Page 1

MIC33M656

Evaluation Board

User’s Guide

2019 Microchip Technology Inc. DS50002914A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Trademarks

The Microchip name and logo, the Microchip logo, Adaptec,

AnyRate, AVR, AVR logo, AVR Freaks, BesTime, BitCloud, chipKIT,

chipKIT logo, CryptoMemory, CryptoRF, dsPIC, FlashFlex,

flexPWR, HELDO, IGLOO, JukeBlox, KeeLoq, Kleer, LANCheck,

LinkMD, maXStylus, maXTouch, MediaLB, megaAVR, Microsemi,

Microsemi logo, MOST, MOST logo, MPLAB, OptoLyzer,

PackeTime, PIC, picoPower, PICSTART, PIC32 logo, PolarFire,

Prochip Designer, QTouch, SAM-BA, SenGenuity, SpyNIC, SST,

SST Logo, SuperFlash, Symmetricom, SyncServer, Tachyon,

TempTrackr, TimeSource, tinyAVR, UNI/O, Vectron, and XMEGA

are registered trademarks of Microchip Technology Incorporated in

the U.S.A. and other countries.

APT, ClockWorks, The Embedded Control Solutions Company,

EtherSynch, FlashTec, Hyper Speed Control, HyperLight Load,

IntelliMOS, Libero, motorBench, mTouch, Powermite 3, Precision

Edge, ProASIC, ProASIC Plus, ProASIC Plus logo, Quiet-Wire,

SmartFusion, SyncWorld, Temux, TimeCesium, TimeHub,

TimePictra, TimeProvider, Vite, WinPath, and ZL are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BlueSky, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity, JitterBlocker,

KleerNet, KleerNet logo, memBrain, Mindi, MiWi, MPASM, MPF,

MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach,

Omniscient Code Generation, PICDEM, PICDEM.net, PICkit,

PICtail, PowerSmart, PureSilicon, QMatrix, REAL ICE, Ripple

Blocker, SAM-ICE, Serial Quad I/O, SMART-I.S., SQI,

SuperSwitcher, SuperSwitcher II, Total Endurance, TSHARC,

USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and

ZENA are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

The Adaptec logo, Frequency on Demand, Silicon Storage

Technology, and Symmcom are registered trademarks of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology Germany

II GmbH & Co. KG, a subsidiary of Microchip Technology Inc., in

other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2019, Microchip Technology Incorporated, All Rights Reserved.

For information regarding Microchip’s Quality Management Systems,

please visit www.microchip.com/quality.

ISBN: 978-1-5224-5089-4

DS50002914A-page 2 2019 Microchip Technology Inc.

Page 3

MIC33M656

EVALUATION BOARD

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 5

Introduction............................................................................................................ 5

Document Layout .................................................................................................. 5

Conventions Used in this Guide ............................................................................ 6

Recommended Reading........................................................................................ 7

The Microchip Website .......................................................................................... 7

Product Change Notification Service..................................................................... 7

Customer Support ................................................................................................. 7

Document Revision History ................................................................................... 7

Chapter 1. Product Overview........................................................................................ 9

1.1 Introduction ..................................................................................................... 9

1.2 MIC33M656 Short Overview .......................................................................... 9

1.3 What is the MIC33M656 Evaluation Board? ................................................ 10

1.4 Contents of the MIC33M656 Evaluation Board Kit ....................................... 10

Chapter 2. Installation and Operation ........................................................................ 11

2.1 Introduction ................................................................................................... 11

2.2 Features ....................................................................................................... 12

2.3 Getting Started ............................................................................................. 12

Chapter 3. GUI Installation and Operation................................................................. 17

3.1 Getting Started ............................................................................................. 17

3.2 Graphical User Interface Installation ............................................................ 17

2

3.3 I

C Monitor Graphical User Interface Uninstall ............................................ 20

Chapter 4. GUI Description ......................................................................................... 21

4.1 Introduction ................................................................................................... 21

4.2 The Graphical User Interface ....................................................................... 22

Appendix A. Schematic and Layouts......................................................................... 29

A.1 Introduction .................................................................................................. 29

A.2 Board – Schematic ....................................................................................... 30

A.3 Board – Top Silk .......................................................................................... 31

A.4 Board – Top Copper and Silk ....................................................................... 31

A.5 Board – Top Copper .................................................................................... 32

A.6 Board – Signal Layer 1 ................................................................................ 32

A.7 Board – Signal Layer 2 ................................................................................ 33

A.8 Board – Bottom Copper ............................................................................... 33

A.9 Board – Bottom Copper and Silk ................................................................. 34

A.10 Board – Bottom Silk ................................................................................... 34

2019 Microchip Technology Inc. DS50002914A-page 3

Page 4

MIC33M656 Evaluation Board User’s Guide

Appendix B. Bill of Materials (BOM) ...........................................................................35

Appendix C. MIC33M656 Internal Registers...............................................................37

C.1 Register Map and I2C Programmability ....................................................... 37

Worldwide Sales and Service .....................................................................................42

DS50002914A-page 4 2019 Microchip Technology Inc.

Page 5

MIC33M656

EVALUATION BOARD

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics, to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MIC33M656 Evaluation Board. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Website

• Product Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the MIC33M656 Evaluation Board as a

development tool. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information about the MIC33M656

device.

• Chapter 2. “Installation and Operation” – Includes instructions on how to get

started with the MIC33M656 Evaluation Board and a description of each function.

• Chapter 3. “GUI Installation and Operation” – Includes instructions on how to

install the Graphical User Interface (GUI).

• Chapter 4. “GUI Description” – Describes the items included in the Graphical

User Interface.

• Appendix A. “Schematic and Layouts” – Shows the schematic and PCB layout

diagrams for the MIC33M656 Evaluation Board.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

MIC33M656 Evaluation Board.

• Appendix C. “MIC33M656 Internal Registers” – Describes the MIC33M656

device’s internal registers.

2019 Microchip Technology Inc. DS50002914A-page 5

Page 6

MIC33M656 Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB® IDE User’s Guide

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

DS50002914A-page 6 2019 Microchip Technology Inc.

Page 7

RECOMMENDED READING

This user’s guide describes how to use the MIC33M656 Evaluation Board. Other

useful documents are listed below. The following Microchip document is available and

recommended as a supplemental reference resource:

• MIC33M656 Data Sheet – “6A, Power Module Buck Converter with

HyperLight Load

THE MICROCHIP WEBSITE

Microchip provides online support via our website at www.microchip.com. This website

is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the website contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

®

and I2C Interface” (DS20006256)

Preface

PRODUCT CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notifications whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip website at www.microchip.com, click on Product

Change Notification and follow the registration instructions.

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the website at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (September 2019)

• Initial Release of this Document.

2019 Microchip Technology Inc. DS50002914A-page 7

Page 8

MIC33M656 Evaluation Board User’s Guide

NOTES:

DS50002914A-page 8 2019 Microchip Technology Inc.

Page 9

Chapter 1. Product Overview

C3

47 µF

C4

47 µF

V

OUT

Enable

V

IN

2.4V to 5.5V

C

10 µF

1.0V/6A

V

IN

SCL

SDA

PG

SW

MIC33M656

OUT

V

OUT

PGND

AGND

PG

SCL

SDA

EN

PV

IN

AUX_PV

IN

SV

IN

SW

AUX_GND

1.1 INTRODUCTION

This chapter provides an overview of the MIC33M656 Evaluation Board and covers the

following topics:

• MIC33M656 Short Overview

• What is the MIC33M656 Evaluation Board?

• Contents of the MIC33M656 Evaluation Board Kit

1.2 MIC33M656 SHORT OVERVIEW

The MIC33M656 is an I2C programmable, high-efficiency, low-voltage input,

6A current, synchronous step-down regulator power module with integrated inductor.

The Constant-On-Time (COT) control architecture with HyperLight Load

vides very high efficiency at light loads, while still having ultra-fast transient response.

The user can program, via the I

voltage, on-time, soft start slope, high-side current limit, HLL or Forced PWM mode of

operation. The 2.4V to 5.5V input voltage range, low shutdown and quiescent currents

make the MIC33M656 ideal for single-cell Li-Ion, battery-powered applications.

An open-drain Power Good (PG) output is provided to indicate when the output voltage

is within 9% of regulation, and facilitates output voltage monitoring and sequencing.

When set in Shutdown mode (EN = GND), the current consumption of MIC33M656 is

reduced to 1.5 µA (typical).

The MIC33M656 is available in a thermally efficient, 53-Lead, 6 mm x 10 mm x 3 mm

QFN package, with an operating junction temperature range from -40°C to +125°C.

More detailed information regarding the capabilities of the MIC33M656 are available in

the “MIC33M656 Data Sheet”.

MIC33M656

EVALUATION BOARD

USER’S GUIDE

®

(HLL) pro-

2

C interface, various parameters, such as output

FIGURE 1-1: Typical MIC33M656 Step-Down Application.

2019 Microchip Technology Inc. DS50002914A-page 9

Page 10

MIC33M656 Evaluation Board User’s Guide

1.3 WHAT IS THE MIC33M656 EVALUATION BOARD?

The MIC33M656 Evaluation Board is used to evaluate and demonstrate Microchip

Technology’s MIC33M656 device. This Evaluation Board demonstrates the

MIC33M656 in a buck converter application, supplied from an external voltage source

(2.4V-5.5V), with an I

comprehensive control and status reporting with the MIC33M656.

1.4 CONTENTS OF THE MIC33M656 EVALUATION BOARD KIT

The MIC33M656 Evaluation Board kit includes:

• MIC33M656 Evaluation Board (DT100108)

• Important Information Sheet

2

C programmed regulated output. The I2C monitor GUI allows

DS50002914A-page 10 2019 Microchip Technology Inc.

Page 11

Chapter 2. Installation and Operation

MCP2221

MIC33M656

USB

I/F

V

USB

Data

PWR

V

IN

V

OUT

PWR

SCL

SDA

V

IN

PG

EN

SCL

SDA

PG

EN

Note 2

Note 1

Note 1: Three-way jumper fitted for selection of I2C pull-up voltage.

2: I

2

C bus (SDA, SCL), EN control and PG status via MCP2221 USB bridge.

2.1 INTRODUCTION

The MIC33M656 Evaluation Board has been developed to test the MIC33M656 module

capabilities, including loading up to 6A, control and monitor through the USB interface

(via the I

communication.

MIC33M656

EVALUATION BOARD

USER’S GUIDE

2

C monitor GUI). Pin headers are also fitted for Bode analysis and external I2C

FIGURE 2-1: MIC33M656 Step-Down Regulator with MCP2221 I

2

C Bridge.

2019 Microchip Technology Inc. DS50002914A-page 11

Page 12

MIC33M656 Evaluation Board User’s Guide

2.2 FEATURES

The MIC33M656 Evaluation Board has the following features:

• Input Voltage Range: 2.4V to 5.5V

• 6A (maximum) Continuous Output Current

• Multiple Faults Indication through I

2

C Programmable:

•I

- Output voltage: 0.6-1.28V, 5 mV resolution

- Slew rate: 0.2-3.2 ms/V

- Switching frequency: up to 2.5 MHz

- High-side current limit: 3.5-10A

- Enable delay: 0.25-3 ms

- Output discharge when disabled

• High Efficiency (up to 95%)

• ±1.5% Output Voltage Accuracy Over Line/Load/Temperature Range

• Safe Start-up with Pre-Biased Output

• Typical 1.5 µA Shutdown Supply Current

• Low Dropout (100% Duty Cycle) Operation

• Ultra-Fast Transient Response

• Latch-Off Thermal Shutdown Protection

• Latch-Off Current Limit Protection

• Power Good Open-Drain Output

2

C

2.3 GETTING STARTED

The MIC33M656 Evaluation Board is fully assembled and tested to evaluate and

demonstrate the MIC33M656 module. This Evaluation Board requires the use of external lab supplies and a PC. The MIC33M656 is offered in four different product options,

depending on the default settings at power-up, prior to any I

differences among the various product options are described in the “MIC33M656 Data

Sheet”. The Evaluation Board carries the HAYMP option, whose default output voltage

is 1.0V. All of the device options may be fitted on the board, as is.

2

C write operation. The

DS50002914A-page 12 2019 Microchip Technology Inc.

Page 13

Installation and Operation

2.3.1 Power Input and Output Connection

2.3.1.1 POWERING THE MIC33M656 EVALUATION BOARD

When the Evaluation Board is ready for evaluation, apply positive input voltage to the

V

terminal and the corresponding return to the GND_IN terminal. The maximum input

IN

voltage should not exceed 5.5V. An electronic load or resistive load can be used for

evaluation. Some electronic loads can sink the programmed current, starting from very

low output voltage levels during start-up. For a more realistic start-up behavior evaluation, a resistive load or Constant Resistance mode for electronic load is recommended.

Connect the positive voltage terminal of the load to the V

Board and connect the negative or return side of the load to the GND_OUT terminal. If

changing the regulator parameters is required, or simply to monitor the part, make sure

to connect the Micro-USB cable between the Evaluation Board and the PC. Then,

install the GUI according to Chapter 3. “GUI Installation and Operation” and follow

the indications in Chapter 2. “Installation and Operation” for more extensive

evaluation.

Note: The inductance associated with long wires on the board input may cause

voltage spikes at load stepping or start-up into a heavy load. If the spikes

exceed the 5.5V maximum input voltage rating, the MIC33M656 may fail.

This can be prevented by populating a 470

C8 footprint.

terminal on the Evaluation

OUT

µF electrolytic capacitor on the

2.3.1.2 EVALUATION BOARD POWER-UP PROCEDURE

For the power-up procedure, follow the steps bellow:

1. Connect the PC, input supply, voltmeter, ammeter and load as shown in

Figure 2-2. Set the ammeter on a 10A range.

2. Fit a jumper on the EN position across the J6 header, as marked on the

silkscreen.

3. Once the input voltage is greater than 2.35V typical at the board input (V

), the

IN

device begins to switch.

4. The voltmeter should now indicate an output voltage according to the preset

register values. Adjusting the input voltage, temperature or load should not

cause the output to vary more than ±1.5% over the operating range of the

converter.

5. Set the input voltage and the load to the desired values, with a maximum of 5.5V

on the input voltage and a maximum load of 6A.

6. Adjust the regulator output and monitor the STATUS Register, as described in

Chapter 4. “GUI Description”.

7. Optionally, for more advanced readings, place Oscilloscope Probe 1 in the “SW”

test point to monitor the switching waveforms and Probe 2 on the output header

to measure the AC ripple of the output voltage. Please note that for a more accurate output voltage ripple measurement, probing is facilitated by the availability

of test points for probe tip and ground spring connections close to the output

capacitor. A U.FL connector is also available for the same purpose.

