Page 1

MCP3905/06

Energy-Metering ICs with Acti ve (Real) Power Pulse Output

Features

• Supplies ac tive (real) power measurement for

single-phase, residential energy-metering

• Supports the IEC 62053 International Energy

Metering Specification and legacy IEC

1036/61036/687 Specifications

• Two multi-bit, Digital-to-Analog Converters

(DACs), second-order, 16-bit, Delta-Sigma

Analog-to-Digital Converters (ADCs)

• 0.1% typical measurement error over 500:1

dynamic range (MCP3905)

• 0.1% typical measurement error over 1000:1

dynamic range (MCP3906)

• Programmable Gain Amplifier (PGA) for smallsignal inputs supports low-value shunt current

sensor

- 16:1 PGA - MCP3905

- 32:1 PGA - MCP3906

• Ultra-low drift on-chip reference: 15 ppm/°C (typ.)

• Direct drive for electromagnetic mechanical

counter and two-phase stepper motors

•Low I

• Tamper output pin for negative power indication

• Industrial Temperature Range: -40°C to +85°C

• Supplies instantaneous active (real) power on

HF

US Patents Pending

of 4 mA (typ.)

DD

for meter calibration

OUT

Description

The MCP3905/06 devices are energy-metering ICs

designed to support the IEC 62053 International

Metering Standard Specification. They supply a

frequency output proportional to the average active

(real) power, as well as a higher-frequency output

proportional to the instantaneous power for meter

calibration. They include two 16-bit, delta-sigma ADCs

for a wide r ange of I

and I

B

currents and/or small

MAX

shunt (< 200 µOhms) meter designs. It includes an

ultra-low drift voltage reference with < 15 ppm/°C

through a specially designed band gap temperature

curve for the minimum gradient across the industrial

temperature range. A fixed-function DSP block is onchip for active (real) power calculation. Strong output

drive for mechanical counters are on-chip to reduce

field failures and mechanical counter sticking. A noload threshold block prevents any current creep measurements. A Power-On Reset (POR) block restricts

meter performance during low-voltage situations.

These accurate energy-metering ICs with high field

reliability are available in the ind us try-s t a nda rd pino ut.

Package Type

24-Pin SSOP

DV

DD

HPF

AV

DD

NC

CH0+

CH0CH1-

CH1+

MCLR

REFIN/OUT

A

GND

F2

1

2

3

4

5

6

7

8

10

11

F

24

F

23

22

HF

D

21

NEG

20

NC

19

18

OSC2

17

OSC1

169G0

15

G1

14

F0

1312F1

OUT0

OUT1

OUT

GND

Functional Block Diagram

G0 G1

CH0+

CH0-

REFIN/

OUT

CH1+

CH1-

© 2007 Microchip Technology Inc. DS21948D-page 1

+

–

2.4V

Reference

+

–

PGA

16-bit

Multi-level

ΔΣ ADC

16-bit

Multi-level

ΔΣ ADC

HPF

HPF1

HPF1

OSC1 OSC2

X

LPF1

POR

F2 F1

HF

F0

E-to-F

conversion

OUT

F

OUT1

MCLR

F

OUT0

NEG

Page 2

MCP3905/06

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings †

VDD...................................................................................7.0V

Digital inputs and outputs w.r.t. A

Analog input w.r.t. A

input w.r.t. A

V

REF

Storage temperature.. .. .. .. .. ....... .. .. .. .. .... .. ..... .-65°C to +150°C

Ambient temp. with power applied................ -65°C to +125°C

Soldering temperature of leads (10 seconds) .............+300°C

ESD on the analog inputs (HBM,MM)... ......... .... .5.0 kV, 500V

ESD on all other pins (HBM,MM)........................5.0 kV, 500V

.........................................-6V to +6V

GND

...............................-0.6V to VDD +0.6V

GND

........-0.6V to VDD +0.6V

GND

† Notice: Stresses above those listed under "Maximum

Ratings" may cause permanent damage to the device. This is

a stress rating only and functional operation of the device at

those or any other conditions above those indicated in the

operation listings of this specification is not implied. Exposure

to maximum rating conditions for extended periods may affect

device reliability.

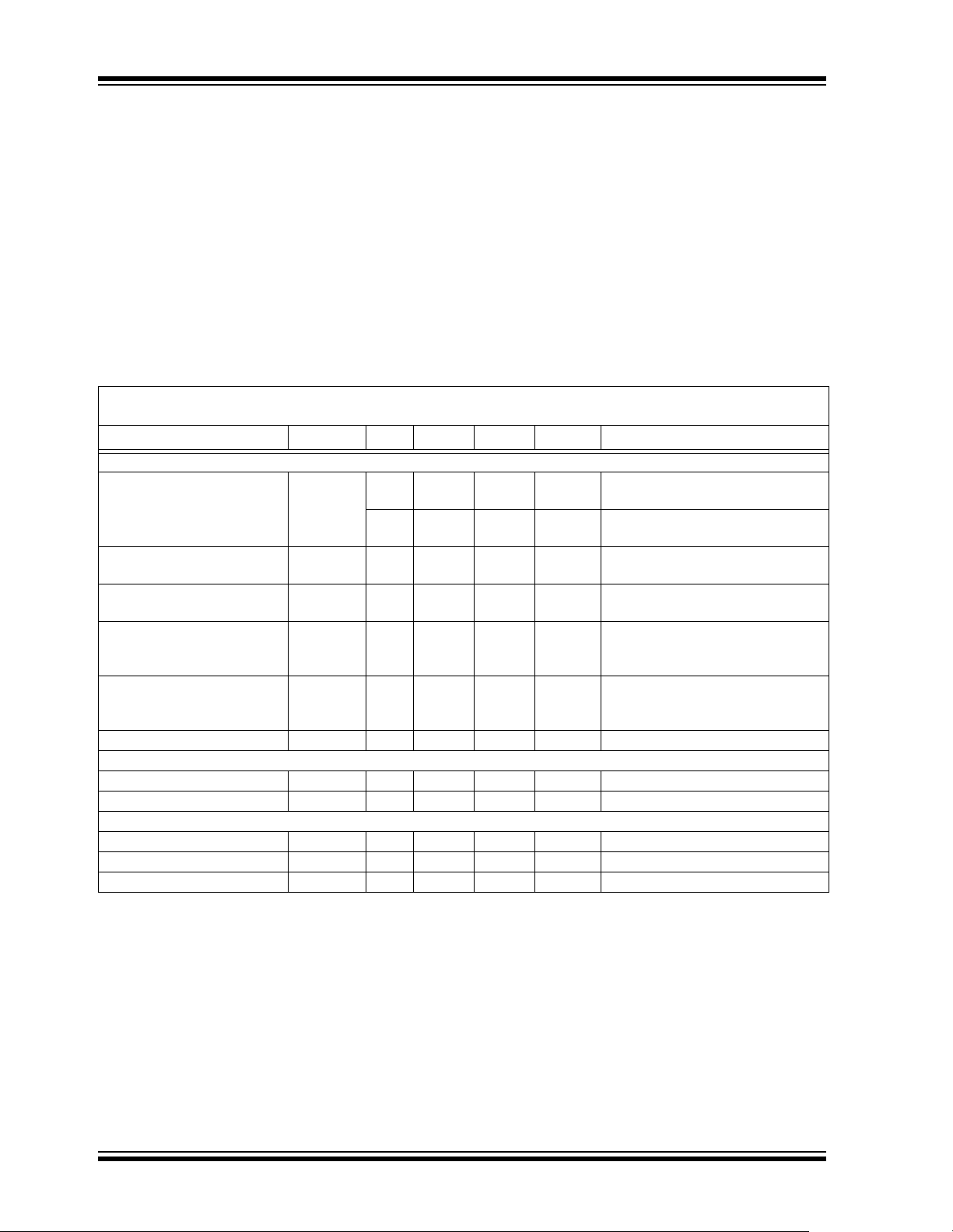

ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, all parameters apply at AV

Internal V

, HPF turned on (AC mode), A

REF

GND

, D

= 0V, MCLK = 3.58 MHz; TA = -40°C to +85°C.

