Page 1

SAM E70 Xplained Ultra User's Guide

Introduction

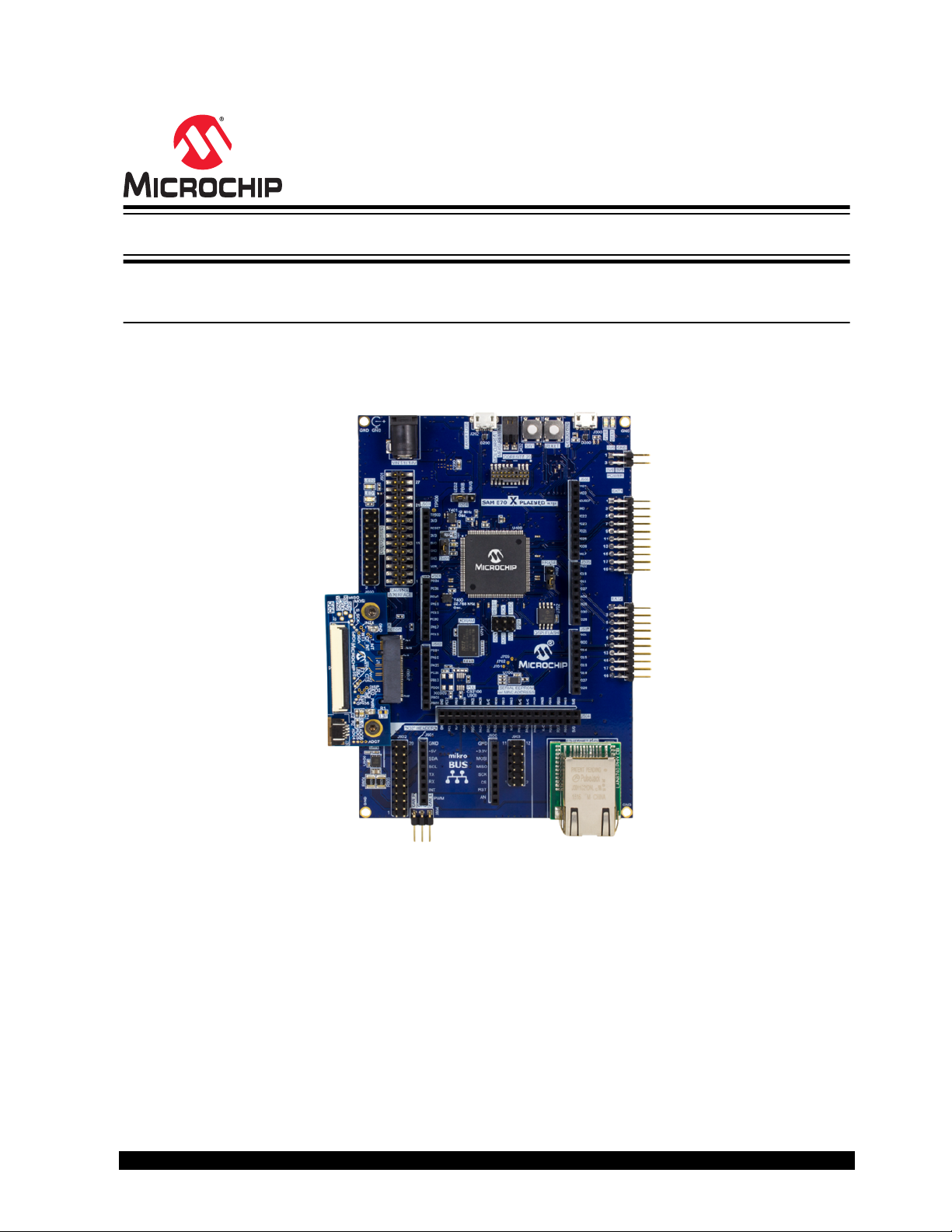

This user’s guide provides detailed information about the SAM E70 Xplained Ultra Evaluation kit and its

various features. Figure below illustrates the SAM E70 Xplained Ultra Evaluation kit.

Figure 1. SAM E70 Xplained Ultra Evaluation Kit with PHY Daughter Board

Features

• ATSAME70Q21 Microcontroller

• One Mechanical Reset Button

• One Mechanical User Push Button

• Two User LEDs

• 12.0 MHz Oscillator (DSC6003)

• 32.768 kHz Oscillator (DSC6083)

• 2-MB SDRAM

• 4-MB QSPI Flash (SST26VF032BA)

© 2019 Microchip Technology Inc.

DS70005389A-page 1

Page 2

• Ethernet Interface with External IEEE 802.3az 10Base-T/100Base-TX Ethernet RMII PHY on a

Daughter Board

• AT24MAC402 256KB EEPROM with EUI-48 Address

• ATA6561 CAN Transceiver

• Micro SD Card Connector with SDIO Support

• Camera Interface Connector

• Two Xplained Pro Extension Headers

• Graphics Card Interface

• CoreSight® 20 Connector for 4-bit ETM

• Arduino MEGA Shield Connector

• External Debugger Connector

• USB Interface, Device and Host Mode

• Embedded Debugger:

– Programming and debugging through USB interface

– Auto-ID for board identification in Atmel Studio and MPLAB® X

– One yellow status LED

– One green board power LED

– Symbolic debug of complex data types including scope information

– Data Gateway Interface: SPI, I2C, four GPIOs

– Virtual COM port (CDC)

• External Power Input (5-14V) or USB Power

• X32 Daughter Board Interface to Support Audio and Bluetooth

®

• One mikroBus™ Interface

Kit Overview

The Microchip PIC32 SAM E70 Xplained Ultra Development Kit (DM320113) provides a modular

development system for Microchip’s line of 32-bit Cortex® microcontrollers.

For a free Microchip demonstration code and additional information, visit the MPLAB Harmony™ web

page at: http://www.microchip.com/MPLABHarmony.

The Atmel SAM E70 Xplained Ultra Dvelopment Kit is a hardware platform to evaluate the Microchip

ATSAME70Q21. The kit offers a set of features that enables the ATSAME70Q21 users to start with the

SAM E70 peripherals and understand how to integrate the device in their design.

The SAM E70 Xlpained Ultra kit contains the following items:

• One SAM E70 Xplained Ultra Development Kit

• One KSZ8061 Ethernet PHY

• One Graphics card set up for 565 (16-bit color) graphics

Note: If any items are missing in the kit, contact Microchip sales office for assistance. A list of Microchip

Sales offices is provided on the last page of this document.

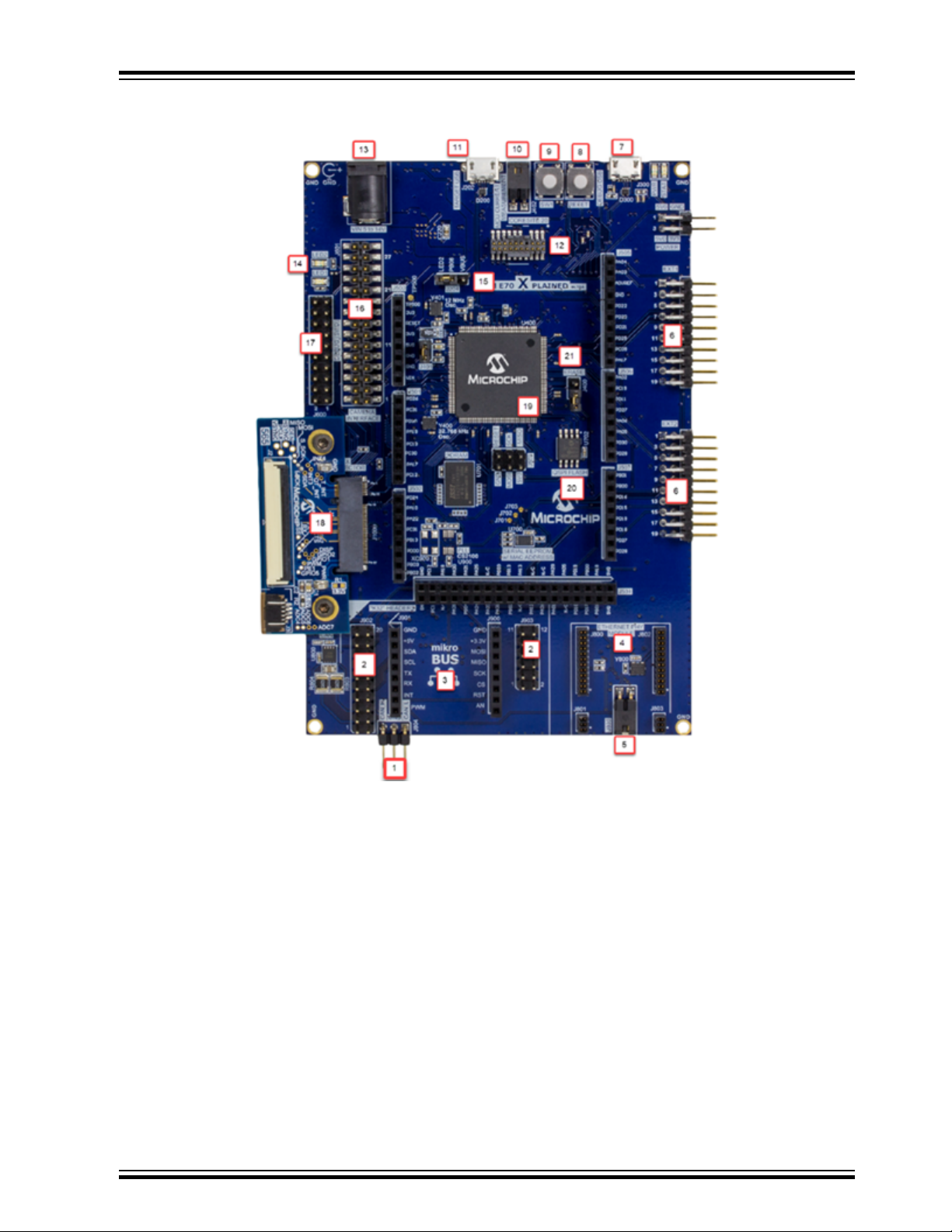

The figure below illustrates the SAM E70 Xplained Ultra Evaluation Kit features.

© 2019 Microchip Technology Inc.

DS70005389A-page 2

Page 3

Figure 2. SAM E70 Xplained Ultra Evaluation Kit

© 2019 Microchip Technology Inc.

