Page 1

MCP3550/1/3

Low-Power, Single-Channel 22-Bit Delta-Sigma ADCs

Features

• 22-bit ADC in Small 8-pin MSOP Package with

Automatic Internal Offset and Gain Calibration

• Low-Output Noise of 2.5 µV

with Effective

RMS

Resolution of 21.9 bits (MCP3550/1)

• 3 µV Typical Offset Error

• 2 ppm Typical Full-Scale Error

• 6 ppm Maximum INL Error

• Total Unadjusted Error Less Than 10 ppm

• No Digital Filter Settling Time, Single-Command

Conversions through 3-wire SPI Interface

• Ultra-Low Conversion Current (MCP3550/1):

-100µA typical (V

= 2.7V)

DD

-120µA typical (VDD = 5.0V)

• Differential Input with V

to VDD Common Mode

SS

Range

• 2.7V to 5.5V Single-Supply Operation

• Extended Temperature Range:

- -40°C to +125°C

Applications

• Weigh Scales

• Direct Temperature Measurement

• 6-digit DVMs

• Instrumentation

• Data Acquisition

• Strain Gauge Measurement

Block Diagram

Description

The Microchip Technology Inc. MCP3550/1/3 devices

are 2.7V to 5.5V low-power, 22-bit Delta-Sigma Analog-to-Digital Converters (ADCs). The devices offer

output noise as low as 2.5 µV

, with a total

RMS

unadjusted error of 10 ppm. The family exhibits 6ppm

Integral Non-Linearity (INL) error, 3 µV offset error and

less than 2 ppm full-scale error. The MCP3550/1/3

devices provide high accuracy and low noise

performance for applications where sensor

measurements (such as pressure, temperature and

humidity) are performed. With the internal oscillator

and high oversampling rate, minimal external

components are required for high-accuracy

applications.

This product line has fully differential analog inputs,

making it compatible with a wide variety of sensor,

industrial control or process co ntrol applications.

The MCP3550/1/3 devices operate from -40°C to

+125°C and are available in the space-saving 8-pin

MSOP and SOIC packages.

Package Types:

MCP3550/1/3

SOIC, MSOP

V

REF

V

VIN–

V

1

2

+

IN

3

4

SS

8

V

DD

CS

7

6

SDO/RDY

5

SCK

V

REF

V

V

SS

DD

Device Selection Table

VIN+

VIN-

© 2007 Microchip Technology Inc. DS21950D-page 1

3rd-Order

DS ADC

Modulator

w/ Internal

Calibration

Internal

Oscillator

4

SINC

V

DD

POR

SCK

SDO

RDY

CS

Serial Inte rface

Part Number

MCP3550-50 12.5 sps 21.9 bits 50 Hz

MCP3550-60 15 sps 21.9 bits 60 Hz

MCP3551 13.75 sps 21.9 bits 50/60 Hz

MCP3553 60 sps 20.6 bits N/A

Sample

Rate

Effective

Resolution

50/60 Hz

Rejection

(simultaneous)

Page 2

MCP3550/1/3

1.0 ELECTRICAL CHARACTERISTICS

1.1 Maximum Ratings*

VDD...................................................................................7.0V

All inputs and outputs w.r.t V

.............. -0.3V to V

SS

Difference Input Voltage .......................................|V

DD

DD

+ 0.3V

- VSS|

† Notice: Stresses above those listed under "Maximum

Ratings" may cause permanent damage to the device. This is

a stress rating only and functional operation of the device at

those or any other conditions above those indicated in the

operation listings of this specification is not implied. Exposure

to maximum rating conditions for extended periods may affect

device reliability.

Output Short Circuit Current .................................Continuous

Current at Input Pins ....... .. ....... .... .... .. .... ....... .... .. .... .. ...±2 m A

Current at Output and Supply Pins ............................±10 mA

Storage Temperature.....................................-65°C to +150°C

Ambient temp. with power applied................-55°C to +125°C

ESD protection on all pins (HBM, MM) ............ ≥ 6kV, ≥ 400V

Maximum Junction Temperature (T

)..........................+150°C

J

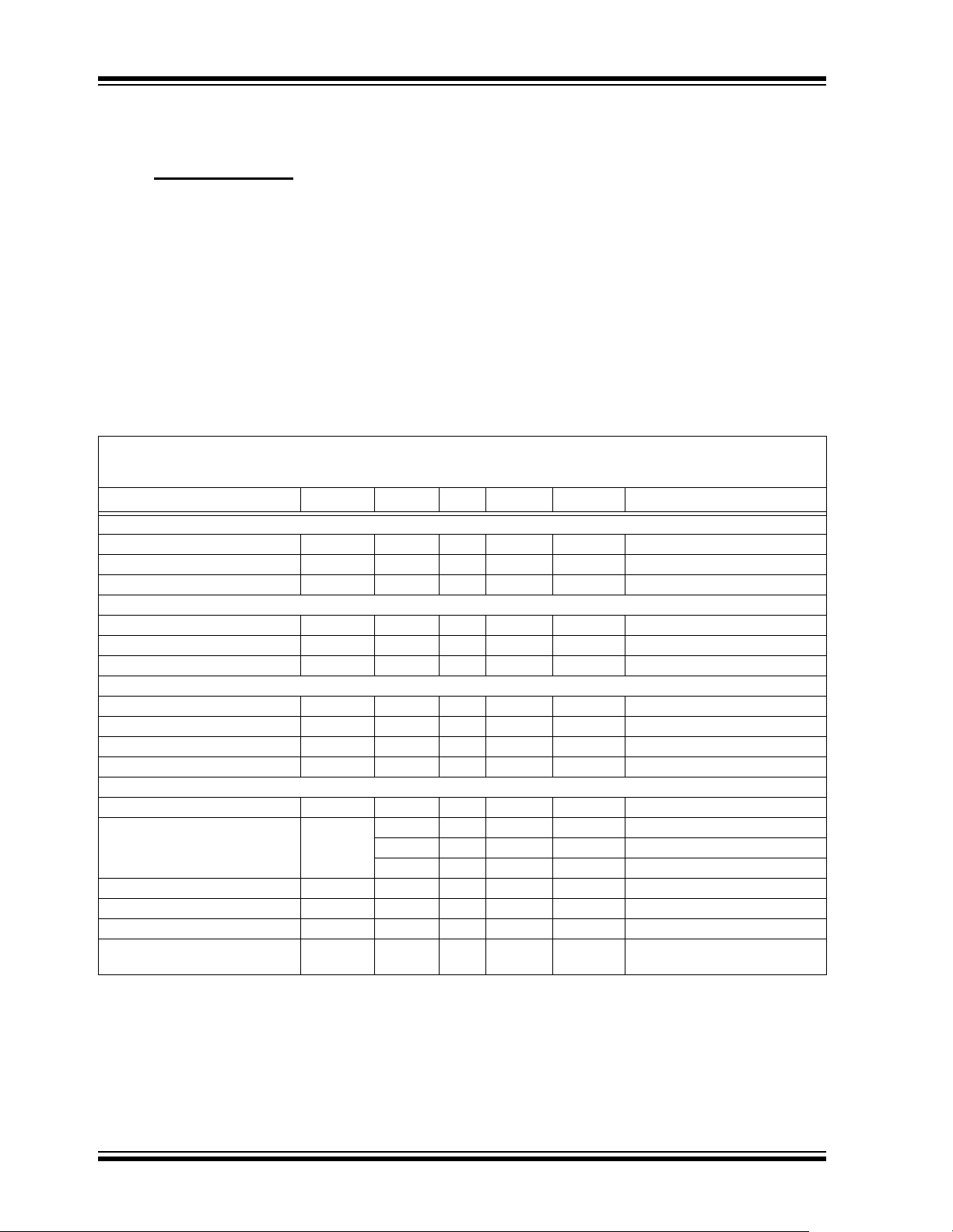

DC CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, all parameters apply at -40°C ≤ TA ≤ +85°C, VDD = 2.7V or 5.0V.

V

= 2.5V. VIN+ = VIN- = VCM = V

REF

applies to entire MCP3550/1/3 family.

Parameters Sym Min Typ Max Units Conditions

Noise Performance (MCP3550/1)

No Missing Codes NMC 22 — — bits At DC (Note 5)

Output Noise e

Effective Resolution ER — 21.9 — bits RMS V

Noise Performance (MCP3553)

No Missing Codes NMC 20 — — bits At DC (Note 5)

Output Noise e

Effective Resolution ER — 20.6 — bits RMS V

Conversion Times

MCP3550-50 t

MCP3550-60 t

MCP3551 t

MCP3553 t

Accuracy

Integral Non-Linearity INL — ±2 6 ppm T

Offset Error V

Positive Full-Scale Error V

Negative Full-Scale Error V

Offset Drift — 0.040 — ppm/°C

Positive/Negative Full-Scale Error

Drift

Note 1: This parameter is established by characterization and not 100% tested.

2: INL is the difference between the endpoints line and the measured code at the center of the quantization band.

3: This current is due to the leakage current and the current due to the offset voltage between V

4: Input impedance is inversely proportional to clock frequency; typical values are for the MCP3550/1 device. V

5: Characterized by design, but not tested.

6: Rejection performance depends on internal oscillator accuracy; see Section 4.0 “Device Overview” for more informa-

tion on oscillator and digital filter design. MCP3550/1 device rejection specifications characterized from 49 to 61 Hz.

/2. All ppm units use 2*V

REF

N

N

CONV

CONV

CONV

CONV

OS

—2.5— µV

—6—µV

-1.0% 80 +1.0% ms

-1.0% 66.67 +1.0% ms

-1.0% 72.73 +1.0% ms

-1.0% 16.67 +1.0% ms

-12 ±3 +12 µV TA = +25°C

—±4— µVT

—±6— µVT

FS,P

FS,N

-10 ±2 +10 ppm TA = +25°C only

-10 ±2 +10 ppm TA = +25°C only

— 0.028 — ppm/°C

as full-scale range. Unless otherwise noted, specification

REF

RMS

= 5V

REF

RMS

= 5V

REF

= +25°C only (Note 2)

A

= +85°C

A

= +125°C

A

+ and VIN-.

IN

REF

=5V.

DS21950D-page 2 © 2007 Microchip Technology Inc.

