Page 1

MCP6021/1R/2/3/4

Rail-to-Rail Input/Output, 10 MHz Op Amps

Features

• Rail-to-Rail Input/Output

• Wide Bandwidth: 10 MHz (typ.)

• Low Noise: 8.7 nV/√Hz, at 10 kHz (typ.)

• Low Offset Voltage:

- Industrial Temperature: ±500 μV (max.)

- Extended Temperature: ±250 μV (max.)

• Mid-Supply V

: MCP6021 and MCP6023

REF

• Low Supply Current: 1 mA (typ.)

• Total Harmonic Distortion: 0.00053% (typ., G = 1)

• Unity Gain Stable

• Power Supply Range: 2.5V to 5.5V

• Temperature Range:

- Industrial: -40°C to +85°C

- Extended: -40°C to +125°C

Typical Applications

• Automotive

• Driving A/D Converters

• Multi-Pole Active Filters

• Barcode Scanners

• Audio Processing

• Communications

• DAC Buffer

• Test Equipment

• Medical Instrumentation

Available Tools

• SPICE Macro Model (at www.microchip.com)

•FilterLab

®

software (at www.microchip.com)

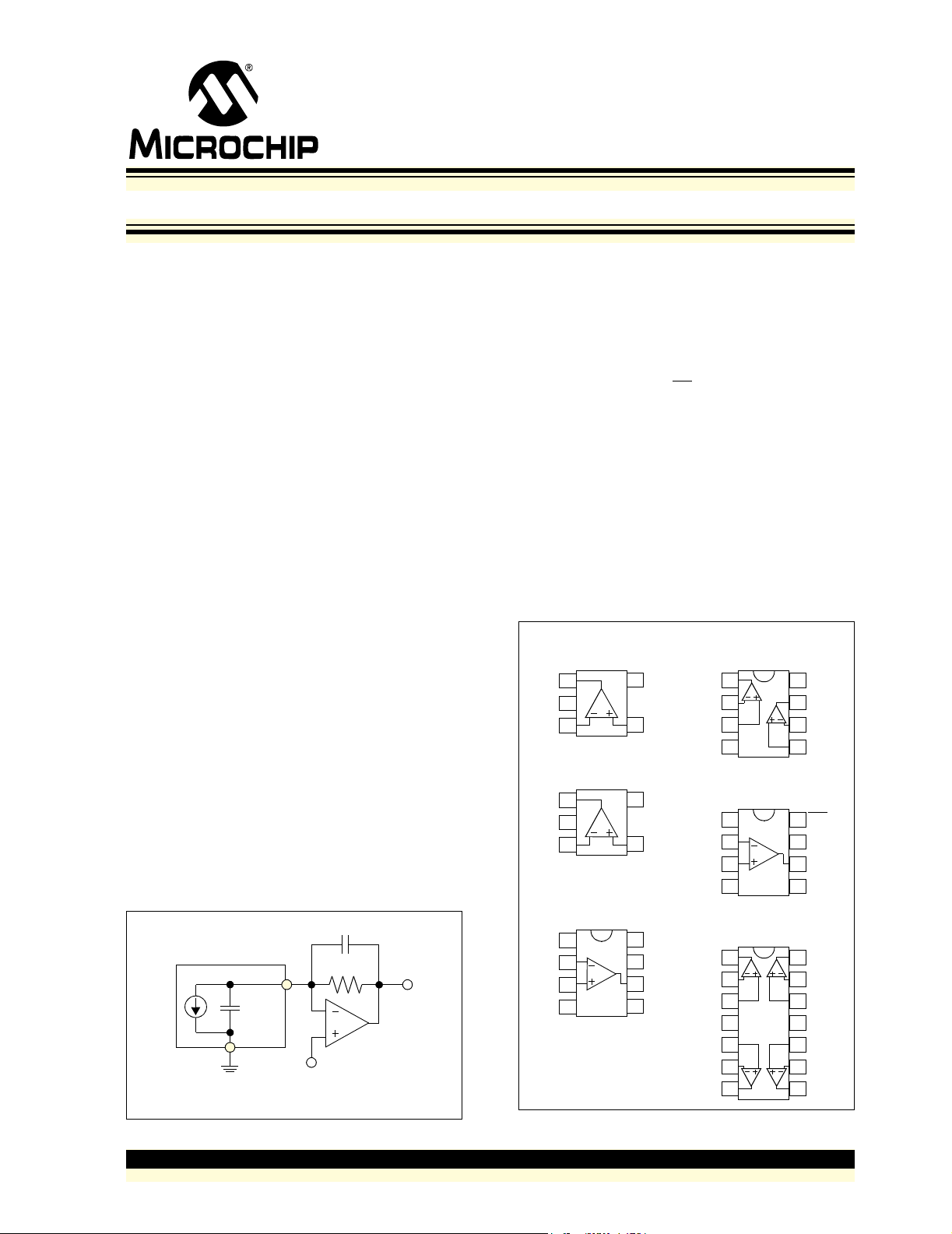

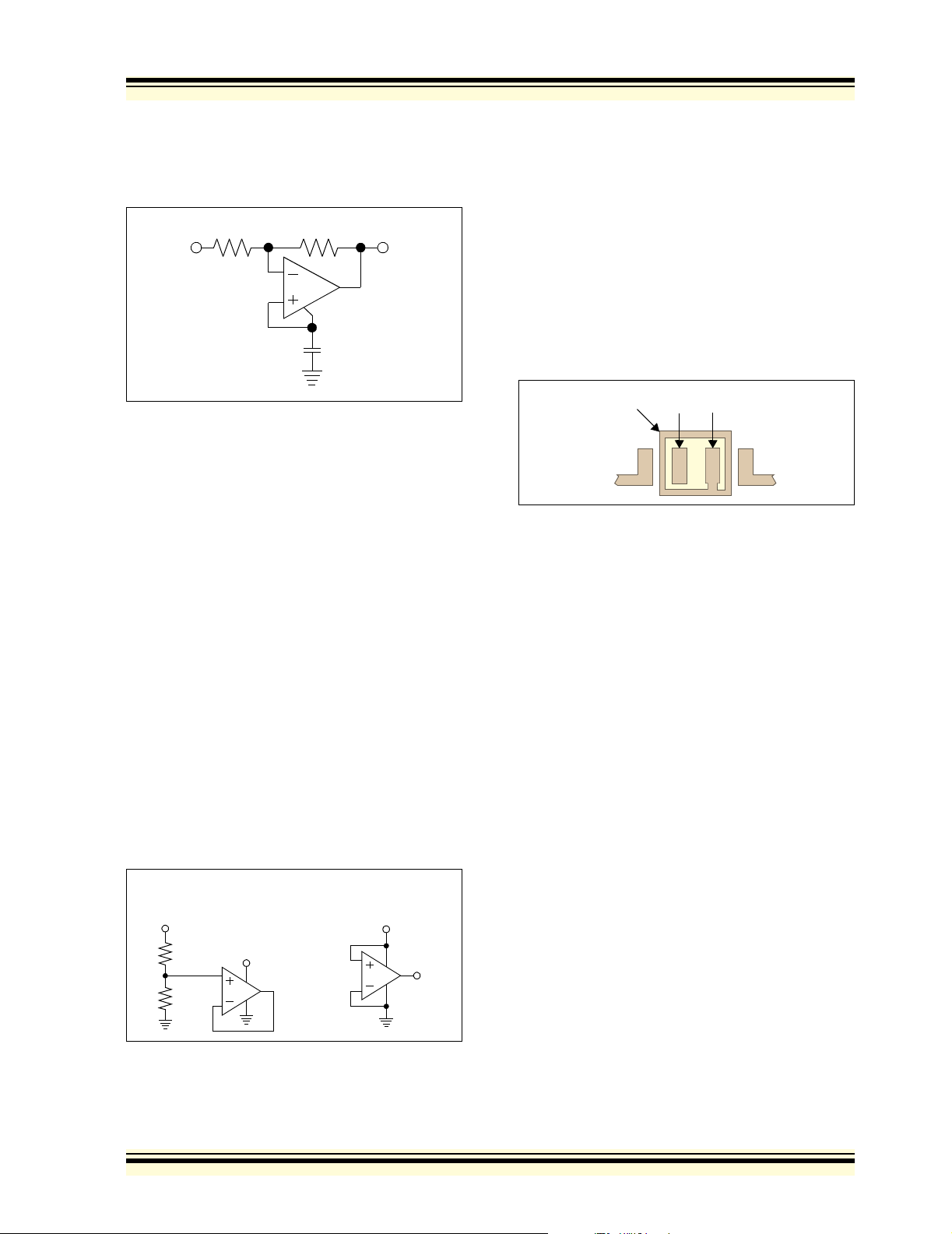

Typical Application

Photo

Detector

100 pF

Transimpedance Amplifier

5.6 pF

100 kΩ

MCP6021

VDD/2

Description

The MCP6021, MCP6021R, MCP6022, MCP6023 and

MCP6024 from Microchip Technology Inc. are rail-torail input and output op amps with high performance.

Key specifications include: wide bandwidth (10 MHz),

low noise (8.7 nV/√Hz), low input offset voltage and low

distortion (0.00053% THD+N). The MCP6023 also

offers a Chip Select pin (CS

) that gives power savings

when the part is not in use.

The single MCP6021 and MCP6021R are available in

SOT-23-5. The single MCP6021, single MCP6023 and

dual MCP6022 are available in 8-lead PDIP, SOIC and

TSSOP. The Extended Temperature single MCP6021

is available in 8-lead MSOP. The quad MCP6024 is

offered in 14-lead PDIP, SOIC and TSSOP packages.

The MCP6021/1R/2/3/4 family is available in Industrial

and Extended temperature ranges. It has a power

supply range of 2.5V to 5.5V.

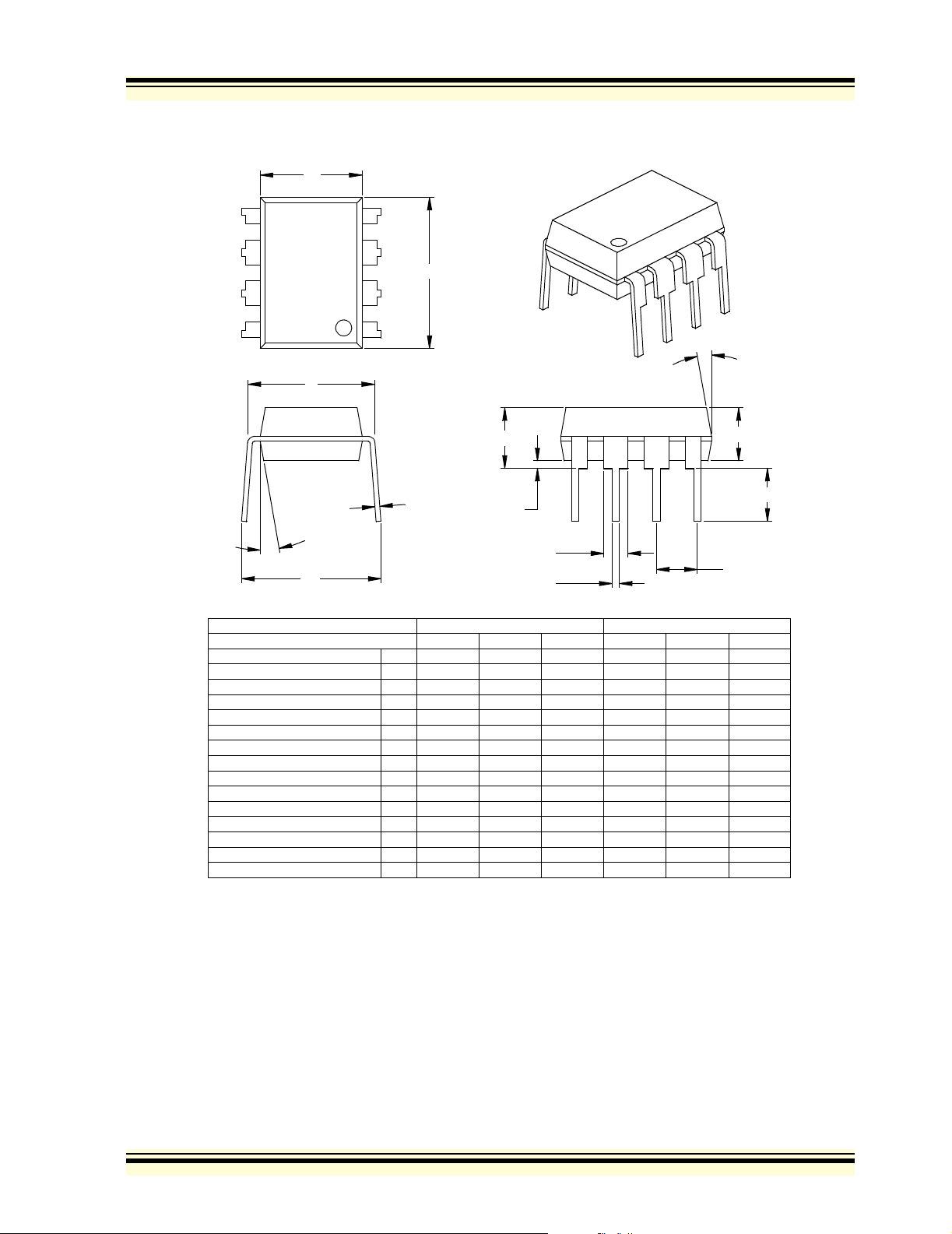

Package Types

MCP6021

SOT-23-5

V

1

OUT

V

2

SS

VIN+

3

MCP6021R

SOT-23-5

V

1

OUT

V

2

DD

VIN+

3

MCP6021

PDIP SOIC,

MSOP, TSSOP

NC

1

–

V

2

IN

VIN+

3

V

4

SS

5

4

5

4

8

7

6

5

V

DD

VIN–

V

SS

VIN–

NC

V

DD

V

OUT

V

REF

V

V

V

V

V

V

V

V

V

MCP6022

PDIP SOIC, TSSOP

1

OUTA

–

2

INA

+

3

INA

V

4

SS

MCP6023

PDIP SOIC, TSSOP

NC

1

VIN–

2

+

V

3

IN

V

4

SS

MCP6024

PDIP SOIC, TSSOP

1

OUTA

–

2

INA

+

3

INA

V

4

DD

+

5

INB

–

6

INB

7

OUTB

14

13

12

11

10

V

8

DD

V

7

OUTB

V

–

6

INB

+

V

5

INB

CS

8

V

7

DD

V

6

OUT

V

5

REF

V

OUTD

V

–

IND

+

V

IND

V

SS

V

+

INC

–

V

9

INC

V

8

OUTC

© 2006 Microchip Technology Inc. DS21685C-page 1

Page 2

MCP6021/1R/2/3/4

1.0 ELECTRICAL CHARACTERISTICS

† Notice: Stresses above those listed under “Absolute

Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only and functional operation of

the device at those or any other conditions above those

Absolute Maximum Ratings †

indicated in the operational listings of this specification is not

implied. Exposure to maximum rating conditions for extended

VDD–VSS........................................................................7.0V

All Inputs and Outputs.................... V

Difference Input Voltage ...................................... |V

– 0.3V to VDD+0.3V

SS

DD–VSS

|

periods may affect device reliability.

