ADC) MCP3221 C 5 See Device Data Sheet (DS21732) for

Supported

On

# of

Pins

Comment

Recommended Component Values:

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

R2C = 10 kΩ

R2D = 10 kΩ

R2A = 10 kΩ

R2C = 10 kΩ

R2D = 10 kΩ

R2A = 10 kΩ

recommended components

© 2006 Microchip Technology Inc. DS51527B-page 37

Voltage Supervisor SOT-23-5/6 Evaluation Board User’s Guide

TABLE C-1: MICROCHIP ANALOG AND PIC®MICRO DEVICES AND SOT-23-5/6 EVALUATION

BOARD CIRCUIT/FOOTPRINT OPTION SELECTION (CONTINUED)

Device Family Device

Low Drop-Out

Regulators (LDOs)

®

PICmicro

Microcontrollers

PFM/PWM Step-Down

DC/DC Controller

Battery Charger

Controller

TC1014 C 5 C3 = 1 µF

TC1015 C 5 See Device Data Sheet (DS21335) for

TC1017 C 5 See Device Data Sheet (DS21813) for

TC1054 C 5 See Device Data Sheet (DS21350) for

TC1055 C 5 See Device Data Sheet (DS21350) for

TC1070 C 5 See Device Data Sheet (DS21353) for

TC1071 C 5 See Device Data Sheet (DS21353) for

TC1185 C 5 See Device Data Sheet (DS21350) for

TC1186 C 5 See Device Data Sheet (DS21353) for

TC1187 C 5 See Device Data Sheet (DS21368) for

TC1223 C 5 See Device Data Sheet (DS21368) for

TC1224 C 5 See Device Data Sheet (DS21368) or

TC2014 C 5 See Device Data Sheet (DS21662) for

TC2015 C 5 See Device Data Sheet(DS21662) for

TC2054 C 5 See Device Data Sheet (DS21663) for

TC2055 C 5 See Device Data Sheet (DS21663) for

TC2185 C 5 See Device Data Sheet (DS21662) for

TC2186 C 5 See Device Data Sheet (DS21663) for

PIC10F200 E 6 C6 = 1 µF

PIC10F202 E 6 C6 = 1 µF

PIC10F204 E 6 C6 = 1 µF

PIC10F206 E 6 C6 = 1 µF

TC105 D 5 See Device Data Sheet (DS21349) for

MCP73826 E 6 See Device Data Sheet (DS21705) for

Option

Supported

On

# of

Pins

Comment

Recommended Component Values:

C5A = 1 µF

C5D = 470 pF

Pad C3 (schematic TP3) connected to pad

V

DD

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

recommended components

DS51527B-page 38 © 2006 Microchip Technology Inc.

Microchip SOT-23-5/6 Device Compatibility

C.3 IDEAS ON EVALUATING AN LDO

One of the characteristics that a designer may wish to evaluate on a LDO is how the

LDO responds to transient loads. Figure C-3 shows a system block diagram for

evaluating a LDO and a typical waveform response (at test point) for the function

generator signal. The output of the function generator connects to a BJT transistor to

simulate the fast switching loads of the circuit.

The value of C2, R3 and C

Look at both the worst-case amplitude load requirements for a loaded and unloaded

system. As the output response of the LDOs become faster, the selection of a smaller

(cheaper) output load capacitor (C

performance).

Power

Supply

Function

Generator

Output

Test

Point

will depend on the LDO used and the load of the circuit.

L

SOT-23 Evaluation Board PCB

LDO

) becomes possible (for the same system

L

R3

C2

C

L

Test Point

From Function

Generator

FIGURE C-3: LDO Evaluation System.

© 2006 Microchip Technology Inc. DS51527B-page 39

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-5160-8631

Fax: 91-11-5160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

02/16/06

DS51527B-page 40 © 2006 Microchip Technology Inc.

Loading...

Loading...