Page 1

PICDEM

TM

4

User’s Guide

2003 Microchip Technology Inc. DS51337A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break microchip’s code protection feature may be a violation of the Digit al Millennium Copyright Act. If suc h a cts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications. No

representation or warranty is given and no liability is assumed by

Microchip T echnology Incorporated with respect to the accuracy

or use of such information, or infringement of patents or other

intellectual property rights arising from such use or otherwise.

Use of Microchip’s products as critical components in life

support systems is not authorized except with express written

approval by Microchip. No licenses are conveyed, implicitly or

otherwise, under any intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, K

EELOQ,

MPLAB, PIC, PICmicro, PICSTART, PRO MATE and

PowerSmart are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

FilterLab, microID, MXDEV , MXLAB, PICMASTE R, SEEVAL

and The Embedded Control Solutions Company are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Accuron, Application Maestro, dsPIC, dsPICDEM,

dsPICDEM.net, ECONOMONITOR, FanSense, FlexROM,

fuzzyLAB, In-Circuit Serial Programming, ICSP, ICEPIC,

microPort, Migratable Memory, MPASM, MPLIB, MPLINK,

MPSIM, PICC, PICkit, PICDEM, PICDEM.net, Powe rCal,

PowerInfo, PowerMate, PowerTool, rfLAB, rfPIC, Select Mode,

SmartSensor, SmartShunt, SmartT el and Total Endurance are

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark of

Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2003, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hoppin g

DS51337A - page ii 2003 Microchip Technology Inc.

Page 3

Tabl e of Conten ts

Chapter 1. Introduction

1.1 Welcome .........................................................................................1

1.2 PICDEM 4 Demonstration Board ........................... ..... ....................2

1.3 Sample Devices ....................................... ..... .... ..............................3

1.4 Sample Programs ............. .... ..... ............................................... .... ..3

1.5 PICDEM 4 User’s Guide .................................................................3

1.6 Reference Documents ....................................................................3

Chapter 2. Getting Started

2.1 PICDEM 4 as a Stand-Alone Board –

Preprogrammed Device ..................................................................5

2.2 PICDEM 4 Used with an In-Circuit Emulat or or

In-Circuit Debugger ....................................... .... ..... ..... ....................6

PICDEM 4 User’s Guide

Chapter 3. Tutorial

3.1 Tutorial Firmware Operation ...........................................................7

3.2 Source Code and Application Notes ...............................................8

2003 Microchip Technology Inc. DS51337A-page iii

Page 4

PICDEM 4 User’s Guide

Appendix A. Hardware Detail

A.1 Processor Sockets ............................... .... .....................................11

A.2 LED DISPLAY ...............................................................................11

A.3 Power Supply ................................................................................11

A.4 RS-232 Serial Port ........................................................................11

A.5 Switches ........................................................................................ 12

A.6 Oscillator Options ..........................................................................12

A.7 Analog Input ..................................................................................12

A.8 ICD Connector ..............................................................................12

A.9 Serial EEPROM ............................................................................13

A.10 Motor .............................................................................................13

A.11 LIN .................................................................................................16

A.12 Supercapacitor ..............................................................................17

A.13 Real-Time Clock ....................................... ..... ..... .... .......................18

A.14 LCD Display ..................................................................................18

A.15 Device Configuration Overview .....................................................19

A.16 Board Layout and Schematics ......................................................20

Index..........................................................................................................23

Worldwide Sal e s a nd Se rvice...... .. ... ........................................... .. ... .......24

DS51337A-page iv 2003 Microchip Technology Inc.

Page 5

1.1 WELCOME

Thank you for purchasing the PICDEM 4 demonstration board from Microchip

Technology Incorporated. The PICDEM 4 demonstrates the capabilities of the 8-, 14-,

and 18-pin PIC16XXXX and PIC18XXXX devices.

The PICDEM 4 can be used stand-alone with a programmed part, with an In-Circuit

Emulator (e.g., MPLAB

Sample programs are provided to demonstrate the unique features of the supported

devices.

The PICDEM 4 Kit comes with the following:

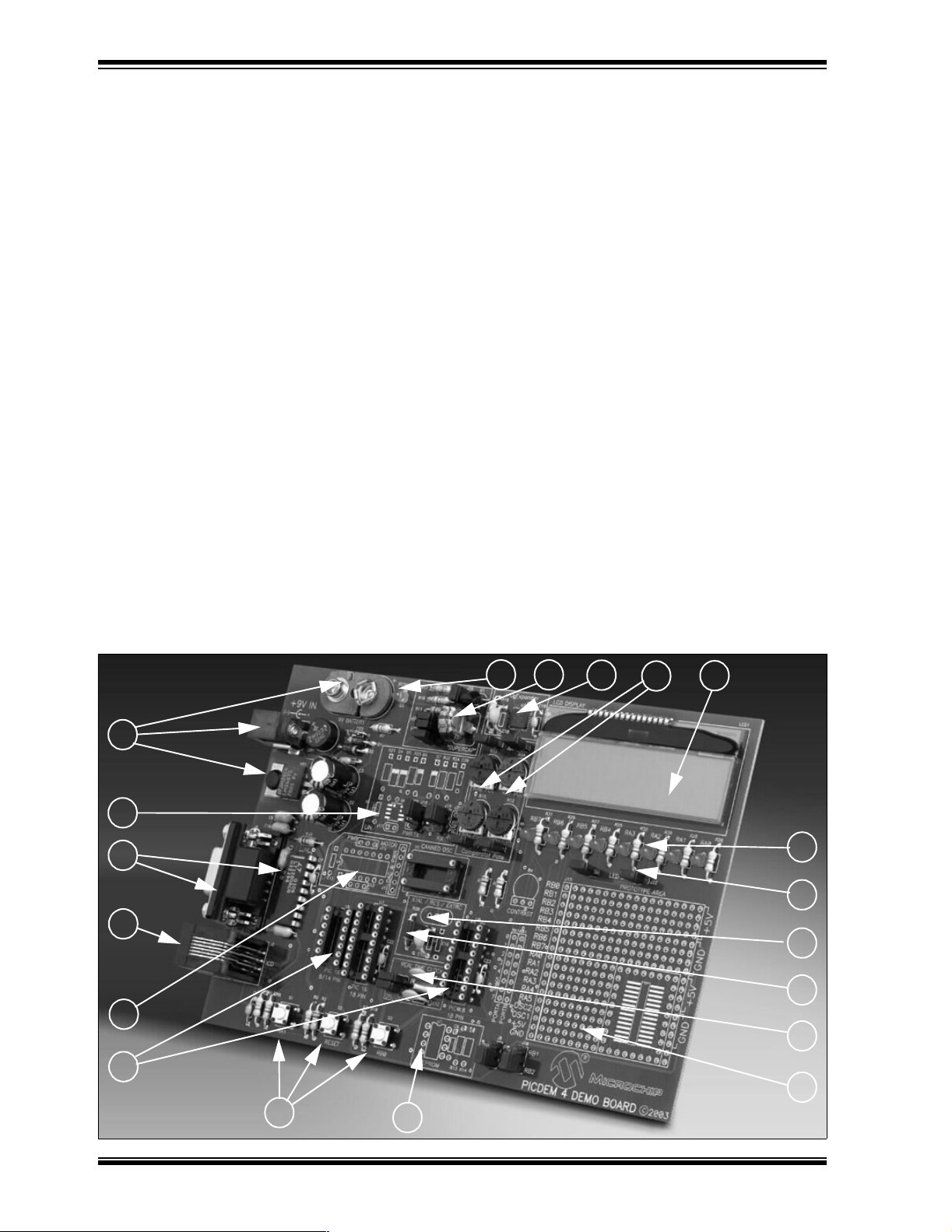

1. PICDEM 4 Demonstration Board (Figure 1-1)

2. Sample Devices

3. CD-ROM, which contains:

If you are missing any part of the kit, please contact your nearest Microchip sales office

listed in the back of this publication for help.

PICDEM 4 User’s Guide

Chapter 1. Introduction

®

ICE), or with an In-Circuit Debugger (e.g., MPLAB ICD 2).

a) Sample Programs

b) PICDEM 4 Demonstration Board User’s Guide

c) Application Notes

2003 Microchip Technology Inc. DS51337A-page 1

Page 6

PICDEM 4 User’s Guide

1.2 PICDEM 4 DEMONSTRATION BOARD

The PICDEM 4 demonstration board has the following hardware features:

1. 8-, 14- and 18-pin DIP sockets. (Although 3 sockets are provided, only one

device may be used at a time.)

2. On-board +5V regulator for direct input from 9V, 100 mA AC/DC wall adapter or

9V battery, or hooks for a +5V , 100 mA regulated DC supply.

3. RS-232 connection and associated hardware for direct connection to RS-232

interface.

4. In-Circuit Debugger (ICD) connector.

5. Four 5 k

6. Three push button switches for external stimulus and RESET.

7. Green power-on indicator LED.

8. Eight red LEDs connected to PORTA and PORTB.

9. Jumpers J21 and J22 to disconnect LEDs from PORTA and PORTB.

10. Unpopulated holes provided for crystal connection.

11. 32.768 kHz crystal for Timer1 Real-Time Clock operation.

12. Jumper J14 to disconnect on-board RC oscillator (R20 and C15, approx. 2 MHz).

13. Unpopulated holes for EEPROM.

14. 2 x 16 LCD display.

15. Prototype area for user hardware.

16. PIC16LF72 I/O expander.

17. Supercapacitor circuitry.

18. Unpopulated holes for a LIN transceiver.

19. Unpopulated holes for a motor driver.

Ω pots for devices with analog inputs and comparators.