DS70005389A-page 3

Page 4

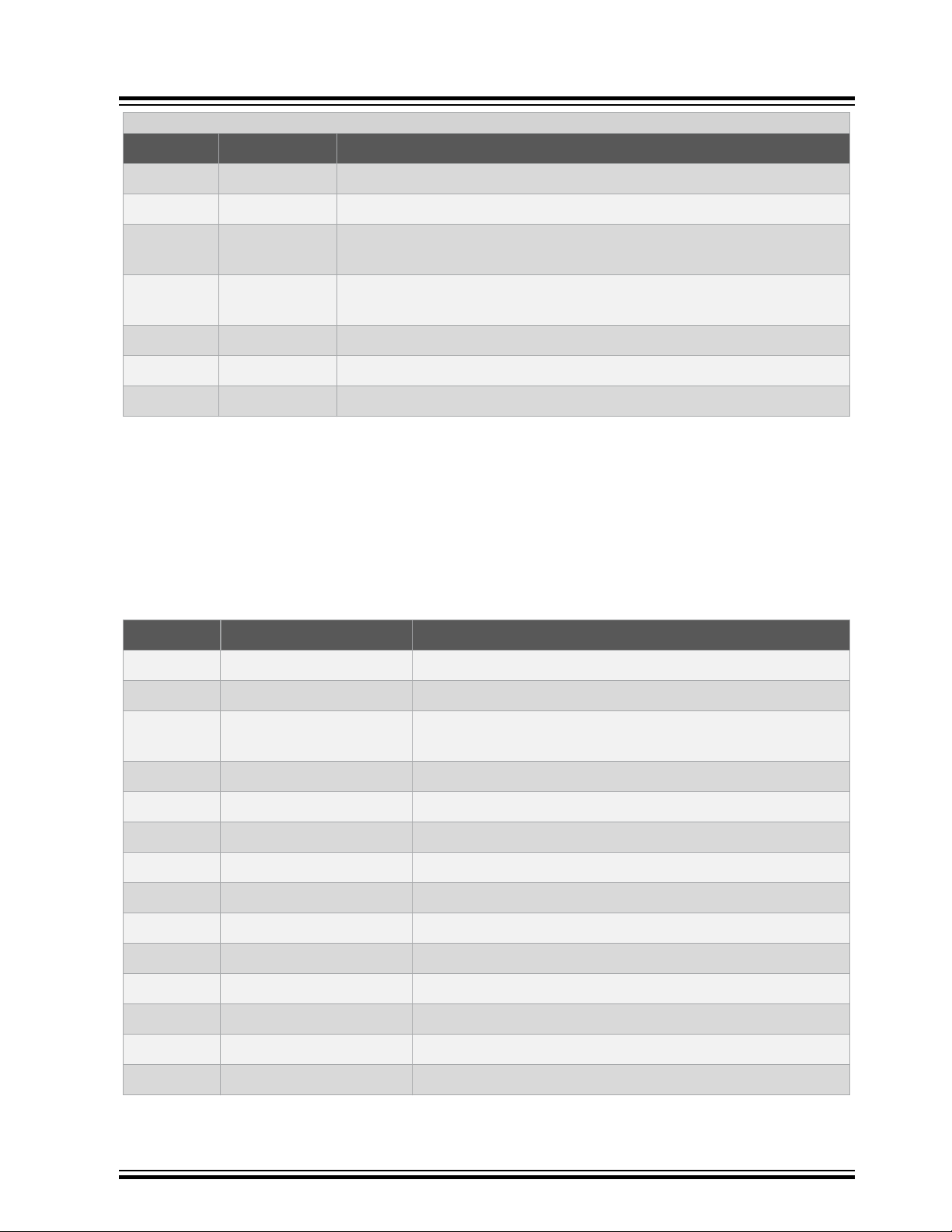

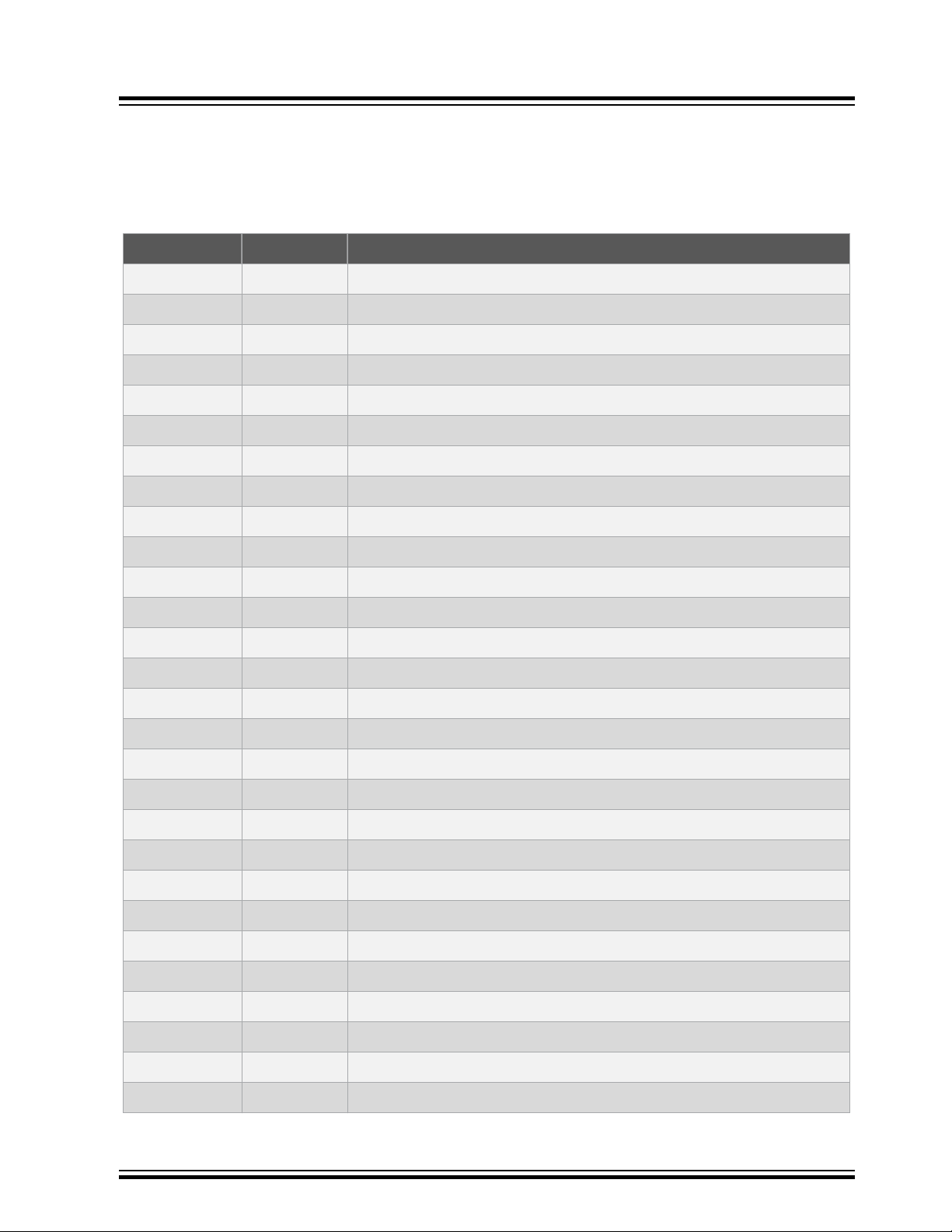

The table below provides the SAM E70 Xplained Ultra Evaluation kit feature descriptions.

Table 1. SAM E70 Xplained Ultra Evaluation Kit Feature and Location

Number Description

1 CAN interface

2 X32 Daughter Board interface

3 Mikro interface

4 Ethernet PHY interface

5 Ethernet Clock enable/disable jumper

1. Shorted = disabled

2. Open = enabled

6 EXT1/EXT2 interface

7 Debugger USB

1. Programming

2. Power

3. DGI

8 External Reset Button

9 User Button

10 MCU current measurement jumper

11 SAM E70 Host/Device USB

12 CoreSite® 20 (SWD + ETM) debugging interface

13 Barrel power input (2.1mm)

14 User defined LEDs

15 LED2/USB detect jumper

16 Image Sensor interface

17 SWD debugger interface

18 Graphics card interface

19 ATSAME70Q21B

20 SQI external Flash memory

© 2019 Microchip Technology Inc.

DS70005389A-page 4

Page 5

Table of Contents

Introduction......................................................................................................................1

1. Getting Started.......................................................................................................... 6

2. Xplained Ultra............................................................................................................8

3. Embedded Debugger................................................................................................ 9

3.1. Hardware Identification System....................................................................................................9

4. System Level Block Diagram...................................................................................11

5. Hardware Features..................................................................................................12

5.1. Xplained Pro Standard Extension Header..................................................................................12

5.2. Graphics Connectors or GFX Card Interface............................................................................. 13

5.3. SDRAM and LCD Connections.................................................................................................. 16

5.4. Camera Connector.....................................................................................................................18

5.5. USB Connectivity....................................................................................................................... 19

5.6. Chip Erase Header.....................................................................................................................20

5.7. Audio Connectivity......................................................................................................................20

5.8. mikroBUS™ Header................................................................................................................... 22

5.9. CAN............................................................................................................................................22

5.10. Ethernet......................................................................................................................................23

5.11. Debug USB Connectivity............................................................................................................24

5.12. Switches.....................................................................................................................................24

5.13. AT24MAC402 Serial EEPROM.................................................................................................. 25

5.14. Power Sources...........................................................................................................................26

6. Hardware.................................................................................................................28

6.1. SAM E70 Xplained Ultra Development Board Schematics........................................................ 28

6.2. Bill of Materials...........................................................................................................................50

The Microchip Web Site................................................................................................ 55

Customer Change Notification Service..........................................................................55

Customer Support......................................................................................................... 55

Microchip Devices Code Protection Feature................................................................. 55

Legal Notice...................................................................................................................56

Trademarks................................................................................................................... 56

Quality Management System Certified by DNV.............................................................57

Worldwide Sales and Service........................................................................................58

© 2019 Microchip Technology Inc.

DS70005389A-page 5

Page 6

1. Getting Started

SAM E70 Xplained Ultra Evaluation Quick Start

Follow these steps to explore the Atmel SAM E70 Xplained Ultra evaluation kit:

1. Download and install MPLAB X.

2. Launch MPLAB X.

3. Install MPLAB Harmony 3™.

Getting Started

When Microchip SAM E70 Xplained Ultra is connected to the computer for the first time, the operating

system will install a driver software. The driver file supports both 32-bit and 64-bit versions of Microsoft

Windows® XP/ Vista /7/8/10.

Once the kit is powered, the green power LED will be lit and MPLAB X will auto-detect the kit and identify

which Xplained Pro extension boards are connected. MPLAB X will provide relevant information like data

sheets and kit documentation. The SAM E70 device is programmed and debugged by the on-board

Embedded Debugger, hence no external programmer or debugger tool is needed.

Design Documentation and Relevant Links

The following list provides links to the relevant documents and software for the SAM E70 Xplained Ultra.

• Xplained Pro products

– Atmel Xplained Pro is a series of small-sized and easy-to-use evaluation kit for Microchip

microcontrollers and other Microchip products. It consists of a series of low-cost MCU boards for

evaluation and demonstration of features and capabilities of different MCU families.

• Microchip MPLAB® Integrated Development Environment

– A free Microchip MPLAB IDE for development of C/C++ and assembler code for Microchip

microcontrollers.

• MPLAB Harmony

– A free MPLAB Harmony code base is available for user application. The latest MPLAB Harmony

code is available for download at:http://www.microchip.com/MPLABHarmony.

• EDBG User Guide

– This user’s guide provides additional information about the on-board Embedded Debugger.

• Data Visualizer

– Data Visualizer is a program used for processing and visualizing data. The Data Visualizer can

receive data from various sources, such as the Embedded Debugger Data Gateway Interface

that is found on the Xplained Pro boards and COM ports.

• IAR Embedded Workbench® for ARM

– A commercial C/C++ compiler that is available for ARM. A 30-day evaluation version and a code

size limited kick-start version are also available for download from their web site. The code size

limit is 16-KB for devices with M0, M0+, M1 cores, and 32-KB for devices with other cores.

• Keil MDK-ARM Microcontroller Development Kit

– The MDK-ARM is a complete software development environment for Cortex®-M, Cortex-R4,

ARM7™, and ARM9™ processor-based devices. The MDK-ARM is specifically designed for

microcontroller applications, it is user friendly yet powerful enough for the most demanding

embedded applications.

• Design Documentation

™

®

®

© 2019 Microchip Technology Inc.

DS70005389A-page 6

Page 7

Getting Started

– Package containing schematics, BOM, assembly drawings, 3D plots, layer plots, and so on.

• Hardware Users Guide

– PDF version of this user guide.

© 2019 Microchip Technology Inc.

DS70005389A-page 7

Page 8

2. Xplained Ultra

The SAM E70 Xplained Ultra implements several Xplained Pro standards like extension headers and

connectors. Xplained Pro is an evaluation platform that provides a full Microchip microcontroller

experience. The platform consists of a series of Microcontroller (MCU) boards and extension boards that

are integrated with the Microchip MPLAB IDE that supports data streaming. The Xplained Pro MCU

boards support a wide range of Xplained Pro extension boards, such as audio DACs/CODECs, Ethernet

PHYs, graphics cards, and mikroBUS™ that are connected through a set of standardized headers and

connectors. Each extension board has an identification (ID) chip to uniquely identify which boards are

connected to a Xplained Pro MCU board. This information is used to present relevant user guides,

application notes, data sheets, and example code through MPLAB X.

Xplained Ultra

© 2019 Microchip Technology Inc.

DS70005389A-page 8

Page 9

3. Embedded Debugger

The SAM E70 Xplained Ultra contains Microchip Embedded Debugger (EDBG) for on-board debugging.

The EDBG is a composite USB device, which is based on the following interfaces:

• Debugger

• Virtual COM Port

• Data Gateway Interface (DGI)

Together with the Microchip MPLAB IDE, the EDBG debugger interface can program and debug the

ATSAME70Q21. On the SAM E70 Xplained Ultra, the SWD interface is connected between the EDBG

and the ATSAME70Q21.

The Virtual COM Port is connected to a UART on the ATSAME70Q21 and provides an easy way to

communicate with the target application through the terminal software. It offers variable baud rate, parity,

and Stop bit settings. The settings on the ATSAME70Q21 must match the settings given in the terminal

software.

Note: If not set automatically, Data Terminal Ready (DTR) must be set in the terminal software.

The DGI consists of several physical interfaces for communication with the host computer.

Communication over the interfaces is bidirectional. It can be used to send events and values from the

ATSAME70Q21, or as a generic printf-style data channel. Traffic over the interfaces can be timestamped

on the EDBG for accurate tracing of events. Note that timestamping imposes an overhead that reduces

maximal throughput. The Data Visualizer is used to send and receive data through DGI.

Embedded Debugger

The EDBG controls two LEDs on SAM E70 Xplained Ultra: a power LED and a status LED.

The following table describes how the LEDs are controlled in different operation modes.

Table 3-1. EDBG LED Control

Operation Mode Power LED Status LED

Normal operation The power LED is lit when power is

applied to the board.

Bootloader mode

(idle)

Bootloader mode

(firmware upgrade)

For additional information on EDBG, refer to the EDBG User Guide.

The power LED and the status LED

blinks simultaneously.

The power LED and the status LED

blinks in an alternating pattern.

3.1 Hardware Identification System

All Xplained Pro-compatible extension boards have an Microchip ATSHA204 CryptoAuthentication™ chip

mounted. This chip contains information that identifies the extension with its name and data. When an

Xplained Pro extension is connected to an Xplained Pro MCU board, the information is read and sent to

the MPLAB X IDE. The Microchip kits extension, installed with MPLAB X, provides relevant information,

such as code examples, and links to relevant documents. The following table provides the data fields

stored in the ID chip with content examples.

Activity indicator, LED flashes when any

communication happens to the EDBG.

The power LED and the status LED

blinks simultaneously.

The power LED and the status LED

blinks in an alternating pattern.

© 2019 Microchip Technology Inc.

