Page 1

查询PIC16C717供应商

18/20-Pin, 8-Bit CMOS Microcontrollers with 10/12-Bit A/D

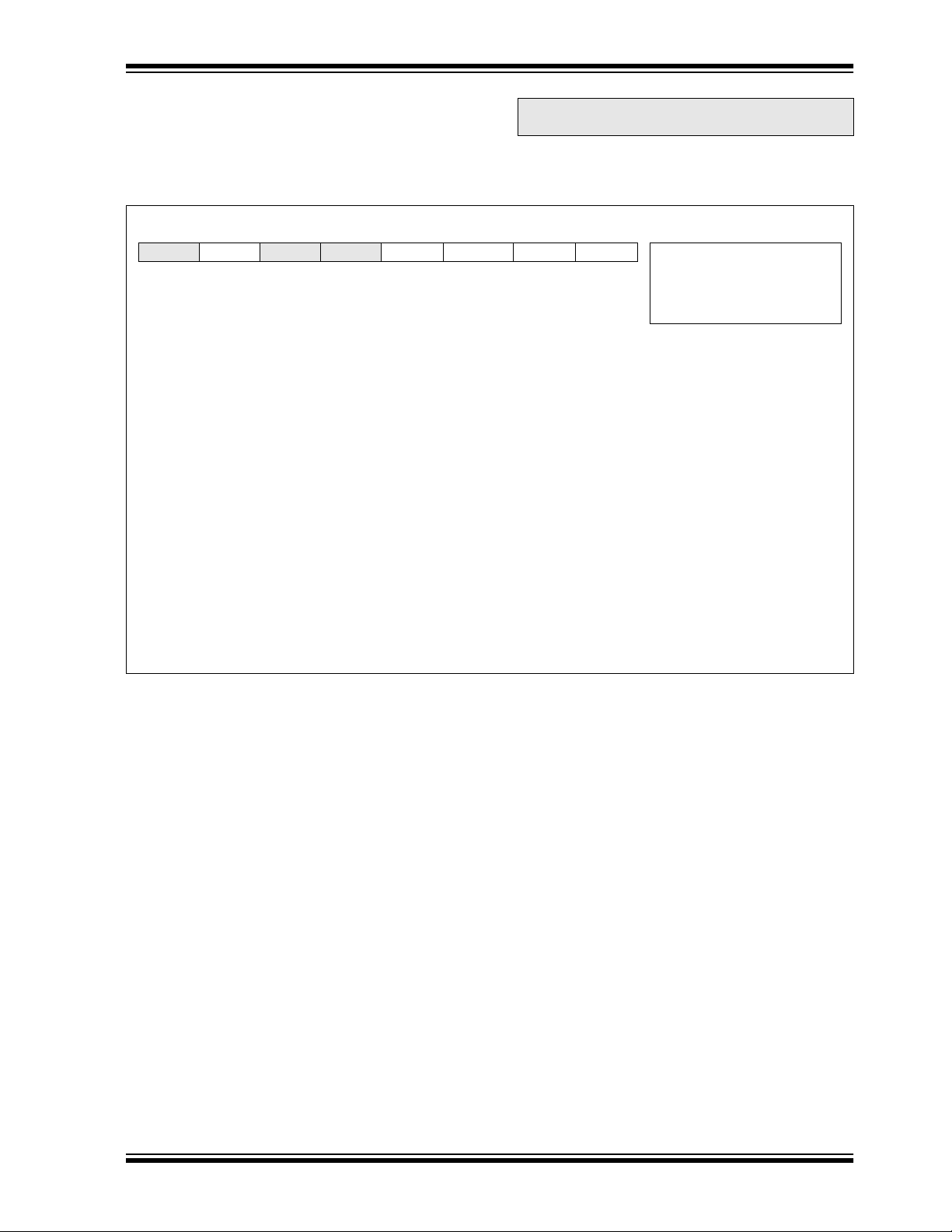

PIC16C717/770/771

Microcontroller Core Features:

• High-performance RISC CPU

• Only 35 single word instructions to learn

• All single cycle instructions except for program

branches which are two cycle

• Operating speed: DC - 20 MHz clock input

DC - 200 ns instruction cycle

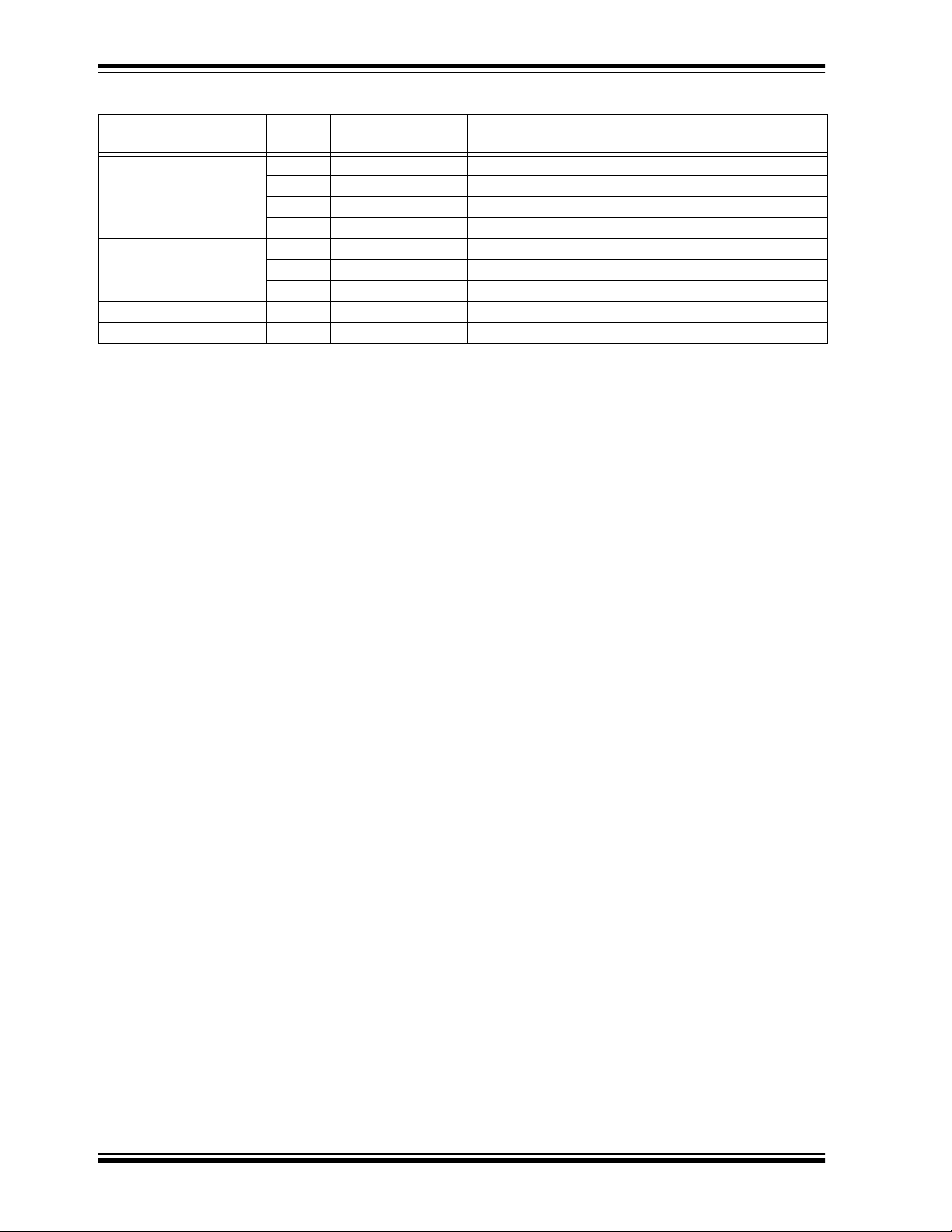

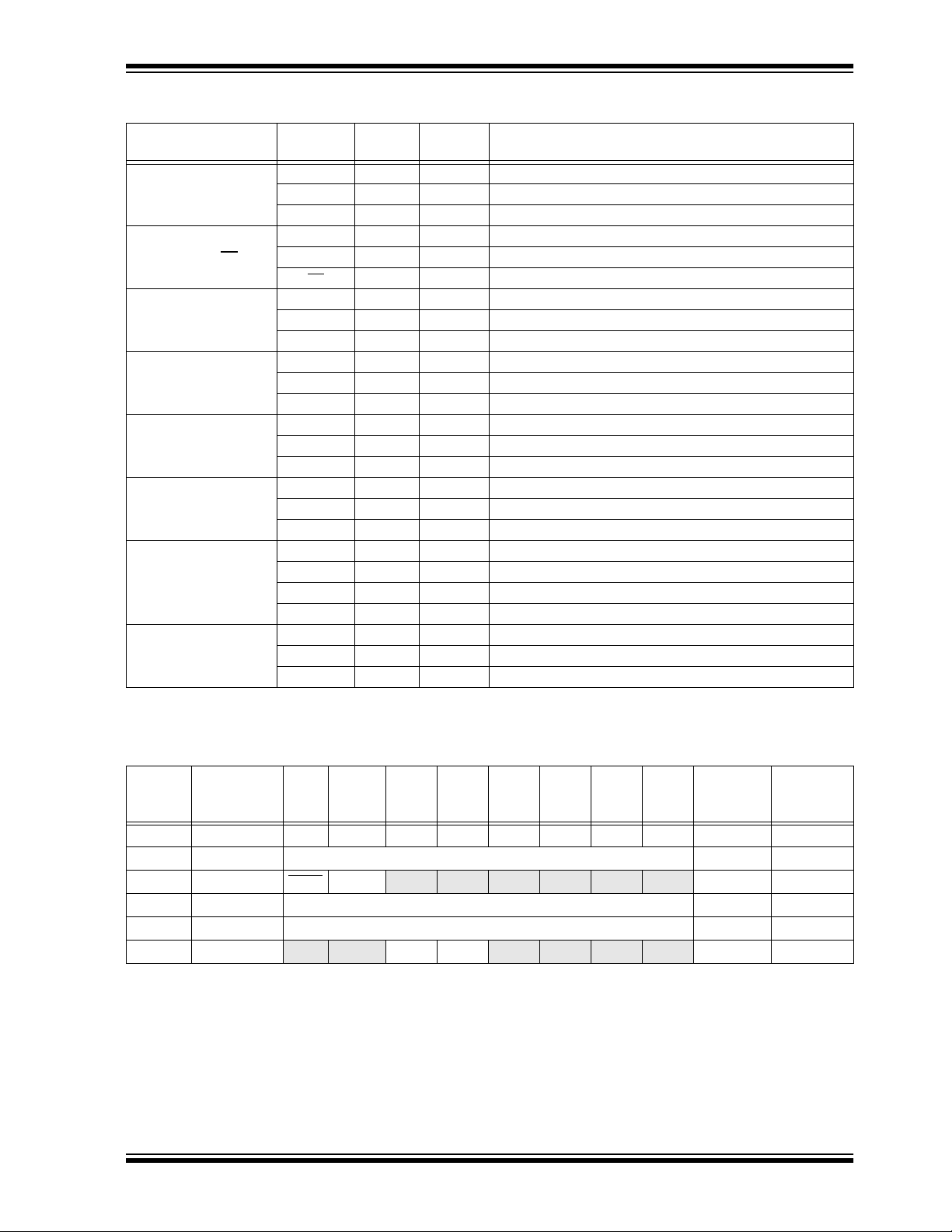

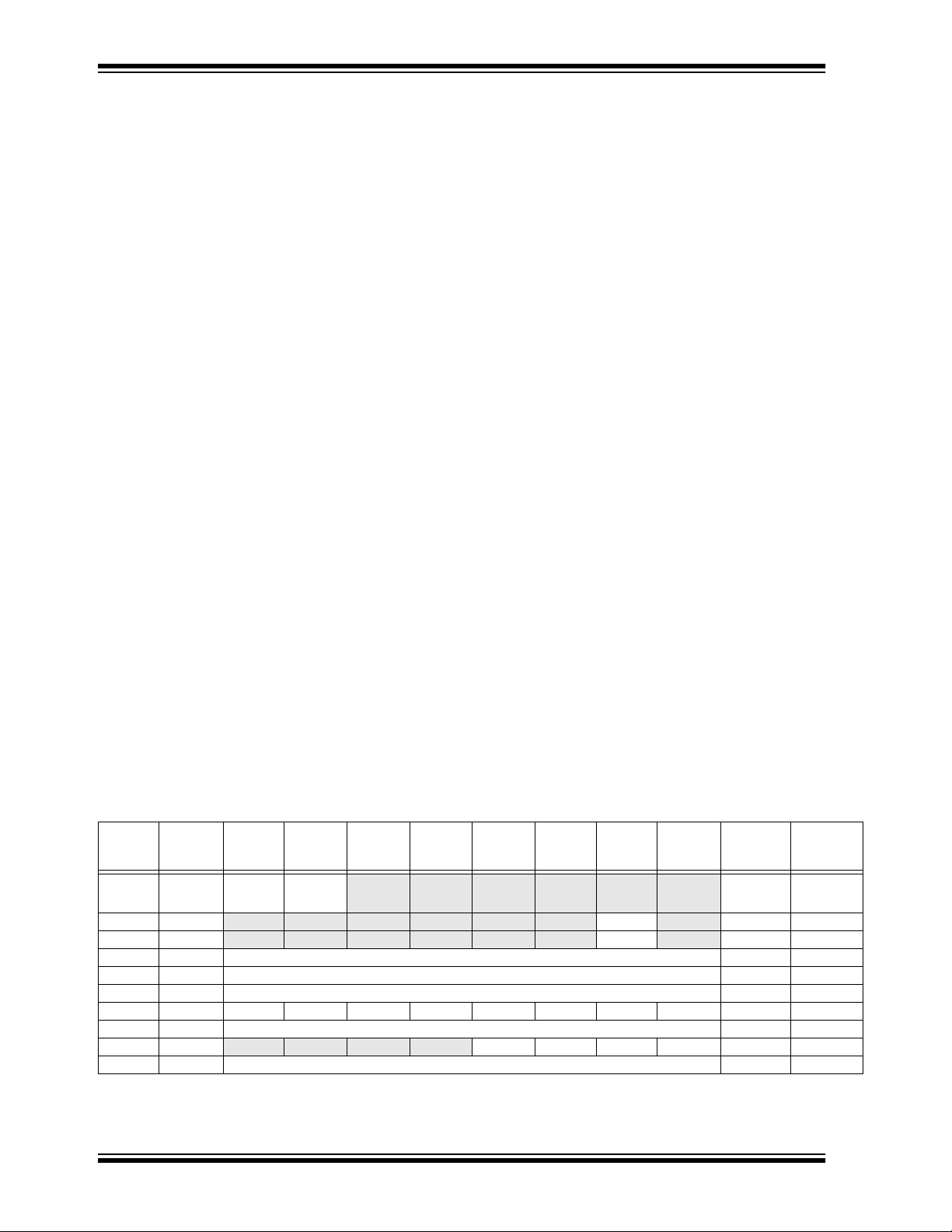

Memory

Device

PIC16C717 2K 256 18, 20 10 bits 6

PIC16C770 2K 256 20 12 bits 6

PIC16C771 4K 256 20 12 bits 6

Program

x14

Data

x8

Pins

• Interrupt capability (up to 10 internal/external

interrupt sources)

• Eight level deep hardware stack

• Direct, indirect and relative addressing modes

• Power-on Reset (POR)

• Power-up Timer (PWRT) and

Oscillator Start-up Timer (OST)

• Watchdog Timer (WDT) with its own on-chip RC

oscillator for reliable operation

• Selectable oscillator options:

- INTRC - Internal RC, dual speed (4MHz and

37KHz) dynamically switchable for pow er savings

- ER - External resistor, dual speed (user

selectable frequency and 37KHz) dynamically switchable for power savings

- EC - External clock

- HS - High speed crystal/resonator

- XT - Crystal/resonator

- LP - Low power crystal

• Low-power, high-speed CMOS EPROM

technology

• In-Circuit Serial Programming™ (ISCP)

• Wide operating voltage range: 2.5V to 5.5V

• 15 I/O pins with individual control for:

- Direction (15 pins)

- Digital/Analog input (6 pins)

- PORTB interrupt on change (8 pins)

- PORTB weak pull-up (8 pins)

- High voltage open drain (1 pin)

• Commercial and Industrial temperature ranges

• Low-power consumption:

- < 2 mA @ 5V, 4 MHz

- 22.5 µA typical @ 3V, 32 kHz

-< 1 µA typical standby current

A/D

Resolution

A/D

Channels

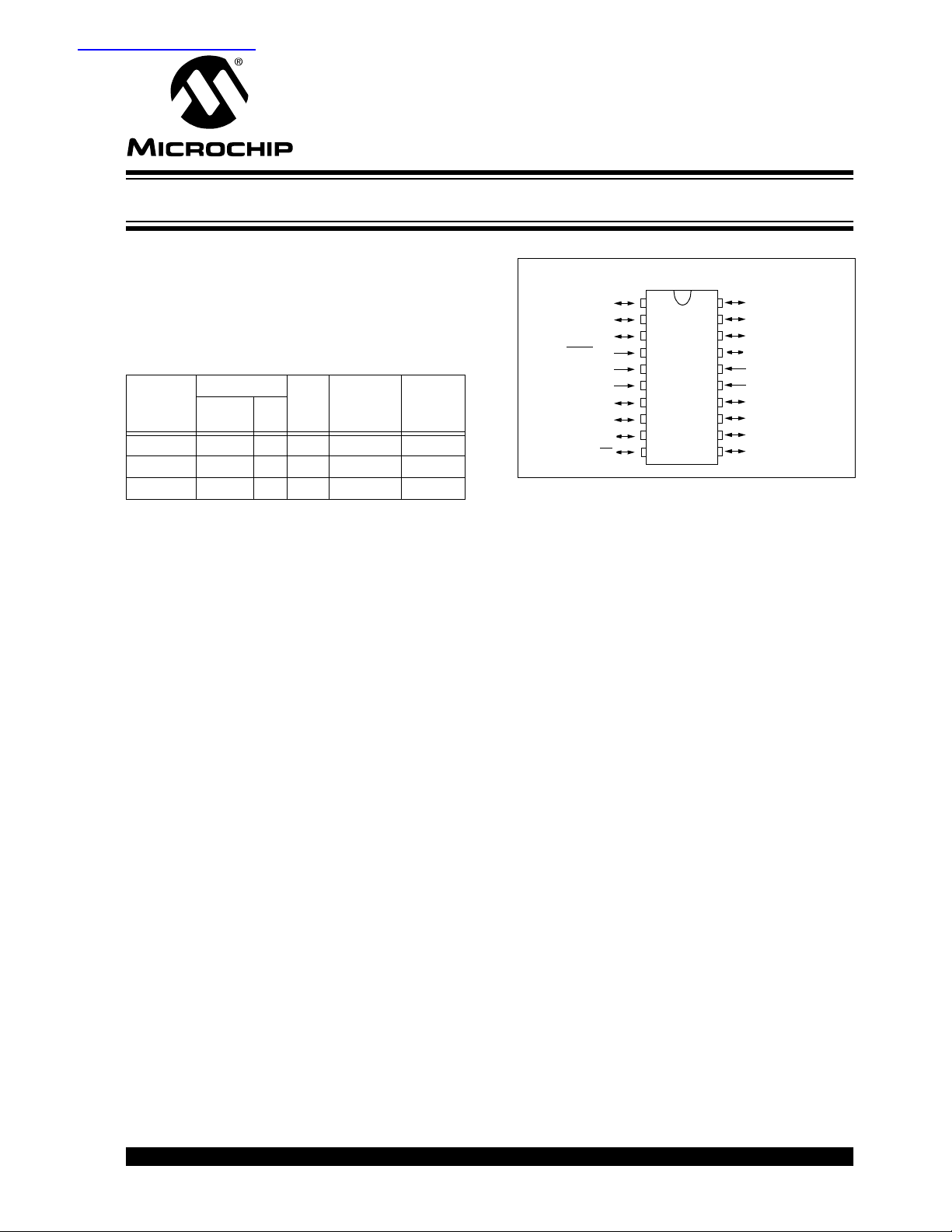

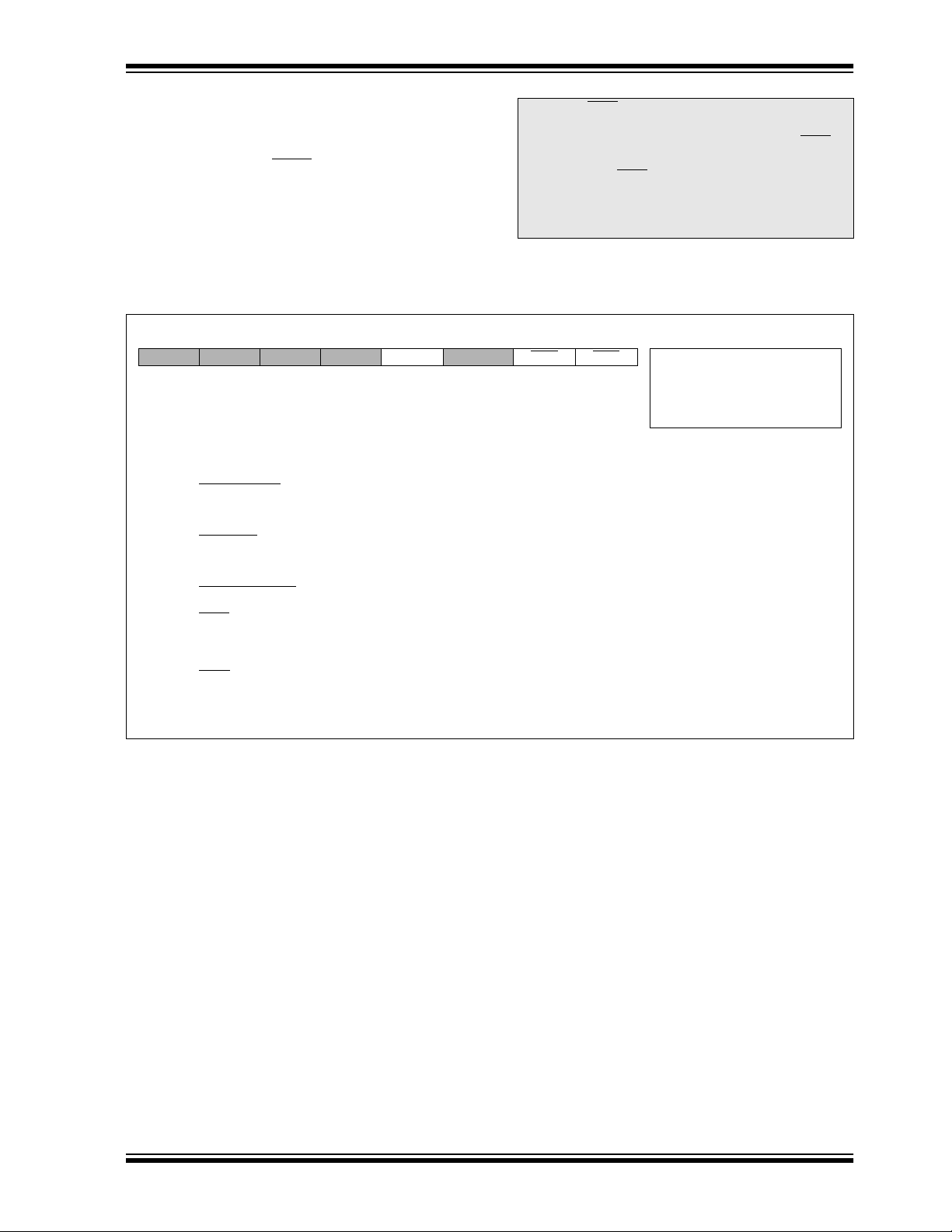

Pin Diagram

20-Pin PDIP, SOIC, SSOP

20

RA0/AN0

RA1/AN1/LVDIN

RA4/T0CKI

RA5/MCLR/VPP

VSS

AVSS

RA2/AN2/VREF-/VRL

RA3/AN3/VREF+/VRH

RB0/AN4/INT

RB1/AN5/SS

1

2

PIC16C770/771

3

4

5

6

7

8

9

10

19

18

17

16

15

14

13

12

11

RB3/CCP1/P1A

RB2/SCK/SCL

RA7/OSC1/CLKIN

RA6/OSC2/CLKOUT

VDD

AVDD

RB7/T1OSI/P1D

RB6/T1OSO/T1CKI/P1C

RB5/SDO/P1B

RB4/SDI/SDA

Peripheral Features:

• Timer0: 8-bit timer/counter with 8-bit prescaler

• Timer1: 16-bit timer/counter with prescaler,

can be incremented during sleep via external

crystal/clock

• Timer2: 8-bit timer/counter with 8-bit period

register, prescaler and postscaler

• Enhanced Capture, Compare, PWM (ECCP)

module

- Capture is 16 bit, max. resolution is 12.5 ns

- Compare is 16 bit, max. resolution is 200 ns

- PWM max. resolution is 10 bit

- Enhanced PWM:

- Single, Half-Bridge and Full-Bridge output

modes

- Digitally prog rammable dea dba nd del ay

• Analog-to-Digital converter:

- PIC16C770/771 12-bit resolution

- PIC16C717 10-bit resolution

• On-chip absolute bandgap voltage reference

generator

• Programmable Brown-out Reset (PBOR)

circuitry

• Programmable Low-Voltage Detection (P LVD)

circuitry

• Master Synchronous Serial Port (MSSP) with two

modes of operation:

- 3-wire SPI™ (supports all 4 SPI modes)

2

C™ compatible including master mode

-I

support

• Program Memory Read (PMR) capability for lookup table, character string storage and checksum

calculation purposes

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 1

Page 2

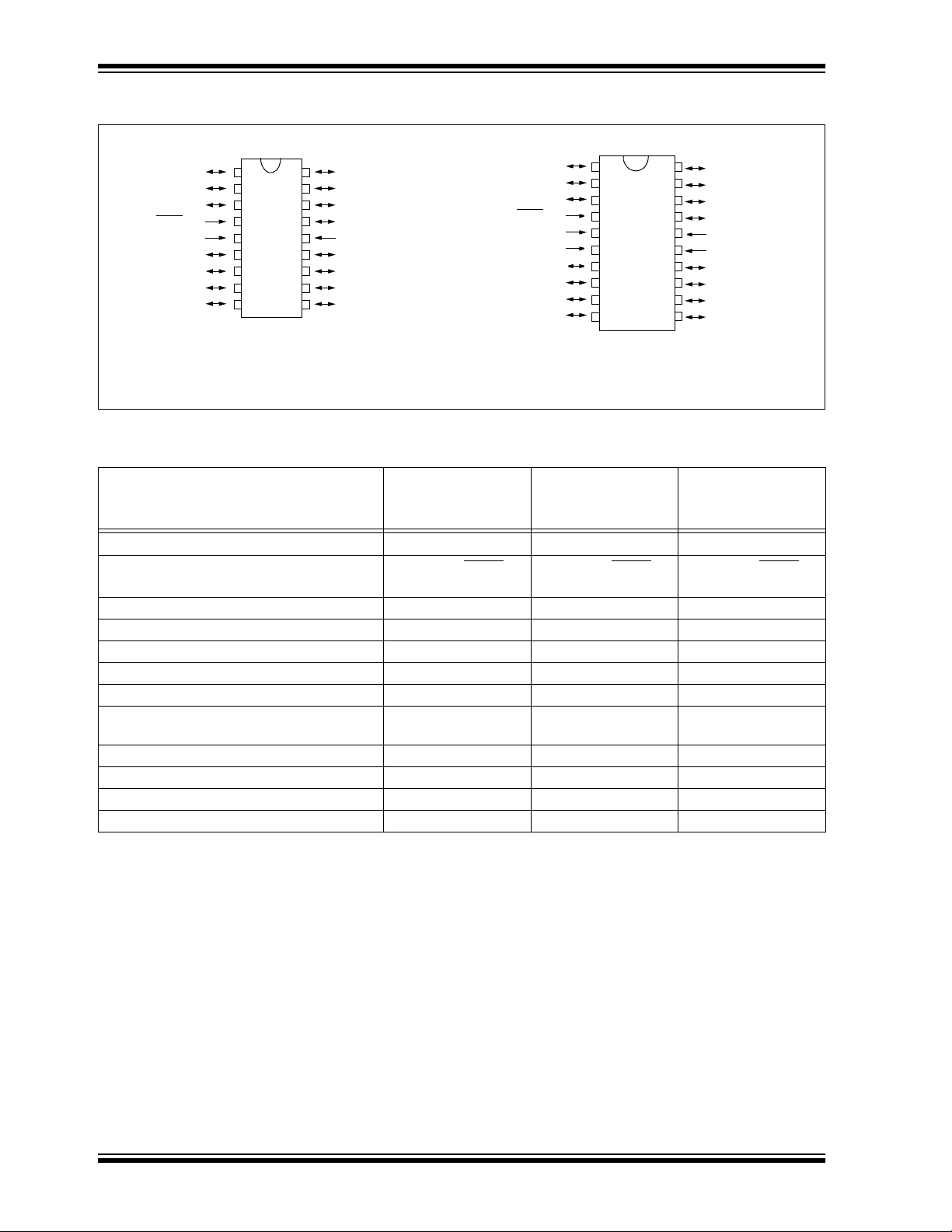

PIC16C717/770/771

Pin Diagrams

18-Pin PDIP, SOIC

RA0/AN0

RA1/AN1/LVDIN

RA4/T0CKI

RA5/MCLR/VPP

VSS

RA2/AN2/VREF-/VRL

RA3/AN3/VREF+/VRH

RB0/AN4/INT

RB1/AN5/SS

18

1

17

2

PIC16C717

16

3

15

4

14

5

13

6

12

7

11

8

10

9

RB3/CCP1/P1A

RB2/SCK/SCL

RA7/OSC1/CLKIN

RA6/OSC2/CLKOUT

VDD

RB7/T1OSI/P1D

RB6/T1OSO/T1CKI/P1C

RB5/SDO/P1B

RB4/SDI/SDA

20-Pin SSOP

RA0/AN0

RA1/AN1/LVDIN

RA4/T0CKI

RA5/MCLR/VPP

VSS

VSS

RA2/AN2/VREF-/VRL

RA3/AN3/VREF+/VRH

RB0/AN4/INT

RB1/AN5/SS

PIC16C717

20

19

18

17

16

15

14

13

12

11

RB3/CCP1/P1A

RB2/SCK/SCL

RA7/OSC1/CLKIN

RA6/OSC2/CLKOUT

(2)

VDD

(2)

VDD

RB7/T1OSI/P1D

RB6/T1OSO/T1CKI/P1C

RB5/SDO/P1B

RB4/SDI/SDA

1

2

3

(1)

(1)

4

5

6

7

8

9

10

Note 1: VSS pins 5 and 6 must be tied together.

2: V

DD pins 15 and 16 must be tied together.