Output Short Circuit Current ..................................continuous

Current at Input Pins ....................................................±2 mA

Current at Output and Supply Pins ............................±30 mA

Storage Temperature.....................................-65°C to +150°C

Junction Temperature..................................................+150°C

ESD Protection on all pins (HBM; MM)................ ≥ 2 kV; 200V

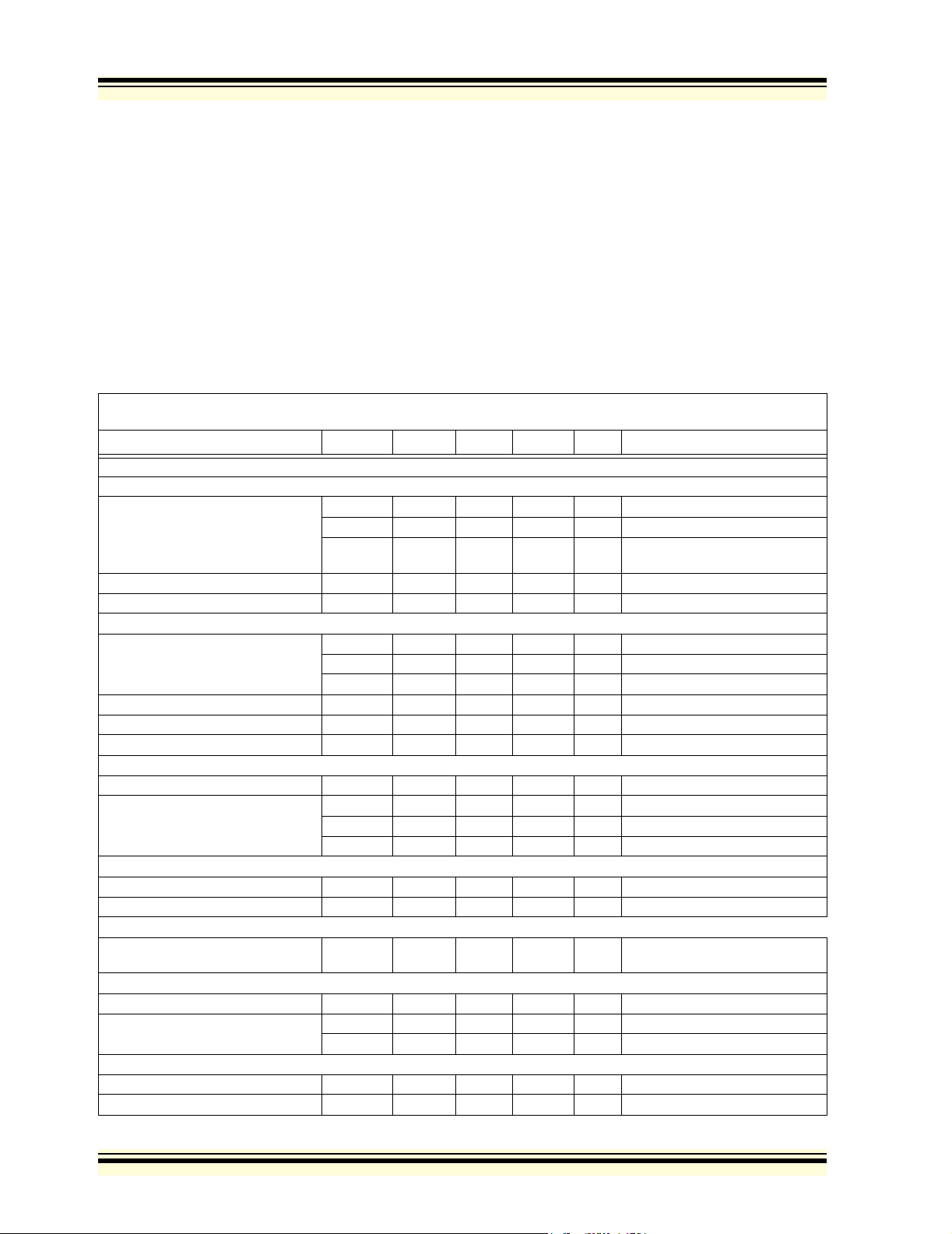

DC ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, TA = +25°C, VDD = +2.5V to +5.5V, VSS = GND, VCM = VDD/2, V

=10kΩ to VDD/2.

and R

L

Parameters Sym Min Typ Max Units Conditions

Input Offset

Input Offset Voltage:

Industrial Temperature Parts V

Extended Temperature Parts V

Extended Temperature Parts V

Input Offset Voltage Temperature Drift ΔV

OS

OS

OS

OS

/ΔT

Power Supply Rejection Ratio PSRR 74 90 — dB V

Input Current and Impedance

Input Bias Current I

Industrial Temperature Parts I

Extended Temperature Parts I

Input Offset Current I

Common-Mode Input Impedance Z

Differential Input Impedance Z

B

B

B

OS

CM

DIFF

Common-Mode

Common-Mode Input Range V

CMR

Common-Mode Rejection Ratio CMRR 74 90 — dB V

CMRR 70 85 — dB V

CMRR 74 90 — dB V

Voltage Reference (MCP6021 and MCP6023 only)

Accuracy (V

V

REF

V

Temperature Drift ΔV

REF

REF–VDD

/2) V

REF_ACC

/ΔT

REF

Open-Loop Gain

DC Open-Loop Gain (Large Signal) A

OL

Output

Maximum Output Voltage Swing V

Output Short Circuit Current I

OL

, V

SC

I

SC

Power Supply

Supply Voltage V

Quiescent Current per Amplifier I

S

Q

-500 — +500 μVVCM = 0V

-250 — +250 μVVCM = 0V, VDD = 5.0V

-2.5 — +2.5 mV VCM = 0V, VDD = 5.0V

= -40°C to +125°C

T

A

—±3.5—μV/°C TA = -40°C to +125°C

A

CM

—1—pA

— 30 150 pA TA = +85°C

— 640 5,000 pA TA = +125°C

—±1—pA

—1013||6 — Ω||pF

—1013||3 — Ω||pF

VSS-0.3 — VDD+0.3 V

DD

DD

DD

-50 — +50 mV

— ±100 — μV/°C TA = -40°C to +125°C

A

90 110 — dB VCM = 0V,

V

OUT

OHVSS

+15 — VDD-20 mV 0.5V output overdrive

—±30—mAVDD = 2.5V

—±22—mAVDD = 5.5V

2.5 — 5.5 V

0.5 1.0 1.35 mA IO = 0

= 0V

= 5V, VCM = -0.3V to 5.3V

= 5V, VCM = 3.0V to 5.3V

= 5V, VCM = -0.3V to 3.0V

= VSS+0.3V to VDD-0.3V

OUT

≈ VDD/2

DS21685C-page 2 © 2006 Microchip Technology Inc.

Page 3

MCP6021/1R/2/3/4

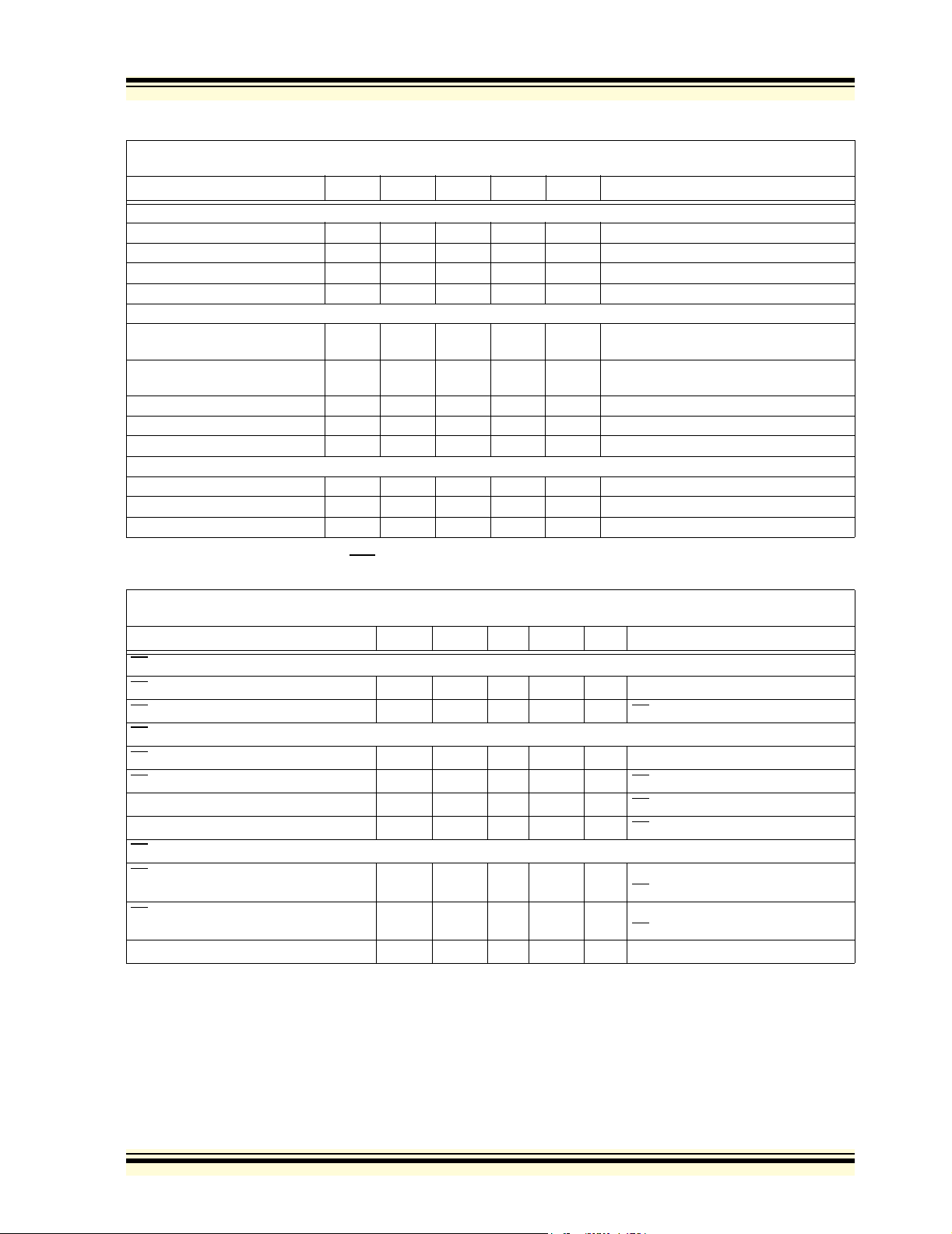

AC ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, TA = +25°C, VDD = +2.5V to +5.5V, VSS = GND, VCM = VDD/2,

≈ VDD/2, RL =10kΩ to VDD/2 and CL = 60 pF.

V

OUT

Parameters Sym Min Typ Max Units Conditions

AC Response

Gain Bandwidth Product GBWP — 10 — MHz

Phase Margin at Unity-Gain PM — 65 — ° G = +1

Settling Time, 0.2% t

SETTLE

Slew Rate SR — 7.0 — V/μs

Total Harmonic Distortion Plus Noise

f = 1 kHz, G = +1 V/V THD+N — 0.00053 — % V

f = 1 kHz, G = +1 V/V, R

= 600Ω THD+N — 0.00064 — % V

L

f = 1 kHz, G = +1 V/V THD+N — 0.0014 — % V

f = 1 kHz, G = +10 V/V THD+N — 0.0009 — % V

f = 1 kHz, G = +100 V/V THD+N — 0.005 — % V

Noise

Input Noise Voltage E

Input Noise Voltage Density e

Input Noise Current Density i

ni

ni

ni

— 250 — ns G = +1, V

OUT

= 5.0V, BW = 22 kHz

V

DD

OUT

= 5.0V, BW = 22 kHz

V

DD

OUT

OUT

OUT

= 100 mV

OUT

= 0.25V to 3.25V (1.75V ± 1.50VPK),

= 0.25V to 3.25V (1.75V ± 1.50VPK),

= 4V

, VDD = 5.0V, BW = 22 kHz

P-P

= 4V

, VDD = 5.0V, BW = 22 kHz

P-P

= 4V

, VDD = 5.0V, BW = 22 kHz

P-P

—2.9—μVp-p f = 0.1 Hz to 10 Hz

—8.7—nV/√Hz f = 10 kHz

—3—fA/√Hz f = 1 kHz

p-p

MCP6023 CHIP SELECT (CS

) ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, T

≈ VDD/2, RL =10kΩ to VDD/2 and CL = 60 pF.

V

OUT

Parameters Sym Min Typ Max Units Conditions

CS

Low Specifications

CS

Logic Threshold, Low V

CS

Input Current, Low I

IL

CSL

CS High Specifications

CS

Logic Threshold, High V

CS

Input Current, High I

GND Current I

Amplifier Output Leakage I

IH

CSH

SS

O(LEAK)