Page 3

MCP3550/1/3

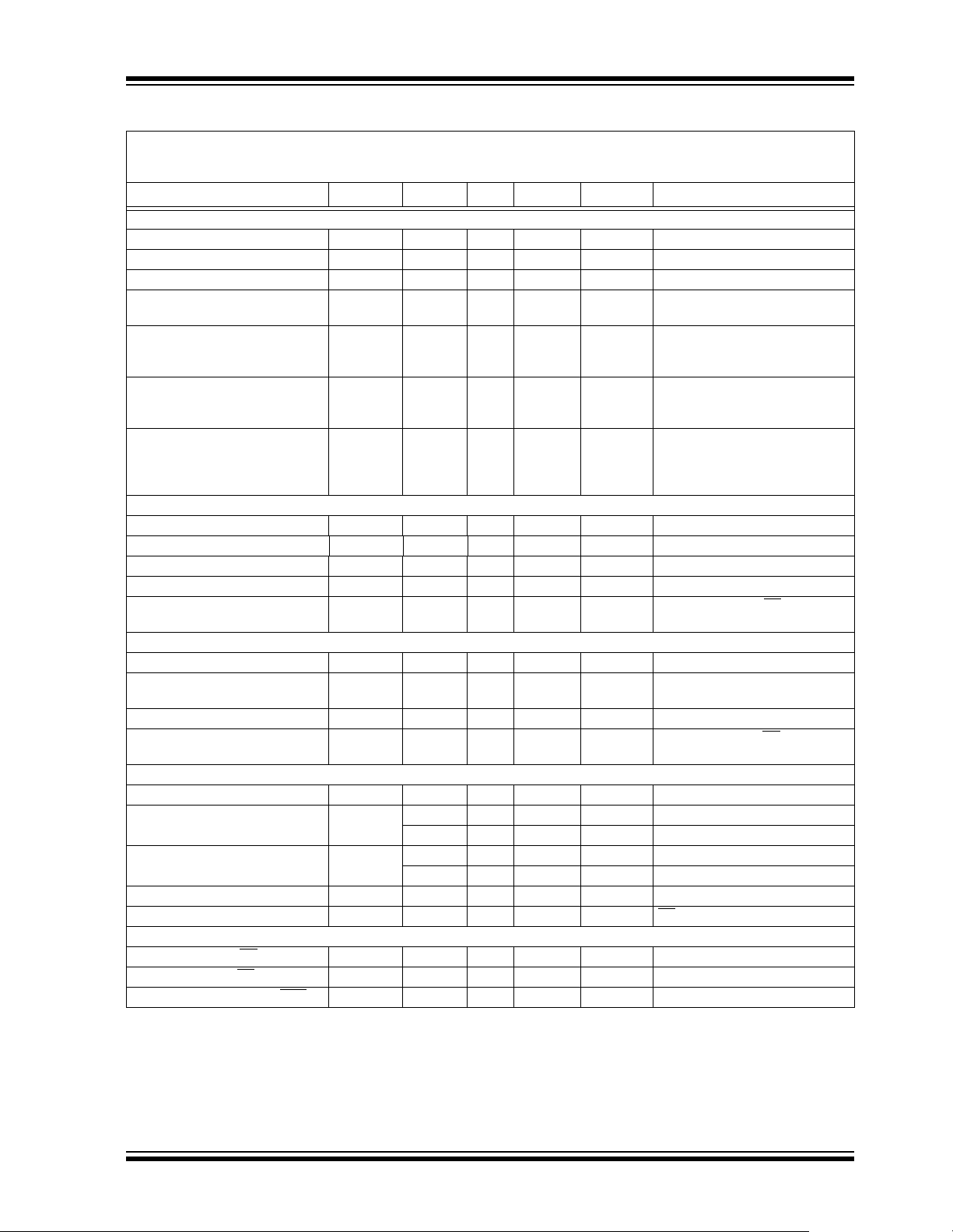

DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise indicated, all parameters apply at -40°C ≤ TA ≤ +85°C, VDD = 2.7V or 5.0V.

= 2.5V. VIN+ = VIN- = VCM = V

V

REF

applies to entire MCP3550/1/3 family.

Parameters Sym Min Typ Max Units Conditions

Rejection Performance

(1,6)

Common Mode DC Rejection — -135 — dB VCM range from 0 to V

Power Supply DC Rejection — -115 — dB

Common Mode 50/60 Hz Rejection CMRR — -135 — dB V

Power Supply 50/60 Hz Rejection PSRR — -85 — dB MCP3551 only, VDD varies from

Power Supply 50/60 Hz Rejection PSRR — -120 — dB MCP3550-50 or MCP3550-60 only

Normal Mode 50 and 60 Hz

Rejection

Normal Mode 50 or 60 Hz

Rejection

Analog Inputs

Differential Input Range V

Absolute/Common Mode Voltages V

Analog Input Sampling Capacitor — 10 — pF Note 5

Differential Input Impedance — 2.4 — MΩ

Shutdown Mode Leakage Current — 1 — nA V

Reference Input

Voltage Range 0.1 — V

Reference Input Sampling

Capacitor

Reference Input Impedance — 2.4 — MΩ Note 4

Shutdown Mode Reference

Leakage Current

Power Requirements

Power Supply Voltage Range V

MCP3550-50, MCP3551 Supply

Current

MCP3550-60, MCP3553 Supply

Current

Supply Current, Sleep Mode I

Supply Current, Shutdown Mode I

Serial Interface

Voltage Input High (CS

Voltage Input Low (CS

, SCK) V

, SCK) V

Voltage Output High (SDO/RDY

Note 1: This parameter is established by characterization and not 100% tested.

2: INL is the difference between the endpoints line and the measured code at the center of the quantization band.

3: This current is due to the leakage current and the current due to the offset voltage between V

4: Input impedance is inversely proportional to clock frequency; typical values are for the MCP3550/1 device. V

5: Characterized by design, but not tested.

6: Rejection performance depends on internal oscillator accuracy; see Section 4.0 “Device Overview” for more informa-

tion on oscillator and digital filter design. MCP3550/1 device rejection specifications characterized from 49 to 61 Hz.

/2. All ppm units use 2*V

REF

as full-scale range. Unless otherwise noted, specification

REF

varies from 0V to V

CM

4.5V to 5.5V

at 50 or 60 Hz respectively, V

varies from 4.5V to 5.5V

NMRR — -85 — dB MCP3551 only,

< VDD,

0 < V

CM

< V

-V

REF

IN

= (V

IN

NMRR — -120 — dB MCP3550-50 or MCP3550-60 only

at 50 or 60 Hz respectively,

< VDD,

0 < V

CM

-V

< V

IN

= (V

IN

IN+

− V

IN-

-V

REF

- 0.3 — V

SS

—+V

REF

+ 0.3 V

DD

REF

V

+ = VIN- = VDD; CS = V

IN

(Note 3)

V

DD

—15— pFNote 5

+ = VIN- = VSS; CS = V

IN

= 2.7V

DD

= 2.7V

DD

DD

+ and VIN-.

IN

DD

I

DD

I

DD

DDSL

DDS

IH

IL

)VOHV

—1— nAV

2.7 — 5.5 V

— 120 170 µA VDD = 5V

— 100 — µA V

— 140 185 µA VDD = 5V

— 120 — µA V

—10 µA

—— 1 µACS = SCK = V

0.7 V

—— V

DD

——0.4 V

- 0.5 — — V VOH = 1 mA, VDD = 5.0V

DD

DD

DD

+ -VIN-) < +V

+ -VIN-) < +V

DD

DD

=5V.

REF

DD

REF

REF

© 2007 Microchip Technology Inc. DS21950D-page 3

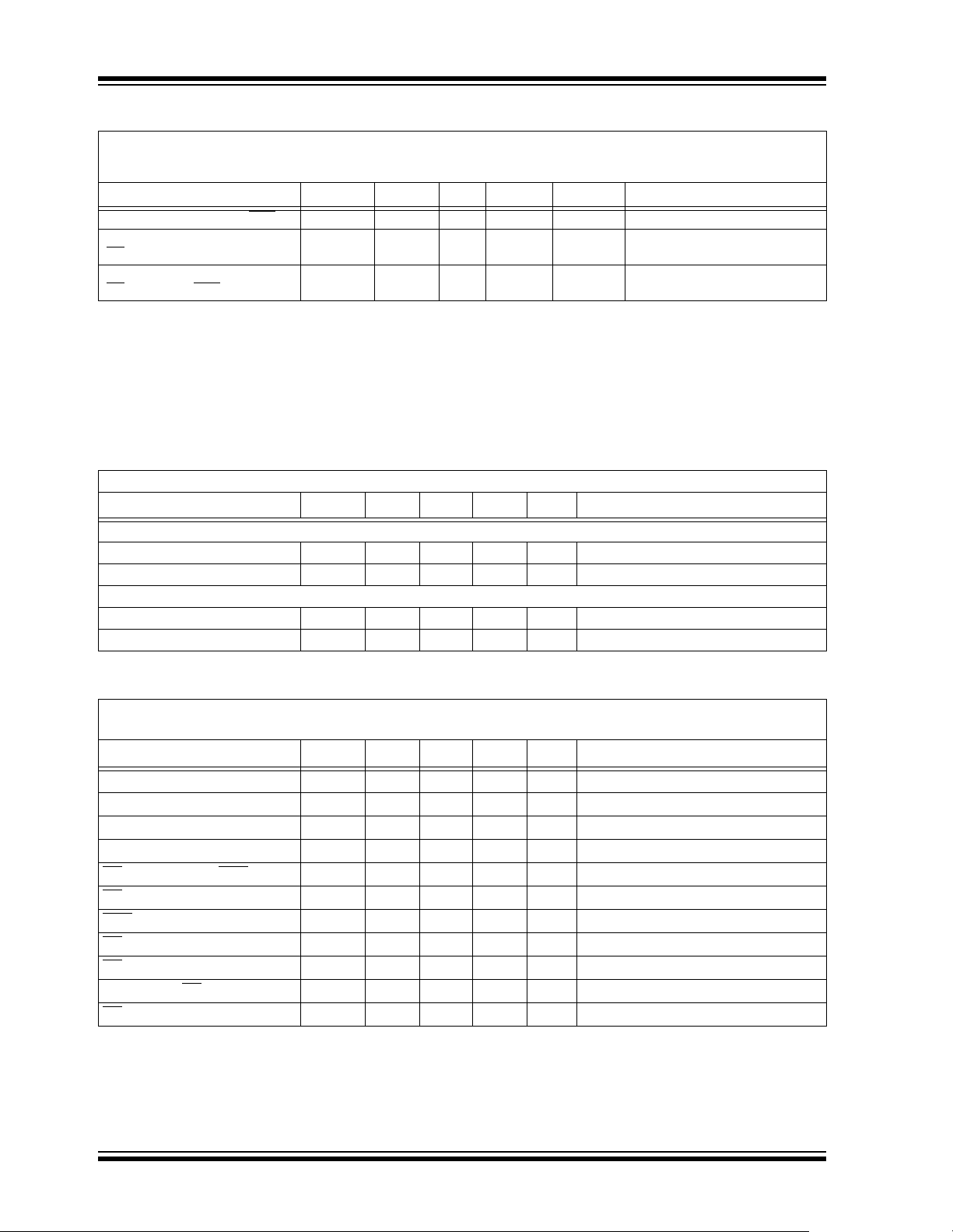

Page 4

MCP3550/1/3

DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise indicated, all parameters apply at -40°C ≤ TA ≤ +85°C, VDD = 2.7V or 5.0V.

