Page 1

PIC24H

Family Overview

High-Performance 16-Bit

Microcontrollers

© 2005 Microchip Technology Inc. Preliminary DS70166A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such ac t s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of M icrochip’s prod ucts as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor,

MPASM, MPLIB, MPLINK, MPSIM, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, rfLAB, rfPICD EM, Select Mode,

Smart Serial, SmartTel, Total Endurance and WiperLock are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2005, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

DS70166A-page ii Preliminary © 2005 Microchip Technology Inc.

Page 3

PIC24H

PIC24H High-Performance 16-Bit MCU Overview

Operating Range

• DC – 40 MIPS ( 40 M IPS @ 3. 0-3 .6 V, -40° to +8 5°C)

• Industrial temperature range (-40° to +85°C)

High-Performance DSC CPU

• Modified Harvard architecture

• C compiler optimized instruction set

• 16-bit wide data path

• 24-bit wide instructions

• Linear program memory addressing up to 4M

instruction words

• Linear data m emory addressing up to 64 Kbytes

• 74 base instructions: mostly 1 word/1 cycle

• Sixteen 16-bit general-purpose registers

• Flexible and powerful addressing modes

• Software stack

• 16 x 16 integer multiply operations

• 32/16 and 16/16 divide operations

• Single-cycle multiply

• Up to ± 16-bit shifts

Direct Memory Access (DMA)

• 8-channel hardware DMA

• Allows data transfer between RAM and a

peripheral while CPU is executing code (no cycle

stealing)

• 2 KB of dual-porte d DM A bu f fe r area (DMA RAM)

to store data transferred via DMA

• Most peripherals support DMA

Interrupt Controller

• 5-cycle latency

• 118 interrupt vectors

• Up to 61 available interrupt sources, up to

5 external interrupts

• 7 programmable priority level s

• 5 processor exceptions

Digital I/O

• Up to 85 programmable digital I/O pins

• Wake-up/Interrupt-on-Change on up to 24 pins

• Output pins can drive from 3.0V to 3.6V

• All digital input pins are 5V tolerant

• 4 mA sink and source on all I/O pins

On-Chip Flash and SRAM

• Flash program memory, up to 256 Kbytes

• Data SRAM (up to 30 Kbytes):

- Includes 2 KB of DMA RA M

System Management

• Flexible clock options:

- External, crystal, resonator, internal RC

- Fully integrated P LL

- Extremely low jitter PLL

• Power-up timer

• Oscillator Start-up Timer/Stabilizer

• Watchdog timer with its own RC oscillator

• Fail-Safe Clock Mo nito r

• Reset by multiple sources

Power Management

• On-chip 2.5V voltage regulator

• Switch between clock sources in real time

• Idle, Sleep and Doze modes with fast wake-up

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 1

Page 4

PIC24H

Timers/Capture/Compare/PWM

• Timer/Counters: up to nine 16-bit timers:

- Can pair up to make four 32-bit timers

- 1 timer runs as Real-Time Clock with external

32 kHz oscill ator

- Programmable prescaler

• Input Capture (up to 8 channels):

- Capture on up, down or both edges

- 16-bit capture input functions

- 4-deep FIFO on each capture

• Output Compare (up to 8 channels):

- Single or Dual 16-Bit Compare mode

- 16-Bit Glitchless PWM mode

Communication Modules

• 3-wire SPI™ (up to 2 modules):

- Framing supports I/O interface to simple

codecs

- Supports 8-bit and 16-bit data

- Supports all serial clock formats and

sampling modes

- 8-word FIFO buffers

2

C™ (up to 2 modules):

•I

- Full Multi-Master Slave mode s upport

- 7-bit and 10-bit addressing

- Bus collision detection and arbitration

- Integrated signal conditioning

-Address masking

• UART (up to 2 modules):

- Interrupt-on-address bit detect

- Wake-up-on-Start bit from Sleep mode

- 4-character TX and RX FIFO buffers

- LIN bus support

®

-IrDA

- High-Speed Baud mode

• Enhanced CAN 2.0B active (up to 2 modules):

- Up to 8 transmit and up to 32 receive buffers

- 16 receive filters and 3 masks

- Loopback, Listen Only and Listen All

- Wake-up on CAN message

- FIFO mode using DMA

encoding and decoding in hardware

Messages modes for diagnostics and bus

monitoring

Analog-to-Digit al Converters (ADC)

• Up to two 10-bit or 12-bit ADC modules in a

device

• 10-bit 2.2 Msps or 12-bit 1 Msps conversion:

- 2, 4 or 8 simultaneous samples

- Up to 32 input channels with auto-scanning

- Conversion start can be manual or

synchronized with 1 of 4 trigger sources

- Conversion possible in Sleep mode

- ±1 LSB max integral nonlinearity

- ±1 LSB max differential nonlinearity

CMOS Flash T echnology

• Low-power, high-speed Flash technology

• Fully static design

• 3.3V (+/- 10%) operating voltage

• Industrial temperature

• Low-power consumption

Packaging:

• 100-pin TQ FP (14x14x1 mm and 12x12x 1 mm)

• 64-pin TQFP (10x10x1 mm)

Note: See Table 1-1 for exact peripheral

features per device.

DS70166A-page 2 Preliminary © 2005 Microchip Technology Inc.

Page 5

1.0 PIC24H PRODUCT FAMILIES

1.1 General-Purpose Family

The PIC24H General-purpose Family (Table 1-1)

is ideal for a wide variety of 16-bit MCU embedded

applications. The variants with codec interfaces are

well-suited for audio applications.

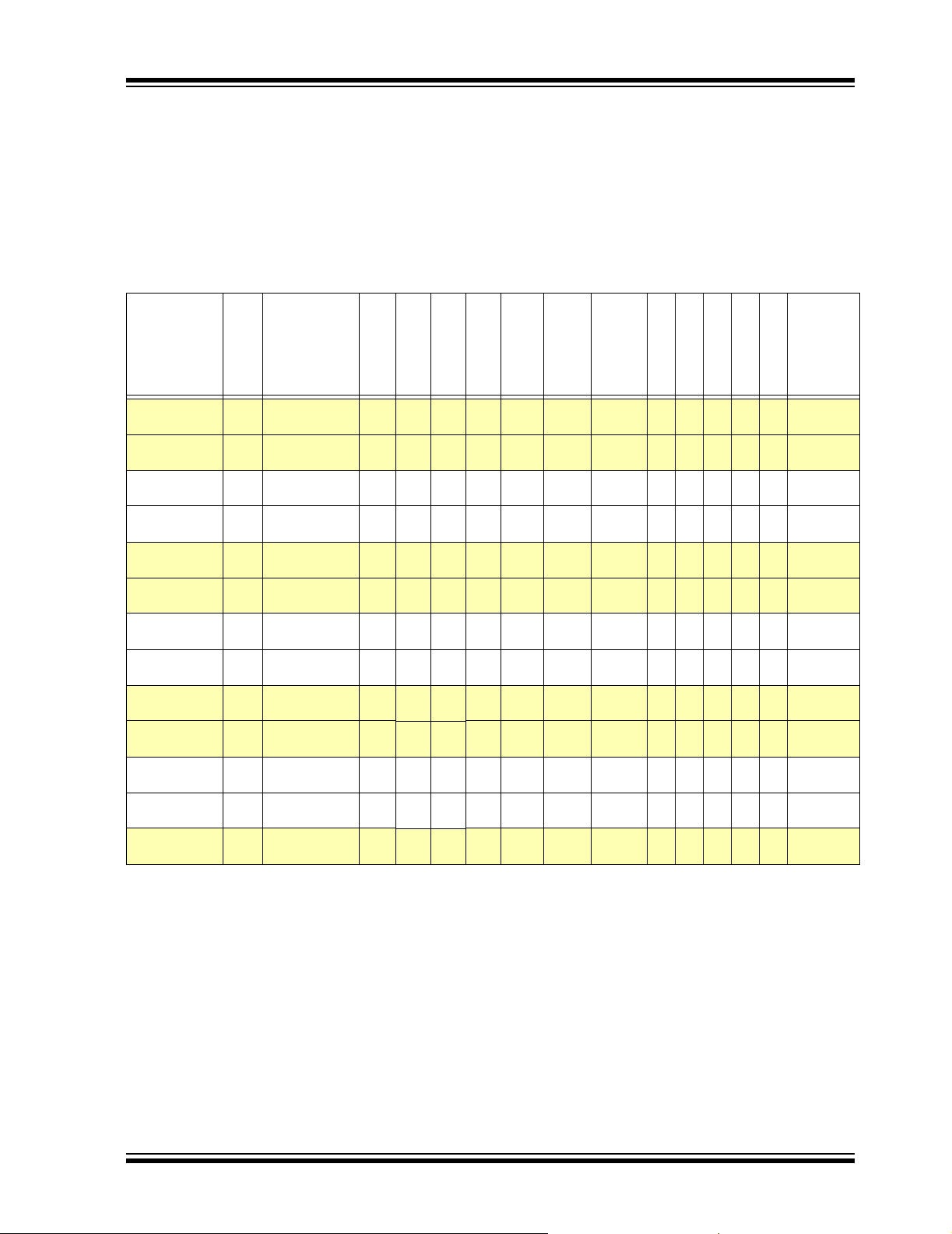

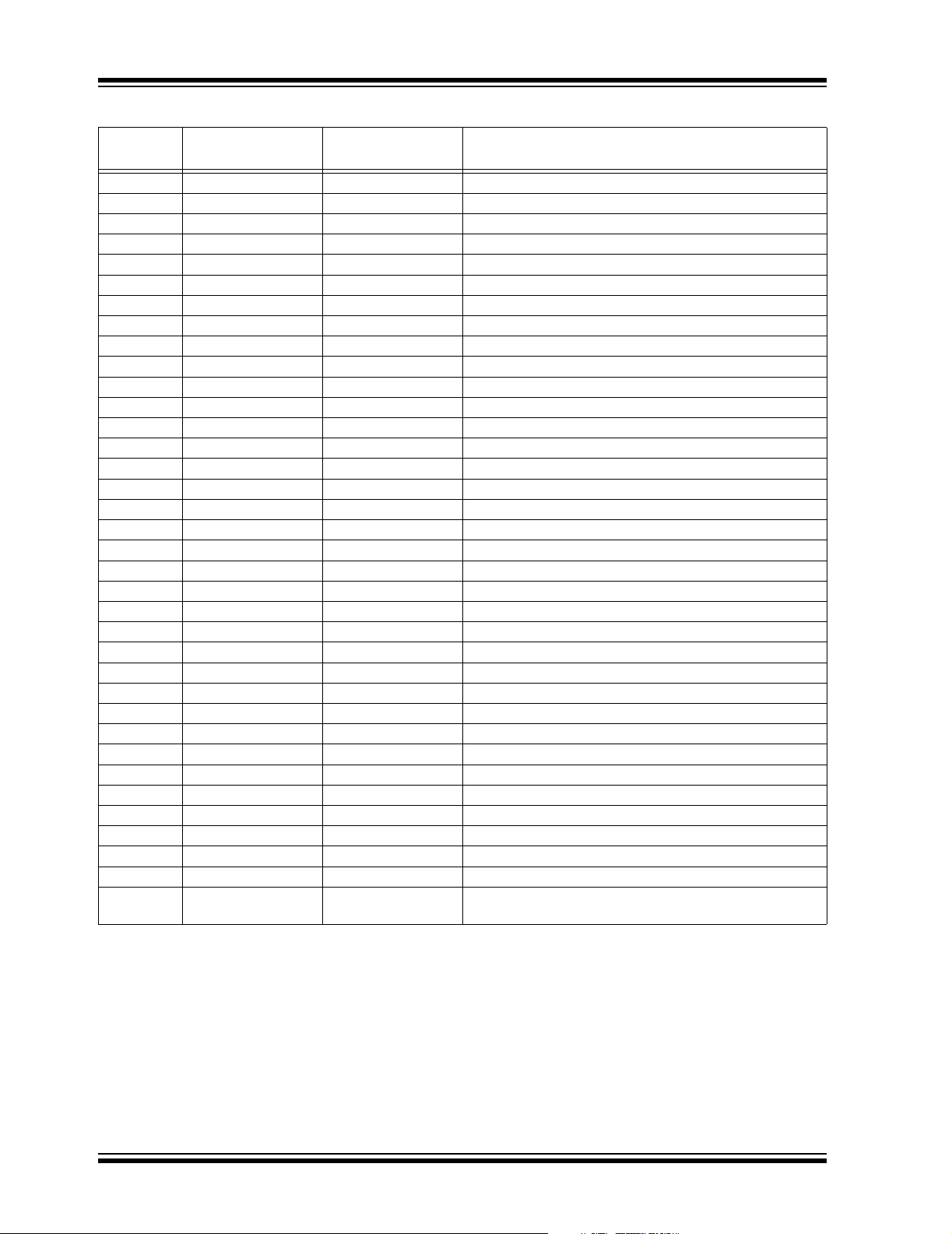

TABLE 1-1: PIC24H GENERAL-PURPOSE FAMILY VARIANTS

PIC24H

(2)

Device Pins

24HJ64GP206 64 64 8 8 9 8 8 0 1 ADC,

24HJ64GP210 100 64 8 8 9 8 8 0 1 ADC,

24HJ64GP506 64 64 8 8 9 8 8 0 1 ADC,

24HJ64GP510 100 64 8 8 9 8 8 0 1 ADC,

24HJ128GP206 64 128 8 8 9 8 8 0 1 ADC,

24HJ128GP210 100 128 8 8 9 8 8 0 1 ADC,

24HJ128GP506 64 128 8 8 9 8 8 0 1 ADC,

24HJ128GP510 100 128 8 8 9 8 8 0 1 ADC,

24HJ128GP306 64 128 16 8 9 8 8 0 1 ADC,

24HJ128GP310 100 128 16 8 9 8 8 0 1 ADC,

24HJ256GP206 64 256 16 8 9 8 8 0 1 ADC,

24HJ256GP210 100 256 16 8 9 8 8 0 1 ADC,

24HJ256GP610 100 256 16 8 9 8 8 0 2 ADC,

Note 1: RAM size is inclusive of 2 KB DMA RAM.