FIGURE 1-1: PICDEM 4 HARDWARE

2

18

3

4

19

1

6

13

7

17

16

5

14

8

9

10

12

11

15

DS51337A-page 2 2003 Microchip Technology Inc.

Page 7

1.3 SAMPLE DEVICES

Two FLASH devices are included. The device types may change, but will generally

include PIC16XXXX and PIC18XXXX 18-pin DIP devices.

1.4 SAMPLE PROGRAMS

The PICDEM 4 Kit includes a CD-ROM with sample demonstration programs. These

programs may be used with the included sample devices, with an In-Circuit Emulator

(ICE), or with an In-Circuit Debugger (ICD). For each type of device (PIC16XXXX or

PIC18XXXX), demo source code (several ASM files) and compiled code (one HEX file)

are provided.

1.5 PICDEM 4 USER’S GUIDE

This document describes the PICDEM 4 demonstration board, tutorial and demonstration software. Detailed information on individual microcontrollers may be found in the

device’s respective data sheet. Detailed information on In-Circuit Emulator (ICE) or

In-Circuit Debugger (ICD) systems may be found in the respective tool’s user’s guide.

Chapter 1: Introduction – This chapter introduces the PICDEM 4 and provides a brief

description of the hardware.

Chapter 2: Getting Started – This chapter goes through a basic step-by-step process

for getting your PICDEM 4 up and running as a stand-alone board, or with an ICE or

ICD.

Chapter 3: Tutorial – This chapter provides a detailed description of the tutorial

program.

Appendix A: Hardware Detail – This appendix describes in detail the hardware of the

PICDEM 4 board.

Introduction

1.6 REFERENCE DOCUMENTS

Reference Documents may be obtained by contacting your nearest Microchip sales

office (listed in the back of this document), or by download from the Microchip web site

(www.microchip.com).

• Technical Library CD-ROM (DS00161) or individual data sheets:

- PIC16F627A/628A/648A Data Sheet (DS40044)

- PIC18F1220/1320 Data Sheet (DS39605)

- PICmicro

- PICmicro

• MPLAB

• MPASM User’s Guide with MPLINK and MPLIB (DS33014)

• PRO MATE

• PICSTART

• MPLAB

• MPLAB

• Microchip Third Party Guide (DS00104)

TM

Mid-Range MCU Family Reference Manual (DS33 023 )

®

18C MCU Family Reference Manual (DS39500)

®

IDE Simulator, Editor User’s Guide (DS51025)

®

II User’s Guide (DS 30 082)

®

Plus User’s Guide (DS51028)

®

ICE Emulator User’s Guide (DS51159)

®

ICD 2 In-Circuit Debugger Quick Start Guide (DS51268)

2003 Microchip Technology Inc. DS51337A-page 3

Page 8

PICDEM 4 User’s Guide

NOTES:

DS51337A-page 4 2003 Microchip Technology Inc.

Page 9

PICDEM 4 User’s Guide

Chapter 2. Getting Started

The PICDEM 4 may be used as a stand-alone board with a preprogrammed device,

with an In-Circuit Emulator (ICE), or with an In-Circuit Debugger (ICD). For a list of

PICmicro microcontroller compatible ICEs or ICDs, please refer to the Development

Systems Ordering Guide or the Microchip Third Party Guide.

2.1 PICDEM 4 AS A STAND-ALONE BOARD – PREPROGRAMMED DEVICE

The PICDEM 4 may be demonstrated immediately by following the steps listed below:

• Place the preprogrammed sample device in the appropriate socket on the

PICDEM 4 board.

• Apply power to the PICDEM 4. For information on acceptable power sources,

see Appendix A.

Note: In the event that the preprogrammed PICDEM 4 demonstration board does

not operate, check the following conditions:

- J8/J10 must be connected for the appropriate device

- J3, J4, J7, J9, and J24 - J27 must be ON

- J23 and J28 must be OFF

The status of all other jumpers will not affect the preprogrammed

demonstration.

To reprogram the sample device, the following will be necessary:

1. Program source code.

User source code may be used to program the device or, if this has previously been

done, the sample program may be restored from the file on the included CD-ROM.

2. An assembler, such as MPASM

compiler, such as MPLAB C18 (PIC18XXXX devices only).

Source code must be assembled or compiled into a HEX file before it can be programmed into the device. Microchip Technology’s MPASM assembler or MPLAB

C18 C compiler may be used. Both are compatible with MPLAB IDE; however,

other assemblers/compilers may be used. For a list of these PICmicro MCU

compatible language tools, please refer to the Microchip Third Party Guide.

3. A device programmer, such as PRO MATE II, PICSTAR T Plus, or MPLAB ICD 2

(programmer functionality available with MPLAB IDE v6.00 or greater).