GND

Parameter Sym Min Typ. Max Units Comment

Overall Measurement Accuracy

Energy Measurement Error E — 0.1 — % F

— 0.1 — % F

No-Load Threshold/

NLT — 0.0015 — % F

Minimum Load

Phase Delay Between

— — 1/MCLK s HPF = 0 and 1, < 1 MCLK

OUT

OUT

OUT

Max

Channels

AC Power Supply

AC PSRR — 0.01 — % F

OUT

Rejection Ratio

(Output Frequency Variation)

DC Power Supply

DC PSRR — 0.01 — % F

OUT

Rejection Ratio

(Output Frequency Variation)

System Gain Error — 3 10 % F

OUT

ADC/PGA Specifications

Offset Error V

OS

Gain Error Match — 0.5 — % F

— 2 5 mV Referred to Input

OUT

Internal Voltage Reference

Voltage — 2.4 — V

Tolerance — ±2 — %

Tempco — 15 — ppm/°C

Note 1: Measurement error = (Energy Measured By Device - True Energy)/True Energy * 100%. Accuracy is

, F

measured with signal (±660 mV) on Channel 1. F

OUT0

pulse outputs. Valid from 45 Hz to 65 Hz.

OUT1

See Section 2.0 “Typical Performance Curves” for higher frequencies and increased dynamic range.

2: Does not include internal V

. Gain = 1, CH0 = 470 mVDC, CH1 = 660 mVDC, difference between

REF

measured output frequency and expected transfer function.

3: Percent of HF

50 Hz, CH2 = 100 mVRMS @ 50 Hz, AV

output frequency variation; Includes external V

OUT

= 5V + 1Vpp @ 100 Hz. DC PSRR: 5V ±500 mV.

DD

REF

4: Error applies down to 60° lead (PF = 0.5 capacitive) and 60° lag (PF = 0.5 inductive).

5: Refer to Section 4.0 “Device Overview” for complete description.

6: Specified by characterization, not production tested.

7: 1 MCLK period at 3.58 MHz is equivalent to less than <0.005 degrees at 50 or 60 Hz.

8: Gain error match is measured from CH0 G = 1 to any other gain setting.

= DVDD = 4.5V – 5.5V,

DD

Channel 0 swings 1:500 range,

MCP3905 only (Note 1, Note 4)

Channel 0 swings 1:1000 range,

MCP3906 only (Note 1, Note 4)

Disabled when F2, F1, F0 = 0, 1, 1

(Note 5, Note 6)

(Note 4, Note 6, Note 7)

F2, F1, F0 = 0, 1, 1 (Note 3)

HPF = 1, Gain = 1 (Note 3)

Note 2, Note 5

Note 8

= 2.5V, CH1 = 100 mVRMS @

DS21948D-page 2 © 2007 Microchip Technology Inc.

Page 3

MCP3905/06

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise indicated, all parameters apply at AV

Internal V

, HPF turned on (AC mode), A

REF

GND

, D

= 0V, MCLK = 3.58 MHz; TA = -40°C to +85°C.

GND

Parameter Sym Min Typ. Max Units Comment

Reference Input

Input Range 2.2 — 2.6 V

Input Impedance 3.2 — — kΩ

Input Capacitance — — 10 pF

Analog Inputs

Maximum Signal Level — — ±1 V CH0+,CH0-,CH1+,CH1- to A

Differential Input Voltage

— — ±470/G mV G = PGA Gain on Channel 0

Range Channel 0

Differential Input Voltage

——±660mV

Range Channel 1

Input Impedance 390 — — kΩ Proportional to 1/MCLK frequency

Bandwidth

— 14 — kHz Proportional to MCLK frequency,

(Notch Frequency)

Oscillator Input

Frequency Range MCLK 1 — 4 MHz

Power Specifications

Operating Voltage 4.5 — 5.5 V AV

I

DD,A

I

DD,D

I

DD,A

I

DD,D

—2.7 3.0 mAAV

—1.2 2.0 mADV

Note 1: Measurement error = (Energy Measured By Device - True Energy)/True Energy * 100%. Accuracy is

measured with signal (±660 mV) on Channel 1. F

OUT0

, F

pulse outputs. Valid from 45 Hz to 65 Hz.

OUT1

See Section 2.0 “Typical Performance Curves” for higher frequencies and increased dynamic range.

2: Does not include internal V

. Gain = 1, CH0 = 470 mVDC, CH1 = 660 mVDC, difference between

REF

measured output frequency and expected transfer function.

3: Percent of HF

50 Hz, CH2 = 100 mVRMS @ 50 Hz, AV

output frequency variation; Includes external V

OUT

= 5V + 1Vpp @ 100 Hz. DC PSRR: 5V ±500 mV.

DD

REF

4: Error applies down to 60° lead (PF = 0.5 capacitive) and 60° lag (PF = 0.5 inductive).

5: Refer to Section 4.0 “Device Overview” for complete description.

6: Specified by characterization, not production tested.

7: 1 MCLK period at 3.58 MHz is equivalent to less than <0.005 degrees at 50 or 60 Hz.

8: Gain error match is measured from CH0 G = 1 to any other gain setting.

= DVDD = 4.5V – 5.5V,

DD

MCLK/256

DD, DVDD

pin only

DD

pin only

DD

= 2.5V, CH1 = 100 mVRMS @

GND

TEMPERATURE CHAR ACTERISTICS

Electrical Specifications: Unless otherwise indicated, V

= 4.5V – 5.5V, A

DD

Parameters Sym Min Typ Max Units Conditions

Temperature Ranges

Specified Temperature Range T

Operating Temperature Range T

Storage Temperature Range T

-40 — +85 °C

A

-40 — +125 °C Note

A

-65 — +150 °C

A

Note: The MCP3905/06 operate over this extended temperature range, but with reduced performance. In any

case, the Junction Temperature (T

© 2007 Microchip Technology Inc. DS21948D-page 3

) must not exceed the Absolute Maximum specification of +150°C.

J

GND

, D

GND

= 0V.

Page 4

MCP3905/06

TIMING CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, all parameters apply at AV

A

, D

GND

= 0V, MCLK = 3.58 MHz; TA = -40°C to +85°C.

GND

Parameter Sym Min Typ Max Units Comment

Frequency Output

F

OUT0

and F

Pulse Width

OUT1

t

FW

— 275 — ms 984376 MCLK periods

(Logic-Low)

Pulse Width t

HF

OUT

and F

F

OUT0

Pulse Period t

HF

OUT

F

to F

OUT0

F

to F

OUT0

F

and F

OUT0

F

and F

OUT0

HF

Output High Voltage V

OUT

Output Low Voltage V

HF

OUT

Pulse Period t

OUT1

Falling-Edge Ti me t

OUT1

Min Separation t

OUT1

Output High Voltage V

OUT1

Output Low Voltage V

OUT1

High-Level Input Voltage

HW

HP

FS2

V

FP

FS

OH

OL

OH

OL

IH

— 90 — ms 322160 MCLK periods

Refer to Equation 4-1 s

Refer to Equation 4-2 s

— 0.5 t

— 4/MCLK —

FP

—

4.5 ——VIOH = 10 mA, DVDD = 5.0V

——0.5 V I

4.0 ——VIOH = 5 mA, DVDD = 5.0V

——0.5 V I

2.4 ——VDVDD = 5.0V

(All Digital Input Pins)

Low-Level Input Voltage

V

IL

——0.85 V DV

(All Digital Input Pins)

Input Leakage Current

——±3 µA V

Pin Capacitance ——10 pF Note 3

Note 1: If output pulse period (tFP) falls below 984376*2 MCLK periods, then tFW = 1/2 tFP.

2: If output pulse period (tHP) falls below 322160*2 MCLK periods, then tHW = 1/2 tHP.

3: Specified by characterization, not production tested.

= DVDD = 4.5V – 5.5V,

DD

(Note 1)

(Note 2)

= 10 mA, DVDD = 5.0V

OL

= 5 mA, DVDD = 5.0V

OL

DD

= 0, VIN = DV

IN

= 5.0V

DD

t

FP

t

FW

F

OUT0

t

FS

F

HF

OUT1

OUT

t

HW

t

HP

t

FS2

NEG

FIGURE 1-1: Output Timings for Pulse Outputs and Negative Power Pin.

DS21948D-page 4 © 2007 Microchip Technology Inc.