CS Dynamic Specifications

CS

Low to Amplifier Output Turn-on Time t

CS

High to Amplifier Output High-Z Time t

Hysteresis V

ON

OFF

HYST

= +25°C, VDD = +2.5V to +5.5V, VSS = GND, VCM = VDD/2,

A

V

-1.0 0.01 — μACS = V

0.8 V

—0.012.0 μACS = V

-2 -0.05 — μACS = V

—0.01— μACS = V

—0.2VDDV

SS

—VDDV

DD

SS

DD

DD

DD

—210μs G = +1, VIN = VSS,

= 0.2VDD to V

CS

OUT

—0.01— μs G = +1, VIN = VSS,

CS

= 0.8VDD to V

OUT

—0.6— VVDD = 5.0V, Internal Switch

= 0.45VDD time

= 0.05VDD time

© 2006 Microchip Technology Inc. DS21685C-page 3

Page 4

MCP6021/1R/2/3/4

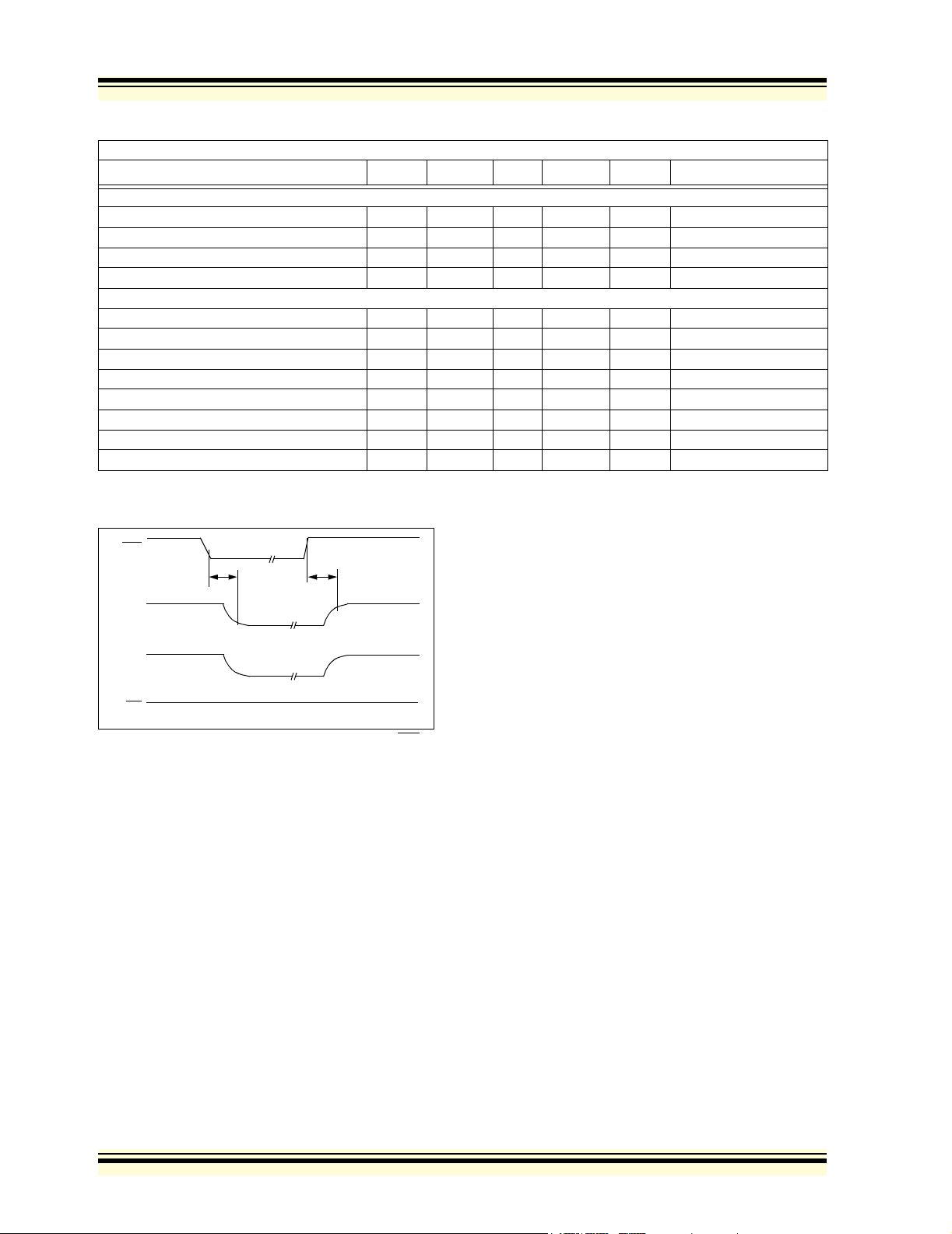

TEMPERATURE CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, VDD = +2.5V to +5.5V and VSS = GND.

Parameters Sym Min Typ Max Units Conditions

Temperature Ranges

Industrial Temperature Range T

Extended Temperature Range T

Operating Temperature Range T

Storage Temperature Range T

Thermal Package Resistances

Thermal Resistance, 5L-SOT-23 θ

Thermal Resistance, 8L-PDIP θ

Thermal Resistance, 8L-SOIC θ

Thermal Resistance, 8L-MSOP θ

Thermal Resistance, 8L-TSSOP θ

Thermal Resistance, 14L-PDIP θ

Thermal Resistance, 14L-SOIC θ

Thermal Resistance, 14L-TSSOP θ

Note 1: The industrial temperature devices operate over this extended temperature range, but with reduced performance. In any

case, the internal junction temperature (T

A

A

A

A

JA

JA

JA

JA

JA

JA

JA

JA

) must not exceed the absolute maximum specification of 150°C.

J

-40 — +85 °C

-40 — +125 °C

-40 — +125 °C Note 1

-65 — +150 °C

—256— °C/W

—85—°C/W

—163— °C/W

—206— °C/W

—124— °C/W

—70—°C/W

—120— °C/W

—100— °C/W

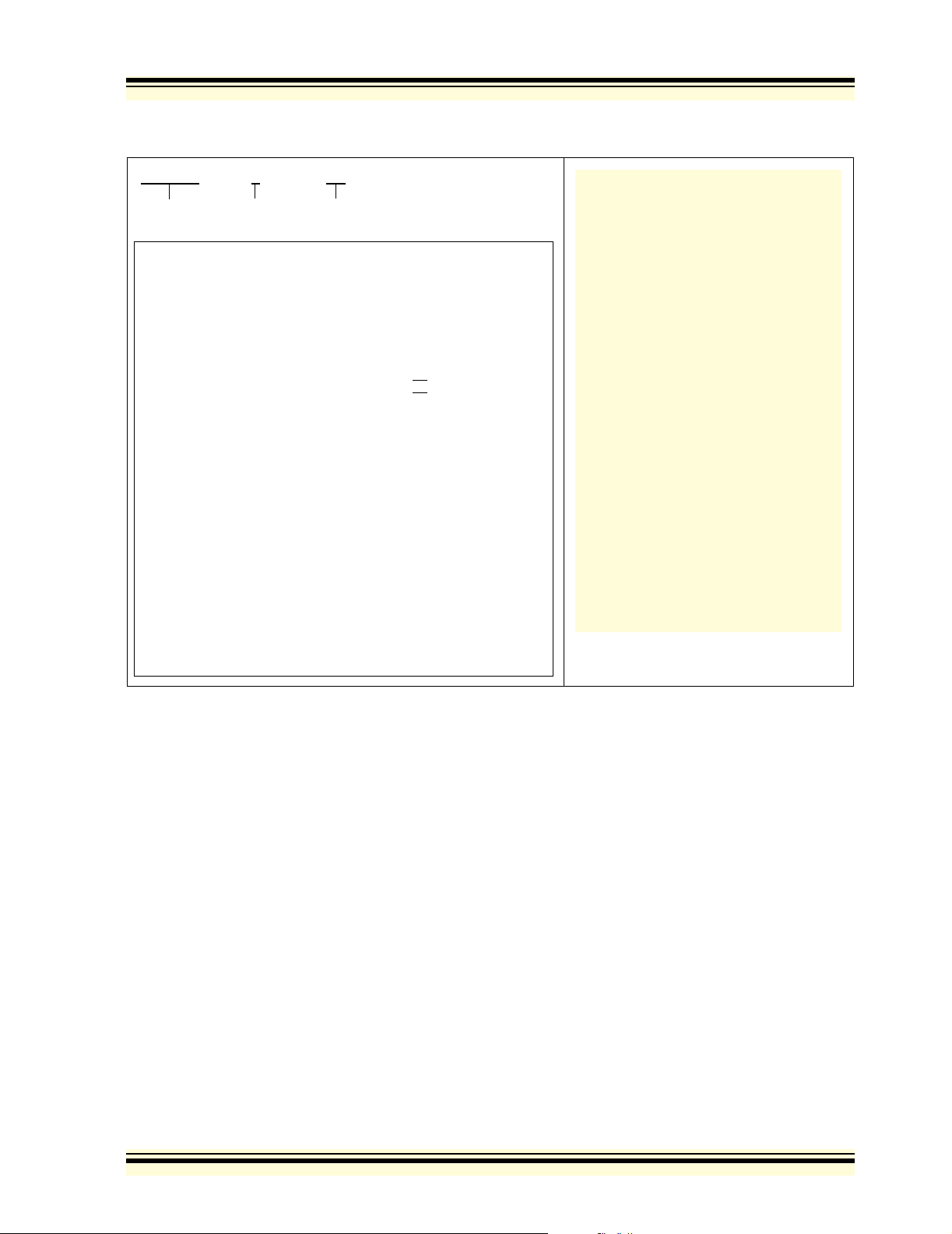

CS

V

OUT

I

SS

I

CS

t

ON

High-Z

-50 nA (typ.)

10 nA (typ.)

Amplifier On

-1 mA (typ.)

10 nA (typ.) 10 nA (typ.)

t

OFF

High-Z

-50 nA (typ.)

FIGURE 1-1: Timing diagram for the CS pin on the MCP6023.

DS21685C-page 4 © 2006 Microchip Technology Inc.

Page 5

MCP6021/1R/2/3/4

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated, TA=+25°C, VDD=+2.5Vto+5.5V, VSS= GND, VCM=VDD/2, V

=10kΩ to VDD/2 and CL=60 pF.

R

L

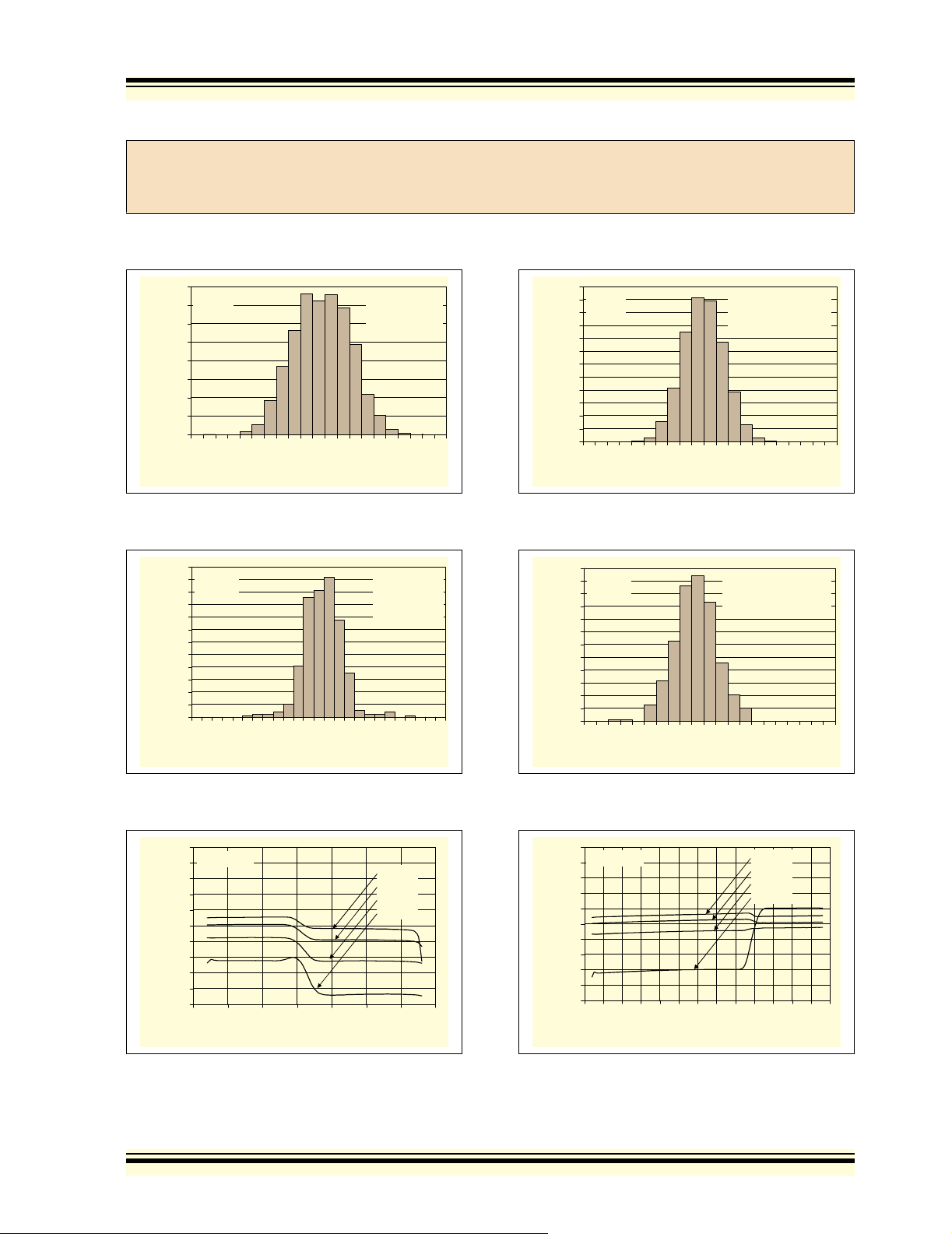

16%

14%

12%

10%

Percentage of Occurances

8%

6%

4%

2%

0%

I-Temp

Parts

-500

-400

-300

-200

-100

Input Offset Voltage (μV)

0

1192 Samples

V

CM

T

= +25°C

A

100

200

= 0V

300

FIGURE 2-1: Input Offset Voltage, (Industrial Temperature Parts).

24%

22%

20%

18%

16%

14%

12%

10%

Percentage of Occurances

8%

6%

4%

2%

0%

E-Temp

Parts

-240

-200

0

-80

-160

-40

-120

Input Offset Voltage (μV)

40

80

438 Samples

V

= 5.0V

DD

= 0V

V

CM

T

= +25°C

A

120

160

400

200

500

240

24%

22%

20%

18%

16%

14%

12%

10%

8%

6%

4%

Percentage of Occurances

2%

0%

I-Temp

Parts

-20

-16

-8

-12

Input Offset Voltage Drift (μV/°C)

-4

1192 Samples

= 0V

V

CM

T

= -40°C to +85°C

A

0

4

8

FIGURE 2-4: Input Offset Voltage Drift, (Industrial Temperature Parts).

24%

22%

20%

18%

16%

14%

12%

10%

Percentage of Occurances

8%

6%

4%

2%

0%

E-Temp

Parts

-20

-16

-8

-12

Input Offset Voltage Drift (μV/°C)

-4

438 Samples

V

= 0V

CM

T

= -40°C to +125°C

A

0

4

8

OUT

12

12

≈ VDD/2,

16

20

16

20

FIGURE 2-2: Input Offset Voltage, (Extended Temperature Parts).

500

VDD = 2.5V

400

300

200

100

0

-100

-200

-300

Input Offset Voltage (μV)

-400

-500

-0.50.00.51.01.52.02.53.0

Common Mode Input Voltage (V)

-40°C

+25°C

+85°C

+125°C

FIGURE 2-3: Input Offset Voltage vs.

Common Mode Input Voltage with V

= 2.5V.

DD

FIGURE 2-5: Input Offset Voltage Drift, (Extended Temperature Parts).

Input Offset Voltage (μV)

500

400

300

200

100

-100

-200

-300

-400

-500

VDD = 5.5V

0

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

Common Mode Input Voltage (V)

3.0

3.5

-40°C

+25°C

+85°C

+125°C

4.0

4.5

5.0

5.5

FIGURE 2-6: Input Offset Voltage vs. Common Mode Input Voltage with VDD = 5.5V.

6.0

© 2006 Microchip Technology Inc. DS21685C-page 5

Page 6

MCP6021/1R/2/3/4

Note: Unless otherwise indicated, TA=+25°C, VDD=+2.5Vto+5.5V, VSS= GND, VCM=VDD/2, V

=10kΩ to VDD/2 and CL=60 pF.

