Page 1

M

IrDA® Standard Protocol Stack Controller

MCP2150

Supporting DTE Applications

Features

• Implements the IrDA® standard including:

-IrLAP

-IrLMP

-IAS

-TinyTP

- IrCOMM (9-wire “cooked” service class)

• Provides IrDA standard physical signal layer

support including:

- Bidirectional communication

- CRC implementation

- Data communication rates up to 115.2 kbaud

• Includes UART to IrDA standard encoder/decoder

functionality:

- Easily interfaces with industry standard

UARTs and infrared transceivers

• UART interface for connecting to Data Terminal

Equipment (DTE) systems

• Transmit/Receive formats (bit width) supported:

-1.63µs

• Hardware baud rate selection for UART:

- 9.6 kbaud

- 19.2 kbaud

- 57.6 kbaud

- 115.2 kbaud

• Infrared baud rates supported:

- 9.6 kbaud

- 19.2 kbaud

- 38.4 kbaud

- 57.6 kbaud

- 115.2 kbaud

• 64 Byte Data Packet Size

• Programmable Device ID String

• Operates as Secondary Device

CMOS Technology

• Low power, high-speed CMOS technology

• Fully static design

• Low voltage operation

• Industrial temperature range

• Low power consumption

- < 1 mA @ 3.3 V, 11.0592 MHz (typical)

- 3 µA typical @ 5.0 V when disabled

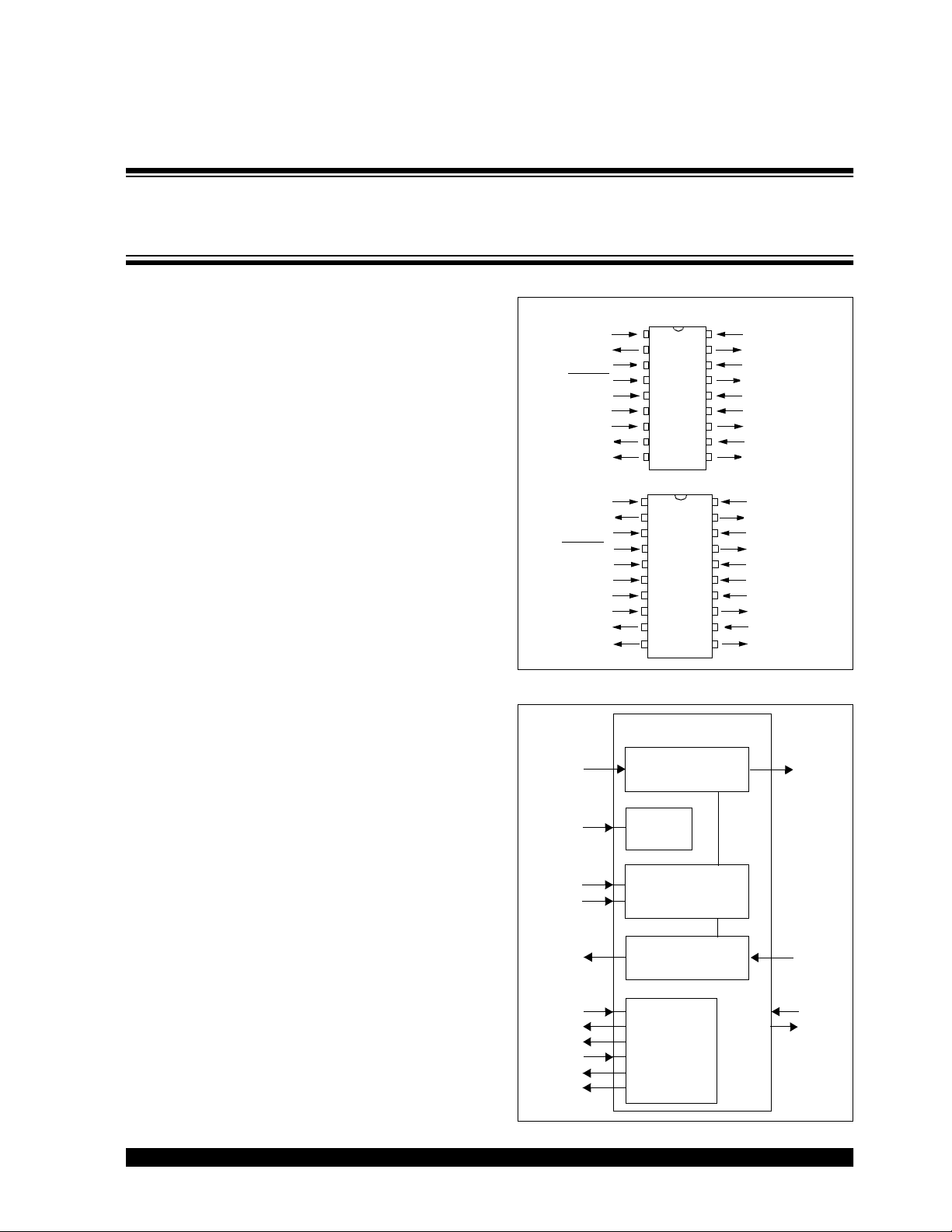

Package Types

PDIP, SOIC

18

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

17

16

MCP2150

15

14

13

12

11

10

20

19

18

MCP2150

17

16

15

14

13

12

11

SSOP

BAUD0

TXIR

RXIR

RESET

V

SS

EN

TX

RX

RI

BAUD0

TXIR

RXIR

RESET

V

SS

SS

V

EN

TX

RX

RI DSR

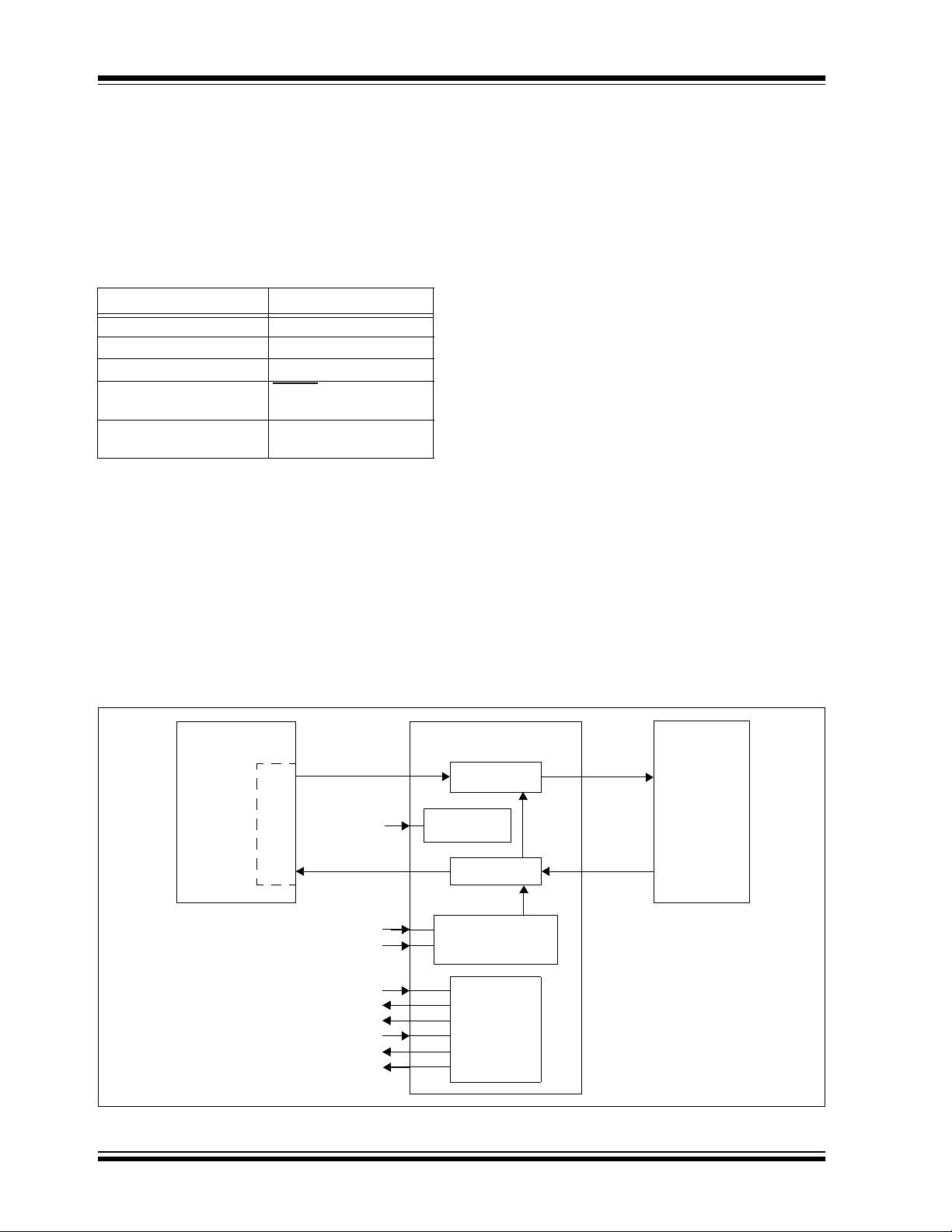

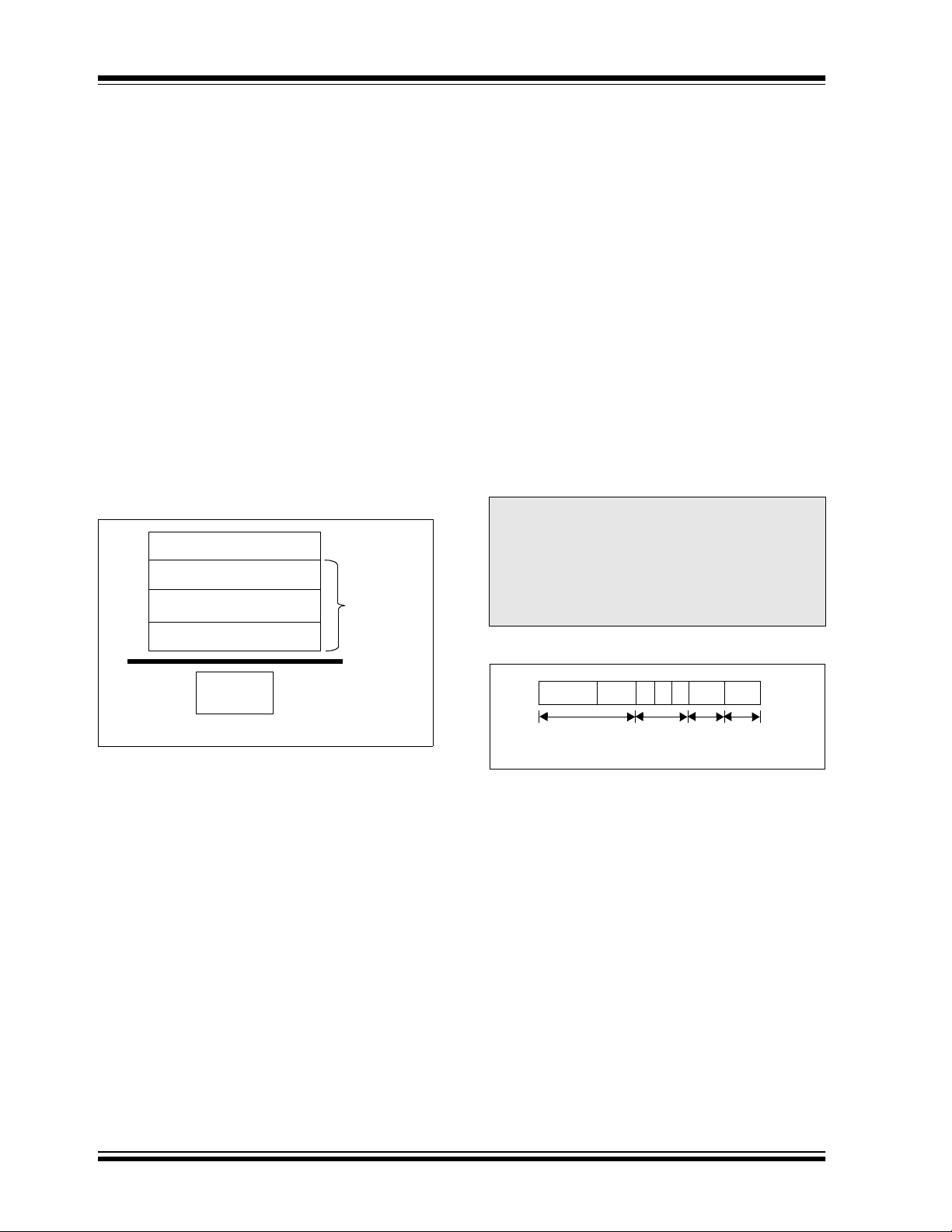

Block Diagram

MCP2150

TX TXIR

EN

BAUD1

BAUD0

RX

RTS

CTS

DSR

DTR

CD

RI

Encode and

Protocol Handler

Logic

Baud Rate

Generator

Protocol Handler

and Decode

UART

Control

BAUD1

CD

OSC1/CLKI

OSC2

DD

V

RTS

CTS

DTR

DSR

BAUD1

CD

OSC1/CLKI

OSC2

DD

V

DD

V

RTS

CTS

DTR

RXIR

OSC1

OSC2

2002 Microchip Technology Inc. Preliminary

DS21655B-page 1

Page 2

MCP2150

NOTES:

DS21655B-page 2

Preliminary 2002 Microchip Technology Inc.

Page 3

MCP2150

1.0 DEVICE OVERVIEW

This document contains device specific information for

the following device:

• MCP2150

The MCP2150 is a cost effective, low pin count (18-pin),

easy to use device for implementing IrDA standard wireless connectivity. The MCP2150 provides support for

the IrDA standard protocol “stack” plus bit encoding/

decoding.

The serial interface baud rates are user selectable to

one of four IrDA standard baud rates between 9600

baud and 115.2 kbaud (9600, 19200, 57600, 115200).

The IR baud rates are user selectable to one of five

IrDA standard baud rates between 9600 baud and

115.2 kbaud (9600, 19200, 37400, 57600, 115200).

