Page 1

MCP73833/4

Stand-Alone Linear Li-Ion / Li-Polymer Charge

Management Controller

Features

• Complete Linear Charge Management Controller

- Integrated Pass Transistor

- Integrated Current Sense

- Integrated Reverse Discharge Protection

• Constant Current / Constant Voltage Operation

with Thermal Regulation

• High Accuracy Preset Voltage Regulation:

- 4.2V, 4.35V, 4.4V, or 4.5V, +

0.75%

• Programmable Charge Current: 1A Maximum

• Preconditioning of Deeply Depleted Cells

- Selectable Current Ratio

- Selectable Voltage Threshold

• Automatic End-of-Charge Control

- Selectable Current Threshold

- Selectable Safety Time Period

• Automatic Recharge

- Selectable Voltage Threshold

• Two Charge Status Outputs

• Cell Temperature Monitor

• Low-Dropout Linear Regulator Mode

• Automatic Power-Down when Input Power

Removed

• Under Voltage Lockout

• Numerous Selectable Options Available for a

Variety of Applications:

- Refer to Section 1.0 “Electrical

Characteristics” for Selectable Options

- Refer to the ”Product Identification

System” for Standard Options

• Available Packages:

- 3mm x 3mm DFN-10

- MSOP-10

Applications

• Lithium-Ion / Lithium-Polymer Battery Chargers

• Personal Data Assistants

• Cellular Telephones

• Digital Cameras

• MP3 Players

• Bluetooth Headsets

• USB Chargers

Description

The MCP73833/4 is a highly advanced linear charge

management controller for use in space-limited, cost

sensitive applications. The MCP73833/4 is available in

a 10-Lead, 3mm x 3mm DFN package or a 10-Lead,

MSOP package. Along with its small physical size, the

low number of external components required makes

the MCP73833/4 ideally suited for portable applications. For applications charging from a USB port, the

MCP73833/4 can adhere to all the specifications

governing the USB power bus.

The MCP73833/4 employs a constant current/constant

voltage charge algorithm with selectable preconditioning and charge termination. The constant voltage

regulation is fixed with four available options: 4.20V,

4.35V, 4.40V, or 4.50V, to accomodate new, emerging

battery charging requirements. The constant current

value is set with one external resistor. The

MCP73833/4 limits the charge current based on die

temperature during high power or high ambient conditions. This thermal regulation optimizes the charge

cycle time while maintaining device reliability.

Several options are available for the preconditioning

threshold, preconditioning current value, charge

termination value, and automatic recharge threshold.

The preconditioning value and charge termination

value are set as a ratio, or percentage, of the

programmed constant current value. Preconditioning

can be set

to 100%. Refer to Section 1.0 “Electrical

Characteristics” for available options and the

“Product Indentification System” for standard

options.

The MCP73833/4 is fully specified over the ambient

temperature range of -40°C to +85°C.

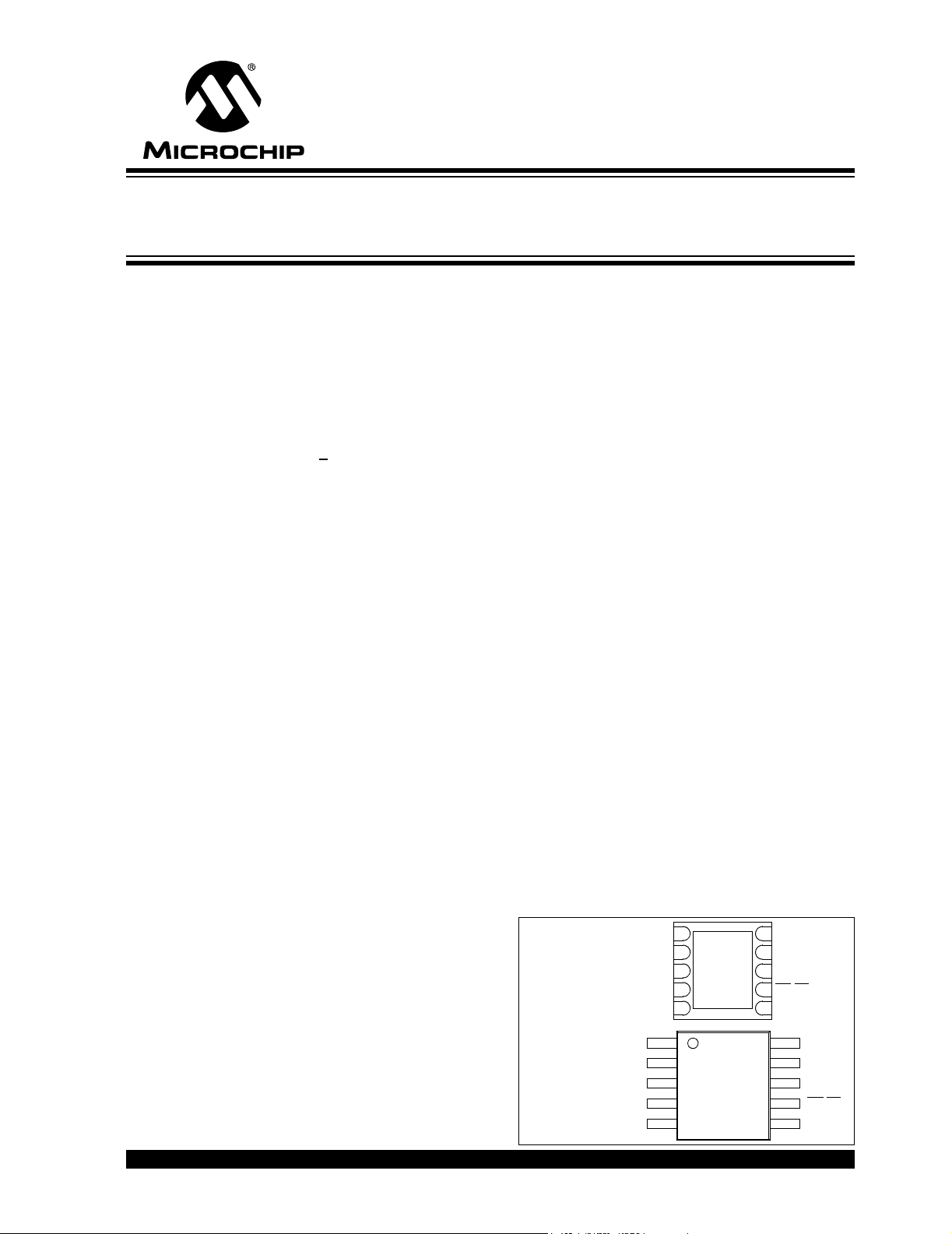

Package Types

DFN-10

MSOP-10

V

V

STAT1

STAT2

V

STAT1

STAT2

DD

DD

SS

V

1

DD

V

2

DD

3

4

56

V

SS

110

2

3

4

5

10

9

8

7

9

8

7

6

V

V

THERM

PG(TE)

PROG

BAT

BAT

V

BAT

V

BAT

THERM

PG

(TE)

PROG

© 2006 Microchip Technology Inc. DS22005A-page 1

Page 2

MCP73833/4

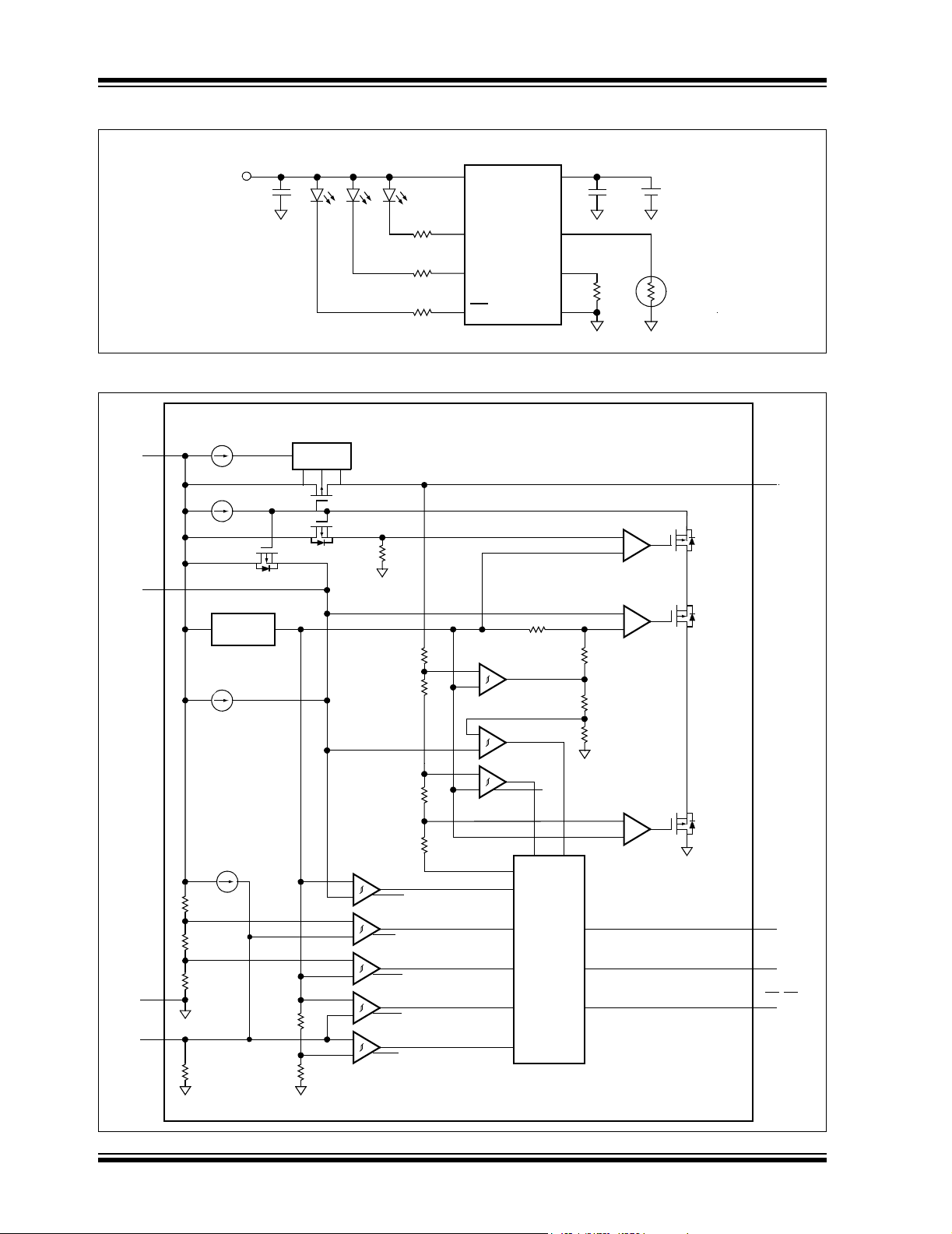

Typical Application

V

IN

1µF

Functional Block Diagram

V

DD

10 µA

Direction

Control

1A Li-Ion Battery Charger

1,2

V

DD

38

470Ω

4

470Ω

7

STAT1

STAT2

PG

THERM

PROG

470Ω

MCP73833

9,10

V

BAT

6

5

V

SS

1µF

1kΩ

Single

+

Li-Ion

Cell

T

10 kΩ

V

BAT

PROG

V

SS

THERM

175 kΩ

54 kΩ

121 kΩ

1MΩ

6µA

Reference

Generator

(1.21V)

V

REF

6µA

50 µA

121 kΩ

G=0.001

G=0.001

+

-

+

-

+

-

+

-

+

-

1kΩ

310 kΩ

72.7 kΩ

6kΩ

157.3 kΩ

SHDN

LDO

UVLO

HTVT470.6kΩ

LTV T

111 kΩ

+

PRECONDITION

+

TERMINATIO N

+

-

CHARG E

Charge

Control,

Timer,

and

Status

Logic

10 kΩ

470.6 kΩ

48 kΩ

CURRENT

LIMIT

+

-

CA

+

-

VA

+

-

STAT1

STAT2

PG (TE)

DS22005A-page 2 © 2006 Microchip Technology Inc.

Page 3

MCP73833/4

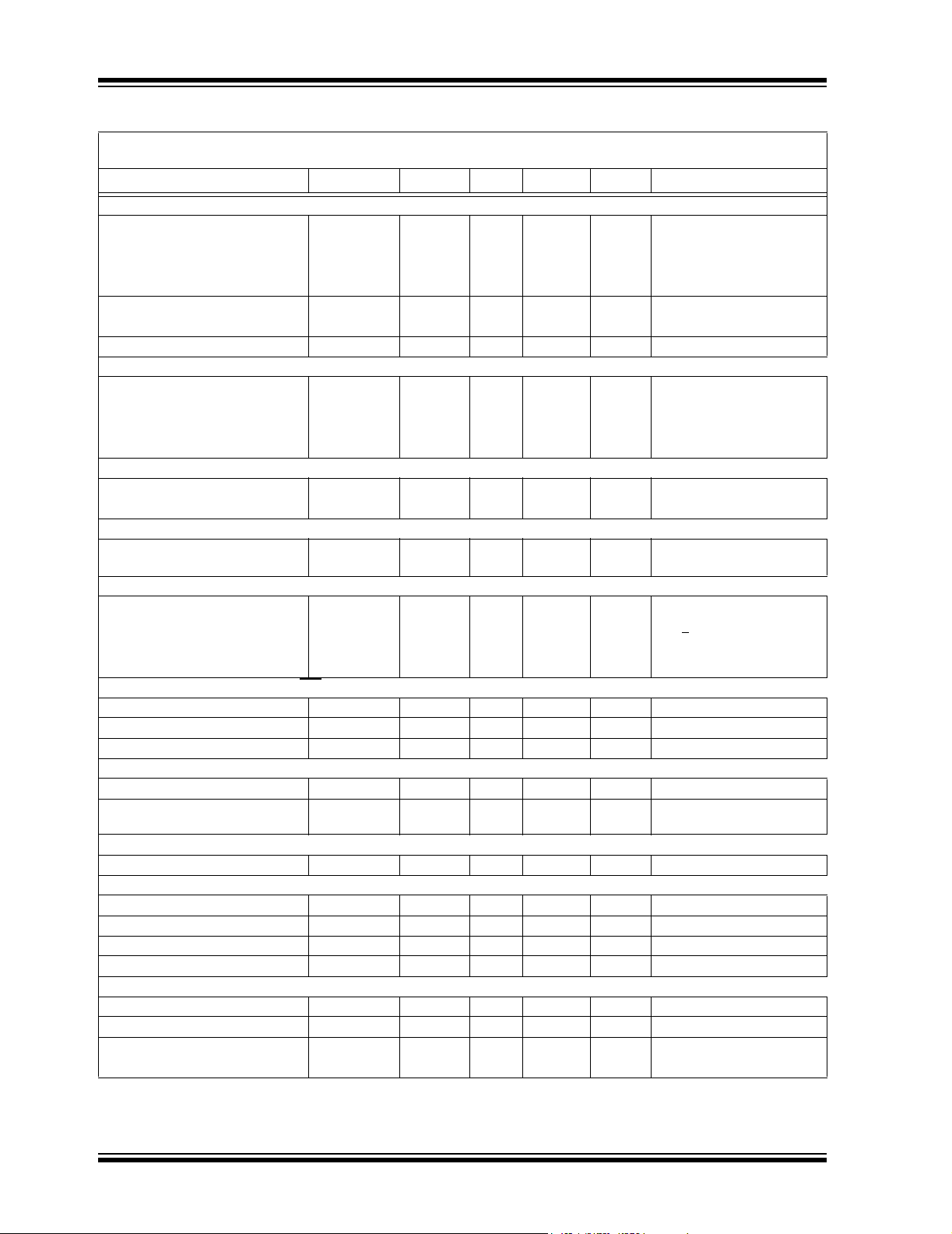

1.0 ELECTRICAL CHARACTERISTICS

*Notice: Stresses above those listed under “Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of

the device at those or any other conditions above those

Absolute Maximum Ratings

VDD........................................................................7.0V

All Inputs and Outputs w.r.t. V

Maximum Junction Temperature, T

.....-0.3 to (VDD+0.3)V

SS

. Internally Limited

J

indicated in the operational listings of this specification

is not implied. Exposure to maximum rating conditions

for extended periods may affect device reliability.

Storage temperature .......................... -65°C to +150°C

ESD protection on all pins:

Human Body Model (HBM)

(1.5 kΩ in Series with 100 pF)............................... ≥ 4kV

Machine Model (MM)

(200 pF, No Series Resistance) ...........................300V

DC CHARACTERISTICS

Electrical Specifications: Unless otherwise specified, all limits apply for VDD= [V

Typical values are at +25°C, V

DD

= [V

(Typ)+1.0V]

REG

Parameters Sym Min Typ Max Units Conditions

Supply Input

Supply Voltage V

Supply Current I

DD

SS

3.75 — 6 V Charging

V

REG

(Typ)

+0.3V

— 6 V Charge Complete, Standby

— 2000 3000 µA Charging

— 150 300 µA Charge Complete

— 100 300 µA Standby (No Battery or PROG

— 50 100 µA Shutdown (V

UVLO Start Threshold V

UVLO Stop Threshold V

UVLO Hysteresis V

START

STOP

HYS

3.4 3.55 3.7 V VDD Low to High

3.3 3.45 3.6 V VDD High to Low

— 100 — mV

Voltage Regulation (Constant Voltage Mode, System Test Mode)

Regulated Output Voltage V

REG

4.168 4.20 4.232 V VDD=[V

4.318 4.35 4.382 V I

4.367 4.40 4.433 V T

4.467 4.50 4.533 V

)

Line Regulation |(ΔV

Load Regulation |ΔV

BAT/VBAT

/ΔV

DD

/ V

BAT

|

BAT

— 0.10 0.30 %/V V

| — 0.10 0.30 % I

Supply Ripple Attenuation PSRR — 58 — dB I

—47— dBI

—25— dBI

Current Regulation (Fast Charge Constant Current Mode)

Fast Charge Current Regulation I

REG

90 100 110 mA PROG = 10 kΩ

900 1000 1100 mA PROG = 1.0 kΩ

Maximum Output Current Limit I

MAX

— 1200 — mA PROG < 833Ω

(Typ)+0.3V] to 6V, TA=-40°C to 85°C.

REG

Floating)

< V

V

< V

DD

OUT

=-5°C to +55°C

A

=[V

DD

I

OUT

OUT

V

=[V

DD

OUT

OUT

OUT

=-5°C to +55°C

T

A

DD

)

STOP

(Typ)+1V]

REG

=10 mA

(Typ)+1V] to 6V

REG

=10 mA

=10 mA to 100 mA

(Typ)+1V]

REG

=10 mA, 10Hz to 1 kHz

=10 mA, 10Hz to 10 kHz

=10 mA, 10Hz to 1 MHz

BAT

, or

© 2006 Microchip Technology Inc. DS22005A-page 3

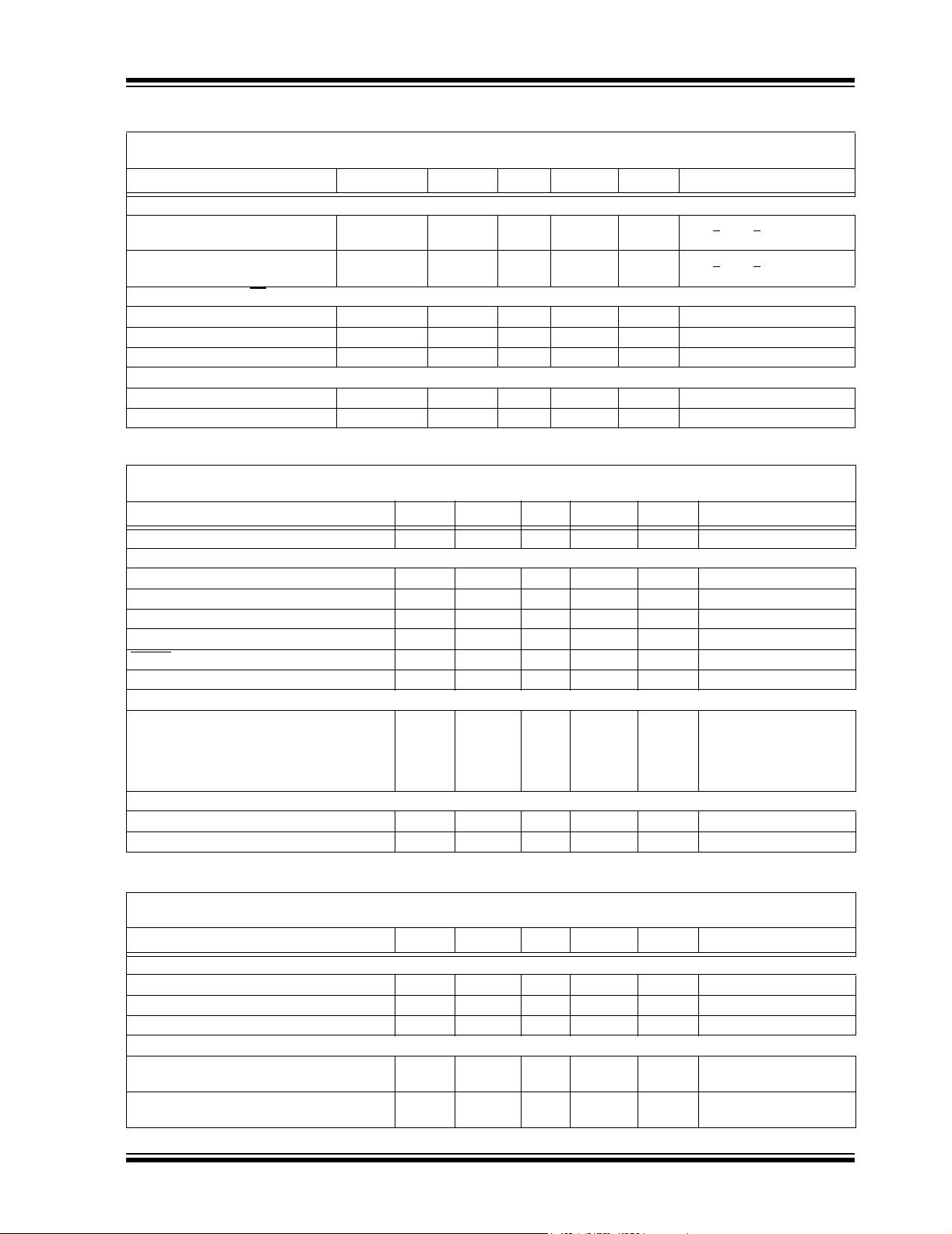

Page 4

MCP73833/4

DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise specified, all limits apply for VDD= [V

Typical values are at +25°C, V

Parameters Sym Min Typ Max Units Conditions

Preconditioning Current Regulation (Trickle Charge Constant Current Mode)

Precondition Current Ratio I

Precondition Voltage Threshold

Ratio

Precondition Hysteresis V

Charge Termination

Charge Termination Current Ratio I

Automatic Recharge

Recharge Voltage Threshold Ratio V

Pass Transistor ON-Resistance

ON-Resistance R

Battery Discharge Current

Output Reverse Leakage Current I

Status Indicators - STAT1, STAT2, PG

Sink Current I

Low Output Voltage V

Input Leakage Current I

PROG Input

Charge Impedance Range R

Standy Impedance R

Thermistor Bias

Thermistor Current Source I

Thermistor Comparator

Upper Trip Threshold V

Upper Trip Point Hysteresis V

Lower Trip Threshold V

Lower Trip Point Hysteresis V

System Test (LDO) Mode

Input High Voltage Level V

THERM Input Sink Current I

Bypass Capacitance C

DD

= [V

(Typ)+1.0V]

REG

PREG

V

PTH

TERM

RTH

DISCHARGE

THERM

T1HYS

T2HYS

/ I

/ V

PHYS

/ I

/ V

DSON

SINK

OL

LK

PROG

PROG

T1

T2

IH

SINK

BAT

REG

REG

REG

REG

7.5 10 12.5 % PROG = 1.0 kΩ to 10 kΩ

15 20 25 % T

30 40 50 %

— 100 — %

64 66.5 70 % V

69 71.5 75 %

— 100 — mV V

3.75 5 6.25 % PROG = 1.0 kΩ to 10 kΩ

5.6 7.5 9.4 % T

7.5 10 12.5 %

15 20 25 %

— 94.0 — % V

— 96.5 — %

— 300 — mΩ VDD = 3.75V

— 0.15 2 µA PROG Floating

—0.25 2 µAV

—0.15 2 µAVDD < V

— -5.5 -15 µA Charge Complete

—1525mA

—0.4 1 VI

— 0.01 1 µA High Impedance, 6V on pin

1—20kΩ

70 — 200 kΩ Minimum Impedance for

47 50 53 µA 2 kΩ < R

1.20 1.23 1.26 V V

—-50—mV

0.235 0.25 0.265 V V

—50—mV

(VDD-0.1)

—— V

3 6 20 µA Stand-by or system test mode

1——µFI

4.7 — — µF I

(Typ)+0.3V] to 6V, TA=-40°C to 85°C.

REG

=-5°C to +55°C

A

Low to High

BAT

High to Low

BAT

=-5°C to +55°C

A

High to Low

BAT

= 105°C

T

J

< V

DD

BAT

STOP

= 4 mA

SINK

Standby

THERM

Low to High

THERM

High to Low

THERM

< 250 mA

OUT

> 250 mA

OUT

< 50 kΩ

DS22005A-page 4 © 2006 Microchip Technology Inc.

Page 5

DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise specified, all limits apply for VDD= [V

Typical values are at +25°C, V

DD

= [V

(Typ)+1.0V]

REG

Parameters Sym Min Typ Max Units Conditions

Automatic Power Down

Automatic Power Down Entry

Threshold

Automatic Power Down Exit Thresh-

old

Timer Enable Input (TE

)

V

PDEXIT

Input High Voltage Level V

Input Low Voltage Level V

Input Leakage Current I

V

PD

—V

—V

IH

IL

LK

2.0 — — V

——0.6 V

—0.01 1 µAV

+

BAT

50 mV

+

BAT

150 mV

Thermal Shutdown

Die Temperature T

Die Temperature Hysteresis T

SD

SDHYS

— 150 — °C

—10— °C

AC CHARACTERISTICS

Electrical Specifications: Unless otherwise specified, all limits apply for VDD= [V

Typical values are at +25°C, V

Parameters Sym Min Typ Max Units Conditions

UVLO Start Delay t

Current Regulation

Transition Time Out of Preconditioning t

Current Rise Time Out of Preconditioning t

Preconditioning Comparator Filter Time t

Termination Comparator Filter Time t

Comparator Filter Time t

Charge

Thermistor Comparator Filter Time t

Elapsed Timer

Elapsed Timer Period t

Status Indicators

Status Output turn-off t

Status Output turn-on t

DD

= [V

(Typ)+1.0V]

REG

START

DELAY

RISE

PRECON

TERM

CHARGE

THERM

ELAPSED

OFF

ON

—— 5 msV

—— 1 msV

—— 1 msI

0.4 1.3 3.2 ms Average V

0.4 1.3 3.2 ms Average I

0.4 1.3 3.2 ms Average V

0.4 1.3 3.2 ms Average THERM Rise/Fall

0 0 0 Hours Timer Disabled

3.6 4.0 4.4 Hours

5.4 6.0 6.6 Hours

7.2 8.0 8.8 Hours

— — 200 µs I

— — 200 µs I

MCP73833/4

(Typ)+0.3V] to 6V, TA=-40°C to 85°C.

REG

— V 2.3V < V

VDD Falling

— V 2.3V < V

VDD Rising

(Typ)+0.3V] to 6V, TA=-40°C to 85°C.

REG

BAT

BAT

= 6V

TE

Low to High

DD

BAT<VPTH

Rising to 90% of I

OUT

= 1 mA to 0 mA

SINK

= 0 mA to 1 mA

SINK

< V

< V

to V

BAT

OUT

BAT

REG

REG

BAT>VPTH

REG

Rise/Fall

Falling

Falling

TEMPERATURE SPECIFICATIONS

Electrical Specifications: Unless otherwise specified, all limits apply for V

Typical values are at +25°C, V

DD

= [V

(Typ)+1.0V]

REG

Parameters Symbol Min Typ Max Units Conditions

Temperature Ranges

Specified Temperature Range T

Operating Temperature Range T

Storage Temperature Range T

A

A

A

-40 — +85 °C

-40 — +125 °C

-65 — +150 °C

Thermal Package Resistances

Thermal Resistance, MSOP-10 θ

Thermal Resistance, 3mm x 3mm DFN-10 θ

JA

JA

— 113 — °C/W 4-Layer JC51-7 Standard

— 41 — °C/W 4-Layer JC51-7 Standard

© 2006 Microchip Technology Inc. DS22005A-page 5

DD

= [V

REG

(Typ)+0.3V] to 6V.

Board, Natural Convection

Board, Natural Convection

Page 6

MCP73833/4

P

:

:

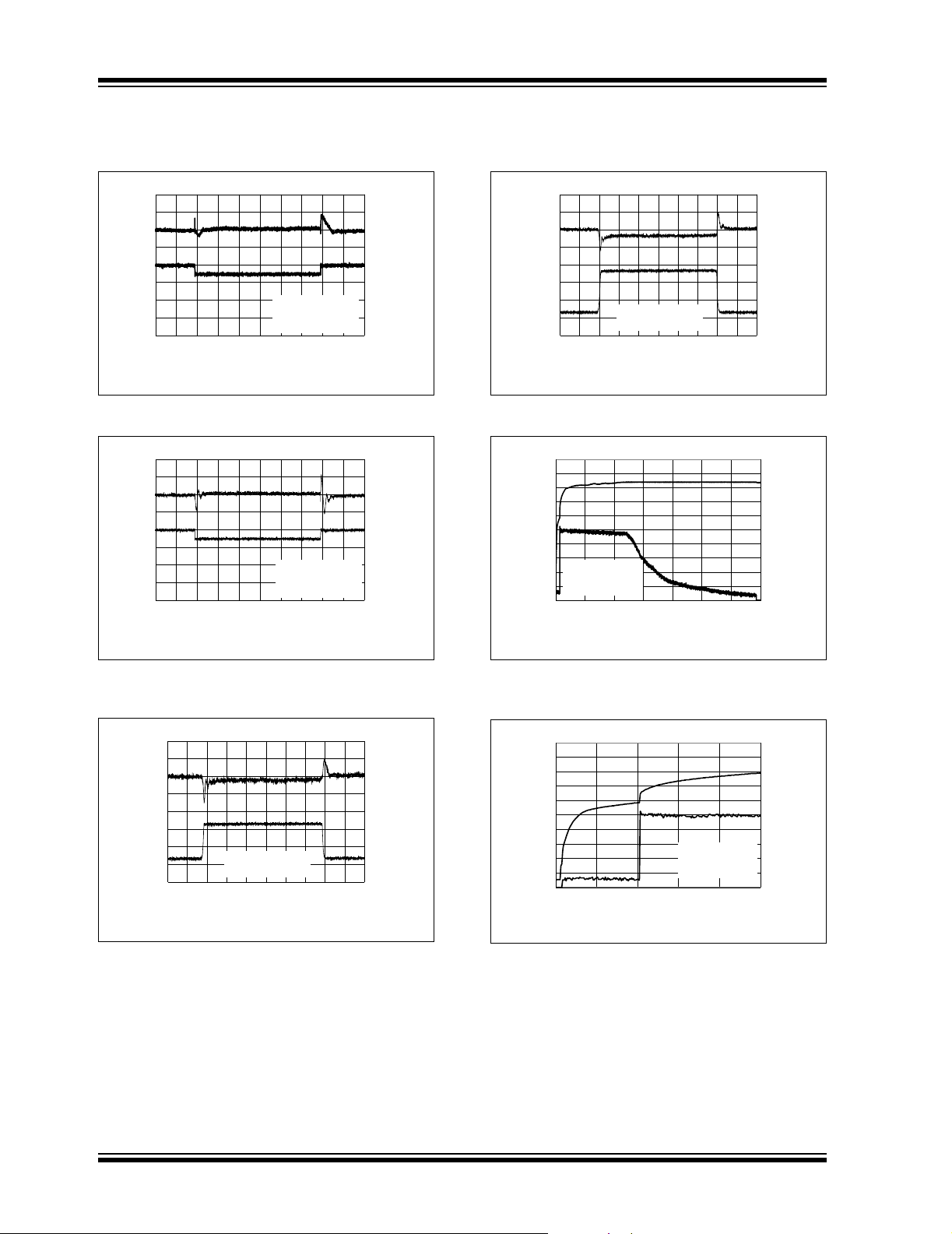

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated, VDD = 5.2V, V

REG

= 4.20V, I

= 10 mA and TA= +25°C, Constant-voltage mode.

OUT

4.210

4.205

4.200

4.195

4.190

(V)

4.185

4.180

4.175

Battery Regulation Voltage

4.170

4.50 4.75 5.00 5.25 5.50 5.75 6.00

Supply Voltage (V)

MCP73833

I

= 10 mA

OUT

I

= 100 mA

OUT

I

= 500 mA

OUT

I

= 900 mA

OUT

FIGURE 2-1: Battery Regulation Voltage

(V

) vs. Supply Voltage (VDD).

BAT

4.220

MCP73833

4.210

4.200

4.190

4.180

I

= 500 mA

4.170

4.160

Battery Regulation Voltage (V)

OUT

I

= 900 mA

OUT

-40

-30

0

-20

-10

Ambient Temperature (°C)

10203040506070

I

OUT

I

OUT

= 10 mA

= 100 mA

80

1000

100

Charge Current (mA)

10

1 3 5 7 9 11 13 15 17 19 21

Programming Resistor (k:)

FIGURE 2-4: Charge Current (I

Programming Resistor (R

104

103

102

101

100

99

98

Charge Current (mA)

97

96

4.50 4.75 5.00 5.25 5.50 5.75 6.00

Supply Voltage (V)

PROG

).

R

PROG

OUT

= 10 k

) vs.

FIGURE 2-2: Battery Regulation Voltage

) vs. Ambient Temperature (TA).

(V

BAT

0.40

A)

0.35

+85°C

0.30

-40°C

0.25

0.20

+25°C

0.15

0.10

0.05

Output Leakage Current (

0.00

3.00 3.20 3.40 3.60 3.80 4.00 4.20

Battery Regulation Voltage (V)

FIGURE 2-3: Output Leakage Current

(I

DISCHARGE

(V

BAT

) vs. Battery Regulation Voltage

).

FIGURE 2-5: Charge Current (I

Supply Voltage (V

1004

1002

1000

998

996

994

992

990

Charge Current (mA)

988

986

4.50 4.75 5.00 5.25 5.50 5.75 6.00

).

DD

Supply Voltage (V)

FIGURE 2-6: Charge Current (I

Supply Voltage (V

DD

).

) vs.

OUT

R

= 1 k

PROG

) vs.

OUT

DS22005A-page 6 © 2006 Microchip Technology Inc.

Page 7

TYPICAL PERFORMANCE CURVES (Continued)

:

:

P

MCP73833/4

Note: Unless otherwise indicated, VDD = 5.2V, V

120

100

80

60

40

20

Charge Current (mA)

0

25354555657585

Junction Temperature (°C)

FIGURE 2-7: Charge Current (I

Junction Temperature (T

1200

1000

800

600

400

200

Charge Current (mA)

0

25354555657585

Junction Temperature (°C)

).

J

R

= 10 k

PROG

95

105

115

125

135

) vs.

OUT

R

= 1 k

PROG

95

105

115

125

135

REG

145

145

= 4.20V, I

155

155

= 10 mA and TA= +25°C, Constant-voltage mode.

OUT

52.0

51.5

51.0

50.5

50.0

49.5

49.0

48.5

48.0

Thermistor Bias Current (µA)

-40

-30

0

-20

Ambient Temperature (°C)

10203040506070

-10

FIGURE 2-10: Thermistor Bias Current

(I

THRERM

) vs. Ambient Temperature (TA).

0

VAC = 100 mVp-p

= 10 mA

I

OUT

-10

= 4.7 µF, X7R

C

OUT

-20

Ceramic

-30

-40

-50

Attenuation (dB)

-60

-70

0.01 0.1 1 10 100 1000

Frequency (kHz)

80

FIGURE 2-8: Charge Current (I

Junction Temperature (T

52.0

A)

51.5

51.0

50.5

50.0

49.5

49.0

48.5

Thermistor Bias Current (

48.0

4.50 4.75 5.00 5.25 5.50 5.75 6.00

).

J

Supply Voltage (V)

FIGURE 2-9: Thermistor Bias Current

(I

THRERM

) vs. Supply Voltage (VDD).

OUT

) vs.

FIGURE 2-11: Power Supply Ripple Rejection (PSRR).

0

VAC = 100 mVp-p

= 100 mA

I

OUT

-10

= 4.7 µF, X7R

C

OUT

Ceramic

-20

-30

-40

Attenuation (dB)

-50

-60

0.01 0.1 1 10 100 1000

Frequency (kHz)

FIGURE 2-12: Power Supply Ripple Rejection (PSRR).

© 2006 Microchip Technology Inc. DS22005A-page 7

Page 8

MCP73833/4

:

:

TYPICAL PERFORMANCE CURVES (Continued)

Note: Unless otherwise indicated, VDD = 5.2V, V

14

12

10

8

6

4

I

2

Source Voltage (V)

0

-2

0

204060

Time (µs)

= 10 mA

OUT

= 4.7 µF, X7R

C

OUT

Ceramic

80

100

120

140

160

180

REG

0.10

0.05

0.00

-0.05

-0.10

-0.15

-0.20

-0.25

-0.30

200

FIGURE 2-13: Line Transient Response.

14

12

10

8

6

4

2

Source Voltage (V)

0

-2

0

204060

80

100

Time (µs)

I

= 100 mA

OUT

= 4.7 µF, X7R

C

OUT

Ceramic

120

140

160

0.10

0.05

0.00

-0.05

-0.10

-0.15

-0.20

-0.25

-0.30

180

200

= 4.20V, I

Output Ripple (V)

Output Ripple (V)

= 10 mA and TA= +25°C, Constant-voltage mode.

OUT

Output Current (A)

1.40

1.20

1.00

0.80

0.60

0.40

0.20

0.00

-0.20

0

C

Ceramic

204060

= 4.7 µF, X7R

OUT

80

Time (µs)

100

120

140

0.10

0.05

0.00

-0.05

-0.10

-0.15

-0.20

-0.25

-0.30

160

180

200

FIGURE 2-16: Load Transient Response.

5.0

4.0

3.0

2.0

MCP73833-FCI/MF

1.0

Battery Voltage (V)

V

= 5.2V

DD

R

= 10.0 k

PROG

0.0

0

30

60

90

Time (Minutes)

120

150

180

200

160

120

80

40

0

210

Output Ripple (V)

Charge Current (A)

FIGURE 2-14: Line Transient Response.

Output Current (A)

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0.00

-0.05

0

204060

C

= 4.7 µF, X7R

OUT

Ceramic

80

Time (µs)

100

120

140

0.04

0.02

0.00

-0.02

-0.04

-0.06

-0.08

-0.10

-0.12

160

180

200

FIGURE 2-15: Load Transient Response.

Output Ripple (V)

FIGURE 2-17: Complete Charge Cycle

(180 mA Li-Ion Battery).

5.0

4.0

3.0

2.0

Battery Voltage (V)

1.0

0.0

0246810

Time (Minutes)

MCP73833-FCI/MF

V

DD

R

= 10.0 k

PROG

= 5.2V

200

160

120

80

40

0

FIGURE 2-18: Charge Cycle Start Preconditioning (180 mAh Li-Ion Battery).

Charge Current (A)

DS22005A-page 8 © 2006 Microchip Technology Inc.

Page 9

3.0 PIN DESCRIPTIONS

Descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

MCP73833/4

Pin No.

DFN MSOP

11 V

22 V

3 3 STAT1 Charge Status Output

4 4 STAT2 Charge Status Output

55 V

6 6 PROG Current Regulation Set and Charge Control Enable

77 PG,

8 8 THERM Thermistor input

99 V

10 10 V

3.1 Battery Management Input Supply

)

(V

DD

A supply voltage of [V

recommended. Bypass to VSS with a minimum of 1 µF.

3.2 Charge Status Outputs (STAT1,

STAT2)

STAT1 and STAT2 are open-drain logic outputs for connection to a LED for charge status indication.

Alternatively, a pull-up resistor can be applied for

interfacing to a host microcontroller.

3.3 Battery Management 0V Reference

)

(V

SS

Connect to negative terminal of battery and input

supply.

Symbol Function

DD

DD

SS

TE MCP73833: Power Good output, MCP73834: Timer Enable input

BAT

BAT

Battery Management Input Supply

Battery Management Input Supply

Battery Management 0V Reference

Battery Charge Control Output

Battery Charge Control Output

3.6 Timer Enable Input (TE)

(typ.) + 0.3V] to 6V is

REG

The timer enable (TE) input option is used to enable or

disable the internal timer. A low signal on this pin

enables the internal timer and a high signal disables

the internal timer. The TE

the timer when the charger is supplying current to

charge the battery and power the system load. The TE

input is compatible with 1.8V logic.

3.7 Thermistor Input (THERM)

An internal 50 µA current source provides the bias for

most common 10 kΩ negative-temperature coefficient

thermistors (NTC). The MCP73833/4 compares the

voltage at the THERM pin to factory set thersholds of

1.20V and 0.25V, typically.

MCP73834 Only

3.8 Battery Charge Control Output

3.4 Current Regulation Set (PROG)

Preconditioning, fast charge, and termination currents

are scaled by placing a resistor from PROG to V

The charge management controller can be disabled by

allowing the PROG input to float.

SS

.

Connect to positive terminal of battery. Drain terminal

of internal P-channel MOSFET pass transistor. Bypass

to VSS with a minimum of 1 µF to ensure loop stability

when the battery is disconnected.

(V

BAT

input can be used to disable

)

3.5 Power Good Indication (PG)

MCP73833 Only

The power good (PG) option is a pseudo open-drain

output. The PG

current. However, there is a diode path back to the

input, and, as such, the PG

pulled up to the input. The PG

the input to the MCP73833 is above the UVLO

threshold and greater than the battery voltage.

© 2006 Microchip Technology Inc. DS22005A-page 9

output can sink current, but not source

output should only be

output is low whenever

Page 10

MCP73833/4

4.0 FUNCTIONAL DESCRIPTION

The MCP73833/4 is a highly advanced linear charge

management controller. Refer to the functional block

diagram and Figure 4-1 that depicts the operational

flow algorithm from charge initiation to completion and

automatic recharge.

SYSTEM TEST (LDO) MODE

V

> (VDD - 100 mv)

THERM

PROG > 20 kΩ

STAT1 = LOW

STAT2 = LOW

PG = LOW

Timer Suspended

TEMPERATURE FAULT

No Charge Current

STAT1 = Hi-Z

STAT2 = Hi-Z

PG = LOW

Timer Suspended

SHUTDOWN MODE *

< V

V

DD

UVLO

VDD < V

BAT

STAT1 = HI-Z

STAT2 = HI-Z

PG = HI-Z

STANDBY MODE *

(V

V

BAT

PRECONDITIONING MODE

Charge Current (I

FAST CHARGE MODE

Charge Current (I

+ 100 mv)

REG

PROG > 200 kΩ

STAT1 = HI-Z

STAT2 = HI-Z

PG = LOW

V

BAT

STAT1 = LOW

STAT2 = Hi-Z

PG = LOW

Timer Reset

V

BAT

STAT1 = LOW

STAT2 = Hi-Z

PG = LOW

Timer Enabled

< V

PREG

> V

REG

PTH

PTH

* Continuously Monitored

V

> V

BAT

PTH

Timer Expired

V

< V

BAT

RTH

TIMER FAULT

No Charge Current

STAT1 = Hi-Z

STAT2 = Hi-Z

PG = LOW

Timer Suspended

V

= V

BAT

REG

CONSTANT VOLTAGE MODE

Charge Voltage (V

STAT1 = LOW

STAT2 = Hi-Z

PG = LOW

CHARGE COMPLETE MODE

No Charge Current

STAT1 = HI-Z

STAT2 = LOW

PG = LOW

Timer Reset

REG

V

< I

BAT

TERM

Timer Expired

FIGURE 4-1: Flow Chart.

DS22005A-page 10 © 2006 Microchip Technology Inc.

Page 11

MCP73833/4

4.1 Under Voltage Lockout (UVLO)

An internal under voltage lockout (UVLO) circuit

monitors the input voltage and keeps the charger in

shutdown mode until the input supply rises above the

UVLO threshold. The UVLO circuitry has a built in

hysteresis of 100 mV.

In the event a battery is present when the input power

is applied, the input supply must rise +150 mV above

the battery voltage before the MCP73833/4 becomes

operational.

The UVLO circuit places the device in shutdown mode

if the input supply falls to within +50 mV of the battery

voltage.

The UVLO circuit is always active. At any time the input

supply is below the UVLO threshold or within +50 mV

of the voltage at the V

placed in a shutdown mode.

During any UVLO condition, the battery reverse

discharge current shall be less than 2 µA.

pin, the MCP73833/4 is

BAT

4.2 Charge Qualification

For a charge cycle to begin, all UVLO conditions must

be met and a battery or output load must be present.

A charge current programming resistor must be

connected from PROG to V

or floating, the MCP73833/4 is disabled and the battery

reverse discharge current is less than 2 µA. In this

manner, the PROG pin acts as a charge enable and

can be used as a manual shutdown.

If the input supply voltage is above the UVLO

threshold, but below V

MCP73833/4 will pulse the STAT1 and PG outputs as

the device determines if a battery is present.

. If the PROG pin is open

SS

(Typ)+0.3V, the

REG

4.4 Constant Current - Fast Charge Mode

During the constant current mode, the programmed

charge current is supplied to the battery or load. The

charge current is established using a single resistor

from PROG to V

charge current are calculated using Equation 4-1:

. The program resistor and the

SS

EQUATION 4-1:

1000V

REG

---------------- -=

R

PROG

REG

.

Where:

R

PROG

I

REG

Constant current mode is maintained until the voltage

at the V

When constant current mode is invoked, the internal

timer is reset.

4.4.1 TIMER EXPIRED DURING CONSTANT

If the internal timer expires before the recharge voltage

threshold is reached, a timer fault is indicated and the

charge cycle terminates. The MCP73833/4 remains in

this condition until the battery is removed, the input

power is removed, or the PROG pin is opened. If the

battery is removed or the PROG pin is opened, the

MCP73833/4 enters the Standby mode where it

remains until a battery is reinserted or the PROG pin is

reconnected. If the input power is removed, the

MCP73833/4 is in Shutdown. When the input power is

reapplied, a normal start-up sequence ensues.

pin reaches the regulation voltage, V

BAT

CURRENT - FAST CHARGE MODE

I

= kilo-ohms

= milliampere

4.5 Constant Voltage Mode

4.3 Preconditioning

If the voltage at the V

preconditioning threshold, the MCP73833/4 enters a

preconditioning or trickle charge mode. The

preconditioning threshold is factory set. Refer to

Section 1.0 “Electrical Characteristics” for

preconditioning threshold options.

In this mode, the MCP73833/4 supplies a percentage

of the charge current (established with the value of the

resistor connected to the PROG pin) to the battery. The

percentage or ratio of the current is factory set. Refer to

Section 1.0 “Electrical Characteristics” for

preconditioning current options.

When the voltage at the V

conditioning threshold, the MCP73833/4 enters the

constant current or fast charge mode.

© 2006 Microchip Technology Inc. DS22005A-page 11

pin is less than the

BAT

pin rises above the pre-

BAT

When the voltage at the V

regulation voltage, V

begins. The regulation voltage is factory set to 4.20V,

4.35V, 4.40V, or 4.50V with a tolerance of ± 0.75%.

, constant voltage regulation

REG

4.6 Charge Termination

The charge cycle is terminated when, during constant

voltage mode, the average charge current diminishes

below a percentage of the programmed charge current

(established with the value of the resistor connected to

the PROG pin) or the internal timer has expired. A 1 ms

filter time on the termination comparator ensures that

transient load conditions do not result in premature

charge cycle termination. The percentage or ratio of the

current is factory set. The timer period is factory set

and can be disabled. Refer to Section 1.0 “Electrical

Characteristics” for charge termination current ratio

and timer period options.

The charge current is latched off and the MCP73833/4

enters a charge complete mode.

pin reaches the

BAT

Page 12

MCP73833/4

4.7 Automatic Recharge

The MCP73833/4 continuously monitors the voltage at

the V

pin in the charge complete mode. If the

BAT

voltage drops below the recharge threshold, another

charge cycle begins and current is once again supplied

to the battery or load. The recharge threshold is factory

set. Refer to Section 1.0 “Electrical Characteristics”

for recharge threshold options.

4.8 Thermal Regulation

The MCP73833/4 limits the charge current based on

the die temperature. The thermal regulation optimizes

the charge cycle time while maintaining device reliability. Figure 4-2 depicts the thermal regulation for the

MCP73833/4.

1200

1000

800

600

400

200

Charge Current (mA)

0

25354555657585

Junction Temperature (°C)

R

= 1 k

Ω

PROG

95

105

115

125

135

145

155

4.9 Thermal Shutdown

The MCP73833/4 suspends charge if the die

temperature exceeds +150°C. Charging will resume

when the die temperature has cooled by approximately

+10°C. The thermal shutdown is a secondary safety

feature in the event that there is a failure within the

thermal regulation circuitry.

FIGURE 4-2: Thermal Regulation.

DS22005A-page 12 © 2006 Microchip Technology Inc.

Page 13

MCP73833/4

5.0 DETAILED DESCRIPTION

5.1 Analog Circuitry

5.1.1 BATTERY MANAGEMENT INPUT

SUPPLY (V

The VDD input is the input supply to the MCP73833/4.

The MCP73833/4 automatically enters a Power-down

mode if the voltage on the VDD input falls below the

UVLO voltage (V

the battery pack when the VDD supply is not present.

STOP

5.1.2 CURRENT REGULATION SET

(PROG)

Fast charge current regulation can be scaled by placing

a programming resistor (R

. The program resistor and the charge current

to V

SS

are calculated using the Equation 5-1:

EQUATION 5-1:

Where:

R

PROG

I

REG

The preconditioning trickle-charge current and the

charge termination current are ratiometric to the fast

charge current based on the selected device options.

I

= kilo-ohms

= milliampere

5.1.3 BATTERY CHARGE CONTROL

OUTPUT (V

The battery charge control output is the drain terminal

of an internal P-channel MOSFET. The MCP73833/4

provides constant current and voltage regulation to the

battery pack by controlling this MOSFET in the linear

region. The battery charge control output should be

connected to the positive terminal of the battery pack.

5.1.4 TEMPERATURE QUALIFICATION

(THERM)

The MCP73833/4 continuously monitors battery

temperature during a charge cycle by measuring the

voltage between the THERM and V

50 µA current source provides the bias for most

common 10 kΩ negative-temperature coefficient

(NTC) or positive-temperature coefficient (PTC)

thermistors.The current source is controlled, avoiding

measurement sensitivity to fluctuations in the supply

voltage (V

at the THERM pin to factory set thersholds of 1.20V

and 0.25V, typically. Once a volage outside the

thresholds is detected during a charge cycle, the

MCP73833/4 immediately suspends the charge cycle.

The MCP73833/4 suspends charge by turning off the

). The MCP73833/4 compares the voltage

DD

)

DD

). This feature prevents draining

) from the PROG input

PROG

1000V

---------------- -=

REG

R

PROG

)

BAT

pins. An internal

SS

pass transistor and holding the timer value. The charge

cycle resumes when the voltage at the THERM pin

returns to the normal range.

If temperature monitoring is not required, place a

standard 10 kΩ resistor from THERM to V

SS

5.1.4.1 System Test (LDO) Mode

The MCP73833/4 can be placed in a system test mode.

In this mode, the MCP73833/4 operates as a low

dropout linear regulator (LDO). The output voltage is

regulated to the factory set voltage regulation option.

The available output current is limitted to the

programmed fast charge current. For stability, the V

output must be bypassed to VSS with a minimum

capacitance of 1 µF for output currents up to 250 mA.

A minimum capacitance of 4.7 µF is required for output

currents above 250 mA.

The system test mode is entered by driving the THERM

input greater than (V

connected to the output. In this mode, the MCP73833/4

can be used to power the system without a battery

present.

Note 1: I

THERM

stand-by, and system test modes.

2: A pull-down current source on the

THERM input is active only in stand-by

and system test modes.

3: During system test mode, the PROG

input sets the available output current

limit.

4: System test mode shall be exited by

releasing the THERM input or cycling

input power.

-100 mV) with no battery

DD

is disabled during shutdown,

BAT

5.2 Digital Circuitry

5.2.1 STATUS INDICATORS AND POWER

GOOD (PG

The charge status outputs have two different states:

Low (L), and High Impedance (Hi-Z). The charge status

outputs can be used to illuminate LEDs. Optionally, the

charge status outputs can be used as an interface to a

host microcontroller. Table 5-1 summarize the state of

the status outputs during a charge cycle.

TABLE 5-1: STATUS OUTPUTS

CHARGE CYCLE STATE STAT1 STAT2 PG

Shutdown Hi-Z Hi-Z Hi-Z

Standby Hi-Z Hi-Z L

Charge in Progress L Hi-Z L

Charge Complete (EOC) Hi-Z L L

Temperature Fault Hi-Z Hi-Z L

Timer Fault Hi-Z Hi-Z L

System Test Mode L L L

- OPTION)

© 2006 Microchip Technology Inc. DS22005A-page 13

Page 14

MCP73833/4

5.2.2 POWER GOOD (PG) OPTION

The power good (PG) option is a pseudo open-drain

output. The PG

current. However, there is a diode path back to the

input, and as such, the PG output should only be pulled

up to the input. The PG

input to the MCP73833 is above the UVLO threshold

and greater than the battery voltage. If the supply voltage is above the UVLO, but below V

the MCP73833 will pulse the PG output as the device

determines if a battery is present.

output can sink current, but not source

output is low whenever the

(Typ)+0.3V,

REG

5.2.3 TIMER ENABLE (TE) OPTION

The timer enable (TE) input option is used to enable or

disable the internal timer. A low signal on this pin

enables the internal timer and a high signal disables

the internal timer. The TE

the timer when the charger is supplying current to

charge the battery and power the system load. The TE

input is compatible with 1.8V logic.

input can be used to disable

5.2.4 DEVICE DISABLE (PROG)

The current regulation set input pin (PROG) can be

used to terminate a charge at any time during the

charge cycle, as well as to initiate a charge cycle or

initiate a recharge cycle.

Placing a programming resistor from the PROG input to

enables the device. Allowing the PROG input to

V

SS

float or by applying a logic-high input signal, disables

the device and terminates a charge cycle. When

disabled, the device’s supply current is reduced to

100 µA, typically.

DS22005A-page 14 © 2006 Microchip Technology Inc.

Page 15

6.0 APPLICATIONS

:

:

The MCP73833/4 is designed to operate in conjunction

with a host microcontroller or in stand-alone applications. The MCP73833/4 provides the preferred charge

algorithm for Lithium-Ion and Lithium-Polymer cells

C

IN

LED

Regulated

Wall Cube

FIGURE 6-1: Typical Application Circuit.

LED LED

Constant-current followed by Constant-voltage.

Figure 6-1 depicts a typical stand-alone application

circuit, while Figures 6-2 and 6-3 depict the

accompanying charge profile.

Li-Ion Battery Charger

1,2

V

DD

38

STAT1

STAT2

PG

THERM

PROG

R

LED

4

R

LED

7

R

LED

MCP73833

9,10

V

BAT

6

5

V

SS

MCP73833/4

+

Single

Li-Ion

-

Cell

10 kΩT

R

C

T1

R

OUT

PROG

R

T2

5.0

4.0

3.0

2.0

MCP73833-FCI/MF

1.0

Battery Voltage (V)

V

= 5.2V

DD

R

= 1.00 k

PROG

0.0

0

20

40

60

Time (Minutes)

80

100

120

140

2.00

1.60

1.20

0.80

0.40

Charge Current (A)

0.00

160

FIGURE 6-2: Typical Charge Profile with

Thermal Regulation (1700 mAh Li-Ion Battery).

5.0

4.0

3.0

2.0

Battery Voltage (V)

1.0

0.0

0

2

MCP73833-FCI/MF

4

6

Time (Minutes)

V

DD

R

= 1.00 k

PROG

= 5.2V

8

2.00

1.60

1.20

0.80

Charge Current (A)

0.40

0.00

10

6.1 Application Circuit Design

Due to the low efficiency of linear charging, the most

important factors are thermal design and cost, which

are a direct function of the input voltage, output current

and thermal impedance between the battery charger

and the ambient cooling air. The worst-case situation is

when the device has transitioned from the

Preconditioning mode to the Constant-current mode. In

this situation, the battery charger has to dissipate the

maximum power. A trade-off must be made between

the charge current, cost and thermal requirements of

the charger.

6.1.1 COMPONENT SELECTION

Selection of the external components in Figure 6-1 is

crucial to the integrity and reliability of the charging

system. The following discussion is intended as a guide

for the component selection process.

6.1.1.1 Current Programming Resistor

(R

The preferred fast charge current for Lithium-Ion cells

is at the 1C rate, with an absolute maximum current at

the 2C rate. For example, a 500 mAh battery pack has

a preferred fast charge current of 500 mA. Charging at

this rate provides the shortest charge cycle times

without degradation to the battery pack performance or

life.

PROG

)

FIGURE 6-3: Typical Charge Cycle Start

with Thermal Regulation (1700 mAh Li-Ion

Battery).

© 2006 Microchip Technology Inc. DS22005A-page 15

Page 16

MCP73833/4

6.1.1.2 Thermal Considerations

The worst-case power dissipation in the battery

charger occurs when the input voltage is at the

maximum and the device has transitioned from the

Preconditioning mode to the Constant-current mode. In

this case, the power dissipation is:

PowerDissipation V

–()I

DDMAXVPTHMIN

×=

REGMAX

Where:

V

DDMAX

I

REGMAX

V

PTHMIN

= the maximum input voltage

= the maximum fast charge current

= the minimum transition threshold

voltage

Power dissipation with a 5V, ±10% input voltage source

is:

PowerDissipation 5.5V 2.7 V–()550mA× 1.54W==

This power dissipation with the battery charger in the

MSOP-10 package will cause thermal regulation to be

entered as depicted in Figure 6-3. Alternatively, the

3 mm x 3 mm DFN package could be utilized to reduce

charge cycle times.

6.1.1.3 External Capacitors

The MCP73833/4 is stable with or without a battery

load. In order to maintain good AC stability in the Constant-voltage mode, a minimum capacitance of 4.7 µF

is recommended to bypass the V

pin to VSS. This

BAT

capacitance provides compensation when there is no

battery load. In addition, the battery and interconnections appear inductive at high frequencies. These

elements are in the control feedback loop during

Constant-voltage mode. Therefore, the bypass

capacitance may be necessary to compensate for the

inductive nature of the battery pack.

Virtually any good quality output filter capacitor can be

used, independent of the capacitor’s minimum

Effective Series Resistance (ESR) value. The actual

value of the capacitor (and its associated ESR)

depends on the output load current. A 4.7 µF ceramic,

tantalum or aluminum electrolytic capacitor at the

output is usually sufficient to ensure stability for output

currents up to a 500 mA.

6.1.1.4 Reverse-Blocking Protection

The MCP73833/4 provides protection from a faulted or

shorted input. Without the protection, a faulted or

shorted input would discharge the battery pack through

the body diode of the internal pass transistor.

6.1.1.5 Charge Inhibit

The current regulation set input pin (PROG) can be

used to terminate a charge at any time during the

charge cycle, as well as to initiate a charge cycle or

initiate a recharge cycle.

Placing a programming resistor from the PROG input to

enables the device. Allowing the PROG input to

V

SS

float or by applying a logic-high input signal, disables

the device and terminates a charge cycle. When

disabled, the device’s supply current is reduced to

100 µA, typically.

6.1.1.6 Temperature Monitoring

The charge temperature window can be set by placing

fixed value resistors in series-parallel with a thermistor.

The resistance values of R

and RT2 can be

T1

calculated with the following equations in order to set

the temperature window of interest.

For NTC thermistors:

RT2R

×

COLD

24k

Ω

5k Ω R

R

T1

T1

---------------------------------+=

RT2R

+

RT2R

×

-----------------------------+=

R

+

T2RHOT

COLD

HOT

Where:

R

is the fixed series resistance

T1

is the fixed parallel resistance

R

T2

is the thermistor resistance at the

R

COLD

lower temperature of interest

is the thermistor resistance at the upper

R

HOT

temperature of interest.

For example, by utilizing a 10 kΩ at 25C NTC

thermistor with a sensitivity index, β, of 3892, the

charge temperature range can be set to 0C - 50C by

placing a 1.54 kΩ resistor in series (R

), and a

T1

69.8 kΩ resistor in parallel (RT2) with the thermistor as

depicted in Figure 6-1.

6.1.1.7 Charge Status Interface

A status output provides information on the state of

charge. The output can be used to illuminate external

LEDs or interface to a host microcontroller. Refer to

Table 5-1 for a summary of the state of the status

output during a charge cycle.

DS22005A-page 16 © 2006 Microchip Technology Inc.

Page 17

6.2 PCB Layout Issues

For optimum voltage regulation, place the battery pack

as close as possible to the device’s V

recommended to minimize voltage drops along the

high current-carrying PCB traces.

If the PCB layout is used as a heatsink, adding many

vias in the heatsink pad can help conduct more heat to

the backplane of the PCB, thus reducing the maximum

junction temperature. Figures 6-4 and 6-5 depict a

typical layout with PCB heatsinking.

MCP73833

V

SS

C

IN

V

DD

STAT1

STAT2

R

PROG

and VSS pins,

BAT

C

V

THERM

PG

OUT

BAT

MCP73833/4

FIGURE 6-4: Typical Layout (Top).

V

SS

V

DD

V

BAT

FIGURE 6-5: Typical Layout (Bottom).