2019 Microchip Technology Inc. DS50002914A-page 13

Page 14

MIC33M656 Evaluation Board User’s Guide

Oscilloscope

CH1

CH2

Power –

I2C Monitor

(PC)

Supply +

Ammeter (10A)

Voltmeter

Load

V

IN

5V/div

V

OUT

50 mV/div

AC Coupled

SW

5V/div

Io

5A/div

FIGURE 2-2: MIC33M656 Evaluation Board Test Setup.

2.3.1.3 PERFORMANCE EVALUATION

The oscilloscope screen capture in Figure 2-3 displays the MIC33M656 switching

waveforms during normal operation, when supplied from a 5V input at full load (6A).

FIGURE 2-3: Normal Operation at 1V Output, 6A Load.

2.3.1.4 LOOP GAIN MEASUREMENT

The MIC33M656 Evaluation Board provides injection points and a termination resistor

(R12) for AC loop gain measurements. If needed, the value of R12 can be changed to

optimize the injection signal level. Inject the oscillator at J9 through the insulation

transformer (i.e., across resistor R12) and connect the A (CH1) and B (CH2) channels

to J9 Pin 1 and J9 Pin 2, respectively, or as indicated by the operating instructions of

the particular loop gain analyzer in use.

DS50002914A-page 14 2019 Microchip Technology Inc.

Page 15

Installation and Operation

2.3.1.5 I2C PULL-UP VOLTAGE SELECTION

The MIC33M656 Evaluation Board is equipped with a jumper for selecting the I

pull-up supply voltage. The J8 header can be used to select the I

either V

or VIN. If a different pull-up voltage is desired, it can be injected into the

USB

2

C pull-up voltage to

PWR pin of J2. In this case, make sure that no jumper is installed on header J8 to

prevent shorting of the externally injected pull-up voltage to either V

USB

or VIN.

2

C

2.3.1.6 USING THE MIC33M656 EVALUATION BOARD WITH THE EXTERNAL

2

I

C MASTER

In order to use the MIC33M656 with an external I

microprocessor or another I

2

C master), the on-board MCP2221 must be disabled. To

2

C master (such as a microcontroller,

accomplish this, the pull-down resistor R10 must be populated to avoid any

interference between the MCP2221 and the external I

2

C master. If the MCP2221 is not

powered (e.g., by disconnecting the USB cable), then R8 and R11 must also be

2

removed. Then, the desired I

master already provides pull-up resistors for the SDA and SCL lines, then the I

C master can be connected to J2. If the external I2C

2

C

pull-up resistors, R6 and R9, present on the MIC33M656 Evaluation Board, are not

needed and must be removed to prevent pull-up voltage conflicts.

2.3.1.7 STARTING THE MIC33M656 WITH A CUSTOM OUTPUT VOLTAGE

To power up the MIC33M656 with a custom output voltage, the MIC33M656 Evaluation

Board must be first powered up with the MIC33M656 disabled (either by placing the EN

jumper on the J6 header in the SDN position, or applying a logic ‘0’ voltage on the EN

test point). Program the module via the I

2

C interface (using the PC GUI interface) to

the desired output voltage and then start it by placing the EN jumper on J6, EN position

(or by applying a logic ‘1’ voltage on the EN test point). The MIC33M656 does not retain

the set voltage and returns to the default configuration after a power cycle.

2.3.1.8 MIC33M656 EVALUATION BOARD ENABLE OPTIONS

In order to enable the MIC33M656 on the Evaluation Board, three options are provided:

1. The EN jumper placed on the J6 header – By placing a jumper on the EN

position, as described by the silkscreen, and by having EN_INT (bit 1) of the

CTRL1 register (address 0x00) set to ‘1’, the MIC33M656 is enabled. By placing

a jumper on the SDN position, the MIC33M656 is disabled. The MIC33M656

Evaluation Board features a pull-down resistor R3 connected to the EN pin, so

by default, without any jumper connected, the regulator will be disabled.

2. Software controlled – By clearing EN_INT (bit 1) of the CTRL1 register

(address 0x00), the MIC33M656 status is controlled by EN_CON (bit 0) of the

CTRL1 register and the EN pin status is ignored. By setting the EN_CON bit, the

MIC33M656 is enabled and by clearing the EN_CON bit, the MIC33M656 is

disabled.

3. MCP2221 GPIO control – By checking “Enable GP0 Control” in the I2CMonitor

GUI, the EN pin is controlled by the GP0 output of the MCP2221, and by using

the GP0 active button, the MIC33M656 is enabled or disabled.

Note: When using MCP2221 GPIO control, remove any low-impedance connec-

tion between the EN pin and V

or GND (e.g., a jumper on the J6 header)

IN

as this may cause undefined behavior.

2019 Microchip Technology Inc. DS50002914A-page 15

Page 16

MIC33M656 Evaluation Board User’s Guide

2.3.1.9 PCB LAYOUT CONSIDERATIONS WHEN DESIGNING WITH

MIC33M656

For the best performance with the minimum occupied board space, some proper layout

techniques should be applied. First, the input and output capacitors should be placed

as close to the MIC33M656 as possible and on the same layer as the IC. This will

ensure low ripple and lower switching noise. Then, vias must be used under the

MIC33M656, from its exposed pad to the GND plane, in order to improve heat

dissipation.

2.3.1.10 BENCH TESTING AT HIGH CURRENTS

When testing the MIC33M656 device at high load currents, or when checking the

overcurrent protection behavior, it may be necessary to remove the series ammeter

shown in Figure 2-2 or to replace it with a very low-value shunt resistor. This is because

the internal resistance of many Digital Multimeters (DMMs) used for current

measurements is generally too high.

2.3.1.11 THERMAL CONSIDERATIONS

The MIC33M656 Junction-to-Ambient (

Evaluation Board, is approximately +31°C/W. Depending on the loading conditions,

ambient temperature and device settings, the junction temperature might exceed the

rated operating limit of +125°C due to internal power dissipation. Continuous operation

above the maximum operating limits stated in the data sheet should be avoided.

thermal resistance, as measured on the

JA)

DS50002914A-page 16 2019 Microchip Technology Inc.

Page 17

Chapter 3. GUI Installation and Operation

3.1 GETTING STARTED

In order to install, use and evaluate the product, several software and hardware tools

are required.

3.1.1 Required Software

MIC33M656

EVALUATION BOARD

USER’S GUIDE

•I2C Monitor Graphical User Interface (minimum v.4.0)

•Microsoft

• Adobe

®

.NET™ Framework 4.5 or higher

®

Acrobat® Reader

3.1.2 Required Hardware

• MIC33M656 Evaluation Board

• USB to Micro-USB Cable

3.2 GRAPHICAL USER INTERFACE INSTALLATION

The following steps describe how to install the I2C Monitor Graphical User Interface:

1. If Microsoft.NET Framework is already installed, go to Step 3. If not, download

Microsoft.NET Framework from www.microsoft.com and follow the installation

instructions.

2. If Adobe Acrobat Reader is already installed, go to Step 3. If not, download

Adobe Acrobat Reader from http://get.adobe.com/reader/ and follow the

installation instructions.

3. Download the I

www.microchip.com/MIC33M656 under “Documentation&Software”.

4. Unzip the I

setup.exe file.

Note: If an older version or a corrupted version of the current I

Graphical User Interface is already installed on the computer, please see

Section 3.3 “I

proceeding with the installation.

2

C Monitor Graphical User Interface (v.4.0) archive from

2

C Monitor Graphical User Interface archive, which contains the

2

C Monitor Graphical User Interface Uninstall” before

2

C Monitor

5. Double click the setup.exe file to open the InstallShield Wizard window and

wait for the extraction to complete. If required, the installation can be stopped by

pressing the Cancel button.

2019 Microchip Technology Inc. DS50002914A-page 17

Page 18

MIC33M656 Evaluation Board User’s Guide

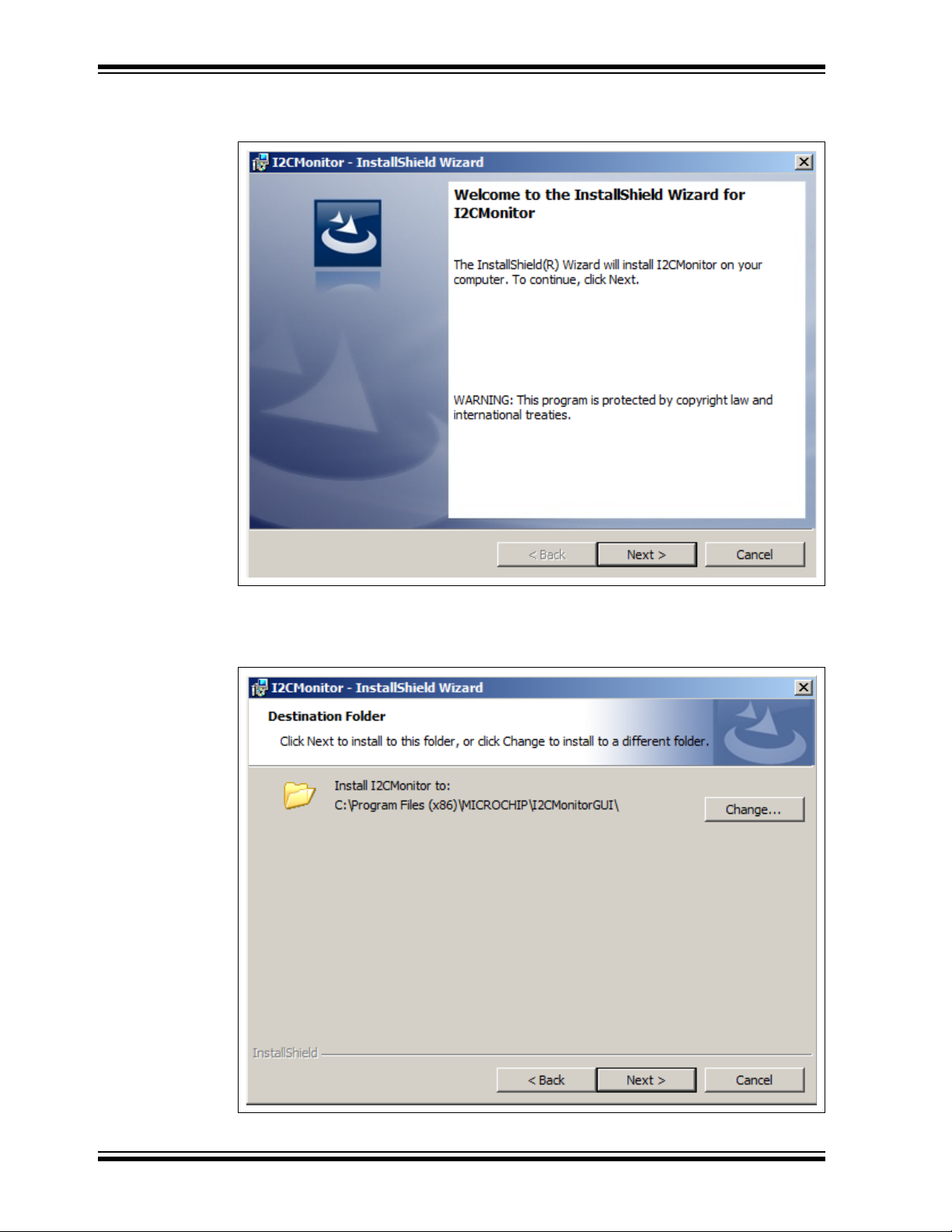

6. In the Welcome to the InstallShield Wizard for I2CMonitor window, click the Next

button to start the installation.

FIGURE 3-1: Starting the I

7. The installation path can be changed, although it is recommended to keep the

default path. Click Next to continue.

2

C Monitor Graphical User Interface Installation.

FIGURE 3-2: Selecting the Destination Folder.

DS50002914A-page 18 2019 Microchip Technology Inc.

Page 19

GUI Installation and Operation

8. In the Ready to Install the Program window, click the Install button and wait for

the application to proceed with the installation. The progress can be observed in

the “Status” bar.

.

FIGURE 3-3: Installing the I2C Monitor Graphical User Interface.

2019 Microchip Technology Inc. DS50002914A-page 19

Page 20

MIC33M656 Evaluation Board User’s Guide

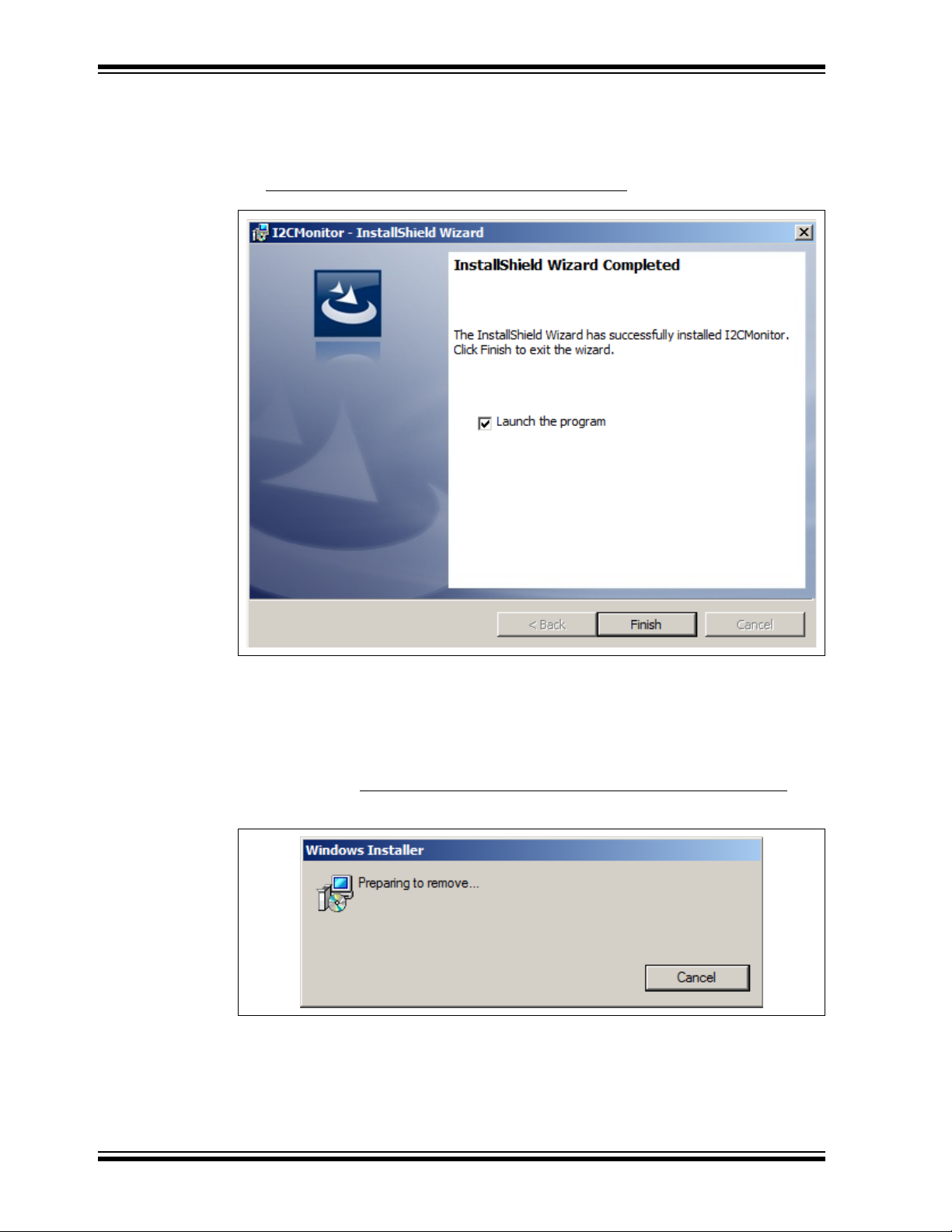

9. Once the installation is complete, leave the “Launch the program” box checked

to automatically start the I

GUI at a later stage. Click Finish to end the installation.

