Page 1

PIC12F635/PIC16F636/639

Data Sheet

8/14-Pin Flash-Based,

8-Bit CMOS Microcontrollers

with nanoWatt Technology

*8-bit, 8-pin Devices Protected by Microchip’s Low Pin Count Patent: U. S. Patent No. 5,847,450. Additional U.S. and

foreign patents and applications may be issued or pending.

© 2005 Microchip Technology Inc. Preliminary DS41232B

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Millennium Copyright Act. If suc h a c t s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of M icrochip’s prod ucts as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programmin g, IC SP, ICEPIC, MPASM, MPLIB, MPLI N K ,

MPSIM, PICkit, PICDEM, PICDEM.net, PICLAB, PICtail,

PowerCal, PowerInfo, PowerMate, PowerTool, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel and Total

Endurance are trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2005, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

DS41232B-page ii Preliminary © 2005 Microchip Technology Inc.

Page 3

PIC12F635/PIC16F636/639

8/14-Pin Flash-Based, 8-Bit CMOS Microcontrollers

With nanoWatt Technology

High-Performance RISC CPU:

• Only 35 instructions to learn:

- All single-cycle instructions except branches

• Operating speed:

- DC – 20 MHz oscillator/clock input

- DC – 200 n s instruction cy cle

• Interrupt capability

• 8-level deep hardware stack

• Direct, Indirect and Relative Addressing modes

Special Microcontroller Features:

• Precision Internal Oscillator:

- Factory calibrated to ±1%

- Software selectable frequency range of

8 MHz to 31 kHz

- Software tunable

- Two-Speed Start-up mode

- Crystal fail detect for critical applications

• Clock mode switching for low power operation

• Power-saving Sleep mode

• Wide operating voltage range (2.0V-5.5V)

• Industrial and Extended Temperature range

• Power-on Reset (POR)

• Wake-up Reset (WUR)

• Independent weak pull-up/pull-down resistors

• Programmable Low-Voltage Detect (PLVD)

• Power-up Timer (PWRT) and Oscillator Start-up

Timer (OST)

• Brown-out Detect (BOD) with software control

option

• Enhanced Low-Current Watchdog Timer (WDT)

with on-chip oscillator (software selectable

nominal 268 seconds with full prescaler) with

software enable

• Multiplexed Master Clear with pull-up/input pin

• Programmable code protection (program and

data independent)

• High-Endurance Flash/EEPROM cell:

- 100,000 write Flash endurance

- 1,000,000 write EEPROM endurance

- Flash/Data EEPROM Retention: > 40 years

Low Power Features:

• Standby Current:

- 1 nA @ 2.0V, typical

• Operating Current:

-8.5μA @ 32 kHz, 2.0V, typical

-100μA @ 1 MHz, 2.0V , typical

• Watchdog Timer Current:

-1μA @ 2.0V, typical

Peripheral Features:

• 6/12 I/O pins with individual dire ct ion contro l:

- High-current source/sink for direct LED drive

- Interrupt-on-pin change

- Individually programmable weak pull-ups/

pull-downs

- Ultra Low-Power Wake-up

• Analog comparator module with:

- Up to tw o analog comparators

- Programmable on-chip voltage reference

REF) module (% of VDD)

(CV

- Comparator inputs and outputs externally

accessible

• Timer0: 8-bit timer/counter with 8-bit

programmable prescaler

• Enhanced Timer1:

- 16-bit timer/counter with prescaler

- External Gate Input mode

- Option to use OSC1 and OSC2 in LP mode

as Timer1 oscillator if INTOSC mode

selected

®

EELOQ

•K

module

• In-Circuit Serial ProgrammingTM (ICSPTM) via

two pins

compatible hardware Cryptographic

Low Frequency Analog Front-End Features

(PIC16F639 only):

• Three input pins for 125 kHz LF input signals

• High input detection sensitivity (3mV

• Demodulated data, Carrier clock or RSSI output

selection

• Input carrier frequency: 125 kHz, typical

• Input modulation frequency: 4 kHz, maximum

• 8 internal configuration regi st ers

• Bidirectional transponder communication

(LF talk back)

• Programmable antenna tuning capacitance

(up to 63 pF, 1 pF/step)

• Low standby current: 5 μA (with 3 channels

enabled), typical

• Low operating current: 15 μA (with 3 channels

enabled), typical

• Serial Peripheral Interface (SPI™) with internal

MCU and external devices

• Supports Battery Back-up mode and batteryless

operation with external circuits

PP, typical)

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 1

Page 4

PIC12F635/PIC16F636/639

Device

Program Memory Data Memory

I/O Comparators

Flash (words) SRAM (bytes) EEPROM (bytes)

Low Frequency

Analog

Front-End

PIC12F635 1024 64 128 6 1 N

PIC16F636 2048 128 256 12 2 N

PIC16F639 2048 128 256 12 2 Y

Pin Diagrams

8-Pin PDIP, SOIC, DFN-S

8

GP5/T1CKI/OSC1/CLKIN

GP4/T1G

14-Pin PDIP, SOIC, TSSOP

RA5/T1CKI/OSC1/CLKIN

RA4/T1G

/OSC2/CLKOUT

GP3/MCLR

/OSC2/CLKOUT

RA3/MCLR

/VPP

DD VSS

V

/VPP

RC5

RC4/C2OUT

RC3

1

2

7

3

6

PIC12F635

5

4

1

14

2

13

3

12

4

11

5

10

6

9

PIC16F636

7

8

VSSVDD

GP0/C1IN+/ICSPDAT/ULPWU

GP1/C1IN-/ICSPCLK

GP2/T0CKI/INT/C1OUT

RA0/C1IN+/ICSPDAT/ULPWU

RA1/C1IN-/V

RA2/T0CKI/INT/C1OUT

RC0/C2IN+

RC1/C2INRC2

REF/ICSPCLK

20-Pin SSOP

RA5/T1CKI/OSC1/CLKIN

/OSC2/CLKOUT

RA4/T1G

RC3/LFDATA/RSSI/CCLK/SDIO

RA3/MCLR

VDD

/VPP

RC5

RC4/C2OUT

V

DDT

LCZ

LCY

1

20

2

19

3

18

4

17

5

16

6

15

7

14

(3)

PIC16F639

8

13

9

12

10

11

VSS

RA0/C1IN+/ICSPDAT/ULPWU

RA1/C1IN-/V

RA2/TOCKI/INT/C1OUT

RC0/C2IN+

RC1/C2IN-/CS

RC2/SCLK/ALERT

VSST

LCCOM

LCX

REF/ICSPCLK

(4)

Note 1: Any references to PORT A, RAn, TRISA and TRISAn refer to GPIO, GPn, TRISIO and TRISIOn, respectively.

®

2: Additional information on I/O ports may be found in the “PICmicro

Mid-Range MCU Family Reference

Manual” (DS33023).

DDT is the supply voltage of the Analog Front-End section (PIC16F639 only). VDDT is treated as VDD in

3: V

this document unless otherwise stated.

SST is the ground reference voltage of the Analog Front-End section (PIC16F639 only). VSST is treated

4: V

as V

SS in this document unless otherwise stated.

DS41232B-page 2 Preliminary © 2005 Microchip Technology Inc.

Page 5

PIC12F635/PIC16F636/639

Table of Contents

1.0 Device Overview.......................................................................................................................................................................... 5

2.0 Memory Organization................................................................................................................................................................. 11

3.0 Clock Sources............................................................................................................................................................................29

4.0 I/O Ports................................ ........................................ ............................ ................................................................................. 39

5.0 Timer0 Module ........................................................................................................................................................................... 53

6.0 Timer1 Module with Gate Control............................................................................................................................................... 56

7.0 Comparator Module.................................................................................................................................................................... 61

8.0 Programmable Low-Voltage Detect (PLVD) Module.................................................................................................................. 71

9.0 Data EEPROM Memory................... ........................... ............................ ........................... ........................................................ 73

10.0 KeeLoq Compatible Cryptographic Module................................................................................................................................77

11.0 Analog Front-End (AFE) Functional Description (PIC16F639 Only) .......................................................................................... 79

12.0 Special Features of the CPU......................... ........................... ........................................ ........................................................ 111

13.0 Instruction Set Summary.......................................................................................................................................................... 131

14.0 Development Support............................................................................................................................................................... 141

15.0 Electrical Specifications............................................................................................................................................................147

16.0 DC and AC Characteristics Graphs and Tables....................................................................................................................... 173

17.0 Packaging Information............................ ........................................ ........................... ...............................................................175

On-Line Support 185

Systems Information and Upgrade Hot Line..................................................................................................................................... 185

Reader Response. ............................................................................................................................................................................ 186

Appendix A: Data Sheet Revision History......................................................................................................................................... 187

Appendix B: Product Identification System....................................................................................................................................... 193

Worldwide Sales and Service ............................................. ........................................ ...................................................................... 19

4

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or c omm ents regarding t his publication, p lease c ontact the M arket ing Co mmunications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 3

Page 6

PIC12F635/PIC16F636/639

NOTES:

DS41232B-page 4 Preliminary © 2005 Microchip Technology Inc.

Page 7

PIC12F635/PIC16F636/639

1.0 DEVICE OVERVIEW

This document contains device specific information for

the PIC12F635/PIC16F636/639 devices. Additional

information may be found in the “PICmicro® Mid-Range

MCU Family Reference Manual” (DS33023), which m ay

be obtained from your local Microchip Sales

Representative or downloaded from the Microchip web

site. The reference manual should be considered a

complementary document to this data sheet and is

highly recommended reading for a better understanding

of the device architecture and operation of the peripheral

modules.

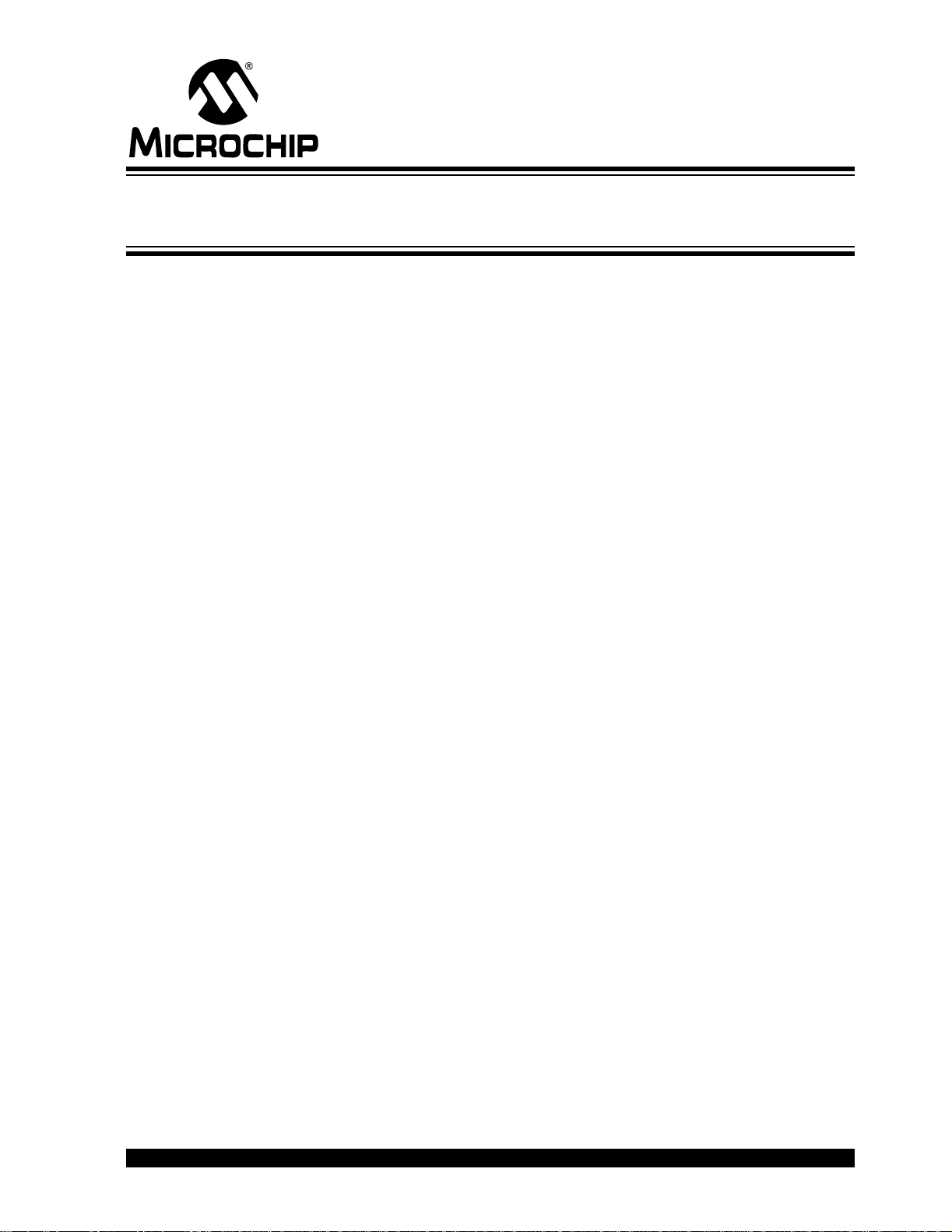

FIGURE 1-1: PIC12F635 BLOCK DIAGRAM

Program

Bus

Configuration

Flash

1K x 14

Program

Memory

14

Instruction reg

13

Program Counter

8-level Stack

(13-bit)

Direct Addr

RAM Addr

7

The PIC12F635/PIC16F636/639 devices are covered

by this data sh eet. Figure 1-1 shows a block diagram of

the PIC12F635/PIC16F636/639 devices. Table 1-1

shows the pinout description.

Data Bus

RAM

64 bytes

File

Registers

Addr MUX

8

FSR reg

9

Indirect

Addr

8

GPIO

GP0/C1IN+/ICSPDAT/ULPWU

GP1/C1IN-/ICSPCLK

GP2/T0CKI/INT/C1OUT

GP3/MCLR

GP4/T1G/OSC2/CLKOUT

GP5/T1CKI/OSC1/CLKIN

/VPP

OSC1/CLKIN

OSC2/CLKOUT

Oscillator

T1G

T1CKI

T0CKI

Cryptographic

8

Instruction

Decode and

Control

Timing

Generation

8 MHz

Internal

Timer0 Timer1

Module

31 kHz

Internal

Oscillator

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Brown-out

Detect

Programmable

Low-Voltage Detect

Wake-up

Reset

VDD

MCLR

Comparator

and Referen ce

C1IN- C1IN+ C1OUT

VSS

1 Analog

Status re g

3

8

MUX

ALU

W reg

EEDAT

128 bytes

Data

EEPROM

EEADDR

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 5

Page 8

PIC12F635/PIC16F636/639

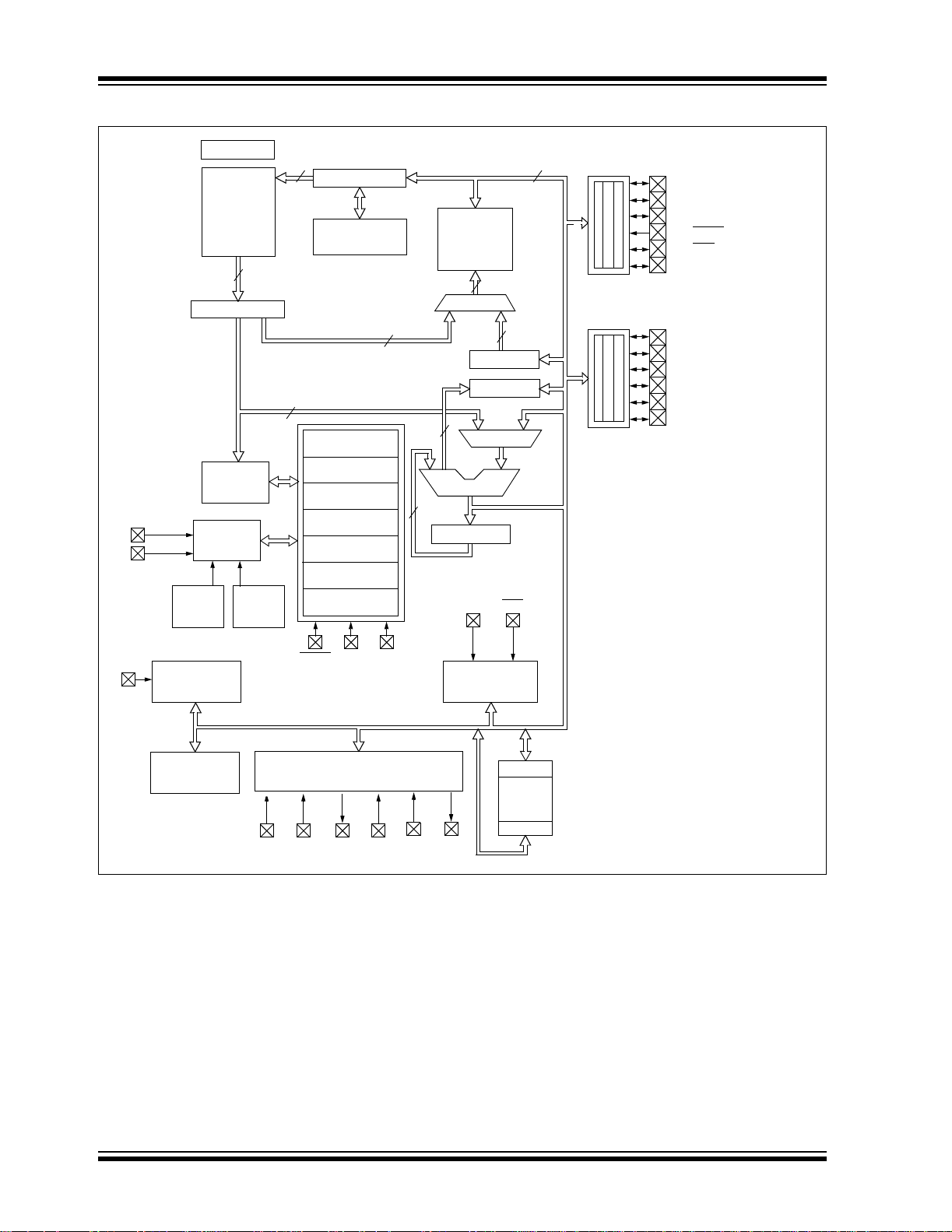

FIGURE 1-2: PIC16F636 BLOCK DIAGRAM

Program

Bus

OSC1/CLKIN

OSC2/CLKOUT

8 MHz

Internal

Oscillator

Configuration

Flash

2K x 14

Program

Memory

14

Instruction reg

Instruction

Decode and

Control

Timing

Generation

31 kHz

Internal

Oscillator

13

Program Counter

8-level Stack

(13-bit)

Direct Addr

8

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Brown-out

Detect

Programmable

Low-Voltage Detect

Wake-up

Reset

RAM Addr

7

3

8

Data Bus

RAM

128

bytes

File

Registers

9

Addr MUX

8

FSR reg

Status reg

MUX

ALU

W reg

T1CKI

Indirect

Addr

T1G

8

PORTA

PORTC

RA0/C1IN+/ICSPDA T/ ULPWU

RA1/C1IN-/VREF/ICSPCLK

RA2/T0CKI/INT/C1OUT

RA3/MCLR

RA4/T1G/OSC2/CLKOUT

RA5/T1CKI/OSC1/CLKIN

RC0/C2IN+

RC1/C2INRC2

RC3

RC4/C2OUT

RC5

/VPP

T0CKI

VDD

MCLR

Timer0 Timer1

Cryptographic

Module

C1IN- C1IN+ C1OUT C2IN- C2IN+ C2OUT

2 Analog Comparators

and Refere nce

VSS

EEDAT

256 bytes

Data

EEPROM

EEADDR

DS41232B-page 6 Preliminary © 2005 Microchip Technology Inc.

Page 9

PIC12F635/PIC16F636/639

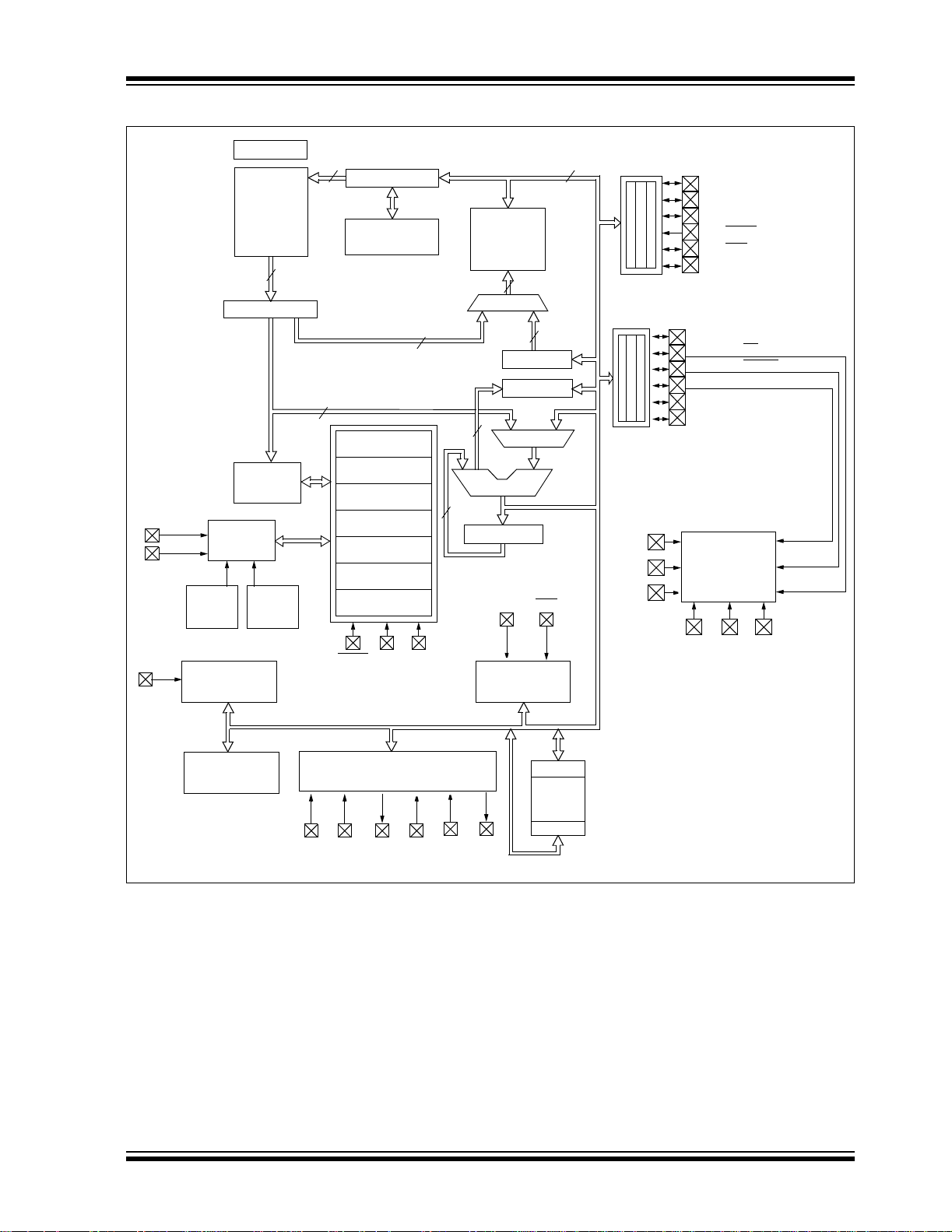

FIGURE 1-3: PIC16F639 BLOCK DIAGRAM

OSC1/CLKIN

OSC2/CLKOUT

T0CKI

Configuration

Flash

2K x 14

Program

Memory

Program

8 MHz

Internal

Oscillator

14

Bus

Instruction reg

Instruction

Decode and

Control

Timing

Generation

31 kHz

Internal

Oscillator

Timer0 Timer1

13

Program Counter

8-level Stack

(13-bit)

Direct Addr

8

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Brown-out

Detect

Programmable

Low-voltage Detect

Wake-up

Reset

VDD

MCLR

RAM Addr

7

3

8

VSS

Data Bus

RAM

128

bytes

File

Registers

(1)

9

Addr MUX

8

FSR reg

Status reg

MUX

ALU

W reg

T1CKI T1G

Indirect

Addr

8

PORTA

PORTC

VDDT

V

SST

LCCOM

RA0/C1IN+/ICSPDAT/ULPWU

RA1/C1IN-/VREF/ICSPCLK

RA2/T0CKI/INT/C1OUT

RA3/MCLR

RA4/T1G/OSC2/CLKOUT

RA5/T1CKI/OSC1/CLKIN

RC0/C2IN+

RC1/C2IN-/CS

RC2/SCLK/ALERT

RC3/LFDATA/RSSI/CCLK/SDIO

RC4/C2OUT

RC5

125 kHz

Analog Front-End

LCX

/VPP

(AFE)

LCY LCZ

KEELOQ Module

2 Analog

Comparators

and Reference

C1IN- C1IN+ C1OUTC2IN-

C2IN+C2OUT

EEDAT

256 bytes

DATA

EEPROM

EEADDR

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 7

Page 10

PIC12F635/PIC16F636/639

TABLE 1-1: PIC12F635 PINOUT DESCRIPTIONS

Name Function

VDD VDD D — Power supply for microcontroller.

GP5/T1CKI/OSC1/CLKIN GP5 TTL CMOS General purpose I/O. Individually controlled interrupt-on-

T1CKI ST — Timer1 clock.

OSC1 XTAL — XTAL connection.

CLKIN ST — T

GP4/T1G

GP3/MCLR

GP2/T0CKI/INT/C1OUT GP2 ST CMOS General purpose I/O. Individually controlled

GP1/C1IN-/ICSPCLK GP1 TTL CMOS General purpose I/O. Individually controlled

GP0/C1IN+/ICSPDAT/ULPWU GP0 TTL — General purpose I/O. Individually controlled

SS VSS D — Ground reference for microcontroller.

V

Legend: AN = Analog input or output CMOS = CMOS compatible input or output D = Direct

/OSC2/CLKOUT GP4 TTL CMOS General purpose I/O. Individually controlled interrupt-on-

T1G

OSC2 — XTAL XTAL co nnection.

CLKOUT — CMOS T

/VPP GP3 TTL — General purpose input. Individually control led

MCLR

VPP HV — Programming voltage.

T0CKI ST — External clock for Timer0.

INT ST — External interrupt.

C1OUT — CMOS Comparator 1 output.

C1IN- AN — Comparator 1 input – negative.

ICSPCLK ST — Serial programming clock.

C1IN+ AN — Comparator 1 input – positive.

ICSPDAT TTL CMOS Serial programming data I/O.

ULPWU AN — Ultra Low-Power Wake-up input.

HV = High Voltage ST = Schmitt Trigger input with CMOS levels

TTL = TTL compatible input XTAL = Crystal

Input

Type

Output

Type

change. Individually enabled pull-up/pull-down.

OSC reference clock.

change. Individually enabled pull-up/pull-down.

ST — Timer1 gate.

OSC/4 reference clock.

interrupt-on-change.

ST — Master Clear Reset. Pull-up enabled when confi gured a s

MCLR

.

interrupt-on-change. Individually enabled

pull-up/pull-down.

interrupt-on-change. Individually enabled

pull-up/pull-down.

interrupt-on-change. Individually enabled

pull-up/pull-down.

Selectable Ultra Low-Power Wake-up pin.

Description

DS41232B-page 8 Preliminary © 2005 Microchip Technology Inc.

Page 11

PIC12F635/PIC16F636/639

TABLE 1-2: PIC16F636 PINOUT DESCRIPTIONS

Name Function

VDD VDD D — Power supply for microcontroller.

RA5/T1CKI/OSC1/ CLKIN RA5 TTL CMOS General purpose I/O. Ind iv i dua ll y c on tro ll ed

T1CKI ST — Timer1 clock.

OSC1 XTAL — XTAL connection.

CLKIN ST — T

RA4/T1G

RA3/MCLR

RC5 RC5 TTL CMOS General purpose I/O.

RC4/C2OUT RC4 TTL CMOS General purpose I/O.

RC3 RC3 TTL CMOS General purpose I/O.

RC2 RC2 TTL CMOS General purpose I/O.

RC1/C2IN- RC1 TTL CMOS General purpose I/O.

RC0/C2IN+ RC0 TTL CMOS General purpose I/O.

RA2/T0CKI/INT/C1OUT RA2 ST CMOS G e neral p urpose I/O. I n dividu ally c o ntroll e d

RA1/C1IN-/V

RA0/C1IN + / I C S P DAT/ULPWU RA0 TTL — General purpose I/O. Ind iv i dua ll y c on tro ll ed

V

Legend: AN = Analog input or output CMOS = CMOS compatible input or output D = Direct

/OSC2/CLKOUT RA4 TTL CMOS General purpose I/O. Ind iv i dua ll y c on tro ll ed

T1G

OSC2 — XTAL XTAL con ne cti on.

CLKOUT — CMOS T

/VPP RA3 TTL — General purpose input. Individually controlled

MCLR

VPP HV — Programming voltage.

C2OUT — CMOS Comparator 2 output.

C2IN- AN — Comparator 1 input – negative.

C2IN+ AN — Comparator 1 in put – positive.

T0CKI ST — External clock for Timer0.

INT ST — External interrupt.

C1OUT — CMOS Comparator 1 output.

REF/ICSPCLK RA1 TTL CMOS General purpose I/O. Individua ll y c on tro ll ed

C1IN- AN — Comparator 1 input – negative.

ICSPCLK ST — Serial programming clock.

C1IN+ AN — Comparator 1 in put – positive.

ICSPDAT TTL CMOS Serial programming data I/O.

ULPWU AN — Ultra Low-Power Wake-up input.

SS VSS D — Ground reference for microcontroller.

HV = High Voltage ST = Schmitt Trigger input with CMOS levels

TTL = TTL compatible input XTAL = Crystal

Input

Type

Output

Type

interrupt-on-change. Individually enabled pull-up/pull-down.

OSC reference clock.

interrupt-on-change. Individually enabled pull-up/pull-down.

ST — Timer1 gate.

OSC/4 reference clock.

interrupt-on-change.

ST — Master Clear Reset. Pull-up enabled when

configured as MCLR

interrupt-on-change. Individually enabled pull-up/pull-down.

interrupt-on-c hange . Indivi duall y enab led pu ll-up /pull -dow n.

interrupt-on-change. Individually enabled pull-up/pull-down.

Selectable Ultra Low-Power Wake-up pin.

Description

.

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 9

Page 12

PIC12F635/PIC16F636/639

TABLE 1-3: PIC16F639 PINOUT DESCRIPTIONS

Name Function

V

DD VDD D — Power supply for microcontroller

RA5/T1CKI/OSC1/CLKIN RA5 TTL CMOS General purpose I/O. Individually controlled interrupt-on-change.

T1CKI ST — Timer1 clock

OSC1 XTAL — XTAL connection

CLKIN ST — T

RA4/T1G/OSC2/CLKOUT

RA3/MCLR

RC5 RC5 TTL CMOS General purpose I/O

RC4/C2OUT RC4 TTL CMOS General purpose I/O

RC3/LFDATA/RSSI/CCLK/SDIO RC3 TTL CMOS General purpose I/O

DDT VDDT D — P owe r supply for Analog Front-End. In this document, VDDT is treated

V

LCZ LCZ AN — 125 kHz analog Z channel input

LCY LCY AN — 125 kHz analog Y channel input

LCX LCX AN — 125 kHz analog X channel input

LCCOM LCCOM AN — Common reference for analog inputs

SST VSST D — Ground reference for Analog Front-End. In this document, VSST is

V

RC2/SCLK/ALERT

RC1/C2IN-/CS

RC0/C2IN+ RC0 TTL CMOS

RA2/T0CKI/INT/C1OUT RA2 ST CMOS General purpose I/O. Individually controlled interrupt-on-change.

RA1/C1IN-/V

RA0/C1IN+/ICSPDAT/ULPWU RA0 TTL — General purpose I/O. Individually controlled interrupt-on-change.

SS VSS D — Ground reference for microcontroller

V

Legend: AN = Analog input or output CMOS = CMOS compatible input or output D = Direct

/VPP

REF/ICSPCLK RA1 TTL CMOS General purpose I/O. Individually controlled interrupt-on-change.

HV = High Voltage ST = Schmitt Trigger input with CMOS levels OD = Direct

TTL = TTL compatible input XTAL = Crystal

RA4 TTL CMOS General purpose I/O. Individually controlled interrupt-on-change.

T1G

OSC2 — X TAL XTAL connecti on

CLKOUT — CMOS TOSC reference clock

RA3 TTL

MCLR

V

PP HV — Programming voltage

C2OUT — CMOS Comparator2 output

LFDATA — CMOS Digital output representation of analog input signal to LC pins.

RSSI — Current Received signal strength indicator. Analog current that is proportional

CCLK — — Carrier clock output

SDIO TTL CMOS Input/Output for SPI communication

RC2 TTL CMOS General purpose I/O

SCLK TTL — Digital clock input for SPI communica tion

ALERT

RC1 TTL CMOS

C2IN- AN —

CS

C2IN+ AN —

T0CKI ST — External clock fo r Timer0

INT ST — External Interrupt

C1OUT — CMOS Comparator1 output

C1IN- AN — Comparator1 input – negative

ICSPCLK ST — Serial Programming Clock

C1IN+ AN — Comparator1 inpu t – positive

ICSPDAT TTL CMOS Serial Programming Data IO

ULPWU AN — Ultra Low-Power Wake-up input

Input

Type

TTL —

Output

Type

Individually enabled pull-up/pull-down.

OSC/4 reference clock

Individually enabled pull-up/pull-down.

ST — Timer1 gate

General purpose input. Individually controlled interrupt-on-change.

—

ST —

—OD

Master Clear Reset. Pull-up enabled when configured as MCLR

to input amplitude.

the same as VDD, un less otherwis e stated.

treated the same as V

Output with internal pull-up resistor for AFE error signal

General purpose I/O

Comparator1 input - negative

Chip select input for SPI communication with internal pull-up resistor

General purpose I/O

Comparator1 input - positive

Individually enabled pull-up/pull-down.

Individually enabled pull-up/pull-down.

Individually enabled pull-up/pull-down. Selectable Ultra Low-Power

Wake-up pin.

Description

SS, unless otherwise stated.

.

DS41232B-page 10 Preliminary © 2005 Microchip Technology Inc.

Page 13

PIC12F635/PIC16F636/639

2.0 MEMORY ORGANIZATION

2.1 Program Memory Organization

The PIC12F635/PIC16F636/639 devices have a 13-bit

program counter capable of addressing an 8K x 14

program memory space. Only the first 1K x 14

(0000h-03FFh, for the PIC12F635) and 2K x 14

(0000h-07FFh, for the PIC16F636/639) is physically

implemented. Accessing a location above these

boundaries will cause a wrap around within the first

2K x 14 space. The Reset vector is at 0000h and the

interrupt vector is at 0004h (see Figure 2-1).

2.2 Data Memory Organization

The data memory (see Figure 2-2) is partitioned into

two banks, which contain the General Purpose

Registers (GPR) and the Special Function Registers

(SFR). The Special Function Registers are located in

the first 32 locations of each bank. Register locations

20h-7Fh in Bank 0 and A0h-BFh in Bank 1 are GPRs,

implemented as static RAM for the PIC16F636/639.

For the PIC12F635, reg ister locat ions 4 0h throug h 7Fh

are GPRs implemented as static RAM. Register

locations F0h-FFh in Bank 1 point to addresses 70h7Fh in Bank 0. All other RAM is unimplemented and

returns ‘0’ when read. RP0 (STATUS<5>) is the bank

select bit.

TABLE 2-1: BANK SELECTION

RP0 RP1 Bank

000

101

012

113

FIGURE 2-1: PROGRAM MEM O R Y M AP AND

STAC K OF THE PIC12F635

PC<12:0>

CALL, RETURN

RETFIE, RETLW

Stack Level 1

Stack Level 8

Reset Vector

Interrupt Vector

On-chip Program

Access 0-3FFh

13

0000h

0004h

0005h

Memory

03FFh

0400h

1FFFh

FIGURE 2-2: PROGRAM MEMORY MAP AND

ST AC K OF T HE PIC16F636/639

PC<12:0>

CALL, RETURN

RETFIE, RETLW

Stack Level 1

Stack Level 8

13

Reset Vector

Interrupt Vector

On-chip Program

Memory

Access 0-7FFh

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 11

0000h

0004h

0005h

07FFh

0800h

1FFFh

Page 14

PIC12F635/PIC16F636/639

2.2.1 GENERAL PURPOSE REGISTER

The register file is organized as 64 x 8 for the

PIC12F635 and 128 x 8 for the PIC16F636/639. Each

register is accessed, either directly or indirectly,

through the File Select R egister, FSR (see Section 2.4

“Indirect Addressing, INDF and FSR Registers”).

2.2.2 SPECIAL FUNCTION REGISTERS

The Special Function Registers (SFRs) are registers

used by the CPU and peripheral functions for controlling

the desired operation of the device (see Figure 2-1).

These registers are static RAM.

The special re gisters can be classifi ed into two sets:

core and peripheral. The Special Function Registers

associated with the “c ore” are des cribed in this sect ion.

Those related to the operation of the peripheral

features are described in the section of that peripheral

feature.

DS41232B-page 12 Preliminary © 2005 Microchip Technology Inc.

Page 15

PIC12F635/PIC16F636/639

FIGURE 2-3: PIC12F635 SPECIAL FUNCTION REGISTERS

File

Address

Indirect addr.

(1)

00h Indirect addr.

TMR0 01h OPTION_REG 81h 101h 181h

PCL 02h PCL 82h 102h 182h

STATUS 03h STATUS 83h 103h 183h

FSR 04h FSR 84h 104h 184h

GPIO 05h TRISIO 85h 105h 185h

06h 86h 106h 186h

07h 87h 107h 187h

08h 88h 108h 188h

09h 89h 109h 189h

PCLATH 0Ah PCLATH 8Ah 10Ah 18Ah

INTCON 0Bh INTCON 8Bh 10Bh 18Bh

PIR1 0Ch PIE1 8Ch

0Dh 8Dh 10Dh 18Dh

TMR1L 0Eh PCON 8Eh 10Eh 18Eh

TMR1H 0Fh OSCCON 8Fh 10Fh 18Fh

T1CON 10h OSCTUNE 90h CRCON 110h

11h 91h

12h 92h

13h 93h

14h LVDCON 94h

15h WPUDA 95h 115h 195h

16h IOCA 96h 116h 196h

17h WDA 97h 117h 197h

WDTCON 18h 98h 118h 198h

CMCON0 19h VRCON 99h

CMCON1 1Ah EEDAT 9Ah 11Ah 19Ah

1Bh EEADR 9Bh 11Bh 19Bh

1Ch EECON1 9Ch 11Ch 19Ch

1Dh EECON2

1Eh 9Eh 11Eh 19Eh

1Fh 9Fh 11Fh 19Fh

20h

Address

(1)

80h

File

Accesses

00h-0Bh

File

Address

100h

Accesses

80h-8Bh

10Ch 18Ch

(2)

CRDAT0

CRDAT1

CRDAT2

CRDAT3

111h 191h

(2)

112h 192h

(2)

113h 193h

(2)

114h 194h

119h 199h

(1)

9Dh 11Dh 19Dh

A0h 120h 1A0h

File

Address

180h

190h

3Fh

General

Purpose

Register

64 Bytes

40h

EFh 16Fh 1EFh

Accesses

7Fh FFh 17Fh 1FFh

70h-7Fh

F0h

Accesses

70h-7Fh

170h

Accesses

Bank 0

1F0h

Bank 0 Bank 1 Bank 2 Bank 3

Unimplemented data memory locations, read as ‘0’.

Note 1: Not a physical register.

®

2: CRDAT<3:0> are K

“K

EELOQ

®

Encoder License Agreement ” regarding imp lemen tat ion of the mo dule and access to relate d

registers. The “K

EELOQ

EELOQ

located at www.microchip.co m/K

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 13

hardware peripheral related registers and require the execution of the

®

Encoder License Agree ment” may be accesse d through the Microc hip web site

EELOQ or by contacting your local Microchip Sales Representative.

Page 16

PIC12F635/PIC16F636/639

e

t

FIGURE 2-4: PIC16F636/639 SPECIAL FUNCTION REGISTERS

File

Address

Indirect addr.

(1)

00h Indirect addr.

TMR0 01h OPTION_REG 81h 101h 181h

PCL 02h PCL 82h 102h 182h

STATUS 03h STATUS 83h 103h 183h

FSR 04h FSR 84h 104h 184h

PORTA 05h TRISA 85h 105h 185h

06h 86h 106h 186h

PORTC 07h TRISC 87h 107h 187h

08h 88h 108h 188h

09h 89h 109h 189h

PCLATH 0Ah PCLATH 8Ah 10Ah 18Ah

INTCON 0Bh INTCON 8Bh 10Bh 18Bh

PIR1 0Ch PIE1 8Ch

0Dh 8Dh 10Dh 18Dh

TMR1L 0Eh PCON 8Eh

TMR1H 0Fh OSCCON 8Fh

T1CON 10h OSCTUNE 90h CRCON 110h 190h

11h 91h

12h 92h

13h 93h

14h LVDCON 94h

15h WPUDA 95h 115h 195h

16h IOCA 96h 116h 196h

17h WDA 97h 117h 197h

WDTCON 18h 98h 118h 198h

CMCON0 19h VRCON 99h 119h 199h

CMCON1 1Ah EEDAT 9Ah

1Bh EEADR 9Bh 11Bh 19Bh

1Ch EECON1 9Ch 11Ch 19Ch

1Dh

EECON2

1Eh 9Eh 11Eh 19Eh

1Fh 9Fh 11Fh 19Fh

20h

General

Purpose

General

Purpose

Register

32 Bytes

Register

96 Bytes

Accesses

7Fh FFh 17Fh 1FFh

70h-7Fh

Bank 0 Bank 1 Bank 2 Bank 3

Unimplemented data memory locations, read as ‘0’.

Note 1: Not a physical register.

2: CRDAT<3:0> are K

EELOQ hardware peripheral related registers and require the execution of the “KEELOQ

Encoder License Agreem ent” regarding im plement ation of the modu le and access to related registe rs. Th

“KEELOQ® Encoder License Agreement” may be accessed through the Microchip web site located a

www.microchip.com/KEELOQ or by contacting your local Microchip Sales Representative.

Address

(1)

80h

File

Accesses

00h-0Bh

File

Address

100h

Accesses

80h-8Bh

10Ch 18Ch

10Eh 18Eh

10Fh 18Fh

(2)

CRDAT0

CRDAT1

CRDAT2

CRDAT3

111h 191h

(2)

112h 192h

(2)

113h 193h

(2)

114h 194h

11Ah 19Ah

(1)

9Dh 11Dh 19Dh

A0h

120h 1A0h

BFh

C0h

EFh 16Fh 1EFh

F0h

Accesses

70h-7Fh

170h

Accesses

Bank 0

File

Address

180h

1F0h

®

DS41232B-page 14 Preliminary © 2005 Microchip Technology Inc.

Page 17

PIC12F635/PIC16F636/639

TABLE 2-2: PIC12F635 SPECIAL FUNCTION REGISTERS SUMMARY BANK 0

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 0

00h INDF Addressing this location uses contents of FSR to address data memory

01h TMR0 Timer0 Module Register xxxx xxxx uuuu uuuu

02h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 0000 0000

03h STATUS IRP RP1 RP0 TO

04h FSR Indirect Data Memory Address Pointer xxxx xxxx uuuu uuuu

05h GPIO

06h — Unimplemented — —

07h — Unimplemented — —

08h — Unimplemented — —

09h — Unimplemented — —

0Ah PCLATH

0Bh INTCON GIE PEIE T0IE INTE RAIE T0IF INTF RAIF

0Ch PIR1

0Dh — Unimplemented — —

0Eh TMR1L Holding Register for the Least Significant Byte of the 16-bit TMR1 xxxx xxxx uuuu uuuu

0Fh TMR1H Holding Register for the Most Significant Byte of the 16-bit TMR1 xxxx xxxx uuuu uuuu

10h T1CON T1GINV TMR1GE T1CKPS1 T1CKPS0 T1OSCEN T1SYNC

11h — Unimplemented — —

12h — Unimplemented — —

13h — Unimplemented — —

14h — Unimplemented — —

15h — Unimplemented — —

16h — Unimplemented — —

17h — Unimplemented — —

18h WDTCON

19h CMCON0

1Ah CMCON1

1Bh — Unimplemented — —

1Ch — Unimplemented — —

1Dh — Unimplemented — —

1Eh — Unimplemented — —

1Fh — Unimplemented — —

Legend: — = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition,

Note 1: Other (non Power-up) Resets include MCLR

2: MCLR

(not a physical register)

PD ZDCC0001 1xxx 000q quuu

— — GP5 GP4 GP3 GP2 GP1 GP0 --xx xx00 --uu uu00

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 ---0 0000

EEIF LVDIF CRIF —C1IFOSFIF—TMR1IF000- 00-0 000- 00-0

TMR1CS TMR1ON 0000 0000 uuuu uuuu

— — — WDTPS3 WDTPS2 WDTPS1 WDTPS0 SWDTEN ---0 1000 ---0 1000

—C1OUT— C1INV CIS CM2 CM1 CM0 -0-0 0000 -0-0 0000

— — — — — — T1GSS CMSYNC ---- --10 ---- --10

shaded = unimplemented

Reset and Watchdog Timer Reset during normal operation.

and WDT Reset do not affect the previous value data latch. The RAIF bit will be cleared upon Reset but will set

again if the mismatch exists.

Value on

POR/BOD/

WUR

xxxx xxxx xxxx xxxx

(2)

0000 0000 0000 0000

Value on

all other

Resets

(1)

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 15

Page 18

PIC12F635/PIC16F636/639

TABLE 2-3: PIC12F635 SPECIAL FUNCTION REGISTERS SUMMARY BANK 1

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 1

80h INDF Addressing this location uses contents of FSR to address data memory

81h OPTION_REG RAPU

82h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 0000 0000

83h STATUS IRP RP1 RP0 TO

84h FSR Indirect Data Memory Address Pointer xxxx xxxx uuuu uuuu

85h TRISIO

86h — Unimplemented — —

87h — Unimplemented — —

88h — Unimplemented — —

89h — Unimplemented — —

8Ah PCLATH

8Bh INTCON GIE PEIE T0IE INTE RAIE T0IF INTF RAIF

8Ch PIE1 EEIE LVDIE CRIE

8Dh — Unimplemented — —

8Eh PCON

8Fh OSCCON

90h OSCTUNE

91h — Unimplemented — —

92h — Unimplemented — —

93h — Unimplemented — —

94h LVDCON

95h WPUDA

96h IOCA

97h WDA

9Bh — Unimplemented — —

99h VRCON VREN

9Ah EEDAT

9Bh EEADR

9Ch EECON1

9Dh EECON2 EEPROM Cont rol Register 2 (not a physical register) ---- ---- ---- ---9Eh — Unimplemented — —

9Fh — Unimplemented — —

Legend: — = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition,

Note 1: Other (non Power-up) Resets include MCLR

(2)

shaded = unimplemented

2: GP3 pull-up is enabled when pin is configured as MCLR

3: MCLR

again if the mismatch exists.

(not a physical register)

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

PD ZDCC0001 1xxx 000q quuu

— — TRISIO5 TRISIO4 TRISIO3 TRISIO2 TRISIO1 TRISIO0 --11 1111 --11 1111

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 ---0 0000

—C1IEOSFIE—TMR1IE000- 00-0 000- 00-0

— — ULPWUE SBODEN WUR —PORBOD --01 q-qq --0u u-uu

— IRCF2 IRCF1 IRCF0 O STS HTS LTS SCS -110 q000 -110 x000

— — — TUN4 TUN3 TUN2 TUN1 TUN0 ---0 0000 ---u uuuu

(2)

— —IRVSTLVDEN— LVDL2 LVDL1 LVDL0 --00 -000 --00 -000

— — WPUDA5 WPUDA4 — WPUDA2 WPUDA1 WPUDA0 --11 -111 --11 -111

— — IOCA5 IOCA4 IOCA3 IOCA2 IOCA1 IOCA0 --00 0000 --00 0000

— — WDA5 WDA4 — WDA2WDA1WDA0--11 -111 --11 -111

—VRR—VR3VR2VR1VR00-0- 0000 0-0- 0000

EEDAT7 EEDAT6 EEDAT5 EEDAT4 EEDAT3 EEDAT2 EEDAT1 EEDAT0 0000 0000 0000 0000

EEADR7 EEADR6 EEADR5 EEADR4 EEADR3 EEADR2 EEADR1 EEADR0 0000 0000 0000 0000

— — — — WRERR WRE N WR RD ---- x000 ---- q000

Reset and Watchdog Timer Res et during normal operation.

in the Configuration Word register.

and WDT Reset do not affect the previous value data latch. The RAIF bit will be cleared upon Reset, but will set

Value on

POR/BOD/

WUR

xxxx xxxx xxxx xxxx

(3)

0000 0000 0000 0000

Value on

all other

Resets

(1)

DS41232B-page 16 Preliminary © 2005 Microchip Technology Inc.

Page 19

PIC12F635/PIC16F636/639

TABLE 2-4: PIC16F636/639 SPECIAL FUNCTION REGISTERS SUMMARY BANK 0

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 0

00h INDF Addressing this location uses contents of FSR to address data memory

01h TMR0 Timer0 Module Register xxxx xxxx uuuu uuuu

02h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 0000 0000

03h STATUS IRP RP 1 RP0 TO

04h FSR Indirect Data Memory Address Pointer xxxx xxxx uuuu uuxx

05h PORTA

06h — Unimplemented — —

07h PORTC

08h — Unimplemented — —

09h — Unimplemented — —

0Ah PCLATH

0Bh INTCON GIE PEIE T0IE INTE RAIE T0IF INTF RAIF

0Ch PIR1

0Dh — Unimplemented — —

0Eh TMR1L Holding Register for the Least Significant Byte of the 16-bit TMR1 xxxx xxxx uuuu uuuu

0Fh TMR1H Holding Register for the Most Significant Byte of the 16-bit TMR1 xxxx xxxx uuuu uuuu

10h T1CON T1GINV TMR1GE T1CKPS1 T1CKPS0 T1OSCEN T1SYNC

11h — Unimplemented — —

12h — Unimplemented — —

13h — Unimplemented — —

14h — Unimplemented — —

15h — Unimplemented — —

16h — Unimplemented — —

17h — Unimplemented — —

18h WDTCON

19h CMCON0 C2OUT C1OUT

1Ah CMCON1

1Bh — Unimplemented — —

1Ch — Unimplemented — —

1Dh — Unimplemented — —

1Eh — Unimplemented — —

1Fh — Unimplemented — —

Legend: — = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition,

Note 1: Other (non Power-up) Resets include MCLR

2: MCLR

(not a physical register)

PD ZDCC0001 1xxx 000q quuu

— — RA5 RA4 RA3 RA2 RA1 RA0 --xx xx00 --uu uu00

— — R C5 RC4 RC3 RC2 RC1 RC0 --xx xx00 --uu uu00

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 ---0 0000

EEIF LVDIF CRIF C2IF C1IF OSFIF —TMR1IF0000 00-0 0000 00-0

TMR1CS TMR1ON 0000 0000 uuuu uuuu

— — — WDTPS3 WDTPS2 WDTPS1 WDTPS0 SWDTEN ---0 1000 ---0 1000

C2INV C1INV CIS CM2 CM1 CM0 0000 0000 0000 0000

— — — — — — T1GSS C2SYNC ---- --10 ---- --10

shaded = unimplemented

Reset and Watchdog Timer Reset during normal operation.

and WDT Reset do not affect the previous value data latch. The RAIF bit will be cleared upon Reset but will set

again if the mismatch exists.

Val ue on

POR/BOD/

WUR

xxxx xxxx xxxx xxxx

(2)

0000 0000 0000 0000

Value on

all other

Resets

(1)

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 17

Page 20

PIC12F635/PIC16F636/639

TABLE 2-5: PIC16F636/639 SPECIAL FUNCTION REGISTERS SUMMARY BANK 1

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 1

80h INDF Addressing this location uses contents of FSR to address data memory

81h OPTION_REG RAPU

82h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 0000 0000

83h STATUS IRP RP1 RP0 TO

84h FSR Indirect Data Memory Address Pointer xxxx xxxx uuuu uuuu

85h TRISA

86h — Unimplemented — —

87h TRISC

88h — Unimplemented — —

89h — Unimplemented — —

8Ah PCLATH

8Bh INTCON GIE PEIE T0IE INTE RAIE T0IF INTF RAIF

8Ch PIE1 EEIE LVDIE CRIE C2IE C1IE OSFIE

8Dh — Unimplemented — —

8Eh PCON

8Fh OSCCON

90h OSCTUNE

91h — Unimplemented — —

92h — Unimplemented — —

93h — Unimplemented — —

94h LVDCON

95h WPUDA

96h IOCA

97h WDA

9Bh — Unimplemented — —

99h VRCON VREN

9Ah EEDAT EEDAT7 EEDAT6 EEDAT5 EEDAT4 EEDAT3 EEDAT2 EEDAT1 EEDAT0 0000 0000 0000 0000

9Bh EEADR EEADR7 EEADR6 EEADR5 EEADR4 EEADR3 EEADR2 EEADR1 EEADR0 0000 0000 0000 0000

9Ch EECON1

9Dh EECON2 EEPROM Control Register 2 (not a physical register) ---- ---- ---- ---9Eh — Unimplemented — —

9Fh — Unimplemented — —

Legend: — = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition,

Note 1: Other (non Power-up) Resets include MCLR

(2)

shaded = unimplemented

2: RA3 pull-up is enabled when pin is configured as MCLR

3: MCLR

again if the mismatch exists.

