Page 1

MPLAB Starter Kit

for PIC24F User’s Guide

© 2008 Microchip Technology Inc. DS51725A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

PICSTART, PRO MATE, rfPIC and SmartShunt are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

FilterLab, Linear Active Thermistor, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, In-Circuit Serial

Programming, ICSP, ICEPIC, Mindi, MiWi, MPASM, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, PICkit, PICDEM,

PICDEM.net, PICtail, PIC

32

logo, PowerCal, PowerInfo,

PowerMate, PowerTool, REAL ICE, rfLAB, Select Mode, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2008, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS51725A-page ii © 2008 Microchip Technology Inc.

Page 3

MPLAB STARTER KIT FOR PIC24F

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 1

Chapter 1. Introduction to the Starter Kit

1.1 Overview ........................................................................................................ 7

1.2 Operational Requirements ............................................................................. 7

1.3 Initial Board Setup .......................................................................................... 8

Chapter 2. The Demonstration Application

2.1 Features Used Throughout the Demo Application ......................................... 9

2.2 Specific Demo Highlights ............................................................................. 11

Chapter 3. Configuring the Starter Kit Hardware

3.1 Overview ...................................................................................................... 15

3.2 Starter Kit Configurations ............................................................................. 15

Chapter 4. Developing an Application

4.1 Setting Up an Example Application for Debug ............................................. 20

4.2 Running the Example Application ................................................................ 21

4.3 Debugging the Example Application ............................................................ 21

4.4 Programming the Debugged Application ...................................................... 24

4.5 Creating Other Applications ......................................................................... 24

4.6 Determining Device Support and Reserved Resources ............................... 24

4.7 Debug Version Information ........................................................................... 24

4.8 Troubleshooting ............................................................................................ 25

Chapter 5. Hardware

5.1 Application Functional Overview .................................................................. 27

5.2 Programmer/Debugger Functional Overview ............................................... 28

5.3 Board Components ...................................................................................... 29

Appendix A. Starter Kit Schematics........................................................................... 31

Index ............................................................................................................................. 37

Worldwide Sales and Service .................................................................................... 38

© 2008 Microchip Technology Inc. DS51725A-page iii

Page 4

MPLAB Starter Kit for PIC24F User’s Guide

NOTES:

DS51725A-page iv © 2008 Microchip Technology Inc.

Page 5

MPLAB STARTER KIT FOR PIC24F

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

INTRODUCTION

®

IDE online help.

This chapter contains general information that will be useful to know before you use the

MPLAB Starter Kit for PIC24F. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the starter kit as a development and demonstrative

tool for PIC24F MCU device capabilities and features. The manual layout is as follows:

• Chapter 1. Introduction to the Starter Kit – This chapter introduces the starter

kit and provides an overview of its features.

• Chapter 2. The Demonstration Application – This chapter describes the

preprogrammed PIC24F demo application.

• Chapter 3. Configuring the Starter Kit Hardware – This chapter describes the

different USB and power configurations available with the starter kit.

• Chapter 4. Developing an Application – This chapter describes how to debug

application software on the starter kit using MPLAB

• Chapter 5. Hardware – This chapter provides a functional overview of the starter

kit and identifies the major hardware components.

• Appendix A. Starter Kit Schematics – This appendix provides detailed schematic

diagrams of the starter kit.

®

IDE.

© 2008 Microchip Technology Inc. DS51725A-page 1

Page 6

MPLAB Starter Kit for PIC24F User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [, var_name...]

A menu path File>Save

A tab Click the Power tab

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

®

IDE User’s Guide

“Save project before build”

any valid filename

[options]

errorlevel {0|1}

void main (void)

{ ...

}

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles you to receive new product updates.

Interim software releases are available at the Microchip web site.

DS51725A-page 2 © 2008 Microchip Technology Inc.

Page 7

RECOMMENDED READING

This user’s guide describes how to use the MPLAB Starter Kit for PIC24F. Other useful

documents are listed below. The following Microchip documents are available and

recommended as supplemental reference resources.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB IDE installation directory. The Readme files

contain update information and known issues that may not be included in this user’s

guide.

PIC24F Family Reference Manual

This reference manual explains the operation of the PIC24F microcontroller family

architecture and peripheral modules. The specifics of each device family are discussed

in the individual family’s device data sheet.

This useful manual is on-line in sections at the Technical Documentation section of the

Microchip web site. Refer to these for detailed information on PIC24F device operation.

Device Data Sheets and Flash Programming Specifications

Refer to the appropriate device Data Sheet for device-specific information and

specifications. Also, refer to the appropriate device Flash Programming Specification

for information on instruction sets and firmware development. These files may be found

on the Microchip web site or from your local sales office.

MPLAB

This document helps you use Microchip Technology’s language tools for PIC24F

devices based on GNU technology. The language tools discussed are the MPLAB

ASM30 Assembler, MPLAB LINK30 Linker, MPLAB LIB30 Archiver/Librarian and other

16-bit device utilities.

MPLAB

This document helps you use Microchip’s MPLAB C30 C compiler to develop your

application. MPLAB C30 is a GNU-based language tool, based on source code from

the Free Software Foundation (FSF). For more information about FSF, see

www.fsf.org

MPLAB

This document describes how to use the MPLAB IDE integrated development environment, as well as the MPLAB IDE Project Manager, MPLAB IDE Editor and MPLAB SIM

Simulator. Use these development tools to help you develop and debug application

code.

®

ASM30, MPLAB® LINK30 and Utilities User’s Guide (DS51317)

®

C30 C Compiler User’s Guide (DS51284)

.

®

IDE User’s Guide (DS51519)

Preface

© 2008 Microchip Technology Inc. DS51725A-page 3

Page 8

MPLAB Starter Kit for PIC24F User’s Guide

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB C18 and MPLAB C30 C compilers; MPASM™

and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 object linkers;

and MPLIB™ and MPLAB LIB30 object librarians.

• In-Circuit Emulators – The latest information on Microchip in-circuit

emulators.These include the MPLAB REAL ICE™ and MPLAB ICE 2000 in-circuit

emulators.

• In-Circuit Debuggers – The latest information on Microchip in-circuit debuggers.

These include MPLAB ICD 2 and PICkit™ 2.

• MPLAB IDE – The latest information on Microchip MPLAB IDE, the Windows

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB IDE Project Manager, MPLAB IDE Editor and

MPLAB SIM Simulator, as well as general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 device programmer and the PICSTART

development programmers.

®

Plus and PICkit 1 and 2

®

DS51725A-page 4 © 2008 Microchip Technology Inc.

Page 9

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (March 2008)

• Initial Release of this Document

Preface

© 2008 Microchip Technology Inc. DS51725A-page 5

Page 10

MPLAB Starter Kit for PIC24F User’s Guide

NOTES:

DS51725A-page 6 © 2008 Microchip Technology Inc.