R

L

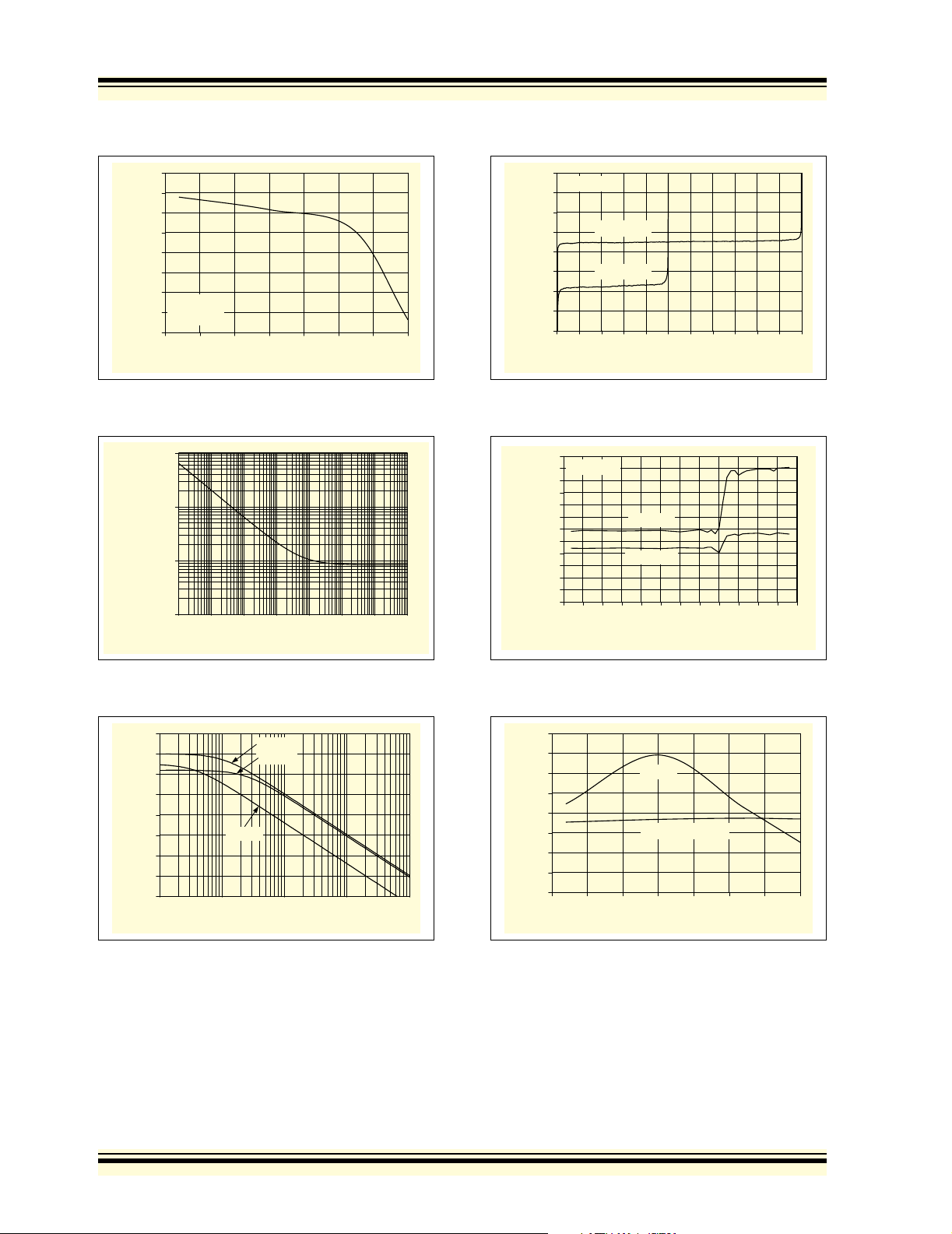

100

50

0

-50

-100

-150

-200

VDD = 5.0V

-250

Input Offset Voltage (μV)

V

= 0V

CM

-300

-50 -25 0 25 50 75 100 125

Ambient Temperature (°C)

FIGURE 2-7: Input Offset Voltage vs. Temperature.

1,000

100

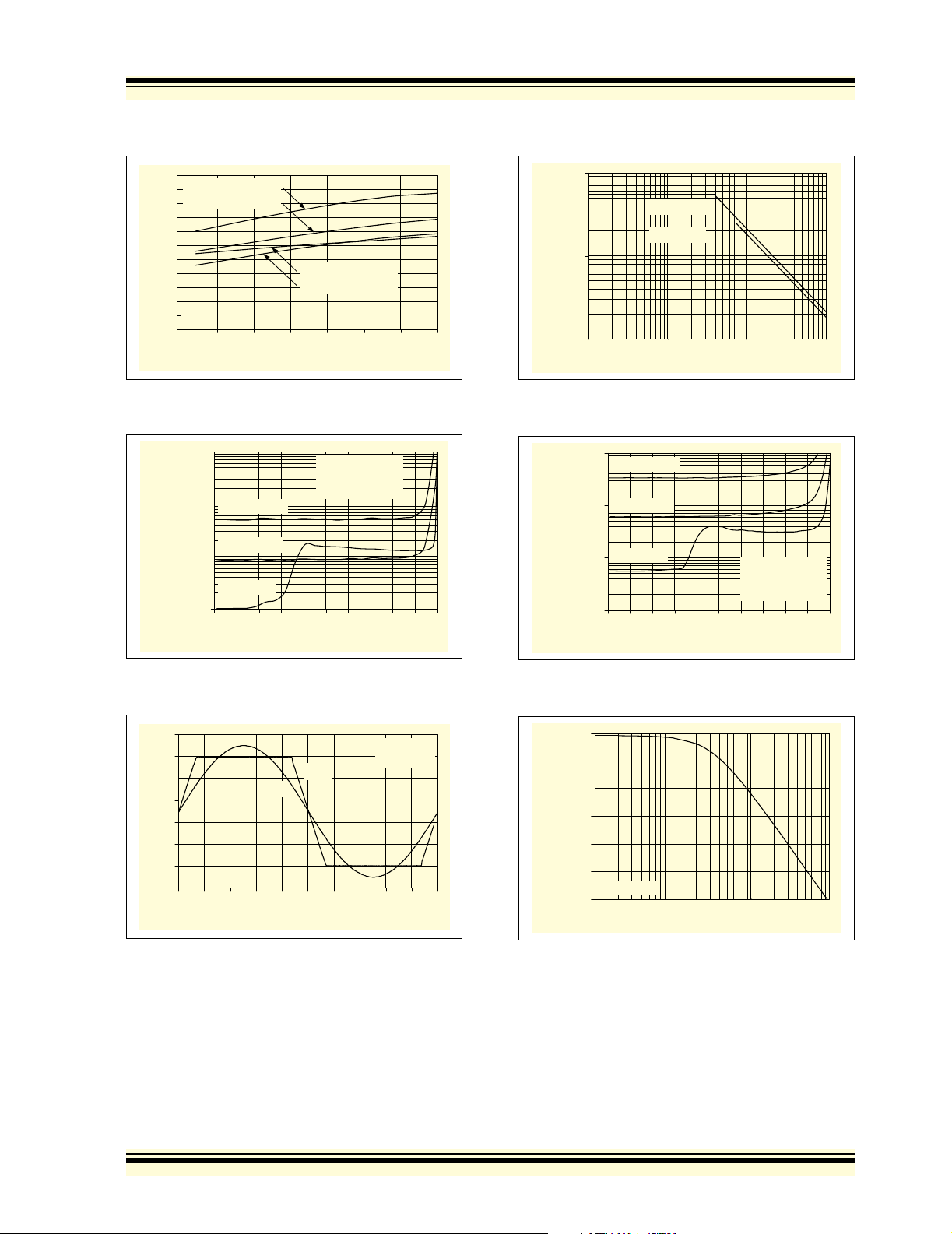

Hz)

(nV/

10

Input Noise Voltage Density

1.E-01 1.E+00 1.E+01 1.E+02 1.E+03 1.E+04 1.E+05 1.E+06

1

0.1 1 10 100 1k 10k 1M100k

Frequency (Hz)

200

VCM = VDD/2

150

Input Offset Voltage (μV)

100

50

0

-50

-100

-150

-200

VDD = 5.5V

VDD = 2.5V

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

Output Voltage (V)

FIGURE 2-10: Input Offset Voltage vs. Output Voltage.

24

VDD = 5.0V

22

20

18

16

14

Hz)

12

10

(nV/

8

6

4

2

Input Noise Voltage Density

0

-0.5

f = 1 kHz

f = 10 kHz

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Common Mode Input Voltage (V)

3.5

OUT

4.0

≈ VDD/2,

4.5

5.0

5.5

FIGURE 2-8: Input Noise Voltage Density vs. Frequency.

100

90

80

70

60

50

40

CMRR, PSRR (dB)

30

1.E+02 1.E+03 1.E+04 1.E+05 1.E+06

20

100 1k 10k 100k 1M

PSRR+

PSRR-

CMRR

Frequency (Hz)

FIGURE 2-9: CMRR, PSRR vs. Frequency.

FIGURE 2-11: Input Noise Voltage Density vs. Common Mode Input Voltage.

110

105

100

95

90

85

80

PSRR, CMRR (dB)

75

70

-50 -25 0 25 50 75 100 125

CMRR

PSRR (VCM = 0V)

Ambient Temperature (°C)

FIGURE 2-12: CMRR, PSRR vs. Temperature.

DS21685C-page 6 © 2006 Microchip Technology Inc.

Page 7

MCP6021/1R/2/3/4

Note: Unless otherwise indicated, TA=+25°C, VDD=+2.5Vto+5.5V, VSS= GND, VCM=VDD/2, V

=10kΩ to VDD/2 and CL=60 pF.

R

L

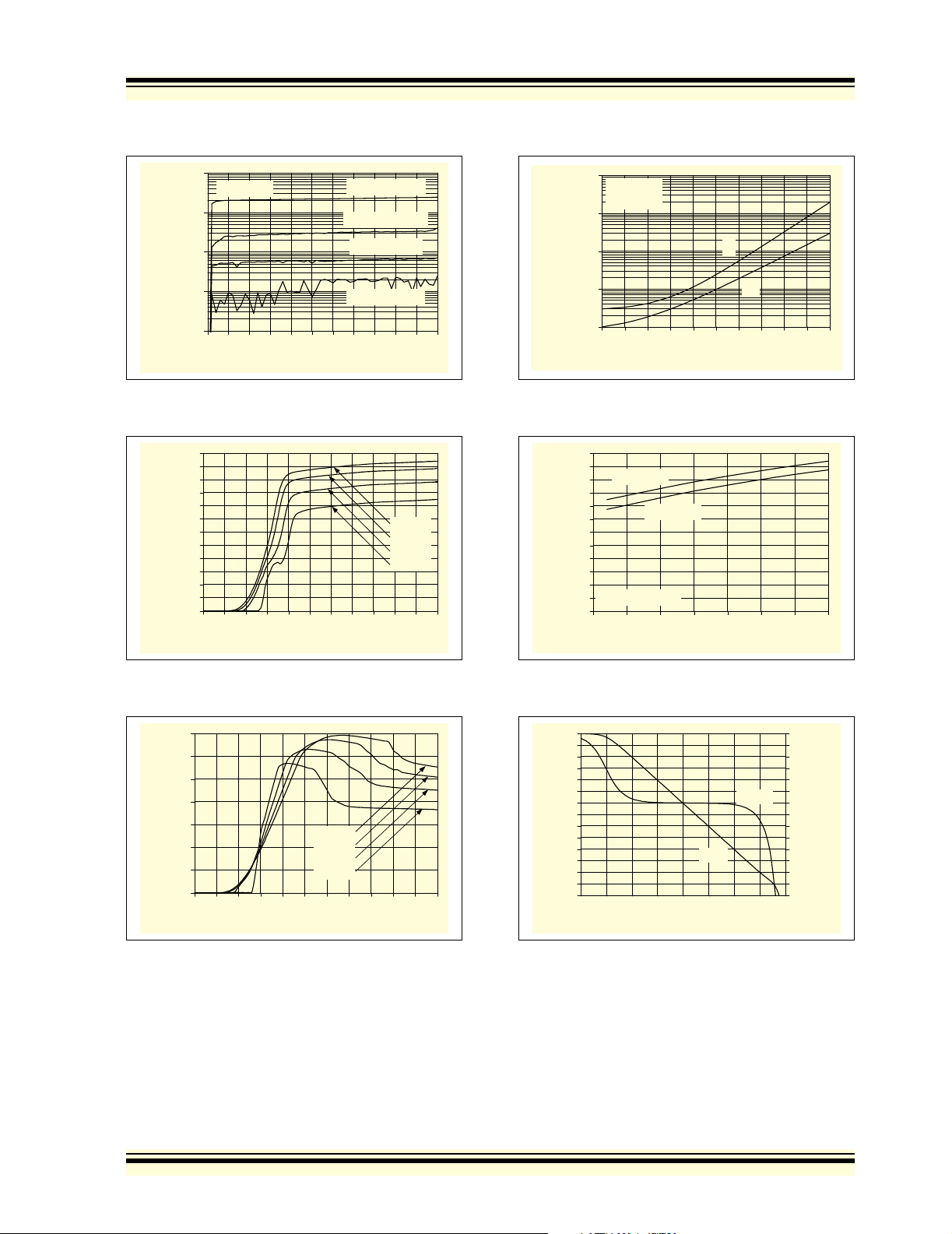

10,000

Input Bias, Offset Currents (pA)

VDD = 5.5V

1,000

100

10

1

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

Common Mode Input Voltage (V)

IB, TA = +125°C

IOS, TA = +125°C

IB, TA = +85°C

IOS, TA = +85°C

FIGURE 2-13: Input Bias, Offset Currents vs. Common Mode Input Voltage.

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

(mA/amplifier)

0.3

Quiescent Current

0.2

0.1

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

Power Supply Voltage (V)

+125°C

+85°C

+25°C

-40°C

10,000

(pA)

Input Bias, Offset Currents

VCM = V

DD

VDD = 5.5V

1,000

I

100

10

1

25 35 45 55 65 75 85 95 105 115 125

Ambient Temperature (°C)

B

I

OS

FIGURE 2-16: Input Bias, Offset Currents vs. Temperature.

1.2

1.1

VDD = 5.5V

1.0

0.9

0.8

0.7

0.6

0.5

0.4

(mA/amplifier)

0.3

Quiescent Current

0.2

VCM = VDD - 0.5V

0.1

0.0

-50 -25 0 25 50 75 100 125

VDD = 2.5V

Ambient Temperature (°C)

OUT

≈ VDD/2,

FIGURE 2-14: Quiescent Current vs. Supply Voltage.

35

30

25

20

(mA)

15

10

5

Output Short Circuit Current

0

0.00.51.01.52.02.53.03.54.04.55.05.5

+125°C

+85°C

+25°C

-40°C

Supply Voltage (V)

FIGURE 2-15: Output Short-Circuit Current vs. Supply Voltage.

FIGURE 2-17: Quiescent Current vs. Temperature.

120

110

100

90

80

70

60

50

40

30

20

10

Open-Loop Gain (dB)

0

-10

1.E+00 1.E+01 1.E+02 1.E+03 1.E+04 1.E+0 5 1.E+06 1.E+07 1.E+ 08

-20

1 10010 1k 100k10k 1M 100M10M

Frequency (Hz)

Gain

Phase

0

-15

-30

-45

-60

-75

-90

-105

-120

-135

-150

-165

-180

-195

-210

Open-Loop Phase (°)

FIGURE 2-18: Open-Loop Gain, Phase vs. Frequency.