= 2.5V. VIN+ = VIN- = VCM = V

V

REF

applies to entire MCP3550/1/3 family.

Parameters Sym Min Typ Max Units Conditions

Voltage Output Low (SDO/RDY

Input leakage Current

, SCK)

(CS

Internal Pin Capacitance

, SCK, SDO/RDY)

(CS

Note 1: This parameter is established by characterization and not 100% tested.

2: INL is the difference between the endpoints line and the measured code at the center of the quantization band.

3: This current is due to the leakage current and the current due to the offset voltage between V

4: Input impedance is inversely proportional to clock frequency; typical values are for the MCP3550/1 device. V

5: Characterized by design, but not tested.

6: Rejection performance depends on internal oscillator accuracy; see Section 4.0 “Device Overview” for more informa-

tion on oscillator and digital filter design. MCP3550/1 device rejection specifications characterized from 49 to 61 Hz.

TEMPERATURE CHAR ACTERISTICS

Electrical Specifications: Unless otherwise indicated

Parameters Sym Min Typ Max Units Conditions

Temperature Ranges

Specified Temperature Range T

Operating Temperature Range T

Thermal Package Resistances

Thermal Resistance, 8L-MSOP θ

Thermal Resistance, 8L-SOIC θ

/2. All ppm units use 2*V

REF

)VOL——0.4 VVOH = -1 mA, VDD = 5.0V

I

LI

C

INT

A

A

JA

JA

-1 — 1 µA

—5— pFNote 1

-40 — +85 °C

-40 — +125 °C

—206—°C/W

—163—°C/W

as full-scale range. Unless otherwise noted, specification

REF

+ and VIN-.

IN

REF

=5V.

SERIAL TIMINGS

Electrical Specifications: Unless otherwise indicated, all parameters apply at -40°C ≤ TA ≤ +85°C,

V

= 3.3V or 5.0V, SDO load = 50 pF.

DD

Parameters Sym Min Typ Max Units Conditions

CLK Frequency f

CLK High t

CLK Low t

CLK fall to output data valid t

low to indicate RDY state t

CS

minimum low time t

CS

flag setup time t

RDY

rise to output disable t

CS

disable time t

CS

Power-up to CS

High to Shutdown Mode t

CS

LOW t

CSHSD

SCK

HI

LO

DO

RDY

CSL

SU

DIS

CSD

PUCSL

—— 5MHz

90 — — ns

90 — — ns

0 — 90 ns

0 — 50 ns

50 — — ns

20 — — ns

20 — — ns

90 — — ns

—10—µs

—10—µs

DS21950D-page 4 © 2007 Microchip Technology Inc.

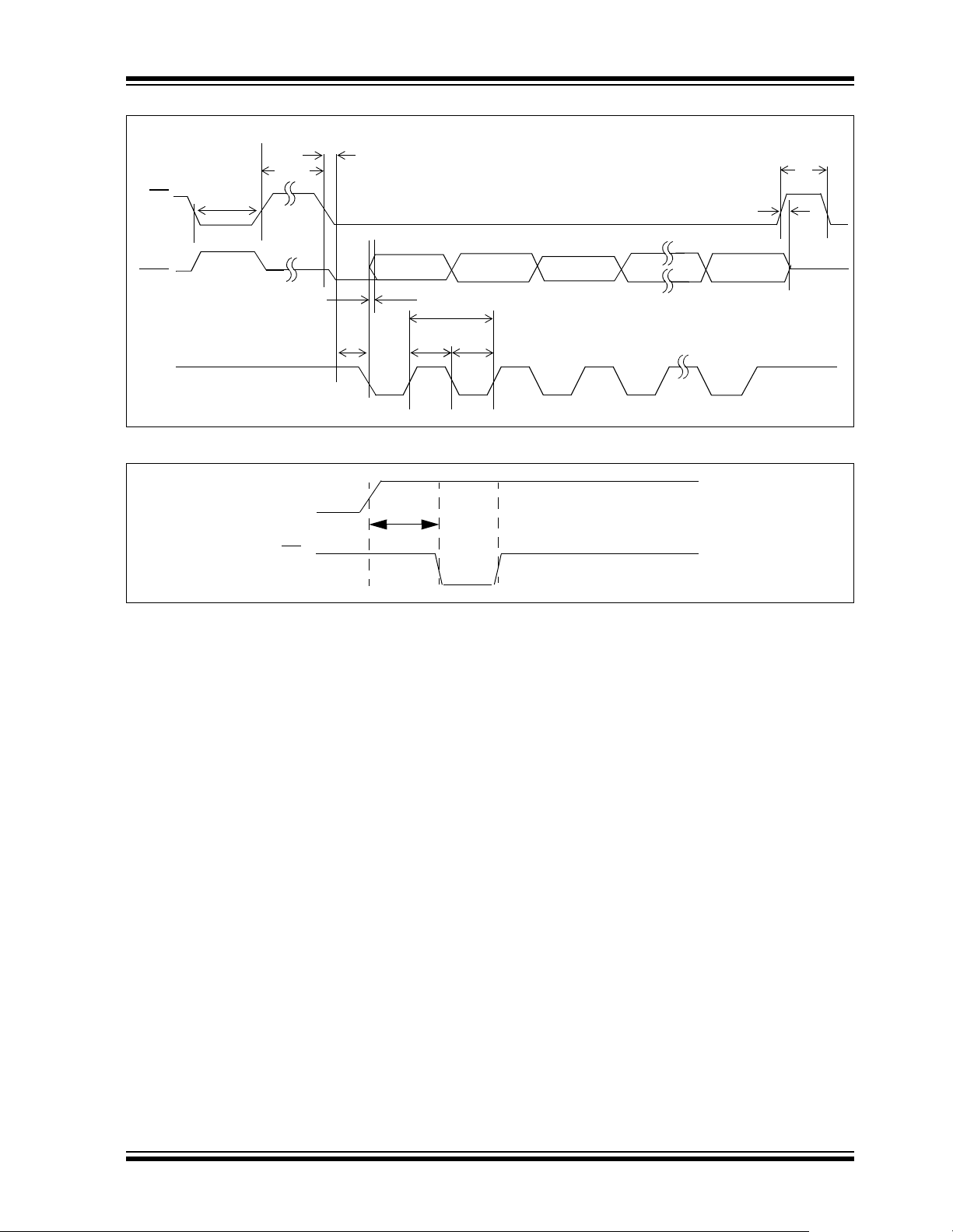

Page 5

t

RDY

t

CSD

t

CS

CSL

SDO

/RDY

t

DO

t

SCK

SU

FIGURE 1-1: Serial Timing.

V

DD

t

PUCSL

f

SCK

t

HItLO

MCP3550/1/3

t

CSHSD

t

DIS

CS

FIGURE 1-2: Power-up Timing.

© 2007 Microchip Technology Inc. DS21950D-page 5

Page 6

MCP3550/1/3

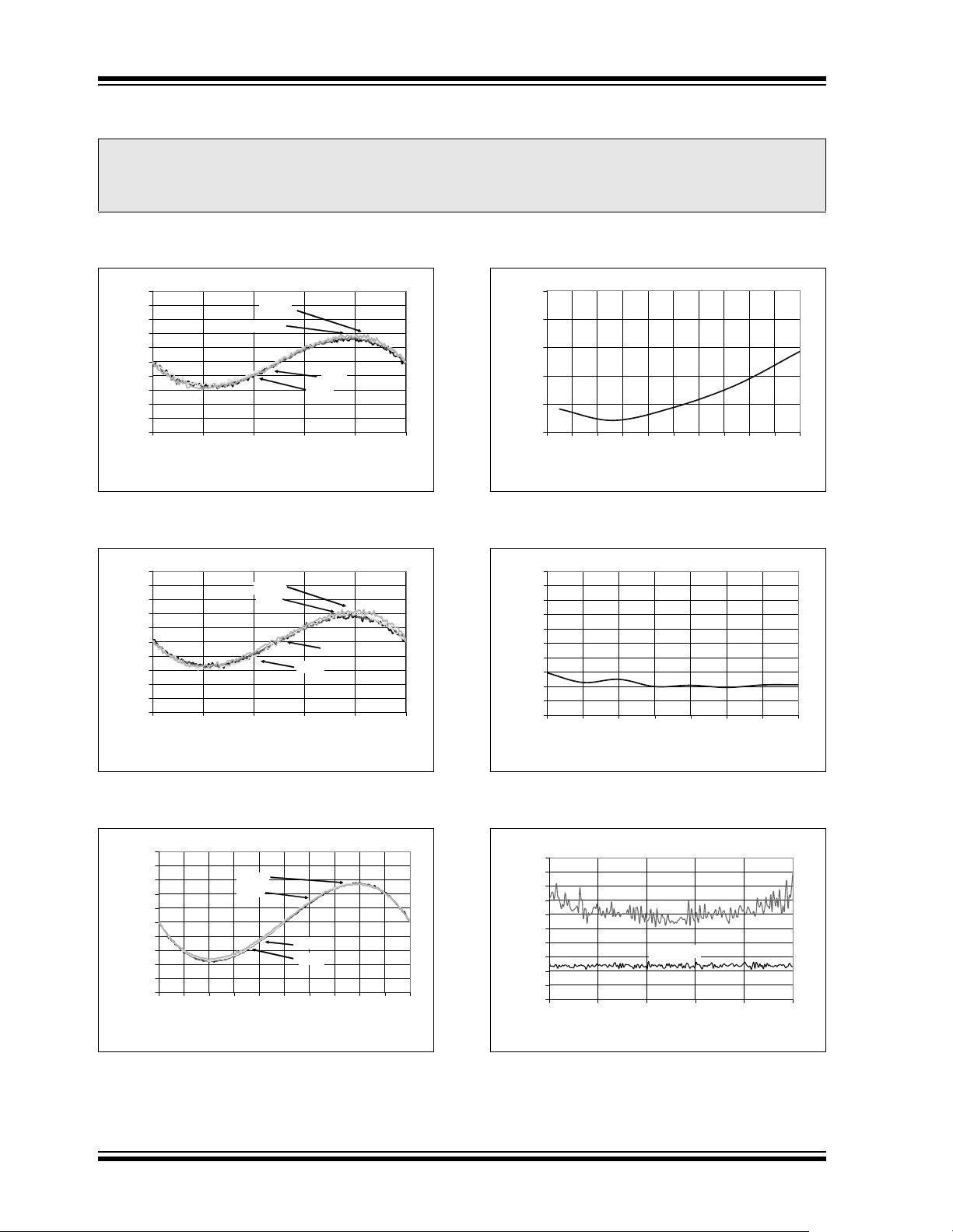

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and ta ble s prov id ed following this n ote are a statistical summ ary based on a l imite d number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise specified, TA = +25°C, VDD = 5V, V

All ppm units use 2*V

5

4

3

2

1

0

-1

INL (ppm)

-2

-3

-4

-5

-2.5 -1.5 -0.5 0.5 1.5 2.5

as full-scale range. Unless otherwise noted, graphs apply to entire MC P35 50 /1/3 famil y.

