*8-bit, 8-pin Devices Protected by Microchip’s Low Pin C ount Patent: U .S. Patent N o. 5,847,450. Addit ional U.S. and

查询PIC12F609-E/MD供应商

PIC12F609/HV609

PIC12F615/HV615

Data Sheet

8-Pin Flash-Based, 8-Bit

CMOS Microcontrollers

foreign patents and applications m ay be issued or pending.

© 2006 Microchip Technology Inc. Preliminary DS41302A

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Millennium Copyright Act. If suc h a c t s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenien ce

and may be su perseded by updates. It is you r responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MAT E, Pow erSm art , rfPIC and SmartS hunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPASM, MPLIB, MPLINK, PIC kit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

8-bit MCUs, KEELOQ

microperipherals, nonvolatile memory and analog products. In addition,

Microchip’s quality system for the design and manufacture of

development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial EEPROMs,

DS41302A-page ii Preliminary © 2006 Microchip Technology Inc.

®

PIC12F609/615/12HV609/615

8-Pin Flash-Based, 8-Bit CMOS Microcontrollers

High-Performance RISC CPU:

• Only 35 instructions to learn:

- All single-cycle instructions except branches

• Operating speed:

- DC – 20 MHz oscillator/clock input

- DC – 200 ns instr uction cycle

• Interrupt capability

• 8-level deep hardware stack

• Direct, Indirect and Relative Addressing modes

Special Microcontroller Features:

• Precision Internal Oscillator:

- Factory calibrated to ±1%, typical

- Software selectable frequency: 4 MHz or

8 MHz

• Power-Saving Sleep mode

• Volt age range:

- PIC12F609/615: 2.0V to 5.5V

- PIC12HV609/615: 2.0V to user defined

maximum (see note)

• Industrial and Extended Temperature range

• Power-on Reset (PO R)

• Power-up Time r (PWRT) and Oscillator Start-up

Timer (OST)

• Brown-out Reset (BOR)

• Watchdog Timer (WDT) with independent

oscillator for reliable operation

• Multiplexed Master Clear with pull-up/input pin

• Programmable code protection

• High Endurance Flash:

- 100,000 write Flash endurance

- Flash r etention: > 40 years

Low-Power Features:

• Standby Current:

- 50 nA @ 2.0V, typical

• Operating Current:

-11μA @ 32 kHz, 2.0V, typical

-260μA @ 4 MHz, 2.0V, typical

• Watchdog Timer Current:

-1μA @ 2.0V, typical

Peripheral Features:

• Shunt Voltage Regulator (PIC12HV609/615 only):

- 5 volt regulation

- 4 mA to 50 mA shunt range

• 5 I/O pins and 1 input only

• High current source/sink for direct LED drive

- Interrupt-on-pin change or pins

- Individually programmable weak pull-ups

• Analog Comparator module with:

- One analog comparator

- Programmable on-chip voltage reference

(CV

REF) module (% of VDD)

- Comparator inputs and output externally

accessible

- Built-In Hysteresis (software selectable)

• Timer0: 8-bit timer/counter with 8-bit

programmable prescaler

• Enhanced Timer1:

- 16-bit timer/counter with prescaler

- External Timer1 Gate (cou nt enab le )

- Option to use OSC1 and OSC2 in LP mode

as Timer1 oscillator if INTOSC mode

selected

- Option to use system clock as Timer1

TM

• In-Circuit Serial Programming

pins

PIC12F615/HV615 ONLY:

• Enhanced Capture, Compare, PWM module:

- 16-bit Capture, max. resolution 12.5 ns

- Compare, max. resolution 200 ns

- 10-bit PWM with 1 or 2 output channels, 1

output channel programmable “dead time”,

max. frequency 20 kHz, auto-shutdown

• A/D Converter:

- 10-bit resolution and 4 channels, samples

internal voltage references

• Timer2: 8-bit timer/counter with 8-bit period

register, prescaler and postscaler

(ICSPTM) via two

Note: Voltage across the shunt regulator should

not exceed 5V.

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 1

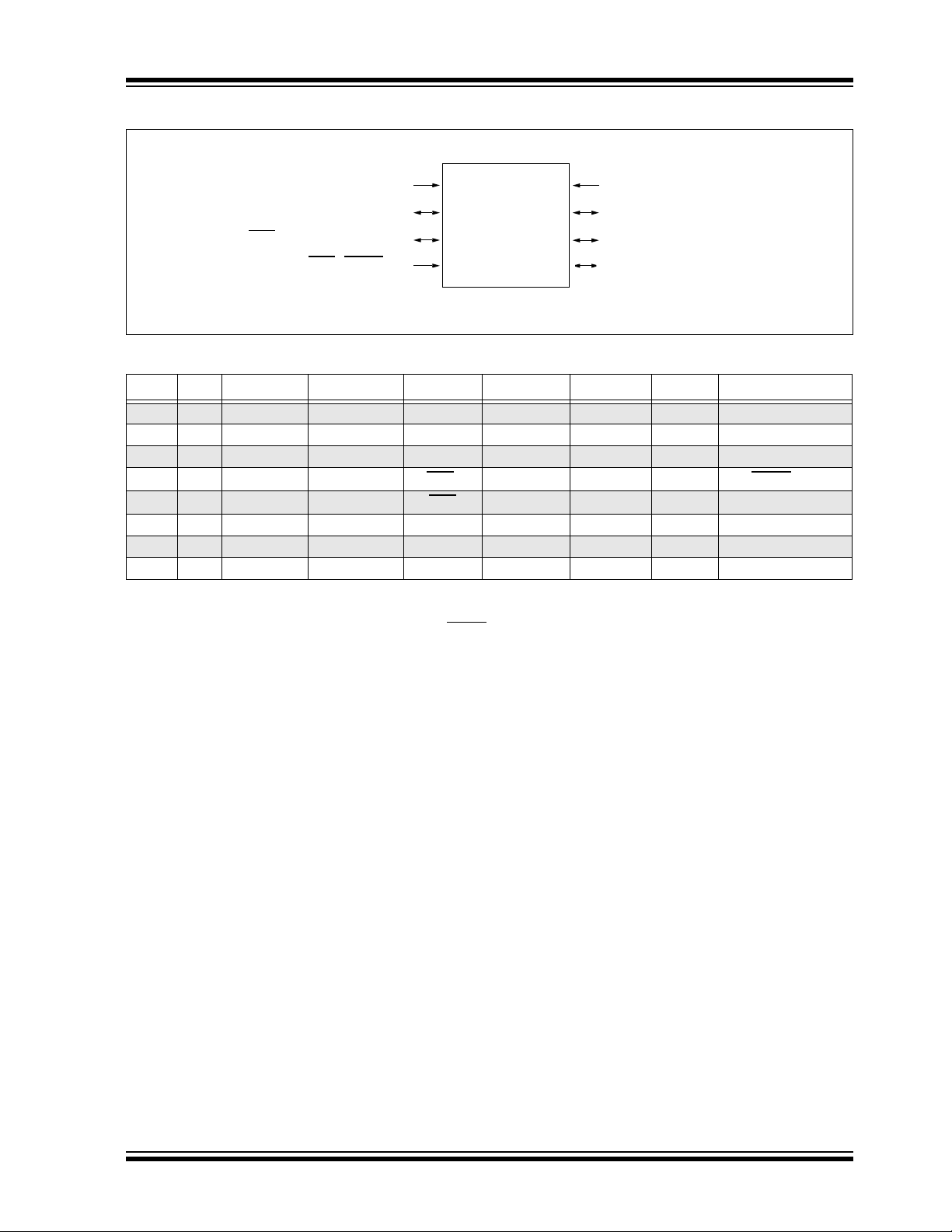

PIC12F609/615/12HV609/615

Program Memory Data Memory

Device

PIC12F609 1024 64 5 0 1 1/1 2.0V-5.5V

PIC12HV609 1024 64 5 0 1 1/1 2.0V-user defined

PIC12F615 1024 64 5 4 1 2/1 2.0V-5.5V

PIC12HV615 1024 64 5 4 1 2/1 2.0V-user defined

Flash

(words)

SRAM (bytes)

I/O

10-bit A/D

(ch)

Comparators

Timers

8/16-bit

Voltage Range

8-Pin Diagram, PIC12F609/HV609 (PDIP, SOIC, TSSOP, DFN)

GP5/T1CKI/OSC1/CLKIN

GP4/CIN1-/T1G

/OSC2/CLKOUT

GP3/MCLR

VDD

/VPP

1

2

PIC12F609/

HV609

3

4

TABLE 1: PIC12F609/HV609 PIN SUMMARY (PDIP, SOIC, TSSOP, DFN)

I/O Pin Comparators Timer Interrupts Pull-ups Basic

GP0 7 CIN+ — IOC Y ICSPDAT

GP1 6 CIN0- — IOC Y ICSPCLK

GP2 5 COUT T0CKI INT/IOC Y —

GP3

(1)

4—

GP4 3 CIN1- T1G IOC Y OSC2/CLKOUT

GP5 2 — T1CKI IOC Y OSC1/CLKIN

— 1 — — — — VDD

—8— ——— VSS

Note 1: Input only.

2: Only when pin is configured for external MCLR.

—

IOC Y

V

8

7

6

5

SS

GP0/CIN+/ICSPDAT

GP1/CIN0-/ICSPCLK

GP2/T0CKI/INT/COUT

(2)

MCLR/VPP

DS41302A-page 2 Preliminary © 2006 Microchip Technology Inc.