Page 5

MCP3905/06

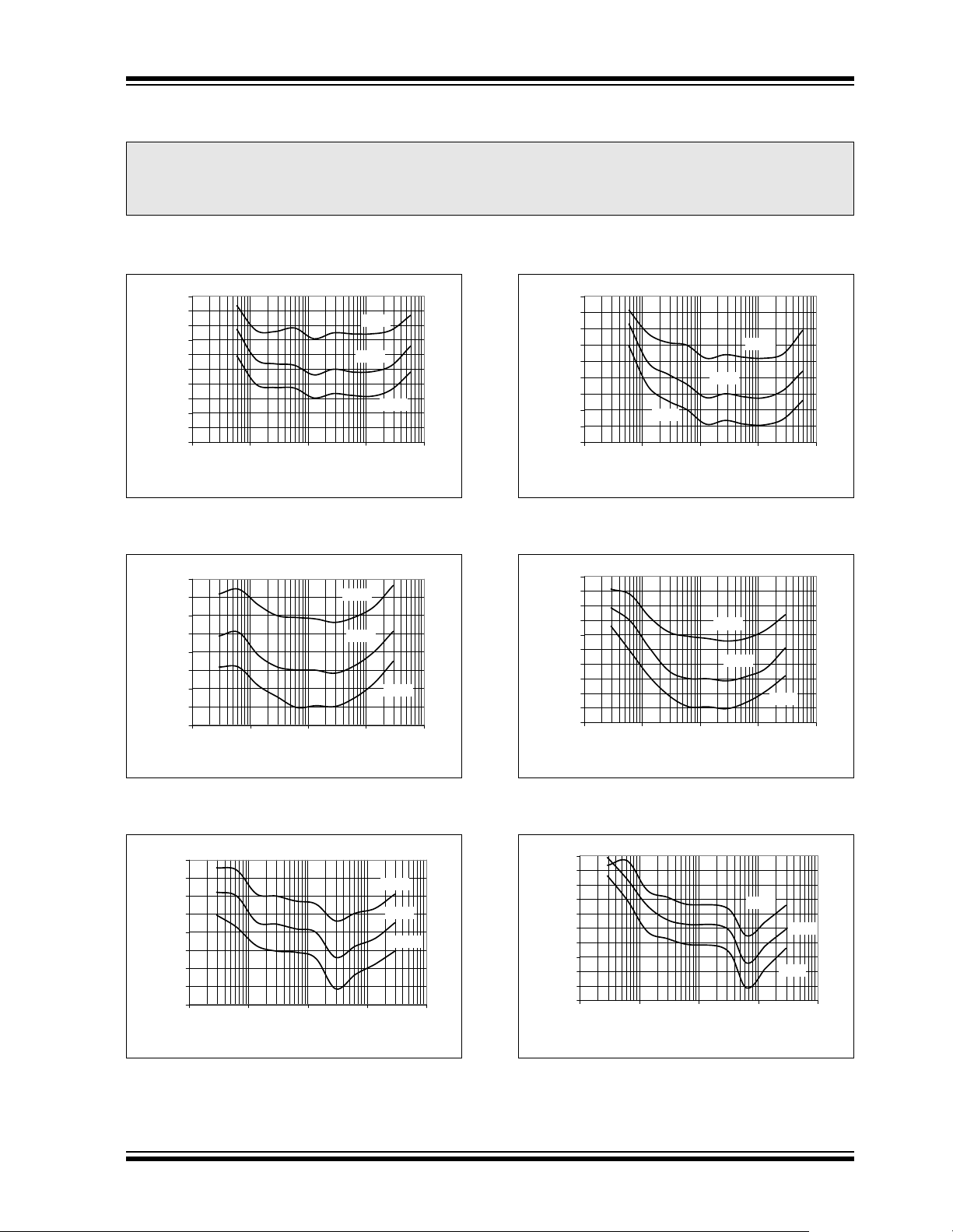

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided fol low i ng thi s n ote are a statistical summ ar y b as ed on a limited num ber of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise specified, DVDD, AVDD = 5V; A

MCLK = 3.58 MHz.

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

Measure ment Error

-0.4

-0.5

0.0000 0.0001 0.0010 0.0100 0.1000

CH1 Vp-p Amplitude (V)

+85°C

+25°C

-40°C

FIGURE 2-1: Measurement Error,

Gain = 8, PF = 1.

0.5

0.4

0.3

0.2

0.1

0

-0.1

Measurement Error

-0.2

-0.3

0.0000 0.0001 0.0010 0.0100 0.1000

CH1 Vp-p Amplitude (V)

+85°C

+25°C

- 40°C

GND

, D

GND

= 0V; V

-0.1

Measurement Error

-0.2

-0.3

= Internal, HPF = 1 (AC mode),

REF

0.6

0.5

0.4

0.3

0.2

0.1

0

-40°C

0.0000 0.0001 0.0010 0.0100 0.1000

CH1 Vp-p Amplitude (V)

+25°C

FIGURE 2-4: Measurement Error,

Gain = 8, PF = 0.5.

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

-0.1

Measurement Error

-0.2

-0.3

0.0000 0.0001 0.0010 0.0100 0.1000

CH1 Vp-p Amplitude (V)

+85°C

+25°C

+85°C

-40°C

FIGURE 2-2: Measurement Error,

Gain = 16, PF = 1.

0.8

0.6

0.4

0.2

0

-0.2

-0.4

Measurement Error

-0.6

-0.8

0.0000 0.0001 0.0010 0.0100 0.1000

CH1 Vp-p Amplitude (V)

+85°C

+25°C

FIGURE 2-3: Measurement Error,

Gain = 32, PF = 1.

- 40°C

FIGURE 2-5: Measurement Error,

Gain = 16, PF = 0.5.

1

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

Measurement Error

-0.8

-1

0.0000 0.0001 0.0010 0.0100 0.1000

CH1 Vp-p Amplitude (V)

+85°C

-40°C

FIGURE 2-6: Measurement Error,

Gain = 32, PF = 0.5.