© 2006 Microchip Technology Inc. DS21685C-page 7

Page 8

MCP6021/1R/2/3/4

Note: Unless otherwise indicated, TA=+25°C, VDD=+2.5Vto+5.5V, VSS= GND, VCM=VDD/2, V

=10kΩ to VDD/2 and CL=60 pF.

R

L

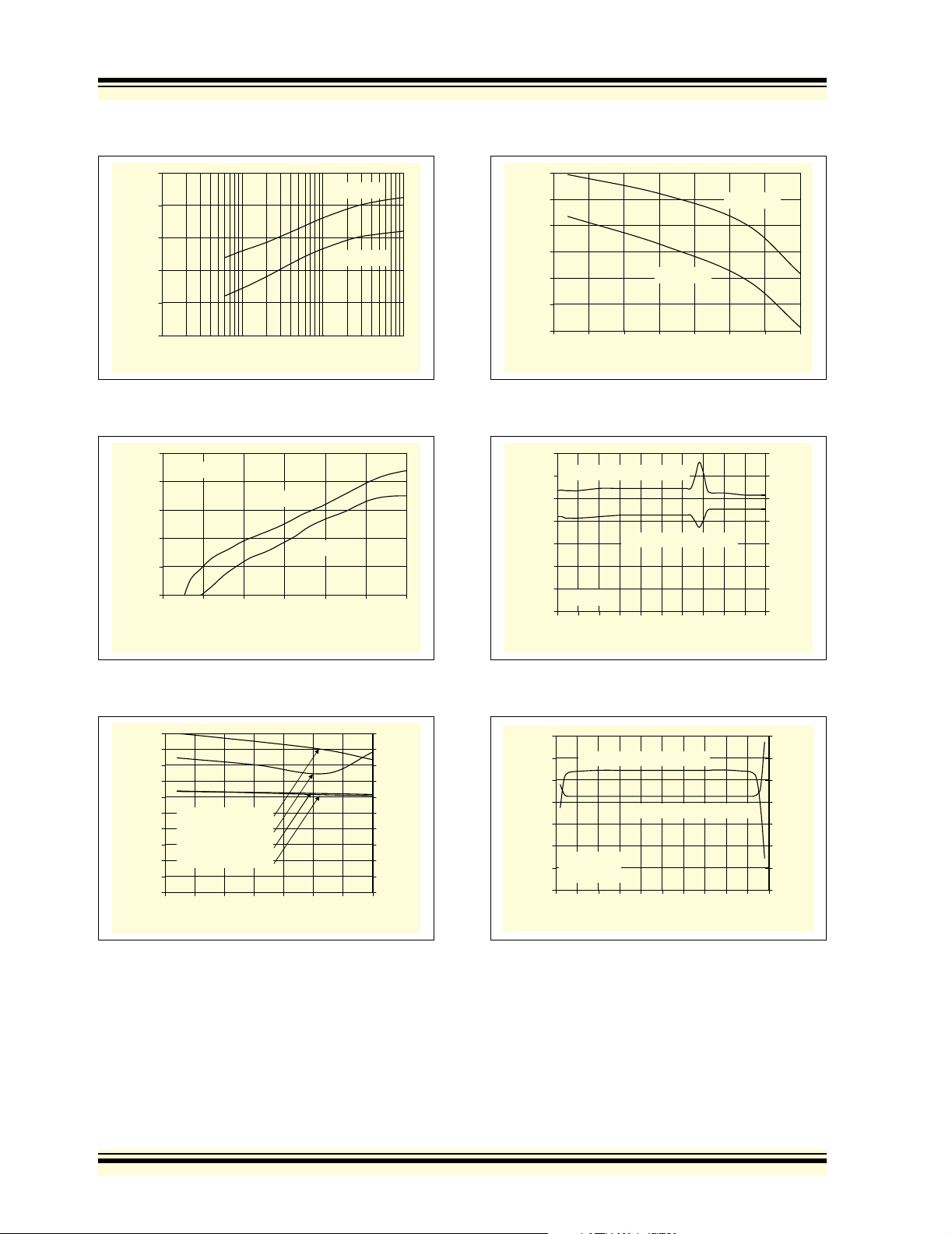

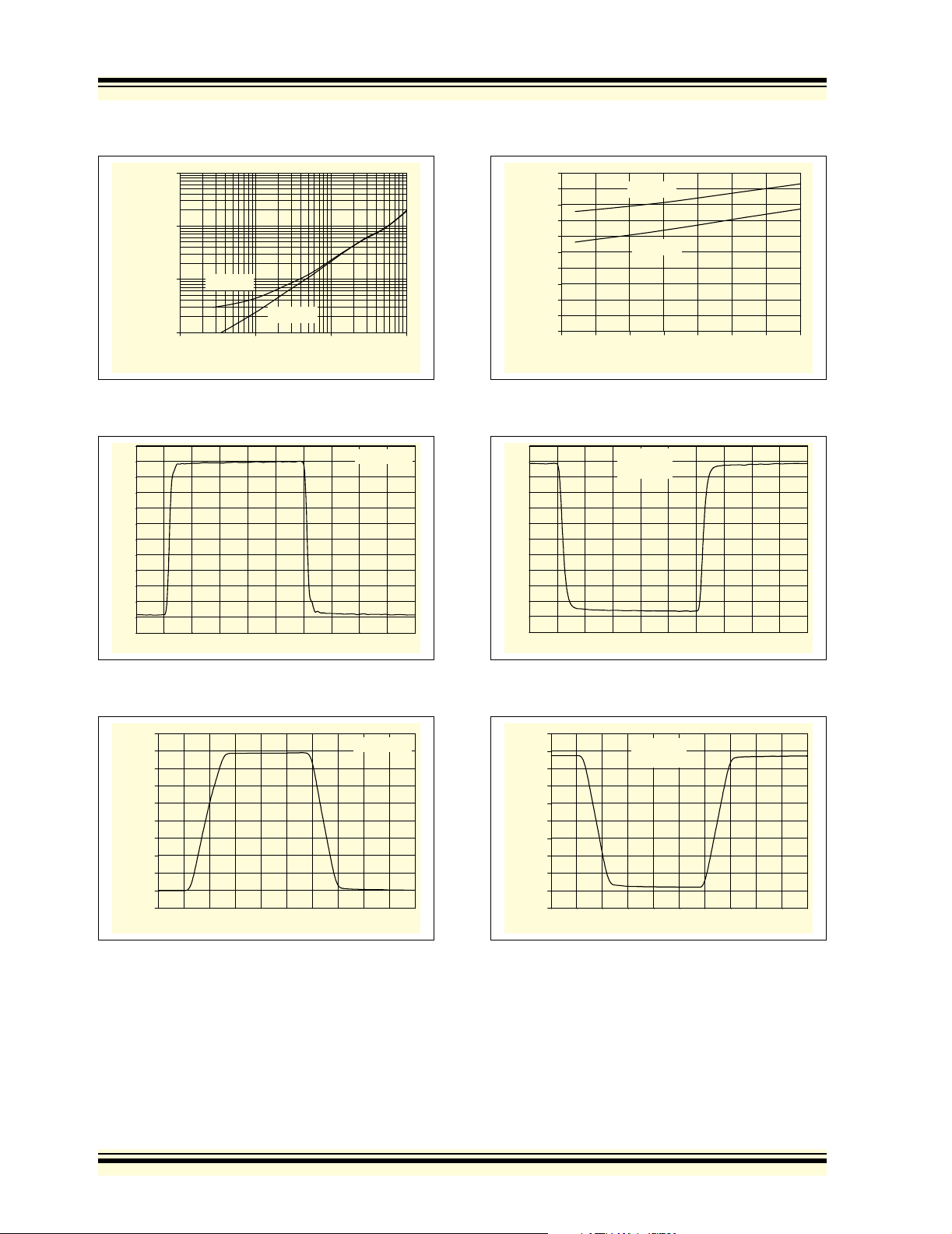

130

VDD = 5.5V

120

110

100

90

DC Open-Loop Gain (dB)

1.E+02 1.E+03 1.E+04 1.E+05

80

100 1k 10k 100k

Load Resistance (Ω)

VDD = 2.5V

FIGURE 2-19: DC Open-Loop Gain vs. Load Resistance.

120

VCM = VDD/2

110

100

90

80

DC Open-Loop Gain (dB)

70

0.00 0.05 0.10 0.15 0.20 0.25 0.30

VDD = 5.5V

VDD = 2.5V

Output Voltage Headroom (V);

- VOH or VOL - V

V

DD

SS

120

115

110

105

100

95

DC Open-Loop Gain (dB)

90

-50 -25 0 25 50 75 100 125

VDD = 2.5V

Ambient Temperature (°C)

VDD = 5.5V

FIGURE 2-22: DC Open-Loop Gain vs. Temperature.

14

Gain Bandwidth Product

12

10

8

(MHz)

6

4

2

Gain Bandwidth Product

VDD = 5.0V

0

0.00.51.01.52.02.53.03.54.04.55.0

Phase Margin, G = +1

Common Mode Input Voltage (V)

OUT

≈ VDD/2,

105

90

75

60

45

30

15

Phase Margin, G = +1 (°)

0

FIGURE 2-20: Small Signal DC Open-Loop Gain vs. Output Voltage Headroom.

10

9

8

7

6

5

GBWP, VDD = 5.5V

(MHz)

4

GBWP, V

PM, V

3

PM, V

2

Gain Bandwidth Product

1

0

-50 -25 0 25 50 75 100 125

= 2.5V

DD

= 2.5V

DD

= 5.5V

DD

Ambient Temperature (°C)

100

90

80

70

60

50

40

30

20

10

0

Phase Margin, G = +1 (°)

FIGURE 2-21: Gain Bandwidth Product, Phase Margin vs. Temperature.

FIGURE 2-23: Gain Bandwidth Product, Phase Margin vs. Common Mode Input Voltage.

14

12

Gain Bandwidth Product

10

8

(MHz)

6

4

VDD = 5.0V

2

Gain Bandwidth Product

V

= VDD/2

CM

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Phase Margin, G = +1

Output Voltage (V)

105

90

75

60

45

30

15

0

Phase Margin, G = +1 (°)

FIGURE 2-24: Gain Bandwidth Product, Phase Margin vs. Output Voltage.

DS21685C-page 8 © 2006 Microchip Technology Inc.

Page 9

MCP6021/1R/2/3/4

Note: Unless otherwise indicated, TA=+25°C, VDD=+2.5Vto+5.5V, VSS= GND, VCM=VDD/2, V

=10kΩ to VDD/2 and CL=60 pF.

R

L

11

Falling, VDD = 5.5V

10

Rising, V

9

8

7

6

5

4

3

Slew Rate (V/μs)

2

1

0

-50 -25 0 25 50 75 100 125

= 5.5V

DD

Falling, VDD = 2.5V

Rising, V

Ambient Temperature (°C)

= 2.5V

DD

FIGURE 2-25: Slew Rate vs. Temperature.

FIGURE 2-28: Maximum Output Voltage

10

VDD = 5.5V

)

P-P

1

Swing (V

Maximum Output Voltage

1.E+04 1.E+05 1. E+06 1.E+07

0.1

10k 100k 1M 10M

VDD = 2.5V

Frequency (Hz)

Swing vs. Frequency.

0.1000%

0.0100%

THD+N (%)

0.0010%

0.0001%

f = 1 kHz

BW

= 22 kHz

Meas

V

= 5.0V

G = +100 V/V

G = +10 V/V

G = +1 V/V

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Output Voltage (V

DD

)

P-P

0.1000%

0.0100%

THD+N (%)

0.0010%

0.0001%

G = +100 V/V

G = +10 V/V

G = +1 V/V

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Output Voltage (V

f = 20 kHz

BW

Meas

V

= 5.0V

DD

P-P

OUT

= 80 kHz

)

≈ VDD/2,

FIGURE 2-26: Total Harmonic Distortion

plus Noise vs. Output Voltage with f = 1 kHz.

6

5

4

3

2

1

0

Input, Output Voltage (V)

-1

0 102030405060708090100

V

OUT

V

IN

Time (10 μs/div)

VDD = 5.0V

G = +2 V/V

FIGURE 2-27: The MCP6021/1R/2/3/4 family shows no phase reversal under overdrive.

FIGURE 2-29: Total Harmonic Distortion

plus Noise vs. Output Voltage with f = 20 kHz.

135

130

125

120

(dB)

115

110

Channel to Channel Separation

G = +1 V/V

1.E+03 1.E+04 1.E+0 5 1.E+0 6

105

1k 1M100k10k

Frequency (Hz)

FIGURE 2-30: Channel-to-Channel Separation vs. Frequency (MCP6022 and MCP6024 only).

© 2006 Microchip Technology Inc. DS21685C-page 9

Page 10

MCP6021/1R/2/3/4

Note: Unless otherwise indicated, TA=+25°C, VDD=+2.5Vto+5.5V, VSS= GND, VCM=VDD/2, V

=10kΩ to VDD/2 and CL=60 pF.

R

L

1,000

(mV)

SS

100

-V

OL

or V

10

OH

-V

DD

V

Output Voltage Headroom;

VOL - V

SS

VDD - V

OH

1

0.01 0.1 1 10

Output Current Magnitude (mA)

FIGURE 2-31: Output Voltage Headroom vs. Output Current.