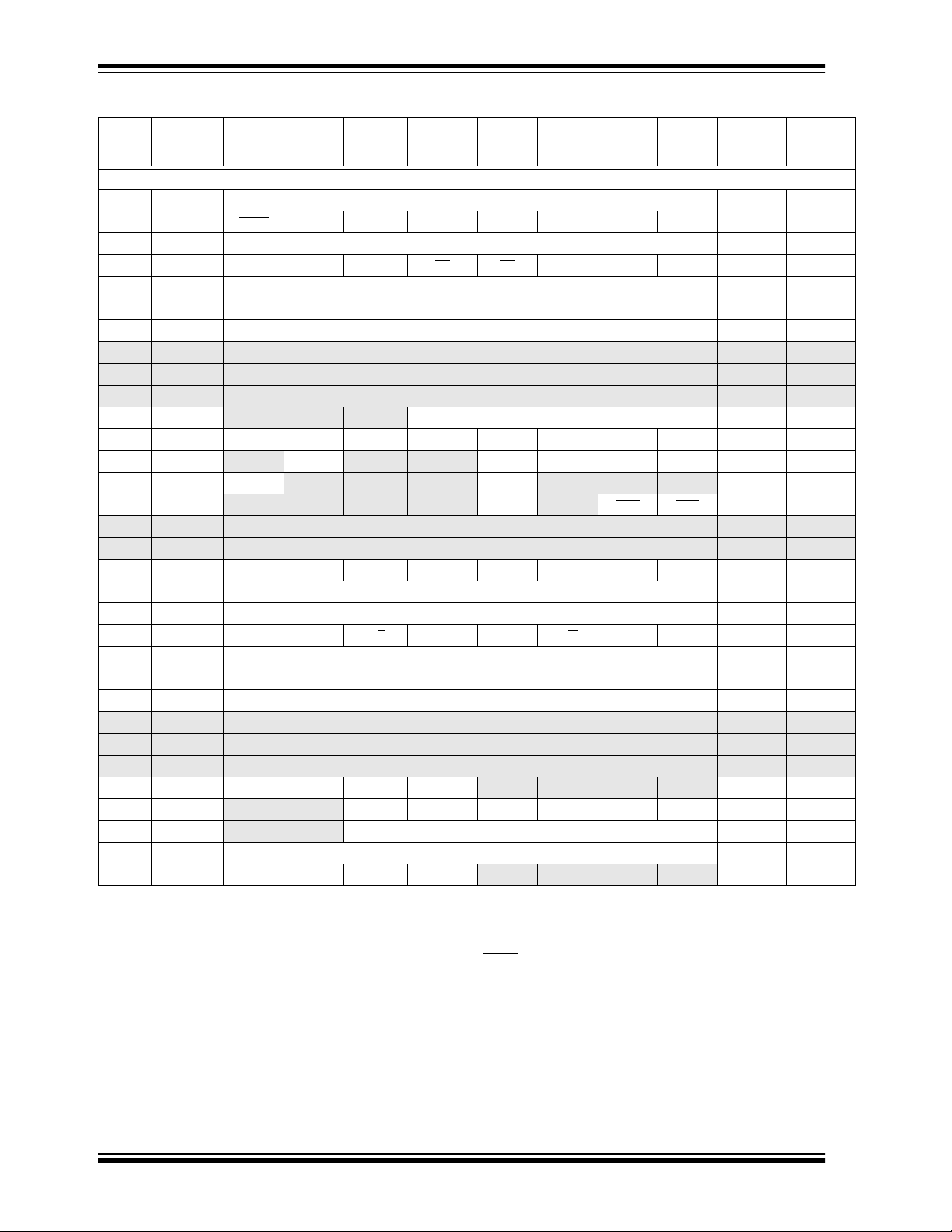

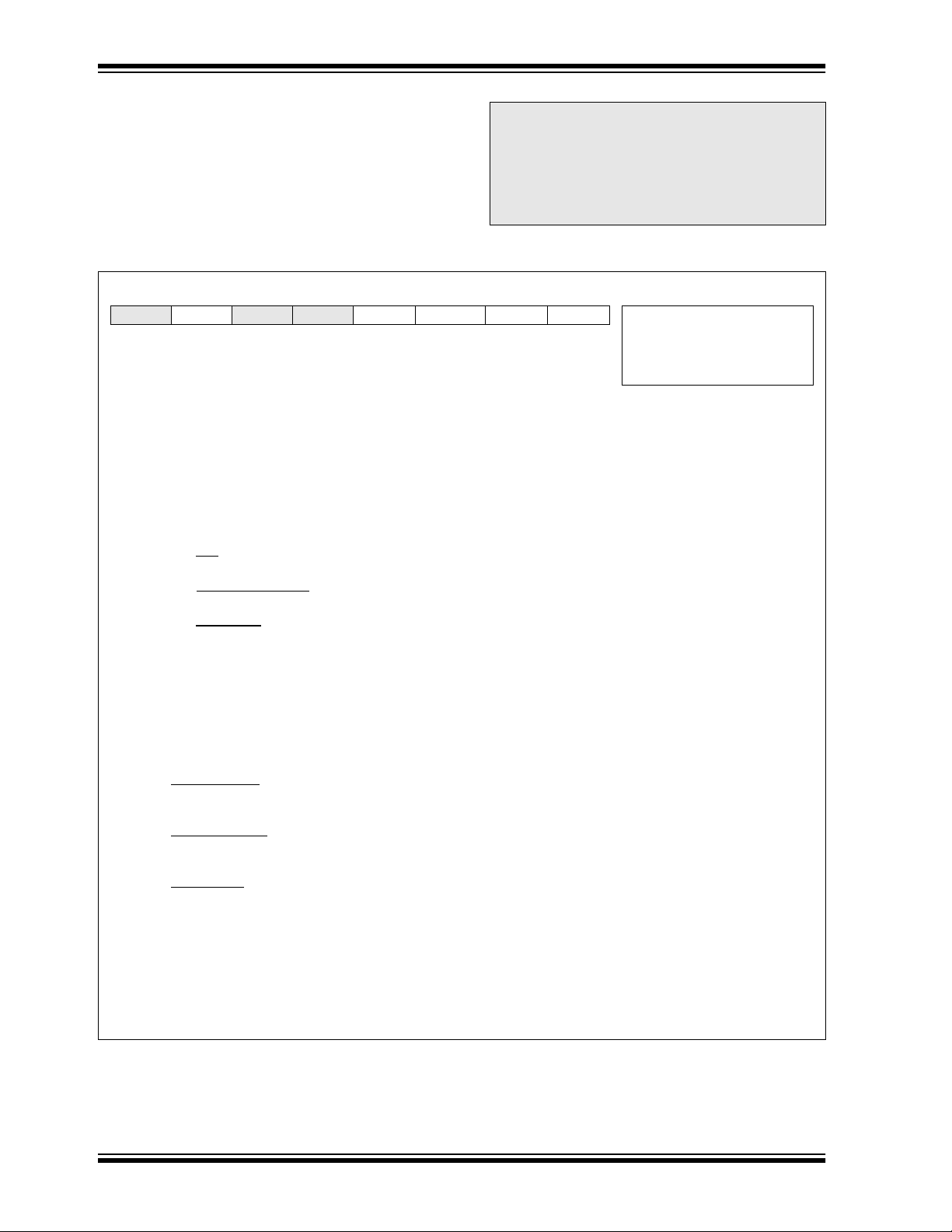

Key Features

PICmicroTM Mid-Range Reference Manual

PIC16C717 PIC16C770 PIC16C771

(DS33023)

Operating Frequency DC - 20 MHz DC - 20 MHz DC - 20 MHz

Resets (and Delays)

POR, BOR, MCLR,

WDT (PWRT, OST)

POR, BOR, MCLR,

WDT (PWRT, OST)

POR, BOR, MCLR,

WDT (PWRT, OST)

Program Memory (14-bit words) 2K 2K 4K

Data Memory (bytes) 256 256 256

Interrupts 10 10 10

I/O Ports Ports A,B Ports A,B Ports A,B

Timers 333

Enhanced Capture/Compare/PWM (ECCP)

111

modules

Serial Communications MSSP MSSP MSSP

12-bit Analog-to-Digital Module 6 input channels 6 input channels

10-bit Analog-to-Digital Module 6 input channels

Instruction Set 35 Instructions 35 Instructions 35 Instructions

DS41120A-page 2 Advanced Information

1999 Microchip Technology Inc.

Page 3

PIC16C717/770/771

Table of Contents

1.0 Device Overv iew......................................................................................... ...... ..... ....................................... ...... ..5

2.0 Memory Organization..........................................................................................................................................11

3.0 I/O Ports..............................................................................................................................................................27

4.0 Program Memory Read (PMR)...........................................................................................................................43

5.0 Timer0 Module....................................................................................................................................................47

6.0 Timer1 Module....................................................................................................................................................49

7.0 Timer2 Module....................................................................................................................................................53

8.0 Enhanced Capture/Compare/PWM(ECCP) Modules .........................................................................................55

9.0 Master Synchronous Serial Port (MSSP) Module...............................................................................................67

10.0 Voltage Reference Module and Low-voltage Detect.........................................................................................109

11.0 Analog-to-Digital Converter (A/D) Module ........................................................................................................113

12.0 Special Features of the CPU............................................................................................................................125

13.0 Instruction Set Summary...................................................................................................................................141

14.0 Development Support.......................................................................................................................................149

15.0 Electrical Characteristics................................................. ...... ..... ...... ................................. ...... ..........................155

16.0 DC and AC Characteristics Graphs and Tables...............................................................................................177

17.0 Packaging Information......................................................................................................................................179

Revision History ........................................................................................................................................................189

Device Differences ............................................................. ...... ...... ..... ...... ................................. ...... ..........................189

Index .......................................................................................................................................................................... 191

On-Line Support..........................................................................................................................................................197

Reader Response.......................................................................................................................................................198

PIC16C717/770/771 Product Identification System....................................................................................................199

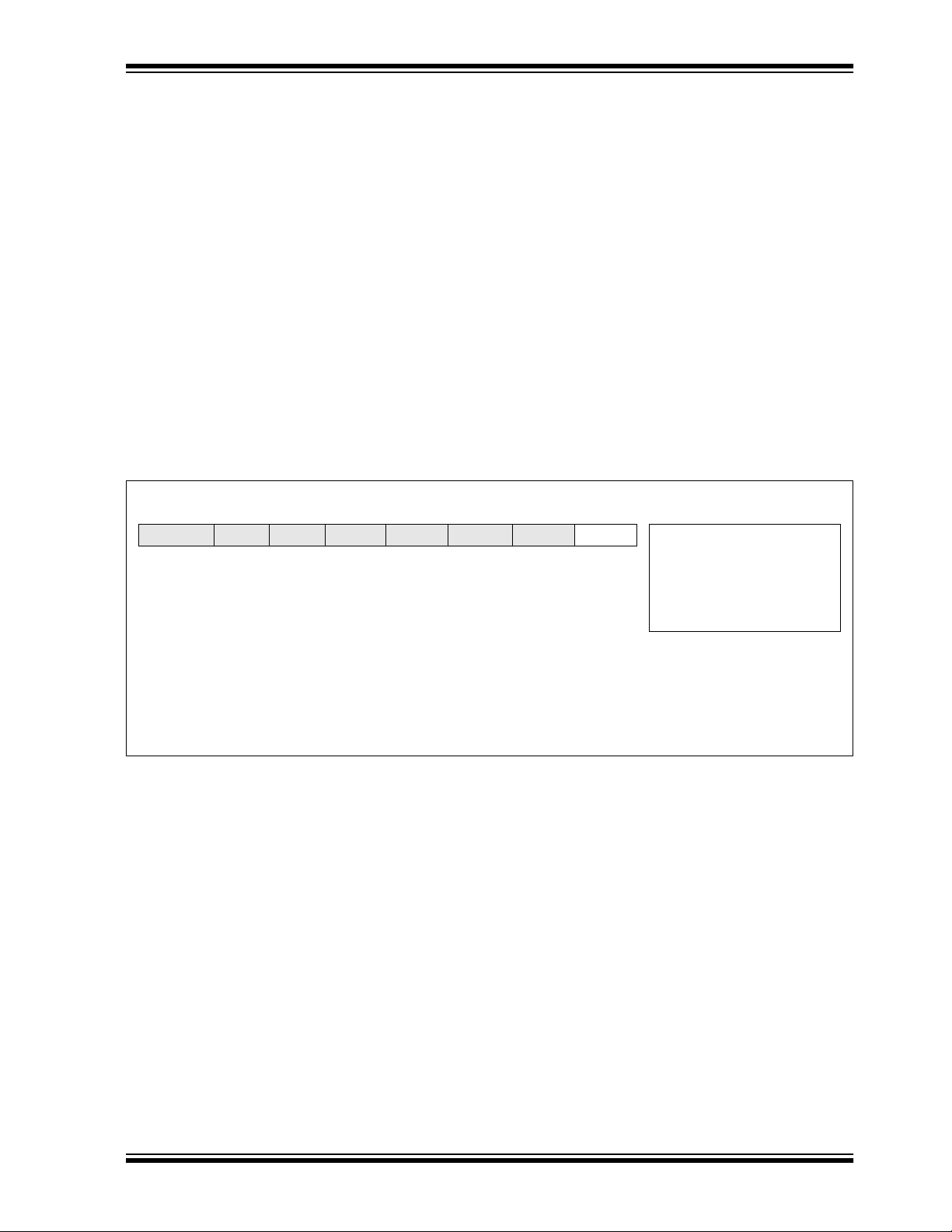

To Our Valued Customers

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number. e.g., DS30000A is version A of document DS30000.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

Errata

An errata sheet may exist for current devices, describing minor operational differences (from the data sheet) and recommended

workarounds. As device/documentation issues become known to us, w e will pub lish an errata sheet. The errata will specify the re vision of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the fo llowing:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

• The Microchip Corporate Literature Center; U.S. FAX: (480) 786-7277

When contacting a sales office or the literature center, please specify which device, revision of silicon and data sheet (include liter-

ature number) you are using.

Corrections to this Data Sheet

We constantly strive to improve the quality of all our products and documentation. We have spent a great deal of time to ensure

that this document is correct. However , w e realize that we ma y have missed a few things. If you fi nd any inf ormation that is missing

or appears in error, please:

• Fill out and mail in the reader response form in the back of this data sheet.

• E-mail us at webmaster@microchip.com.

We appreciate your assistance in making this a better document.

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 3

Page 4

PIC16C717/770/771

NOTES:

DS41120A-page 4 Advanced Information

1999 Microchip Technology Inc.

Page 5

PIC16C717/770/771

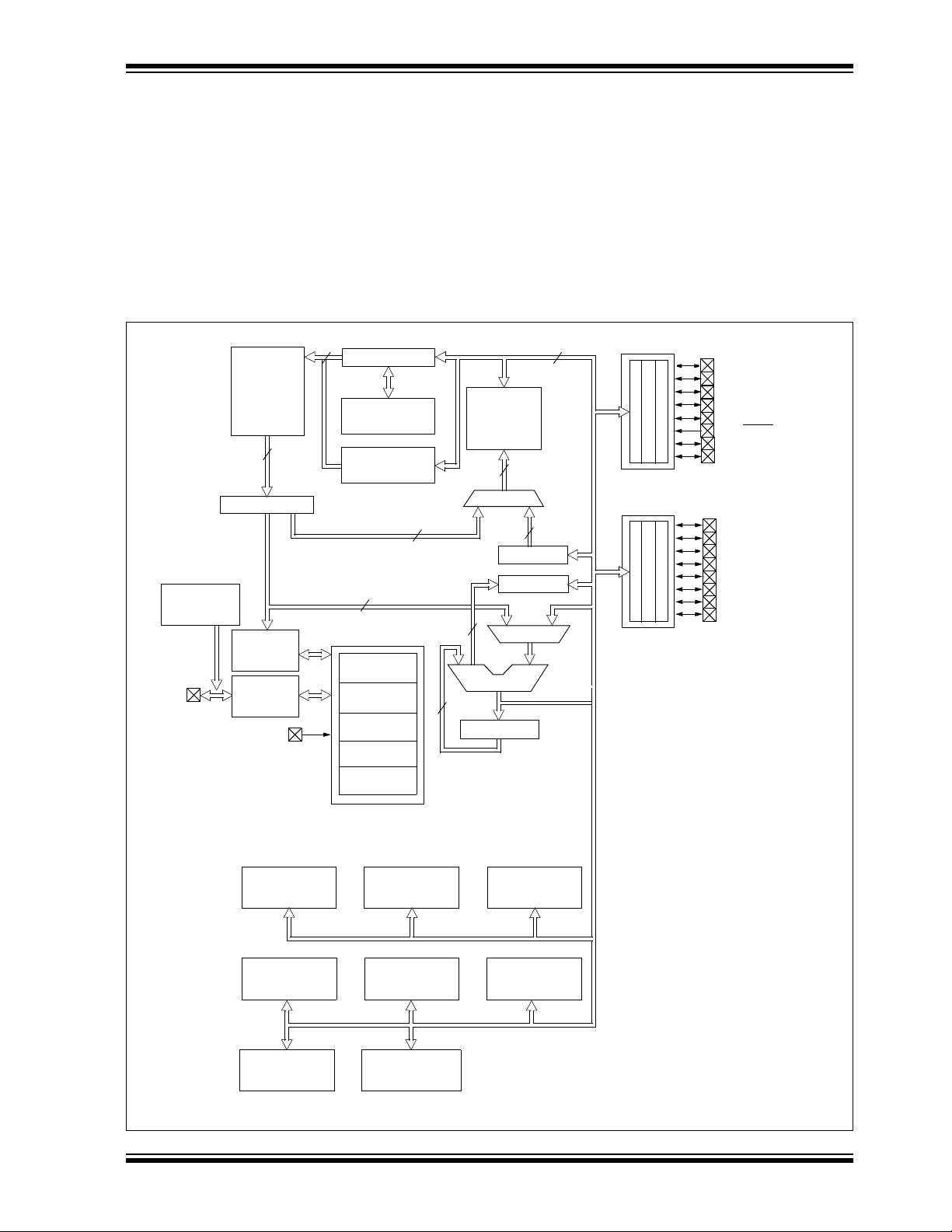

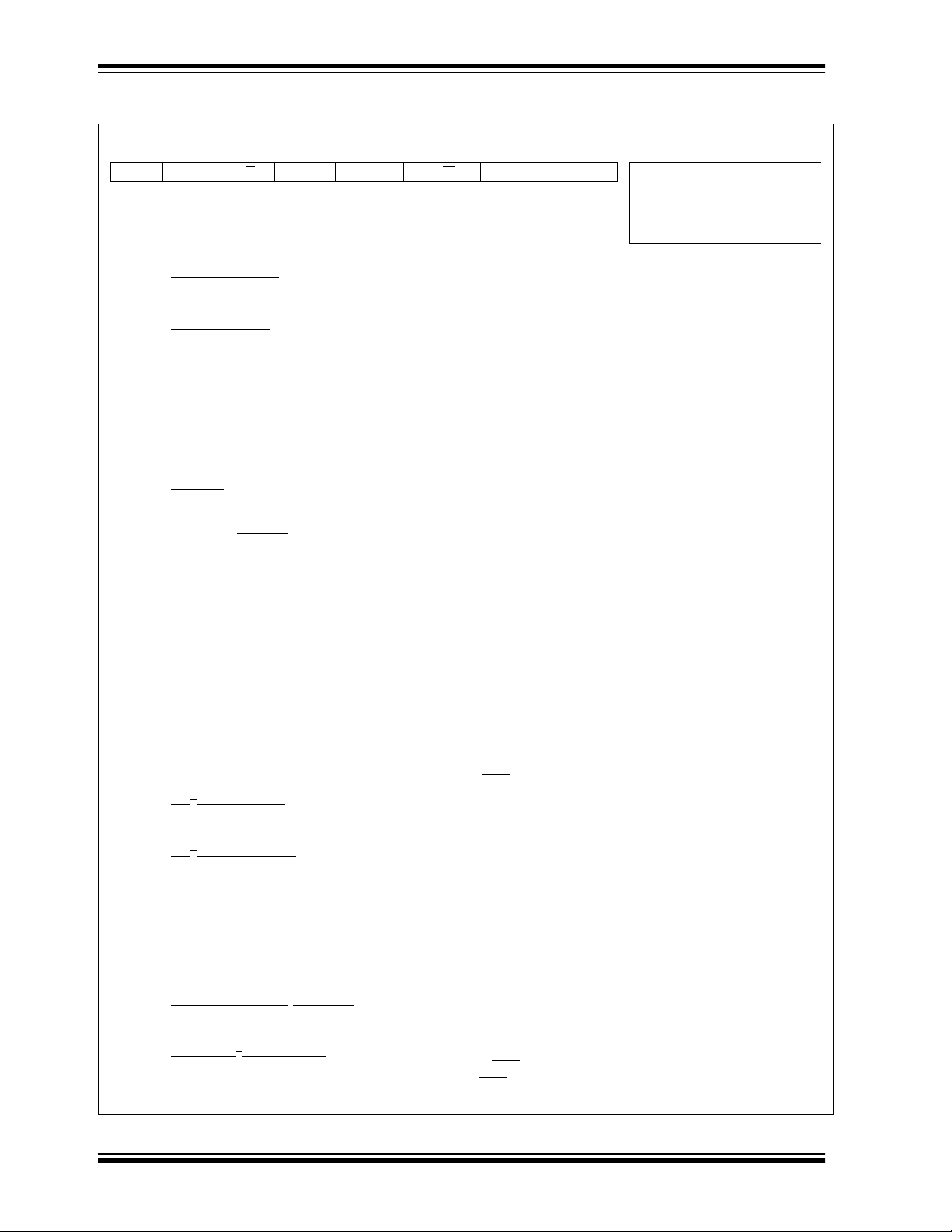

1.0 DEVICE OVERVIEW

This document contains device-specific information.

Additional information may be found in the PICmicro

Mid-Range Reference Manual, (DS33023), which may

be obtained from your local Microchip Sales Representative or downloaded from the Microchip website. The

Reference Manual should be considered a complementary document to this data she et, and is h ighly recommended reading for a better understanding of the

device architecture and operation of the peripheral

modules.