+25°C

© 2007 Microchip Technology Inc. DS21948D-page 5

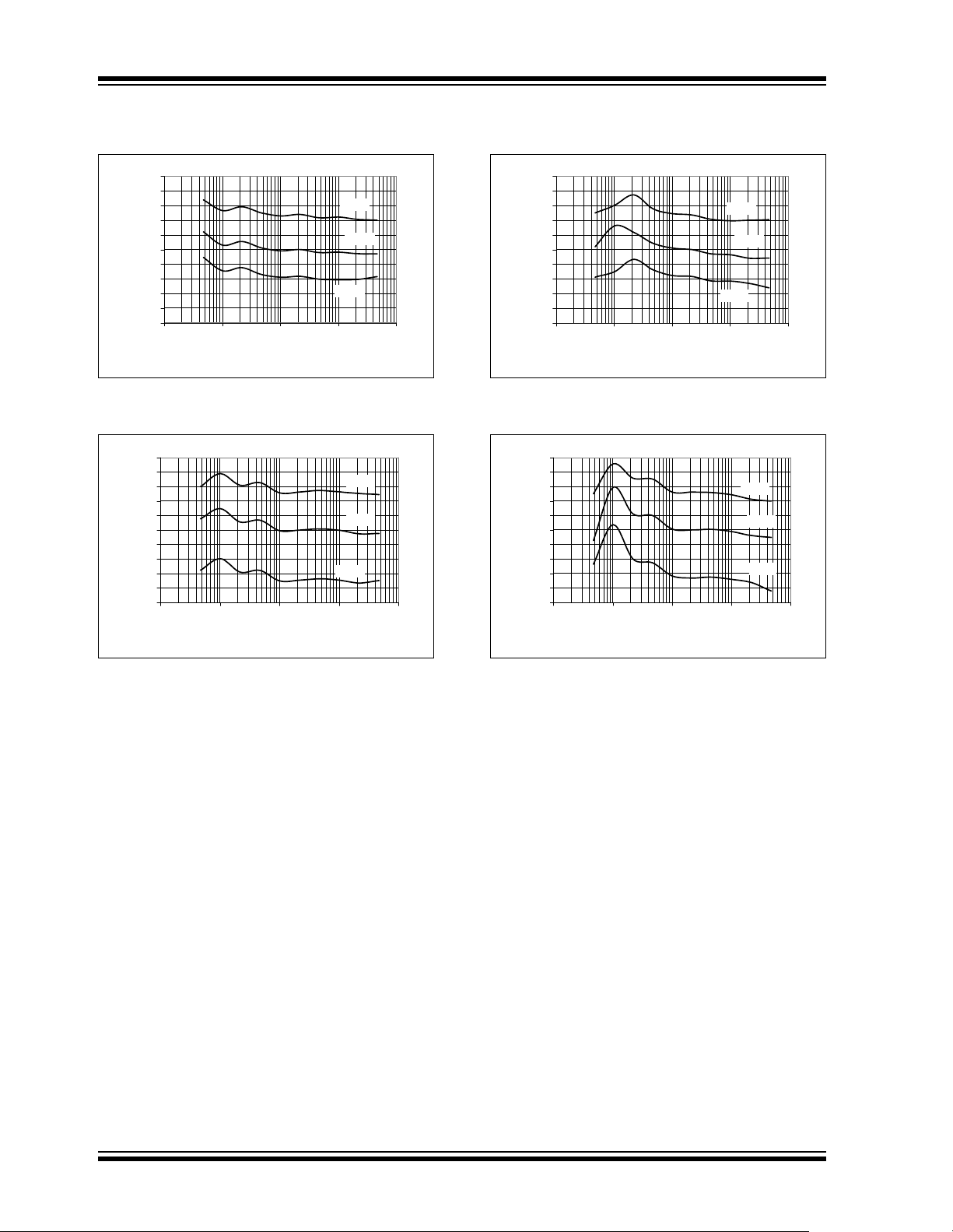

Page 6

MCP3905/06

Note: Unless otherwise specified, DVDD, AVDD = 5V; A

MCLK = 3.58 MHz.

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

Measure ment Error

-0.4

-0.5

0.0001 0.0010 0.0100 0.1000 1.0000

CH0 Vp-p Amplitude (V)

+85°C

+25°C

- 40°C

FIGURE 2-7: Measurement Error,

Gain = 1, PF = 1.

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

Measurement Error

-0.4

-0.5

0.0001 0.0010 0.0100 0.1000 1.0000

CH0 Vp-p Amplitude (V)

+85°C

+25°C

- 40°C

GND

, D

GND

= 0V; V

-0.1

-0.2

-0.3

Measurement Error

-0.4

-0.5

= Internal, HPF = 1 (AC mode),

REF

0.5

0.4

0.3

0.2

0.1

0

0.0001 0.0010 0.0100 0.1000 1.0000

CH1 Vp-p Amplitude (V)

FIGURE 2-9: Measurement Error,

Gain = 1, PF = + 0.5.

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

Measurement Error

-0.4

-0.5

0.0001 0.0010 0.0100 0.1000 1.0000

CH1 Vp-p Amplitude (V)

+85°C

+25°C

-40°C

+85°C

+25°C

-40°C

FIGURE 2-8: Measurement Error,

Gain = 2, PF = 1.

FIGURE 2-10: Measurement Error,

Gain = 2, PF = + 0.5.

DS21948D-page 6 © 2007 Microchip Technology Inc.

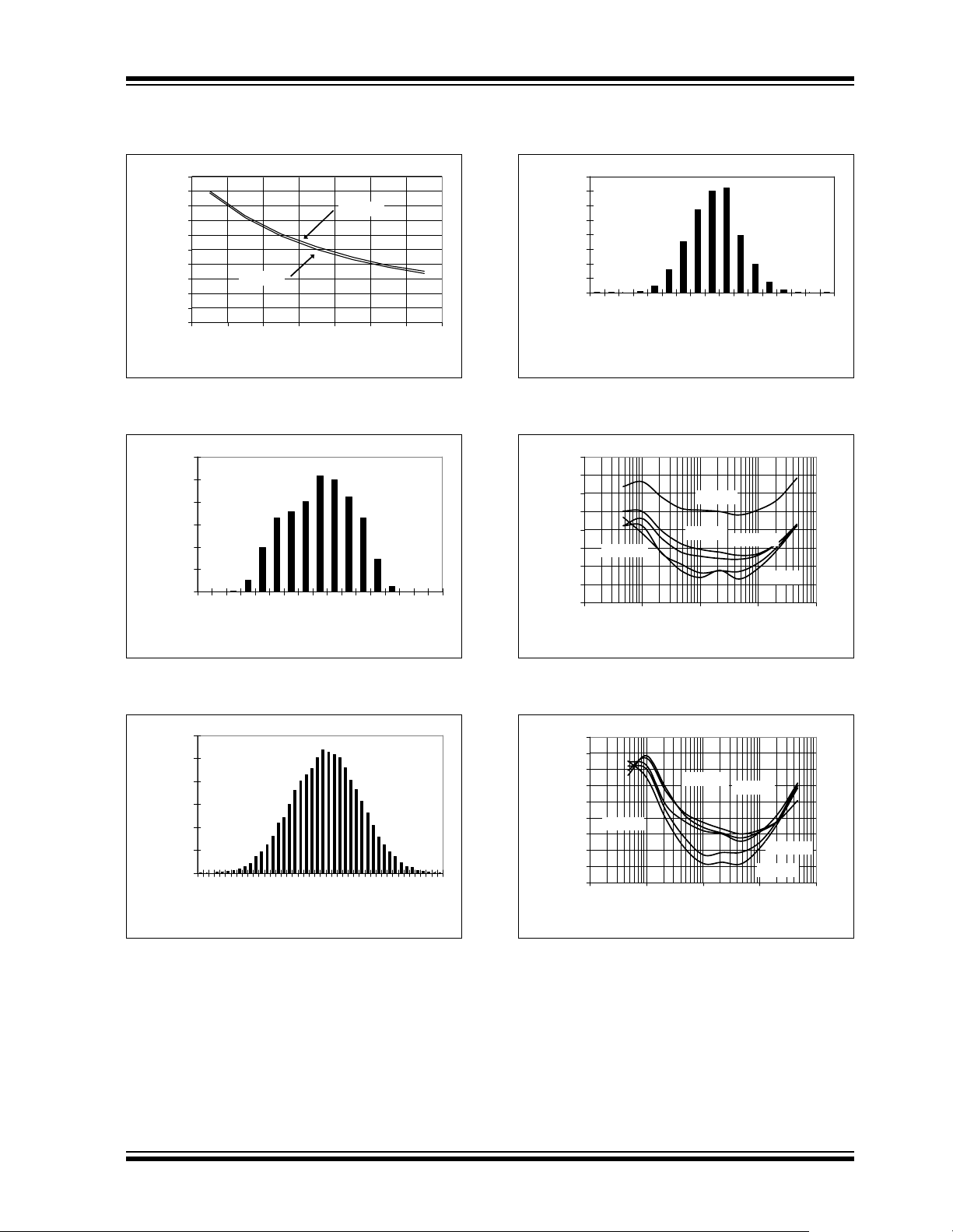

Page 7

MCP3905/06

Note: Unless otherwise specified, DVDD, AVDD = 5V; A

MCLK = 3.58 MHz.

0.5

0.4

0.3

0.2

0.1

0

-0.1

% Error

-0.2

-0.3

-0.4

-0.5

PF = 1.0

45 50 55 60 65 70 75

Frequency (Hz)

PF = 0.5

FIGURE 2-11: Measurement Error vs.

Input Frequency.

3000

16384 Samples

2500

Mean = -1.57 mV

Std. Dev = 52.5 µV

2000

1500

1000

Occurance

500

0

-1.75

-1.70

-1.65

-1.61

-1.56

-1.52

-1.47

-1.43

-1.38

Channel 0 Offset (mV)

GND

, D

GND

= 0V; V

4000

3500

3000

2500

2000

1500

Occurance

1000

= Internal, HPF = 1 (AC mode),

REF

16384 Samples

Mean = - 1.28 mV

Std. dev = - 18.1 µV

500

0

-1.38E-03

-1.37E-03

-1.36E-03

-1.35E-03

-1.34E-03

-1.33E-03

-1.32E-03

-1.31E-03

Bin (mV)

-1.30E-03

-1.29E-03

-1.28E-03

FIGURE 2-14: Channel 0 Offset Error

(DC Mode, HPF Off), G = 16.

0.3

0.2

0.1

0

-0.1

-0.2

VDD=5.25V

-0.3

Measurement Error

-0.4

-0.5

0.0001 0.0010 0.0100 0.1000 1.0000

CH0 Vp-p Amplitude (V)

VDD=5.0V

VDD=4.5V

VDD=4.75V

-1.27E-03

-1.26E-03

VDD=5.5V

-1.25E-03

-1.24E-03

-1.23E-03

-1.22E-03

FIGURE 2-12: Channel 0 Offset Error

(DC Mode, HPF off), G = 1.