The serial interface baud rate will be specified by the

BAUD1:BAUD0 pins, while the IR baud rate is specified

by the Primary Device (during Discover phase). This

means that the baud rates do not need to be the same.

The MCP2150 operates in Data Terminal Equipment

(DTE) applications and sits between a UART and an

infrared optical transceiver.

The MCP2150 encodes an asynchronous serial data

stream, converting each data bit to the corresponding

infrared (IR) formatted pulse. IR pulses received are

decoded and then handled by the protocol handler

state machine. The protocol handler sends the appropriate data bytes to the Host Controller in UART

formatted serial data.

The MCP2150 supports “point-to-point” applications.

That is, one Primary device and one Secondary device.

The MCP2150 operates as a Secondary device. It does

not support “multi-point” applications.

Sending data using IR light requires some hardware

and the use of specialized communication protocols.

These protocol and hardware requirements are

described, in detail, by the IrDA standard specifications. The encoding/decoding functionality of the

MCP2150 is designed to be compatible with the physical layer component of the IrDA standard. This part of

the standard is often referred to as “IrPHY”.

The complete IrDA standard specifications are available for download from the IrDA website

(www.IrDA.org).

2002 Microchip Technology Inc. Preliminary

DS21655B-page 3

Page 4

MCP2150

1.1 Applications

The MCP2150 Infrared Communications Controller

supporting the IrDA standard provides embedded system designers the easiest way to implement IrDA standard wireless connectivity. Figure 1-1 shows a typical

application block diagram. Table 1-2 shows the pin

definitions.

TABLE 1-1: OVERVIEW OF FEATURES

Features MCP2150

Serial Communications UART, IR

Baud Rate Selection Hardware

Low Power Mode Yes

Resets (and Delays) RESET

Packages 18-pin DIP, SOIC,

, POR

(PWRT and OST)

20-pin SSOP

Infrared communication is a wireless two-way data

connection, using infrared light generated by low-cost

transceiver signaling technology. This provides reliable

communication between two devices.

Infrared technology offers:

• Universal standard for connecting portable

computing devices

• Easy, effortless implementation

• Economical alternative to other connectivity

solutions

• Reliable, high-speed connection

• Safe to use in any environment (can even be

used during air travel)

• Eliminates the hassle of cables

• Allows PCs and other electronic devices (such as

PDAs, cell phones, etc.) to communicate with

each other

• Enhances mobility by allowing users to easily

connect

The MCP2150 allows the easy addition of IrDA standard wireless connectivity to any embedded application that uses serial data. Figure 1-1 shows typical

implementation of the MCP2150 in an embedded

system.

The IrDA protocols for printer support are not included

in the IrCOMM 9-wire “cooked” service class.

FIGURE 1-1: SYSTEM BLOCK DIAGRAM

Host Controller

(Microcontroller)

TX

UART

RX

EN

BAUD1

BAUD0

RTS

CTS

DSR

DTR

CD

RI

TX

RX

MCP2150

Encode

Power Down

Logic

Decode

Baud Rate

Generator

UART

Control

TXIR

RXIR

Optical

Transceiver

TXD

RXD

DS21655B-page 4

Preliminary 2002 Microchip Technology Inc.

Page 5

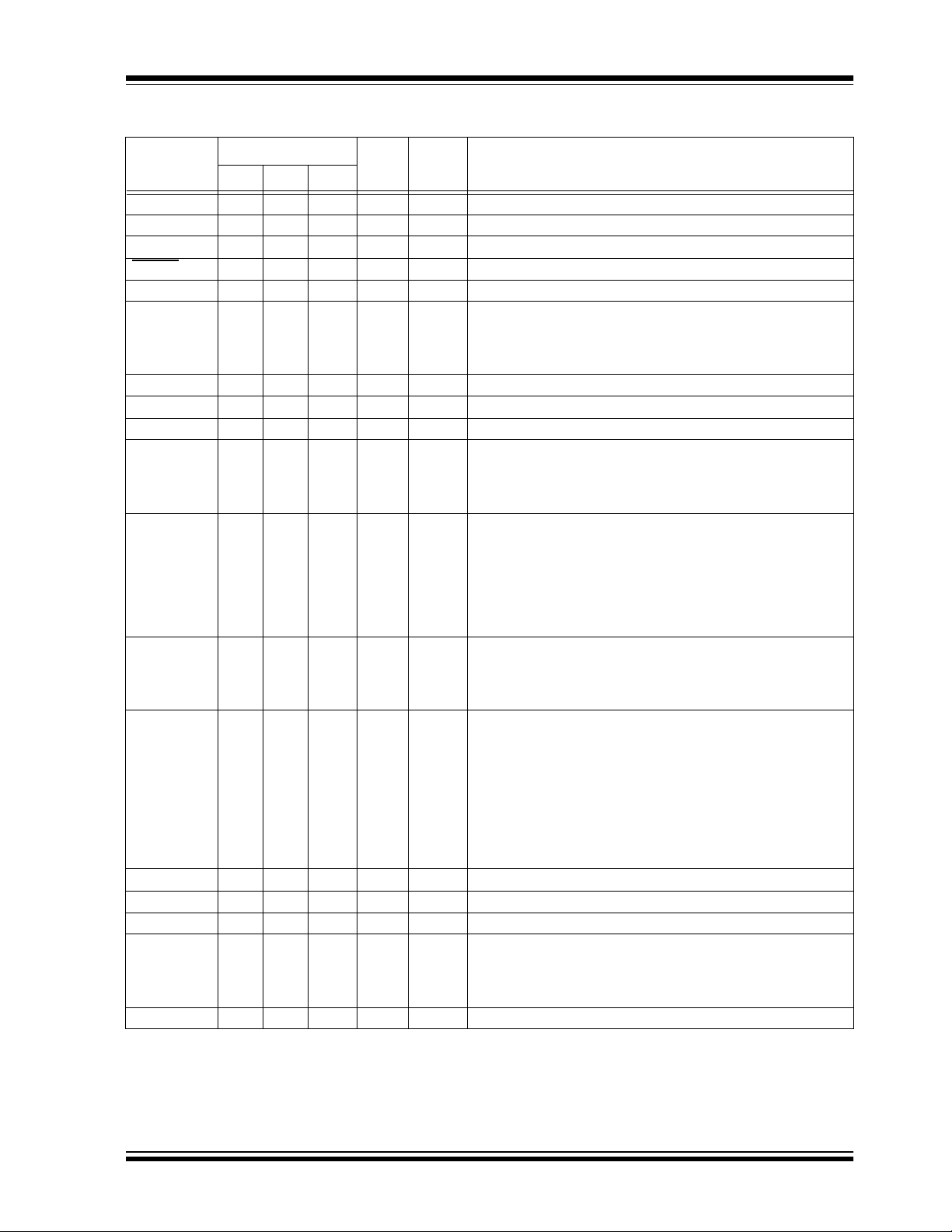

TABLE 1-2: PIN DESCRIPTIONS

MCP2150

Pin Name

BAUD0 1 1 1 I ST BAUD1:BAUD0 specify the baud rate of the device.

TXIR 2 2 2 O — Asynchronous transmit to Infrared transceiver.

RXIR 3 3 3 I ST Asynchronous receive from Infrared transceiver.

4 4 4 I ST Resets the device.

RESET

SS 5 5 5, 6 — P Ground reference for logic and I/O pins.

V

EN 6 6 7 I TTL Device enable.

TX 7 7 8 I TTL Asynchronous receive; from Host Controller UART.

RX 8 8 9 O — Asynchronous transmit; to Host Controller UART.

RI 9 9 10 — — Ring Indicator. The value on this pin is driven high.

DSR 10 10 11 O — Data Set Ready. Indicates that the MCP2150 has completed

DTR 11 11 12 I TTL Data Terminal Ready. The value of this pin is ignored once

CTS 12 12 13 O — Clear to Send. Indicates that the MCP2150 is ready to

RTS 13 13 14 I TTL Request to Send. Indicates that a Host Controller is ready to

V

DD

14 14 15, 16 — P Positive supply for logic and I/O pins.

OSC2 15 15 17 O — Oscillator crystal output.

OSC1/CLKIN 16 16 18 I CMOS Oscillator crystal input/external clock source input.

CD 17 17 19 O — Carrier Detect. Indicates that the MCP2150 has established a

BAUD1 18 18 20 I ST BAUD1:BAUD0 specify the baud rate of the device.

Legend: TTL = TTL compatible input

I = Input

P = Power

Pin Number

PDIP SOIC SSOP

Pin

Buffer

Type

Type

1 = Device is enabled.

0 = Device is disabled (low power). MCP2150 only monitors

this pin when in the NDM state.

reset.

1 = MCP2150 is initialized.

0 = MCP2150 is not initialized.

the MCP2150 is initialized. It is recommended that this pin be

connected so that the voltage level is either V

device power up, this signal is used with the RTS signal to

enter device ID programming.

1 = Enter Device ID programming mode (if RTS is cleared).

0 = Do not enter Device ID programming mode.

receive data from the Host Controller.

1 = Host Controller should not send data.

0 = Host Controller may send data.

receive data from the MCP2150. The MCP2150 prepares to

send data, if available.

1 = Host Controller not ready to receive data.

0 = Host Controller ready to receive data.

At device power up, this signal is used with the DTR signal to

enter device ID programming.

1 = Do not enter Device ID programming mode.

0 = Enter Device ID programming mode (if DTR is set).

valid link with a Primary Device.

1 = An IR link has not been established (No IR Link).

0 = An IR link has been established (IR Link).

ST = Schmitt Trigger input with CMOS levels

O = Output

CMOS = CMOS compatible input

Description

SS or VCC. At

2002 Microchip Technology Inc. Preliminary

DS21655B-page 5

Page 6

MCP2150

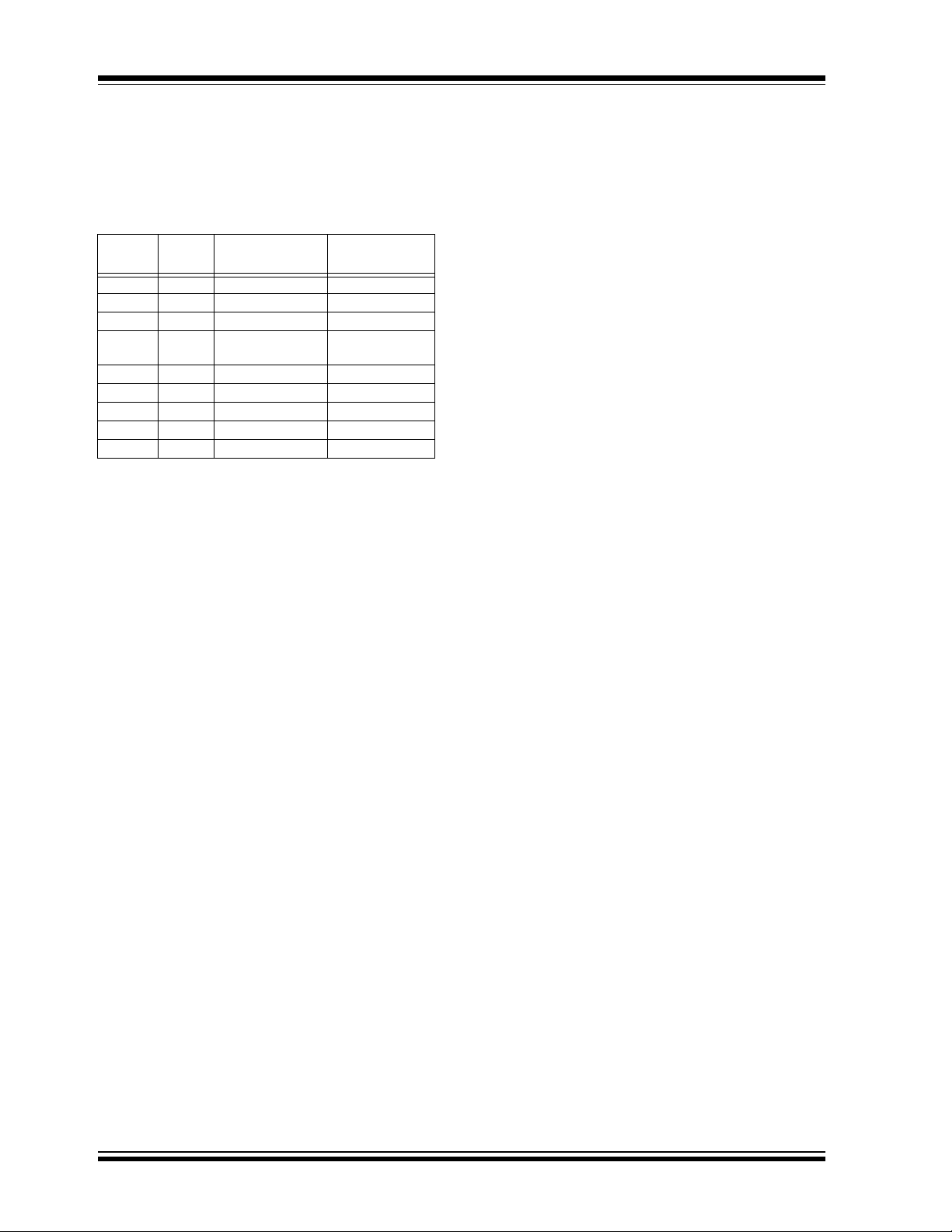

1.1.1 SIGNAL DIRECTIONS

Table 1-3 shows the direction of the MCP2150 signals.

The MCP2150 is designed for use in Data Terminal

Equipment (DTE) applications.

TABLE 1-3: MCP2150 S IGNAL DIRECTION

DB-9

Pin No.

Legend: HC = Host Controller

Note 1: This signal is not implemented in the MCP2150.

Signal Direction Comment

1 CD MCP2150 → HC Carrier Detect

2 RX MCP2150 → HC Received Data

3 TX HC → MCP2150 Transmit Data

4DTR

5 GND — Ground

6 DSR MCP2150 → HC Data Set Ready

7 RTS HC → MCP2150 R equest to Send

8 CTS MCP2150 → HC Clear to Send

9RI

(1)

(1)

— Ring Indicator

— Data Terminal

Ready

DS21655B-page 6

Preliminary 2002 Microchip Technology Inc.

