MCP6546/6R/6U/7/8/9

Open-Drain Output Sub-Microamp Comparators

Features

• Low Quiescent Current: 600 nA/comparator (typ.)

• Rail-to-Rail Input: V

• Open-Drain Output: V

- 0.3V to V

SS

OUT

≤ 10V

DD

+ 0.3V

• Propagation Delay: 4 µs (typ., 100 mV Overdrive)

• Wide Supply Voltage Range: 1.6V to 5.5V

• Single available in SOT-23-5, SC-70-5 * packages

• Available in Single, Dual and Quad

• Chip Select (CS

) with MCP6548

• Low Switching Current

• Internal Hysteresis: 3.3 mV (typ.)

• Temperature Range:

- Industrial: -40°C to +85°C

- Extended: -40°C to +125°C

Typical Applications

• Laptop Computers

• Mobile Phones

• Metering Systems

• Hand-held Electronics

• RC Timers

• Alarm and Monitoring Circuits

• Windowed Comparators

• Multi-vibrators

Description

The Microchip Technology Inc. MCP6546/7/8/9 family

of comparators is offered in single (MCP6546,

MCP6546R, MCP6546U), single with chip select

(MCP6548), dual (MCP6547) and quad (MCP6549)

configurations. The outputs are open-drain and are

capable of driving heavy DC or capacitive loads.

These comparators are optimized for low power,

single-supply application with greater than rail-to-rail

input operation. The output limits supply current surges

and dynamic power consumption while switching. The

open-drain output of the MCP6546/7/8/9 family can be

used as a level-shifter for up to 10V using a pull-up

resistor. It can also be used as a wired-OR logic. The

internal Input hysteresis eliminates output switching

due to internal noise voltage, reducing current draw.

These comparators operate with a single-supply

voltage as low as 1.6V and draw a quiescent current of

less than 1 µA/comparator.

The related MCP6541/2/3/4 family of comparators from

Microchip has a push-pull output that supports rail-torail output swing and interfaces with CMOS/TTL logic.

* SC-70-5 E-Temp parts not avaliable at this release

the data sheet

.

MCP6546U SOT-23-5 is E-Temp only.

of

Related Devices

• CMOS/TTL-Compatible Output: MCP6541/2/3/4

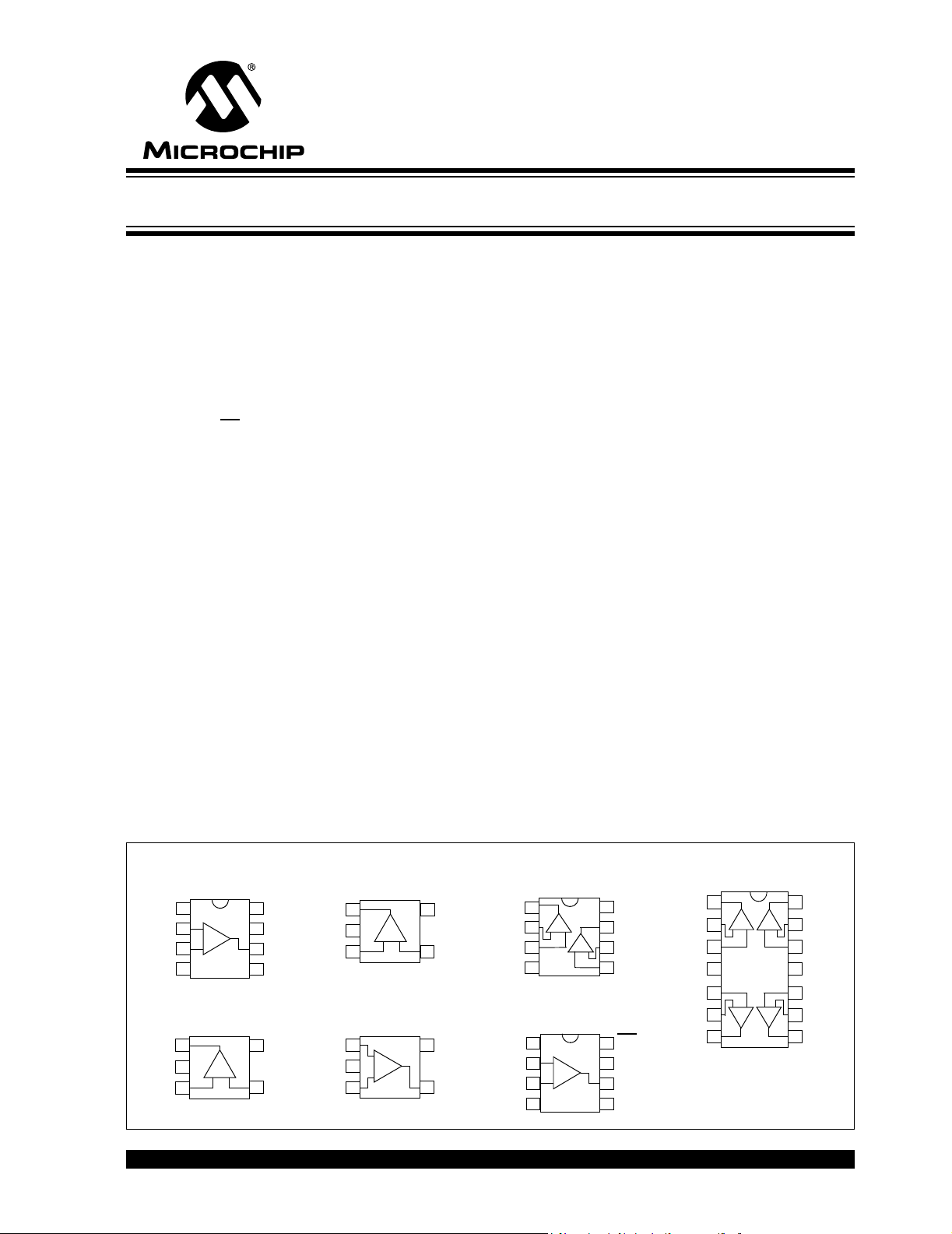

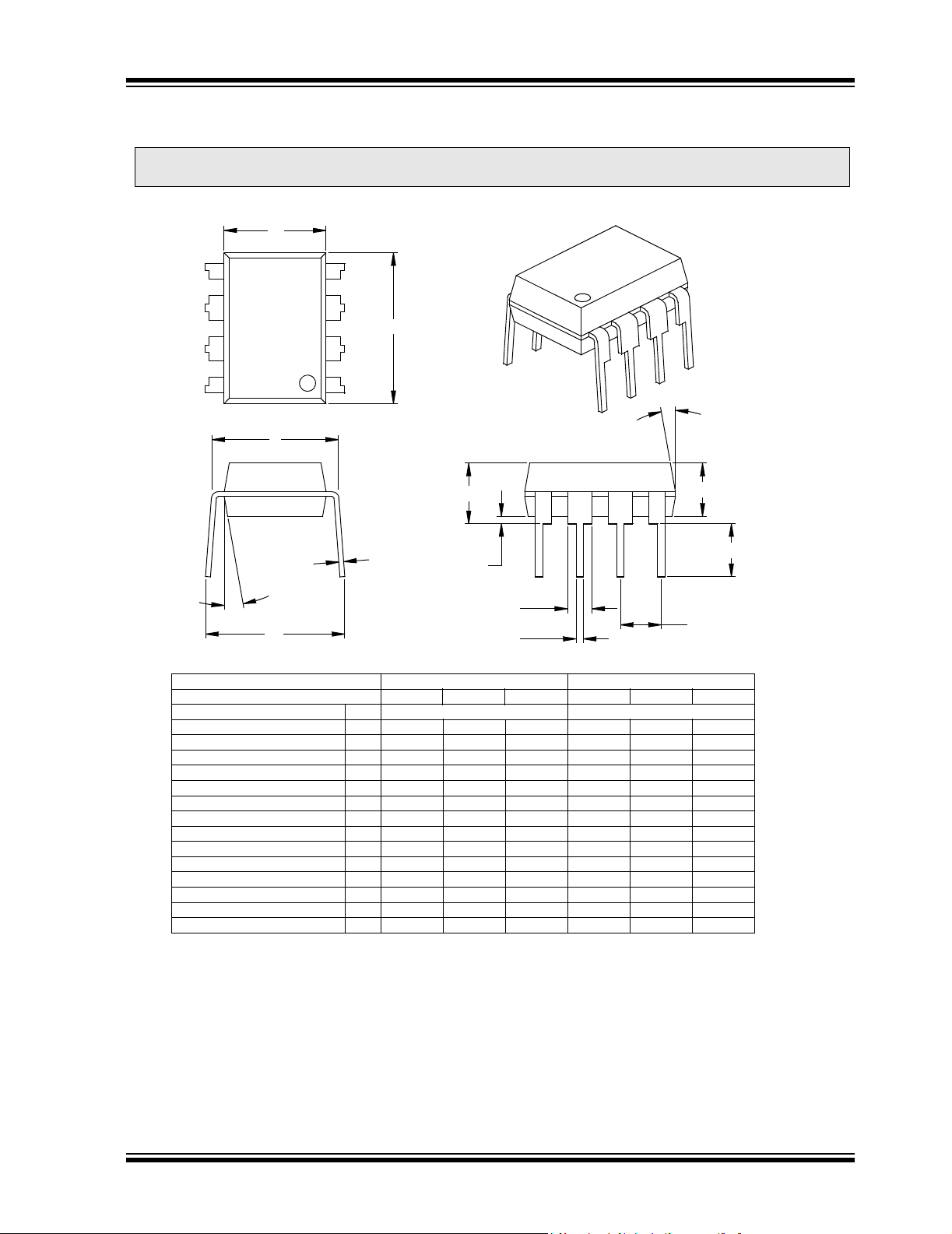

Package Types

MCP6546

PDIP, SOIC, MSOP

1

NC

V

IN

VIN+

V

SS

2

–

+

3

4

8

7

6

5

NC

V

DD

OUT

NC

OUT

V

MCP6546

SOT-23-5, SC-70-5

V

OUT

1

V

2

SS

V

+

3

IN

© 2006 Microchip Technology Inc. DS21714E-page 1

5

+

-

4

DD

VIN–

VIN–

V

MCP6546R MCP6547

SOT-23-5

OUTA

1

V

DD

+

IN

+

2

3

V

5

SS

V

-

4

VIN–

INA

V

INA

V

MCP6546U

SOT-23-5

1

V

SS

+

IN

+

2

3

V

5

DD

V

OUT

4

V

V

PDIP, SOIC, MSOP

SS

1

–

-

2

+

3

4

8

+

7

+

-

6

5

MCP6548

PDIP, SOIC, MSOP

NC

IN

IN

SS

1

2

–

+

+

3

4

8

7

6

5

V

DD

OUTB

V

INB

V

INB

CS

V

DD

OUT

NC

–

+

OUTA

V

INA

V

INA

V

V

INB

V

INB

OUTB

MCP6549

PDIP, SOIC, TSSOP

14

+

13

+

-

12

11

10

-

+

+

9

8

DD

1

2

-

–

3

+

4

+

5

-

–

6

7

OUTD

V

IND

V

IND

V

SS

V

INC

V

INC

OUTC

–

+

+

–

MCP6546/6R/6U/7/8/9

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings †

VDD - VSS.........................................................................7.0V

Open-Drain output............................................... V

Analog Input (V

All other inputs and outputs ........... V

+, VIN-)††............. VSS - 1.0V to VDD + 1.0V

IN

– 0.3V to VDD + 0.3V

SS

Difference Input voltage ...................................... |V

+ 10.5V

SS

DD

– VSS|

† Notice: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of the

device at those or any other conditions above those indicated

in the operational listings of this specification is not implied.

Exposure to maximum rating conditions for extended periods

may affect device reliability.

†† See Section 4.1.2 “Input Voltage and Current

Limits”

Output Short-Circuit Current .................................continuous

Current at Input Pins ....................................................±2 mA

Current at Output and Supply Pins ............................±30 mA

Storage temperature .....................................-65°C to +150°C

Maximum Junction Temperature (T

) .......................... +150°C

J

ESD protection on all pins:

(HBM;MM) .....................................2 kV;200V (MCP6546U)

(HBM;MM) ................................ 4 kV; 200V (all other parts)

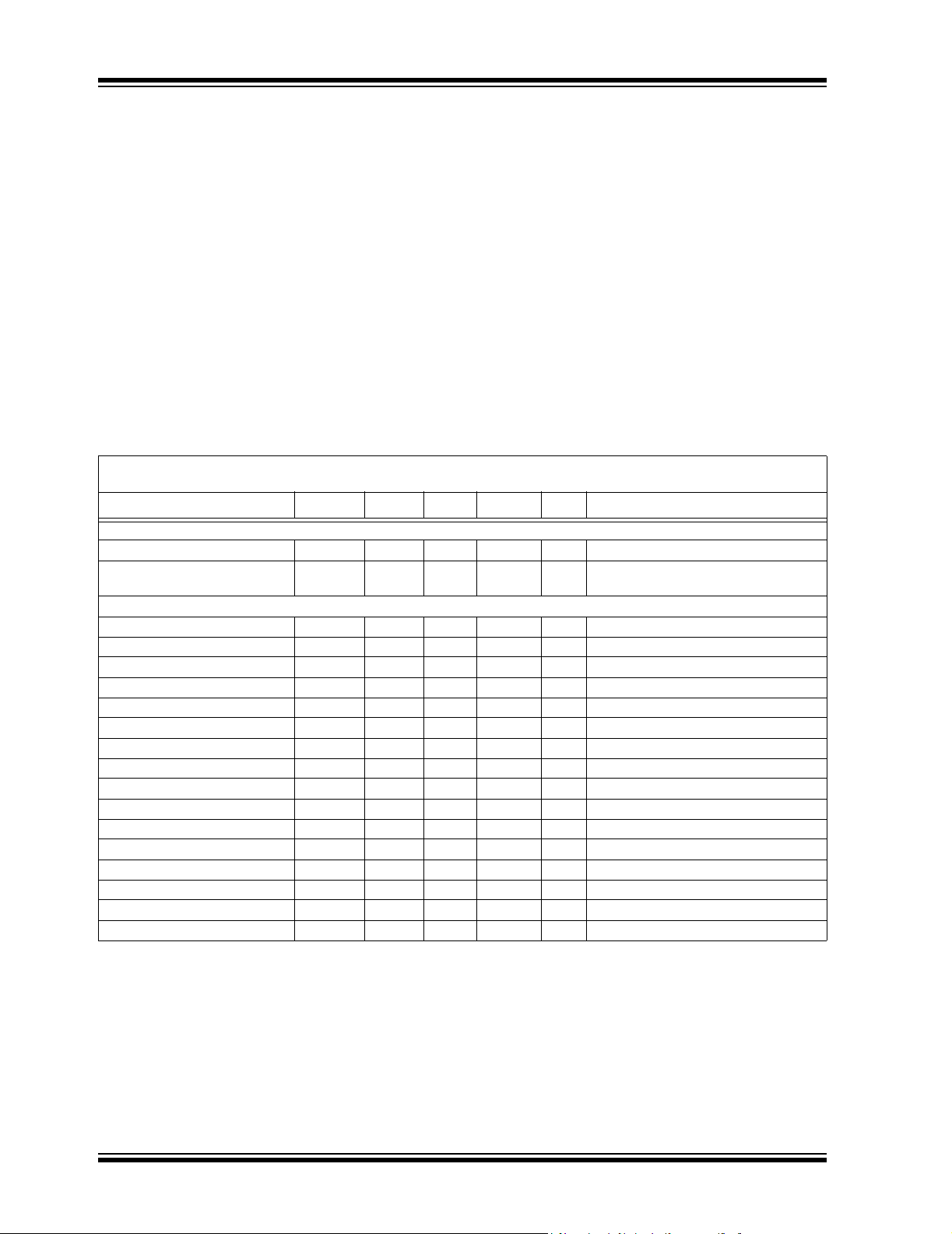

DC CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, VDD = +1.6V to +5.5V, VSS = GND, TA = 25°C, VIN+ = VDD/2, VIN– = VSS,

R

=2.74kΩ to VPU = VDD (Refer to Figure 1-3).