1200

16384 Samples

1000

Mean = -1.64 mV

Std. Dev = 17.4 µV

800

600

400

Occurance

200

0

-1.71

-1.69

-1.68

-1.67

-1.66

-1.65

-1.64

-1.63

-1.62

-1.60

Channel 0 Offset (mV)

FIGURE 2-13: Channel 0 Offset Error

(DC Mode, HPF off), G = 8.

-1.59

FIGURE 2-15: Measurement Error vs. V

(G = 16).

0.3

0.25

0.2

0.15

0.1

0.05

VDD=5.0V

0

-0.05

Measurement Error

-0.1

-0.15

0.0001 0.0010 0.0100 0.1000 1.0000

VDD=4.75V

CH0 Vp-p Amplitude (V)

VDD=4.5V

VDD=5.25V

VDD=5.5V

FIGURE 2-16: Measurement Error vs. V

G = 16, External V

REF

.

DD

DD

,

© 2007 Microchip Technology Inc. DS21948D-page 7

Page 8

MCP3905/06

Note: Unless otherwise specified, DVDD, AVDD = 5V; A

MCLK = 3.58 MHz.

0.3

0.2

0.1

0

-0.1

Measurement Error

-0.2

-0.3

0.0001 0.0010 0.0100 0.1000 1.0000

CH0 Vp-p Amplitude (V)

+85°C

+25°C

- 40°C

FIGURE 2-17: Measurem ent Error

w/ External V

0.3

0.2

0.1

0

-0.1

Measurement Error

-0.2

-0.3

0.0000 0.0001 0.0010 0.0100 0.1000

, (G = 1).

REF

CH1 Vp-p Ampli tude (V)

+85°C

+25°C

-40°C

GND

, D

GND

= 0V; V

-0.1

Measurement Error

-0.2

-0.3

= Internal, HPF = 1 (AC mode),

REF

0.3

0.2

0.1

0

0.0000 0.0001 0.0010 0.0100 0.1000

CH1 Vp-p Amplitude (V)

FIGURE 2-19: Measurement Error

w/ External V

(G = 16).

REF

+85°C

- 40°C

+25°C

FIGURE 2-18: Measurement Error

w/ External V

, (G = 8).

REF

DS21948D-page 8 © 2007 Microchip Technology Inc.

Page 9

3.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3 -1.

TABLE 3-1: PIN FUNCTION TABLE

Pin No. Symbol Function

MCP3905/06

1DV

2 HPF High-Pass Filters Control Logic Pin

3AV

4 NC No Connect

5 CH0+ Non-Inverting Analog Input Pin for Channel 0 (Current Channel)

6 CH0- Inverting Analog Input Pin for Channel 0 (Current Channel)

7 CH1- Inverting Analog Input Pin for Channel 1 (Voltage Channel)

8 CH1+ Non-Inverting Analog Input Pin for Channel 1 (Voltage Channel)

9MCLR

10 REFIN/OUT Voltage Reference Input/Output Pin

11 A

12 F2 Frequency Control for HF

13 F1 Frequency Control for F

14 F0 Frequency Control for F

15 G1 Gain Control Logic Input Pin

16 G0 Gain Control Logic Input Pin

17 OSC1 Oscillator Crystal Connection Pin or Clock Input Pin

18 OSC2 Oscillator Crystal Connection Pin or Clock Output Pin

19 NC No Connect

20 NEG Negative Power Logic Output Pin

21 D

22 HF

23 F

24 F

DD

DD

GND

GND

OUT

OUT1

OUT0

Digital Power Supply Pin

Analog Power Supply Pin

Master Clear Logic Input Pin

Analog Ground Pin, Return Path for internal analog circuitry

Logic Input Pin

OUT

Logic Input Pin

OUT0/1

Logic Input Pin

OUT0/1

Digital Ground Pin, Return Path for Internal Digital Circuitry

High-Frequency Logic Output Pin (Intended for Calibration)

Differential Mechanical Counter Logic Output Pin

Differential Mechanical Counter Logic Output Pin

3.1 Digital VDD (DVDD)

DVDD is the power supply pin for the digital circuitry

within the MCP3905/06.

requires appropriate bypass capacitors and

DV

DD

should be maintained to 5V ±10% for specified

operation. Please refer to Section 5.0 “Application s

Information”.

3.2 High-Pass Filter Input Logic Pin (HPF)

HPF controls the state of the high-pass filter in both

input channels. A logic ‘1’ enables both filters,

removing any DC offset coming from the system or the

device. A logic ‘0’ disables both filters, allowing DC

voltages to be measured.

© 2007 Microchip Technology Inc. DS21948D-page 9

3.3 Analog VDD (AVDD)

AVDD is the power supply pin for the analog circuitry

within the MCP3905/06.

requires appropriate bypass capacitors and

AV

DD

should be maintained to 5V ±10% for specified

operation. Please refer to Section 5.0 “Applications

Information”.

3.4 Current Channel (CH0-, CH0+)

CH0- and CH0+ are the ful ly dif fere ntial a nalog v olt age

input channels for the current me asurement, cont aining

a PGA for sma ll-signal input, such as shunt curre ntsensing. The linear and spe cified region of this channel

is dependant on the PGA gain. This corresponds to a

maximum differential voltage of ±470 mV/GAIN and

maximum absolute voltage, with respect to A

±1V. Up to ±6V can be applied to these pi ns without the

risk of permanent damage.

Refer to Section 1.0 “Electrical Characteristics”.

GND

, of

Page 10

MCP3905/06

3.5 Voltage Channel (CH1-,CH1+)

CH1- and CH1+ are the ful ly dif fere ntial a nalog volt age

input channels fo r the volt age meas urement. The linear

and specified region of these channels have a

maximum differential voltage of ±660mV and a

maximum absolute voltage of ±1V, with respect to

. Up to ±6V can be applied to these pins without

A

GND

the risk of permanent damage.

Refer to Section 1.0 “Electrical Characteristics”.

3.6 Master Clear (MCLR)

MCLR controls the reset for both del ta-sigma ADCs, al l

digital registers, the SINC filters for each channel and

all accumulators post multiplier. A logic ‘0’ resets all

registers and holds both ADCs in a Reset condition.

The charge stored in both ADCs is flushed and their

output is maintained to 0x0000h. The only block

consuming power on the digital power supply during

Reset is the oscillator circuit.

3.7 Reference (REFIN/OUT)

REFIN/OUT is the output for the internal 2.4V

reference. This reference has a typical temperature

coefficient of 15 ppm/°C and a tolerance of ±2%. In

addition, an external reference can also be used by

applying voltage to this pin within the specified range.

REFIN/OUT requires appropriate bypass capacitors to

, even when using the internal reference only.

A

GND

Refer to Section 5 .0 “Applications Information”.

3.8 Analog Ground (A

A

is the ground connection to the internal analog

GND

circuitry (ADCs, PGA, band gap reference, POR). To

ensure accuracy and noise cancellation, this pin must

be connected to the same ground as D

with a star connection. If an analog ground plane is

available, it is recommended that this device be tied to

this plane of the Printed Circuit Board (PCB). This

plane should a lso reference all other a nal og ci rcuitry in

the system.

GND

)

GND

, preferably

3.9 Frequency Control Logic Pins (F2, F1, F0)

F2, F1 and F0 select the high-frequency output and

low-frequency output pin ranges by changing the

value of the constants F

transfer function. F

constants that define the period of the output pulses

for the device.

and HFC used in the device

C

and H

C

are the frequency

FC

3.10 Gain Control Logic Pins (G1, G0)

G1 and G0 select the PGA gain on Channel 0 from

three different values: 1, 8 and 16.

3.11 Oscillator (OSC1, OSC2)

OSC1 and OSC2 provide the master clock for the

device. A resonant crystal or clock source with a similar

sinusoidal waveform must be placed across these pins

to ensure proper operati on. The typic al clock freque ncy

specified is 3.579545 MHz. However, the clock

frequency can be with the range of 1 MHz to 4 MHz

without disturbing measurement error. Appropriate

load capacit ance should b e conne cted to th ese pin s for

proper operation.

A full-swing, single-ended clock source may be

connected to OSC1 with proper resistors in series to

ensure no ringing of the clock source due to fast

transient edges.