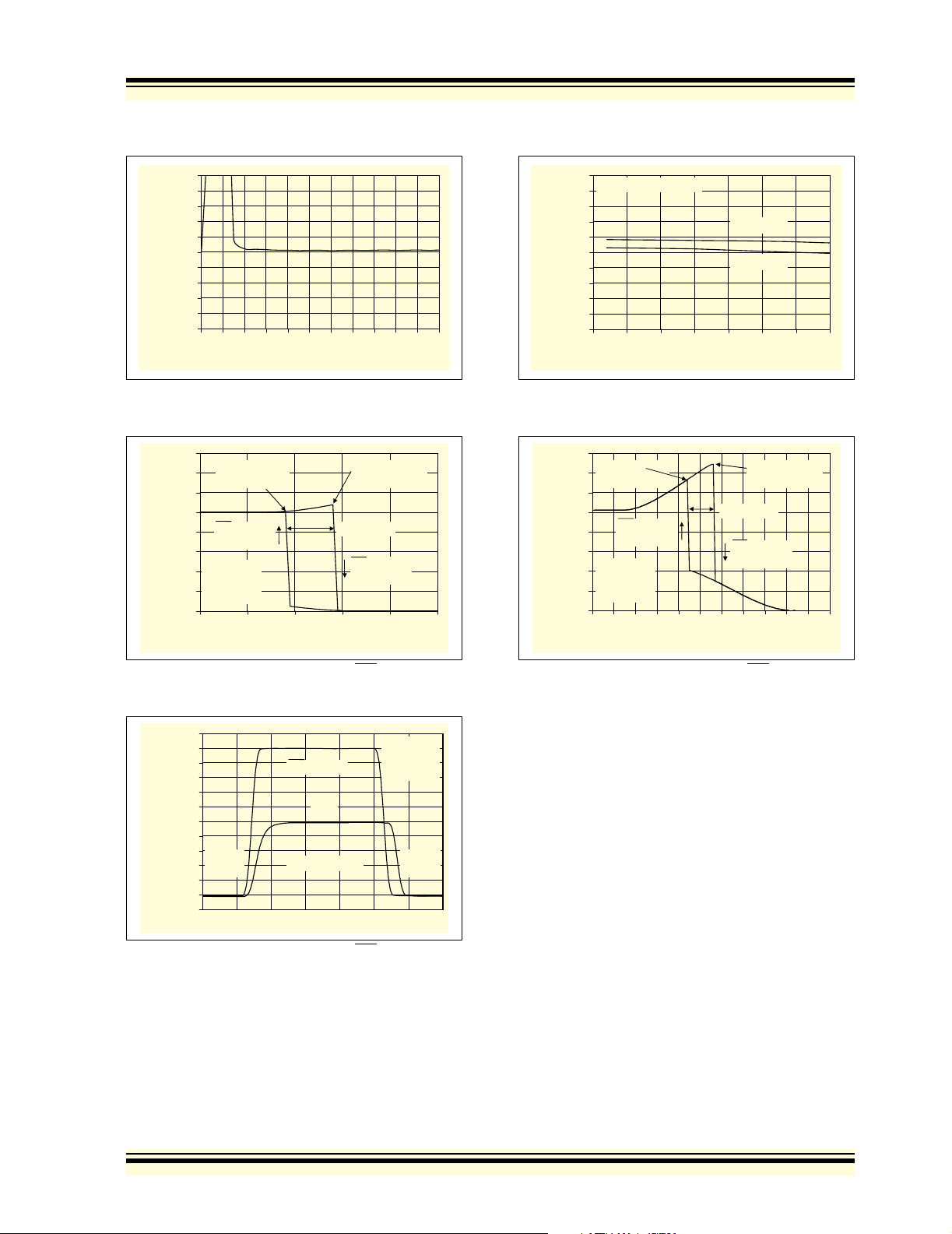

6.E-02

5.E-02

4.E-02

3.E-02

2.E-02

1.E-02

0.E+00

-1.E-02

-2.E-02

-3.E-02

-4.E-02

Output Voltage (10 mV/div)

-5.E-02

-6.E-02

0.E+00 2.E-07 4.E-07 6.E-07 8.E-07 1.E-06 1.E-06 1.E-06 2.E- 06 2.E-06 2.E-06

Time (200 ns/div)

G = +1 V/V

FIGURE 2-34: Output Voltage Headroom vs. Temperature.

10

VOL - V

VDD - V

SS

OH

Output Voltage Headroom

9

8

(mV)

7

SS

6

-V

OL

5

4

or V

OH

3

-V

2

DD

V

1

0

-50 -25 0 25 50 75 100 125

Ambient Temperature (°C)

6.E-02

5.E-02

4.E-02

3.E-02

2.E-02

1.E-02

0.E+00

-1.E-02

-2.E-02

-3.E-02

-4.E-02

Output Voltage (10 mV/div)

-5.E-02

-6.E-02

0.E+00 2.E-07 4.E-07 6.E-07 8 .E-07 1.E-06 1.E-06 1.E-06 2.E-06 2.E-06 2.E-06

G = -1 V/V

= 1 k

R

Ω

F

Time (200 ns/div)

OUT

≈ VDD/2,

FIGURE 2-32: Small-Signal Non-inverting Pulse Response.

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

Output Voltage (V)

1.0

0.5

0.E+00 5.E-07 1.E-06 2.E-06 2 .E-06 3.E-06 3.E-06 4.E-06 4.E-06 5.E-06 5.E-06

0.0

Time (500 ns/div)

G = +1 V/V

FIGURE 2-33: Large-Signal Non-inverting Pulse Response.

FIGURE 2-35: Small-Signal Inverting Pulse Response.

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

Output Voltage (V)

1.0

0.5

0.E+00 5.E-07 1.E-06 2.E-06 2.E -06 3.E-06 3.E-06 4.E-06 4.E-06 5.E -06 5.E-06

0.0

G = -1 V/V

= 1 kΩ

R

F

Time (500 ns/div)

FIGURE 2-36: Large-Signal Inverting Pulse Response.

DS21685C-page 10 © 2006 Microchip Technology Inc.

Page 11

MCP6021/1R/2/3/4

Note: Unless otherwise indicated, TA=+25°C, VDD=+2.5Vto+5.5V, VSS= GND, VCM=VDD/2, V

=10kΩ to VDD/2 and CL=60 pF.

R

L

50

/2

40

DD

30

– V

20

REF

10

0

(mV)

-10

-20

Accuracy; V

-30

REF

-40

V

-50

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

FIGURE 2-37: V

Power Supply Voltage (V)

Accuracy vs. Supply

REF

Voltage (MCP6021 and MCP6023 only).

1.6

Op Amp

1.4

turns on here

1.2

1.0

CS swept

0.8

high to low

0.6

(mA/amplifier)

VDD = 2.5V

0.4

Quiescent Current

G = +1 V/V

0.2

V

= 1.25V

IN

0.0

0.0 0.5 1.0 1.5 2.0 2.5

Chip Select Voltage (V)

Op Amp

shuts off here

Hysteresis

CS swept

low to high

FIGURE 2-40: V

Temperature (MCP6021 and MCP6023 only).

50

/2

DD

– V

REF

Accuracy; V

REF

V

Quiescent Current

Representative Part

40

30

20

10

0

(mV)

-10

-20

-30

-40

-50

-50 -25 0 25 50 75 100 125

Ambient Temperature (°C)

REF

1.6

Op Amp

1.4

turns on here

1.2

1.0

0.8

0.6

(mA/amplifier)

0.4

0.2

0.0

CS swept

high to low

VDD = 5.5V

G = +1 V/V

V

= 2.75V

IN

0.00.51.01.52.02.53.03.54.04.55.05.5

Chip Select Voltage (V)

VDD = 5.5V

VDD = 2.5V

Accuracy vs.

Op Amp

shuts off here

Hysteresis

CS swept

low to high

OUT

≈ VDD/2,

FIGURE 2-38: Chip Select (CS

(MCP6023 only) with V

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

Output

Output Voltage (V)

1.0

Chip Select Voltage,

on

0.5

0.0

0.0E+00 5.0E-06 1.0E-05 1.5E-05 2.0E-05 2.5E-05 3. 0E-05 3.5E-0 5

-0.5

= 2.5V.

DD

CS Voltage

V

OUT

Output High-Z

Time (5 μs/div)

FIGURE 2-39: Chip Select (CS

) Hysteresis

VDD = 5.0V

G = +1 V/V

V

= V

IN

SS

Output

on

) to

Amplifier Output Response Time (MCP6023

only).

FIGURE 2-41: Chip Select (CS

(MCP6023 only) with V

= 5.5V.

DD

) Hysteresis

© 2006 Microchip Technology Inc. DS21685C-page 11

Page 12

MCP6021/1R/2/3/4

3.0 PIN DESCRIPTIONS

Descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

MCP6021

(PDIP,

SOIC,

MSOP,

TSSOP)

(Note 1)

61 1 161V

24 4 222V

33 3 333V

75 2 874V

—— — 5—5V

—— — 6—6V

—— — 7—7V

—— — ——8V

—— — ——9V

—— — ——10V

42 5 4411V

—— — ——12V

—— — ——13V

—— — ——14V

5— ——5—V

—— — —8—CS

1, 8 — — — 1 — NC No Internal Connection

Note 1: The MCP6021 in the 8-pin MSOP package is only available for E-temp (Extended Temperature) parts. The MCP6021

MCP6021

(SOT-23-5)

(Note 1)

in the 8-pin TSSOP package is only available for I-temp (Industrial Temperature) parts.

2: The MCP6021R is only available in the 5-pin SOT-23 package, and for E-temp (Extended Temperature) parts.

MCP6021R

(SOT-23-5)

(Note 2)

MCP6022 MCP6023 MCP6024 Symbol Description

OUT,VOUTA

–, V

IN

+, V

IN

DD

INB

INB

OUTB

OUTC

INC

INC

SS

IND

IND

OUTD

REF

Analog Output (op amp A)

– Inverting Input (op amp A)

INA

+ Non-inverting Input (op amp A)

INA

Positive Power Supply

+ Non-inverting Input (op amp B)

– Inverting Input (op amp B)

Analog Output (op amp B)

Analog Output (op amp C)

– Inverting Input (op amp C)

+ Non-inverting Input (op amp C)

Negative Power Supply

+ Non-inverting Input (op amp D)

– Inverting Input (op amp D)

Analog Output (op amp D)

Reference Voltage

Chip Select

3.1 Analog Outputs

The op amp output pins are low-impedance voltage

sources.

3.5 Power Supply (VSS and VDD)

The positive power supply pin (VDD) is 2.5V to 5.5V

higher than the negative power supply pin (V

SS

). For

normal operation, the other pins are at voltages

3.2 Analog Inputs

The op amp non-inverting and inverting inputs are highimpedance CMOS inputs with low bias currents.

3.3 V

Output (MCP6021 and

REF

MCP6023)

Mid-supply reference voltage provided by the single op

amps (except in SOT-23-5 package). This is an

between VSS and VDD.

Typically, these parts are used in a single (positive)

supply configuration. In this case, V

ground and V

is connected to the supply. VDD will

DD

is connected to

SS

need a local bypass capacitor (typically 0.01 μF to

0.1 μF) within 2 mm of the V

pin. These parts need

DD

to use a bulk capacitor (typically 1 μF or larger) within

100 mm of the VDD pin; it can be shared with nearby

analog parts.

unbuffered, resistor voltage divider internal to the part.

3.4 CS Digital Input

This is a CMOS, Schmitt-triggered input that places the

part into a low power mode of operation.

DS21685C-page 12 © 2006 Microchip Technology Inc.

Page 13

MCP6021/1R/2/3/4

:

4.0 APPLICATIONS INFORMATION

The MCP6021/1R/2/3/4 family of operational amplifiers

are fabricated on Microchip’s state-of-the-art CMOS

process. They are unity-gain stable and suitable for a

wide range of general-purpose applications.

4.1 Rail-to-Rail Input

The MCP6021/1R/2/3/4 amplifier family is designed to

not exhibit phase inversion when the input pins exceed

the supply voltages. Figure 2-27 shows an input voltage exceeding both supplies with no resulting phase

inversion.

The input stage of the MCP6021/1R/2/3/4 family of

devices uses two differential input stages in parallel;

one operates at low common-mode input voltage

), while the other operates at high VCM. With this

(V

CM

topology, the device operates with V

either supply rail (V

– 0.3V to VDD+ 0.3V) at +25°C.

SS

The amplifier input behaves linearly as long as V

kept within the specified V

CMR

voltage is measured at both V

V

+ 0.3V to ensure proper operation.

DD

Input voltages that exceed the input voltage range

) can cause excessive current to flow in or out of

(V

CMR

the input pins. Current beyond ±2 mA introduces

possible reliability problems. Thus, applications that

exceed this rating must externally limit the input current

with an input resistor (R

), as shown in Figure 4-1.

IN

up to 0.3V past

CM

is

CM

limits. The input offset

CM=VSS

–0.3V and

4.2 Rail-to-Rail Output

The Maximum Output Voltage Swing is the maximum

swing possible under a particular output load.

According to the specification table, the output can

reach within 20 mV of either supply rail when

=10kΩ. See Figure 2-31 and Figure 2-34 for more

R

L

information concerning typical performance.

4.3 Capacitive Loads

Driving large capacitive loads can cause stability

problems for voltage feedback op amps. As the load

capacitance increases, the feedback loop’s phase

margin decreases, and the closed loop bandwidth is

reduced. This produces gain-peaking in the frequency

response, with overshoot and ringing in the step

response.

When driving large capacitive loads with these op

amps (e.g., > 60 pF when G = +1), a small series

resistor at the output (R

feedback loop’s phase margin (stability) by making the

load resistive at higher frequencies. The bandwidth will

be generally lower than the bandwidth with no

capacitive load.

V

IN

MCP602X

in Figure 4-2) improves the

ISO

R

ISO

V

C

L

OUT

R

V

IN

R

≥

IN

RIN ≥

MCP602X

IN

(Maximum expected V

2mA

- (Minimum expected VIN)

V

SS

2mA

IN

) - V

DD

V

OUT

FIGURE 4-1: RIN limits the current flow into an input pin.

Total Harmonic Distortion Plus Noise (THD+N) can be

affected by the common mode input voltage (V

CM

). As

FIGURE 4-2: Output resistor R

stabilizes large capacitive loads.

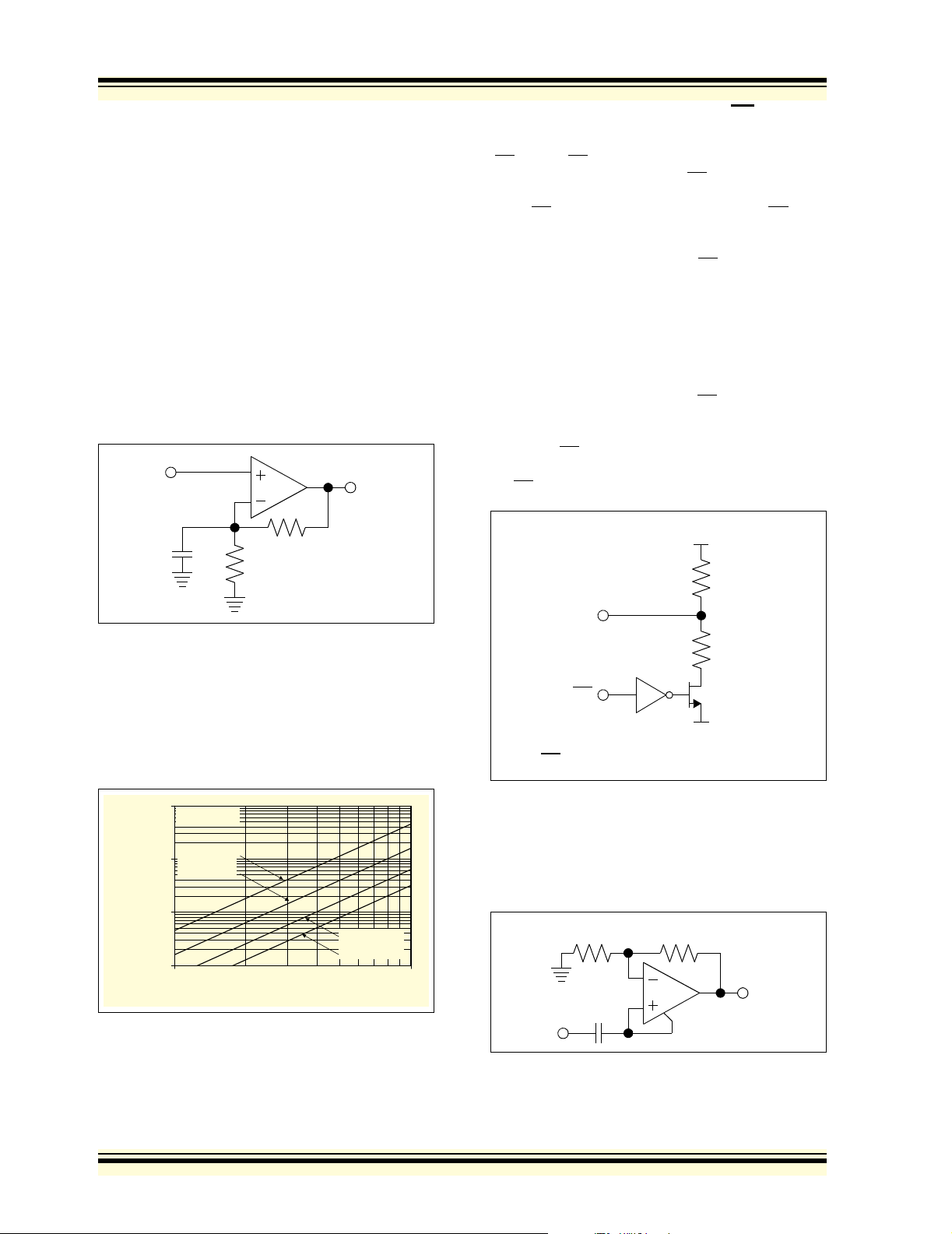

Figure 4-3 gives recommended R

different capacitive loads and gains. The x-axis is the

normalized load capacitance (C

circuit’s noise gain. For non-inverting gains, G

Signal Gain are equal. For inverting gains, G

1+|Signal Gain| (e.g., -1 V/V gives G

1,000

GN tt +1

)

:

(

ISO

100

), where GN is the

L/GN

N

ISO

values for

ISO

and the

N

= +2 V/V).

is

N

shown in Figure 2-3 and Figure 2-6, the input offset

voltage (VOS) is affected by the change from the NMOS

to the PMOS input differential pairs. This change in V

OS

will increase the distortion if the input voltage includes

this transition region. This transition occurs between

VDD– 1.0V and VDD– 2.0V, depending on VDD and

temperature.