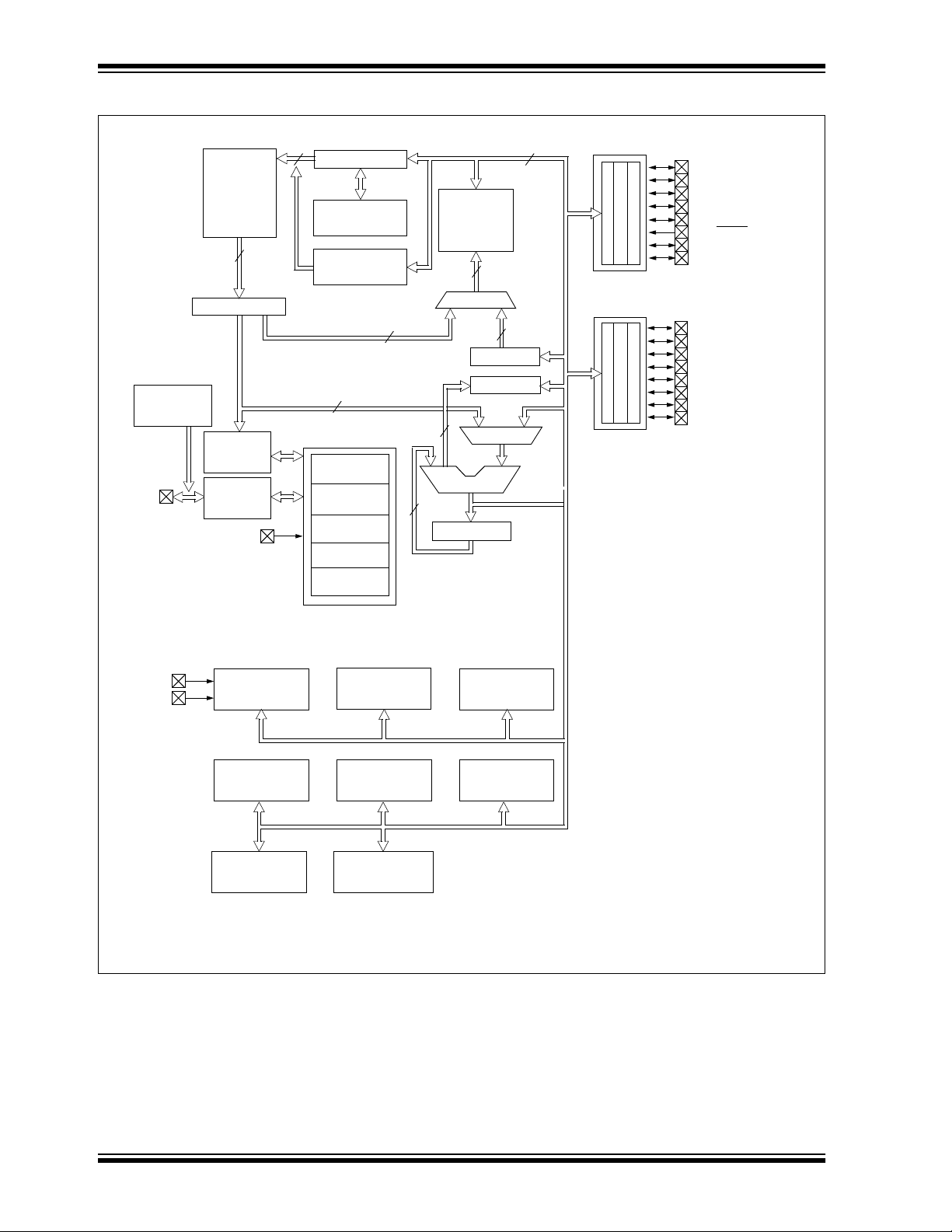

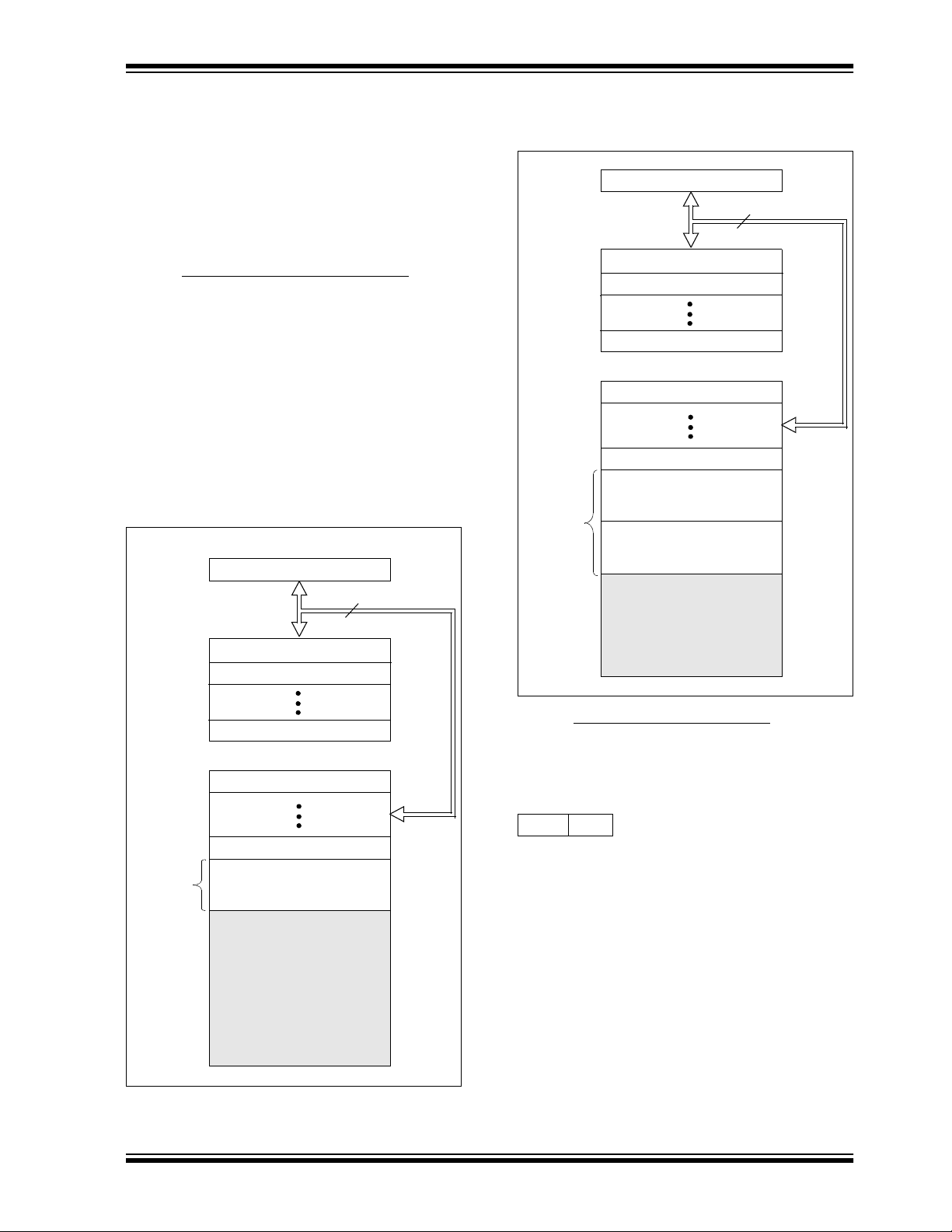

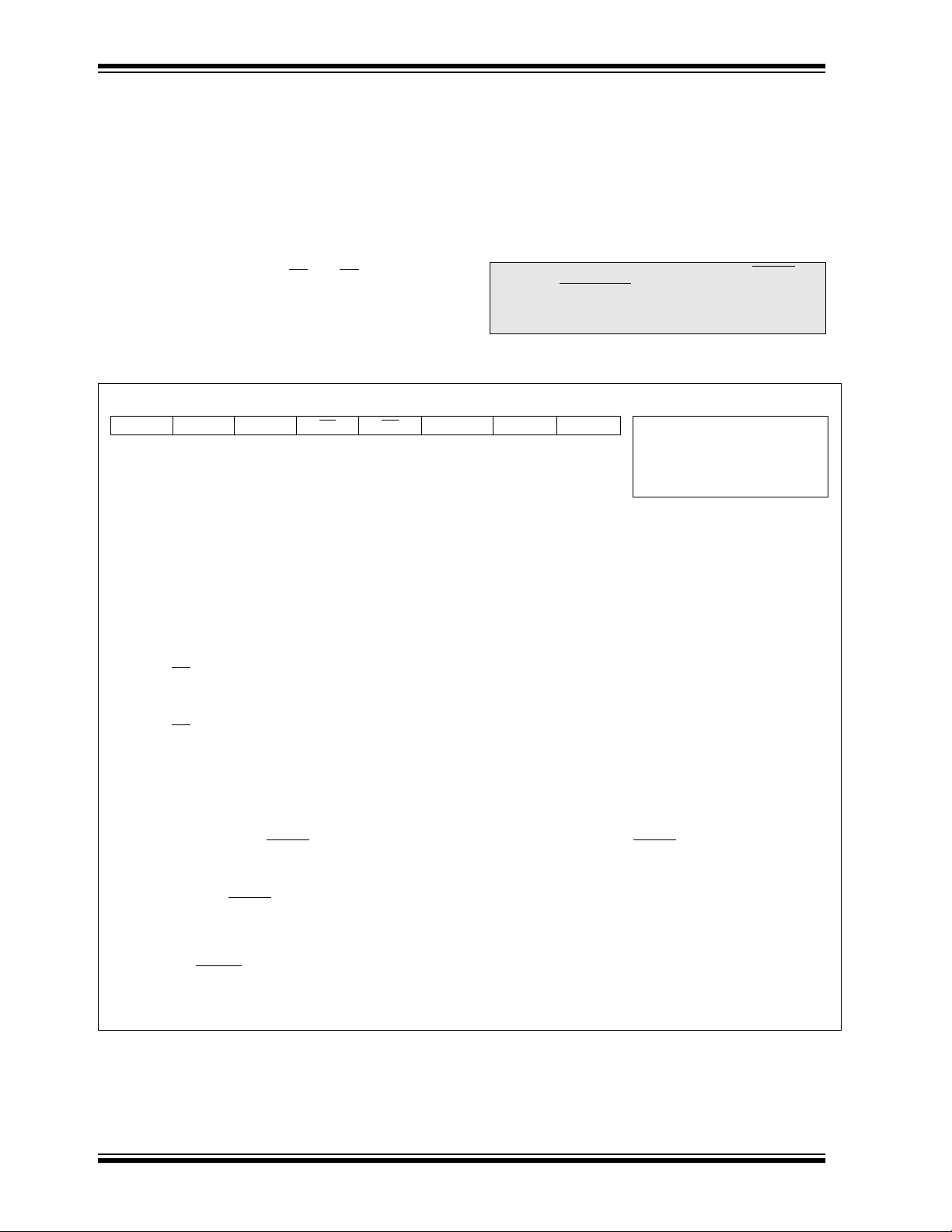

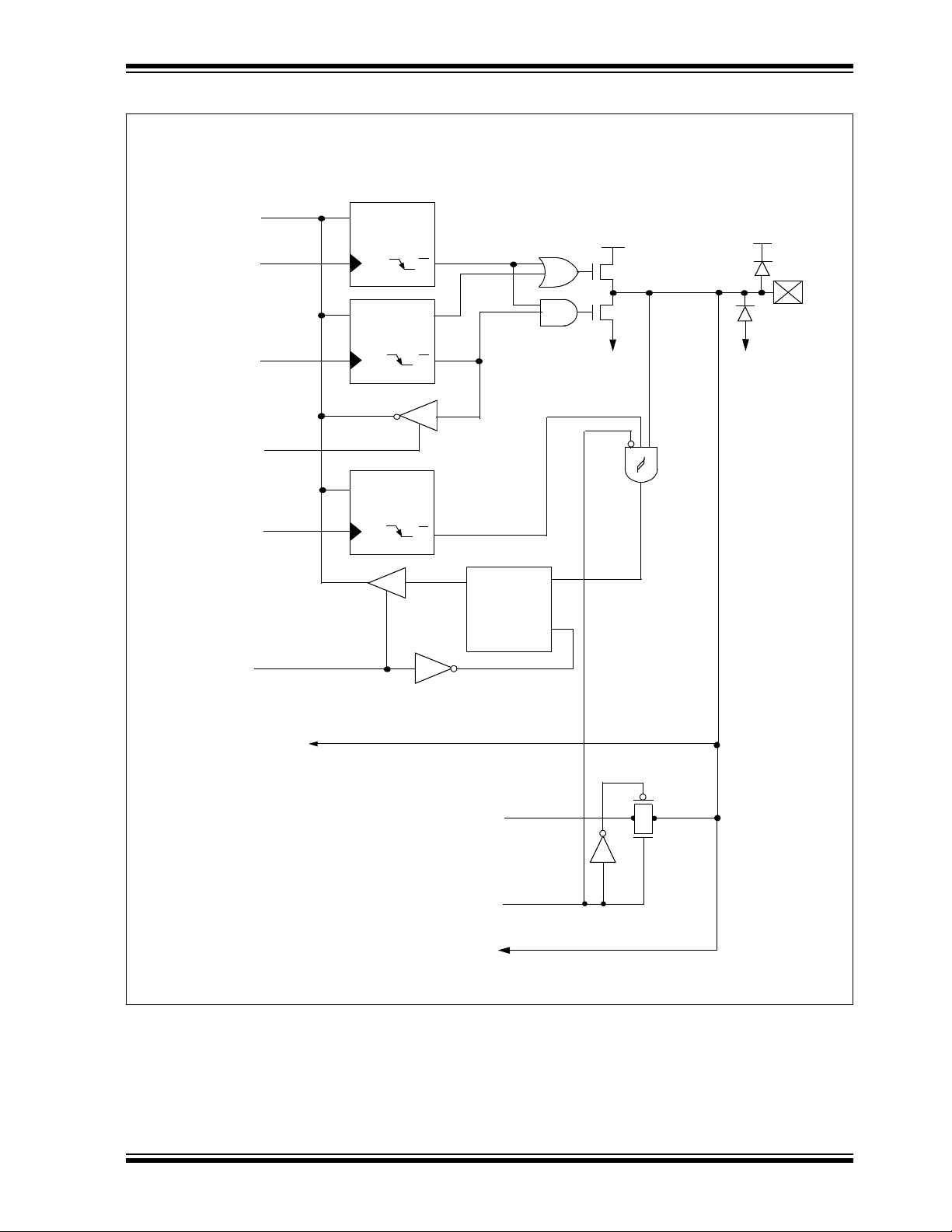

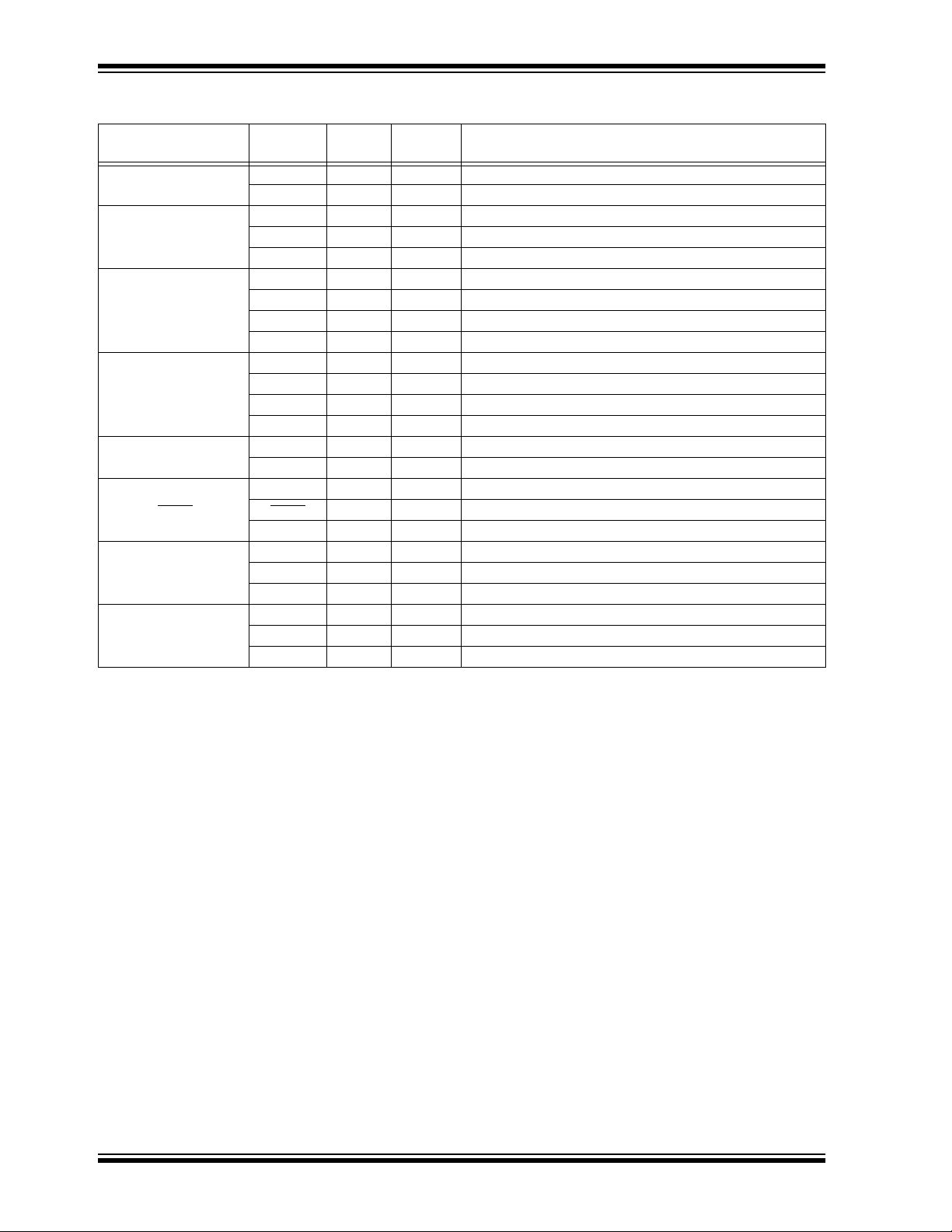

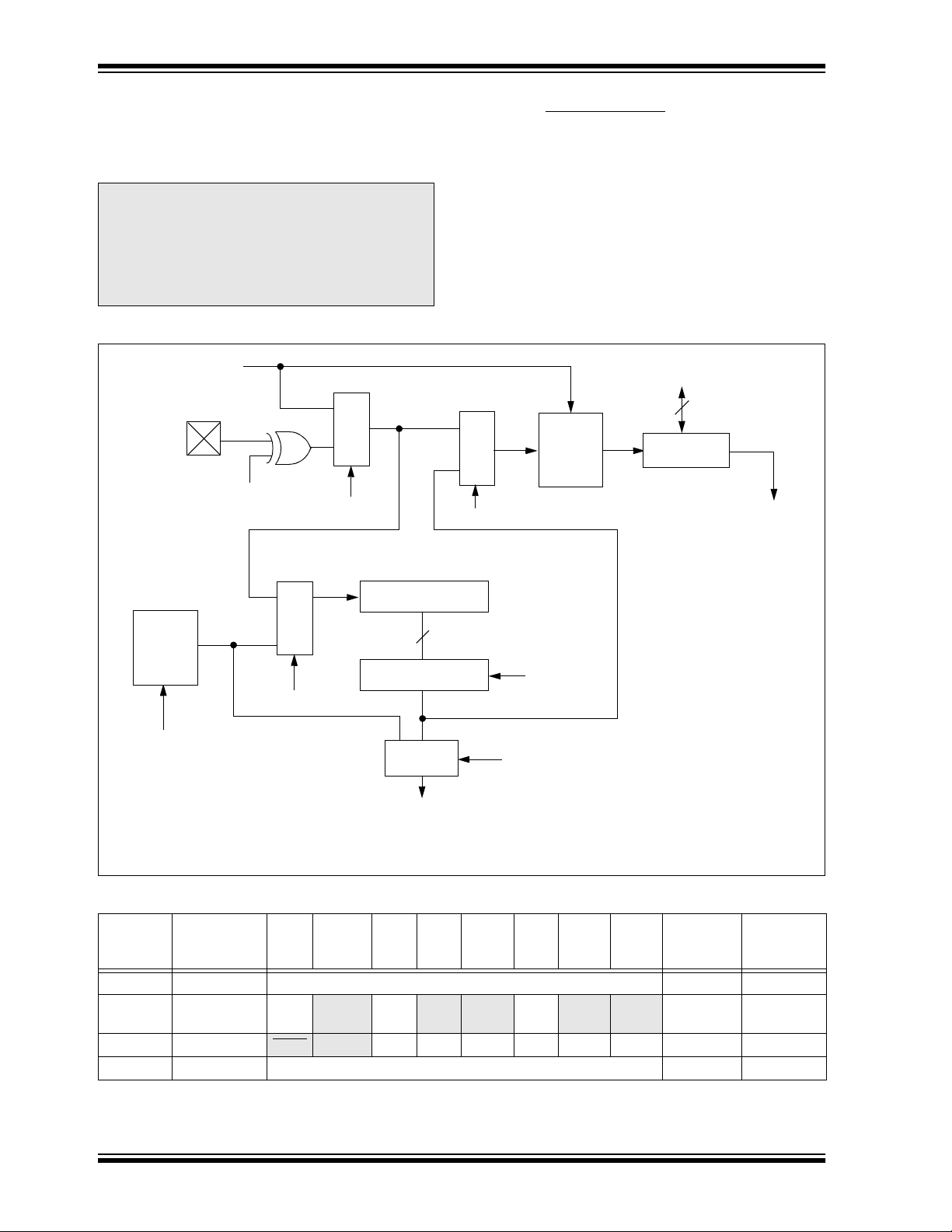

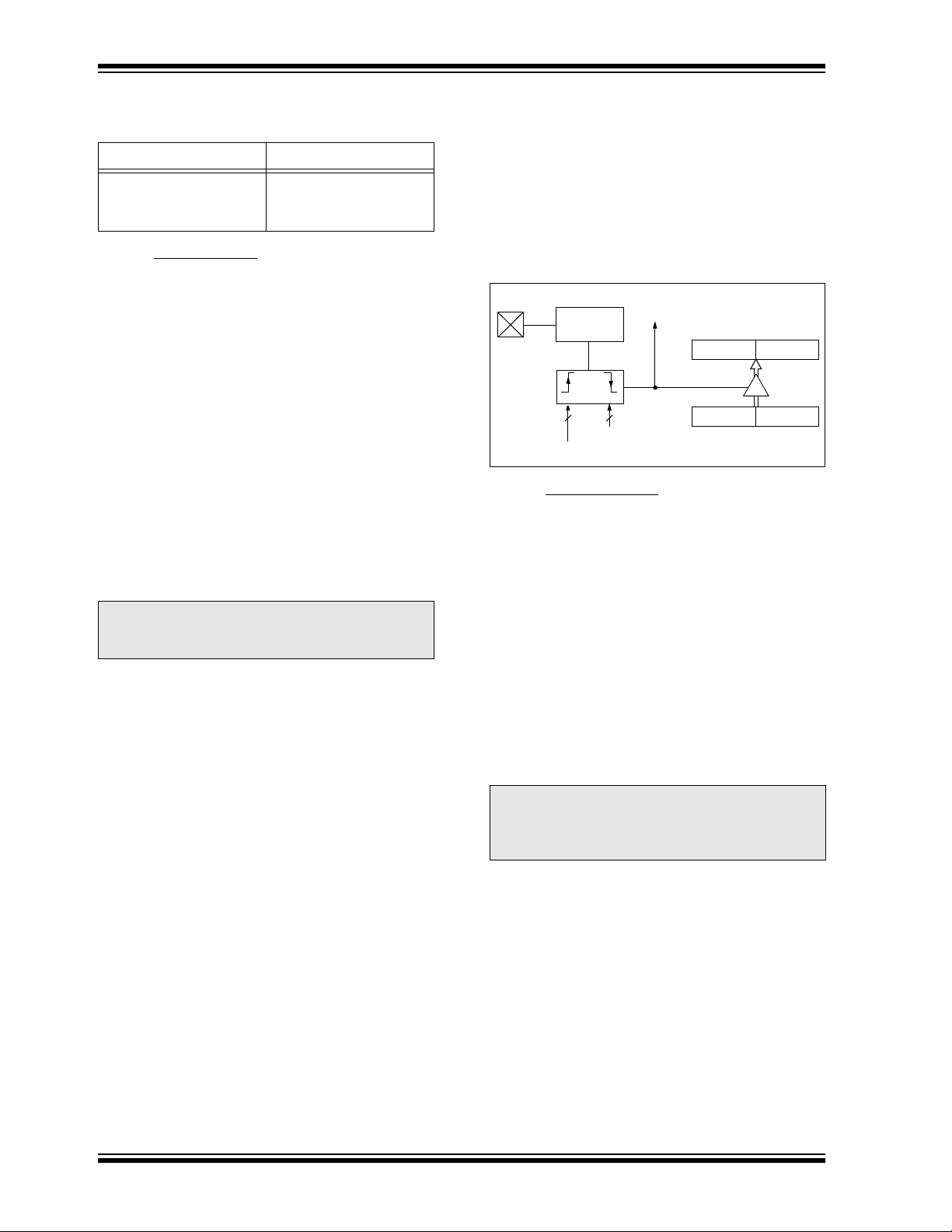

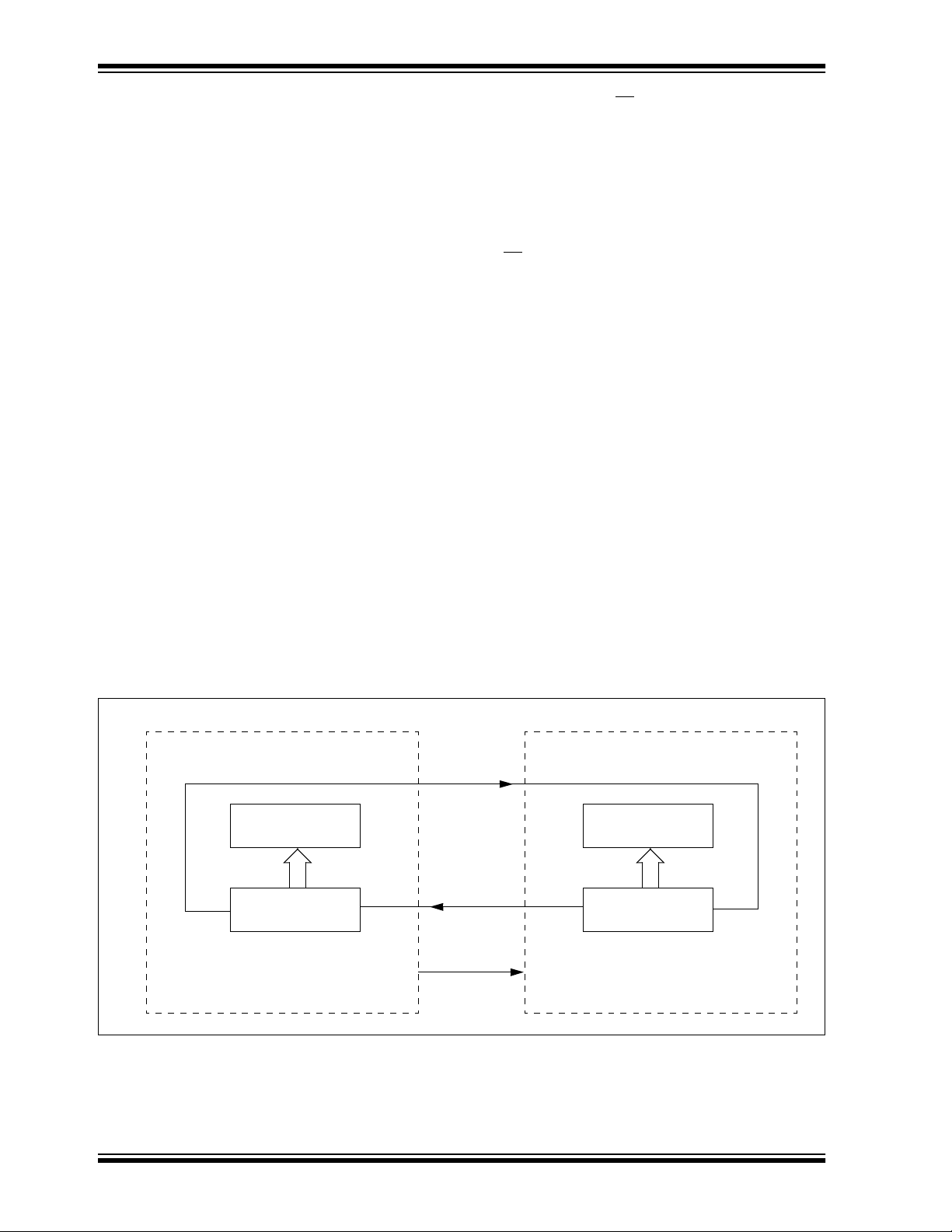

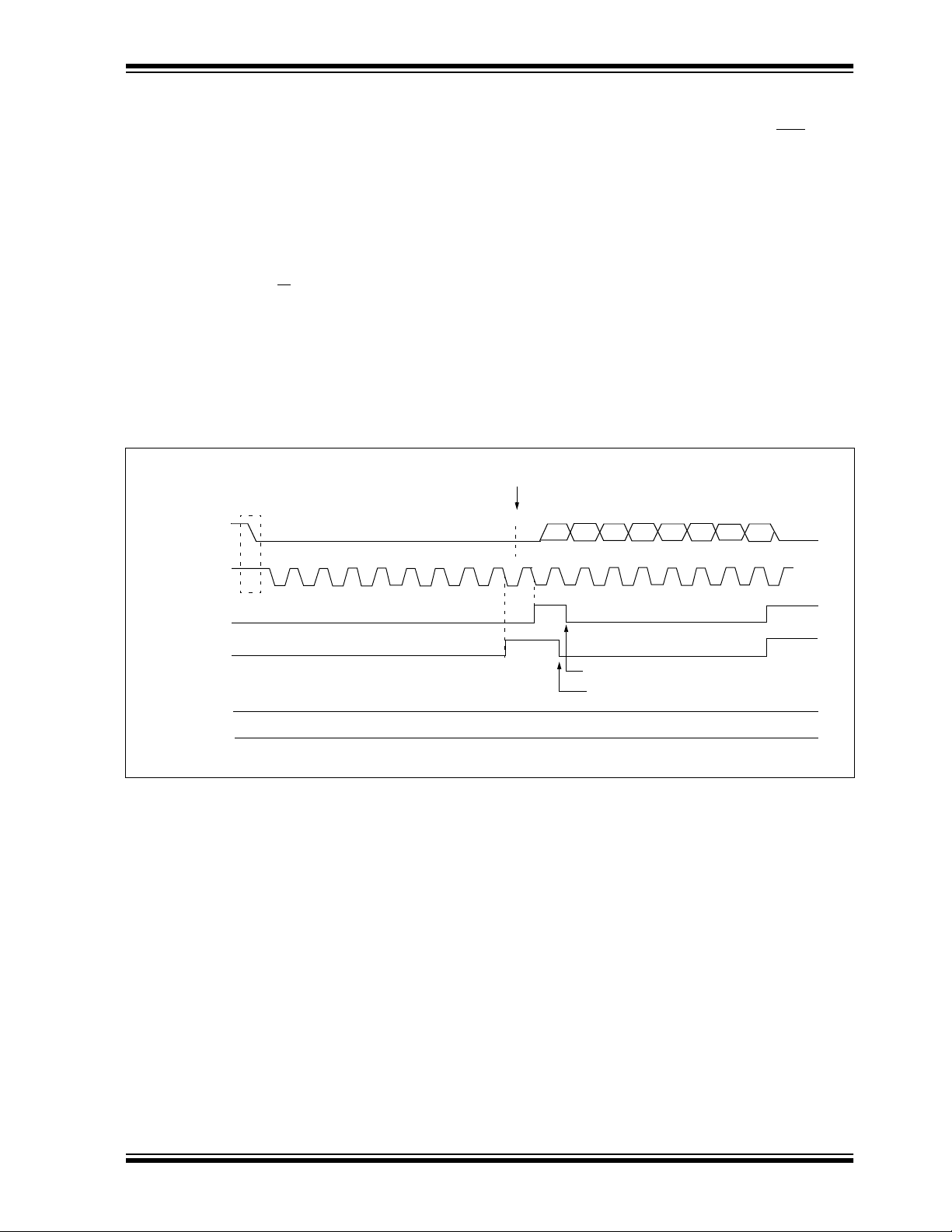

FIGURE 1-1: PIC16C717 BLOCK DIAGRAM

13

Program Counter

8 Level Stack

(13-bit)

Program Memory

Read (PMR)

Direct Addr

8

Power-up

Timer

Oscillator

Start-up Tim er

Power-on

Reset

Watchdog

Timer

Brown-out

Reset

Program

Bus

Internal

4MHz, 37KHz

and ER mode

OSC1/CLKIN

OSC2/CLKOUT

EPROM

Program

Memory

2K x 14

14

Instruction reg

Instruction

Decode &

Control

Timing

Generation

DD, VSS

V

TM

7

3

8

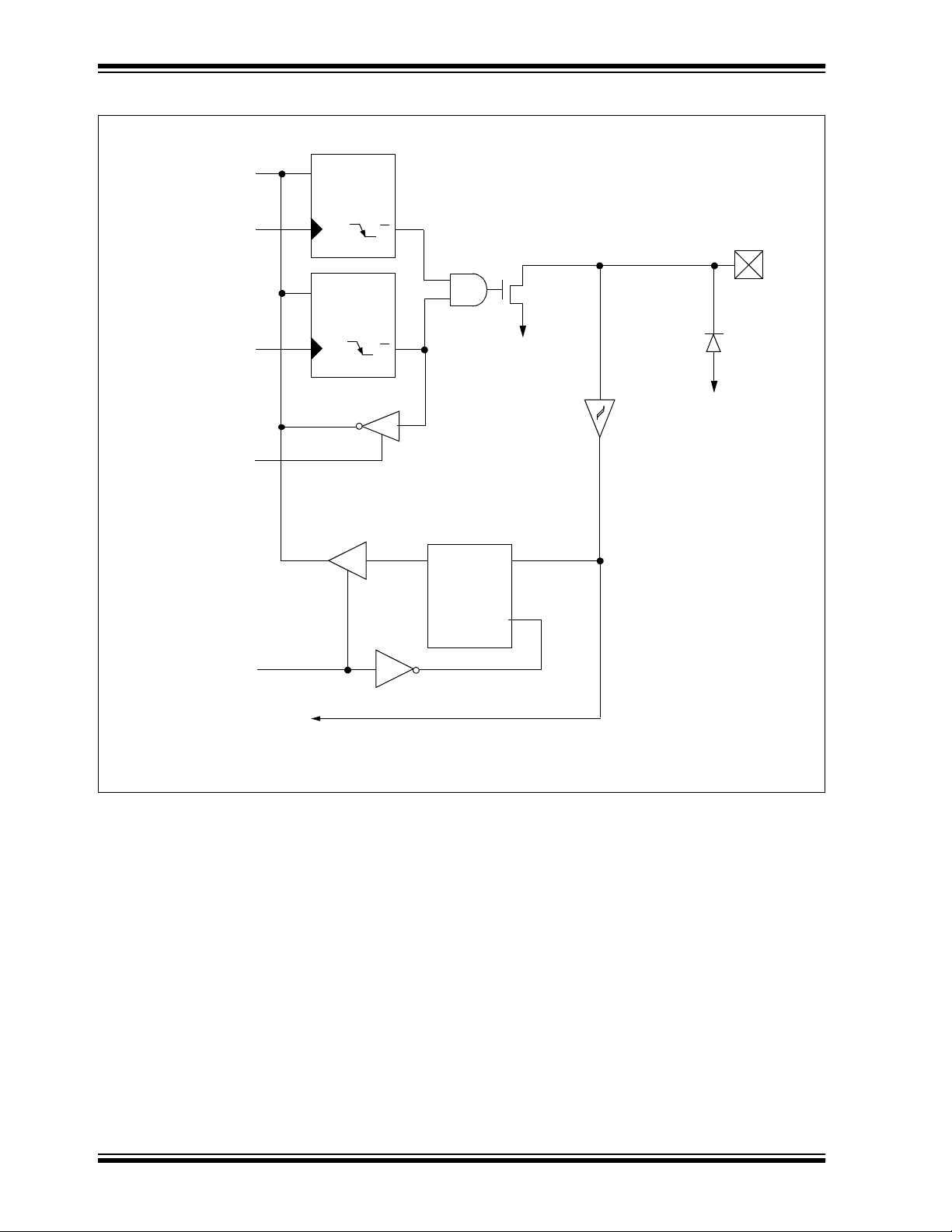

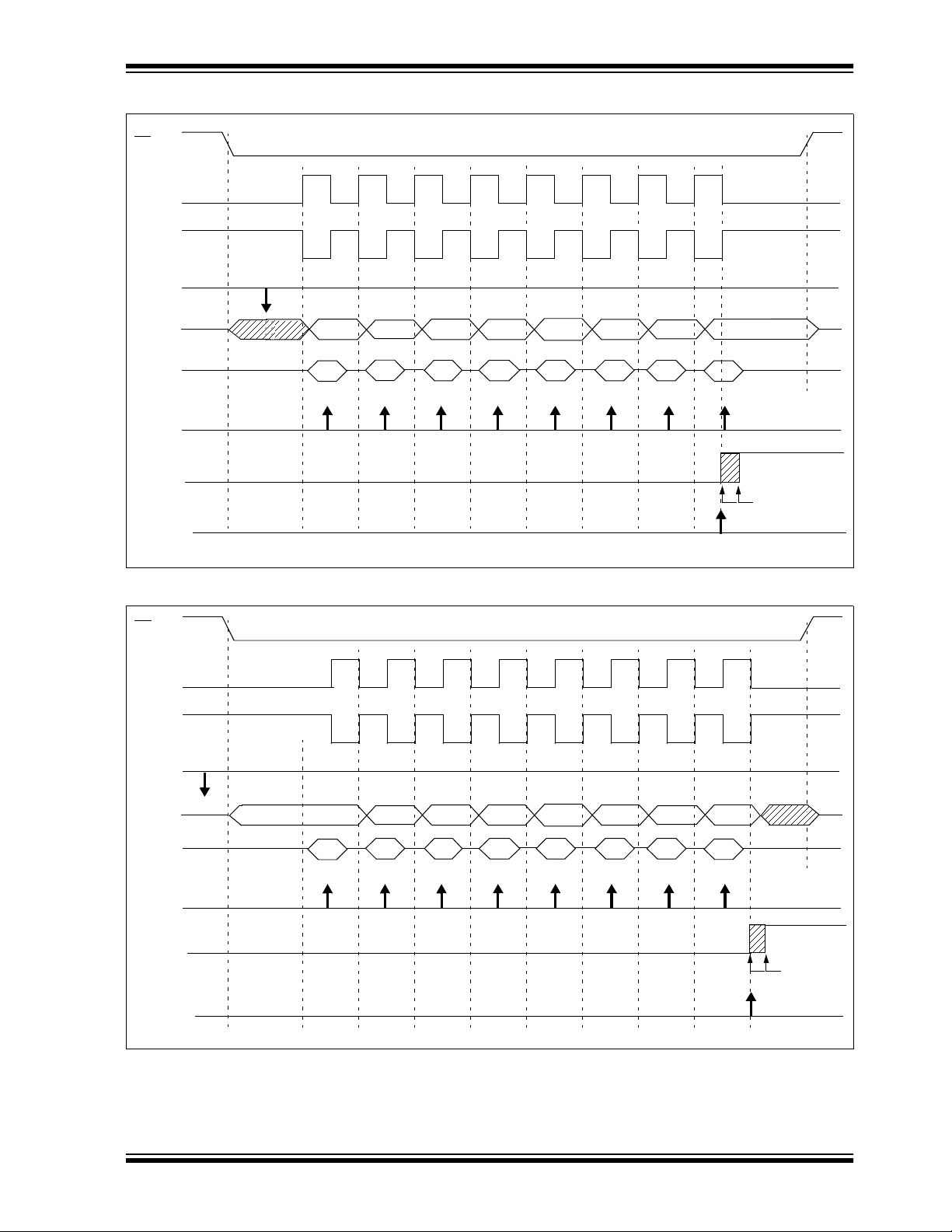

There are three devices (PIC16C717, PIC16C770 and

PIC16C771) covered by this datasheet. The

PIC16C717 device comes in 18/20-pin packages and

the PIC16C770/771 devices come in 20-pin packages.

The following two fig u r es ar e device block di agr am s o f

the PIC16C717 and the PIC16C770/771.

Data Bus

RAM

File

Registers

256 x 8

9

Addr MUX

FSR reg

STATUS reg

ALU

W reg

8

MUX

RAM

Addr

Indirect

Addr

8

(1)

PORTA

PORTB

RA0/AN0

RA1/AN1/LVDIN

RA2/AN2/VREF-/VRL

RA3/AN3/VREF+/VRH

RA4/T0CKI

RA5/MCLR/VPP

RA6/OSC2/CLKOUT

RA7/OSC1/CLKIN

RB0/AN4/INT

RB1/AN5/SS

RB2/SCK/SCL

RB3/CCP1/P1A

RB4/SDI/SDA

RB5/SDO/P1B

RB6/T1OSO/T1CKI/P1C

RB7/T1OSI/P1O

10-bit

ADC

Timer0 Timer1 Timer2

Enhanced CCP

(ECCP1)

Synchronous

Serial Port (MSSP)

Note 1: Higher order bits are from the STATUS register.

