Page 1

PICDEM™ Z

DEMONSTRATION KIT

USER’S GUIDE

2004 Microchip Technology Inc. DS51524A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of Microchip’s products as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, MPASM, MPLIB, MPLINK,

MPSIM, PICkit, PICDEM, PICDEM.net, PICLAB, PICtail,

PowerCal, PowerInfo, PowerMate, PowerTool, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel and Total

Endurance are trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2004, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper. 11/12/04

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

DS51524A-page ii 2004 Microchip Technology Inc.

Page 3

PICDEM™ Z

DEMONSTRATION KIT

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 1

Chapter 1. PICDEM Z Demonstration Kit Overview

1.1 Introduction ..................................................................................................... 5

1.2 What is the PICDEM Z Demonstration Kit? .................................................... 5

1.3 PICDEM Z Demonstration Kit Components ................................................... 5

1.4 Overview of the PICDEM Z Demonstration Kit ............................................... 6

1.5 PICDEM Z Motherboard ................................................................................. 6

1.6 PICDEM Z RF Card ........................................................................................ 8

1.7 PICDEM Z Software CD ................................................................................. 8

Chapter 2. Getting Started with the PICDEM Z Demonstration Kit

2.1 Introduction ..................................................................................................... 9

2.2 Host Computer Requirements ........................................................................ 9

2.3 Using the PICDEM Z Boards for the First Time ............................................. 9

2.3.1 Assembling PICDEM Z Nodes ........................................................ 9

2.3.2 Installing PICDEM Z Software Files .............................................. 10

2.4 Executing Preprogrammed Demo Applications ............................................ 11

Chapter 3. Experimenting with the PICDEM Z Demonstration Kit

3.1 Introduction ................................................................................................... 13

3.2 Modifying Demo Application Configurations ................................................. 13

3.2.1 Modifying Node ID Values ............................................................. 13

3.2.2 Modifying Association and Binding Configurations ........................ 15

3.2.3 Clearing Entire Neighbor and Binding Table ................................. 17

3.2.4 Clearing Individual Association and Binding Entry ........................ 18

3.3 Testing RF Performance .............................................................................. 19

3.4 Modifying the Hardware Configuration ......................................................... 20

3.5 Developing Your Application ........................................................................ 20

3.6 Creating Your Application Source File ......................................................... 20

3.6.1 Programming Your Application ...................................................... 20

3.6.2 Restoring Demo Firmware ............................................................. 21

Chapter 4. Troubleshooting

4.1 Introduction ................................................................................................... 23

4.2 Common Issues ........................................................................................... 23

2004 Microchip Technology Inc. DS51524A-page iii

Page 4

PICDEM™ Z Demonstration Kit User’s Guide

Appendix A. PICDEM Z Motherboard Schematics

A.1 PICDEM Z Motherboard .............................................................................. 25

A.2 PICDEM Z Motherboard Top Assembly ....................................................... 26

A.3 PICDEM Z Motherboard Layer 1 ................................................................. 27

A.4 PICDEM Z Motherboard Layer 2 ................................................................. 28

Appendix B. PICDEM Z 2.4 GHz RF Card

B.1 Introduction .................................................................................................. 31

B.2 What is the PICDEM Z 2.4 GHz RF Card? .................................................. 31

B.3 PICDEM Z 2.4 GHz RF Card Kit Components ............................................ 31

B.4 Overview of the PICDEM Z 2.4 GHz RF Card ............................................. 32

B.5 The PICDEM Z 2.4 GHz RF Card Features ................................................. 33

B.6 The PICDEM Z Software ............................................................................. 34

B.7 Getting Started with the PICDEM Z 2.4 GHz RF Card ............................... 34

B.7.1 Introduction ................................................................................... 34

B.7.2 Motherboard Requirements .......................................................... 34

B.7.3 Using the PICDEM Z 2.4 GHz RF Card for the First Time ............ 34

B.8 PICDEM Z 2.4 GHz RF Card Schematics ................................................... 35

B.9 PICDEM Z 2.4 GHz RF Card Top Assembly ............................................... 36

B.10 PICDEM Z 2.4 GHz RF Card PCB Layer 1 ................................................ 37

B.11 PICDEM Z 2.4 GHz RF Card PCB Layer 2 ................................................ 38

B.12 PICDEM Z 2.4 GHz RF Card PCB Layer 3 ................................................ 39

B.13 PICDEM Z 2.4 GHz RF Card PCB Layer 4 ................................................ 40

Worldwide Sales and Service .....................................................................................42

DS51524A-page iv 2004 Microchip Technology Inc.

Page 5

PICDEM™ Z

DEMONSTRATION KIT

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

®

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

PICDEM Z Demo Kit. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

DOCUMENT LAYOUT

This document describes how to use the PICDEM Z Demo Kit as a development tool

to evaluate and experiment with Microchip solutions for the ZigBee™ protocol. The

manual layout is as follows:

• Chapter 1: PICDEM Z Demonstration Kit Overview – Describes the PICDEM Z

Demonstration Kit and how it works.

• Chapter 2: Getting Started with the PICDEM Z Demonstration Kit – What you

need to know to start using the PICDEM Z Demonstration Kit.

• Chapter 3: Experimenting with the PICDEM Z Demonstration Kit – How to

program and use the PICDEM Z Demonstration Kit.

• Chapter 4: Troubleshooting – How to solve common operation problems with

the PICDEM Z Demo Kit.