Page 11

Chapter 1. Introduction to the Starter Kit

Thank you for purchasing Microchip Technology’s MPLAB Starter Kit for PIC24F. This

board is intended to introduce and demonstrate the capabilities and features of PIC24F

microcontrollers. In addition, the starter kit has on-board in-circuit debug circuitry so

that you may develop and debug your own applications.

This chapter introduces the starter kit and provides an overview of its features. Topics

covered include:

•Overview

• Operational Requirements

• Initial Board Setup

1.1 OVERVIEW

The MPLAB Starter Kit for PIC24F provides an all-in-one solution for debugging and

programming applications using Microchip’s own MPLAB Integrated Development

Environment (IDE). A USB connection to a host computer supplies communications

and power to the board; no additional external power supply is needed. For

independent host-side USB operation, the starter kit may be disconnected from the PC

and powered at test points for independent functionality.

The starter kit includes integrated debug and programmer circuitry that allows

applications to be programmed onto the board’s PIC24F MCU device and then

debugged, all using MPLAB IDE. The need for an additional programmer or hardware

interface has been completely eliminated.

The application side of the starter kit contains a range of hardware components to

demonstrate the utility and processing power of Microchip’s PIC24F family of 16-bit

microcontrollers.

MPLAB STARTER KIT FOR PIC24F

USER’S GUIDE

1.2 OPERATIONAL REQUIREMENTS

To communicate with and program the MPLAB Starter Kit for PIC24F, the following

hardware and software requirements must be met:

• PC compatible system with CD-ROM drive

• One available USB port on the PC, or a powered USB hub

•Microsoft

Note: Only initial testing has been performed on 32-bit Windows Vista for this

In addition, the following is needed for some of the application demos:

• USB Flash Drive (not included)

© 2008 Microchip Technology Inc. DS51725A-page 7

®

Windows® 2000 SP4, Windows XP SP2, or Windows Vista™ (32-bit)

release. The 64-bit version is not supported at this time.

Page 12

MPLAB Starter Kit for PIC24F User’s Guide

1.3 INITIAL BOARD SETUP

With its pre-installed demo application, the MPLAB Starter Kit for PIC24F is designed

to be used straight out of the box. Except for a single connection to a computer, no

additional hardware or configuration is necessary.

1.3.1 Installing the Software

Before connecting the starter kit to any computer for the first time, it is very important

to install the accompanying software on the MPLAB Starter Kit for PIC24F CD first. This

ensures that the proper USB drivers for communicating with the starter kit

programmer/debugger are installed and ready to recognize the board.

To install the software and driver, insert the starter kit CD into the CD-ROM drive. The

installation process starts automatically. The process pauses for user responses to

accept the Microchip software licenses and to confirm the installation directories;

respond appropriately.

1.3.2 Connecting the Hardware

Once the starter kit software is installed, connect the provided USB cable (A to mini-B)

to any available USB port on the PC or powered hub, then to the starter kit at the mini-B

receptacle, J1, on the programmer/debugger side of the board (Figure 1-1). The PC

USB connection provides communication and power to the board. A USB Flash drive,

used for portions of the demo application, may be connected to the starter kit at any

time.

If the cable is connected correctly, the green Power and Target Power LEDs (D2 and

D4) are lit. LED1 displays a reversed raster and start-up screen, while the tri-color LED

cycles through a sequence of colors. After this power-on sequence, LED1 will display

the “PIC24F Starter Kit” main menu.

At the same time, a sequence of pop-up balloons in the system tray (lower right of

desktop) should appear, stating that (1) new hardware has been found, (2) drivers are

being installed and (3) the new hardware is ready for use. If you do not see these

messages and the starter kit does not work, try unplugging and reconnecting the USB.

If this does not work, refer to Section 4.8 “Troubleshooting”.

FIGURE 1-1: STARTER KIT SETUP

A to mini-B USB Cable

DS51725A-page 8 © 2008 Microchip Technology Inc.

Starter Kit

M

USB Flash Drive

(not included)

Page 13

MPLAB STARTER KIT FOR PIC24F

USER’S GUIDE

Chapter 2. The Demonstration Application

This chapter describes the demonstration application that is preprogrammed on the

PIC24F microcontroller, and how various features highlight the device’s processing

power and hardware functionality. These include:

• Features Used Throughout the Demo Application:

- Interactive Display System (Processing Power and Parallel Master Port)

- Touch Interface (CMTU)

- Time and Date (RTCC)

• Specific Demo Highlights:

- RGB LED Control (Three PWMs and Peripheral Pin Select)

- USB Flash Drive Interface (USB Embedded Host)

- Real-Time Data Graphing (A/D and Display Multitasking)

- Real-Time Data Capture (Multitasking with USB Embedded Host)

- Other Interactive Demos

2.1 FEATURES USED THROUGHOUT THE DEMO APPLICATION

2.1.1 Interactive Display System (Processing Power and Parallel Master Port)

With the exception of input and display hardware, the entire demo application runs on

the starter kit’s PIC24FJ256GB106 microcontroller, without the need of additional

interfaces or external logic for processing support. This microcontroller simultaneously

controls and monitors all activities through a processing intensive interactive display

system (Figure 2-1).

The microcontroller directly drives the on-board graphics organic LED (OLED) display

through its Parallel Master Port (PMP). This is an 8-bit parallel, highly-configurable I/O

module that allows users to exchange data with a variety of peripheral devices. In the

demo application, the PMP provides the simple data interface needed to control an

advanced display device.

Even with a simple visual interface, a graphics display requires a great deal of

processing power to maintain and update the display while executing its associated

application. At 16 MIPS, the PIC24FJ256GB106 microcontroller has more than enough

processing power for this type of application.

FIGURE 2-1: STARTER KIT MENU DISPLAY (MAIN MENU SHOWN)

PIC24F Starter Kit

i

Flash Drive

Demos Games

Nov 01, 2007 Tue 10:00:01

Utilities

© 2008 Microchip Technology Inc. DS51725A-page 9

Page 14

MPLAB Starter Kit for PIC24F User’s Guide

2.1.2 Touch Interface (CMTU)

To control most of the demo application’s features, the PIC24F microcontroller uses an

on-chip Charge Time Measurement Unit (CTMU) module to implement a capacitive

touch-sensitive touch pad on the starter kit board. The CTMU allows the microcontroller

to directly sense the touch of a fingertip on the touch pad and interpret this as a control

input.

The touch pad (Figure 2-2) is used to select all menu options and input user choices

for all options. At each of the menu screens, the up/down arrows (1 and 3) and left/right

arrows (2 and 4) serve to highlight a menu option displayed on the OLED, and the center key (5) is used to select the option.

