Page 1

PL360G55CB-EK

PL360G55CB-EK User Guide

Introduction

PL360G55CB-EK is an evaluation kit for the PL360 modem. PL360 is a programmable modem for

narrow-band Power Line Communication (PLC) from Microchip Technology Inc, able to run any PLC

protocol in the frequency band below 500 kHz. The PL360 has been conceived to be driven by external

Microchip host controller devices; in this case a SAMG55 ARM® Cortex®-M4 RISC processor is used. The

Microchip host device loads the corresponding PLC-protocol firmware and then controls the PL360

modem operation.

The PL360G55CB-EK board has been conceived to communicate in CENELEC B-Band (95 kHz to 125

kHz) and it complies with CENELEC standard EN 50065 regulations and Smart Energy applications. It

can be connected directly to AC mains or DC power rails.

Contents

• Welcome letter

• Board:

– One PL360G55CB-EKv2 board

• Cable:

– One Micro A/B-type USB cable

• Jumpers:

– Two jumpers with pitch 1.27 mm

• Pin Headers:

– Two 8-pin headers with pitch 2.54 mm

Features

• PL360G55CB-EK board mounts a PL360 PLC transceiver and a SAMG55J19 ARM Cortex M4

microcontroller.

• PL360G55CB-EK board provides a full featured platform to develop a complete communications

system based on PLC technology working in CENELEC B-Band.

• PL360 is a compact and highly efficient device for a wide range of Smart Grid applications such as

lighting control, industrial/home automation and renewable-energy management, among others.

• PL360G55CB-EK board provides support for:

– PLC band characterization and noise level measurement

– PLC sensitivity level measurement

– Power consumption

– Power fail detection

• PL360G55CB-EK board includes a SWD/JTAG interface for MCU debugging and programming

purposes. Firmware is also upgradable via USB/serial interface

• USB 2.0 full-speed interface

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 1

Page 2

PL360G55CB-EK

• mikroBUS™ add-on connectors to integrate the board itself as a module for interfacing with other

microcontrollers or microprocessors (mikroBUS main board).

• PL360G55CB-EK board can be externally supplied by:

– mikroBUS connector

– Micro-B USB connector

– DC Jack connector

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 2

Page 3

PL360G55CB-EK

Table of Contents

Introduction......................................................................................................................1

Contents.......................................................................................................................... 1

Features.......................................................................................................................... 1

1. Evaluation Kit Specifications..................................................................................... 4

1.1. Safety Recommendations............................................................................................................ 4

1.2. Electrical Specifications................................................................................................................4

2. Getting Started.......................................................................................................... 6

2.1. Powering-Up the Board................................................................................................................ 6

2.2. Running Preloaded Firmware.......................................................................................................7

2.3. Code and Technical Support........................................................................................................ 7

3. PL360G55CB-EK Board............................................................................................9

3.1. Overview...................................................................................................................................... 9

3.2. Features List.................................................................................................................................9

3.3. Hardware Description – System.................................................................................................16

3.4. Hardware Description – MCU Peripherals................................................................................. 26

3.5. Hardware Description – MCU Interface Ports............................................................................ 28

3.6. PL360G55CB-EK Schematics....................................................................................................30

3.7. PL360G55CB-EK Layout........................................................................................................... 34

4. Compliance for Specific Standards......................................................................... 40

5. References.............................................................................................................. 41

6. Revision History.......................................................................................................42

6.1. Rev A - 04/2019......................................................................................................................... 42

The Microchip Web Site................................................................................................ 43

Customer Change Notification Service..........................................................................43

Customer Support......................................................................................................... 43

Microchip Devices Code Protection Feature................................................................. 43

Legal Notice...................................................................................................................44

Trademarks................................................................................................................... 44

Quality Management System Certified by DNV.............................................................45

Worldwide Sales and Service........................................................................................46

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 3

Page 4

1. Evaluation Kit Specifications

CAUTION

1.1 Safety Recommendations

This evaluation board must only be used by expert technicians. The PL360G55CB-EK board is powered

from a DC power source, so only the PLC coupling stage could have a hazardous voltage when is

connected to mains. The risk of electric shock is minimized since all required connectors and

configuration jumpers are galvanically isolated from the coupling stage.

Be careful, there is risk of electric shock in the PLC coupling stage. A normal use of the

PL360G55CB-EK board is for indoor use only.

This evaluation board does not have any switch on mains connection to switch it on or off.

To avoid damage of measurement instruments, do not connect any probe to the high voltage sections if

the board is not isolated from the mains supply.

Temperature operating range should be from 0ºC to +85ºC. Running extended periods at minimum and

maximum values may cause permanent damage to the board. Quartz crystal components could not cover

previous temperature range with desired performance due to aging.

PL360G55CB-EK

Evaluation Kit Specifications

The evaluation board is intended for further engineering, development, demonstration, or evaluation

purposes only. It is not a finished product, unless otherwise noted on the board/kit.

Important: Microchip does not assume any responsibility for the consequences arising from

any improper use of this board.

1.2 Electrical Specifications

This section shows the electrical characteristics of the PL360G55CB-EK board.

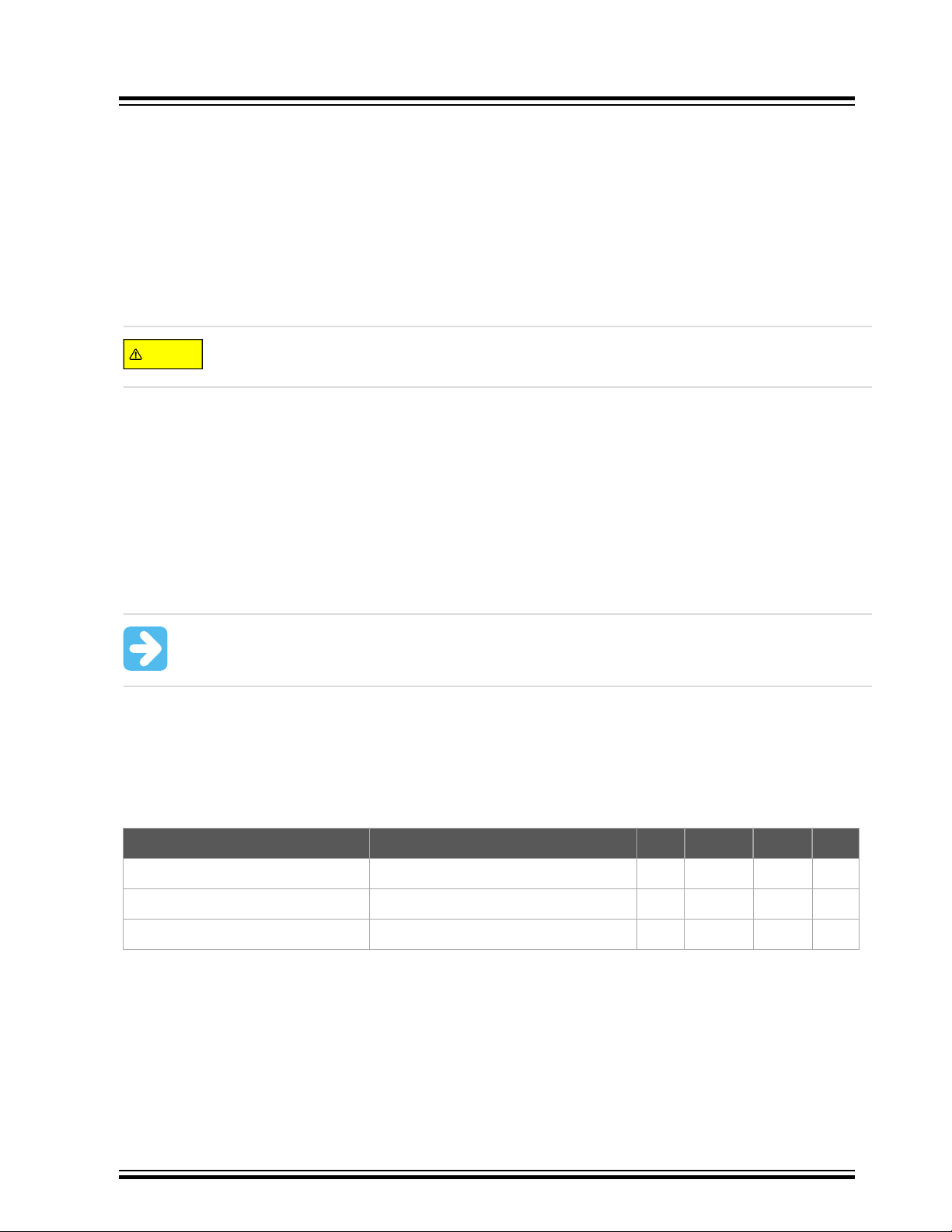

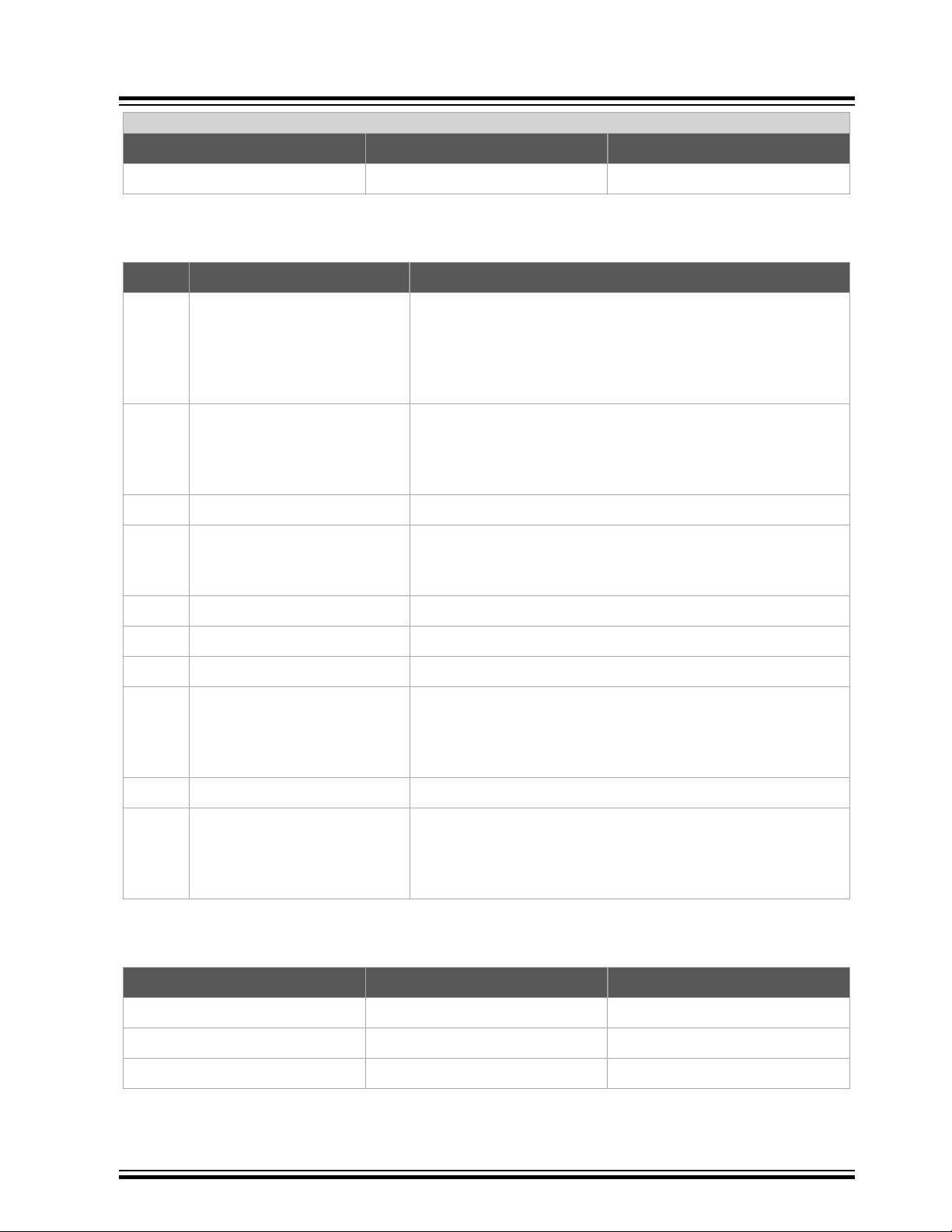

Table 1-1. Power Supply Requirements

Parameter Condition Min. Typ. Max. Unit

DC Mains Voltage Range DC Jack Connector, J8 6 - 30 V

Maximum Input Current DC Jack Connector, J8 590

Isolation Voltage PLC coupling transformer 3000 V

Note that the PL360G55CB-EK can be supplied with several power sources. For more information about

the power supply system, see section 3.3.6 Power Supply System.