Page 7

MCP2150

2.0 DEVICE OPERATION

The MCP2150 is a cost effective, low pin count (18pin), easy to use device for implementing IrDA standard wireless connectivity. The MCP2150 provides

support for the IrDA standard protocol “stack” plus bit

encoding/decoding. The Serial interface and IR baud

rates are independantly selectable.

2.1 Power Up

Any time the device is powered up (parameter D003),

the Power Up Timer delay (parameter 33) occurs, followed by an Oscillator Start-up Timer (OST) delay

(parameter 32). Once these delays complete, communication with the device may be initiated. This communication is from both the infrared transceiver’s side as

well as the controller’s UART interface.

2.2 Device Reset

The MCP2150 is forced into the reset state when the

RESET

pin is in the low state. Once the RESET pin is

brought to a high state, the Device Reset sequence

occurs. Once the sequence completes, functional

operation begins.

2.3 Clock Source

The MCP2150 requires a clock source to operate. The

frequency of this clock is 11.0592 MHz (electrical specification parameter 1A). This clock can be supplied by

either a crystal/resonator or as an external clock input.

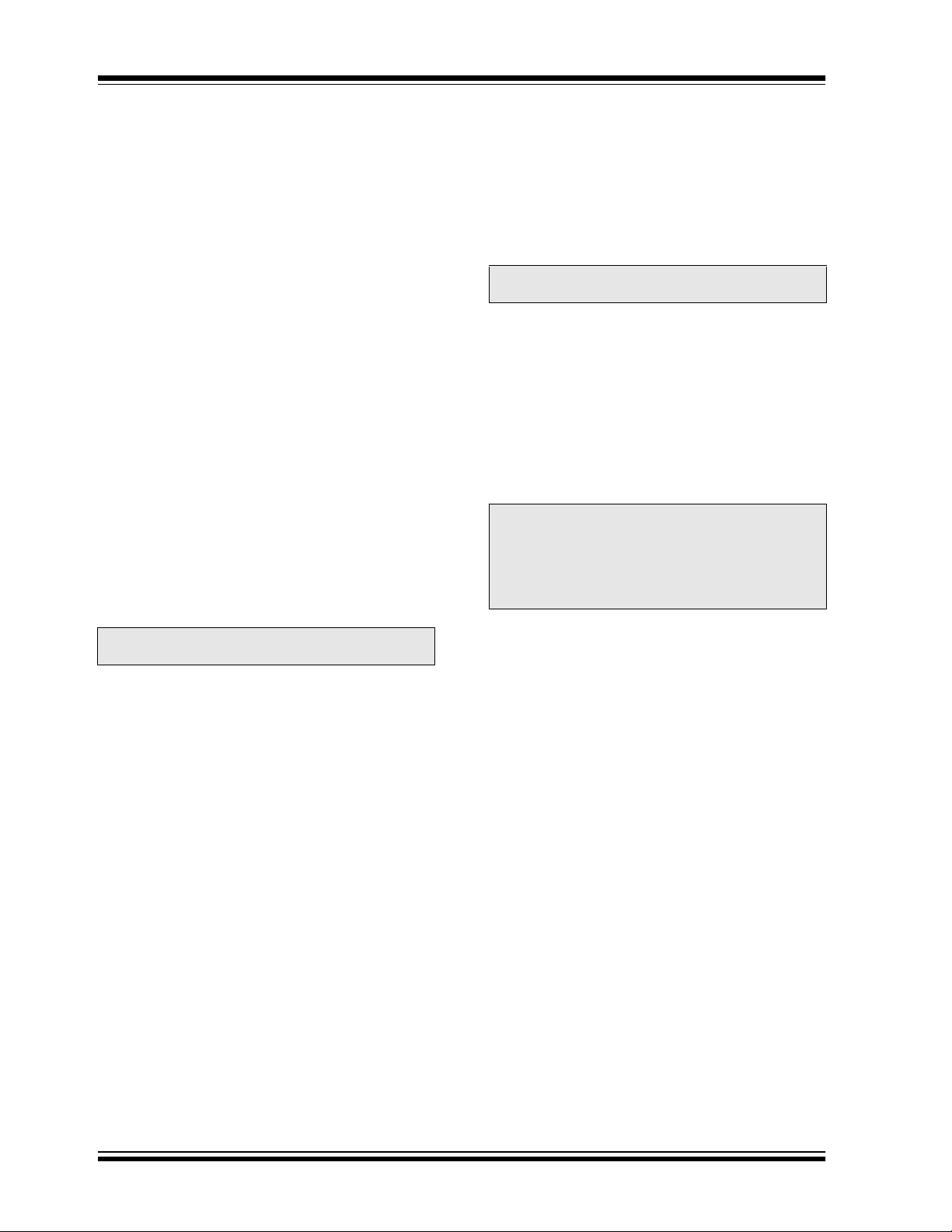

2.3.1 CRYSTAL OSCILLATOR / CERAMIC

RESONATORS

A crystal or ceramic resonator can be connected to the

OSC1 and OSC2 pins to establish oscillation

(Figure 2-1). The MCP2150 oscillator design requires

the use of a parallel cut crystal. Use of a series cut crystal may give a frequency outside of the crystal

manufacturers specifications.

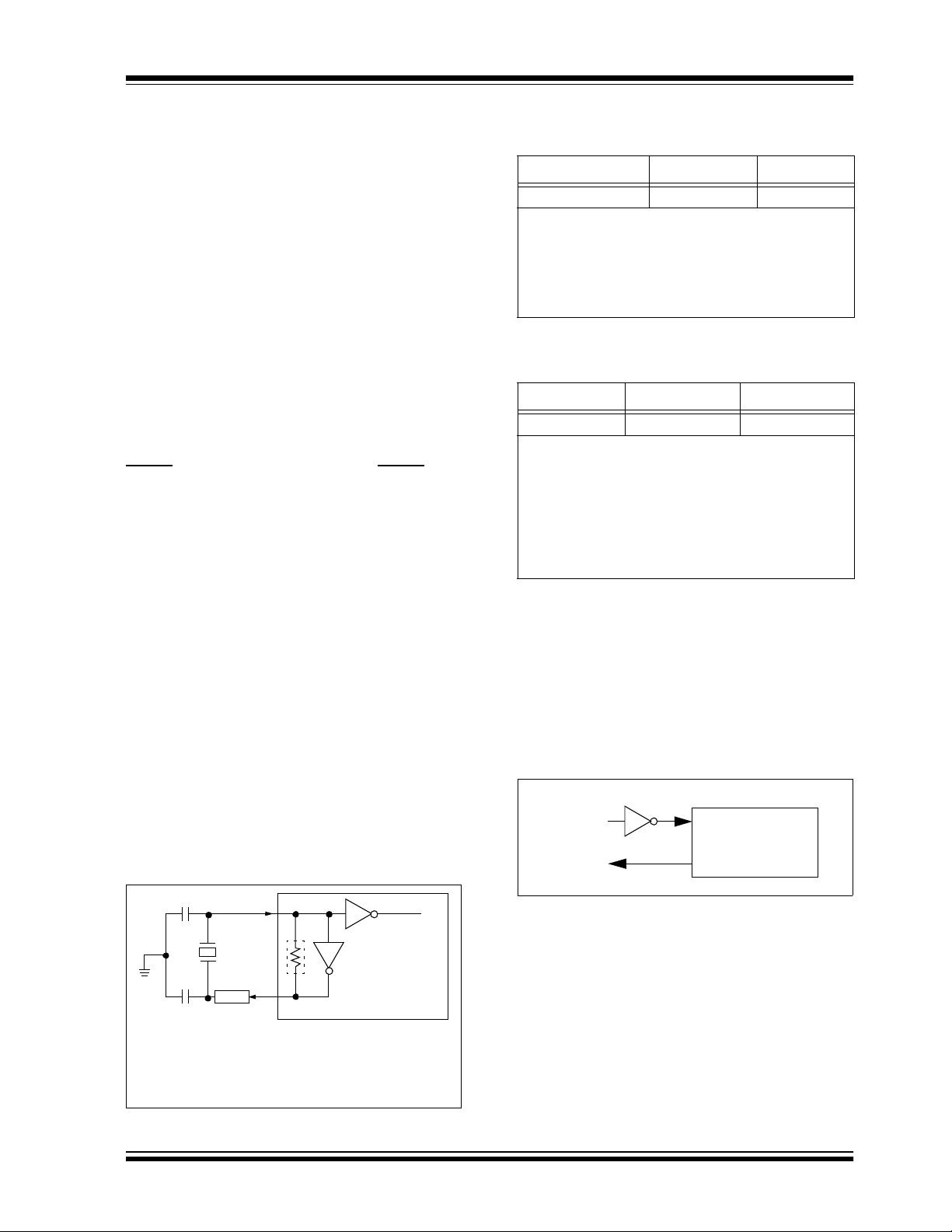

FIGURE 2-1: CRYSTAL OPERATION

(OR CERAMIC

RESONATOR)

TABLE 2-1: CAPACITOR SELECTION FOR

CERAMIC RESONATORS

Freq OSC1 (C1) OSC2 (C2)

11.0592 MHz 10 - 22 pF 10 - 22 pF

Higher capacitance increases the stability of the oscillator but also increases the start-up time. These values are for design guidance only. Since each

resonator has its own characteristics, the user should

consult the resonator manufacturer for appropriate

values of external components.

TABLE 2-2: CAPACITOR SELECTION FOR

CRYSTAL OSCILLATOR

Freq OSC1 (C1) OSC2 (C2)

11.0592 MHz 15 - 30 pF 15 - 30 pF

Higher capacitance increases the stability of the oscillator but also increases the start-up time. These values are for design guidance only. R

to avoid overdriving crystals with low drive level specification. Since each crystal has its own

characteristics, the user should consult the crystal

manufacturer for appropriate values of external

components.

S may be required

2.3.2 EXTERNAL CLOCK IN

For applications where a clock is already available

elsewhere, users may directly drive the MCP2150 provided that this external clock source meets the AC/DC

timing requirements listed in Section 4.3. Figure 2-2

shows how an external clock circuit should be

configured.

FIGURE 2-2: EXTERNAL CLOCK INPUT

OPERATION

Clock From

external

system

Open

OSC1

MCP2150

OSC2

OSC1

C1

XTAL

OSC2

RS

Note

C2

See Tab le 2 -1 and Tab le 2- 2 for recommended values of

C1 and C2.

Note: A series resistor may be required for AT

strip cut crystals.

2002 Microchip Technology Inc. Preliminary

RF

To internal

logic

MCP2150

DS21655B-page 7

Page 8

MCP2150

2.4 Bit Clock

The device crystal is used to derive the communication

bit clock (BITCLK). There are 16 BITCLKs for each bit

time. The BITCLKs are used for the generation of the

start bit and the eight data bits. The stop bit uses the

BITCLK when the data is transmitted (not for

reception).

This clock is a fixed frequency and has minimal

variation in frequency (specified by crystal

manufacturer).

2.5 UART Interface

The UART interface communicates with the "controller". This interface is a half duplex interface, meaning

that the system is either transmitting or receiving, but

not both simultaneously.

2.5.1 BAUD RATE

The baud rate for the MCP2150 serial port (the TX and

RX pins) is configured by the state of the BAUD1 and

BAUD0 pins. These two device pins are used to select

the baud rate at which the MCP2150 will transmit and

receive serial data (not IR data). Table 2-3 shows the

baud rate configurations.

TABLE 2-3: SERIAL BAUD RATE

SELECTION VS. FREQUENCY

BAUD1:BAUD0

00 9600 F

01 19200 F

10 57600 F

11 115200 F

Baud Rate @

11.0592 MHz

Bit Rate

OSC / 1152

OSC / 576

OSC / 192

OSC / 96

2.5.2 TRANSMITTING

When the controller sends serial data to the MCP2150,

the controller’s baud rate is required to match the baud

rate of the MCP2150’s serial port.

2.5.3 RECEIVING

When the controller receives serial data from the

MCP2150, the controller’s baud rate is required to

match the baud rate of the MCP2150’s serial port.

DS21655B-page 8

Preliminary 2002 Microchip Technology Inc.

Page 9

MCP2150

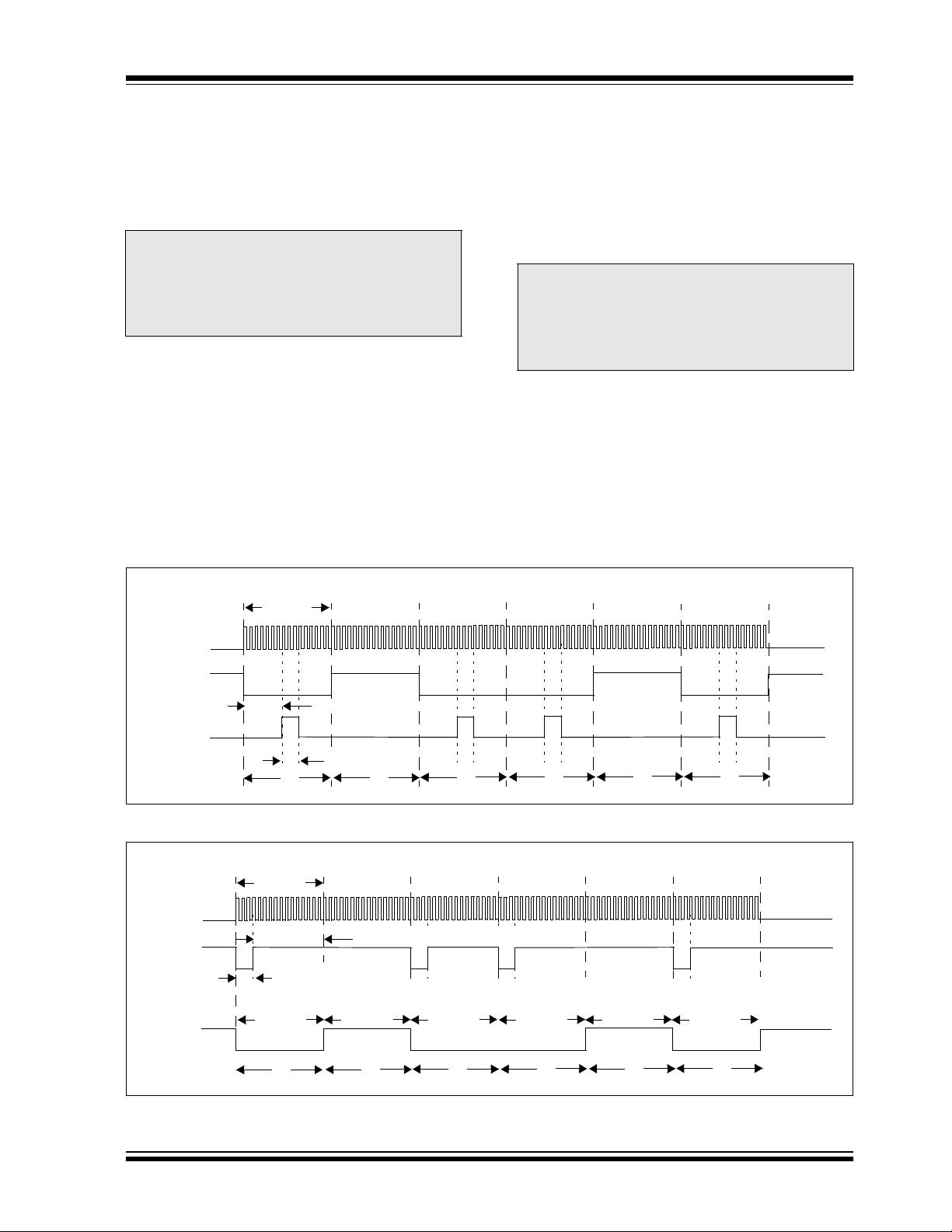

2.6 Modulation

The data that the MCP2150 UART received (on the TX

pin) that needs to be transmitted (on the TXIR pin) will

need to be modulated. This modulated signal drives the

IR transceiver module. Figure 2-3 shows the encoding

of the modulated signal.