3.12 Negative Power Output Logic Pin (NEG)

NEG detects the phase difference between the two

channels and wi ll go to a logi c ‘ 1’ state when the phase

difference is gr ea ter th an 9 0° (i. e., wh en th e m eas ure d

active (real) powe r is negati ve). The output state i s synchronous with the rising-edge of HF

the logic ‘1’ until the active (real) power becomes positive again and HF

shows a pulse.

OUT

3.13 Ground Connection (D

D

is the ground connection to the internal digital

GND

circuitry (SINC filters, multiplier, HPF, LPF, Digital-toFrequency (DTF) converter and oscillator). To ensure

accuracy and noise cancellation, D

connected to the same ground as A

with a star connection. If a digital ground plane is

available, it is recommended that this device be tied to

this plane of the PC B. This pl ane should also refere nce

all other digital circuitry in the system.

3.14 High-Frequency Output (HF

HF

is the high-frequency output of the device and

OUT

supplies the in stant aneous real- power inform ation. The

output is a period ic pul se ou tput, w ith it s p eriod p roportional to the measured active (real) power, and to the

constant defi ned by F0, F1 a nd F2 pin log ic states .

HF

C

This output is the preferred output for calibration due to

faster output frequencies, giving smaller calibration

times. Since this output gives instantaneous active

(real) power, the 2ω ripple on the output should be

noted. However, the average period will show minimal

drift.

3.15 Frequency Output (F

F

and F

OUT0

device that supply th e ave rage real-power informatio n.

The outputs are periodic pulse outputs, with its period

proportional to the measured activ e (real) power , and to

constant, defined by the F0 and F1 pin logic

the F

c

states. These pins include high-output drive capability

for direct use of electromechanical counters and 2phase stepper motors. Since this output supplies

average active (real) pow er , any 2ω ripple on the outp ut

pulse period is minimal.

are the frequency outputs of the

OUT1

and maintains

OUT

)

GND

must be

GND

, preferably

GND

, F

OUT0

OUT

OUT1

)

)

DS21948D-page 10 © 2007 Microchip Technology Inc.

Page 11

MCP3905/06

4.0 DEVICE OVERVIEW

The MCP3905/06 is an energy-metering IC that

supplies a freque ncy output pr oportional to a ctive (real)

power, and higher frequency output proportional to the

instantaneous power for meter calibration. Both channels use 16-bit, second-order, delta-sigma ADCs that

oversample the input at a frequency equal to MCLK/4,

allowing for wide dynamic range input signals. A

Programmable Gain Amplifier (PGA) increases the

usable range on the curren t input chann el (Ch annel 0).

The calculation of the active (real) power, as well as the

filtering associated with this calcul ation, is performe d in

the digital domain, ensuring better stability and drift

performance. Figure 4-1 represents the simplified

block diagram of the MCP3905/06, detailing its main

signal-pro cessing blocks.

Two di git al high-p ass fi lters can cel the sys tem of fset on

both channels such that the real-power calculation

does not include any circuit or system offset. After

being high-pas s filtered, the vo ltage and curre nt signals

are multiplied to give the instantaneous power signal.

This signal doe s not cont ain the DC offset component s,

such that the averaging technique can be efficiently

used to give the desired active (real) power output.

The instantaneous power signal contains the realpower information; it is the DC component of the

instantaneous power. The averaging technique can be

used with both sinusoidal and non-sinusoidal waveforms, as well as for all power factors. The

instantaneous power is thus low-pass filtered in order

to produce the instantaneous real-power signal.

A DTF converter accumulates the instantaneous active

(real) power information to produce output pulses with a

frequency proportional to the average active (real)

power. The low-frequency pulses presented at the

F

OUT0

and F

outputs are designed to drive electro-

OUT1

mechanical counters and two-phase stepper motors

displaying the real-power energy consumed. Each pulse

corresponds to a fixed quantity of real energy, selected

by the F2, F1 and F0 logic settings. The HF

OUT

output

has a higher frequency setting and lower integration

period such that it can represent the instantaneous

active (real) power signal. Due to the shorter accumulation time, it enables the user to proceed to faster calibration under steady load conditions (refer to Section 4.7

“F

OUT0/1

and HF

Output Frequencies”).

OUT

CH0+

CH0-

CH1+

CH1-

Frequency

Content

+

–

PGA

+

–

0 0

Input Signal

with System

Offset and

Line Frequency

ΔΣ

ADC

ANALOG DIGITAL

ΔΣ

ADC

ADC Output

Code Contains

System and

ADC Offset

HPF

HPF

X

DC Offset

Removed

by HPF

LPF

0 00

Instantaneous

Power

MCP3905/06

...1010..

DTF

Instantaneous

Active (Real) Power

FIGURE 4-1: Simplified MCP3905/06 Block Diagram with Frequency Contents.

F

F

HF

OUT0

OUT1

OUT

© 2007 Microchip Technology Inc. DS21948D- page 11

Page 12

MCP3905/06

4.1 Analog Inputs

The MCP3905/06 analog inputs can be connected

directly to the current a nd volt age transd ucers (such a s

shunts or current transformers). Each input pin is

protected by specializ ed Elect rostati c Discharg e (ESD)

structures that are certified to pass 5 kV HBM and

500V MM contact charge. These structures also allow

up to ±6V continuous voltage to be present at their

inputs without the risk of permanen t dam age .

Both channels have fully differential voltage inputs for

better noise performan ce. The absolut e voltage at each

pin relative to A

range during operation in orde r to ensure the mea surement error performance. The common mode signals

should be adapted to respect both the previous

conditions and the differential input voltage range. For

best performance, the common mode signals should

be referenced to A

The current channel com prises a PGA on the fron t-end

to allow for smaller signals to be measured without

additional signal conditioning. The maximum differential voltage specified on Channel 0 is equal to

±470 mV/Gain (see Table 4-1). The maximum peak

voltage specified on Channel 1 is equal to ±660 mV.

TABLE 4-1: MCP3905 GAIN SELECTIONS

G1 G0 CH0 Gain

00 1±470mV

01 2±235mV

10 8±60mV

11 16 ±30 mV

should be maintained in the ±1V

GND

.

GND

Maximum

CH0 Voltage

Both ADCs have a 16-bi t resolution, allow ing wide input

dynamic range sensing . The oversampli ng ratio of both

converters is 64. Both converters are continuously

converting during normal operation. When the MCLR

pin is low, both converters will be in Reset and output

code 0x0000h. If the voltag e at the inpu ts of the ADC is

larger than the specifi ed range, the line arity is no long er

specified. However, the converters will continue to

produce output codes until their saturation point is

reached. The DC saturation po int is around 70 0 mV for

Channel 0 and 1V for Chan nel 1, using intern al vol tag e

reference.

The clocking signals for the ADCs are equally distributed between the two channels in order to minimize

phase delays to less than 1 MCLK period (see

Section 3.2 “High-Pass Filter Input Logic Pin

(HPF)”). The SINC fil ters main notch is posi tioned at

MCLK/256 (14 kHz with MCLK = 3.58 MHz), allowing

the user to be able to measure wide harmonic content

on either channel. The magnitude response of the

SINC filter is shown in F igure 4-2.

0

-20

-40

-60

-80

-100

Normal Mode Rejection (dB)

-120

0 5 10 15 20 25 30

Frequency (kHz)

TABLE 4-2: MCP3906 GAIN SELECTIONS

G1 G0 CH0 Gain

00 1±470mV

01 32 ±15 mV

10 8±60mV

11 16 ±30 mV

Maximum

CH0 Voltage

4.2 16-Bit Delta-Sigma ADCs

The ADCs used in the MCP3905/06 for both current

and voltage channel measurements are delta-sigma

ADCs. They comprise a second-order, delta-sigma

modulator using a mu lti-bit DAC an d a third-order SINC

filter. The delta-sigma architecture is very appropriate

for the application s targeted by th e MCP3905, becaus e

it is a waveform-oriented converter architecture that

can offer both high linearity and low distortion performance throughout a wide input dynamic range. It also

creates minimal requirements for the anti-aliasing filter

design. The multi-bit architecture used in the ADC

minimizes quantization noise at the output of the

converters without disturbing the linearity.

FIGURE 4-2: SINC Filter Magnitude

Response (MCLK = 3.58 MHz).