DC

1

mA

AC

Note:

1. Board supplied with 6 VDC, transmission against very low impedance (2Ω) and all peripherals are

on.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 4

Page 5

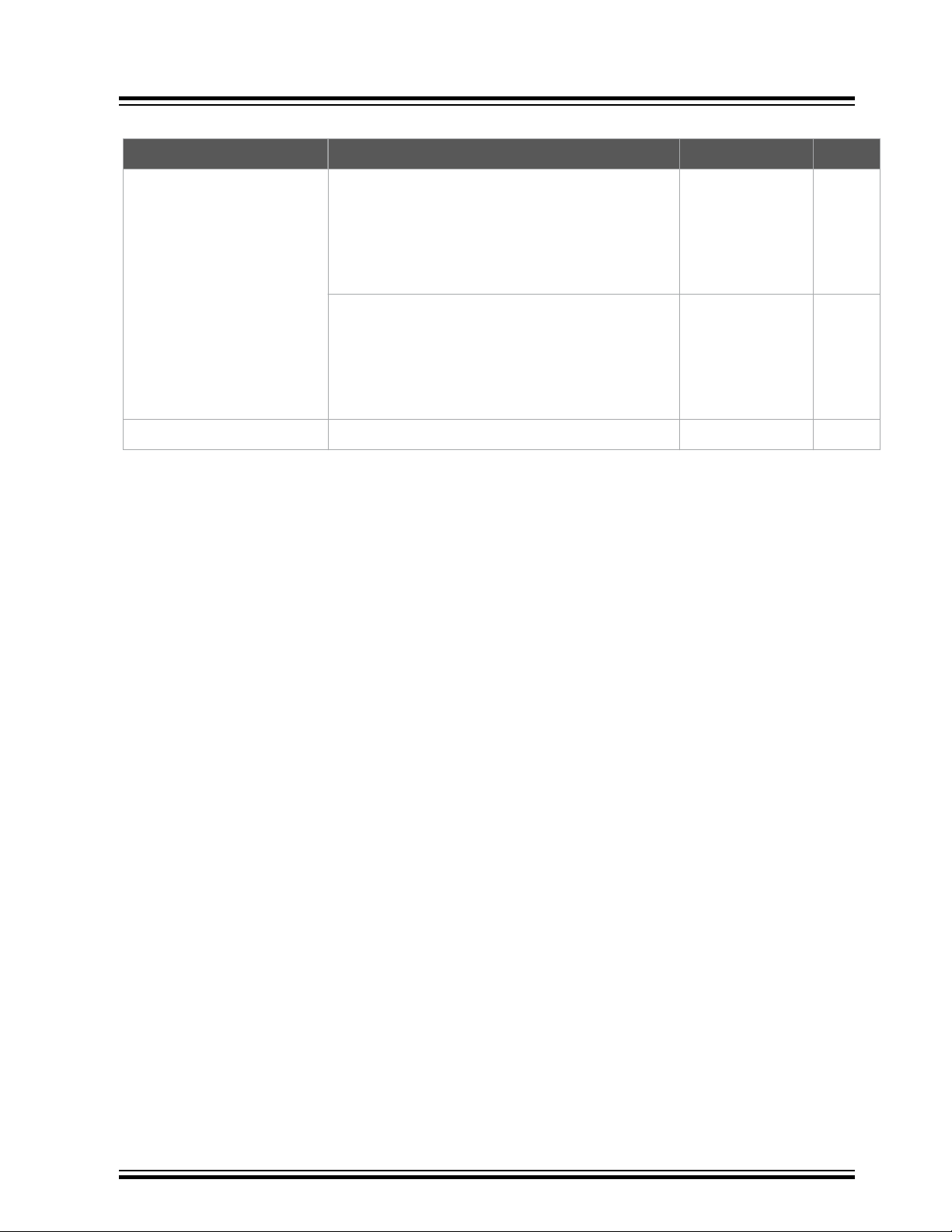

Table 1-2. Power Consumption

Parameter Condition Consumption Unit

Low Impedance Load (2Ω LISN, see Figure C.1

TX Power Consumption

High Impedance Load (CISPR LISN, see Figure

Evaluation Kit Specifications

FW: G3 CEN-B PHY TX Test Console

Application.

of ITU-T G.9901).

Measured on 12V DC/DC output.

FW: G3 CEN-B PHY TX Test Console

Application.

5 of EN 50065-1).

Measured on 12V DC/DC output.

PL360G55CB-EK

1

1932

322

1

mW

mW

RX Power Consumption Measured on 3.3V DC/DC output 264

Notes:

1. These measurements were taken running the PHY TX Test Console project with a default

configuration in TX and RX modes, and correspond to the whole PCBA design and not only to

PL360 and SAMG55J19 devices. All PCB is supplied in the worst consumption conditions (board is

supplied with a minimum input voltage, 6 VDC) and emitting in CENELEC B-band. Refer to PL360

and SAMG55 datasheets for their respective power consumption.

1

mW

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 5

Page 6

2. Getting Started

WARNING

2.1 Powering-Up the Board

Unpack and inspect the kit carefully.

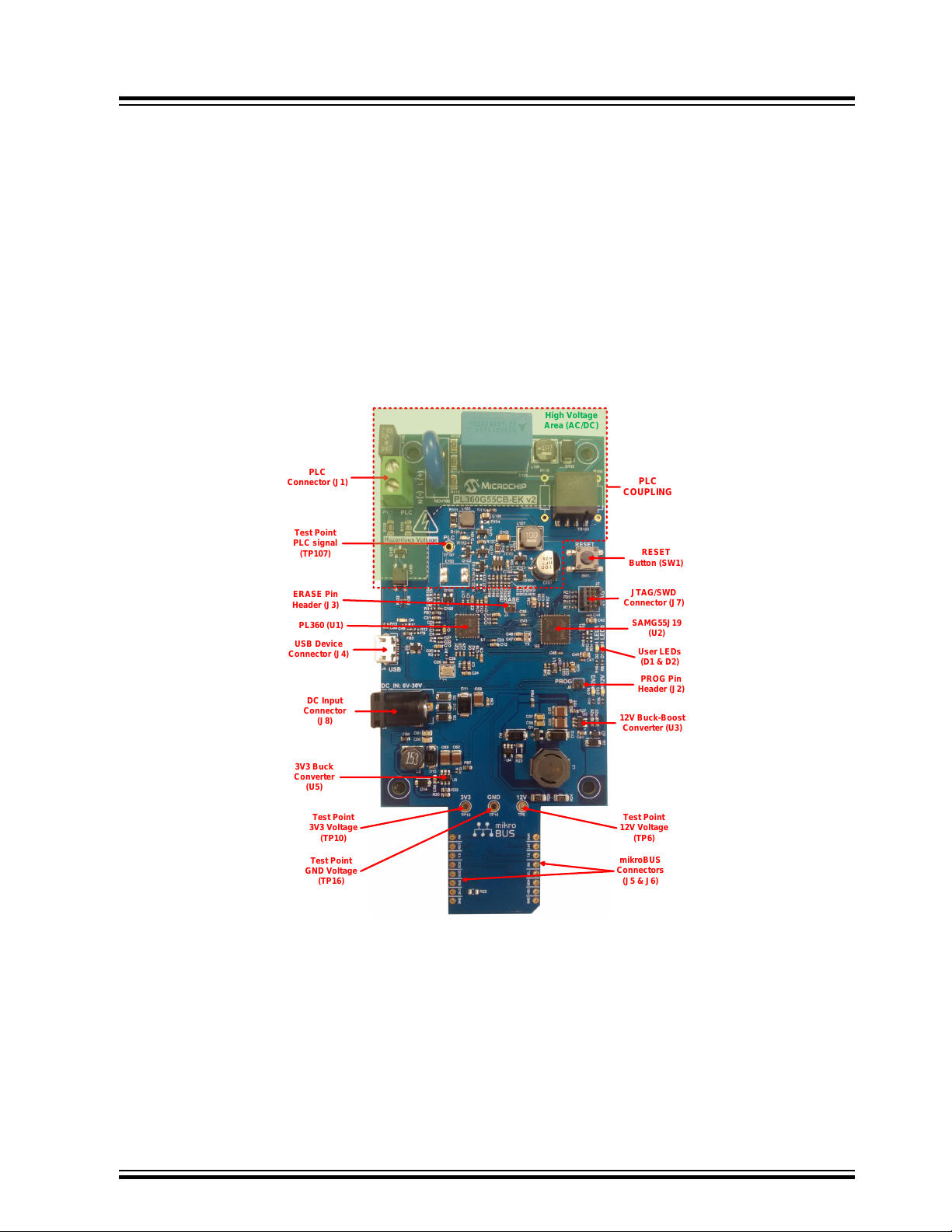

Figure 2-1. Unpacked PL360G55CB-EK

PL360G55CB-EK

Getting Started

Kit contents are covered by anti-static foam. The PL360G55CB-EK board is shipped in an anti-static

shielding bag.

The board must not be subject to high electrostatic discharge. We recommend using a

grounding strap or similar ESD protective device when handling the board in hostile ESD

environments. Avoid touching the components’ pins or any other metallic elements on the

board.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 6

Page 7

Figure 2-2. PL360G55CB-EKv2 Board Top View

PL360G55CB-EK

Getting Started

Take into account that the connectors to supply the board are different than the one for PLC signals. The

board can be supplied by three different ways:

• +5V from USB Micro-B connector (J4)

• +5V from mikroBUS connector (J6)

• DC voltage (from +6V to +30V) from DC Jack connector (J8)

2.2 Running Preloaded Firmware

Once the board is supplied, LEDs will show activity. The PL360G55CB-EK board is delivered with a preprogrammed application in SAMG55 Flash memory: the G3-PLC PHY Tester for CENELEC B-Band. PLC

communications are developed for CENELEC B-Band in AC or DC voltage grid.

The kit includes a USB 2.0 type A to Micro-B cable that can be used to connect the board to a computer.

Connect a suitable cable in the PLC connector (J1) and plug it to an AC/DC voltage grid to communicate.

By means of the PLC PHY Tester PC application, it is possible to send and receive PLC messages using

the PHY layer in the CENELEC B-Band according to the binary flashed in PL360G55CB-EK board.