Note: The signal on the TXIR pin does not actu-

ally line up in time with the bit value that

was transmitted on the TX pin, as shown in

Figure 2-3. The TX bit value is shown to

represent the value to be transmitted on

the TXIR pin.

Each bit time is comprised of 16-bit clocks. If the value

to be transmitted (as determined by the TX pin) is a

logic low, then the TXIR pin will output a low level for

7-bit clock cycles, a logic high level for 3-bit clock

cycles or a minimum of 1.6 µsec. (see parameter

IR121). The remaining 6-bit clock cycles will be low. If

the value to transmit is a logic high, then the TXIR pin

will output a low level for the entire 16-bit clock cycles.

FIGURE 2-3: ENCODING

2.7 Demodulation

The modulated signal (data) from the IR transceiver

module (on RXIR pin) needs to be demodulated to form

the received data (on RX pin). Once demodulation of

the data byte occurs, the data that is received is transmitted by the MCP2150 UART (on the RX pin).

Figure 2-4 shows the decoding of the modulated

signal.

Note: The signal on the RX pin does not actually

line up in time with the bit value that was

received on the RXIR pin, as shown in

Figure 2-4. The RXIR bit value is shown to

represent the value to be transmitted on

the RX pin.

Each bit time is comprised of 16-bit clocks. If the value

to be received is a logic low, then the RXIR pin will be

a low level for the first 3-bit clock cycles or a minimum

of 1.6 µs. The remaining 13-bit clock cycles (or difference up to the 16-bit clock time) will be high. If the value

to be received is a logic high, then the RXIR pin will be

a high level for the entire 16-bit clock cycles. The level

on the RX pin will be in the appropriate state for the

entire 16 clock cycles.

Start Bit Data bit 0 Data bit 1 Data bit 2 Data bit ...

16 CLK

BITCLK

TX Bit

Value

TXIR

7 CLK

24 Tosc

0100 01

FIGURE 2-4: DECODING

Start Bit Data bit 0 Data bit 1 Data bit 2 Data bit ...

16 CLK

BITCLK

(CLK)

RXIR Bit

Valu e

RX

≥ 1.6 µs (up to 3 CLK)

16 CLK 16 CLK 16 CLK 16 CLK 16 CLK 16 CLK

≥ 13 CLK

0100 01

2002 Microchip Technology Inc. Preliminary

DS21655B-page 9

Page 10

MCP2150

2.8 Minimizing Power

The device can be placed in a low power mode by disabling the device (holding the EN pin at the low state).

The internal state machine is monitoring this pin for a

low level and, once this is detected, the device is

disabled and enters into a low power state.

2.8.1 RETURNING TO DEVICE

OPERATION

When disabled, the device is in a low power state.

When the EN pin is brought to a high level, the device

will return to the operating mode. The device requires

a delay of 1024 T

or received.

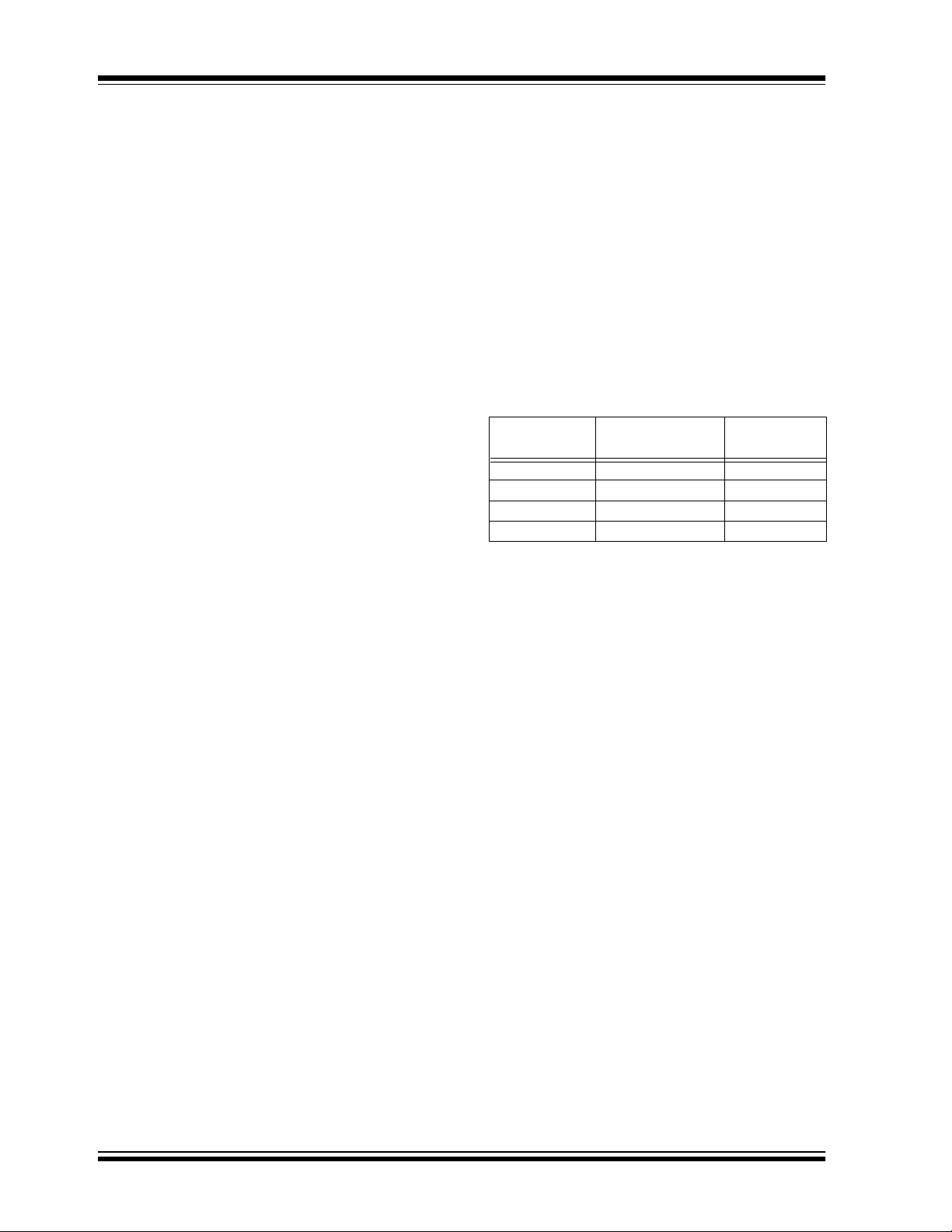

FIGURE 2-5: ISO REFERENCE LAYER MODEL

OSC before data may be transmitted

OSI REFERENCE LAYERS

Application

Presentation

Session

Transport

Network

Data Link Layer

2.9 Network Layering Reference Model

Figure 2-5 shows the ISO Network Layering Reference

Model. The shaded areas are implemented by the

MCP2150, the cross-hatched area is implemented by

an infrared transceiver. The unshaded areas should be

implemented by the Host Controller.

Has to be implemented in Host

Controller firmware

(such as a PICmicro

microcontroller)

Regions implemented

by the MCP2150

Regions implemented

by the Optical Transceiver logic

®

LLC (Logical Link Control)

Acceptance Filtering

Overload Notification

Recovery Management

MAC (Medium Access Control)

Data Encapsulation/Decapsulation

Frame Coding (stuffing, destuffing)

Medium Access Management

Error Detection

Error Signalling

Acknowledgment

Serialization/Deserialization

Physical Layer

PLS (Physical Signalling)

Bit Encoding/Decoding

Bit Timing

Synchronization

PMA (Physical Medium Attachment)

Driver/Receiver Characteristics

MDI (Medium Dependent Interface)

Connectors

Supervisor

Fault

confinement

(MAC-LME)

Bus Failure

management

(PLS-LME)

DS21655B-page 10

Preliminary 2002 Microchip Technology Inc.

Page 11

MCP2150

The IrDA standard specifies the following protocols:

• Physical Signaling Layer (PHY)

• Link Access Protocol (IrLAP)

• Link Management Protocol/Information Access

Service (IrLMP/IAS)

The IrDA data lists optional protocols. They are:

•Tiny TP

• IrTran-P

• IrOBEX

•IrLAN

•IrCOMM

•IrMC

•IrDA Lite

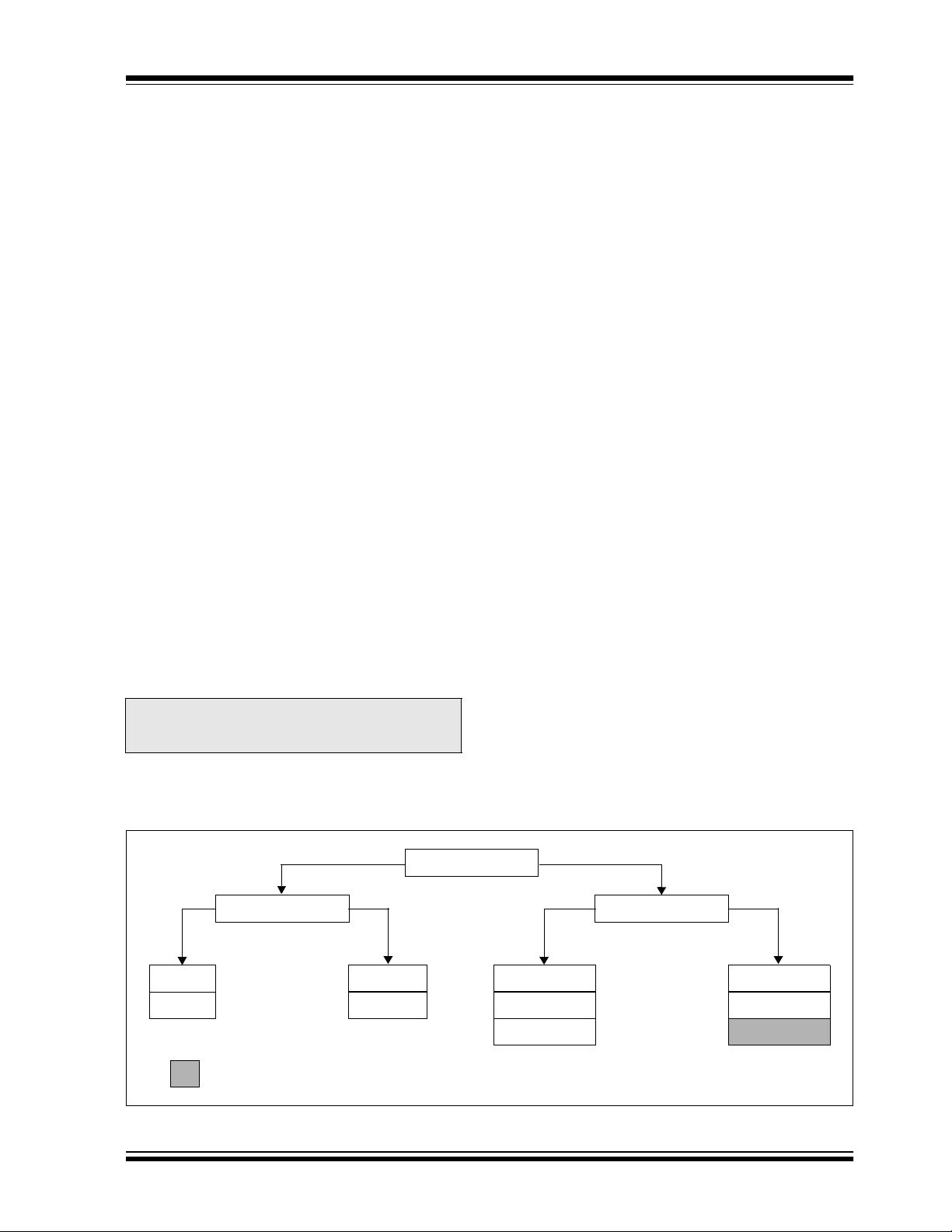

Figure 2-6 shows the IrDA data protocol stack and

which components are implemented by the MCP2150.