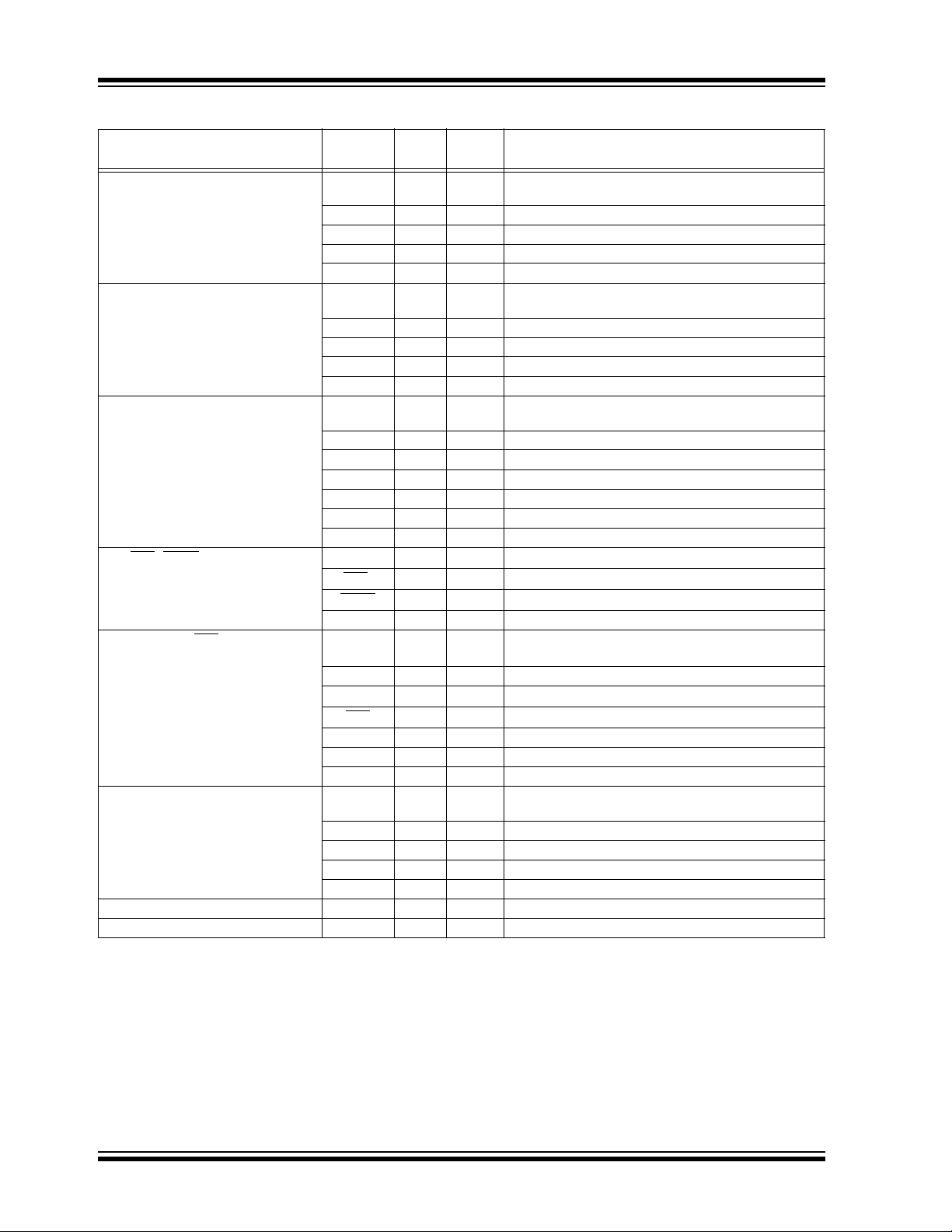

PIC12F609/615/12HV609/615

8-Pin Diagram, PIC12F615/HV615 (PDIP, SOIC, TSSOP, DFN)

VDD

GP5/T1CKI/P1A*/OSC1/CLKIN

GP4/AN3/CIN1-/T1G/P1B*/OSC2/CLKOUT

GP3/T1G

* Alternate pin function.

*/MCLR/VPP

1

2

PIC12F615/

HV615

3

4

V

8

7

6

5

SS

GP0/AN0/CIN+/P1B/ICSPDA T

GP1/AN1/CIN0-/VREF/ICSPCLK

GP2/AN2/T0CKI/INT/COUT/CCP1/P1A

T ABLE 2: PIC12F615/HV615 PIN SUMMARY (PDIP, SOIC, TSSOP, DFN)

I/O Pin Analog Comparators Timer CCP Interrupts Pull-ups Basic

GP0 7 AN0 CIN+ — P1B IOC Y ICSPDAT

GP1 6 AN1 CIN0- — — IOC Y ICSPCLK/VREF

GP2 5 AN2 COUT T0CKI CCP1/P1A INT/IOC Y —

(1)

GP3

GP4 3 AN3 CIN1- T1G P1B* IOC Y OSC2/CLKOUT

GP5 2 — — T1CKI P1A* IOC Y OSC1/CLKIN

— 1 — — — — — — VDD

—8 — — — — — — VSS

Note 1: Input only.

4— — T1G*— IOCY

* Alternate pin function.

2: Only when pin is configured for external MCLR

.

(2)

MCLR/VPP

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 3

PIC12F609/615/12HV609/615

Table of Contents

1.0 Device Overview .......................................................................................................................................................................... 5

2.0 Memory Organization................................................................................................................................................................... 9

3.0 Oscillator Module........................................................................................................................................................................ 25

4.0 I/O Ports................. ....................................................................................................................................................................31

5.0 Timer0 Module ........................................................................................................................................................................... 41

6.0 Timer1 Module with Gate Control.............................................................. .................................................................................45

7.0 Timer2 Module (PIC12F615/HV615 only).......................................................................... ........................................................51

8.0 Comparator Module....................................................................................................................................................................53

9.0 Analog-to-Digital Converter (ADC) Module (PIC12F615/HV615 only) ....................................................................................... 65

10.0 Enhanced Capture/Compare/PWM (With Auto-Shutdown and Dead Band) Module (PIC12F615/HV615 only)........................ 75

11.0 Special Features of the CPU....................................... ............................................................................................................... 93

12.0 Voltage Regulator............................................................................. .. .. .. .. .. ....... .. .. .. .. .. .. ........................................................... 111

13.0 Instruction Set Summary.......................................................................................................................................................... 113

14.0 Development Support. ..............................................................................................................................................................123

15.0 Electrical Specifications............................................................................................................................................................ 127

16.0 DC and AC Characteristics Graphs and Tables.......................................................................................................................149

17.0 Packaging Information..................................................... ......................................................................................................... 151

Appendix A: Data Sheet Revision History..........................................................................................................................................157

Appendix B: Migrating from other PIC® Devices...............................................................................................................................157

Index ........................................................................... ... .................................................................................................................... 159

The Microchip Web Site..................................................................................................................................................................... 163

Customer Change Notification Service ..................................... ...... ............. ...... ............... ...... ........................................................... 163

Customer Support.............................................................................................................................................................................. 163

Reader Response............................................................................ .................................................................................................. 164

Product Identification System............................................................................................................................................................. 165

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best docum entation possible to ensure s uccessful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine t he version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision of

silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

DS41302A-page 4 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

1.0 DEVICE OVERVIEW

Block Diagrams and pinout descriptions of the devices

are as follows:

The PIC12F609/615/12HV609/615 devices are covered

by this data sheet. They are available in 8-pin PDIP,

SOIC, TSSOP and DFN packages.

• PIC12F609/HV609 (Figure1-1, Table 1-1)

• PIC12F615/HV615 (Figure1-2, Table 1-2)

FIGURE 1-1: PIC12F609/HV609 BLOCK DIAGRAM

13

Program Counter

8-Level Stack

Direct Addr

INT

(13-Bit)

RAM Addr

7

Program

Bus

Configuration

Flash

1K X 14

Program

Memory

14

Instruction Reg

8

Data Bus

RAM

64 Bytes

File

Registers

Addr MUX

STATUS Reg

9

8

FSR Reg

Indirect

Addr

8

GPIO

GP0

GP1

GP2

GP3

GP4

GP5

OSC1/CLKIN

OSC2/CLKOUT

T1G

T1CKI

T0CKI

Internal

Oscillator

Block

Instruction

Decode &

Control

Timing

Generation

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Brown-out

Reset

VDD

MCLR

Timer0 Timer1

Comparator Voltage Reference

Absolute Voltage Reference

VSS

3

ALU

8

W Reg

Shunt Regulator

(PIC12HV609 only)

MUX

Analog Comparator

and Reference

CIN+

CIN0-

CIN1-

COUT

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 5

PIC12F609/615/12HV609/615

FIGURE 1-2: PIC12F615/HV615 BLOCK DIAGRAM

OSC1/CLKIN

OSC2/CLKOUT

T1G*

T1G

Program

Bus

Internal

Oscillator

Block

Configuration

Flash

1K X 14

Program

Memory

14

Instruction Reg

Instruction

Decode &

Control

Timing

Generation

13

8

MCLR

INT

Program Counter

8-Level Stack

(13-Bit)

Direct Addr

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Brown-out

Reset

VDD

VSS

7

RAM Addr

3

8

Data Bus

RAM

64 Bytes

File

Registers

9

Addr MUX

Indirect

8

Addr

FSR Reg

STATUS Reg

MUX

ALU

W Reg

Shunt Regulator

(PIC12HV615 only)

8

GPIO

GP0

GP1

GP2

GP3

GP4

GP5

T1CKI

T0CKI

VREF

Analog-To-Digital Converter

AN0

AN1

AN2

AN3

* A lte rn ate pi n func ti on.

Timer0 Timer1

Comparator Voltage Reference

Absolute Voltage Reference

Timer2

Analog Comparator

and Reference

CIN1-

COUT

ECCP

CIN+

CIN0-

CCP1/P1A

P1B

P1A*

P1B*

DS41302A-page 6 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

TABLE 1-1: PIC12F609/HV609 PINOUT DESCRIPTION

Name Function

GP0/CIN+/ICSPDAT GP0 TTL CMOS General purpose I/O with prog. pull-up and interrupt-on-change

CIN+ AN — Comparator non-inverting input

ICSPDAT ST CMOS Serial Programming Data I/O

GP1/CIN0-/ICSPCLK GP1 TTL CMOS General purpose I/O with prog. pull-up and int errupt-on-c hange

CIN0- AN — Comparator inverting input

ICSPCLK ST — Serial Programming Clock

GP2/T0CKI/INT/COUT GP2 ST CMOS General purpose I/O with prog. pull-up and interrupt-on-change

T0CKI ST — Timer0 clock input

INT ST — External Interrupt

COUT — CMOS Comparator output

CLR/VPP GP3 TTL — General purpose input with interrupt-on-change

GP3/M

MCLR

PP HV — Programming voltage

V

GP4/CIN1-/T1G

CLKOUT

GP5/T1CKI/OSC1/CLKIN GP5 TTL CMOS General purpose I/O with prog. pull-up and interrupt -on-c hange

DD VDD Power — Positive supply

V

SS VSS Power — Ground reference

V

Legend: AN = Analog input or output CMOS= CMOS com patible input or output HV = High Voltage

/OSC2/

ST = Schmitt Trigger input with CMOS levels TTL = T TL compatible input XTAL = Crystal

GP4 TTL CMOS General purpose I/O with prog. pull-up and interrupt-on-change

CIN1-

T1G

OSC2 — XTAL Crystal/Resonator

CLKOUT — CMOS F

T1CKI ST — Timer1 clock input

OSC1 XTAL — Crystal/Resonator

CLKIN ST — External clock input/RC oscillator connection

Input

Type

Output

Type

ST — Master Clear w/internal pull-up

AN — Comparator inverting input

ST — Timer1 gate (count enable)

OSC/4 output

Description

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 7

PIC12F609/615/12HV609/615

TABLE 1-2: PIC12F615/HV615 PINOUT DESCRIPTION

Name Function

GP0/AN0/CIN+/P1B/ICSPDAT GP0 TTL CMOS General purpose I/O with prog. pull-up and interrupt-on-

AN0 AN — A/D Channel 0 input

CIN+ AN — Comparator non-inverting input

P1B — CMOS PWM output

ICSPDAT ST CMOS Serial Programming Data I/O

GP1/AN1/CIN0-/V

GP2/AN2/T0CKI/INT/COUT/CCP1/

P1A

GP3/T1G

GP4/AN3/CIN1-/T1G

CLKOUT

GP5/T1CKI/P1A*/OSC1/CLKIN GP5 TTL CMOS General purpose I/O with prog. pull-up and interrupt-on-

V

V

Legend: AN = Analog input or output CMOS=CMOS compatible input or output HV = High Voltage

*/MCLR/VPP GP3 TTL — G eneral purpose input with interrupt-on-change

DD VDD Power — Positive supply

SS VSS Power — Ground reference

* Alternate pin function.