2.3 Code and Technical Support

Firmware developers can not only run the given example code, but also implement their own applications

based on the provided firmware stacks.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 7

Page 8

PL360G55CB-EK

Getting Started

Please note that the latest software code, documentation and support materials are available online.

Follow instructions described in the welcome letter for more information.

For any technical support requests, please visit http://support.microchip.com.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 8

Page 9

3. PL360G55CB-EK Board

JTAG/SWD

Connector (J7)

mikroBUS

Connectors

(J5 & J6)

USB Device

Connector (J4)

ERASE Pin

Header (J3)

Test Point

12V Voltage

(TP6)

Test Point

3V3 Voltage

(TP10)

PROG Pin

Header (J2)

RESET

Button (SW1)

PLC

Connector (J1)

Test Point

PLC signal

(TP107)

DC Input

Connector

(J8)

PL360 (U1)

3V3 Buck

Converter

(U5)

12V Buck-Boost

Converter (U3)

User LEDs

(D1 & D2)

SAMG55J19

(U2)

PLC

COUPLING

Test Point

GND Voltage

(TP16)

High Voltage

Area (AC/DC)

3.1 Overview

This section summarizes the PL360G55CB-EK board design. It introduces system-level concepts, such

as power supply, MCU, PLC coupling, peripherals and interface board.

PL360G55CB-EK is a PLC modem board based on the PL360 transceiver and on the SAMG55 ARM

Cortex-M4 RISC processor. This evaluation board can be used as a PLC modem reference design for

modular architectures; or, in any case to provide a platform to develop a complete communications

system over PLC technology.

Figure 3-1. PL360G55CB-EKv2 Board Description

PL360G55CB-EK

PL360G55CB-EK Board

3.2 Features List

The PL360G55CB-EK board includes the following features:

• PL360 PLC Transceiver:

© 2019 Microchip Technology Inc.

– Multi-protocol PLC modem:

• G3-PLC

• PRIME 1.3 and PRIME 1.4

User Guide

DS50002871A-page 9

Page 10

PL360G55CB-EK

PL360G55CB-EK Board

– One SPI peripheral to external MCU

– Zero-Cross Detection

– Embedded PLC Analog Front End (AFE)

– Low-power consumption in transmission and reception

• SAMG55 MCU:

– Core:

• ARM Cortex-M4 running at up to 120 MHz

• Memory Protection Unit (MPU)

• DSP instruction set

• Floating-Point Unit (FPU)

• Thumb®-2 instruction set

• Instruction and Data Cache Controller with 2 Kbytes cache memory

• Up to 512 Kbytes of embedded Flash, 176 Kbytes of embedded SRAM, 8 Kbytes of ROM

– Memories:

• Up to 512 Kbytes of embedded Flash

• Up to 176 Kbytes of embedded SRAM

• Up to 8 Kbytes of ROM with embedded bootloader, single-cycle access at full speed

• PLC Coupling designed to communicate in CENELEC B-Band (95 kHz to 125 kHz)

• A 3.3V buck converter for the digital circuitry and a 12V Buck-Boost converter for supplying the PLC

Power Amplifier. It allows supply of the board with any of the three different power sources

• Mains Zero-Crossing Detector Circuit

• Peripherals:

– Supply monitor

– User LEDs

– Reset button

– Chip Erase jumper

– Chip Programming jumper

• Interfaces:

– USB Device

– mikroBUS add-on connectors

– SWD/JTAG debugging port

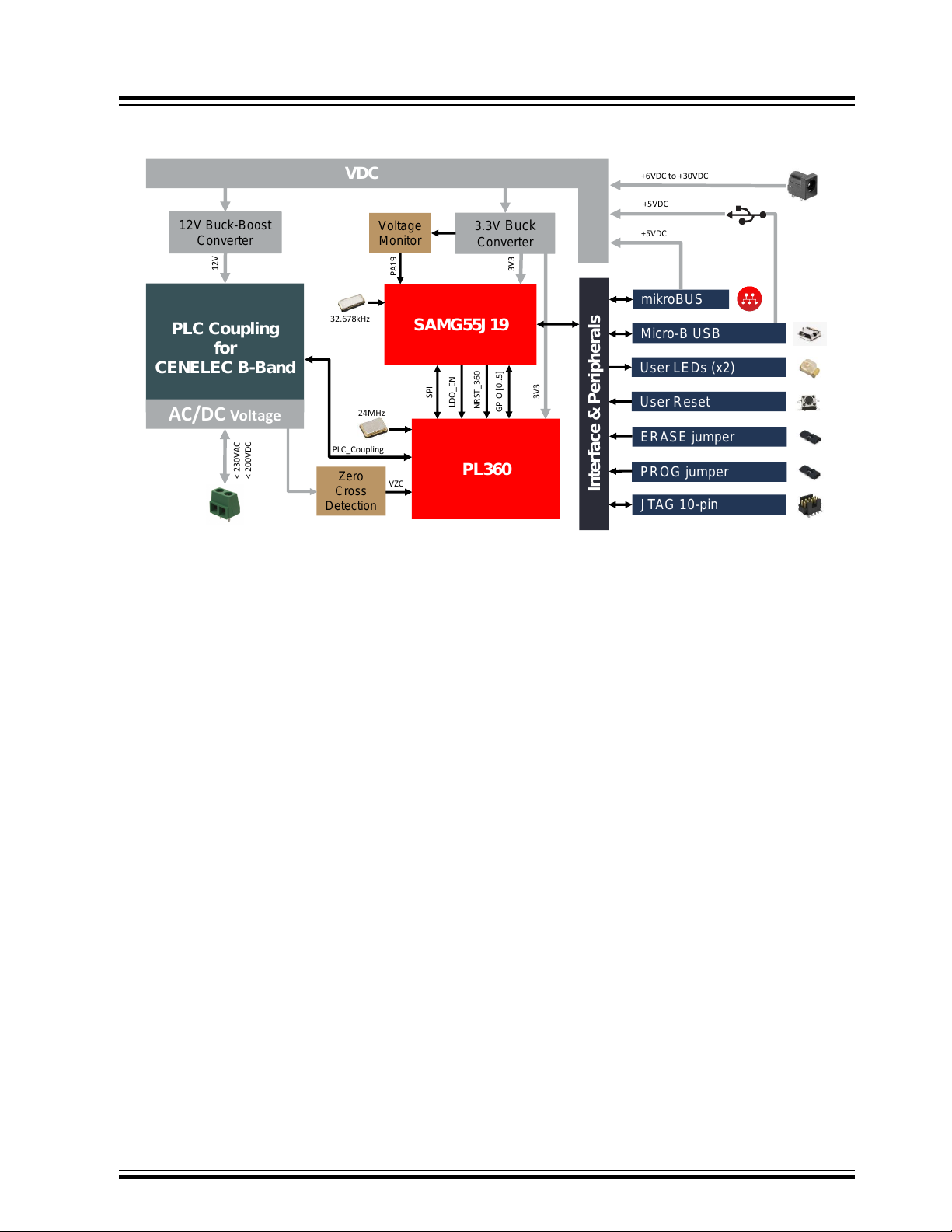

3.2.1 PL360G55CB-EK Block Diagram

The following figure shows the block diagram of the PL360G55CB-EK board.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 10

Page 11

Figure 3-2. PL360G55CB-EK Block Diagram

Interface & Peripherals

VDC

3.3V Buck

Converter

mikroBUS

ERASE jumper

JTAG 10-pin

User LEDs (x2)

User Reset

12V Buck-Boost

Converter

SAMG55J19

PLC Coupling

for

CENELEC B-Band

AC/DC Voltage

Zero

Cross

Detection

SPI

GPIO [0..5]

LDO_EN

NRST_360

+5VDC

< 230VAC

< 200VDC

+5VDC

PLC_Coupling

PROG jumper

+6VDC to +30VDC

PA19

PL360

VZC

Micro-B USB

32.678kHz

24MHz

Voltage

Monitor

12V

3V3

3V3

PL360G55CB-EK

PL360G55CB-EK Board

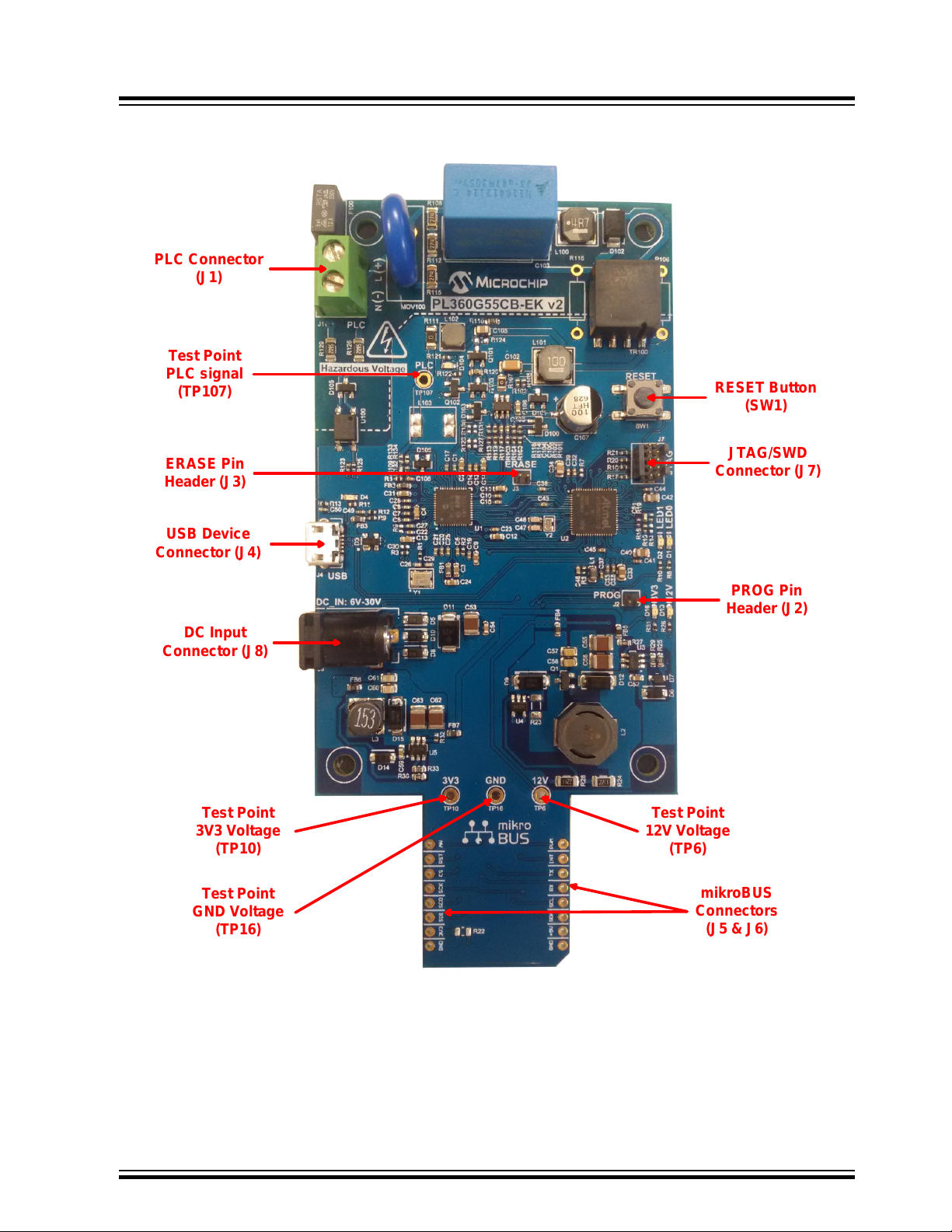

3.2.2 Interface Connection

The PL360G55CB-EK board includes hardware interfaces such as jumpers, connectors and a button.