2: Maximum I/O pin count includes pins shared by the peripheral functions.

Program Flash

Memory (KB)

(1)

RAM

(KB)

Interface

18 ch

32 ch

18 ch

32 ch

18 ch

32 ch

18 ch

32 ch

18 ch

32 ch

18 ch

32 ch

32 ch

ADC

Codec

Timer 16-bit

DMA Channels

Input Capture

Std. PWM

Output Compare

CAN

Packages

I/O Pins (Max)

C™

2

I

SPI™

UART

2 2 1 0 53 PT

2 2 2 0 85 PT

222153 PF, PT

222185 PT

2 2 2 0 53 PT

2 2 2 0 85 PF, PT

222153 PT

222185 PT

2 2 2 0 53 PF, PT

2 2 2 0 85 PT

222053 PT

222085 PF, PT

2 2 2 2 85 PF, PT

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 3

Page 6

PIC24H

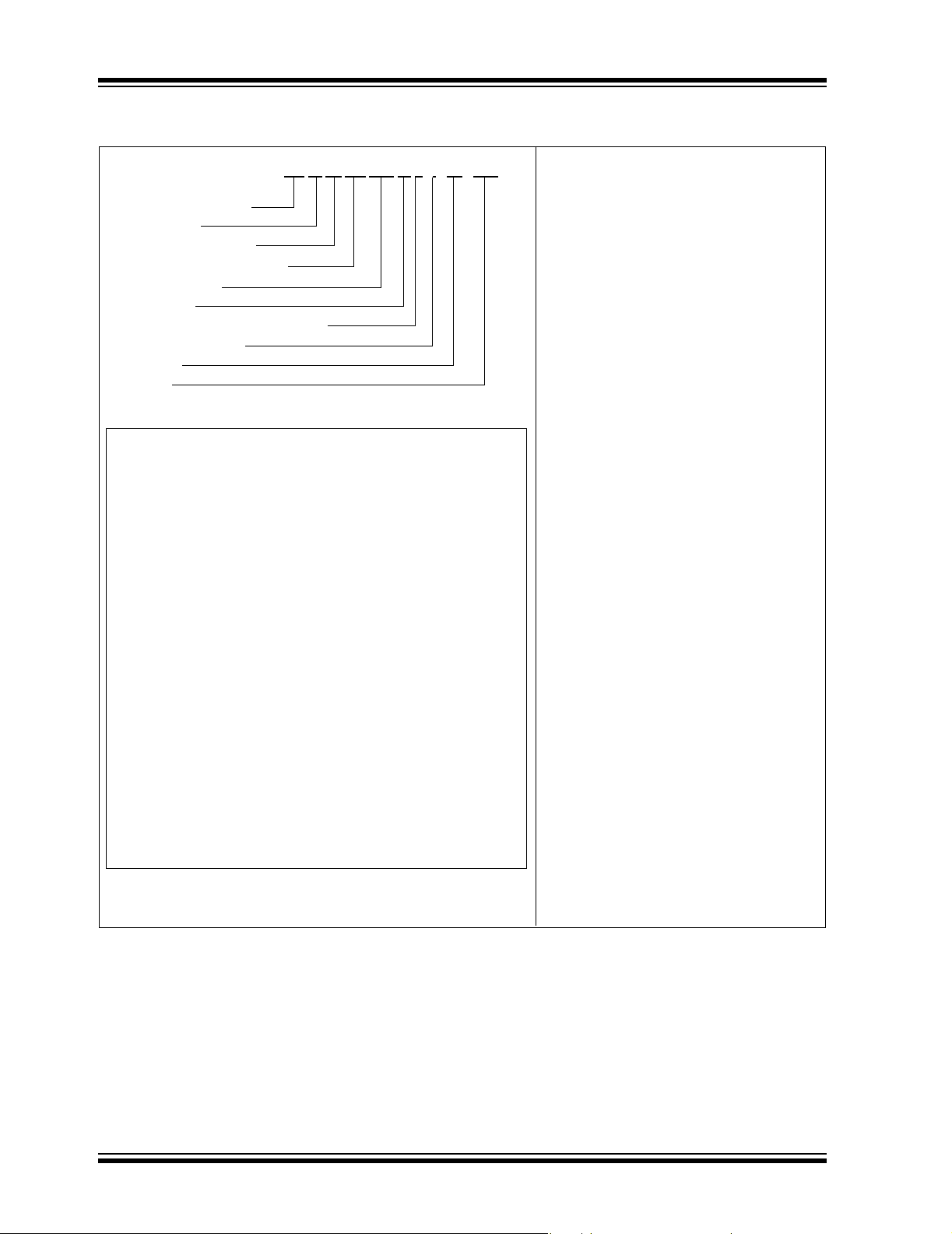

PRODUCT IDENTIFICATION SYSTEM

24 HJ 256 GP6 10 T I / PT - XXX

PIC

Microchip Trademark

Architecture

Flash Memory Family

Program Memory Size (KB)

Product Group

Pin Count

Tape and Reel Flag (if applicable)

Temperature Range

Package

Pattern

Architecture 24 = 16-bit Microcontroller

Flash Memory Family HJ = Flash program memory, 3.3V, high-speed

Program Memory Size 64 = 64 Kbytes

Product Group GP2 = General Purpose family

128 = 128 Kbytes

256 = 256 Kbytes

GP3 = Gene ra l Purp ose fami ly

GP5 = Gene ra l Purp ose fami ly

GP6 = Gene ra l Purp ose fami ly

Examples:

a) dsPIC24HJ64GP610I/PT:

General Purpose dsPIC24H, 64 KB program

memory, 100-pin, Industrial temp.,

TQFP package.

b) dsPIC24HJ64GP206I/PT-ES:

Motor Control dsPIC24H, 64 KB program

memory, 64-pin, Industrial temp.,

TQFP package, Engineering Sample.

Tape & Reel T = Applicable

Pin Count 06 = 64-pin

Temperature Range I = -40°C to +85°C (Industrial)

Package PT = 10x10 or 12x12 mm TQFP (Thin Quad Flatpack)

Pattern Three-digit QTP, SQTP, Code or Special Requirements

Blank = Not applicable

10 = 100-pin

PF = 14x14 mm TQFP (Thin Quad Flatpack)

(blank otherwise)

ES = Engineering Sample

DS70166A-page 4 Preliminary © 2005 Microchip Technology Inc.

Page 7

PIC24H

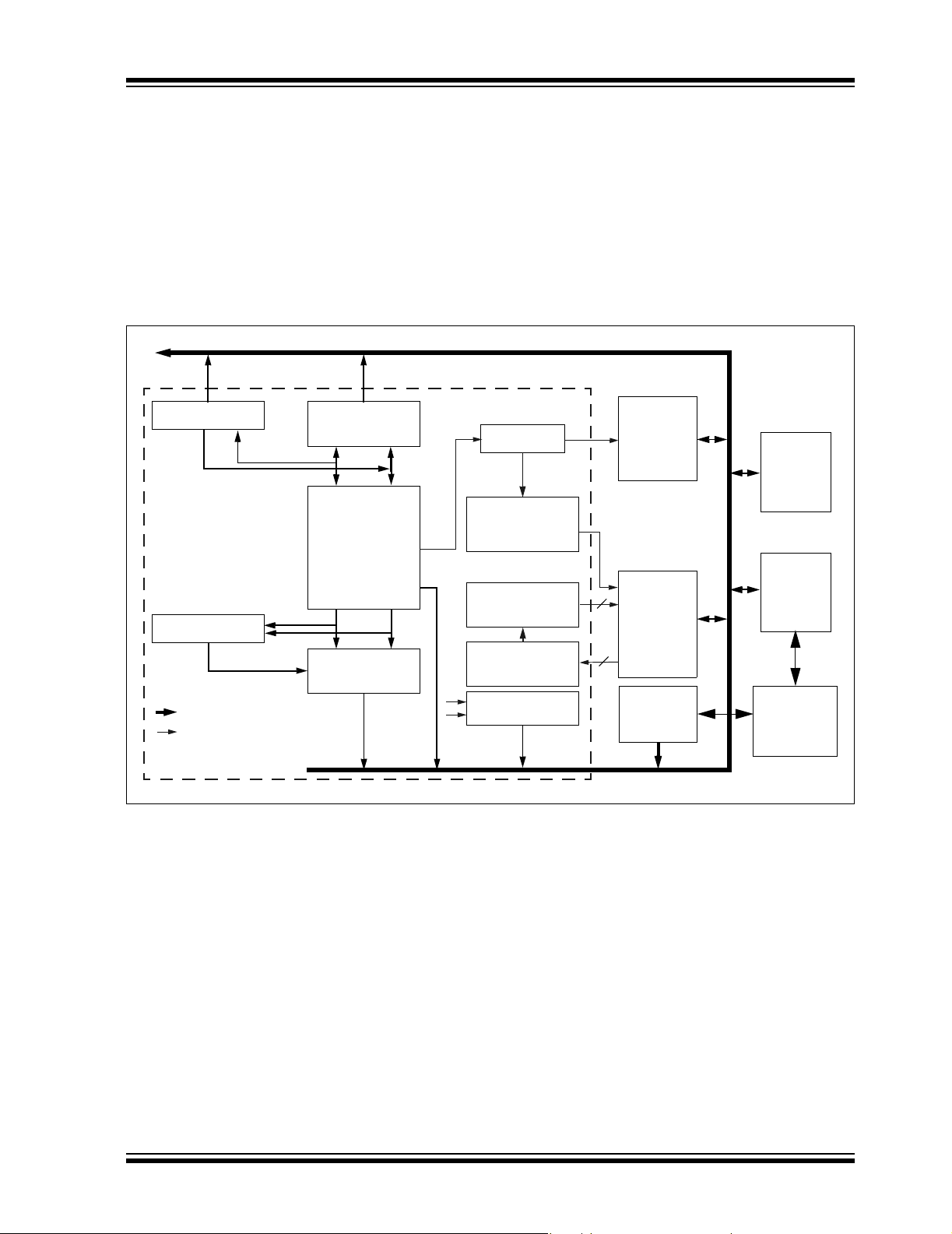

2.0 PIC24H DEVICE FAMILY OVERVIEW

The PIC24H device family employs a powerful 16-bit

microcontroller (MCU). The res ulti ng CPU fun cti ona lity

is ideal for applications that rely on high-speed,

repetitive comput at ion s, as well as contro l.

Flexible and deterministic interrupt handling, coupled

with a powerful array of peripherals, renders the

PIC24H devices suitable for control applications.

FIGURE 2-1: PIC24H DEVICE BLOCK DIAGRAM

X-Data Bus <16-bit>

Shifter

Divide Control

Legend:

MCU/DSP X-Data Path

Address Path

17 x 17 Multiplier

W Register

Array

16 x 16

Memory

Mapped

16-bit ALU

Program Flash

Memory Data

Access

Program Counter

<23 bits>

Instruction

Prefetch & Decode

STATUS Register

Further, Direct Memory Access (DMA) enables

overhead-free transfer of data between several

peripherals and a dedicated DMA RAM. Reliable, field

programmable Flash program memory ensures

scalability of applications that use PIC24H devices.

Figure 2-1 shows a sample device block diagram

typical of the PIC24H product family.