FIGURE 2-6: IRDA DATA - PROTOCOL

STACKS

IrTran-P IrObex IrLan IrMC

LM-IAS Tiny Transport Protocol (Tiny TP)

IR Link Management - Mux (IrLMP)

IR Link Access Protocol (IrLAP)

Asynchronous

Serial IR

(9600 -115200 b/s)

Supported by

the MCP2150

(2)

Synchronous

IrComm

Serial IR

(1.152 Mb/s)

Optional IrDA data

protocols not

supported by

the MCP2150

(1)

Synchronous

4 PPM

(4 Mb/s)

2.9.1 IrDA DATA PROTOCOLS

SUPPORTED BY MCP2150

The MCP2150 supports these required IrDA standard

protocols:

• Physical Signaling Layer (PHY)

• Link Access Protocol (IrLAP)

• Link Management Protocol/Information Access

Service (IrLMP/IAS)

The MCP2150 also supports some of the optional protocols for IrDA data. The optional protocols that the

MCP2150 implements are:

•Tiny TP

•IrCOMM

2.9.1.1 Physical Signal Layer (PHY)

The MCP2150 provides the following Physical Signal

Layer specification support:

• Bidirectional communication

• Data Packets are protected by a CRC

- 16-bit CRC for speeds up to 115.2 kbaud

• Data Communication Rate

- 9600 baud minimum data rate

The following Physical Layer Specification is dependant on the optical transceiver logic used in the

application. The specification states:

• Communication Range, which sets the end user

expectation for discovery, recognition and performance.

- Continuous operation from contact to at least

1 meter (typically 2 meters can be reached)

- A low power specification reduces the objective for operation from contact to at least

20 cm (low power and low power) or 30 cm

(low power and standard power).

Note 1: The MCP2155 implements the 9-wire

“cooked" service class serial replicator.

2: An optical transceiver is required.

2002 Microchip Technology Inc. Preliminary

DS21655B-page 11

Page 12

MCP2150

2.9.1.2 IrLAP

The MCP2150 supports the IrLAP protocol. The IrLAP

protocol provides:

• Management of communication processes on the

link between devices.

• A device-to-device connection for the reliable,

ordered transfer of data.

• Device discover procedures.

• Hidden node handling.

Figure 2-7 identifies the key parts and hierarchy of the

IrDA protocols. The bottom layer is the Physical layer,

IrPHY. This is the part that converts the serial data to

and from pulses of IR light. IR transceivers can’t transmit and receive at the same time. The receiver has to

wait for the transmitter to finish sending. This is sometimes referred to as a “Half-Duplex” connection. The IR

Link Access Protocol (IrLAP) provides the structure for

packets (or “frames”) of data to emulate data that would

normally be free to stream back and forth.

FIGURE 2-7: IRDA STANDARD

PROTOCOL LAYERS

Host O.S. or Application

IrCOMM

IrLMP – IAS

IrLAP

Protocols

resident in

MCP2150

Figure 2-8 shows how the IrLAP frame is organized.

The frame is proceeded by some number of Beginning

of Frame characters (BOFs). The value of the BOF is

generally 0xC0, but 0xFF may be used if the last BOF

character is a 0xC0. The purpose of multiple BOFs is to

give the other station some warning that a frame is

coming.

The IrLAP frame begins with an address byte (“A”

field), then a control byte (“C” field). The control byte is

used to differentiate between different types of frames

and is also used to count frames. Frames can carry status, data or commands. The IrLAP protocol has a command syntax of it’s own. These commands are part of

the control byte. Lastly, IrLAP frames carry data. This

data is the information (or “I”) field. The integrity of the

frame is ensured with a 16-bit CRC, referred to as the

Frame Check Sequence (FCS). The 16-bit CRC value

is transmitted LSB first. The end of the frame is marked

with an EOF character, which is always a 0xC1. The

frame structure described here is used for all versions

of IrDA protocols used for serial wire replacement for

speeds up to 115.2 kbaud.

Note 1: Another IrDA standard that is entering

general usage is IR Object Exchange

(IrOBEX). This standard is not used for

serial connection emulation.

2: IrDA communication standards faster

than 115.2 kbaud use a different CRC

method and physical layer.

FIGURE 2-8: IRLAP FRAME

IrPHY

IR pulses

transmitted

and

received

X BOFs BOF A C FCSI EOF

2

(1+N) of C0h payload

In addition to defining the frame structure, IrLAP provides the “housekeeping” functions of opening, closing

and maintaining connections. The critical parameters

that determine the performance of the link are part of

this function. These parameters control how many

BOFs are used, identify the speed of the link, how fast

either party may change from receiving to transmitting,

etc. IrLAP has the responsibility of negotiating these

parameters to the highest common set so that both

sides can communicate as quickly, and as reliably, as

possible.

bytes

C1h

DS21655B-page 12

Preliminary 2002 Microchip Technology Inc.

Page 13

MCP2150

2.9.1.3 IrLMP

The MCP2150 implements the IrLMP protocol. The

IrLMP protocol provides:

• Multiplexing of the IrLAP layer. This allows multiple channels above an IrLAP connection.

• Protocol and service discovery. This is via the

Information Access Service (IAS).

When two devices that contain the IrDA standard feature are connected, there is generally one device that

has something to do and the other device that has the

resource to do it. For example, a laptop may have a job

to print and an IrDA standard compatible printer has the

resources to print it. In IrDA standard terminology, the

laptop is a Primary device and the printer is the Secondary device. When these two devices connect, the

Primary device must determine the capablities of the

Secondary device to determine if the Secondary device

is capable of doing the job. This determination is made

by the Primary device asking the Secondary device a

series of questions. Depending on the answers to

these questions, the Primary device may or may not

elect to connect to the Secondary device.

The queries from the Primary device are carried to the

Secondary device using IrLMP. The responses to these

queries can be found in the Information Access Service

(IAS) of the Secondary device. The IAS is a list of the

resources of the Secondary device. The Primary

device compares the IAS responses with its requirements and then makes the decision if a connection

should be made.

The MCP2150 identifies itself to the Primary device as

a modem.

2.9.1.4 Link Management - Information

Access Service (LM-IAS)

The MCP2150 implements the LM-IAS. Each LM-IAS

entity maintains an information database to provide:

• Information on services for other devices that

contain the IrDA standard feature (Discovery).

• Information on services for the device itself.

• Remote accessing of another device’s information

base.

This is required so that clients on a remote device can

find configuration information needed to access a

service.

2.9.1.5 Tiny TP

Tiny TP provides the flow control on IrLMP connections. An optional service of Segmentation and

Reassembly can be handled.

2.9.1.6 IrCOMM

IrCOMM provides the method to support serial and parallel port emulation. This is useful for legacy COM

applications, such as printers and modem devices.

The IrCOMM standard is just a syntax that allows the

Primary device to consider the Secondary device as a

serial device. IrCOMM allows for emulation of serial or

parallel (printer) connections of various capabilities.

The MCP2150 supports the 9-wire “cooked” service

class of IrCOMM. Other service classes supported by

IrCOMM are shown in Figure 2-9.

Note: The MCP2150 identifies itself as a modem

to ensure that it is identified as a serial

device with a limited amount of memory.

The MCP2150 is not a modem, and the non-data circuits are not handled in a modem fashion.

FIGURE 2-9: IRCOMM SERVICE CLASSES

IrCOMM Services

Uncooked Services Cooked Services

Parallel Serial

IrLPT

Supported by MCP2150

3-wire Raw

Parallel

Centronics

IEEE 1284

Serial

3-wire Cooked

9-wire Cooked

2002 Microchip Technology Inc. Preliminary

DS21655B-page 13

Page 14

MCP2150

2.9.2 OTHER OPTIONAL IrDA DATA

PROTOCOLS

Other IrDA data protocols have been developed to specific application requirements. These optional protocols

are not supported by the MCP2150. These IrDA data

protocols are briefly described in the following sub-sections. For additional information, please refer to the

IrDA website (www.IrDA.org).

2.9.2.1 IrTran-P

IrTran-P provides the protocol to exchange images with

digital image capture devices/cameras.

2.9.2.2 IrOBEX

IrOBEX provides OBject EXchange services. This is

similar to HTTP.

2.9.2.3 IrLAN

IrLAN describes a protocol to support IR wireless

access to a Local Area Network (LAN).

2.9.2.4 IrMC

IrMC describes how mobile telephony and communication devices can exchange information. This information includes phonebook, calender and message data.

Also how call control and real-time voice are handled

(RTCON).

2.9.2.5 IrDA Lite

IrDA Lite describes how to reduce the application code

requirements, while maintaining compatibility with the

full implementation.

DS21655B-page 14

Preliminary 2002 Microchip Technology Inc.

Page 15

MCP2150

2.9.3 HOW DEVICES CONNECT

When two devices implementing the IrDA standard feature establish a connection using the IrCOMM protocol,

the process is analogous to connecting two devices

with serial ports using a cable. This is referred to as a

"point-to-point" connection. This connection is limited

to half-duplex operation because the IR transceiver

cannot transmit and receive at the same time. The purpose of the IrDA protocol is to allow this half-duplex link

to emulate, as much as possible, a full-duplex connection. In general, this is done by dividing the data into

“packets”, or groups of data. These packets can then

be sent back and forth, when needed, without risk of

collision. The rules of how and when these packets are

sent constitute the IrDA protocols. The MCP2150 supports elements of this IrDA protocol to communicate

with other IrDA standard compatible devices.

When a wired connection is used, the assumption is

made that both sides have the same communications

parameters and features. A wired connection has no

need to identify the other connector because it is

assumed that the connectors are properly connected.

In the IrDA standard, a connection process has been

defined to identify other IrDA compatible devices and

establish a communication link. There are three steps

that these two devices go through to make this

connection. They are:

• Normal Disconnect Mode (NDM)

• Discovery Mode

• Normal Connect Mode (NCM)

Figure 2-10 shows the connection sequence.

2.9.3.1 Normal Disconnect Mode (NDM)

When two IrDA standard compatible devices come into

range they must first recognize each other. The basis

of this process is that one device has some task to

accomplish and the other device has a resource

needed to accomplish this task. One device is referred

to as a Primary device and the other is referred to as a

Secondary device. This distinction between Primary

device and Secondary device is important. It is the

responsibility of the Primary device to provide the

mechanism to recognize other devices. So the Primary

device must first poll for nearby IrDA standard compatible devices. During this polling, the defaut baud rate of

9600 baud is used by both devices.

For example, if you want to print from an IrDA

equipped laptop to an IrDA printer, utilizing the IrDA

standard feature, you would first bring your laptop in

range of the printer. In this case, the laptop is the one

that has something to do and the printer has the

resource to do it. The laptop is called the Primary

device and the printer is the Secondary device. Some

data-capable cellphones have IrDA standard infrared

ports. If you used such a cellphone with a Personal Dig-

ital Assistant (PDA), the PDA that supports the IrDA

standard feature would be the Primary device and the

cellphone would be the Secondary device.

When a Primary device polls for another device, a

nearby Secondary device may respond. When a Secondary device responds, the two devices are defined to

be in the Normal Disconnect Mode (NDM) state. NDM

is established by the Primary device broadcasting a

packet and waiting for a response. These broadcast

packets are numbered. Usually 6 or 8 packets are sent.

The first packet is number 0, the last packet is usually

number 5 or 7. Once all the packets are sent, the Primary device sends an ID packet, which is not numbered.

The Secondary device waits for these packets and then

responds to one of the packets. The packet it responds

to determines the “time slot” to be used by the Secondary device. For example, if the Secondary device

responds after packet number 2, then the Secondary

device will use time slot 2. If the Secondary device

responds after packet number 0, then the Secondary

device will use time slot 0. This mechanism allows the

Primary device to recognize as many nearby devices

as there are time slots. The Primary device will continue to generate time slots and the Secondary device

should continue to respond, even if there’s nothing to

do.

Note 1: The MCP2150 can only be used to

implement a Secondary device.

2: The MCP2150 supports a system with

only one Secondary device having exclusive use of the IrDA standard infrared link

(known as "point-to-point" communication).

3: The MCP2150 always responds to packet

number 2. This means that the MCP2150

will always use time slot 2.

4: If another Secondary device is nearby,

the Primary device may fail to recognize

the MCP2150, or the Primary device may

not recognize either of the devices.

During NDM, the MCP2150 handles all of the

responses to the Primary device (Figure 2-10) without

any communication with the Host Controller. The Host

Controller is inhibited by the CTS signal of the

MCP2150 from sending data to the MCP2150.

2002 Microchip Technology Inc. Preliminary

DS21655B-page 15

Page 16

MCP2150

2.9.3.2 Discovery Mode

Discovery mode allows the Primary device to determine the capabilities of the MCP2150 (Secondary

device). Discovery mode is entered once the MCP2150

(Secondary device) has sent an XID response to the

Primary device and the Primary device has completed

sending the XIDs and then sends a Broadcast ID. If this

sequence is not completed, then a Primary and

Secondary device can stay in NDM indefinitely.

When the Primary device has something to do, it

initiates Discovery. Discovery has two parts. They are:

• Link initialization

• Resource determination

The first step is for the Primary and Secondary devices

to determine, and then adjust to, each other’s hardware

capabilities. These capabilities are parameters like:

• Data rate

• Turn around time

• Number of packets without a response

• How long to wait before disconnecting

Both the Primary and Secondary device begin communications at 9600 baud, which is the default baud rate.

The Primary device sends its parameters, then the

Secondary device responds with its parameters. For

example, if the Primary supports all data rates up to

115.2 kbaud and the Secondary device only supports

19.2 kbaud, the link will be established at 19.2 kbaud.

Note: The MCP2150 is limited to a data rate of

115.2 kbaud.

Once the hardware parameters are established, the

Primary device must determine if the Secondary device

has the resources it requires. If the Primary device has

a job to print, then it must know if it’s talking to a printer,

not a modem or other device. This determination is

made using the Information Access Service (IAS). The

job of the Secondary device is to respond to IAS queries made by the Primary device. The Primary device

must ask a series of questions like:

• What is the name of your service?

• What is the address of this service?

• What are the capabilities of this device?

When all the Primary device’s questions are answered,

the Primary device can access the service provided by

the Secondary device.

During Discovery mode, the MCP2150 handles all

responses to the Primary device (see Figure 2-10)

without any comm unication with the Host Controller.

The Host Controller is inhibited by the CTS signal of the

MCP2150 from sending data to the MCP2150.

2.9.3.3 Normal Connect Mode (NCM)

Once discovery has been completed, the Primary

device and MCP2150 (Secondary device) can freely

exchange data.