FIGURE 2-2: CAPACITIVE TOUCH PAD

UP

1

LEFT

45

CENTER

3

DOWN

2

RIGHT

2.1.2.1 TOUCH PAD CALIBRATION

By default, the application is preprogrammed with a CTMU calibration that responds

appropriately to the touch of an average person’s finger tip. However, there are many

factors (ambient temperature and humidity, skin moisture, etc.) that may affect the

touch pad’s performance. To accommodate these differences, the demo application

includes a calibration routine to adjust the touch pad’s response.

To run the calibration, select “Utilities” from the main menu, then “Calibrate” from the

“Utilities” menu. A series of prompts appears, asking the user to touch and release

each individual pad in turn. When the sequence is completed, the “Calibration complete!” message appears. The application automatically returns to the main menu

afterwards.

Calibration is reset to the default application value on power-up.

Note: It is important to respond to each prompt as quickly as possible, to maintain

contact with a pad until instructed to release it, and to be certain that none

of the pads are being touched during the “release” intervals. Otherwise, one

or more of the individual pads may be incorrectly calibrated, and the

application may act erratically or start responding to “phantom” inputs.

DS51725A-page 10 © 2008 Microchip Technology Inc.

Page 15

2.1.3 Time and Date (RTCC)

The PIC24F microcontroller has an on-chip Real-Time Clock and Calendar (RTCC)

module that the application uses to provide a continuous display of the date and time

(in 24-hour format) on the main menu. As the starter kit does not have an on-board

battery, the date and time must be set each time power is applied to the board.

To set the RTCC, select “Utilities” from the main menu, then “Date/Time” from the

“Utilities” menu. Use the left/right arrow keys to scroll between fields; the border of the

selected field becomes bolded. Use the up/down keys to set the value. When finished,

press the center touch pad to return directly to the main menu.

FIGURE 2-3: SET DATE/TIME DISPLAY

2.2 SPECIFIC DEMO HIGHLIGHTS

The Demonstration Application

Set Date/Time

i

Nov

10

+

+

01

-

+

01

+

2007

+

-

-

2.2.1 RGB LED Control (Three PWMs and Peripheral Pin Select)

Three of the PIC24F microcontroller’s PWM modules control the three-color LED (D6),

and can be adjusted to control the LED’s brightness and color. To provide more current

to the LED channels and increase brightness, each channel is tied to two of the microcontroller’s output pins. The Peripheral Pin Select feature of PIC24F devices allows

users to map the output of a single module (in this case, a PWM) to more than one pin,

avoiding any issues of coordinating separate pins in the process. The use of multiple

pins for a single PWM is transparent to the rest of the application.

To access this feature, select “Demos” from the Main display, then “RGB LED” from the

“Demonstrations menu”. The LED lights up at this point. By default, all three colors are

set at their brightness midpoint (Figure 2-4).

Use the up/down touch pads to select a color component, and the left/right touch pads

to adjust that color’s intensity. When finished, press the center touch pad to extinguish

the LED and return to the main display.

FIGURE 2-4: DEFAULT RGB LED CONTROL DISPLAY

RGB LED

i

Red

Green

Blue

© 2008 Microchip Technology Inc. DS51725A-page 11

Page 16

MPLAB Starter Kit for PIC24F User’s Guide

2.2.2 USB Flash Drive Interface (USB Embedded Host)

This demo shows the ability of the PIC24F microcontroller to function as an embedded

host by reading data from a USB Flash drive. To access the demo, select “Flash Drive”

from the main menu.

If a USB Flash drive with files is plugged in to the USB A-receptacle (J4), the display

shows the drive volume name and top level file structure in a list box (Figure 2-5). Long

file and directory names are truncated according to earlier Microsoft 8+3 file system

conventions (e.g., Longfilename.doc would be truncated as LONGFI~1.doc). Use

the up/down arrow keys to scroll through the directory.

Subdirectories are indicated by names with a folder symbol next to them, and are

opened by pressing the center touch pad. To move up a directory level, select the “..”

entry at the top of the menu window and press the center touch pad.

If a Flash drive is not present, the display shows an empty menu window and the message “Insert media”. If the Flash drive has no content, the display will show only the

drive volume name.

To exit the Flash Drive demo and return to the main menu, press the left arrow touch pad.

FIGURE 2-5: TYPICAL DISPLAYS FOR THE FLASH DRIVE INTERFACE

Insert media...

i

\THUMB

i

.\SUBDIR~1

.\TRANSFER

CAPTURE.CSV

2.2.3 Real-Time Data Graphing (A/D and Display Multitasking)

As an additional demonstration of the application’s ability to interact with users in real

time, the Data Graphing demo shows the capture and conversion of analog data to

graphic information as it happens. In this demo, the input from the potentiometer (R44)

is converted by the microcontroller’s A/D converter to digital information, and plotted as

a time vs. amplitude graph on the OLED display.

To access this demo, select “Demos” from the main menu, then “Graph” from the

“Demonstrations” menu. A horizontally scrolling graph appears with a solid line indicating the current position of the potentiometer. Turning the potentiometer through its

entire range changes the y-coordinate of the line in real time. At its default setting, the

application updates the value from the potentiometer every 100 ms; each time axis

division represents approximately 2 seconds. To increase or decrease the graph’s

update rate, press the right or left arrow touch pads, respectively.

To exit the demo and return to the main menu, press the center touch pad.

FIGURE 2-6: DATA GRAPHING DISPLAY

Potentiometer Graph

i

DS51725A-page 12 © 2008 Microchip Technology Inc.

Page 17

The Demonstration Application

2.2.4 Real-Time Data Capture (Multitasking with USB Embedded Host)

An extension of the Data Graphing demo shows many of the capabilities of the PIC24F

microcontroller, all running at the same time: interactive display, multitasking and USB

embedded host functionality. This feature allows users not only to graph data and view

the results in real time, but also accurately record the results to an external device.

To access this demo, first insert a USB Flash drive into the USB A-receptacle (J4).

Select “Demos” from the main menu, then “Capture” from the “Demonstrations” menu.

A graph identical in operation to that in the Data Graphing demo appears. (If a Flash

drive is not present, a prompt screen will appear instead.) The difference is that the

digital value from the potentiometer conversion is written to the Flash drive to a new

comma delimited file, CAPTURE.csv. Data is written with a second value representing

the time of capture. As the application is configured, the capture interval is 10 ms, and

is independent of the graphic display’s update rate.

To exit the demo and return to the main menu, press the center touch pad.

FIGURE 2-7: DATA GRAPHING DISPLAYS

Pot. Capture

i

Insert USB flash drive...

Pot. Capture

i

2.2.5 Other Interactive Demos

As a final demonstration of the starter kit’s processing power and graphics display

capabilities, several other interactive demos are provided for the user to investigate.

These are accessed by selecting “Games” from the main menu.

Users may find that the three demos provided (“Shu Box”, “Shapelet” and “Blaster”)

similar to some vintage video games. As such, the operations of these demos are

regarded to be self-explanatory. Users who require more information will find additional

instructions in the comments accompanying the application source code.