PU

Parameters Sym Min Typ Max Units Conditions

Power Supply

Supply Voltage V

Quiescent Current

(per comparator)

DD

I

Q

Input

Input Voltage Range V

CMRVSS

Common Mode Rejection Ratio CMRR 55 70 — dB V

Common Mode Rejection Ratio CMRR 50 65 — dB V

Common Mode Rejection Ratio CMRR 55 70 — dB V

Power Supply Rejection Ratio PSRR 63 80 — dB V

Input Offset Voltage V

Drift with Temperature ΔV

Input Hysteresis Voltage V

Linear Temp. Co. TC

Quadratic Temp. Co. TC

Input Bias Current I

At Temperature (I-Temp parts) I

At Temperature (E-Temp parts) I

Input Offset Current I

Common Mode Input Impedance Z

Differential Input Impedance Z

OS

OS

HYST

B

B

B

OS

CM

DIFF

/ΔT

1

2

Note 1: The input offset voltage is the center of the input-referred trip points. The input hysteresis is the difference between the

input-referred trip points.

2: V

at differential temperatures is estimated using: V

HYST

3: Input bias current at temperature is not tested for the SC-70-5 package

4: Do not short the output above V

V

test limit was VDD before Dec. 2004 (week code 52).

PU

1.6 — 5.5 V VPU ≥ V

0.3 0.6 1 µA I

− 0.3 — V

+ 0.3 V

DD

-7.0 ±1.5 +7.0 mV VCM = V

— ±3 — µV/°C TA = -40°C to +125°C, VCM = V

A

1.5 3.3 6.5 mV VCM = V

—6.7 —µV/°CT

— -0.035 — µV/°C2TA = -40°C to +125°C, VCM = V

—1 —pAV

— 25 100 pA TA = +85°C, VCM = V

— 1200 5000 pA TA = +125°C, VCM = V

— ±1 — pA V

DD

= 0

OUT

= 5V, VCM = -0.3V to 5.3V

DD

= 5V, VCM = 2.5V to 5.3V

DD

= 5V, VCM = -0.3V to 2.5V

DD

= V

CM

SS

(Note 1)

SS

SS

(Note 1)

SS

= -40°C to +125°C, VCM = VSS (Note 2)

A

(Note 2)

SS

CM = VSS

(Note 3)

SS

(Note 3)

SS

CM = VSS

—1013||4 — Ω||pF

—1013||2 — Ω||pF

(TA) = V

HYST

+ 10V. Limit the output current to Absolute Maximum Rating of 30 mA. The minimum

SS

+ (TA -25°C) TC1 + (TA - 25°C)2TC2.

HYST

DS21714E-page 2 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise indicated, VDD = +1.6V to +5.5V, VSS = GND, TA = 25°C, VIN+ = VDD/2, VIN– = VSS,

R

=2.74kΩ to VPU = VDD (Refer to Figure 1-3).

PU

Parameters Sym Min Typ Max Units Conditions

Open-Drain Output

Output Pull-Up Voltage V

High-Level Output Current I

Low-Level Output Voltage V

Short-Circuit Current I

Output Pin Capacitance C

OH

I

SC

OUT

PU

OL

SC

Note 1: The input offset voltage is the center of the input-referred trip points. The input hysteresis is the difference between the

input-referred trip points.

2: V

at differential temperatures is estimated using: V

HYST

3: Input bias current at temperature is not tested for the SC-70-5 package

4: Do not short the output above V

V

test limit was VDD before Dec. 2004 (week code 52).

PU

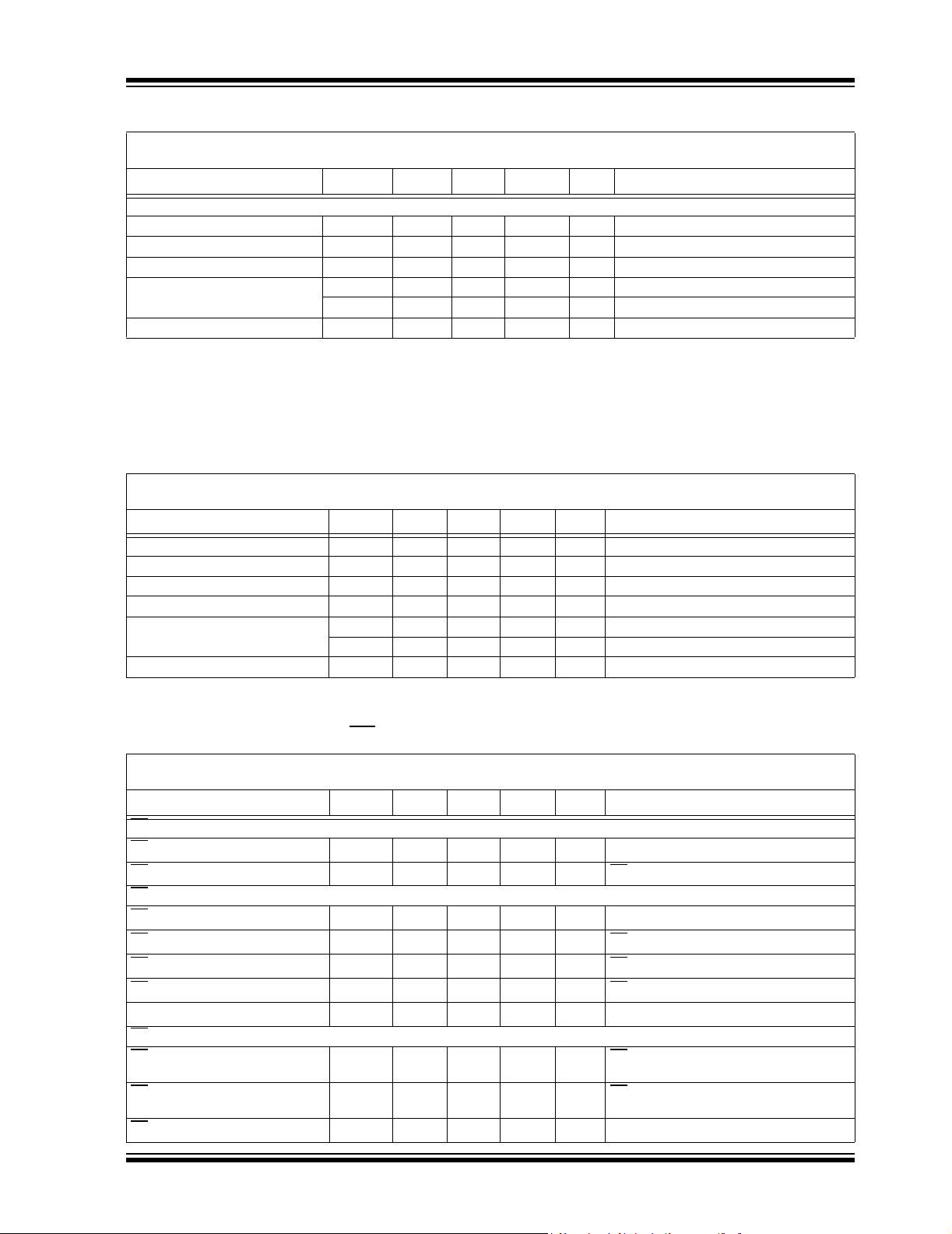

AC CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, V

Step = 200 mV, Overdrive = 100 mV, R

Parameters Sym Min Typ Max Units Conditions

Fall Time t

Propagation Delay (High-to-Low) t

Propagation Delay (Low-to-High) t

Propagation Delay Skew t

Maximum Toggle Frequency f

Input Noise Voltage E

Note 1: t

and t

R

depend on the load (RL and CL); these specifications are valid for the indicated load only.

PLH

2: Propagation Delay Skew is defined as: t

=2.74kΩ to VPU = VDD, and CL = 36 pF (Refer to Figure 1-2 and Figure 1-3).

PU

F

PHL

PLH

PDS

MAX

f

MAX

ni

1.6 — 10 V (Note 4)

-100 — — nA VDD = 1.6V to 5.5V, VPU = 10V (Note 4)

V

SS

—V

SS

+ 0.2 V I

= 2 mA, VPU = VDD = 5V

OUT

—±1.5 — mAVPU = VDD = 1.6V (Note 4)

–30—mAV

= VDD = 5.5V (Note 4)

PU

—8 —pF

(TA) = V

HYST

+ 10V. Limit the output current to Absolute Maximum Rating of 30 mA. The minimum

SS

= +1.6V to +5.5V, VSS = GND, TA = 25°C, VIN+ = VDD/2,

DD

+ (TA -25°C) TC1 + (TA - 25°C)2TC2.

HYST

—0.7—µs(Note 1)

—4.08.0µs

—3.08.0µs(Note 1)

—-1.0— µs(Notes 1 and 2)

— 225 — kHz VDD = 1.6V

— 165 — kHz VDD = 5.5V

— 200 — µV

= t

- t

PDS

PLH

PHL

.

10 Hz to 100 kHz

P-P

MCP6548 CHIP SELECT (CS) CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, VDD = +1.6V to +5.5V, VSS = GND, TA = 25°C, VIN+ = VDD/2, VIN– = VSS,

R

=2.74kΩ to VPU = VDD, and CL = 36 pF (Refer to Figures 1-1 and 1-3).

PU

Parameters Sym Min Typ Max Units Conditions

CS Low Specifications

Logic Threshold, Low V

CS

CS

Input Current, Low I

IL

CSL

CS High Specifications

Logic Threshold, High V

CS

CS

Input Current, High I

CS Input High, VDD Current I

CS Input High, GND Current I

Comparator Output Leakage I

Dynamic Specifications

CS

Low to Comparator Output Low

CS

Turn-on Time

CS High to Comparator Output

High Z Turn-off Time

CS Hysteresis V

IH

CSH

DD

SS

O(LEAK)

t

ON

t

OFF

CS_HYST

© 2006 Microchip Technology Inc. DS21714E-page 3

V

SS

—5—pACS = V

0.8 V

—1—pACS = V

—18—pACS = V

—-20—pACS = V

—1—pAV

— 0.2 V

—VDDV

DD

DD

V

SS

DD

DD

DD

= VSS+10V, CS = V

OUT

—250msCS = 0.2VDD to V

V

– = V

IN

DD

—10—µsCS = 0.8VDD to V

V

– = V

IN

DD

—0.6— VVDD = 5V

OUT

OUT

DD

= VDD/2,

= VDD/2,

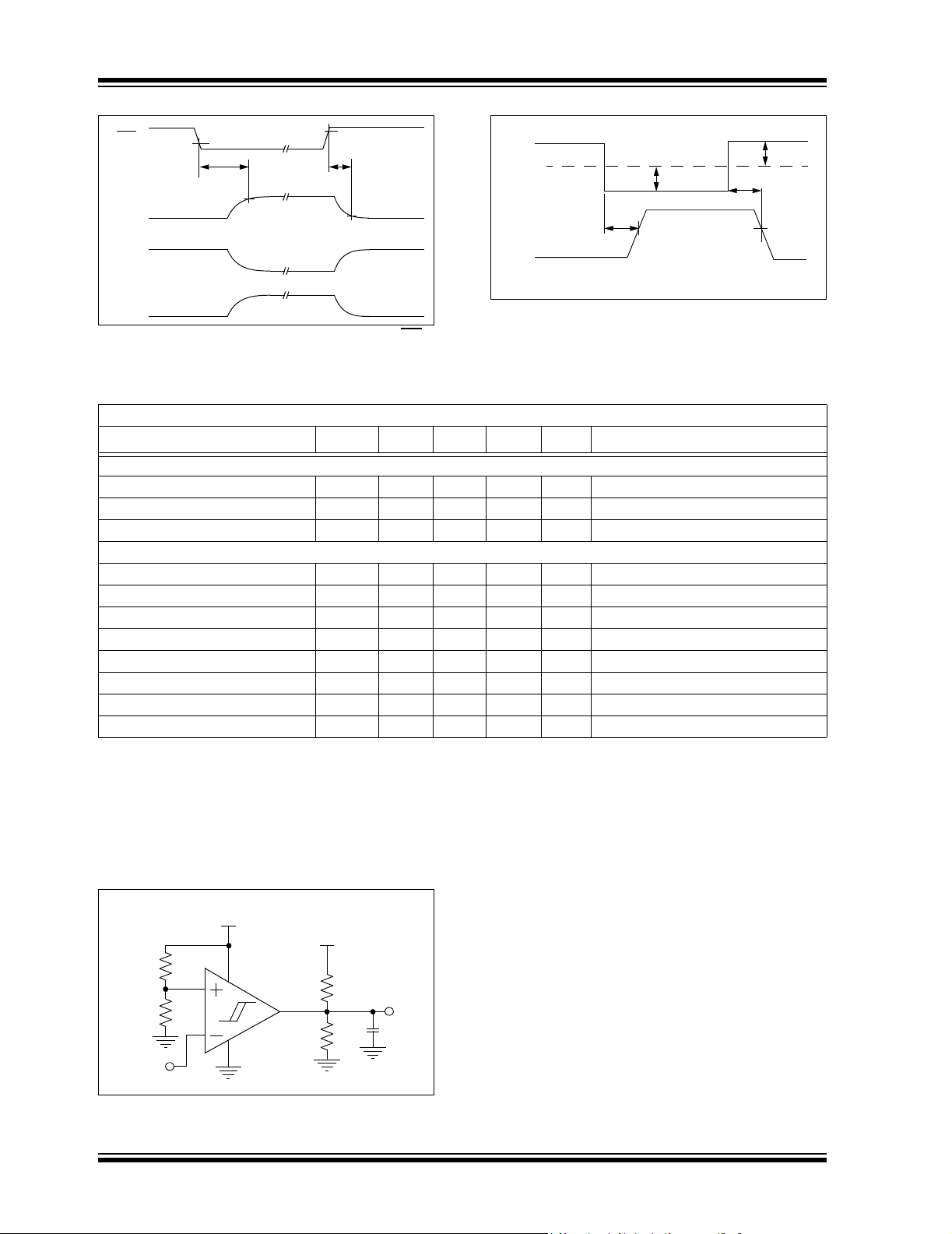

MCP6546/6R/6U/7/8/9

V

t

IL

ON

CS

V

High-Z

OUT

I

-20 pA (typ.)