REF/ICSPCLK GP1 TTL CMOS General purpose I/O with prog. pull-up and interrupt-on-

AN1 AN — A/D Channel 1 input

CIN0- AN — Comparator inverting input

REF AN — External Voltage Reference for A/D

V

ICSPCLK ST — Serial Programming Clock

GP2 ST CMOS General purpose I/O with prog. pull-up and interrupt-on-

AN2 AN — A/D Channel 2 input

T0CKI ST — Timer0 clock input

INT ST — External Interrupt

COUT — CMOS Comparator output

CCP1 ST CMOS Capture input/Compare input/PWM output

P1A — CMOS PWM output

T1G

MCLR

V

PP HV — Programming voltage

/P1B*/OSC2/

ST = Schmitt Trigger input with CMOS levels TTL =T T L compatible input XTAL= Crystal

GP4 TTL CMOS General purpose I/O with prog. pull-up and interrupt-on-

AN3 AN — A/D Channel 3 input

CIN1-

T1G

P1B* — CMOS PWM output, alternate pin

OSC2 — XTAL Crystal/Resonator

CLKOUT — CMOS F

T1CKI ST — Timer1 clock input

P1A* — CMOS PWM output, alternate pin

OSC1 XTAL — Crystal/Resonator

CLKIN ST — External clock input/RC oscillator connection

Input

Type

* ST — Timer1 gate (count enable), alternate pin

Output

Type

change

change

change

ST — Master Clear w/internal pull-up

change

AN — Comparator inverting input

ST — Timer1 gate (count enable)

OSC/4 output

change

Description

DS41302A-page 8 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

2.0 MEMORY ORGANIZATION

2.1 Program Memory Organization

The PIC12F609/615/12HV609/615 has a 13-bit program counter capable of addressing an 8K x 14 program memory space. Only the first 1K x 14 (0000h03FFh) for the PIC12F609/615/12HV609/615 is physically implemented. Accessing a location above these

boundaries will cause a wraparound within the first 1K

x 14 space. T he Rese t vec tor is at 0000 h and the int errupt vector is at 0004h (see Figure 2-1).

FIGURE 2-1: PROGRAM MEMORY MAP

AND STACK FOR THE

PIC12F609/615/12HV609/615

PC<12:0>

CALL, RETURN

RETFIE, RETLW

Stack Level 1

Stack Level 2

Stack Level 8

Reset Vector

13

0000h

2.2 Data Memory Organization

The data memory (see Figure 2-2) is partitioned into two

banks, which contain the General Purpose Registers

(GPR) and the Special Function Registers (SFR). The

Special Function Registers are located in the first 32

locations of each bank. Register locations 40h-7Fh in

Bank 0 are General Purpose Registers, implemented as

static RAM. Register locations F0h-FFh in Bank 1 point

to addresses 70h-7Fh in Bank 0. All other RAM is

unimplemented and returns ‘0’ when read. The RP0 bit

of the STATUS register is the bank select bit.

RP0

0 → Bank 0 is selected

1 → Bank 1 is selected

Note: The IRP and RP1 bits of the STATUS

register are reserved and should always be

maintained as ‘0’s.

2.2.1 GENERAL PURPOSE REGISTER

FILE

The register file is organized as 64 x 8 in the

PIC12F609/615/12HV609/615. Each register is

accessed, either directly or indirectly, through the File

Select Register (FSR) (see Section 2.4 “Indirect

Addressing, INDF and FSR Registers” ).

Interrupt Vector

On-chip Program

Memory

Wraps to 0000h-07FFh

0004h

0005h

03FFh

0400h

1FFFh

2.2.2 SPECIAL FUNCTION REGISTERS

The Special Function Registers are registers used by

the CPU and peripheral functions for controlling the

desired operation of the device (see Table2-1). These

registers are static RAM.

The special registers can be classified into two sets:

core and peripheral. The Special Function Registers

associated with the “core” are described in this section.

Those related to the operation of the peripheral features

are described in the section of that peripheral feature.

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 9

PIC12F609/615/12HV609/615

FIGURE 2-2: DATA MEMORY MAP OF

THE PIC12F609/HV609

Indirect Addr.

TMR0

PCL

STATUS

FSR

GPIO

PCLATH

INTCON

PIR1

TMR1L

TMR1H

T1CON

VRCON

CMCON0

CMCON1

(1)

File

Address

00h

01h

02h

03h

04h

05h

06h

07h

08h

09h

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

1Bh

1Ch

1Dh

1Eh

1Fh

20h

Indirect Addr.

OPTION_REG

PCL

STATUS

FSR

TRISIO

PCLATH

INTCON

PIE1

PCON

OSCTUNE

WPU

IOC

ANSEL

(1)

File

Address

80h

81h

82h

83h

84h

85h

86h

87h

88h

89h

8Ah

8Bh

8Ch

8Dh

8Eh

8Fh

90h

91h

92h

93h

94h

95h

96h

97h

98h

99h

9Ah

9Bh

9Ch

9Dh

9Eh

9Fh

A0h

FIGURE 2-3: DATA MEMORY MAP OF

THE PIC12F615/HV615

Indirect Addr.

TMR0

PCL

STATUS

FSR

GPIO

PCLATH

INTCON

PIR1

TMR1L

TMR1H

T1CON

TMR2

T2CON

CCPR1L

CCPR1H

CCP1CON

PWM1CON

ECCPAS

VRCON

CMCON0

CMCON1

ADRESH

ADCON0

(1)

File

Address

00h

01h

02h

03h

04h

05h

06h

07h

08h

09h

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

1Bh

1Ch

1Dh

1Eh

1Fh

20h

Indirect Addr.

OPTION_REG

PCL

STATUS

FSR

TRISIO

PCLATH

INTCON

PIE1

PCON

OSCTUNE

PR2

APFCON

WPU

IOC

ADRESL

ANSEL

(1)

File

Address

80h

81h

82h

83h

84h

85h

86h

87h

88h

89h

8Ah

8Bh

8Ch

8Dh

8Eh

8Fh

90h

91h

92h

93h

94h

95h

96h

97h

98h

99h

9Ah

9Bh

9Ch

9Dh

9Eh

9Fh

A0h

3Fh

General

Purpose

Registers

64 Bytes

Bank 0

Unimplemented data memory locations, read as ‘0’.

Note 1: Not a physical register.

40h

7Fh

Accesses 70h-7Fh

Bank 1

EFh

F0h

FFh

General

Purpose

Registers

64 Bytes

Bank 0

Unimplemented data memory locations, read as ‘0’.

Note 1: Not a physical register.

3Fh

40h

7Fh

Accesses 70h-7Fh

Bank 1

EFh

F0h

FFh

DS41302A-page 10 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

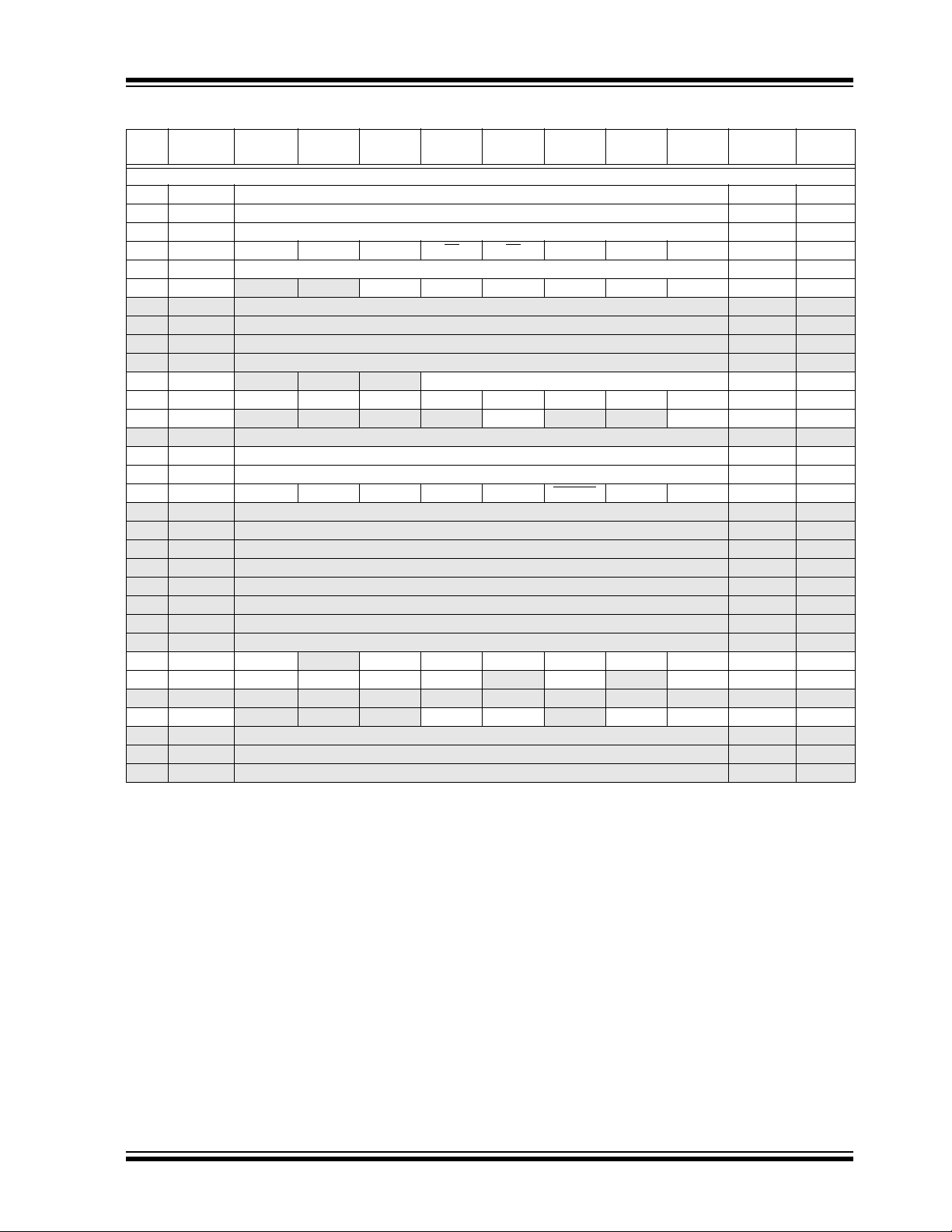

TABLE 2-1: PIC12F609/HV609 SPECIAL FUNCTION REGISTERS SUMMARY BANK 0

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 B it 2 Bit 1 Bit 0

Bank 0

00h INDF Addressing this location uses contents of FSR to address data memory (not a physical register) xxxx xxxx 22, 100

