Page 1

查询PIC12C671T-10I/SM供应商

PIC12C67X AND PIC12CE67X

EPROM Memory Programming Specification

This document includes the programming

specifications for the following devices:

• PIC12C671

• PIC12C672

• PIC12CE673

• PIC12CE674

1.0 PROGRAMMING THE

PIC12C67X AND PIC12CE67X

The PIC12C67X and PIC12CE67X can be programmed using a serial method. In serial mode the

PIC12C67X and PIC12CE67X can be programmed

while in the users system. This allows for increased

design flexibility.

1.1 Har

The PIC12C67X and PIC12CE67X requires two programmable power supplies, one for V

recommended) and one for V

supplies should have a minimum resolution of 0.25V.

1.2 Pr

The programming mode for the PIC12C67X and

PIC12CE67X allows programming of user program

memory, special locations used f or ID, and the configuration word for the PIC12C67X and PIC12CE67X.

dware Requirements

PP

ogramming Mode

(2.0V to 6.0V

DD

(12V to 14V). Both

Pin Diagram:

PDIP

VDD

GP5/OSC1/CLKIN

GP4/OSC2/AN3/

CLKOUT

GP3/MCLR

/VPP

PIC12CE67X

1

2

3

4

PIC12C67X

8

7

6

5

VSS

GP0/AN0

GP1/AN1/V

GP2/T0CKI/

AN2/INT

REF

PIN DESCRIPTIONS (DURING PROGRAMMING): PIC12C671/672 and PIC12CE673/674

During Programming

Pin Name

GP1 CLOCK I Clock input

GP0 DATA I/O Data input/output

/V

GP3/MCLR

V

V

Legend: I = Input, O = Output, P = Power

1998 Microchip Technology Inc. DS40175A-page 1

PP

DD

SS

Pin Name Pin Type Pin Description

V

PP

DD

V

V

SS

P Programming Power

P Power Supply

P Ground

Page 2

PIC12C67X and PIC12CE67X

2.0 PROGRAM MODE ENTRY

2.1 User Pr

The user memory space extends from 0x0000 to

0x1FFF (8K). Table 2-1 shows actual implementation

of program memory in the PIC12C67X family.