DS70005389A-page 9

Page 10

Embedded Debugger

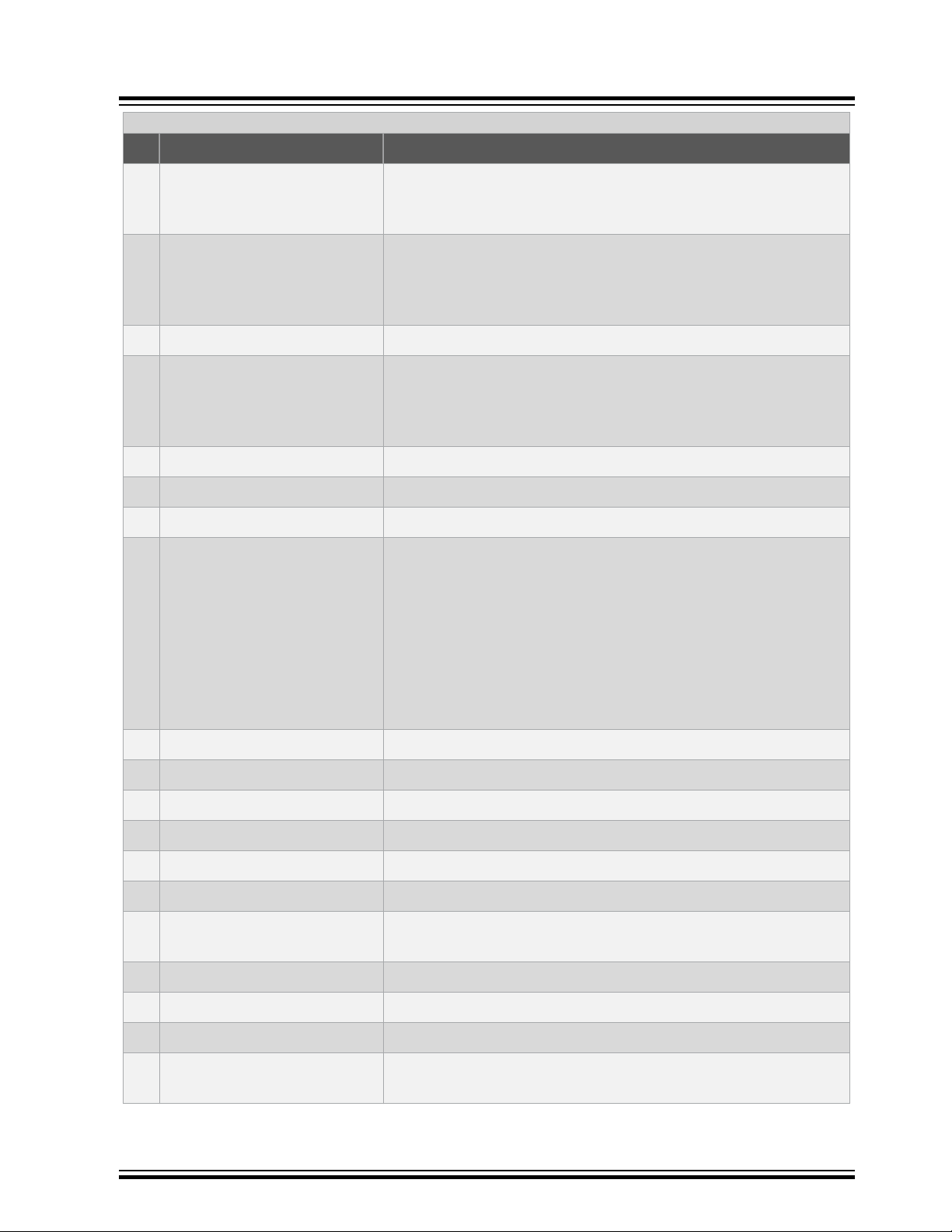

Table 3-2. Xplained Pro ID Chip Content Example

Data Field Data Type Example

Manufacture ASCII string Microchip’\0’

Product Name ASCII string

Product Revision ASCII string 04’\0’

Product Serial number ASCII string 1774020200000010’\0’

Minimum Voltage (mV) uint16_t 3000

Maximum Voltage (mV) uint16_t 3600

Maximum Current (mA) uint16_t 30

© 2019 Microchip Technology Inc.

DS70005389A-page 10

Page 11

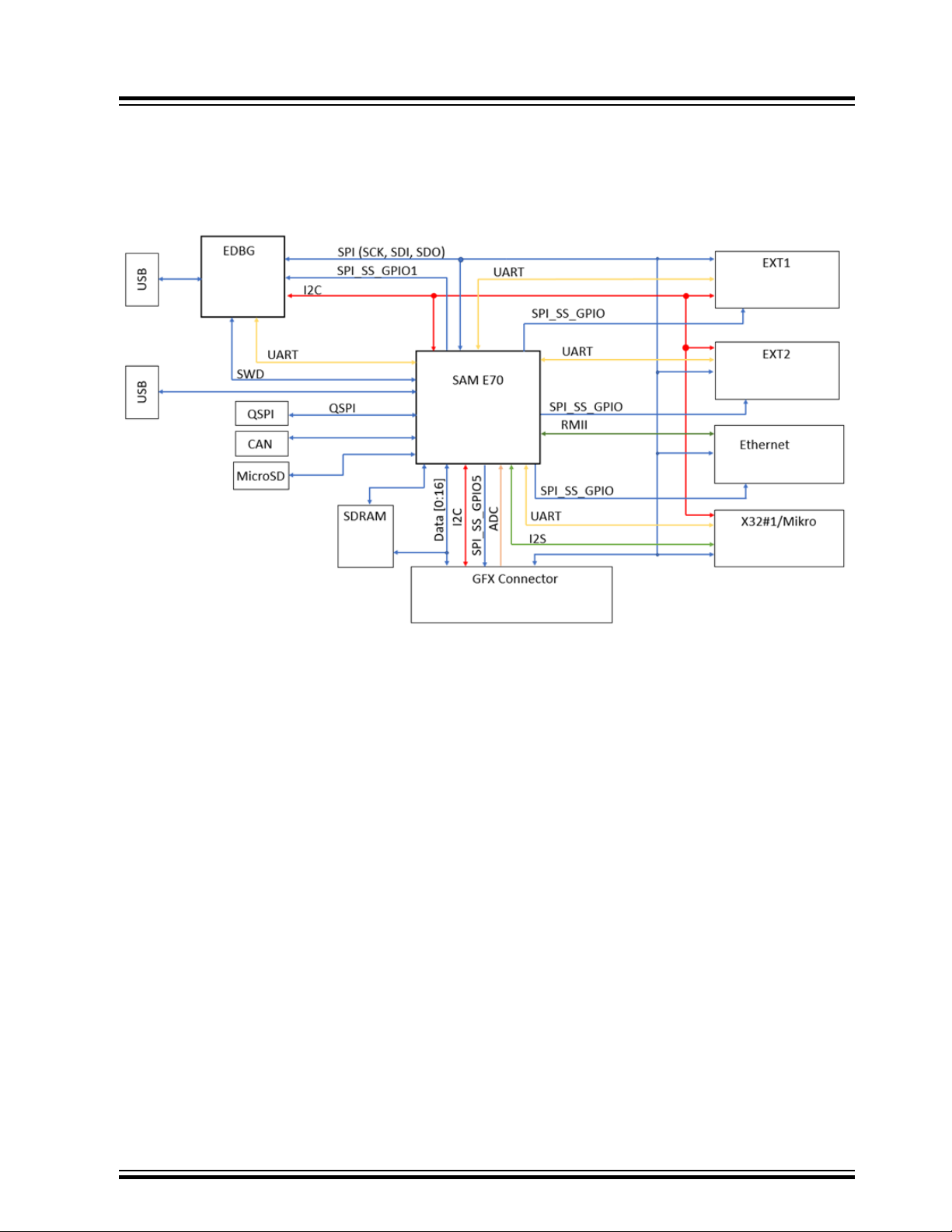

4. System Level Block Diagram

The following figure illustrates the high-level signal block diagram of the SAM E70 Xplained Ultra

Development Kit.

Figure 4-1. Signal Level Block Diagram

System Level Block Diagram

Wire buses that are tied together are connected together. In this system the SPI bus data and clock are

shared across several interfaces. The SPI Slave selects are addressed individually with GPIO.

System I2C uses I2C0 and connects to the debugger, EXT1, EXT2, and mikroBus/X32. Touch I2C uses

I2C2 and only goes from the microcontroller to the graphics connector.

The debugger has the following interfaces connected: DGI SPI, DGI I2C, DGI UART, and SWD.

UART wires from the microcontroller to the blocks are not shared with each other.

© 2019 Microchip Technology Inc.

DS70005389A-page 11

Page 12

5. Hardware Features

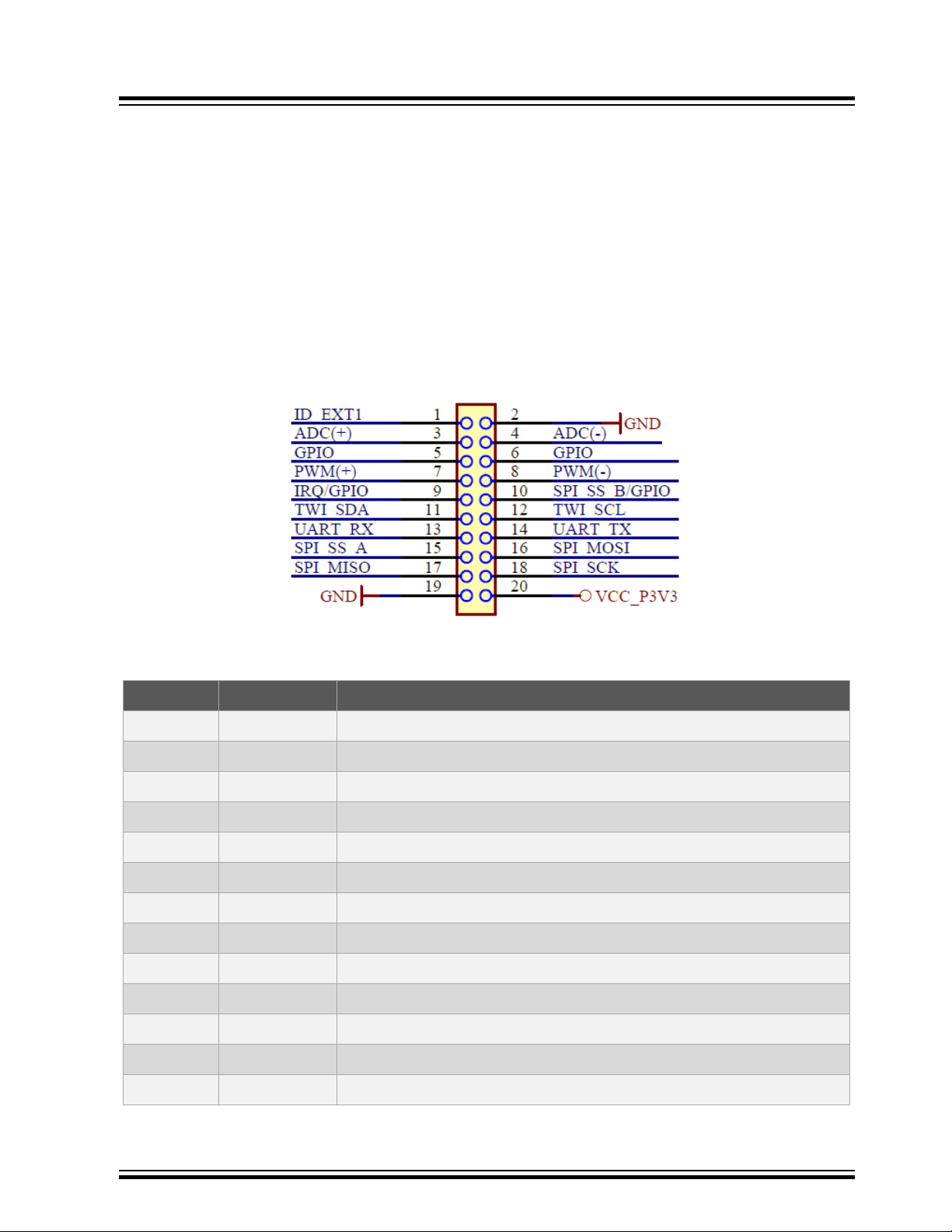

5.1 Xplained Pro Standard Extension Header

All Xplained Ultra Kits have many dual row, 20-pin, 100 mil extension headers. Xplained Ultra MCU

boards have male headers, while Xplained Ultra extensions have their female counterparts as shown in

the image below.

Note: All pins are not always connected.

The extension headers can be used to connect a variety of Xplained Pro extensions to Xplained Ultra

MCU boards or to access the pins of the target MCU on Xplained Ultra MCU boards directly.

Figure 5-1. Extension Headers

Hardware Features

All connected pins follow the defined pinout description as shown in the following table.

Table 5-1. Xplained Pro Standard Extension Header

Pin number Name Description

1 ID Communication line to the ID chip on an extension board

2 GND Ground

3 ADC(+) Analog-to-Digital Converter, alternatively positive part of differential ADC

4 ADC(-) Analog-to-Digital Converter, alternatively negative part of differential ADC

5 GPIO1 General purpose I/O

6 GPIO2 General purpose I/O

7 PWM(+) Pulse-Width Modulation, alternatively positive part of differential PWM

8 PWM(-) Pulse-Width Modulation, alternatively negative part of differential PWM

9 IRQ/INT/GPIO Interrupt request line and general purpose I/O

10 SPI SS B/GPIO SPI Slave Select or general purpose I/O

11 I2C SDA Data line for I2C interface. Always implemented, bus type

12 I2C SCL Clock line for I2C interface. Always implemented, bus type

13 UART RX Receiver line of target device UART

© 2019 Microchip Technology Inc.

DS70005389A-page 12

Page 13

Hardware Features

...........continued

Pin number Name Description

14 UART TX Transmitter line of target device UART

15 SPI SS A/GPIO SPI Slave Select or general purpose I/O

16 SPI MOSI Master Out Slave In line of serial peripheral interface. Always

implemented, bus type.

17 SPI MISO Master In Slave Out line of serial peripheral interface. Always

implemented, bus type.

18 SPI SCK Clock for serial peripheral interface. Always implemented, bus type.

19 GND Ground

20 V

CC

Power for extension boards (3.3V)

5.2 Graphics Connectors or GFX Card Interface

The SAM E70 Xplained Ultra Development Kit is designed to have a modular graphics interface. This

interface enables using several graphics cards, which allow for expandability and different use cases. A

565 adapter card is included in the kit, which takes 16-bit parallel LCD data and converts it to 24-bit data.

This card also provides access to ADC for resistive touch screens, hence an external controller is not

needed. See table below for pin descriptions.

Table 5-2. Graphics Interface Pinout

Pin Number Name Description

1 GND Ground

2 GND Ground

3 MCLR Master Clear, Controlled by the debuggers. Allows for a

complete system reboot.