Recommended R

10

10 100 1,000 10,000

Normalized Capacitance; C

L/GN

FIGURE 4-3: Recommended R

(pF)

ISO

values

for capacitive loads.

© 2006 Microchip Technology Inc. DS21685C-page 13

Page 14

MCP6021/1R/2/3/4

:

After selecting R

for your circuit, double-check the

ISO

resulting frequency response peaking and step

response overshoot. Modify R

’s value until the

ISO

response is reasonable. Evaluation on the bench and

simulations with the MCP6021/1R/2/3/4 Spice macro

model are helpful.

4.4 Gain Peaking

Figure 2-35 and Figure 2-36 use RF=1kΩ to avoid

(frequency response) gain peaking and (step

response) overshoot. The capacitance to ground at the

inverting input (C

input capacitance plus board parasitic capacitance. C

is in parallel with RG, which causes an increase in gain

at high frequencies for non-inverting gains greater than

1 V/V (unity gain). C

of the feedback loop for both non-inverting and

inverting gains.

V

IN

) is the op amp’s common mode

G

also reduces the phase margin

G

V

OUT

R

C

G

F

R

G

4.5 MCP6023 Chip Select (CS)

The MCP6023 is a single amplifier with chip select

). When CS is high, the supply current is less than

(CS

10 nA (typ) and travels from the CS

pin to VSS, with the

amplifier output being put into a high-impedance state.

When CS

is low, the amplifier is enabled. If CS is left

floating, the amplifier may not operate properly.

Figure 1-1 and Figure 2-39 show the output voltage

and supply current response to a CS

pulse.

4.6 MCP6021 and MCP6023 Reference

Voltage

G

The single op amps (MCP6021 and MCP6023), not in

the SOT-23-5 package, have an internal mid-supply

reference voltage connected to the V

Figure 4-6). The MCP6021 has CS

, which always keeps the op amp on and always

V

SS

pin (see

REF

internally tied to

provides a mid-supply reference. With the MCP6023,

taking the CS pin high conserves power by shutting

down both the op amp and the V

pin low turns on the op amp and V

the CS

circuitry. Taking

REF

V

DD

REF

circuitry.

50 kΩ

V

REF

FIGURE 4-4: Non-inverting gain circuit with parasitic capacitance.

The largest value of RF in Figure 4-4 that should be

used is a function of noise gain (see G

“Capacitive Loads”) and C

. Figure 4-5 shows results

G

in Section 4.3

N

for various conditions. Other compensation techniques

may be used, but they tend to be more complicated to

the design.

1.E+05

100k

)

:

(

1.E+04

F

10k

GN > +1 V/V

CG = 7 pF

C

= 20 pF

G

FIGURE 4-6: Simplified internal V

circuit (MCP6021 and MCP6023 only).

See Figure 4-7 for a non-inverting gain circuit using the

internal mid-supply reference. The DC-blocking

capacitor (CB) also reduces noise by coupling the op

amp input to the source.

1k

1.E+03

Maximum R

100

1.E+02

110

Noise Gain; G

(V/V)

N

CG = 50 pF

C

= 100 pF

G

FIGURE 4-5: Non-inverting gain circuit with parasitic capacitance.

FIGURE 4-7: Non-inverting gain circuit

using V

CS

(CS tied internally to VSS for MCP6021)

R

G

C

B

V

IN

(MCP6021 and MCP6023 only).

REF

50 kΩ

V

SS

REF

R

F

V

V

REF

OUT

DS21685C-page 14 © 2006 Microchip Technology Inc.

Page 15

MCP6021/1R/2/3/4

To use the internal mid-supply reference for an

inverting gain circuit, connect the V

pin to the

REF

non-inverting input, as shown in Figure 4-8. The

capacitor C

helps reduce power supply noise on the

B

output.

R

G

V

IN

R

F

V

OUT

V

REF

C

B

FIGURE 4-8: Inverting gain circuit using

V

(MCP6021 and MCP6023 only).

REF

If you don’t need the mid-supply reference, leave the

pin open.

V

REF

4.7 Supply Bypass

With this family of operational amplifiers, the power

supply pin (V

for single supply) should have a local

DD

bypass capacitor (i.e., 0.01 μF to 0.1 μF) within 2 mm

for good, high-frequency performance. It also needs a

bulk capacitor (i.e., 1 μF or larger) within 100 mm to

provide large, slow currents. This bulk capacitor can be

shared with nearby analog parts.

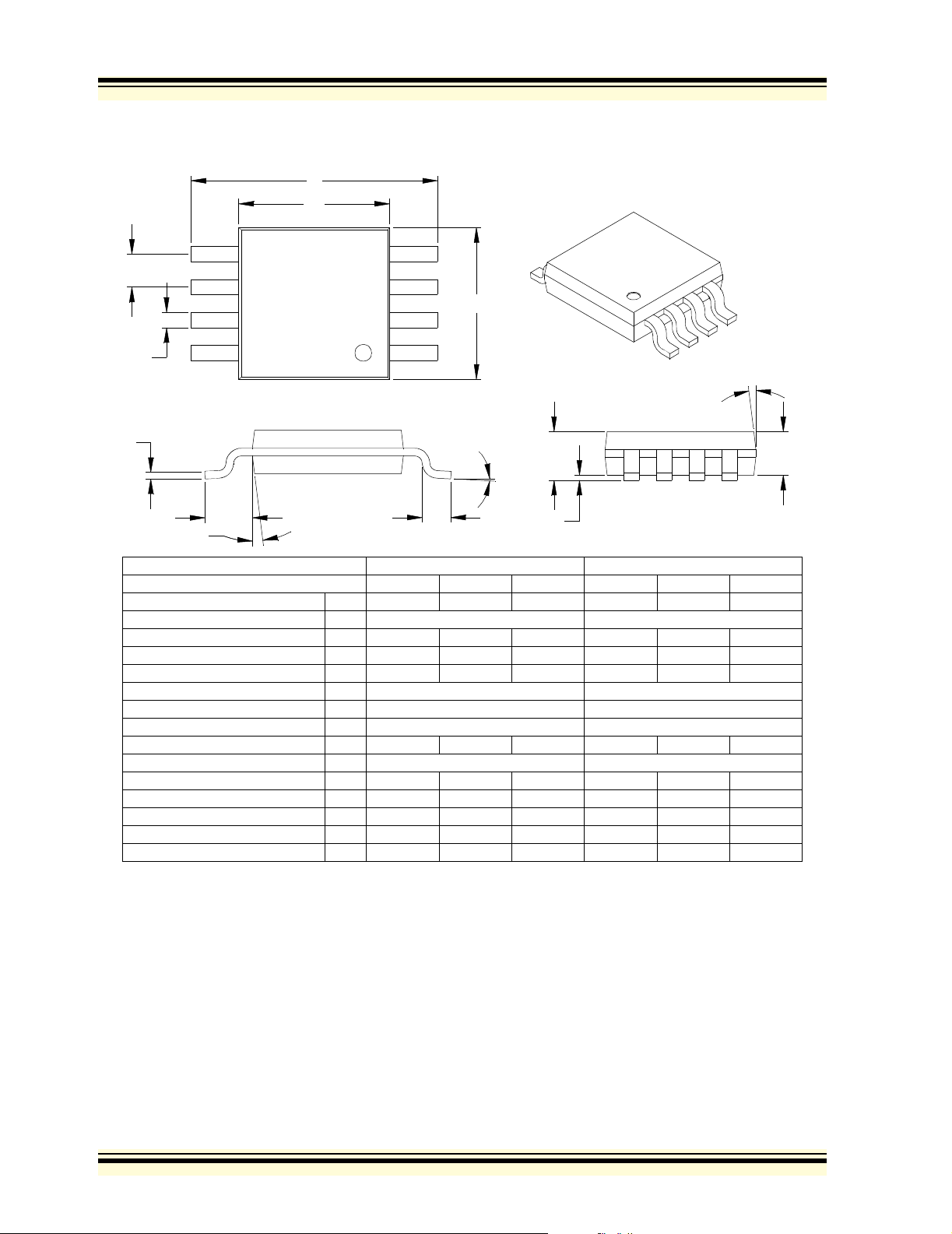

4.8 Unused Op Amps

An unused op amp in a quad package (MCP6024)

should be configured as shown in Figure 4-9. These

circuits prevent the output from toggling and causing

crosstalk. Circuit A can use any reference voltage

between the supplies, provides a buffered DC voltage,

and minimizes the supply current draw of the unused

op amp. Circuit B uses the minimum number of components and operates as a comparator; it may draw more

current.

4.9 PCB Surface Leakage

In applications where low input bias current is critical,

PCB (printed circuit board) surface-leakage effects

need to be considered. Surface leakage is caused by

humidity, dust or other contamination on the board.

Under low humidity conditions, a typical resistance

between nearby traces is 10

cause 5 pA of current to flow, which is greater than the

MCP6021/1R/2/3/4 family’s bias current at +25°C

(1 pA, typ).

The easiest way to reduce surface leakage is to use a

guard ring around sensitive pins (or traces). The guard

ring is biased at the same voltage as the sensitive pin.

Figure 4-10 shows an example of this type of layout.

Guard Ring VIN–VIN+

FIGURE 4-10: Example Guard Ring Layout.

1. Non-inverting Gain and Unity-Gain Buffer.

a) Connect the guard ring to the inverting input

pin (V

common mode input voltage.

b) Connect the non-inverting pin (V

input with a wire that does not touch the

PCB surface.

2. Inverting (Figure 4-10) and Transimpedance

Gain Amplifiers (convert current to voltage, such

as photo detectors).

a) Connect the guard ring to the non-inverting

input pin (V

to the same reference voltage as the op

amp’s input (e.g., VDD/2 or ground).

b) Connect the inverting pin (VIN–) to the input

with a wire that does not touch the PCB

surface.

–); this biases the guard ring to the

IN

12

Ω. A 5V difference would

+) to the

IN

+). This biases the guard ring

IN

¼ MCP6144 (A) ¼ MCP6144 (B)

V

DD

V

DD

4.10 High Speed PCB Layout

Due to their speed capabilities, a little extra care in the

PCB (Printed Circuit Board) layout can make a

V

R

DD

significant difference in the performance of these op

amps. Good PC board layout techniques will help you

R

achieve the performance shown in Section 1.0 “Elec-

trical Characteristics” and Section 2.0 “Typical Performance Curves”, while also helping you minimize

EMC (Electro-Magnetic Compatibility) issues.

FIGURE 4-9: Unused Op Amps.

Use a solid ground plane and connect the bypass local

capacitor(s) to this plane with minimal length traces.

This cuts down inductive and capacitive crosstalk.

© 2006 Microchip Technology Inc. DS21685C-page 15

Page 16

MCP6021/1R/2/3/4

Separate digital from analog, low speed from high

speed and low power from high power. This will reduce

interference.

Keep sensitive traces short and straight. Separating

them from interfering components and traces. This is

especially important for high-frequency (low rise-time)

signals.

Sometimes it helps to place guard traces next to victim

traces. They should be on both sides of the victim

trace, and as close as possible. Connect the guard

trace to ground plane at both ends, and in the middle

for long traces.

Use coax cables (or low inductance wiring) to route

signal and power to and from the PCB.

4.11 Typical Applications

4.11.1 A/D CONVERTER DRIVER AND

ANTI-ALIASING FILTER

Figure 4-11 shows a third-order Butterworth filter that

can be used as an A/D converter driver. It has a bandwidth of 20 kHz and a reasonable step response. It will

work well for conversion rates of 80 ksps and greater (it

has 29 dB attenuation at 60 kHz).

4.11.2 OPTICAL DETECTOR AMPLIFIER

Figure 4-12 shows the MCP6021 op amp used as a

transimpedance amplifier in a photo detector circuit.

The photo detector looks like a capacitive current

source, so the 100 kΩ resistor gains the input signal to

a reasonable level. The 5.6 pF capacitor stabilizes this

circuit and produces a flat frequency response with a

bandwidth of 370 kHz.

Photo

Detector

100 pF

5.6 pF

100 kΩ

MCP6021

VDD/2

FIGURE 4-12: Transimpedance Amplifier for an Optical Detector.

1.0 nF

8.45 kΩ

1.2 nF

14.7 kΩ 33.2 kΩ

100 pF

MCP602X

FIGURE 4-11: A/D converter driver and

anti-aliasing filter with a 20 kHz cutoff frequency.

This filter can easily be adjusted to another bandwidth

by multiplying all capacitors by the same factor.

Alternatively, the resistors can all be scaled by another

common factor to adjust the bandwidth.

DS21685C-page 16 © 2006 Microchip Technology Inc.

Page 17

MCP6021/1R/2/3/4

5.0 DESIGN TOOLS

Microchip provides the basic design tools needed for

the MCP6021/1R/2/3/4 family of op amps.