1999 Microchip Technology Inc.

Bandgap

Reference

Master

Low-voltage

Detect

Advanced Information DS41120A-page 5

Page 6

PIC16C717/770/771

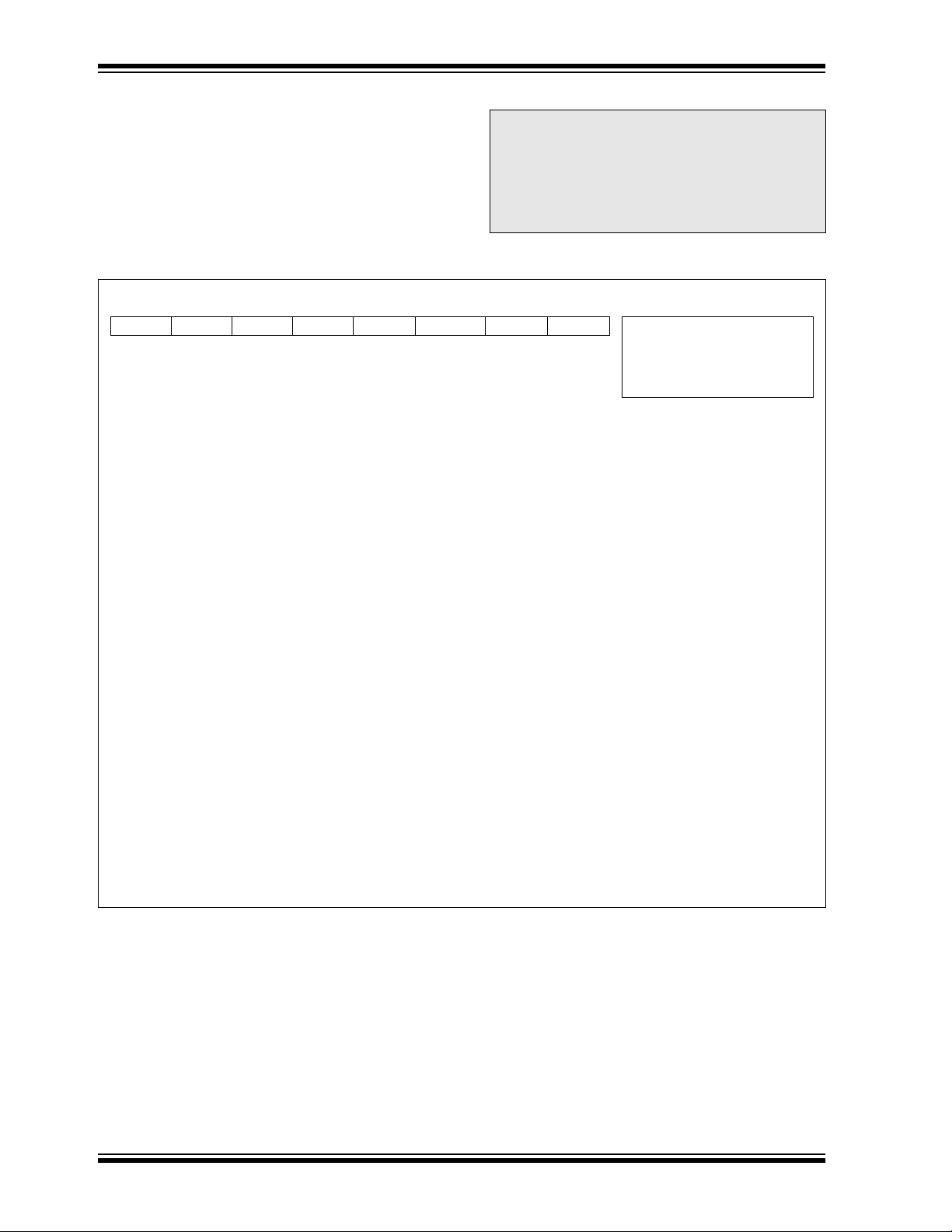

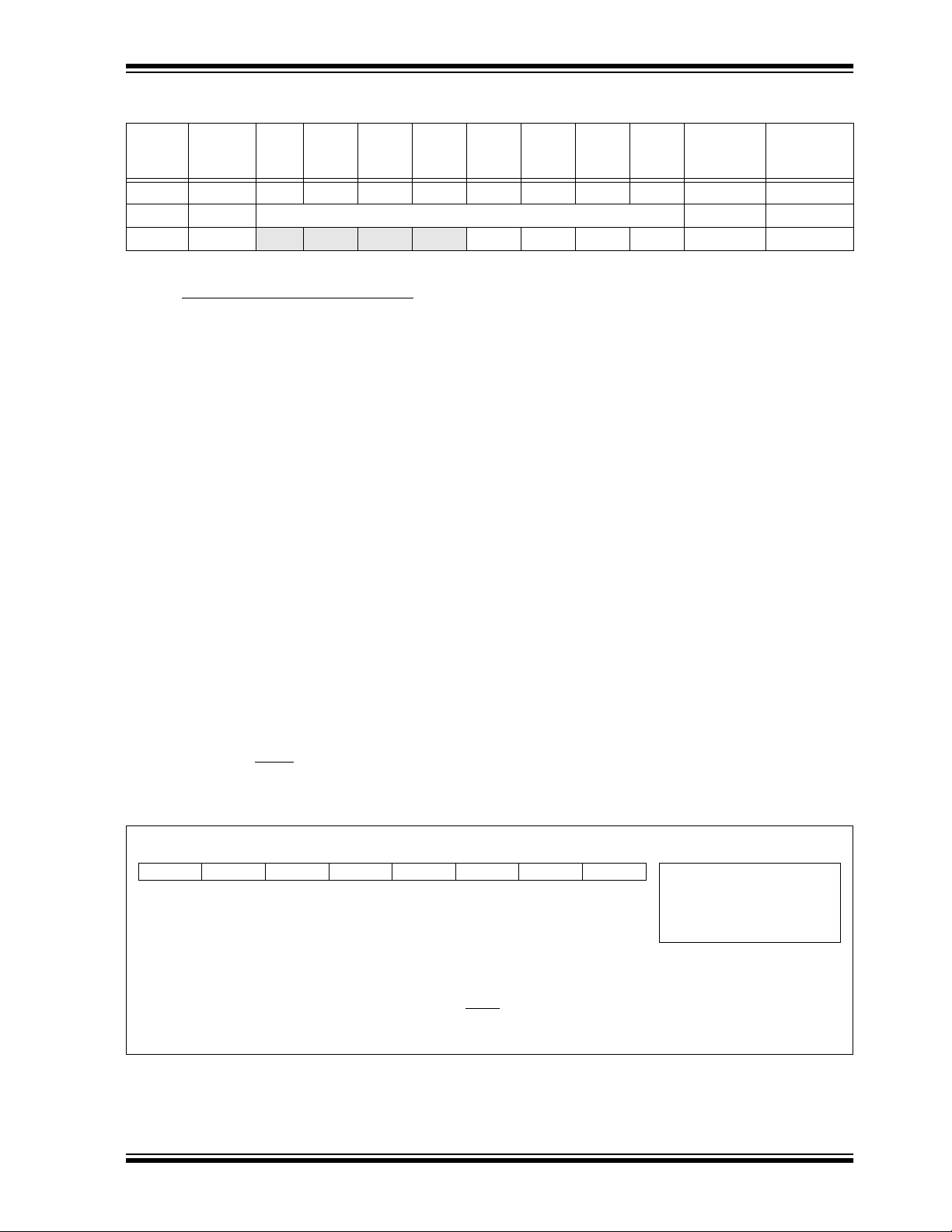

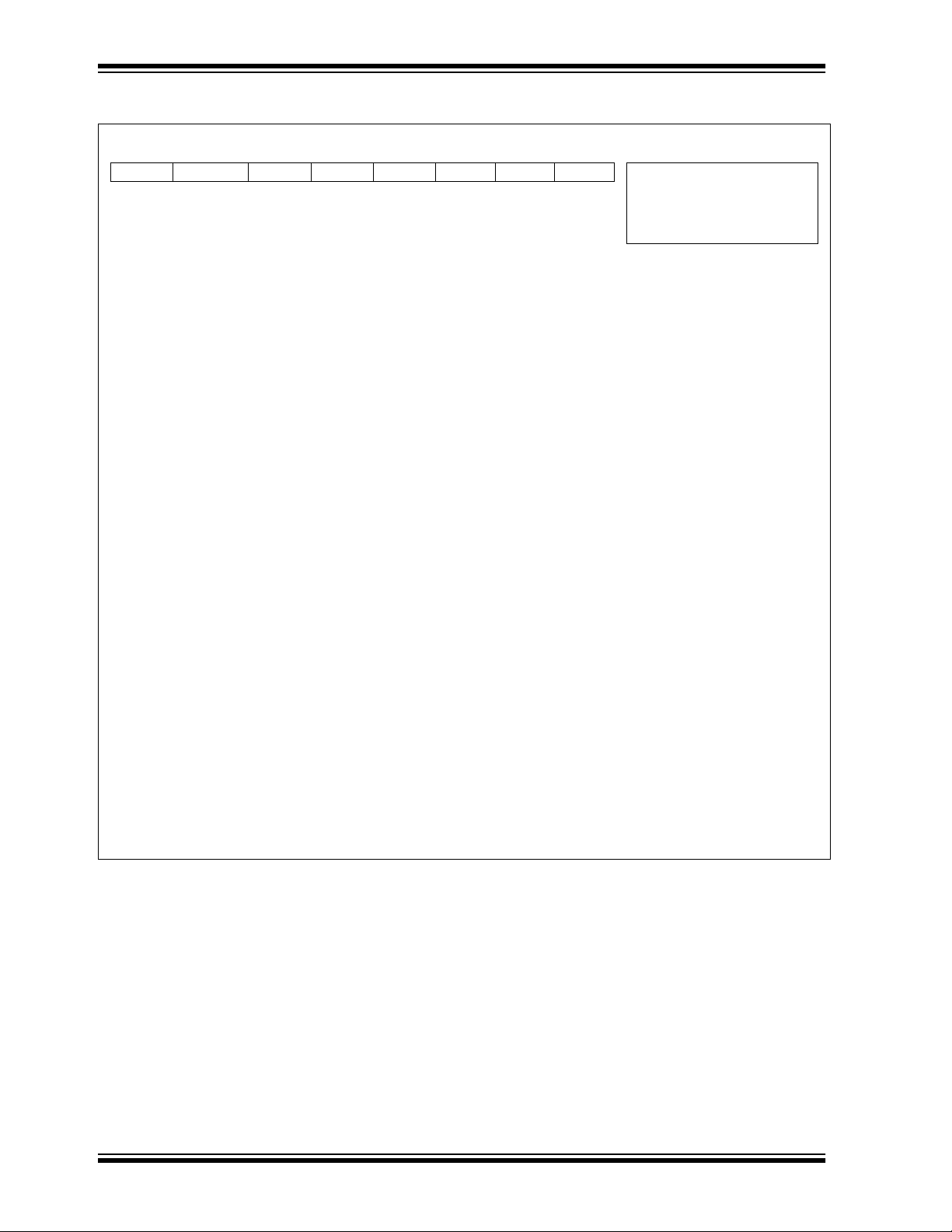

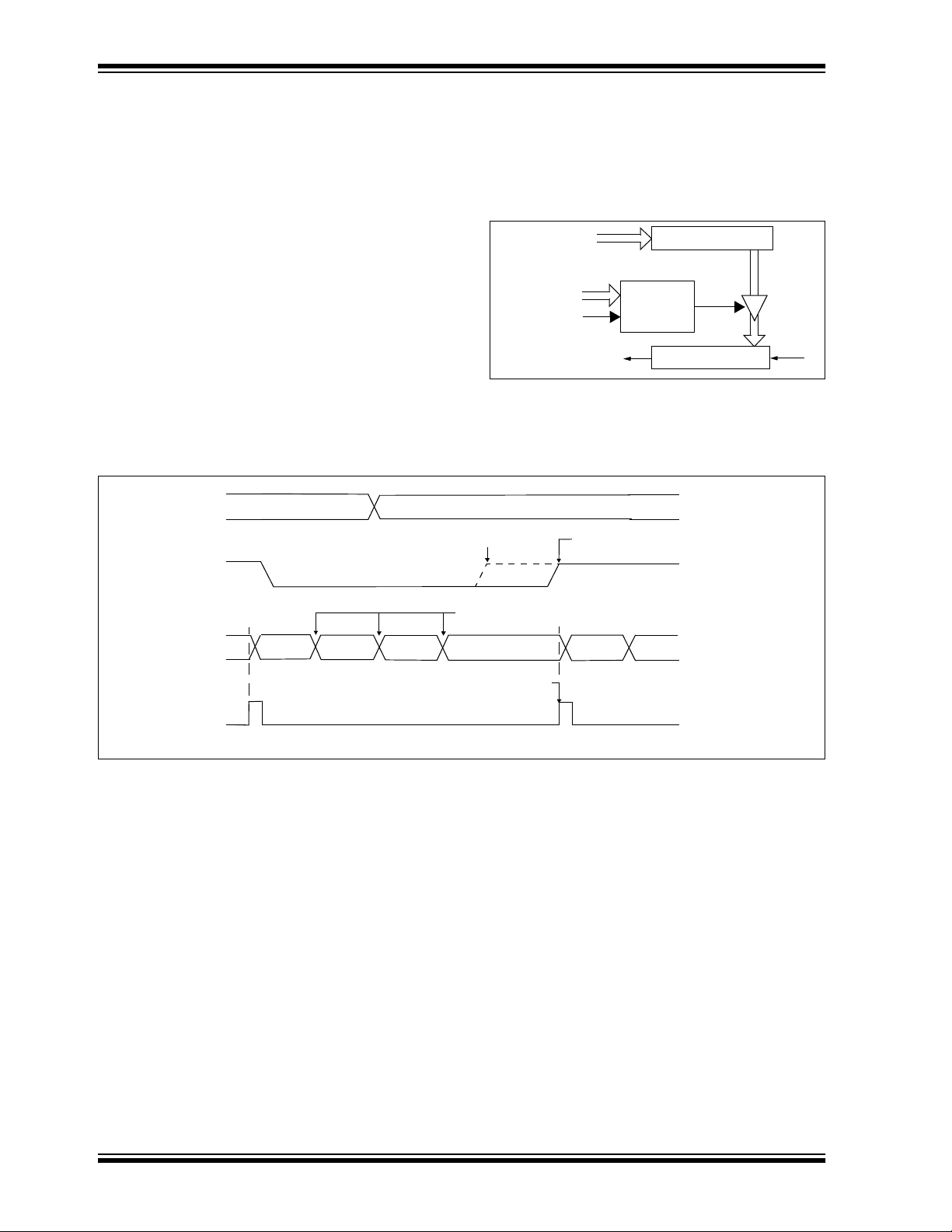

FIGURE 1-2: PIC16C7 70/7 71 BLOCK DIAGRAM

Program

Bus

Internal

4MHz, 37KHz

and ER mode

OSC1/CLKIN

OSC2/CLKOUT

EPROM

Program

(2)

Memory

14

Instruction reg

Instruction

Decode &

Control

Timing

Generation

DD, VSS

V

13

Program Counter

8 Level Stack

Program Memory

Read (PMR)

Direct Addr

8

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Brown-out

Reset

(13-bit)

9

8

MUX

RAM

Addr

Indirect

Addr

8

(1)

Data Bus

RAM

File

Registers

256 x 8

Addr MUX

7

FSR reg

STATUS reg

3

ALU

8

W reg

PORTA

RA0/AN0

RA1/AN1/LVDIN

RA2/AN2/VREF-/VRL

RA3/AN3/VREF+/VRH

RA4/T0CKI

RA5/MCLR/VPP

RA6/OSC2/CLKOUT

RA7/OSC1/CLKIN

PORTB

RB0/AN4/INT

RB1/AN5/SS

RB2/SCK/SCL

RB3/CCP1/P1A

RB4/SDI/SDA

RB5/SDO/P1B

RB6/T1OSO/T1CKI/P1C

RB7/T1OSI/P1O

AVDD

AVSS

12-bit

ADC

Timer0 Timer1 Ti m e r2

Enhanced CCP

(ECCP1)

Bandgap

Reference

Master

Synchronous

Serial Port (MSSP)

Low-voltage

Detect

Note 1: Higher order bits are from the STATUS register.

2: Program memory for PIC16C770 is 2K x 14. Program memory for PIC16C771 is 4K x 14.

DS41120A-page 6 Advanced Information

1999 Microchip Technology Inc.

Page 7

TABLE 1-1: PIC16C770/771 PINOUT DESCRIPTION

Name Function

RA0/AN0

RA0 ST CMOS Bi-directional I/O

AN0 AN A/D input

RA1 ST CMOS Bi-directional I/O

RA1/AN1/LVDIN

AN1 AN A/D input

LVDIN AN LVD input reference

RA2 ST CMOS Bi-directional I/O

RA2/AN2/V

REF-/VRL

AN2 AN A/D input

REF- AN Negative analog reference input

V

VRL AN Internal voltage reference low output

RA3 ST CMOS Bi-directional I/O

RA3/AN3/V

REF+/VRH

AN3 AN A/D input

REF+ AN Positive analog reference input

V

VRH AN Internal voltage reference high output

RA4/T0CKI

RA4 ST OD Bi-directional I/O

T0CKI ST TMR0 clock input

RA5 ST Input port

RA5/MCLR

/VPP

MCLR

PP Power Programming voltage

V

RA6 ST CMOS Bi-directional I/O

RA6/OSC2/CLKOUT

OSC2 XTAL Crystal/resonator

CLKOUT CMOS F

RA7 ST CMOS Bi-directional I/O

RA7/OSC1/CLKIN

OSC1 XTA L Crystal/resonator

CLKIN ST External clock input/ER resistor connection

RB0 TTL CMOS Bi-directional I/O

RB0/AN4/INT

AN4 AN A/D input

INT ST Interrupt input

RB1 TTL CMOS Bi-directional I/O

RB1/AN5/SS

AN5 AN A/D input

SS

RB2 TTL CMOS Bi-directional input

RB2/SCK/SCL

SCK ST CMOS Serial clock I/O for SPI

SCL ST OD Serial clock I/O for I

RB3 TTL CMOS Bi-directional input

RB3/CCP1/P1A

CCP1 ST CMOS Capture 1 input/Compare 1 output

P1A CMOS PWM P1A output

RB4 TTL CMOS Bi-directional input

RB4/SDI/SDA

SDI ST Serial data in for SPI

SDA ST OD Serial data I/O for I

RB5 ST CMOS Bi-directional I/O

RB5/SDO/P1B

SDO CMOS Serial data out for SPI

P1B CMOS PWM P1B output

Note 1: Bit programmable pull-ups.

Input

Type

ST Master clear

ST SSP slave select input

Output

Type

OSC/4 output

PIC16C717/770/771

Description

(1)

(1)

(1)

2

C

(1)

(1)

2

C

(1)

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 7

Page 8

PIC16C717/770/771

TABLE 1-1: PIC16C770/771 PINOUT DESCRIPTION (CONTINUED)

Name Function

RB6 TTL CMOS Bi-directional I/O

RB6/T1OSO/T1CKI/P1C

RB7/T1OSI/P1D

SS VSS Power Ground reference for logic and I/O pins

V

DD VDD Power Positive supply for logic and I/O pins

V

SS AVSS Power Ground reference for analog

AV

DD AVDD Power Positive supply for analog

AV

Note 1: Bit programmable pull-ups.

T1OSO XTAL Crystal/Resonator

T1CKI ST TMR1 clock input

P1C CMOS PWM P1C output

RB7 TTL CMOS Bi-directional I/O

T1OSI XTAL TMR1 crystal/resonator

P1D CMOS PWM P1D output

Input

Type

Output

Type

(1)

(1)

Description

DS41120A-page 8 Advanced Information

1999 Microchip Technology Inc.

Page 9

TABLE 1-2: PIC16C717 PINOUT DESCRIPTION

Name Function

RA0/AN0

RA0 ST CMOS Bi-directional I/O

AN0 AN A/D input

RA1 ST CMOS Bi-directional I/O

RA1/AN1/LVDIN

AN1 AN A/D input reference

LVDIN AN LVD input reference

RA2 ST CMOS Bi-directional I/O

RA2/AN2/V

REF-/VRL

AN2 AN A/D input

REF- AN Negative analog reference input

V

VRL AN Internal voltage reference low output

RA3 ST CMOS Bi-directional I/O

RA3/AN3/V

REF+/VRH

AN3 AN A/D input

REF+ AN Positive analog reference high output

V

VRH AN Internal voltage reference high output

RA4/T0CKI

RA4 ST OD Bi-directional I/O

T0CKI ST TMR0 clock input

RA5 ST Input port

RA5/MCLR

/VPP

MCLR

PP Power Programming Voltage

V

RA6 ST CMOS Bi-directional I/O

RA6/OSC2/CLKOUT

OSC2 XTAL Crystal/Resonator

CLKOUT CMOS F

RA7 ST CMOS Bi-directional I/O

RA7/OSC1/CLKIN

OSC1 XTAL Crystal/Resonator

CLKIN ST External clock input/ER resistor connection

RB0 TTL CMOS Bi-directional I/O

RB0/AN4/INT

AN4 AN A/D input

INT ST Interrupt input

RB1 TTL CMOS Bi-directional I/O

RB1/AN5/SS

AN5 AN A/D input

SS

RB2 TTL CMOS Bi-directional input

RB2/SCK/SCL

SCK ST CMOS Serial clock I/O for SPI

SCL ST OD Serial clock I/O for I

RB3 TTL CMOS Bi-directional input

RB3/CCP1/P1A

CCP1 ST CMOS Capture 1 input/Compare 1 output

P1A CMOS PWM P1A output

RB4 TTL CMOS Bi-directional input

RB4/SDI/SDA

SDI ST Serial data in for SPI

SDA ST OD Serial data I/O for I

RB5 ST CMOS Bi-directional I/O

RB5/SDO/P1B

SDO CMOS Serial data out for SPI

P1B CMOS PWM P1B output

Note 1: Bit programmable pull-ups.

Input

Type

ST Master Clear

ST SSP slave select input

Output

Type

PIC16C717/770/771

Description

OSC/4 output

(1)

(1)

(1)

2

C

(1)

(1)

2

C

(1)

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 9

Page 10

PIC16C717/770/771

TABLE 1-2: PIC16C717 PINOUT DESCRIPTION (CONTINUED)

Name Function

RB6 TTL CMOS Bi-directional I/O

RB6/T1OSO/T1CKI/P1C

RB7/T1OSI/P1D

SS VSS Power Ground

V

DD VDD Power Positive Supply

V

Note 1: Bit programmable pull-ups.

T1OSO XTAL TMR1 Crystal/Resonator

T1CKI ST TMR1 Clock input

P1C CMOS PWM P1C output

RB7 TTL CMOS Bi-directional I/O

T1OSI XTAL TMR1 Crystal/Resonator

P1D CMOS PWM P1D output

Input

Type

Output

Type

Description

(1)

(1)

DS41120A-page 10 Advanced Information

1999 Microchip Technology Inc.

Page 11

PIC16C717/770/771

2.0 MEMORY ORGANIZATION

There are two memory blocks in each of these

PICmicro

gram Memory and Data Memory) has its own bu s,

so that concurrent access can occur.

Additional inf ormation on de vice m emory may be f ound

in the PICmicro Mid-Range Reference Manual,

(DS33023).