REF

+125 C

+85 C

-40 C

+25 C

V

(V)

IN

FIGURE 2-1: INL Error vs. Input Voltage

(V

= 2.7V).

DD

5

4

3

2

1

0

-1

INL (ppm)

-2

-3

-4

-5

-2.5 -1.5 -0.5 0.5 1.5 2.5

+125 C

+85 C

V

- 40 C

+25 C

(V)

IN

= 2.5V, VSS = 0V, VCM = V

REF

10

8

6

4

INL Error (ppm)

2

0

00.511.522.533.544.55

/2, VIN+ = VIN-.

REF

V

(V)

REF

FIGURE 2-4: Maximum INL Error vs.

V

.

REF

10

9

8

7

6

5

4

3

Max INL (ppm)

2

1

0

-50 -25 0 25 50 75 100 125

Temperature (°C)

FIGURE 2-2: INL Error vs. Input Voltage

= 5.0V).

(V

DD

10

8

6

4

2

0

-2

INL (ppm)

-4

-6

-8

-10

-5 -4 -3 -2 -1 0 1 2 3 4 5

+125 C

+85 C

+25 C

-40 C

V

(V)

IN

FIGURE 2-3: INL Error vs. Input Voltage

(V

DD

= 5.0V, V

REF

= 5V).

FIGURE 2-5: Maximum INL Error vs.

Temperature.

10

)

9

RMS

8

7

6

5

4

3

2

Output Noise (µV

1

0

-2.5 -1.5 -0.5 0.5 1.5 2.5

MCP3553

MCP3550/1

(Volts)

V

IN

FIGURE 2-6: Output Noise vs. Input

Voltage (V

= 2.7V).

DD

DS21950D-page 6 © 2007 Microchip Technology Inc.

Page 7

MCP3550/1/3

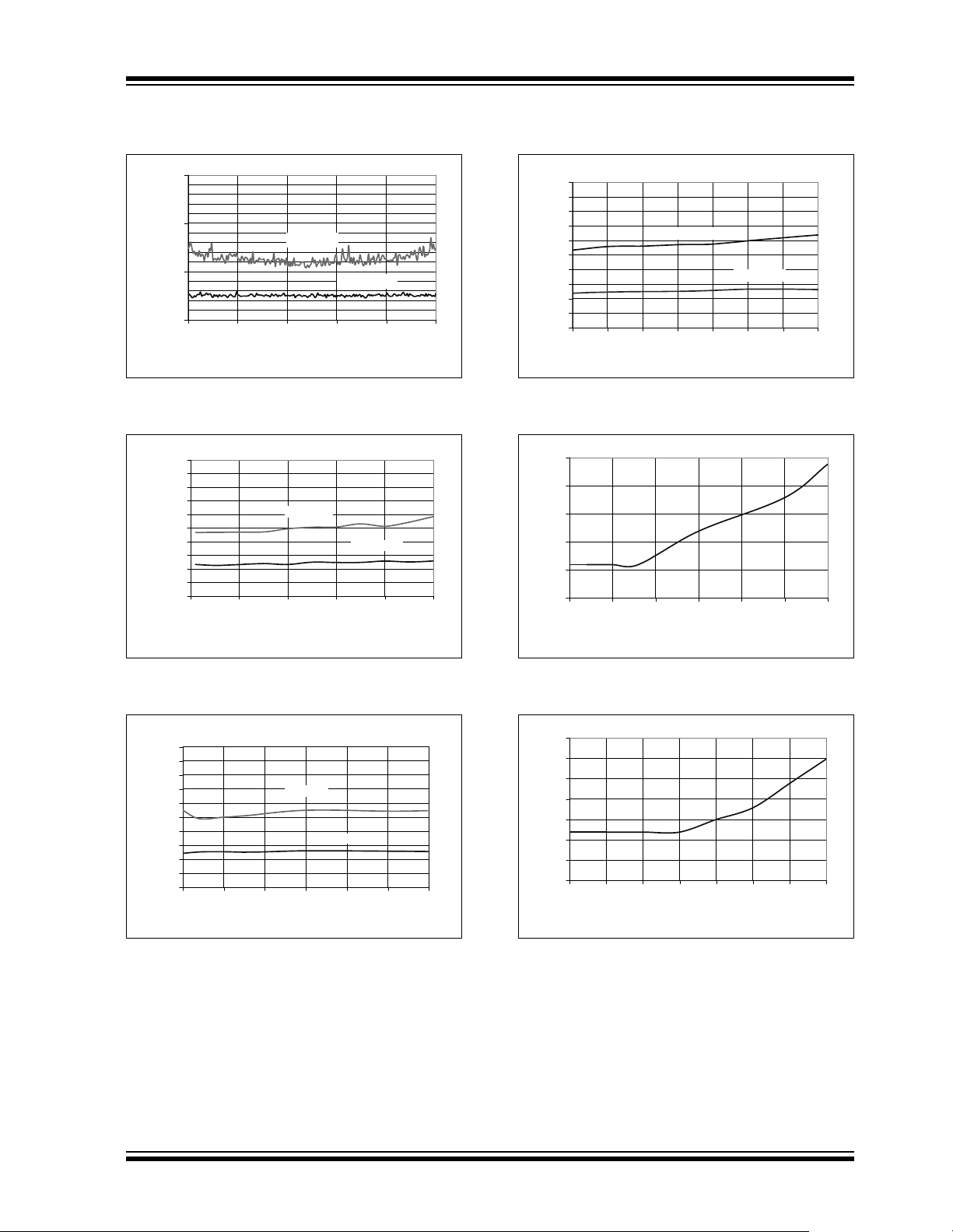

MCP3550/1

MCP3550/1

Note: Unless otherwise specified, TA = +25°C, VDD = 5V, V

All ppm units use 2*V

15

)

RMS

10

5

Output Noise (µV

0

-2.5 -1.5 -0.5 0.5 1.5 2.5

as full-scale range. Unless otherwise noted, graphs apply to entire MCP3550/1/3 family.

REF

MCP3553

MCP3550/1

V

(V)

IN

FIGURE 2-7: Output Noise vs. Input

Voltage (V

u

10.0

9.0

)

8.0

RMS

7.0

6.0

5.0

4.0

3.0

2.0

Output Noise (µV

1.0

0.0

= 5.0V).

DD

MCP3553

0.0 1.0 2.0 3.0 4.0 5.0

V

(V)

REF

= 2.5V, VSS = 0V, VCM = V

REF

10

9

)

8

RMS

7

6

5

4

3

2

Output Noise (µV

1

0

-50-250 255075100125

Temperature (°C)

/2, VIN+ = VIN-.

REF

MCP3553

FIGURE 2-10: Output Noise vs.

Temperature.

5

4

3

2

Offset (µV)

1

0

2.533.544.555.5

(V)

V

DD

MCP3550/1

FIGURE 2-8: Output Noise vs. V

10

)

9

8

RMS

7

6

5

4

3

2

Output Noise (µV

1

0

2.533.544.555.5

MCP3553

V

(V)

DD

FIGURE 2-9: Output Noise vs.V

REF

DD

.

.

FIGURE 2-11: Offset Error vs V

(V

=0V).

CM

7

6

5

4

3

Offset (µV)

2

1

0

-50 -25 0 25 50 75 100 125

Temperature (°C)

FIGURE 2-12: Offset Error vs.

Temperature (V

REF

= 5.0V).

DD

© 2007 Microchip Technology Inc. DS21950D-page 7

Page 8

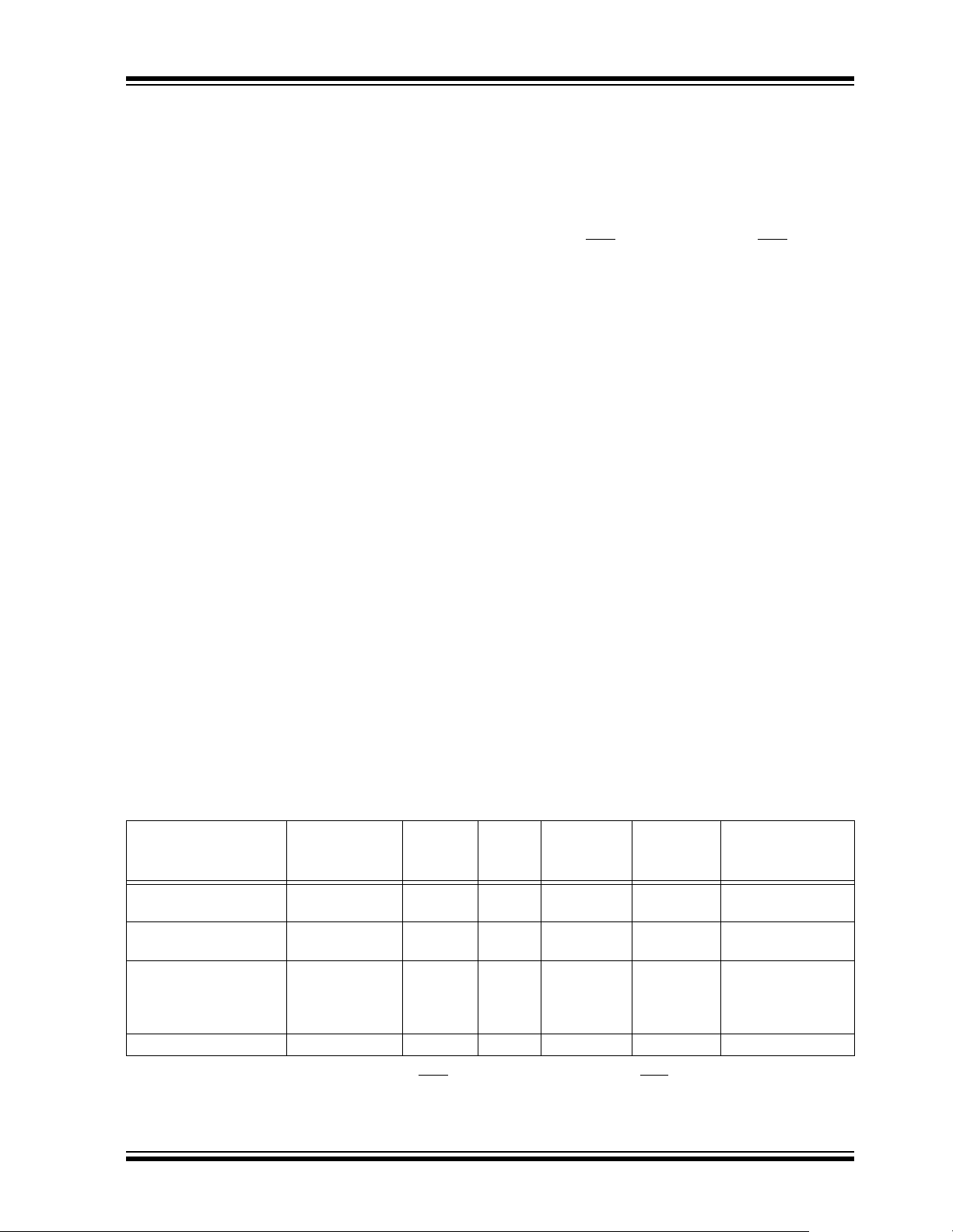

MCP3550/1/3

consecutive

16384 consecutive

Note: Unless otherwise specified, TA = +25°C, VDD = 5V, V

All ppm units are ratioed against 2*V

5

4

3

2

1

0

-1

-2

-3

Full-Scale Error (ppm)

-4

-5

2.533.544.555.5

Positive Full-Scale

Negative Full-Scale

V

(V)

DD

Unless otherwise noted, graphs apply to entire MCP3550/1/3 family.