(not a physical register)

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

PD ZDCC0001 1xxx 000q quuu

— — TRISA5 TRISA4 TRISA3 TRISA2 TRISA1 TRISA0 --11 1111 --11 1111

— — TRISC5 TRISC4 TRISC3 TRISC2 TRISC1 TRISC0 --11 1111 --11 1111

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 ---0 0000

—TMR1IE0000 00-0 0000 00-0

— — ULPWUE SBODEN WUR —PORBOD --01 q-qq --0u u-uu

— IRCF2 IRCF1 IRCF0 OSTS HTS LTS SCS -110 q000 -110 x000

— — — TUN4 TUN3 TUN2 TUN1 TUN0 ---0 0000 ---u uuuu

(2)

— —IRVSTLVDEN— LVDL2 LVDL1 LVDL0 --00 -000 --00 -000

— — WPUDA5 WPUDA4 — WPUDA2 WPUDA1 WPUDA0 --11 -111 --11 -111

— — IOCA5 IOCA4 IOCA3 IOCA2 IOCA1 IOCA0 --00 0000 --00 0000

— — WDA5 WDA4 — WDA2 WDA1 WDA0 --11 -111 --11 -111

—VRR— VR3 VR2 VR1 VR0 0-0- 0000 0-0- 0000

— — — — WRERR WREN WR RD ---- x000 ---- q000

Reset and Watchdog Timer Res et during normal operation.

in the Configuration Word register.

and WDT Reset do not affect the previous value data latch. The RAIF bit will be cleared upon Reset but will set

Value on

POR/BOD/

WUR

xxxx xxxx xxxx xxxx

(3)

0000 0000 0000 0000

Value on

all other

Resets

(1)

DS41232B-page 18 Preliminary © 2005 Microchip Technology Inc.

Page 21

PIC12F635/PIC16F636/639

TABLE 2-6: PIC12F635/PIC16F636/639 SPECIAL FUNCTION REGISTERS SUMMARY BANK 2

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 2

10Ch — Unim plemented — —

10Dh — Unim plemented — —

10Eh — Unimplemented — —

10Fh — Unimplemented — —

110h CRCON GO/DONE

111h CRDAT0

112h CRDAT1

113h CRDAT2

114h CRDAT3

115h — Unimplemented — —

116h — Unimplemented — —

Legend: — = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition,

Note 1: Other (non Power-up) Resets include MCLR

2: CRDAT<3:0> are KEELOQ® hardware peri ph era l rel ate d reg iste rs and requ ir e the ex ec utio n of the “KEELOQ Encoder Lice nse Agre emen t”

(2)

Cryptographic Data Register 0 0000 0000 0000 0000

(2)

Cryptographic Data Register 1 0000 0000 0000 0000

(2)

Cryptographic Data Register 2 0000 0000 0000 0000

(2)

Cryptographic Data Register 3 0000 0000 0000 0000

shaded = unimplemented

regarding implementation of the module and access to related registers. The “K

through the Microchip web site located at www.microchip.com/K

ENC/DEC — — — — CRREG1 CRR EG0 00-- --00 00-- --00

Reset and Watchdog Timer Reset during normal operation.

EELOQ Encoder License Agreement” may be a ccessed

EELOQ or by contacting your local Microchip Sales Representative.

Value on

POR/BOD/

WUR

Value on

all other

Resets

(1)

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 19

Page 22

PIC12F635/PIC16F636/639

2.2.2.1 Status Register

The Status register, shown in Register 2-1, contains:

• the arithmetic status of the ALU

• the Reset status

• the bank select bits for data memory (SRAM)

The Status register can be the destination for any

instruction, like any other register . If the S tatus register is

the destination for an instruction that affects the Z, D C or

C bits, then the write to these three bits is disabled.

These bits are set or cleared according to the device

logic. Furthermore, the TO

Therefore, the result of an instruction with the Status

register as destination may be different than intended.

and PD bits are not writable.

For example, CLRF STATUS, w ill c lear the upper three

bits and set the Z bit. Thi s leaves the Status regis ter as

000u u1uu (where u = unchanged).

It is recommended, therefore, that only BCF, BSF, SWAPF

and MOVWF instructions are used to alter the Status

register, because these instructions do not affect any

Status bits. For other instructions not affecting any Status

bits, see Section 13.0 “Instruction Set Summary”.

Note 1: The C and DC bits operate as a Borrow

and Digit Borrow out bit, respectively, in

subtraction. See the SUBLW and SUBWF

instructions for examples.

REGISTER 2-1: STATUS – STATUS REGISTER (ADDRESS: 03h OR 83h)

R/W-0 R/W-0 R/W-0 R-1 R-1 R/W-x R/W-x R/W-x

IRP RP1 RP0 TO

bit 7 bit 0

bit 7 IRP: Register Bank Select bit (used for indire ct addressing)

1 = Bank 2, 3 (100h-1FFh)

0 = Bank 0, 1 (00h-FFh)

bit 6-5 RP<1:0>: Register Bank Select bits (used for direct addressing)

11 = Bank 3 (180h-1FFh)

10 = Bank 2 (100h-17Fh)

01 = Bank 1 (80h-FFh)

00 = Bank 0 (00h-7Fh)

Each bank is 128 bytes.

bit 4 TO

bit 3 PD

bit 2 Z: Zero bit

bit 1 DC: Digit Carry/B

bit 0 C: Carry/Borrow bit (ADDWF, ADDLW, SUBLW, SUBWF instructions)

: Time-out bit

1 = After power-up, CLRWDT instruction or SLEEP instruction

0 = A WDT time-out occurred

: Power-down bit

1 = After power-up or by the CLRWDT instruction

0 = By execution of the SLEEP instruction

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

orrow bit (ADDWF, ADDLW, SUBLW, SUBWF instructions)

For Borrow, the polarity is reversed.

1 = A carry-out from the 4th low-order bit of the result occurred

0 = No carry-out from the 4th low-order bit of the result

1 = A carry-out from the Most Significant bit of the result occurred

0 = No carry-out from the Most Significant bit of the result occurred

PD ZDCC

Note: For Borrow, the polarity is reversed. A subtraction is executed by adding the two’s

complement of the second operand. For rotate (RRF, RLF) instructions, this bit is

loaded with either the high-order or low-order bit of the source register.

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

- n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

DS41232B-page 20 Preliminary © 2005 Microchip Technology Inc.

Page 23

PIC12F635/PIC16F636/639

2.2.2.2 Option Register

The Option register is a readable and writable register

which contains various control bits to configure:

• TMR0/WDT prescaler

• External RA2/INT interrupt

•TMR0

• Weak pull-up/pull-downs on PORTA

REGISTER 2-2: OPTION_REG – OPTION REGISTER (ADDRESS: 81h)

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

RAPU

bit 7 bit 0

INTEDG T0CS T0SE PSA PS2 PS1 PS0

Note: To achieve a 1:1 prescaler assignment for

TMR0, assign the prescaler to the WDT by

setting the PSA bit to ‘1’

(OPTION_REG<3>). See Section 5.4

“Prescaler”.

bit 7 RAPU

bit 6 INTEDG: Interrupt Edge Select bit

bit 5 T0CS: TMR0 Clock Source Select bit

bit 4 T0SE: TMR0 Source Edge Select bit

bit 3 PSA: Prescaler Assignment bit

bit 2-0 PS<2:0>: Prescaler Rate Select bits

: PORTA Pull-up/Pull-down Enable bit

1 = PORTA pull-ups/pull-downs are disabled

0 = PORTA pull-ups/pull-downs are enabled by individual port latch values

1 = Interrupt on rising edge of RA2/INT pin

0 = Interrupt on falling edge of RA2/INT pin

1 = Transition on RA 2/T0CKI pin

0 = Internal instruction cycle clock (CLKOUT)

1 = Increment on high-to-low transition on RA2/T0CKI pin

0 = Increment on low-to-high transition on RA2/T0CKI pin

1 = Prescaler is assigned to the WDT

0 = Prescaler is assigned to the Timer0 module

Bit V alue TMR0 Rate WDT Rate

000

001

010

011

100

101

110

111

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

1 : 256

1 : 1

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

- n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 21

Page 24

PIC12F635/PIC16F636/639

2.2.2.3 INTCON Register

The INTCON register is a readable and writable

register which co nta ins th e vari ous e nable and fl ag bit s

for TMR0 register overflow, PORTA change and

external RA2/INT pin interrupts.

Note: Interrupt flag bits are set when an interrupt

condition occurs, regard less of the state of

its corresponding enable bit or the Global

Interrupt Enable bit, GIE (INTCON<7>).

User software should ensu re the appropriate interrupt flag bits are clear prior to

enabling an interrupt.

REGISTER 2-3: INTCON – INTERRUPT CONTROL REGISTER (ADDRESS: 0Bh OR 8Bh)

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

GIE PEIE T0IE INTE RAIE

bit 7 bit 0

bit 7 GIE: Global Interrupt Enable bit

1 = Enables all unmasked interrupts

0 = Disables all interrupts

bit 6 PEIE: Peripheral Interrupt Enable bit

1 = Enables all unmasked peripheral interrupts

0 = Disables all peripheral interrupts

bit 5 T0IE: TMR0 Overflow Interrupt Enable bit

1 = Enables the TMR0 interrupt

0 = Disables the TMR0 interrupt

bit 4 INTE: RA2/INT External Interrupt Enable bit

1 = Enables the RA2/INT external interrupt

0 = Disables the RA2/INT external interrupt

bit 3 RAIE: PORTA Change Interrupt Enable bit

1 = Enables the PORTA change interrupt

0 = Disables the PORTA change interrupt

bit 2 T0IF: TMR0 Overflow Interrupt Flag bit

1 = TMR0 regis ter has over flowed (must be cleared in software)

0 = TMR0 register did not overflow

bit 1 INTF: RA2/INT External Interrupt Flag bit

1 = The RA2/INT external interru pt occurred (must be cleared in software)

0 = The RA2/INT external interrupt did not occur

bit 0 RAIF: PORTA Change Interrupt Flag bit

1 = When at least one of the PORTA <5:0> pins changed state (must be cleared in software)

0 = None of the PORTA <5:0> pins have changed state

(2)

(3)

(1)

(1)

T0IF

(2)

INTF RAIF

(3)

Note 1: IOCA register must also be enabled.