Once the sample program is in HEX file format, a programmer may be used to program a FLASH device. Microchip T echnology’s PRO MATE II device programmer,

PICSTART Plus development programmer, or MPLAB ICD 2 may be used. All are

compatible with MPLAB IDE. However, other programmers may be used. For a list

of these PICmicro MCU compatible programmers, please refer to the Microchip

Third Party Guid e.

If the code protection bit(s) have not been programmed, the on-chip program

memory can be read out for verification purposes.

TM

assembler (available with MPLAB IDE), or a

2003 Microchip Technology Inc. DS51337A-page 5

Page 10

PICDEM 4 User’s Guide

2.2 PICDEM 4 USED WITH AN IN-CIRCUIT EMULATOR OR IN-CIRCUIT DEBUGGER

To use PICDEM 4 with an In-Circuit Emulator (ICE) or In-Circuit Debugger (ICD), refer

to the tool’s user’s guide for instructions on how to power-up and configure the

ICE/ICD, as well as how to connect to target boards (e.g., Figure 2-1).

FIGURE 2-1: PICDEM 4 CONNECTED TO MPLAB ICD 2 USING USB

Configure the PICDEM 4 for the desired oscillator as described in Table 2-1. Refer to

the ICE/ICD user’s guide for any oscillator configuration requirements.

TABLE 2-1: OSCILLATOR SELECTION

Oscillator Selection on

PICDEM 4

RC J14 ON, Y3 empty, Y1 empty

Crystal J14 OFF, Y1 empty, crystal in Y3, caps in C15 and C16

Canned Oscillator J14 OFF, oscillator in Y1 (Y3, C15, C16 empty)

Device Internal Oscillator J14 OFF, Y1 empty, Y3 empty

Resonator - no internal caps J14 OFF, Y1 empty, resonator in Y3, caps in C15 and C16

Resonator - with internal

caps

DS51337A-page 6 2003 Microchip Technology Inc.

J14 OFF, Y1 empty, resonator in Y3, C15 and C16 empty

Modification on PICDEM 4

Page 11

PICDEM 4 User’s Guide

Chapter 3. Tutorial

The tutorial program is preprogrammed into the sample device (for example,

p16PDEM4_Demo.hex for a PIC16XXXX device and p18PDEM4_Demo.hex for a

PIC18XXXX device). Also, this program is on the included CD-ROM program disk for

user reference (i.e., if the sample device has been reprogrammed with another

program, the tutorial may be reprogrammed into the device).

For detailed information on the PICDEM 4 hardware, please refer to Appendix A.

3.1 TUTORIAL FIRMWARE OPERATION

The PIC18F tutorial firmware is made up of two components, which are individually

displayed on the LCD. The PIC

system clock source.

1. Voltmeter

This mode uses the A/D module to measure the voltage of the R33 pot and displays a voltage between 0.00V and 5.00V on the LCD. Voltage is continually

updated until the mode is exited by pressing SW3 (RB0).

2. Clock

Once this mode is entered from the main menu, a real-time clock will start counting from 00:00:00. The Timer1 module and a 32 kHz clock crystal is used to

establish a Real-Time Clock. By pressing SW1, the clock time can be set to the

user's preference. After SW1 has been pressed, the cursor will flash over the

hours digits. Press SW1 and the cursor will now flash over the minutes digits.

SW3 is used to increment hours and minutes whenever the cursor is flashing

over either. After the minutes have been set, press SW1 and the time will be set

and the LCD is returned to an active clock display.

The PIC16F tutorial firmware is made up of one component, which uses the comparator

module and potentiometers R12, R15, R33, and R34. Turning the potentiometers will

vary the voltages to the PIC16 inputs, thereby changing the results of the comparator

outputs. The LCD will be used for displaying these results.

®

microcontroller’s internal RC oscillator is used as the

2003 Microchip Technology Inc. DS51337A-page 7

Page 12

PICDEM 4 User’s Guide

FIGURE 3-1: PIC18F TUTORIAL PROGRAM FLOW CHART

Power-up

"Microchip

Voltmeter

SW1 = Next

SW3 = Now

Real-Time Clock

SW1 = Next

SW3 = Now

PICDEM 4"

SW3

SW1

SW3

SW1 SW3

Volts = 1.93V

SW3 = Exit Test

00:00:00

SW1 = Set

SW3 = Menu

00:00:00

SW1 = -> SW3 = ++

SW3

SW1

SW1 (2x)

3.2 SOURCE CODE AND APPLICATION NOTES

In addition to the assembled tutorial programs (HEX files), source code used to create

these HEX files is included on the PICDEM 4 CD-ROM. Both source code and related

HEX file are found in device specific directories.

Application Notes are also included on the CD-ROM for additional examples of use.

For information on how to reprogram the device with new or modified code, or how to

restore the tutorial program, please see Section 2.1.

DS51337A-page 8 2003 Microchip Technology Inc.