• Appendix A: PICDEM Z Motherboard Schematics – Hardware information on

the PICDEM Z demonstration board

• Appendix B: PICDEM Z 2.4 GHz RF Card – Hardware information on the

PICDEM Z RF card

2004 Microchip Technology Inc. DS51524A-page 1

Page 6

PICDEM™ Z Demonstration Kit User’s Guide

CONVENTIONS USED IN THIS GUIDE

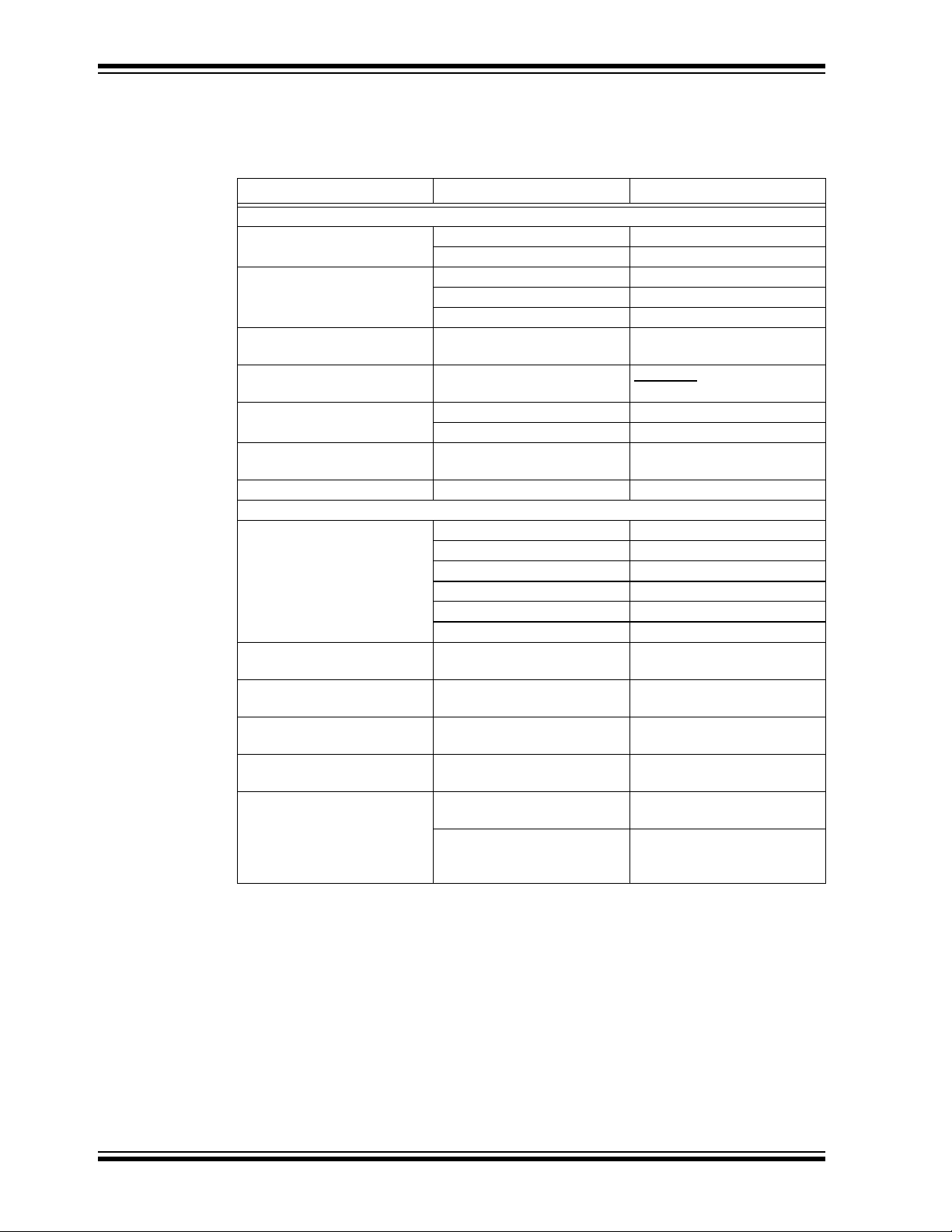

Where applicable, this manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

‘bnnnn A binary number where n is a

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier font:

Plain Courier Sample source code #define START

Italic Courier A variable argument file.o, where file can be

0xnnnn A hexadecimal number where

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

digit

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

n is a hexadecimal digit

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

‘b00100, ‘b10

any valid filename

0xFFFF, 0x007A

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS51524A-page 2 2004 Microchip Technology Inc.

Page 7

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user's guide describes how to use the PICDEM Z Demo Kit. Other useful

documents are listed below. The following Microchip documents are available and

recommended as supplemental reference resources.

Microchip Stack for the ZigBee™ Protocol (AN965)

This application note describes how you can use the Microchip Stack for ZigBee

protocol to quickly build your application without the need to acquire detailed

knowledge of ZigBee specifications. To illustrate the usage of the stack, two working

demo applications are included. These demo applications can be used as a reference

or simply modified and adapted to your requirements.

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQ), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

2004 Microchip Technology Inc. DS51524A-page 3

Page 8

PICDEM™ Z Demonstration Kit User’s Guide

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB C17, MPLAB C18 and MPLAB C30 C compilers;

MPASM™ and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30

object linkers; and MPLIB™ and MPLAB LIB30 object librarians.

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB ICE 2000 and MPLAB ICE 4000.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2.

• MPLAB IDE – The latest information on Microchip MPLAB IDE, the Windows

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM and MPLAB SIM30 simulators, MPLAB

IDE Project Manager and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 and PRO MATE

Plus and PICkit

®

1 development programmer.

®

II device programmers and the PICSTART®

®

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

In addition, there is a Development Systems Information Line which lists the latest

versions of Microchip's development systems software products. This line also

provides information on how customers can receive currently available upgrade kits.

The Development Systems Information Line numbers are:

1-800-755-2345 – United States and most of Canada

1-480-792-7302 – Other International Locations

DS51524A-page 4 2004 Microchip Technology Inc.

Page 9

DEMONSTRATION KIT

Chapter 1. PICDEM Z Demonstration Kit Overview

1.1 INTRODUCTION

This chapter presents an overview of the features and requirements of the PICDEM Z

Demonstration Kit. Topics covered in this chapter include:

• What is the PICDEM Z Demonstration Kit?

• PICDEM Z Demonstration Kit Components

• Overview of the PICDEM Z Demonstration Kit

• PICDEM Z Motherboard

• PICDEM Z RF Card

• PICDEM Z Software CD

1.2 WHAT IS THE PICDEM Z DEMONSTRATION KIT?

The PICDEM Z Demonstration Kit is designed to allow developers to evaluate and

experiment with Microchip solutions for the ZigBee protocol. The PICDEM Z

Demonstration Kit provides two ZigBee nodes to create a simple two-node network. If

required, additional nodes may be purchased to expand the network. The

preprogrammed demo application firmware allows multiple operational configurations

without modifying a single line of code. Using the Microchip Stack for ZigBee Protocol

source code, available free-of-charge from the Microchip web site, developers can

develop their own applications or modify the supplied demo applications.

PICDEM™ Z

USER’S GUIDE

1.3 PICDEM Z DEMONSTRATION KIT COMPONENTS

Your demonstration kit contains the following items:

1. Two PICDEM Z demonstration motherboards.

2. Two PICDEM Z RF cards (Exact RF transceiver is dependent upon your kit P/N).

3. Two 9V batteries.

4. The Microchip Software CD for ZigBee CD-ROM, which contains demo

applications and source code for the Microchip Stack.

5. This manual (included on the CD-ROM in Adobe

6. A warranty registration card.

®

Acrobat® format).

2004 Microchip Technology Inc. DS51524A-page 5

Page 10

PICDEM™ Z Demonstration Kit User’s Guide

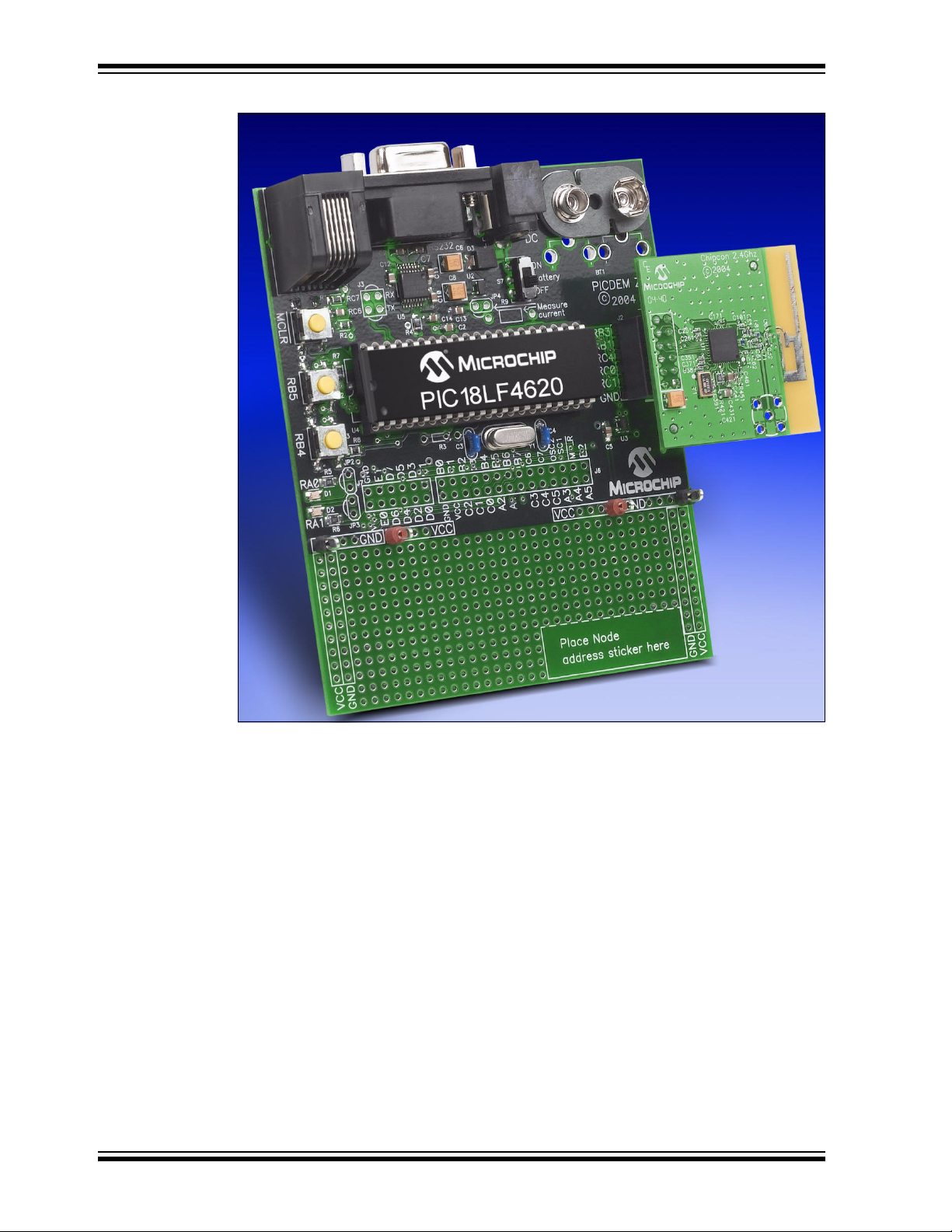

1.4 OVERVIEW OF THE PICDEM Z DEMONSTRATION KIT

The PICDEM Z Demonstration Kit (also referred to as the PICDEM Z kit) is designed