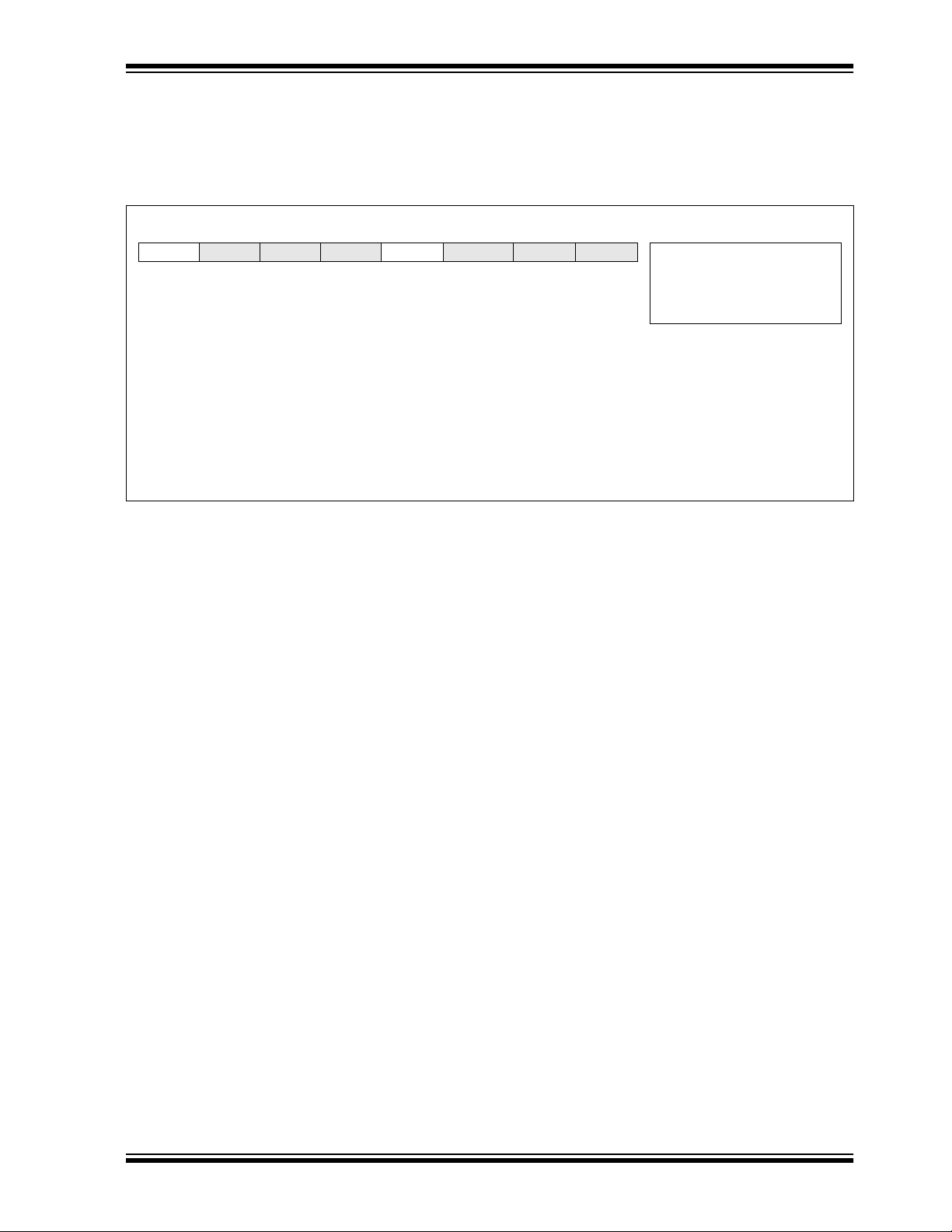

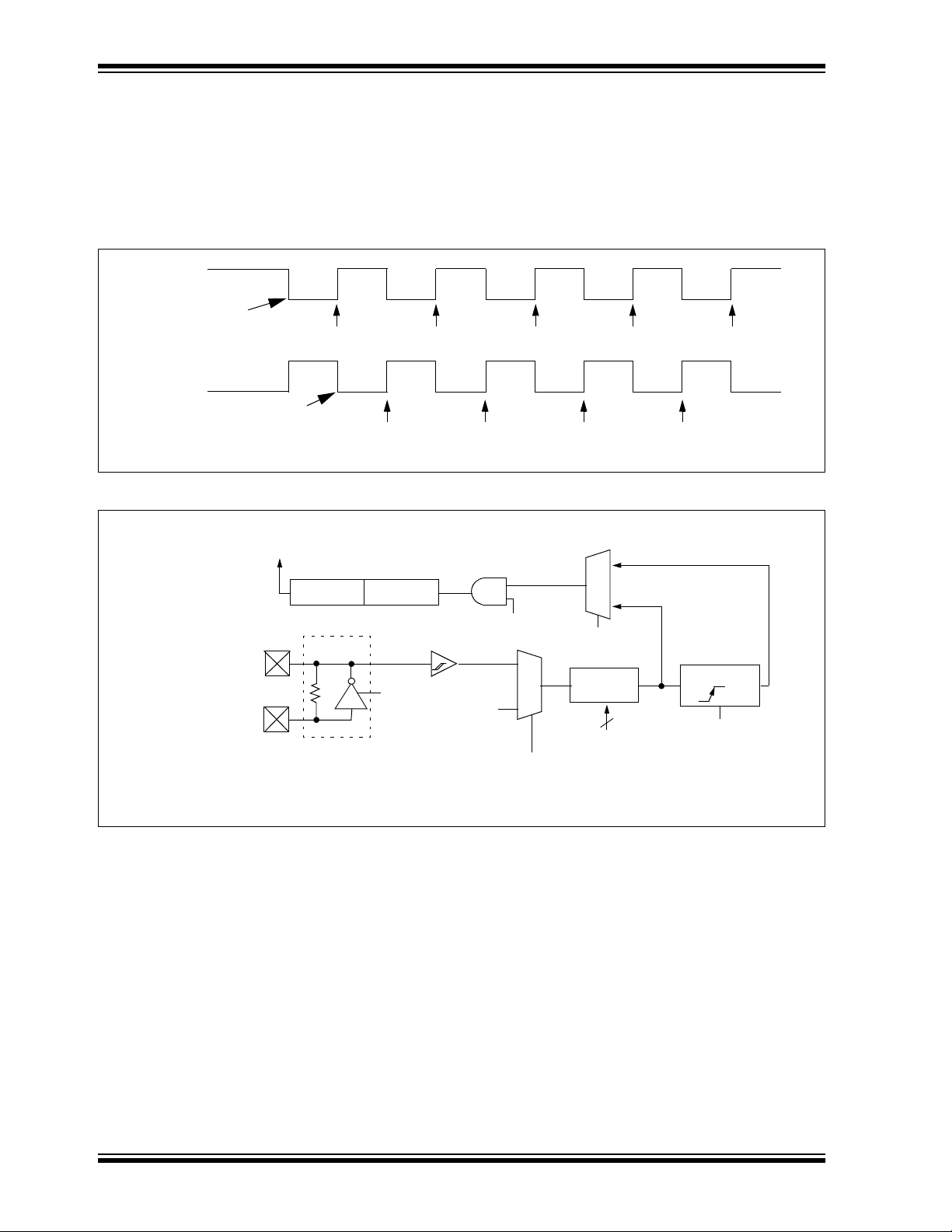

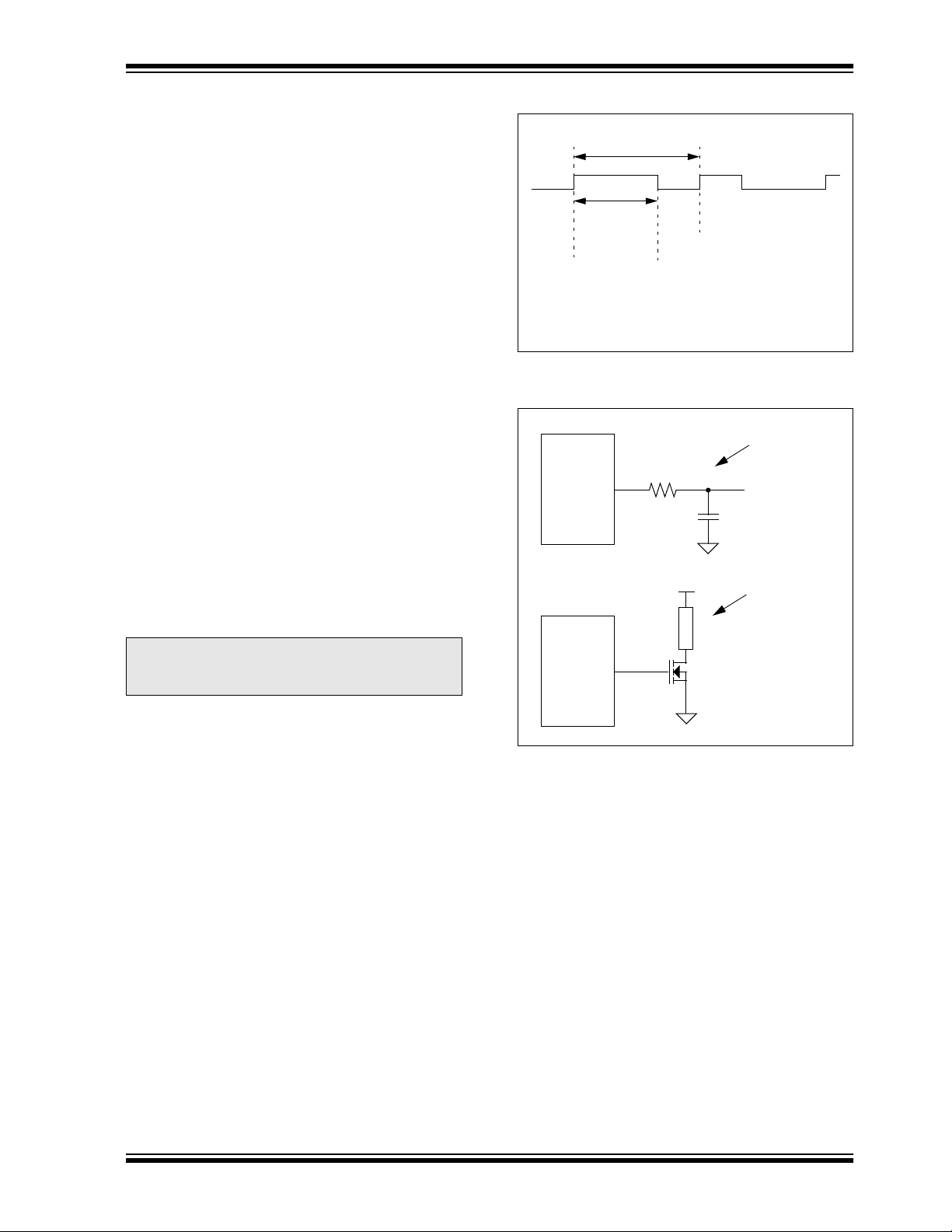

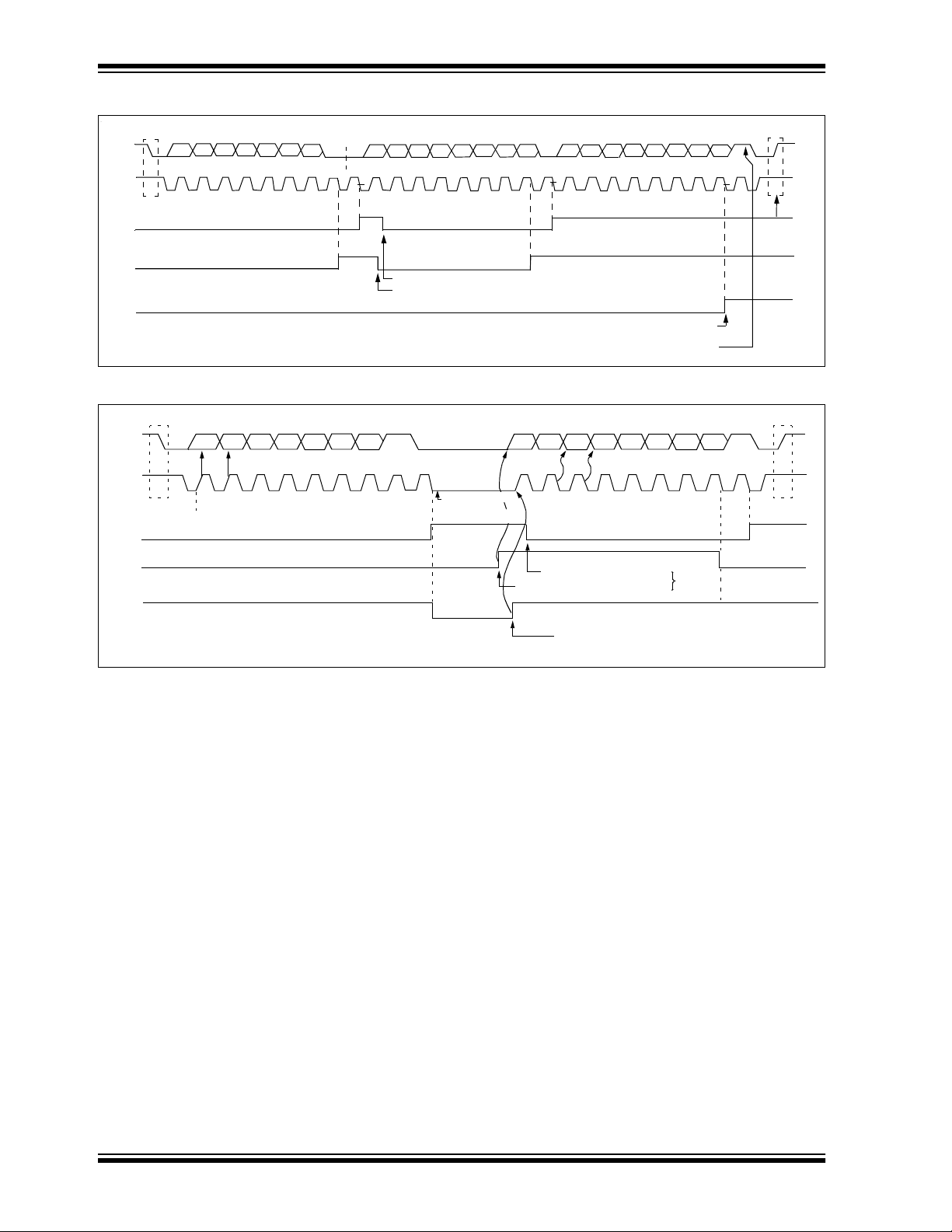

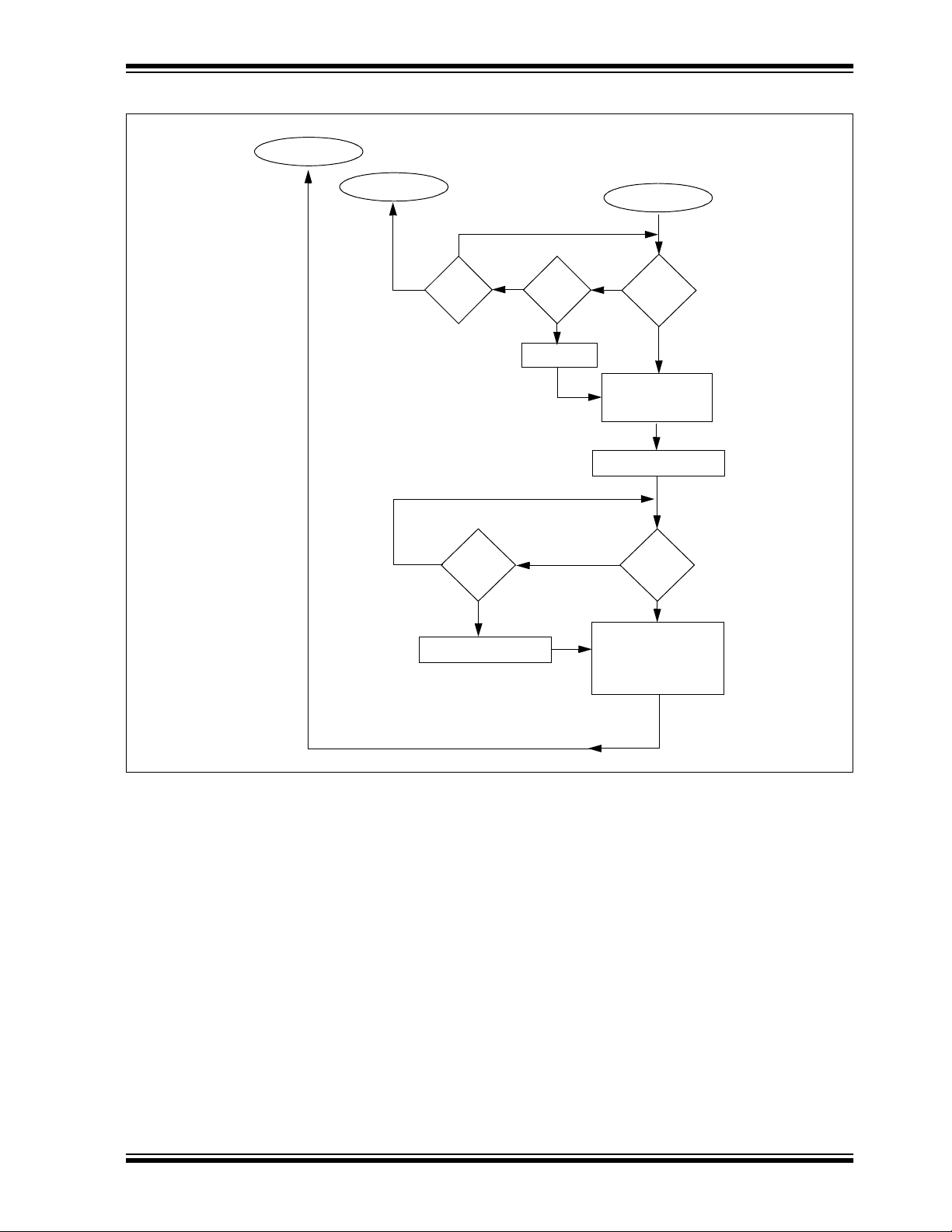

2.1 Program Memory Organization

The PIC16C717/770/771 devices have a 13-bit program counter capable of addressing an 8K x 14 program memory space. The PIC16C717 and the

PIC16C770 have 2K x 14 words of program memory.

The PIC16C771 has 4K x 14 words of program memory. Accessing a location above the physically implemented address will cause a wraparound.

The reset vector is at 0000h and the interrupt vector is

at 0004h.

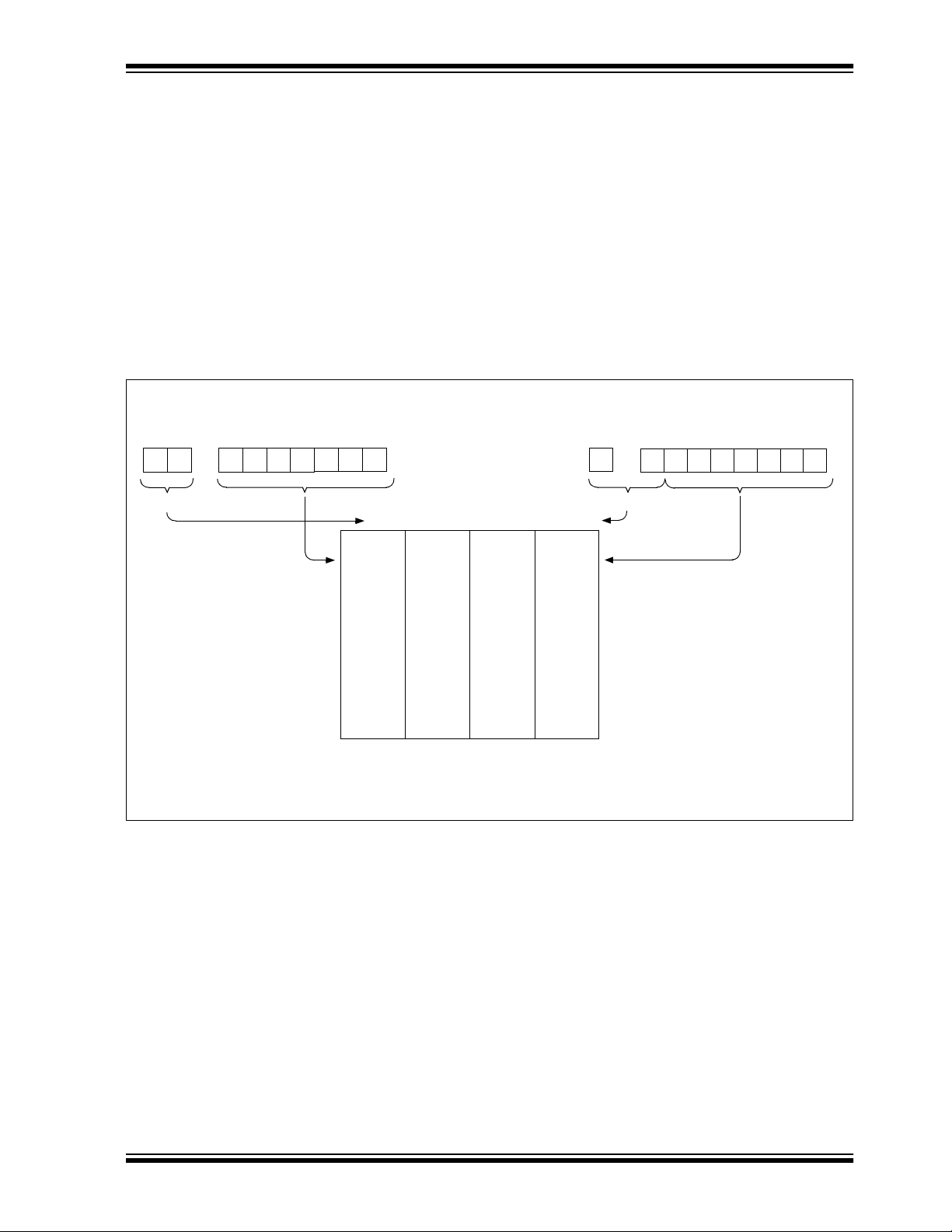

FIGURE 2-1: PROGRAM MEMORY MAP

®

microcontrollers. Each block (Pro-

AND STACK OF THE

PIC16C717 AND PIC16C770

PC<12:0>

CALL, RETURN

RETFIE, RETLW

13

FIGURE 2-2: PROGRAM MEMORY MAP

AND STACK OF THE

PIC16C771

PC<12:0>

CALL, RETURN

RETFIE, RETLW

On-chip

Program

Memory

Stack Level 1

Stack Level 2

Stack Level 8

Reset Vector

Interrupt Vector

Page 0

Page 1

13

0000h

0004h

0005h

07FFh

0800h

0FFFh

1000h

On-chip

Program

Memory

Stack Level 1

Stack Level 2

Stack Level 8

Reset Vector

Interrupt Vector

Page 0

0000h

0004h

0005h

07FFh

3FFFh

3FFFh

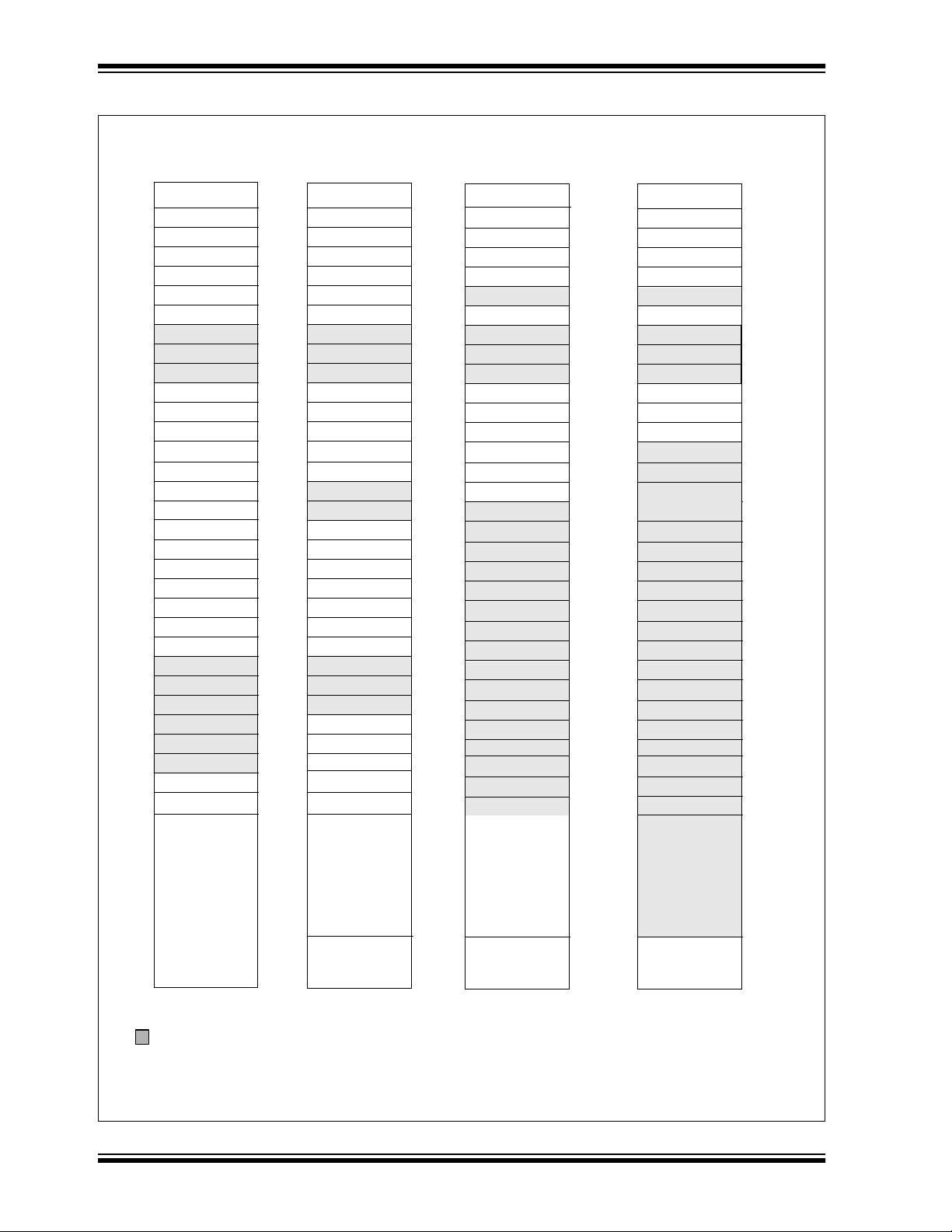

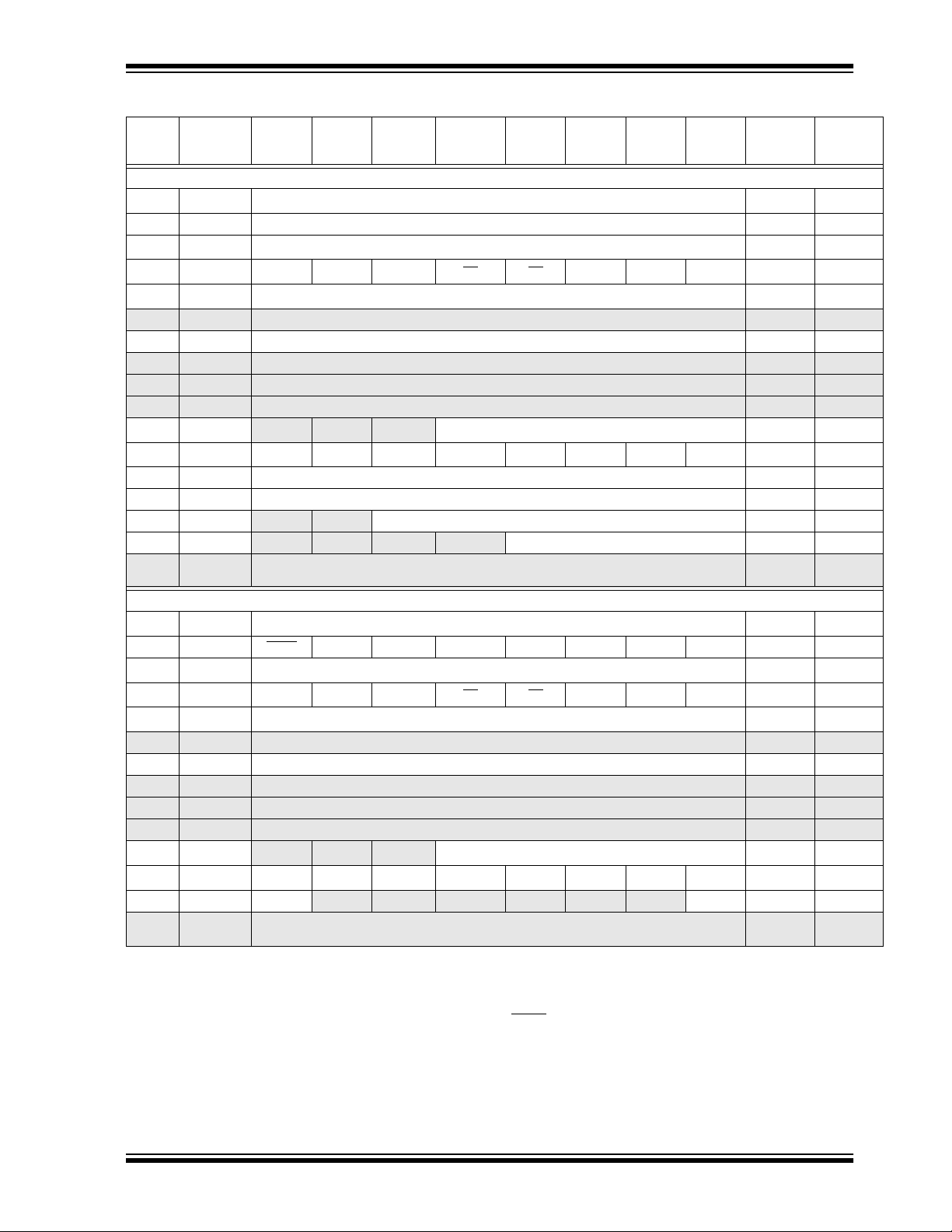

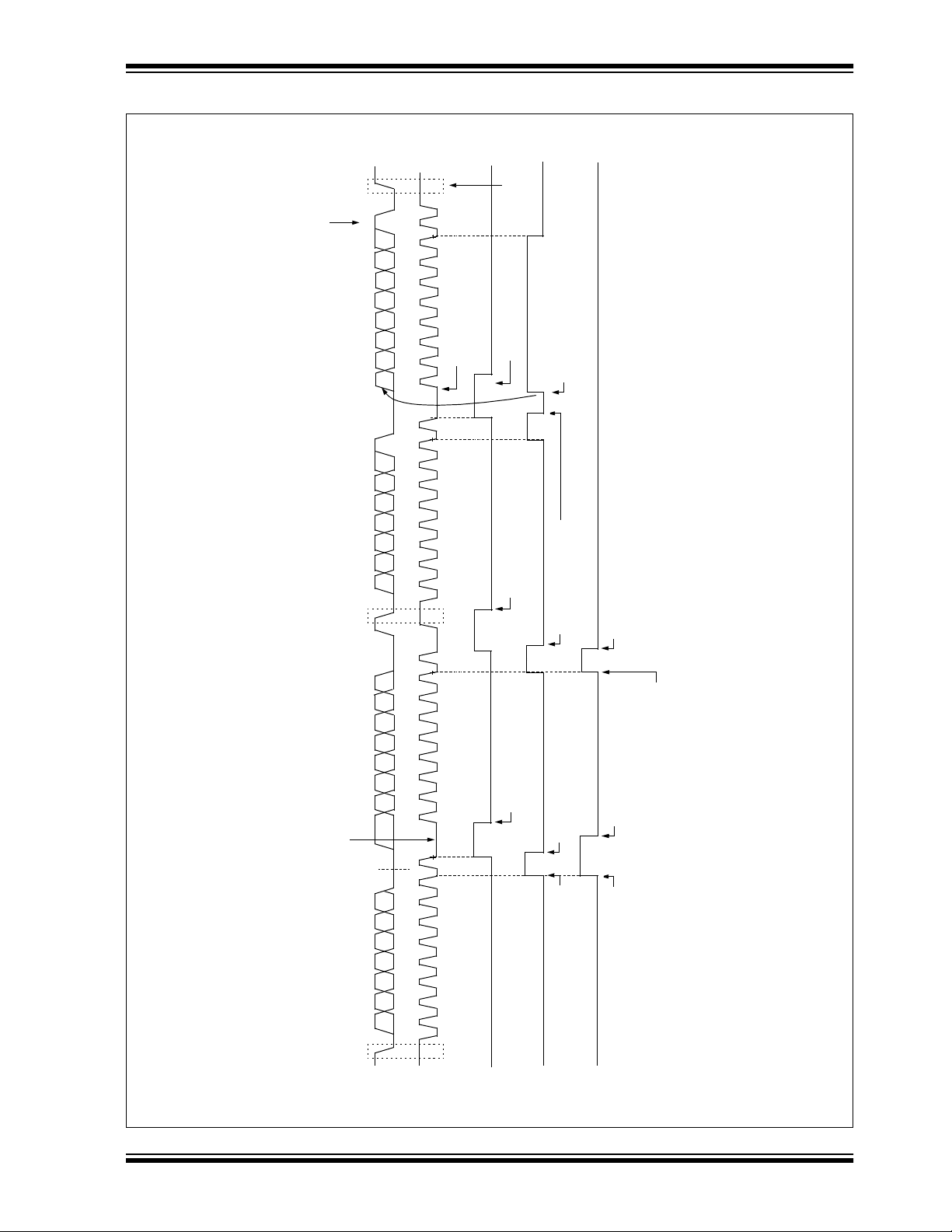

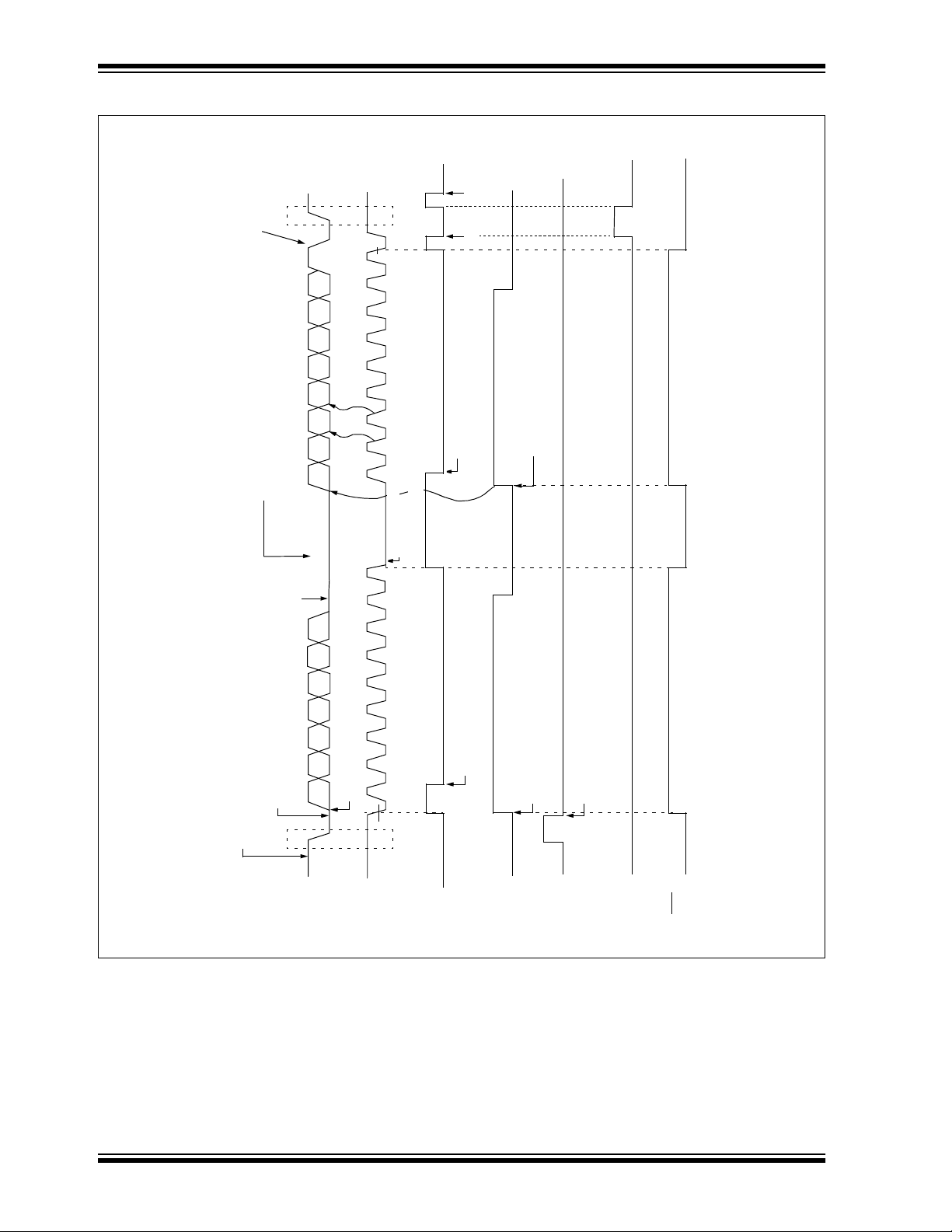

2.2 Data Memory Organization

The data memory is partitioned into multiple banks,

which contain the General Purpose Registers and the

Special Function Registers. Bits RP1 and RP0 are the

bank select bits.

RP1 RP0 (STATUS<6:5>)

= 00 → Bank0

= 01 → Bank1

= 10 → Bank2

= 11 → Bank3

Each bank extends up to 7Fh (128 bytes). The lower

locations of each bank are reserved for the Special

Function Registers . Abo v e the Spec ial Fun ction Re gisters are General Purpose Registers, implemented as

static RAM. All implemented banks contain special

function registers. Some frequently used special function registers from one bank are mirrored in another

bank for code reduction and quicker access.

2.2.1 GENERAL PURPOSE REGISTER FILE

1999 Microchip Technology Inc.

The register file can be a ccessed ei ther direc tly, or indirectly, through the File Select Register FSR.

Advanced Information DS41120A-page 11

Page 12

PIC16C717/770/771

FIGURE 2-3: REGISTER FILE MAP

File

Address

Indirect addr.

TMR0

PCL

STATUS

FSR

PORTA

PORTB

PCLATH

INTCON

PIR1

PIR2

TMR1L

TMR1H

T1CON

TMR2

T2CON

SSPBUF

SSPCON

CCPR1L

CCPR1H

CCP1CON

ADRESH

ADCON0

General

Purpose

Register

96 Bytes

Bank 0 Bank 1

(*)

00h

Indirect addr.

01h

02h

03h

04h

05h

06h

07h

08h

09h

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

1Bh

1Ch

1Dh

1Eh

1Fh

20h

7Fh

OPTION_REG

PCLATH

INTCON

SSPCON2

SSPADD

SSPSTAT

REFCON

LVDCON

ADRESL

ADCON1

General

Purpose

Register

80 Bytes

accesses

70h-7Fh

PCL

STATUS

FSR

TRISA

TRISB

PIE1

PIE2

PCON

PR2

WPUB

IOCB

P1DEL

ANSEL

File

Address

(*)

80h

81h

82h

83h

84h

85h

86h

87h

88h

89h

8Ah

8Bh

8Ch

8Dh

8Eh

8Fh

90h

91h

92h

93h

94h

95h

96h

97h

98h

99h

9Ah

9Bh

9Ch

9Dh

9Eh

9Fh

A0h

EFh

F0h

FFh

Indirect addr.

TMR0

PCL

STATUS

FSR

PORTB

PCLATH

INTCON

PMDATL

PMADRL

PMDATH

PMADRH

General

Purpose

Register

80 Bytes

accesses

70h - 7Fh

Bank 2

Address

(*)

File

100h

101h

102h

103h

104h

105h

106h

107h

108h

109h

10Ah

10Bh

10Ch

10Dh

10Eh

10Fh

110h

111h

112h

113h

114h

115h

116h

117h

118h

119h

11Ah

11Bh

11Ch

11Dh

11Eh

11Fh

120h

6Fh

70h

17Fh

Indirect addr.

OPTION_REG

PCL

STATUS

FSR

TRISB

PCLATH

INTCON

PMCON1

accesses

70h - 7Fh

Bank 3

File

Address

(*)

180h

181h

182h

183h

184h

185h

186h

187h

188h

189h

18Ah

18Bh

18Ch

18Dh

18Eh

18Fh

190h

191h

192h

193h

194h

195h

196h

197h

198h

199h

19Ah

19Bh

19Ch

19Dh

19Eh

19Fh

1A0h

1EFh

1F0h

1FFh

Unimplemented data memory locations, read as ’0’.

* Not a physical register.

DS41120A-page 12 Advanced Information

1999 Microchip Technology Inc.

Page 13

PIC16C717/770/771

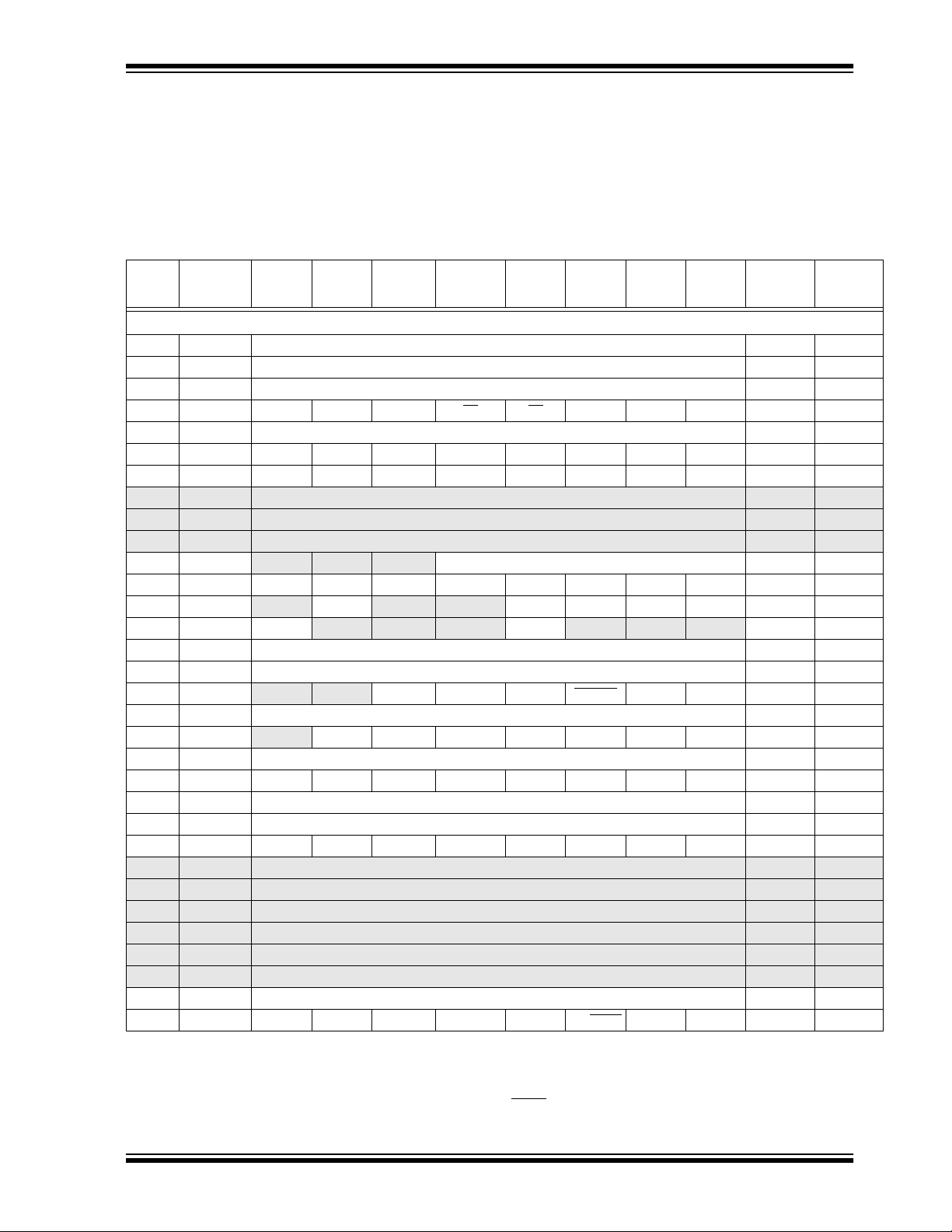

2.2.2 SPECIAL FUNCTION REGISTERS

The special fu nction re gisters can b e classifi ed into two

sets; core (CPU) and periphe ral. Those registers asso-

The Special Function Registers are registers used by

the CPU and Peripheral Modules for controlling the

desired operation of the device. These registers are

implemented as static RAM. A list of these registers is

given in Table 2-1.

ciated with the core functions are described in detail in

this section. Those related to the operation of the

peripheral features are described in detail in that

peripheral feature section.