SS

I

1 pA (typ.) 1 pA (typ.)5 pA (typ.)

CS

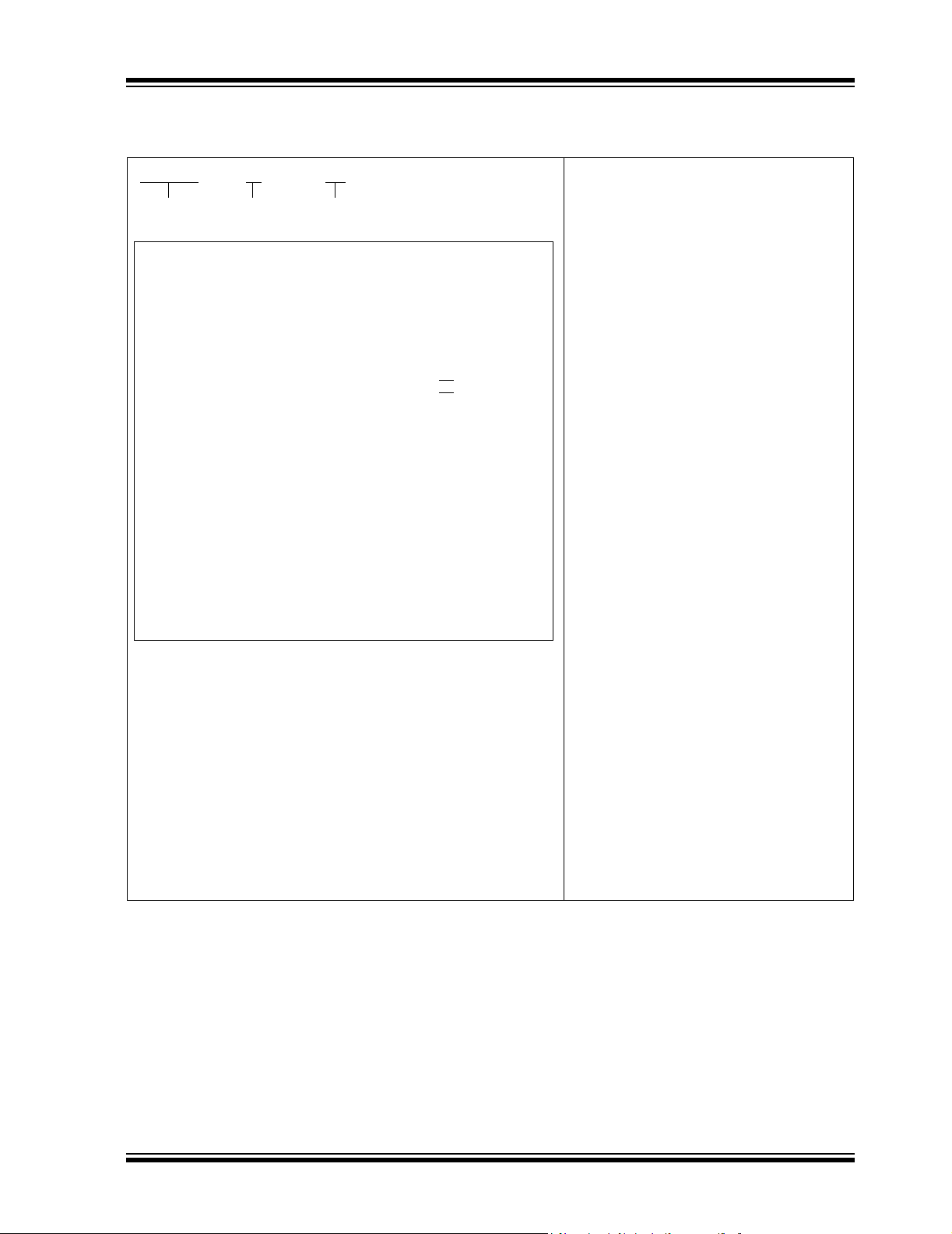

FIGURE 1-1: Timing Diagram for the CS

V

IH

t

OFF

High-Z

-20 pA (typ.)-0.6 µA (typ.)

VIN–

VIN+ = VDD/2

V

OUT

100 mV

100 mV

t

PLH

V

OL

t

PHL

V

OH

V

FIGURE 1-2: Propagation Delay Timing Diagram.

pin on the MCP6548.

TEMPERATURE CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, VDD = +1.6V to +5.5V and VSS = GND.

Parameters Sym Min Typ Max Units Conditions

Temperature Ranges

Specified Temperature Range T

Operating Temperature Range T

Storage Temperature Range T

A

A

A

Thermal Package Resistances

Thermal Resistance, 5L-SC-70 θ

Thermal Resistance, 5L-SOT-23 θ

Thermal Resistance, 8L-PDIP θ

Thermal Resistance, 8L-SOIC θ

Thermal Resistance, 8L-MSOP θ

Thermal Resistance, 14L-PDIP θ

Thermal Resistance, 14L-SOIC θ

Thermal Resistance, 14L-TSSOP θ

JA

JA

JA

JA

JA

JA

JA

JA

Note: The MCP6546/7/8/9 I-temp family operates over this extended temperature range, but with reduced

performance. In any case, the Junction Temperature (T

specification of +150°C.

-40 — +85 °C

-40 — +125 °C Note

-65 — +150 °C

— 331 — °C/W

— 256 — °C/W

—85—°C/W

— 163 — °C/W

— 206 — °C/W

—70—°C/W

— 120 — °C/W

— 100 — °C/W

) must not exceed the absolute maximum

J

OL

1.1 Test Circuit Configuration

This test circuit configuration is used to determine the

AC and DC specifications.

V

DD

= V

V

PU

DD

200 kΩ

MCP654X

200 kΩ

100 kΩ

VIN = V

SS

VSS = 0V

FIGURE 1-3: AC and DC Test Circuit for the Open-Drain Output Comparators.

DS21714E-page 4 © 2006 Microchip Technology Inc.

R

=

PU

(2 mA)/ V

36 pF

V

DD

OUT

MCP6546/6R/6U/7/8/9

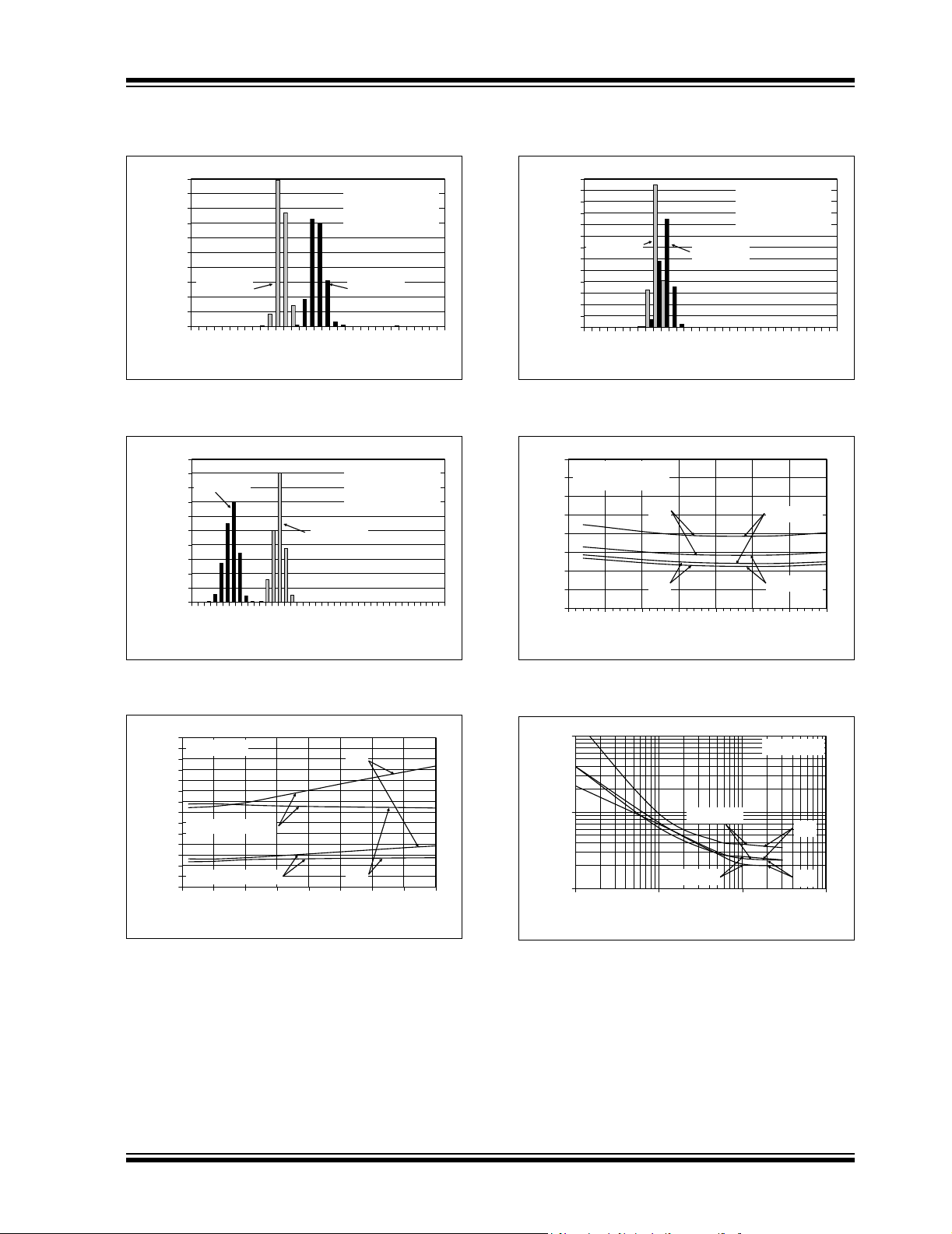

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated, VDD = +1.6V to +5.5V, VSS = GND, TA = +25°C, VIN+ = VDD/2, VIN– = GND,

R

= 2.74 kΩ to VPU=VDD, and CL = 36 pF.

PU

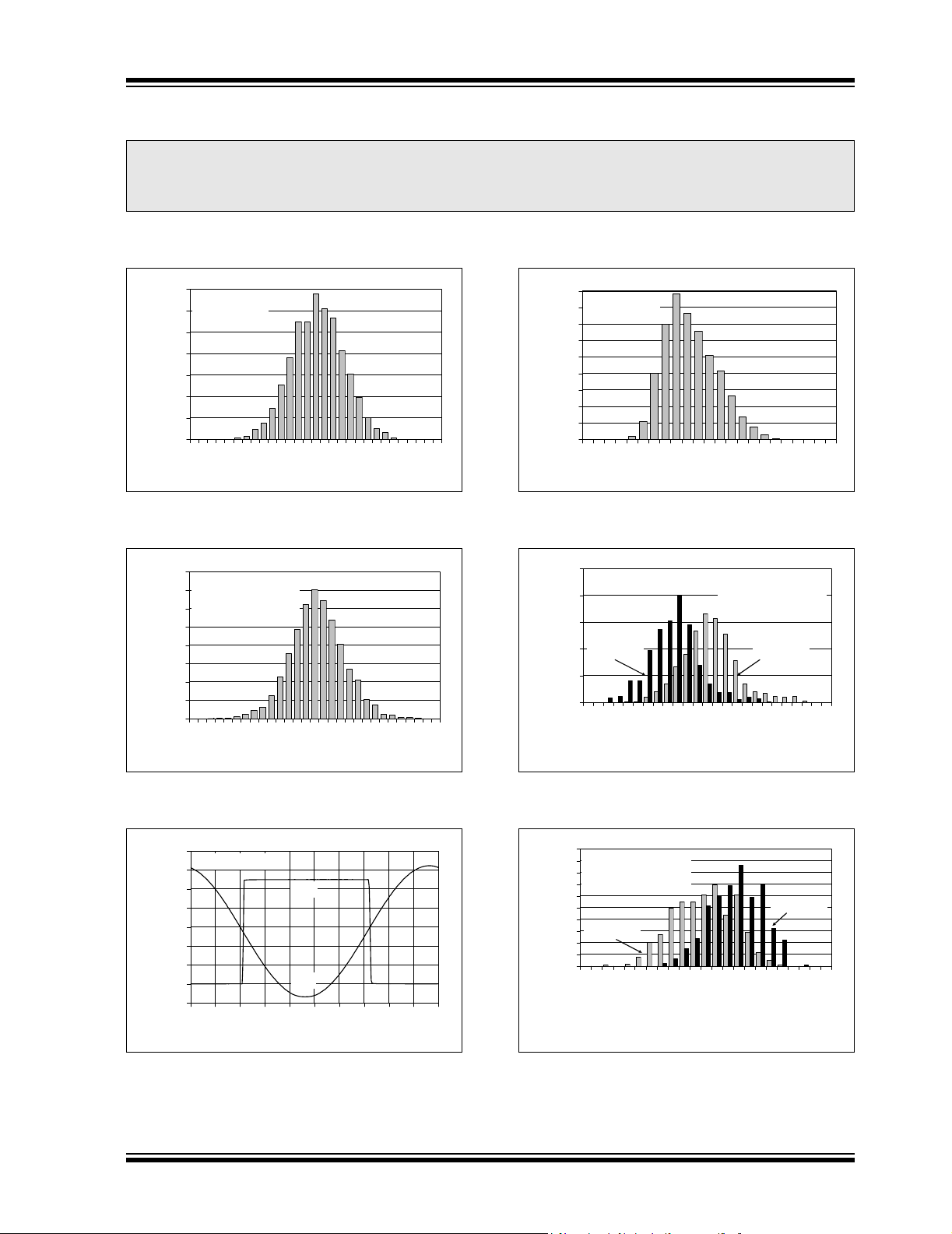

14%

1200 Samples

Percentage of Occurrences

12%

10%

8%

6%

4%

2%

0%

= V

V

CM

SS

-7-6-5-4-3-2-101234567

Input Offset Voltage (mV)

FIGURE 2-1: Input Offset Voltage at

V

CM=VSS

Percentage of Occurrences

.

