Page 1

PIC16C55X(A)

EPROM-Based 8-Bit CMOS Microcontroller

Devices included in this data sheet:

Referred to collectively as PIC16C55X(A).

• PIC16C554 PIC16C554A

PIC16C556A

• PIC16C558 PIC16C558A

High Performance RISC CPU:

• Only 35 instructions to learn

• All single-cycle instructions (200 ns), except for

program branches which are two-cycle

• Operating speed:

- DC - 20 MHz clock input

- DC - 200 ns instruction cycle

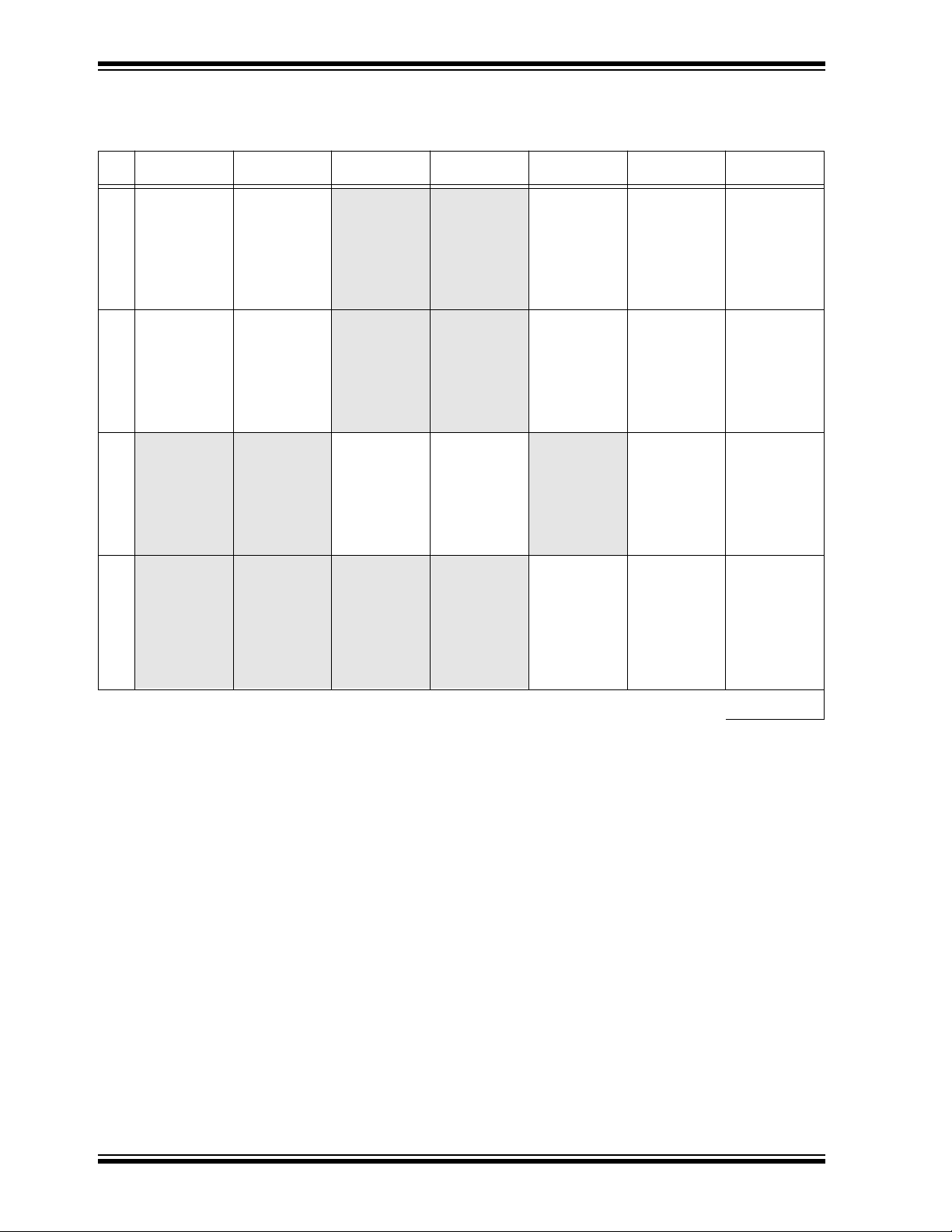

Device Program

Memory

Data

Memory

PIC16C554 512 80

PIC16C554A 512 80

PIC16C556A 1K 80

PIC16C558 2K 128

PIC16C558A 2K 128

• Interrupt capability

• 16 special function hardware registers

• 8-level deep hardware stack

• Direct, Indirect and Relative addressing modes

Peripheral Features:

• 13 I/O pins with individual direction control

• High current sink/source for direct LED drive

• Timer0: 8-bit timer/counter with 8-bit

programmable prescaler

Special Microcontroller Features:

• Power-on Reset (POR)

• Power-up Timer (PWRT) and Oscillator Start-up

Timer (OST)

• Watchdog Timer (WDT) with its own on-chip RC

oscillator for reliable operation

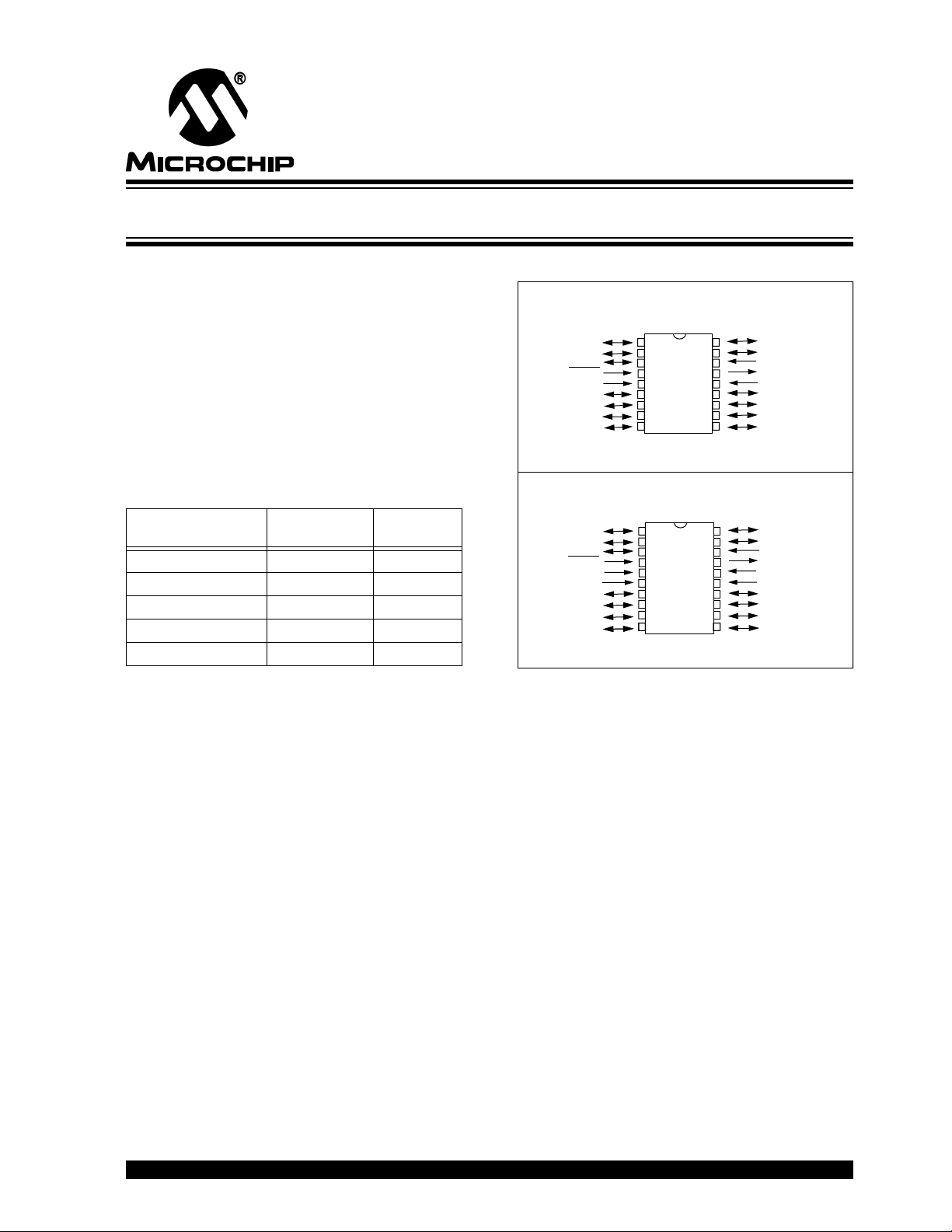

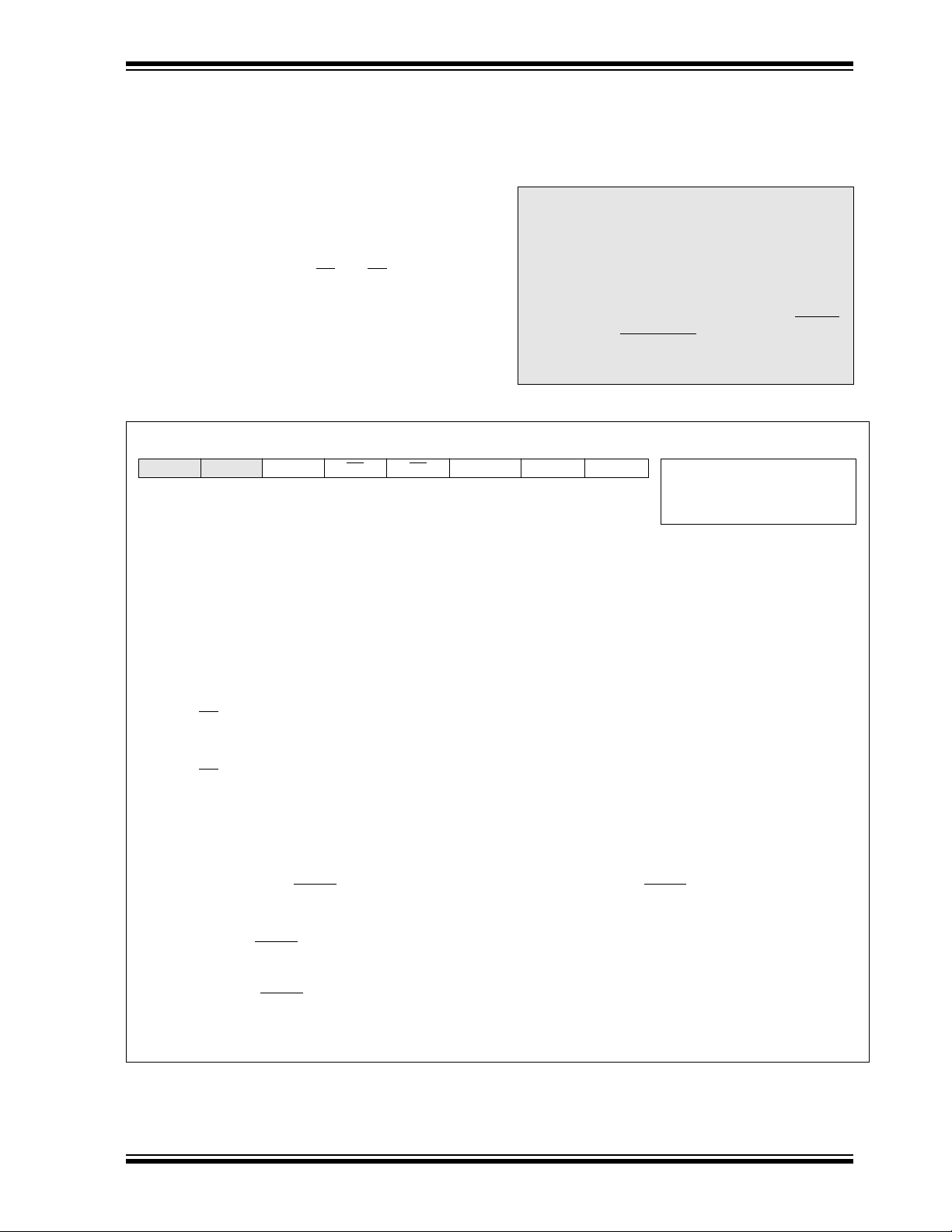

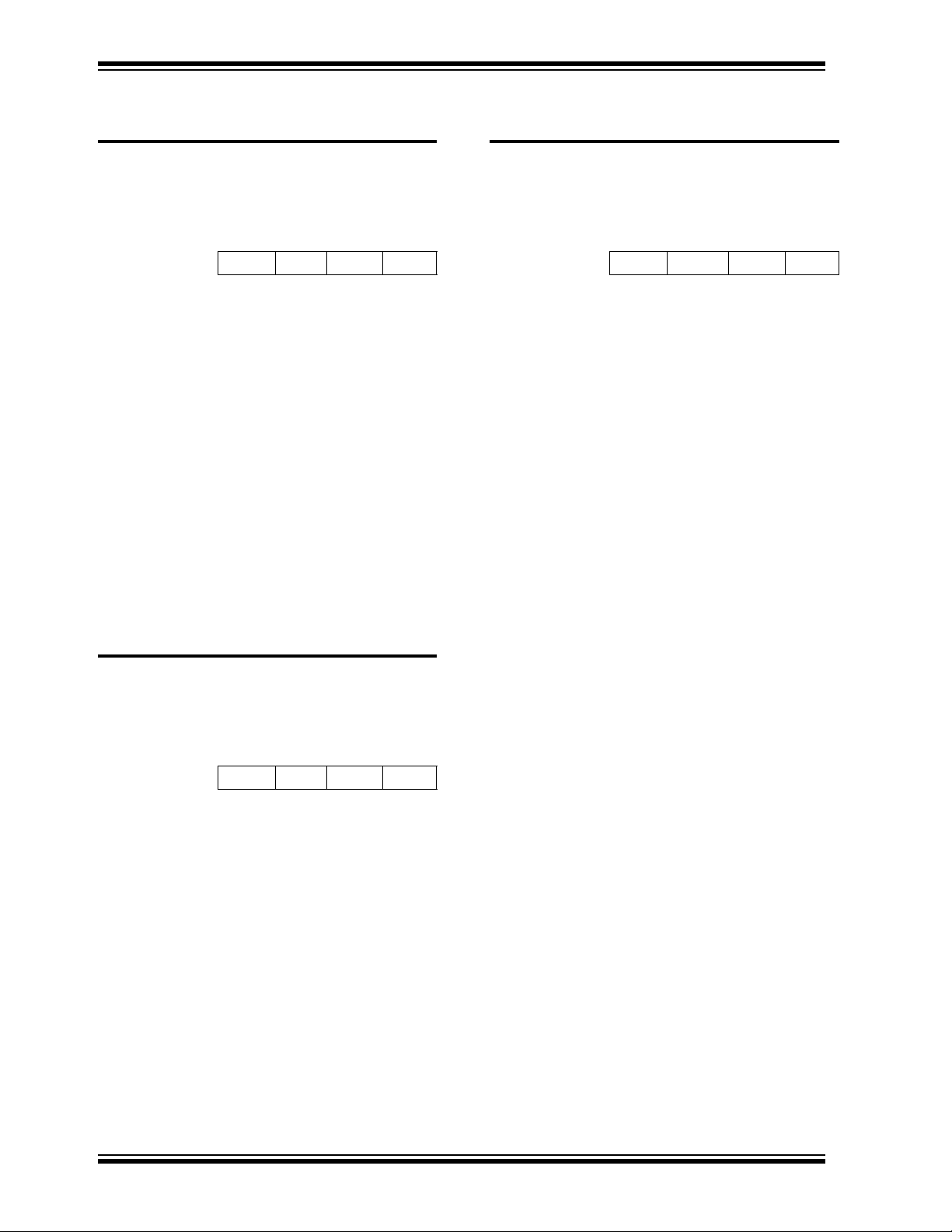

Pin Diagram

PDIP, SOIC, Windowed CERDIP

RA2

RA3

RA4/T0CKI

MCLR

VSS

RB0/INT

RB1

RB2

RB3

PIC16C55X(A)

•1

2

3

4

5

6

7

8

9

18

17

16

15

14

13

12

11

10

RA1

RA0

OSC1/CLKIN

OSC2/CLKOUT

DD

V

RB7

RB6

RB5

RB4

SSOP

RA2

RA3

RA4/T0CKI

MCLR

VSS

VSS

RB0/INT

RB1

RB2

RB3RB3

PIC16C55X(A)

•1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

RA1

RA0

OSC1/CLKIN

OSC2/CLKOUT

V

DD

VDD

RB7

RB6

RB5

RB4

Special Microcontroller Features (cont’d)

• Programmable code protection

• Power saving SLEEP mode

• Selectable oscillator options

• Serial in-circuit programming (via two pins)

• Four user programmable ID locations

CMOS Tec hnology:

• Low-power , high-speed CMOS EPR OM technology

• Fully static design

• Wide operating voltage range

- 2.5V to 5.5V PIC16C55X

- 3.0 to 5.5V PIC16C55XA

• Commercial, industrial and extended temperature range

• Low power consumption

- < 2.0 mA @ 5.0V, 4.0 MHz

- 15 µ A typical @ 3.0V, 32 kHz

- < 1.0 µ A typical standby current @ 3.0V

1997 Microchip Technology Inc.

Preliminary

DS40143B-page 1

Page 2

PIC16C55X(A)

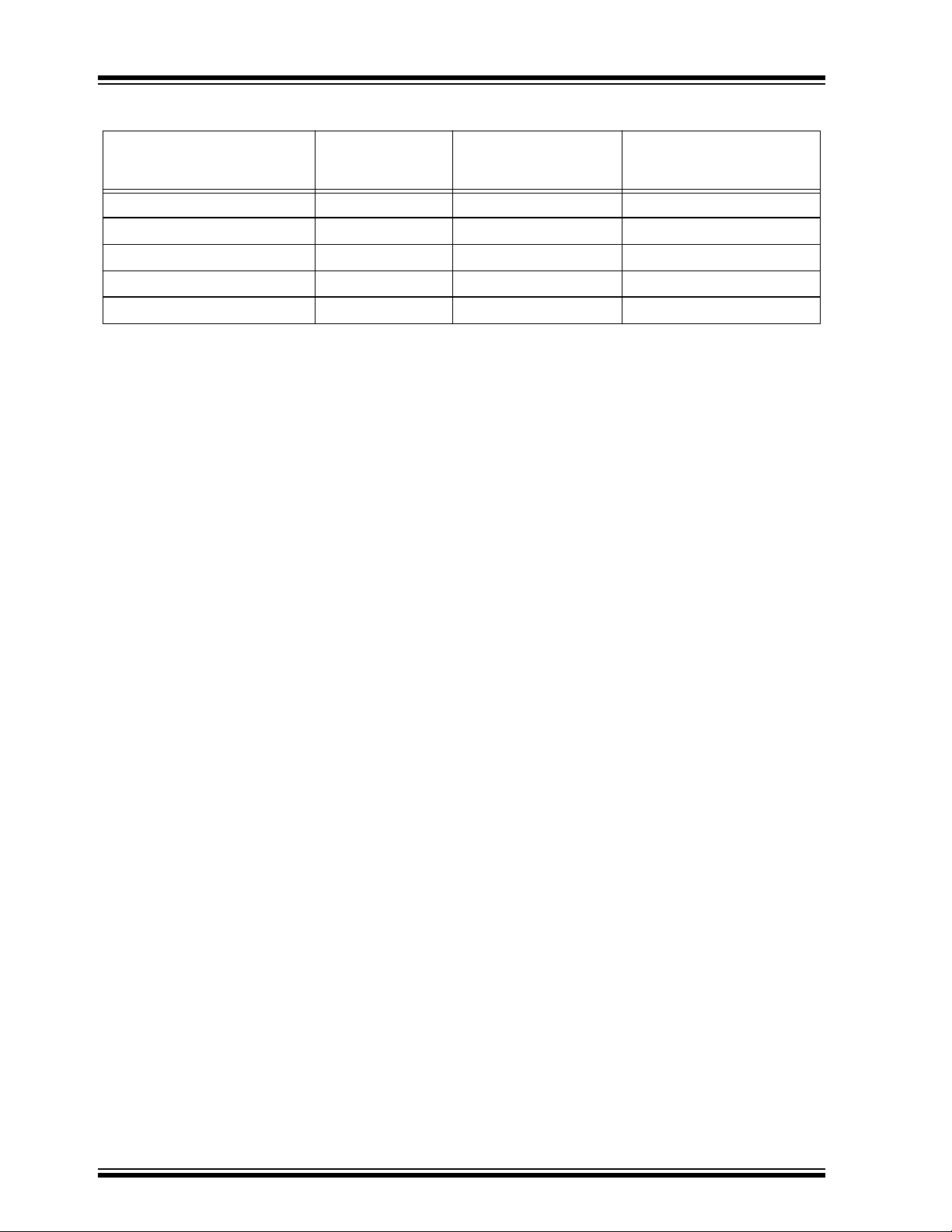

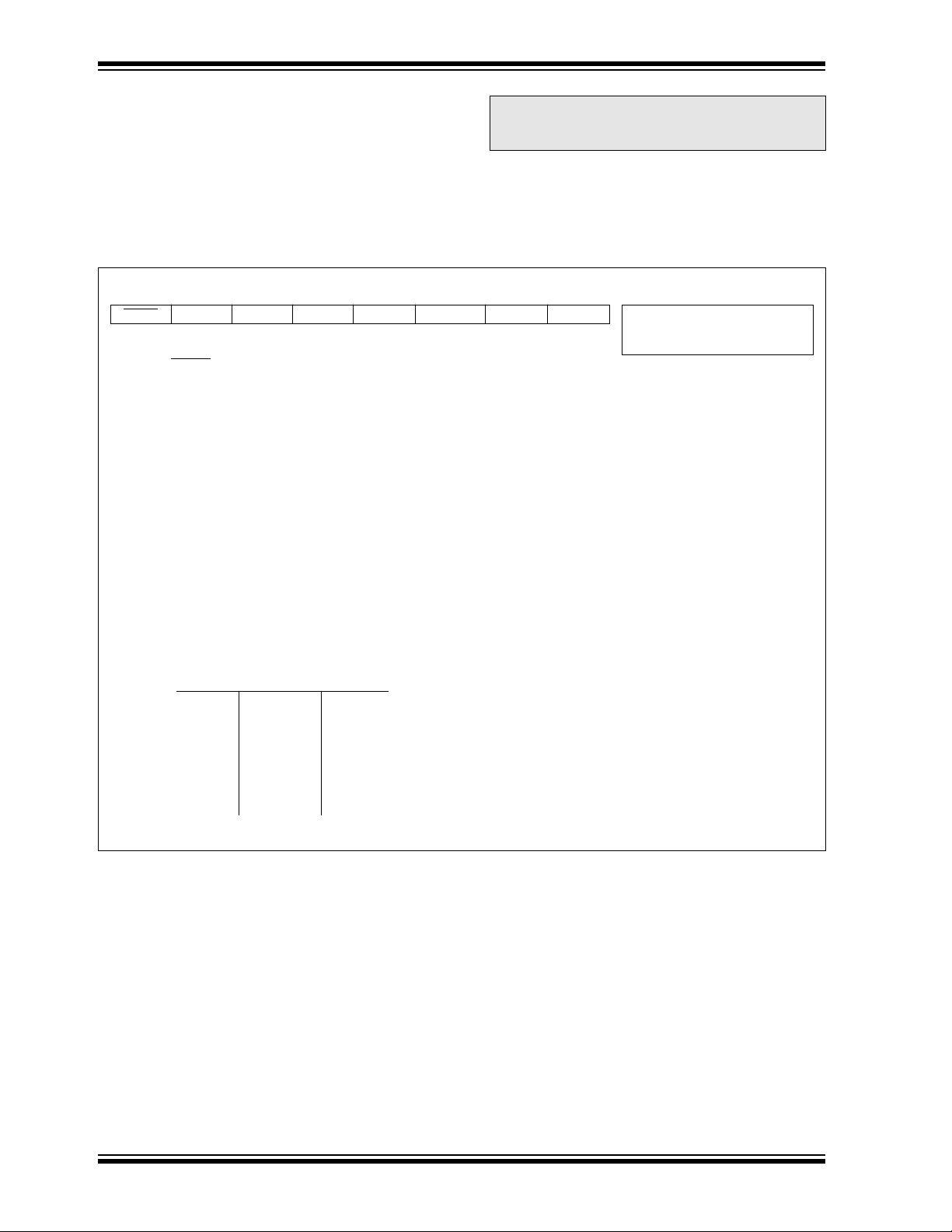

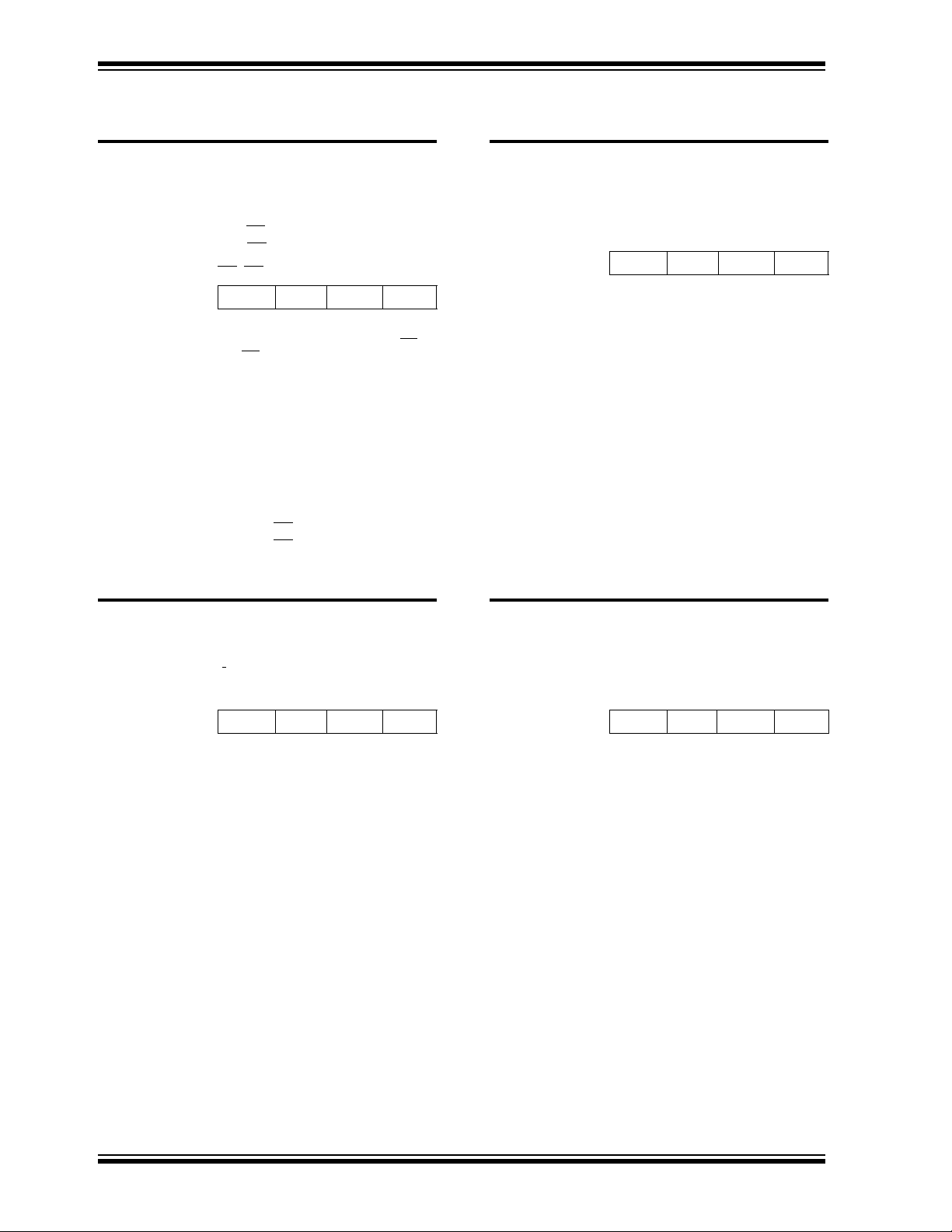

Device Differences

Device

PIC16C554 2.5 - 5.5 See Note 1 0.9

PIC16C554A 3.0 - 5.5 See Note 1 0.7

PIC16C556A 3.0 - 5.5 See Note 1 0.7

PIC16C558 2.5 - 5.5 See Note 1 0.9

PIC16C558A 3.0 - 5.5 See Note 1 0.7

Note 1: If you change from this device to another device, please verify oscillator characteristics in your application.

Voltage

Range

Oscillator

Process

Technology

(Microns)

DS40143B-page 2

Preliminary

1997 Microchip Technology Inc.

Page 3

PIC16C55X(A)

Table of Contents

1.0 General Description......................................................................................................................................................................5

2.0 PIC16C55X(A) Device Varieties...................................................................................................................................................7

3.0 Architectural Overview .................................................................................................................................................................9

4.0 Memory Organization................................................................................................................................................................ 13

5.0 I/O Ports.................................................................................................................................................................................... 23

6.0 Timer0 Module .......................................................................................................................................................................... 29

7.0 Special Features of the CPU..................................................................................................................................................... 35

8.0 Instruction Set Summary........................................................................................................................................................... 51

9.0 Development Support................................................................................................................................................................ 63

10.0 Electrical Specifications............................................................................................................................................................. 67

11.0 Packaging Information............................................................................................................................................................... 79

Appendix A: Enhancements............................................................................................................................................................ 87

Appendix B: Compatibility............................................................................................................................................................... 87

INDEX.................................................................................................................................................................................................. 89

PIC16C55X(A) Product Identification System...................................................................................................................................... 95

To Our Valued Customers

We constantly strive to improve the quality of all our products and documentation. To this end, we recently converted to a new publishing software package which we believe will enhance our entire documentation process and

product. As in any conversion process, information may have accidently been altered or deleted. We have spent an

exceptional amount of time to ensure that these documents are correct. However, we realize that we may have

missed a few things. If you find any information that is missing or appears in error from the previous version of this

data sheet (PIC16C55X(A) Data Sheet, Literature Number DS40143B), please use the reader response form in the

back of this data sheet to inform us. We appreciate your assistance in making this a better document.

1997 Microchip Technology Inc.

Preliminary

DS40143B-page 3

Page 4

PIC16C55X(A)

NOTES:

DS40143B-page 4

Preliminary

1997 Microchip Technology Inc.

Page 5

PIC16C55X(A)

1.0 GENERAL DESCRIPTION

The PIC16C55X(A) are 18 and 20-Pin EPROM-based

members of the versatile PIC16CXX family of low-cost,

high-performance, CMOS, fully-static, 8-bit

microcontrollers.

All PICmicro™ microcontrollers employ an advanced

RISC architecture. The PIC16C55X(A) have enhanced

core features, eight-le vel deep stack, and multiple internal and external interrupt sources. The separate

instruction and data buses of the Harvard architecture

allow a 14-bit wide instruction word with the separate

8-bit wide data. The two-stage instruction pipeline

allows all instructions to execute in a single-cycle,

except for program branches (which require two

cycles). A total of 35 instructions (reduced instruction

set) are available . Additionally , a large register set giv es

some of the architectural innovations used to achie ve a

very high performance.

PIC16C55X(A) microcontrollers typically achieve a 2:1

code compression and a 4:1 speed improvement over

other 8-bit microcontrollers in their class.

The PIC16C554(A) and PIC16C556A have 80 bytes of

RAM. The PIC16C558(A) has 128 bytes of RAM. Each

device has 13 I/O pins and an 8-bit timer/counter with

an 8-bit programmable prescaler.

PIC16C55X(A) devices hav e special features to reduce

external components, thus reducing cost, enhancing

system reliability and reducing power consumption.

There are four oscillator options, of which the single pin

RC oscillator provides a low-cost solution, the LP

oscillator minimizes power consumption, XT is a

standard crystal, and the HS is for High Speed crystals.

The SLEEP (power-down) mode offers power saving.

The user can wake up the chip from SLEEP through

several external and internal interrupts and reset.

A highly reliable Watchdog Timer with its own on-chip

RC oscillator provides protection against software

lock- up.

A UV-erasable CERDIP-packaged version is ideal for

code development while the cost-effective One-Time

Programmable (OTP) version is suitable for production

in any volume.

Table 1-1 shows the features of the PIC16C55X(A)

mid-range microcontroller families.

A simplified block diagram of the PIC16C55X(A) is

shown in Figure 3-1.

The PIC16C55X(A) series fit perfectly in applications

ranging from motor control to low-power remote sensors. The EPROM technology makes customization of

application programs (detection levels, pulse generation, timers, etc.) extremely fast and convenient. The

small footprint packages make this microcontroller

series perfect for all applications with space limitations.

Low-cost, low-power, high-performance, ease of use

and I/O flexibility make the PIC16C55X(A) very versatile.

1.1 F

Those users familiar with the PIC16C5X family of

microcontrollers will realize that this is an enhanced

version of the PIC16C5X architecture. Please refer to

Appendix A for a detailed list of enhancements. Code

written for PIC16C5X can be easily ported to

PIC16C55X(A) family of devices (Appendix B).

The PIC16C55X(A) f amily fills the niche for users w anting to migrate up from the PIC16C5X family and not

needing various peripheral features of other members

of the PIC16XX mid-range microcontroller family.

1.2 De

amily and Upward Compatibility

velopment Support

1997 Microchip Technology Inc.

The PIC16C55X(A) family is suppor ted by a full-featured macro assembler, a software simulator, an in-circuit emulator, a lo w-cost dev elopment programmer and

a full-featured programmer. A “C” compiler and fuzzy

logic support tools are also available.

Preliminary

DS40143B-page 5

Page 6

PIC16C55X(A)

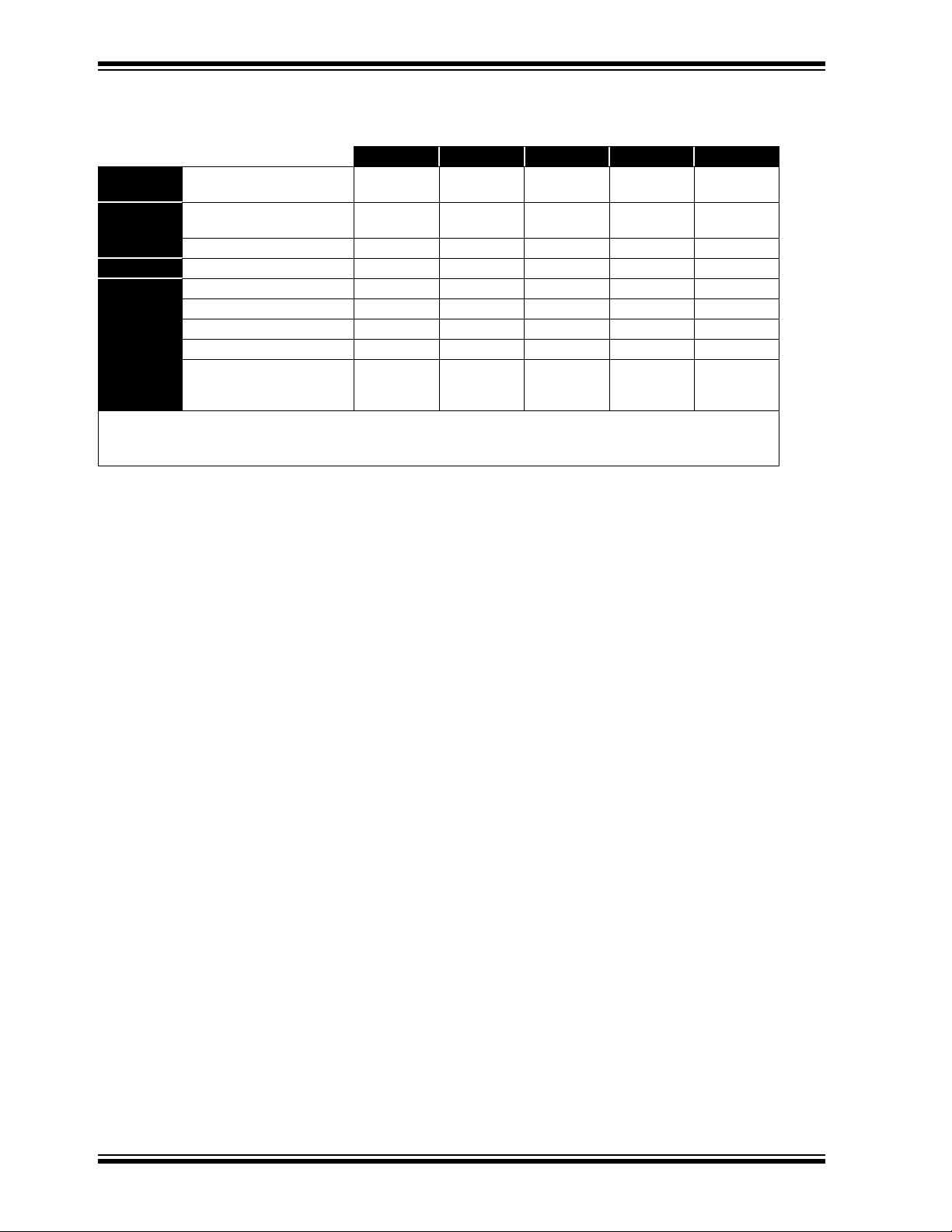

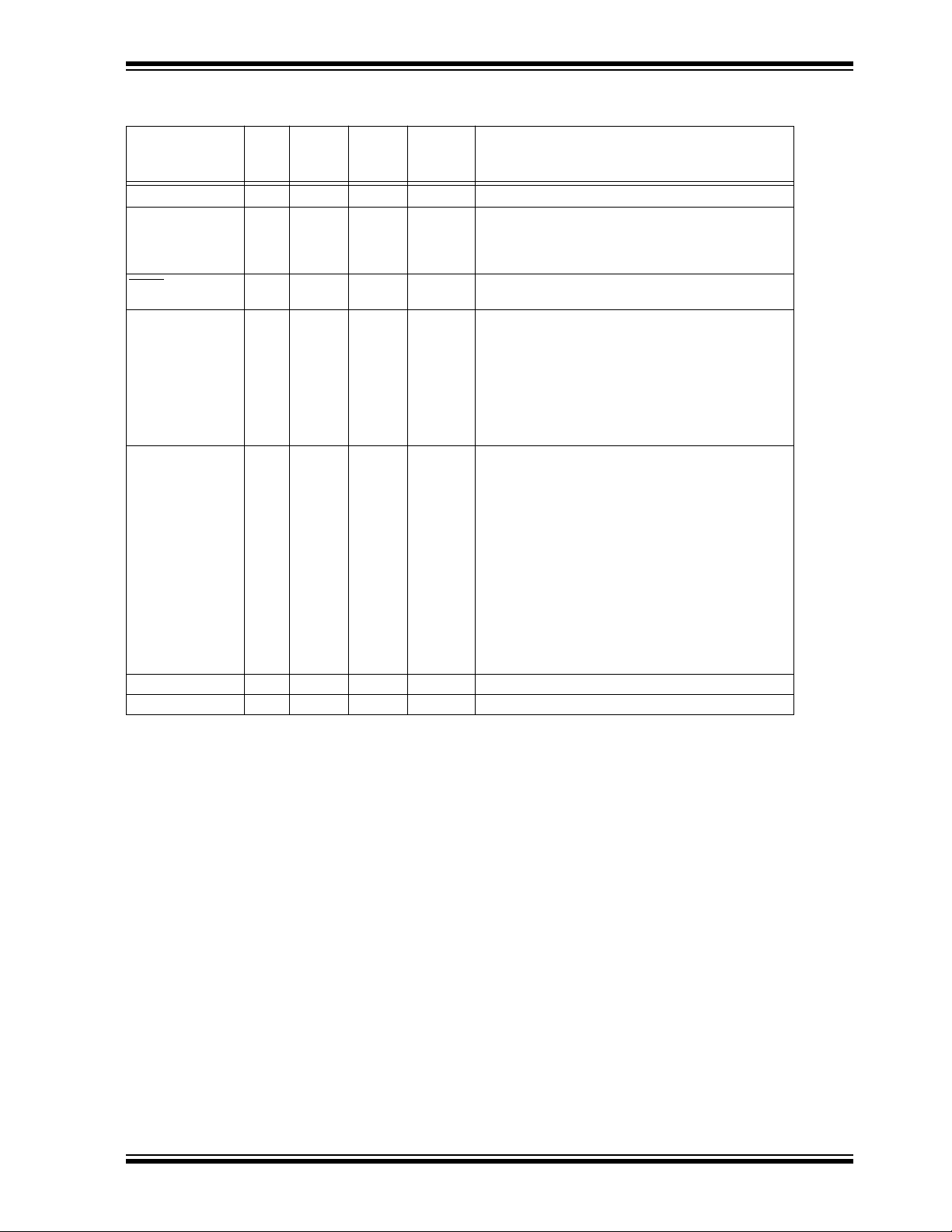

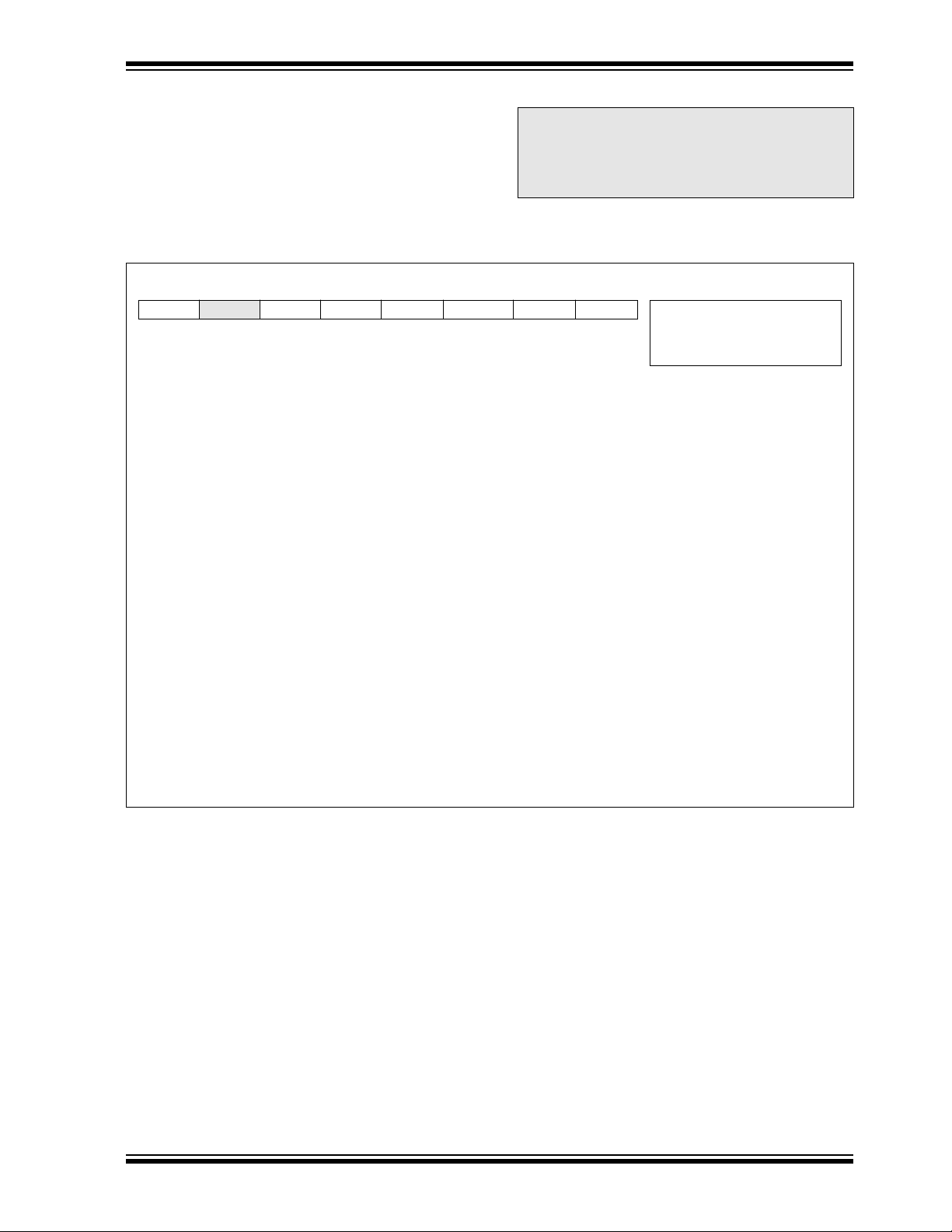

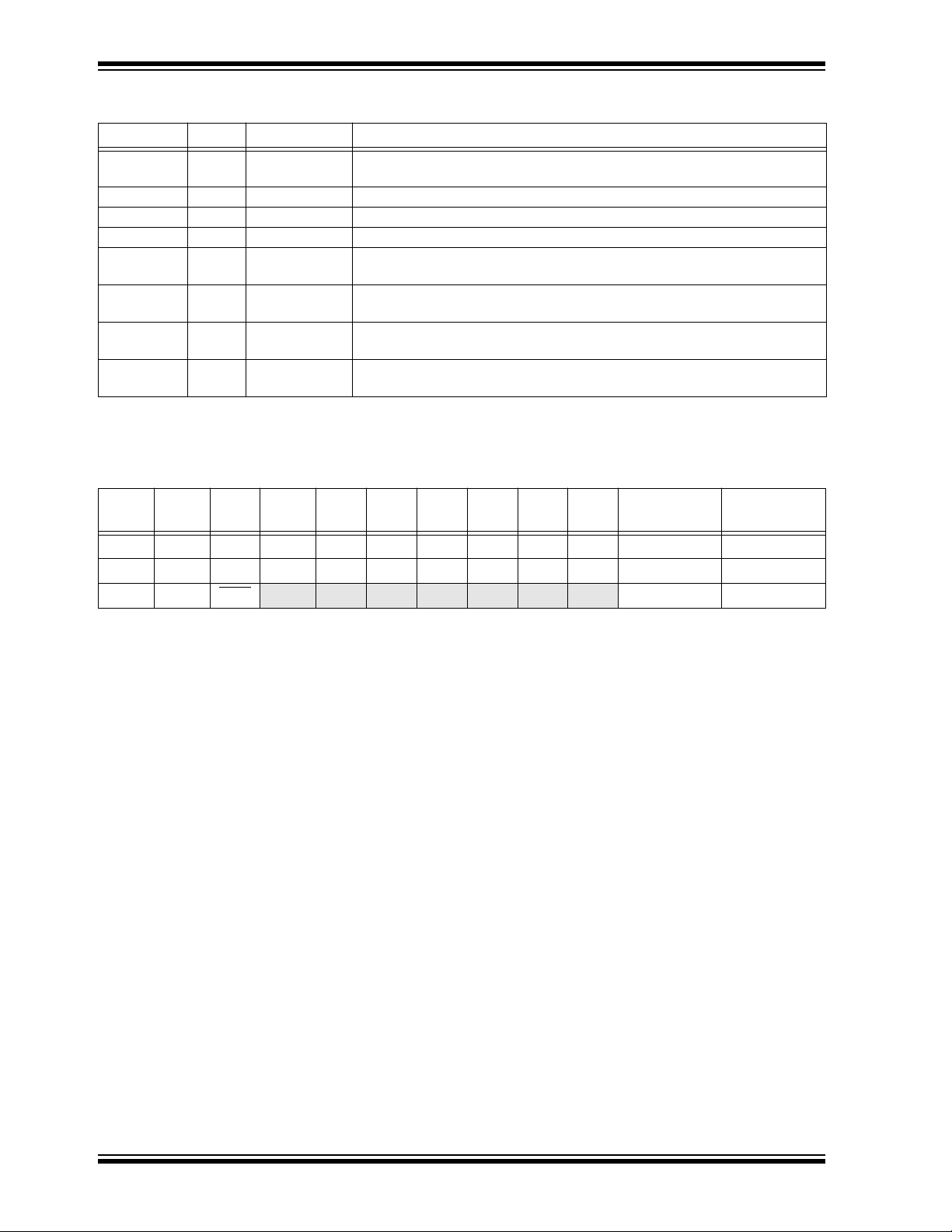

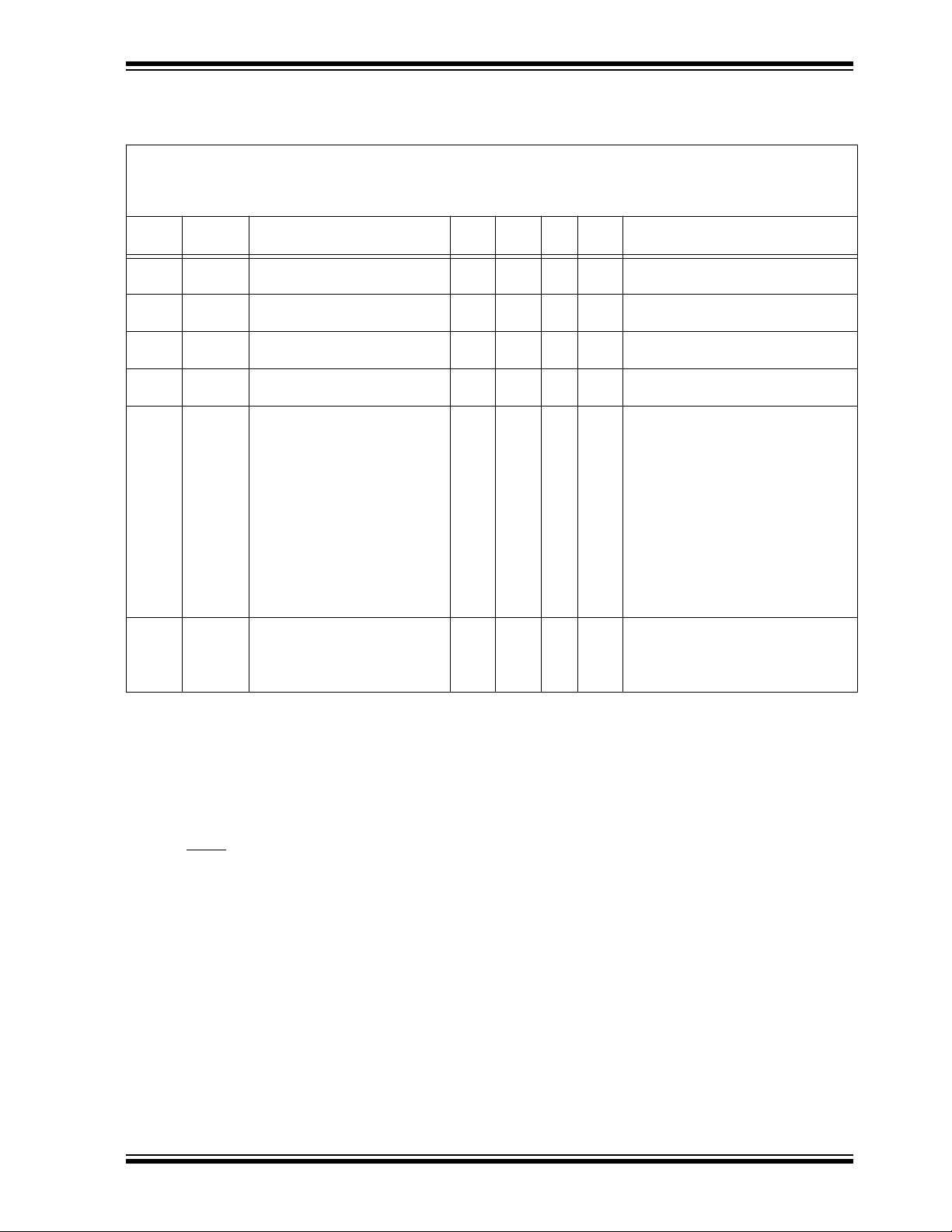

TABLE 1-1: PIC16C55X(A) FAMILY OF DEVICES

PIC16C554

Clock

Memory

Peripherals Timer Module(s) TMR0 TMR0 TMR0 TMR0 TMR0

Features

All PICmicro™ Family devices have Power-on Reset, selectable Watchdog Timer, selectable code protect and high

I/O current capability. All PIC16C55X(A)Family devices use serial programming with clock pin RB6 and data pin RB7.

Maximum Frequency of Operation (MHz)

EPROM Program Memory

(x14 words)

Data Memory (bytes) 80 80 80 128 128

Interrupt Sources 3 3 3 3 3

I/O Pins 13 13 13 13 13

Voltage Range (Volts) 2.5-5.5 3.0-5.5 3.0-5.5 2.5-5.5 3.0-5.5

Brown-out Reset — — — — —

Packages 18-pin DIP,

20 20 20 20 20

512 512 1K 2K 2K

SOIC;

20-pin SSOP

PIC16C554A PIC16C556A PIC16C558 PIC16C558A

18-pin DIP,

SOIC;

20-pin SSOP

18-pin DIP,

SOIC;

20-pin SSOP

18-pin DIP,

SOIC;

20-pin SSOP

18-pin DIP,

SOIC;

20-pin SSOP

DS40143B-page 6

Preliminary

1997 Microchip Technology Inc.

Page 7

PIC16C55X(A)

2.0 PIC16C55X(A) DEVICE

VARIETIES

A variety of frequency ranges and packaging options are

available . Depending on application and production

requirements the proper device option can be selected

using the information in the PIC16C55X(A) Product

Identification System section at the end of this data

sheet. When placing orders, please use this page of the

data sheet to specify the correct part number.

2.1 UV Erasab

The UV erasable version, offered in CERDIP package

is optimal for prototype development and pilot

programs. This version can be erased and

reprogrammed to any of the oscillator modes.

Microchip's PICSTART

programmers both support programming of the

PIC16C55X(A).

2.2 One-Time-Pr

Devices

The availability of OTP devices is especially useful for

customers who need the flexibility for frequent code

updates and small volume applications. In addition to

the program memory, the configuration bits must also

be programmed.

le Devices

and PROMATE

ogrammable (OTP)

2.3 Quic

k-Turnaround-Production (QTP)

Devices

Microchip offers a QTP Programming Service for

factory production orders. This service is made

available for users who choose not to program a

medium to high quantity of units and whose code patterns have stabilized. The devices are identical to the

OTP devices but with all EPROM locations and configuration options already programmed by the factory.

Certain code and prototype verification procedures

apply before production shipments are available.

Please contact your Microchip Technology sales office

for more details.

2.4 Serializ

Microchip offers a unique programming service where

a few user-defined locations in each device are

programmed with different serial numbers. The serial

numbers may be random, pseudo-random or

sequential.

Serial programming allows each device to have a

unique number which can serve as an entry-code,

password or ID number.

Quick-Turnaround-Production

(SQTP

ed

SM

Devices

)

1997 Microchip Technology Inc.

Preliminary

DS40143B-page 7

Page 8

PIC16C55X(A)

NOTES:

DS40143B-page 8

Preliminary

1997 Microchip Technology Inc.

Page 9

PIC16C55X(A)

3.0 ARCHITECTURAL OVERVIEW

The high performance of the PIC16C55X(A) family can

be attributed to a number of architectural features

commonly found in RISC microprocessors. To begin

with, the PIC16C55X(A) uses a Harvard architecture,

in which, program and data are accessed from separate memories using separate busses. This improves

bandwidth over traditional von Neumann architecture

where program and data are fetched from the same

memory. Separating program and data memory further

allows instructions to be sized differently than 8-bit

wide data words. Instruction opcodes are 14-bits wide

making it possible to have all single word instructions.

A 14-bit wide program memory access bus fetches a

14-bit instruction in a single cycle. A two-stage pipeline

overlaps fetch and execution of instructions.

Consequently, all instructions (35) execute in a single-cycle (200 ns @ 20 MHz) except for program

branches.

The PIC16C554(A) addresses 512 x 14 on-chip program memory. The PIC16C556A addresses 1K x 14

program memory. The PIC16C558(A) addresses 2K x

14 program memory. All program memory is internal.

The PIC16C55X(A) can directly or indirectly address its

register files or data memory. All special function

registers including the program counter are mapped

into the data memory. The PIC16C55X(A) have an

orthogonal (symmetrical) instruction set that makes it

possible to carry out any operation on any register

using any addressing mode. This symmetrical nature

and lack of ‘special optimal situations’ make programming with the PIC16C55X(A) simple yet efficient. In

addition, the learning curve is reduced significantly.

The PIC16C55X(A) devices contain an 8-bit ALU and

working register. The ALU is a general purpose

arithmetic unit. It performs arithmetic and Boolean

functions between data in the working register and any

register file.

The ALU is 8-bits wide and capable of addition,

subtraction, shift and logical operations. Unless

otherwise mentioned, arithmetic operations are two's

complement in nature. In two-operand instructions,

typically one operand is the working register

(W register). The other operand is a file register or an

immediate constant. In single operand instructions, the

operand is either the W register or a file register.

The W register is an 8-bit working register used for ALU

operations. It is not an addressable register.

Depending on the instruction executed, the ALU may

affect the values of the Carry (C), Digit Carry (DC), and

Zero (Z) bits in the STATUS register. The C and DC bits

operate as a Bo

respectively, in subtraction. See the

SUBWF

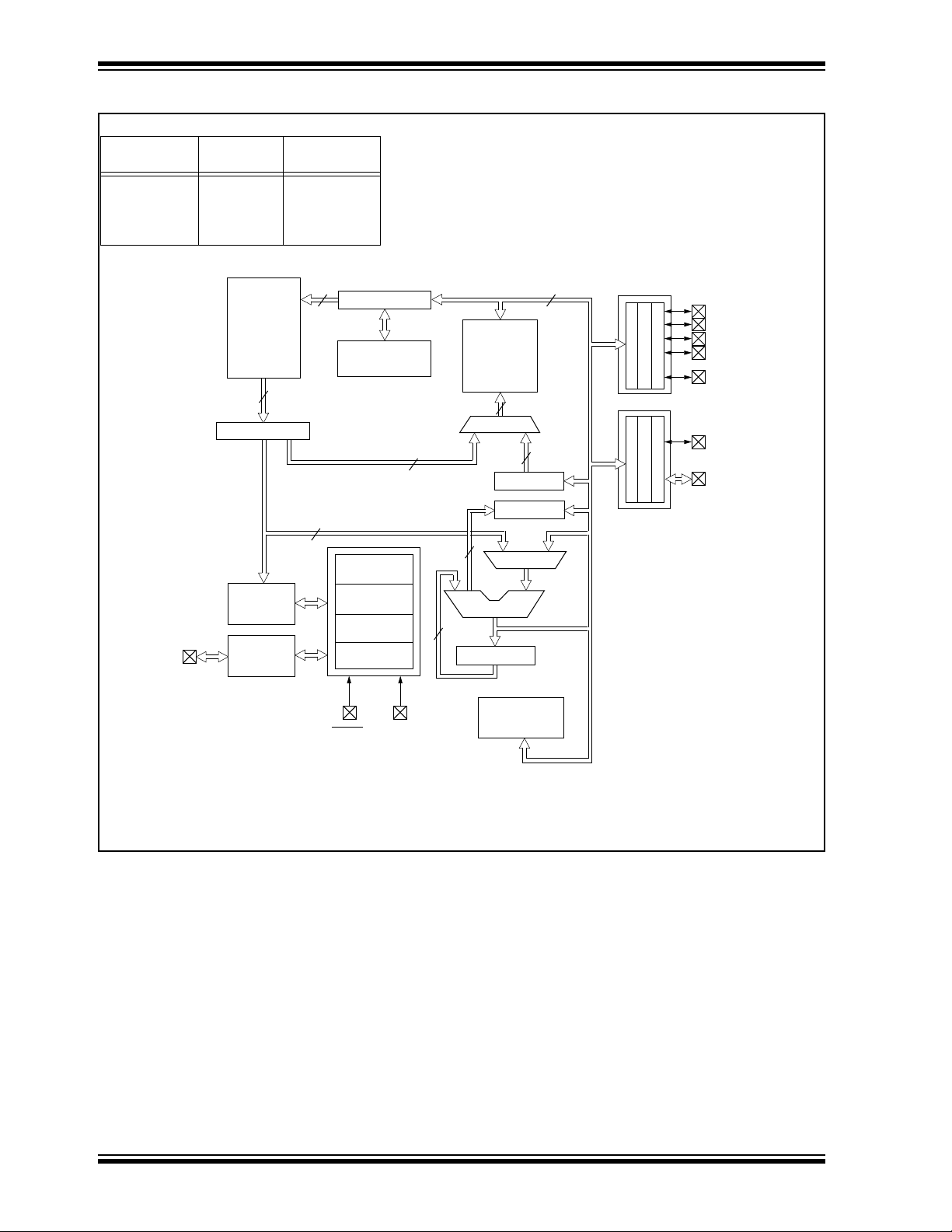

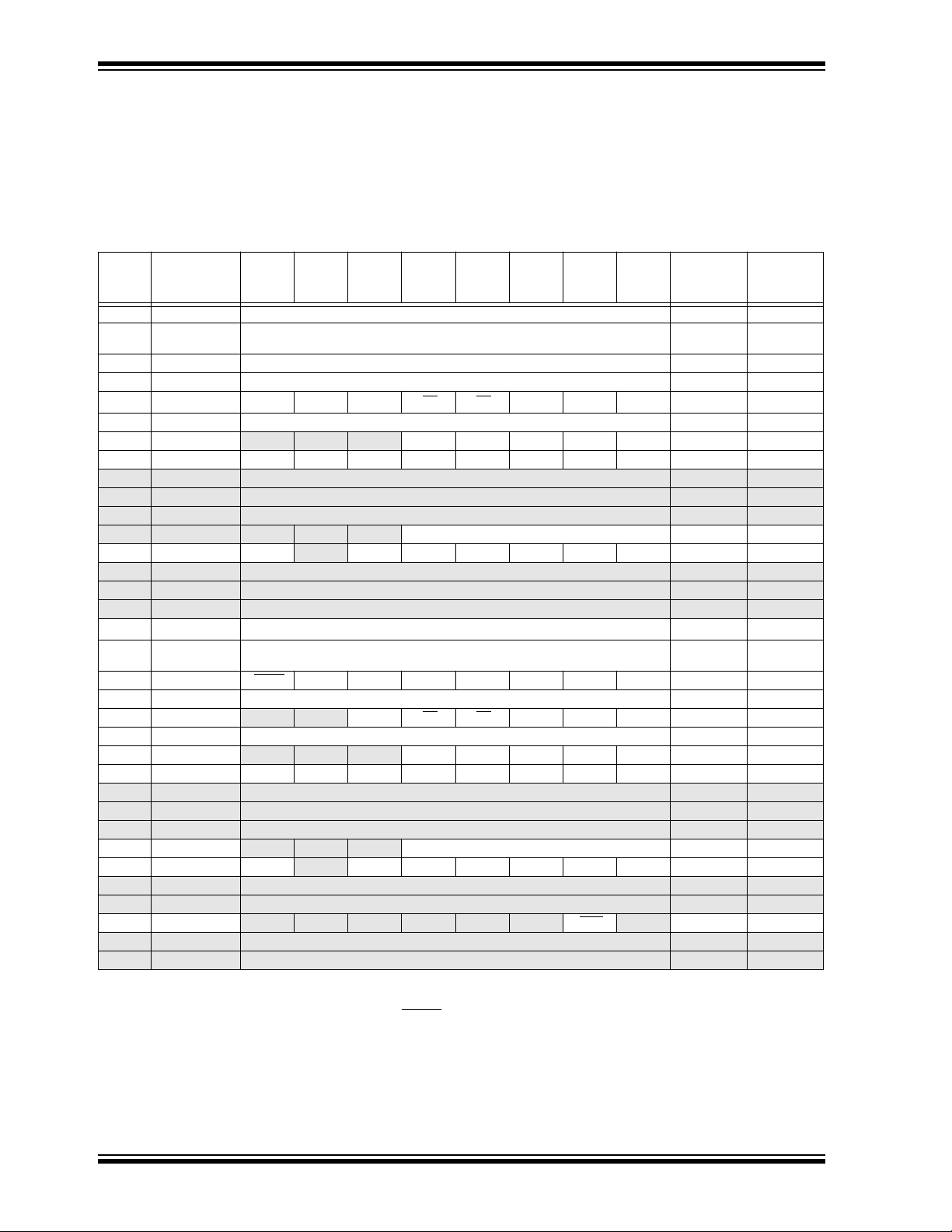

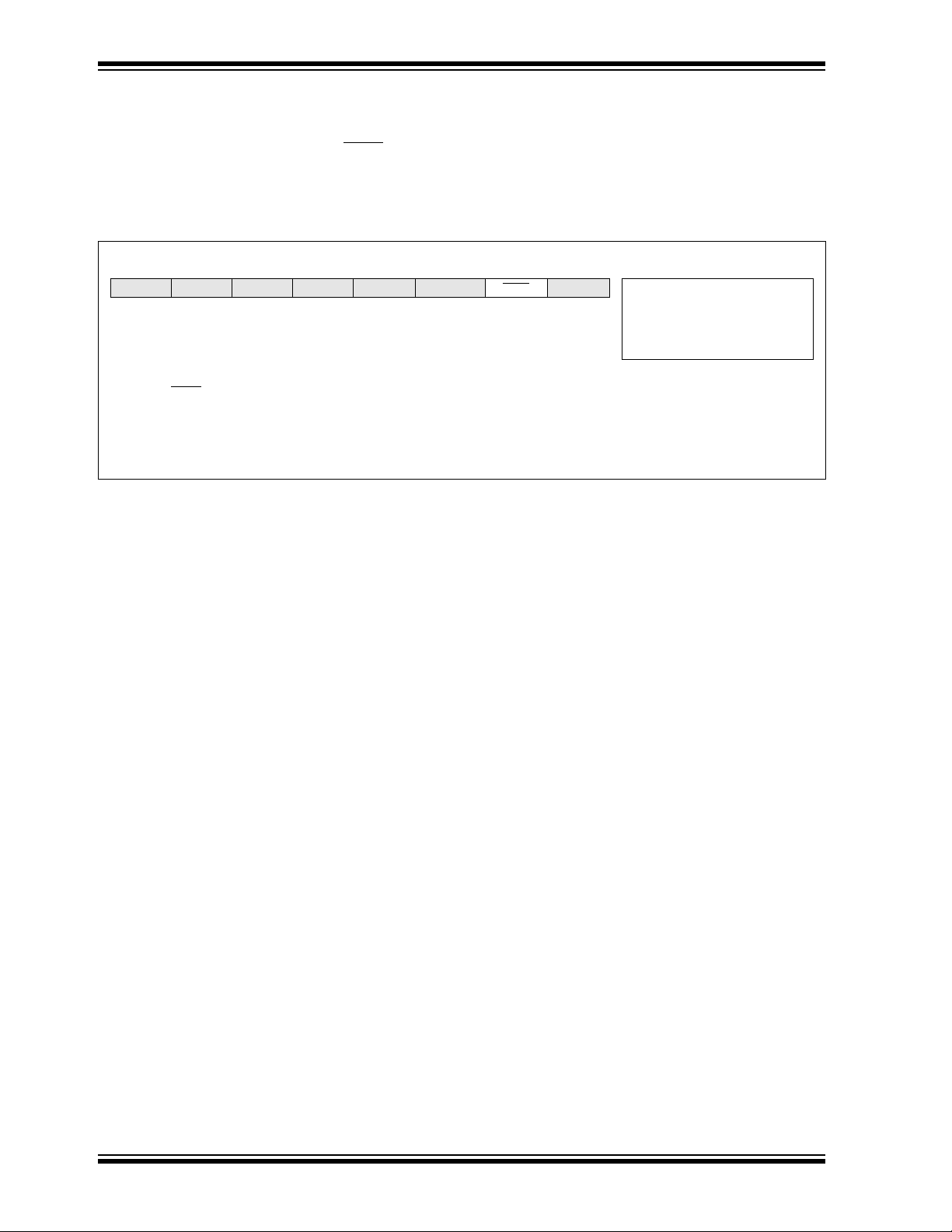

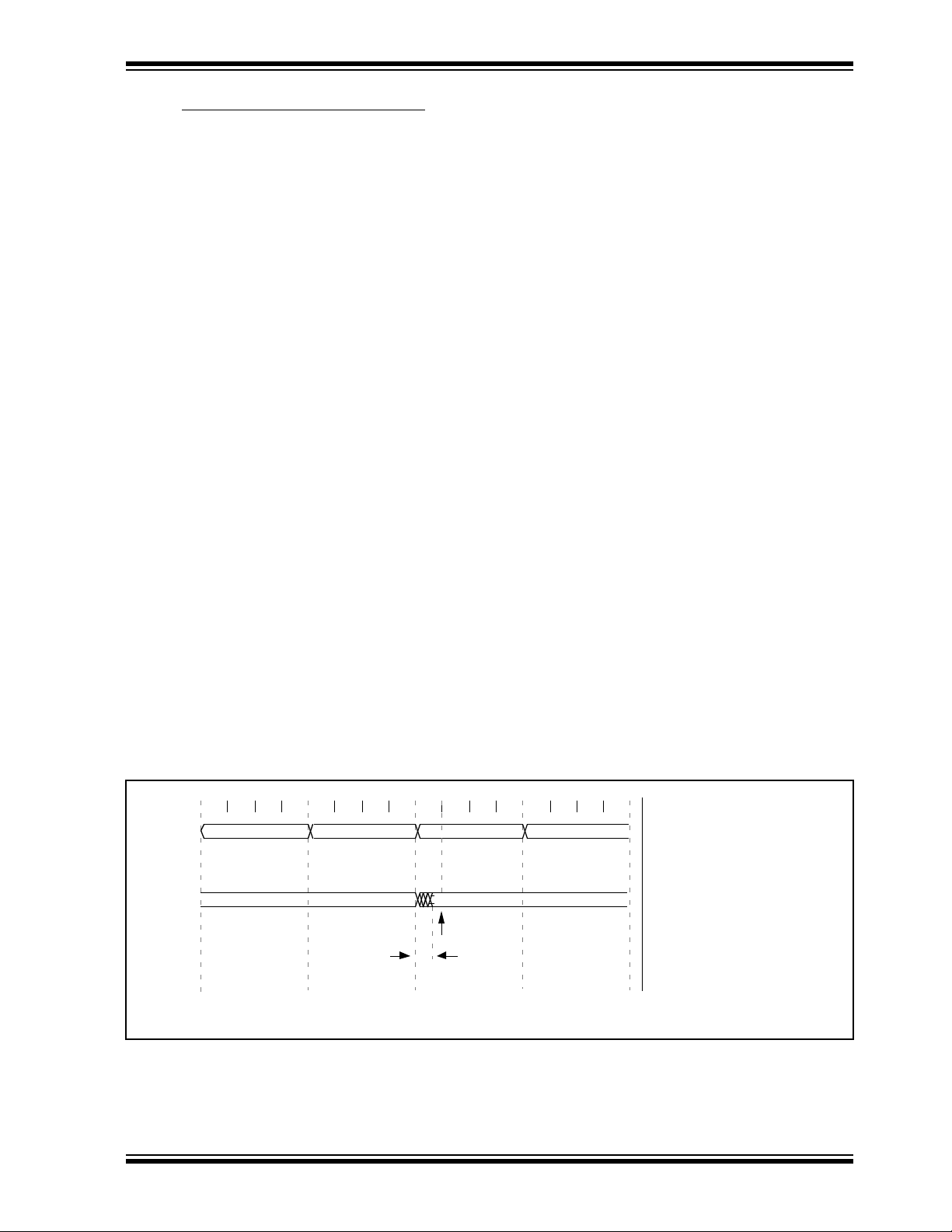

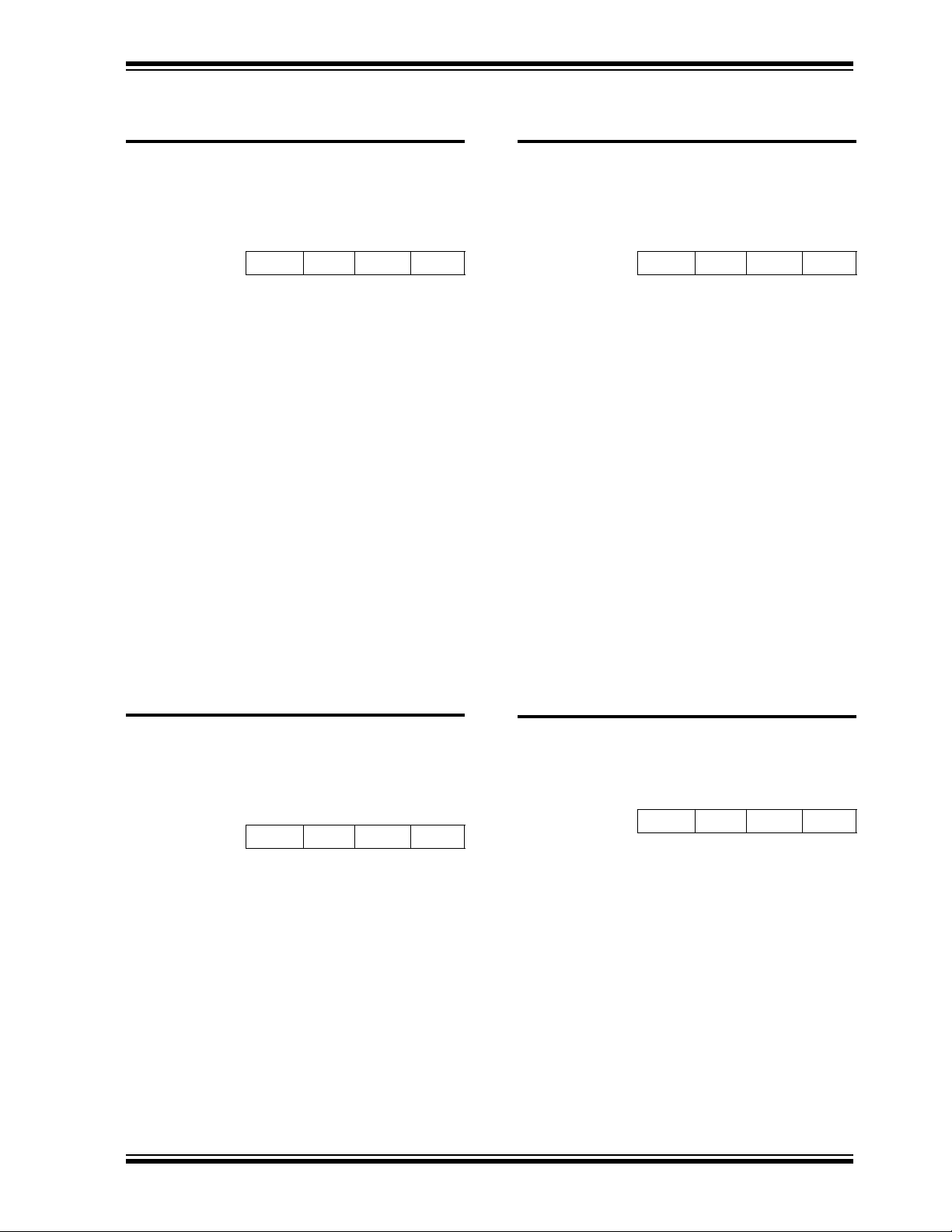

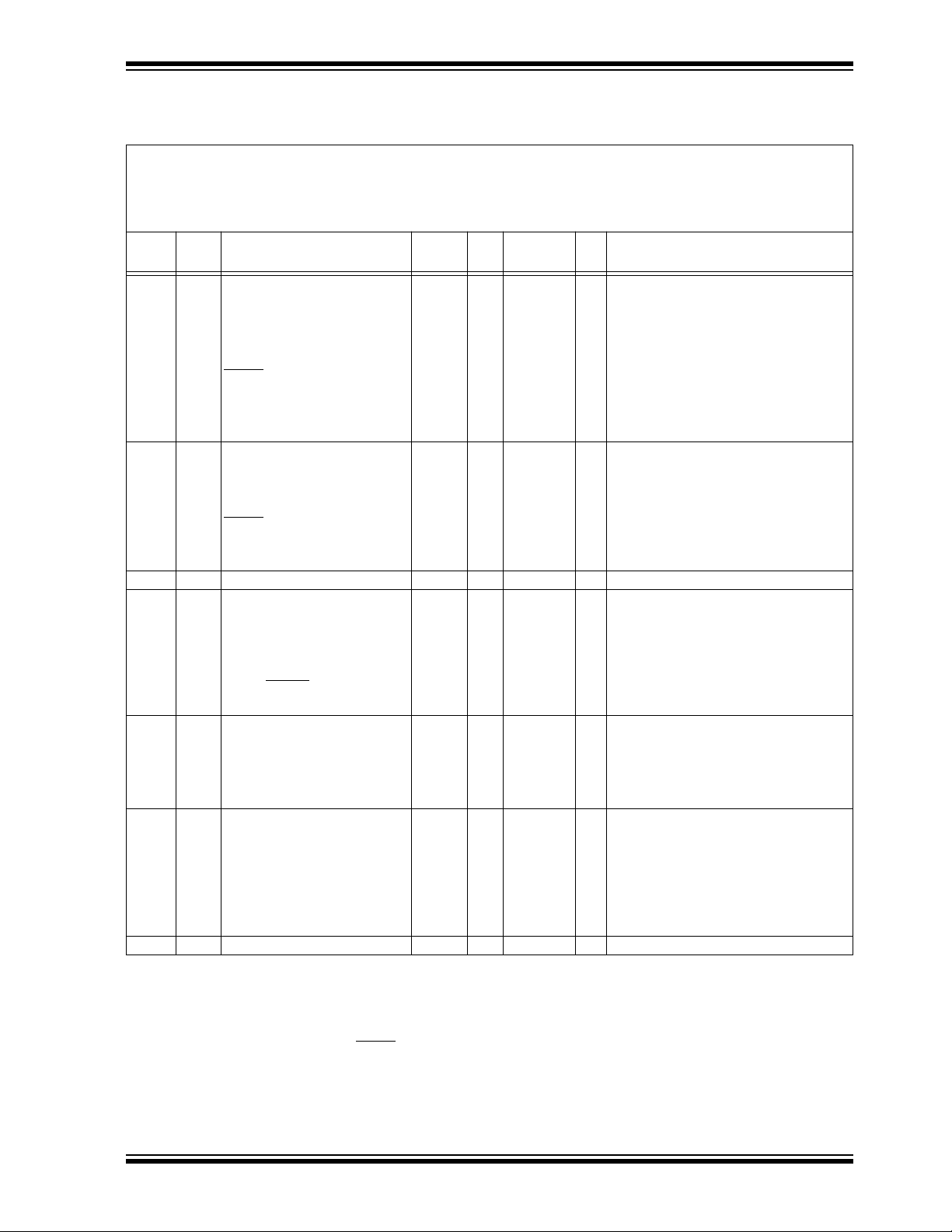

A simplified block diagram is shown in Figure 3-1, with

a description of the device pins in Table 3-1.

instructions for examples.

rrow and Digit Borrow out bit,

SUBLW

and

1997 Microchip Technology Inc.

Preliminary

DS40143B-page 9

Page 10

PIC16C55X(A)

FIGURE 3-1: BLOCK DIAGRAM

Device

PIC16C554

PIC16C554A

PIC16C556A

PIC16C558

PIC16C558A

OSC1/CLKIN

OSC2/CLKOUT

512 x 14

512 x 14

1K x 14

2K x 14

2K x 14

Program

Bus

Program

Memory

EPROM

Program

Memory

512 x 14

to

2K x 14

14

Instruction reg

Instruction

Decode &

Control

Timing

Generation

Data Memory

(RAM)

80 x 8

80 x 8

80 x 8

128 x 8

128 x 8

13

Direct Addr

8

Program Counter

8 Level Stack

(13-bit)

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

RAM Addr

7

3

8

Data Bus

RAM

File

Registers

80 x 8 to

128 x 8

(1)

Addr MUX

FSR reg

STATUS reg

ALU

W reg

8

8

MUX

8

Indirect

Addr

PORTA

RA0

RA1

RA2

RA3

RA4/T0CKI

PORTB

RB0/INT

RB7:RB1

MCLR

VDD, VSS

Note 1: Higher order bits are from the status register.

Timer0

DS40143B-page 10

Preliminary

1997 Microchip Technology Inc.

Page 11

PIC16C55X(A)

TABLE 3-1: PIC16C55X(A) PINOUT DESCRIPTION

DIP

Name

OSC1/CLKIN 16 18 I ST/CMOS Oscillator crystal input/external clock source input.

OSC2/CLKOUT 15 17 O — Oscillator crystal output. Connects to crystal or resonator

/V

MCLR

RA0 17 19 I/O ST

RA1 18 20 I/O ST

RA2 1 1 I/O ST

RA3 2 2 I/O ST

RA4/T0CKI 3 3 I/O ST Can be selected to be the clock input to the Timer0

RB0/INT 6 7 I/O

RB1 7 8 I/O TTL

RB2 8 9 I/O TTL

RB3 9 10 I/O TTL

RB4 10 11 I/O TTL Interrupt on change pin.

RB5 11 12 I/O TTL Interrupt on change pin.

RB6 12 13 I/O TTL/ST

RB7 13 14 I/O TTL/ST

V

V

PP

SS

DD

SOIC

Pin #

SSOP

Pin #

4 4 I/P ST Master clear (reset) input/programming voltage input.

5 5,6 P — Ground reference for logic and I/O pins.

14 15,16 P — Positive supply for logic and I/O pins.

Legend: O = output I/O = input/output P = power

— = Not used I = Input ST = Schmitt Trigger input

TTL = TTL input

Note 1: This buffer is a Schmitt Trigger input when configured as the external interrupt.

Note 2: This buffer is a Schmitt Trigger input when used in serial programming mode.

I/O/P

Type

Buffer

Type

TTL/ST

Description

in crystal oscillator mode. In RC mode, OSC2 pin outputs

CLKOUT which has 1/4 the frequency of OSC1, and

denotes the instruction cycle rate.

This pin is an active low reset to the device.

PORTA is a bi-directional I/O port.

timer/counter. Output is open drain type.

PORTB is a bi-directional I/O port. PORTB can be

software programmed for internal weak pull-up on all

inputs.

(1)

(2)

(2)

RB0/INT can also be selected as an external

interrupt pin.

Interrupt on change pin. Serial programming clock.

Interrupt on change pin. Serial programming data.

1997 Microchip Technology Inc.

Preliminary

DS40143B-page 11

Page 12

PIC16C55X(A)

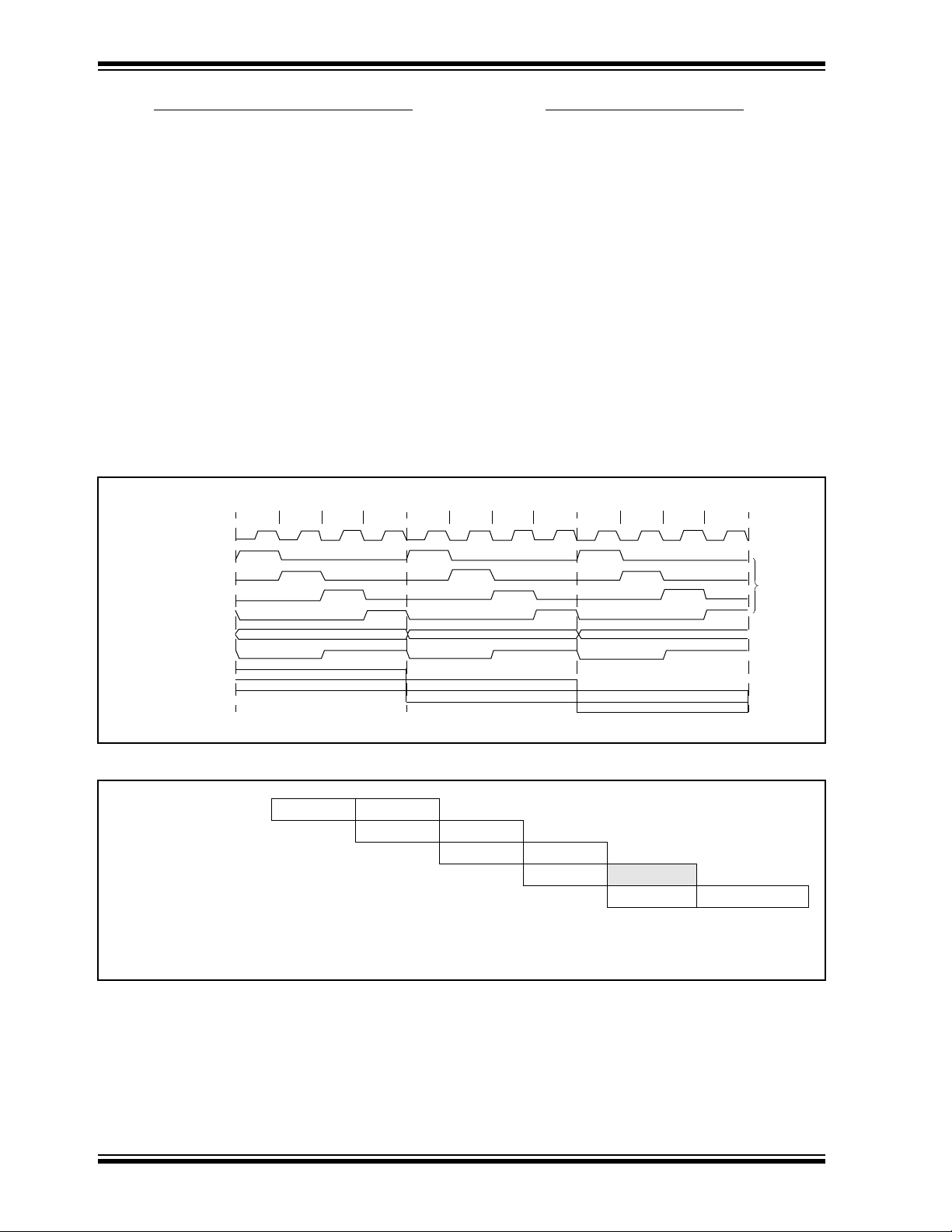

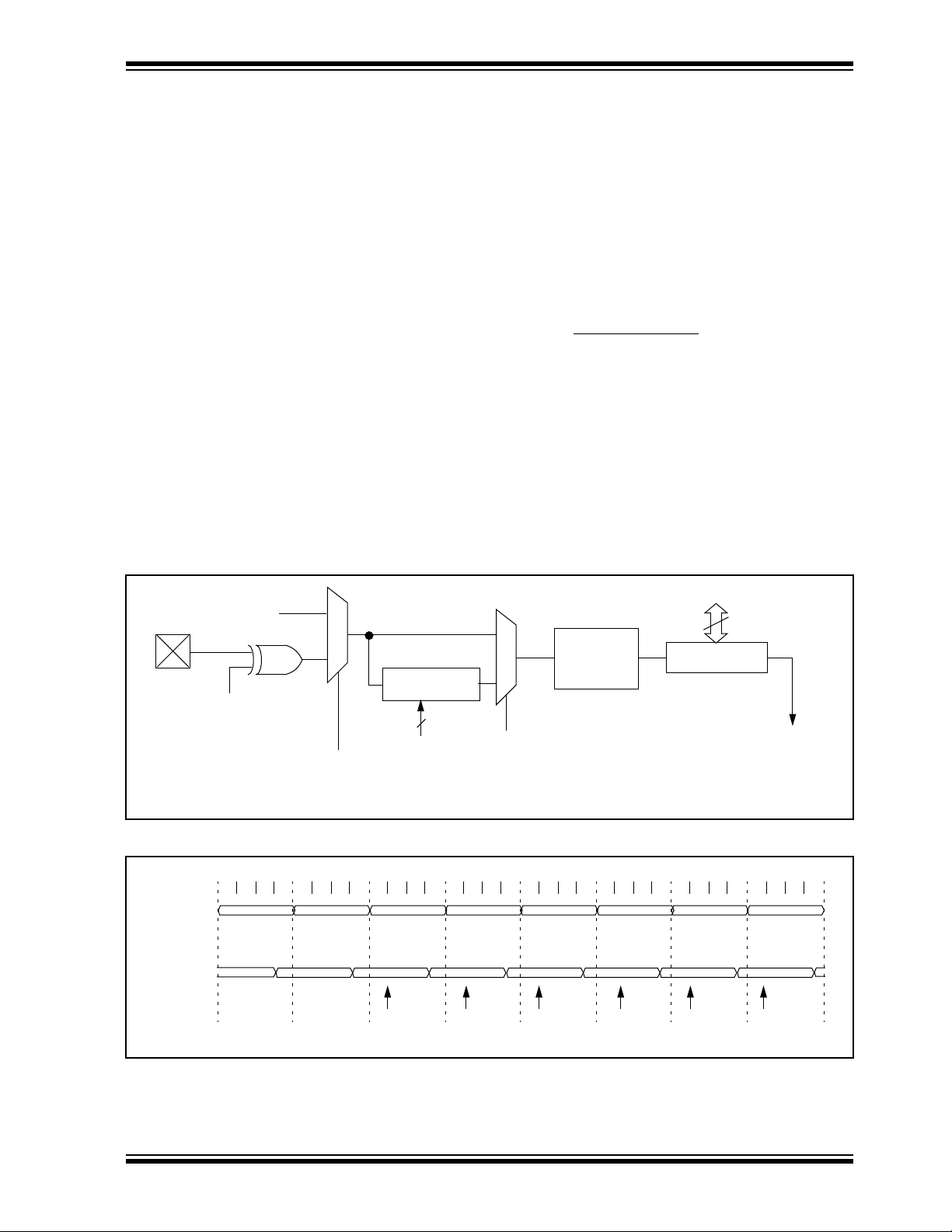

3.1 Cloc

king Scheme/Instruction Cycle

The clock input (OSC1/CLKIN pin) is internally divided

by four to generate four non-overlapping quadrature

clocks namely Q1, Q2, Q3 and Q4. Internally, the

program counter (PC) is incremented every Q1, the

instruction is fetched from the program memory and

latched into the instruction register in Q4. The

instruction is decoded and executed during the

following Q1 through Q4. The clocks and instruction

execution flow are shown in Figure 3-2.

FIGURE 3-2: CLOCK/INSTRUCTION CYCLE

Q2 Q3 Q4

OSC1

Q1

Q2

Q3

Q4

PC

OSC2/CLKOUT

(RC mode)

Q1

PC PC+1 PC+2

Fetch INST (PC)

Execute INST (PC-1) Fetch INST (PC+1)

Q1

3.2 Instruction Flo

w/Pipelining

An “Instruction Cycle” consists of four Q cycles (Q1,

Q2, Q3 and Q4). The instruction fetch and execute are

pipelined such that fetch takes one instruction cycle

while decode and execute takes another instruction

cycle. However, due to the pipelining, each instruction

effectively executes in one cycle. If an instruction

causes the program counter to change (e.g.,

then two cycles are required to complete the instruction

(Example 3-1).

A fetch cycle begins with the program counter (PC)

incrementing in Q1.

In the execution cycle , the fetched instruction is latched

into the “Instruction Register (IR)” in cycle Q1. This

instruction is then decoded and executed during the

Q2, Q3, and Q4 cycles. Data memory is read during Q2

(operand read) and written during Q4 (destination

write).

Q2 Q3 Q4

Execute INST (PC) Fetch INST (PC+2)

Q2 Q3 Q4

Q1

Execute INST (PC+1)

Internal

phase

clock

GOTO

)

EXAMPLE 3-1: INSTRUCTION PIPELINE FLOW

1. MOVLW 55h

2. MOVWF PORTB

3. CALL SUB_1

4. BSF PORTA, BIT3

All instructions are single cycle, except for any program branches. These take two cycles since the fetch

instruction is “flushed” from the pipeline while the new instruction is being fetched and then executed.

DS40143B-page 12

Fetch 1 Execute 1

Fetch 2 Execute 2

Preliminary

Fetch 3 Execute 3

Fetch 4 Flush

Fetch SUB_1 Execute SUB_1

1997 Microchip Technology Inc.

Page 13

PIC16C55X(A)

4.0 MEMORY ORGANIZATION

4.1 Pr

The PIC16C55X(A) has a 13-bit prog ram counter capable of addressing an 8K x 14 program memory space.

Only the first 512 x 14 (0000h - 01FFh) for the

PIC16C554(A), 1K x 14 (0000h - 03FFh) for the

PIC16C556A and 2K x 14 (0000h - 07FFh) for the

PIC16C558(A) are physically implemented. Accessing

a location above these boundaries will cause a

wrap-around within the first 512 x 14 space

PIC16C554(A) or 1K x 14 space PIC16C556A or 2K x

14 space PIC16C558(A). The reset vector is at 0000h

and the interrupt vector is at 0004h (Figure 4-1,

Figure 4-2, Figure 4-3).

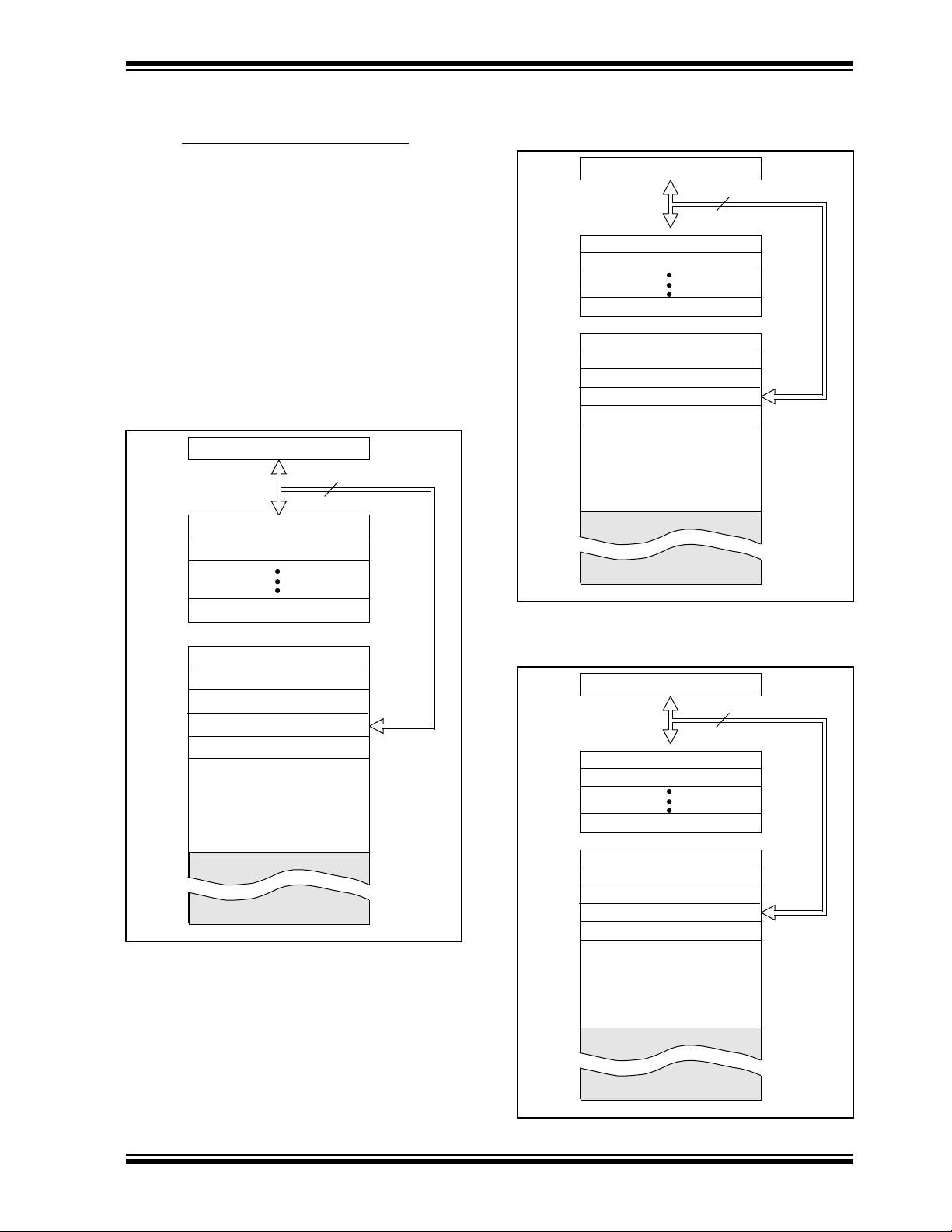

FIGURE 4-1: PROGRAM MEMORY MAP

ogram Memory Organization

AND STACK FOR THE

PIC16C554/PIC6C554A

PC<12:0>

CALL, RETURN

RETFIE, RETLW

Stack Level 1

Stack Level 2

13

FIGURE 4-2: PROGRAM MEMORY MAP

AND STACK FOR THE

PIC16C556A

PC<12:0>

CALL, RETURN

RETFIE, RETLW

Stack Level 1

Stack Level 2

Stack Level 8

Reset Vector

Interrupt Vector

On-chip Program

Memory

13

000h

0004

0005

03FFh

0400h

Stack Level 8

Reset Vector

Interrupt Vector

On-chip Program

Memory

000h

0004

0005

01FFh

0200h

1FFFh

1FFFh

FIGURE 4-3: PROGRAM MEMORY MAP

AND STACK FOR THE

PIC16C558/PIC16C558A

PC<12:0>

CALL, RETURN

RETFIE, RETLW

Stack Level 1

Stack Level 2

Stack Level 8

Reset Vector

Interrupt Vector

On-chip Program

Memory

13

000h

0004

0005

07FFh

0800h

1997 Microchip Technology Inc.

Preliminary

1FFFh

DS40143B-page 13

Page 14

PIC16C55X(A)

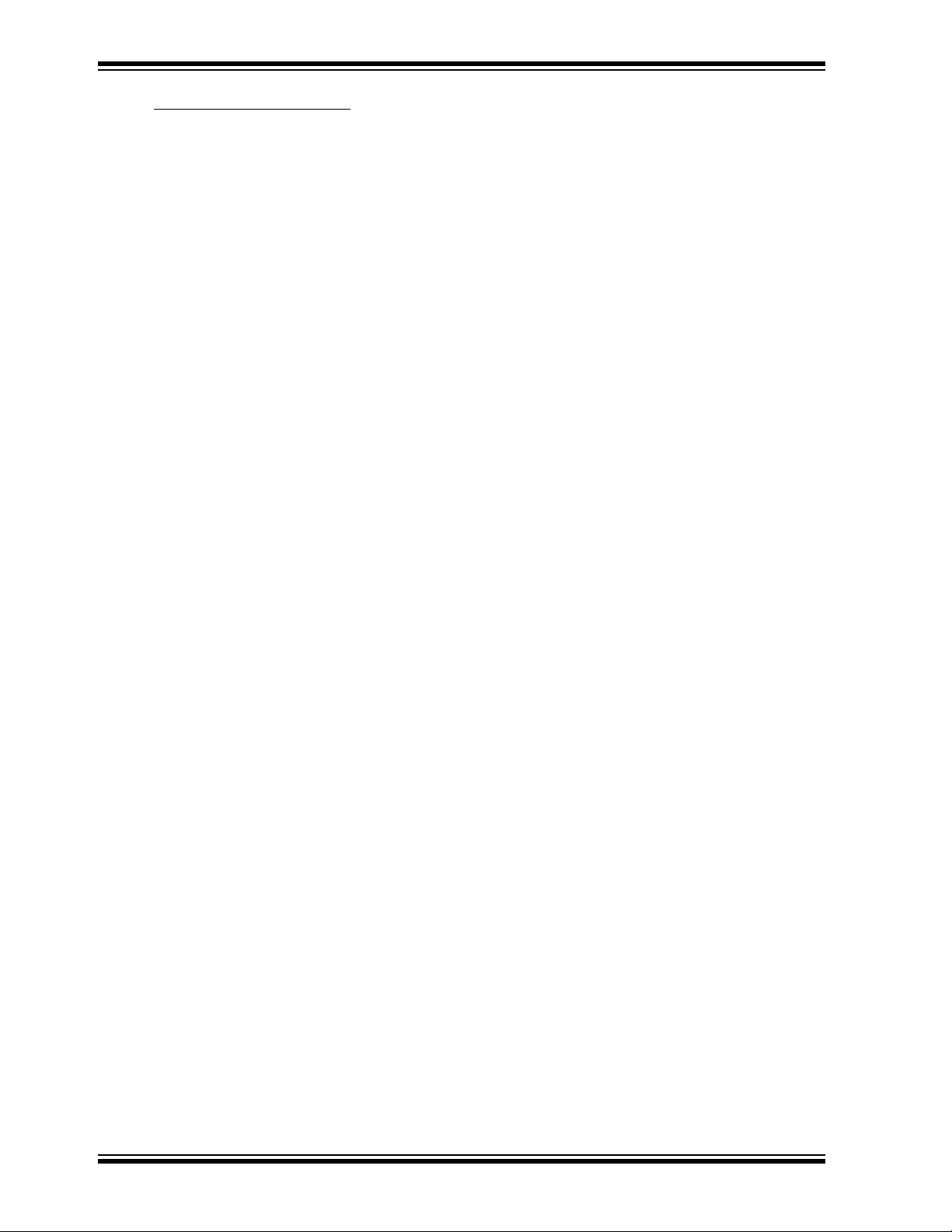

4.2 Data Memor

The data memory (Figure 4-4 and Figure 4-5) is

partitioned into two Banks which contain the general

purpose registers and the special function registers.

Bank 0 is selected when the RP0 bit is cleared. Bank 1

is selected when the RP0 bit (STATUS <5>) is set. The

Special Function Registers are located in the first 32

locations of each Bank. Register locations 20-6Fh

(Bank0) on the PIC16C554(A)/556A and 20-7Fh

(Bank0) and A0-BFh (Bank1) on the PIC16C558(A) are

general purpose registers implemented as static RAM.

Some special purpose registers are mapped in Bank 1.

y Organization

4.2.1 GENERAL PURPOSE REGISTER FILE The register file is organized as 80 x 8 in the

PIC16C554(A)/556A and 128 x 8 in the PIC16C558(A).

Each is accessed either directly or indirectly through

the File Select Register, FSR (Section 4.4).

DS40143B-page 14

Preliminary

1997 Microchip Technology Inc.

Page 15

PIC16C55X(A)

FIGURE 4-4: DATA MEMORY MAP FOR

THE PIC16C554(A)/556A

File

Address

00h

01h

02h

03h

04h

05h

06h

07h

08h

09h

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

1Bh

1Ch

1Dh

1Eh

1Fh

20h

6Fh

70h

(1)

INDF

TMR0

PCL

STATUS

FSR

PORTA

PORTB

PCLATH

INTCON

General

Purpose

Register

(1)

INDF

OPTION

PCL

STATUS

FSR

TRISA

TRISB

PCLATH

INTCON

PCON

File

Address

80h

81h

82h

83h

84h

85h

86h

87h

88h

89h

8Ah

8Bh

8Ch

8Dh

8Eh

8Fh

90h

91h

92h

93h

94h

95h

96h

97h

98h

99h

9Ah

9Bh

9Ch

9Dh

9Eh

9Fh

A0h

FIGURE 4-5: DATA MEMORY MAP FOR

THE PIC16C558(A)

File

Address

00h

01h

02h

03h

04h

05h

06h

07h

08h

09h

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

1Bh

1Ch

1Dh

1Eh

1Fh

20h

(1)

INDF

TMR0

PCL

STATUS

FSR

PORTA

PORTB

PCLATH

INTCON

General

Purpose

Register

(1)

INDF

OPTION

PCL

STATUS

FSR

TRISA

TRISB

PCLATH

INTCON

PCON

General

Purpose

Register

File

Address

80h

81h

82h

83h

84h

85h

86h

87h

88h

89h

8Ah

8Bh

8Ch

8Dh

8Eh

8Fh

90h

91h

92h

93h

94h

95h

96h

97h

98h

99h

9Ah

9Bh

9Ch

9Dh

9Eh

9Fh

A0h

BFh

C0h

7Fh

Unimplemented data memory locations, read as '0'.

Note 1: Not a physical register.

1997 Microchip Technology Inc. Preliminary DS40143B-page 15

Bank 0 Bank 1

FFh

7Fh

Unimplemented data memory locations, read as '0'.

Note 1: Not a physical register.

Bank 0 Bank 1

FFh

Page 16

PIC16C55X(A)

4.2.2 SPECIAL FUNCTION REGISTERS

The special function registers can be classified into two

sets (core and peripheral). The special function regis-

The special function registers are registers used by the

CPU and Peripheral functions for controlling the

desired operation of the device (Table 4-1). These

registers are static RAM.

ters associated with the “core” functions are described

in this section. Those related to the operation of the

peripheral features are described in the section of that

peripheral feature.

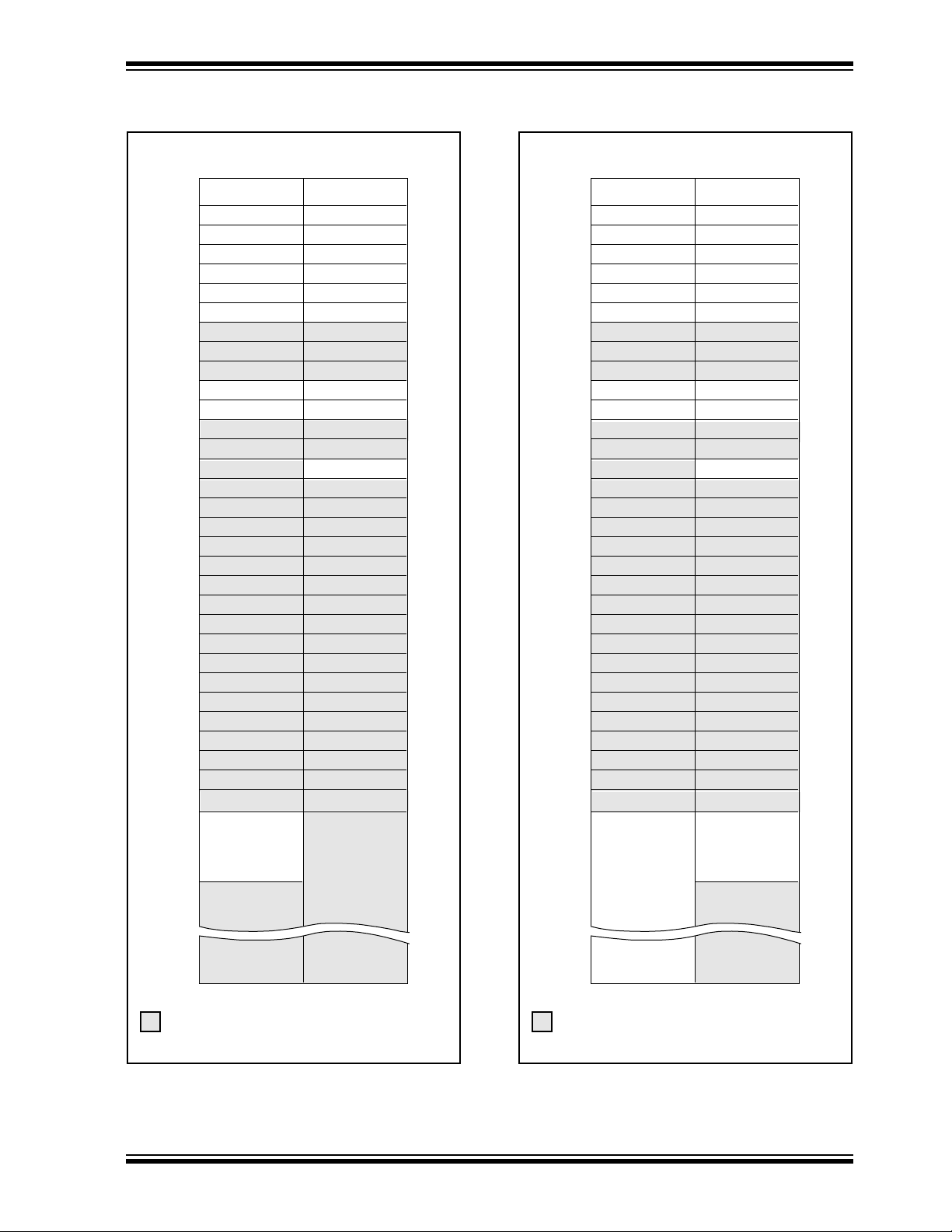

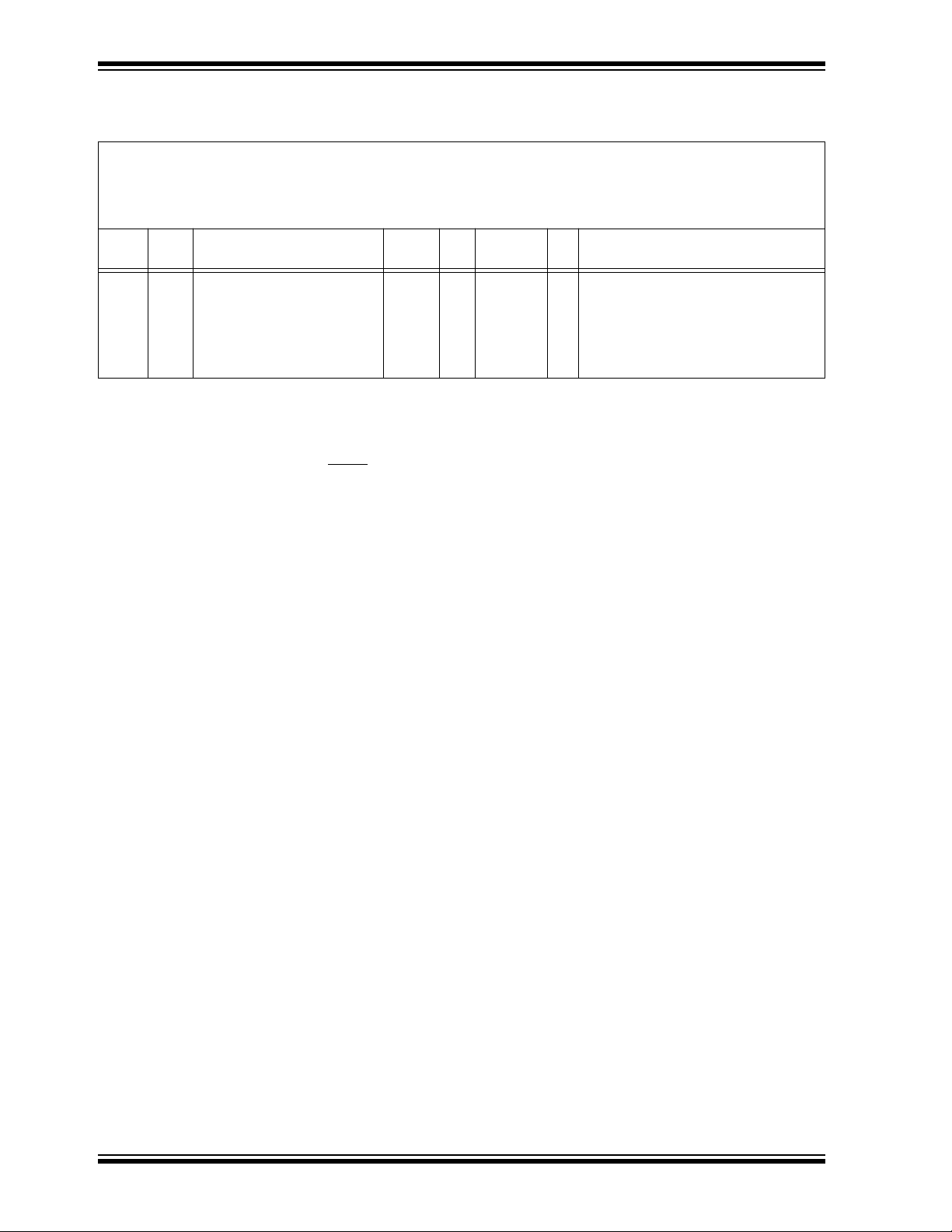

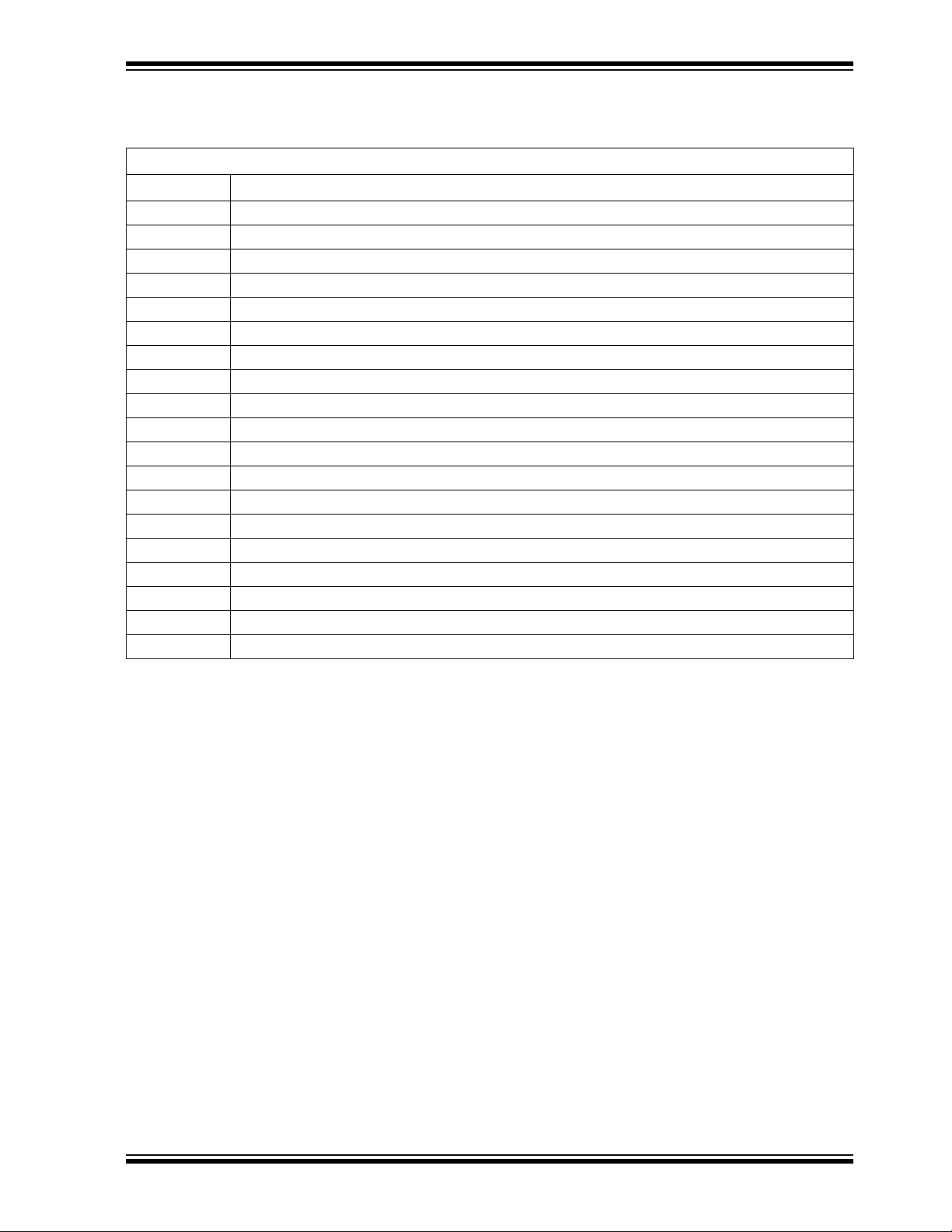

TABLE 4-1: SPECIAL REGISTERS FOR THE PIC16C55X(A)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 0

00h INDF

01h TMR0 Timer0 Module’s Register xxxx xxxx uuuu uuuu

02h PCL Program Counter's (PC) Least Significant Byte 0000 0000 0000 0000

03h STATUS

04h FSR Indirect data memory address pointer xxxx xxxx uuuu uuuu

05h PORTA — — — RA4 RA3 RA2 RA1 RA0 ---x xxxx ---u uuuu

06h PORTB RB7 RB6 RB5 RB4 RB3 RB2 RB1 RB0 xxxx xxxx uuuu uuuu

07h Unimplemented — —

08h Unimplemented — —

09h Unimplemented — —

0Ah PCLATH — — — Write buffer for upper 5 bits of program counter ---0 0000 ---0 0000

0Bh INTCON GIE

0Ch Unimplemented — —

0Dh-1Eh Unimplemented — —

1Fh Unimplemented — —

Bank 1

80h INDF

81h OPTION RBPU

82h PCL Program Counter's (PC) Least Significant Byte 0000 0000 0000 0000

83h STATUS

84h FSR Indirect data memory address pointer xxxx xxxx uuuu uuuu

85h TRISA

86h TRISB TRISB7 TRISB6 TRISB5 TRISB4 TRISB3 TRISB2 TRISB1 TRISB0 1111 1111 1111 1111

87h Unimplemented — —

88h Unimplemented — —

89h Unimplemented — —

8Ah PCLATH

8Bh INTCON GIE

8Ch Unimplemented — —

8Dh Unimplemented — —

8Eh PCON

8Fh-9Eh Unimplemented — —

9Fh Unimplemented — —

Addressing this location uses contents of FSR to address data memory (not a physical

register)

(2)

IRP

Addressing this location uses contents of FSR to address data memory (not a physical

register)

— — RP0 TO PD Z DC C 0001 1xxx 000q quuu

— — — TRISA4 TRISA3 TRISA2 TRISA1 TRISA0 ---1 1111 ---1 1111

— — — Write buffer for upper 5 bits of program counter ---0 0000 ---0 0000

— — — — — — POR — ---- --0- ---- --u-

(2)

RP1

(3) T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000x

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

(3) T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000x

RP0 TO PD Z DC C

Value on

POR Reset

xxxx xxxx xxxx xxxx

0001 1xxx 000q quuu

xxxx xxxx xxxx xxxx

Legend: — = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition,

shaded = unimplemented

Note 1: Other (non power-up) resets include MCLR reset and Watchdog Timer reset during normal operation.

Note 2: IRP & RPI bits are reserved, always maintain these bits clear.

Note 3: Bit 6 of INTCON register is reserved for future use. Always maintain this bit as clear.

Value on

all other

resets

(1)

DS40143B-page 16 Preliminary 1997 Microchip Technology Inc.

Page 17

PIC16C55X(A)

4.2.2.1 STATUS REGISTER

The STATUS register, shown in Figure 4-6, contains

the arithmetic status of the ALU, the RESET status and

the bank select bits for data memory.

The STATUS register can be the destination for any

instruction, like any other register. If the STATUS

register is the destination for an instruction that affects

the Z, DC or C bits, then the write to these three bits is

disabled. These bits are set or cleared according to the

device logic. Furthermore, the T

writable. Therefore, the result of an instruction with the

STATUS register as the destination may be different

than intended.

For example, CLRF STATUS will clear the upper-three

bits and set the Z bit. This lea ves the status register as

000uu1uu (where u = unchanged).

O and PD bits are not

It is recommended, therefore, that only BCF, BSF,

SWAPF and MOVWF instructions be used to alter the ST ATUS register because these instructions do not affect

any status bits. For other instructions, not affecting any

status bits, see the “Instruction Set Summary”.

Note 1: The IRP and RP1 bits (STATUS<7:6>)

are not used by the PIC16C55X(A) and

should be programmed as ’0'. Use of

these bits as general purpose R/W bits is

NOT recommended, since this may

affect upward compatibility with future

products.

Note 2: The C and DC bits operate as a Borro

and Digit Borrow out bit, respectively, in

subtraction. See the SUBLW and SUBWF

instructions for examples.

FIGURE 4-6: STATUS REGISTER (ADDRESS 03H OR 83H)

Reserved Reserved R/W-0 R-1 R-1 R/W-x R/W-x R/W-x

IRP RP1 RP0 TO PD Z DC C R = Readable bit

bit7 bit0

bit 7: IRP: Register Bank Select bit (used for indirect addressing)

1 = Bank 2, 3 (100h - 1FFh)

0 = Bank 0, 1 (00h - FFh)

The IRP bit is reserved on the PIC16C55X(A), always maintain this bit clear.

bit 6-5: RP1:RP0: Register Bank Select bits (used for direct addressing)

11 = Bank 3 (180h - 1FFh)

10 = Bank 2 (100h - 17Fh)

01 = Bank 1 (80h - FFh)

00 = Bank 0 (00h - 7Fh)

Each bank is 128 bytes. The RP1 bit is reserved on the PIC16C55X(A), always maintain this bit clear.

bit 4: T

bit 3: PD

bit 2: Z: Zero bit

bit 1: DC: Digit carry/borro

bit 0: C: Carry/borro

O: Time-out bit

1 = After power-up, CLRWDT instruction, or SLEEP instruction

0 = A WDT time-out occurred

: Power-down bit

1 = After power-up or by the CLRWDT instruction

0 = By execution of the SLEEP instruction

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

w bit (ADDWF, ADDLW,SUBLW,SUBWF instructions)(for borrow the polarity is reversed)

1 = A carry-out from the 4th low order bit of the result occurred

0 = No carry-out from the 4th low order bit of the result

w bit (ADDWF, ADDLW,SUBLW,SUBWF instructions)

1 = A carry-out from the most significant bit of the result occurred

0 = No carry-out from the most significant bit of the result occurred

Note: For borro

second operand. For rotate (RRF, RLF) instructions, this bit is loaded with either the high or low order bit of

the source register.

w the polarity is reversed. A subtraction is executed by adding the two’s complement of the

W = Writable bit

- n = Value at POR reset

- x = Unknown at POR reset

w

1997 Microchip Technology Inc. Preliminary DS40143B-page 17

Page 18

PIC16C55X(A)

4.2.2.2 OPTION REGISTER

The OPTION register is a readable and writable

register which contains various control bits to configure

Note: To achieve a 1:1 prescaler assignment for

TMR0, assign the prescaler to the WDT

(PSA = 1).

the TMR0/WDT prescaler, the external RB0/INT

interrupt, TMR0 and the weak pull-ups on PORTB.

FIGURE 4-7: OPTION REGISTER (ADDRESS 81H)

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

RBPU INTEDG T0CS T0SE PSA PS2 PS1 PS0 R = Readable bit

bit7 bit0

bit 7: RBPU: PORTB Pull-up Enable bit

1 = PORTB pull-ups are disabled

0 = PORTB pull-ups are enabled by individual port latch values

bit 6: INTEDG: Interrupt Edge Select bit

1 = Interrupt on rising edge of RB0/INT pin

0 = Interrupt on falling edge of RB0/INT pin

bit 5: T0CS: TMR0 Clock Source Select bit

1 = Transition on RA4/T0CKI pin

0 = Internal instruction cycle clock (CLKOUT)

bit 4: T0SE: TMR0 Source Edge Select bit

1 = Increment on high-to-low transition on RA4/T0CKI pin

0 = Increment on low-to-high transition on RA4/T0CKI pin

bit 3: PSA: Prescaler Assignment bit

1 = Prescaler is assigned to the WDT

0 = Prescaler is assigned to the Timer0 module

bit 2-0: PS2:PS0: Prescaler Rate Select bits

Bit Value TMR0 Rate WDT Rate

000

001

010

011

100

101

110

111

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

1 : 256

1 : 1

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

W = Writable bit

- n = Value at POR reset

DS40143B-page 18 Preliminary 1997 Microchip Technology Inc.

Page 19

PIC16C55X(A)

4.2.2.3 INTCON REGISTER

The INTCON register is a readable and writable

register which contains the various enable and flag bits

for all interrupt sources.

Note: Interrupt flag bits get set when an interrupt

condition occurs regardless of the state of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>).

FIGURE 4-8: INTCON REGISTER (ADDRESS 0BH OR 8BH)

R/W-0 Reserved R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-x

GIE — T0IE INTE RBIE T0IF INTF RBIF R = Readable bit

bit7 bit0

bit 7: GIE: Global Interrupt Enable bit

1 = Enables all un-masked interrupts

0 = Disables all interrupts

bit 6:

bit 5: T0IE: TMR0 Overflow Interrupt Enable bit

bit 4: INTE: RB0/INT External Interrupt Enable bit

bit 3: RBIE: RB Port Change Interrupt Enable bit

bit 2: T0IF: TMR0 Overflow Interrupt Flag bit

bit 1: INTF: RB0/INT External Interrupt Flag bit

bit 0: RBIF: RB Port Change Interrupt Flag bit

— = Reserved for future use. Always maintain this bit clear.

1 = Enables the TMR0 interrupt

0 = Disables the TMR0 interrupt

1 = Enables the RB0/INT external interrupt

0 = Disables the RB0/INT external interrupt

1 = Enables the RB port change interrupt

0 = Disables the RB port change interrupt

1 = TMR0 register has overflowed (must be cleared in software)

0 = TMR0 register did not overflow

1 = The RB0/INT external interrupt occurred (must be cleared in software)

0 = The RB0/INT external interrupt did not occur

1 = When at least one of the RB7:RB4 pins changed state (must be cleared in software)

0 = None of the RB7:RB4 pins have changed state

W = Writable bit

- n = Value at POR reset

- x = Unknown at POR reset

1997 Microchip Technology Inc. Preliminary DS40143B-page 19

Page 20

PIC16C55X(A)

4.2.2.4 PCON REGISTER

The PCON register contains flag bits to differentiate

between a Po wer-on Reset, an e xternal MCLR

WDT reset. See Section 7.3 and Section 7.4 for

detailed reset operation.

FIGURE 4-9: PCON REGISTER (ADDRESS 8Eh)

U-0 U-0 U-0 U-0 U-0 U-0 R/W-0 U-0

— — — — — — POR — R = Readable bit

bit7 bit0

bit 7-2: Unimplemented: Read as '0'

bit 1: POR

bit 0: Unimplemented: Read as '0'

: Power-on Reset Status bit

1 = No Power-on Reset occurred

0 = Power-on Reset occurred

reset or

W = Writable bit

U = Unimplemented bit,

- n = Value at POR reset

read as ‘0’

DS40143B-page 20 Preliminary 1997 Microchip Technology Inc.

Page 21

PIC16C55X(A)

4.3 PCL and PCLATH

The program counter (PC) is 13-bits wide. The low byte

comes from the PCL register, which is a readable and

writable register. The high bits (PC<12:8>) are not directly

readable or writable and come from PCLATH. On any

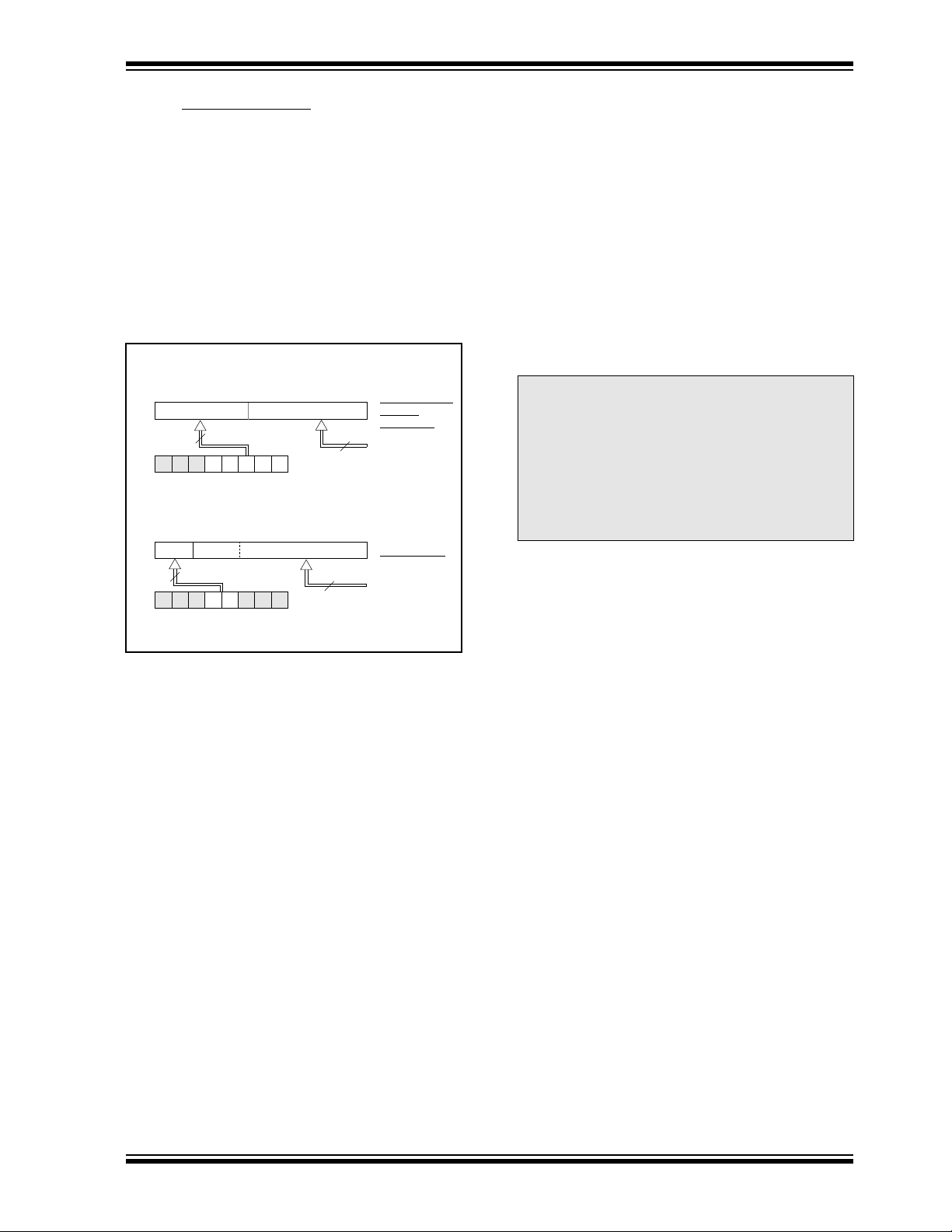

reset, the PC is cleared. Figure 4-10 shows the two

situations for the loading of the PC. The upper example in

the figure shows how the PC is loaded on a write to PCL

(PCLATH<4:0> → PCH). The lo wer example in the figure

shows how the PC is loaded during a CALL or GOTO

instruction (PCLATH<4:3> → PCH).

FIGURE 4-10: LOADING OF PC IN

DIFFERENT SITUATIONS

PCH PCL

12 8 7 0

PC

PCLA TH<4:0>

5

PCLA TH

PCH PCL

12 11 10 0

PC

2

8 7

PCLATH<4:3>

11

8

Instr

uction with

PCL as

Destination

ALU result

GOTO, CALL

Opcode <10:0>

4.3.2 STACK The PIC16C55X(A) family has an 8 level deep x 13-bit

wide hardware stack (Figure 4-1, Figure 4-2 and

Figure 4-3). The stack space is not part of either program or data space and the stack pointer is not readable or writable. The PC is PUSHed onto the stack

when a CALL instruction is executed or an interrupt

causes a branch. The stack is POPed in the event of a

RETURN, RETLW or a RETFIE instruction execution.

PCLATH is not affected by a PUSH or POP operation.

The stack operates as a circular buff er . This means that

after the stack has been PUSHed eight times, the ninth

push overwrites the value that was stored from the first

push. The tenth push overwrites the second push (and

so on).

Note 1: There are no STATUS bits to indicate

stack overflow or stack underflow

conditions.

Note 2: There are no instructions mnemonics

called PUSH or POP. These are actions

that occur from the execution of the

CALL, RETURN, RETLW and RETFIE

instructions, or vectoring to an interrupt

address.

PCLATH

4.3.1 COMPUTED GOTO A computed GOTO is accomplished by adding an

offset to the program counter (ADDWF PCL). When doing

a table read using a computed GOTO method, care

should be exercised if the tab le location crosses a PCL

memory boundary (each 256 byte block). Refer to the

application note

“Implementing a Table Read"

(AN556).

1997 Microchip Technology Inc. Preliminary DS40143B-page 21

Page 22

PIC16C55X(A)

N

4.4 Indirect Addressing, INDF and FSR

Registers

The INDF register is not a physical register . Addressing

A simple program to clear RAM locations 20h-2Fh

using indirect addressing is shown in Example 4-1.

EXAMPLE 4-1: INDIRECT ADDRESSING

the INDF register will cause indirect addressing.

Indirect addressing is possible by using the INDF reg-

ister. Any instruction using the INDF register actually

accesses data pointed to by the file select register

EXT clrf INDF ;clear INDF register

(FSR). Reading INDF itself indirectly will produce 00h.

Writing to the INDF register indirectly results in a

no-operation (although status bits may be affected). An

effective 9-bit address is obtained b y concatenating the

8-bit FSR register and the IRP bit (STATUS<7>), as

CONTINUE:

shown in Figure 4-11. However, IRP is not used in the

PIC16C55X(A).

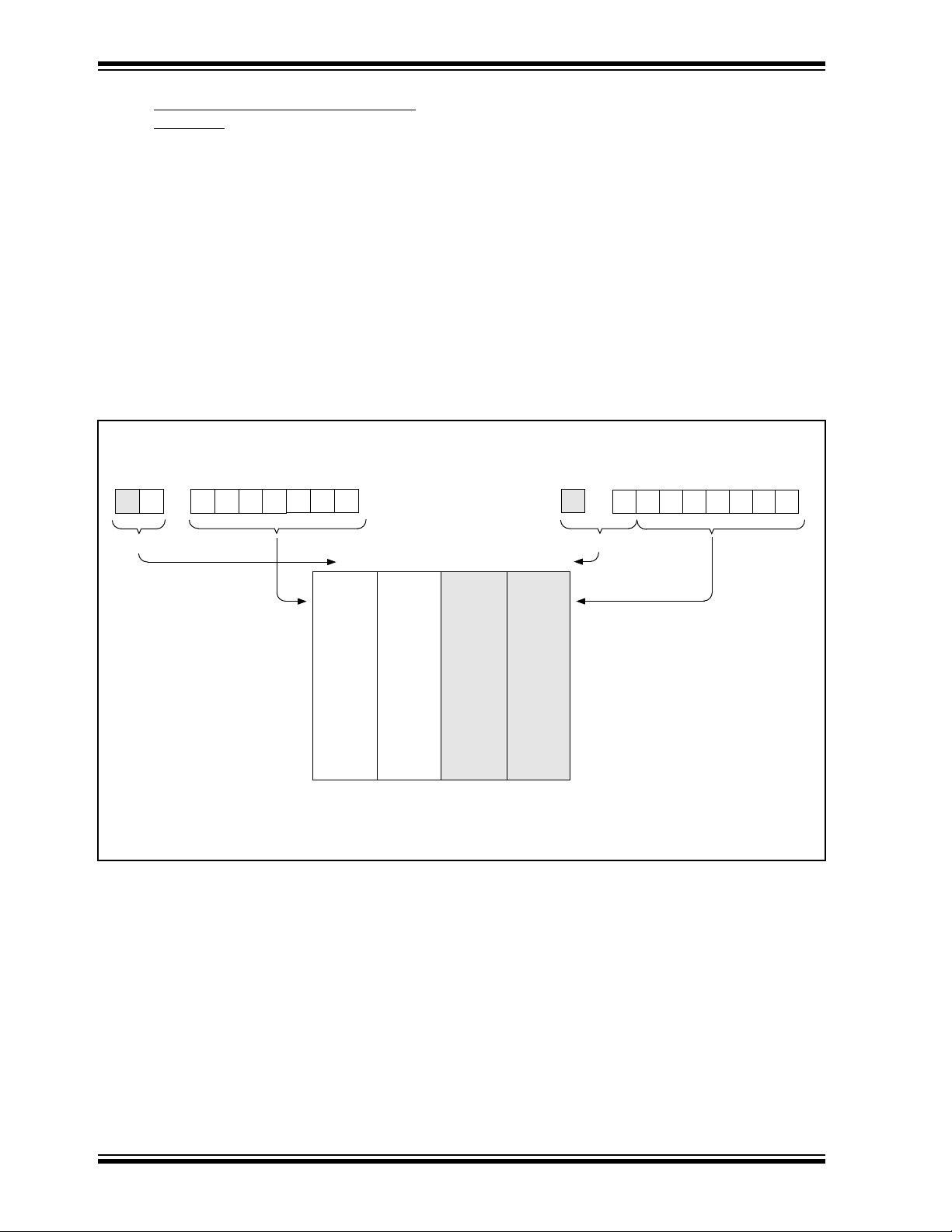

FIGURE 4-11: DIRECT/INDIRECT ADDRESSING PIC16C55X(A)

(1)

RP1 RP0 6

bank select location select

from opcode

00h

0

00 01 10 11

movlw 0x20 ;initialize pointer

movwf FSR ;to RAM

incf FSR ;inc pointer

btfss FSR,4 ;all done?

goto NEXT ;no clear next

;yes continue

Indirect AddressingDirect Addressing

(1)

IRP

bank select

00h

7

FSR register

location select

0

Data

not used

Memory

7Fh

7Fh

Bank 0 Bank 1 Bank 2 Bank 3

For memory map detail see Figure 4-4 and Figure 4-5.

Note 1: The RP1 and IRP bits are reserved, always maintain these bits clear.

DS40143B-page 22 Preliminary 1997 Microchip Technology Inc.

Page 23

PIC16C55X(A)

5.0 I/O PORTS

The PIC16C55X(A) ha ve two ports, PORT A and POR TB.

5.1 PORT A and TRISA Registers

PORTA is a 5-bit wide latch. RA4 is a Schmitt Trigger input

and an open drain output. P ort RA4 is multiplexed with the

T0CKI clock input. All other RA port pins have Schmitt

Trigger input levels and full CMOS output driv ers. All pins

have data direction bits (TRIS registers) which can configure these pins as input or output.

A '1' in the TRISA register puts the corresponding output

driver in a hi- impedance mode. A '0' in the TRISA register

puts the contents of the output latch on the selected pin(s).

Reading the PORTA register reads the status of the pins,

whereas writing to it will write to the port latch. All write

operations are read-modify-write operations. So a write

to a port implies that the port pins are first read, then this

value is modified and written to the port data latch.

Note: On reset, the TRISA register is set to all inputs.

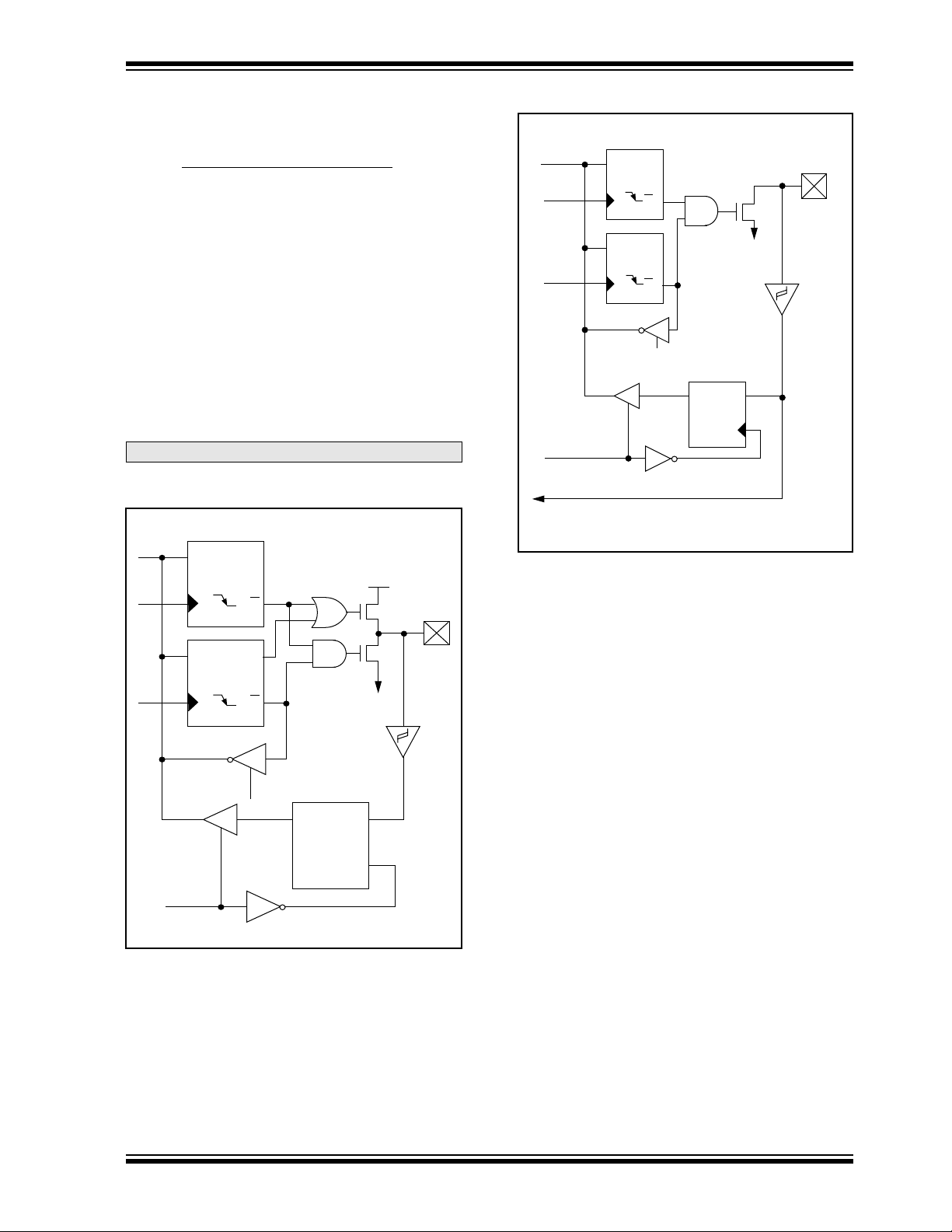

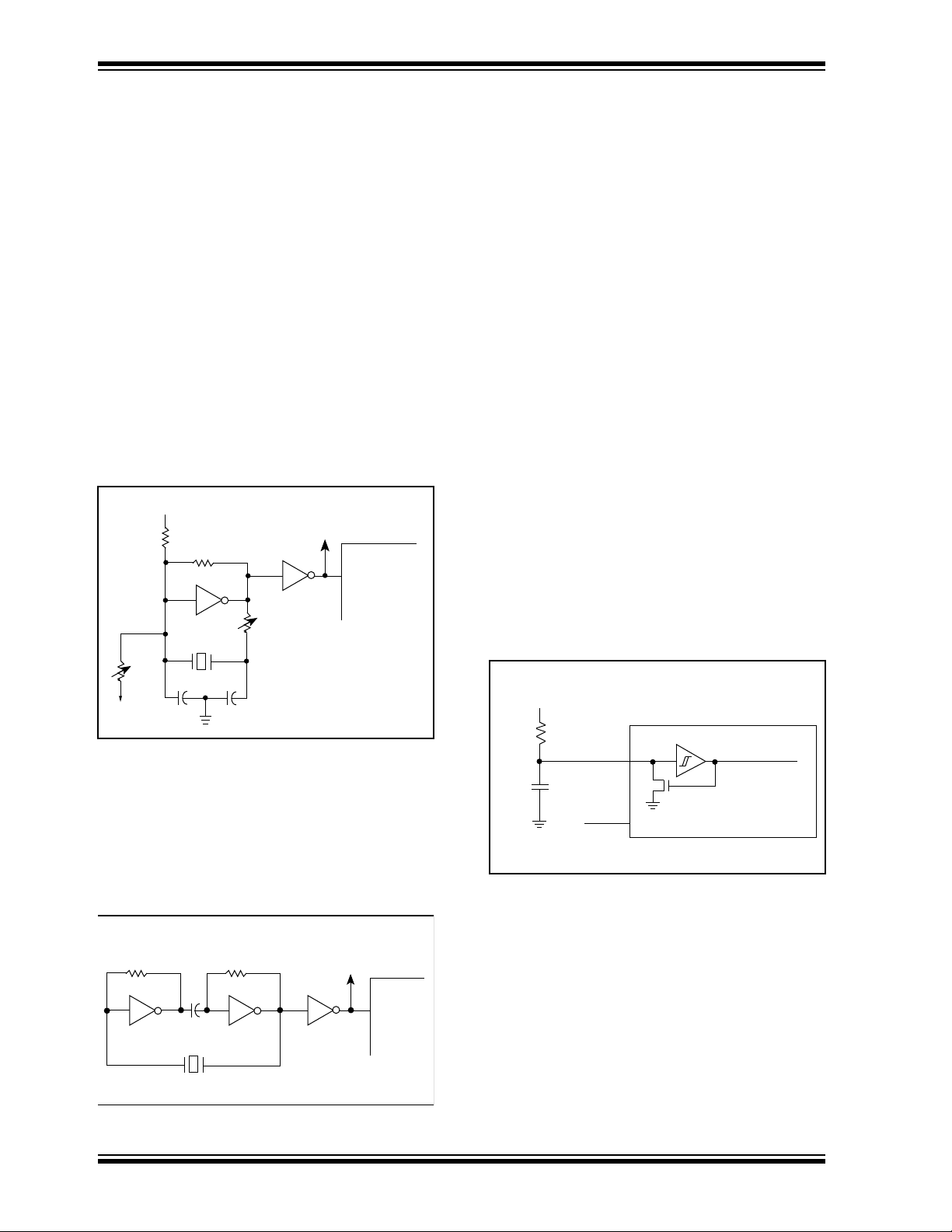

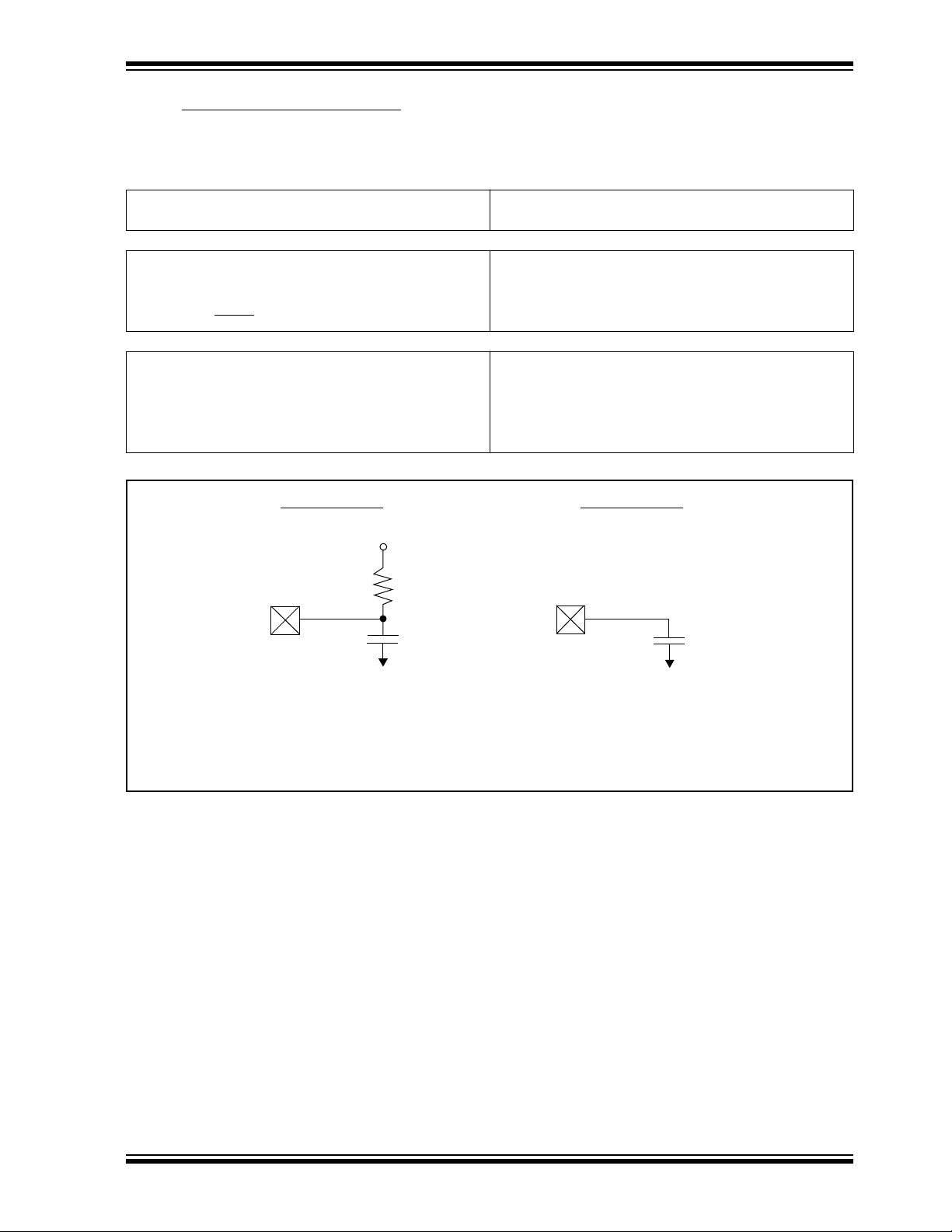

FIGURE 5-1: BLOCK DIAGRAM OF

PORT PINS RA<3:0>

Data

bus

WR

PortA

CK

Data Latch

D

QD

VDD

Q

Q

P

N

I/O pin

FIGURE 5-2: BLOCK DIAGRAM OF RA4 PIN

Data

bus

WR

PORTA

WR

TRISA

RD PORTA

TMR0 clock input

Note 1: I/O pin has protection diodes to V

QD

Q

CK

Data Latch

QD

Q

CK

TRISA Latch

RD TRISA

Schmitt

Trigger

input

buffer

Q D

EN

EN

(1)

I/O pin

N

V

SS

SS only.

WR

TRISA

RD PORTA

CK

TRIS Latch

Q

RD TRISA

Schmitt

Trigger

input

buffer

Q D

EN

SS

V

1997 Microchip Technology Inc. Preliminary DS40143B-page 23

Page 24

PIC16C55X(A)

TABLE 5-1: PORTA FUNCTIONS

Name Bit #

Buffer

Type

Function

RA0 bit0 ST Input/output

RA1 bit1 ST Input/output

RA2 bit2 ST Input/output

RA3 bit3 ST Input/output

RA4/T0CKI bit4 ST Input/output or external clock input for TMR0. Output is open drain type.

Legend: ST = Schmitt Trigger input

TABLE 5-2: SUMMARY OF REGISTERS ASSOCIATED WITH PORTA

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

05h PORTA — — — RA4 RA3 RA2 RA1 RA0

85h TRISA — — — TRISA4 TRISA3 TRISA2 TRISA1 TRISA0

Legend: — = Unimplemented locations, read as ‘0’

Note: Note: Shaded bits are not used by PORTA.

Value on

POR

---x xxxx ---u uuuu

---1 1111 ---1 1111

Value on

All Other Resets

DS40143B-page 24 Preliminary 1997 Microchip Technology Inc.

Page 25

PIC16C55X(A)

5.2 PORTB and TRISB Registers

PORTB is an 8-bit wide bi-directional port. The

corresponding data direction register is TRISB. A '1' in

the TRISB register puts the corresponding output driver

in a high impedance mode. A '0' in the TRISB register

puts the contents of the output latch on the selected

pin(s).

Reading PORTB register reads the status of the pins,

whereas writing to it will write to the port latch. All write

operations are read-modify-write operations. So a write

to a port implies that the por t pins are first read, then

this value is modified and written to the port data latch.

Each of the PORTB pins has a weak internal pull-up

(≈200 µA typical). A single control bit can turn on all the

pull-ups. This is done by clearing the RBPU

(OPTION<7>) bit. The weak pull-up is automatically

turned off when the port pin is configured as an output.

The pull-ups are disabled on Power-on Reset.

Four of PORTB’s pins, RB7:RB4, have an interrupt on

change feature. Only pins configured as inputs can

cause this interrupt to occur (i.e., any RB7:RB4 pin

configured as an output is excluded from the interrupt

on change comparison). The input pins (of RB7:RB4)

are compared with the old value latched on the last

read of PORTB. The “mismatch” outputs of RB7:RB4

are OR’ed together to generate the RBIF interrupt (flag

latched in INTCON<0>).

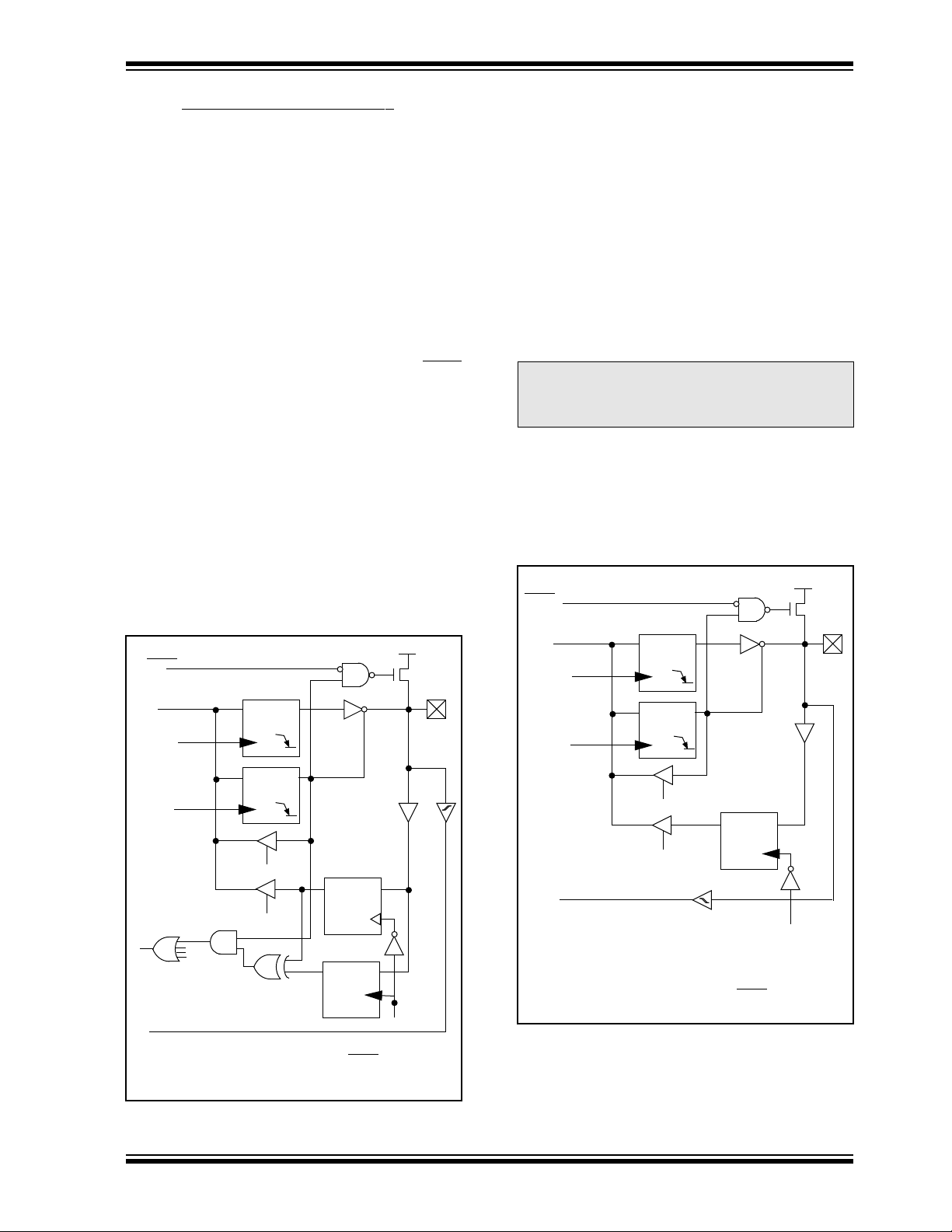

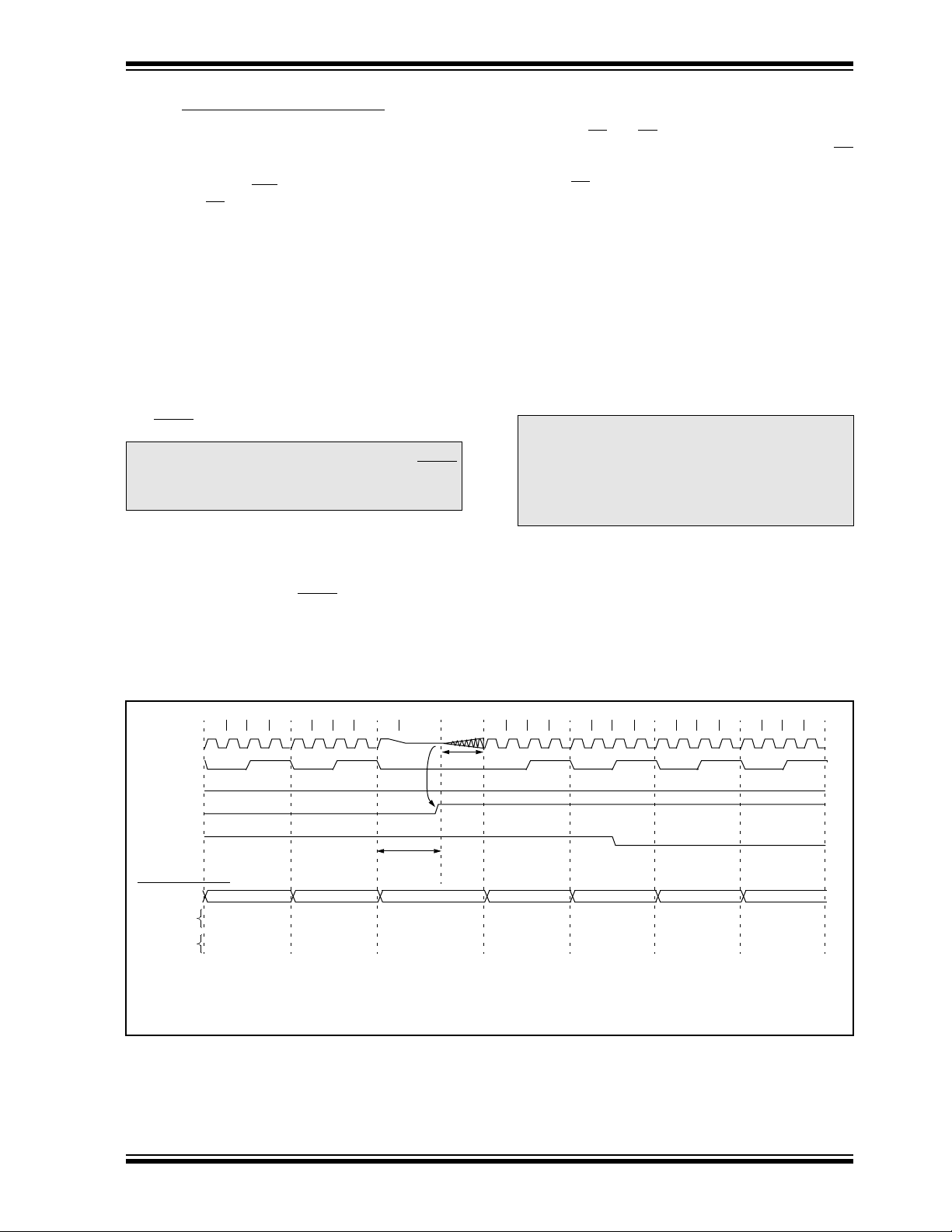

FIGURE 5-3: BLOCK DIAGRAM OF

RB7:RB4 PINS

DD

EN

TTL

Input

Buffer

V

P

weak

pull-up

I/O

pin

ST

Buffer

(1)

RBPU

Data bus

WR PortB

WR TRISB

Set RBIF

(2)

Data Latch

QD

CK

TRIS Latch

QD

CK

RD TRISB

RD PortB

Latch

Q D

This interrupt can wake the device from SLEEP. The

user, in the interrupt service routine, can clear the

interrupt in the following manner:

a) Any read or write of PORTB. This will end the

mismatch condition.

b) Clear flag bit RBIF.

A mismatch condition will continue to set flag bit RBIF.

Reading PORTB will end the mismatch condition, and

allow flag bit RBIF to be cleared.

This interrupt on mismatch feature, together with

software configurable pull-ups on these four pins allow

easy interface to a key pad and make it possible for

wake-up on key-depression. (See AN552 in the

Microchip

Note: If a change on the I/O pin should occur when the

Embedded Control Handbook

.)

read operation is being executed (start of the Q2

cycle), then the RBIF interrupt flag may not

get set.

The interrupt on change feature is recommended for

wake-up on key depression operation and operations

where PORTB is only used for the interrupt on change

feature. Polling of PORTB is not recommended while

using the interrupt on change feature.

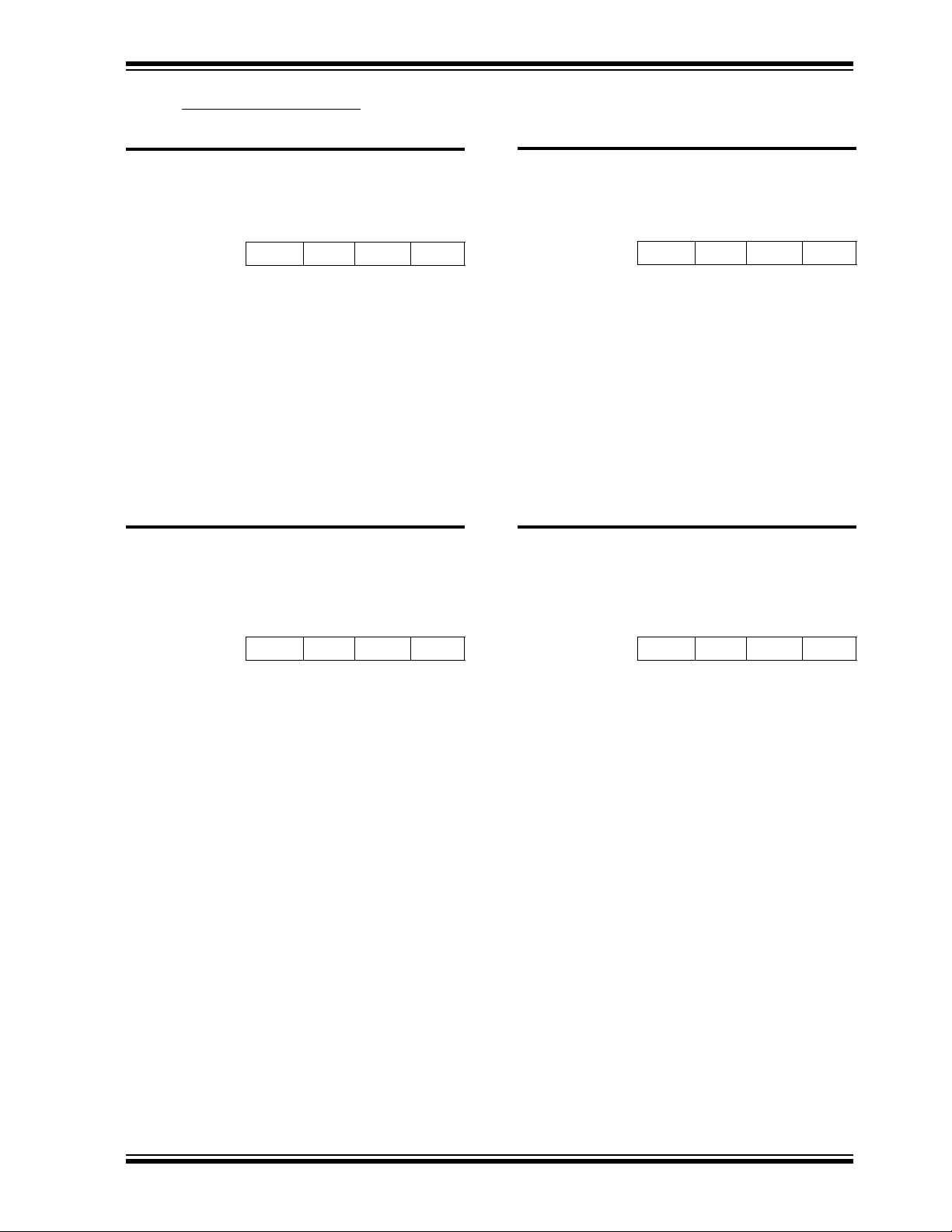

FIGURE 5-4: BLOCK DIAGRAM OF

RB3:RB0 PINS

DD

TTL

Input

Buffer

V

weak

P

pull-up

RD Port

I/O

pin

(1)

RBPU

Data bus

WR PortB

WR TRISB

RB0/INT

(2)

Data Latch

QD

CK

QD

CK

RD TRISB

Q D

RD PortB

ST

Buffer

EN

From other

RB7:RB4 pins

RB7:RB6 in serial programming mode

Note 1: I/O pins have diode protection to VDD and VSS.

Note 2: TRISB = 1 enables weak pull-up if RBPU

(OPTION<7>).

Q D

EN

= '0'

RD Port

Note 1: I/O pins have diode protection to VDD and VSS.

Note 2: TRISB = 1 enables weak pull-up if RBPU

(OPTION<7>).

= '0'

1997 Microchip Technology Inc. Preliminary DS40143B-page 25

Page 26

PIC16C55X(A)

TABLE 5-3: PORTB FUNCTIONS

Name Bit # Buffer Type Function

(1)

RB0/INT bit0

TTL/ST

RB1 bit1 TTL Input/output pin. Internal software programmable weak pull-up.

RB2 bit2 TTL Input/output pin. Internal software programmable weak pull-up.

RB3 bit3 TTL Input/output pin. Internal software programmable weak pull-up.

RB4 bit4 TTL Input/output pin (with interrupt on change). Internal software

RB5 bit5 TTL Input/output pin (with interrupt on change). Internal software

RB6 bit6

RB7 bit7

TTL/ST

TTL/ST

Legend: ST = Schmitt Trigger, TTL = TTL input

Note 1: This buffer is a Schmitt Trigger input when configured as the external interrupt.

Note 2: This buffer is a Schmitt Trigger input when used in serial programming mode.

TABLE 5-4: SUMMARY OF REGISTERS ASSOCIATED WITH PORTB

Input/output or external interrupt input. Internal software programmable

weak pull-up.

programmable weak pull-up.

programmable weak pull-up.

(2)

Input/output pin (with interrupt on change). Internal software

programmable weak pull-up. Serial programming clock pin.

(2)

Input/output pin (with interrupt on change). Internal software

programmable weak pull-up. Serial programming data pin.

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

06h PORTB RB7 RB6 RB5 RB4 RB3 RB2 RB1 RB0

86h TRISB TRISB7 TRISB6 TRISB5 TRISB4 TRISB3 TRISB2 TRISB1 TRISB0

81h OPTION RBPU INTEDG T0CS T0SE PSA PS2 PS1 PS0

Note: Shaded bits are not used by PORTB.

Value on

POR

uuuu uuuu xxxx xxxx

1111 1111 1111 1111

1111 1111 1111 1111

Value on

All Other Rests

DS40143B-page 26 Preliminary 1997 Microchip Technology Inc.

Page 27

PIC16C55X(A)

5.3 I/O Programming Considerations

5.3.1 BI-DIRECTIONAL I/O PORTS Any instruction which writes, operates internally as a

read followed by a write operation. The BCF and BSF

instructions, for example, read the register into the

CPU, ex ecute the bit operation and write the result back

to the register. Caution must be used when these

instructions are applied to a port with both inputs and

outputs defined. For example, a BSF operation on bit5

of PORTB will cause all eight bits of PORTB to be read

into the CPU. Then the BSF operation takes place on

bit5 and PORTB is written to the output latches. If

another bit of PORTB is used as a bidirectional I/O pin

(e.g., bit0) and it is defined as an input at this time, the

input signal present on the pin itself would be read into

the CPU and re-written to the data latch of this

particular pin, overwriting the previous content. As long

as the pin stays in the input mode, no problem occurs.

However, if bit0 is switched into output mode later on,

the content of the data latch may now be unknown.

Reading the port register, reads the values of the port

pins. Writing to the port register writes the value to the

port latch. When using read modify write instructions

(ex. BCF, BSF , etc.) on a port, the value of the port pins

is read, the desired operation is done to this value, and

this value is then written to the port latch.

Example 5-1 shows the effect of two sequential

read-modify-write instructions (ex., BCF, BSF, etc.) on

an I/O port.

A pin actively outputting a Low or High should not be

driven from external devices at the same time in order

to change the level on this pin (“wired-or”, “wired-and”).

The resulting high output currents may damage

the chip.

EXAMPLE 5-1: READ-MODIFY-WRITE

INSTRUCTIONS ON AN

I/O PORT

;;Initial PORT settings: PORTB<7:4> Inputs

; PORTB<3:0> Outputs

;;PORTB<7:6> have external pull-up and are not

connected to other circuitry

;

; PORT latch PORT pins

; ---------- ----------

BCF PORTB, 7 ; 01pp pppp 11pp pppp

BCF PORTB, 6 ; 10pp pppp 11pp pppp

BSF STATUS,RP0 ;

BCF TRISB, 7 ; 10pp pppp 11pp pppp

BCF TRISB, 6 ; 10pp pppp 10pp pppp

;

; Note that the user may have expected the pin

; values to be 00pp pppp. The 2nd BCF caused

; RB7 to be latched as the pin value (High).

5.3.2 SUCCESSIVE OPERATIONS ON I/O PORTS The actual write to an I/O port happens at the end of an

instruction cycle, whereas for reading, the data must be

valid at the beginning of the instruction cycle

(Figure 5-5). Therefore, care must be exercised if a

write followed by a read operation is carried out on the

same I/O port. The sequence of instructions should be

such to allow the pin voltage to stabilize (load

dependent) before the next instruction which causes

that file to be read into the CPU is executed. Otherwise ,

the previous state of that pin may be read into the CPU

rather than the new state. When in doubt, it is better to

separate these instructions with an NOP or another

instruction not accessing this I/O port.

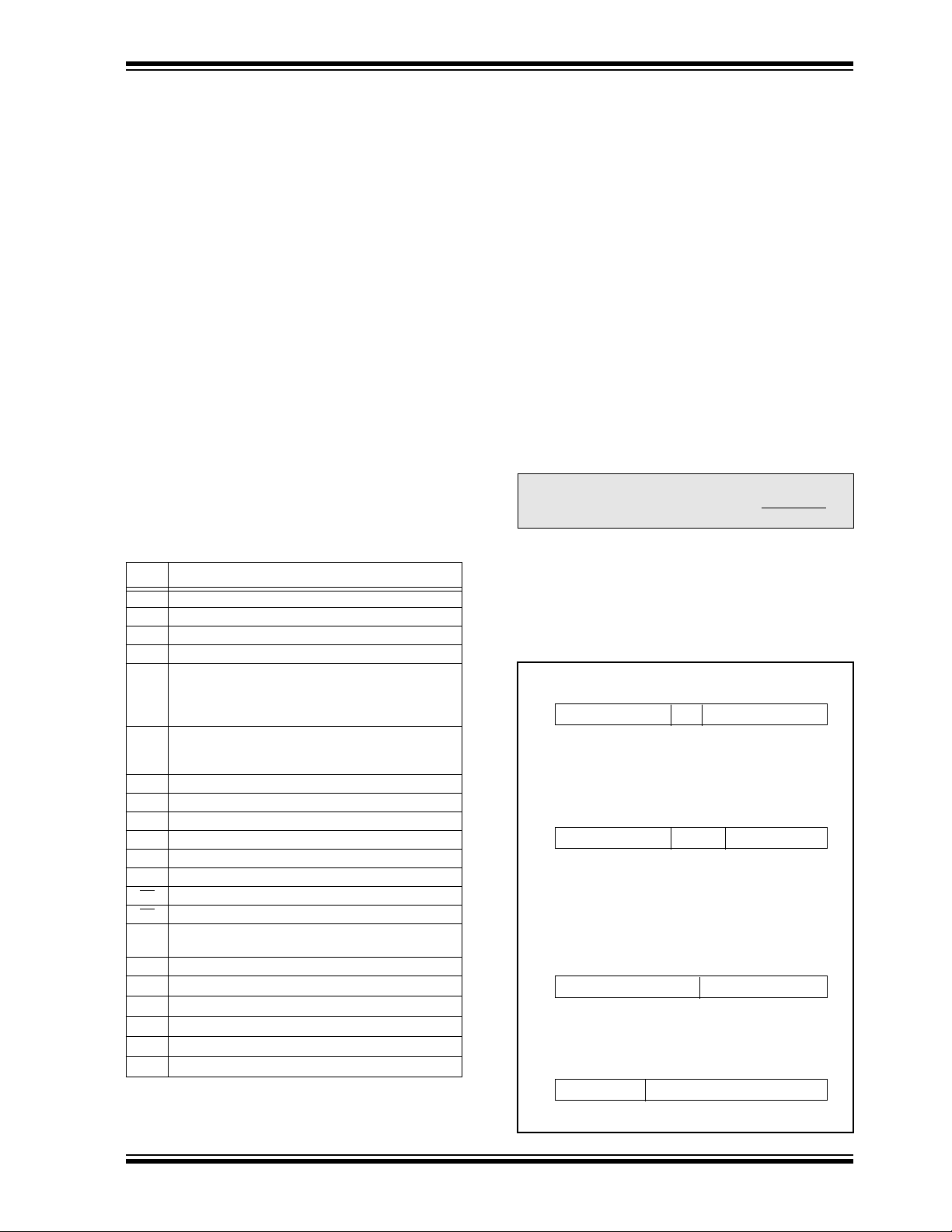

FIGURE 5-5: SUCCESSIVE I/O OPERATION

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

PC

Instruction

fetched

RB7:RB0

RB <7:0>

1997 Microchip Technology Inc. Preliminary DS40143B-page 27

PC

MOVWF PORTB

Write to

PORTB

PC + 1 PC + 2 PC + 3

Read PORTB

Port pin

TPD

Execute

MOVWF

PORTB

sampled here

Execute

MOVF

PORTB, W

NOPNOPMOVF PORTB, W

Execute

NOP

Note:

This example shows write to PORTB

followed by a read from PORTB.

Note that:

data setup time = (0.25 T

where TCY = instruction cycle and

TPD = propagation delay of Q1 cycle

to output valid.

Therefore, at higher clock frequencies,

a write followed by a read may be

problematic.

CY - TPD)

Page 28

PIC16C55X(A)

NOTES:

DS40143B-page 28 Preliminary 1997 Microchip Technology Inc.

Page 29

PIC16C55X(A)

6.0 TIMER0 MODULE

The Timer0 module timer/counter has the following

features:

• 8-bit timer/counter

• Readable and writable

• 8-bit software programmable prescaler

• Internal or external clock select

• Interrupt on overflow from FFh to 00h

• Edge select for external clock

Figure 6-1 is a simplified block diagram of the Timer0

module.

Timer mode is selected by clearing the T0CS bit

(OPTION<5>). In timer mode , the TMR0 will increment

every instruction cycle (without prescaler). If Timer0 is

written, the increment is inhibited for the following two

cycles (Figure 6-2 and Figure 6-3). The user can work

around this by writing an adjusted value to TMR0.

Counter mode is selected by setting the T0CS bit. In

this mode Timer0 will increment either on every rising

or falling edge of pin RA4/T0CKI. The incrementing

edge is determined by the source edge (T0SE) control

bit (OPTION<4>). Clearing the T0SE bit selects the

rising edge. Restrictions on the e xternal clock input are

discussed in detail in Section 6.2.

The prescaler is shared between the Timer0 module

and the WatchdogTimer. The prescaler assignment is

controlled in software by the control bit PSA

(OPTION<3>). Clearing the PSA bit will assign the

prescaler to Timer0. The prescaler is not readable or

writable. When the prescaler is assigned to the Timer0

module, prescale value of 1:2, 1:4, ..., 1:256 are

selectable. Section 6.3 details the operation of the

prescaler.

6.1 TIMER0 Interrupt

Timer0 interrupt is generated when the TMR0 register

timer/counter overflows from FFh to 00h. This overflow

sets the T0IF bit. The interrupt can be masked by

clearing the T0IE bit (INTCON<5>). The T0IF bit

(INTCON<2>) must be cleared in software by the

Timer0 module interrupt service routine before

re-enabling this interrupt. The Timer0 interrupt cannot

wake the processor from SLEEP since the timer is shut

off during SLEEP. See Figure 6-4 for Timer0 interrupt

timing.

FIGURE 6-1: TIMER0 BLOCK DIAGRAM

RA4/T0CKI

pin

Note 1: Bits, T0SE, T0CS, PS2, PS1, PS0 and PSA are located in the OPTION register.

2: The prescaler is shared with Watchdog Timer (Figure 6-6)

FOSC/4

T0SE

0

1

T0CS

Programmable

Prescaler

PS2:PS0

1

0

PSA

PSout

Sync with

Internal

clocks

(2 cycle delay)

PSout

FIGURE 6-2: TIMER0 (TMR0) TIMING: INTERNAL CLOCK/NO PRESCALER

PC

(Program

Counter)

Instruction

Fetch

TMR0

Instruction

Executed

Q1 Q2 Q3 Q4

PC-1

T0

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

PC PC+1 PC+2 PC+3 PC+4 PC+5 PC+6

MOVWF TMR0

T0+1 T0+2 NT0 NT0 NT0 NT0+1 NT0+2

MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W

Write TMR0

executed

Read TMR0

reads NT0

Read TMR0

reads NT0

Read TMR0

reads NT0

Read TMR0

reads NT0 + 1

Data bus

TMR0

8

Set Flag bit T0IF

on Overflow

Read TMR0

reads NT0 + 2

T0

1997 Microchip Technology Inc. Preliminary DS40143B-page 29

Page 30

PIC16C55X(A)

FIGURE 6-3: TIMER0 TIMING: INTERNAL CLOCK/PRESCALE 1:2

PC

(Program

Counter)

Instruction

Fetch

TMR0

Instruction

Execute

Q1 Q2 Q3 Q4

PC-1

T0 NT0+1

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

PC PC+1 PC+2 PC+3 PC+4 PC+5 PC+6

MOVWF TMR0

MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W MOVF TMR0,W

T0+1

Write TMR0

executed

Read TMR0

reads NT0

FIGURE 6-4: TIMER0 INTERRUPT TIMING

Q2Q1 Q3 Q4Q2Q1 Q3 Q4 Q2Q1 Q3 Q4 Q2Q1 Q3 Q4 Q2Q1 Q3 Q4

OSC1

CLKOUT(3)

TMR0 timer

T0IF bit

(INTCON<2>)

GIE bit

(INTCON<7>)

UCTION FLOW

INSTR

PC

Instruction

fetched

FEh

1

PC

Inst (PC)

FFh 00h 01h 02h

1

PC +1 PC +1 0004h 0005h

Inst (PC+1)

NT0

Read TMR0

reads NT0

Read TMR0

reads NT0

Interrupt Latency Time

Read TMR0

reads NT0

Read TMR0

reads NT0 + 1

Inst (0004h) Inst (0005h)

Instruction

executed

Inst (PC-1)

Inst (PC)

Note 1: T0IF interrupt flag is sampled here (every Q1).

2: Interrupt latency = 4Tcy, where Tcy = instruction cycle time.

3: CLKOUT is available only in RC oscillator mode.

Inst (0004h)Dummy cycle Dummy cycle

DS40143B-page 30 Preliminary 1997 Microchip Technology Inc.

Page 31

PIC16C55X(A)

6.2 Using Timer0 with External Clock

When a prescaler is used, the external clock input is

divided by the asynchronous ripple-counter type

When an external clock input is used for Timer0, it must

meet certain requirements. The external clock

requirement is due to internal phase clock (T

OSC)

synchronization. Also, there is a delay in the actual

incrementing of Timer0 after synchronization.

6.2.1 EXTERNAL CLOCK SYNCHRONIZATION When no prescaler is used, the external clock input is

the same as the prescaler output. The synchronization

of T0CKI with the internal phase clocks is

accomplished by sampling the prescaler output on the

Q2 and Q4 cycles of the internal phase clocks

(Figure 6-5). Therefore, it is necessary for T0CKI to be

high for at least 2T

and low for at least 2T

OSC (and a small RC delay of 20 ns)

OSC (and a small RC delay of

20 ns). Refer to the electrical specification of the

desired device.

prescaler so that the prescaler output is symmetrical.

For the external clock to meet the sampling

requirement, the ripple-counter must be taken into

account. Therefore, it is necessary for T0CKI to have a

period of at least 4T

40 ns) divided by the prescaler value. The only

requirement on T0CKI high and low time is that the y do

not violate the minimum pulse width requirement of

10 ns. Refer to parameters 40, 41 and 42 in the

electrical specification of the desired device.

6.2.2 TIMER0 INCREMENT DELAY Since the prescaler output is synchronized with the

internal clocks, there is a small delay from the time the

external clock edge occurs to the time the TMR0 is

actually incremented. Figure 6-5 shows the delay from

the external clock edge to the timer incrementing.

FIGURE 6-5: TIMER0 TIMING WITH EXTERNAL CLOCK

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

External Clock Input or

Prescaler output

External Clock/Prescaler

Output after sampling

Increment Timer0 (Q4)

(2)

(1)

(3)

OSC (and a small RC delay of

Small pulse

misses sampling

Timer0

Note 1: Delay from clock input change to Timer0 increment is 3Tosc to 7Tosc. (Duration of Q = Tosc).

Therefore, the error in measuring the interval between two edges on Timer0 input = ±4Tosc max.

2: External clock if no prescaler selected, Prescaler output otherwise.

3: The arrows indicate the points in time where sampling occurs.

T0 T0 + 1 T0 + 2

1997 Microchip Technology Inc. Preliminary DS40143B-page 31

Page 32

PIC16C55X(A)

6.3 Prescaler

The PSA and PS2:PS0 bits (OPTION<3:0>) determine

the prescaler assignment and prescale ratio.

An 8-bit counter is available as a prescaler for the

Timer0 module, or as a postscaler for the Watchdog

Timer, respectively (Figure 6-6). For simplicity, this

counter is being referred to as “prescaler” throughout

this data sheet. Note that there is only one prescaler

available which is mutually exclusive between the

Timer0 module and the Watchdog Timer. Thus, a

When assigned to the Timer0 module, all instructions

writing to the TMR0 register (e.g., CLRF 1, MOVWF 1,

BSF 1,x....etc.) will clear the prescaler. When

assigned to WDT, a CLRWDT instruction will clear the

prescaler along with the Watchdog Timer. The

prescaler is not readable or writable.

prescaler assignment for the Timer0 module means

that there is no prescaler for the Watchdog Timer, and

vice-versa.

FIGURE 6-6: BLOCK DIAGRAM OF THE TIMER0/WDT PRESCALER

CLKOUT (=Fosc/4)

T0CKI

pin

T0SE

0

1

T0CS

M

U

X

1

M

U

0

X

PSA

SYNC

2

Cycles

Data Bus

8

TMR0 reg

Set flag bit T0IF

on Overflow

0

M

U

1

Watchdog

Timer

WDT Enable bit

Note: T0SE, T0CS, PSA, PS0-PS2 are bits in the OPTION register.

X

PSA

8-bit Prescaler

8

8-to-1MUX

0

M U X

WDT

Time-out

1

PS0 - PS2

PSA

DS40143B-page 32 Preliminary 1997 Microchip Technology Inc.

Page 33

PIC16C55X(A)

6.3.1 SWITCHING PRESCALER ASSIGNMENT The prescaler assignment is fully under software

control (i.e., it can be changed “on the fly” during

program execution). To avoid an unintended device

RESET, the following instruction sequence

(Example 6-1) must be executed when changing the

prescaler assignment from Timer0 to WDT. Lines 5-7

are required only if the desired postscaler rate is 1:1

(PS<2:0> = 000) or 1:2 (PS<2:0> = 001).

EXAMPLE 6-1: CHANGING PRESCALER

(TIMER0→WDT)

1.BCF STATUS, RP0 ;Skip if already in

; Bank 0

2.CLRWDT ;Clear WDT

3.CLRF TMR0 ;Clear TMR0 & Prescaler

4.BSF STATUS, RP0 ;Bank 1

5.MOVLW '00101111’b; ;These 3 lines (5, 6, 7)

6.MOVWF OPTION ; are required only if

; desired PS<2:0> are

7.CLRWDT ; 000 or 001

8.MOVLW '00101xxx’b ;Set Postscaler to

9.MOVWF OPTION ; desired WDT rate

10.BCF STATUS, RP0 ;Return to Bank 0

To change prescaler from the WDT to the TMR0

module use the sequence shown in Example 6-2. This

precaution must be taken even if the WDT is disabled.

EXAMPLE 6-2: CHANGING PRESCALER

(WDT→TIMER0)

CLRWDT ;Clear WDT and

;prescaler

BSF STATUS, RP0

MOVLW b'xxxx0xxx' ;Select TMR0, new

;prescale value and

;clock source

MOVWF OPTION

BCF STATUS, RP0

TABLE 6-1: REGISTERS ASSOCIATED WITH TIMER0

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

01h TMR0 Timer0 module’s register uuuu uuuu xxxx xxxx

0Bh/8Bh INTCON GIE

81h OPTION

85h TRISA

RBPU INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

— — — TRISA4 TRISA3 TRISA2 TRISA1 TRISA0 ---1 1111 ---1 1111

+ T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000x

Value on

POR

Legend: — = Unimplemented locations, read as ‘0’.

+ = Reserved for future use.

Note: Shaded bits are not used by TMR0 module.

Value on

All Other Resets

1997 Microchip Technology Inc. Preliminary DS40143B-page 33

Page 34

PIC16C55X(A)

NOTES:

DS40143B-page 34 Preliminary 1997 Microchip Technology Inc.

Page 35

PIC16C55X(A)

7.0 SPECIAL FEATURES OF THE

CPU

What sets a microcontroller apart from other

processors are special circuits to deal with the needs of

real time applications. The PIC16C55X(A) family has a

host of such features intended to maximize system

reliability, minimize cost through elimination of external

components, provide power saving operating modes

and offer code protection.

These are:

1. OSC selection

2. Reset

Power-on Reset (POR)

Power-up Timer (PWRT)

Oscillator Start-Up Timer (OST)

3. Interrupts

4. Watchdog Timer (WDT)

5. SLEEP

6. Code protection

7. ID Locations

8. In-circuit serial programming™

The PIC16C55X(A) has a Watchdog Timer which is

controlled by configuration bits. It runs off its own RC

oscillator for added reliability. There are two timers that

offer necessary delays on power-up. One is the

Oscillator Start-up Timer (OST), intended to keep the

chip in reset until the crystal oscillator is stable. The

other is the Pow er-up Timer (PWRT), which pro vides a

fixed delay of 72 ms (nominal) on power-up only,

designed to keep the part in reset while the power

supply stabilizes. With these two functions on-chip,

most applications need no external reset circuitry.

The SLEEP mode is designed to offer a very low

current power-down mode. The user can wake-up from

SLEEP through external reset, Watchdog Timer

wake-up or through an interrupt. Several oscillator

options are also made available to allow the part to fit

the application. The RC oscillator option saves system

cost while the LP crystal option saves power. A set of

configuration bits are used to select various options.

1997 Microchip Technology Inc. Preliminary DS40143B-page 35

Page 36

PIC16C55X(A)

7.1 Configuration Bits

The user will note that address 2007h is beyond

the user program memory space. In fact, it belongs

The configuration bits can be programmed (read as '0')

or left unprogrammed (read as '1') to select various

device configurations. These bits are mapped in

to the special test/configuration memory space

(2000h – 3FFFh), which can be accessed only during

programming.

program memory location 2007h.

FIGURE 7-1: CONFIGURATION WORD

CP1

bit13 bit0

bit 13-8 CP<1:0>: Code protection bits

5-4: 11 = Code protection off

bit 7: Unimplemented: Read as '1'

bit 6: Reserved: Do not use

bit 3: PWRTE: Power-up Timer Enable bit

bit 2: WDTE: Watchdog Timer Enable bit

bit 1-0: FOSC1:FOSC0: Oscillator Selection bits

1

CP1

CP0

10 = Upper half of program memory code protected

01 = Upper 3/4th of program memory code protected

00 = All memory is code protected

1 = PWRT disabled

0 = PWRT enabled

1 = WDT enabled

0 = WDT disabled

11 = RC oscillator

10 = HS oscillator

01 = XT oscillator

00 = LP oscillator

CP0

1

CP1

CP0

1

(1)

— Reserved CP1

1

PWRTE WDTE F0SC1 F0SC0

CP0

CONFIG Address

REGISTER: 2007h

Note 1: All of the CP1:CP0 pairs have to be given the same value to enable the code protection scheme listed.

DS40143B-page 36 Preliminary 1997 Microchip Technology Inc.

Page 37

PIC16C55X(A)

7.2 Oscillator Configurations

7.2.1 OSCILLATOR TYPES

The PIC16C55X(A) can be operated in four different

oscillator options. The user can program two

configuration bits (FOSC1 and FOSC0) to select one of

these four modes:

• LP Low Power Crystal

• XT Crystal/Resonator

• HS High Speed Crystal/Resonator

• RC Resistor/Capacitor

7.2.2 CRYSTAL OSCILLATOR / CERAMIC

RESONATORS

In XT, LP or HS modes a crystal or ceramic resonator

is connected to the OSC1 and OSC2 pins to establish

oscillation (Figure 7-2). The PIC16C55X(A) oscillator

design requires the use of a parallel cut crystal. Use of

a series cut crystal may give a frequency out of the

crystal manufacturers specifications. When in XT, LP or

HS modes, the device can have an external clock

source to drive the OSC1 pin (Figure 7-3).

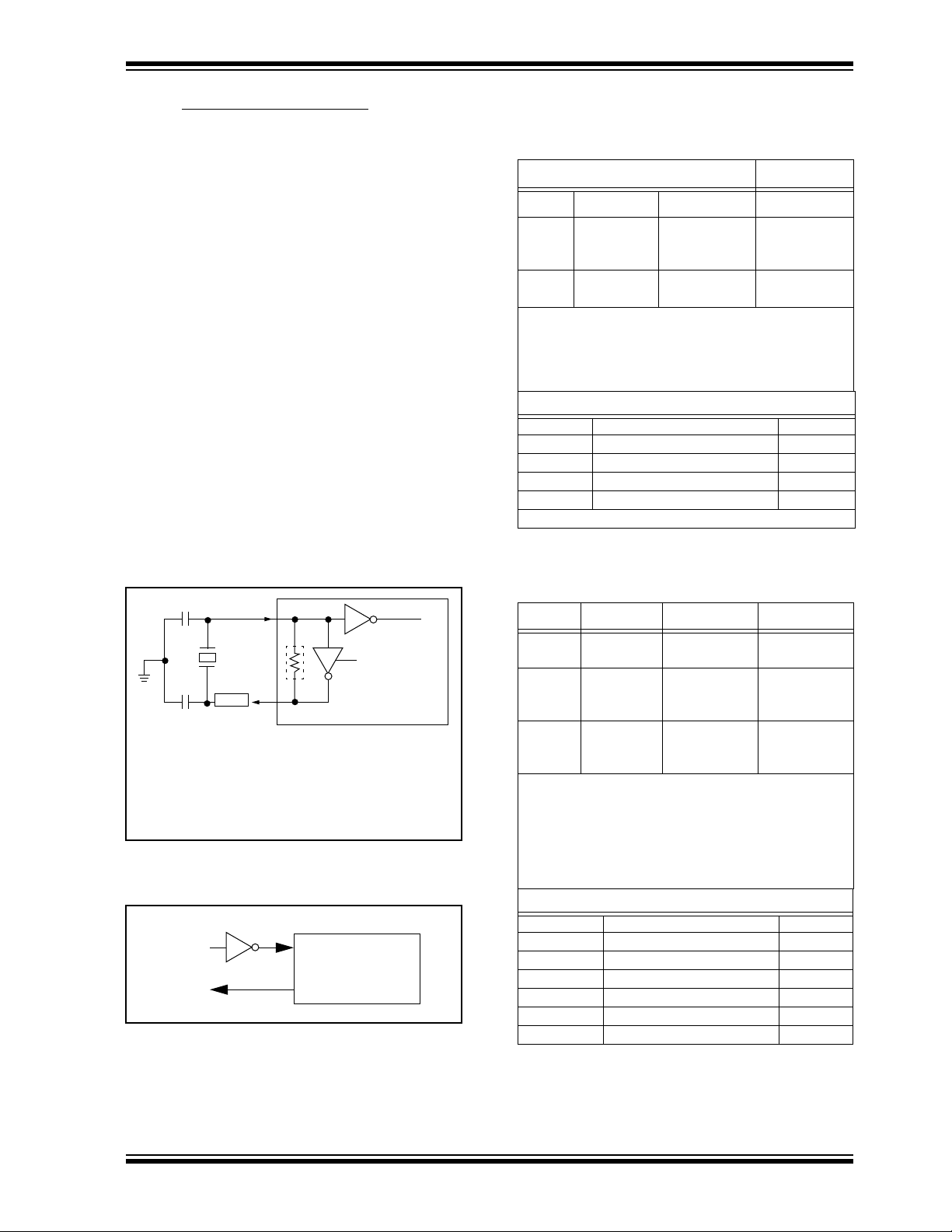

FIGURE 7-2: CRYSTAL OPERATION

(OR CERAMIC RESONATOR)

(HS, XT OR LP OSC

CONFIGURATION)

OSC1

C1

XTAL

OSC2

RS

see Note

C2

RF

To internal logic

SLEEP

PIC16C55X(A)

See Table 7-1 and Table 7-2 for recommended

values of C1 and C2.

Note: A series resistor may be required for

AT strip cut crystals.

FIGURE 7-3: EXTERNAL CLOCK INPUT

OPERATION (HS, XT OR LP

OSC CONFIGURATION)

Clock from

ext. system

Open

OSC1

PIC16C55X(A)

OSC2

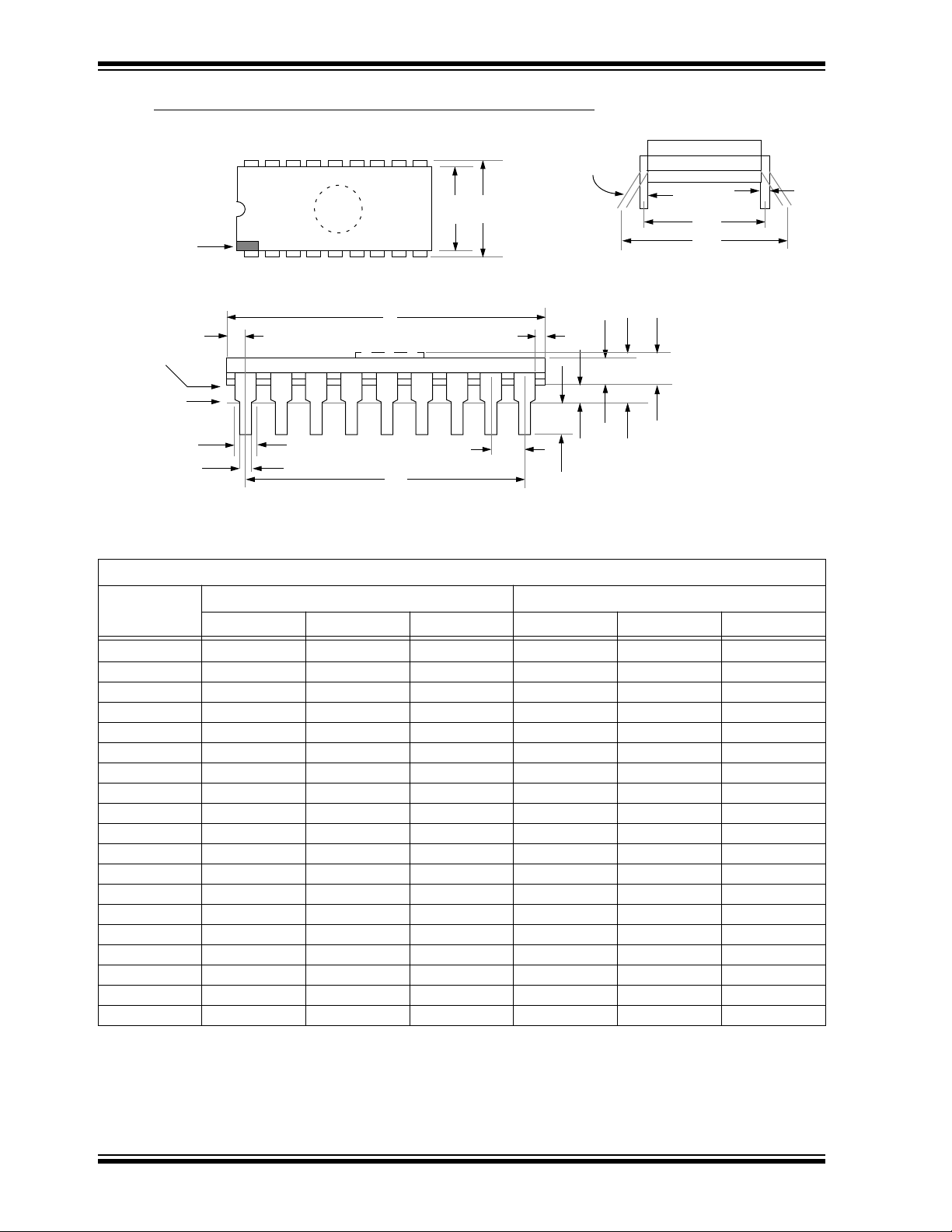

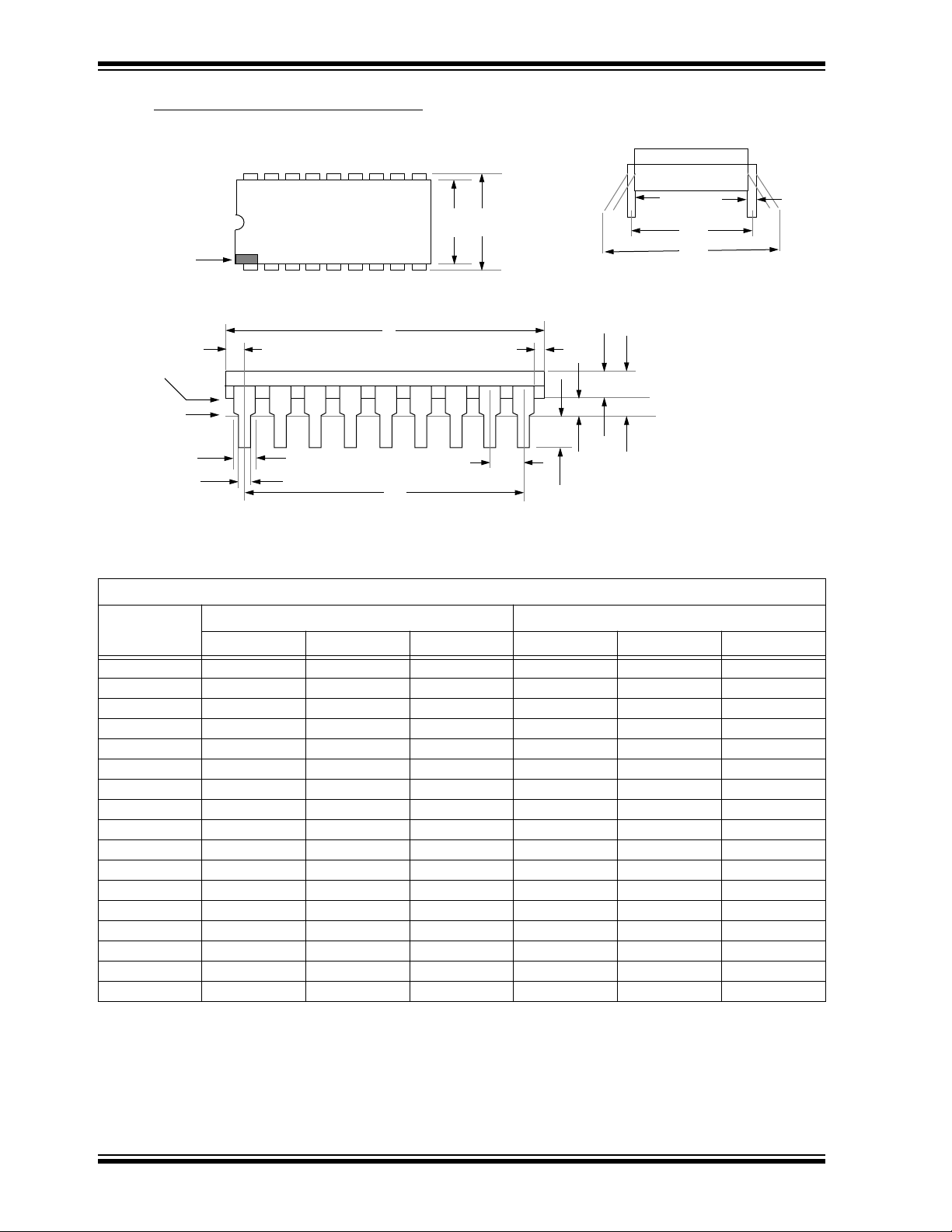

TABLE 7-1: CAPACITOR SELECTION

FOR CERAMIC RESONATORS

(PRELIMINARY)

Ranges Characterized:

Mode Freq OSC1(C1) OSC2(C2)

XT 455 kHz

2.0 MHz

4.0 MHz

HS 8.0 MHz

16.0 MHz

Higher capacitance increases the stability of the oscillator

but also increases the start-up time. These values are for

design guidance only. Since each resonator has its own

characteristics, the user should consult the resonator manufacturer for appropriate values of external components.

Resonators to be Characterized:

455 kHz Panasonic EFO-A455K04B ±0.3%

2.0 MHz Murata Erie CSA2.00MG ±0.5%

4.0 MHz Murata Erie CSA4.00MG ±0.5%

8.0 MHz Murata Erie CSA8.00MT ±0.5%

16.0 MHz Murata Erie CSA16.00MX ±0.5%

All resonators used did not have built-in capacitors.

22 - 100 pF

15 - 68 pF

15 - 68 pF

10 - 68 pF

10 - 22 pF

22 - 100 pF

15 - 68 pF

15 - 68 pF

10 - 68 pF

10 - 22 pF

T ABLE 7-2: CAPACITOR SELECTION

FOR CRYSTAL OSCILLATOR

(PRELIMINARY)

Mode Freq OSC1(C1) OSC2(C2)

LP

XT

HS

Higher capacitance increases the stability of the oscillator

but also increases the start-up time. These values are for

design guidance only. Rs may be required in HS mode as

well as XT mode to avoid overdriving crystals with low drive

level specification. Since each crystal has its own

characteristics, the user should consult the crystal manufacturer for appropriate values of external components.

Crystals to be Characterized:

32.768 kHz Epson C-001R32.768K-A ± 20 PPM

100 kHz Epson C-2 100.00 KC-P ± 20 PPM

200 kHz STD XTL 200.000 kHz ± 20 PPM

2.0 MHz ECS ECS-20-S-2 ± 50 PPM

4.0 MHz ECS ECS-40-S-4 ± 50 PPM

10.0 MHz ECS ECS-100-S-4 ± 50 PPM

20.0 MHz ECS ECS-200-S-4 ± 50 PPM

32 kHz

200 kHz

100 kHz

2 MHz

4 MHz

8 MHz

10 MHz

20 MHz

68 - 100 pF

15 - 30 pF

68 - 150 pF

15 - 30 pF

15 - 30 pF

15 - 30 pF

15 - 30 pF

15 - 30 pF

68 - 100 pF

15 - 30 pF

150 - 200 pF

15 - 30 pF

15 - 30 pF

15 - 30 pF

15 - 30 pF

15 - 30 pF

1997 Microchip Technology Inc. Preliminary DS40143B-page 37

Page 38

PIC16C55X(A)

)

7.2.3 EXTERNAL CRYSTAL OSCILLATOR

CIRCUIT

Either a pre-packaged oscillator can be used or a simple oscillator circuit with TTL gates can be built.

Prepackaged oscillators provide a wide operating

range and better stability. A well-designed crystal

oscillator will provide good performance with TTL

gates. Two types of crystal oscillator circuits can be

used; one with series resonance, or one with parallel

resonance.

Figure 7-4 shows implementation of a parallel resonant

oscillator circuit. The circuit is designed to use the

fundamental frequency of the crystal. The 74AS04

inverter performs the 180° phase shift that a parallel