Data SRAM

24

up to

28 Kbytes

Flash

Program

Memory

up to

256 Kbytes

Dual Port

RAM

2 Kbytes

I/O Ports

Peripherals

DMA

Controller

AGU

23

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 5

Page 8

PIC24H

3.0 CPU ARCHITECTURE

3.1 Overview

The PIC24H C P U mo du l e has a 1 6 -bi t ( data ) mo dif i ed

Harvard architecture with an enhanced instruction set.

The CPU has a 24-bit instruction word with a variable

length opcode field. The Program Counter (PC) is

23 bits wide and addresses up to 4M x 24 bits of user

program memory spac e. The actual amou nt of program

memory implemented, as illustrated in Figure 3-1,

varies from one device to another. A single-cycle

instruction prefetch mechanism is used to help

maintain throughput and provides predictable

execution. All instructions execute in a single cycle,

with the exception of instructions that change the

program flow, the double word move (MOV.D)

instruction and the table instructions. Overhead-free

program loop constructs are supported using the

REPEAT instruction, which is interruptible at any point.

The PIC24H devices have sixteen 16-bit working

registers in the programmer’s model. Each of the

working registers can serve as a data, address or

address offset register. The 16th working register

(W15) operates as a software Stack Pointer (SP) for

interrupts and calls.

The PIC24H instruction set includes many addressing

modes and is designed for optimum C compiler

efficiency.

3.1.1 DATA MEMORY OVERVIEW

The data space can be addressed as 32K words or

64 Kbytes . Reads and w rites are per formed usin g an

Address Generation Unit (AGU), which accesses the

entire memory map as one linear data space.

DS70166A-page 6 Preliminary © 2005 Microchip Technology Inc.

Page 9

PIC24H

3.1.2 ADDRESSING MODES OVERVIEW

The CPU supports Inherent (no operand), Relative,

Literal, Memory Direct, Register Direct and Register

Indirect Addressing modes. Each instruction is

associated with a predefined addressing mode group

depending upon its functional requirements. As many

as 6 addressing modes are supported for each

instruction.

For most instructions, the PIC24H is capable of

executing a data (or program data) memory read, a

working register (data) read, a data memory write and

a program (instruction) memory read per instruction

cycle. As a result, three parameter instructions can be

supported, allowing A + B = C operations to be

executed in a single cycle.

3.1.3 SPECIAL MCU FEATURES

The PIC24H features a 17-bit by 17-bit, single-cycle

multiplier. The multiplier can perform signed, unsigned

and mixed-sign multiplication. Using a 17-bit by 17-bit

multiplier for 16-bit by 16-bit multiplication allows you to

perform mixed-sign multiplication.

The PIC24H supports 16/16 and 32/16 divide

operations, both fractional and integer. All divide

instructions are iterative operations. They must be

executed within a REPEAT loop, resulting in a total

execution time of 19 instruction cycles. The divide

operation can be interrupted during any of those 19

cycles without loss of data.

A 40-bit data shifter is used to perform up to a 16-bit left

or right shift in a single cycle.

3.1.5 FEATURES TO ENHANCE COMPILER EFFICIENCY

The CPU architecture possesses several features that

lead to a more efficient (code size and speed) C

compiler.

1. For most instructions, three-parameter instruc-

tions can be supported, allowing A + B = C

operations to be executed in a single cycle.

2. Instruction addressing modes are extremely

flexible to meet compiler needs.

3. The working re gister array consis ts of 16 x 16-b it

registers, each of which can act as data,

address or offse t registers. One w orking regist er

(W15) operates as the software Stack Pointer

for interrupts and calls.

4. Linear indirect access of all data space is

possible, plus the memory direct address range

is up to 8 Kbytes. This capability, together with

the addition of 16-bit direct address MOV-based

instructions, has provided a contiguous linear

addressing space.

5. Linear indirect access of 32K word (64 Kbyte)

pages within program space is possible, using

any working register via new table read and

write instructions.

6. Part of dat a sp a ce c an be mapped into program

space, allowi ng const ant dat a to be acc essed as

if it were in data space.

3.1.4 INTERRUPT OVER VIE W

The PIC24H has a vectored exception scheme with up

to 5 sources of non-maskable traps and 67 interrupt

sources. Each interrup t source can be assign ed to one

of seven priority levels.

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 7

Page 10

PIC24H

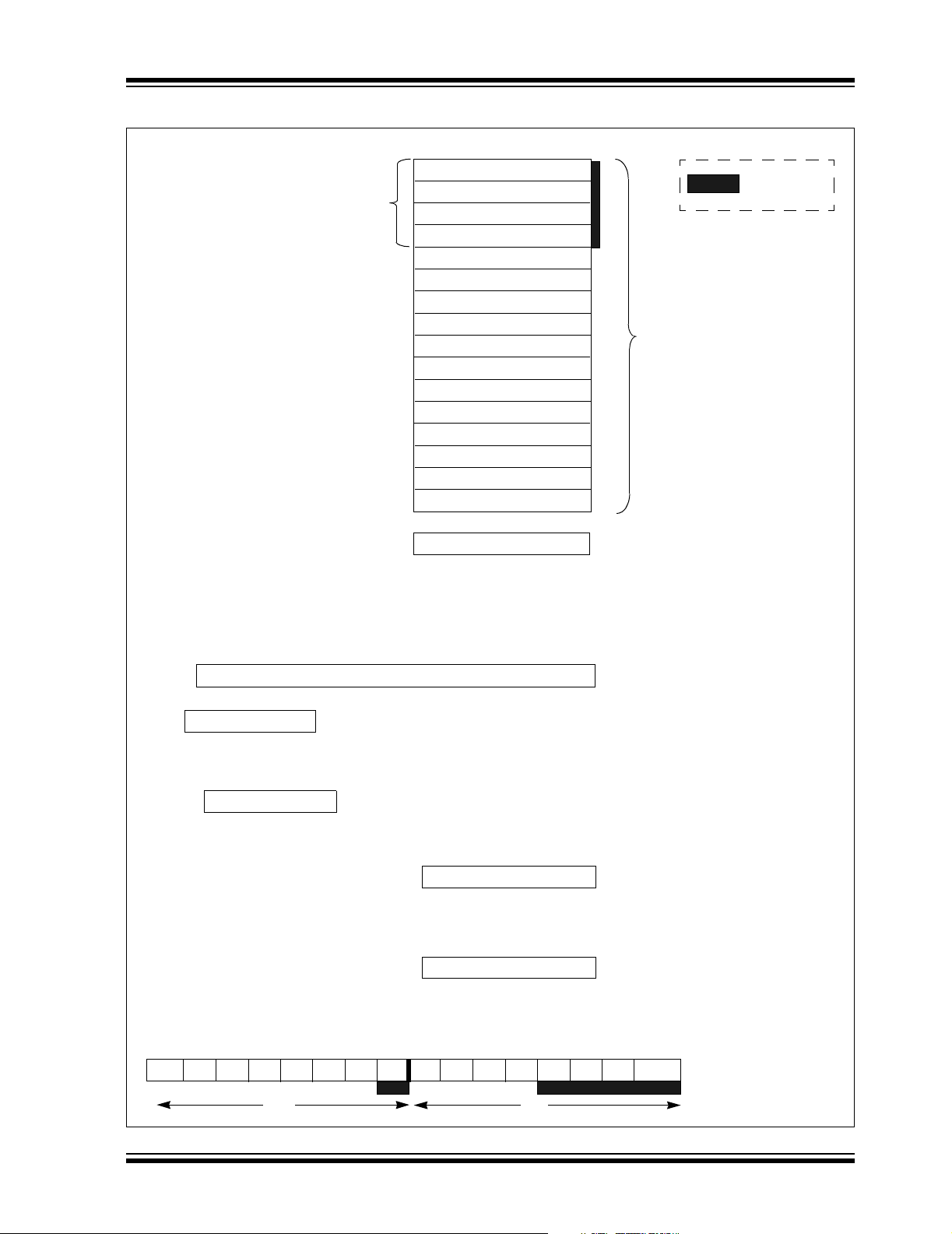

3.2 Programmer’s Model

The programmer’s model, shown in Figure 3-2,

consists of 16 x 16-bit working registers (W0 through

W15), STATUS reg ister (SR), Dat a Table Page register

(TBLPAG), Program Space Visibility Page register

(PSVPAG), REPEAT count register (RCOUNT) and

Program Counter (PC). The working registers can act

as data, addres s or offset registers. A ll registers are

memory mapped. W0 is the W register for all

instructions that perform file register addressing.

Some of these registers have a shadow register

associated with them (see the legend in Figure 3-2).

The shadow register is used as a temporary holding

register and can tran sfe r it s co ntents to or from its host

register upon some event occurring in a single cycle.

None of the shadow registers are accessible directly.

When a byte operation is performed on a working

register, only the Least Significant Byte (LSB) of the

target register is affected. However, a benefit of

memory mapped working registers is that both the

Least and Most Significant Bytes (MSBs) can be

manipulated through byte-wide data memory space

accesses.

W15 is the dedicated software Stack Pointer (SP). It is

automatically modified by exception processing and

subroutine calls and returns. However, W15 can be

referenced by any instruction in the same manner as all

other W registers. This simplifies the reading, writing

and manipulation of the Stack Pointer (e.g., creating

stack frames).

W14 has been dedica ted as a Stack Frame Pointer, as

defined by the LNK and ULNK instructions. However,

W14 can be referenced by any instruction in the same

manner as all other W registers.

The Stack Pointer always points to the first available

free word and grows from lower addresses towards

higher addresses. It pre-decrements for stack pops

(reads) and post-increments for stack pushes (writes).

DS70166A-page 8 Preliminary © 2005 Microchip Technology Inc.

Page 11

FIGURE 3-2: PROGRAMMER’S MODEL

PIC24H

DIV and MUL

Result Registers

015

W0/WREG

W1

W2

W3

W4

W5

W6

W7

W8

W9

W10

W11

W12

W13

W14/Frame Pointer

W15*/Stack Pointer

SPLIM* Stack Pointer Limit Register

Legend:

Working Registers

*W15 and SPLIM not shadowed

PUSH.S Shadow

22

7

TABPAG

TBLPAG

7

PSVPAG

PSVPAG

— — — —

SRH

0

0

— —

Data Table Page Address

Program Space Visibility Page Address

15

RCOUNT

15

CORCON

—DC

IPL2 IPL1

IPL0 OV

RA

SRL

N

0

0

0

Program Counter

REPEAT Loop Counter

Core Configuration Register

Z

C

STATUS Register

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 9

Page 12

PIC24H

3.3 Data Address Sp ace

The data space is accessed as one unified linear

address range (for MCU instructions). The data space

is accessed using the Address Generat ion Unit (AG U).

All Effective Addre sses (EAs) are 16 b its wide and poi nt

to bytes within the data space. Therefore, the data

space address range is 64 Kbytes or 32K words,

though the implemented memory locations vary from

one device to another.

3.3.1 DMA RAM

Every PIC24H device contains 2 Kbytes of DMA RAM

located at the end of Y data space. Memo ry locations in

the DMA RAM space are accessible simultaneously by

the CPU and the DMA Controller module. DMA RAM is

utilized by the DMA Controller to store data to be

transferred to various peripherals using DMA, as well as

data transferred from various peripherals using DMA.

When the CPU and the DMA Controller attempt to

concurrently write to the same DMA RAM location, the

hardware ensures tha t the C PU is giv en prec edenc e in

accessing the DMA RAM location. Therefore, the DMA

RAM provides a reliable means of transferring DMA

data without ever having to stall the CPU.

3.3.2 DATA SPACE WIDTH

The core data width is 16 bits. All internal registers are

organized as 16 -bit wide word s. Dat a space memory is

organized in byte addressable, 16-bit wide blocks.