16%

1200 Samples

14%

12%

10%

8%

6%

4%

2%

0%

= V

V

CM

TA = -40°C to +125°C

-14

-12

SS

-8-6-4

-10

Input Offset Voltage Drift (µV/°C)

02468

-2

101214

18%

1200 Samples

16%

V

= V

CM

SS

1.62.02.42.83.23.64.04.44.85.25.66.0

Input Hysteresis Voltage (mV)

Percentage of Occurrences

14%

12%

10%

8%

6%

4%

2%

0%

FIGURE 2-4: Input Hysteresis Voltage at

V

CM=VSS

Percentage of Occurrences

25%

20%

15%

10%

5%

0%

.

4.6

5.0

5.4

Input Hysteresis Voltage –

Linear Temp. Co.; TC

5.8

6.2

TA = -40°C to +125°C

6.6

7.0

7.4

7.8

(µV/°C)

1

596 Samples

= V

V

CM

VDD = 1.6VVDD = 5.5V

8.2

8.6

9.0

SS

9.4

FIGURE 2-2: Input Offset Voltage Drift at

V

CM=VSS

Inverting Input, Output

.

7

VDD = 5.5V

6

5

4

3

2

Voltage (V)

1

0

-1

012345678910

V

OUT

VIN–

Time (1 ms/div)

FIGURE 2-3: The MCP6546/6R/6U/7/8/9 comparators show no phase reversal.

FIGURE 2-5: Input Hysteresis Voltage

Linear Temp. Co. (TC

20%

596 Samples

18%

V

= V

CM

SS

TA = -40°C to +125°C

VDD = 1.6V

-0.060

-0.056

Quadratic Temp. Co.; TC

Percentage of Occurrences

16%

14%

12%

10%

8%

6%

4%

2%

0%

) at VCM=VSS.

1

-0.052

-0.048

-0.044

-0.040

-0.036

Input Hysteresis Voltage –

-0.032

(µV/°C2)

2

VDD = 5.5V

-0.028

-0.024

-0.020

FIGURE 2-6: Input Hysteresis Voltage

Quadratic Temp. Co. (TC

) at VCM=VSS.

2

-0.016

© 2006 Microchip Technology Inc. DS21714E-page 5

MCP6546/6R/6U/7/8/9

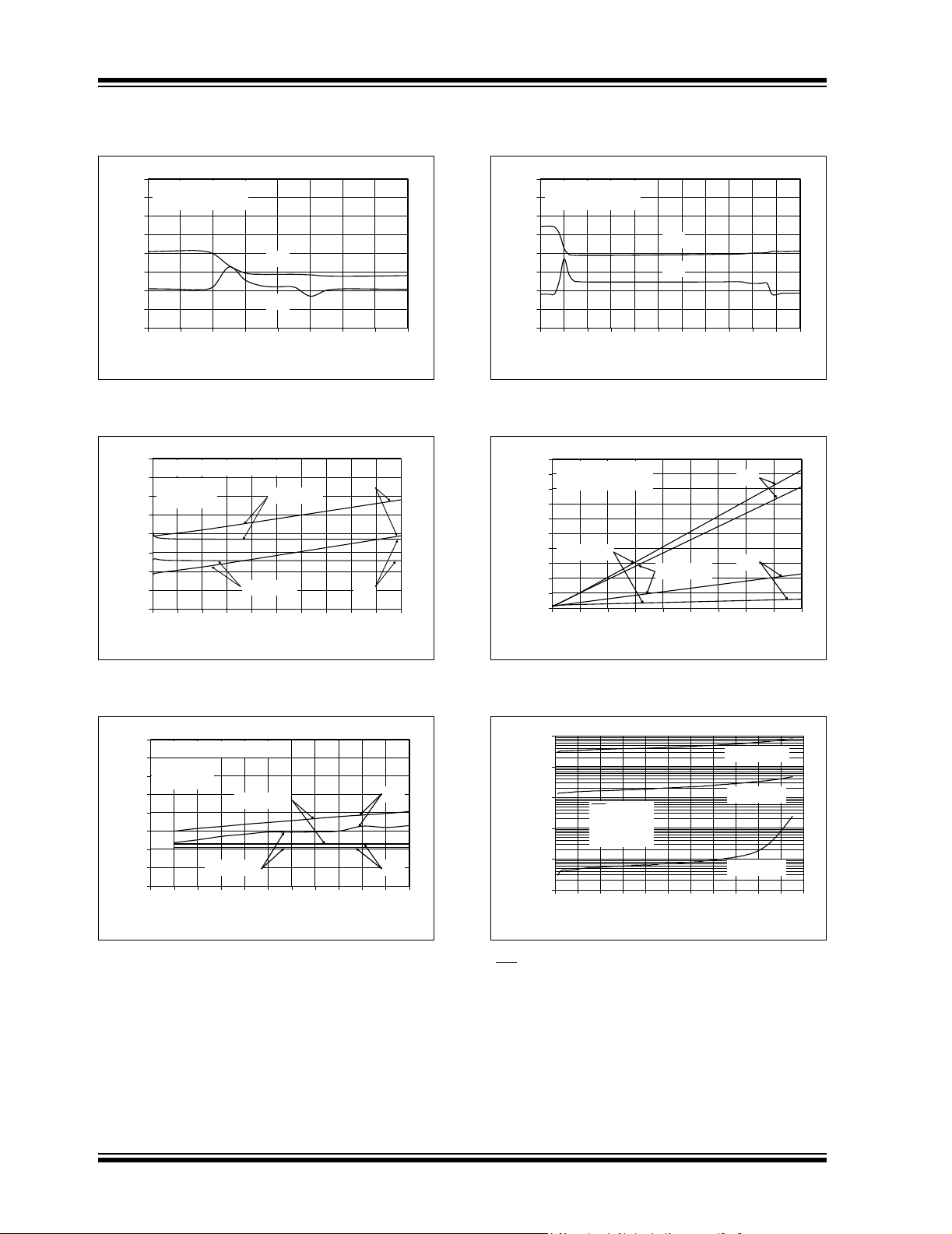

Note: Unless otherwise indicated, VDD= +1.6V to +5.5V, VSS= GND, TA= +25°C, VIN+=VDD/2, VIN– = GND,

RPU=2.74kΩ to VPU=VDD, and CL=36pF.

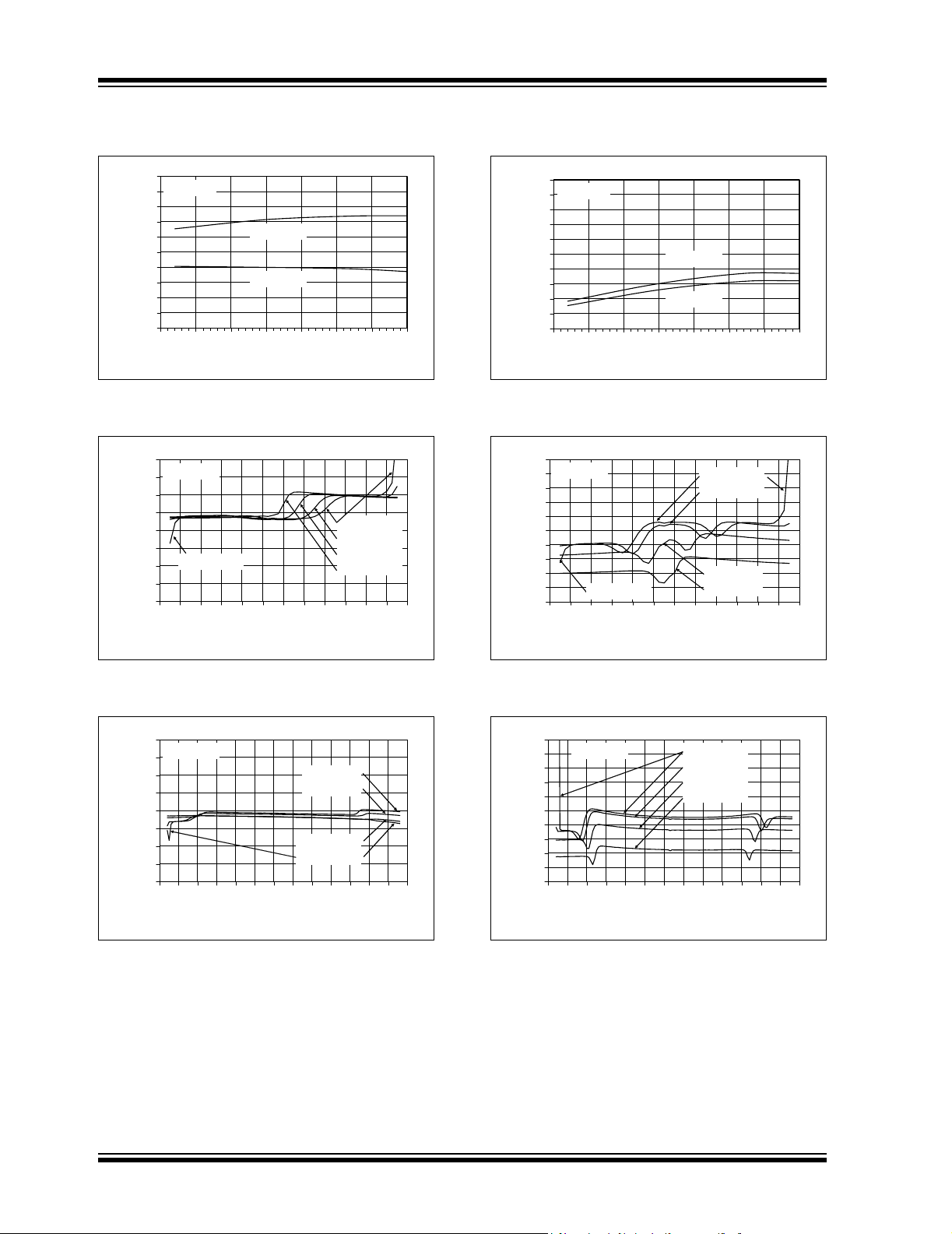

1.0

VCM = V

0.8

0.6

0.4

0.2

0.0

-0.2

-0.4

-0.6

-0.8

Input Offset Voltage (mV)

-1.0

-50 -25 0 25 50 75 100 125

SS

VDD = 1.6V

VDD = 5.5V

Ambient Temperature (°C)

FIGURE 2-7: Input Offset Voltage vs.

Ambient Temperature at V

2.0

VDD = 1.6V

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

Input Offset Voltage (mV)

-2.0

TA = +125°C

0.0

0.2

0.4

-0.4

-0.2

Common Mode Input Voltage (V)

0.6

CM=VSS

0.8

1.0

.

TA = +125°C

T

= +85°C

A

T

= +25°C

A

T

= -40°C

A

1.2

1.4

1.6

1.8

6.5

VCM = V

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

Input Hysteresis Voltage (mV)

-50-250 255075100125

SS

VDD = 1.6V

VDD = 5.5V

Ambient Temperature (°C)

FIGURE 2-10: Input Hysteresis Voltage vs.

Ambient Temperature at V

6.5

VDD = 1.6V

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

Input Hysteresis Voltage (mV)

2.0

TA = +125°C

0.0

-0.4

0.2

-0.2

Common Mode Input Voltage (V)

0.4

CM=VSS

0.6

0.8

.

TA = +125°C

T

= +85°C

A

TA = +25°C

T

= -40°C

A

1.0

1.2

1.4

1.6

1.8

2.0

FIGURE 2-8: Input Offset Voltage vs.

Common Mode Input Voltage at V

2.0

VDD = 5.5V

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

Input Offset Voltage (mV)

-2.0

0.0

0.5

1.0

1.5

-0.5

Common Mode Input Voltage (V)

2.0

2.5

TA = -40°C

T

TA = +85°C

T

A

3.0

DD

= +25°C

A

= +125°C

3.5

4.0

=1.6V.

4.5

5.0

FIGURE 2-9: Input Offset Voltage vs.

Common Mode Input Voltage at V

= 5.5V.

DD

FIGURE 2-11: Input Hysteresis Voltage vs.

3.5

DD

4.0

=1.6V.

4.5

5.0

5.5

6.0

Common Mode Input Voltage at V

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

Input Hysteresis Voltage (mV)

5.5

6.0

VDD = 5.5V TA = +125°C

0.0

0.5

1.0

-0.5

1.5

Common Mode Input Voltage (V)

T

T

T

2.0

2.5

3.0

= +85°C

A

= +25°C

A

= -40°C

A

FIGURE 2-12: Input Hysteresis Voltage vs.

Common Mode Input Voltage at V

DD

=5.5V.

DS21714E-page 6 © 2006 Microchip Technology Inc.