4 IRQ1 (LCD Touch) Interrupt request line for cap touch device

5 5.0v V

6 IRQ2 (Q Touch) Interrupt request line for Q touch devices

CC

5.0v

7 LCDEN LCD Data Enable

8 IRQ3 (Display Controllers) Interrupt request line for external display controllers

9 LCDHSYNC/NCS3 LCD Horizontal Sync

10 IRQ4 (Resistive touch) Interrupt request line for resistive touch controllers

11 LCDVSYNC/nWE LEC Vertical Sync or Write enable (active-low)

12 5.0v V

13 LCDPCK/nRD LCD pixel Clock or Read Enable (active-low)

14 I2C SDA Data line for I2C interface. Always implemented, bus type.

© 2019 Microchip Technology Inc.

CC

+5.0v

DS70005389A-page 13

Page 14

Hardware Features

...........continued

Pin Number Name Description

15 LCD D0 LCD Data bit 0

16 I2C SCL Clock line for I2C interface. Always implemented, bus type.

17 LCD D1 LCD Data bit 1

18 SPI SCK Clock for serial peripheral interface. Always implemented, bus

type.

19 LCD D2 LCD Data bit 2

20 SPI MOSI Master Out Slave In line of serial peripheral interface.

21 LCD D3 LCD Data bit 3

22 SPI MISO Master In Slave Out line of serial peripheral interface.

23 LCD D4 LCD Data bit 4

24 SPI SS SPI Slave Select

25 LCD D5 LCD Data bit 5

26 UART RX Receiver line of target device UART

27 LCD D6 LCD Data bit 6

28 UART TX Transmitter line of target device UART. (from MCU to GFX

card)

29 LCD D7 LCD Data bit 7

30 UART RTS UART Ready To Send (from MCU to GFX card)

31 LCD D8 LCD Data bit 8

32 UART CTS UART Clear To Send (from MCU to GFX card)

33 LCD D9 LCD Data bit 9

34 LCD PWM LCD PWM back light control

35 LCD D10 LCD Data bit 10

36 PWM2 Pulse-Width Modulation,

37 LCD D11 LCD Data bit 11

38 GPIO1 General purpose I/O

39 LCD D12 LCD Data bit 12

40 GPIO2 General purpose I/O

41 LCD D13 LCD Data bit 13

42 GPIO3 General purpose I/O

43 LCD D14 LCD Data bit 14

© 2019 Microchip Technology Inc.

DS70005389A-page 14

Page 15

Hardware Features

...........continued

Pin Number Name Description

44 STBY/RST/GPIO4 Standby/Reset or general purpose I/O. For resetting devices

attached to the GFX connector.

45 LCD D15 LCD Data bit 15

46 STBY/RST/GPIO5 Standby2/Reset2 or general purpose I/O

47 LCD D16 LCD Data bit 16 (Not Implemented on this design)

48 ID pin Communication line to the ID chip on an extension board

49 LCD D17 LCD Data bit 17 (Not Implemented on this design)

50 ADC 0 Analog-to-Digital Converter to MCU

51 LCD D18 LCD Data bit 18 (Not Implemented on this design)

52 ADC1 Analog-to-Digital Converter to MCU

53 LCD D19 LCD Data bit 19 (Not Implemented on this design)

54 ADC2 Analog-to-Digital Converter to MCU

55 LCD D20 LCD Data bit 20 (Not Implemented on this design)

56 ADC3 Analog-to-Digital Converter to MCU

57 LCD D21 LCD Data bit 21 (Not Implemented on this design)

58 ADC4 Analog-to-Digital Converter to MCU

59 LCD D22 LCD Data bit 22

60 ADC5 Analog-to-Digital Converter to MCU

61 LCD D23 LCD Data bit 23

62 ADC6 Analog-to-Digital Converter to MCU

63 3.3V V

CC

+3.3V V

CC

64 ADC7 Analog-to-Digital Converter to MCU

65 GND Ground

66 3.3V V

CC

+3.3V V

CC

67 GND Ground

68 GND TAB Mounting Tab

69 GND TAB Mounting Tab

© 2019 Microchip Technology Inc.

DS70005389A-page 15

Page 16

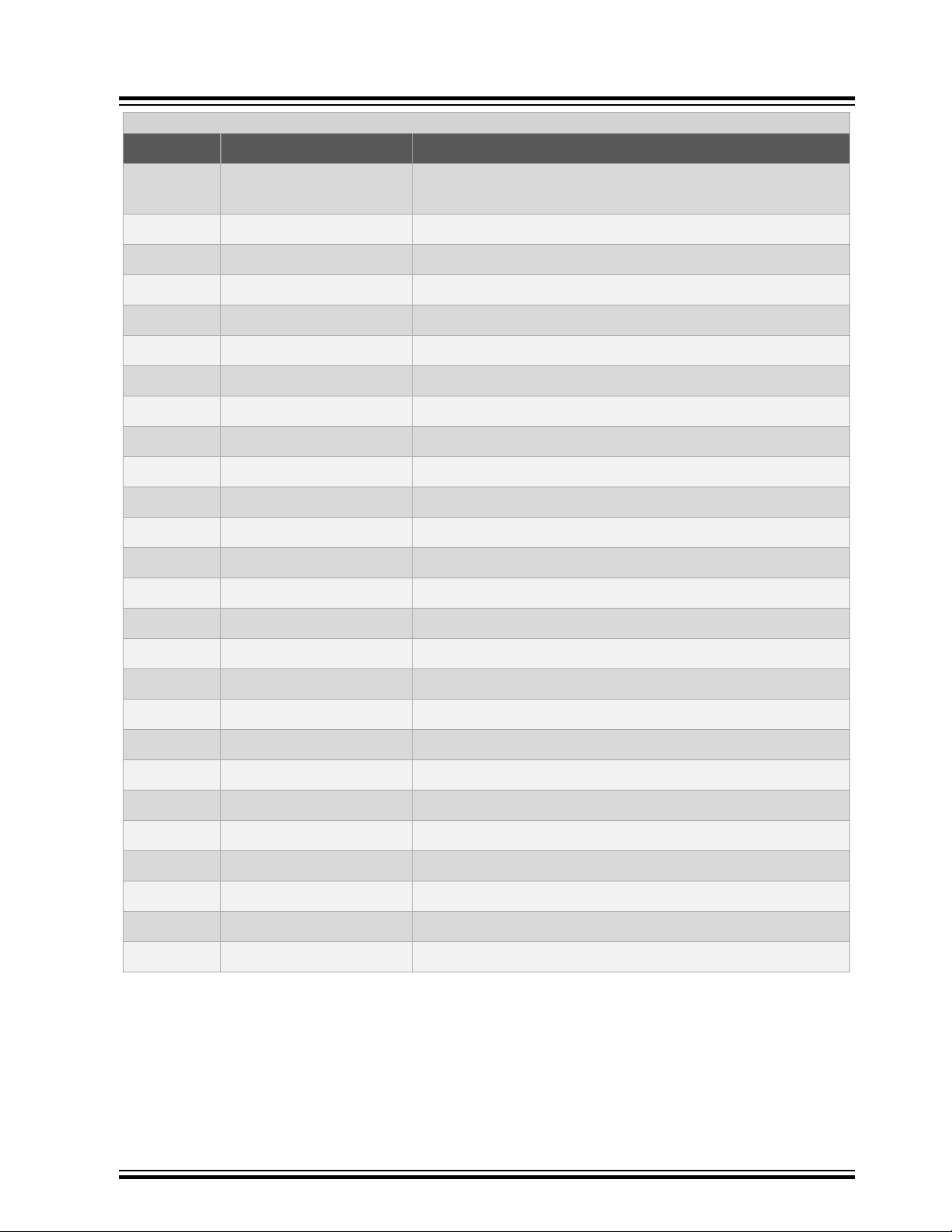

5.3 SDRAM and LCD Connections

The external bus interface (EBI) on SAM E71 Xplaned Ultra is controlled by the static memory controller

(SMC) and SDRAM controllers modules in the ATSAME70Q21B.

ATSAME70Q21B has on-die series termination on very I/O pin as shown in figure below.

Figure 5-2. On-Die Termination

Hardware Features

The EBI is connected to the on-board SDRAM and the Xplained Pro Graphics connector. The following

figure shows how the SDRAM and LCD share the same sets of data pins, and displays the location of the

series termination resistors.

Figure 5-3. LCD and SDRAM

As the I/O pins have on-die series termination, the impedance of the drivers must be matched to the

impedance of the EBI tracks on the PCB using series resistors. The EBI tracks are routed as 50Ω on

SAM E70 Xplained Ultra. The clock and address lines are only driven by the ATSAME70Q21B, while the

data lines are driven by the ATSAME70Q21B and the on-board SDRAM.

© 2019 Microchip Technology Inc.

DS70005389A-page 16

Page 17

Hardware Features

Simulation of the transmissions lines using IBIS files for the ATSAME70Q21B and the SDRAM gave the

results are shown in the table below.

Table 5-3. EBI Simulation Results

Driving Circuit Signal Type Driver Impedance

(from ibis)

ATSAME70Q21B Data/Address 22Ω 24Ω ≈ 22Ω 50Ω

Clock 21Ω 25Ω ≈ 22Ω 50Ω

SDRAM Data 11Ω 32Ω ≈ 33Ω 50Ω

The routing of the data lines to the LCD connector causes stubs on the data lines at the SDRAM (the

stubs are even longer when a cable is plugged in). The 200Ω resistors are placed close to the SDRAM to

create a high-impedance path for the signal to the stubs, improving the signal integrity when

communicating with the SDRAM.

TIP:

• The series-termination is always placed near to the driving pin.

• The 200Ω resistors are placed close to the intersection between the SDRAM routing and the routing

to the LCD connector.

• All designs must be simulated using an IBIS file for the ATSAMV71Q21B and the target peripherals

to check whether the signals are within the limits of the devices.

Series

Termination

Z

0

© 2019 Microchip Technology Inc.

DS70005389A-page 17

Page 18

5.4 Camera Connector

A 2 x 15, 100 mil pin-header camera connector is implemented to provide access to the SAM E70's

parallel Image Sensor Interface (ISI).

Table 5-4. Camera Interface Pin Description

Pin Number Name Function

Hardware Features

1 V

2 GND Ground

3 V

4 GND Ground

5 Reset Reset

6 PWD ISI PWD

7 I2C SCK Clock line for I2C interface. Always implemented, bus type.

8 I2C SDA Data line for I2C interface. Always implemented, bus type.

9 GND Ground

10 MCK Master Clock

11 GND Ground

12 VSYNC Image Sensor Vertical Sync

13 GND Ground

14 HSYNC Image Sensor Horizontal Sync

15 GND Ground

CC

CC

+3.3v

+3.3v

16 Pixel Clock Image Sensor Pixel Clock

17 GND Ground

18 ISI D0 Image Sensor Data Bit 0

19 ISI D1 Image Sensor Data Bit 1

20 ISI D2 Image Sensor Data Bit 2

21 ISI D3 Image Sensor Data Bit 3

22 ISI D4 Image Sensor Data Bit 4

23 ISI D5 Image Sensor Data Bit 5

24 ISI D6 Image Sensor Data Bit 6

25 ISI D7 Image Sensor Data Bit 7

26 ISI D8 Image Sensor Data Bit 8

27 ISI D9 Image Sensor Data Bit 9

28 ISI D10 Image Sensor Data Bit 10

© 2019 Microchip Technology Inc.

DS70005389A-page 18

Page 19

...........continued

Pin Number Name Function

29 ISI D11 Image Sensor Data Bit 11

30 GND Ground

5.5 USB Connectivity

Users can connect to the PIC32 USB microcontroller using any one of the following modes:

• Host mode: If connecting the device to the Type-A/B Micro connector, an adapter is required. Using

this method, a maximum of 400 mA can be supplied from the debug USB port to the host port. If a

full 500 mA supply is needed, an external supply must be connected to the application board.

• Device mode: Connect the SAM E70 to the target USB Micro-A/B port using a USB cable. This is

enough to power the board as a device. If programming and debugging is required, connect the

Debug USB Micro-A/B port. The other end of the cable must have a Type-A connector, to connect it

to a USB host.

• On-The-Go (OTG) mode: Connect the starter kit to the OTG device by using an OTG Micro-A/B

cable to the Micro-A/B port.

Hardware Features

There is a 1x3, 100mil pin-header marked VBUS on the kit. The PB08 pin on the SAM E70 can be

connected to the LED2 or to the target USB VBUS DETECT signal by placing a jumper between pin 1

and pin 2, or pin 2 and pin 3 on this pin-header. The USB VBUS DETECT is the target USB voltage

divided by 1.64. When connected to the PB08 pin the signal can be used to detect power on the target

USB connector.

Table 5-5. USB Jumper Description

Pin number Name Description

1 LED2 LED2 active-low

2 PB08 Pin and Port to microcontroller

3 VBUS_ Detect VBUS Detect, used to detect when a device cable (micro-B) is plugged

into the SAM E70

The SAM E70 Xplained Ultra has a Micro-USB connector to use with the SAM E70 USB module labeled

as TARGET USB on the kit. In USB Host mode, the VBUS voltage is provided by the kit, and must be

enabled by setting the VBUS Host Enable pin to low. When a USB OTG cable is plugged in, it will

automatically trigger the power supply.

Table 5-6. USB Interface Pin Description

Pin on SAM USB Function

PA08 VBUS Host Enable

HSDM USB -

HSDP USB +

© 2019 Microchip Technology Inc.

DS70005389A-page 19

Page 20

5.6 Chip Erase Header

A 1x2 pin-header is connected to the SAM E70 chip erase pin, PB12, and 3V3 is marked ERASE. This

header can be used to chip erase the SAM E70 by placing the jumper on the header and toggle power to

the board. After the power is toggled, the jumper must be removed. Using the chip erase jumper may be

the only way to erase a chip with the security bit set, and applications that immediately set invalid clock

options, or go into deep sleep without any wake-up sources enabled.