Page 13

PICDEM 4 User’s Guide

Appendix A. Hardware Detail

The PICDEM 4 hardware is uncomplicated and is intended to illustrate the ease of use

of various PICmicro MCUs. The PICDEM 4 features the following hardware elements.

Note: Many of the following hardware sections will require specific demo board

jumper configurations. If a jumper is not listed in a particular section, then

that jumper has no effect on the circuitry within the hardware section you

are working. Figure A-1 shows a diagram of the PICDEM 4 silkscreen with

all necessary jumpers highlighted. Also, refer to the schematic for circuit

connections.

2003 Microchip Technology Inc. DS51337A-page 9

Page 14

PICDEM 4 User’s Guide

FIGURE A-1: PICDEM 4 DEMONSTRATION BOARD PARTS LAYOUT (SILKSCREEN)

J22

J21

J15

J10

J8

J25

J24

J28

J4

J3

J23

J19 J20

J16 J18

J27

J26

J14

J7

J9

J11

J17

J12

J13

DS51337A-page 10 2003 Microchip Technology Inc.

Page 15

A.1 PROCESSOR SOCKETS

Although three sockets are provided, only one device may be used at a time.

• 8- or 14-pin socket (U5) used for 8- or 14-pin devices (8-pin devices are inserted

in the upper 8 pins of U5)

• 18-pin PIC16 socket (U7)

• 18-pin PIC18 socket (U8)

A.2 LED DISPLAY

Eight red LEDs are connected to PORTA and PORTB of U7 and U8, while five of the

eight LEDs are connected to U5. PORTA and PORTB pins are set high to light the

LEDs. These LEDs may be disconnected from PORTA and PORTB by removing

jumpers J21 and J22.

One green LED is provided to determine whether there is power to the PICDEM 4

board (LED on) or not (LED off).

A.3 POWER SUPPLY

There are three ways to supply power to PICDEM 4:

• A 9V battery can be plugged into J2.

• A 9V, 100 mA unregulated AC or DC supply can be plugged into J1. A power

supply can be purchased through Microchip, Part # AC162039.

• A +5V, 100 mA regulated DC supply can be connected to the hooks provided.

Hardware Detail

Note 1: There are two jumpers (J3 and J4) associated with the power

MPLAB ICE 2000 users have a regulated +5V power supply available in the logic probe

connector and can easily connect to the hooks on PICDEM 4 (Red probe to +5V and

Black probe to GND).

MPLAB ICD 2 users may use the ICD to power the target board to 5V , up to 200 mA, if

the MPLAB ICD 2 is connected to the PC with a serial cable.

A.4 RS- 2 32 SERIAL PORT

An RS-232 level shifting IC has been provided with all necessary hardware to support

connection of an RS-232 host through the DB9 connector. The port is configured as

DCE, and can be connected to a PC using a straight through cable.

The PIC16/PIC18 RX and TX pins are tied to the RX and TX lines of the LT1280ACN.

Unlike previous demo boards, the RS-232 chip has an ON/OFF pin which is connected

to I/O pin RB3. For RS-232 operation, these jumpers must be configured as follows:

PIC16

• J18/19 - Upper two pins ON

• J20 - OFF (if populated)

supply circuit. These jumpers must be on for all functions,

with the exception of the Supercapacitor Circuit. Refer to

Section A.12 “Supercapacitor” for further details.

2: The PICDEM 4 kit does not include a power supply.

PIC18

• J18/19 - Lower two pins ON

2003 Microchip Technology Inc. DS51337A-page 11

Page 16

PICDEM 4 User’s Guide

A.5 SWITCHES

Three switches provide the following functions:

• S1 - Active low switch connected to RA4

• S2 - MCLR

• S3 - Active low switch connected to RB0

Switch S2 has a debounce capacitor, whereas S1 and S3 do not, allowing the user to

investigate debounce techniques.

When pressed, the switches are grounded; when idle, they are pulled high (+5V).

A.6 OSCILLATOR OPTIONS

• RC oscillator (2 MHz approximately) supplied. This oscillator may be disabled by

removing jumper J14.

• Pads provided for user furnished crystal/resonator and two capacitors (Y3).

• Socket provided for a canned oscillator (Y1).

• 32.768 kHz (watch type) crystal for Timer1 (Y2). This oscillator can be disabled by

removing jumpers J7 and J9.

A.7 ANALOG INPUT

to hard reset the processor

There are four 5 kΩ potentiometers (R12, R15, R33, R34) on the PICDEM 4 board.

These are all connected to PORTA (RA0-RA3), and can be adjusted from V

to provide an analog input to the devices with an A/D or Comparator module.

Potentiometers R12, R15, R33, and R34 all have individual jumpers. For a potentiometer to function, its specific jumper must be on. The jumper removed will allow for other

I/O functi ons to t ake plac e. For all of the pot entiomet ers to be f unctiona l, thes e jumpers

must be configured as follows:

• J22 - OFF (PORTA LEDs)

•J24 - ON

•J25 - ON

• If J26 is ON, then J23 is OFF

• If J27 is ON, then J28 is OFF

The above conditions will enab le all potent iom ete rs .