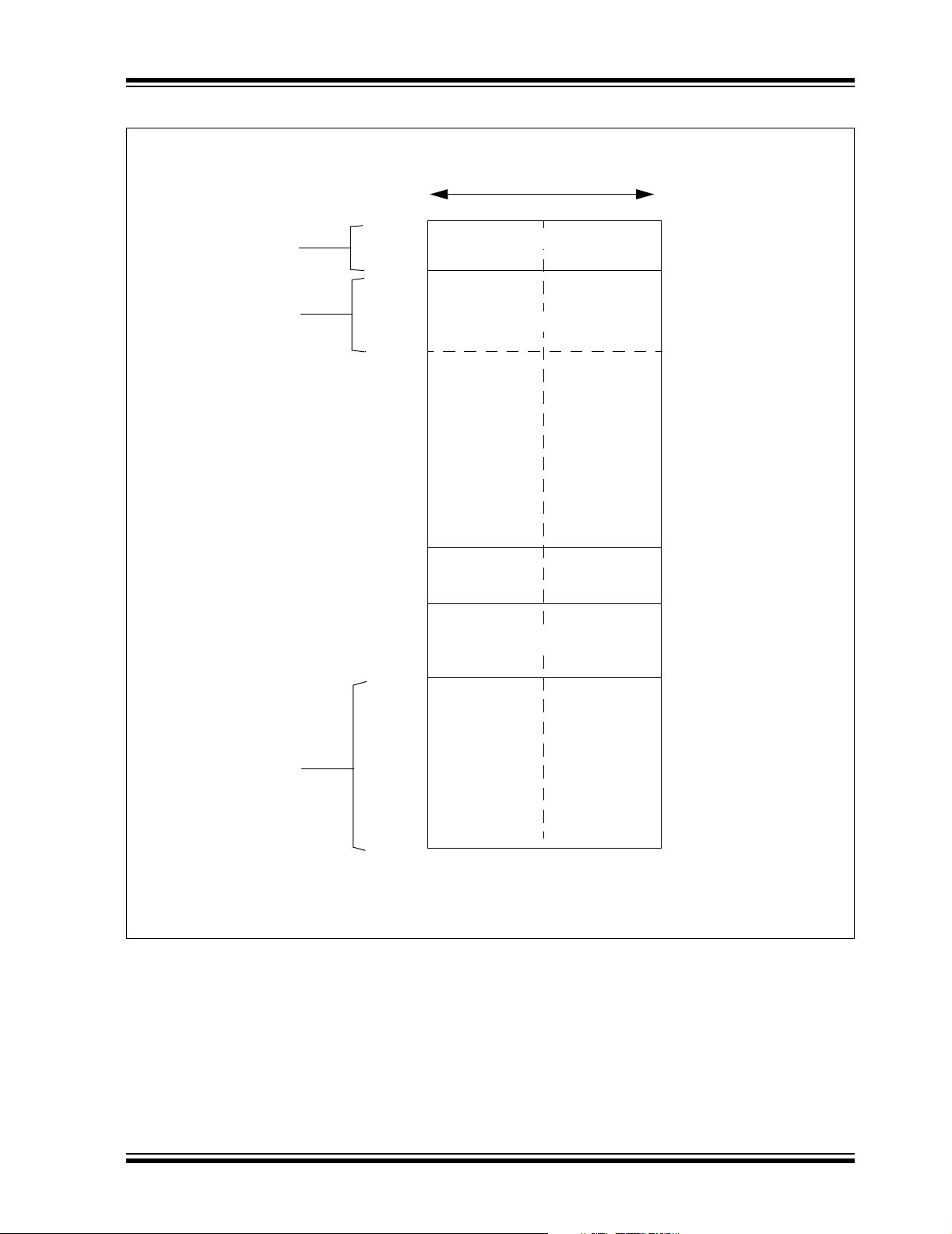

Figure 3-3 depicts a sam ple data space memo ry map

for the PIC24H device with 16 Kbytes of RAM.

3.3.3 DATA ALIGNMENT

To help maintain backward compatibility with

PICmicro

memory usage efficiency, the PIC24H instruction set

supports both word and byte operations. Data is

aligned in data memory and registers as words, but all

data space EAs resolv e to byt es. Data b yte rea ds will

read the complete word which contains the byte, using

the Least Significant bit (LSb) of any EA to determine

which byte to select.

As a consequence of t his byte accessib ility , all Effec tive

Address calculations are internally scaled. For

example, the core would recognize that Post-Modified

Register Indi rect Ad dressin g mode, [Ws+ +], wil l result

in a value of Ws + 1 for byt e op erations and Ws + 2 for

word operations.

All word accesses m ust be al igned to an even a ddress.

Misaligned word data fetches are not supported.

Should a misaligned read or write be attempted, a trap

will then be ex ec ut e d, al l ow in g t he sys tem an d/ o r use r

to examine the machine state prior to execution of the

address Fault.

®

MCU devices and improve data space

DS70166A-page 10 Preliminary © 2005 Microchip Technology Inc.

Page 13

FIGURE 3-3: SAMPLE DATA SPACE MEMORY MAP

PIC24H

2-Kbyte

SFR Space

8-Kbyte

Data Space

Most Significant Byte

Address

0x0001

0x07FF

0x0801

0x1FFF 0x1FFE

0x3FFF

0x4001

0x47FF 0x47FE

0x4801 0x4800

16 Bits

LSBMSB

SFR Space

Data RAM

DMA RAM

Unimplemented

Least Significant Byte

Address

0x0000

0x07FE

0x0800

0x3FFE

0x4000

0x8001 0x8000

Optionally

Mapped

into Program

Memory

0xFFFF

Note: This data memory map is for the largest memory PIC24H devic e. Data memory map s for other de vices

may vary.

0xFFFE

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 11

Page 14

PIC24H

4.0 DIRECT MEMORY ACCESS

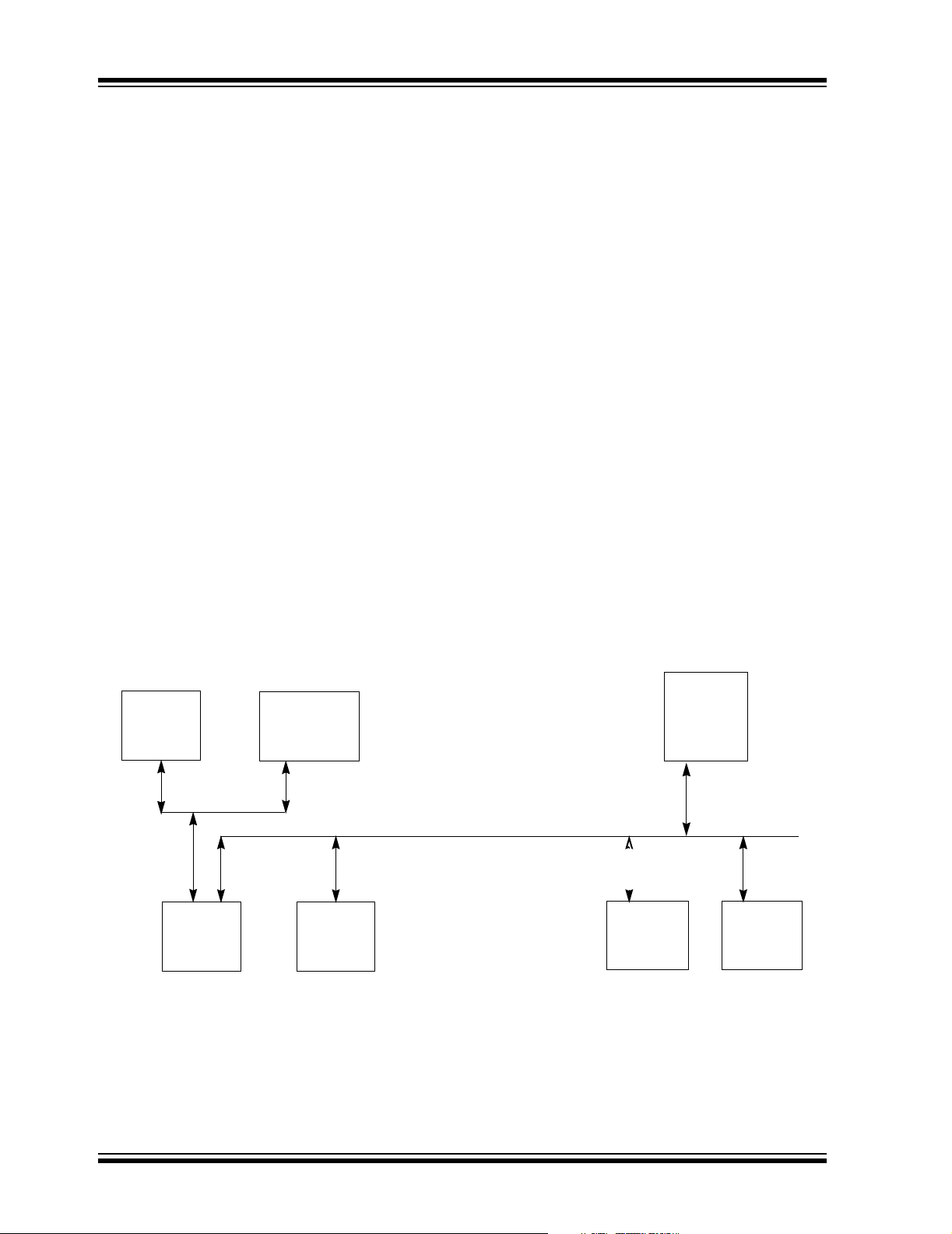

Direct Memory Access (DMA) is a very efficient

mechanism of copying data between peripheral SFRs

(e.g., UART Receive register, Input Capture 1 buffer)

and buffers or variables stored in RAM with minimal

CPU intervention. The DMA Controller can

automatically copy entire blocks of data, without the

user software havin g to read or w rite peripheral Special

Function Registers (SFRs) every time a peripheral

interrupt occurs. To exploit the DMA capability, the

corresponding user buffers or variables must be

located in DMA RAM space.

The DMA Controller features eight identical data

transfer channels, each with its own set of control and

status registers. The UART, SPI, DCI, Input Capture,

Output Compare, ECAN™ technology and ADC

modules can utilize DMA. Each DMA channel can be

configured to copy data either from buffers stored in

DMA RAM to peripheral SFRs o r fro m periph eral SF Rs

to buffers in DMA RAM.

Each channel support s the fol low i ng feat ures :

• Word or byte-sized data transfers

• Transfers from peripheral to DMA RAM or DMA

RAM to peripheral

• Indirect addressing of DMA RA M loc ation s with or

without automatic post-increment

• Peripheral Indirect Addressing – In some

peripherals, the DMA RAM read/write addresses

may be partially derived from the peripheral

• One-Shot Block Transfers – Terminating DMA

transfer after one block transfer

• Continuous Block Transfers – Reloading DMA

RAM buffer start address aft er every block

transfer is complete

• Ping-Pong Mode – Switching between two DMA

RAM start addresses between successive block

transfers, thereby filling two buffers alternately

• Automatic or manual initiation of block transfers

• Each channel can select from 32 possible

sources of data sources or destinations

For each DMA channel, a DMA interrupt request is

generated when a block transfer is complete.

Alternatively , an interrupt can be ge nerated when half of

the block has been filled. Additionally, a DMA error trap

is generated in either of the following Fault conditions:

• DMA RAM data write collision between the CPU

and a peripheral

• Peripheral SFR data wri te collision between the

CPU and the DMA Controller

FIGURE 4-1: TOP LEVEL SYSTEM ARCHITECTURE USING A DEDICATED TRANSACTION BUS

DMA

Ready

Peripheral 3

DMA

Ready

Peripheral 2

SRAM

SRAM X-Bus

CPU

DMA RAM

PORT 1

PORT 2

CPU Peripheral DS Bus

Non-DMA

Ready

Peripheral

DMA

Ready

Peripheral 1

DS70166A-page 12 Preliminary © 2005 Microchip Technology Inc.

Page 15

PIC24H

5.0 EXCEPTION PROCESSING

The PIC24H has four pro cessor ex ception s (trap s) and

up to 61 sources o f interrupt s, whi ch must be arbitrate d

based on a pr iority sche me.

The processor core is responsible for reading the

Interrupt Vector Table (IVT) and transferring the

address contained in the interrupt vector to the

Program Counter.

The Interrupt Vector Table (IVT) and Alternate In terrupt

Vector Table (AIVT) are placed near the beginning of

program memory (0x000004) for ease of debugging.

The interrupt controller hardware pre-processes the

interrupts before they are presented to the CPU.

The interrupts and traps are enabled, prioritized and

controlled using centralized Special Function Registers.

