Page 1

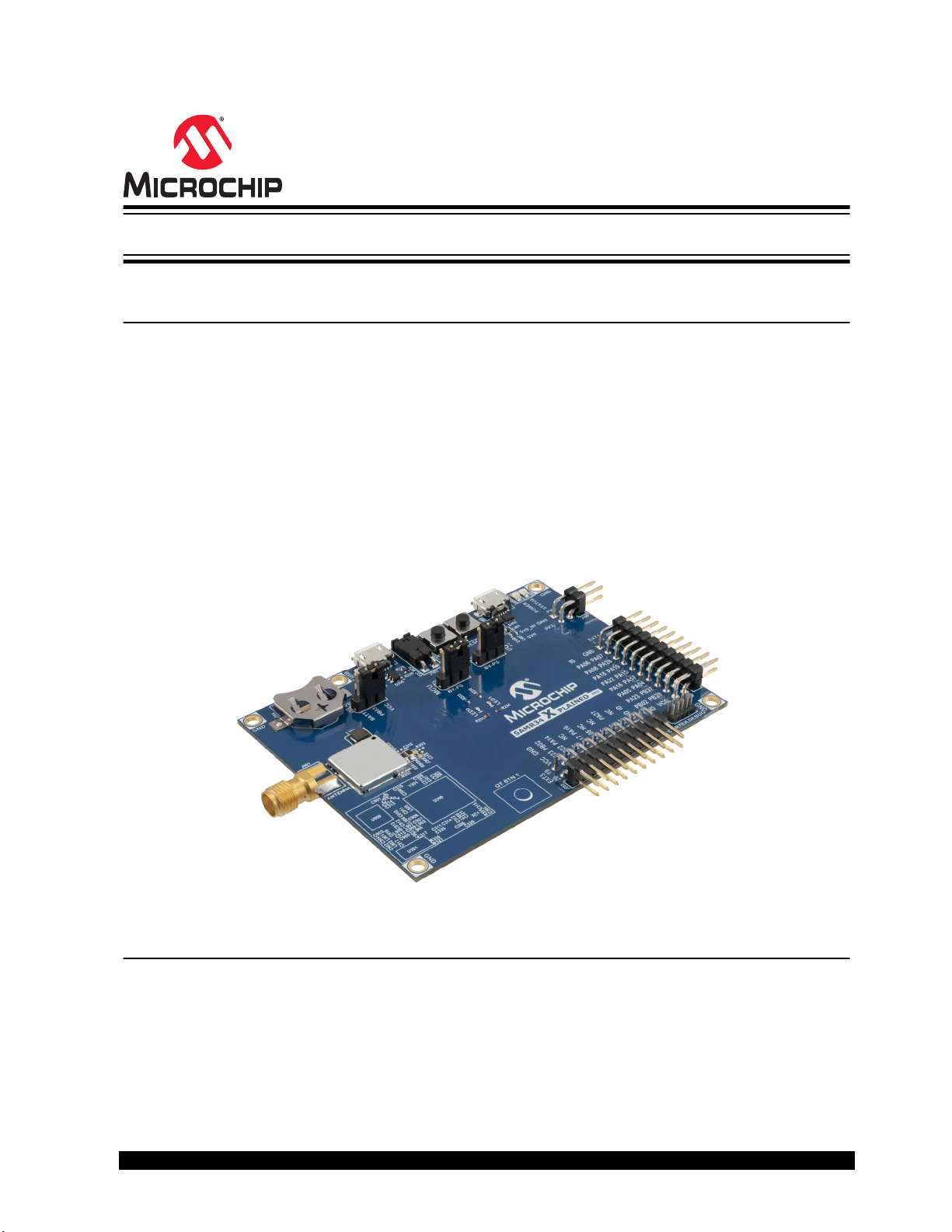

SAM R34 Xplained Pro

Evaluation Kit (DM320111)

SAM R34 Xplained Pro User Guide

Introduction

Microchip's SAM R34 Xplained Pro Evaluation Kit is a hardware platform used to evaluate the

ATSAMR34 Low Power LoRa® Sub-GHz SiP.

Supported by the Atmel Studio integrated development platform, the kit provides easy access to the

features of the SAM R34 SiP and explains how to integrate the device in a custom design.

The Xplained Pro MCU series evaluation kits include an on-board Embedded Debugger, and no external

tools are necessary to program or debug the SAM R34 devices.

The Xplained Pro extension kits offer additional peripherals to extend the features of the board and ease

the development of custom designs.

Figure 1. SAM R34 Xplained Pro Evaluation Board (DM320111)

Features

• SAM R34 SiP with Cortex® M0+ CPU and LoRa Transceiver

• Supports 868 MHz and 915 MHz Operation

• On-Board EDBG Debugger and Support for Atmel Studio 7 ICE

• Two Extension Headers for Signal Breakout and Expansion Boards

• On-Board Power Management System with Current Monitoring and USB Power Conditioning

• XPRO Current Measurement System Data Visualizer Support

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 1

Page 2

SAM R34 Xplained Pro Evaluation Kit...

• USB Power Inlet with ESD Protection and Buck Converter

• On-Board TCXO

• Up to +20 dBm Maximum Output Power

• +13 dBm High-Efficiency Operation

• +17 dBm High-Power Operation

• SMA RF Antenna Port with External Whip Antenna Included

• Manual Reset Button

• GPIO Button

• Indicator LEDs for Status and Power

• Auxiliary 10-Pin Cortex Programming Header

• Direct USB Connection to SAM R34 with ESD Protection

• Qtouch® Button

• CR1220 Backup Battery Holder

• Supported by Studio 7 Integrated Development Platform

• Software Examples Supported in Advanced Software Framework (ASF)

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 2

Page 3

SAM R34 Xplained Pro Evaluation Kit...

Table of Contents

Introduction......................................................................................................................1

Features.......................................................................................................................... 1

1. Kit Overview.............................................................................................................. 5

2. Xplained Pro Getting Started.....................................................................................6

2.1. Xplained Pro Quick Start.............................................................................................................. 6

2.2. Design Documentation and Relevant Links................................................................................. 6

2.3. Chip-Down Design Package ....................................................................................................... 7

3. Xplained Pro..............................................................................................................8

3.1. Xplained Pro.................................................................................................................................8

3.2. Embedded Debugger................................................................................................................... 8

3.3. Xplained Pro Analog Module........................................................................................................9

3.4. Hardware Identification System..................................................................................................11

3.5. Power Sources........................................................................................................................... 11

3.6. Xplained Pro Headers and Connectors......................................................................................12

4. Hardware User Guide..............................................................................................15

4.1. Schematics and BOM.................................................................................................................15

4.2. Power Distribution...................................................................................................................... 15

4.3. Connectors................................................................................................................................. 16

4.4. Peripherals................................................................................................................................. 19

4.5. Embedded Debugger Implementation........................................................................................20

4.6. Kit Modifications......................................................................................................................... 24

4.7. Limitations.................................................................................................................................. 25

5. Agency Certification.................................................................................................27

5.1. Antenna Considerations............................................................................................................. 27

5.2. A09-3167 Usage Instructions under Limited Modular Approval (FCC)...................................... 27

5.3. United States..............................................................................................................................27

5.4. Canada.......................................................................................................................................28

5.5. Europe........................................................................................................................................30

6. Hardware Revision History......................................................................................31

6.1. Identifying Product ID and Revision........................................................................................... 31

6.2. Hardware Revision..................................................................................................................... 31

7. Document Revision History..................................................................................... 33

The Microchip Web Site................................................................................................ 34

Customer Change Notification Service..........................................................................34

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 3

Page 4

SAM R34 Xplained Pro Evaluation Kit...

Customer Support......................................................................................................... 34

Microchip Devices Code Protection Feature................................................................. 34

Legal Notice...................................................................................................................35

Trademarks................................................................................................................... 35

Quality Management System Certified by DNV.............................................................36

Worldwide Sales and Service........................................................................................37

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 4

Page 5

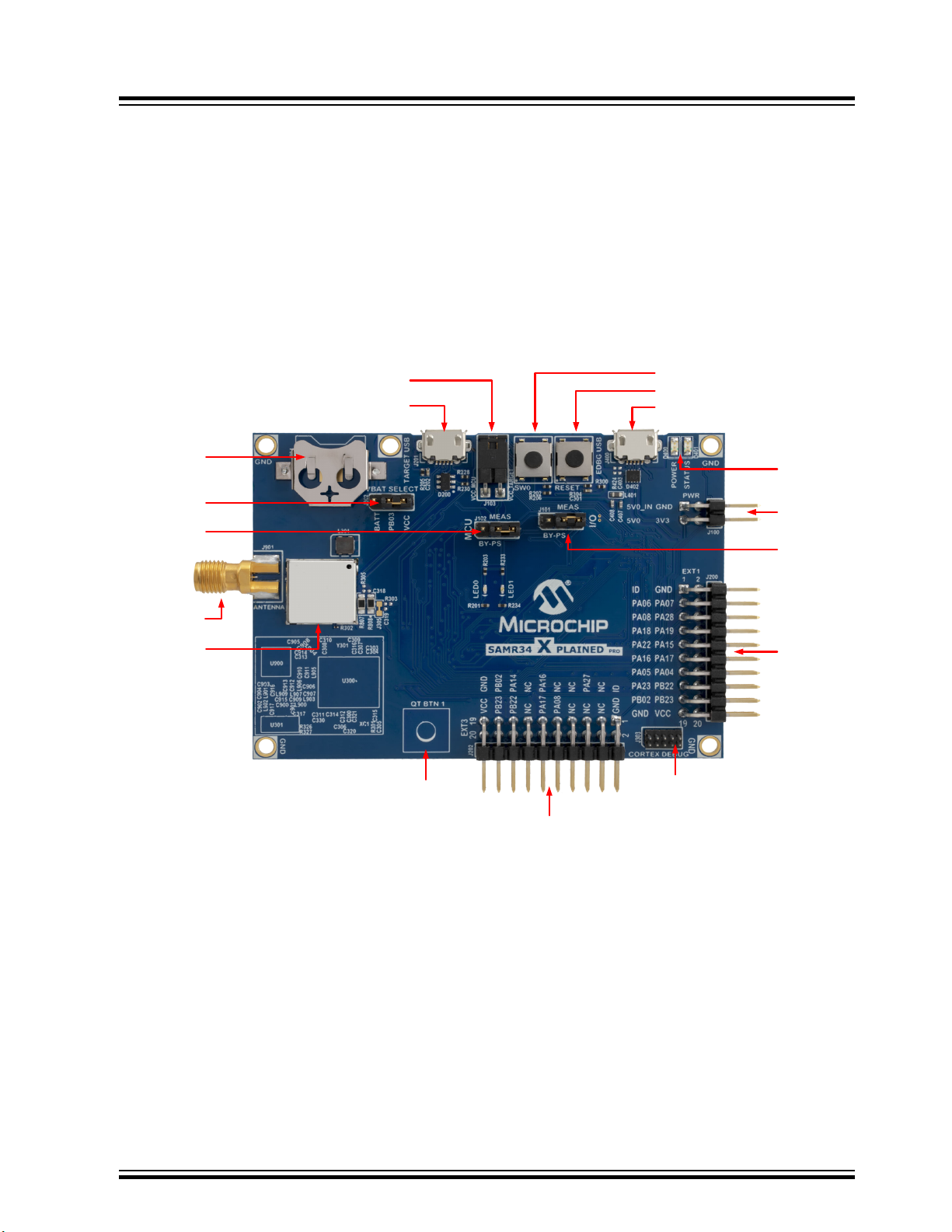

1. Kit Overview

Reset

SW0 User Button

Debug USB

Current Measurement

Header

Target USB

Power and

Status LED

Power Header

J101

Extension 1

Header

Cortex® Programming

Header

Extension 3 Header

Qtouch® Button

Battery

Power Source

J102

SMA

ATSAMR34J18B

The SAM R34 Xplained Pro Evaluation Kit is a hardware platform used to evaluate the ATSAMR34 Low

Power LoRa® Sub-GHz SiP module.