A.8 ICD CONNECTOR

By way of the modular connector (J5), the MPLAB ICD 2 can be connected for low cost

debugging. The ICD connector utilizes RB6 and RB7 of the microcontroller for in-circuit

debugging. For ICD operation, the Real-time Clock connections to the microcontroller

must be disabled. For ICD operation, these jumpers must be configured as follows:

• J7 - OFF (RTC)

• J9 - OFF (RTC)

• J21 - OFF (PORTB LEDs)

SS to VDD

DS51337A-page 12 2003 Microchip Technology Inc.

Page 17

A.9 SERIAL EEPROM

For EEPROM operation, these jumpers must be configured as follows:

PIC16

• J8/10 - Upper two pins ON

• J21 - OFF (PORTB LEDs)

PIC18

• J8/10 - Lower two pins ON

• J21 - OFF (PORTB LEDs)

For more information on the serial EEPROM, please refer to the most recent version of

the Technical Library CD-ROM.

A.10 MOTOR

There are three headers (J11, J12, and J13) for the motor driver circuit. These will allow

for external power and load connections. For motor control operation, these jumpers

must be configured as follows:

J11

Hardware Detail

• Left 2 pins: Board PWR

• Right 2 pins: External PWR

J13

• Left 2 pins: Board GND

• Right 2 pins: External GND

J12

• Connect External Power Source and Load. Lower pin (1) is PWR, top pin is GND.

•J19 - OFF

2003 Microchip Technology Inc. DS51337A-page 13

Page 18

PICDEM 4 User’s Guide

A.10.1 PICDEM 4 Motor Control Demo

The TC4467 devices are a family of four output CMOS buffers/MOSFET drivers. The

PICmicro MCU PWM output is connected to these drivers to create a variety of possible

driving conditions. The following figures show a few of these possible configurations.

The driver can directly drive the small load, or can act as a MOSFET driver for a bigger

load request.

FIGURE A-2: SINGLE OUTPUT MODE PWM

PA

RB3

TC4467

L

PA

RB3

1Y

1Y

TC4467

PA

TC4467

RB3

L

L = Load

A = Amplifier

1Y

L

A

FIGURE A-3: DIRECT H-BRIDGE DRIVER IN ECCP HALF-BRIDGE

OUTPUT MODE

PA

RB3

PB

RB2

TC4467

1Y

2Y

L

L = Load

A = Amplifier

DS51337A-page 14 2003 Microchip Technology Inc.

Page 19

FIGURE A-4: HALF-BRIDGE MODE PWM

Hardware Detail

PA

RB3

PB

RB2

PA

RB3

PB

RB2

TC4467

TC4467

1Y

2Y

2Y

1Y

A

A

A

A

L

L

L = Load

A = Amplifier

FIGURE A-5: DUAL OUTPUT PWM IN H-BRIDGE CONFIGURATION

PA

TC4467

RB3

PB

RB2

L = Load

A = Amplifier

1Y

2Y

A

A

A

L

A

PA

RB3

PB

RB2

TC4467

1Y

2Y

A

A

A

L

A

2003 Microchip Technology Inc. DS51337A-page 15

Page 20

PICDEM 4 User’s Guide

A.11 LIN

The PICDEM 4 is designed with an optional LIN circuit (not populated). This circuit

provides the essential circuitry to interface a PICmicro microcontroller to a Local

Interconnect Network (LIN). The circuit includes a MCP201 LIN transceiver, reverse

voltage protection, and over voltage protection.

Jumpers J16, J17, J18, J19, and J20 are provided to set up and connect a PICmicro

microcontroller on PICDEM 4 to the LIN bus. External jumper J16 provides the connection to the LIN bus. With the MCP201 installed, power to the PICDEM 4 can be supplied

from the LIN bus battery connection via J16; shorting J17 enables bus power to the

circuitry beyond the LIN interface circuit (refer to the MCP201 voltage regulator

specifications for maximum conditions).

Jumpers J18, J19, and J20 provide connections to the microcontroller on the

PICDEM 4. Shorting the appropriate pins (shown on the schematic) can connect either

a PIC16 or PIC18 device to the LIN transceiver. J18 connects the LIN TX pin to either

a PIC16 or PIC18 microcontroller. J19 connects the LIN RX pin to either a PIC16 or

PIC18 microcontroller. J20 provides an additional receive connection for PIC16

devices. For LIN operation, these jumpers must be configured as follows:

•J17 - ON

PIC18

• J18/J19 - Lower two pins ON

•J21 - OFF

PIC16

• J18/J19 - Upper two pins ON

•J20 - ON

•J21 - OFF

DS51337A-page 16 2003 Microchip Technology Inc.