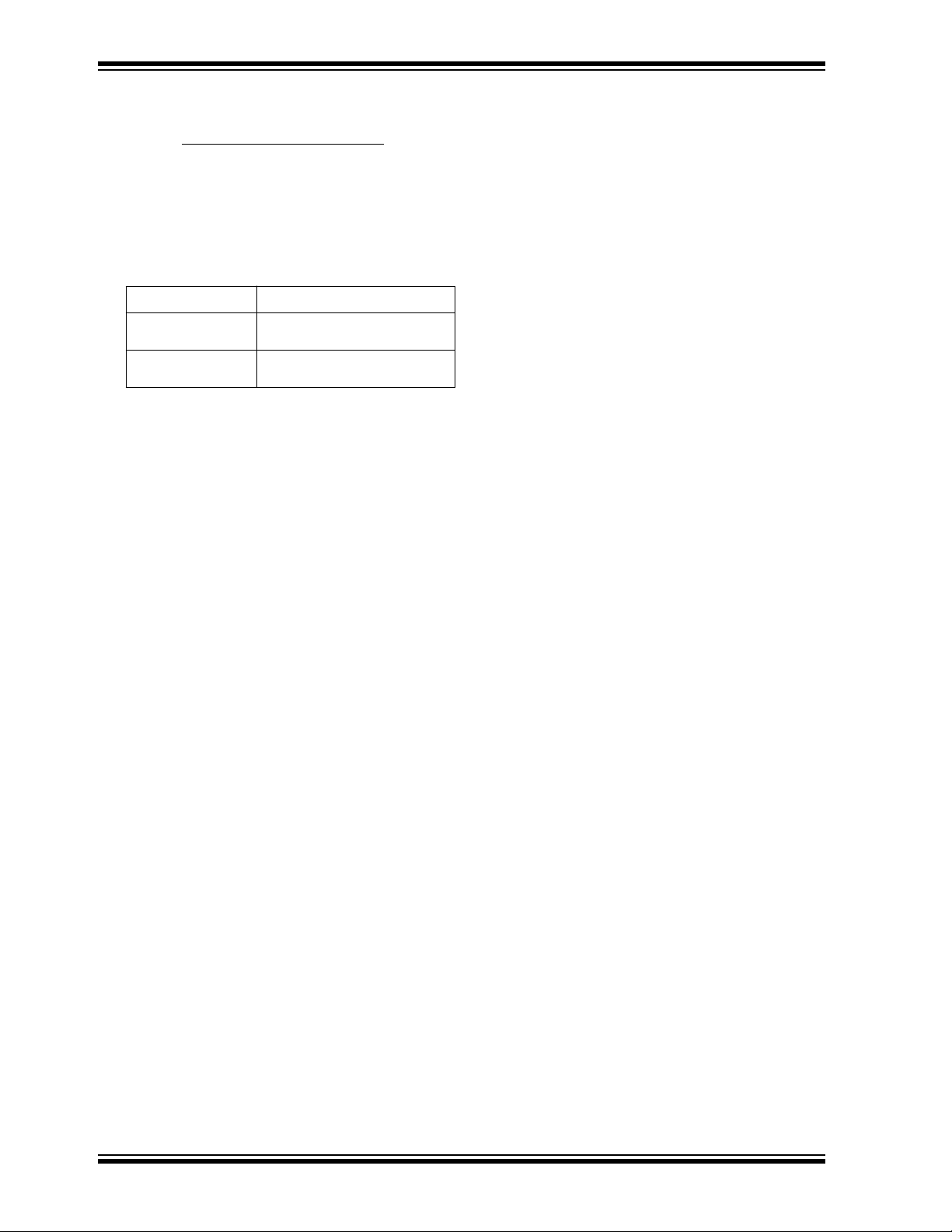

TABLE 2-1: IMPLEMENTATION OF

Device Program Memory Size

PIC12C671/

PIC12CE673

PIC12C672/

PIC12CE674

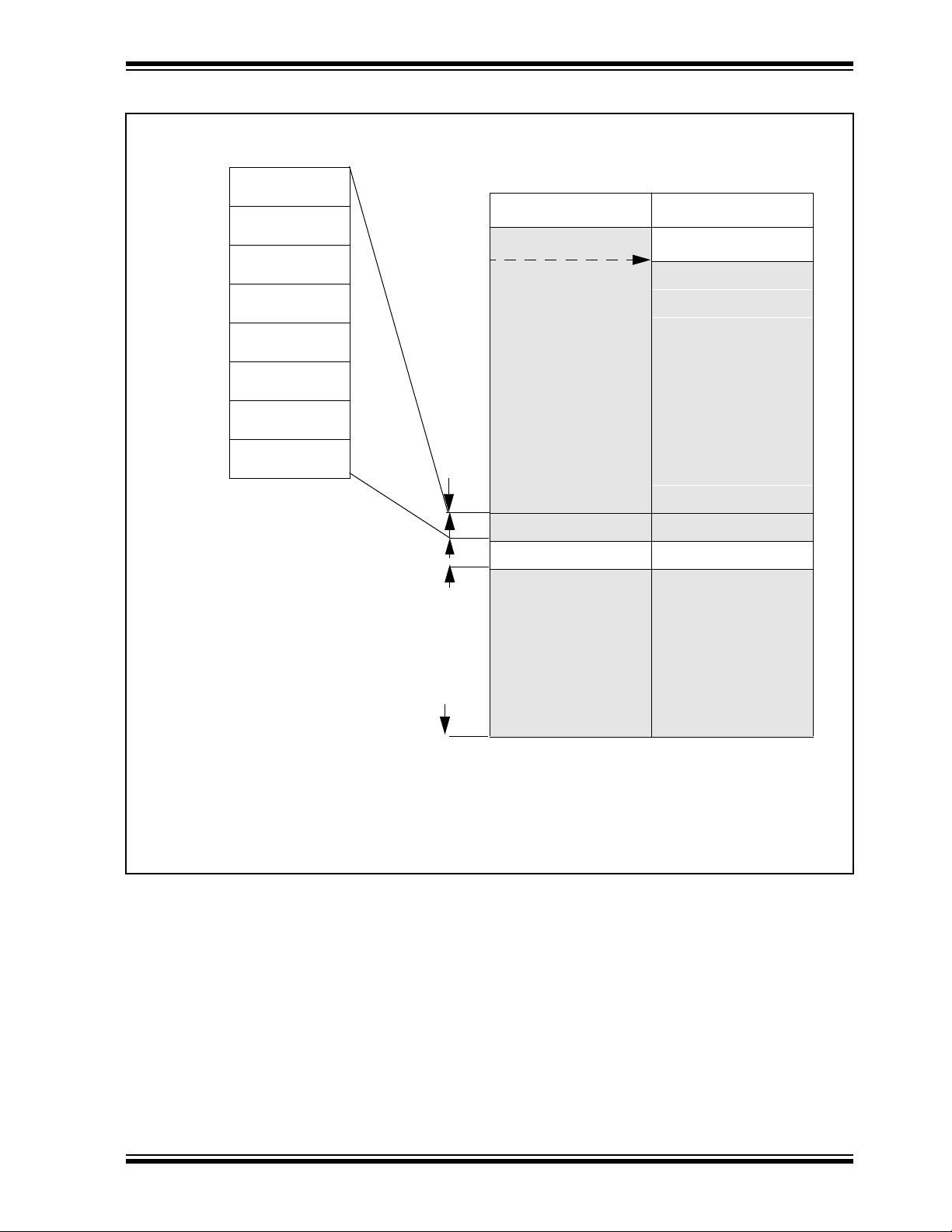

When the PC reaches the last location of the implemented program memory, it will wrap around and

address a location within the physically implemented

memory (see Figure 2-1).

In programming mode the program memory space

extends from 0x0000 to 0x3FFF, with the first half

(0x0000-0x1FFF) being user program memory and the

second half (0x2000-0x3FFF) being configuration

memory. The PC will increment from 0x0000 to

0x1FFF and wrap to 0x000 or 0x2000 to 0x3FFF and

wrap around to 0x2000 (not to 0x0000). Once in configuration memory, the highest bit of the PC stays a '1',

thus always pointing to the configuration memory. The

only way to point to user program memory is to reset

the part and reenter program/verify mode, as described

in Section 2.2.

The last location of the program memory space holds

the factory programmed oscillator calibration value.

This location should not be programmed except when

blank (a non-blank value should not cause the device

to fail a blank check). If blank, the programmer should

program it to a RETL W XX statement where "XX" is the

calibration value.

ogram Memory Map

PROGRAM MEMORY IN THE

PIC12C67X

0x000 - 0x3FF (1K)

0x000 - 0x7FF (2K)

In the configuration memory space, 0x2000-0x20FF

are utilized. When in configuration memory, as in the

user memory, the 0x2000-0x2XFF segment is repeatedly accessed as the PC exceeds 0x2XFF (see

Figure 2-1).

A user may store identification information (ID) in four

ID locations. The ID locations are mapped in [0x2000 :

0x2003].