Following figure shows an overview of the connectors, jumpers and button of the PL360G55CB-EK

board.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 11

Page 12

Figure 3-3. PL360G55CB-EK Connectors, Button and Jumpers Overview

JTAG/SWD

Connector (J7)

mikroBUS

Connectors

(J5 & J6)

USB Device

Connector (J4)

ERASE Pin

Header (J3)

Test Point

12V Voltage

(TP6)

Test Point

3V3 Voltage

(TP10)

PROG Pin

Header (J2)

RESET Button

(SW1)

PLC Connector

(J1)

Test Point

PLC signal

(TP107)

DC Input

Connector (J8)

Test Point

GND Voltage

(TP16)

PL360G55CB-EK

PL360G55CB-EK Board

3.2.2.1 Connectors

The PL360G55CB-EK board includes the following connectors:

1. PLC connector (for an AC/DC grid), J1.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 12

Page 13

Table 3-1. PLC Connector (for an AC/DC grid), J1

Pin Signal Name Description

1 L / +VDC Line / Positive Voltage

2 N / -VDC Neutral / Negative Voltage

2. Micro-B female USB connector, J4.

Table 3-2. USB Device Connector, J4

Pin Signal Name Description

1 VUSB 5V power

2 D+ Data Plus

3 D- Data Minus

4 ID On the Go Identification

5 GND Ground

PL360G55CB-EK

PL360G55CB-EK Board

3. mikroBUS add-on connectors, J5 and J6.

Table 3-3. mikroBUS Connector, J5

Pin Mnemonic Description

1 AN Analog

2 RST Reset

3 CS SPI Chip Select

4 SCK SPI Clock

5 SDO SPI Master Input Slave Output

6 SDI SPI Master Output Slave Input

7 3V3 VCC - 3.3V power

8 GND Reference Ground

Table 3-4. mikroBUS Connector, J6

Pin Mnemonic Description

1 PWM PWM

2 INT Hardware Interrupt

3 TX UART Transmit

4 RX UART Receive

5 SCL I2C Clock

6 SDA I2C Data

7 5V VCC - 5V power

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 13

Page 14

...........continued

Pin Mnemonic Description

8 GND Reference Ground

4. JTAG/SWD 10-pin connector for SAMG55J19, J7.

Table 3-5. SW-DP Connector, J7

Pin Mnemonic Description

This is the target reference voltage. It is used to check if the

target has power, to create the logic-level reference for the

1 VCC

2 SWDIO/TMS

input comparators, and to control the output logic levels to the

target. It is normally fed from VCC on the target board and

must not have a series resistor.

Serial Wire Input Output / Test Mode Select. JTAG mode set

input of target CPU. This pin should be pulled up on the

target. Output signal that sequences the target's JTAG state

machine, sampled on the rising edge of the TCK signal.

PL360G55CB-EK

PL360G55CB-EK Board

3 GND Ground.

Serial Wire Clock / Test Clock. JTAG clock signal to target

4 SWDCLK/TCK

5 GND Ground.

6 SWO/TDO Test Asynchronous Data Out from target CPU.

7 KEY -

8 NC/TDI

9 GND Detect Ground.

10 nRESET

5. DC Input connector, J8.

Table 3-6. DC Input Connector, J8

CPU (output timing signal, for synchronizing test logic and

control register access).

Not Connected / Test Data Input. JTAG data input of target

CPU (serial data output line, sampled on the rising edge of the

TCK signal). It is recommended that this pin is pulled to a

defined state on the target board.

JTAG Reset (active-low output signal that resets the target).

Output from SAM-ICE™ to the Reset signal on the target JTAG

port. This pin is normally pulled HIGH on the target to avoid

unintentional resets when there is no connection.

Pin Signal Name Description

1 DC_IN DC Input voltage (6 - 30V)

2 GND Ground

3 - -

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 14

Page 15

3.2.2.2 Jumper Configurations

The following table describes the functionality of the jumpers.

Table 3-7. Jumper Configuration

Jumper Label Default Setting Function

PL360G55CB-EK

PL360G55CB-EK Board

J3 ERASE Open

J2 PROG Open

Note: Pitch jumpers are 1.27 mm (0.050").

3.2.2.3 Test Points

Some test points (probes and pads) have been placed on the PL360G55CB-EK board for the verification

of the main signals.

Table 3-8. Test Point Probes

Table 3-9. Test Point Pads

Reference Function Reference Function

SAMG55J19 Flash memory code erase

(closed = erase).

SAMG55J19 Flash memory upgrade

(closed = programming).

Reference Function

TP6 12V

TP10 3V3

TP16 GND

TP107 PLC signal

TP1 PROG TP24 PL360 pin PA7

TP2 ERASE TP25 PL360 pin PA8

TP3 SAMG55J19 pin PA12, LED D1 TP26 PL360 pin PA9

TP4 SAMG55J19 pin PA15, LED D2 TP27 PL360 pin PA0

TP5 NRST TP28 PL360 pin PA3

TP7 12V TP100 PL360 pin TXRX1

TP8 DC_IN TP101 P Channel MOSFET

TP9 VDC TP102 Line

TP11 3V3 TP103 N Channel MOSFET

TP12 Ground TP104 Neutral

TP13 Ground TP105 Zero cross signal, VZC

TP14 Ground TP106 PL360 pin TXRX0

TP15 Ground TP108 PLC RX

TP23 PL360 pin PA6 - -

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 15

Page 16

3.3 Hardware Description – System

13

24MHz

Y1

GND

MISO

MOSI

SCK

CS

GPIO3

GPIO2

GPIO1

GPIO0

GPIO5

GPIO4

GPIO[0..5]

GND

GND AGND

0.1uFC15

0.1uFC16

0.1uFC17

0.1uFC18

0.1uFC19

0.1uFC20

0.1uFC21

0.1uFC22

GND

4.7uFC13

4.7uFC12

4.7uFC11

0.1uFC10

4.7uFC9

3V3

3V3

2.2uFC2

2.2uFC3

0.1uFC1

0.1uFC5

GND

0.1uFC25

4.7uFC24

GND

470R

FB1

0.1uFC27

0.1uFC28 AGND

AGC

TXRX0

EMIT0

EMIT1

EMIT2

EMIT3

EMIT[0..3]

10000pFC7

0.022uFC8

0.022uFC6

AGND

VIN

3V3A

1uFC30

10kR3

GND

3V3

NRST_PL360

GND

LDOEN

TXRX1

10000pFC4

VZC

10k

R2

4.7uFC14

0.1uFC23

0RR1

PA3

16

VIN

39

VREFN

43

VREFP

41

VREFC

42

PA0

13

NRST

1

XIN

2

XOUT

3

PA7/SPCK

18

PA8/MOSI

19

PA9/MISO

20

EMIT0

23

EMIT1

25

EMIT2

27

EMIT3

31

PA11/TXRX1

33

PA10/TXRX0

34

AGC

35

PA6/NPCS0

17

TST

48

PA4/SWDIO

10

PA5/SWCLK

11

PA1

14

PA2/TRACESWO

15

PA12/VZC

47

PL360B

U1A

VDDIO

4

VDDCORE

7

VDDIO

12

VDDIO

21

VDDIO

24

VDDPLL

5

VDDIN_AN

40

VDDIN_AN

45

VDDIN

8

AGND

44

AGND

38

GND

37

VDDIO

26

VDDIO

28

VDDIO

32

VDDCORE

29

VDDIO

36

VDDIO

46

GND

30

GND

22

GNDOSC

6

LDO ENABLE

9

GND

49

PL360B

U1B

TP100

33pFC26

33pFC29

3.3.1 PL360

The PL360G55CB-EK board is equipped with a PL360 device in 48-pin QFN (0.4 mm pitch).

PL360 is a multi-protocol (G3-PLC, PRIME 1.3 and PRIME 1.4) modem for Power Line Communication

implementing a very flexible architecture, which allows implementation of standard and customized PLC

solutions.

PL360 transceiver has been conceived to be easily managed by an external Microchip MCU through a 4line standard Serial Peripheral Interface (SPI) accessing the internal peripheral registers. Two additional

signals are used by the host microcontroller to control the PL360 transceiver: LDO enable and NRST.

Figure 3-4. PL360 PLC Modem

PL360G55CB-EK

PL360G55CB-EK Board

Important: Some GPIOs of PL360 device must be connected to the external MCU for the right

implementation of the firmware of the PLC standard. G3-PLC requires a GPIO for an external

interrupt line (EINT) and PRIME requires two GPIOs for an external interrupt and carrier detect

indication lines (EINT and CD). Please, check this point with the firmware user guide.

Remember: The PL360 control lines from MCU perspective (SPI lines, EINT in GPIO3 and CD

in GPIO0) are accessible via test points.

Microchip provides highly efficient, reduced BOM reference designs for different coupling options,

targeting common configurations in all PLC bands (<500 kHz) complying with existing regulations.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 16

Page 17

Figure 3-5. PLC Bands Supported by PL360

G3-PLC

CEN-A

0

100 200 300 400 500

Frequency

(kHz)

G3-

PLC

CEN-B

CENELEC [3...148,5 kHz]

G3-PLC ARIB

ARIB [10...450 kHz]

G3-PLC FCC

FCC [10...490 kHz]

USA

JAPAN

EUROPE

CH3 CH4 CH5 CH6 CH7 CH8

CH3 CH4 CH5 CH6 CH7

PRIME 1.4

CH1 CH2

PRIME 1.3 & 1.4

PRIME 1.4

PL360G55CB-EK

PL360G55CB-EK Board

For a further description of the PL360 device see the corresponding PL360 datasheet.

3.3.2 SAMG55J19

The PL360G55CB-EK board is equipped with a SAMG55J19 device in 64-pin QFN. The SAM G55

devices are general-purpose low-power microcontrollers which offer high performance, processing power

and small package options combined with a rich and flexible peripheral set.