Page 21

A.12 SUPERCAPACITOR

The 0.33F (C5) Supercapacitor is used to demonstrate the low power capabilities of

PICmicro devices. This circuit requires all other peripherals to be disconnected from

the circuit. The Supercapacitor code, included on your PICDEM 4 CD, is configured so

that the device will remain in SLEEP most of the time, while a 32 kHz watch crystal (Y2)

connected to Timer1 keeps the PICmicro MCU running.

The device wakes up every second and toggles a port pin, and a second port pin indicates the power start-up. If a power source is present, a high level is maintained;

otherwise, in the absence of power, the pin will go low.

In the event of a power failure, the Supercapacitor will supply the PICmicro MCU with

power through an internal protection diode on a port pin. If the user desires to measure

the Supercapacitor supply time, they will have to observe the power signals with an

oscilloscope or another demo board.

Note: The Supercapacitor circuit described in this manual is used only to demon-

strate the low power cap ability of the device. Th e Supercap acitor is us ed as

an example for the low power source. DO NOT use this circuit as a

general design practice.

For Supercapacitor operation, these jumpers must be configured as follows:

• J3 - OFF (Power Supply)

• J4 - OFF (Power Supply)

• J22 - OFF (PORTA LEDs)

• J23 - ON (Supercapacitor)

• J26 - OFF (Potentiometer)

• J27 - OFF (Potentiometer)

• J28 - ON (LVD)

Hardware Detail

2003 Microchip Technology Inc. DS51337A-page 17

Page 22

PICDEM 4 User’s Guide

A.13 REAL-TIME CLOCK

This circui t all ows the user to conf igur e a PI Cmicr o MC U in eithe r th e U7 or U8 sock et

for timekeeping, using a 32.768 kHz clock crystal connected to Timer1’s T1OSO and

T1OSI pins. ICD operation will not be functional when the Real-Time Clock circuit is

enabled. For RTC operation, these jumpers must be configured as follows:

•J7 - ON

•J9 - ON

•J21 - OFF

A.14 LCD DISPLAY

An LCD display with two lines, 16 characters per line, is connected to the I/O Expander

(U3), which can be driven by all three device sockets.

A 10K pot may be installed into R4 to adjust contrast on the LCD. If this is done, R5 and

R6 need to be removed.

The LCD is connected to the I/O Expander by three control lines (E, R/W, RS), and four

data lines (DB7:DB4). For LCD operation, these jumpers must be configured as

follows:

PIC16

• J8/10 - Upper two pins ON

• J21 - OFF (PORTB LEDs)

PIC18

• J8/10 - Lower two pins ON

• J21 - OFF (PORTB LEDs)

DS51337A-page 18 2003 Microchip Technology Inc.

Page 23

A.15 DEVICE CONFIGURATION OVERVIEW

Table A-1 lists the I/O features and port connections for each processor type.

TABLE A-1: PORT CONNECTIONS

Connection Type

LEDs RA0:RA2, RB4, RB5 ALL ALL

RS-232 RB1/RB4 RB2/RB5 RB1/RB4

S1 RA4 RA4 RA4

S2 RA5 RA5 RA5

S3 RB0 RB0 RB0

R33 Pot RA0 RA0 RA0

R34 Pot RA1 RA1 RA1

R15 Pot RA2 RA2 RA2

R12 Pot N/A RA3 RA3

LCD RB1/RB4 RB1/RB4 RB1/RB4

EEPROM RB1/RB4 RB1/RB4 RB1/RB4

ICD N/A RB6/RB7 RB6/RB7

LIN N/A RB2/RB5/RB1 RB1/RB4

MOTOR RB2/RB3 RB2/RB3 RB2/RB3

RTC N/A RB6/RB7 RB6/RB7

CANNED OSC OSC1 OSC1 OSC1

RC OSCILLATOR OS C1 OSC1 OSC1

CRYSTAL/RESONATOR OSC1/OSC2 OSC1/OSC2 OSC1/OSC2

SUPERCAPACITOR

CIRCUITS

PIC12/PIC16

8- or 14-Pin

N/A RA2/RA3 RA2/RA3

Hardware Detail

Device

PIC16 18-Pin PIC18 18-Pin

2003 Microchip Technology Inc. DS51337A-page 19

Page 24

PICDEM 4 User’s Guide

A.16 BOARD LAYOUT AND SCHEMATICS

The following figures show the parts layout (silkscreen) and schematics for the

PICDEM 4 board.

FIGURE A-6: PICDEM 4 PARTS LAYOUT

J22

J21

J15

J10

J8

J25

J24

J20

J28

J3

J4

J23

J19

J18

J16

J27

J26

J14

J9

J7

J11

J17

J12

J13

DS51337A-page 20 2003 Microchip Technology Inc.