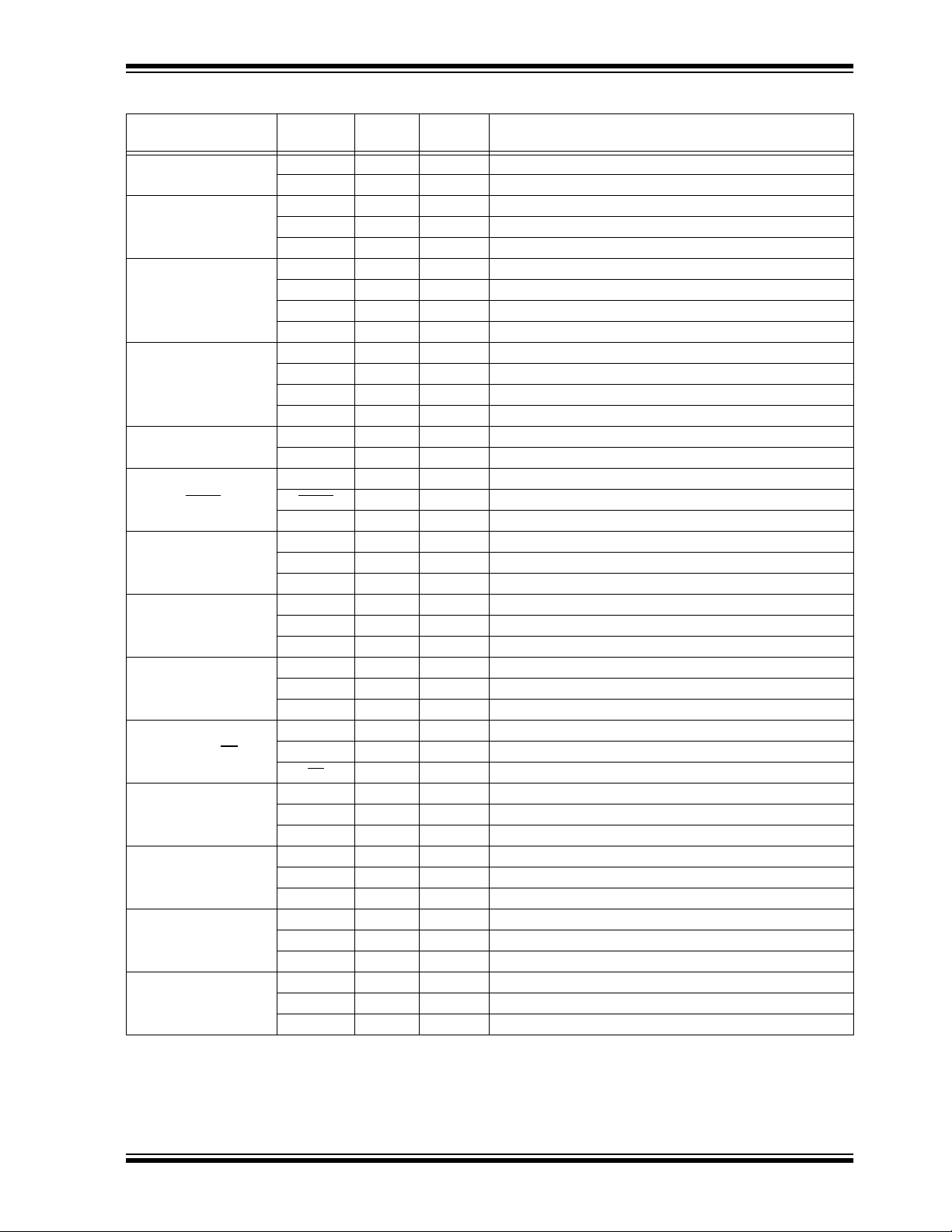

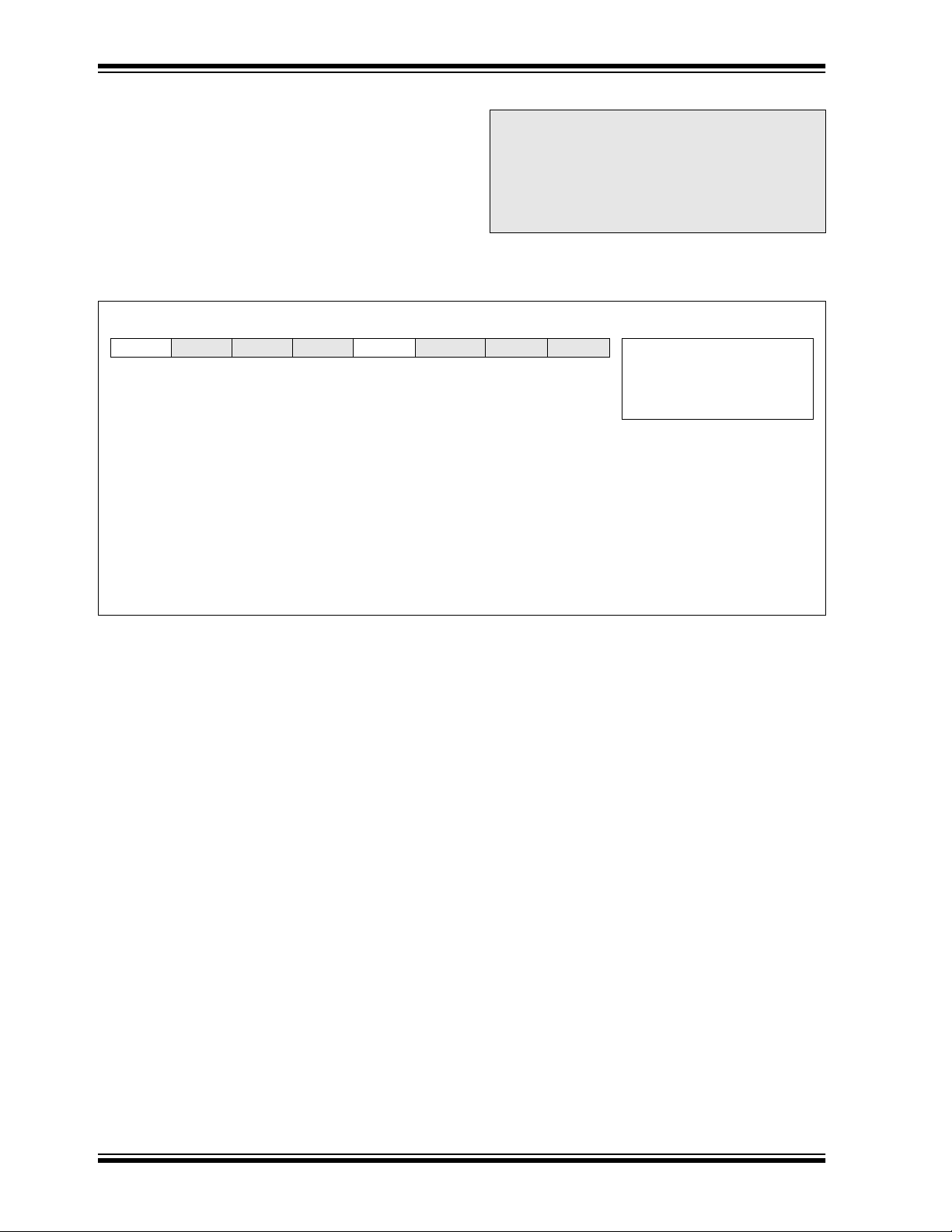

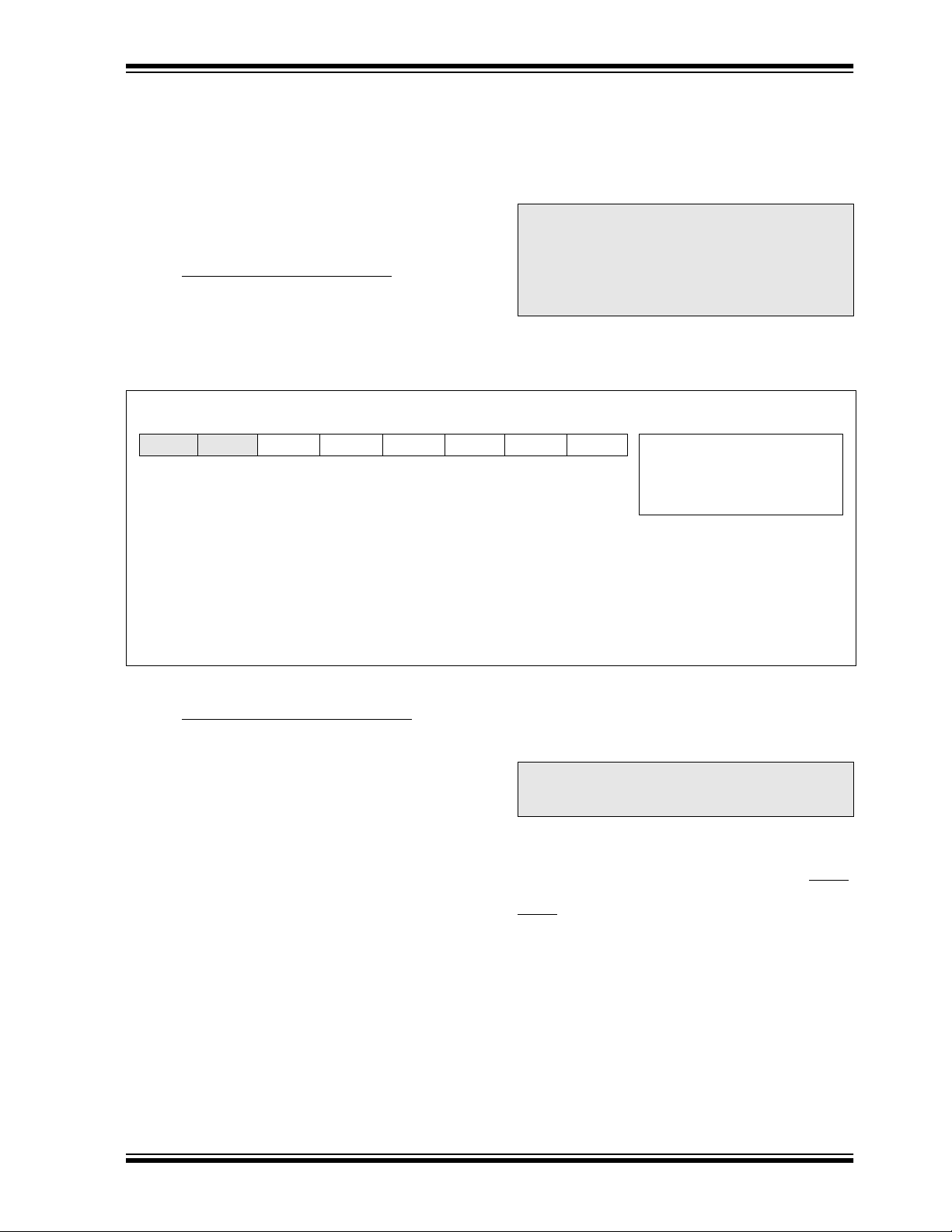

TABLE 2-1: PIC16C717/770/771 SPECIAL FUNCTION REGISTER SUMMARY

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Bank 0

(3)

00h

01h TMR0 Timer0 module’s register xxxx xxxx uuuu uuuu

02h

03h

04h

05h PORTA RA7 RA6 RA5 RA4 RA3 RA2 RA1 RA0 xxxx 0000 uuuu 0000

06h PORTB RB7 RB6 RB5 RB4 RB3 RB2 RB1 RB0 xxxx xx00 uuuu uu00

07h — Unimplemented — —

08h — Unimplemented — —

09h — Unimplemented — —

0Ah

0Bh

0Ch PIR1

0Dh PIR2 LVDIF

0Eh TMR1L Holding register for the Least Significant Byte of the 16-bit TMR1 register xxxx xxxx uuuu uuuu

0Fh TMR1H Holding register for the Most Significant Byte of the 16-bit TMR1 register xxxx xxxx uuuu uuuu

10h T1CON

11h TMR2 Timer2 module’s register 0000 0000 0000 0000

12h T2CON

13h SSPBUF Synchronous Serial Port Receive Buffer/Transmit Register xxxx xxxx uuuu uuuu

14h SSPCON WCOL SSPOV SSPEN CKP SSPM3 SSPM2 SSPM1 SSPM0 0000 0000 0000 0000

15h CCPR1L Capture/Compare/PWM Register1 (LSB) xxxx xxxx uuuu uuuu

16h CCPR1H Capture/Compare/PWM Register1 (MSB) xxxx xxxx uuuu uuuu

17h CCP1CON PWM1M1 PWM1M0 DC1B1 DC1B0 CCP1M3 CCP1M2 CCP1M1 CCP1M0 0000 0000 0000 0000

18h — Unimplemented — —

19h — Unimplemented — —

1Ah — Unimplemented — —

1Bh — Unimplemented — —

1Ch — Unimplemented — —

1Dh — Unimplemented — —

1Eh ADRESH A/D High Byte Result Register xxxx xxxx uuuu uuuu

1Fh ADCON0 ADCS1 ADCS0 CHS2 CHS1 CHS0 GO/DONE

Legend:x = unknown, u = unchanged, q = value depends on condition, - = unimplemented read as ’0’.

Note 1: The upper byte of the program counter is not directly accessible. PCLATH is a holding register for the PC<12:8> whose con-

INDF Addressing this location uses contents of FSR to address data memory (not a physical register) 0000 0000 0000 0000

(3)

PCL Program Counter's (PC) Least Significant Byte 0000 0000 0000 0000

(3)

ST ATUS IRP RP1 RP0 TO PD ZDCC0001 1xxx 000q quuu

(3)

FSR Indirect data memory address pointer xxxx xxxx uuuu uuuu

(1,3)

PCLATH — — — Write Buffer for the upper 5 bits of the Program Counter ---0 0000 ---0 0000

(3)

INTCON GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

—ADIF— — SSPIF CCP1IF TMR2IF TMR1IF -0-- 0000 -0-- 0000

— — —BCLIF— — — 0--- 0--- 0--- 0---

— — T1CKPS1 T1CKPS0 T1OSCEN T1SYNC TMR1CS TMR1ON --00 0000 --uu uuuu

— TOUTPS3 TOUTPS2 TOUTPS1 TOUTPS0 TMR2ON T2CKPS1 T2CKPS0 -000 0000 -000 0000

CHS3 ADON 0000 0000 0000 0000

Shaded locations are unimplemented, read as ‘0’.

tents are transferred to the upper byte of the program counter.

2: Other (non power-up) resets include external reset through MCLR

and Watchdog Timer Reset.

3: These registers can be addressed from any bank.

Value on all

other resets

(2)

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 13

Page 14

PIC16C717/770/771

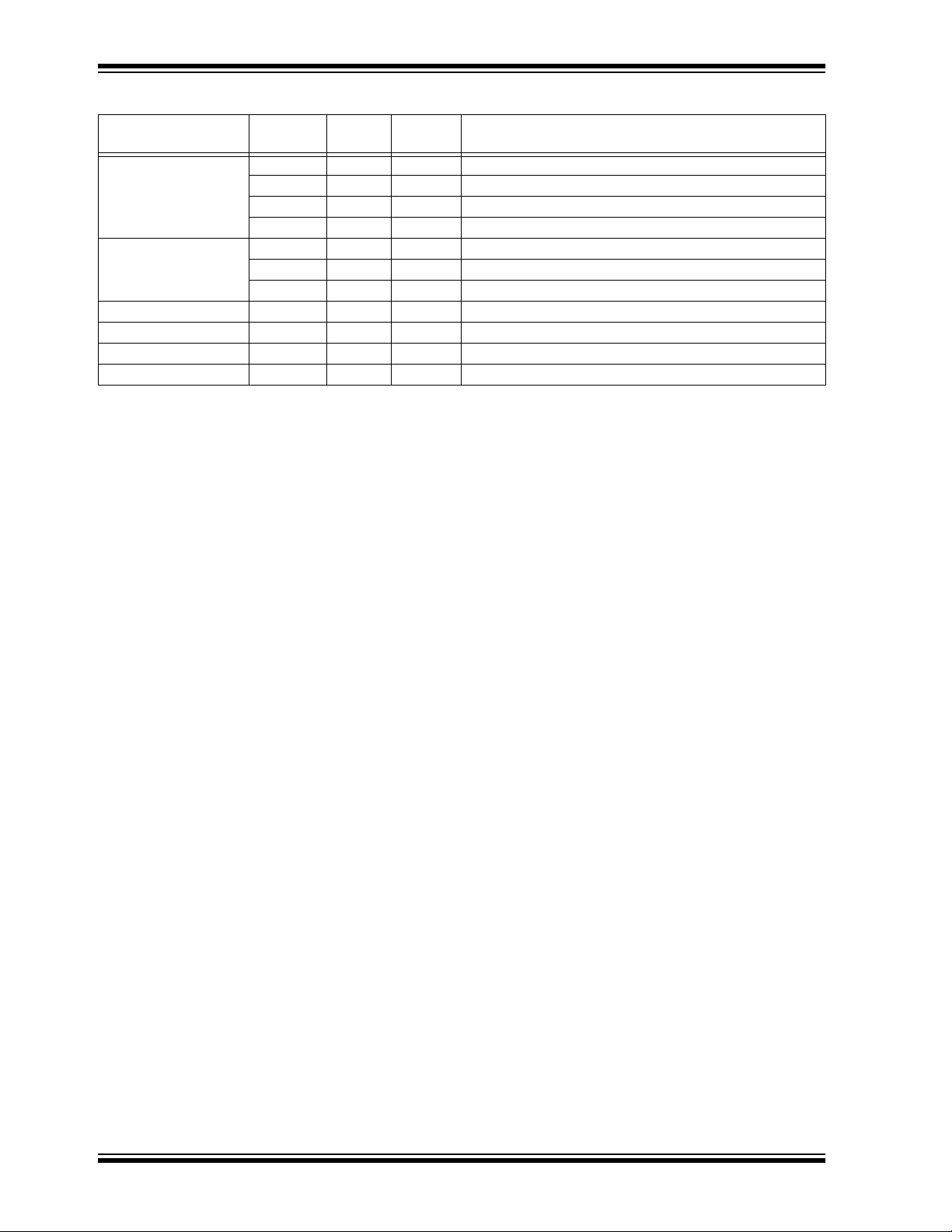

TABLE 2-1: PIC16C717/770/771 SPECIAL FUNCTION REGISTER SUMMARY (CONTINUED)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 1

(3)

80h

81h OPTION_REG RBPU

82h

83h

84h

85h TRISA PORTA Data Direction Register 1111 1111 1111 1111

86h TRISB PORTB Data Direction Register 1111 1111 1111 1111

87h — Unimplemented — —

88h — Unimplemented — —

89h — Unimplemented — —

8Ah

8Bh

8Ch PIE1

8Dh PIE2 LVDIE

8Eh PCON

8Fh — Unimplemented — —

90h — Unimplemented — —

91h SSPCON2 GCEN ACKSTAT ACKDT ACKEN RCEN PEN RSEN SEN 0000 0000 0000 0000

92h PR2 Timer2 Period Register 1111 1111 1111 1111

93h SSPADD Synchronous Serial Port (I

94h SSPSTAT SMP CKE D/A

95h WPUB PORTB Weak Pull-up Control 1111 1111 1111 1111

96h IOCB PORTB Interrupt on Change Control 1111 0000 1111 0000

97h P1DEL PWM 1 Delay value 0000 0000 0000 0000

98h — Unimplemented — —

99h — Unimplemented — —

9Ah — Unimplemented — —

9Bh REFCON VRHEN VRLEN VRHOEN VRLOEN

9Ch LVDCON

9Dh ANSEL

9Eh ADRESL A/D Low Byte Result Register xxxx xxxx uuuu uuuu

9Fh ADCON1 ADFM VCFG2 VCFG1 VCFG0

INDF Addressing this location uses contents of FSR to address data memory (not a physical register) 0000 0000 0000 0000

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

(3)

PCL Program Counter’s (PC) Least Significant Byte 0000 0000 0000 0000

(3)

ST ATUS IRP RP1 RP0 TO PD ZDCC0001 1xxx 000q quuu

(3)

FSR Indirect data memory address pointer xxxx xxxx uuuu uuuu

(1,3)

PCLATH — — — Write Buffer for the upper 5 bits of the Program Counter ---0 0000 ---0 0000

(3)

INTCON GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

—ADIE — — SSPIE CCP1IE TMR2IE TMR1IE -0-- 0000 -0-- 0000

— — —BCLIE— — — 0--- 0--- 0--- 0---

— — — —OSCF—PORBOR ---- 1-qq ---- 1-uu

2

C mode) Address Register 0000 0000 0000 0000

PSR/WUA BF 0000 0000 0000 0000

— — — — 0000 ---- 0000 ----

— — BGST LVDEN LVV3 LVV2 LVV1 LVV0 --00 0101 --00 0101

Analog Channel Select

Value on:

POR,

BOR

1111 1111 1111 1111

0000 0000 0000 0000

Legend:x = unknown, u = unchanged, q = value depends on condition, - = unimplemented read as ’0’.

Shaded locations are unimplemented, read as ‘0’.

Note 1: The upper byte of the program counter is not directly accessible. PCLATH is a holding register for the PC<12:8> whose con-

tents are transferred to the upper byte of the program counter.

2: Other (non power-up) resets include external reset through MCLR

and Watchdog Timer Reset.

3: These registers can be addressed from any bank.

Value on all

other resets

(2)

DS41120A-page 14 Advanced Information

1999 Microchip Technology Inc.

Page 15

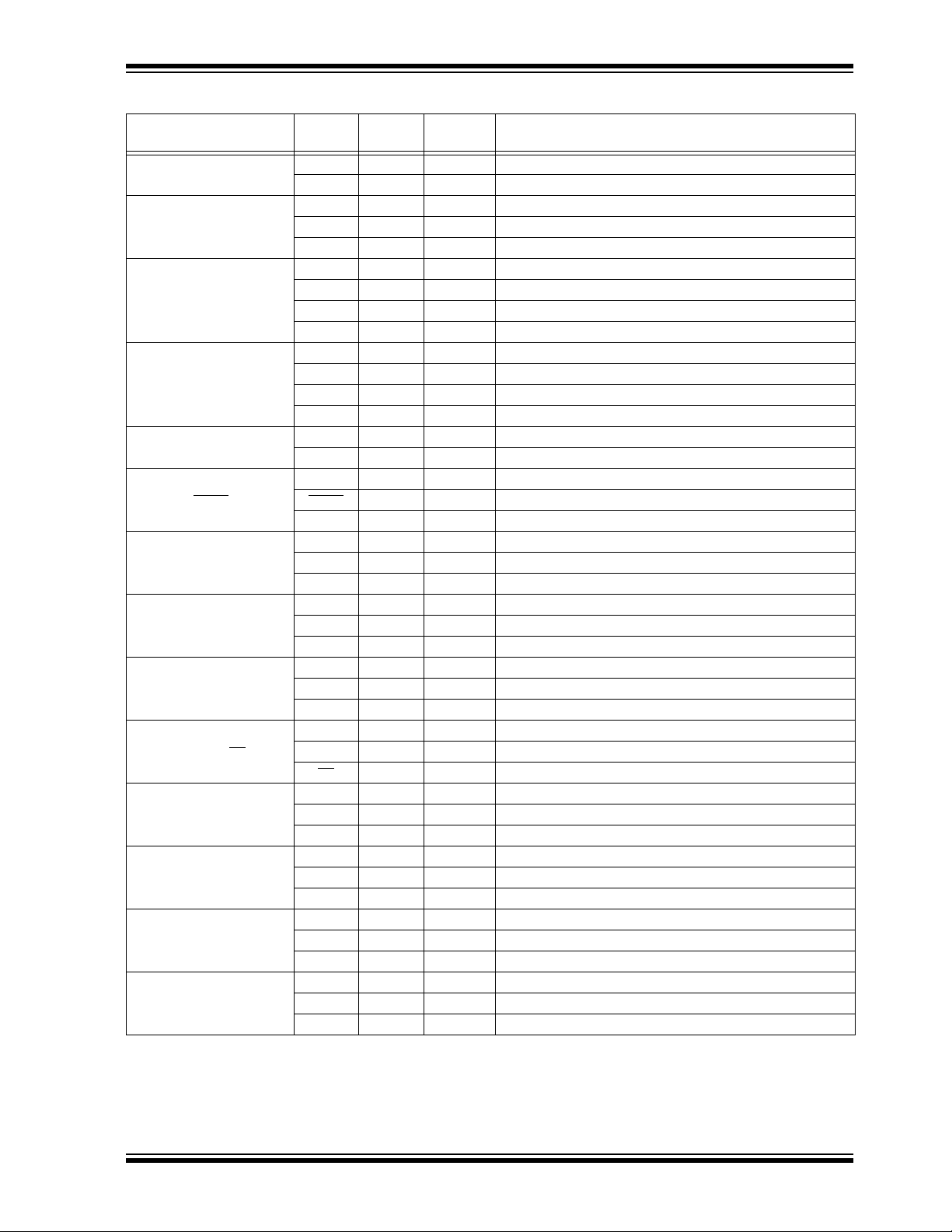

PIC16C717/770/771

TABLE 2-1: PIC16C717/770/771 SPECIAL FUNCTION REGISTER SUMMARY (CONTINUED)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 2

(3)

100h

101h TMR0 Timer0 module’s register xxxx xxxx uuuu uuuu

102h

103h

104h

105h — Unimplemented — —

106h PORTB PORTB Data Latch when written: PORTB pins when read xxxx xx00 uuuu uu00

107h — Unimplemented — —

108h — Unimplemented — —

109h — Unimplemented — —

10Ah

10Bh

10Ch PMDATL Program memory read data low xxxx xxxx uuuu uuuu

10Dh PMADRL Program memory read address low xxxx xxxx uuuu uuuu

10Eh PMDATH

10Fh PMADRH

110h-

11Fh

INDF Addressing this location uses contents of FSR to address data memory (not a physical register) 0000 0000 0000 0000

(3)

PCL Program Counter's (PC) Least Significant Byte 0000 0000 0000 0000

(3)

STATUS IRP RP1 RP0 TO PD Z DC C 0001 1xxx 000q quuu

(3)

FSR Indirect data memory address pointer xxxx xxxx uuuu uuuu

(1,3)

PCLATH — — — Write Buffer for the upper 5 bits of the Program Counter ---0 0000 ---0 0000

(3)

INTCON GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

— — Program memory read data high --xx xxxx --uu uuuu

— — — — Program memory read address high ---- xxxx ---- uuuu

— Unimplemented — —

Value on:

POR,

BOR

Bank 3

(3)

180h

181h OPTION_REG RBPU

182h

183h

184h

185h — Unimplemented — —

186h TRISB PORTB Data Direction Register 1111 1111 1111 1111

187h — Unimplemented — —

188h — Unimplemented — —

189h — Unimplemented — —

18Ah

18Bh

18Ch PMCON1 Reserved

18Dh-

18Fh

INDF Addressing this location uses contents of FSR to address data memory (not a physical register) 0000 0000 0000 0000

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

(3)

PCL Program Counter's (PC) Least Significant Byte 0000 0000 0000 0000

(3)

STATUS IRP RP1 RP0 TO PD Z DC C 0001 1xxx 000q quuu

(3)

FSR Indirect data memory address pointer xxxx xxxx uuuu uuuu

(1,3)

PCLATH — — —

(3)

INTCON GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

— — — — — — RD 1--- ---0 1--- ---0

— Unimplemented — —

Write Buffer for the upper 5 bits of the Program Counter

---0 0000 ---0 0000

Legend:x = unknown, u = unchanged, q = value depends on condition, - = unimplemented read as ’0’.

Shaded locations are unimplemented, read as ‘0’.

Note 1: The upper byte of the program counter is not directly accessible. PCLATH is a holding register for the PC<12:8> whose con-

tents are transferred to the upper byte of the program counter.

2: Other (non power-up) resets include external reset through MCLR

and Watchdog Timer Reset.

3: These registers can be addressed from any bank.

Value on all

other resets

(2)

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 15

Page 16

PIC16C717/770/771

2.2.2.1 STATUS REGISTER

The STATUS register, shown in Register 2-1, contains

the arithmetic status of th e ALU , the RE SET status an d

the bank select bits for data memory.

The STATUS register can be the destination for any

instruction, as with any other register. If the STATUS

register is the destination for an instruction that affects

the Z, DC or C bits, then the write to these three bits is

disabled. The se bi ts ar e set or c leared accordi ng to the

device logic. Fur th er more, the TO

writable. Therefore, the result of an instruction with the

STATUS regi ster as destina tion may be different th an

intended.

and PD bits are not

For example, CLRF STATUS will clear the up p er- t h ree

bits and set th e Z bi t. T his l ea v es the STATUS register

as 000u u1uu (where u = unchanged).

It is recommended, therefore, that only BCF, BSF,

SWAPF and MOVWF instructions are used to alter the

STATUS register, because these instructions do not

affect the Z, C or DC b its from the STA TU S regist er . F or

other instructions not affecting any status bits, see the

"Instruction Set Summary."

Note 2: The C and DC bits oper ate as a borro w and

digit borrow

See the SUBLW and SUBWF instructions for

examples.

REGISTER 2-1: STATUS REGISTER (STATUS: 03h, 83h, 103h, 183h)

R/W-0 R/W-0 R/W-0 R-1 R-1 R/W-x R/W-x R/W-x

IRP RP1 RP0 TO

bit7 bit0

bit 7: IRP: Register Bank Select bit (used for indirect addressing)

1 = Bank 2, 3 (100h - 1FFh)

0 = Bank 0, 1 (00h - FFh)

bit 6-5: RP<1:0>: Register Bank Select bits (used for direct addressing)

11 = Bank 3 (180h - 1FFh)

10 = Bank 2 (100h - 17Fh)

01 = Bank 1 (80h - FFh)

00 = Bank 0 (00h - 7Fh)

Each bank is 128 bytes

bit 4: TO

bit 3: PD

bit 2: Z: Zero bit

bit 1: DC: Digit carry/borrow

bit 0: C: Carry/borrow

: Time-out bit

1 = After power-up, CLRWDT instruction, or SLEEP instruction

0 = A WDT time-out occurred

: Power-down bit

1 = After power-up or by the CLRWDT instruction

0 = By execution of the SLEEP instruction

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

bit (ADDWF, ADDLW,SUBLW,SUBWF instructions) (for borrow the p ol arity is reversed)

1 = A carry-out from the 4th low order bit of the result occurr ed

0 = No carry-out from the 4th low order bit of the result

bit (ADDWF, ADDLW,SUBLW,SUBWF instructions)

1 = A carry-out from the most significant bit of the result occurred

0 = No carry-out from the most significant bit of the result occurred

PD Z DC C R = Readable bit

bit, respectively , in subtraction.

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

Note: For borrow, the polarity is reversed. A subtraction is executed by adding the two’s complement of the sec-

ond operand. For rotate (RRF, RLF) instructions, this bit is loaded with either the high or low order bit of

the source register.

DS41120A-page 16 Advanced Information

1999 Microchip Technology Inc.

Page 17

PIC16C717/770/771

2.2.2.2 OPTION_REG REGISTER

The OPTION_REG register is a readable and writable

register , which contai ns various c ontrol bits to c onfigure

the TMR0 prescaler/WDT postscaler (single assignable regist er kno wn also as the prescale r), the Ext ernal

INT Interrupt, TMR0 and the w eak pul l-ups on PO R TB .

REGISTER 2-2: OPTION REGISTER (OPTION_REG: 81h, 181h)

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

RBPU

bit7 bit0

bit 7: RBPU: PORTB Pull-up Enable bit

bit 6: INTEDG: Interrupt Edge Select bit

bit 5: T0CS: TMR0 Clock Source Select bit

bit 4: T0SE: TMR0 Source Edge Select bit

bit 3: PSA: Prescaler Assignment bit

bit 2-0: PS<2:0>: Prescaler Rate Select bits

INTEDG T0CS T0SE PSA PS2 PS1 PS0 R = Readable bit

(1)

1 = PORTB weak pull-ups are disabled

0 = PORTB weak pull-ups are enabled by the WPUB register

1 = Interrupt on rising edge of RB0/INT pin

0 = Interrupt on falling edge of RB0/INT pin

1 = Transition on RA4/ T0CKI pin

0 = Internal instructio n cycle clock (CLKOUT)

1 = Increment on high-to-low transition on RA4/T0CKI pin

0 = Increment on low-to-h igh transition on RA4/T0CKI pin

1 = Prescaler is assigned to the WDT

0 = Prescaler is assigned to the Timer0 module

Bit Value TMR0 Rate WDT Rate

000

001

010

011

100

101

110

111

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

1 : 256

1 : 1

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

Note: To achieve a 1:1 prescaler assignme nt for

the TMR0 register, assign the prescaler to

the Watchdog Timer.

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

Note 1: Individual weak pull-up on RB pins can be enabled/disabled from the weak pull-up PORTB Register

(WPUB).

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 17

Page 18

PIC16C717/770/771

2.2.2.3 INTCON REGISTER

The INTCON Regi ster i s a rea dab le a nd w ritabl e regi s-

ter, which contains various enable and flag bits for the

TMR0 register overflow, RB Port change and External

RB0/INT pin interrupts.