4.3 Ultra-Low Drift V

The MCP3905/06 contains an internal voltage reference source specially designed to minimize drift over

temperature. This internal V

voltage to both c urrent and vo ltage c hannel ADC s. The

typical value of this voltage reference is 2.4V, ±100 mV.

The internal reference has a very low typical temperature coefficient of ±15ppm/°C, allowing the output

frequencies to have minimal variation with respect to

temperature since they are proportional to (1/V

REFIN/OUT is the outpu t pin for th e vo lt a ge re ference.

Appropriate bypass capacitors mu st be connected t o

the REFIN/OUT pin for proper operation (see

Section 5.0 “Applications Information”). The

voltage reference source impedance is typically 4kΩ,

which enables this voltage reference to be overdriven

by an external voltage reference source.

REF

supplies reference

REF

REF

)².

DS21948D-page 12 © 2007 Microchip Technology Inc.

Page 13

MCP3905/06

If an external voltage reference source is connected to

the REFIN/OUT pin, the external voltage will be used

as the reference for both current and voltage channel

ADCs. The voltage across the source resistor will then

be the difference between the internal and external

voltage. The allowed input range for the external voltage source goes from 2.2V to 2.6V for accurate measurement error. A V

value outside of this range will

REF

cause additional heating and power consumption due

to the source resi stor, which might affect measure ment

error.

4.4 Power-On Reset (POR)

The MCP3905/06 contains an internal POR circuit that

monitors analog su pply volt age A V

This circuit ensures correct device startup at system

power-up/power-down events. The POR circuit has

built-in hysteresis and a timer to give a high degree of

immunity to potential ripple and noise on the power

supplies, allowing proper settling of the power supply

during power-up. A 0.1 µF decoupling capacitor should

be mounted as close as possible to the AV

providing additional transient immunity (see

Section 5.0 “Applications Information”).

The threshold voltage is typically set at 4V, with a

tolerance of about ± 5%. If the supply volt age falls below

this threshold, the MCP3905/06 will be held in a Reset

condition (equiva le nt to a ppl yi ng l ogic ‘0’ on the MCLR

pin). The typical hysteresis value is approximately

200 mV in order to prevent glitches on the power

supply.

Once a power-up event has occurred , an interna l timer

prevents the p art fro m outpu t tin g an y pulse for approximately 1s (with MCLK = 3.58 MHz), thereby preventing potential metastability due to intermittent resets

caused by an unsettled regulated power supply.

Figure 4-3 illustrates the different conditions for a

power-up and a power-down event in the typical

conditions.

AV

DD

5V

4.2V

4V

1s

during operation.

DD

DD

pin,

4.5 High-Pass Filters and Multiplier

The active (real) power value is extracted from the DC

instantaneous power. Therefore, any DC offset

component present on Channel 0 and Channel 1

affects the DC component of the instantaneous power

and will cause the real-power calculation to be

erroneous. In order to remove DC offset components

from the instantaneous power signal, a high-pass filter

has been introduced on each channel. Since the highpass filtering introduces phase delay, identical highpass filters are implemented on both channels. The

filters ar e cloc ked by the sa me dig ital sig nal, ensuri ng

a phase difference between the two channels of less

than one MCLK period. Under typical conditions

(MCLK = 3.58 MHz), this phase difference is less than

0.005°, with a line frequency of 50 Hz. The cut-off

frequency of the filter (4.45 Hz) has been chosen to

induce minimal gain error at typical line frequencies,

allowing sufficient settling time for the desired applications. The two high-pass filters can be disabled by

applying a logic ‘0’ to the HPF pin.

0

-5

-10

-15

-20

-25

-30

-35

Normal Mode Rejection (dB)

-40

0.1 1 10 100 1000

Frequency (Hz)

FIGURE 4-4: HPF Magnit ude Respon se

(MCLK = 3.58 MHz).

The multiplier output gives the prod uc t of the tw o hig hpass-filtered cha nnels, c orresponding to inst antane ous

active (real) power. Multiplying two sine wave signals

by the same ω frequency gives a DC compo nent an d a

2ω component. The instantaneous power signal contains the active (real) power of it s DC component, w hile

also containing 2ω components coming from the line

frequency multiplication. These 2ω components come

for the line frequency (and its harmonics) and must be

removed in order to extrac t th e rea l-pow er i nfo rma tio n.

This is accompli sh ed using the low-pass filter and DTF

converter.

DEVICE

MODE

0V

RESET

NO

PULSE

OUT

PROPER

OPERATION

RESET

Time

FIGURE 4-3: Power-on Reset Operation.

© 2007 Microchip Technology Inc. DS21948D- page 13

Page 14

MCP3905/06

4.6 Low-Pass Filter and DTF Converter

The MCP3905/06 low-pass filter is a first-order IIR filter

that extracts the active (real) power information (DC

component) from the instantaneous power s ignal. The

magnitude response of thi s filter is detailed in Figure 4-

5. Due to the fact t hat the instantaneous powe r signal

has harmonic content (coming from the 2ω components

of the inputs), and since the filt er is not i deal, th ere will

be some ripple at the output of the low-pass filter at the

harmonics of the line frequency.

The cut-off frequency of the filter (8.9 Hz) has been

chosen to have sufficient rejection for commonly-used

line frequencies (50 Hz and 60 Hz). With a standard

input clock (MCLK = 3.58 MHz) and a 50 Hz line

frequency, the rejection of the 2ω component (100 Hz)

will be more than 20 dB. This equates to a 2ω

component containing 10 times less power than the

main DC component (i.e., the average active (real)

power).

0

-5

-10

-15

-20

-25

-30

-35

Normal Mode Rejection (dB)

-40

0.1 1 10 100 1000

Frequency (Hz)

The output of the low-pass filter is accumulated in the

DTF converter. This accumulation is compared to a

different digital threshold for F

OUT0/1

and HF

OUT

representing a quantit y of real e nergy meas ured by th e

part. Every time the digital threshold on F

HF

is crossed, the part will output a pulse (See

OUT

Section 4.7 “F

OUT0/1

and HF

Output Frequen-

OUT

OUT0/1

or

cies”).

The equivalent quantity of real energy required to

output a pulse is much larger for the F

than the HF

for the F

. This is such that the integration period

OUT

outputs is much larger. This larger

OUT0/1

OUT0/1

outputs

integration period act s as another low-pas s filter so that

the output ripple due to th e 2ω components is mi ni mal.

However, these components are not totally removed,

since realized low-pass filters are never ideal. This will

create a small jitter in the output frequency. Averaging

the output pulses with a counter or a Microcontroller

Unit (MCU) in the applic ation will then remove the small

sinusoidal content of the output frequen cy and filte r out

the remaining 2ω ripple.

is intended to be used for calibration purposes

HF

OUT

due to its instantaneous power content. The shorter

integration period of HF

demands that the 2ω

OUT

component be give n more attent ion. Since a s inusoida l

signal average is zero, averaging the HF

OUT

signal in

steady-state c ond iti ons wil l gi ve the proper real energy

value.

,

FIGURE 4-5: LPF Magnitude Response

(MCLK = 3.58 MHz).

DS21948D-page 14 © 2007 Microchip Technology Inc.

Page 15

MCP3905/06

4.7 F

OUT0/1

and HF

OUT

Output

Frequencies

The thresholds for the accumulated energy are different for F

transfer functions). The F

frequencies are quite low in order to allow superior

integration time (see Section 4.6 “Low-Pass Filter

and DTF Converter”). The F

can be calculated with the followi ng equ atio n:

EQUATION 4-1: F

Where:

V

0

V1= the RMS differential voltage on Channel 1

G=the PGA gain on Channel 0

FC= the frequency constant selected

V

REF

OUT0/1

and HF

(i.e., they have different

OUT

OUT

allowed output

OUT0/1

output frequency

OUT0/1

FREQUENCY

OUTPUT EQUATION

8.06 V0× V1× GF

-----------------------------------------------------------

Hz()

F

OUT

=

V

()

REF

= the RMS differential voltage on Channel 0

(current channel)

= the voltage reference

××

C

2

For a given DC input V, the DC and RMS values are

equivalent. For a given AC input signal with peak-topeak amplitude of V, the equivalent RMS value is

V/sqrt(2), assuming pu rely sinusoidal si gnals. Note that

since the active (real ) p ow er i s the product of two R MS

inputs, the output frequencies of an AC signal is half

that of the DC equiv alent signa l, again assum ing purely

sinusoidal AC signals. The constant F

F

OUT0

F

OUT0/1

and F

output frequencies for the different logic set-

digital settings. Table 4-3 shows

OUT1

depends on the

C

tings.