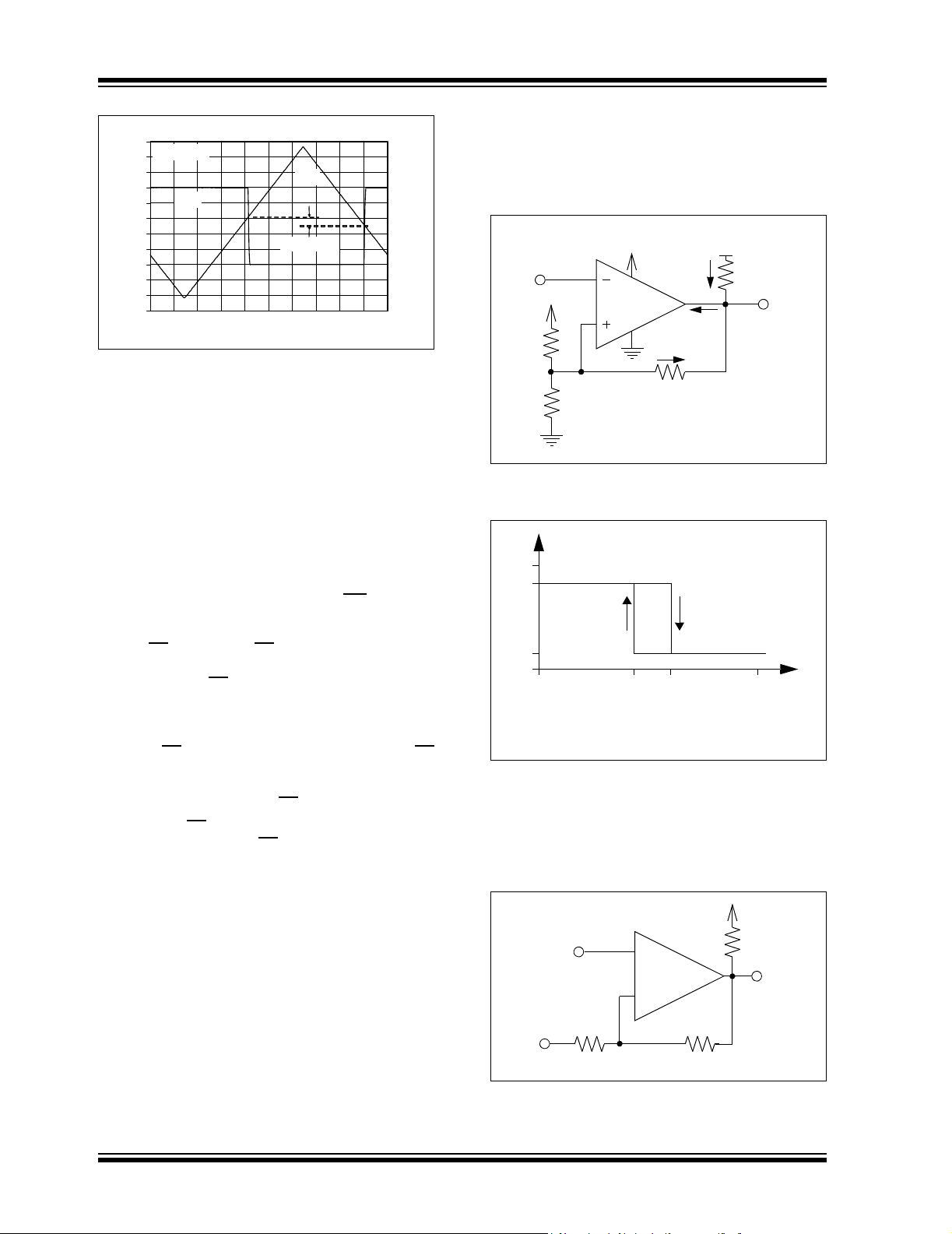

MCP6546/6R/6U/7/8/9

Note: Unless otherwise indicated, VDD= +1.6V to +5.5V, VSS= GND, TA= +25°C, VIN+=VDD/2, VIN– = GND,

RPU=2.74kΩ to VPU=VDD, and CL=36pF.

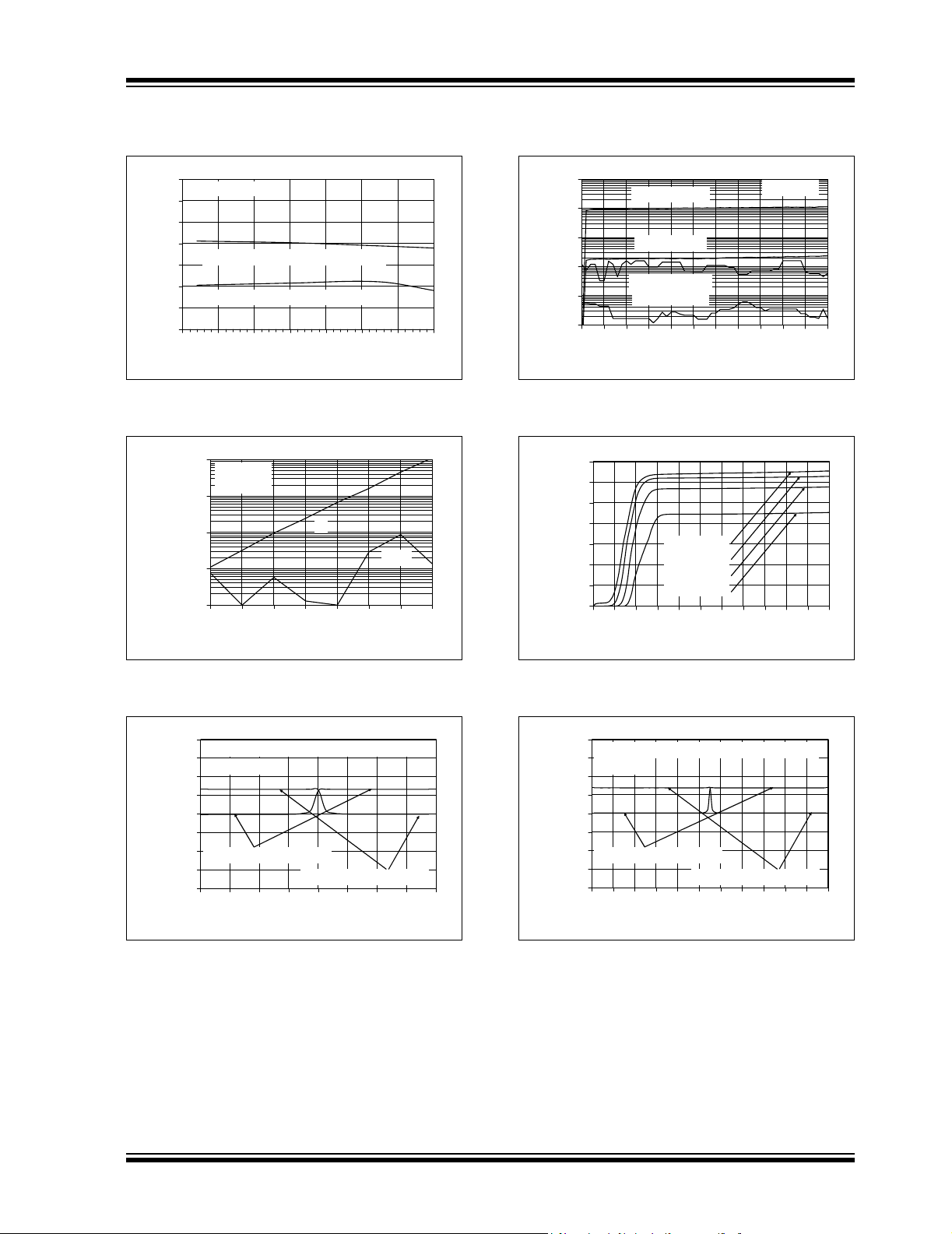

10n

90

Input Referred

85

80

75

PSRR, VIN+ = VSS, VDD = 1.6V to 5.5V

70

65

CMRR, PSRR (dB)

CMRR, VIN+ = -0.3 to 5.3V, VDD = 5.0V

60

55

-50 -25 0 25 50 75 100 125

Ambient Temperature (°C)

10000

1n

1000

100p

100

(A)

10p

10

1

1p

Input Bias, Offset Currents

100f

0.1

0.00.51.01.52.02.53.03.54.04.55.05.5

IB, TA = +125°C

IB, TA = +85°C

IOS, TA = +125°C

IOS, TA = +85°C

Common Mode Input Voltage (V)

VDD = 5.5V

FIGURE 2-13: CMRR,PSRR vs. Ambient Temperature.

1000

VDD = 5.5V

V

= V

CM

100

10

(pA)

1

Input Bias, Offset Currents

0.1

55 65 75 85 95 105 115 125

DD

I

B

Ambient Temperature (°C)

| IOS |

FIGURE 2-14: Input Bias Current, Input Offset Current vs. Ambient Temperature.

0.8

IQ does not include pull-up resistor current

0.7

VDD = 1.6V

0.6

0.5

0.4

0.3

0.2

Quiescent Current

Sweep VIN+, VIN– = VDD/2

per Comparator (µA)

0.1

0.0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Common Mode Input Voltage (V)

Sweep VIN–, VIN+ = VDD/2

FIGURE 2-16: Input Bias Current, Input Offset Current vs. Common Mode Input Voltage.

0.7

0.6

0.5

0.4

0.3

0.2

Quiescent Current

per Comparator (µA)

0.1

0.0

0.00.51.01.52.02.53.03.54.04.55.05.5

TA = +125°C

T

= +85°C

A

T

= +25°C

A

T

= -40°C

A

Power Supply Voltage (V)

FIGURE 2-17: Quiescent Current vs. Power Supply Voltage.

0.8

IQ does not include pull-up resistor current

0.7

VDD = 5.5V

0.6

0.5

0.4

0.3

0.2

Quiescent Current

Sweep VIN+, VIN– = VDD/2

per Comparator (µA)

0.1

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

Common Mode Input Voltage (V)

Sweep VIN–, VIN+ = VDD/2

FIGURE 2-15: Quiescent Current vs.

Common Mode Input Voltage at V

DD

=1.6V.

FIGURE 2-18: Quiescent Current vs.

Common Mode Input Voltage at VDD=5.5V.

© 2006 Microchip Technology Inc. DS21714E-page 7

MCP6546/6R/6U/7/8/9

Note: Unless otherwise indicated, VDD= +1.6V to +5.5V, VSS= GND, TA= +25°C, VIN+=VDD/2, VIN– = GND,

RPU=2.74kΩ to VPU=VDD, and CL=36pF.

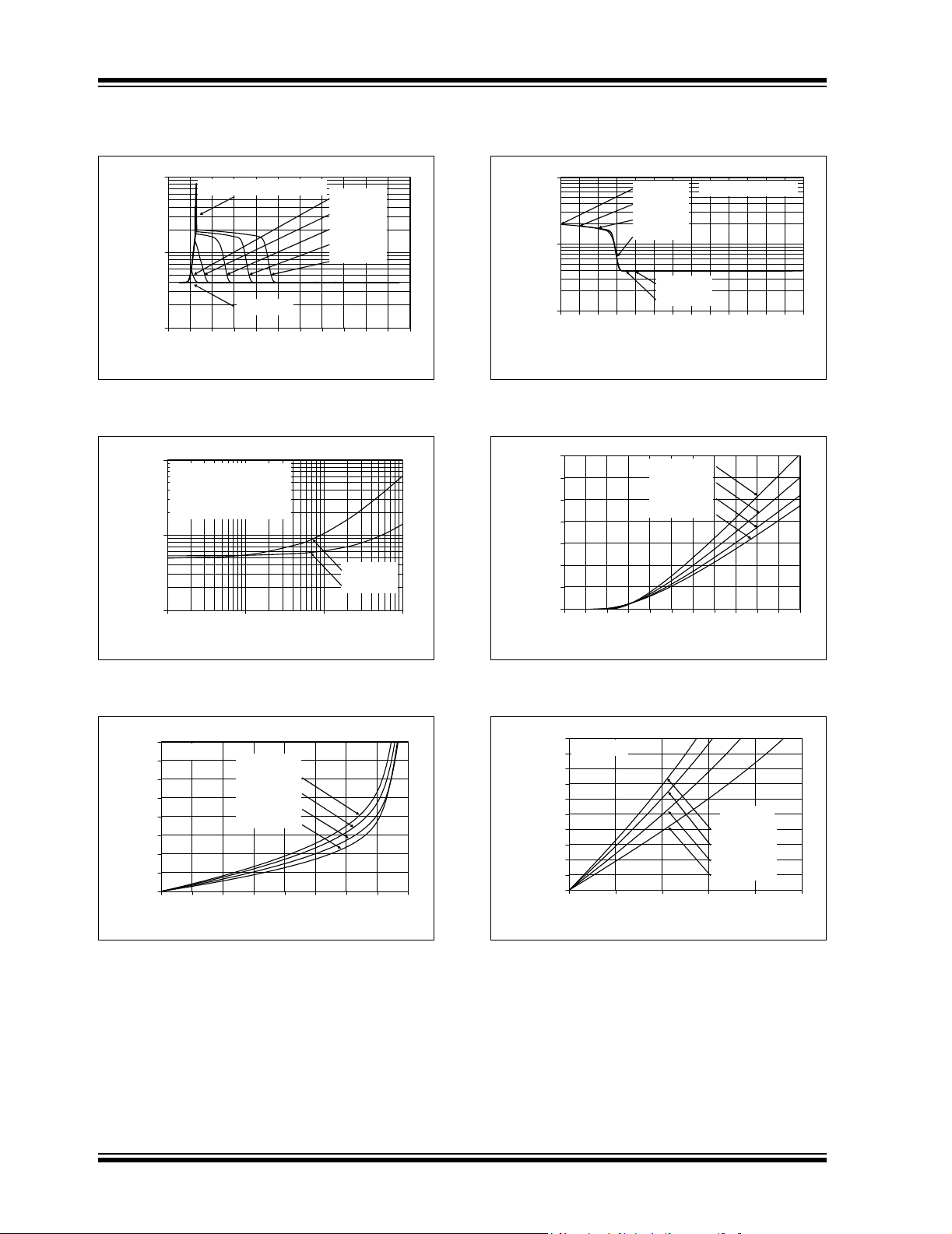

10

Supply Current

per Comparator (µA)

0.1

IDD spike near VPU = 1.3V

1

VDD = 1.6V

01234567891011

Pull-Up Voltage, V

VDD = 2.1V

V

= 2.6V

DD

V

= 3.6V

DD

V

= 4.6V

DD

V

= 5.6V

DD

(V)

PU

FIGURE 2-19: Supply Current vs. Pull-Up

Voltage.