The Microchip's SAM G55 embeds a Cortex-M4 CPU with an FPU (floating point unit). This ensures

maximum throughput. This is very important as it allows minimization of the active power consumption

and getting to sleep faster in order to reduce the overall power consumption. Additionally, the device has

30 DMA channels, which gives extremely high throughput.

The SAMG55J19 operates at a maximum speed of 120 MHz and features 512 Kbytes of Flash and up to

176 Kbytes of SRAM. The peripheral set includes eight flexible communication units comprising of

USARTs, SPIs and I2C-bus interfaces (TWIs), two three-channel general-purpose 16-bit timers, two I2S

controllers, one-channel pulse density modulation, one 8-channel 12-bit ADC, one Real-Time Timer

(RTT) and one Real-Time Clock (RTC), both located in the ultra-low power backup area.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 17

Page 18

Figure 3-6. SAMG55 Microcontroller

EP

65

TEST

10

RESET

2

JTAGSEL

63

VREFP

28

VDDUSB

26

VDDOUT

30

VDDIO

64

VDDIO

32

VDDIO

31

VDDIO

27

VDDIO

1

GND

53

GND

29

GND

13

VDDCORE

45

VDDCORE

9

PA08/XOUT3 2

12

PA07/XIN32

11

PA17/AD0

33

PA18/AD1

34

PA19/AD2

35

PA20/AD3

36

PB08/XOUT

59

PB09/XIN

60

PB00/AD4

37

PB01/AD5

38

PB02/AD6

39

PB03/AD7

40

PA00

6

PA01

7

PA02

61

PA03

5

PA04

4

PA05

8

PA06

17

PA09

49

PA10

48

PA11

44

PA12

43

PA13

42

PA14

41

PA15

22

PA16

18

PA21

25

PA22

24

PA23

23

PA24

58

PA25

56

PA26

52

PA27

51

PA28

21

PA29

20

PA30

19

PA31

16

PB10

46

PB11

47

PB12

3

PB13

57

PB14

15

PB15

14

PB04/TDI

62

PB05/TDO/TR ACESWO

50

PB06/TMS/SWDIO

54

PB07/TCK/SWTCK

55

ATSAMG55J19B

U2

PA2

PA5

PA3

PA6

PA4

PA24

PA23

PA9

PA10

PA12

PA11

PA13

PA14

PA19

PA20

PA0

PA1

PA[0..31]

PA16

PA15

PA17

PA18

PA27

PA26

PA25

PA[0..31]

PB2

PB5

PB3

PB6

PB4

PB7

PB8

PB9

PB10

PB12

PB11

PB13

PB14

PB0

PB1

PB15

PB[0..15]

PB[0..15]

PA28

PA31

PA30

PA29

GND

PB[0..15]

PB[0..15]

PB[0..15]

PB[0..15]

PA[0..31]

PA[0..31]

PB00 -> SP I0_CL K (mikr oBUS)

PB01 -> No t Conn ected

PB02 -> T WCK1 (m ikr oBUS)

PB03 -> T WD1 (mik roBUS)

PB04 -> T DI

PB05 -> T DO/TRA CESWO

PB06 -> T MS/SWDI O

PB07 -> T CK/SWC LK

4.7uF

C40

4.7uF

C42

0.1uF

C43

0.1uF

C41

0.1uF

C35

0.1uF

C36

0.1uF

C45

0.1uF

25V

0402

C32

GND

NRST

0R

R7

3V3

0.1uF

C44

VDDCORE

GND

Near pin 30

GND

ADVREF

GND

GND

Near pin 28

ADVREF

3V3

1R

R6

4.7uF

C46

4.7uF

C34

4.7uF

C33

0.1uF

C37

0.1uF

C38

0.1uF

C39

GND

3V3

3V3

USB_DP

USB_DN

USB_Device

USB_Device

32.768Khz

Y2

22pF

C48

22pF

C47

10uH

L1

EP

65

TEST

10

RESET

2

JTAGSEL

63

VREFP

28

VDDUSB

26

VDDOUT

30

VDDIO

64

VDDIO

32

VDDIO

31

VDDIO

27

VDDIO

1

GND

53

GND

29

GND

13

VDDCORE

45

VDDCORE

9

PA08/XOUT3 2

12

PA07/XIN32

11

PA17/AD0

33

PA18/AD1

34

PA19/AD2

35

PA20/AD3

36

PB08/XOUT

59

PB09/XIN

60

PB00/AD4

37

PB01/AD5

38

PB02/AD6

39

PB03/AD7

40

PA00

6

PA01

7

PA02

61

PA03

5

PA04

4

PA05

8

PA06

17

PA09

49

PA10

48

PA11

44

PA12

43

PA13

42

PA14

41

PA15

22

PA16

18

PA21

25

PA22

24

PA23

23

PA24

58

PA25

56

PA26

52

PA27

51

PA28

21

PA29

20

PA30

19

PA31

16

PB10

46

PB11

47

PB12

3

PB13

57

PB14

15

PB15

14

PB04/TDI

62

PB05/TDO/TR ACESWO

50

PB06/TMS/SWDIO

54

PB07/TCK/SWTC K

55

U2

PA2

PA5

PA3

PA6

PA4

PA24

PA23

PA9

PA10

PA12

PA11

PA13

PA14

PA19

PA20

PA0

PA1

PA[0..31]

PA16

PA15

PA17

PA18

PA27

PA26

PA25

PA[0..31]

PB2

PB5

PB3

PB6

PB4

PB7

PB8

PB9

PB10

PB12

PB11

PB13

PB14

PB0

PB1

PB15

PB[0..15]

PB[0..15]

PA28

PA31

PA30

PA29

GND

PB[0..15]

PB[0..15]

PA[0..31]

PA[0..31]

4.7uF

C40

4.7uF

C42

0.1uF

C43

0.1uF

C41

0.1uF

C35

0.1uF

C36

0.1uF

C45

0.1uF

25V

0402

C32

GND

NRST

0R

R7

3V3

0.1uF

C44

VDDCORE

GND

Near pin 30

GND

Near pin 28

ADVREF

4.7uF

C34

4.7uF

C33

0.1uF

C37

0.1uF

C38

0.1uF

C39

GND

3V3

3V3

USB_DP

USB_DN

USB_Device

USB_Device

3V3

PB12

Er ase pin

32.768Khz

Y2

22pF

C48

22pF

C47

1 2

J3

PRO G pin h eader

1 2J2PA18

GND

TP1

TP2

Procedure for SAMG55 chiperase:

1) Connect the two pins of the he ader w

2) Remove power fro m the kit

3) Connect pow er to the kit

4) Remove jumper

The ERASE pin has an internal pul l-dow

not configu red as GPIO in the user appl

Procedure for SAMG55 programming:

1) Power off the board

2) Place jumper in PROG header

3) Power on th e board

4) Remove jumper aft er programming

The PROG pin has an internal pull -up if

not configu red as GPIO in the user appli

PL360G55CB-EK

PL360G55CB-EK Board

Table 3-10 and Table 3-11 summarize the functionality of each input/output line of the SAMG55J19

microcontroller in PL360G55CB-EK board.

Table 3-10. Pinout of SAMG55J19 PortA in PL360G55CB-EK Board

I/O LINE Function I/O LINE Function

PA0 PL360 GPIO3 PA16 PL360 GPIO4

PA1 PL360 GPIO2 PA17 AD0 (mikroBUS)

PA2 Not Connected PA18 PROG

PA3 PL360 MOSI PA19 Voltage Monitor

PA4 PL360 MISO PA20 Not Connected

PA5 PL360 GPIO1 PA21

PA6 PL360 GPIO5 PA22 USB Device Diff Positive

PA7 XIN32 PA23 TIOA1 (mikroBUS)

© 2019 Microchip Technology Inc.

PA8 XOUT32 PA24 Not Connected

PA9 SPI0 MISO (mikroBUS) PA25 SPI0 CS0 (mikroBUS)

PA10 SPI0 MOSI (mikroBUS) PA26 Not Connected

PA11 USB Detect PA27 Not Connected

PA12 User LED0 PA28 Not Connected

PA13 Not Connected PA29 PL360 NRST

PA14 WKUP8 (mikroBUS) PA30 PL360 LDO_EN

User Guide

USB Device Diff

Negative

DS50002871A-page 18

Page 19

...........continued

13

24MHz

Y1

GND

MISO

MOSI

SCK

CS

GPIO3

GPIO2

GPIO1

GPIO0

GPIO5

GPIO4

GPIO[0..5]

GND

AGC

TXRX0

EMIT0

EMIT1

EMIT2

EMIT3

EMIT[0..3]

10000pFC7

0.022uFC8

0.022uFC6

AGND

VIN

1uFC30

10kR3

GND

3V3

NRST_PL360

TXRX1

10000pFC4

VZC

0RR1

PA3

16

VIN

39

VREFN

43

VREFP

41

VREFC

42

PA0

13

NRST

1

XIN

2

XOUT

3

PA7/SPCK

18

PA8/MOSI

19

PA9/MISO

20

EMIT0

23

EMIT1

25

EMIT2

27

EMIT3

31

PA11/TXRX1

33

PA10/TXRX0

34

AGC

35

PA6/NPCS0

17

TST

48

PA4/SWDIO

10

PA5/SWCLK

11

PA1

14

PA2/TRACESWO

15

PA12/VZC

47

PL360B

U1A

TP100

33pFC26

33pFC29

I/O LINE Function I/O LINE Function

PA15 User LED1 PA31 PL360 GPIO0

Table 3-11. Pinout of SAMG55J19 PortB in PL360G55CB-EK Board

I/O LINE Function I/O LINE Function

PB0 SPI0 CLK (mikroBUS) PB8 Not Connected

PB1 Not Connected PB9 Not Connected

PB2 TWCK1 (mikroBUS) PB10 TXD4 (mikroBUS)

PB3 TWD1 (mikroBUS) PB11 RXD4 (mikroBUS)

PB4 TDI PB12 ERASE

PB5 TDO/TRACESWO PB13 PL360 SCK

PB6 TMS/SDWIO PB14 PL360 CS

PB7 TCK/SWCLK PB15 Not Connected

PL360G55CB-EK

PL360G55CB-EK Board

The right implementation of the PLC standards require some GPIOs of the transceiver PL360 connected

to the SAMG55. G3-PLC requires a GPIO for an external interrupt line (PA0 of SAMG55) and PRIME

requires two GPIOs for an external interrupt and carrier detect (PA0 and PA31 of SAMG55) indication

lines. Please check this point with the firmware user guide.

For a further description of the SAMG55J19 capabilities see the corresponding SAMG55 datasheet.

3.3.3 Clock Circuitry

Besides the embedded RC oscillators of SAMG55J19, two crystal oscillators are assembled on the

PL360G55CB-EK board to obtain a more precise and stable system clock reference:

• A 24 MHz clock signal, Y1, generated for the PLC transceiver PL360

• A low-power 32.768 kHz crystal oscillator, Y2, for the SAMG55J19

Figure 3-7. 24 MHz Crystal Oscillator Scheme

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 19

Page 20

Figure 3-8. 32.768 kHz Crystal Oscillator Scheme

EP

65

TEST

10

RESET

2

JTAGSEL

63

VREFP

28

VDDUSB

26

VDDOUT

30

VDDIO

64

VDDIO

32

VDDIO

31

VDDIO

27

VDDIO

1

GND

53

GND

29

GND

13

VDDCORE

45

VDDCORE

9

PA08/XOU T32

12

PA07/XIN3 2

11

PA17/AD0

33

PA18/AD1

34

PA19/AD2

35

PA20/AD3

36

PB08/XOUT

59

PB09/XIN

60

PB00/AD4

37

PB01/AD5

38

PB02/AD6

39

PB03/AD7

40

PA00

6

PA01

7

PA02

61

PA03

5

PA04

4

PA05

8

PA06

17

PA09

49

PA10

48

PA11

44

PA12

43

PA13

42

PA14

41

PA15

22

PA16

18

PA21

25

PA22

24

PA23

23

PA24

58

PA25

56

PA26

52

PA27

51

PA28

21

PA29

20

PA30

19

PA31

16

PB10

46

PB11

47

PB12

3

PB13

57

PB14

15

PB15

14

PB04/TDI

62

PB05/TDO/ TRACESWO

50

PB06/TMS/SWDI O

54

PB07/TCK/SWT CK

55

ATSAMG55J19B

U2

PA2

PA5

PA3

PA6

PA4

PA24

PA23

PA9

PA10

PA12

PA11

PA13

PA14

PA19

PA20

PA0

PA1

PA[0..31]

PA16

PA15

PA17

PA18

PA27

PA26

PA25

PA[0..31]

PB2

PB5

PB3

PB6

PB4

PB7

PB8

PB9

PB10

PB12

PB11

PB13

PB14

PB0

PB1

PB15

PB[0..15]

PB[0..15]

PA28

PA31

PA30

PA29

GND

PB[0..15]

PB[0..15]

PB[0..15]

PB[0..15]

PA[0..31]

PA[0..31]

4.7uF

C42

0.1uF

C43

0.1uF

C41

0.1uF

C35

0.1uF

C36

0.1uF

25V

0402

C32

GND

NRST

0R

R7

3V3

0.1uF

C44

VDDCORE

GND

GND

ADVREF

0.1uF

C37

0.1uF

C38

0.1uF

C39

GND

3V3

3V3

USB_DP

USB_DN

USB_Device

32.768Kh z

Y2

22pF

C48

22pF

C47

PL360G55CB-EK

PL360G55CB-EK Board

3.3.4 Reset

The reset sources of the PL360G55CB-EK board are:

• Power-on Reset function, embedded in the SAMG55 device.

• Push button reset. Both devices, SAMG55J19 and PL360, have a NRST pin: “NRST” for

SAMG55J19 and “NRST_360” for PL360. The user can manually reset the SAMG55J19, which

manages the PL360 reset, by using the push button SW1. See section 3.4.2.2 Push Buttons.

• JTAG reset from an in-circuit emulator.

3.3.5 PLC Coupling Circuitry Description

The European regulations concerning Power Line Communications are described in CENELEC standard

EN 50065. This standard applies to electrical equipment using signals in the frequency range 3 kHz to

148,5 kHz to transmit information on low voltage electrical systems, either on the public supply system or

within installations in consumers' premises. The following figure shows the different frequency bands

allocated to the different applications.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 20

Page 21

PL360G55CB-EK

PL360G55CB-EK Board

Figure 3-9. CENELEC Frequency Bands

The PL360G55CB-EK evaluation board communicates in the CENELEC B-Band frequency. The use of

frequencies in this band shall be restricted to consumer use; for example, for end-user applications such

as industrial applications.

Microchip has designed five coupling reference designs for CENELEC B-Band with variations in the BOM

cost and the communication performance. Table 3-12 summarizes the main features of the available

designs.

Table 3-12. Characteristics of PLCOUPxxx Boards for CENELEC B-Band

Board Name

PLCOUP012-

ISO

PLCOUP012-

NONISO

PLCOUP013

PLCOUP014-

ISO

PLCOUP014-

NONISO

Description

Low cost with internal

driver G3 CENELEC B

compliant

Low cost with internal

driver G3 CENELEC B

compliant

Ultra low cost with

internal driver and

non-Isolated G3

CENELEC B

compliant

G3 CENELEC B

compliant

G3 CENELEC B

compliant

Frequency

Band (kHz)

95 - 125 Single Yes -

95 - 125 Single No -

95 - 125 Single No -

95 - 125 Single Yes -

95 - 125 Single No -

Branch

Electrical

Isolation

PRIME

Channel

G3-PLC

Band

G3

CENELEC B

G3

CENELEC B

G3

CENELEC B

G3

CENELEC B

G3

CENELEC B

Applicable

Regulation

CENELEC

EN 50065

CENELEC

EN 50065

CENELEC

EN 50065

CENELEC

EN 50065

CENELEC

EN 50065

The PL360G55CB-EK board is assembled with the PLCOUP014-ISO coupling design. The goal is to

provide a cost-optimized fully-featured design according to the G3-PLC requirements. Still, the

PL360G55CB-EK board is designed to allow using all the other coupling designs by changing the

corresponding components and firmware configurations.

Important: Check the online resources from Microchip website to download the proper files

according to your desired CENELEC B-Band design.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 21

Page 22

1

2

4

3

PL360G55CB-EK

PL360G55CB-EK Board

The following figure shows the PLC Coupling assembled (PLCOUP014-ISO) which is composed of four

sub-circuits:

1. Transmission Stage

2. Filtering Stage

3. Coupling Stage

4. Reception Stage

Figure 3-10. PLC Coupling Schematic on PL360G55CB-EK Board

Remember: PLC Coupling circuitry adds a yellow LED, D104, for visual indication of PLC

frames transmission.

The following sections describe the aim of every sub-circuit assembled in the PL360G55CB-EK board.

3.3.5.1 PLC Transmission Circuit

The transmission stage adapts the EMIT signals and amplifies them. In the PL360G55CB-EK board, see

Figure 3-10, it is a single branch composed of:

• Driver: It adapts the EMIT signals to either control the amplifier or to be filtered by the next stage

• Amplifier: A Class-D amplifier generating a square waveform from 0 to 12V

• Bias and protection: It provides a DC component and provides protection from received disturbances

The transmission stage is followed by a filtering stage.

3.3.5.2 PLC Filtering Circuit

The in-band flat response filtering stage reduces spurious emission to the limits set by the corresponding

regulation and blocks potential interferences from other transmission channels without distorting the

injected signal.

The filtering stage used in PL360G55CB-EK, see Figure 3-10, has three aims:

• Band-pass filtering of high frequency components of the square waveform generated by the

transmission stage

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 22

Page 23

• Adapt Input/Output impedance for optimal reception/transmission. This is controlled by TXRX0 signal

CAUTION

• A band-pass filtering for received signals

3.3.5.3 PLC Coupling Circuit

PLC coupling circuit connects the PLC signal directly to the mains grid or even to DC power rails without

requiring any hardware adaptation. The main purpose of the circuit is to block the mains voltage of the

grid to/from which the signal is injected/received. This is carried out in PL360G55CB-EK, see Figure 3-10,

by a high voltage capacitor, C103. Resistors R108, R112 and R115 allow the high voltage capacitor to

discharge after disconnection from mains.

PLC coupling components are designed for a maximum voltage of 230 VAC or 200 VDC.

The TR100 transformer (with turn ratio 1:1) provides galvanic isolation from mains. A non-isolated version

could easily be implemented removing TR100, soldering R106 and R116 resistors and updating the value

of L103 according to the PLCOUP014-NONISO design.

MOV100 varistor, F100 fuse and D102 TVS diode protect the coupling circuit from the overvoltages and

high transient voltages (surges and spikes) from mains.

PL360G55CB-EK

PL360G55CB-EK Board

3.3.5.4 PLC Reception Circuit

The PLC reception circuit used in PL360G55CB-EK, see Figure 3-10, is the reference design for the

reception stage and it is composed of:

• Single-pole low pass filter, R133 and C109

• Automatic Gain Control (AGC) circuit. A resistor, R134, is used to attenuate the incoming PLC signal

in case its amplitude is high enough to exceed the input dynamic range of the embedded ADC

• A resistor, R132, for impedance matching

• DC decoupling capacitor, C106

3.3.6 Power Supply System

The PL360G55CB-EK board can be powered by several power sources. Supply the board via:

• the DC jack 2.0 mm connector J8, DC_IN, with a DC source from 6V to 30V (±5%) and 4.2W

• the USB connector (+5V), J4

• the power supply pin (+5V) of mikroBUS standard

Table 3-13. Power Sources for PL360G55CB-EK Board

Power Input Voltage Requirements Power Requirements Connector Marking

DC Jack connector +6V to +30V (±5%) 4.2 Watts DC_IN

Target USB +5V

According to USB

specifications

USB

mikroBUS Power pin

(+5V)

The PL360G55CB-EK board has two voltage rails:

• +3.3V for the digital part of the PLC modem, PL360, and the SAMG55J19 MCU

• +12V to power the class-D amplifier of the PLC coupling circuit

© 2019 Microchip Technology Inc.

+5V

According to mainboard

specifications

User Guide

+5V

DS50002871A-page 23

Page 24

CAUTION

BOOST

VIN

EN

GND

VFB

SW

VDD

IN

OUT

GND

GND

3V3

GREEN

D16

GND

600mA max

3.3 Volts

VDC

GND

GND

GND

TP10

TP11

300R

R31

10k

R33

470R

FB6

BOOST

GND

2

VFB

3

EN

4

SW

6

VIN

5

U5

MCP16301

GND

1M

R32

4.7uF

50V

C62

4.7uF

50V

C63

0.1uF

C59

B140-13-F

D15

1N4448W

D14

10uF

C60

10uF

C61

15uH

L3

31.6k

R30

3V3 Buck C onver ter

470R

FB7

PL360G55CB-EK

PL360G55CB-EK Board

Note that the PL360G55CB-EK board does not provide a power supply protection circuit; only a

TVS diode is used to protect from voltage spikes at the DC rail.

The 12V voltage rail is obtained from the MC16301 buck-boost converter. For a further description about

the buck-boost converter see the MCP16301 Buck-Boost Converter User's Guide. If the VDC voltage is

always higher than 12V, it is possible to improve the power efficiency by transforming the converter mode

from buck-boost to buck, see MCP16301 datasheet for a further explanation.

Figure 3-11. 12V Voltage Design

Restriction: Note that some power sources, such as USB port and mikroBUS rail, might have

limited current capabilities and they could not supply enough current for the class-D amplifier

transmitting against low impedance values. In this case, an external AC/DC power supply with

enough current rating is recommended to maintain the PLC performance at its best. In case of

using one, we recommend a module complying to national regulations or CISPR 32:2015.

Another buck converter, MC16301, is used to generate a regulated 3.3V voltage rail required by the

PL360 modem and the SAMG55J19 MCU. For a further description about the buck converter see the

MCP16301 Buck Converter User's Guide.

Figure 3-12. 3.3V Buck Converter Design

There are one LED and two test points on each voltage rail to check whether all power supplies are

operating properly.

To avoid on board self-generated disturbances within the PLC signal band, both converters are switching

at 500 kHz fixed frequency, out of the PLC band (95 to 125 kHz).

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 24

Page 25

Tip: In case of choosing a different SMPS in the customer design, it is important to analyze its

PL360G55CB-EK

PLC

Rejection

Filter

Power

Source

(Very Low Z

for PLC signal)

PLC Coupling

Power Supply

(3V3 Buck Converter & 12V

Buck-Boost Converter)

560uH

560uH

100nF

N / DC-

L / DC+

potential interference on the PLC frequency band.

Attention: To avoid noise interferences, the switching frequency of the SMPS must be out of

the PLC band and preferably in frequencies above it to avoid harmonics influence. This is

essential to obtain a good reception performance.

3.3.6.1 PLC Rejection Filter

When the PLC coupling circuit is in parallel with the power supply circuit, the input impedance of the final

equipment could be affected. If the requirements about total input impedance are not satisfied, an

appropriate input filter is needed at the power supply input to increase the input impedance.

Apart from the input filter, it is also recommended to add a PLC rejection filter to avoid the absorption of

the PLC signals by the power supply circuit. This filter also increases the input impedance, so it helps to

achieve the requisites about input impedance.

PL360G55CB-EK

PL360G55CB-EK Board

Notice: The PL360G55CB-EK board has PLC coupling and power supply circuits separated,

so the PLC rejection filter is not included. A PLC rejection filter is needed in case of low input

impedance after connecting in the same point the PLC Coupling connector J1 and the power

source of the board.

An example of PLC rejection filter is composed of two inductance in-series (L = 560 μH) and a capacitor

in-parallel (C = 100 nF) at the power supply input as shown in the following picture.

Figure 3-13. PLC Rejection Filter Example

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 25

Page 26

3.3.7 Zero-Crossing Detector Circuit

VZC

3V3

GND

PLC+

PLC-

0R

R125

4.7k

R123

TP105

3 4

1 6

TLP183(GB-TPL,E

U100

BAT54

D105

56kR126

56kR129

PA17/AD0

33

PA18/AD1

34

PA19/AD2

35

PA20/AD3

36

PB00/AD4

37

PB01/AD5

38

PB02/AD6

39

PB03/AD7

40

PB10

PB11

47

PB12

3

PB13

57

PB14

15

PB15

14

PB04/TDI

62

PB05/TDO/TRACESWO

50

PB06/TMS/SWDIO

54

PB07/TCK/SWTCK

55

PA19

PA20

PA17

PA18

PB2

PB3

PB0

PB1

PA[0..31]

PA[0..31]

Phase identification is an important feature of devices that are connected to a Smart Grid network. A

typical implementation is based on measuring the time difference between a specific PLC frame reception

and the last zero crossing event of the mains single-phase to which the device is connected.

Important: The phase identification feature is mandatory for G3-PLC and PRIME1.4, but not

for PRIME1.3.

Figure 3-14 shows the Zero-Crossing Detection circuit used in the PL360G55CB-EK board, which

features detection of rising edges of the mains voltage. The output signal of the detection circuit “VZ

CROSS” is connected to VZ pin of PL360 and a synchronization algorithm is applied in order to obtain an

accurate measurement of the time between PLC frame reception and zero crossing events.

Figure 3-14. Zero-Crossing Detection Circuit

PL360G55CB-EK

PL360G55CB-EK Board

Notice: Designs that do not require galvanic isolation can use a simpler Zero-Crossing

Detector circuit, such as a Zener diode, instead of the previous circuit.

3.4 Hardware Description – MCU Peripherals

3.4.1 Voltage Monitor

The input pin PA19 of SAMG55J19 is used to monitor the 3.3V voltage rail through external voltage

divisors. It can be used to monitor the VDC voltage rail mounting R14 and removing R15 resistor.

Important: The R14 resistor value depends on the voltage value of the input source power.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 26

Page 27

Figure 3-15. Voltage Monitor Circuit

PA19

VDC 3V3

1k

1%

R15

10k

1%

R19

1%

R14

470pF

C51

1k1%

R16

GND

In case to sense VDC

voltage, select the right

value of the resistor, R14,

according to your voltage

value. And remove

resistor, R15.

3V3

3V3

(LED0)

(LED1)PA15

PA12

GREEN

D1

RED

D2

300R

R8

300R

R10

TP3

TP4

GND NRST

NRST

TP5

1 4

2 3

SW1

The voltage monitor circuit allows the implementation of multiple applications such as:

• Detection of fault conditions

• Detection of Low-Power mode entering conditions

• Detection of wake-up situations

3.4.2 LEDs and Buttons

The PL360G55CB-EK board is equipped with several LEDs and one user push button.

PL360G55CB-EK

PL360G55CB-EK Board

3.4.2.1 User LEDs

The PL360G55CB-EK board includes two general purpose LEDs, one green connected to PA12 (LED0)

and one red connected to PA15 (LED1).

Figure 3-16. User LEDs

In addition, this board disposes of two green LEDs, D13 and D16, connected to 12V and 3.3V supplies

for visual status of these voltages, and a yellow LED, D104, for visual indication of PLC frames

transmission.

3.4.2.2 Push Buttons

The PL360G55CB-EK board is equipped with a momentary push button switch mounted directly to the

board. When the button is pressed it will drive the SAMG55 reset line, NRST, to GND. And PA29 will drive

the PL360 reset line, NRST_PL360, to GND.

Figure 3-17. Reset Button

3.4.3 Chip Programming

The 1x2 pin-header J2 marked as “PROG” is connected to the SAMG55J19 chip input pin (PA18) and

GND. This header can be used to upgrade (using a bootloader binary file of the SAMG55J19) the PLC

stack running on the SAMG55 by the USB/serial port. See Smart Energy: Serial Bootloader User Guide

for more information.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 27

Page 28

3.4.4 Chip Erase

VUSBD

DUSB_N

GNDGND

DUSB_P

GND

GND

PA11

USB_DP

USB_DN

USB_Device

USB_Device

123450

ID D+ D- +5VGND

USB2.0 MICRO-B FEMALE

J4

GND

YELLOW

D4

300R

R11

1M

R13

27kR9

47k

R12

470RFB3

4700pF

C50

0.1uF

C49

1

2

4

3

D3

PRTR5V0U2X

GND

CAUTION

The 1x2 pin-header J3 marked as “ERASE” is connected to the SAMG55J19 chip erase pin (PB12) and

3.3V. This header can be used to re-initialize the Flash content (and some of its NVM bits) to an erased

state (all bits read as logic level 1) by placing a jumper on the header and pressing the reset switch

button. After a while, the erase jumper should be removed and the PCBA must be turned off and turned

on by disconnecting and connecting it again to the selected power supply. See section “ERASE Pin” in

the SAMG55J19 datasheet for more information.

Notice: Take into account that when Flash is erased, the bootloader application will also be

removed; therefore the SAMG55J19 device will be programmable only via JTAG.

3.5 Hardware Description – MCU Interface Ports

3.5.1 USB Device Port

The USB Device Port (UDP) is compliant with the Universal Serial Bus (USB) 2.0 full-speed device

specification. There is a USB available on the PL360G55CB-EK board that can act as both host and

device. It has a Micro-B female USB connector with the silk screen USB.

PL360G55CB-EK

PL360G55CB-EK Board

The I/O line PA11 allows the application to check if VUSBD is available.

Figure 3-18. USB Circuit

Important: Check online resources from the Microchip Website to download the drivers

according to your Operating System.

The USB connector is not isolated from mains. Please make use of proper isolation (i.e.: USB

isolator device) in case of using this connector when the board is not galvanically isolated (using

a PLC Coupling design which it is not isolated from mains). Take into account the possible noise

interference that these isolators could be adding to the PLC network. For instance, you can use

the UH401.

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 28

Page 29

3.5.2 SAMG55J SWD/JTAG Port

3V3

GND

NRST

PB6

PB7

PB5

PB4

3V3

100kR18

100kR17

100kR20

100kR21

1

2

3

4

5

6

7

8

9

10

J7

nRESET

NC/TDI

SWO/TDO

SWDCLK/TCK

SWDIO/TMSVCC

GND

GND

KEY

GNDDetect

CAUTION

The PL360G55CB-EK board includes an SWD (Serial Wire Debug) / JTAG interface port to provide

debug level access to the system-on-chip. It also embeds a serial wire trace. This connector provides the

required interface for in-circuit emulators, like the Atmel-ICE or SAM-ICE. The SW-DP/JTAG port is a 10pin, dual row, 0.1-inch male connector (J7). When using the SAM-ICE, a JTAG adapter for 20 to 10 pins

is necessary, e.g., this one.

Important: Note that the PL360G55CB-EK kit does not include either Atmel SAM-ICE or

Atmel-ICE JTAG emulators.

Please refer to the SAMG55 datasheet for further description of the JTAG debug port.

Figure 3-19. JTAG/SWD Interface Schematic

PL360G55CB-EK

PL360G55CB-EK Board

The JTAG/SWD connector is not isolated from mains. Please make use of proper isolation (i.e.:

USB isolator device) if using this connector when the board is not galvanically isolated (using a

PLC Coupling design which it is not isolated from mains). Take into account the possible noise

interference that these isolators could be adding to the PLC network. For instance, you can use

the UH401.

3.5.3 mikroBUS Connector

The PL360G55CB-EK board incorporates mikroBUS add-on connectors (J5 and J6) to integrate the

board itself as a module which is able to interface with other microcontrollers or microprocessors (main

board).

The mikroBUS standard specifies the size and shape of the add-on boards, but because of special

constraints, the board exceeds those limits although keeping the smallest size model S as a reference for

the plug-in area.

The PL360G55CB-EK board is designed to operate only from the +5V power supply rail of the mikroBUS

socket. Therefore, +3.3V power supply pin is not connected.

Important: By default, J5 and J6 headers are not populated in the board. The 8-pin headers

are included in a zip bag as kit contents.

This mikroBUS standard has a pair of 1x8 male headers with the following pinout:

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 29

Page 30

• SPI

AN

RST

CS

SCK

SDO

SDI

3V3

GND GND

5V

SDA

SCL

RX

TX

INT

PWM

5V

GND

3V3

GND

PA23

PB10

PB11

PA9

PA10

PA14

PA17

PA25

PB0

PB2

PB3

1

2

3

4

5

6

7

8

J6

1

2

3

4

5

6

7

8

J5

NRST

0R

R22

• UART

• I2C

• PWM

• Interrupt

• Analog input

• Reset

• Chip Select

• +3.3V

• +5V

• Two GND pins

Figure 3-20. mikroBUS Connector

PL360G55CB-EK

PL360G55CB-EK Board

Notice: The mikroBUS Xplained Pro is an extension board which contains the female header

to connect the mikroBUS add-on boards to the Xplained Pro MCU boards.

3.6 PL360G55CB-EK Schematics

This section contains the schematics for the PL360G55CB-EKv2 board:

• Top Level Schematic, Figure 3-21

• PL360 Schematic, Figure 3-22

• SAMG55 MCU Schematic, Figure 3-23

• Interface and Peripherals SAMG55 Schematic, Figure 3-24

• Power Supply Schematic, Figure 3-25

• PLC Coupling Schematic, Figure 3-26

User Guide

DS50002871A-page 30

© 2019 Microchip Technology Inc.

Page 31

Figure 3-21. Top Level Schematic

1

1

2

2

3

3

4

4

5

5

6

6

D D

C C

B B

A A

1 of 6

PL360G55CB-EK

01/04/2019 12: 26:12

Main.SchDoc

Project Title

Sch #: Date:

File:

Revision: Sheet

Designed with

Drawn By:

R. Navarro

Sheet Title

Top Level Schematic

Engineer:

J.L. Caceres

03-**

2

Size

B

**

PartNumber:

Altium.com

REV ECO# DESCRIPTION DATE

Top Level Schematic

PLC

VZC

PLC_Coupling

U_PL360

PL360.SchDoc

VZC

PLC_Coupling

N

L

U_PLC Coupling

PLC_Coupling.SchDoc

PA[0..31]

NRST

PB[0..15]

PLC

USB_Device

U_SAMG55

SAMG55.SchDoc

PA[0..31]

PB[0..15]

NRST

USB_Device

U_INTERFACE

Interface.SchDoc

AC/DC volt age

U_Power Supply

Power_Supply.SchDoc

12

J1

PLC Connector

PAD2 PAD4PAD3PAD1

2

Adding PROG header & minor changes 01/04/2019

1

1

2

2

3

3

4

4

5

5

6

6

D D

C C

B B

A A

2 of 6

PL360G55CB-EK

01/04/2019 12: 26:12

PL360.SchDoc

Project Title

Sch #: Date:

File:

Revision: Sheet

Designed with

Drawn By:

R. Navarro

Sheet Title

PL360 Modem

Engineer:

J.L. Caceres

03-**

2

Size

B

**

PartNumber:

Altium.com

13

24MHz

Y1

GND

MISO

MOSI

SCK

CS

GPIO3

GPIO2

GPIO1

GPIO0

GPIO5

GPIO4

GPIO[0..5]