© 2006 Microchip Technology Inc. DS22005A-page 17

Page 18

MCP73833/4

7.0 PACKAGING INFORMATION

7.1 Package Marking Information

10-Lead DFN

1

XXXX

2

XYWW

3

NNN

4

56

10

9

8

7

10-Lead MSOP

XXXXXX

YWWNNN

Part Number *

Marking

Code

Part Number *

Marking

Code

MCP73833-AMI/MF AAAA

MCP73833-BZI/MF AAAB

MCP73833-FCI/MF AAAC MCP73834-FCI/MF BAAC

MCP73833-GPI/MF AAAD MCP73834-GPI/MF BAAD

MCP73833-NVI/MF AAAF MCP73834-NVI/MF BAAF

MCP73833-CNI/MF AAAK MCP73834-CNI/MF BAAK

* Consult Factory for Alternative Device Options.

Part Number *

Marking

Code

Part Number *

Marking

Code

MCP73833-AMI/UN 833AMI

MCP73833-BZI/UN 833BZI

MCP73833-FCI/UN 833FCI MCP73834-FCI/UN 834FCI

MCP73833-GPI/UN 833GPI MCP73834-GPI/UN 834GPI

MCP73833-NVI/UN 833NVI MCP73834-NVI/UN 834NVI

MCP73833-CNI/UN 833CNI MCP73834-CNI/UN 834CNI

* Consult Factory for Alternative Device Options.

Example:

1

AAAA

2

0633

3

256

4

56

10

9

8

7

Example:

8336SI

633256

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

3

e

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designator ( )

3

e

can be found on the outer packaging for this package.

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

DS22005A-page 18 © 2006 Microchip Technology Inc.

Page 19

MCP73833/4

10-Lead Plastic Dual-Flat No-Lead Package (MF) 3x3x0.9 mm Body (DFN) – Saw Singulated

Note: For the most current package drawings, please

see the Microchip Packaging Specification located

at http://www.microchip.com/packaging

E

A

INCHES

NOM

K

EXPOSED

METAL

PAD

(

NOTE 2

EXPOSED

TIE BAR

(

NOTE 3

10

.035

.001

.118

.094

.118

.065

.010

.016

)

MAX

BOTTOM VIEW

)

MILLIMETERS

MIN

.039

.002

.124

.096

.124

.067

.015

.020

0.80

0.00

2.85

2.08

2.85

1.30

0.18

0.30

D

PIN 1

ID INDEX

AREA

NOTE 1

(

A3

Number of Pins

Pitch

Overall Height

Standoff

Lead Thickness

Overall Length

Exposed Pad Length

Overall Width

Exposed Pad Width

Lead Width

Contact Length §

Contact-to-Exposed Pad § K .008 — — 0.20 — —

*

Controlling Parameter

§

Significant Characteristic

Notes:

1.

Pin 1 visual index feature may vary, but must be located within the hatched area.

2.

Exposed pad varies according to die attach paddle size.

3.

Package may have one or more exposed tie bars at ends.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

REF: Reference Dimension, usually without tolerance, for information purposes only.

See ASME Y14.5M

JEDEC equivalent: Not Registered

Drawing No. C04-063

)

TOP VIEW

Dimension Limits

(

Note 3

Note 3

)

(

A1

Units

MIN

n

e

A

A1

A3

E

)

E2

D

D2

b

L

.020 BSC

.031

.000

.008 REF.

.112

.082

.112

.051

.008

.012

pb

n

21

E2

NOM

10

0.50 BSC

0.90

0.02

0.20 REF.

3.00

2.39

3.00

1.65

0.25

0.40

Revised 09-12-05

D2

*

MAX

1.00

0.05

3.15

2.45

3.15

1.70

0.30

0.50

L

© 2006 Microchip Technology Inc. DS22005A-page 19

Page 20

MCP73833/4

10-Lead Plastic Micro Small Outline Package (UN) (MSOP)

Note: For the most current package drawings, please

see the Microchip Packaging Specification located

at http://www.microchip.com/packaging

E

E1

p

D

2

n

B

1

α

c

L

β

Units

Dimension Limits

Number of Pins

Pitch

Overall Height

Molded Package Thickness

Standoff

Overall Width

Molded Package Width

Overall Length

Foot Length

Foot Angle

Lead Thickness

Lead Width

Mold Draft Angle Top

Mold Draft Angle Bott om

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010" (0.254 mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

REF: Reference Dimension, usually witho ut tolerance, for information purposes only.

See ASME Y14.5M

JEDEC Equivalent: MO-187 BA

Drawing No. C04-021

n

p

A

A2

A1

E

E1

D

L

φ

c

B

α

β

(F)

MIN

.030

.000

.016 .024

0° – 8°

.003

.006

5° –

5° –

INCHES

NOM

.020 BSC

.193 BSC

.118 BSC

.118 BSC

.037 REFFFootprint

φ

10

.033

.009

A

A1

MAX NOM

.043

.037

.006

.031

–

.009

.012

MIN

15°

15°

MILLIMETERS

0.50 BSC

–

0.75

0.00

4.90 BSC

3.00 BSC

3.00 BSC

0.40

0.95 REF

0.08

0.15

5° 15°

5° 15°

Revised 09-16-05

*

MAX

10

–

0.85

0.60

–

–

0.23

–

–

A2

1.10

0.95

0.15

0.80

8°0°

0.23

0.30

DS22005A-page 20 © 2006 Microchip Technology Inc.

Page 21

APPENDIX A: REVISION HISTORY

Revision A (September 2006)

• Original Release of this Document.

MCP73833/4

© 2006 Microchip Technology Inc. DS22005A-page 23

Page 22

MCP73833/4

NOTES:

DS22005A-page 24 © 2006 Microchip Technology Inc.

Page 23

MCP73833/4

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. XX

Device

Output

X/

Tem p.XXPackage

Options*

Device: MCP73833: 1A Fully Integrated Charger,

MCP73833T: 1A Fully Integrated Charger,

MCP73834: 1A Fully Integrated Charger,

MCP73834T: 1A Fully Integrated Charger,

Output Options * * * Refer to table below for different operational options.

* * Consult Factory for Alternative Device Options.

Temperature: I = -40°C to +85°C

function on pin 7

PG

PG

function on pin 7

(Tape and Reel)

function on pin 7

TE

function on pin 7

TE

(Tape and Reel)

Examples: * *

a) MCP73833-AMI/UN: 10-lead MSOP pkg.

b) MCP73833-BZI/UN: 10-lead MSOP pkg.

c) MCP73833-CNI/MF: 10-lead DFN pkg.

d) MCP73833-FCI/UN: 10-lead MSOP pkg.

e) MCP73833-GPI/UN: 10-lead MSOP pkg.

f) MCP73833-NVI/MF: 10-lead DFN pkg.

a) MCP73834-CNI/MF: 10-lead DFN pkg.

b) MCP73834-FCI/UN: 10-lead MSOP pkg.

c) MCP73834-GPI/UN: 10-lead MSOP pkg.

d) MCP73834-NVI/MF: 10-lead DFN pkg.

* * Consult Factory for Alternative Device Options

Package Type: MF = Plastic Dual Flat No Lead (DFN)

Part Number V

(3x3x0.9 mm Body), 10-lead

UN = Plastic Micro Small Outline Package (MSOP),

10-lead

REG

I

PREG/IREG

V

PTH/VREG

I

TERM/IREG

V

RTH/VREG

Timer Period

MCP73833-AMI/MF 4.20V 10% 71.5% 7.5% 96.5% 0 hours

MCP73833-BZI/MF 4.20V 100% N/A 7.5% 96.5% 0 hours

MCP73833-CNI/MF 4.20V 10% 71.5% 20% 94% 4 hours

MCP73833-FCI/MF 4.20V 10% 71.5% 7.5% 96.5% 6 hours

MCP73833-GPI/MF 4.20V 100% N/A 7.5% 96.5% 6 hours

MCP73833-NVI/MF 4.35V 10% 71.5% 7.5% 96.5% 6 hours

MCP73833-AMI/UN 4.20V 10% 71.5% 7.5% 96.5% 0 hours

MCP73833-FCI/UN 4.20V 10% 71.5% 7.5% 96.5% 6 hours

MCP73834-BZI/MF 4.20V 100% N/A 7.5% 96.5% 0 hours

MCP73834-CNI/MF 4.20V 10% 71.5% 20% 94% 4 hours

MCP73834-FCI/MF 4.20V 10% 71.5% 7.5% 96.5% 6 hours

MCP73834-NVI/MF 4.35V 10% 71.5% 7.5% 96.5% 6 hours

MCP73834-FCI/UN 4.20V 10% 71.5% 7.5% 96.5% 6 hours

© 2006 Microchip Technology Inc. DS22005A-page 25

Page 24

MCP73833/4

NOTES:

DS22005A-page 26 © 2006 Microchip Technology Inc.

Page 25

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPASM, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its

PICmicro

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping devices, Serial

© 2006 Microchip Technology Inc. DS22005A-page 27

Page 26

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-3910

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

08/29/06

DS22005A-page 28 © 2006 Microchip Technology Inc.

Loading...

Loading...