To start the GUI at a later stage, either click the desktop icon or browse to

Windows Start>All Programs>Microchip>I2C Monitor

2

C Monitor GUI or deselect this check box to start the

.

FIGURE 3-4: The Installation Complete Window.

3.3 I2C MONITOR GRAPHICAL USER INTERFACE UNINSTALL

In order to install a new version of the I2C Monitor Graphical User Interface, any

previous version or corrupted version should be removed from the computer.

To uninstall, go to Windows Start>Control Panel>Uninstall a program>I2CMonitor

2

I

C Monitor GUI will automatically close once the uninstallation process is complete.

FIGURE 3-5: Uninstalling the I

2

C Monitor Graphical User Interface.

. The

DS50002914A-page 20 2019 Microchip Technology Inc.

Page 21

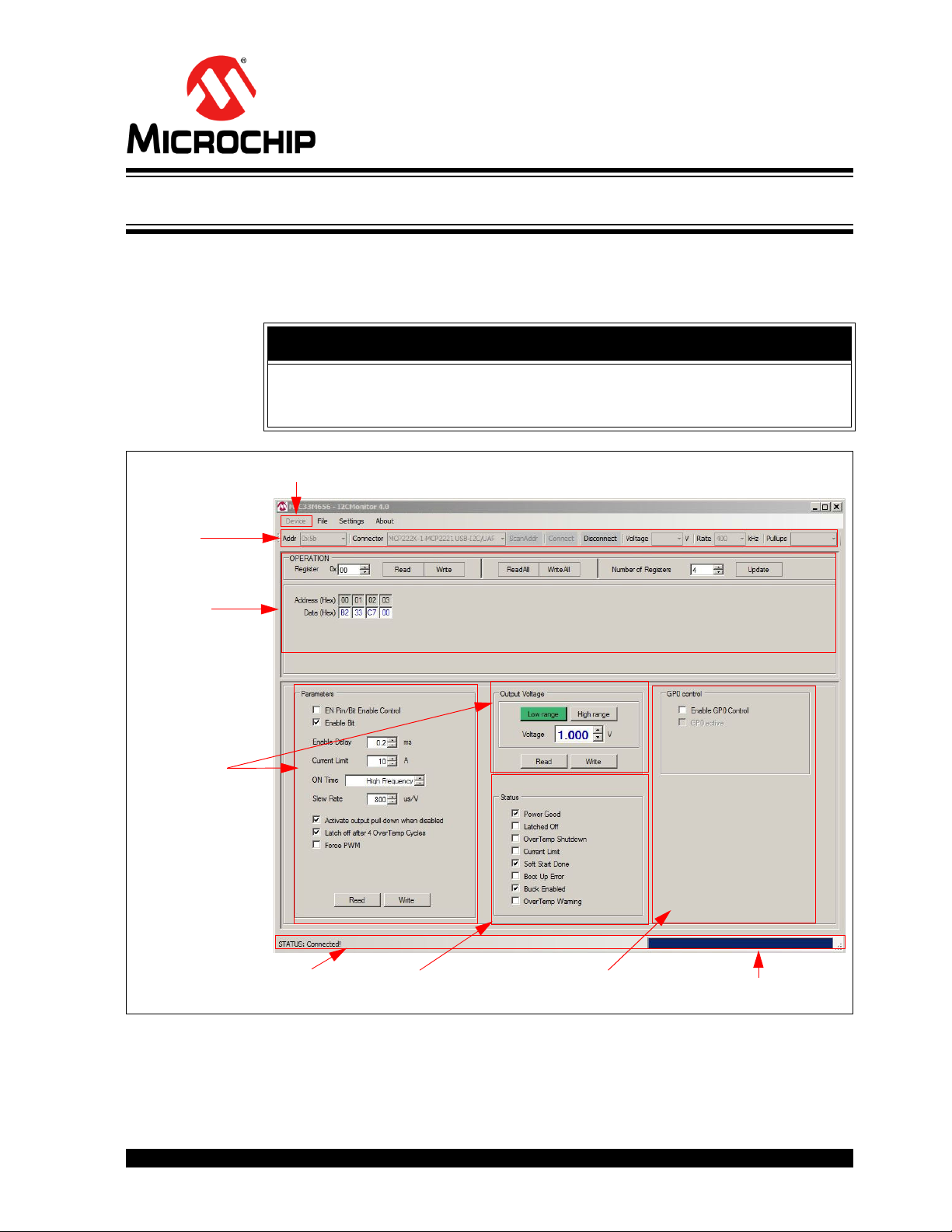

4.1 INTRODUCTION

Device Menu

I

2

C Monitor

Status and

Control Bar

I2C Generic

Register View

MIC33M656 I

2

C

Programmable

Features

Status Bar

MIC33M656 I2C

Diagnostic

MIC33M656

Control by MCP2221 GP0 Output

Progress Bar

This chapter describes how to use the I2C Monitor Graphical User Interface, using the

MIC33M656 Evaluation Board included in the kit.

MIC33M656

EVALUATION BOARD

USER’S GUIDE

Chapter 4. GUI Description

NOTICE

This chapter provides information regarding the use of the GUI only in the case of the

MIC33M656 device. For other devices using the I

see their specific Data Sheets and User’s Guides.

2

C Monitor Graphical User Interface,

2

FIGURE 4-1: I

2019 Microchip Technology Inc. DS50002914A-page 21

C Monitor Graphical User Interface Main Window – MIC33M656 View.

Page 22

MIC33M656 Evaluation Board User’s Guide

4.2 THE GRAPHICAL USER INTERFACE

The following sections describe the items in the Graphical User Interface.

4.2.1 Device Menu

The Device drop-down menu allows the user to select the device to be evaluated. If an

Evaluation (or added custom) Board is used, the profile will automatically change to the

preselected profile.

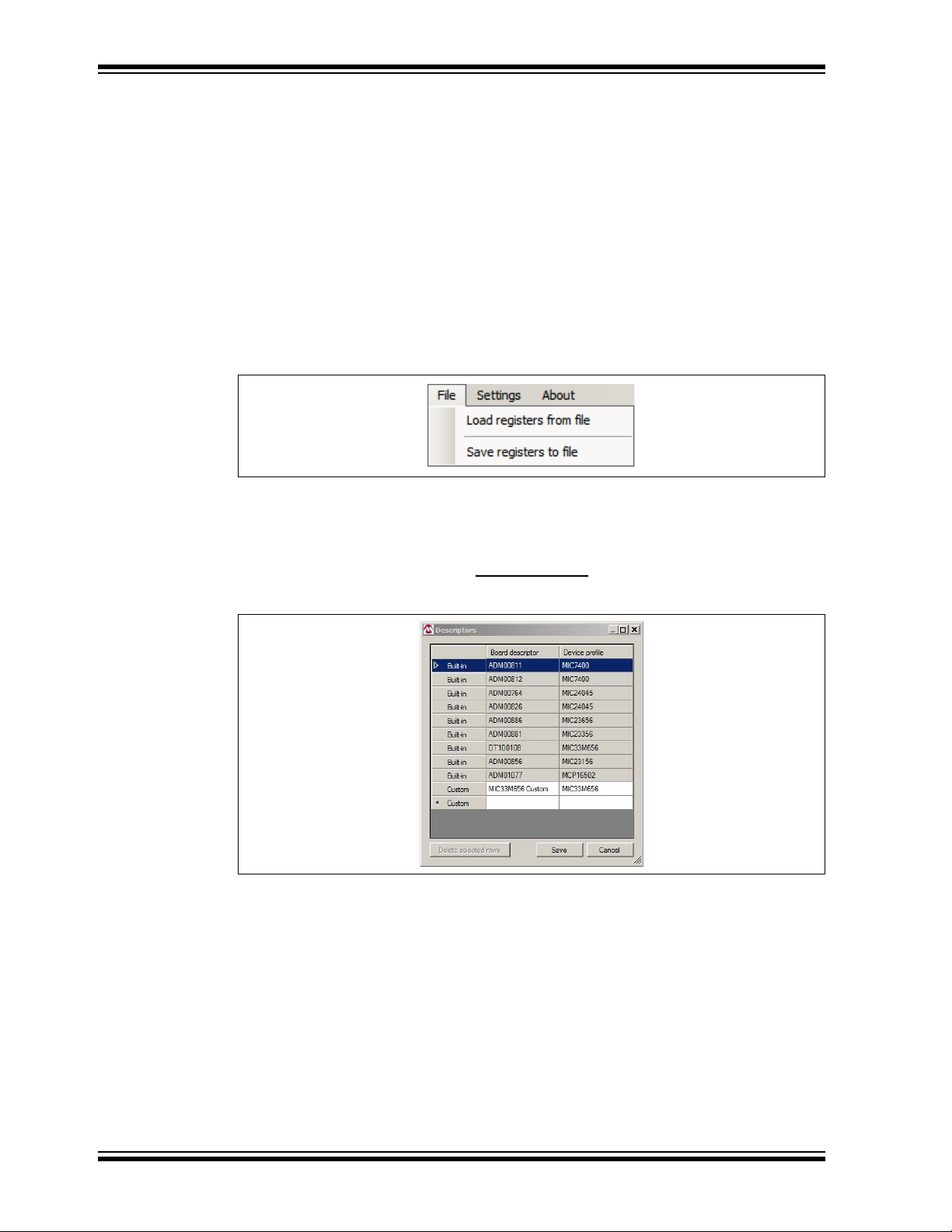

4.2.2 File Menu

The File menu allows the user to save (“Save registers to file”) the registers of the

currently selected device to a file that can then be loaded into the GUI by using the

Load registers from file button. The saved file can also be edited (open it with a text

editor).

FIGURE 4-2: File Menu.

4.2.3 Settings Menu

From the Settings menu, add a new custom board to be automatically detected and

switch to its profile. To do this, go to Settings>Device

window, add the desired “Board” descriptor and select the desired “Device” profile.

FIGURE 4-3: Custom Board Menu.

descriptors, and in the Descriptors

DS50002914A-page 22 2019 Microchip Technology Inc.

Page 23

GUI Description

4.2.4 I2C Monitor Status and Control Bar

The Status and Control bar contains the items listed in Ta b le 4 -1 .

FIGURE 4-4: I

2

C Monitor Status and Control Bar.

TABLE 4-1: MONITOR STATUS AND CONTROL BAR

Item Description

Addr This drop-down menu shows the address of the available devices.

Connector This drop-down menu shows the type of connector used to connect the board.

ScanAddr This button is used to scan for a valid address.

Connect/Disconnect

Voltage This drop-down menu is used to select the voltage level of the communication when using

Rate This drop-down menu is used to select the corresponding communication rate for the

Pull Ups

Note 1: Optional. PICkit Serial Analyzer should first be connected on the I2C pin header on the MIC33M656

Evaluation Board.

These buttons are used to connect/disconnect the current selected device.

the PICkit™ Serial Analyzer.

device.

This drop-down menu is used to activate the internal pull-ups from the PICkit

Serial Analyzer.

(1)

(1)

In the Status and Control bar, the user can choose the hardware tool for communication

with the device and the settings it should allow.

In order to connect to a device, the user must follow the steps described in

Section 2.3 “Getting Started”. After connecting the Micro-USB cable, the user must

scan for a valid address. Once a valid address is detected, clicking the Connect button

will initialize the connection with the device, and the registers will be available for read

and write operations.