© 2008 Microchip Technology Inc. DS51725A-page 13

Page 18

MPLAB Starter Kit for PIC24F User’s Guide

NOTES:

DS51725A-page 14 © 2008 Microchip Technology Inc.

Page 19

Chapter 3. Configuring the Starter Kit Hardware

This chapter discusses how to configure the hardware of the MPLAB Starter Kit for

PIC24F for various USB prototypes. Topics covered include:

•Overview

• Starter Kit Configurations

3.1 OVERVIEW

In its default configuration, the application side of the starter kit functions as a USB

embedded host. Even though the board is drawing power from its connection to the

host PC as a bus-powered device, the demo application functions independently of the

host PC in communicating with USB peripheral devices.

However, the starter kit can also be used as a platform for developing USB device

(peripheral) applications. The mini-B receptacle (J4) on the application side provides

the interface for an external USB host.

When setting it up as a prototyping platform, the starter kit board can be configured as

either a USB embedded host or a USB device (peripheral). At the same time, the starter

kit can be configured to operate with or without the functionality of the

programmer/debugger. In terms of the MPLAB IDE environment, we can think of the

application as being in Debug or Release mode.

The hardware configurations described here cover the vast majority of cases that the

user is likely to see in developing USB applications. Other configurations and USB

applications may be possible.

MPLAB STARTER KIT FOR PIC24F

USER’S GUIDE

3.2 STARTER KIT CONFIGURATIONS

3.2.1 Embedded Host, Debug Mode

This is the default configuration used when the starter kit is first connected to a host PC

(see Section 1.3 “Initial Board Setup”). It is also used when USB embedded host

applications are still being developed and debugged. In both instances, power to the

starter kit is provided through the USB cable.

3.2.2 Device, Debug Mode

In this configuration, application code for a USB device is still being developed and

debugged. This requires connections to both the programmer/debugger and

application sides of the board, using two A to mini-B USB cables (Figure 3-1):

1. Connected from the host PC to the programmer/debugger (J1).

2. Connected from the host PC to the application side (J5).

The programmer side cable provides the interface to MPLAB IDE, while the application

side cable provides the interface between the device and host applications. Both

cables provide power to the board.

© 2008 Microchip Technology Inc. DS51725A-page 15

Page 20

MPLAB Starter Kit for PIC24F User’s Guide

FIGURE 3-1: STARTER KIT SETUP (DEVICE, DEBUG MODE)

1

A to mini-B (Programmer)

Starter Kit

M

2

A to mini-B (Application)

3.2.3 Device, Release Mode

In this configuration, the starter kit has been programmed with a debugged,

stand-alone USB device application; programmer/debugger support is not needed.

The only connection required is a USB cable between J5 and the host PC (Figure 3-2).

The cable provides both power and data connection to the host side application,

making it a bus-powered application.

FIGURE 3-2: STARTER KIT SETUP (DEVICE, DEBUG MODE)

A to mini-B (Application)

Starter Kit

M

DS51725A-page 16 © 2008 Microchip Technology Inc.

Page 21

Configuring the Starter Kit Hardware

3.2.4 Embedded Host, Release Mode (Stand-Alone Mode)

In this configuration, the starter kit has been programmed with a debugged,

stand-alone USB embedded host application; programmer/debugger support is not

needed. Because of the absence of a host PC, this configuration can truly be

considered a “stand-alone” operation.

Since there are no connections to a host PC, the starter kit board must be physically

modified to accept an external power supply. A regulated power supply providing 5 V

must be available.

Make the following modifications to the starter kit (Figure 3-3):

1. Install posts at the V

2. Populate the site for R16 (adjacent to the V

3. Supply +5 V

V

BUS and GND connections on the board.

DC and ground connections from the external power supply to the

BUS and GND test points on the board.

BUS test point) with a 0 ohm resistor.

FIGURE 3-3: STARTER KIT MODIFICATIONS FOR STAND-ALONE POWER

OPERATION

Ground

DC

R16 (populate)

+5.0V

M

If the modifications are done correctly, and power is connected correctly, the green

Target Power LED (D4) is lit. The starter kit also goes through its power-on sequence

before LED1 displays the “PIC24 Starter Kit” main menu.

When configured for external power operation, the programmer/debugger function is

essentially disabled. To re-enable these functions, disconnect the external power from

the board and remove the resistor/jumper from R16 before connecting the USB cable

to J1.

CAUTION

If you externally power VBUS via the test point, please make certain that you first

disconnect any USB cables connected to a computer or hub. Otherwise, damage to the

PC’s USB port or the external hub may result.

© 2008 Microchip Technology Inc. DS51725A-page 17

Page 22

MPLAB Starter Kit for PIC24F User’s Guide

NOTES:

DS51725A-page 18 © 2008 Microchip Technology Inc.

Page 23

MPLAB STARTER KIT FOR PIC24F

USER’S GUIDE

Chapter 4. Developing an Application

The MPLAB Starter Kit for PIC24F may be used with MPLAB® IDE, the free intergrated

development environment available on Microchip’s web site. MPLAB IDE allows the

starter kit to be used as an in-circuit debugger as well as a programmer for the featured

device.

In-circuit debugging allows you to run, examine and modify your program for the device

embedded in the starter kit hardware. This greatly assists you in debugging your

firmware and hardware together.

Special starter kit software interacts with the MPLAB IDE application to run, stop and

single-step through programs. Breakpoints can be set and the processor can be reset.

Once the processor is stopped, the register’s contents can be examined and modified.

For more information on how to use MPLAB IDE, reference the following

documentation:

• MPLAB

• MPLAB

• MPLAB

This chapter includes the following:

• Setting Up an Example Application for Debug

• Running the Example Application

• Debugging the Example Application

• Programming the Debugged Application

• Creating Other Applications

• Determining Device Support and Reserved Resources

• Debug Version Information

• Troubleshooting

®

IDE User’s Guide (DS51519)

®

IDE Quick Start Guide (DS51281)

®

IDE On-line Help

© 2008 Microchip Technology Inc. DS51725A-page 19

Page 24

MPLAB Starter Kit for PIC24F User’s Guide

4.1 SETTING UP AN EXAMPLE APPLICATION FOR DEBUG

The MPLAB IDE software that is installed on your PC by the starter kit CD-ROM automatically opens an example application that you may use to examine debug features

of the starter kit. To prepare the application for debug:

1. Launch MPLAB IDE. The example application project and related workspace will

open. For information on projects and workspaces, see the MPLAB IDE

documentation mentioned at the beginning of this chapter.

2. Select Project>Build All

visible in the Build tab of the Output window.

3. Select Debugger>Select Tool>Starter Kits

kit debug features (Figure 4-1):

(1) the status bar will show Starter Kits as the debug tool

(2) a Starter Kit debug toolbar will be added

(3) the Debugger menu will change to add Starter Kit debug functions

(4) the Output window will display communication status between MPLAB IDE

and the starter kit on the Starter Kit Debugger tab.