01h TMR0 Timer0 Module’s Register xxxx xxxx 41, 100

02h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 22, 100

03h STA TUS IRP

04h FSR Indirect Data Memory Address Pointer xxxx xxxx 22, 100

05h GPIO

06h — Unimplemented — —

07h — Unimplemented — —

08h — Unimplemented — —

09h — Unimplemented — —

0Ah PCLATH

0Bh INTCON GIE PEIE T0IE INTE GPIE T0IF INTF GPIF 0000 0000 17, 100

0Ch PIR1

0Dh — Unimplemented — —

0Eh TMR1L Holding Register for the Least Significant Byte of the 16-bit TMR1 Register xxxx xxxx 45, 100

0Fh TMR1H Holding Register for the Most Significant Byte of the 16-bit TMR1 Register xxxx xxxx 45, 100

10h T1CON T1GINV TMR1GE T1CKPS1 T1CKPS0 T1OSCEN T1SYNC

11h — Unimplemented — —

12h — Unimplemented — —

13h — Unimplemented — —

14h — Unimplemented — —

15h — Unimplemented — —

16h — Unimplemented — —

17h — Unimplemented — —

18h — Unimplemented — —

19h VRCON CMVREN

1Ah CMCON0 CMON COUT CMOE CMPOL

1Bh — — — — —

1Ch CMCON1

1Dh — Unimplemented — —

1Eh — Unimplemented — —

1Fh — Unimplemented — —

Legend: – = Unimplemented locations rea d as ‘0’, u = unchanged, x = unknown, q = value depends on condition, shaded = unimplemented

Note 1: IRP and RP1 bits are reserved, always maintain these bits clear.

(1)

— — GP5 GP4 GP3 GP2 GP1 GP0 --x0 x000 31, 100

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 22, 100

— — — —CMIF— —TMR1IF---- 0--0 19, 100

— — — T1ACS CMHYS — T1GSS CMSYNC ---0 0-10 59, 101

(1)

RP1

— VRR FVREN VR3 VR2 VR1 VR0 0-00 0000 62, 101

RP0 TO PD ZDCC0001 1xxx 15, 100

TMR1CS TMR1ON 0000 0000 49, 100

—CMR—CMCH0000 -0-0 58, 101

Value on

POR, BOR

Page

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 11

PIC12F609/615/12HV609/615

TABLE 2-2: PIC12F615/HV615 SPECIAL FUNCTION REGISTERS SUMMARY BANK 0

Addr Name Bit 7 B it 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 0

00h INDF Addressing this location uses contents of FSR to address data memory (not a physical register) xxxx xxxx 22, 101

01h TMR0 Timer0 Module’s Register xxxx xxxx 41, 101

02h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 22, 101

03h STA TUS IRP

04h FSR Indirect Data Memory Address Pointer xxxx xxxx 22, 101

05h GPIO

06h — Unimplemented — —

07h — Unimplemented — —

08h — Unimplemented — —

09h — Unimplemented — —

0Ah PCLATH

0Bh INTCON GIE PEIE T0IE INTE GPIE T0IF INTF GPIF 0000 0000 17, 101

0Ch PIR1

0Dh — Unimplemented — —

0Eh TMR1L Holding Register for the Least Significant Byte of the 16-bit TMR1 Register xxxx xxxx 45, 101

0Fh TMR1H Holding Register for the Most Significant Byte of the 16-bit TMR1 Register xxxx xxxx 45, 101

10h T1CON T1GINV TMR1GE T1CKPS1 T1CKPS0 T1OSCEN T1SYNC

11h TMR2 Timer2 Module Register 0000 0000 51, 101

12h T2CON

13h CCPR1L Capture/Compare/PWM Register 1 Low Byte XXXX XXXX 76, 101

14h CCPR1H Capture/Compare/PWM Register 1 High Byte XXXX XXXX 76, 101

15h CCP1CON P1M

16h PWM1CON PRSEN PDC6 PDC5 PDC4 PDC3 PDC2 PDC1 PDC0 0000 0000 91, 101

17h ECCPAS ECCPASE ECCPAS2 ECCPAS1 ECCPAS0 PSSAC1 PSSAC0 PSSBD1 PSSBD0 0000 0000 88, 101

18h — Unimplemented — —

19h VRCON CMVREN

1Ah CMCON0 CMON COUT CMOE CMPOL

1Bh — — — — —

1Ch CMCON1

1Dh — Unimplemented — —

1Eh ADRESH Most Significant 8 bits of the left shifted A/D result or 2 bits of right shifted result xxxx xxxx 71, 101

1Fh ADCON0 ADFM VCFG

Legend: – = Unimplemented locations rea d as ‘0’, u = unchanged, x = unknown, q = value depends on condition, shaded = unimplemented

Note 1: IRP and RP1 bits are reserved, always maintain these bits clear.

(1)

— — GP5 GP4 GP3 GP2 GP1 GP0 --x0 x000 31, 101

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 22, 101

— ADIF CCP1IF —CMIF— TMR2IF TMR1IF -00- 0-00 19, 101

— TOUTPS3 TOUTPS2 TOUTPS1 TOUTPS0 TMR2ON T2CKPS1 T2CKPS0 -000 0000 52, 101

— — — T1ACS CMHYS — T1GSS CMSYNC ---0 0-10 59, 101

(1)

RP1

— DC1B1 DC1B0 CCP1M3 CCP1M2 CCP1M1 CCP1M0 0-00 0000 75, 101

— VRR FVREN VR3 VR2 VR1 VR0 0-00 0000 62, 101

RP0 TO PD ZDCC0001 1xxx 15, 101

TMR1CS TMR1ON 0000 0000 49, 101

—CMR—CMCH0000 -0-0 58, 101

— CHS2 CHS1 CHS0 GO/DONE ADON 00-0 0000 70, 101

Value on

POR, BOR

Page

DS41302A-page 12 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

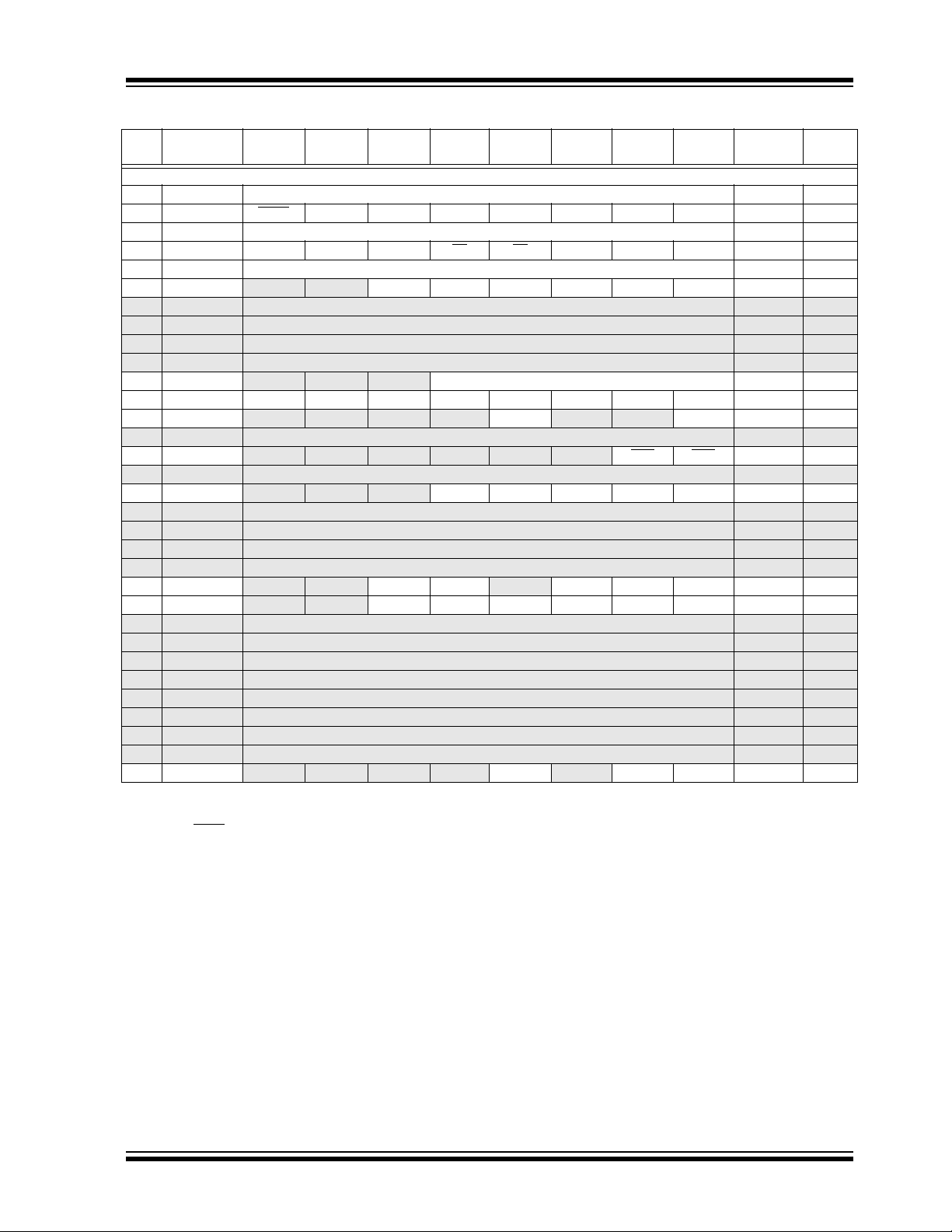

TABLE 2-3: PIC12F609/HV609 SPECIAL FUNCTION REGISTERS SUMMARY BANK 1

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 1

80h INDF Addressing this location uses contents of FSR to address data memory (not a physical register) xxxx xxxx 22, 101

81h OPTION_REG GPPU

82h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 22, 101

83h STATUS IRP

84h FSR Indirect Data Memory Address Pointer xxxx xxxx 22, 101

85h TRISIO

86h — Unimplemented — —

87h — Unimplemented — —

88h — Unimplemented — —

89h — Unimplemented — —

8Ah PCLATH

8Bh INTCON GIE PEIE T0IE INTE GPIE T0IF INTF GPIF

8Ch PIE1

8Dh — Unimplemented — —

8Eh PCON

8Fh — Unimplemented — —

90h OSCTUNE

91h — Unimplemented — —

92h — Unimplemented — —

93h — Unimplemented — —

94h — Unimplemented — —

95h WPU

96h IOC

97h — Unimplemented — —

98h — Unimplemented — —

99h — Unimplemented — —

9Ah — Unimplemented — —

9Bh — Unimplemented — —

9Ch — Unimplemented — —

9Dh — Unimplemented — —

9Eh — Unimplemented — —

9Fh ANSEL

Legend: – = Unimplemented locations read as ‘0’, u = unchanged, x = unknown, q = value depends on condition, shaded = unimplemented

Note 1: IRP and RP1 bits are reserved, always maintain these bits clear.