10

100 mV Overdrive

= VDD/2

V

CM

does not include

I

DD

pull-up resistor current

1

Supply Current

per Comparator (µA)

0.1

0.1 1 10 100

Toggle Frequency (kHz)

VDD = 5.5V

V

= 1.6V

DD

10

1

Supply Current

per Comparator (µA)

0.1

-4-3-2-10123456789

VDD = 5.6V

= 4.6V

V

DD

V

= 3.6V

DD

= 2.6V

V

DD

Pull-up to Supply Voltage Difference,

V

VDD = 1.6V

= 2.1V

V

DD

– VDD (V)

PU

VPU = 1.6V to 10.5V

FIGURE 2-22: Supply Current vs. Pull-Up

to Supply Voltage Difference.

35

30

25

20

15

10

Magnitude (mA)

5

Output Short Circuit Current

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

TA = -40°C

= +25°C

T

A

= +85°C

T

A

= +125°C

T

A

Power Supply Voltage (V)

FIGURE 2-20: Supply Current vs. Toggle Frequency.

0.8

VDD = 1.6V

0.7

0.6

0.5

0.4

0.3

0.2

0.1

Output Voltage Headroom (V)

0.0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

VOL–VSS:

T

= +125°C

A

T

= +85°C

A

T

= +25°C

A

T

= -40°C

A

Output Current (mA)

FIGURE 2-21: Output Voltage Headroom

vs. Output Current at V

DD

=1.6V.

FIGURE 2-23: Output Short Circuit Current Magnitude vs. Power Supply Voltage.

1.0

VDD = 5.5V

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

Output Voltage Headroom (V)

0.0

0 5 10 15 20 25

Output Current (mA)

VOL – VSS:

TA = +125°C

T

= +85°C

A

T

= +25°C

A

T

= -40°C

A

FIGURE 2-24: Output Voltage Headroom

vs. Output Current at VDD=5.5V.

DS21714E-page 8 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

Note: Unless otherwise indicated, VDD= +1.6V to +5.5V, VSS= GND, TA= +25°C, VIN+=VDD/2, VIN– = GND,

RPU=2.74kΩ to VPU=VDD, and CL=36pF.

50%

45%

40%

35%

30%

25%

20%

15%

10%

5%

Percentage of Occurrences

0%

012345678

High-to-Low Propagation Delay (µs)

408 Samples

100 mV Overdrive

= VDD/2

V

CM

VDD = 5.5VVDD = 1.6V

FIGURE 2-25: High-to-Low Propagation Delay.

50%

45%

VDD = 5.5V

40%

35%

30%

25%

20%

15%

10%

5%

Percentage of Occurrences

0%

-2.0

-1.6

-1.2

Propagation Delay Skew (µs)

-0.8

VDD = 1.6V

0.0

-0.4

408 Samples

100 mV Overdrive

V

= VDD/2

CM

0.4

0.8

1.2

1.6

65%

60%

55%

50%

45%

40%

VDD = 1.6V

35%

30%

25%

20%

15%

10%

5%

Percentage of Occurrences

0%

012345678

Low-to-High Propagation Delay (µs)

VDD = 5.5V

408 Samples

100 mV Overdrive

= VDD/2

V

CM

FIGURE 2-28: Low-to-High Propagation Delay.

8

100 mV Overdrive

7

= VDD/2

V

CM

6

5

4

3

2

1

Propagation Delay (µs)

2.0

0

-50 -25 0 25 50 75 100 125

t

PHL

t

PLH

Ambient Temperature (°C)

VDD = 5.5V

VDD = 1.6V

FIGURE 2-26: Propagation Delay Skew.

14

VCM = VDD/2

13

12

11

10

9

8

7

6

10 mV Overdrive

5

4

3

2

Propagation Delay (µs)

1

100 mV Overdrive

0

1.52.02.53.03.54.04.55.05.5

Power Supply Voltage (V)

t

PHL

t

PLH

FIGURE 2-27: Propagation Delay vs. Power Supply Voltage.

FIGURE 2-29: Propagation Delay vs. Ambient Temperature.

100

10

Propagation Delay (µs)

1

1 10 100 1000

VDD = 5.5V

VDD = 1.6V

Input Overdrive (mV)

VCM = VDD/2

t

PHL

t

PLH

FIGURE 2-30: Propagation Delay vs. Input Overdrive.

© 2006 Microchip Technology Inc. DS21714E-page 9

MCP6546/6R/6U/7/8/9

Note: Unless otherwise indicated, VDD= +1.6V to +5.5V, VSS= GND, TA= +25°C, VIN+=VDD/2, VIN– = GND,

RPU=2.74kΩ to VPU=VDD, and CL=36pF.

8

VDD = 1.6V

7

100 mV Overdrive

6

5

4

3

2

1

Propagation Delay (µs)

0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Common Mode Input Voltage (V)

t

PHL

t

PLH

FIGURE 2-31: Propagation Delay vs.

Common Mode Input Voltage at V

8

VIN– = 100 mV Overdrive

7

VCM = VDD/2

6

+ = V

V

IN

5

4

3

2

Propagation Delay (µs)

1

0

0 102030405060708090100

CM

Pull-up Resistor, R

VDD = 5.5V

VDD = 1.6V

PU

(k:)

DD

=1.6V.

t

PLH

t

PHL

8

VDD = 5.5V

7

100 mV Overdrive

6

5

4

3

2

1

Propagation Delay (µs)

0

0.00.51.01.52.02.53.03.54.04.55.05.5

Common Mode Input Voltage (V)

t

PHL

t

PLH

FIGURE 2-34: Propagation Delay vs.

Common Mode Input Voltage at VDD=5.5V.

200

100 mV Overdrive

180

160

140

120

100

Propagation Delay (µs)

= VDD/2

V

CM

80

VDD = 5.5V

60

40

20

0

0 102030405060708090

VDD = 1.6V

Load Capacitance (nF)

t

PLH

t

PHL

FIGURE 2-32: Propagation Delay vs.

Pull-up Resistor.

8

VIN– = 100 mV Overdrive

7

VCM = VDD/2

6

V

+ = V

IN

5

4

3

2

1

Propagation Delay (µs)

0

CM

VDD = 5.5V

VDD = 1.6V t

01234567891011

Pull-up Voltage (V)

FIGURE 2-33: Propagation Delay vs.

Pull-up Voltage.

FIGURE 2-35: Propagation Delay vs. Load Capacitance.

10n

1.E+04

1n

1.E+03

t

PHL

PLH

100p

1.E+02

1.E+01

10p

1.E+00

Output Leakage Current (A)

1.E-01

100f

1p

CS = V

DD

VIN+ = VDD/2

V

– = V

IN

SS

01234567891011

Output Voltage (V)

TA = +125°C

TA = +85°C

TA = +25°C

FIGURE 2-36: Output Leakage Current

=VDD) vs. Output Voltage (MCP6548 only).

(CS

DS21714E-page 10 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

r

f

r

f

Note: Unless otherwise indicated, VDD= +1.6V to +5.5V, VSS= GND, TA= +25°C, VIN+=VDD/2, VIN– = GND,

RPU=2.74kΩ to VPU=VDD, and CL=36pF.

1m

1.E-03

1m

Comparator

100µ

Turns On

10µ

1µ

100n

10n

1n

100p

VDD = 1.6V

10p

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

CS

High-to-Low

Chip Select (CS) Voltage (V)

Supply Current

1.E-04

1.E-05

1.E-06

1.E-07

1.E-08

1.E-09

per Comparator (A)

1.E-10

1.E-11

Comparato

Shuts Of

CS Hysteresis

CS

Low-to-High

1.E-03

Comparator

100µ

1.E-04

Turns On

10µ

1.E-05

1µ

1.E-06

100n

1.E-07

10n

1.E-08

Supply Current

1.E-09

per Comparator (A)

100p

1.E-10

10p

1.E-11

CS

1n

Low-to-High

0.00.51.01.52.02.53.03.54.04.55.05.5

Chip Select (CS) Voltage (V)

CS

Hysteresis

High-to-Low

VDD = 5.5V

Comparato

Shuts Of

CS

FIGURE 2-37: Supply Current (shoot

through current) vs. Chip Select (CS

V

= 1.6V (MCP6548 only).

DD

30

25

20

VDD = 1.6V

15

10

5

0

Supply Current (µA)

Charging output

capacitance

01234567891011121314

Time (1 ms/div)

V

OUT

CS

Start-up

I

DD

) Voltage at

1.6

0.0

-1.6

-3.2

Output Voltage,

-4.9

-6.5

-8.1

FIGURE 2-38: Supply Current (charging

current) vs. Chip Select (CS

) pulse at VDD=1.6V

(MCP6548 only).

6.0

5.5

5.0

4.5

4.0

3.5

3.0

(V)

2.5

2.0

1.5

1.0

0.5

0.0

Chip Select, Output Voltage

-0.5

012345678910

VDD = 5.5V

V

OUT

CS

Time (ms)

FIGURE 2-40: Supply Current (shoot

through current) vs. Chip Select (CS

V

= 5.5V (MCP6548 only).

DD

200

180

V

OUT

160

140

120

100

80

Chip Select Voltage (V),

60

40

20

Supply Current

0

per Comparator (µA)

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

CS

Start-up I

VDD = 5.5V

Charging output

capacitance

Time (0.5 ms/div)

) Voltage at

6

3

0

-3

-6

DD

-9

-12

-15

-18

-21

-24

Output Voltage,

Chip Select Voltage (V)

FIGURE 2-41: Supply Current (charging

current) vs. Chip Select (CS

) pulse at VDD=5.5V

(MCP6548 only).

1.E-02

10m

1.E-03

1m

1.E-04

100µ

1.E-05

10µ

1.E-06

1µ

100n

1.E-07

10n

1.E-08

1n

1.E-09

100p

1.E-10

10p

1.E-11

Input Current Magnitude (A)

1p

1.E-12

-1.0 -0.9 -0.8 -0.7 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1 0.0

+125°C

+85°C

+25°C

-40°C

Input Voltage (V)

FIGURE 2-39: Chip Select (CS

Response (MCP6548 only).

) Step

FIGURE 2-42: Input Bias Current vs. Input Voltage.

© 2006 Microchip Technology Inc. DS21714E-page 11

MCP6546/6R/6U/7/8/9

3.0 PIN DESCRIPTIONS

Descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

MCP6546

(PDIP,

SOIC,

MSOP)

————5—5V

————6—6V

— — — — 7 — 7 OUTB Digital Output (comparator B)

— — — — — — 8 OUTC Digital Output (comparator C)

——————9V

——————10V

——————12V

——————13V

— — — — — — 14 OUTD Digital Output (comparator D)

—————8—CS

1, 5, 8 — — — — 1, 5 — NC No Internal Connection

MCP6546

(SOT-23-5,

SC-70-5)

MCP6546R

MCP6546U

MCP6547

MCP6548

Symbol Description

MCP6549

6 1 1 4 1 6 1 OUT, OUTA Digital Output (comparator A)

2441222V

3333333V

IN

IN

–, V

– Inverting Input (comparator A)

INA

+, V

+ Non-inverting Input (comparator A)

INA

7525874VDDPositive Power Supply

+ Non-inverting Input (comparator B)

INB

– Inverting Input (comparator B)

INB

– Inverting Input (comparator C)

INC

+ Non-inverting Input (comparator C)

INC

42524411V

SS

IND

IND

Negative Power Supply

+ Non-inverting Input (comparator D)

– Inverting Input (comparator D)

Chip Select

3.1 Analog Inputs

The comparator non-inverting and inverting inputs are

high-impedance CMOS inputs with low bias currents.

3.2 CS Digital Input

This is a CMOS, Schmitt-triggered input that places the

part into a low power mode of operation.

3.3 Digital Outputs

The comparator outputs are CMOS, open-drain digital

outputs. They are designed to make level shifting and

wired-OR easy to implement.

3.4 Power Supply (VSS and VDD)

The positive power supply pin (VDD) is 1.6V to 5.5V

higher than the negative power supply pin (V

normal operation, the other pins are at voltages

between VSS and VDD, except the output pins which

can be as high as 10V above V

SS

.

Typically, these parts are used in a single (positive)

supply configuration. In this case, V

is connected to

SS

ground and VDD is connected to the supply. VDD will

need a local bypass capacitor (typically 0.01 µF to

0.1 µF) within 2 mm of the V

pin. These can share a

DD

bulk capacitor with nearby analog parts (within

100 mm), but it is not required.

SS

). For

DS21714E-page 12 © 2006 Microchip Technology Inc.

4.0 APPLICATIONS INFORMATION

The MCP6546/7/8/9 family of push-pull output

comparators are fabricated on Microchip’s state-of-theart CMOS process. They are suitable for a wide range

of applications requiring very low power consumption.

4.1 Comparator Inputs

4.1.1 PHASE REVERSAL

The MCP6546/6R/6U/7/8/9 comparator family uses

CMOS transistors at the input. They are designed to

prevent phase inversion when the input pins exceed

the supply voltages. Figure 2-3 shows an input voltage

exceeding both supplies with no resulting phase

inversion.

4.1.2 INPUT VOLTAGE AND CURRENT

LIMITS

The ESD protection on the inputs can be depicted as

shown in Figure 4-1. This structure was chosen to protect the input transistors, and to minimize input bias

current (IB). The input ESD diodes clamp the inputs

when they try to go more than one diode drop below

. They also clamp any voltages that go too far

V

SS

above V

allow normal operation, and low enough to bypass ESD

events within the specified limits.

FIGURE 4-1: Simplified Analog Input ESD Structures.