2: T0IF bit is set when Timer0 rolls over. Timer0 is unchanged on Reset and should

be initialized before clearing the T0IF bit.

3: MCLR

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

- n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

DS41232B-page 22 Preliminary © 2005 Microchip Technology Inc.

and WDT Reset do not af fect the prev ious va lue dat a latc h. The R AIF bit w ill

be cleared upon Reset but will set again if the mismatch exists.

Page 25

PIC12F635/PIC16F636/639

2.2.2.4 PIE1 Register

The PIE1 register contai ns th e in terru pt enable bits, as

shown in Register 2-4.

REGISTER 2-4: PIE1 — PERIPHERAL INTERRUPT ENABLE REGISTER 1 (ADDRESS: 8Ch)

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 U-0 R/W-0

EEIE LVDIE CRIE C2IE

bit 7 bit 0

bit 7 EEIE: EE Write Complete Interrupt Enable bit

1 = Enables the EE write complete interrupt

0 = Disables the EE write complete interrupt

bit 6 LVDIE: Low-Voltage Detect Interrupt Enable bit

1 = Enables the LVD interrupt

0 = Disables the LVD interrupt

bit 5 CRIE: Cryptographic Interrupt Enable bit

1 = Enables the cryptographic interrupt

0 = Disables the cryptographic interrupt

bit 4 C2IE: Comparator 2 Interrupt Enable bit

1 = Enables the Comparator 2 interrupt

0 = Disables the Comparator 2 interrupt

bit 3 C1IE: Comparator 1 Interrupt Enable bit

1 = Enables the Comparator 1 interrupt

0 = Disables the Comparator 1 interrupt

bit 2 OSFIE: Oscillator Fail Interrupt Enable bit

1 = Enables the oscillator fail interrupt

0 = Disables the oscillator fail interrupt

bit 1 Unimplemented: Read as ‘0’

bit 0 TMR1IE: Timer1 Interrupt Enable bit

1 = Enables the Timer1 interrupt

0 = Disables the Timer1 interrupt

Note: Bit PEIE (INTCON<6>) must be set to

enable any peripheral interrupt.

(1)

(1)

C1IE OSFIE —TMR1IE

Note 1: PIC16F636/639 only.

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

- n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 23

Page 26

PIC12F635/PIC16F636/639

2.2.2.5 PIR1 Register

The PIR1 register contains the interrupt flag bits, as

shown in Register 2-5.

REGISTER 2-5: PIR1 – PERIPHERAL INTERRUPT REQUEST REGISTER 1 (ADDRESS: 0Ch)

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 U-0 R/W-0

EEIF LVDIF CRIF C2IF

bit 7 bit 0

bit 7 EEIF: EEPROM Write Operation Interrupt Flag bit

1 = The write operation completed (must be cleared in software)

0 = The write operation has not completed or has not been started

bit 6 LVDIF: Low-Voltage Detect Interrupt Flag bit

1 = The supply voltage has crossed selected LVD voltage (must be cleared in software)

0 = The supply voltage has not crossed selected LVD voltage

bit 5 CRIF: Cryptographic Interrupt Flag bit

1 = The Cryptographic module has completed an operation (must be cleared in software)

0 = The Cryptographic module has not completed an operation or is Idle

bit 4 C2IF: Comparator 2 Interrupt Flag bit

1 = Comparator output (C2OUT bit) has changed (must be cleared in software)

0 = Comparator output (C2OUT bit) has not changed

bit 3 C1IF: Comparator 1 Interrupt Flag bit

1 = Comparator output (C1OUT bit) has changed (must be cleared in software)

0 = Comparator output (C1OUT bit) has not changed

bit 2 OSFIF: Oscillator Fail Interrupt Flag bit

1 = System oscillator failed, clock input has changed INTOSC (must be cleared in software)

0 = System clock operating

bit 1 Unimplemented: Read as ‘0’

bit 0 TMR1IF: Timer1 Interrupt Flag bit

1 = Timer1 rolled ov er (must be cleared in software)

0 = Timer1 has not rolled over

Note: Interrupt flag bits are set when an interrupt

condition occurs, regar dless of the st ate of

its corresponding enable bit or the Global

Interrupt Enable bit, GIE (INTCON<7>).

User software should ensure the

appropriate interrupt flag bits are clear

prior to enabling an interrupt.

(1)

(1)

C1IF OSFIF —TMR1IF

Note 1: PIC16F636/639 only.

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

- n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

DS41232B-page 24 Preliminary © 2005 Microchip Technology Inc.

Page 27

PIC12F635/PIC16F636/639

2.2.2.6 PCON Register

The Power Control (PCON) register (see Table 12-3)

contains flag bit s to differentiate between a:

• Power-on Reset (POR

• Wake-up Reset (WUR)

• Brown-out Detect (BOD

• Watchdog Timer Reset (WDT)

• External MCLR Reset

)

)

The PCON register also controls the Ultra Low-Power

Wake-up and software enable of the BOD

The PCON register bits are shown in Register 2-6.

REGISTER 2-6: PCON – POWER CONTROL REGISTER (ADDRESS: 8Eh)

U-0 U-0 R/W-0 R/W-1 R/W-x U-0 R/W-0 R/W-x

— — ULPWUE SBODEN

bit 7 bit 0

bit 7-6 Unimplemented: Read as ‘0’

bit 5 ULPWUE: Ultra Low-Power Wake-up Enable bit

1 = Ultra Low-Power Wake-up enabled

0 = Ultra Low-Power Wake-up disabled

bit 4 SBODEN: Software BOD Enable bit

1 = BOD enabled

0 = BOD disabled

bit 3 WUR

bit 2 Unimplemented: Read as ‘0’

bit 1 POR

bit 0 BOD

: Wake-up Reset Status bit

1 = No Wake-up Reset occurred

0 = A Wake-up Reset occurred (must be set in software after a Power-on Reset occurs)

: Power-on Reset Status bit

1 = No Power-on Reset occurred

0 = A Power-on Reset occurred (must be set in software after a Power-on Reset occurs)

: Brown-out Detect Status bit

1 = No Brown-out Detect occurred

0 = A Brown-out Detect occurred (must be set in software after a Brown-out Detect occurs)

(1)

(1)

WUR —PORBOD

.

Note 1: BODEN<1:0> = 01 in the Configuration Word register for SBODEN to control the

Brown-out Detect module.

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

- n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 25

Page 28

PIC12F635/PIC16F636/639

2.3 PCL and PCLATH

The Program Counter (PC) is 13 bits wide. The low byte

comes from the PCL register, which is a readable and

writable register. The high byte (PC<12:8>) is not

directly readable or writable and comes from PCLATH.

On any Reset, the PC is cleared. Figure 2-5 shows the

two situations for the loading of the PC. The upper

example in Figure 2-5 shows how the PC is loaded on a

write to PCL (PCLATH<4:0> → PCH). The lower

example in Figure 2-5 shows how the PC is loaded

during a CALL or GOTO instruction (PCLATH<4:3> →

PCH).

FIGURE 2-5: LOADING OF PC IN

DIFFERENT SITUATIONS

PCH PCL

12 8 7 0

PC

PCLATH<4:0>

5

PCLATH

PCH PCL

12 11 10 0

PC

2

87

PCLATH<4:3>

PCLATH

11

Instruction with

PCL as

Destination

8

ALU Result

GOTO, CALL

Opcode<10:0>

2.3.1 COMPUTED GOTO

A computed GOTO is accomplished by adding an offset

to the program counter (ADDWF PCL). When

performing a table read using a computed GOTO

method, care should be exercised if the table location

crosses a PCL memory boundary (each 256-byte

block). Refer to the Application Note AN556,

“Implementing a Table Read” (DS00556).

2.3.2 STACK

The PIC12F635/PIC16F636/639 family has an 8level x 13-bit wide hardware stack (see Figure 2-1).

The stack space is not part of either program or data

space and the S ta ck Pointer i s not rea dable or writa ble.

The PC is PUSHed onto the stack when a CALL

instruction is execute d or an interrupt ca uses a branc h.

The stack is POP ed in the event of a RETURN, RETLW

or a RETFIE instruction execution. PCLATH is not

affected by a P USH or POP operation.

The stack operat es as a circular buf fer . This means th at

after the stack has been PUSHed eight times, the ninth

push overwrites the va lue tha t was s tored fro m the first

push. The tenth pus h ov erwr i tes the se co nd push (and

so on).

Note 1: There are no Status bits to indicate stack

overflow or stack underflow conditions.

2: There are no instructions/mnemonics

called PUSH or POP. These are actions

that occur from the exec ution of the CALL,

RETURN, RETLW and RETFIE instru ction s

or the vectoring to an interrupt address.

DS41232B-page 26 Preliminary © 2005 Microchip Technology Inc.

Page 29

PIC12F635/PIC16F636/639

2.4 Indirect Addressing, INDF and

FSR Registers

The INDF register is not a physi cal register. Addres sing

the INDF register will cause indirect addressing.

Indirect addressing is possible by using the INDF

register. Any instruction using the INDF register

actually accesses data pointed to by the File Select

Register (FSR). Reading INDF itself indirectly will

produce 00h. Writing to the INDF register indirectly

results in a no operation (although Status bits may be

A simple program to clear RAM lo catio n 20h-2Fh usin g

indirect addressing is shown in Example 2-1.

EXAMPLE 2-1: INDIRECT ADDRESSING

MOVLW 0x20 ;initialize pointer

MOVWF FSR ;to RAM

NEXT CLRF INDF ;clear INDF register

INCF FSR ;INC POINTER

BTFSS FSR,4 ;all done?

GOTO NEXT ;no clear next

CONTINUE ;yes continue

affected). An effective 9-bit address is obtained by

concatenating the 8-bit FSR and the IRP bit

(STATUS<7>), as shown in Figure 2-6.

FIGURE 2-6: DIRECT/INDIRECT ADDRESSING PIC12F635/PIC16F636/639

Indirect A ddressingDirect Addressing

From Opcode

RP1 RP0

Bank Select Location Select

6

00h

0

00 01 10 11

IRP File Select Register

Bank Select

7

180h

0

Location Select

Data

Memory

7Fh

Bank 0 Bank 1 Bank 2 Bank 3

Note: For memory map det ail, see Figure2-2.

1FFh

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 27

Page 30

PIC12F635/PIC16F636/639

NOTES:

DS41232B-page 28 Preliminary © 2005 Microchip Technology Inc.

Page 31

PIC12F635/PIC16F636/639

3.0 CLOCK SOURCES

3.1 Overview

The PIC12F635/PIC16F636/639 has a wide variety of

clock sources and selection features to allow it to be

used in a wide range of applications, while maximizing

performance and minimizing power consumption.

Figure 3-1 illustrates a block diagram of the

PIC12F635/PIC16F636/639 clock sources.

Clock sources can be configured from external oscillators,

quartz crystal resonators, ceramic resonators and

Resistor-Capacitor (RC) circuits. In add ition, the system

clock source can be configured from one of two in ternal

oscillators, with a choice of speeds selectable via

software. Additional clock features include:

• Selectable system clock source between external

or internal via software.

• Two-Speed Clock Start-up mode, which

minimizes latency between external oscillator

start-up and code execu t io n.

• Fail-Safe Clock Monitor (FSCM) designed to

detect a failure of the external clock source (LP,

XT, HS, EC or RC modes) and switch to the

internal oscillator.

The PIC12F635/PIC16F636/639 can be configured in

one of eight clock modes.

1. EC – External clock with I/O on RA4.

2. LP – Low gain crystal or Ceramic Resonator

Oscillator mode.

3. XT – Medium gain c rysta l or Ce ramic Resonat or

Oscillator mode.

4. HS – High gain crystal or Ceramic Resonator

mode.

5. RC – External Resistor-Capacitor (RC) with

OSC/4 out put on RA4.

F

6. RCIO – External Resistor-Capacitor (RC) with I/O

on RA4.

7. INTOSC – Internal oscillator with F

OSC/4 output

on RA4 and I/O on RA5.

8. INTOSCIO – Internal oscillator with I/O on RA4

and RA5.

Clock source modes are configured by the FOSC<2:0>

bits in the Configuration Word register (see

Section 12.0 “Special Features of the CPU”). The

internal clock can be generated by two oscillators. The

HFINTOSC is a high-frequency calibrated oscillator . The

LFINTOSC is a low-frequency uncalibrated oscillator.

FIGURE 3-1: PIC12F635/PIC16F636 /639 CLOCK SOURCE BLOCK DIAGRAM

FOSC<2:0>

External Oscillator

OSC2

Sleep

OSC1

IRCF<2:0>

(OSCCON<6:4>)

8 MHz

Internal Oscillator

HFINTOSC

LFINTOSC

Note 1: HFINTOSC = High-Frequency Calibrated Internal Oscillator.

2: LFINTOSC = Low-Frequency Internal Oscillator is not calibrated.

(1)

8 MHz

(2)

31 kHz

Postscaler

4 MHz

2 MHz

1 MHz

500 kHz

250 kHz

125 kHz

31 kHz

111

110

101

100

011

010

001

000

LP, XT, HS, RC, RCIO, EC

MUX

(Configuration Word)

SCS

(OSCCON<0>)

MUX

(CPU and Peripherals)

Power-up Timer (PWRT)

Watchdog Time r (WDT)

Fail-Safe Clock Monitor (FSCM)

System Clock

© 2005 Microchip Technology Inc. Preliminary DS41232B-page 29

Page 32

PIC12F635/PIC16F636/639

3.2 Clock Source Modes

Clock source modes can be classified as external or

internal.

External cloc k modes rely on exter nal circuitry for the

clock source. Examples are oscillator modules (EC

mode), quartz crystal re sonators or c eramic resonators

(LP, XT and HS modes) and Resistor-Capacitor (RC

mode) circuits.

Internal clock sources are contained internally within

PIC12F635/PIC16F636 /63 9. The devic e has two in ternal oscillators: the 8 MHz High-Frequency Internal

Oscillator (HFINTOSC) and 31 kHz Low-Frequency

Internal Oscillator (LFINTOSC).

The system clock can be selected between extern al or

internal clock sources via the System Clock Selection

(SCS) bit (see Section 3.5 “Clock Switching”).

3.3 External Clock Modes

3.3.1 OSCILLATOR START-UP TIMER (OST)

If the PIC12F635/PIC16F636/639 is configured for LP,

XT or HS modes, the Oscillator Start-up Timer (OST)

counts 1024 oscillations from the OSC1 pin following a

Power-on Reset (POR) and the Power-up Timer

(PWRT) has expired (if configured), or a wake-up from

Sleep. During this time, the program counter does not

increment and program execution is suspended. The

OST ensures that the oscillator circuit, using a quartz

crystal resonator or ceramic resonator, has started and

is providing a stable system clock to the PIC12F635/

PIC16F636/639.

When switching between clock sources, a delay is

required to allow the new clock to stabilize. Table 3-1

shows oscillator delay examples.

In order to minimize latency between external oscillator

start-up and code execution, the T wo-Speed Clock S tartup mode can be selected (see Section 3.6 “T wo-Speed

Clock Start-up Mode”).

TABLE 3-1: OSCILLATOR DELAY EXAMPLES

Switch From Switch To Frequency Oscillator Delay

Sleep/POR

LFINTOSC (31 kHz) EC, RC DC – 20 MHz

Sleep/POR LP, XT, HS 31 kHz-20 MHz 1024 Clock Cycles (OST)

LFINTOSC (31 kHz) HFINTOSC 125 kHz-8 MHz 1 μs (approx.)

LFINTOSC

HFINTOSC

31 kHz

125 kHz-8 MHz

5 μs-10 μs (approx.)

CPU Start-upSleep/POR EC, RC DC – 20 MHz

DS41232B-page 30 Preliminary © 2005 Microchip Technology Inc.

Page 33

PIC12F635/PIC16F636/639

3.3.2 EC MODE

The External Clock (EC) mode allows an externally

generated logic level as the system clock source.

When operating in this mode, an external clock source

is connected to the OSC1 pin and the RA5 pin is

available for general purpose I/ O. Figure 3-2 shows the

pin connections for EC mode.

The Oscillator Start-up Timer (OST) is disabled when

EC mode is selected. Therefore, there is no delay in

operation after a Power-on Reset (POR) or wake-up

from Sleep. Because the PIC12F635/PIC16F636/639

design is full y static, stoppi ng the extern al clock input

will have the ef fect of halting th e device while leaving all

data intact. Upon restarting the external clock, the

device will resum e ope ration as if no ti me ha d elap se d.

FIGURE 3-2: EXTERNAL CLOCK (EC)

MODE OPERATION

Clock from

Ext. System

RA4

OSC1/CLKIN

PIC12F635/PIC16F636/639

I/O (OSC2)

3.3.3 LP, XT, HS MODES

The LP, XT and HS modes support the use of quartz

crystal resonators or ceramic resonators connected to

the OSC1 and OSC2 pins (Figure 3-1). The mode

selects a low, medium or high gain setting of the

internal inverter-amplifier to support various resonator

types and speed.

LP Oscillator mode selects the lowest gain setting of

the internal inverter-amplifier. LP mode current

consumption is the least of the three modes. T his mode

is best suited to drive resonators with a low drive level

specification, for example, tuning fork type crystals.

XT Oscillator mode selects the intermediate gain

setting of the internal inverter-amplifier. XT mode

current consumption is the medi um of the three modes.

This mode is better suited to drive resonators with a

medium drive level specification, for example, lowfrequency AT-cut quartz crystal resonators.

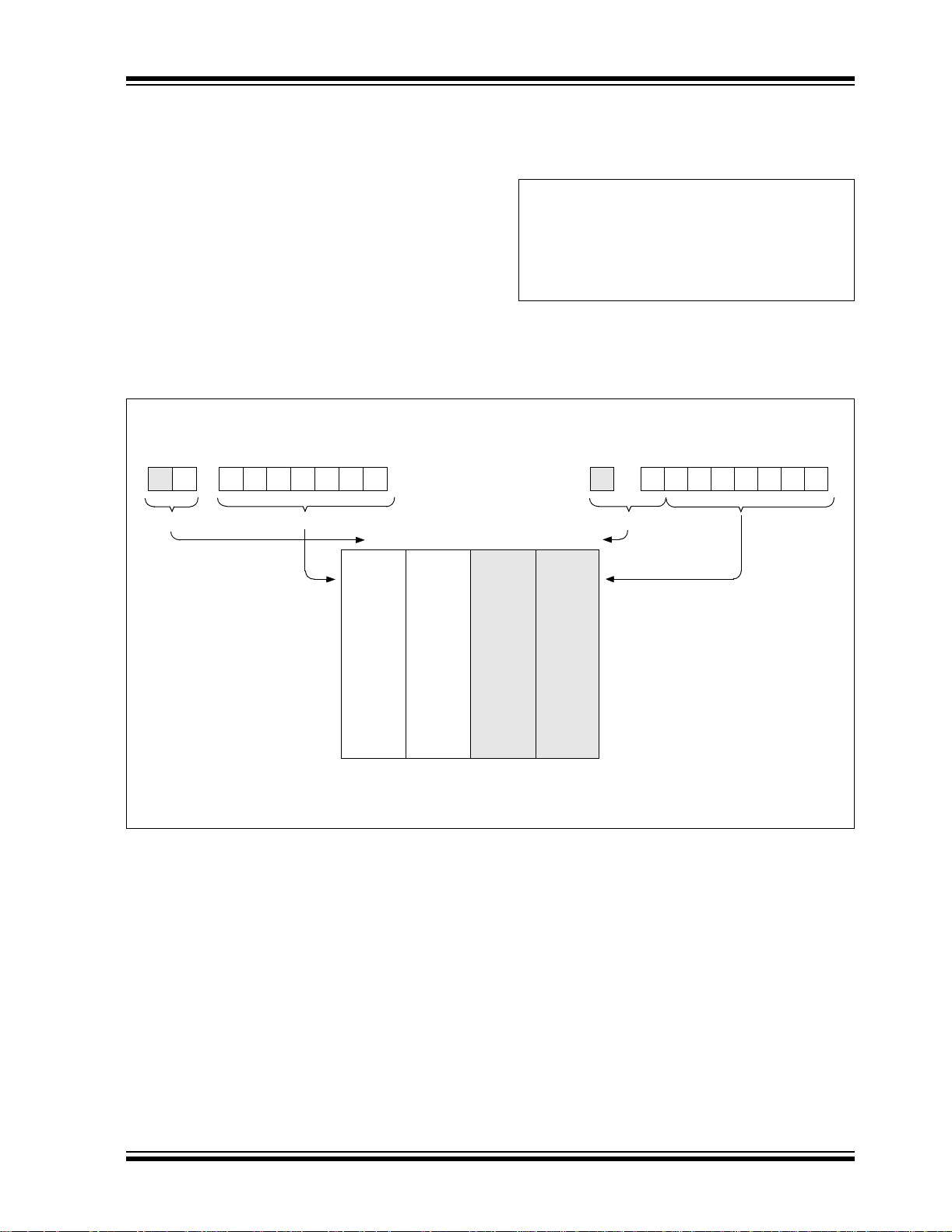

HS Oscillator mode selects the highest gain setting of