Page 25

FIGURE A-7: PICDEM 4 SCHEMATIC SHEET 1

Hardware Detail

2003 Microchip Technology Inc. DS51337A-page 21

Page 26

PICDEM 4 User’s Guide

FIGURE A-8: PICDEM 4 SCHEMATIC SHEET 2

Note: The Supercapacitor circuit described in this manual is used only to demonstrate the low power capability of the

device. The Supercapacitor is used as an example for the low power source. DO NOT use this circuit as a

general design practice.

DS51337A-page 22 2003 Microchip Technology Inc.

Page 27

PICDEM 4 User’s Guide

Index

A

A/D Input ........................................................... ...... ..2

B

Board ............................................................ 1, 2, 5, 9

Parts Layout ...............................................10, 20

Power Supply ............................................... 5, 11

Silkscreen .................................................. 10, 20

C

Clock ......................................................................... 7

D

Demonstration Board. See Board

Demonstration Programs. See Sample Programs

E

EEPROM, Serial .......................................................2

H

Hardware ..................................................................9

K

Kit Components ........................................................ 1

L

LCD .........................................................................18

LEDs

Green Power ................................................ 2, 11

Red Display ................................................. 2, 11

LIN, Transceiver ........................................................ 2

M

Microchip Third Party Guide ......................................3

MPASM Assembler ...................................................5

MPASM Assembler User’s Guide with

MPLINK Linker and MPLIB Librarian ................. 3

MPLAB C18 ..............................................................5

MPLAB ICD 2 ........................................1, 5, 6, 11, 12

MPLAB ICD 2 Quick Start Guide .............................. 3

MPLAB ICE ..................................................... 1, 6, 11

MPLAB ICE User’s Guide .........................................3

MPLAB IDE ............................................................... 5

MPLAB IDE User’s Guide .........................................3

O

Oscillator Options .................................................... 12

Oscillator Selection ...................................................6

P

PIC16F62XA Data Sheet ..........................................3

PIC16XXXX ...............................................................1

Tutorial Program ............ ...... ...... ..... ...... ............. 7

PIC18F1X20 Data Sheet ................................... ...... ..3

PIC18XXXX ...............................................................1

Tutorial Program ............ ...... ...... ..... ...... ............. 7

PICDEM 4 Board. See Board

PICDEM 4 Kit. See Kit Components

PICmicro 18C MCU Family Reference Manual ......... 3

PICmicro Mid-Range MCU Family

Reference Manual ..............................................3

PICSTART Plus ........................................................5

PICSTART Plus User’s Guide ................................... 3

PRO MATE II ............................................................5

PRO MATE II User’s Guide ....................................... 3

Push Buttons. See Switches

R

Reference Documents ..............................................3

RS-232 ................................................................ 2, 11

S

Sample Devices ....................................................1, 3

Sample Programs .................................................1, 3

Sockets ...................................................................11

Supercapacitor .......................................................... 2

Switches ..............................................................2, 12

T

Tutorial ...................................................................... 7

V

Voltmeter ................................................................... 7

2003 Microchip Technology Inc. DS51337A-page 23

Page 28

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Atlanta

3780 Mansell Road, Suite 130

Alpharetta, GA 30022

Tel: 770-6 40- 003 4 Fax: 770- 640 -03 07

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-6 92- 384 8 Fax: 978- 692 -38 21

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-8 18- 742 3 Fax: 972- 818 -29 24

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-2 63- 188 8 Fax: 949- 263 -13 38

Phoenix

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-4338

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-4 36- 795 0 Fax: 408- 436 -79 55

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Cana da

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Marketing Support Division

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beij ing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401-2402, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-86766200 Fax: 86-28-86766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Hong Kong SAR

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1812, 18/F, Building A, United Plaza

No. 5022 Binhe Road, Futian District

Shenzhen 518033, China

Tel: 86-755-82901380 Fax: 86-755-82966626

China - Qingdao

Rm. B505A, Fullhope Plaza,

No. 12 Hong Kong Central Rd.

Qingdao 266071, China

Tel: 86-532-5027355 Fax: 86-532-5027205

India

Microchip Technology Inc.

India Liaison Office

Marketing Support Division

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Microchip Technology (Barbados) Inc.,

Taiwan Branch

11F-3 , No . 207

Tung Hua North Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Austria

Microchip Technology Austria GmbH

Durisolstrasse 2

A-4600 Wels

Austria

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark

Microchip Technology Nordic ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53 -63-20 Fax: 33-1-69-30-90-79

Germany

Microchip Technology GmbH

Steinheilstrasse 10

D-85737 Ismaning, Germany

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy

Microchip Technology SRL

Via Quasimodo, 12

20025 Legnano (MI)

Milan, Italy

Tel: 39-0331-742611 Fax: 39-0331-466781

United Kingdom

Microchip Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG41 5TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

03/25/03

DS51337A-page 24 2003 Microchip Technology Inc.

Loading...

Loading...