(2)

2: GP3 pull-up is enabled when MCLRE is ‘1’ in the Configuration Word register.

3: MCLR

exists.

4: TRISIO3 always reads as ‘1’ since it is an input only pin.

— — TRISIO5 TRISIO4 TRISIO3

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 22, 101

— — — —CMIE— —TMR1IE---- 0--0 18, 101

— — — — — —PORBOR ---- --qq 20, 101

— — — TUN4 TUN3 TUN2 TUN1 TUN0 ---0 0000 29, 101

— —WPU5WPU4— WPU2 WPU1 WPU0 --11 -111 34, 101

— — IOC5 IOC4 IOC3 IOC2 IOC1 IOC0 --00 0000 34, 101

— — — —ANS3— ANS1 ANS0 ---- 1-11 33, 101

and WDT Reset does not affect the previous value data latch. The GPIF bit will clear upon Reset but will set again if the mismatch

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 16, 101

(1)

RP1

(1)

RP0 TO PD ZDCC0001 1xxx 15, 101

(4)

TRISIO2 TRISIO1 TRISIO0 --11 1111 31, 101

Value on

POR, BOR

(3)

0000 0000 17, 101

Page

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 13

PIC12F609/615/12HV609/615

TABLE 2-4: PIC12F615/HV615 SPECIAL FUNCTION REGISTERS SUMMARY BANK 1

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 1

80h INDF Addressing this location uses contents of FSR to address data memory (not a physical register) xxxx xxxx 22, 101

81h OPTION_REG GPPU

82h PCL Program Counter’s (PC) Least Significant Byte 0000 0000 22, 101

83h STATUS IRP

84h FSR Indirect Data Memory Address Pointer xxxx xxxx 22, 101

85h TRISIO

86h — Unimplemented — —

87h — Unimplemented — —

88h — Unimplemented — —

89h — Unimplemented — —

8Ah PCLATH

8Bh INTCON GIE PEIE T0IE INTE GPIE T0IF INTF GPIF

8Ch PIE1

8Dh — Unimplemented — —

8Eh PCON

8Fh — Unimplemented — —

90h OSCTUNE

91h — Unimplemented — —

92h PR2 Timer2 Module Period Register 1111 1111 51, 101

93h APFCON

94h — Unimplemented — —

95h WPU

96h IOC

97h — Unimplemented — —

98h — Unimplemented — —

99h — Unimplemented — —

9Ah — Unimplemented — —

9Bh — Unimplemented — —

9Ch — Unimplemented — —

9Dh — Unimplemented — —

9Eh ADRESL Least Significant 2 bits of the left shifted result or 8 bits of the right shifted result xxxx xxxx 71, 101

9Fh ANSEL

Legend: – = Unimplemented locations rea d as ‘0’, u = unchanged, x = unknown, q = value depends on condition, shaded = unimplemented

Note 1: IRP and RP1 bits are reserved, always maintain these bits clear.

(2)

2: GP3 pull-up is enabled when MCLRE is ‘1’ in the Configuration Word register.

3: MCLR

4: TRISIO3 always reads as ‘1’ since it is an input only pin.

and WDT Reset does not affect the previous value data latch. The GPIF bit will clear upon Reset but will set again if the mismatch

exists.

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 16, 101

(1)

— — TRISIO5 TRISIO4 TRISIO3

— — — Write Buffer for upper 5 bits of Program Counter ---0 0000 22, 101

— ADIE CCP1IE —CMIE— TMR2IE TMR1IE -00- 0-00 18, 101

— — — — — —PORBOR ---- --qq 20, 101

— — — TUN4 TUN3 TUN2 TUN1 TUN0 ---0 0000 29, 101

— — — T1GSEL — — P1BSEL P1ASEL ---0 --00 18, 101

— —WPU5WPU4— WPU2 WPU1 WPU0 --11 -111 34, 101

— — IOC5 IOC4 IOC3 IOC2 IOC1 IOC0 --00 0000 34, 101

— ADCS2 ADCS1 ADCS0 ANS3 ANS2 ANS1 ANS0 -000 1111 33, 101

RP1

(1)

RP0 TO PD ZDCC0001 1xxx 15, 101

(4)

TRISIO2 TRISIO1 TRISIO0 --11 1111 31, 101

Value on

POR, BOR

(3)

0000 0000 17, 101

Page

DS41302A-page 14 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

2.2.2.1 STATUS Register

The STATUS registe r, shown in Register 2-1, contains:

• the arithmetic status of the ALU

• the Reset status

• the bank select bits for data memory (RAM)

The STATUS register can be the destination for any

instruction, like any other register. If the STATUS

register is the destination for an instruction that affects

the Z, DC or C bits, then the write to these three bits is

disabled. These bit s are set or cleared ac cording to the

device logic. Furthermore, the TO

writable. Therefore, the result of an instruction with the

STATUS regis ter as destina tion may be differ ent than

intended.

For example, CLRF STATUS, will clear the upper three

bits and set the Z bit. This leaves the STATUS register

as ‘000u u1uu’ (where u = unchanged).

and PD bits are not

It is recommended, therefore, that only BCF, BSF,

SWAPF and MOVWF instructions are used to alter the

STATUS register, because these instructions do not

affect any Status bits. For other instructions not affecting any Status bits, see the Section 13.0 “Instruction

Set Summary”.

Note 1: Bits IRP and RP1 of the ST ATUS register

are not used by the PIC12F609/615/

12HV609/615 and should be maintained

as clear. Use of these bits is not recommended, since this may affect upward

compatibility with future products.

2: The C and DC bits operate as a Borrow

and Digit Borrow out bit, respectively, in

subtraction. See the SUBLW and SUBWF

instructions for examples.

REGISTER 2-1: STATUS: STATUS REGISTER

Reserved Reserved R/W-0 R-1 R-1 R/W-x R/W-x R/W-x

IRP RP1 RP0 T O PD ZDCC

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 IRP: This bit is reserved and should be maintained as ‘0’

bit 6 RP1: This bit is reserved and should be maintained as ‘0’

bit 5 RP0: Register Bank Select bit (used for direct addressing)

1 = Bank 1 (80h – FFh)

0 = Bank 0 (00h – 7Fh)

bit 4 TO

bit 3 PD

bit 2 Z: Zero bit

bit 1 DC: Digit Carry/Borrow bit (ADDWF, ADDLW,SUBLW,SUBWF instructions), For Borrow, the polarity is

bit 0 C: Carry/Bo

: Time-out bit

1 = After power-up, CLRWDT instruction or SLEEP instruction

0 = A WDT time-out occurred

: Power-down bit

1 = After power-up or b y the CLRWDT instruction

0 = By execution of the SLEEP instruction

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

reversed.

1 = A carry-out from the 4th low-order bit of the result occurred

0 = No carry-out from the 4th low-order bit of the result

(1)

rrow bit

1 = A carry-out from the Most Significant bit of the result occurred

0 = No carry-out from the Most Significant bit of the result occurred

(ADDWF, ADDLW, SUBLW, SUBWF instructions)

Note 1: For Bo

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 15

rrow, the polarity is reversed. A subtraction is executed by adding the two’s complement of the

second operand. For rotate (RRF, RLF) instructi ons, this bit is loa ded with either the high-orde r or low-o rder

bit of the source register.

PIC12F609/615/12HV609/615

2.2.2.2 OPTION Register

The OPTION register is a readable and writable register, which contains various control bits to configure:

• Timer0/WDT prescaler

• External GP2/INT interrupt

•Timer0

• Weak pull-ups on GPIO

REGISTER 2-2: OPTION_REG: OPTION REGISTER

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

GPPU

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

INTEDG T0CS T0SE PSA PS2 PS1 PS0

Note: To achieve a 1:1 prescaler assignment for

Timer0, assign the prescaler to the WDT

by setting PSA bit to ‘1’ of the OPTION

register. See Section 5.1.3 “Software

Programmable Prescaler”.

bit 7 GPPU

: GPIO Pull-up Enable bit

1 = GPIO pull-ups are disabled

0 = GPIO pull-ups are enabled by individual PORT latch values

bit 6 INTEDG: Interrupt Edge Select bit

1 = Interrupt on rising edge of GP2/INT pin

0 = Interrupt on falling edge of GP2/INT pin

bit 5 T0CS: Timer0 Clock Source Select bit

1 = Transition on GP2/T0CKI pin

0 = Internal instruction cyc le clock (F

bit 4 T0SE: Timer0 Source Edge Select bit

1 = Increment on high-to -low transition on GP2/T0CKI pin

0 = Increment on low-to-high transition on GP2/T0CKI pin

bit 3 PSA: Prescaler Assignment bit

1 = Prescaler is assigned to the WDT

0 = Prescaler is assigned to the Timer0 module

bit 2-0 PS<2:0>: Prescaler Rate Select bits

BIT VALUE TIMER0 RATE WDT RATE

000

001

010

011

100

101

110

111

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

1 : 256

OSC/4)

1 : 1

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

DS41302A-page 16 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

2.2.2.3 INTCON Register

The INTCON register is a readable and writable

register , which c ontains the various en able and fl ag bit s

for TMR0 register ove rflo w, GPIO change and externa l

GP2/INT pin interrupts.

Note: Interrupt flag bits are set w hen an in terrupt

condition occurs, regar dless of the st ate of

its corresponding enable bit or the Global

Enable bit, GIE of the INTCON register.

User software should ensure the

appropriate interrupt flag bits are clear

prior to enabling an interrupt.

REGISTER 2-3: INTCON: INTERRUPT CONTROL REGISTER

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

GIE PEIE T0IE INTE GPIE T0IF INTF GPIF

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 GIE: Global Interrupt Enable bit

1 = Enables all unmasked interrupts

0 = Disables all interrupts

bit 6 PEIE: Peripheral Interrupt Enable bit

1 = Enables all unmasked peripheral interrupts

0 = Disables all peripheral interrupts

bit 5 T0IE: Timer0 Overflow Interru pt Enab le bit

1 = Enables the Timer0 interrupt

0 = Disables the Timer0 interrupt

bit 4 INTE: GP2/INT External Interrupt Enable bit

1 = Enables the GP2/INT external interrupt

0 = Disables the GP2/INT external interrupt

bit 3 GPIE: GPIO Change Interrupt Enable bit

1 = Enables the GPIO change interrupt

0 = Disables the GPIO change interrupt

bit 2 T0IF: Timer0 Overflow Interrupt Flag bit

1 = Timer0 register has overflowed (must be cleared in software)

0 = Timer0 register did not overflow

bit 1 INTF: GP2/INT External Interrupt Flag bit

1 = The GP2/INT external interrupt occurred (must be cleared in software)

0 = The GP2/INT external interrupt did not occur

bit 0 GPIF: GPIO Change Interrupt Flag bit

1 = When at least one of the GPIO <5:0> pins changed state (must be cleared in software)

0 = None of the GPIO <5:0> pins have changed state

(1)

(2)

Note 1: IOC register must also be enabled.

2: T0IF bit is set when TMR0 rolls over. TMR0 is unchanged on Reset and should be initialized before

clearing T0IF bit.

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 17

PIC12F609/615/12HV609/615

2.2.2.4 PIE1 Register

The PIE1 register contains the Peripheral Interrupt

Enable bits, as shown in Register 2-4.

REGISTER 2-4: PIE1: PERIPHERAL INTERRUPT ENABLE REGISTER 1

U-0 R/W-0 R/W-0 U-0 R/W-0 U-0 R/W-0 R/W-0

—ADIE

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 Unimplemented: Read as ‘0’

bit 6 ADIE: A/D Converter (ADC) Interrupt Enable bit

1 = Enables the ADC interrupt

0 = Disables the ADC interrupt

bit 5 CCP1IE: CCP1 Interrupt Enable bit

1 = Enables the CCP1 interrupt

0 = Disables the CCP1 interrupt

bit 4 Unimplemented: Read as ‘0’

bit 3 CMIE: Comp ara tor Interrupt Enable bit

1 = Enables the Comparator interrupt

0 = Disables the Comparator interrupt

bit 2 Unimplemented: Read as ‘0’

bit 1 TMR2IE: Timer2 to PR2 Match Interrupt Enable bit

1 = Enables the Timer2 to PR2 match interrupt

0 = Disables the Timer2 to PR2 match interrupt

bit 0 TMR1IE: Timer1 Overflow Interrupt Enable bit

1 = Enables the Timer1 overflow interrupt

0 = Disables the Timer1 overflow inter rupt

(1)

CCP1IE

(1)

—CMIE —TMR2IE

(1)

Note: Bit PEIE of the INTCON register must be

set to enable any peripheral interrupt.

(1)

TMR1IE

(1)

(1)

Note 1: PIC12F615/HV615 only. PIC12F609/HV609 unimplemented, read as ‘0’.

DS41302A-page 18 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

2.2.2.5 PIR1 Register

The PIR1 register cont ains the Peri pheral Interrup t flag

bits, as shown in Register 2-5.

REGISTER 2-5: PIR1: PERIPHERAL INTERRUPT REQUEST REGISTER 1

U-0 R/W-0 R/W-0 U-0 R/W-0 U-0 R/W-0 R/W-0

—ADIF

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 Unimplemented: Read as ‘0’

bit 6 ADIF: A/D In terrupt Flag bit

1 = A/D conversion complete

0 = A/D conversion has not completed or has not been started

bit 5 CCP1IF: CCP1 Interrupt Flag bit

Capture mode:

1 = A TMR1 register capture occurred (must be cleared in software)

0 = No TMR1 register captu re occurred

Compare mode

1 = A TMR1 register compare match occurred (must be cleared in software)

0 = No TMR1 register compare match occurred

PWM mode

Unused in this mode

bit 4 Unimplemented: Read as ‘0’

bit 3 CMIF: Comparator Interrupt Flag bit

1 = Comparator output has changed (must be cleared in software)

0 = Comparator output has not changed

bit 2 Unimplemented: Read as ‘0’

bit 1 TMR2IF: Timer2 to PR2 Match Interrupt Flag bit

1 = Timer2 to PR2 match occurred (must be cleared in software)

0 = Timer2 to PR2 match has not occurred

bit 0 TMR1IF: Timer1 Overflow Interrupt Flag bit

1 = Timer1 register overflowed (must be cleared in software)

0 = Timer1 has not overflowed

(1)

CCP1IF

:

:

(1)

—CMIF —TMR2IF

(1)

(1)

Note: Interrupt flag bits are set when an interrupt

condition occurs, regardless of the state of

its corresponding enable bit or the Global

Enable bit, GIE of the INTCON register.

User software should ensure the

appropriate interrupt flag bits are clear prior

to enabling an interrupt.

(1)

TMR1IF

(1)

Note 1: PIC12F615/HV615 only. PIC12F609/HV609 unimplemented, read as ‘0’.

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 19

PIC12F609/615/12HV609/615

2.2.2.6 PCON Register

The Power Control (PCON) register (see Table 11-2)

contains flag bits to differentiate between a:

• Power-on Reset (POR

• Brown-out Reset (BOR)

• Watchdog Timer Reset (WDT)

• External MCLR

The PCON register also co ntrols the software ena ble of

the BOR

The PCON register bits are shown in Register 2-6.

.

REGISTER 2-6: PCON: POWER CONTROL REGISTER

U-0 U-0 U-0 U-0 U-0 U-0 R/W-0 R/W-0

— — — — — —PORBOR

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

)

Reset

(1)

bit 7-2 Unimplemented: Read as ‘0’

bit 1 POR

bit 0 BOR

Note 1 : Reads as ‘0’ if Brown-out Reset is disabled.

: Power-on Re set Status bit

1 = No Power-on Reset occurred

0 = A Power-on Reset occurred (must be set in software after a Power-on Reset occurs)

: Brown-out Reset Status bit

1 = No Brown-out Reset occurred

0 = A Brown-out Reset occurred (must be set in software after a Brown-out Reset occurs)

DS41302A-page 20 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

2.2.2.7 APFCON Register

(PIC12F615/HV615 only)

The Alternate Pin Function Control (APFC ON) reg ist er

is used to steer specific peripheral input and output

functions between different pins. For this device, the

P1A, P1B and Timer1 Gate functions can be moved

between different pins.

The APFCON register bits are shown in Register 2-7.

REGISTER 2-7: APFCON: POWER CONTROL REGISTER

U-0 U-0 U-0 R/W-0 U-0 U-0 R/W-0 R/W-0

— — — T1GSEL — — P1BSEL P1ASEL

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-5 Unimplemented: Read as ‘0’

bit 4 T1GSEL: TMR1 Input Pin Select bit

1 = T1G function is on GP3/T1G

0 = T1G function is on GP4/AN3/CIN1-/T1G/P1B

bit 3-2 Unimplemented: Read as ‘0’

bit 1 P1BSEL: P1B Output Pin Select bit

1 = P1B function is on GP4/AN3/CIN1-/T1G

0 = P1B function is on GP0/AN0/CIN+/P1B/ICSPDAT

bit 0 P1ASEL: P1A Output Pin Select bit

1 = P1A function is on GP5/T1CKI/P1A

0 = P1A function is on GP2/AN2/T0CKI/INT/COUT/CCP1/P1A

(2)

/MCLR/VPP

(2)

(2)

/OSC2/CLKOUT

(2)

/P1B

/OSC2/CLKOUT

/OSC1/CLKIN

(1)

Note 1: PIC12F615/HV615 only.

2: Alternate pin function.

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 21

PIC12F609/615/12HV609/615

h

>

s

n

2.3 PCL and PCLATH

The Program Counter (PC) is 13 bits wide. The lo w byte

comes from the PCL register, which is a readable and

writable register . The hig h byte (PC<12:8>) is not directl y

readable or writable and comes from PCLATH. On any

Reset, the PC is cleared. Figure 2-4 shows the two

situations for the loading of the PC. The upper example

in Figure 2-4 shows how the PC is loaded on a write to

PCL (PCLATH<4:0> → PCH). The lower example in

Figure 2-4 shows h ow the PC is l oaded during a CALL or

GOTO instruction (PCLATH<4:3> → PCH).

FIGURE 2-4: LOADING OF PC IN

DIFFERENT SITUATIONS

PCH PCL

12 8 7 0

PC

PCLATH<4:0>

5

PCLATH

PCH PCL

12 11 10 0

PC

2

87

PCLATH<4:3>

PCLATH

8

11

2.3.1 MODIFYING PCL

Executing any instruction with the PCL register as the

destination simultaneously causes the Program

Counter PC< 12:8> bits (PCH) to be replaced by the

contents of the PCLATH register . Th is allo ws the enti re

contents of the program counter to be changed by

writing the desired up per 5 bit s to the PCLATH register .

When the lower 8 bits are written to the PCL regis ter , all

13 bits of the program counter will chan ge to the values

contained in the PCLATH register and those being

written to the PCL register.

A computed GOTO is accomplish ed by adding an offset

to the program counter (ADDWF PCL). Care should be

exercised when jumping into a look-up table or

program b ranch table (computed GOTO) by modifying

the PCL register. Assuming that PCLATH is set to the

table start address, if the table length is greater than

255 instructions or if the lower 8 bits of the memory

address rolls over from 0xFF to 0x00 in the middle of

the table, then PCLATH must be incremented for each

address rollover that occurs between the table

beginning and the target location within the table.

For more information refer to Application Note AN556,

“Implementing a Table Read” (DS00556).

Instruction wit

PCL a

Destinatio

ALU Result

GOTO, CALL

OPCODE <10:0

2.3.2 STACK

The PIC12F609/615/12HV609/615 Family has an 8level x 13-bit wide hardware stack (see Figure 2-1).

The stack space is not part of either program or data

space and the S ta ck Pointer i s not rea dable or writa ble.

The PC is PUSHed onto the stack when a CALL

instruction is execute d or an interrupt ca uses a branc h.

The stack is POPed in the even t of a RETURN, RETLW

or a RETFIE instruction execution. PCLATH is not

affected by a P USH or POP operation.

The stack operat es as a circular buf fer . This means th at

after the stack has been PUSHed eight times, the ninth

push overwrites the va lue tha t was s tored fro m the first

push. The tenth pus h ov erwr i tes the se co nd push (and

so on).

Note 1: There are no Status bits to indicate stack

overflow or stack underflow conditions.

2: There are no instructions/mnemonics

called PUSH or POP. These are actions

that occur from the execution of the

CALL, RETURN, RETLW and RETFIE

instructions or the vectoring to an

interrupt address.

2.4 Indirect Addressing, INDF and

FSR Registers

The INDF register is not a physica l register . Addr essing

the INDF register will cause indirect addressing.

Indirect addressing is possible by using the INDF

register. Any instruction using the INDF register

actually accesses data pointed to by the File Select

Register (FSR). Reading INDF itself indirectly will

produce 00h. Writing to the INDF register indirectly

results in a no operation (although Status bits may be

affected). An effective 9-bit address is obtained by

concatenating the 8-bit FSR and the IRP bit of the

STATUS register, as shown in Figure 2-5.

A simple program to clear RAM location 40h-7Fh using

indirect addressing is shown in Example 2-1.

EXAMPLE 2-1: INDIRECT ADDRESS ING

MOVLW 0x40 ;initialize pointer

MOVWF FSR ;to RAM

NEXT CLRF INDF ;clear INDF register

INCF FSR ;inc pointer

BTFSS FSR,7 ;all done?

GOTO NEXT ;no clear next

CONTINUE ;yes continue

DS41302A-page 22 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

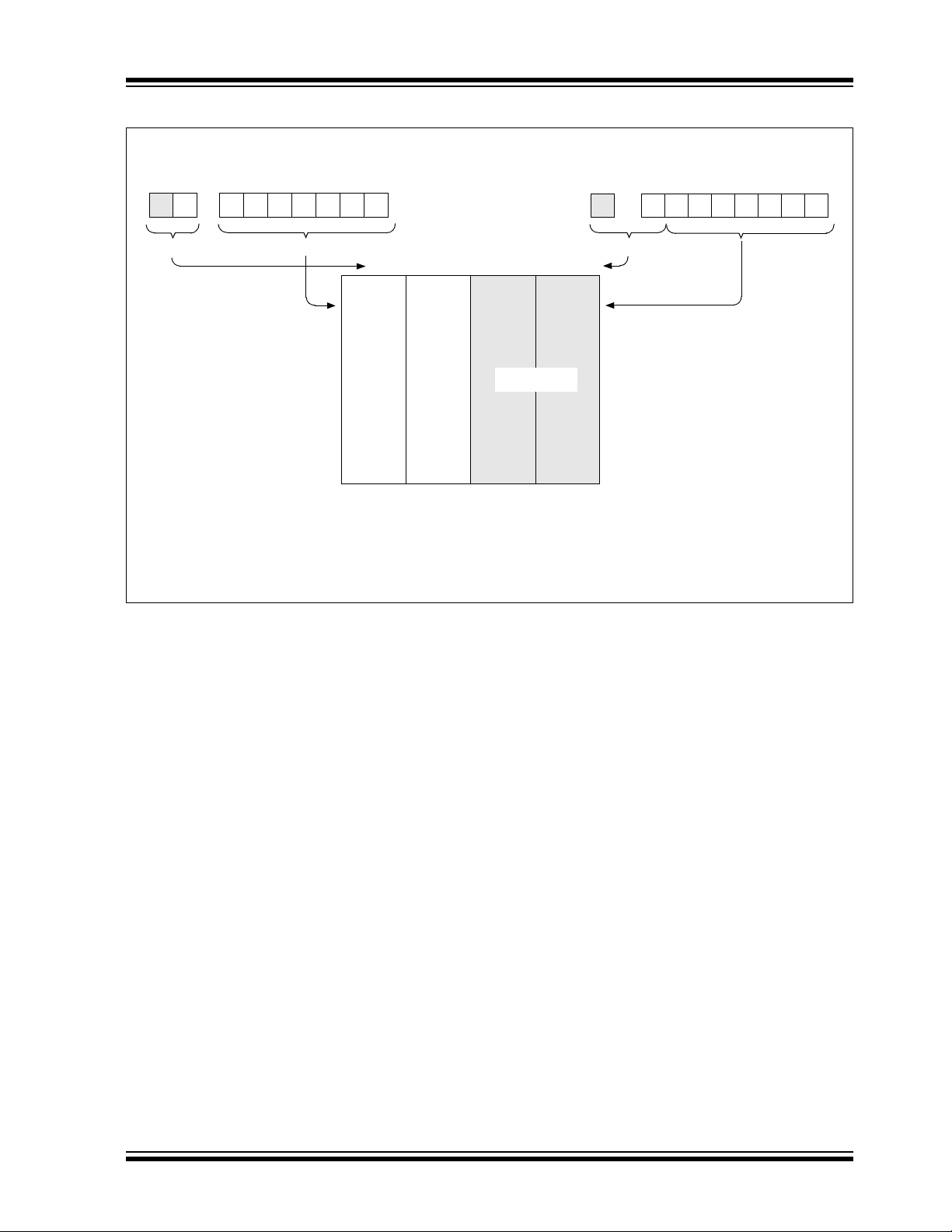

FIGURE 2-5: DIRECT/INDIRECT ADDRESSING PIC12F609/615/12HV609/615

Indirect AddressingDirect Addressing

RP1

(1)

RP0 6

From Opcode

0

IRP

(1)

7

File Select Register

0

Bank Select Location Select

00h

Data

Memory

7Fh

For memory map detail, see Figure 2-2.

Note 1: The RP1 and IRP bits are reserved; always maintain these bits clear.

2: Accesses in this area are mirrored back into Bank 0 and Bank 1.

00 01 10 11

NOT USED

Bank 0 Bank 1 Bank 2 Bank 3

(2)

Bank Select

180h

1FFh

Location Select

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 23

PIC12F609/615/12HV609/615

NOTES:

DS41302A-page 24 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

3.0 OSCILLATOR MODULE

The Oscillator mod ule can be c onfigured in one of eig ht

clock modes.

3.1 Overview

The Oscillator module has a wide variety of clock

sources and selection features that allow it to be used

in a wide range of applicati ons while maximiz ing performance and minimizing power consumption. Figure 3-1

illustrates a block diagram of the Oscillator module.

Clock sources can be configured from external

oscillators, quartz cryst al resonators , ceramic resonators

and Resistor-Capacitor (RC) circuits. In addition, the

system clock source can be configured with a choice of

two selectable speeds: internal or external system clock

source.

1. EC – External clock w ith I/O on OSC2/C LKOUT.

2. LP – 32 kHz Low-Power Crystal mode.

3. XT – Medium Gain Crystal or Ceramic Resonator

Oscillator mode.

4. HS – High Gain Crystal or Ceramic Resonator

mode.

5. RC – External Resistor-Capacitor (RC) with

OSC/4 output on OSC2/CLKOUT.

F

6. RCIO – External Resistor-Capacitor (RC) with

I/O on OSC2/CLKOUT.

7. INTOSC – Internal oscillator with F

on OSC2 and I/O on OSC1/CLKIN.

8. INTOSCIO – Internal oscillator with I/O on

OSC1/CLKIN and OSC2/CLKOUT.

Clock Source modes are configured by the FOSC <2:0>

bits in the Configuration Word register (CONFIG). The

Internal Oscillator mo dule provides a select able system

clock mode of either 4 MHz (Postscaler) or 8 MHz

(INTOSC).

FIGURE 3-1: PIC® MCU CLOCK SOURCE BLOCK DIAGRAM

OSC/4 output

OSC2

OSC1

External Oscillator

INTOSC

8 MHz

Sleep

Internal Oscillator

Postscaler

4 MHz

(Configuration Word Register)

LP, XT, HS, RC, RCIO, EC

INTOSC

FOSC<2:0>

IOSCFS<7>

MUX

System Clock

(CPU and Peripherals)

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 25

PIC12F609/615/12HV609/615

3.2 Clock Source Modes

Clock Source modes can be classified as external or

internal.

• External Clock mod es rely on e xternal circui try fo r

the clock source. Examples are: Oscillator modules (EC mode), quartz crystal resonators or

ceramic resonators (LP, XT and HS modes) and

Resistor-Capacitor (RC) mode circuits.

• Internal clock sources are contained internally

within the Oscillator module. The Oscillator

module has two selectable clock frequencies:

4 MHz and 8 M Hz

The system clock can be selected between external or

internal clock sources via the FOSC<2:0> bits of the

Configuration Word register.

3.3 External Clock Modes

3.3.1 OSCILLATOR START-UP TIMER (OST)

If the Oscillator module is configured for LP, XT or HS

modes, the Oscillator Start-up Timer (OST) counts

1024 oscillations from OSC1. This occurs following a

Power-on Reset (POR) and when the Power-up Timer

(PWRT) has expired (if configured), or a wake-up from

Sleep. During this time, the program counter does not

increment and program execution is suspended. The

OST ensures that the oscillator circuit, using a quartz

crystal resonator o r ce ramic res onator, has started and

is providing a stable system clock to the Oscillator

module. When switching between clock sources, a

delay is required to allow the new clock to stabilize.

These oscillator delays are shown in Table 3-1.

TABLE 3-1: OSCILLATOR DELAY EXAMPLES

Switch From Switch To Frequency Oscillator Delay

Sleep/POR INTOSC 125 kHz to 8 MHz Oscillator Warm-Up Delay (T

Sleep/POR EC, RC DC – 20 MHz 2 instruction cycles

Sleep/POR LP, XT, HS 32 kHz to 20 MHz 1024 Clock Cycles (OST)

3.3.2 EC MODE

The External Clock (EC) mode allows an externally

generated logic level as the system clock source. When

operating in this mode, an external clock source is

connected to the OSC1 input and the OSC2 is available

for general purpose I/O. Figure 3-2 shows the pin

connections for EC mode.

The Oscillator Start-up Timer (OST) is disabled when

EC mode is selected. Therefore, there is no delay in

operation after a Power-on Reset (POR) or wake-up

from Sleep. Because the PIC

static, stopping the external clock input will have the

effect of halting the device while leaving all data intact.

Upon restarting the external clock, the device will

resume operation as if no time had elapsed.

®

MCU design is fully

WARM)

FIGURE 3-2: EXTERNAL CLOCK (EC)

MODE OPERATION

Clock from

Ext. System

I/O

Note 1: Alternate pin functions are listed in the

Section 1.0 “Device Overview”.

DS41302A-page 26 Preliminary © 2006 Microchip Technology Inc.

OSC1/CLKIN

®

MCU

PIC

OSC2/CLKOUT

(1)

PIC12F609/615/12HV609/615

3.3.3 LP, XT, HS MODES

The LP, XT and HS modes support the use of quartz

crystal resonators or ceram ic resonators connected to

OSC1 and OSC2 (Figu re 3-3). The mod e selects a low ,

medium or high gain setting of the internal

inverter-amplifier to support various resonator types

and speed.

LP Oscillator mode selects the lowest gain setting of

the internal inverter-amplifier. LP mode current

consumption is the least of the three modes. T his mode

is designed to drive only 32.768 kHz tuning-fork type

crystals (watch crystals).

XT Oscillator mode selects the intermediate gain

setting of the internal inverter-amplifier. XT mode

current consumption is the medi um of the three modes.