Note 1: All other locations in PIC configuration

memory are reserved and should not be

programmed.

Note 2: Due to the secure nature of the on-board

EEPROM memory in the

PIC12CE673/674, it can be accessed only

by the user program.

DS40175A-page 2

1998 Microchip Technology Inc.

Page 3

EPROM Memory Programming Specification

FIGURE 2-1: PROGRAM MEMORY MAPPING

2000

2001

2002

2003

2004

2005

2006

Configuration Word

2007

ID Location

ID Location

ID Location

ID Location

Reserved

Reserved

Reserved

1FF

3FF

400

7FF

800

BFF

C00

FFF

1000

1FFF

2000

2008

2100

0

1KW 2KW

Implemented Implemented

Implemented

Reserved

Reserved

Reserved Reserved

3FFF

Reserved Reserved

1998 Microchip Technology Inc. DS40175A-page 3

Page 4

PIC12C67X and PIC12CE67X

2.2 Pr

ogram/Verify Mode

The program/verify mode is entered by holding pins

GP1 and GP0 low while raising MCLR

IHH

V

(high voltage). VDD is then raised from VIL to

pin from V

IL

to

VIH.Once in this mode the user program memory and

the configuration memory can be accessed and programmed in serial fashion. The mode of operation is

serial, and the memory that is accessed is the user program memory. GP1 is a Schmitt Trigger input in this

mode.

The sequence that enters the device into the programming/verify mode places all other logic into the reset

state (the MCLR

pin was initially at V

). This means

IL

that all I/O are in the reset state (High impedance

inputs).

Note 1: The MCLR

IHH

V

before V

pin must be raised from V

DD

is applied. This is to

IL

to

ensure that the device does not have the

PC incremented while in valid operation

range.

Note 2: Do not power GP2, GP4 or GP5 before

V

is applied.