2019 Microchip Technology Inc. DS50002914A-page 23

Page 24

MIC33M656 Evaluation Board User’s Guide

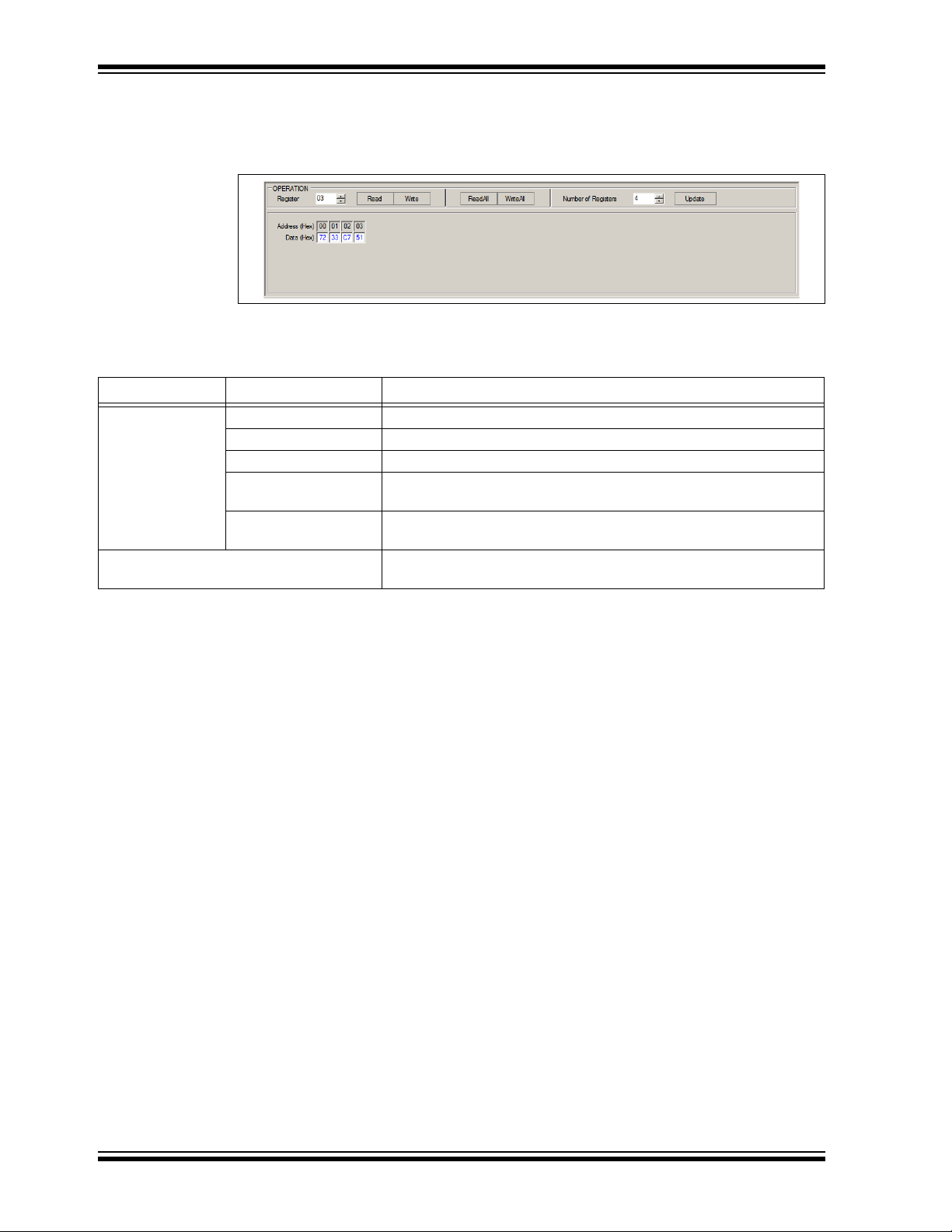

4.2.5 I2C Generic Register View

The I2C Generic Register View area contains the items listed in Tab le 4- 2. This section

of the I

FIGURE 4-5: Generic Register View Area.

TABLE 4-2: I2C GENERIC REGISTER VIEW ITEMS

Panel Item Description

Operation Register This section shows the registers available for read/write operations.

Read/Write These buttons are used for single register read/write operations.

ReadAll/WriteAll These buttons are used for reading/writing all the available registers.

Number of Registers In this section, the user can set the number of available registers for

Update This button sets the number of available registers for read/write

Register area This section shows the current status of the registers’ address and

2

C Monitor GUI is common for any device that is evaluated.

read/write operations.

operations in the register area.

their content.

The specific registers for MIC33M656 are described in Appendix C. “MIC33M656

Internal Registers”.

DS50002914A-page 24 2019 Microchip Technology Inc.

Page 25

GUI Description

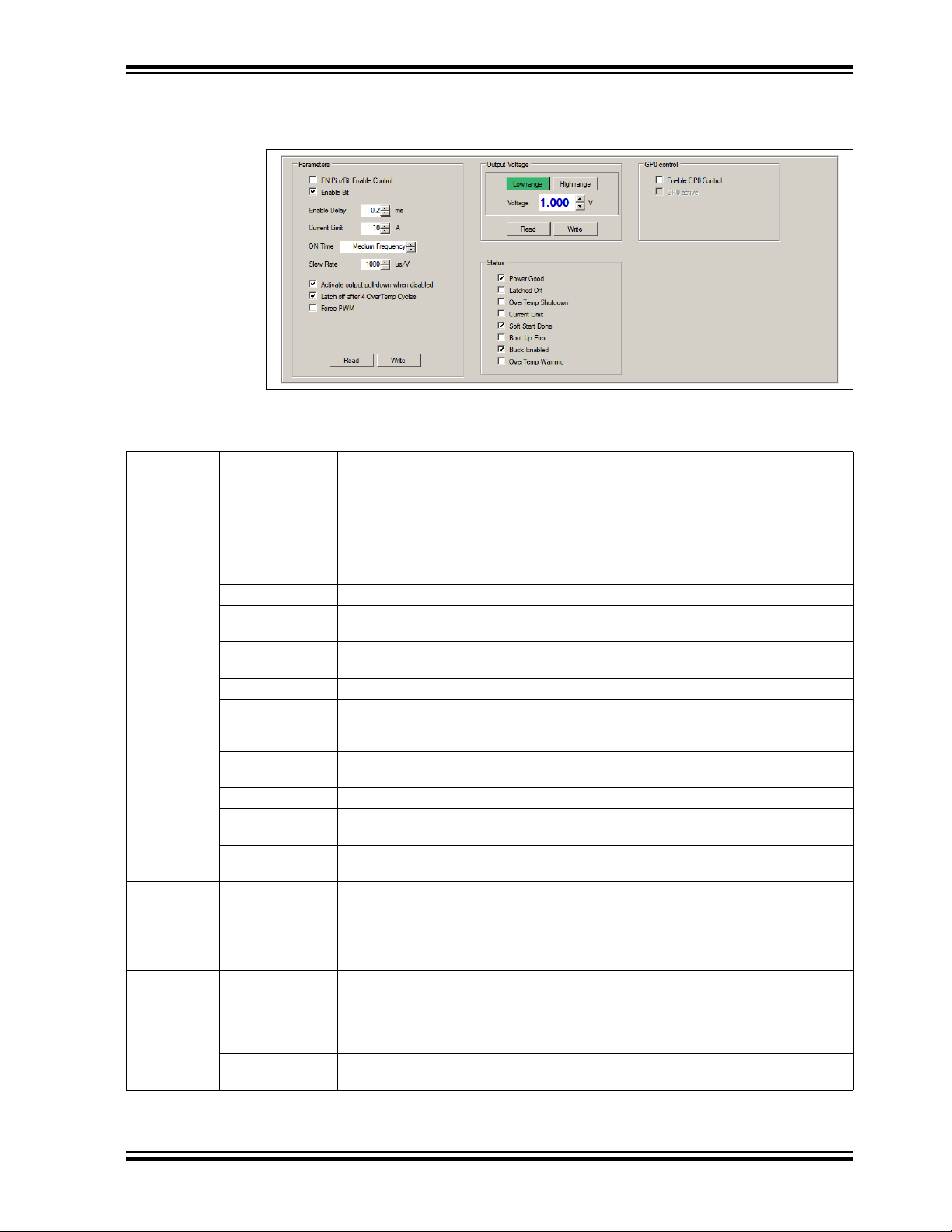

4.2.6 MIC33M656 I2C Programmable Features

The MIC33M656 I2C Programmable Features area contains the items listed in Table 4-3.

2

FIGURE 4-6: MIC33M656 I

TABLE 4-3: MIC33M656 I2C PROGRAMMABLE FEATURES

Panel/Button Items Description

Parameters EN Pin/Bit Enable

Control

Enable Bit This check box sets the MIC33M656 Enable Bit register. Check the box for regulator

Enable Delay This spin box allows setting the available start time delays.

Current Limit This spin box allows setting the available high-side current limits in order to obtain the

ON Time This spin box allows setting the available on-time values that determine slower (high

Slew Rate This spin box allows setting the available output slew rates.

Activate output

pull-down when

disabled

Latch off after

4 OverTemp Cycles

Force PWM This check box sets forced PWM mode, regardless of output loading.

Disable 100% Duty

Cycle

Read/Write These buttons are used to read/write the registers that contain the information

Output Voltage Voltage This spin box allows setting the available output voltages. If the evaluated chip option is

Read/Write These buttons are used to read/write the registers that contain the information

GP0 control Enable GP0

Control

GP0 active This check box sets the state of the MCP2221 GP0 pin. Leave unchecked to disable the

This check box allows switching between the I

and pin controlled enable (unchecked). Leave this box unchecked to enable by jumper

or MCP2221 GP0.

enabling, uncheck for disabling. This bit value is considered only if EN Pin/Bit Enable

Control is checked.

nominal load currents.

T

) or faster (lower TON) switching frequencies.

ON

This check box activates the automatic output pull-down resistor when the MIC33M656

is disabled.

This check box sets the latch off after four overtemperature (thermal shutdown) cycles.

This check box disables 100% duty cycle operation on the high side when V

V

. This feature is available only in High-Range mode (option MIC33M656-SAYMP).

OUT

described above.

MIC33M656-HAYMP or MIC33M656-FAYMP, the Low Range option must be selected. If

the evaluated chip is MIC33M656-SAYMP, the High Range must be selected.

described above.

This check box allows enable control from the MCP2221 GP0 pin. If unchecked, pin

GP0 is tri-state.

To enable access to this feature and allow pin enable control, uncheck EN Pin/Bit

Enable Control.

The enable jumper must first be removed to prevent short circuiting GP0 with the jumper.

MIC33M656 through Enable pin or check the box to enable the MIC33M656 regulator.

This area of the GUI allows the user to modify the device features. For additional

information on the part, refer to the data sheet.

C Programmable Features Area.

2

C controlled device enable (checked)

is close to

IN

2019 Microchip Technology Inc. DS50002914A-page 25

Page 26

MIC33M656 Evaluation Board User’s Guide

4.2.7 MIC33M656 I2C Diagnostic

The MIC33M656 Diagnostic area contains the items listed in Ta b le 4 - 4.

2

FIGURE 4-7: MIC33M656 I

TABLE 4-4: MIC33M656 I2C DIAGNOSTIC AREA ITEMS

Panel Items Description

Status Power Good This box is checked if the output voltage reaches 91% of its set

value.

Latched Off This box is checked if the regulator output is latched off due to four

consecutive hiccup events or thermal shutdown.

OverTemp Shutdown This box is checked if the MIC33M656 enters Thermal Shutdown

(typical, T

Current Limit This box is checked if the high-side sensed current reaches the

value set in the “Current Limit” spin box.

Soft Start Done This box is checked after a successful regulator soft start ramp.

Boot Up Error This box is checked if an error occurs while loading the trim and

configuration data into the digital core. At successful start-up, this

box remains unchecked (clear).

Buck Enabled This box indicates the internal state of the regulator determined by

enable commands (via the EN pin or I

OverTemp Warning This box is checked if the MIC33M656 junction temperature

exceeds +118°C. This does not affect the normal operation of the

device.

C Diagnostic Area.

= +165°C).

J

2

C).

The MIC33M656 I2C Diagnostic area resumes the information contained in the STATUS

Register. The STATUS Register contains latched (Flag) or non-latched (Status) bits. Flag

bits are set when the corresponding Fault condition occurs and do not return to zero once

the Fault condition ceases. If such a Fault occurs, the user can clear the Faults by

toggling the enable function or power cycling the device. Status bits are set when the

corresponding Fault condition has occurred and return to zero automatically once the

Fault condition has ceased. This information is refreshed once every two seconds.

Because of this refresh traffic when using a logic analyzer, it is more difficult to

synchronize the exact moment of a certain command. In order to simplify this, an

auxiliary trigger signal is provided on pin GP2 of the MCP2221. This signal is triggered

for each user Read/Write command.

DS50002914A-page 26 2019 Microchip Technology Inc.

Page 27

GUI Description

TABLE 4-5: STATUS BAR ITEMS

Item Description

Status Label The status label shows if there is any device connected to the board. Refer to Table 4-6 for a list of

possible labels.

Progress Bar This bar shows the level of completion for a given command.

TABLE 4-6: STATUS LABELS

Status Label Description

STATUS: Connected! This message is shown when the GUI connects to a device.

STATUS: Disconnected! This message is shown when the GUI does not detect a connected device.

2019 Microchip Technology Inc. DS50002914A-page 27

Page 28

MIC33M656 Evaluation Board User’s Guide

NOTES:

DS50002914A-page 28 2019 Microchip Technology Inc.

Page 29

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the following schematic and layouts for the MIC33M656

Evaluation Board:

• Board – Schematic

• Board – Top Silk

• Board – Top Copper and Silk

• Board – Top Copper

• Board – Signal Layer 1

• Board – Signal Layer 2

• Board – Bottom Copper

• Board – Bottom Copper and Silk

• Board – Bottom Silk

MIC33M656

EVALUATION BOARD

USER’S GUIDE

2019 Microchip Technology Inc. DS50002914A-page 29

Page 30

DS50002914A-page 30 2019 Microchip Technology Inc.