TABLE 4-3: OUTPUT FREQUENCY CONSTANT FC FOR FOUT0/1 (V

F

Frequency (Hz)

F1 F0 FC (Hz)

00MCLK/2

01MCLK/2

10MCLK/2

11MCLK/2

21

20

19

18

FC (Hz)

(MCLK = 3.58 MHz)

1.71 0.74 0.37

3.41 1.48 0.74

6.83 2.96 1.48

13.66 5.93 2.96

OUT

with Full-Scale

DC Inputs

REF

=2.4V)

F

OUT

Frequency (Hz)

with Full-Scale

AC Inputs

© 2007 Microchip Technology Inc. DS21948D- page 15

Page 16

MCP3905/06

The high-frequency output HF

has lower

OUT

integration times and, thus, higher frequencies. The

output frequency value can be calculated with the

following equation:

EQUATION 4-2: HF

FREQUENCY

OUT

OUTPUT EQUATION

8.06 V0× V1G×× HF

HF

OUT

----------------------------------------------------------------

Hz()

=

V

()

Where:

V

= the RMS differential voltage on Channel 0

0

V1= the RMS differential voltage on Channel 1

G=the PGA gain on Channel 0

(current channel)

FC= the frequency constant selected

V

= the voltage reference

REF

The constant HFC depends on the F

digital settings with the Table 4-4.

The detailed timin gs of the o utput pulse s are d esc ribed

in the Timing Characteristics table (see Section 1.0

“Electrical Characteristics” and Figure 1-1).

REF

2

OUT0

×

and F

C

OUT1

MINIMAL OUTPUT FREQUENCY FOR

NO-LOAD THRESHOLD

The MCP3905/06 also includes, on each output

frequency, a no-load threshold circuit that will eli mina te

any creep effects in the meter. The outputs will not

show any pulse if the output frequency falls below the

no-load threshold. The minimum output frequency on

OUT0/1

and HF

F

maximum output frequency (respectively F

for each of the F2, F1 and F0 selec tions (se e Table 4-3

and Table 4-4); except when F2, F1, F0 = 011. In this

last configuration, the no-load threshold feature is

disabled. The selec tion of F

current load. In order to respect the IEC standards

requirements, the meter will have to be designed to

allow start-up currents compatible with the standards

by choosing the FC value matching these

requirements. For additional applications information

on no-load threshold, startup current and other meter

design points, refer to AN994, "IEC Compliant Active

Energy Meter Design Using The MCP3905/6”,

(DS00994).

is equal to 0.0015% of the

OUT

will determine the st art-up

C

and HFC)

C

TABLE 4-4: OUTPUT FREQUENCY CONSTANT HFC FOR HF

F2 F1 F0 HF

C

000 64 x F

001 32 x F

010 16 x F

0112048 x F

100128 x F

101 64 x F

110 32 x F

111 16 x F

HFC (Hz)

C

C

C

C

C

C

C

C

MCLK/2

MCLK/2

MCLK/2

MCLK/2

MCLK/2

MCLK/2

MCLK/2

MCLK/2

15

15

15

7

16

16

16

16

HFC (Hz)

(MCLK = 3.58 MHz)

109.25 27.21

109.25 27.21

109.25 27.21

27968.75 6070.12

219.51 47.42

219.51 47.42

219.51 47.42

219.51 47.42

OUT

(V

REF

=2.4V)

HF

Frequency (Hz) with

OUT

full-scale AC Inputs

DS21948D-page 16 © 2007 Microchip Technology Inc.

Page 17

5.0 APPLICATIONS INFORMATION

5.1 Meter Design using the MCP3905/06

For all applications information, refer to AN994, "IEC

Compliant Active Energy Meter Design Using The

MCP3905/6” (DS00994). This application note

includes all required energy meter design information,

including t he following:

• Meter rating and current sense choices

• Shunt design

• PGA selection

• F2, F1, F0 selection

• Meter calibration

• Anti-aliasing filter design

• Compensation for parasitic shunt inductance

• EMC design

• Power supply design

• No-load threshold

• Start-up current

• Accuracy testing results from MCP3905-based

meter

• EMC testin g results from MCP3905-based meter

MCP3905/06

© 2007 Microchip Technology Inc. DS21948D- page 17

Page 18

MCP3905/06

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

24-Lead SSOP

XXXXXXXXXXX

XXXXXXXXXXX

YYWWNNN

Examples:

MCP3905

I/SS^^

0739256

3

e

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

3

e

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designa tor ( )

can be found on the outer packaging for this package.

Note: In the event the full Microchip part nu mber ca nnot be m arked o n one line, it w ill

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

DS21948D-page 18 © 2007 Microchip Technology Inc.

3

e

Page 19

24-Lead Plastic Shrink Small Outline (SS) – 5.30 mm Body [SSOP]

N

1

2

3

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

B

http://www.microchip.com/packaging

D

N

E

E1

12

NOTE 1

b

e

MCP3905/06

c

A

A1

Dimension Limits MIN NOM MAX

Number of Pins N 24

Pitch e 0.65 BSC

Overall Height A – – 2.00

Molded Package Thickness A2 1.65 1.75 1.85

Standoff A1 0.05 – –

Overall Width E 7.40 7.80 8.20

Molded Package Width E1 5.00 5.30 5.60

Overall Length D 7.90 8.20 8.50

Foot Length L 0.55 0.75 0. 95

Footprint L1 1.25 REF

Lead Thickness c 0.09 – 0.25

Foot Angle φ 0° 4° 8°

Lead Width b 0.22 – 0.38

otes:

. Pin 1 visual index feature may vary, but must be located within the hatched area.

. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.20 mm per side.

. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimen sion, usually without tolerance, for information purposes only.

A2

L1

Units MILLIMETERS

Microchip Technology Drawing C04-132

φ

L

© 2007 Microchip Technology Inc. DS21948D- page 19

Page 20

MCP3905/06

NOTES:

DS21948D-page 20 © 2007 Microchip Technology Inc.

Page 21

APPENDIX A: REVISION HISTORY

Revision A (July 2005)

Original Release of this Document.

Revision B (August 2005)

Replace Figures 2-1 thru 2-6 in Section 2. 0 “Typical

Performance Curves”

Revision C (October 2005)

Added references to MCP3905/06 throughout

document.

Revision D (February 2007)

This revision includes updates to the packaging

diagrams.

MCP3905/06

© 2007 Microchip Technology Inc. DS21948D- page 21

Page 22

MCP3905/06

NOTES:

DS21948D-page 22 l © 2007 Microchip Technology Inc.

Page 23

MCP3905/06

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. –X /XX

Device

Device: MCP3905: Energy-Metering IC

Temperature Range: I = -40°C to +85°C

Range

MCP3905T: Energy-Metering IC (Tape and Reel)

MCP3906: Energy-Metering IC

MCP3906T: Energy-Metering IC (Tape and Reel)

PackageTemperature

Examples:

a) MCP3905-I/SS: Industrial Temperature,

b) MCP3905T-I/SS: Tape and Reel,

a) MCP3906-I/SS: Industrial Temperature,

b) MCP3906T-I/SS: Tape and Reel,

24LD SSOP.

Industrial Temperature,

24LD SSOP.

24LD SSOP.

Industrial Temperature,

24LD SSOP.

Package: SS = Plastic Shrink Small Outline (209 mil Body),

24-lead

© 2007 Microchip Technology Inc. DS21948D- page 23

Page 24

MCP3905/06

NOTES:

DS21948D-page 24 © 2007 Microchip Technology Inc.

Page 25

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of it s kind on the market today , when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are com mitted to continuously improving the code protect ion f eatures of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Mill ennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for yo ur convenience

and may be su perseded by upda te s . I t is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPAS M, MPLIB, MPLINK, PIC kit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, Pow e rTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartT el, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Inco rporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

MCUs and dsPIC DSCs, KEELOQ

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial

© 2007 Microchip Technology Inc. Confidential DS21948D-page 25

®

Page 26

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

12/08/06

DS21948D-page 26 Confidential © 2007 Microchip Technology Inc.

Loading...

Loading...