REF .

FIGURE 2-13: Full-Scale Error vs. VDD.

10

8

6

4

2

0

-2

-4

-6

Full-Scale Error (ppm)

-8

-10

-50 -25 0 25 50 75 100 125

Positive Full-Scale

Negative Full -S c a le

Temperature (°C)

= 2.5V, VSS = 0V, VCM = V

REF

4000

V

= 5V

3500

3000

2500

2000

1500

DD

V

= 2.5V

REF

V

= 1.25V

CM

V

= 0V

IN

T

= 25C

A

16384

readings

/2, VIN+ = VIN-.

REF

1000

500

Number of Occurrences

0

-15 -10 -5 0 5 10 15

Output Code (LSB)

FIGURE 2-16: MCP3550/1 Output Noise

Histogram.

1800

V

= 5V

DD

1600

V

= 2.5V

REF

V

= 1.25V

CM

1400

V

= 0V

IN

1200

T

= 25°C

A

1000

readings

800

600

400

200

Number of Occurrences

0

-15 -10 -5 0 5 10 15

Output Code (LSB)

FIGURE 2-14: Full-Scale Error vs.

Temperature.

10

8

6

4

Positive Full-Scale

2

0

-2

-4

-6

Full-Scale Error (ppm)

-8

Negative Full-Scale

-10

-50 -25 0 25 50 75 100 125

Temperature (°C)

FIGURE 2-15: Full-Scale Error vs.

Temperature (V

REF

= 5.0V).

FIGURE 2-17: MCP3553 Output Noise

Histogram.

5.0

4.0

3.0

2.0

1.0

0.0

-1.0

TUE (ppm)

-2.0

-3.0

-4.0

-5.0

-2.5 -2.0 -1.5 -1.0 -0.5 0.0 0.5 1.0 1.5 2.0 2.5

(V)

V

IN

FIGURE 2-18: Total Unadjusted Error

(TUE) vs. Input Voltage (VDD = 2.7V).

DS21950D-page 8 © 2007 Microchip Technology Inc.

Page 9

MCP3550/1/3

Note: Unless otherwise specified, TA = +25°C, VDD = 5V, V

All ppm units use 2*V

5

4

3

2

1

0

-1

TUE (ppm)

-2

-3

-4

-5

-2.5 -2 -1.5 -1 -0.5 0 0.5 1 1.5 2 2.5

as full-scale range.

REF

(V)

V

IN

Unless otherwise noted, graphs apply to enti re M CP355 0/1/3 family.

FIGURE 2-19: Total Unadjusted Error

(TUE) vs. Input Voltage.

10

8

6

4

2

0

-2

TUE (ppm)

-4

-6

-8

-10

-5-4-3-2-1012345

V

(V)

IN

= 2.5V, VSS = 0V, VCM = V

REF

6

5

4

3

2

1

Maximum TUE (ppm)

0

-50 -25 0 25 50 75 100 125

Temperature (°C)

/2, VIN+ = VIN-.

REF

FIGURE 2-22: Maximum TUE vs.

Temperature.

5

4.5

4

3.5

3

2.5

2

TUE (ppm)

1.5

1

0.5

0

2.5 2.7 3 3.3 4 5 5.5

V

(V)

DD

FIGURE 2-20: Total Unadjusted Error

(TUE) vs. Input Voltage (V

10

9

8

7

6

5

4

3

2

Maximum TUE (ppm)

1

0

012345

FIGURE 2-21: Maximum TUE vs. V

V

REF

REF

(V)

= 5.0V).

REF

FIGURE 2-23: Maximum TUE vs. V

0.6

0.5

0.4

0.3

(µA)

0.2

DDS

I

0.1

0

-0.1

-50-25 0 255075100125

.

FIGURE 2-24: I

MCP3550/1

MCP3553

Temperatur e ( °C)

vs. Temperature.

DDS

DD

.

© 2007 Microchip Technology Inc. DS21950D-page 9

Page 10

MCP3550/1/3

Note: Unless otherwise specified, TA = +25°C, VDD = 5V, V

All ppm units use 2*V

200

180

160

140

120

100

(µA)

DD

80

I

60

40

20

MCP3550-60, MCP3553

0

2.5 3 3.5 4 4.5 5 5.5

as full-scale range. Unless otherwise noted, graphs apply to entire MC P35 50 /1/3 famil y.

REF

MCP3550-50, MCP3550/1

(V)

V

DD

= 2.5V, VSS = 0V, VCM = V

REF

160

MCP3550-60, MCP3553

140

120

100

80

(µA)

DD

I

60

40

20

0

-50 -25 0 25 50 75 100 125

/2, VIN+ = VIN-.

REF

MCP3550-50, MCP3550/1

Temperature (°C)

FIGURE 2-25: IDD vs. VDD. FIGURE 2-26: IDD vs. Temperature.

DS21950D-page 10 © 2007 Microchip Technology Inc.

Page 11

3.0 PIN DESCRIPT IONS

TABLE 3-1: PIN FUNCTION TABLE

Pin No. Symbol I/O/P Function

1V

2V

3V

4V

5 SCK I Serial Clock Digital Input Pin

6 SDO/RDY

7CS

8V

Type Identification: I = Input; O = Output; P = Power

REF

+ I Non-inverting Analog Input Pin

IN

- I Inverting Analog Input Pin

IN

SS

DD

I Reference Voltage Analog Input Pin

P Ground Pin

O Data/Ready Digital Output Pin

I Chip Select Digital Input Pin

P Positive S upply Voltage Pin

MCP3550/1/3

3.1 Voltage Reference (V

The MCP3550/1/3 devices accept single-ended reference voltages from 0.1V to V

output noise is dominated by thermal noise, which is

independent of the reference voltage, the output noise

is not significantly improved by diminishing the reference voltage at th e V

reference will significantly improve the INL performance (see Figure 2-4); the INL max error is

proportional to V

REF

input pin. A reduced voltage

REF

2

.

. Since the converter

DD

REF

)

3.2 Analog Inputs (VIN+, VIN-)

The MCP3550/1/3 devices accept a fully differential

analog input voltage to be connected on the V

V

- input pins. The differential voltage that is con-

IN

verted is defined by V

voltage range specified for ensured accuracy is from

-V

to +V

REF

valid and usable codes with the inputs overranged by

up to 12% (see Section 5.0 “Serial Interface”) at

room temperature. This overrange is clearly specified

by two overload bits in the output code.

The absolute voltage range on these input pins extends

from V

SS

below this range will create leak age currents through

the Electrostatic Discharge (ESD) diodes. T his current

will increase exponentially, degrading the accuracy and

noise performance of the device. The common mode of

the analog inputs should be chose n such that both the

differential analog input range and the absolute voltage

range on each pin are within the specified operating

range defined in Section 1.0 “Electrical Characteris-

tics”.

. However, the converter will still output

REF

– 0.3V to VDD + 0.3V. Any voltage above or

= VIN+ – VIN-. The diffe ren tial

IN

+ and

IN

3.3 Supply Voltage (VDD, VSS)

VDD is the power supply pin for the analog and digital

circuitry within the MCP3550/1/3. This pin requires an

appropriate bypass capacitor of 0.1 µF. The voltage on

this pin should be maint ain ed in th e 2.7V to 5.5 V range

for specified operation. V

current return path for both analog and digital circuitry

of the MCP3550/1/3. If an analog ground plane is

available, it is recommended that this device be tied to

the analog ground plane of the Printed Circuit Board

(PCB).

is the ground pin and the

SS

3.4 Serial Clock (SCK)

SCK synchronizes data communication with the

device. The device operates in both SPI mode 1,1 and

SPI mode 0,0. D ata is shif ted o ut of the device on the

falling edge of SCK. Data is latched in on the rising

edge of SCK. During CS

idle either high or low.

high times, the SCK pin can

3.5 Data Output (SDO/RDY)

SDO/RDY is the output data pin for the device. Once a

conversion is complete, this pin will go active-low,

acting as a ready flag. Subsequent falling clock edges

will then place the 24-bit data word (two overflow bits

and 22 bits of data, see Section 5.0 “Serial Inter-

face”) on the SPI bus through the SDO pin. Data is

clocked out on the falling edge of SCK.

3.6 Chip Select (CS)

CS gates all communication to the device and can be

used to select multiple devices that share the same

SCK and SDO/RDY

control the internal conversions, which begin on the

falling edge of CS. Raising CS before the first internal

conversion is complete places the device in Single

Conversion mode. Leaving CS

device in Continuo us Co nversion mode (i .e., additi onal

internal conv ersi ons will au toma tically occur) . CS

be tied permanently low for two-wire Continuous

Conversion mode op erati on. SDO/ RDY

impedance state with CS

pins. This pin is also used to

low will place the

may

enters a high-

high.

© 2007 Microchip Technology Inc. DS21950D-page 11

Page 12

MCP3550/1/3

4.0 DEVICE OVERVIEW

The MCP3550/1/3 devices are 22-bit delta-sigma

ADCs that include fully differential analog inputs, a

third-order delta-sigma modulator, a fourth-order

modified SI NC deci mation filter, an on- chip, low-noi se

internal oscilla tor , a power supp ly monitorin g circuit and

an SPI 3-wire digital interface. These devices can be

easily used to measure low-frequency, low-level

signals such as those found in pressure transducers,

temperature, strai n ga uge, i ndust rial c ontrol or p roces s

control applications. The power supply range for this

product family is 2.7V to 5 .5V ; the temperatu re range i s

-40°C to +125°C. The functional block diagram for the

MCP3550/1/3 devices is shown in Figure 4-1.

A Power-On Reset (POR) monitoring circuit is incl uded

to ensure proper power supply voltages during the

conversion process. The clock source for the part is

internally generated to ±0.5% over the full-power

supply voltage range and in dustrial tempe ratu re rang e.