Also, several device resources are used for debug. For details, see

Section 4.6 “Determining Device Support and Reserved Resources”.

FIGURE 4-1: STARTER KIT AS DEBUG TOOL

to build the application code. The build’s progress will be

. MPLAB IDE will change to add starter

2

3

1

4. Select Debugger>Program

PIC24FJ256GB106 device on the starter kit. The debug programming progress

will be visible in the Starter Kit tab of the Output window.

to program the application code into the

4

Note: Debug executive code is automatically programmed in the upper program

memory of the starter kit device when the starter kit is selected as a debugger. Debug code must be programmed into the target device to use the

in-circuit debugging capabilities of the starter kit.

DS51725A-page 20 © 2008 Microchip Technology Inc.

Page 25

Developing an Application

4.2 RUNNING THE EXAMPLE APPLICATION

The starter kit executes in either real time (Run) or steps (Step Into, Step Over,

Animate.) Real-time execution occurs when you select Run in MPLAB IDE. Once the

device code is halted, either by Halt or a breakpoint, you can step.

The following toolbar buttons can be used for quick access to commonly used debug

operations:

Debugger Menu Toolbar Buttons

Run

Halt

Animate

Step Into

Step Over

Reset

To see how these options function, do the following:

1. Select Debugger>Reset>Processor Reset

program.

2. Select Debugger>Run

operates.

3. Select Debugger>Halt

green solid arrow will mark the line of code in the File window where the program

halted.

4. Select Debugger>Step Into

cution once. The green solid arrow will move down one line of code in the File

window. Click the button several times to step through some code.

5. Select Debugger>Reset>Processor Reset

program again. The arrow will disappear, meaning the device is reset.

or click the Run button. Observe how the application

or click the Halt button to stop the program execution. A

or click the Step Into button to step the program exe-

or click the Reset button to reset the

, click the Reset button to reset the

4.3 DEBUGGING THE EXAMPLE APPLICATION

For the example code given, everything works fine. However, when you are developing

code, it will likely not work the first time and need to be debugged. MPLAB IDE provides

an editor and several debug features, such as breakpoints and Watch windows, to aid

in application code debugging.

This section includes:

• Editing Application Code

• Using Breakpoints and Mouseovers

• Using Watch Windows

© 2008 Microchip Technology Inc. DS51725A-page 21

Page 26

MPLAB Starter Kit for PIC24F User’s Guide

4.3.1 Editing Application Code

To view application code so it may be edited, do one of the following:

•Select Edit>New

existing code file.

• Double-click on a file in the Project window to open an existing code file. See an

example Project window in Figure 4-2.

FIGURE 4-2: EXAMPLE PROJECT

to create new code or Edit>Open to search for and open an

Existing Code File

For more information on using the editor to create and edit code, see MPLAB IDE

Editor Help.

4.3.2 Using Breakpoints and Mouseovers

To set a breakpoint in code, use one of the following methods:

• Double-Click in Gutter: Double-click in the window gutter next to the line of code

where you want the breakpoint. Double-click again to remove the breakpoint.

• Pop-up Menu: Place the cursor over the line of code where you want the break-

point. Then, right click to pop up a menu and select “Set Breakpoint”. Once a

breakpoint is set, “Set Breakpoint” will become “Remove Breakpoint” and “Disable

Breakpoint”. Other options on the pop-up menu under Breakpoints are for

deleting, enabling or disabling all breakpoints.

• Breakpoint Dialog: Open the Breakpoint dialog (Debugger>Breakpoints

delete, enable or disable breakpoints. See MPLAB IDE Help for more information

on this dialog.

A breakpoint set in code appears as a red “stop sign” with a “B”. Once code is halted,

hovering over variables pops up the current value of those variables (Figure 4-3.)

Note: This feature must be set up. From the menu bar, select Edit>Properities

from the Properties dialog, select the Tooltips tab, then click the checkbox

for “Enable Variable Mouseover Values”.

) to set,

;

DS51725A-page 22 © 2008 Microchip Technology Inc.

Page 27

Developing an Application

FIGURE 4-3: EXAMPLE BREAKPOINT

4.3.3 Using Watch Windows

To use a Watch window:

1. The Watch window is made visible on the desktop by selecting View>Watch

contains four selectable watch views (via tabs) in which to view variables (SFRs,

symbols and absolute addresses).

2. Select an SFR or symbol from the list and click the related Add button to add it

to the Watch window, or click in the “Address” column and enter an absolute

address.

A Watch window populated with the SFRs and Symbols will look like Figure 4-4. For

more on using Watch windows, see MPLAB IDE Help.

. It

FIGURE 4-4: EXAMPLE WATCH

© 2008 Microchip Technology Inc. DS51725A-page 23

Page 28

MPLAB Starter Kit for PIC24F User’s Guide

4.4 PROGRAMMING THE DEBUGGED APPLICATION

When the program is successfully debugged and running, the next step is to program

the device for stand-alone operation in the finished design. When doing this, the

resources reserved for debug are released for use by the application. To program the

application, use the following steps:

1. Disable starter kits as a debug tool by selecting Debugger>Select Tool>None

2. Select starter kits as the programmer in the Programmer>Select Programmer

menu.

3. Select Programmer>Program

Now the starter kit will run independently.

4.5 CREATING OTHER APPLICATIONS

This starter kit is just one way to use Microchip PIC24F microcontrollers in an

application. Other tools and resources exist to support these devices.

• PIC24 Demo Boards: Several boards, such as the Explorer 16 Starter Kit, are

available for developing applications.

• MPLAB C30 C Compiler, Full Version: More optimization options than the student

version for full-scale development.

• Application Notes: Libraries and example applications with source code for using

the PIC24F family of microcontrollers.

For more information on demo boards on application notes, see the design center at

the Microchip web site (www.microchip.com

version of the MPLAB C30 Compiler, go to http://www.microchip.com/c30

.

). For additional information on the full

.

.

4.6 DETERMINING DEVICE SUPPORT AND RESERVED RESOURCES

Due to the built-in in-circuit debugging capability of ICD devices and the In-Circuit Serial

Programming™ (ICSP™) function offered by the debugger, the starter kit uses some

on-chip resources when debugging. It also uses program memory and file register

locations in the target device during debugging. These locations are not available for

use by user code. In the MPLAB IDE, registers marked with an “R” in register displays

represent reserved registers.

For information on device resources that are needed for in-circuit debugging, please

refer to the MPLAB ICD 2 Help, found in the MPLAB IDE under Help>Topics

device reserved resource information found under “Resources Used By MPLAB ICD 2”

is the same for the starter kit.