J15 J19

J20

TP LOOP Red

J21

TP LOOP Red

J14

J18

GND

2k

0603

R6

100k

0603

R7

SDA

49.9R

0603

R1

1 2

J3

J17

470 μF

16V

C8

1

2

3

HDR-2.54 Male 1x3

J6

1

2

J1

J4

J5

47 μF

10V

1210

DNP

C4

47 μF

10V

1210

DNP

C5

12

J1312J12

GND

SW

2k

0603

R9

1M

0603

R3

SCL

PWR

Net Tie

0.5 mm

NT1

AGND GND

DD+

GNDGND

GND

0R

R8

0R

R11

SCL

SDA

EN

PG

V

IN

1

2

3

HDR-2.54 Male 1x3

J8

PWR

0R

R5

0R

R4

V

DD

1

GP0

2

GP1

3

RST

4

UART RX

5

UART TX

6

GP2

7

GP3

8

SDA

9

SCL

10

V

USB

11

D-

12

D+

13

V

SS

14

MCP2221A

U2

GND

DD+

GND

ID

4

V

BUS

1

GND

5

D-

2

D+

3

0

USB 2.0 Micro-B Female

J7

GND

SCL

SDA

1234

J2

PWR

4.7 μF

10V

0805

C2

4.7 μF

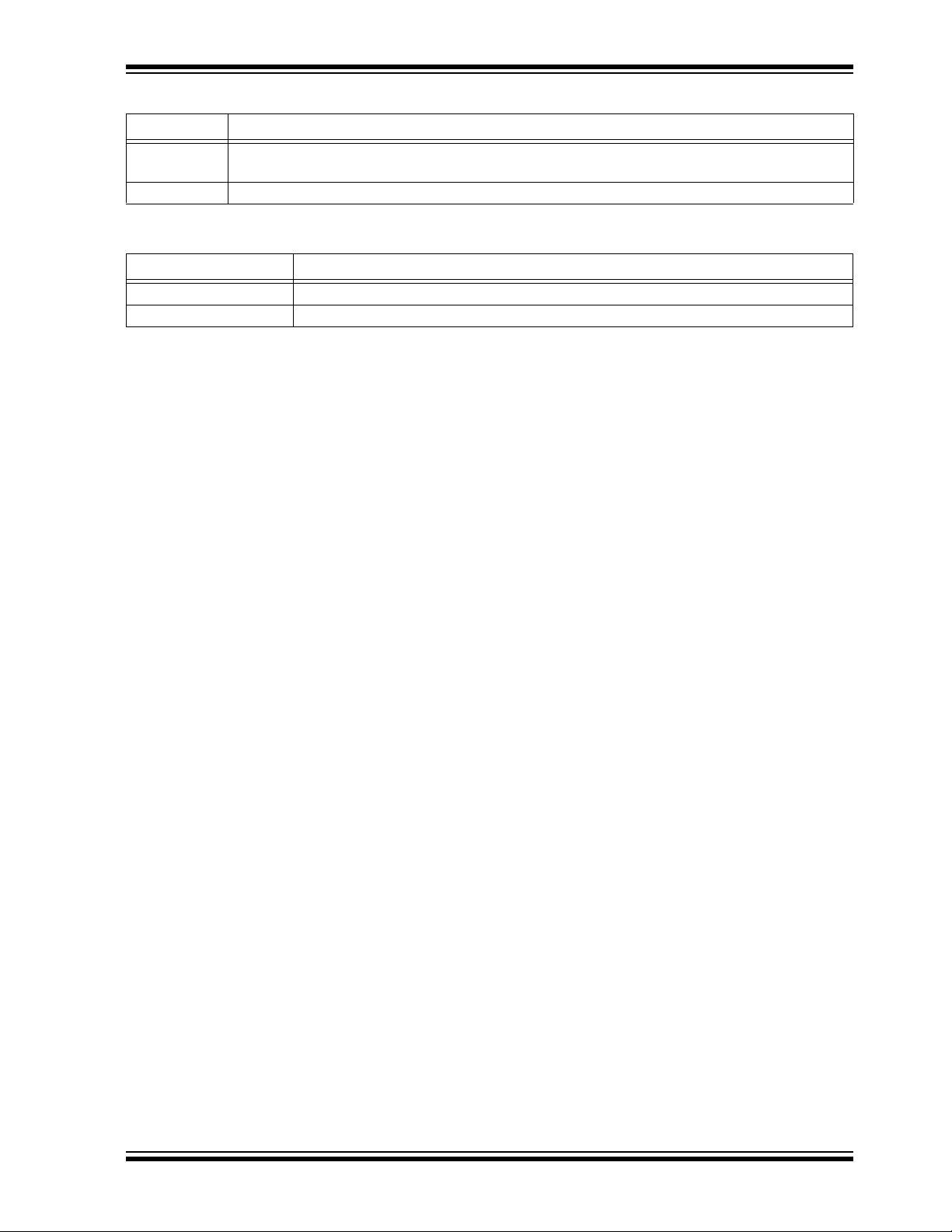

10V

0805

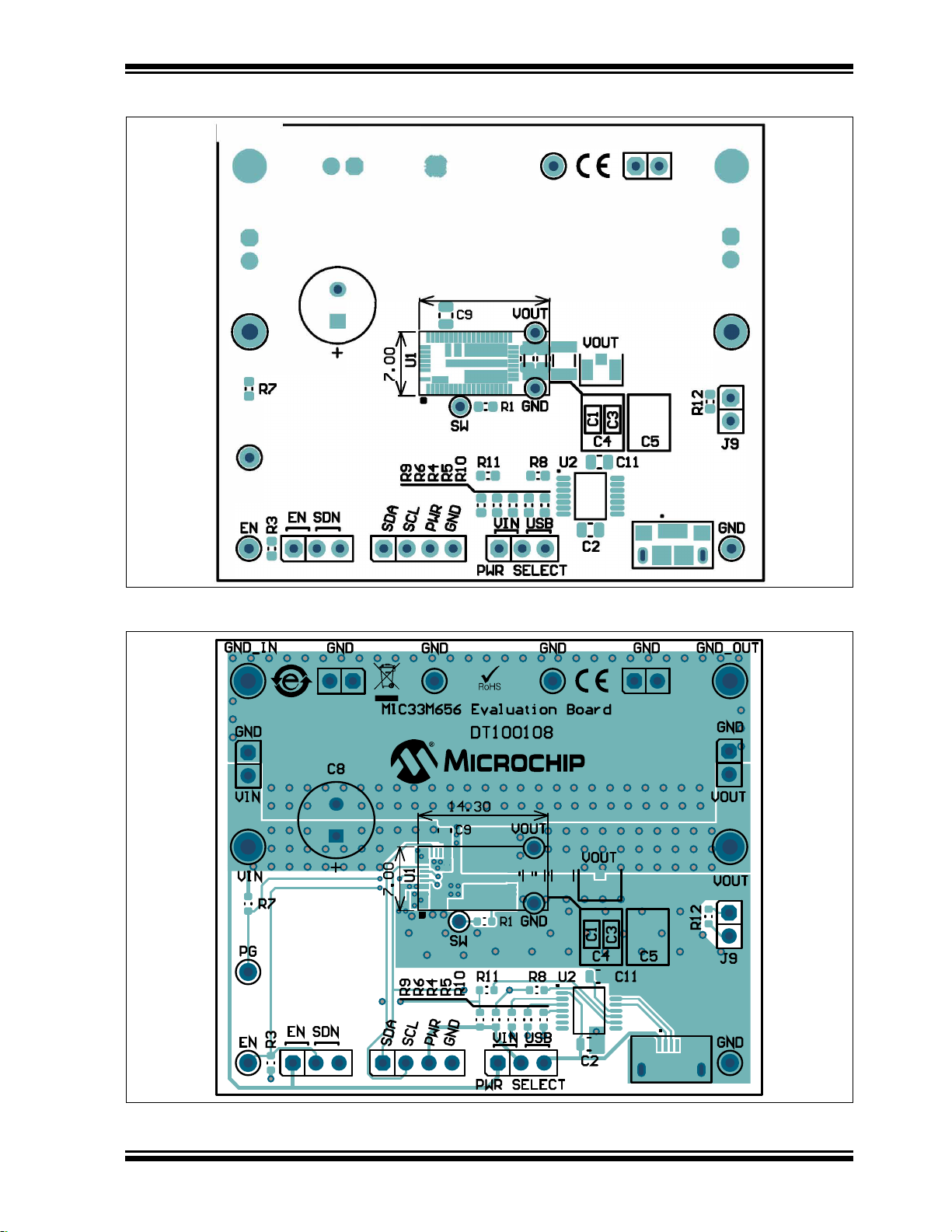

C11

10R

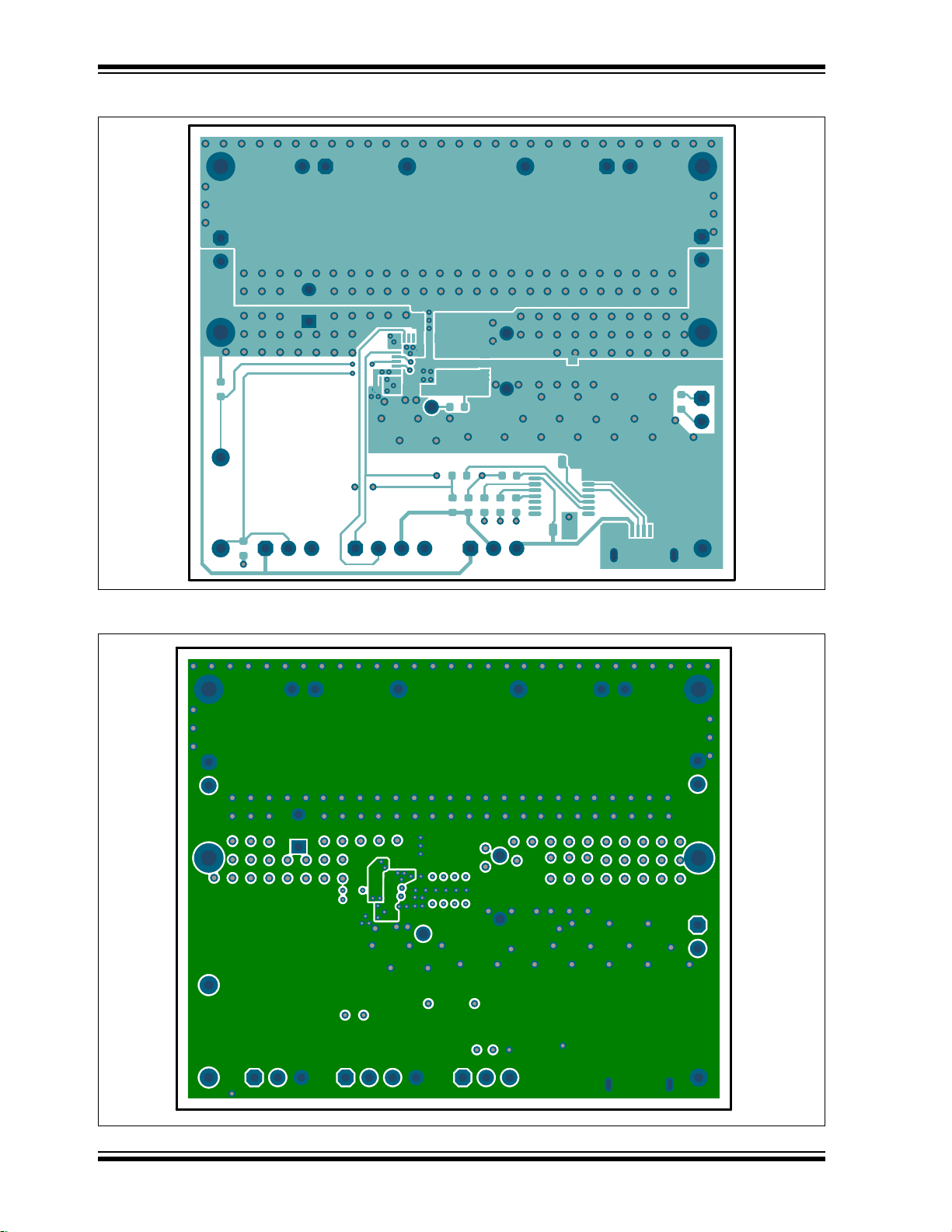

0603

1%

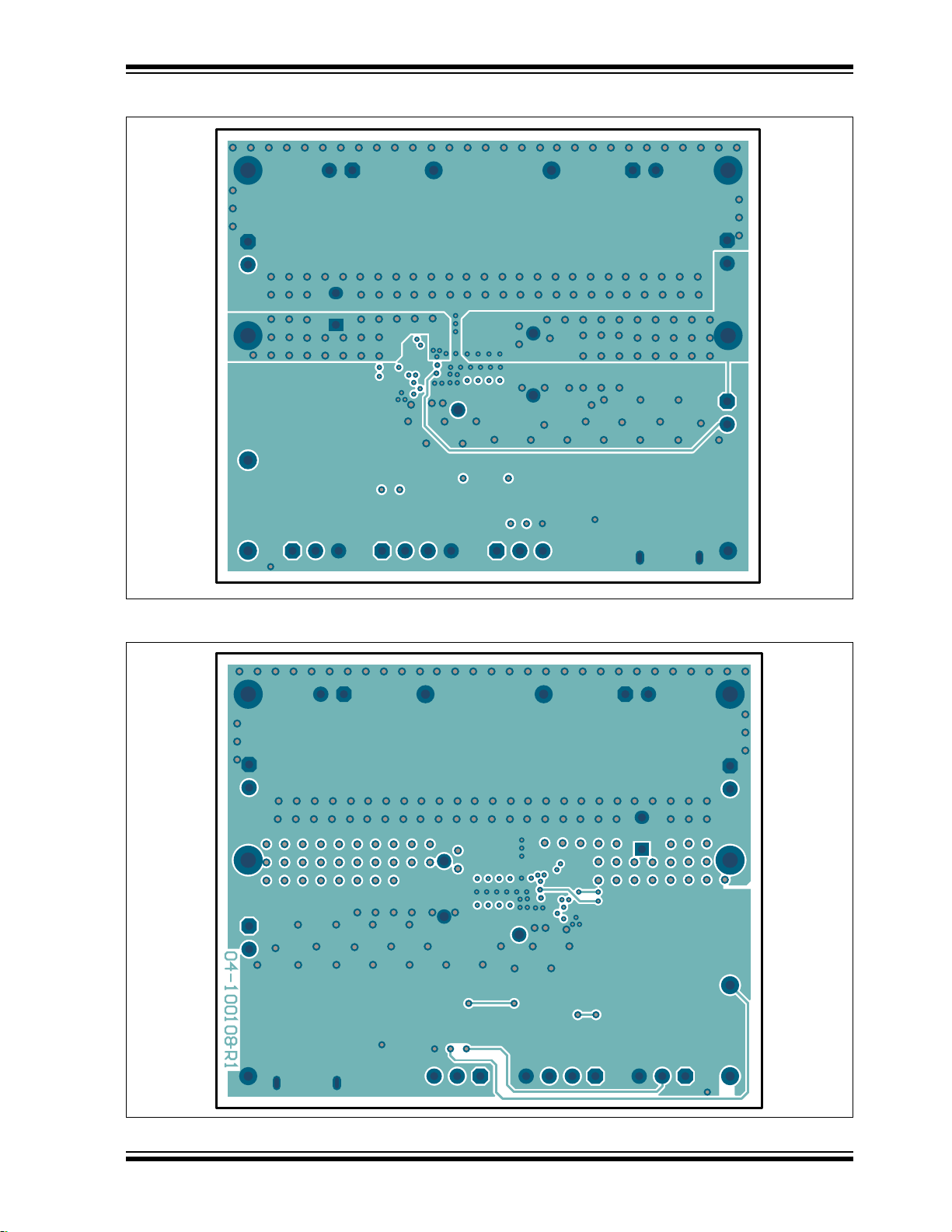

R12

1

2

DNP

J9

22 μF

10V

0805

C9

JP1

JP2

0R

DNP

R10

JP2 should be mounted on 1-2 pins J8

GND

GND

V

IN

V

IN

EN

V

IN

GND

PG

AGND

JP1 should be mounted on 1-2 pins J6

GNDGND

GND

GND

GND GND

PWR

47 μF

10V

0805

C1

47 μF

10V

0805

C3

GND GND

J10

U.FL

GND

PGND

2

AUX_AGND

47

PGND

4

SW

14

PV

IN

42

PGND

40

PG

50

SDA

48

AUX_PV

IN

1

EN

49

SW

6

OUT

38

SW

21

AUX_AGND

46

PGND

39

SW

10

V

OUT

51

PGND

3

SCL

45

PGND

5

SW

7

SW

8

AGND

52

SW

11

SW

12

OUT

31

OUT

32

OUT

33

OUT

34

SW

15

SW

16

SW

17

SW

18

SW

19

SW

22

PGND

23

PGND

24

OUT

25

OUT

26

OUT

27

OUT

28

OUT

29

OUT

37

OUT

36

PV

IN

41

SV

IN

43

SV

IN

44

SW

9

SW

13

SW

20

OUT

30

OUT

35

AUX_PV

IN

53

EP (PGND)