The MCP2150 can receive IR data or serial data, but

not both simultaneously. The MCP2150 uses a hardware handshake to stop the local serial port from

sending data while the MCP2150 is receiving IR data.

Note: Data loss will result if this hardware

handshake is not observed.

Both the Primary device and the MCP2150 (Secondary

device) check to make sure that data packets are

received by the other without errors. Even when data is

required to be sent, the Primary and Secondary

devices will still exchange packets to ensure that the

connection hasn’t, unexpectedly, been dropped. When

the Primary device has finished, it then transmits the

close link command to the MCP2150 (Secondary

device). The MCP2150 will confirm the close link command and both the Primary device and the MCP2150

(Secondary device) will revert to the NDM state.

Note: If the NCM mode is unexpectedly termi-

nated for any reason (including the Primary

device not issuing a close link command),

the MCP2150 will revert to the NDM state

10 seconds after the last frame has been

received.

It is the responsability of the Host Controller program to

understand the meaning of the data received and how

the program should respond to it. It’s just as if the data

were being received by the Host Controller from a

UART.

DS21655B-page 16

Preliminary 2002 Microchip Technology Inc.

Page 17

FIGURE 2-10: CONNECTION SEQUENCE

Primary Device Secondary Device

Normal Disconnect Mode (NDM)

Send XID Commands

(timeslots n, n+1, ...)

(approximately 70ms

between XID commands)

Finish sending XIDs

(max timeslots - y frames)

Broadcast ID

MCP2150

(ex. MCP2150)

No Response

XID Response in timeslot y,

claiming this timeslot, (MCP2150

always claims timeslot 2)

No Response to these XIDs

No Response to Broadcast ID

Discovery

Normal Response Mode (NRM)

Send SNRM Command

(w/ parameters and

connection address)

Open channel for IAS Queries

Send IAS Queries

Open channel for data

Send Data or Status

Send Data or Status

UA response with parameters

using connect address

Confirm channel open for IAS

Provide IAS responses

Confirm channel open for data

(MCP2150 CD pin driven low)

Send Data or Status

Send Data or Status

Shutdown link

2002 Microchip Technology Inc. Preliminary

Confirm shutdown

(back to NDM state)

DS21655B-page 17

Page 18

MCP2150

2.10 Operation

The MCP2150 emulates a null modem connection. The

application on the DTE device sees a virtual serial port.

This serial port emulation is provided by the IrDA standard protocols. The link between the DTE device and

the embedded application is made using the

MCP2150. The connection between the MCP2150 and

the embedded application is wired as if there were a

null modem connection.

The Carrier Detect (CD) signal of the MCP2150 is used

to indicate that a valid IrDA standard infrared link has

been established between the MCP2150 and the Primary device. The CD signal should be monitored

closely to make sure that any communication tasks can

be completed. The MCP2150 DSR signal indicates that

the device has powered-up, successfully initialized and

is ready for service. This signal is intended to be connected to the DSR input of the Host Controller. If the

Host Controller was directly connected to an IrDA standard Primary device using a serial cable (the MCP2150

is not present), the Host Controller would be connected

to the Primary device’s DTR output signal.

The MCP2150 generates the CTS signal locally

because of buffer limitations.

Note 1: The MCP2150 generates non-data

signals locally.

2: Only transceiver’s TXD and RXD signals

are carried back and forth to the Primary

device. The MCP2150 emulates a 3-wire

serial connection (TXD, RXD and GND).

2.10.1 HARDWARE HANDSHAKING

2.10.2 BUFFERS AND THROUGHPUT

The maximum IR data rate of the MCP2150 is

115.2 kbaud. The actual throughput will be less, due to

several factors. The most significant factors are under

the control of the developer. One factor beyond the

control of the designer is the overhead associated with

the IrDA standard. The MCP2150 uses a fixed data

block size of 64 bytes. To carry 64 bytes of data, the

MCP2150 must send 72 bytes (64+8). The additional 8

bytes are used by the protocol. When the Primary

device receives the frame, it must wait for a minimum

latency period before sending a packet of its own. This

turnaround time is set by IrLAP when the parameters of

the link are negotiated. A common turnaround time is

1 ms, although longer and shorter times may be

encountered. 1 ms represents approximately 12 byte

times at a data rate of 115.2 kbaud. The minimum size

frame the Primary device can respond with is 6 bytes.

The MCP2150 will add the 12 byte-time latency on its

own, again assuming a 1 ms latency. This means that

the maximum throughput will be 64 data bytes out of a

total of 64 + 38 byte times. Thus, the maximum theoretical throughput will be limited to about 64/(64+38)=63%

of the IR data rate. Actual maximum throughput will be

dependent on both the MCP2150 and the

characteristics of the Primary device.

The most significant factor in data throughput is how

well the data frames are filled. If only 1 byte is sent at a

time, then the maximum throughput is 1/(1+38)=2.5%

of the IR data rate. The best way to maximize throughput is to align the amounts of data with the packet size

of the MCP2150. Throughput examples are shown in

Table 2-4.

The MCP2150 uses a 64-byte buffer for incoming data

from the IR Host. Another 64-byte buffer is provided to

buffer data from the UART serial port. When an IR

packet begins the IrComm, the MCP2150 handles IR

data exclusively (the UART serial port buffer is not

available). A hardware handshaking pin (CTS) is provided to inhibit the Host Controller from sending serial

data while IR Data is being sent or received.

Note: When the CTS output from the IrComm is

high, no data should be sent from the Host

Controller. The UART FIFO will store up to

2 bytes. Any additional data bytes will be

lost.

Note: IrDA throughput is based on many factors

associated with characteristics of the Primary and Secondary devices. These characteristics may cause your application

throughput to be less than the theoretical

example shown in Tab le 2- 4.

TABLE 2-4: THEORETICAL IrDA STANDARD THROUGHPUT EXAMPLES @ 115.2 KBAUD

MCP2150

Data Packet

Size (Bytes)

64 8 6 12 12 102 62.7%

18 6 12 12 392.6%

Note 1: Number of bytes calculated based on a common turnaround time of 1 ms.

Overhead

(Bytes)

Primary Device

Minimum

Response (Bytes)

Primary Device

Turn-around Time

(Bytes)

MCP2150

(1)

Turn-around

Time

(1)

(Bytes)

Total Bytes

Transmit ted

Throughput

% (Data/Total)

DS21655B-page 18

Preliminary 2002 Microchip Technology Inc.

Page 19

MCP2150

2.11 Turnaround Latency

An IR link can be compared to a one-wire data connection. The IR transceiver can transmit or receive, but not

both at the same time. A delay of one bit time is recommended between the time a byte is received and

another byte is transmitted.

2.12 IR Port Baud Rate

The baud rate for the MCP2150 IR port (the TXIR and

RXIR pins) is, initially, at the default rate of 9600 baud.

The Primary device determines the maximum baud

rate that the MCP2150 will operate at. This information

is used during NDM, with the Primary device setting the

baud rate of the IR link. The maximum IR baud rate is

not required to be the same as the MCP2150’s serial

port (UART) baud rate (as determined by the

BAUD1:BAUD0 pins).

2.13 Programmable Device ID

The MCP2150 has a flexible feature that allows the

MCP2150 Device ID to be changed by the Host Controller. The default ID is “Generic IrDA” and is stored in

non-volatile, electrically erasable programmable memory (EEPROM). The maximum ID String length is 19

bytes. The format of the ID EEPROM is shown in

Figure 2-11.

The ID String must only contain the ASCII characters

from 20h to 7Ah (inclusive).

The MCP2150 enters into ID String programming when

it exits the reset state and detects that the DTR pin is

high and the RTS pin is low.

A Host Controller connected to the MCP2150 would,

typically, perform the following steps to place the

MCP2150 into ID String programming mode:

1. Force the MCP2150 into reset (RESET pin

forced low).

2. Force the DTR pin high and the RTS pin low.

3. Release the MCP2150 from reset (RESET pin

forced high).

4. Wait for device to complete initialization.

TABLE 2-5: DTR/RTS STATE & DEVICE

MODE

DTR RTS After Device Reset *

0XEnter Normal Mode

10Enter Programmable Device ID

11Enter Normal Mode

* Until device initialization is complete.

Once the MCP2150 is ready to receive data, the CTS

pin will be forced low. Data may now be transferred, following the format in Figure 2-11. The CTS pin determines the flow control and the Host Controller must

monitor this signal to ensure that the data byte may be

sent.

Once the Host Controller has sent its last byte, the DTR

pin must be set low. This ensures that, if another reset

occurs, the MCP2150 will not reenter ID String programming mode. The MCP2150 uses the String Length

(1st byte transmitted) to determine when the ID String

programming mode has completed. This returns the

MCP2150 to normal operation.

Note 1: If a non-valid ID String (containing an ASCII

character not in the valid range) is

programmed, the MCP2150 will not create

a link with a Primary device.

2: The communication program supplied with

Microsoft’s Windows

(called HyperTerminal) may leave the DTR

signal high and the RTS signals low when

the program disconnects, or is closed. Care

should be taken to ensure that this does not

accidently cause the MCP2150 to enter

Device ID String Programming.

Example 2-1 shows the firmware code for a

PIC16CXXX acting as the Host Controller to modify the

MCP2150 Device ID String.

®

operating system

FIGURE 2-11: ID STRING FORMAT

1st Byte

Transferred

Length ID String

1 Byte 1 to 19 Bytes

2002 Microchip Technology Inc. Preliminary

Last Byte

Transferred

DS21655B-page 19

Page 20

MCP2150

EXAMPLE 2-1: PIC16FXX Code to Program the Device ID

;#define dtr PORTx, Pinx ; Must specify which Port and Which Pin

;#define cts PORTx, Pinx ; Must specify which Port and Which Pin

;#define rts PORTx, Pinx ; Must specify which Port and Which Pin

;#define clr PORTx, Pinx ; Must specify which Port and Which Pin

;

;*****************************************************************

; String Tabl e

; This table stores a string, breg is the offset. The string

; is termin at ed by a null character.

;*****************************************************************

string 1 clr f PCLA TH ; this routine is on pa ge 0

movf breg, W ; get the off se t

addwf PCL, F ; add the offset to PC

DT D'15' ; the first byte is the byte cou nt

DT "My IR ID String"

;

UpdateID

call deviceIn it ; Initialize the PIC16Fxx x

bcf clr ; place the MCP2150 in re set

bsf dtr ; Force the DTR pin high for program mo de

bcf rts ; Force the RTS pin low for program mode

call delay1mS ; delay for 1 ms.

bsf clr ; allow the MCP2150 to co me ou t of res et

;

clrf LoopCnt ; LoopCnt = 0

ctsLP1 call dela y1 mS ; delay for 1 ms.

btfss cts ; if cts=0 then we're ready to program

goto ctsLow ; MCP215 0 is re ad y to receive data

decfsz Loop Cnt, F ;

goto ctsLP1 ; NO, wait fo r MC P2 15 0 to be ready

goto StuckRes et ; The MCP2150 did not exit reset , do you r rec overy

; in this routine.

DS21655B-page 20

Preliminary 2002 Microchip Technology Inc.

Page 21

MCP2150

EXAMPLE 2-1: PIC16FXX Code to Program the Device ID (Continued)

ctsLow clrf breg ; clear the offset

call string1 ; get the byte count

; (ID length byte + # bytes in string)

movwf creg ; use creg as the loo p co unt er

incf creg, f ; add 1 to the lo op cou nt since

; we're jumping into the middle

movwf areg ; save the coun t in are g to se nd it

goto sndwt ; start sending the count + ID string

;

sndlp call strin g1 ; get the byte

movwf areg ; save the byte

sndwt btfsc cts ; check the cts input

goto sndwt ; wait if cts=1

call txser ; send the byte using the Transmit Routine

incf breg,f ; increment the table pointer

decfsz creg, f ; more bytes to send?

goto sndlp ; YES, send more bytes

;

bcf clr ; NO, place the MCP2150 in reset

bcf dtr ; Force the DTR pin low for normal mode

bsf rts ; Force the RTS pin high for normal mod e

call delay1mS ; delay for 1 ms.

bsf clr ; allow the MCP2150 to co me ou t of res et

;