4.7 DEBUG VERSION INFORMATION

Selecting either Debugger>Settings or Programmer Settings from the menu bar opens

the Starter Kit Settings dialog. Currently, there is only one (Info) tab on this dialog,

displaying the following information:

• Firmware Version: The version of firmware on the starter kit board.

• Debug Exec Version: The version of the debug executive that is loaded into the

PIC24F device program memory to enable debug operation.

. The

DS51725A-page 24 © 2008 Microchip Technology Inc.

Page 29

4.8 TROUBLESHOOTING

Debug Connection Problems

While using the starter kit as a debugger, you may get the error “Unable to Enter Debug

Mode” when programming the device. This can result from communication being lost

between the starter kit and MPLAB IDE. To resolve this:

1. Unplug the USB cable from the starter kit.

2. Plug the USB cable back into the starter kit.

MPLAB IDE should automatically reconnect to the starter kit. If this does not work, do

the following:

1. Check the USB connection between the PC and starter kit at both ends.

2. If using a USB hub, make sure it is powered.

3. Make sure the USB port is not in use by another device.

Programming Problems

• If during the course of developing your own application you can no longer pro-

gram the device on the starter kit, you may have set device Configuration bits to

code-protect or some other state that prevents programming. To view the settings

of the Configuration bits, select Configure>Configuration Bits

Developing an Application

.

© 2008 Microchip Technology Inc. DS51725A-page 25

Page 30

MPLAB Starter Kit for PIC24F User’s Guide

NOTES:

DS51725A-page 26 © 2008 Microchip Technology Inc.

Page 31

MPLAB STARTER KIT FOR PIC24F

Chapter 5. Hardware

This chapter provides a functional overview of the MPLAB Starter Kit for PIC24F, and

identifies the major hardware components. Topics covered include:

• Application Functional Overview

• Programmer/Debugger Functional Overview

• Board Components

5.1 APPLICATION FUNCTIONAL OVERVIEW

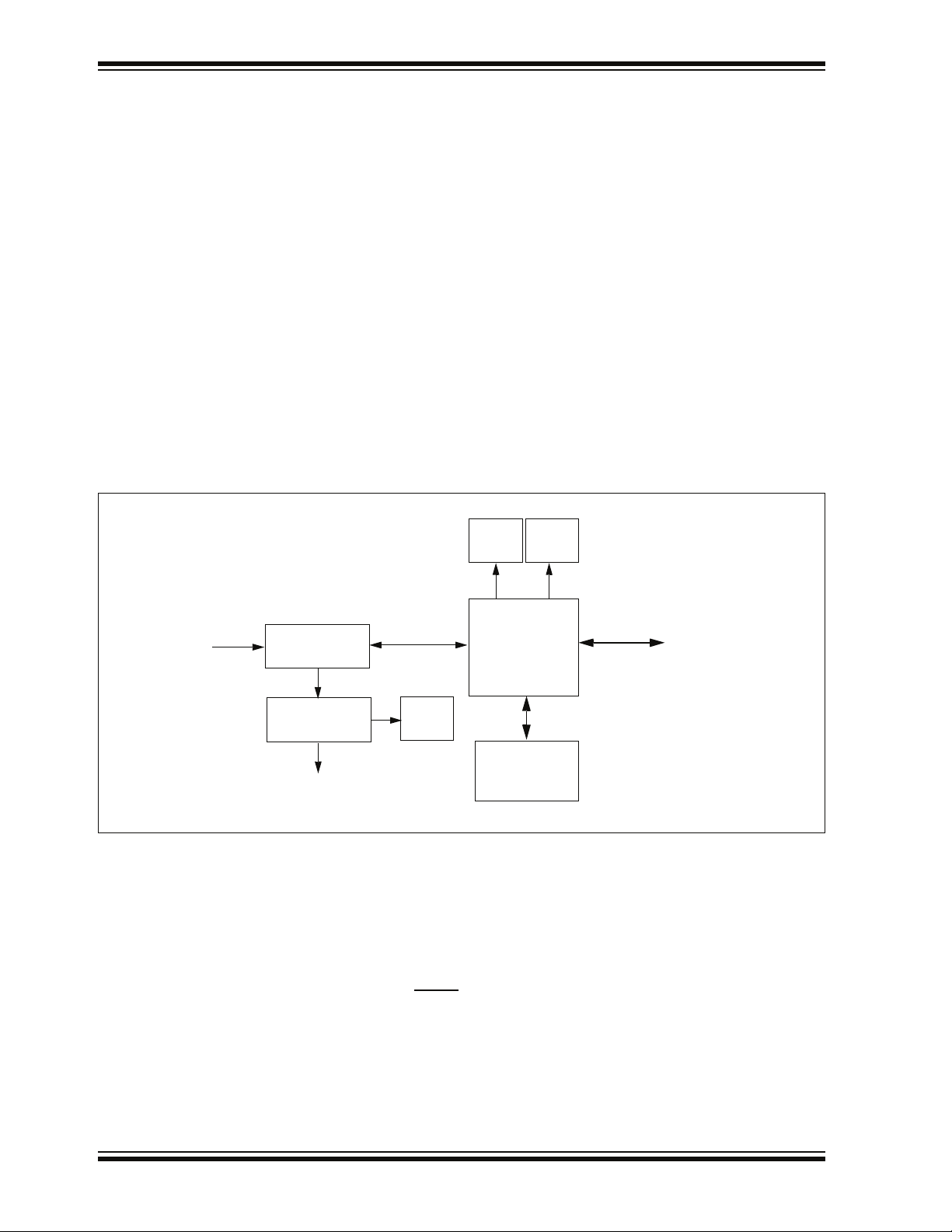

Figure 5-1 illustrates the main functions of the starter kit:

FIGURE 5-1: APPLICATION SIDE BLOCK DIAGRAM

PIC24FJ256GB106

USER’S GUIDE

To Debugger Side

(PIC18F67J50)

Potentiometer

Keypads

The application side of the starter kit is centered on the PIC24F256GB106

microcontroller, which requires very little additional hardware to perform its tasks. All

application code is stored in the device’s Flash program memory. In addition to the

application core, the preloaded demo uses substantial parts of the Microchip USB

Stack Library, the Microchip Memory Disk Drive File System and the Microchip

Graphics Library to function.

The application accepts user inputs from the capacitive touch pad (S1) and the

potentiometer (R44). The microcontroller uses one of its A/D converter channels to

sample and convert the potentiometer’s value to a digital value for the Data Graphing

and Data Capture demos. Five additional A/D channels are used to monitor the

individual touch pads of S1. The values from these channels are analyzed with the

CTMU to determine when a touch-and-release event occurs on any of the pads. The

application firmware determines which action to take based on the application’s current

context.