54

EP (SW)

55

EP (PGND)56EP (OUT)

57

EP (PGND)

58

EP (PVIN)

59

MIC33M656

U1

VOUT_TP

GND_TP

A.2 BOARD – SCHEMATIC

MIC33M656 Evaluation Board User’s Guide

Page 31

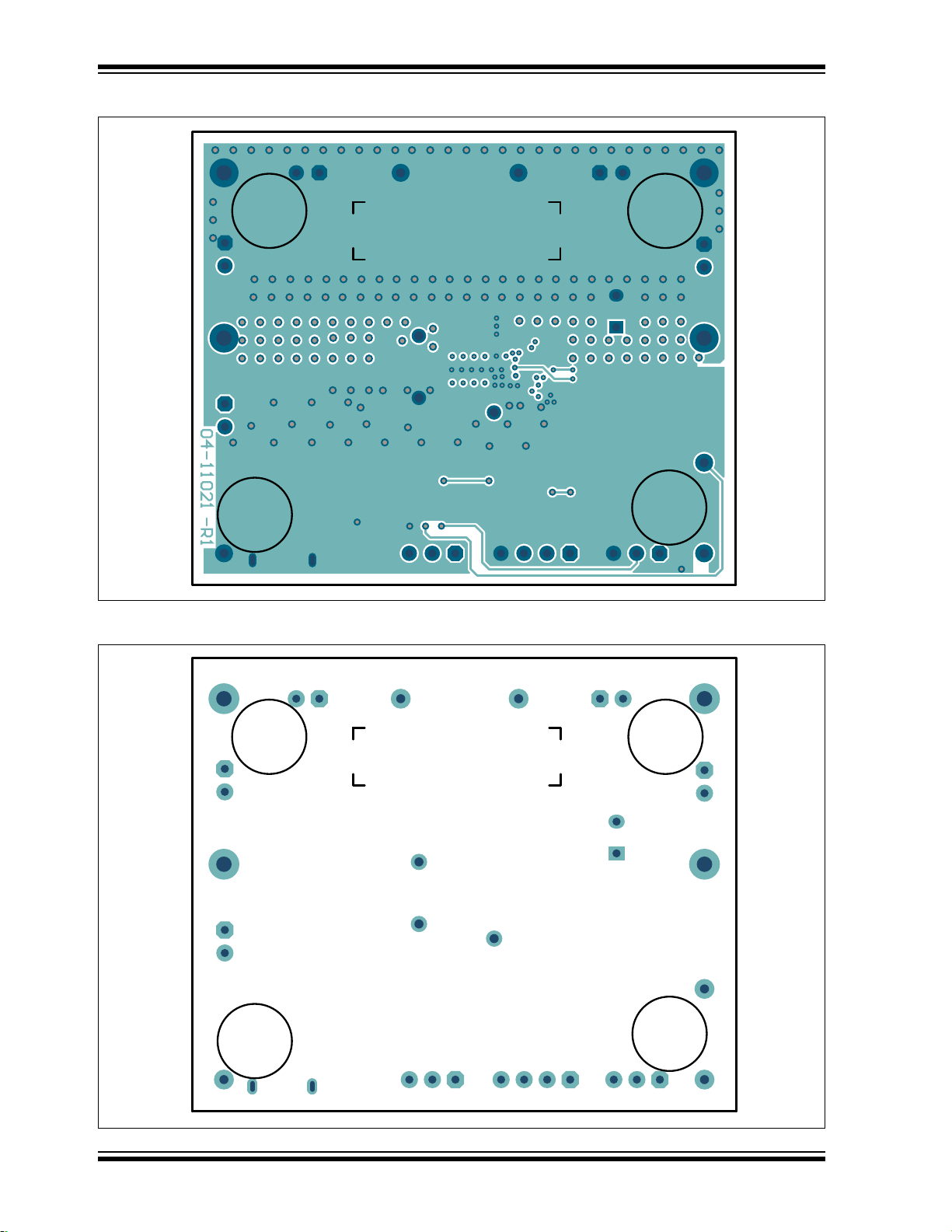

A.3 BOARD – TOP SILK

(

Schematic and Layouts

A.4 BOARD – TOP COPPER AND SILK

2019 Microchip Technology Inc. DS50002914A-page 31

Page 32

MIC33M656 Evaluation Board User’s Guide

A.5 BOARD – TOP COPPER

A.6 BOARD – SIGNAL LAYER 1

DS50002914A-page 32 2019 Microchip Technology Inc.

Page 33

A.7 BOARD – SIGNAL LAYER 2

Schematic and Layouts

A.8 BOARD – BOTTOM COPPER

2019 Microchip Technology Inc. DS50002914A-page 33

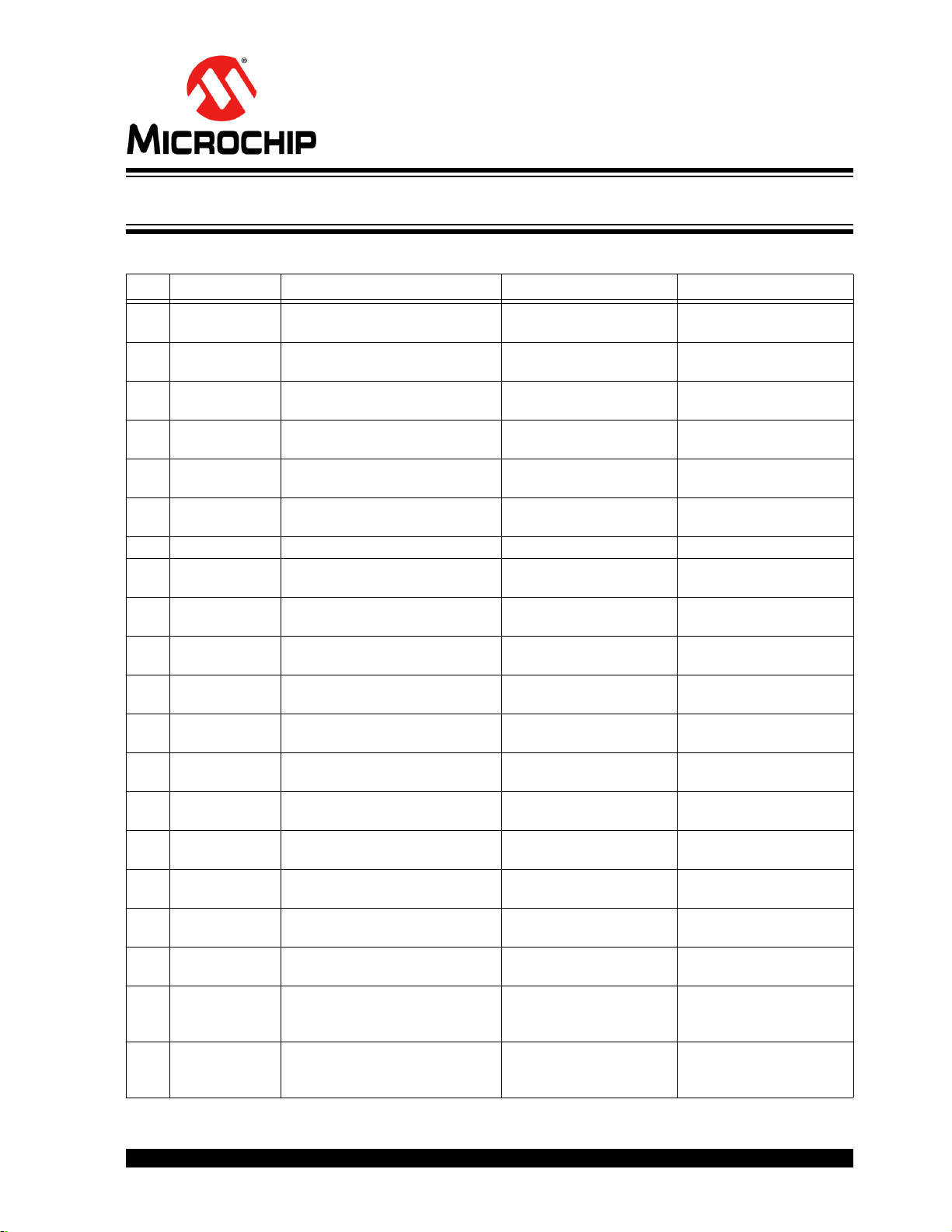

Page 34

MIC33M656 Evaluation Board User’s Guide

A.9 BOARD – BOTTOM COPPER AND SILK

A.10 BOARD – BOTTOM SILK

DS50002914A-page 34 2019 Microchip Technology Inc.

Page 35

EVALUATION BOARD

USER’S GUIDE

Appendix B. Bill of Materials (BOM)

MIC33M656

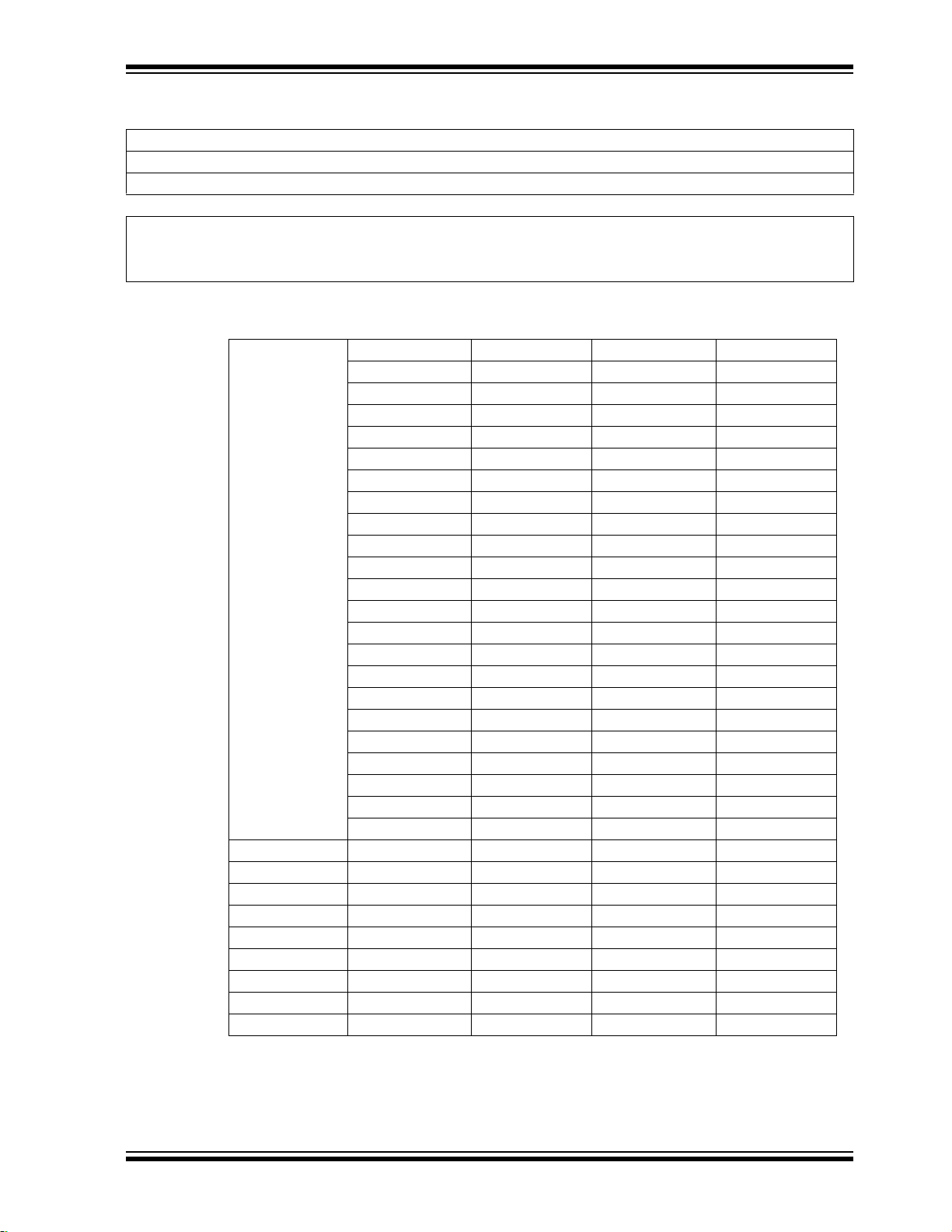

TABLE B-1: BILL OF MATERIALS (BOM)

Qty. Reference Description Manufacturer Part Number

2 C1, C3 Capacitor, Ceramic, 47 µF, 10V,

20%, X5R, SMD, 0805

2 C2, C11 Capacitor, Ceramic, 4.7 µF, 10V,

10%, X7R, SMD, 0805

1 C8 Capacitor, Aluminum, 470 µF,

16V, 20%, RAD, P3.5D8H11.5

1 C9 Capacitor, Ceramic, 22 µF, 10V,

20%, X7S, SMD, 0805

4 J1, J3, J12, J13 Connector, Header, 2.54 Male,

1x2, Gold, 5.84 MH, TH, Vertical

1 J2 Connector, Header, 2.54 Male,

1x4, Tin, 5.84 MH, TH, Vertical

4 J4, J5, J15, J19 Connector, TP, Pin, Tin, TH Harwin Plc. H2121-01

2 J6, J8 Connector, Header, 2.54 Male,

1x3, Tin, 5.84 MH, TH, Vertical

1 J7 Connector, USB 2.0, Micro-B,

Female, SMD, R/A

1 J10 Connector, RF, Coaxial,

Ultra Miniature, Male, SMD, Vertical

2 J14, J21 Miscellaneous, Test Point,

Multipurpose, Mini, Red

3 J17, J18, J20 Miscellaneous, Test Point,

Multipurpose, Mini, Black

1 R1 Resistor, TKF, 49.9R, 1%, 1/10W,

SMD, 0603

1 R3 Resistor, TKF, 1M, 1%, 1/10W,

SMD, 0603

4 R4, R5, R8, R11 Resistor, TKF, 0R, 1/10W, SMD,

0603

2 R6, R9 Resistor, TKF, 2k, 1%, 1/10W,

SMD, 0603

1 R7 Resistor, TKF, 100k, 1%, 1/10W,

SMD, 0603

1 R12 Resistor, TKF, 10R, 1%, 1/10W,

SMD, 0603

1 U1 Microchip Analog Switcher Buck,

0.6V to 3.3V, 6A,

MIC33M656-HAYMP-TR, QFN-53

1 U2 Microchip Interface, USB, I

UART, MCP2221A-I/ST,

TSSOP-14

(1)

TDK Corporation C2012X5R1A476M125AC

TDK Corporation C2012X7R1A475K125AC

Nichicon Corporation UVZ1C471MPD

TDK Corporation C2012X7S1A226M125AC

Amphenol ICC 77311-118-02LF

Amphenol FCI 68002-404HLF

Samtec, Inc. TSW-103-07-T-S

Amphenol ICC 10118193-0001LF

Hirose Electric Co., Ltd. U.FL-R-SMT-1(10)

Keystone Electronics

Corp.

Keystone Electronics

Corp.

Panasonic

Panasonic ERJ-3EKF1004V

Panasonic ERJ-3GEY0R00V

Panasonic ERJ-3EKF2001V

Panasonic ERJ3EKF1003V

Panasonic ERJ3EKF10R0V

Microchip Technology Inc. MIC33M656-HAYMP

2

C,

Microchip Technology Inc. MCP2221A-I/ST

®

ERJ3EKF49R9V

5000

5001

2019 Microchip Technology Inc. DS50002914A-page 35

Page 36

MIC33M656 Evaluation Board User’s Guide

TABLE B-1: BILL OF MATERIALS (BOM)

Qty. Reference Description Manufacturer Part Number

2 JP1, JP2 Mechanical Hardware, Jumper,

2.54 mm, 1x2

1 LABEL1 Label, Assembly w/Revision Level

(Small Modules) per MTS-0002

4PAD1, PAD2,

PAD3, PAD4

1 PCB1 Printed Circuit Board Microchip Technology Inc. 04-11021-R1

0C4, C5 DO NOT POPULATE Taiyo Yuden Co., Ltd. LMK325B7476MM-TR

0J9 DO NOT POPULATE Amphenol ICC 77311-118-02LF

0R10 DO NOT POPULATE Panasonic

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Mechanical Hardware, Rubber

Pad, Cylindrical, D7.9, H5.3,

Black

(1)

(CONTINUED)

3M 969102-0000-DA

3M 70006431483

——

®

ERJ-3GSY0R00V

DS50002914A-page 36 2019 Microchip Technology Inc.

Page 37

EVALUATION BOARD

Appendix C. MIC33M656 Internal Registers

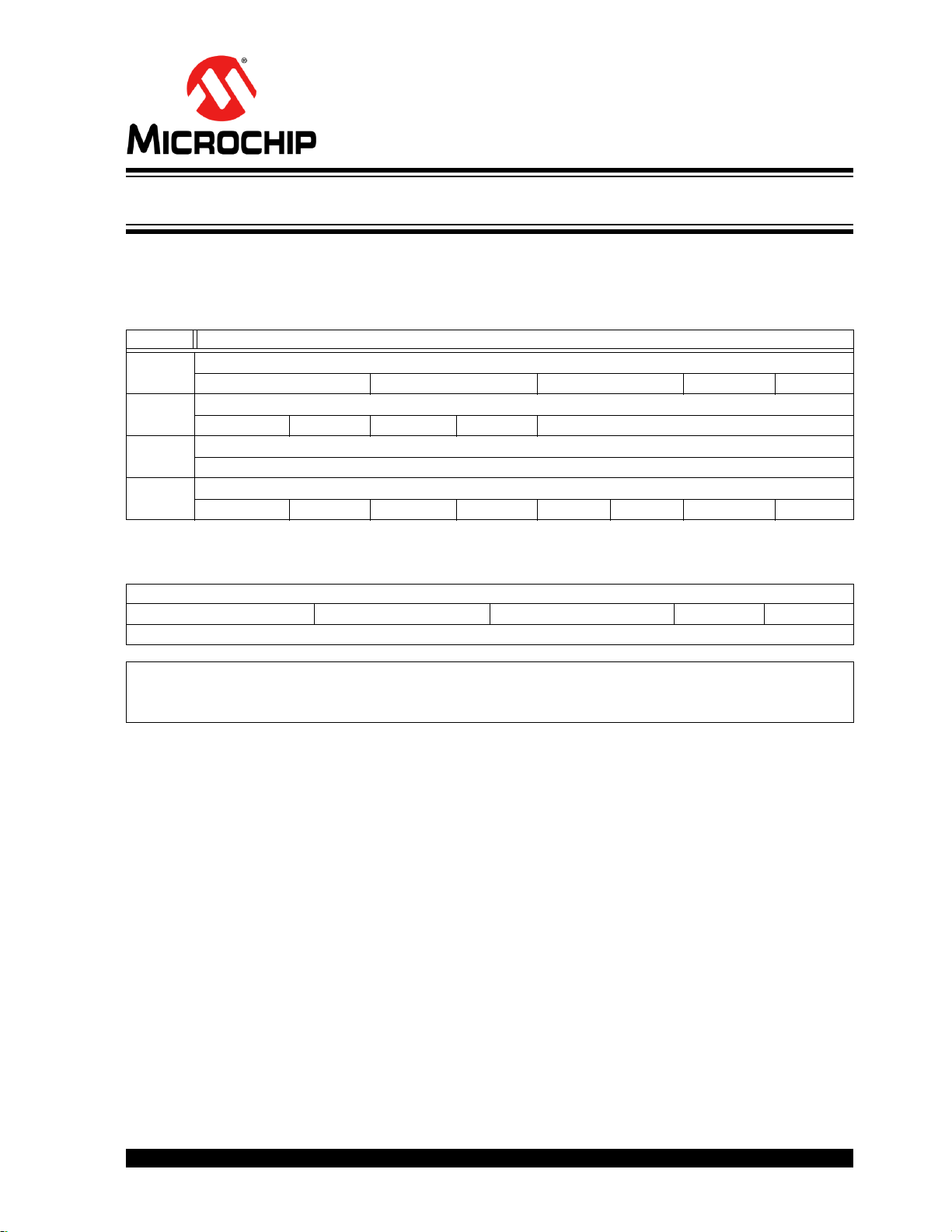

C.1 REGISTER MAP AND I2C PROGRAMMABILITY

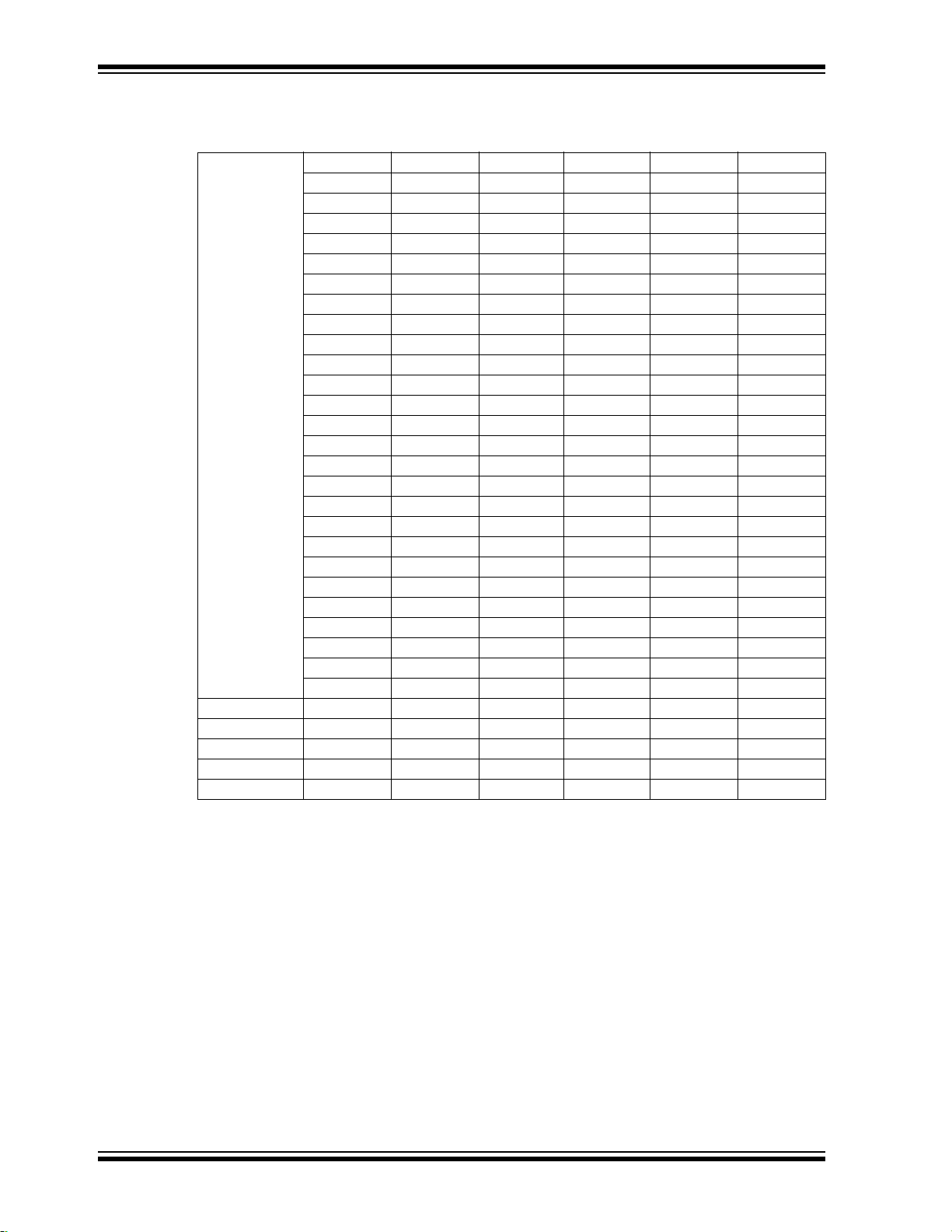

The MIC33M656 internal registers are summarized in Ta bl e C - 1 .

TABLE C-1: MIC33M656 REGISTER MAP

Address Register Name

0x00 Control Register (CTRL1)

TON[1:0] ILIM[1:0] EN_DELAY[1:0] EN_INT EN_CON

0x01 Output Control Register (CTRL2)

DIS_100PCT FPWM OT_LATCH PULL_DN SLEW_RATE[3:0]

0x02 Output Voltage Control Register (VOUT)

VO[7:0]

0x03 STATUS and Fault Register (FAULT)

OT_WARN EN_STAT BOOT_ERR SSD HICCUP OT LATCH_OFF PG

MIC33M656

USER’S GUIDE

REGISTER C-1: CTRL1: CONTROL REGISTER (ADDRESS 0x00)

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

TON[1:0] ILIM[1:0] EN_DELAY[1:0] EN_INT EN_CON

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-6 TON[1:0]: On Time

00 = Low frequency

01 = Medium frequency

10 = High frequency

11 = Very fast frequency

bit 5-4 ILIM[1:0]: High-Side Peak Current Limit

00 = 4.5A

01 = 6A

10 = 8.5A

11 = 10.0A

bit 3-2 EN_DELAY[1:0]: Enable Delay

00 = 250 µs

01 = 1 ms

10 = 2 ms

11 = 3 ms

bit 1 EN_INT: Enable Bit Register Control

0 = Register controlled

1 = Enable pin controlled

bit 0 EN_CON: Enable Control

0 = Off

1 = On

2019 Microchip Technology Inc. DS50002914A-page 37

Page 38

MIC33M656 Evaluation Board User’s Guide

REGISTER C-2: CTRL2: OUTPUT CONTROL REGISTER (ADDRESS 0x01)

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

DIS_100PCT FPWM OT_LATCH PULLDN SLEW_RATE[3:0]

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 DIS_100PCT: Disable 100% Duty Cycle

0 = 100% DC

1 = Disable 100% DC

bit 6 FPWM: Force PWM

0 = HLL

1 = FPWM

bit 5 OT_LATCH: Overtemperature Latch

0 = Latch off immediately

1 = Latch off after four OT cycles

bit 4 PULLDN: Enable/Disable Regulator Pull Down when Power-Down

0 = No pull down

1 = Pull down

bit 3-0 SLEW_RATE[3:0]: Step Slew Rate Time in µs/V

0000 = 200

0001 = 400

0010 = 600

0011 = 800

0100 = 1000

0101 = 1200

0110 = 1400

0111 = 1600

1000 = 1800

1001 = 2000

1010 = 2200

1011 = 2400

1100 = 2600

1101 = 2800

1110 = 3000

1111 = 3200

DS50002914A-page 38 2019 Microchip Technology Inc.

Page 39

MIC33M656 Internal Registers

0x00-0x76 = 0.6V 0x80 = 0.645 0xA0 = 0.805V 0xC0 = 0.965 0xE0 = 1.125V

0x81 = 0.65V 0xA1 = 0.81V 0xC1 = 0.97V 0xE1 = 1.13V

0x82 = 0.655V 0xA2 = 0.815V 0xC2 = 0.975V 0xE2 = 1.135V

0x83 = 0.66V 0xA3 = 0.82V 0xC3 = 0.98V 0xE3 = 1.14V

0x84 = 0.665V 0xA4 = 0.825V 0xC4 = 0.985V 0xE4 = 1.145V

0x85 = 0.67V 0xA5 = 0.83V 0xC5 = 0.99V 0xE5 = 1.15V

0x86 = 0.675V 0xA6 = 0.835V 0xC6 = 0.995V 0xE6 = 1.155V

0x87 = 0.68V 0xA7 = 0.84V 0xC7 = 1V 0xE7 = 1.16V

0x88 = 0.685V 0xA8 = 0.845V 0xC8 = 1.005V 0xE8 = 1.165V

0x89 = 0.69V 0xA9 = 0.85V 0xC9 = 1.01V 0xE9 = 1.17V

0x8A = 0.695V 0xAA = 0.855V 0xCA = 1.015V 0xEA = 1.175V

0x8B = 0.7V 0xAB = 0.86V 0xCB = 1.02V 0xEB = 1.18V

0x8C = 0.705V 0xAC = 0.865V 0xCC = 1.025V 0xEC = 1.185V

0x8D = 0.71V 0xAD = 0.87V 0xCD = 1.03V 0xED = 1.19V

0x8E = 0.715V 0xAE = 0.875V 0xCE = 1.035V 0xEE = 1.195V

0x8F = 0.72V 0xAF = 0.88V 0xCF = 1.04V 0xEF = 1.2V

0x90 = 0.725V 0xB0 = 0.885V 0xD0 = 1.045V 0xF0 = 1.205V

0x91 = 0.73V 0xB1 = 0.89V 0xD1 = 1.05V 0xF1 = 1.21V

0x92 = 0.735V 0xB2 = 0.895V 0xD2 = 1.055V 0xF2 = 1.215V

0x93 = 0.74V 0xB3 = 0.9V 0xD3 = 1.06V 0xF3 = 1.22V

0x94 = 0.745V 0xB4 = 0.905V 0xD4 = 1.065V 0xF4 = 1.225V

0x95 = 0.75V 0xB5 = 0.91V 0xD5 = 1.07V 0xF5 = 1.23V

0x96 = 0.755V 0xB6 = 0.915V 0xD6 = 1.075V 0xF6 = 1.235V

0x77 = 0.6V 0x97 = 0.76V 0xB7 = 0.92V 0xD7 = 1.08V 0xF7 = 1.24V

0x78 = 0.605V 0x98 = 0.765V 0xB8 = 0.925V 0xD8 = 1.085V 0xF8 = 1.245V

0x79 = 0.61V 0x99 = 0.77V 0xB9 = 0.93V 0xD9 = 1.09V 0xF9 = 1.25V

0x7A = 0.615V 0x9A = 0.775V 0xBA = 0.935V 0xDA = 1.095V 0xFA = 1.255V

0x7B = 0.62V 0x9B = 0.78V 0xBB = 0.94V 0xDB = 1.1V 0xFB = 1.26V

0x7C = 0.625V 0x9C = 0.785V 0xBC = 0.945V 0xDC = 1.105V 0xFC = 1.265V

0x7D = 0.63V 0x9D = 0.79V 0xBD = 0.95V 0xDD = 1.11V 0xFD = 1.27V

0x7E = 0.635V 0x9E = 0.795V 0xBE = 0.955V 0xDE = 1.115V 0xFE = 1.275V

0x7F = 0.64V 0x9F = 0.8V 0xBF = 0.96V 0xDF = 1.12V 0xFF = 1.28V

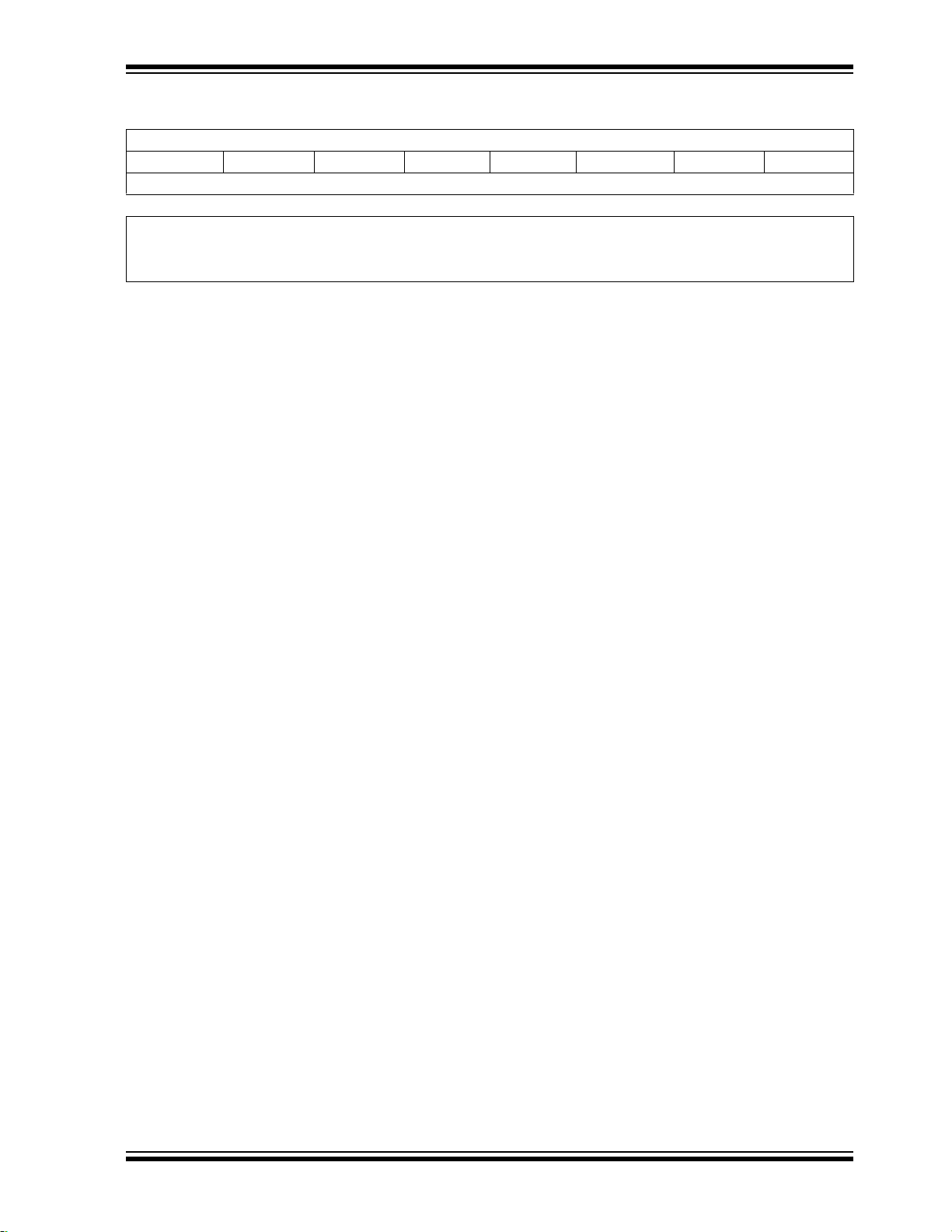

REGISTER C-3: VOUT: OUTPUT VOLTAGE CONTROL REGISTER (ADDRESS 0x02)

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

VO[7:0]

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-0 VO[7:0]: Output Voltage Control (-HAYMP, -FAYMP options)

2019 Microchip Technology Inc. DS50002914A-page 39

Page 40

MIC33M656 Evaluation Board User’s Guide

REGISTER C-3: VOUT: OUTPUT VOLTAGE CONTROL REGISTER (ADDRESS 0x02) (CONTINUED)

bit 7-0 VO[7:0]: Output Voltage Control (-SAYMP option)

0x00-0x3B = 0.6V 0x40 = 0.65V 0x60 = 0.97V 0x80 = 1.3V 0xA0 = 1.94V 0xC0 = 2.58V 0xE0 = 3.22V

0x41 = 0.66V 0x61 = 0.98V 0x81=1.32V 0xA1 = 1.96V 0xC1 = 2.6V 0xE1 = 3.24V

0x42 = 0.67V 0x62 = 0.99V 0x82 = 1.34V 0xA2 = 1.98V 0xC2 = 2.62V 0xE2 = 3.26V

0x43 = 0.68V 0x63 = 1V 0x83 = 1.36V 0xA3 = 2V 0xC3 = 2.64V 0xE3 = 3.28V

0x44 = 0.69V 0x64 = 1.01V 0x84 = 1.38V 0xA4 = 2.02V 0xC4 = 2.66V 0xE4 = 3.3V

0x45 = 0.7V 0x65 = 1.02V 0x85 = 1.4V 0xA5 = 2.04V 0xC5 = 2.68V 0xE5 = 3.32V

0x46 = 0.71V 0x66 = 1.03V 0x86 = 1.42V 0xA6 = 2.06V 0xC6 = 2.7V 0xE6 = 3.34V

0x47 = 0.72V 0x67 = 1.04V 0x87 = 1.44V 0xA7 = 2.08V 0xC7 = 2.72V 0xE7 = 3.36V

0x48 = 0.73V 0x68 = 1.05V 0x88 = 1.46V 0xA8 = 2.1V 0xC8 = 2.74V 0xE8 = 3.38V

0x49 = 0.74V 0x69 = 1.06V 0x89 = 1.48V 0xA9 = 2.12V 0xC9 = 2.76V 0xE9 = 3.4V

0x4A = 0.75V 0x6A = 1.07V 0x8A = 1.5V 0xAA = 2.14V 0xCA = 2.78V 0xEA = 3.42V

0x4B = 0.76V 0x6B = 1.08V 0x8B = 1.52V 0xAB = 2.16V 0xCB = 2.8V 0xEB = 3.44V

0x4C = 0.77V 0x6C = 1.09V 0x8C = 1.54V 0xAC = 2.18V 0xCC = 2.82V 0xEC = 3.46V

0x4D = 0.78V 0x6D = 1.1V 0x8D = 1.56V 0xAD = 2.2V 0xCD = 2.84V 0xED = 3.48V

0x4E = 0.79V 0x6E = 1.11V 0x8E = 1.58V 0xAE = 2.22V 0xCE = 2.86V 0xEE = 3.5V

0x4F = 0.8V 0x6F=1.12V 0x8F = 1.6V 0xAF = 2.24V 0xCF = 2.88V 0xEF = 3.52V

0x50 = 0.81V 0x70 = 1.13V 0x90 = 1.62V 0xB0 = 2.26V 0xD0 = 2.9V 0xF0 = 3.54V

0x51 = 0.82V 0x71 = 1.14V 0x91 = 1.64V 0xB1 = 2.28V 0xD1 = 2.92V 0xF1 = 3.56V

0x52 = 0.83V 0x72 = 1.15V 0x92 = 1.66V 0xB2 = 2.3V 0xD2 = 2.94V 0xF2 = 3.58V

0x53 = 0.84V 0x73 = 1.16V 0x93 = 1.68V 0xB3 = 2.32V 0xD3 = 2.96V 0xF3 = 3.6V

0x54 = 0.85V 0x74 = 1.17V 0x94 = 1.7V 0xB4 = 2.34V 0xD4 = 2.98V 0xF4 = 3.62V

0x55 = 0.86V 0x75 = 1.18V 0x95 = 1.72V 0xB5 = 2.36V 0xD5 = 3V 0xF5 = 3.64V

0x56 = 0.87V 0x76=1.19V 0x96 = 1.74V 0xB6 = 2.38V 0xD6 = 3.02V 0xF6 = 3.66V

0x57 = 0.88V 0x77 = 1.2V 0x97 = 1.76V 0xB7 = 2.4V 0xD7 = 3.04V 0xF7 = 3.68V

0x58 = 0.89V 0x78 = 1.21V 0x98 = 1.78V 0xB8 = 2.42V 0xD8 = 3.06V 0xF8 = 3.7V

0x59 = 0.9V 0x79 = 1.22V 0x99 = 1.8V 0xB9 = 2.44V 0xD9 = 3.08V 0xF9 = 3.72V

0x5A = 0.91V 0x7A = 1.23V 0x9A = 1.82V 0xBA = 2.46V 0xDA = 3.1V 0xFA = 3.74V

0x3B = 0.6V 0x5B = 0.92V 0x7B = 1.24V 0x98 = 1.84V 0xBB = 2.48V 0xDB = 3.12V 0xFB = 3.76V

0x3C = 0.61V 0x5C = 0.93V 0x7C = 1.25V 0x9C = 1.86V 0xBC = 2.5V 0xDC = 3.14V 0xFC = 3.78V

0x3D = 0.62V 0x5D = 0.94V 0x7D = 1.26V 0x9D = 1.88V 0xBD = 2.52V 0xDD = 3.16V 0xFD = 3.8V

0x3E = 0.63V 0x5E = 0.95V 0x7E = 1.27V 0x9E = 1.9V 0xBE = 2.54V 0xDE = 3.18V 0xFE = 3.82V

0x3F = 0.64V 0x5F = 0.96V 0x7F = 1.28V 0x9F = 1.92V 0xBF = 2.56V 0xDF = 3.2V 0xFF = 3.84V

DS50002914A-page 40 2019 Microchip Technology Inc.

Page 41

MIC33M656 Internal Registers

REGISTER C-4: FAULT: STATUS AND FAULT REGISTER (ADDRESS 0x03)

R-0 R-0 R-0 R-0 R-0 R-0 R-0 R-0

OT_WARN EN_STAT BOOT_ERR SSD HICCUP OT LATCH_OFF PG

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 OT_WARN: Overtemperature Warning

0 = No Fault

1 = Fault

bit 6 EN_STAT: Buck On/Off Control

0 = Off

1 = On

bit 5 BOOT_ERR: Boot-up Error

0 = No Fault

1 = Fault

bit 4 SSD: Soft Start Done

0 = Ramp not done

1 = Ramp done

bit 3 HICCUP: Current Limit Hiccup

0 = Not in Hiccup mode

1 = In Hiccup mode

bit 2 OT: Overtemperature

0 = No Fault

1 = Fault

bit 1 LATCH_OFF: Overcurrent or Overtemperature Output Latch Off

0 = No Fault

1 = Fault

bit 0 PG: Power Good

0 = Power not good

1 = Power good

2019 Microchip Technology Inc. DS50002914A-page 41

Page 42

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

China - Beijing

Tel: 86-10-8569-7000

China - Chengdu

Tel: 86-28-8665-5511

China - Chongqing

Tel: 86-23-8980-9588

China - Dongguan

Tel: 86-769-8702-9880

China - Guangzhou

Tel: 86-20-8755-8029

China - Hangzhou

Tel: 86-571-8792-8115

China - Hong Kong SAR

Tel: 852-2943-5100

China - Nanjing

Tel: 86-25-8473-2460

China - Qingdao

Tel: 86-532-8502-7355

China - Shanghai

Tel: 86-21-3326-8000

China - Shenyang

Tel: 86-24-2334-2829

China - Shenzhen

Tel: 86-755-8864-2200

China - Suzhou

Tel: 86-186-6233-1526

China - Wuhan

Tel: 86-27-5980-5300

China - Xian

Tel: 86-29-8833-7252

China - Xiamen

Tel: 86-592-2388138

China - Zhuhai

Tel: 86-756-3210040

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

India - New Delhi

Tel: 91-11-4160-8631

India - Pune

Tel: 91-20-4121-0141

Japan - Osaka

Tel: 81-6-6152-7160

Japan - Tokyo

Tel: 81-3-6880- 3770

Korea - Daegu

Tel: 82-53-744-4301

Korea - Seoul

Tel: 82-2-554-7200

Malaysia - Kuala Lumpur

Tel: 60-3-7651-7906

Malaysia - Penang

Tel: 60-4-227-8870

Philippines - Manila

Tel: 63-2-634-9065

Singapore

Tel: 65-6334-8870

Taiwan - Hsin Chu

Tel: 886-3-577-8366

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Taiwan - Taipei

Tel: 886-2-2508-8600

Thailand - Bangkok

Tel: 66-2-694-1351

Vietnam - Ho Chi Minh

Tel: 84-28-5448-2100

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

Finland - Espoo

Tel: 358-9-4520-820

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-72400

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Israel - Ra’anana

Tel: 972-9-744-7705

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-7288-4388

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

DS50002914A-page 42 2019 Microchip Technology Inc.

05/14/19

Loading...

Loading...