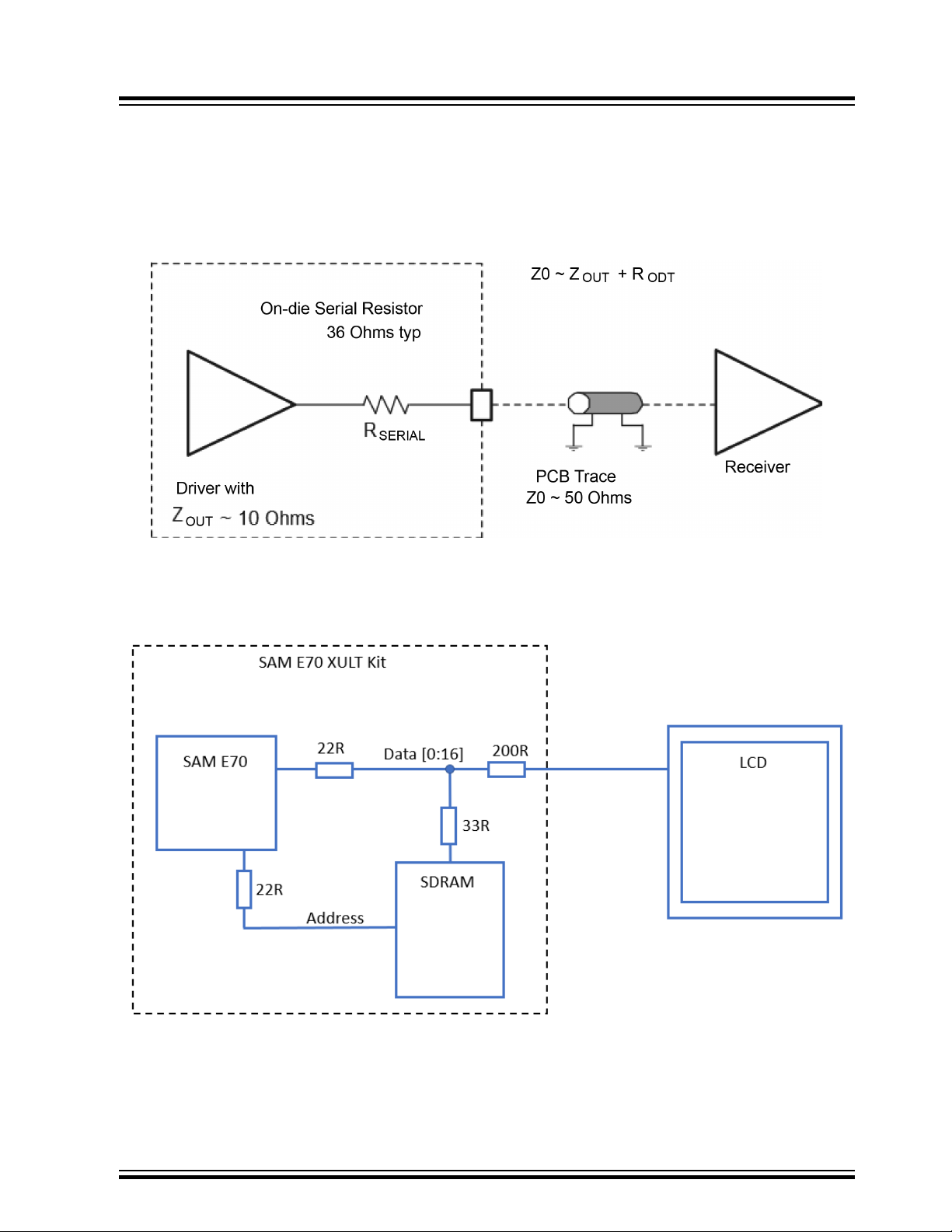

5.7 Audio Connectivity

The SAM E70 provides an audio connection through the X32 interface to the two main audio modules in

the chip, such as the SSC and the I2S. On this board the SSC interface is considered the main audio

interface. See image below.

There is a 32-pin interface to the board to support the audio codec or DACs and Bluetooth radios. This

interface has two audio supply interfaces, such as the SSC and the I2S. Addition to this other control lines

and data interfaces are available.

Figure 5-4. SSC/I2S Block Diagram

Hardware Features

Table 5-7. X32 Audio Interface Pin Description

Pin Number Name Description Interface

1 GND Ground Power

© 2019 Microchip Technology Inc.

DS70005389A-page 20

Page 21

Hardware Features

...........continued

Pin Number Name Description Interface

2 GND Ground Power

3 UART RX UART RX, receive to MCU from DB UART

4 UART CTS UART Clear to send UART

5 UART TX UART TX, transmit from MCU to DB UART

6 UART RTS UART Ready to send UART

7 I2C SCL Clock line for I2C interface I2C

8 STBY/RST Standby/Reset control GPIO

9 I2C SDA Data line for I2C interface I2C

10 Audio WS/LRCLK Audio Word Select/ Left Right Clock SSC

11 Audio In Audio into MCU, out from CODEC SSC

12 Audio CLK Audio clock SSC

13 Audio out Audio out of MCU, in to CODEC/DAC SSC

14 REFCLK/MCK Reference clock #1 REFCLK

15 GND Ground -

16 GND Ground -

17 NC Legacy hold over -

18 +3.3v V

19 NC Legacy hold over -

20 +5.0v V

21 (1) Audio WS/ Audio LRCLK Audio Word Select/ Left Right Clock I2S

22 (2) ADC/Card ID pin Analog-to-Digital Converter to read voltage on the

23 (3) Audio CLK Audio Clock I2S

24 (4) NC - -

25 (5) Audio IN Audio into MCU, out from CODEC I2S

26 (6) NC -

27 (7) Audio OUT Audio out of MCU, in to CODEC/DAC I2S

DD

DD

daughter card

-

-

ADC

28 (8) NC - -

29 (9) REFCLK2/MCK2 Reference clock #2 REFCLK

30 (10) NC - -

31 (11) GND Ground -

© 2019 Microchip Technology Inc.

DS70005389A-page 21

Page 22

...........continued

Pin Number Name Description Interface

32 (12) GND Ground -

5.8 mikroBUS™ Header

The mikroBUS™ interface enables using the additional click boards. For additional information and to

identify the boards to be used with this development kit, visit the following web site: https://

www.mikroe.com/.

Table 5-8. mikroBUS™ interface Pin Description

Pin Number Name Function

1 GND Ground

2 +5V +5.0V

3 SDA I2C SDA

4 SCL I2C SCL

Hardware Features

5 TX UART TX

6 RX UART RX

7 INT Interrupt request line

8 PWM Pulse-Width Modulation

9 GND Ground

10 +3.3V Ground

11 MOSI Master Out Slave In line of serial peripheral interface

12 MISO Master In Slave Out line of serial peripheral interface

13 SCK Clock for serial peripheral interface

14 CS Chip Select for serial peripheral interface. (Active-low)

15 RST Reset

16 AN Analog-to-Digital Converter.

5.9 CAN

The development kit provides access to the a CAN-FD interface that is post transceiver. The SAM E70

Xplained Ultra has two MCAN modules that perform communications according to ISO11898-1 (Robert

Bosch GmbH CAN specification 2.0 part A and B). Bosch CAN FD specification V1.0. MCAN1 is

connected to an on-board ATA6561 CAN physical-layer transceiver. These connections are described in

the following table.

© 2019 Microchip Technology Inc.

DS70005389A-page 22

Page 23

Table 5-9. Connections Between the ATSAME70Q21 and the ATA6561

Pin Number Name Description

1 CAN_H CAN High Signal

2 GND Ground

3 CAN_L CAN Low Signal

5.10 Ethernet

The SAM E70 Xplained Ultra kit has a modular Ethernet PHY system that allows for different PHYs to be

plugged into the board. This interface is set up to use a Reduced Media-Independent Interface (RMII), as

well as a SPI bus interface with GPIO.

Figure 5-5. Ethernet PHY Header Configuration

Hardware Features

Table 5-10. Ethernet Interface Pinout Description

Pin Number Name Description

1 GPIO General purpose I/O

2 GPIO General purpose I/O

3 RXD1 Receive Data 1

4 RXD0 Receive Data 0

© 2019 Microchip Technology Inc.

DS70005389A-page 23

Page 24

...........continued

Pin Number Name Description

5 RXER Receive Error

6 RXDV Receive Data Valid

7 MDC -

8 MDIO -

9 IRQ Interrupt request line

10 RESET Reset control to the Ethernet PHY

11 GPIO General purpose I/O

12 EGND Shield Ground

13 (1) TXEN Transmit Enable

14 (2) TXD0 Transmit Data

15 (3) TDX1 Transmit Data

Hardware Features

16 (4) MOSI Master Out Slave In line of serial peripheral interface

17 (5) MISO Master In Slave Out line of serial peripheral interface

18 (6) GND Ground

19 (7) NC No Connect

20 (8) REFCLK (in) Reference Clock input (50 MHz)

21 (9) GND GND

22 (10) +3.3v V

23 (11) CS Chip Select for serial peripheral interface

24 (12) SCK Clock for serial peripheral interface

25 -30 EGND Shield Ground

DD

5.11 Debug USB Connectivity

The starter kit includes an EDBG USB microcontroller that provides debugger connectivity over the USB.

The EDBG MCU is hard-wired to the SAM E70 device to provide protocol translation.

An external programmer, such as MPLAB ICD4, may be used with the development kit through either the

SWD interface or through the Coresite 20 interface.

+3.3V V

DD

5.12 Switches

The starter kit provides the following two push button switches. The push button switches do not have

any debounce circuitry and require the use of internal pull-up resistors. This enables the user to

investigate the software debounce techniques. When Idle, the switches are pulled high (+3.3V,) and when

pressed, they are grounded.

© 2019 Microchip Technology Inc.

DS70005389A-page 24

Page 25

• User switch

• Reset switch

5.13 AT24MAC402 Serial EEPROM

The development board has an on-board 2-Kbit I2C serial EEPROM which is available for user

applications. This serial EEPROM has a unique EUI-48, EUI-64, and 128-bit serial number. The unique

number can be seen in the Microchip MPLAB Xplained window or Atmel Studio Xplained window after the

kit has been plugged into the PC.

Figure 5-6. SAM E70 Xplained Ultra Window

Hardware Features

Note: The above figure provides an example of the Xplained window with the MAC48 address.

Users can change the device address using the solder pads on the board, but all address bits have been

defaulted to one, refer to schematics for additional information. For additional usage information of on this

part, refer to “AT24MAC402 and AT24MAC602 data sheet”, which is available for download from the

© 2019 Microchip Technology Inc.

DS70005389A-page 25

Page 26

following location: http://ww1.microchip.com/downloads/en/DeviceDoc/Atmel-8807-SEEPROM-

AT24MAC402-602-Datasheet.pdf.

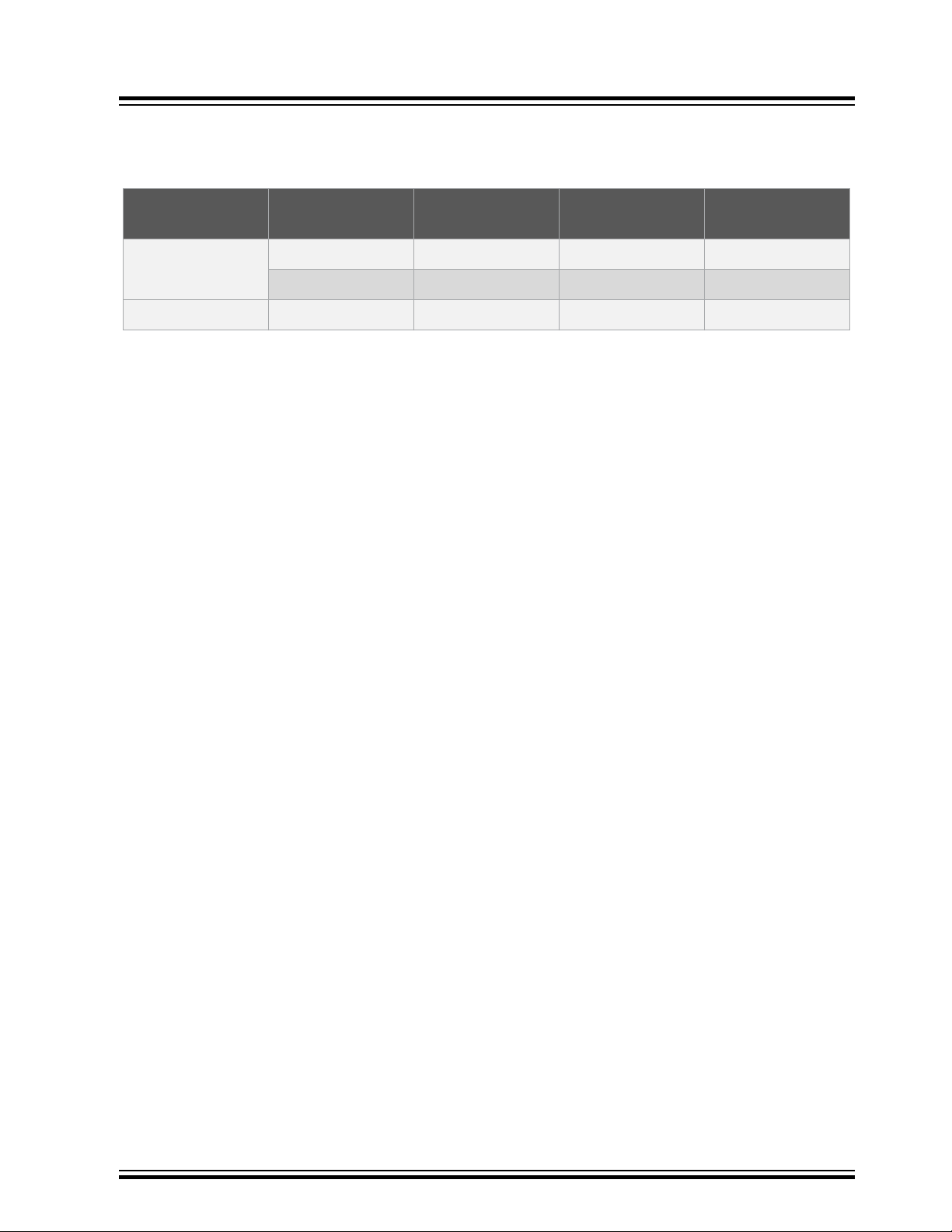

5.14 Power Sources

The SAM E70 Xlplained Ultra evaluation kit has several power systems to it. This section covers the

power sub system in detail. Figure below shows a high-level block diagram of the power system.

Figure 5-7. Power Sources Block Diagram

Hardware Features

The following options can be used to power the development kit:

• Using the Micro-USB connector that is connected to the EDBG known as Debug USB.

• Using the Micro-USB connector which is known as Target USB.

• Using the Barrel Jack. This input can take a large range of power inputs from 5.5V to 19V.

• Using the Arduino headers. This has several options one must be careful of when using this method.

Not all power rails are protected from the user error. VIN connects to the input side of the main buck

supply (step down), and it is similar to the barrel jack (2.1 mm).

• Using the 2 x 2 x 0.1 header, located on the side of the board, which has a 3.3v and 5.0v capable

inputs.

The SAM E70 Xplained Ultra kit can be powered by several power sources as described in the following

table.

© 2019 Microchip Technology Inc.

DS70005389A-page 26

Page 27

Table 5-11. Power Sources for SAM E70 Xplained Ultra

Hardware Features

Power Input Voltage Requirements Current Requirements

External Power 5V ±2% (±100 mV) for USB

host operation. 4.3V to 5.5V if

USB host operation is not

required.

Embedded

Debugger USB

Target USB 4.4V to 5.25V (according to

External Jack

Input

The development kit will detech and choose the available power sources based on the following options:

• External jack input

• External power

• Embedded debugger USB

• Target USB

4.4V to 5.25V (according to

USB spec.)

USB spec.)

5.5v to 19V 1A minimum, 2.5A is recommended.

Recommended minimum current is

1A to be able to provide enough

current for the connected USB

devices and the board.

Recommended maximum current is

2A due to the input protection

maximum current specification.

500 mA (according to USB spec.) DEBUG USB

500 mA (according to USB spec.) TARGET USB

6A maximum.

Connector

Marking

5V0

VIN

© 2019 Microchip Technology Inc.

DS70005389A-page 27

Page 28

6. Hardware

SJ-5076

E1

SJ-5076

E3

SJ-5076

E2

SJ-5076

E4

EDBG_UART

DGI_I2C

DGI_SPI

DGI_GPIO

ID_SYS

EDBG_SWD

TARGET_RESET_SENSE

EDBG_TARGET_RESET

TARGET_VOLTAGE

U_SHT_3_EDBG_R4

SHT_3_EDBG_R4.SchDoc

DIG

SPI

DGI_GPIO

DGI_SPI

EDBG_UART

SWD

QSPI

ADCL

ADCH

COM

IOL

I2C

IOH

MikroBUS

EBI

SDRAM

SD_CARD

AUDIO

CAMERA

TRACE

CAN

EXT2

EXT1

ETHERNET

TARGET_RESET_SENSE

TARGET_RESET

EDBG_TARGET_RESET

TARGET_USB_N

TARGET_USB_P

DGI_I2C

EDBG_SWD

PC11

GFX-SYNC

GFX-CTRL

VBUS_HOST_EN

DETECT/LED

U_SHT_4_Target_MCU_R4

SHT_4_Target_MCU_R4.SchDoc

IOH

IOL

COM

ADCL

ADCH

DIG

SPI

U_SHT_5_Shield Headers_R4

SHT_5_Shield Headers_R4.SchDoc

CAMERA

EXT1

EXT2

ID_SYS

TRACE

SWD

ID3/ID4

TARGET_RESET

U_SHT_6_Ext and Test Headers_R4

SHT_6_Ext and Test Headers_R4.SchDoc

EBI

SDRAM

SD_CARD

I2C

QSPI

PC11

EBI-GFX-DATA

U_SHT_7_Memory_R4

SHT_7_Memory_R4.SchDoc

ETHERNET

CAN

U_SHT_8_Ethernet and CAN_R4

SHT_8_Ethernet and CAN_R4.SchDoc

A08-2907

SAME70 Xplained Ultra PCB

PCB1

A12-1342

TESTDOC1

A11-0422

FE AB2 6E0

FF FFFF FF

9F 0C4 D00

F3 57E 896

F4 649 80 2

35 07 928 6

62 87 5F0 E

FW1

A11-0423

$ >_

TEST1

A12-1341

PCBADOC1

M2.5x5mm Pan Phillip ScrewS1SCREW

M2.5x5mm Pan Phillip ScrewS2SCREW

Product number/revision

Serial number

A09-0611

Label PCBA

LABEL1

TARGET_VOLTAGE

TARGET_USB_N

TARGET_USB_P

VBUS_HOST_EN

DETECT/LED

U_SHT_2_Power_R4

SHT_2_Power_R4.SchDoc

TARGET_RESET

ID3/ID4

GFX-CTRL

EBI-GFX-DATA

GFX-SYNC

D8

D9

D10

U_SHT_10_GFX Connector_R4

SHT_10_GFX Connector_R4.SchDoc

AUDIO

MikroBUS D8

D9

D10

U_SHT_9_MikroBUS and X32 Audio_R4

SHT_9_MikroBUS and X32 Audio_R4.SchDoc

6.1 SAM E70 Xplained Ultra Development Board Schematics

Hardware

© 2019 Microchip Technology Inc.

DS70005389A-page 28

Page 29

VCC_EXT_P5V0_P14V0

VCC_IN_P5V0

123

NEB 21 R

J201

GND

5V to 14V input, 5V out Power Supply, 2A

CC_EXT_P5V0_P14V

0

CC_IN_P5V

0

1

NEB 21 R

201

GN

D

5V to 14V input, 5V out Power Supply, 2

A

3

1

2

IRLML5203PBF

Q200

GND

5 - 14V DC - 1.5 A

VIN

3.3V linear regulator EDBG and Accessories

GND GND GND

N

D

N

D

N

D

VCC_E

DBG_P3V3

VCC_P3V3

GND GND

GND GND

BLM18PG471SN1

L202

BLM18PG471SN1

L203

100n

C215

100n

C217

0R

R214

TARGET_VOLTAGE

GND

3.3V linear regulator Target

GND

GND

GNDGND

GN

D

N

D

N

D

N

D

22u/10V

C214

BLM18PG471SN1

L204

0R

R215

10n

C213

47k

R216

47k

R217

BLM18PG471SN1

L201

VCC_TARGET_P3V3

MBR230LSFT1

2 1

D204

VCC_P5V0

1uF

C216

1uF

C218

VCC_EDBG_USB_P5V0

GND

Power Connector

VCC_TARGET_P3V3

TARGET_USB_P

TARGET_USB_N

GND

GND

1M

R201

4.7n

DNP

C200

EGND_MCU

0R

R200

EGND_MCU

GND

VCC_TARGET_USB_P5V0

TARGET_USB_N

TARGET_USB_P

MBR230LSFT1

2 1

D202

MBR230LSFT1

2 1

D203

BoS

12

3

4

1125-1202S0R138R1

J202

HEADER 2x2

3 5

GND

VCC

2

1IO1

IO2

IO3

4

D200

TPD3E001DRLR

Polarity Protection

GND

100k

R211

100k

R212

1

3 2

AO3413

Q201

GND

PA08

VCC_P3V3

330R

R213

GREEN

GND

VBUS_HOST_EN

PB08

123

MTSW-103-08-L-S-276

J203

VBUS_DETECT

1

3 2

FDN304P

Q203

MBR230LSFT1

1

D2

02

DETECT/LED

VCC_TARGET_USB_P5V0

LED2

JS203

21

EL17-21SYGC

D205

3

1

2

IRLML5203PBF

Q204

MOSFET_P_GSD

VCC_P3V3

1k

R204

VBUS

1

D-

2

D+

3

GND

5

SHIELD16SHIELD2

7

ID

4

SHIELD38SHIELD4

9

ZX62D-AB-5P8

J200

30k

R206

16k

R205

VOUT1VOUT

2

GND

3

EN4VIN

6

NC

5

EP

7

MIC5528-3.3YMT

U202

1uF

C211

1uF

C210 1uF

C212

EN

3

GND

2

VIN

1

VOUT

5

NC

4

MIC5504-3.3YM5

U201

2.2uF

C202

10k

R202

4.7uF

C205

10k

R203

4.7uF

C204

GND

2 1

MBR230LSFT1

D201

100n

C206

100n

C207

XAL4020-222ME

L200

GND

SGND

4.7nF

C208

100uF/16V

C209

PGND6PGND

8

PVIN

13

PGND

7

PGND5P

G

N

D

P

G

N

D

P

V

IN

PGNDP

G

N

D

SW4SW9SW10SW

11

PVIN14PVIN18PVIN17PVIN16PVIN

15

BST

20

PVIN

19

PGND

21

PVDD

1

PGND

2

NC

3

SW

12

CS

22

VIN

27

EN

26

PG

25

FB

24

SGND

23

VDD

28

MIC24052YJL-TR

U200

R208

19.6K

Vout=5.00

R210

475R

GND

1uF

C203

SGND

GND

Vout=0.8 (1+(R209/R210))

R209

2.49K

1.2R

R207

102C Fu22

GND

When Vin = 5V the regulator uses a 100% duty-cycle mode

(passthrough).

Iout max = 300mA

Accuracy 2%

Low noise: 175 uVrms (10 Hz to 100 kHz)

Dropout 150mV at full load

Quiescent current 38 uA (no load)

Current limit 900 mA (Max)

Thermal shutdown and current limit protection

Minimum capacitance required on output is 1uF (< 200mOhm ESR)

500mA low noise LDO voltage regulator

N

oise: 28uVrms

Accuracy 2%

Dropout 500 mV at 500 mA (maximum)

Quiescent current 38 uA

Current limit 525 mA (minimum)

Thermal shutdown and current limit protection

Hardware

© 2019 Microchip Technology Inc.

DS70005389A-page 29

Page 30

AT32UC3A4256J-C1URAT

3

2

UC3

A42

56J

-

C

1

UR

PA00 / PA18

G8

VDDIO

F6

VDDIO

F2

VDDIO

B6

GNDIO

C8

VDDIO

J5

GNDIO

E2

GNDIO

H3

GNDIO

F5

VDDIO

B5

GNDIO

E6

GNDIO

C3

GNDCORE

F10

VDDCORE

E10

GNDPLL

B10

VDDIN

D10

VDDANA

J6

VDDIN

D9

GNDANA

H8

VDDIO

E5

PA01 / PA17

G10

PA02 / PX47

E1

PA03

F9

PA04

E9

PA05

G9

PA06 / PA13

E8

PA07 / PA19

H10

PA08F8PA09D8PA10

C10

PA11C9PA12 / PA25G7PA14 / PX11K7PA15 / PX45J7PA16E7PA20 / PX18H9PA21 / PX22

K10

PA23 / PX46

G6

PA24 / PX17

J10

PA26 / PB05F7PA27A2PA28A1PA29B4PA30A4PA31

C2

PA22 / PX20

H6

PC00/PX14

K5

PC01

K6

PC02

A5

PC03

A6

PC04

B7

PC05

A7

TMS

H7

TDO

J8

TDI

K8

TCK

K9

RESET_N

J9

DMHS

A9

DPHSA8DMFSB9DPFS

B8

USB_VBUS

A10

USB_VBIAS

C7

PB00

B1

PB01

B2

PB02

B3

PB03

C4

PB04

A3

PB06

D7

PB07

D6

PB08

C6

PB09

C5

PB10

D5

PB11

C1

PX00G4PX01

G2

PX02

G3

PX03

J1

PX04H1PX05G1PX06

F3

PX07

F4

PX08

E3

PX09

E4

PX10

D2

PX12D1PX13

D3

PX15 / PX32K4PX16 / PX53

D4

PX19 / PX59

F1

PX21

H2

PX23

K1

PX24

J2

PX25

H4

PX26J3PX27

K2

PX28

K3

PX29

J4

PX30

G5

PX31

H5

U300

TXD

RXD

EDBG_UART

EDBG_UART

DGI_I2C

EDBG_CDC_USART_RX

GND

GND

VCC_EDBG_P3V3

GND

GND

GND

GND

GND

VCC_EDBG_USB_P5V0

EDBG_USB_HS_N

EDBG_USB_HS_P

EDBG_USB_FS_P

EDBG_USB_FS_N

Shield

EDBG_CDC_USART_TX

STATUS_LED_CTRL

POWER_LED_CTRL

XIN0

XOUT0

MISO

MOSI

SCK

SS

DGI_SPI

DGI_SPI

EDBG_SPI_DGI_MISO

EDBG_SPI_DGI_MOSI

EDBG_SPI_DGI_SCK

EDBG_SPI_DGI_SS

VCC_EDBG_P3V3

EDBG_DGI_SDA

EDBG_DGI_SCL

DGI_GPIO0

DGI_GPIO1

DGI_GPIO2

DGI_GPIO3

DGI_GPIO

DGI_GPIO0

DGI_GPIO1

DGI_GPIO

ID_1

ID_2

ID_4

ID_SYS

ID_SYS

ID1

ID1

ID2

EDBG_FORCE_BOOT

Current limiters, 10mA @3.3V

Current limiter, 10mA @3.3V

GND

GND

EDBG_FORCE_BOOT

EDBG_RESET_N

EDBG_JTAG_TMS

EDBG_JTAG_TDO

EDBG_JTAG_TDI

EDBG_JTAG_TCK

VCC_EDBG_P3V3

GND

VCC_EDBG_P3V3

EDBG Power and Status LEDs

GND

SCL

SDA

DGI_I2C

EDBG_ADC0

ID2

GND

VCC_EDBG_P3V3

GND

SWCLK

SWDIO

TARGET_CHIP_RESET

TRACESWO

EDBG_SWD

EDBG_SWD

EDBG_SWDIO

EDBG_SWCLK

EDBG_RESET

TARGET_RESET_SENSE

DGI_GPIO2

DGI_GPIO3

21

EL17-21SYGC

D301

21

EL17-21UYC/A3

D302

4

5

3

2N7002DW

Q302A

2

1 6

2N7002DW

Q302B

330R

R331

330R

R333

0R

R321

330R

R326

0R

R3290RR327

TP302

TP303

TP304

TP306

TP305

TP307

39R

R318

39R

R316

BLM18PG471SN1

L300

1 nF C0G

C301

1 nF C0G

C302

BLM18PG471SN1

L301

100n

C305

1 nF C0G

C307

2.2uF

C306

GND

100n

C310

2.2uF

C308

1k

R313

1k

R314

0R

R3030RR304

TP301TP300

330R

R307

330R

R308

330R

R309

330R

R310

330R

R306

0R

R305

0R

R311

0R

R312

132 4

12.00MHz

XC300

4.7n

DNP

C300

10p

C303

22p

C304

22p

C309

1M1M

R300

1M1M

R330

1M1M

R332

6.81k

R320

VCC_EDBG_P3V3

330R

R322

330R

R323

330R

R324

330R

R325

GND

GND

0R

R301

EGND_EDBG

EGND_EDBG

GND

EDBG_TARGET_RESET

GND

0R

R302

1k

R315

ID4

TARGET_VOLTAGE

GND

100n

C311

100n

C312

100n

C313

2.2uF

C314

2.2uF

C315

VCC_EDBG_P3V3

GREEN

YELLOW

39R

39R

R328

CONN USB MICRO B RECPT SMT R/A

VBUS

1

D-

2

D+

3

GND

5

SHIELD16SHIELD2

7

ID

4

SHIELD3

8

SHIELD4

9

J300

3 5

GND

VCC

2

1IO1

IO2

IO3

4

D300

TPD3E001DRLR

GND

GND

VCC_EDBG_P3V3

100k

R319

1

2 3

DMN2075U

Q301

MOSFET_N_GSD

3

1

2

IRLML5203PBF

Q300

MOSFET_P_GSD

100k

R317

LED 1 LED 2

Input filter on USB

ower input.

Connect the test points during startup o

f

the EDBG to force it into bootloader

mode.

The test points should be covered with

solder so that it is easier to get a good

contact.

Programming interface of the

embedded debugger. The test

oints will be connected by needles

in the test fixture for programming.

GND test point is TP400.

Hardware

© 2019 Microchip Technology Inc.

DS70005389A-page 30

Page 31

PC31

PC00

PC01

PC02

PC03

PC04

PC05

PC06

PC07

PC08

PC09

PC10

PC11

PC12

PC13

PC14

PC15

PC16

PC17

PC18

PC19

PC20

PC21

PC22

PC23

PC24

PC25

PC26

PC27

PC28

PC29

PC30

PD02

PD03

PD04

PD05

PD06

PD07

PD08

PD09

PD10

PD11

PD12

PD13

PD14

PD15

PD16

PD17

PD18

PD19

PD20

PD21

PD22

PD23

PD24

PD25

PD26

PD27

PD28

PD29

PD30

PD31

PE00

PE01

PE02

PE03

PE04

PE05

PA00

PA01

PA02

PA03

PA04

PA05

PA06

XIN_32

PA08

PA09

PA10

PA11

PA12

PA13

PA14

PA15

PA16

PA17

PA18

PA19

PA20

PA21

PA22

PA23

PA24

PA25

PA26

PA27

PA28

PA29

PA30

PA31

PB00

PB01

PB02

PB03

PB04

PB05

PB06

PB07

XIN_12

PB12

PB13

GND

VDDOUT

100n

C413

GND GND

+

2.2uF

C417

100n

C415

100n

C412

JS401

GND

GND

VDDCORE

BLM18PG471SN1

L404

BLM18PG471SN1

L403

VDDPLL

VDDUTMIC

100n

C407

100n

C408

GND

GND

BLM18PG471SN1

L402

BLM18PG471SN1

L401

VCC_TARGET_P3V3

GND

10p

C404

5.62k

R406

GND

BLM18PG471SN1

L400

100n

C401

GND

VDDPLLUSB

VDDUTMII

TP402

TP401

TST

JTAGSEL

TARGET_RESET

PD00

PD01

DIG

DIG22

DIG23

DIG24

DIG25

DIG26

DIG27

DIG28

DIG29

DIG30

DIG31

DIG32

DIG33

DIG34

DIG35

DIG36

DIG37

DIG38

DIG39

DIG40

DIG41

DIG42

DIG43

DIG44

DIG45

DIG46

DIG47

DIG48

DIG49

DIG50

DIG51

DIG52

DIG53

DIG

SPI

SPI_MISO

SPI_MOSI

SPI_SCK

RESET

SPI

TARGET_RESET

0R

R404

SPI0_SPCK

SPI0_MOSI

SPI0_MISO

PD22

PD20

PD21

PA18

PCK2

PA21

RXD1

PB00TFPD19

CTS2

39R39R

R401

DGI_GPIO

DGI_SPI

EDBG_UART

PA23

PA02

GPIO / BTN0

GPIO / LED0

GPIO / EXT2 PIN9

PD21

PD20

PD22

SPI0_MOSI

SPI0_MISO

SPI0_SPCK

PD12

SPI0_NPCS2

PA09

PA21

RXD1

PD28

GPIO / EXT1 PIN9

PB04

TXD1

SWCLK

SWDIO

TARGET_CHIP_RESET

TRACESWO

SWD

SWD

PB12

ERASE

PB05

TRACESWO

PB06

SWDIO

PB07

SWCLK

MISO

MOSI

SCK

SS

DGI_SPI

DGI_GPIO0

DGI_GPIO1

DGI_GPIO2

DGI_GPIO3

DGI_GPIO

RXD

TXD

EDBG_UART

IO0

IO1

IO2

IO3

CLK

CS

QSPI

QSPI

PA13

PA12

PA17

PD31

PA14

PA11

PWMC1_PWML1

PWMC1_PWMH0

PWMC0_PWMH3

ISI_D11

WKUP7/PIODC5(3)

GPIO_INT

ADCL

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

ADCL

ADCH

AD8

AD9

AD10

AD11

DAC0

DAC1

CANRX

CANTX

ADCH

COM

DIG14

DIG15

DIG16

DIG17

DIG18

DIG19

DIG20

DIG21

COM

ADVREF

IOL

DIG0

DIG1

DIG2

DIG3

DIG4

DIG5

DIG6

DIG7

IOL

0R

R4140RR415

PA04

PA03

TWD0

TWCK0

PB03

PB02

CANRX0

CANTX0

PB13

PD00

DAC0

DAC1

SPI0_SPCK

SPI0_MOSI

SPI0_MISO

PD22

PD20

PD21

PD25

SPI0_NPCS1

PD27

SPI0_NPCS3

PD26

TD

PD24RFPA10RDPA22

RK

0R

R424

0R

DNP

R420

0R

DNP

R419

0R

DNP

R418

AFE0_AD8

PC13

AFE1_AD1

PA05

PA06

PWMC1_L3

GPIO

PD11

PC19

PA02

PWMC0_H0

PWMC0_H2

PWMC0_H1

LED_TIOB7

PD16

PD15

TXD2

RXD2

PD19

PD18

UTXD4

URXD4

PD27

PD28

TWD2

TWCK2

PB01

TXD0

PB00

RXD0

PC30

PA17

PC12

PC31

AFE1_AD5

AFE1_AD6

AFE0_AD3

AFE0_AD3

0R

R4210RR4220RR423

0R

R417

39R

39R

R413

0R

R416

PA19

PD30

AFE0_AD0

PC31

AFE1_AD06

PD28

URXD3

PD30

UTXD3

PC09

I2C

PA03

PA04

TWCK0

TWD0

PD10

PWMC0_L2

IOH

DIG9

DIG10

DIG11

DIG12

DIG13

DIG8

AREF

I2C_SCL

I2C_SDA

IOH

PD11

GTSUCOMP

PA17

PWMC0_PWMH3

0R

DNP

R407

0R

R408

0R

DNP

R409

0R

R410

SDA

SCL

I2C

1k1

k

R412

1k

1

k

R411

PIN1_ADC(+)

PIN2_RST

PIN3_CS

PIN4_SCK

PIN5_MISO

PIN6_MOSI

PIN11_SDA

PIN12_SCL

PIN13_TX

PIN14_RX

PIN15_IRQ

PIN16_PWM(+)

MikroBUS

MikroBUS

PC31

AFE1_AD06

PA00

PWMC0_H0

PD28

WKUP5

PB01

TXD0

PB00

RXD0

0R

R4270RR428

PA03

TWD0

PA04

TWCK0

PD21

SPI0_MOSI

PD20

SPI0_MISO

PD22

SPI0_SPCK

39R39R

R426

PA05

GPIO

PD11

VCC_TARGET_P3V3

D0D1D2D3D4D5D6D7D8D9D10

D11

D12

D13

D14

D15

EBI

EBI

SDRAM

PC00

PC01

PC02

PC03

PC04

PC05

PC06

PC07

PE00

PE01

PE02

PE03

PE04

PE05

PA15

PA16

D0D1D2D3D4D5D6D7D8D9D10

D11

D12

D13

D14

D15

A2A3A4A5A6A7A8A9A10

A11

SDA10

BA0

CASB

SDCKE

SDCK

SDCS

A0/NBS0

RASB

NWR1/NBS1

SDWE

PC20

PC21

PC22

PC23

PC24

PC25

PC26

PC27

PC28

PC29

PD13

PA20

PD17

PD14

PD23

PC15

PC18

PD16

PD15

PD29

MCCDA

MCCK

MCDA3

MCDA2

MCDA1

MCDA0

DETECT

SD_CARD

SD_CARD

PC16

GPIO

MCDA0

MCDA1

MCDA2

MCDA3

MCCK

MCCDA

PA30

PA31

PA26

PA27

PA25

PA28

AUDIO

PIN9_I2C_SDA

PIN7_I2C_SCL

PIN14_PCK2

PIN5_TXD0

PIN4_CTS0

PIN6_RTS0

PIN11_RD

PIN13_TD

PIN8_IRQ

REFCLK

PIN3_RXD0

PIN10_RF

PIN12_TKRKPIN10_TF

PIN2_ADC(+)

PIN9_AFEO_AD8

PIN3_BAO

AUDIO

PA03

PA04

0R

R4350RR4370RR4410RR4380RR4390RR4360RR434

TWCK0

TWD0

0R

R440

PB00

RXD0

PB01

TXD0

PB02

CTS0

PB03

RTS0

PA18

PCK2

PD21

TIOA11

PD11

GPIO

0R

R4290RR4300RR4310RR432

PD24

RF

PB01TKPA22RKPB00TFPA10RDPD26

TD

0R

R442

0R

R433

PD30

AFE0_AD0

CAS

RASCSCLK

CKEWELDQM

UDQM

A0A1A2A3A4A5A6A7A8A9A10

A11

SDRAM

0R

R443PA19

PA20

TIOA11

BAO

CAMERA

MCK

VSYNC

HSYNC

PCKD0D1D2D3D4D5D6D7D8D9

D10

D11

I2C_SCK

I2C_SDA

RST

PWD

CAMERA

PD21

PB03

PA09

PA05

PD11

PD12

PA27

PD27

PD28

PD30

PD31

PD24

PA06

PA24

PC19

PA13

PD25

PA04

TWCK0

ISI_PWD

GPIO

PCK0

ISI_PCK

ISI_HSYNC

ISI_VSYNC

ISI_D0

ISI_D1

ISI_D2

ISI_D3

ISI_D4

ISI_D5

ISI_D6

ISI_D7

ISI_D8

ISI_D9

ISI_D10

ISI_D11

39R39R

R484

PA03

TWD0

PD22

PA02

WKUP2

PD28

WKUP5

PA06

GPIO

IRQ4 (R Touch)

IRQ2 (Q Touch)

IRQ3 (Display Cntrl)

0R

R485

PD28

WKUP5

PA03

PA04

PD20

PD21

PD25

PD22

TWCK0

TWD0

SPI0 SPCK

SPI0 MOSI

SPI0 MISO

SPI0 NPCS1

LCDPWM

USART_RX

USART_TX

USART_RTS

USART_CTS

LED TIOB7

ADC0

ADC1

ADC2

ADC3

ADC4

ADC5

ADC6

ADC7

LCDDISP

STBY/RST

AFE0 AD0

RXD1

AFE1 AD06

AFE1 AD1

PB01 TXD0

GPIO4

ONE WIRE INTERFACE ID3 / ID4

RESET2

GPIO1

PWMC0 H2

GPIO2

GPIO3

GPIO5

PC09

PC13

PD30

PA21

PC31

PC13

PD19

PD11

TRACE

SWDIO

SWCLK

TRACECLK

TRACED0

TRACED1

TRACED2

TRACED3

nRESET

SWO

TRACE

PB06

PB07

TARGET_RESET

PD08

PD04

PD05

PD06

PD07

TRACECLK

TRACED0

TRACED1

TRACED2

TRACED3

PB05

TRACESWO

SWDIO

SWCLK

CANTX

CANRX

CAN

CAN

PC14

PC12

CANTX1

CANRX1

EXT2

EXT1

PIN10_SPI_SS_B/GPIO

PIN11_TWI_SDA

PIN12_TWI_SCL

PIN13_UART_RX

PIN14_UART_TX

PIN15_SPI_SS_A

PIN16_SPI_MOSI

PIN17_SPI_MISO

PIN18_SPI_SCK

PIN3_ADC(+)