DD

1.0.1 PROGRAM/VERIFY OPERATION

The GP1 pin is used as a clock input pin, and the GP0

pin is used for entering command bits and data

input/output during serial operation. To input a command, the clock pin (GP1) is cycled six times. Each

command bit is latched on the falling edge of the clock

with the least significant bit (LSB) of the command

being input first. The data on pin GP0 is required to

have a minimum setup and hold time (see AC/DC

specs) with respect to the falling edge of the clock.

Commands that have data associated with them (read

and load) are specified to have a minimum dela y of 1 µ s

between the command and the data. After this delay

the clock pin is cycled 16 times with the first cycle being

a start bit and the last cycle being a stop bit. Data is

also input and output LSB first. Therefore, during a

read operation the LSB will be transmitted onto pin

GP0 on the rising edge of the second cycle, and during

a load operation the LSB will be latched on the falling

edge of the second cycle. A minimum 1 µ s delay is also

specified between consecutive commands.

All commands are transmitted LSB first. Data words

are also transmitted LSB first. The data is transmitted

on the rising edge and latched on the falling edge of the

clock. To allow for decoding of commands and rev ersal

of data pin configuration, a time separation of at least

1 µ s is required between a command and a data word

(or another command).

The commands that are available are listed

in Table 1-1.

1.0.1.1 LOAD CONFIGURATION

After receiving this command, the program counter

(PC) will be set to 0x2000. By then applying 16 cycles

to the clock pin, the chip will load 14-bits a “data word”

as described above, to be programmed into the configuration memory . A description of the memory mapping

schemes for normal operation and configuration mode

operation is shown in Figure 2-1. After the configuration memory is entered, the only way to get back to the user program memory is to exit the program/verify test mode by taking MCLR

low (V

).

IL

TABLE 1-1: COMMAND MAPPING

Command Mapping (MSB ... LSB) Data

Load Configuration

Load Data

Read Data

Increment Address

Begin programming

End Programming

0 0 0 0 0 0

0 0 0 0 1 0

0 0 0 1 0 0

0 0 0 1 1 0

0 0 1 0 0 0

0 0 1 1 1 0

0, data(14), 0

0, data(14), 0

0, data(14), 0

DS40175A-page 4

1998 Microchip Technology Inc.

Page 5

EPROM Memory Programming Specification

FIGURE 1-1: PROGRAM FLOW CHART - PIC12C67X AND PIC12CE67X PROGRAM MEMORY

Start

Increment Address

Command

Set VPP = V

Set VDD = V

Program Cycle

Read Data

Command

Data Correct?

Apply 3N Additional

Program Cycles

No

All Locations Done?

Verify all Locations

@ V

V

PP

N = 0

DD MIN.•

= V

IHH1

Yes

IHH2

DDP

Yes

•

No

N > 25

N = N + 1

N = # of Program Cycles

No

Yes

Report Programming

Failure

Prog

Load Data

Command

Begin Programming

Command

Wait 100 µs

ram Cycle

Data Correct?

Verify all Locations

@ V

DD MAX.

V

= V

PP

IHH2

Data Correct?

Yes

Done

• V

= VDD range for programming (typically 4.75V - 5.25V).

DDP

V

= Minimum V

DD MIN.

V

= Maximum V

DD MAX.

1998 Microchip Technology Inc. DS40175A-page 5

for device operation.

DD

for device operation.

DD

No

Yes

No

Report Verify

@ V

DD MIN.

Report Verify

@ V

DD MAX

Error

Error

End Programming

Command

Page 6

PIC12C67X and PIC12CE67X

FIGURE 1-2: PROGRAM FLOW CHART - PIC12C67X AND PIC12CE67X CONFIGURATION WORD

& ID LOCATIONS

Start

Increment Address

Command

No

Address = 2004

Increment Address

Command

Set VPP = V

Load Configuration

Command

N = 0

No Yes

Yes

Program ID Loc?

IHH1

Program Cycle

N = N + 1

N = # of Program

Cycles

No

ID/Configuration

N > 25

Yes

Error

Read Data

Command

No

Data Correct?

Yes

Apply 3N

Program Cycles

Increment Address

Command

Increment Address

Command

Done

Yes

Report Program

ID/Config. Error

No

Data Correct?

Program Cycle

100 Cycles

No

Data Correct?

Set VDD = VDDmax

Read Data Command

Set V

PP

Yes

VDDmax

= V

IHH2

Read Data

Command

No

Data Correct?