to demonstrate the Microchip solution for the ZigBee protocol. The PICDEM Z kit

includes two ZigBee nodes, each preprogrammed with demo Coordinator and

Reduced Function Device (RFD) applications. Each node consists of two boards – one

motherboard and one RF card. The PICDEM Z motherboard is designed to support

different types of RF transceivers. Microchip will be adding support for new RF

transceivers as time progresses. For the complete list of supported RF transceivers,

please visit the Microchip web site.

In addition to demonstrating standard ZigBee functionality, the PICDEM Z kit can also

be used to develop custom applications based on the ZigBee protocol. The kit includes

the complete source code for the Microchip Stack for the ZigBee protocol. The

Microchip application note AN965, Microchip Stack for the ZigBee™ Protocol

(DS00965) discusses the Microchip Stack in more detail.

1.5 PICDEM Z MOTHERBOARD

The PICDEM Z demonstration board or motherboard, has all of the features necessary

to begin developing ZigBee protocol-based applications using the Microchip PIC18

family of microcontrollers. The preprogrammed firmware allows users to begin

evaluating the board right out of the box, with no additional programming or

configuration.

FIGURE 1-1: PICDEM Z MOTHERBOARD

7

6

5

4

3

10

11

1

2

8

9

12

DS51524A-page 6 2004 Microchip Technology Inc.

Page 11

PICDEM Z Demonstration Kit Overview

Features on the PICDEM Z demonstration board include:

1. Microcontroller Socket (U4): 40- and 28-pin DIP sockets are provided for the

user’s choice of Microchip PIC18 microcontrollers. The board is equipped from

the factory with a PIC18LF4620 high-performance microcontroller, clocked at

4 MHz and preprogrammed with the demo application firmware using the

Microchip Stack. The microcontroller on each board included in the

demonstration kit contains a label that identifies it as either a ZigBee Coordinator

or ZigBee RFD.

2. Temperature Sensor (U3: TC77): This is a 5-pin thermal sensor with an SPI

interface from Microchip.

3. User-defined LEDs (D1, D2): These two LEDs are driven by digital I/O pins of

the controller, and may be used to simulate a digital output to an embedded

device. These LEDs are enabled/disabled by jumpers JP2 and JP3. By default,

LEDs are enabled by permanently shorting jumpers via PCB traces. If required,

you may cut the traces and install your own jumpers.

4. User-defined Push Buttons (S2, S3): These switches are connected to digital

I/O pins on the controller, and may be used to simulate a digital input in an

embedded application. These switches do not have external pull-up resistors; as

a result you must enable the internal pull-up option on PORTB to correctly read

the switch status.

5. Reset Push Button (S1): This switch is tied to the MCLR

and is used to reset the board.

6. RJ-11 (six-wire) Modular Connector (J5): This connector allows the

demonstration board to be connected to Microchip MPLAB ICD 2 systems for

advanced microcontroller debugging and programming.

7. RS-232 (DB9F) Connector (P1): This connector allows the demonstration board to

be connected to any other board or PC serial port. The preprogrammed demo

application firmware uses this connector to communicate with a PC and offer

application configuration options. If required, you may disconnect the on-board

RS-232 driver circuit from the controller by breaking the PCB traces on the J3 jumper.

8. RF Card Connector (J2): This is a common connector to connect all supported

RF cards. This connector provides +3.3V DC, an SPI bus, and a few discrete

digital I/O control signals.

9. Prototype Area: A prototype area is provided to breadboard additional circuitry

for development. Connections are provided for +3.3V DC, ground, and all I/O

ports of a microcontroller.

10. On-board Power: An on-board regulator provides 9V DC to 3.3V DC rated at

100 mA. The board may be powered via either an external 9V DC input (J1) or

the on-board 9V battery (B1). The board contains a diode to protect against an

accidental reverse power connection. When using a 9V battery to power the

board, switch S7 must be set to ON. The 2.5 mm 9V DC jack is wired such that

when a 9V DC plug is inserted, the on-board battery is automatically

disconnected from the circuit.

11. Measure Current (JP4): This jumper can be used to measure current drawn by

all of the circuits on the board. By default, this jumper is shorted via a PCB trace.

To measure the current, cut the JP4 trace and insert an ammeter between the

JP4 terminals. You may also install your choice of resistor at R9 and measure

voltage across it to determine the current.

12. Node ID: This unique serial number is used by the preprogrammed

demonstration application firmware to create a unique 64-bit extended Medium

Access Control (MAC) address. The extended MAC address of the board can be

changed by either serial configuration or by modifying firmware.

13. Revision Level Indicator (Back Side): The text on the solder side of the board

indicates the hardware revision level.

pin on the controller,

2004 Microchip Technology Inc. DS51524A-page 7

Page 12

PICDEM™ Z Demonstration Kit User’s Guide

1.6 PICDEM Z RF CARD

The PICDEM Z motherboard is designed to support RF cards using RF transceivers

from various vendors. Microchip is planning to add support for new RF transceivers.

Please check the Microchip web site for the list of supported RF transceivers. You may

find details of an individual RF card in its respective user’s guide document.

See Appendix B. “PICDEM Z 2.4 GHz RF Card” for information on the RF cards

supplied in your PICDEM Z Demonstration Kit.

1.7 PICDEM Z SOFTWARE CD

The CD provides the complete source code for the Microchip Stack for the ZigBee

protocol. It also includes two demo applications based on the Microchip Stack.

You may download the latest version of the Microchip Stack from the Application

Design Center at the Microchip web site.

DS51524A-page 8 2004 Microchip Technology Inc.

Page 13

PICDEM™ Z

DEMONSTRATION KIT

USER’S GUIDE

Chapter 2. Getting Started with the PICDEM Z Demonstration Kit

2.1 INTRODUCTION

Topics covered in this chapter include:

• Host Computer Requirements

• Using the PICDEM Z Boards for the First Time

• Executing Preprogrammed Demo Applications

2.2 HOST COMPUTER REQUIREMENTS

The preprogrammed demo applications do not require the host computer to observe

the functionality. However, a host computer is required if you want to change the default

demo application configuration.

To change the default demo application configuration, you must have a system that

meets the following hardware and software requirements:

• Any computer system with one available standard serial port (DB9)

• Any operating system that provides a standard RS-232 terminal program using

the available hardware serial port

The PICDEM Z Demonstration Kit includes a CD that contains the complete source

code for both demo applications and the Microchip Stack. To view the contents of the

CD, modify demo applications or develop your own application, you must have a

system that meets Microchip MPLAB system requirements. Please visit the Microchip

web site for up-to-date system requirements and to download the Microchip MPLAB

software.

2.3 USING THE PICDEM Z BOARDS FOR THE FIRST TIME

2.3.1 Assembling PICDEM Z Nodes

The PICDEM Z Demonstration Kit consists of two ZigBee node boards. Each node

consists of one motherboard and one RF card packaged separately. You must

assemble each node before applying power.

Perform the following steps to prepare each node:

1. Unbox and unwrap each board and place on a non-conductive surface.

2. Carefully plug the RF card into the J2 connector on the motherboard. Note that

the connectors on the motherboard and the RF card are polarized and will not

allow incorrect insertion.