Each individual interrupt source has its own vector

address and can be individ ually enabled and prioritized

in user software. Each interrupt source a lso has it s own

status flag. This indepe ndent control and monitoring of

the interrupt eliminates the need to poll various status

flags to determine the interrupt source

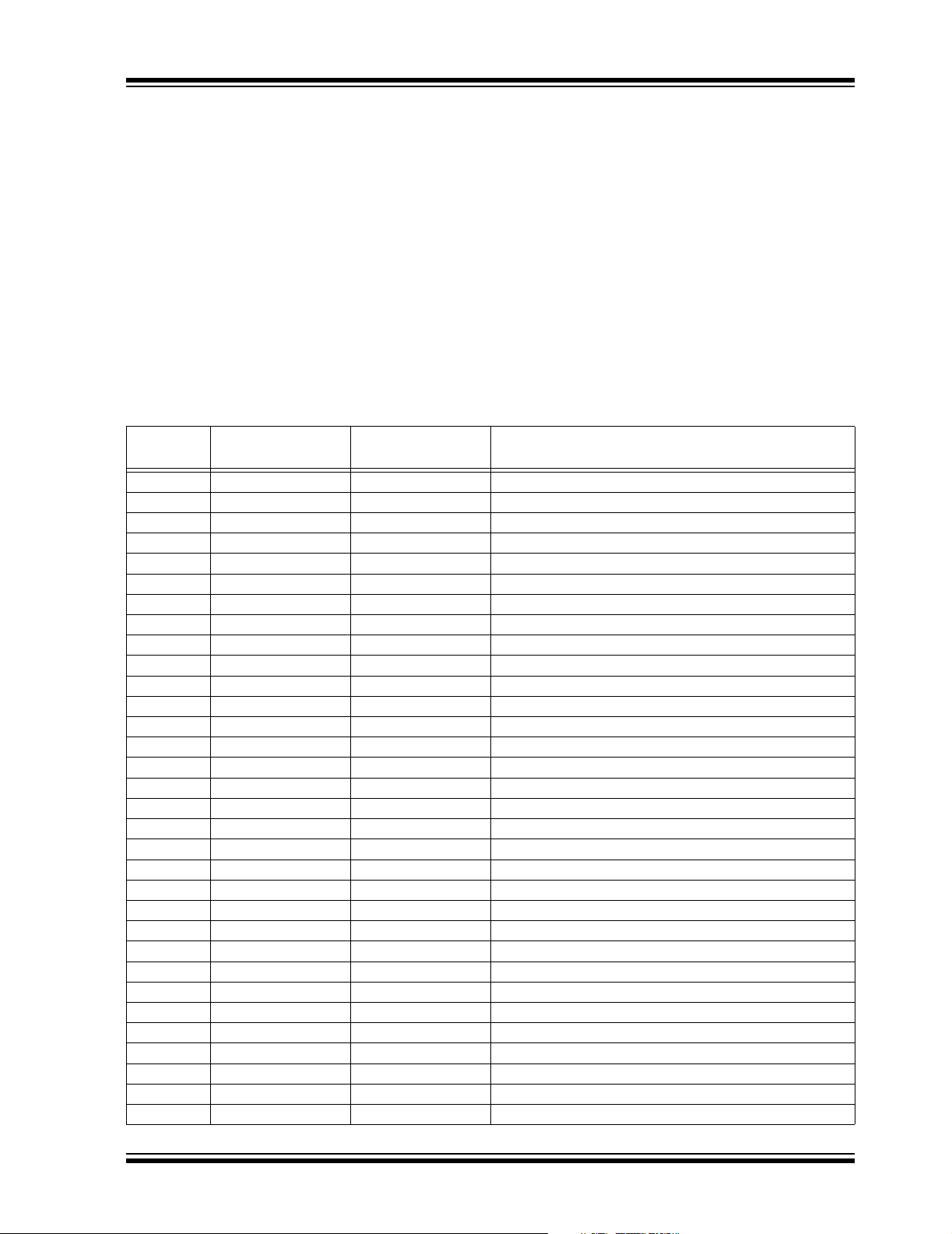

Table 5-1 contains information about the interrupt

vector.

Certain interrupts have specialized control bits for

features like edge or level triggered interrupts, interrupton-change, etc. Control of these features remains within

the peripheral m od ul e, which generates the interr upt.

The special DISI instruction ca n be used to disable

the processing of interru pt s of pri orit ies 6 and lowe r for

a certain number of instruction cycles, during which

the DISI bit remains set.

TABLE 5-1: INTERRUPT VECTORS

Vector

Number

8 0x000014 0x000114 INT0 – External Interrupt 0

9 0x000016 0x000116 IC1 – Input Compare 1

10 0x000018 0x000118 OC1 – Output Compare 1

11 0x00001A 0x00011A T1 – Timer1

12 0x00001C 0x00011C DMA0 – DMA Channel 0

13 0x00001E 0x00011E IC2 – Input Capture 2

14 0x000020 0x000120 OC2 – Output Compare 2

15 0x000022 0x000122 T2 – Timer2

16 0x000024 0x000124 T3 – Timer3

17 0x000026 0x000126 SPI1E – SPI1 Error

18 0x000028 0x000128 SPI1 – SPI1 Transfer Done

19 0x00002A 0x00012A U1RX – UART1 Receiver

20 0x00002C 0x00012C U1TX – UART1 Transmitter

21 0x00002E 0x00012E ADC1 – ADC 1

22 0x000030 0x000130 DMA1 – DMA Channel 1

23 0x000032 0x000132 Reserved

24 0x000034 0x000134 I2C1S – I2C1 Slave Event

25 0x000036 0x000136 I2C1M – I2C1 Master Event

26 0x000038 0x000138 Reserved

27 0x00003A 0x00013A Change Notification Interrupt

28 0x00003C 0x00013C INT1 – External Interrupt 1

29 0x00003E 0x00013E ADC2 – ADC 2

30 0x000040 0x000140 IC7 – Input Capture 7

31 0x000042 0x000142 IC8 – Input Capture 8

32 0x000044 0x000144 DMA2 – DMA Channel 2

33 0x000046 0x000146 OC3 – Output Compare 3

34 0x000048 0x000148 OC4 – Output Compare 4

35 0x00004A 0x00014A T4 – Timer4

36 0x00004C 0x00014C T5 – Timer5

37 0x00004E 0x00014E INT2 – External Interrupt 2

38 0x000050 0x000150 U2RX – UART2 Receiver

39 0x000052 0x000152 U2TX – UART2 Transmitter

IVT Address AIVT Address Interrupt Source

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 13

Page 16

PIC24H

TABLE 5-1: INTERRUPT VECTORS (CONTINUED)

Vector

Number

40 0x000054 0x000154 SPI2E – SPI2 Error

41 0x000056 0x000156 SPI1 – SPI1 Transfer Done

42 0x000058 0x000158 C1RX – ECAN1 Receive Data Ready

43 0x00005A 0x00015A C1 – ECAN1 Event

44 0x00005C 0x00015C DMA3 – DMA Channel 3

45 0x00005E 0x00015E IC3 – Input Capture 3

46 0x000060 0x000160 IC4 – Input Capture 4

47 0x000062 0x000162 IC5 – Input Capture 5

48 0x000064 0x000164 IC6 – Input Capture 6

49 0x000066 0x000166 OC5 – Output Compare 5

50 0x000068 0x000168 OC6 – Output Compare 6

51 0x00006A 0x00016A OC7 – Output Compare 7

52 0x00006C 0x00016C OC8 – Output Compare 8

53 0x00006E 0x00016E Reserved

54 0x000070 0x000170 DMA4 – DMA Channel 4

55 0x000072 0x000172 T6 – Timer6

56 0x000074 0x000174 T7 – Timer7

57 0x000076 0x000176 I2C2S – I2C2 Slave Event

58 0x000078 0x000178 I2C2M – I2C2 Master Event

59 0x00007A 0x00017A T8 – Timer8

60 0x00007C 0x00017C T9 – Timer9

61 0x00007E 0x00017E INT3 – External Interrupt 3

62 0x000080 0x000180 INT4 – External Interrupt 4

63 0x000082 0x000182 C2RX – ECAN2 Receive Data Ready

64 0x000084 0x000184 C2 – ECAN2 Event

65-68 0x000086-0x00008C 0x000186-0x00018C Reserved

69 0x00008E 0x00018E DMA5 – DMA Channel 5

70-72 0x000090-0x000094 0x000190-0x000194 Reserved

73 0x000096 0x000196 U1E – UART1 Error

74 0x000098 0x000198 U2E – UART2 Error

75 0x00009A 0x00019A Reserved

76 0x00009C 0x00019C DMA6 – DMA Channel 6

77 0x00009E 0x00019E DMA7 – DMA Channel 7

78 0x0000A0 0x0001A0 C1TX – ECAN1 Transmit Data Request

79 0x0000A2 0x0001A2 C2TX – ECAN2 Transmit Data Request

80-125 0x0000A4-

IVT Address AIVT Address Interrupt Source

0x0000FE

0x0001A4-

0x0001FE

Reserved

DS70166A-page 14 Preliminary © 2005 Microchip Technology Inc.

Page 17

PIC24H

5.1 Interrupt Priority

Each interrupt source can be user-assigned to one of

8 priority levels, 0 through 7. Levels 7 and 1 represent

the highest and lowest maskable priorities,

respectively. A priority level of 0 disables the interrupt.

Since more than one interrupt request source may be

assigned to a user-specified priority level, a means is

provided to assign priority within a given level. This

method is called “Natural Order Priority”.

The Natural Order Priori ty of an interrup t is nu merica lly

identical to its vector number. The Natural Order

Priority scheme has 0 as the highe st pri orit y and 74 as

the lowest priority.

The ability for the user to assign every interrupt to one

of eight priority levels implies that the user can assign

a very high overall priority level to an interrupt with a

low Natural Order Priority, thereby providing much

flexibility in designing applications that use a large

number of peripherals.

5.2 Interrupt Nesting

Interrupts, by default, are nestable. Any ISR that is in

progress may be interrupted by another source of

interrupt with a higher user-assigned priority level.

Interrupt nesting may be optionally disabled by

setting the NSTDIS control bit (INTCON1<15>).

When the NSTDIS control bit is se t, all interrupts in

progress will force the CPU priority to level 7 by

setting IPL<2:0> = 111. This action will effectively

mask all other sources of interrupt until a RETFIE

instruction is executed. When interrupt nesting is

disabled, the user-assigned in terrupt priority levels

will have no effect, except to resolve conflicts

between simultaneous pending interrupts.

The IPL<2:0> bits become read-only when interrupt

nesting is disabled. This prevents the user software

from settin g IPL<2:0> to a lower va lue, which would

effectively re-enable interrupt nesting.

5.3 Traps

Traps can be considered as non-maskable, nestable

interrupts that adhere to a fixed priority structure.

Traps are intended to provide the user a means to

correct erroneous operation during debug and when

operating within the application. If the user does not

intend to ta ke corrective ac tion in the even t of a trap

error condition, these vectors must be loaded with the

address of a software routi ne th at w il l reset the device.

Otherwise, the trap vector is programmed with the

address of a service routine that will correct the trap

condition.

The PIC24H has five implemented sources of

non-maskable traps:

• Oscillator Failure Trap

• Address Error Trap

• Stack Error Trap

• Math Error Trap

• DMA Error Trap

Many of these trap conditions can only be detected

when they happen. Consequently, the instruction that

caused the trap is allowed to complete before

exception processing begins. Therefore, the user may

have to correct the action of the instruction that

caused the trap.

Each trap s ource h as a fixe d priori ty as de fined by its

position in the IVT. An oscillator failure trap has the

highest priority, while an arithmetic error trap has the

lowest priority.

Table 5-2 contains information about the trap vector.

5.4 Generating a Software Interrupt

Any available interrupt can be manually generated by

user software (even if the corresponding peripheral is

disabled), simply by enabling the interrupt and then

setting the interrupt flag bit when required.