This stable clock source allows for superior conversion

repeatability and minimal drift across conversions.

The MCP3550/1/3 devices employ a delta-sigma

conversion technique to realize up to 22 bits of no

missing code per f or ma nc e wit h 21 . 9 Effec tiv e Num be r

of Bits (ENOB). These devices provide single-cycle

conversions with no digital filter settling time. Every

conversion includes an internal offset and gain autocalibration to reduce device error. These calibrations

are transparent to the user and are done in real-time

during the conversi on. There fore, t hese de vice s do not

require any additional time or conversion to proceed,

allowing easy usage of the devices for multiplexed

applications. The MCP3550/1/3 devices incorporate a

fourth-order digital decimation filter in order to allow

superior averaging performance, as well as excellent

line frequency rejection capabilities. The oversampling

frequency also reduces any external anti-aliasing filter

requirements.

The MCP3550/1/3 device s communicate with a sim pl e

3-wire SPI interface. The interface controls the

conversion start event, with an added feature of an

auto-conversion at system power-up by tying the CS

pin to logic-low. The device can communicate with bus

speeds of up to 5 MHz, with 50 pF capacitive loading.

The interface offers two conversion modes: Single

Conversion mode for multiplexed applications and a

Continuous Conversion mode for multiple conversions

in series. Every conversion is independent of each

other . That is, all i nternal regis ter s are flushed betw een

conversions. When the de vice is not convert ing, it automatically goes into Shutdown mode and, while in this

mode, consumes less than 1 µA.

Reference

Input

Differential

Analog Input

Gain and

Offset

Calibration

Charge

Transfer

Third-Order

ΔΣ

Modulator

Clock

Internal

Oscillator

Bit

Stream

Digital

Decimation

Filter (SINC

Conversion

4

)

Code

SPI 3-wire

Interface

Output

Code

FIGURE 4-1: MCP3550/1/3 Functional Block Diagram.

DS21950D-page 12 © 2007 Microchip Technology Inc.

Page 13

MCP3550/1/3

4.1 MCP3550/1/3 Delt a-Sigma Modulator with Internal Offset and Gain Calibration

The converter core of the MCP3550/1/3 devices is a

third-order delta-sigma modulator with automatic gain

and offset error cal ibrations. The mo dulator uses a 1-b it

DAC structure. The delta-sigma modulator processes

the sampled charges through switched capacitor

structures controlled by a very low drift oscillator for

reduced clock jitter.

During the conversion process, the modulator outputs

a bit stream with the bit frequency equivalent to the

/4 (see Table 4-1). The high oversampling

f

OSC

implemented in the modulator ensures very high

resolution and high averaging factor to achieve lownoise specifications. The bit stream output of the modulator is then processed by the digital decimation filter

in order to provide a 22-bit outp ut code at a da ta rate of

12.5 Hz for the MCP3550-50, 15 Hz for the MCP3550-

60, 13.75 Hz for the MCP3551 and 60 Hz for the

MCP3553. S ince the overs ampling rat io is lower with

the MCP3553 device, a mu ch higher output da ta rate is

achieved while still ac hieving 20 bit s No M issing Codes

(NMC) and 20.6 ENOB.

A self-calibration of offset and gain occurs at the onset

of every conversion. The conversion data available at

the output of the device is always calibrated for offset

and gain through this process. This offset and gain

auto-calibration is performed internally and has no

impact on the speed of the converter since the offset

and gain errors are calibrated in real-time during the

conversion. The real-time offset and gain calibration

schemes do not affect the conversion process.

4.2 Digital Filter

The MCP3550/1/3 devices include a digital decimation

filter, which is a fourth-order modified SINC filter. This

filter averages the incoming bit stream from the modulator and outputs a 22-bit conversion word in binary

two's complement. When all bits have been processed

by the filter, the output code is ready for SPI communication, the RDY

the internal registers are reset in order to process the

next conversion.

Like the common ly use d SINC fi lter, the modified SINC

filter in the MCP3550/1/3 family has the main notch

frequency located at f

stream sample frequency. OSR is the Oversampling

Ratio and L is the order of the filter.

The MCP3550-50 device has the main filter notch

located at 50 Hz. For the MCP3550-60 device, the

notch is located at 60Hz. The MCP3551 device has it s

notch located at 55 Hz, and for the MCP3553 device,

the main notch is located at 240 Hz, with an OSR of

128. (see Table 4-1 for rejection performance).

The digital decimation SINC filter has been modified in

order to offer staggered zeros in its transfer function.

This modification i s intended to widen the main notch i n

order to be less sensitive to oscillator deviation or linefrequency drift. The MCP3551 filter has staggered

zeros spread in order to reject both 50 Hz and 60 Hz

line frequencies simultaneously (see Figure 4-2).

flag is set on the SDO/RDY pin and all

/(OSR*L), where fS is the bit

S

T ABLE 4-1: DATA RATE, OUTPUT NOISE AND DIGITAL FILTER SPECIFICATIONS BY DEVICE

Output Data

Device

MCP3550-50 80.00 ms 2.5 50 25600 Hz 102.4 kHz -120 dB min. at

MCP3550-60 66.67 ms 2.5 60 30720 Hz 122.88 kHz -120 dB min. at

MCP3551 72.73 ms 2.5 55 28160 Hz 112.64 kHz -82 dB min. from

MCP3553 16.67 ms 6 240 30720 Hz 122.88 kHz Not Applicable

Note: For the first conversion after exiting Shutdown, t

the conversion is complete and the RDY

© 2007 Microchip Technology Inc. DS21950D-page 13

Rate (t

(Note)

CONV

)

Output

Noise

(µV

Primary

Notch

)

RMS

(Ready) flag appears on SDO/RDY.

(Hz)

CONV

Sample

Frequency

(fS)

must include an additional 144 f

Internal

Clock

f

OSC

50/60 Hz Rejection

50 Hz

60 Hz

48 Hz to 63 Hz. -

82 dB at 50 Hz and

-88 dB at 60 Hz

periods before

OSC

Page 14

MCP3550/1/3

:

0

-20

-40

-60

-80

Attenuation (dB)

-100

-120

0 50 100 150 200

Frequency (Hz)

0

-20

-40

-60

-80

-100

Normal Mode Rejection (dB)

-120

-140

0 28160 56320 84480 112640 140800 168960 197120 225280 253440

Frequency (Hz)

FIGURE 4-2: SINC Filter Response,

MCP3550-50 Device.

:

0

-20

-40

-60

-80

Attenuation (dB)

-100

-120

0 60 120 180 240

Frequency (Hz)

FIGURE 4-3: SINC Filter Response,

MCP3550-60 Device.

:

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

Attenuation (dB)

-100

-110

-120

0 102030405060708090100110

Frequency (Hz)

FIGURE 4-4: SINC Filter Response,

MCP3551 Device, Simultaneous 50/60 Hz

Rejection.

FIGURE 4-5: SINC Filter Response at

Integer Multiples of the Sampling Frequency (f

s

4.3 Internal Oscillator

The MCP3550/1/3 devices include a highly stable and

accurate internal oscillator that provides clock signals

to the delta-s igma A DC with minimu m jitte r. The oscillator is a spec ialized st ructure wit h a low temp erature

coefficient across the full range of specified operation.

See Table 4-1 for oscillator frequencies.

The conversion time is an integer multiple of the internal clock period and, th erefore, has the same accu racy

as the internal clock frequency. The internal oscillator

frequency is 102.4kHz ±1% for the MCP3550-50,

112.64 kHz ±1% for the MCP3551, and 122.88 kHz

±1% for the MCP3550-60 and MCP3553 devices,

across the full power supply voltage and specified

temperature ranges.

The notch of the digital filter is proportional to the

internal oscillator frequency, with the exact notch

frequency equivalent to the oscillator accuracy (< 1%

deviation). This high accuracy, combined with wide

notches, will ensure tha t the MCP3551 will hav e simu ltaneous 50 Hz and 60 Hz line frequency rejection and

the MCP3550-50 or MCP3550-60 devices will have

greater than 120 dB rejection (at either 50 or 60 Hz) by

the digital filtering, even when jitter is present.

The internal oscillator is held in the reset condition

when the par t is in Shutdown mode to ensure very low

power consumption (< 1µA in Shutdown mode). The

internal oscillator is independent of all serial digital

interface edges (i.e., state machine processing the

digital SPI in terface is asy nchronous w ith respect to the

internal clock edges).

).

DS21950D-page 14 © 2007 Microchip Technology Inc.

Page 15

MCP3550/1/3

4.4 Differential Analog Inpu ts

The MCP3550/1/3 devices accept a fully differential

analog input voltage to be connected to the V

input pins. The differential voltage that is converted

V

IN-

is defined by V

= VIN+ – VIN-. The differen tia l vol tage

IN

range specified for ensured accuracy is from -V

.

+V

REF

The converter will outp ut valid an d usabl e code s from 112% to 112% of output range (see Section 5.0

“Serial Interface”) at room temperature. The ±12%

overrange is clearly specified by two overload bits in

the output code: O VH an d O V L . Th is fe ature a llo w s for

system calibration of a positive gain error.

The absolute volt age range on th ese input pins ext ends

from V

- 0.3V to V

SS

+ 0.3V. If the input voltages are

DD

above or below this range, the leakage currents of the

ESD diodes will increase exponentially, degrading the

accuracy and noise performance of the converter. The

common mode of the analog inputs should be chosen

such that both the differential analog input range and

absolute voltage range on each pin are within the

specified operating range defined in Section 1.0

“Electrical Characte ristics”.

Both the analog differential inputs and the reference

input have switched-capacitor input structures. The

input capacit ors are charged a nd discharged a lternatively with the input and the reference in order to

process a conversi on. The charg e and discharge of the

input capacitors create dynamic input currents at the

+ and VIN- input pins inversely proportional to the

V

IN

sampling capacitor. This current is a function of the

differential input voltages and their respective common

modes. The typical va lue of the differenti al input impedance is 2.4 MΩ, with V

= 2.5V , V

CM

DD

= V

REF

DC leakage current caused by the ESD input diodes,

even though on the ord er of 1nA, can cause additional

offset errors proporti onal to the source resi stance at the

+ and VIN- input pins .

V

IN

From a transient response standpoint and as a firstorder approximation, these input structures form a

simple RC filtering c ircui t with the sour ce imped an ce in

series with the R

(switched resist anc e when closed)

ON

of the input switc h a nd the sampling capac ito r. In order

to ensure the accuracy of the sampled charge, proper

settling time of the input circuit has to be considered.

Slow settling of the input circuit will create additional

gain error. As a rule of thumb, in order to obtain 1 ppm

absolute measurement accuracy, the sampling period

must be 14 time s g rea ter than the input ci rcu it RC tim e

constant.

and

IN+

to

REF

= 5V . The

4.5 Voltage Reference Input Pin

The MCP3550/1/3 devices accept a single-ended

external reference voltage, to be connected on the

input pin. Internally, the reference voltage for the

V

REF

ADC is a differential voltage with the non-inverting input

connected to the V

connected to the V

voltage is V

REF - VSS

reference is always (V

pin and the inverting input

REF

pin. The value of the reference

SS

and the common mode of the

- VSS)/2.

REF

The MCP3550/1/3 devices accept a single-ended

reference voltage from 0.1V to V

The converter

DD.

output noise is dominated by thermal noise that is

independent of the reference voltage. Therefore, the

output noise is not significantly improved by lowering

the reference volta ge at the V

input pin. However, a

REF

reduced reference v olt age will signi ficant ly im prove th e

INL performance since the INL max error is

proportional to V

2

(see Figure 2-4).

REF

The charge and discha rge of the input c apa citor c reate

dynamic input currents at the V

input pin inversely

REF

proportional to the sampling capacitor, which is a function of the input reference voltage. The typical value of

the single-ended input impedance is 2.4 MΩ, with

V

DD=VREF

= 5V. The DC leakage current caused by

the ESD input diodes, though on the order of 1 nA

typically , can cause additi onal gain error pr oportional to

the source resistance at the V

REF

pin.

4.6 Power-On Reset (POR)

The MCP3550/1/3 devices contain an internal PowerOn Reset (POR) circuit that monitors power supply

voltage VDD during operation. This circuit ensures

correct device start-u p at syste m power-up and pow erdown events. The POR has built-in hysteresis and a

timer to give a high degree of immunity to potential

ripple and noise on the power supplies, as well as to

allow proper settlin g of the p ower sup ply durin g pow erup. A 0.1 µ F deco upling capacitor should be mounted

as close as possib le to the V

transient immunity.

The threshold v ol t ag e is s et at 2.2V, with a tolerance of

approximately ±5%. If the supply voltage falls below

this threshold, the MCP3550 /1/3 devic es wil l be he ld in

a reset condition or in Shutdown mode. When the part

is in Shutdown mode, the power consumption is less

than 1 µA. The typical hysteresis value is around

200 mV in order to prevent reset during brown-out or

other glitches on the power supply.

pin, providing add itional

DD

© 2007 Microchip Technology Inc. DS21950D-page 15

Page 16

MCP3550/1/3

Once a power-up event has occurred, the device must

require additional time before a conversion can take

place. During this time, all inte rnal analog circ uitry must

settle before the first conversion can occur. An internal

timer counts 32 internal clock periods before the

internal oscillator can provide clock to the conversion

process. This allows all internal analog circuitry to

settle to their proper operating point. This timing is

typically less than 3 00 µs, which is negligible c ompared

to one conversion time (e.g. 72.7ms for the

MCP3551). Figure 4-6 illustrates the conditions for a

power-up and power-down event unde r typica l st art-up

conditions.

V

DD

2.2V

2.0V

300 µs

0V

Reset

Normal

Operation

ResetStart-up

Time

4.8 Sleep Mode

During Sleep mode, the device is not co nv erti ng and i s

awaiting data retrieval; the internal analog circuitry is

still running and the device typically consumes 10 µA.

In order to restart a conversion while in Sleep mode,

toggling CS

down mode) and t hen back t o a logi c-low will restart th e

conversion. Sleep can only be entered in Single

Conversion mode. Once a conversion is complete in

Single Conversion mode, the device automatically

enters Sleep mode.

to a logic-high (placing the part in Shut-

FIGURE 4-6: Power-On Reset Operation.

4.7 Shutdown Mode

When not internally converting, the two modes of

operation for the MCP3550/1/3 devices are

Shutdown and Sleep modes. During Shutdown mode,

all internal analog circui try , including the POR, is turned

off and the device consumes less than 1 µA. When

exiting Shutd own m ode , th e devi ce mu st re qui re ad ditional time before a conversion can take place. During

this time, all internal analog circuitry must settle before

the first conversion can occur. An internal timer counts

32 intern al clock peri ods before th e internal osc illator

can provide clock to the conversion process. This

allows all internal analog circuitry to settle to their

proper operating point. Th is timing is typically less than

300 µs, which is neglig ible comp ared to one con version

time (72.7 ms for MCP3551).

the

DS21950D-page 16 © 2007 Microchip Technology Inc.

Page 17

MCP3550/1/3

5.0 SERIAL INTERFACE

5.1 Overview

Serial communication between the microcontroller and

REF

, SCK

– 1 LSB,

, OVL

REF

the MCP3550/1/3 devices is achieved using CS

and SDO/RDY

. There are two modes of operation:

Single Conversion and Continuous Conversion. CS

controls the conversion start. There are 24 bits in the

data word: 22 bits of conv ers io n dat a and two ov erfl ow

bits. The conversion process takes place via the internal oscillator and the status of this conversion must be

detected. The typical method of communication is

shown in Figure5-1. The status of the internal conversion is the SDO/RDY

A High state on SDO/RDY

pin and is available with CS low.

means the device is busy

converting, while a Low state means the conversion is

finished and data is ready for transfer using SCK.

SDO/RDY

CS

data using SCK and SDO/RDY

Bit 22 is Overflow High (OVH) when V

remains in a high-impedance state when

is held high. CS must be low when cl ock in g o ut the

.

> V

IN

OVH toggles to logic ‘1’, detecting an overflow high in

the analog input voltage.

Bit 23 is Overflow Low (OVL) when V

IN

< -V

toggles to logic ‘1’, detecting an overflow low in the

analog input voltage. The state OVH = OVL = ‘1’ is not

defined an d should be co nsidered as an i nterrupt for

the SPI interface meaning erroneo us co mm uni ca tio n.

Bit 21 to bit 0 represents the output code in 22-bit

binary two's complement. Bit 21 is the sign bit and is

logic ‘0’ when the differential analog input is positive

and logic ‘1’ when the differential analog input is

negative. From Bit 20 to bit 0, the output code is given

MSb first (MSb is bit 20 and LSB is Bit 0). When the

analog input value is comprised between -V

– 1 LSB, the two overflow bits are set to logic ‘0’.

V

REF

REF

and

The relationship between input voltage and output

code is shown in Figure 5-1.

The delta-sigma modulator saturation point for the

differential analog input is located at around ±112% of

(at room temp erat ure), m ean ing that the mo dul a-

V

REF

tor will still give accurate output codes with an overrange of 12% below or above the reference voltage.

Unlike the usual 22-bit device, the 22-bit output code

will not lock at 0x1FFFFF for positive sign inputs or

0x200000 for negative sign inputs in order to take

advantage of the overrange capabilities of the device.

This can be practical for closed-loop operations, for

instance. In case of an overflow, the output code

becomes a 23-bit two's complement output code,

where the sign bit will be the OVL bit. If an overflow high

or low is detected, OVL (bit 23) becomes the sign bit

(instead of bit 21), the MSb is then bit 21 and the converter can be us ed as a 23 - bit t wo' s co mp l em ent co de

converter, with output code from bits B21 to B0, and

OVL as the sign bit. Figure 5 -1 summarizes the output

coding data format with or without overflow high and

low.

CS

SCK

SDO/RDY

READY

DOO

21 20 19 18 17 16 15 14 13 12 11 10 9

HLR

765 4321

8

HI-Z

0

FIGURE 5-1: Typical Serial Device Communication and Example Digital Output Codes for Specific

Analog Input Voltages.

© 2007 Microchip Technology Inc. DS21950D-page 17

Page 18

MCP3550/1/3

5.2 Controlling Internal Conversions and the Internal Oscillator

During Shutdown mode, on the falling edge of CS, the

conversion process begins. During this process, the

internal oscillat or clocks the delt a-sigma m odulator and

the SINC filter until a conversion is complete. This

conversion time is t

Figure 5-2. At the end of t

settled complete ly and the re is no l atency in volved wi th

the digital SINC filter of the MCP3550/1/3.

The two modes of conversion for the MCP3550/1/3

devices are Single Conversion and Continuous

Conversion. In Single C onversi on mo de, a co nsecutiv e

conversion will not au tomatica lly b egin. Instea d, after a

single conversion is complete and all four filters have

settled, the device put s the data into the output regis ter

and enters shutdown.

CS

Int. Osc

and the timing is shown in

CONV

t

CONV

, the digital filter has

CONV

Sleep

In Continuous Conversion mode, a consecutive

conversion will be automatic. In this mode, the device

is continuously converting, independent of the serial

interface. The most recent conversion data will always

be available in the Output regis ter.

When the device exits Shutdown, there is an internal

power-up delay that must be observed.

Shutdown

SCK (opt)

SDO/RDY

Hi-Z

FIGURE 5-2: Single Conversion Mode.

CS

Int. Osc

t

CONV

SCK (opt)

SDO/RDY

t

CONV

t

CONV

x24

Hi-Z

Shutdown

x24

Hi-Z

FIGURE 5-3: Continuous Conversion Mode.

DS21950D-page 18 © 2007 Microchip Technology Inc.

Page 19

MCP3550/1/3

5.3 Single Conversion Mode

If a rising edge of Chip Select (CS) occurs during t

a subsequen t conversion will not take place and the

device will enter low-power Shutdown mode after

completes. This is referred to as Single

t

CONV

Conversion mode. This operation is demonstrated in

Figure 5-3. Note that a falling edge of CS

same conversion that detected a rising edge, as in

Figure 5-2, will not initiate a new conversion. Once a

rising edge is seen, the device will enter Sleep, then

Shutdown mode. Once the device has been put into

Single Conversion m ode, the dat a mus t be clo cked o ut

in order for a new conversion to take place. A

subsequent falling edg e on CS

during Shutdown mode

will not initiate a new conversion, unless the prior

conversion data has been clocked out of the device.

After the final data bit has been c locked out o n the 25th

clock, the SDO/RDY

pin will go active-high.

5.3.1 READY FUNCTION OF SDO/RDY

PIN, SINGLE CONVERSION MODE

At every falling edge of CS during the internal conversion, the state of the internal conversion is latched on

the SDO/RDY pin to give ready or busy information. A

High state means the dev ice is cu rrently performin g an

internal conversion and data cannot be clocked out. A

Low state m eans the device has finished its c onversio n

and the data is read y f or re trieval on the fallin g ed ge of

SCK. This operation is demonstrated in Figure 5-4.

Note that the device has been put into Single

Conversion mode with the first rising edge of CS

Note: The Ready state is latched on each falling

edge of CS

update if CS

and will not dynamically

is held low. CS must be

toggled high through low.

CS

Int. Osc

t

CONV

SDO/RDY

Hi-Z

FIGURE 5-4: RDY Functionality in Single

Conversion Mode.

CONV

during the

.

5.4 Continuous Conversion Mode

,

If no rising edge of CS occurs durin g any given conv ersion per Figure5-2, a subsequent conversion will take

place and the contents of the previous conversion will

be overwritten. This operation is demonstrated in

Figure 5-5. Once conversio n outpu t dat a has s ta rted to

be clocked out, the output buffer is not refreshed until

all 24 bits have been clocked. A complete read must

occur in order to read the ne xt conve rsion in this m ode.