Touch

32 kHz

Crystal

ICSP™

PMD7:PMD0

PGC/EMUC

PGD/EMUD

MCLR

AN0

AN8:AN12

SOSCI:SOSCO

PMRD

PMWR

PMCS1

PMA0

RG6/RG7

RG8/RG9

RF4/RF5

D+/D-

OLED

Display

Tri-Color

LED

USB

A Receptacle

USB mini-B

Receptacle

© 2008 Microchip Technology Inc. DS51725A-page 27

Page 32

MPLAB Starter Kit for PIC24F User’s Guide

The microcontroller directly drives the OLED display (LED1) and the tri-color LED (D6,

D10 or D11, depending on the board’s manufacturing option). The microcontroller uses

the Parallel Master Port to drive the OLED through the PMD7:PMD0 data lines, while

PMA0, PMCS2, PMRD and PMWR serve as control signals. A DC boost circuit

comprised of power MOSFET Q4, along with D5 and L3, provides the operating voltage

for the OLED.

The individual channels of the tri-color LED are driven directly by three of the

microcontroller’s PWM modules, assigned to outputs on pins RF4/RF5, RG6/RG7 and

RG8/RG9. Two output pins are used for each PWM to ensure sufficient drive strength

for each LED component.

The microcontroller uses an on-chip USB On-The-Go (OTG) engine and transceiver to

communicate with USB A and mini-B receptacles on the application side. While both

receptacles are populated, only the A receptacle is used in this version of the demo

application. The mini-B receptacle is available for users who may wish to design a

peripheral application.

5.2 PROGRAMMER/DEBUGGER FUNCTIONAL OVERVIEW

Figure 5-2 illustrates the debugging/programming operation of the starter kit.

FIGURE 5-2: STARTER KIT PROGRAMMER/DEBUGGER BLOCK DIAGRAM

From Host PC

USB mini-B

Jack

BUS

V

3.3V LDO

Regulator

VDD to Starter Kit

Debug

LED

USB Data

Power

LED

Serial EEPROM

12 MHz

Crystal

PIC18F67J50

SPI

25LC010A

ICSP™

To Application Side

(PIC24FJ256GB106)

In its default configuration, the Starter Kit functions as a USB bus-powered device.

Power is provided via the USB cable; the nominal 5 volt unregulated supply is regulated

by a Microchip MC1727 3.3 volt low-dropout (LDO) linear regulator. Proper main

system power is indicated by the green LED (D2).

The debugging and programming side of the Starter Kit is controlled by a PIC18F67J50

microcontroller running at 48 MHz. The PIC18F67J50’s built-in USB engine provides

the communications interface between the Starter Kit and the host PC. The

microcontroller manages debugging or programming of the target PIC24FJ256GB106

by controlling the target’s MCLR

power is switched on and off via a low V

, PGC1/EMUC1, and PGD1/EMUD1 signals. Target

CE saturation PNP transistor (Q1) configured

as a high-side switch. Target clocking is also provided by the PIC18F67J50.

A Microchip 25LC010A serial EEPROM is used to store the starter kit’s serial number

and debug control information.

DS51725A-page 28 © 2008 Microchip Technology Inc.

Page 33

5.3 BOARD COMPONENTS

Figure 5-3 identifies the key hardware components for the starter kit.

FIGURE 5-3: PIC24F STARTER KIT COMPONENT LAYOUT

Hardware

D3 D4

D5

A2

A1

A5

A6

D1

D2

A4

D8

A3

D9

D10

M

D7

D6

A9

TABLE 5-1: PIC24F STARTER KIT COMPONENT DESCRIPTIONS

Ref Debug/Programmer Component Ref Application Component

D1 mini-B USB Receptacle (J1) A1 PIC24F256GB106 Microcontroller (U6)

D2 PIC18F67J50 Microcontroller (U2) A2 Tri-Color LED Pads (D6, D10 or D11)

D3 MCP1727 Voltage Regulator (U1) A3 OLED Display (LED1)

D4 Target Power LED (D4) A4 Capacitive Touch Pad (S1)

D5 Low V

D6 Debugger/Programmer Clock Crystal (Y1) A6 USB A (Embedded Host) Receptacle (J4)

D7 25LC010A Serial EEPROM (U3) A7 mini-B USB (Peripheral) Receptacle (J5)

D8 V

D9 System Power LED (D2) A9 OLED Voltage Boost Cicuitry

D10 Debug LED (D3)

CE Saturation PNP Transistor Switch (Q1) A5 32.768 kHz (RTCC) Crystal (Y2)

BUS and GND Test Points A8 Potentiometer (R44)

A7

A8

5.3.1 Programmer/Debugger Components

The components listed here (in order of their reference tags in Figure 5-3) are the key

components of the programmer/debugger side of the starter kit:

D1. mini-B USB Receptacle (J1): Provides system power and bidirectional

communication between the host PC and starter kit.

D2. PIC18F67J50 Microcontroller (U2): Controls the programming/debugging

operations of the target PIC24FJ256GB106 microcontroller. It also provides the

12 MHz clock for the PIC24F microcontroller.

D3. MCP1727 Voltage Regulator (U1): The 3.3V linear regulator regulates the USB

unregulated voltage to 3.3 volts (with respect to V

with system power.

D4. Target Power LED (D4): When lit, indicates that power is being supplied to the

application side of the starter kit from V

the V

BUS test point).

© 2008 Microchip Technology Inc. DS51725A-page 29

BUS (either from a USB connection or from

SS) and supplies the starter kit

Page 34

MPLAB Starter Kit for PIC24F User’s Guide

D5. Low VCE Saturation PNP Transistor Switch (Q1): Provides target power (via

high-side switching) to the application side components via control by the

PIC18F67J50.

D6. Debugger/Programmer Clock Crystal (Y1): Provides an accurate 12 MHz

frequency reference for the PIC18F67J50 microcontroller for stable USB

operations in Programming and Debugging modes. The PIC18F67J50 also uses

this to generate a second 12 MHz clock for use by the PIC24FJ256GB106

microcontroller.

D7. 25LC010A Serial EEPROM (U3): Provides nonvolatile parameter storage for

the PIC18F67J50.

D8. V

BUS and GND Test Points: These unpopulated pads may be equipped with

appropriate connectors and furnished with power to operate the board in

Stand-Alone mode.

D9. System Power LED (D2): When lit, indicates that the starter kit is powered via

the USB.

D10. Debug LED (D3): When lit, indicates that communication between the starter

kit and MPLAB IDE has been successfully established.

5.3.2 Application Components

The components listed here (in order of their reference tags in Figure 5-3) are the key

components of the application side of the starter kit:

A1. PIC24F256GB106 Microcontroller (U6): This provides the processing power

for the demo applications and application development on the starter kit.

The microcontroller features 256 Kbytes of Flash program memory and

16 Kbytes RAM.

The demo application uses an external 12 MHz signal from the programmer side

as clock source. Custom applications that do not use the USB module may also

use the microcontroller’s on-chip FRC oscillator as a clock source. (USB applications must use the 12 MHz programmer clock source, as the tolerance of the

FRC oscillator exceeds USB specifications.)