In order to prevent damage and/or improper operation

of these amplifiers, the circuits they are in must limit the

currents (and voltages) at the V

Absolute Maximum Ratings † at the beginning of

Section 1.0 “Electrical Characteristics”). Figure 4-3

shows the recommended approach to protecting these

inputs. The internal ESD diodes prevent the input pins

(V

IN

the resistors R1 and R2 limit the possible current drawn

out of the input pin. Diodes D

pin (V

When implemented as shown, resistors R1 and R2 also

limit the current through D

; their breakdown voltage is high enough to

DD

Bond

V

DD

Pad

VIN+

V

SS

Bond

Pad

Bond

Pad

Input

Stage

Bond

+ and VIN– pins (see

IN

Pad

VIN–

+ and VIN–) from going too far below ground, and

and D2 prevent the input

+ and VIN–) from going too far above VDD.

IN

1

and D2.

1

MCP6546/6R/6U/7/8/9

V

DD

D

1

V

1

R

1

D

2

V

2

R

2

VSS– (minimum expected V1)

R

≥

1

VSS– (minimum expected V2)

R

≥

2

FIGURE 4-2: Protecting the Analog Inputs.

It is also possible to connect the diodes to the left of the

resistors R1 and R2. In this case, the currents through

the diodes D1 and D2 need to be limited by some other

mechanism. The resistor then serves as in-rush current

limiter; the DC current into the input pins (V

VIN–) should be very small.

A significant amount of current can flow out of the

inputs when the common mode voltage (V

ground (VSS); see Figure 2-42. Applications that are

high impedance may need to limit the useable voltage

range.

4.1.3 NORMAL OPERATION

The input stage of this family of devices uses two

differential input stages in parallel: one operates at low

input voltages and the other at high input voltages.

With this topology, the input voltage is 0.3V above V

and 0.3V below VSS. The input offset voltage is

measured at both V

proper operation.

The MCP6546/6R/6U/7/8/9 family has internally-set

hysteresis that is small enough to maintain input offset

accuracy (<7 mV), and large enough to eliminate

output chattering caused by the comparator’s own

input noise voltage (200 µV

this capability.

SS

+

MCP6G0X

–

R

3

2mA

2mA

- 0.3V and V

). Figure 4-3 illustrates

P-P

V

OUT

) is below

CM

+ 0.3V to ensure

DD

+ and

IN

DD

© 2006 Microchip Technology Inc. DS21714E-page 13

MCP6546/6R/6U/7/8/9

8

VDD = 5.0V

7

6

5

V

4

3

2

1

0

Output Voltage (V)

-1

-2

-3

OUT

Time (100 ms/div)

VIN–

Hysteresis

FIGURE 4-3: The MCP6546/7/8/9

comparators’ internal hysteresis eliminates

output chatter caused by input noise voltage.

4.2 Open-Drain Output

25

20

15

10

5

0

-5

-10

-15

-20

-25

-30

Input Voltage (10 mV/div)

4.4.1 INVERTING CIRCUIT

Figure 4-4 shows an inverting circuit for a single-supply

application using three resistors, besides the pull-up

resistor. The resulting hysteresis diagram is shown in

Figure 4-5.

V

DD

V

IN

V

DD

R

2

R

3

MCP654X

I

RF

R

V

PU

I

PU

F

I

OL

R

PU

V

OUT

The open-drain output is designed to make levelshifting and wired-OR logic easy to implement. The

output can go as high as 10V for 9V battery-powered

applications. The output stage minimizes switching current (shoot-through current from supply-to-supply)

when the output changes state. See Figures 2-15, 2-18

and 2-37 through 2-41, for more information.

4.3 MCP6548 Chip Select (CS)

The MCP6548 is a single comparator with a Chip

Select (CS) pin. When CS is pulled high, the total

current consumption drops to 20 pA (typ.). 1 pA (typ.)

flows through the CS

pin, 1 pA (typ.) flows through the

output pin and 18 pA (typ.) flows through the VDD pin,

as shown in Figure 1-1. When this happens, the

comparator output is put into a high-impedance state.

By pulling CS

low, the comparator is enabled. If the CS

pin is left floating, the comparator will not operate

properly. Figure 1-1 shows the output voltage and

supply current response to a CS

The internal CS

circuitry is designed to minimize

pulse.

glitches when cycling the CS pin. This helps conserve

power, which is especially important in battery-powered

applications.

4.4 Externally Set Hysteresis

Greater flexibility in selecting hysteresis, or input trip

points, is achieved by using external resistors.

Input offset voltage (V

(input-referred) low-high and high-low trip points. Input

hysteresis voltage (V

the same trip points. Hysteresis reduces output

chattering when one input is slowly moving past the

other, thus reducing dynamic supply current. It also

helps in systems where it is best not to cycle between

states too frequently (e.g., air conditioner thermostatic

control).

) is the center (average) of the

OS

) is the difference between

HYST

FIGURE 4-4: Inverting circuit with hysteresis.

V

OUT

V

PU

V

OH

High-to-LowLow-to-High

V

OL

V

SS

V

SS

V

= trip voltage from low to high

TLH

= trip voltage from high to low

V

THL

V

TLHVTHL

V

IN

V

DD

FIGURE 4-5: Hysteresis diagram for the inverting circuit.

In order to determine the trip voltages (V

for the circuit shown in Figure 4-4, R

simplified to the Thevenin equivalent circuit with

respect to VDD, as shown in Figure 4-6.

-

MCP654X

+

V

23

R

23

R

F

and V

THL

and R3 can be

2

V

R

PU

PU

V

TLH

OUT

FIGURE 4-6: Thevenin Equivalent Circuit.

)

DS21714E-page 14 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

EQUATION 4-1:

R2R

------------------

R2R3+

R

3

3

VDD×=

=

R

23

------------------

V

23

R2R3+

Using this simplified circuit, the trip voltage can be

calculated using the following equation:

EQUATION 4-2:

R

V

THL

V

V

TLH

THL

⎛⎞

V

⎜⎟

PU

⎝⎠

V

TLH

= trip voltage from low to high

= trip voltage from high to low

23

---------------------------------------R23RFR

++

V

OL

PU

R

⎛⎞

23

---------------------- -

⎜⎟

R23RF+

⎝⎠

+=

V

+=

V

Figure 2-21 and Figure 2-24 can be used to determine

typical values for V

. This voltage is dependent on the

OL

output current IOL as shown in Figure 4-4. This current

can be determined using the equation below:

RFRPU+

⎛⎞

---------------------------------------

23

⎝⎠

++

R

23RFRPU

R

F

⎛⎞

--------------------- -

23

⎝⎠

R23RF+

EQUATION 4-3:

I

OLIPUIRF

VPUVOL–

⎛⎞

I

--------------------------

OL

⎝⎠

R

VOH can be calculated using the equation below:

PU

+=

V

–

23VOL

⎛⎞

------------------------

+=

⎝⎠

R

+

23RF

4.6 Capacitive Loads

Reasonable capacitive loads (e.g., logic gates) have

little impact on propagation delay (see Figure 2-27).

The supply current increases with increasing toggle

frequency (Figure 2-30), especially with higher

capacitive loads.

4.7 Battery Life

In order to maximize battery life in portable

applications, use large resistors and small capacitive

loads. Avoid toggling the output more than necessary.

Do not use Chip Select (CS

) too frequently in order to

conserve power. Capacitive loads will draw additional

power at start-up.

4.8 PCB Surface Leakage

In applications where low input bias current is critical,

PCB (Printed Circuit Board) surface leakage effects

need to be considered. Surface leakage is caused by

humidity, dust or other contamination on the board.

Under low-humidity conditions, a typical resistance

between nearby traces is 10

would cause 5 pA of current to flow. This is greater

than the MCP6546/6R/6U/7/8/9 family’s bias current at

25°C (1 pA, typ.).

The easiest way to reduce surface leakage is to use a

guard ring around sensitive pins (or traces). The guard

ring is biased at the same voltage as the sensitive pin.

An example of this type of layout is shown in

Figure 4-7.

VIN-V

12

Ω. A 5V difference

+

IN

V

SS

EQUATION 4-4:

R

+

23RF

⎛⎞

--------------------------------------

V

VPUV23–()

OH

As explained in Section 4.1 “Comparator Inputs”, it

is important to keep the non-inverting input below

+0.3V when VPU > VDD.

V

DD

4.5 Supply Bypass

With this family of comparators, the power supply pin

for single supply) should have a local bypass

(V

DD

capacitor (i.e., 0.01 µF to 0.1 µF) within 2 mm for good

edge rate performance.

© 2006 Microchip Technology Inc. DS21714E-page 15

×=

⎝⎠

R

++

23RFRPU

Guard Ring

FIGURE 4-7: Example Guard Ring Layout for Inverting Circuit.

1. Inverting Configuration (Figures 4-4 and 4-7):

a. Connect the guard ring to the non-inverting

input pin (V

to the same reference voltage as the

comparator (e.g., VDD/2 or ground).

b. Connect the inverting pin (V

pad without touching the guard ring.

+). This biases the guard ring

IN

–) to the input

IN

MCP6546/6R/6U/7/8/9

4.9 Unused Comparators

An unused amplifier in a quad package (MCP6549)

should be configured as shown in Figure 4-8. This

circuit prevents the output from toggling and causing

crosstalk. It uses the minimum number of components

and draws minimal current (see Figure 2-15 and

Figure 2-18).

¼ MCP6549

V

DD

–

+

FIGURE 4-8: Unused Comparators.

4.10 Typical Applications

4.10.1 PRECISE COMPARATOR

Some applications require higher DC precision. An

easy way to solve this problem is to use an amplifier

(such as the MCP6041) to gain-up the input signal

before it reaches the comparator. Figure 4-9 shows an

example of this approach.

V

DD

V

REF

MCP6041

V

V

V

IN

R

1

R

2

V

REF

MCP6546

FIGURE 4-9: Precise Inverting Comparator.

4.10.2 WINDOWED COMPARATOR

Figure 4-10 shows one approach to designing a

windowed comparator. The wired-OR connection

produces a high output (logic 1) when the input voltage

is between V

and VRT (where VRT > VRB).

RB

DD

PU

R

PU

V

OUT

V

1/2

V

RT

V

IN

V

RB

MCP6547

1/2

PU

R

PU

V

OUT

MCP6547

FIGURE 4-10: Windowed Comparator.

DS21714E-page 16 © 2006 Microchip Technology Inc.

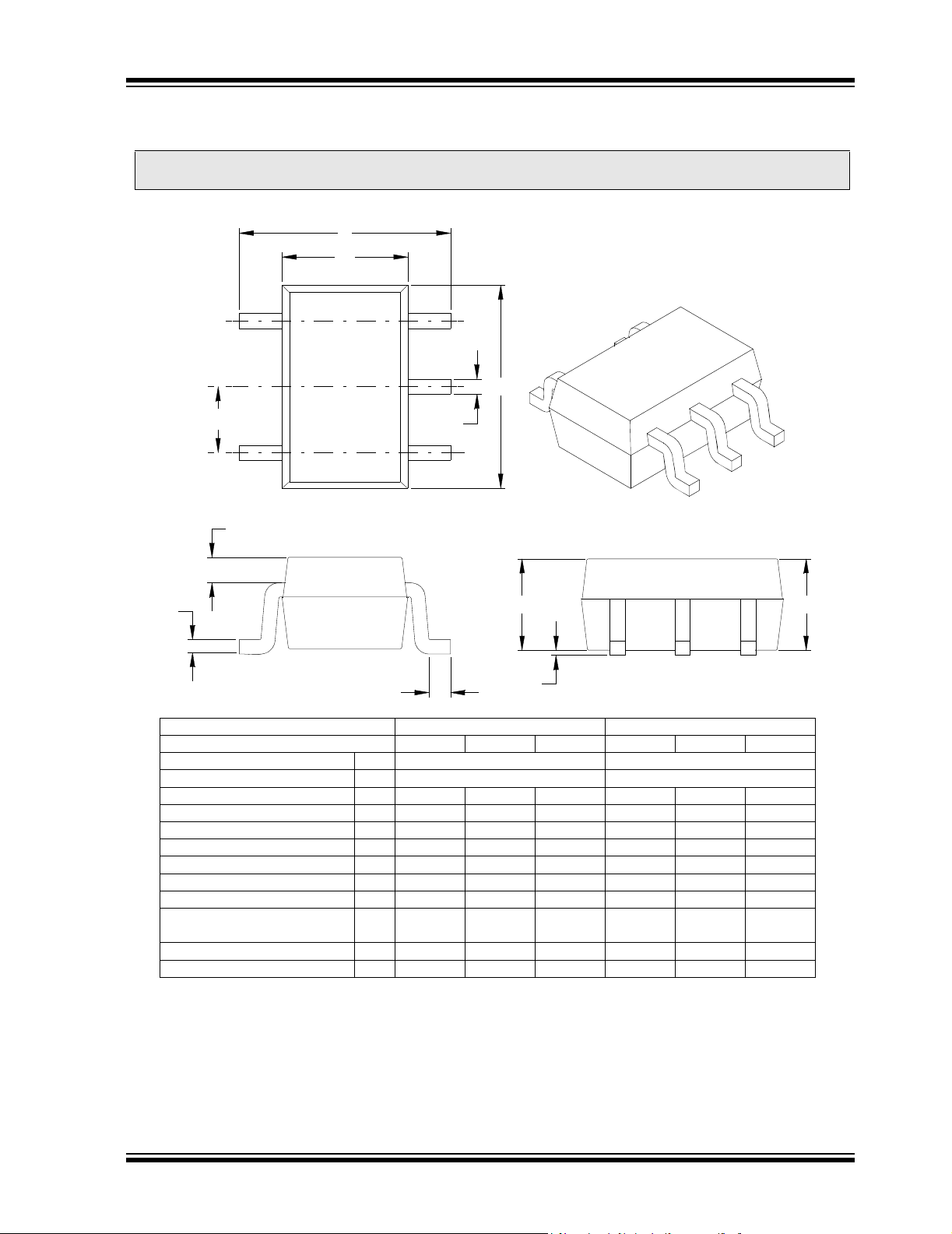

5.0 PACKAGING INFORMATION

5.1 Package Marking Information

5-Lead SC-70 (MCP6546)

MCP6546/6R/6U/7/8/9

Example: (I-temp)

I-Temp

Code

2005 are marked “ACN”

available at this release of

the data sheet.