Yes

Set VDD = VDDmin

Read Data Command

Set V

PP

VDDmin

= V

IHH2

DS40175A-page 6

1998 Microchip Technology Inc.

Page 7

EPROM Memory Programming Specification

1.0.1.2 LOAD DATA

After receiving this command, the chip will load in a

14-bit “data word” when 16 cycles are applied, as

described previously . A timing diagr am for the load data

command is shown in Figure 4-1.

1.0.1.3 READ DATA

After receiving this command, the chip will transmit

data bits out of the memory currently accessed starting

with the second rising edge of the clock input. The GP0

pin will go into output mode on the second rising clock

edge, and it will revert back to input mode (hi-impedance) after the 16th rising edge. A timing diagram of

this command is shown in Figure 4-2.

1.0.1.4 INCREMENT ADDRESS

The PC is incremented when this command is

received. A timing diagram of this command is shown

in Figure 4-3.

1.0.1.5 BEGIN PROGRAMMING

A load command (load configuration or load data)

must be given before every begin programming

command. Programming of the appropriate memory

(test program memory or user program memory) will

begin after this command is received and decoded.

Programming should be performed with a series of

100 µ s programming pulses. A programming pulse is

defined as the time between the begin programming

command and the end programming command.

1.1 Pr

ogramming Algorithm Requires

Variable V

DD

The PIC12C67X and PIC12CE67X uses an intelligent

algorithm. The algorithm calls for program verification

at V

min as well as V

DD

max. Verification at V

DD

DD

min

guarantees good “erase margin”. Verification at

V

DD

max guarantees good “program margin”.

in the

The actual programming must be done with V

V

range (4.75 - 5.25V).

DDP

V

V

V

DDP

DD

DD

= V

range required during programming.

CC

min. = minimum operating V

max.= maximum operating V

DD

spec for the part.

spec for the part.

DD

DD

Programmers must verify the PIC12C67X and

PIC12CE67X at its specified V

max and V

DD

min lev-

DD

els. Since Microchip may introduce future versions of

the PIC12C67X and PIC12CE67X with a broader V

DD

range, it is best that these levels are user selectable

(defaults are ok).

Note: Any programmer not meeting these

requirements may only be classified as

“prototype” or “development” programmer

but not a “production” quality progr ammer .

1.0.1.6 END PROGRAMMING

After receiving this command, the chip stops program-

ming the memory (configuration program memory or

user program memory) that it was programming at the

time.

1998 Microchip Technology Inc. DS40175A-page 7

Page 8

PIC12C67X and PIC12CE67X

2.0 CONFIGURATION WORD

The PIC12C67X and PIC12CE67X family members

have several configuration bits. These bits can be programmed (reads '0') or left unprogrammed (reads '1') to

select various device configurations. Figure 2-1 provides an overview of configuration bits.

FIGURE 2-1: CONFIGURATION WORD

Bit Number:

13

12

CP0CP1

bit 13-8, 6-5: CP1:CP0: Code Protection bits (1) (2)

bit 7: MCLRE: GP3/MCLR pin function select

bit 4: PWRTE: Power-up Timer Enable bit (1)

bit 3: WDTE: Watchdog Timer Enable bit

bit 2-0: FOSC2:FOSC0: Oscillator Selection bits

Note 3: All of the CP1:CP0 pairs have to be given the same value to enable the code protection scheme listed.

10 9 8

11

CP0CP1

CP1

CP0

11 = Code protection off

10 = 0400h-07FFh code protected;

01 = 0200h-07FFh code protected;

00 = 0000h-07FFh code protected;

1 = GP3/MCLR pin function is MCLR

0 = GP3/MCLR pin function is digital I/O, MCLR internally tied to Vdd

1 = PWRT disabled

0 = PWRT enabled

1 = WDT enabled

0 = WDT disabled

111 = EXTRC oscillator / CLKOUT function on GP4/OSC2/CLKOUT pin

110 = EXTRC oscillator / GP4 function on GP4/OSC2/CLKOUT pin

101 = INTRC oscillator / CLKOUT function on GP4/OSC2/CLKOUT pin

100 = INTRC oscillator / GP4 function on GP4/OSC2/CLKOUT pin

011 = invalid selection

010 = HS oscillator

001 = XT oscillator

000 = LP oscillator

4: 07FFh is always uncodeprotected on the 12C672 and 03FFh is alwa ys uncodeprotected on the 12C671. This location

contains the RETLW xx calibration instruction for the INTRC.