ctsLP2 btfss cts ; if cts=1 then MCP2150 is in Normal mode

goto ctsLP2 ; NO, wait fo r MC P2 15 0 to be ready

goto NormalOperation ; The MCP2150 in now programmed with new ID,

; and is ready to establish an IR link

2002 Microchip Technology Inc. Preliminary

DS21655B-page 21

Page 22

MCP2150

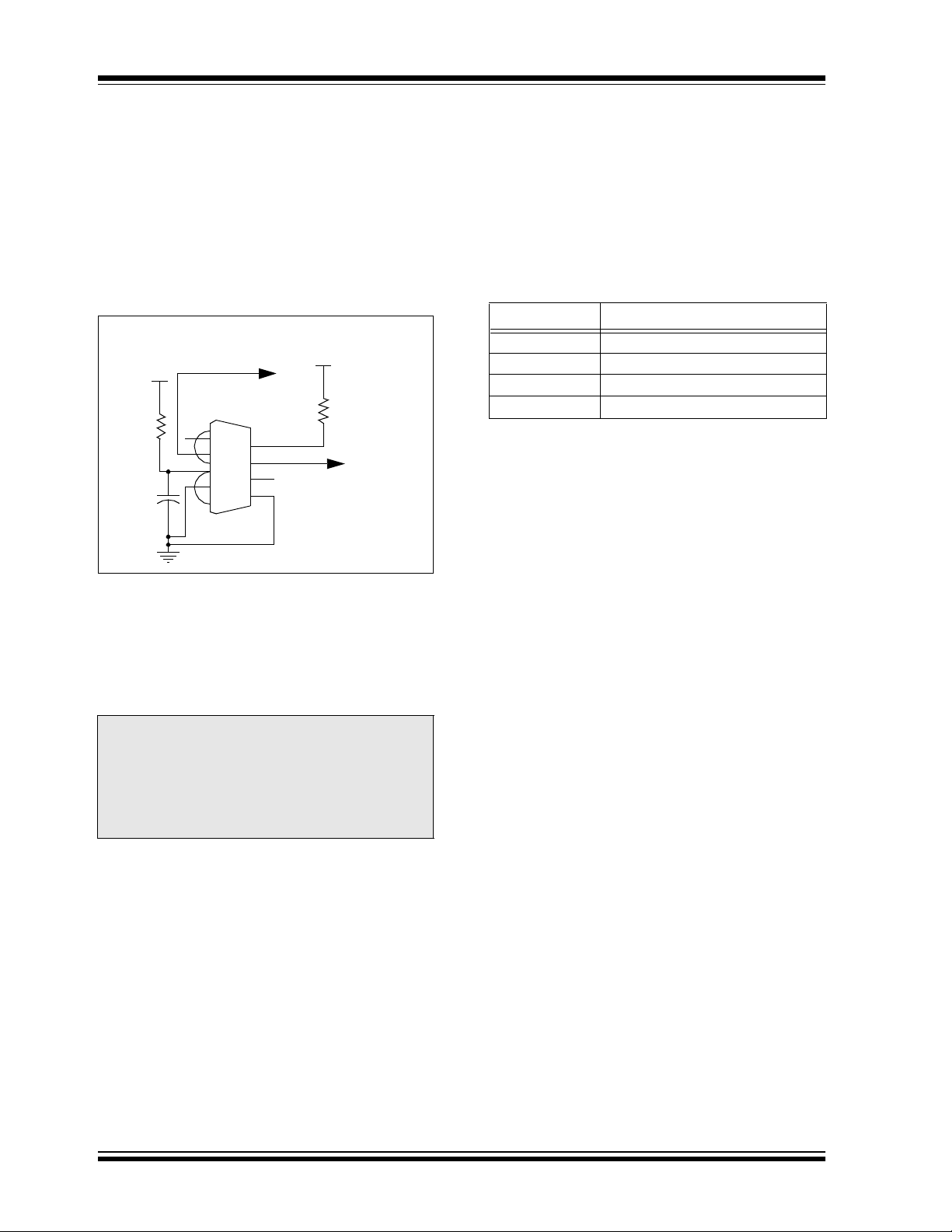

2.14 Optical Transceiver

The MCP2150 requires an infrared transceiver. The

transceiver can be an integrated solution. Table 2-6

shows a list of common manufacturers of integrated

optical transceivers. A typical optical transceiver circuit, using a Vishay/Temic TFDS4500, is shown in

Figure 2-12.

FIGURE 2-12: TYPICAL OPTICAL

TRANSCEIVER

CIRCUIT

RXIR

R13

47 Ω

C18

.1 µF

(To MCP2150

+5 V

Pin 3)

U6

1

2

3

4

TFDS4500

8

7

6

5

+5 V

R11

22 Ω

TXIR

(To MCP2150

Pin 2)

2.15 References

The IrDA Standards download page can be found at:

http://www.irda.org/standards/specifications

Some common manufacturers of Optical Transceivers

are shown in Ta bl e 2 -6 .

TABLE 2-6: COMMON OPTICAL

TRANSCEIVER

MANUFACTURERS

Company Company Web Site Address

Infineon www.infineon.com

Agilent www.agilent.com

Vishay/Temic www.vishay.com

Rohm www.rohm.com

The optical transceiver logic can be implemented with

discrete components for cost savings. Care must be

taken in the design and layout of the photo detect circuit, due to the small signals that are being detected

and their sensitivity to noise. A discrete implementation

of the optical transceiver logic is implemented on the

MCP2120 and MCP2150 Developer’s Kit boards.

Note: The discrete optical transceiver implemen-

tation on the MCP2120 and MCP2150

Developer’s Kit boards may not meet the

IrDA specifications for the physical layer

(IrPHY). Any discrete solution will require

appropriate validation for the user’s

application.

DS21655B-page 22

Preliminary 2002 Microchip Technology Inc.

Page 23

MCP2150

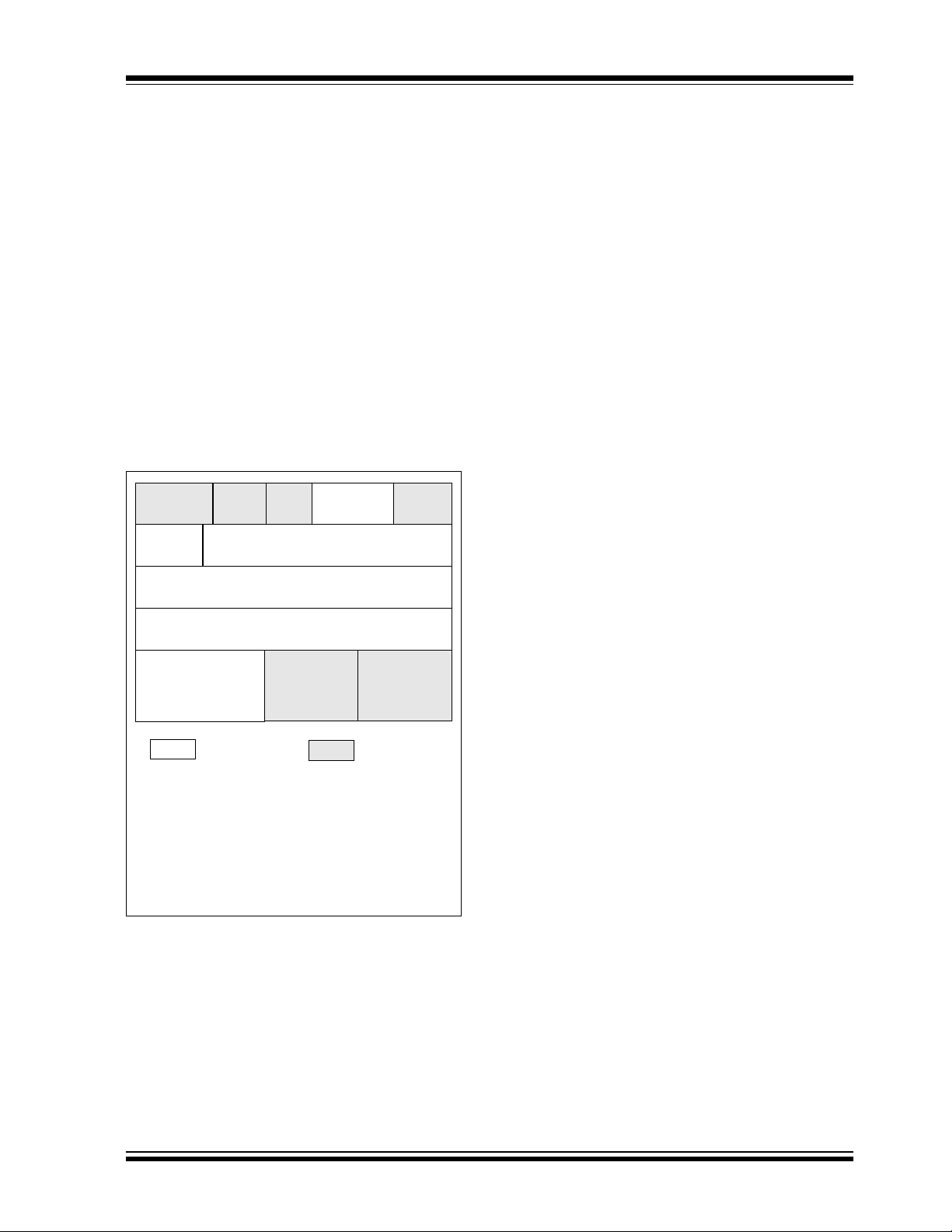

3.0 DEVELOPMENT TOOLS

The MCP2150 is supported by the MCP2120/

MCP2150 Developer’s Kit (order number DM163008).

This kit allows the user to evaluate the operation of the

MCP2150.

Each kit comes with two MCP2120 Developer’s Boards

and one MCP2150 Developer’s Board to demonstrate

transmission/reception of infrared data streams.

Figure 3-1 shows a block diagram of the MCP2150

Developer’s Board.

As can be seen, the user has jumper options for both

the interface to the Host Controller (UART or Header)

and the transceiver solution (Integrated or discrete

component).

The UART interface allows a direct connection to a PC

(use a terminal emulation program), or a header, to

allow easy connection to host prototypes (or one of the

Microchip PICDEM™ boards).

The transceiver logic is jumpered to allow the selection

of either a single chip transceiver solution, or a low cost

discrete solution. This low cost discrete solution allows

a lower system cost to be achieved. With the lower cost

come some trade-offs of the IrDA standard physical

layer specifications. These trade-offs need to be evaluated to ensure the characteristics of the component

solution meet the requirements of the system.

This kit comes with two identical MCP2120 Developer’s Boards and a single MCP2150 Developer’s

Board. This allows a complete system (Transmitter and

Receiver) to be implemented with either system

requirement (simple encoder/decoder or IrDA standard

protocol stack plus encoder/decoder).

FIGURE 3-1: MCP2150 DEVELOPER’S KIT BLOCK DIAGRAM

Power LED

Power

Supply

MCP2150

4

DB9

Power

7

GND

+5V

9V Battery

SP3238E

Transceiver

MCP601

Component

Integrated

Header

4

Host Interface

Encoder/

Decoder

2002 Microchip Technology Inc. Preliminary

DS21655B-page 23

Page 24

MCP2150

NOTES:

DS21655B-page 24

Preliminary 2002 Microchip Technology Inc.

Page 25

MCP2150

4.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

Ambient Temperature under bias...........................................................................................................–40°C to +125°C

Storage Temperature ............................................................................................................................. –65°C to +150°C

Voltage on V

Voltage on RESET

Voltage on all other pins with respect to V

Total Power Dissipation

Max. Current out of V

Max. Current into V

Input Clamp Current, I

Output Clamp Current, I

Max. Output Current sunk by any Output pin.......................................................................................................... 25 mA

Max. Output Current sourced by any Output pin..................................................................................................... 25 mA

Note 1: Power Dissipation is calculated as follows:

†

NOTICE: Stresses above those listed under “Maximum ratings” may cause permanent damage to the device. This

is a stress rating only and functional operation of the device at those or any other conditions above those indicated in

the operational listings of this specification is not implied. Exposure to maximum rating conditions for extended periods

may affect device reliability.

DD with respect to VSS ......................................................................................................... -0.3 V to +6.5 V

with respect to VSS .................................................................................................... -0.3 V to +14 V

SS ............................................................................... –0.3 V to (VDD + 0.3 V)

(1)

................................................................................................................................... 800 mW

SS pin ..................................................................................................................................300 mA

DD pin ..................................................................................................................................... 250 mA

IK (VI < 0 or VI > VDD) ...................................................................................................................±20 mA

OK (V0 < 0 or V0 > VDD).............................................................................................................±20 mA

P

DIS = VDD x {IDD - ∑ IOH} + ∑ {(VDD-VOH) x IOH} + ∑(VOL x IOL)

2002 Microchip Technology Inc. Preliminary

DS21655B-page 25

Page 26

MCP2150

FIGURE 4-1: VOLTAGE-FREQUENCY GRAPH, -40°C ≤ TA ≤ +85°C

6.0

5.5

5.0

5.0

V

DD

(Volts)

4.5

4.0

3.5

3.0

2.5

0

410

81216

11.0592

Frequency (MHz)

20

DS21655B-page 26

Preliminary 2002 Microchip Technology Inc.

Page 27

4.1 DC Characteristics

DC Specifications

MCP2150

Electrical Characteristics:

Standard Operating Conditions (unless otherwise specified)

Operating Temperature: -40°C ≤ T

A ≤ +85°C (industrial)

Param.

No.

D001 V

D002 V

D003 V

Sym Characteristic Min Typ

DD Supply Voltage 3.0 — 5.5 V See Figure 4-1

DR RAM Data Retention

Voltage

PORVDD

(2)

Start Voltage to

2.0 — — V Device Oscillator/Clock stopped

—VSS—V

(1)

Max Units Conditions

ensure Power-on Reset

D004 SV

DD VDD Rise Rate to

0.05 — — V/ms

ensure Power-on Reset

D010 I

D020 I

DD Supply Current

PD Device Disabled

Current

(3, 4)

(3)

—

—

—

—

—

4.0

—

—

2.2

7.0

2.2

9

mAmAFOSC = 11.0592 MHz, VDD = 3.0 V

F

OSC

= 11.0592 MHz, VDD = 5.5 V

µAµAVDD = 3.0 V

V

DD = 5.5 V

Note 1: Data in the Typical (“Typ”) column is based on characterization results at 25°C. This data is for design

guidance only and is not tested.

2: This is the limit to which V

DD can be lowered without losing RAM data.

3: The supply current is mainly a function of the operating voltage and frequency. Pin loading, pin rate and

temperature have an impact on the current consumption.

a) The test conditions for all I

OSC1 = external square wave, from rail-to-rail; all input pins pulled to V

R

ESET = VDD;

DD measurements are made when device is enabled (EN pin is high):

SS, RXIR = VDD,

b) When device is disabled (EN pin is low), the conditions for current measurements are the same.

4: When the device is disabled (EN pin is low), current is measured with all input pins tied to V

DD or VSS and

the output pins driving a high or low level into infinite impedance.

2002 Microchip Technology Inc. Preliminary

DS21655B-page 27

Page 28

MCP2150

4.1 DC Characteristics (Continued)

Electrical Characteristics:

DC Specifications

Param

No.

Sym Characteristic Min Typ Max Units Conditions

Input Low Voltage

V

IL

Input pins

D030 with TTL buffer

(TX, RI, DTR, RTS, and EN)

D030A V

D031 with Schmitt Trigger buffer

(BAUD1, BAUD0, and RXIR)

D032 RESET

D033 OSC1 V

Input High Voltage

V

IH Input pins —

D040 with TTL buffer

(TX, RI, DTR, RTS, and EN)

D040A 0.25 V

D041 with Schmitt Trigger buffer

(BAUD1, BAUD0, and RXIR)

D042 RESET

0.8 VDD —VDD V

D043 OSC1 0.7 V

Input Leakage Current

(Notes 1, 2)

D060 I

IL Input pins — — ±1 µA VSS ≤ VPIN ≤ VDD, Pin at

D061 RESET

D063 OSC1 — — ±5 µA VSS ≤ VPIN ≤ VDD

Note 1: The leakage current on the RESET

levels represent normal operating conditions. Higher leakage current may be measured at different input

voltages.