A2. Tri-Color LED Pads (D6, D10 or D11): One of these locations is populated with

a three-channel (RGB) LED; the choice of the populated site depends on the

availability of components at the time of the board’s assembly. Functionally, the

LEDs at any of these sites are interchangeable.

A3. OLED Display (LED1): A 128 x 64 pixel, monochrome organic LED array

provides a wide range of graphics and alphanumeric display options.

A4. Capacitive Touch Pad (S1): This 5-element keypad is an integral part of the

board’s top layer. The application responds to capacitive changes induced by

direct contact with the user by monitoring each of the touch pad’s elements with

the microcontroller’s integrated CTMU module.

A5. RTCC Crystal (Y2): Provides an accurate 32.768 kHz reference for the micro-

controller’s secondary oscillator. This is used in turn as the time base for the

on-chip Real-Time Clock (RTC).

A6. USB A Receptacle (J4): The application uses this receptacle to connect with

USB peripherals while operating as an embedded host.

A7. Mini-B USB Receptacle (J5): Physically identical to J1, this provides USB con-

nectivity for the application side when it is functioning as a peripheral device.

A8. Potentiometer (R44): Provides an analog input to the microcontroller for certain

demo applications.

A9. OLED Voltage Boost Circuitry: L3, D5 and Q4 (along with other passive

components) are connected in a voltage boost topology. This provides the OLED

display with its nominal operating voltage of 13 V

DC.

DS51725A-page 30 © 2008 Microchip Technology Inc.

Page 35

MPLAB STARTER KIT FOR PIC24F

USER’S GUIDE

Appendix A. Starter Kit Schematics

The following schematic diagrams are included in this appendix:

Programmer/Debugger:

• Figure A-1: Programmer/Debugger Control System and EEPROM

• Figure A-2: Programmer/Debugger USB Interface, Target Power Switching and

Regulation

Application:

• Figure A-3: Application Microcontroller, Touch Switches and Associated

Components

• Figure A-4: OLED Display, LED and Application Side USB Connectors

© 2008 Microchip Technology Inc. DS51725A-page 31

Page 36

MPLAB Starter Kit for PIC24F User’s Guide

FIGURE A-1: STARTER KIT SCHEMATIC, SHEET 1: PROGRAMMER/DEBUGGER CONTROL

SYSTEM AND EEPROM

Serial EEPROM

Debug

DS51725A-page 32 © 2008 Microchip Technology Inc.

Page 37

Starter Kit Schematics

FIGURE A-2: STARTER KIT SCHEMATIC, SHEET 2: PROGRAMMER/DEBUGGER USB

INTERFACE, TARGET POWER SWITCHING AND REGULATION

Host MCU Switchable

Host MCU Switchable

VBUS Unregulated Supply

Target Power Indicator (VBUS)

3.3 V Regulated Supply

Status LED -

System Power

3.3 V LDO

Linear Regulator

USB Interface

(Bus Powered)

© 2008 Microchip Technology Inc. DS51725A-page 33

Page 38

MPLAB Starter Kit for PIC24F User’s Guide

FIGURE A-3: STARTER KIT SCHEMATIC, SHEET 3: APPLICATION MICROCONTROLLER,

TOUCH SWITCHES AND ASSOCIATED COMPONENTS

Data Logging

DS51725A-page 34 © 2008 Microchip Technology Inc.

Page 39

Starter Kit Schematics

FIGURE A-4: STARTER KIT SCHEMATIC, SHEET 4: OLED DISPLAY, LED AND

APPLICATION SIDE USB CONNECTORS

*

RGB LED

*

* Manufacturing option

(128 x 64)

Organic LED Display

© 2008 Microchip Technology Inc. DS51725A-page 35

Page 40

MPLAB Starter Kit for PIC24F User’s Guide

NOTES:

DS51725A-page 36 © 2008 Microchip Technology Inc.

Page 41

MPLAB STARTER KIT FOR PIC24F

USER’S GUIDE

Index

B

Block Diagrams

Starter Kit

Application Side......................................... 27

Programmer/Debugger Side...................... 28

Board Components

Capacitive Touch Pad....................................... 30

Debug LED ....................................................... 30

Debugger/Programmer Clock Crystal............... 30

mini-B USB Connector.................................29

OLED Display ................................................... 30

OLED Voltage Boost Circuitry .......................... 30

PIC18F67J50.................................................... 29

PIC24F256GB110 Microcontroller.................... 30

PNP Transistor Switch...................................... 30

Potentiometer ................................................... 30

RTCC Crystal.................................................... 30

Serial EEPROM ................................................ 30

Target Power LED ............................................ 29

Tri-Color LED.................................................... 30

USB A Receptacle ............................................ 30

BUS and GND Test Points..........................30, 29

V

Breakpoints .............................................................. 21

, 30

C

Charge Time Measurement Unit (CTMU) ................ 10

Configuration Bits..................................................... 25

Customer Notification Service.................................... 4

Customer Support...................................................... 5

D

Debug ........................................................................ 7

Executive .......................................................... 20

Reserved Resources ........................................ 24

Setup ................................................................ 20

Demonstration Applications ....................................... 9

Interactive Display System ................................. 9

Other Interactive Demos................................... 13

Real-Time Data Capture................................... 13

Real-Time Data Graphing................................. 12

RGB LED Control ............................................. 11

Time and Date .................................................. 11

Touch Interface................................................. 10

Calibration ................................................. 10

USB Flash Drive Interface ................................ 12

Device, Debug Mode ............................................... 15

Device, Release Mode............................................. 16

Documentation

Conventions........................................................ 2

Layout ................................................................. 1

E

Embedded Host, Debug Mode................................. 15

Embedded Host, Release Mode .............................. 17

H

Halt........................................................................... 21

Host Computer Requirements.................................... 7

I

Initial Board Setup...................................................... 8

Internet Address......................................................... 4

M

Microchip Internet Web Site ....................................... 4

MPLAB IDE .......................................................... 7

, 19

P

Power Options.......................................................... 15

Programmer ............................................................. 24

R

Reading, Recommended ........................................... 3

Real-Time Clock and Calendar (RTCC)................... 11

Reserved Resources................................................ 24

Reset........................................................................ 21

Run........................................................................... 21

S

Schematic Diagrams................................................ 31

Stand-Alone Mode ................................................... 17

Starter Kit

Board Components........................................... 29

Step.......................................................................... 21

T

Troubleshooting ....................................................... 25

U

Unable to Enter Debug Mode................................... 25

W

Warranty Registration ................................................ 2

Watch Window ......................................................... 21

WWW Address........................................................... 4

© 2008 Microchip Technology Inc. DS51725A-page 37

Page 42

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

01/02/08

DS51725A-page 38 © 2008 Microchip Technology Inc.

Loading...

Loading...