7

6 5 4

MCLRE CP1

CP0

PWRTE

3

WDTE

2

FOSC2

1

FOSC10FOSC0

Register: CONFIG

Address 2007h

DS40175A-page 8 1998 Microchip Technology Inc.

Page 9

EPROM Memory Programming Specification

3.0 CODE PROTECTION

The program code written into the EPROM can be protected by writing to the CP0 & CP1 bits of the configuration word.

For PIC12C67X and PIC12CE67X devices, once code

protection is enabled, all protected segments read '0's

(or “garbage values”) and are prevented from further

programming. All unprotected segments, including ID

and configuration word locations , and calibration word

location read normally and can be programmed.

3.1 Embedding Configuration Word and ID Information in the Hex File

T o allow portability of code, the programmer is required to read the configuration word and ID locations from the hex

file when loading the hex file. If configuration word information was not present in the hex file then a simple warning

message may be issued. Similarly, while saving a hex file, configuration word and ID information must be included.

An option to not include this information may be provided.

Microchip Technology Inc. feels strongly that this feature is important for the benefit of the end customer.

TABLE 3-1: CONFIGURATION WORD

PIC12C671, PIC12CE673

To code protect:

• Protect all memory 00 0000 X00X XXXX

• Protect 0200h-07FFh 01 0101 X01X XXXX

• No code protection 11 1111 X11X XXXX

Program Memory Segment R/W in Protected Mode R/W in Unprotected Mode

Configuration Word (0x2007) Read Unscrambled, Write Enabled Read Unscrambled, Write Enabled

Unprotected memory segment Read Unscrambled, Write Enabled Read Unscrambled, Write Enabled

Protected memory segment Read All 0’s, Write Disabled Read Unscrambled, Write Enabled

ID Locations (0x2000 : 0x2003) Read Unscrambled, Write Enabled Read Unscrambled, Write Enabled

INTRC Calibration Word (0X3FF) Read Unscrambled, Write Enabled Read Unscrambled, Write Enabled

PIC12C672, PIC12CE674

To code protect:

• Protect all memory 00 0000 X00X XXXX

• Protect 0200h-07FFh 01 0101 X01X XXXX

• Protect 0400h-07FFh 10 1010 X10X XXXX

• No code protection 11 1111 X11X XXXX

Program Memory Segment R/W in Protected Mode R/W in Unprotected Mode

Configuration Word (0x2007) Read Unscrambled, Write Enabled Read Unscrambled, Write Enabled

Unprotected memory segment Read Unscrambled, Write Enabled Read Unscrambled, Write Enabled

Protected memory segment Read All 0’s, Write Disabled Read Unscrambled, Write Enabled

ID Locations (0x2000 : 0x2003) Read Unscrambled, Write Enabled Read Unscrambled, Write Enabled

INTRC Calibration Word (0X7FF) Read Unscrambled, Write Enabled Read Unscrambled, Write Enabled

1998 Microchip Technology Inc. DS40175A-page 9

Page 10

PIC12C67X and PIC12CE67X

3.2 Checksum

3.2.1 CHECKSUM CALCULATIONS

Checksum is calculated by reading the contents of the

PIC12C67X and PIC12CE67X memory locations and

adding the opcodes up to the maximum user addressable location, excluding the oscillator calibration location in the last address, e.g., 0x3FE for the

PIC12C671/CE673. Any carry bits exceeding 16-bits

are neglected. Finally, the configuration word (appropriately masked) is added to the checksum. Checksum

computation for each member of the PIC12C67X and

PIC12CE67X devices is shown in Table 3-2.

The checksum is calculated by summing the following:

• The contents of all program memory locations

• The configuration word, appropriately masked

• Masked ID locations (when applicable)

TABLE 3-2: CHECKSUM COMPUTATION

Device

PIC12C671

PIC12CE673

PIC12C672

PIC12CE674

Code

Protect

OFF

1/2

ALL

OFF

1/2

3/4

ALL

SUM[0x000:0x3FE] + CFGW & 0x3FFF

SUM[0x000:0x1FF] + CFGW & 0x3FFF + SUM_ID

CFGW & 0x3FFF + SUM_ID

SUM[0x000:0x7FE] + CFGW & 0x3FFF

SUM[0x000:0x3FF] + CFGW & 0x3FFF + SUM_ID

SUM[0x000:0x1FF] + CFGW & 0x3FFF + SUM_ID

CFGW & 0x3FFF + SUM_ID

The least significant 16 bits of this sum is the checksum.