2: Negative current is defined as coming out of the pin.

Standard Operating Conditions (unless otherwise specified)

Operating temperature: -40°C ≤ T

Operating voltage V

SS —0.8V V4.5V ≤ VDD ≤ 5.5 V

V

SS —0.15VDD V otherwise

SS —0.2VDD V

V

SS

V

SS

2.0 — V

DD

DD range as described in DC spec Section 4.1.

—0.2VDDV

—0.3VDDV

DD V4.5V ≤ VDD ≤ 5.5 V

—V

DD V

+ 0.8

0.8 V

DD —VDD V

DD —VDD V

A ≤ +85°C (industrial)

otherwise

high-impedance

——±5µAVSS ≤ VPIN ≤ VDD

pin is strongly dependent on the applied voltage level. The specified

DS21655B-page 28

Preliminary 2002 Microchip Technology Inc.

Page 29

MCP2150

4.1 DC Characteristics (Continued)

Electrical Characteristics:

DC Specifications

Param

No.

Sym Characteristic Min Typ Max Units Conditions

Output Low Voltage

D080 V

OL

TXIR, RX, DSR, CTS, and

CD pins

D083 OSC2 — — 0.6 V IOL = 1.6 mA, VDD = 4.5 V

Output High Voltage

D090 V

OH TXIR, RX, DSR, CTS, and

CD pins (Note 1)

D092 OSC2 V

Capacitive Loading Specs

on Output Pins

D100 C

D101 C

OSC2 OSC2 pin — — 15 pF when external clock is used

IO All Input or Output pins — — 50 pF

Note 1: Negative current is defined as coming out of the pin.

Standard Operating Conditions (unless otherwise specified)

Operating temperature: -40°C ≤ T

Operating voltage V

DD range as described in DC spec Section 4.1

——0.6VI

A ≤ +85°C (industrial)

OL

= 8.5 mA, VDD = 4.5 V

VDD - 0.7 — — V IOH = -3.0 mA, VDD = 4.5 V

DD

- 0.7 — — V IOH = -1.3 mA, VDD = 4.5 V

to drive OSC1.

2002 Microchip Technology Inc. Preliminary

DS21655B-page 29

Page 30

MCP2150

4.2 Timing Parameter Symbology and Load Conditions

The timing parameter symbols have been created following one of the following formats:

4.2.1 TIMING CONDITIONS

The temperature and voltages specified in Ta b l e 4 - 2 apply to all timing specifications unless otherwise noted. Figure 4-2

specifies the load conditions for the timing specifications.

TABLE 4-1: SYMBOLOGY

1. TppS2ppS 2. TppS

T

F Frequency T Time

EError

Lowercase letters (pp) and their meanings:

pp

io Input or Output pin osc Oscillator

rx Receive tx Transmit

bitclk RX/TX BITCLK RST Reset

drt Device Reset Timer

Uppercase letters and their meanings:

S

FFall PPeriod

HHigh RRise

I Invalid (high-impedance) V Valid

L Low Z High-impedance

TABLE 4-2: AC TEMPERATURE AND VOLTAGE SPECIFICATIONS

Electrical Characteristics:

AC Specifications

Standard Operating Conditions (unless otherwise stated):

Operating temperature: -40°C ≤ T

Operating voltage V

DD range as described in DC spec Section 4.1.

A ≤ +85°C (industrial)

FIGURE 4-2: LOAD CONDITIONS FOR DEVICE TIMING SPECIFICATIONS

PIN

CL

VSS

CL = 50 pF for all pins except OSC2

15 pF for OSC2 when external clock is used to drive OSC1

DS21655B-page 30

Preliminary 2002 Microchip Technology Inc.

Page 31

4.3 Timing Diagrams and Specifications

FIGURE 4-3: EXTERNAL CLOCK TIMING

MCP2150

Q4

Q1 Q2

Q3 Q4 Q1

OSC1

1

33

44

2

TABLE 4-3: EXTERNAL CLOCK TIMING REQUIREMENTS

Electrical Characteristics:

AC Specifcations

Param.

No.

1T

1A F

Sym Characteristic Min Typ

OSC

External CLKIN Period

Oscillator Period

OSC External CLKIN

Frequency

(2)

(2, 3)

Oscillator Frequency

1B F

1C E

4TosR,

ERR Error in Frequency — — ± 0.01 %

CLK External Clock Error — — ± 0.01 %

Clock in (OSC1)

To s F

Rise or Fall Time

Note 1: Data in the Typical (“Typ”) column is at 5 V, 25°C unless otherwise stated. These parameters are for design

guidance only and are not tested.

2: All specified values are based on oscillator characterization data under standard operating conditions.

Exceeding these specified limits may result in unstable oscillator operation and/or higher than expected

current consumption. When an external clock input is used, the “max” cycle time limit is “DC” (no clock) for

all devices.

3: A duty cycle of no more than 60% (High time/Low time or Low time/High time) is recommended for external

clock inputs.

Standard Operating Conditions (unless otherwise specified):

A

Operating Temperature: -40°C ≤ T

Operating Voltage V

(2, 3)

90.422

90.422

DD range is described in Section 4.1

(1)

—

—

Max Units Conditions

90.422

—

≤ +85°C (industrial)

nsnsDevice Operation

Disable Clock for low power

90.422 — 90.422 ns

11.0592 — 11.0592 MHz

(2)

11.0592 — 11.0592 MHz

— — 15 ns

2002 Microchip Technology Inc. Preliminary

DS21655B-page 31

Page 32

MCP2150

FIGURE 4-4: OUTPUT WAVEFORM

Q4

OSC1

Output Pin

Note: Refer to Figure 4-2 for load conditions.

Old Value

Q1

20, 21

Q2 Q3

TABLE 4-4: OUTPUT TIMING REQUIREMENTS

Electrical Characteristics:

AC Specifications

Param.

No.

20 ToR RX and TXIR pin rise time

21 ToF RX and TXIR pin fall time

Note 1: Data in the Typical (“Typ”) column is at 5 V, 25°C unless otherwise stated.

Sym Characteristic Min Typ

2: See Figure 4-2 for loading conditions.

Standard Operating Conditions (unless otherwise specified):

Operating Temperature: -40°C ≤ T

Operating Voltage V

(2)

(2)

—1025ns

—1025ns

DD range is described in Section 4.1

(1)

Max Units Conditions

New Value

A ≤ +85°C (industrial)

DS21655B-page 32

Preliminary 2002 Microchip Technology Inc.

Page 33

FIGURE 4-5: RESET AND DEVICE RESET TIMING

VDD

RESET

MCP2150

Reset

Detected

PWRT

Timeout

OSC

Timeout

Internal

RESET

Output Pin

TABLE 4-5: RESET

AC Specifications

Param.

No.

30 T

32 T

33 TPWRT Power up Timer Period 28 72 132 ms VDD = 5.0 V

34 T

Note 1: Data in the Typical (“Typ”) column is at 5 V, 25°C unless otherwise stated.

Sym Characteristic Min Typ

RSTL RESET Pulse Width (low) 2000 — — ns VDD = 5.0 V

OST

Oscillator Start-up Timer Period 1024 — 1024 T

IOZ

Output High-impedance from

RESET

33

32

34

AND DEVICE RESET REQUIREMENTS

Electrical Characteristics:

Standard Operating Conditions (unless otherwise specified):

Operating Temperature: -40°C ≤ T

Operating Voltage V

——2 µs

Low or device Reset

30

34

A ≤ +85°C (industrial)

DD range is described in Section 4.1

(1)

Max Units Conditions

OSC

2002 Microchip Technology Inc. Preliminary

DS21655B-page 33

Page 34

MCP2150

FIGURE 4-6: UART ASYNCHRONOUS TRANSMISSION WAVEFORM

Start Bit Data Bit Data Bit Data Bit

IR100

TX pin

IR103

Note: Refer to Figure 4-2 for load conditions.

TABLE 4-6: UART ASYNCHRONOUS TRANSMISSION REQUIREMENTS

Electrical Characteristics:

AC Specifications

Param.

No.

IR100 T

IR101 E

IR102 E

IR103 T

Note 1: This error is not additive to IR101 parameter.

Sym Characteristic Min Typ Max Units Conditions

TXBIT Transmit Baud rate 1152 — 1152 TOSC BAUD2:BAUD0 = 00

TXBIT Transmit (TX pin) Baud rate

Error (into MCP2150)

TXIRBIT Transmit (TXIR pin) Baud rate

Error (out of MCP2150)

TXRF TX pin rise time and fall time — — 25 ns

(1)

Standard Operating Conditions (unless otherwise specified):

Operating Temperature: -40°C ≤ T

Operating Voltage V

IR100 IR100 IR100

IR103

A ≤ +85°C (industrial)

DD

range is described in Section 4.1

576 — 576 T

192 — 192 T

96 — 96 T

——±2%

——±1%

OSC BAUD2:BAUD0 = 01

OSC

OSC BAUD2:BAUD0 = 11

BAUD2:BAUD0 = 10

DS21655B-page 34

Preliminary 2002 Microchip Technology Inc.

Page 35

FIGURE 4-7: UART ASYNCHRONOUS RECEIVE TIMING

Start Bit Data Bit Data Bit Data Bit

IR110

IR110 IR110 IR110

RX pin

IR113

IR113

Note: Refer to Figure 4-2 for load conditions.

TABLE 4-7: UART ASYNCHRONOUS RECEIVE REQUIREMENTS

Electrical Characterisitcs:

AC Specifications

Param.

No.

IR110 T

IR 111 E

Sym Characteristic Min Typ Max Units Conditions

RXBIT Receive Baud Rate 1152 — 1152 TOSC BAUD2:BAUD0 = 00

RXBIT Receive (RXIR pin) Baud rate

Error (into MCP2150)

IR112 E

RXBIT Receive (RX pin) Baud rate

Error (out of MCP2150)

IR113 T

TXRF RX pin rise time and fall time — — 25 ns

Note 1: This error is not additive to the IR111 parameter.

Standard Operating Conditions (unless otherwise specified):

Operating Temperature: -40°C ≤ T

Operating Voltage V

DD range is described in Section 4.1

576 — 576 T

192 — 192 T

96 — 96 T

——±1%

(1)

——±1%

MCP2150

A ≤ +85°C (industrial)

OSC BAUD2:BAUD0 = 01

OSC BAUD2:BAUD0 = 10

OSC BAUD2:BAUD0 = 11

2002 Microchip Technology Inc. Preliminary

DS21655B-page 35

Page 36

MCP2150

FIGURE 4-8: TXIR WAVEFORMS

Start Bit Data bit 7 Data bit 6 Data bit 5 Data bit ...

IR100A

BITCLK

IR122 IR122 IR122 IR122 IR122 IR122

TXIR

IR121

0100 01

TABLE 4-8: TXIR REQUIREMENTS

AC Specifications

Param.

No.

IR100A T

IR121 T

IR122 T

Note 1: T

Sym Characteristic Min Typ Max Units Conditions

TXIRBIT Transmit Baud Rate 1152 — 1152 TOSC BAUD = 9600

TXIRPW TXIR pulse width 24 — 24 TOSC

TXIR

P TXIR bit period

BITCLK = TTXBIT/16.

(1)

Electrical Characteristics:

Standard Operating Conditions (unless otherwise specified):

Operating Temperature: -40°C ≤ T

Operating Voltage V

DD range is described in Section 4.1

576 — 576 T

288 — 288 T

192 — 192 T

96 — 96 T

—16—T

A ≤ +85°C (industrial)

OSC BAUD = 19200

OSC BAUD = 38400

OSC BAUD = 57600

OSC BAUD = 115200

BITCLK

DS21655B-page 36

Preliminary 2002 Microchip Technology Inc.

Page 37

FIGURE 4-9: RXIR WAVEFORMS

Start Bit Data bit 7 Data bit 6 Data bit 5 Data bit ...

IR110A

BITCLK

RXIR

IR131A

MCP2150

IR131B IR131B

0100 01

Start Bit Data bit 7 Data bit 6 Data bit 5 Data bit ...

TABLE 4-9: RXIR REQUIREMENTS

AC Specifications

Param.

No.

IR110A T

IR131A T

IR132 TRXIRP RXIR bit period

Note 1: T

Sym Characteristic Min Typ Max Units Conditions

RXIRBIT Receive Baud Rate 1152 — 1152 TOSC BAUD = 9600

RXIRPW RXIR pulse width 2 — 24 TOSC

(1)

BITCLK

= T

RXBIT

/16.

IR131B

IR131B IR131B

IR131B

Electrical Characteristics:

Standard Operating Conditions (unless otherwise specified):

Operating Temperature: -40°C ≤ T

Operating Voltage V

DD range is described in Section 4.1

576 — 576 T

288 — 288 T

192 — 192 T

96 — 96 T

A ≤ +85°C (industrial)

OSC BAUD = 19200

OSC

BAUD = 38400

OSC BAUD = 57600

OSC BAUD = 115200

—16—TBITCLK

2002 Microchip Technology Inc. Preliminary

DS21655B-page 37

Page 38

MCP2150

NOTES:

DS21655B-page 38

Preliminary 2002 Microchip Technology Inc.

Page 39

5.0 DC AND AC CHARACTERISTICS GRAPHS AND TABLES

Not available at this time.

MCP2150

2002 Microchip Technology Inc. Preliminary

DS21655B-page 39

Page 40

MCP2150

NOTES:

DS21655B-page 40

Preliminary 2002 Microchip Technology Inc.

Page 41

6.0 PACKAGING INFORMATION

6.1 Package Marking Information

18-Lead PDIP (300 mil) Example:

MCP2150

XXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXX

XXXXXYYWWNNN

18-Lead SOIC (300 mil) Example:

XXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXX

XXXXXYYWWNNN

20-Lead SSOP (209 mil, 5.30 mm) Example:

XXXXXXXXXXX

XXXXXXXXXXX

XXXYYWWNNN

XXXXXXXXXXXXXXXXX

XXXXXYYWWNNN

XXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXX

XXXXXYYWWNNN

MCP2150I/SS

XXXXXXXXXXX

XXXYYWWNNN

MCP2150-I/P

MCP2150-I/SO

Legend: XX...X Customer specific information*

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Note: In the event the full Microchip part number cannot be marked on one line, it will