5.1 SPICE Macro Model

The latest SPICE macro model available for the

MCP6021/1R/2/3/4 op amps is on Microchip’s web site

at www.microchip.com. This model is intended as an

initial design tool that works well in the op amp’s linear

region of operation at room temperature. Within the

macro model file is information on its capabilities.

Bench testing is a very important part of any design and

cannot be replaced with simulations. Also, simulation

results using this macro model need to be validated by

comparing them to the data sheet specifications and

characteristic curves.

5.2 FilterLab® Software

Microchip’s FilterLab® software is an innovative tool

that simplifies analog active filter (using op amps)

design. It is available free of charge from our web site

at www.microchip.com. The FilterLab software tool

provides full schematic diagrams of the filter circuit with

component values. It also outputs the filter circuit in

SPICE format, which can be used with the macro

model to simulate actual filter performance.

© 2006 Microchip Technology Inc. DS21685C-page 17

Page 18

MCP6021/1R/2/3/4

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

5-Lead SOT-23 (MCP6021/MCP6021R)

Device E-Temp Code

XXNN EY25

8-Lead PDIP (300 mil)

XXXXXXXX

XXXXXNNN

YYWW

8-Lead SOIC (150 mil)

XXXXXXXX

XXXXYYWW

NNN

MCP6021 EYNN

MCP6021R EZNN

Note: Applies to 5-Lead SOT-23

Example:

MCP6021

I/P256

0331

Example:

MCP6021

I/SN0331

256

Example: (E-temp)

OR

OR

MCP6021

3

e

E/P^^256

0549

MCP6021E

3

e

SN^^0549

256

8-Lead MSOP

XXXXXX

YWWNNN

8-Lead TSSOP

XXXX

YYWW

NNN

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

3

e

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

Example:

Example:

6021E

549256

6021

E549

256

3

e

DS21685C-page 18 © 2006 Microchip Technology Inc.

Page 19

Package Marking Information (Continued)

14-Lead PDIP (300 mil) (MCP6024) Example:

MCP6021/1R/2/3/4

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

YYWWNNN

14-Lead SOIC (150 mil) (MCP6024)

XXXXXXXXXX

XXXXXXXXXX

YYWWNNN

OR

OR

MCP6024-I/P

XXXXXXXXXXXXXX

Example:

0331256

MCP6024

E/P^^

3

e

0549256

MCP6024ISL

XXXXXXXXXX

0331256

MCP6024

E/SL^^

0549256

3

e

14-Lead TSSOP (MCP6024)

XXXXXX

YYWW

NNN

© 2006 Microchip Technology Inc. DS21685C-page 19

Example:

6024E

0331

256

Page 20

MCP6021/1R/2/3/4

5-Lead Plastic Small Outline Transistor (OT) (SOT-23)

E

E1

p

B

p1

D

n

c

β

Units

Number of Pins

Pitch

Outside lead pitch (basic)

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .005" (0.127mm) per side.

EIAJ Equivalent: SC-74A

Drawing No. C04-091

p1

1

A

φ

L

n

p

f

c

a

b

A1

*

MILLIMETERSINCHES

0.95.038

1.90.075

Revised 09-12-05

A2

MAXNOMMINMAXNOMMINDimension Limits

55

1.451.180.90.057.046.035AOverall Height

1.301.100.90.051.043.035A2Molded Package Thickness

0.150.080.00.006.003.000A1Standoff

3.002.802.60.118.110.102EOverall Width

1.751.631.50.069.064.059E1Molded Package Width

3.102.952.80.122.116.110DOverall Length

0.550.450.35.022.018.014LFoot Length

0.200.150.09.008.006.004

0.500.430.35.020.017.014BLead Width

α

10501050

10501050

10501050

DS21685C-page 20 © 2006 Microchip Technology Inc.

Page 21

8-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

D

2

MCP6021/1R/2/3/4

n

E

β

eB

Number of Pins

Pitch

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

Dimension Limits MIN NOM MAX MIN NOM MAX

1

α

A

c

Units INCHES* MILLIMETERS

n

p

c

α

β

.008 .012 .015 0.20 0.29 0.38

A1

B1

B

88

.100 2.54

51015 51015

51015 51015

A2

L

p

© 2006 Microchip Technology Inc. DS21685C-page 21

Page 22

MCP6021/1R/2/3/4

8-Lead Plastic Small Outline (SN) – Narrow, 150 mil (SOIC)

E

E1

p

D

2

B

Number of Pins

Pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-057

n

45°

c

β

n

p

φ

c

α

β

1

h

A

φ

L

048048

A1

MILLIMETERSINCHES*Units

1.27.050

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004A1Standoff §

6.206.025.79.244.237.228EOverall Width

3.993.913.71.157.154.146E1Molded Package Width

5.004.904.80.197.193.189DOverall Length

0.510.380.25.020.015.010hChamfer Distance

0.760.620.48.030.025.019LFoot Length

0.250.230.20.010.009.008

0.510.420.33.020.017.013BLead Width

1512015120

1512015120

DS21685C-page 22 © 2006 Microchip Technology Inc.

Page 23

MCP6021/1R/2/3/4

8-Lead Plastic Thin Shrink Small Outline (ST) – 4.4 mm (TSSOP)

E

E1

p

D

2

1

n

B

A

c

β

Number of Pins

Pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .005" (0.127mm) per side.

JEDEC Equivalent: MO-153

Drawing No. C04-086

L

n

p

φ

c

α

β

0° 4° 8° 0° 4° 8°

φ

INCHESUnits

A1

MILLIMETERS

A2

*

MAXNOMMINMAXNOMMINDimension Limits

88

0.65.026

1.101.051.00.043.041.039AOverall Height

0.950.900.85.037.035.033A2Molded Package Thickness

0.150.100.05.006.004.002A1Standoff

6.506.386.25.256.251.246EOverall Width

4.504.404.30.177.173.169E1Molded Package Width

3.103.002.90.122.118.114DMolded Package Length

0.700.600.50.028.024.020LFoot Length

0.200.150.09.008.006.004

0.300.250.19.012.010.007BLead Width

Revised 07-21-05

α

10°5°0°10°5°0°

10°5°0°10°5°0°

© 2006 Microchip Technology Inc. DS21685C-page 23

Page 24

MCP6021/1R/2/3/4

8-Lead Plastic Micro Small Outline Package (MS) (MSOP)

E

E1

p

D

2

n1

B

α

c

F

β

Units

Dimension Limits

Number of Pins

Pitch

Overall Height

Molded Package Thickness

Standoff

Overall Width

Molded Package Width

Overall Length

Foot Length

Foot Angle

Lead Thickness

Lead Width

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010" (0.254mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

REF: Reference Dimension, usually without tolerance, for information purposes only.

See ASME Y14.5M

JEDEC Equivalent: MO-187

Drawing No. C04-111

n

p

A

A2

A1

E

E1

D

L

φ

c

B

α

β

MIN

.030

.000

.016 .024

0° - 8°

.003

.009

5°

5° -

L

INCHES

NOM

.026 BSC

.193 BSC

.118 BSC

.118 BSC

.037 REFFFootprint (Reference)

φ

8

--

.033

--

.006

.012

-

A

A1

MILLIMETERS

MAX NOM

.043

.037

.006

.031

.009

.016

15°

15°

MIN

0.65 BSC

-

0.75

0.00

4.90 BSC

3.00 BSC

3.00 BSC

0.40

0.95 REF

0°

0.08

0.22

*

8

-

0.85

0.60

-

-

-

Revised 07-21-05

A2

MAX

1.10

0.95

0.15

0.80

8°

0.23

0.40

15°5° 15°5° -

DS21685C-page 24 © 2006 Microchip Technology Inc.

Page 25

14-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

D

2

MCP6021/1R/2/3/4

n

E

β

eB

Number of Pins

Pitch

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width

Overall Length D .740 .750 .760 18.80 19.05 19.30

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-005

1

A

c

A1

Dimension Limits MIN NOM MAX MIN NOM MAX

Units INCHES* MILLIMETERS

n

p

E1

c

α

β

.240 .250 .260 6.10 6.35 6.60

.008 .012 .015 0.20 0.29 0.38

5 10 15 5 10 15

5 10 15 5 10 15

B1

B

14 14

.100 2.54

α

A2

L

p

© 2006 Microchip Technology Inc. DS21685C-page 25

Page 26

MCP6021/1R/2/3/4

14-Lead Plastic Small Outline (SL) – Narrow, 150 mil (SOIC)

E

E1

p

D

2

B

n

1

45°

c

β

Number of Pins

Pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-065

h

A

φ

L

n

p

φ

c

α

β

A1

048048

α

MILLIMETERSINCHES*Units

1.27.050

A2

MAXNOMMINMAXNOMMINDimension Limits

1414

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004A1Standoff §

6.205.995.79.244.236.228EOverall Width

3.993.903.81.157.154.150E1Molded Package Width

8.818.698.56.347.342.337DOverall Length

0.510.380.25.020.015.010hChamfer Distance

1.270.840.41.050.033.016LFoot Length

0.250.230.20.010.009.008

0.510.420.36.020.017.014BLead Width

1512015120

1512015120

DS21685C-page 26 © 2006 Microchip Technology Inc.

Page 27

MCP6021/1R/2/3/4

14-Lead Plastic Thin Shrink Small Outline (ST) – 4.4 mm (TSSOP)

E

E1

p

D

2

n

B

1

A

c

β

Number of Pins

Pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold fla sh or protrusions. Mold flash or protrusions shall not exceed .005" (0.127mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

REF: Reference Dimension, usually without tole rance, for information purposes only.

See ASME Y14.5M

JEDEC Equivalent: MO-153 AB-1

Drawing No. C04-087

n

p

φ

c

α

β

0°

φ

L

INCHESUnits

12° REF

12° REF

MILLIMETERS

1414

0.65 BSC.026 BSC

12° REF

12° REF

Revised: 08-17-05

A2A1

*

MAXNOMMINMAXNOMMINDimension Limits

1.101.051.00.043.041.039AOverall Height

0.950.900.85.037.035.033A2Molded Package Thickness

0.150.100.05.006.004.002A1Standoff

6.506.386.25.256.251.246EOverall Width

4.504.404.30.177.173.169E1Molded Package Width

5.105.004.90.201.197.193DMolded Package Length

0.700.600.50.028.024.020LFoot Length

8°4°0°8°4°

0.200.150.09.008.006.004

0.300.250.19.012.010.007BLead Width

α

© 2006 Microchip Technology Inc. DS21685C-page 27

Page 28

MCP6021/1R/2/3/4

NOTES:

DS21685C-page 28 © 2006 Microchip Technology Inc.

Page 29

APPENDIX A: REVISION HISTORY

Revision C (March 2006)

The following is the list of modifications:

1. Added SOT-23-5 package option for single op

amps MCP6021 and MCP6021R (E-temp only).

2. Added MSOP-8 package option for E-temp

single op amp (MCP6021).

3. Corrected package drawing on front page for

dual op amp (MCP6022).

4. Clarified spec conditions (I

in Section 2.0 “Typical Performance

Curves”.

5. Added Section 3.0 “Pin Descriptions”.

6. Updated Section 4.0 “Applications informa-

tion” for THD+N, unused op amps, and gain

peaking discussions.

7. Corrected and updated package marking information in Section 6.0 “Packaging Informa-

tion”.

8. Added Appendix A: “REVISION HISTORY”.

, PM and THD+N)

SC

MCP6021/1R/2/3/4

Revision B (November 2003)

• Second Release of this Document

Revision A (November 2001)

• Original Release of this Document

© 2006 Microchip Technology Inc. DS21685C-page 29

Page 30

MCP6021/1R/2/3/4

NOTES:

DS21685C-page 30 © 2006 Microchip Technology Inc.

Page 31

MCP6021/1R/2/3/4

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. X /XX

Device

PackageTemperature

Range

Device: MCP6021 Single Op Amp

Temperature Range: I = -40°C to +85°C

Package: OT = Plastic Small Outline Transistor (SOT-23), 5-lead

MCP6021T Single Op Amp

MCP6021R Single Op Amp

MCP6021RT Single Op Amp

MCP6022 Dual Op Amp

MCP6022T Dual Op Amp

MCP6023 Single Op Amp w/ CS

MCP6023T Single Op Amp w/ CS

MCP6024 Quad Op Amp

MCP6024T Quad Op Amp

E = -40°C to +125°C

MS = Plastic MSOP, 8-lead

P = Plastic DIP (300 mil Body), 8-lead, 14-lead

SN = Plastic SOIC (150mil Body), 8-lead

SL = Plastic SOIC (150 mil Body), 14-lead

ST = Plastic TSSOP, 8-lead

ST = Plastic TSSOP, 14-lead

(Tape and Reel for SOT-23, SOIC, TSSOP,

MSOP)

(Tape and Reel for SOT-23)

(Tape and Reel for SOIC and TSSOP)

(Tape and Reel for SOIC and TSSOP)

(Tape and Reel for SOIC and TSSOP)

(MCP6021, E-Temp; MCP6021R, E-Temp)

(MCP6021, E-Temp)

(MCP6021,I-Temp; MCP6022, I-Temp, E-Temp;

MCP6023, I-Temp, E-Temp;)

Examples:

a) MCP6021T-E/OT: Tape and Reel,

b) MCP6021-E/P: Extended temperature,

c) MCP6021-E/SN: Extended temperature,

a) MCP6021RT-E/OT:Tape and Reel,

a) MCP6022-I/P: Industrial temperature,

b) MCP6022-E/P: Extended temperature,

c) MCP6022T-E/ST: Tape and Reel,

a) MCP6023-I/P: Industrial temperature,

b) MCP6023-E/P: Extended temperature,

c) MCP6023-E/SN: Extended temperature,

a) MCP6024-I/SL: Industrial temperature,

b) MCP6024-E/SL: Extended temperature,

c) MCP6024T-E/ST: Tape and Reel,

Extended temperature,

5LD SOT-23.

8LD PDIP.

8LD SOIC.

Extended temperature,

5LD SOT-23.

8LD PDIP.

8LD PDIP.

Extended temperature,

8LD TSSOP.

8LD PDIP.

8LD PDIP.

8LD SOIC.

14LD SOIC.

14LD SOIC.

Extended temperature,

14LD TSSOP.

© 2006 Microchip Technology Inc. DS21685C-page 31

Page 32

MCP6021/1R/2/3/4

NOTES:

DS21685C-page 32 © 2006 Microchip Technology Inc.

Page 33

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of Microchip devices in life support and/or safety

applications is entirely at the buyer’s risk, and the buyer agrees

to defend, indemnify and hold harmless Microchip from any and

all damages, claims, suits, or expenses resulting from such

use. No licenses are conveyed, implicitly or otherwise, under

any Microchip intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor,

MPASM, MPLIB, MPLINK, MPSIM, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, Real ICE, rfLAB, rfPICDEM, Select

Mode, Smart Serial, SmartTel, Total Endurance, UNI/O,

WiperLock and ZENA are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

© 2006 Microchip Technology Inc. DS21685C-page 33

Page 34

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-5160-8631

Fax: 91-11-5160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

02/16/06

DS21685C-page 34 © 2006 Microchip Technology Inc.

Loading...

Loading...