The following table describes how to calculate the

checksum for each de vice. Note that the chec ksum calculation differs depending on the code protect setting.

Since the program memory locations read out differently depending on the code protect setting, the table

describes how to manipulate the actual program memory values to simulate the values that would be read

from a protected device. When calculating a checksum

by reading a device, the entire program memory can

simply be read and summed. The configuration word

and ID locations can always be read.

Note that some older devices have an additional value

added in the checksum. This is to maintain compatibility with older device programmer checksums.

Checksum*

Blank

Value

3B3F

4E5E

3B4E

373F

5D6E

4A5E

374E

Ox25E6 at

0 and max

address

070D

0013

071C

030D

0F23

FC13

031C

Legend: CFGW = Configuration Word

SUM[a:b] = [Sum of locations a through b inclusive]

SUM_ID = ID locations masked by 0xF then made into a 16-bit value with ID0 as the most significant nibble.

For example,

ID0 = 0x12, ID1 = 0x37, ID2 = 0x4, ID3 = 0x26, then SUM_ID = 0x2746.

*Checksum = [Sum of all the individual expressions] MODULO [0xFFFF]

+ = Addition

& = Bitwise AND

DS40175A-page 10 1998 Microchip Technology Inc.

Page 11

EPROM Memory Programming Specification

4.0 PROGRAM/VERIFY MODE ELECTRICAL CHARACTERISTICS

TABLE 4-1: AC/DC CHARACTERISTICS

TIMING REQUIREMENTS FOR PROGRAM/VERIFY TEST MODE

Standard Operating Conditions

Operating Temperature: +10°C ≤ T

Operating Voltage: 4.5V ≤ V

A ≤ +40°C, unless otherwise stated, (25°C is recommended)

DD ≤ 5.5V, unless otherwise stated.

Parameter

No.

Sym. Characteristic Min. Typ. Max. Units Conditions

General

PD1 V

PD2 I

DDP Supply voltage during programming 4.75 5.0 5.25 V

DDP Supply current (from VDD)

during programming

PD3 V

PD4 V

DDV Supply voltage during verify VDDmin VDDmax V Note 1

IHH1 Voltage on MCLR/VPP during

12.75 13.25 V Note 2

programming

PD5 V

PD6 I

PD9 V

PD8 V

IHH2 Voltage on MCLR/VPP during verify VDD + 4.0 13.5

PP Programming supply current (from

V

PP)

IH1 (GP0, GP1) input high level 0.8 VDD V Schmitt Trigger input

IL1 (GP0, GP1) input low level 0.2 VDD V Schmitt Trigger input

Serial Program Verify

P1 T

R MCLR/VPP rise time (VSS to VIHH)

for test mode entry

P2 Tf MCLR

Fall time 8.0 µs

P3 Tset1 Data in setup time before clock ↓ 100 ns

P4 Thld1 Data in hold time after clock ↓ 100 ns

P5 Tdly1 Data input not driven to next clock

1.0 µs

input (delay required between command/data or command/command)

P6 Tdly2 Delay between clock ↓ to clock ↑ of

1.0 µs

next command or data

P7 Tdly3 Clock ↑ to data out valid

200 ns

(during read data)

P8 Thld0 Hold time after V

P9 T

PPDP Hold time after VPP↑ 5 µs

Note 1: Program must be verified at the minimum and maximum V

Note 2: V

IHH must be greater than VDD + 4.5V to stay in programming/verify mode.

DD↑ 2 µs

DD limits for the part.

20 mA

50 mA

8.0 µs

1998 Microchip Technology Inc. DS40175A-page 11

Page 12

EPROM Memory Programming Specification

FIGURE 4-1: LOAD DATA COMMAND (PROGRAM/VERIFY)

VDD

VDD

P9

P8

P9

P8

100ns

21

P3

100n

100ns

21

P3

}

100n

min.

}

min.

0

100ns

1

P4

}

s

100ns

P4

}

s

0

0

43

0

0

0

Program/Verify Mode

43

0

1

0

00

P6

1µs min.

P5

1µs min.

P6

1µs min.

P5

1µs min.

155432165

0

P4

P3

}

}

100ns

min.