GND

GND AGND

0RR4

0RR5

GND AGND

0.1uFC15

0.1uFC16

0.1uFC17

0.1uFC18

0.1uFC19

0.1uFC20

0.1uFC21

0.1uFC22

GND

4.7uFC13

4.7uFC12

4.7uFC11

0.1uFC10

4.7uFC9

3V3

3V3

2.2uFC2

2.2uFC3

0.1uFC1

0.1uFC5

GND

0.1uFC25

4.7uFC24

GND

470R

FB1

0.1uFC27

0.1uFC28 AGND

AGC

TXRX0

EMIT0

EMIT1

EMIT2

EMIT3

EMIT[0..3]

10000pFC7

0.022uFC8

0.022uFC6

AGND

VIN

3V3A

470RFB2

3V3

1uFC30

10kR3

GND

3V3

NRST_PL360

GND

LDOEN

VZC

PL360

MISO

MOSI

SCK

CS

GPIO[0..5]

NRST_PL360

LDOEN

PLC

PLC

EMIT[0..3]

TXRX0

TXRX1

AGC

VIN

PLC_Coupling

PLC_Coupling

MISO

MOSI

SCK

CS

GPIO[0..5]

NRST_PL360

TXRX1

LDOEN

EMIT[0..3]

TXRX0

TXRX1

AGC

VIN

VZC

10000pFC4

VZC

10k

R2

4.7uFC14

0.1uFC23

4.7uF

C31

3V3A

AGND

0RR1

TP23

MISO

MOSI

SCK

CS

TP24

TP25

TP26

TP27

TP28

GPIO3

GPIO0

PA3

16

VIN

39

VREFN

43

VREFP

41

VREFC

42

PA0

13

NRST

1

XIN

2

XOUT

3

PA7/SPCK

18

PA8/MOSI

19

PA9/MISO

20

EMIT0

23

EMIT1

25

EMIT2

27

EMIT3

31

PA11/TXRX1

33

PA10/TXRX0

34

AGC

35

PA6/NPCS0

17

TST

48

PA4/SWDIO

10

PA5/SWCLK

11

PA1

14

PA2/TRACESWO

15

PA12/VZC

47

PL360B

U1A

VDDIO

4

VDDCORE

7

VDDIO

12

VDDIO

21

VDDIO

24

VDDPLL

5

VDDIN_AN

40

VDDIN_AN

45

VDDIN

8

AGND

44

AGND

38

GND

37

VDDIO

26

VDDIO

28

VDDIO

32

VDDCORE

29

VDDIO

36

VDDIO

46

GND

30

GND

22

GNDOSC

6

LDO ENABLE

9

GND

49

PL360B

U1B

TP100

33pFC26

33pFC29

PL360G55CB-EK

PL360G55CB-EK Board

Figure 3-22. PL360 Schematic

© 2019 Microchip Technology Inc.

User Guide

DS50002871A-page 31

Page 32

Figure 3-23. SAMG55 MCU Schematic

1

1

2

2

3

3

4

4

5

5

6

6

D D

C C

B B

A A

3 of 6

PL360G55CB-EK

01/04/2019 12: 26:12

SAMG55.SchDoc

Project Title

Sch #: Date:

File:

Revision: Sheet

Designed with

Drawn By:

R. Navarro

Sheet Title

SAMG55 MCU

Engineer:

J.L. Caceres

03-**

2

Size

B

**

PartNumber:

Altium.com

SAMG55 MCU

EP

65

TEST

10

RESET

2

JTAGSEL

63

VREFP

28

VDDUSB

26

VDDOUT

30

VDDIO

64

VDDIO

32

VDDIO

31

VDDIO

27

VDDIO

1

GND

53

GND

29

GND

13

VDDCORE

45

VDDCORE

9

PA08/XOUT32

12

PA07/XIN32

11

PA17/AD0

33

PA18/AD1

34

PA19/AD2

35

PA20/AD3

36

PB08/XOUT

59

PB09/XIN

60

PB00/AD4

37

PB01/AD5

38

PB02/AD6

39

PB03/AD7

40

PA00

6

PA01

7

PA02

61

PA03

5

PA04

4

PA05

8

PA06

17

PA09

49

PA10

48

PA11

44

PA12

43

PA13

42

PA14

41

PA15

22

PA16

18

PA21

25

PA22

24

PA23

23

PA24

58

PA25

56

PA26

52

PA27

51

PA28

21

PA29

20

PA30

19

PA31

16

PB10

46

PB11

47

PB12

3

PB13

57

PB14

15

PB15

14

PB04/TDI

62

PB05/TDO/TRACESWO

50

PB06/TMS/SWDIO

54

PB07/TCK/SWTCK

55

ATSAMG55J19B

U2

PA2

PA5

PA3

PA6

PA4

PA24

PA23

PA9

PA10

PA12

PA11

PA13

PA14

PA19

PA20

PA0

PA1

PA[0..31]

PA16

PA15

PA17

PA18

PA27

PA26

PA25

PA[0..31]

PB2

PB5

PB3

PB6

PB4

PB7

PB8

PB9

PB10

PB12

PB11

PB13

PB14

PB0

PB1

PB15

PB[0..15]

PB[0..15]

PA28

PA31

PA30

PA29

GND

PB[0..15]

PB[0..15]

PB[0..15]

PB[0..15]

PA[0..31]

PA[0..31]

SAMG55 PINOUT

PA00 -> PL 360 GPI O3

PA01 -> PL 360 GPI O2

PA02 -> Not Connect ed

PA03 -> PL 360 MOSI

PA04 -> PL 360 MISO

PA05 -> PL 360 GPI O1

PA06 -> PL 360 GPI O5

PA07 -> XIN 32

PA08 -> XOUT 32

PA09 -> SPI 0_MISO (mikr oBUS)

PA10 -> SPI 0_MOSI (mikr oBUS)

PA11 -> USB Det ect

PA12 -> User LED0

PA13 -> Not Connect ed

PA14 -> WK UP8 (mik roBUS)

PA15 -> User LED1

PA16 -> PL 360 GPI O4

PA17 -> AD0 (m ikroB US)

PA18 -> PR OG

PA19 -> Volt age Mon itor

PA20 -> Not Connect ed

PA21 -> USB Device Diff_Negativ e

PA22 -> USB Device Diff_Positi ve

PA23 -> TI OA1 (mik roBUS)

PA24 -> Not Connect ed

PA25 -> SPI 0_CS0 (m ikroBUS)

PA26 -> Not Connect ed

PA27 -> Not Connect ed

PA28 -> Not Connect ed

PA29 -> PL 360 NRST

PA30 -> PL 360 LDO_E N

PA31 -> PL 360 GPI O0

PB00 -> SPI 0_CLK (mikr oBUS)

PB01 -> Not C onnected

PB02 -> TW CK1 (mik roBUS)

PB03 -> TW D1 (mikr oBUS)

PB04 -> TDI

PB05 -> TDO /TRAC ESWO

PB06 -> TM S/SWDIO

PB07 -> TC K/SWCL K

PB08 -> Not C onnected

PB09 -> Not C onnected

PB10 -> TXD4 (mikr oBUS)

PB11 -> RXD4 (mikr oBUS)

PB12 -> ER ASE

PB13 -> PL 360 SCK

PB14 -> PL 360 CS

PB15 -> Not C onnected

4.7uF

C40

4.7uF

C42

0.1uF

C43

0.1uF

C41

0.1uF

C35

0.1uF

C36

0.1uF

C45

0.1uF

25V

0402

C32

GND

MISO

MOSI

SCK

CS

GPIO[0..5]

NRST_PL360

LDOEN

NRST

NRST

NRST

0R

R7

3V3

0.1uF

C44

VDDCORE

GND

Near pin 30

GND

ADVREF

GND

GND

Near pin 28

ADVREF

3V3

1R

R6

4.7uF

C46

4.7uF

C34

4.7uF

C33

0.1uF

C37

0.1uF

C38

0.1uF

C39

GND

3V3

PA3

PA4

PB13

PB14

PA0

PA1

PA30

PA29

PA31

PA5

GPIO3

GPIO2

GPIO1

GPIO0

GPIO5

GPIO4

GPIO[0..5]

3V3

USB_DP

USB_DN

USB_Device

USB_Device

JP2

3V3

PB12

Era se pin

MISO

MOSI

SCK

CS

GPIO[0..5]

NRST_PL360

LDOEN

PLC

PLC

PA16

PA6

32.768Khz

Y2

22pF

C48

22pF

C47

1 2

J3

10uH

L1

JP1

PROG pin hea der

1 2J2PA18

GND

TP1

TP2

Procedure for SAMG55 chipe rase:

1) Place jumper in ERASE h eader

2) Power off the board

3) Power on the board

4) Remove jumper

The ERASE pin has an internal pull-down if

not configured as GP IO in the user applicat ion.

Procedure for SAMG55 progra mming:

1) Power off the board

2) Place jumper in PROG he ader

3) Power on the board

4) Remove jumper after programm ing

The PROG pin has an i nternal pull-up if

not configured as GP IO in the user applicat ion.

1

1

2

2

3

3

4

4

5

5

6

6

D D

C C

B B

A A

4 of 6

PL360G55CB-EK

01/04/2019 12: 26:12

Interface.SchDoc

Project Title

Sch #: Date:

File:

Revision: Sheet

Designed with

Drawn By:

R. Navarro

Sheet Title

Interface & Peripherals SAMG55

Engineer:

J.L. Caceres

03-**

2

Size

B

**

PartNumber:

Altium.com

Interface & Peripherals SAMG55

PB[0..15]

PA2

PA3

PA4

PA17

PA20

PA18

PA19

PA5

PA6

PA8

PA7

PA9

PA10

PA15

PA16

PA0

PA1

PA27

PA26

PA[0..31]

PA12

PA11

PA13

PA14

PA23

PA22

PA24

PA25

PA21

PA[0..31]

PA30

PA29

PA31

PA28

PB2

PB3

PB4

PB5

PB6

PB8

PB7

PB9

PB10

PB15

PB1

PB12

PB11

PB13

PB14

PB[0..15]

PB0

VUSBD

DUSB_N

GNDGND

DUSB_P

GND

GND

PA11

USB_DP

USB_DN

USB_Device

USB_Device

GND NRST

NRST

3V3

3V3

(LED0)

(LED1)PA15

PA12

Voltage M onitor

PA19

VDC 3V3

1k

1%

R15

10k

1%

R19

1%

R14

470pF

C51

1k1%

R16

Connect or for J TAG/SWD p rogra mmer/d ebugger

3V3

GND

NRST

PB6

PB7

PB5

PB4

3V3

GREEN

D1

User LE Ds

RED

D2

AN

RST

CS

SCK

SDO

SDI

3V3

GND GND

5V

SDA

SCL

RX

TX

INT

PWM

5V

GND

3V3

GND

PA23

PB10

PB11

PA9

PA10

PA14

PA17

PA25

PB0

PB2

PB3

123450

ID D+ D-+5VGND

USB2.0 MICRO-B FEMALE

J4

mikr oBUS Socket

GND

YELLOW

D4

GND

300R

R8

300R

R10

300R

R11

100kR18

100kR17

100kR20

100kR21

1M

R13

27kR9

47k

R12

470RFB3

4700pF

C50

0.1uF

C49

TP3

TP4

TP5

1 4

2 3

SW1

Reset

1

2

4

3

D3

PRTR5V0U2X

GND

1

2

3

4

5

6

7

8

J6

1

2

3

4

5

6

7

8

J5

NRST

USB

1

2

3

4

5

6

7

8

9

10

J7

nRESET

NC/TDI

SWO/TDO

SWDCLK/TCK

SWDIO/TMSVCC

GND

GND

KEY

GNDDetect

0R

R22

PA11 can be used to c heck if power is

available on the targe t USB.