This mode is best suited to drive resonators with a

medium drive level specification.

HS Oscillator mode selects the highest gain setting of

the internal inverter-amplifier. HS mode current

consumption is the highest of the three modes. This

mode is best suited for resonato rs that req uire a hi gh

drive setting.

Figure 3-3 and Figure 3-4 show typical circuits for

quartz crystal and ceramic resonators, respectively.

Note 1: Quartz crystal char acteristics vary a ccording

to type, package and manufacturer. The

user should consult the manu facturer data

sheets for sp ecifi catio ns an d reco mmen ded

application.

2: Always verify oscillator performance over

DD and temperature range that is

the V

expected for the application.

3: For oscillator design assistance, reference

the following Microchip Applications Notes:

• AN826, “Crystal Oscillator Basics and

Crystal Selection for rfPIC

®

and PIC®

Devices” (DS00826)

®

• AN849, “Basic PIC

Oscillator Design”

(DS00849)

®

• AN943, “Practical PIC

Oscillator

Analysis and Design” (DS00943)

• AN949, “Making Your Oscillator Work”

(DS00949)

FIGURE 3-4: CERAMIC RESONATOR

OPERATION

(XT OR HS MODE)

FIGURE 3-3: QUARTZ CRYSTAL

OPERATION (LP, XT OR

HS MODE)

PIC® MCU

OSC1/CLKIN

C1

Quartz

Crystal

C2

Note 1: A series resistor (RS) may be required for

2: The value of R

(1)

S

R

quartz crystals with low drive level.

selected (typically between 2 MΩ to 10 MΩ).

F varies with the Oscillator mode

(2)

RF

OSC2/CLKOUT

To Internal

Logic

Sleep

PIC® MCU

OSC1/CLKIN

C1

(3)

RP

C2

Ceramic

Resonator

Note 1: A series resistor (RS) may be required for

ceramic resonators with low drive level.

2: The value of R

selected (typically between 2 MΩ to 10 MΩ).

3: An additional parallel feedback resistor (R

may be required for proper ceramic resonator

operation.

(1)

R

S

F varies with the Oscillator mode

(2)

RF

OSC2/CLKOUT

To Internal

Logic

Sleep

P)

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 27

PIC12F609/615/12HV609/615

3.3.4 EXT ERNAL RC MODES

The external Resistor-Capacitor (RC) modes support

the use of an external RC circuit. This allows the

designer maximum flexibility in frequency choice while

keeping costs to a minimum when clock accuracy is not

required. There are two modes: RC and RCIO.

In RC mode, the RC circuit connects to OSC1.

OSC2/CLKOUT outputs the RC oscillator frequency

divided by 4. This signal may be us ed to provide a cl ock

for external circuitry, synchronization, calibration, test

or other application requirements. Figure 3-5 shows

the external RC mode connections.

FIGURE 3-5: EXTERNAL RC MODES

REXT

CEXT

VSS

VDD

OSC/4 or

F

(2)

I/O

OSC1/CLKIN

OSC2/CLKOUT

PIC® MCU

Internal

Clock

(1)

3.4 Internal Clock Modes

The Oscillator module provides a selectable system

clock source of either 4 MHz or 8 MHz. The selectable

frequency is configured through the IOSCFS bit of the

Configuration Word.

The frequency of the int erna l os ci llator can be trimmed

with a calibration value in the OSCTUNE register.

3.4.1 INTOSC AND INTOSCIO MODES

The INTOSC and INTOSCIO modes configure the

internal oscillators as the system clock source when

the device is progra mmed usi ng the osc illator se lectio n

or the FOSC<2:0> bits in the Configuration Word

register (CONFIG). See Section 11.0 “Special

Features of the CPU” for more information.

In INTOSC mode, OSC1/CLKIN is available for general

purpose I/O. OSC2/CLKOUT outputs the selected

internal oscillator fre quency divide d by 4. The CLKO UT

signal may be used to provide a clock for external

circuitry, synchronization, calibration, test or other

application requirements.

In INTOSCIO mode, OSC1/CLKIN and OSC2/CLKOUT

are available for general purpose I/O.

Recommended values: 10 kΩ ≤ REXT ≤ 100 kΩ, <3V

3 kΩ ≤ R

C

Note 1: Alternate pin functions are listed in

Section 1.0 “Device Overview”.

2: Output depends upon R C or RCIO Clock

mode.

EXT ≤ 100 kΩ, 3-5V

EXT > 20 pF, 2-5V

In RCIO mode, the RC circuit is connected to OSC1.

OSC2 becomes an additional general purpose I/O pin.

The RC oscillator frequency is a function of the supply

voltage, the resistor (REXT) and capacito r (CEXT) values

and the operating temperature. Other factors affecting

the oscillator frequency are:

• threshold voltage variation

• component tolerances

• packaging variations in capacitance

The user also needs to take into account variation due

to tolerance of external RC components used.

DS41302A-page 28 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

3.4.1.1 OSCTUNE Register

The oscillator is factory calibrated but can be adjusted

in software by writing to the OSCTUNE register

(Register 3-1).

The default value of the OSCTUNE register is ‘0’. The

value is a 5-bit two’s complement number.

When the OSCTUNE register is modified, the frequency

will begin shifting to the new frequency . Code execution

continues during this shift. There is no indication that the

shift has occurred.

REGISTER 3-1: OSCTUNE: OSCILLATOR TUNING REGISTER

U-0 U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

— — — TUN4 TUN3 TUN2 TUN1 TUN0

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-5 Unimplemented: Read as ‘0’

bit 4-0 TUN<4:0>: Frequency Tuning bits

01111 = Maximum frequen cy

01110 =

•

•

•

00001 =

00000 = Oscillator module is running at the calibrated frequency.

11111 =

•

•

•

10000 = Minimum frequency

TABLE 3-2: SUMMARY OF REGISTERS ASSOCIATED WITH CLOCK SOURCES

Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

CONFIG

OSCTUNE

Legend: x = unknown, u = unchanged, – = unimplemented locations read as ‘0’. Shaded cells are not used by oscillators.

Note 1: Other (non Power-up) Resets include MCLR

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 29

(2)

IOSCFS CP MCLRE PWRTE WDTE FOSC2 FOSC1 FOSC0 — —

— — — TUN4 TUN3 TUN2 TUN1 TUN0 ---0 0000 ---u uuuu

Reset and Watchdog Timer Reset during normal operation.

2: See Configuration Word register (Register 11-1) for operation of all register bits.

Val ue on

POR, BOR

Val ue on

all other

(1)

Resets

PIC12F609/615/12HV609/615

NOTES:

DS41302A-page 30 Preliminary © 2006 Microchip Technology Inc.

PIC12F609/615/12HV609/615

4.0 I/O PORT

There are as many as six general purpose I/O pins

available. Depending on which peripherals are enabled,

some or all of the pins may not be available as general

purpose I/O. In gen eral, when a periphe ral is enabled,

the associated pin may not be used as a general

purpose I/O pin.

4.1 GPIO and the TRISIO Registers

GPIO is a 6-bit wide port with 5 bidirectional and 1

input-only pin. The corres pond ing dat a di rec tion register

is TRISIO (Register 4-2). Setting a TRISIO bit (= 1) will

make the corresponding GPIO pin an input (i.e., disable

the output driver). Clearing a TRISIO bit (= 0) will m ake

the corresponding GPIO pin an output (i.e., enables

output driver and puts the content s of the ou tput latch on

the selected pin). The exception is GP3, which is input

only and its TRIS bit will always read as ‘1’. Example 4-1

shows how to initialize GPIO.

Reading the GPIO register (Register 4-1) reads the

status of the pins, whereas writing to it will write to the

PORT latch. All write operations are read-modify-write

operations. Therefore, a write to a port implies that the

REGISTER 4-1: GPIO: GPIO REGISTER

port pins are read, this value is modified and then

written to the PORT data latch. GP3 reads ‘0’ when

MCLRE = 1.

The TRISIO register controls the direction of the

GPIO pins, even when they are being used as analog

inputs. The user must ensure the bits in the TRISIO

register are maintained set when using the m as analog

inputs. I/O pins co nfigure d a s analo g i nput a lways read

‘0’.

Note: The ANSEL register must be initialized to

configure an analog channel as a digital

input. Pins configu red as analo g inputs will

read ‘0’ and cannot generate an interrupt.

EXAMPLE 4-1: INITIALIZING GPIO

BANKSEL GPIO ;

CLRF GPIO ;Init GPIO

BANKSEL ANSEL ;

CLRF ANSEL ;digital I/O, ADC clock

;setting ‘don’t care’

MOVLW 0Ch ;Set GP<3:2> as inputs

MOVWF TRISIO ;and set GP<5:4,1:0>

;as outputs

U-0 U-0 R/W-x R/W-0 R-x R/W-0 R/W-0 R/W-0

— — GP5 GP4 GP3 GP2 GP1 GP0

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-6 Unimplemented: Read as ‘0’

bit 5-0 GP<5:0>: GPIO I/O Pin bit

1 = GPIO pin is > V

0 = GPIO pin is < VIL

IH

REGISTER 4-2: TRISIO: GPIO TRI-STATE REGISTER

U-0 U-0 R/W-1 R/W-1 R-1 R/W-1 R/W-1 R/W-1

— — TRISIO5 TRISIO4 TRISIO3 TRISIO2 TRISIO1 TRISIO0

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-6 Unimplemented: Read as ‘0’

bit 5-0 TRISIO<5:0>: GPIO Tri-State Control bit

1 = GPIO pin configured as an input (tri-stated)

0 = GPIO pin configured as an output

Note 1: TRISIO<3> always reads ‘1’.

2: TRISIO<5:4> always reads ‘1’ in XT, HS and LP Oscillator modes.

© 2006 Microchip Technology Inc. Preliminary DS41302A-page 31

PIC12F609/615/12HV609/615

4.2 Additional Pin Functions

Every GPIO pin on the PIC12F609/615/12HV609/615

has an interrupt-on-change option and a weak pull-up

option. The next three sections describe these

functions.

4.2.1 ANSEL REGISTER

The ANSEL register is used to configure the Input

mode of an I/O pin to analog. Setting the appropriate

ANSEL bit high will cause all digi t al read s on the pi n to

be read as ‘0’ and allow analog functions on the pin to

operate correctly.

The state of the ANSEL bits has no affect on digital

output functions. A pin with TRIS clear and ANSEL set

will still operate as a digital output, but the Input mode

will be analog. This can cause unexpected behavior

when executing read-modify-write instructions on the

affected port.

4.2.2 WEAK PULL-UPS

Each of the GPIO pins, ex cept GP3, has an individuall y

configurable internal weak pull-up. Control bits WPUx

enable or disable each pull-up. Refer to Register 4-5.

Each weak pull-up is automatically turned off when the