The kit offers a set of features that enable the user to get started with the ATSAMR34 Low Power LoRa

Sub-GHz SiP peripherals right away, and to understand how to integrate the device in their own design.

The SAM R34 Xplained Pro Evaluation Kit contains the following items:

• One SAM R34 Xplained Pro Evaluation Board

• One external antenna

SAM R34 Xplained Pro Evaluation Kit...

Kit Overview

®

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 5

Page 6

SAM R34 Xplained Pro Evaluation Kit...

2. Xplained Pro Getting Started

2.1 Xplained Pro Quick Start

The steps to start exploring the Xplained Pro platform are listed below. See also: SAM R34 Xplained Pro

Evaluation Kit (DM320111) Quick Start Guide.

1. Download and install Atmel Studio.

2. Launch Atmel Studio.

When the Xplained Pro kit is connected to the computer for the first time, the operating system installs the

driver software automatically. This driver supports 32-bit and 64-bit versions of Microsoft® Windows® XP,

Windows Vista®, Windows 7, Windows 8, Windows 10, and Windows Server 2012.

When the Xplained Pro board is powered:

• The green power LED D400 is lit

• Atmel Studio automatically detects the connected Xplained Pro and extension board(s)

• In Atmel Studio, the landing page of the kit presents an option to launch the associated ASF. For

more details, see the SAM R34 MLS Getting Started Guide (DS50002812).

• The SAM R34 device is programmed and debugged by the on-board Embedded Debugger

• No external programmer or debugger tool is required

Xplained Pro Getting Started

2.2 Design Documentation and Relevant Links

The following list contains links to the most relevant documents and software for the SAM R34 Xplained

Pro Evaluation Kit.

• Ordering Code – The SAM R34 Xplained Pro Evaluation Kit can be ordered from

www.microchipdirect.com using Ordering Code “DM320111”.

• Atmel Studio – Atmel Studio presents Free Atmel IDE for development of C/C++ and assembler code

for microcontrollers and relevant documentation.

• Microchip sample store – Microchip sample store where samples of devices can be ordered.

• EDBG User Guide – User guide containing more information about the on-board Embedded

Debugger.

• Data Visualizer – Data Visualizer is a program used for processing and visualizing data. Data

Visualizer can receive data from various sources such as the Embedded Debugger Data Gateway

Interface found on Xplained Pro boards and COM ports.

• AN2842 SAM R34/R35 RF Hardware Design Guidelines Application Note – This application note

provides the RF design guidelines and circuit optimization techniques to design using the SAM R34.

This document is available in the SAM R34 Chip-Down Design Package.

• SAM R34/R35 Low Power LoRa® Sub-GHz SiP Data Sheet (DS70005356)

• SAM R34 MLS Getting Started User Guide (DS50002812)

• SAM R34 Xplained Pro Evaluation Kit (DM320111) Quick Start Guide (DS30010200)

• SAM L21 Family Data Sheet (DS60001477A)

• Semtech SX1276/77/78/79 Data Sheet rev 5

• SAM R34 Chip-down Design Package – Includes SAMR34-XPRO Design Database and MCHPRT

Test Application.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 6

Page 7

2.3 Chip-Down Design Package

The Chip-Down Design Package is a guide for customers wanting to do their own chip-level RF PCB

designs. In addition, it contains software tools for manufacturing and regulatory testing. The package

includes the following:

• AN2842 RF Hardware Design Guidelines

• Complete CAD source for SAMR34-XPRO

• MCHPRT PC Application for Production and Regulatory Testing

• Example Python® scripts

• SAMR34 Radio Utility Firmware

SAM R34 Xplained Pro Evaluation Kit...

Xplained Pro Getting Started

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 7

Page 8

3. Xplained Pro

3.1 Xplained Pro

Xplained Pro is an evaluation platform which contains a series of microcontroller boards (evaluation kits)

and extension boards. Atmel Studio is used to program and debug the microcontrollers on these boards.

Atmel Studio includes Advanced Software Framework (ASF) and Atmel START, which has drivers and

demo code, and Data Visualizer, which supports data streaming and advanced debugging. Xplained Pro

evaluation kits can be connected to a wide range of Xplained Pro extension boards through standardized

headers and connectors. Xplained Pro extension boards have identification (ID) chips to uniquely identify

which boards are connected to the Xplained Pro evaluation kits.

3.2 Embedded Debugger

The SAM R34 Xplained Pro contains an Embedded Debugger (EDBG) for on-board debugging. The

EDBG is a USB composite device with the following interfaces:

• Debugger

• Virtual COM Port

• Data Gateway Interface (DGI)

SAM R34 Xplained Pro Evaluation Kit...

Xplained Pro

The EDBG can program and debug the SAM R34 with the help of Atmel Studio. The Serial Wire Debug

(SWD) interface is connected between the EDBG and the SAM R34 on the SAM R34 Xplained Pro.

The Virtual COM Port is connected to a UART on the SAM R34 and provides an easy way to

communicate with the target application through terminal software. It offers variable baud rate, parity, and

stop bit settings. The settings on the SAM R34 must match the settings given in the terminal software.

Info: The Virtual COM Port in the EDBG requires the terminal software to set the Data

Terminal Ready (DTR) signal to enable the UART pins connected to the SAM R34. If the DTR

signal is not enabled, the UART pins on the EDBG are kept in tri-state (high-Z) to render the

COM Port not usable. The DTR signal is automatically set by terminal software, but it may have

to be manually enabled in your terminal.

The DGI consists of several physical interfaces for bidirectional communication with the host computer.

Communication over the interfaces is bidirectional. It can be used to send event values and data from the

SAM R34. Traffic over the interfaces can be timestamped by the EDBG for more accurate tracking of

events, but timestamping reduces the maximal data throughput. The Data Visualizer is used to send and

receive data through DGI.

The EDBG controls two LEDs on the SAM R34 Xplained Pro; a power LED and a status LED. The

following table provides details on how the LEDs are controlled in different operation modes.

Table 3-1. EDBG LED Control

Mode Power LED Status LED

Normal mode The power LED is ON when

power is applied to the board.

© 2019 Microchip Technology Inc.

User Guide

Activity indicator, the LED flashes

when any communication

happens to the EDBG.

DS50002803C-page 8

Page 9

SAM R34 Xplained Pro Evaluation Kit...

...........continued

Mode Power LED Status LED

Bootloader mode (idle) The power LED and the status LED blink simultaneously.

Xplained Pro

Bootloader mode (firmware

upgrade)

For additional information on the EDBG, see the EDBG User Guide.

3.3 Xplained Pro Analog Module

3.3.1 Overview

The Xplained Pro Analog Module (XAM) extends the embedded debugger with high dynamic range

current measurement. This enables power profiling of the target system.

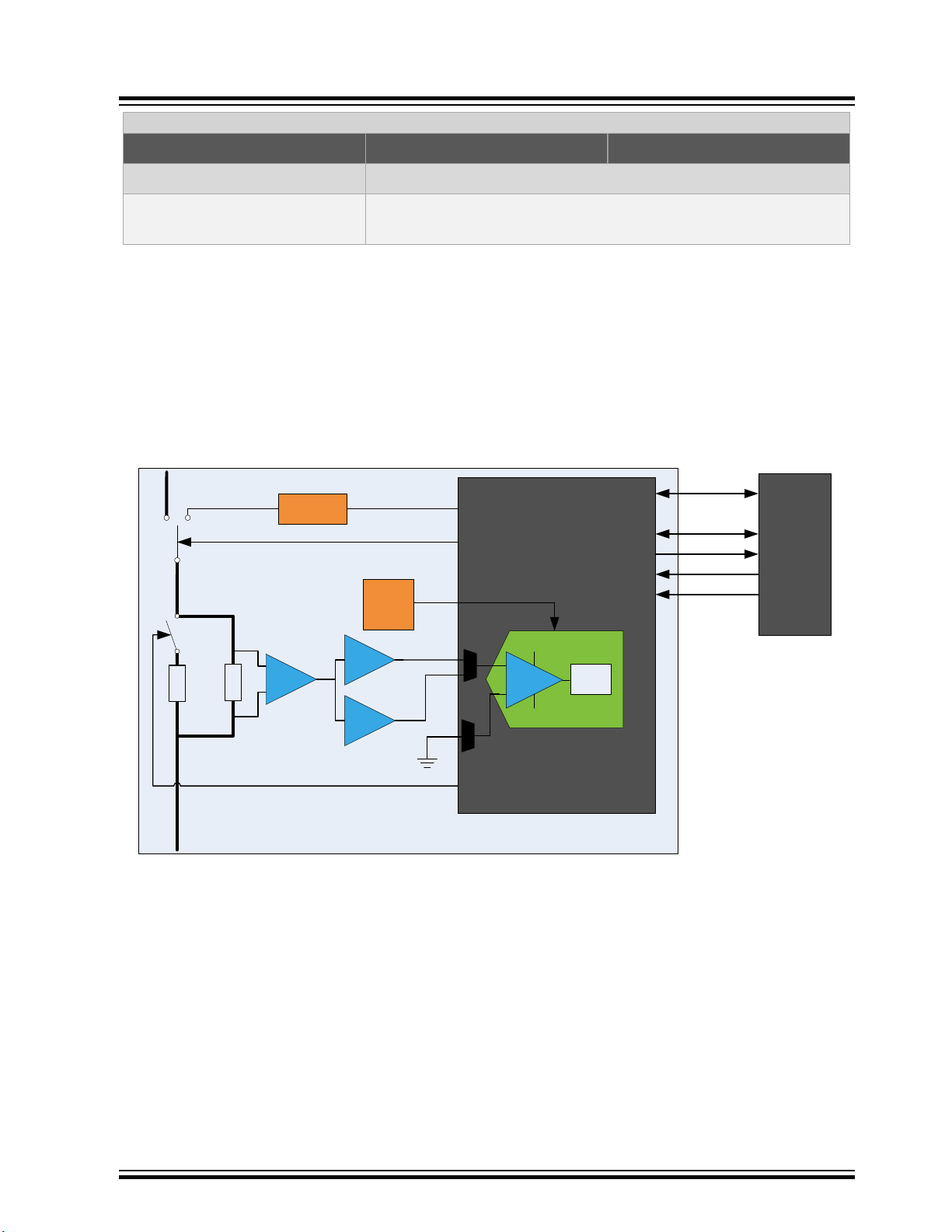

Figure 3-1. XAM Block Diagram

Calibration

circuitry

Current output

Range selection

Calibration ON/OFF

100 mOhm

Pre-amplifier

20x

100 Ohm

20x

2x

16x

Active filter with

gain

The power LED and the status LED blink in an alternating pattern.