The subsequent conversion d ata to be read wil l then be

the most recent conversion. The conversion time is

fixed and cannot b e shortened by the ris ing edge of CS

This rising edge will place the part in Shutdown mode

and all conversion data will be lost.

The transfer of data from the SINC filter to the output

buffer is demonstrated in Figure 5-5. If the previous

conversion data is not clocked out of the device, it will

be lost and replaced by the new conversion. When the

device is in Continuous Conversion mode, the most

recent conversion data is always present at the output

register for data retrieval.

CS

Int. Osc

SCK & SDO/RDY

t

CONV

A

Conversion B data is clocked

out of the device here.

t

CONV

t

B

CONV

C

FIGURE 5-5: Most Current Continuous

Conversion Mode Data.

If a conversion is in process, it cannot be terminated

with the rising edge of CS

. SDO/RDY must first

transition to a Low state, which will indicate the end of

conversion.

5.4.1 READY FUNCTION OF SDO/RDY

PIN IN CONTINUOUS CONVERSION

MODE

The device enters Continuous Conversion mode if no

rising edge of CS

is seen during t

tive conversions ensue. SDO/RDY

indicating that a conversion is in process. When a

conversion is complete, SDO/RDY

Low state. With the Low state of SDO/RDY

first conversion, the conversion data can be accessed

with the combination of SCK and SDO/RD Y. If the dat a

ready event happens during the clocking out of the

data, the data ready bit will be displayed after the

complete 24-bit word communication (i.e., the data

ready event will not interrupt a data transfer).

and consecu-

CONV

will be high,

will change to a

after this

.

© 2007 Microchip Technology Inc. DS21950D-page 19

Page 20

MCP3550/1/3

If 24 bits of da ta are re quired from this con version, they

must be accessed duri ng th is c om mu nic ation. You can

terminate data transition by bringing CS high, but the

remaining data wil l be lost and the con verter will go in to

Shutdown mode. Once the data has been transmitted

by the converter, the SDO/RDY

LSB state until the 25th falling edge of SCK. At this

point, SDO/RDY

mode and changed to the RDY

Note: The RDY state is not latched to CS in this

is released from the Data Acquisition

mode; the RDY flag dynamically updates

on the SDO/R DY pin and remains in this

state until data is clocked out using the

SCK pin.

5.4.2 2-WIRE CONTINUOUS

CONVERSION OPERATION,

(CS

TIED PERMANENTLY LOW)

It is possible to use o nly two wire s to com municat e with

the MCP3550/1/3 devices. In this state, the device is

always in Co ntinuous Conv ersion mode, with intern al

conversions continuously occurring. This mode can be

entered by hav ing CS

it to a low position a fter power-up. If CS

up, the first conversion of the converter is initiated

approximately 300 µs after the power supply has

stabilized.

low during power-up or changin g

pin will remain in the

state.

is low at power-

DS21950D-page 20 © 2007 Microchip Technology Inc.

Page 21

MCP3550/1/3

5.5 Using The MCP3550/1/3 with Microcontroller (MCU) SPI Ports

It is required that the m icrocontrol ler SPI port be co nfigured to clock out data on the falling edge of clock and

latch data in on the rising edge. Figure 5-6 depicts the

operation shown in SPI mode 1,1, which requires that

the SCK from the MCU idles in the High state, while

Figure 5-7 shows the similar case of SPI Mode 0,0,

where the clock idles in the Low state. The waveforms

in the figures are examples of an MCU operating the

SPI port in 8-bit mode, and the MCP3550/1/3 devices

do not require data in 8-bit groups.

CS

SCK

DOO

SDO/RDY

MCU

Receive

Buffer

21

RHL

OL OH 21 20 19 18 17 16

Data stored into MCU receive

register after transmission of

first byte

20 19 18 17

16

15 14 13 12 11 10 9

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Data stored into MCU receive

register after transmission of

second byte

In SPI mode 1, 1, data is read using only 24 clocks or

three byte transfers. The data ready bit must be read

by testing the SDO/RDY

line prior to a falling edge of

the clock.

In SPI mode 0,0, data is read using 25 clocks or four

byte transfers. Please note that the data ready bit is

included in the transfer as the first bit in this mode.

8 7654321 0

Data stored into MCU receive

register after transmission of

third byte

FIGURE 5-6: SPI Communication – Mode 1,1.

CS

SCK

OO

DR

SDO/RDY

MCU

Receive

Buffer

21 20 19 18 17

HL

OH OL 21 20 19 18 17

DR

Data stored into MCU receive

register after transmission of

first byte

16 14 13 12 11 10 9

15

15 14 13 12 11 10 9 7 6 5 4 3 2 1 0

16

Data stored into MCU receive

register after transmission of

second byte

FIGURE 5-7: SPI Communication – Mode 0,0.

65432

7

8

8

Data stored into MCU receive

register after transmission of

third byte

1

0

Data stored into MCU receive

register after transmission of

fourth byte

© 2007 Microchip Technology Inc. DS21950D-page 21

Page 22

MCP3550/1/3

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

8-Lead MSOP

XXXXXX

YWWNNN

8-Lead SOIC (150 mil)

XXXXXXXX

XXXXYYWW

NNN

Example:

Examples:

MCP3551E

3

e

SN^^ 0715

3553E

715256

256

3

e

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanu meric traceability code

3

e

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designat or ( )

can be found on the outer packaging for this package.

Note: In the event the full Mic rochip part nu mber ca nnot be m arked o n one lin e, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

DS21950D-page 22 © 2007 Microchip Technology Inc.

3

e

Page 23

8-Lead Plastic Micro Small Outline Package (MS) [MSOP]

N

1

2

3

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

B

http://www.microchip.com/packaging

D

N

E

E1

NOTE 1

2

1

e

MCP3550/1/3

b

A

A1

Number of Pins N 8

Pitch e 0.65 BSC

Overall Height A – – 1.10

Molded Package Thickness A2 0.75 0.85 0.95

Standoff A1 0.00 – 0.15

Overall Width E 4.90 BSC

Molded Package Width E1 3.00 BSC

Overall Length D 3.00 BSC

Foot Length L 0.40 0.60 0.80

Footprint L1 0.95 REF

Foot Angle φ 0° – 8°

Lead Thickness c 0.08 – 0.23

Lead Width b 0.22 – 0.40

otes:

. Pin 1 visual index feature may vary, but must be located within the hatched area.

. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15 mm per side.

. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

A2

Dimension Limits MIN NOM MAX

c

L1

Units MILLIMETERS

Microchip Technology Drawing C04-111

φ

L

© 2007 Microchip Technology Inc. DS21950D-page 23

Page 24

MCP3550/1/3

8-Lead Plastic Small Outline (SN) – Narrow, 3.90 mm Body [SOIC]

N

1

2

3

4

B

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

D

e

N

E

E1

NOTE 1

12 3

b

h

h

α

φ

A

A1

A2

L

L1

β

c

Units MILLMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 8

Pitch e 1.27 BSC

Overall Height A – – 1.75

Molded Package Thickness A2 1.25 – –

Standoff

§

A1 0.10 – 0.25

Overall Width E 6.00 BSC

Molded Package Width E1 3.90 BSC

Overall Length D 4.90 BSC

Chamfer (optional) h 0.25 – 0.50

Foot Length L 0.40 – 1.27

Footprint L1 1.04 REF

Foot Angle φ 0° – 8°

Lead Thickness c 0.17 – 0.25

Lead Width b 0.31 – 0.51

Mold Draft Angle Top α 5° – 15°

Mold Draft Angle Bottom β 5° – 15°

otes:

. Pin 1 visual index feature may vary, but must be located within the hatched area.

. § Significant Characteristic.

. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15 mm per side.

. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

Microchip Tec hnology Drawing C04-057

DS21950D-page 24 © 2007 Microchip Technology Inc.

Page 25

APPENDIX A: REVISION HISTORY

Revision A (September 2005)

• Original Release of this Document.

Revision B (October 2005)

• Changed LSb refefences to LSB.

Revision C (December 2005)

• Added MCP3550-50, MCP3550-60 references

throughout this document.

Revision D (January 2007)

• This update includes revisions to the packaging

diagrams.

MCP3550/1/3

© 2007 Microchip Technology Inc. DS21950D-page 25

Page 26

MCP3550/1/3

NOTES:

DS21950D-page 26 © 2007 Microchip Technology Inc.

Page 27

MCP3550/1/3

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. –X /XX

Device

PackageTemperature

Range

Device: MCP3550-50: Single Channel 22-Bit Delta-Sigma ADC

Temperature Range: E = -40°C to +125°C

Package: MS = Plastic MSOP, 8-lead

MCP3550T-50: Single Channel 22-Bit Delta-Sigma ADC

MCP3550-60: Single Channel 22-Bit Delta-Sigma ADC

MCP3550T-60: Single Channel 22-Bit Delta-Sigma ADC

MCP3551: Single Channel 22-Bit Delta-Sigma ADC

MCP3551T: Single Channel 22-Bit Delta-Sigma ADC

MCP3553: Single Channel 22-Bit Delta-Sigma ADC

MCP3553T: Single Channel 22-Bit Delta-Sigma ADC

SN = Plastic SOIC (150 mil Body), 8-lead

(Tape and Reel)

(Tape and Reel)

(Tape and Reel)

(Tape and Reel)

Examples:

a) MCP3550-50-E/MS: Extended Temp.,

b) MCP3550/1T-50E/ MS:Tape and Reel,

c) MCP3550-60-E/SN: Extended Temp.,

d) MCP3550/1T-60E/ SN:Tape and Reel,

a) MCP3551-E/MS: Extended Temp.,

b) MCP3551T-E/MS: Tape and Reel,

c) MCP3553-E/SN: Extended Temp.,

d) MCP3553T-E/SN: Tape and Reel,

8LD MSOP.

Extended Temp.,

8LD MSOP.

8LD SOIC.

Extended Temp.,

8LD SOIC.

8LD MSOP.

Extended Temp.,

8LD MSOP.

8LD SOIC.

Extended Temp.,

8LD SOIC.

© 2007 Microchip Technology Inc. DS21950D-page 27

Page 28

MCP3550/1/3

NOTES:

DS21950D-page 28 © 2007 Microchip Technology Inc.

Page 29

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market t oday, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are com mitted to continuously improving the code protect ion f eatures of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Mill ennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . I t is y o u r r es ponsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPAS M, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, Pow e rTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporat ed, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

MCUs and dsPIC DSCs, KEELOQ

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial

© 2007 Microchip Technology Inc. DS21950D-page 29

®

Page 30

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

12/08/06

DS21950D-page 30 © 2007 Microchip Technology Inc.

Loading...

Loading...