155432165

P7

RB7 = output

Program/Verify Mode

VIHH

MCLR/

VPP

GP1

(CLOCK)

GP0

(DATA)

Reset

FIGURE 4-2: READ DATA COMMAND (PROGRAM/VERIFY)

VIHH

MCLR

/VPP

GP1

(CLOCK)

GP0

(DATA)

Reset

0

RB7

input

FIGURE 4-3: INCREMENT ADDRESS COMMAND (PROGRAM/VERIFY)

VDD

P9

1 2 3 4 5 6

1

1

00 0

P3

P4

}

}

100ns

min

Program/Verify Mode

P6

1µs min.

0

1µs min.

MCLR/VPP

GP1

(CLOCK)

GP0

(DATA)

Reset

VIHH

P5

Next Command

1

0

2

0

1998 Microchip Technology Inc. DS40175A-page 12

Page 13

EPROM Memory Programming Specification

NOTES:

1998 Microchip Technology Inc. DS40175A-page 13

Page 14

M

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

Microchip Technology Inc.

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 602-786-7200 Fax: 602-786-7277

Technical Support:

Web:

http://www.microchip.com

Atlanta

Microchip Technology Inc.

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

Microchip Technology Inc.

5 Mount Royal Avenue

Marlborough, MA 01752

Tel: 508-480-9990 Fax: 508-480-8575

Chicago

Microchip Technology Inc.

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

Microchip Technology Inc.

14651 Dallas Parkway, Suite 816

Dallas, TX 75240-8809

Tel: 972-991-7177 Fax: 972-991-8588

Dayton

Microchip Technology Inc.

Two Prestige Place, Suite 150

Miamisburg, OH 45342

Tel: 937-291-1654 Fax: 937-291-9175

Los Angeles

Microchip Technology Inc.

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 714-263-1888 Fax: 714-263-1338

New York

Microchip Technology Inc.

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 516-273-5305 Fax: 516-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

Microchip Technology Inc.

5925 Airport Road, Suite 200

Mississauga, Ontario L4V 1W1, Canada

Tel: 905-405-6279 Fax: 905-405-6253

602 786-7627

ASIA/PACIFIC

Hong Kong

Microchip Asia Pacific

RM 3801B, Tower Two

Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2-401-1200 Fax: 852-2-401-3431

India

Microchip Technology Inc.

India Liaison Office

No. 6, Legacy, Convent Road

Bangalore 560 025, India

Tel: 91-80-229-0061 Fax: 91-80-229-0062

Japan

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa 222 Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Shanghai

Microchip Technology

RM 406 Shanghai Golden Bridge Bldg.

2077 Yan’an Road West, Hong Qiao District

Shanghai, PRC 200335

Tel: 86-21-6275-5700

Fax: 86 21-6275-5060

Singapore

Microchip Technology Taiwan

Singapore Branch

200 Middle Road

#07-02 Prime Centre

Singapore 188980

Tel: 65-334-8870 Fax: 65-334-8850

ASIA/PACIFIC (CONTINUED)

Taiwan, R.O.C

Microchip Technology Taiwan

10F-1C 207

Tung Hua North Road

Taipei, Taiwan, ROC

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

United Kingdom

Arizona Microchip Technology Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG41 5TU

Tel: 44-1189-21-5858 Fax: 44-1189-21-5835

France

Arizona Microchip Technology SARL

Zone Industrielle de la Bonde

2 Rue du Buisson aux Fraises

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann-Ring 125

D-81739 Müchen, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-39-6899939 Fax: 39-39-6899883

1/13/98

Microchip received ISO 9001 Quality

System certification for its worldwide

headquarters, design, and wafer

fabrication facilities in January , 1997.

Our field-programmable PICmicro™

8-bit MCUs, Serial EEPROMs,

related specialty memory products

and development systems conform

to the stringent quality standards of

the International Standard

Organization (ISO).

All rights reserved. © 1998, Microchip Technology Incorporated, USA. 2/98 Printed on recycled paper.

Information contained in this publication regarding device applications and the like is intended for suggestion only and may be superseded by updates. No representation or warranty is given and no

liability is assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement of patents or other intellectual property rights arising from such use

or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with express written approval by Microchip. No licenses are conveyed, implicitly or

otherwise, under any intellectual property rights. The Microchip logo and name are registered trademarks of Microchip Technology Inc. in the U.S.A. and other countries. All rights reserved. All other

trademarks mentioned herein are the property of their respective companies.

DS40175A-page 14 1998 Microchip Technology Inc.

Page 15

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...