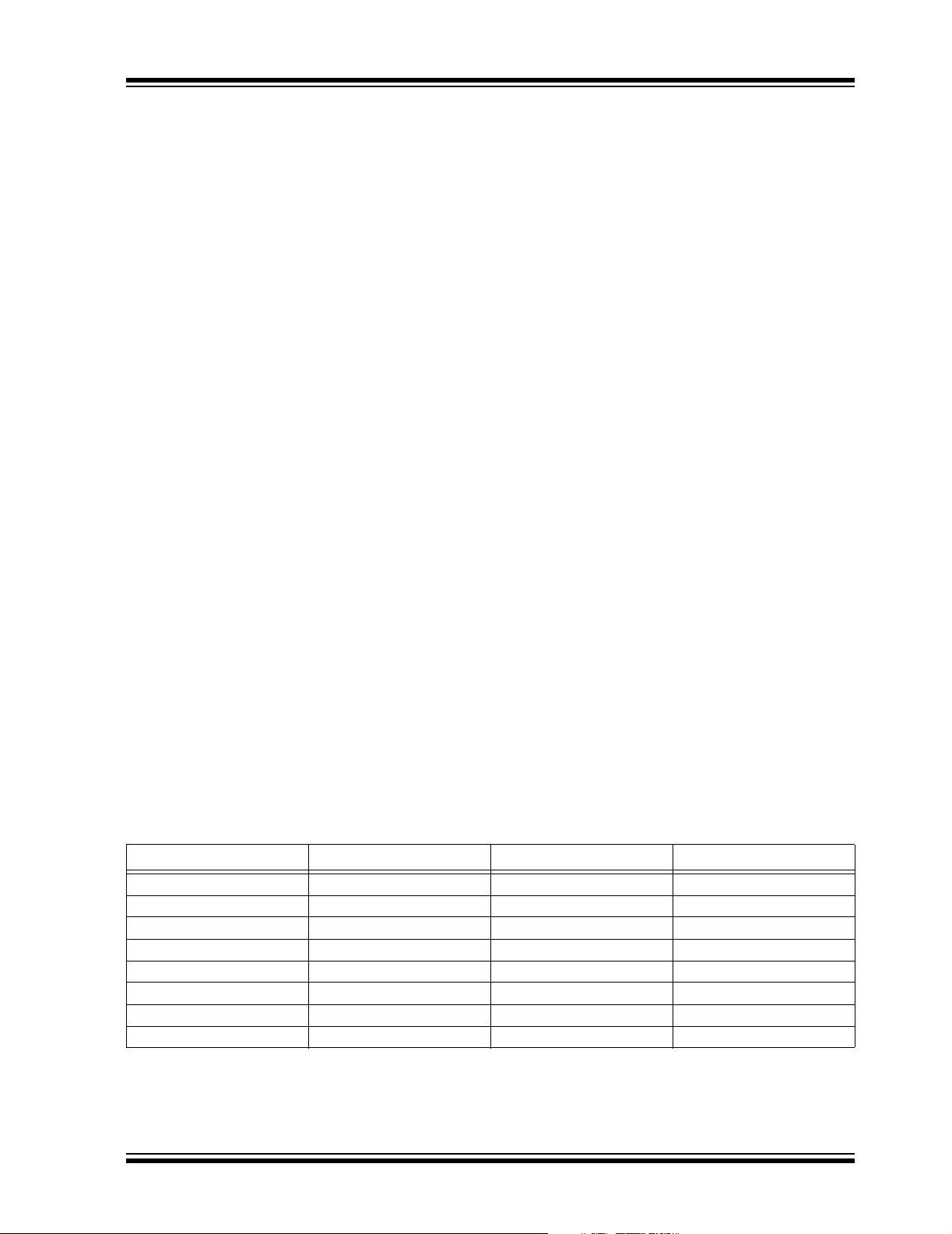

TABLE 5-2: TRAP VECTORS

Vector Number IVT Address AIVT Address Trap Source

0 0x000004 0x000084 Reserved

1 0x000006 0x000086 Oscillator Failure

2 0x000008 0x000088 Address Error

3 0x0 000 0A 0x00008A Stack Error

4 0x00000C 0x00008C Math Error

5 0x00000E 0x00008E DMA Error Trap

6 0x000010 0x000090 Reserved

7 0x000012 0x000092 Reserved

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 15

Page 18

PIC24H

6.0 SYSTEM INTEGRATION

System managemen t servic es provided by the PI C24H

device family include:

• Control of clock options and oscillators

• Power-on Reset

• Oscillator Start-up Timer/Stabilizer

• Watchdog Timer with RC oscillator

• Fail-Safe Clock Monitor

• Reset by multiple sources

6.1 Clock Options and Oscillators

There are 7 clock options provided by the PIC24H:

• FRC Oscillator

• FRC Oscillator with PLL

• Primary (XT, HS or EC) Oscillator

• Primary Oscillator with PLL

• Secondary (LP) Oscillator

• LPRC Oscillator

The FRC (Fast RC) inte rnal osci llator runs at a nom inal

frequency of 7.37 MHz. The user s oftware can tune th e

FRC frequency. User software can specify a factor by

which this clock frequency is scaled.

The primary oscillator can use one of the following as

its clock source:

1. XT (Cryst al): Cryst als and c eramic re sonators i n

the range of 3 MHz to 10 MHz. The crystal is

connected to the OSC1 and OSC2 pins.

2. HS (High-Speed Crystal): Crystals in the range

of 10 MHz to 40 MHz. The crysta l is conn ected

to the OSC1 and OSC2 pins.

3. EC (External Clock): External clock signal in the

range of 0.8 MHz to 64 MHz. The extern al cloc k

signal is directly applied to the OSC1 pin.

The secondary (LP) os cillator is design ed for low power

and uses a 32 kHz cryst al or ceramic resonator . The LP

oscillator uses the SOSCI and SOSCO pins.

The LPRC (Low-Power RC) internal oscIllator runs at a

nominal frequency of 32.768 kHz. Another scaled

reference clock is used by the Watchdog Timer (WDT)

and Fail-Safe Clock Monitor (FSCM).

The clock signals generated by the FRC and primary

oscillators can be optionally applied to an on-chip

Phase Locked Loop (PLL) to provide a wide range of

output frequencies for device operation. The input to

the PLL can be in the range of 1.6 MH z to 16 MHz, and

the PLL Phase Detector Input Divider, PLL Multiplier

Ratio and PLL Voltage Controlled Osc illato r (VCO) ca n

be individually conf igured b y user so ftware to genera te

output frequencies in the range of 25 MHz to 160 MHz.

The output of the oscillator (or the output of the PLL if

a PLL mode has been selected) is divided by 2 to

generate the device instruction clock (F

CY). FCY

defines the operating speed of the device, and speeds

up to 40 MHz are supported by the PIC24H

architecture.

The PIC24H oscillator system provides:

• Various external and internal oscillator options as

clock sources

• An on-chip PLL to scale the internal operating

frequency to the required system clock frequency

• The internal FRC oscillator can also be used with

the PLL, thereby allowing full-speed operation

without any external clock generation hardware

• Clock switching between various clock sources

• Programmable clock postscaler f or s ystem po w er

savings

• A Fail-Safe Clock Monitor (FSCM) that detects

clock failure and takes fail-safe measures

• A Clock Control register (OSCCON)

• Nonvolatile Configuration bits for main oscillator

selection.

A simplified block diagram of the oscillator system is

shown in Figure 6-1.

DS70166A-page 16 Preliminary © 2005 Microchip Technology Inc.

Page 19

FIGURE 6-1: OSCILLATOR SYSTEM BLOCK DIAGRAM

PIC24H

OSC1

OSC2

SOSCO

SOSCI

Primary

Oscillator

Internal Fast

RC (FRC)

Oscillator

Secondary

Oscillator

32 kHz

PLL

Module

Primary Osc

Secondary Osc

Internal Low-Power

RC (LPRC)

Oscillator

Clock

Switching

and

Control

Block

FOSC

Divide by 2

To Timer1

FCY

6.2 Power-on Reset (POR)

When a supply voltage is applied to the device, a

Power-on Reset (POR) is generated. A new Power-on

Reset event is generated if the supply voltage falls

below the device threshold voltage (V

POR). An internal

POR pulse is gene rated w hen the ri sing suppl y vol tag e

crosses the POR circuit threshold voltage.

6.3 Oscillator St art-up Timer/St abilizer (OST)

An Oscillator Start-up Timer (OST) is included to

ensure that a crystal oscillator (or ceramic resonator)

has started and stabilized. The OST is a simple, 10-bit

counter that counts 1024 T

the oscillator clock to the rest of the system. The timeout period is designated as T

involved every time the oscillator has to restart (i.e ., o n

Power-on Reset and wake-up from Sleep). The

Oscillator Start-up Timer is applied to the LP oscillator,

XT and HS modes (upon wake-up from Sleep, POR

and Brown-out Reset (BOR)) for the prima ry oscilla tor .

OSC cycles before releasing

OST. The TOST time is

6.4 Watchdog Ti mer (WDT)

The primary function of the Watchdog Timer (WDT) is

to reset the processor in the event of a software

malfunction. The WDT is a fre e-run nin g ti me r tha t run s

off the on-chip LPRC oscillator, requiring no external

component. The WDT continues to operate even if the

main proces sor clock (e.g., the crys tal oscillator) fails.

The Watchdog Timer can be “Enabled” or “Disabled”

either through a Configuration bit (FWDTEN) in the

Configuration register, or through an SFR bit

(SWDTEN).

Any device programmer capable of programming

®

DSC devices (such as Microchip’s MPLAB

dsPIC

PM3 Programmer) allows programming of this and

other Configuration bit s to the d esired st ate. If enab led,

the WDT increments until it overflows or “times out”. A

WDT time-out forces a device Reset (except during

Sleep).

®

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 17

Page 20

PIC24H

6.5 Fail-Safe Clock Monitor (FSCM)

The Fail-Safe Clock Monit or (FSC M) al lows the dev ic e

to continue to ope rate ev en in th e eve nt of an oscil lator

failure. The FSCM fu nction is enab led by programmin g.

If the FSCM function is enabled, the LPRC internal

oscillator run s at all tim es (ex cep t du ri ng Sl eep mode )

and is not subject to control by the W atc hd og Timer.

In the event of an oscillator failure, the FSCM

generates a clock failure trap event and switches the

system clock over to the FRC oscillato r . The application

program then can ei ther attempt to res tart the oscillato r ,

or execute a controlled shutdown. The trap can be

treated as a warm Reset by simply loading the Reset

address into the oscillator fail trap vector.

6.6 Reset System

The Reset system combines all Reset sources and

controls the device Master Reset signal.

Device Reset sources include:

• POR: Power-on Reset

• BOR: Brown-out Reset

•SWR: RESET Instruction

• EXTR: MCLR

• WDTR: Watchdog Timer Time-out Reset

• TRAPR: Trap Conflict

• IOPUWR: Attempted execution of an Illegal

Opcode, or Indirect Addressing, using an

Uninitialized W register

Reset

DS70166A-page 18 Preliminary © 2005 Microchip Technology Inc.

Page 21

PIC24H

7.0 DEVICE POWER MANAGEMENT

Power management services provided by the PIC24H

devices include:

• Real-Time Clock Source Switching

• Power-Saving Modes

7.1 Real-Time Clock Source Switching

Configuration bits determine the clock source upon

Power-on Reset (POR) and Brown-out Reset (BOR).

Thereafter, the clock source can be changed between

permissible clock sources. The OSCCON register

controls the clock switching and reflects system clock

related status bits. To reduce power consumption, the

user can switch to a slower clock source.

7.2 Power-Saving Modes

The PIC24H devices have two reduced power modes

that can be entered through execution of the PWRSAV

instruction.

• Sleep Mode: The CPU, system clock source and

any peripherals that operate on the system clock

source are disabled. This is the lowest power

mode of the device.

• Idle Mode: The CPU is disabled but the system

clock source continues to operate. Peripherals

continue to operate but can optionally be disabled.

• Doze Mode: The CPU clock is tempora rily s lowed

down relative to the peripheral clock by a

user-selectab le fac tor.

These modes provide an effective way to reduce power

consumption during periods when the CPU is n ot in use.

7.2.1 SLEEP MODE

When the device enters Sleep mode:

• System clock source is shut down. If an on-chip

oscillator is used, it is turned off.

• Device current consumption is at minimum

provided that no I/O pin is sourcing current.

• Fail-Safe Clock Monitor (FSCM) does not op erate

during Sleep mode because the system clock

source is disabled.

• LPRC clock continues to run in Sleep mode if the

WDT is enabled.

• BOR circuit, if enabled, remains operative during

Sleep mode

• WDT, if enabled, is automatically cleared prior to

entering Sleep mode.

• Some peripherals may continue to operate in

Sleep mode. These peripherals include I/O pins

that detect a change in the input signal, or

peripherals that use an external clock input. Any

peripheral that is operating on the system clock

source is disabled in Sleep mode.

The processor exits (wakes up) from Sleep on one of

these events:

• Any interrupt source that is individually enabled

• Any form of device Reset

• A WDT time-out

7.2.2 IDLE MODE

When the device enters Idle mode:

• CPU stops executing ins tructions

• WDT is automatically cleared

• System clock source remains active

• Peripheral modules, by default, continue to

operate normally from the system clock source

• Peripherals, optionally, can be shut down in Idle

mode using their ‘stop-in-idle’ control bit.

• If the WDT or FSCM is enabled, the LPRC also

remains active

The processor wakes from Idle mode on th ese events:

• Any interrupt that is individually enabled

• Any source of device Reset

• A WDT time-out

Upon wake-up from Idle, the clock is re-applied to the

CPU and instruction execution begins immediately

starting with the instruction following the PWRSAV

instruction, or the first instruction in the Interrupt

Service Routine (ISR).

7.2.3 DOZE MODE

The Doze mode provides the user software the ability

to temporarily reduce the processor instruction cycle

frequency relative to the peripheral frequency. Clock

frequency ratios of 1:1, 1:2, 1:4, 1:8, 1:16, 1:32, 1:64

and 1:128 are supported.

For example, suppose the device is operating at

20 MIPS and the CAN module has been co nfigure d for

500 kbps bit rate based on this device operating speed.

If the device is now placed in Doze mode with a clock

frequency ratio of 1:4 , the C AN mod ul e w ill co nti nue to

communicat e at the re quired bi t rate o f 500 kbps, bu t

the CPU now starts executing instructions at a

frequency of 5 MIPS.

This feature further reduces the power consumption

during periods where relatively less CPU activity is

required.

When the device is operating in Doze mode, the

hardware ensures that there is no loss of

synchronization between peripheral events and SFR

accesses by the CPU.