3. If you have a 9V DC power supply with a 2.5 mm plug, power-up the board. If not,

connect one of the supplied 9V batteries to the BT1 connector and slide switch

S7 to the ON position. Observe that LEDs D1 and D2 have flashed. This confirms

that the boards are working properly.

2004 Microchip Technology Inc. DS51524A-page 9

Page 14

PICDEM™ Z Demonstration Kit User’s Guide

FIGURE 2-1: MOTHERBOARD AND RF CARD CONNECTION

2.3.2 Installing PICDEM Z Software Files

The PICDEM Z Demonstration Kit contains the complete source code for the Microchip

Stack for the ZigBee protocol and demo applications. The Microchip Stack for the

ZigBee protocol is available free-of-charge to Microchip customers. As part of the

installation process, you must accept a no-cost electronic software license to continue

installation.

To install the files:

1. Insert the PICDEM Z software CD into your system’s CD-ROM drive.

2. Using Windows Explorer, open the CD and start the installation process by

double-clicking the MpZBeev1.00.00.exe icon. The version number may

change as new versions are made available.

3. When presented, review the software license agreement and click I accept to

accept the license agreement and continue the installation process. If you decide

to click I do not accept, the installation will terminate.

4. After successful completion, a new program group named “Microchip Stack for

ZigBee” will be created and all source files will be copied to the “MpZBee”

directory on the root drive of your computer. This program group provides

shortcuts for all of the documents.

DS51524A-page 10 2004 Microchip Technology Inc.

Page 15

Getting Started with the PICDEM Z Demonstration Kit

2.4 EXECUTING PREPROGRAMMED DEMO APPLICATIONS

In order to observe full functionality of the demo applications, you must have one demo

Coordinator node and one demo RFD node with similar RF cards. As discussed later

in this document, you may reconfigure boards such that you may use more than one

RFD node.

The preprogrammed demo Coordinator and RFD applications implement a custom

remote control switch and LED application. For more information about these demo

applications, please refer to the Microchip application note AN965, Microchip Stack for

the ZigBee™ Protocol (DS00965).

The demo applications are completely stand-alone and do not require an interface to a

host computer. However, if you have access to a host computer, you may use it to

observe the activity logs of the applications. An interface to a host computer is useful

to understand and troubleshoot any setup issues you might have.

Do the following to execute a preprogrammed demo application:

1. Make sure that you have assembled each node by plugging the RF card into the

motherboard.

2. Remove power from both boards, if it was previously applied.

3. Locate the Coordinator node by looking for the “COORD…” label on the

controller.

4. Optional: Connect the Coordinator node to a PC serial port and launch your

favorite terminal program. Select the appropriate COM port and set it to 19200

bps, 8-N-1, no flow control.

5. Apply power to the Coordinator node. Observe that both D1 and D2 flash

simultaneously, followed by D2 flashing by itself. If connected to a PC, observe

that the terminal program displays the message “New network

successfully started”.

6. Now locate the RFD node by looking for the “RFD…” label on the controller.

7. Optional: Connect the RFD node to a PC serial port and launch your favorite

terminal program. Select the appropriate COM port and set it to 19200 bps,

8-N-1, no flow control.

8. While keeping the Coordinator node still powered, apply power to the RFD node.

Observe that both LEDs D1 and D2 flash simultaneously, followed by multiple

flashes of D2. If connected to a PC, observe that in one to two seconds, the

terminal program displays the message “Rejoin successful”. If you do not

see any message or see the message “Rejoin failed”, make sure that you

have the Coordinator node powered and running properly; reset the RFD node

and try again.

9. At this point, the RFD node has successfully associated with the Coordinator

node.

10. Press S2 on the RFD node and observe that D1 on the Coordinator node

switches on/off.

11. Press S2 on the Coordinator and observe that D1 on the RFD node switches

on/off. When you press S2 on the Coordinator, the D1 on the RFD node will toggle after few moments. This delay occurs due to the frequency at which the RFD

node polls the Coordinator node.

Note: The actual radio range for the PICDEM Z nodes depends on the type of RF

card and antenna in use. Please refer to the user’s guide of the respective

RF card for range information.

2004 Microchip Technology Inc. DS51524A-page 11

Page 16

PICDEM™ Z Demonstration Kit User’s Guide

NOTES:

DS51524A-page 12 2004 Microchip Technology Inc.

Page 17

PICDEM™ Z

DEMONSTRATION KIT

USER’S GUIDE

Chapter 3. Experimenting with the PICDEM Z Demonstration Kit

3.1 INTRODUCTION

Topics covered in this chapter include:

• Modifying Demo Application Configurations

• Testing RF Performance

• Modifying the Hardware Configuration

• Developing Your Application

• Creating Your Application Source File

3.2 MODIFYING DEMO APPLICATION CONFIGURATIONS

The preprogrammed demo applications are factory configured with certain configurations such as node identifier, network association and binding information. If required,

you may easily change these configurations through a PC running a standard RS-232

terminal program or via a stand-alone binding process.

The Demo Coordinator and Demo RFD applications use a similar terminal interface

with minor differences in available configuration options. Some of the options require

the use of standard terminal software, while other options are performed by a sequence

of switch presses without the need for terminal software. To be able to perform the

terminal-dependent steps, you must have access to at least one RS-232 (DB9,

male-to-female) cable, a host computer with at least one serial port available and a

standard serial terminal program.

3.2.1 Modifying Node ID Values

As specified in the IEEE 802.15.4 specification, each ZigBee node must contain a

unique 64-bit MAC address value. One part of the 64-bit address consists of a 24-bit

IEEE assigned Organization Unique Identifier (OUI) and the other a 40-bit organization

assigned number. The PICDEM Z demo applications create a complete MAC address

by combining the Microchip OUI of 00-04-a3 and zero padded 16-bits of the node ID

value label found on the board. The node ID value is stored in the microcontroller Flash

memory. The PICDEM Z boards are factory-configured with their respective node ID

values. If required, you may easily change the node ID values by performing the steps

that follow.

Note: The following procedure assumes that you are using the Microsoft

HyperTerminal program. You may use any terminal program of your choice

provided the required port settings are set.

2004 Microchip Technology Inc. DS51524A-page 13

Page 18

PICDEM™ Z Demonstration Kit User’s Guide

Perform the following steps to modify a Node ID value:

1. Connect a PICDEM Z node to an available serial port on the computer, using a

straight male-to-female DB9 RS-232 cable.

2. Launch HyperTerminal (Start>Programs>Accessories>Communications

3. In the “Connection Description” dialog box, enter any convenient name for the

connection, then click OK.

4. In the “Connect To” dialog box, select the COM port that the PICDEM Z board is

connected to. Click OK.

5. Configure the serial port connected to the PICDEM Z node with these settings:

19200 bps, 8 data bits, 1 Stop bit, and no parity, no flow control

6. Click OK to initiate the connection.

7. Open the “Properties” dialog box by selecting File>Properties

8. Select the “Settings” tab and click ASCII Setup….

9. Check “Echo typed characters locally”.

10. Click OK to close all open dialog boxes.

11. Apply power to the node while holding the S3 switch, or press and hold both

Reset and S3 switches; then release the Reset switch.

The following configuration menu would appear in the terminal window (Exact

header text would depend on the type of node you are trying to reconfigure and

date of build):

***************************************************************************

ZigBee Demo RFD Application v1.0 (Microchip Stack for ZigBee v1.0.0)

Built on Nov 11 2004

***************************************************************************

1. Set node ID...

2. Join a network.

3. Perform quick demo binding (Must perform #2 first)

4. Leave a previously joined network (Must perform #2 first)

5. Change to next channel.

6. Transmit unmodulated signal.

7. Transmit random modulated signal.

0. Save changes and exit.

).

.

Enter a menu choice:

12. Type 1 to change the Node ID value.

13. Follow the instructions to enter the Node ID value.

14. Press the Reset switch on the node or type 0 to exit configuration mode and run

the application.

DS51524A-page 14 2004 Microchip Technology Inc.

Page 19

Experimenting with the PICDEM Z Demonstration Kit

3.2.2 Modifying Association and Binding Configurations

The PICDEM Z nodes are factory-configured with the following settings:

1. The demo RFD node is associated with the demo Coordinator node.

2. Switch S2 on the demo RFD node is bound to LED D1 on the demo Coordinator

node.

3. Switch S2 on the demo Coordinator node is bound to LED D1 on the demo RFD

node.

It is these configurations that allow you to press S2 on one node and control LED D1

on the other node. If required, you may easily modify these configurations using the

custom binding procedure implemented in the demo applications. For example, you

may bind S2 on RFD node to D1 on the same node or on another RFD node (assuming

that you have more than one RFD node).

Although the following procedure does not require a PC, you may use one to observe

the setup messages displayed by the demo applications. These messages are useful

to understand and troubleshoot setup issues. You may view the setup messages using

a terminal program set to 19200 bps, 8-N-1, no flow control.

Do the following to modify association and binding configurations:

1. Remove power from all nodes.

2. Apply power to the Coordinator node (a node with a “COORD…” label on its

controller) without pressing any switches, or if already powered, simply reset the

board by pressing the Reset switch. This puts the demo Coordinator node in the

normal mode of operation. Observe that D1 and D2 flash momentarily followed

by a brief flash of D2. If connected to a terminal program, note that the message

“New network successfully started” is displayed. If you see an error

message, it means that the demo Coordinator could not find an empty RF

channel.

3. While keeping the Coordinator node powered up, apply power to the RFD node

(a node with the “RFD…” label on its controller) while holding the S3 switch, or

press and hold both the Reset and S3 switches; then release the Reset switch.

Observe that D1 and D2 are on. If connected to a terminal program, note that the

configuration menu is displayed.

4. If you have more than one RFD node, you may continue step 3 for each RFD

node.

5. Press S2 on the RFD node to begin the association sequence with the

Coordinator. If connected to a terminal program, note that the message

“Successfully associated” is displayed. If you do not see this message,

make sure that the demo Coordinator node is powered and running in normal

mode. If your computer has two serial ports and the demo Coordinator node is

still connected to the computer, note that the terminal displays the message “A

new node has just joined”.

6. If you have more than one RFD node, press S2 on each RFD node to associate

them to the Coordinator node.

7. Since there are many different possible combinations of binding a configuration,

Table 3-1 is used to describe the necessary sequence of steps for each

combination:

2004 Microchip Technology Inc. DS51524A-page 15

Page 20

PICDEM™ Z Demonstration Kit User’s Guide

TABLE 3-1: STEPS FOR BINDING A CONFIGURATION

To Bind Switch S2 On To Bind LED D1 On Result

RFD: Press and hold S3 first

then press S2 and release S2,

followed by S3

Coordinator: Press and hold

S3 first then press S2 and

release S2, followed by S3

RFD: Press and hold S3 first

then press S2 and release S2,

followed by S3

RFD1: Press and hold S3 first

then press S2 and release S2,

followed by S3

Coordinator: N/A Coordinator: N/A Not allowed

Note: As each step is performed, LEDs D1 and D2 on the respective node will be

toggled between on and off, to off and on. Also note that the terminal program connected to the RFD node displays the message “Attempting to

bind...” and the terminal connected to the Coordinator node displays the

“Received valid...” message.

Coordinator: Press and hold

S3 first then press S2 and

release S3, followed by S2

RFD: Press and hold S3 first

then press S2 and release S3,

followed by S2

RFD: Press and hold S3 first

then press S2 and release S3,

followed by S2

RFD2: Press and hold S3 first

then press S2 and release S3,

followed by S2

S3 on RFD is bound to D1 on

Coordinator

S3 on Coordinator is bound to

D1 on RFD

S3 on RFD is bound to D1 on

same RFD

S3 on RFD #1 is bound to D1

on RFD #2

To complete the binding process, you must perform both “To Bind Switch

S2 On” and “To Bind LED D1 On” actions.

8. Press the Reset switch on each RFD node to begin normal execution. If

connected to a terminal program, note that the message “Rejoin

successful” is displayed.

9. Depending on how binding was performed, press S2 on one node to confirm that

D1 on the same or other node toggles.

Note: To successfully control D1 on the same or other node, the Coordinator node

must be powered and running in normal mode.

DS51524A-page 16 2004 Microchip Technology Inc.

Page 21

Experimenting with the PICDEM Z Demonstration Kit

3.2.3 Clearing Entire Neighbor and Binding Table

As specified in the ZigBee protocol specification, the Coordinator stores all association

and binding information in separate tables in its local memory. The Microchip demo

Coordinator application uses on-chip Flash memory to store this information.

You may either erase an individual association and binding entry or an entire table. To

erase the entire table on the demo Coordinator, perform the following steps:

1. Remove power from all nodes.

2. Connect the Coordinator node to a PC using a standard RS-232 cable.

3. Launch a terminal program on the PC and open the appropriate COM port with

these settings: 19200 bps, 8-N-1, and no flow control.

4. Apply power to the Coordinator node (the node with “COORD…” label on its

controller) while holding the S3 switch, or press and hold both the Reset and S3

switches, then release the Reset switch. Observe that D1 and D2 are on. Note

that the terminal program displays following configuration menu:

***************************************************************************

ZigBee Demo Coordinator Application v1.0 (Microchip Stack for ZigBee v1.0.0)

Built on Nov 11 2004

***************************************************************************

1. Set node ID...

2. Clear Neighbor Table.

3. Clear Binding Table.

4. Change to next channel.

5. Transmit unmodulated signal.

6. Transmit random modulated signal.

0. Save changes and exit.

Enter a menu choice:

5. To clear the association table, type 3. Upon successful completion, the

configuration menu will be redisplayed. Note that clearing the association table

automatically clears the associated binding table.

6. To clear the binding table, type 4. Upon successful completion, the configuration

menu will be redisplayed.

2004 Microchip Technology Inc. DS51524A-page 17

Page 22

PICDEM™ Z Demonstration Kit User’s Guide

3.2.4 Clearing Individual Association and Binding Entry

If you want to clear an individual table entry related to a specific RFD node, you must

execute a configuration command on that RFD node. To do this, perform the following

steps:

1. Remove power from all nodes.

2. Power-up the Coordinator node in normal mode and make sure that LEDs D1

and D2 flash once followed by a single flash of D2.

3. Select the RFD node whose association and binding entry needs to be cleared

and connect it to a PC using a standard RS-232 cable.

4. Launch a terminal program on the PC and open the appropriate COM port with

these settings: 19200 bps, 8-N-1 and no flow control.

5. Apply power to the RFD node while holding the S3 switch, or press and hold both

the Reset and S3 switches; then release the Reset switch. Observe that D1 and

D2 are on. Note that the terminal program displays the following configuration

menu:

***************************************************************************

ZigBee Demo RFD Application v1.0 (Microchip Stack for ZigBee v1.0.0)

Built on Nov 11 2004

***************************************************************************

1. Set node ID...

2. Join a network.

3. Perform quick demo binding (Must perform #2 first)

4. Leave a previously joined network (Must perform #2 first)

5. Change to next channel.

6. Transmit unmodulated signal.

7. Transmit random modulated signal.

0. Save changes and exit.

Enter a menu choice:

6. Type 2 to first join the already powered and running demo Coordinator node.

7. Type 4 to leave the already powered and running demo Coordinator node. Upon

successful completion, the configuration menu will be redisplayed. This step will

automatically remove all binding entries associated with this node.

Note: After completing these steps, you must associate and bind this RFD node

with your choice of Coordinator to resume normal application operations.

Refer to Section 3.2.2 “Modifying Association and Binding

Configurations” for more information.

DS51524A-page 18 2004 Microchip Technology Inc.

Page 23

Experimenting with the PICDEM Z Demonstration Kit

3.3 TESTING RF PERFORMANCE

The PICDEM Z demo applications also provide two special menu options to test the RF

performance. Menu options 6 and 7 allow you to transmit either a continuous

unmodulated signal or a random modulated signal.

Perform the following steps:

1. Remove power from all nodes.

2. Connect the node to a PC using a standard RS-232 cable.

3. Launch a terminal program on the PC and open the appropriate COM port with

these settings: 19200 bps, 8-N-1, and no flow control.

4. Power-up the node while holding the S3 switch, or press and hold both the Reset

and S3 switches, then release the Reset switch. Observe that D1 and D2 are on.

Note that the terminal program displays following configuration menu (Exact

header text would depend on the type of node you are trying to test):

***************************************************************************

ZigBee Demo RFD Application v1.0 (Microchip Stack for ZigBee v1.0.0)

Built on Nov 11 2004

***************************************************************************

1. Set node ID...

2. Join a network.

3. Perform quick demo binding (Must perform #2 first)

4. Leave a previously joined network (Must perform #2 first)

5. Change to next channel.

6. Transmit unmodulated signal.

7. Transmit random modulated signal.

0. Save changes and exit.

Enter a menu choice:

5. On power-up, the demo application selects the very first channel available in the

RF transceiver specific band. For example, for the 2.4 GHz frequency band, on

power-up, channel 11 is selected. You may change to the next channel by

selecting the “Change to next channel” option repeatedly until you reach

the desired channel. Note that the demo application does not display any

channel number information. You must count the number of times the menu

option is typed.

6. Type 6 (or 5 if testing demo Coordinator) to transmit a continuous unmodulated

signal, or type 7 (or 6 if testing demo Coordinator) to transmit a continuous

random modulated signal. You may now use any standard RF network analyzer

to evaluate the RF performance.

7. Once you select either test option, you must reset the board to perform any other

action.

2004 Microchip Technology Inc. DS51524A-page 19

Page 24

PICDEM™ Z Demonstration Kit User’s Guide

3.4 MODIFYING THE HARDWARE CONFIGURATION

The PICDEM Z boards are designed to be flexible in terms of enabling/disabling

on-board components and adding your own circuit.

Jumper Purpose

J2

JP2 To enable/disable D1 LED (Factory enabled by PCB trace shorts)

JP3 Enable/Disable D2 LED (Factory enabled by PCB trace shorts)

JP4 To measure current draw of entire board (Factory shorted via PCB trace)

3.5 DEVELOPING YOUR APPLICATION

The PICDEM Z kit is shipped with complete source files for the Microchip Stack for the

ZigBee protocol. Please refer to the Microchip application note AN965 (DS00965) for

detailed information. Microchip is committed to continually improve and add new

features to the existing version of the Microchip Stack. Please check the Microchip web

site for the latest revision of the Microchip Stack source files.

3.6 CREATING YOUR APPLICATION SOURCE FILE

To connect/disconnect on-board RS-232 driver to PICmicro (RC7 and RC6 are

shorted via PCB trace to RX and TX respectively)

The Microchip Stack includes source files for both the demo Coordinator and RFD

applications. You may either modify one of the demo applications to suit your

application or use them as a reference to create your application. Please refer to the

Microchip application note AN965 (DS00965) for detailed instructions on how to create

your own application.

3.6.1 Programming Your Application

Once you have developed your application, you must program it into one of the

PICDEM Z nodes. To facilitate easy identification of the Coordinator and RFD node, it

is recommended that you program your Coordinator and RFD application into the

respective node only. However, note that all PICDEM Z motherboards are exactly the

same and can be programmed to run Coordinator, RFD or FFD applications.

The PICDEM Z kit does not include the tools for clearing and reprogramming the

microcontroller. To do this, you must use an appropriate device programmer. You may

also use the MPLAB ICD 2 Development System, which provides a complete

development suite for device debugging and programming. The PICDEM Z

motherboard contains a modular connector to connect MPLAB ICD 2, PRO MATE and

other compatible programmers.

Use the following configuration options when programming the microcontroller:

1. HS-PLL (or HS) Oscillator Mode depending on your application requirement

2. Watchdog Timer Disabled (Demo applications use software enabled Watchdog)

3. Low-Voltage Programming Disabled

4. All other options should be changed as per your requirements

DS51524A-page 20 2004 Microchip Technology Inc.

Page 25

Experimenting with the PICDEM Z Demonstration Kit

3.6.2 Restoring Demo Firmware

You may restore the original demo firmware by reprogramming and reconfiguring the

PICDEM Z node. You may either use the factory built hex file or a rebuilt hex file to

program the microcontroller. The factory built hex file is available in the PICDEM Z

Software CD.

Use the file DemoCoordApp.hex for the Demo Coordinator application, and

DemoRFDApp.hex for the Demo RFD application. If you want to rebuild the demo

firmware, please refer to the Microchip application note AN965 (DS00965) for detailed

instructions. The demo firmware is embedded with the necessary PICmicro

configuration options appropriate for the PICDEM Z hardware. You must have access

to a compatible PICmicro device programmer to program the on-board microcontroller.

Since the configuration information such as node ID, association and binding

information are stored in on-chip Flash memory, reprogramming a microcontroller

requires that you reconfigure each node before you can observe demo application

functionality. A newly programmed board will automatically enter into configuration

mode. Refer to Section 3.2 “Modifying Demo Application Configurations” for a

detailed procedure for reconfiguring the applications.

2004 Microchip Technology Inc. DS51524A-page 21

Page 26

PICDEM™ Z Demonstration Kit User’s Guide

NOTES:

DS51524A-page 22 2004 Microchip Technology Inc.

Page 27

Chapter 4. Troubleshooting

4.1 INTRODUCTION

This chapter discusses common operational issues and how to resolve them. Topics

covered in this chapter include:

• Common Issues

4.2 COMMON ISSUES

1. When I power up a node, the LEDs are not lit or blinking.

The primary reason for this issue would be the lack of power and/or incorrectly

programmed firmware.

Check the PICDEM Z motherboard for power:

• If using an external power supply,

- Verify that the power supply is plugged in and the wall outlet has power.

- Check the external 9V power plug for correct polarity.

- Check that voltage is available at the plug.

• If using a 9V battery,

- Verify that the battery is fully charged and correctly plugged into BT1.

- Verify that the battery power switch S7 is set to On.

- Disconnect the external 9V power plug from the J1 socket.

• Verify that the on-board microcontroller is programmed correctly with the

appropriate hex file. Refer to Section 3.6.2 “Restoring Demo Firmware” for

details.

• If you have installed JP2 and JP3 jumpers on the motherboard, make sure

that on-board LEDs are enabled by shorting the JP2 and JP3 jumpers.

• Make sure that the RF card is correctly plugged into the motherboard.

• Connect the board to a PC terminal program and see if it displays any error

messages.

PICDEM™ Z

DEMONSTRATION KIT

USER’S GUIDE

2. A PICDEM Z node does not communicate with the host system.

The primary reason for this issue would be the lack of power and/or incorrectly

programmed firmware.

• Verify that the on-board microcontroller is programmed correctly with the

appropriate hex file. Refer to Section 3.6.2 “Restoring Demo Firmware” for

details.

• Make sure that the on-board RS-232 driver is connected to the microcontroller

by appropriately shorting the J3 jumper.

• Make sure that your terminal program is set to use 19200 bps, 8-N-1, no flow

control.

• Make sure that the RF card is correctly plugged into the motherboard.

2004 Microchip Technology Inc. DS51524A-page 23

Page 28

PICDEM™ Z Demonstration Kit User’s Guide

3. A PICDEM Z node displays the message “Unexpected reset occurred” on

the terminal.

The on-board firmware is stuck in some unexpected infinite loop. This may occur

if there is a short or open on certain RF card signals, or if there is a programming

mistake in the firmware.

• Verify that the on-board microcontroller is programmed correctly with the

appropriate hex file. Refer to Section 3.6.2 “Restoring Demo Firmware” for

details.

• Make sure that the RF card is correctly plugged into the motherboard.

• If you have modified the hardware, make sure that any of the RF card signals

are not shorted or open.

• If you have reprogrammed the firmware, verify that the Watchdog Timer

prescaler is set to maximum.

• Try plugging in a different RF card to eliminate a bad RF card problem.

4. LEDs D1 and D2 on a node blink continually.

The on-board firmware is stuck in some unexpected infinite loop.

• See issue #3.

5. Cannot control the LEDs on another node.

The primary reason for this issue would be that the demo Coordinator is not

running and/or the switch is not correctly bound to the target LED.

• Make sure that on-board LEDs on the node you are controlling are enabled by

shorting the JP3 jumper.

• Make sure that nodes are bound properly using the procedure described in

Section 3.2 “Modifying Demo Application Configurations”.

• Make sure that the demo Coordinator is powered and running.

• Make sure that two nodes are within the radio sphere of the Coordinator.

6. Cannot control the LEDs on the same node.

The primary reason for this issue would be that the demo Coordinator is not

running and/or the switch is not correctly bound to the LED.

• Make sure that you have performed the proper binding operation using the

procedure described in Section 3.2 “Modifying Demo Application

Configurations”.

• Make sure that the demo Coordinator is powered and running.

• Make sure that the node is within the radio sphere of the Coordinator.

• Note that binding of the switch and LED on the same Coordinator node is not

allowed.

7. RFD node does not associate with the demo Coordinator node.

• Make sure that both the RFD and the Coordinator are within each other’s

radio sphere.

• Make sure that the RFD is put in Configuration mode, and the appropriate

Join sequence is performed.

8. RFD node does not rejoin with a demo Coordinator node.

• Make sure that both the RFD and the demo Coordinator are within each

other’s radio sphere.

• Make sure that the RFD node was successfully associated with the Coordinator.

• Make sure that the demo Coordinator is running in normal mode. Press and

release the Reset switch on the demo Coordinator and try again.

DS51524A-page 24 2004 Microchip Technology Inc.

Page 29

Appendix A. PICDEM Z Motherboard Schematics

A.1 PICDEM Z MOTHERBOARD

PICDEM™ Z

DEMONSTRATION KIT

USER’S GUIDE

3

15

V+

VCC

C1+

C1-5C2+6C2-

2

4

7

89

13

16

10

12

V-

INVALID

FORCEON

FORCEOFF

EN

GND

1

14

11

2004 Microchip Technology Inc. DS51524A-page 25

Page 30

PICDEM™ Z Demonstration Kit User’s Guide

A.2 PICDEM Z MOTHERBOARD TOP ASSEMBLY

DS51524A-page 26 2004 Microchip Technology Inc.

Page 31

PICDEM Z Motherboard Schematics

A.3 PICDEM Z MOTHERBOARD LAYER 1

2004 Microchip Technology Inc. DS51524A-page 27

Page 32

PICDEM™ Z Demonstration Kit User’s Guide

A.4 PICDEM Z MOTHERBOARD LAYER 2

DS51524A-page 28 2004 Microchip Technology Inc.

Page 33

PICDEM Z Motherboard Schematics

TABLE A-1: PICDEM Z MOTHERBOARD BILL OF MATERIALS (BOM)

Reference Description Vendor Vendor P/N

D3 Diode Schottky 20V 1A SMD MELF Diodes Inc. 1N5817M-13

BT1 Conn Batt Male 9V Horz Snap-on Keystone Electronics 593

BT1 Conn Batt Fem 9V Horz Snap-on Keystone Electronics 594

Conn PC Vert 9V Snap-on Keystone Electronics 968

C3, C4 22PF 100V 5% Monolith Cerm Cap Panasonic - ECG ECU-S2A220JCA

C1, C2, C5, C7,

C9, C10, C11,

C12, C13, C14

C6 Capacitor Tant 2.2UF 25V 10% SMD Kemet T491B225K025AS

C8 Capacitor Tant 3.3UF 16V 10% SMD Kemet T491B335K016AS

Y1 Crystal 4.000 MHZ 20PF HC-49/US ECS Inc. ECS-40-20-4

P1 DB9 F

J1 Conn Powerjack Mini .1" R/A PCMT Switchcraft Inc. RAPC712

J3

J2 2 x 6 .100" Socket/Terminal Samtec LST-106-07-F-D

JP2, JP3, JP4

D1, D2 LED Thin 565NM Grn Diff 0805 SMD Lumex Opto SML-LXT0805GW-TR

U2 IC Reg LDO Micropower SOT23-5 National Semiconductor LP2981AIM5-3.3

U5 Maxim MAX3221CAE

U1 28-pin Socket Mill-Max 110-99-328-41-001

U4 40-pin Socket (needs to have no internal ribs) Mill-Max 110-99-640-41-001

U4 PICmicro® MCU Microchip PIC18LF4620-I/P

R3 No Load

R5, R6 Res 330 OHM 1/8W 5% 0805 SMD Yageo America 9C08052A3300JLHFT

R2, R7, R8 Res 470 OHM 1/8W 5% 0805 SMD Yageo America 9C08052A4700JLHFT

R1 Res 4.7K OHM 1/8W 5% 0805 SMD Yageo America 9C08052A4701JLHFT

R4 Res 1.0M OHM 1/8W 5% 0805 SMD Yageo America 9C08052A1004JLHFT

J5 Conn Mod Jack 6-6 R/A PCB 50AU AMP/Tyco 520470-3

S1, S2, S3 Switch Tact 6MM SMD MOM 230GF Omron Electronics B3S-1002

S7 Switch Slide SPDT PC MNT L=2MM E-Switch, Inc. EG1271

U3 IC Sensor Thermal SPI 3.3V SOT235 Microchip TC77-3.3MCTTR

Cap .1UF 16V Ceramic X7R 0805 Panasonic - ECG ECJ-2VB1C104K

Test Point PC Multi Purpose Blk Keystone Electronics 5011

Test Point PC Multi Purpose Red Keystone Electronics 5010

2004 Microchip Technology Inc. DS51524A-page 29

Page 34

PICDEM™ Z Demonstration Kit User’s Guide

NOTES:

DS51524A-page 30 2004 Microchip Technology Inc.

Page 35

Appendix B. PICDEM Z 2.4 GHz RF Card

B.1 INTRODUCTION

This appendix presents an overview of the features and requirements of the PICDEM Z

2.4 GHz RF card. Topics covered in this appendix include:

• What is the PICDEM Z 2.4 GHz RF Card?

• PICDEM Z 2.4 GHz RF Card Kit Components

• Overview of the PICDEM Z 2.4 GHz RF Card

• The PICDEM Z 2.4 GHz RF Card Features

• The PICDEM Z Software

• Getting Started with the PICDEM Z 2.4 GHz RF Card

• PICDEM Z 2.4 GHz RF Card Schematics

• PICDEM Z 2.4 GHz RF Card Top Assembly

• PICDEM Z 2.4 GHz RF Card PCB Layer 1

• PICDEM Z 2.4 GHz RF Card PCB Layer 2

• PICDEM Z 2.4 GHz RF Card PCB Layer 3

• PICDEM Z 2.4 GHz RF Card PCB Layer 4

• PICDEM Z 2.4 GHz RF Card Bill of Materials (BOM)

PICDEM™ Z

DEMONSTRATION KIT

USER’S GUIDE

B.2 WHAT IS THE PICDEM Z 2.4 GHz RF CARD?

The PICDEM Z 2.4 GHz RF card is designed to plug into a PICDEM Z motherboard.

This board uses the CC2420 RF 2.4 GHz transceiver manufactured by Chipcon. The

CC2420 is an IEEE 802.15.4 compatible RF transceiver for the 2.4 GHz band. Please

refer to www.chipcon.com for more information on the CC2420 RF transceiver.

The PICDEM Z 2.4 GHz RF card uses a PCB trace antenna. If required, the card may

be easily modified to use a standard monopole antenna. The RF schematic and PCB

design are a straight adoption of the CC2420 reference design published by Chipcon.

B.3 PICDEM Z 2.4 GHz RF CARD KIT COMPONENTS

The PICDEM Z 2.4 GHz RF card is designed to be part of the PICDEM Z

Demonstration Kit.

Your PICDEM Z 2.4 GHz RF Card Kit contains the following items:

1. One PICDEM Z 2.4 GHz RF card

2. A warranty registration card

You may download the complete schematic and PCB design files from the Microchip

web site.

2004 Microchip Technology Inc. DS51524A-page 31

Page 36

PICDEM™ Z Demonstration Kit User’s Guide

B.4 OVERVIEW OF THE PICDEM Z 2.4 GHz RF CARD

The PICDEM Z 2.4 GHz RF card is designed to demonstrate the Microchip solution for

the ZigBee protocol for the 2.4 GHz frequency band. All design files related to the RF

card are available from the Microchip web site. You may use this board directly in your

design or plug it into a PICDEM Z motherboard to complete the ZigBee node. The

current version of the Microchip Stack for the ZigBee Protocol provides the necessary

software to support this card.

FIGURE B-1: PICDEM Z 2.4 GHz RF CARD

DS51524A-page 32 2004 Microchip Technology Inc.

Page 37

PICDEM Z 2.4 GHz RF Card

B.5 THE PICDEM Z 2.4 GHz RF CARD FEATURES

The PICDEM Z 2.4 GHz RF card is designed to use the CC2420 RF transceiver. The

CC2420 is an IEEE 802.15.4 compliant RF transceiver in the 2.4 GHz frequency band.

The card provides a 2-row header to connect to a PICDEM Z motherboard.

The current version of the PICDEM Z 2.4 GHz RF card with on-board PCB trace

antenna was found to provide a line sight radio range of about 200 ft. Exact range

depends on many factors, including but not limited to obstacles, PCB and antenna

design. Microchip has not characterized the RF performance of the Chipcon CC2420

transceiver. For more information about RF characteristics, please refer to Chipcon

web site.

FIGURE B-2: PICDEM Z 2.4 GHz RF CARD

1

2

4

3

Features on the PICDEM Z 2.4 GHz RF card include:

1. RF Transceiver (U1): 48-pin QLP packaged CC2420 RF transceiver. This chip

implements complete PHY and part of the MAC layer.

2. RF Board Connector (J2): This connector is used to connect to the PICDEM Z

motherboard. This connector includes +3.3V DC, an SPI bus, and a few discrete

digital I/O control signals.

3. Optional SMA Connector (P5): This is an optional connector to use with an

external antenna. You must remove C63 and install C62 to connect P5 to the

transceiver. This connector is designed to accept a mini-SMA connector.

4. PCB Antenna: This is the inverted F-type PCB antenna, which is adopted from

the Chipcon CC2420 DBK board design. Refer to Chipcon’s CC2420DBK User

Manual (available for download from the Chipcon web site) for more information.

5. Revision Level Indicator (back side): The text on the solder side of the board

indicates the hardware revision level.

2004 Microchip Technology Inc. DS51524A-page 33

Page 38

PICDEM™ Z Demonstration Kit User’s Guide

B.6 THE PICDEM Z SOFTWARE

You may download the latest version of the PICDEM Z software from the Microchip web

site.

B.7 GETTING STARTED WITH THE PICDEM Z 2.4 GHZ RF CARD

B.7.1 Introduction

This section covers the following topics:

• Motherboard Requirements

• Using the PICDEM Z 2.4 GHz RF Card for the First Time

B.7.2 Motherboard Requirements

The PICDEM Z 2.4 GHz RF card is designed for use with a PICDEM Z motherboard or

similar board. If you are planning to use the RF card with your custom board, use the

PICDEM Z motherboard schematic as a reference (see Section A.1 “PICDEM Z

Motherboard”).

B.7.3 Using the PICDEM Z 2.4 GHz RF Card for the First Time

The PICDEM Z 2.4 GHz RF card must be properly plugged into the PICDEM Z

motherboard to complete the setup. Refer to Figure 2-1 for an example.

Perform the following steps to prepare each node:

1. Remove from box and unwrap each board and place on a non-conductive

surface.

2. Carefully plug the PICDEM Z 2.4 GHz RF card into the J2 connector on the main

board. Note that the connectors on the main board and RF card are polarized

and will not allow incorrect insertion.

3. Power the PICDEM Z motherboard. Observe that LEDs D1 and D2 have flashed.

This confirms that the boards are working properly.

Note: Before transmitting an RF signal, check with your local telecommunication

authorities to ensure that no restriction on the use of the 2400-2483.5 MHz

ISM band is in effect.

The CC2420 operates in the 2.4 GHz frequency band; however, be advised

that even though this band is commonly thought of as a world-wide band,

some countries do not allow unlicensed operation in this band.

DS51524A-page 34 2004 Microchip Technology Inc.

Page 39

PICDEM Z 2.4 GHz RF Card

B.8 PICDEM Z 2.4 GHz RF CARD SCHEMATICS

2004 Microchip Technology Inc. DS51524A-page 35

Page 40

PICDEM™ Z Demonstration Kit User’s Guide

B.9 PICDEM Z 2.4 GHz RF CARD TOP ASSEMBLY

DS51524A-page 36 2004 Microchip Technology Inc.

Page 41

PICDEM Z 2.4 GHz RF Card

B.10 PICDEM Z 2.4 GHz RF CARD PCB LAYER 1

2004 Microchip Technology Inc. DS51524A-page 37

Page 42

PICDEM™ Z Demonstration Kit User’s Guide

B.11 PICDEM Z 2.4 GHz RF CARD PCB LAYER 2

DS51524A-page 38 2004 Microchip Technology Inc.

Page 43

PICDEM Z 2.4 GHz RF Card

B.12 PICDEM Z 2.4 GHz RF CARD PCB LAYER 3

2004 Microchip Technology Inc. DS51524A-page 39

Page 44

PICDEM™ Z Demonstration Kit User’s Guide

B.13 PICDEM Z 2.4 GHz RF CARD PCB LAYER 4

DS51524A-page 40 2004 Microchip Technology Inc.

Page 45

PICDEM Z 2.4 GHz RF Card

TABLE B-1: PICDEM Z 2.4 GHz RF CARD BILL OF MATERIALS (BOM)

Reference Description Vendor Vendor P/N

C1 Capacitor TANT 2.2UF 25V 10% SMD Kemet T491B225K025AS

C61, C81 CAP Ceramic .5PF 50V NP0 0402 Yageo America 0402CG508C9B200

C63 CAP Ceramic 5.6PF 50V NP0 0402 BC Components 0402N5R6D500NT

C62

C381, C391 CAP Ceramic 22PF 50V NP0 0402 BC Components 0402N220J500NT

C171, C371, C441, C481 CAP 68PF 50V Ceramic 0402 SMD Panasonic - ECG ECJ-0EC1H680J

C101 CAP 10000PF 16V Ceramic X7R 0402 Kemet C0402C103K4RACTU

C11, C71, C251, C261,

C351

C421, C431 CAP 10UF 6.3V Ceramic X5R 0805 Panasonic - ECG ECJ-2FB0J106M

U1 CC2420 Single-chip transceiver Chipcon CC2420-STB1 QLP48

L62 Inductor 5.6NH +/-0.2NH 0402 Susumu Co Ltd HPL1005-5N6

L61, L81 Inductor 7.5NH 570MA 0402 Murata Electronics LQW15AN7N5J00D

R421 RES 2.00 OHM 1/8W 1% 0805 SMD Yageo America 9C08052A2R00FGHFT

R451 RES 43.0K OHM 1/16W 1% 0402 SMD Yageo America 9C04021A4302FLHF3

Y1 Crystal (second vendor) Crystek CSX3-AA-1816.000

Y1 Crystal TOYOCOM TSX-10A 16M 16pf

J2 .100" Socket/Terminal Samtec LST-106-07-F-D

P5 Conn Recept Straight PCB .110" G Johnson Components 142-0701-231

CAP .10UF 10V Ceramic X5R 0402 Kemet C0402C104K8PACTU

2004 Microchip Technology Inc. DS51524A-page 41

Page 46

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westford, MA

Tel: 978-692-3848

Fax: 978-692-3821

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Tor ont o

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Qingdao

Tel: 86-532-502-7355

Fax: 86-532-502-7205

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-2229-0061

Fax: 91-80-2229-0062

India - New Delhi

Tel: 91-11-5160-8631

Fax: 91-11-5160-8632

Japan - Kanagawa

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Taiwan - Hsinchu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

EUROPE

Austria - Weis

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Ballerup

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Massy

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Ismaning

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

England - Berkshire

Tel: 44-118-921-5869

Fax: 44-118-921-5820

10/20/04

DS51524A-page 42 2004 Microchip Technology Inc.

Loading...

Loading...