Note: Interrupt flag bits get set when an interrupt

condition occurs , regardless of the sta te of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>). User software should ensure the appropriate interrupt flag bits are clear prior to enabling an

interrupt.

REGISTER 2-3: INTERRUPT CONTROL REGISTER (INTCON: 0Bh, 8Bh, 10Bh, 18Bh)

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-x

GIE PEIE T0IE INTE RBIE T0IF INTF RBIF R = Readable bit

bit7 bit0

bit 7: GIE: Global Interrupt Enable bit

1 = Enables all un-masked interrupts

0 = Disables all interrupts

bit 6: PEIE: Peripheral Interrupt Enable bit

1 = Enables all un-masked peripheral interrupts

0 = Disables all peripheral interrupts

bit 5: T0IE: TMR0 Overflow Interrupt Enable bit

1 = Enables the TMR0 interrupt

0 = Disables the TMR0 interrupt

bit 4: INTE: RB0/INT External Interrupt Enable bit

1 = Enables the RB0/INT external interrupt

0 = Disables the RB0/INT external interrupt

bit 3: RBIE: RB Port Change Interrupt Enable bit

(1)

1 = Enables the RB port change interrupt

0 = Disables the RB port change interrupt

bit 2: T0IF: TMR0 Overflow Interrupt Flag bit

1 = TMR0 register has overflowed (must be cleared in software)

0 = TMR0 register did not overflow

bit 1: INTF: RB0/INT External Interrupt Flag bit

1 = The RB0/INT external interrupt occurred (must be cleared in software)

0 = The RB0/INT external interrupt did not occur

bit 0: RBIF : RB Port Change Interrupt Flag bit

(1)

1 = At least one of the RB<7:0> pins changed state (must be cleared in software)

0 = None of the RB<7:0> pins have changed state

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

Note 1: Individual RB pin interrupt on change can be enabled/disabled from the Interrupt on Change PORTB register (IOCB).

DS41120A-page 18 Advanced Information

1999 Microchip Technology Inc.

Page 19

PIC16C717/770/771

2.2.2.4 PIE1 REGISTER

This register contains the individual enable bits for the

peripheral interrupts.

Note: Bit PEIE (INTCON<6>) must be set to

enable any peripheral interrupt.

REGISTER 2-4: PERIPHERAL INTERRUPT ENABLE REGISTER 1 (PIE1: 8Ch)

U-0 R/W-0 U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0

—ADIE— — SSPIE CCP1IE TMR2IE TMR1IE R = Readable bit

bit7 bit0

bit 7: Unimplemented: Read as ’0’

bit 6: ADIE: A/D Converter Interrupt Enable bit

1 = Enables the A/D interrupt

0 = Disables the A/D interrupt

bit 5-4: Unimplemented: Read as ’0’

bit 3: SSPIE: Synchronous Serial Port Interrupt Enable bit

1 = Enables the SSP interrupt

0 = Disables the SSP interrupt

bit 2: CCP1 IE: CCP1 Interrupt Enable bit

1 = Enables the CCP1 interrupt

0 = Disables the CCP1 interrupt

bit 1: TMR2IE: TMR2 to PR2 Match Interrupt Enable bit

1 = Enables the TMR2 to PR2 match interrupt

0 = Disables the TMR2 to PR2 match interrupt

bit 0: TMR1IE: TMR1 Overflow Interrupt Enable bit

1 = Enables the TMR1 overflow interrupt

0 = Disables the TMR1 overflow interrupt

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 19

Page 20

PIC16C717/770/771

2.2.2.5 PIR1 R EGISTER

This register contains the individual flag bits for the

peripheral interrupts.

Note: Interrupt flag bits get set when an interrupt

condition occurs , regardless of the sta te of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>). User software should ensure the appropriate interrupt flag bits are clear prior to enabling an

interrupt.

REGISTER 2-5: PERIPHERAL INTERRUPT REGISTER 1 (PIR1: 0Ch)

U-0 R/W-0 U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0

—

bit7 bit0

ADIF

— —

bit 7: Unimplemen ted: Read as ‘0’.

bit 6: ADIF : A/D Converter Interrupt Flag bit

1 = An A/D conversion completed

0 = The A/D conversion is not complete

bit 5-4: Unimplemented: Read as ‘0’.

bit 3: SSPIF: Synchronous Serial Port (SSP) Interrupt Flag

1 = The SSP interrupt condition has o ccurred, an d mu st be clea red in s oftw are bef o re returning from the

interrupt service routine. The conditions that will set this bit are:

SPI

A transmission/reception has taken place.

2

C Slave / Master

I

A transmission/reception has taken place.

I2C Master

The initiated start condition was completed by the SSP module.

The initiated stop condition was completed by the SSP module.

The initiated restart condition was completed by the SSP module.

The initiated acknowledge condition was completed by the SSP module.

A start condition occurred while the SSP module was idle (Multimaster system).

A stop condition occurred while the SSP module was idle (Multimaster system).

0 = No SSP interrupt condition has occurred.

bit 2: CCP1 IF: CCP1 Interrupt Flag bit

Capture Mode

1 = A TMR1 register capture occurred (must be cleared in software)

0 = No TMR1 register captur e occurred

ompare Mode

C

1 = A TMR1 register compare match occurred (must be cleared in software)

0 = No TMR1 register compare match occurred

WM Mode

P

Unused in this mode

bit 1: TMR2IF: TMR2 to PR2 Match Interrupt Flag bit

1 = TMR2 to PR2 match occur red (must be cleared in sof tware)

0 = No TMR2 to PR2 match occurred

bit 0: TMR1IF: TMR1 Overflow Interrupt Flag bit

1 = TMR1 register overflowed (must be cleared in software)

0 = TMR1 register did not overflow

SSPIF CCP1IF TMR2IF TM R1IF R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

DS41120A-page 20 Advanced Information

1999 Microchip Technology Inc.

Page 21

PIC16C717/770/771

2.2.2.6 PIE2 REGISTER

This register contains the individual enable bits for the

SSP bus collision and low voltage detect interrupts.

REGISTER 2-6: PERIPHERAL INTERRUPT REGISTER 2 (PIE2: 8Dh)

R/W-0 U-0 U-0 U-0 R/W-0 U-0 U-0 U-0

LVDIE

bit7 bit0

bit 7: LVDIE: Low-voltage Detect Interrupt Enable bit

bit 6-4: Unimplemented: Read as ’0’

bit 3: BCLI E: Bus Collision Interrupt Enable bit

bit 2-0: Unimplemented: Read as ’0’

— — —BCLIE — — — R = Readable bit

1 = LVD Interrupt is enabled

0 = LVD Interrupt is disabled

1 = Bus Collision interrupt is enabled

0 = Bus Collision interrupt is disabled

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 21

Page 22

PIC16C717/770/771

2.2.2.7 PIR2 R EGISTER

This register contains the SSP Bus Collision and low-

voltage detect interrupt flag bits.

.

Note: Interrupt flag bits get set when an interrupt

condition occurs , regardless of the sta te of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>). User software should ensure the appropriate interrupt flag bits are clear prior to enabling an

interrupt.

REGISTER 2-7: PERIPHERAL INTERRUPT REGISTER 2 (PIR2: 0Dh)

R/W-0 U-0 U-0 U-0 R/W-0 U-0 U-0 U-0

LVDIF

bit7 bit0

bit 7: LVDIF: Low-voltage Detect Interrupt Flag bit

bit 6-4: Unimplemented: Read as ’0’

bit 3: BCLI F: Bus Collision Interrupt Flag bit

bit 2-0: Unimplemented: Read as ’0’

— — —BCLIF — — — R = Readable bit

1 = The supply voltage has fallen below the specified LVD voltage (must be cleared in software)

0 = The supply voltage is greater than the specified LVD voltage

1 = A bus collision has occurred while the SSP module configured in I

(must be cleared in software)

0 = No bus collision occurred

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

2

C Master was transmitting

DS41120A-page 22 Advanced Information

1999 Microchip Technology Inc.

Page 23

PIC16C717/770/771

2.2.2.8 PCON REGISTER

The Power Control (PCON) register contains a flag bit

to allow differentiation between a Power-on Reset

(POR) to an external MCLR Reset or WDT Reset.

Those devices with brown-out detection circuitry contain an additional bit to differentiate a Brown-out Reset

condition from a Power-on Reset condition.

The PCON register also contains the frequency select

bit of the INTRC or ER oscillator.

Note: BOR is unknown on Power-on Reset. It

must then be set by the user and checked

on subsequent resets to see if BOR is

clear , i ndi ca ting a brown-out has o ccurre d.

The BOR status bit is a don’t care and is

not necessarily predictab le if the brow n-out

circuit is disabled (by clearing the BODEN

bit in the Configuration word).

REGISTER 2-8: POWER CONTROL REGISTER (PCON: 8Eh)

U-0 U-0 U-0 U-0 R/W-1 U-0 R/W-q R/W-q

— — — — OSCF —PORBOR R = Readable bit

bit7 bit0

bit 7-4,2:Unimplemented: Read as ’0’

bit 3: OSCF: Oscillator speed

INTRC Mode

1 = 4 MHz nominal

0 = 37 KHz nominal

ER Mode

1 = Oscillator frequency depends on the external resistor value on the OSC1 pin.

0 = 37 KHz nominal

All other modes

x = Ignored

bit 1: POR

bit 0: BO

: Power-on Reset Status bit

1 = No Power-on Reset occurred

0 = A Power-on Reset occurred (must be set in software after a Power-on Reset occurs)

R: Brown-out Reset Status bit

1 = No Brown-ou t Reset occurr ed

0 = A Brown-out Reset occurred (must be set in softwar e after a Brown- out Reset occurs)

W = Writable bit

U = Unimplemented bit,

- n = Value at POR reset

read as ‘0’

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 23

Page 24

PIC16C717/770/771

2.3 PCL and PCLATH

The program counter (PC) specifies the address of the

instruction to fetch for execution. The PC is 13 bits

wide. The low byte is called the PCL register. This register is readable and writable. The high byte is called

the PCH register. This register contains the PC<12:8>

bits and is not dir ect ly read able or writable. All updates

to the PCH register occ ur through the PCLATH register .

2.3.1 PROGRAM MEMORY PAGING

PIC16C717/770/771 devices are capable of address-

ing a continuous 8K word block of program memory.

The CALL and GOTO instructions prov ide only 11 bits of

address to allow branching within any 2K program

memory page. When doing a CALL or GOTO instruction,

the upper 2 bits of the address are provided by

PCLATH<4:3>. Wh en doing a CALL or GOTO instruction, the user must ensure that the page select bits are

programmed so that the desired program memory

page is addressed. A return instruction pops a PC

address off the stack onto the PC register. Therefore,

manipulation of the PCLA TH<4:3> bits are not required

for the return instructions (which POPs the address

from the stack).

2.4 Stack

The stack al lows a co mbinatio n of up to 8 pro gram ca lls

and interrupts to occur. The stack contains the return

address from this branch in program execution.

Mid-range devices have an 8-level deep x 13-bit wide

hardware stack. The stack space is not part of either

program or data space and the stack pointer is not

readable or writab le. The PC is PUSHed onto the stac k

when a CALL instruction is executed or an interrupt

causes a branch. The stack is POPed in the event of a

RETURN, RETLW or a RETFIE instruction execution.

PCLATH is not modified when the stack is PUSHed or

POPed.

After the stack has been PUSHed eight times, the ninth

push ov erwrites th e value that was stored from the first

push. The tenth push overwrites the sec ond pus h (an d

so on).

DS41120A-page 24 Advanced Information

1999 Microchip Technology Inc.

Page 25

PIC16C717/770/771

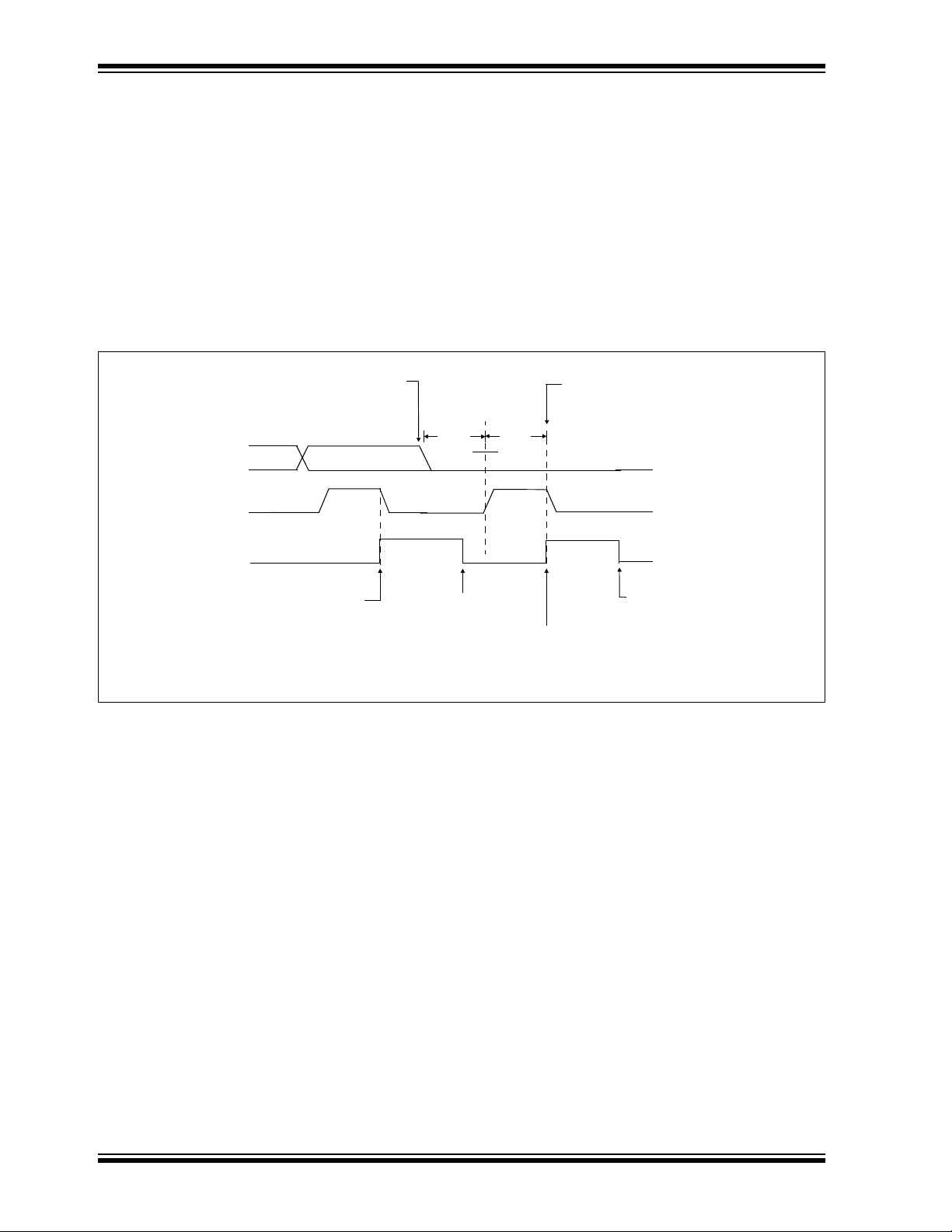

The INDF register is not a physical r e gis ter. Addressing INDF actually addresses the register whose

address is contained in the FSR register (FSR is a

pointer

). This is indirect ad dressi ng .

Reading INDF itself indirectly (FSR = 0) will produce

00h. Writing to the INDF register indirectly results in a

no-operation (although STATUS bits may be affected).

A simple program to clear RAM locations 20h-2Fh

using indirect addressing is shown in Example 2-1.

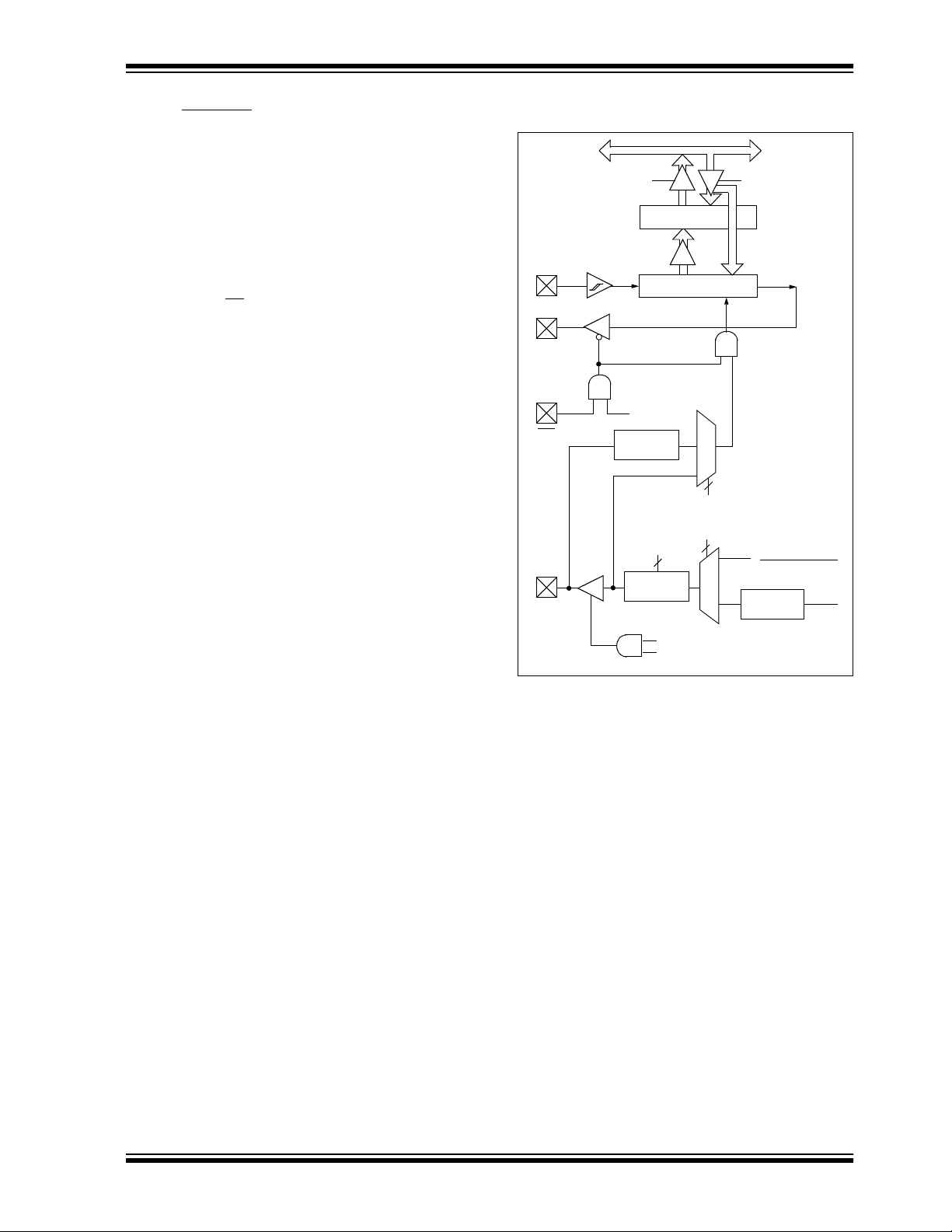

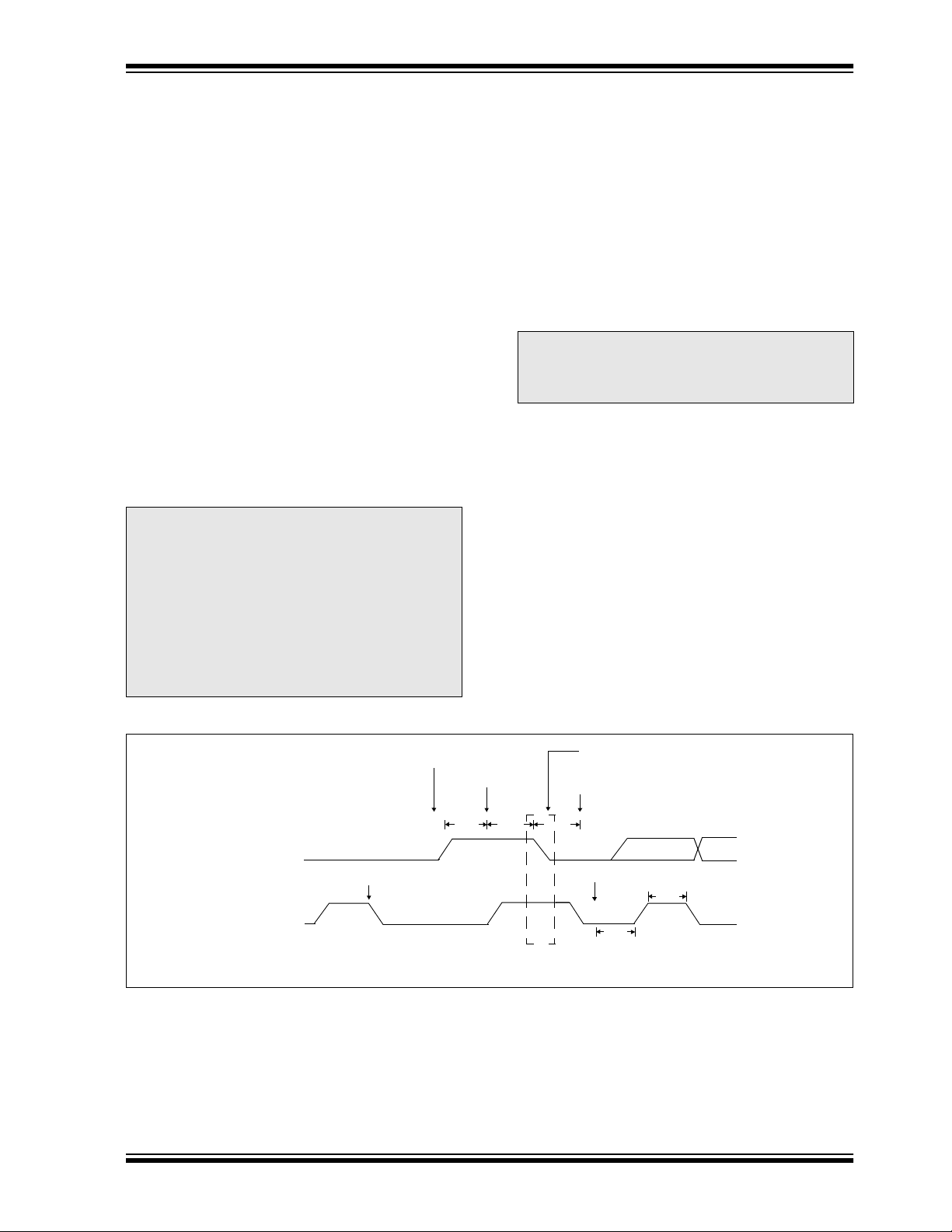

FIGURE 2-4: DIRECT/INDIRECT ADDRESSING

RP1:RP0 6

bank select location select

from opcode

0

00 01 10 11

00h

80h

EXAMPLE 2-1: HOW TO CLEAR RAM

USING INDIRECT

ADDRESSING

movlw 0x20 ;initialize pointer

movwf FSR ; to RAM

NEXT clrf INDF ;clear INDF register

incf FSR ;inc pointer

btfss FSR,4 ;all done?

goto NEXT ;NO, clear next

CONTINUE

: ;YES, continue

An effective 9-bit add res s is obtained by c on ca tena tin g

the 8-bit FSR register an d the IRP b it (STATUS<7>), as

shown in Figure 2-4.

Indirect AddressingDirect Addressing

7

location select

100h

IRP FSR register

bank select

180h

0

Data

(1)

Memory

7Fh

Bank 0 Bank 1 Bank 2 Bank 3

Note 1: For register file map detail see Figure 2-3.

FFh

17Fh

1FFh

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 25

Page 26

PIC16C717/770/771

NOTES:

DS41120A-page 26 Advanced Information

1999 Microchip Technology Inc.

Page 27

PIC16C717/770/771

3.0 I/O PORTS

Some pins for these I/O ports are multiplexed with an

alternate function for the peripheral features on the

device. In general, when a peripheral is enabled, that

pin may not be used as a general purpose I/O pin.

Additional information on I/O ports ma y be found i n th e

PICmicro™ Mid-Range Reference Manual,

(DS33023).

3.1 I/O Port Analog/Digital Mode

The PIC16C717/770/771 have two I/O ports: PORTA

and PORTB . Some of thes e port pins are mix ed-si gnal

(can be digital or analog). When an analog signal is

present on a pin, the pin must be co nfigured as an analog input to prev e nt unneces sary current dr a w from the

power supply. The Analog Select Register (ANSEL)

allows the user to individually select the digital/analog

mode on these pins. When the analog mode is active,

the port pin will always read 0.

Note 1: On a P o wer-on Reset , the ANSEL reg ister

configures these mixed-signal pins as

analog mode.

2: If a pin is configured as analog mode, the

pin will always read '0', even if the digital

output is active.

REGISTER 3-1: ANALOG SELECT REGISTER (ANSEL: 9Dh)

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

ANS5 ANS4 ANS3 ANS2 ANS1 ANS0 R = Readable bit

bit7 bit0

bit 7-6: Reserved: Do not use

bit 5-0: ANS<5:0>: Analog Select between analog or digital function on pins AN<5:0>, respectively.

0 = Digital I/O. Pin is assigned to port or special function.

1 = Analog Input. Pin is assigned as analog input.

W = Writable bit

U = Unimplemented bit, read as

‘0’

-n = Value at POR reset

Note: Setting a pin to an analog input disables digital inputs and any pull-up that may be present. The corre-

sponding TRIS bit should be set to input mode when using pins as analog inputs.

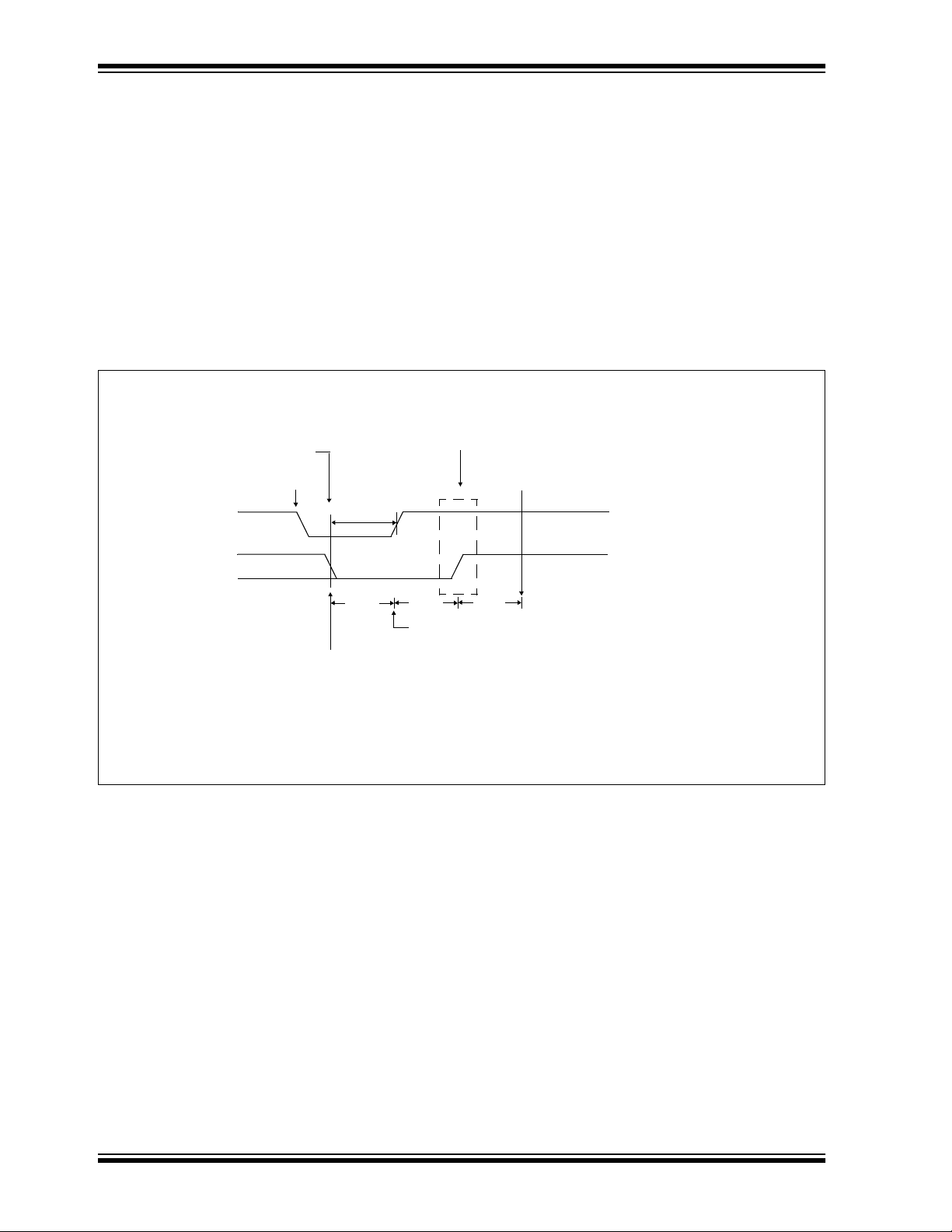

3.2 PORTA and the TRISA Register

PORTA is a 8-bit wide bi-directional port. The corresponding data direction register is TRISA. Setting a

TRISA bit (=1) will m ake the correspo ndi ng PO RTA pin

an input, i.e., put the corresponding output driver in a

hi-impedance mode. Clearing a TRISA bit (=0) will

make the corre sp ond ing PORTA pin an output, i.e., p ut

the contents of the output latch on the selected pin.

Reading the PORTA register reads the status of the

pins, whereas writing to it will write to th e p ort latch. All

write operations are read-modify-write operations.

Therefore , a write to a port implies that the port pins are

read, this val ue is modifie d, and then written to th e port

data latch.

Pins RA<3:0> are multiplexed with analog functions,

such as analog inputs to the A/D converter, analog

VREF inputs, and the on-board b andgap ref erence outputs. When the analog peripherals are using any of

these pins as analog input/output, the ANSEL register

must have the proper value to individually select the

analog mode of the corresponding pins.

Note: Upon reset, the ANSEL register configures

the RA<3:0> pins as analog inputs. All

RA<3:0> pins will read as ’0’.

Pin RA4 is multiplexed with the Timer0 module clock

input to become the RA4/T0CKI pin. The RA4/T0CKI

pin is a Schmitt Trigger input and an open d ra in output.

Pin RA5 is multiplexed with the device reset (MCLR

and programming input (V

/VPP input only pin has a Schmitt Trigger input

MCLR

buffer . All other RA port pins hav e Schmitt Trigger input

buffers and full CMOS output buffers.

Pins RA6 and RA7 are multiplexed with the oscillator

input and output functions.

The TRISA register controls the direction of the RA

pins, even when they are being used as analog inputs.

The user must ensure the bi ts in the TRISA registe r are

maintained set when using them as analog inputs.

PP) functions. The RA5/

)

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 27

Page 28

PIC16C717/770/771

EXAMPLE 3-1: INITIALIZING PORTA

BCF STATUS, RP0 ; Select Bank 0

CLRF PORTA ; Initialize PORTA by

; clearing output

; data latches

BSF STATUS, RP0 ; Select Bank 1

MOVLW 0Fh ; Value used to

; initialize data

; direction

MOVWF TRISA ; Set RA<3:0> as inputs

; RA<7:4> as outputs. RA<7:6>availability depends on oscillator selection.