XXNN (Front)

YWW (Back)

Device

MCP6546 ACNN Note 2

Note 1: I-Temp parts prior to March

2: SC-70-5 E-Temp parts not

5-Lead SOT-23 (MCP6546, MCP6546R, MCP6546U)

Device

XXNN AC25

MCP6546 ACNN GWNN

MCP6546R AHNN GXNN

MCP6546U — AWNN

Note: Applies to 5-Lead SOT-23

I-Temp

Code

8-Lead PDIP (300 mil)

XXXXXXXX

XXXXXNNN

YYWW

8-Lead SOIC (150 mil)

E-Temp

Code

E-Temp

Code

MCP6546

I/P256

0636

AC25(Front)

636 (Back)

Example: (I-temp)

Example:

OR

Example:

MCP6546

3

e

I/P^^256

0636

XXXXXXXX

XXXXYYWW

NNN

8-Lead MSOP

XXXXXX

YWWNNN

MCP6546

I/SN0636

256

OR

Example:

MCP6546I

3

e

SN^^0636

256

6546I

636256

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Pb-free JEDEC designator for Matte Tin (Sn)

3

e

* This package is Pb-free. The Pb-free JEDEC designator ( )

3

e

can be found on the outer packaging for this package.

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

© 2006 Microchip Technology Inc. DS21714E-page 17

MCP6546/6R/6U/7/8/9

Package Marking Information (Continued)

14-Lead PDIP (300 mil) (MCP6549) Example:

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

YYWWNNN

14-Lead SOIC (150 mil) (MCP6549)

XXXXXXXXXX

XXXXXXXXXX

YYWWNNN

OR

OR

MCP6549-I/P

XXXXXXXXXXXXXX

MCP6549E/P

Example:

0636256

e

0636256

MCP6549

I/P^^

3

e

0636256

MCP6549ISL

XXXXXXXXXX

0636256

3

14-Lead TSSOP (MCP6549)

XXXXXXXX

YYWW

NNN

OR

Example:

MCP6549I

0636

256

MCP6549

e

E/SL^^

0636256

3

DS21714E-page 18 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

5-Lead Plastic Package (LT) (SC-70)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E

E1

D

p

n

Q1

c

Number of Pins

Pitch

Top of Molded Pkg to

Lead Shoulder

Lead Thickness

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .005" (0.127mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

JEITA (EIAJ) Standard: SC-70

Drawing No. C04-061

n

p

Q1

c

B

1

A2 A

A1

L

INCHESUnits

.004 .016 0.10

MILLIMETERS

55

0.65 (BSC).026 (BSC)

Revised 07-19-05

*

MAXNOMMINMAXNOMMINDimension Limits

1.100.80.043.031AOverall Height

1.000.80.039.031A2Molded Package Thickness

0.100.00.004.000A1Standoff

2.401.80.094.071EOverall Width

1.351.15.053.045E1Molded Package Width

2.201.80.087.071DOverall Length

0.300.10.012.004LFoot Length

0.40

0.180.10.007.004

0.300.15.012.006BLead Width

© 2006 Microchip Technology Inc. DS21714E-page 19

MCP6546/6R/6U/7/8/9

5-Lead Plastic Small Outline Transistor (OT) (SOT23)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E

E1

B

n

c

β

Number of Pins

Pitch

Outside lead pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .005" (0.127mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

JEITA (formerly EIAJ) equivalent: SC-74A

Drawing No. C04-120

L

Units

n

p

p1

φ

c

α

β

p1

D

1

α

A1

A

*

MILLIMETERSINCHES

0.95 BSC.038 BSC

1.90 BSC.075 BSC

Revised 09-12-05

A2

MAXNOMMINMAXNOMMINDimension Limits

66

1.451.180.90.057.046.035AOverall Height

1.301.100.90.051.043.035A2Molded Package Thickness

0.150.080.00.006.003.000A1Standoff

3.002.802.60.118.110.102EOverall Width

1.751.631.50.069.064.059E1Molded Package Width

3.102.952.80.122.116.110DOverall Length

0.550.450.35.022.018.014LFoot Length

10501050

0.200.150.09.008.006.004

0.500.430.35.020.017.014BLead Width

10501050

10501050

φ

DS21714E-page 20 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

8-Lead Plastic Dual In-line (P) – 300 mil Body (PDIP)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E1

D

2

n

E

β

eB

Dimension Limits MIN NOM MAX MIN NOM MAX

Number of Pins

Pitch

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing §

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

1

α

A

c

Units INCHES* MILLIMETERS

n

p

A1

c

eB

α

β

.015 0.38

.008 .012 .015 0.20 0.29 0.38

.310 .370 .430 7.87 9.40 10.92

A1

B1

B

88

.100 2.54

51015 51015

51015 51015

A2

L

p

© 2006 Microchip Technology Inc. DS21714E-page 21

MCP6546/6R/6U/7/8/9

8-Lead Plastic Small Outline (SN) – Narrow, 150 mil (SOIC)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E

E1

p

D

2

B

Number of Pins

Pitch

Standoff §

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-057

n

45°

c

β

n

p

A1

φ

c

α

β

1

h

A

φ

L

048048

A1

MILLIMETERSINCHES*Units

.050

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.27

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004

6.206.025.79.244.237.228EOverall Width

3.993.913.71.157.154.146E1Molded Package Width

5.004.904.80.197.193.189DOverall Length

0.510.380.25.020.015.010hChamfer Distance

0.760.620.48.030.025.019LFoot Length

0.250.230.20.010.009.008

0.510.420.33.020.017.013BLead Width

1512015120

1512015120

DS21714E-page 22 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

8-Lead Plastic Micro Small Outline Package (MS) (MSOP)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E

E1

p

D

2

n1

B

α

c

F

β

Units

Dimension Limits

Number of Pins

Pitch

Overall Height

Molded Package Thickness

Standoff

Overall Width

Molded Package Width

Overall Length

Foot Length

Foot Angle

Lead Thickness

Lead Width

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010" (0.254mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

REF: Reference Dimension, usually without tolerance, for information purposes only.

See ASME Y14.5M

JEDEC Equivalent: MO-187

Drawing No. C04-111

n

p

A

A2

A1

E

E1

D

L

φ

c

B

α

β

MIN

.030

.000

.016 .024

0° - 8°

.003

.009

5°

5° -

L

INCHES

NOM

.026 BSC

.193 BSC

.118 BSC

.118 BSC

.037 REFFFootprint (Reference)

φ

8

--

.033

--

.006

.012

-

A

A1

MILLIMETERS

MAX NOM

.043

.037

.006

.031

.009

.016

15°

15°

MIN

0.65 BSC

-

0.75

0.00

4.90 BSC

3.00 BSC

3.00 BSC

0.40

0.95 REF

0°

0.08

0.22

*

8

-

0.85

0.60

-

-

-

Revised 07-21-05

A2

MAX

1.10

0.95

0.15

0.80

8°

0.23

0.40

15°5° -

15°5° -

© 2006 Microchip Technology Inc. DS21714E-page 23

MCP6546/6R/6U/7/8/9

14-Lead Plastic Dual In-line (P) – 300 mil Body (PDIP)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E1

D

2

n

E

β

eB

Number of Pins

Pitch

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .740 .750 .760 18.80 19.05 19.30

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing §

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-005

1

A

c

A1

Dimension Limits MIN NOM MAX MIN NOM MAX

Units INCHES* MILLIMETERS

n

p

A2

c

eB

α

β

.115 .130 .145 2.92 3.30 3.68

.008 .012 .015 0.20 0.29 0.38

.310 .370 .430 7.87 9.40 10.92

5 10 15 5 10 15

5 10 15 5 10 15

B1

B

14 14

.100 2.54

α

A2

L

p

DS21714E-page 24 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

14-Lead Plastic Small Outline (SL) – Narrow, 150 mil (SOIC)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E

E1

p

D

2

B

n

1

45°

c

β

Number of Pins

Pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-065

h

A

φ

L

n

p

φ

c

α

β

A1

.050

048048

α

A2

MILLIMETERSINCHES*Units

MAXNOMMINMAXNOMMINDimension Limits

1414

1.27

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004A1Standoff §

6.205.995.79.244.236.228EOverall Width

3.993.903.81.157.154.150E1Molded Package Width

8.818.698.56.347.342.337DOverall Length

0.510.380.25.020.015.010hChamfer Distance

1.270.840.41.050.033.016LFoot Length

0.250.230.20.010.009.008

0.510.420.36.020.017.014BLead Width

1512015120

1512015120

© 2006 Microchip Technology Inc. DS21714E-page 25

MCP6546/6R/6U/7/8/9

14-Lead Plastic Thin Shrink Small Outline (ST) – 4.4 mm (TSSOP)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E

E1

p

D

2

n

B

1

A

c

β

Number of Pins

Pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold fla sh or protrusions. Mold flash or protrusions shall not exceed .005" (0.127mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

REF: Reference Dimension, usually without tole rance, for information purposes only.

See ASME Y14.5M

JEDEC Equivalent: MO-153 AB-1

Drawing No. C04-087

n

p

φ

c

α

β

0°

φ

L

INCHESUnits

12° REF

12° REF

MILLIMETERS

1414

0.65 BSC.026 BSC

12° REF

12° REF

Revised: 08-17-05

A2A1

*

MAXNOMMINMAXNOMMINDimension Limits

1.101.051.00.043.041.039AOverall Height

0.950.900.85.037.035.033A2Molded Package Thickness

0.150.100.05.006.004.002A1Standoff

6.506.386.25.256.251.246EOverall Width

4.504.404.30.177.173.169E1Molded Package Width

5.105.004.90.201.197.193DMolded Package Length

0.700.600.50.028.024.020LFoot Length

8°4°0°8°4°

0.200.150.09.008.006.004

0.300.250.19.012.010.007BLead Width

α

DS21714E-page 26 © 2006 Microchip Technology Inc.

APPENDIX A: REVISION HISTORY

Revision E (September 2006)

The following is the list of modifications:

1. Added MCP6546U pinout for the SOT-23-5

package.

2. Clarified Absolute Maximum Analog Input

Voltage and Current Specifications.

3. Added applications writeups on unused

comparators.

4. Added disclaimer to package outline drawings.

Revision D (May 2006)

The following is the list of modifications:

1. Added E-temp parts.

2. Changed minimum pull-up voltage specification

) to 1.6V for parts starting Dec. 2004 (week

(V

PU

code 52); previous parts are specified at a

minimum of V

3. Changed V

linear and quadratic temperature coefficients.

4. Changed specifications and plots to include ETemp parts.

5. Added Section 3.0 “Pin Descriptions”.

6. Corrected package markings (Section 5.1

“Package Marking Information”).

7. Added Appendix A: “Revision History”.

.

DD

temperature specifications to

HYST

MCP6546/6R/6U/7/8/9

Revision C (May 2003)

Revision B (December 2002)

Revision A (February 2002)

• Original Release of this Document.

© 2006 Microchip Technology Inc. DS21714E-page 27

MCP6546/6R/6U/7/8/9

NOTES:

DS21714E-page 28 © 2006 Microchip Technology Inc.

MCP6546/6R/6U/7/8/9

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. –X /XX

Device

PackageTemperature

Range

Device: MCP6546: Single Comparator

Temperature Range: I = -40°C to +85°C

Package: LT = Plastic Package (SC-70), 5-lead

MCP6546T: Single Comparator (Tape and Reel)

MCP6546RT: Single Comparator (Rotated - Tape and

MCP6546UT: Single Comparator (Tape and Reel)

MCP6547: Dual Comparator

MCP6547T: Dual Comparator

MCP6548: Single Comparator with CS

MCP6548T: Single Comparator with CS

MCP6549: Quad Comparator

MCP6549T: Quad Comparator

E * = -40°C to +125°C

* SC-70-5 E-Temp parts not available at this release of the

data sheet.

OT = Plastic Small Outline Transistor (SOT-23), 5-lead

MS = Plastic MSOP, 8-lead

P = Plastic DIP (300 mil Body), 8-lead, 14-lead

SN = Plastic SOIC (150 mil Body), 8-lead

SL = Plastic SOIC (150 mil Body), 14-lead (MCP6549)

ST = Plastic TSSOP (4.4mm Body), 14-lead (MCP6549)

(SC-70, SOT-23, SOIC, MSOP)

Reel) (SOT-23 only)

(SOT-23-5 is E-Temp only)

(Tape and Reel for SOIC and MSOP)

(Tape and Reel for SOIC and MSOP)

(Tape and Reel for SOIC and TSSOP)

Examples:

a) MCP6546T-I/LT: Tape and Reel,

b) MCP6546T-I/OT: Tape and Reel,

c) MCP6546-E/P: Extended Temperature,

d) MCP6546RT-I/OT: Tape and Reel,

e) MCP6546-E/SN: Extended Temperature,

f) MCP6546UT-E/OT:Tape and Reel,

a) MCP6547-I/MS: Industrial Temperature,

b) MCP6547T-I/MS: Tape and Reel,

c) MCP6547-I/P: Industrial Temperature,

d) MCP6547-E/SN: Extended Temperature,

a) MCP6548-I/SN: Industrial Temperature,

b) MCP6548T-I/SN: Tape and Reel,

c) MCP6548-I/P: Industrial Temperature,

d) MCP6548-E/SN: Extended Temperature,

a) MCP6549T-I/SL: Tape and Reel,

b) MCP6549T-E/SL: Tape and Reel,

c) MCP6549-I/P: Industrial Temperature,

d) MCP6549-E/ST: Extended Temperature,

Industrial Temperature,

5LD SC-70.

Industrial Temperature,

5LD SOT-23.

8LD PDIP.

Industrial Temperature,

5LD SOT23.

8LD SOIC.

Extended Temperature,

5LD SOT23.

8LD MSOP.

Industrial Temperature,

8LD MSOP.

8LD PDIP.

8LD SOIC.

8LD SOIC.

Industrial Temperature,

8LD SOIC.

8LD PDIP.

8LD SOIC.

Industrial Temperature,

14LD SOIC.

Extended Temperature,

14LD SOIC.

14LD PDIP.

14LD TSSOP.

© 2006 Microchip Technology Inc. DS21714E-page 29

MCP6546/6R/6U/7/8/9

NOTES:

DS21714E-page 30 © 2006 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro,

PICSTART, PRO MATE, PowerSmart, rfPIC, and

SmartShunt are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPASM, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its

PICmicro

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping devices, Serial

© 2006 Microchip Technology Inc. DS21714E-page 31

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi