Page 1

Miniature Atomic Clock (MAC)

SA5X

User’s Guide

2019 Microchip Technology Inc. DS50002938A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Trademarks

The Microchip name and logo, the Microchip logo, Adaptec,

AnyRate, AVR, AVR logo, AVR Freaks, BesTime, BitCloud, chipKIT,

chipKIT logo, CryptoMemory, CryptoRF, dsPIC, FlashFlex,

flexPWR, HELDO, IGLOO, JukeBlox, KeeLoq, Kleer, LANCheck,

LinkMD, maXStylus, maXTouch, MediaLB, megaAVR, Microsemi,

Microsemi logo, MOST, MOST logo, MPLAB, OptoLyzer,

PackeTime, PIC, picoPower, PICSTART, PIC32 logo, PolarFire,

Prochip Designer, QTouch, SAM-BA, SenGenuity, SpyNIC, SST,

SST Logo, SuperFlash, Symmetricom, SyncServer, Tachyon,

TempTrackr, TimeSource, tinyAVR, UNI/O, Vectron, and XMEGA

are registered trademarks of Microchip Technology Incorporated in

the U.S.A. and other countries.

APT, ClockWorks, The Embedded Control Solutions Company,

EtherSynch, FlashTec, Hyper Speed Control, HyperLight Load,

IntelliMOS, Libero, motorBench, mTouch, Powermite 3, Precision

Edge, ProASIC, ProASIC Plus, ProASIC Plus logo, Quiet-Wire,

SmartFusion, SyncWorld, Temux, TimeCesium, TimeHub,

TimePictra, TimeProvider, Vite, WinPath, and ZL are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BlueSky, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity, JitterBlocker,

KleerNet, KleerNet logo, memBrain, Mindi, MiWi, MPASM, MPF,

MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach,

Omniscient Code Generation, PICDEM, PICDEM.net, PICkit,

PICtail, PowerSmart, PureSilicon, QMatrix, REAL ICE, Ripple

Blocker, SAM-ICE, Serial Quad I/O, SMART-I.S., SQI,

SuperSwitcher, SuperSwitcher II, Total Endurance, TSHARC,

USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and

ZENA are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

The Adaptec logo, Frequency on Demand, Silicon Storage

Technology, and Symmcom are registered trademarks of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology Germany

II GmbH & Co. KG, a subsidiary of Microchip Technology Inc., in

other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2019, Microchip Technology Incorporated, All Rights Reserved.

For information regarding Microchip’s Quality Management Systems,

please visit www.microchip.com/quality.

ISBN: 978-1-5224-5327-7

DS50002938A-page 2 2019 Microchip Technology Inc.

Page 3

MAC-SA5X USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB® IDE online help.

Select the Help menu, and then Topics, to open a list of available online help files.

PURPOSE OF THIS GUIDE

The MAC-SA5X User's Guide provides basic recommendations for designing products

to use Microchip's Miniature Atomic Clock (MAC) SA5X. The guidelines in the document are generic because specific product requirements vary between applications.

This material consists of a brief description of SA5X design supported by block diagrams, description of environmental issues, installation guidelines, and unit operation.

WHO SHOULD READ THIS GUIDE

This document is intended for engineers and telecommunications professionals who

are designing, installing, operating, or maintaining time, frequency, and synchronization systems that require a low profile and highly precise frequency generator.

To use this document effectively, you must have a good understanding of digital telecommunications technologies, analog frequency generation, and synthesis techniques.

DOCUMENT LAYOUT

This guide contains the following sections and appendixes:

• Chapter 1. “Product Overview”: Provides an overview of the product, describes

the major hardware and software features, and lists the system specifications.

• Chapter 2. “Installation”: Contains procedures for unpacking and installing the

system, and for powering up the unit.

• Chapter 3. “Operation”: Describes procedures for frequency adjustment and

toggling on/off various features.

• Chapter 4. “Command Line Interface”: Describes the CLI command conven-

tions, functions, and features.

• Chapter 5. “Maintenance and Troubleshooting”: Contains maintenance and

troubleshooting procedures for the product. Also contains procedures for returning the MAC.

• Appendix A. “Principle of Operation”: Briefly explains Atomic Interrogation and

2019 Microchip Technology Inc. DS50002938A-page 3

Page 4

MAC-SA5X User’s Guide

Coherent Population Trapping

• Appendix B. “Legacy Command Set (SA.3Xm)”: Describes the Legacy CLI

command conventions, functions, and features. For backwards compatibility.

• Appendix C. “Reference Designs”: Provides generic sample schematics for

converting MAC input/output signals.

• Appendix D. “Evaluation Kit”: Describes the evaluation kit for use with the

MAC.

• Appendix E. “Software License Agreements”: Describes the open source soft-

ware that portions of the SA5X software makes use of.

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

• Acronyms and Abbreviations: Terms are spelled out the first time they appear in

Thereafter, only the acronym or abbreviation is used. This guide uses “SA5X”

text.

and “MAC” interchangeably. SA5X is the latest generation of Miniature Atomic

Clock (MAC).

• Unless explicitly labeled with Hz, MHz, etc, all references to “frequency offset”

throughout this document imply the industry-standard fractional frequency ∆f/f,

where “∆f” is the dif

is the nominal frequency (in Hz).

ference between nominal and measured value (in Hz), and “f”

WARNINGS, CAUTIONS, RECOMMENDATIONS, AND NOTES

Warnings, Cautions, Recommendations, and Notes attract attention to essential or critical information in this guide. The types of information included in each are displayed

in a style consistent with the examples below.

WARNING

To avoid serious personal injury or death, do not disregard warnings. All warnings use

this style. Warnings are installation, operation, or maintenance procedures, practices,

or statements that, if not strictly observed, may result in serious personal injury or

even death.

CAUTION

To avoid personal injury, do not disregard cautions. All cautions use this style. Cautions are installation, operation, or maintenance procedures, practices, or statements

that, if not strictly observed, may result in damage to, or destruction of, the equipment.

Cautions are also used to indicate long-term health hazards.

Note: All notes use this style. Notes contain installation, operation, or mainte-

nance procedures, practices, conditions, or statements that alert you to

important information that may make your task easier or increase your

understanding.

DS50002938A-page 4 2019 Microchip Technology Inc.

Page 5

Preface

WHERE TO FIND ANSWERS TO PRODUCT AND DOCUMENT QUESTIONS

For additional information about the products described in this guide, please contact

your Microchip representative or your local sales office. You can also contact us on the

web at www.microsemi.com/ftdsupport.

When this manual is updated the latest version will be available for downloading from

Microchip’s web site. Manuals are provided in PDF format for ease of use. After downloading, you can view the manual on a computer or print it using Adobe Acrobat

Reader.

Manual updates are available at: www.microsemi.com/ftdsupport

RELATED DOCUMENTS AND INFORMATION

See your Microchip representative or sales office for a complete list of available documentation. To order any accessory, contact the Microchip Sales Department. See

www.microsemi.com/sales-contacts/0 for sales support contact information. If you

encounter any difficulties installing or using the product, contact Microchip Frequency

and Time Systems (FTS) Services and Support:

U.S.A. Call Center: including Americas, Asia and Pacific Rim

Frequency and Time Systems

3870 N 1st St.

San Jose, CA 95134

Toll-free in North America: 1-888-367-7966

Telephone: 408-428-7907

Fax: 408-428-7998

email: ftd.support@microsemi.com

Internet: www.microsemi.com/ftdsupport

Europe, Middle East, and Africa (EMEA)

Microchip FTS Services and Support EMEA

Altlaufstrasse 42

85635 Hoehenkirchen-Siegertsbrunn

Germany

Telephone: +49 700 3288 6435

Fax: +49 8102 8961 533

email: ftd.emeasupport@microsemi.com

email: ftd.emea_sales@microsemi.com

THE MICROCHIP WEBSITE

Microchip provides online support via our website at www.microchip.com. This website

is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the website contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

2019 Microchip Technology Inc. DS50002938A-page 5

Page 6

MAC-SA5X User’s Guide

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the website at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (November 2019)

• Initial release of this document as Microchip DS50002938A.

- Under Microsemi’s literature system, this document is number

900-44500-000, Rev. A.

DS50002938A-page 6 2019 Microchip Technology Inc.

Page 7

MAC-SA5X USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 3

Purpose of This Guide........................................................................................... 3

Who Should Read This Guide............................................................................... 3

Document Layout .................................................................................................. 3

Conventions Used in this Guide ............................................................................ 4

Warnings, Cautions, Recommendations, and Notes............................................. 4

Where to Find Answers to Product and Document Questions .............................. 5

Related Documents and Information..................................................................... 5

The Microchip Website.......................................................................................... 5

Customer Support ................................................................................................. 6

Document Revision History ................................................................................... 6

Chapter 1. Product Overview

1.1 MAC-SA5X Overview ...................................................................................... 9

1.1.1 Key Features .............................................................................................. 10

1.2 Physical Description ...................................................................................... 10

1.2.1 Communications Connections.................................................................... 11

1.2.2 Input Connections....................................................................................... 11

1.2.3 Output Connections.................................................................................... 11

1.2.4 Power and Ground Connections ................................................................12

1.3 Functional Description................................................................................... 12

1.4 Configuration Management ........................................................................... 13

1.5 Alarms ........................................................................................................... 13

Chapter 2. Installation

2.1 Handling Considerations .............................................................................. 15

2.2 Mounting Considerations .............................................................................. 15

2.21 Absolute Minimum and Maximum Ratings .................................................. 19

2.3 Start-Up Sequence ....................................................................................... 19

Chapter 3. Operation

3.1 Configure the Serial Port ............................................................................... 21

3.2 Analog Tuning ............................................................................................... 21

3.3 Digital Tuning ................................................................................................ 22

3.3.1 Calibration ..................................................................................................22

3.4 1PPS Disciplining .......................................................................................... 23

3.4.1 Theory ........................................................................................................23

3.4.2 Selection of Disciplining Time Constant, “Tau”........................................... 25

3.4.3 JamSync..................................................................................................... 26

3.4.4 1PPS Phase Measurement Mode .............................................................. 26

3.4.5 Cable Length Compensation...................................................................... 26

2019 Microchip Technology Inc. DS50002938A-page 7

Page 8

MAC-SA5X User’s Guide

3.4.6 PPS Quantization Error Correction .............................................................27

3.5 Device Information and Status ...................................................................... 27

3.6 Time of Day (TOD) ........................................................................................ 27

Chapter 4. Command Line Interface

4.1 Command Structure ...................................................................................... 30

4.1.1 Sequence Number ......................................................................................30

4.1.2 Arguments...................................................................................................30

4.1.3 Command Checksum .................................................................................31

4.2 Response Structure....................................................................................... 31

4.2.1 Error Response...........................................................................................31

4.2.2 Response Checksum..................................................................................32

4.3 Announcement Structure............................................................................... 33

4.4 Parameters.................................................................................................... 33

4.4.1 Parameter Index .........................................................................................33

4.4.2 Parameter Attributes ...................................................................................35

4.4.2.1 Parameter Units Attribute............................................................35

4.4.3 Alarms Parameter .......................................................................................36

4.5 Commands .................................................................................................... 37

4.5.1 Command Index..........................................................................................37

4.5.2 Command Usage ........................................................................................38

Chapter 5. Maintenance and Troubleshooting

5.1 Preventative Maintenance............................................................................. 43

5.2 Electrostatic Discharge (ESD) Considerations.............................................. 43

5.3 Troubleshooting............................................................................................. 43

5.4 Repairing the MAC ........................................................................................ 43

5.5 Upgrading the Firmware................................................................................ 43

5.6 Returning the MAC........................................................................................ 43

Appendix A. Principle of Operation ............................................................................45

Appendix B. Legacy Command Set (SA.3Xm)

B.1 Legacy Command Structure ......................................................................... 47

B.2 Legacy Command Index ............................................................................... 48

B.3 Legacy Command Usage ............................................................................. 48

Appendix C. Reference Designs .................................................................................51

Appendix D. Evaluation Kit

D.1 Overview and Key Features ......................................................................... 55

D.2 Physical Description ..................................................................................... 56

D.2.1 Communications Connections....................................................................57

D.2.2 Input Connections ......................................................................................58

D.2.3 Output Connections....................................................................................58

D.2.4 Power Connections ....................................................................................58

D.2.5 Functional Description and Operation ........................................................58

D.2.5.1 Troubleshooting..........................................................................59

Appendix E. Software License Agreements ..............................................................61

Worldwide Sales and Service .....................................................................................63

DS50002938A-page 8 2019 Microchip Technology Inc.

Page 9

Chapter 1. Product Overview

1.1 MAC-SA5X OVERVIEW

The MAC is a source of stable output frequency. Because it relies on the Atomic resonance of Rubidium Isotope 87 (87Rb) gas to generate the RF output, it is less susceptible to instabilities produced from the mechanical and thermal stresses inherent in

Quartz oscillators, enabling superior mid- to long-term accuracy. This stability makes it

suitable as a holdover reference in GPS denied environments. Frequency errors can

be corrected by applying a digital command or external correction voltage to the MAC.

(See Frequency steering and Section 3.2 “Analog Tuning”). Frequency drift (Aging

rate) can also be corrected by implementing the 1PPS disciplining feature of the MAC.

When combined with a GNSS receiver, this feature allows the system designer to combine the short-term stability of a Rb reference with the long-term stability of the GNSS,

approaching the performance of laboratory-grade Cesium Beam Tube frequency standards (see Section 3.4 “1PPS Disciplining”).

The Miniature Atomic Clock (MAC) SA5X is Microchip's seventh generation gas cell

atomic oscillator technology product. It was designed to accommodate a variety of timing applications as well as to replace several legacy Rubidium products (SA.22c, x72

and MAC-SA.3Xm). The footprint is compatible with the SA.3Xm, but with several

advancements in technology and features. Users of the previous generation (SA.3Xm)

can now expect improvements to frequency stability, warm-up time, input voltage

range, and operational temperature range. Additionally, 1PPS disciplining and USB

connections via a new embedded Molex™ connector allow greater design capabilities.

The 1PPS input allows users to quickly calibrate frequency and phase of the MAC to a

primary clock such as GPS, while the RF and 1PPS outputs provide highly stable holdover references.

MAC-SA5X USER’S GUIDE

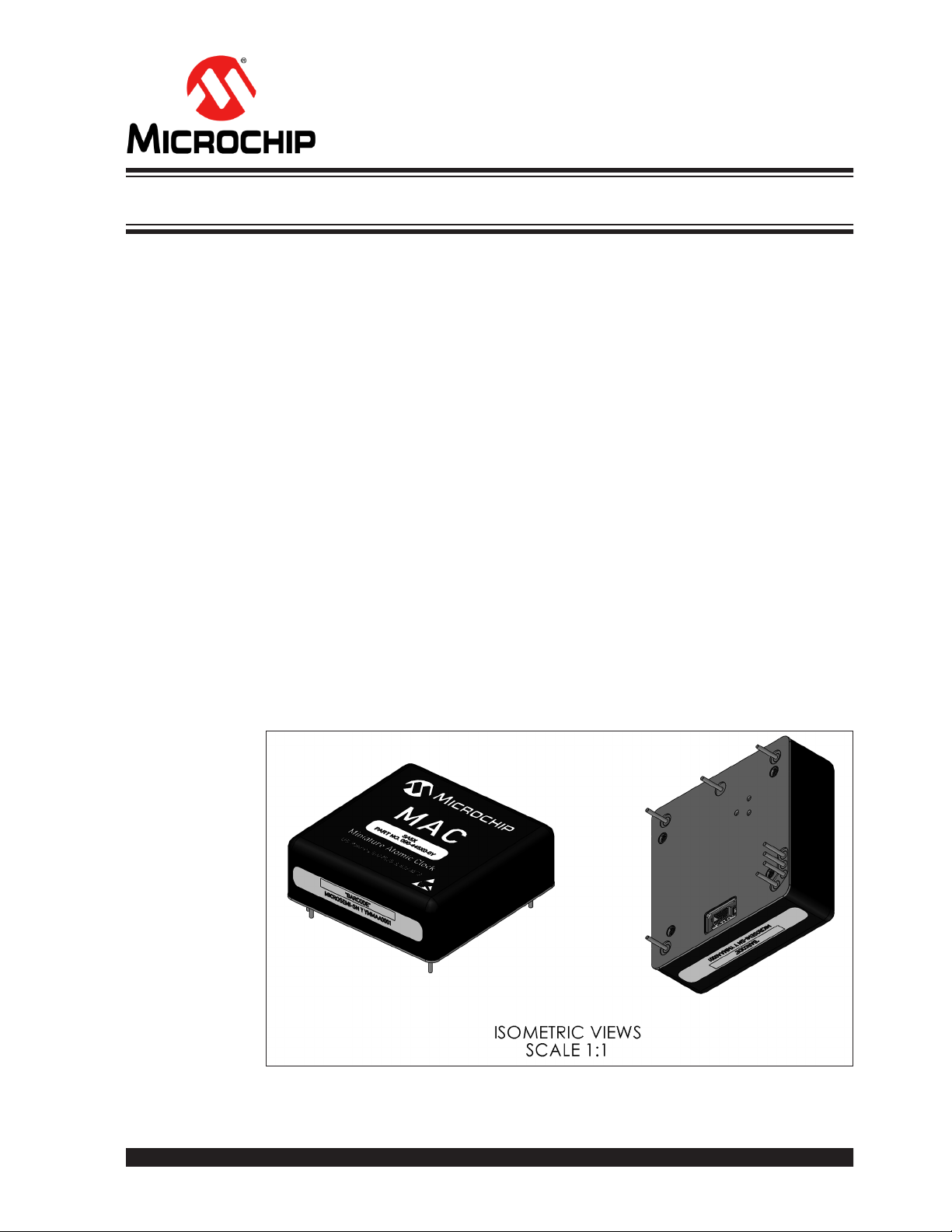

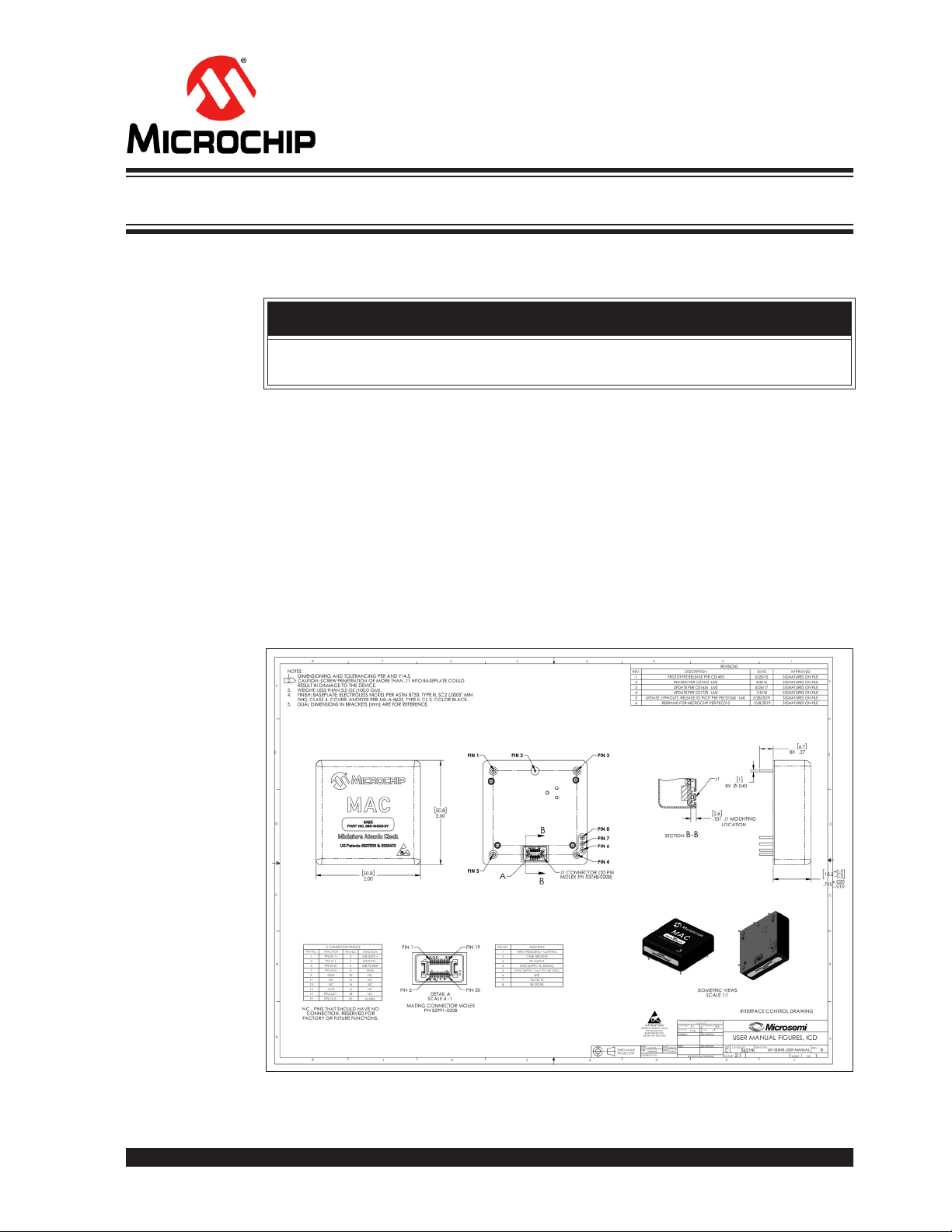

FIGURE 1-1: The Miniature Atomic Clock (MAC) SA5X.

2019 Microchip Technology Inc. DS50002938A-page 9

Page 10

MAC-SA5X User’s Guide

The MAC reflects significant advances in physics miniaturization and atomic interrogation algorithms that serve to reduce size and power while providing a stable reference

frequency that is resistant to environmental perturbation. The SA5X comes in several

performance levels to meet a range of system requirements. The SA5X offers a low

height (18.3 mm/0.72 in), a small footprint (50.8 mm × 50.8 mm, or 2 in × 2 in), and an

industrial operating temperature range of –40°C to +75°C (measured at the baseplate).

It is refined for cost effective mass production and can be easily integrated into time,

frequency, and synchronization systems. The SA5X requires a single supply voltage

and can be mounted directly onto a circuit board as a component of a module used in

20 mm (0.8 in) wide card slots. The design produces a stable frequency with good

short and long term stability, and excellent phase noise performance.

This user guide provides engineering information for use of the SA5X. It also provides

supporting information for use of the Evaluation Kit (p/n 090-44500-000). Furthermore,

the design details of the Evaluation Kit can be used to assist with host system design

(for example, power conditioning, signal buffering, and so on). This user guide must be

used in conjunction with the current data sheet for the SA5X, which is available on the

Microchip web site.

1.1.1 Key Features

•10 MHz CMOS Output

• 1PPS Disciplining

• 1PPS LVDS Inputs and Output

• –40°C to +75°C Operating Temperature (Baseplate)

• –55°C to +100°C Storage Temperature

• USB 2.0-Compatible Communication Pins

• Wide Range Allowable DC Input (4.5 to 32V)

• Fast Warm-Up Time (<7 Minutes from –10°C to +75°C)

• <5x10

• <100 ns Time Error in 24 hrs (Calculated Based on 5x10

• Serial/USB Interface for Digital Steering, Configuration, and Diagnostics

-11

Monthly Aging Rate (On for 30 Days Prior)

Assuming Zero Initial Phase/Frequency Offset, Static Environment, On for 30

Days Prior to Holdover)

-11

/mo. Aging Rate,

1.2 PHYSICAL DESCRIPTION

Labels will contain information about the part number and the serial number. The serial

number indicates the initial time of manufacture in the following manner. The first two

digits of serial number indicate the year of manufacture (18 = 2018). Digits three and

four indicate the month of manufacture (01 = January).

The MAC consists of a 2 in x 2 in x 0.7 in PCB-mountable chassis, consisting of a

Nickel-plated Aluminum baseplate and black anodized Aluminum cover. All connections for the MAC are on the baseplate. Figure 1-2 shows the top cover on the left and

the bottom baseplate on the right.

See Figure 2-1 for a complete mechanical drawing.

DS50002938A-page 10 2019 Microchip Technology Inc.

Page 11

Product Overview

FIGURE 1-2: Top Cover and Bottom Baseplate.

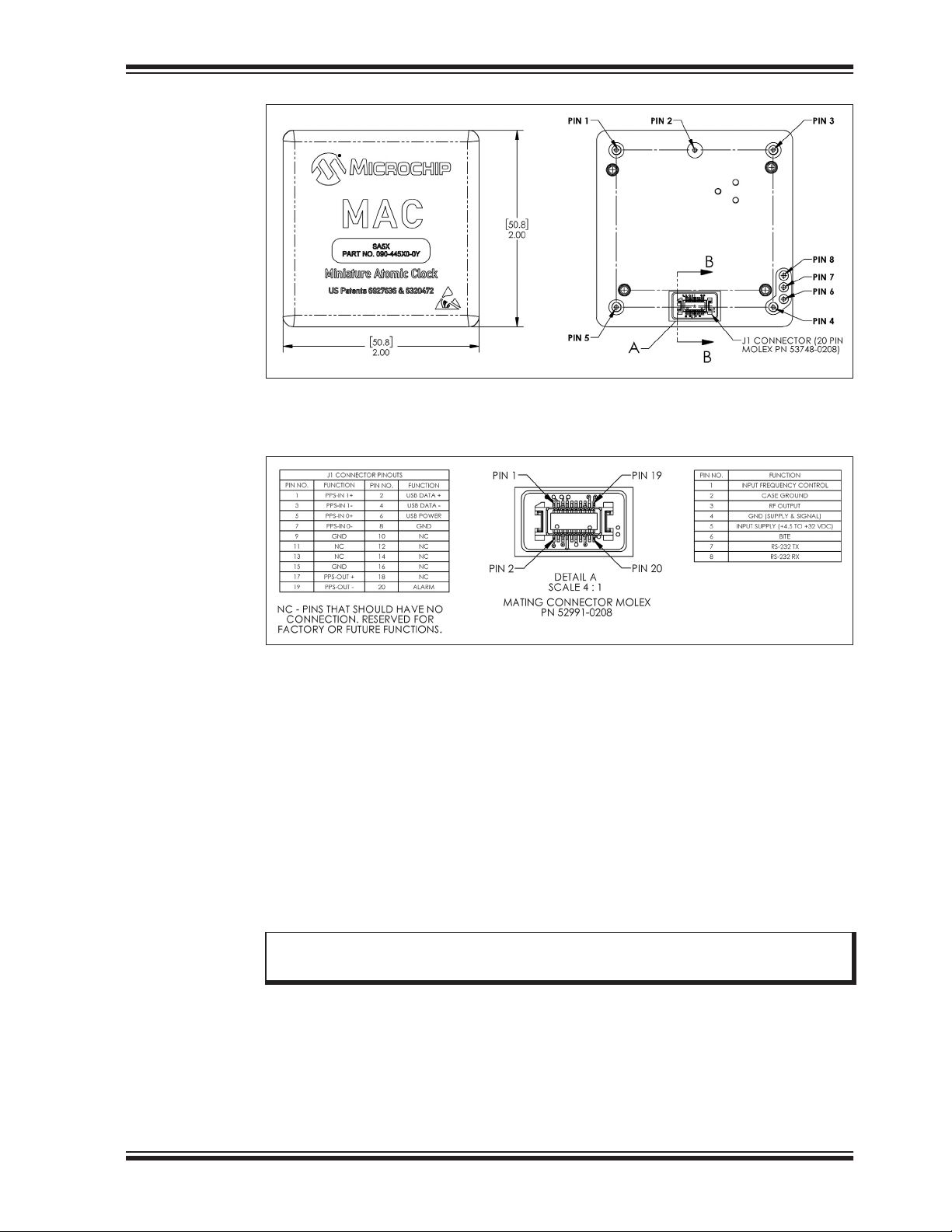

The baseplate consists of eight backwards-compatible gold-plated pins and recessed

20-lead Molex™ connector for new features (1PPS, USB, etc).

FIGURE 1-3: Pinout.

1.2.1 Communications Connections

The MAC is controlled either by the legacy serial port pins or with the high speed

USB-compatible pins on the Molex connector.

• Serial Console Port: The serial port connection is made through pins 7 and 8 on

the baseplate of the MAC. This port allows a user to connect to a terminal or computer using a terminal emulation software package. When connecting to this port,

use an appropriate converter chip such as the TRS3122E or similar to attain the

required LVCMOS levels. Figure 1-2 shows the serial port pins 7 and 8 in the

lower-right region of the baseplate. The default speed is 57600 bps and higher

speeds of 230400 bps and 921600 bps are available.

• USB Port: The USB port is capable of making high speed communication with the

MAC though the Molex (J1) connector pins J-2, 4, and 6.

Note: “Compatibility” commands are not supported when communicating via USB

port. See Appendix B. “Legacy Command Set (SA.3Xm)”.

1.2.2 Input Connections

• Analog Tuning: Analog Tuning is available on pin 1 for steering the MAC output

frequency by means of an externally supplied DC voltage. This method is for legacy applications that cannot steer the MAC digitally via the serial/USB interface.

• 1PPS Input (x2): Two selectable LVDS 1PPS inputs can be provided on pins

J1-5,7 (PPS0-IN) or J1-1,3 (PPS1-IN) for aligning the MAC’s frequency and timing

2019 Microchip Technology Inc. DS50002938A-page 11

Page 12

MAC-SA5X User’s Guide

output with an externally applied 1PPS reference signal. The PPS input is

selected via digital interface. Default input is PPS0-IN.

1.2.3 Output Connections

• 10 MHz RF Output: One CMOS output is available on pin 3.

• 1PPS Output:

J1-17, 19.

• Built-In Test Equipment (BITE): An active-low CMOS output on pin 6 signifies

that the MAC has achieved atomic lock.

• Alarm Output:

condition is present. The user can read the Alarm bits through the USB/Serial

interface to determine which alarm was triggered.

1.2.4 Power and Ground Connections

The MAC is not equipped with a power switch. DC power is applied on pin 5 with

ground pins located on pins 2 and 4. If the J1 connector is used, pins J1-8, J1-9, and

J1-15 should be grounded. Remaining pins should remain as “No Connect” (NC)

unless indicated otherwise in Figure 1-3. If J1 connector is unused, all pins should

remain as “No Connect”.

A single differential LVDS 1PPS output is available on pins

An active-low CMOS output on pin J1-20 indicates if an alarm

Recommendation: It is recommended to tie ground (Pin 4) to same node as the

baseplate ground Pin 2.

1.3 FUNCTIONAL DESCRIPTION

Communication Ports

These ports can be used to configure the MAC with Microchip’s C3 software commands using a terminal or a computer with terminal emulation software. The default

settings for the serial port are:

• Baud = 57.6K

• Data Bits = 8 bits

• Parity = None

• Stop bits = 1

• Flow Control = None

Commands allow the user to:

• Turn Analog tuning on or off

• Digitally adjust the output frequency

• Configure 1PPS Disciplining settings

• Query the MAC’s health/lock/alarm status

• Configure the Time of Day

Analog Tuning Input

Analog tuning is a means of steering the MAC's output frequency by applying a DC tuning voltage to Pin 1. This is useful for legacy applications where digital frequency steering is not possible.

1PPS Inputs

The MAC offers two selectable 1PPS inputs for use in steering the output RF (and

1PPS Output, simultaneously). PPS_Input_0 (pins J1-5,7) and PPS_Input_1 (pin

J1-1,3) are selectable with the PpsSource parameter. Their 1PPS Disciplining set-

DS50002938A-page 12 2019 Microchip Technology Inc.

Page 13

Product Overview

tings can be adjusted independently, however, the MAC can only discipline to one input

at a time. If a valid PPS signal on the selected input is present, then the parameter

PpsInDetected = 1. See Section 3.4 “1PPS Disciplining” for more details.

CAUTION

An LVDS square wave 1PPS is the allowable input.

10 MHz Output

The 10 MHz RF output appears on Pin 3 as soon as the MAC is switched ON and is

always present, regardless of the lock status. When the MAC is out of lock

(Locked = 0/Logic-High BITE pin), the output frequency is provided by the free-running

TCXO, which has frequency accuracy specification of ±2 ppm over its operating range.

The output format is 3.3V LVCMOS compatible.

Note: If a high-level (high-power) output driver is required, a driver circuit must be

implemented external to the MAC.

1PPS Output

An LVDS 1 pulse-per-second (1PPS) square wave output is available on pins J1-17,19

upon power-up. The 1PPS output is derived by digital division of the RF reference frequency and cannot be de-coupled. Therefore, the 1PPS and 10 MHz outputs are

always synchronized (within ±50 nanoseconds, regardless of Lock status).

PPS output timing relative to average PPS input timing is adjustable via the digital interface with 10 ns steps using PpsOffset parameter.

Default PPS Pulse Width is 20 μs. Pulse width may be modified via the PpsWidth

parameter.

BITE Output

The SA5X provides an active logic low indication through Pin 6, the BITE signal, when

the internal quartz oscillator is frequency-locked to the rubidium atomic resonance. As

long as the BITE signal is low, the user can be assured that the short-term stability

specifications are satisfied. The lock status is also available through the C3 Protocol

Locked parameter.

If the BITE signal is high (Locked = 0), then atomic Lock is not attained (or is lost) and

the SA5X is in its start-up sequence. During this sequence, signal output amplitude is

maintained but the stability performance is driven by the internal TCXO. Lock acquisition typically takes 5 minutes at room temperature.

Alarm Output

The Alarm Output provides an indication if an alarm is present (active logic low). It will

persist until cleared with the ackalm software command. A user can learn the exact

alarm condition from the value of the Alarms parameter (See Section 4.4.3 “Alarms

Parameter”).

1.4 CONFIGURATION MANAGEMENT

The Command Line Interface can be used to control specific functions of the MAC from

a terminal connected to the RS-232 serial port or the USB port.

Refer to Chapter 4. “Command Line Interface” for further details.

2019 Microchip Technology Inc. DS50002938A-page 13

Page 14

MAC-SA5X User’s Guide

1.5 ALARMS

The MAC uses alarms to notify the user when certain conditions are deteriorating

below specified levels or when issues arise, such as failure to acquire Lock or temperature warning. These alarms are indicated by CLI status and the alarm pin. For more

information, see Section 3.5 “Device Information and Status” and

Section 4.4.3 “Alarms Parameter”.

DS50002938A-page 14 2019 Microchip Technology Inc.

Page 15

Chapter 2. Installation

2.1 HANDLING CONSIDERATIONS

To avoid electrostatic discharge (ESD) damage, proper ESD handling procedures must

be observed in unpacking, assembling, and testing the MAC.

The MAC is delivered in ESD-safe packaging. The MAC must be removed from the

ESD-protective bag in an ESD-safe environment. Once installed on the test fixture, it

is recommended that the entire assembly be treated as ESD-sensitive.

Retain the original MAC ESD-safe packaging material in the event that the device

needs to be returned to Microchip for service.

2.2 MOUNTING CONSIDERATIONS

For initial testing and evaluation, it is recommended that the pins not be modified or soldered to a PCB. The recommended socket for PCB attachment is Mill-Max

0332-0-43-80-18-27-10-0. After evaluation, the pins can be hand-soldered to a PCB.

Below is the mechanical drawing (ICD). Contact Microchip for latest revision.

MAC-SA5X USER’S GUIDE

CAUTION

FIGURE 2-1: ICD 697-00498-000 for MAC.

2019 Microchip Technology Inc. DS50002938A-page 15

Page 16

MAC-SA5X User’s Guide

Solder

The MAC is a lead-free device. See the data sheet for RoHS compliance. Use SAC305

solder Sn96.5/Ag3.0/Cu0.5 or similar for hand-soldering to a PCB.

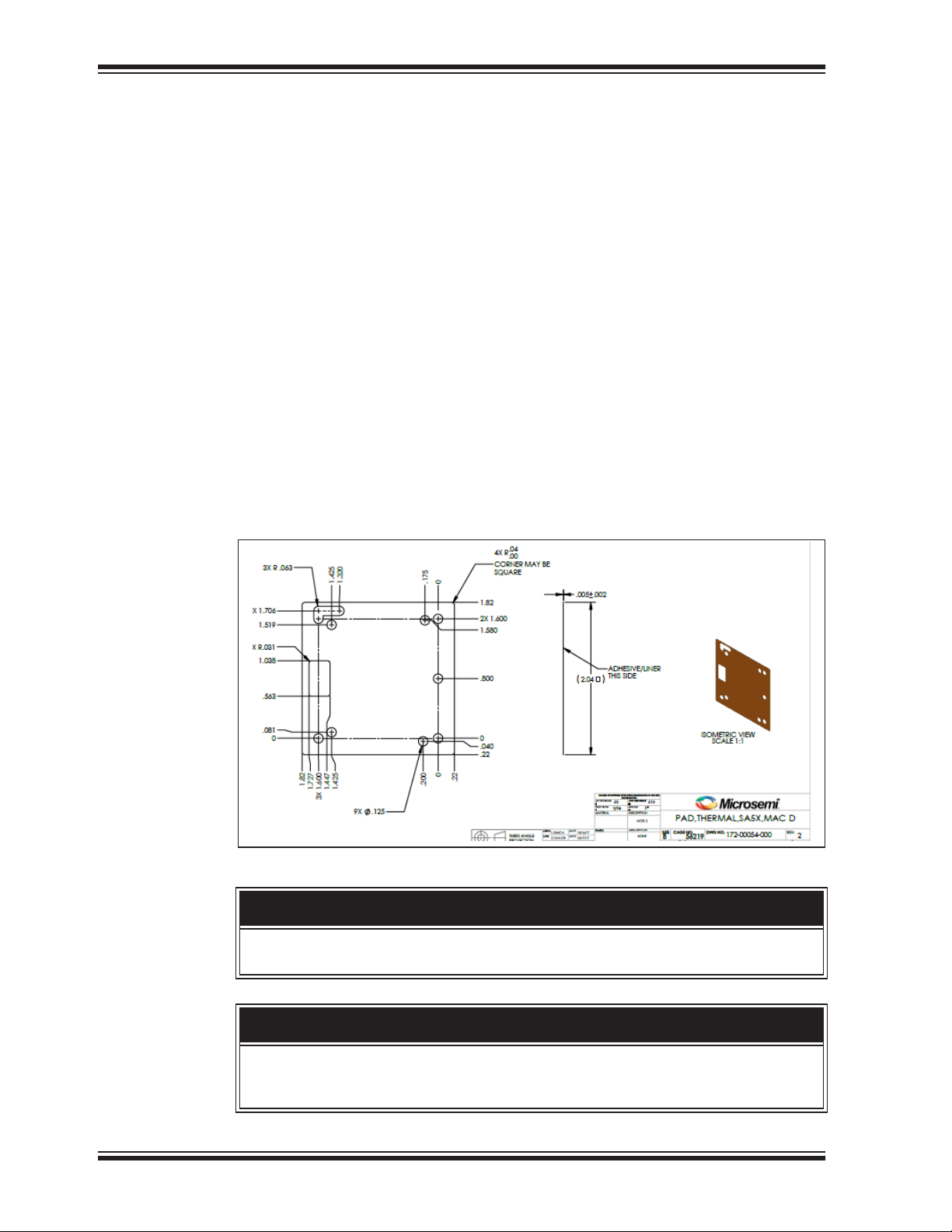

Heat Sink and Thermal Management

To allow the highest ambient operating temperature for the SA5X, it is recommended

that the bottom (baseplate) of the SA5X have good thermal contact with the mounting

surface (no air gap between baseplate and external PCB/heat sink etc). To ensure

good thermal contact, Microchip recommends that the SA5X is secured using (4) 2-56

screws. The location of the four screw holes is shown in Figure 2-1.

If the baseplate temperature rises above +75°C, the physics package heater shuts

down as control point temperatures are exceeded and the unit temperature coef

increase. The unit eventually loses lock above +75°C.

When practical, it is recommended to monitor the baseplate temperature with a thermocouple to ensure it remains below +75°C. Alternatively, one may query the telemetry

parameter Temperature to get a rough estimate of the external baseplate temperature. The Temperature parameter is measured internally on the PCB and is generally

~10°C to 15°C warmer than the actual baseplate temperature.

It is also important to maintain a uniform temperature into the baseplate of the SA5X

through its mounting points.

conductivity between a heat sink and the MAC's outer case. Figure 2-2 shows the

mechanical drawing for a thermal pad.

ficients

A thermal pad or thermal grease may improve thermal

FIGURE 2-2: ICD 172-00054-000 Thermal Pad.

CAUTION

To avoid damage to the SA5X, the mounting screws must not penetrate the unit by

more than 0.11 in. (2.79 mm).

WARNING

To avoid the possibility of a burn, mount the SA5X to a heat-dissipating surface. The

SA5X operates at a temperature that is hot to the touch and may cause handling distress.

DS50002938A-page 16 2019 Microchip Technology Inc.

Page 17

Installation

RF Noise Mitigation

If the system that the MAC is designed into is sensitive to RF or microwave frequencies

(especially 3.417 GHz and its harmonics), care must be taken to dampen those frequencies at locations that might be adversely affected. One way to do this is to determine the appropriate capacitor that has its "zero-ohm" characteristic at the frequency

of interest and use that capacitor to ef

might a problem. For example, it has been determined that at 3.417 GHz, the

"zero-ohm" capacitor value for an 0603-sized SMT component is 4.3 pF; for an

0402-sized capacitor, the value must be 6.8 pF; and for an 0201-sized capacitor, 8.2 pF

is ideal.

From this, it is recommended to place the appropriate-valued capacitor at the node of

interest. It is important that this cap be exactly on the node where the noise must be

squelched, and is grounded right at the cap as well. In addition, a good RF ground

plane is required, otherwise the improvement can be nullified.

The nulling capacitors are placed as close to the MAC I/O pins as possible. Because

the 3.417 GHz frequency is used within the MAC, the above mentioned nulling capacitors are recommended to be installed on pins 1,3,5-8.

EMI and Noise Considerations

When a user has an application where the phase noise and spur integrity are crucial,

the SA5X must be provided with a clean source of DC power (free of spurious current

or voltage noise). Connecting fans, heaters, and other switching devices to the DC supply powering the SA5X can result in degraded performance.

This noise is coupled through the power line to cause modulation spurs on the output

signal. Special care must be taken to avoid noise at 100 Hz and its harmonics (roughly

up to the tenth harmonic).

If power line filtering is added at the power input pin of the SA5X, this filtering cannot

have any resonance points greater than the specified impedance of less than 0.1Ω

from DC to 100 kHz in order to avoid the potential for noise peaking or oscillations in

the internal power regulators.

In addition, the input operating voltage range specified for the SA5X during turn-on

must continue to be met during operation of the unit. For example, using a 0.3Ω DC

source resistance for the input supply line may not be appropriate because the voltage

drop resulting from this resistance (caused by the turn-on current or quiescent operating current) could cause the input voltage to drop below the specified allowable value.

Signal Connections

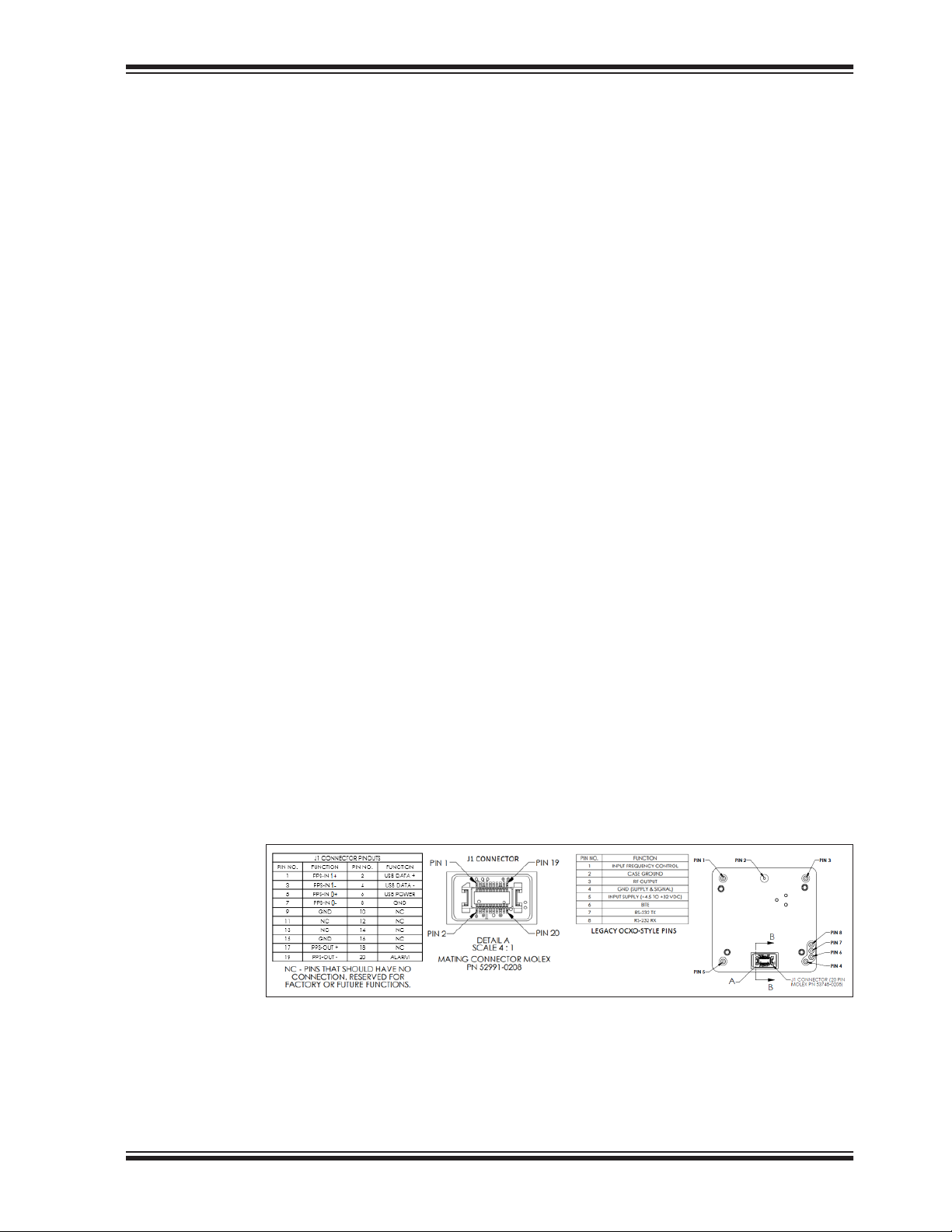

The SA5X pinout is shown in Figure 2-3.

fectively short that frequency to ground where it

FIGURE 2-3: Pinout.

2019 Microchip Technology Inc. DS50002938A-page 17

Page 18

MAC-SA5X User’s Guide

The electrical function of each pin is shown in Table 2-1.

TABLE 2-1: PIN FUNCTION TABLE

Connector

OCXO Style 1

OCXO Style 2 Baseplate — Note 3

OCXO Style 3 RF output CMOS 3.3V

OCXO Style 4 GND — Note 5

OCXO Style 5

OCXO Style 6

OCXO Style 7, 8

J1 Molex 1, 3 PPS1-IN LVDS —

J1 Molex 5, 7 PPS0-IN LVDS —

J1 Molex 8, 9, 15 GND — —

J1 Molex 17, 19 PPS-OUT –,+ LVDS square wave, 4 ns, 100Ω —

J1 Molex 20 Alarm

J1 Molex 2, 4, 6 USB USB —

Note 1: Analog tuning input sensitivity is 0V to 5V into 5 kΩ, 2.5V for no pull.

2: Analog tuning is disabled by default. Digital tuning is recommended instead.

3: Shall be connected to GND externally

4: 10 MHz, CMOS square wave, VL < 0.3V, VH > 3V. Amplitude is dependent on load.

5: Signal and Supply

6: BITE output (active-low):

7: If connecting to COM port of a computer

Pin

Number

Analog tuning

input

Supply voltage

(V

Built-In Test

Equipment (BITE)

Serial

communication

ground Pin 2.

0 = Normal Operation

1 = Unlock Condition

adapter is necessary.

Function Range/Format Note

0V to 5.0V

nominal Note 4

PP

4.5VDC to 32VDC

)

CC

. It is recommended to tie this ground to same node as baseplate

(5VDC recommended)

CMOS: Logic_H > 3V,

Logic_L < 0.3V

2.8V < Logic_H < 3.8V

0V < Logic_L < 0.3V

CMOS: Logic_H > 3V,

Logic_L < 0.3V

.

, a TTL/RS-232 (or HCMOS/RS-232)

Note 1,

Note 2

—

Note 6

Note 7

—

DS50002938A-page 18 2019 Microchip Technology Inc.

Page 19

2.2.1 Absolute Minimum and Maximum Ratings

Table 2-2 indicates the absolute minimum and maximum ratings to which the MAC can

be subjected without permanent unrecoverable damage.

Note: The MAC cannot be expected to perform normally when operated outside

of the recommended operating conditions noted on the product data sheet.

All ratings apply at +25°C, unless otherwise noted.

TABLE 2-2: MINIMUM AND MAXIMUM RATINGS

Supply Voltage (V

1PPS Inputs –0.5V to +3.6V

Analog Tuning Voltage 0V to +5V (into 5 kΩ)

Maximum Current Draw

Storage Temperature –55°C to +100°C

2.3 START-UP SEQUENCE

Installation

Parameter Rating

) 0VDC to +32VDC

CC

RS-232, BITE, Alarm: ±8 mA

RF output: ±8 mA

CAUTION

To avoid severe damage to the unit, do not apply power to the incorrect terminals. The

SA5X does not have reverse voltage protection.

When the MAC is initially powered on, it performs an acquisition sequence, which

includes stabilizing the temperature of the physics package, optimizing physics package operating parameters, and acquiring frequency lock to the atomic resonance.

A typical warm-up sequence is shown in Figure 2-4. When power is connected to the

MAC, its RF and 1PPS output signals (orange dashed line) will appear immediately.

The short-term stability specification of these signals will not be satisfied until the Lock

sequence is completed (after ~300 seconds in this example). Prior to Lock, the output

signal will have an inaccuracy of several ppm and drift per the MAC’s internal TCXO.

All MAC’s have their (Locked) output frequency calibrated to within ±5x10

prior to shipment. However, environmental conditions and transit time will affect the calibration to an unknown degree. Therefore, some additional frequency offset should be

expected when the MAC is first powered on by the user. Offsets may be corrected, as

explained in the Frequency Steering section. The re-trace specification provides some

guidance for frequency offsets due to powering off the unit; however, the specification

is not comprehensive.

Power consumption is displayed as a solid black trace. Initially, the power consumption

will draw >10W to bring the internal unit temperature up to operational level. Once the

temperature has stabilized, the steady state power consumption will drop to ~6W.

Steady state power consumption will be higher for colder ambient temperatures

because more heating will be required to maintain the correct internal temperature.

Similarly, the duration of the heat-up period (maximum power consumption) will be longer for colder ambient temperatures.

The baseplate temperature (solid orange trace) will generally rise ~15°C during the

start-up sequence, but this varies greatly with thermal management (heat sink, airflow,

etc). Generally, the temperature rise will be smaller at warmer temperatures, larger at

colder temperatures.

-11

Hz/Hz

2019 Microchip Technology Inc. DS50002938A-page 19

Page 20

MAC-SA5X User’s Guide

Care should be used to ensure that the maximum operating temperature is not violated.

For instance, a MAC that is powered up in a 70°C ambient environment will likely rise

above the maximum operating temperature during the start-up period unless careful

thermal management is employed. (See Section 2.2 “Mounting Considerations”)

The LockProgress parameter (not pictured) will reveal the Lock acquisition status in

terms of percentage-complete. Once the unit finishes the sequence, the BITE pin

(black dashed trace) will indicate Lock (logic low). Generally

be shorter at warmer temperatures, longer at colder temperatures. If this sequence

should fail, the Alarms parameter will signify “Acquisition Failed”. If this should occur,

check that the environmental specifications have not been violated (operating temperature, input voltage, magnetic field exposure, etc) and reboot the device. Contact Customer support if the alarm persists.

Note: Sequence times and power levels vary according to environmental condi-

tions, especially temperature.

, Lock acquisition times will

FIGURE 2-4: Start-Up Sequence.

Once power is supplied to the unit, it will output the following strings on the serial port:

[>Loading...]

[>Microchip SA5X]

After a typical warm-up time of 5 to 7 minutes, the oscillator is fully operational and the

operator may choose to adjust the device parameters. The MAC meets all short-term

stability specifications as soon as Lock is achieved. Long-term stability specifications

(Monthly Aging frequency drift rate) is satisfied within 30 days of continuous power at

room temperature. There are no maintenance procedures or adjustments needed,

aside from frequency adjustment which is described in a later section.

DS50002938A-page 20 2019 Microchip Technology Inc.

Page 21

Chapter 3. Operation

This section will cover the following topics:

• Configure the Serial Port

• Analog Tuning

• Digital Frequency Adjustment

• Configure 1PPS Discipline Settings

• Query the MAC’s Health/Lock/Alarm Status

• Configure the Time of Day

3.1 CONFIGURE THE SERIAL PORT

The default settings for the RS-232 interface are listed below.

• Speed: 57600 bps

• Data Bits: 8 bits

• Parity: None

• Stop Bits: 1

• Flow Control: None

The baud rate can be configured via the bootstrap loader (BSL). The following

sequence illustrates how to query and set the baud rate. The following interaction

sequence begins with the SA5X unit already powered on:

MAC-SA5X USER’S GUIDE

TABLE 3-1: BOOTSTRAP LOADER INTERACTION SEQUENCE

Serial Communication Description

{reset} User resets the CPU to access the bootloader.

[>Loading...] After reset, BSL announces it is ready (waits 3 seconds).

{bsl} User requests the BSL command mode (within 3 seconds).

[=BSL] BSL confirms it is now in command mode.

{baud?} User queries the currently configured baud rate (optional).

[=57600]<CR><LF> BSL returns the configured baud rate.

{baud,921600,now} User requests a new baud rate to take effect immediately.

[=921600] BSL confirms the newly configured baud rate.

{reset} User resets the CPU for the new rate to take effect.

[>Loading...] After reset, BSL announces its presence at 921600 bps.

See Chapter 4. “Command Line Interface” for reference on proper command syntax.

3.2 ANALOG TUNING

Analog tuning allows a user to correct the RF and 1PPS output frequency by applying

a DC correction voltage. Analog tuning is an inferior approach compared to Digital tuning or 1PPS Disciplining because its resolution is only parts in 1011. However, it has

been carried forward to support legacy applications.

Omission of “,now” argument will defer the change until the

next reset.

2019 Microchip Technology Inc. DS50002938A-page 21

Page 22

MAC-SA5X User’s Guide

The analog frequency control is derived from the analog voltage applied to Pin 1. This

voltage is digitized, scaled, and applied to the SA5X frequency servo. Analog tuning

(AT) voltages above mid-point (2.5VDC) increase the output frequency, and, conversely, tuning voltages below midpoint decrease the output frequency. Because the

tuning range is ±1x10-8 from 0V to 5V, this corresponds to roughly 1x10

2.5 mV change in AT voltage.

If the analog frequency tuning is disabled (by default), the analog frequency control

value is zero. It may be enabled with the AnalogTuningEnabled Parameter

Analog Tuning input voltage may be read via the AnalogTuning parameter, regardless if it is enabled or not.

Recommendation: If Analog Tuning is the desired method, it is highly recommended that it be used exclusively. Do not try to implement Analog Tuning with Digital Tuning or 1PPS Disciplining simultaneously into one system.

3.3 DIGITAL TUNING

The MAC RF (and 1PPS) output may be adjusted by the user via the DigitalTuning

parameter. Relative steering values are entered in (integer) units of parts in 1015,

though the resolution realized by the MAC hardware is approximately 1 part in 1014.

Digital adjustment is clamped to ±2 parts in 108. Consult Section 3.3.1 “Calibration”

if a larger correction is desired.

-11

for every

. The

Note: Steering commands may be entered during acquisition (Locked = 0) but

will not take effect until lock is achieved.

Frequency steering is volatile (unless the store command is used). Upon reboot, the

MAC returns to its nominal (calibrated) frequency setting. To update the non-volatile

calibration, see Section 3.3.1 “Calibration”.

3.3.1 Calibration

In the unlikely event that the adjustment range of DigitalTuning has been

exhausted beyond the limits of ±2x10-8 (perhaps due to cumulative frequency aging offsets) it may be desirable to update the calibration. When this is the case, manual calibration of the MAC is accomplished in the following manner. First, the MAC output

should be compared to a superior Frequency Reference with a frequency counter or

other suitable test equipment. Next, the MAC is steered onto frequency by adjusting

the DigitalTuning parameter, (see Section 3.3 “Digital Tuning” or

Section 3.4 “1PPS Disciplining”). Finally, the present value of the DigitalTuning

parameter is summed into the non-volatile calibration register via the latch command.

This command will simultaneously reset DigitalTuning to zero at the new center

frequency. The user may then adjust the output ±2x10-8 from its current value.

Note: Once a calibration is overwritten, it cannot be recalled.

Note: The latch command is only valid when the MAC is locked (Locked = 1).

Note: Total net steering range is limited to ±1x10-6. See data sheet for exact

specification.

DS50002938A-page 22 2019 Microchip Technology Inc.

Page 23

3.4 1PPS DISCIPLINING

For further reduction of phase and frequency errors, disciplining can be enabled/disabled with the Disciplining parameter. The algorithm implements a high-resolution

phase meter within the MAC to automatically correct the phase and frequency relative

to a reference 1PPS input once per second with a resolution of 450 ps. The algorithm

will simultaneously steer the phase and frequency to that of the external reference

(1PPS input), ultimately achieving accuracies of <1 ns and 1×10

depending on the stability of the 1PPS input and ignoring external cabling delays, etc

(See Section 3.4.5 “Cable Length Compensation”).

3.4.1 Theory

The 1PPS input is user selectable from pins J1-5,7 or J1-1,3 via the PpsSource

parameter. If a valid 1PPS is present on the selected input, PpsInDetected = 1 and

the user will notice the DigitalTuning parameter automatically adjust, once Dis-

ciplining is enabled. The LastCorrection parameter will tell the user how much

the MAC was digitally steered (in frequency) since its last correction; it is simply the difference between the last two successive DigitalTuning values. Similarly, the

Phase parameter will report the most recent phase meter measurement to indicate the

time-difference between input and output 1PPS signals.

The speed and effectiveness of the disciplining algorithm can be adjusted by the time

constant “Tau”, which is user selectable through the TauPps0 (or TauPps1) parameter. See Section 3.4.2 “Selection of Disciplining Time Constant, “Tau”” for advice

on choosing an appropriate time constant.

When disciplining is turned on, it will make a correction once per second based on its

most recent internal phase meter measurement. The disciplining algorithm will attempt

to dampen an initial phase and/or frequency error E0 by ~63% after an elapsed time of

one Tau, 99% after five Tau per the equation:

Operation

-13

, respectively,

EQUATION 3-1:

t

--–

EE01e

=

–

Where:

E = The instantaneous error.

E0 = The initial error calculated from the moving average of the previous errors observed over

time duration τ, updated once per second.

τ = The user-selectable time constant, tau, in seconds.

t = Elapsed time, in seconds.

Any subsequent additional errors after E0 will prolong the settling time of the algorithm.

In the event that the reference 1PPS input is removed from the selected input (pins

J1-5,7 or J1-1,3) while disciplining, the MAC remains in holdover and preserves the

most recent DigitalTuning value. If the 1PPS reference subsequently reappears,

disciplining continues where it left off. The exception being if the measured instantaneous Phase > PhaseLimit, whereby a JamSync will be implemented and the Disciplining algorithm will start anew. (Phase outliers are ignored. See

Section 3.4.3 “JamSync”)

The status of disciplining is indicated by the DisciplineLocked parameter in the

telemetry. DisciplineLocked = 0 upon algorithm startup or when a valid PPS input

signal is not detected. DisciplineLocked = 1 when magnitude of the phase mea-

2019 Microchip Technology Inc. DS50002938A-page 23

Page 24

MAC-SA5X User’s Guide

surement is less than the DisciplineThresholdPps0 setting for two time constants of duration (see Section 3.4.2 “Selection of Disciplining Time Constant,

“Tau””).

The following state diagram provides the concept behind the disciplining and

phase-metering algorithms. For more information on phase-metering, see

Section 3.4.4 “1PPS Phase Measurement Mode”.

FIGURE 3-1: PPS State Diagram.

Note: Discipline settings are volatile, that is, not preserved across power cycles

unless the store command is used.

Note: The user is allowed to adjust the DigitalTuning parameter while in Dis-

ciplining mode. However, this is discouraged because it could prolong and

disrupt the disciplining algorithm.

DS50002938A-page 24 2019 Microchip Technology Inc.

Page 25

Operation

3.4.2 Selection of Disciplining Time Constant, “Tau”

Algorithm performance will be predicated on the selection of the disciplining time constant Tau. When possible, it is advisable to choose a Tau that corresponds to the “least

noisy” averaging time of your 1PPS input source. Generally, a longer Tau is required

for a noisy 1PPS input reference (such as a simple GPS receiver); shorter Tau is

acceptable for stable lab-grade instruments (such as a Cesium Beam Tube). Furthermore, shortening the Tau may be necessary to quickly adjust the MAC if its inherent

stability is under influence of external environmental conditions (such as g-forces, rapid

temperature changes, etc.).

FIGURE 3-2: Sample ADEV Curves.

Figure 3-2 shows the performance of several frequency references. For optimum Dis-

ciplining performance when disciplining to a GNSS reference, a time constant should

be selected where the MAC and GNSS ADEV curves intersect (τ = 25,000 seconds, in

this example). In this way, the resulting performance of the Disciplined-MAC will have

short and mid-term stability of a free-running MAC, combined with the long-term stability of GNSS.

Note: The above set of curves is very generic and a designer should inde-

pendently quantify the stability of their own GNSS source. Usually, ADEV

information for GNSS receivers is not published because the stability will

vary according to a variety of environmental conditions; the designer will

have to generate this plot on their own. A rough approximation would be to

measure the 1s ADEV performance of a GNSS and extrapolate the curve

proportional to 1/√(Tau).

2019 Microchip Technology Inc. DS50002938A-page 25

Page 26

MAC-SA5X User’s Guide

Caution should be used when using a longer time constant. Initial frequency errors at

the start of Disciplining produce phase errors that will grow proportionally with elapsed

time. For slow (long Tau) Disciplining algorithms, the initial errors could grow outside

the DisciplineThreshold or PhaseLimit settings before an adequate correction can

be made by the algorithm, resulting in a JamSync and DisciplineLocked = 0. Generally, a good Discipline approach is to use a short Tau to make quick coarse corrections,

then apply a longer T

3.4.3 JamSync

When Disciplining is first enabled, the algorithm will implement a JamSync (Observable

with the JamSyncing parameter). It will also occur whenever the Phase is beyond the

PhaseLimit parameter. A JamSync has the benefit of speeding up the disciplining

routine by quickly synchronizing the output 1PPS after one clock cycle (phase is briefly

aligned, but frequency is not). The disciplining algorithm can then continue onward by

further refining the frequency and phase errors. However, the drawback of a JamSync

is that the user will observe a phase “jump” during the JamSync, rather than a slow

steer as predicated by disciplining alone. To avoid said “jump”, the user can adjust the

PhaseLimit parameter. This is particularly useful for long Disciplining time constants.

However, the initial JamSync (when disciplining is initialized) cannot be avoided.

au to further reduce the MAC’s phase and frequency error.

NOTICE

3.4.4 1PPS Phase Measurement Mode

Phase measurement mode does not steer or Discipline the MAC’s output frequency.

Rather, it makes use of the MAC’s internal phase meter by reporting the time difference

between the MAC’s internally-generated 1PPS output (pins J1-17,19) and the externally applied reference 1PPS active input (pins J1-5,7 or J1-1,3) once per second.

Measurement resolution is approximately 450 ps. The mode is enabled with the

PhaseMetering parameter and the internal phase difference can be read via the

Phase parameter.

Note: Tau has no effect on the Phase parameter.

3.4.5 Cable Length Compensation

The zero point of disciplining can be adjusted to accommodate cable and other instrumentation delays (or advances) that impact the arrival time of the 1PPS at the MAC

1PPS input pin. The compensation value can be adjusted with the CableDelay

parameter.

The maximum compensation adjustment is ±0.5 seconds, where the positive sign indicates phase advancement of the input 1PPS. For example, if there is 45 ns of delay

(approximately 33 feet of RG-58 coaxial cable) between the on-time point and the MAC

1PPS input then the compensation value would be +45.

Note: Compensation is implemented in the disciplining algorithm, not in the phase

measurement itself. The phase measurement, as reported through telemetry, reports the actual phase measurement. That is, if the MAC is disciplined

with +50 ns of compensation, the phase meter reports –50 ns of phase difference when disciplining is settled.

DS50002938A-page 26 2019 Microchip Technology Inc.

Page 27

3.4.6 PPS Quantization Error Correction

For use with certain GNSS receivers, the PpsQErr parameter may be used to correct

known dynamic quantization errors due to the receiver itself. This is a picosecond

adjustment to the next MAC 1PPS phase measurement to account for the error.

3.5 DEVICE INFORMATION AND STATUS

Consult Section 4.4 “Parameters” for a comprehensive list of all available device

telemetry parameters. They provide insight into device settings, discipline/atomic lock

status, time of day, and alarm conditions.

Several commands provide insight into hardware/software revision, device identification, environmental extremes, and estimated NVRAM health:

• app?

• device?

• platform?

• describe?

• swrev?

• hwrev?

• serial?

• extremes?

• health?

See Section 4.5 “Commands” for details.

Operation

3.6 TIME OF DAY (TOD)

The MAC maintains a TOD parameter TimeOfDay as a 32-bit unsigned integer, which

is incremented synchronously with the rising edge of the 1PPS output. Until set otherwise, TOD begins counting from zero when the MAC is powered on.

2019 Microchip Technology Inc. DS50002938A-page 27

Page 28

MAC-SA5X User’s Guide

NOTES:

DS50002938A-page 28 2019 Microchip Technology Inc.

Page 29

MAC-SA5X USER’S GUIDE

Chapter 4. Command Line Interface

This section describes the communication interface provided by the Microchip MAC

SA5X Rubidium Oscillator. The device supports the Microchip proprietary C3 protocol.

The C3 protocol provides read/write access to the device’s parameters. The device’s

state is exposed through these parameters; modifying their values produces changes

in state.

identification functions, and device telemetry.

Key Features

Key features of the C3 protocol include:

• Text-based: Compatible across many architectures; avoids number representa-

• Orthogonal: All commands and responses share the same format.

• Parameter-based: Command set is based on exposing information and controls

• Error-detecting: With checksums, garbled commands/responses are more detect-

Message Flow

For each command message sent to the device, one response message will be

returned. In certain situations, such as device startup, announcement messages are

sent asynchronously.

The C3 protocol also provides access to flash memory operations, device

tion issues.

as a set of parameters.

able.

Note: Protocol is character case-sensitive.

4.1 COMMAND STRUCTURE

The structure of a C3 command follows:

{command#XX,argument1,|CC}

Where:

TABLE 4-1: COMMAND STRUCTURE

Field Description Required?

{ Signifies the beginning of a command. Yes

command The name of the command being issued. Yes

#XX

,argument1

|CC

} Signifies the end of a command. Yes

The sequence number, arguments, and checksum fields are optional. If a command is

entered incorrectly, MAC will reply with the appropriate error message (See

Section 4.2.1 “Error Responses”).

The sequence number of the command. (XX = two hex digits).

The start of the argument list, beginning with a comma and

containing quoted or un-quoted arguments.

The 8 bit checksum of the command message. (CC = two

hex digits).

No

Per Command

No

2019 Microchip Technology Inc. DS50002938A-page 29

Page 30

MAC-SA5X User’s Guide

Note: Spaces are not used within the command structure.

4.1.1 Sequence Number

The optional sequence number is used to match a response to an earlier command.

Commands issued with a sequence number between #01 and #FF will trigger a

response message that includes the same sequence number.

4.1.2 Arguments

The argument list follows the command name (or the sequence number, if included),

and always begins with a comma before each argument. Numbers and alphanumeric

arguments can be written as-is, but arguments that may contain punctuation should be

enclosed in double quotes to prevent ambiguity when parsing the command.

Within a quoted argument, the backslash character is a special escape character. It can

be used to escape the following sequences (Any other sequences result in the removal

of the backslash.):

TABLE 4-2: ESCAPE SEQUENCES

Escape Sequence Resulting Character

\r Carriage return.

\n New line/line feed.

\t Horizontal tab.

\\ Backslash.

4.1.3 Command Checksum

An optional 8-bit checksum provides a measure of reliability to commands and

responses. If a checksum is included with a command, the response will also include

a checksum for verification purposes.

The checksum of a command is calculated as a running XOR of all the characters

between the opening ‘{‘ and the ‘|’ checksum delimiter. It is a two-byte ASCII representation (in hexadecimal) of the XOR.

{command#XX,argument1,”argument2”|CC}

For example, the hexadecimal checksum of the {device?} command would be

entered as:

{device?|27}

If the command is garbled in transmission, causing a mismatch between the contents

and the checksum, the C3 response will be [!3] indicating a bad checksum error (See

Section 4.2.1 “Error Responses”). The command should be re-sent.

4.2 RESPONSE STRUCTURE

The structure of a C3 response follows:

[#XX=value|XX]<CR><LF>

Where:

TABLE 4-3: RESPONSE STRUCTURE

Field Description Usage

[ Indicates the start of a response. Always

DS50002938A-page 30 2019 Microchip Technology Inc.

Page 31

Command Line Interface

TABLE 4-3: RESPONSE STRUCTURE

Field Description Usage

#XX

=

value

|CC

] Indicates the end of a response. Always

<CR> A carriage return character. Always

<LF> A linefeed/newline character. Always

The sequence number in the corresponding command (XX

= two hex digits).

The response type. A normal response type is indicated by

a ‘=’ character. An error response is indicated by a ‘!’ char

acter.

The response value. It may be a number, alphanumeric, or

quoted string. The meaning of the value depends upon the

command. Max Length is 4096 characters.

The 8-bit checksum of the response message. (CC = two

hex digits).

A sequence number will be included in a response if one was provided in the command.

Similarly, a checksum will be included in a response if a checksum was given for the

command.

Only when a

sequence

command is sent

-

Always

Always

Only when a

checksum

command is sent

4.2.1 Error Responses

An error response indicates a problem with the command. It is identified by a ‘!’ character instead of ‘=’ following the optional message sequence number.

The following table lists all error numbers returned by the device:

TABLE 4-4: ERROR RESPONSES

Error Number Error Message Cause(s)

1 Invalid command Unrecognized command name, invalid syntax.

2 Insufficient arguments

3 Bad checksum

100 Invalid parameter

101 Invalid argument

102 Read-only parameter

301, 303 Corrupt file contents The firmware file contents are corrupted.

302 Bad file checksum There was an error in the file transfer.

304 Incomplete file The firmware file contents are incomplete.

310

311

312 Synchronization error A file transfer synchronization error occurred.

313

Transfer failed –

too many retries

Transfer failed –

canceled by client

Transfer failed –

Unsupported request

Not enough arguments provided for the command.

Checksum does not match the message

received.

The given parameter name or id is unrecognized.

One of the command arguments was semantically invalid. See the command’s documentation for details.

The parameter’s value cannot be written by the

user.

The file transfer was aborted after too many

retries.

The client aborted the file transfer.

The file transfer was aborted due to an unsupported request.

2019 Microchip Technology Inc. DS50002938A-page 31

Page 32

MAC-SA5X User’s Guide

TABLE 4-4: ERROR RESPONSES

Error Number Error Message Cause(s)

320 Erase failed An error occurred while erasing flash memory.

321 Write failed An error occurred while writing to flash memory.

For example, the response to the invalid command {type7} would be:

[!1]<CR><LF>

4.2.2 Response Checksum

The checksum of a response is calculated as a running XOR of all the characters

between the opening ‘[‘ and the ‘|’ checksum delimiter. See the double underlined portion of the response below:

[

#XX=value|CC]<CR><LF>

For example, the checksum-response to the {device?|27} command would be:

[=sa5x|62]<CR><LF>

4.3 ANNOUNCEMENT STRUCTURE

The structure of a C3 announcement follows:

[>message|CC]<CR><LF>

Where:

TABLE 4-5: ANNOUNCEMENT STRUCTURE

Field Description Usage

message

|CC

<CR> A carriage return character. Always

<LF> A linefeed/newline character. Always

Currently, announcements only occur immediately after applying power to the unit (or

resetting the microprocessor):

[>Loading...]<CR><LF>

[>Microchip SA5X]<CR><LF>

4.4 PARAMETERS

The state of the device is exposed as a set of parameters: named values with semantic

attributes. Certain parameters are readable/writable to allow the device to be controlled

and configured, while other read-only parameters present useful status information.

Parameters are uniquely identified by either a numeric id (e.g. 769) or a name (e.g.

PpsSource). The device provides a set of commands to indicate which parameters

are available to the user and to describe each one, including name string, real world

units, whether it’s writable, etc.

[ Indicates the start of an announcement Always

>

] Indicates the end of an announcement Always

Identifies this as an announcement, versus a response or

.

error

The announcement message. It may be alphanumeric or a

quoted string.

The 8-bit checksum of the announcement message.

(CC = two hex digits)

Always

Always

Currently unused

feature

DS50002938A-page 32 2019 Microchip Technology Inc.

Page 33

Command Line Interface

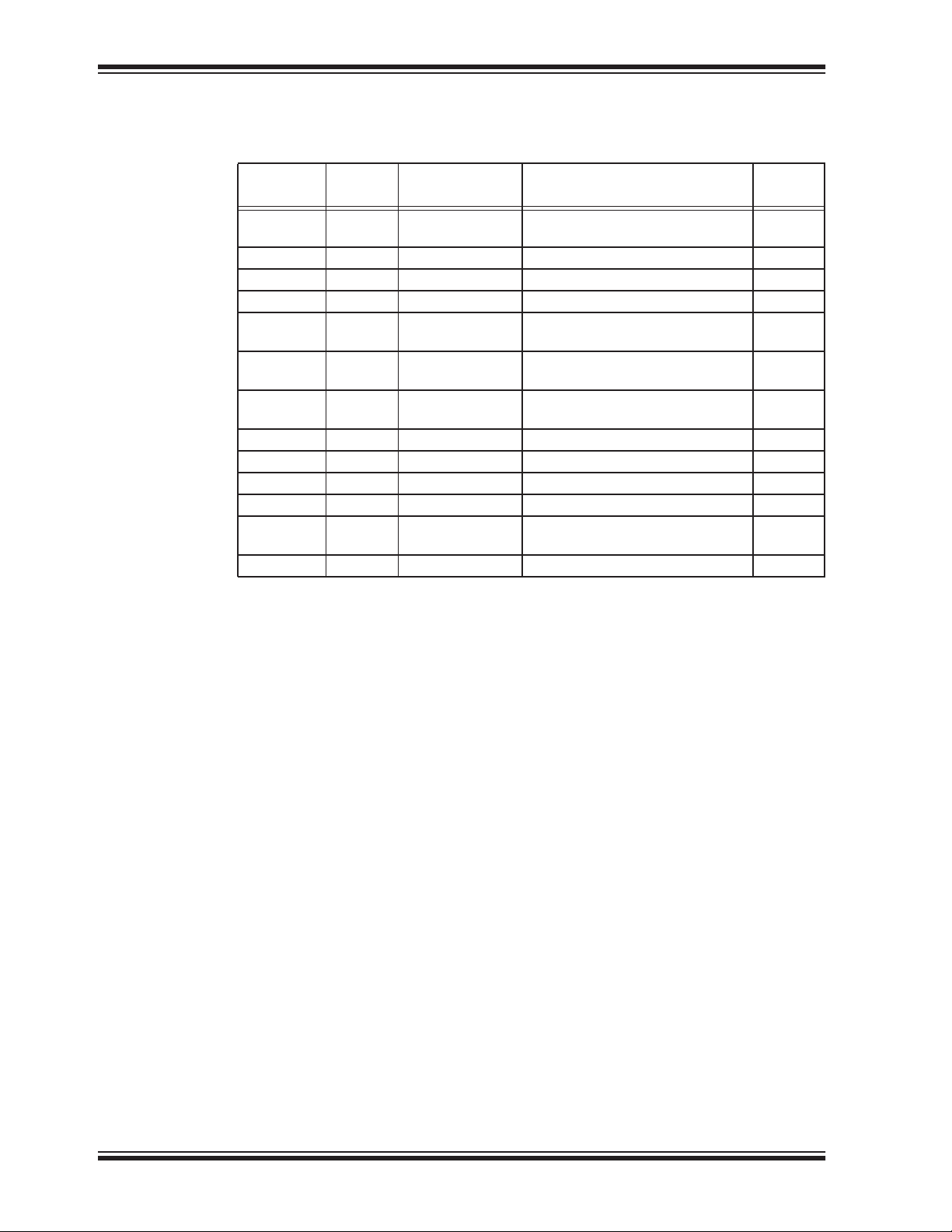

4.4.1 Parameter Index

The parameters provided by the device are listed in the table below.

TABLE 4-6: PARAMETER INDEX

ID Name R/W Description Units

General Status Parameters

256 Alarms RO Bitfield of all active alarm conditions. Bitfield 32 bits

257 PpsInDetected RO

263 Locked RO

264 TimeOfDay R/W

265 DisciplineLocked RO

Configuration Parameters

512 PpsOffset R/W

513 PpsWidth R/W

515 CableDelay R/W

Disciplining Parameters

768 Disciplining R/W

769 PpsSource R/W

770 TauPps0 R/W

771 PpsQErr R/W

772 PhaseLimit R/W

773 JamSyncing RO

774 Phase RO

775 LastCorrection RO

777 TauPps1 R/W

778 PhaseMetering R/W

A signal is detected on the selected

PPS source.

The unit is in a locked and stable

state.

Time of day at the next 1PPS output

pulse. This is a configurable second

counter.

Disciplining servo is locked to the

selected PPS source.

Offset of the output pulse. Default is

0

ns.

Width of the output pulse. Default is

20,000

ns.

1PPS input cable delay compensation. Default is 0 ns.

Disciplining to 1PPS input is

enabled. Default is false.

Selected 1PPS input source:

0 = PPS Input 0, 1 = PPS Input 1.

Default is 0.

Disciplining time constant when

using PPS Input 0.

Time error of the next input pulse

due to quantization. For compatibility

with GNSS receivers.

Limit of phase offset between 1PPS

input and 1PPS output before jam

syncing. Default is 1,000

ns.

A jam sync to remove phase offset is

in progress.

Most recent measurement of phase

offset between 1PPS input and

1PPS output.

Most recent frequency correction

due to disciplining.

Disciplining time constant when

using PPS Input 1.

Metering of 1PPS phase offset without corrections is enabled. Default is

false. Cannot be enabled simultane

ously with disciplining.

Boolean 0 or 1

Boolean 0 or 1

seconds

Boolean 0 or 1

ns

ns

ns ±500,000,000

Boolean 0 or 1

— 0 or 1

seconds 10 to 45,000

ps ±1,000,000

ns ±1,000,000

Boolean 0 or 1

ns ±500,000,000.0

-15

x 10

seconds 10 to 45,000

Boolean 0 or 1

-

Allowable

Range (

0 to

2,147,483,647

±83,886,080

(10 ns step)

0 to 83,886,080

(10 ns step)

±20,000,000

Note 1)

2019 Microchip Technology Inc. DS50002938A-page 33

Page 34

MAC-SA5X User’s Guide

TABLE 4-6: PARAMETER INDEX (CONTINUED)

ID Name R/W Description Units

779 DisciplineThresholdPps0 R/W

780 DisciplineThresholdPps1 R/W

Oscillator Parameters

1293 AnalogTuning RO

1296 Temperature RO Ambient temperature of the unit. m°C

1300 DigitalTuning R/W

1306 PowerSupply RO

1312 AnalogTuningEnabled R/W

1321 EffectiveTuning RO

1332 LockProgress RO Progress toward acquiring lock. % 0 to 100

Note 1: Allowable ranges are integer-only

Phase threshold for determining a

disciplining lock to PPS Input 0.

Phase threshold for determining a

disciplining lock to PPS Input 1.

The measured analog tuning input

voltage.

Digital tuning of the oscillator frequency. Default is 0. Values are volatile (not preserved across a

power-cycle).

The measured voltage of the external power supply.

Analog tuning is enabled. Default is

false.

Total effective digital frequency tune.

This provides little insight to the user

since its value will vary depending

upon a number of constantly changing internal adjustments.

, unless indicated otherwise.

mV 0 to 5,000

x 10

mV 0 to 36,300

Boolean 0 or 1

x 10

Range (Note 1)

ns 1 to 1,000

ns 1 to 1,000

–40,000 to

100,000

-15

±20,000,000

-15

±2,147,483,647

Allowable

4.4.2 Parameter Attributes

Each parameter has a set of fixed attributes that describe semantic information about

itself: read-only, stored to flash, etc. These attributes are represented as a 32-bit field,