PIN4_ADC(-)

PIN5_GPIO

PIN6_GPIO

PIN7_PWM(+)

PIN8_PWM(-)

PIN9_IRQ/GPIO

EXT1

PIN10_SPI_SS_B/GPIO

PIN11_TWI_SDA

PIN12_TWI_SCL

PIN13_UART_RX

PIN14_UART_TX

PIN15_SPI_SS_A

PIN16_SPI_MOSI

PIN17_SPI_MISO

PIN18_SPI_SCK

PIN3_ADC(+)

PIN4_ADC(-)

PIN5_GPIO

PIN6_GPIO

PIN7_PWM(+)

PIN8_PWM(-)

PIN9_IRQ/GPIO

EXT2

0R

R4860RR487

PB03

PB02

PC30

PA00

PC17

PA04

PA03

PB00

PB01

PD25

PD21

PD20

PD22

RTS0

CTS0

TIOB5

PWMC0_H0

GPIO

TWD0

TWCK0

RXD0

TXD0

SPI0_NPCS1

SPI0_MOSI

SPI0_MISO

SPI0_SPCK

PC13

PA06

PD11

PC19

PD26

PA02

PA24

PD27

PD21

PD20

PD22

SPI0_MOSI

SPI0_MISO

SPI0_SPCK

AFE1_AD1

GPIO

GPIO

PWMC0_H2

PWMC0_L2

WKUP2

GPIO

SPI0_NPCS3

0R

R489

39R

39R

R490

39R

39R

R488

PA04

PA03

TWD0

TWCK0

AFE0_AD8

PA19

PA21

RXD1

PC31

AFE1_AD06

PD30

AFE0_AD0

PD28

WKUP5

PB04

TXD1

TXD0

TXD1

TXEN

TXCK

RXD0

RXD1

MDC

MDIO

RXER

RXDV

RESET

SIGDET

MOSI

MISO

SCLKCSGPIO0

GPIO1

GPIO2

ETHERNET

ETHERNET

PA29

GPIO

GPIO

PD00

PD01

PD02

PD03

PD04

PD05

PD06

PD07

PD08

PD09

PC10

GTXCK

GTXEN

GTX0

GTX1

GRXDV

GRX0

GRX1

GRXER

GMDC

GMDIO

GPIO

PA19

0R

R5030RR5040RR5050RR506

0R

DNP

R507

0R

R5020RR5010RR5000RR4990RR498

39R

39R

R497

39R

39R

R496

39R

39R

R494

39R

39R

R493

0R

R492

39R

39R

R491

0R

R495

PD21

SPI0_MOSI

PD20

SPI0_MISO

PD22

SPI0_SPCK

PC19

ISI_PWD

GND

39R

R405

GN

D

3

9

R

R

4

0

5

TP400

21

EL17-21UYC/A3

D400

VCC_P3V3

330R

R400

USER BUTTONUSER LED

PA05

USER_LED0

PA11

USER_BUTTON0

GND

VCC_P3V3

GND

N

D

_

N

D

RESET button with current limit and noise filter

0R

R515

TARGET_RESET

2.2k

R512

100pF

C421

330R

R513

330R

R510

PA05

USER_LED0

USER_BUTTON0

PA11

ADVREF

22R

22R

R448

22R

22R

R449

22R

22R

R450

22R

22R

R451

22R

22R

R452

22R

22R

R453

22R

22R

R454

22R

22R

R455

22R

22R

R456

22R

22R

R457

22R

22R

R458

22R

22R

R459

22R

22R

R460

22R

22R

R461

22R

22R

R462

22R

22R

R463

22R

22R

R464

22R

22R

R465

22R

22R

R466

22R

22R

R467

22R

22R

R468

22R

22R

R469

22R

22R

R470

22R

22R

R471

22R

22R

R472

22R

22R

R473

22R

22R

R474

22R

22R

R475

22R

22R

R476

22R

22R

R477

22R

22R

R478

22R

22R

R479

22R

22R

R480

22R

22R

R481

22R

22R

R482

22R

22R

R483

0R

R425

0R

R516

TARGET_RESET_SENSE

YELLOW

0R

R5080RR509

100n

C416

100n

C414

100n

C411

100n

C410

100n

C406

100n

C405

100n

C403

100n

C402

100n

C400

GNDGND

VDDCOREVDDIO

1

00n

40

6

1

00n

40

5

1

00n

403

1

00n

40

2

1

00n

40

0

N

D

DDI

O

VDDIO De-Coupling

close to pins 30, 43, 72, 80 and 96

1

00n

41

6

1

00n

41

4

1

00n

411

1

00n

41

0

N

D

DD

CO

RE

VDDCORE De-Coupling

close to pins 29, 33, 50, 81 and 107

100n

C418

PB12

ERASE

VCC_TARGET_P3V3

JS400

TARGET_RESET

EDBG_TARGET_RESET

10uF/10V

C409

TARGET_USB_N

TARGET_USB_P

SDA

SCL

DGI_I2C

DGI_I2C

PA03

PA04

TWCK0

TWD0

GPIO

SWCLK

SWDIO

TARGET_CHIP_RESET

TRACESWO

EDBG_SWD

EDBG_SWD

PB12

ERASE

PB05

TRACESWO

PB06

SWDIO

PB07

SWCLK

PD28

WKUP5

PA02

WKUP2

PWMC1_PWML3

PA05

PA29

TCLK2

PB03

RTS0

PB13

SCK0

PA13

PWMC1_PWML1

PA25

CTS1

PA30

PWMC1_PWMEXTRG0

PB02

CTS0

PC14

CANTX1

PC12

CANRX1

PA18

PWMC1_PWMEXTRG1

0R

R403 PB01

TK

PD17

SCK2

PA01

WKUP1(1)

PA26

PWMC1_PWMFI1

PD18

RTS2

PA12

PWMC1_PWMH0

PA31

PWMC1_PWMH2

PB04

TXD1

PA24

RTS1

PA23

PWMC0_PWMH0

PA28

PWMC1_PWMFI2

JS402

GPIO

PC11

VDDIO

PC11

ATSAME70Q21B-ANT

TSAME70

Q

21B-ANT

PA00

102

PA0199PA0293PA0391PA0477PA0573PA06

114

PA0735PA0836PA0975PA1066PA1164PA1268PA1342PA1451PA1549PA1645PA1725PA1824PA1923PA2022PA2132PA2237PA2346PA2456PA2559PA2662PA2770PA28

112

PA29

129

PA30

116

PA31

118

PC0011PC0138PC0239PC0340PC0441PC0558PC0654PC0748PC0882PC0986PC1090PC1194PC1217PC1319PC1497PC1518PC16

100

PC17

103

PC18

111

PC19

117

PC20

120

PC21

122

PC22

124

PC23

127

PC24

130

PC25

133

PC2613PC2712PC2876PC2916PC3015PC31

14

PD001PD01

132

PD02

131

PD03

128

PD04

126

PD05

125

PD06

121

PD07

119

PD08

113

PD09

110

PD10

101

PD1198PD1292PD1388PD1484PD15

106

PD1678PD1774PD1869PD1967PD2065PD2163PD2260PD2357PD2455PD2552PD2653PD2747PD2871PD29

108

PD3034PD31

2

PB0021PB0120PB0226PB0331PB04

105

PB05

109

PB0679PB0789PB08

141

PB09

142

PB1287PB13

144

HSDP

137

HSDM

136

NRST83TST85JTAGSEL

104

VREFP9VREFN8VBG

140

PE004PE016PE027PE0310PE0427PE05

28

GND_0144GND_0261GND_0395GND_04

115

GND_05

135

GND_06

138

VDDIO_01

30

VDDIO_02

43

VDDIO_03

72

VDDIO_04

80

VDDIO_05

96

VDDIN

5

VDDUTMII

134

VDDPLLUSB

143

VDDPLL

123

VDDUTMIC

139

VDDOUT

3

VDDCORE_01

29

VDDCORE_02

33

VDDCORE_03

50

VDDCORE_04

81

VDDCORE_05

107

U400

TP403

1

2

J400

HEADER 1x2

1

2

J401

HEADER 1x2

1

2

Pin header 1x2 RA

J402

1 3

42

TS604VM1-035CR

SW400

1 3

42

TS604VM1-035CR

SW401

GFX-CTRL

PIN6_IRQ2

PIN8_IRQ3

PIN10_IRQ4

PIN4_IRQ1

PIN14_D0

PIN16_D1

PIN18_D2

PIN20_D3

PIN22_D4

PIN24_D5

PIN26_D6

PIN28_D7

PIN30_D8

PIN32_D9

PIN34_D10

PIN36_D11

PIN38_D12

PIN40_D13

PIN42_D14

PIN44_D15

PIN60_D23

PIN58_D22

PIN56_D21

PIN54_D20

PIN52_D19

PIN46_D16

PIN48_D17

PIN50_D18

PIN62_D24

PIN64_D25

GFX-CTRL

PC30

PC11

PD19

nCS

NWR

DCX

nRD

PC08

PIN11_LCDVSYNC

PIN13_LCDPCLK

PIN9_LCDHSYNC

PIN7_LCDEN

GFX-SYNC

GFX-SYNC

PA08

PB08

VBUS HOST EN

VBUS_HOST_EN

DETECT/LED

330R

R444

10n

C422

LED 3

12 MHz Oscillator

XIN_12

0R

R511

STB

1

GND

2

OUT3VDD

4

DSC6003CI2A-012.0000

Y401

GND

100n

C419

GND

VCC_TARGET_P3V3

XIN_1

2

R

11

1

ST

B

GN

D

O

U

T

DD

SC6003CI2A-012.000

0

4

01

ND

1

00n

41

9

GND

CC_TARGET_P3V

3

32.768 kHz Oscillator

XIN_32

0R

R514

OUT1GND

2

NC

3

VDD

4

DSC6083CE2A-032K768

Y400

100n

C420

GND

GND

XIN_3

2

R

R

5

1

4

1

T

ND N

C

D

D

D

SC

6083

C

E2A-032K768

4

00

1

00n

42

0

GN

D

GN

D

VCC_TARGET_P3V3

PB08

Resistors R448 thru R467 are

critical impedance

termination resistors which

must be placed as close as

Hardware

© 2019 Microchip Technology Inc.

DS70005389A-page 31

Page 32

IOH

DIG9

DIG10

DIG11

DIG12

DIG13

AREF

I2C_SCL

I2C_SDA

DIG8

IOH

IOL

DIG0

DIG1

DIG2

DIG3

DIG4

DIG5

DIG6

DIG7

IOL

COM

DIG14

DIG21

DIG15

DIG16

DIG17

DIG18

DIG19

DIG20

COM

ADCL

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

ADCL

ADCH

AD8

AD9

AD10

AD11

DAC0

DAC1

CANRX

CANTX

ADCH

SSQ-108-21-F-S

1234567

8

J501

1234567

8

SSQ-108-21-F-S

J506

123456789

10

SSQ-110-21-F-S

J505

1

2

3

4

5

6

HMTSW-103-23-F-D-237

J503

1234567

8

SSQ-108-21-F-S

J500

1234567

8

SSQ-108-21-F-S

J502

1234567

8

SSQ-108-21-F-S

J507

DIG

DIG22

DIG23

DIG24

DIG25

DIG26

DIG27

DIG28

DIG29

DIG30

DIG31

DIG32

DIG33

DIG34

DIG35

DIG36

DIG37

DIG38

DIG39

DIG40

DIG41

DIG42

DIG43

DIG44

DIG45

DIG46

DIG47

DIG48

DIG49

DIG50

DIG51

DIG52

DIG53

DIG

SPI

SPI_MISO

SPI_MOSI

SPI_SCK

RESET

SPI

VCC_TARGET_P3V3

VCC_P5V0

TARGET_RESET

VCC_TARGET_P3V3

IOREF

VCC_3V3

VCC_5V0

GND

GND

VIN

VCC_EXT_P5V0_P14V0

GND

GND

TARGET_RESET

SPI_SCK

SPI_MISO

GND

SPI_MOSI

VCC

VCC_P5V0GND

GND

VCC_P5V0

VCC_P5V0

GND

GND

D22D23

D24D25

D26D27

D28D29

D30D31

D32D33

D34D35

D36D37

D38D39

D40D41

D42D43

D44D45

D46D47

D48D49

D50D51

D52D53

12

34

56

78

910

1112

1314

1516

1718

1920

21

23

25

27

29

31

33

35

22

24

26

28

30

32

34

36

SSQ-118-01-G-D

J504

TD

AFE0_AD0

AFE1_AD1

AFE0_AD3

AFE1_AD06

CANRX0

CANTX0

DAC0

DAC1

RFRDRK

AFE0_AD3

TWD0

TWCK0

SPI0_SPCK

SPI0_MOSI/GTSUCOMP

SPI0_MISO

SPI0_NPCS1

PWMC0_PWMH3

LED TIOB7

SPI0_NPCS3

PWMC1_PWML3

GPIO

PWMC0_H0

PWMC0_H2

PWMC0_H1

URXD3

UTXD3

TXD2

RXD2

UTXD4

URXD4

TWD2

TWCK2

TXD0

RXD0

PCK2

TFPB00

CTS2

RTS0

CTS1

RXD1

CANRX1

TK

RTS2

CTS0

RTS1

TXD1

CANTX1

SPI0_SPCK

SPI0_MISO

SPI0_MOSI

PA02

PC19

PD11

PD27

PA06 / PD10

PA05

PD30

PD28

PA17

PC09

PD25

PD21/PD11