MOVLW 03 ; Set RA<1:0> as analog inputs, RA<7:2> are digital I/O

MOVWF ANSEL

BCF STATUS, RP0 ; Return to Bank 0

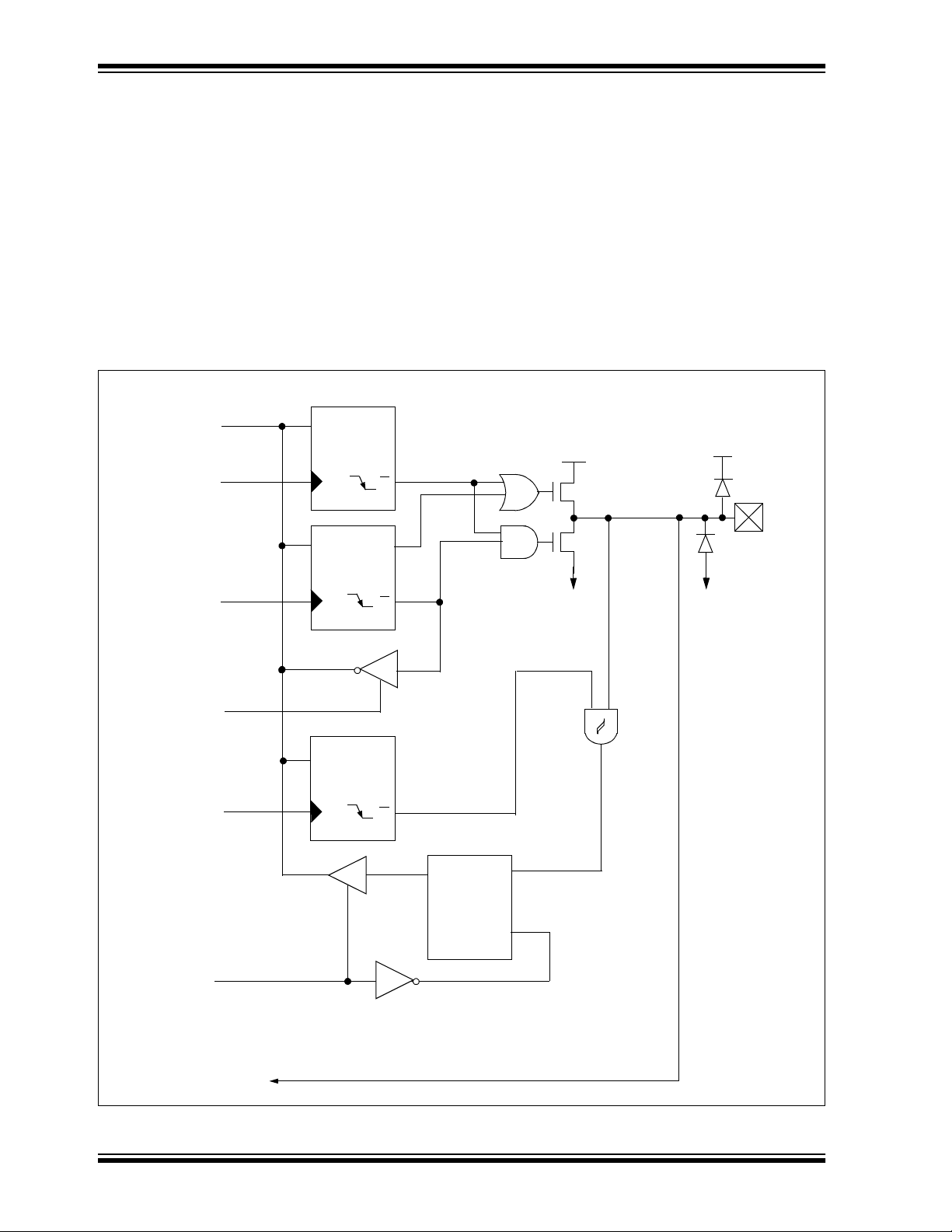

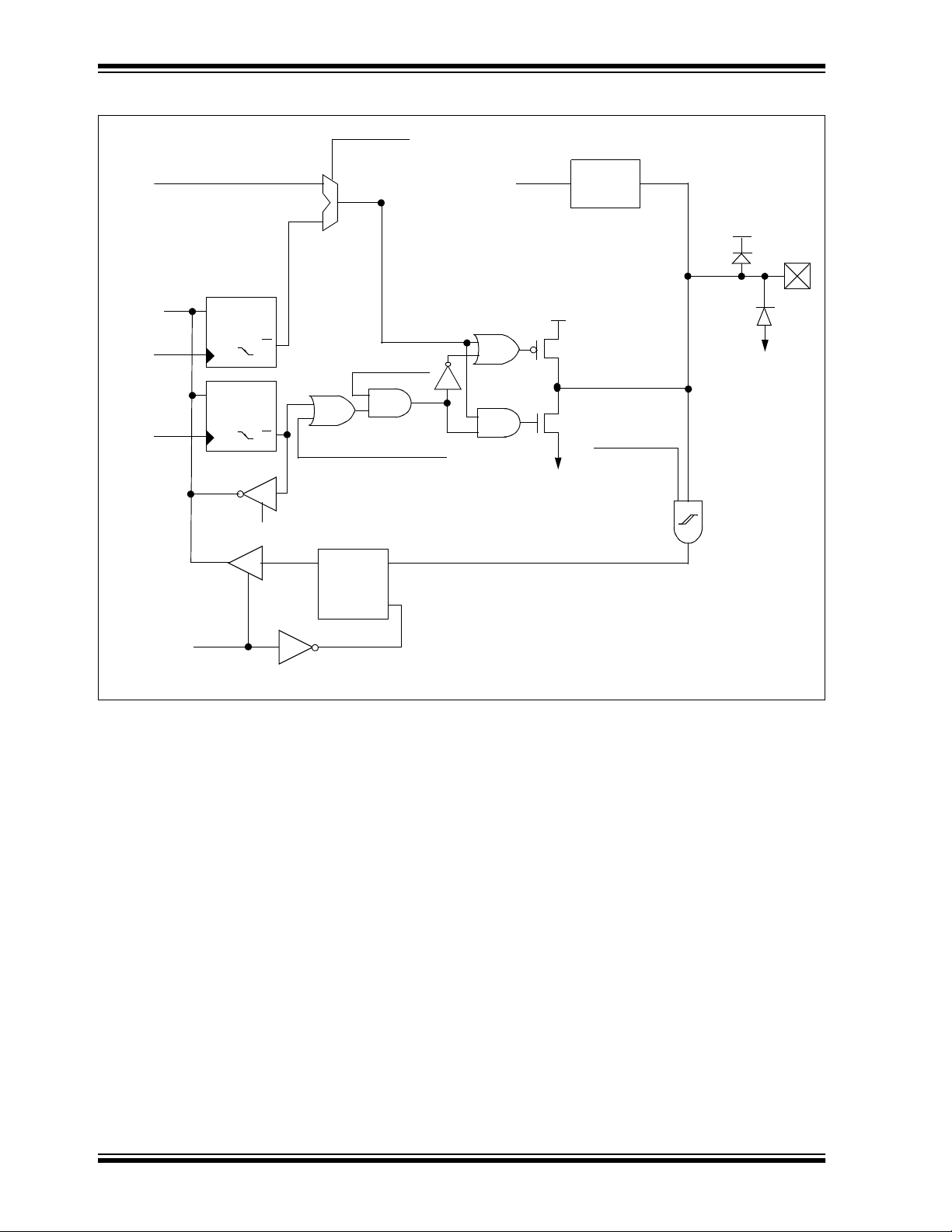

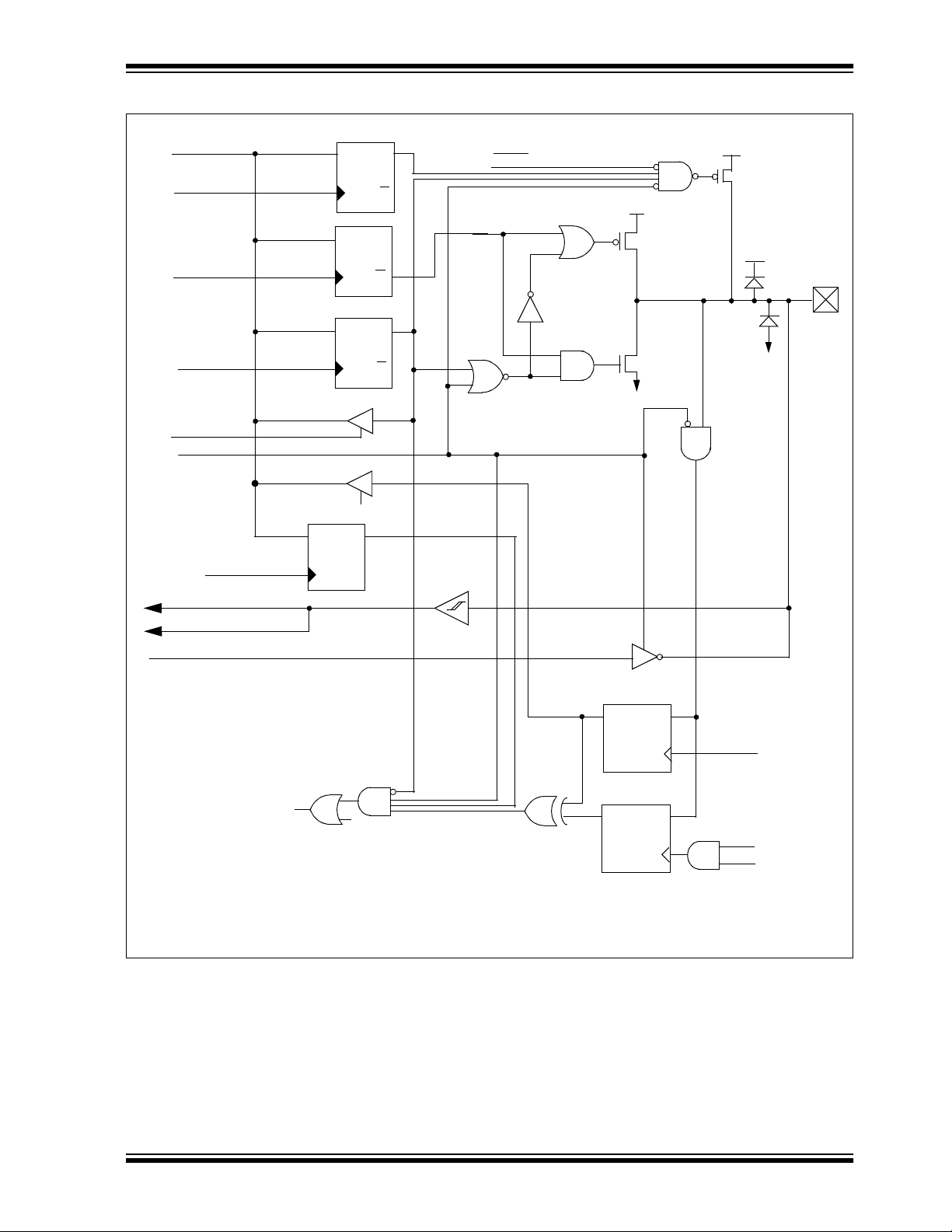

FIGURE 3-1: BLOCK DIAGRAM OF RA0/AN0, RA1/AN1/LVDIN

Data

Bus

WR

PORT

WR

TRIS

RD

TRIS

WR

ANSEL

Data Latch

CK

TRIS Mode

CK

Analog Select

CK

Q

Q

Q

QD

VDD

P

QD

QD

N

SS

V

Schmitt

Trigger

VDD

VSS

QD

EN

RD

PORT

To A/D Converter input or LVD Module input

DS41120A-page 28 Advanced Information

1999 Microchip Technology Inc.

Page 29

PIC16C717/770/771

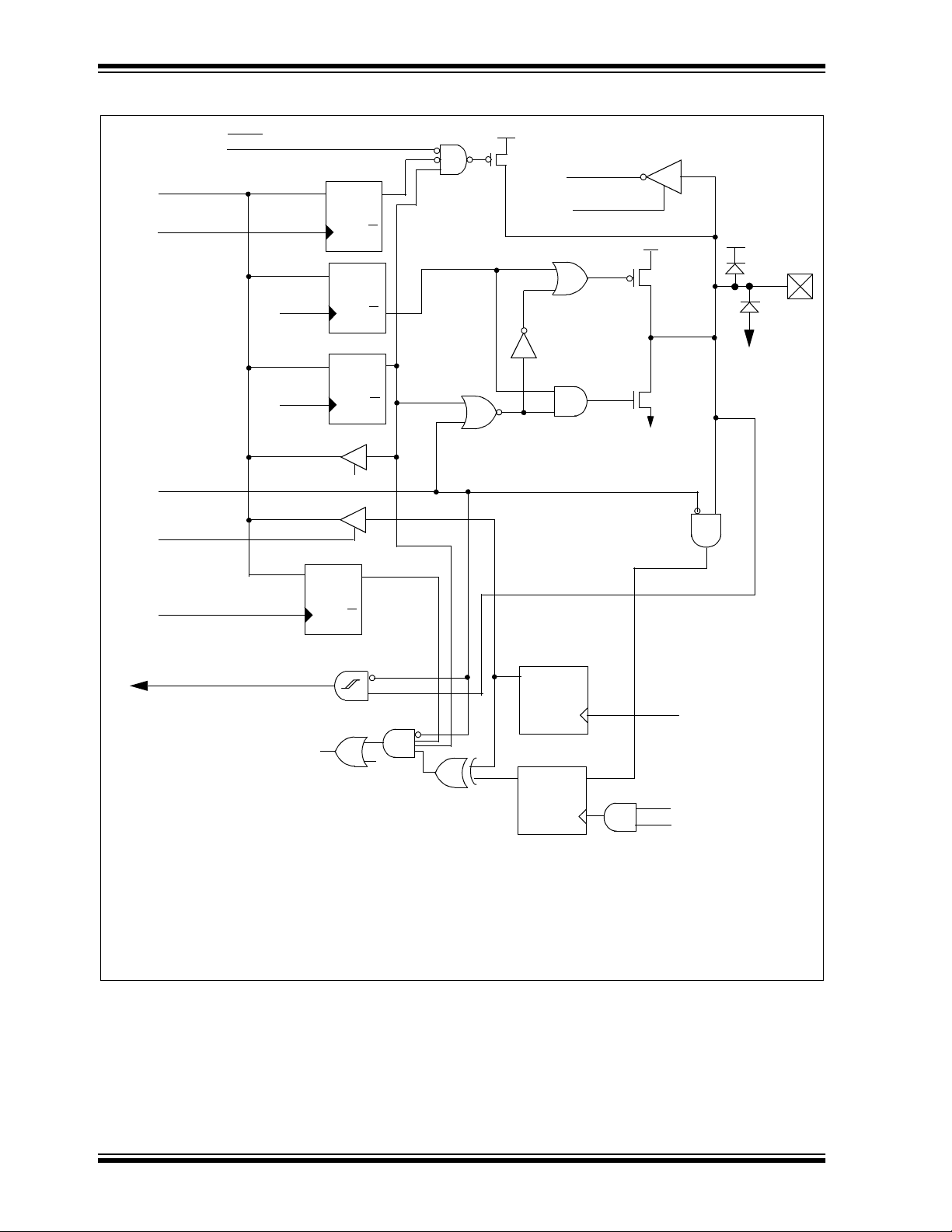

FIGURE 3-2: BLOCK DIAGRAM OF RA2/AN2/VREF-/VRL AND RA3/AN3/VREF+/VRH

Data

Bus

WR

PORT

WR

TRIS

RD

TRIS

WR

ANSEL

RD

PORT

Data Latch

CK

TRIS Mode

CK

Analog Select

CK

Q

Q

Q

QD

VDD

P

QD

QD

QD

EN

N

SS

V

Schmitt

Trigger

VDD

VSS

To A/D Converter input

and Vref+, Vref- inputs

1999 Microchip Technology Inc.

VRH, VRL outputs

(From Vref-LVD-BO R Module)

VRH, VRL output enable

Sense input for

VRH, VRL amplifier

Advanced Information DS41120A-page 29

Page 30

PIC16C717/770/771

FIGURE 3-3: BLOCK DIAGRAM OF RA4/T0CKI

Data

Bus

WR

Port

WR

TRIS

RD

TRIS

Data Latch

CK

TRIS Latch

CK

QD

Q

QD

Q

QD

N

SS

V

VSS

Schmitt Trigger

Input Buffer

RD

PORT

TMR0 clock input

EN

DS41120A-page 30 Advanced Information

1999 Microchip Technology Inc.

Page 31

FIGURE 3-4: BLOCK DIAGRAM OF RA5/MCLR/VPP

PIC16C717/770/771

To MCLR Circuit

Program Mode

Data

Bus

RD

TRIS

MCLR Filter

HV Detect

VSS

VSS

Schmitt

Trigger

QD

EN

RD PORT

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 31

Page 32

PIC16C717/770/771

FIGURE 3-5: BLOCK DIAGRAM OF RA6/OSC2/CLKOUT PIN

INTRC or ER with CLKOUT

CLKOUT (FOSC/4)

Data

Bus

WR

PORTA

WR

TRISA

CK

Data Latch

D

CK

TRIS Latch

RD TRISA

1

0

QD

Q

INTRC or ER

Q

Q

INTRC or ER with CLKOUT

EN

From OSC1

DQ

VDD

P

N

V

Oscillator

Circuit

INTRC or ER without CLKOUT

SS

VDD

VSS

Schmitt Trigger

Input Buffer

RD PORTA

DS41120A-page 32 Advanced Information

1999 Microchip Technology Inc.

Page 33

PIC16C717/770/771

FIGURE 3-6: BLOCK DIAGRAM OF RA7/OSC1/CLKIN PIN

Data

Bus

WR

PORTA

WR

TRISA

CK

Data Latch

D

CK

TRIS Latch

RD PORTA

QD

Q

Q

Q

RD TRISA

INTRC

EN

To OSC2

To Chip Clock Drivers

VDD

P

N

SS

V

DQ

Oscillator

Circuit

Schmitt Trigger

Input Buffer

EC Mode

INTRC

VDD

Schmitt Trigger

Input Buffer

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 33

Page 34

PIC16C717/770/771

TABLE 3-1: PORTA FUNCTIONS

Name Function

RA0/AN0

RA1/AN1/LVDIN

RA2/AN2/V

RA3/AN3/V

RA5/MCLR

RA6/OSC2/CLKOUT

RA7/OSC1/CLKIN

REF-/VRL

REF+/VRH

RA4/T0CKI

/VPP

Input

Type

RA0 ST CMOS Bi-directional I/O

AN0 AN A/D input

RA1 ST CMOS Bi-directional I/O

AN1 AN A/D input

LVDIN AN LVD input reference

RA2 ST CMOS Bi-directional I/O

AN2 AN A/D input

REF- AN Negative analog reference input

V

VRL AN Internal voltage reference low output

RA3 ST CMOS Bi-directional I/O

AN3 AN A/D input

V

REF+ AN Positive analog reference input

VRH AN Internal voltage reference high output

RA4 ST OD Bi-directional I/O

T0CKI ST TMR0 clock input

RA5 ST Input port

MCLR

PP Power Programming voltage

V

RA6 ST CMOS Bi-directional I/O

OSC2 XTAL Crystal/resonator

CLKOUT CMOS F

RA7 ST CMOS Bi-directional I/O

OSC1 XTAL Crystal/resonator

CLKIN ST External clock input/ER resistor connection

ST Master clear

Output

Type

Description

OSC/4 output

DS41120A-page 34 Advanced Information

1999 Microchip Technology Inc.

Page 35

PIC16C717/770/771

TABLE 3-2: SUMMARY OF REGISTERS ASSOCIATED WITH PORTA

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

05h PORTA RA7 RA6 RA5 RA4 RA3 RA2 RA1 RA0

85h TRISA PORTA Data Direction Register

9Dh ANSEL

Legend: x = unknown, u = unchanged, - = unimplemented locations read as ’0’. Shaded cells are not used by PORTA.

3.3 P

ORTB and the TRISB Register

ANS5 ANS4 ANS3 ANS2 ANS1 ANS0 1111 1111 1111 1111

enables the w ea k pull-up resist ors . Th e weak pull-u p is

Value on:

POR,

BOR

xxxx 0000 uuuu 0000

1111 1111 1111 1111

automatically turned off when the port pin is confi gured

PORTB is an 8-bit wide bi-directional port. The corresponding data direction register is TRISB. Setting a

TRISB bit (=1) will make the correspon ding POR TB pin

an input, i.e., put the corresponding output driver in a

hi-impedance mode. Clearing a TRISB bit (=0) will

make the corr espond ing PO R TB pi n an outpu t, i.e . , put

the contents of the output latch on the selected pin.

EXAMPLE 3-2: INITIALIZING PORTB

BCF STATUS, RP0 ;

CLRF PORTB ; Initialize PORTB by

; clearing output

; data latches

BSF STATUS, RP0 ; Select Bank 1

MOVLW 0xCF ; Value used to

; initialize data

; direction

MOVWF TRISB ; Set RB<3:0> as inputs

; RB<5:4> as outputs

; RB<7:6> as inputs

MOVLW 03 ; Set RB<1:0> as analog

inputs

MOVWF ANSEL ;

BCF STATUS, RP0 ; Return to Bank 0

Each of the PORTB pins has an internal pull-up, which

can be individually enabled from the WPUB register. A

single global en able bit can turn on/off the ena bled pul lups. Clearing the R

BPU bit, (OPTION_REG<7>),

as an output. The pull-ups are disabled on a Power-on

Reset.

Each of the PORTB pins, if configured as input, also

has an interrupt on change feature, which can be individually selected from the IOCB register. The RBIE bit

in the INTCON registe r fun cti ons a s a global enabl e b it

to turn on/off the interrupt on change feature. The

selected inputs are compared to the old value latched

on the last read of PO RTB . The "mi smatch" output s are

OR’ed together to generate the RB Port Change Interrupt with flag bit RBIF (INTCON<0>).

This interrupt can wake the device from SLEEP. The

user, i n the interrupt service routine , can clea r the interrupt in the following manner:

a) Any read or write of PORTB. This will end the

mismatch condition.

b) Clear flag bit RBIF.

A mismatch condition will continue to set flag bit RBIF.

Reading PORTB will end the mismatch condition and

allow flag bit RBIF to be cleared.

The interrupt on change feature is recommended for

wake-up on key depression operation and opera tions

where PORTB is only used for the interrupt on change

feature. Polling of PORTB is not recommended while

using the interrupt on change feature.

Value on all

other resets

REGISTER 3-2: WEAK PULL UP PORTB REGISTER (WPUB: 95h)

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

WPUB7 WPUB6 WPUB5 WPUB4 WPUB3 WPUB2 WPUB1 WPUB0 R = Readable bit

bit7 bit0

bit 7-0: WPUB<7:0>: PORTB Weak Pull-Up Control

Note 1: For the WPUB register setting to take effect, the RBPU

1999 Microchip Technology Inc.

1 = Weak pull up enabled.

0 = Weak pull up disabled

bit in the OPTION_REG Register must be cleared.

2: The weak pull up device is automatically disabled if the pin is in output mode (TRIS = 0).

Advanced Information DS41120A-page 35

W = Writable bit

U = Unimplemented bit, read

as ‘0’

-n = Value at POR reset

Page 36

PIC16C717/770/771

REGISTER 3-3: INTERRUPT ON CHANGE PORTB REGISTER (IOCB: 96h)

R/W-1 R/W-1 R/W-1 R/W-1 R/W-0 R/W-0 R/W-0 R/W-0

IOCB7 IOCB6 IOCB5 IOCB4 IOCB3 IOCB2 IOCB1 IOCB0 R = Readable bit

bit7 bit0

bit 7-0: IOCB<7:0>: Interrupt on Change POR TB Control

1 = Interrupt on change enabled.

0 = Interrupt on change disabled.

Note 1: The interrupt enable bits GIE and RBIE in the INTCON Register must be set for individual interrupts to be

recognized.

W = Writable bit

U = Unimplemented bit, read

as ‘0’

-n = Value at POR reset

DS41120A-page 36 Advanced Information

1999 Microchip Technology Inc.

Page 37

PIC16C717/770/771

The RB0 pin is multipl e x ed with the A/D con v e rter analog input 4 an d the exter nal inter rupt inp ut (RB0/A N4/

INT). When the pin is us ed as analog i nput, the AN SEL

register must have the proper value to select the RB0

pin as analog mode.

The RB1 pin is multiplexed wi th the A/D con v e rter analog input 5 and the MSSP module slave select input

(RB1/AN5/SS). When the pin is used as analog input,

the ANSEL register must have the proper value to

select the RB1 pin as analog mode.

Note: Upon reset, the ANSEL register configures

the RB1 and RB0 pins as analog inputs.

Both RB1 and RB0 pins will read as ’0’.

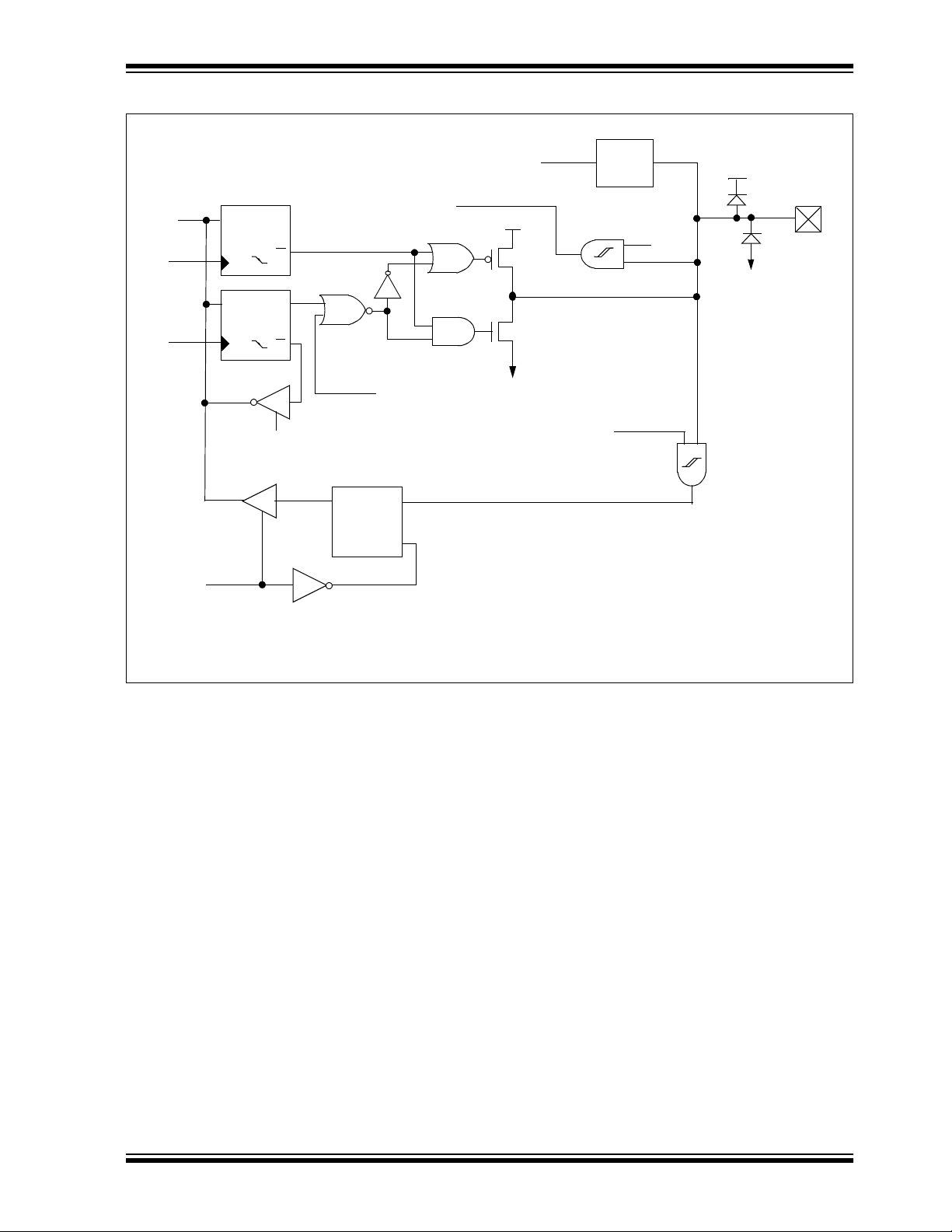

FIGURE 3-7: BLOCK DIAGRAM OF RB0/AN4/INT, RB1/AN5/SS PIN

Data Bus

WR

WPUB

WR

PORT

WR

TRIS

WPUB Reg

Q

D

CK

Q

PORTB Reg

D

Q

Q

CK

TRIS Reg

D

Q

CK

Q

RBPU

VDD

P

N

VSS

VDD

P

weak

pull-up

V

DD

RD

TRIS

Analog Select

WR

ANSEL

WR

IOCB

RD

PORT

To INT input or MSSP modu le

To A/D Converter

CK

IOCB Reg

D

CK

VSS

QD

Q

TTL

Q

Set

RBIF

Q

...

From

RB<7:0> pins

QD

EN

EN

Q

D

EN

Q

D

EN

Schmitt

Trigger

Q1

Q3

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 37

Page 38

PIC16C717/770/771

FIGURE 3-8: BLOCK DIAGRAM OF RB2/SCK/SCL, RB3/CCP1/P1A, RB4/SDI/SDA,

RB5/SDO/P1B

Data Bus

WR

WPUB

Spec. Func En.

SDA, SDO, SCK, CCPL, P1A, P1B

WR

PORT

WR

TRIS

RD

TRIS

WR

IOCB

WPUB Reg

D

CK

PORTB Reg

D

CK

TRIS Reg

D

CK

IOCB Reg

D

CK

Q

Q

RBPU

1

Q

0

Q

Q

Q

Q

Set

RBIF

Q

...

From

RB<7:0> pins

VDD

P

N

VSS

Q

EN

VDD

V

weak

P

pull-up

TTL

D

Q1

DD

VSS

Schmitt

Trigger

RD

PORT

SCK, SCL, CC, SDI, SDA inputs

QD

EN

EN

Q

D

EN

Q3

DS41120A-page 38 Advanced Information

1999 Microchip Technology Inc.

Page 39

PIC16C717/770/771

FIGURE 3-9: BLOCK DIAGRAM OF RB6/T1OSO/T1CKI/P1C

Data Bus

WR

WPUB

WR PORTB

WR TRISB

RD TRISB

T1OSCEN

WR

IOCB

TMR1 Clock

Serial programming clock

From RB 7

WPUB Reg

D

CK

D

CK

Data Latch

D

CK

TRIS Latch

RD PORTB

IOCB Reg

D

CK

Q

Q

Q

Q

Q

Q

Q

Q

Schmitt

Trigger

RBPU

VDD

P

N

SS

V

VDD

P

weak pull-up

VDD

TTL

Input

Buffer

TMR1 Oscillator

QD

EN

Set RBIF

...

From

RB<7:0> pins

Note: The TMR1 oscillator enable (T1OSCEN = 1) overrides the RB6 I/O port and P1C functions.

QD

EN

Q1

RD Port

Q3

1999 Microchip Technology Inc.

Advanced Information DS41120A-page 39

Page 40

PIC16C717/770/771

FIGURE 3-10: BLOCK DIAGRAM OF THE RB7/T1OSI/P1D

VDD

weak pull-up

P

Data Bus

WR

WPUB

RBPU

WPUB Reg

D

Q

Q

CK

D

Q

To RB6

T1OSCEN

TMR1 Oscillator

VDD

P

VDD

WR PORTB

WR TRISB

T10SCEN

RD PORTB

WR

IOCB

Serial programming input

CK

Data Latch

D

CK

TRIS Latch

RD TRISB

IOCB Reg

D

Q

CK

Q

Schmitt Trigger

Set RBIF

From

RB<7:0> pins

Q

Q

Q

QD

EN

...

QD

EN

N

SS

V

RD Port

TTL

Input

Buffer

Q1

Q3

Note: The TMR1 oscillator enable (T1OSCEN = 1) overrides the RB7 I/O port and P1D functions.

DS41120A-page 40 Advanced Information

1999 Microchip Technology Inc.

Page 41

TABLE 3-3: PORTB FUNCTIONS

PIC16C717/770/771

Name Function

RB0 TTL CMOS Bi-directional I/O

RB0/AN4/INT

RB1/AN5/SS

RB2/SCK/SCL

RB3/CCP1/P1A

RB4/SDI/SDA

RB5/SDO/P1B

RB6/T1OSO/T1CKI/P1C

RB7/T1OSI/P1D

Note 1: Bit programmable pull-ups.

AN4 AN A/D input

INT ST Interrupt input

RB1 TTL CMOS Bi-directional I/O

AN5 AN A/D input

SS

RB2 TTL CMOS Bi-directional input

SCK ST CMOS Serial clock I/O for SPI

SCL ST OD Serial clock I/O for I

RB3 TTL CMOS Bi-directional input

CCP1 ST CMOS Capture 1 input/Compare 1 output

P1A CMOS PWM P1A output

RB4 TTL CMOS Bi-directional input

SDI ST Serial data in for SPI

SDA ST OD Serial data I/O for I

RB5 ST CMOS Bi-directional I/O

SDO CMOS Serial data out for SPI

P1B CMOS PWM P1B output

RB6 TTL CMOS Bi-directional I/O

T1OSO XTAL Crystal/Resonator

T1CKI ST TMR1 clock input

P1C CMOS PWM P1C output

RB7 TTL CMOS Bi-directional I/O

T1OSI XTAL TMR1 crystal/resonator

P1D CMOS PWM P1D output

Input

Type

ST SSP slave select input

Output

Type

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

2

2

C

C

Description

TABLE 3-4: SUMMARY OF REGISTERS ASSOCIATED WITH PORTB

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0