Sync GPIO

I2C

SPI

Clock sync

SWD

EDBG

voltage

reference

2.7V

GPIO(s)

GPIO

AREF

ADC0

ADC1

Control MCU

S&H

ADC

GND

GPIO

Current input

Xplained Pro Analog Module (XAM)

The XAM consists of:

• Calibration circuitry

• Voltage reference circuitry

• Analog front-end:

– Shunt resistors with a range selection switch

– Pre-amplifier

– Two active filters with gain

• Control MCU

– Analog-to-Digital Converter

– Signal processing

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 9

Page 10

– Control/communication interface to the EDBG

The current measurement front-end is a high side shunt measurement with a pre-amplifier and a second

active filter stage with gain as shown in Figure 3-1. The wide dynamic range is achieved by four

measurement ranges, which are defined by two shunt resistors and the two parallel second stage active

filters with gain.

3.3.2 EDBG Interface

The XAM is connected to the EDBG with the following interfaces:

• I2C: This is used to control and configure the XAM.

• SPI: Current measurement data is streamed to the EDBG via this interface. This is a unidirectional

channel from the XAM to the EDBG.

• SWD: The MCU in the XAM is programmed via SWD from the EDBG.

• Clock sync: Signal used to synchronize ADC measurements with the EDBG.

• Reference clock: Reference clock for the XAM.

3.3.3 Sample Rate

The raw sampling rate of the XAM is up to 250 kHz and with the default averaging configuration (average

of 16 samples), the actual output of the XAM is 16.67 ksps.

SAM R34 Xplained Pro Evaluation Kit...

Xplained Pro

Info: The XAM output sample rate is not an integer fraction of the raw sampling.

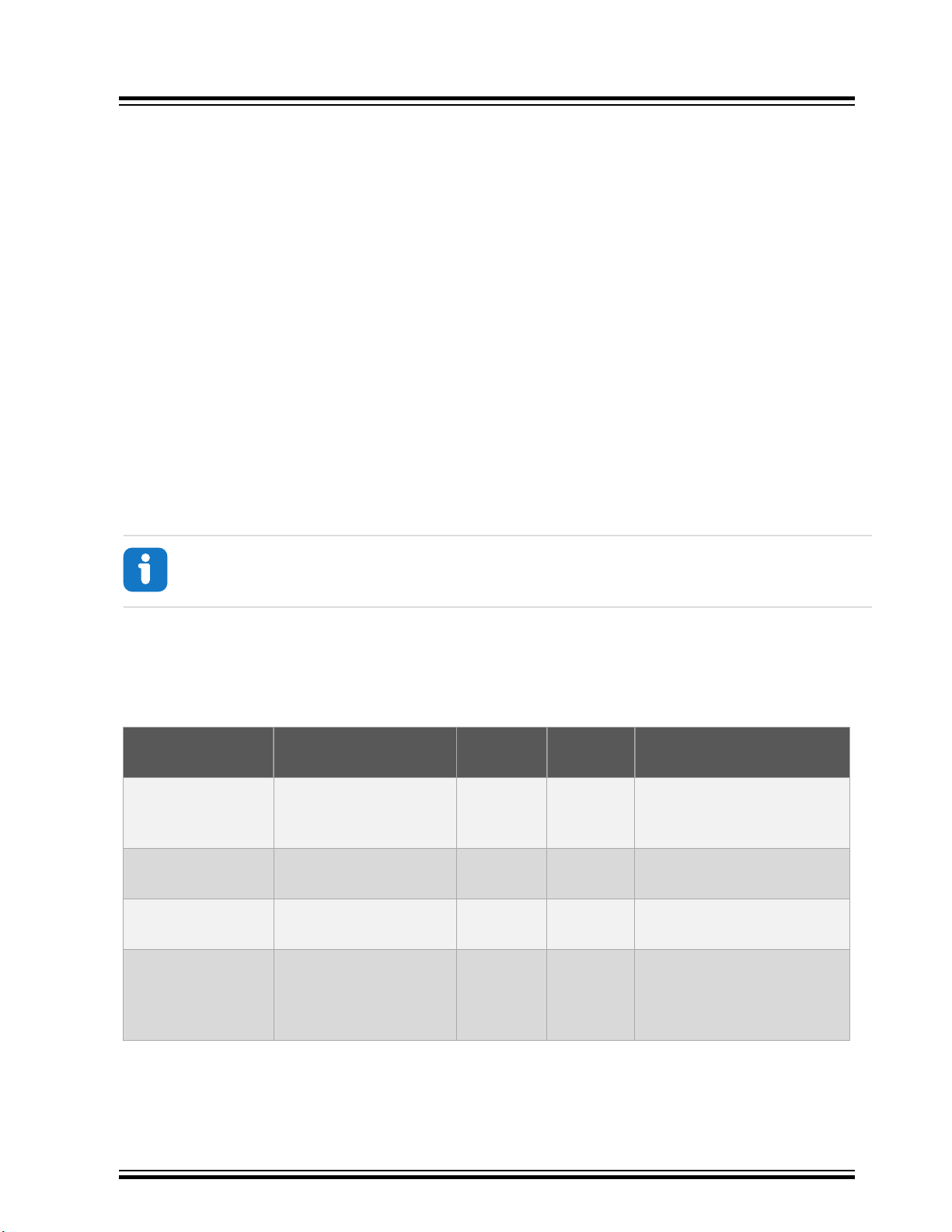

3.3.4 Measurement Ranges and Accuracy

The XAM has four measurement ranges. These are defined by two shunt resistors and two gain stages.

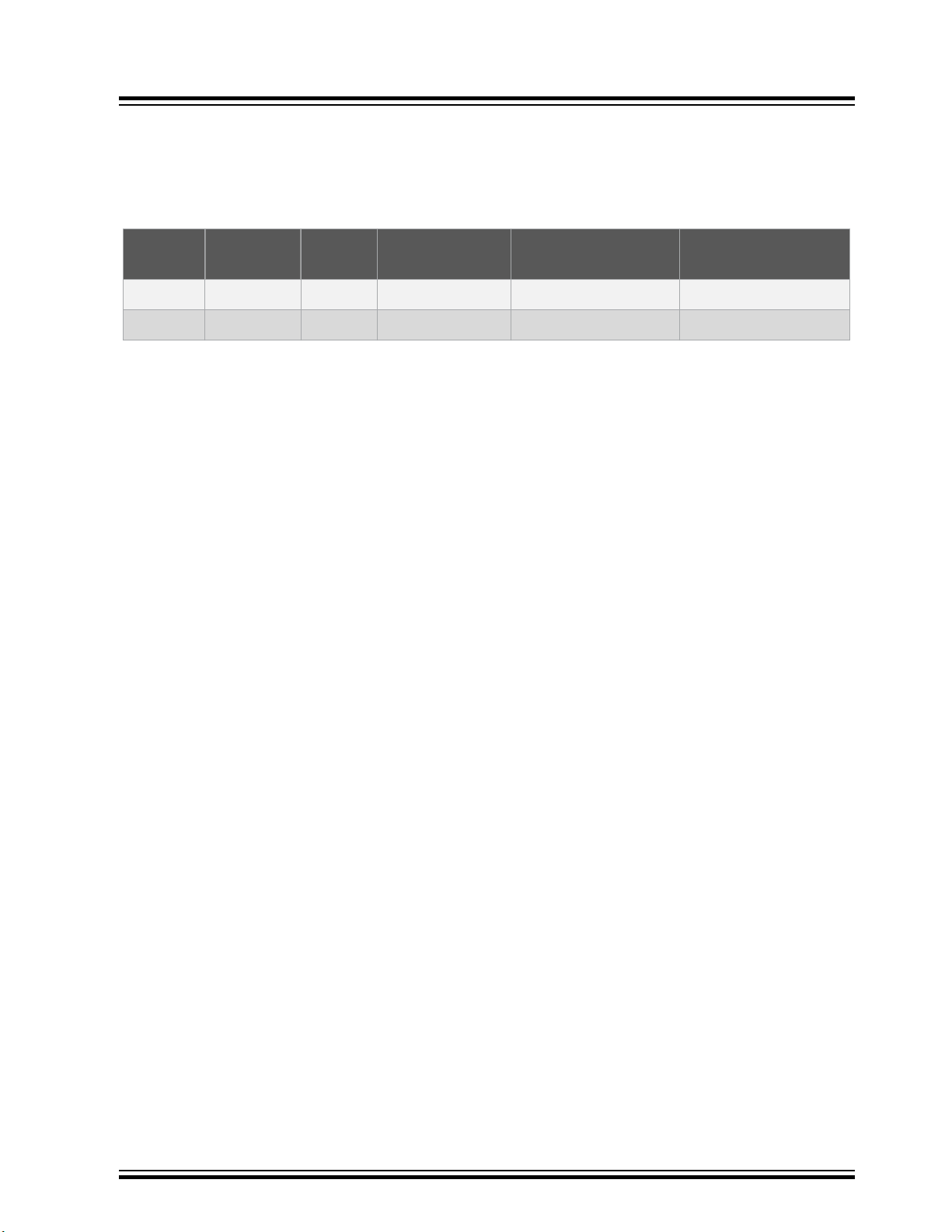

Table 3-2. XAM Measurement Ranges and Accuracy

Measurement

Range

Range 1 Low current shunt and

Range 2 Low current shunt and

Range 3 High current shunt and

Range 4 High current shunt and

Hardware Resolution Accuracy Comments

high gain stage

low gain stage

high gain stage

low gain stage

20 nA 1 LSB ±1% Accuracy will decrease below

1 μA. Typical accuracy for

300 nA is 1 LSB ±10%.

150 nA 1 LSB ±1%

10 μA 1 LSB ±1%

100 μA 1 LSB ±1% Accuracy will decrease above

100 mA. Typical accuracy is

1 LSB ±5% at 400 mA.

Maximum current is 400 mA.

The ranges are automatically switched by the XAM to achieve the best measurement results, and the

currently active range is visualized in the Data Visualizer front-end tool. The maximum voltage drop over

the shunt resistor is 100 mV, and the XAM switches the range automatically before reaching this limit.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 10

Page 11

SAM R34 Xplained Pro Evaluation Kit...

3.4 Hardware Identification System

All Xplained Pro extension boards come with an identification chip (ATSHA204A CryptoAuthentication

chip) to uniquely identify the boards that are connected to the Xplained Pro Evaluation Kit. This chip

contains information that identifies the extension with its name and some extra data. When an Xplained

Pro extension is connected to an Xplained Pro Evaluation Kit, the information is read and sent to the

Atmel Studio. The following table shows the data fields stored in the ID chip with example content.

Table 3-3. Xplained Pro ID Chip Content

Data Field Data Type Example Content

Manufacturer ASCII string Microchip'\0'

Product name ASCII string Segment LCD1 Xplained Pro'\0'

Product revision ASCII string 02'\0'

Product serial number ASCII string 1774020200000010’\0’

Minimum voltage [mV] uint16_t 3000

Maximum voltage [mV] uint16_t 3600

Xplained Pro

™

Maximum current [mA] uint16_t 30

3.5 Power Sources

The SAM R34 Xplained Pro Evaluation Kit can be powered by several power sources, as listed in the

table below.

Table 3-4. Power Sources for SAM R34 Xplained Pro

Power input Voltage requirements Current requirements Connector marking

External power 5V ±2% (±100 mV) for

Embedded Debugger

USB

USB host operation.

4.3V to 5.5V if USB host

operation is not

required.

4.4V to 5.25V (according

to USB spec.)

Recommended

minimum is 1A to be

able to provide enough

current for connected

USB devices and the

board itself.

Recommended

maximum is 2A due to

the input protection

maximum current

specification.

500 mA (according to

USB spec.)

PWR

DEBUG USB

Target USB 4.4V to 5.25V (according

to USB spec.)

The kit will automatically detect which power sources are available and choose which one to use

according to the following priority:

© 2019 Microchip Technology Inc.

500 mA (according to

USB spec.)

User Guide

TARGET USB

DS50002803C-page 11

Page 12

SAM R34 Xplained Pro Evaluation Kit...

1. External power

2. Embedded Debugger USB

3. Target USB

Note: If powering the board from the Target USB connector then jumpers J101 and J102 MUST be in

the bypass position.

Info: External power is required when 500 mA from a USB connector is not enough to power

the board with possible extension boards. A connected USB device in a USB host application

might easily exceed this limit.

3.6 Xplained Pro Headers and Connectors

3.6.1 Xplained Pro Standard Extension Header

All Xplained Pro kits have many dual-row, 20-pin, 100 mil extension headers. The Xplained Pro MCU

boards have male headers, while the Xplained Pro extensions have their female counterparts. The

following table provides the pin description of all the connected pins.

Xplained Pro

Info: Not all pins are always connected on all extension headers.

The extension headers can be used to connect a variety of Xplained Pro extensions to Xplained Pro MCU

boards or to access the pins of the target microcontroller on the Xplained Pro boards.

Table 3-5. Xplained Pro Standard Extension Header

Pin Number Pin Name Description

1 ID Pin to communicate with the ID chip on an extension board.

2 GND Ground

3 ADC(+) Analog-to-Digital Converter; alternatively, a pin for the positive

terminal of a differential ADC.

4 ADC(-) Analog-to-Digital Converter; alternatively, a pin for the negative

terminal of a differential ADC.

5 GPIO1 General purpose I/O pin.

6 GPIO2 General purpose I/O pin.

7 PWM(+) Pulse-Width Modulation; alternatively, a pin for the positive part of a

differential PWM.

8 PWM(-) Pulse-Width Modulation; alternatively, a pin for the negative part of a

differential PWM.

9 IRQ/GPIO Interrupt request pin and/or general purpose I/O pin.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 12

Page 13

SAM R34 Xplained Pro Evaluation Kit...

...........continued

Pin Number Pin Name Description

Xplained Pro

10 SPI_SS_B/

GPIO

11 I2C_SDA Data pin for I2C interface. Always connected, bus type.

12 I2C_SCL Clock pin for I2C interface. Always connected, bus type.

13 UART_RX Receiver pin of target device UART.

14 UART_TX Transmitter pin of target device UART.

15 SPI_SS_A Slave select for SPI. This pin should preferably not be connected to

16 SPI_MOSI SPI master out slave in pin. Always connected, bus type.

17 SPI_MISO SPI master in slave out pin. Always connected, bus type.

18 SPI_SCK SPI clock pin. Always connected, bus type.

19 GND Ground pin for extension boards.

20 VCC Power pin for extension boards.

3.6.2 Xplained Pro Power Header

The power header can be used to connect external power to the SAM R34 Xplained Pro kit. The kit

automatically detects and switches to an external power source, if supplied. The power header can also

be used to supply power to external peripherals or extension boards. Ensure that the total current does

not exceed the recommended current limit of the on-board regulator when using the 3.3V pin.

Slave select pin for Serial Peripheral Interface (SPI) and/or general

purpose I/O pin.

anything else.

Table 3-6. Xplained Pro Power Header

Pin Number Pin Name Description

1 VEXT_P5V0 External 5V input pin

2 GND Ground pin

3 VCC_P5V0

4 VCC_P3V3

3.6.3 Interconnect with BTLC1000 XPRO Extension

The SAMR34 SERCOM5 is used for the UART connection to the EXT1 header. For more details, see

Peripherals section. This UART port does not support the CTS/RTS hardware flow-control needed for

BTLC1000 operation. To connect SAMR34-XPRO to BTLC1000-XPRO, use SERCOM 5 for the console

UART and SERCOM 0 to connect to BTLC1000. The connection mapping is shown in the following table.

Unregulated 5V pin (an output, derived from one of

the input sources)

Regulated 3.3V pin (an output, used as the main

power supply for the kit)

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 13

Page 14

SAM R34 Xplained Pro Evaluation Kit...

Table 3-7. SAMR34-XPRO to BTLC1000-XPRO Connection Mapping

Xplained Pro

SAMR34 XPRO

PIN SIGNAL

J200.3 PA06 (S0 UART RTS) J100.16 16 (UART CTS) BLE UART

J200.4 PA07 (S0 UART CTS) J100.18 18 (UART RTS) BLE UART

J200.13 PA05 (S0 UART RXD) J100.15 15 (UART TXD) BLE UART

J200.14 PA04 (S0 UART TXD) J100.17 17 (UART RXD) BLE UART

J200.5 PA08 J100.3 3 GPIO - WAKEUP

J200.7 PA18 J100.7 7 GPIO - CHIP EN

J200.9 PA22 J100.9 9 IRQ

J200.15 PB02 S5 CONSOLE

TXD

J200.17 PA23 S5 CONSOLE

RXD

5 (Yellow) FTDI Yellow

4 (Orange) FTDI Orange

FTDI

TTL-232R-3V3

PLUG

RECEPTICAL

BTLC1000 XPRO

J100 PIN SIGNAL

RTS/CTS

RTS/CTS

PIN

Console UART

Cable RXD

Console UART

Cable TXD

J200.19 GND 1 (Black) J100.19 Power

J200.20 VCC J100.20 Power

Note:

1. SERCOM 5 will be used for console UART.

2. SERCOM 0 will be used for BTLC1000 connection

Cryptographic and Authentication demos

Developers using CryptoAuthentication demo boards, such as 88CKSCKT or ECC608, must use EXT3.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 14

Page 15

4. Hardware User Guide

4.1 Schematics and BOM

Complete and up-to-date schematics, Bill of Materials (BOM) and design documentation for SAM R43

XPRO is available in the SAM R34 Chip-Down Design Package.

Additionally, this package includes the MCHPRT test firmware, Python scripts and Radio Utility

Commands Reference documentation for evaluation and test.

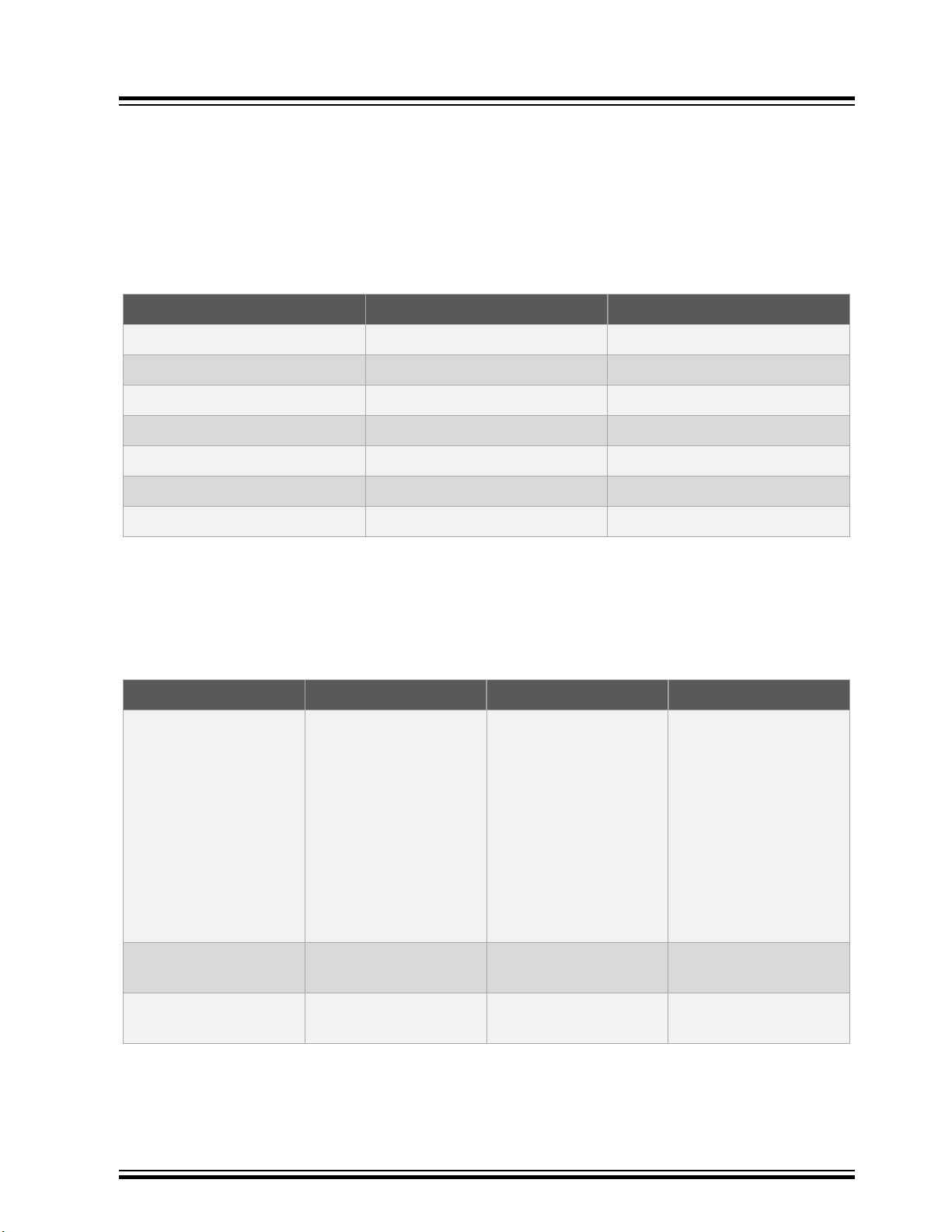

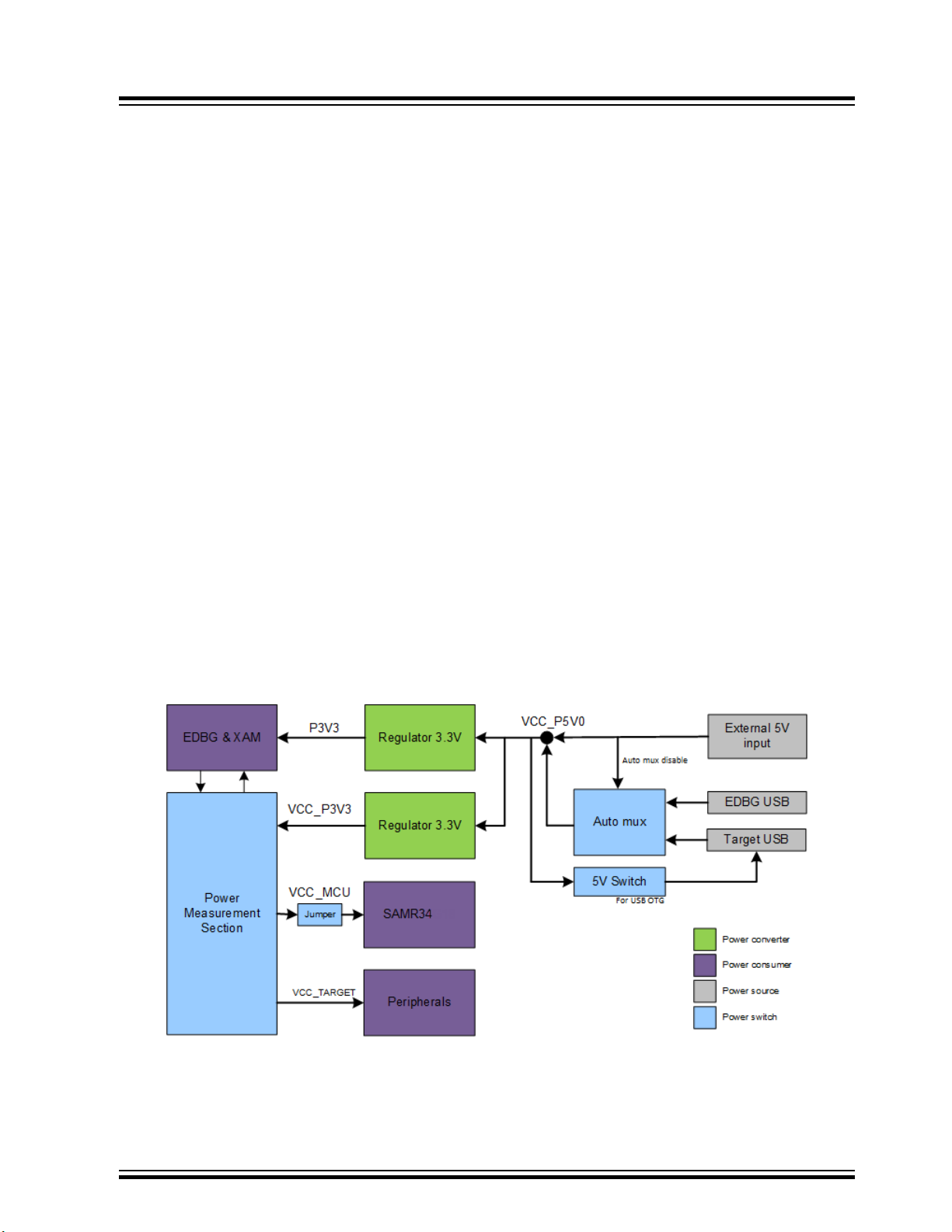

4.2 Power Distribution

The SAM R34 Xplained Pro Evaluation Kit can be powered by:

• EDBG USB

• TARGET USB

• External (5V)

The kit has a power mux which automatically chooses the power source if two or all three of the power

sources are available to the kit at the same time.

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

The kit contains:

• Two on-board voltage regulators (3.3V):

– One for an EDBG and XAM section

– Another one for SAM R34

• IO peripherals

• Power Measurement Section (XAM)

Figure 4-1. Power Supply Block Diagram

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 15

Page 16

4.3 Connectors

The following sections describe the implementation of the relevant connectors and headers on the SAM

R34 Xplained Pro Evaluation Kit and their connection to the SAM R34. The tables of connections in the

sections also describe which signals are shared between the headers and on-board functionality.

4.3.1 Xplained Pro Extension Headers

The SAM R34 Xplained Pro Evaluation Kit headers EXT1 and EXT3 offer access to the I/O of the

microcontroller in order to expand the board e.g., by connecting extensions to the board. These headers

are based on the standard extension header specified in 3.6.1 Xplained Pro Standard Extension Header.

The headers have a pitch of 2.54 mm.

Table 4-1. Extension Header EXT1

EXT1 SAM R34 Shared Functionality

Pin Signal Port Pin

1 ID - - -

2 GND - - -

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

3 ADC(+) PA06 E3 -

4 ADC(-) PA07 F3 -

5 GPIO1 PA08 F4 EXT3

6 GPIO2 PA28 C6 4.4.2 Mechanical Buttons

7 PWM(+) PA18 E7 -

8 PWM(-) PA19 E8 -

9 IRQ PA22 D8 -

10 SPI_SS PA15 G8 -

11 TWI_SDA PA16 F7 EXT3

12 TWI_SCL PA17 E6 EXT3

13 UART_RX PA05 C4 4.5.2 Virtual COM Port

14 UART_TX PA04 D3 4.5.2 Virtual COM Port

15 SPI_SS PA23 D7 -

16 SPI_MOSI PB22 E5 EXT3

17 SPI_MISO PB02 B4 EXT3

18 SPI_SCK PB23 C7 EXT3

19 GND - - -

20 VCC - - -

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 16

Page 17

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

Table 4-2. Extension Header EXT3

EXT3 SAM R34 Shared Functionality

Pin Signal Port Pin

1 ID - - -

2 GND - - -

3 ADC(+) - - -

4 ADC(-) - - -

5 GPIO1 PA27 E4 -

6 GPIO2 - - -

7 PWM(+) - - -

8 PWM(-) - - -

9 IRQ - - -

10 SPI_SS PA08 F4 EXT1

11 TWI_SDA PA16 F7 EXT1

12 TWI_SCL PA17 E6 EXT1

13 UART_RX - - -

14 UART_TX - - -

15 SPI_SS PA14 F8 -

16 SPI_MOSI PB22 E5 EXT1

17 SPI_MISO PB02 B4 EXT1

18 SPI_SCK PB23 C7 EXT1

19 GND - - -

20 VCC - - -

4.3.2 Direct USB Connection

For USB applications on SAM R34, there is a directly connected USB port designated TARGET_USB.

This is exposed as a Micro-B jack designated J201. The TARGET_USB port includes required ESD

suppression and power management circuitry. A GPIO is used to detect the VBUS voltage on the

connector, to detect when a TARGET USB cable is connected in Self-Powered mode. In USB Host mode,

VBUS voltage is provided by the kit and cannot identify the connected device; therefore, another GPIO is

used to detect the USB ID of the device.

Note: The SAMR35 does not have a USB PHY. The EDBG port is not directly connected to the SAM

R34 USB PHY.

Table 4-3. USB Connections

SAM R34 Pin USB Function Shared Functionality

PA07 VBUS Detection EXT1

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 17

Page 18

...........continued

CAUTION

SAM R34 Pin USB Function Shared Functionality

PA15 USB ID EXT3

PA24 USB D- -

PA25 USB D+ -

4.3.3 Current Measurement Header

A right-angled 1x2, 100 mil pin header marked with the MCU current measurement is located at the upper

edge of the SAM R34 Xplained Pro. All power to the SAM R34 is exclusively routed through this header

(excluding power to extension headers and peripherals). To measure the power consumption of the

device, remove the jumper and replace it with an ammeter.

Removing the jumper from the pin header while the kit is powered may cause the SAM R34 to

be powered through its I/O pins. This may cause permanent damage to the device.

4.3.4 Cortex Debug Connector

SAM R34 Xplained Pro Evaluation Kit has a 10-pin 50-mil Cortex Debug Connector that can be used to

attach external debuggers to the SAM R34.

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

Table 4-4. Cortex Debug Connector

Cortex Debug

Connector pin

1 VCC_TARGET_P3V3 SAM R34 voltage -

2 PA31_SWDIO SWD data signal 4.5.1 Serial Wire Debug

3 GND Ground -

4 PA30_SWDCLK SWD clock signal 4.5.1 Serial Wire Debug

5 GND Ground -

6 - - -

7 - - -

8 - - -

9 GND Ground -

10 RESET* Target reset signal 4.4.2 Mechanical

Note: The target reset (RESET* pin on the ATSAMR34 Low Power LoRa® Sub-GHz SiP) is isolated

from the Cortex Debug Connector by R300 (0 Ohm link) which is not mounted by default in the PCBA.

Pin / Net Function Shared functionality

Buttons

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 18

Page 19

4.4 Peripherals

4.4.1 External Clock

The SAM R34 Xplained Pro Evaluation Kit contains one mounted 32.768 kHz crystal that can be used as

a clock source for the SAM R34. The RF transceiver uses a 32 MHz external TCXO for optimal

performance at long range.

Table 4-5. External Clock

SAM R34 pin Function

A3 PA00_XIN32

A4 PA01_XOUT32

Table 4-6. External TCXO

SAM R34 pin Function

H6 RF_XTA

H7 NC

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

4.4.2 Mechanical Buttons

SAM R34 Xplained Pro Evaluation Kit contains two mechanical buttons:

• RESET button connected to the SAM R34 reset line

– When the RESET button is pressed it drives the I/O line to ground

• Generic user configurable button

– When the user button is pressed it drives the I/O line to target voltage

Note: There is no pull-up resistor connected to the generic user button. Remember to enable the

internal pull up in the SAM R34 to use the button.

Table 4-7. Mechanical Buttons

SAM R34 pin Silkscreen text Shared functionality

RESET* RESET 4.5.1 Serial Wire Debug

PA28 SW0 EXT1

4.4.3 LEDs

There is one yellow LED available on the SAM R34 Xplained Pro board that can be turned on and off.

The LED can be activated by driving the connected I/O line to GND.

Table 4-8. LED Connections

SAM R34 Pin Function Shared Functionality

PA19 Yellow LED0 EXT1

PA18 Green LED1

© 2019 Microchip Technology Inc.

User Guide

EXT1

DS50002803C-page 19

Page 20

4.4.4 UART Connection

The SAM R34 Xplained Pro Evaluation Kit exposes the UART on EXT1. This is useful for command line

interfaces, debugging and application layer code.

Info: The TXD/RXD UART signals exposed on EXT1 are connected to SERCOM 5 which is in

low-power domain PD0. Because of low-power constraints, SERCOM 5 does not support

CTS/RTS flow-control signals.

The following table provides the UART signals pin description.

Table 4-9. UART Signals Pin Description

SAM R34 pin Function Shared Functionality

D3 PA04_S0_UART_TX EXT1, EDBG

C4 PA05_S0_UART_RX EXT1, EDBG

4.4.5 CryptoAuthentication Device

The SAM R34 Xplained Pro Evaluation Kit has a depopulated socket for ATECC608 Security IC. This is

reserved for future revisions of the board.

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

4.4.6 QTouch Button

The SAM R34 Xplained Pro Evaluation Board contains a self-capacitance button, which can be used as

an I/O. This QTouch button is intended to be driven by the built-in Peripheral Touch Controller (PTC) of

the device. A zero ohm resistor is added on the board to easily disconnect the on-board touch buttons

from the extension header since the I/O lines are shared between the QTouch button and extension

header 1 (EXT1).

note: To get started with QTouch, refer to the QTouch® Library and QTouch® Composer.

Table 4-10. QTouch Connection

SAM R34 Pin Silkscreen Text Shared Functionality

PA06 QT BTN1 EXT1

4.4.7 Backup Battery

The SAM R34 Xplained Pro Evaluation Kit is equipped with a CR1220 backup battery holder. This

provides 35 mAH of power for SRAM Backup.

Note: To comply with shipping regulations, Lithium batteries are not included in this product.

4.5 Embedded Debugger Implementation

The SAM R34 Xplained Pro Evaluation Kit contains an Embedded Debugger (EDBG) that can be used to

program and debug the SAM R34 using Serial Wire Debug (SWD). The Embedded Debugger also

includes a Virtual Com port interface over UART, a Data Gateway Interface (DGI) over SPI, and I2C , and

also includes four of the SAM R34 GPIOs. The kit also includes a XAM extension processor to the

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 20

Page 21

Embedded Debugger for on-board current measurement. Atmel Studio can be used as a front-end for the

Embedded Debugger.

4.5.1 Serial Wire Debug

The Serial Wire Debug (SWD) uses two pins to communicate with the target. For further information on

how to use the programming and debugging capabilities of the EDBG, see 3.2 Embedded Debugger.

Table 4-11. SWD Connections

SAM R34 pin Function

PA30 SWD clock

PA31 SWD data

4.5.2 Virtual COM Port

The Embedded Debugger acts as a Virtual Com Port gateway by using one of the SAM R34 UARTs. For

further information on how to use the Virtual COM port, see 3.2 Embedded Debugger.

Table 4-12. Virtual COM Port Connections

SAM R34 pin Function Shared functionality

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

PA05 RX line EXT1, EXT3

PA04 TX line EXT1, EXT3

4.5.3 Data Gateway Interface

The Embedded Debugger features a Data Gateway Interface (DGI) by using either an SPI or I²C. The

DGI can be used for sending data from the SAM R34 to the host PC. For further information on how to

use the DGI interface, refer to the Data Visualizer and the EDBG User Guide.

Table 4-13. DGI Interface Connections When Using SPI

SAM R34 Pin Function Shared Functionality

PA27 GPIO/SPI SS (Slave Select) (SAM R34

is Master)

PB02 SERCOM5 PAD[0] SPI MISO (Master

In, Slave Out)

PB22 SERCOM5 PAD[2] SPI MOSI (Master

Out, Slave in)

PB23 SERCOM5 PAD[3] SPI SCK (Clock Out) EXT1 and EXT3

Table 4-14. DGI Interface Connections When Using I²C

-

EXT1 and EXT3

EXT1 and EXT3

SAM R34 Pin Function Shared Functionality

PA16 SERCOM1 PAD[0] SDA (Data line) EXT1 and EXT3

PA17 SERCOM1 PAD[1] SCL (Clock line) EXT1 and EXT3

Three GPIO lines are connected to the Embedded Debugger. The EDBG can monitor these lines and

time stamp pin value changes. This makes it possible to accurately timestamp events in the SAM R34

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 21

Page 22

SAM R34 Xplained Pro Evaluation Kit...

application code. For further information on how to configure and use the GPIO monitoring features, refer

to the Data Visualizer and the EDBG User Guide.

Table 4-15. GPIO Lines Connected to the EDBG

SAM R34 Pin Function Shared Functionality

PA08 GPIO0 EXT3

PA09 GPIO1 -

PA14 GPIO3 EXT3

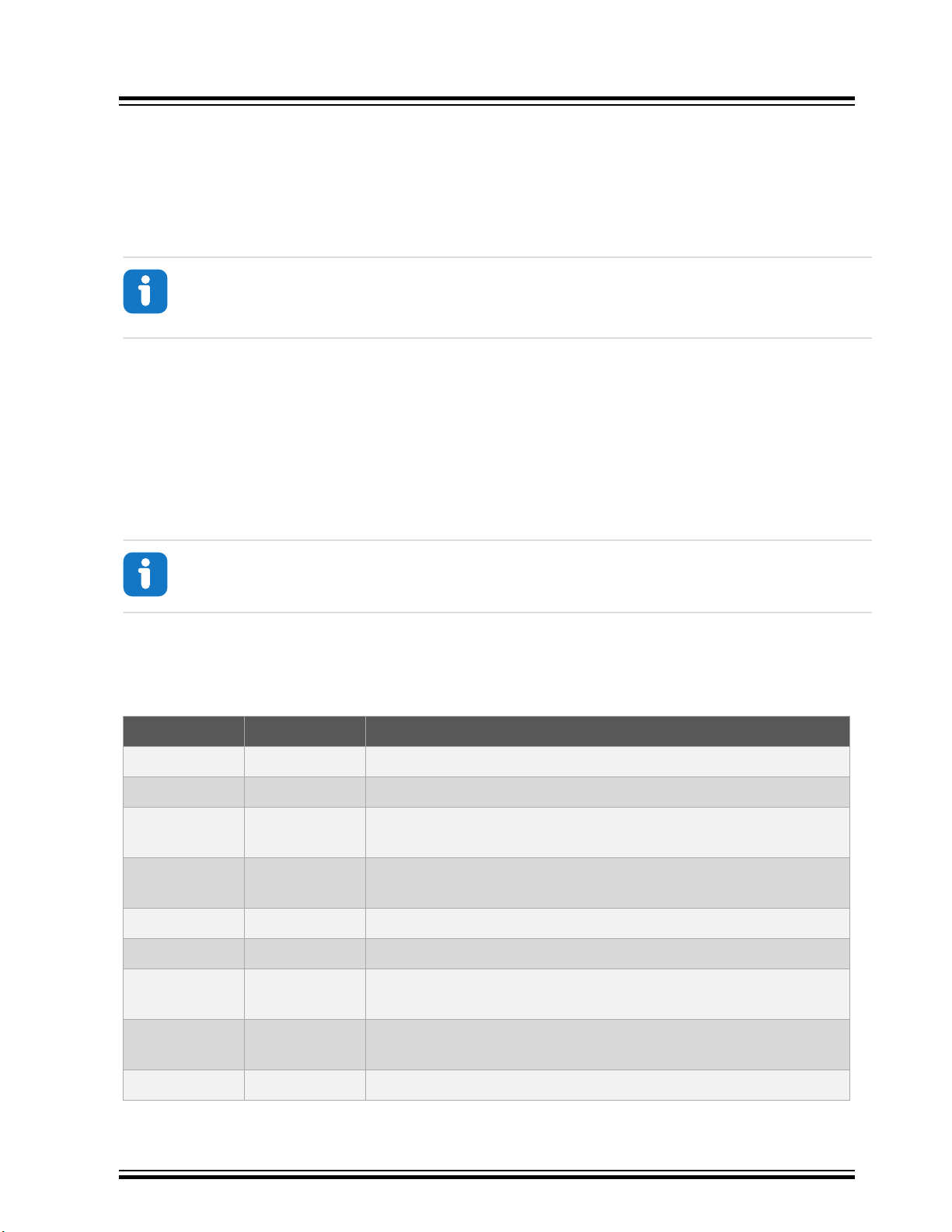

4.5.4 SAM R34 Xplained Pro Evaluation Kit XAM Configuration

On the SAM R34 Xplained Pro Evaluation Kit the MCU and the MCU peripherals (e.g., extensions) are

powered by their own regulator, as shown in the following figure. All other parts of the board, mainly the

Embedded Debugger and accompanying Xplained Pro Analog Module (XAM), are powered from a

separate regulator. The current to the MCU and peripherals can be measured by connecting them to the

XAM output through jumper settings.

Hardware User Guide

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 22

Page 23

SAM R34 Xplained Pro Evaluation Kit...

Figure 4-2. SAM R34 XAM Implementation Block Diagram

Hardware User Guide

On the SAM R34 Xplained Pro Evaluation Kit, the XAM can be used in four configurations:

1. No current measurement or external MCU current measurement: The XAM is bypassed and

thus the MCU and peripherals are supplied directly by the regulator. Set both jumpers in the

"BYPASS" position. In this configuration it is also possible to connect external measurement tools

on the Xplained Pro MCU power measurement header to measure MCU current directly instead of

using the XAM.

2. MCU current measurement: The XAM measures only the MCU current while the peripherals are

supplied directly by the regulator. For this configuration, place the jumper for "I/O" (peripherals) into

the "BYPASS" position and the for "MCU" into the "MEASURE" position.

3. Peripherals measurement: The XAM measures only the peripherals current while the MCU is

directly supplied by the regulator. For this configuration, place the jumper for "MCU" into the

"BYPASS" position and the "I/O" jumper into the "MEASURE" position.

4. MCU and peripherals measurement: In this configuration both MCU and peripherals are

measured by the XAM. Place both jumpers on "I/O" and "MCU" headers in the "MEASURE"

position.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 23

Page 24

4.6 Kit Modifications

The SAM R34 Xplained Pro Evaluation Kit contains several resistors that can be used to disconnect I/O

pins of the SAM R34 SiP from connectors and on-board ICs, and to disconnect power signals.

Table 4-16. EDBG Disconnect Resistors

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

Design

ator

R322 0R EDBG SWDIO PA31 SWDIO Debug interface from the EDBG to

R323 0R EDBG SWDCLK PA30 SWCLK

R324 0R EDBG TARGET RESET TARGET MCU

R310 0R EDBG SPI SS PA27 GPIO EDBG CDC and DGI interfaces to

R311 0R EDBG SPI SCK PB23 SPI SCK

R312 0R EDBG SPI MOSI PB22 SPI MOSI

R313 0R EDBG SPI MISO PB02 SPI MISO

R314 0R EDBG DGI SDA PA16 I2C SDA

R315 0R EDBG DGI SCL PA17 I2C SCL

R316 0R EDBG CDC RX PA04 UART TX

R317 0R EDBG CDC TX PA05 UART RX

R318 0R EDBG DGI_GPIO0 PA08 GPIO

R319 0R EDBG DGI_GPIO1 PA09 GPIO

Value From To Comment

the SAM R34

RESET

the SAM R34

R320 0R EDBG DGI_GPIO2 PA12 GPIO

R321 0R EDBG DGI_GPIO3 PA14 GPIO

R229 0R TARGET VUSB DETECT PA07 ADC7 Used to detect if a USB cable is

R109 47K VCC_P3V3_CM_IN TARGET VOLTAGE Used in the voltage divider

R325 0R RESET TARGET RESET

4.6.1 Operating at Other Voltages

The SAM R34 Xplained Pro board operates at 3.3V by default, but it is also possible to run the board at

lower voltages from an external supply. The EDBG is designed to run from a 3.3V supply and won't work

on other voltages; therefore, all connections from the EDBG and from the on-board 3.3V regulator to the

SAM R34 SoC must be removed.

To completely disconnect the EDBG and the on-board power supply from the SAM R34 SoC, do the

following:

SENSE

connected to the TARGET USB

connector.

network to detect the target

voltage of 3.3V.

Reset sense signal to EDBG,

used to detect external resets.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 24

Page 25

CAUTION

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

• Remove the two jumpers from the on-board 3-pin current measurement headers (J101 and J102),

and connect the two center pins (pin 2) together with a wire or an ammeter as shown in Figure 4-3.

• Remove all the EDGB disconnect resistors (refer to Table 4-16).

• Power ON the SAM R34 Xplained Pro via pin 4 (3V3) and pin 2 (GND) of the Power Header J100.

• Program SAM R34 using industry standard 2x5 50-mil Cortex Debug Connector and external

programmer such as Atmel ICE.

Info: Operating the SAM R34 SiP at voltages other than 3.3V requires physical modifications

on the kit using a soldering iron and an external debugger for programming the SAM R34 SiP.

The on-board current measurement only works at 3.3V. The on-board LED is selected for 3.3V

operation; the LED brightness at 1.8V operation is dull. To increase the emitted light level, the

value of the series resistor can be lowered. EDBG functionality can be restored by re-soldering

the removed components.

The voltage supplied through the power header is applied directly to the SAM R34 SoC and the

extension headers. Applying a voltage greater than 3.3V may damage the board permanently.

Figure 4-3. SAM R34 Xplained Pro Current Measurement Headers

Related Links

3.6.2 Xplained Pro Power Header

4.3.4 Cortex Debug Connector

4.7 Limitations

The SAM R34 Xplained Pro Evaluation Kit is optimized for operation in the 902-928 and 868 MHz bands.

The RF signal path is not designed to operate in the 470 MHz band. The RFI_LF and RFO_LF signals

are not connected. Contact Microchip technical support for advice on 470 MHz band operation.

The XPRO system includes an RF Switch and a Temperature Controlled Crystal Oscillator (TCXO). The

TCXO is required to achieve the exceptionally low receiver-sensitivity and generous link-budget. The RF

switch directs TX/RX signal flow in the RF signal path. It also allows users to evaluate both the high-

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 25

Page 26

SAM R34 Xplained Pro Evaluation Kit...

Hardware User Guide

power PA_BOOST and high-efficiency RFO_HF modes. Both the TCXO and RF Switch consume

additional power when compared to the SAMR34 Data Sheet specifications. The additional consumption

needs to be factored into laboratory measurements with the SAM R34 XPRO. See the following table for

details.

Table 4-17. SAM R34 Xplained Pro Evaluation Kit Additional Power Consumers

REF_DES Description MFG MPN Typical Sleep Current

U900 RF Switch Skyworks SKY13373-460LF 5 µA 60 µA

XC1 TCXO Epson TG2016SMN N/A 1.8 mA

Typical Active

Current

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 26

Page 27

SAM R34 Xplained Pro Evaluation Kit...

Agency Certification

5. Agency Certification

This equipment (SAM R34 Xplained Pro Evaluation Kit / A09-3167) is intended for evaluation purposes

only. The following regulatory notices are to cover the requirements under the regulatory approval.

5.1 Antenna Considerations

The following table provides the list of approved antennas along with the manufacturer and part number

details.

Table 5-1. A09-3167 with Antenna Types

S. No. Part Number Vendor Antenna Gain at 824 ~ 960 MHz Band Antenna Type

1 AL-A80355-UB701 Alead Technology 2 dBi Dipole

5.2 A09-3167 Usage Instructions under Limited Modular Approval (FCC)

When used in USA and Canada, the Evaluation Kit will only work on the 902-928 MHz Frequency band,

with hopping activated if the 125 kHz channels are enabled.

The host product manufacturer must ensure that the RF behavior adheres to the certification (e.g. FCC,

ISED) requirements when the module is installed in the final host product.

5.3 United States

The A09-3167 module has received Federal Communications Commission (FCC) CFR47

Telecommunications, Part 15 Subpart C “Intentional Radiators” limited single-modular approval in

accordance with Part 15.212 Modular Transmitter approval.

The user must comply with all of the instructions provided by the Grantee, which indicate installation

and/or operating conditions necessary for compliance.

5.3.1 Labeling and User Information Requirements

The A09-3167 has been labeled with their own FCC ID number. If the FCC ID is not visible when the

module is installed inside another device, then the outside of the finished product into which the module is

installed must display a label referring to the enclosed module. This exterior label can use wording as

follows:

For the A09-3167:

Contains Transmitter Module FCC ID: 2ADHKA093167

or

Contains FCC ID: 2ADHKA093167

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

A user's manual for the finished product should include the following statement:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 27

Page 28

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy, and if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected

• Consult the dealer or an experienced radio/TV technician for help

Additional information on labeling and user information requirements for Part 15 devices can be found in

KDB Publication 784748, which is available at the FCC Office of Engineering and Technology (OET)

Laboratory Division Knowledge Database (KDB) https://apps.fcc.gov/oetcf/kdb/index.cfm

5.3.2 RF Exposure

All transmitters regulated by FCC must comply with RF exposure requirements. KDB 447498 General RF

Exposure Guidance provides guidance in determining whether proposed or existing transmitting facilities,

operations or devices comply with limits for human exposure to Radio Frequency (RF) fields adopted by

the Federal Communications Commission (FCC).

SAM R34 Xplained Pro Evaluation Kit...

Agency Certification

From the FCC Grant: Output power listed is conducted.

This transmitter is restricted for use with the specific antenna(s) tested in this application for Certification

and must not be co-located or operating in conjunction with any other antenna or transmitters within a

host device, except in accordance with FCC multi-transmitter product procedures. The antenna of this

transmitter must be installed to provide a separation distance of at least 20 cm from all persons.

5.3.3 Information for the OEMs or Integrators

This grant is valid only when the device is sold to OEM integrators and installation is done under the

control of the Grantee.

5.3.4 Approved Antenna Types

To maintain modular approval in the United States, only the antenna types that have been tested shall be

used.

Antennas approved for A09-3167 with the antenna types are listed in Table 5-1.

5.3.5 Helpful Web Sites

Federal Communications Commission (FCC): http://www.fcc.gov

FCC Office of Engineering and Technology (OET) Laboratory Division Knowledge Database (KDB):

https://apps.fcc.gov/oetcf/kdb/index.cfm

5.4 Canada

The A09-3167 has been certified for use in Canada under Innovation, Science and Economic

Development Canada (ISED, formerly Industry Canada) Radio Standards Procedure (RSP) RSP-100,

Radio Standards Specification (RSS) RSS-Gen and RSS-247.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 28

Page 29

SAM R34 Xplained Pro Evaluation Kit...

5.4.1 Labeling and User Information Requirements

Label Requirements (from RSP-100 Issue 11, Section 3): The host device shall be properly labeled to

identify the module within the host device.

The Innovation, Science and Economic Development Canada certification label of a module shall be

clearly visible at all times when installed in the host device, otherwise the host device must be labeled to

display the Innovation, Science and Economic Development Canada certification number of the module,

preceded by the words “Contains”, or similar wording expressing the same meaning, as follows:

For the A09-3167:

Contains IC: 20266-093167

User Manual Notice for License-Exempt Radio Apparatus (from Section 8.4 RSS-Gen, Issue 5, April

2018): User manuals for license-exempt radio apparatus shall contain the following or equivalent notice in

a conspicuous location in the user manual or alternatively on the device or both:

This device contains licence-exempt transmitter(s)/receiver(s) that comply with Innovation,

Science and Economic Development Canada’s licence-exempt RSS(s). Operation is subject to the

following two conditions:

(1) This device may not cause interference;

Agency Certification

(2) This device must accept any interference, including interference that may cause undesired

operation of the device.

L’émetteur/récepteur exempt de licence contenu dans le présent appareil est conforme aux CNR

d’Innovation, Sciences et Développement économique Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes:

• L’appareil ne doit pas produire de brouillage;

• L’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

Transmitter Antenna (From Section 6.8 RSS-GEN, Issue 5, April 2018): User manuals, for transmitters

shall display the following notice in a conspicuous location:

This radio transmitter [IC: 20266-093167] has been approved by Innovation, Science and

Economic Development Canada to operate with the antenna types listed below, with the maximum

permissible gain indicated. Antenna types not included in this list that have a gain greater than

the maximum gain indicated for any type listed are strictly prohibited for use with this device.

Le présent émetteur radio [IC: 20266-093167] a été approuvé par Innovation, Sciences et

Développement économique Canada pour fonctionner avec les types d'antenne énumérés

ci‑dessous et ayant un gain admissible maximal. Les types d'antenne non inclus dans cette liste,

et dont le gain est supérieur au gain maximal indiqué pour tout type figurant sur la liste, sont

strictement interdits pour l'exploitation de l'émetteur.

Immediately following the above notice, the manufacturer shall provide a list of all antenna types which

can be used with the transmitter, indicating the maximum permissible antenna gain (in dBi) and the

required impedance for each antenna type.

5.4.2 RF Exposure

All transmitters regulated by ISED must comply with RF exposure requirements listed in RSS-102 - Radio

Frequency (RF) Exposure Compliance of Radio communication Apparatus (All Frequency Bands).

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 29

Page 30

This transmitter is restricted for use with a specific antenna tested in this application for certification, and

must not be co-located or operating in conjunction with any other antenna or transmitters within a host

device, except in accordance with Canada multi-transmitter product procedures.

The installation of the transmitter must ensure compliance is demonstrated according to the ISED SAR

procedures.

5.4.3 Helpful Websites

Industry Canada: http://www.ic.gc.ca/

5.5 Europe

This equipment (A09-3167) has been assessed under the Radio Equipment Directive (RED) for use in

European Union countries. A Declaration of Conformity must be issued for each of these standards and

kept on file as described in Radio Equipment Directive.

Furthermore, the manufacturer must maintain a copy of the module's documentation and ensure the final

product does not exceed the specified power ratings, antenna specifications, and/or installation

requirements as specified in the user manual. If any of these specifications are exceeded in the final

product, a submission must be made to a notified body for compliance testing to all required standards.

SAM R34 Xplained Pro Evaluation Kit...

Agency Certification

Important:

On account of the nature of radio equipment, the height of the CE marking affixed to radio

equipment may be lower than 5 mm, provided that it remains visible and legible.

More detailed information about CE marking requirements, refer Article 19 of "DIRECTIVE

2014/53/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL" of 16 April 2014.

SIMPLIFIED EU DECLARATION OF CONFORMITY

Hereby, Microchip Technology Inc. declares that the radio equipment type [A09-3167] is in compliance

with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address (refer product

specific pages): http://www.microchip.com/design-centers/wireless-connectivity/

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 30

Page 31

SAM R34 Xplained Pro Evaluation Kit...

6. Hardware Revision History

6.1 Identifying Product ID and Revision

There are two ways to find the revision and product identifier of the Xplained Pro boards: either through

Atmel Studio or by looking at the sticker on the bottom side of the PCB.

When an Xplained Pro MCU board is connected to a computer with Atmel Studio running, an information

window with the serial number is shown. The first six digits of the serial number contain the product

identifier and revision. Information about connected Xplained Pro extension boards is also shown in the

window.

The same information can be found on the sticker on the bottom side of the PCB. Most kits have stickers

that have the identifier and revision printed in plain text as A09-nnnn/rr, where nnnn is the identifier and rr

is the revision. Boards with limited space have a sticker with only a data matrix code, which contains a

serial number string.

The serial number string has the following format:

Hardware Revision History

"nnnnrrssssssssss"

n = product identifier

r = revision

s = serial number

The product identifier for the SAM R34 Xplained Pro is A09-3167.

6.2 Hardware Revision

Revision 1

This is an internal release of a small lot for engineering validation testing.

Revision 2

This is an internal release of a small lot for regulatory pre-testing.

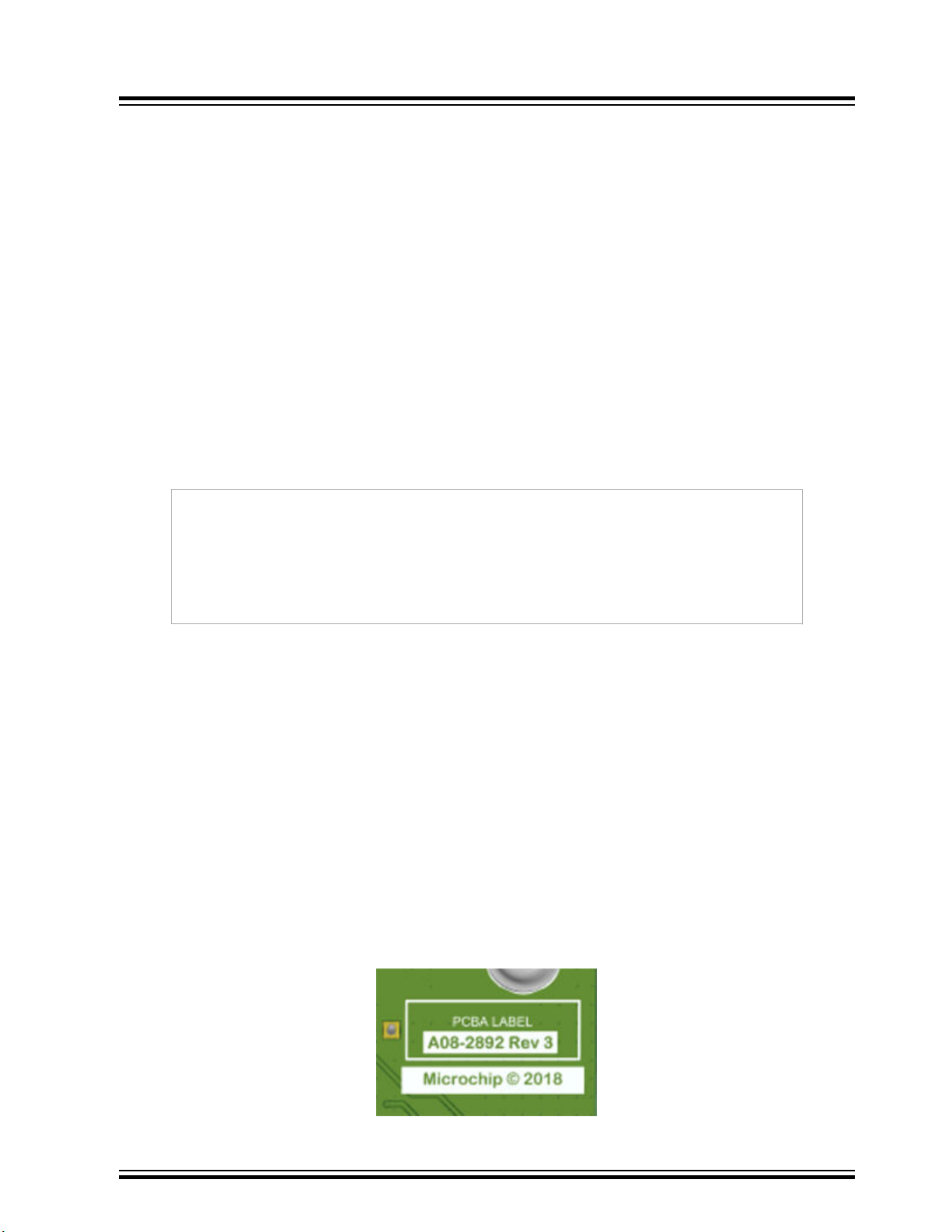

Revision 3

This is the first public release. This revision contains known errors on the silkscreen. The reference

designators for EXT1.15 and EXT1.10 are mismarked. For extension header (EXT1) pin details, see

Table 4-1. Revision 3 may be identified on the bottom side silkscreen as shown in the following image.

Figure 6-1. Bottom Side of Silkscreen

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 31

Page 32

SAM R34 Xplained Pro Evaluation Kit...

Hardware Revision History

Revision 4

This revision is the second public release. Silkscreen errors were corrected. Revision 4 PCB may be

identified by the markings shown below.

Figure 6-2. Revision 4 Bottom Side Silkscreen

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 32

Page 33

SAM R34 Xplained Pro Evaluation Kit...

7. Document Revision History

Revision Date Section Description

C 05/2019 Introduction Updated Figure 1.

Document Revision History

Kit Overview Updated image.

Hardware Revision

History

B 03/2019 Limitations Added a new section.

Reference Schematics Added a new section.

Bill of Materials Added a new section.

A 10/2018 Document Initial Release

Added Revision 4

description and image.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 33

Page 34

SAM R34 Xplained Pro Evaluation Kit...

The Microchip Web Site

Microchip provides online support via our web site at http://www.microchip.com/. This web site is used as

a means to make files and information easily available to customers. Accessible by using your favorite

Internet browser, the web site contains the following information:

• Product Support – Data sheets and errata, application notes and sample programs, design

resources, user’s guides and hardware support documents, latest software releases and archived

software

• General Technical Support – Frequently Asked Questions (FAQ), technical support requests, online

discussion groups, Microchip consultant program member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip press releases,

listing of seminars and events, listings of Microchip sales offices, distributors and factory

representatives

Customer Change Notification Service

Microchip’s customer notification service helps keep customers current on Microchip products.

Subscribers will receive e-mail notification whenever there are changes, updates, revisions or errata

related to a specified product family or development tool of interest.

To register, access the Microchip web site at http://www.microchip.com/. Under “Support”, click on

“Customer Change Notification” and follow the registration instructions.

Customer Support

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or Field Application Engineer (FAE) for support.

Local sales offices are also available to help customers. A listing of sales offices and locations is included

in the back of this document.

Technical support is available through the web site at: http://www.microchip.com/support

Microchip Devices Code Protection Feature

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the

market today, when used in the intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of

these methods, to our knowledge, require using the Microchip products in a manner outside the

operating specifications contained in Microchip’s Data Sheets. Most likely, the person doing so is

engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 34

Page 35

SAM R34 Xplained Pro Evaluation Kit...

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their

code. Code protection does not mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the

code protection features of our products. Attempts to break Microchip’s code protection feature may be a

violation of the Digital Millennium Copyright Act. If such acts allow unauthorized access to your software

or other copyrighted work, you may have a right to sue for relief under that Act.

Legal Notice

Information contained in this publication regarding device applications and the like is provided only for

your convenience and may be superseded by updates. It is your responsibility to ensure that your

application meets with your specifications. MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL, STATUTORY

OR OTHERWISE, RELATED TO THE INFORMATION, INCLUDING BUT NOT LIMITED TO ITS

CONDITION, QUALITY, PERFORMANCE, MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and its use. Use of Microchip devices in life

support and/or safety applications is entirely at the buyer’s risk, and the buyer agrees to defend,

indemnify and hold harmless Microchip from any and all damages, claims, suits, or expenses resulting

from such use. No licenses are conveyed, implicitly or otherwise, under any Microchip intellectual

property rights unless otherwise stated.

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR, AVR logo, AVR Freaks, BitCloud,

chipKIT, chipKIT logo, CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo, JukeBlox, KeeLoq,

Kleer, LANCheck, LINK MD, maXStylus, maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip Designer, QTouch, SAM-BA, SpyNIC, SST,

SST Logo, SuperFlash, tinyAVR, UNI/O, and XMEGA are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

ClockWorks, The Embedded Control Solutions Company, EtherSynch, Hyper Speed Control, HyperLight

Load, IntelliMOS, mTouch, Precision Edge, and Quiet-Wire are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any Capacitor, AnyIn, AnyOut, BodyCom,

CodeGuard, CryptoAuthentication, CryptoAutomotive, CryptoCompanion, CryptoController, dsPICDEM,

dsPICDEM.net, Dynamic Average Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial Programming,

ICSP, INICnet, Inter-Chip Connectivity, JitterBlocker, KleerNet, KleerNet logo, memBrain, Mindi, MiWi,

motorBench, MPASM, MPF, MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach, Omniscient

Code Generation, PICDEM, PICDEM.net, PICkit, PICtail, PowerSmart, PureSilicon, QMatrix, REAL ICE,

Ripple Blocker, SAM-ICE, Serial Quad I/O, SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and ZENA are

trademarks of Microchip Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology Germany II GmbH & Co. KG, a subsidiary of

Microchip Technology Inc., in other countries.

All other trademarks mentioned herein are property of their respective companies.

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 35

Page 36

SAM R34 Xplained Pro Evaluation Kit...

©

2019, Microchip Technology Incorporated, Printed in the U.S.A., All Rights Reserved.

ISBN: 978-1-5224-4456-5

Quality Management System Certified by DNV

ISO/TS 16949

Microchip received ISO/TS-16949:2009 certification for its worldwide headquarters, design and wafer

fabrication facilities in Chandler and Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures are for its PIC® MCUs and dsPIC

DSCs, KEELOQ® code hopping devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design and manufacture of development

systems is ISO 9001:2000 certified.

®

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 36

Page 37

Worldwide Sales and Service

AMERICAS ASIA/PACIFIC ASIA/PACIFIC EUROPE

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

Australia - Sydney

Tel: 61-2-9868-6733

China - Beijing

Tel: 86-10-8569-7000

China - Chengdu

Tel: 86-28-8665-5511

China - Chongqing

Tel: 86-23-8980-9588

China - Dongguan

Tel: 86-769-8702-9880

China - Guangzhou

Tel: 86-20-8755-8029

China - Hangzhou

Tel: 86-571-8792-8115

China - Hong Kong SAR

Tel: 852-2943-5100

China - Nanjing

Tel: 86-25-8473-2460

China - Qingdao

Tel: 86-532-8502-7355

China - Shanghai

Tel: 86-21-3326-8000

China - Shenyang

Tel: 86-24-2334-2829

China - Shenzhen

Tel: 86-755-8864-2200

China - Suzhou

Tel: 86-186-6233-1526

China - Wuhan

Tel: 86-27-5980-5300

China - Xian

Tel: 86-29-8833-7252

China - Xiamen

Tel: 86-592-2388138

China - Zhuhai

Tel: 86-756-3210040

India - Bangalore

Tel: 91-80-3090-4444

India - New Delhi

Tel: 91-11-4160-8631

India - Pune

Tel: 91-20-4121-0141

Japan - Osaka

Tel: 81-6-6152-7160

Japan - Tokyo

Tel: 81-3-6880- 3770

Korea - Daegu

Tel: 82-53-744-4301

Korea - Seoul

Tel: 82-2-554-7200

Malaysia - Kuala Lumpur

Tel: 60-3-7651-7906

Malaysia - Penang

Tel: 60-4-227-8870

Philippines - Manila

Tel: 63-2-634-9065

Singapore

Tel: 65-6334-8870

Taiwan - Hsin Chu

Tel: 886-3-577-8366

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Taiwan - Taipei

Tel: 886-2-2508-8600

Thailand - Bangkok

Tel: 66-2-694-1351

Vietnam - Ho Chi Minh

Tel: 84-28-5448-2100

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

Finland - Espoo

Tel: 358-9-4520-820

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-67-3636

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Israel - Ra’anana

Tel: 972-9-744-7705

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-72884388

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

© 2019 Microchip Technology Inc.

User Guide

DS50002803C-page 37

Loading...

Loading...