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 19

Page 22

PIC24H

8.0 PIC24H PERIPHERALS

The Digital Signal Controller (DSC) family of 16-bit

DSC devices provides the integrated functionality of

many peripherals. Specific peripheral functions

include:

• Analog-to-Digital Converters (ADC)

- 10-bit High-Speed ADC

- 12-bit High-Resolution ADC

• General-purpose 16-Bit Timers

• M otor Control PWM module

• Quadrature Encoder Interface module

• Input Capture module

• Output Compare/PWM module

• Data Converter Interface

• Serial Peripheral Interface (SPI™) module

•UART module

2

•I

C™ module

• Controller Area Network (CAN) module

• I/O pins

8.1 Analog-to-Digital Converters

The Analog-to-Digital Converters provide up to 32

analog inputs with both single-ended and differential

inputs. These mod ules o f fer on -board s ample and hold

circuitry.

To minimize control loop errors due to finite update

times (conversion plus computations), a high-speed

low-latency ADC is required.

In addition, several hardware features have been

included in the perip heral interface to improve real -time

performance in a typical DSP-based application.

• Result alignment options

• Automated sampling

• Automated channel scanning

• Dual port data buffer

• External con version start control

The ADC can be configured by the user application in

either of the following configurations:

• 10-bit, 1.1 Msps ADC module (2.2 Msps ADC

conversion using 2 A/D modules)

• 12-bit, 500 ksps ADC module (1 Msps ADC

conversion using 2 A/D modules)

Key features of the ADC module include:

• 10-bit or 12-bit resolution

• Unipolar differential sample/hold amplifiers

• Up to 32 input channels

• Selectable voltage reference sources (external

REF+ and VREF- pins available)

V

• ±1 LSB max Differential Nonlinearity (DNL)

(3.3V ±10%)

• ±1 LSB max Integral Nonlinearity (INL)

(3.3V ±10%)

• Up to 4 on-chip sample and hold amplifiers in

each ADC (enables s imultan eous sampling of 2, 4

or 8 analog inputs)

• Automated channel scanning

• Single-supply operation: 3.0-3.6V

• 2.2 Msps or 1 Msps sampling rate at 3.0V

• Ability to convert during CPU Sleep and Idle

modes

• Conversion start can be manual or synchronized

with 1 of 4 trigger sources (automatic, T imer3 or 5,

external interrupt, PWM period match )

• ADC can use DMA for buffer storage

8.2 General-Purpose Timer Modules

The General-Purpose (GP) timer modules provide the

time base elements for input capture and output

compare/PWM. They can be configured for Real-Time

Clock operation as well as various timer/counter

modes. The timer modes count pulses of the internal

time base, whereas counter modes count external

pulses that appear on the timer clock pin.

The PIC24H device supports up to nine 16-bit timers

(Timer1 through Timer9). Eight of the 16-bit timers can

be configured as four 32-bit timers (T imer2/ 3, T imer4/5,

Timer6/7 and Timer8/9). Each timer has several

selectable operating modes.

8.2.1 TIMER1

The Timer1 module (Figure 8-1) is a 16-bit timer that can

serve as the time counter for an asynchronous RealTime Clock, or operate as a free-running interval timer/

counter. The 16-bit timer has the follow ing mode s:

•16-Bit Timer

• 16-Bit Synchronous Counter

• 16-Bit Asynchronous Counter

Further, the following operational characteristics are

supported:

• Timer gated by external pulse

• Selectable prescaler settings

• Timer operation during CPU Idle and Sleep modes

• Interrupt on 16-Bit Period register match or falling

edge of external gate signal

Timer1, when operating in Real-Time Clock (RTC)

mode, provides time of day and event time-stamping

capabilitie s. Key operational feat ures of the RTC are:

• Operation from 32 kHz LP oscillator

• 8-bit prescaler

•Low power

• Real-Time Clock interrupts

DS70166A-page 20 Preliminary © 2005 Microchip Technology Inc.

Page 23

FIGURE 8-1: 16-BIT TIMER1 MODULE BLOCK DIAGRAM

PIC24H

T1IF

Event Flag

SOSCO/

T1CK

SOSCI

0

1

TGATE

Equal

Reset

LPOSCEN

PR1

Comparator x 16

TMR1

QD

Q

8.2.2 TIMER2/3

The Timer2/3 module is a 32-bit timer (which can be

configured as two 16-bit timers) with selectable

operating modes. These timers are used by other

peripheral modules, such as:

• Input Capture

• Output Compare/Simple PWM

Timer2/3 has the following modes:

• Two independent 16-bit timers (Timer2 and

Timer3) with Timer and Synchronous Counter

modes

• Single 32-Bit Timer

• Single 32-Bit Synchronous Counter

Further, the following operational characteristics are

supported:

• ADC conversion start trigger

• 32-bit timer gated by external pulse

• Selectable p rescaler s ettings

• Timer counter operation during Idle and Sleep

modes

• Interrupt on a 32-Bit Period register match

• Timer2/3 can use DMA for buffer storage

CK

Gate

Sync

CY

T

TSYNC

1

Sync

0

TGATE

TCS

1 x

0 1

0 0

TGATE

TON

TCKPS<1:0>

2

Prescaler

1, 8, 64, 256

8.2.3 TIMER4/5, TIMER6/7, TIMER8/9

The Timer4/5, Timer6/7 and Timer8/9 modules are

similar in operation to the T imer2/3 modul e. Differen ces

include:

• These modules do not support the ADC event

trigger feature

• These modules can not be used by other

peripheral modules, su ch as input cap ture and

output compare

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 21

Page 24

PIC24H

8.3 Input Capture Module

The input capture module is useful in applications

requiring frequency (period) and pulse measurement.

The PIC24H devices support up to eight input capture

channels.

The input capture module captures the 16-bit value of

the selected time base register when an event occurs

at the ICx pin. Th e events that caus e a capture ev ent

are listed below in three categories:

1. Simple Capture Event modes

- Capture timer value on every falling edge of

input at ICx pin

- Capture timer value on every rising edg e of

input at ICx pin

2. Capture timer value on every edge (rising and falling)

3. Prescaler Capture Event modes

- Capture timer value on every 4th rising

edge of input at ICx pin

- Capture timer value on every 16th rising

edge of input at ICx pin

Each input capture channel can select between one of

two 16-bit timers (Timer2 or Timer3) for the time base.

The selected timer can use either an internal or an

external clock.

Other operational features include:

• Device wake-up from capture pin during CPU

Sleep and Idle modes

• Interrupt on input capture event

• 4-word FIFO buffer for capture values

- Interrupt optionally generated after 1, 2, 3 or

4 buffer locations are filled

• Input capture can also be used to provide

additional sources of external interrupts.

Input capture channels IC1 and IC2 support DMA data

transfers.

8.4 Output Compare/PWM Module

The output compare module featur es are quite useful i n

applications that require controlled timing pulses or

PWM modulated pulse streams.

The output compare module has the ability to compare

the value of a selected time base with the value of one

or two compare registers (depending on the operation

mode selected). Furthermore, it has the ability to

generate a single output pulse, or a repetitive

sequence of outpu t pulses, o n a comp are matc h event.

Like most PIC24H peripherals, it also has the ability to

generate interrupts on compare match events.

The PIC24H device may have up to eight output

compare channels, designated OC1 through OC8.

Refer to the specific device data sheet for the number

of channels available in a particular device. All output

compare channels are functionally identical.

Each output compare channel can use one of two

selectable t im e bases. The time base is se lec ted using

the OCTSEL bit (OCxCON<3>). An ‘x’ in the pin,

register or bit name denotes the specific output

compare channel . Refer to the dev ice data shee t for the

specific timers that can be used with each output

compare channel number.

Each output compare module has the following modes

of operation:

• Single Compare Match mode

• Dual Compare Match mode generating

- Single Output Pulse

- Continuous Output Pulses

• Simple Pulse-Width Modulation mode

- With Fault Protection Input

- Without Fault Protection Input

Output compare channels, OC1 and OC2, support

DMA data transfers.

8.5 SPI Module

The Serial Peripheral Interface (SPI) module is a

synchronous serial interface for communicating with

other peripheral or microcontroller devices such as

serial EEPROMs, shift registers, display drivers, ADC,

etc. It is compatible with Motorola

interfaces.

This SPI module includes all SPI modes. A Frame

Synchronization mode is also included for support of

voice band codecs.

Four pins make up the serial interface: SDI, Serial Data

Input; SDO, Serial Data Ou tpu t; SCK, Shi ft Cl ock Input

or Output; SS

serves as the FSYNC (Frame Synchronization Pulse).

A device set up as an SPI master provides the serial

communication clock signal on its SCK pin.

A series of 8 or 16 clock pulses (depending on mode)

shift out the 8 or 16 bits (depending on whether a byte

or word is being transferred) and simu ltaneously shift in

8 or 16 bits of data from the SDI pin. An interrupt is

generated when the transfer is complete.

Slave select sync hroni zati on al lows se lecti ve en abli ng

of SPI slave devices, which is particularly useful when

a single master is connected to multiple slaves.

The SPI1 and SPI2 modules support DMA data

transfers.

, Active-Low Slave Select, which also

®

SPI and SIOP

DS70166A-page 22 Preliminary © 2005 Microchip Technology Inc.

Page 25

PIC24H

8.6 UART Module

The UART is a full-duplex asynchronous system that

can communicate with peripheral devices, such as

personal computers, RS-232 and RS-485 interfaces.

The PIC24H devices have one or more UARTs.

The key features of the UART module are:

• Full-duplex operation with 8 or 9-bit data

• Even, odd or no parity options (for 8-bit data)

• One or two Stop bits

• Fully integrated Baud Rate Generator (BRG) with

16-bit prescaler

• Baud rates range from up to 10 Mbps and down to

38 Hz at 40 MIPS

• 4-character deep transmit data buffer

• 4-character deep receive data buffer

• Parity, framing and buffer overrun error detection

•Full IrDA

and decoding of IrDA

• LIN bus support

- Auto wake-up from Sleep or Idle mode on

- Auto-baud detection

- Break character support

• Support for interrupt on address detect (9th bit = 1)

• Separate transmit and receive interrupts

- On transmission of 1 or 4 characters

- On reception of 1, 3 and 4 characters

• Loopback mode for diagnostics

The UART1 and UART2 modules support DMA data

transfers.

®

support, including hardware encoding

Start bit detect

®

messages

8.7 I2C Module

The Inter-Integrated Circuit (I2C) module is a

synchronous serial interface, useful for communicating

with other peripheral or microcontroller devices. These

peripheral devices may be serial EEPROMs, shift

registers, display drivers, ADC, etc.

2

C module offers full hardware support for both

The I

slave and multi-master operations.

2

The key features of the I

2

C slave operation supports 7 and 10-bit address

•I

•I2C master opera t i on su pp orts 7 and 10-bit add r ess

2

•I

C port allows bidirectional transfers between

master and slaves

• Serial clock synchronization for I

used as a handshake mechanism to s uspen d and

resume serial transfer (serial clock stretching)

•I2C supports multi-master operation; detects bus

collision and will arbitrate accordingly

• Slew rate control for 100 kHz and 400 kHz bus speeds

2

C mode, pin SCL is clock and pin SDA is data. The

In I

module will override the data direction bits for these pins.

C module are:

2

C port can be

8.8 Controller Area Network (CAN) Module

The Controller Area Network (CAN) module is a serial

interface useful for communicating with other CAN

modules or microcontroller devices. This interface/

protocol was designed to allow communications within

noisy environment s .

The CAN module is a communication controller

implementing the CAN 2.0 A/B protocol, as defined in

the BOSCH specification. The module supports

CAN 1.2, CAN 2.0A, CAN 2.0B Passive and CAN 2.0B

Active versions of the protocol. Details of these protocols

can be found in the BOSCH CAN specification.

The CAN module features :

• Implementation of the CAN protocol CAN 1.2,

CAN 2.0A and CAN 2.0B

• Standard and extended data frames

• Data lengths of 0-8 bytes

• Programmable bit rate up to 1 Mbit/sec

• Automatic response to remote frames

• Up to 32 receive buffers in DMA RAM

• FIFO Buffer mode (up to 32 messages deep)

• 16 full (standard/extended identifier) acceptance

filters

• 3 full acceptance filter masks

• Up to 8 transmit buffers in DMA RAM

• DMA can be used for transmission and reception

• Programmable wake-up functionality with

integrated low-pass fil ter

• Programmable Loopback mode suppo rts self-test

operation

• Signaling via interrupt capabilities for all CAN

receiver and transmitter error states

• Programmable clock source

• Programmable link to timer module for

time-stamping and network synchronization

• Low-power Sleep and Idl e mode

The CAN bus module cons ists of a protoc ol engine and

message buffering/control. The CAN protocol engine

handles all functions for receiving and transmitting

messages on the CAN bus. Messages are transmitted

by first loading the appropriate data registers. Status

and errors can be checked by reading the appropriate

registers. Any message detected on the CAN bus is

checked for errors and then matched against filters to

see if it should be received and stored in one of the

receive registers.

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 23

Page 26

PIC24H

8.9 I/O Pins

Some pins for the I/O p in funct ions are multip lexed w ith

an alternate function for the peripheral features on the

device. In general, when a peripheral is enabled, that

pin may not be used as a general-purpose I/O pin.

All I/O port pins have three registers directly associated

with the operation of the port pin. The Data Direction

register determines whether the pin is an input or an

output. The Port Data Latch register provides latched

output data for t h e I/ O p i ns . Th e Por t re gi st e r pr o vi d es

visibility of the logic state of the I/O pins. Reading the

Port register provides the I/O pin logic state, while

writes to the Port register write the dat a to the Port Da ta

Latch register.

I/O port pins have latch bits (Port Data Latch register).

This register, when read, yields the contents of the I/O

latch and when written , modifies the co ntents of the I/O

latch, thus modifying the value driven out on a pin if the

corresponding Data Direction register bit is configured

for output. This can be used in read-modify-write

instructions that allow the user to modify the contents

of the Port Data Latch register , re gard le ss o f t he status

of the corresponding pins.

The I/O pins have the following features:

• Schmitt Trigger input

• CMOS output drivers

• Weak internal pull-up

All I/O pins configured as digital inputs can accept 5V

signals. This provides a degree of compatibility with

external signals of dif ferent voltage levels. How ever , al l

digital outputs and analog pins can only generate

voltage levels up to 3.6V.

The input change notification module gives PIC24H

devices the ability to gen era te inte rrup t reque st s to the

processor in resp onse to a chan ge of s tat e on sele cted

input pins. This module is capable of detecting input

changes of st ate, even in Sleep mode , when th e clocks

are disabled. There are up to 24 external signals (CN0

through CN23) that can be selected (enabled) for

generating an interrupt request on a change of state.

Each of the CN pins also has an optional weak pull-up

feature.

DS70166A-page 24 Preliminary © 2005 Microchip Technology Inc.

Page 27

PIC24H

9.0 PIC24H INSTRUCTION SET

9.1 Introduction

The PIC24H instruction set provides a broad suite of

instructions which supports traditional microcontroller

applications, and a class of in struction s which sup port s

math-intensive applications. Since almost all of the

functionality of the PICmicro MCU instruction set has

been maintained, this hybrid instruction set allows a

friendly migration path for users already familiar with

the PICmicro microcontroller.

9.2 Instruction Set Overview

The PIC24H instruction set contains 76 instructions

which can be gr ouped into th e ten function al categorie s

shown in Table 9-1. Table 9-2 defines the symbols

used in the instruction summary tables, Table 9-3

through Table 9-11. These tables define the syntax,

description, storage and execution requirements

for each instruction. Storage requirements are represented in 24-bit instruction words and execution

requirements are represented in instruction cycles.

Most instructions have several different addressing

modes and execution flows which require different

instruction variants. For instance, there are six unique

ADD instructions and each instruction variant has its

own instruction encoding.

TABLE 9-1: PIC24H INSTRUCTION

GROUPS

Functional Group Summary Table

Move Instructions Table 9-3

Math Instructions Table 9-4

Logic Instructions Table9-5

Rotate/Shift Instructions Table 9-6

Bit Instructions Table 9-7

Compare/Skip Instructions Table 9-8

Program Flow Instructions Table 9-9

Shadow/Stack Instructions Table 9-10

Control Instructions Table 9-11

9.2.1 MULTI-CYCLE INSTRUCTIONS

As the instruction summary tables show, most

instructions execute in a single cycle with the following

exceptions:

• Instructions MOV.D, POP.D, PUSH.D,

TBLRDH, TBLRDL, TBLWTH and TBLWTL

require 2 cycles to execute.

• Instructions DIVF, DIV.S, DIV.U are single-

cycle instructions, which should be executed

18 consecutive times as the target REPEAT

instruction.

• Instructions that change the Program Counter

also require 2 cycles to execute, with the extra

cycle executed as a NOP. Skip instructions, which

skip over a 2-word instruction, require 3

instruction cycles to execute with 2 cycles

executed as a NOP.

•The RETFIE, RETLW and RETURN are special

cases of instructions that change the Program

Counter. These execute in 3 cycles unless an

exception is pending, and then they execute in

2 cycles.

Note: Instructions that access progr am memor y

as data, using Program Space Visibility,

incur some cycle count overhead.

9.2.2 MULTI-WORD INSTRUCTIONS

As the instruction summary tables show, almost all

instructions consume one instruction word (24 bits),

with the exception of the CALL and GOTO instructions,

which are flow instructions listed in Table 9-9. These

instructions require two words of memory because their

opcodes embed large literal operands.

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 25

Page 28

PIC24H

TABLE 9-2: SYMBOLS USED IN SUMMARY TABLES

Symbol Description

# Literal operand designation

bit4 4-bit wide bit position (0:15)

Expr Absolute address, label or expression (resolved by the linker)

f File register address

lit1 1-bit literal (0:1)

lit4 4-bit literal (0:15)

lit5 5-bit literal (0:31)

lit8 8-bit literal (0:255)

lit10 10-bit literal (0:255 for Byte mode, 0:1023 for Word mode)

lit14 14-bit literal (0:16383)

lit16 16-bit literal (0:65535)

lit23 23-bit literal (0:8388607)

Slit4 Signed 4-bit literal (-8:7)

Slit6 Signed 6-bit literal (-16:16)

Slit10 Signed 10-bit literal (-512:511)

Slit16 Signed 16-bit literal (-32768:32767)

TOS Top-of-Stack

Wb Base working register

Wd Destination working register (direct and indirect addressing)

Wm, Wn Working register divide pair (dividend, divisor)

Wm*Wm Working register multiplier pair (same source register)

Wm*Wn Working register multiplier pair (different source registers)

Wn Both source and destination working register (direct addressing)

Wnd Destination working register (direct addressing)

Wns Source working register (direct addressing)

WREG Default working register

Ws Source working register (direct and indirect addressing)

DS70166A-page 26 Preliminary © 2005 Microchip Technology Inc.

Page 29

PIC24H

TABLE 9-3: MOVE INSTRUCTIONS

Assembly Syntax Description Words Cycles

EXCH Wns,Wnd Swap Wns and Wnd 1 1

MOV f {,WREG} Move f to destination 1 1

MOV WREG,f Move WREG to f 1 1

MOV f,Wnd Move f to Wnd 1 1

MOV Wns,f Move Wns to f 1 1

MOV.b #lit8,Wnd Move 8-bit literal to Wnd 1 1

MOV #lit16,Wnd Move 16-bit literal to Wnd 1 1

MOV [Ws+Slit10],Wnd Move [Ws + signed 10-bit offset] to Wnd 1 1

MOV Wns,[Wd+Slit10] Move Wns to [Wd + signed 10-bit offset] 1 1

MOV Ws,Wd Move Ws to Wd 1 1

MOV.D Ws,Wnd Move double Ws to Wnd:Wnd + 1 1 2

MOV.D Wns,Wd Move double Wns:Wns + 1 to Wd 1 2

SWAP Wn Wn = byte or nibble swap Wn 1 1

TBLRDH Ws,Wd Read high program word to Wd 1 2

TBLRDL Ws,Wd Read low program word to Wd 1 2

TBLWTH Ws,Wd Write Ws to high program word 1 2

TBLWTL Ws,Wd Write Ws to low program word 1 2

Note: When the optional {,WREG} operand is specified, the destination of the instruction is WREG. When

{,WREG} is not specified, the destination of the instruction is the file register f.

Note: Table 9-3 through Table9-11 present the base instruction syntax for the PIC24H. These instructions do not

include all of the available addressing modes. For example, some instructions show the Byte Addressing

mode and others do not.

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 27

Page 30

PIC24H

TABLE 9-4: MATH INSTRUCTIONS

Assembly Syntax Description Words Cycles

ADD f {,WREG} Destination = f + WREG 1 1

ADD #lit10,Wn Wn = lit10 + Wn 1 1

ADD Wb,#lit5,Wd Wd = Wb + lit5 1 1

ADD Wb,Ws,Wd Wd = Wb + Ws 1 1

ADDC f {,WREG} Destination = f + WREG + (C) 1 1

ADDC #lit10,Wn Wn = lit10 + Wn + (C) 1 1

ADDC Wb,#lit5,Wd Wd = Wb + lit5 + (C) 1 1

ADDC Wb,Ws,Wd

DS70166A-page 28 Preliminary © 2005 Microchip Technology Inc.

Page 31

PIC24H

TABLE 9-5: LOGIC INSTRUCTIONS

Assembly Syntax Description Words Cycles

AND f {,WREG} Destination = f .AND. WREG 1 1

AND #lit10,Wn Wn = lit10 .AND. Wn 1 1

AND Wb,#lit5,Wd Wd = Wb .AND. lit5 1 1

AND Wb,Ws,Wd Wd = Wb .AND. Ws 1 1

CLR f f = 0x0000 1 1

CLR WREG WREG = 0x0000 1 1

CLR Wd Wd = 0x0000 1 1

COM f {,WREG} Destination = f

COM Ws,Wd Wd = Ws

IOR f {,WREG} Destination = f .IOR. WREG 1 1

IOR #lit10,Wn Wn = lit10 .IOR. Wn 1 1

IOR Wb,#lit5,Wd Wd = Wb .IOR. lit5 1 1

IOR Wb,Ws,Wd Wd = Wb .IOR. Ws 1 1

NEG f {,WREG} Destination = f

NEG Ws,Wd Wd = Ws

SETM f f = 0xFFFF 1 1

SETM WREG WREG = 0xFFFF 1 1

SETM Wd Wd = 0xFFFF 1 1

XOR f {,WREG} Destination = f .XOR. WREG 1 1

XOR #lit10,Wn Wn = lit10 .XOR. Wn 1 1

XOR Wb,#lit5,Wd Wd = Wb .XOR. lit5 1 1

XOR Wb,Ws,Wd Wd = Wb .XOR. Ws 1 1

Note: When the optional {,WREG} operand is specified, the destination of the instruction is WREG. When

{,WREG} is not specified, the destination of the instruction is the file register f.

11

11

+ 1 1 1

+ 1 1 1

© 2005 Microchip Technology Inc. Preliminary DS70166A-page 29

Page 32

PIC24H

TABLE 9-6: ROTATE/SHIFT INSTRUCTIONS

Assembly Syntax Description Words Cycles

ASR f {,WREG} Destination = arithmetic right shift f 1 1

ASR Ws,Wd Wd = arithmetic right shift Ws 1 1

ASR Wb,#lit4,Wnd W nd = arithmetic right shift Wb by lit4 1 1

ASR Wb,Wns,Wnd Wnd = arithmetic right shift Wb by Wns 1 1

LSR f {,WREG} Destination = logical right shift f 1 1

LSR Ws,Wd Wd = logical right shift Ws 1 1

LSR Wb,#lit4,Wnd Wnd = logical right shift Wb by lit4 1 1

LSR Wb,Wns,Wnd Wnd = logical right shift Wb by Wns 1 1

RLC f {,WREG} Destination = rotate left through Carry f 1 1

RLC Ws,Wd Wd = rotate left through Carry Ws 1 1

RLNC f {,WREG} Destination = rotate left (no Carry) f 1 1

RLNC Ws,Wd Wd = rotate left (no Carry) Ws 1 1

RRC f {,WREG} Destination = rotate right through Carry f 1 1

RRC Ws,Wd Wd = rotate right through Carry Ws 1 1

RRNC f {,WREG} Destination = rotate right (no Carry) f 1 1

RRNC Ws,Wd Wd = rotate right (no Carry) Ws 1 1

SL f {,WREG} Destination = left shift f 1 1

SL Ws,Wd Wd = left shift Ws 1 1

SL Wb,#lit4,Wnd Wnd = left shift Wb by lit4 1 1

SL Wb,Wns,Wnd Wnd = left shift Wb by Wns 1 1

Note: When the optional {,WREG} operand is specified, the destination of the instruction is WREG. When

{,WREG} is not specified, the destination of the instruction is the file register f.

TABLE 9-7: BIT INSTRUCTIONS

Assembly Syntax Description Words Cycles

BCLR f,#bit4 Bit clear f 1 1

BCLR Ws,#bit4 Bit clear Ws 1 1

BSET f,#bit4 Bit set f 1 1

BSET Ws,#bit4 Bit set Ws 1 1

BSW.C Ws,Wb Write C bit to Ws<Wb> 1 1

BSW.Z Ws,Wb Write S

BTG f,#bit4 Bit toggle f 1 1

BTG Ws,#bit4 Bit toggle Ws 1 1

BTST f,#bit4 Bit test f 1 1

BTST.C Ws,#bit4 Bit test Ws to C 1 1

BTST.Z Ws,#bit4 Bit test Ws to SZ 1 1

BTST.C Ws,Wb Bit test Ws<Wb> to C 1 1